Page 1

GM32

In-situ Gas Analyzer

Measuring Probe Version

Installation

Start-up

Maintenance

OPERATING INSTRUCTIONS

Page 2

Document Information

Glossary

Described Product

Product name: GM32

Variants: GM32 Probe (measuring probe)

Document Identification

Title: Operating Instructions GM32

Part No.: 8012707

Version: 1.3

Release: 2009-03

Publisher

SICK MAIHAK GmbH

Nimburger Str. 11 · D-79276 Reute · Germany

Phone: +49 7641 469-0

Fax: +49 7641 469-11 49

E-Mail: info.pa@sick.de

Guarantee Information

Specified product characteristics and technical data do not serve

as guarantee declarations.

© SICK MAIHAK GmbH. All rights reserved.

CAN-Bus: Control Area Network. A field bus.

CompactFlash®-Disc: Memory card.

CUSUM board: Quality control chart (Data Sheet).

Ethernet: Computer networking technology. Basis for network pro-

tocols, e.g. TCP/IP.

Check point: Test point at approx. 70% of the upper measuring

range value.

Check cycle: Test cycle with check of the zero and check point.

OPC: Openness, Productivity, Collaboration. Standardized data

interface (OPC Foundation

QAL3: Quality monitoring according to DIN EN 14181.

Reference cycle: Test cycle with correction of internal drifts.

SCU: Operating unit for the control of several analyzers with SCU

capability.

SOPAS (SICK Open Portal for Applications and Systems): SICK

Parameter Setting and Data Calculation Software.

SOPAS ET: SOPAS PC Engineering Tool. Configuration protocol.

TM

).

2 GM32 Operating Instructions V1.3 8012707 © SICK MAIHAK GmbH

Page 3

Warning Symbols

Hazard (general)

Hazard by voltage

Hazard in potentially explosive atmospheres

Hazard by unhealthy substances

Hazard by high temperature or hot surface

Warning levels / Signal words

DANGER

Risk or hazardous situation which will result in severe personal

injury or death.

WARNING

Risk or hazardous situation which could result in severe personal

injury or death.

CAUTION

Hazard or unsafe practice which could result in personal injury or

property damage.

NOTICE

Hazard which could result in material damage.

Information Symbols

Important technical information for this product

Important information on electrical or electronic functions

Nice to know

Supplementary information

Link to information at another place

GM32 Operating Instructions V1.3 8012707 © SICK MAIHAK GmbH 3

Page 4

Inhaltsverzeichnis

Operating Instructions

1 Important Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1 Main instructions for operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.2 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.2.1 Purpose of the device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.3 Responsibility of user. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.4 Additional documentation/information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2 Product Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.1 Product identification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.2 Product description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.2.1 Device variants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.2.2 Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.3 SOPAS ET (PC program). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.4 Reference cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.5 Check cycle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.6 Design of GM32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.6.1 Measuring probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.7 Purge air unit (for GMP measuring probe) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3 Preparation on the Gas Duct Side. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.1 Preparation of sampling point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.1.1 Checking the scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.2 Overview of the installation steps (duct-side work). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.2.1 Work steps (overview) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.2.2 Installing the “flange with tube” on the gas duct . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.3 Installing the connection unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.4 Installing the purge air unit (for GMP probe) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.5 Laying the electrical connection lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.5.1 General information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.5.2 Connecting I/O interfaces (option). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.5.3 Laying the electrical connection lines to the SR-unit. . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.5.4 Preparing the power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4 GM32 Operating Instructions V1.3 8012707 © SICK MAIHAK GmbH

Page 5

Operating Instructions

4Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

4.1 Necessary technical knowledge for start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.2 Required material (not included in the scope of delivery) . . . . . . . . . . . . . . . . . . . . . . . . 26

4.3 Overview of assembly steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.4 Transport safety devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.5 Installing the device flange on the purge air fixture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.6 Aligning the measuring probe in flow direction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.6.1 When the probe alignment has to be set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.7 For the GPP probe: Electric connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.8 SR-unit electric connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.9 Switching on the power supply of the GM32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

4.10 For GMP probe: Start-up of the purge air supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.11 Installing the measuring probe in the gas duct . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.12 Installing the SR-unit on the device flange . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

4.13 Optical fine alignment of the SR-unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.1 Recognition of an unsafe operational state . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

5.2 Operator panel (for the “Pro” variant). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

5.2.1 Status indicators (LEDs) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.2.2 Assignment of buttons. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.2.3 Contrast setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.2.4 Language setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5.2.5 Menu tree . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5.2.5.1 Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5.2.5.2 Alignment check (automatic optical alignment) (option). . . . . . . . . . . . . . . . . . . .41

5.2.5.3 Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5.2.5.4 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

6 Putting Out of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6.1 Putting out of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

6.1.1 Putting out of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

6.1.2 Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

6.2 Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

6.3 Environmentally compatible disposal/ recycling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

7Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

7.1 Maintenance plan (operator) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

7.1.1 Recommended expendable and wearing parts for 2 years operation . . . . . . . . . . . 50

7.2 Preparation work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

7.2.1 Swiveling out and removing the SR-unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

7.3 Visual inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

7.4 Cleaning the window. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

7.5 Replacing the sender lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

7.6 Checking and replacing the drying agent cartridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

7.7 Cleaning the purge air unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

GM32 Operating Instructions V1.3 8012707 © SICK MAIHAK GmbH 5

Page 6

Operating Instructions

8 Clearing Malfunctions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

8.1 General hazard caused by electrical voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

8.2 Measured value blinks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

8.3 Error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

8.3.1 Example of an error message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

8.3.2 Error messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

8.4 Inadequate purge air supply (for GMP probe) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

8.5 Malfunctions on the connection unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

9 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

9.1 Conformities. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

9.1.1 Electrical protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

9.2 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

6 GM32 Operating Instructions V1.3 8012707 © SICK MAIHAK GmbH

Page 7

Important Information

GM32

1 Important Information

Main safety information

Main instructions for operation

Intended use

Own responsibility

GM32 Operating Instructions V1.3 8012707 © SICK MAIHAK GmbH 7

Page 8

Important Information

1.1

Main instructions for operation

WARNING: Danger resulting from escaping gas when the SR-unit is swiveled

out

Excess pressure in the gas duct can cause hot and/or noxious gases to escape

when the SR-unit is swiveled out.

b

Swivel the SR-unit out only when you have taken suitable safety measures.

CAUTION: If the hinge pin has not been correctly inserted (→p. 35, Figure 15),

the SR-unit can drop when swiveled out.

b

Check whether the hinge pin is completely pressed down before the SR-unit

is swiveled out.

CAUTION: Danger of contamination caused by purge air failure (for GM32

with GMP probe)

b

If a failure of the purge air supply occurs, take immediate measures to protect the measuring system (

1.2 Intended use

1.2.1 Purpose of the device

The GM32 serves exclusively for emission and process monitoring of gases in industrial

plants.

GM32 measures continuously directly in the gas duct (in-situ).

→

p. 59, §8.3)

1.3 Responsibility of user

Designated users

The GM32 may be operated by competent persons only who, based on their device-specific

training and knowledge of the device as well as knowledge of the relevant regulations, can

assess the tasks given and recognize the dangers involved.

Correct use

b

Use the device only as described in these Operating Instructions.

The manufacturer bears no responsibility for any other use.

b

Perform the specified maintenance work.

⊗ Do not remove, add or modify any components to or on the device unless described and

specified in the official manufacturer information.

Otherwise:

– Any warranty by the manufacturer becomes void.

– The device could become dangerous.

Special local conditions

b

Follow all local laws, regulations and company-internal operating directives applicable

at the respective installation location of the equipment.

Retention of documents

These Operating Instructions:

b

Must be available for reference.

b

Must be passed on to new owners.

8 GM32 Operating Instructions V1.3 8012707 © SICK MAIHAK GmbH

Page 9

Important Information

1.4

Additional documentation/information

b

Pay attention to the supplied documents.

Additional instructions

The following documents are applicable in addition to these Operating Instructions:

● Technical Information GM32 (option)

● Operating Instructions for purge air supply (for GMP probe)

● Technical Information “Modular I/O System” (option)

● Final inspection record

● CD-Rom with SOPAS ET PC operating program

GM32 Operating Instructions V1.3 8012707 © SICK MAIHAK GmbH 9

Page 10

Important Information

10 GM32 Operating Instructions V1.3 8012707 © SICK MAIHAK GmbH

Page 11

Product Description

GM32

2 Product Description

Product identification

Functional principle

Characteristics

Variants

GM32 Operating Instructions V1.3 8012707 © SICK MAIHAK GmbH 11

Page 12

Product Description

2.1

Product identification

Product name GM32

Product variant Version with measuring probe

Manufacturer SICK MAIHAK GmbH · Nimburger Str. 11

Location of type plates SR-unit: On the right and in the intermediate housing

2.2 Product description

The GM32 gas analyzer serves for continuous measurement of the gas concentrations in

industrial plants.

GM32 is an in-situ measuring system. Measurement is performed directly in the gas carrying duct.

● Components: SO

, NO, NO2 and NH3 (device-specific) as well as the temperature and

2

pressure reference values.

● Measuring principle: Differential Optical Absorption Spectroscopy (DOAS).

2.2.1 Device variants

“Basic” variant

● Reference cycle (

● Automatic mirror tracking: Automatic adjustment of optical axis.

● System messages are recorded in a logbook.

● Ethernet interface with OPC standard.

→

p. 13, §2.4): Correction of internal drifts. Zero point check.

