Page 1

GM32 Ex

In-situ Gas Analyzer Cross-Duct Version

Installation, Operation, Maintenance

O P E R A T I N G I N S T R U C T I O N S

Page 2

Described product

GM32 Ex

Cross-Duct version

Manufacturer

SICK AG

Erwin-Sick-Str. 1

79183 Waldkirch

Germany

Production location

SICK AG

Nimburger Str. 11

79276 Reute

Germany

Legal information

This work is protected by copyright. Any rights derived from the copyright shall be

reserved for SICK AG. Reproduction of this document or parts of this document is only

permissible within the limits of the legal determination of Copyright Law. Any modifica‐

tion, shortening or translation of this document is prohibited without the express written

permission of SICK AG.

The trademarks stated in this document are the property of their respective owner.

© SICK AG. All rights reserved.

Original document

This document is an original document of SICK AG.

2

O PE R AT I NG IN S TR U CT I ON S | GM32 Ex 8015594/YV18/V1-8/2017-08 | SICK

Subject to change without notice

Page 3

Contents

CONTENTS

1 About this document........................................................................ 7

1.1 Function of this document....................................................................... 7

1.2 Scope of application................................................................................. 7

1.3 Target groups / qualification requirements............................................ 7

1.4 Further information................................................................................... 7

1.5 Data integrity............................................................................................. 7

1.6 Symbols and document conventions...................................................... 8

1.6.1 Warning symbols...................................................................... 8

1.6.2 Warning levels / Signal words................................................. 8

1.6.3 Information symbols................................................................ 9

2 Safety information............................................................................ 10

2.1 Main operating information..................................................................... 10

2.2 Warnings on the device............................................................................ 12

2.3 Intended use............................................................................................. 12

2.3.1 Purpose of the device.............................................................. 13

2.3.2 Operation in potentially explosive atmosphere...................... 13

2.4 Responsibility of user............................................................................... 14

3 Product description........................................................................... 15

3.1 Product identification............................................................................... 15

3.2 Device version........................................................................................... 15

3.3 Device variants......................................................................................... 16

3.4 Options...................................................................................................... 16

3.5 SOPAS ET (PC program)............................................................................ 16

3.6 Reference cycle......................................................................................... 17

3.7 Check cycle............................................................................................... 17

3.8 Layout and function.................................................................................. 19

3.9 Purge air unit............................................................................................. 20

3.10 Explosion protection in accordance with ATEX....................................... 20

3.10.1 Zone separation GM32 EX ATEX 3G....................................... 20

3.10.2 Pressurized enclosure............................................................. 21

3.10.2.1 ................................................................................. 21

3.11 Connecting hose between SR-unit and junction box.............................. 22

4 Transport and storage....................................................................... 23

4.1 Transport safety device............................................................................ 23

4.2 Storage...................................................................................................... 23

5 Mounting............................................................................................. 24

5.1 Information on installation in potentially explosive atmospheres......... 24

5.2 Preparing the sampling point................................................................... 25

5.3 Scope of delivery....................................................................................... 25

5.3.1 Checking the delivery state..................................................... 26

8015594/YV18/V1-8/2017-08 | SICK O PE R AT I NG IN S TR U CT I ON S | GM32 Ex

Subject to change without notice

3

Page 4

CONTENTS

5.4 Installation sequence............................................................................... 26

5.4.1 Overview of the installation steps (duct-side preparation)... 26

5.4.2 Install flanges with tube.......................................................... 26

5.4.3 Installing the connection unit................................................. 28

5.4.3.1 Fitting the FS850S.................................................. 29

5.4.4 Installing the purge air unit..................................................... 30

5.4.4.1 Start-up of the purge air supply............................. 30

6 Electrical installation........................................................................ 32

6.1 Electrical installation safety information................................................. 32

6.2 Connection overview................................................................................ 34

6.2.1 Lines......................................................................................... 35

6.3 Connecting interfaces ............................................................................. 35

6.3.1 Connecting I/O interfaces (option)......................................... 35

6.3.1.1 Connection diagram for variant 3G....................... 36

6.3.1.2 Default values for interfaces.................................. 38

6.4 Connecting the connection hose to the SR-unit on the junction box.... 39

6.5 Connecting pressure, temperature and purge air monitor ................... 40

6.6 Connecting the potential equalization on the purge air fixture............. 40

6.7 Connecting the Ex overpressure control FS850S................................... 41

6.8 Electrical connection of SR-unit............................................................... 42

6.9 Preparing the power supply...................................................................... 43

6.10 Connecting the potential equalization to the SR-unit............................. 44

7 Commissioning.................................................................................. 45

7.1 Safety information for start-up................................................................. 45

7.2 Material required ..................................................................................... 46

7.3 Check before start-up............................................................................... 46

7.4 Overview of start-up steps....................................................................... 46

7.5 Fitting the purge air fixtures on the flange with tube............................. 47

7.6 Installing the device flange on the purge air fixture............................... 47

7.7 Aligning device flanges and purge air fixtures........................................ 49

7.8 Connecting the protective gas on the SR-unit........................................ 50

7.8.1 Feeding protective gas............................................................ 51

7.8.2 Switching the pressurized enclosure on................................. 51

7.9 Installing the SR-unit and reflector unit on the device flange............... 52

7.10 Optical fine alignment of the SR-unit ..................................................... 52

7.11 Fitting the weatherproof cover (option)................................................... 53

8 Operation............................................................................................ 55

8.1 Safety......................................................................................................... 55

8.2 GM32 operator panel............................................................................... 55

8.2.1 LEDs.......................................................................................... 56

8.2.2 Function buttons...................................................................... 57

8.2.3 Setting the display contrast.................................................... 58

8.2.4 Menu tree................................................................................. 58

4

O PE R AT I NG IN S TR U CT I ON S | GM32 Ex 8015594/YV18/V1-8/2017-08 | SICK

Subject to change without notice

Page 5

CONTENTS

8.2.4.1 Diagnosis................................................................. 59

8.2.4.2 Check cycle - results of last check cycle............... 59

8.2.4.3 Alignment check (option) - automatic optical

alignment check..................................................... 60

8.2.4.4 Alignment adjust - manual optical alignment....... 60

8.2.4.5 Maintenance mode - set Maintenance mode ...... 62

9 Maintenance...................................................................................... 64

9.1 Safety ........................................................................................................ 64

9.2 Maintenance plan .................................................................................... 66

9.2.1 Consumable parts, expendable parts and spare parts........ 66

9.3 Preparation work....................................................................................... 67

9.4 Function test of the pressurized enclosure system................................ 67

9.5 Swiveling out and removing the SR-unit or reflector unit....................... 68

9.6 Visual inspection....................................................................................... 69

9.7 Cleaning the window................................................................................. 70

9.8 Check/replace the desiccant cartridge................................................... 70

9.9 Replacing the activated charcoal bag..................................................... 71

9.10 Replacing the sender lamp...................................................................... 72

10 Troubleshooting................................................................................. 75

10.1 Safety......................................................................................................... 75

10.2 Visual inspection....................................................................................... 76

10.3 Device not functioning.............................................................................. 77

10.4 Overpressure monitoring failure.............................................................. 77

10.5 Measured values clearly incorrect........................................................... 78

10.6 Sample gas penetrating........................................................................... 78

10.7 Corrosion on flange.................................................................................. 78

10.8 Measured value blinks............................................................................. 78

10.9 Error messages......................................................................................... 78

10.9.1 Example of an error message................................................. 78

10.9.2 Error messages........................................................................ 80

10.10 Repairing inadequate purge air supply................................................... 84

10.11 Malfunctions on the connection unit ..................................................... 84

11 Decommissioning............................................................................. 85

11.1 Safety information on shutting down...................................................... 85

11.2 Decommissioning of subassemblies with explosion relevance............. 87

11.3 Removing the device................................................................................ 87

11.4 Environmentally compatible disposal ..................................................... 87

12 Technical data.................................................................................... 89

12.1 System: GM32 Ex..................................................................................... 89

12.2 GM32 Ex sender/receiver unit................................................................ 90

12.3 Reflector unit GM32 Ex............................................................................ 90

12.4 Purge air fixture: Sender/receiver unit GM32 Ex................................... 91

12.5 Purge air fixture: Reflector unit GM32 Ex................................................ 91

8015594/YV18/V1-8/2017-08 | SICK O PE R AT I NG IN S TR U CT I ON S | GM32 Ex

Subject to change without notice

5

Page 6

CONTENTS

12.6 Connection unit, Ex version I/O module................................................. 91

12.7 Dimension drawings: Sender/receiver unit Ex version.......................... 92

12.8 Dimension drawings: Reflector unit........................................................ 93

12.9 Dimension drawings: Ex purge air fixtures (on SR and reflector side).. 94

12.10 Dimension drawings: Connection unit version 3G................................. 95

12.11 Dimension drawings: Mounting flange DN100....................................... 96

12.12 Dimension drawing, weatherproof cover, SR-unit................................... 96

12.13 Technical data for enclosure pressurization system.............................. 96

12.13.1 Technical data protective gas................................................. 96

12.13.2 Technical data enclosure........................................................ 97

12.13.3 Pressurized enclosure system settings.................................. 97

13 Annex.................................................................................................. 98

13.1 Conformities.............................................................................................. 98

13.2 Electrical protection.................................................................................. 98

13.3 Ex certifications........................................................................................ 98

14 Index.................................................................................................... 100

6

O PE R AT I NG IN S TR U CT I ON S | GM32 Ex 8015594/YV18/V1-8/2017-08 | SICK

Subject to change without notice

Page 7

ABOUT THIS DOCUMENT 1

1 About this document

1.1 Function of this document

These Operating Instructions describe:

Device components

•

Installation

•

Operation

•

Maintenance work required for reliable operation

•

1.2 Scope of application

These Operating Instructions are only valid for the in-situ gas analyzer with the designa‐

tion GM32 Ex Cross-Duct.

They are not valid for other in-situ gas analyzers from SICK.

1.3 Target groups / qualification requirements

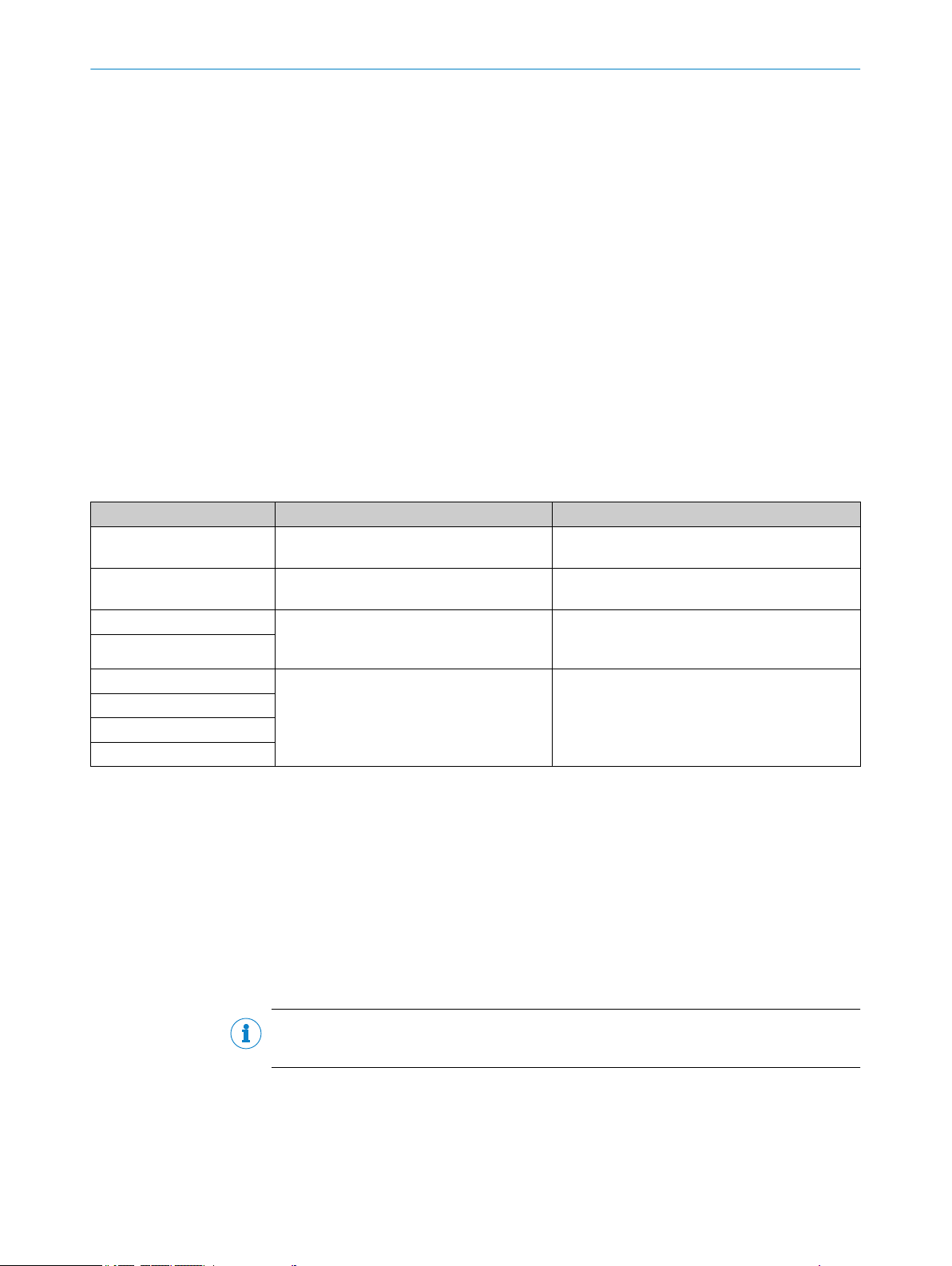

Table 1: Qualification requirements

Tasks User groups Qualification

Assembly Operator / system integrator e.g. plant operator, unskilled in measurement

technology

Electrical installation Qualified personnel Authorized electrician (authorized skilled electri‐

cian or person with similar training)

Initial start-up

Returning to operation

Decommissioning

Operation

Maintenance

Troubleshooting

Authorized operator Ü

Operator / system integrator

•

Authorized operator Ü

•

General knowledge in measurement technology,

specialist device knowledge (possibly customer

training at SICK)

e.g. plant operator, unskilled in measure‐

•

ment technology

Authorized electrician (authorized skilled

•

electrician or person with similar training)

1.4 Further information

Operating Instructions of the purge air supply

•

Final inspection record

•

CD-ROM with SOPAS ET

•

Optional: Technical information

•

Optional: Operating Instructions Modular System I/O

•

3G / Zone 2

FS850S Pressurized Enclosure Manual

•

Manual, Purge medium valve SVD.L.2.-AI00

•

NOTE

Observe all supplied documents.

b

1.5 Data integrity

SICK AG uses standardized data interfaces such as, for example, standard IP technol‐

ogy, in its products. The focus here is on product availability and features.

