Page 1

GM700

In-Situ Gas Analyzer Probe Version

Installation, Operation, Maintenance

O P E R A T I N G I N S T R U C T I O N S

Page 2

Described product

GM700

Measuring Probe Version

Version GM700-02, GM700-03, GM700-04, GM700-05, GM700-07, GM700-08,

GM700-09

Manufacturer

SICK AG

Erwin-Sick-Str. 1

79183 Waldkirch

Germany

Production location

SICK AG

Nimburger Str. 11 · D-79276 Reute · Germany

Legal information

This work is protected by copyright. Any rights derived from the copyright shall be

reserved for SICK AG. Reproduction of this document or parts of this document is only

permissible within the limits of the legal determination of Copyright Law. Any modifica‐

tion, abridgment or translation of this document is prohibited without the express writ‐

ten permission of SICK AG.

The trademarks stated in this document are the property of their respective owner.

© SICK AG. All rights reserved.

Original document

This document is an original document of SICK AG.

2

O PE R AT I NG IN S TR U CT I ON S | GM700 8022447/0000/2018-01 | SICK

Subject to change without notice

Page 3

Contents

CONTENTS

1 About this document........................................................................ 7

1.1 Function of this document....................................................................... 7

1.2 Scope of application................................................................................. 7

1.3 Target groups (and document structure)................................................. 7

1.4 Further information................................................................................... 7

1.5 Data integrity............................................................................................. 7

1.6 Symbols and document conventions...................................................... 8

1.6.1 Warning symbols...................................................................... 8

1.6.2 Warning levels / Signal words................................................. 8

1.6.3 Information symbols................................................................ 8

2 Safety information............................................................................ 10

2.1 Main operating information..................................................................... 10

2.2 Warning information on the device.......................................................... 13

2.3 Intended use............................................................................................. 15

2.4 Responsibility of user............................................................................... 15

3 Product description........................................................................... 16

3.1 Product identification............................................................................... 16

3.2 Product characteristics............................................................................ 16

3.3 Device variants......................................................................................... 16

3.4 Options...................................................................................................... 16

3.5 Layout and function.................................................................................. 17

3.6 Purge air unit............................................................................................. 17

3.7 Check cycle............................................................................................... 18

3.8 GMP and GPP measuring probes ........................................................... 18

3.8.1 GMP measuring probe in detail.............................................. 19

3.8.1.1 Gas connection for sample gas sampling on

purge air fixture of GMP measuring probe............ 20

3.8.2 GPP gas diffusion probe in dry or wet version....................... 20

3.8.2.1 GPP measuring probe gas connections for zero

and span gas........................................................... 21

4 Transport and storage....................................................................... 22

4.1 Transport protection................................................................................. 22

4.2 Storage...................................................................................................... 22

5 Mounting............................................................................................. 24

5.1 Assembly information............................................................................... 24

5.2 Tools required............................................................................................ 24

5.3 Preparing the measuring point................................................................ 24

5.4 GM700 scope of delivery......................................................................... 25

5.5 Installation sequence............................................................................... 25

5.5.1 Installation example................................................................ 25

5.5.2 Overview of installation steps (duct-side preparation).......... 26

8022447/0000/2018-01 | SICK OP E RA T IN G I N ST R UC T IO N S | GM700

Subject to change without notice

3

Page 4

CONTENTS

5.5.3 Installation preparation for the purge air unit........................ 26

5.5.4 Installing the flange with tube................................................. 26

5.5.5 Installing the control units...................................................... 27

5.5.5.1 Install the control unit away from the SR-unit....... 29

5.5.6 Installing the terminal box (option)......................................... 30

5.5.7 Installing the purge air unit..................................................... 30

6 Electrical installation........................................................................ 31

6.1 Electrical installation safety information................................................. 31

6.2 Connection overview................................................................................ 32

6.2.1 Lines......................................................................................... 33

6.2.2 Information on laying lines...................................................... 33

6.3 Connecting I/O interfaces........................................................................ 34

6.3.1 Leading the CAN bus line correctly through the PG screw

fitting........................................................................................ 34

6.3.2 Wiring the evaluation unit....................................................... 35

6.3.3 Customer wiring of the terminal box (optional)...................... 37

6.4 Connecting the SR-unit............................................................................. 38

6.5 Grounding conductor, evaluation unit..................................................... 38

7 Commissioning.................................................................................. 40

7.1 Safety information on commissioning..................................................... 40

7.2 Prerequisites for successful commissioning.......................................... 40

7.3 Overview of commissioning steps........................................................... 41

7.4 Material required ..................................................................................... 42

7.4.1 Material required - included in scope of delivery................... 42

7.5 Fitting the SR-unit on the purge air fixture of the measuring probe...... 43

7.6 Optical fine alignment for device versions for NH3 and HF measure‐

ment.......................................................................................................... 43

7.7 Optical fine alignment on the version for HCI measurement................ 45

7.8 Two types of zero point checks................................................................ 46

7.8.1 Selecting the ambient temperature range............................. 46

7.8.2 Carrying out zero adjust (on the measuring path free from

sample gas).............................................................................. 47

7.8.3 Zero point check with GPP measuring probe......................... 47

7.9 Repositioning the probe reflector............................................................ 48

7.10 Fitting the measuring probe on the flange with tube............................. 51

7.11 Putting the purge air unit into operation................................................. 52

7.12 Fitting the sender/receiver unit on the intermediate housing............... 52

7.13 Installing the weatherproof cover ........................................................... 53

7.14 Starting measuring operation.................................................................. 54

7.14.1 Operating states...................................................................... 55

7.14.2 Select the ambient temperature range.................................. 55

8 Operation............................................................................................ 56

8.1 Safety......................................................................................................... 56

8.1.1 Check before start-up.............................................................. 56

4

O PE R AT I NG IN S TR U CT I ON S | GM700 8022447/0000/2018-01 | SICK

Subject to change without notice

Page 5

CONTENTS

8.2 Operating and display elements (evaluation unit).................................. 56

8.3 Menu tree of the evaluation unit............................................................. 58

8.3.1 Menu tree Measuring.............................................................. 58

8.3.2 Menu tree Diagnosis............................................................... 58

8.3.3 Menu tree Parameter.............................................................. 59

8.3.4 Menu tree Calibration.............................................................. 61

8.3.5 Menu tree Maintenance.......................................................... 61

8.4 Operating using the serial interface........................................................ 62

8.4.1 Significance of command line elements................................ 62

8.4.2 Setting for serial interfaces..................................................... 62

8.4.3 Serial interface commands - Meas........................................ 62

8.4.3.1 Serial interface command - MEAS ........................ 62

8.4.4 Serial interface commands - Diag.......................................... 62

8.4.4.1 Table with warning messages................................ 62

8.4.4.2 Error messages Table ............................................ 63

8.4.4.3 View the device configuration................................ 63

8.4.4.4 Check the system state and configuration........... 63

8.4.4.5 Call up diagnostic data........................................... 63

9 Maintenance...................................................................................... 64

9.1 Safety......................................................................................................... 64

9.2 Maintenance plan..................................................................................... 65

9.2.1 Maintenance protocol.............................................................. 65

9.2.2 Expendable, wearing and spare parts.................................... 65

9.3 Preparatory work....................................................................................... 66

9.4 Removing the SR-unit from the intermediate housing........................... 66

9.5 Visual check.............................................................................................. 67

9.6 Cleaning the optical interfaces................................................................ 67

9.7 Cleaning the purge air unit....................................................................... 69

10 Troubleshooting................................................................................. 70

10.1 Safety......................................................................................................... 70

10.2 Monitoring and diagnostic system........................................................... 70

10.3 Device not functioning.............................................................................. 71

10.4 Evaluation unit not functioning................................................................ 71

10.4.1 Communication fault between evaluation unit and receiver 72

10.5 Error messages......................................................................................... 72

10.5.1 Error messages........................................................................ 72

10.5.2 Warning messages.................................................................. 74

10.6 Repairing inadequate purge air supply................................................... 74

10.7 Corrosion on flange.................................................................................. 75

11 Decommissioning............................................................................. 76

11.1 Safety information for decommissioning................................................ 76

11.2 Removing the device................................................................................ 77

11.3 Preparing the device ready for shipping.................................................. 77

8022447/0000/2018-01 | SICK OP E RA T IN G I N ST R UC T IO N S | GM700

Subject to change without notice

5

Page 6

CONTENTS

11.4 Environmentally compatible disposal ..................................................... 78

12 Technical data.................................................................................... 79

12.1 System: GM700........................................................................................ 79

12.2 Sender/receiver unit................................................................................ 80

12.3 GMP measuring probe.............................................................................. 80

12.4 GPP measuring probe............................................................................... 80

12.5 Evaluation unit: Sheet steel enclosure.................................................... 81

12.6 Evaluation unit: Cast metal enclosure..................................................... 82

12.7 Terminal box.............................................................................................. 82

12.8 Dimension drawings, sender/receiver unit ............................................ 83

12.9 Dimension drawings, open measuring probe (GMP).............................. 84

12.10 Dimension drawings GPP measuring probe (Gas Permeable Probe).... 85

12.11 Dimension drawing evaluation unit......................................................... 86

12.12 Dimension drawings: Mounting flange DN125....................................... 87

12.13 Dimension drawing terminal box............................................................. 87

12.14 Dimension drawing, purge air unit........................................................... 88

12.15 Dimension drawing, weatherproof cover, sender/receiver unit............. 88

13 Annex.................................................................................................. 89

13.1 Possible ambient temperatures............................................................... 89

13.1.1 Ambient temperature ranges (closed cell)............................. 89

13.2 User information on laser safety GM700................................................ 89

14 Index.................................................................................................... 91

6

O PE R AT I NG IN S TR U CT I ON S | GM700 8022447/0000/2018-01 | SICK

Subject to change without notice

Page 7

1 About this document

1.1 Function of this document

These Operating Instructions describe:

Device components

•

Installation

•

Operation

•

Maintenance work required for reliable operation

•

1.2 Scope of application

These Operating Instructions are only applicable for the measuring device described in

the product identification.

They are not applicable for other SICK measuring devices.

The standards referred to in these Operating Instructions are to be observed in the

respective valid version.

1.3 Target groups (and document structure)

ABOUT THIS DOCUMENT 1

This Manual is intended for persons installing, operating and maintaining the device.

Operation

The device may only be operated by qualified persons who, based on their device-spe‐

cific training and knowledge as well as knowledge of the relevant regulations, can

assess the tasks given and recognize the hazards involved.

Installation and maintenance

Skilled persons are required for installation and maintenance.

Please observe the information at the beginning of the respective Sections.

1.4 Further information

Operating Instructions of the purge air supply

•

Final inspection record

•

NOTE

Observe all supplied documents.

b

1.5 Data integrity

SICK AG uses standardized data interfaces such as, for example, standard IP technol‐

ogy, in its products. The focus here is on product availability and features.

SICK AG always assumes that the customer is responsible for the integrity and confi‐

dentiality of data and rights involved in connection with using the products.

In all cases, the customer is responsible for the implementation of safety measures

suitable for the respective situation, e.g., network separation, firewalls, virus protection

and patch management.