79276 Reute · Germany

For GMP probe: On the purge air fixture

For GPP probe: On the flange attachment

“Pro” variant

As “Basic” variant. In addition:

● “TÜV” tested for suitability.

● Check cycle (

cycle to check and output the zero and check point.

The check cycle generates the QAL3 values. These can be displayed with SOPAS ET.

● Operator panel: Measured values, operating mode and malfunction message are dis-

played in clear text on a monitor.

● QAL3 Tool (CUSUM chart)

2.2.2 Options

● I/O modules (Analog Out, Digital Out, Digital In, Analog In).

● Ethernet rail switch. Contains additional interfaces:

4 * Cu connection.

1 * fiber optics connection (sender and receiver).

● SCU: Operating unit to control several analyzers with SCU capability (→ SCU Operating

Instructions).

● Super Calibration: Several applications/calibrations. For example, for spare devices.

→

p. 13, §2.5): Reference cycle (according to “Basic” variant) followed by a

12 GM32 Operating Instructions V1.3 8012707 © SICK MAIHAK GmbH

Page 13

Product Description

2.3

SOPAS ET (PC program)

SOPAS ET can be used to set the GM32 parameters and provides access to the GM32 logbook.

SOPAS ET runs on an external PC connected via the Ethernet interface (

GM32.

More information on SOPAS ET:

→ Technical Information GM32

→ SOPAS ET Help menu

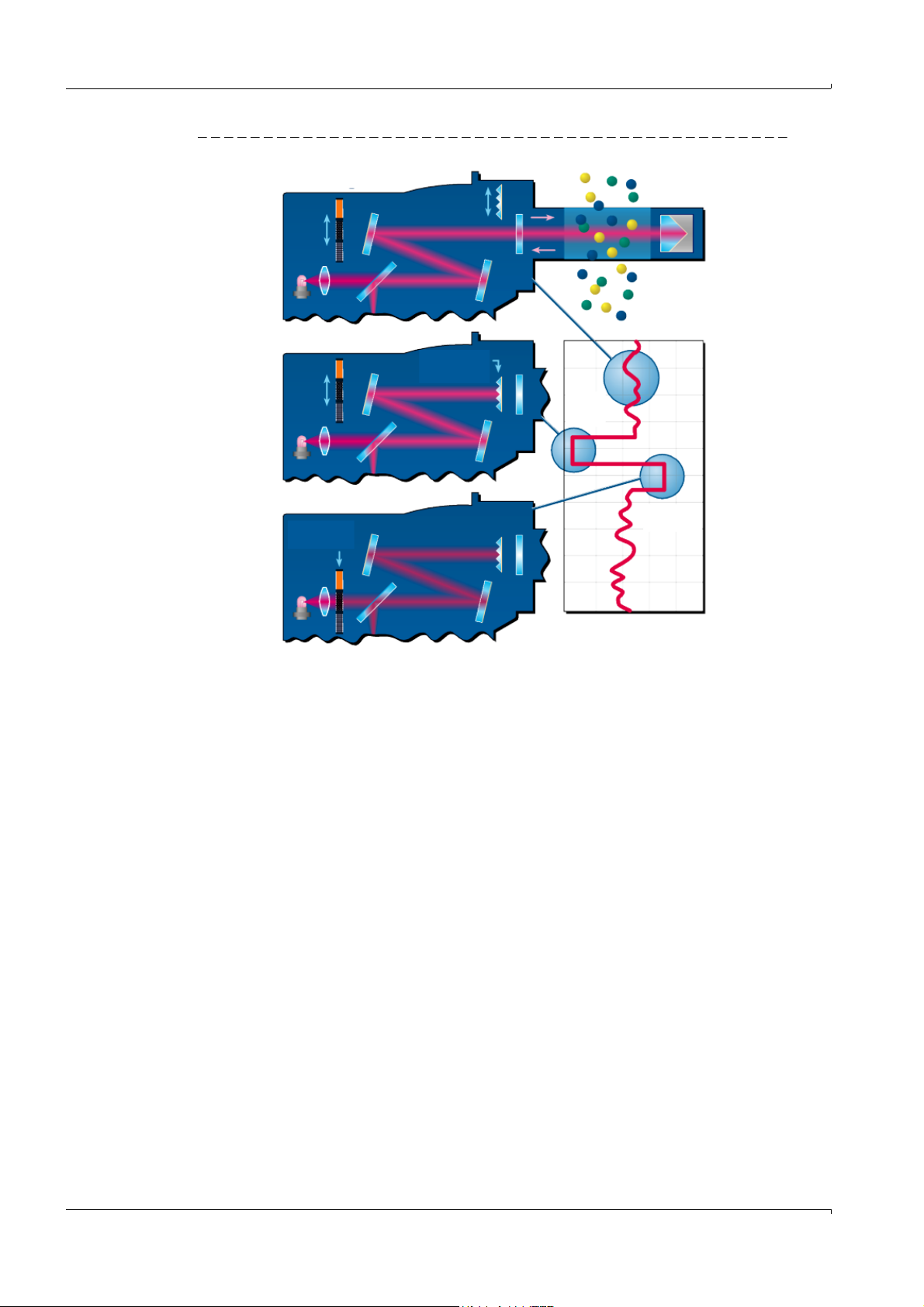

2.4 Reference cycle

Correction of internal drifts in an adjustable interval (standard: 1 hour, setting: SOPAS ET),

via a command (with SOPAS ET) or via an external signal (option).

Measured value output during the reference cycle: Last valid measured value.

2.5 Check cycle

The check cycle is made up of the reference cycle, followed by the check and output of the

zero and check point (70% of upper measuring range value).

It is performed in an adjustable interval (with SOPAS ET), via a command (with SOPAS ET)

or via an external signal (option).

With the check cycle, the device is capable of performing the check of the zero point and a

reference point for each component without feeding test gases. The check cycle meets the

requirements of EN14181 and makes drift monitoring with test gases according to QAL3

unnecessary.

● Zero point

An internal zero point reflector is swiveled in time-controlled in adjustable intervals. The

emitted light is reflected back in the sender/receiver unit to the detector, the zero spectrum is evaluated with the calibration function and thus the zero points of all ducts

measured and output.

If the deviation from zero is > ±2% of the FS, Maintenance request is signaled.

● Check point

An internal swivel element with two reference filters and an NO-filled cell is swiveled in

during the check cycle in addition to the zero point reflector and the reference value or

concentration value measured. These check values are scaled to 70% of the selected

measuring range.

Maintenance request is signaled if the deviation from the setpoint value is > ±2% of the

FS.

→

p. 22, Figure 4) to

GM32 Operating Instructions V1.3 8012707 © SICK MAIHAK GmbH 13

Page 14

Figure 1 Check point

Measuring

Zero point

Check

Zero point

reflector

Swivel

element

Zero point

Control

point

(70% fsc)

Data recorder

Product Description

● Output of measured values during the check cycle: Last valid measured value.

● Signal during the check cycle: Not_measuring. (Optionally digital output or OPC inter-

face).

● The determined zero and reference values can be output on analog outputs depending

on the parameter settings:

– Directly after the check cycle.

– On request (via a digital input, option).

– Signal during the output: Output_control_values. (Optionally digital output or OPC

interface).

– First output of zero values for 90 s.

– Then output of reference values for 90 s.

–The Not_measuring signal is not active during the output.

● The zero and reference values of the last check cycle are displayed in SOPAS ET (menu:

Diagnosis/Check values).

The required QAL3 values can be read there.

