Page 1

Title Page

FLOWSIC100

Gas Flow Rate Measuring Device

Description

Installation

Operation

OPERATING INSTRUCTIONS

Page 2

Document Information

Product

Product name: FLOWSIC100

Document ID

Title: Operating Instructions FLOWSIC100

Part No.: 8012513

Version: 2-1

Release: 2016-07

Manufacturer

SICK Engineering GmbH

Bergener Ring 27 · D-01458 Ottendorf-Okrilla · Germany

Phone: +49 35 20552410

Fax: +49 35 20552450

E-Mail: info.pa@sick.de

Original documents

The English version 8012513 of this document is an original

document from SICK Engineering GmbH.

SICK Engineering GmbH assumes no liability for the correctness of

an unauthorized translation.

In case of doubt, please contact SICK Engineering GmbH or your

local representative.

Legal information

Subject to change without notice.

© SICK Engineering GmbH. All rights reserved.

Warning Symbols

Warni ng

Warning Levels / Signal Words

HAZARD

Risk or hazardous situation which will result in severe personal

injury or death.

WARNING

Risk or hazardous situation which could result in severe personal

injury or death.

CAUTION

Hazard or unsafe practice which could result in personal injury or

property damage.

NOTICE

Hazard which could result in property damage.

Information Symbols

Important technical information for this product

Important information on electric or electronic

functions

Supplementary information

2 FLOWSIC100 · Operating Instructions · 8012513/YSA5/V2-1/2016-07 · © SICK Engineering GmbH

Page 3

Contents

Contents

1Important Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1 Intended use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.2 Responsibility of user . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.2.1 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.3 Safety information and protective measures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.3.1 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.3.2 Hazard through electrical equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.3.3 Hazard through hot, corrosive and/or pressurized gases . . . . . . . . . . . . . . . . . . . . . . . 9

1.3.4 Hazards through ultrasonic signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.3.5 Behavior during a purge/cool air failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

1.3.6 Detecting malfunctions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.3.7 Preventing damage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2 Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

2.1 System features and areas of application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.2 System overview and functional principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.2.1 System overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.2.2 Communication between sender/receiver units and control unit . . . . . . . . . . . . . . . 14

2.2.3 Functional principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.3 System components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.3.1 FLSE100 sender/receiver unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.3.1.1 Standard sender/receiver units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

2.3.1.2 Sender/receiver units with internal cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2.3.1.3 Purged sender/receiver units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2.3.2 Flange with tube . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2.3.3 Weatherproof cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2.3.4 MCU control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2.3.5 Connection cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

2.3.6 Purge air unit option. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

2.3.7 Cooling air control option for device types M-AC and H-AC . . . . . . . . . . . . . . . . . . . . . 41

2.3.8 Optional sets for emergency air supply for device types with purge and cooling

air operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

2.3.8.1 Emergency air supply for device types M-AC and H-AC . . . . . . . . . . . . . . . . . . . . . 42

2.3.8.2 Emergency air supply for device types PM, PH and PH-S . . . . . . . . . . . . . . . . . . . 43

2.3.9 Measuring tube option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

2.4 Computations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

2.4.1 Calculating and calibrating the volume flow. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

2.4.2 Temperature calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

2.4.3 Damping time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

2.5 Check cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

2.5.1 Zero point control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

2.5.2 Span test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

2.5.3 Check cycle output on the analog output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

FLOWSIC100 · Operating Instructions · 8012513/YSA5/V 2-1/2016-07 · © SICK Engineering GmbH 3

Page 4

Contents

3 Assembly and Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

3.1 Project planning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

3.1.1 Determining the measurement and installation location . . . . . . . . . . . . . . . . . . . . . . 51

3.1.2 Further planning information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

3.1.3 Selecting the flanges with tube. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

3.2 Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

3.2.1 Installing the flanges with tube. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

3.2.1.1 Duct/pipe diameter > 0.5 m . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

3.2.1.2 Duct/tube diameter < 0.5 m. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

3.2.2 Installing the control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

3.2.3 Installing the junction box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

3.2.4 Installing the sender/receiver units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

3.2.5 Installation of the weatherproof cover for the sender/receiver units . . . . . . . . . . . 68

3.2.6 Installing the purge air unit option (device type PM, PH, PH-S) . . . . . . . . . . . . . . . . 69

3.2.7 Installing the emergency air supply option for device types PM, PH and PH-S . . . 70

3.2.8 Installing the weatherproof cover for the purge air unit option . . . . . . . . . . . . . . . . . 72

3.2.9 Installting the impact protector / dust protector options . . . . . . . . . . . . . . . . . . . . . . 73

3.2.9.1 Impact protection for FLSE100-H, HAC, PH and PHS . . . . . . . . . . . . . . . . . . . . . . 73

3.2.9.2 Dust protector for FLSE100-PR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

3.2.10 Installing the structure-borne noise damping set option K100/K75. . . . . . . . . . . . 75

3.3 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

3.3.1 General instructions, prerequisites . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

3.3.2 Installing the purge/cooling air supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

3.3.2.1 Control unit MCU-P with integrated cooling air supply (device type M-AC

and H-AC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

3.3.2.2 Separate cooling air supply in connection box (device type M-AC and H-AC) . 79

3.3.2.3 Purge air unit (device type PM, PH, PH-S) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

3.3.2.4 Installing the purge air and cooling air reducer option . . . . . . . . . . . . . . . . . . . . . 81

3.3.3 Installing the cooling air control option for device types M-AC and H-AC . . . . . . . . 82

3.3.4 Installing optional sets for emergency air supply for devices with purge/cooling

air operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

3.3.4.1 Emergency air supply for device types M-AC and H-AC. . . . . . . . . . . . . . . . . . . . . 87

3.3.4.2 Emergency air supply for device types PM, PH and PHS

3.3.5 Installing the sender/receiver unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

3.3.6 Connecting the control unit MCU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

3.3.7 Connecting the control unit in a 19" housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

3.3.8 Terminating the sender/receiver units when operating the FLOWSIC100 with

"2-path measuring" configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

3.3.8.1 Checking the sender/receiver unit(s) - MCU connection . . . . . . . . . . . . . . . . . . 106

3.3.8.2 Bus addressing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

3.3.8.3 Hardware addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

3.3.9 Installing and connecting the interface and I/O module options . . . . . . . . . . . . . . 107

. . . . . . . . . . . . . . . . . . . 93

4 FLOWSIC100 · Operating Instructions · 8012513/YSA5/V 2-1/2016-07 · © SICK Engineering GmbH

Page 5

Contents

4 Start-up and Parameter Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .113

4.1 Basics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .114

4.1.1 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

4.1.2 Installing SOPAS ET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .114

4.1.3 Connecting the device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .116

4.1.3.1 Changing the language . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .116

4.1.3.2 Connecting to the device via the “Device family” mode (recommended

search settings). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .117

4.1.3.3 Connecting to the device with advanced mode . . . . . . . . . . . . . . . . . . . . . . . . . . .119

4.1.4 Information on using SOPAS ET. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .122

4.2 Standard start-up procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .126

4.2.1 Setting "Maintenance" mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .127

4.2.2 Setting the system data parameters on the FLOWSIC100 sensor . . . . . . . . . . . . .127

4.2.3 Setting the check cycle parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .130

4.2.4 Configuring the analog output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .131

4.2.5 Configuring the analog inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .133

4.2.6 Setting the damping time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .134

4.2.7 Data backup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

4.2.8 Starting normal measuring operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .138

4.2.9 Signal waveform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

4.3 Advanced start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .144

4.3.1 Changing the application setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .144

4.3.2 Configuring optional analog modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .145

4.3.3 Configuring the optional interface module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .146

4.3.4 Configuring the Ethernet module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .147

4.3.4.1 Changing the field bus address for the Profibus module . . . . . . . . . . . . . . . . . .149

4.3.5 Configuring the temperature curve for the cooling air control option for device

types M-AC and H-AC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

4.3.6 Calibrating flow rate and temperature measurement . . . . . . . . . . . . . . . . . . . . . . . .151

4.4 Operating / Configuring with the LC-Display option. . . . . . . . . . . . . . . . . . . . . . . . . . . . .152

4.4.1 General information on use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

4.4.2 Menu structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

4.4.3 Configuring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .154

4.4.4 Changing the application setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .154

4.4.5 Changing the display settings with SOPAS ET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

FLOWSIC100 · Operating Instructions · 8012513/YSA5/V 2-1/2016-07 · © SICK Engineering GmbH 5

Page 6

Contents

5 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

5.1 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

5.2 Maintaining the sender/receiver units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

5.2.1 Removing the sender/receiver units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

5.2.2 Cleaning the sender/receiver unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

5.3 Maintaining the cooling air supply of the internally cooled types M-AC and H-AC. . 161

5.3.1 Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

5.3.2 Control unit with integrated cooling air supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

5.4 Maintaining the external purge air unit option. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

5.4.1 Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

5.4.2 Replacing the filter element . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

6 Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

6.1 Technical Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

6.2 Standard components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

6.3 Dimensions, Part No. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

6.3.1 Sender/receiver units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

6.3.2 Flange with tube . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

6.3.3 MCU control unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

6.3.4 Cooling air supply in connection box for FLOWSIC100 M-AC and H-AC. . . . . . . . . 179

6.3.5 Junction box for connection cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

6.3.6 Miscellaneous . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

6.3.7 Control unit, MCU 19“ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

6.3.8 Consumable parts for 2-years operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

6.3.9 Control unit MCU with integrated purge air supply . . . . . . . . . . . . . . . . . . . . . . . . . . 183

6.3.10 Optional external purge air unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

6 FLOWSIC100 · Operating Instructions · 8012513/YSA5/V 2-1/2016-07 · © SICK Engineering GmbH

Page 7

Important Information

FLOWSIC100

1 Important Information

Intended use

Responsibility of user

Safety information and protective measures

Subject to change w ithout notice

FLOWSIC100 · Operating Instructions · 8012513/YSA5/V 2-1/2016-07 · © SICK Engineering GmbH 7

Page 8

1.1 Intended use

Purpose of the device

The FLOWSIC100 measuring system is designed for no-contact measurement of the gas

flow rate and temperature or of the volume flow.

Correct use

Use the device only as described in these Operating Instructions. The manufacturer

bears no responsibility for any other use.

Carry out all measures required to maintain the device, e.g. maintenance and inspec-

tion, transport and storage.

Do not remove, add or modify any components to or on the device unless described and

specified in the official manufacturer information. Otherwise:

– The device could become dangerous.

– Any warranty by the manufacturer becomes void.

1.2 Responsibility of user

1.2.1 General information

Designated users

The FLOWSIC100 measuring system may only be operated by skilled technicians who,

based on their technical training and knowledge as well as knowledge of the relevant

regulations, can assess the tasks given and recognize the hazards involved.

Important Information

Special local conditions

The relevant legal stipulations and associated technical regulations must be observed

when preparing and carrying out work on the respective system

All work must be carried out in accordance with the local, system-specific conditions

and with due consideration paid to the operating dangers and specifications.

Retention of documents

The Operating Instructions for the measuring system as well as system documentation

must be kept on site and be available for reference. Pass the respective documentation on

to any new owner of the measuring system.

8 FLOWSIC100 · Operating Instructions · 8012513/YSA5/V2-1/2016-07 · © SICK Engineering GmbH

Subject to change w ithout notice

Page 9

Important Information

1.3 Safety information and protective measures

1.3.1 General information

Handling or using the device incorrectly can result in personal injury or material damage.

Read this Chapter carefully and ensure you observe the safety precautions during all work

on the FLOWSIC100. Always observe the warnings provided in these Operating

Instructions.

The following applies at all times:

● The relevant legal stipulations and associated technical regulations must be observed

when preparing and carrying out work on the installation.

● Extreme caution must be exercised in installations with high hazard potential (pressure

pipes, installations with explosive atmospheres). The applicable special regulations

must be followed at all times.

● All work must be carried out in accordance with the local, system-specific conditions

and with due consideration paid to the operating dangers and specifications.

● The Operating Instructions for the measuring system as well as system documentation

must be available on site. The instructions for preventing danger and damage contained in these documents must be observed at all times.

1.3.2 Hazard through electrical equipment

The FLOWSIC100 measuring system is an item of electrical equipment designed for use in

industrial high-voltage systems. Make sure the power supply is switched off before working

on mains connections or live components. If necessary, replace shock protection

measures before reconnecting the power supply.

1.3.3 Hazard through hot, corrosive and/or pressurized gases

The sender/receiver units are mounted directly on the gas-carrying duct. In installations

with a low hazard potential (no risk of injury, ambient pressure, low temperatures, no risk of

explosion), these units can be installed and removed while the installation is in operation,

providing the applicable specifications and safety regulations for the system are adhered

to and all necessary and suitable protective measures are taken.

WARNING:

Systems and processes with toxic gases, high pressure or high temperatures

must be shut down before the sender/receiver units are installed or removed.

DANGER: Hot gas

Hot gas can escape should the purge air supply fail when using externally

purged devices (device types PM, PH and PH-S) in pressurized pipelines and

ducts. This can lead to serious damage to health and material damage to the

system. The system owner must take suitable protective measures to prevent

such damage. Technical solutions for the FLOWSIC100 to prevent gas escaping should the purge air fail are available from the manufacturer on request.

1.3.4 Hazards through ultrasonic signals

Do not expose unprotected hearing to the sonic beam of the transducer (especially type H).

Subject to change w ithout notice

Wearing suitable hearing protection is recommended when inspecting the duct, connecting

the device outside the duct or similar activities.

FLOWSIC100 · Operating Instructions · 8012513/YSA5/V 2-1/2016-07 · © SICK Engineering GmbH 9

Page 10

1.3.5 Behavior during a purge/cool air failure

Some system versions are equipped with a purge/cooling air unit to protect the ultrasonic

transducers from hot or corrosive gases. The transducers can be severely damaged should

the purge/cooling air supply fail. For this reason, the operator must ensure:

● The power supply for the purge/cooling air unit operates reliably and without interruption,

● A failure of the purge/cooling air supply is detected immediately (for example, by using

pressure controllers).

● The sender/receiver units are removed from the duct in the event of a purge air failure

and the duct openings are covered (for example, with a flange cover).

1.3.6 Detecting malfunctions

Any deviations from normal operation must be regarded as a serious indication of a

functional impairment. These include:

● Significant drifts in the measuring results.

● Increased power input.

● A rise in system component temperatures.

● Triggering of monitoring devices.

● Unusually strong vibrations or unusual operating noise from a purge/cooling air blower.

● Smoke or unusual odors.

Important Information

1.3.7 Preventing damage

To prevent personal injury or damage to the system, the operator must ensure:

● The maintenance personnel responsible can reach the site immediately, and at any

time.

● The maintenance personnel is sufficiently qualified to respond to malfunctions on the

FLOWSIC100 and any resulting operational malfunctions.

● In case of doubt, switch the defective equipment off immediately.

● Switching off the equipment does not indirectly cause further malfunctions.

10 FLOWSIC100 · Operating Instructions · 8012513/YSA5/V2-1/2016-07 · © SICK Engineering GmbH

Subject to change w ithout notice

Page 11

Product Description

FLOWSIC100

2 Product Description

System features and areas of application

System overview and functional principle

System components

Computations

Check cycle

Subject to change w ithout notice

FLOWSIC100 · Operating Instructions · 8012513/YSA5/V 2-1/2016-07 · © SICK Engineering GmbH 11

Page 12

2.1 System features and areas of application

The FLOWSIC100 measuring system conducts simultaneous measurements of the gas

flow rate and temperature. The volume flow under actual conditions can be calculated and

output from the gas flow rate by including the gas temperature and internal duct pressure

in the standard state.

Features and benefits

● Modular design

By selecting the right modules, you can combine the components to suit your application and fulfill a wide range of requirements. As a result, the FLOWSIC100 can be used

for very many applications.

● Integrated measurement of the gas flow rate across the duct diameter, independent of

the pressure, temperature, and gas composition

● Digital processing of measured values ensures high accuracy and low susceptibility to

interference

● Self-test by means of automatic check cycle

● No pressure-reducing fittings in the gas flow, which ensures the gas flow is not dis-

rupted

● Easy to install

● Low wear and tear by selecting the most suitable modules for the application

● Minimum maintenance requirements

Product Description

Applications

The measuring devices in the FLOWSIC100 series can be used to measure gas flows in

pipelines, flue-gas and exhaust gas ducts, as well as chimneys. If configured accordingly,

the devices can measure the flow rate in both clean and raw gases upstream of filter

installations. As a result, applications range from determining the volume flow in open and

closed-loop control systems used in process control to flow monitoring for emission

measurements.