8015594/YV18/V1-8/2017-08 | SICK O PE R AT I NG IN S TR U CT I ON S | GM32 Ex

Subject to change without notice

7

Page 8

1 ABOUT THIS DOCUMENT

SICK AG always assumes that the customer is responsible for the integrity and confi‐

dentiality of data and rights involved in connection with using the products.

In all cases, the customer is responsible for the implementation of safety measures

suitable for the respective situation, e.g., network separation, firewalls, virus protection

and patch management.

1.6 Symbols and document conventions

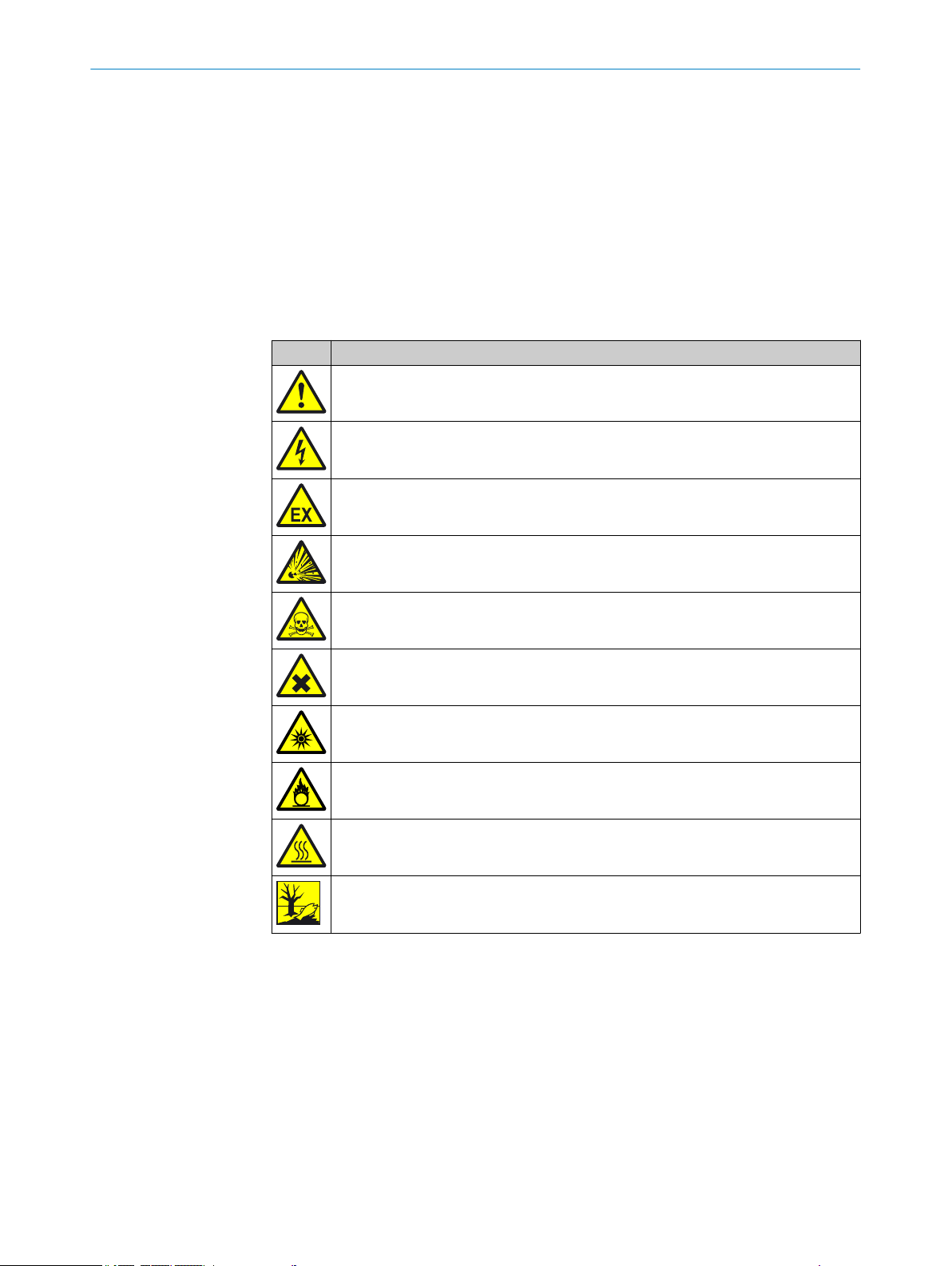

1.6.1 Warning symbols

Table 2: Warning symbols

Symbol Significance

Hazard (general)

Hazard by voltage

Hazard in potentially explosive atmospheres

Hazard by explosive substances/mixtures

Hazard by toxic substances

Hazard by unhealthy substances

Hazard by ultraviolet radiation (UV light)

Hazard by oxidizing substances

Hazard by high temperature

Hazard for the environment/nature/organic life

1.6.2 Warning levels / Signal words

DANGER

Risk or hazardous situation which will result in severe personal injury or death.

WARNING

Risk or hazardous situation which could result in severe personal injury or death.

CAUTION

Hazard or unsafe practice which could result in less severe or minor injuries.

Notice

Hazard which could result in property damage.

8

O PE R AT I NG IN S TR U CT I ON S | GM32 Ex 8015594/YV18/V1-8/2017-08 | SICK

Subject to change without notice

Page 9

Note

Hints

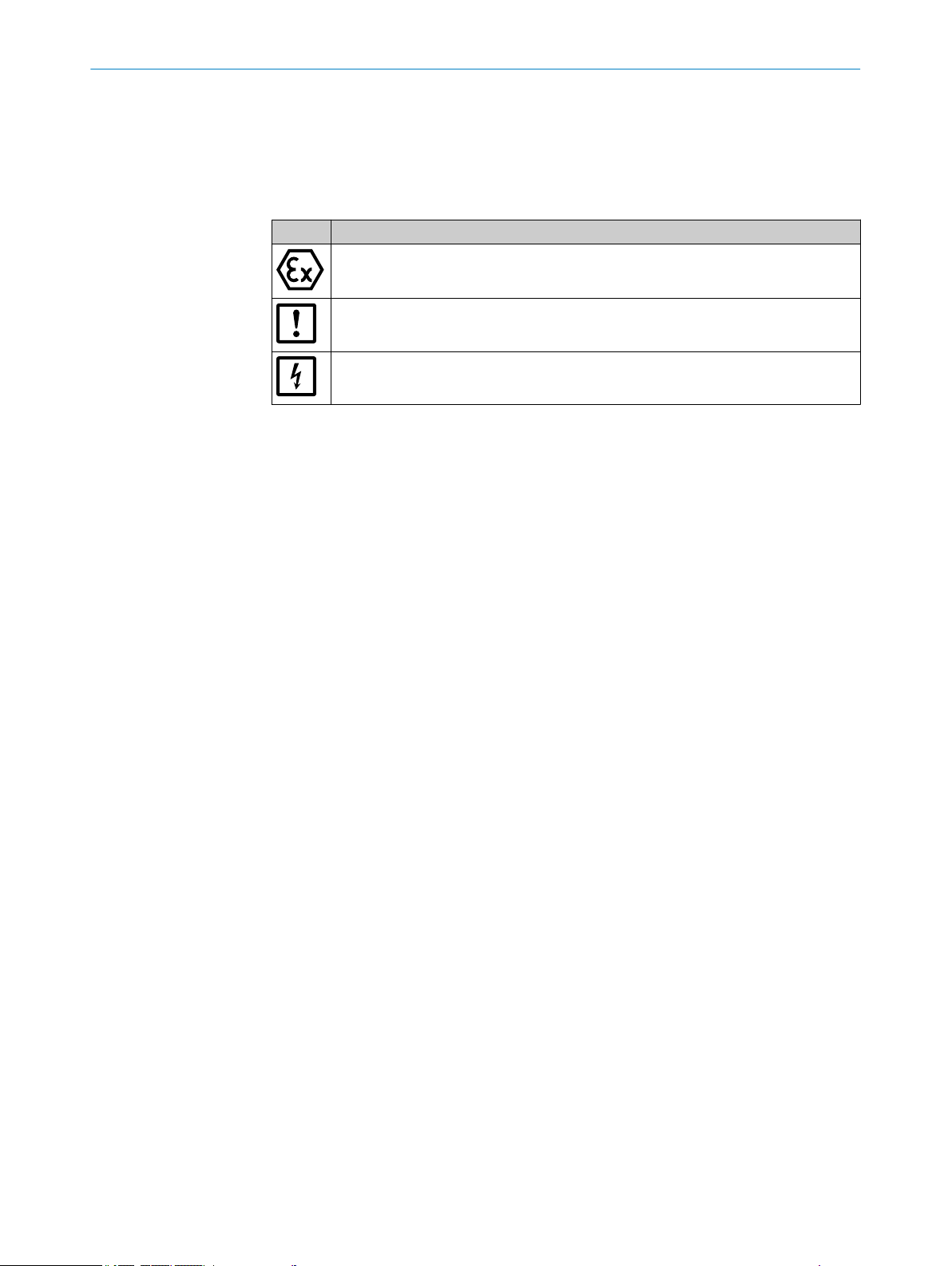

1.6.3 Information symbols

Table 3: Information symbols

Symbol Significance

ABOUT THIS DOCUMENT 1

Information on consistency of the product relative to Guideline 2014/34/EU (ATEX)

