Page 1

I

GM35 Probe

Gas Analyzer for CO, N2O, CO2 and H2O

Version with Measuring Probe

Installation, Operation, Maintenance

MMMOPERATING INSTRUCTIONS

OPERATING INSTRUCTIONS

MMM

Page 2

Document ID

Title: Operating Instructions GM35

Part No.: 8009389

Release: 2015-08

Described Product

Product name: GM35

Version: 3-0

Manufacturer

SICK AG

Erwin-Sick-Str. 1 · 79183 Waldkirch · Germany

Phone: +49 7641 469-0

Fax: +49 7641 469-1149

E-Mail: info.pa@sick.de

Place of Manufacture

SICK AG

Nimburger Str. 11 · D-79276 Reute · Germany

Legal Information

This work is protected by copyright. All rights derived from the copyright shall

be reserved for SICK AG. Reproduction of this document or parts of this document is

only permissible within the limits of the legal determination of Copyright Law.

Any modification, shortening or translation of this document is prohibited without the

written permission of SICK AG.

The trademarks stated in this document are the property of their respective owner.

© SICK AG. All rights reserved.

Original document

This document is an original document of SICK AG.

2

8009389/YN39/V3-0/2015-08| SICKOPERATING INSTRUCTIONS | GM35

Subject to change without notice

Page 3

Contents

Contents

CONTENTS

1 Safety Information..................................................................................... 9

1.1 Permissible users............................................................................................ 9

1.2 Correct handling.............................................................................................. 9

1.3 Safety............................................................................................................... 9

1.4 Behavior during purge air failure..................................................................10

2 Product Overview .....................................................................................11

2.1 Use and proper application ..........................................................................11

2.1.1 Conformities and certifications ....................................................11

2.1.2 Overview of standard components ..............................................12

2.1.2.1 Measuring probe in detail.........................................14

2.1.2.2 GMP – probe with open measuring gap and vertical

purge air outlet..........................................................14

2.1.3 GM35 options and accessories ...................................................18

2.2 Functional principle ......................................................................................19

2.2.1 Opto-electronic in-situ measuring principle.................................19

2.2.2 Signal evaluation ..........................................................................20

2.2.3 Automatic check cycles ................................................................21

3 Project Planning Information................................................................. 22

3.1 Work steps from system selection to start-up .............................................22

3.2 Project Planning Checklist ............................................................................23

3.3 Initial onsite installation ...............................................................................26

3.3.1 Assembly preparation at the measuring point ............................26

3.3.2 Uncovering the duct......................................................................27

3.3.3 Installing the flange with tube......................................................27

3.3.3.1 Installation steps: Fitting the flange with tube ........28

3.3.4 Installation preparation for the purge air unit .............................29

3.3.5 Duct insulation..............................................................................29

3.3.6 Installation preparation for the evaluation unit ..........................30

3.4 Preparations for electrical installation .........................................................30

3.5 Electrical protection ......................................................................................30

3.6 Specifications on electric isolation of the EvU.............................................30

3.6.1 Electrical installation safety information .....................................30

3.7 Electrical protection ......................................................................................32

3.8 Specifications on electric isolation of the EvU.............................................32

3.9 Laying connection lines ................................................................................33

3.9.1 CAN bus wiring ..............................................................................34

4 Installation ................................................................................................36

4.1 Preparations..................................................................................................36

4.1.1 Checking the scope of delivery ....................................................36

4.1.2 Installation prerequisites..............................................................36

8009389/YN39/V3-0/2015-08| SICK OPERATING INSTRUCTIONS | GM35

Subject to change without notice

3

Page 4

CONTENTS

4.2 Fitting system components .......................................................................... 37

4.2.1 Information on the SR-unit and measuring probe ...................... 37

4.2.2 Installing the purge air unit.......................................................... 37

4.2.3 Terminal box (option) ................................................................... 38

4.3 Installing the evaluation unit........................................................................ 39

4.3.1 Installing the evaluation unit – sheet metal enclosure version. 39

4.3.2 Installing the evaluation unit – cast enclosure version.............. 40

4.4 Electrical connection of system components.............................................. 41

4.4.1 Electrical connection for the purge air unit................................. 41

4.4.2 CAN bus wiring options ................................................................ 42

4.4.3 Electrical connection of the evaluation unit ............................... 44

5 Handling the Evaluation Unit .................................................................47

5.1 User qualifications........................................................................................ 47

5.2 Operating elements ...................................................................................... 47

5.2.1 Function buttons and menu overview ......................................... 48

5.2.2 Display contents........................................................................... 49

5.2.3 Menu structure............................................................................. 49

5.2.3.1 Menu structure Measuring Mode ............................ 49

5.2.3.2 Menu structure Diagnosis ........................................ 50

5.2.3.3 Menu structure Calibration ...................................... 50

5.2.3.4 Menu structure Configuration .................................. 51

5.2.3.5 Menu structure Maintenance Mode (Maint) ........... 52

6 Connecting the System Control Unit - SCU........................................... 53

6.1 SCU connection to the GM35....................................................................... 53

6.1.1 Electrical connection of the SCU to the GM35 ........................... 53

6.1.2 Configuring and operating using SOPAS ..................................... 53

6.1.3 Connecting the GM35 evaluation unit via the SCU operating

unit................................................................................................ 55

6.1.4 Direct serial connection to the GM35 evaluation unit .............. 57

6.1.5 Changing the user level ............................................................... 59

6.1.6 Menu overview (menu tree) ........................................................ 60

6.1.7 Measured values.......................................................................... 60

6.1.8 Menu Parameter .......................................................................... 61

6.1.9 Menu Adjustment ......................................................................... 66

6.1.10 Menu Diagnosis............................................................................ 70

6.1.11 Menu Maintenance ...................................................................... 72

7 Start-up...................................................................................................... 75

7.1 Preparations ................................................................................................. 75

7.1.1 Required qualifications and further prerequisites...................... 75

7.1.2 Start-up procedure overview........................................................ 75

7.2 General preparation ..................................................................................... 75

7.2.1 Required tools and materials for the installation ....................... 76

4

8009389/YN39/V3-0/20 15-08| SICKOPERATING INSTRUCTIONS | GM35

Subject to change without notice

Page 5

CONTENTS

7.3 Mechanical preparations for the SR-unit and reflector ...............................77

7.3.1 Checking the scope of delivery ....................................................77

7.3.2 Transport safety devices ..............................................................77

7.3.3 Cleaning the optical interface ......................................................78

7.4 Aligning the measuring probe in flow direction ...........................................79

7.4.1 Installing the SR-unit on the measuring probe............................80

7.5 Adjustment work ...........................................................................................82

7.5.1 Prerequisites and location selection for adjustment work .........82

7.5.2 Adjustment preparations..............................................................83

7.5.3 Aligning the optical axis of the measuring probe ........................84

7.5.4 Performing zero adjust .................................................................87

7.6 Starting measuring operation.......................................................................88

7.6.1 Starting up the purge air supply...................................................88

7.6.2 GPP measuring probes: Power supply .........................................89

7.6.3 Installing the GM35 SR-unit and measuring probe on the duct.89

7.6.4 Electrical connections and checking the optical alignment .......90

7.6.5 Weatherproof cover ......................................................................92

7.6.6 Evaluation unit start-up ................................................................93

7.6.7 Setting up the SCU System Control Unit .....................................93

7.6.7 Mapping Table...........................................................93

7.6.7 Measured values on SCU – Measured value (MV) ..93

7.6.7 Control values on SCU – Monitor values (MO).........93

7.6.7 Operating state of the GM35 – State (S) .................94

8 Test Gas Measurement with GPP Measuring Probes.........................96

8.1 One-off preliminary measurement/determining the settings .....................97

8.2 Manual gas test ............................................................................................98

9 Maintenance............................................................................................. 99

9.1 Safety.............................................................................................................99

9.2 Preparation and general preparatory work ............................................... 101

9.3 Maintenance work on SR-unit and measuring probe ............................... 103

9.3.1 Taking the SR-unit with measuring probe off the sample

gas duct...................................................................................... 103

9.3.2 Visual inspection and enclosure cleaning ................................ 104

9.3.3 Cleaning the optical interfaces on the SR-unit......................... 104

9.4 Maintenance work on the purge air supply .............................................. 106

9.4.1 Safety ......................................................................................... 106

9.4.2 General information on maintenance work on the purge

air supply.................................................................................... 106

9.4.3 Preparation and general inspection ......................................... 106

9.4.4 Checking and replacing the purge air filter .............................. 107

9.4.5 Restarting and checking the purge air unit .............................. 109

8009389/YN39/V3-0/2015-08| SICK OPERATING INSTRUCTIONS | GM35

Subject to change without notice

5

Page 6

CONTENTS

9.5 Resuming Measuring mode .......................................................................109

9.5.1 Inserting in the sample gas duct ...............................................109

9.5.2 Electrical connection..................................................................110

9.5.3 Checking and adjusting the optical alignment of GM35 .........111

9.5.4 Completing maintenance work at the measuring point ...........112

9.6 Evaluation unit (EvU) ..................................................................................112

9.7 Box measuring: Checking the measuring ducts for CO or N

and CO

......................................................................................113

2

O

2

9.7.1 Determining the necessary test gas concentration ..................113

9.7.2 Carrying out measurement ........................................................113

9.7.3 Restart Measuring mode ...........................................................115

9.8 Box measuring: Checking the measuring ducts for H

CO

..............................................................................................116