The system is suitable for use in the following areas:

● Operating measurements and emissions monitoring in:

– Energy supply: Power station and industrial boilers for all energy sources

– Waste disposal: Waste and residual waste incineration plants

– Basic industries: Systems in the cement and steel industry

● Process control engineering

– Chemical industry

– Drying and processing systems in the pharmaceutical, food, and foodstuffs indus-

tries

– Heat treatment and extraction plants used in plastics processing

● Flow measurements in ventilation, heating, and air-conditioning systems in both

industry and agriculture

Certification

The measuring system complies with the requirements defined in the following standards:

DIN EN 15267-1: 2009, DIN EN 15267-2: 2009, DIN EN 15267-3: 2008, DIN EN 14181:

2004 and DIN EN ISO 16911-2.

The measuring system is suitable for use in plants requiring approval (13th BlmSchV, 17th

BlmSchV, 30th BlmSchV, TI Air) as well as plants of the 27th BlmSchV.

Subject to change w ithout notice

12 FLOWSIC100 · Operating Instructions · 8012513/YSA5/V2-1/2016-07 · © SICK Engineering GmbH

Page 13

Product Description

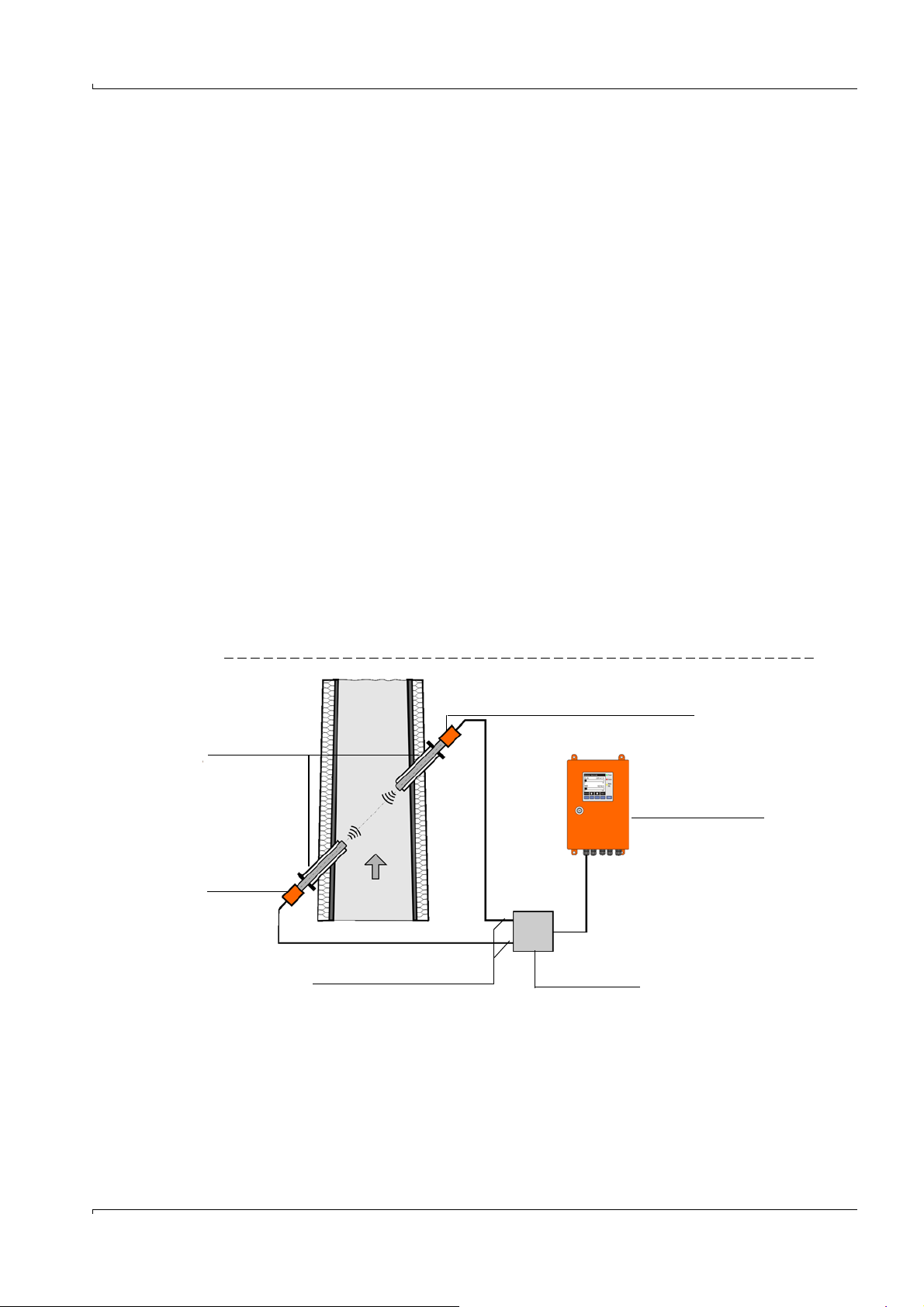

Sender/receiver unit

FLSE100 Slave (B)

Duct

MCU control unit

Connection cable

Junction box

Sender/receiver

unit FLSE100

Master (A)

Flange with tube

2.2 System overview and functional principle

2.2.1 System overview

The measuring system comprises the following components:

● FLSE100 sender/receiver unit

For transmitting and receiving ultrasonic pulses, signal processing and controlling the

system functions

● Flange with tube

For mounting the sender/receiver units on the gas duct

● MCU control unit

For control, evaluation and output of the data of the sensors connected via RS485

interface

● Connection cables

For signal transmission between the sender/receiver units and control unit

● Junction box for connection cable

For connecting the connection cables

● Purge air unit option

For using purged sender/receiver units to keep the ultrasonic transducers clean and

cool at high gas temperatures

● Cool air unit option

For using internal cooled sender/receiver units to keep the ultrasonic transducers cool

at high gas temperatures

● Measuring tube option

Tube piece with flanges, preassembled for installation in an existing pipeline; with

flanges with tube to fit the sender/receiver units

Subject to change w ithout notice

Fig. 1 FLOWSIC100 system components

● Cooling air control option for device types M-AC and H-AC

Used to control the cooling air supply for sender/receiver units with internal cooling by

switching the cooling air blower on and off automatically depending on the transducer

temperature.

● Emergency air supply option for sender/receiver units with internal cooling (FLSE100MAC and HAC)

Set for connecting and operating a temporary emergency air supply of instrument air (to

be provided by customer) for sender/receiver units with internal cooling.

● Emergency air supply option for externally purged sender/receiver units (FLSE100-PM,

PH, PH-S)

FLOWSIC100 · Operating Instructions · 8012513/YSA5/V 2-1/2016-07 · © SICK Engineering GmbH 13

Page 14

Set for connecting and operating a temporary emergency air supply of instrument air (to

Bus line

Junction box

be provided by customer) for externally purged sender/receiver units.

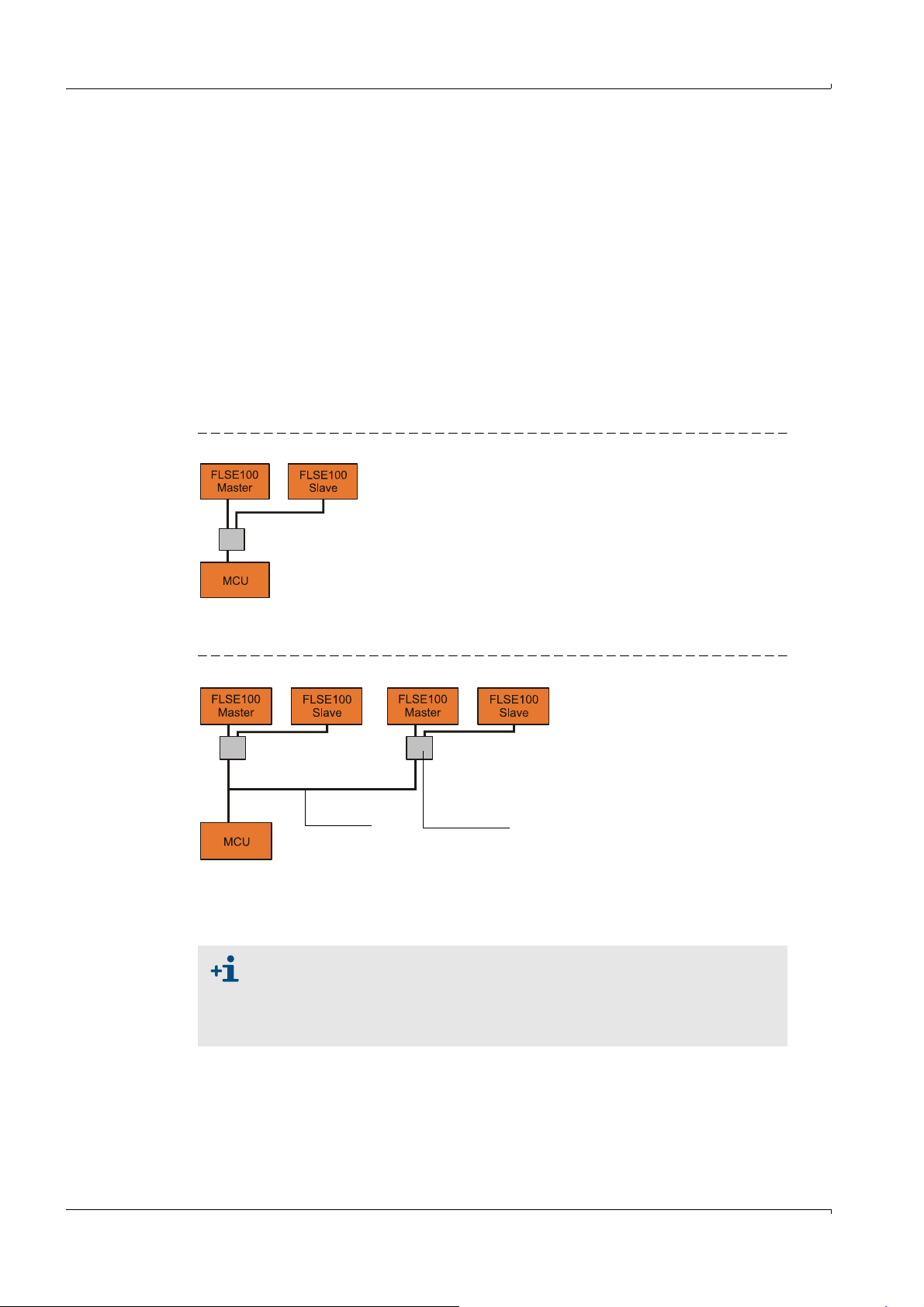

2.2.2 Communication between sender/receiver units and control unit

Standard version

The two sender/receiver units work as master and slave. The master FLSE has a second

interface to be able to completely separate communication to the slave FLSE and to the

MCU. The master triggers the slave and controls measurement. The MCU can request the

measured values from the master units independently of the measuring cycle

(asynchronous).

For the cabling, the junction box used to separate the interfaces has to be installed on the

master FLSE. The junction box is optional for FLOWSIC100 types PR and S (for longer cable

lengths).

Fig. 2 Standard version (1 sensor pair)

Product Description

Bus version with several measuring systems connected

Fig. 3 Bus connection FLSE100 - MCU (2 sensor pairs)

With the bus version, two autonomous measuring paths (2 x 2 FLSE100) can be connected

to a control unit MCU for 2-path-measurement. The MCU computes both measuring paths

to one measuring result.

● For bus wiring, the set termination set at the factory must be deactivated in

those system components not at the line end (see Service Manual Section

3.1).

● Other sensor types (e.g. sensor for dust measurement) can also be connected to the MCU.

14 FLOWSIC100 · Operating Instructions · 8012513/YSA5/V2-1/2016-07 · © SICK Engineering GmbH

Subject to change w ithout notice

Page 15

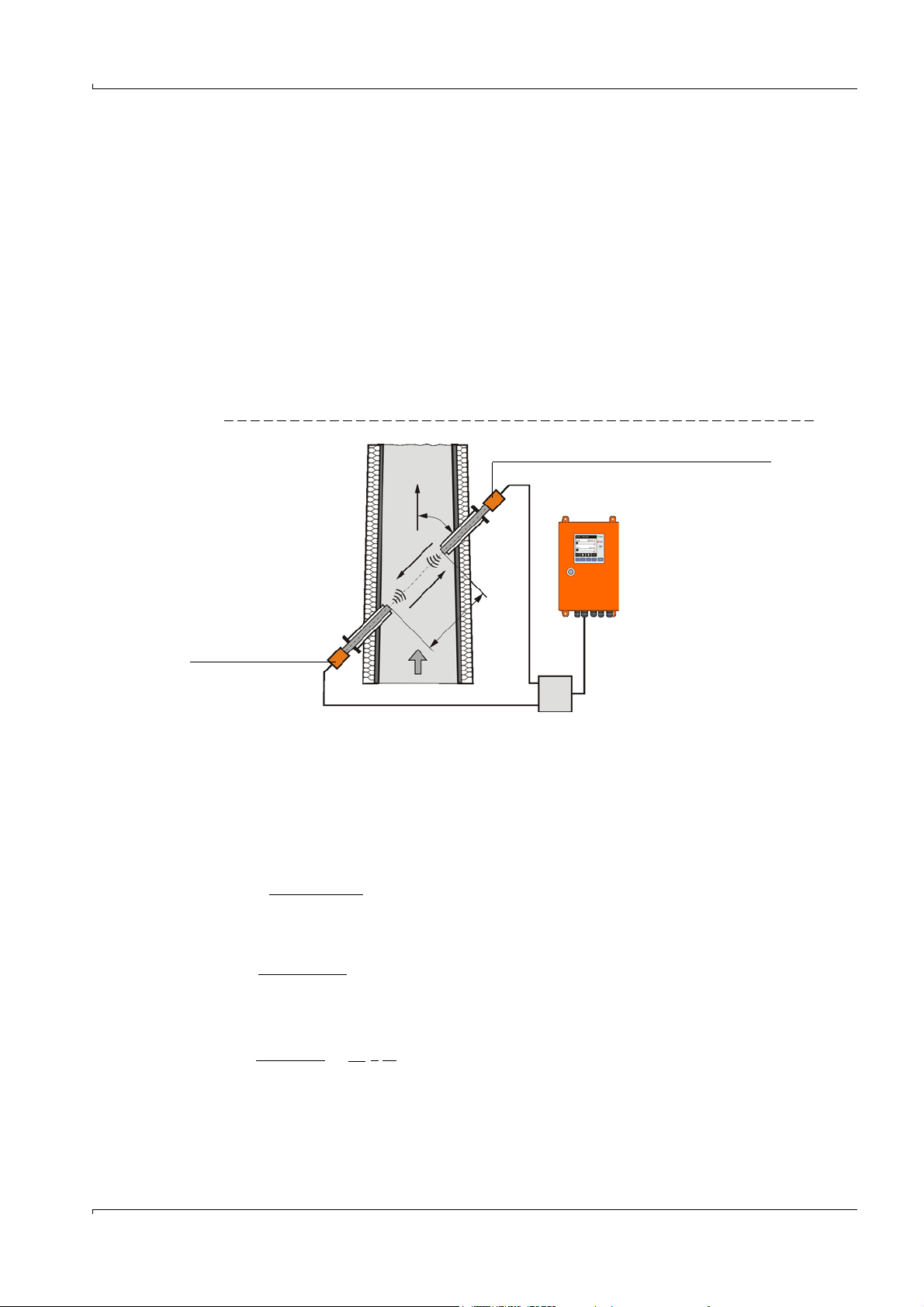

Product Description

Sender/receiver unit FLSE100 - Slave (B)

v = Gas flow rate in m/s

L= Measuring path in m

= Angle of inclination in °

t

v

= Signal transit time

in flow direction

t

r

= Signal transit time

against flow direction

Sender/receiver

unit

FLSE100 Master (A)

t

v

v

a

t

r

L

v = · ()

L 1 1

2 · cos tvt

r

tr =

L

c - v · cos

t

v

=

L

c + v · cos

2.2.3 Functional principle

The FLOWSIC100 gas flow rate measuring devices operate according to the principle of

ultrasonic transit time difference measurement. Sender/receiver units are mounted on

both sides of a duct/pipeline at a certain angle to the gas flow (

These sender/receiver units contain piezoelectric ultrasonic transducers that function

alternately as senders and receivers. The sound pulses are emitted at an angle to the

flow direction of the gas. Depending on the angle and the gas flow rate v, the transit time

of the respective sound direction varies as a result of certain "acceleration and braking

effects" (formulas 2.1 and 2.2). The higher the gas flow rate and the smaller the angle to

the flow direction are, the higher the difference in the transit times of the sound pulses.

Gas flow rate v is calculated from the difference between both transit times, independent

of the sound velocity value. Therefore changes in the sound velocity caused by pressure or

temperature fluctuations do not affect the calculated gas flow rate with this method of

measurement.