8022447/0000/2018-01 | SICK OP E RA T IN G I N ST R UC T IO N S | GM700

Subject to change without notice

7

Page 8

1 ABOUT THIS DOCUMENT

1.6 Symbols and document conventions

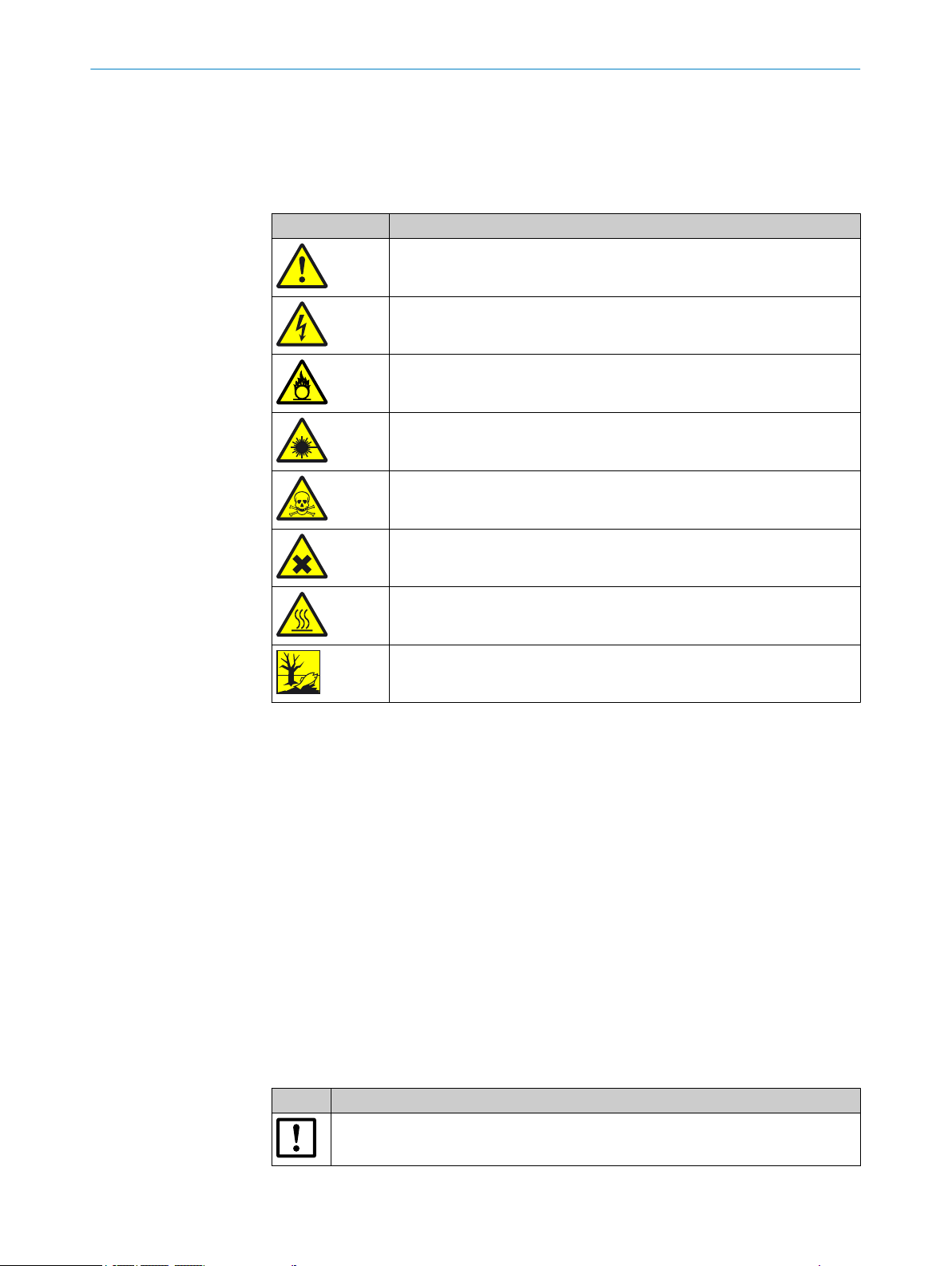

1.6.1 Warning symbols

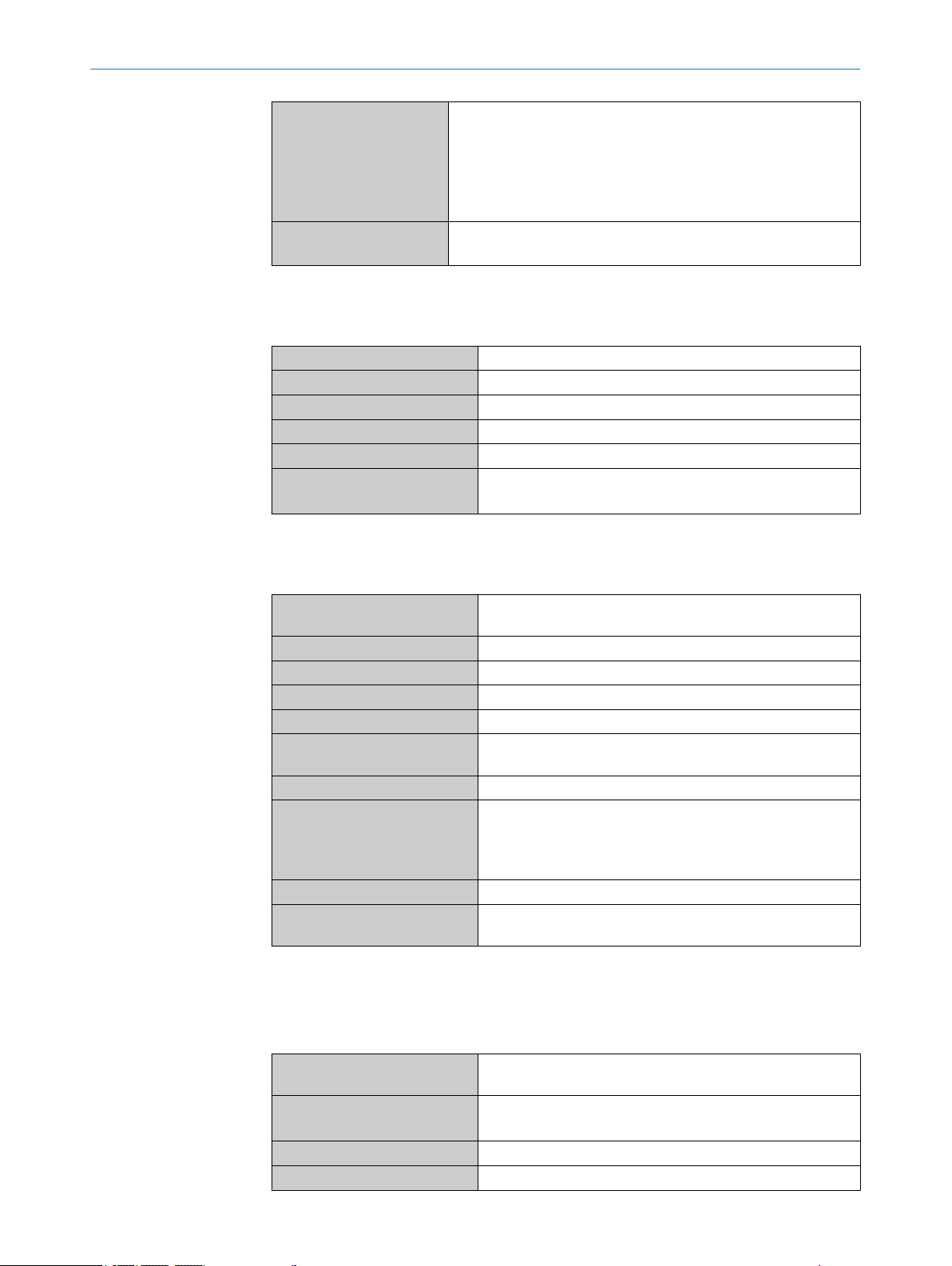

Table 1: Warning symbols

Symbol Significance

Hazard (general)

Hazard by voltage

Hazard by oxidizing substances

Hazard by laser radiation

Hazard by toxic substances

1.6.2 Warning levels / Signal words

DANGER

Risk or hazardous situation which will result in severe personal injury or death.

WARNING

Risk or hazardous situation which could result in severe personal injury or death.

CAUTION

Hazard or unsafe practice which could result in less severe or minor injuries.

Notice

Hazard which could result in property damage.

Note

Hazard by noxious substances

Hazard by high temperature

Hazard for the environment/nature/organic life

Hints

1.6.3 Information symbols

Table 2: Information symbols

Symbol Significance

8

O PE R AT I NG IN S TR U CT I ON S | GM700 8022447/0000/2018-01 | SICK

Important technical information for this product

Subject to change without notice

Page 9

Symbol Significance

Important information on electric or electronic functions

ABOUT THIS DOCUMENT 1

8022447/0000/2018-01 | SICK OP E RA T IN G I N ST R UC T IO N S | GM700

Subject to change without notice

9

Page 10

2 SAFETY INFORMATION

2 Safety information

2.1 Main operating information

Lifting and carrying

WARNING

Injury risk through incorrect lifting and carrying of the device

Injuries can occur due to the weight and projecting enclosure parts when the equip‐

ment tips over or drops.

Consider the device weight before lifting.

b

Observe the regulations for protective clothing (e.g., safety shoes, non-slip gloves).

b

Grip underneath the equipment when possible to carry it safely.

b

Do not use projecting parts on the device to carry the device.

b

Call in further personnel for assistance as required.

b

Use a hoist or transport equipment as an option.

b

Pay attention to the transport safety device.

b

Clear obstacles that could cause falls and collisions out of the way.

b

DANGER

Risk for system safety through work on the device not described in these Operating

Instructions

Carrying out work on the device not described in these Operating Instructions or associ‐

ated documents can lead to unsafe operation of the measuring system and therefore

endanger plant safety.

Only carry out the work on the device described in these Operating Instructions

b

and associated documents.

Laser radiation

WARNING

Eye injuries through laser radiation

The invisible laser beam within the SR-unit is not accessible when fitted. Observe the

following when the SR-unit of the device is swiveled open during installation work for

test purposes and the laser beam is activated:

Never look directly into the laser aperture when opening the SR-unit.

b

Laser protection class 1: Wear laser protection glasses despite low radiation.

b

Observe national valid limit values and standards that refer to these for industrial

b

safety.

Laser radiation, HF version

CAUTION

Pay attention to device software version

As the limit values of laser class 1 of the IEC 60825-1:2014-5 are neither exceeded in

single case malfunctions nor normal operation under consideration of the service and

measuring state, the device is classified as laser class 1. Prerequisite is using device

software 9105060_YEK0 or newer.

10

Laser class 1 of the IEC 60825-1:2014-5: Only use device software

b

9105060_YEK0 or a newer software version.

O PE R AT I NG IN S TR U CT I ON S | GM700 8022447/0000/2018-01 | SICK

Subject to change without notice

Page 11

SAFETY INFORMATION 2

DANGER

Important information for safe handling of the GM700 SR-unit on the device version

with HF measurement

For device software versions before 9105060_YEK0, a higher laser radiation might

occur.

Laser class 1 of the IEC 60825-1:2014-5: Only use device software

b

9105060_YEK0 or a newer software version.

Never look directly into the laser aperture when opening the SR-unit.

b

Always wear laser goggles or switch the device off during maintenance work.

b

Observe valid national limit values and respective standards for work safety.

b

NOTICE

Deviations of EN60825-1:2014-08 “Laser safety” from the Directive 2006/25/EC

The Directive has been adapted to cover changes in the health and safety regulation for

artificial optical radiation. Deviations occurred through changes in EN60825-1:2014-08

“Laser safety” from Directive 2006/25/EC.

Always observe the user information in the Annex of these Operating Instructions!

b

Escaping hot gas

DANGER

Risk of fire through hot gas escaping in installations with overpressure conditions

On installations with overpressure, the purge air hose can be severely damaged by

escaping hot gas and can catch fire depending on the temperature. On installations

with overpressure and gas temperatures over 200°C at the same time:

Regularly check the functionality of the reverse flow safeguard in the purge air fix‐

b

tures.

DANGER

Danger to life by leaking hot/toxic gases

Hot and/or noxious gases can escape during work on the gas duct, depending on the

plant conditions.

Work on the gas duct may only be performed by skilled technicians who, based on

b

their technical training and knowledge as well as knowledge of the relevant regula‐

tions, can assess the tasks given and recognize the hazards involved.

8022447/0000/2018-01 | SICK OP E RA T IN G I N ST R UC T IO N S | GM700

Subject to change without notice

11

Page 12

2 SAFETY INFORMATION

Electrical safety

WARNING

Endangerment of electrical safety during installation and maintenance work when the

power supply is not switched off

An electrical accident can occur during installation and maintenance work when the

power supply to the device and/or lines is not switched off using a power isolating

switch/circuit breaker.

b

b

b

b

DANGER

Endangerment of electrical safety through missing power isolating switch

An electrical accident can occur during installation and maintenance work when the

power supply to the device and/or lines cannot be switched off using a power isolating

switch/circuit breaker.

Before starting the work, ensure the power supply can be switched off using a

power isolating switch/circuit breaker in accordance with DIN EN 61010.

Make sure the power isolating switch is easily accessible.

An additional separation device is mandatory when the power isolating switch can‐

not be accessed or only with difficulty after installation of the device connection.

The power supply may only be switched on again after work completion or for test

purposes by the persons carrying out the work under consideration of the valid

safety regulations.

Ensure the power supply can be switched off using a power isolating switch/circuit

b

breaker in accordance with DIN EN 61010-1:2010.

An additional separation device is mandatory when the power isolating switch can‐

b

not be accessed or only with difficulty after installation of the device connection.

WARNING

Endangerment of electrical safety through power cables with incorrect rating

Electrical accidents can occur when the specifications for replacement of a removable

power cable have not been adequately observed.

Always observe the exact specifications in the Operating Instructions (Technical

b

Data Chapter) when replacing a removable power line.

Potential equalization

CAUTION

Device damage through incorrect or non-existing grounding

To avoid device damage, a correctly connected potential equalization is mandatory on

all system components with external ground connections in all operating conditions.

Connect a potential equalization on all planned points on the device components.

b

Ensure the potential equalization is connected during all work on the device

b

described in these Operating Instructions.

12

O PE R AT I NG IN S TR U CT I ON S | GM700 8022447/0000/2018-01 | SICK

Subject to change without notice

Page 13

Contamination caused by purge air failure

112 2

CAUTION

A faulty purge air supply can damage the measuring system

The measuring system can no longer be protected from contaminated sample gas and

is damaged.

When the purge air supply appears faulty, immediately perform all actions

b

described in these Operating Instructions.

Responsibility for system safety

NOTICE

Responsibility for system safety

The person setting the system up is responsible for the safety of the system in which

the device is integrated.