Important technical information for this product

Important information on electric or electronic functions

8015594/YV18/V1-8/2017-08 | SICK O PE R AT I NG IN S TR U CT I ON S | GM32 Ex

Subject to change without notice

9

Page 10

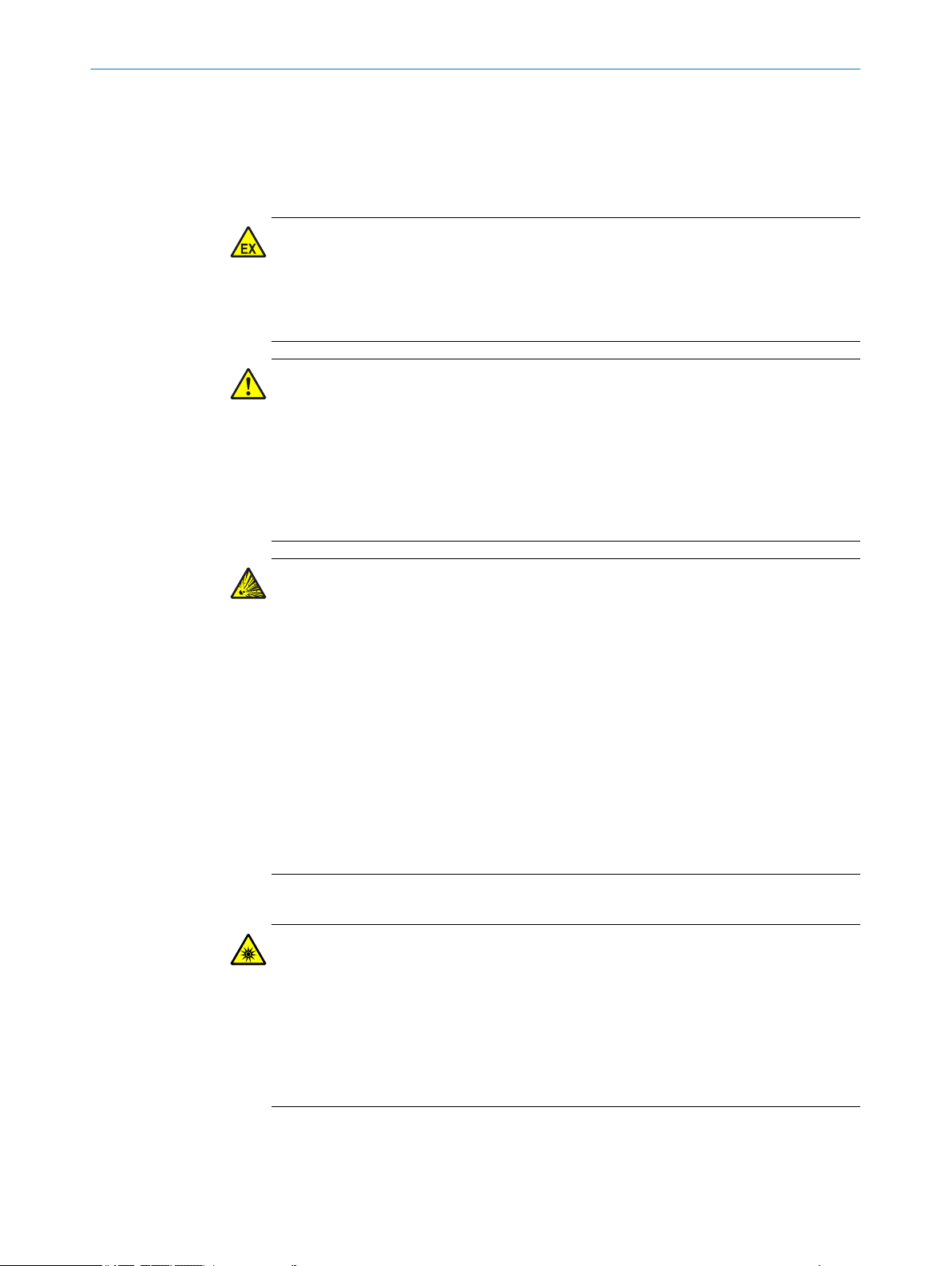

2 SAFETY INFORMATION

2 Safety information

2.1 Main operating information

Work on the device

WARNING

Risk of explosion

Work on the device assumes an Ex free zone at the installation location otherwise there

is an explosion risk.

Ensure the work area is Ex free when working on the device.

b

DANGER

Risk for system safety through work on the device not described in these Operating

Instructions

Carrying out work on the device not described in these Operating Instructions or associ‐

ated documents can lead to unsafe operation of the measuring system and therefore

endanger plant safety.

Only carry out the work on the device described in these Operating Instructions

b

and associated documents.

DANGER

Risk of explosion through incorrect performance of maintenance work

Incorrect performance of maintenance work in potentially explosive atmospheres can

cause serious injuries to people and damage during operation.

Maintenance work and start-up activities as well as checks must be performed by

•

experienced/trained technicians having knowledge of the relevant rules and regu‐

lations for potentially explosive atmospheres, especially:

– Ignition protection types

– Installation procedures

– Zone classification

Standards to be applied:

•

– IEC 60079-14, Annex F: Knowledge, skills and competencies of responsible

persons, operatives and designers

– IEC 60079-17: Electrical installations inspection and maintenance

– IEC 60079-19: Equipment repair, overhaul and reclamation

Noxious UV radiation

DANGER

Damage to eyes and skin by UV radiation

The in-situ gas measuring device GM32 emits UV radiation when the SR-unit or reflec‐

tor unit is opened during operation. Exposure of the unprotected skin and eyes to radia‐

tion is dangerous to health.

10

Disconnect the power supply of the device before opening the device.

b

Wear suitable protective goggles and protective gloves when work on the open

b

device with the power supply connected is performed.

O PE R AT I NG IN S TR U CT I ON S | GM32 Ex 8015594/YV18/V1-8/2017-08 | SICK

Subject to change without notice

Page 11

SAFETY INFORMATION 2

Escaping hot gas

DANGER

Risk of fire through hot gas escaping in installations with overpressure conditions

On installations with overpressure, the purge air hose can be severely damaged by

escaping hot gas and can catch fire depending on the temperature. On installations

with overpressure and gas temperatures over 200°C at the same time:

Regularly check the functionality of the reverse flow safeguard in the purge air fix‐

b

tures.

Potential equalization

CAUTION

Device damage through incorrect or non-existing grounding

To avoid device damage, a correctly connected potential equalization is mandatory on

all system components with external ground connections in all operating conditions.

Connect a potential equalization on all planned points on the device components.

b

Ensure the potential equalization is connected during all work on the device

b

described in these Operating Instructions.

Contamination caused by purge air failure

CAUTION

A faulty purge air supply can damage the measuring system

The measuring system can no longer be protected from contaminated sample gas and

is damaged.

When the purge air supply is faulty, immediately perform all actions described in

b

these Operating Instructions.

Responsibility for system safety

ATTENTION

Responsibility for the safety of a system

The person setting the system up is responsible for the safety of the system in which

the device is integrated.

8015594/YV18/V1-8/2017-08 | SICK O PE R AT I NG IN S TR U CT I ON S | GM32 Ex

Subject to change without notice

11

Page 12

1

2

3

4

5

6

7

8

9

1 2 3

2 SAFETY INFORMATION

2.2 Warnings on the device

GM32 Ex SR-unit

Figure 1: Sender/receiver unit from the front, the side and with the intermediate housing open

Sender/receiver unit, front side

1 Warning sign protective gas:

°

°

°

2 Warning sign: Pull power plug before opening the device

3 Mandatory sign: Wear eye protection

4 Warning sign: Do not disconnect when live

Sender/receiver unit, right side

5 Type plate GM32 Ex 3G

6 Sampling point designation (optional)

7 Danger sign: UV light

Sender/receiver unit, intermediate housing

8 Type plate GM32 Ex 3G

9 Warning sign: Hot surface

Protective gas outlet

Risk of suffocation when using inert gases

20 minutes waiting time before opening the enclosure

GM32 Ex connection unit

Connection unit for GM32 Ex, front side

1 Warning sign protective gas:

Protective gas outlet

°

Risk of suffocation when using inert

°

gases

20 minutes waiting time before open‐

°

ing the enclosure

2 Warning sign: Pull power plug before open‐

ing the device

3 General warning sign: Warning of a danger

area

Figure 2: GM32 Ex connection unit

2.3

12

Intended use

O PE R AT I NG IN S TR U CT I ON S | GM32 Ex 8015594/YV18/V1-8/2017-08 | SICK

Subject to change without notice

Page 13

2.3.1 Purpose of the device

The device serves exclusively for emission and process monitoring of gases in industrial

plants.

The device measures continuously directly in the gas duct (in-situ).

2.3.2 Operation in potentially explosive atmosphere

3G / Zone 2: Connection unit and sender/receiver unit

The GM32 Ex corresponds to the ATEX category (according to

•

ATEX 2014/34/EC):

X II 3G Ex pzc op is [ia] IIC T3 Gc

GM32 Ex meets the following IECEx qualification:

•

Ex pzc op is [ia] IIC T3 Gc

Special conditions (X identification)

•

A measuring function for explosion protection is not part of

°

the EC type approval

The duct with sample gas contact must be a non-potentially

°

explosive atmosphere when overpressure against the

atmosphere is present in the duct

If the duct has underpressure against the atmosphere, this

°

area may correspond to Zone 2

Observe the Ex identification.

•

The Ex identification is on the type plate. Example:

SICK

GM32-xxx-EX3G (xxx=internal type number)

SN: yyyy yyyyy (serial number)

-20 °C ≤ Ta ≤ 55 °C

X

Explosion protection relating to optical radiation in the measur‐

•

ing channel

The explosion protection relating to optical radiation in the meas‐

uring channel is satisfied in accordance with the temperature

range (-20°... +60 °C) specified by ATX/IECEx. The plant opera‐

tor must evaluate Ex atmospheres possibly present for exhaust

gas temperatures exceeding this range separately and take suit‐

able protective measures!

Location of Ex relevant subassemblies, see Chapter “Design

w

and Function”.

Do not remove, add or modify any components to or on the

w

device unless described and specified in the official manu‐

facturer information. Otherwise the approval for the device

for use in potentially explosive atmospheres becomes void.

Adhere to the maintenance intervals, see Chapter “Mainte‐

w

nance plan”.

After switching off the main power supply: Wait 20 minutes

w

before opening the enclosure.

SAFETY INFORMATION

2

8015594/YV18/V1-8/2017-08 | SICK O PE R AT I NG IN S TR U CT I ON S | GM32 Ex

Subject to change without notice

13

Page 14

2 SAFETY INFORMATION

2.4 Responsibility of user

Designated users

see "Target groups / qualification requirements", page 7.

Correct project planning

Basis of this Manual is the delivery of the device according to the preceding

•

project planning (e.g., based on the SICK application questionnaire) and the rele‐

vant delivery state of the device (see delivered System Documentation).

Contact SICK Customer Service if you are not sure whether the device corre‐

w

sponds to the state defined during project planning or to the delivered system

documentation.

Special local conditions

In addition to the information in these Operating Instructions, follow all local laws, tech‐

nical rules and company-internal operating directives applicable wherever the device is

installed.

Read the Operating Instructions

Read and observe these Operating Instructions.

b

Observe all safety instructions.

b

If anything is not clear: Please contact SICK Customer Service.

b

Retain documents

These Operating Instructions:

Must be available for reference.

b

Must be passed on to new owners.

b

14

O PE R AT I NG IN S TR U CT I ON S | GM32 Ex 8015594/YV18/V1-8/2017-08 | SICK

Subject to change without notice

Page 15

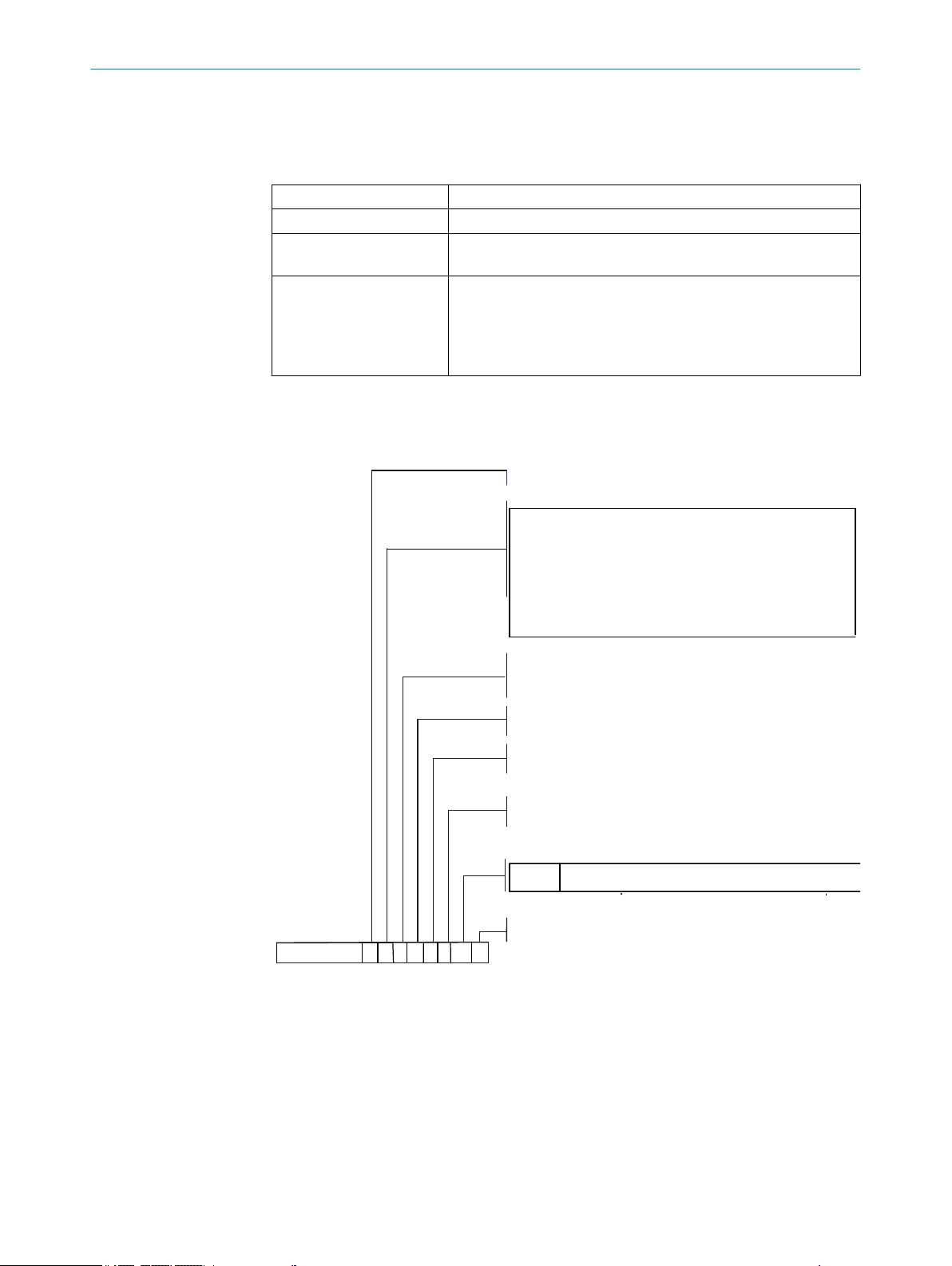

3 Product description

a*

Ausführung/Device

Komponenten/Components

Messlanze/ Measuring probe

Cross-Duct

Ausführung und Kalibierung / calibration

Geräteart 1

Device type 1

Geräteart 2

Device type 2

Dokumentation / Documentation

GM32 -

Ex2G

Ex3G

Ex-Gerät 2G (Zone1)