14 GM32 Operating Instructions V1.3 8012707 © SICK MAIHAK GmbH

Page 15

Product Description

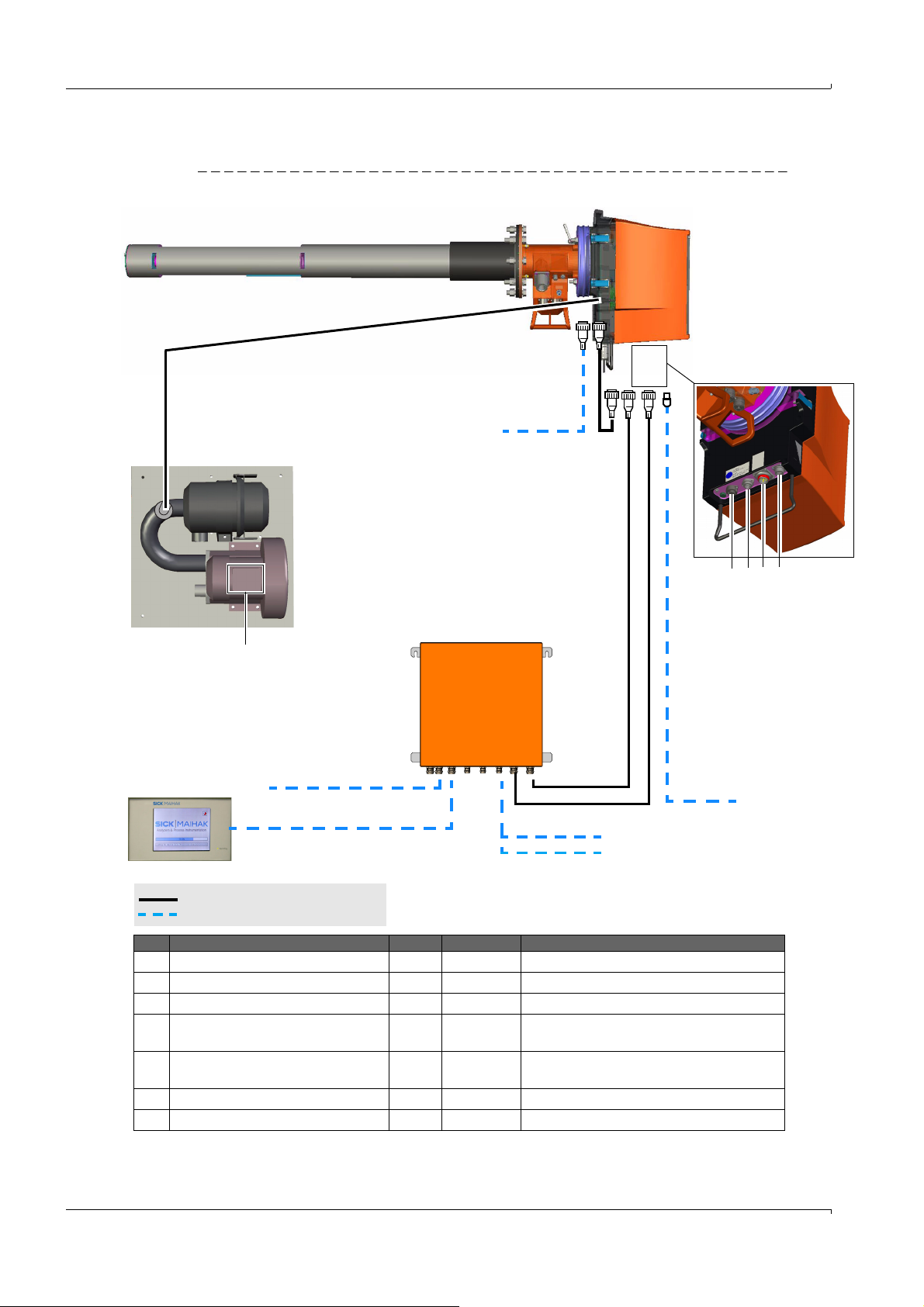

SR-unit GMP or GPP measuring probe

Measuring gap

(active measuring path)

Operator panel

(Option)

GMP probe: Purge air fixture

GPP probe: Flange attachment

Purge air unit (for GMP probe)

2.6

Design of GM32

The GM32 Probe version comprises

● Sender/receiver unit (SR-unit)

The SR-unit contains optical and electronic subassemblies.

The concentration calculation of the sample gas according to the absorption spectro-

scope principle is performed in the SR-unit.

● Measuring probe with flange resp. purge air fixture (

● Purge air unit (for GMP measuring probe) (

Figure 2 GM32 Probe (version shown: GMP measuring probe)

→

§ 2.7)

→

§ 2.6.1)

2.6.1

Measuring probe

Probe types:

● Measuring probe with open measuring gap (GMP probe)

GMP probes require a purge air supply to protect the window against contamination.

● Gas diffusion probe (GPP probe) with gas permeable ceramic filter.

GPP probes are fitted with an automatically controlled heater to prevent condensate on

the windows.

Both probe versions have an integrated temperature and pressure sensor.

2.7 Purge air unit (for GMP measuring probe)

The purge air unit supplies filtered ambient air to the purge air fixtures and protects the

windows of the SR-unit from contamination and high gas temperatures.

The purge air is blown into the gas duct through the “flange with tube”.

More information on the purge air unit → Technical Information of purge air

unit.

GM32 Operating Instructions V1.3 8012707 © SICK MAIHAK GmbH 15

Page 16

Product Description

16 GM32 Operating Instructions V1.3 8012707 © SICK MAIHAK GmbH

Page 17

Preparation on the Gas Duct Side

GM32

3 Preparation on the Gas Duct Side

Setup

Installation

GM32 Operating Instructions V1.3 8012707 © SICK MAIHAK GmbH 17

Page 18

Preparation on the Gas Duct Side

3.1

Preparation of sampling point

● The basis for the determination of the sampling point is the preceding proj-

ect planning (e.g. based on the SICK application questionnaire), the information in the final inspection record of the GM32 and the regulations of

the local authorities.

● The equipment operator is responsible for the determination of the sam-

pling point (e.g. the determination of a representative sampling point).

● The equipment operator is responsible for the preparation of the sampling

point (e.g. load carrying capacity of the welded flange).

b

Determine the installation location.

Observe the ambient conditions of the GM32 (

b

Observe the space requirements for the SR-unit (→ p. 72, §).

Provide for additional space for maintenance work (swiveling the housing door open,

pulling the measuring probe out).

b

Determine the installation location for the connection unit.

Observe the maximum line lengths (

b

Provide the power supply for the connection unit and, when necessary, for the GPP

→

p. 22, Figure 4 or as planned).

probe.

Observe the power requirements (

b

Lay the signal lines.

b

For GMP probe: Determine the installation location for the purge air unit (→p. 22,

→

p. 67, §9.2).

Figure4 resp. as planned).

Provide clearance for changing the filter element (→ Technical Data of purge air unit).

→

p. 67, §9.2).

3.1.1 Checking the scope of delivery

b

Compare the data of the final test record with the data of the order confirmation - they must be identical.

b

Check the scope of delivery according to the order confirmation/delivery note.

18 GM32 Operating Instructions V1.3 8012707 © SICK MAIHAK GmbH

Page 19

Preparation on the Gas Duct Side

30

L

50

470

Ø13

3

Weatherproof cover

“Flange with tube”: L = 240 mm (standard)

Attachment (e.g. 4 steel

pipes, 50 x 5 mm)

for purge air unit

SR-unit

Approx. 1.5 m

Min. 700 mm

Angle: Approx. 1°

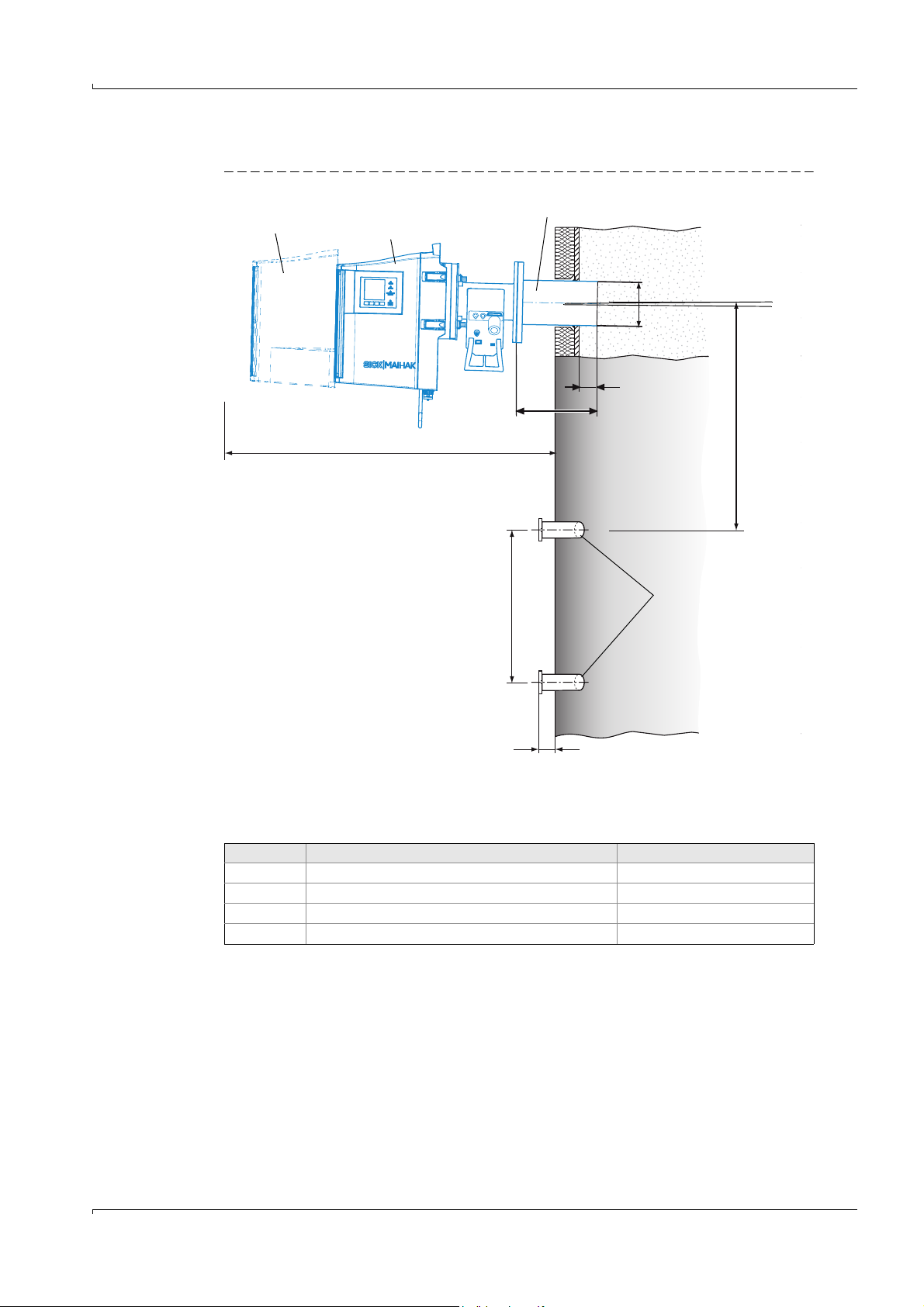

3.2

Figure 3 Installation overview

Overview of the installation steps (duct-side work)

3.2.1

Work steps (overview)

Step Procedure Reference

1 Installing the “flange with tube”

2 Installing the connection unit

3 For GMP probe: Installing the purge air unit

4 Laying the electrical connection lines

→

p. 20, §3.2.2

→

p. 20, §3.3

→

p. 21, §3.4

→

p. 22, §3.5

GM32 Operating Instructions V1.3 8012707 © SICK MAIHAK GmbH 19

Page 20

3.2.2 Installing the “flange with tube” on the gas duct

WARNING: Danger resulting from gases in the gas duct

Hot and/or noxious gases can escape during work on the gas duct, depending

on the equipment conditions.

b

Work on the gas duct may only be performed by skilled persons who, based

on their technical training and knowledge as well as knowledge of the relevant regulations, can assess the tasks given and recognize the hazards

involved.