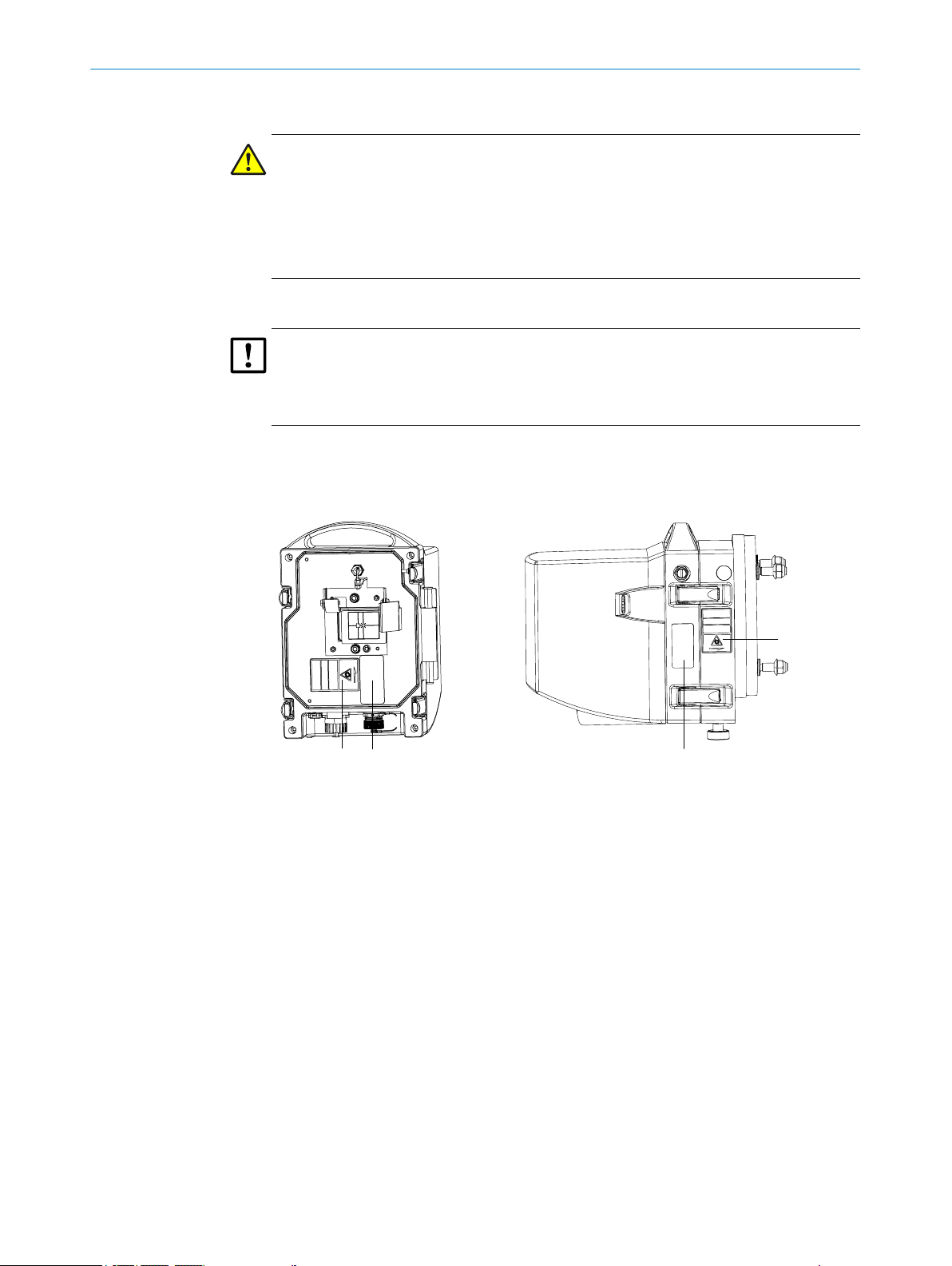

2.2 Warning information on the device

GM700 SR-unit

SAFETY INFORMATION 2

Figure 1: Warning information on the sender/receiver unit

SR-unit, front side

1 Danger sign: Laser radiation

2 Type plate GM700

SR-unit, right side

1 Danger sign: Laser radiation

2 Type plate GM700

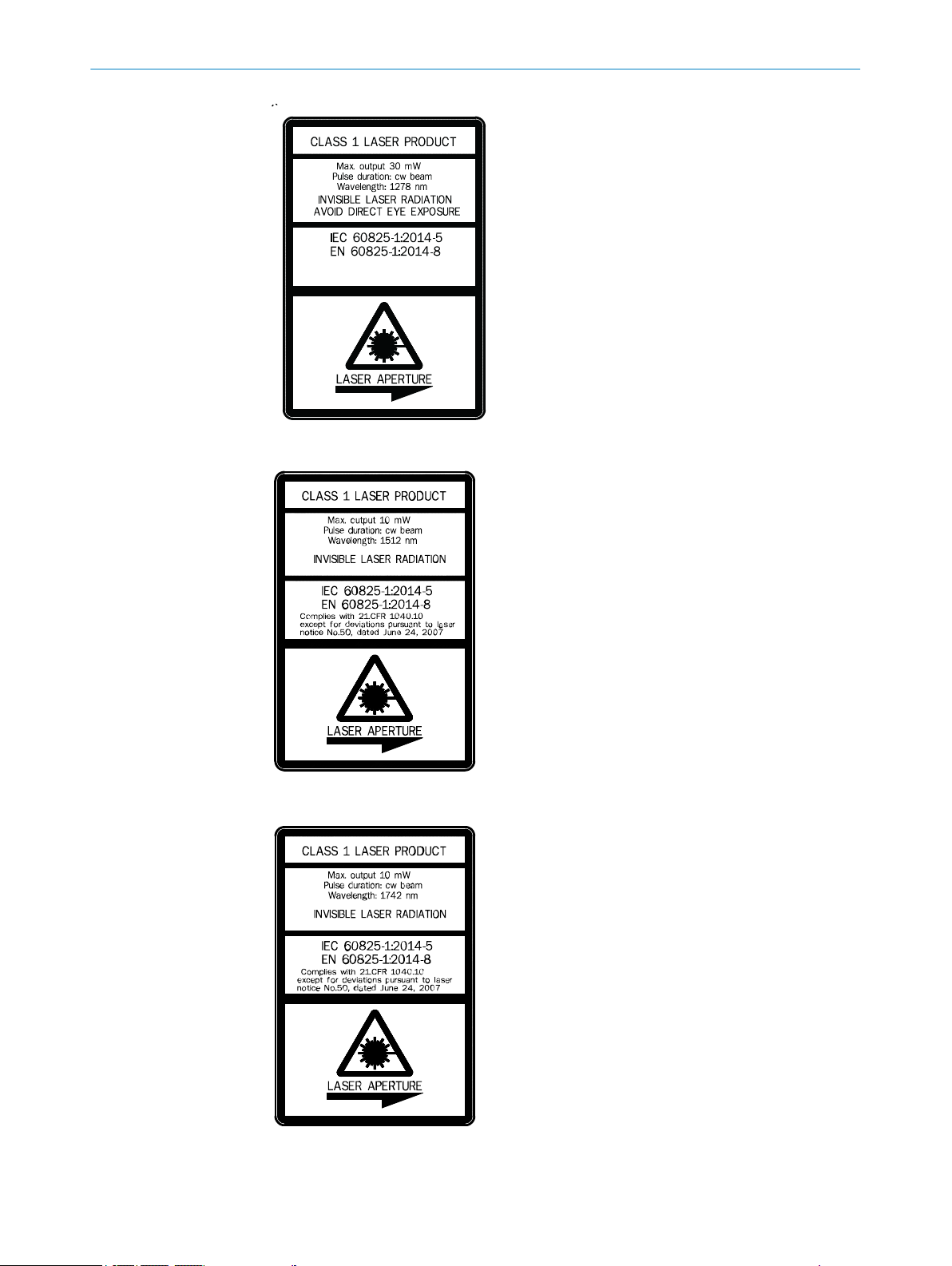

Laser sign

The wavelength of the laser varies for the respective measuring components (NH3, HF,

HCl). The maximum laser output at the optical interface depends on the respective

measuring component and is shown on the laser warning sign.

8022447/0000/2018-01 | SICK OP E RA T IN G I N ST R UC T IO N S | GM700

Subject to change without notice

13

Page 14

2 SAFETY INFORMATION

Figure 2: Laser sign for HF measurement

14

Figure 3: Laser sign for NH3 measurement

Figure 4: Laser sign for HCI measurement

O PE R AT I NG IN S TR U CT I ON S | GM700 8022447/0000/2018-01 | SICK

Subject to change without notice

Page 15

2.3 Intended use

The device serves exclusively for emission and process monitoring of gases in industrial

plants.

The device measures continuously directly in the gas duct (in-situ).

2.4 Responsibility of user

Designated users

see "Target groups (and document structure)", page 7.

Correct project planning

Basis of this Manual is the delivery of the device according to the preceding

•

project planning (e.g., based on the SICK application questionnaire) and the rele‐

vant delivery state of the device (see delivered System Documentation).

w

Contact SICK Customer Service if you are not sure whether the device corre‐

sponds to the state defined during project planning or to the delivered system

documentation.

Special local conditions

SAFETY INFORMATION 2

In addition to the information in these Operating Instructions, follow all local laws, tech‐

nical rules and company-internal operating directives applicable wherever the device is

installed.

Read the Operating Instructions

Read and observe these Operating Instructions.

b

Observe all safety instructions.

b

If anything is not clear: Please contact SICK Customer Service.

b

Document retention

Must be kept for reference.

b

Must be passed on to new owners.

b

8022447/0000/2018-01 | SICK OP E RA T IN G I N ST R UC T IO N S | GM700

Subject to change without notice

15

Page 16

3 PRODUCT DESCRIPTION

3 Product description

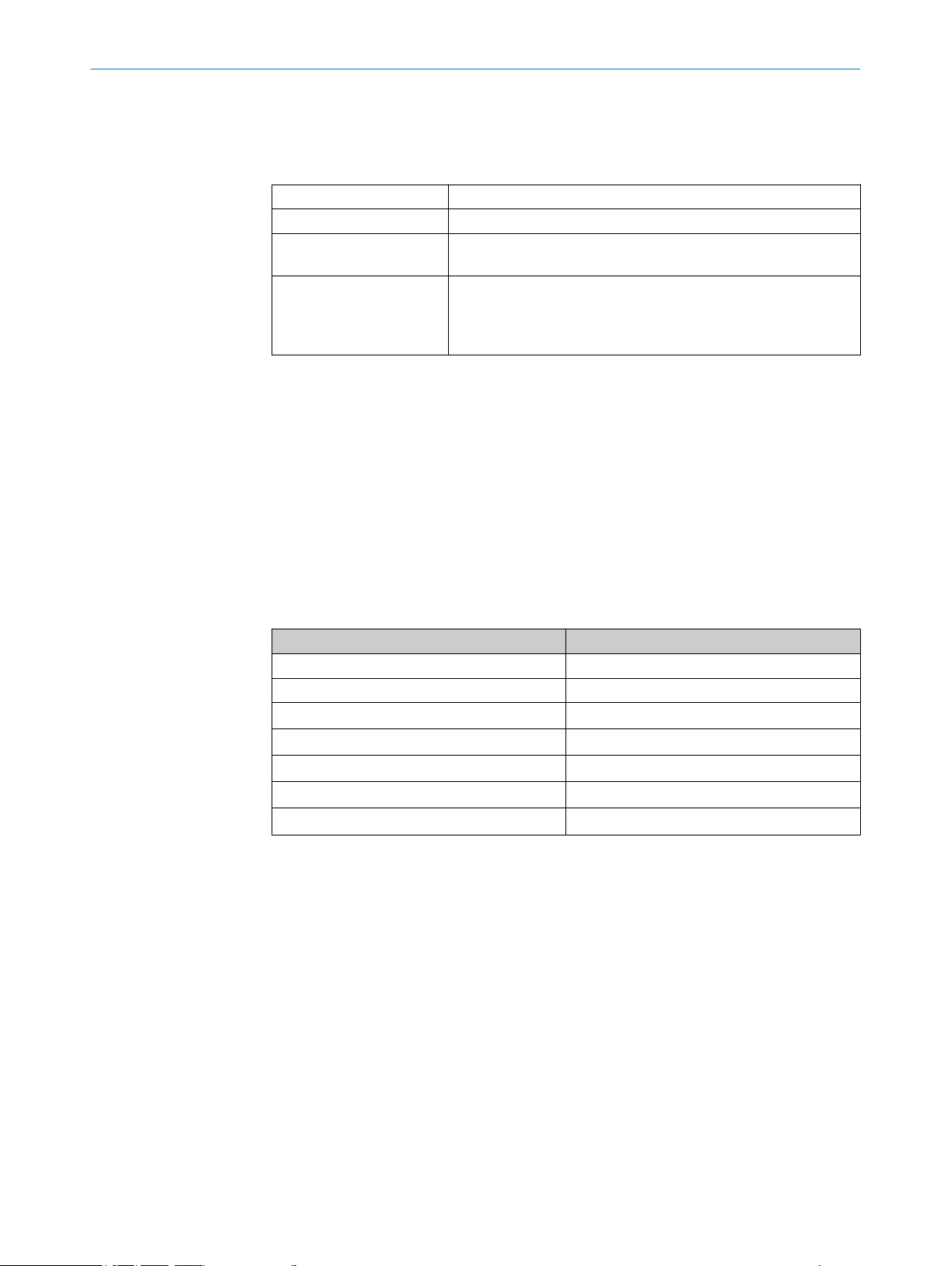

3.1 Product identification

Product name GM700

Device version Measuring Probe Version

Manufacturer SICK AG

Type plates Measuring Probe Version

3.2 Product characteristics

■

The device serves for continuous measurement of gas concentrations in industrial

plants

■

For application with high water ratios, i.e. waste incineration, we offer a specific

version, the GM700-04 or GM700-07.

■

The device is an in-situ measuring system which means measuring is done directly

in the gas carrying duct

■

Measuring components: HF, HCI, NH3, NH3 + H2O, HCI + H2O

■

Measuring principle: Diode laser spectroscopy (TDLS)

Erwin-Sick-Str. 1 · D-79183 Waldkirch · Germany

Sender/receiver unit: On right side

•

On purge air fixture: On tube

•

3.3 Device variants

Variants Measured components

GM700-02 HF

GM700-03 HCI

GM700-04 NH3, high humidity

GM700-05 NH

GM700-07 NH3 / H2O, high humidity

GM700-08 HCI / H2O

GM700-09 NH3 / H2O

3.4 Options

•

•

•

•

3

Terminal box: For CAN bus with 24 V power supply.

The optional terminal box is available for distances between SR-unit and EvU >4

meters via a CAN bus cable provided by the customer.

Cover plate: For the purge air fixture of the SR-unit.

To maintain purge air supply in cases where this must remain in operation at the

measuring point when the SR-unit is dismounted.

Weatherproof cover: Required for installation outdoors

Air heater for purge air supply: For special application conditions to prevent con‐

densate. An air heater is required when the difference between gas temperature

and dew point temperature is too small. The following practical rule of thumb

serves as guideline:

Gas temperature [°C] – dew point temperature [°C] < abs. humidity [Vol.-%].

Values are compared without considering the units of measure.

16

O PE R AT I NG IN S TR U CT I ON S | GM700 8022447/0000/2018-01 | SICK

Subject to change without notice

Page 17

3.5 Layout and function

1

2 3

1

4

5

6

6

PRODUCT DESCRIPTION 3

3.6 Purge air unit

Figure 5: GM700 layout (version representation)

Sender/receiver unit GM700 (SR-unit)

1

Purge air fixture

2

Flange with tube

3

Evaluation unit

4

Purge air unit

5

CAN lines

6

Function

The device serves for continuous measurement of gas concentrations in industrial

•

plants.

The device is an in-situ measuring system which means measuring is done directly

•

in the gas carrying duct.

Measuring components: see "Device variants", page 16.

•

Measuring principle: Diode laser spectroscopy (TDLS) (laser protection class 1).

•

To safeguard measuring reliability, a permanent air flow (optics purge air) keeps

•

the optics free from soot and dust particles.

This protects the front window of the SR-unit and the reflector in the measuring

•

probe against contamination and high gas temperatures

The purge air is blown into the gas duct through the “flange with tube”.

•

Further information on the purge air unit, see Operating Instructions of the purge air

unit.

8022447/0000/2018-01 | SICK OP E RA T IN G I N ST R UC T IO N S | GM700

Subject to change without notice

NOTE

17

Page 18

3 PRODUCT DESCRIPTION

3.7 Check cycle

Cyclic check cycle for zero and sensitivity checks

Start a check cycle via

•

•

Purpose of check cycle

■

Check cycle procedure

The measuring sequence to determine the zero and check point is performed. The digi‐

tal input uses a falling edge for triggering, i.e. performance of a check cycle is sup‐

pressed as long as the signal is high (e.g., for control purposes).

Signaling

“Function control” (relay 3) is signaled per digital output during output of the zero and

check point.

Timer trigger: Configurable 0 ... 1440 minutes (= 1 day), see menu “Settings /

Check Cycle”

External digital input signal (Di 1)

Checking the zero point and span point without feeding span gases.

Output

The output runs for 90 seconds each for the zero point followed by the check point.

Unit and scaling for the current zero point according to the settings.

•

Check or span point is displayed as percentage scaled to 70% of the measuring

•

range.

The same calculation method is used for the deviation as for the gas concentration with

the exception of correction factors which result from a gas adjustment as well as cus‐

tomer correction factors from menu PAR/SETTINGS / REGRESS. FUNCT. During the

check cycle output, the zero and span point are displayed in the lower display line paral‐

lel to the analog output. These can be viewed in menu DIAG/CHECK VALUES/<GAS> for

subsequent checks. Prerequisite is that the output has already been made via an ana‐

log output.

Deviations

A warning message is output, e.g., “AO1 NH3 ZEROPoint” when the zero or check point

deviation is above 2% of the upper display limit of an analog output.

The warning message remains until the next check cycle output is within the tolerance.

3.8 GMP and GPP measuring probes

The measuring probe included in the scope of delivery was defined during project plan‐

ning in accordance with the application requirements.

18

This Table shows an overview of the features of the different measuring probes. All

measuring probe versions are compatible with all SR-units. The SR-unit is calibrated to

the respective probe length before delivery.

Table 3: Measuring probes

Measuring probe GMP (open measuring probe) GPP (for dry gases)

Version Measuring path open in flow

direction; purge air guidance

with outlet aligned 90° to gas

flow

O PE R AT I NG IN S TR U CT I ON S | GM700 8022447/0000/2018-01 | SICK

Gas diffusion probe with

ceramic filter, for dry sample

gas

Subject to change without notice

Page 19

pen Close

2

5

7

6

4

3

1

4

PRODUCT DESCRIPTION 3

Measuring probe GMP (open measuring probe) GPP (for dry gases)

Max. gas temperature 250°C 430°C

Gas test according to EPA reg‐

ulation

Purge air supply required Yes No

Optical interface heating in

measuring probe

Sample gas flow velocity 1 ... 40 m/s < 40 m/s

Suitable for wet sample gas Yes No

Maximum duct pressure ±120 hPa, depending on

Measurable components NH3, HF, HCl NH3, HCl

System response time (T90) > 5 s > 120 s

Duct diameter > 360 mm > 300 mm

Dust concentration < 2 g/m3 in operating state < 30 g/m3 in operating state

Probe lengths available "Dimension drawings, open measuring probe (GMP)",

Active measuring paths avail‐

able [mm]

No Yes

No Yes, with integrated control

±120 hPa

purge air supply

page 84 and "Dimension drawings GPP measuring probe

(Gas Permeable Probe)", page 85.

