Page 1

I

Front page

EuroFID3010 Inline UEG

Total Hydrocarbon Analysis

Installation, Operation, Service

MMMOPERATING INSTRUCTIONS

OPERATING INSTRUCTIONS

MMM

Page 2

Document information

Glossary

Described Product

Product name: EuroFID3010 Inline UEG

Document ID

Title: Operating Instructions EuroFID3010 Inline UEG

Part No.: 8016307

Version: 2-2

Release: 2018-04

Manufacturer

SICK AG

Erwin-Sick-Str. 1 · 79183 Waldkirch · Germany

Tel.: +49 7641 469-0

Fax: +49 7641 469-1149

Email: info.pa@sick.de

Production Site

SICK AG

Poppenbütteler Bogen 9b · 22399 Hamburg · Germany

Trademarks

Kalrez and Viton are trademarks of DuPont Performance

Elastomers.

Other product names used in this document may also be

trademarks and are used here for identification purposes only.

Original Documents

The English version 8016307 of this document is an original

document from SICK AG.

SICK AG assumes no liability for the correctness of an

unauthorized translation.

In case of doubt, please contact SICK AG or your local

representative.

Legal Information

Subject to change without notice.

© SICK AG. All rights reserved.

AC Alternating current

ATEX Atmosphères Explosifs: Abbreviation for European

standards regarding safety in potentially explosive

atmospheres.

CSA Canadian Standards Association (www.csa.ca)

DC Direct current

Span gas Concentration of the test gas at the upper

measuring range value

FID Flame ionization detector

Firmware Internal device software, typically in erasable

memory chips (EEPROMs)

IP XY Ingress protection; protection type of a device in

accordance with IEC/DIN EN 60529. The digit X

designates the level of protection against contact

and foreign bodies, Y against moisture.

Adjustment Refer to “calibration.”

Calibration The measured value is adjusted to the (known)

value of a test gas.

LED Light emitting diode (small indicator lamp)

PC Personal computer

PTFE Polytetrafluorethylene (Teflon)

Reference

gas

LEL Lower explosive limit (minimum concentration of a

SELV

Refer to “span gas.”

combustible gas in a mixture or vapor above which

the gas mixture can be ignited)

Safety extra low voltage is a small electrical voltage

that provides particular protection against electrical

shock compared to circuits of higher voltage thanks

to its small magnitude and insulation.

Devices operating on SELV that do not generate hig-

her voltages themselves are categorized as Class III

appliances in accordance with DIN EN 61140 (VDE

0140-1).

2 EuroFID3010 Inline UEG · Operating Instructions · 8016307/YL25/V2-2/2018-04 · © SICK AG

Page 3

Warning Symbols

Information Symbols

Hazard (general)

Hazard from electrical voltage

Hazard in potentially explosive atmospheres

Hazard from explosive substances/mixtures

Hazard from poisonous substances

Hazards through high temperature or hot surfaces

Warning Levels / Signal Words

WARNING

Risk or hazardous situation which could result in severe injury or

death.

Information about usage in potentially explosive

atmospheres

Important technical information about this device

Important information on electrical or electronic

functions

Supplementary information

Link to information found elsewhere

Nice to know

CAUTION

Hazard or unsafe practice which could result in personal injury or

property damage.

NOTICE

Hazard which could result in property damage.

EuroFID3010 Inline UEG · Operating Instructions · 8016307/YL25/V 2-2/2018-04 · © SICK AG 3

Page 4

Contents

Contents

1 Important information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.1 Main hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.1.1 Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.2 Product identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.2.1 Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.3 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.3.1 Purpose of the device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.3.2 Installation location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.4 Responsibility of the user . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1.5 Additional documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2 Product description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.1 Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.1.1 Response time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.2 Measuring principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.3 Device overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.4 Device modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.4.1 Analyzer unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.4.1.1 Sample gas filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.4.2 Operating unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.4.3 Terminal box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.4.4 V2 terminal module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3 Project planning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.1 Included in delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.2 Information about project planning and installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.3 Overview of installation work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.3.1 Required resources (overview) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.3.2 Mechanical installations (overview) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.3.3 AC power connection (overview) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.4 Supply of operational gases . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.4.1 Screw fittings for the gas connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.4.2 General information on the gas supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.4.3 Connecting instrument air . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.4.4 Connecting fuel gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.4.5 Connecting the calibration gas (“span gas”) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.4.6 Information on connecting a cylinder pressure monitor . . . . . . . . . . . . . . . . . . . . . . 30

3.5 Exhaust gas lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3.5.1 Connecting the “Outlet” gas outlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3.5.2 Gas outlet “Bypass” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3.6 Sample gas supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4 EuroFID3010 Inline UEG · Operating Instructions · 8016307/YL25/V 2-2/2018-04 · © SICK AG

Page 5

Contents

4 Installing the analyzer unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.1 Preparing for Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.2.1 Clearance for the analyzer unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

4.2.2 Preparing to install the analyzer unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

4.2.3 Installing the analyzer unit on the flange . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

4.2.4 Gas connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.3 Electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4.3.1 Electrical compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4.3.1.1 Electrical safety through disconnector switches properly installed . . . . . . . . . . 40

4.3.1.2 Electrical safety through lines with correct rating . . . . . . . . . . . . . . . . . . . . . . . . . 40

4.3.1.3 Grounding the equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4.3.2 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

5 Installing the terminal box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5.1 Installing the terminal box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5.2 Electrical connections of the terminal box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

