Page 1

OPERATING INSTRUCTIO

NS

Flexi Classic

Gateways

en

Page 2

Operating Instructions

Flexi Classic Gateways

This document is protected by the law of copyright, whereby all rights established therein remain with the

company SICK AG. Reproduction of this document or parts of this document is only permissible within the limits

of the legal determination of Copyright Law. Alteration or abridgement of the document is not permitted without

the explicit written approval of the company SICK AG.

2 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8011834/YT28/2016-03-15

Subject to change without notice

Page 3

Operating Instructions

Flexi Classic Gateways

Contents

Contents

1 About this document......................................................................................................... 7

1.1 Function of this document....................................................................................7

1.2 Target group ..........................................................................................................7

1.3 Information depth .................................................................................................7

1.4 Scope .....................................................................................................................8

1.5 Symbols used ........................................................................................................ 8

2 On safety.............................................................................................................................9

2.1 Qualified safety personnel.................................................................................... 9

2.2 Correct use ............................................................................................................ 9

2.3 Environmental protection ...................................................................................10

2.3.1 Disposal.............................................................................................10

2.3.2 Separation of materials ....................................................................10

3 Flexi Classic gateways ...................................................................................................11

3.1 System information transmitted by the modules..............................................11

3.2 Status information of all Flexi Classic gateways (system bytes) ......................12

3.2.1 DIG-OUT .............................................................................................12

3.2.2 REQ-ID................................................................................................12

3.2.3 CRC1 and CRC2 ................................................................................13

3.2.4 BAS1 ..................................................................................................14

3.2.5 BAS2 ..................................................................................................14

3.2.6 BAS3 ..................................................................................................15

3.2.7 BAS4 ..................................................................................................15

3.2.8 RSP-ID................................................................................................15

3.2.9 B1-B10 (REQ-ID 1-13/2133)............................................................16

3.2.10 B1-B10 (REQ-ID 255)........................................................................16

3.2.11 MED ...................................................................................................16

3.2.12 MQD ...................................................................................................17

3.2.13 MKD1.................................................................................................18

3.2.14 MKD2.................................................................................................18

3.2.15 MFD....................................................................................................19

3.2.16 MFCLASS1-MFCODE2.......................................................................19

3.2.17 MOD-ID...............................................................................................24

3.2.18 SW-VERSION_H and SW-VERSION_L ...............................................25

3.2.19 FUNCTION..........................................................................................25

3.2.20 KONF..................................................................................................26

3.2.21 CRC_H CODE and CRC_L CODE .......................................................26

3.2.22 DIAG-VERSION_H and DIAG-VERSION_L..........................................26

3.2.23 System interface status (only UE410-EN3) .....................................26

4 PROFIBUS DP Gateway...................................................................................................27

4.1 Interfaces and operation ....................................................................................27

4.1.1 Controls and status indicators .........................................................27

4.1.2 Application diagnostic outputs UE410-PRO ....................................28

4.1.3 Plug assignment................................................................................28

4.1.4 Bus cable...........................................................................................28

4.1.5 Cable parameters..............................................................................29

4.1.6 Data transmission rate .....................................................................29

8011834/YT28/2016-03-15 © SICK AG • Industrial Safety Systems • Germany • All rights reserved

Subject to change without notice

3

Page 4

Contents

4.2 Planning .............................................................................................................. 30

4.2.1 GSD file ............................................................................................. 30

4.2.2 Documenting with PROFIBUS-DP Master Simulator....................... 31

4.2.3 Diagnostics data UE410-PRO .......................................................... 31

5 CANopen Gateway .......................................................................................................... 32

5.1 Interfaces and operation.................................................................................... 32

5.1.1 Control and status indicators........................................................... 32

5.1.2 Application diagnostic outputs UE410-CAN.................................... 33

5.1.3 Plug assignment ............................................................................... 34

5.1.4 Bus cable .......................................................................................... 34

5.2 Planning .............................................................................................................. 35

5.2.1 EDS file..............................................................................................35

5.2.2 PCS .................................................................................................... 35

5.2.3 Format of diagnostics data .............................................................. 35

5.2.4 TxPDO1.............................................................................................. 36

5.2.5 TxPDO2.............................................................................................. 36

5.2.6 TxPDO3.............................................................................................. 37

5.2.7 TxPDO4.............................................................................................. 37

5.2.8 RxPDO1 ............................................................................................. 38

5.2.9 NMT Network Management ............................................................. 38

5.2.10 Pre-Operational................................................................................. 38

5.2.11 Operational ....................................................................................... 38

5.2.12 Prepared/Stopped............................................................................ 38

5.2.13 Reset node........................................................................................38

5.2.14 Reset communication ...................................................................... 39

5.2.15 SYNC.................................................................................................. 39

5.2.16 Node-guarding .................................................................................. 39

5.2.17 Emergency ........................................................................................ 40

5.2.18 SDO communication......................................................................... 40

5.2.19 SDO Download expedited (Write SDO) ............................................ 40

5.2.20 SDO Upload expedited (Read SDO) ................................................. 41

5.2.21 Object list SDO .................................................................................. 41

5.2.22 Configuration objects ....................................................................... 42

5.2.23 Input/output objects ........................................................................ 43

5.2.24 Module list objects ...........................................................................43

5.2.25 Mapping/communication parameter objects ................................. 44

5.2.26 Flexi-Classic-ERROR list object ........................................................45

5.2.27 Status objects ................................................................................... 46

Operating Instructions

Flexi Classic Gateways

6 DeviceNet Gateway ......................................................................................................... 47

6.1 Interfaces and operation.................................................................................... 47

6.1.1 Characteristics of the DeviceNet implementation.......................... 47

6.1.2 Controls and status indicators......................................................... 47

6.1.3 Application diagnostic outputs UE410-DEV....................................48

6.1.4 Plug assignment ............................................................................... 49

6.1.5 Bus cable .......................................................................................... 49

6.2 Planning .............................................................................................................. 50

6.2.1 EDS file..............................................................................................50

6.2.2 Diagnostics data UE410-DEV...........................................................50

4 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8011834/YT28/2016-03-15

Subject to change without notice

Page 5

Operating Instructions

Flexi Classic Gateways

Contents

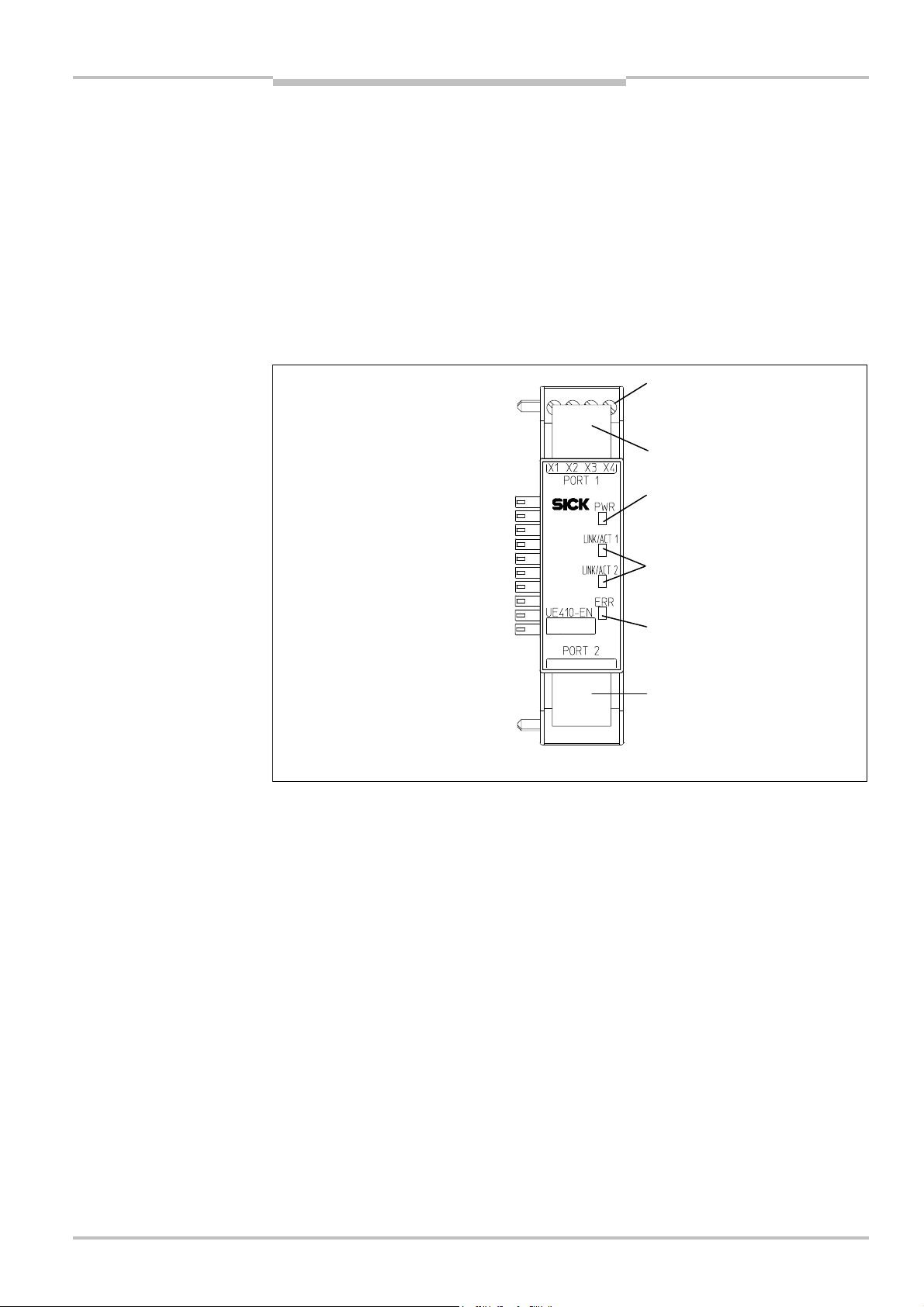

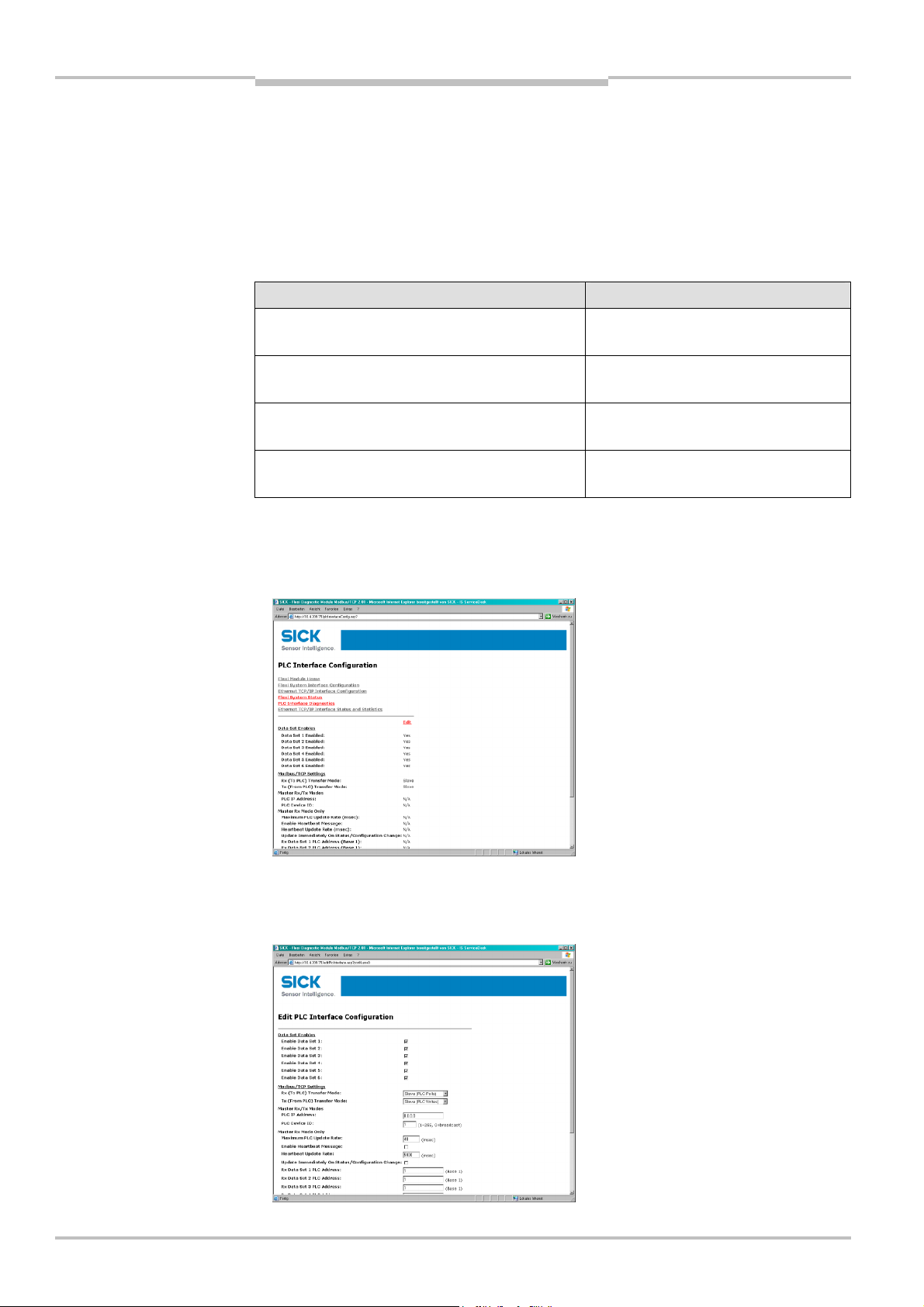

7 Modbus/TCP Ethernet Gateway ....................................................................................51

7.1 Interfaces and operation ....................................................................................51

7.2 Basic configuration — assigning an IP address.................................................52

.3 Configuration of the interface to the PLC — how the data are

7

transferred...........................................................................................................54

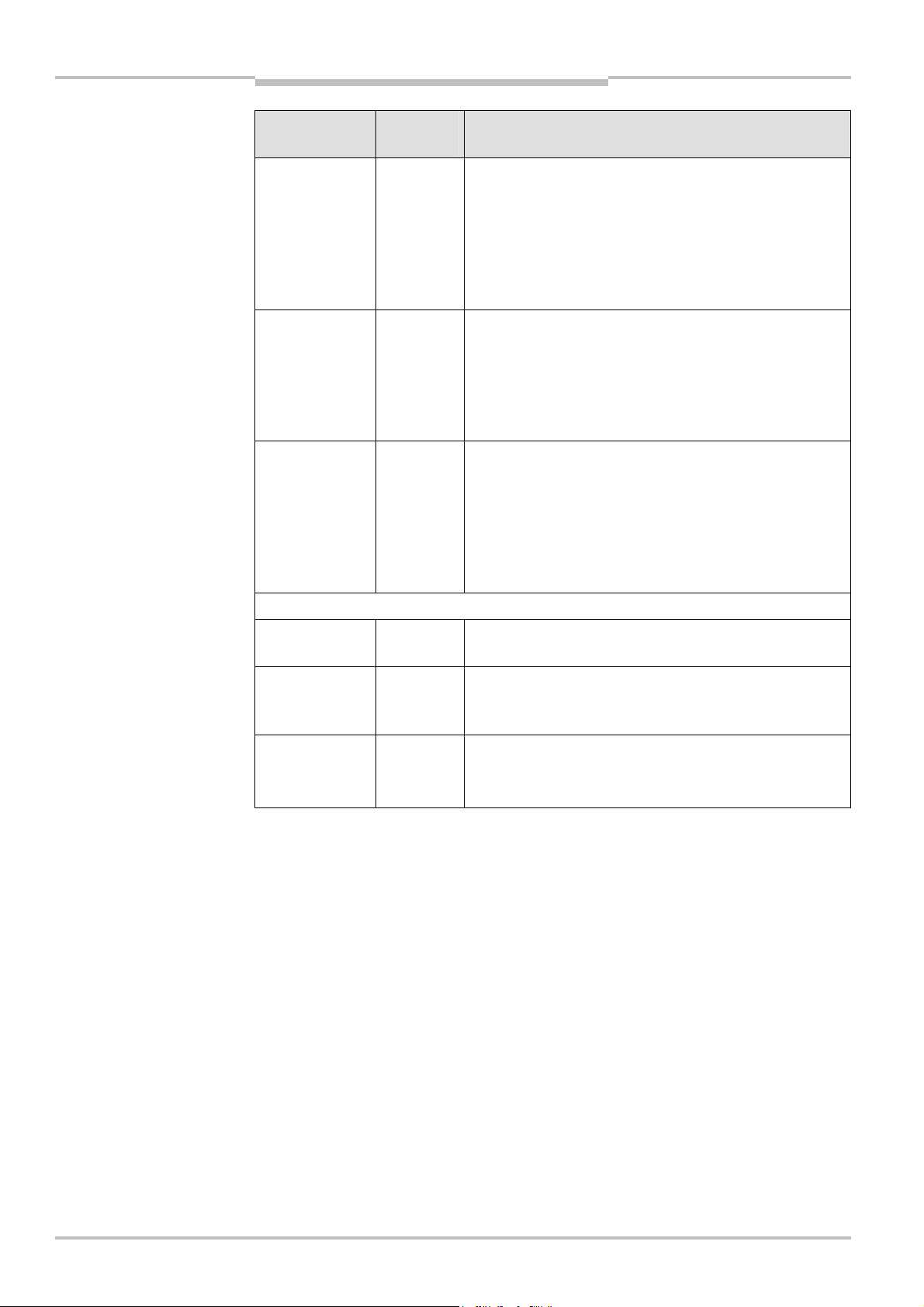

7.3.1 Operating modes in the transfer mode RX (To PLC) .......................56

7.3.2 Operating modes in the transfer mode Tx (From PLC)....................58

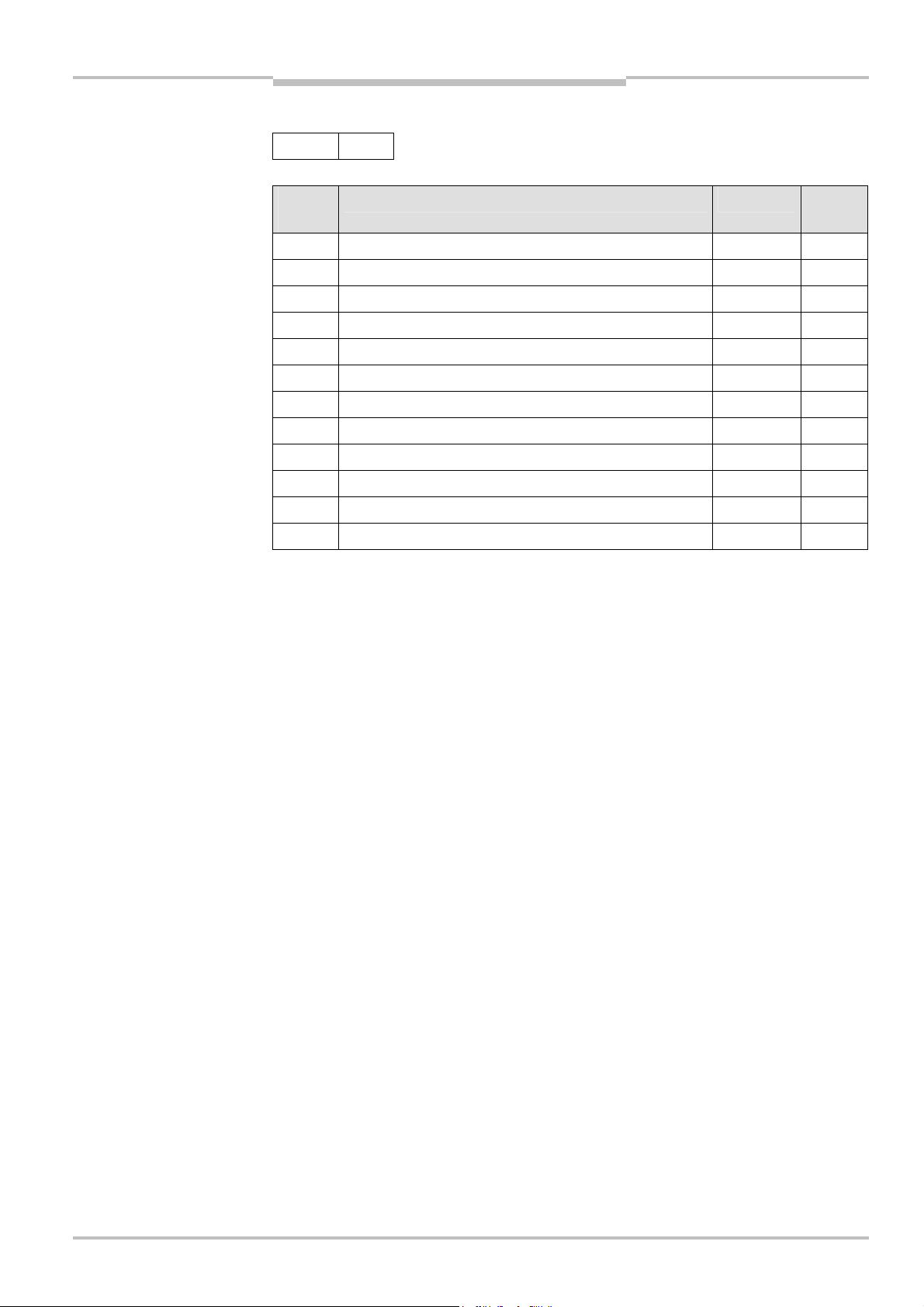

7.3.3 Modbus commands and error messages........................................58

7.4 Configuration of the gateway — which data are transferred.............................59

7.5 Status of the interface to the PLC......................................................................61

7.6 Resetting to factory settings...............................................................................64

7.7 Troubleshooting ..................................................................................................65

7.8 Description of the data sets ...............................................................................67

7.8.1 Data sets 1-5.....................................................................................67

7.8.2 Data set 6, can be compiled by the user.........................................69

8 Ethernet TCP/IP Gateway ..............................................................................................71

8.1 Interfaces and operation ....................................................................................71

8.2 Basic configuration — assigning an IP address.................................................72

8.3 Configuration of the TCP/IP interface — who establishes the connection.......74

8.4 Data transfer method — how the data are transferred.....................................76

8.4.1 General telegram structure ..............................................................76

8.4.2 Error response to invalid messages.................................................77

8.4.3 Auto Update Mode ............................................................................77

8.4.4 Polling Mode......................................................................................80

8.5 Ethernet TCP/IP interface status and statistics................................................83

8.6 Resetting to factory settings...............................................................................85

8.7 Troubleshooting ..................................................................................................86

8.8 Description of the data sets ...............................................................................88

8.8.1 Data sets 1-5.....................................................................................88

8.8.2 Data set 6, can be compiled by the user.........................................90

9 EtherNet/IP Gateway......................................................................................................92

9.1 Interfaces and operation ....................................................................................92

9.2 Basic configuration — assigning an IP address.................................................93

9.3 Device name........................................................................................................94

9.4 Configuration of the interface to the PLC — how the data are

transferred...........................................................................................................95

9.4.1 Operating modes in the transfer mode Rx (to PLC) ........................98

9.4.2 Operating modes in the transfer mode Tx (from PLC) ....................99

9.5 Configuration of the gateway — which data are transferred.......................... 100

9.6 Status of the interface to the PLC................................................................... 102

9.7 EtherNet/IP objects ......................................................................................... 105

9.7.1 Full Data Set Transfer Object (72hex — one instance per

UE410FEN1 module)...................................................................... 105

9.7.2 Individual Data Set Transfer object (73hex — one instance

per data set)................................................................................... 106

9.7.3 Discrete Output Point object definition (09hex — 4

instances; one instance per digital output).................................. 113

9.8 Resetting to factory settings............................................................................ 115

9.9 Troubleshooting ............................................................................................... 116

9.10 Description of the data sets ............................................................................ 118

9.10.1 Data sets 1-5.................................................................................. 118

9.10.2 Data set 6, can be compiled by the user...................................... 120

8011834/YT28/2016-03-15 © SICK AG • Industrial Safety Systems • Germany • All rights reserved

Subject to change without notice

5

Page 6

Contents

10 PROFINET IO Gateway ..................................................................................................122

10.1 Interfaces and operation..................................................................................122

10.2 Basic configuration — assigning an IP address ..............................................123

0.2.1 Web server based...........................................................................123

1

10.2.2 PROFINET IO conform.....................................................................125

10.3 PROFINET configuration of the gateway — how the data are transferred .....125

10.3.1 STEP 1 — Install the generic station description file (GSD file)

125

10.3.2 STEP 2 — Add the gateway to the project......................................126

10.3.3 STEP 3 — Configure the properties of the gateway ......................126

10.3.4 STEP 4 — Assign the device name.................................................127

10.4 PROFINET configuration of the gateway — which data are transferred.........129

10.4.1 Cyclic data.......................................................................................129

10.4.2 Acyclic data — record read .............................................................130

10.4.3 Alarms .............................................................................................136

10.5 Status of the interfaces....................................................................................137

10.5.1 Status of the interface to the PLC .................................................137

10.5.2 Status of the Flexi system ..............................................................138

10.6 Resetting to factory settings ............................................................................140

10.7 Troubleshooting................................................................................................141

10.8 Error type definitions in PROFINET IO..............................................................143

Operating Instructions

Flexi Classic Gateways

11 Technical specifications ..............................................................................................147

11.1 Technical specifications fieldbus.....................................................................147

11.1.1 PROFIBUS........................................................................................147

11.1.2 CANopen .........................................................................................147

11.1.3 DeviceNet........................................................................................148

11.1.4 Modbus/TCP, EtherNet/IP, PROFINET IO......................................148

11.2 Technical specifications, supply circuit...........................................................149

11.3 Technical specifications application diagnostic outputs................................149

11.4 General technical specifications......................................................................149

11.5 Dimensional drawing........................................................................................151

11.6 Device overview/part numbers........................................................................152

11.7 Accessories/spare parts ..................................................................................152

11.7.1 PROFIBUS master simulator ..........................................................152

11.7.2 CD-ROM Flexi Classic......................................................................152

6 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8011834/YT28/2016-03-15

Subject to change without notice

Page 7

Operating Instructions Chapter 1

Note

Flexi Classic Gateways

About this document

1 About this document

lease read this chapter carefully before working with these operating instructions and the

P

Flexi Classic gateways.

1.1 Function of this document

These operating instructions only apply in conjunction with the “Flexi Classic Modular Safety Controller” operating instructions and provide the technical personnel at the machine

manufacturer or machine operating organisation information on safe mounting, adjustment, electrical installation, commissioning as well as on operation and maintenance of

the Flexi Classic gateways.

These operating instructions do not provide information on the operation of the machine in

which a Flexi Classic safety controller with Flexi Classic gateways is integrated. Information

on this is to be found in the appropriate operating instructions for the machine.

1.2 Target group

WARNING

These operating instructions are addressed to planning engineers, machine designers and

the operators of systems in which a Flexi Classic modular safety controller is integrated

and who want to transmit data to a fieldbus (a controller) via a gateway.

They are also addressed to people who are placing a Flexi Classic gateway in operation for

the first time or maintaining it.

1.3 Information depth

These operating instructions contain information on Flexi Classic gateways on the following

subjects:

mounting

status information on fieldbus, planning and related mapping

part numbers

Warning!

Pay attention to the safety notes and safety measures on the Flexi Classic safety controller!

We also refer you to our homepage on the Internet at

http://www.ue410flexi.com

There you will find the following files for download:

EDS file

GSD file

flexi_config_list.xls (system requirements Excel 2000 or higher)

8011834/YT28/2016-03-15 © SICK AG • Industrial Safety Systems • Germany • All rights reserved

Subject to change without notice

7

Page 8

Chapter 1 Operating Instructions

N

otes

About this document

Flexi Classic Gateways

1.4 Scope

hese operating instructions are original operating instructions.

T

hese operating instructions apply to all Flexi Classic gateway modules (UE410FPR03,

Note

T

FPR04, FCAN3, FCAN4, FDEV3, FDEV4, -EN1, -EN3, -EN4). In addition, follow the related

concise operating instructions (see type label entry on the modules).

1.5 Symbols used

Refer to notes for special features of the device.

Warning!

WARNING

A warning notice indicates an actual or potential risk or health hazard. They are designed

to help you to prevent accidents.

Read carefully and follow the warning notices!

8 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8011834/YT28/2016-03-15

Subject to change without notice

Page 9

Operating Instructions Chapter 2

Flexi Classic Gateways

On safety

2 On safety

This chapter deals with your own safety and the safety of the equipment operators.

Please read this chapter carefully before working with a Flexi Classic gateway.

2.1 Qualified safety personnel

The Flexi Classic gateway must only be installed, commissioned and serviced by qualified

safety personnel.

Qualified safety personnel are defined as persons who …

have undergone the appropriate technical training

and

have been instructed by the responsible machine operator in the operation of the

machine and the current valid safety guidelines

and

have access to the operating instructions “Flexi Classic Gateways” and “Flexi Classic

Modular Safety Controller” and have read and familiarised themselves with them.

WARNING

WARNING

2.2 Correct use

The Flexi Classic gateways can only be operated with a Flexi Classic system.

The Flexi Classic gateways are not suitable for operation on a safety fieldbus!

These gateways only generate non-safety-related fieldbus data (status bytes) for control

and diagnostics purposes.

These modules may only be used by qualified personnel and only on the machine where

they have been installed and initialised by qualified personnel in accordance with the

operating instructions.

Pay attention to the safety notes and safety measures on the Flexi Classic safety

controller!

If the device is used for any other purposes or modified in any way — also during mounting

and installation — any warranty claim against SICK AG shall become void.

During the mounting, installation and usage of the Flexi Classic safety controller, ob-

serve the standards and directives applicable in your country.

The national/international rules and regulations apply to the installation, commissioning,

use and periodic technical inspection of the Flexi Classic safety controller, in

particular …

– the Machinery Directive

– the EMC directive

– the Work Equipment Directive

– the Low Voltage Directive

– the work safety regulations/safety rules

8011834/YT28/2016-03-15 © SICK AG • Industrial Safety Systems • Germany • All rights reserved

Subject to change without notice

9

Page 10

Chapter 2 Operating Instructions

Note

Tab.1:

Overview on disposal

WARNING

On safety

Flexi Classic Gateways

The operating instructions must be made available to the operator of the machine

where a Flexi Classic safety controller is used. The machine operator is to be instructed

in the use of the device by specialist personnel and must be instructed to read the operating instructions.

The Flexi Classic system complies, as per the “radiated emissions” generic standard, with

the requirements of class A (industrial applications). the Flexi Classic system is therefore

only suitable for use in an industrial environment.

2.3 Environmental protection

The Flexi Classic gateways are designed for minimum impact on the environment, they

consume only a minimum of energy and resources.

At work, always act in an environmentally responsible manner.

2.3.1 Disposal

Unusable or irreparable devices should always be disposed as per the applicable national

regulations on waste disposal (e.g. European waste code 16 02 14).

We would be pleased to be of assistance to you on the disposal of these devices. Contact

us.

by components

WARNING

2.3.2 Separation of materials

Only qualified safety personnel are allowed to separate materials!

Caution is required when dismantling devices. There is a risk of injuries.

Before you send the devices for appropriate recycling, it is necessary to separate the different materials in the Flexi Classic gateways.

Separate the housing from the rest of the parts (in particular the circuit board).

Send the separated parts for recycling as appropriate (see Tab. 1).

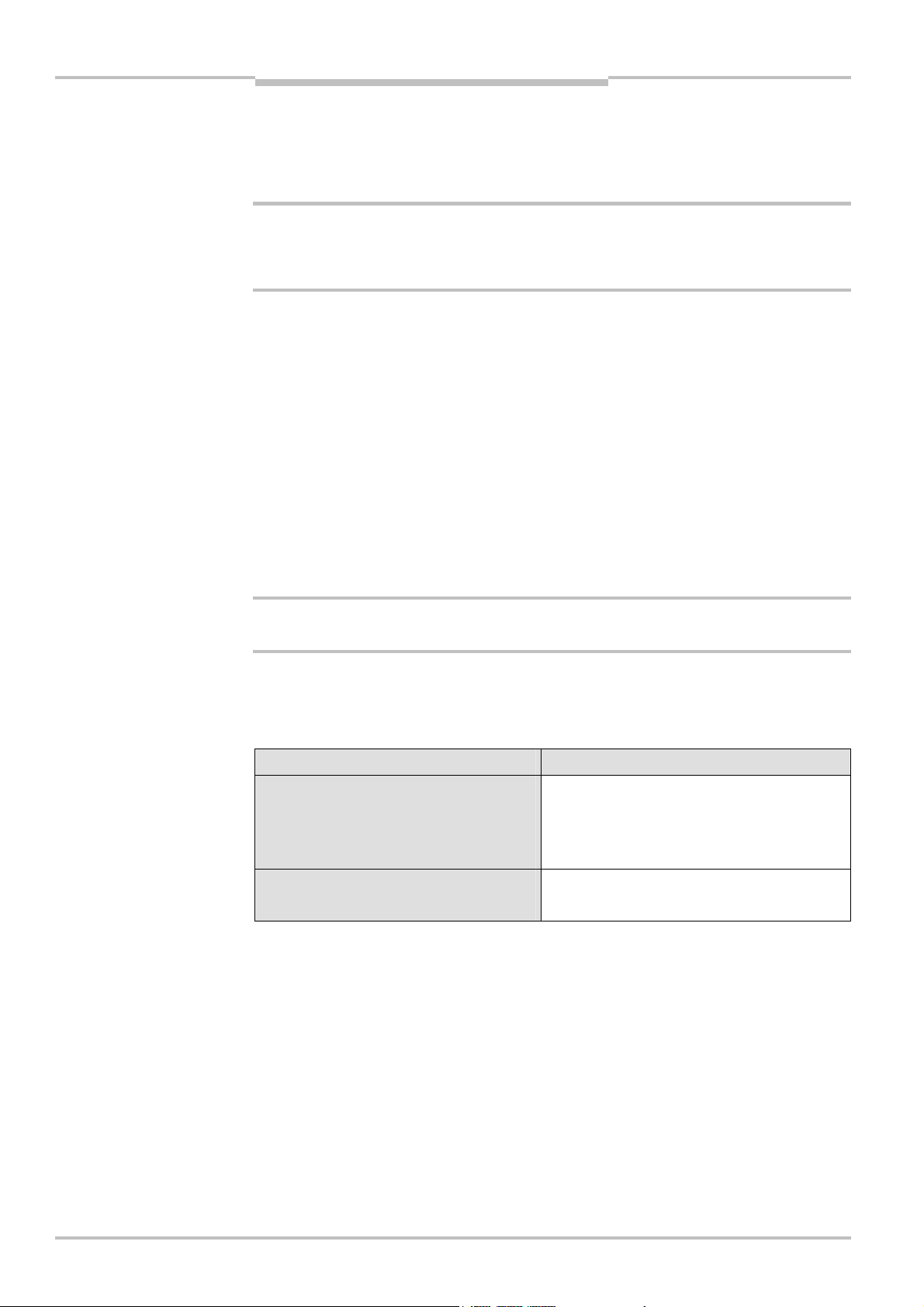

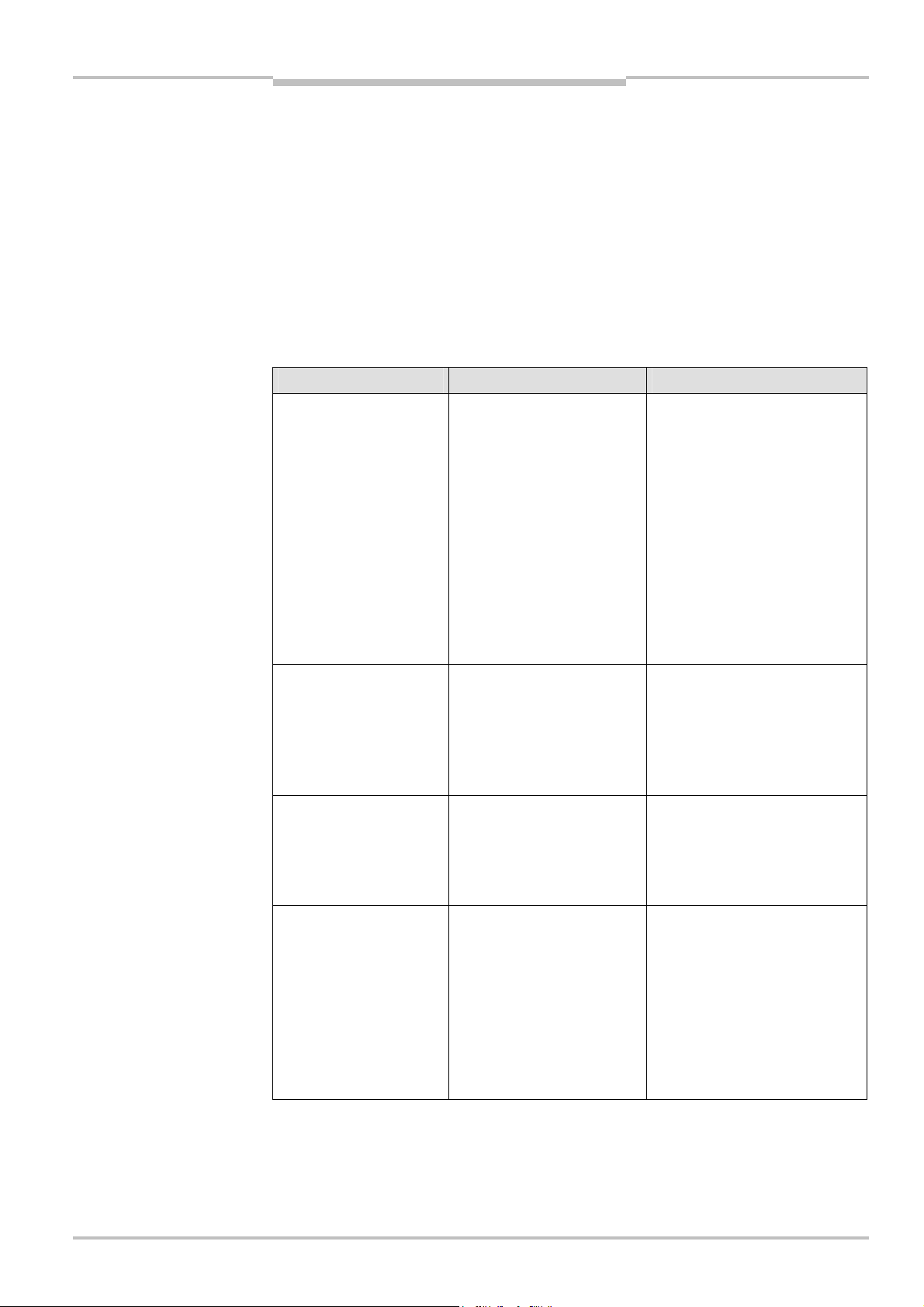

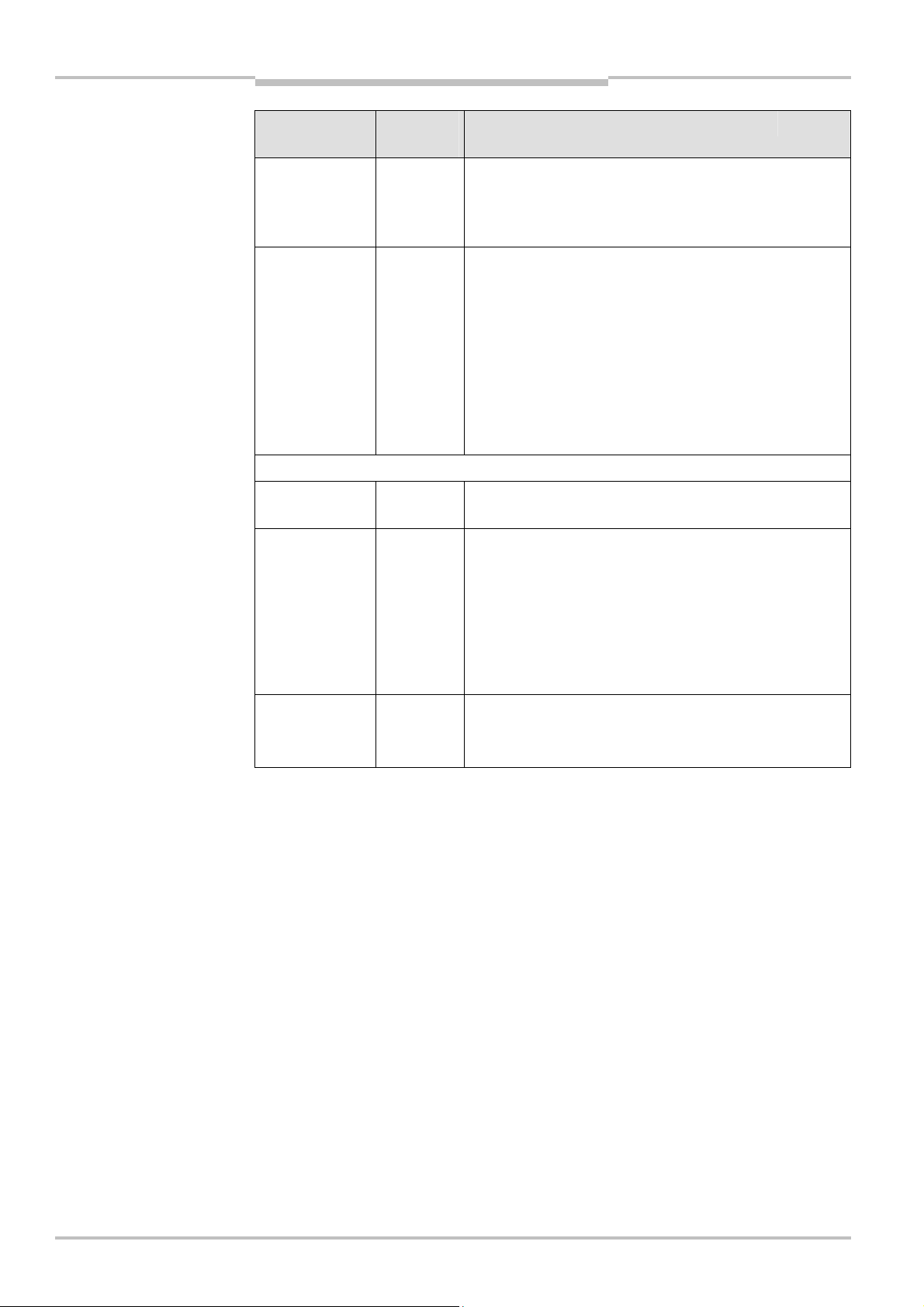

Components Disposal

Product

Housing, circuit boards, cables,

connectors and electrical connecting

pieces

Packaging

Cardboard, paper

Electronic recycling

Paper/cardboard recycling

10 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8011834/YT28/2016-03-15

Subject to change without notice

Page 11

Operating Instructions Chapter 3

Flexi Classic Gateways

Flexi Classic gateways

3 Flexi Classic gateways

he Flexi Classic gateways generate non-safety-related fieldbus data (status bytes) for con-

T

trol and diagnostics purposes. These status bytes contain the input and output states as

well as fault and status information. The nature and scope of the diagnostic data are de-

ined during planning and for the mapping.

f

n addition, you can save status bytes and diagnostic data on a PC with the aid of the PRO-

I

FIBUS-DP Master Simulator and the file flexi_config_list.xls, and document the settings for

the entire system (see section 4.2.2 “Documenting with PROFIBUS-DP Master Simulator”.

A Flexi Classic gateway has four short circuit-proof application diagnostic outputs for controlling non-safety functions. It is not allowed to connect any safety-related loads or inputs

of the Flexi Classic system with a safety function to these four application diagnostic outputs.

The operation of the safety-related functions of the Flexi Classic system is not affected by

the bus coupling. There is no information flow from external fieldbus systems over the

gateway to the safety system.

The modules are not suitable for operation on a safety fieldbus. They do not monitor the

functionality of the fieldbus or the digital application diagnostic outputs (X1-X4).

A Flexi Classic gateway can only be operated on a Flexi Classic system. It does not have a

dedicated voltage supply. It is only possible to use one Flexi Classic gateway per system.

The gateways are fitted in a 22.5 mm wide housing for 35-mm rails in accordance with

EN 50022. The devices have a removable screw terminal for each of the control outputs.

3.1 System information transmitted by the modules

system configuration

– input states on all Flexi Classic modules

– state of all safety outputs (Q1-Q4 or O

– control circuit configuration for all Flexi Classic modules

– settings for all program and function switches on the Flexi Classic modules

error and status information on all Flexi Classic modules

– erroneous system configuration, feedback circuits

– exceeding the synchronous monitoring time (closing a safety door)

– process error on dual-channel applications (e.g. on opening/closing a safety door)

– cross circuit on the inputs

– cross-circuit on the safety outputs, internal error (error classes)

, Q1, Q2 and ON)

P

8011834/YT28/2016-03-15 © SICK AG • Industrial Safety Systems • Germany • All rights reserved

Subject to change without notice

11

Page 12

Chapter 3 Operating Instructions

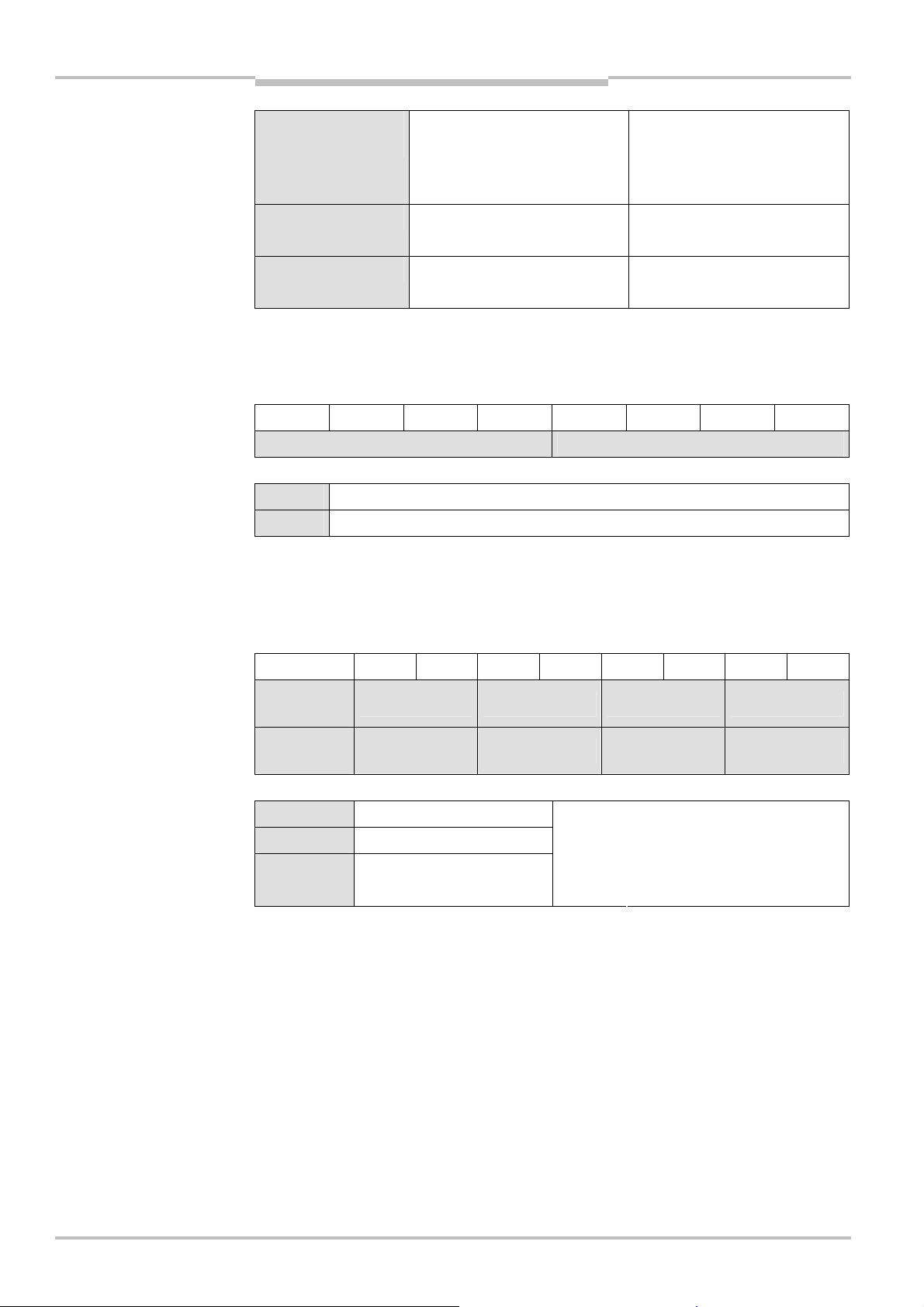

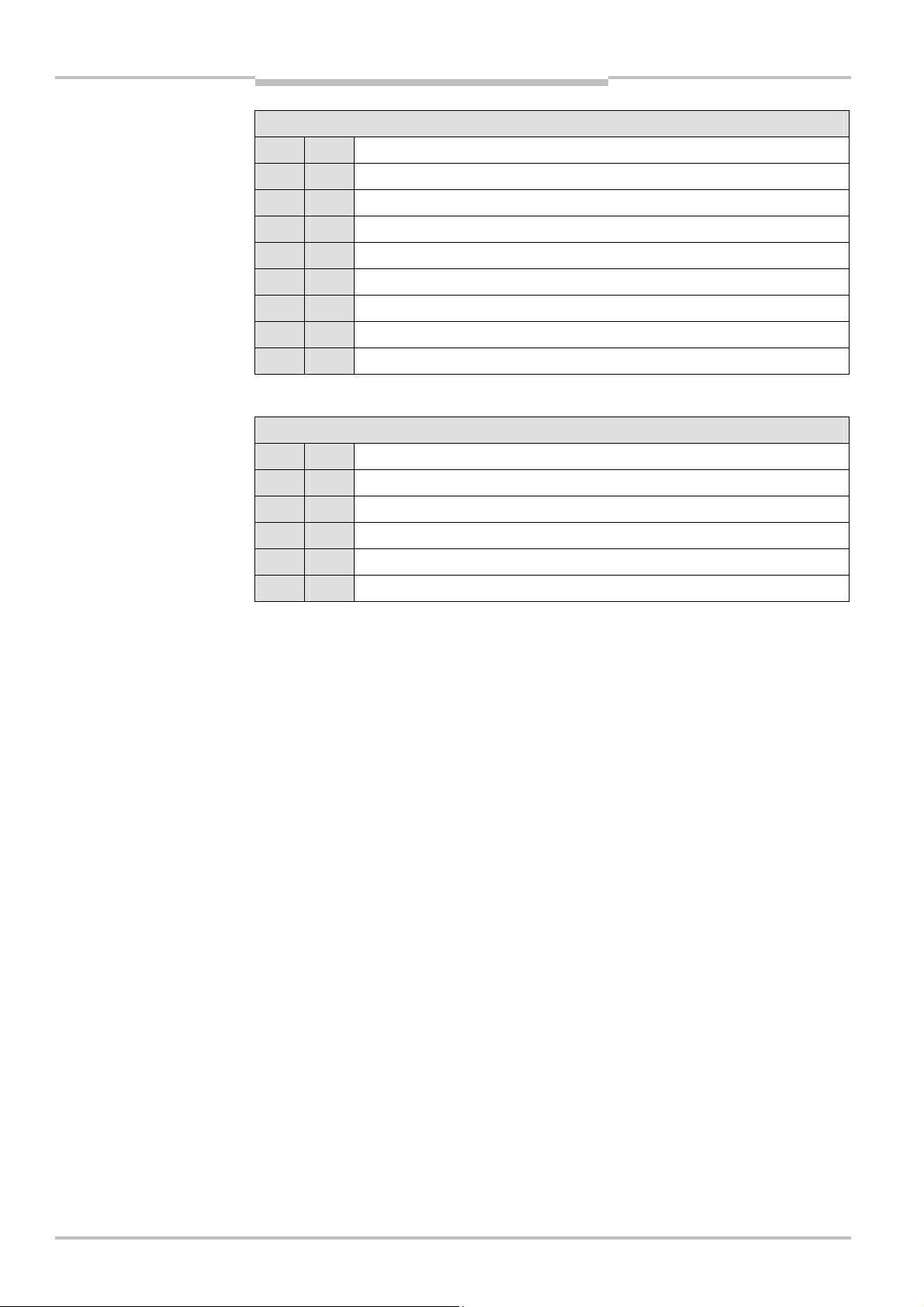

Tab.2:

DIG-OUT

Tab.3:

REQ-ID

Flexi Classic gateways

Flexi Classic Gateways

3.2 Status information of all Flexi Classic gateways

(system bytes)

The status information is contained in the system and status bytes described below. The

ignificance of these bytes is independent of the fieldbus used and applies to all gateways.

s

The grouping of the data bytes is described in the related chapters on the gateways in the

“Planning” sections.

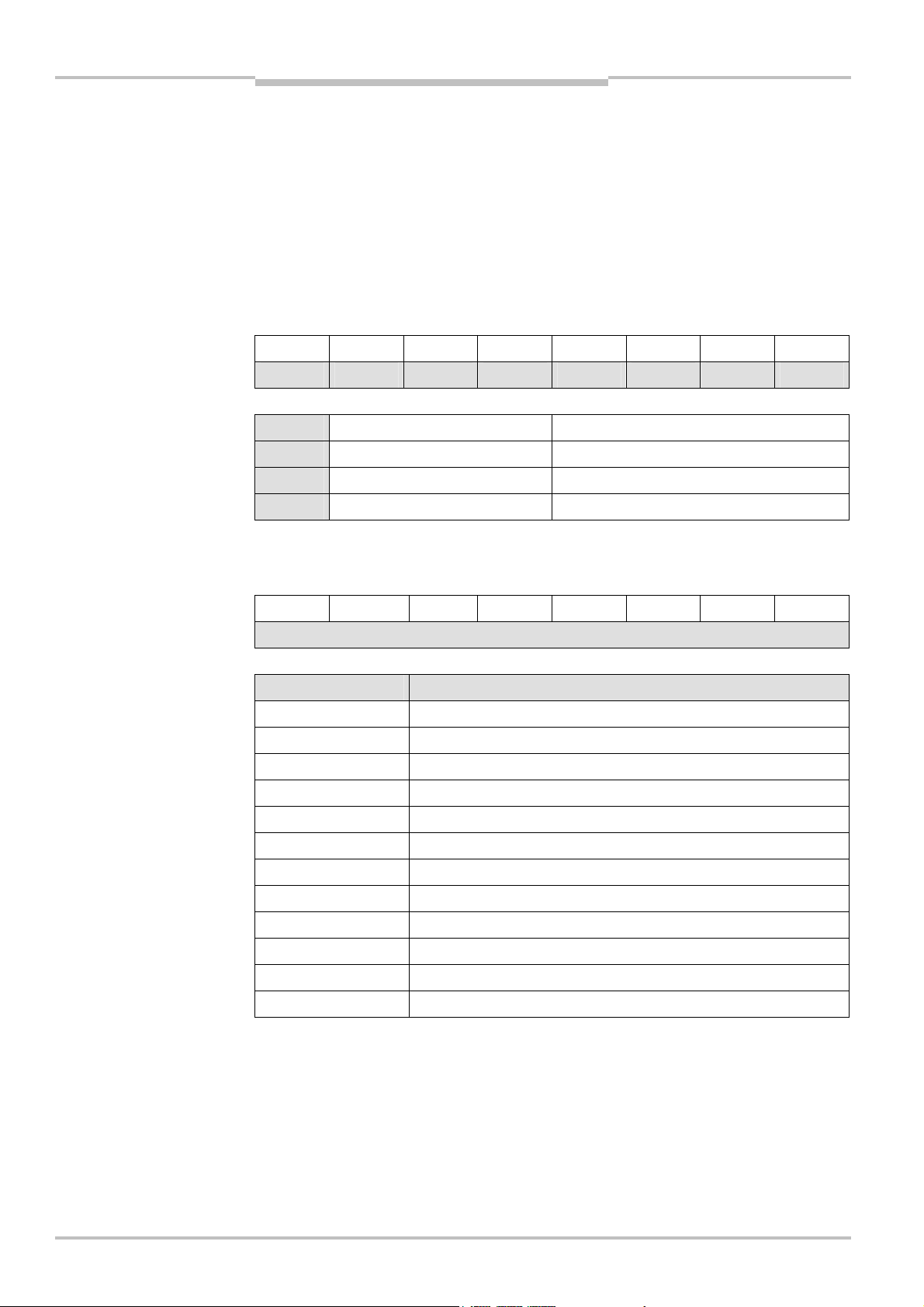

3.2.1 DIG-OUT

4 digital control outputs on the Flexi Classic gateways

Bit 7 6 5 4 3 2 1 Bit 0

– – – – X4 X3 X2 X1

X4

X3 Output X3

X2 Output X2

X1 Output X1 1 = Output switched on

Output X4

–

–

0 = Output switched off

3.2.2 REQ-ID

Control byte for the content of bytes B1-B10.

Bit 7 6 5 4 3 2 1 Bit 0

REQ-ID

REQ-ID Assignment B1–B10

0 Space

1 Status data module 1

2 Status data module 2

3 Status data module 3

: :

13 Status data module 13

21 Configuration module 1

22 Configuration module 2

23 Configuration module 3

: :

33 Configuration module 13

255 Internal diagnostics modules

12 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8011834/YT28/2016-03-15

Subject to change without notice

Page 13

Operating Instructions Chapter 3

Tab.4:

CRC and CRC2

Flexi Classic Gateways

Flexi Classic gateways

3.2.3 CRC1 and CRC2

High byte/low byte for the 16-bit checksum on the system configuration.

The system configuration contains all function settings, the configuration jumpers, the

number and order of the Flexi Classic modules inserted, the software versions etc. CRC1

and CRC2 together form the 16-bit checksum.

Bit 7 6 5 4 3 2 1 Bit 0

CRC1 (High byte)

CRC2 (Low byte)

Note

We recommend you to make a note of the slot list CRC and keep this information in the

control cabinet.

8011834/YT28/2016-03-15 © SICK AG • Industrial Safety Systems • Germany • All rights reserved

Subject to change without notice

13

Page 14

Chapter 3 Operating Instructions

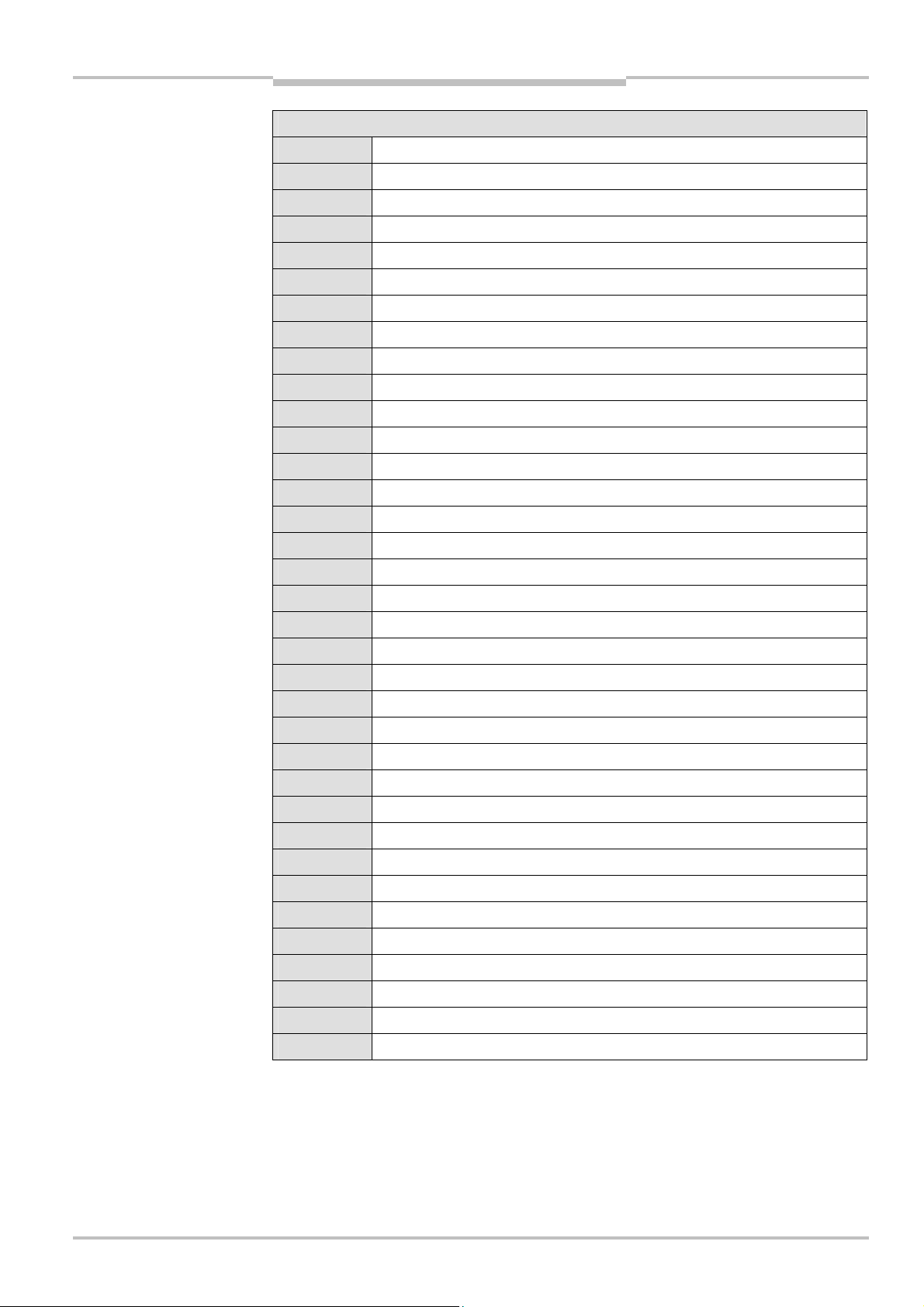

Tab.5:

BAS1

Tab.6:

BAS2

Flexi Classic gateways

Flexi Classic Gateways

3.2.4 BAS1

Group error bits on the overall system and output data on the UE410-MU, UE410-MM and

UE410-GU.

Bit 7 6 5 4 3 2 1 Bit 0

UE410-MU

UE410-MM

UE410-GU

IF Internal error 0 = No internal errors

QS Cross circuit error

(not on UE410-GU)

AF Process error

(not on UE410-GU)

ZF Time error

(not on UE410-GU)

RO EDM contacts open

(not on UE410-GU)

FM Program or function switch changed 0 = Switches have not been actuated

IF

QS AF ZF RO X1/2 X3/4

– – – –

1 = An internal error has occurred on one of the

Flexi Classic modules

0 = No cross circuit error

1 = Cross circuit error detected on an input pair

on the overall system

0 = No process error

1 = A process error has occurred on one of the

Flexi Classic modules in a safety circuit

0 = No time error

1 = An internal error has occurred on one of the

Flexi Classic modules

0 = No EDM error

1 = An error has occurred on the EDM contacts

on one of the modules. EDM contact was open

1 = Switches have been changed during

operation

FM

Q1 Q2

X1/2 Outputs Q1/Q2

UE410-MU/MM

X3/4 Outputs Q3/Q4

UE410-MU/MM

Q1 Output Q1

UE410-GU

Q2 Output Q2

UE410-GU

0 = Q1/Q2 inactive

1 = Q1/Q2 active

0 = Q3/Q4 inactive

1 = Q3/Q4 active

0 = Q1 inactive

1 = Q1 active

0 = Q2 inactive

1 = Q2 active

3.2.5 BAS2

Output data from the A/B function groups on the UE410-XU main module, the UE410-8DI

expansion modules and the UE410-XM, UE410-MDI muting modules.

Bit 7 6 5 4 3 2 1 Bit 0

MOD2 MOD3 MOD4 MOD5

14 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8011834/YT28/2016-03-15

Subject to change without notice

Page 15

Operating Instructions Chapter 3

Tab.7:

BAS3

Tab.8:

BAS4

Tab.9:

Definitions for BAS2,

Flexi Classic Gateways

Flexi Classic gateways

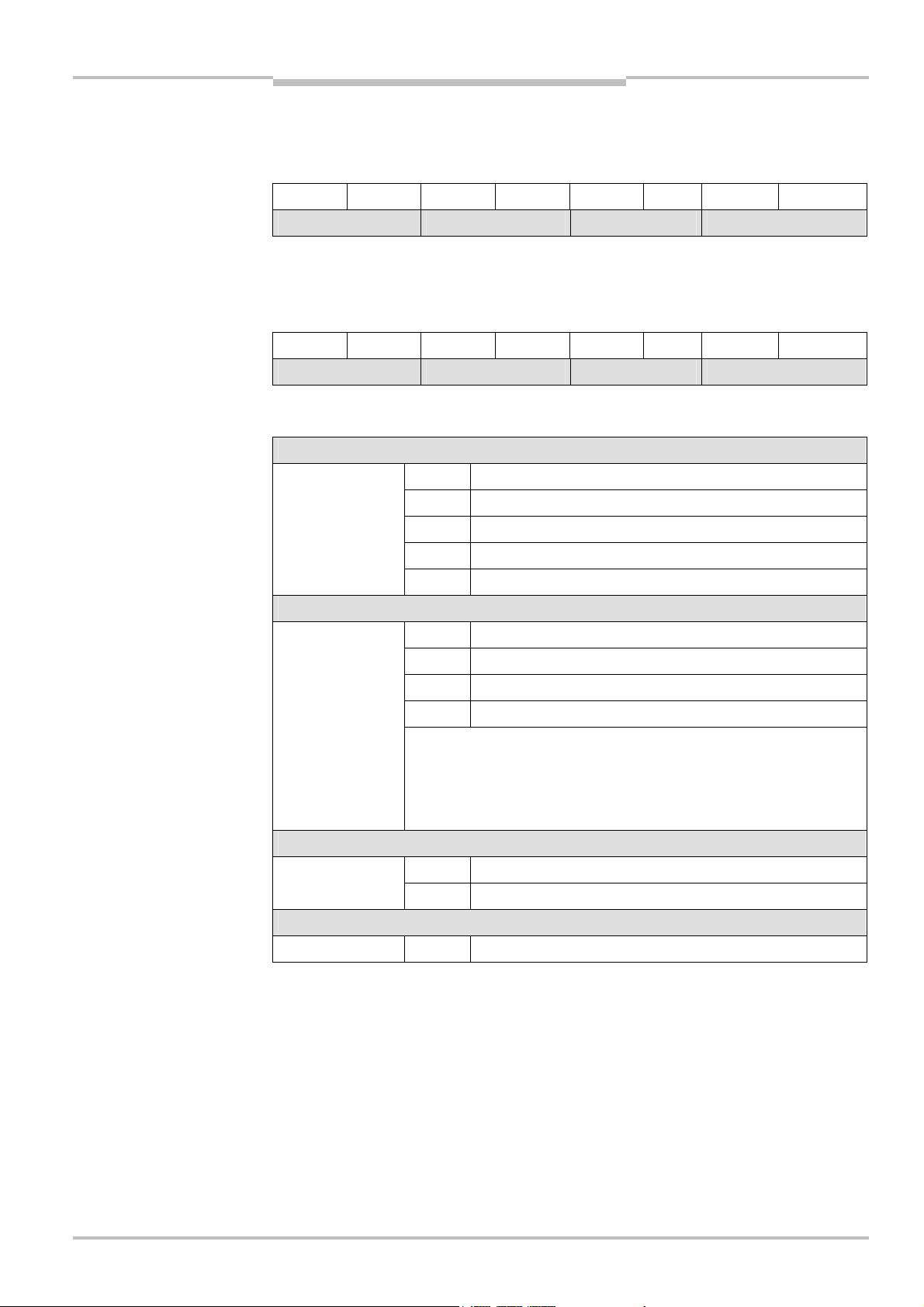

3.2.6 BAS3

Output data from the A/B function groups on the UE410-XU main module, the UE410-8DI

expansion modules and the UE410-XM, UE410-MDI muting modules.

Bit 7 6 5 4 3 2 1 Bit 0

MOD6 MOD7 MOD8 MOD9

3.2.7 BAS4

Output data from the A/B function groups on the UE410-XU main module, the UE410-8DI

expansion modules and the UE410-XM, UE410-MDI muting modules.

Bit 7 6 5 4 3 2 1 Bit 0

MOD10 MOD11 MOD12 MOD13

BAS3, BAS4

Note

For BAS2, BAS3, BAS4 the following definitions apply:

UE410-XU

MODn

UE410-8DI

MODn

UE410-XM

UE410-MDI

00 = Q1/Q2 inactive and Q4 inactive

01 = Q1/Q2 inactive and Q4 active

10 = Q1/Q2 active and Q4 inactive

11 = Q1/Q2 active and Q4 active

X = Unused

00 = QAinactive and QBinactive

01 = QAinactive and QBactive

10 = QAactive and QBinactive

11 = QAactive and QBactive

QA/ QBare set if:

• all inputs on the function group (A or B) are in the valid ON state

• the OR function is valid

• the bypass function is valid

00 = Q

10 = Q

1/2

1/2

and Q

active

3/4

inactive MODn

8011834/YT28/2016-03-15 © SICK AG • Industrial Safety Systems • Germany • All rights reserved

Subject to change without notice

Note

MODn 00 = Always 0, as module has no outputs

3.2.8 RSP-ID

Status byte for the assignment of the 10 bytes B1-B10.

The RSP-ID is used to confirm that the required contents have been provided by the gateway in B1-B10. When the RSP-ID has the same value as the REQ-ID, the data transfer is

complete.

As PLC cycles, fieldbus cycles and diagnostics cycles are generally not synchronised, on a

change in the REQ-ID the PLC should always wait for the RSP-ID prior to the evaluation of

the bytes B1-B10.

15

Page 16

Chapter 3 Operating Instructions

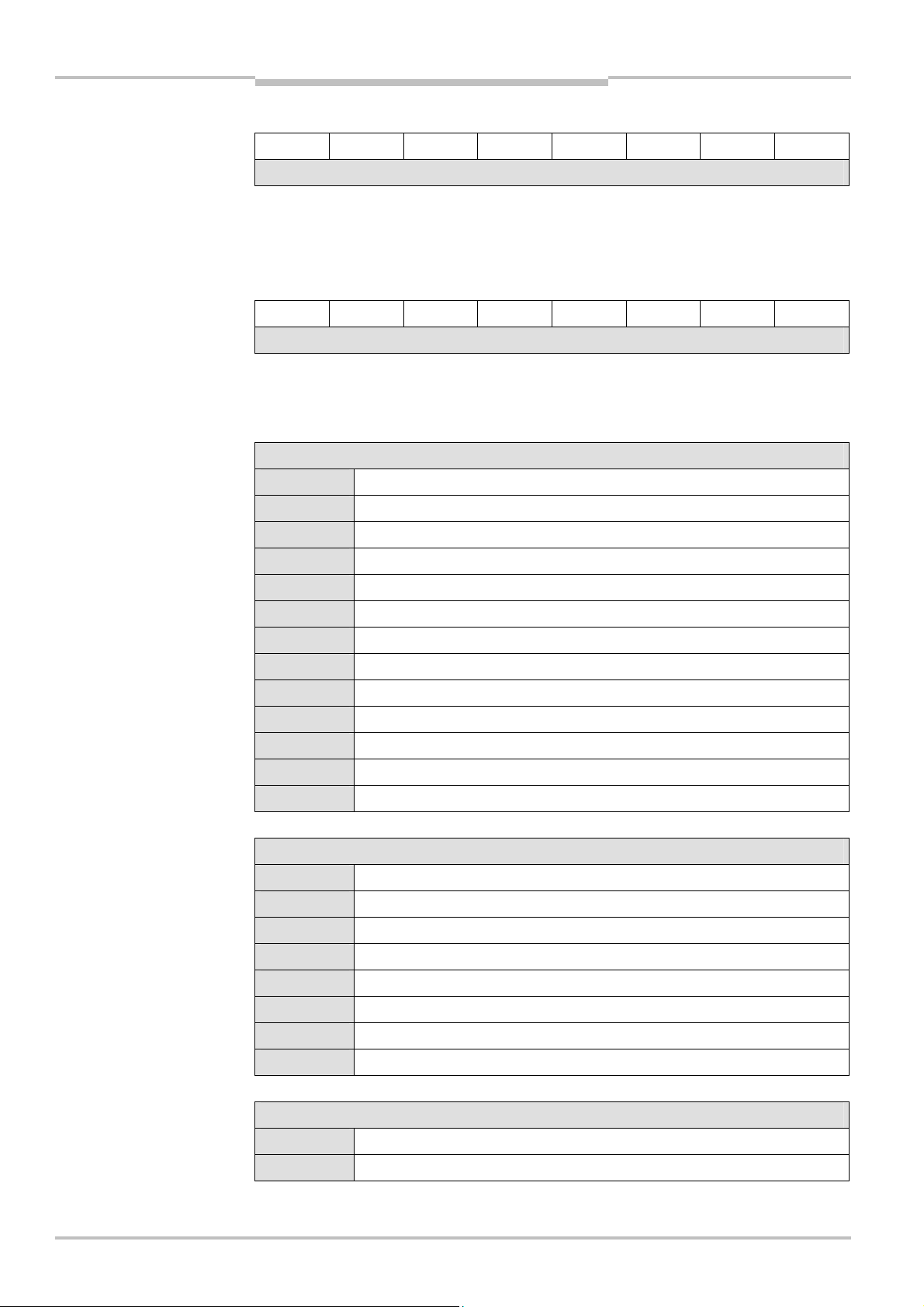

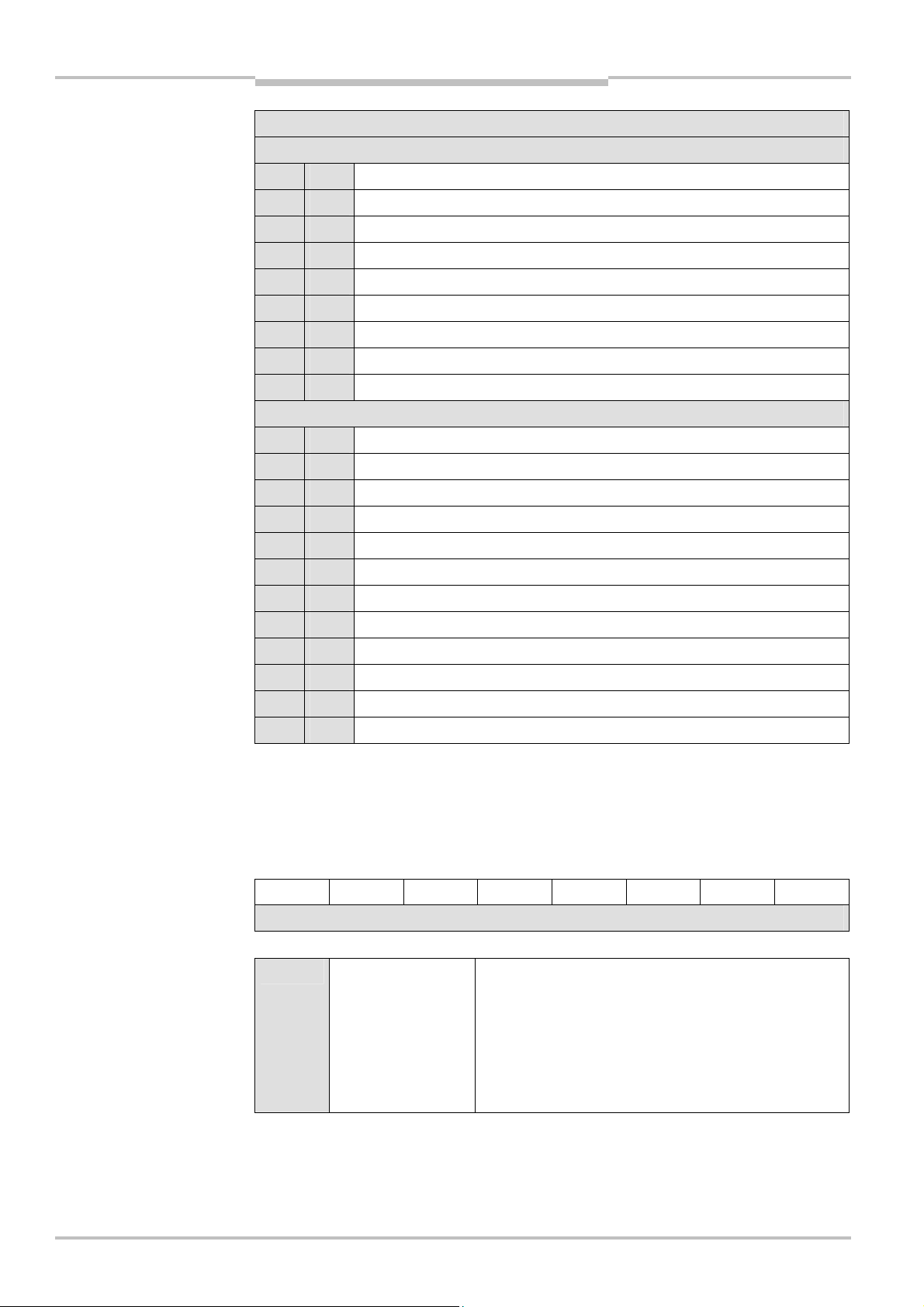

Tab.10:B1-

B10

Tab.11:B1-

B10

Tab.12:

MED

Flexi Classic gateways

Flexi Classic Gateways

3.2.9 B1-B10 (REQ-ID 1-13/2133)

The following assignment of configuration data to B1-B10 applies for the REQ-IDs 21-33:

(REQ0ID 21033)

B1 MED MOD-ID

B2 MQD SW-VERSION_H

B3 MKD1 SW-VERSION_L

B4 MKD2 FUNCTION

B5 MFD KONF

B6 MFCLASS1 CRC_H CODE

B7 MFCODE1 CRC_L CODE

B8 MFCLASS2 –

B9 MFCODE2 –

B10 RSP-ID RSP-ID

REQ-ID 1-13 REQ-ID 21-33

3.2.10 B1-B10 (REQ-ID 255)

Control byte for PROFIBUS communication

For the REQ-ID 255 the following assignment of configuration data to B1-B10 applies:

(REQ0ID 255)

B1 DIAG-VERSION_H

B2 DIAG-VERSION_L

B3 BUS ADDR Contains the fieldbus address currently set

(dynamic)

B4 NOISE

B5 FRAME

B6 BREAK

B7 PARITY

B8 –

B9 –

B10 RSP-ID

4 bytes that contain the number of transmission

errors that have occurred on a bus system

3.2.11 MED

Module input data (input states)

Bit 7 6 5 4 3 2 1 Bit 0

UE410-MU

UE410-XU

UE410-GU I4 I3 I2 I1 I

UE410-8DI I8 I7 I6 I5 I4 I3 I2 I1

UE410-MM

UE410-XM

S3 S2 S1 EN I4 I3 I2 I1

N

I2 I1 S1 EN M4 M3 M2 M1

I6 I5 I

P

UE410-MDI 0 0 0 0 S4 OVR CS C1

Input states 0 = Input is inactive

1 = Input is active

16 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8011834/YT28/2016-03-15

Subject to change without notice

Page 17

Operating Instructions Chapter 3

Tab.13:

MQD

Flexi Classic gateways

Flexi Classic Gateways

3.2.12 MQD

Module status and output data (output states/module output data)

Bit 7 6 5 4 3 2 1 Bit 0

UE410-MU

BYP MUTE StRq B StRq A Q4 Q3 Q2 Q1

UE410-XU

UE410-GU O

P

UE410-8DI - - – – Q

UE410-MM

OVR MUTE OVReq StRq Q4 Q3 Q2 Q1

O

StRq

N

local

StRq

global

Q2 Q2 Q1 Q1

B

– Q

A

–

UE410-XM

UE410-MDI – – – – S4 OVR CS C1

With the UE410-MU/XU, the functions StRq A and MUTE are output on Q3 in program 3.

For this reason you would be better using the status bits 4 and 7 for the output of these

states.

Q1-Q4 Output states UE410-MU/

UE410FGU/UE410-XU/UE410-MM/

UE410-XM

QA, Q

B

Module output data UE410-8DI

QA/ QBare set if:

• all inputs on the function group (A or B) are in the valid ON state

• the OR function is valid

• the bypass function is valid

0 = Output is inactive

1 = Output is active

0 = Output is inactive

1 = Output is active

S4, OVR, CS, C1

Module output data UE410-MDI 0 = Output is inactive

1 = Output is active

Module output data are the same as module input data.

See module input data (input states)

OVR Req

(only UE410@MM/XM)

Override request, waiting for

override

0 = Not currently waiting

1 = The System is in the Override

required state and is expecting the

actuation of the restart button

StRq A,

StRq B

Reset request, waiting for reset

input group A/B

0 = Not currently waiting

1 = Waiting for a reset signal; is

deleted, once the reset has been

made

StRq Reset request, waiting for reset 0 = Not currently waiting

1 = Waiting for a reset signal; is

deleted, once the reset has been

made

StRq local,

StRq global

(only UE410-GU)

Reset request, waiting for local

reset, waiting for global reset

0 = Not currently waiting

1 = Waiting for a reset signal; is

deleted, once the reset has been

made

8011834/YT28/2016-03-15 © SICK AG • Industrial Safety Systems • Germany • All rights reserved

Subject to change without notice

17

Page 18

Chapter 3 Operating Instructions

Tab.14:

MKD1

Tab.15:

MKD2

Flexi Classic gateways

Flexi Classic Gateways

OP, O

N

(only UE410-GU)

MUTE Status bit for Muting 0 = Muting is inactive

BYP Status bit for Bypass 0 = Bypass is inactive

Communication for global

emergency stop to the previous or

next module

0 = Global emergency stop is

inactive

1 = Global emergency stop is

active

1 = Muting is active

1 = Bypass is active

3.2.13 MKD1

Module configuration data 1: Position of the program switch/function switch/time range

(not UE410-GU)

Bit 7 6 5 4 3 2 1 Bit 0

SW1 SW2

SW1 Top switch setting 0-9

SW2 Bottom switch setting 0-9

3.2.14 MKD2

Module configuration data 2: (UE410-MU/XU configuration on S1, S2, S3)

(UE410-MM/XM: configuration on S1)

(not UE410-GU)

Bit 7 6 5 4 3 2 1 Bit 0

UE410-MU

UE410-XU

UE410-MM

UE410-XM

S1 Configuration jumper on S1 00 = Open

S2 Configuration jumper on S2 01 = On X1

– S3 S2 S1

– – – S1

10 = On X2 S3 Configuration jumper on S3

11 =

Active at +U

B

18 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8011834/YT28/2016-03-15

Subject to change without notice

Page 19

Operating Instructions Chapter 3

Tab.16:

MFD

Tab.17:

MFCLASS1

Tab.18:

MFCLASS2

Flexi Classic Gateways

Flexi Classic gateways

3.2.15 MFD

Module error data: (external errors on all Flexi Classic modules)

(not UE410-GU)

Bit 7 6 5 4 3 2 1 Bit 0

UE410-MU

UE410-XU

UE410-8DI I7/I8 I5/I6 I3/I4 I1/I2

UE410-MM

UE410-XM

UE410-MDI I7/I8 I5/I6 I3/I4 I1/I2

S1 S1 (feedback circuit)

S2 S2 (feedback circuit)

S3 S3 (feedback circuit)

I1/2 Error code input pair I1/I2

I3/4 Error code input pair I3/I4

I5/6 Error code input pair I5/I6

I7/8 Error code input pair I7/I8

S3 S2 S1 - I3/I4 I1/I2

– M3/4 M1/2 I1/2

0 = No error in the feedback circuit

1 = Feedback circuit open

00 = No error

01 = Time error

10 = Process error

11 = Cross circuit error

3.2.16 MFCLASS1-MFCODE2

The bytes MFCLASS1 and MFCLASS2 contain the error class, the bytes MFCODE1 and

MFCODE2 the error codes on a system error that has occurred in processing channel 1 or

2. MFCLASS and MFCODE together provide a 16-bit error code that describes the error

category and reason for the error, and the processing channel affected.

Error code:

XX - MFCLASS1 or MFCLASS2 (hex)

ZZ - MFCODE1 or MFCODE2 (hex)

Bit 7 6 5 4 3 2 1 Bit 0

MFCLASS1 - ErrClass VK1

ErrClass VK1 contains the error class for a system error that has occurred in processing

channel 1.

Bit 7 6 5 4 3 2 1 Bit 0

MFCLASS2 - ErrClass VK2

ErrClass VK2 contains the error class for a system error that has occurred in processing

channel 2. Codes for ErrClass VK1 and ErrClass VK2:

01h= Flex bus error

02h= Resource error

03h= Program memory error

04h= Self diagnostics error

05h= Internal input test error

06h= External input test error

07h= Output test error

08h= Voltage monitoring error

09h= Configuration and diagnostics error

0Ah= Logical error

8011834/YT28/2016-03-15 © SICK AG • Industrial Safety Systems • Germany • All rights reserved

Subject to change without notice

19

Page 20

Chapter 3 Operating Instructions

Tab.19:

MFCODE1

Tab.20:

MFCODE2

Flexi Classic gateways

Flexi Classic Gateways

Bit 7 6 5 4 3 2 1 Bit 0

MFCODE1 - ErrCode VK1

ErrCode VK1 contains the error code for a system error that has occurred in processing

channel 1. Together with MFCLASS1 a 16-bit error code is produced: MFCLASS1 contains

a code for the error category and MFCODE1 contains the detail code that describes the

reason for the error.

Bit 7 6 5 4 3 2 1 Bit 0

MFCODE2 - ErrCode VK2

ErrCode VK2 contains the error class for a system error that has occurred in processing

channel 2. Together with MFCLASS2 a 16-bit error code is produced: MFCLASS2 contains

a code for the error category and MFCODE2 contains the detail code that describes the

reason for the error.

ErrCode for ErrClass 01h:

06 Unknown SDO type (read, write)

07 Error on the reception of the data frame, parity, noise, etc.

08 No frame bytes received

09 Checksum error detected

0A No frame bytes received in the slave

10 Data frame could not be sent

11 Unknown error in RecFrameErrorCheck()

12 Invalid frame revision received

14 Continuous indexing check erroneous

15 TX error: hold-register not clear

16 Not all characters received within timeout

17 SDO.cnt Timeout

18 Error in frame counter

ErrCode for ErrClass 02h:

01 Internal error in Delay ()

02 Error on handling with T0

03 Error on deleting the flash page

04 Error in FlashWriteByte()

05 Timer management error in SAPL

06 Error on AdcStartSample()

07 Error on AdcDone()

08 Cross comparison SL-CRCs negative

ErrCode for ErrClass 03h:

41 Flashtest error

42 RAMTest error

20 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8011834/YT28/2016-03-15

Subject to change without notice

Page 21

Operating Instructions Chapter 3

Flexi Classic Gateways

Flexi Classic gateways

ErrCode for ErrClass 04h:

01 System tick 1ms exceeded in HAL SystemTickhandler()

02 System tick 4 ms exceeded

03 System tick 4_1 ms exceeded

04 Self-test asynchronous

05 Error during cross comparison (Tx)

06 Error during cross comparison (Rx)

07 Error on watchdog relay (does not open)

08 Error on HAL_Synchronized

1B Error invalid bits in the output configuration

ErrCode for ErrClass 05h:

M 01 Internal test pulse not present on I1

M 02 Internal test pulse not present on I2

M 04 Internal test pulse not present on I3

M 08 Internal test pulse not present on I4

M 10 Internal test pulse not present on I5

M 20 Internal test pulse not present on I6

M 40 Internal test pulse not present on I7

M 80 Internal test pulse not present on I8

(M = Bit mask; several errors can occur simultaneously)

ErrCode for ErrClass 06h:

For base module

M 01 External test pulse not present on I1

M 02 External test pulse not present on I2

M 04 External test pulse not present on I3

M 08 External test pulse not present on I4

M 10 External test pulse not present on I5

M 20 External test pulse not present on I6

M 40 External test pulse not present on I7

M 80 External test pulse not present on I8

For muting input extension:

M 01 External test pulse not present on I1

M 02 External test pulse not present on I2

M 04 External test pulse not present on I3

M 08 External test pulse not present on I4

(M = Bit mask; several errors can occur simultaneously)

8011834/YT28/2016-03-15 © SICK AG • Industrial Safety Systems • Germany • All rights reserved

Subject to change without notice

21

Page 22

Chapter 3 Operating Instructions

Flexi Classic gateways

Flexi Classic Gateways

ErrCode for ErrClass 07h:

M 01 Output X1 not off (cross circuit)

M 02 Output X2 not off (cross circuit)

M 03 Cross-circuiting OSSD

M 04 Output X3 not off (cross circuit)

M 08 Output X4 not off (cross circuit)

M 10 Output X1 not on (short circuit)

M 20 Output X2 not on (short circuit)

M 40 Output X3 not on (short circuit)

M 80 Output X4 not on (short circuit)

(M = Bit mask; several errors can occur simultaneously)

ErrCode for ErrClass 08h:

M 01 I/O undervoltage

M 02 Power supply undervoltage

M 03 Undervoltage power supply unit and undervoltage I/O

M 04 I/O overvoltage

M 08 Power supply overvoltage

M 20 Error power supply monitoring

(M = Bit mask; several errors can occur simultaneously)

22 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8011834/YT28/2016-03-15

Subject to change without notice

Page 23

Operating Instructions Chapter 3

Flexi Classic Gateways

Flexi Classic gateways

ErrCode for ErrClass 09h:

01 Modules incompatible

02 Configuration change detected

09 SDO client invalid state

0A Unknown SDO-cnf

0B Unused SDO index

0C SDO7 in slot list missing for at least 1 module

0D Index error in slot list

0E Invalid position switch 0

0F Invalid position switch 1

10 CRC monitoring module list

11 Monitoring time range constant

12 SALI monitoring event

14 Extension unit has emergency bit set

15 Main unit has high emergency bit set

16 Program execution error

17 Slot list in extension module is faulty

18 System tick exceeded

19 Slot index error

1A Enter key not released while LED was flashing

1C External error hardware reset

1D Illegal error Opcode Reset

1E Error Clock generator reset

1F Unexpected reset

20 Unknown mask revisions

21 Error Clock generator loss of lock

41 Cross comparison input configuration erroneous

42 Cross comparison output state erroneous

81 Too many modules found

82 Unknown module ID found

83 Invalid jumper S1

84 Invalid jumper S2

85 Invalid jumper S3

86 Erroneous module configuration

87 Rotary switch changed during operation

88 Incomplete data frame on IndexAssign

8011834/YT28/2016-03-15 © SICK AG • Industrial Safety Systems • Germany • All rights reserved

Subject to change without notice

23

Page 24

Chapter 3 Operating Instructions

Tab.21:

MOD-ID

Flexi Classic gateways

Flexi Classic Gateways

ErrCode for ErrClass 0Ah:

For base module

M 01 Logical error in input group A

M 10 Logical error in input group B

M 11 Logical error in input groups A and B

M 02 Logical error in the start function group A

M 20 Logical error in the start function group B

M 22 Logical error in the start function groups A and B

M 08 Logical error in the bypass function group A

M 80 Logical error in the bypass function group B

M 88 Logical error in the bypass function groups A and B

For muting master/slave:

M 01 Logical error in input group A

M 10 Logical error in input group B

M 11 Logical error in input groups A and B

Note

M 02 Logical error in the start function group A

M 20 Logical error in the start function group B

M 22 Logical error in the start function groups A and B

M 04 Logical error in the output function group A

M 40 Logical error in the output function group B

M 44 Logical error in the output function groups A and B

M 08 Logical error in the bypass function group A

M 80 Logical error in the bypass function group B

M 88 Logical error in the bypass function groups A and B

(M = Bit mask; several errors can occur at the same time)

On the occurrence of error codes other than those listed here, please contact the SICK

technical hotline.

3.2.17 MOD-ID

Module identifier for the selected Flexi Classic module (not UE410-GU).

Bit 7 6 5 4 3 2 1 Bit 0

MOD-ID

MOD-ID Module identifier 1 = UE410-MU

2 = UE410-XU

3 = UE410-8DI

4 = UE410-MM

5 = UE410-XM

6 = UE410-MDI

24 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8011834/YT28/2016-03-15

Subject to change without notice

Page 25

Operating Instructions Chapter 3

Tab.22:SW-

VERSION_H and

Tab.23:

FUNCTION

Flexi Classic Gateways

Flexi Classic gateways

3.2.18 SW-VERSION_H and SW-VERSION_L

High byte/low byte for the software version for the selected Flexi Classic module.

The software version is supplied as a 16-bit-hex number, e.g. 0624 = 2006, week 24.

SW-VERSION_L

Bit 7 6 5 4 3 2 1 Bit 0

SW-VERSION H

SW-VERSION L

3.2.19 FUNCTION

FUNCTION describes the setting of the rotary switch on the selected Flexi Classic module

(not UE410-GU). This byte is to be interpreted differently depending on the module type,

e.g. as program switch, switch for off delay or function switch.

Bit 7 6 5 4 3 2 1 Bit 0

UE410-MU

UE410-XU

UE410-MM

UE410-XM

UE410-8DI INPUT A INPUT B

UE410-MDI FUNC C –

FUNC Program switch

UE410FMU/UE410FXU

FUNC A See description UE410-MM/UE410-XM

FUNC TIME

FUNC A FUNC B

0 = Invalid

1-8 = Function 1 to 8

9 = Invalid

FUNC B See description UE410-MM/UE410-XM

FUNC C See description UE410-MDI

TIME Reactivation delay UE410-MU/

UE410-XU. The value defines a

factor that must be multiplied with

the time variant T from KONF to

obtain the reactivation delay in sec.

INPUT_A Input circuit function group A

UE410-8DI

INPUT_B Input circuit function group B

UE410-8DI

0 = Factor 0

1 = Factor 0.5

2 = Factor 1

3 = Factor 1.5

4 = Factor 2

5 = Factor 2.5

6 = Factor 3

7 = Factor 3.5

8 = Factor 4

9 = Factor 5

0 = Not used

1-9 = Function 1 to 9

0 = Not used

1-9 = Function 1 to 9

8011834/YT28/2016-03-15 © SICK AG • Industrial Safety Systems • Germany • All rights reserved

Subject to change without notice

25

Page 26

Chapter 3 Operating Instructions

Tab.24:

KONF

Tab.25:

CRC_H CODE and

Tab.26:

DIAG-VERSION_H

Tab.27:

System interface

Flexi Classic gateways

Flexi Classic Gateways

3.2.20 KONF

Configuration setting for the selected Flexi Classic module (not UE410-GU). On a UE4108DI and UE410-MDI this byte is set to zero, as apart from the input circuit functions there

re no other configuration options.

a

Bit 7 6 5 4 3 2 1 Bit 0

UE410-MU

UE410-XU

UE410-MM

UE410-XM

UE410-8DI

UE410-MDI

T Time variant UE410-MU. UE410-

S1 Configuration jumper on S1

S2 Configuration jumper on S2

S3 Configuration jumper on S3

T S3 S2 S1

– – – S1

–

11 = Factor 1 s

MU are supplied in three time

variants. The time variant defines

the reactivation delay.

10 = Factor 10 s

01 = Factor 1 min

00 = Open

01 = Connected to X1

10 = Connected to X2

11 = Connected to +U

B

3.2.21 CRC_H CODE and CRC_L CODE

High byte/low byte for the 16-bit checksum via the code area on the selected Flexi Classic

module.

CRC_L CODE

and DIAG-VERSION_L

status (only UE410-EN3)

Bit 7 6 5 4 3 2 1 Bit 0

CRC_H CODE

CRC_L CODE

3.2.22 DIAG-VERSION_H and DIAG-VERSION_L

High byte/low byte for the software version on the selected UE410-PRO/UE410-DEV.

The software version is supplied as a 16-bit-hex number, e.g. 0624 = 2006, week 24.

Bit 7 6 5 4 3 2 1 Bit 0

DIAG-VERSION_H

DIAG-VERSION_L

3.2.23 System interface status (only UE410-EN3)

Bit 7 6 5 4 3 2 1 Bit 0

0= Flex bus

–

communication OK

1= Flex bus

communication faulty

26 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8011834/YT28/2016-03-15

Subject to change without notice

Page 27

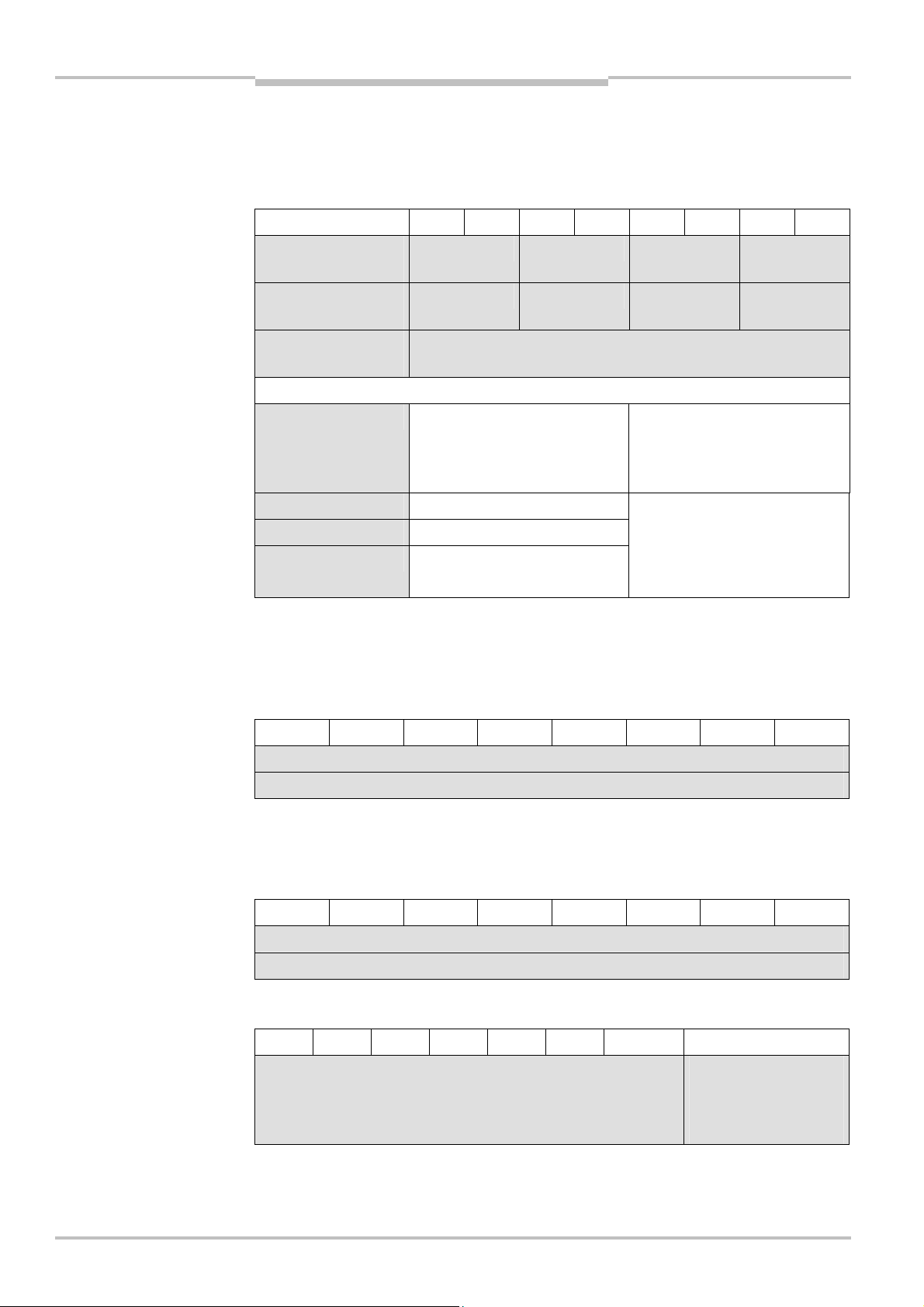

Operati ng Instructions Chapter 4

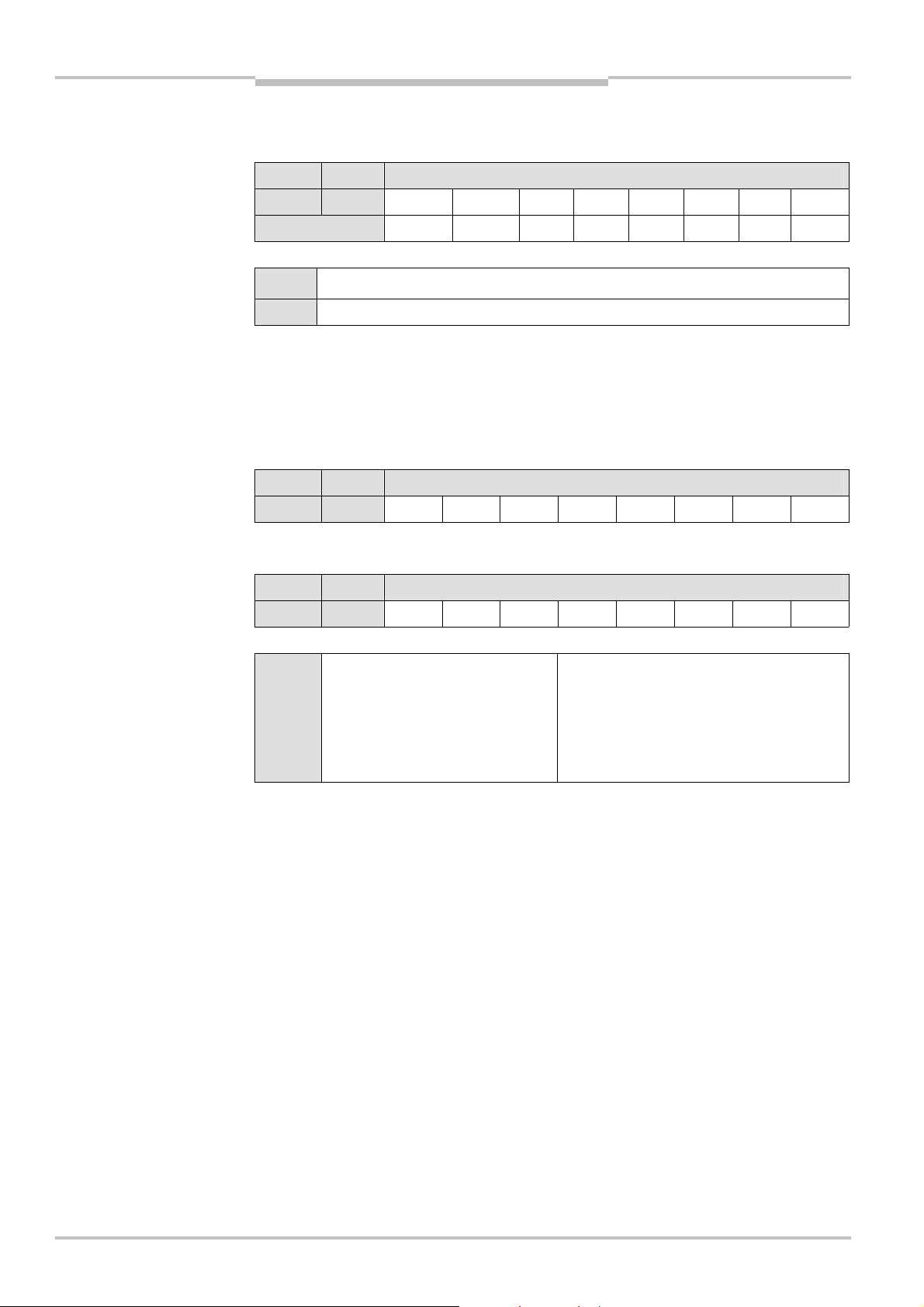

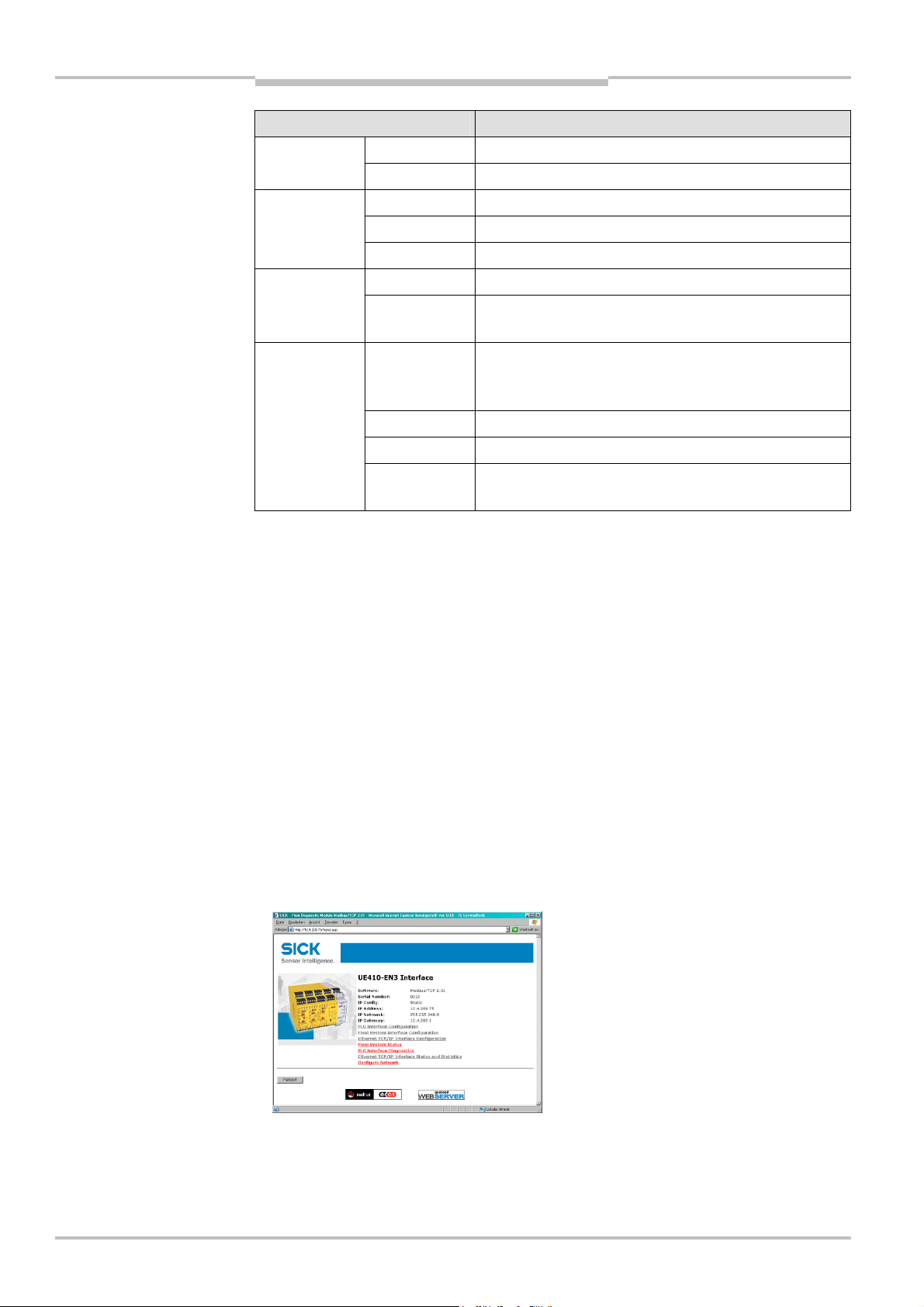

Fig.1:

Controls and statu

s

Tab.28:

Indication LED

Tab.29:

Address switch

Flexi Classic Gateways

PROFIBUS DP Gateway

4 PROFIBUS DP Gateway

The following Flexi Classic gateways can be used for PROFIBUS DP:

• UE410-Pro3, UE410-Pro4

4.1 Interfaces and operation

4.1.1 Controls and status indicators

indicators UE410-PRO

UE410-PRO

UE410-PRO

Notes

Display Meaning

PWR (green) Supply volt ag e present

BF (red)

DIA (red) No function (not used)

Switch/button Function

× 10

× 1

No bus connection, fieldbus cable break or master is not (or no

longer) writing to the bus

Address switch 1

10-position rotary switch for setting the module address

(tens)

Address switch 2

10-position rotary switch for setting the module address

(units)

• The occurrence of random or systematic errors in the gateway or in its o peration does

not result in the degradation of the safety functions on t he Flexi Classic system.

• With the operating voltage switched on, no gateways are allowed to be disconnected

from the Flexi Classic system or added by plugging in.

• The PROFIBUS master cannot overwrite the address set.

• A modified address setting only becomes effective after switching off and switching on

the Flexi Cla ssic system.

8011834/YT28/2016-03-15 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 27

Subject to change without notice

Page 28

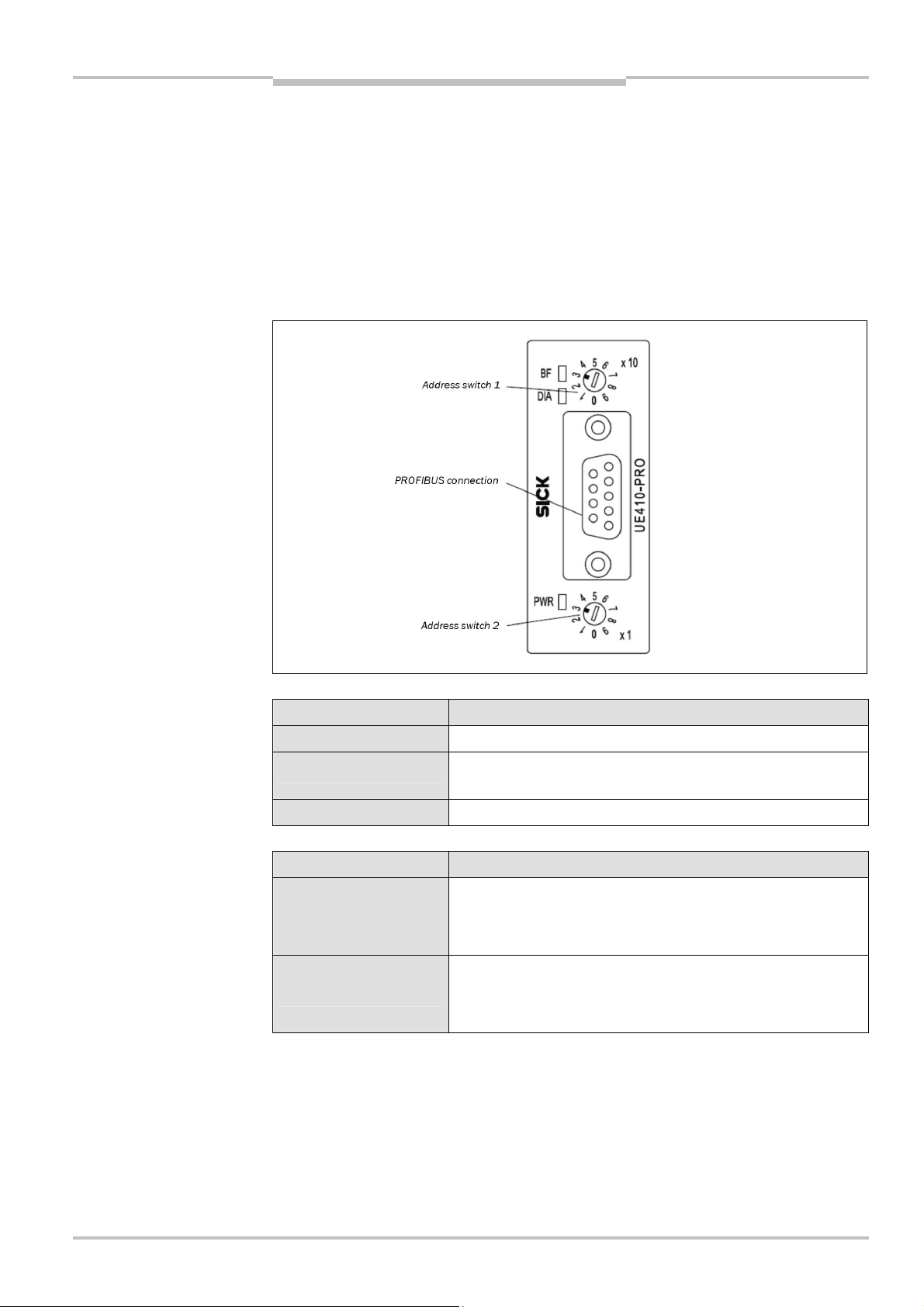

Chapter 4 Operating Instructions

Tab.30: Application

Fig.2:D-

Sub socket and plug

Fig.3:

Bus cable UE410

-

PRO

Tab.31:

Explanatio

n bus

PROFIBUS DP Gateway

Flexi Classic Gateways

4.1.2 Application diagnostic outputs UE410-PRO

diagnostic outputs

pin assignments UE410-PRO

Assignment Description

X1-X4 Short circuit and overload detecting control outputs (PNP) supplied via Flexi

Classic system

4.1.3 Plug assignment

The connection to the PROFIBUS-DP fieldbus is made using a 9-pin Sub-D socket.

Pin Description

1 SHLD

2 NC

3 RxD/TxD-P

4 CNTR-P

5 GND-EXT

6 +5V-EXT

7 NC

8 RxD/TxD-N

9 CNTR-N (GND-EXT)

4.1.4 Bus cable

cable UE410-PRO

The bus topology for PROFIBUS-DP is a linear structure comprising a screened, twisted

2Fcore cable with active bus termination at both ends. The possible bus lengths are 100 m

at 12 MBit/s up to 1,200 m at 94 KBit/s.

Position Description

1

2

3

PROFIBUS user grey

Screened bus cable

PROFIBUS termination yellow

(with integrated terminating resistors)

28 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8011834/YT28/2016-03-15

Subject to change without notice

Page 29

Operating Instructions Chapter 4

Tab.32:

Cable parameters

Tab.33:

Maximum cable

Flexi Classic Gateways

PROFIBUS DP Gateway

4.1.5 Cable parameters

The properties of the bus cable are specified in EN 50170 as cable type A.

UE410-PRO

Property Value

Characteristic impedance

Capacitance per unit length

Loop resistance

Core diameter

Core cross-section

135-165 (at a frequency of 3-20 MHz)

< 30 pF/m

T 110 /km

> 0.64 mm

> 0.34 mm

2

With these cable parameters, the following maximum physical sizes are possible for a bus

segment:

lengths UE410-PRO

Baud rate (Kbit/s) Max. cable length (m)

9.6 1200

19.2 1200

93.75 1200

187.5 1000

500 400

1500 200

12000 100

4.1.6 Data transmission rate

The data transmission rate is set automatically.

The maximum baud rate is 12 MBit/s.

8011834/YT28/2016-03-15 © SICK AG • Industrial Safety Systems • Germany • All rights reserved

Subject to change without notice

29

Page 30

Chapter 4 Operating Instructions

Tab.34:

Possible planning

PROFIBUS DP Gateway

Flexi Classic Gateways

4.2 Planning

4.2.1 GSD file

In the normal case the UE410-PRO is used on a DP master that looks up the device

characteristics in the so-called GSD file.

You will find the GSD file for PLC interfacing with Profibus support in the Internet at

www.ue410flexi.com.

The UE410-PRO provides at least 4 bytes of input data and 4 bytes of output data (2 bytes

of which are unused). The GSD identifier for this I/O module SCB1 Basic1 4 Byte in/out is

33h. If the DP master is configured with the aid of a GSD file, it is imperative this module is

included in the planning.

The UE410-PRO can provide further I/O modules as an option if included in the DP master

during the planning by the user. For more detailed diagnostics, the I/O module SCB2

Basic2 2 Byte in with the GSD identifier 11h is available.

A further optional I/O module is DIAG 10 Byte in with the GSD identifier 19h. Up to 4 units

of this module can be included in the planning.

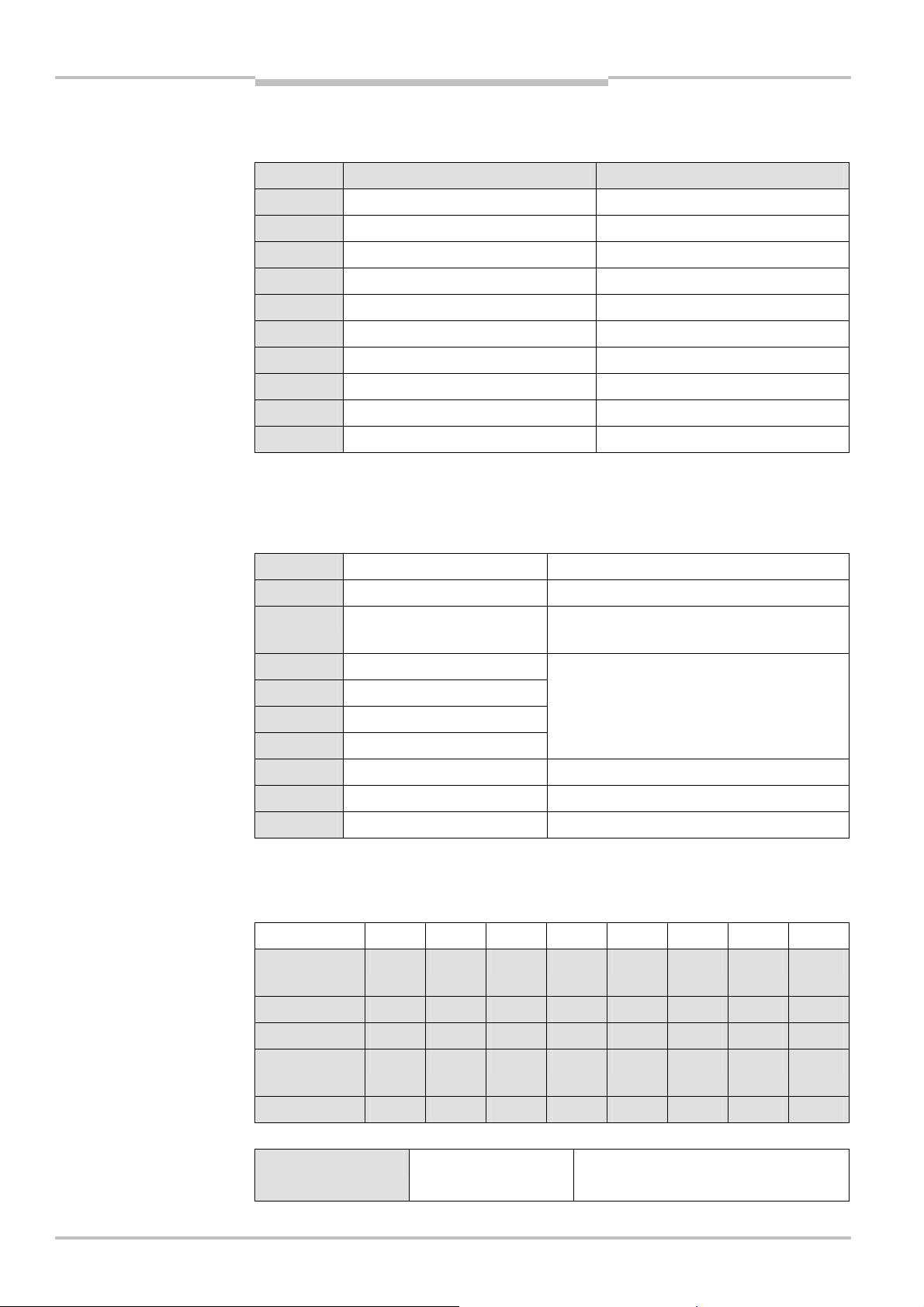

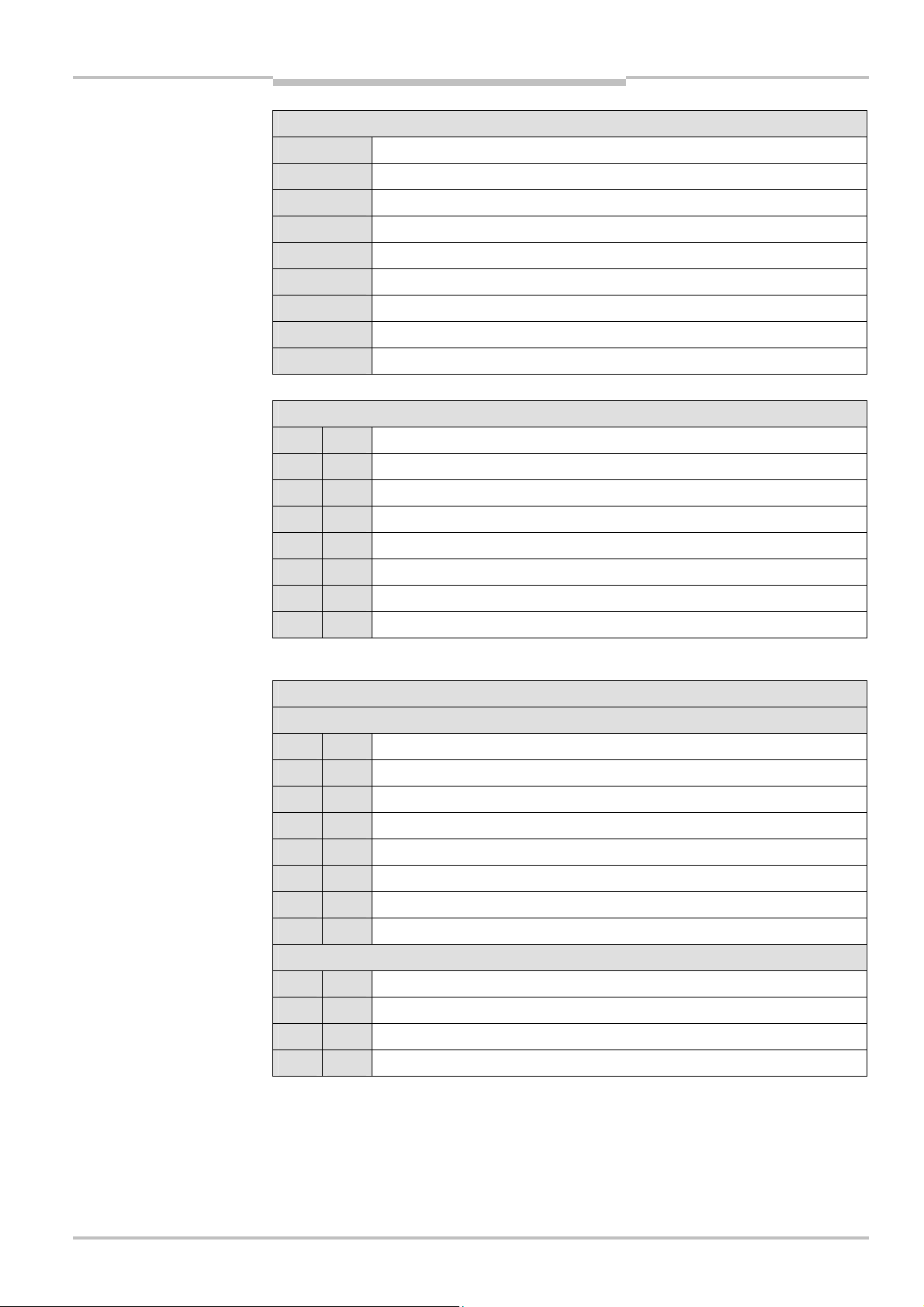

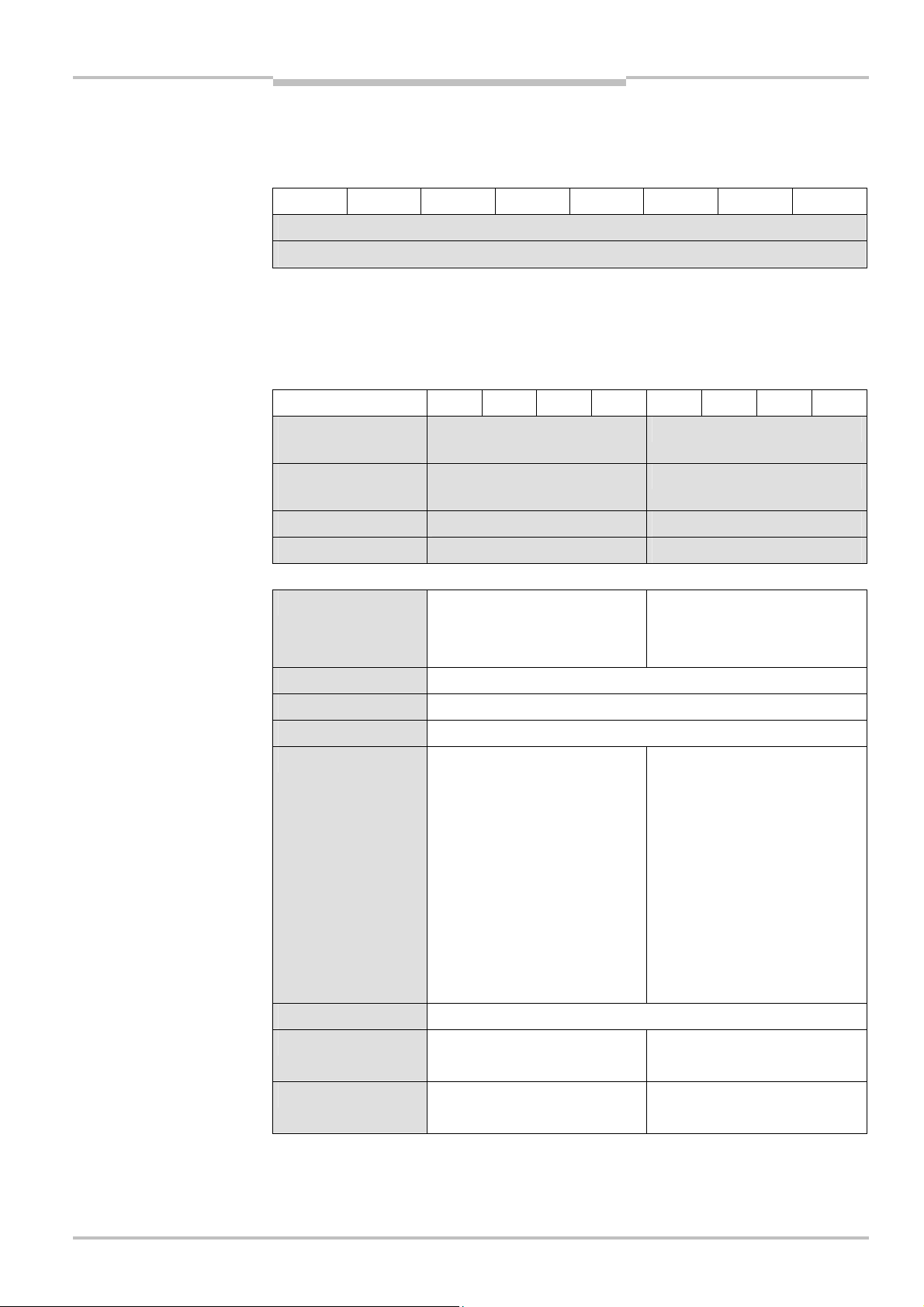

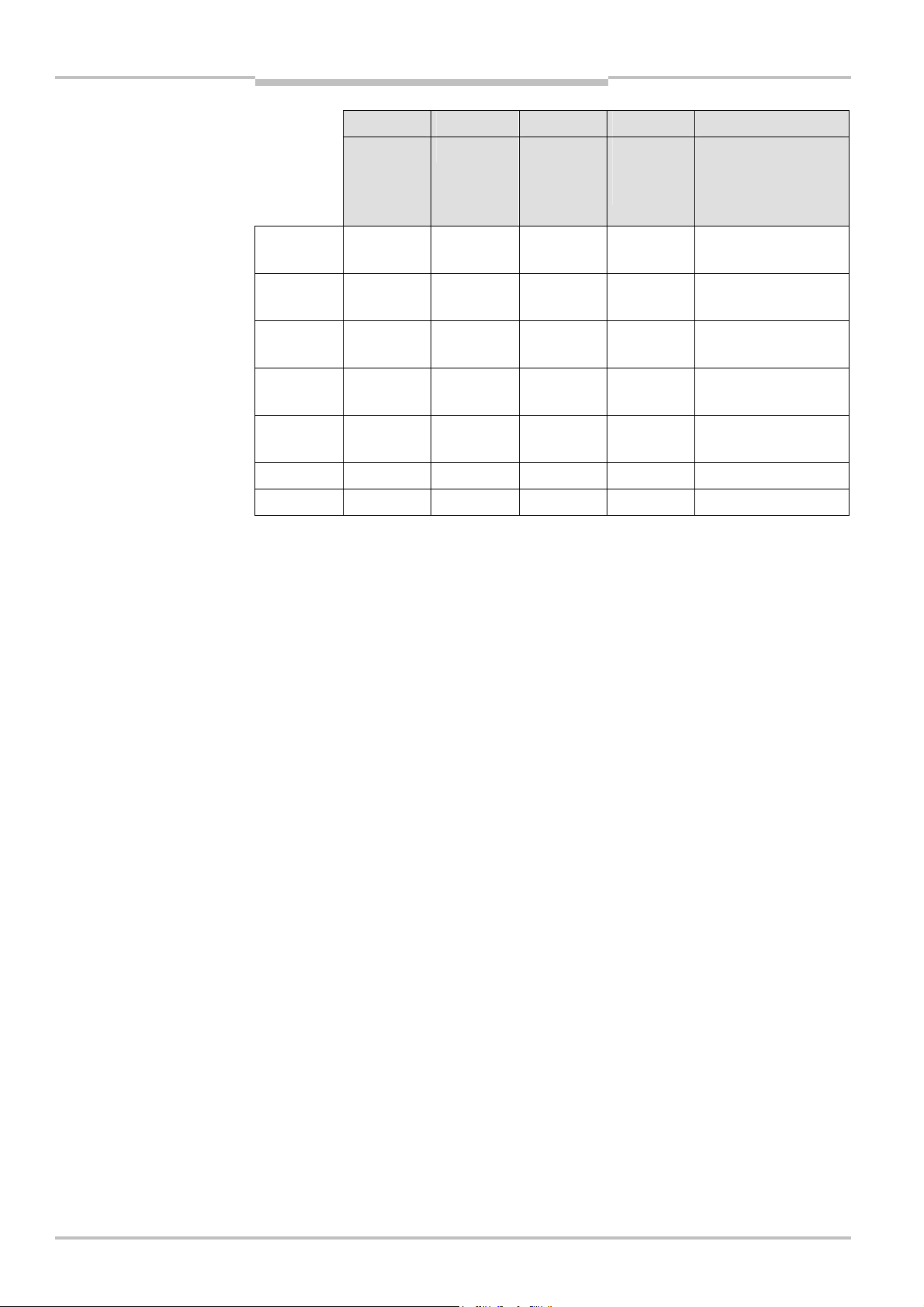

There are therefore six possible ways of planning the UE410-PRO. Shown is the order of

the GSD identifiers for each plan:

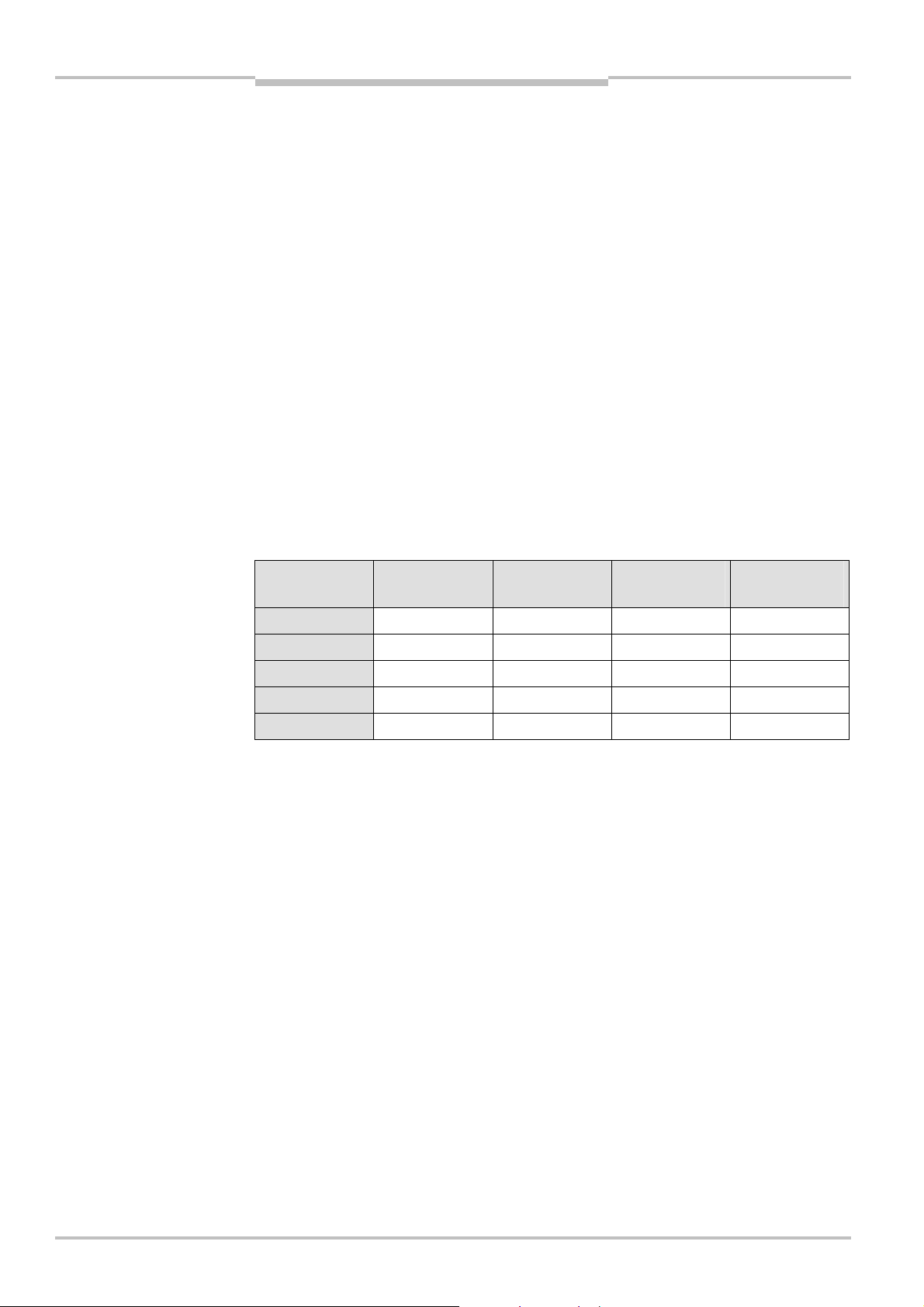

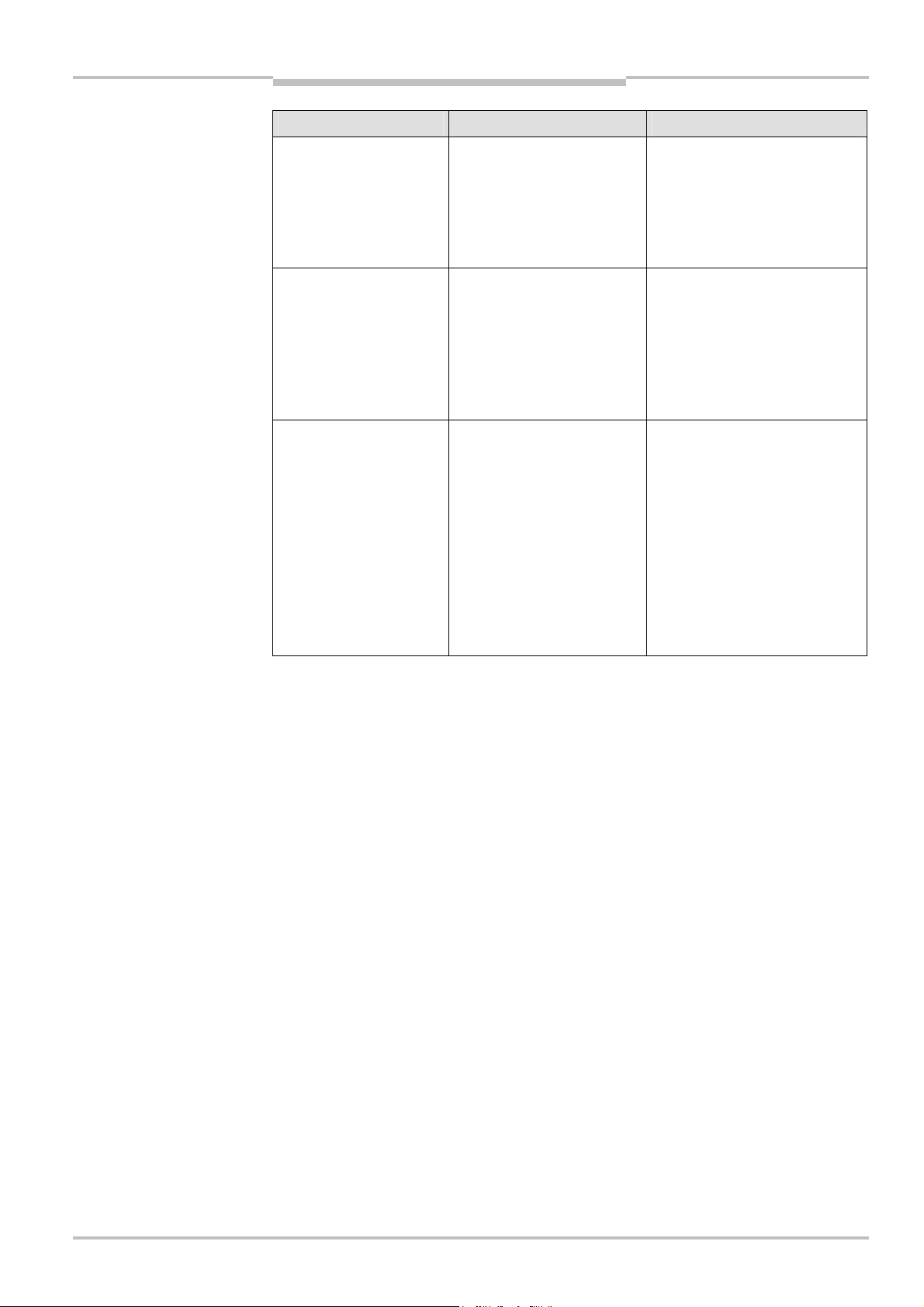

UE410-PRO

Possible

planning

SCB1 Basic1

4 Byte in/out

SCB2 Basic2

2 Byte in

DIAG

10 Byte in

MED

13 Byte in

1 33h

2 33h 11h

3 33h 11h 19h

4 33h 11h 1Ch

5 33h 11h 19h 1Ch

30 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8011834/YT28/2016-03-15

Subject to change without notice

Page 31

Operating Instructions Chapter 4

Tab.35:

Format of the diag

-

Flexi Classic Gateways

PROFIBUS DP Gateway

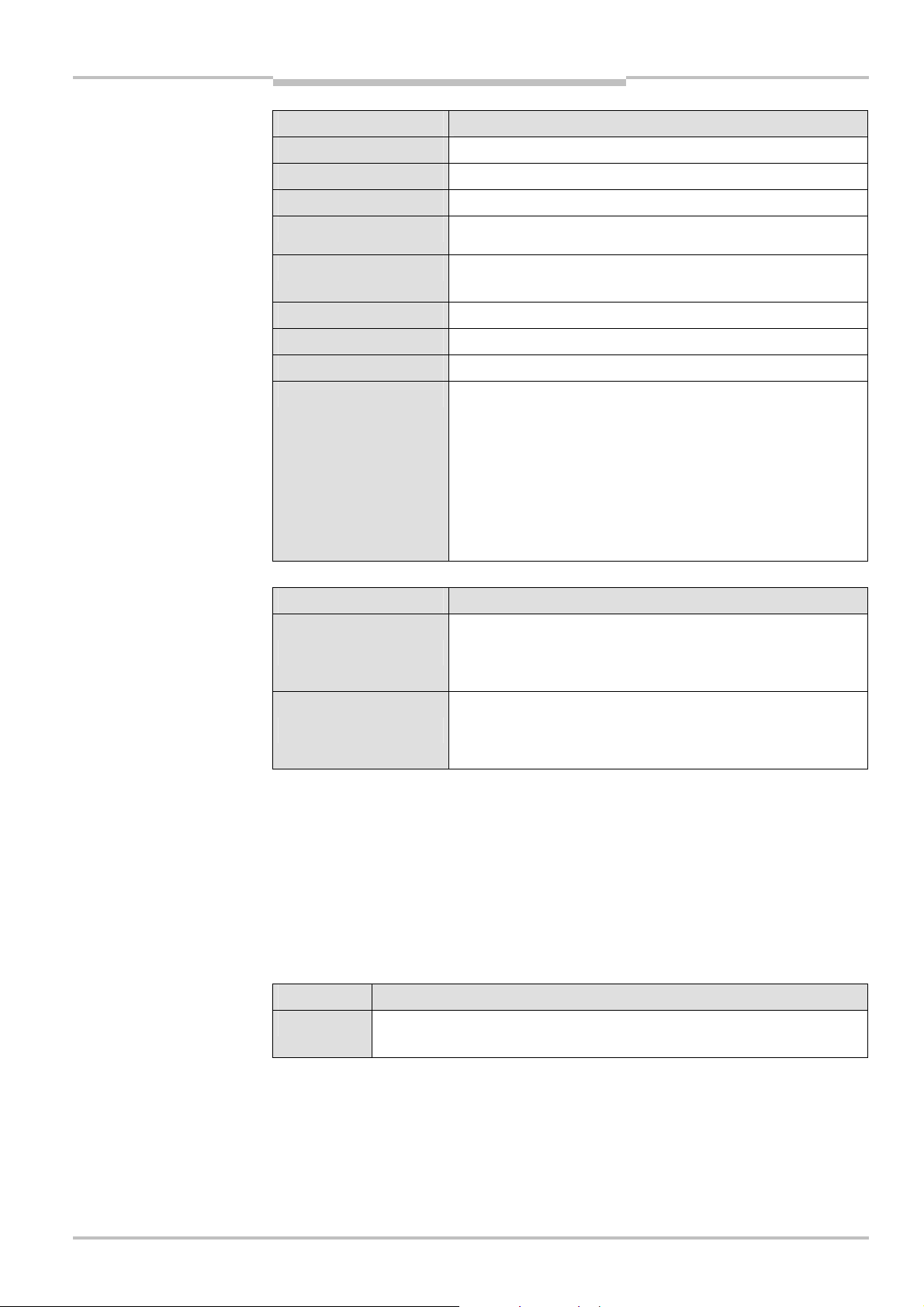

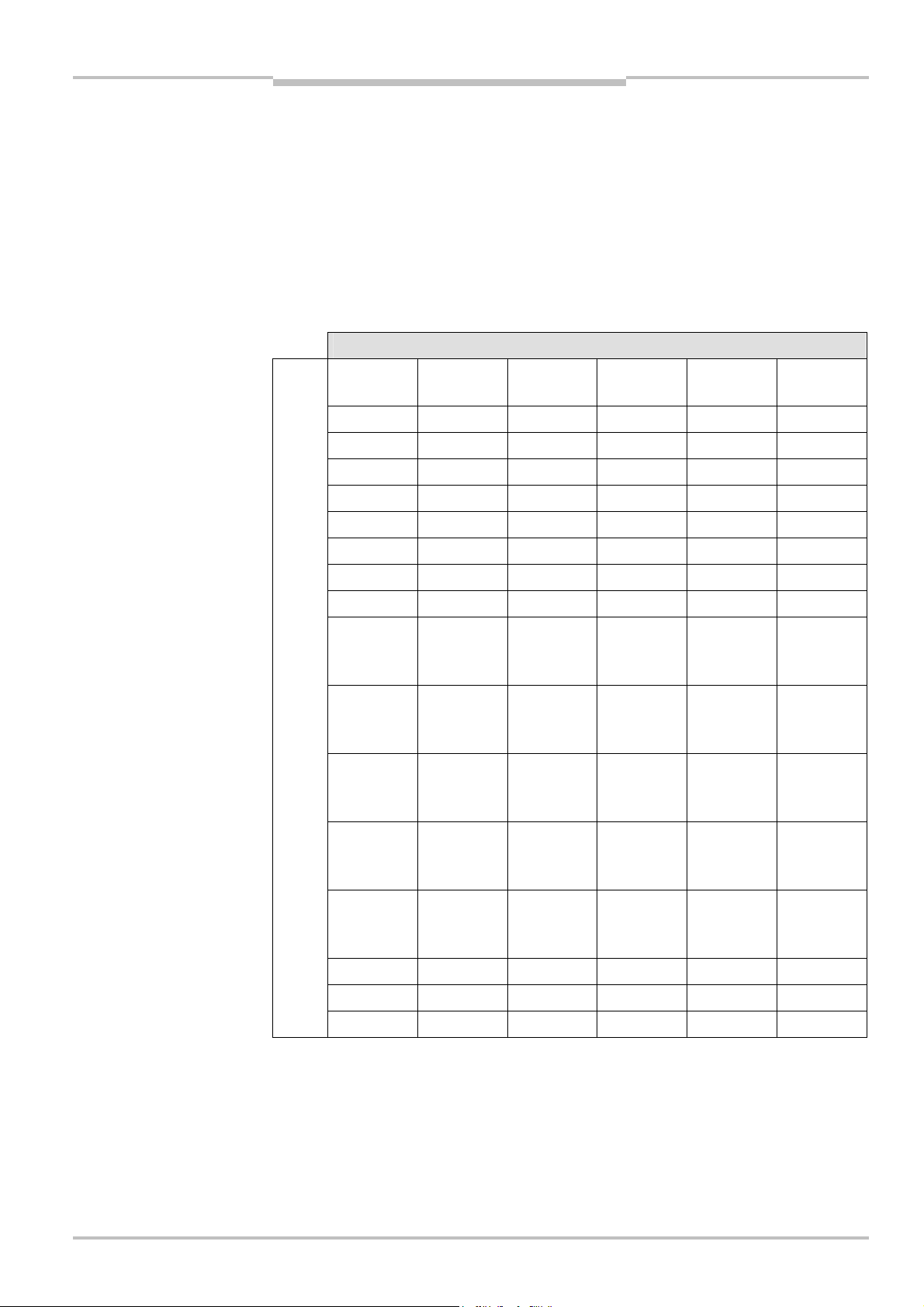

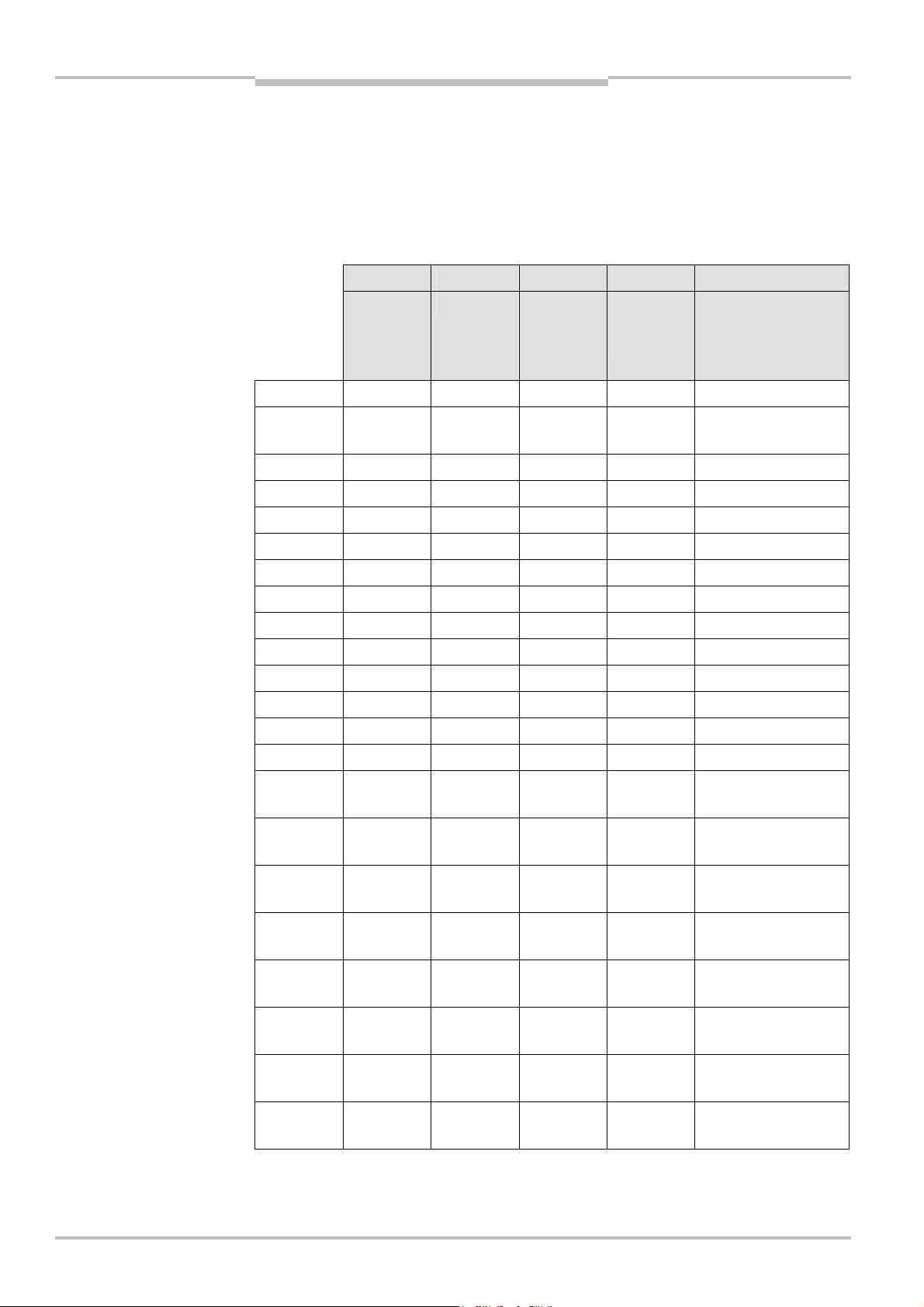

Design variant 4 is shown in the following table.

nostics data UE410-PRO

I/O modules GSD identifier

SCB1 Basic1 4 Byte in/out

Contains configuration checksum

and basic diagnostics

Contains extended basic diagnostics

DIAG 10 Byte in

Depending on the REQ-ID this

module contains

10 bytes diagnostics with varying

content

MED 13 Byte

Contains the input signals for all Flexi

Classic modules fitted

E.g. MED7 contains the input data

for module 7

ID: 33h (mandatory)

ID: 11h (optional)

ID: 19h (optional)

ID: 1Ch (optional)

Data direction

Read Write

CRC1 DIG-OUT

CRC2 REQ-ID

BAS1 Reserved

BAS2 Reserved

BAS3 – SCB2 Basic2 2 Byte in

BAS4 –

B1 –

B2 –

: :

B10 –

MED1 –

MED2 –

: :

MED13 –

See also section 3.2 “Status information of all Flexi Classic gateways (system bytes)”.

If a DP master is used that does not send any planning data to the UE410-PRO (e.g.

PROFIBUS Master Simulator PR-MSV01 (6022458) from SICK in the “Start without GSD

file” mode), the UE410-PRO supplies the diagnostic data as for plan 5 (see Tab. 34 on

page 30).

4.2.2 Documenting with PROFIBUS-DP Master Simulator

You can save diagnostics data on a PC with the aid of the PROFIBUS-DP Master Simulator

(see section 11.7 “Accessories/spare parts”) and the file flexi_config_list.xls.

For this purpose, connect a data cable between PC, PROFIBUS-DP Master Simulator and

UE410-PRO (RS-232-D-Sub). Install the file “flexi_config_list.xls” on your PC, Excel 2000 or

later must be installed on the PC.

You can then save and document the diagnostics data and settings for the overall system

with the aid of your PC.

We also refer you to our homepage on the Internet at

http://www.ue410flexi.com

There you will find the following files for download:

GSD file

flexi_config_list.xls

4.2.3 Diagnostics data UE410-PRO

You will find the description of the status bytes in the section “Status information of all

Flexi Classic gateways (system bytes)”.

8011834/YT28/2016-03-15 © SICK AG • Industrial Safety Systems • Germany • All rights reserved

Subject to change without notice

31

Page 32

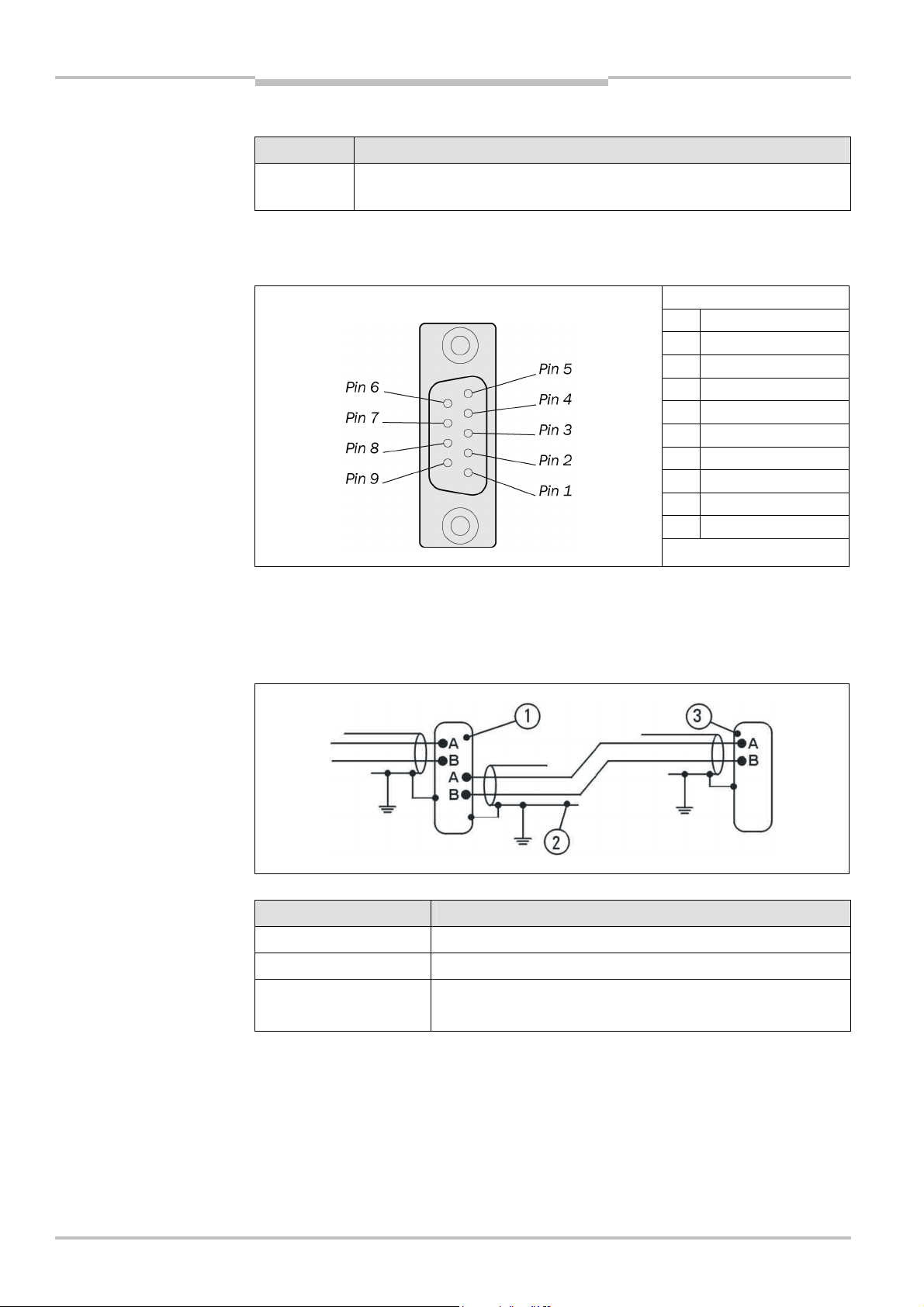

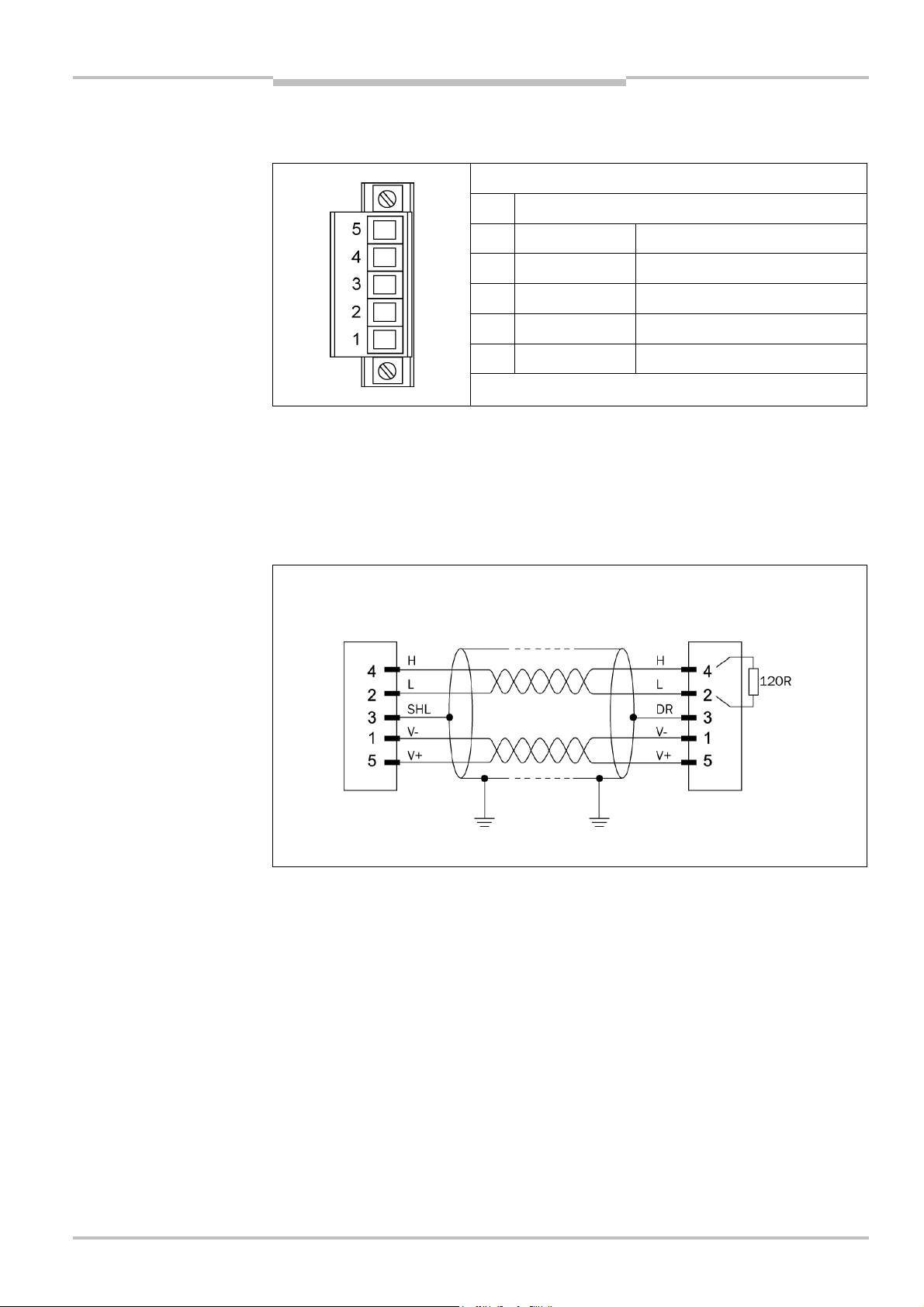

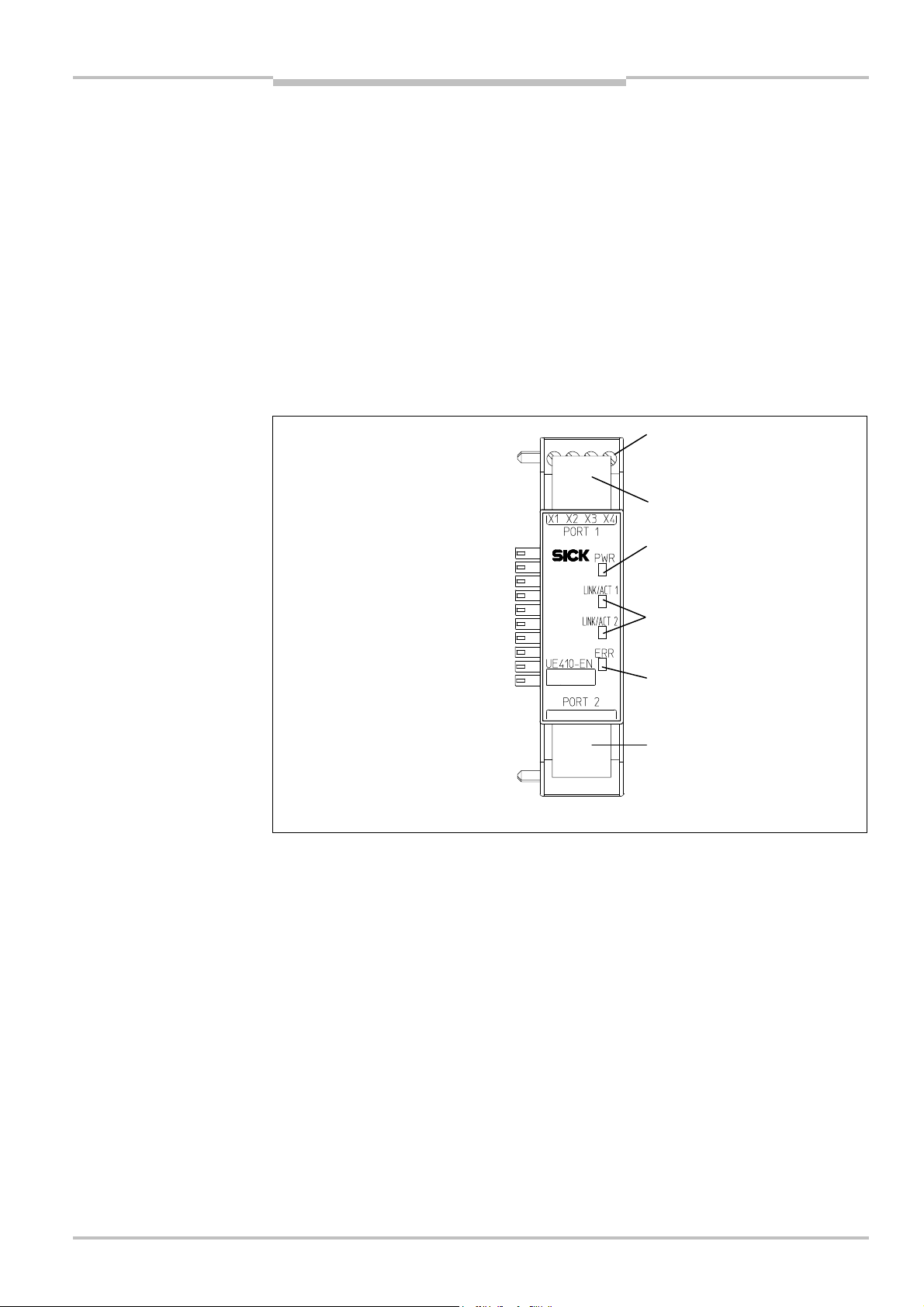

Chapter 5 Operating Instructions

Fig.4:

Controls and status

Address switch 1

DIP switch

CANopen

Address switch 2

1000

Baud rate kBit/s

800

500

250

125

CANopen Gateway

Flexi Classic Gateways

5 CANopen Gateway

he following Flexi Classic gateways can be used for CANopen:

T

UE410-CAN3, -CAN4

5.1 Interfaces and operation

5.1.1 Control and status indicators

indicators UE410-CAN

connection

32 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8011834/YT28/2016-03-15

Subject to change without notice

Page 33

Operating Instructions Chapter 5

Tab.36:

Indication LE

D

Tab.37:

Address switch

Tab.38:

Application

Flexi Classic Gateways

CANopen Gateway

UE410-CAN

Display Meaning

PWR (green) Supply voltage present

NS

Green flashing CANopen status: Pre-Operational (SDO data exchange)

Green CANopen status: Operational (PDO + SDO Data Exchange)

Red flashing Node-guarding Time out (the NMT master is no longer monitoring

the slave).

MS

Green flashing After cable break or node guarding failure

Green CANopen is ready

Red flashing fast CAN status: Bus Off

No error-free access to the CAN-BUS possible

Possible errors:

• wrong baud rate selected

• eiring error in the network

• another CAN controller in the network has a hardware error

• module faulty

UE410-CAN

diagnostic outputs

Switch/button Function

Address switch 1

× 10

× 1

10-position rotary switch for setting the module address

(tens)

Address switch 2

10-position rotary switch for setting the module address

(units)

The occurrence of random or systematic errors in the gateway or in its operation does

not result in the degradation of the safety functions on the Flexi Classic system.

With the operating voltage switched on, no gateways are allowed to be disconnected

from the Flexi Classic system or added by plugging in.

The CANopen master cannot overwrite the address set.

A modified address setting only becomes effective after switching off and switching on

the Flexi Classic system.

5.1.2 Application diagnostic outputs UE410-CAN

Assignment Description

X1-X4 Short circuit and overload detecting control outputs (PNP) supplied via Flexi

Classic system

8011834/YT28/2016-03-15 © SICK AG • Industrial Safety Systems • Germany • All rights reserved

Subject to change without notice

33

Page 34

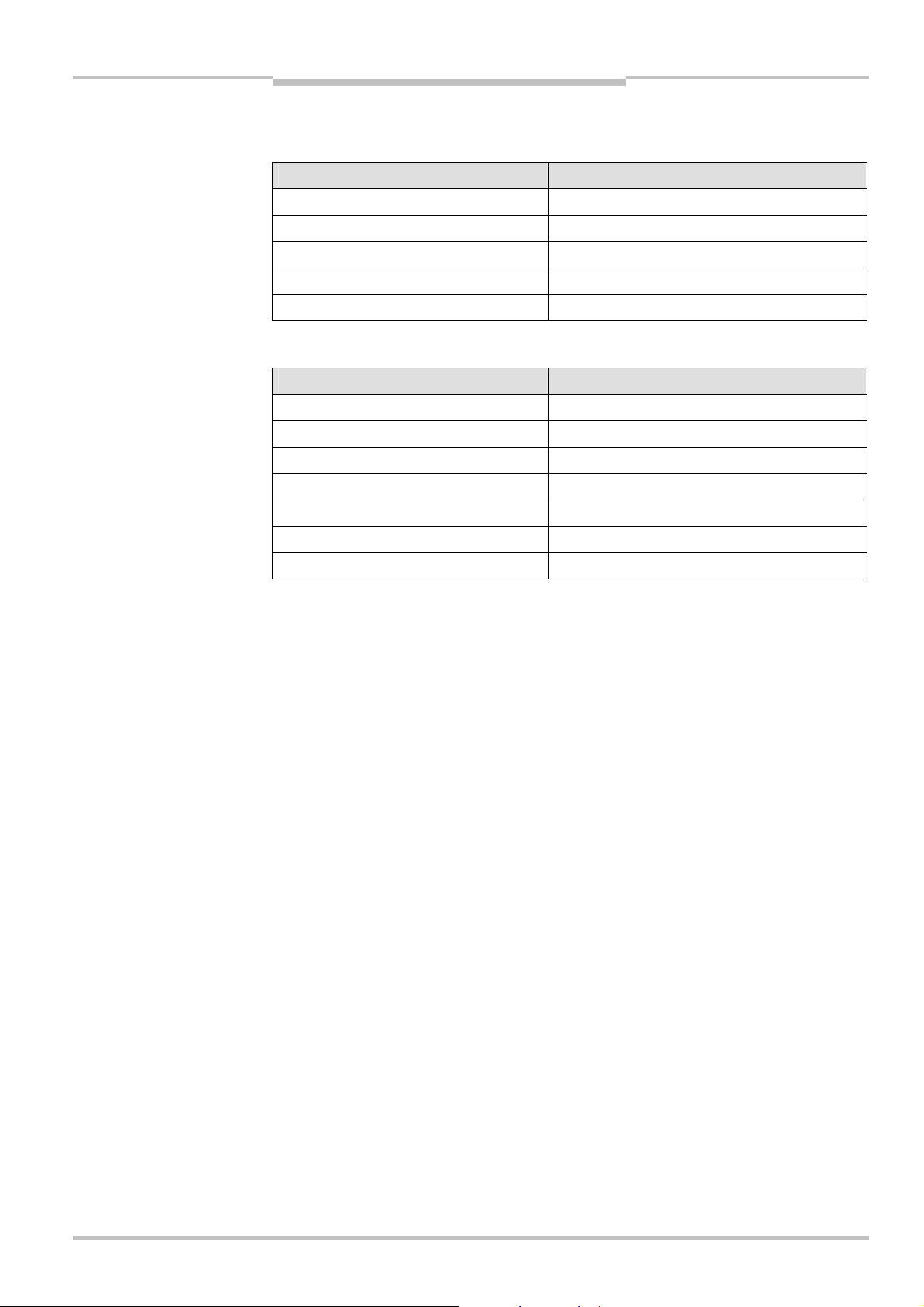

Chapter 5 Operating Instructions

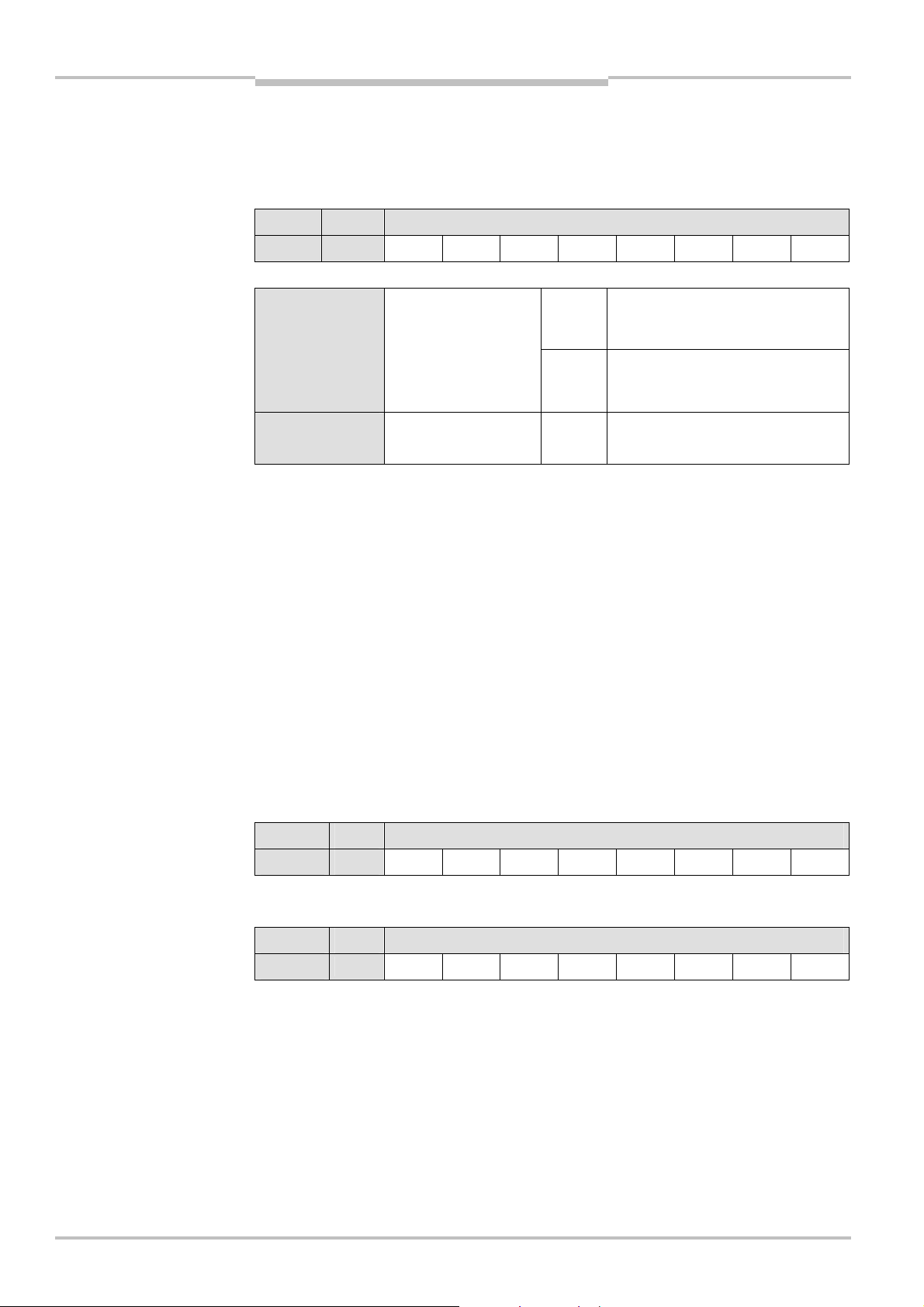

Fig.5:

Open style connector

Fig.6:

Bus cable

Terminating

CANopen Gateway

Flexi Classic Gateways

5.1.3 Plug assignment

The connection to the CANopen fieldbus is made using a 5-pin open style connector.

and pin assignment

UE4100CAN

Pin Description

5 V+ CAN_V+ Voltage supply

4 H CAN_H CAN High

3 DR (CAN_SHILD) Screen connection

(optional)

2 L CAN_L CAN Low

1 V– CAN_GND Ground/0V

5.1.4 Bus cable

Note

CANopen is based on a linear topology with screened, twisted pair 2-core cable and terminating resistors at both ends of the bus. The screen is connected to ground at both ends.

The transmission rate, depending on the network length, is between 10 kBit/s (>1000 m)

and 1 MBit/s (25 m).

Node

resistance

It is not necessary to connect a voltage supply (pin 1/5) to the UE410-CAN.

34 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8011834/YT28/2016-03-15

Subject to change without notice

Page 35

Operating Instructions Chapter 5

Tab.39: Format of diagnos

-

Flexi Classic Gateways

CANopen Gateway

5.2 Planning

5.2.1 EDS file

The device characteristics are described using the Electronic Data Sheet (EDS), which

every standard bus configuration tool uses.

5.2.2 PCS

With so-called PDO linking (the arbitrary assignment of CAN identifiers to the individual

ProcessDataObjects), CANopen makes it possible to setup multi-master networks.

However, if the CANopen devices are to be controlled from a central instance, the CAN

identifiers to be used can be restricted to a pre-defined set, the Predefined Connection Set

PCS. Then the CAN controller only accepts CAN messages addressed to the related device.

A CANopen device (e.g. the UE410-CAN Gateway) makes its inputs and outputs available

as “communication objects” that can be addressed or sent using the PCS identifiers.

The PCS operating mode provides two crucial advantages:

The CANopen-PCS protocol can be implemented on a controller or a PC without major

effort. Planning is significantly simplified, as within the PCS all CAN identifiers are

unique in relation to the node address. As a result, time and costs for setting up simple

networks are reduced.

Due to the PCS addressing, the UE410-CAN is insensitive particularly to high bus loads

and ensures vary fast I/O communication. With synchronous communication, response

times of approx. 300 Vs are achieved. All four reply PDOs are sent in a period < 1 ms

after receipt of a Sync (baud rate = 1000 KBit/s).

The PCS comprises 2 broadcast objects SYNC and NMT and a total of 12 peer-to-peer

objects. Each of these objects has a unique 11-bit CAN identifier that comprises a function

code and a device address. The device address for the broadcast objects is 0, for the other

objects 1…127.

tics data

5.2.3 Format of diagnostics data

Object CAN identifier

NMT 00h Network management

SYNC 80h Sync message

EMERGENCY 081h..0FFh Status message

TxPDO1 181h..1FFh

RxPDO1 201h..27Fh Process data object 1 (see following page)

TxPDO2 281h..2FFh Process data object 2 (see following page)

RxPDO2 301h..37Fh Process data object 2 (see following page)

TxPDO3 381h..3FFh Process data object 3 (see following page)

RxPDO3 401h..47Fh Process data object 3 (see following page)

TxPDO4 481h..4FFh Process data object 4 (see following page)

RxPDO4 501h..57Fh Process data object 4 (see following page)

TxSDO 581h..5FFh Sending service data

RxSDO 601h..67Fh Receiving service data

NMT-ErrorControl 701h..77Fh Node-guarding

Meaning

Process data object 1 (see following page)

(from the viewpoint of the CANopen server: Tx=Transmit, Rx=Receive)

8011834/YT28/2016-03-15 © SICK AG • Industrial Safety Systems • Germany • All rights reserved

Subject to change without notice

35

Page 36

Chapter 5 Operating Instructions

Tab.40:

Transmit PDO

T

ab.41:

Transmit PDO

CANopen Gateway

Flexi Classic Gateways

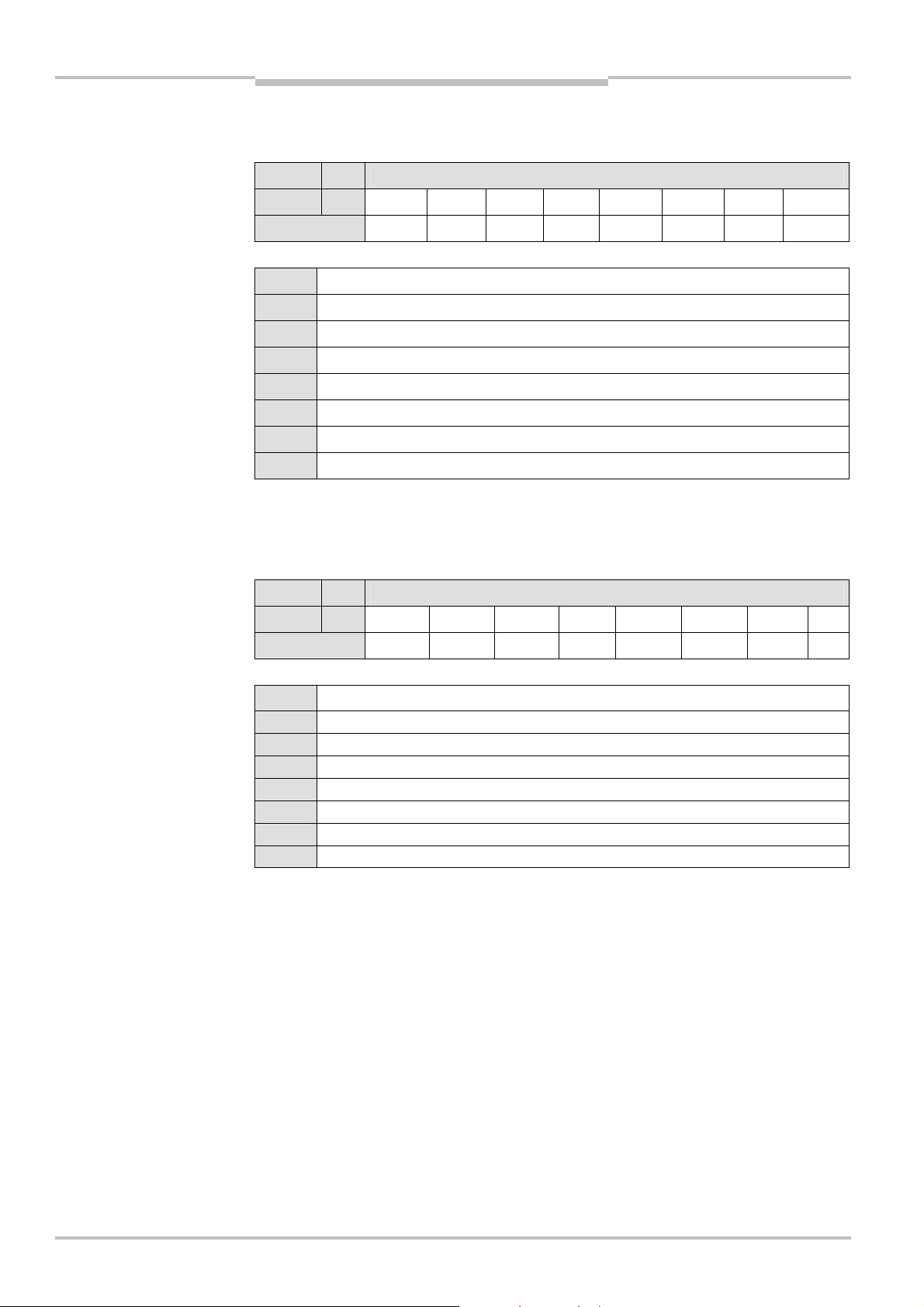

5.2.4 TxPDO1

Transmit PDO (process data object) 1.

(process data object) 1

CAN-ID DLC DATA

181..1FF 8 BAS1 MQD1 MED1 MED2 MED3 MED4 MED5 MED6

Mapping 3100.2 3101.2 3101.1 3102.1 3103.1 3104.1 3105.1 3106.1

BAS1 Group error bits

MQD1 Output data module 1 (UE410-MU…)

MED1 Input data module 1 (UE410-MU…)

MED2 Input data module 2

MED3 Input data module 3

MSD4 Input data module 4

MED5 Input data module 5

MED6 Input data module 6

See also section 3.2 “Status information of all Flexi Classic gateways (system bytes)”.

(process data object) 2

5.2.5 TxPDO2

Transmit PDO (process data object) 2.

CAN-ID DLC DATA

281..2FF 7 MED7 MED8 MED9 MED10 MED11 MED12 MED13 -

Mapping 3107.1 3108.1 3109.1 310A,1 310B,1 310C,1 310D,1 -

MED7

MED8

MED9

MED10

MED11

MED12

MED13

Input data module 7

Input data module 8

Input data module 9

Input data module 10

Input data module 11

Input data module 12

Input data module 13

- Unused

See also section 3.2 “Status information of all Flexi Classic gateways (system bytes)”.

36 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8011834/YT28/2016-03-15

Subject to change without notice

Page 37

Operating Instructions Chapter 5

Tab.42:

Transmit PDO

Tab.43:

Transmit PDO

Flexi Classic Gateways

CANopen Gateway

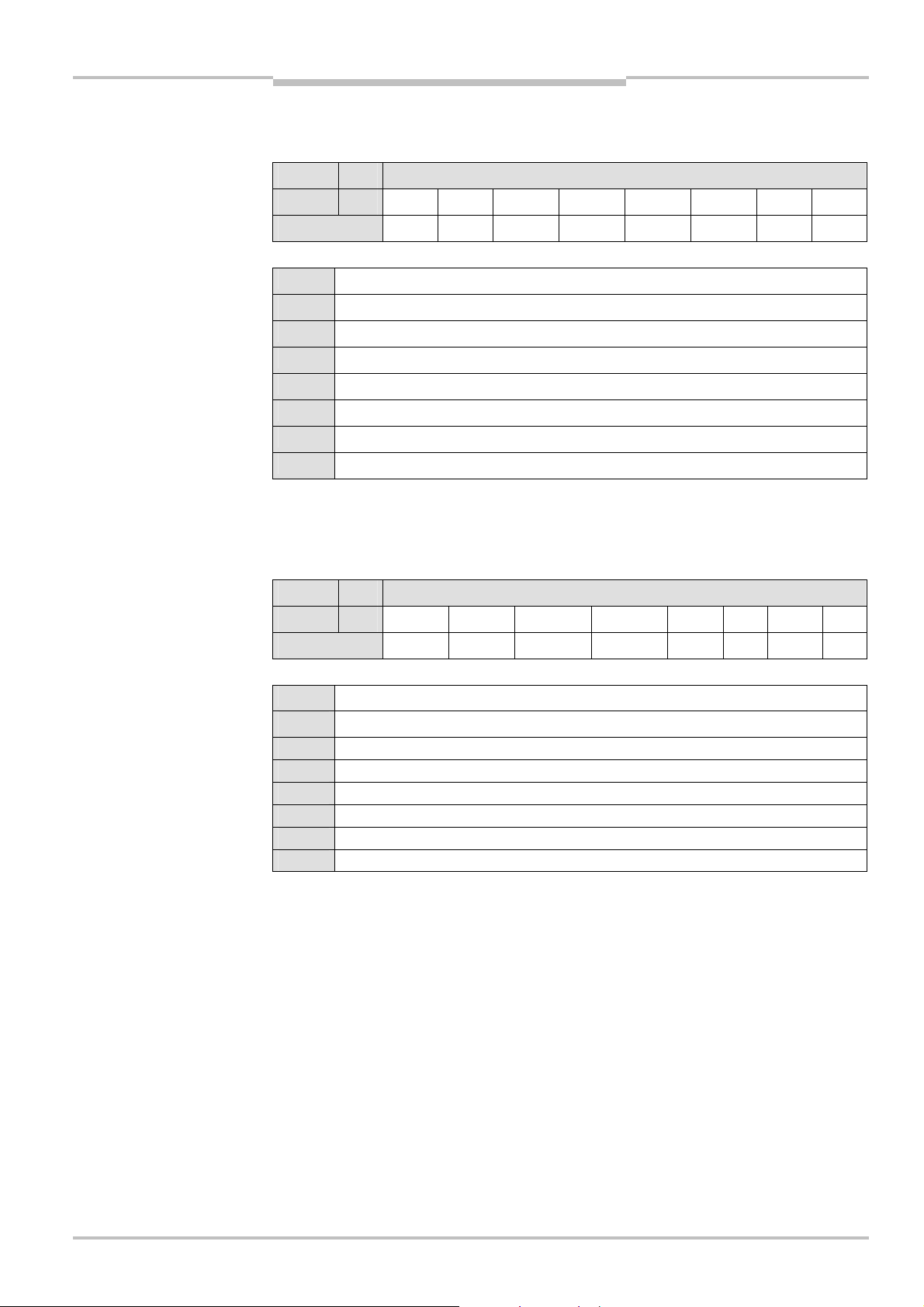

5.2.6 TxPDO3

Transmit PDO (process data object) 3.

(process data object) 3

CAN-ID DLC DATA

381..3FF 8 MQD2 MQD3 MQD4 MQD5 MQD6 MQD7 MQD8 MQD9

Mapping 3102.2 3103.2 3104.2 3105.2 3106.2 3107.2 3108.2 3109.2

MQD2 Output data module 2

MQD3 Output data module 3

MQD4 Output data module 4

MQD5 Output data module 5

MQD6 Output data module 6

MQD7 Output data module 7

MQD8 Output data module 8

MQD9 Output data module 9

See also section 3.2 “Status information of all Flexi Classic gateways (system bytes)”.

(process data object) 4

5.2.7 TxPDO4

Transmit PDO (process data object) 4.

CAN-ID DLC DATA

481..4FF 4 MQD10 MQD11 MQD12 MQD13 - - - -

Mapping 310A,2 310B,2 310C,2 310D,2 - - - -

MQD10

MQD11 Output data module 11

MQD12

MQD13

Output data module 10

Output data module 12

Output data module 13

-

Unused

-

Unused

-

Unused

- Unused

See also section 3.2 “Status information of all Flexi Classic gateways (system bytes)”.

8011834/YT28/2016-03-15 © SICK AG • Industrial Safety Systems • Germany • All rights reserved

Subject to change without notice

37

Page 38

Chapter 5 Operating Instructions

Tab.44:

Receive PDO

Tab.45:Network

Tab.46:

Network

CANopen Gateway

Flexi Classic Gateways

5.2.8 RxPDO1

Receive PDO (process data object) 1

(process data object) 1

CAN-ID DLC DATA

201..27F 1 DIG-OUT - - - - - - -

Mapping 6200.1 - - - - - - -

management for one NMT

slave with address N

management for all NMT

slaves

DIG-OUT

Digital outputs on the diagnostics module

- Unused

5.2.9 NMT Network Management

The NMT objects are used to start, stop or initialise CANopen devices. For this purpose a

device in the CANopen network must take over the role of the NMT master. All devices are

regarded as NMT slaves. NMT services are broadcast services, i.e. the slaves do not generate a reply.

For an NMT slave with address N:

CAN-ID DLC DATA

00h 2 OP N

For all NMT slaves:

CAN-ID DLC DATA

00h 2 OP 0

OP NMT Operation 80h = Change to “Pre-Operational”

01h = Change to “Operational”

02h = Change to “Prepare/Stopped”

81h = Change to “Reset Node”

82h = Change to “Reset Communication”

5.2.10 Pre-Operational

After booting an NMT slave automatically enters the “Pre-Operational” state. In this state,

communication is allowed with the SDO, but not with the PDO. The NMT slave can be

changed from another state to this state.

5.2.11 Operational

The “Operational” state is reached from the “Pre-Operational” state. In this state communication via PDO is possible and the CANopen slave reacts to SYNC.

Note

TPDOs with the transmission mode 255 are sent once on the transition to the NMT status

“Operational”, so that the NMT master is informed of the current input configuration.

5.2.12 Prepared/Stopped

In this state, communication is not possible with SDO or PDO, there is also no reaction to

SYNC.

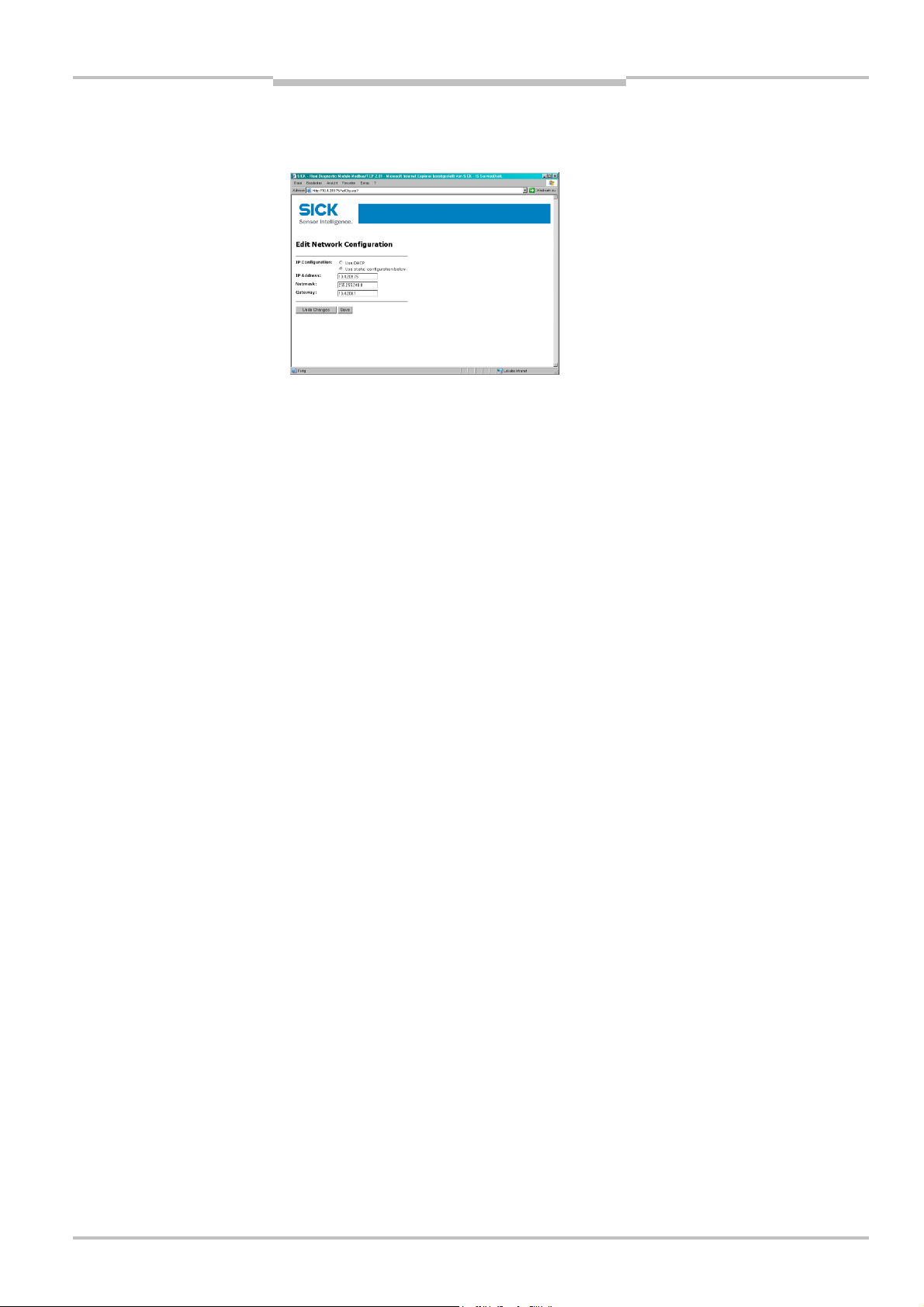

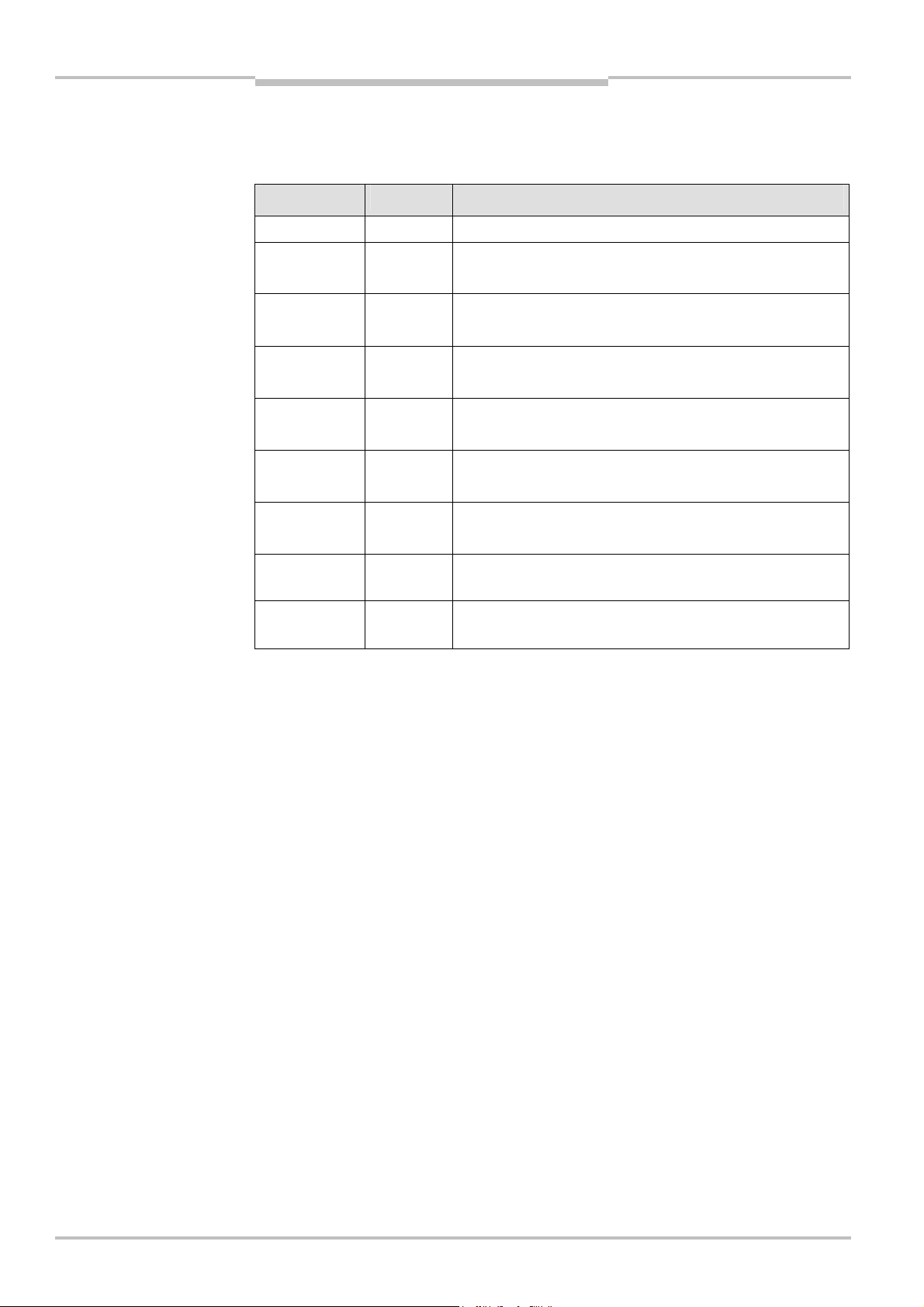

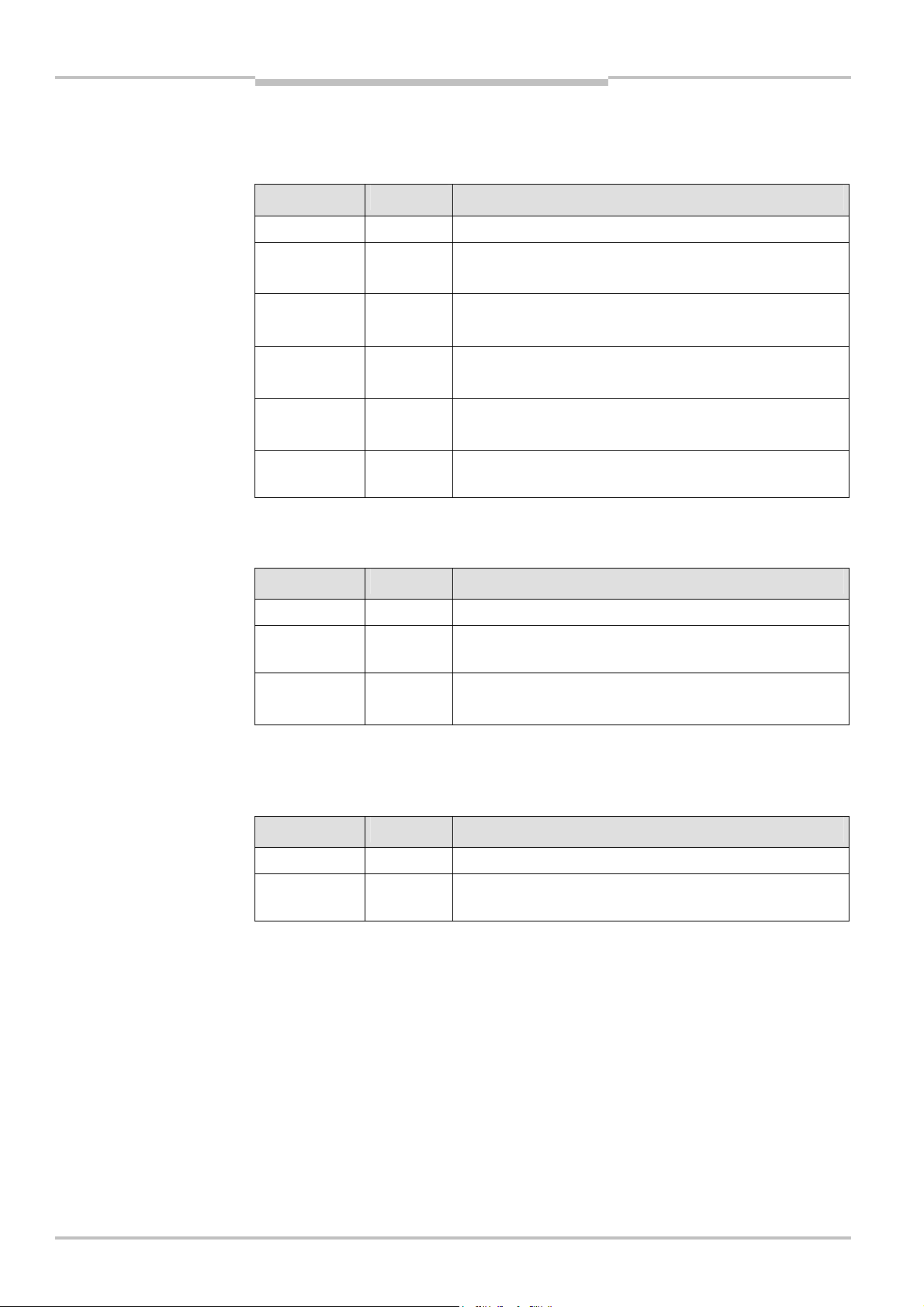

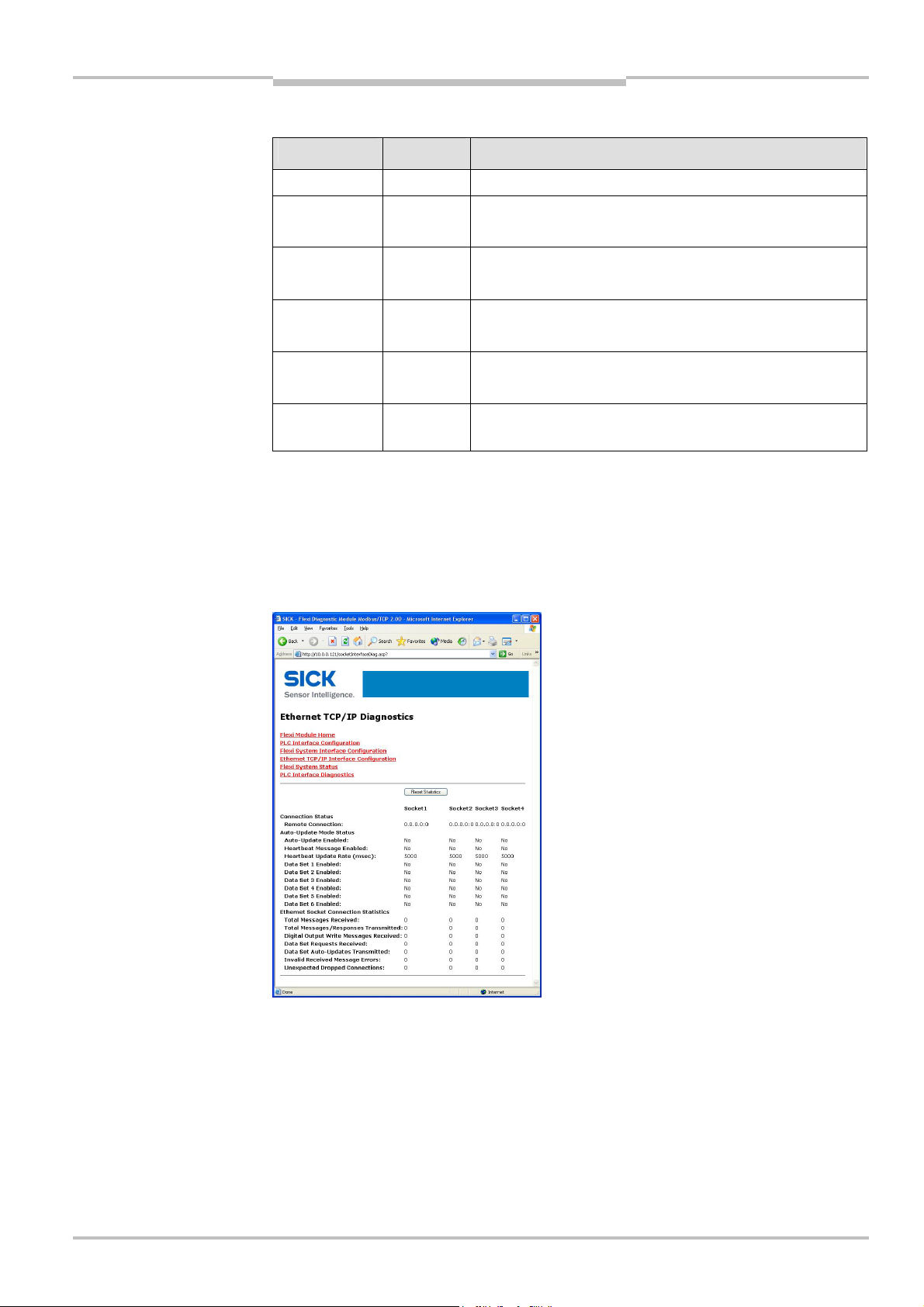

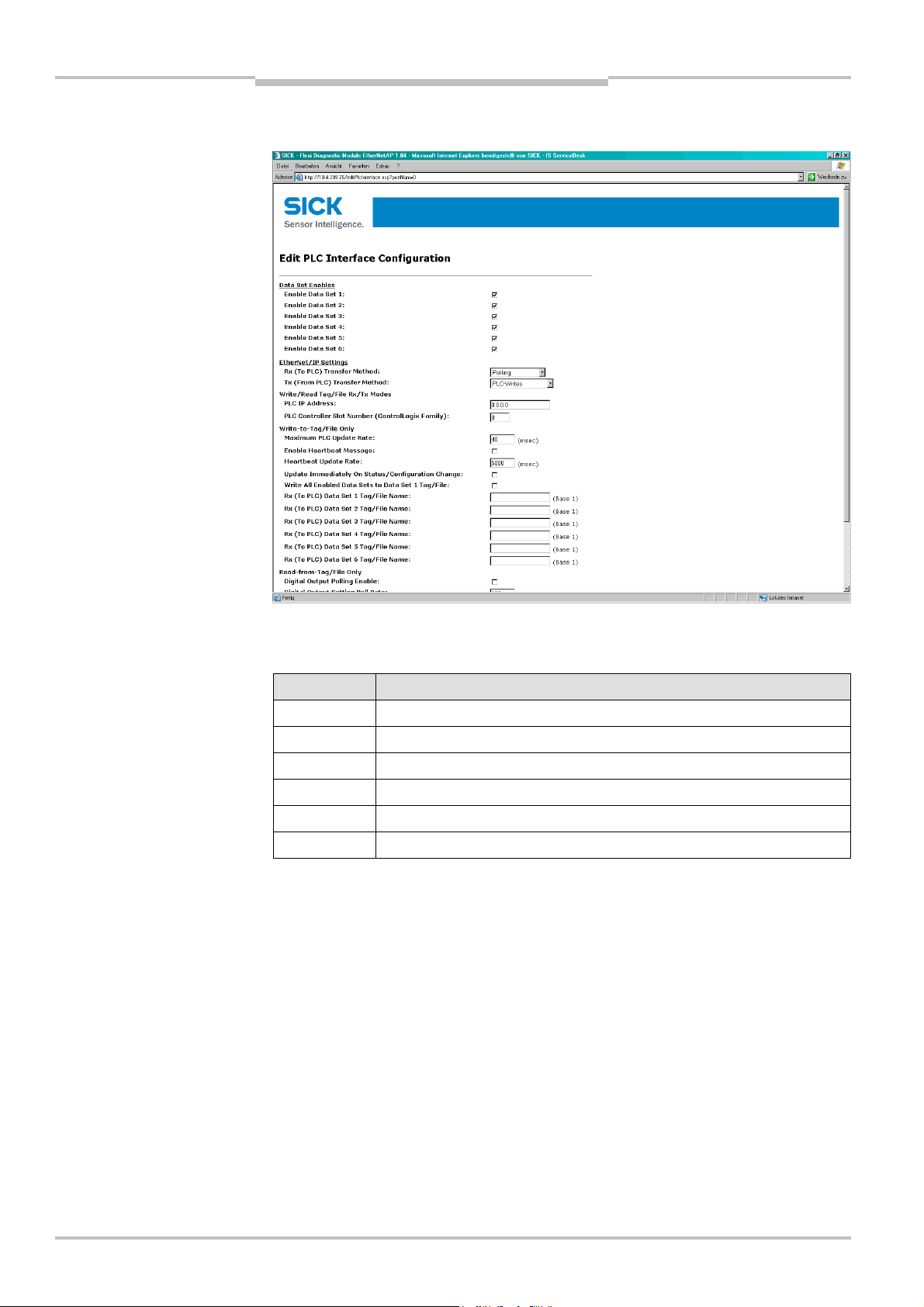

5.2.13 Reset node