250/500/750/1000/1250 250/500/750/1000

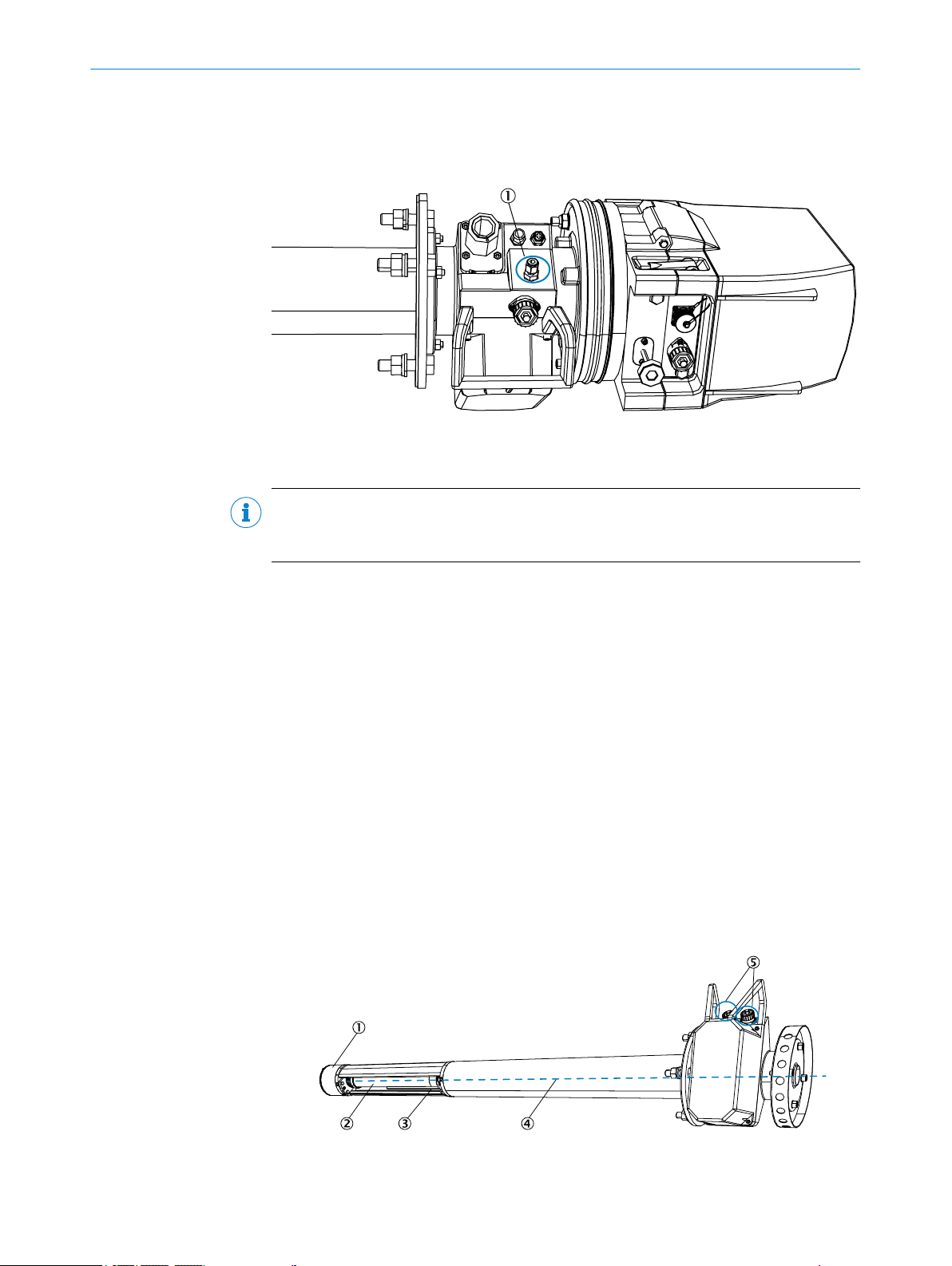

3.8.1 GMP measuring probe in detail

Figure 6: GMP measuring probe description

1

2

3

4

5

6

7

Reflector unit

PT1000 temperature sensor

Purge air outlet: Air outlet in the duct 90° to gas flow direction (directed purge air)

Locking device for opening between measuring probe and SR-unit

Light beam, sender-reflector

Purge air connection

CAN connection

8022447/0000/2018-01 | SICK OP E RA T IN G I N ST R UC T IO N S | GM700

Subject to change without notice

19

Page 20

3 PRODUCT DESCRIPTION

3.8.1.1 Gas connection for sample gas sampling on purge air fixture of GMP measuring probe

For the reference measurement, sample gas can be extracted from the gas duct via a

gas sampling valve on the purge air fixture of the GMP measuring probe.

Figure 7: Gas sampling valve on the GMP measuring probe

Gas sampling screw fitting

1

NOTE

The reference measurement is not part of maintenance tasks carried out by the cus‐

tomer.

3.8.2 GPP gas diffusion probe in dry or wet version

Project planning information: There are two versions of the GMP measuring probe that

differ in the filter used. This supports differing application areas regarding the moisture

content of the sample gas.

Characteristics

Suitable for higher dust contents than the GMP probes.

•

For EPA-conform audit measurement.

•

For applications with low flow velocities or varying flow profiles.

•

Integrated sensors

Temperature sensor PT 1000: Continuously measures the media temperature on

•

the active measuring path of the probe

Pressure sensor

•

The measured data are transferred via the CAN bus interface of the measuring

•

probe and can then be displayed on the evaluation unit.

20

Figure 8: GPP measuring probe description

Reflector unit

1

O PE R AT I NG IN S TR U CT I ON S | GM700 8022447/0000/2018-01 | SICK

Subject to change without notice

Page 21

Ceramic filter (gas permeable)

2

PT1000 temperature sensor

3

Light beam, sender-reflector

4

CAN connection

5

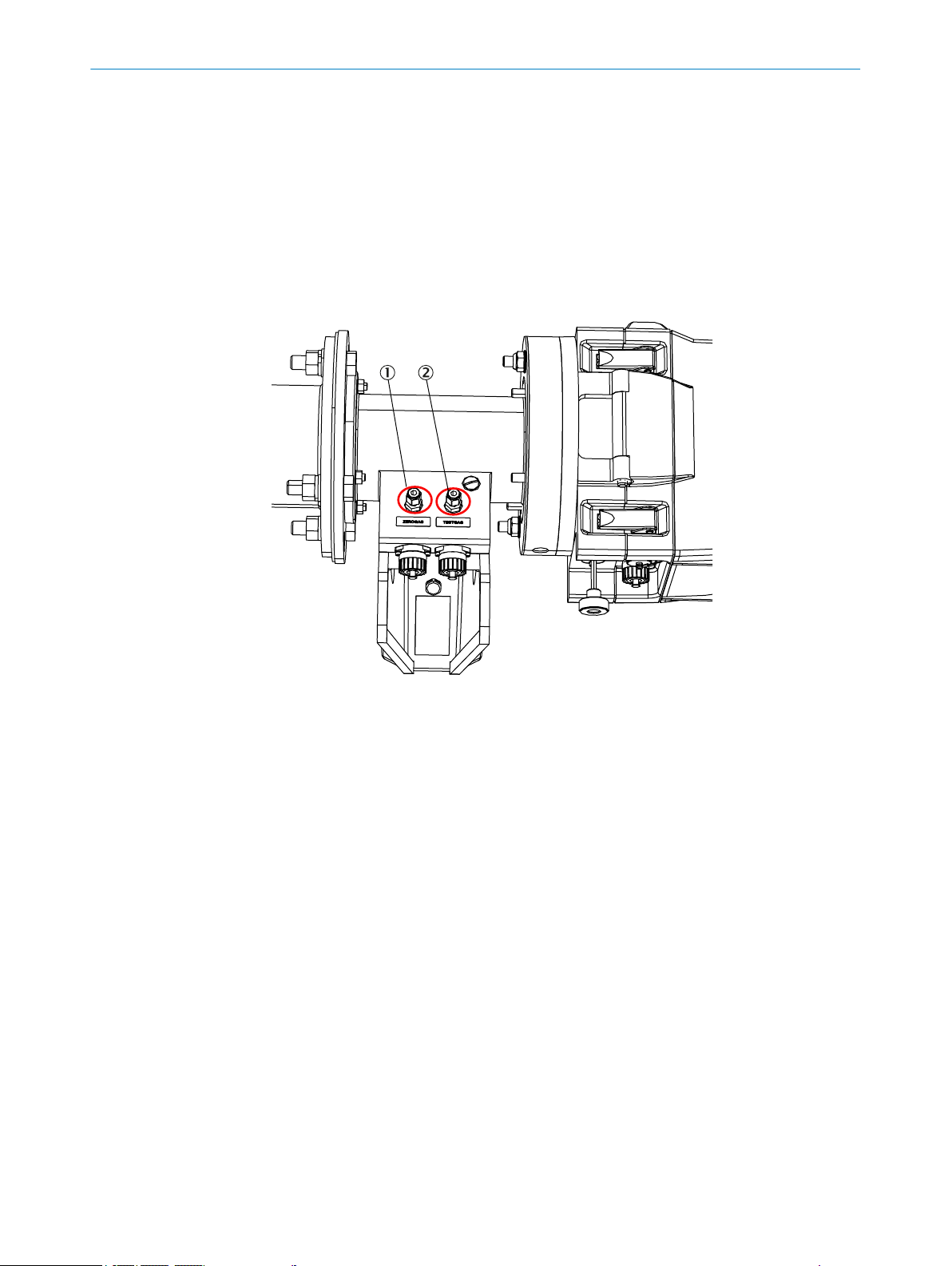

3.8.2.1 GPP measuring probe gas connections for zero and span gas

Two gas inlets are located on the purge air fixture of the GPP measuring probe for the

zero point test.

PRODUCT DESCRIPTION 3

Figure 9: Gas inlets on the measuring probe

Zero gas connection

1

Test gas connection

2

8022447/0000/2018-01 | SICK OP E RA T IN G I N ST R UC T IO N S | GM700

Subject to change without notice

21

Page 22

4 TRANSPORT AND STORAGE

4 Transport and storage

4.1 Transport protection

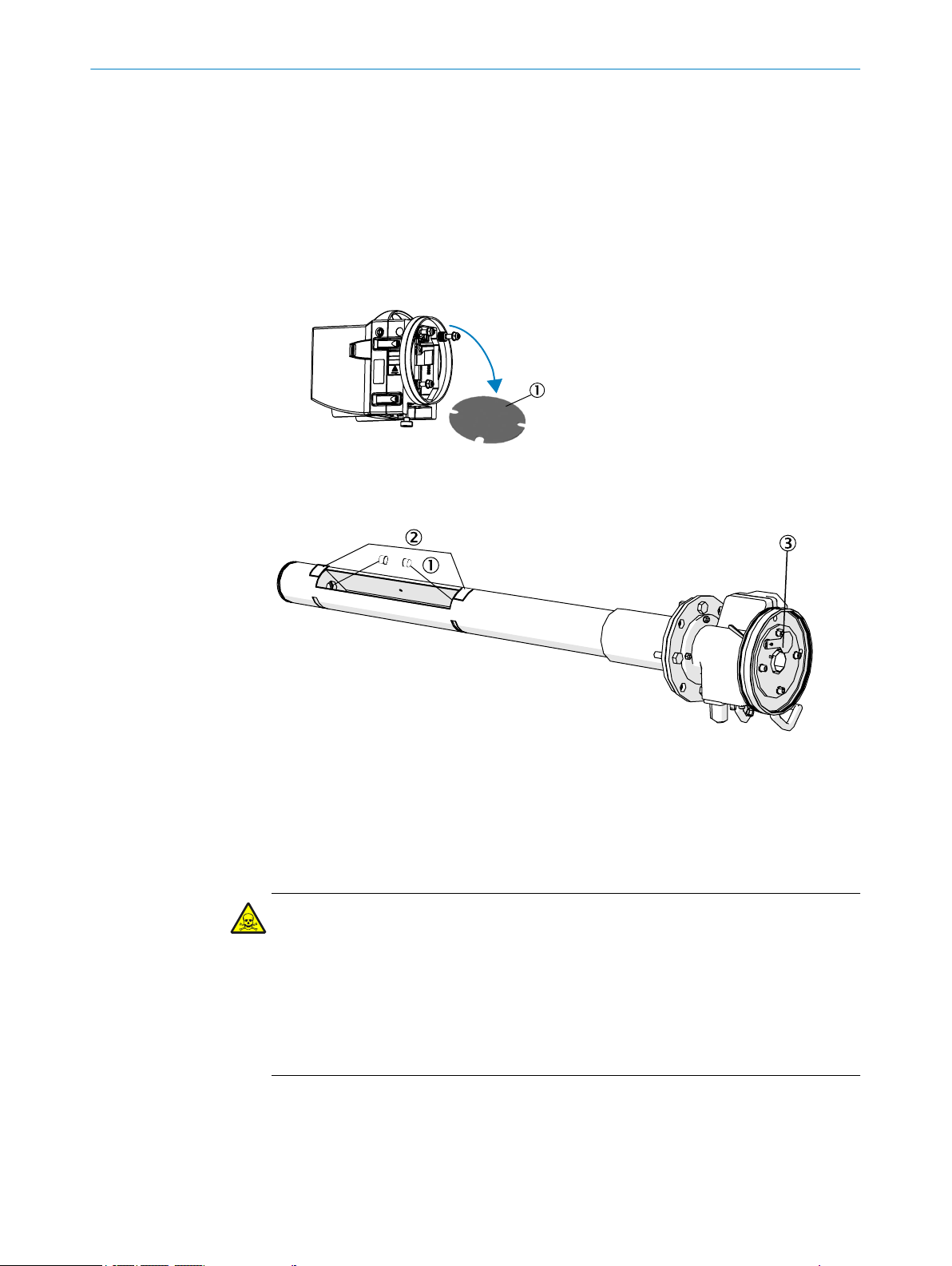

Removing the transport safety device on the SR-unit

1 Open the lock and swivel the flange fixture open.

2 Check the transport safety device for damage.

3 Remove the transport safety devices (see Figure).

4 Store the transport safety device.

Figure 10: Transport safety device on the SR-unit

Remove the front cover of the sender/receiver unit

1

4.2 Storage

Figure 11: Transport safety device on the GMP measuring probe

2 plastic protective caps to cover the optics

1

Remove the protective stickers

2

Set the locking device to the “close” position

3

DANGER

Risk to health through contaminated measuring probe

Depending on the composition of the gas in the measuring channel, the measuring

probe could be contaminated with substances which could result in serious health

damage.

Decontaminate the measuring probe before storage.

b

Wear the specified protective clothing for all work with a contaminated measuring

b

probe.