1 Make a cut-out in the gas duct for the “flange with tube”.

2 Insert the “flange with tube” so that the mark (TOP)

spective of the gas duct angle) and attach the “flange with tube”.

– The tube must project at least 30 mm into the gas duct.

– Make sure the probe does not collide with other devices or fittings.

– Tilt the tube slightly downwards (approx. 1°).

This allows any condensate to drain off.

3 Now fix the “flange with tube” properly to the gas duct.

Make sure that the alignment of the flange does not change.

4 If necessary, attach duct insulation (protect GM32 from heat).

Preparation on the Gas Duct Side

▴ points upwards vertically (irre-

IMPORTANT: Observe the ambient temperature of the GM32

b

When the gas duct is hot, insulate the duct and flanges so that the

GM32 is protected from excess temperatures (

3.3 Installing the connection unit

● The length of the line to the GM32 complies with project planning.

b

Provide threaded bolts (4) to screw on the connection unit (→ p. 72, §31) and screw on

the connection unit.

⊗ Do not make the electrical connection to the connection unit yet.

→

p. 67, §9.2).

20 GM32 Operating Instructions V1.3 8012707 © SICK MAIHAK GmbH

Page 21

Preparation on the Gas Duct Side

3.4

Installing the purge air unit (for GMP probe)

● Maximum length of line to GM32 complies with project planning.

IMPORTANT: Adequate purge air pressure

b

Ensure the purge air pressure is adequate to push the purge air into the gas

duct.

If required, please contact SICK Customer Service or your local representative.

Installation of purge air unit → Data Sheet of purge air unit.

GM32 Operating Instructions V1.3 8012707 © SICK MAIHAK GmbH 21

Page 22

Preparation on the Gas Duct Side

Sender/

receiver unit (SR)

Measuring probe

Purge air unit SLV 4

(for GMP measuring probe)

Connection unit (AE)

Wiring and technical data,

see Data Sheet SLV4

(3) (5) (4) (6)

(3) Connection:

Purge air fixture

(4) Connection:

Power supply

(5) Connection: CAN cable

(6) Connection: PC (SOPAS

ET)

(3)

(1)

(4) (5)

(6)

For configuration and connections,

see “Operating Instructions SCU”

SCU (option)

For on-site terminal connections

(inputs/outputs), see Operating

Instructions “Modular I/O System”

(7)

Power supply:

100 ... 240 V AC, 50/60 Hz

Power supply (GPP):

115 ... 230 V AC, 50/60 Hz

(2)

No. Signal cable for connection of Length Part No. Remarks

(1) Filter monitoring 5 m 2032143 Included in the purge air fixture (probe)

(2) GPP probe power supply 10 m 2017519 Included in the GPP probe

(3) SR – purge air fixture (CAN cable) 0.8 m 2023704 Included in the purge air fixture (probe)

(4) AU – SR (CAN cable) 10 m

20 m

2028786

2045422

Order separately

(5) Power supply SR (standard) 10 m

20 m

2046548

2046549

Order separately

(6) Ethernet cable – PC/network – No, on-site

(7) CAN cable – SCU – No, on-site

Scope of delivery

On-site wiring

3.5

Figure 4 Electrical connection diagram

Laying the electrical connection lines

22 GM32 Operating Instructions V1.3 8012707 © SICK MAIHAK GmbH

Page 23

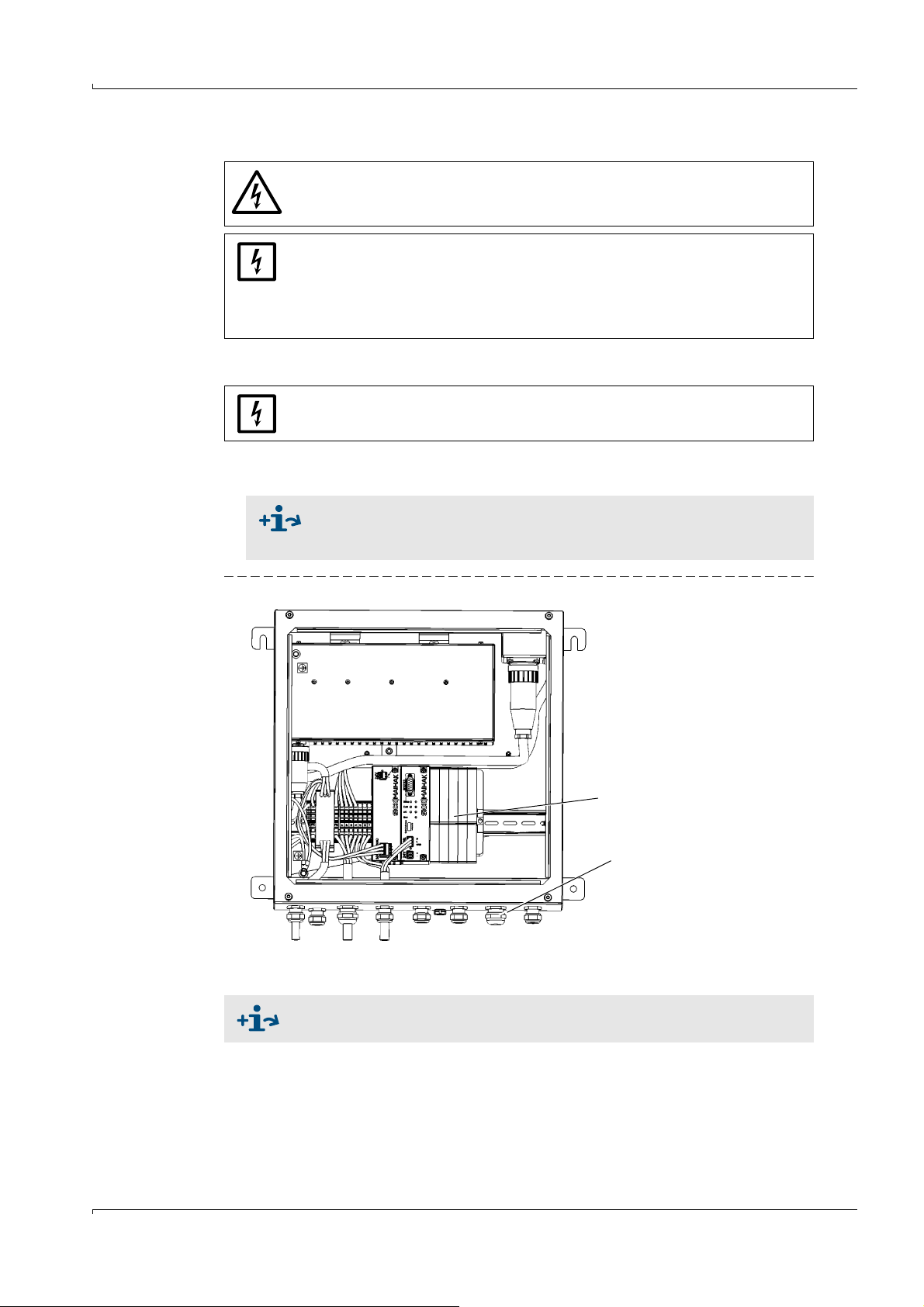

Preparation on the Gas Duct Side

I/O module

PG screw fittings

3.5.1 General information

CAUTION: Hazards caused by electric voltages

b

Only let the work described in the following be carried out by skilled electricians familiar with potential risks.

IMPORTANT:

Before signal connections are established (also with plug connections):

b

Disconnect the GM32 and any connected devices from the electrical supply.

Otherwise the internal electronics can be damaged.

3.5.2 Connecting I/O interfaces (option)

⊗ Do not lay power supply cables immediately next to signal cables.

b

Route the data lines through the PG screw fittings.

b

Connect the data line to the I/O modules.

b

Connections of I/O modules → Technical Information “Modular I/O System”.

b

Terminal assignment → final test record.

Figure 5 Connection unit (inside): Location of I/O modules

3.5.3 Laying the electrical connection lines to the SR-unit

Electrical connections on GM32 →Figure4

1 Lay the electrical connection lines from the connection unit to the SR-unit.

2 For GMP probe: Lay the signal line from the purge air unit (connection on the purge air

unit → Technical Information of the purge air unit) to the purge air fixture.

GM32 Operating Instructions V1.3 8012707 © SICK MAIHAK GmbH 23

Page 24

3.5.4 Preparing the power supply

Power supply

100 .. 240 V / 50 .. 60 Hz

Take precautions to prevent switching off the purge air supply accidentally.

b

Attach a clearly visible warning against accidental switching off the separation equipment for the purge air unit.

1 Provide separate external fuses for:

– Connection unit (max. power input

– For GMP probe: Purge air unit (→ Technical Data of the purge air unit)

– For GPP probe: Heater (max. power input

2 Lay the electric lines of the power supply to the connection unit and connect the power

supply in the connection unit.