Ex-Gerät 3G (Zone2)

Ex-device 2G (Zone1)

Ex-device 3G (Zone2)

**** **

*

0

7

6

5

4

3

2

1

9

Sonderausführung

SO2

SO2, NO, NOx

SO2, NO, NO2, NOx

NO, NOx

SO2, NO, NH3, NOx

SO2, NO, NH3, NOx

NO, NO2, NOx

SO2, NO, NO2, NH3, NOx

special model

3.1 Product identification

Product name GM32 Ex

Device version Cross-Duct version

Manufacturer SICK AG

Type plates

3.2 Device version

Type code for Ex device versions

PRODUCT DESCRIPTION 3

Erwin-Sick-Str. 1 D-79183 Waldkirch · Germany

Sender/receiver unit: On the right side and on the intermedi‐

•

ate enclosure

Connection unit: On the right and inside

•

On the purge air fixture: On the tube

•

On the reflector

•

8015594/YV18/V1-8/2017-08 | SICK O PE R AT I NG IN S TR U CT I ON S | GM32 Ex

Subject to change without notice

Figure 3: Type code for GM32 Ex

Ex version designation

*a

15

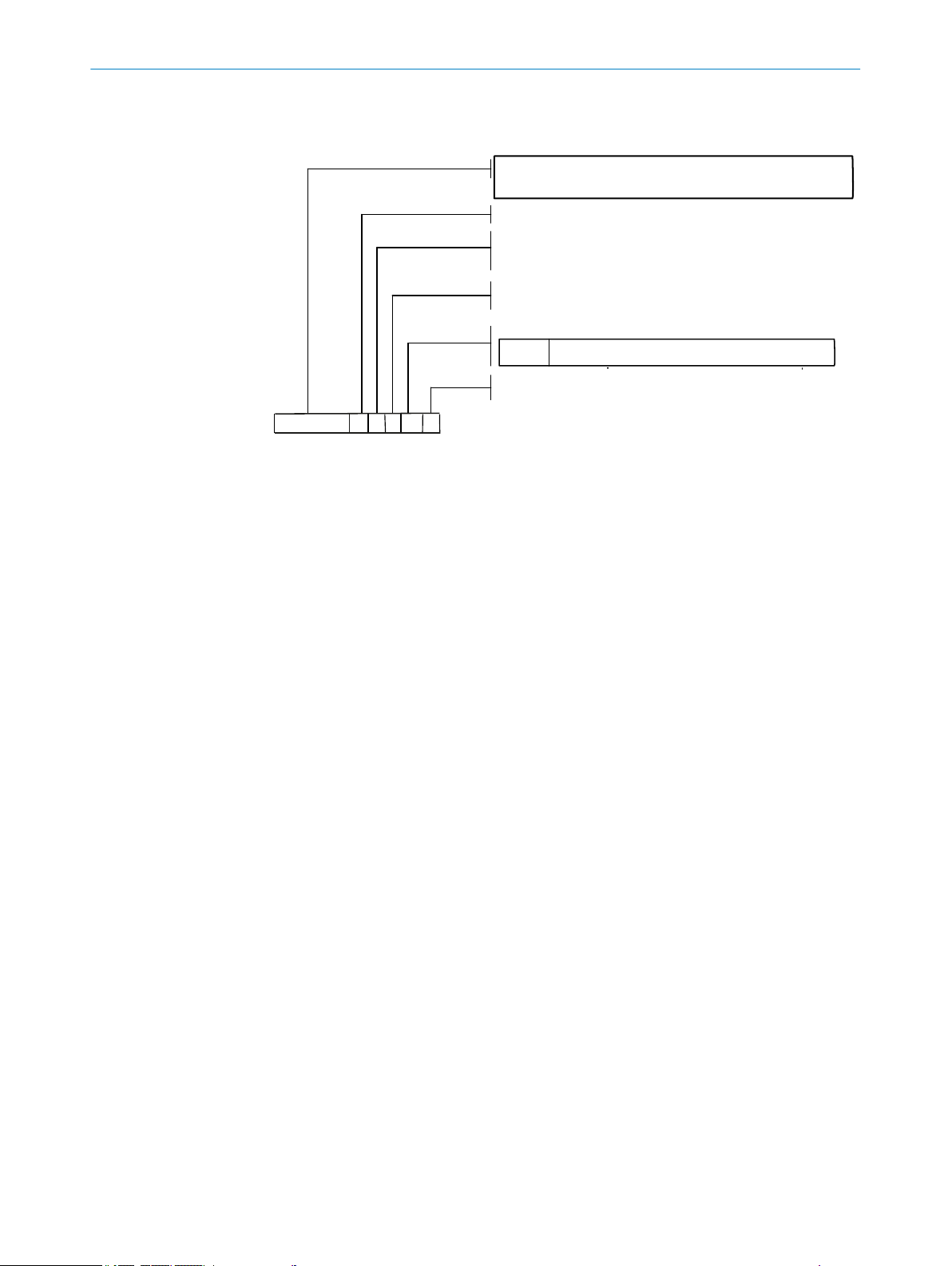

Page 16

Ausführung Device

Anschlusseinheit - Connection unit housing

Anschlusseinheit - Analoge/Digitale Schnittstellen

Connection unit - I/Os

Anschlusseinheit - Zusatzbestückung

Connection unit - additional assembly

Geräteart Device type

Dokumentation / Documentation

Ex2G

Ex3G

Ex-Gerät 2G (Zone1)

Ex-Gerät 3G (Zone2)

Ex-device 2G (Zone1)

Ex-device 3G (Zone2)

GM32Gasmessgerät

Typ

Measuring system for gas

Type

-A

Anschlusseinheit

Connection unit

a*

GM32 - A

***

*

3 PRODUCT DESCRIPTION

Type code for Ex connection unit

Figure 4: Type code for GM32 Ex connection unit

a*

Ex connection unit designation

3.3 Device variants

“Basic” variant

Reference cycle, see "Reference cycle", page 17: Correction of internal drifts.

•

Zero point check

Automatic mirror tracking: Automatic adjustment of optical axis

•

Logbook: System messages are recorded in a logbook

•

Network: Ethernet interface with OPC standard

•

Ethernet: 1 x fiber optics connection on connection unit

•

“Pro” variant

As “Basic” variant. In addition:

TÜV-tested for equipment subject to authorization

•

Check cycle, see "Check cycle", page 17: Reference cycle (as in the “Basic” var‐

•

iant) followed by a cycle to check and output the zero and check point. The check

cycle creates the QAL3 values (quality assurance of automated measuring sys‐

tems). The QAL3 values can be displayed with SOPAS ET.

Operator panel: Measured values, operational state and malfunction messages

•

are displayed in clear text on a monitor

QAL3 Tool (CUSUM chart)

•

3.4 Options

3.5 SOPAS ET (PC program)

16

O PE R AT I NG IN S TR U CT I ON S | GM32 Ex 8015594/YV18/V1-8/2017-08 | SICK

I/O modules (Analog Out, Digital Out, Digital In, Analog In)

•

SCU: Operating unit to control several analyzers with SCU capability (see SCU Oper‐

•

ating Instructions)

Super calibration: Several applications/calibrations, e.g., for spare devices

•

Measuring range switch-over (analog outputs). The valid measuring range is sig‐

•

naled via a digital output (configured).

Weatherproof cover

•

SOPAS ET enables:

Subject to change without notice

Page 17

•

•

SOPAS ET runs on an external PC connected via the Ethernet interface, see "Connection

overview", page 34, to the GM32.

NOTE

Further information on SOPAS ET:

•

•

3.6 Reference cycle

Internal drifts correction in an adjustable interval (standard: 1 hour, setting: SOPAS ET)

or per command (with SOPAS ET).

Measured value output during the reference cycle: Last valid measured value.

3.7 Check cycle

Check cycle = reference cycle + following check and output of the zero and check points

(70% of full scale value).

PRODUCT DESCRIPTION 3

Additional configuration

Access to logbook GM32

Technical Information GM32

SOPAS ET Help menu

Start a check cycle via

Set interval (SOPAS ET)

•

Command via SOPAS ET

•

External signal (optional)

•

Purpose of check cycle

Check of the zero point and a reference point for each component without feeding

•

test gases

Meets the requirements of EN14181

•

Replaces drift monitoring with test gases according to QAL3

•

Zero point

An internal zero point reflector is swiveled in time-controlled in adjustable intervals. The

emitted light is reflected back in the sender/receiver unit to the detector, the zero spec‐

trum is evaluated with the calibration function and thus the zero points of all ducts

measured and output.

Signaling of maintenance request: Deviation from zero > ± 2% of the FS.

Check cycle

An internal swivel element with two reference filters and an NO-filled cell is swiveled in

during the check cycle in addition to the zero point reflector and the reference value

and concentration value measured. These control values are scaled to 70% of the

selected measuring range.

Signaling of maintenance request: Deviation from setpoint value > ± 2% of the FS.

8015594/YV18/V1-8/2017-08 | SICK O PE R AT I NG IN S TR U CT I ON S | GM32 Ex

Subject to change without notice

17

Page 18

1

2

3

4

7

8

5

6

3 PRODUCT DESCRIPTION

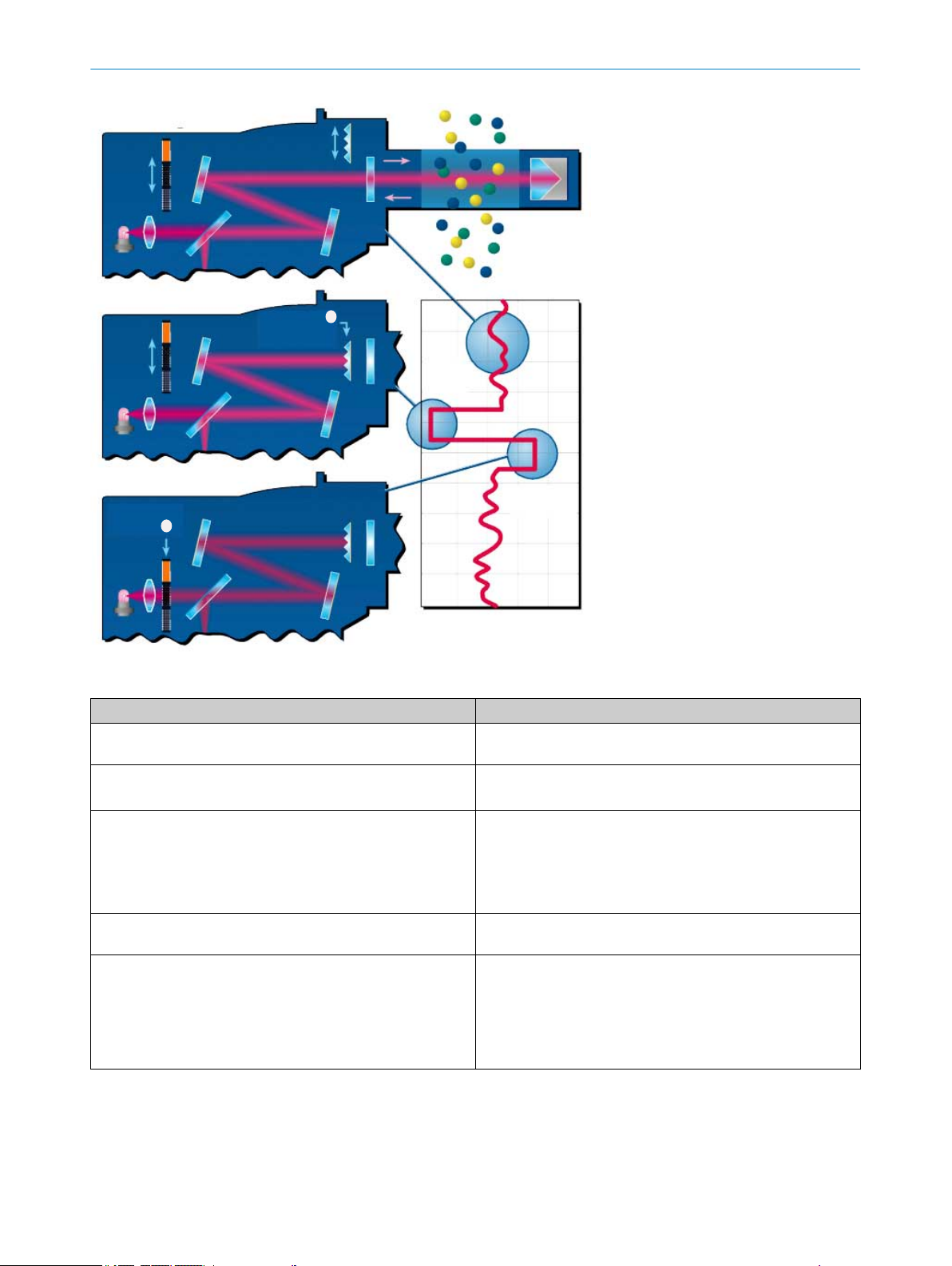

Measuring

1

Zero point

2

Check

3

Data recorder

4

Swivel element

5

Zero point reflector

6

Zero point

7

Figure 5: Measuring principle of check cycle

Check point (70% fsc)