Clean all components of the measuring system with slightly damp cleaning cloths.

b

Use a mild cleaning agent here.

Protect the openings of the SR-unit and measuring probe from atmospheric influ‐

b

ences, preferably with the original transport safety devices.

22

O PE R AT I NG IN S TR U CT I ON S | GM700 8022447/0000/2018-01 | SICK

Subject to change without notice

Page 23

TRANSPORT AND STORAGE 4

Pack all components for storage or transport. Preferably use the original packing.

b

Store all components of the measuring system in a dry, clean room.

b

8022447/0000/2018-01 | SICK OP E RA T IN G I N ST R UC T IO N S | GM700

Subject to change without notice

23

Page 24

5 MOUNTING

5 Mounting

5.1 Assembly information

Project planning for measuring channel

NOTICE

Observe information in Chapter “Main operating information”.

Correct installation

DANGER

Risk for system safety through work on the device not described in these Operating

Instructions

Carrying out work on the device not described in these Operating Instructions or associ‐

ated documents can lead to unsafe operation of the measuring system and therefore

endanger plant safety.

Only carry out the work on the device described in these Operating Instructions

b

and associated documents.

WARNING

Risk of injury when the device drops down

The weight of the device can cause it to drop down and cause injuries during the work

described in this Chapter.

Carry out assembly work on parts of the device together with another person when

b

necessary.

5.2 Tools required

Tools Part No. Required for

Adjustment device 2034121 Alignment of "flanges with tube"

19 mm jaw wrench Flange screw fitting

Screwdriver Connections

Allen key Connections

5.3 Preparing the measuring point

The operator is responsible for preparing the measuring point

NOTICE

Basis for determining the measuring point:

24

Preceding project planning (e.g., based on the SICK application questionnaire)

•

Final inspection specifications for device

•

Regulations of local authorities

•

Responsibility of the operator:

The operator is responsible for preparing the measuring point

Determination of measuring point (e.g. determining a representative sampling

•

point)

Preparing the measuring point (e.g. load capacity of welded on flange)

•

O PE R AT I NG IN S TR U CT I ON S | GM700 8022447/0000/2018-01 | SICK

Subject to change without notice

Page 25

MOUNTING 5

5.4 GM700 scope of delivery

Check the scope of delivery according to the order confirmation/delivery note.

Ensure the specified supply voltages correspond with the plant conditions.

5.5 Installation sequence

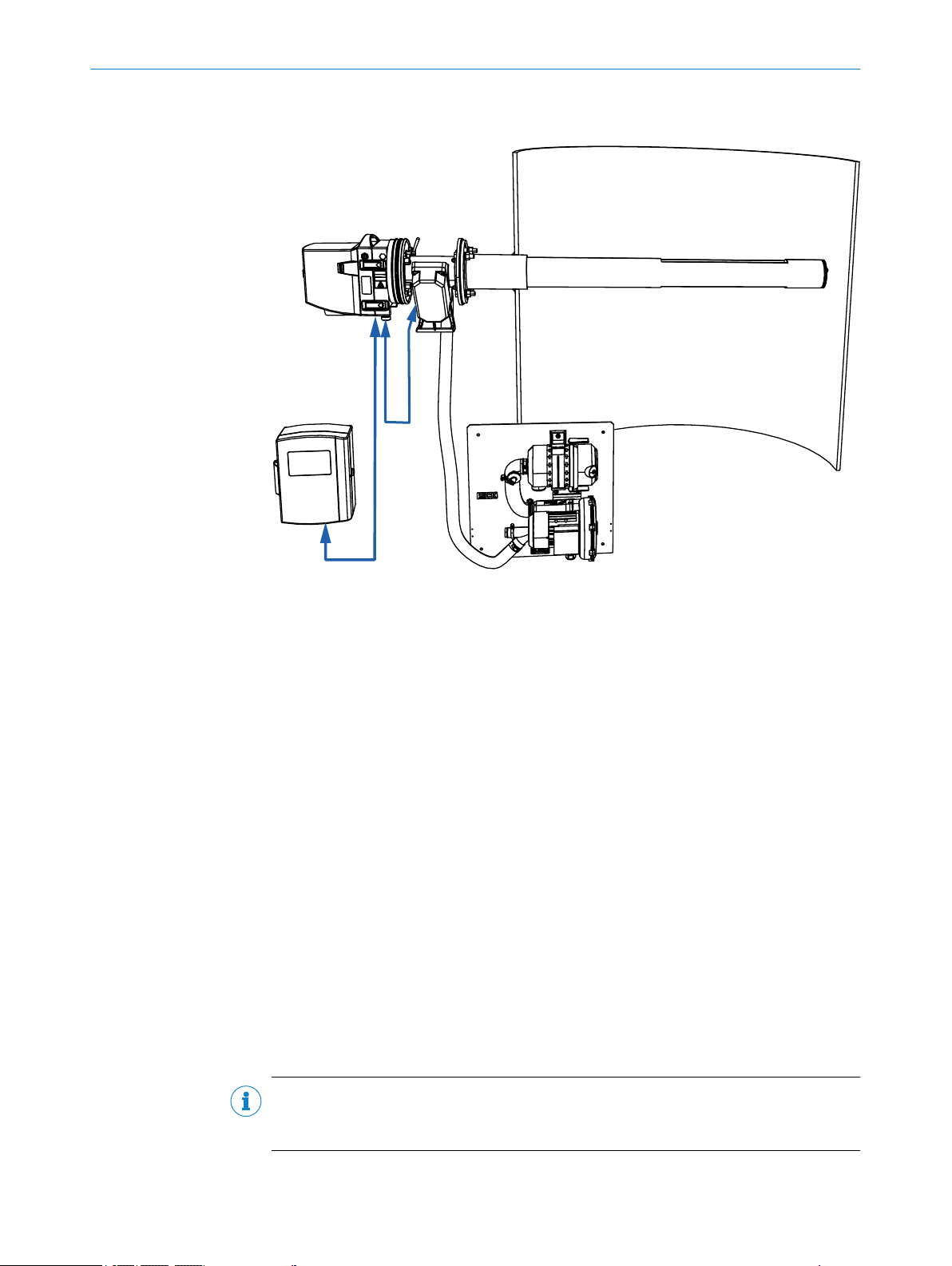

5.5.1 Installation example

Carry out assembly according to the project planning and the Inspection protocol. The dimensions specified in the

drawings are guidelines and can deviate strongly from the project planning.

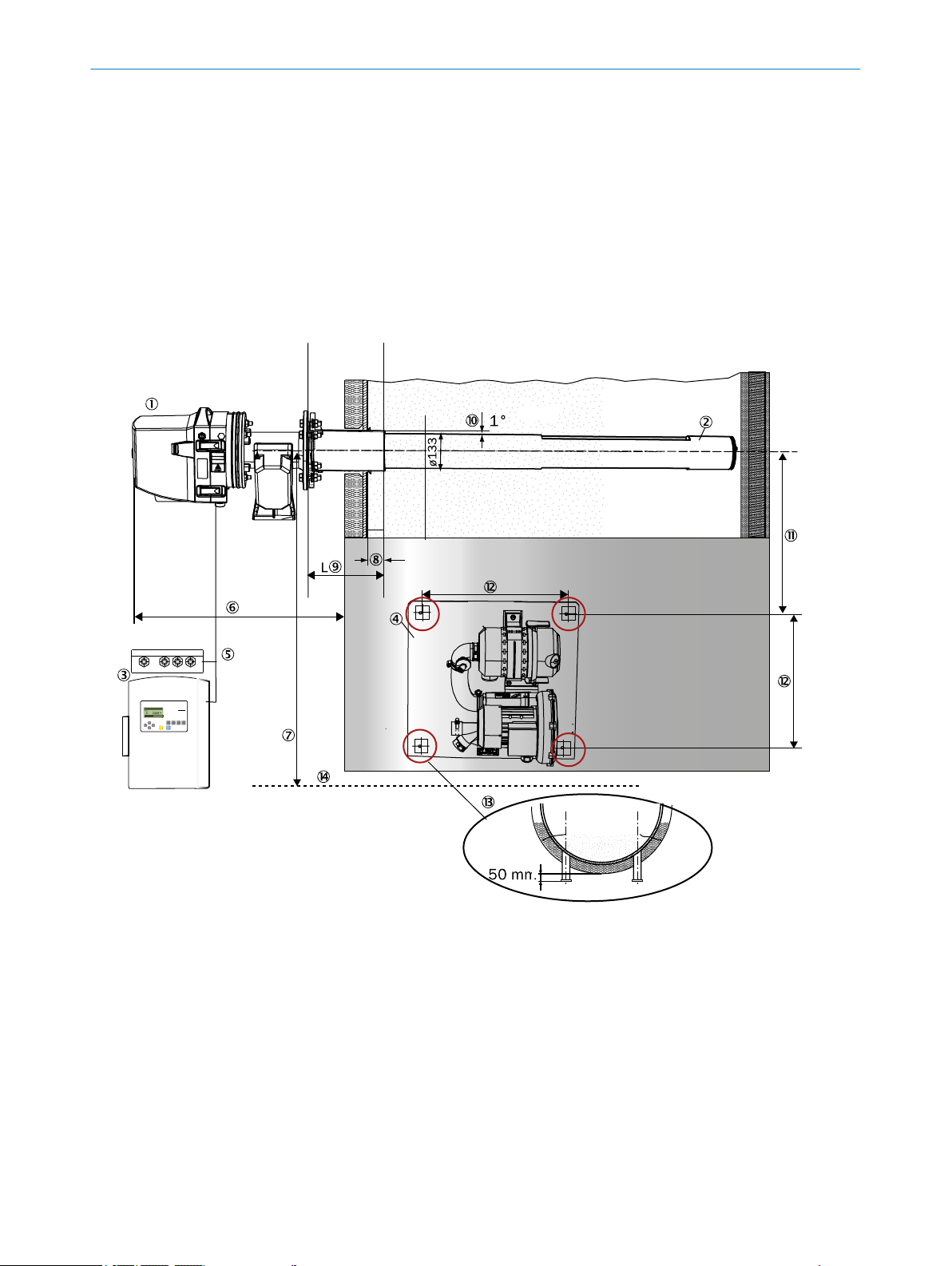

Figure 12: Assembly example, all dimensions in mm

Sender/receiver unit (SR-unit)

1

Measuring probe (GMP version)

2

Evaluation unit (EvU) and optional terminal box

3

Purge air unit

4

Dimensions

Max. distance SR-unit - EvU: 4 m CAN line

5

When using a terminal box, extension up to 1000 m overall length

Duct wall - SR-unit: Depending on flange with tube length

6

a Consider space required for fitting and removing the measuring probe in the duct!

Minimum clearance (center) - working platform: 1300 - 1500 mm

7

Min. flange length in gas duct: 30 mm

8

L = flange with tube length: Standard 240 mm

9

8022447/0000/2018-01 | SICK OP E RA T IN G I N ST R UC T IO N S | GM700

Subject to change without notice

25

Page 26

5 MOUNTING

Angle of flange inclination: Max. 1°

ß

Minimum clearance flange (center) to purge air supply: >700 mm

à

Horizontal and vertical clearance of fastening drill holes - purge air supply assembly plate: 470 mm

á

Purge air unit fastening: 50 mm protrusion for circular duct cross-section

â

Miscellaneous

Working platform

ã

5.5.2 Overview of installation steps (duct-side preparation)

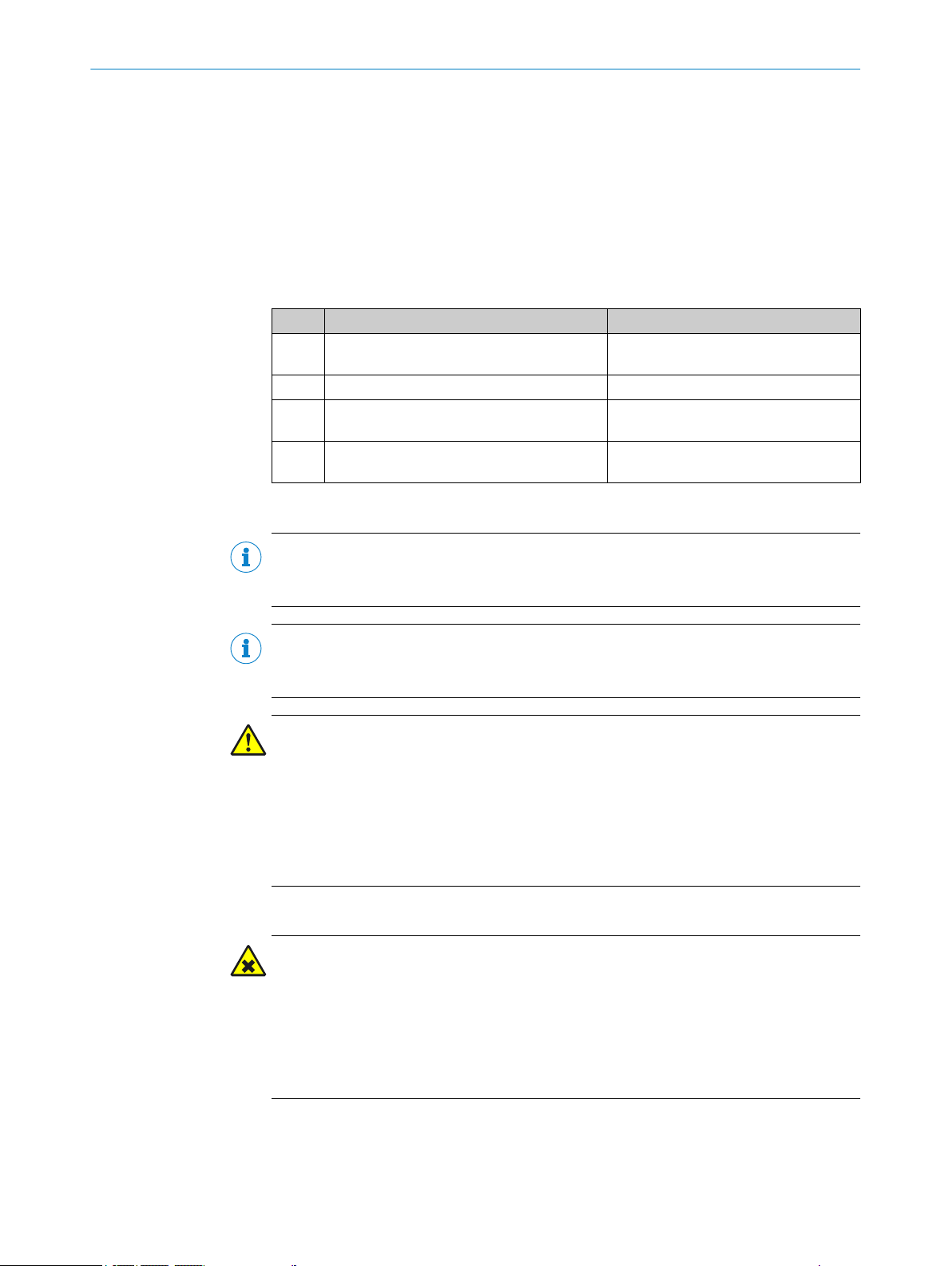

Table 4: Installation steps overview

Step Procedure Reference

1 Fit flange with tube. "Installing the flange with tube",

page 26.