6 Installing the operating unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

6.1 Installing the operating unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

6.2 Installing the 19” rack type operating unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

6.3 Installing the operating unit, ½-19” rack type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

6.4 AC power connection of the operating unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

6.4.1 External AC power switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

6.4.2 Connecting the AC power cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

6.5 Signal connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

6.5.1 Overview of signal connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

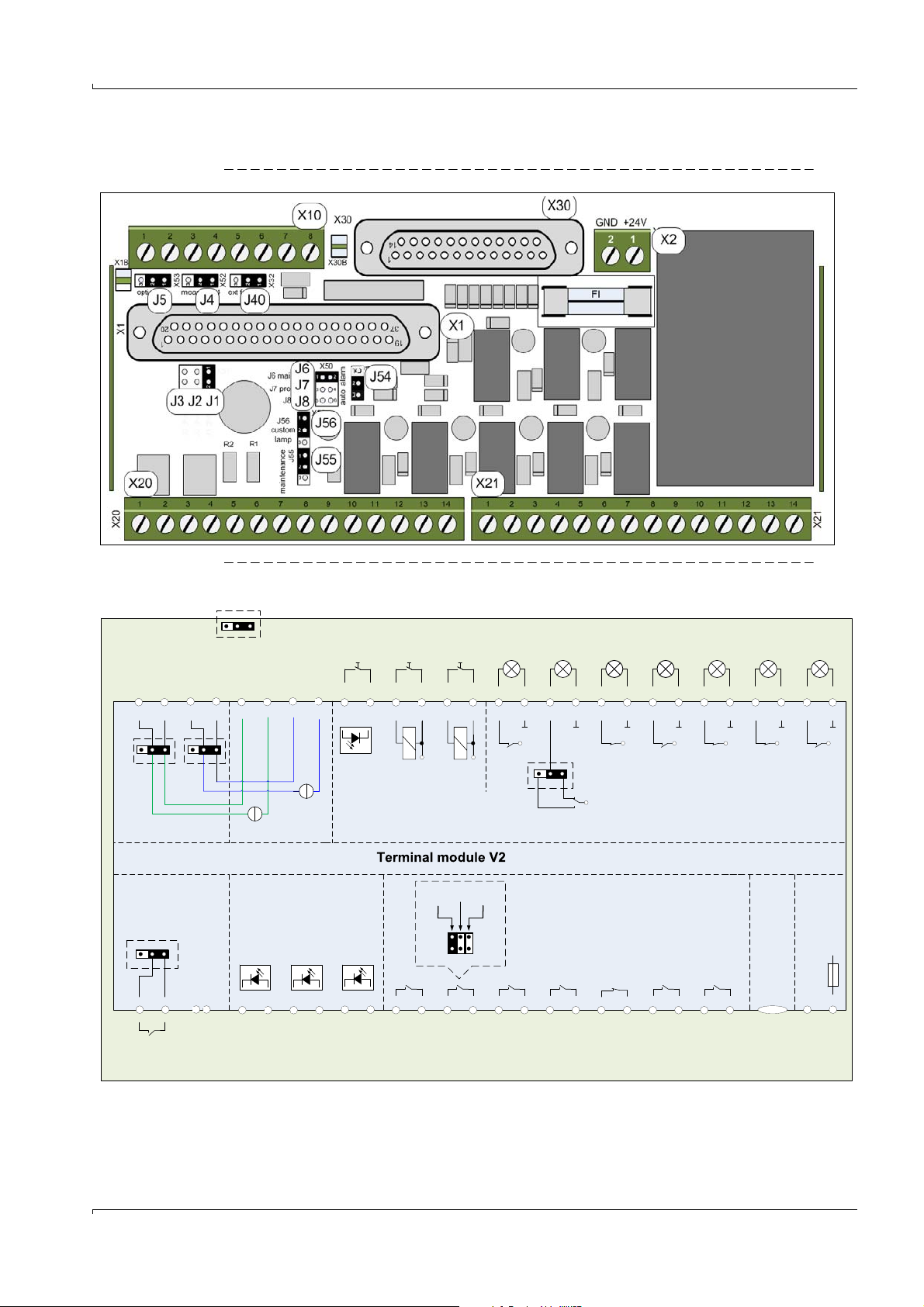

7 V2 terminal module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

7.1 Functional description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

7.1.1 Terminal and connector pin assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

7.2 Analog outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

7.2.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

7.2.1.1 Analog output “Measured value” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

7.2.1.2 Analog output “Reference value” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

7.2.2 Terminal assignment X10 and X20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

7.2.3 Configuration (jumpers) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

7.3 Digital outputs (threshold value alarm, status) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

7.3.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

7.3.2 Terminal assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

7.3.2.1 X21 terminal assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

7.3.2.2 X30 terminal assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

7.4 Digital inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

7.4.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

7.4.2 Terminal assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

7.4.2.1 X20 terminal assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

7.4.2.2 X10 terminal assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

7.4.2.3 X30 terminal assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

EuroFID3010 Inline UEG · Operating Instructions · 8016307/YL25/V 2-2/2018-04 · © SICK AG 5