2

O and

2

9.8.1 Setpoint values........................................................................... 116

9.8.2 Carrying out measurement ........................................................116

9.8.3 Restart Measuring mode ...........................................................118

10 Troubleshooting and Clearing Malfunctions......................................119

10.1 Malfunction categories/possible effects................................................... 119

10.2 Purge air failure .......................................................................................... 119

10.3 Integrated monitoring and diagnosis system ............................................120

10.3.1 Troubleshooting and clearing malfunctions, evaluation unit...121

10.3.2 Error messages for the GM35 SR-unit ......................................121

10.3.3 Error messages for the measuring probe .................................124

10.3.4 Warning messages for the GM35 SR-unit.................................124

10.3.5 Warning messages for the measuring probes ..........................126

10.3.6 Further tips on troubleshooting .................................................126

11 Technical Data, Consumables and Spare Parts...............................128

11.1 Data Tables.................................................................................................128

11.1.1 Measuring components and accuracy ......................................128

11.1.2 Stability....................................................................................... 129

11.1.3 GM35-system components

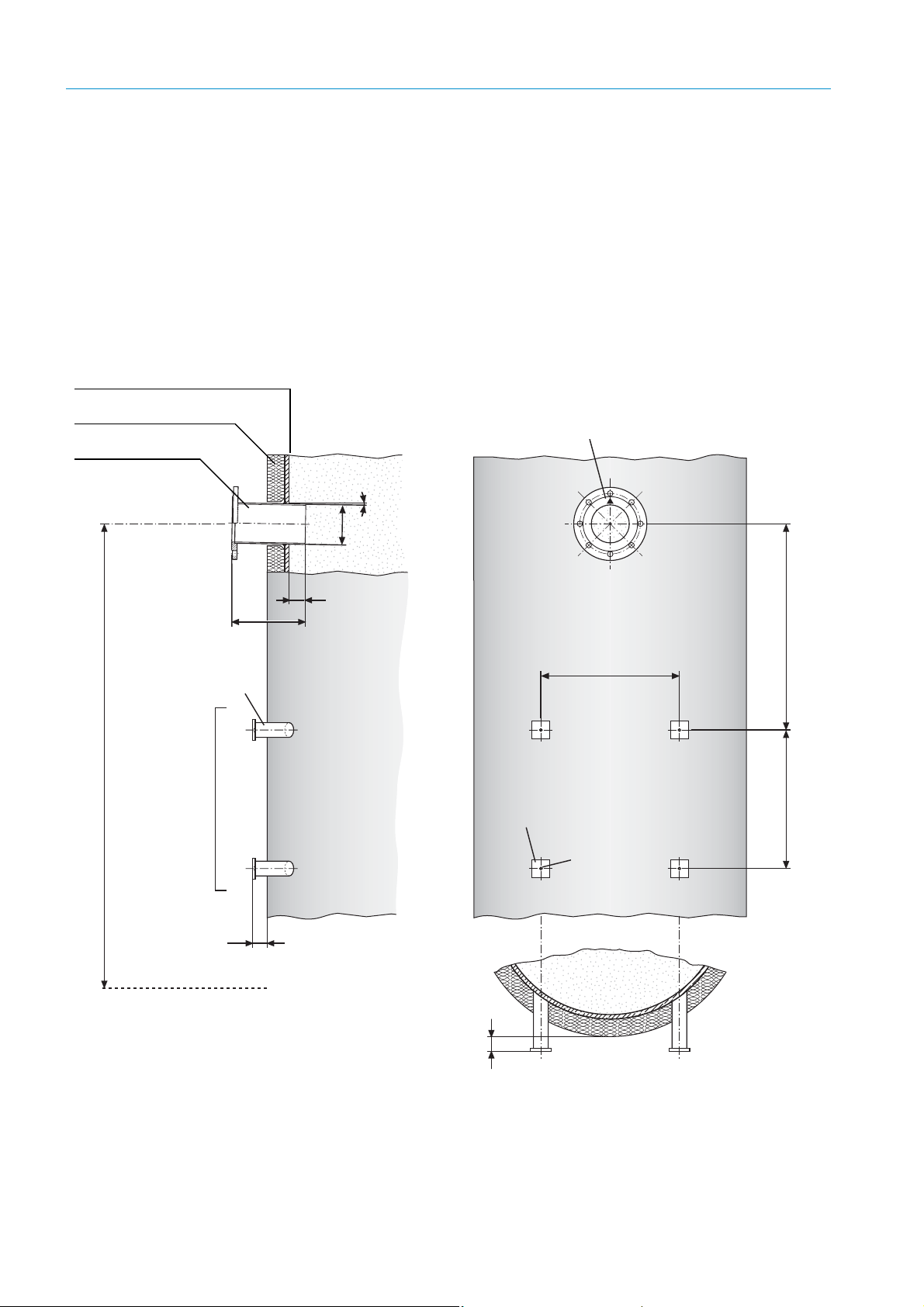

11.2 Dimension drawings ...................................................................................132

11.2.1 GM35 SR-unit dimensions........................................................132

11.2.2 Open measuring probe - GMP, dimensions...............................133

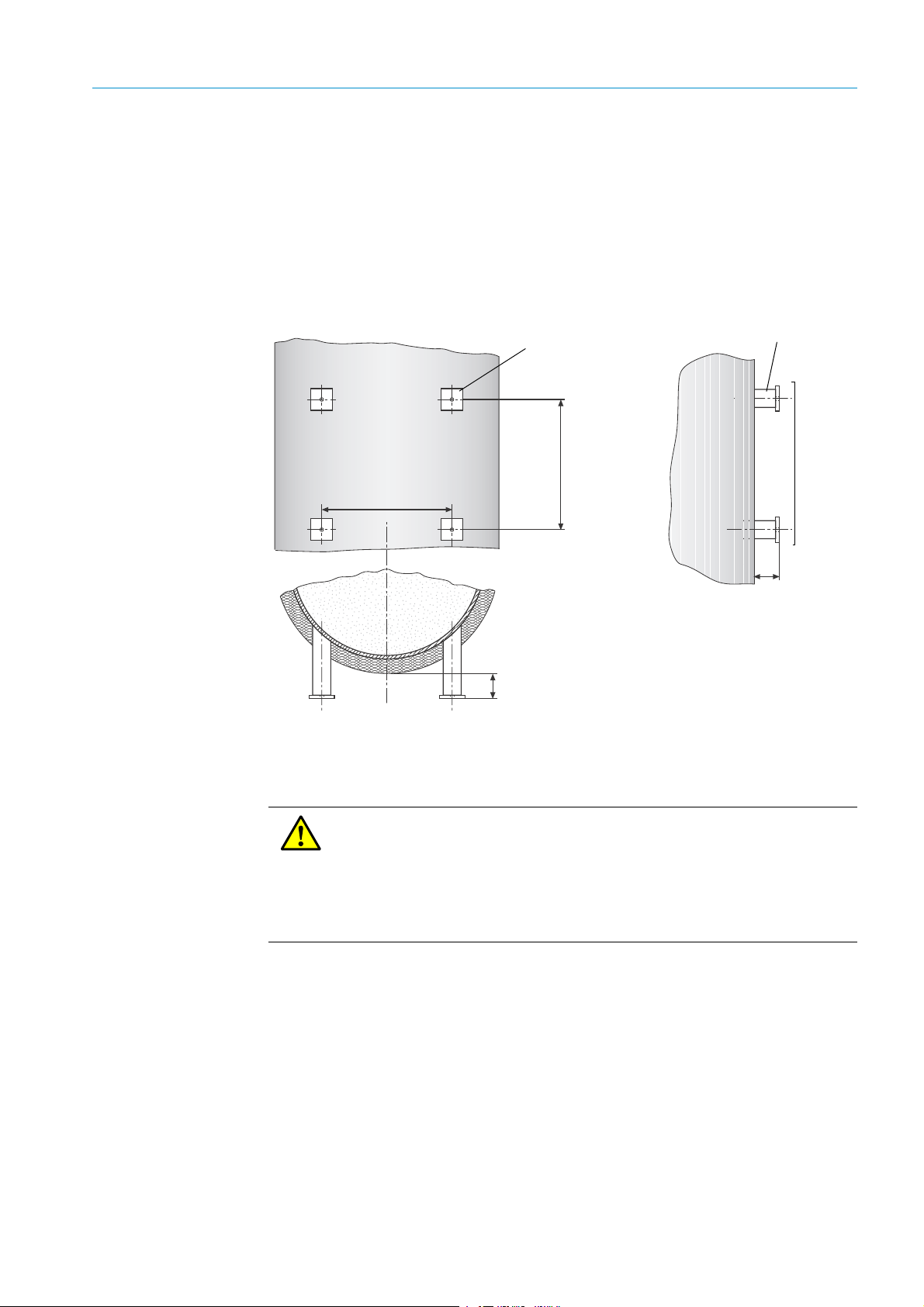

11.2.3 GPP measuring probes dimensions .......................................... 134

11.2.4 Dimension drawing of GM35 evaluation unit, sheet metal

enclosure ....................................................................................135

11.2.5 Dimension drawing for GM35 evaluation unit, cast enclosure136

11.2.6 Purge air unit dimension drawing.............................................. 137

11.2.7 Weatherproof covers dimension drawings................................ 137

11.2.8 Terminal box for CAN bus connection, dimension drawing......139

11.2.9 Flange with tube, dimension drawing and Version Table......... 139

................................................ 130

6

8009389/YN39/V3-0/20 15-08| SICKOPERATING INSTRUCTIONS | GM35

Subject to change without notice

Page 7

CONTENTS

11.3 Consumables and spare parts .................................................................. 140

11.3.1 Consumable parts for 2-years operation .................................. 140

11.3.2 Spare parts for the sender/receiver unit.................................. 140

11.3.3 Probe spare parts ...................................................................... 143

11.3.4 Spare parts for the evaluation unit........................................... 144

11.3.5 Spare parts for purge air unit.................................................... 145

11.3.6 Spare parts, miscellaneous....................................................... 145

11.3.7 Fixing accessories...................................................................... 145

11.3.7 Fixing accessories, measuring probe - flange....... 145

11.3.7 Fixing accessories, SR-unit - measuring probe ..... 145

8009389/YN39/V3-0/2015-08| SICK OPERATING INSTRUCTIONS | GM35

Subject to change without notice

7

Page 8

CONTENTS

8

8009389/YN39/V3-0/20 15-08| SICKOPERATING INSTRUCTIONS | GM35

Subject to change without notice

Page 9

1 Safety Information

The following information and guidelines apply to the Gas Analyzer with Measuring Probe

GM35 described in this “Operating Instructions” document, and are valid for all user

groups performing any work on or using the analyzer.

1.1 Permissible users

All planning, assembly, installation, start-up, maintenance and repair work must be carried

out by adequately instructed personnel only and checked by skilled persons.

Persons responsible for safety must ensure the following:

• All safety-relevant work is carried out by qualified personnel only.

• Qualified persons are those who, based on their training, experience or instruction as

well as their knowledge of relevant standards, regulations, accident prevention rules and

plant conditions, are authorized by those responsible for safety for personnel and the

plant to carry out such work. It is decisive that these persons can recognize and avoid

possible hazards in a timely manner. Skilled persons are persons according to

DIN VDE 0105 or IEC 364 or directly comparable standards such as DIN 0832.

• These persons have access to the documentation supplied with the system as well as the

relevant technical documentation for all work carried out, and these persons adhere to

the information in this documentation in order to prevent danger or damage.

SAFETY INFORMATION

1.2 Correct handling

To ensure safety precautions are observed and the device is used for its intended purpose,

it is important that:

• The system be used in accordance with the technical data and specifications regarding

permissible usage, assembly, connection, ambient, and operating conditions. These

conditions are governed by the order documents, user information (type plates etc.), as

well as the documentation supplied with the system, which includes these

Operating Instructions.

• Users act in accordance with local, system-specific conditions and with due

consideration paid to operational hazards and specifications.

• All measures necessary for conservation of value are observed, e.g. during transport and

storage and/or maintenance and inspection.

1.3 Safety

WARNING: Risk through incorrect use

Equipment-internal protection devices can be impaired when the device is not

used as defined.

▸ Read the Manual before installation, start-up, operation and

maintenance and observe all information on using the equipment.

NOTICE: Responsibility for the safety of a system

The safety of the system in which the equipment is integrated is the

responsibility of the person setting up the system.

Basic measures to prevent property damage and injury to persons

Improper usage or improper handling of Gas Analyzer GM35 can damage health or

material.

8009389/YN39/V3-0/2015-08| SICK OPERATING INSTRUCTIONS|GM35

Subject to change without notice

9

Page 10

SAFETY INFORMATION

▸ Therefore, in order to prevent damage, the relevant safety information and valid safety

If the GM35 is used as a sensor in combination with a control system, the operator must

ensure that a failure or malfunction on the GM35 cannot lead to unallowed hazardous

operating states or damage.

Protection against hazards through electrical equipment

GM35 system components include electrical equipment designed for use in industrial highvoltage plants where the relevant standards and regulations must be observed.

▸ Disconnect mains lines before working on mains connections or live parts.

Protection against hazards through gases

▸ Wear suitable protective clothing and mask when using hot and/or aggressive sample

▸ Never open the enclosure or switch off the purge air feed without taking appropriate

Troubleshooting precautions

The operator must ensure that:

• Maintenance personnel can be alerted immediately and at any time.

• Maintenance personnel are trained to be able to respond to malfunctions on the GM35

• Suitable protective equipment, tools and auxiliary means are available at all times.

• Malfunctions are analyzed by qualified personnel, faults corrected, and operation

regulations must be observed.

gases resp. with high dust loads.

protective measures when the duct is pressurized.

and correctly clear the operational malfunction involved.

optimized to prevent similar malfunctions in the future.

1.4 Behavior during purge air failure

The GM35 measuring system configurations demand immediate measures to protect the

measuring system should the purge air supply fail.

▸ Measures for purge air supply failure,

see “Purge air failure”, page 119.

10

8009389/YN39/V3-0/2015-08| SICKOPERATING INSTRUCTIONS|GM35

Subject to change without notice

Page 11

2Product Overview

2.1 Use and proper application

PRODUCT OVERVIEW

The GM35 in-situ gas analyzer continuously measures the concentration of CO

CO or N2O, and in gas ducts – as single or simultaneous measurement depending on the

device variant. As in-situ measuring system, the GM35 determines the measured values

directly in the gas-carrying duct without extracting any samples.

• Emission monitoring

The GM35 determines and quantifies pollutants and reference values in gases reliably,

quickly and precisely.

• Process analysis and control

The reliability, precision, and short response time of the GM35 are decisive advantages in

the efficiency of control circuits in all processing creating CO, N

and drying plants are reliably monitored and efficiently controlled.

2.1.1 Conformities and certifications

Many areas of application require conformity with certain specifications. The Gas Analyzer

with Measuring Probe GM35 complies with the following requirements:

• Guidelines regarding qualification tests for measuring equipment intended for

continuous emission measurements

• Performance testing of ± 2% precision of the measuring range end value (TÜV certified)

• Conformity according to EN 14181 and suitability for emission measurement in plants

according to the 13

components CO, CO

• Conformity with the GOST regulation, Certificate No. DE.C.31.001.A No. 11933

• Conformity with the U.S. EPA regulation CFR 40, Parts 60, 75 and 29 CFR 1310

• KAITEC certified (Korea)

• EMV conformity in accordance with EN 50081-1/EN 50082-2

• CE conformity in accordance with EC Directive EMC 89/336/EWG

• The manufacturer SICK is certified according to ISO 9001

• EC Directive LVD 2006/95/EC

• EU Directive EMC 2004/108/EC

• Applied EN standards:

• EN 61010-1, Safety requirements for electrical equipment for measurement, control and

laboratory use

• EN 61326, Electrical equipment for measurement, control and laboratory use - EMC

requirements

O- and CO2. Incinerating

2

th

, 17th BImSchV and the TI Air, KAITEC certified (Korea) for

and H2O (Cross-Duct and GMP measuring probe versions)

2

2, H2

O and

8009389/YN39/V3-0/2015-08| SICK OPERATING INSTRUCTIONS|GM35

Subject to change without notice

11

Page 12

PRODUCT OVERVIEW

maintcalpardiag

GM 35

Evaluation Unit

CO

CO

2

H 2 O

mg/

m

3

236

Ref. conditions

Hum: wet

Measuring

Operation

Service

Warnin

Malfunction

Purge air unit SLV4

(not required when

using GPP measuring

probes)

GM35 sender/receiver unit

with GMP measuring probe

Temperature

sensor

Evaluation unit

EvU

CAN bus

CAN

Inputs/outputs

analog, binary

Interfaces to plant

peripherals:

•Host computer

•Sensors

• Measured data

processing

• Status signals

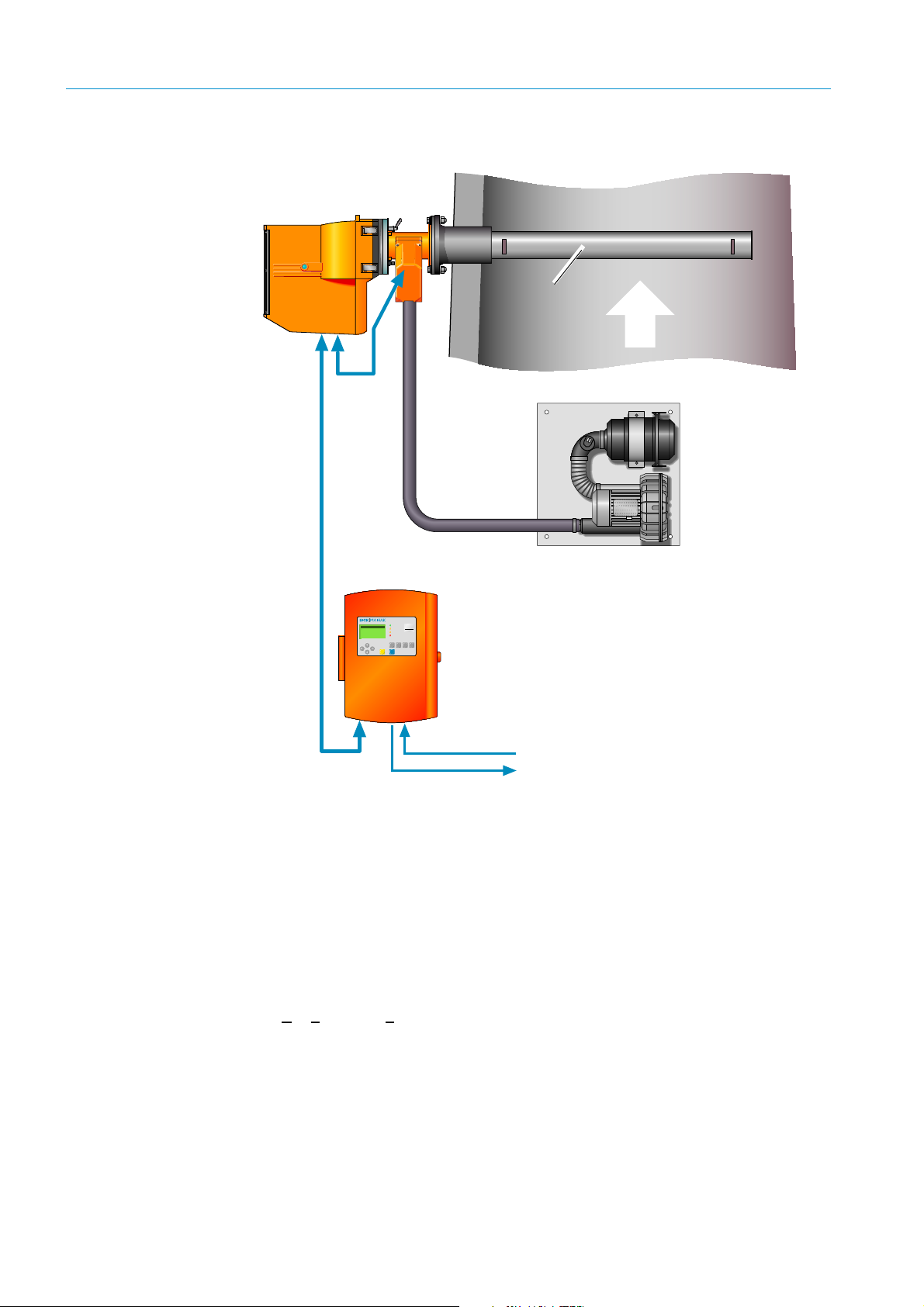

2.1.2 Overview of standard components

Fig. 1: GM35 system overview

• Sender/receiver unit (SR-unit)

Contains the main optical and electronic subassemblies of the measuring system. Records

gas concentrations, calculates measured values, measures components CO or N

and H

O; both singly and simultaneously in combinations.

2

O, CO2

2

• Measuring probe

Measuring probes are available in open design versions with integrated purge air guidance

system (GMP) as well as versions with a gas-permeable diaphragm not requiring purge air

(GPP: G

as Permeable Probe). Both versions are described from page 14 onwards.

• Purge air unit

Provides purge air supply for the SR-unit with a GMP measuring probe (open design) and

protects against contamination and high gas temperatures. The blower types for the

SR-unit resp. reflector are designed differently depending on the application.

12

8009389/YN39/V3-0/2015-08| SICKOPERATING INSTRUCTIONS|GM35

Subject to change without notice

Page 13

PRODUCT OVERVIEW

• Evaluation unit

The evaluation unit in the GM35 measuring systems serves as user interface and

prepares and outputs the measured values and performs control and monitoring

functions. The EvU can be installed near the SR-unit; if necessary, however, it can also

be installed up to 1000 m from the measuring point, e.g. in a central control/monitoring

room in an industrial plant.

The evaluation unit carries out the following tasks, for example:

– Output of measured values, computed data and operating states

– Communication with the peripheral equipment

– Output of error messages and other status signals

– Control of automatic test functions and access during service (diagnosis)

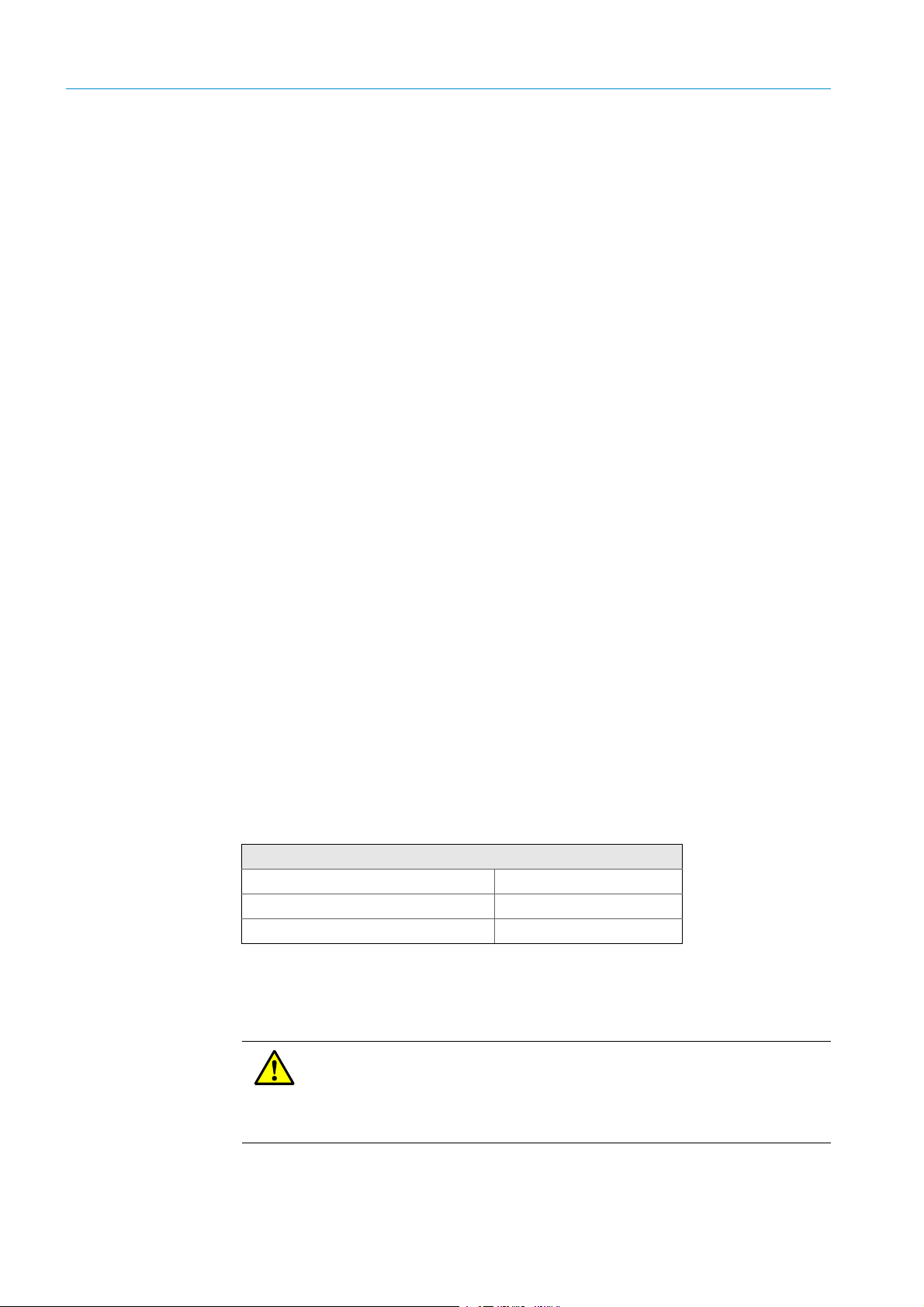

• Connection cables

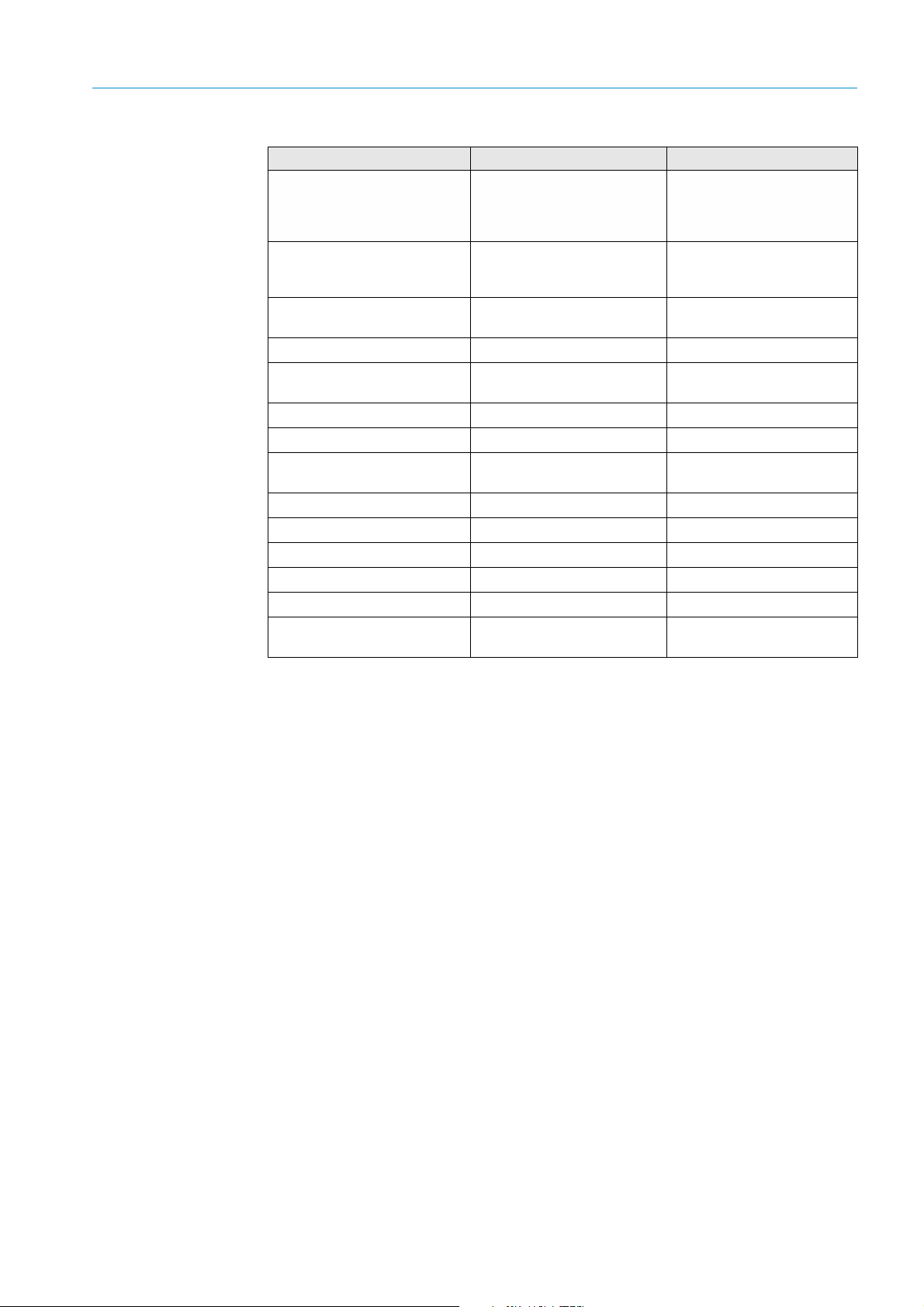

Cable type Part No.