2 Fit control unit. "Installing the control units", page 27.

3 Optional: Fit terminal box. "Installing the terminal box (option)",

page 30.

4 Fit purge air unit or units. "Installing the purge air unit",

page 30.

5.5.3 Installation preparation for the purge air unit

NOTE

Observe the maximum line length between purge air unit and measuring device accord‐

ing to project planning.

NOTE

For information on installing the purge air unit, see the Operating Instructions of the

purge air unit.

CAUTION

Risk of purge air failure when purge air pressure too low

The purge air cannot enter the gas duct when the purge air pressure is too low. This can

lead to a purge air deficit which will cause the device to fail.

Pay attention to the correct purge air pressure during project planning.

b

If you have questions concerning the purge air pressure, contact SICK Customer

b

Service or your local SICK representative.

5.5.4 Installing the flange with tube

DANGER

Hazard through hot, explosive or toxic flue gases

Hot and/or noxious gases can escape during installation work on the gas duct, depend‐

ing on the plant condition.

26

Work on the gas duct may only be performed by skilled persons who, based on

b

their technical training and knowledge as well as knowledge of the relevant regula‐

tions, can assess the tasks given and recognize the hazards involved.

O PE R AT I NG IN S TR U CT I ON S | GM700 8022447/0000/2018-01 | SICK

Subject to change without notice

Page 27

1

200

18

4

5

°

MOUNTING 5

CAUTION

Device damage through incorrect/missing insulation of the duct when the measuring

channel is hot

When the gas duct is hot, insulate the duct and flanges so that the device is pro‐

b

tected from high temperatures.

Installing the flange with tube on the gas duct

1 Cut openings on the gas duct for the flange with tube.

2 Insert the flange with tube. Pay attention to the following:

The "Top" marking must point upwards vertically, irrespective of the gas duct

°

angle.

The tube must project at least 30 mm into the gas duct

°

Figure 13: "Top" marking on flange with tube

1

3 Attach the flange with tube.

NOTE

The measuring probe must not collide with other devices or fittings.

4 Tilt the tube slightly downwards (max. 1°) to allow any condensate to drain off.

5 Now fix the flange with tube properly to the gas duct. Make sure that the alignment

of the flange does not change.

6 If necessary, attach duct insulation to protect the device from heat.

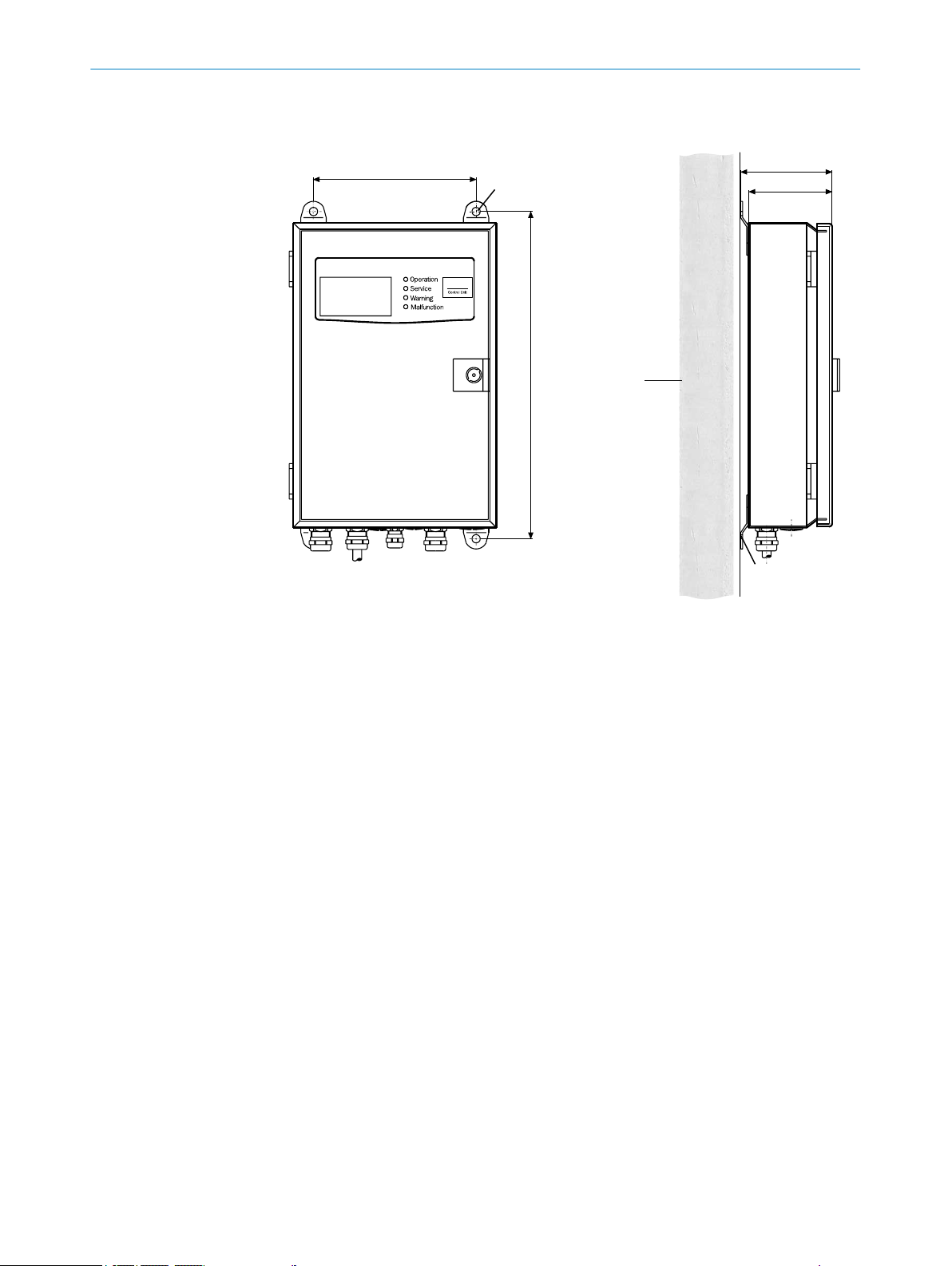

5.5.5 Installing the control units

NOTE

The following criteria must be observed when selecting the installation location of the

control unit:

Good access

•

Sufficient space to open the swivel door of the evaluation unit

•

Protected from weather

•

Even, vertical installation surface

•

Marking “Top”

8022447/0000/2018-01 | SICK OP E RA T IN G I N ST R UC T IO N S | GM700

Subject to change without notice

Dimension drawings, see "Dimension drawing evaluation unit", page 86.

27

Page 28

160

322

90

82

1

2

3

MOUNTING

5

Control unit version with sheet metal enclosure

Figure 14: Fitting the control unit (sheet metal housing version)

4 x mounting holes: ø 7.2 mm

1

Mounting surface

2

Fastening brackets

3

1 Bore the mounting holes according to the drilling plan.

2 Fasten the control unit to the four fastening brackets with M8 screws.

28

O PE R AT I NG IN S TR U CT I ON S | GM700 8022447/0000/2018-01 | SICK

Subject to change without notice

Page 29

Control unit version with cast metal enclosure

117.5

330

235

MOUNTING 5

Figure 15: Fitting the control unit (cast metal version)

1 Bore the mounting holes according to the drilling plan.

2 Fasten the control unit to the three mounting holes with M8 x 20 bolts.

NOTE

The mounting holes are accessible with the swivel door open.

5.5.5.1 Install the control unit away from the SR-unit

NOTE

The total length of the CAN bus connections may be up to 1000 m.

A terminal box with 24 V power supply unit is used to install the control unit at a longer

distance from the SR-unit. This is connected to the SR-unit using the delivered CAN bus

line (4 m).

A suitable customer 6-pole line (twisted pair wires and shielded), suitable for CAN bus

applications, leads to the control unit. The total length of the CAN bus lines, including

the one to the reflector, may be up to 1000 m. When performing maintenance or ser‐

vice, it must be possible to deinstall the control unit temporarily and connect it directly

to the SR-unit at the measuring point.

Further information on laying lines, see "Information on laying lines", page 33.

8022447/0000/2018-01 | SICK OP E RA T IN G I N ST R UC T IO N S | GM700

Subject to change without notice

29

Page 30

1

1

5 MOUNTING

5.5.6 Installing the terminal box (option)

Install the terminal box with 24 V power supply unit in the vicinity of the measuring

•

point.

Fasten the enclosure on both mounting holes.

•

The line length available from the terminal box to the SR-unit is 4 m.

•

NOTE

Take the empty conduits laid for the prefabricated lines during onsite preinstallation

into account.

Figure 16: Mounting fixtures of the terminal box

Mounting holes Ø 5 mm

1

5.5.7 Installing the purge air unit

NOTE

Purge air hose to the device according to project planning.

NOTE

For information on installing the purge air unit, see the Operating Instructions of the

purge air unit.

30

O PE R AT I NG IN S TR U CT I ON S | GM700 8022447/0000/2018-01 | SICK

Subject to change without notice

Page 31

6 Electrical installation

6.1 Electrical installation safety information

Electrical safety

WARNING

Endangerment of electrical safety during installation and maintenance work when the

power supply is not switched off

Before starting the work on the device, ensure the power supply can be switched

b

off using a power disconnector switch/circuit breaker in accordance with DIN EN

61010-1:2010.

Make sure the power disconnector switch is easily accessible.

b

An additional disconnecting device is mandatory when the power disconnector

b

switch cannot be accessed or only with difficulty after installation of the device

connection.

After completion of the work or for test purposes, the power supply may only be

b

activated again by authorized personnel complying with the safety regulations.

WARNING

Endangerment of electrical safety through power cable with incorrect rating

Electrical accidents can occur when the specifications for replacement of a power line

have not been adequately observed.

ELECTRICAL INSTALLATION 6

Always observe the exact specifications in the Operating Instructions (Technical

b

Data Chapter) when replacing a power line.

DANGER

Danger of electrical accidents

Incorrect performance of electrical work could result in serious electrical accidents.

Only let the work described in the following be carried out by electricians familiar

b

with potential hazards.

CAUTION

Risk of device damage

Electronic components are accessible when the enclosure is open. The circuit board

can be severely damaged when a contact is not grounded when the power supply is

switched on.

First switch the power supply on when the sender/receiver unit and the control

b

unit are closed.

NOTICE

Observe connection values for power supply

The evaluation unit is configured to 230 V AC on delivery.

Plug the respective bridges for 115 V AC as shown on the connection plate of the

b

evaluation unit.

8022447/0000/2018-01 | SICK OP E RA T IN G I N ST R UC T IO N S | GM700

Subject to change without notice

31

Page 32

1

2

3

4

1

1

5

5 m

6 7

max. 100 m

3

2

0,8 m

4 m

6 ELECTRICAL INSTALLATION

CAUTION

Device damage through short circuit on the device

The internal electronics can be damaged when signal connections are established and

the power supply is switched on. This is also valid for plug connections.

Disconnect the GM32 Ex and any connected devices from the voltage supply.

b

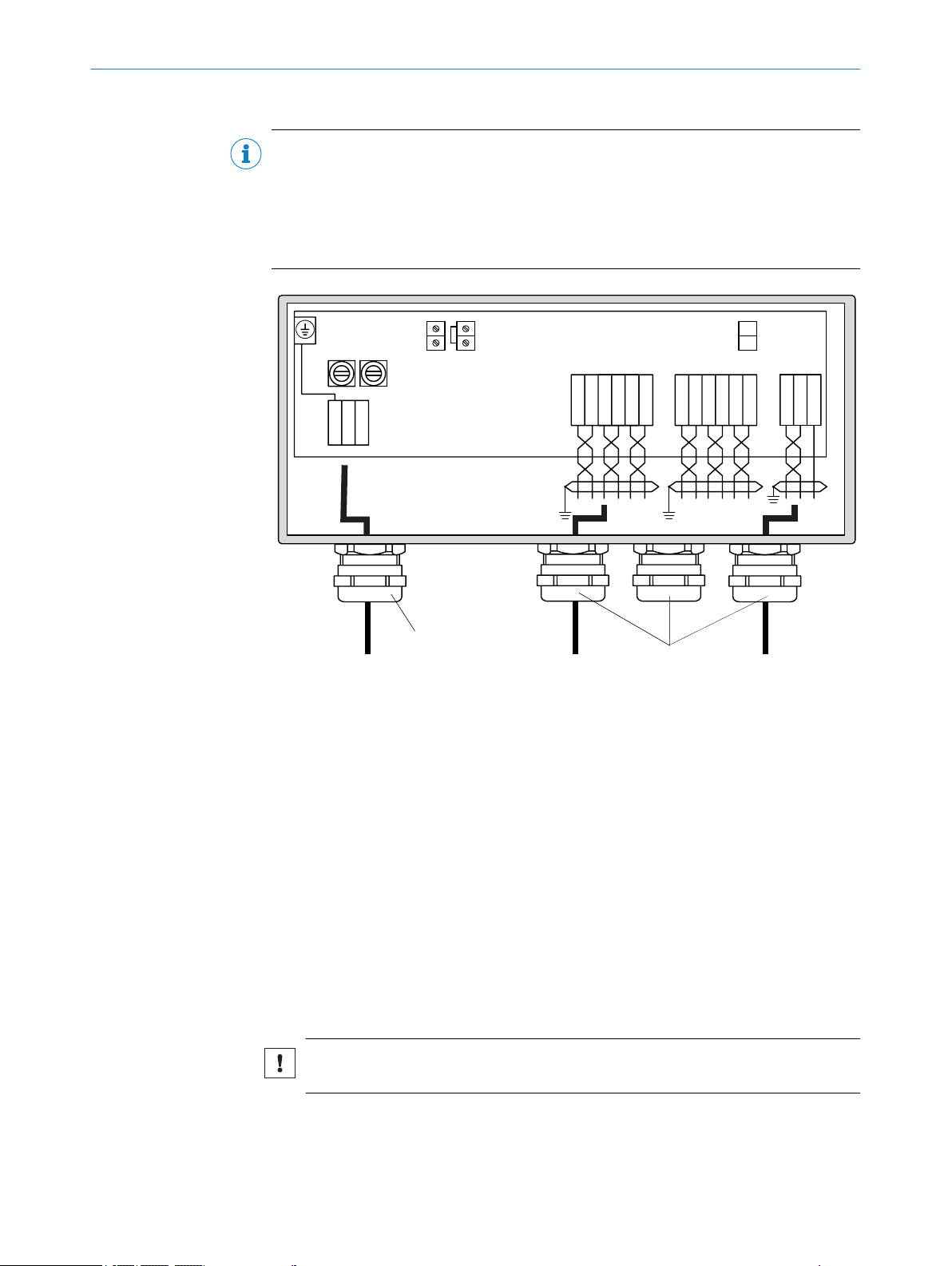

6.2 Connection overview

32

Figure 17: Overview of electrical connections, GM700

Power supply 230 /115 V AC; 50/ 60 Hz

1

•

EvU: 3 x 0.75 mm

•

SLV: 4 x 1.5 mm

•

Terminal box: 4 x 1.5 mm

CAN line standard, in scope of delivery

2

Optional: Can bus line extension:

3

•

EvU - terminal box, ready for connection, 15 m

•

Terminal box - SR-unit (from customer) up to 100 m

Optional: Terminal box:

4

To extend the CAN bus connection (1 x 2 x 0.5 mm2, twisted pair, shielded)

SLV4 filter monitoring (standard for GMP measuring probe):

5

•

2 x 0.6 mm2, on pressure controller with flat pin bushings

•

6.3 x 0.8 mm (DIN 46247) pressure connection

•

2 m and 3 m extensions possible

Inputs (6 x 0.5 mm2):

6

O PE R AT I NG IN S TR U CT I ON S | GM700 8022447/0000/2018-01 | SICK

2

2

2

Subject to change without notice

Page 33

6.2.1 Lines

ELECTRICAL INSTALLATION 6

•

3 x digital inputs

•

2 x analog inputs

Outputs (6 x 0.5 mm2):

7

•

3 x digital outputs

•

3 x analog outputs

Table 5: PG screw fittings

Line opening size Line diameter (clamp‐

ing range)

PG9 4-8 mm 4 Nm SW17(GG9) 1

PG11 5-10 mm 8 Nm SW20(PG11) 1

PG13.5 6-12 mm 10 Nm SW22(PG13.5) 3

Table 6: Technical data, lines

Lines Remark

Power supply From customer: 3 x 1.5 mm

Power supply of control unit From customer: 3 x 1.5 mm

Control unit - sender/receiver unit with

connecting hose

Pressure/temperature input From customer

Service interface From customer, RS232

Inputs/outputs From customer: Terminal connections: 6 x 0.75

Control unit - temperature sensor From customer

Control unit - pressure sensor From customer

Tightening torque Key width Qty.

2

2

In accordance with project planning

5 m

•

10 m

•

2

mm

6.2.2 Information on laying lines

CAN bus

Installation location of the control unit close to the measuring point :

Control unit - SR-unit connection: 4 m CAN bus line (in scope of delivery).

•

No extra installation effort.

•

Fitting the control unit at a distance

Terminal box with a 24 V power supply unit (available from SICK).

•

Terminal box - SR-unit: 4 m CAN bus line (in scope of delivery).

•

Terminal box - control unit: Suitable 6-pole cable for CAN bus applications (pro‐

•

vided by customer).

The total length of the CAN bus connections may be up to 1000 m.

•

When performing maintenance or service, it must be possible to deinstall the con‐

•

trol unit temporarily and connect it directly to the SR-unit at the measuring point.

Laying the cables

Provide adequate cable lengths at the connection points.

•

Do not lay power supply and signal lines immediately next to each other.

•

Protect open ends of preinstalled cables against weather effects until device

•

installation.

8022447/0000/2018-01 | SICK OP E RA T IN G I N ST R UC T IO N S | GM700

Subject to change without notice

33

Page 34

6 ELECTRICAL INSTALLATION

Install separate power supply cables and circuit breakers for:

•

– Purge air units. Additionally install motor circuit breakers and protective

phase failure switches.

– Control unit.

Install easily accessible cable ducts or empty conduits for the prefabricated cables

•

or those delivered with the system, marked with one or two plug-in connectors.

Approx. 2 m cable lengths each should be available at the measuring point for

later maintenance work on the measuring system when dismounted from the duct.

Wire cross-section specifications are recommendations from which cables for ana‐

•

log and digital signals can slightly deviate (not however for the CAN bus connec‐

tions and/or power supply cables).

Start with the system internal connections of the device.

•

Status and signal cables from the control unit to the connection terminals of the

•

customer's status/message devices can be added later as required.

6.3 Connecting I/O interfaces

1 Route the data lines through the M screw fittings.

2 Connect the data line.

NOTE

The analog input assignment shown in the following Chapter is the factory setting and

may not be modified.

6.3.1 Leading the CAN bus line correctly through the PG screw fitting

CAUTION

Risk of injury when touching the cable gland

The temperature on the cable glands can be >60 °C.

Let the device cool down before performing work on the CAN screw fitting.

b

34

O PE R AT I NG IN S TR U CT I ON S | GM700 8022447/0000/2018-01 | SICK

Subject to change without notice

Page 35

ELECTRICAL INSTALLATION 6

Figure 18: CAN bus line fitted correctly (shown on the EvU)

PG screw fitting on the evaluation unit

1

CAN bus line

2

Shielding of CAN cable

3

PG screw fitting fitted in the control unit

4

6.3.2 Wiring the evaluation unit

1. Check that the power supply is switched off.

2. Open enclosure door of evaluation unit.

3. Check that the power supply has been installed in accordance with the project planning (under consideration

of national requirements).

4. Connect protective conductor (PE) to the terminal on the enclosure base.

5. Lead signal lines for inputs and outputs through the PG screw fitting on the housing base of the EvU.

6. Wire the evaluation unit,

7. When using a CAN line provided by the customer, connect the wires to the “Sensor” terminal strip. Do not

connect +24 V and GND (ground).

8022447/0000/2018-01 | SICK OP E RA T IN G I N ST R UC T IO N S | GM700

Subject to change without notice

35

Page 36

+ – + – + –

+ – + – + –

+ – + – + –

PE

N

L1

PE N L1

V

4

2+

T

H

NA

C

L

N

A

C

T

V

4

2+

+ – + – + –

115/230 V AC;

50/60 Hz

(3 x 1.52)

+ – + – + –

1 2

1 2 3

Power

+5V +24V

Power CAN

+24V

+ – H L GND

Digital inAnalog in

0... 20mA

100 100 100

40...60Hz

230V

or

115V

AO1 AO2 AO3DI1 DI2 DI3

AI1 AI2 AI3

Sensor

DO1 DO2 DO3

Digital out

AC/DC 48V 30VA 1A

Analog out

0.. 20mA

Sensor

Fuse 2.5 AT 250V

PE N L1

contrast

T p

Enter meas

diag par cal maint

Operation

Service

Warning

Malfunction

GMA700

Evaluation Unit

PROFIBUS

1

2

3

4

5

6

7

! " §

8

6 ELECTRICAL INSTALLATION

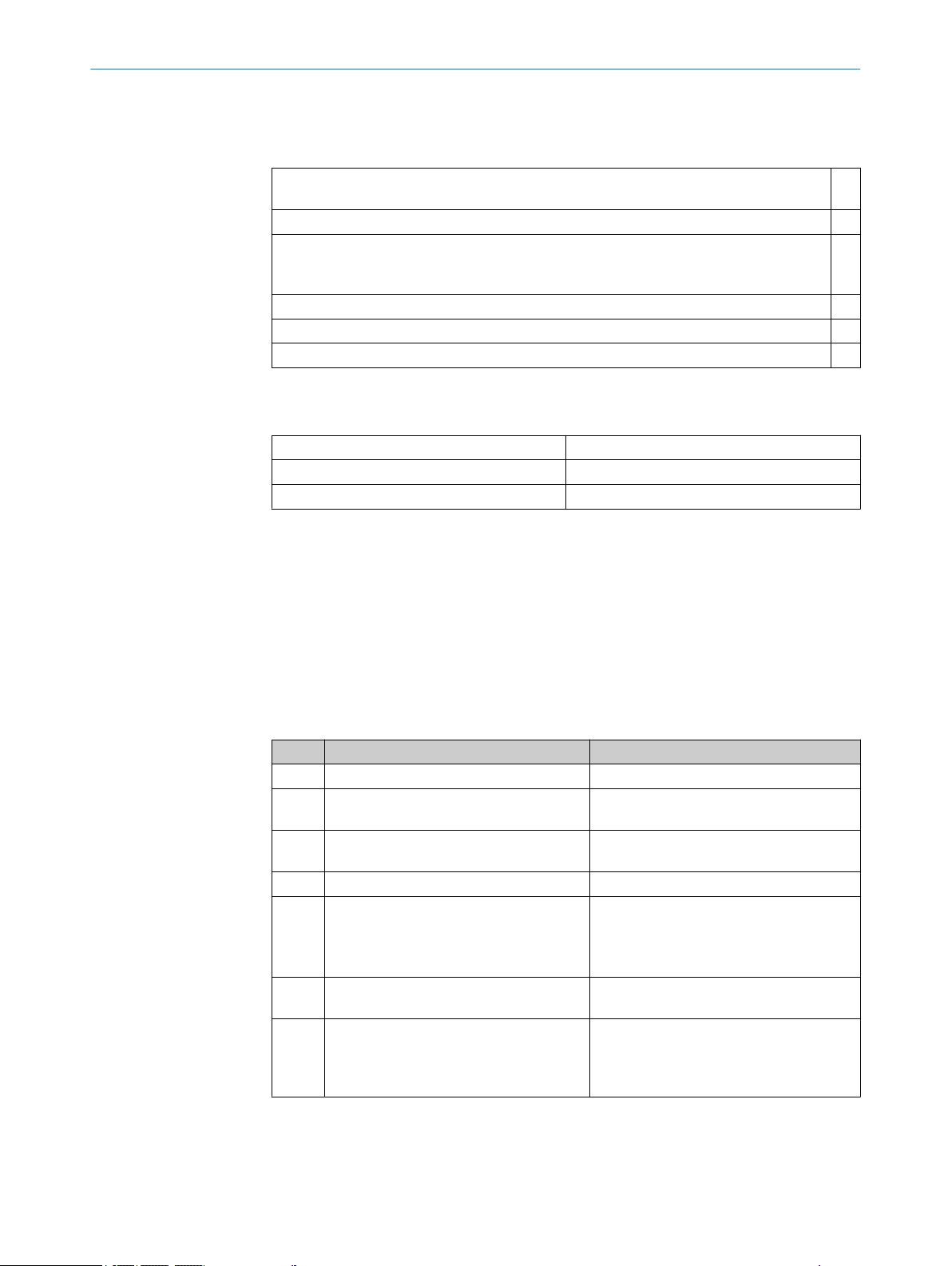

Figure 19: Electrical wiring of evaluation unit GMA700

1

2

3

4

5

6

7

8

Operating elements board

Connections board

Plug this bridge for 115 V or 120 V pow supply

CAN H + L, twisted pair, shielded. Connection for GM700 SR-unit or terminal box

Analog inputs: 0 ... 20 mA (6 x 0.52)

Digital inputs: Potential-free contacts (6 x 0.752)

Analog outputs: 0 ... 20 mA (6 x 0.752)

Digital outputs: 48 V AC/DC; 60 VA, 1 A (6 x 0.752)

! Failure (NC contact)

" Maintenance request (NO contact)

§ Function check (NO contact)

36

O PE R AT I NG IN S TR U CT I ON S | GM700 8022447/0000/2018-01 | SICK

Subject to change without notice

Page 37

6.3.3 Customer wiring of the terminal box (optional)

Fuse 2.5 AT

230/115 V AC

40 … 60 Hz

1

250 V

2

3

2

1

PENL1

6

3

5 4

PG 13.5

PG 13.5

CAN- L

+24

GND

CAN- H

CAN GN D

NC

5

4

3

2

1

6

CAN- L

CAN- H

CAN GN D

3

2

1

CAN- L

+24

GND

CAN- H

CAN GN D

5

4

3

2

1

NC

6

CAN

Terminator

NOTE CAN BUS WIRING PROJECT PLANNING

The following options are available for wiring the CAN bus connection between SR-unit

and control unit:

Standard cable, 4 m, prefabricated.

•

Terminal box with prefabricated 4 m long cable to SR-unit; a customer line is used

•

to connect to the control unit.

ELECTRICAL INSTALLATION 6

Figure 20: Customer wiring for terminal box

Power supply 115 V / 230 V

1

Operating voltage selection: 115 V / 230 V

2

CAN terminator

3

Sensor CAN connection 1*: Prefabricated line to SR-unit with plug, 4 m long

4

Sensor CAN connection 2

5

Evaluation unit CAN connection

6

*

Only one of the two CAN connection terminal strips available is required for the device

Connecting the CAN line to the terminal box

1. Check that the power supply is switched off.

2. Connect bridge (jumper) according to suitable voltage supply (ST2).

3. Lead CAN line for the evaluation unit through the right PG screw fitting to terminal

strip.

4. Connect shielding on the PG screw fitting on the housing.

5. Connect leads, see Figure.

6. Connect the respective signals in the control unit and terminal box.

NOTICE

The CAN-H and CAN-L lines must be twisted pairs.

8022447/0000/2018-01 | SICK OP E RA T IN G I N ST R UC T IO N S | GM700

Subject to change without notice

37

Page 38

6 ELECTRICAL INSTALLATION

Color marking of wiring in the control unit

Wiring Color code

CAN-H Yellow

CAN-L Green

CAN GND Brown

0 ... 20 mA White

GND Black

NOTE

Line length between terminal box and evaluation unit is maximum 1000 m.

Color marking of wiring in the SR-unit

Wiring Color code

+24 V Pink

GND Grey

CAN-H Yellow

CAN-L Green

CAN-GND Brown

6.4 Connecting the SR-unit

Figure 21: Connections on SR-unit

Temperature sensor PT1000

1

Low-pressure monitor SLV (SR side)

2

CAN line connection, control unit to SR-unit (via terminal box when necessary)

3

CAN line connection to control unit (via terminal box when necessary)

4

6.5 Grounding conductor, evaluation unit

38

Connect the grounding conductor on the EvU

1 Lead the potential equalization (4 mm2) of the plant ground with one eyelet over

the bolt.

2 Position and tighten the M6 nut.

O PE R AT I NG IN S TR U CT I ON S | GM700 8022447/0000/2018-01 | SICK

Subject to change without notice

Page 39

1 2

3

ELECTRICAL INSTALLATION 6

Figure 22: Connections for grounding conductors on the two EvU versions

EvU, cast metal version

1

EvU, sheet metal version

2

Connection for grounding conductor

3

8022447/0000/2018-01 | SICK OP E RA T IN G I N ST R UC T IO N S | GM700

Subject to change without notice

39

Page 40

7 COMMISSIONING

7 Commissioning

7.1 Safety information on commissioning

NOTICE

Observe information in Chapter “Main operating information”.

Technical knowledge needed / requirements for commissioning

NOTICE

You have fundamental knowledge of the GM700

•

You are familiar with conditions at the installation location, especially possible haz‐

•

ards through the gases in the gas duct (hot/dangerous to health). You are capable

of recognizing and preventing danger by possibly escaping gases.

If one of these requirements is not met:

Contact SICK Customer Service or your local SICK representative.

b

Laser radiation

WARNING

Eye injuries through laser radiation

The invisible laser beam within the SR-unit is not accessible when fitted. Observe the

following when the SR-unit of the device is swiveled open during installation work for

test purposes and the laser beam is activated:

Never look directly into the laser aperture when opening the SR-unit.

b

Laser protection class 1: Wear laser protection glasses despite low radiation.

b

Observe national valid limit values and standards that refer to these for industrial

b

safety.

Grounding

CAUTION

Device damage through incorrect or missing grounding

It must be ensured during installation and maintenance work that the protective

grounding of the device or lines involved is established in accordance with EN

61010-1:2010.

System safety

NOTICE

Responsibility for system safety

The person setting the system up is responsible for the safety of the system in which

the device is integrated.

7.2 Prerequisites for successful commissioning

Required Operating Instructions:

Operating Instructions, measuring system GM700

•

Operating Instructions, purge air supply

•

40

O PE R AT I NG IN S TR U CT I ON S | GM700 8022447/0000/2018-01 | SICK

Subject to change without notice

Page 41

COMMISSIONING 7

Final inspection protocol

•

Table 7: Prerequisites for successful commissioning

All specifications are met in accordance with the project planning. Inspection based on the

Final inspection protocol carried out.

Electrical installation - completed and checked.

The measuring system is installed and electrically connected.

SR-unit, measuring probe and purge air fixture are first fitted and connected electrically

during commissioning.

Function test (blower rotation direction) of the purge air unit has been carried out.

Sampling point has been checked for free access without hazards.

The optical interfaces of the device have been cleaned.

Technical data of the measuring point (customer's notes)

Table 8: Technical data of the measuring point

Measuring range

Limit values

Inputs and outputs to be used

7.3 Overview of commissioning steps

Commissioning comprises two main steps:

1 Zero adjust on the measuring path free from sample gas.

2 Fitting and zero adjust in measuring duct.

The purge air unit and the SR-unit are put into operation with the measuring probe. The

control unit is then switched on and checked. This can then be configured for the plantspecific requirements.

Table 9: Commissioning steps, Part 1: Before installation in gas duct

Step Procedure Reference

1 Remove the transport safety devices. "Transport protection", page 22.

2 Fit the SR-unit on the measuring probe. "Fitting the SR-unit on the purge air fixture

3 Electrical connection of sender/receiver

unit.

4 Preheat the measuring probe. Approx. 30 minutes.

5 Carry out fine optical adjustment.

6 Carry out zero adjust on the measuring

path free from sample gas.

7 Remove the SR-unit from the measuring

probe

ÉFor this step, disconnect the SR-unit

from the power supply

of the measuring probe", page 43.

"Connecting the SR-unit", page 38.

"Optical fine alignment for device versions

for NH3 and HF measurement", page 43.

"Optical fine alignment on the version for

HCI measurement", page 45.

"Carrying out zero adjust (on the measuring

path free from sample gas)", page 47.

"Removing the SR-unit from the intermedi‐

ate housing", page 66.

8022447/0000/2018-01 | SICK OP E RA T IN G I N ST R UC T IO N S | GM700

Subject to change without notice

41

Page 42

7 COMMISSIONING

Table 10: Commissioning steps, Part 2: On gas duct

Step Procedure Reference

8 When necessary, reposition reflector on

GMP measuring probe

9 Fit the measuring probe on the gas duct. "Fitting the measuring probe on the flange

10 Put the purge air supply into operation. "Putting the purge air unit into operation",

11 Configure I/O connections. "Connecting I/O interfaces", page 34.

12 Connect CAN bus lines on all compo‐

nents.

13 Preheat the measuring probe. Approx. 30 minutes.

14 Carry out fine optical adjustment. "Optical fine alignment for device versions

15 Carry out zero adjust. "Carrying out zero adjust (on the measuring

16 Optional: Fit the weatherproof cover. "Installing the weatherproof cover ",

17 When necessary: Make specific parame‐

ter settings on the control unit for the

measuring point.

18 Starting measuring operation. "Starting measuring operation", page 54.

"Repositioning the probe reflector",

page 48.

with tube", page 51.

page 52 and purge air unit Operating

Instructions.

"Leading the CAN bus line correctly through

the PG screw fitting", page 34.

for NH3 and HF measurement", page 43

and

"Optical fine alignment on the version for

HCI measurement", page 45.

path free from sample gas)", page 47.

page 53.

"Menu tree Parameter", page 59.

7.4 Material required

Not contained in the scope of delivery

Optical adjusting device

•

19 mm open-end wrench

•

Insulated screwdriver set

•

Allen key set

•

Optical cleaning cloth without cleaner

•

Personal protective equipment

•

– Hot surfaces on device

– In accordance with local regulations

7.4.1 Material required - included in scope of delivery

Per purge air fixture: Installation on duct-side flanges with tube:

•

4 screws M16 x 60 with washers

°

4 nuts M16-Cu

°

Per purge air fixture: Installation on SR-unit and reflector:

•

3 self-locking nuts M12

°

3 spherical washers

°

3 x 10 cup springs

°

To seal the connection between SR-unit, reflector and purge air fixture:

•

Rubber sealing ring

°

42

O PE R AT I NG IN S TR U CT I ON S | GM700 8022447/0000/2018-01 | SICK

Subject to change without notice

Page 43

2

1

3

4

6

5

COMMISSIONING 7

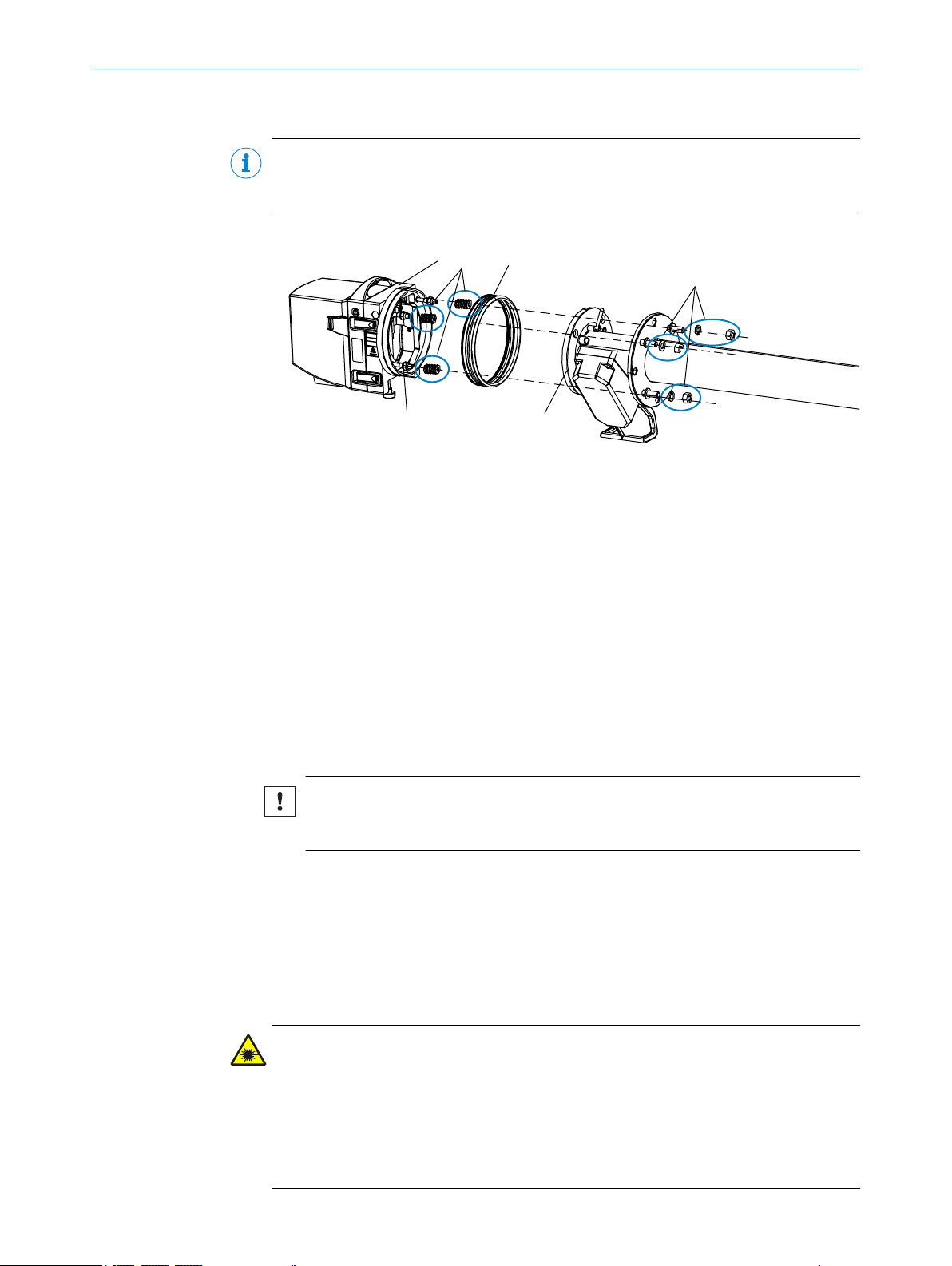

7.5 Fitting the SR-unit on the purge air fixture of the measuring probe

NOTE

The installation procedure is identical for all measuring probe versions. The fixing parts

are supplied with the GM700 measuring system.

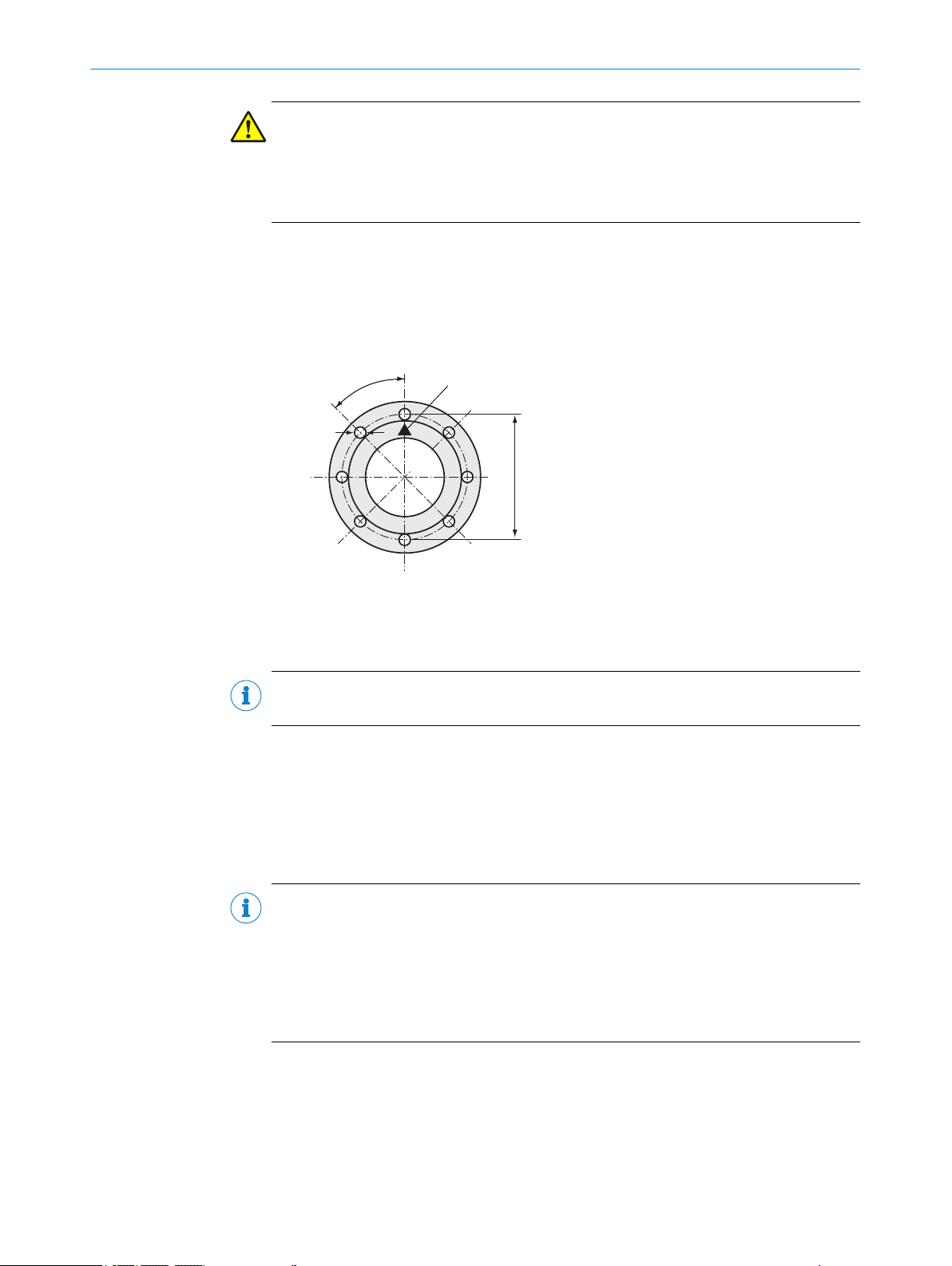

Figure 23: Fitting the purge air fixture on the device flange

Intermediate flange of SR-unit (removable)

1

Cup springs, 10 per fastening

2

Rubber sealing ring

3

Threaded pin of flange fixture

4

Device flange

5

Centering disc and nut

6

Fitting the device flange

1. Put 10 cup springs each, back-to-back, onto the three threaded bolts on the inter‐

mediate housing.

2. Pull the sealing ring over the flange of the measuring probe and hang it loosely

over the purge air unit.

3. Push the device flange onto the measuring probe.

4. Position the centering discs.

NOTICE

Observe the direction of the centering disc: The convex side must fit into the

groove on the purge air fixture.

5. Tighten the self-locking nuts with a wrench (19 mm) so that the cup springs are

slightly compressed and an even gap of approx. 4 mm remains.

Fitting the SR-unit on the intermediate housing

see "Fitting the sender/receiver unit on the intermediate housing", page 52.

7.6 Optical fine alignment for device versions for NH3 and HF measurement

CAUTION

Hazard by laser radiation

Device with a laser with protection class 1.

Do not hold any reflecting objects or objects that bundle the laser beam in the

b

laser beam.

During installation or maintenance: Switch the power supply off before opening

b

the device.

8022447/0000/2018-01 | SICK OP E RA T IN G I N ST R UC T IO N S | GM700

Subject to change without notice

43

Page 44

1

3

4

2

5

6

7

8

1.

2.

1

7 COMMISSIONING

WARNING

Eye injuries through laser radiation

The invisible laser beam within the SR-unit is not accessible when fitted. Observe the

following when the SR-unit of the device is swiveled open during installation work for

test purposes and the laser beam is activated:

Never look directly into the laser aperture when opening the SR-unit or the reflec‐

b

tor.

Laser protection class 1: Wear laser protection glasses despite low radiation.

b

Observe national valid limit values and standards that refer to these for industrial

b

safety.

Description of the alignment tool on the SR-unit

Figure 24: Alignment tool on the SR-unit

Visor of the optical alignment

1

LED display for rough view of optical alignment

2

Target of the alignment tool

3

(Alignment on probe version)

4

Alignment on Cross-Duct version

5

Adjusting screw for X alignment; horizontal

6

Adjusting screw for Y alignment; vertical

7

Alignment tool lever

1

Bring the alignment tool into the adjustment position:

1. Turn lever

2. Pull lever down

44

O PE R AT I NG IN S TR U CT I ON S | GM700 8022447/0000/2018-01 | SICK

Subject to change without notice

Page 45

COMMISSIONING 7

On the control unit:

1. Switch to Maintenance mode

a) Press button “maint”.