Page 1

Title Page

FLOWSIC500

Ultrasonic Gas Flow Meter with

Optional Volume Conversion

Installation

Operation

Maintenance

OPERATING INSTRUCTIONS

Page 2

Document Information

Glossary

Described Product

Product name: FLOWSIC500

Document ID

Title: Operating Instructions FLOWSIC500

Part No.: 8015391

Document ID: 9186957

Version: 2-3

Release: 2016-10

Manufacturer

SICK Engineering GmbH

Bergener Ring 27 · D-01458 Ottendorf-Okrilla · Germany

Phone: +49 35205 52410

Fax: +49 35205 52450

E-Mail: info.pa@sick.de

Original Documents

The English version 8015391 of this document is an original document from SICK Engineering GmbH.

SICK Engineering GmbH assumes no liability for the correctness of

an unauthorized translation.

Please contact SICK Engineering GmbH or your local representative in case of doubt.

Legal Information

Subject to change without notice.

© SICK Engineering GmbH. All rights reserved.

AC Alternating Current

Al Aluminium

ATEX ATEX: Atmosphères Explosifs: Abbreviation for Euro-

pean standards that govern safety in potentially

explosive atmospheres

CSA Canadian Standards Association (www.csa.ca)

DC Direct Current

HF High frequency, e. g. HF pulses

IEC International Electronical Commission

IECEx IEC system for certification in accordance with stan-

dards for devices for use in potentially explosive

atmospheres

IPxy Ingress Protection: Degree of protection of a device

in accordance with IEC/DIN EN 60529; x specifies

the protection against contact and impurities, y protection against moisture.

LF Low frequency, e. g. LF pulses

MDR Manufacturer Data Record

NAMUR Abbreviation for "Normen-Arbeitsgemeinschaft für

Mess- und Regeltechnik in der chemischen Industrie", now "Interessengemeinschaft Automatisierungstechnik der Prozessindustrie" (www.namur.de)

pTZ Volume conversion as a function of the pressure,

the temperature and with consideration of the compression factor

TZ Volume conversion as function of the temperature

and a fixed pressure value and with consideration

of the compression factor

2 FLOWSIC500 · Operating Instructions · 8015391/Z261/V2-3/2016-10 · © SICK Engineering GmbH

Page 3

Warning Symbols

Information Symbols

IMMEDIATE HAZARD

of severe injuries or death

Hazard (general)

Hazard by electrical voltage

Hazard in potentially explosive atmospheres

Hazard by explosive substances/mixtures

Hazard by unhealthy substances

Hazard by toxic substances

Warning Levels / Signal Words

Information on product condition with regard to protection against explosions (general)

Information on product characteristics related to European Directive ATEX

Information on product characteristics related to explosion protection in accordance with the IECEx scheme.

Important technical information for this product

Important information on electric or electronic functions

Nice to know

Supplementary information

Link referring to information at another place

DANGER

Risk or hazardous situation which will result in severe personal

injury or death.

WARNING

Risk or hazardous situation which could result in severe personal

injury or death.

CAUTION

Hazard or unsafe practice which could result in personal injury or

property damage.

NOTICE

Hazards which could result in property damage

FLOWSIC500 · Operating Instructions · 8015391/Z261/V 2-3/2016-10 · © SICK Engineering GmbH 3

Page 4

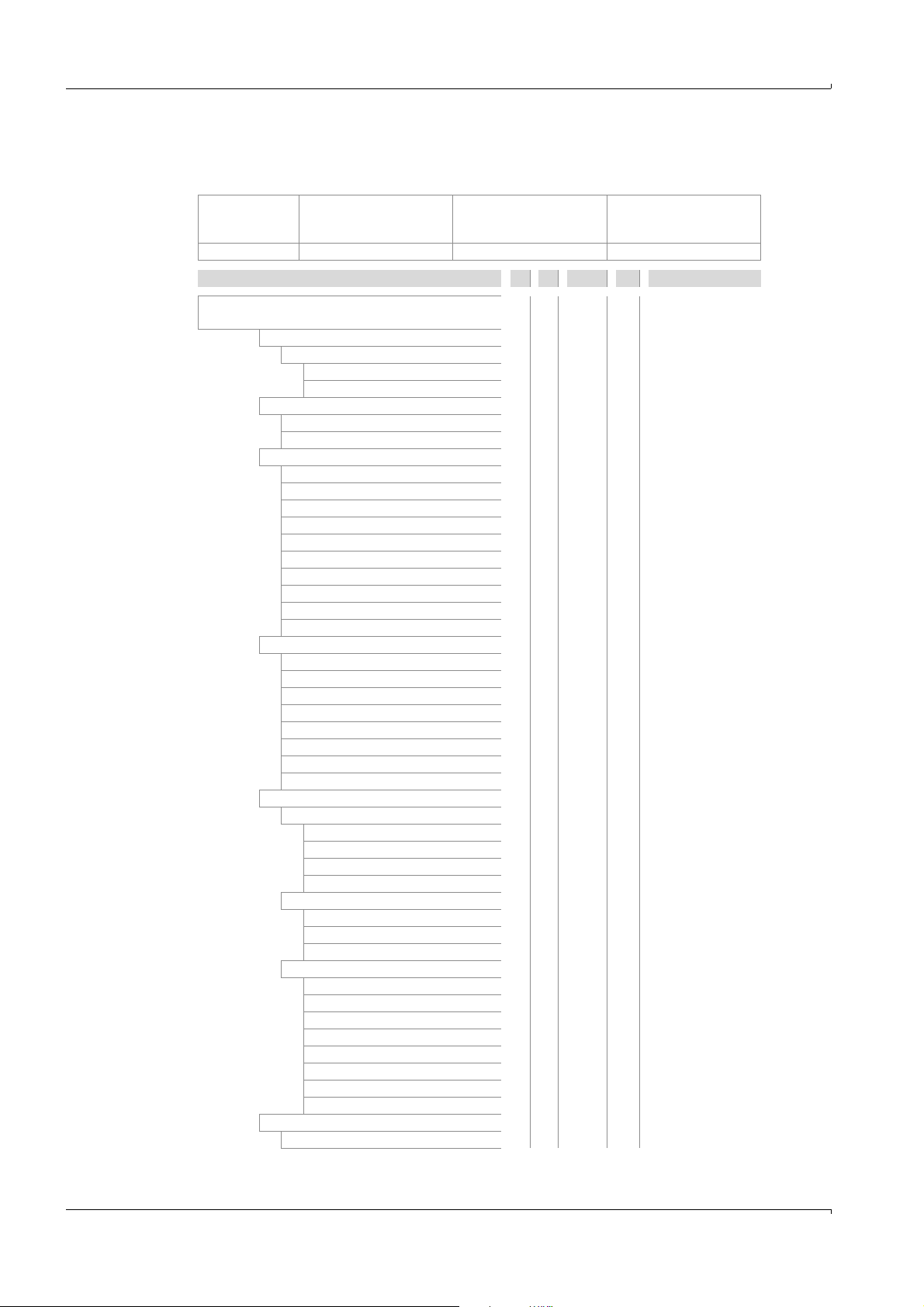

Contents

Contents

1 Important Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.1 Main hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.2 About this document . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.3 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.3.1 Purpose of the device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.3.2 Product identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.3.3 Operation in potentially explosive atmospheres . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.3.4 Combustible gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.3.5 Restrictions of use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.3.6 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.4 Responsibility of user . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.5 Additional documentation/information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2 Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.1 Operating principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.1.1 Gas flow meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.1.2 Volume conversion (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.2 FLOWSIC500 measuring system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.2.1 Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.2.2 Gas flow meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.3 Meter sizes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.4 Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.5 Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.5.1 Pulse and status outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.5.2 Encoder totalizer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.5.3 Serial data interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.5.4 Optical data interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.6 Device option: Volume conversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.6.1 Volume conversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.6.2 Integrated pressure and temperature transmitters . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.6.3 External pressure and temperature transmitters . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.7 Totalizers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.7.1 Device status and totalizers used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.7.2 Reverse flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.8 Logbooks and Archives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.9 Parameter protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.9.1 Parameter locking switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.9.2 Metrology logbook . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.10 Sealing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.1 Hazards during installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.2 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.2.1 Delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.2.2 Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3.3 Mechanical installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3.3.1 Preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3.3.2 Choosing flanges, gaskets and other components . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3.3.3 Fitting the FLOWSIC500 in the pipeline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4 FLOWSIC500 · Operating Instructions · 8015391/Z261/V2-3/2016-10 · © SICK Engineering GmbH

Page 5

Contents

3.4 Electrical installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3.4.1 Requirements for use in potentially explosive atmospheres . . . . . . . . . . . . . . . . . . . 37

3.4.2 Criteria for electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3.4.3 Opening and closing the electronics cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3.4.4 Rotating the control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

3.4.5 Electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

3.4.6 Pin assignment of plug-in connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

3.4.7 Cable specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

3.4.8 Operation with external power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

3.4.9 Operation with batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

3.5 Installing the external pressure and temperature transmitters . . . . . . . . . . . . . . . . . . . 46

3.5.1 Fitting the plug-in connector cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

3.5.2 Installing the pressure transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

3.5.3 Installing the temperature transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

4Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

4.1 Sequence of start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

4.1.1 Start-up of gas flow meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

4.1.2 Start-up of gas flow meter with device option volume conversion . . . . . . . . . . . . . .54

4.2 Setting the date and time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

4.3 Configuring volume conversion (device option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

4.3.1 Setting fixed values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

4.3.2 Checking the configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

4.3.3 Configuring the gas composition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

4.4 Checking the device status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

5Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

5.1 Control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

5.2 Operating using the display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

5.2.1 Display in the symbol bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

5.2.2 Battery fill level display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

5.2.3 Main screen (without device option volume conversion) . . . . . . . . . . . . . . . . . . . . . . 60

5.2.4 Main display (with device option volume conversion) . . . . . . . . . . . . . . . . . . . . . . . . . 62

5.2.5 Configuration of main display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

5.2.6 FLOWSIC500 menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

5.2.7 Changing the user level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

5.2.8 Setting the language . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

5.2.9 Changing the device mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

5.2.10 Changing parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

5.2.11 Resetting the error volume . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

5.2.12 Resetting the event summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

5.2.13 Confirming battery replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

5.2.14 Checking the external power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

5.2.15 Testing the display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

5.3 Operating using the optical data interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

5.4 FLOWgate500 operating software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

FLOWSIC500 · Operating Instructions · 8015391/Z261/V 2-3/2016-10 · © SICK Engineering GmbH 5

Page 6

Contents

6 Clearing Malfunctions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

6.1 Contacting Customer Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

6.2 Status messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

6.3 Additional messages in the Event logbook . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

7 Maintenance and Meter Replacement . . . . . . . . . . . . . . . . . . . . . . . . . 81

7.1 Information on handling lithium batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

7.1.1 Information on storage and transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

7.1.2 Disposal information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

7.2 Maintenance when using external power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

7.2.1 Service life of backup battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

7.2.2 Changing the backup battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

7.3 Maintenance when using battery power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

7.3.1 Service life of battery packs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

7.3.2 Changing the battery packs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

7.4 Meter exchange . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

7.4.1 Prerequisites for meter replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

7.4.2 Hazards during meter replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

7.4.3 Sequence of meter replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

7.4.4 Required tools and auxiliary material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

7.4.5 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

7.4.6 Back-up of user-specific configuration of installed gas flow meter . . . . . . . . . . . . . 90

7.4.7 Disconnecting electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

7.4.8 Removing the installed gas flow meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

7.4.9 Installing the replacement gas flow meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

7.4.10 Performing a leak tightness check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

7.4.11 Checking the function of the gas flow meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

7.4.12 Securing metrologically . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

7.5 Function check of a pressure or temperature transmitter . . . . . . . . . . . . . . . . . . . . . . 100

7.6 Exchanging an external pressure or temperature transmitter . . . . . . . . . . . . . . . . . . . 100

7.6.1 Exchanging the pressure transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

7.6.2 Exchanging the temperature transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

8 Accessories and Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

8.1 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

8.1.1 Gas flow meter accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

8.1.2 Volume conversion (device option) accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

8.1.3 Transport accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

8.2 Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

8.2.1 Gas flow meter spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

8.2.2 Volume conversion (device option) spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

6 FLOWSIC500 · Operating Instructions · 8015391/Z261/V2-3/2016-10 · © SICK Engineering GmbH

Page 7

Contents

9 Annex . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .107

9.1 Conformities and Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .108

9.1.1 CE certificate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .108

9.1.2 Standards compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

9.1.3 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .109

9.1.4 Flow rates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

9.1.5 Overload protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .111

9.2 Type code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .112

9.3 Type plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .114

9.3.1 Metrology and electronics type plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .114

9.3.2 PED type plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .116

9.4 Dimensional drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .117

9.5 Internal terminal assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

9.6 Installation examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

9.7 Connection diagrams for operation of the FLOWSIC500 in accordance with CSA .122

9.8 Connection diagrams for operation of the FLOWSIC500 in accordance with

ATEX/IECEx . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .129

FLOWSIC500 · Operating Instructions · 8015391/Z261/V 2-3/2016-10 · © SICK Engineering GmbH 7

Page 8

Contents

8 FLOWSIC500 · Operating Instructions · 8015391/Z261/V2-3/2016-10 · © SICK Engineering GmbH

Page 9

Important Information

FLOWSIC500

1 Important Information

Main hazards

About this document

Intended use

Responsibility of user

Subject to change w ithout notice

FLOWSIC500 · Operating Instructions · 8015391/Z261/V 2-3/2016-10 · © SICK Engineering GmbH 9

Page 10

1.1 Main hazards

23

-

23 I/O (Interface configurations)

FL5 F

DANGER: Risk of explosion when the gas flow meter is damaged

Natural gas flows with line pressure through the gas flow meter. Natural gas

can escape when the gas flow meter is damaged which creates a risk of

explosion.