Page 6

Contents

7.5 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

7.5.1 Mounting rails . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

7.5.2 Signal cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

7.6 Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

7.6.1 Attach connection cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

7.6.2 Connect supply voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

8 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

8.1 Initial commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

8.2 Activation procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

8.2.1 How to ascertain that the device is in proper operating condition . . . . . . . . . . . . . 69

8.2.2 Recognizing a special state . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

9 Operation (General) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

9.1 Controls and indicators/displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

9.1.1 LEDs (indicators) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

9.1.2 Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

9.1.2.1 Navigation principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

10 Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

10.1 Menu structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

10.2 Main menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

10.3 Measurement display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

10.4 Calibration (note) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

10.5 Flame ignition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

10.6 Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

10.6.1 Accessing the diagnosis messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

10.6.2 Malfunction messages in the diagnosis function . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

10.6.3 Operational displays in the diagnosis function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

10.7 Maintenance (note) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

10.8 Language (language selection) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

10.9 General help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

11 Maintenance menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

11.1 Maintenance menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

11.2 Standby . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

11.3 Error archives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

11.3.1 Function of the error archives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

11.3.2 Displaying the error archives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

11.3.3 Deleting the error archive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

11.4 Filter change special state (menu) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

11.5 System parameters (overview) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

11.6 User level (activation) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

11.7 Temperature of the sensor block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

11.8 Display of measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

11.9 Configuring threshold value indicators (alarms) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

11.10 Special state “System in service” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

6 EuroFID3010 Inline UEG · Operating Instructions · 8016307/YL25/V 2-2/2018-04 · © SICK AG

Page 7

Contents

11.11 Threshold reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

11.12 Time settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .101

11.12.1 Time and date set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

11.12.2 Summer/winter time (automatic switchover) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .102

11.13 Supplementary text for physical unit (unit of measurement) . . . . . . . . . . . . . . . . . . . .102

11.14 Name of analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .103

11.15 Hardware check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .103

11.15.1 Testing inputs/outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

11.15.1.1 Analog output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .104

11.15.2 Digital inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .105

11.15.2.1 Digital outputs, operating unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .105

11.15.2.2 Digital input, analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .106

11.15.2.3 Digital outputs, analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .106

11.15.3 Interface Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

11.15.4 Front panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

11.15.4.1 LED testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

11.15.4.2 LCD (Display) testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

11.15.4.3 Keypad testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .106

11.15.5 Watchdog testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

11.16 Restart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .107

12 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .109

12.1 When is calibration necessary? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .110

12.2 Requirements for calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .110

12.3 General sequence of a calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .110

12.4 Calibration gases . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .112

12.4.1 Zero gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .112

12.4.2 Span gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .112

12.5 Calibration parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .112

12.5.1 Calibration gas value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

12.5.2 Conversion factors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

12.6 Cross calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .114

12.6.1 Table of response factors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .115

12.6.1.1 Performance-tested response factors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .115

12.6.1.2 Performance-tested response factor for Parafol 1014 . . . . . . . . . . . . . . . . . . . .115

12.6.1.3 Non-performance-tested response factors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .116

12.7 Purging parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .117

12.8 Calibration control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .118

12.8.1 Types of calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

12.8.1.1 Start manual calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .119

12.8.1.2 Scheduled calibration (auto) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .120

12.8.1.3 Calibration time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

12.8.1.4 Externally controlled calibration (Ex.auto) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .121

12.8.1.5 Maximum calibration duration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .121

12.8.1.6 Calibration block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

12.9 Diagnosis, calibration drift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .121

12.10 Zero check and calibration gas check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .122

12.10.1 Zero check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .122

12.10.2 Sensitivity test (calibration gas check) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .122

EuroFID3010 Inline UEG · Operating Instructions · 8016307/YL25/V 2-2/2018-04 · © SICK AG 7

Page 8

Contents

12.11 Special states . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

12.12 Ending a special state . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

12.13 Signaling a special state . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

13 Decommissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

13.1 Preparing decommissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

13.1.1 Secure connected systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

13.1.2 Protect against condensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

13.2 Deactivation procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

13.3 Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

13.4 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

13.5 Declaration of clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

14 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

14.1 Safety instructions for maintenance work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

14.2 Technical knowledge needed for maintenance work . . . . . . . . . . . . . . . . . . . . . . . . . . 131

14.3 Maintenance plan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

14.3.1 Maintenance by the user . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

14.3.2 Maintenance by the manufacturer's service technicians . . . . . . . . . . . . . . . . . . . 133

14.4 Cleaning of the enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

14.5 Servicing the sample gas filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

14.5.1 Accessing the sample gas filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

14.5.2 Replacement/cleaning of the filter insert (procedure) . . . . . . . . . . . . . . . . . . . . . . 135

14.5.3 Cleaning the filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

14.5.4 Spare parts for the sample gas filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

14.5.5 Checking the overtemperature shutoff . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

15 Clearing malfunctions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

15.1 Safety instructions when clearing malfunctions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

15.2 If the EuroFID3010 Inline UEG does not work at all… . . . . . . . . . . . . . . . . . . . . . . . . . 144

15.3 If the measured values are obviously incorrect … . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

15.4 Electrical fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

15.4.1 Power fuse of the operating unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

15.4.2 Fuses in the terminal box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

15.5 Overtemperature shutoff on the analyzer unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

15.5.1 Function of overtemperature shutoff (explosion protection) . . . . . . . . . . . . . . . . . 148

15.5.2 Resetting the overtemperature shutoff (after tripping) . . . . . . . . . . . . . . . . . . . . . . 148

15.5.3 Overtemperature shutoff (thermostat) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

15.6 Malfunction messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

15.6.1 Malfunction messages on the display (general) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

15.6.2 Possible malfunction messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

8 EuroFID3010 Inline UEG · Operating Instructions · 8016307/YL25/V 2-2/2018-04 · © SICK AG

Page 9

Contents

16 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .155

16.1 Conformity and approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .156

16.1.1 Electrical protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .156

16.1.2 ATEX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .156

16.1.3 Approvals (suitability tests) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

16.2 Parameter input ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .157

16.3 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

16.3.1 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .158

16.3.2 Operating units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .160

16.3.3 Terminal box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

16.4 Housing specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .162

16.4.1 Operating units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .162

16.4.2 Analyzer units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

16.4.3 Terminal box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

16.4.4 V2 terminal module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .162

16.4.5 Flange specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .162

16.5 Ambient conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

16.6 Electrical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .164

16.6.1 Operating unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .164

16.6.2 Terminal box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .164

16.6.3 Analyzer unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

16.6.4 V2 terminal module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .164

16.6.5 Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .165

16.7 Gas connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .166

16.8 Auxiliary gases . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .166

16.8.1 Instrument air . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .166

16.8.2 Fuel gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .167

16.8.3 Span gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .167

16.9 Sample gas conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .167

16.10 Measuring characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

16.11 Accessories and order numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .169

16.11.1 Mounting flange . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .169

16.11.2 Heat insulation flange . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

16.11.3 Shut-off fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .170

16.11.4 Plug connector for the operating unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .171

16.11.5 V2 terminal module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .171

16.11.6 Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .171

16.12 Internal gas flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .172

EuroFID3010 Inline UEG · Operating Instructions · 8016307/YL25/V 2-2/2018-04 · © SICK AG 9

Page 10

Contents

10 EuroFID3010 Inline UEG · Operating Instructions · 8016307/YL25/V 2-2/2018-04 · © SICK AG

Page 11

Important information

EuroFID3010 Inline UEG

1 Important information

Main hazards

Main operating information

Intended use

Personal responsibility

Subject to change without notice

EuroFID3010 Inline UEG · Operating Instructions · 8016307/YL25/V 2-2/2018-04 · © SICK AG 11

Page 12

1.1 Main hazards

Important safety instructions in abbreviated form

▸

Always observe the full safety instructions (see cross references).

Health risks

CAUTION: Risk of hydrogen explosion

The EuroFID3010 Inline UEG requires H

▸

Always observe instructions to prevent explosions → p. 30, §3.4.4.

CAUTION: Health risk from exhaust gas

▸

Vent exhaust gases in a safe manner. → p. 31, §3.5

1.1.1 Safety instructions

NOTICE: Observe the reaction time of the FID during a hydrogen supply

failure

During a hydrogen supply failure, the flame of the FID keeps burning for some

time until it goes out completely.

It is possible that the measured value of the FID does not correspond to the

true value during this time.

The reaction time can be up to 50 seconds depending on the version of the

equipment.

▸

In order to monitor for a hydrogen supply failure, monitor the inlet pressure

of the fuel gas using a pressure controller, which emits an electric signal at

a certain minimum pressure (e.g. < 3 bar).

to operate.

2

Important information

NOTICE: Responsibility for the safety of a system

The person setting the system up is responsible for the safety of the system in

which the device is integrated.

The EUROFID3010 Inline UEG fulfills the minimum requirements of DIN EN 50271:2011

for detecting and measuring combustible gases and vapors.

Additional requirements for compliance with a safety integrity level (SIL1) in the EN 61508

series are not fulfilled.

▸

The temperature of the heated sensor block must be 25°C below the classification temperature (TC) and may not be set above 195°C.

▸

The cutout temperature of the overtemperature shutoff must be checked annually in

accordance with the operating instructions.

▸

Malfunctions and alarms are to be reported (as a group message as necessary) visually

and acoustically to a continuously staffed location.

▸

To ensure reliable alerting, the “Measured value valid” and “Service/Maintenance

switch” contacts should also always be monitored along with the “ALARM” relay contact.

▸

The signal “Service/maintenance switch” must be forwarded to a higher-ranking level

(e.g. control center).

▸

Execute the contact of the service/maintenance switch as an N/C contact (closed

current principle).

▸

Following a restart, a gas calibration must be carried out at the zero or end point.

▸

After replacing the test gas cylinder, enter the new test gas concentration in the

“Calibration Gas Value” menu.

▸

For safety-relevant measurement, only the approved response factors may be used.

▸

When monitoring the lower explosive limit (LEL), the operating unit with the V2 terminal

module must be used.

Subject to change without notice

12 EuroFID3010 Inline UEG · Operating Instructions · 8016307/YL25/V 2-2/2018-04 · © SICK AG

Page 13

Important information

▸

The exhaust gas from the exhaust outlet may not be returned to the process.

▸

The analog measured value output may not be used for safety-relevant monitoring.

▸

A failure of operating voltage is to be treated as an alarm.

▸

Before using the device in a gas detection system, make sure the response times are

short enough to ensure that the warning triggered by the device occurs quickly enough

to avoid unsafe situations. It may be necessary to set the alarm thresholds considerably

lower than the safety-relevant threshold.

▸

When the device is used as intended to warn against a potentially explosive

atmosphere, use the currently recognized local value for the LEL.

▸

The trigger delay for the alarm thresholds must be set to 0.

▸

Transmission errors between the analysis component and the control unit can cause

delays up to 2 seconds before a malfunction message is triggered.

Subject to change without notice

EuroFID3010 Inline UEG · Operating Instructions · 8016307/YL25/V 2-2/2018-04 · © SICK AG 13

Page 14

1.2 Product identification

Product name: EuroFID3010 Inline UEG

Housing configurations: Inline

Manufacturer:

SICK AG

Erwin-Sick-Str. 1 · 79183 Waldkirch · Germany

Type plates are located on:

● Analyzer

● Terminal box

● Operating unit

1.2.1 Firmware

This handbook is valid as of the following firmware versions:

● Operating unit: 6.005 and later

● Analyzer unit: V2.05 and later

1.3 Intended use

1.3.1 Purpose of the device

● The EuroFID3010 Inline UEG gas analyzer is a gas detector for continuous

measurement and monitoring of LEL concentrations of combustible gases and vapors

in processes in accordance with DIN EN 60079-29-1.

Important information

1.3.2 Installation location

WARNING: Risk of explosion in potentially explosive atmospheres

▸

Do not use the EuroFID3010 Inline UEG in areas subject to explosion

hazards.

● EuroFID3010 Inline UEG is intended for indoor operation.

● The analyzer unit can be used outdoors if a weatherproof cover (option) has been

installed.

● This product was designed for specific applications in large-scale fixed installations

according to Article 2 (4) e, RoHS 2011/65/EU and accordingly may be used only in

such installations. The product is neither suited nor authorized for use outside these

installations; SICK can therefore not accept any warranty or liability whatsoever for such

use.

14 EuroFID3010 Inline UEG · Operating Instructions · 8016307/YL25/V 2-2/2018-04 · © SICK AG

Subject to change without notice

Page 15

Important information

1.4 Responsibility of the user

These operating instructions have been submitted to and certified by DEKRA

EXAM and must be carefully observed.

When used as a gas detector, make sure that the operating conditions stated

in the operating instructions are complied with, especially when it comes to

ambient conditions, vibration and safety instructions.

Authorized personnel

The EuroFID3010 Inline UEG may only be installed, connected, started up, and maintained

by authorized personnel.

Authorized personnel refers to those with sufficient skills, training and experience in the

following areas, enabling them to assess whether the device is in a safe state or not and

recognize and avoid hazards:

● Relevant occupational health and safety regulations, accident prevention regulations,

guidelines and generally accepted engineering standards (e.g. norms, directives).

● Regulations at the operator’s facility.

● Professional installation and maintenance of the hydrogen supply.

Proper use

▸

Use the device only as described in these Operating Instructions. The manufacturer

bears no responsibility for any other use.

▸

Observe the information on the type plates and comply with the corresponding

specifications.

▸

Perform the stipulated maintenance work.

▸

Do not remove, add or change any components in or on the device unless such changes

are officially allowed and specified by the manufacturer. Otherwise:

– The device could pose a hazard

– Any warranty by the manufacturer becomes void.

– The approvals according to the suitability test for the device are rendered invalid.

▸

The safety of the system in which the EUROFID3010 Inline UEG is integrated is the

responsibility of the user.

The system user must undertake sufficient measures to prevent hydrogen from

collecting in closed or unventilated areas (e.g. by installing a ventilation system, a

hydrogen detector, or similar).

Special local conditions

▸

In addition to these Operating Instructions, follow all local laws, technical rules and

company-internal operating directives applicable wherever the device is installed.

Safeguarding of documents

▸

Keep these Operating Instructions at hand for reference at all times.

▸

Carefully read the Operating Instructions

▸

Safeguard them for later use.

▸

Be sure to pass them on to new owners.

1.5 Additional documents

● The EuroFID3010 Inline UEG is supplied with a test log.

Subject to change without notice

EuroFID3010 Inline UEG · Operating Instructions · 8016307/YL25/V 2-2/2018-04 · © SICK AG 15

Page 16

Important information

16 EuroFID3010 Inline UEG · Operating Instructions · 8016307/YL25/V 2-2/2018-04 · © SICK AG

Subject to change without notice

Page 17

Product description

EuroFID3010 Inline UEG

2 Product description

Functional principle

Characteristics

Subject to change without notice

EuroFID3010 Inline UEG · Operating Instructions · 8016307/YL25/V 2-2/2018-04 · © SICK AG 17

Page 18

2.1 Characteristics

The EuroFID3010 Inline UEG gas analyzer is a gas detector for continuous measurement

and monitoring of LEL concentrations of combustible gases and vapors in processes in

accordance with DIN EN 60079-29-1.

● Measuring range: 0-100% LEL.

A relay for threshold monitoring may be activated depending on the measured gas

concentration and the alarm threshold settings. (→ p. 57, §7.3).

There is also an extractive version of the EuroFID3010 gas analyzer, observe

the special additional EuroFID3010 Extractive UEG Operating Instructions.

2.1.1 Response time

The response time for activating the alarm contact is approx. 2-3 seconds, depending on

the sample gas flow.

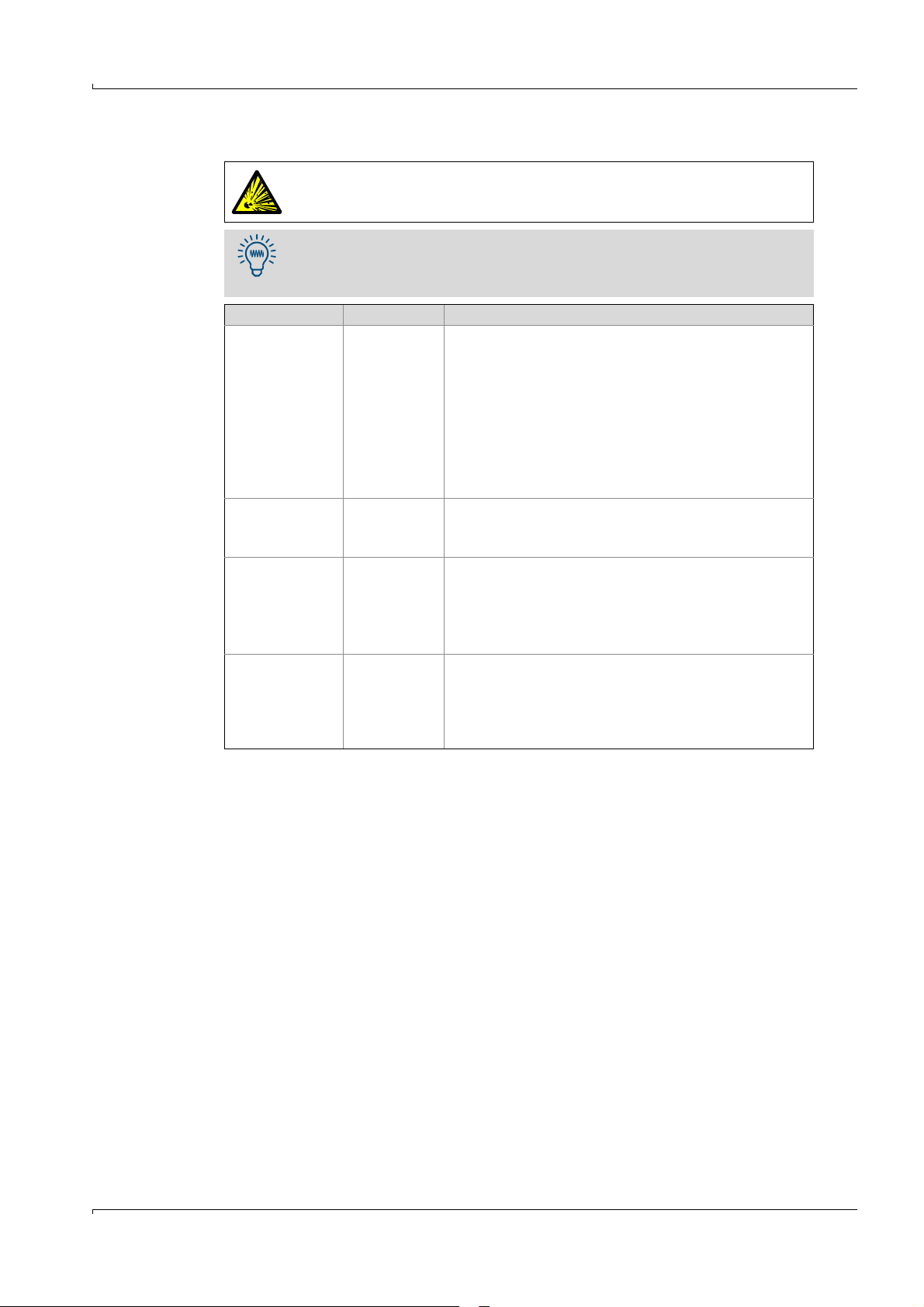

WARNING: Delayed reaction when soiled

The response time is longer if the sample gas filter is soiled.

▸

Check the sample gas filter regularly (→ p. 132, § 14.3.1.)

Product description

18 EuroFID3010 Inline UEG · Operating Instructions · 8016307/YL25/V 2-2/2018-04 · © SICK AG

Subject to change without notice

Page 19

Product description

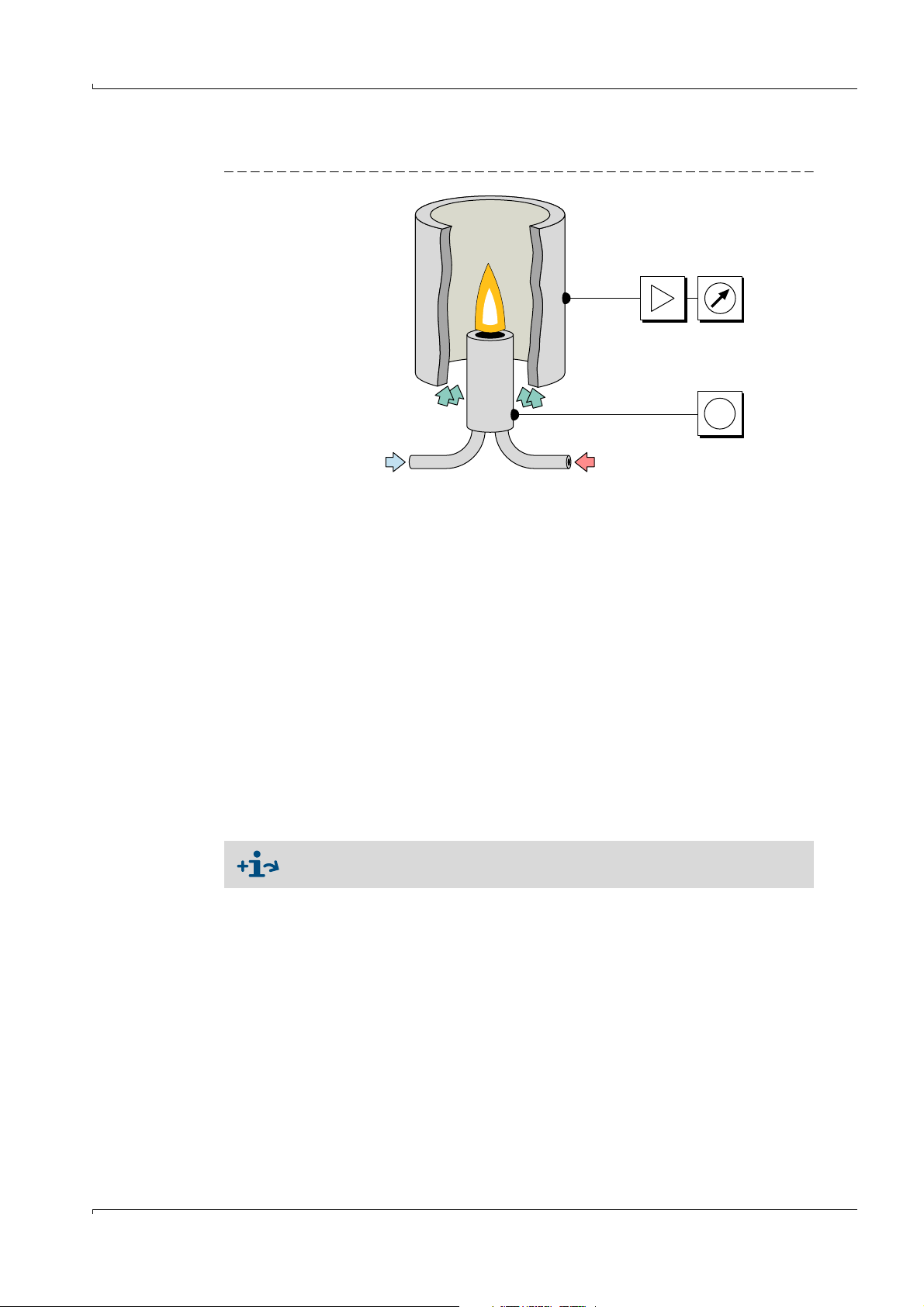

U=

Sample gas Fuel gas

Combustion air (instrument air)

2.2 Measuring principle

Fig. 1 Measuring principle

The EuroFID3010 Inline UEG uses a flame ionization detector (FID) to measure

hydrocarbons. A hydrogen flame burns in an electric field in the FID, fed by fuel gas and

combustion air. The sample gas is routed into this flame. The hydrocarbons contained in

the sample gas are split, and the resulting CH fragments are ionized. A stream of ions forms

in the electric field and this electrical current is measured.

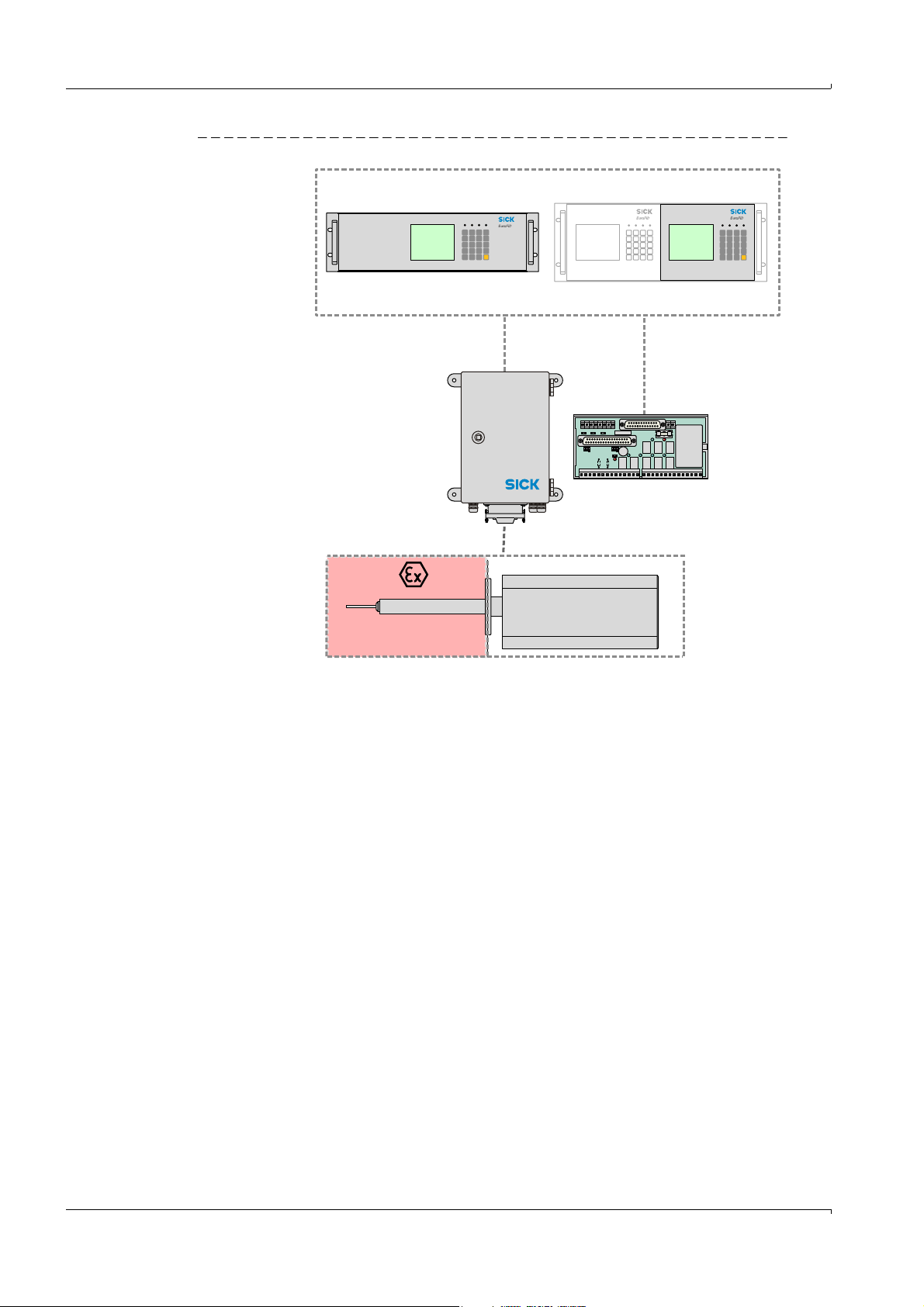

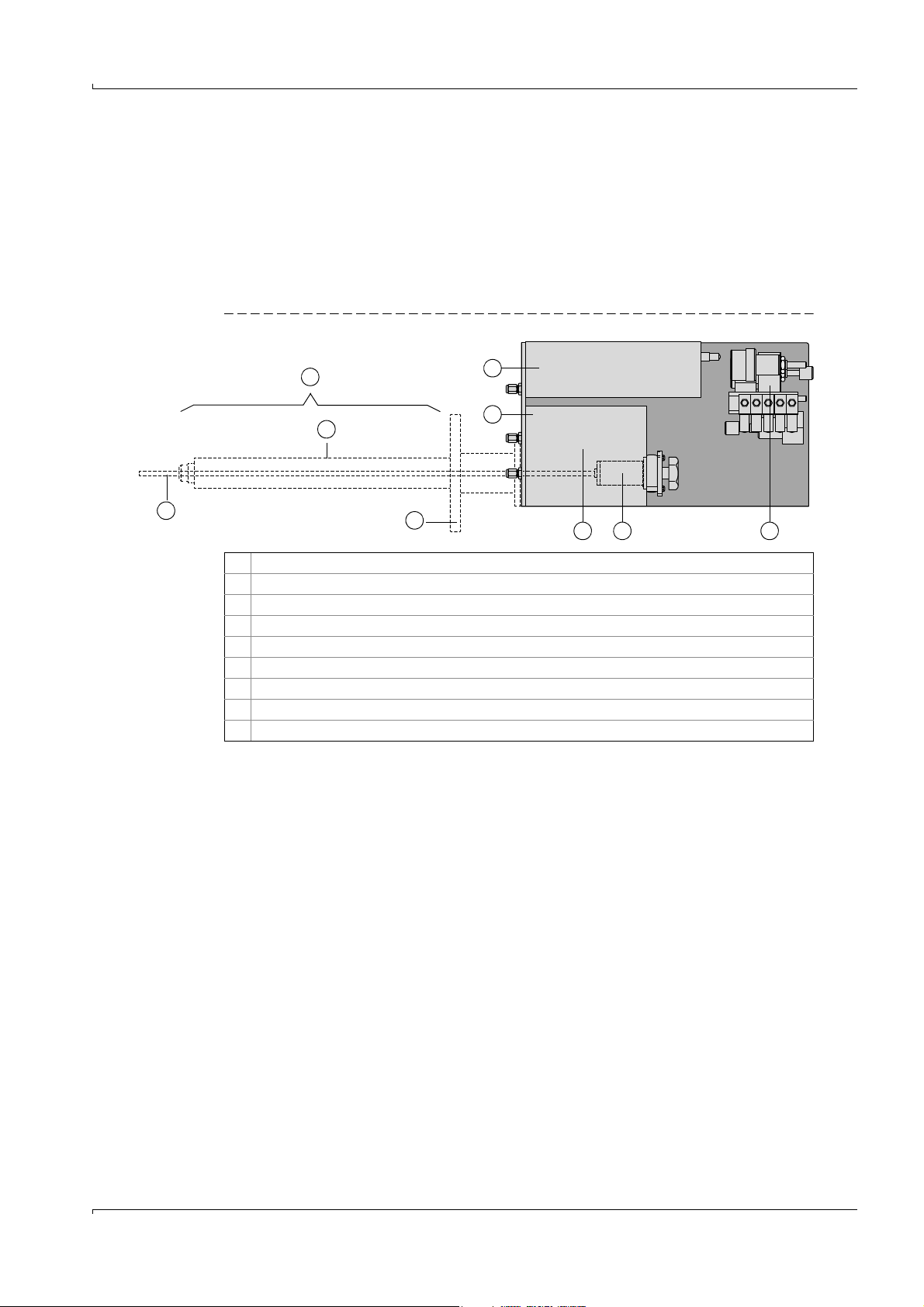

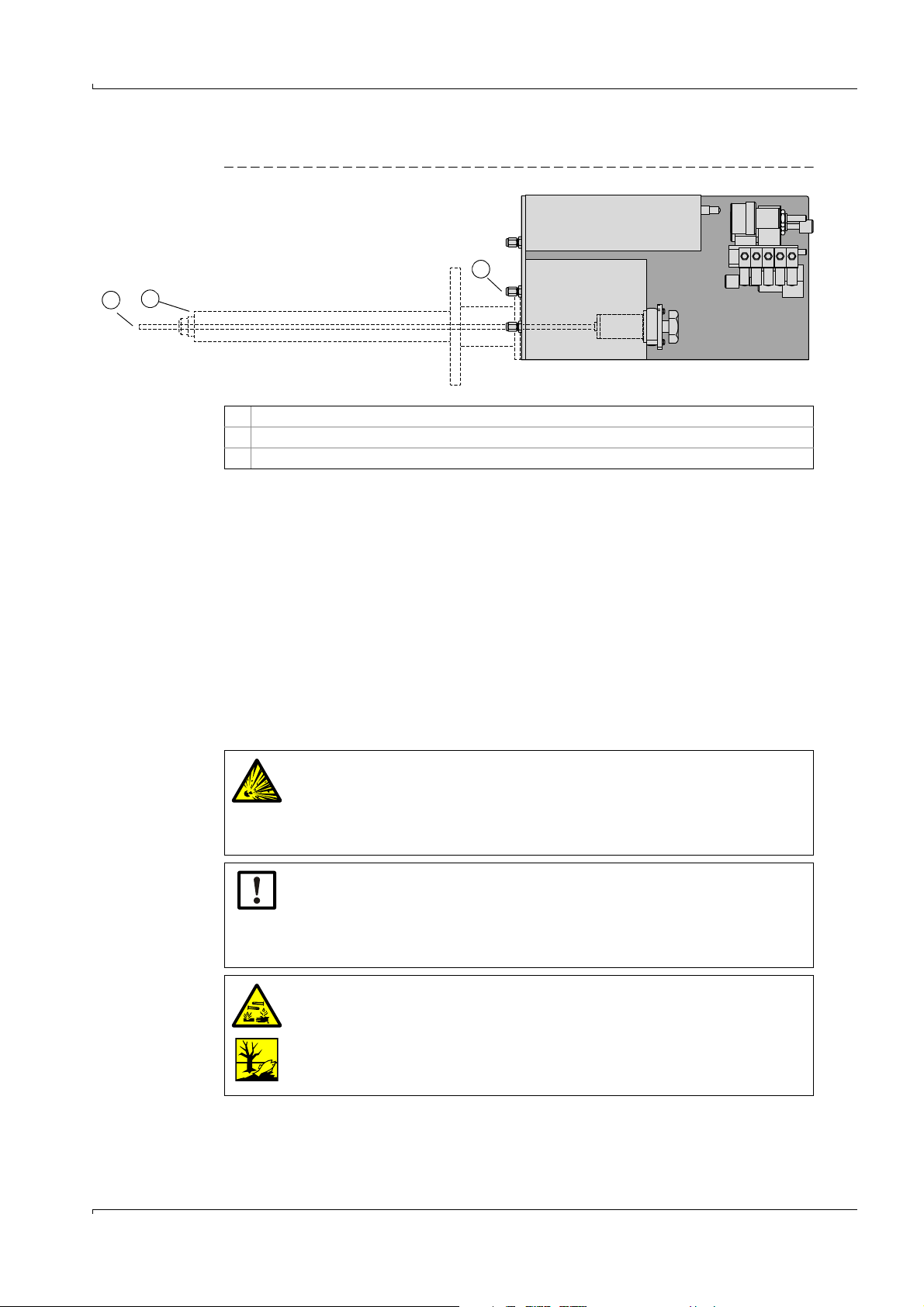

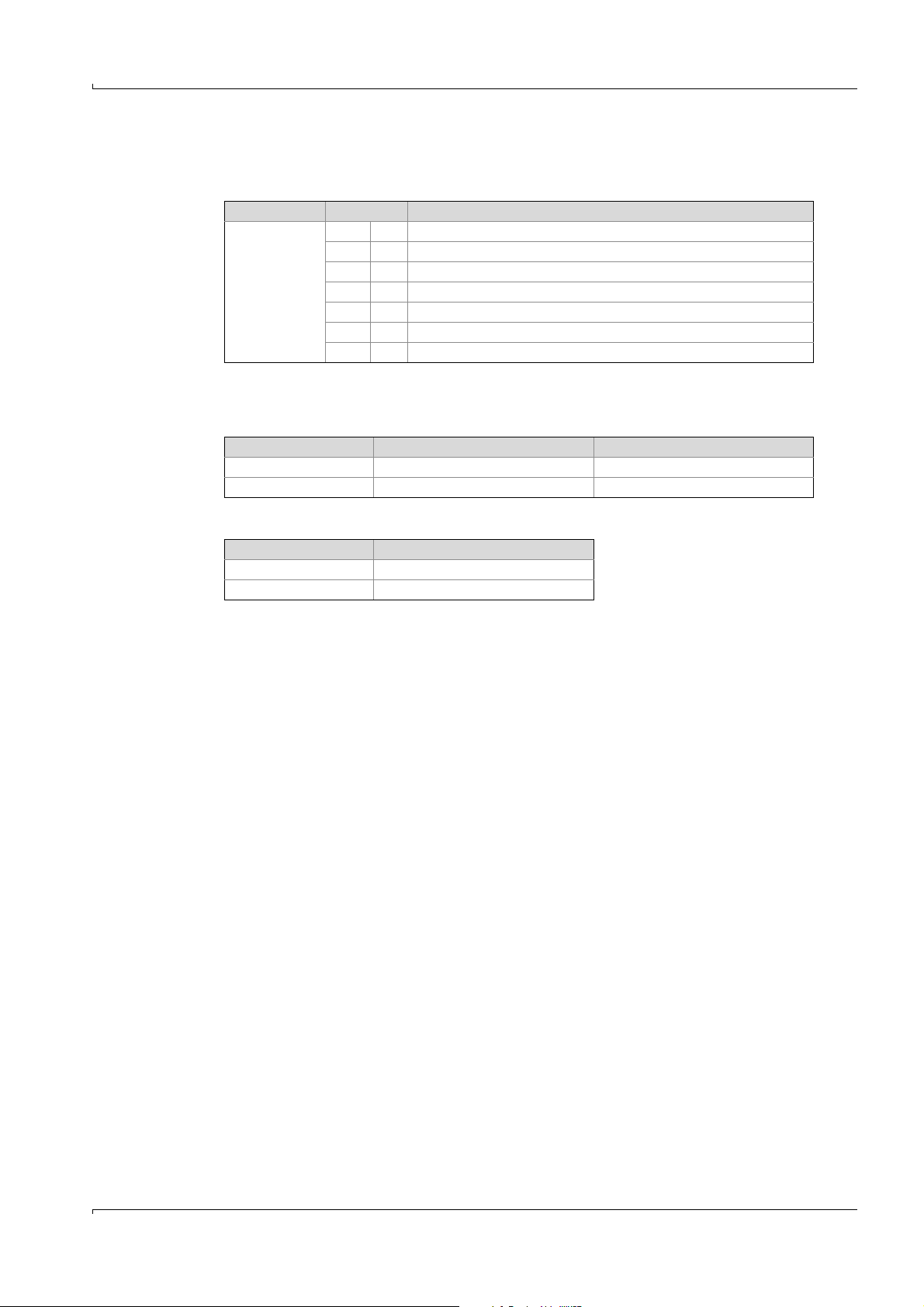

2.3 Device overview

Device modules

The EuroFID3010 Inline UEG consists of 4 device modules:

● Analyzer unit:

– Analyzer (electronics, pneumatics, FID)

– