Page 1

O P E R A T I N G I N S T R U C T I O N S

Flexi Soft Modular Safety Controller

Hardware

Page 2

Described product

F

lexi Soft Modular Safety Controller

Hardware

Manufacturer

SIC

K AG

Erwin-Sick-Str. 1

79183 Waldkirch

Germany

Legal information

his work is protected by copyright. Any rights derived from the copyright shall be

T

reserved for SICK AG. Reproduction of this document or parts of this document is only

permissible within the limits of the legal determination of Copyright Law. Any modifica‐

tion, abridgment or translation of this document is prohibited without the express writ‐

ten permission of SICK AG.

The trademarks stated in this document are the property of their respective owner.

© SICK AG. All rights reserved.

Original document

T

his document is an original document of SICK AG.

2

O PE R AT I NG IN S TR U CT I ON S | Flexi Soft Modular Safety Controller 8012478/15UF/2019-10-31 | SICK

Subject to change without notice

Page 3

Contents

CONTENTS

1 About this document........................................................................ 7

1.1 Purpose of this document........................................................................ 7

1.2 Scope......................................................................................................... 8

1.3 Information depth..................................................................................... 9

1.4 Target group.............................................................................................. 9

1.5 Further information................................................................................... 9

1.6 Symbols and document conventions...................................................... 9

2 On safety............................................................................................. 11

2.1 General safety notes................................................................................ 11

2.2 Intended use............................................................................................. 11

2.3 Requirements for the qualification of personnel.................................... 12

3 Product description........................................................................... 13

3.1 System characteristics............................................................................. 13

3.2 Version, compatibility, and features........................................................ 14

3.3 Construction and function........................................................................ 16

3.4 Modules..................................................................................................... 18

3.4.1 FX3-CPU0 main module.......................................................... 19

3.4.2 FX3-CPU1 main module.......................................................... 19

3.4.3 FX3-CPU2 main module.......................................................... 20

3.4.4 FX3-CPU3 main module.......................................................... 21

3.4.5 FX3-MPL0 and FX3-MPL1 system plugs................................ 23

3.4.6 FX3-XTIO I/O module............................................................... 23

3.4.7 FX3-XTDI I/O module............................................................... 27

3.4.8 FX3-XTDS I/O module.............................................................. 29

3.4.9 FX0-STIO I/O module............................................................... 31

3.4.10 Drive Monitor FX3-MOC0......................................................... 33

3.4.11 Drive Monitor FX3-MOC1......................................................... 36

3.4.12 FX3-ANA0 analog input module.............................................. 39

3.4.13 UE410-2RO/UE410-4RO relay modules................................ 41

3.5 Interfaces.................................................................................................. 43

3.5.1 RS-232..................................................................................... 43

3.5.2 USB........................................................................................... 44

3.5.3 Enhanced Function Interface (EFI)......................................... 44

3.6 Special functions...................................................................................... 45

3.6.1 Flexi Link................................................................................... 45

3.6.2 Flexi Line.................................................................................. 46

3.6.3 Muting....................................................................................... 47

3.6.4 Automatic configuration recovery (ACR)................................. 48

4 Mounting............................................................................................. 49

5 Electrical installation........................................................................ 51

8012478/15UF/2019-10-31 | SICK O P ER A TI N G I NS T RU C TI O NS | Flexi Soft Modular Safety Controller

Subject to change without notice

3

Page 4

CONTENTS

5.1 Requirements to be met by the electrical installation........................... 51

5.2 Description of the terminals.................................................................... 53

5.2.1 FX3-CPU0 main module.......................................................... 53

5.2.2 FX3-CPU1 and FX3-CPU2 main modules............................... 54

5.2.3 FX3-CPU3 main module.......................................................... 55

5.2.4 FX3-XTIO I/O module............................................................... 56

5.2.5 FX3-XTDI I/O module............................................................... 57

5.2.6 FX3-XTDS I/O module.............................................................. 58

5.2.7 FX0-STIO I/O module............................................................... 59

5.2.8 Drive Monitor FX3-MOCx......................................................... 59

5.2.9 FX3-EBX1, FX3-EBX3, and FX3-EBX4 encoder/motor feed‐

bac

k connection boxes............................................................ 60

5.2.10 Encoder connection cables..................................................... 69

5.2.11 FX3-ANA0 analog input module.............................................. 72

5.2.12 UE410-2RO and UE410-4RO relay modules......................... 72

5.3 Wiring for the power supply to a Flexi Soft system................................. 74

5.4 Connection of devices.............................................................................. 74

5.4.1 Safety command devices and electro-mechanical safety

switches.................................................................................... 76

5.4.2 Non-contact safety switches................................................... 82

5.4.3 Testable single-beam photoelectric safety switches............. 83

5.4.4 Electro-sensitive protective devices....................................... 87

5.4.5 Safe outputs Q1 to Q4............................................................. 87

5.4.6 Connection of EFI-enabled devices........................................ 88

5.4.7 Connection of a Pro-face HMI................................................. 89

5.4.8 Connection of encoders.......................................................... 89

5.4.9 Connecting analog sensors..................................................... 94

5.4.10 Connection of a Flexi Link system.......................................... 96

5.4.11 Connecting a Flexi Line system............................................... 98

5.4.12 EMC measures for Flexi Link and Flexi Line........................... 99

6 Configuration..................................................................................... 100

7 Commissioning.................................................................................. 102

7.1 Overall acceptance of the application..................................................... 102

7.2 Checks before initial commissioning....................................................... 102

8 Operation............................................................................................ 104

8.1 Status messages on the FX3-CPUx main module.................................. 104

8.2 Status messages for the FX3-XTIO I/O module...................................... 105

8.3 Status messages for the FX3-XTDI I/O module...................................... 106

8.4 Status messages for the FX3-XTDS I/O module..................................... 107

8.5 Status messages for the FX0-STIO I/O module...................................... 108

8.6 Status signals of the FX3-ANA0 analog input module........................... 109

8.7 Status messages of the Drive Monitor FX3-MOCx.................................. 110

8.8 Status messages of the UE410-2RO and UE410-4RO relay modules.. 111

4

O PE R AT I NG IN S TR U CT I ON S | Flexi Soft Modular Safety Controller 8012478/15UF/2019-10-31 | SICK

Subject to change without notice

Page 5

CONTENTS

9 Maintenance...................................................................................... 112

9.1 Regular thorough check of the safety function by qualified safety per‐

l........................................................................................................ 112

sonne

9.2 Device replacement.................................................................................. 112

10 Diagnostics......................................................................................... 114

10.1 Response to errors................................................................................... 114

10.2 Error states................................................................................................ 114

10.3 Error displays shown by status LEDs, error messages, and trou‐

bleshooting measures.............................................................................. 115

10.4 Error history............................................................................................... 123

10.5 SICK support............................................................................................. 123

11 Decommissioning............................................................................. 124

11.1 Disassembling the modules.................................................................... 124

11.2 Disposal..................................................................................................... 125

11.3 Separation of materials............................................................................ 125

12 Technical data....................................................................................126

12.1 Minimum switch-off time.......................................................................... 126

12.2 Maximum response time of the Flexi Soft system................................. 126

12.2.1 Calculation of the response time............................................ 128

12.3 Data sheet................................................................................................. 135

12.3.1 Main modules FX3-CPU0, FX3-CPU1, FX3-CPU2, and FX3-

CPU3......................................................................................... 135

12.3.2 FX3-XTIO I/O module............................................................... 137

12.3.3 FX3-XTDI I/O module............................................................... 142

12.3.4 FX3-XTDS I/O module.............................................................. 145

12.3.5 FX0-STIO I/O module............................................................... 148

12.3.6 FX3-ANA0 analog input module.............................................. 149

12.3.7 Drive Monitor FX3-MOC0......................................................... 151

12.3.8 Drive Monitor FX3-MOC1......................................................... 157

12.3.9 FX3-EBX1, FX3-EBX3, and FX3-EBX4 for FX3-MOCx

encoder/motor feedback connection boxes.......................... 163

12.3.10 UE410-2RO/UE410-4RO relay modules................................ 165

12.3.11 Diode module DM8-A4K......................................................... 171

12.4 Dimensioned drawings............................................................................. 172

12.4.1 FX3-CPUx main modules with system plug............................ 172

12.4.2 FX3-XTIO, FX3-XTDI, FX3-XTDS, and FX0-STIO I/O modules,

UE410-2RO and UE410-4RO relay modules......................... 173

12.4.3 FX3-ANA0 analog input module.............................................. 174

12.4.4 Drive Monitor FX3-MOCx......................................................... 175

12.4.5 FX3-EBX1, FX3-EBX3, and FX3-EBX4 encoder/motor feed‐

back connection boxes............................................................ 176

12.4.6 Diode module DM8-A4K......................................................... 179

13 Ordering information........................................................................ 180

8012478/15UF/2019-10-31 | SICK O P ER A TI N G I NS T RU C TI O NS | Flexi Soft Modular Safety Controller

Subject to change without notice

5

Page 6

CONTENTS

13.1 System plugs and modules...................................................................... 180

13.2 Accessories............................................................................................... 182

14 List of abbreviations..........................................................................185

15 Appendix............................................................................................. 186

15.1 Compliance with EU directives................................................................. 186

15.2 Checklist for the manufacturer................................................................ 187

16 List of figures..................................................................................... 188

17 List of tables....................................................................................... 190

6

O PE R AT I NG IN S TR U CT I ON S | Flexi Soft Modular Safety Controller 8012478/15UF/2019-10-31 | SICK

Subject to change without notice

Page 7

ABOUT THIS DOCUMENT 1

1 About this document

1.1 Purpose of this document

These operating instructions contain the information required during the life cycle of the

lexi Soft modular safety controller.

F

These operating instructions are to be made available to all those who work with the

Flexi Soft modular safety controller.

For the Flexi Soft system, there are operating instructions and mounting instructions, each covering clearly defined

f

ields of application.

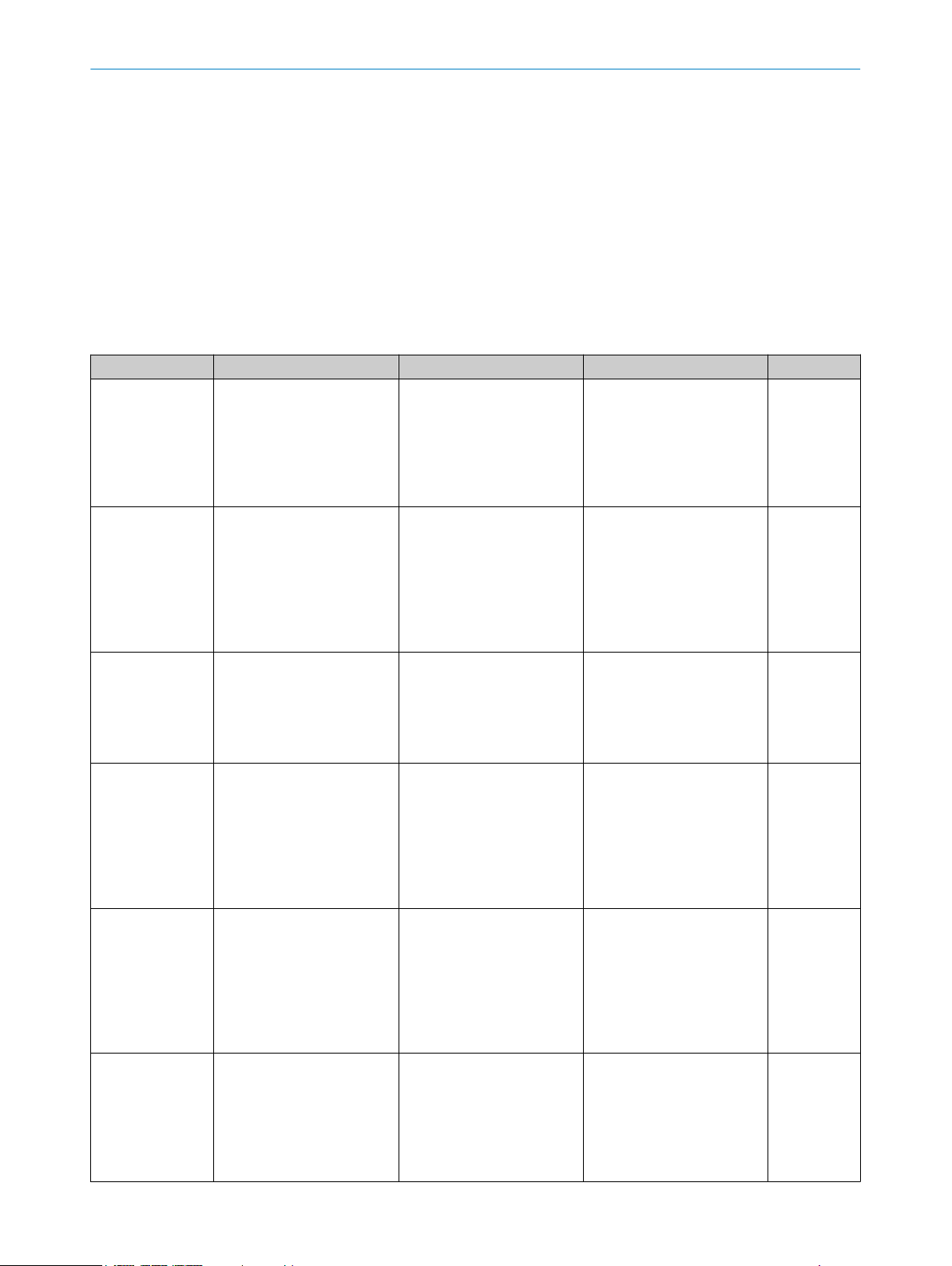

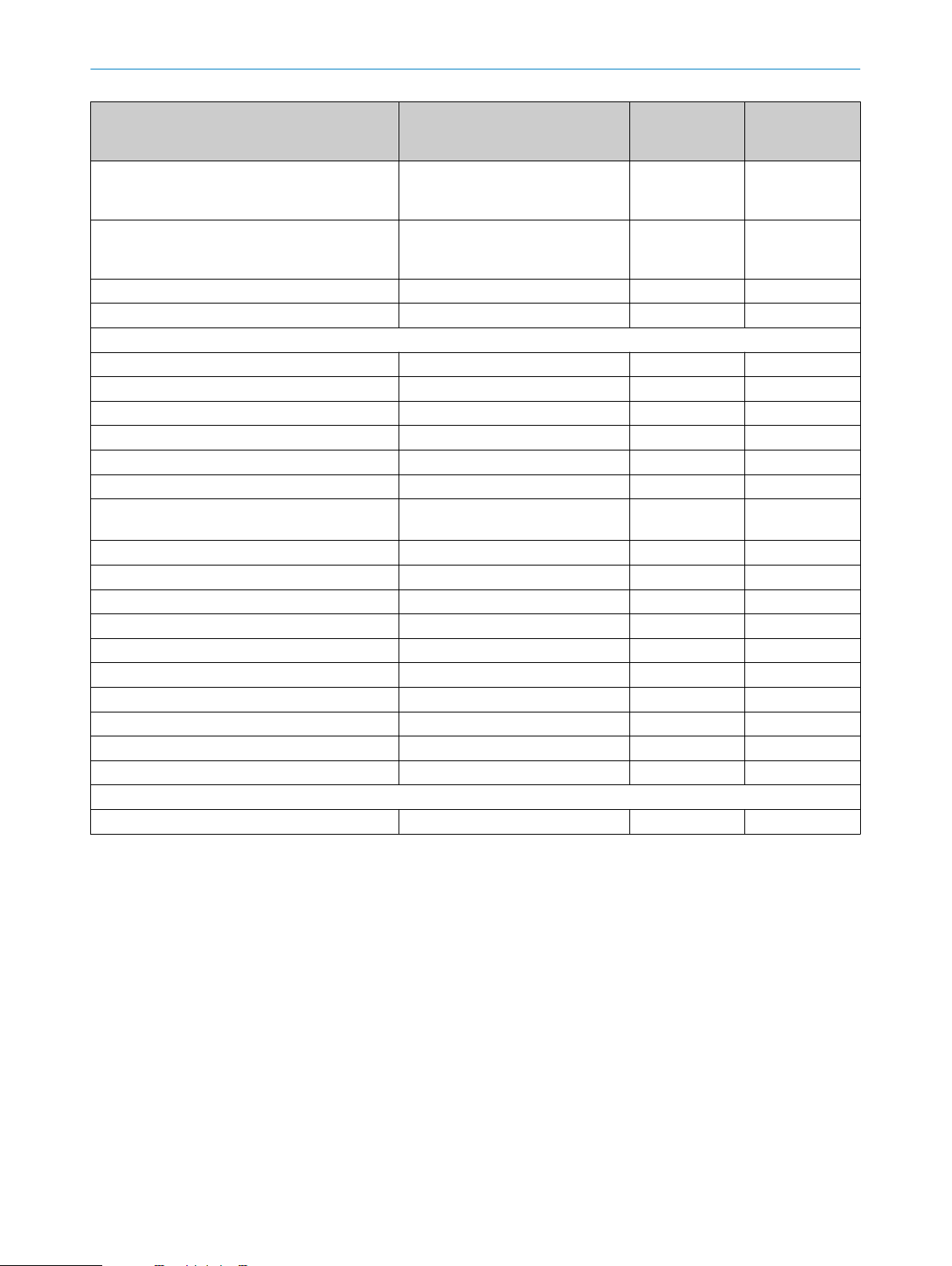

Table 1: Overview of the Flexi Soft documentation

Document type Title Contents Purpose Part number

Operating instruc‐

ions

t

Operating instruc‐

tions

Operating instruc‐

tions

Operating instruc‐

ions

t

Operating instruc‐

tions

Operating instruc‐

tions

Flexi Soft Modular

Safety Controller

Hardware

Flexi Soft in the

Flexi Soft Designer

Configuration software

Safety Designer

Configuration software

Flexi Soft in the

Safety Designer

Configuration software

Flexi Soft Gateways

Hardware

Flexi Soft Gateways in

Flexi Soft Designer

Configuration software

Description of the Flexi Soft

modules and their functions

Description of the softwarebased configuration of the

Flexi Soft safety controller

along with important diag‐

nostics functions and

detailed notes on identifying

and rectifying errors

Description of the installa‐

tion and general basic princi‐

ples of operation

Description of the softwarebased configuration of the

Flexi Soft safety controller

along with important diag‐

nostics functions and

detailed notes on identifying

and rectifying errors

Description of the Flexi Soft

gateways and their functions

Description of the softwarebased configuration of the

Flexi Soft gateway, informa‐

tion about data exchange in

networks as well as about

the status, planning, and

associated mapping

Instructions for technical

personnel working for the

machine manufacturer or

operator on the safe mount‐

ing, electrical installation,

and maintenance of the

Flexi Soft safety controller

Instructions for technical

personnel working for the

machine manufacturer or

operator on the safe configu‐

ration and commissioning,

as well as the safe opera‐

tion, of the Flexi Soft safety

controller

To provide technical person‐

nel working for the machine

manufacturer/operator with

instructions so that they can

use the Safety Designer con‐

figuration software

Instructions for technical

personnel working for the

machine manufacturer or

operator on the safe configu‐

ration and commissioning,

as well as the safe opera‐

tion, of the Flexi Soft safety

controller

To provide technical person‐

nel working for the machine

manufacturer/operator with

instructions so that they can

safely carry out the mount‐

ing, electrical installation,

and maintenance work for

the Flexi Soft gateways

To provide technical person‐

nel working for the machine

manufacturer/operator with

instructions so that they can

safely configure and com‐

mission the Flexi Soft gate‐

ways

8012999

8012998

8018178

8013926

8012662

8012483

8012478/15UF/2019-10-31 | SICK OP E RA T IN G I N ST R UC T IO N S | Flexi Soft Modular Safety Controller

Subject to change without notice

7

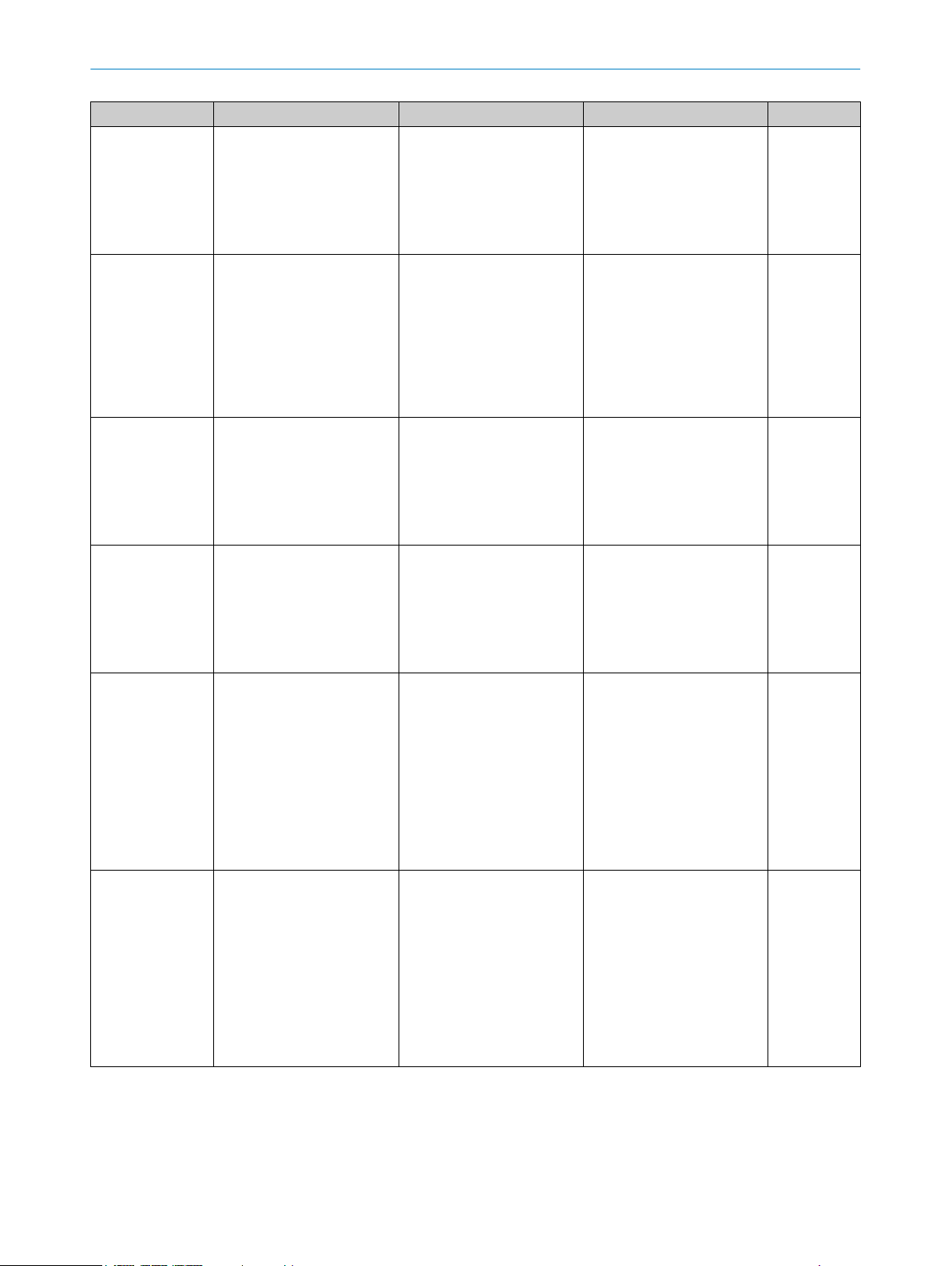

Page 8

BOUT THIS DOCUMENT

1 A

Document type Title Contents Purpose Part number

Operating instruc‐

t

ions

Operating instruc‐

tions

Operating instruc‐

tions

Operating instruc‐

tions

Mounting instruc‐

tions

Mounting instruc‐

tions

Flexi Soft Gateways in the

Safety Designer

Configuration software

Flexi Loop

safe series connection

Hardware

Flexi Loop in Safety Designer

Configuration software

Flexi Loop in the

Flexi Soft Designer

configuration software

Flexi Soft FX3-EBX3 and

FX3-EBX4 Encoder/Motor

Feedback Connection Boxes

Flexi Soft FX3-EBX1 Opti‐

mized Dual Encoder/Motor

Feedback Connection Box

Description of the softwarebased configuration of the

Flexi Soft gateway, informa‐

tion about data exchange in

networks as well as about

the status, planning, and

associated mapping

Description of the Flexi Loop

safe series connection and

its functions

Description of how to config‐

ure and set the parameters

for the Flexi Loop safe series

connection using software

Description of how to config‐

ure and set the parameters

for the Flexi Loop safe series

connection using software

Description of FX3-EBX3 and

FX3-EBX4 encoder/motor

feedback connection boxes

Description of the FX3-EBX1

optimized dual encoder/

motor feedback connection

box

To provide technical person‐

nel working for the machine

manufacturer/operator with

instructions so that they can

safely configure and com‐

mission the Flexi Soft gate‐

ways

To provide technical person‐

nel working for the machine

manufacturer/operator with

instructions so that they can

safely carry out the mount‐

ing, electrical installation,

and maintenance work for

the Flexi Loop safe series

connection

To provide technical person‐

nel working for the machine

manufacturer/operator with

instructions so that they can

safely configure and com‐

mission the Flexi Loop safe

series connection

To provide technical person‐

nel working for the machine

manufacturer/operator with

instructions so that they can

safely configure and com‐

mission the Flexi Loop safe

series connection

To provide technical person‐

nel working for the machine

manufacturer/operator with

instructions so that they can

safely carry out the mount‐

ing, electrical installation,

commissioning, and mainte‐

nance work for FX3-EBX3

and FX3-EBX4 encoder/

motor feedback connection

boxes

To provide technical person‐

nel working for the machine

manufacturer/operator with

instructions so that they can

safely carry out the mount‐

ing, electrical installation,

commissioning, and mainte‐

nance work for the FX3EBX1 optimized dual

encoder/motor feedback

connection box

8018170

8015834

8018174

8014521

8015600

8019030

1.2 Scope

8

O PE R AT I NG IN S TR U CT I ON S | Flexi Soft Modular Safety Controller 8012478/15UF/2019-10-31 | SICK

These operating instructions apply to all modules of the Flexi Soft safety controller with

he exception of the Flexi Soft gateway.

t

Subject to change without notice

Page 9

This document forms an integral part of SICK part number 8012999 (the “Flexi Soft

modular s

guages).

These operating instructions provide technical personnel of the machine manufacturer

or the machine operator instructions regarding the safe assembly, electrical installa‐

tion, commissioning, operation and maintenance of the Flexi Soft modular safety con‐

troller.

These operating instructions do not provide information on operating the machine in

which a safety controller is integrated. For information about this, refer to the operating

instructions of the specific machine.

1.3 Information depth

These operating instructions contain information about the modular Flexi Soft safety

cont

roller on the following topics:

ABOUT THIS DOCUMENT 1

afety controller hardware” in operating instructions in all available lan‐

Mount

•

Electrical installation

•

Hardware commissioning

•

The planning and use of SICK protective devices requires technical skills that are not

vered by this document.

co

The official and legal regulations for operating the Flexi Soft modular safety controller

must always be complied with.

1.4 Target group

These operating instructions are intended for planning engineers, developers, and oper‐

a

tors of plants and systems that are to be protected by means of a Flexi Soft modular

safety controller. They are also intended for people who integrate the Flexi Soft safety

controller into a machine, carry out its commissioning, or who are in charge of mainte‐

nance.

1.5 Further information

www.sick.com

T

he following information is available via the Internet:

The Flexi Soft operating instructions in various languages for viewing and printing

•

The Flexi Soft Designer configuration software

•

The Safety Designer configuration software

•

Configuration aids

•

Example applications

•

Data sheets

•

Product and application animations

•

CAD data for drawings and dimensional drawings

•

EDS, ESI, GSD, and GSDML files

•

Certificates (such as the EU declaration of conformity)

•

Guide for Safe Machinery (six steps to a safe machine)

•

ing

Fault diagnosis and troubleshooting

•

Ordering information

•

Conformity and approval

•

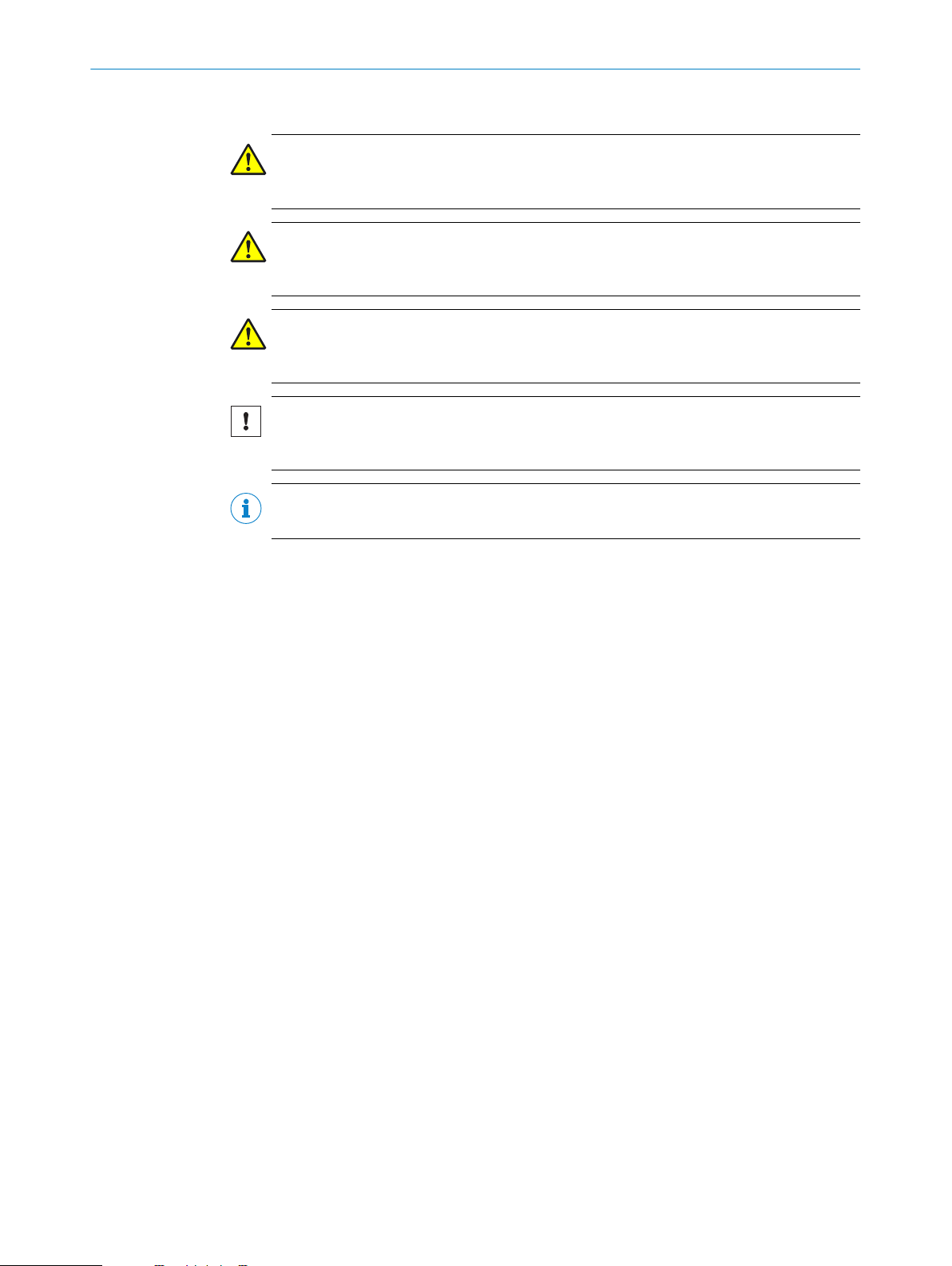

1.6 Symbols and document conventions

The following symbols are used in these operating instructions:

8012478/15UF/2019-10-31 | SICK OP E RA T IN G I N ST R UC T IO N S | Flexi Soft Modular Safety Controller

Subject to change without notice

9

Page 10

1 A

BOUT THIS DOCUMENT

Safety notes and other notes

DANGER

ates a situation presenting imminent danger, which will lead to death or serious

Indic

injuries if not prevented.

WARNING

Indic

ates a situation presenting possible danger, which may lead to death or serious

injuries if not prevented.

CAUTION

Indicates a situation presenting possible danger, which may lead to moderate or minor

injuries if not prevented.

NOTICE

ates a situation presenting possible danger, which may lead to property damage if

Indic

not prevented.

NOTE

Indic

ates useful tips and recommendations.

Instructions to action

he arrow denotes instructions to action. Read carefully and follow the instructions

T

b

for action.

LED symbols

These symbols indicate the status of an LED:

The LED is off.

o

The LED is flashing.

Ö

The LED is illuminated continuously.

O

10

O PE R AT I NG IN S TR U CT I ON S | Flexi Soft Modular Safety Controller 8012478/15UF/2019-10-31 | SICK

Subject to change without notice

Page 11

2 On safety

This chapter contains general safety information about the Flexi Soft modular safety

roller.

cont

More safety information about specific usage situations for the Flexi Soft modular

safety controller is provided in the respective chapters.

2.1 General safety notes

WARNING

proper mounting or use

Im

The target safety-related level may not be achieved in the event of non-compliance.

When mounting, installing, and using the Flexi Soft safety controller, remember to

b

observe all applicable standards and directives.

Observe the relevant national and international legal provisions for the installation

b

and use of the Flexi Soft safety controller, its commissioning, and technical inspec‐

tions repeated at regular intervals.

The manufacturer and operator of the machine on which the Flexi Soft safety con‐

b

troller is used are responsible for liaising with the relevant authorities about all

applicable safety regulations/rules and for ensuring compliance with these.

The notes, in particular the test notes, in these operating instructions (e.g. regard‐

b

ing use, mounting, installation, or integration into the machine controller) must

always be observed.

The thorough checks must be carried out by qualified safety personnel or specially

b

qualified and authorized personnel, and must be recorded and documented by a

third party to ensure that the tests can be reconstructed and retraced at any time.

ON SAFETY 2

2.2 Intended use

The Flexi Soft modular safety controller is an adjustable control for safety applications.

It is t

•

•

•

The safety level actually achieved is determined by the external wiring, how the wiring is

implemented, the configuration, the selection of command triggers, and how they are

arranged on the machine.

The Flexi Soft system satisfies the requirements for industrial areas in accordance with

t

only suitable for use in industrial environments.

The Flexi Soft system must only be used within the limits of the prescribed and speci‐

fied technical data and operating conditions at all times.

NOTICE

Incor

date any warranty from SICK; in addition, any responsibility and liability of SICK for dam‐

age and secondary damage caused by this is excluded.

The external power supply of the Flexi Soft modules must be capable of buffering brief

po

SELV power supply units are available as accessories from SICK.

o be used in accordance with the following standards:

IEC 61508 up to SIL3

EN 62061 up to SILCL3

EN ISO 13849-1 up to performance level e

he generic standard for emitted interference. Consequently, the Flexi Soft system is

rect use, improper modification or manipulation of the Flexi Soft system will invali‐

wer failures of 20 ms as specified in EN 60204-1, for example. Suitable PELV and

8012478/15UF/2019-10-31 | SICK OP E RA T IN G I N ST R UC T IO N S | Flexi Soft Modular Safety Controller

Subject to change without notice

11

Page 12

2 ON S

AFETY

UL/CSA applications:

If t

he product is being used in accordance with UL 508 or CSA C 22.2 No. 142, the fol‐

lowing conditions must also be met:

To protect the device’s 24-volt voltage supply, use a fuse with a maximum voltage

•

of 4 A and a minimum of 30 V DC in accordance with UL 248.

For wiring, only use copper wires with a temperature resistance of at least

•

60 °C / 75 °C, wire cross-section AWG 30–12 for screw terminals and/or

AWG 24–16 for spring terminals.

Tighten the screw terminals with a torque of 5 to 7 lb-in.

•

Only use the devices in an environment with maximum degree of contamination 2.

•

NOTE

he safety functions have not be evaluated by UL. Authorization is in accordance with

T

UL 508, general applications.

2.3 Requirements for the qualification of personnel

Only qualified safety personnel are permitted to configure, mount, connect, commis‐

sion, and maint

ain the Flexi Soft modular safety controller.

Project planning

A person who has expertise and experience in the selection and use of protective

devices on machines and is familiar with the relevant technical rules and national work

safety regulations is considered qualified for project planning.

Mechanical mounting and commissioning

A person who has expertise and experience in the relevant field and is sufficiently famil‐

iar with the application of the protective device on the machine to assess whether or

not it can be operated safely is considered qualified for mechanical installation and

commissioning.

Electrical installation

A person who has expertise and experience in the relevant field and is sufficiently famil‐

iar with the application of the protective device on the machine to assess whether or

not it can be operated safely is considered qualified for electrical installation and com‐

missioning.

Configuration

A person who has expertise and experience in the relevant field and is sufficiently famil‐

iar with the application of the protective device on the machine to assess whether or

not it can be operated safely is considered qualified for configuration.

Operation and maintenance

12

A person who has expertise and experience in the relevant field, is familiar with the

application of the protective device on the machine, and has received instructions from

the operator in how to operate the machine is considered qualified for operation and

maintenance.

O PE R AT I NG IN S TR U CT I ON S | Flexi Soft Modular Safety Controller 8012478/15UF/2019-10-31 | SICK

Subject to change without notice

Page 13

3 Product description

This chapter provides information about the properties of the Flexi Soft system and

scribes its construction and operating principle.

de

3.1 System characteristics

Sensors and switching elements (e.g. light curtains, laser scanners, switches, sensors,

encoder

controller and are linked logically. The corresponding actuators of the machines or sys‐

tems can be switched off safely via the switching outputs of the safety controller.

The Flexi Soft system is distinguished by the following system characteristics:

•

•

•

•

•

•

•

•

•

•

•

s, emergency stop pushbutton) are connected to the Flexi Soft modular safety

Modular design: 1 main module, up to 2 different gateways, and up to 12 expan‐

sion modules

Up to 96 safe digital inputs

Up to 12 safe analog inputs

Up to 48 safe digital outputs or up to 96 non-safe digital outputs

Configurable

.Use of up to 255 logic and application-specific function blocks

Logic function blocks, including, e.g., AND, OR, NOT, XNOR, XOR

Application-specific function blocks including, e.g., emergency stop, two-hand,

muting, presses, ramp-down detection, operating mode selector switch, reset,

restart

Can be integrated into different networks with gateways (EtherNet/IP™, Modbus

TCP, PROFINET IO, PROFIBUS DP, DeviceNet, CANopen and EtherCAT)

Safe gateway for EFI-pro

2 EFI interfaces on FX3-CPU1, FX3-CPU2, and FX3-CPU3 main modules (see "FX3-

CPU1 main module", page 19)

PRODUCT DESCRIPTION 3

1)

2)

The Flexi Soft Designer and Safety Designer configuration softwares are available for

configuration of the control tasks.

NOTE

T

he available range of performance of the Flexi Soft systems depends on the configura‐

tion software used, see "Version, compatibility, and features", page 14.

You will find the configuration software on the Internet: www

1)

The number of expansion modules is limited by the capacity of the FLEXBUS+ backplane bus. A Drive Monitor (FX3-MOCx) requires twice

the bus capacity of the other expansion modules. Therefore, each FX3-MOCx reduces the maximum possible number of expansion mod‐

ules that can be used by two.

2)

Each FX3-ANA0 expansion module provides two analog inputs, which are combined to form one safe channel. An FX3-ANA0 can there‐

fore safely detect an analog process variable using two sensors.

.sick.com

8012478/15UF/2019-10-31 | SICK OP E RA T IN G I N ST R UC T IO N S | Flexi Soft Modular Safety Controller

Subject to change without notice

13

Page 14

3 PRODUCT DESCRIPTION

3.2 Version, compatibility, and features

There are different firmware versions and function packages (so-called “Steps”) for the

lexi Soft product family that permit realization of the different functions. This section

F

provides an overview of which firmware version, which function package and/or which

version of the Flexi Soft Designer configuration software or Safety Designer configura‐

tion software is needed to use a certain function or a certain device.

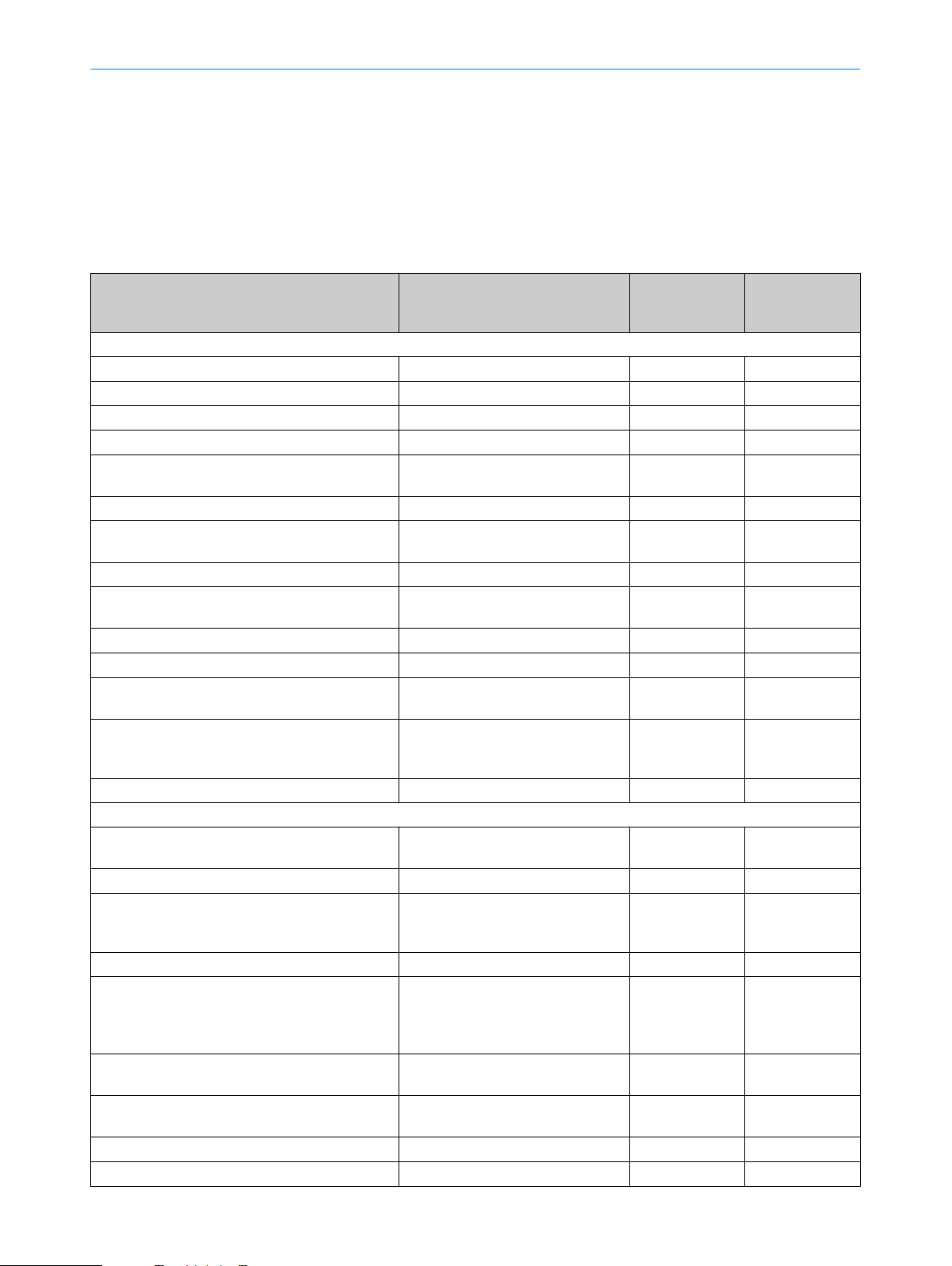

Table 2: Modules, firmware versions, and software versions you will need

Necessary module with firmware

fr

om version

Function blocks and logic

Offline simulation of logic Unrestricted V1.2.0 V1.6.x

Import and export of partial applications Unrestricted V1.3.0 V1.6.x

Automatic circuit diagrams Unrestricted V1.3.0 V1.6.x

Central tag name editor Unrestricted V1.3.0 V1.6.x

Documentation for function blocks of main mod‐

s in logic editor

ule

Matrix of input and output connections Unrestricted V1.3.0 V1.6.x

Invertible inputs for the function blocks AND, OR,

RS Flip-Flop and Routing n:n

Function block for ramp-down detection FX3-CPUx V1.11.0 (Step 1.xx) V1.3.0 V1.6.x

Function blocks for configurable switch-on delay

and conf

Speed to Bool function block FX3-MOC0 V1.10.0 V1.7.0 V1.6.x

Motion Status to Bool function block FX3-MOC0 V1.10.0 V1.7.0 V1.6.x

Verification possible even without identical hard‐

w

Status input data and status output data in logic FX3-CPUx V2.00.0 (Step 2.xx)

Easy applications for FX3-MOC0 FX3-MOC0 V1.10.0 V1.7.1 N. a.

Special functions

Two S3000 safety laser scanners at one EFI

int

Flexi Link FX3-CPU1 V2.00.0 (Step 2.xx) V1.3.0 N. a.

Flexi Loop FX3-CPUx V3.00.0 (Step 3.xx)

Flexi Line FX3-CPU3 V3.00.0 (Step 3.xx) V1.6.0 N. a.

Automatic configuration of connected EFIenabled s

recovery)

Deactivation of test signals Q1 to Q4 on the FX3X

Fast shut-off with bypass at FX3-XTIO FX3-CPUx and FX3-XTIO, each

Multiple safety mats at FX3-XTIO/FX3-XTDI FX3-XTIO or FX3-XTDI, each V1.13.0 V1.3.0 V1.6.x

Data recorder FX3-CPUx V2.00.0 (Step 2.xx) V1.5.0 V1.6.x

igurable switch-off delay

are

erface

afety sensors (automatic configuration

TIO possible

Unrestricted V1.3.0 N. a.

FX3-CPUx V2.00.0 (Step 2.xx) V1.3.0 V1.6.x

FX3-CPUx V2.00.0 (Step 2.xx) V1.3.0 V1.6.x

FX3-CPUx V2.00.0 (Step 2.xx) V1.3.0 V1.6.x

and FX3-XTIO, FX3-XTDI, or FX3XTDS, each V2.00.0 (Step 2.xx)

FX3-CPU1 V1.00.0 V1.2.2 N. a.

and FX3-XTIO, FX3-XTDI, or FX3XTDS, each V3.00.0 (Step 3.xx)

FX3-CPU2 V3.00.0 (Step 3.xx) V1.5.0

FX3-XTIO V2.00.0 (Step 2.xx) V1.3.0 V1.6.x

V2.00.0 (Step 2.xx)

Available from

Flexi Soft

Designer

V1.3.0 V1.6.x

V1.6.0 V1.8.0

(FX3-CPU2)

V1.6.0

(FX3-CPU3)

V1.3.0 V1.6.x

Available from

Safety Designer

N. a.

1)

14

O PE R AT I NG IN S TR U CT I ON S | Flexi Soft Modular Safety Controller 8012478/15UF/2019-10-31 | SICK

Subject to change without notice

Page 15

PRODUCT DESCRIPTION 3

Necessary module with firmware

fr

om version

Available from

Flexi Soft

Available from

Safety Designer

Designer

Extended cross-circuit detection time for the

FX3-XTIO V3.00.0 (Step 3.xx) V1.6.0 V1.6.x

switching of increased capacitive loads at FX3XTIO

Configurable filter time for in/out filters and

in filters at inputs I1 to I8 at FX3-XTIO/FX3-

out/

FX3-XTIO, FX3-XTDI, or FX3-XTDS,

each V3.00.0 (Step 3.xx)

V1.6.0 V1.6.x

XTDI/FX3-XTDS

Optimization of logic execution time FX3-CPUx V4.00.0 (Step 4.xx) V1.7.1 V1.6.x

Automated download No limitation V1.9.1 n.a.

Devices

FX3-CPU0 No limitation V1.2.0 V1.6.x

FX3-CPU1 No limitation V1.2.0 N. a.

FX3-CPU2 No limitation V1.2.0 N. a.

FX3-CPU3 No limitation V1.2.0 N. a.

FX3-XTIO No limitation V1.2.0 V1.6.x

FX3-XTDI No limitation V1.2.0 V1.6.x

Gateways for PROFINET IO, Modbus TCP and Eth‐

et/IP™

erN

FX3-CPUx V1.11.0 (Step 1.xx) V1.2.0 V1.6.x

CC-Link gateway FX3-CPUx V1.11.0 (Step 1.xx) V1.3.0 N. a.

CANopen gateway FX3-CPUx V1.11.0 (Step 1.xx) V1.3.0 V1.6.x

EtherCAT gateway FX3-CPUx V2.00.0 (Step 2.xx) V1.3.0 V1.6.x

EFI-pro gateway FX3-CPUx V4.00.0 (Step 4.xx) N. a. V1.6.x

Speed Monitor MOC3SA Unrestricted V1.3.0 V1.6.x

FX3-MOC0 FX3-CPUx V2.50.0 V1.5.0 N. a.

FX3-MOC1 FX3-CPUx V2.50.0 V1.8.0 V1.6.x

FX3-XTDS Unrestricted V1.6.0 V1.6.x

FX0-STIO Unrestricted V1.6.0 V1.6.x

FX3-ANA0 FX3-CPUx V4.00.0 (Step 4.xx) V1.8.0 V1.7.0

Conformities

RoHS conformity FX3-XTIO FX3-XTIO V1.01.0 – –

1)

N. a. = Not available

2)

All other modules as from market introduction.

8012478/15UF/2019-10-31 | SICK OP E RA T IN G I N ST R UC T IO N S | Flexi Soft Modular Safety Controller

Subject to change without notice

15

Page 16

3 P

RODUCT DESCRIPTION

NOTE

e recent modules are backward compatible so that each module can be

Mor

•

replaced by one with a higher firmware version.

Flexi Soft Designer Version ≥ V1.4.0 can also be used to configure devices with a

•

later version of the firmware, even if Flexi Soft Designer does not yet recognize the

new firmware. In such cases, the user will only be able to access the function

packages (Step 1.xx, Step 2.xx, Step 3.xx, or Step 4.xx) that are supported by the

available version of Flexi Soft Designer.

A corresponding new version of the configuration software is needed in order to

•

use the full functional scope of modules with a later firmware version.

The configuration software is not upwards-compatible. In other words, a project

•

created with a more recent version of the configuration software cannot be

opened with an older version.

The function package (Step 1.xx, Step 2.xx, Step 3.xx, or Step 4.xx) must be

•

selected in the hardware configuration menu of the configuration software. The

availability of a desired function package in the configuration software is shown in

the table.

To use the Step N.xx function package, the relevant module must have a minimum

•

firmware version of VN.00.0. If you try to transfer a configuration in a module with

a lower firmware version, an error message is displayed.

The hardware version of the Flexi Soft modules can be seen in the hardware con‐

•

figuration of the configuration software in online status or in the report if the sys‐

tem was previously online.

You will find the firmware version of the Flexi Soft modules on the type label of the

•

Flexi Soft modules in the firmware version field.

The date of manufacture of a device can be found in the S/N field on the type

•

label in the format yywwnnnn (yy = year, ww = calendar week, nnnn = sequential

serial number in the calendar week).

The version of the configuration software can be found by selecting Info in the

•

Extras menu.

The latest version of the configuration software can be found on the Internet at

•

www.sick.com.

3.3 Construction and function

System construction

lexi Soft system consists of the following modules:

A F

1 Flexi Soft system plug

•

1 Flexi Soft main module

•

Up to 2 Flexi Soft gateways

•

Up to 12 Flexi Soft expansion modules

•

In addition, up to 8 UE410-2RO relay modules and/or up to 4 UE410-4RO relay

•

modules (i.e., a maximum of 16 safe relay outputs)

NOTE

Onl

y those modules listed here can be connected to a Flexi Soft system; other modules

are not permitted.

3)

he number of expansion modules is limited by the capacity of the FLEXBUS+ backplane bus. A Drive Monitor (FX3-MOCx) requires twice

T

the bus capacity of the other expansion modules. Therefore, each FX3-MOCx reduces the maximum possible number of expansion mod‐

ules that can be used by two.

16

O PE R AT I NG IN S TR U CT I ON S | Flexi Soft Modular Safety Controller 8012478/15UF/2019-10-31 | SICK

3)

Subject to change without notice

Page 17

PRODUCT DESCRIPTION 3

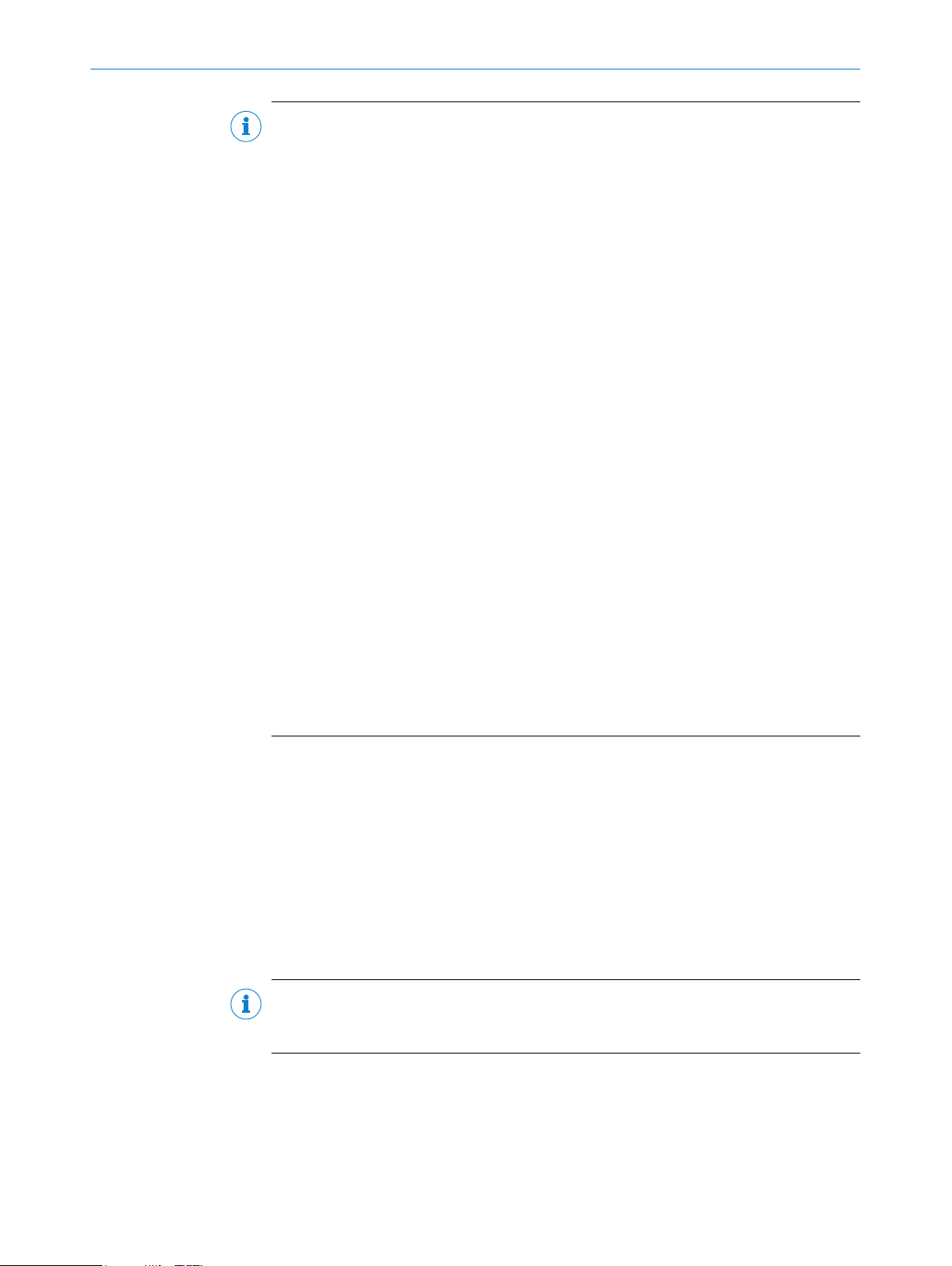

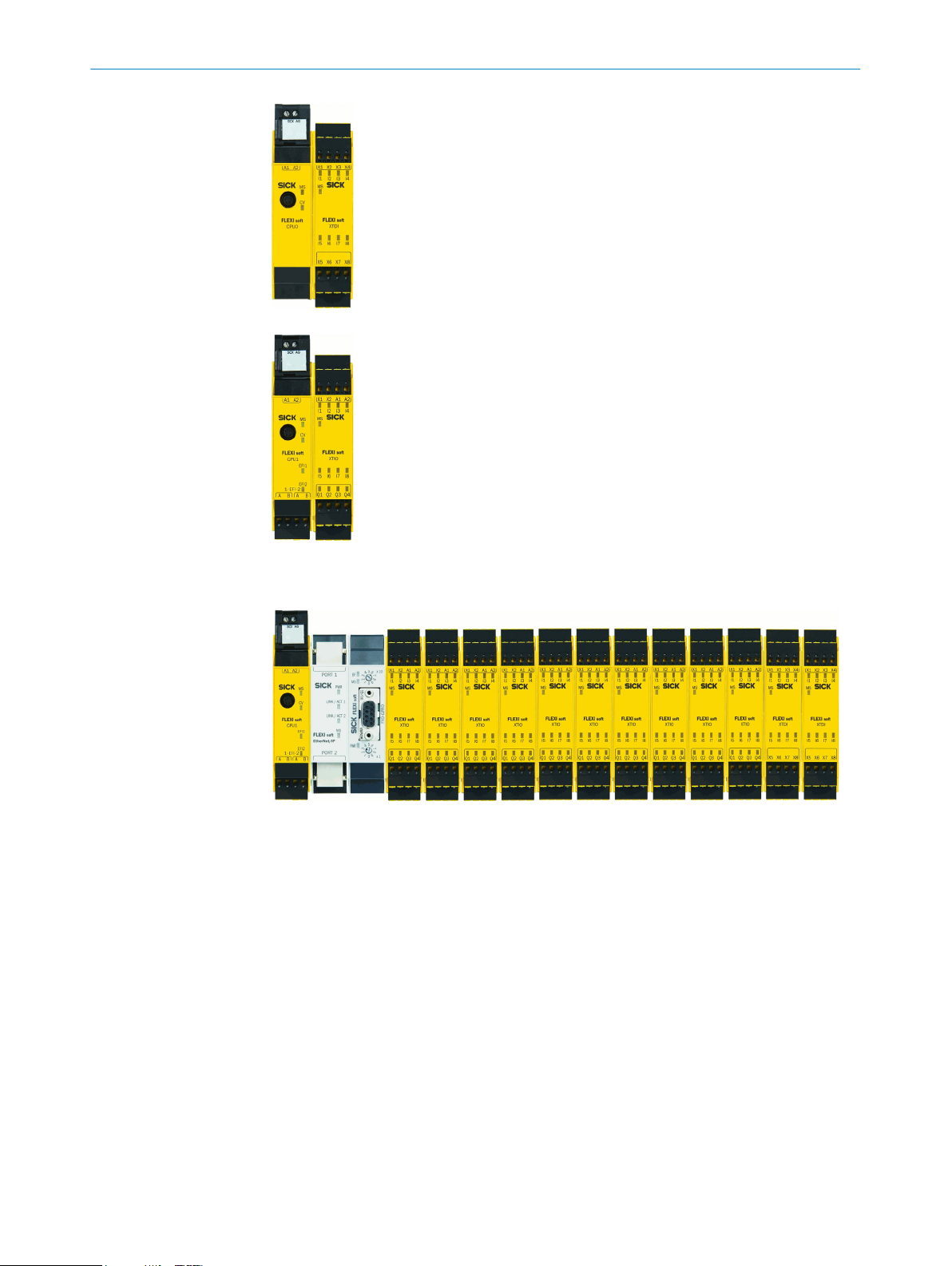

Figure 1: Example minimum construction of the Flexi Soft system with FX3-CPU0 and FX3-XTDI or

FX3-

CPU1 and FX3-XTIO

Figure 2: Maximum structure of the Flexi Soft system (without relay modules)

8012478/15UF/2019-10-31 | SICK OP E RA T IN G I N ST R UC T IO N S | Flexi Soft Modular Safety Controller

Subject to change without notice

17

Page 18

3 PRODUCT DESCRIPTION

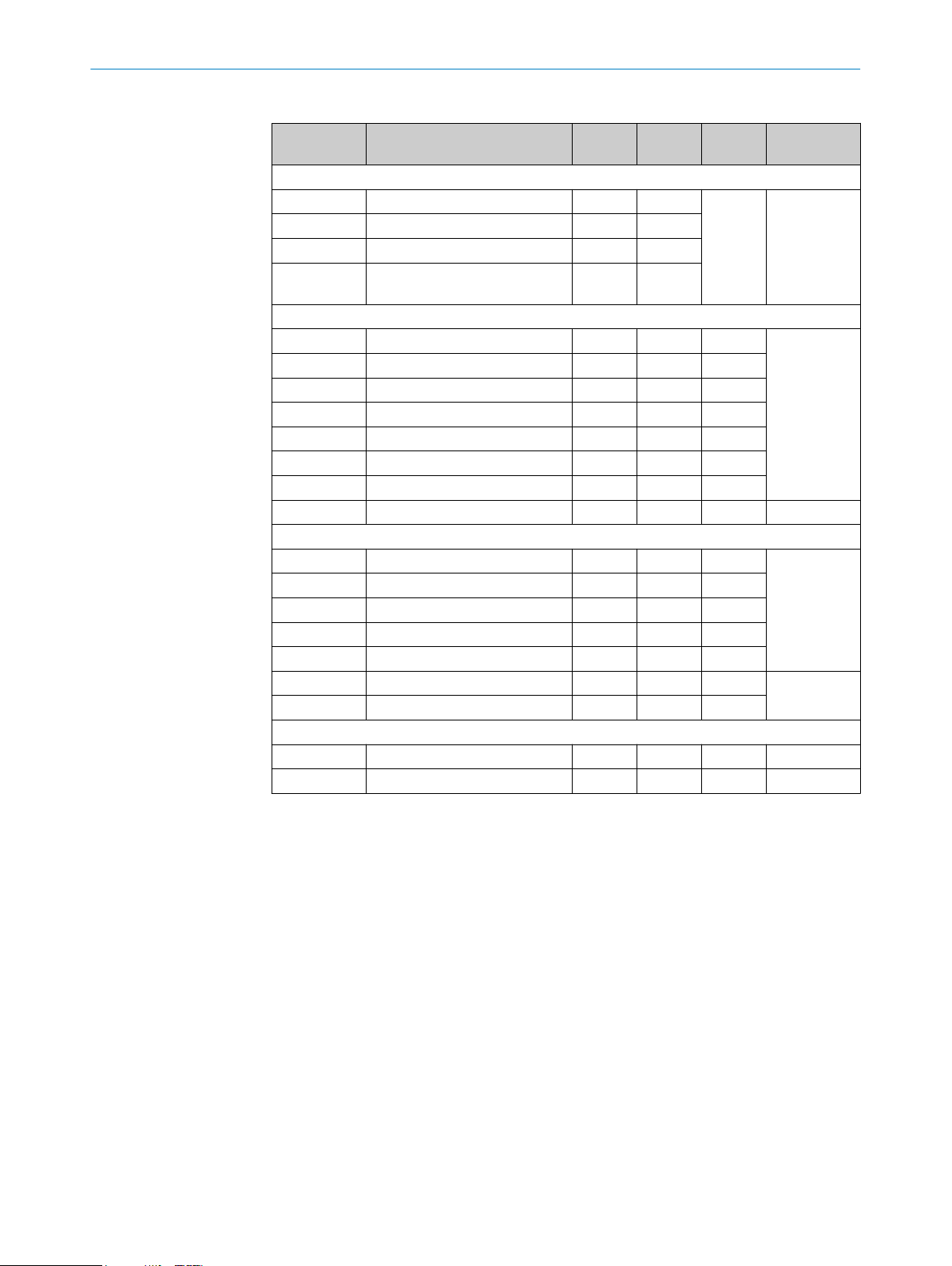

Table 3: Overview of modules

Model Type Inputs Outputs Function

Main modules

FX3-CPU0 Main module – –

FX3-CPU1 Main module with EFI 4

FX3-CPU2 Main module with EFI and ACR 4

FX3-CPU3 Main module with EFI and ACR

Gateways

FX0-GENT EtherNet/IP™ gateway 2

FX0-GMOD Modbus TCP gateway 2

FX0-GPNT PROFINET IO gateway 2

FX0-GETC EtherCAT gateway 2

FX0-GPRO PROFIBUS DP gateway 1

FX0-GCAN CANopen gateway 1

FX0-GDEV DeviceNet gateway 1

FX3-GEPR EFI-pro gateway 2

Expansion modules

FX3-XTIO I/O module 8 4 –

FX3-XTDI I/O module 8 – –

FX3-XTDS I/O module 8 4–6

FX0-STIO I/O module 6–8

FX3-ANA0 Analog input module 2

FX3-MOC0 Drive Monitor – – 10 6

FX3-MOC1 Drive Monitor – – 25

Relay modules

UE410-2RO Relay module – 2 – 8

UE410-4RO Relay module – 4 – 4

1)

EFI connections.

2)

EFI and Flexi Line connections.

3)

RJ-45 female connectors.

4)

RS-485 female connector.

5)

Non-safe outputs. Test outputs XY1 and XY2 can be used as additional non-safe outputs.

6)

The FX0-STIO features 6 non-safe inputs and 6 non-safe outputs. In addition, connections IY7 and IY8

c

7)

Each FX3-ANA0 expansion module provides two analog inputs, which are combined to form one safe

channel. An FX3-ANA0 can therefore safely detect the size of an analog process using two sensors.

8)

Each FX3-MOCx module reduces the maximum possible number of expansion modules that can be used

by two.

9)

Maximum 16 safe relay outputs.

8

lexi Line

and F

an be used as non-safe inputs as well as non-safe outputs.

Max. number

bloc

ks

1)

1)

2)

3)

3)

3)

3)

4)

4)

4)

3)

6)

7)

–

–

255 1

–

– –

– –

– –

– –

– –

– –

– –

– – 1

6–8

5)

6)

–

–

– –

2

12

8)

9)

9)

3.4 Modules

18

O PE R AT I NG IN S TR U CT I ON S | Flexi Soft Modular Safety Controller 8012478/15UF/2019-10-31 | SICK

This chapter provides information about the properties and functions of the available

module

s and system components.

Subject to change without notice

Page 19

3.4.1 FX3-CPU0 main module

Description

T

he FX3-CPU0 main module is the CPU for the entire system. It is where all signals are

monitored and their logic is processed on the basis of the configuration stored in the

system plug. The system outputs are switched further to the processing of the signals.

The FLEXBUS+ internal bus provides the data interface.

NOTE

The FX3-CPU0 main module can only be operated together with the FX3-MPL0 system

plug.

PRODUCT DESCRIPTION 3

Figure 3: FX3-CPU0 main module

FX3-MPL0 system plug

1

RS-232 interface

2

MS LED (Module St

3

CV LED (Configuration Verified)

4

3.4.2 FX3-CPU1 main module

Description

T

he functions of the FX3-CPU1 main module are the same as those of the FX3-CPU0

main module.

Additionally, this module has 2 EFI interfaces. When EFI-enabled devices are con‐

nected, the following functions are supported:

Transfer configuration to the connected EFI-enabled devices

•

Import configuration from the connected EFI-enabled devices

•

Diagnose the connected EFI-enabled devices

•

Exchange process data between main module and EFI-enabled devices

•

Connect up to four FX3-CPU1 main modules to one Flexi-Link system (see "Flexi

•

Link", page 45)

More information about EFI interfaces: see "Enhanced Function Interface (EFI)",

page 44

atus)

NOTE

T

he FX3-CPU1 main module can only be operated together with the FX3-MPL0 system

plug.

8012478/15UF/2019-10-31 | SICK OP E RA T IN G I N ST R UC T IO N S | Flexi Soft Modular Safety Controller

Subject to change without notice

19

Page 20

3 PRODUCT DESCRIPTION

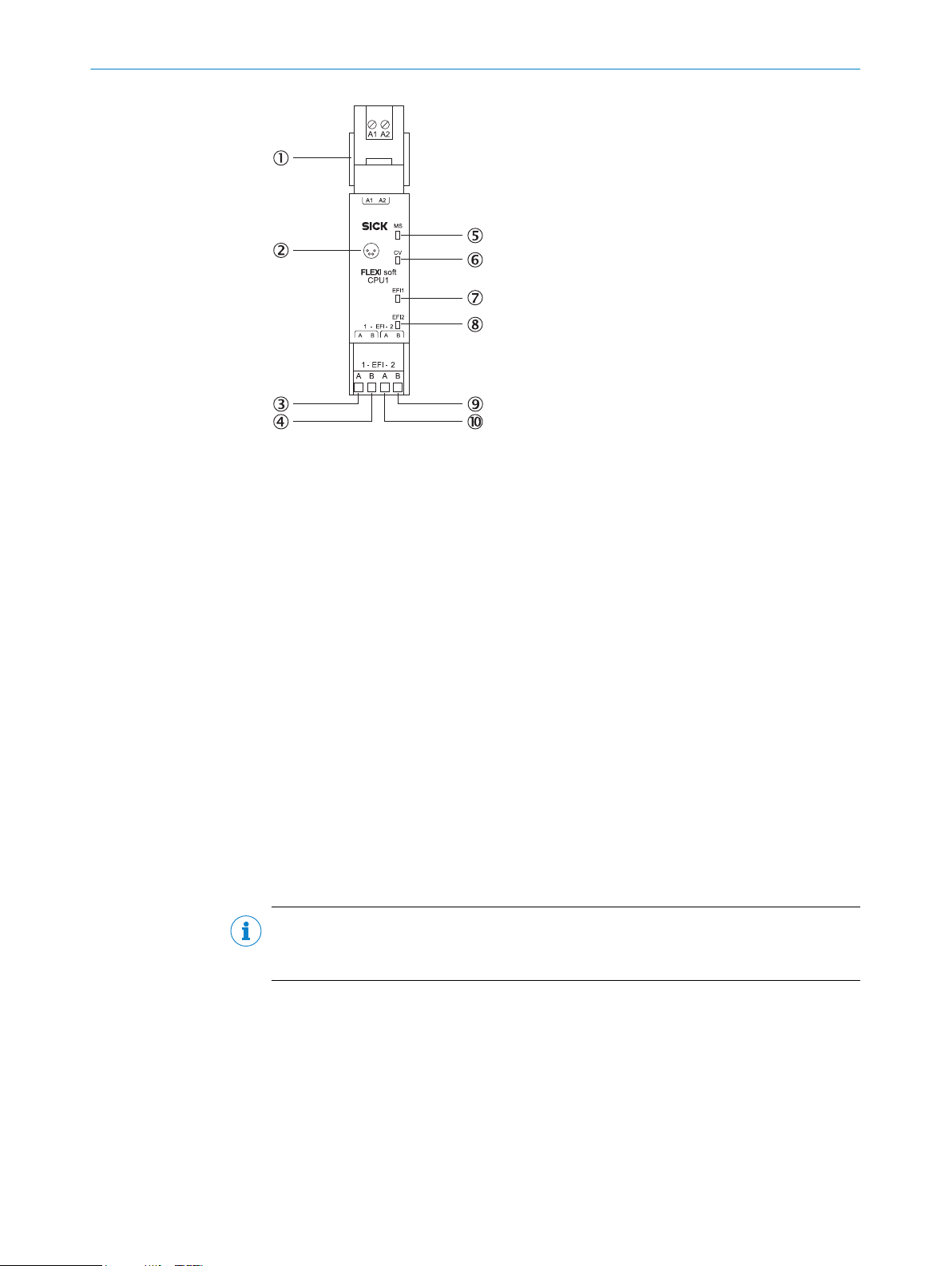

Figure 4: FX3-CPU1 main module

1

2

3

4

5

6

7

8

9

ß

FX3-MPL0 system plug

RS-232 interface

EFI1_A

EFI1_B

MS LED (Module Status)

CV LED (Configuration Verified)

EFI1 LED

EFI2 LED

EFI2_B

EFI2_A

3.4.3 FX3-CPU2 main module

Description

T

he functions of the FX3-CPU2 main module are the same as those of the FX3-CPU1

main module.

Furthermore, the FX3-CPU2 main module has an automated function for configuring

connected EFI-enabled devices (ACR). More information: see "Automatic configuration

recovery (ACR)", page 48 and the “Flexi Soft in the Flexi Soft Designer Configuration

Software” operating instructions.

NOTE

T

he FX3-CPU2 main module can only be operated together with the FX3-MPL1 system

plug.

20

O PE R AT I NG IN S TR U CT I ON S | Flexi Soft Modular Safety Controller 8012478/15UF/2019-10-31 | SICK

Subject to change without notice

Page 21

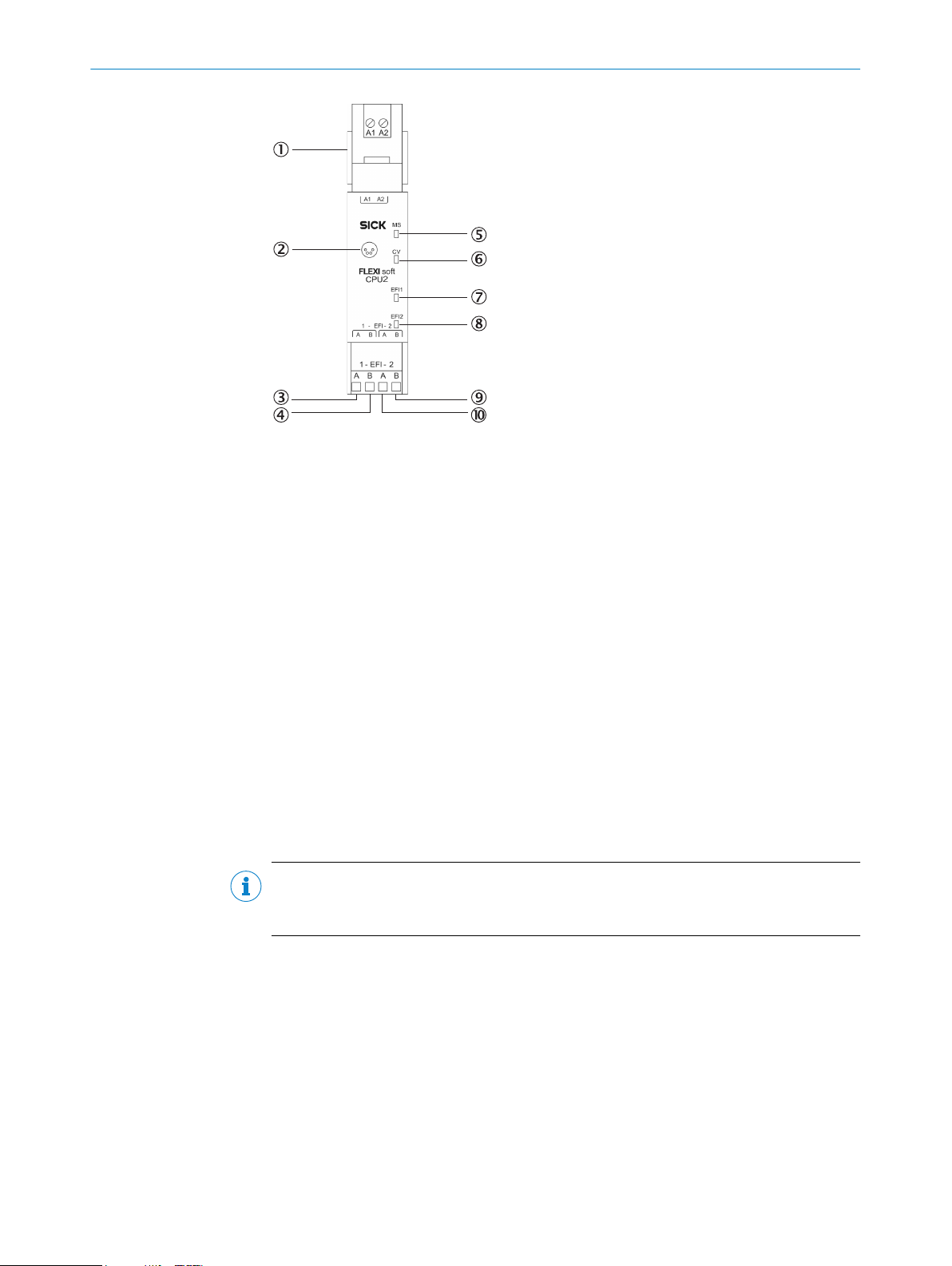

Figure 5: FX3-CPU2 main module

FX3-MPL1 system plug

1

RS-232 interface

2

EFI1_A

3

EFI1_B

4

MS LED (Module St

5

CV LED (Configuration Verified)

6

EFI1 LED

7

EFI2 LED

8

EFI2_B

9

EFI2_A

ß

atus)

PRODUCT DESCRIPTION 3

3.4.4 FX3-CPU3 main module

Description

T

he functions of the FX3-CPU3 main module are the same as those of the FX3-CPU2

main module.

This module also has a Flexi Line interface to support the safe networking of up to 32

Flexi Soft stations (see "Flexi Line", page 46).

NOTE

T

he FX3-CPU3 main module can only be operated together with the FX3-MPL1 system

plug.

8012478/15UF/2019-10-31 | SICK OP E RA T IN G I N ST R UC T IO N S | Flexi Soft Modular Safety Controller

Subject to change without notice

21

Page 22

3 PRODUCT DESCRIPTION

Figure 6: FX3-CPU3 main module

1

2

3

4

5

6

7

8

9

ß

à

á

â

ã

ä

FX3-MPL1 system plug

RS-232 interface

USB interface

Line_PRE_A (previous)

Line_PRE_B (previous)

EFI1_A

EFI1_B

MS LED (Module St

CV LED (Configuration Verified)

LINE LED

EFI1 and EFI2 LEDs

Line_NEXT_B (next)

Line_NEXT_A (next)

EFI2_B

EFI2_A

atus)

22

USB interface

T

he FX3-CPU3 main module has a USB interface which supports the following func‐

tions:

Transfer of the configuration from the configuration software to the system plug

•

Import of the configuration into the configuration software from the system plug

•

Diagnosis of the Flexi Soft safety controller in conjunction with the configuration

•

software

Table 4: USB interface on the FX3-CPU3 main module

USB version Connection type

2.0 Mini-B

O PE R AT I NG IN S TR U CT I ON S | Flexi Soft Modular Safety Controller 8012478/15UF/2019-10-31 | SICK

Subject to change without notice

Page 23

3.4.5 FX3-MPL0 and FX3-MPL1 system plugs

There is a system plug at each main module. The system configuration for the entire

F

lexi Soft system is stored only in the system plug. This is beneficial when replacing

modules, because it means that a full reconfiguration of the Flexi Soft system is not

required.

System plug variants

There are two system plug variants, each of which can only be used in conjunction with

certain main modules.

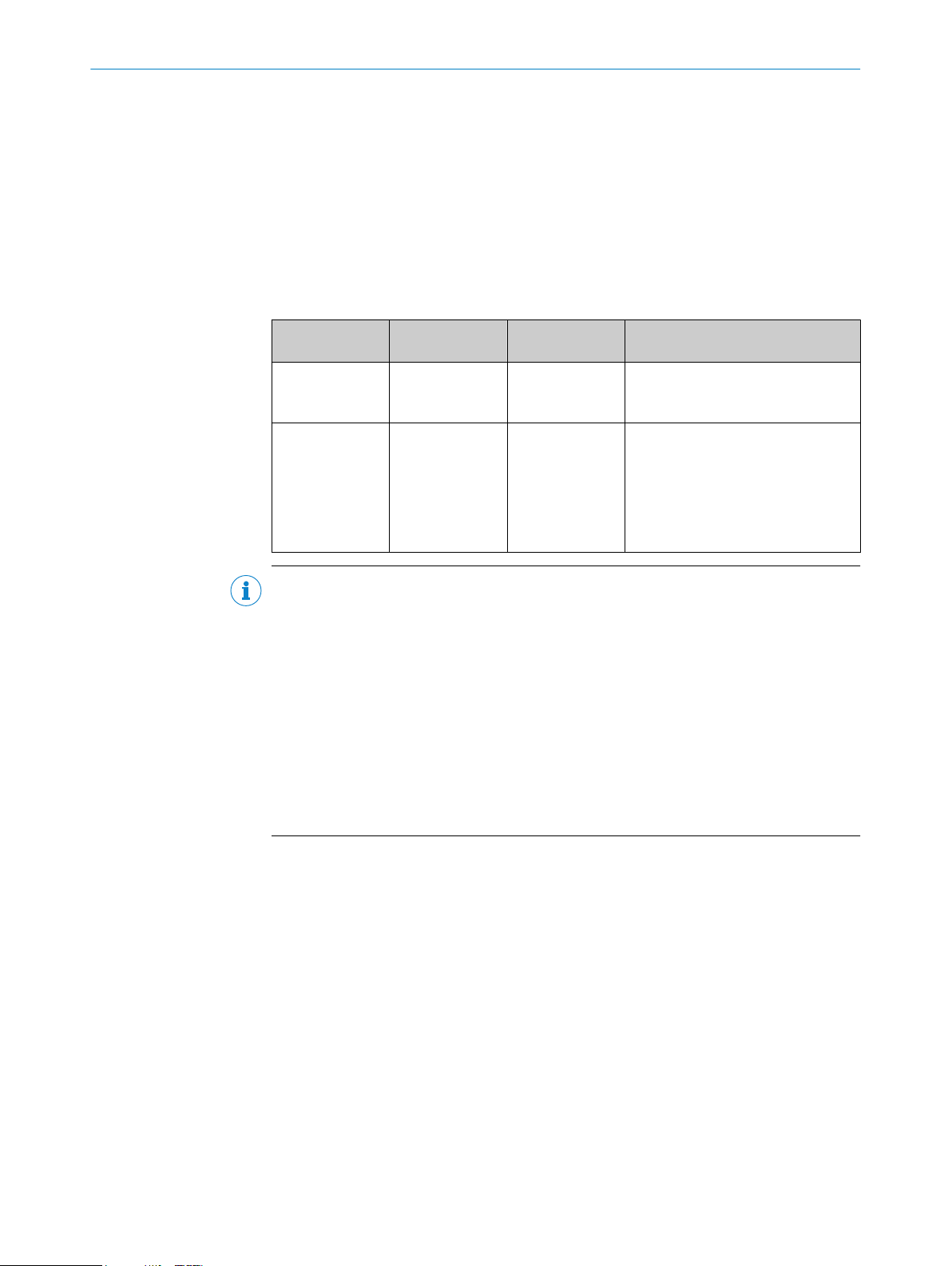

Table 5: System plug variants

System plug Terminal color Compatible main

FX3-MPL0 Black

FX3-MPL1 Yellow

module

FX3-

•

FX3-CPU1

•

FX3-CPU2

•

FX3-CPU3

•

s

CPU0

PRODUCT DESCRIPTION 3

Functions

Flexi Soft system power supply

•

Storage of system configuration

•

(without EFI-enabled devices)

Flexi Soft system power supply

•

Storage of system configuration

•

(with EFI-enabled devices)

Automated configuration of con‐

•

nected EFI-capable safety sen‐

sors (automated configuration

recovery)

NOTE

T

•

modules and gateways on the FLEXBUS+, and its inputs (I1 to I8) and test outputs

(X1 to X8 plus XY1 and XY2) is provided exclusively via the system plug. The power

for the outputs (Q1 to Q4, Y1 to Y6, and IY7 and IY8), on the other hand, is sup‐

plied separately.

The data saved in the system plug is retained even in the event of a power supply

•

failure.

Clearly and unambiguously mark all connections (connecting cables and plug con‐

•

nectors) on the safety controller to avoid mix-ups. The Flexi Soft system features

several connections of the same design. Therefore, you must make sure that no

unplugged connecting cables or plug connectors are accidentally connected to the

wrong connection point.

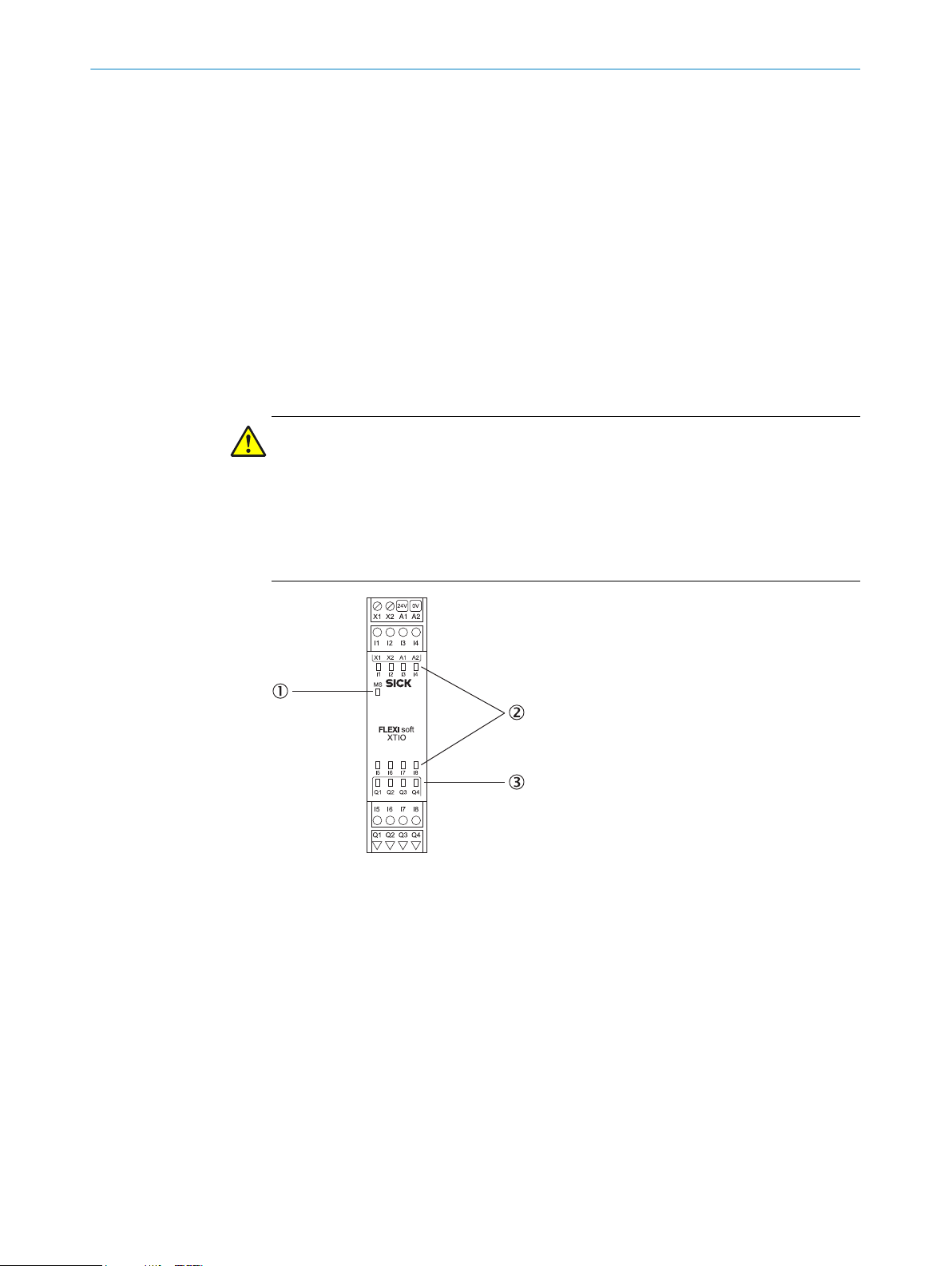

3.4.6 FX3-XTIO I/O module

Description

T

he FX3-XTIO module is an input/output expansion module with 8 safe inputs and

4 safe outputs. It has 2 test pulse generators, one for test output X1 and one for test

output X2.

The FX3-XTIO module supports the following functions:

Monitoring of the connected safety devices (see "Connection of devices",

•

page 74)

Forwarding of information at inputs I1 to I8 to the main module

•

Receipt of control signals from the main module and corresponding switching of

•

outputs

Fast shut-off: direct shutdown of the actuators connected to the module.

•

he electrical power supply for the main module, the internal logic of all expansion

8012478/15UF/2019-10-31 | SICK OP E RA T IN G I N ST R UC T IO N S | Flexi Soft Modular Safety Controller

Subject to change without notice

23

Page 24

RODUCT DESCRIPTION

3 P

This reduces the response time of the overall system. The response times of the

de

vices at the inputs and outputs are extended by 8 ms in order to shut down the

outputs. Run times on the FLEXBUS+ internal bus and the logic execution time are

not relevant in this case (see "Maximum response time of the Flexi Soft system",

page 126).

A

ctivation or deactivation of the test signals at outputs Q1 to Q4

•

The FX3-XTIO module cannot be operated alone; an FX3-CPUx main module is always

necessary.

Multiple FX3-XTIO modules can be used at the same time (see "Construction and func‐

tion", page 16).

The power supply to the internal logic and the test outputs is provided via the system

plug and the FLEXBUS+ internal bus.

The power supply to outputs Q1 to Q4 on the FX3-XTIO must be provided directly via

A1/A2 at the corresponding module.

WARNING

Ine

ffectiveness of the protective device due to unrecognized short-circuits between the

test pulse generators

The dangerous state may not be stopped or not be stopped in a timely manner in the

event of non-compliance.

Configure the test outputs of the Flexi Soft expansion modules with test gaps

b

≤ 4 ms and a test period ≥ 200 ms.

Figure 7: FX3-XTIO I/O module

MS LED (Module St

1

8 input LEDs

2

4 output LEDs

3

atus)

24

O PE R AT I NG IN S TR U CT I ON S | Flexi Soft Modular Safety Controller 8012478/15UF/2019-10-31 | SICK

Subject to change without notice

Page 25

3.4.6.1 Internal structure

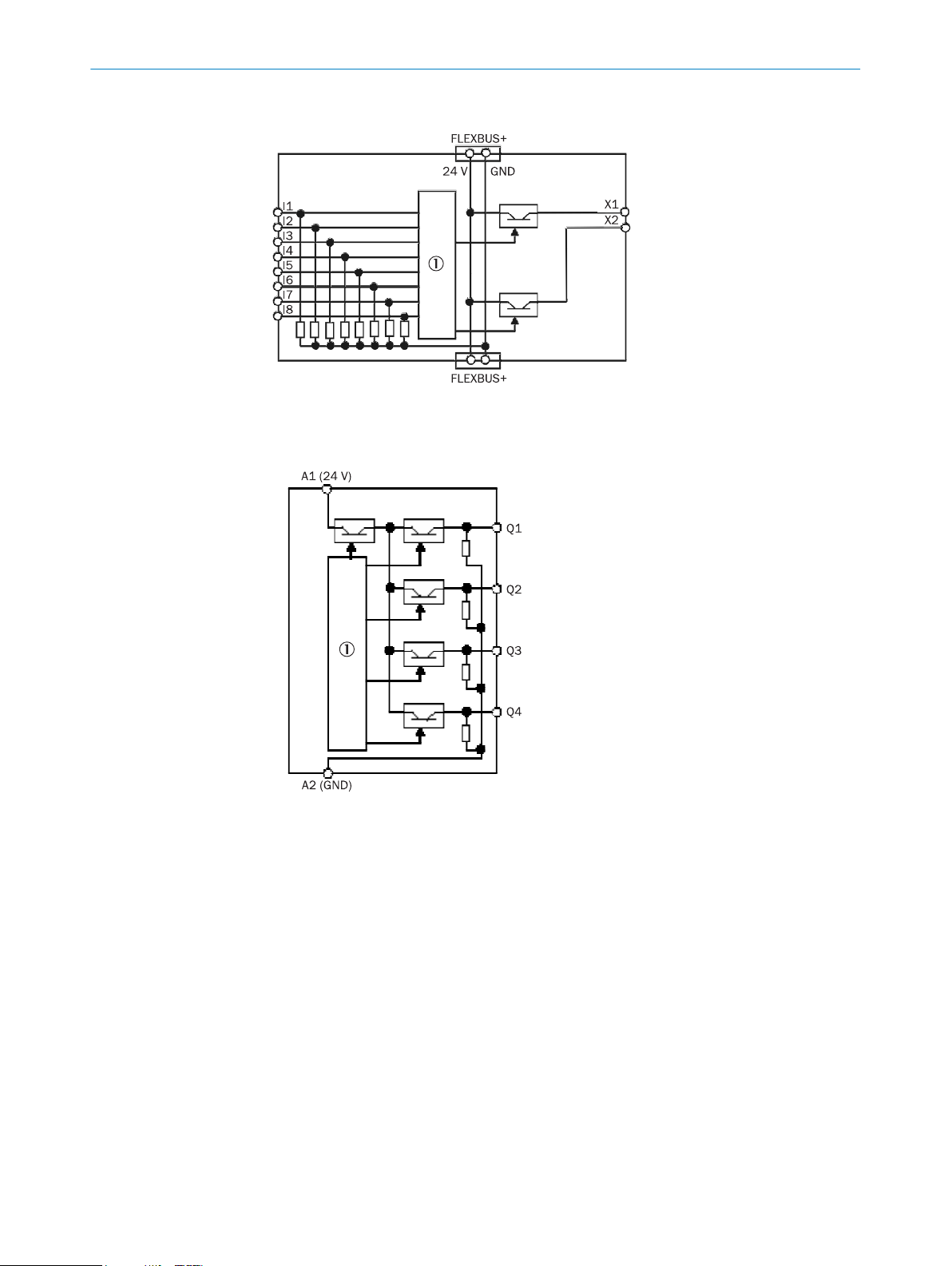

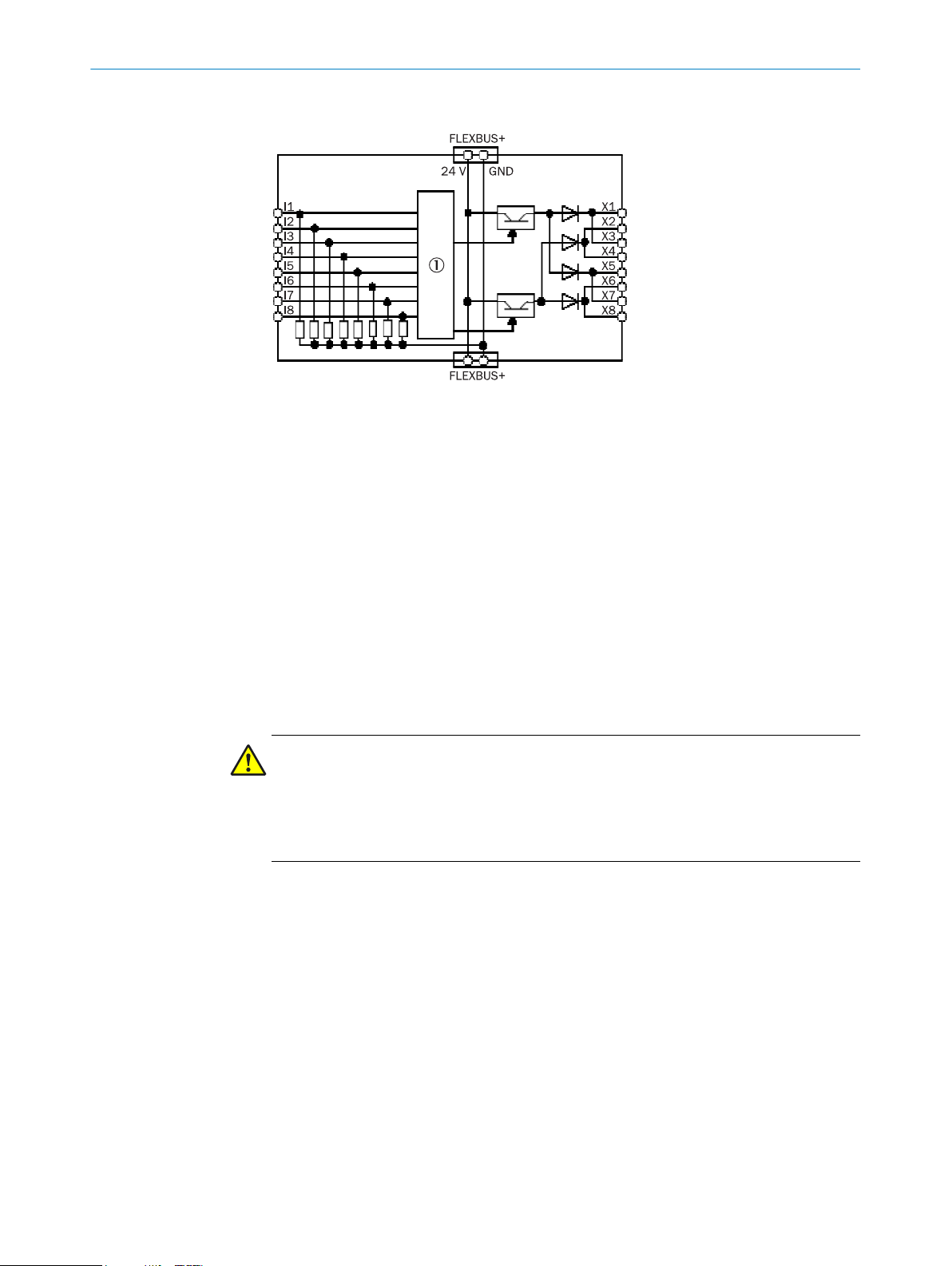

Figure 8: Internal structure of the FX3-XTIO – safe inputs and test outputs

1

PRODUCT DESCRIPTION 3

Internal logic

Figure 9: Internal structure of the FX3-XTIO – safe outputs

Internal logic

1

3.4.6.2 Deactivation of test signals at outputs Q1 to Q4 on the FX3-XTIO

With the FX3-XTIO Step ≥ 2.xx (firmware versions V2.00.0), it is possible to deactivate

t

he test pulses at one or more outputs of FX3-XTIO modules.

Deactivating the test pulses at one or more of the outputs (Q1 to Q4) of an FX3-XTIO

module reduces the safety parameters of all the outputs (Q1 to Q4) of the module con‐

cerned. If the test pulses are deactivated, a short-circuit cannot be recognized after

24 V if the output is high. Therefore, in the case of a recognized internal hardware error,

the switch-off capability of the other outputs can be impaired by the reverse current of

24 V via the output whose test pulse has been deactivated. This must be taken into

account to ensure that the application is in line with an appropriate risk analysis and

risk avoidance strategy.

8012478/15UF/2019-10-31 | SICK OP E RA T IN G I N ST R UC T IO N S | Flexi Soft Modular Safety Controller

Subject to change without notice

25

Page 26

RODUCT DESCRIPTION

3 P

WARNING

educed safety parameters by deactivating test pulses

R

The target safety-related level may not be achieved in the event of non-compliance.

If the test pulse is deactivated at one or several of the safe outputs Q1 to Q4, take the

following measures:

Use protected or separate cabling.

b

At least once a year, either switch off all outputs without test pulses simultane‐

b

ously for at least one second using the logic program of the main module or

restart the Flexi Soft system by switching off the voltage supply.

3.4.6.3 Extended error detection time for cross-circuits at outputs Q1 to Q4 on the FX3-XTIO for the switching

eased capacitive loads

of incr

WARNING

Ext

ended error recognition time due to switching of higher capacitive loads

The target safety-related level may not be achieved in the event of non-compliance.

Pay attention to the extended error recognition time.

b

With the FX3-XTIO Step ≥ 3.xx (firmware version V3.00.0), it is possible to configure an

xtended fault detection time for cross-circuits that affect outputs Q1 to Q4 of FX3-XTIO

e

modules.

This may be necessary to switch loads where the voltage at the load does not drop to

the Low level as quickly as expected, with the result that if the standard error detection

time is set, a cross-circuit error occurs immediately after switching off (change from

High to Low). Examples of such instances include:

Loads with a capacitance that is higher than the standard level permitted for the

•

output, such as the supply voltage of PLC output cards that require safety-related

switching.

For this application, the test signal for the input must also be deactivated (see

eactivation of test signals at outputs Q1 to Q4 on the FX3-XTIO", page 25).

"D

Safety-capable inputs on fail-safe PLCs generally also have capacitance at the

inputs.

Induc

•

tive loads which cause an overshoot in the positive voltage range after the

induction voltage has died down.

Table 6: Maximum permissible time until Low level is reached after output (Q1 to Q4) is deacti‐

vated

FX3-XTIO firmware

ersion

v

≤ V2.11.0 Not possible 3 ms

≥ V3.00.0 Deactivated 3 ms

Switching of increased capacitive

loads

Activated 43 ms

Maximum permissible time until

Low level (≤ 3.5 V) is reached after

output (Q1 to Q4) is deactivated

Once the output has been deactivated, the capacitance that exceeds the standard

v

alue permitted for the output must be discharged by the user until the Low level is

reached. If this condition is not met within the maximum permissible time, it results in a

cross-circuit fault at the corresponding output regardless of whether test pulses are

activated or deactivated for the output concerned.

26

O PE R AT I NG IN S TR U CT I ON S | Flexi Soft Modular Safety Controller 8012478/15UF/2019-10-31 | SICK

Subject to change without notice

Page 27

PRODUCT DESCRIPTION 3

WARNING

oss or impairment of the safety-related switch-off capability due to PLC output card

L

errors

The dangerous state may not be stopped or not be stopped in a timely manner in the

event of non-compliance.

Use a PLC output card that is suitable for safety-related deactivation of the outputs

b

by means of supply voltage switching.

Take suitable measures to prevent a cross-circuit, e.g., using protected cable lay‐

b

ing.

When using a buffer capacitor in the voltage supply of the PLC output card,

b

observe the possibly extended response time.

For information about this, see also the “Flexi Soft in the Flexi Soft Designer Configura‐

t

ion Software” and “Flexi Soft in the Safety Designer Configuration Software” operating

instructions.

3.4.6.4 Fault detection time and fault response time when using single-channel outputs on the FX3-XTIO

The fault detection time plus the fault response time of the FX3-XTIO depends on the

conf

iguration of the respective output.

In the case of an internal hardware fault, outputs (Q1 to Q4), which would normally be

on low, may switch off with a delay and/or may briefly switch to high until the fault has

been recognized and the fault reaction has been carried out.

WARNING

Ine

ffectiveness of the protective device due to brief switching to high for single-channel

outputs

The dangerous state may not be stopped or not be stopped in a timely manner in the

event of non-compliance.

The target safety-related level may not be achieved in the event of non-compliance.

For risk analysis and risk avoidance strategy, consider the following:

b

°

°

Table 7: Fault detection time and fault response time on the FX3-XTIO

FX3-XTIO firmware

v

ersion

≤ V2.11.0 Not possible ≤ 10 ms

≥ V3.00.0 Deactivated ≤ 10 ms

3.4.7 FX3-XTDI I/O module

Brief switching to high or delayed switching off of single-channel outputs

Fault detection time and fault response time

Switching higher capacitive loads Fault detection time + fault

response time

Enabled ≤ 50 ms

Description

T

he FX3-XTDI module is an input expansion module with 8 safe inputs. It has 2 test

pulse generators, one for test outputs X1, X3, X5 and X7 and one for test outputs X2,

X4, X6 and X8.

The FX3-XTDI module supports the following functions:

Monitoring of the connected safety devices (see "Connection of devices",

•

page 74)

Forwarding of information at inputs I1 to I8 to the main module

•

8012478/15UF/2019-10-31 | SICK OP E RA T IN G I N ST R UC T IO N S | Flexi Soft Modular Safety Controller

Subject to change without notice

27

Page 28

3 P

RODUCT DESCRIPTION

The FX3-XTDI module cannot be operated alone; an FX3-CPUx main module is always

nece

ssary.

Multiple FX3-XTDI modules can be used at the same time (see "Construction and func‐

tion", page 16).

The power supply to the internal logic and the test outputs is provided via the system

plug and the FLEXBUS+ internal bus.

WARNING

Ine

ffectiveness of the protective device due to unrecognized short-circuits between the

test pulse generators

The dangerous state may not be stopped or not be stopped in a timely manner in the

event of non-compliance.

Exclude short-circuits between the odd-numbered test outputs X1, X3, X5 and X7

b

through suitable wiring (e.g. separate routing, protected cables).

Exclude short-circuits between the even-numbered test outputs X2, X4, X6 and X8

b

through suitable wiring (e.g. separate routing, protected cables).

Configure the test outputs of the Flexi Soft expansion modules with test gaps

b

≤ 4 ms and a test period ≥ 200 ms.

28

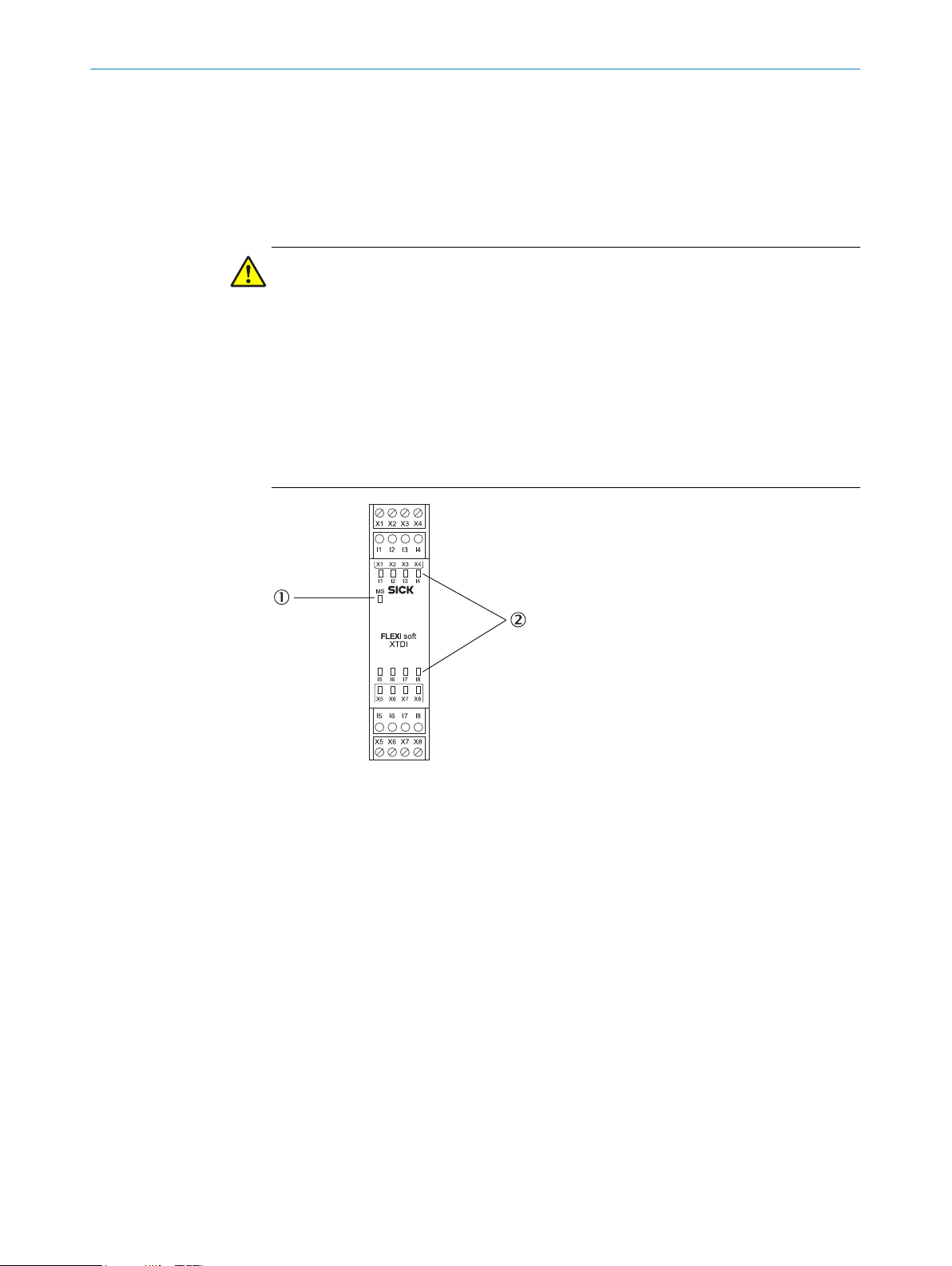

Figure 10: FX3-XTDI I/O module

MS LED (Module St

1

8 input LEDs

2

O PE R AT I NG IN S TR U CT I ON S | Flexi Soft Modular Safety Controller 8012478/15UF/2019-10-31 | SICK

atus)

Subject to change without notice

Page 29

3.4.7.1 Internal structure

Figure 11: Internal structure of the FX3-XTDI – safe inputs and test outputs

Internal logic

1

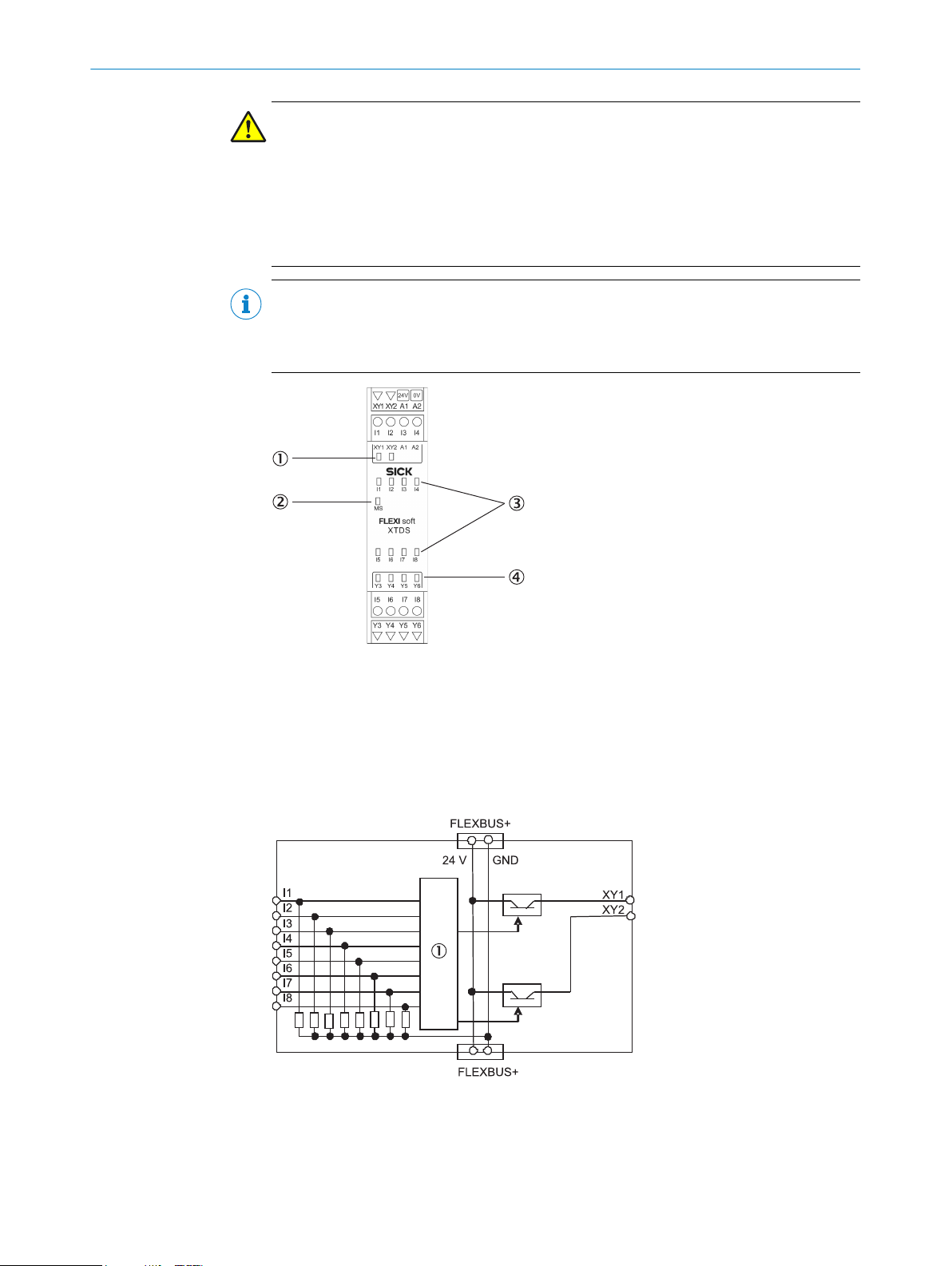

3.4.8 FX3-XTDS I/O module

Description

PRODUCT DESCRIPTION 3

T

he FX3-XTDS module is an input/output expansion module with 8 safe inputs and

4 non-safe outputs. It has 2 test pulse generators, one for test output XY1 and one for

test output XY2.

The FX3-XTDS module supports the following functions:

Monitoring of the connected safety devices (see "Connection of devices",

•

page 74)

Forwarding of information at inputs I1 to I8 to the main module

•

Receipt of control signals from the main module and corresponding switching of

•

outputs

Outputs XY1 and XY2 can be used as either test outputs or non-safe outputs.

•

WARNING

proper use of the non-safe outputs

Im

The dangerous state may not be stopped or not be stopped in a timely manner in the

event of non-compliance.

Do not use the FX3-XTDS outputs for safety functions.

b

The FX3-XTDS module cannot be operated alone; an FX3-CPUx main module is always

nece

ssary.

Multiple FX3-XTDS modules can be used at the same time (see "Construction and func‐

tion", page 16).

The power supply to the internal logic and the test outputs is provided via the system

plug and the FLEXBUS+ internal bus.

The power supply to outputs Y3 to Y6 on the FX3-XTDS must be provided directly via

A1/A2 at the corresponding module.

8012478/15UF/2019-10-31 | SICK OP E RA T IN G I N ST R UC T IO N S | Flexi Soft Modular Safety Controller

Subject to change without notice

29

Page 30

3 PRODUCT DESCRIPTION

WARNING

ffectiveness of the protective device due to unrecognized short-circuits between the

Ine

test pulse generators

The dangerous state may not be stopped or not be stopped in a timely manner in the

event of non-compliance.

b

NOTE

If bo

sible to connect a tested element to one of these inputs I1 to I8. However, this element

is marked red in the hardware configuration as a warning.

Configure the test outputs of the Flexi Soft expansion modules with test gaps

≤ 4 ms and a test period ≥ 200 ms.

th outputs XY1 and XY2 are used as non-safe outputs, then it is nevertheless pos‐

Figure 12: FX3-XTDS I/O module

1

2

3

4

3.4.8.1 Internal structure

Figure 13: Internal structure of the FX3-XTDS – safe inputs and test outputs

1

2 LEDs for test outputs or non-safe outputs

MS LED (Module St

8 input LEDs

4 output LEDs

Internal logic

atus)

30

O PE R AT I NG IN S TR U CT I ON S | Flexi Soft Modular Safety Controller 8012478/15UF/2019-10-31 | SICK

Subject to change without notice

Page 31

PRODUCT DESCRIPTION 3

Figure 14: Internal structure of the FX3-XTDS – non-safe outputs

Internal logic

1

3.4.9 FX0-STIO I/O module

Description

T

he FX0-STIO module is an expansion module with 6 non-safe inputs, 6 non-safe out‐

puts, and 2 connections that can be used as either non-safe inputs or non-safe out‐

puts.

The FX0-STIO module supports the following functions:

Forwarding of information at inputs I1 to I6 to the main module

•

Receipt of control signals from the main module and corresponding switching of

•

outputs

WARNING

Im

proper use of the non-safe modules

The dangerous state may not be stopped or not be stopped in a timely manner in the

event of non-compliance.

The target safety-related level may not be achieved in the event of non-compliance.

Do not use the FX0-STIO for safety-related functions.

b

The FX0-STIO module cannot be operated alone; an FX3-CPUx main module is always

nece

ssary.

Multiple FX0-STIO modules can be used at the same time (see "Construction and func‐

tion", page 16).

The power supply to the internal logic is provided via the system plug and the FLEXBUS

+ internal bus.

The power supply to outputs Y1 to Y6 as well as to connections IY7 and IY8 on the FX0STIO must be provided directly via A1/A2 at the corresponding module.

8012478/15UF/2019-10-31 | SICK OP E RA T IN G I N ST R UC T IO N S | Flexi Soft Modular Safety Controller

Subject to change without notice

31

Page 32

3 PRODUCT DESCRIPTION

Figure 15: FX0-STIO I/O module

1

2

3

4

5

6

2 output LEDs

MS LED (Module St

2 input LEDs

4 output LEDs

4 input LEDs

2 LEDs for configurable inputs or outputs

atus)

Use of connections IY7 and IY8 on the FX0-STIO

T

he IY7 and IY8 connections on a FX0-STIO module can be used either as non-safe

inputs or non-safe outputs.

3.4.9.1 Internal structure

Figure 16: Internal structure of the FX0-STIO – non-safe inputs

1

Internal logic

32

O PE R AT I NG IN S TR U CT I ON S | Flexi Soft Modular Safety Controller 8012478/15UF/2019-10-31 | SICK

Subject to change without notice

Page 33

PRODUCT DESCRIPTION 3

Figure 17: Internal structure of the FX0-STIO – non-safe outputs

Internal logic

1

3.4.10 Drive Monitor FX3-MOC0

Description

T

he Drive Monitor FX3-MOC is an expansion module for the safe movement monitoring

of drive systems. In this context, movement means the speed level, speed ramp and

standstill position. The module has an interface to connect two encoders (e.g. A/B

incremental encoders, linear encoders, motor feedback systems or linear distance

measurement systems).

The FX3-MOC0 supports the following functions:

Connection of two encoders for one or two axes

•

°

°

°

°

Standstill monitoring

•

Speed monitoring

•

Direction monitoring

•

Processing of information from the encoders and control signals from the main

•

module in the internal logic of the FX3-MOC0. A dedicated logic editor with a num‐

ber of function blocks is available for this purpose.

Forwarding of information from the internal logic to the main module

•

A/B incremental encoders HTL 24 V, HTL 12 V, TTL, max. 300 kHz

A/B incremental encoder RS-422, max. 1 MHz

4)

Sine-cosine encoder 1 VPP, max. 120 kHz

SSI encoder, RS-422, max. 1 MBaud

NOTE

he sine/cosine signals of a HIPERFACE® interface can also be connected to

T

the encoder connection of the FX3-MOC0. In this way, the HIPERFACE® interface can

be used like a sine/cosine encoder.

Other HIPERFACE® functions cannot be used.

4)

8012478/15UF/2019-10-31 | SICK OP E RA T IN G I N ST R UC T IO N S | Flexi Soft Modular Safety Controller

Subject to change without notice

y possible for encoder 1 (ENC1).

Onl

33

Page 34

3 PRODUCT DESCRIPTION

The FX3-MOC0 cannot be operated alone, but always requires an FX3-CPUx main mod‐

ule w

•

•

Up to 6 FX3-MOC0 modules can be used at the same time (see "Construction and func‐

tion", page 16). Each FX3-MOC0 connected reduces the possible number of other

expansion modules by two.

The power supply to the internal logic is provided via the system plug and the FLEXBUS

+ internal bus.

ith the following firmware version:

FX3-CPU0 and FX3-CPU1: ≥ V2.50.0

All other FX3-CPUx modules (FX3-CPU2, etc): all firmware versions

Figure 18: Drive Monitor FX3-MOC0

MS LED (Module St

1

atus)

WARNING

Ine

ffectiveness of the protective device due to selection of an unsuitable encoder

The target safety-related level may not be achieved in the event of non-compliance.

Select a suitable encoder.

b

Take suitable measures against the encoder’s systematic errors and common

b

causes of error.

Choosing the right encoder is crucial to achieving the desired safety integrity level (SIL) and performance level (PL).

ystematic faults and common cause faults (CCF), in particular, need to be minimized in this case.

S

Table 8: Achievable SIL and PL

Use of encoders Possible

a

xes per

FX3-MOC0

One sine-cosine safety encoder

.g., DFS60S Pro)

(e

2 SIL2, SILCL2, PL d

Achievable

SIL (IEC 61508),

SILCL (EN 62061) or

PL (EN ISO 13849-1)

Available functions for detecting encoder errors

1)

ine-cosine analog voltage monitoring

S

•

Monitoring of the ID code of the encoder/

•

motor feedback connection box in order to

detect a break in the FX3-MOC0 connection

3)

cable

2)

34

O PE R AT I NG IN S TR U CT I ON S | Flexi Soft Modular Safety Controller 8012478/15UF/2019-10-31 | SICK

Subject to change without notice

Page 35

PRODUCT DESCRIPTION 3

Use of encoders Possible

a

xes per

FX3-MOC0

Two encoders with relative position,

hosen from the following:

c

A/B

•

Sine-cosine

•

SSI

•

They can be the same type or differ‐

ent types

1)

Actual values: see

2)

Can be configured for sine-cosine encoders in the hardware configuration of the configuration software.

3)

Can be used by any type of encoder supported in the hardware configuration of the configuration software.

4)

Can be used in the FX3-MOC0 logic. For detailed information, see the “Flexi Soft in the Flexi Soft Designer Configuration Software” operat‐

ing instructions.

table 142, page 152.

1 SIL3, SILCL3, PL e

Achievable

SIL (IEC 61508),

SILCL (EN 62061) or

PL (EN ISO 13849-1)

Available functions for detecting encoder errors

1)

Speed c

•

Monitoring of the ID code of the encoder/

•

motor feedback connection box in order to

detect a break in the FX3-MOC0 connection

cable

omparison function block

3)

4)

Suitable measures against common causes of error

T

he following notes are identical for all FX3-MOCx modules.

In particular when both encoders are used for redundant monitoring of an axis, the fol‐

lowing possibilities must be taken into account, among others:

The common GND connection can be interrupted by the common connecting cable

•

on the FX3-MOCx for both encoders as a common reference potential for both

encoders.

The supply voltage for the encoder can be too low or completely interrupted.

•

The common supply voltage for both encoders can be too high. This may damage

•

both encoders. When using PELV/SELV voltage supplies without additional protec‐

tive measures, you must usually assume a voltage increase to 60 V here.

The entire encoder connection to the FX3-MOCx can be interrupted.

•

The following options are available to detect errors in the encoder system with the Flexi

Soft safety controller:

Use at least one encoder/motor feedback connection box. A description of this

•

function can be found in the “Flexi Soft in the Flexi Soft Designer Configuration

Software” and “Flexi Soft in the Safety Designer Configuration Software” operating

instructions in the “Encoder connection type and monitoring of ID identifier” sec‐

tion.

Use a sine/cosine encoder with activated sine/cosine analog voltage monitoring.

•

A description of this function can be found in the “Flexi Soft in the Flexi Soft

Designer Configuration Software” and “Flexi Soft in the Safety Designer Configura‐

tion Software” operating instructions in the “Sine-cosine analog voltage monitor‐

ing” section.

Use an SSI encoder with evaluation of error bits. A bit in the SSI data is needed

•

which takes on an inverted state if the watched error occurs, for example because

the supply voltage of the encoders is too low or because one or several of the

cables from the encoder to the FX3-MOCx are disconnected. A description of this

function can be found in the “Flexi Soft in the Flexi Soft Designer Configuration

Software” and “Flexi Soft in the Safety Designer Configuration Software” operating

instructions in the “SSI encoder” section.

5)

5)

C

onfigurable for sine/cosine encoders in the hardware configuration of the configuration software.

8012478/15UF/2019-10-31 | SICK OP E RA T IN G I N ST R UC T IO N S | Flexi Soft Modular Safety Controller

Subject to change without notice

35