Fig. 4 Functional principle of the FLOWSIC100

Fig. 4).

Subject to change w ithout notice

FLOWSIC100 · Operating Instructions · 8012513/YSA5/V 2-1/2016-07 · © SICK Engineering GmbH 15

Calculating the gas flow rate

Measuring path L is equal to the active measuring path, that is, the area through which the

gas flows. Given measuring path L, sound velocity c, and angle of inclination between the

sound and flow direction, the sound transit time in the direction of the gas flow (forward

direction) when the signal is transmitted can be expressed as:

(2.1)

Against the gas flow (backward direction):

(2.2)

After the resolution to v:

Apart from the two measured transit times, this relation only contains the active measuring

path and the angle of inclination as constants.

(2.3)

Page 16

Product Description

c = c0 ·

1 +

273 °C

= 273°C · ( () - 1)

4 · c

0

²

t

v

·

t

r

L

²

tv + t

r

²

c = · ()

L tv + t

r

2 tv ·t

r

Sound velocity

Sound velocity c can be calculated by resolving formulas 2.1 and

2.2.

(2.4)

Based on the dependencies in formulas 2.5 and 2.7, the sound velocity can be used to

determine the gas temperature and for diagnosis purposes.

(2.5)

Calculating the gas temperature

Since the sound velocity is dependent on the temperature, the gas temperature can also

be calculated from the transit times (by resolving formulas 2.4 and 2.5 to derive

).

(2.6)

Formula 2.6 shows that, in addition to the measured transit times, the square of the values

of L and the standard velocity are included in the calculation.

This means precise temperature measurement is only possible when the gas

composition is constant, measuring path L has been measured extremely

accurately and a calibration has been carried out (see Section

p. 151, 4.3.6).

Determining the volume flow

The volume flow in operating state is computed using the geometric constants of the duct.

The process parameters pressure, temperature and moisture content are required to

calculate the volume flow in the standard state. A detailed description is provided in

Section § 2.4, page 44.

Path compensation

When the FLOWSIC100 is operated with a 2-path configuration, the device runs with an

integrated algorithm for automatic "path compensation".

During trouble-free operation, gas and sound velocity relations between both measuring

paths are recorded and saved. Should one path then fail, the system can replace invalid

measured values from the failed path with theoretical values based on the "learned" path

relations. The system signals "Maintenance request" status at the same time.

This means a single path can be compensated temporarily and measurement continued

with a slightly higher uncertainty until the malfunction has been cleared.

16 FLOWSIC100 · Operating Instructions · 8012513/YSA5/V2-1/2016-07 · © SICK Engineering GmbH

Subject to change w ithout notice

Page 17

Product Description

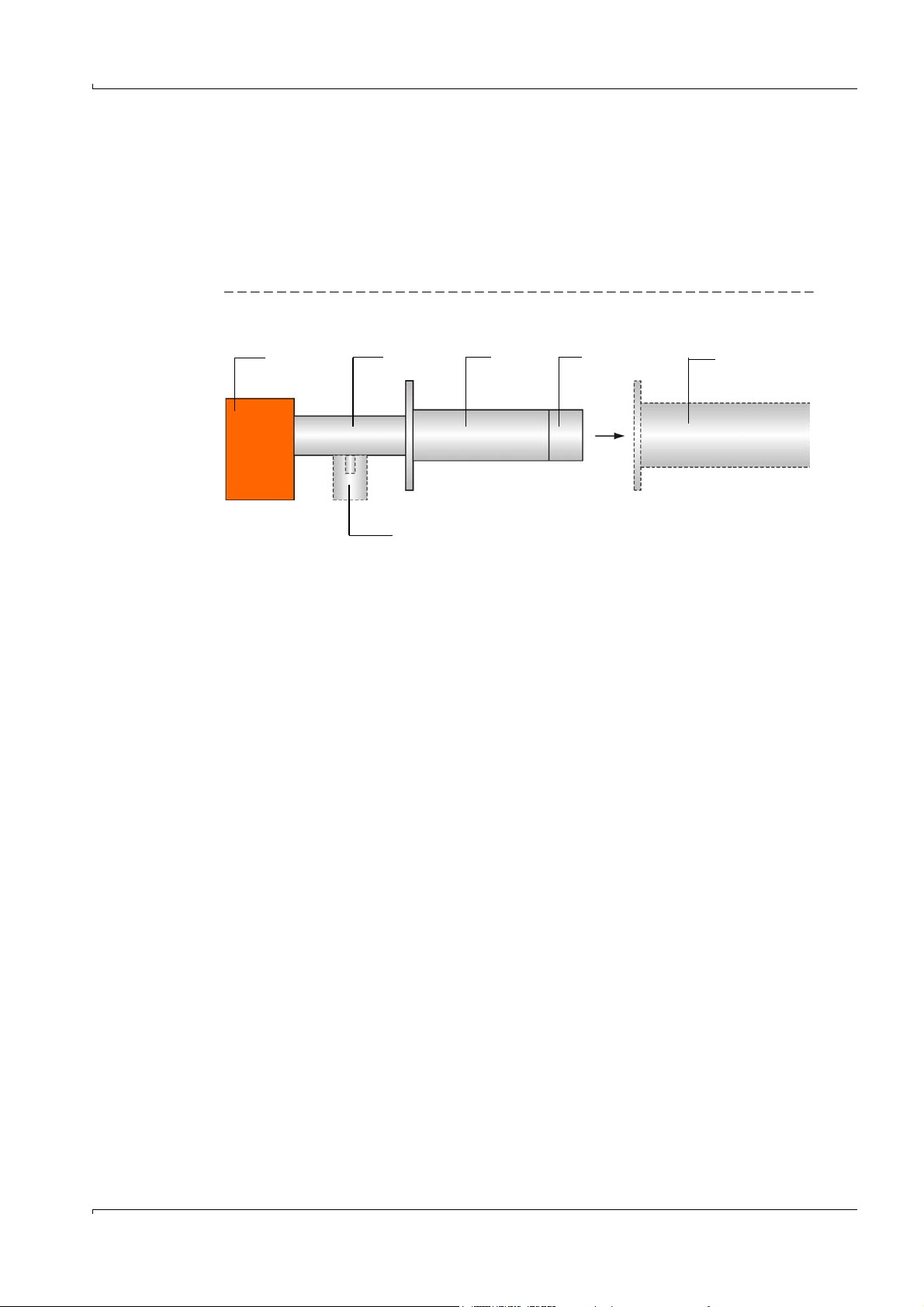

1

1 Electronics unit 4 Transducer

2 Connection piece 5 Flange with tube

3 Duct probe 6 Purge air connection (only for purged versions PM, PH, PHS)

Cooling air connection (only for internally cooled versions MAC, HAC)

2

34

5

6

2.3 System components

2.3.1 FLSE100 sender/receiver unit

The sender/receiver unit consists of the electronics, connector, duct probe, and transducer

modules. These modules are available in different versions that can be combined on the

basis of the relevant application data to produce the optimum configuration for the

application in question.

Fig. 5 Schematic diagram with modules of the sender/receiver unit and flange with tube

Subject to change w ithout notice

FLOWSIC100 · Operating Instructions · 8012513/YSA5/V 2-1/2016-07 · © SICK Engineering GmbH 17

Page 18

Product Description

The modules are selected on the basis of the following criteria:

● Gas temperature

Decide whether the sender/receiver unit must or can be used with or without internal

cooling air so that the duct probe can be selected with regard to type of material (steel,

titanium) and the transducer type (with/without internal cooling)

● Gas composition (corrosive / slightly corrosive or not corrosive)

The duct probe and transducers are selected on the basis of their resistance to corrosion (probe made from stainless steel / titanium, transducers made from titanium /

hastelloy)

● Duct diameter, sound dampening, dust content

The transducers are selected on the basis of the required transmitter power (medium

power / high power)

● Dust properties

Decide whether purged sender/receiver units need to be used (prevention of contamination with very sticky dust).

● Wall and insulation thickness of the gas duct

Selection of the duct probe and flange with tube according to the nominal length

(graded standard lengths). Other lengths can be supplied on request.

● Assembly type

On two sides, each with a sender/receiver unit on the opposite duct walls, or on one

side with one sender/receiver unit (as measuring probe version)

● Flange size

Small or large flange dimensions

(pitch diameter of the fixing holes 75 mm, 100 mm or 114 mm)

● Internal duct pressure

Pressure resistant versions must be used with pressures above 100 mbar (see OI

FLOWSIC100 PROCESS)

● Certification requirements

Selection after performance tests for emission measuring.

The various configuration options are identified by a type key structured as follows:

18 FLOWSIC100 · Operating Instructions · 8012513/YSA5/V2-1/2016-07 · © SICK Engineering GmbH

Subject to change w ithout notice

Page 19

Product Description

Type key sender/receiver unit: FLSE100-XXX (X) XX XX XX

Purge air supply yes/no

- P: Purged

Ultrasonic transducer

- M: Medium power

- H: High power

- S: Low power with small dimensions

(Small size)

- PR: Low power with small dimensions

and measuring probe version

Signal transmission

- D: Digital (identification for FLSE100-SD only)

- A: Analog (identification for FLSE100-SA only

- Empty: Digital

Identification

- Empty: No special features

- AC: Internal cooling of ultrasonic transducer

Nominal length of duct probe

- 12: 125 mm

- 20: 200 mm

- 35: 350 mm

- 55: 550 mm

- 75: 750 mm

Duct probe material

- SS: 1.4571 (stainless steel)

- TI: Titanium

- HS: Hastelloy

Transducer material

- TI: Titanium

- HS: Hastelloy

Example: FLSE100-M 35SSTI

Medium transducer power

Duct probe nominal length 350 mm

Duct probe material 1.4571

Transducer made of titanium

The possible versions, areas of application, configurations, and characteristics are listed in

the following Tables.

Subject to change w ithout notice

FLOWSIC100 · Operating Instructions · 8012513/YSA5/V 2-1/2016-07 · © SICK Engineering GmbH 19

Page 20

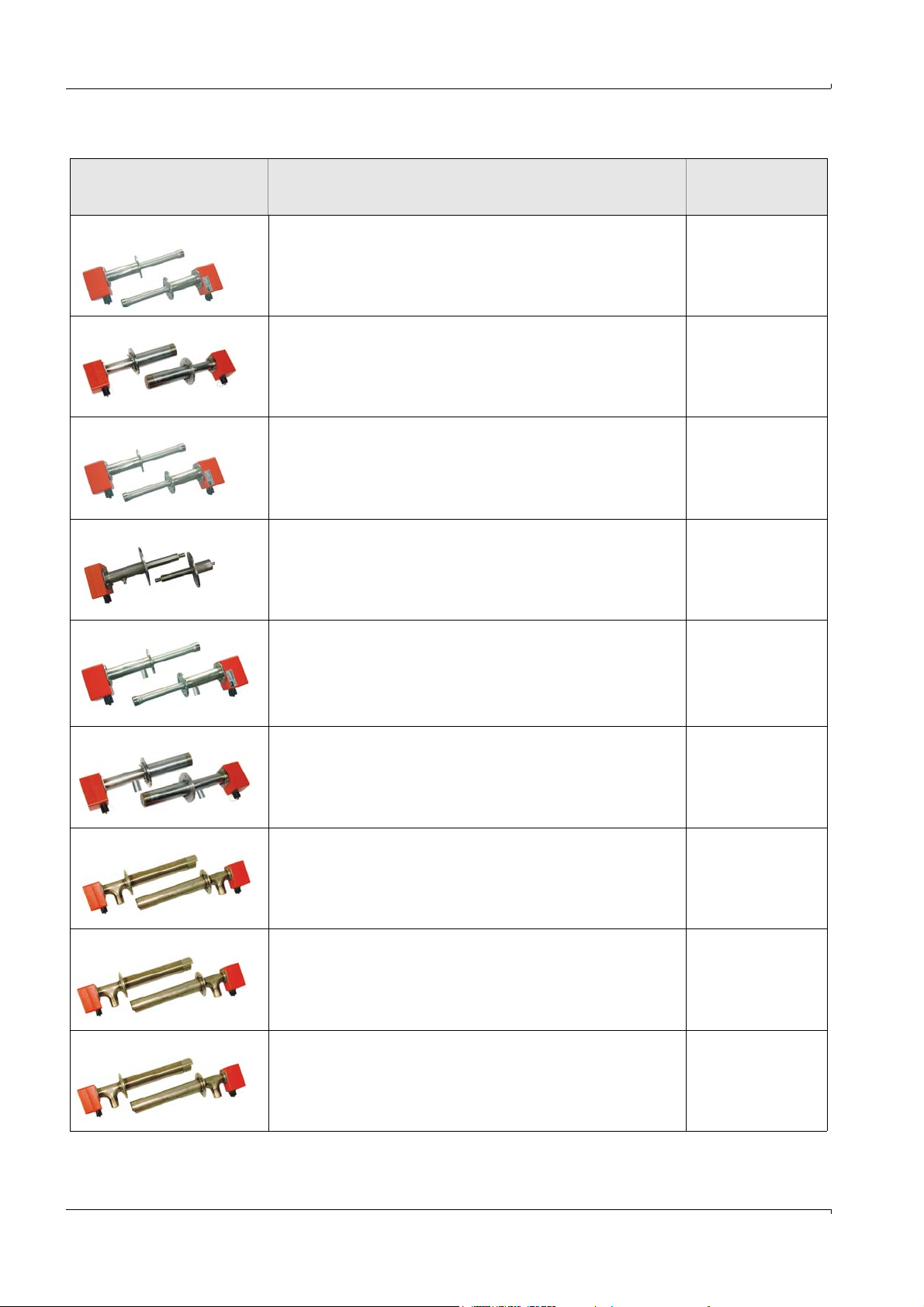

Basic versions

Typ e F LSE10 0 Description

M

● Not purged

● Medium power

● Digital signal transmission to control unit

Product Description

Number of

FLSE100 per

system

2

H

● Not purged

● High power

● Digital signal transmission to control unit

PR ● Not purged

● With two transducers, small size and high frequency

● Version as measuring probe for installation on one duct

side

● Digital signal transmission to control unit

SA/SD

● Not purged

● With one small size and high frequency transducer

● Digital signal transmission to control unit (SD)

MAC ● Air cooled (internal)

● Medium power

● Digital signal transmission to control unit

HAC

● Air cooled (internal)

● High power

● Digital signal transmission to control unit

2

1

1 each

2

2

PM

● Purged

● Medium power

2

PH

● Digital signal transmission to control unit

● Purged

● High power

2

PHS

● Digital signal transmission to control unit

● Purged

● Very high power

● Digital signal transmission to control unit

20 FLOWSIC100 · Operating Instructions · 8012513/YSA5/V2-1/2016-07 · © SICK Engineering GmbH

2

Subject to change w ithout notice

Page 21

Product Description

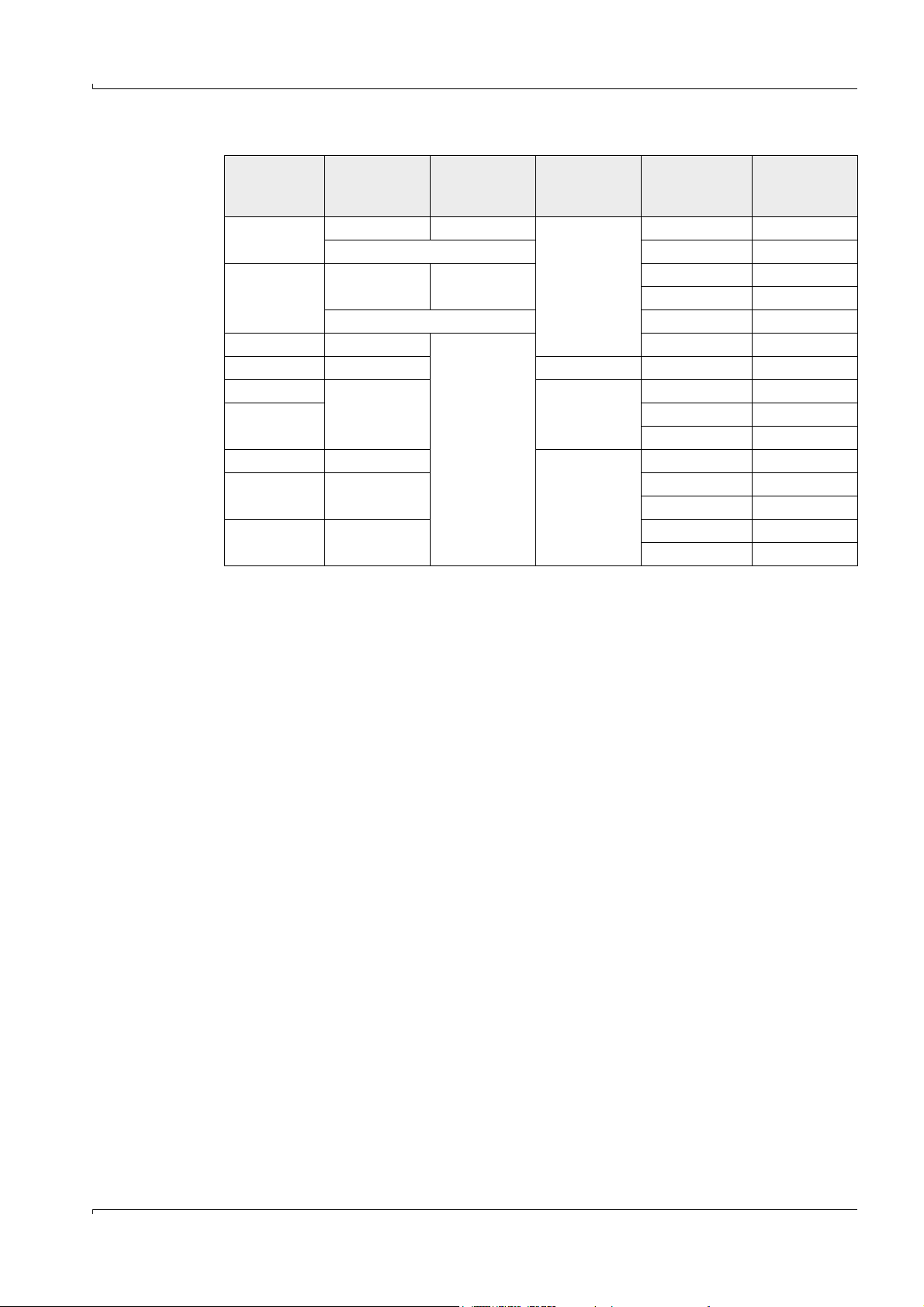

Application range

Type FLSE100

M

H

Material

Duct probe

SS, TI TI

Hastelloy 0.2 - 2 0.15 - 1.7

SS, TI TI

Material

Tra nsdu cer

Max. gas

temperature

[°C]