8

Output of measured values during the check cycle Last valid measured value

Signal output during the check cycle (optional digital output or

Not_measuring

OPC interface)

Output of determined zero and reference values on analog

outputs

Directly after the check cycle

•

On request via a digital input (option)

•

Signal output during the output Output_control values (optional digital output or OPC inter‐

face)

Output sequence:

1 Zero values for 90 s

2 Reference values for 90 s

Display of zero and reference values, the last check cycle as

well as QAL3 values in SOPAS ET

Display when check of NO cell failed

Menu: Diagnosis/check values

All interfaces: Results of NO cell

•

All interfaces: “0” is output instead of zero and refer‐

•

ence values

Analog output: Live Zero

•

Results of zero and reference measurement are irrele‐

•

vant

18

O PE R AT I NG IN S TR U CT I ON S | GM32 Ex 8015594/YV18/V1-8/2017-08 | SICK

Subject to change without notice

Page 19

3.8 Layout and function

1

ß

9

8

6

6

5

4

3

2

7

ß

PRODUCT DESCRIPTION 3

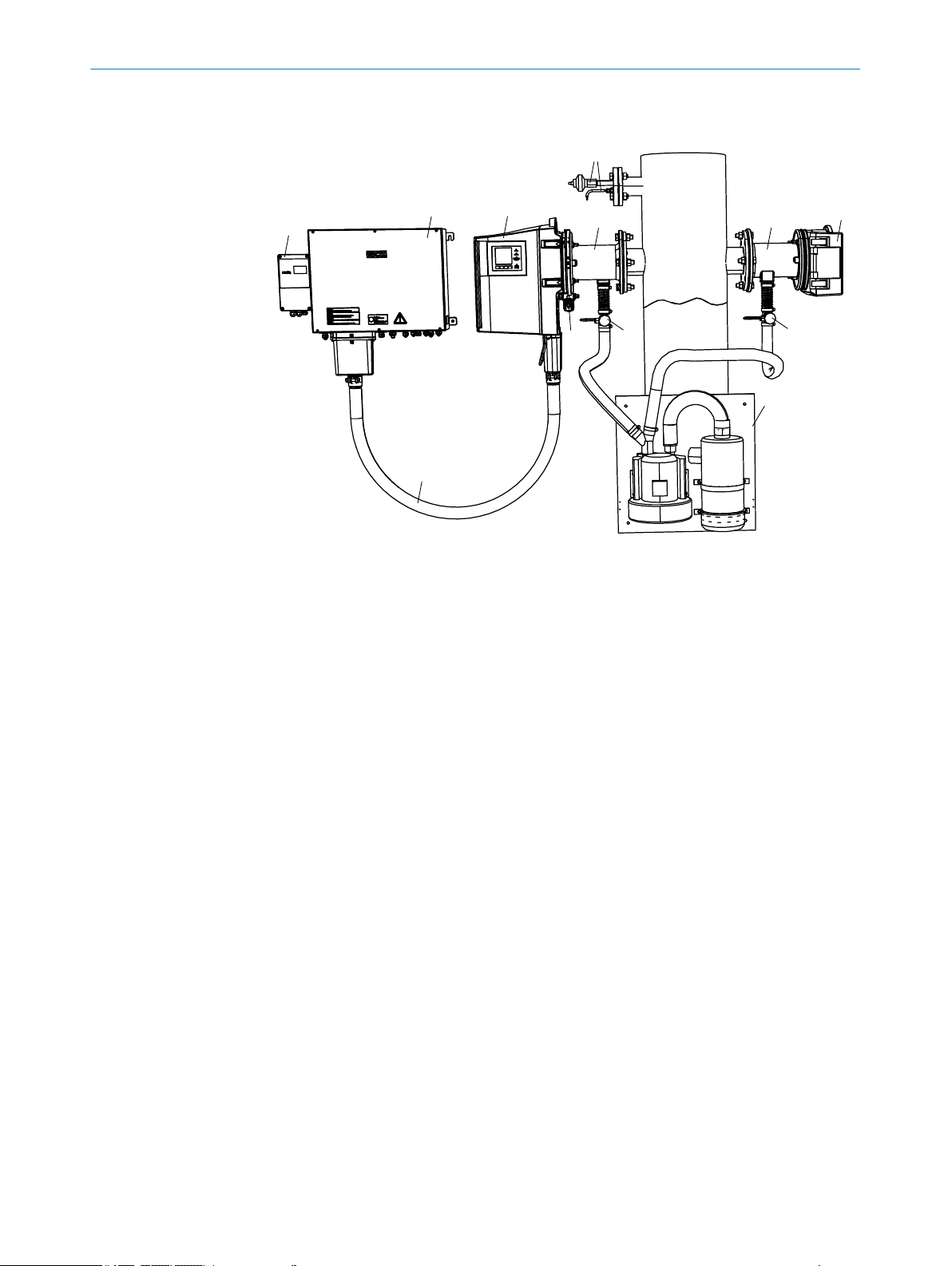

Figure 6: Components of the GM32 Ex 3G version

Sender/receiver unit GM32-xxxxxxEX3G (SR-unit)

1

Connection unit GM32- A2xxEX3G

2

Control unit FS850S EEx p

3

Metallic connecting hose between sender/receiver unit and connection unit

4

Purge valve SVP3 G 3/8“-300L EEx p

5

Purge air fixture (without electronics)

6

Reflector unit (without electronics)

7

Temperature and pressure measurement

8

Purge air supply

9

Pressure switch for purge air monitor

ß

Function

The device serves for continuous measurement of gas concentrations in industrial

•

plants

The device is an in-situ measuring system which means measuring is done directly

•

in the gas carrying duct

erence variables temperature and pressure

Measuring principle: Differential Optical Absorption Spectroscopy (DOAS)

•

To maintain measuring reliability, a permanent air flow (optics purge air) protects

•

Measuring components: SO2, NO, NO2 and NH3 (device specific) as well as the ref‐

•

and keeps the optics free from soot and dust particles as well as condensate and

moisture condensation

Ignition protection type “pressurized enclosure” is applicable when using the

•

GM32 Ex in potentially explosive atmospheres. All relevant enclosures of the

sender/receiver unit and connection unit connected together via a pressure-proof

metal hose are purged with a protective gas. The protective gas can be air suc‐

tioned in from the non-potentially explosive atmosphere or an inert gas.

8015594/YV18/V1-8/2017-08 | SICK O PE R AT I NG IN S TR U CT I ON S | GM32 Ex

Subject to change without notice

19

Page 20

DIV 1

DIV 2

Non Ex

1G

2G

Non Ex

3G

Zone 0

Non Ex

Zone 2Zone 1

DI/DOAI

/AO

230 /115 V

GM32 Ex ATEX 3G

Ex p

[op is]

p/t

Ex ia

Ex m

Ex p/ Ex i

Ex eb

mb [ib]

1

Non Ex

ß

à

9

á

7

6

8

5

3

4

ã ä å

2

9

à

ââ

æ

ç

3 PRODUCT DESCRIPTION

3.9 Purge air unit

The purge air unit supplies filtered ambient air to the purge air fixtures.

•

Protects the window of the SR-unit and the reflector against contamination and

•

high gas temperatures

One purge air unit each for SR-unit and reflector unit

•

The purge air is blown into the gas duct through the “flange with tube”.

•

NOTE

Further information on the purge air unit, see Operating Instructions of the purge air

unit.

3.10 Explosion protection in accordance with ATEX

3.10.1 Zone separation GM32 EX ATEX 3G

Figure 7: Zone separation GM32 Ex 3G

Components

Control station / measuring station

1

Sender/receiver unit

2

Reflector unit

3

Light source

4

Ex p valve

5

Evaluation unit

6

Overpressure control

7

p/T sensor

8

p sensor

9

20

O PE R AT I NG IN S TR U CT I ON S | GM32 Ex 8015594/YV18/V1-8/2017-08 | SICK

Subject to change without notice

Page 21

Optics purge air according to plant operator's selection

ß

Lines

Purge air hose, optics

à

Connecting hose Ex p

á

Pressure controller, optics purge air Ex i nA

â

Ex p error case signal

ã

Service interface

ä

Feed, Ex p protective gas, provided by operator

å

Feed, optics purge air

æ

Measuring channel

Measuring channel Ex-free; Zone 2 possible with partial vacuum

ç

3.10.2 Pressurized enclosure

Ignition protection type, pressurized enclosure for Zone 2

Purging

All relevant enclosures of the sender/receiver unit and connection unit connected

together via a pressure-proof metal hose are purged with a protective gas. This purging

before the start of the device ensures any possibly present ignitable mixture is safely

removed.

PRODUCT DESCRIPTION 3

Controlling the overpressure in the enclosure

The control FS850P ensures the complete enclosure is held at an overpressure of at

least 0.8 mbar against the atmosphere after the purging which in turn ensures no ignit‐

able gas mixture can penetrate the enclosure.

Protective gas types

Instrument air suctioned in from the area outside the potentially explosive atmos‐

•

phere

Inert gas

•

More information, see "Technical data protective gas", page 96 and Pressurized

Enclosure Operating Instructions.

Alarm signal of the pressurized enclosure when a malfunction occurs

Ex control unit FS850S for category 3G:

Ex control unit FS850S will trigger an alarm signal when the pressurized enclosure

is not in the correct operating state (malfunction).

WARNING

Risk of explosion through incorrect parameter settings

Unauthorized changing of parameters can cause an explosion with fatal consequences.

Never change parameters without authorization.

b

NOTICE

The operating company is responsible for the evaluation of the alarm signal. See the

Pressurized Enclosure System Manual.