▸

Prevent any possible damage to the gas flow meter. When necessary, fit

protection devices.

▸

If the gas flow meter is damaged: Stop natural gas feed immediately and

purge the FLOWSIC500 with inert gas.

WARNING: Hazards through leaks

Operation in leaky condition is not allowed and potentially dangerous.

▸

Regularly check leak tightness of equipment.

1.2 About this document

This Manual describes:

– Device components

– Installation

– Operation of the FLOWSIC500.

It contains the main safety information for safe operation of the FLOWSIC500.

Important Information

Scope of document

Make sure that your FLOWSIC500 is equipped with optically isolated inputs and outputs:

▸

Check the type code, position 23 "I/O", on the type plate (→ Fig.2) of your FLOWSIC500:

–

FLOWSIC500 with interface configurations F, G H, I and J have optically isolated

inputs and outputs.

–

For information on FLOWSIC500 with interface configurations A, B, C, D and E,

please refer to document "8018707, Addendum to Operating Instructions

FLOWSIC500: Interface Configurations".

Fig. 1 Ty pe co d e

▸

For a complete description of the type code refer to → p. 112, §9.2.

NOTICE: Interface Configurations

This document only applies to FLOWSIC500 gas flow meters with optically isolated inputs and outputs.

2523 24

10 FLOWSIC500 · Operating Instructions · 8015391/Z261/V2-3/2016-10 · © SICK Engineering GmbH

Subject to change w ithout notice

Page 11

Important Information

5

3

1 Type plate, metrological and electrical parameters

(metrology and electronics)

4 Type plate, electrical parameters (electronics)

2 Pin assignment of plug-in connectors 5 Type plate, metrological parameters (metrology)

3 Type plate PED

Labelling according to CSA

Labelling according to ATEX/IECEx

4

1

3

2

1.3 Intended use

1.3.1 Purpose of the device

The FLOWSIC500 serves for measuring the gas volume, volume flow rate and gas velocity

of natural gas in pipelines.

The FLOWSIC500 with optional volume conversion serves for measuring the gas volume

and converting the gas volume measured to base conditions as well as registering data on

meter readings, maximums and other data.

1.3.2 Product identification

Product name: FLOWSIC500

Manufacturer:

The type plates for metrological and electrical parameters are located on the gas flow

meter. The type plate for the Pressure Equipment Directive is located on the adapter.

Examples for the type plates see → p. 114, § 9.3.

SICK Engineering GmbH

Bergener Ring 27

01458 Ottendorf-Okrilla

Germany

Fig. 2 Location of type plates

Subject to change w ithout notice

FLOWSIC500 · Operating Instructions · 8015391/Z261/V 2-3/2016-10 · © SICK Engineering GmbH 11

Page 12

1.3.3 Operation in potentially explosive atmospheres

The FLOWSIC500 is suitable for use in potentially explosive atmospheres:

ATEX: II 2G Ex ia [ia] IIB T4 Gb, II 2G Ex ia [ia] IIC T4 Gb,

IECEx: Ex ia [ia] IIB T4 Gb, Ex ia [ia] IIC T4 Gb,

US/C: Class I Division 1, Groups C, D T4, Ex/AEx ia IIB T4 Ga

Further information on potentially explosive atmospheres → p. 37, § 3.4.1.

1.3.4 Combustible gas

▸

The FLOWSIC500 is suitable for measuring combustible and occasionally ignitable

gases corresponding to zones 1 and 2.

1.3.5 Restrictions of use

▸

Refer to the type plate for the configuration of your FLOWSIC500.

▸

Check the FLOWSIC500 is suitably equipped for your application (e.g. gas conditions).

WARNING: Hazard through material fatigue

The FLOWSIC500 has been designed for use under mainly static loads.

▸

Maximum allowed gradient of static pressure: 3 bar/s (45psi/sec)

The number of complete pressure application and release processes should

be kept low during operation.

▸

Replace the device when 500 cycles have been reached.

Important Information

II 2G Ex op is IIC T4 Gb

Ex op is IIC T4 Gb

NOTICE:

The FLOWSIC500 is designed for measuring clean and dry natural gas.

▸

The operator should install a suitable filter or cone screen ahead of the gas

flow meter when the gas is contaminated.

NOTICE:

● The FLOWSIC500 is suitable for use in pressurized lines within the parameters specified in the device. The device complies with Pressure Equipment

Directive 2014/68/EU.

● It is the user's responsibility to ensure the maximum values specified for

pressure and temperature on the type plate are not exceeded during operation.

12 FLOWSIC500 · Operating Instructions · 8015391/Z261/V2-3/2016-10 · © SICK Engineering GmbH

Subject to change w ithout notice

Page 13

Important Information

1.3.6 Cleaning

WARNING: Risk of ignition due to electrostatic charge

Under certain extreme circumstances, in Gas Group IIC, exposed plastic and

unearthed metal parts of the enclosure may store an ignition-capable level of

electrostatic charge.

▸

Implement precautions to prevent the build up of electrostatic charge, e.g.

locate the equipment where a charge-generating mechanism (such as

wind-blown dust) might occur and clean with a damp cloth.

NOTICE: Cleaning instructions

▸

Only clean the FLOWSIC500 with a damp cloth.

▸

Do not use solvents for cleaning.

▸

Only use materials for cleaning which do not damage the surface of the

FLOWSIC500.

1.4 Responsibility of user

▸

Only put the FLOWSIC500 into operation after reading the Operating Instructions.

▸

Observe all safety information.

▸

If anything is not clear: Please contact the SICK Customer Service.

Designated users

The FLOWSIC500 may only be operated by skilled technicians who, based on their technical training and knowledge as well as knowledge of the relevant regulations, can assess

the tasks given and recognize the hazards involved.

NOTICE:

Skilled persons are persons in accordance with DIN VDE 0105 or IEC 364, or

directly comparable standards.

These persons must have exact knowledge on hazards arising from operation,

e.g. through hot, toxic, explosive gases or gases under pressure, gas-liquid

mixtures or other media as well as adequate knowledge of the measuring

system gained through training.

Correct use

▸

Only use the FLOWSIC500 as described in these Operating Instructions (→ p. 11, § 1.3.1).

The manufacturer bears no responsibility for any other use.

▸

Do not carry out any work or repairs on the FLOWSIC500 not described in this manual.

▸

Do not remove, add or change any components in or on the FLOWSIC500 unless such

changes are officially allowed and specified by the manufacturer.

Otherwise

– Any warranty by the manufacturer becomes void

– The FLOWSIC500 can become dangerous

– The approval for use in potentially explosive atmospheres is no longer valid

– The approval fur use in lines pressurized above 0.5 bar (7.25 psi) bar is no longer

valid.

Subject to change w ithout notice

FLOWSIC500 · Operating Instructions · 8015391/Z261/V 2-3/2016-10 · © SICK Engineering GmbH 13

Page 14

Danger identification on device

WARNING: Danger identification on device

The following symbol draws attention to important dangers directly on the

device:

▸

Consult the Operating Instructions in all cases where the symbol is

attached to the device or shown on the display.

Special local conditions

▸

Follow all local laws, regulations and company-internal operating directives applicable

at the installation location.

Retention of documents

These Operating Instructions must be

▸

Kept available for reference

▸

Passed on to new owners.

1.5 Additional documentation/information

Some parameter settings, components and characteristics depend on the individual

device configuration. This individual device configuration is described in the device documentation delivered with the device.

● Certificate of conformity/EX certificates (depending on configuration)

● Material certificate

● Inspection certificate

– Device configuration sheet

– Encoder test protocol (if configured)

– Low-pressure calibration test protocol (if ordered)

– Labels according to Pressure Equipment Directive 2014/68/EU, Annex 1 Part 3.3

● Printout of the Data Book

● Product CD with:

– Operating Instructions

– Operating program FLOWgate500

– FLOWgate500 Software Manual

–Key code

– Instructions for Kamstrup test valve BDA04

Important Information

14 FLOWSIC500 · Operating Instructions · 8015391/Z261/V2-3/2016-10 · © SICK Engineering GmbH

Subject to change w ithout notice

Page 15

Product Description

FLOWSIC500

2 Product Description

Operating principle

Device components

Meter sizes

Power supply

Interfaces

Device option: Volume conversion

Totalizers

Logbooks and Archives

Parameter protection

Sealing

Subject to change w ithout notice

FLOWSIC500 · Operating Instructions · 8015391/Z261/V 2-3/2016-10 · © SICK Engineering GmbH 15

Page 16

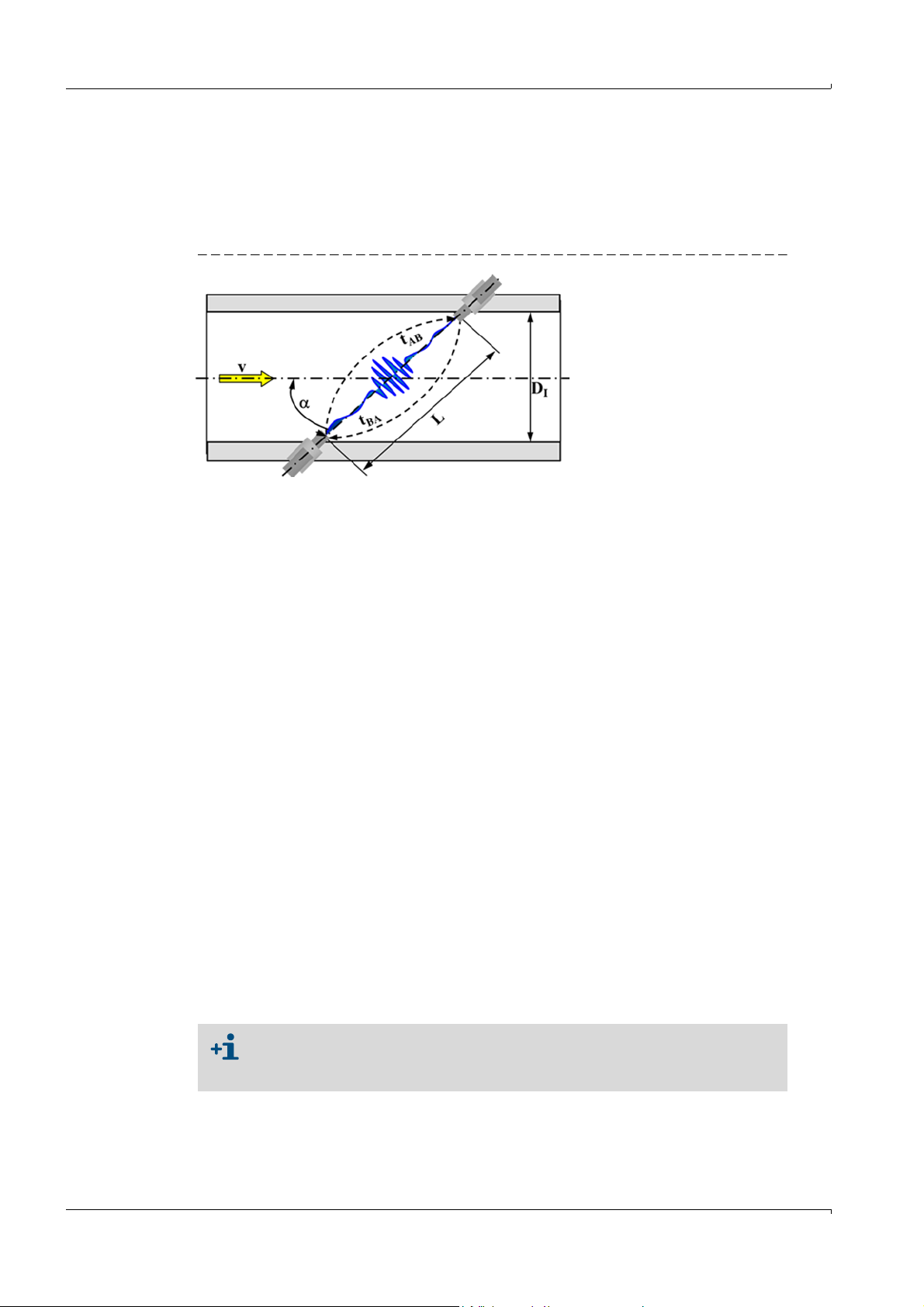

2.1 Operating principle

v= Gas velocity

L= Measuring path

= Angle of inclination in °

t

AB

= Sound transit time

in flow direction

t

BA

= Sound transit time

against flow direction

D

I

= Pipe inner diameter

Q= Volume flow

Q

4

-- -

D

I

2

L

2 cos

--------------- -

t

BAtAB

–

t

ABtBA

----------------------

=

V

b

CV

m

=

Vb= Volume at base conditions

C = Conversion factor

V

m

= Volume at measurement conditions

p = Gas pressure at measurement conditions

p

b

= Pressure at base conditions

T = Gas temperature at measurement conditions

T

b

= Temperature at base conditions

Z

b

= Compression factor at base conditions

Z = Compression factor at measurement conditions

C

p

p

b

-----

T

b

T

----- -

Z

b

Z

----- -

=

2.1.1 Gas flow meter

The FLOWSIC500 works according to the principle of ultrasonic transit time difference

measurement.

Fig. 3 Functional principle

Measured signal transit times tAB and tBA are defined by the current sound and gas velocity.

Gas velocity v is determined from the difference between the signal transit times. Therefore changes in the sound velocity caused by pressure or temperature fluctuations do not

affect the calculated gas velocity with this measurement method.

The FLOWSIC500 calculates the volume flow rate internally from the gas velocity and the

diameter of the measuring section of the gas flow meter.

Product Description

2.1.2 Volume conversion (optional)

The integrated volume conversion converts the measured gas volume from measurement

conditions to base conditions.

Calculation according to EN 12405:

The measurement conditions are either determined with pressure and temperature transmitters or entered as fixed value.

The following short forms are used in this document for better readability:

● Volume at base conditions = base volume

● Volume at measurement conditions = measurement volume

16 FLOWSIC500 · Operating Instructions · 8015391/Z261/V2-3/2016-10 · © SICK Engineering GmbH

Subject to change w ithout notice

Page 17

Product Description

Gas flow meter

Adapter

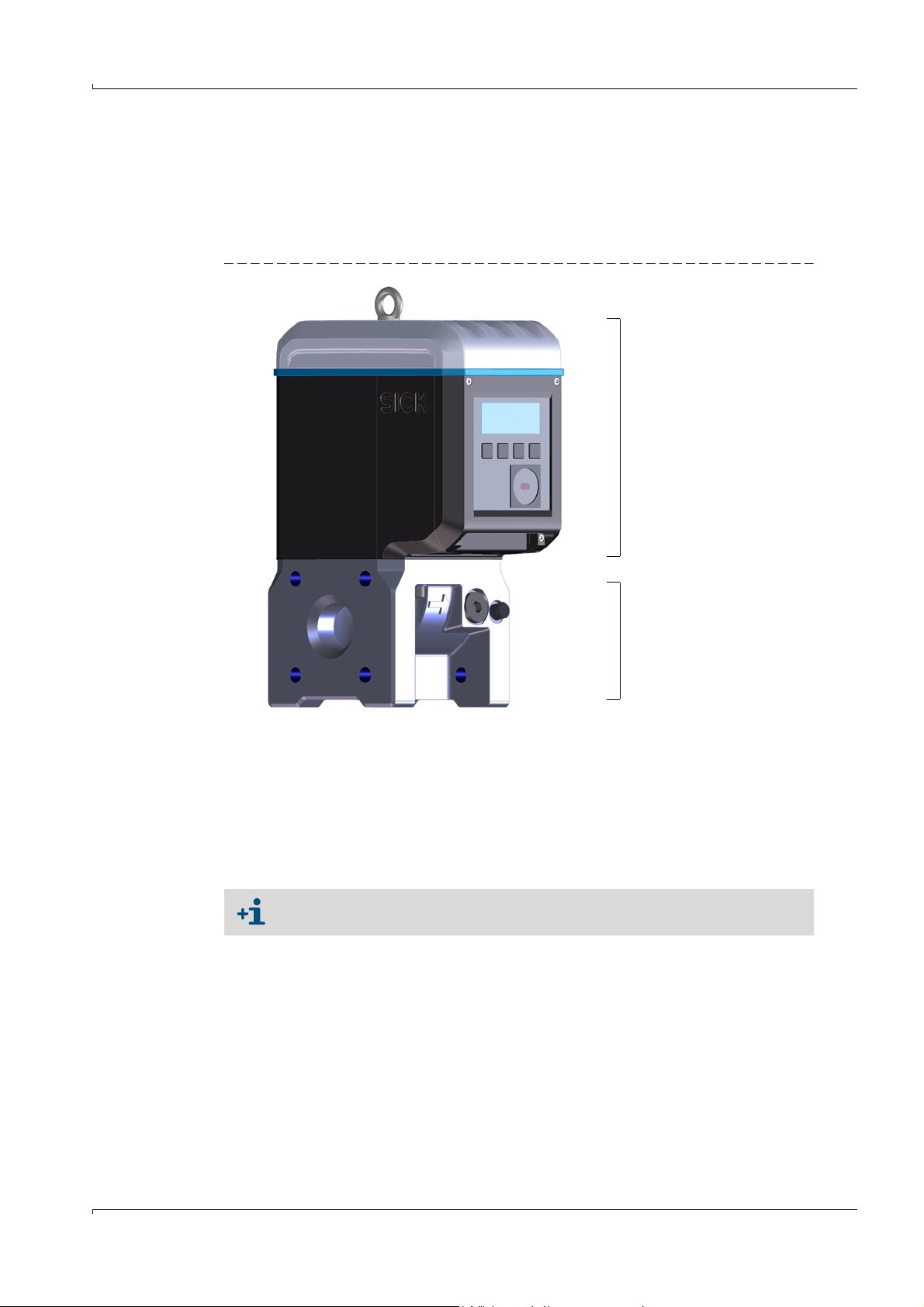

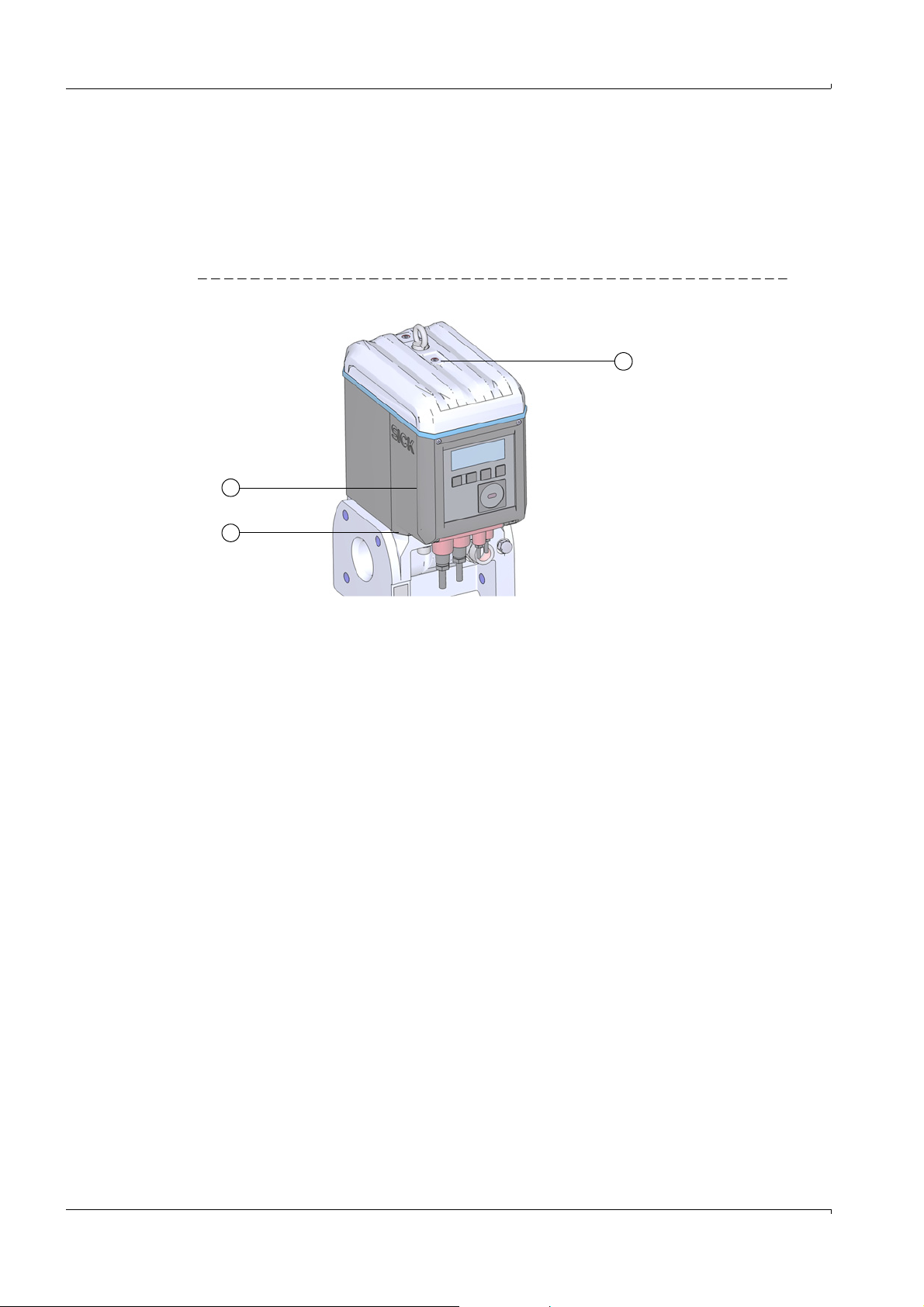

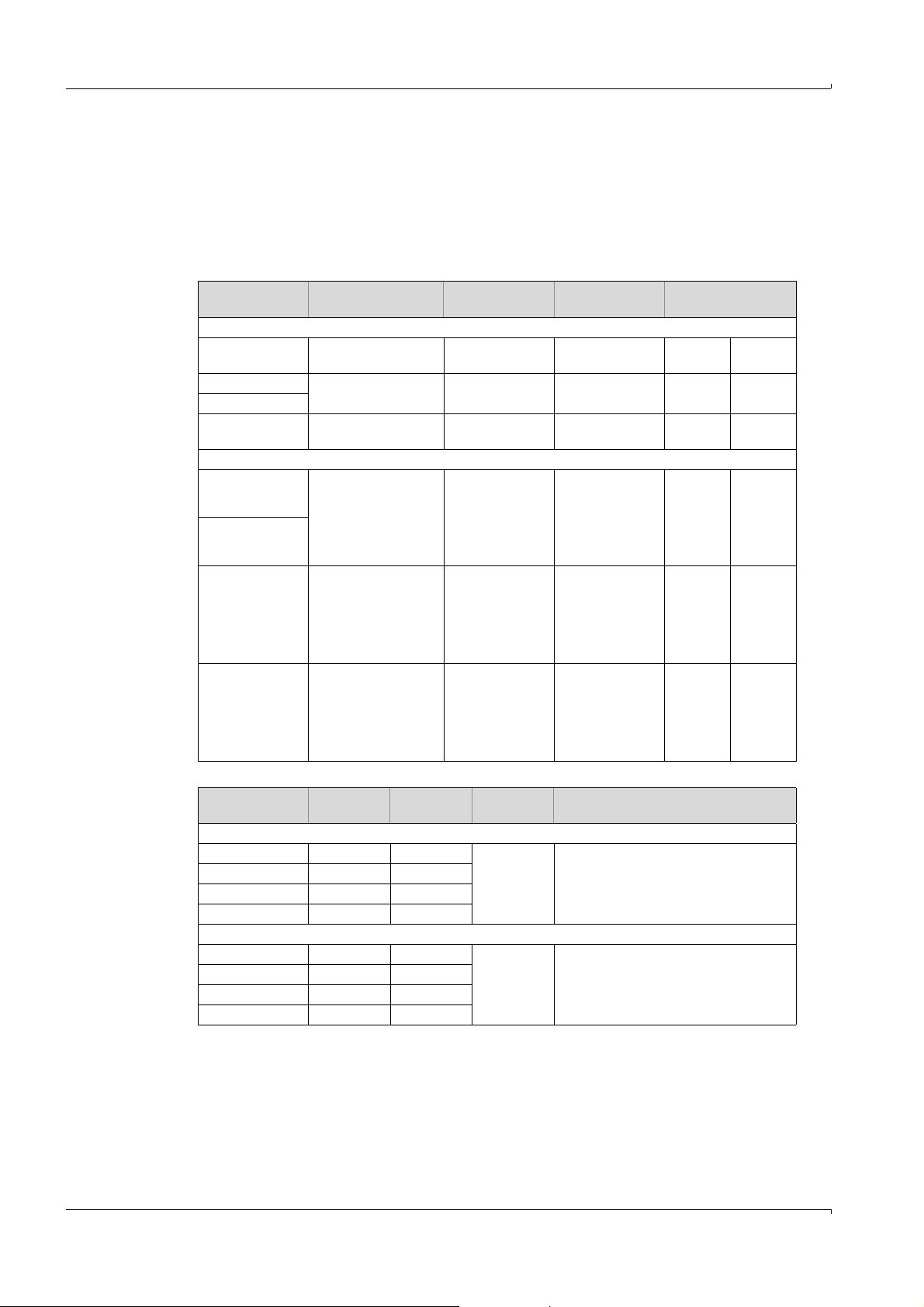

2.2 FLOWSIC500 measuring system

The FLOWSIC500 measuring system comprises:

● FLOWSIC500 gas flow meter,

● Adapter for installation in pipeline and

● optional p&T sensors for the volume conversion device option.

Fig. 4 FLOWSIC500 components

2.2.1

Adapter

The adapter is available in various flange standards and fitting lengths to connect the gas

flow meter to the system pipeline.

Depending on the version, the adapter is designed for assembly on line flanges PN16 in

accordance with DIN EN1092-1, CL150 in accordance with ASME B16.5, or 1.6MPa in

accordance with GOST 12815-80.

Fitting lengths available: → p. 117, § 9.4.

Subject to change w ithout notice

FLOWSIC500 · Operating Instructions · 8015391/Z261/V 2-3/2016-10 · © SICK Engineering GmbH 17

Page 18

2.2.2 Gas flow meter

An internal flow conditioner rectifies the gas flow in the gas flow meter so that flow profile

disturbances caused by pipe bends in the inlet or outlet sections or components projecting

into the pipe (e.g., a thermowell) have no influence on measuring results.

The gas flow meter can be replaced without taking the adapter out of the pipeline.

The gas flow meter is fitted with:

● Control unit

● Optical and electrical interfaces

● Measuring cell with ultrasonic transducers

● Electronics.

The product variant with volume conversion and integrated pressure and temperature

transmitters also has the calibrated pressure transmitter and calibrated temperature

transmitter fitted in the gas flow meter.

2.3 Meter sizes

Available meter sizes → p. 117, §9.4.

2.4 Power supply

The FLOWSIC500 is available with two configurations:

● For operation with external intrinsically safe power supply with backup battery (backup

duration: Approx. 3 months).

● Self-sufficient power configuration: 2 internal longlife battery packs (typical service life:

At least 5 years).

The second battery pack is activated automatically when the first pack is empty and a

message displayed (→ p. 58, § 5.2).

Product Description

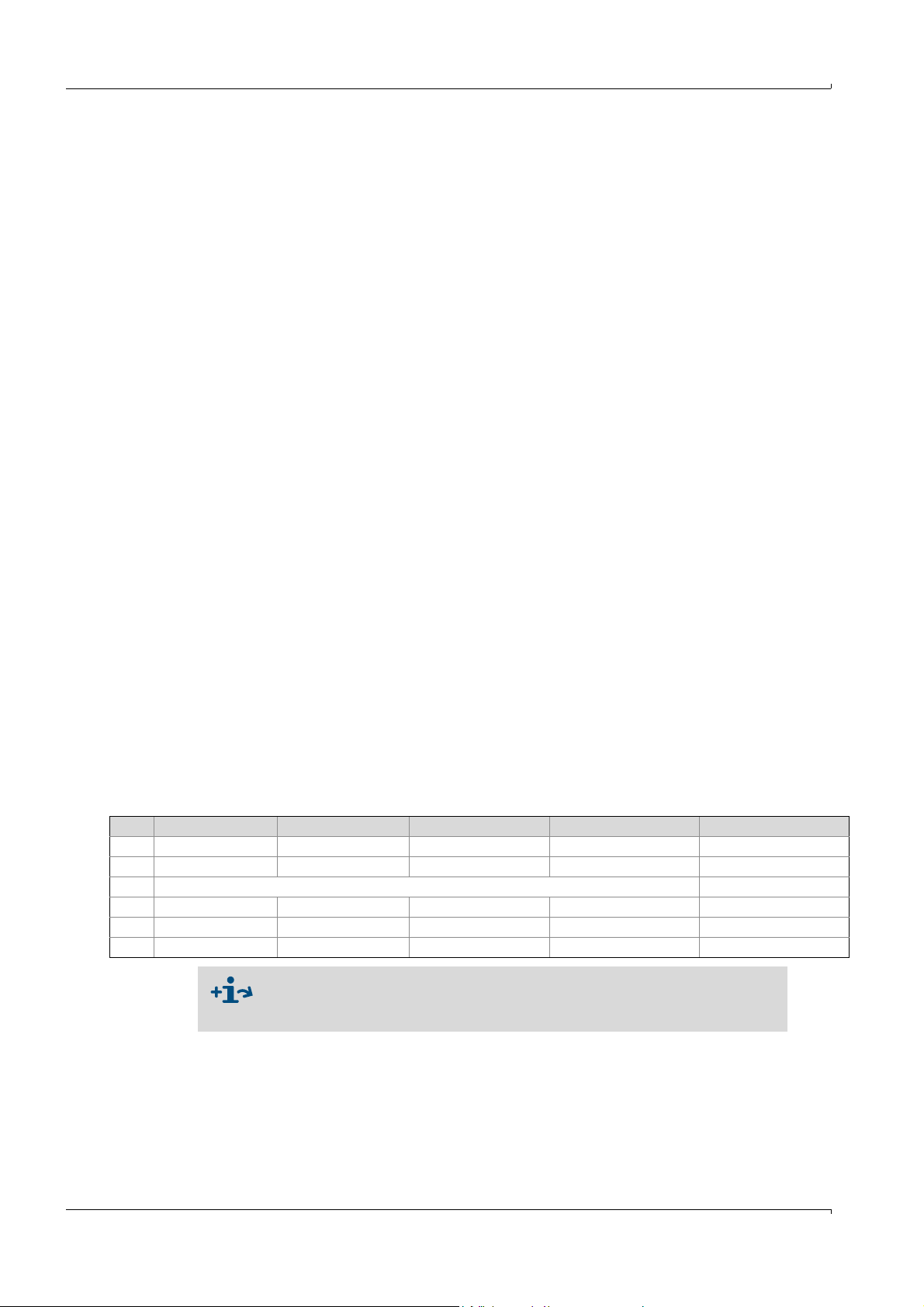

2.5 Interfaces

The FLOWSIC500 supports various digital and serial interfaces.

The configuration of the interfaces as delivered is described in the delivery documents pro-

vided with the respective device.

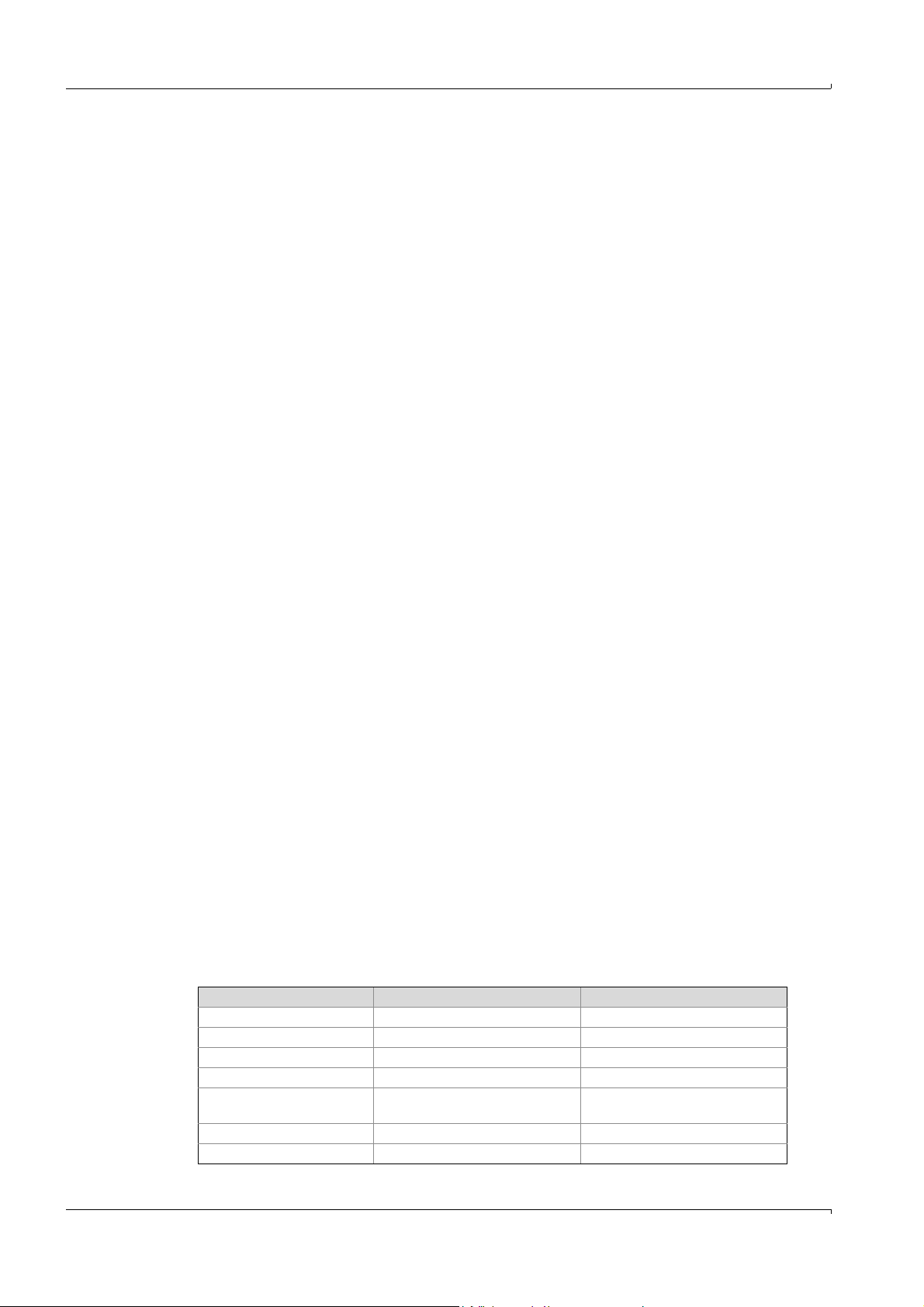

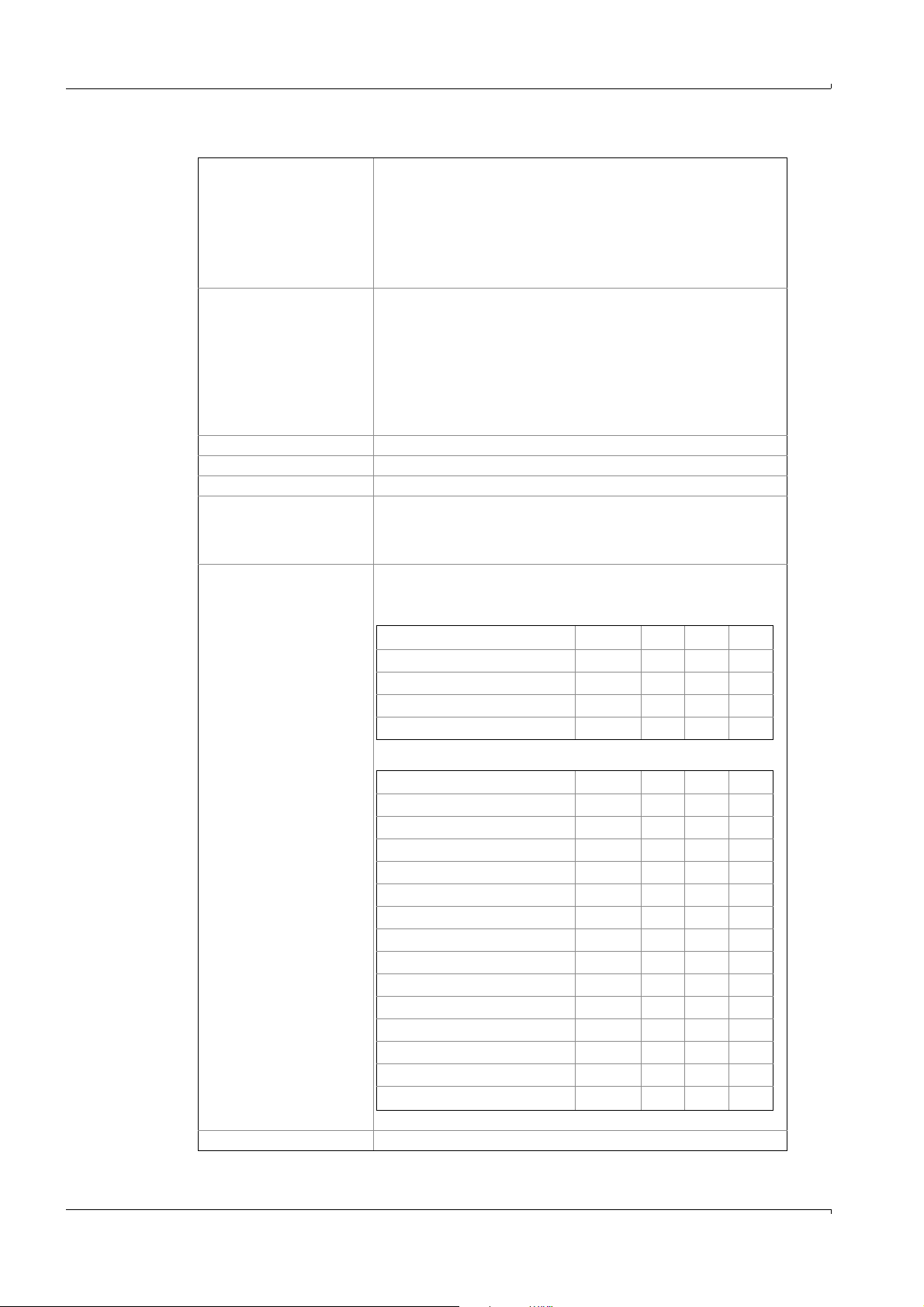

Table 1 Interface configurations

Config. 1 (LF) Config. 2 (HF) Config 3 (Encoder + LF) Config. 4 (RS485) Config. 5 (Encoder + HF)

Type code I/O: F Type code I/O: G Type code I/O: H Type code I/O: I or J Type code I/O: K

DO_0 - HF pulses Encoder - Encoder

DO_1 Normal mode: Diagnosis warning, test mode: Test pulses HF pulses

DO_2 LF pulses - - - DO_3 Malfunction Malfunction LF pulses - Malfunction

Serial - - RS485 -

● Information on explosion-technical characteristics and rated voltage

→ p. 37, § 3.4.

● Details on standard interface configurations available → p. 42, § 3.4.6.

Subject to change w ithout notice

18 FLOWSIC500 · Operating Instructions · 8015391/Z261/V2-3/2016-10 · © SICK Engineering GmbH

Page 19

Product Description

2.5.1 Pulse and status outputs

FLOWSIC500 has 4 digital switching outputs. Digital switching outputs DO_0, DO_2 and

DO_3 are electrically isolated according to EN 60947-5-6.

Alternatively, digital switching outputs DO_2 and DO_3 can also be configured as Open Collector.

When used as pulse output, maximum 2 kHz can be output on digital switching output

DO_0 and maximum 100 Hz on digital switching outputs DO_2 and DO_3. When used as

status output, status information "Validity of measurement" or the result of the self-diagnosis can be represented.

Digital switching output DO_1 is not electrically isolated. In normal mode, the diagnosis

warning is output on DO_1, test pulses are output in test mode.

The digital switching outputs are updated synchronously once per second.

2.5.2 Encoder totalizer

Alternatively, NAMUR switching output DO_0 can be configured so that the reading of totalizer Vm, the meter status and a meter identification are output via asynchronous serial

communication. This allows the connection of volume convertors with a suitable input for

encoder totalizers.

NOTICE:

If encoder communication has been configured, ensure that the transferred

number of digits and the counter resolution can be processed by a connected

volume converter.

When the parameter locking switch is open, a parameter change can be performed at the FLOWSIC500 using the FLOWgate500 operating software.

2.5.3 Serial data interface

The serial interface is designed as externally powered RS485 and requires an external

intrinsically safe power supply for operation. The RS485 interface has no internal line termination.

2.5.4 Optical data interface

An optical interface according to IEC 62056-21 with serial bit, asynchronous data transmission is located on the front of the FLOWSIC500.

The interface can be used to read out data and parameter settings and to configure the

FLOWSIC500.

Subject to change w ithout notice

FLOWSIC500 · Operating Instructions · 8015391/Z261/V 2-3/2016-10 · © SICK Engineering GmbH 19

Page 20

2.6 Device option: Volume conversion

2.6.1 Volume conversion

The FLOWSIC500 gas flow meter with volume conversion captures the gas volume under

measurement conditions and converts it to a volume under base conditions.

Gas volume conversion can run selectively (set at the factory) as PTZ or TZ volume conversion: The configuration as temperature volume conversion uses the default value for measurement pressure for calculations.

Measurement conditions are recorded with the pressure and temperature transmitters or

entered as fixed values.

By default, measured values recording and subsequent conversion to the volume under

base conditions are performed every 30 seconds. The update interval can be adjusted

→ p. 69, § 5.2.6.5, “Calculation”.

Depending on the configuration, the compressibility factor (K-factor) is determined with

one of the following calculation methods or can be entered as a fixed value.

● SGERG88,

● AGA 8 Gross method 1

● AGA 8 Gross method 2

● AGA NX-19

● AGA NX-19 mod.

● Fixed value

The FLOWSIC500 checks the permissible entry limits of the parameters for the selected

calculation method. If one of the entry values is outside the limit values, the FLOWSIC500

switches to malfunction state and uses the fixed value of the compressibility factor for calculation of the basis volume.

An absolute pressure transmitter EDT 23 (optional: relative pressure transmitter EDT 23)

and a temperature transmitter EDT 34 measure current measurement conditions and

transfer the transmitter type, measured value as well as the transmitter status via a digital

interface.

The FLOWSIC500 reads the valid measuring range automatically and, periodically, the current status and measured value.

A transmitter is only activated for measurement when the configured serial number

matches the serial number transferred for the transmitter.

If no transmitter is detected or a transmitter is not functioning correctly, the

FLOWSIC500 automatically uses the stored default value (= fixed value) of the state vari-

able.

In this case, the FLOWSIC500 switches to malfunction state and, using the default value,

stores the volume under base conditions calculated for pressure or temperature in the

error volume counter.

If not specified otherwise, the FLOWSIC500 is supplied with the following standard settings:

Table 2 Standard settings

Unit system SI Imperial

T unit °C ° F

P unit bar psi

Symbols according to EN 12405 API

Calculation method SGERG88 AGA 8 Gross method 1

Reference conditions for den-

sity and heating value

(T1/T2/p2)

25 °C/0 °C/1.01325 bar (a)

Base pressure 1.01325 bar (a) 14.7300 psi (a)

Base temperature 0 °C 60 °F

Product Description

Subject to change w ithout notice

(T1/T2/p2)

60 °F/60 °F/14.7300 psi (a)