260

Active meas.

distance

1)

[m]

Duct/pipe

diameter [m]

0.2 - 4 0.15 - 3.4

2 - 15 1.4 - 13

1.5 - 2.5

2)

1.1 - 2.5

Hastelloy 2 - 5 1.4 - 4.3

PR

SA/SD

MAC

HAC

PM

PH

PHS

SS, TI

0.27 - 0.28 > 0.40

SS 150 0.2 - 2 0.15 - 1.7

0.2 - 4 0.15 - 3.4

SS, TI 450

SS

SS, TI

Tl

450

SS

2 - 13 1.4 - 11.3

1.5 - 2.5

2)

1.1 - 2.5

0.5 - 3 0.35 - 2.5

1 - 10 0.7 - 8.7

2)

1 - 2

0.7 - 2

2 - 13 1.4 - 11.3

1.5 - 2.5

2)

1.1 - 2.5

1): The maximum possible measuring path depends on the dust content, gas temperature,

and gas composition

2): For extremely high dust concentrations up to max. 100 g/m³

3): For installation across secant (

p. 57, 3.1.3)

3)

3)

3)

3)

Subject to change w ithout notice

FLOWSIC100 · Operating Instructions · 8012513/YSA5/V 2-1/2016-07 · © SICK Engineering GmbH 21

Page 22

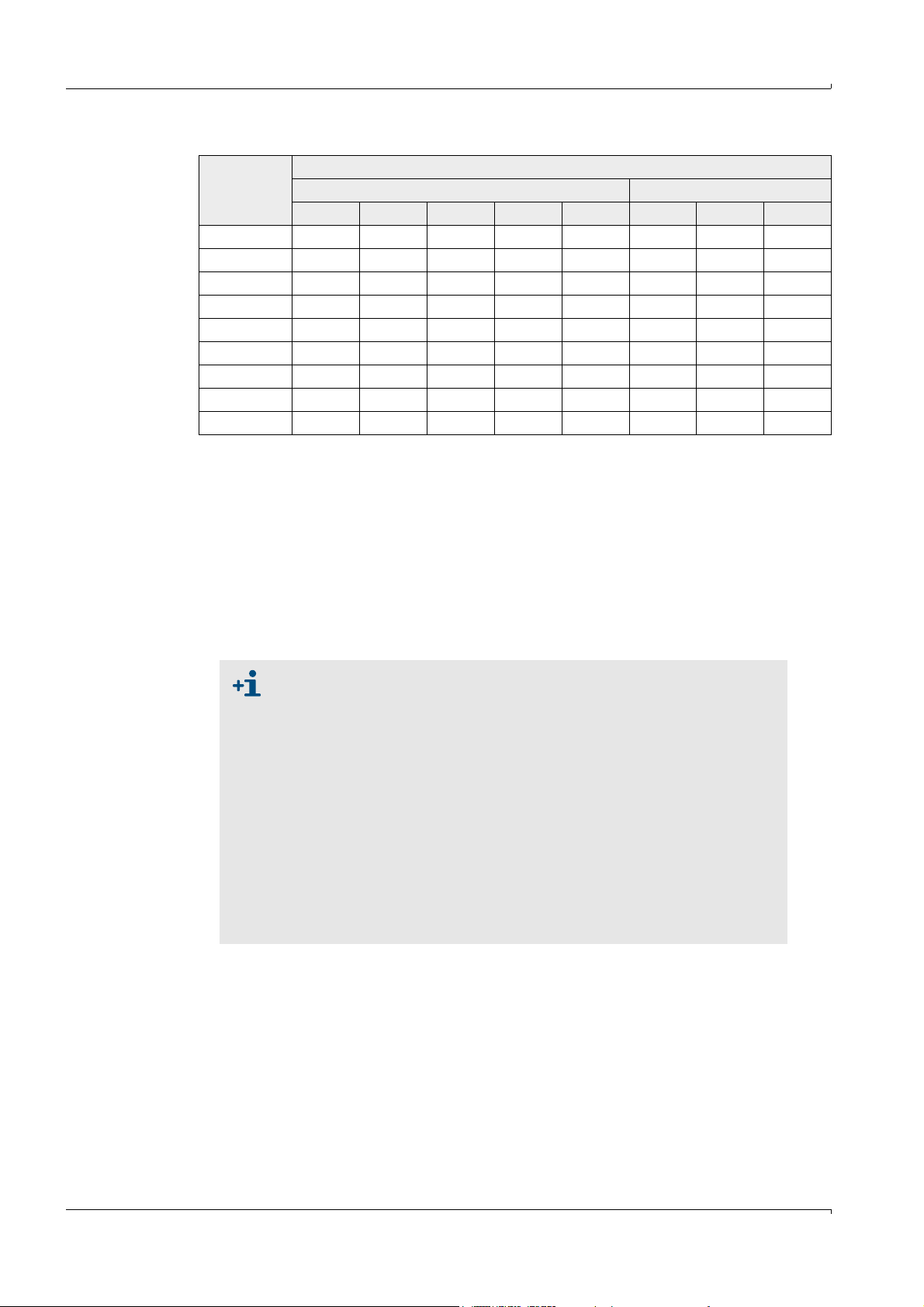

Duct probe configuration options

Type FLSE100

Nominal length in mm Material

125 200 350 550 750 SS TI HS

M xxx xxx

H xxxxxxx

PR xxxxx

SA/SD xxx x

MAC x x x x

HAC x x x x

PM xxxxx

PH xxxxxx

PHS x x x x

2.3.1.1 Standard sender/receiver units

A special transducer design makes it possible to use these sender/receiver units without

cooling by external purge air even with higher gas temperatures. A purge air unit is

therefore not necessary. The advantages are:

● Lower expense for mounting and installation

● Easier maintenance

● Lower operating costs.

For these reasons, standard sender/receiver units should be used where possible.

Product Description

Duct probe

● The types FLSE100-M, H and PR are intended for use with gas

temperatures up to max. 260

°C. The types FLSE100-SA and SD are

intended for use up to 150°C.

● The measuring system FLOWSIC100 S contains one sender/receiver

unit FLSE100-SA and FLSE100-SD and one connection cable between

the sender/receiver units.

● The type FLSE100-SA has no electronics unit. Communication to the

FLSE100-SD as master (which communicates with the MCU control

unit) runs via an analog connection cable (fixed length: 3m). Install one

FLSE100-SA and one FLSE100-SD per sampling point (1-path configuration).

● Fit the sender/receiver units at an angle of 60° to the flow direction for

dust concentrations > 1 g/m³ (only applicable for FLSE100-H, H-AC, PH

and PH-S). The downstream sender/receiver unit (B in

p. 15, Fig. 4) has

to be equipped with an impact protector.

Subject to change w ithout notice

22 FLOWSIC100 · Operating Instructions · 8012513/YSA5/V2-1/2016-07 · © SICK Engineering GmbH

Page 23

Product Description

NL = 200 mm, 350 mm, 550 mm

NL

A

A

A - A

1 Electronics unit 4 Transducer

2 Connection piece 5 Connection for connection cable

3 Duct probe

1

2

34

5

A - A

NL = 200 mm, 350 mm, 550 mm, 750 mm

A

A

NL

1

2

34

5

1 Electronics unit 4 Transducer

2 Connection piece 5 Connection for connection cable

3 Duct probe

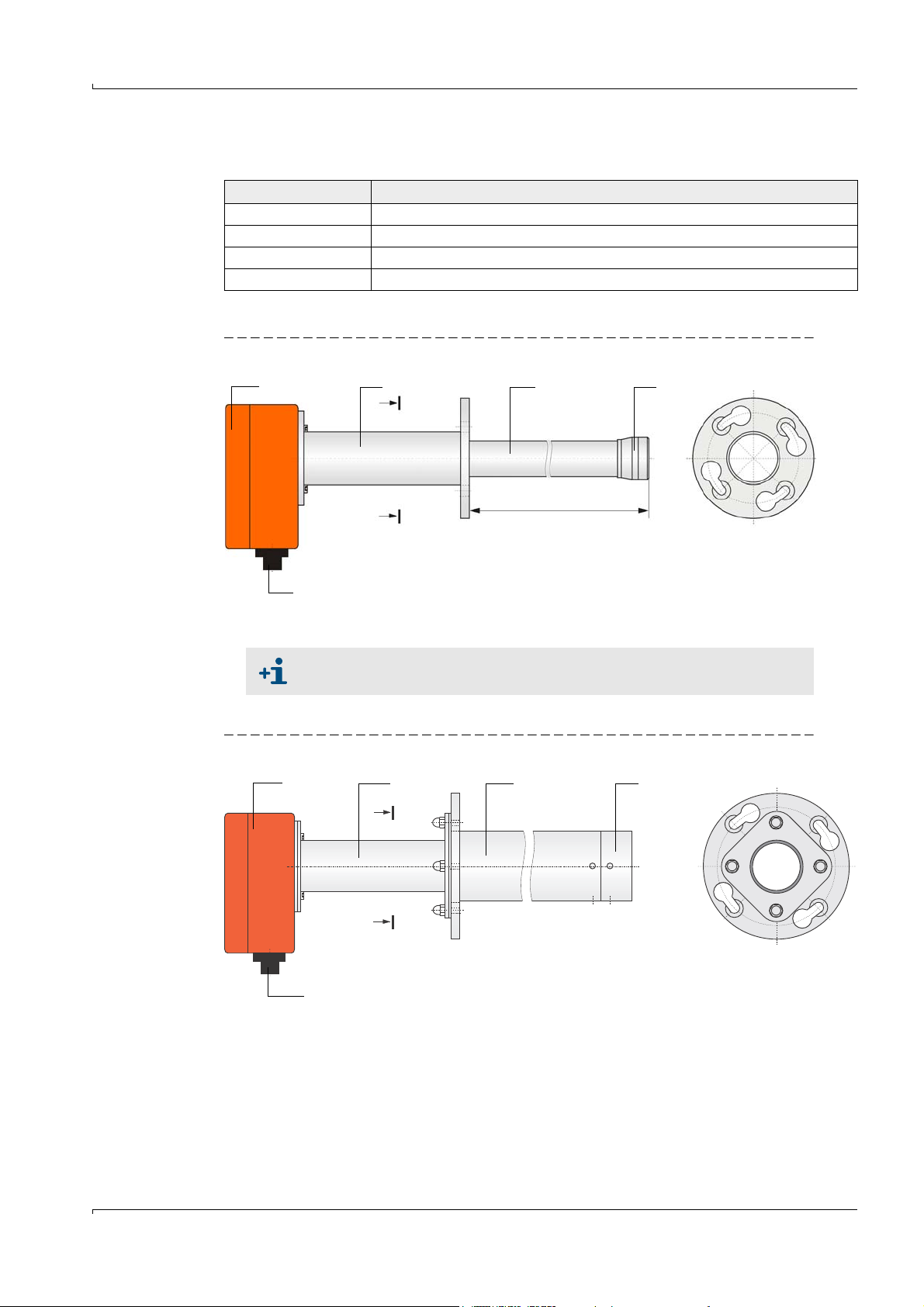

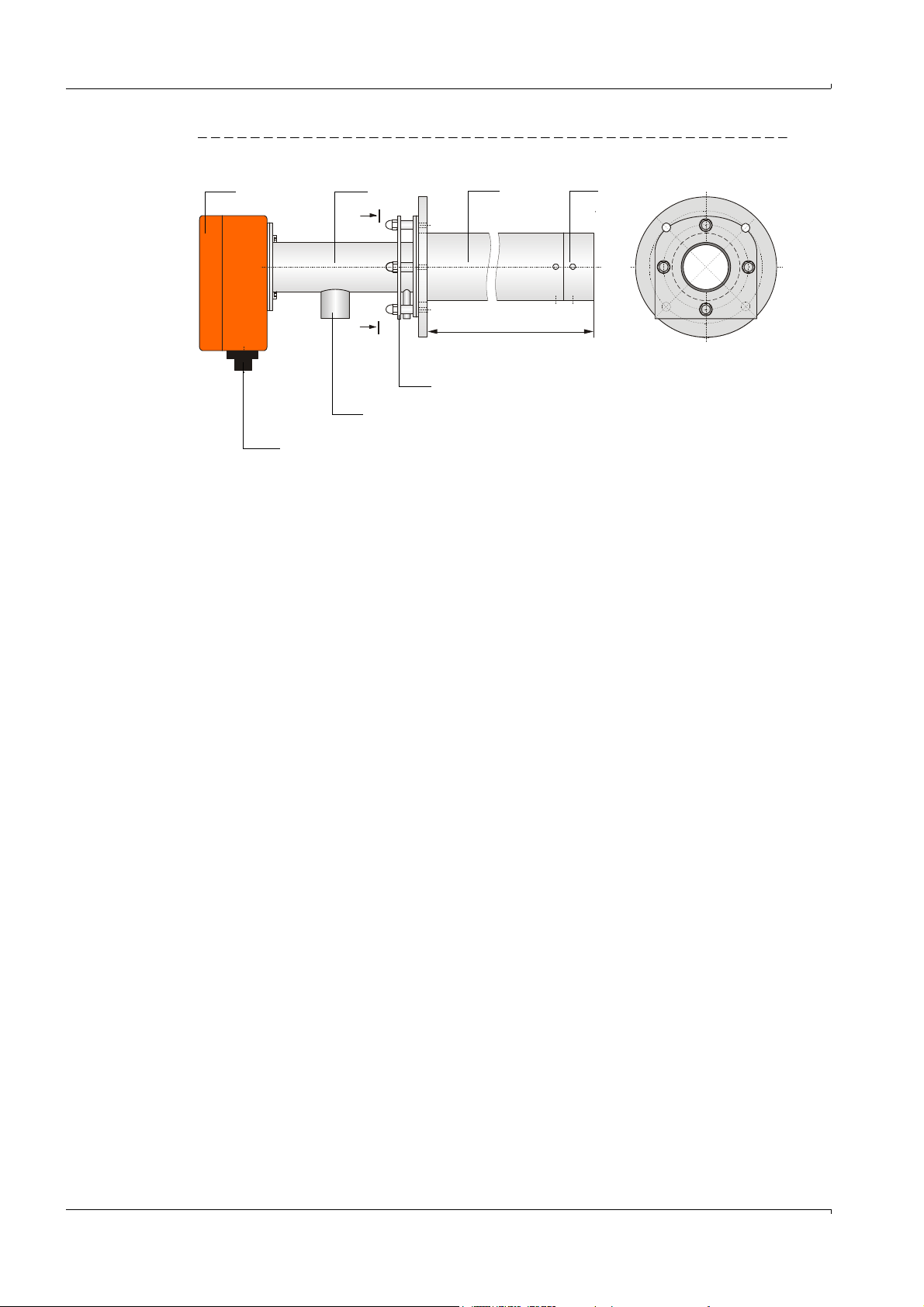

Fig. 6 FLSE100-M

The following differences exist in addition to the possible versions:

Type FLSE Transducer and duct probe

M Nominal diameter 35 mm

H Nominal diameter 60 mm

PR Measuring probe version (2 transducers)

SA, SD Duct probe Ø 35 mm, transducer 15 mm

The type FLSE100-M is also available with other flanges on request (p.

169, 6.3.1).

Fig. 7 FLSE100-H

Subject to change w ithout notice

FLOWSIC100 · Operating Instructions · 8012513/YSA5/V 2-1/2016-07 · © SICK Engineering GmbH 23

Page 24

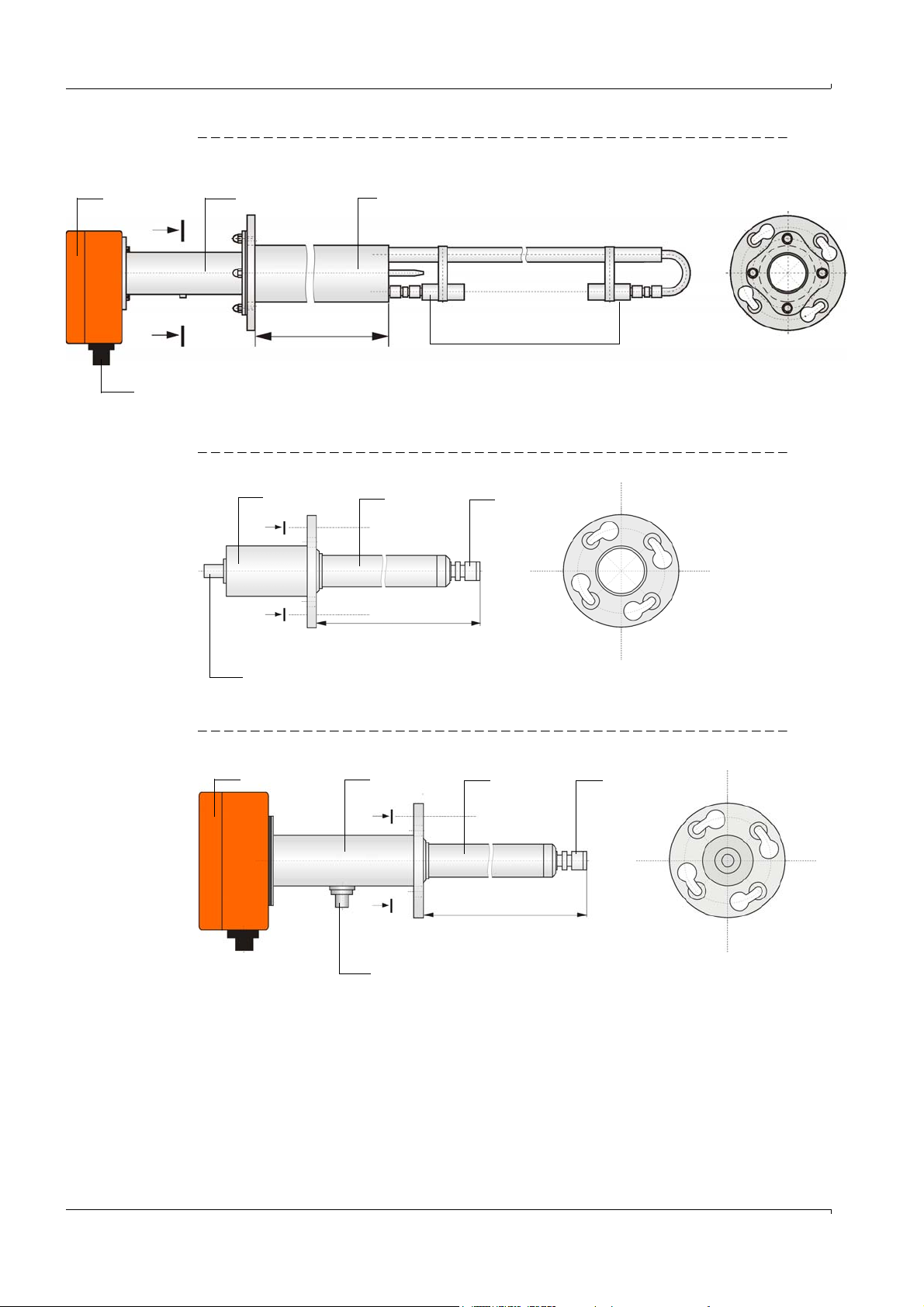

Fig. 8 FLSE100-PR

A - A

NL = 350 mm, 550 mm, 750 mm

A

A

NL

1

2

3

4

5

A

A

NL

A - A

NL = 125 mm, 200 mm, 350 mm

2

3

4

5

NL

A

A

A - A

NL = 125 mm, 200 mm, 350 mm

1 Electronics unit 4 Transducer

2 Connection piece 5 Connection for connection cable

3 Duct probe

1

2

4

5

3

Fig. 9 FLSE100-SA

Product Description

Fig. 10 FLSE100-SD

Subject to change w ithout notice

24 FLOWSIC100 · Operating Instructions · 8012513/YSA5/V2-1/2016-07 · © SICK Engineering GmbH

Page 25

Product Description

A - A

NL =350 mm, 550 mm

A

A

NL

6

1

2

4

3

5

1 Electronics unit 4 Transducer

2 Connection piece 5 Connection for connection cable

3 Duct probe 6 Cooling air connection

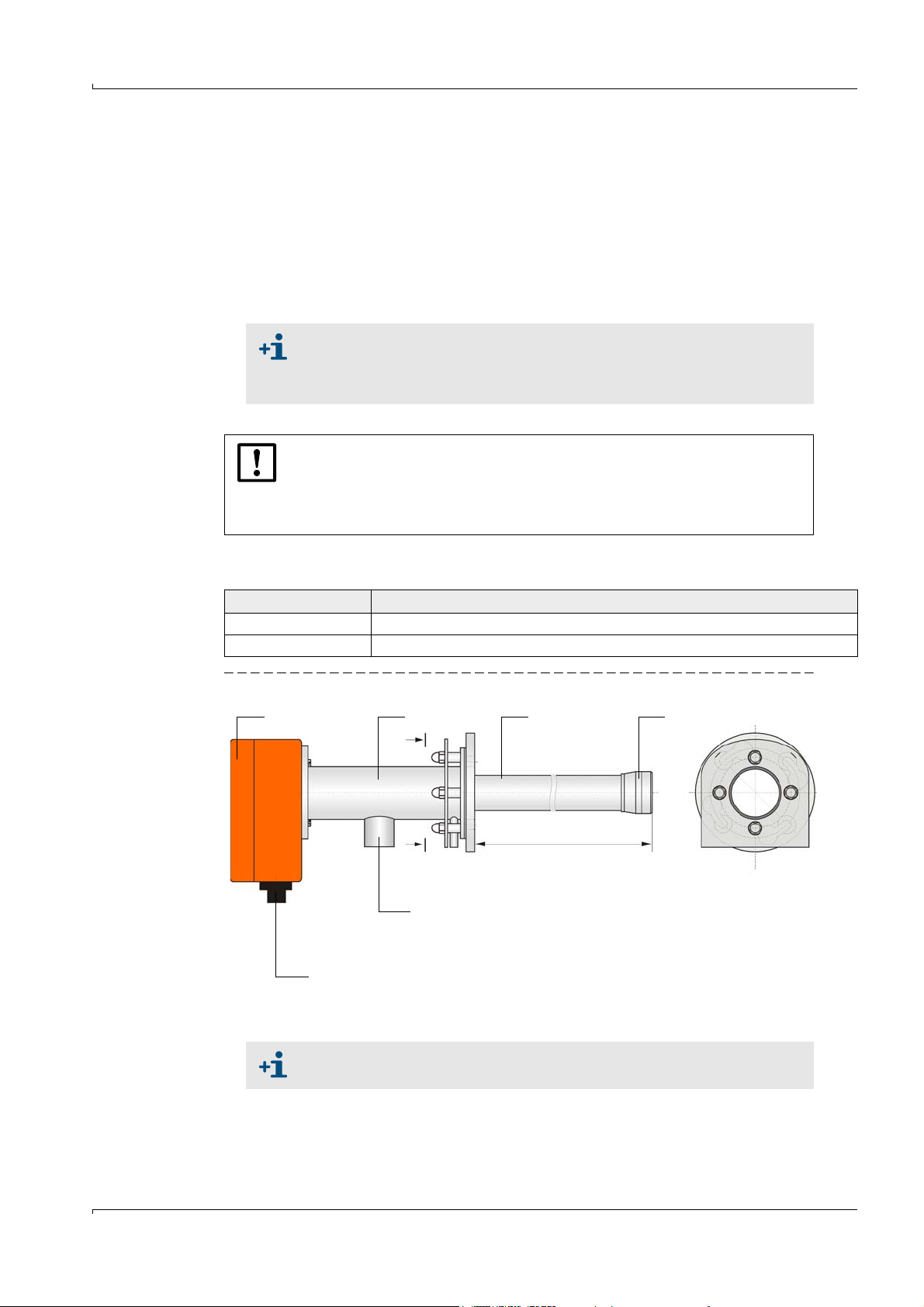

2.3.1.2 Sender/receiver units with internal cooling

The types FLSE100-MAC and HAC can be used for gas temperatures up to maximum

450°C when fitted with internal cooling for the ultrasonic transducers. A control unit with

integrated filter and blower supplies the cooling air (

The advantages over the purged versions are:

● Lower costs for installation and operation.

● No flow of cooling air into the measured medium, therefore no direct influence on gas

flow and flow rate.

● Lower risk of dropping below the dew point with condensate on the probe head.

Fit the sender/receiver units at an angle of 60° to the flow direction for dust

concentrations > 1 g/m³ (only applicable for FLSE100-HAC). The downstream sender/receiver unit (B in Fig. 4, page 15) must be equipped with an

impact protector.

NOTICE:

Wet or sticky dust can cause strong contamination of the transducer and

disrupt the measuring function. In this case, the cooling air control option, Part

No. 2050814, should be used on device versions with internal cooling (M-AC

and H-AC). Use an external device version when necessary.

p. 29, 2.3.3).

The following differences exist in addition to the possible versions:

Type FLSE100 Transducer and duct probe

MAC Nominal diameter 35 mm

HAC Nominal diameter 60 mm

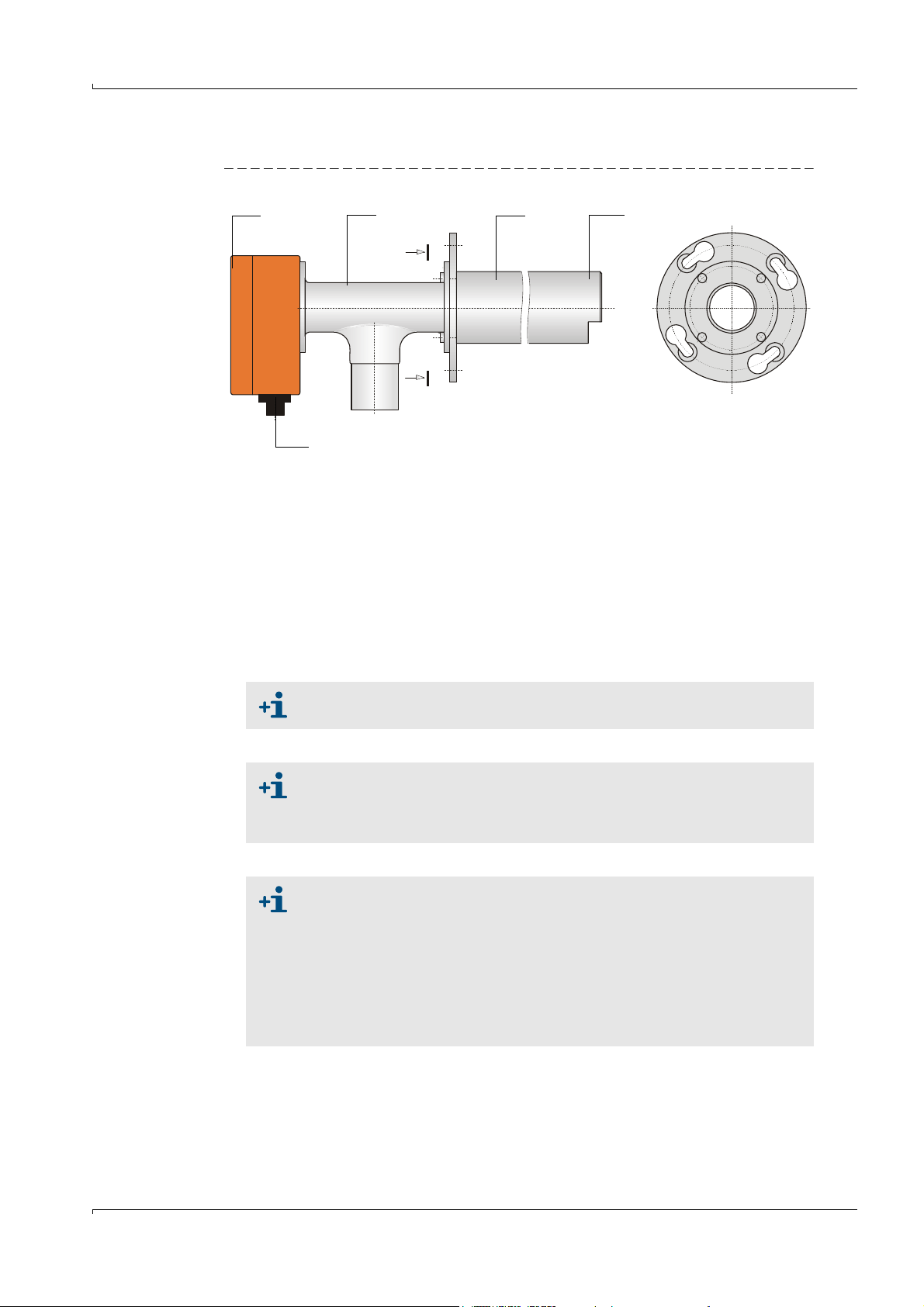

Fig. 11 FLSE100-MAC

The type FLSE100-MAC is also available with other flanges on request (p.

Subject to change w ithout notice

FLOWSIC100 · Operating Instructions · 8012513/YSA5/V 2-1/2016-07 · © SICK Engineering GmbH 25

169, 6.3.1).

Page 26

Fig. 12 FLSE100-HAC

NL =350 mm, 550 mm

A

A

NL

1 Electronics unit 5 Connection for connection cable

2 Connection piece 6 Cooling air connection

3 Duct probe 7 Guard plate

4 Transducer

6

7

1

2

4

3

5

A -

Product Description

26 FLOWSIC100 · Operating Instructions · 8012513/YSA5/V2-1/2016-07 · © SICK Engineering GmbH

Subject to change w ithout notice

Page 27

Product Description

NL = 200 mm (only PM and PH)

350 mm

550 mm

750 mm

NL

A

A

1 Electronics unit 4 Transducer

2 Connection piece 5 Connection for connection cable

3 Duct probe

1

2

4

3

5

A -

2.3.1.3 Purged sender/receiver units

Fig. 13 FLSE100-PM, PH, PHS

These sender/receiver units are intended only for use with wet and sticky dust when the

transducer surface is in high danger of contamination. Purge air is supplied by a purge air

unit to keep the active transducer surface clean and therefore protect against

contamination (

p. 43, 2.3.9). The purge air flow is optimized to maximize the directivity of

the ultrasound beam.

An integrated temperature sensor records the transducer temperature which can then be

displayed in SOPAS ET.

See the Application Range Table on page 21 for limitations of use

For dust concentrations > 1 g/m³, install the sender/receiver units at an

angle of 60° to the flow direction (only applicable for FLSE100-PH and

PHS). The downstream sender/receiver unit (B in

p. 15, Fig. 4) has to be

equipped with an impact protector.

At low gas temperatures, the purge air supply can cause the temperature to

drop below the dew point. To minimize the possible corrosion on the probe

head (for example, due to acid formation with corrosive gas compositions),

duct probes with a nominal length greater than that actually required for

the flanges with tube must be selected for temperatures between 150

and 200

350 mm

°C (for example, if the nominal length of the flange with tube is

a duct probe with a nominal length of 550 mm should be

°C

used). The purge air is then heated by the gas temperature in the probe

tube which minimizes temperature drops below the dew point.