8015594/YV18/V1-8/2017-08 | SICK O PE R AT I NG IN S TR U CT I ON S | GM32 Ex

Subject to change without notice

21

Page 22

3 PRODUCT DESCRIPTION

3.11 Connecting hose between SR-unit and junction box

The connection hose between the sender/receiver unit and the junction box

is part of the pressurized enclosure

•

contains electrical connection lines

•

is under overpressure

•

22

O PE R AT I NG IN S TR U CT I ON S | GM32 Ex 8015594/YV18/V1-8/2017-08 | SICK

Subject to change without notice

Page 23

4 Transport and storage

1

2

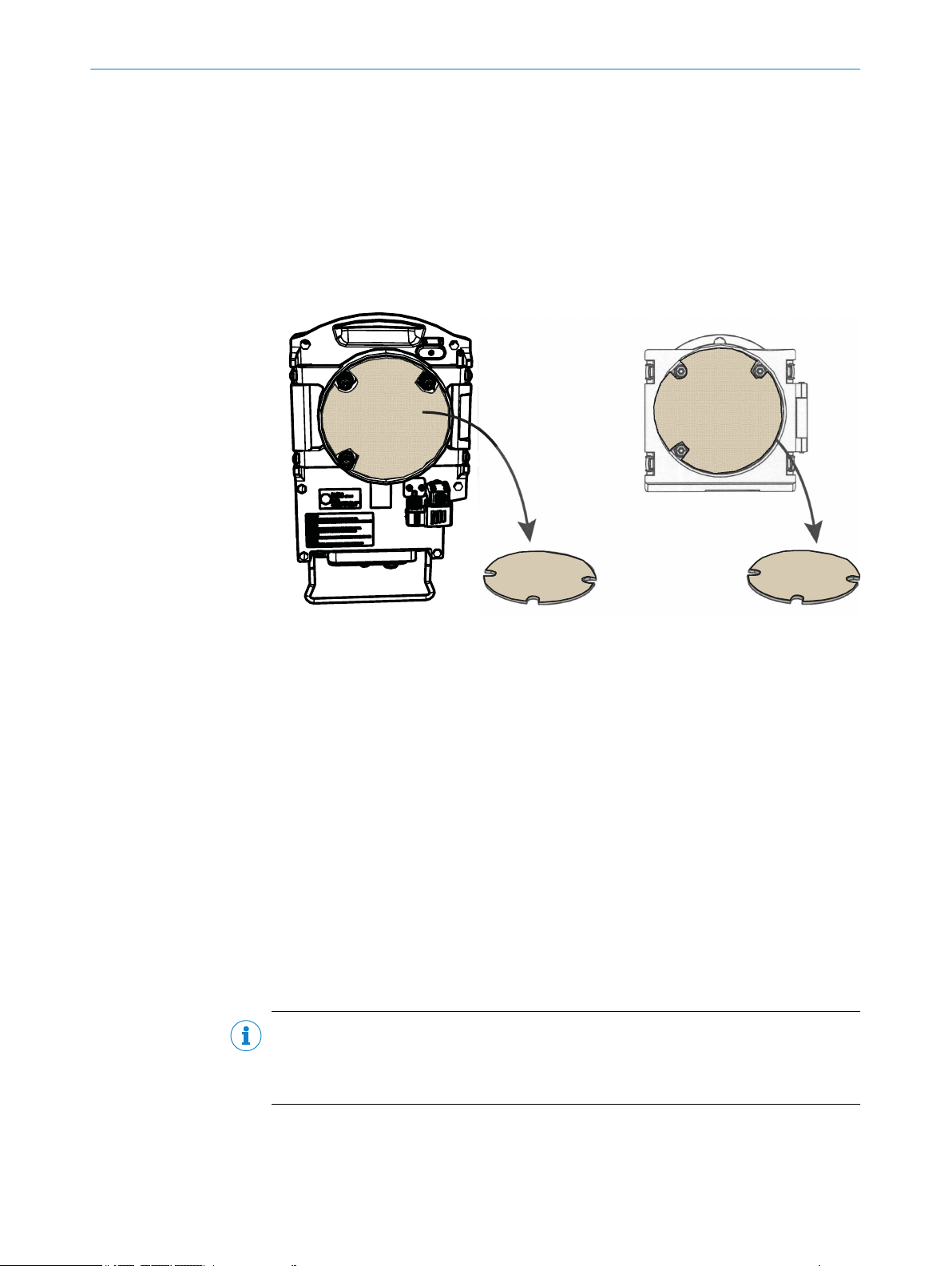

4.1 Transport safety device

Removing the transport safety device of the SR-unit and the reflector unit

1 Open the lock and swivel the flange fixture up

2 Check the transport safety device for damage

3 Remove the transport safety devices (see Figure)

4 Store the transport safety device

TRANSPORT AND STORAGE 4

4.2 Storage

Figure 8: Remove the transport safety device

Open the lock and swivel the flange fixture up

1

Remove the transport safety device

2

Clean all components of the measuring system with slightly damp cleaning cloths.

b

Use a mild cleaning agent here.

Check the desiccant cartridges and replace, if necessary.

b

After replacing the desiccant cartridges:

Perform a leak tightness check.

b

Protect the openings of the SR-unit and reflector unit from atmospheric influences,

b

preferably with the original transport safety devices.

Pack all components for storage or transport. Preferably use the original packing.

b

Store all components of the measuring system in a dry, clean room.

b

NOTE

The check of the desiccant cartridges and of the leak tightness of the device is descri‐

bed in the Maintenance Chapter, see "Check/replace the desiccant cartridge",

page 70.

8015594/YV18/V1-8/2017-08 | SICK O PE R AT I NG IN S TR U CT I ON S | GM32 Ex

Subject to change without notice

23

Page 24

5 MOUNTING

5 Mounting

5.1 Information on installation in potentially explosive atmospheres

Project planning for measuring channel

NOTICE

Observe information in Chapter "Main operating information".

NOTICE

Hazard when exceeding the temperature classes for hot gas ducts

The temperature class T4 (max. 135 °C), for which the explosion protection of this

device is designed, can be exceeded on hot gas ducts.

Plan appropriate insulation of the duct and the flange during project planning/

b

assembly.

When necessary, ensure adequate ventilation or cooling.

b

Correct installation

DANGER

Risk for system safety through work on the device not described in these Operating

Instructions

Carrying out work on the device not described in these Operating Instructions or associ‐

ated documents can lead to unsafe operation of the measuring system and therefore

endanger plant safety.

Only carry out the work on the device described in these Operating Instructions

b

and associated documents.

DANGER

Risk of explosion through incorrect installation

Incorrect assessment of the installation location as well as all further installation work

in potentially explosive atmospheres can cause serious injuries to people and damage

during operation.

Installation, commissioning, maintenance and inspection may only be carried out

•

by skilled persons having knowledge of the relevant rules and regulations for

potentially explosive atmospheres, especially:

– Ignition protection types

– Installation regulations

– Zone classification

Standards to be applied:

•

– IEC 60079-14, Annex F: Knowledge, skills and competencies of responsible

persons, operatives and designers

– IEC 60079-17: Electrical installations inspection and maintenance

– IEC 60079-19: Equipment repair, overhaul and reclamation

24

Local work safety regulations

•

O PE R AT I NG IN S TR U CT I ON S | GM32 Ex 8015594/YV18/V1-8/2017-08 | SICK

Subject to change without notice

Page 25

WARNING

Risk of injury when the device drops down

The weight of the device can cause it to drop down and cause injuries during the work

described in this Chapter.

Carry out assembly work on parts of the device together with another person when

b

necessary.

Purge air

DANGER

Risk of explosion through suctioning optics purge air from an Ex zone

Zone separation is no longer ensured when the purge air supply to purge the optics is

suctioned in within the Ex zone. This can lead to an explosion.

Always make sure the air for the purge air supply is suctioned in from an Ex free

b

zone.

5.2 Preparing the sampling point

MOUNTING 5

The operator is responsible for preparing the sampling point

NOTICE

Basis for determining the sampling point:

Preceding project planning (e.g., based on the SICK application questionnaire)

•

Regulations of the local authorities

•

Responsibility of the operator

Determine sampling point

•

Preparing the sampling point

•

Feed and drain for protective gas

•

DANGER

Risk of explosion through suctioning optics purge air from an Ex zone

Zone separation is no longer ensured when the purge air supply to purge the optics is

suctioned in within the Ex zone. This can lead to an explosion.

Always make sure the air for the purge air supply is suctioned in from an Ex free

b

zone.

NOTICE

Observe zone separation, see "Zone separation GM700 EX ATEX 3G".

5.3 Scope of delivery

NOTICE

Check the scope of delivery according to the order confirmation/delivery note.

b

8015594/YV18/V1-8/2017-08 | SICK O PE R AT I NG IN S TR U CT I ON S | GM32 Ex

Subject to change without notice

25

Page 26

5 MOUNTING

5.3.1 Checking the delivery state

NOTICE

Check all components have no exterior damage.

b

Ensure the supply voltages on the type plates match the plant conditions.

b

5.4 Installation sequence

5.4.1 Overview of the installation steps (duct-side preparation)

Step Procedure Reference

1 Installing the flange with tube. see "Install flanges with tube",

2 Installing the connection unit. see "Installing the connection unit",

3 Fitting the purge air unit or units. see "Installing the purge air unit",

4 Observing protective gas discharge line (con‐

nection unit).

5 Connecting pressure, temperature and purge

air monitor.

6 Connecting protective gas feed to SR-unit. see "Connecting the protective gas on

page 26.

page 28.

page 30.

see "Fitting the FS850S", page 29.

see "Connecting pressure, temperature

and purge air monitor ", page 40.

the SR-unit", page 50.

5.4.2 Install flanges with tube

DANGER

Hazard through hot, explosive or toxic flue gases

Hot and/or noxious gases can escape during assembly work on the gas duct depending

on the plant conditions.

Work on the gas duct may only be performed by skilled persons who, based on

b

their technical training and knowledge as well as knowledge of the relevant regula‐

tions, can assess the tasks given and recognize the hazards involved.

DANGER

Hazard through hot, toxic and corrosive flue gases

Hot and/or noxious gases can escape during assembly work on the gas duct depending

on the plant conditions.

Switch the plant off when working on the gas duct

b

or

the operator determines the safety measures to be observed during work on the

b

plant when switched on.

CAUTION

Device damage through incorrect/missing insulation of the duct when the measuring

channel is hot

26

When the measuring channel is hot, plan the duct and flange insulation so that

b

the device is protected against high temperatures.

O PE R AT I NG IN S TR U CT I ON S | GM32 Ex 8015594/YV18/V1-8/2017-08 | SICK

Subject to change without notice

Page 27

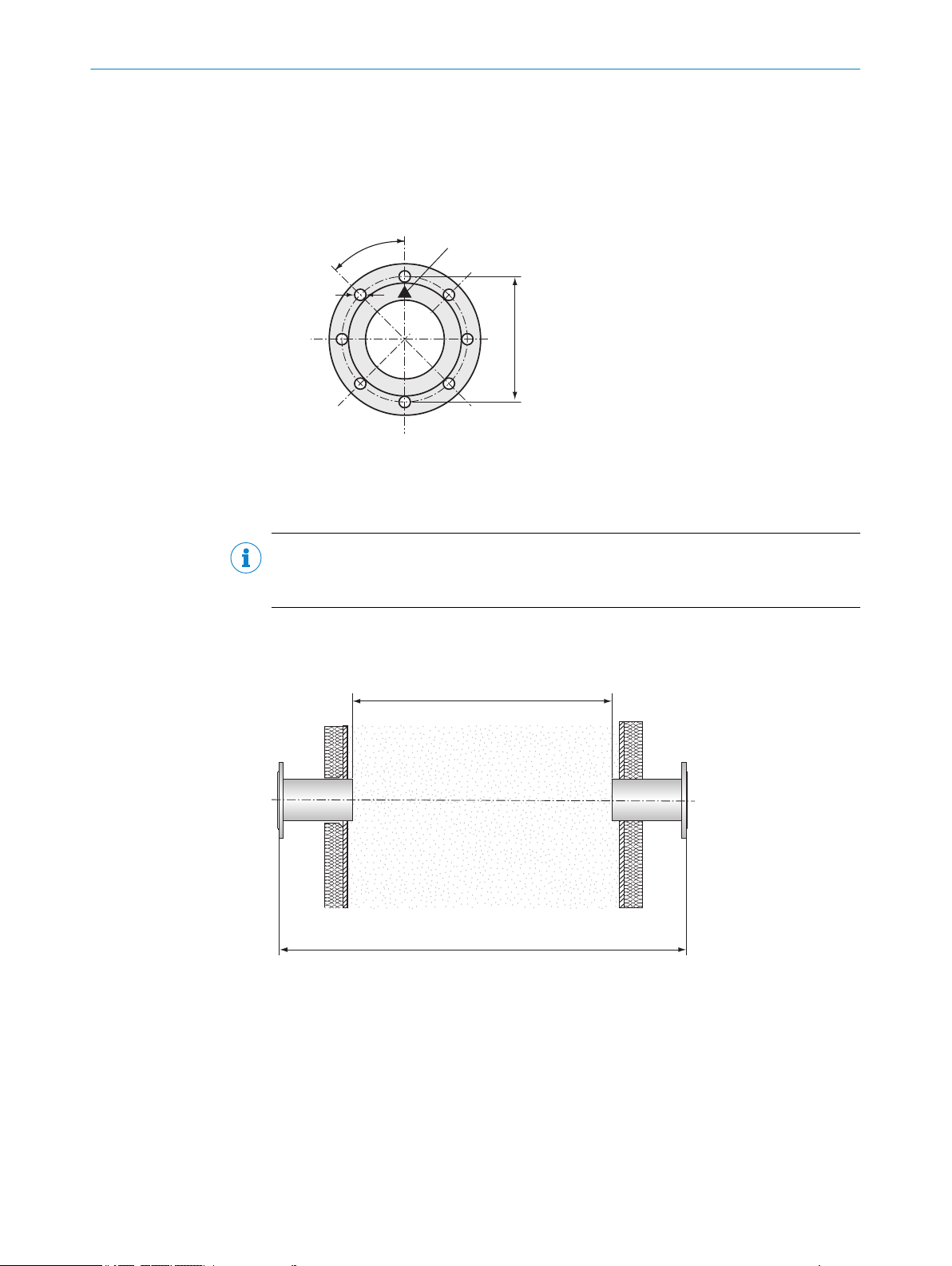

Installing the flange with tube on the gas duct

1

200

18

4

5

°

1

2

1 Cut openings on the gas duct for the flange with tube.

2 Insert the flange with tube. Pay attention to the following:

°

The "Top" marking must point upwards vertically, irrespective of the gas duct

angle.

°

The tube must project at least 30 mm into the gas duct.

Figure 9: "Top" marking on flange with tube

"Top" marking

1

3 Attach the flange with tube.

MOUNTING 5

NOTE

Make sure other devices or installations do not intersect or interrupt the beam path of

the measuring device.

4 Cut the flange opening for the reflector unit accordingly. Caution: Deviation of tube

axis between SR-unit and reflector unit: Max. 1°.