Figure 6 Mains connection in the connection unit

→

p. 67, §9.2)

→

p. 67, §9.2)

Preparation on the Gas Duct Side

The power supply must remain switched off until the GM32 is to be put into

operation.

3 For GMP probe: Lay the electric lines to the purge air unit.

For GPP probe: Lay the electric lines for the probe heater.

24 GM32 Operating Instructions V1.3 8012707 © SICK MAIHAK GmbH

Page 25

Start-up

GM32

4 Start-up

Preparation

Assembly

Alignment

GM32 Operating Instructions V1.3 8012707 © SICK MAIHAK GmbH 25

Page 26

Start-up

4.1

Necessary technical knowledge for start-up

The following requirements must be met for the start-up:

● You are basically familiar with GM32.

● You are familiar with the local situation, especially the potential risks

caused by gases in the gas duct (hot/noxious). You are capable of recognizing and preventing danger by possibly escaping gases.

● The specifications according to project planning have been complied with

(→ final inspection record).

● The assembly location has been prepared according to

on the Gas Duct Side«.

If one of these requirements is not met:

b

Please contact SICK Customer Service or your local representative.

WARNING: Hazard by voltage

b

All connectors of the power supply to the involved subassemblies or lines

must be disconnected before the installation work.

WARNING: Danger resulting from gases in the gas duct

Hot and/or noxious gases can escape during work on the gas duct, depending

on the equipment conditions.

b

Work on the gas duct may only be performed by skilled persons who, based

on their technical training and knowledge as well as knowledge of the relevant regulations, can assess the tasks given and recognize the hazards

involved.

→

p. 17, »Preparation

4.2 Required material (not included in the scope of delivery)

Material required Part No. Required for

Optical cleaning cloth 4003353 Cleaning the windows

Personal protective equipment --- Protection when working on the

stack

26 GM32 Operating Instructions V1.3 8012707 © SICK MAIHAK GmbH

Page 27

Start-up

Transport safety device

4.3

Overview of assembly steps

Procedure Reference

Removing the transport safety devices

Installing the device flange on the purge air fixture

Aligning the measuring probe

For the GPP probe: Electrical connection of heater

SR-unit electric connection

Switching on the power supply

For GMP probe: Purge air supply start-up

Installing the measuring probe in the gas duct

Fitting the SR-unit on the device flange

Optical fine alignment of the SR-unit

4.4 Transport safety devices

1 Remove the transport safety device of the SR-unit.

Figure 7 SR-unit transport safety device

→

p. 27, §4.4

→

p. 29, §4.5

→

p. 30, §4.6

→

p. 31, §4.7

→

p. 32, §4.8

→

p. 32, §4.9

→

p. 33, §4.10

→

p. 34, §4.11

→

p. 35, §4.12

→

p. 35, §4.13

GM32 Operating Instructions V1.3 8012707 © SICK MAIHAK GmbH 27

Page 28

2 Remove the probe transport safety device.

Plugs

Stickers

The probe transport safety devices depend on the type of probe.

a) Remove the protective stickers.

b) Take out the plugs.

Figure 8 Probe transport safety devices (shown here on a GPP probe)

Start-up

3 Store the transport safety devices.

28 GM32 Operating Instructions V1.3 8012707 © SICK MAIHAK GmbH

Page 29

Start-up

Device flange

Purge air fixture

Gap: 3.5 ± 0.5 mm

Sealing ring

12 cup springs

Centering disc

Nut

4.5

Installing the device flange on the purge air fixture

Remark on the GPP probe: The procedure for the GPP probe flange attachment corresponds to the procedure shown here for the purge air fixture.

1 Recommendation: For easier handling during installation:

Remove the SR-unit from the device flange before installation (

2 Installation on the SR-unit side:

Figure 9 Installing the device flange on the purge air fixture

→

p. 51, §7.2.1).

a) Plug 12 cup springs each, individually arranged opposite each other, onto the

threaded bolts on the device flange.

b) Pull the sealing ring over the flange of the purge air fixture and hang it loosely over

the purge air unit.

c) Plug the device flange onto the purge air fixture.

d) Plug on the centering discs.

Notice: Observe the direction of the centering disc: The convex side must fit into the

groove on the purge air fixture.

e) Tighten the self-locking nuts with a wrench (19 mm) so that the cup springs are

slightly compressed and an even gap of 3...4 mm remains.

f) Install the sealing ring above the gap (

→

Figure9).

GM32 Operating Instructions V1.3 8012707 © SICK MAIHAK GmbH 29

Page 30

Start-up

Flow direction sticker

Mounting ring screws (4 pcs.)

Device flange

4.6

Aligning the measuring probe in flow direction

The fitting angle of the probe is already set before delivery when the gas flow direction has

been defined during project planning for the GM32.

A sticker marks the setting.

Figure 10 Flow direction marking and setting

4.6.1

When the probe alignment has to be set

● The measuring gap must be aligned in sample gas flow direction.

● The SR-unit must be fitted vertically.

Rotate the device flange to align the probe.

To change the measuring probe alignment:

1 Loosen the 4 screws on the mounting ring (

2 Rotate the device flange:

– The measuring gap must point in flow direction.

– The device flange must be positioned so that the SR-unit can be fitted in a vertical

position.

3 Fasten the device flange in this position by tightening the screws on the mounting ring

again.

→

Figure10).

30 GM32 Operating Instructions V1.3 8012707 © SICK MAIHAK GmbH

Page 31

Start-up

Fuse holder

Switch to set voltage

4.7

For the GPP probe: Electric connection

1 Unscrew and take off the purge air fixture cover.

2 Check the switch setting for swapping the voltage to the available mains voltage and

correct when necessary.

Figure 11 Switch to select voltage and fuses

3 Check the fuses according to the available mains voltage and replace when necessary.

IMPORTANT: The fuses depend on the available mains voltage.

b

Only use the correct fuses.

– 230 V: 1.6 A (slow)

– 115 V: 2.5 A (slow)

4 Connect the power supply to the mains voltage.

Line with three wires:

– Green-yellow: PE

–Blue: N

–Brown: L1

IMPORTANT: Danger of condensation

The GPP probe must have reached its operating temperature before being

inserted in the gas duct.

b

First fit the GPP probe during final installation in the gas duct (→ p. 34,

§4.11).

b

Attach clearly visible warnings against accidental switching-off to all

switching devices where the GPP probe heater can be switched off.

GM32 Operating Instructions V1.3 8012707 © SICK MAIHAK GmbH 31

Page 32

Start-up

Earthing conductor

connection

4.8

SR-unit electric connection

Connecting diagram →p. 22, Figure 4

1 Connect the electric lines from the connection unit to the SR-unit.

2 For GMP probe: Connect the electric line from the purge air unit to the purge air fixture

(terminal: SLV filter).

3 Screw the earthing conductor (2.5 mm

minal (

→

Figure 12).

Figure 12 Connection of the earthing conductor at the bottom of the SR-unit

4.9 Switching on the power supply of the GM32

2

) of the equipment earth tight to the screw ter-

1 Switch on the power supply on the operator-side fuse of the connection unit.

2 An initialization screen is shown on the operator panel (for the “Pro” variant).

3 Measured values are then shown.

Ignore the displays until the start-up of the GM32 is complete.

32 GM32 Operating Instructions V1.3 8012707 © SICK MAIHAK GmbH

Page 33

Start-up

SLV filter terminal

Purge air connection

(shown with protective cap)

4.10

Figure 13 Connection of the purge air supply

For GMP probe: Start-up of the purge air supply

1 Switch on the power supply of the purge air unit on the (operator-side) fuse of the purge

air unit.

– Check the function: A strong air flow must be noticeable.

If it is not noticeable: → Data Sheet of purge air unit.

– Blow out the dust that may have entered the purge air hose.

2 Check the switch function of the pressure controller in the purge air unit, e.g. by partly

closing the suction opening of the purge air unit.

The “Purge air signal” warning must be shown.

3 Switch the power supply off again.

4 Connect the purge air hose to the purge air connection with a hose clamp (

necessary, remove the protective cap from the purge air connection.

5 Switch the power supply of the purge air unit on.

→

Figure13). If

The purge air supply protects the measuring system from contamination and

overheating.

b

Ensure the purge air pressure is adequate to push the purge air into the gas

duct.

The purge air supply may not be switched off while the measuring system is on

the gas duct.

b

Attach clearly visible warnings against accidental switching-off to all switching devices where the purge air supply can be switched off.

GM32 Operating Instructions V1.3 8012707 © SICK MAIHAK GmbH 33

Page 34

Start-up

For GMP probe: Purge air fixture

For GPP probe: Flange attachment

Seal

“Flange with tube”

Screw

Washer

Spring sheet

Nut

4.11

Installing the measuring probe in the gas duct

IMPORTANT: With the GPP probe: Danger of condensation

The GPP probe must have reached its operating temperature before the measuring probe is inserted in the gas duct.

b

Wait until the probe has reached its operating temperature before inserting

the probe.

Do not switch the GPP probe heater off as long as the GPP probe measuring

system is in the gas duct.

b

Attach clearly visible warnings against accidental switching-off to all switching devices where the GPP probe heater could be switched off.

1 Insert the measuring probe with purge air fixture resp. flange attachment (without SR-

unit) in the “flange with tube” on the channel side.

– For GMP measuring probe: Do not interrupt the purge air feed.

– For GPP measuring probe: Do not interrupt the power supply to the measuring

probe.

2 Screw the measuring probe with purge air fixture resp. flange attachment tight to the

“flange with tube” (seal with 4 screws).

Figure 14 Fitting the probe in the gas channel

34 GM32 Operating Instructions V1.3 8012707 © SICK MAIHAK GmbH

Page 35

Start-up

Hinge pin

Hinge

Device flange

SR-unit

Lever of the

locking device

“Open” resp. “close”

marking

4.12

Installing the SR-unit on the device flange

1 Installing the SR-unit:

a) Insert the SR-unit on the device flange into the hinge (swiveling-out direction prefer-

ably to the “left”).

b) Insert the hinge pin from above.

IMPORTANT: If the hinge pin has not been correctly inserted, the SR-unit

can drop when swiveled out.

b

Figure 15 Installing the SR-unit:

Ensure that the hinge pin is fully inserted.

c) Check the window for cleanness and clean, if required (→ p. 52, §7.4).

d) Check whether the drying agent cartridge is dry (

e) Close the SR-unit with the 4 quick-release fasteners.

f) For GMP probe: Set the lever on the purge air fixture to the “open” position.

Figure 16 Lever for the locking device (for GMP probe)

4.13

Optical fine alignment of the SR-unit

Optical alignment of the SR-unit:

b

With SOPAS ET: → Leave this work to a skilled person familiar with SOPAS ET.

b

With operating unit: →p. 42

→

p. 54, §7.6).

GM32 Operating Instructions V1.3 8012707 © SICK MAIHAK GmbH 35

Page 36

Start-up

36 GM32 Operating Instructions V1.3 8012707 © SICK MAIHAK GmbH

Page 37

Operation

GM32

5 Operation

Operation

Status messages

GM32 Operating Instructions V1.3 8012707 © SICK MAIHAK GmbH 37

Page 38

Operation

5.1

Recognition of an unsafe operational state

CAUTION: Danger caused by unsafe operational state

If the device is or could be in an unsafe state:

b

Take the device out of operation, disconnect from the mains voltage and

signal voltage and secure against unallowed or accidental start-up.

Indication Action

Smoke escaping from the housing

Gas escaping from the housing

Water or a different liquid penetrates

into the device

Humidity or moisture condensation on

electrical connections

Electric lines are damaged or broken

Surface is damaged or deformed

Unusual noises can be heard inside the device

Malfunctions remain inexplicable despite

having been cleared

1 Immediately put the device out of operation.

2 Have the device repaired.

1 Immediately check whether the gas is noxious or

combustible.

2 If this is the case: Immediately check the local

Operating Instructions which control the behavior

during uncontrolled escape of gas.

Examples of behavior:

b

Trigger an alarm. Start emergency measures.

b

Immediately evacuate all persons from the

affected operational room.

b

Use breathing protection.

b

Stop the affected gas supply.

b

Put the measuring system out of operation.

1 Immediately put the device out of operation.

2 Locate and stop the liquid source.

3 Have the device repaired.

1 Put the device out of operation.

2 Dry the connections.

1 Put the device out of operation.

2 Have the damage repaired.

1 Put the device out of operation.

2 Have the device repaired.

b

If caused by heat from inside the device: Immediately put the device out of operation.

b

If caused by acute external influence: Locate the

heat source and protect the device provisionally

against heat.

b

Otherwise: Have the device checked immediately

by a skilled person.

1 Check malfunction displays and malfunction mes-

sages of the device.

2 Have the device checked by a skilled person.

b

Contact the manufacturer's after-sales service

department.

38 GM32 Operating Instructions V1.3 8012707 © SICK MAIHAK GmbH

Page 39

Operation

Operating mode

Status indicators (LEDs)

(

→

p. 40, §5.2.5.1)

Current menu with

menu level (numeric display)

Menu level

Significance of button

(

→

§ 5.2.2)

Contrast setting

(

→

§ 5.2.3)

MEAS button

(

→

§ 5.2.2)

Buttons

5.2

Operator panel (for the “Pro” variant)

The operator panel is located on the right side of the SR-unit housing.

Figure 17 Significance of display

5.2.1 Status indicators (LEDs)

Significance of LEDs

● The green LED goes on: Power supply is in order.

● The yellow LED goes on: Maintenance request.

● The red LED goes on: Malfunction.

More information on the significance of the LEDs → p. 40, §5.2.5.1

5.2.2 Assignment of buttons

The assignment of the buttons depends on the selected menu and is shown above the

respective button.

Assignment of buttons Significance

MEAS Back to the display of the measured value screen from any menu.

All inputs that have not been terminated with Save are discarded.

F

If the MEAS button is depressed for more than 3 seconds: The contrast setting is

displayed (

Menu Opens the main menu (menu tree)

Diag Diag is shown only when there is a message.

When this button is pressed, the current message is shown.

More information on diagnosis

List of error messages

Enter Opens the selected menu level

Save Saves the changed parameters

Start Starts the displayed action

5.2.3 Contrast setting

1 Press the MEAS button for more than 3 seconds.

2 Set the desired contrast level with both middle buttons

→

p. 39, §5.2.3)

→

p. 59, §8.3

→

p. 40, §5.2.5.1

§ and ¨.

GM32 Operating Instructions V1.3 8012707 © SICK MAIHAK GmbH 39

Page 40

5.2.4 Language setting

The texts of the menus are shown in English

5.2.5 Menu tree

1

1.1 Failure

1.2 Maintenance (request)→ p. 40, §5.2.5.1

1.3 Uncertain

2 Alignment check

3 Adjustments

3.1 Alignment adjust

3.2 Check cycle

3.3 Reference cycle

4 IP Configuration View the IP settings

4.1 IP IP address

4.2 M Subnetmask

4.2 GW Gateway

5 Maintenance

Diagnosis

→

p. 40, §5.2.5.1

→

p. 40, §5.2.5.1

→

p. 40, §5.2.5.1

→

p. 41, §5.2.5.2

→

p. 42, §5.2.5.3

→

p. 42

→

p. 43

→

p. 43

→

p. 44, §5.2.5.4

Operation

5.2.5.1 Diagnosis

The “Diagnosis” menu shows the current error messages.

The GM32 creates a logbook.

b

Access to the logbook is performed exclusively via SOPAS ET

→

p. 13, §2.3.

The GM32 signals a malfunction or an unsafe operational state with status signals (option) (→ electrical connection diagram).

List of error messages and measures for clearing malfunctions

→

p. 59, §8.3

40 GM32 Operating Instructions V1.3 8012707 © SICK MAIHAK GmbH

Page 41

Operation

Status messages, status indicators and system states

Status Status indicators

(LED)

Significance Measured

value dis-

Analog

outputs

play

Power On Green Power supply is in order --- --- --Uncertain Green, however,

measured value

blinks

Measured value uncertain (e.g. outside

calibration range)

Cause: Press the DIAG button

Current Current According to

All messages → SOPAS ET Logbook.

Maintenance

request

Clearing malfunctions

Yellow Irregularities (e.g. gas temperature too

high, deviation from check cycle too high)

→

p. 59, §8.3

Current Current According to

that require a review of the cause.

The measured values are valid.

Cause: Press the DIAG button

All messages → SOPAS ET Logbook.

Clearing malfunctions

Failure Red Device failure (e.g. lamp failed)

Cause: Press the DIAG button

All messages → SOPAS ET Logbook.

Clearing malfunctions

1

Option

2

Option. Refer to the delivered System Documentation for the assignment of the status outputs.

3

See SOPAS ET in the “Digital outputs” menu.

→

p. 59, §8.3

→

p. 59, §8.3

Last valid

measured

value held

Last valid measured value

held

1

nal

2,3

setting

setting

According to

setting

Status sig-

5.2.5.2 Alignment check (automatic optical alignment) (option)

The optical alignment of GM32 is automatically adjusted in this menu.

b

Perform this work only when the SR-unit is at operating temperature (in

operation for at least 30 minutes).

b

Automatic mirror adjustment - do not perform manual adjustments.

More information→ p. 42, §5.2.5.3

b

Arrow buttons: Switch from “deviation” to “performed steps of tracking mirror”

b

To exit the Menu item: Press the “Back” button.

GM32 Operating Instructions V1.3 8012707 © SICK MAIHAK GmbH 41

Page 42

Operation

Light energy

Focal point

Value X

Value Y

5.2.5.3

Adjustments

Alignment adjustment (manual optical alignment)

b

Perform this work only when the SR-unit is at operating temperature (in

operation for at least 30 minutes).

Figure 18 Manual alignment of optical axis

Manual optical alignment of the GM32.

1 Press the “Start” button: The GM32 goes to a defined state.

A crosshair with a focal point and X/Y values is shown on the screen.

2 Tole ranc es:

X: –0.05 ... +0.05

Y: –0.05 ... +0.05.

The focal point is then in the center of the crosshair.

Adjustment:

Adjust the optical alignment by turning both adjustment screws on the device flange of

the SR-unit (19 mm wrench).

The display on the monitor reacts to the adjustment with a delay.

b

Perform adjustments slowly and wait for approx. 20 seconds until the

display on the monitor has been updated.

42 GM32 Operating Instructions V1.3 8012707 © SICK MAIHAK GmbH

Page 43

Operation

Horizontal adjustment

Vertical adjustment

Figure 19 Alignment on the device flange

– Horizontal adjustment of the probe causes a horizontal adjustment of the focus.

– Vertical adjustment of the probe causes a vertical adjustment of the focus.

3 The values for the light energy V1 .. V4 must be in the range from 250 .. 500 and

approximately have the same size.

● If you cannot see a focal point or adjustment is not possible:

– Is the gap between the device flange and the purge air fixture correctly adjusted? (

p. 29, §4.5)

– For GMP probe: Diaphragm (lever) open? (

– Very much dust or humidity in the gas duct?

–Window dirty? (

– Sender lamp defective? (Replacing the sender lamp

→

p. 52, §7.4)

→

p. 35, §4.12)?

→

p. 53, §7.5)

→

Check cycle

Start the check cycle manually.

Information on the check cycle → p. 13, §2.5

Reference cycle

Start the reference cycle manually.

Information on the reference cycle → p. 13, §2.4

GM32 Operating Instructions V1.3 8012707 © SICK MAIHAK GmbH 43

Page 44

Operation

5.2.5.4

Maintenance

The operating mode “Maintenance” is signaled via this menu.

● “Maintenance” is displayed in the operating mode line.

● The “Maintenance mode active” message is displayed.

● A continuous display of “*” is shown.

● The “Maintenance” status signal (→ electric connection diagram) is set.

Figure 20 “Maintenance” screen

● Assignment of buttons:

– “Back” : Show the “Measuring” menu - maintenance signal remains set.

–“MEAS”: Show the “Measuring” menu - maintenance signal is reset.

44 GM32 Operating Instructions V1.3 8012707 © SICK MAIHAK GmbH

Page 45

Putting Out of Operation

GM32

6 Putting Out of Operation

Putting out of operation

Storage

Disposal

GM32 Operating Instructions V1.3 8012707 © SICK MAIHAK GmbH 45

Page 46

Putting Out of Operation

6.1

Putting out of operation

WARNING: Danger resulting from gases in the gas duct

Hot and/or noxious gases can escape during work on the gas duct, depending

on the equipment conditions.

b

Work on the gas duct may only be performed by skilled persons who, based

on their technical training and knowledge as well as knowledge of the relevant regulations, can assess the tasks given and recognize the hazards

involved.

IMPORTANT: Do not switch off the purge air immediately

⊗ Do not switch the purge air unit off as long as the SR-unit is still on the gas

duct.

IMPORTANT: With the GPP probe: Danger of condensation

⊗ Do not switch off the heater of the GPP probe as long as the probe is in the

gas duct.

6.1.1 Putting out of operation

b

Switch off the power supply of the connection unit.

The analyzer can remain on the gas duct as long as the purge air supply (for GMP probe)

resp. the heater (for GPP probe) is in operation.

IMPORTANT: In case of a failure, no message by the analyzer

The analyzer no longer outputs a message when the purge air supply resp. the

heater fails.

b

Install suitable monitoring or remove the subassemblies.

6.1.2 Disassembly

Material required Part No. Required for

Personal protective equipment --- Protection when working on the stack

Flange lid --- Covering the flange

1 Disconnect all connections between connection unit and SR-unit.

2 Remove the SR-unit (

3 Unscrew the purge air fixture or flange fixture (

the probe and lay it down

4 For GPP probe: Switch off the power supply of the heater.

5 For GMP probe: Switch the purge air supply off and disconnect the purge air hose on

the device flange.

6 Close off the flange on the gas duct with a cover.

→

p. 51, §7.2.1).

WARNING: Hazards when removing the SR-unit

b

Observe the information concerning the removal of the SR-unit (→ p. 51,

§7.2.1).

→

p. 15, Figure 2) from the flange, pull out

.

WARNING: Measuring probe can be hot

When the temperatures in the gas duct are high, the removed measuring

probe is hot.

b

Wear suitable heat-resistant gloves.

b

Provide a heat-resistant support.

46 GM32 Operating Instructions V1.3 8012707 © SICK MAIHAK GmbH

Page 47

Putting Out of Operation

6.2

Storage

1 Clean the exterior of all housings, the measuring probe and all further components

including the purge air unit (when fitted)) with damp cleaning cloths. A mild cleaning

agent can be used.

2 Check the drying agent cartridges and replace, if required (

→

3 Protect the openings of the SR-unit and measuring probe from atmospheric influences

(preferably with the transport safety devices, according to

→

p. 27, §4.4).

4 Pack the GM32 for storage or transport (preferably in the original packing).

5 Store the GM32 in a dry, clean room.

6.3 Environmentally compatible disposal/ recycling

The GM32 can be disposed off as industrial waste.

Observe the relevant local conditions for the disposal of industrial waste.

The following subassemblies could contain substances that have to be disposed of separately:

● Electronics: Capacitors, rechargeable batteries, batteries.

● Display: Liquid of LC display.

● Probes: Probes can be contaminated with pollutants.

p. 54, §7.6).

GM32 Operating Instructions V1.3 8012707 © SICK MAIHAK GmbH 47

Page 48

Putting Out of Operation

48 GM32 Operating Instructions V1.3 8012707 © SICK MAIHAK GmbH

Page 49

Maintenance

GM32

7 Maintenance

Maintenance plan

Spare parts, recommended

Maintenance work

Preventative maintenance

GM32 Operating Instructions V1.3 8012707 © SICK MAIHAK GmbH 49

Page 50

Maintenance

7.1

Maintenance plan (operator)

Maintenance task Reference W

Check if measured and control values (zero/test point) are valid x x

Visual inspection

Cleaning the window

Checking/drying agent cartridges, replace when necessary.

→

p. 52, §7.3 x

→

p. 52, §7.4 x

→

p. 54, §7.6 x

Replace at the latest after 6 months.

Checking the purge air unit (for GMP probe)

Checking optical alignment

1

W = weekly, Q = quarterly

7.1.1 Recommended expendable and wearing parts for 2 years operation

Spare part Number Part No.

→

p. 55, §7.7 x

→

p. 41, §5.2.5.2 x

1

Sender lamp 2 pcs 2033796

Drying agent cartridge 8 pcs 2010549

Optical cleaning cloth 8 pcs 4003353

Filter insert for purge air unit 8 pcs 5306091

1

Per piece

1

1

Q

50 GM32 Operating Instructions V1.3 8012707 © SICK MAIHAK GmbH

Page 51

Maintenance

Hinge pin

Hinge

Device flange

SR-unit

7.2

Preparation work

IMPORTANT: Some tasks cause GM32 to switch to malfunction

b

Activate the Maintenance mode before starting the work (→p. 44).

IMPORTANT: Do not switch off the purge air

⊗ Do not switch the purge air unit off as long as the SR-unit is still on the gas

duct.

IMPORTANT: With the GPP probe: Danger of condensation

⊗ Do not switch off the heater of the GPP probe as long as the probe is in the

gas duct.

7.2.1 Swiveling out and removing the SR-unit

WARNING: Danger resulting from escaping gas when the SR-unit is swiveled

out

Excess pressure in the gas duct can cause hot and/or noxious gases to escape

when the SR-unit is swiveled out.

b

Swivel the SR-unit out only when you have taken suitable safety measures.

b

For GMP probe: Set the lever on the purge air fixture to the “Close” position

(

→

p. 35, Figure 16).

CAUTION: If the hinge pin (→p. 35, Figure 15) has not been correctly inserted,

the SR-unit can drop when swiveled out.

b

Check whether the hinge pin is completely pressed down before the SR-unit

is swiveled out.

Figure 21 Swiveling out the SR-unit

1 For GMP probe: Set the lever on the purge air fixture to the “Close” position (→p. 35,

Figure 16).

2 Open the 4 quick-release fasteners of the SR-unit and swivel out the SR-unit.

3 To remove the SR-unit:

Hold the SR-unit tight, pull out the hinge pin and take the SR-unit off

IMPORTANT: The SR-unit is heavy

b

Hold the SR-unit tight when pulling out the pin.

GM32 Operating Instructions V1.3 8012707 © SICK MAIHAK GmbH 51

Page 52

Maintenance

Window

7.3

Visual inspection

b

Check the housings of the SR-unit housing and connection unit for mechanical damage.

b

Clean the respective housings if contaminated.

b

Check all cables for damage.

Pay attention to chafe marks and kinks on cable ducts.

b

Check flanges and screw fittings for firm seating.

7.4 Cleaning the window

Figure 22 SR-unit window

1 Swivel out the SR-unit out (→ p. 51, §7.2.1).

2 Clean the window.

Use an optical cleaning cloth for cleaning.

The cleaning cloth can be moistened with demineralized water.

Do not use cleaning agents.

3 Close the SR-unit again.

4 For GMP probe: Set the lever on the purge air fixture to the “Open” position again.

52 GM32 Operating Instructions V1.3 8012707 © SICK MAIHAK GmbH

Page 53

Maintenance

Lamp cover

Screw of plug

Screws of sender lamp

7.5

Replacing the sender lamp

1 Switch off the GM32 using the fuse on the operator side.

2 Loosen 5 screws on the rear side of the SR-unit and swivel out the rear side.

3 Pull out the lamp cover.

Figure 23 Lamp cover

Figure 24 Sender lamp

4 Loosen screw (Philips head screw) of the plug and disconnect the plug.

5 Loosen 2 screws (5 mm Allen screw) on the sender lamp and loosen the sender lamp

.

WARNING: The sender lamp is hot

b

Wear suitable heat-resistant gloves.

b

Provide a heat-resistant support.

6 Remove the cap from the new sender lamp.

7 Plug in new sender lamp and screw tight.

8 Connect the plug and screw tight.

9 Plug in the lamp cover.

10 Screw the rear cover tight.

GM32 Operating Instructions V1.3 8012707 © SICK MAIHAK GmbH 53

Adjustment is not required.

Page 54

Maintenance

2 drying agent cartridges

7.6

Figure 25 Drying agent cartridges

Checking and replacing the drying agent cartridges

1 Swivel out the SR-unit (→ p. 51, §7.2.1).

2 The drying agent cartridge is light blue: The drying agent cartridge is dry.

The drying agent cartridge is white: Replace the drying agent cartridge.

3 Replacing the drying agent cartridge:

a) Unscrew the drying agent cartridge.

b) Screw in the new drying agent cartridge.

4 Close the SR-unit.

5 For GMP probe: Set the lever on the purge air fixture to the “Open” position again.

54 GM32 Operating Instructions V1.3 8012707 © SICK MAIHAK GmbH

Page 55

Maintenance

7.7

Cleaning the purge air unit

IMPORTANT: Inadequate purge air supply can damage the measuring system.

b

The purge air unit must be in perfect condition.

The filter of the purge air unit must be exchanged at the latest when the low-pressure monitor on the filter outlet triggers.

Preparation

b

If the purge air unit is not immediately functional: Remove the SR-unit from the gas duct

(swiveling out is sufficient for short-time work).

Procedure

1 Put the purge air unit out of operation and completely remove the purge air hoses.

2 Replace the air filter in the purge air unit and clean the inside of the purge air unit.

Details → Data Sheet of purge air unit.

3 Fully swivel out the SR-unit so that any dust blown through the purge air hose is not

deposited on the window.

4 Put the purge air unit back into operation

→

p. 33, §4.10.

GM32 Operating Instructions V1.3 8012707 © SICK MAIHAK GmbH 55

Page 56

Maintenance

56 GM32 Operating Instructions V1.3 8012707 © SICK MAIHAK GmbH

Page 57

Clearing Malfunctions

GM32

8 Clearing Malfunctions

General malfunctions

Malfunction messages

Screen messages (for “Pro” variant)

GM32 Operating Instructions V1.3 8012707 © SICK MAIHAK GmbH 57

Page 58

Clearing Malfunctions

8.1

General hazard caused by electrical voltage

CAUTION: General hazards caused by electrical voltage

b

If it is necessary to open the device for adjustment or repair: Disconnect

the device from all power sources before starting work.

b

If the open device must be live during work: This work has to be performed

by skilled persons who are familiar with potential hazards. If it is necessary

to remove or open internal components, live parts could be exposed.

b

If liquids have penetrated electrical components: Take the device out of

operation and disconnect the mains voltage externally (e.g. disconnect the

mains cable). Then contact service technicians of the manufacturer or correspondingly trained skilled persons to have the device repaired.

b

If hazard-free operation of the device is no longer possible: Take the device

out of operation and secure against unauthorized start-up.

b

Do not disconnect the protective conductor connections inside or outside

the device.

IMPORTANT: Damage by voltage

Before signal connections are established (also with plug connections):

b

Disconnect the GM32 and any connected devices from the electrical supply.

Otherwise the internal electronics can be damaged.

8.2 Measured value blinks

If a measured value blinks: Measured value is “uncertain” (e.g. calibration range

exceeded).

For GMP probe: When all measured values blink: Is the lever for the diaphragm in the

“open” position (

→

p. 35, §4.12)?

58 GM32 Operating Instructions V1.3 8012707 © SICK MAIHAK GmbH

Page 59

Clearing Malfunctions

Status (→p. 41)

Message number/

number of messages

Date (dd/mm)

Time (hh:mm:ss)

Initiator (footnote

→

p. 63)

Error message (

→

§ 8.3.2)

8.3

8.3.1 Example of an error message

Figure 26 Example of an error message

Error messages

GM32 Operating Instructions V1.3 8012707 © SICK MAIHAK GmbH 59

Page 60

8.3.2 Error messages

Initiator1Tex t Classifi-

Description Possible clearance

cation

System EEPROM Failure EEPROM parameters corrupted or not com-

patible after software upgrade.

Spectro com. Communication fault with spectrometer. Error in I2C connection with spectrometer. Check

Zero com. Communication fault with zero point reflec-

tor.

Temp control

com.

Communication fault with temperature control unit.

Visor com. Communication fault with visor module. Error in I2C connection with visor module. Check

Filter com. Communication fault with control filter ele-

ment.

Mirror com. Communication fault with mirror tracking. Error in I2C connection with mirror tracking.

Lamp com. Communication fault with lamp electronics. Error in I2C connection with lamp electronics.

Visor fault Error of visor signals. Signal distorted or

zero.

Visor values Visor signals outside the valid range. Hardware defect. Electronics not adjustable

Visor no signal All 4Q signals below threshold parameter. Check alignment, reflector, contamination.

Lamp fault Lamp does not go on. Lamp is defective. Replace the lamp (

Mirror adj. End Mirror tracking has reached maximum posi-

tion.

Zero adj. mc adj. Beam tracking during adjustment not possi-

ble.

Spectro para. No correct parameters saved in spectrome-

ter.

Purge air signal Digital input signals purge air error. Check the purge air supply (

Temp control out

of range

Temperature regulation measurement out-

side the valid range.

Extinction calc Error in extinction calculation. Please contact SICK Customer Service.

Reference calc Error in reference calculation.

IIR Filter Error during IIR filtering.

Interpolation Error in interpolation calculation.

Eval modul com. Error in communication with software evalu-

ation module.

File conditions Error during condition file access.

File espec Error during extinction file access.

File cact Error during lambda coefficient file access.

File measval Error during measured value file access.

Clearing Malfunctions

2

Software upgrade: Reset parameters.

Load saved parameters.

Defect: Reload backup.

Replace hardware, if possible.

plug connector or hardware defect.

Error in I2C connection with zero point reflector.

Check plug connector or hardware defect.

Error in I2C connection.

Check plug connector or hardware defect.

plug connector or hardware defect.

Error in I2C connection with control filter element.

Check plug connector or hardware defect.

Check plug connector or hardware defect.

Check plug connector or hardware defect.

Check signals and parameters.

(amplification too high).

→

p. 53,

§7.5).

Check alignment (

Check alignment (

→

p. 41, §5.2.5.2).

→

p. 41, §5.2.5.2).

Please contact SICK Customer Service.

→

p. 55, §7.7).

Excess temperature switch-off active for temperatures > 70 °C. Switches back on automatically

when < 65 °C.

60 GM32 Operating Instructions V1.3 8012707 © SICK MAIHAK GmbH

Page 61

Clearing Malfunctions

Initiator1Text Classifi-

cation

System Lamp perfor-

mance

Maintenance

Lamp performance limit

Lamp minimum During lamp adjustment, an excess signal

Lamp 4Q max The lamp current must be set to 1000 mA

Flashcard missing

IO com. Communication fault to IO block. Connection interrupted, check the cable.

Spectro no

answer

Cycle span drift The measurement on the control filters

Cycle zero drift The zero point measurement of a measured

Cycle wavelength drift

Cycle peak position

Cycle peak width The check of the peak width of the NO cell

Cycle cell empty During the check of the NO cell it is deter-

Temp control

voltage low

Temp control

lamp fan

Temp control

optic fan

Temp control

spectro fan

Temp control

electronic temp

Temp control

spectro temp

Data logging:

writing data

Data logging:

open file

Description Possible clearance

Warning for lamp performance

Prepare to exchange the lamp (→ p. 53, §7.5).

2

Lamp performance < 20 %

→

Lamp performance too low Replace the lamp (

p. 53, §7.5).

Check the parameter settings.

was determined with minimum lamp current

and exposure.

(stop) in the alignment procedure.

Alignment, check the optics (

Possible lamp change (

→

p. 41, §5.2.5.2).

→

p. 53, §7.5) or correct

parameter settings.

No Flashcard found. Insert the Flashcard, replace a possibly defective

card.

Defective CAN-bus interface.

No data received from spectrometer. Malfunction on the interface to the spectrometer.

Check the plug.

The reference from the adjustment is not correct.

showed an excess deviation.

Check limit value parameter setting.

Check limit value parameter setting.

value showed an excess deviation.

The check of the current Lambda_C0 coeffi-

Check limit value parameter setting.

cient showed an excess deviation.

The check of the position of the peak of the

NO cell showed an excess deviation.

Check limit value parameter setting. Defective NO

cell.

Check limit value parameter setting. Defective NO

showed an excess deviation.

cell.

Cell is empty.

mined that the highest measured extinction

value in the evaluation range is smaller than

0.1.

The measured voltage supply value is too

Malfunction of temperature control unit.

small (< 20 V).

The lamp fan has a malfunction. Malfunction of the temperature control unit or fan

or cabling.

The fan of the optic carrier has a malfunc-

tion.

The fan of the spectrometer has a malfunc-

tion.

The temperature of the temperature control

Malfunction of the temperature control unit or fan

or cabling.

Malfunction of the temperature control unit or fan

or cabling.

Malfunction of temperature control unit.

electronics exceeds 100 °C.

SR-unit is too warm or too cold. In the heating phase: Normal.

When running: Check ambient temperature.

Error when writing logging data to the Flash-

Flashcard memory full, Flashcard defective.

card.

Error when opening a file for logging data on

Flashcard memory full, Flashcard defective.

the Flashcard.

GM32 Operating Instructions V1.3 8012707 © SICK MAIHAK GmbH 61

Page 62

Clearing Malfunctions

Initiator1Tex t Classifi-

Description Possible clearance

cation

Probe EL. too hot Mainte-

nance