Subject to change w ithout notice

FLOWSIC100 · Operating Instructions · 8012513/YSA5/V 2-1/2016-07 · © SICK Engineering GmbH 27

Page 28

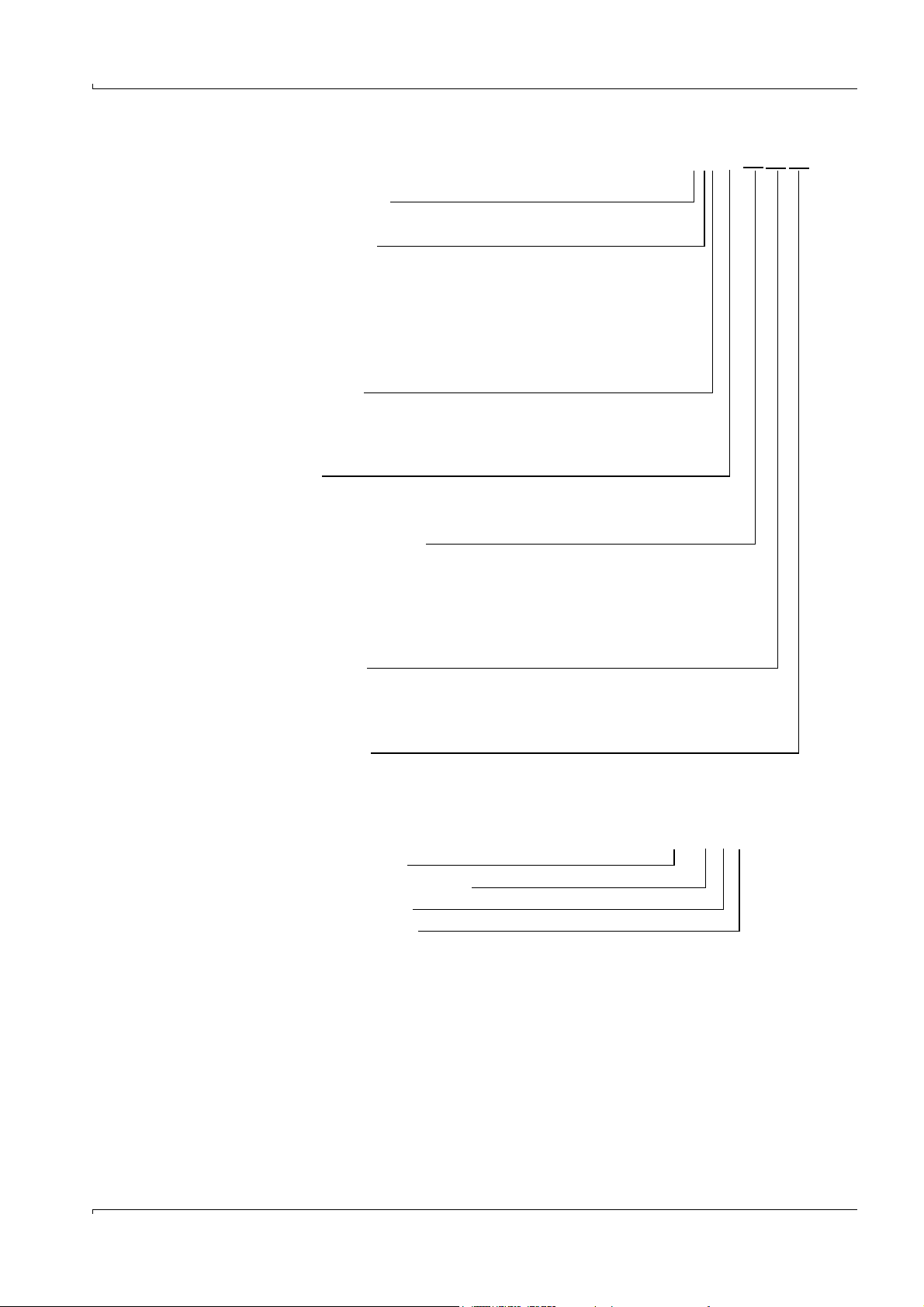

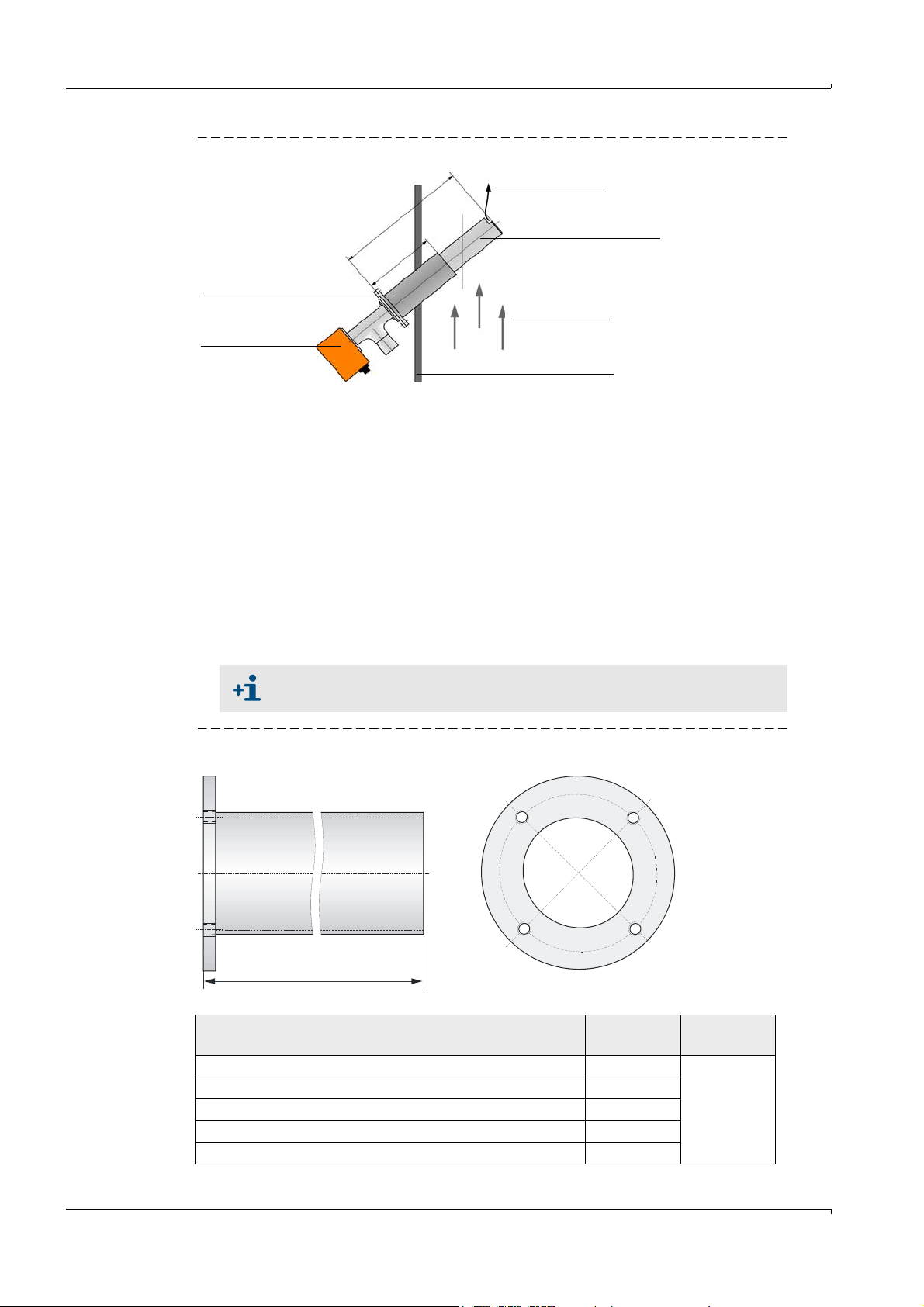

Fig. 14 Using sender/receiver units with a nominal length greater than the flange with tube

Flange with tube

Sender/receiver

unit

Purge air

Area heated by

the gas flow

Gas flow

Duct wall

N

L

F

L

S

E

1

0

0

N

L

F

NL

FLSE100

= Nominal length sender/receiver unit

NL

F

= Nominal length flange with tube

L

L = NL - 12

Type FLSE100 Nominal

length in mm

Material

S 125

St37, V4A

(others on

request)

S, M, PM, PH 200

S, M, MAC, H, HAC, PR, PM, PH, PHS 350

M, MAC, H, HAC, PR, PM, PH, PHS, 550

H, PR, PM, PH, PHS 750

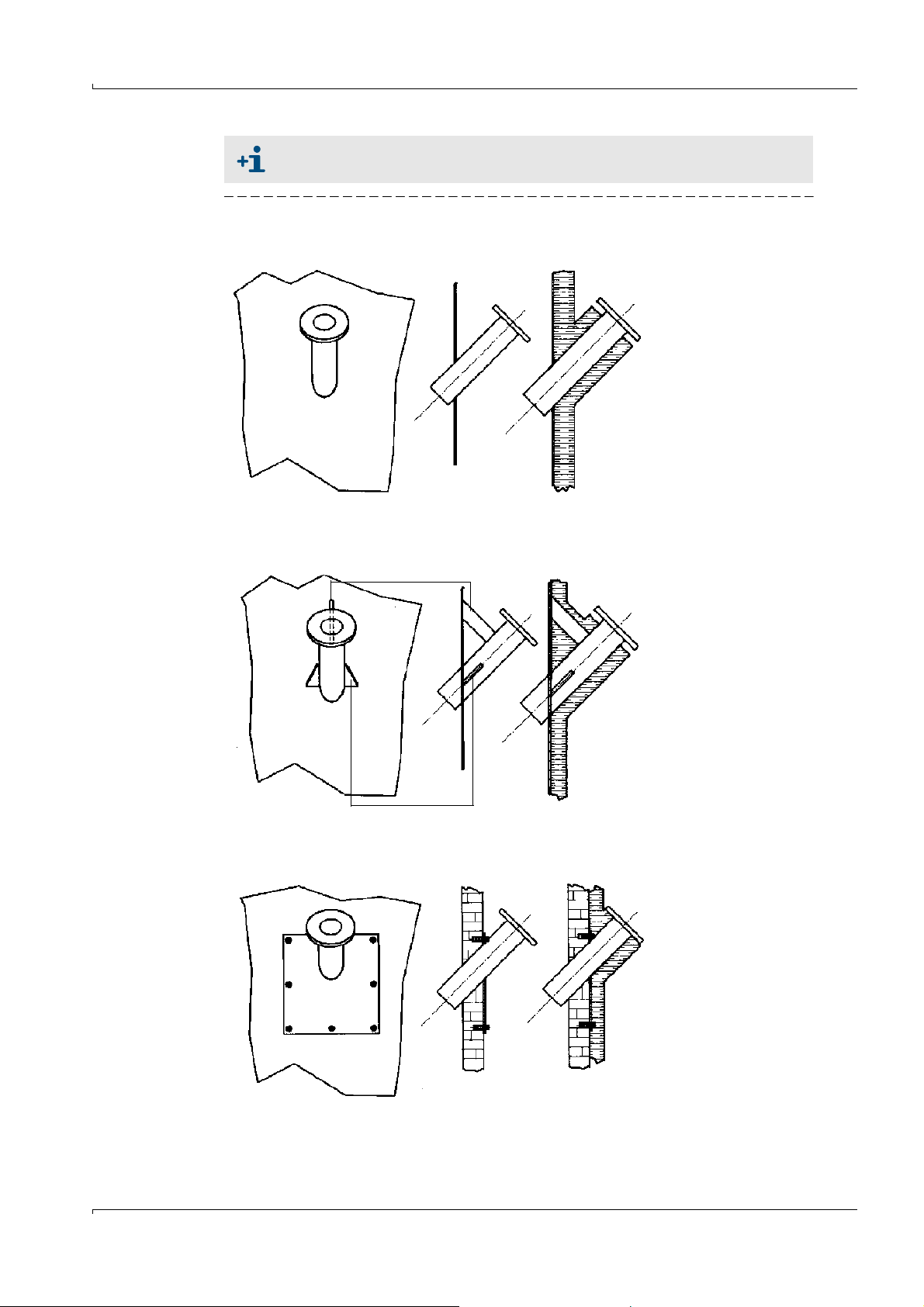

2.3.2 Flange with tube

The sender/receiver units are mounted in flanges with tube available in graded nominal

lengths, different steel types and pitch diameters.

Selection of a flange with tube depends on:

● Installation angle and wall and insulation thickness of duct wall

Determining the nominal length (Assembly and Installation Chapter,

● Type of sender/receiver unit

Pitch diameter of flange, pipe diameter

● Duct material

Steel type

Product Description

p. 49)

If required, the flanges with tube can also be delivered in advance.

Fig. 15 Flange with tube

28 FLOWSIC100 · Operating Instructions · 8012513/YSA5/V2-1/2016-07 · © SICK Engineering GmbH

Subject to change w ithout notice

Page 29

Product Description

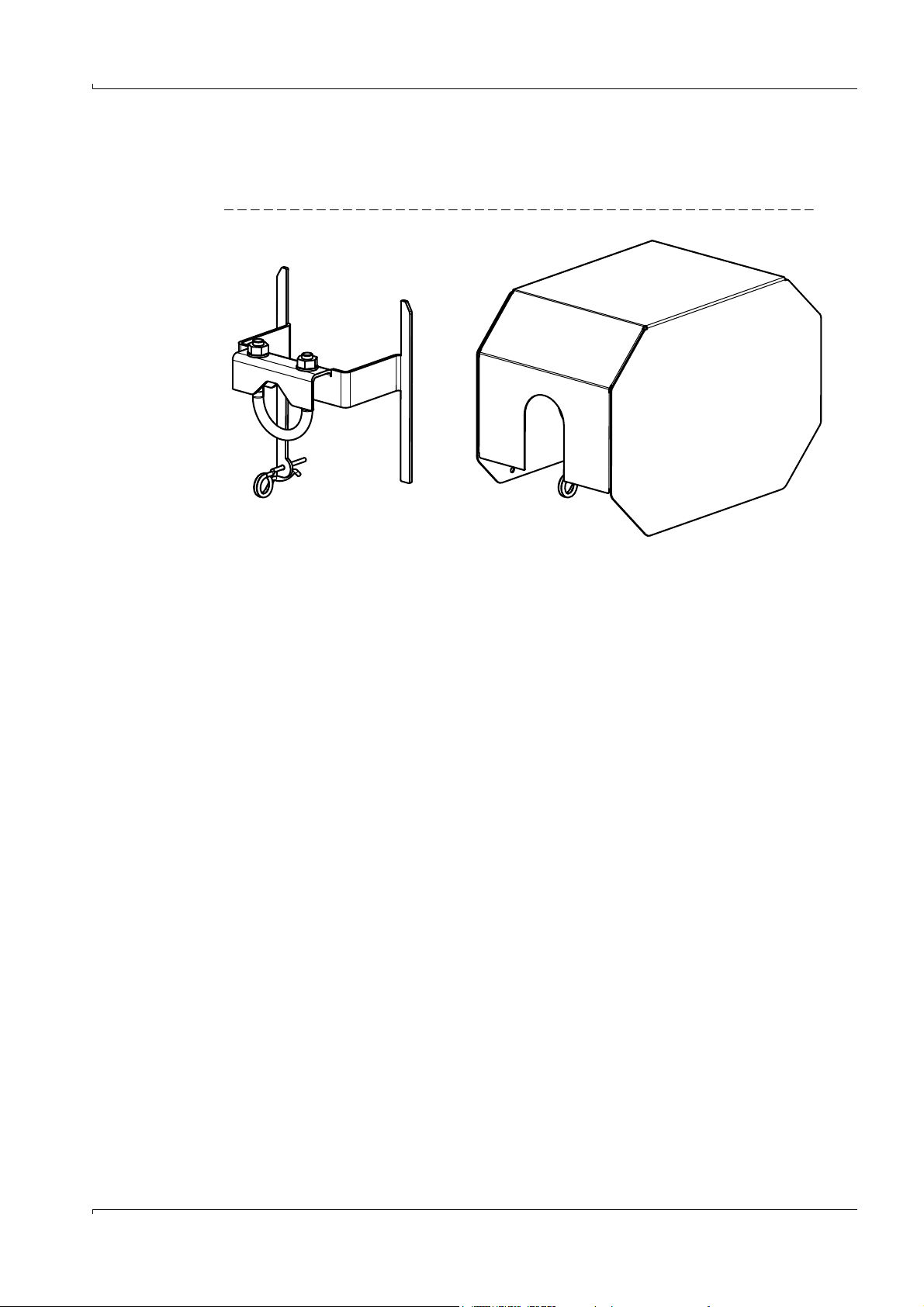

2.3.3 Weatherproof cover

The weatherproof cover protects the electronics of the sender/receiver unit against

sunlight and rain.

Fig. 16 Weather protection with holder

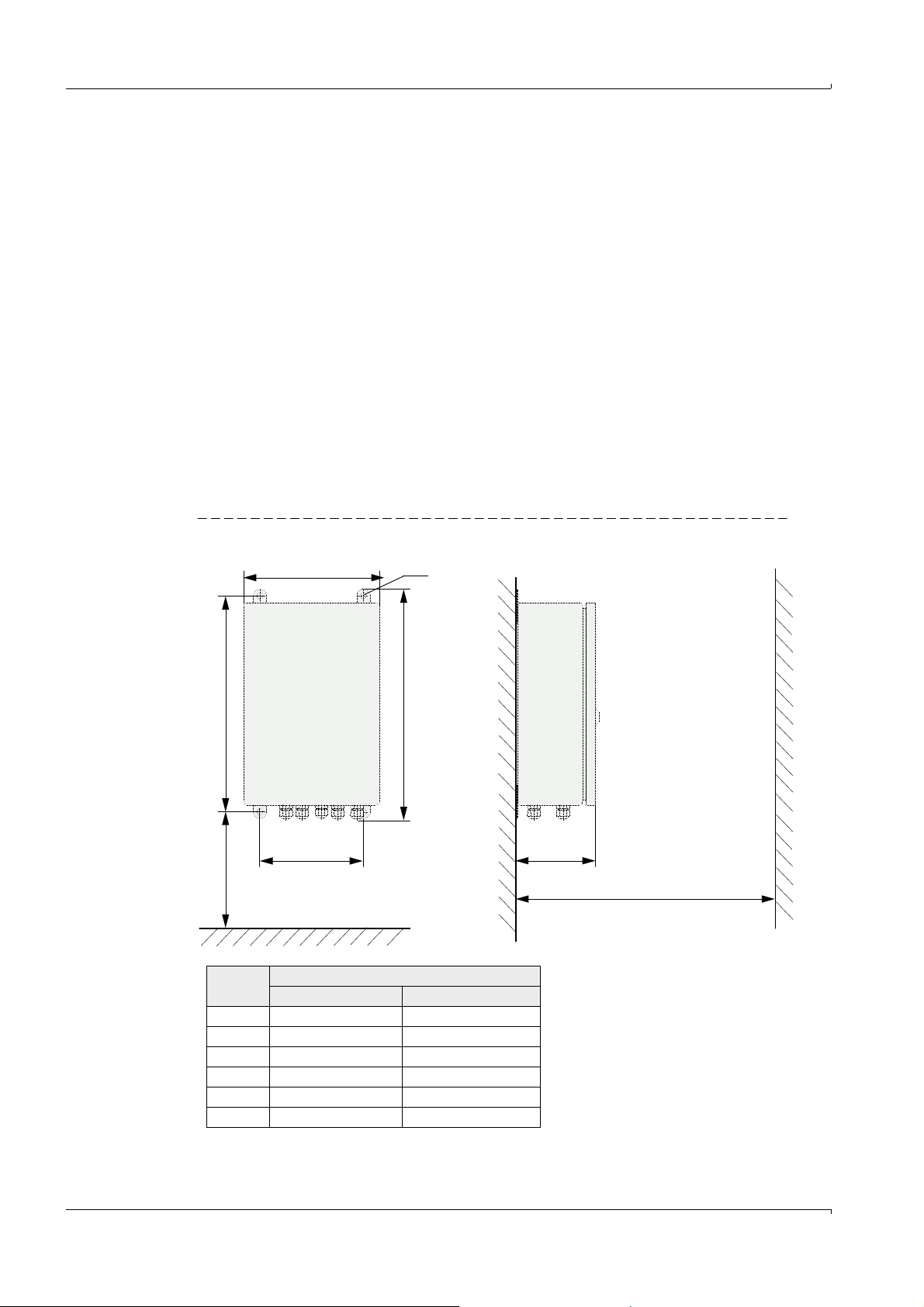

2.3.4 MCU control unit

The control unit has the following functions:

● Control of data transfer and processing the data from the sender/receiver units

connected via RS485 interface

● Signal output via analog outputs (measured value) and relay outputs (device status)

● Signal input via analog and digital inputs

● Voltage supply for the connected sender/receiver units

● Communication with host control systems via optional modules

System and device parameters can be set easily and conveniently via a USB interface

using a laptop and the user-friendly SOPAS ET operating software. The parameters are

stored reliably even in the case of a power failure.

The control unit is usually installed in a steel plate housing. It is available as 19" rack as an

option.

Subject to change w ithout notice

FLOWSIC100 · Operating Instructions · 8012513/YSA5/V 2-1/2016-07 · © SICK Engineering GmbH 29

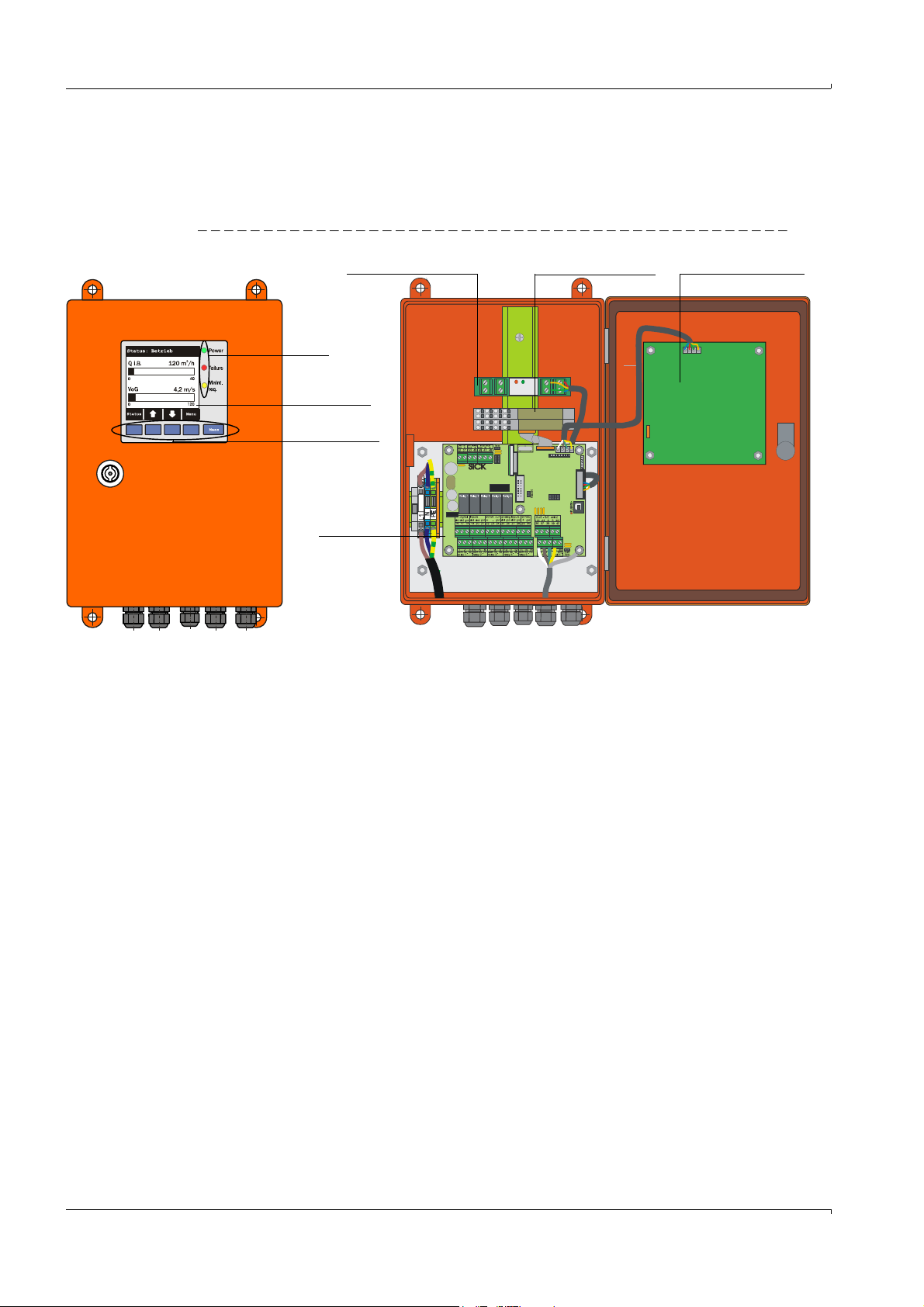

Page 30

Versions

LED

LC-Display

option

Control buttons

Connection

board

Interface module option

I/O module option

Display module option

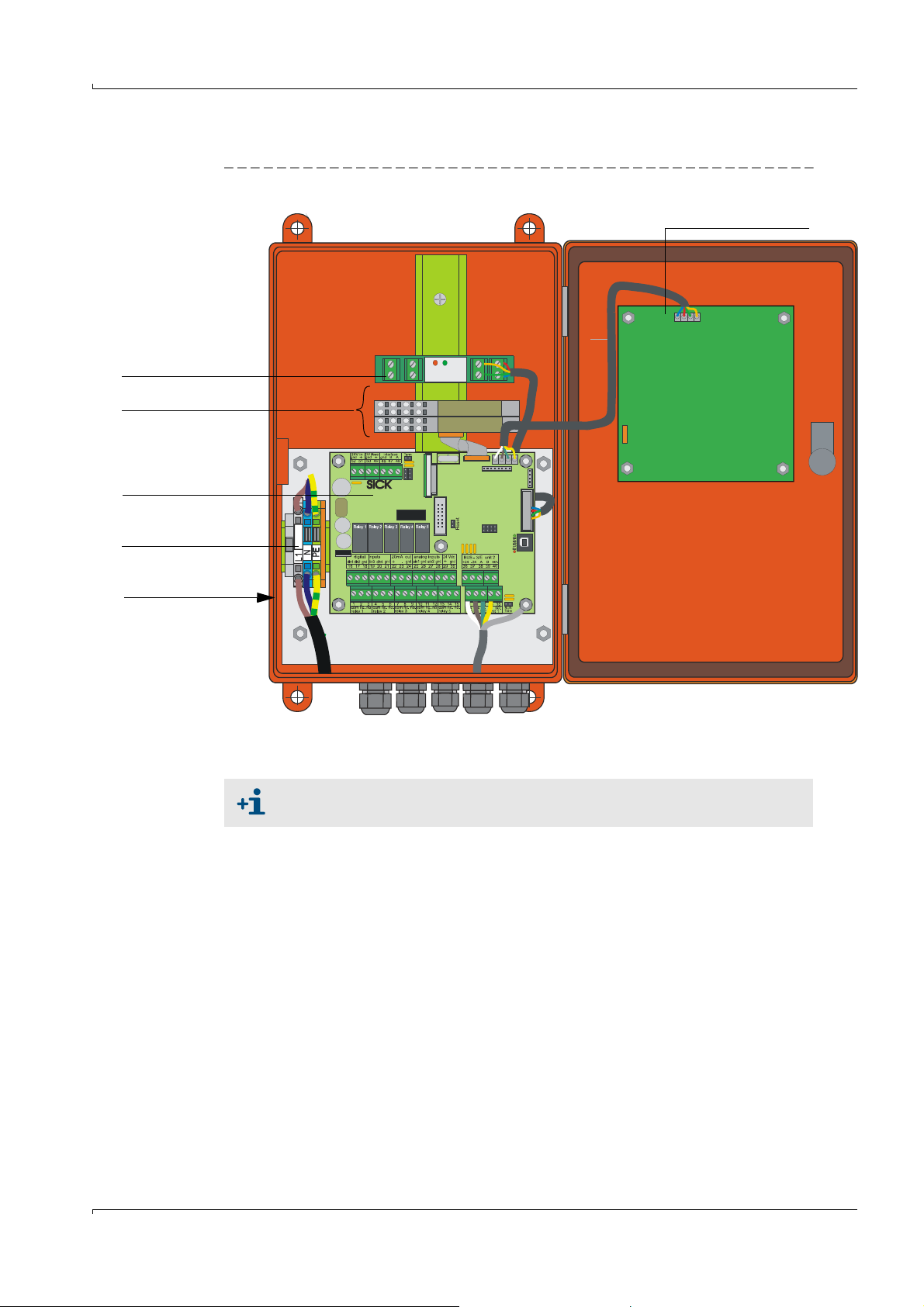

1 Control unit without cooling air supply

This control unit serves for connecting sender/receiver units FLSE100-M, H, PR, S, PM,

PH and PHS (optional for FLSE100-MAC and HAC).

Fig. 17 Control unit MCU with options

Product Description

2 Control unit with integrated cooling air supply (only for types M-AC and H-AC)

This version is additionally equipped with a purge air blower, air filter and purge air connection for connecting DN 25 purge air hoses (must be ordered separately

p. 171,

Fig. 138) for sender/receiver units with internal cooling (types FLSE100-MAC and HAC).

Subject to change w ithout notice

30 FLOWSIC100 · Operating Instructions · 8012513/YSA5/V2-1/2016-07 · © SICK Engineering GmbH

Page 31

Product Description

Purge air connection

Power supply unit (on back of installation plate)

Purge air inlet

Processor board

Option

LC-Display

Air filter

Purge air blower

Installation plate

Fig. 18 Control unit with integrated cooling air supply

Standard interfaces

Analog output Analog inputs Relay outputs Digital inputs Communication

1 output 0/2/4 ... 22 mA

(active) for selectable output of measured variables:

● Velocity

● Volume flow act.

● Volume flow std.

● Temperature

● Resolution 12

Subject to change w ithout notice

2 inputs 0 ... 20 mA

(standard; without

electric isolation) or

0 ... 5/10 V for selectable

input of optional entry of

calculation variables

(temperature, pressure,

moisture) resolution

12 bit

5 changeover contacts

(48 V 1 A) to output

status signals:

● Operation/malfunction

● Maintenance

● Check cycle

● Warning

● Limit value

2 inputs for connecting

potential-free contacts

(e.g. for connecting a

maintenance switch or

triggering a check cycle)

● USB 1.1 and RS232

(on terminals) for

measured value

inquiries, setting

parameters and firmware updates

● RS485 to connect

sensors

FLOWSIC100 · Operating Instructions · 8012513/YSA5/V 2-1/2016-07 · © SICK Engineering GmbH 31

Page 32

Control unit MCU in 19” enclosure with options

SICK

M

ULTI CONTROL UNIT

POWER

FAILURE

MAINTENANCE

REQUEST

INTERFACE-MODULE

I/O-MODULE

POWER

ERROR

TxD RxD

Slots for optional I/O modules

Backplane with terminal connections for wiring by customer

Power

Slot for interface module option

Display module option

Product Description

32 FLOWSIC100 · Operating Instructions · 8012513/YSA5/V2-1/2016-07 · © SICK Engineering GmbH

Subject to change w ithout notice

Page 33

Product Description

MCU

Relay 5

Relay 4

Relay 3

Relay 2

Relay 1

Processor

Optional I/O module(s)

Display module option

Interface module option

RS232

USB 1.1

Analog

inputs

1 and 2

Analog

output

Digital

inputs

1 to 4

Wide-range

power pack

Relays

1 to 5

90 ... 250 V AC

Block Diagram

Fig. 19 MCU block circuit diagram

Subject to change w ithout notice

FLOWSIC100 · Operating Instructions · 8012513/YSA5/V 2-1/2016-07 · © SICK Engineering GmbH 33

Page 34

Product Description

Options

Using the following options, the functionality of the MCU can be extended considerably:

1 Display module

Module to display measured values and status information of the connected sensors

using control buttons (capacitive sensors). The integration of this module into already

delivered control units can only be done by the supplier.

Displays

Typ e Display

Power (green) Voltage supply OK

LED

Failure (red) Functional failure

Maint. request (yellow) Maintenance request

Two of a variety of possible measured values:

Volume flow in operating state (Q a.c.)

Volume flow in standard state (Q std.)

Gas flow rate (VoG)

LC-Display

Graphical display

(main display)

Sound velocity (SoS)

Acoustic temperature (T ac)

Transducer temperature A (T A)

Transducer temperature B (T B)

Signal to noise ratio A (SNR A)

Signal to noise ratio B (SNR B)

Mass flow

Text display 6 possible measured values (see graphical display)

The measurement screen displays bar graphs of two selectable main measured values

of a connected sensor or of the MCU. Alternatively, up to 8 individual measured values

of a sensor can be displayed (switching with button “Meas”).

Fig. 20 LC-Display in graphical display (left) and in text display (right)

If a limit value is exceeded, the display alternates between the measured value and an

alarm message.

Subject to change w ithout notice

34 FLOWSIC100 · Operating Instructions · 8012513/YSA5/V2-1/2016-07 · © SICK Engineering GmbH

Page 35

Product Description

Control buttons

Button Function

● Selects the single measured value to be displayed

Meas

● Toggles between text display and graphical display

● Displays the contrast settings (after 2.5 s)

Arrows ● Selects next/previous measured value screen

Status ● Displays alarm or error messages

Menu ● Display of main menu

The following functions are additionally available in the display module:

–Entering parameters for start-up

– Initiating a check cycle

– Switching to Maintenance mode.

2 I/O module

For installation on module carriers, communication via I²C bus, or in rack (MCU in 19”

enclosure), selectable as:

– 2x analog output 0/4 ... 22 mA to output further measured variables (load 500

– 2x analog input 0/4 ... 22 mA to read in values from external sensors

)

● One module carrier is necessary for each module (to insert on top

hat rail). One module carrier has to be connected to the processor

board with a special cable, other module carriers can be docked to

it.

● Maximum for installation and use:

–2 optional AO modules

–1 optional AI module

3 Interface module

Modules to pass measured values, system status and service information to higher

level control systems, optional for Profibus DP, Ethernet and Modbus, for insertion in

slot (

p. 36, Fig. 21).

Profibus DP-V0 for transfers via RS485 according to DIN 19245 Part 3 as

well as IEC 6115

Subject to change w ithout notice

FLOWSIC100 · Operating Instructions · 8012513/YSA5/V 2-1/2016-07 · © SICK Engineering GmbH 35

Page 36

MCU processor board connections

12 34

98

10

11

12

5

6

7

1 Supply voltage 24 V DC

2RS232

3 Connection for I/O module

option

4 Connection for display module

5 Connection for LEDs

6 Connection for interface

module option

7 USB plug-in connector

8 Connections for sender/

receiver units

9 Connections for relays 1 to 5

10 Connections for analog inputs 1

and 2

11 Connection for analog output

12 Connections for digital inputs 1

to 4 (digital inputs 3 and 4 not

supported at present)

Fig. 21 MCU processor board connections

Product Description

36 FLOWSIC100 · Operating Instructions · 8012513/YSA5/V2-1/2016-07 · © SICK Engineering GmbH

Subject to change w ithout notice

Page 37

Product Description

Control unit type key: MCU-X X X X X X X X X X X X X X

Integrated cooling air supply

- N: Without blower

- P: With blower

- C: Without blower + cooling air control option 24 V

- D: Without blower + cooling air control option 230 V

- E: With blower + cooling air control 24 V

Voltage supply

- W: 90 ... 250 V AC

- 2: Optional 24 V DC

Housing variant

- O: Wall enclosure compact, painted SICK orange,

stainless steel 1.4016 or equivalent

- R: 19“- housing

Display module

- N: Without

- D: With

Other options

- N: Without

Analog input option (plug-in module; 0/4...20 mA; 2 inputs per module)

- 0: Without

- n: With, n = 1. 2 2)

Analog output option (plug-in module; 0/4...22 mA; 2 outputs per module)

- 0: Without

- n: With, n = 1. 2 2)

Digital input option (plug-in module; 4 inputsper module)

- 0: Without

- n: Number on request

Digital output power option (plug-in module; 48 V DC, 5 A; 2 changeover contacts

per module)

- 0: Without

- n: Number on request

Digital output low power option (plug-in module; 48 V DC, 0.5 A; 4 NO contacts

per module)

- 0: Without

- n: Number on request

Optional Interface module

- N: Without

- B: T/P-MOD Ethernet V1,COLA-B, pulse 3)

- V: T/P-MOD Ethernet V1, COLA-B, 3-fold, pulse 3)

- Q: T/P-MOD Ethernet V2,MODBUS TCP, pulse 3)

- D: T/P-MOD RS485,MODBUS ASCII/RTU, pulse 3)

- F: T/P-MOD RS485,PROFIBUS, pulse 3)

Special features

- N: Without special version

Ex certification

- N: Without Ex certification

Typ e key MCU

The various configuration options are defined by the following type key:

Subject to change w ithout notice

FLOWSIC100 · Operating Instructions · 8012513/YSA5/V 2-1/2016-07 · © SICK Engineering GmbH 37

Page 38

Product Description

Software

- E: Emission

2): Up to 4 analog modules on request

3): Pulse not available

Example: MCU-NWODN01000PNNE

Without cooling air suppy

Wide-range power pack 90…250V AC

Wall enclosure SICK orange

With display module

Without other options

Without optional analog input module

With one optional analog output module

Without optional digital input module

Without optional digital output module, 2 changeover contacts

Without optional digital output module, 4 NO contacts

With optional interface module Profibus DP

Without special version

Without Ex certification

Software Emission

38 FLOWSIC100 · Operating Instructions · 8012513/YSA5/V2-1/2016-07 · © SICK Engineering GmbH

Subject to change w ithout notice

Page 39

Product Description

Onsite cable

Standard cables

Master (lengths 5 m, 10 m, 50 m)

Slave (5 m, 10 m, 50 m)

FLSE100 Master (A)

FLSE100 Slave (B)

Connection cable, Master

(Li2YCYv(TP) 3x2x0.5 mm²)

Connection cable, Slave

(Li2YCYv(TP) 2x2x0.5 mm²)

2.3.5 Connection cable

The connection cables master (Master FLSE100) and slave (Slave FLSE100) are used to

connect the sender/receiver units with the control unit MCU. Both cables are available in

different lengths. The connection cable master is marked with a red marker behind the

cable box.

Fig. 22 Connection cable

Cables provided onsite must fulfill the following requirements (see also

page 97, § 3.3.6):

● Lead/lead operational capacity less than 110 pF/m

● Min. lead cross-section 0.5 mm

We recommend cable type UNITRONIC Li2YCYv(TP) 2x2x0.5 mm

2

(AWG20).

2

with reinforced outer

sheath (from Lappkabel).

The total length of the cable between junction box and MCU (onsite cable) can be up to

1000 m.

When connecting bus versions with several sensors (p. 14, Fig. 3), the maximum cable length is reduced as follows depending on the number of sam-

Subject to change w ithout notice

pling points connected:

● Cable length with + 1 sampling point = 1000 m

● Cable length with + 2 sampling points = 500 m

FLOWSIC100 · Operating Instructions · 8012513/YSA5/V 2-1/2016-07 · © SICK Engineering GmbH 39

Page 40

2.3.6 Purge air unit option

Air filter

Blower

Base plate

Purge air hose

The purge air unit is used to supply the sender/receiver units of the types FLSE100-PM, PH

and PHS with clean purged air.

Fig. 23 Purge air unit SLV 1

Depending on the internal duct pressure, use additional reducers

(optional purge air reducer set) or a purge air unit with a more powerful blower as shown in

the following Table.

Product Description

Internal duct pressure (mbar) Reducer Blower type

-100 ... -20 40/7

2BH1300-20 ... -10 40/10

-10 ... +30 -

+30 ... +100 - 2BH1400

40 FLOWSIC100 · Operating Instructions · 8012513/YSA5/V2-1/2016-07 · © SICK Engineering GmbH

Subject to change w ithout notice

Page 41

Product Description

2.3.7 Cooling air control option for device types M-AC and H-AC

The "Cooling air control for device types M-AC and H-AC" subassembly serves minimizing

the number of temperature drops below the dewpoint on the ultrasonic transducer. The

cooling air blower is switched on or off depending on the transducer temperature. Cooling

therefore only runs for appropriately high gas or transducer temperatures. This prevents

permanent cooling air operation overcooling the probe. Setting the required limit values for

switching the cooling air supply on and off is made in SOPAS ET (

2.3.8 Optional sets for emergency air supply for device types with purge and cooling air

p. 150, 4.3.5).

operation

The optional sets for emergency air supply serve preventing severe damage to transducers

should the purge/cooling air supply fail. The sets are usable as described in the respective

written versions for the FLOWSIC100 measuring system with 1-path configuration, SOPAS

application setting "FLOWSIC100". The emergency air supply systems monitor failures in

supply voltage for the purge air blower. Prerequisite for using the sets for emergency air

supply is the on-site provision of compressed air free from oil and dust.

WARNING:

The emergency air supply systems only provide temporary protection for transducers against overheating (several hours) and must never be used as alternatives for standard purge/cooling air supply because there is a risk that the

emergency air supply systems create interfering noise on the transducers and

therefore influence measurement. On devices purged externally (FL100 PM,

PH and

PH-S), there is also a risk of the emergency air not keeping transducer surfaces

sufficiently clean.

Subject to change w ithout notice

FLOWSIC100 · Operating Instructions · 8012513/YSA5/V 2-1/2016-07 · © SICK Engineering GmbH 41

Page 42

2.3.8.1 Emergency air supply for device types M-AC and H-AC

Prerequisites:

1 Compressed air free from oil, dust and water provided by the customer.

2 Compressed air requirement about 9…11 m3/h

3 Primary pressure at least 1.5 bar (measurable with emergency air in operation).

Product Description

Cooling function during normal device operation (

p. 87, 3.3.4.1)

In normal operation, cooling air for sender/receiver units is supplied via the MCU blower

unit or, optionally, via a blower unit in a separate enclosure (

p. 180, Fig. 147).

Air path in normal operation (cooling air supply via MCU blower unit):

- Air entry in the MCU suction opening - air filter - blower unit - flexible DN25 hoses backflow valve - cooling air inlet S/R unit - cooling air discharges from S/R unit (after

deflection in probe tube).

The "backflow valve" is open in forward direction (rubber poppet valve).

Cooling function in emergency operation (cooling air failure due to interruption or

failure of the voltage supply to the cooling air blower)

An installed solenoid valve releases a flow of compressed air should the standard cooling

air fail. If the compressed air flow is pressurized, the emergency air valve (

p. 87, Fig. 57)

with integrated backflow valve closes in the blocking direction and the compressed air

flows into the cooling channels of both S/R units (

p. 87, Fig. 57).

42 FLOWSIC100 · Operating Instructions · 8012513/YSA5/V2-1/2016-07 · © SICK Engineering GmbH

Subject to change w ithout notice

Page 43

Product Description

Fitting on

both sides

Tube and flanges

made of St37 or

1.4571 (other materials on request)

L = 5 x DN

for DN 150

to DN 200

L = 3 x DN

for DN > 200

to DN 500

Flange according to

DIN 2573

Fitting on one

side

A

A

A

A

L

A - A

A - A

2.3.8.2 Emergency air supply for device types PM, PH and PH-S

Prerequisites:

1 Compressed air free from oil, dust and water provided by the customer.

2 Compressed air requirement:

Gas temperature Primary pressure Consumption

Up to 200°C 1.0 bar Approx. 6 m3/h

Up to 300°C 1.5 bar Approx. 8 m3/h

Up to 400°C 2.0 bar Approx. 10 m3/h

Versions:

Designation Part No.

Emergency air supply for 1 purge air unit 380 V AC 7042118

Emergency air supply for 1 purge air unit 230 V AC 7042117

Emergency air supply for 2 purge air units 230 V AC 7042119

Emergency air supply for 2 purge air units 380 V AC 7042120

2.3.9 Measuring tube option

A tube piece, as shown in Fig. 24, can be supplied for pipelines with diameters up to max.

DN500 for easy mounting (welding the flanges with tube). Basis for exact design are

customer-specific data.

Subject to change w ithout notice

Fig. 24 Measuring tube option

FLOWSIC100 · Operating Instructions · 8012513/YSA5/V 2-1/2016-07 · © SICK Engineering GmbH 43

Page 44

2.4 Computations

k

v

A

v

------- -=

2.4.1 Calculating and calibrating the volume flow

Volume flow in operating state

Acoustic velocity monitors from the FLOWSIC100 series are usually used to determine the

volume flow in closed pipes and ducts. The volume flow Q

cross-sectional area A and the mean gas flow rate across the cross-section v

velocity) is defined as:

Q

= v

· A

act.

A

The FLOWSIC100, however, determines the representative mean value of the flow velocity

on a sound path v (path velocity) between the two sender/receiver units. The sound path is

generally arranged across the diameter (

p. 51, 3.1.1).

Since the mean values of the path and area velocity are not identical (particularly in small

duct diameters), a functional, systematic correlation between the calculated path velocity

and the mean area velocity similar to the point-based flow measurement (for example, a

pitot tube probe) has been introduced.

v

= K · v K = correction function

A

The correction factor k can be used for K with unimpeded, axial-symmetric flow profiles in

round pipes.

0.9 < k < 1

In many cases, however, an unimpeded, axial-symmetric flow profile is not guaranteed due

to the installation conditions (short inlet sections, rectangular ducts, unsymmetrical flow

profiles, and so on). For this reason, a second degree calibration function has been

implemented in FLOWSIC to show the relation between middle path and area velocity.

v

= Cv_2 · v

A

2

+ Cv_1 · v + Cv_0

Product Description

through the representative

a.c.

(area

A

If the flow in a round pipeline is unimpeded and axial-symmetric, Cv_1 is

equal to the correction factor k.

The coefficients in this calibration function can be determined by means of network

measurements and regression analysis (see DIN EN 13284-1). The calculated regression

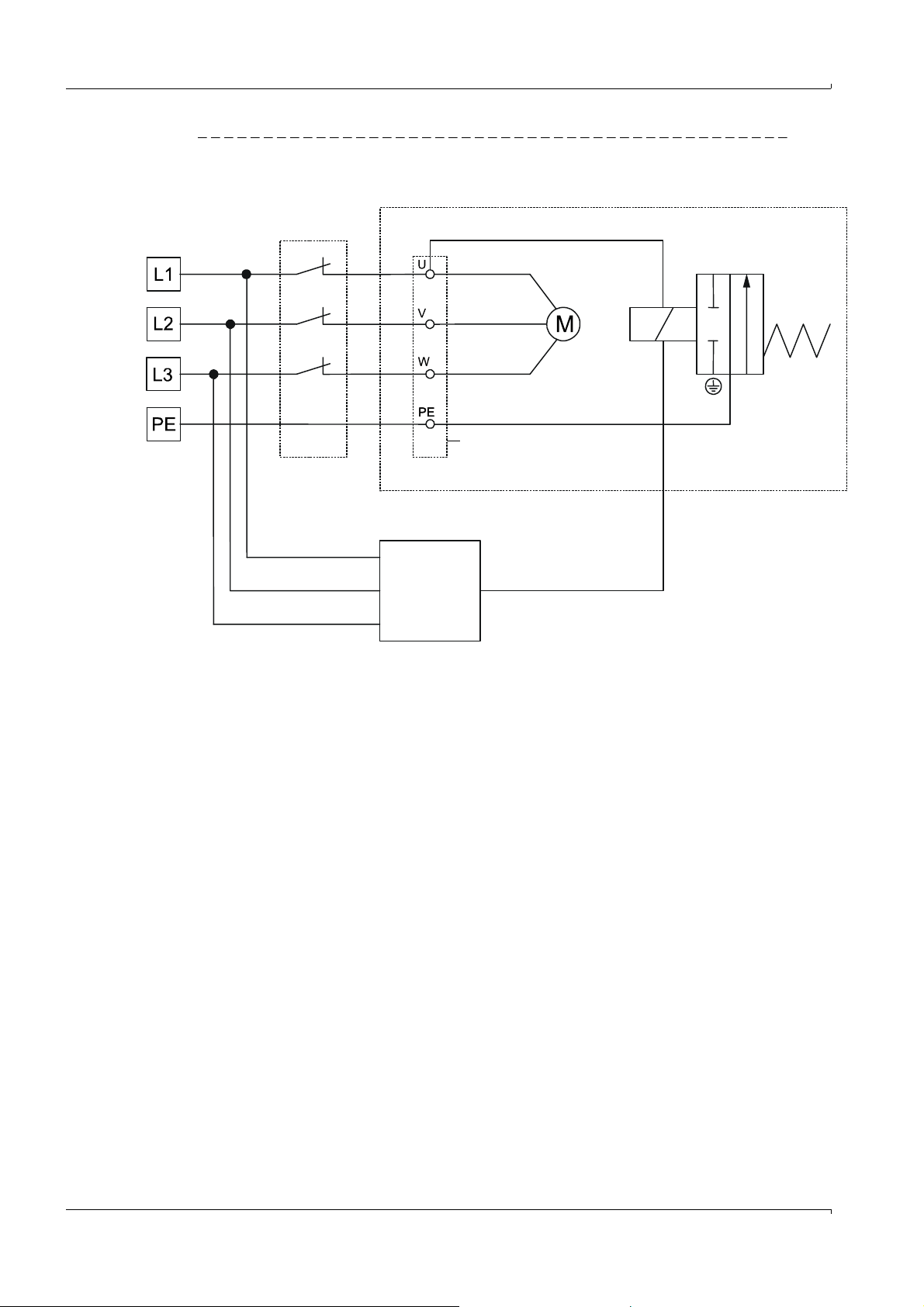

coefficients must then be entered in the measuring device using SOPAS ET (