Figure 10: Define the measuring path

Active measuring path

1

Active measuring path "flange - flange"

2

4 Align the flange visually

Remove the protective cap from the adjustment tube.

w

Install the adjustment device (light source on SR-unit side, adjustment tube

w

on reflector side) onto the flanges.

8015594/YV18/V1-8/2017-08 | SICK O PE R AT I NG IN S TR U CT I ON S | GM32 Ex

Subject to change without notice

27

Page 28

2

1

5 MOUNTING

Light source

1

Adjustment tube

2

NOTE

The alignment is performed on the flange where the adjustment tube is located.

– Look in the window of the adjustment tube and focus the light spot of the light

source by shifting the optical beam tube.

– Alignment: The light spot must be shown centrally in the target of the adjustment

tube.

Not aligned correctly

1

Aligned correctly

2

5 Attach the flanges with tube on the gas duct.

NOTICE

In doing so, the alignment of the flanges may not be changed!

6 Perform the check:

– Active measuring path dimension

– Flange - flange dimension

– Alignment

7 Remove the adjustment device again.

8 If necessary, attach duct insulation to protect the measuring device from heat.

5.4.3 Installing the connection unit

The lengths of the lines to the sender/receiver unit match the project planning.

Install the connection unit using the 4 threaded bolts according to project plan‐

b

ning.

NOTE

Dimension drawings of the connection unit and specifications on screw fittings for the

lines, see "Dimension drawings: Connection unit version 3G", page 95.

28

O PE R AT I NG IN S TR U CT I ON S | GM32 Ex 8015594/YV18/V1-8/2017-08 | SICK

Subject to change without notice

Page 29

5.4.3.1 Fitting the FS850S

1

2

Information on fitting

When setting up outdoors, it is recommended to protect the explosion-proof device

against direct atmospheric influences, e.g, with a protective roof.

The fitting position is independent of the location but it should be ensured that the pro‐

tective gas inlet and outlet are in a horizontal axis

MOUNTING 5

Figure 11: Protective gas outlet

Protective gas outlet: Thread G 1"

1

Reference opening (M5 inner thread)

2

Protective gas quality

Instrument air or inert gas

•

Compressed air, class 533 according to ISO 8573-1

•

Solid matter 40 µm (class 1)

•

Pressure dew point ≤ 20 °C (class 3)

•

Oil quality ≤ 0.01 mg/m3 (class 1)

•

The air quality may possibly have to be better depending on the requirements of the

devices fitted in the pressurized enclosure.

Protective gas outlet

It is important that protective gas can flow out of the protective gas outlet against the

atmospheric pressure.

Ensure the unhindered flow of the protective gas.

b

Reference opening

The reference opening must be located in the Ex area.

Make sure the opening is always clear.

b

Line lengths for protective gas supply

Large pressure losses occur during the purge phase (high purge medium throughput)

depending on the supply line diameter. Consider this when dimensioning the supply

line:

Reference values: With 4 mm line diameter (inner diameter), a pressure loss of 500

mbar per meter must be calculated during purging with 2 l/s.

Pressure losses are apparent due to the purge medium throughput being too low and

lead to a longer or never-ending purge phase.

8015594/YV18/V1-8/2017-08 | SICK O PE R AT I NG IN S TR U CT I ON S | GM32 Ex

Subject to change without notice

29

Page 30

5 MOUNTING

NOTE

More information on protective gas,

see "Connecting the Ex overpressure control FS850S", page 41.

•

see "Technical data protective gas", page 96.

•

5.4.4 Installing the purge air unit

NOTE

Purge air hose to the device according to project planning.

NOTE

For information on installing the purge air unit, see the Operating Instructions of the

purge air unit.

5.4.4.1 Start-up of the purge air supply

CAUTION

Risk of device damage caused by inadequate purge air pressure

The purge air supply protects the measuring system from contamination and overheat‐

ing. If the purge air pressure is inadequate, the purge air can not enter the gas duct.

This can result in inadequate provision with purge air and therefore a device failure.

Ensure the purge air pressure is adequate to force the purge air into the gas duct.

b

If you have questions concerning the purge air pressure, contact SICK Customer

b

Service or your local SICK representative.

CAUTION

Risk of device damage through accidentally switching off the power supply

The purge air supply may not be switched off while the measuring system is on the gas

duct.

Attach clearly visible warnings against accidental switching-off to all switching devi‐

b

ces where the purge air supply can be switched off.

30

O PE R AT I NG IN S TR U CT I ON S | GM32 Ex 8015594/YV18/V1-8/2017-08 | SICK

Subject to change without notice

Page 31

2

6

5

7

4

3

1

MOUNTING 5

Purge air fixture

1

Hose adapter

2

Spiral hose

3

Pressure monitor

4

Purge air connection

5

Purge air hose

6

Hose clamps

7

Figure 12: Installing the GM32 purge air unit

Preparing the purge air unit:

1 Switch the power supply of the purge air unit on at the disconnecting device (fitted

by the operator) for the purge air unit

2 Check the function of the purge air unit: A strong air flow must be noticeable.

NOTE

Clarify the cause when no strong air flow is noticeable. Refer to Purge Air Unit

Operating Instructions.

3 Blow out any dust that may have entered the purge air hose.

4 Switch the power supply off again.

Connecting the purge air supply:

1 Pull the spiral hose over the hose adapter (top) and pressure monitor connection

(bottom) and secure each with a hose clamp.

2 Pull the purge air hose over the purge air connection of the differential pressure

sensor and secure with a hose clamp.

3 Switch the power supply of the purge air unit on again.

8015594/YV18/V1-8/2017-08 | SICK O PE R AT I NG IN S TR U CT I ON S | GM32 Ex

Subject to change without notice

31

Page 32

6 ELECTRICAL INSTALLATION

6 Electrical installation

6.1 Electrical installation safety information

Electrical safety

WARNING

Endangerment of electrical safety during installation and maintenance work when the

power supply is not switched off

Before starting the work on the device, ensure the power supply can be switched

b

off using a power disconnector switch/circuit breaker in accordance with DIN EN

61010-1.

Make sure the power disconnector switch is easily accessible.

b

An additional disconnecting device is mandatory when the power disconnector

b

switch cannot be accessed or only with difficulty after installation of the device

connection.

After completion of the work or for test purposes, the power supply may only be

b

activated again by authorized personnel complying with the safety regulations.

WARNING

Endangerment of electrical safety through power cable with incorrect rating

Electrical accidents can occur when the specifications for replacement of a power line

have not been adequately observed.

Always observe the exact specifications in the Operating Instructions (Technical

b

Data Section) when replacing a power line.

DANGER

Danger of electrical accidents

Incorrect performance of electrical work could result in serious electrical accidents.

Only let the work described in the following be carried out by electricians familiar

b

with potential hazards.

CAUTION

Hazard of device damage

Electronic components are accessible when the enclosure is open. The circuit board

can be severely damaged when a contact is not grounded when the power supply is

switched on.

First switch the power supply on when the sender/receiver unit and the control

b

unit are closed.

CAUTION

Device damage through short circuit on the device

The internal electronics can be damaged when signal connections are established and

the power supply is switched on. This is also valid for plug connections.

32

Disconnect the GM32 Ex and any connected devices from the voltage supply.

b

O PE R AT I NG IN S TR U CT I ON S | GM32 Ex 8015594/YV18/V1-8/2017-08 | SICK

Subject to change without notice

Page 33

ELECTRICAL INSTALLATION 6

Ex information

DANGER

Risk of explosion through incorrect performance of maintenance work

Incorrect performance of maintenance work in potentially explosive atmospheres can

cause serious injuries to people and damage during operation.

Maintenance work and start-up activities as well as checks must be performed by

•

experienced/trained technicians having knowledge of the relevant rules and regu‐

lations for potentially explosive atmospheres, especially:

– Ignition protection types

– Installation procedures

– Zone classification

Standards to be applied:

•

– IEC 60079-14, Annex F: Knowledge, skills and competencies of responsible

persons, operatives and designers

– IEC 60079-17: Electrical installations inspection and maintenance

– IEC 60079-19: Equipment repair, overhaul and reclamation

WARNING

Risk of explosion

Some of the work described in this Chapter assumes an Ex free zone.

Wait 20 minutes after switching off the main power supply before opening the

b

enclosure.

WARNING

The Ex certification becomes void when line inlets and plugs without approval are

used

The line inlets and plugs are part of the Ex protection and therefore require approval.

Do not replace line inlets or plugs with other types.

b

Line inlet dimensions, see "Dimension drawings: Connection unit version 3G",

b

page 95.

DANGER

The Ex certification becomes void when line inlets and plugs without approval are

used

The line inlets and plugs are part of the Ex protection and therefore require approval.

Do not replace line inlets or plugs with other types.

b

Line inlet dimensions, see "Dimension drawings, evaluation unit with enclosure

b

pressurization system FS840".

DANGER

Risk of explosion through non-Ex conform installation of the lines to the device

Incorrect installation of the supply lines (power supply, signal and communication lines)

through Ex zones can lead to an electrostatic charge. This creates an increased risk of

explosion.

Install all lines in accordance with EN61010-1 and EN60079-14.

b

Protect lines against electrostatic charges.

b

8015594/YV18/V1-8/2017-08 | SICK O PE R AT I NG IN S TR U CT I ON S | GM32 Ex

Subject to change without notice

33

Page 34

1

9

8

6

7

4

3

2

ß

1

5

8

6 ELECTRICAL INSTALLATION

DANGER

Risk of explosion through incorrect connection of the external sensors

The explosion protection is endangered when the external sensors p/T (in the stack) as

well as the optics purge air monitor (on the purge air fixture) are not connected to the

intrinsically safe terminals provided in the connection unit.

Always connect the external sensors p/T (in the stack) as well as the optics purge

b

air monitor (on the purge air fixture) to the intrinsically safe terminals specified in

the connection unit for this purpose.

Observe the intrinsically safe connection values for the Ex barriers fitted in the

b

evaluation unit in the Operating Instructions delivered.

DANGER

Risk of explosion through unsuitable screw fittings and lines

Only use lines (according to EN60079-14) with suitable outer diameters.

b

Close off cable inlets “vapor-proof” (virtually gas-tight).

b

Protect lines against electrostatic charges.

b

Only open those cable inlets to be used for installing cables. Keep the plugs. Refit

b

the original plug when a cable inlet must be closed again afterwards.

6.2 Connection overview

Figure 13: Overview of electrical connections GM32 Ex 3G / Zone 2

Power supply 115 V / 230 V

1

Warning signal Ex-p control

2

Fiber optics (Ethernet)

3

I/O signal lines

4

34

O PE R AT I NG IN S TR U CT I ON S | GM32 Ex 8015594/YV18/V1-8/2017-08 | SICK

Protective gas supply

5

Connection line, pressure sensor

6

Connection line, temperature sensor

7

Connection line, purge air monitor, pressure switch

8

Connection line, purge valve SVP3 G3G 8"-300L EEx p

9

Subject to change without notice

Page 35

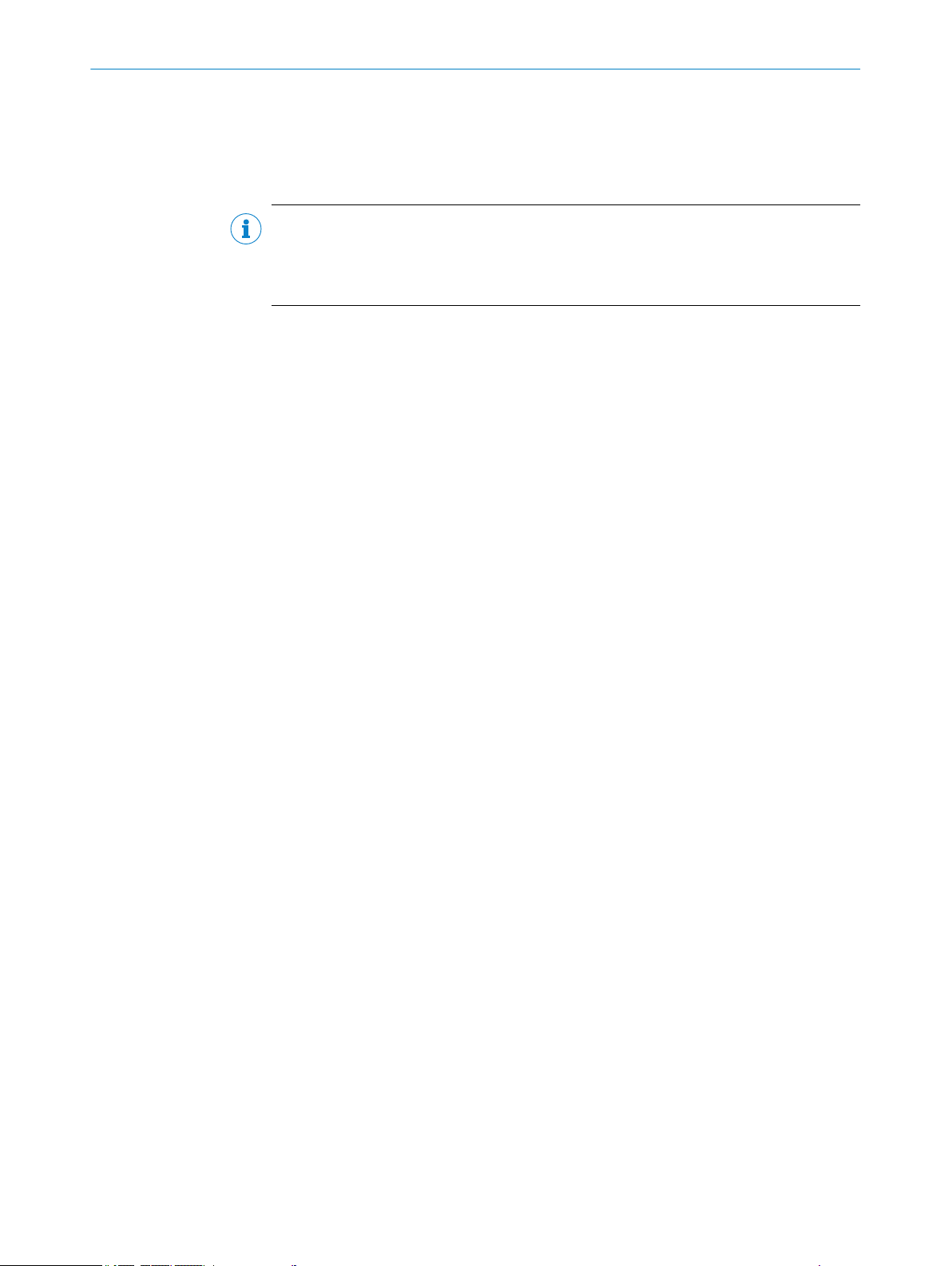

6.2.1 Lines

1

2

3

4

ELECTRICAL INSTALLATION 6

Metallic connecting hose between sender/receiver unit and connection unit

ß

Figure 14: Connection unit version 3G (all specifications in mm)

No. Line opening size Line diameter (clamping

range)

1

2

3

4

Lines Remark

Connection unit — sender/receiver unit with

connecting hose

Differential pressure sensor — connection unit On-site, intrinsically safe I/O connection

Pressure/temperature input On-site, intrinsically safe I/O connection

Ethernet PC/network (fiber optics) On-site, fiber optics

Inputs/outputs On-site: Terminal connection

Connection unit — SCU-P100 (CAN cable) On-site

Table 4: Technical data, M screw fittings

Outer thread M20 x 1.5 M16 x 1.5

Thread length 6 mm

H 23 mm

Cable diameter 10 ... 14 mm 6 ... 10 mm

Key width 24 mm 20 mm

Continuous service temperature -20 ... 95 °C

Material Nickel-plated brass

M16 x 1.5 5 - 11 mm 8

M20 x 1.5 10 - 14 mm 2

M16 x 1.5 5 - 11 mm 3

M16 x 1.5 4 - 8 mm 2

In accordance with project planning:

5 m

•

10 m

•

Number

6.3 Connecting interfaces

6.3.1 Connecting I/O interfaces (option)

CAUTION

Never lay power supply cables directly next to signal cables.

8015594/YV18/V1-8/2017-08 | SICK O PE R AT I NG IN S TR U CT I ON S | GM32 Ex

Subject to change without notice

35

Page 36

1

â

á

ß98

7

6

5

4

3

ã

ä

2

à

å

á

ß9à

æ

Ex ia

ç

ä

æ

ELECTRICAL INSTALLATION

6

DANGER

Risk of explosion when laying the I/O lines

It is possible that the I/O lines have to be laid within the Ex zone. There is a risk of

explosion when signals are accessed unprotected within the Ex zone.

Carry out wiring work under increased safety.

b

Do not access the I/O signals in the Ex zone unprotected.

b

Protect lines against electrostatic charges.

b

1 Route the data lines through the M screw fittings.

2 Connect the data line.

NOTE

Description of I/O modules, see Operating Instructions Modular I/O System.

6.3.1.1 Connection diagram for variant 3G

Figure 15: Connection diagram of connection unit for variant 3G / Ex zone 2

36

O PE R AT I NG IN S TR U CT I ON S | GM32 Ex 8015594/YV18/V1-8/2017-08 | SICK

Subject to change without notice

Page 37

ELECTRICAL INSTALLATION 6

Power supply 100 - 240 V /50 - 60 Hz

1

Power supply GM32

2

CAN GM32

3

CAN to EvU /SCU

4

Gateway module

5

I/O module

6

Ethernet bus

7

Fiber optics connection

8

Connections of temperature sensor (3-wire circuit): Pins , 1,2 and 3

9

Connections of pressure sensor: Pins 4 and 5

ß

Pressure controller for purge air monitor, sender: Pins 6 and 7

à

Fit a bridge between pins 8 and 9

á

Ex-p control unit

â

Connection, Ex p valve

ã

Status signal output (contact closed currentless)

ä

Power supply of control unit

å

Fitted bridges (by manufacturer)

æ

Connection area for intrinsically safe components

ç

NOTICE

In area æ , the intrinsically safe connections for temperature 9, pressure ß and two digital inputs à + á to

connect the pressure controller are provided. Only connect intrinsically safe simple operating means with suitable

connection data to these terminals in accordance with the Table below. Otherwise the explosion protection of the

connected sensors is not ensured.

Only connect intrinsically safe devices with suitable connection data to these terminals.

b

Table 5: Connection data for intrinsically safe connections

Termi‐

Inlet sizes Gas

nal

1 Inlet, temperature sensor

PT100, 3-wire circuit RMA42

2 IIB ≤ 360 nF ≤ 2 mH k.A.

3 IIB ≤ 530 nF ≤ 5 mH k.A.

4 Analog input, pressure sensor

4-20 mA RMA42

5 IIB ≤ 683 nF ≤ 17 mH k.A.

6 Digital input, pressure switch 1

KCD2-SR-Ex

7 IIB ≤ 16.8 µF ≤ 486.3 mH 1628

8 Digital input, pressure switch 2

KCD2-SR-Ex

9 IIB ≤ 16.8 µF ≤ 486.3 mH 1628

1

Max. inner capacity

2

Max. inner inductivity

3

Max. outer capacity

4

Max. outer inductivity

5

L/R ratio (inductivity/resistance)

Uo Io Po Ui Ci1Li Co

group

IIC ≤ 27.3 V ≤ 22.1mA151mWk.A. 8 nF 75 μH ≤ 85 nF ≤ 500 μH k.A.

IIC ≤ 27.3 V ≤ 96.5mA659mWk.A. 8 nF 75 μH ≤ 88 nF ≤ 4 mH k.A.

IIA ≤ 2 280 nF ≤ 34 mH k.A.

IIC 10.5V 17.1mA45mW12 V 0 0 2.41 µF ≤ 121.5 mH 801

IIA ≤ 75 µF ≤ 972.7 mH 1628

IIC 10.5V 17.1mA45mW12 V 0 0 ≤ 2.41 µF ≤ 121.5 mH 801

IIA ≤ 75 µF ≤ 972.7 mH 1628

3

Lo

4

μH/ Ω

8015594/YV18/V1-8/2017-08 | SICK O PE R AT I NG IN S TR U CT I ON S | GM32 Ex

Subject to change without notice

37

Page 38

State

Analog

Output

0...20mA

Load

500

AO1 AO2

- -

1 2

Shield

State

Analog

Input

0...20mA

Sense

100

AI1 AI2

- -

1

2

Shield

State

Digital

Output

Signal

Relais

DO1

DO3

State

Digital

Input

DI1 DI2

DI3 DI4

1 2

43

DO4

DO2

1 2

4

3

23

22

21

13

12

2414

22

13

2414

11

11

112121

21

11

12

12

12

23

23

23

22

22

13

13

141424

24

6 ELECTRICAL INSTALLATION

6.3.1.2 Default values for interfaces

Figure 16: Example: I/O module pin assignment

Analog input Pin assignment Function

AI 1 11, 12 Temperature (internally wired)

AI 2 21, 23 Pressure (internally wired)

AI 3 11, 12 Humidity

NOTE

The analog input assignment shown in the Table is the default setting. The assignment

of the inputs can be freely configured with SOPAS. For more information, see the SOPAS

Operating Instructions.

38

O PE R AT I NG IN S TR U CT I ON S | GM32 Ex 8015594/YV18/V1-8/2017-08 | SICK

Subject to change without notice

Page 39

ELECTRICAL INSTALLATION 6

Analog output Pin assignment Function

AO1 11, 12 User-specific

AO 2 21, 23 User-specific

Digital output Pin assignment Function

DO 1 11, 12 Failure

DO 2 21, 22 Maintenance_Request

DO 3 13, 14 Not_measuring

DO 4 23, 24 Output_control_values

DO 5 11, 12

DO 6 21, 22

DO 7 13, 14

DO 8 23, 24

Configurable Configurable Measuring range switch-over (see GM32 Tech‐

1

On second module

Digital input Pin assignment Function

DI 1 11, 12 Check_cycle

DI 2 21, 22 Maintenance

DI 3 13, 14 Output_control_values

DI 4 23, 24 Disable_check_cycle

DI 5 11, 12

DI 6 21, 22

DI 7 13, 14

DI 8 23, 24

1

On second module

1

1

1

1

Uncertain

Extended

Purge_air_failure

No_function

nical Information)

1

1

1

1

Purge_air_status

--

--

--

NOTE

Information concerning the customer-specific module assignment

■

The module layout from the left to the right always has the sequence: AO-AI-DO-DI

■

The number of inlets and outlets is defined:

– AO: 2x

– AI: 2 x

– DO: 4 x

– DI: 4 X

■

Second measuring range: AO is always on the right next to the respective compo‐

nent.

6.4

Connecting the connection hose to the SR-unit on the junction box

NOTICE

The connecting hose between the SR-unit and the junction box is part of the pressur‐

ized enclosure. It is under overpressure.

Protect the connecting hose from possible damage.

b

8015594/YV18/V1-8/2017-08 | SICK O PE R AT I NG IN S TR U CT I ON S | GM32 Ex

Subject to change without notice

39

Page 40

2

1

3

1

6 ELECTRICAL INSTALLATION

1 Lead the cable through the 2 M screw fittings, see Figure below.

2 Plug in the M12 Ethernet connector and screw tight, see Figure below.

3 Connect the cables in the connection unit, see "Preparing the power supply",

page 43.

4 Screw the M4 screws tight.

5 Push on the connector housing and screw tight.

Figure 17: Connecting hose SR-unit/connection

unit

2 M screw fittings

1

Ethernet connector

2

Connector housing

3

6.5 Connecting pressure, temperature and purge air monitor

NOTE

Purge air monitor - pressure controller for purge air monitoring

Wiring diagram, see "Connection overview", page 34

•

Terminal assignment, see "Connection diagram for variant 3G", page 36.

•

Observe the Operating Instructions of the sensors and the purge air monitor.

•

6.6 Connecting the potential equalization on the purge air fixture

Figure 18: Potential equalization on the purge air fixture

Connection of potential equalization

1

Screw the grounding conductor tight on the screw terminal.

b

40

O PE R AT I NG IN S TR U CT I ON S | GM32 Ex 8015594/YV18/V1-8/2017-08 | SICK

Subject to change without notice

Page 41

6.7 Connecting the Ex overpressure control FS850S

Electrical safety

WARNING

Risk of injury through electric voltage

Switch the power supply off before working on terminals and laying lines.

Observe the installation regulations according to VDE DIN 57 165 and Test Certifi‐

b

cate BVS 06 ATEX E088.

Risk of explosion

DANGER

Risk of explosion through incorrect settings for the pressurized enclosure

The pressurized enclosure is a central safety part of the device. All work is described in

this Manual and the relevant specified documents. If work is performed which is not

described in this Manual, the risk of explosion of the measuring system increases and

the ATEX certification for the device becomes void.

Carry out all work skillfully and in accordance with the delivered documentation.

b

ELECTRICAL INSTALLATION 6

Unsafe measuring operation

CAUTION

Risk of unsafe measuring operation through loss of degree of protection IP64

Ineffective seals of the connection unit and insufficient closed openings for unused line

inlets can lead to loss of degree of protection IP64. Penetration by dust or moisture can

lead to unsafe operation of the FS850S.

Close off unused openings for line inlets with impact resistant sealing plugs that

b

have been checked against self-loosening and turning.

Check the seals on the Ex-e enclosure for damage and replace as necessary.

b

Tighten the terminals, especially in the Ex-e area.

b

Check the terminals for discoloration. This could indicate increased temperatures.

b

Check the gland screw fittings, sealing plugs and flanges for leak tightness and

b

tight seat.

8015594/YV18/V1-8/2017-08 | SICK O PE R AT I NG IN S TR U CT I ON S | GM32 Ex

Subject to change without notice

41

Page 42

1

2

3

6 ELECTRICAL INSTALLATION

Terminal assignment

Figure 19: Connecting the Ex overpressure control

Connection, Ex p valve

1

Status signal output

2

•

3

•

•

N on terminal 15

L1 on terminal 17