20 FLOWSIC500 · Operating Instructions · 8015391/Z261/V2-3/2016-10 · © SICK Engineering GmbH

Page 21

Product Description

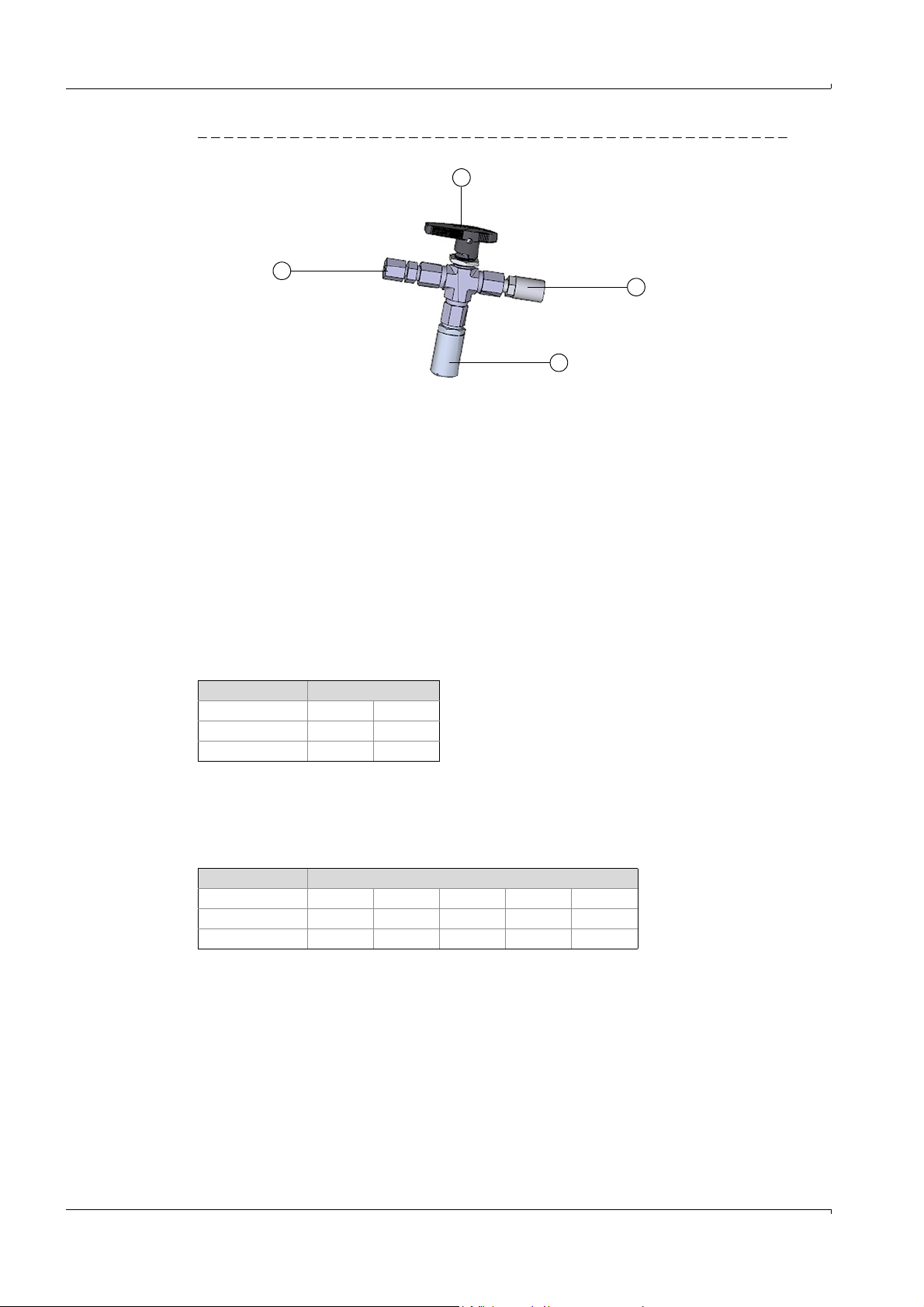

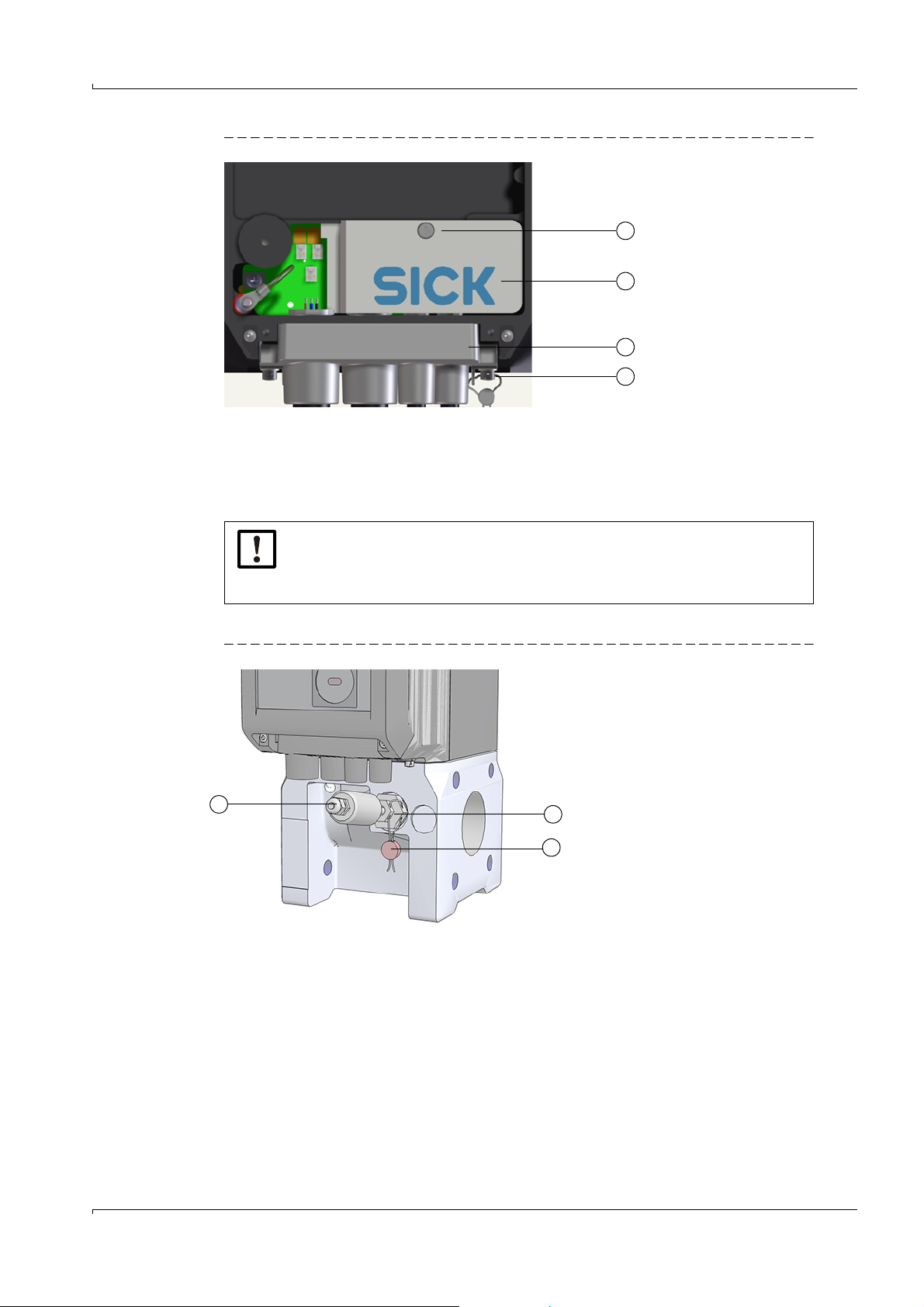

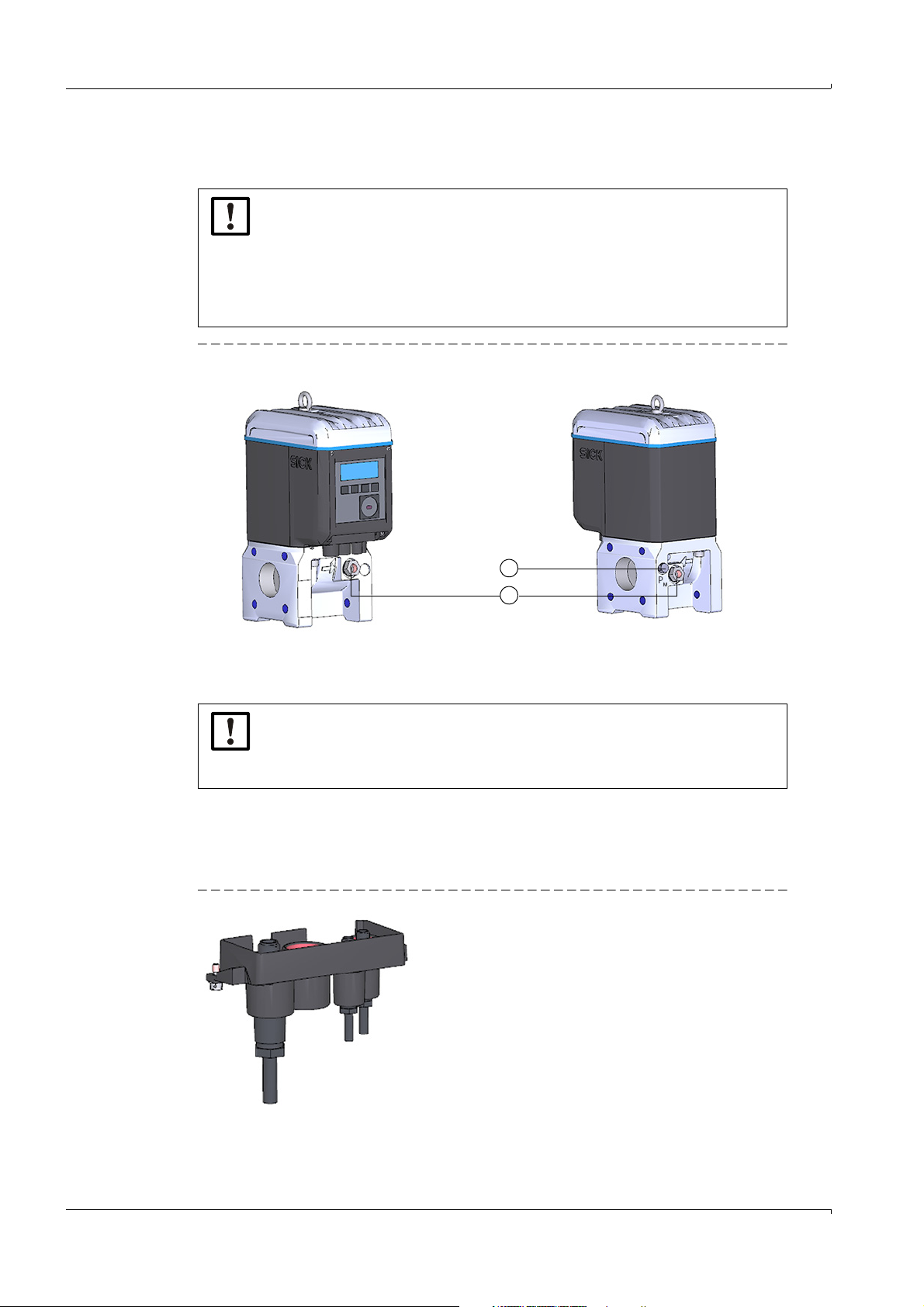

1 Pressure transmitter

2 Kamstrup test valve BDA04

3 Temperature transmitter

2

3

1

2.6.2 Integrated pressure and temperature transmitters

The FLOWSIC500 with volume conversion and integrated pressure and temperature transmitters does not have any external components. The internal pressure and temperature

transmitters are already fitted and calibrated at the factory. The measuring ports are

located in the gas flow meter.

This means the FLOWSIC500 does not require any additional installation of transmitters to

determine the measurement conditions and is immediately ready for operation after volume conversion has been configured.

2.6.3 External pressure and temperature transmitters

The FLOWSIC500 with volume conversion and external transmitters is used at measuring

ports where a test/calibration of the pressure or temperature transmitter in the system

may be required.

It is recommended to install a three-way test valve that separates the pressure transmitter

from the measurement pressure and provides a test connection to test the pressure transmitter.

→ Fig. 5 shows a FLOWSIC500 with external transmitters and Kamstrup test valve BDA04

for gas temperatures to -25°C.

Fig. 5 FLOWSIC500 with external transmitters and Kamstrup test valve BDA04

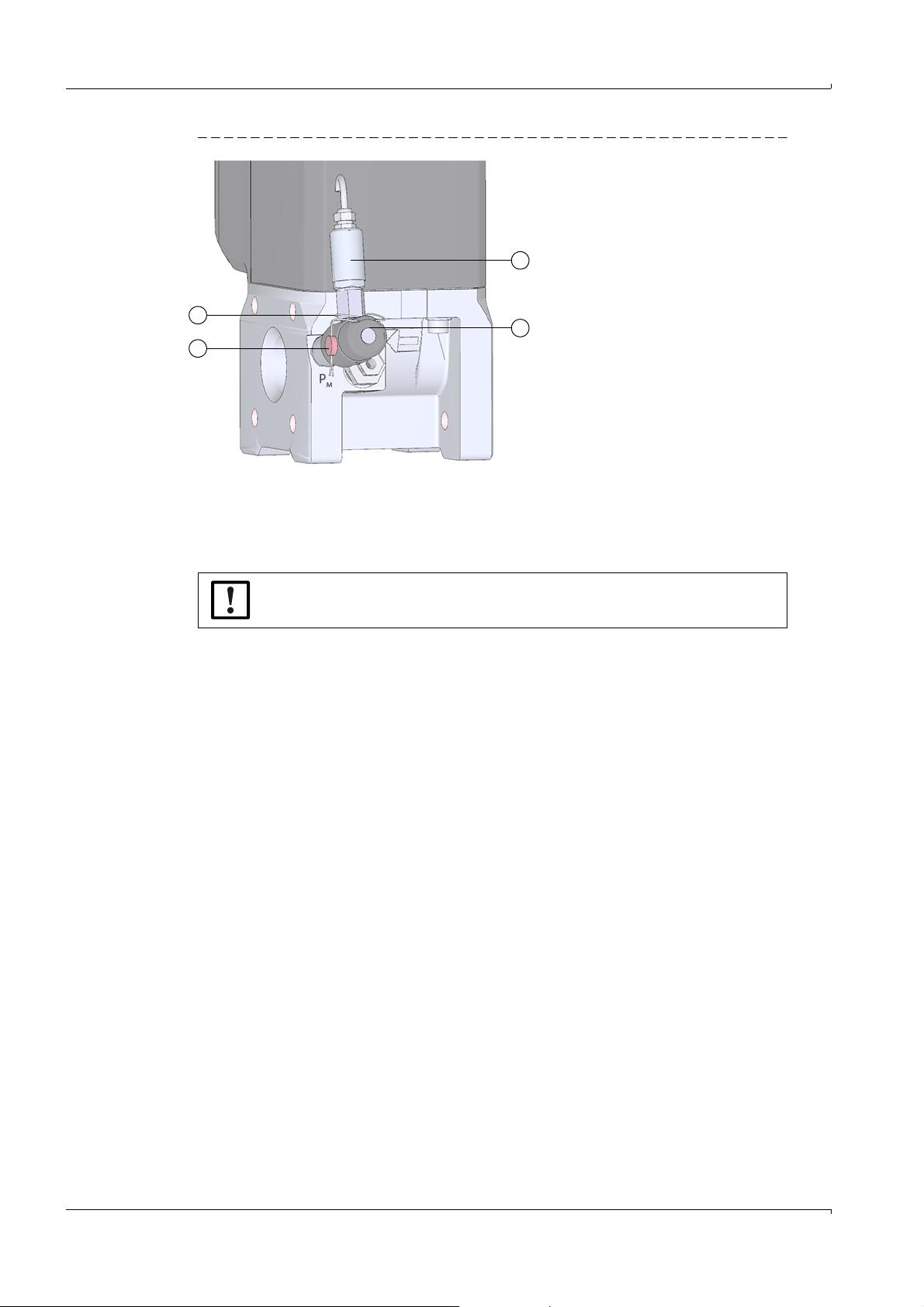

A three-way test valve (→ Fig. 6) that is fitted next to the FLOWSIC500 is used for gas temperatures to -40°C.

Subject to change w ithout notice

FLOWSIC500 · Operating Instructions · 8015391/Z261/V 2-3/2016-10 · © SICK Engineering GmbH 21

Page 22

Fig. 6 Three-way test valve with p transmitter and Minimess coupling

1FLOWSIC500 connection

2 Three-way test valve

3 Test connection (Minimess coupling)

4 Pressure transmitter

1

2

3

4

Product Description

2.7 Totalizers

2.7.1 Device status and totalizers used

Various volume totalizers are fitted on the FLOWSIC500 depending on the configuration.

Meter V is used in the configuration as gas flow meter. If the gas flow meter has a malfunc-

tion, the measured volume is also recorded in the error volume counter errV.

Table 3 Device status and totalizers used

Status Totalize r

VerrV

Operation

Malfunction

●

●●

A gas flow meter Vm, a base volume meter Vb and a total volume meter Vbtot are used in

the configuration as gas flow meter with integrated volume conversion (device option). If

malfunctions occur, the measured values are not recorded in the base volume meter Vb,

but the converted volume is recorded in the error volume meter errVb.

Table 4 Device status and totalizers used (with device option volume conversion)

Status Totalize r

Vb errVb Vbtot Vm errVm

Operation

Malfunction

Authorized users (user level "Authorized user") can reset the error volume counters → p. 73,

§5.2.11.

●●●

●●●●

22 FLOWSIC500 · Operating Instructions · 8015391/Z261/V2-3/2016-10 · © SICK Engineering GmbH

Subject to change w ithout notice

Page 23

Product Description

2.7.2 Reverse flow

The FLOWSIC500 is designed as unidirectional type and has a configurable zero-flow cutoff

which is factory set to a value of 1 m

The totalizers are stopped during reverse flow and this volume is counted in a separate buffer totalizer. When normal operation resumes, the buffer totalizer is first computed with the

flow.

The totalizers are first incremented again after the reverse flow volume has passed

through.

During reverse flow, the meter first switches to malfunction when the preconfigured buffer

volume has been exceeded. An error message is output on the device.

2.8 Logbooks and Archives

The integrated data registration stores meter readings, maximums and other data in the

following archives:

● Measuring period archive

Totalizers and data saved after the measuring period elapses (standard = 60 min.). The

measuring period can be adjusted → p. 71, §5.2.6.9.

● Daily archive

Totalizers and data saved at the defined gas hour time (standard = 06:00)

● Monthly archive

Totalizers and data saved at the defined gas day time (standard = 1st day of month)

3

(35 ft3) as default.

Explanations on data structure and storage depth are available in Technical

Bulletin "Data Registration").

The FLOWSIC500 stores events and parameter changes in the following logbooks:

● Event logbook

All events with timestamp, user logged on and totalizer reading, max. number of

entries: 1000

When the Event logbook is 90% full, the FLOWSIC500 changes to device status "Warn-

ing", warning W-2001 is shown on the display.

When the Event logbook is full, the FLOWSIC500 changes to device status "Malfunc-

tion", error E-3001 is shown on the display (→ p. 78, § 6.2, “Status messages”).

● Parameter logbook

All parameter changes with timestamp, user logged on, totalizer reading and old and

new parameter value, max. number of entries: 250

The oldest entries are overwritten when the Parameter logbook is full.

● Metrology logbook

All changes to selected calibration-relevant parameters (→ p. 24, §2.9.2), with parameter

locking switch activated with timestamp, user logged on, totalizer reading and old and

new parameter value, max. number of entries: 100

When the Metrology logbook is full, calibration-relevant parameters can be modified

only after the parameter locking switch has been opened. The FLOWSIC500 changes to

device status "Warning", warning W-2002 is shown on the display (→ p. 78, § 6.2, “Status

messages”).

Subject to change w ithout notice

The data are stored in non-volatile memory. All logbooks can be viewed, stored and reset

with operating software FLOWgate500. The Event logbook can be viewed after logon as

"User" or "Authorized user" on the device.

FLOWSIC500 · Operating Instructions · 8015391/Z261/V 2-3/2016-10 · © SICK Engineering GmbH 23

Page 24

The following parameters are displayed:

EXT. POWER

BAT1

N.c.

DO3

DO0

+-

RS485

*

-

+

-

+

A

B

P1P2T1

T2

SENSORS

DISPLAY

LOCK

OFF ON

5..12V

NAMUR

4,5..16V

1.5 mm²

(AWG 16)

W

R :100

S

2..16V

2..16V

4074419

DO2

*Optional

V see module

CC

.

OC NAM

UR

2..16V

DO1

+-

BAT2

+-

+-

OC NAM

UR

+- +-

● Event type

● Number of events

● Short description

● Timestamp

2.9 Parameter protection

2.9.1 Parameter locking switch

A parameter locking switch is located on the circuit board to secure the calibration-relevant

parameters. This covers all values that influence volume metering and volume conversion.

Fig. 7 Parameter locking switch on the circuit board

Product Description

The parameter locking switch is secured by the terminal compartment cover and a seal.

2.9.2 Metrology logbook

Selected calibration-relevant parameters can be modified when the parameter locking

switch is closed and after logging in as authorized user.

To ensure traceability of these parameter changes, an entry is created in the Metrology logbook. This entry contains the timestamp, old and new value of the parameter changed,

meter reading V (for gas flow meters) or Vb (for gas flow meters with device option volume

conversion) and the logged on user.

The Metrology logbook can have a maximum of 100 entries. The FLOWSIC500 switches to

status "Warning" when the Metrology logbook is full.

The Metrology logbook can be cleared when the parameter locking switch is open. Parameter changes to the following parameters are entered in the Metrology logbook as long as

entries are possible

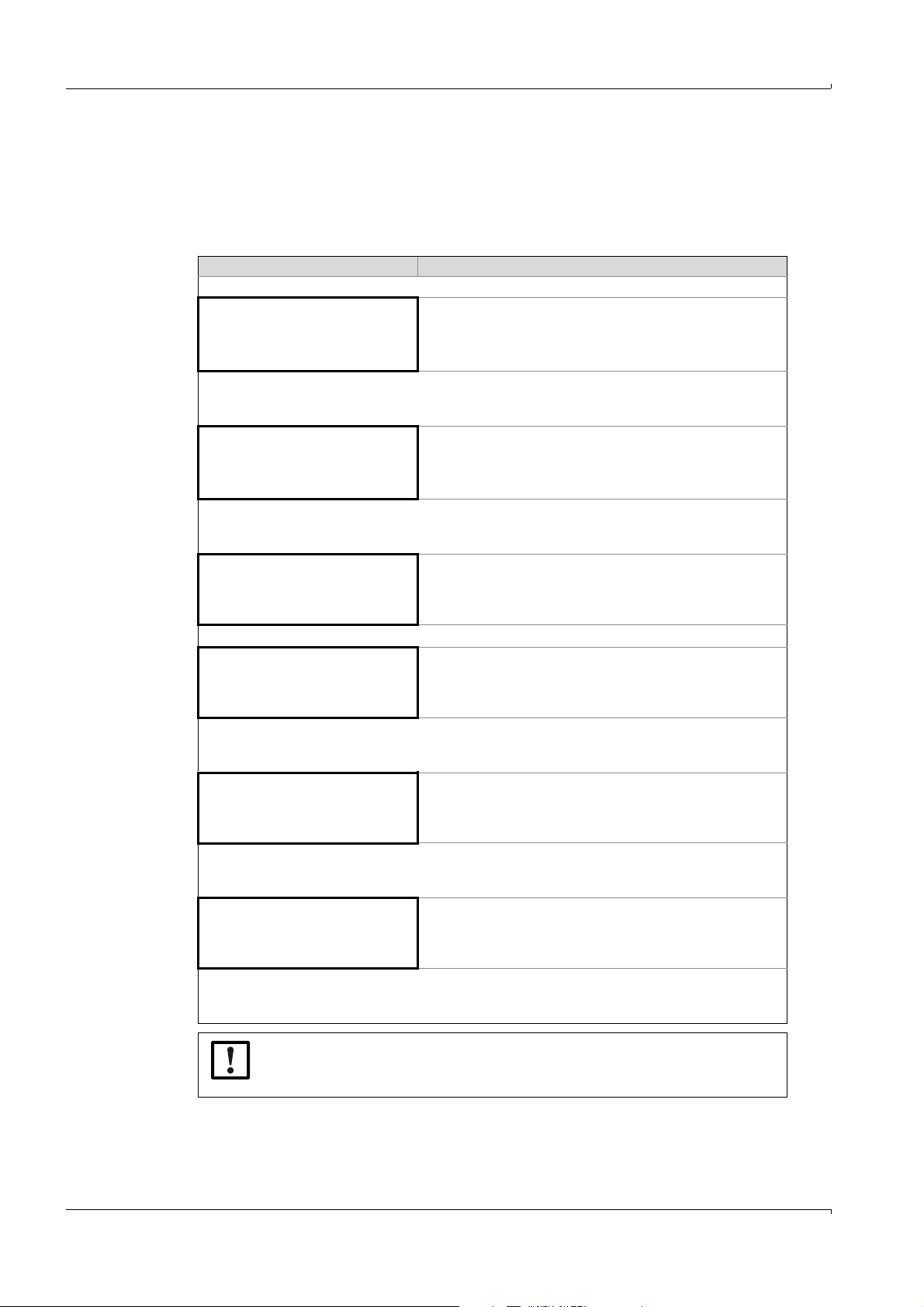

Table 5 Calibration-relevant parameters - gas flow meter

Parameter Description

Reverse flow limit Buffer volume for reverse flow

Symbols for measured value displays Symbols used on the display (formula symbols)

24 FLOWSIC500 · Operating Instructions · 8015391/Z261/V2-3/2016-10 · © SICK Engineering GmbH

Subject to change w ithout notice

Page 25

Product Description

Tab le 6 Calibration-relevant parameters - gas flow meter with volume conversion

Parameter Description

Reverse flow limit Buffer volume for reverse flow

Symbols for measured value displays Symbols used on the display (formula symbols)

Flow - lower warning limit Lower warning limit for the flow which can be set by the cus-

tomer

Flow - upper warning limit Upper warning limit for the flow which can be set by the cus-

tomer

Calculation method Calculation method for the compressibility factor

Calculation interval Cycle time for updating measured values (pressure, tem-

perature) and calculation of the compressibility factor

Standard pressure Standard pressure

Standard temperature Standard temperature

Reference conditions Reference conditions for density and heating value

Atmospheric pressure Ambient pressure

K-factor (fixed) Figure for method "Fixed value" when the calculation of the

K-factor is incorrect.

CO2 CO

H2 H

N2 N

proportion in gas

2

proportion in gas

2

proportion in gas

2

Relative density Relation between gas density and air density under refer-

ence conditions

Reference density Gas reference density under reference conditions

Heating value Gas heating (under reference conditions)

Heating value unit Heating value unit

p Default value Fixed value of measurement pressure

p Unit Unit for pressure values, used for entry and display

p Lower alarm limit Lower warning limit for the pressure which can be set by the

customer

p Upper alarm limit Upper warning limit for the pressure which can be set by the

customer

p Unit Unit for pressure values

T Default value Fixed value of measurement temperature

T Unit Unit for temperature values, used for entry and display

T Lower alarm limit Lower warning limit for the temperature which can be set by

the customer

T Upper alarm limit Upper warning limit for the temperature which can be set by

the customer

T Unit Unit for temperature values, used for entry and display

Gas hour Billing hour for the day archive

Gas day Billing day for month archive

Measuring period Period for billing archive

Subject to change w ithout notice

FLOWSIC500 · Operating Instructions · 8015391/Z261/V 2-3/2016-10 · © SICK Engineering GmbH 25

Page 26

2.10 Sealing

1 Seal position

2 Possible position of the adapter seal

3 Possible position of the electronic cover seal

1

2

3

The FLOWSIC500 is secured at the factory with a seal on the cover.

Gas flow meter and adapter can be secured at the joint by a user seal (adhesive label)

glued with approximately equal spread on gas flow meter and adapter.

Optionally, the electronics cover can also be protected by the customer after the end of the

installation against unauthorized opening.

Fig. 8 Factory seal of the cover on the gas flow meter

Product Description

In addition, the FLOWSIC500 has seal positions on the terminal compartment cover and

the plug-in connector cover.

An adhesive label secures the interfaces and the parameter locking switch by the terminal

cover compartment.

During the start-up, the plug-in connector cover must be secured according to national regulations. This can be performed with an adhesive label which is glued with approximately

equal spread on the cover and the enclosure or alternatively by using capstan screws and a

tensioned sealing wire and a wire seal.

Subject to change w ithout notice

26 FLOWSIC500 · Operating Instructions · 8015391/Z261/V2-3/2016-10 · © SICK Engineering GmbH

Page 27

Product Description

1

2

1Seal position

2 Terminal compartment cover (securing the terminal compartment)

3 Plug-in connector cover

4 Capstan screw, wire and wire seal (securing of plug-in connector cover)

3

4

1 Temperature transmitter

2 Locknut

3Wire seal

3

2

1

Fig. 9 Seals on the terminal compartment and plug-in connector cover

NOTICE:

▸

Secure the terminal compartment cover and the plug-in connector cover

with at least one verification seal against unauthorized removal of the

cover!

Fig. 10 Seal on the temperature transmitter (example)

Subject to change w ithout notice

FLOWSIC500 · Operating Instructions · 8015391/Z261/V 2-3/2016-10 · © SICK Engineering GmbH 27

Page 28

Fig. 11 Seal on the pressure transmitter (example)

1 Pressure transmitter

2 Kamstrup test valve BDA04

3Wire seal

4 Wire loop

3

1

2

4

Product Description

NOTICE:

Make sure that the wire loop is placed tight around the pressure transmitter.

28 FLOWSIC500 · Operating Instructions · 8015391/Z261/V2-3/2016-10 · © SICK Engineering GmbH

Subject to change w ithout notice

Page 29

Installation

FLOWSIC500

3 Installation

Hazards during installation

General information

Mechanical installation

Electrical installation

External pressure and temperature transmitters installation

Subject to change w ithout notice

FLOWSIC500 · Operating Instructions · 8015391/Z261/V 2-3/2016-10 · © SICK Engineering GmbH 29

Page 30

3.1 Hazards during installation

CAUTION: General risks during installation

▸

Observe applicable valid regulations, general standards and guidelines.

▸

Observe local safety regulations, operating instructions and special regulations.

▸

Observe the safety information in → p. 10, §1.1.

▸

Comply with the safety requirements of Pressure Equipment Directive

2014/68/EU or ASME B31.3 when installing pressure devices including

connection of various pressure devices.

▸

Persons carrying out installation work must be familiar with the directives

and standards applicable for pipeline construction and have the corresponding qualifications, e.g. in accordance with DIN EN 1591-4.

WARNING: Hazards through the gas in the system

The following conditions can increase the risk:

• Toxic gas or gas dangerous to health

•Explosive gas

• High gas pressure

▸

Only carry out installation, pre and repair work when the system is nonpressurized.

Installation

WARNING: Hazards during installation work

▸

Do not carry out any welding work on lines with meters fitted.

▸

Comply exactly with mandatory and approved methods.

▸

Observe and comply with regulations of the plant operator.

▸

Meticulously check completed work. Ensure leak tightness and strength.

Otherwise hazards are possible and safe operation is not ensured.

3.2 General information

3.2.1 Delivery

The FLOWSIC500 is delivered preassembled in sturdy packaging.

▸

Inspect for transport damage when unpacking the device.

▸

Document any damage found and report this to the manufacturer.

NOTICE:

Do not put the FLOWSIC500 into operation if you notice any damage!

▸

Check the scope of delivery for completeness.

The standard scope of delivery comprises:

● FLOWSIC500 (gas flow meter and adapter, already fitted),

● Backup battery (if device is configured for external power supply), or

● 2 battery packs (if device is configured for battery operation).

30 FLOWSIC500 · Operating Instructions · 8015391/Z261/V2-3/2016-10 · © SICK Engineering GmbH

Subject to change w ithout notice

Page 31

Installation

3.2.2 Transport

▸

During all transport and storage work, ensure:

– The FLOWSIC500 is always well secured

– Measures to prevent mechanical damage have been taken

– Ambient conditions are within specified limits.

3.3 Mechanical installation

CAUTION: General risks during installation

▸

Observe applicable valid regulations, general standards and guidelines.

▸

Observe local safety regulations, operating instructions and special regulations.

▸

Observe the safety information in → p. 10, §1.1.

▸

Comply with the safety requirements of Pressure Equipment Directive

2014/68/EU or ASME B31.3 when installing pressure devices including

connection of various pressure devices.

▸

Persons carrying out installation work must be familiar with the directives

and standards applicable for pipeline construction and have the corresponding qualifications, e.g. in accordance with DIN EN 1591-4.

The FLOWSIC500 normally does not need straight inlet and outlet sections and can be fitted directly after bends in the pipe.

NOTICE: Requirements on installation

▸

▸

▸

3.3.1 Preparations

▸

Select a suitable mounting location. Ensure adequate mounting clearances (→ Table 9).

▸

The following tools and materials are required to install the FLOWSIC500:

– Hoisting equipment (lifting capacity according to the weight specifications → p. 117,

§9.4)

– Box wrench with size suitable for flange installation

– Torque wrench

– Flange gaskets

– Anti-seize paste, metal-free or suitable for aluminium, e.g. OKS 235, to prevent

thread mountings seizing up

At a distance up to 5 DN upstream to the adapter, the following elements

must not occur:

– a valve which is not always fully open during operation,

– a pressure regulator.

The temperature sensor must not be disposed more than 5 DN down-

stream of the gas meter. The temperature sensor can be inserted in the

optional thermowells at the adapter alternatively.

In concrete application, observe limitations resulting from type approval!

NOTICE:

Do not use copper paste!

– 3 mm Allen key

Subject to change w ithout notice

FLOWSIC500 · Operating Instructions · 8015391/Z261/V 2-3/2016-10 · © SICK Engineering GmbH 31

– Leak detection.

Page 32

3.3.2 Choosing flanges, gaskets and other components

For flange connections only use pipeline flanges, bolts, nuts and gaskets suitable for the

maximum operating pressure, maximum operating temperature as well as ambient and

operating conditions (external and internal corrosion).

→ Table 7 contains a list of recommended bolts and → Table 8 contains a list of recom-

mended gaskets.

Table 7 Bolts and tightening torques

Device/flange

Bolts Washers Nuts Tightening torque

type

PN16 / EN1092-1

DN50/ PN16 4 pc. DIN835-

M16x45-A2-70

DN80/ PN16 8 pc. DIN835DN100/ PN16

M16x45-A2-70

DN150/ PN16 8 pc. DIN835-

M20x55-A2-70

4 pc. DIN125A17-A4

8 pc. DIN125A17-A4

8 pc. DIN125A21-A2

4 pc. ISO4032M16-A4-70

8 pc. ISO4032M16-A4-70

8 pc. ISO4032M20-A2-70

Class 150 / ASME B16.5

2"/ Cl150 4 pc. Double end

3"/ Cl150

4"/ Cl150 8 pc. Double end

6"/ Cl150 8 pc. Double end

Table 8 Gaskets

Device/flange

type

threaded stud Ø 5/8",

length 3.5"- ASME

B18.31.2,

ASTM A193 Grade

B8M

threaded stud Ø 5/8",

length 3.5"- ASME

B18.31.2,

ASTM A193 Grade

B8M

threaded stud Ø 3/4",

length 4.0"- ASME

B18.31.2,

ASTM A193 Grade

B8M

[1]

Da

[mm]

Di [mm] S [mm]

4 pc. Type A plain

washer (narrow

series) Ø 5/8" ANSI B18.22.1,

grade 8 stainless

steel

8 pc. Type A plain

washer (narrow

series) Ø 5/8" ANSI B18.22.1,

grade 8 stainless

steel

8 pc. Type A plain

washer (narrow

series) Ø 3/4" ANSI B18.22.1,

grade 8 stainless

steel

4 pc. Hex flat nut

(UNC series)

Ø 5/8" ANSI B18.2.2,

ASTM A194

Grade 8MA

8 pc. Hex flat nut

(UNC series)

Ø 5/8" ANSI B18.2.2,

ASTM A194

Grade 8MA

8 pc. Hex flat nut

(UNC series)

Ø 3/4" ANSI B18.2.2,

ASTM A194

Grade 8MA

Material

PN16 / EN1092-1

DN50/ PN16 107 61

DN80/ PN16 142 90

DN100/ PN16 162 115

2 novapress® FLEXIBLE/815

DN150/ PN16 218 169

Class 150 / ASME B16.5

2"/ Cl150 105 60

3"/ Cl150 137 89

4"/ Cl150 175 114

2 novapress® FLEXIBLE/815

6"/ Cl150 222 168

[1] Da = outer diameter, Di = inner diameter, S = thickness, → Fig. 12

Installation

130 Nm 96 lbf ft

130 Nm 96 lbf ft

250 Nm 184 lbf ft

140 Nm 103 lbf ft

140 Nm 103 lbf ft

240 Nm 177 lbf ft

32 FLOWSIC500 · Operating Instructions · 8015391/Z261/V2-3/2016-10 · © SICK Engineering GmbH

Subject to change w ithout notice

Page 33

Installation

Fig. 12 Dimensions of gaskets

Subject to change w ithout notice

FLOWSIC500 · Operating Instructions · 8015391/Z261/V 2-3/2016-10 · © SICK Engineering GmbH 33

Page 34

3.3.3 Fitting the FLOWSIC500 in the pipeline

Marking for flow direction

Direction of gas flow

NOTICE:

The lifting lug is designed for transporting the measuring device only.

Do not lift or transport the FLOWSIC500 with additional loads using this lug.

▸

The FLOWSIC500 must not swing or tilt on the hoisting equipment during

transport.

▸

The FLOWSIC500 must not turn during transport otherwise the lifting lug

could be screwed out.

NOTICE: Observe the gas flow direction

The prescribed flow direction is marked on the adapter with an arrow.

Arrow direction and gas flow direction must match.

▸

Install the FLOWSIC500 in flow direction.

The device signals a malfunction when the FLOWSIC500 is installed

against the prescribed flow direction.

The FLOWSIC500 can be installed horizontal or vertical.

The control unit can be rotated ± 90° (→ p. 40, § 3.4.4).

Fig. 13 Installation examples

Installation

34 FLOWSIC500 · Operating Instructions · 8015391/Z261/V2-3/2016-10 · © SICK Engineering GmbH

Subject to change w ithout notice

Page 35

Installation

1

1

2

2

1 Clearance at the top

2 Clearance at the bottom

3.3.3.1 Mounting clearances

Adequate mounting clearances must be maintained to ensure that sufficient space is available for exchanging the gas flow meter.

The clearance at the top is required for removing the gas flow meter and placing it back on

the adapter. The clearance at the bottom is required for loosening and removing or reinserting the screws and applying the tool accordingly.

Fig. 14 Mounting clearances

NOTICE:

Depending on the tools used and the mounting location, sufficient clearances

to the left and right must be ensured.

Tab le 9 Required minimum clearance based on the pipe axis

Meter size Clearance at the top,

without lifting lug

Clearance at the top,

with lifting lug

Clearance at the

bottom

[mm] [in] [mm] [in] [mm] [in]

DN50/2" 300 11.81 340 13.39 200 7.87

DN80/3" 460 18.11 510 20.08 250 9.84

DN100/4" 520 20.47 570 22.44 320 12.6

DN100/6" 520 20.47 570 22.44 320 12.6

Subject to change w ithout notice

FLOWSIC500 · Operating Instructions · 8015391/Z261/V 2-3/2016-10 · © SICK Engineering GmbH 35

Page 36

3.3.3.2 Torque on the pipeline

NOTICE:

If the FLOWSIC500 is installed so that the gas flow meter projects sideways

from the pipeline, the gas flow meter weight creates a torque on the pipeline.

▸

Make sure the pipeline is capable of holding the gas flow meter → p. 36,

Table 10.

Table 10 Pipeline torque

Meter size Torque

DN50/2" 6 5

DN80/3" 16 12

DN100/4" 31 23

DN150/6" 31 23

3.3.3.3 Installation in pipeline

1 Select suitable bolts.

Recommended bolts → Table 7.

2 Use the hoisting equipment to position the FLOWSIC500 in the desired location in the

pipeline.

Lay the pipelines without tension to the device to be installed!

3 Insert and align the gaskets.

4 Apply anti-seize paste to the bolts.

5 First screw the bolts by hand into the adapter to the stop.

– Screw in the bolts according to DIN835 with the shorter thread end.

– The bolts according to ASME B18.31.2 can be screwed in with any end.

6 Check the thread length in the adapter is fully utilized.

7 Then install the washers and nuts, and tighten them by hand.

8 Check whether the thread length of the nut is fully utilized.

If necessary, use a different bolt length.

9 Check correct positioning of flange gaskets.

10 Tighten nuts evenly and crosswise in small steps until the specified tightening torque is

reached (→ Table 7).

Make sure the flange sits free of tension.

11 Slowly increase the pressure in the pipeline.

Gradient: Max. 3bar/min (45psi/min)

12 Carry out a leak tightness check on the pipeline (in accordance with the pipeline manu-

facturer's specifications).

Installation

[Nm] [lbf ft]

36 FLOWSIC500 · Operating Instructions · 8015391/Z261/V2-3/2016-10 · © SICK Engineering GmbH

Subject to change w ithout notice

Page 37

Installation

3.4 Electrical installation

3.4.1 Requirements for use in potentially explosive atmospheres

The FLOWSIC500 is suitable for use in potentially explosive atmospheres:

ATEX: II 2G Ex ia [ia] IIB T4 Gb, II 2G Ex ia [ia] IIC T4 Gb,

IECEx: Ex ia [ia] IIB T4 Gb, Ex ia [ia] IIC T4 Gb,

US/C: Class I Division 1, Groups C, D T4, Ex/AEx ia IIB T4 Ga

For a FLOWSIC500 used in potentially explosive atmospheres:

▸

Installation, start-up, maintenance and inspection may only be carried out

by skilled persons having knowledge of the relevant rules and regulations

for potentially explosive atmospheres, especially:

– Ignition protection types

– Installation regulations

– Category classification

▸

Comply with all valid IEC standards.

The FLOWSIC500 is suitable for measuring combustible and occasionally ignitable gases

corresponding to zones 1 and 2.

Basic requirements

▸

The documentation for zone categorization in accordance with IEC60079-10 must be

available

▸

The FLOWSIC500 must have been checked for suitability for the actual installation location and the Ex marking on the device must match the requirements.

▸

After installation and before initial start-up, the complete equipment and the system

must be inspected in compliance with IEC 60079-17.

II 2G Ex op is IIC T4 Gb

Ex op is IIC T4 Gb

WARNING: Risk of explosion

All electrical connections of the FLOWSIC500 are approved for connection to

the certified intrinsically safe power circuits only.

▸

Proof of the intrinsic safety in compliance with IEC 60079-14 must be

presented for interconnection with the associated intrinsically safe equipment.

Otherwise the intrinsic safety of the FLOWSIC500 can be endangered, i.e.

the ignition protection for the FLOWSIC500 can no longer be ensured.

Subject to change w ithout notice

FLOWSIC500 · Operating Instructions · 8015391/Z261/V 2-3/2016-10 · © SICK Engineering GmbH 37

Page 38

Operating conditions for the ultrasonic sensors

● The pipeline contains a nonexplosive mixture. The gas mixture can be combustible.

● Gas pressure and gas temperature can be within the range

specified on the type plate of the

gas flow meter.

Case 2:

● The area inside the pipeline is classified as potentially explosive atmosphere Zone 1 or 2.

● The gas pressure must be within the

range 0.8 (11.6 psi) to 1.1 bar

(15.95 psi) (normal atmospheric

conditions).

● Gas temperature must be within the

permitted ambient temperature

range specified by the type plate on

the gas flow meter

Zone 1 or 2

Case 1:

Zone 1 or 2

Non-explosive gas mixture

Zone 1 or 2

The FLOWSIC500 is designed for use in potentially explosive atmospheres solely under

normal atmospheric conditions within the following limits.

– Ambient pressure range 0.8 bar (11.6 psi) to 1.1 bar (15.95 psi)

– Air with normal oxygen content, normally 21 percent by volume

The ambient temperature must be within the range specified on the type plate.

The gas flow meter becomes part of the pipeline as soon as the FLOWSIC500 is installed in

the pipeline.

The walls of the pipeline and the gas flow meter then serve as zone-separating barrier. The

following Figure shows the different situations for a possible application and the operating

conditions that apply.

Fig. 15 Ex zones

Installation

WARNING: Risk of ignition due to impact on the ultrasonic transducers

T

he ultrasonic transducers are manufactured from titanium. The pipeline

adaptor and part of the electronic enclosure may be made from aluminium. In

rare cases, ignition sources due to impact and friction sparks could occur.

The maximum piezo-electric energy released by impact on the ultrasonic transducers exceeds the limit for Gas Group IIC specified in Clause 10.7 of

EN60079-11:2012.

▸

For this reason, the ultrasonic transducers may only be used in zone 1

when risks of ignition arising from impacts or friction on the sensor housing

can be ruled out within the application.

▸

Only ultrasonic transducers provided by SICK may be used!

38 FLOWSIC500 · Operating Instructions · 8015391/Z261/V2-3/2016-10 · © SICK Engineering GmbH

Subject to change w ithout notice

Page 39

Installation

4 screws

3.4.2 Criteria for electrical connection

Installation work → p. 31, § 3.3 must be completed.

WARNING: Risk of explosion - hazard for intrinsic safety

▸

The following work may only be carried out by skilled technicians familiar

with the special characteristics of the intrinsic safety of the ignition protection type and who have knowledge of the relevant standards and regulations for interconnection of intrinsically safe power circuits.

3.4.3 Opening and closing the electronics cover

The Ex i terminal compartment of the FLOWSIC500 can be accessed after the

electronics cover has been opened. The cover may also be opened in the

hazardous area when under voltage. However, safe separation between the

various intrinsically safe power circuits must not be breached.

Opening the electronics cover

1 Loosen the 4 screws (captive) on the electronics cover using a 3 mm Allen key.

Fig. 16 Position of electronics cover screws

2 Open the electronics cover.

Closing the electronic cover

1 Close the electronics cover.

▸

Make sure no battery and display cables are pinched.

2 Screw the electronics cover tight again.

Tightening torque: 2.0 Nm (18 lbf in)

Subject to change w ithout notice

FLOWSIC500 · Operating Instructions · 8015391/Z261/V 2-3/2016-10 · © SICK Engineering GmbH 39

Page 40

3.4.4 Rotating the control unit

4 display screws

1 Open the electronics cover (→ p. 37, § 3.4)

2 Loosen the 4 display screws with a 3 mm Allen key, → Fig. 17.

Fig. 17 Position of display screws

Installation

3 Rotate the display in the desired direction.

4 Tighten the display screws evenly.

Tightening torque: 1.0 Nm (9 lbf in)

5 Close the electronics cover again.

40 FLOWSIC500 · Operating Instructions · 8015391/Z261/V2-3/2016-10 · © SICK Engineering GmbH

Subject to change w ithout notice

Page 41

Installation

1 2 3 4

1 Plug-in connector 1 (B-coded): External power supply and signal output

2 Plug-in connector 2 (A-coded): Signal output

3 Ground screw