Page 1

I

GM700

TDLS Analyzer for NH3, HF or HCI

Version with Measuring Probe

Installation, Operation, Maintenance

MMMOPERATING INSTRUCTIONS

OPERATING INSTRUCTIONS

MMM

Page 2

Document ID

Title: Operating Instructions GM700

Part No.: 8010100/YK22

Release: 2015-12

Described Product

Product name: GM700

Product variant: Measuring probe

Version: V4-0

Manufacturer

SICK AG

Erwin-Sick-Str. 1 · 79183 Waldkirch · Germany

Phone: +49 7641 469-0

Fax: +49 7641 469-1149

E-Mail: info.pa@sick.de

Place of Manufacture

SICK AG

Nimburger Str. 11 · D-79276 Reute · Germany

Original Documents

The English version 8010100/YK22 of this document is an original document from

SICK AG.

SICK AG assumes no liability for the correctness of an unauthorized translation.

In case of doubt, contact SICK AG or your local representative.

Legal Information

Subject to change without notice.

© SICK AG. All rights reserved.

2

8010100/YK22/V4-0/2015-12 | SICKOPERATING INSTRUCTIONS | GM700

Subject to change without notice

Page 3

IMMEDIATE HAZARD

of severe injuries or death

Hazard (general)

Please consult the documentation

Hazard by corrosive substances

Hazard by voltage

Hazard by unhealthy substances

Hazard by toxic substances

Hazard by laser radiation

DANGER

Risk or hazardous situation which will result in severe personal injury or death.

WARNING

Risk or hazardous situation which could result in severe personal injury or death.

CAUTION

Hazard or unsafe practice which could result in personal injury or property damage.

NOTICE

Hazard which could result in property damage.

Information about the use in potentially

explosive atmospheres

Important technical information for this

product

Important information on electric or

electronic functions

Nice to know

Supplementary information

Link to information at another place

8010100/YK22/V4-0/2015-12 | SICK OPERATING INSTRUCTIONS | GM700

Subject to change without notice

3

Page 4

4

8010100/YK22/V4-0/2015-12 | SICKOPERATING INSTRUCTIONS | GM700

Subject to change without notice

Page 5

CONTENTS

1 Safety Information................................................................................... 10

1.1 Main hazards.................................................................................................10

1.1.1 Electrical safety.............................................................................10

1.1.2 Grounding the device ...................................................................10

1.1.3 Protection against hazards through gases .................................11

1.1.4 Protection against laser radiation................................................12

1.1.5 Behavior during purge air failure .................................................14

1.2 Intended use .................................................................................................14

1.2.1 Purpose of the device ...................................................................14

1.3 Responsibility of user....................................................................................14

1.3.1 Disposing of device parts harmful to the environment ..............15

2 Product Overview .....................................................................................16

2.1 Product identification ...................................................................................16

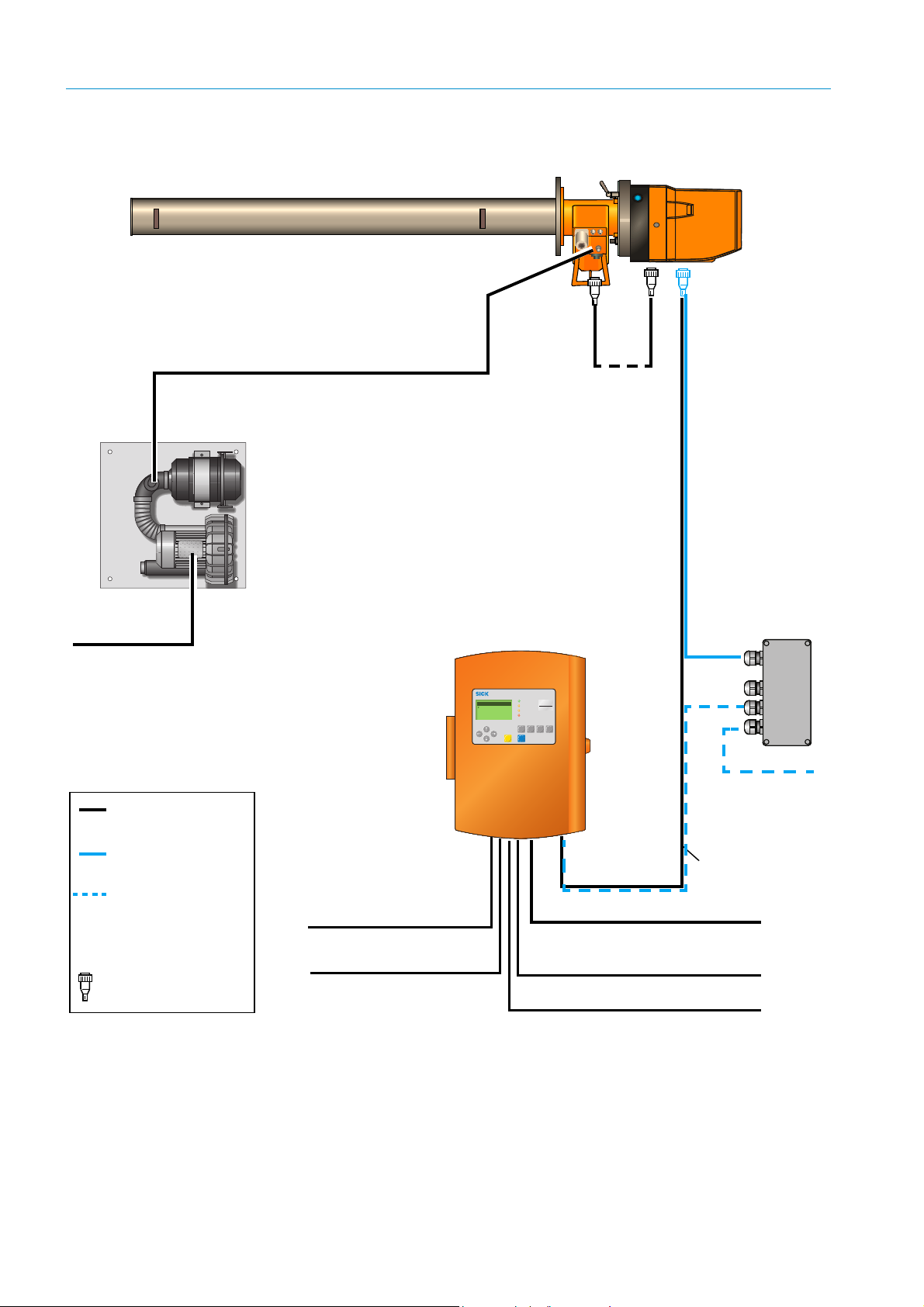

2.2 GM700 system, measuring probe version, layout .......................................17

2.2.1 Measuring probe in detail ............................................................19

2.2.1.1 GMP probe with open measuring gap ......................20

2.2.1.2 GPP gas diffusion probe in dry or wet version .........21

2.2.1.3 GM700 measuring probes in comparison ...............22

2.2.1.4 Special versions ........................................................22

2.3 GM700 options and accessories .................................................................22

2.4 Measuring principle ......................................................................................23

2.4.1 Reference cuvette for wavelength stabilization ..........................23

2.4.2 Signal evaluation ..........................................................................23

3 Project Planning Information................................................................. 24

3.1 Work steps from system selection to start-up .............................................24

3.2 Project Planning Checklist ............................................................................24

3.3 Initial onsite installation ...............................................................................27

3.3.1 Installation preparation at the sampling point ............................27

3.3.2 Uncovering the duct......................................................................28

3.3.3 Installing the flanges with tube ....................................................28

3.3.3.1 Installing the flange with tube ..................................29

3.3.4 Installation preparation for the purge air unit (for GMP probe)..30

3.3.5 Duct insulation..............................................................................30

3.3.6 Installation preparation for the evaluation unit ..........................30

3.4 Preparations for electrical installation .........................................................31

3.4.1 Signal and power supply cables...................................................31

3.4.2 CAN bus wiring ..............................................................................33

4 Installation ................................................................................................ 34

4.1 Preparations ..................................................................................................34

4.1.1 Checking the scope of delivery ....................................................34

4.1.2 Installation prerequisites..............................................................34

8010100/YK22/V4-0/2015-12 | SICK OPERATING INSTRUCTIONS | GM700

Subject to change without notice

5

Page 6

CONTENTS

4.2 Fitting system components .......................................................................... 35

4.2.1 Information on the SR-unit and measuring probe ...................... 35

4.3 Installing the purge air units (for GMP probe) ............................................. 35

4.3.1 Terminal box with 24 V power supply unit (option)..................... 35

4.4 Installing the evaluation unit........................................................................ 36

4.4.1 Installing the evaluation unit – sheet metal enclosure version . 36

4.4.2 Installing the evaluation unit – cast-metal enclosure version ... 37

4.5 Electrical connection of system components.............................................. 38

4.5.1 CAN bus wiring options ................................................................ 38

4.5.2 Electrical connection in the evaluation unit EvU ........................ 40

5 Handling the Evaluation Unit .................................................................42

5.1 User qualifications ........................................................................................ 42

5.2 Operating elements ...................................................................................... 42

5.2.1 Menu overview ............................................................................. 43

6 Start-up...................................................................................................... 46

6.1 Preparations ................................................................................................. 46

6.1.1 Required qualifications and further prerequisites...................... 46

6.2 Start-up steps overview ................................................................................ 46

6.3 Mechanical preparation .............................................................................. 47

6.3.1 Checking the scope of delivery .................................................... 47

6.3.1.1 Transport safety devices .......................................... 47

6.3.2 Fitting the SR-unit on the measuring probe ................................ 48

6.3.3 Electrical connections on the sender/receiver unit.................... 49

6.3.4 Optical alignment ......................................................................... 50

6.3.4.1 Optical alignment for device version for NH3 and

HF measurement ...................................................... 50

6.3.4.2 Optical alignment of device version for HCl

measurement .......................................................... 51

6.3.5 Zero adjust.................................................................................... 52

6.3.5.1 Types of zero point checks ....................................... 52

6.3.6 Fitting the weatherproof cover for the SR-unit............................ 54

6.3.7 Evaluation unit start-up................................................................ 56

6.3.8 Operating states ........................................................................... 57

6.3.8.1 Gas connections on the GPP measuring probe for

zero gas and/or test gas .......................................... 57

6.3.9 Starting operating mode .............................................................. 58

7 Maintenance............................................................................................. 60

7.1 Maintenance intervals.................................................................................. 60

7.1.1 Maintenance protocol .................................................................. 60

7.2 Preparation and general preparatory work ................................................. 60

7.3 Maintenance work on SR-unit ...................................................................... 61

7.3.1 Visual inspection and enclosure cleaning................................... 61

7.3.2 Cleaning the front window on the SR-unit .................................. 61

7.4 Evaluation unit (EvU) .................................................................................... 62

6

8010100/YK22/V4-0/2015-12 | SICKOPERATING INSTRUCTIONS | GM700

Subject to change without notice

Page 7

CONTENTS

7.5 Controlling and tracking the laser working point during measurement .....63

7.5.0.1 Selecting the ambient temperature range ..............63

7.5.1 Filter box measurement to check the measuring channels for

NH

, HF or HCl ..............................................................................63

3

7.5.2 Determining the necessary test gas concentration ....................65

7.5.3 Installing the filter box ..................................................................65

7.5.4 Carry out filter box measurement ................................................66

7.6 Checking the gas analyzer with test cell GMK10 ........................................68

7.6.1 Installation of the GM700 components with the test cell

GMK10 ..........................................................................................69

7.6.2 Carrying out measurement...........................................................70

8 Troubleshooting and Clearing Malfunctions........................................73

8.1 Malfunction categories/possible effects .....................................................73

8.2 Purge air failure.............................................................................................73

8.3 Integrated monitoring and diagnosis system ..............................................73

8.3.1 Display and retrieval of messages on the evaluation unit..........74

8.3.2 Troubleshooting and clearing malfunctions, evaluation unit .....75

8.3.3 Error messages .............................................................................76

8.3.4 Warning messages .......................................................................78

8.3.5 Further tips on troubleshooting ...................................................79

9 Technical Data, Expendable and Spare Parts ..................................... 80

9.1 Technical data GM700 probe system ..........................................................80

9.2 Dimension drawing .......................................................................................85

9.2.1 Dimension drawing sender/receiver unit GM700 (dimensions

in mm) ...........................................................................................85

9.2.2 Dimensions of open measuring probe - GMP ..............................86

9.2.3 Dimensions of GPP measuring probes ........................................87

9.2.4 Dimension drawing evaluation unit GM700: Sheet steel

enclosure (dimensions in mm).....................................................88

9.2.5 Dimension drawing evaluation unit GM700: Cast metal

enclosure (dimensions in mm).....................................................88

9.2.6 Connection unit GM700 (Can bus option) (dimensions in mm) .88

9.2.7 Dimensions of weatherproof cover for GM700 SR-unit .............89

9.2.8 Dimension drawings of flange with tube ....................................89

9.3 Accessories, expendable and spare parts ...................................................90

9.3.1 Consumable parts for 2-years operation .....................................90

9.3.2 Spare parts for the sender/receiver unit.....................................90

9.3.3 Spare parts for the measuring probe ..........................................90

9.3.4 Spare parts for the evaluation unit ..............................................92

9.3.5 Fixing accessories.........................................................................92

9.3.6 Spare parts assignment for sender/receiver unit .......................93

10 Annex ......................................................................................................... 97

10.1 User information “Laser safety” ...................................................................97

10.2 Positioning the probe reflector when the probe must be realigned ...........99

8010100/YK22/V4-0/2015-12 | SICK OPERATING INSTRUCTIONS | GM700

Subject to change without notice

7

Page 8

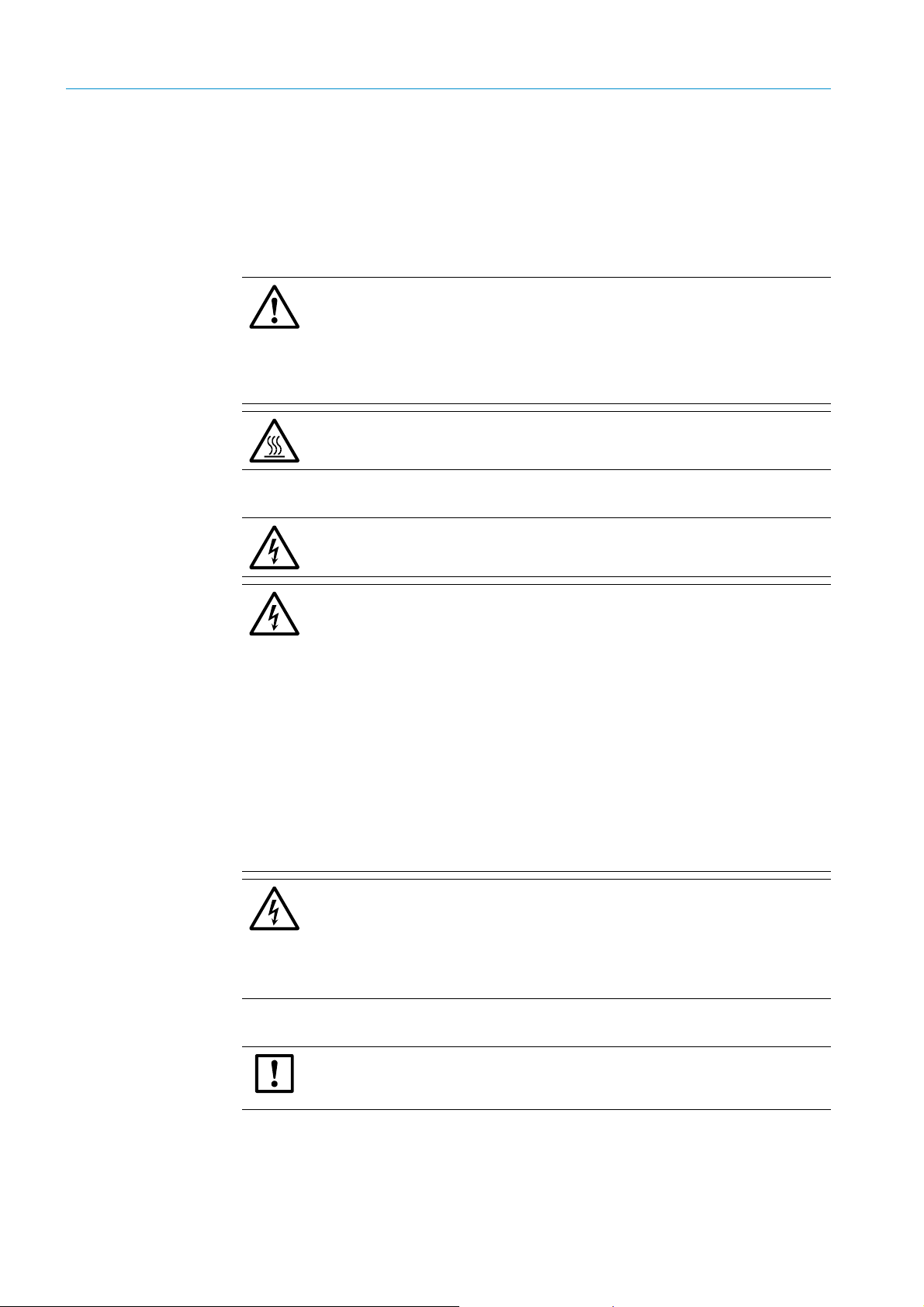

1 SAFETY INFORMATION

1 Safety Information

1.1 Main hazards

Important safety information in short form.

Operational safety

DANGER: Hazards through defective device

The GM700 is likely to be unsafe when it:

● Has been penetrated by moisture.

● Has been stored or operated under irregular conditions.

When safe operation is no longer possible:

▸ Put the GM700 out of operation, separate all connections from the power supply

WARNING: Hot surfaces when enclosure open

Pay attention to hot surfaces on the measuring cell when opening the GM700

enclosure.

1.1.1 Electrical safety

and secure against unauthorized start-up.

WARNING: Hazard by voltage

▸ Pay careful attention to power supply connections.

▸ Do not interrupt protective conductor connections.

WARNING: Endangerment of electrical safety by not switching the power

supply off during installation and maintenance work.

An electrical accident can occur when the power supply to the equipment or

the lines is not switched off using a power isolating switch/circuit breaker for

installation and maintenance work.

▸ Before starting work on the equipment, ensure the power supply can be

switched off using a power isolating switch/circuit breaker in accordance

with DIN EN 61010.

▸ Make sure the power isolating switch is easily accessible.

▸ An additional disconnecting device is mandatory when the power isolating

switch is difficult to access or cannot be accessed when connecting the

equipment after installation.

▸ After completion of the work or for test purposes, the power supply may

only be activated again by authorized personnel complying with the safety

regulations.

WARNING: Endangerment of electrical safety through power cable with

incorrect rating

When a removable power cable is used, electrical accidents can occur when

the specifications are not fully observed.

▸ Always observe the exact specifications in the Operating Instructions

(Technical Data Section) when replacing a removable power cable.

1.1.2 Grounding the device

10

CAUTION: Equipment damage through erroneous or missing grounding

Ensure the protective grounding of the equipment and/or lines involved during

installation and maintenance work in accordance with EN 61010-1.

8010100/YK22/V4-0/2015-12 | SICKOPERATING INSTRUCTIONS | GM700

Subject to change without notice

Page 9

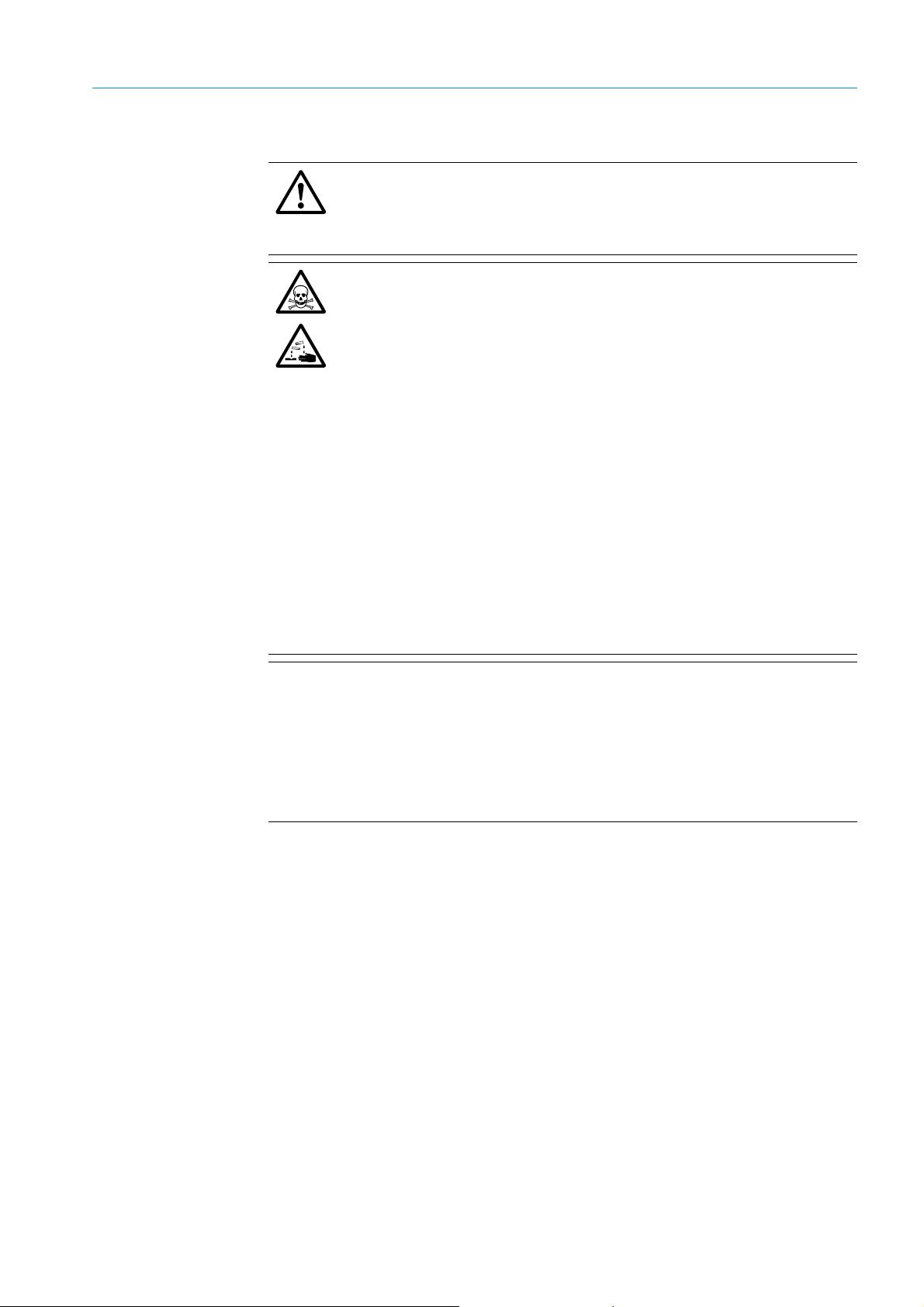

1.1.3 Protection against hazards through gases

WARNING: Hot and/or aggressive sample gases

▸ Wear suitable protective clothing and mask when using hot and/or aggressive

sample gases and/or with high dust loads.

▸ Never open the enclosure or switch off the purge air feed without taking appropriate

protective measures when the duct is pressurized.

WARNING: Toxic and caustic substances in parts in contact with sample gas

● Depending on the sample gas composition, parts of the GM700 in contact with

sample gas can contain toxic or caustic substances.

● When fitted in the measuring device, the reference cuvette contains the respective

gases to be measured. These gases must not escape.

Special care must be taken with the GME700-2 (HF) because this cell not only

contains gaseous HF but also a certain amount of liquid (max. 0.1 g HF for 8 cm

cell). HF / hydrofluoric acid is extremely toxic and caustic. It is imperative to avoid

inhaling or skin contact at all times. Particularly when there are indications of leaks

or defects, wear protective clothing (protective goggles, latex gloves) and carry out

work in a well ventilated room/area. Never open the cuvette under any circumstances. Check replacement cuvettes for any possible transport damage.

● Handle with care when test gases are used:

▸ When handling HF, keep an HF emergency set (including calcium gluconate gel)

available.

▸ Before working on the gas path, ask the operator which gases have been applied to

the GM700.

▸ Ask the operator whether, and how, the gas path of the GM700 has been cleaned.

▸ If necessary, clean the gas path with a suitable method.

▸ In case of doubt, take appropriate protective measures before working on the gas

path: Ensure adequate ventilation at the workplace or work under a vent. Wear

protective goggles or a safety mask, protective gloves and acid-proof protective

clothes.

SAFETY INFORMATION 1

WARNING: Risk of fire through hot gas escaping in installations with

overpressure conditions

On installations with overpressure, the purge air hose can be severely

damaged by escaping hot gas and can catch fire depending on the

temperature.

On plants with overpressure as well as gas temperatures over 200°C:

▸ Ensure reverse flow is prevented by fitting a (trip) flap or a valve.

▸ Regularly check the functionality of the reverse flow safeguard.

8010100/YK22/V4-0/2015-12 | SICK OPERATING INSTRUCTIONS | GM700

Subject to change without notice

11

Page 10

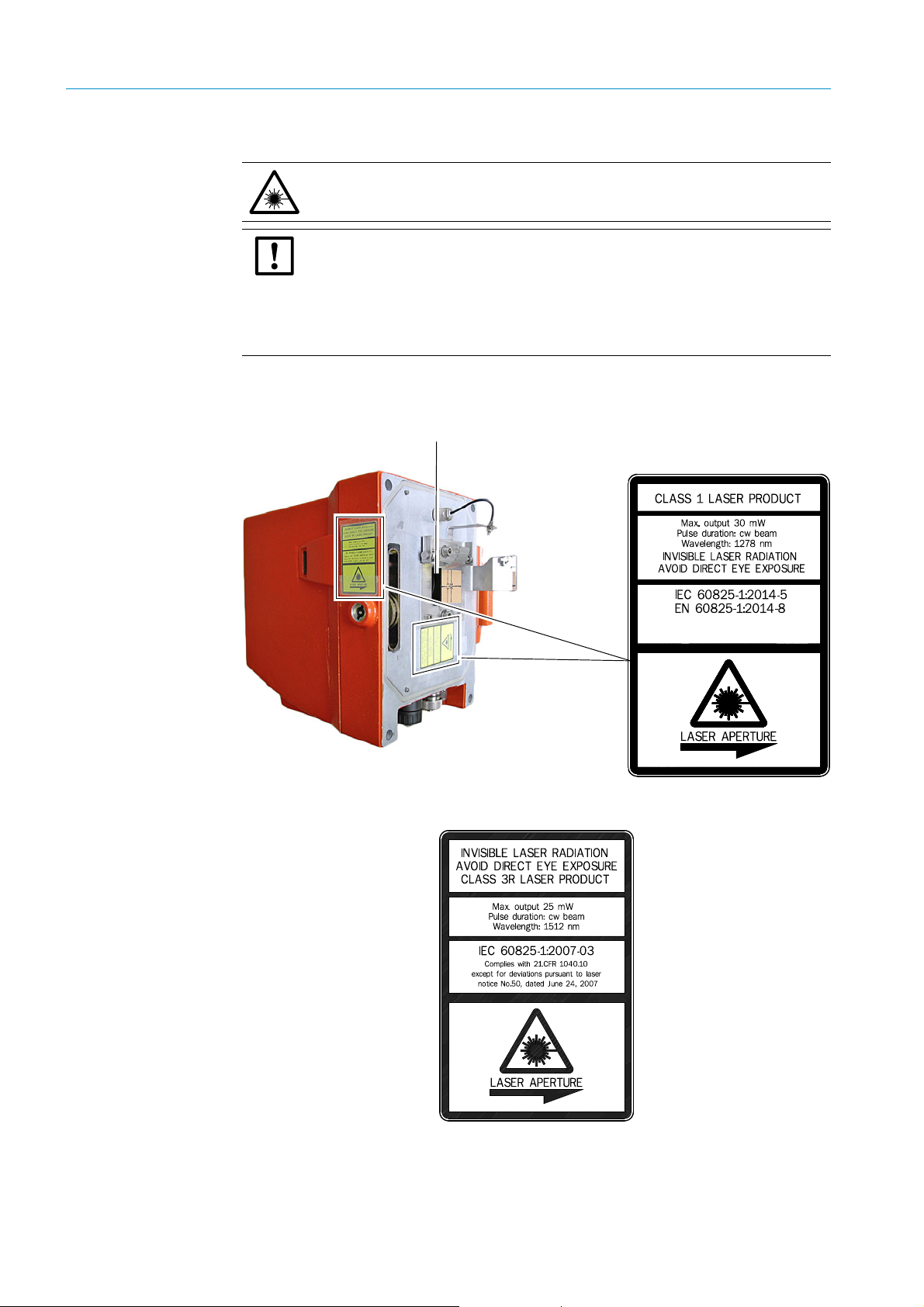

1 SAFETY INFORMATION

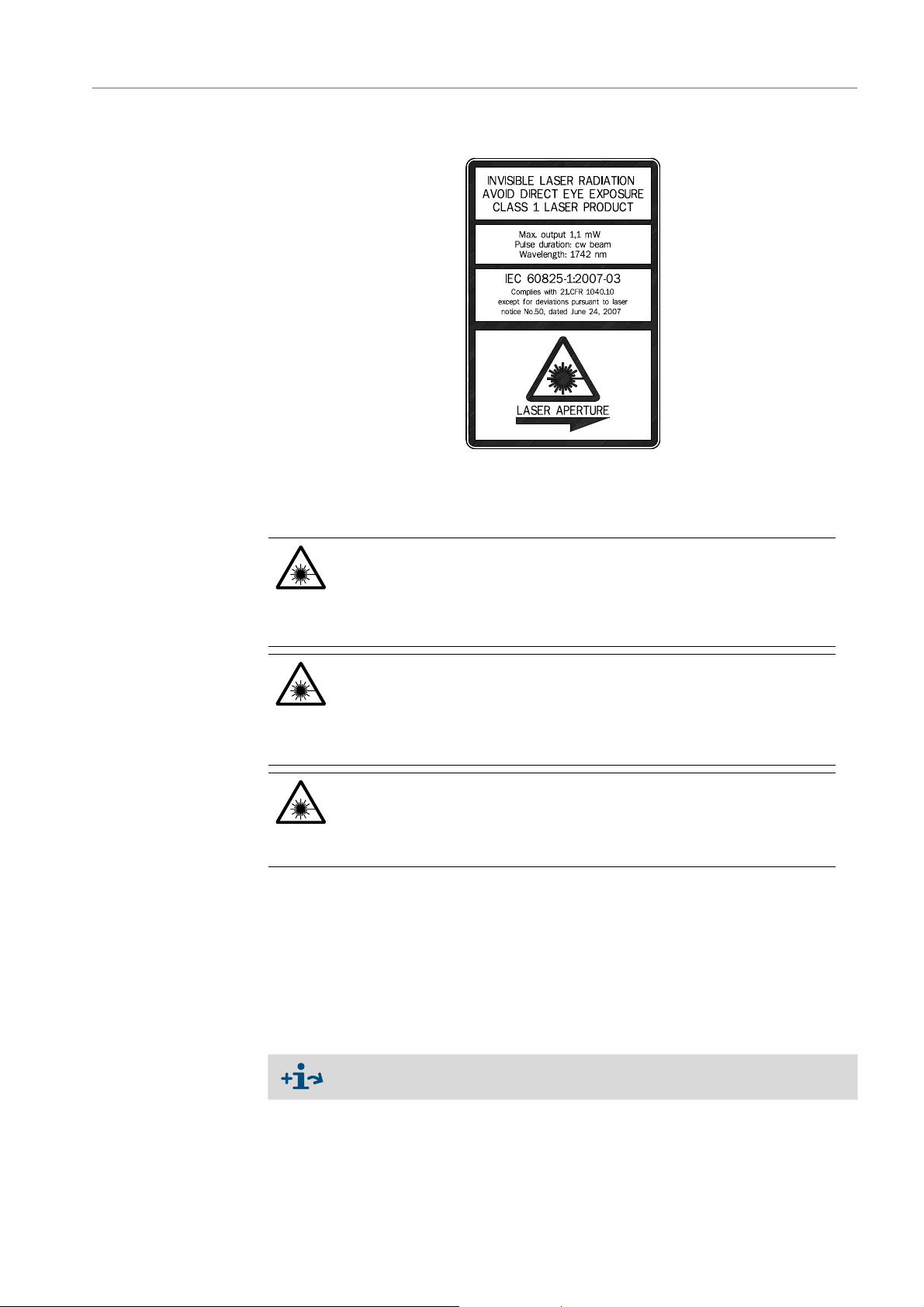

Laser outlet

Laser warning sign

1.1.4 Protection against laser radiation

WARNING: Eye injuries possible due to laser radiation

Observe all relevant information in these Operating Instructions.

NOTE: Deviations of EN60825-1:2014-08 “Laser safety” from the Directive

2006/25/EC

Due to the Implemented health and safety regulation for artificial optical radiation

concerning the Directive, deviations of EN60825-1:2014-08 “Laser safety” from

Directive 2006/25/EC have occurred.

▸ Always observe the user information in the Annex of these Operating Instructions!

“User information “Laser safety””, page 97.

The GM700 laser warning sign is located on the sender/receiver unit.

Fig. 1: Laser warning sign on the GM700 sender/receiver unit

12

Fig. 2: Laser sign for NH

measurement

3

8010100/YK22/V4-0/2015-12 | SICKOPERATING INSTRUCTIONS | GM700

Subject to change without notice

Page 11

SAFETY INFORMATION 1

Fig. 3: Laser sign for HCI measurement

The invisible laser beam within the SR-unit is not accessible when fitted. There is no risk for

the human eye when looking into the optic visor on the right side of the SR-unit.

CAUTION: Observe the following for the GM700 HF version:

As the limit values of laser class 1 of the IEC 60825-1:2014-5 are neither exceeded

in single case malfunctions nor normal operation under consideration of the service

and measuring state, the device is classified as laser class 1.

Requirement: Use of device software 9105060_YEK0 or a newer software version

with equal functionality.

CAUTION: Important information for safe handling of the GM700 SR-unit HF

version

For device software versions older than 9105060_YEK0, a higher laser radiation

might occur.

▸ Laser class 1 of the IEC 60825-1:2014-5: Only use device software

9105060_YEK0 or a newer software version.

CAUTION: Important information for safe handling of the GM700 SR-unit

(all versions)

▸ Never look directly into the output lens when opening the SR-unit or the reflector.

▸ Always wear laser goggles or switch the device off during maintenance work.

▸ Observe valid national limit values and respective standards for work safety.

Laser capacity

The wavelength of the laser varies for the respective measuring components (NH

HCl).

The maximum laser output capacity on the optical interface (front window) depends on the

respective measuring component and is shown on the laser warning sign.

–HF: “Laser warning sign on the GM700 sender/receiver unit”, page 12.

–NH

: “Laser sign for NH3 measurement”, page 12.

3

– HCI: “Laser sign for HCI measurement”, page 13.

, HF,

3

The emitted radiation is harmless to human skin.

8010100/YK22/V4-0/2015-12 | SICK OPERATING INSTRUCTIONS | GM700

Subject to change without notice

13

Page 12

1 SAFETY INFORMATION

1.1.5 Behavior during purge air failure

GM700 measuring system configurations demand immediate or short-term measures to

protect the measuring system should the purge air supply fail.

Measures for purge air feed failure

▸ Refer to Purge Air Unit Operating Instructions.

1.2 Intended use

1.2.1 Purpose of the device

The gas analyzer GM700 measures the sample gas component concentration, e.g. HF,

NH3 or HCl in a gas mixture (sample gas). For this purpose, the GM700 analyzer is

assembled at the measuring location and measures directly onsite (in-situ measurement).

!▸

Do not use the device to expose persons to radiation.

1.3 Responsibility of user

Intended users

The GM700 may be operated by competent persons only who, based on their devicespecific training and knowledge of the device as well as knowledge of the relevant

regulations, can assess the tasks given and recognize the dangers involved.

Correct use

▸ Use the device only as described in these Operating Instructions. The manufacturer

bears no responsibility for any other use.

▸ Carry out the specified maintenance work.

▸ Do not remove, add or change any components in or on the device unless such changes

are officially allowed and specified by the manufacturer. Otherwise

– the device may become dangerous

– the manufacturer’s warranty becomes void

– the approval for usage in potentially explosive atmospheres becomes void.

Special local requirements

Follow local laws, regulations and company-internal operating directives applicable at the

installation location.

Responsibility for dangerous substances

WARNING: Mortal/health danger as a result of a gas path leakage

When the device is used to measure toxic gases: A leak, for example in the purge air

supply, can be an acute hazard for persons.

▸ Take sui tab l e sa fet y me asu res .

▸ Make sure these safety precautions are followed.

Safety precautions examples:

● Marking the device with warning signs

● Marking the operating area with warning signs

● Safety-related instruction of personnel who could be in the vicinity of the installation

site.

14

Retention of documents

▸ Keep these Operating Instructions available for reference.

▸ Pass on to a new owner/operator.

8010100/YK22/V4-0/2015-12 | SICKOPERATING INSTRUCTIONS | GM700

Subject to change without notice

Page 13

1.3.1 Disposing of device parts harmful to the environment

DANGER: Possible materials harmful to the environment and health

GM700 components can have small shares of pollutants or hazardous substances

such as low lead content in printed circuit boards. The optional permanent cuvette

contains low concentrations of HF or HCl (according to device configuration, see scope

of delivery).

▸ Dispose of all GM700 components according to local laws, regulations and

company-internal operating directives applicable at the installation location such as:

▸ Printed circuit boards and similar electronic components

▸ Dispose of the permanent cuvette, when fitted, safely because it contain low

concentrations of HCl or HF. Therefore, do not simply destroy the cuvette.

SAFETY INFORMATION 1

8010100/YK22/V4-0/2015-12 | SICK OPERATING INSTRUCTIONS | GM700

Subject to change without notice

15

Page 14

2 PRODUCT OVERVIEW

2Product Overview

2.1 Product identification

Product name: GM700

Device versions GM700 version with probe

Manufacturer:

Type plates:

GM700 version: Measuring component:

GM700-2 HF

GM700-3 HCI

GM700-5 NH

GM700-8 HCI / H2O

GM700-9 NH

SICK AG

Erwin-Sick-Str. 1 · 79183 Waldkirch · Germany

● SR-unit: On the right side

● On the purge air fixture

3

O

3/H2

16

8010100/YK22/V4-0/2015-12 | SICKOPERATING INSTRUCTIONS | GM700

Subject to change without notice

Page 15

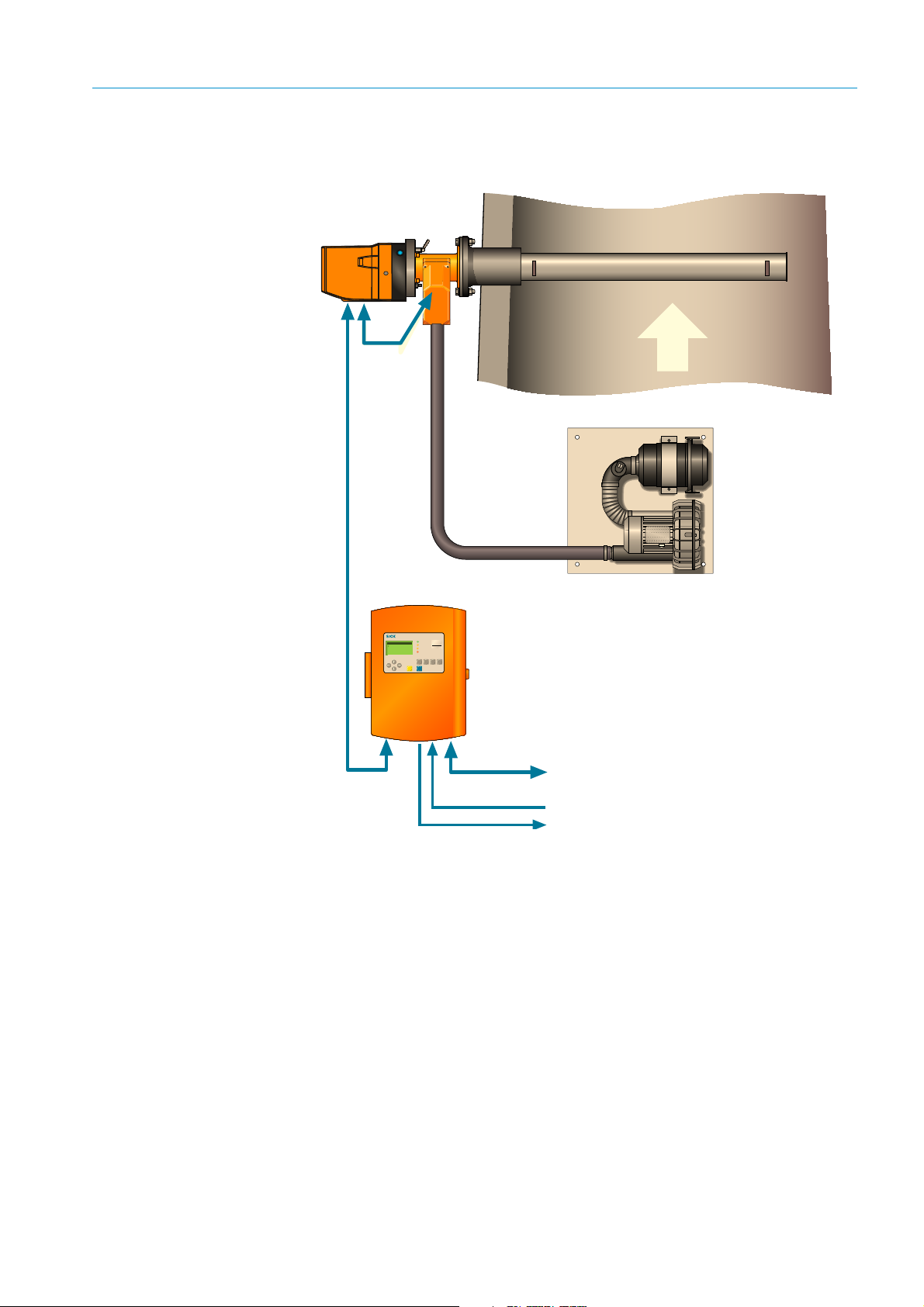

2.2 GM700 system, measuring probe version, layout

maintcalpardiag

GM

Evaluation Unit

CO

CO

2

H2O

mg/

m

3

236

Ref. conditions

Hum: wet

Measuring

Operation

Service

Warnin

Malfunction

Sender/receiver unit

with GMP measuring probe

Evaluation unit

EvU

CAN bus

CAN

Inputs/outputs,

analog, binary

Interfaces to plant peripherals:

● Measured data processing

● Status signals

Purge air unit SLV 4

(not fitted for GPP

probes)

Fig. 4: GM700 system overview (measuring probe version)

PRODUCT OVERVIEW 2

8010100/YK22/V4-0/2015-12 | SICK OPERATING INSTRUCTIONS | GM700

Subject to change without notice

17

Page 16

2 PRODUCT OVERVIEW

Sender/receiver unit (SR-unit)

The sender/receiver unit contains the optic and electronic subassemblies of the

measuring system. The gas concentration is captured here and the measured value

determined.

Measuring probe

Measuring probes are available in open design versions with integrated purge air guidance

system (GMP) as well as versions with a gas permeable sinter filter not requiring purge air

(GPP: G

detail”, page 19 onwards.

Purge air unit

To supply purge air to the SR-unit with open measuring probe (GMP) and thus to protect

against contamination and high gas temperatures. Use a certain purge air unit each for the

SR-unit depending on the application. The blower types for the SR-unit are designed

differently depending on the application.

as Permeable Probe). Both versions are described from “Measuring probe in

Further information on the purge air unit

▸ Refer to Purge Air Unit Operating Instructions.

Evaluation unit

The evaluation unit in the GM700 measuring system serves as user interface and is

responsible for measured value processing and output as well as control and monitoring

functions. The EvU can be located in the vicinity of the SR-unit. It can also be located up to

about 1000 meters from the sampling point, e.g. installed in the switch center or

monitoring center, and performs functions such as:

● Output of measured values, computed data and operating states

● Communication with the peripheral equipment

● Output of error messages and other status signals

● Control of automatic test functions and access during service (diagnosis)

Connection cables

Cable type Part No.

Cable (CAN bus) SR-unit – purge air fixture measuring probe, length 0.8 m 2 023 704

● Cable (CAN bus), SR-unit – evaluation unit, length 4 m

● Extension up to 1000 m, with terminal box ; with 24 V supply

[1]

Cable

(only for version Cross-Duct and GMP probe)

2 cables

extension (only for GMP probe)

Cable SR-unit purge air fixture – filter monitor of purge air unit, length 3 m

extension (only for Cross-Duct and GMP probe version)

Tab le 1 : Connection cable Part Nos.

[1] One length included in scope of delivery

[2] Included in scope of delivery

SR-unit purge air fixture – filter monitor of purge air unit, 5 m

[2]

SR-unit purge air fixture - filter monitor of purge air unit, length 2 m

● Scope of delivery

● Option: 2020440

2 032 143

6 025 923

6 028 663

18

8010100/YK22/V4-0/2015-12 | SICKOPERATING INSTRUCTIONS | GM700

Subject to change without notice

Page 17

Flange with tube

2.2.1 Measuring probe in detail

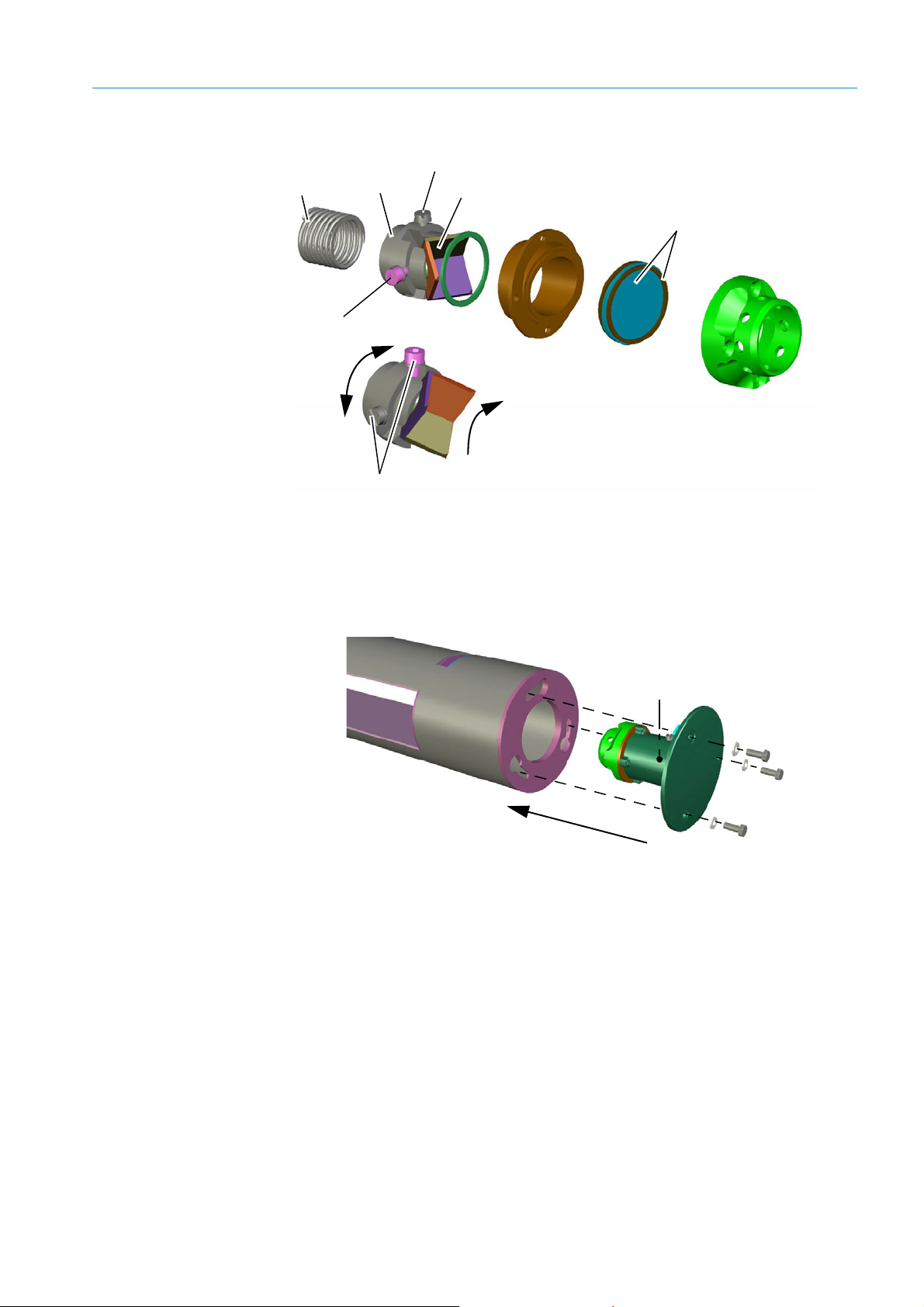

Fig. 5: GPP measuring probe with ceramic filter

PRODUCT OVERVIEW 2

To install the purge air fixtures of the SR-unit and reflector on

the gas duct. The purge air fixture is fitted on the flange and

then the SR-unit is fitted on the purge air fixture. ANSI or DIN

flanges provided by the customer can be used alternatively to

the flanges supplied.

Integrated sensors

All probe versions have a built-in pressure sensor as well as an integrated temperature

sensor PT 1000 that continually measures the medium temperature of the probe in the

active measuring path. The measured data are transferred via the CAN bus interface of the

measuring probe and can then be displayed on the evaluation unit.

EPA conformity

When using a GPP probe, an audit measurement conforming to EPA CFR 40 Part 60 and/

or Part 75 can be carried out with the device fitted as far as usable for the application.

8010100/YK22/V4-0/2015-12 | SICK OPERATING INSTRUCTIONS | GM700

Subject to change without notice

19

Page 18

2 PRODUCT OVERVIEW

Temperature sensor

PT 1000

Purge air outlet

Open measuring

path (measuring

gap)

Lever position

Lever and locking device:

Open

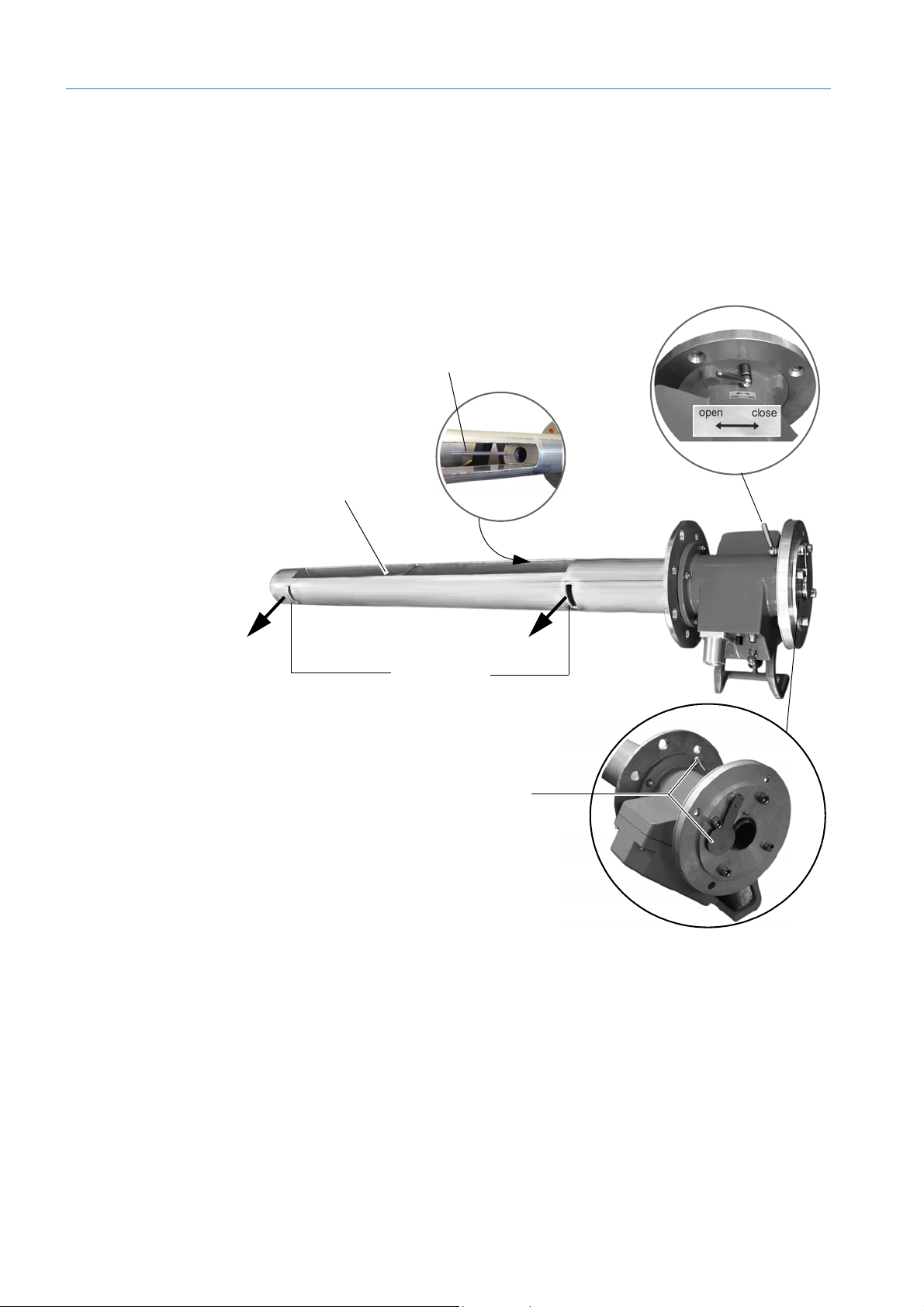

2.2.1.1 GMP probe with open measuring gap

Shortest reaction times and high temperature stability characterize the GMP series

measuring probes. Continuous purge air feed is required for operation. In the current GMP

probe series, the air is outlet into the duct at 90° to the gas flow (directed purge air). The

GMP probe has a locking device on the opening for sample gas that is activated with a

lever on the probe flange.

Fig. 6: GMP measuring probe (with open measuring gap)

20

8010100/YK22/V4-0/2015-12 | SICKOPERATING INSTRUCTIONS | GM700

Subject to change without notice

Page 19

2.2.1.2 GPP gas diffusion probe in dry or wet version

Temperature sensor PT 1000

Gas permeable ceramic filter

This version is more suitable for higher dust contents because, on GPP probes, dust

particles are separated on the filter element and therefore kept away from the measuring

path. The GPP (G

as Permeable Probe) should also be chosen to allow an EPA-conform

audit measurement as well as for low flow speeds or irregular flow profiles.

Fig. 7: Measuring gap of the GPP measuring probe

PRODUCT OVERVIEW 2

Both variants of the GPP differ in the respective filter which provides suitability for different

application areas in accordance with Table “GM700 measuring probes in comparison”,

page 22.

Advantages of GPP probes

GPP probes do not require a purge air supply and are easy to maintain. They are fitted with

an automatically controlled heater to reliably prevent condensate on the optical interfaces.

The electronics for heating control, temperature and pressure measurement are located

reliably protected in a sturdy cast-metal enclosure acting as measuring probe section

between duct flange and SR-unit. Both the electric connections for CAN bus and power

supply as well as the test gas connection with which the audit measurement according to

EPA Guideline CFR 40, Part 60 or Part 75 can be carried out are located on the enclosure

as shown.

8010100/YK22/V4-0/2015-12 | SICK OPERATING INSTRUCTIONS | GM700

Subject to change without notice

21

Page 20

2 PRODUCT OVERVIEW

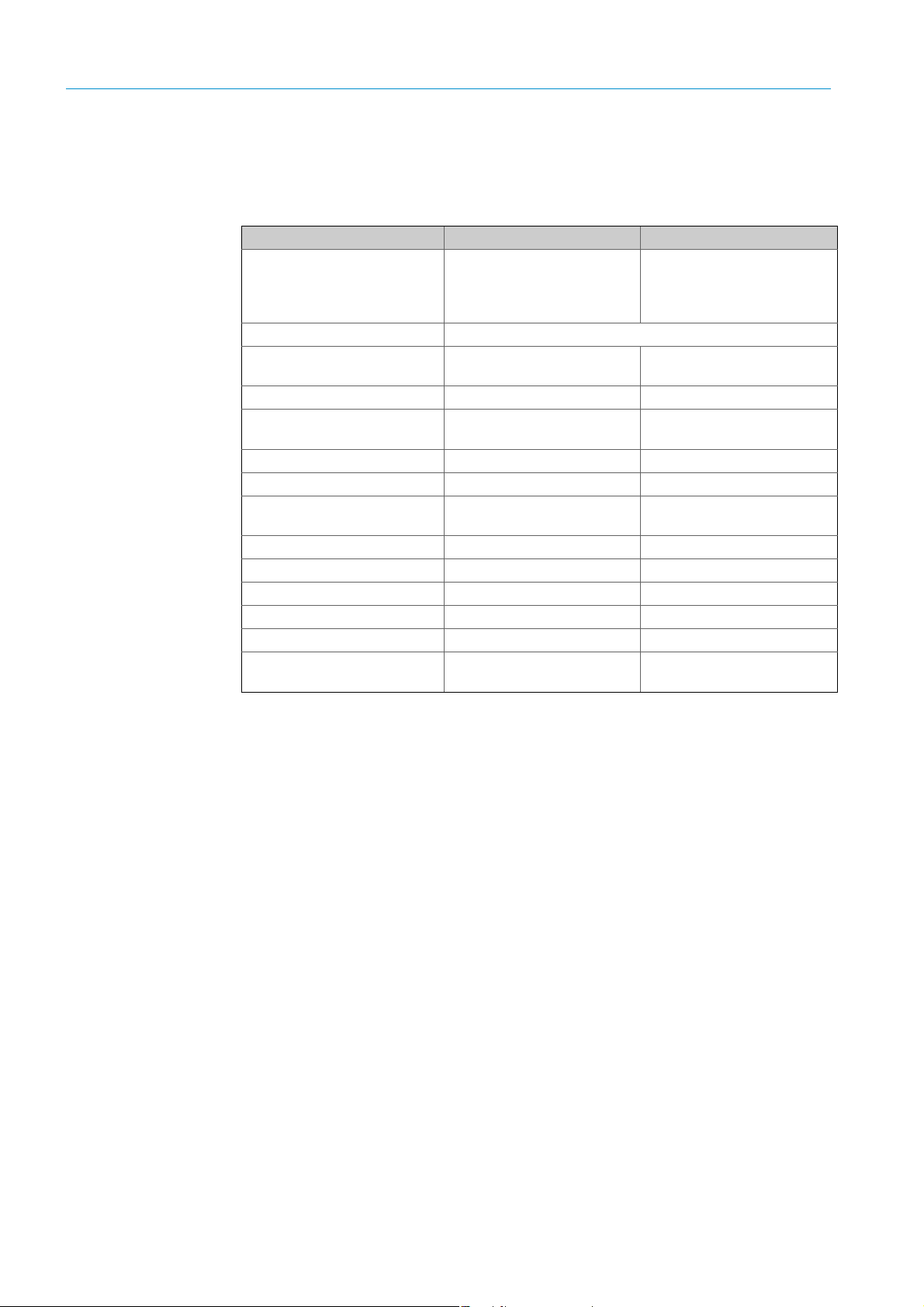

2.2.1.3 GM700 measuring probes in comparison

This Table shows an overview of the features of the different measuring probes. All

measuring probe versions are compatible with all SR-units. The SR-unit is calibrated to the

respective probe length before delivery.

Measuring probe GMP (open probe) GPP (dry)

Design

Max. gas temperature. 430°C

Gas check according to EPA

specification possible

Purge air supply required Yes –

Heating on optical interfaces in

the probe

Flow rate of sample gas 1...40 m/s < 40 m/s

Suitable for wet sample gas Yes –

Maximum duct pressure

Measurable components NH

System-response time (T90) ≥ 5s ≥ 120 s

Duct diameter

Dust concentration <2g/m

Probe lengths available [m] 1.0/1.5/ 2.0 1.0/1.5 / 2.0

Active measuring paths available

[mm]

Tab le 2 : Measuring probes in comparison

[1] The maximum temperature used for the measurement depends on the application.

[2] As from gas temperature 300 °C

[3] As from a gas temperature of minimum 130 °C

[4] Probes with shorter active measuring paths on request (possibly required for higher concentrations or

narrower duct diameters)

[4]

Measuring path open in flow

direction; purge air guidance

with outlet aligned 90° to gas

flow

[1]

Gas diffusion probe with

ceramic filter, for dry sample

gas

–Yes

– Yes, with integrated control

±120 hPa, depending on purge

air supply

, HF, HCl NH

3

±120 hPa

[2]

, HCl

3

[3]

> 360 mm > 300 mm

3

act. <30g/m3 act.

250/500/750/1000/1250 250/500/750/1000

2.2.1.4 Special versions

Apart from the standard probes shown, other versions made from stainless steel type

1.4539 especially resistant to acid are available. Special versions can be manufactured

according to customer demands on request.

2.3 GM700 options and accessories

● Terminal b ox for CAN bus with 24 V power supply

The optional terminal box is available for distances between SR-unit and EvU larger than

4 meters via a CAN bus cable provided by the customer. The total length of all the CAN

bus connections in the GM700 measuring system can be up to 1000 m in this case.

● Cover plate for purge air fixture of the sender/receiver unit

To maintain purge air supply in cases where this must remain in operation at the

measuring location when the SR-unit is dismounted.

● Weatherproof cover for SR-unit and purge air unit

Required for outdoor installation - dimension drawings, see “Dimensions of weatherproof

cover for GM700 SR-unit”, page 89.

22

8010100/YK22/V4-0/2015-12 | SICKOPERATING INSTRUCTIONS | GM700

Subject to change without notice

Page 21

● Chart recorder, single or multi-channel, for measured value recording. Protocol(s) can of

course be produced using customer systems.

● Air heater for purge air supply

For special application conditions to prevent condensate. An air heater is required when

the difference between gas temperature and dew point temperature is too small. The

following practical rule of thumb serves as guideline:

An air heater is recommended when

Gas temperature [°C] – dew point temperature [°C] < abs. humidity [%].

Values are compared without considering the units of measure.

2.4 Measuring principle

The light of the laser diode radiates through the sample gas and is then detected by a

photo diode. The laser diode wavelength is set to a single absorption line of the sample gas

component. This absorption line is scanned by modulating the wavelength and then the

transmission signal (relation between signal sent and received) captured by a photo diode.

An appropriate signal evaluation returns the magnitude of the absorption line from which

the gas concentration is then calculated. This method is called Tunable Diode Laser

Spectroscopy (TDLS) or Tunable Diode Laser Absorption Spectroscopy (TDLAS).

A laser specially developed for gas analysis is used as light source in the GM700. This laser

diode radiates a wavelength with a narrow line width so that an absorption line can be

reliably scanned. A Peltier element and a temperature sensor fitted in the laser diode

enclosure ensure a precise temperature and therefore exact wavelength stabilization of the

system.

PRODUCT OVERVIEW 2

The laser beam from the sender/receiver unit travels through the active measuring path

and then impinges on the reflector on the other side of the gas duct. The beam is then

reflected back to the sender/receiver unit. After the beam has passed through the

measuring path twice, during which laser light absorption specific to the gas occurs, the

light is focused on a receiver optics.

2.4.1 Reference cuvette for wavelength stabilization

The GM700 is equipped with:

● A permanently filled cuvette for the adjustment of the analyzer laser diode to the

reference position of the gas absorption line (Line-Locking).

2.4.2 Signal evaluation

The optimized algorithms of the GM700 evaluation electronics process the measurement

signal of the receiver element together with the corresponding parameters based on the

TDLS measuring method. This is based on the physical characteristics of the gas

molecules that absorb light energy in certain wavelengths. These optimized algorithms

ensure the concentrations of sample gas components are determined without crosssensitivities to other gases. The differential absorption measurement also eliminate dust

influences.

8010100/YK22/V4-0/2015-12 | SICK OPERATING INSTRUCTIONS | GM700

Subject to change without notice

23

Page 22

3 PROJECT PLANNING INFORMATION

3 Project Planning Information

3.1 Work steps from system selection to start-up

Application changes

If you make changes to the specifications ordered for your application or if a device is to be

used for an application different to the one originally planned, please pass this information

onto your local sales representative so that we can determine the application options

under changed conditions and whether new adjustment/parameter settings are required.

The following steps are normally taken before starting-up the measuring system

● Project planning

“Project Planning Checklist”, page 24.

● Initial onsite installation

▸ The following preparatory work normally carried out by the customer is described in

“Initial onsite installation”, page 27:

▸ Flange installation, “Installing the flanges with tube”, page 28.

▸ Preparation for installing the purge air unit, “Installation preparation for the purge air unit

(for GMP probe)”, page 30.

▸ Laying the signal and power supply cables to the measuring point, “Signal and power

supply cables”, page 31.

● Installation preparation for the EvU, “Electrical connection in the evaluation unit EvU”, page 40

▸ Possibly preparation of signal cables for the interface to the peripheral equipment,

“Signal and power supply cables”, page 31.

● Device installation

To allow speedy start-up, the following components are normally installed ready for

operation before the start-up date; see also “Installation”, page 34.

– Purge air unit

– Evaluation unit(s).

● Start-up

The actual start-up is carried out by trained personnel or Customer Service. This work is

described in “Start-up”, page 46. The main activities are adjustment tasks on the

GM700 system related to the application.

3.2 Project Planning Checklist

Project planning, step by step

The following Checklist simplifies performing and controlling project planning measures

required before start-up in the correct sequence. Technical data and dimensional drawings

of system components, see “Dimension drawing”, page 85 and following.

24

8010100/YK22/V4-0/2015-12 | SICKOPERATING INSTRUCTIONS | GM700

Subject to change without notice

Page 23

PROJECT PLANNING INFORMATION 3

D

4F (Cross-sectional area)

U (Circumference)

-------------------------------------------------------------------------------------=

Top ic Tas k Measure/determination

Provide for unhindered inlet and outlet paths:

▸ For round duct cross-sections: 3 times the duct diameter

▸ For rectangular cross-sections: Hydraulic diameter

▸ If these specifications cannot be met: Inlet section > outlet section,

2

/3 : 1/3; uniform concentration spread whenever possible

e.g.

Determine sampling point

Observe national regulations

such as VDI 3950

Emission sampling

point

Application conditions

Pressure conditions at

the sampling point

▸ Obtain official approval for emission sampling point.

▸ Provide for calibration openings at an easily accessible place.

▸ Ensure the GM700 and calibration probe do not influence each

other; the calibration gland should be located at a minimum

distance of 0.5 m away from the measuring device, upstream

▸ Observe Technical Data for duct/ambient conditions!

▸ Gas temperature above/below dew point (dry/wet)

▸ A fitting location with partial vacuum in the duct is ideal.

▸ For duct pressures > 10 mbar, contact SICK on correct selection of

the purge air blower.

▸ Flange fitting is planned in steel ducts as standard; corresponding

flanges with tube are normally included in the GM700 scope of

delivery.

▸ Stone stacks or ducts with thick walls demand an onsite retaining

plate and, possibly, a longer version of the flange with tube; “Install-

ing the flanges with tube”, page 28.

● “Dimension drawings of flange with tube”, page 89.

▸ Provide an opening of suitable size for the flange tube.

▸ Plan adequate clearance for installation and maintenance activities

for the duct insulation cutout.

▸ Plan clearances for handling the SR-unit

▸ Ensure the ambient temperature for the SR-unit is within the

specified range.

SR-unit

→

p. 25, §3.3.1

Select suitable flange

with tube

Duct openings

selection

▸ For installation outside, plan a weatherproof cover

Tools for start-up and

maintenance

▸ When working on the zero path; prerequisites: Clean ambient

atmosphere free from sample gas; weatherproof: Plan the zero

path or order from SICK.

▸ Plan installation location on the duct in immediate vicinity (5 m) of

the GM700 SR-unit.

▸ Keep purge air hoses to the purge air fixture (SR-unit) as short as

possible (pressure loss approx. 1.2 mbar per meter).

Purge air unit

→

p. 28, §3.3.4

Fitting location

selection

▸ Ensure secure cable laying.

▸ Ensure dry and, whenever possible, dust-free intake air on the

purge air unit, use a preliminary filter as necessary.

▸ The intake air temperature should be between 0 and 55 °C. Heat

the purge air for T < 0 °C; see air heater option ( “GM700 options

and accessories”, page 22).

▸ For installation outside, plan a weatherproof cover

Evaluation unit

→

p. 28, §3.3.6

Determine the fitting

location

Tab le 3 : Project Planning Checklist

▸ Plan assembling the unit at an easily accessible location

▸ Ambient temperature within the specifications, “Technical data

GM700 probe system”, page 80.

8010100/YK22/V4-0/2015-12 | SICK OPERATING INSTRUCTIONS | GM700

Subject to change without notice

25

Page 24

3 PROJECT PLANNING INFORMATION

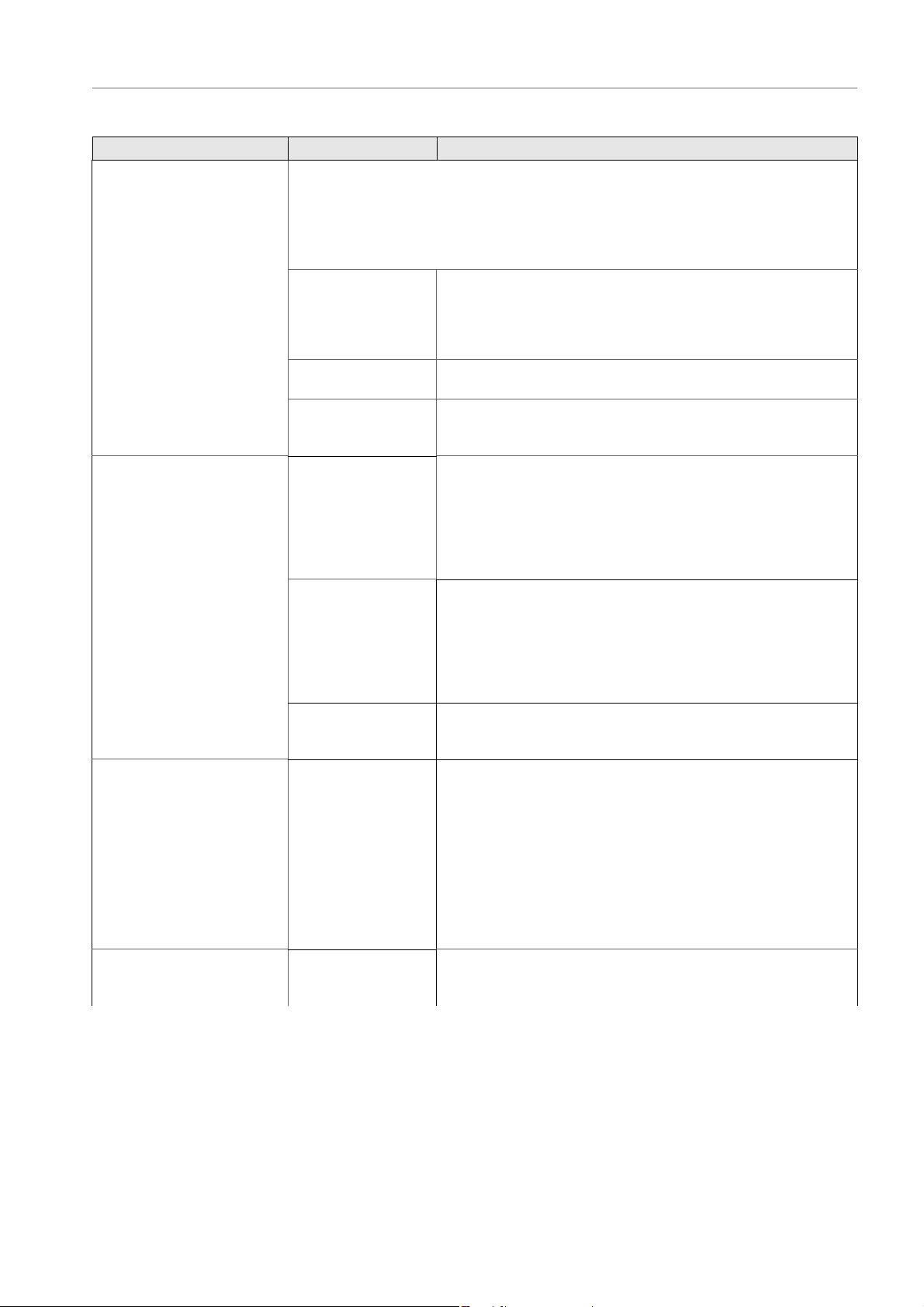

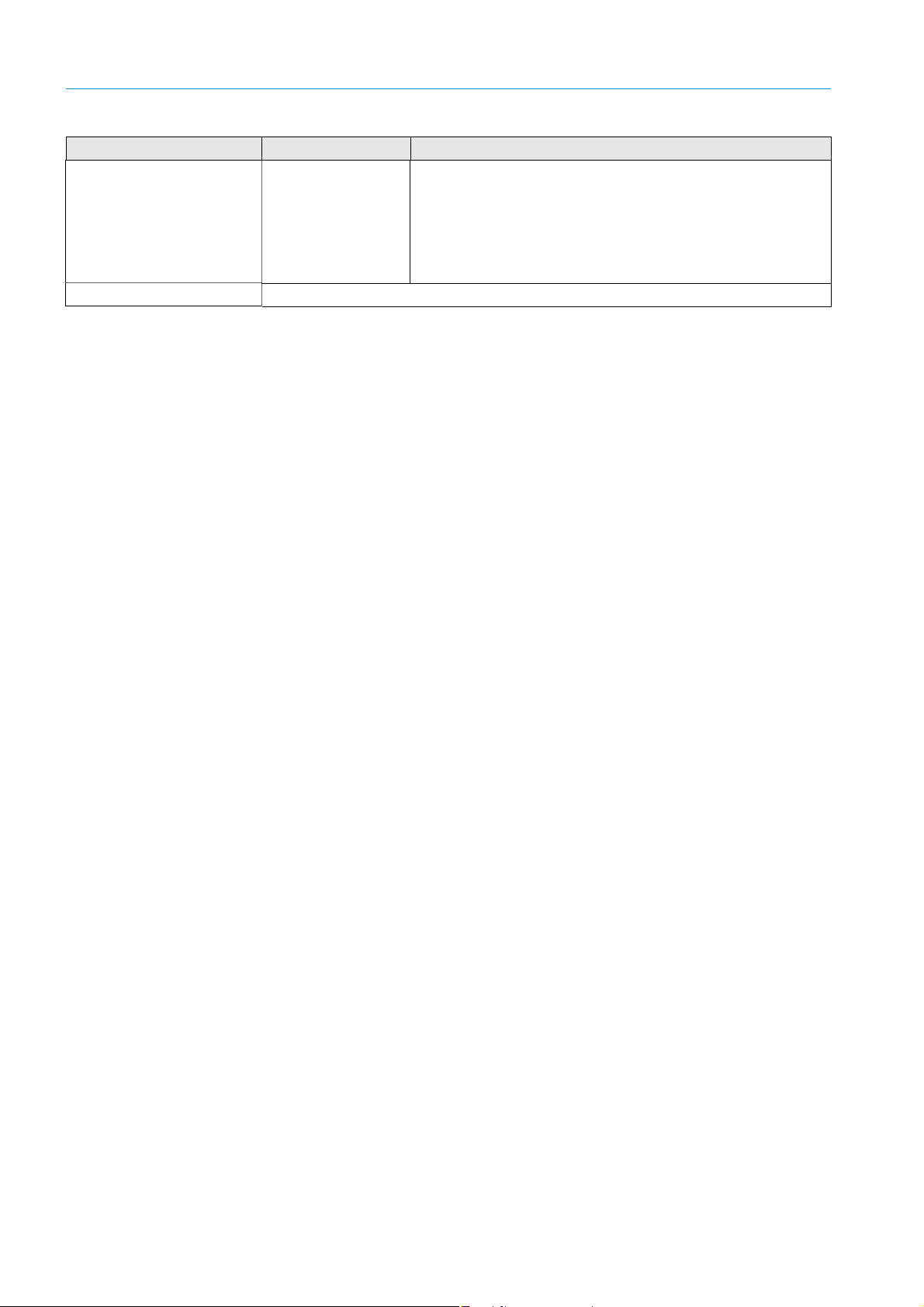

Topic Task Measure/determination

▸ Provide a suitable working platform for installation on the outside of

a duct/stack.

▸ The fitting location of the GM700 SR-unit should be about 1.3 to

1.5 m above the platform.

▸ The platform must be large enough, secured and positioned so that

all device parts can be accessed without danger. This is especially

important when fitting and removing the SR-unit

Installation platform

Accident prevention

Specify the installation

platform

▸ Applicable (national) regulations on accident prevention must be observed.

Tab le 3 : Project Planning Checklist

26

8010100/YK22/V4-0/2015-12 | SICKOPERATING INSTRUCTIONS | GM700

Subject to change without notice

Page 25

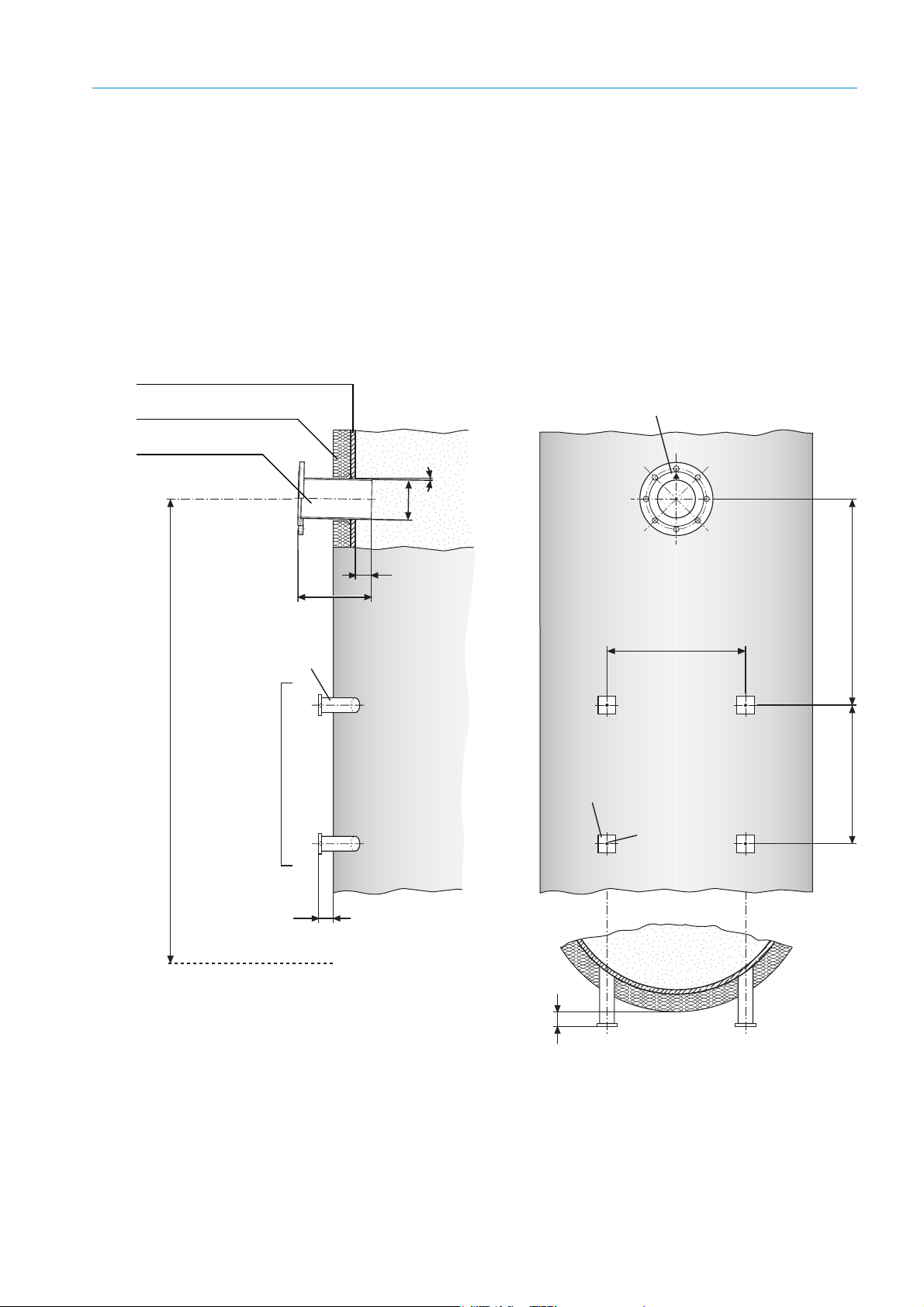

3.3 Initial onsite installation

30

L

50

470

M10

Ø13

3

1

FL. 60x8x60

D I N 174

min. 700

1,3 – 1,5 m

470

Duct wall (steel)

Duct insulation

Flange with tube,

standard: L = 240 mm

▴ : Marking for fitting position,

pointing in flow direction

Steel pipe

50 x 5

DIN 2391

Purge air unit fastening

Platform

50 mm protrusion for circular duct cross-section

The work described in the following can be carried out by the customer's installers.

Prerequisite is that all the required specifications have been made based on the Project

Planning Checklist.

3.3.1 Installation preparation at the sampling point

This Section describes the welding work on the duct including making fixing elements

onsite.

Fig. 8: Installation recommendation: Mounting flange and purge air unit (duct diameter not representative)

PROJECT PLANNING INFORMATION 3

8010100/YK22/V4-0/2015-12 | SICK OPERATING INSTRUCTIONS | GM700

Subject to change without notice

27

Page 26

3 PROJECT PLANNING INFORMATION

o

CAUTION: Protective measures at the sampling point

▸ Always shut down the installation before any work on the duct!

▸ Secure parts to be separated, e.g. with wire binding, to prevent damage caused

by falling par ts.

▸ Take appropriate protective measures against hot, explosive gases or toxic gases

that could possibly escape from the duct.

▸ Take all the necessary safety measures during welding work, among others

against the risk of explosion or fire in the duct atmosphere and on the duct

insulation.

▸ If necessary, seal off the mounting flange with a cover securely until device

installation (e,g, for overpressure in duct).

3.3.2 Uncovering the duct

▸ Remove any duct insulation to uncover an area of approx. 800 x 1500 mm (W x H) to

prepare the duct for the following work.

▸ Keep the insulation material removed for later refitting and/or provide new suitable

insulation material.

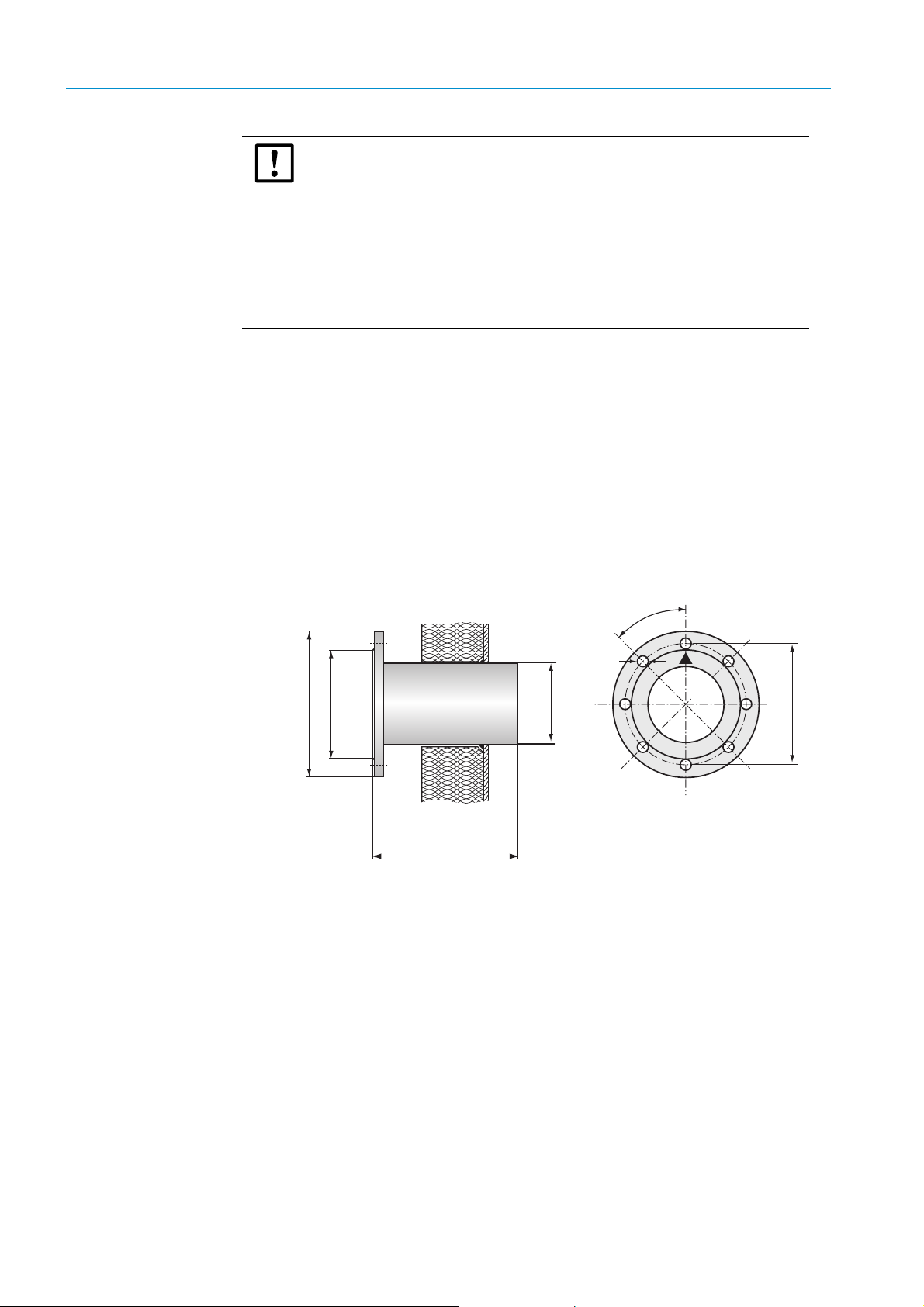

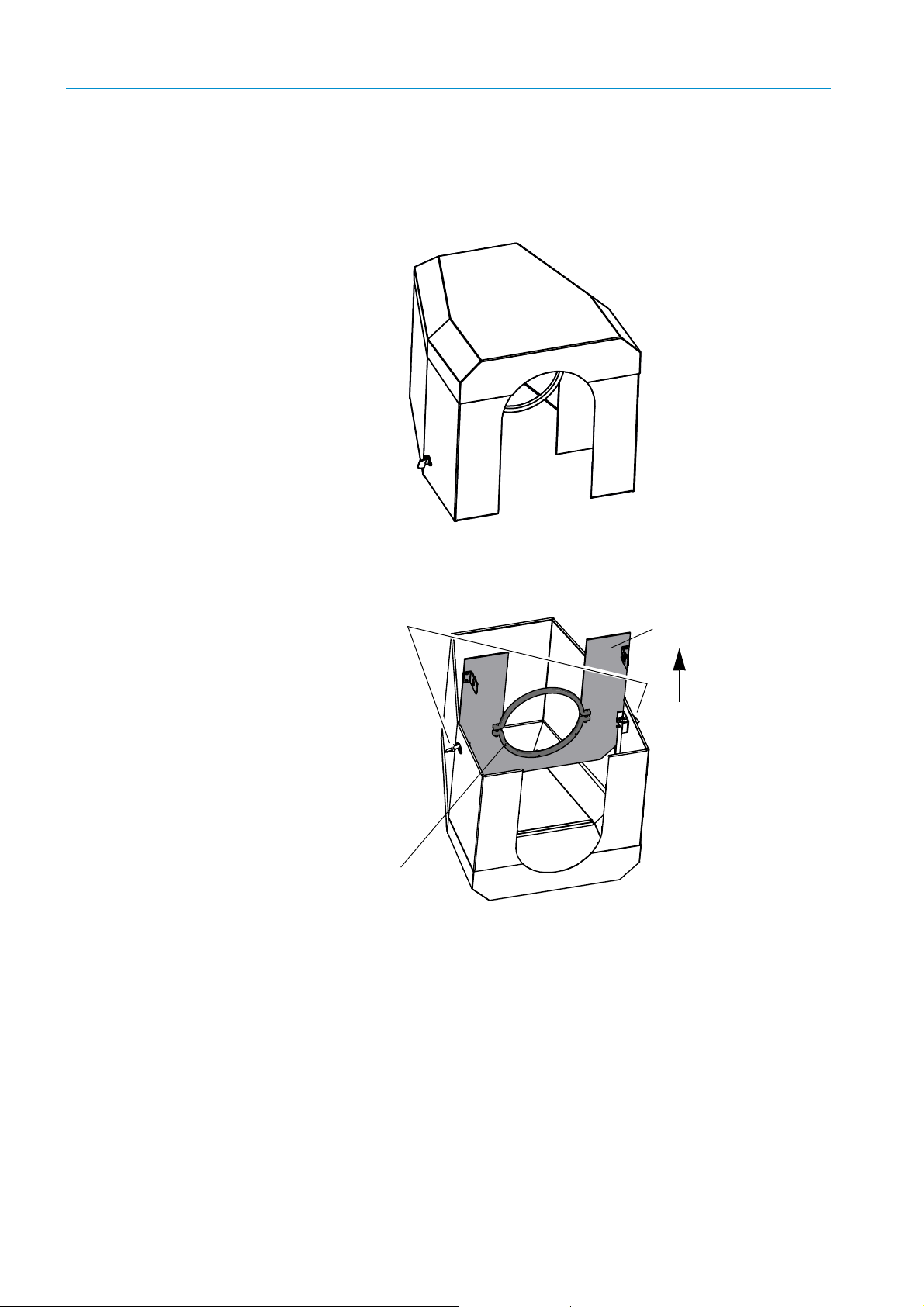

3.3.3 Installing the flanges with tube

SICK delivers two flanges with tube with 240 mm total length and 125 mm inner diameter

as standard. A version with 500 mm total length is available for installation locations with

thicker insulation or for stone stacks. Special versions can be manufactured on request.

Onsite flanges, including ANSI flanges, can also be used.

Fig. 9: Standard flange with tube

Reinforcement with junction plates recommended

Due to the weight of the sender/receiver unit, we recommend reinforcing the flange tube

fixture onsite with junction plates.

28

8010100/YK22/V4-0/2015-12 | SICKOPERATING INSTRUCTIONS | GM700

Subject to change without notice

Page 27

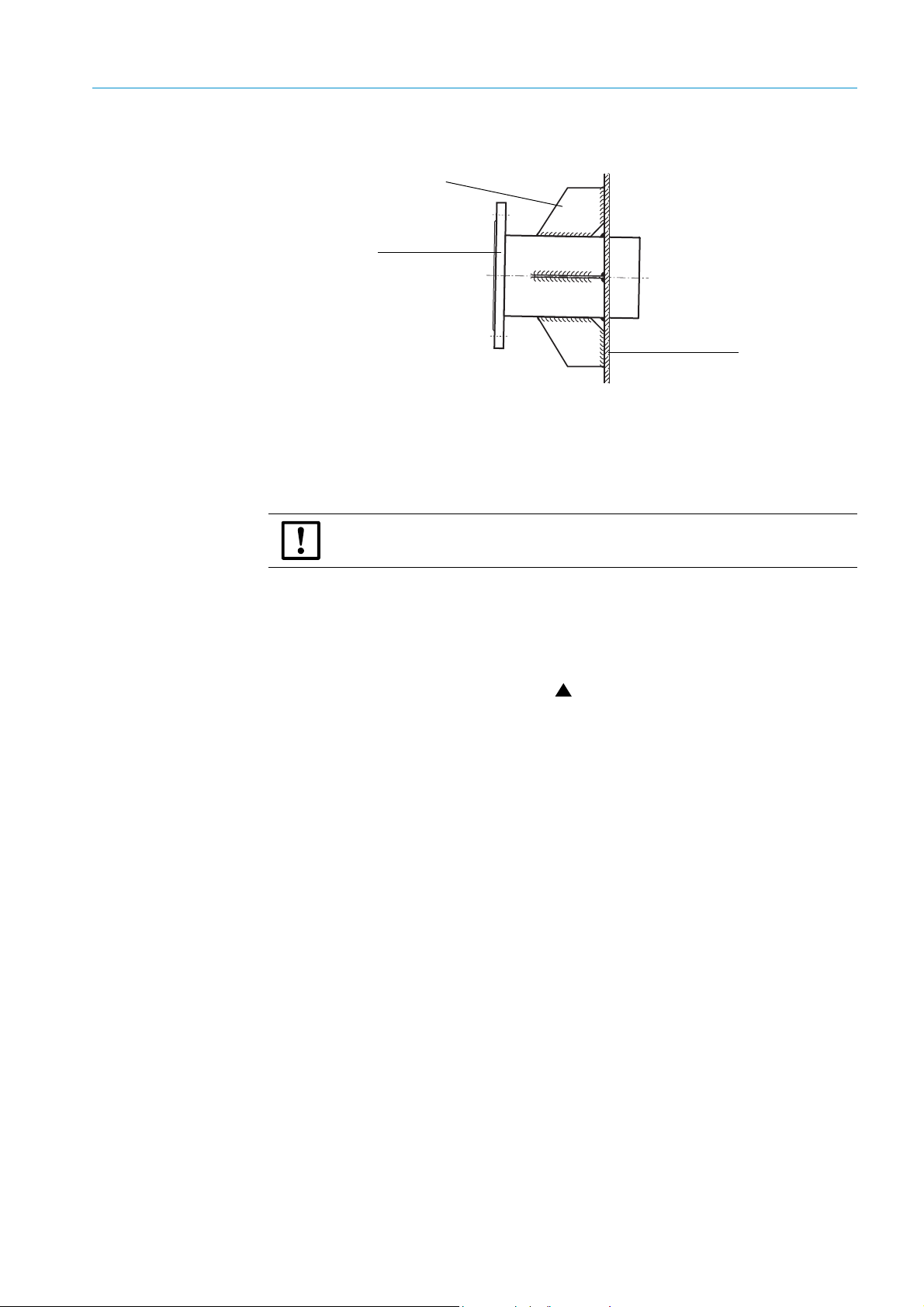

Fig. 10: Reinforcing with junction plates

Duct wall (steel)

Flange with tube

Reinforcing sheets (onsite)

Gas carrying duct made of stone/concrete

An additional retaining plate with suitable opening can be manufactured for ducts not

made of steel and in which the flange with tube can be welded.

3.3.3.1 Installing the flange with tube

PROJECT PLANNING INFORMATION 3

CAUTION: Always observe safety information on “Main hazards”, page 10!

1 Mark the flange center point exactly on the duct wall.

– On ducts made of stone/concrete: Cut the duct opening out approx. 2 cm larger than

the outer flange tube diameter; at the same time, plan a light downward incline of the

flange tube by approx. 1°. Provide a suitable retainer plate.

2 Cut an opening matching the outer flange tube diameter (standard Ø

= 133 mm) out of

a

the duct wall and/or retainer plate.

3 Position the flange tube so that marking points exactly in gas flow direction. Incline

the tube slightly downwards in the duct resp. on the retainer plate (approx. 1°, “Stan-

dard flange with tube”, page 28) to prevent condensate deposits later between tube and

probe.

4 Affix in the fitting position.

– Whenever possible, weld on junction plates as reinforcement; cf. “Reinforcing with

junction plates”, page 29. For ducts made of stone/concrete: Anchor the retainer

plate with flange with tube welded on securely to the duct.

5 Weld the flange tube on.

8010100/YK22/V4-0/2015-12 | SICK OPERATING INSTRUCTIONS | GM700

Subject to change without notice

29

Page 28

3 PROJECT PLANNING INFORMATION

3.3.4 Installation preparation for the purge air unit (for GMP probe)

● Maximum length of cable to measuring device complies with project planning.

Installation of purge air unit , see Operating Instructions of purge air unit.

NOTE: Adequate purge air pressure

▸ During project planning, make sure the purge air pressure is sufficient to force the

purge air into the gas duct. Please contact SICK Customer Service or your local

representative when necessary.

3.3.5 Duct insulation

▸ Refit the thermal duct insulation; reinforce the insulation when necessary.

WARNING: Observe the ambient temperature!

The SR-unit of the GM700 is designed for an ambient temperature of max. +50 °C.

Radiant heat on the enclosure surface can, among others, create temperatures higher

than the measured air temperature. Therefore, design insulation and radiation

shielding so that temperature limits are reliably maintained.

3.3.6 Installation preparation for the evaluation unit

The installation location for the evaluation unit was defined within the project planning

framework ( “Project Planning Checklist”, page 24). The maximum total cable length of all

CAN bus connections in the GM700 measuring system of 1 000 m was taken into account,

bearing in mind that the closer the device is to the measuring point, the easier it is to use.

Installation location preparation

The evaluation unit has fastening openings in the enclosure for easy fixing.

▸ Based on the EvU dimensional drawing according to “Dimension drawing evaluation

unit GM700: Sheet steel enclosure (dimensions in mm)”, page 88 and/or “Dimension

drawing evaluation unit GM700: Cast metal enclosure (dimensions in mm)”, page 88

ensure enough space is available at the planned installation location to attach these, for

wiring as well as opening the enclosure door.

▸ Drill suitable openings as installation points as required.

30

8010100/YK22/V4-0/2015-12 | SICKOPERATING INSTRUCTIONS | GM700

Subject to change without notice

Page 29

3.4 Preparations for electrical installation

The onsite supply and signal cables are laid beforehand to facilitate subsequent

installation and start-up of the GM700 system components. Suitable cable ducts and/or

empty conduits are installed for cables already prefabricated and delivered with the

GM700 system. Suitably qualified personnel or Customer Service connect the prepared

cables to the device during installation and/or start-up.

3.4.1 Signal and power supply cables

WARNING: Observe safety information!

● Always observe safety information and relevant safety regulations.

● During all work on electrical equipment, disconnect such equipment from the mains,

check that the equipment is potential free and make sure that no third person can

switch the equipment back on again without authorization. Leave the power supply

switched off during the following device installation.

● The power connection must be made via a circuit-breaker switch.

● The grounding cable must be connected.

PROJECT PLANNING INFORMATION 3

8010100/YK22/V4-0/2015-12 | SICK OPERATING INSTRUCTIONS | GM700

Subject to change without notice

31

Page 30

3 PROJECT PLANNING INFORMATION

maintcalpardiag

GM 35

Evaluation Unit

CO

CO

2

H2O

mg/

m

3

236

Ref. conditions

Hum: wet

Measuring

Operation

Service

Warnin

Malfunction

SR-unit

Measuring probe (example: GMP)

CAN *

0.8 m

Evaluation unit

CAN bus extension,

ready for connection, 15 m

(option)

CAN bus cable (standard), 4 m *

Terminal box (option)

Standard cable

connection

Cable connection,

option

Cable in scope of

delivery

*

Prefabricated with plug-in

connector(s)

Purge air unit SLV 4

(Standard for GMP measuring probe)

Power supply (230/115 V AC)

3 x 0.75 mm

2

3 binary inputs 6 x 0.5 mm

2

3 analog inputs 6 x 0.5 mm

2

3 binary outputs 6 x 0.5 mm

2

3 analog outputs 6 x 0.5 mm

2

to extend the CAN bus

connection with a cable

(1 x 2 x 0.5 mm2, twisted pair,

shielded) provided by the

customer

Cable connection for

optional terminal box

Power supply

115/230 V AC;

50/60 Hz

4 x 1.5 mm

2

(see safety information)

Signal cable for:

Filter monitoring of the SLV 4 – 2 x 0.6 mm

2

, on pressure

controller with flat pin bushings 6.3 x 0.8 mm (DIN 46247)

Pressure connection

Power supply 4 x 1.5 mm

2

(see safety information)

Fig. 11: Circuit diagram (probe version)

32

8010100/YK22/V4-0/2015-12 | SICKOPERATING INSTRUCTIONS | GM700

Subject to change without notice

Page 31

3.4.2 CAN bus wiring

PROJECT PLANNING INFORMATION 3

Standard cables

An installation location in the vicinity of the sampling point is generally selected for the EvU

so that the 4 m CAN bus cable in the scope of delivery is sufficient for cabling without

additional installation effort.

Installation away from the evaluation unit

A terminal box with a 24 V power supply unit can be delivered when the EvU is to be located

at a greater distance from the SR-unit. This is then connected to the SR-unit using the 4 m

CAN bus cable delivered with the measuring system. A customer cable suitable for CAN

bus applications, 6-pole cable (twisted pair wires and shielded), then leads to the EvU. The

total length of the CAN bus connections, including the one to the reflector, may be up to

1000 meters. When performing maintenance or service, it must be possible to deinstall

the EvU temporarily and connect it directly to the SR-unit at the sampling point.

Laying the cables

▸ Provide adequate cable lengths at the connection points.

▸ Whenever possible, do not lay power supply cables immediately next to signal cables.

▸ Protect open ends of preinstalled cables against weather effects until device

installation.

▸ Install separate power supply cables and circuit breakers for:

– Purge air units; additional motor circuit breakers and optional protective phase failure

switches.

– Evaluation unit

WARNING: Take precautions to prevent accidental switching off of the purge

air supply.

▸ Attach a clearly visible warning against accidental switching off the separation

equipment for the purge air unit.

▸ Install easily accessible cable ducts or empty conduits for the prefabricated cables to

those delivered with the system ( “Circuit diagram (probe version)”, page 32) marked

with one or two plug-in connectors . Approx. 2 m cable lengths each should be

available at the sampling point for later maintenance work on the measuring system

when dismounted from the duct.

▸ Lay onsite cables (shown without plugs) according to “Circuit diagram (probe version)”,

page 32.

– Wire cross-section specifications are recommendations from which cables for analog

and binary signals can slightly deviate (not however for the CAN bus connections

and/or power supply cables).

– Start with the system internal connections of the GM700.

Status and signal cables from the EvU to the connection terminals of the customer's

status/message devices can be added later as required.

8010100/YK22/V4-0/2015-12 | SICK OPERATING INSTRUCTIONS | GM700

Subject to change without notice

33

Page 32

4 INSTALLATION

4 Installation

4.1 Preparations

This Section describes the installation and installation work for the GM700 measuring

system before the actual start-up. Completion of the onsite preinstallation in accordance

with “Preparations”, page 34 is assumed.

4.1.1 Checking the scope of delivery

▸ Check the delivery against the belonging delivery note and make sure the complete

measuring system has been delivered as ordered.

▸ Check the specifications on mains voltage and frequency on the type plates of the

GM700 components match the installation conditions, delivery note and the order.

4.1.2 Installation prerequisites

The following prerequisites are applicable for the work described in the following:

▸ Plan safe usage/application within the limits defined in “Technical data GM700 probe

system”, page 80.

▸ Compliance with the specifications made during project planning (according to “Project

Planning Checklist”, page 24) and correct performance of onsite preinstallation

according to “Mechanical preparation”, page 47.

WARNING: Power supply OFF!

During the following work, it must be ensured that the power supply to the devices and

cables involved is switched off and can only be activated by the personnel carrying out

the work when the work is completed and/or for test purposes and then under

consideration of valid safety regulations.

34

8010100/YK22/V4-0/2015-12 | SICKOPERATING INSTRUCTIONS | GM700

Subject to change without notice

Page 33

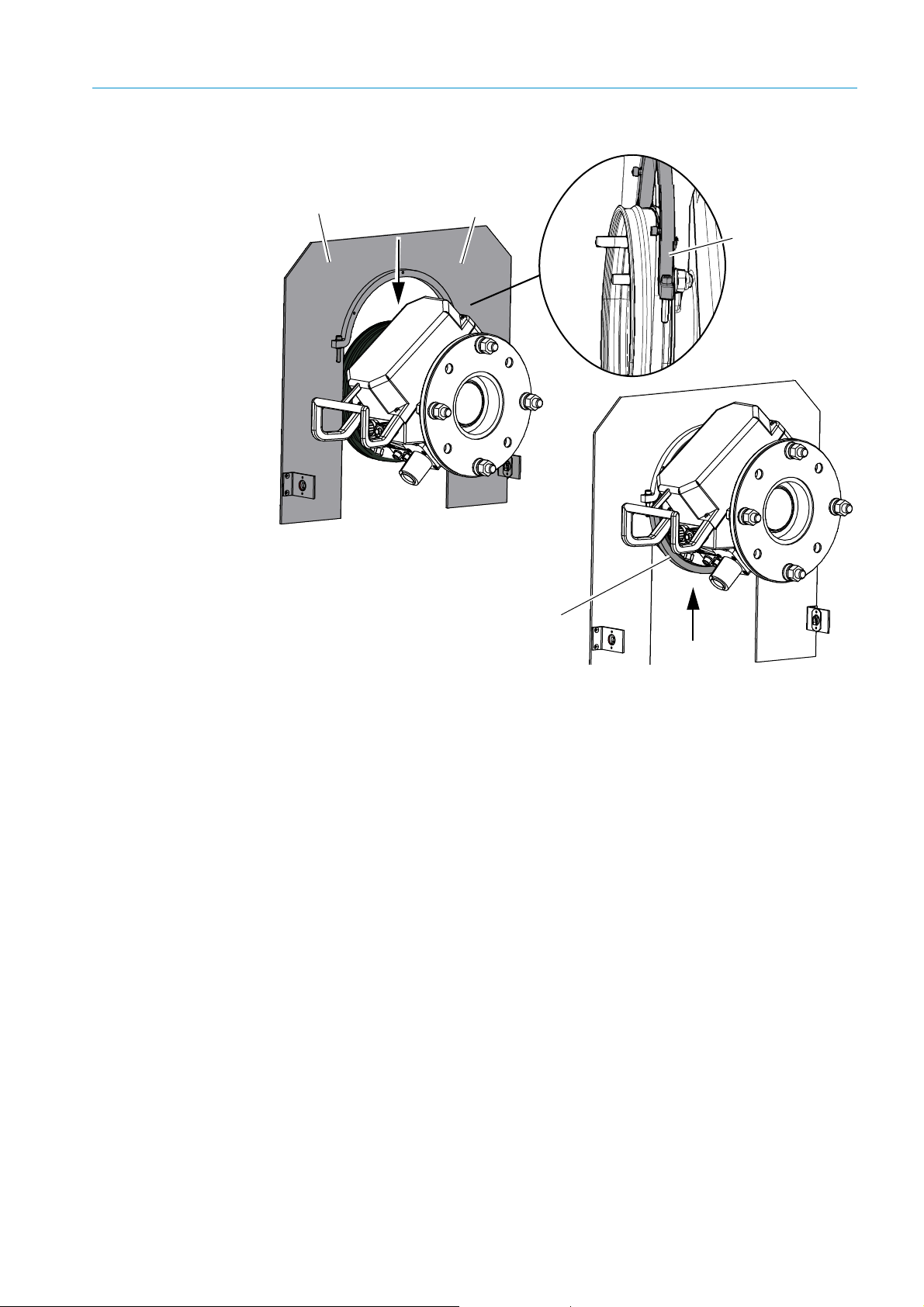

4.2 Fitting system components

52

163

4.5

Mounting holes

4.2.1 Information on the SR-unit and measuring probe

The GM700 SR-unit and measuring probe are first fitted on the duct during start-up ( “Fit-

ting the SR-unit on the measuring probe”, page 48) because these components first

require an adjustment away from the gas-carrying duct. To avoid problems during start-up,

the SR-unit and measuring probe must be stored in a dry place free from dust, preferably

at room temperature, until start-up.

CAUTION: Do not fit the SR-unit and measuring probe before start-up

Unfavorable ambient conditions or atmosphere in the measuring channel can

damage the measuring system which prevents start-up.

Apart from that, there is a health risk when opening the duct depending on the pressure,

gas temperature and composition in the sample gas duct.

4.3 Installing the purge air units (for GMP probe)

Installation of purge air unit

→ Operating Instructions of purge air unit.

INSTALLATION 4

4.3.1 Terminal box with 24 V power supply unit (option)

▸ Install the terminal box with 24 V power supply unit in the vicinity of the sampling point.

▸ Secure the enclosure using both mounting holes (∅ 5 mm)

▸ The cable length available from the terminal box to the SR-unit is 4 m.Take the empty

conduits laid for the prefabricated cables during onsite preinstallation into account.

Fig. 12: Fitting the terminal box with power supply unit

8010100/YK22/V4-0/2015-12 | SICK OPERATING INSTRUCTIONS | GM700

Subject to change without notice

35

Page 34

4 INSTALLATION

4 mounting holes

∅ 8mm

Mounting surface

Fastening brackets

4.4 Installing the evaluation unit

The fitting location for the evaluation unit was defined during project planning ( “Project

Planning Checklist”, page 24) and prepared during onsite preinstallation as required.

▸ Make sure the CAN bus connection to the SR-unit selected during project planning is

usable at the planned installation location. The CAN bus connection cable delivered as

standard is 4 m long and serves to connect the evaluation unit directly at the sampling

point.

▸ Ensure easy access without problems. In particular, make sure the swivel door of the

evaluation unit can be opened without hindrance after fitting.

4.4.1 Installing the evaluation unit – sheet metal enclosure version

▸ Drill mounting holes ∅7.2 mm (for M8) at the fitting location according to the Drilling

plan.

▸ Attach the evaluation unit at the installation location using the 4 planned fastening

brackets with suitable screws.

Fig. 13: Installing the evaluation unit (sheet metal enclosure version)

36

8010100/YK22/V4-0/2015-12 | SICKOPERATING INSTRUCTIONS | GM700

Subject to change without notice

Page 35

4.4.2 Installing the evaluation unit – cast-metal enclosure version

117.5

330

235

Swivel door

Mounting holes ∅ 7.2 mm

Mounting surface

The mounting holes are

accessible when the swivel

door is open.

Mounting holes

∅ 7.2 mm

1.

2.

▸ Drill mounting holes ∅7.2 mm (for M8) at the fitting location according to the Drilling plan.

Fig. 14: Mounting holes layout (Drilling plan) to fit the EvU (cast-metal enclosure)

INSTALLATION 4

▸ Open the enclosure cover with a control cabinet key and swivel open.

▸ Attach the evaluation unit at the installation location using the 3 planned mounting

holes with suitable screws (M8 x 20).

Fig. 15: Fitting the evaluation unit (cast enclosure)

▸ Close and lock the cover again.

8010100/YK22/V4-0/2015-12 | SICK OPERATING INSTRUCTIONS | GM700

Subject to change without notice

37

Page 36

4 INSTALLATION

4.5 Electrical connection of system components

Onsite preparation for electrical installation has been described in “Preparations for elec-

trical installation”, page 31. The cables laid as described there are now connected to the

system components.

CAUTION: Observe safety information as well as relevant safety regulations!

During all work on electrical equipment, disconnect such equipment from the mains,

check that the equipment is potential free and make sure that no third person can

switch the equipment back on again without authorization.

Electrical connections for purge air unit → Purge air unit Operating Instructions.

4.5.1 CAN bus wiring options

As already described in the project planning on “Preparations for electrical installation”,

page 31, the following options are available for wiring the CAN bus connection between SR-

unit and evaluation unit:

● Standard cable, 4 m, prefabricated

● Terminal box with prefabricated 4 m long cable to SR-unit; a cable provided by the

customer is used to connect to the evaluation unit.

Information on selecting a suitable type of wiring can be found under “Circuit diagram

(probe version)”, page 32.

38

8010100/YK22/V4-0/2015-12 | SICKOPERATING INSTRUCTIONS | GM700

Subject to change without notice

Page 37

INSTALLATION 4

Fuse 2.5 AT

230 /115 V AC

40…60 Hz

ST 1

250 V

ST 2

3

2

1

PENL1

ST 5ST 6 ST 7

ST 4

PG 13.5

PG 13.5

CAN-L

+24

GND

CAN-H

CAN GND

NC

5

4

3

2

1

6

CAN-L

CAN-H

CAN GND

3

2

1

CAN-L

+24

GND

CAN-H

CAN GND

5

4

3

2

1

NC

6

CAN

Terminator

Power supply

115 V/230 V AC

Sensor

Evaluation unit

Sensor

Prefabricated cable with plug,

4 m long, to SR-unit

Cable to evaluation unit

(provided by customer)

Cable to power supply

(provided by customer) (see

safety information)

CAN cable signals

Color Signal

Pink +24 V

Grey GND

Yel low C AN- H

Green CAN-L

Brown CAN-GND

White n.c.

WARNING: Endangerment of electrical safety

● The power cables must be adequately dimensioned.

● The power connection must be made via a circuit-breaker switch.

● The grounding cable must be connected.

Wiring in terminal box

Connections in the terminal box are wired as follows:

Fig. 16: Terminal box for CAN bus connection between SR-unit and evaluation unit

▸ Connect bridge (jumper) according to suitable voltage supply (ST2).

▸ Lead CAN cable (provided by customer) through the right PG screw fitting to terminal

strip.

▸ Connect shielding on the PG screw fittings on the enclosure.

▸ Connect wires to terminal strip ST5 as shown in “Evaluation unit connections”, page 40;

check that a twisted pair cable is used for CAN-H and CAN-L. Connect the respective

signals in the EvU and terminal box.

8010100/YK22/V4-0/2015-12 | SICK OPERATING INSTRUCTIONS | GM700

Subject to change without notice

39

Page 38

4 INSTALLATION

+ – + – + –

+ – + – + –

+ –

+ – + –

PE

N

L1

PE N L1

V 42+

H NAC

L NAC

V 42+

+– +– +–

115/230 V AC;

50/60 Hz

(3 x 1.5

2

)

+– +– +–

12

12 3

Power

+5V +24V

Power CAN

+24V

+ – H L GND

Digital in

Analog i n

0.. 20mA

100 100 100

40..60Hz

230V

or

115V

AO1 AO2 AO3DI1 DI2 AI1 AI2 AI3

Sensor

DO1 DO2 DO3

Digital out

AC/DC 48V 30VA 1A

Analog out

0.. 20mA

Sensor

Fuse 2.5 AT 250V

PE N L1

contrast

Tp

Enter meas

diag par cal maint

Operation

Service

Warning

Malfunction

GM 35

Evaluation Unit

Plug this bridge for 115 V and/or 120 V

voltage supply.

48 V AC/DC; 60 VA,

1 A (6 x 0.75

2

)

relay outputs

0...20 mA (6 x 0.75

2

)

Analog outputs

0...20 mA (6 x 0.5

2

)

Analog inputs

Pot.-free contact (6 x 0.75

2

)

Digital inputs

Failure

1)

Maintenance request

2)

Function contr.

2)

(CAN H, L twisted

pair, shielded)

GM700 SR-unit

and/or terminal

box

Operating elements board

Connections board

Cast-metal enclosure shown

1)

N/C contact

2)

N/O contact

WARNING: Endangerment of electrical safety

● The power cables must be adequately dimensioned.

● The power connection must be made via a circuit-breaker switch.

● The grounding cable must be connected.

(see safety information)

4.5.2 Electrical connection in the evaluation unit EvU

Cable laying to the evaluation unit and relevant specifications have already been shown in

“Circuit diagram (probe version)”, page 32.

Fig. 17: Evaluation unit connections

40

8010100/YK22/V4-0/2015-12 | SICKOPERATING INSTRUCTIONS | GM700

Subject to change without notice

Page 39

INSTALLATION 4

3

4

2

1

CAN cable

shielding

PG screw fitting on the

evaluation unit

CAN bus cable

PG screw fitting on

the EvU

▸

Open enclosure door of evaluation unit.

WARNING: Observe connection values for power supply!

The evaluation unit is configured to 230 V AC on delivery.

▸ Plug the respective bridges for 115 and/or 120 V AC as shown on the connection

plate of the evaluation unit.

▸ Ensure the power supply has been installed (see evaluation unit connections) according

to the specifications (observe national requirements), but with the power switched off.

▸ Connect protective conductor (PE) to the terminal on the enclosure floor

▸ Lead the signal cable for inputs and outputs through the PG screw fittings on the EvU

enclosure floor and wire according to “Evaluation unit connections”, page 40.

▸ When using the CAN cable provided by the customer, connect the wires to the “Sensor”

terminal strip. Do not connect +24 V and GND (ground).

Fig. 18: See steps 1 to 4 below Connecting the CAN bus cable to the evaluation unit

WARNING: Burns by touching the cable glands

The temperature on the cable glands can be >60 °C.

8010100/YK22/V4-0/2015-12 | SICK OPERATING INSTRUCTIONS | GM700

Subject to change without notice

41

Page 40

5 HANDLING THE EVALUATION UNIT

GM700

Evaluation Unit

NH3

mg/

m

3

236

Operation

Service

Warning

Malfunction

GM

Evaluation Unit

NH3

mg/

m

3

236

Ref. conditions

Hum: wet

Enter meas

diag par cal maint

Measuring

Operation

Service

Warning

Malfunction

GM 35

Evaluation Unit

CO

CO

2

H2O

mg/

m

3

236

Ref. conditions

Hum: wet

Enter meas

diag par cal maint

Measuring

Measuring

Enter meas

maintcalpardiag

Operation

Service

Warning

Malfunction

Ref. conditions

Hum: wet

Graphic display for measured value

display and navigation

Status LEDs to indicate operating and

malfunction states

Key pad for navigation and

entering data

Key pad for menu selection

5 Handling the Evaluation Unit

5.1 User qualifications

This Section describes how to operate the GM700 measuring system with the evaluation

unit (EvU). The evaluation unit is available with either a sheet metal enclosure (protection

class IP 65) or a cast-metal enclosure (protection class IP 67). The work described in this

Section can be carried out by qualified customer operating personnel. Setting parameters

does however demand comprehensive knowledge of the measuring system, measuring

technology and specific measuring task.

5.2 Operating elements

The evaluation unit of the analysis system serves to display, enter and set parameters and

control functions on the system. The operator panel with the display, status indicators and

key pad is accessible when the enclosure door is opened.

Fig. 19: Evaluation unit display and operating elements (shown with sheet metal enclosure)

42

Arrow keys

Enter

Display in measuring

mode

Navigate, select, scroll or edit menu items, variables, units or digits.

Execute the selected menu contents or commands.

Displays all current measured values (temperature values resp, gas

concentration);

Displays computed values

8010100/YK22/V4-0/2015-12 | SICKOPERATING INSTRUCTIONS | GM700

Subject to change without notice

Page 41

LEDs

Measuring

T=150 °C

←

● Operation

● Service

● Warning

● Malfunction

Display contents

HANDLING THE EVALUATION UNIT 5

Measuring operation

Service mode

Warning messages, see Diagnostic mode (diag)

Device malfunction, error message, see Diagnostic mode (diag)

● The header line shows the selected operating mode (e,g,

parameter settings) or the menu items just selected during

navigation.

● 4 lines to show submenus, plain-text messages or settings

(values)

● Function line:

←

back Use button Arrow ← to return to next higher level

edit Enter Use button Enter to activate menu item or confirm

input

select Use button Enter to select a variable

↑ (↓) When selecting a variable requiring numeric input,

use buttons

per digit

Password When a password is prompted, enter the code

1 2 3 4 using↑ (↓).

Arrow ↑ (↓) to set the numeric value

5.2.1 Menu overview

Mode Menu

Measuring Measuring

operation

Diagnosis Malfunction

Warning

Sensor values

GM700 Sens. values

Sample Cross-Duct: OH

Parameters Setting

Physical

Unit

GM700

Cross-Duct Refl.

Component Unit:

Ref. condition:

Average Avg. Time:

Meas. Distance Active:

Gas Temperature Source:

Subst.

Pressure Source:

Subst.

Tab le 4 : GM700 menu overview

● Current measured values depending on device

version

● Reference variables (wet, dry)

● Current error messages (plain-text)

● Current warning messages (plain-text)

● Displays diagnostic values and control values

● Current monitored sensor values (amplification

setting, internal temperature control, control

values, etc.)

● Parameter settings/display of system

components

● mg/m

● t: actual, 25 °C, 20 °C, 0 °C

● p: actual, 1013 mbar

● Hum.: wet, dry

● 0 ... 300 s

● 200 ... 8000 mm

● Probe, Subst. Analog In

● –100 ... 2000 °C

● Probe, Subst. Analog In

● 600 ... 15000 hPa

3

, ppm

8010100/YK22/V4-0/2015-12 | SICK OPERATING INSTRUCTIONS | GM700

Subject to change without notice

43

Page 42

5 HANDLING THE EVALUATION UNIT

Humidity Subst.

Analog Out Live Zero

Output 1

Output 2

Output 3

Analog In Input 1 T

Input 2 p

Coefficients

Funct.

Span (HF)

Zero (HF)

Ambient Temp. Range

t (Feed Test Gas) Period

Check cycle Period

Zero Adjust Enable

Repet.

t (purge)

t (delay)

Delta T

Device Serial Number Head.

Laser

EvU

Software Revision

Tab le 4 : GM700 menu overview

● 0 ... 93.0 percent by volume

● 0, 4 mA

● Component: e.g. HF, - -, p, T

● Range low: 0 ... 999999

● Range high: 0 ... 999999

● Cycle Out: No, Yes

● Component: e.g. HF, - -, p, T

● Range low: 0 ... 999999

● Range high: 0 ... 999999

● Cycle Out: No, Yes

● Component: e.g. HF, - -, p, T

● Range low: 0 ... 999999

● Range high: 0 ... 999999