Cable*) (CAN bus), SR-unit – measuring probe, length 1.0 m 2023704

[1]

Cable

Cable

(CAN bus), SR-unit – evaluation unit, length 4 m

*)

, measuring probe – filter monitor for purge air unit, length

5m

*)

2 cables

, measuring probe – filter monitor for purge air unit, length

2 m as extension

Cable, measuring probe – filter monitor for purge air unit, length 3 m

as extension

Scope of

delivery

2032143

6025923

6028663

[1]Included in scope of delivery

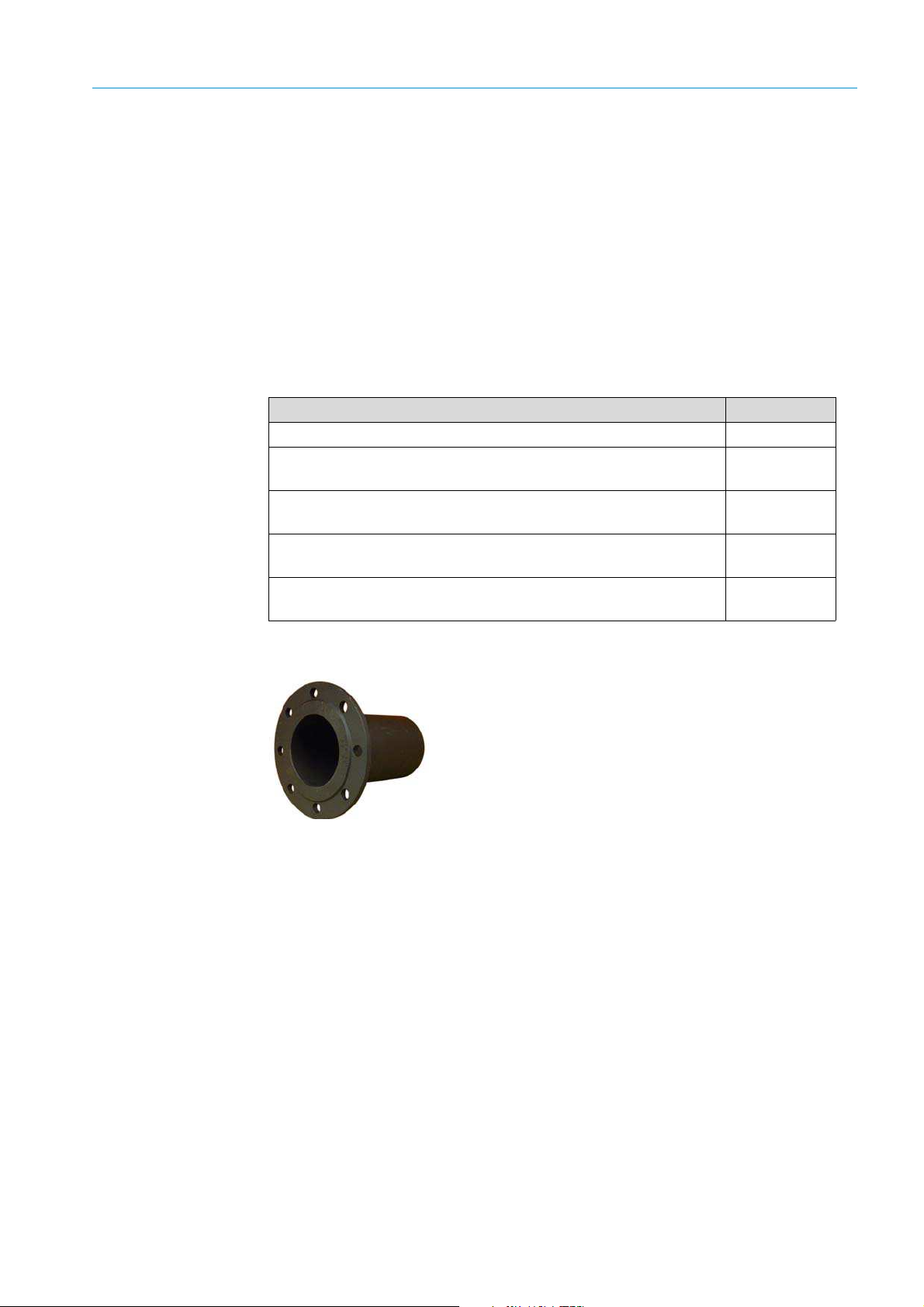

• Flanges with tube

To install the SR-unit with measuring probe on the gas duct.

The purge air fixtures onto which the SR-unit and reflector are

later mounted are secured to the flanges. Dimension drawing

and order data,

page 139. ANSI or DIN flanges provided by the

customer can be used alternatively to the flanges supplied.

8009389/YN39/V3-0/2015-08| SICK OPERATING INSTRUCTIONS|GM35

Subject to change without notice

13

Page 14

PRODUCT OVERVIEW

2.1.2.1 Measuring probe in detail

EPA conformity When using a GPP probe, an audit measurement in compliance with EPA CFR 40 Part 60 or

Part 75 can be performed with the device mounted.

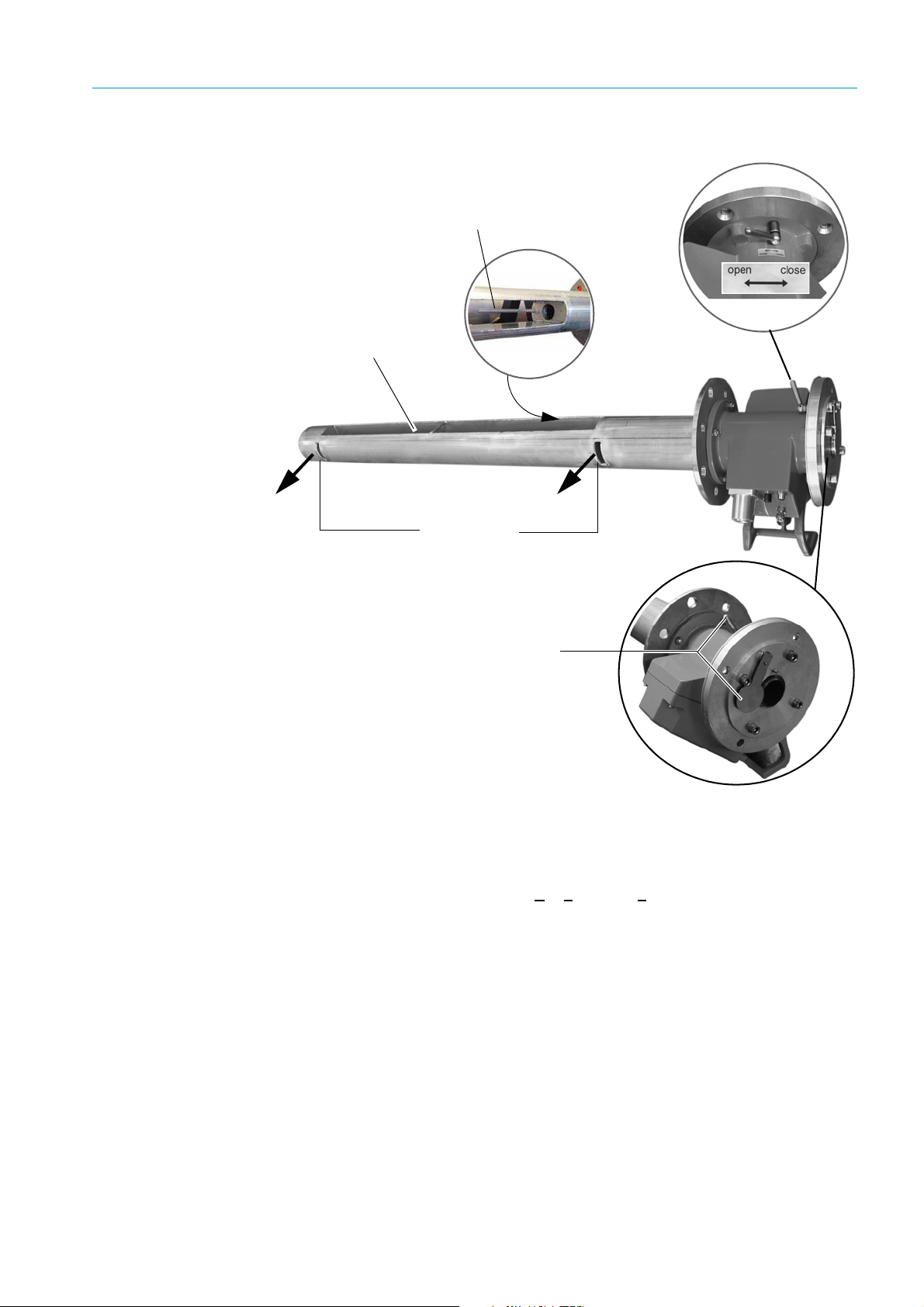

2.1.2.2 GMP – probe with open measuring gap and vertical purge air outlet

Shortest response times and resistance against high temperatures characterize measuring

probes of the GMP series. A continuous purge air supply is required for operation. In the

current GMP probe series, the air is outlet into the duct at 90° to the gas flow (directed

purge air).

The GMP probe has a closing device towards the opening for sample gas and is operated

using the lever on the probe flange.

14

8009389/YN39/V3-0/2015-08| SICKOPERATING INSTRUCTIONS|GM35

Subject to change without notice

Page 15

PRODUCT OVERVIEW

Tempera ture sensor

PT 1000

Purge air outlet

Open measuring path

(measuring gap)

Lever position

Lever and closing

device: Open

Fig. 2: GMP measuring probe (with open measuring gap)

GPP – gas diffusion probe as dry or wet version

These GPP probe versions are more suitable for higher dust contents than GMP probes

because the GMP probes separate dust particles at the filter element which keeps the dust

away from the measuring path. The GPP (G

as Permeable Probe) is also the best measuring

probe choice for audit measurements according to EPA specifications as well as for low

flow rates or irregular flow profiles.

8009389/YN39/V3-0/2015-08| SICK OPERATING INSTRUCTIONS|GM35

Subject to change without notice

15

Page 16

PRODUCT OVERVIEW

Temperature sensor PT 1000

Ceramic filter or Teflon/

ceramic filter, gas permeable

Fig. 3: Measuring gap for GPP measuring probe

The two versions of the GPP differ with regard to the respective filter making them suitable

for different applications,

see page 17.

Advantages of GPP

probes

GPP probes do not require a purge air supply and are easy to maintain. They are fitted with

an automatic heater for reliable prevention of condensate on the optical interfaces. The

electronic components for the heater regulator, and temperature and pressure

measurements, are located protected in a stable cast housing which forms the measuring

probe section between the duct flange and the SR-unit.

The Figure below shows this housing fitted with the electrical connections for the CAN bus

and power supply as well as the test gas connection which supports audit measurement

according to EPA Directive CFR 40, Part 60 or Part 75.

16

Fig. 4: Electronic connections on the GPP probe

GM35 measuring probes in comparison

This Table shows an overview of the features of the different measuring probes. All

measuring probe versions are compatible with all SR-units. The SR-unit is calibrated to the

respective probe length on delivery.

8009389/YN39/V3-0/2015-08| SICKOPERATING INSTRUCTIONS|GM35

Subject to change without notice

Page 17

PRODUCT OVERVIEW

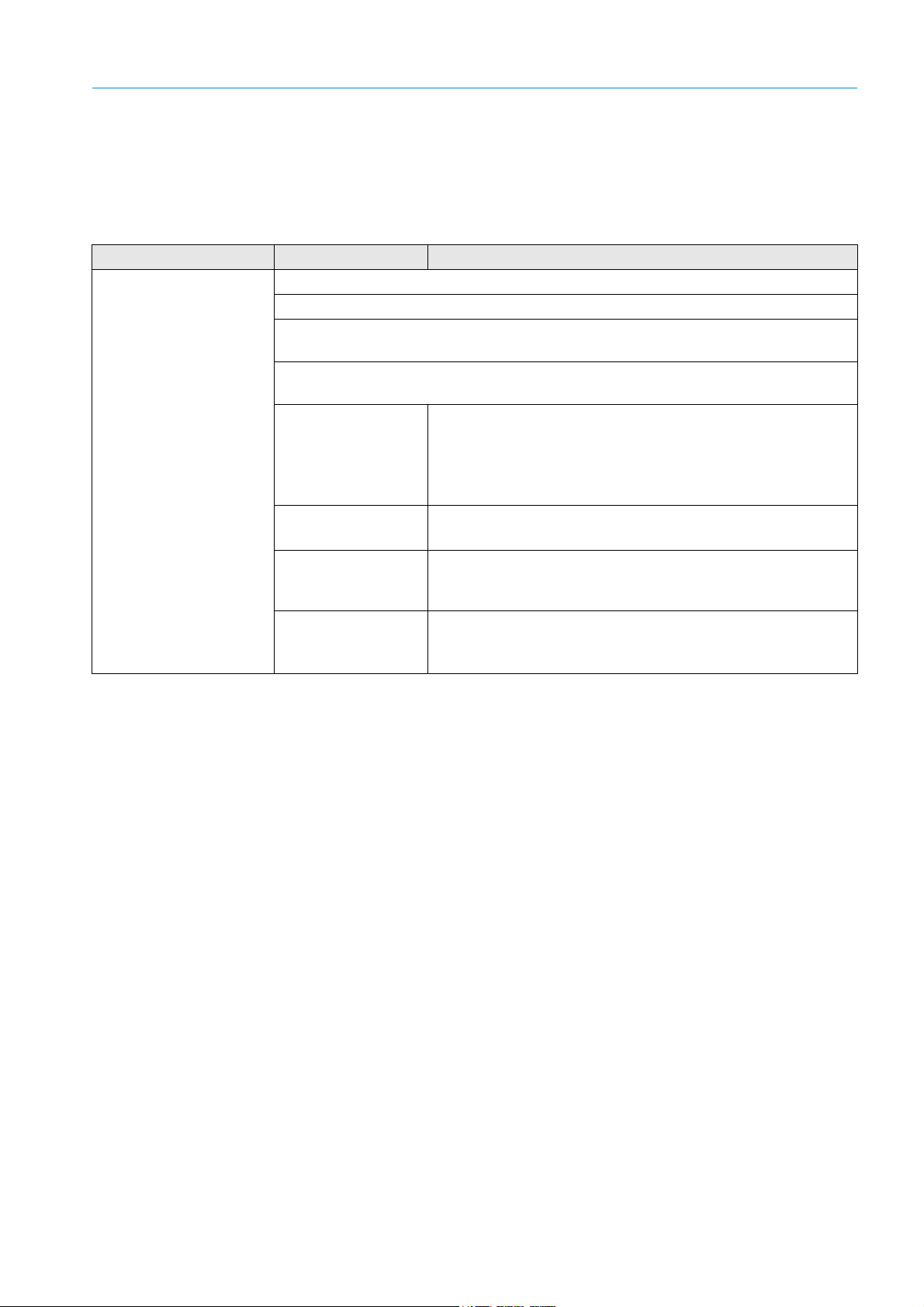

Measuring probe GMP (open probe) GPP (dry)

Measuring path open in flow

Version

direction; purge air guidance

with outlet aligned 90° to

gas flow

[1]

Max. gas temperature

430 °C

N20 measurement up to

180 °C

Gas check according to EPA

specification possible

–Yes

Purge air supply required Yes –

Heating on optical interfaces

in the probe

– Yes, with integrated control

Flow rate of sample gas 1...40 m/s < 40 m/s

Suitable for wet sample gas Yes –

Maximum duct pressure

Measurable components

System-response time (T

Duct diameter

[3]

Dust concentration < 2 g/m

±120 hPa, depending on

purge air supply

[2]

CO or N20, CO2, H2OCO or N

) ≥ 5s ≥ 120 s

90

> 360 mm > 300 mm

3

act < 30 g/m3 act

Probe lengths available [m] 1.0/1.5/2.0 / 2.5 1.0/ 1.5/2.0

Active measuring paths

available [mm]

**

250/500/750/1000/1250 250/500/750/1000

Gas diffusion probe with

ceramic filter, for dry

sample gas

430 °C

N20 measurement up to

180 °C

±120 hPa

0, CO2, H2O

2

Table 1: Comparison Table for GM35 measuring probes (dimension

drawings,

[1] The maximum temperature used for the measurement depends on the application.

[2] Probes are fitted with gold-plated hollow triples when CO or N20 is measured as component or with other

components, otherwise probes with quartz glass are used.

[3] Probes with shorter active measuring paths are available on request (may be required for higher concentrations

or smaller duct diameters)

see page 128)

8009389/YN39/V3-0/2015-08| SICK OPERATING INSTRUCTIONS|GM35

Subject to change without notice

17

Page 18

PRODUCT OVERVIEW

Special versions Apart from the standard probes shown above, other versions made from materials

especially resistant to acid are available (1.4539 and PVDF). Special versions can be

manufactured according to customer demands on request.

2.1.3 GM35 options and accessories

• Automatic beam tracking

Ensures exact alignment of the measuring path to the probe (open and GPP version) under

difficult and changing measurement conditions, such as, for example, large temperature

fluctuations.

• CAN bus extension cable 15 m

A 15 m extension cable, ready for connection, is available when the evaluation unit is to be

installed more than 2 m away from the SR-unit.

• Terminal box for CAN bus

For even greater distances between SR-unit and EvU, an optional terminal box can be used

for the connection via the CAN bus cable provided by the customer. The total length of the

CAN bus connections in the GM35 measuring system can be up to 1000 m in this case.

However, the EvU is normally installed close to the SR-unit for easy operating at the

measuring point. Section

to use the terminal box.

• Angle flange for zero point measurement

Some adjustments must be made outside the duct in an atmosphere free from sample

gas. A suitable angle flange that can be screwed to the mounting flange is available to

enable carrying out these adjustments easily and directly at the measuring point. The duct

is sealed and the SR-unit with measuring probe is mounted in front of the duct opening, at

a right angle to the duct, using this bracket.

“Preparations for electrical installation”, page 30 describes how

• Weatherproof covers for SR-unit and purge air unit

Required for outdoor installation – dimension drawings,

see page 128.

• Line writer, single or multi-duct

For measured value recording. Protocol(s) can of course be produced using customer

systems.

• Air heater for purge air supply

For special application conditions to prevent condensate. An air heater is required when

the difference between gas temperature and dew point temperature is too low. The

following practical rule of thumb serves as guideline:

An air heater is required when :

Gas temperature [°C] – dew point temperature [°C] < abs. humidity [%]

Values are compared without considering the units of measure.

18

8009389/YN39/V3-0/2015-08| SICKOPERATING INSTRUCTIONS|GM35

Subject to change without notice

Page 19

2.2 Functional principle

Reflector of

the measuring

probe

Front window of the SR-unit

Measuring path in the gas

duct (Measuring gap or

diffusion filter depending on

the probe)

Deflection mirror

Filter wheel and detector for

CO2 and H2O

CO detector

Cell wheel CO/N

2

Filter for CO measurement

Visor with opto-electronic adjustment tool

IR transmitter

lamp

Chopper

Lens mirror Reference filter pivot segment

Beam splitter

Zero point reflector

and blanking

diaphragm

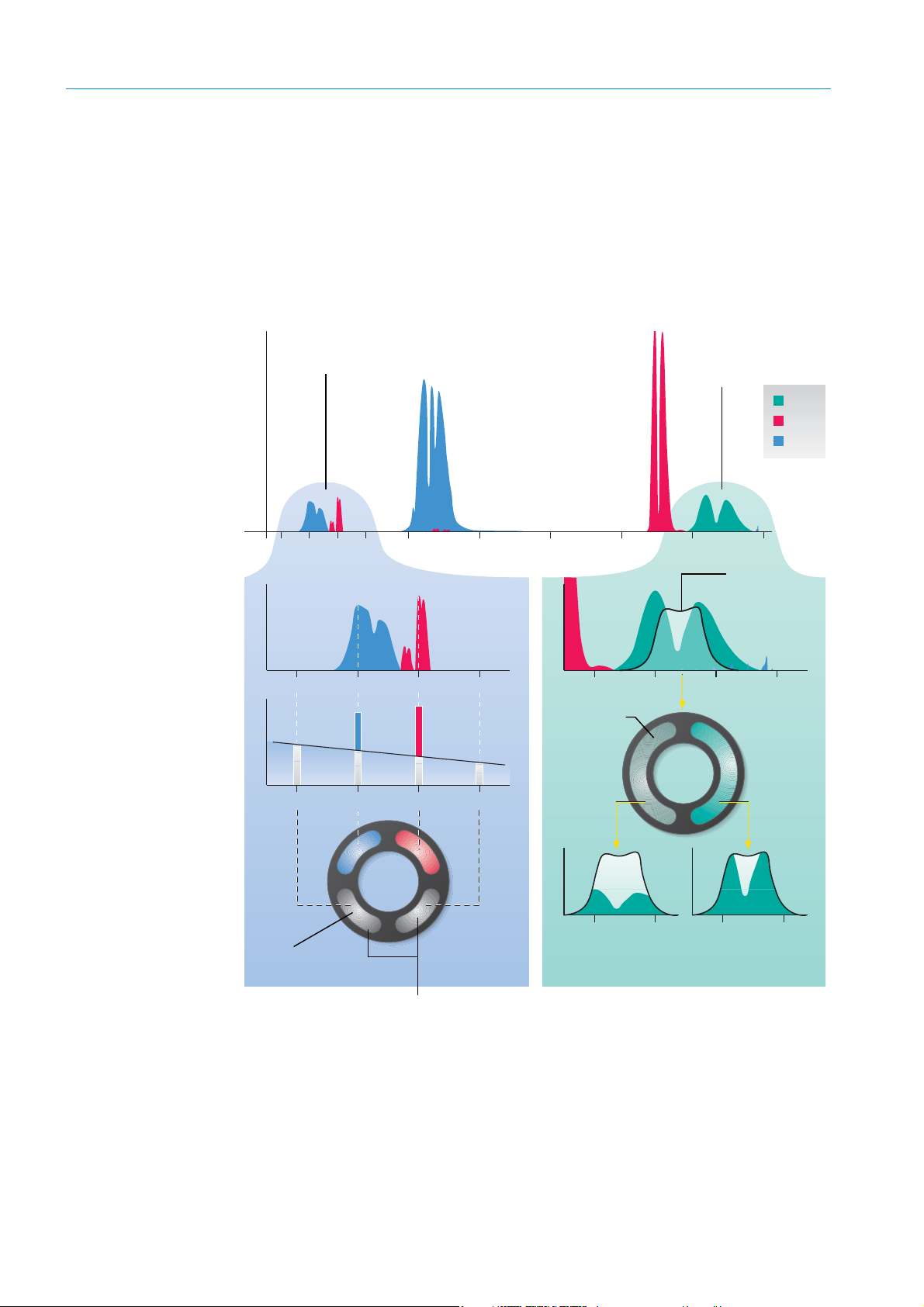

2.2.1 Opto-electronic in-situ measuring principle

The Gas Analyzer with Measuring Probe GM35 is based on in-situ technology with optoelectronic direct measurement. Measured values are recorded through no-contact

measurement directly in the gas flow across the entire duct cross-section (cross-duct). The

GM35 SR-unit determines the concentration of the respective gas component based on

wavelength-specific light absorption by the gas mixture in the active measuring path.

PRODUCT OVERVIEW

Fig. 5: Optics layout of the GM35

The beam from the sender/receiver unit (SR-unit) passes lengthwise through the active

measuring path (

see page 26) and is reflected by the reflector at the other end. The

reflected light from the beam splitter then passes through a filter or cell wheel to detectors

configured optionally to measure CO or N

received into its spectral components, the receiver elements record the absorption of the

gas molecules at characteristic points of the spectrum in the IR range of 1.6 to 4.9 µm.

0 as well as CO2 and H2O. By filtering the light

2

8009389/YN39/V3-0/2015-08| SICK OPERATING INSTRUCTIONS|GM35

Subject to change without notice

19

Page 20

PRODUCT OVERVIEW

CO

CO

2

H2O

2000 2500 3000 3500 4000

λ

[nm]

4500 50001500

18001600 2000 2200

Ref. 2 H2OCO2Ref. 1

Absorpti

H2OCO

2

46004400 4800 5000

CO

N

2

CO

4600 4800 4600 4800

CO2 and H2O measurement in the

range of 1600– 2200 nm

CO or N

2

O measurement

in the range of

approx. 4500–4900 nm

Cell wheel

N

2

/CO

Absorption CO

≈ measured value

Absorption CO

= 100%

Filter wheel for

CO

2

and H2O

Reference filter for determining the

background absorption, free of crosssensitivities with other gas components

The CO or N

2

O- measured values are

determined from the signals at the detector with

absorption by the sample gas and with a cell

filled with the component to be measured.

Interference is eliminated

Tra nsmi ssi on

characteristic

line of the CO

measurement

filter

Absorption

Cross-sensitivities with gases other than those to be measured are avoided by selecting

these evaluation ranges within the IR spectrum in conjunction with the evaluation

algorithms used (see

2.2.2 Signal evaluation

The optimized algorithms of the GM35 evaluation electronics process the measurement

signals of the receiver elements together with the associated parameters in accordance

with the correlation procedure with optical filters for CO

gas for CO or N

O.

2

page 20).

and H2O and with cells filled with

2

Fig. 6: Evaluation of absorption spectrums for sample gases with the GM35

20

8009389/YN39/V3-0/2015-08| SICKOPERATING INSTRUCTIONS|GM35

Subject to change without notice

Page 21

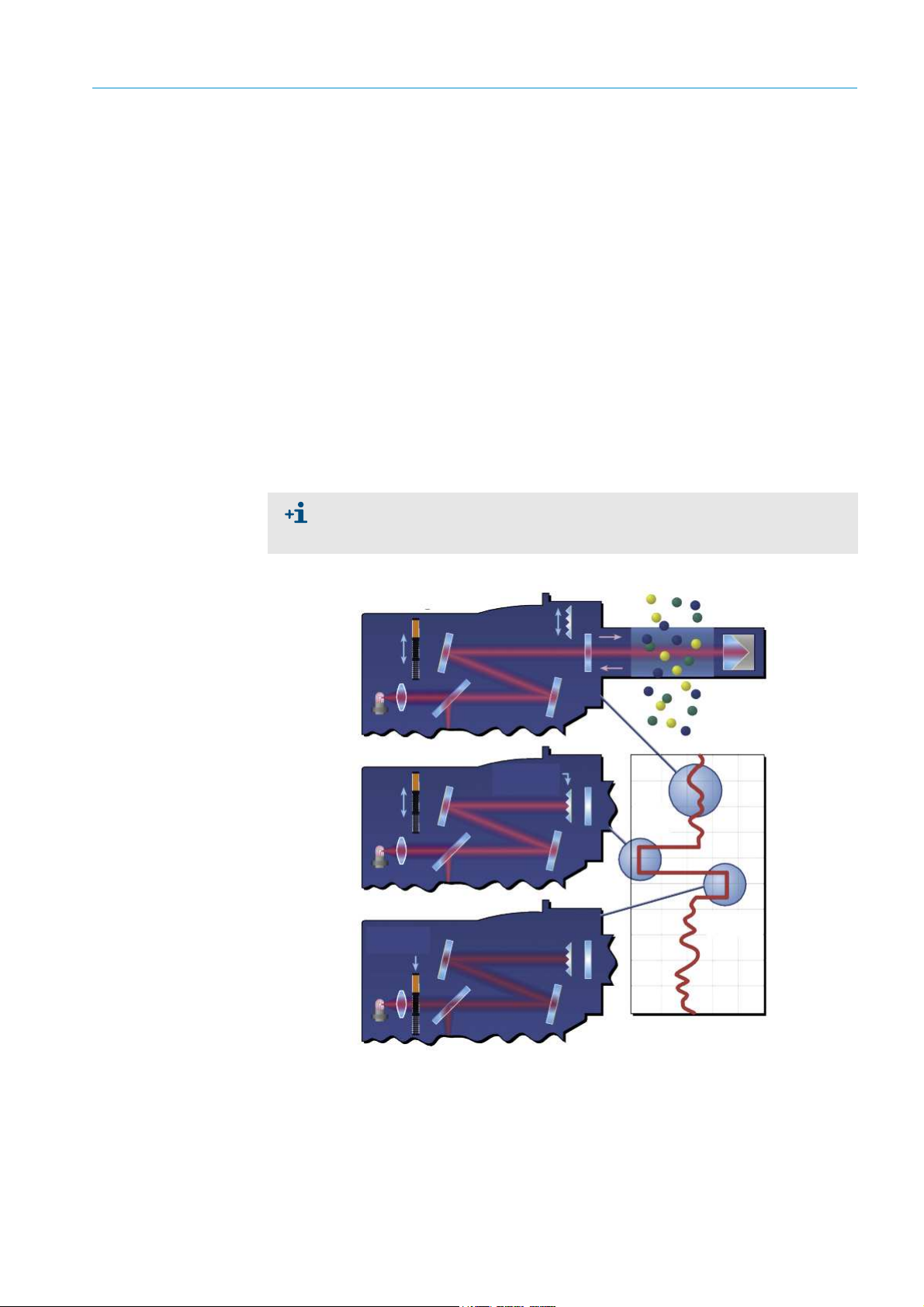

2.2.3 Automatic check cycles

Measure

Zero point

Check

Zero point

Check point

(70% fsc)

Zero point reflector

Swivel element

Data recorder

To ensure a consistently high level of measuring precision, the GM35 SR-unit performs a

regular automatic check cycle in an adjustable interval (standard: Every 2 hours). In this

check cycle, the zero point is first determined by swiveling a zero point reflector into the

beam path. Reference filters are then moved into position to control the check point. The

spectral properties of the device are checked using a test gas cell. If a check cycle reveals

that the system is not functioning in accordance with the operation specifications, the

GM35 measuring system outputs appropriate error or warning messages.

Triggering options

1 Di 1 (falling edge): The check cycle can also be suppressed with this function.

2 Time interval, adjustable via the menu of the EvU.

Sequence

1 Check cycle is started.

2 Internal reference measurement is executed. Signal: Relay 3 (function check)

3 The zero point and check point are output on the EvU display and the assigned analog

outputs for 90 seconds each. Relay 3 remains active.

PRODUCT OVERVIEW

Observe the following for connecting to an emission computer: Measure the

time from the start to the output to compensate differences in the device

settings.

Fig. 7: Determining the check point

8009389/YN39/V3-0/2015-08| SICK OPERATING INSTRUCTIONS|GM35

Subject to change without notice

21

Page 22

PROJECT PLANNING INFORMATION

3 Project Planning Information

3.1 Work steps from system selection to start-up

Application changes

If the information regarding your application submitted with your purchase order has

changed, or if a device is to be used for an application other than the one that was

originally intended, please contact your local sales representative or our project planning

department to determine whether the device(s) can be used under the new conditions, and

whether readjustment or reparametrization is necessary.

The following steps are generally carried out before the measuring system is started up:

The version of the TCU-MS operating unit is selected according to the external signals to be

processed or output.

• Project planning

See planning checklist below

• Initial onsite installation

Following preparatory work normally carried out by the customer is described on

page 26:

• Flange assembly,

– Preparation for assembling the purge air unit, see page 29.

– Laying the signal and power supply cables to the measuring point, see Chapter 3.9 ,

page -33.

– Preparations for installing the EvU, see “Installation preparation for the evaluation unit”,

page 30

.

– Possibly preparation of signal cables for the interface to peripheral equipment, see

“Preparations for electrical installation”, page 30

• Device installation

To allow speedy start-up, the following components are normally installed ready for

operation before the start-up date;

see page 27.

see “Installation”, page 36.

– Purge air unit

– Evaluation unit

• Start-up

The actual start-up procedure is carried out by trained personnel or SICK Customer

Service. This work is described on

page 53. The main activities are adjustment tasks on

the GM35 system related to the application.

22

8009389/YN39/V3-0/2015-08| SICKOPERATING INSTRUCTIONS|GM35

Subject to change without notice

Page 23

PROJECT PLANNING INFORMATION

3.2 Project Planning Checklist

The following Checklist simplifies performing and controlling project planning measures

required before start-up in the correct sequence. Technical data and dimensional drawings

of system components,

Topic Task Measure/determination

Determination of

measuring point

Observe national

regulations such as

VDI 3950

Provide for unhindered inlet and outlet paths:

▸ For round duct cross-sections: 3 times the duct diameter

▸ For rectangular cross-sections: Hydraulic diameter

page 128 and following.

▸ If these specifications cannot be met: Inlet path > outlet path,

2

/3 : 1/3; uniform concentration spread whenever possible

e.g.

▸ Obtain official approval for emission measuring point.

Emission measuring

point

Application conditions

▸ Provide for calibration openings at easily accessible places.

▸ Ensure the GM35 and calibration probe do not influence

each other; the calibration gland should be located at a

minimum distance of 0.5 m away from the measuring device.

▸ Observe Technical Data for duct/ambient conditions!

▸ Gas temperature above/below dew point (dry/wet)

▸ Acc. to FGD wet :

Installation location

Pressure conditions

at the measuring

point

Select a version with active measuring path ≤ 500 mm when

a GMP probe is used.

▸ A fitting location with partial vacuum in the duct is ideal.

▸ For duct pressures > 10 mbar, please contact SICK to select

the correct purge air blower type.

4F (Cross-sectional area)

-------------------------------------------------------------------------------------=

D

U (Circumference)

Table 2: Project planning checklist

8009389/YN39/V3-0/2015-08| SICK OPERATING INSTRUCTIONS|GM35

Subject to change without notice

23

Page 24

PROJECT PLANNING INFORMATION

Topic Task Measure/determination

SR-unit, probe

See 3.3.1 “Assembly preparation at the measuring

point”, page 26

Select suitable flange

with tube

▸ Flange fitting is planned in steel ducts as standard;

corresponding flanges with tube are normally included in the

GM35 scope of delivery.

▸ Brick stacks or thick-walled ducts require a holding plate, to

be provided by the customer, and, if necessary, a longer

flange with tube, see Chapter 3.3.3 , page -27.

▸ If some of the components have not yet been delivered, you

may need to arrange an advance delivery of the flanges with

tube so that you can mount these as part of the preparations

for installation onsite.Alternatively, you can use a suitable

flange prepared onsite (or ANSI flange, check the Technical

Data, see page 128).

▸ Determine the alignment of the measuring gap of the GM35

measuring probe in gas flow direction.

▸ Provide a suitably sized opening for the tube of the mounting

flange.

▸ Install the flange with tube tilted slightly downwards (> 1°) to

prevent condensate deposits and therefore corrosion.

Duct openings

selection

▸ Provide for adequate clearance for installation and

maintenance activities for the duct insulation cutout.

▸ Plan sufficient clearance for pivoting the GM35 SR-unit,

removing the cable connector from the device, and pulling

the measuring probe out of the duct.

▸ Ensure the ambient temperature for the GM35 SR-unit is

between -20 and +55 °C (–40 °C during continuous

operation).

▸ For installation outdoors, plan a weatherproof cover.

▸ If adjustments are to be made at the measuring point

(prerequisites: clean, atmosphere free from sample gas;

protected from weather): order the angle flange for zero point

measurement (Part No. 2 017 833); when necessary, plan a

longer version of the flange with tube to ensure sufficient

distance from the duct.

▸ Plan installation location on the duct in immediate vicinity

(5 m) of the GM35 SR-unit.

▸ Keep the purge air hose to the measuring probe as short as

possible (approx. 1.2 mbar pressure loss per meter).

▸ Ensure secure cable laying.

▸ Ensure dry and, whenever possible, dust-free intake air on

the purge air unit, use a preliminary filter when necessary.

Purge air unit

● Only relevant when

using a purge air unit,

i.e. not on systems

using a GPP probe

● See Section 3.3.1:

Assembly preparation

at the measuring point

Tools for start-up and

maintenance

Fitting location

selection

▸ The intake air temperature should be between 0 and 55 °C.

For T < 0 °C, heat the purge air.

▸ Provide sufficient clearance for exchanging the filter element.

▸ Plan a weatherproof cover for installation outdoors as well as

sufficient clearance for fitting (and removing) the cover.

24

Table 2: Project planning checklist

8009389/YN39/V3-0/2015-08| SICKOPERATING INSTRUCTIONS|GM35

Subject to change without notice

Page 25

PROJECT PLANNING INFORMATION

Topic Task Measure/determination

Evaluation unit

• See 3.3.6 “Installation

preparation for the

evaluation unit”, page

30

Determine the fitting

location

▸ Install the evaluation unit at an easily accessible location,

preferably at the measuring point. If necessary, install it at a

distance from the measuring point, whereby the total length

of all CAN bus connections in the GM35 measuring system

must not exceed 1000 m.

▸ Ambient temperature between –20 °C and +55 °C.

▸ During continuous operation –40 °C.

▸ Is the 4 m CAN bus cable sufficient for the connection

between EvU and SR-unit at the selected installation

location?

Options for CAN bus

wiring

Assembly platform

Specify the assembly

platform

If not, select a suitable cable (see page 13):

If the distance is less than 19 m: Plan a 15 m prefabricated CAN

bus cable with plug-in connectors.

For larger distances: Use a CAN bus terminal box and the cable

provided by the customer (see page 43).

▸ Provide a suitable working platform for installation on the

outside of a duct/stack.

▸ The fitting location of the GM35 SR-unit should be about 1.3

to 1.5 m above the platform.

▸ The platform must be large enough, secured and positioned

so that all device parts can be accessed without danger. This

is especially important when fitting and removing the SR-unit.

Accident prevention ▸ Applicable (national) regulations on accident prevention must be observed.

▸ Always observe and follow the relevant safety information provided for the

corresponding texts in these Instructions.

Table 2: Project planning checklist

8009389/YN39/V3-0/2015-08| SICK OPERATING INSTRUCTIONS|GM35

Subject to change without notice

25

Page 26

PROJECT PLANNING INFORMATION

30

L

50

470

M10

Ø133

1

°

FL. 60x8x60

DIN 174

min. 700

Stahlrohr

50 x 5

DIN 2391

▴

: Markierung für Einbaulage

in Strömungsrichtung zeigend

Befestigung der Spüllufteinheit

1,3 – 1,5 m

50 mm Überstand bei kreisförmigem Kanalquerschnitt

Arbeitsbühne/Plattform

470

Duct wall (steel)

Duct insulation

Flange with tube,

standard: L = 240 mm

▴ : Marking for fitting position,

pointing in flow direction

Steel pipe

50 x 5

DIN 2391

Purge air unit fastening

Platform

50 mm protrusion for circular duct cross-section

3.3 Initial onsite installation

The following work can be carried out by the customer's technicians. Requirement: The

project planning checklist has been processed beforehand.

3.3.1 Assembly preparation at the measuring point

This Section describes the welding work on the duct including making fixing elements

onsite.

Already completed? If you have already used the separate document “Product Information and Planning Guide”

to complete the work described here prior to delivery of the device, please check that the

work done corresponds to the following instructions.

26

Fig. 8: Installation recommendation: Mounting flange and purge air unit (duct diameter not representative)

8009389/YN39/V3-0/2015-08| SICKOPERATING INSTRUCTIONS|GM35

Subject to change without notice

Page 27

CAUTION: Protective measures at the measuring point

Duct wall (steel)

Reinforcing sheets (onsite)

Flange with tube

▸ Always shut down the installation before any work on the duct!

▸ Secure parts to be separated with, for example, wire binding, to prevent

damage by falling objects.

▸ Take appropriate protective measures against hot, explosive gases or toxic

gases that could possibly escape from the duct.

▸ Always take all necessary safety precautions during welding work to prevent

explosions or fire in the duct atmosphere and on the duct insulation.

▸ If necessary, seal off the mounting flange with a cover securely until device

assembly (e.g. for overpressure in duct).

3.3.2 Uncovering the duct

▸ If necessary, remove approx. 800 x 1500 mm (W x H) of the duct insulation to be able to

access the duct during subsequent work.

▸ Keep the insulation material removed for later refitting resp. provide new suitable

insulation material.

3.3.3 Installing the flange with tube

PROJECT PLANNING INFORMATION

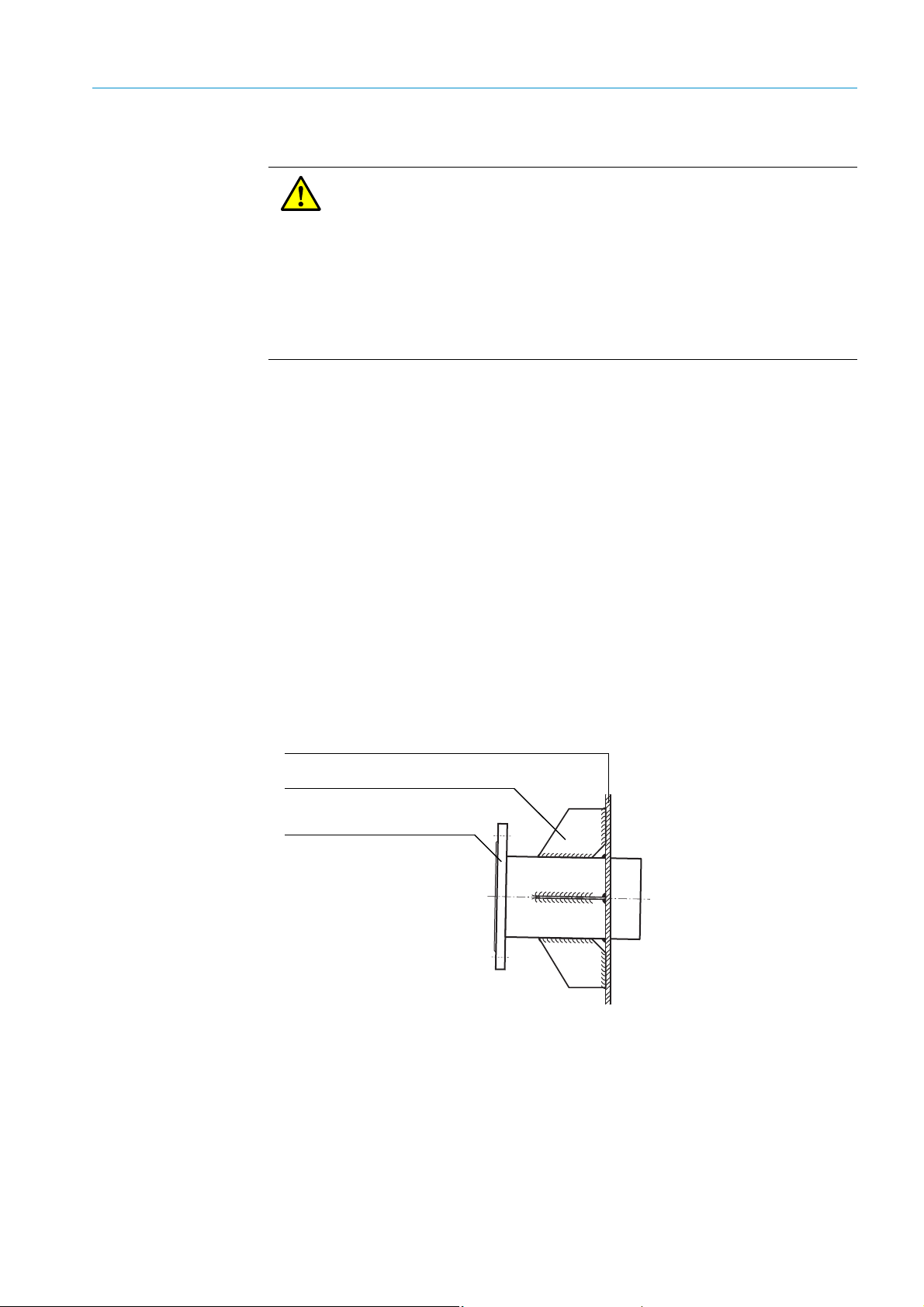

Notes on flange

installation

• Standard flanges and special versions

SICK delivers one flange with tube with 240 mm total length and 125 mm inner diameter

as standard. A version with 500 mm total length is available for installation locations with

thicker insulation or for stone stacks.

Special versions can be manufactured on request. Onsite flanges, including ANSI

flanges, can also be used.

• Reinforcement with junction plates recommended

Due to the weight of the GM35 sender/receiver unit, it is recommended to reinforce the

flange tube onsite with junction plates.

8009389/YN39/V3-0/2015-08| SICK OPERATING INSTRUCTIONS|GM35

Subject to change without notice

Fig. 9: Reinforcing with junction plates

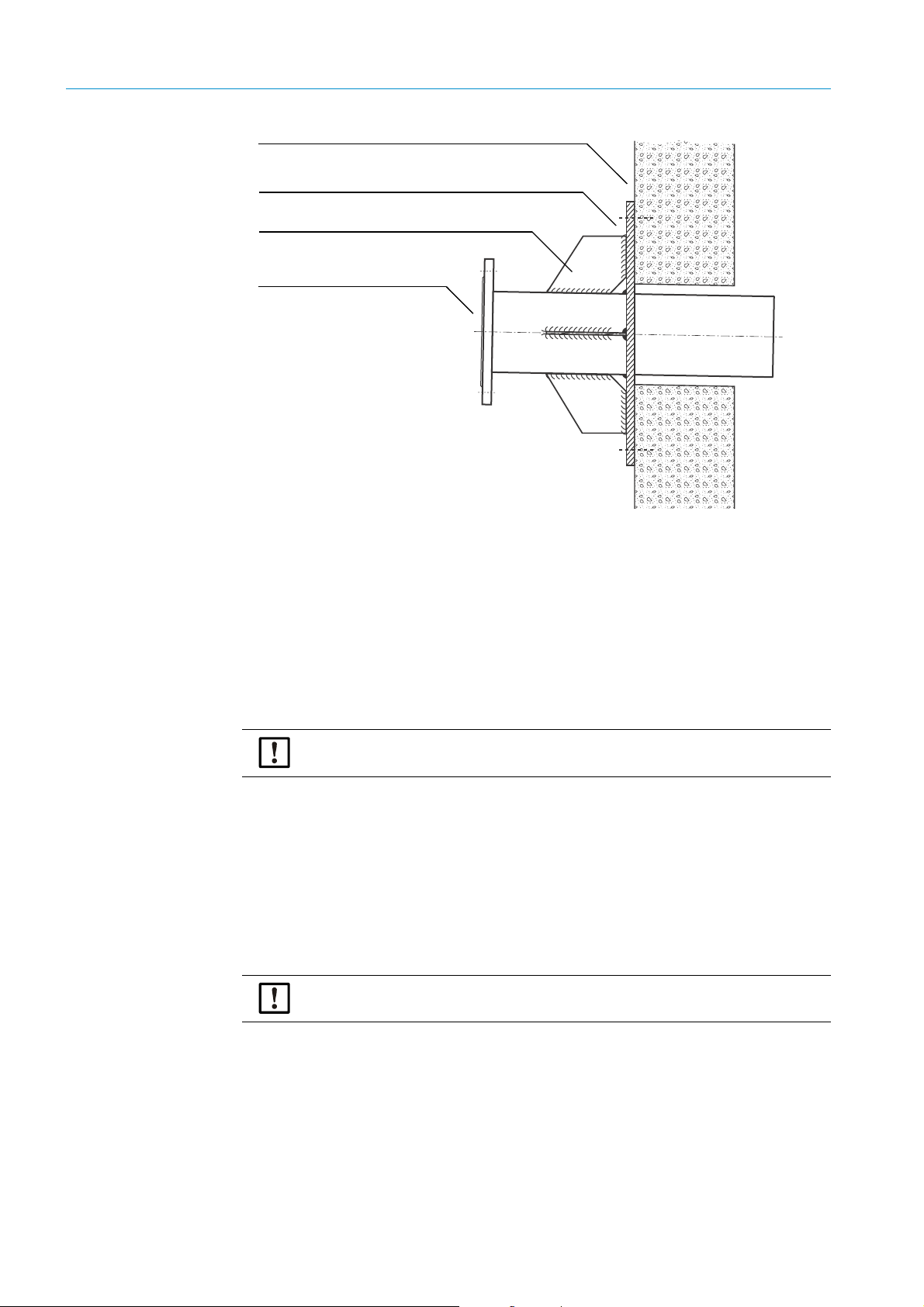

• Gas-carrying duct made of brick/concrete

An additional retaining plate with suitable opening should be manufactured for ducts not

made of steel and the flange with tube then welded into the opening.

27

Page 28

PROJECT PLANNING INFORMATION

Wall of the gas-carrying duct (brick/concrete)

Retaining plate (onsite)

Flange with tube

(example: Version 500 mm long)

Reinforcement plates (recommended, onsite)

Fig. 10: Installation on a brick/concrete duct

• Using the angle flange for zero point measurement

To use the angle flange (Part No. 2 017 833) for zero point measurement, make sure the

SR-unit with mounted measuring probe can be attached without hindrance to the duct

using the angle flange. Avoid obstacles in the vicinity of the flange with tube, such as, for

example, protruding duct insulation. A longer flange with tube or an angle flange with

spacer (to be provided by the customer) may be required to ensure the distance from the

duct wall is sufficient.

3.3.3.1 Installation steps: Fitting the flange with tube

1 For brick/concrete ducts: Cut the duct opening approx. 2 cm larger than the flange tube

outer diameter.

2 Cut an opening matching the outer flange tube diameter (standard Ø

the duct wall resp. retainer plate.

3 Position the flange tube so that the marking points exactly in gas flow direction

(compare

plate (approx. 1°, see page 26) to prevent condensate deposits later between tube and

probe. Affix in the fitting position.

4 Weld the flange tube on.

5 Weld on with junction plates as reinforcement when possible; see

NOTICE: Observe the safety information on page 26 at all times!

= 133 mm) out of

a

page 26). Incline the tube slightly downwards in the duct resp. on the retainer

page 27 or page 28.

28

NOTICE: Brick/concrete ducts: Anchor the holding plate with the welded flange

with tube to the duct as shown on

page 28.

8009389/YN39/V3-0/2015-08| SICKOPERATING INSTRUCTIONS|GM35

Subject to change without notice

Page 29

3.3.4 Installation preparation for the purge air unit

Steel pipe 50 x 5

DIN 2391

Purge air unit fastening

50 mm protrusion for circular duct cross-section

Flange 60 x 8 60

DIN 174

PROJECT PLANNING INFORMATION

Is a purge air unit to

be used?

This step is only relevant for device configurations containing a purge air unit. GM35

configurations with GPP measuring probes do not require purge air.

1 Make brackets from steel pipes (e.g. 50 x 5) with flanges (e.g. FL 60 x 8 x 60) for the

four fixing points of the purge air unit ; bore M10 threads in the mounting holes.

2 Weld the brackets on as shown when using steel ducts.

For stone stacks, fit retainer plates to each steel pipe or use a different, suitable mounting

for the purge air unit.

3.3.5 Duct insulation

3

Fitting recommendation for purge air units (duct diameter not representative)

▸ Refit the thermal duct insulation; reinforce the insulation when necessary.

CAUTION: Device failure due to high ambient temperatures

The SR-unit of the GM35 is designed for a maximum ambient temperature of

+55 °C. Radiant heat on the enclosure surface can, under certain

circumstances, lead to temperatures higher than the measured air

temperature.

▸ Therefore, design insulation and radiation shielding so that temperature

limits are reliably maintained.

8009389/YN39/V3-0/2015-08| SICK OPERATING INSTRUCTIONS|GM35

Subject to change without notice

29

Page 30

PROJECT PLANNING INFORMATION

3.3.6 Installation preparation for the evaluation unit

Requirements The installation location for the evaluation unit was determined during project planning.

The maximum total cable length of all CAN bus connections in the GM35 measuring

system of 1000 m was taken into account, bearing in mind that the closer the device is to

the measuring point, the easier it is to use.

Installation location preparation

The evaluation unit is fitted with clips which enable it to be mounted easily using 4 screws,

even on an uneven surface.

▸ Based on the dimension drawing of the EvU according to

space is available at the planned installation location to fit and wire the EvU as well as to

pivot the enclosure door.

▸ Drill suitable openings as assembly points as required.

3.4 Preparations for electrical installation

The onsite supply and signal cables are laid beforehand to facilitate subsequent

installation and start-up of the GM35 system components. Suitable cable ducts or

conduits are installed for the prefabricated cables and delivered with the GM35 system

(marked with * in

“Cable routing diagram”).

page 135, make sure sufficient

The prepared cables are connected to the devices during installation or start-up by suitably

qualified personnel or by SICK Customer Service.

Already completed? If you have already used the separate document “Product Information and Planning Guide”

to complete the work described here prior to delivery of the device, please check that the

work done corresponds to the following instructions.

3.5 Electrical protection

Evaluation units of GM35, Power Supply 24 V; SCU I/O

• Insulation: Protection class 1 in accordance with EN 61140

• Insulation coordination: Overvoltage category II in accordance with EN61010-1

• Contamination: Degree of contamination II in accordance with DIN EN 61010-1

3.6 Specifications on electric isolation of the EvU

Connections SCU I/O

Relay contact <-> PE 860 V AC

Relay contact <-> relay contact 860 V AC

Relay contact <-> actuation 1376 V AC

Table 3: Characteristic data for electric isolation

3.6.1 Electrical installation safety information

WARNING: Hazard by voltage.

▸ Only allow an authorized electrician to work on the electric system.

▸ Observe the relevant safety regulations during all installation work.

▸ Take suitable protective measures against local risks and those arising

from the plant.

30

8009389/YN39/V3-0/2015-08| SICKOPERATING INSTRUCTIONS|GM35

Subject to change without notice

Page 31

PROJECT PLANNING INFORMATION

WARNING: Endangerment of electrical safety during installation and

maintenance work when the power supply is not switched off

An electrical accident can occur during installation and maintenance work

when the power supply to the device and/or lines is not switched off using a

disconnector switch/circuit breaker.

▸ Before starting the work, ensure the power supply can be switched off

using a power isolating switch/circuit breaker in accordance with

DINEN61010.

▸ Make sure the disconnector switch is easily accessible.

▸ An additional disconnecting device is mandatory when the power isolating

switch is difficult to access or cannot be accessed when connecting the

equipment after installation.

▸ The power supply may only be activated again after the work or for test

purposes by personnel carrying out the work under consideration of valid

safety regulations.

WARNING: Endangerment of electrical safety through power cable with

incorrect rating

When a removable power cable is used, electrical accidents can occur when

the specifications are not fully observed.

▸ Always observe the exact specifications in the Operating Instructions

(Technical Data Section) when replacing a removable power cable.

CAUTION: Device damage through incorrect or missing grounding.

During installation and maintenance work, it must be ensured that the

protective grounding to the devices and/or lines involved is effective in

accordance with EN 61010-1.

NOTICE: Responsibility for the safety of a system

The safety of the system in which the equipment is integrated is the

responsibility of the person setting up the system.

WARNING: Risk of fire due to hot gas escaping in installations with

overpressure conditions

On installations with overpressure, the purge air hose can be severely

damaged by escaping hot gas and can catch fire depending on the

temperature.

On plants with overpressure as well as gas temperatures over 200°C:

▸ Ensure reverse flow is prevented by fitting a (trip) flap or a valve.

▸ Regularly check the functionality of the reverse flow safeguard.

8009389/YN39/V3-0/2015-08| SICK OPERATING INSTRUCTIONS|GM35

Subject to change without notice

31

Page 32

PROJECT PLANNING INFORMATION

WARNING: Endangerment of electrical safety through heat damage to lines

When planning the lines, take into account that the connection unit can reach

a temperature >60°C due to self-heating at maximum ambient temperature.

▸ Only use lines specified for temperatures >80°C.

3.7 Electrical protection

Evaluation units of GM35, Power Supply 24 V; SCU I/O

• Insulation: Protection class 1 in accordance with EN 61140

• Insulation coordination: Overvoltage category II in accordance with EN61010-1

• Contamination: Degree of contamination II in accordance with DIN EN 61010-1

3.8 Specifications on electric isolation of the EvU

Connections SCU I/O

Relay contact <-> PE 860 V AC

Relay contact <-> relay contact 860 V AC

Relay contact <-> actuation 1376 V AC

Table 4: Characteristic data for electric isolation

32

8009389/YN39/V3-0/2015-08| SICKOPERATING INSTRUCTIONS|GM35

Subject to change without notice

Page 33

3.9 Laying connection lines

maintcalpardiag

GM 35

Evaluation Unit

CO

CO

2

H2O

mg/

m

3

236

Ref. conditions

Hum: wet

Measuring

Operation

Service

Warnin

Malfunction

Power supply

(230/115 V AC) *

4m, 3 x 1.5mm

2

SR-unit

Measuring probe (example: GMP)

CAN *

1m

Evaluation unit

CAN bus extension, ready

for connection, 15 m

CAN bus cable (stan-

dard), 4 m *

Terminal box (option)

Standard cable

connection

Cable connection,

option

Cable in scope of

delivery

*

Prefabricated with plug-in

connector(s)

Purge air unit SLV4

(Standard for GMP

measuring probe)

Power supply 4 x

1.5 mm

2

Signal cable for:

• Filter monitoring of the SLV 4 – 2 x 0.6 mm

2

,

on pressure controller with flat pin bushings

6.3 x 0.8 mm (DIN 46247)

• Pressure connection

Functional

earth 2.5 mm

2

Power supply (230/115 V AC)

3 x 0.75 mm

2

3 binary inputs 6 x 0.5 mm

2

3 analog inputs 6 x 0.5 mm

2

3 binary outputs 6 x 0.5 mm

2

3 analog outputs 6 x 0.5 mm

2

to lengthen the CAN bus

connection with a cable

(1 x 2x 0.5mm

2

, twisted

pair, shielded) provided by

the customer

Cable connection for

optional terminal box

PROJECT PLANNING INFORMATION

8009389/YN39/V3-0/2015-08| SICK OPERATING INSTRUCTIONS|GM35

Subject to change without notice

Fig. 11: Cable routing diagram

33

Page 34

PROJECT PLANNING INFORMATION

3.9.1 CAN bus wiring

Standard cables

An installation location in the vicinity of the measuring point is generally selected for the

EvU so that the 4 m CAN bus cable delivered is sufficient for cabling without additional

installation effort. CAN bus extensions, ready for connection with plug-in connectors, are

also available in various lengths (

Installation away from the evaluation unit

A 6-pole terminal box can be supplied when the EvU is to be located some distance from

the SR-unit. This is then connected to the SR-unit using the 4 m CAN bus cable delivered

with the measuring system. A customer cable suitable for CAN bus applications, 6-pole

cable (twisted pair wires and shielded), then leads to the EvU. The total length of the CAN

bus connections, including the one to the reflector, may be up to 1000 meters. When

performing maintenance or service, it must be possible to deinstall the EvU temporarily

and connect it directly to the SR-unit at the measuring point.

Laying the cables

▸ Provide adequate cable lengths at the connection points.

▸ Whenever possible, do not lay power supply cables immediately next to signal cables.

▸ Protect open ends of preinstalled cables against weather effects until device

installation.

▸ Install separate power supply cables and circuit breakers for:

– GM35 SR-unit (via connection unit or terminal strip in control cabinet)

– Purge air units; additional motor circuit breakers and optional protective phase failure

switches.

– Evaluation unit

see “Connection cables”).

CAUTION: Risk of device damage due to switching off the voltage supply

unintentionally

The purge air supply may not be switched off while the measuring system is on

the gas duct.

▸ Attach clearly visible warnings against accidental switching-off to all

switching devices where the purge air supply can be switched off.

WARNING: Risk of fire due to hot gas escaping in installations with

overpressure conditions

On installations with overpressure, the purge air hose can be severely

damaged by escaping hot gas and can catch fire depending on the

temperature.

On plants with overpressure as well as gas temperatures over 200°C:

▸ Ensure reverse flow is prevented by fitting a (trip) flap or a valve.

▸ Regularly check the functionality of the reverse flow safeguard.

▸ Install easily accessible cable ducts or empty tubes for prefabricated cables or cables

delivered with the system,

two plug-in connectors ). Approx. 2 m cable lengths each should be available at the

measuring point for later maintenance work on the measuring system when dismounted

from the duct.

see “Cable routing diagram”, page 33 (marked with one or

▸ Lay cables provided by the customer (shown without plug-in connectors) according to

see “Cable routing diagram”, page 33.

34

8009389/YN39/V3-0/2015-08| SICKOPERATING INSTRUCTIONS|GM35

Subject to change without notice

Page 35

PROJECT PLANNING INFORMATION

– The specifications for the lead cross-sections are recommendations whereby cables

for analog and binary signals may differ slightly from these (but not the CAN bus

connections or the power supply cables).

– Start with the system internal connections of the GM35.

Status and signal cables from the EvU to the connection terminals of the customer's

status/signaling equipment can be connected later when required.

8009389/YN39/V3-0/2015-08| SICK OPERATING INSTRUCTIONS|GM35

Subject to change without notice

35

Page 36

INSTALLATION

4 Installation

This Section describes assembling and installing the GM35 measuring system prior to the

actual start-up. It is assumed that the onsite preinstallation has been completed, see “Proj-

ect Planning Information”, page 22

4.1 Preparations

4.1.1 Checking the scope of delivery

▸ Check the delivery against the associated delivery note and make sure the complete

measuring system has been delivered as ordered. The typical scope of delivery

comprises the components described in Section

tion”.

▸ Inspect the delivery for visible external transport damage or damage to the packing.

▸ Check the specifications on mains voltage and frequency on the type plates of the

GM35 components match the installation conditions, delivery note and the order.

4.1.2 Installation prerequisites

The following prerequisites are applicable for the work described in the following:

.

“Preparations for electrical installa-

▸ Plan safe usage/application within the limits defined in

and Spare Parts”, page 128.

“Technical Data, Consumables

▸ Compliance with the specifications made during project planning (according to “Project

Planning Checklist”, page 23) and correct performance of onsite preinstallation

according to

“Initial onsite installation”, page 26.

WARNING: Endangerment of electrical safety during installation and

maintenance work when the power supply is not switched off

An electrical accident can occur during installation and maintenance work

when the power supply to the device and/or lines is not switched off using a

disconnector switch/circuit breaker.

▸ Before starting the work, ensure the power supply can be switched off

using a power isolating switch/circuit breaker in accordance with

DIN EN 61010.

▸ Make sure the disconnector switch is easily accessible.

▸ An additional disconnecting device is mandatory when the power isolating

switch is difficult to access or cannot be accessed when connecting the

equipment after installation.

WARNING: The power supply may only be activated again after the work or for

test purposes by personnel carrying out the work under consideration of valid

safety regulations.

36

8009389/YN39/V3-0/2015-08| SICKOPERATING INSTRUCTIONS|GM35

Subject to change without notice

Page 37

4.2 Fitting system components

Assembly holes

Base plate

Y-distributor

4.2.1 Information on the SR-unit and measuring probe

The GM35 SR-unit and measuring probe are first fitted on the duct during start-up (

“Connecting the System Control Unit - SCU”) because these components first require an

adjustment away from the gas-carrying duct. To avoid problems during start-up, the SR-unit

and measuring probe must be stored in a dry place free from dust, preferably at room

temperature, until start-up.

CAUTION: Damage to the measuring system due to assembly of the SR-unit

and/or measuring probe before start-up

Unfavorable ambient conditions or atmosphere in the measuring duct can

damage the measuring system which prevents start-up. Apart from that, there

is a health risk when opening the duct depending on the pressure, gas

temperature and composition in the sample gas duct.

4.2.2 Installing the purge air unit

Note A dimension drawing can be seen in “Purge air unit dimension drawing”, page 137.

Brackets should have M8 threadholes or M8 separator bolts for fastening to the base

plate.

INSTALLATION

see

Fig. 12: Installing the purge air unit

1 Secure the base plate for the purge air unit using 4 M10 x 45 screws on the brackets

provided by the customer.

2 Cut the purge air hose to a suitable length for the respective purge air fixture, attach it to

the open outlet of the Y-distributor and secure it with a hose clamp.

3 Close off the hose ends when the purge air unit is not going to be used for a longer

period.

If the purge air unit is not connected electrically immediately:

4 For outdoor installations, fit the weatherproof cover planned during project planning

(optional in scope of delivery).

5 Protect the open end of the purge air hose from humidity or contamination until SR-unit

start-up.

8009389/YN39/V3-0/2015-08| SICK OPERATING INSTRUCTIONS|GM35

Subject to change without notice

37

Page 38

INSTALLATION

Mounting holes

4.2.3 Terminal box (option)

▸ Install the terminal box in the vicinity of the measuring point.

– Secure the enclosure on the two mounting holes (∅ 5 mm).

▸ The cable length available from the terminal box to the SR-unit is 4 m.Take the empty

conduits laid for the prefabricated cables during onsite preinstallation into account.

Fig. 13: Fitting the terminal box

38

8009389/YN39/V3-0/2015-08| SICKOPERATING INSTRUCTIONS|GM35

Subject to change without notice

Page 39

4.3 Installing the evaluation unit

4 mounting holes

∅ 8mm

Mounting surface

Fastening brackets

The fitting location for the evaluation unit was defined during project planning (see “Project

Planning Checklist”, page 23) and prepared during onsite preinstallation as required.

▸ Make sure the CAN bus connection to the SR-unit selected during project planning is

usable at the planned installation location. The CAN bus connection cable delivered as

standard is 4 m long and serves to connect the evaluation unit directly at the measuring

point.

▸ Ensure easy access without problems. In particular, make sure the swivel door of the

evaluation unit can be opened without hindrance after fitting.

4.3.1 Installing the evaluation unit – sheet metal enclosure version

▸ Make ∅7.2 mm (for M8) mounting holes at the installation location according to the

Drilling plan.

▸ Attach the evaluation unit at the installation location using the 4 planned fastening

brackets with suitable screws.

INSTALLATION

8009389/YN39/V3-0/2015-08| SICK OPERATING INSTRUCTIONS|GM35

Subject to change without notice

Fig. 14: Installing the evaluation unit (sheet metal enclosure version)

39

Page 40

INSTALLATION

117.5

330

235

Swivel door

Mounting holes

∅ 7mm

Mounting surface

The mounting holes

are accessible

when the swivel door is

open.

Mounting holes

∅ 7mm

1.

2.

4.3.2 Installing the evaluation unit – cast enclosure version

1 Make ∅7.2 mm (for M8) mounting holes at the installation location according to the

Drilling plan.

40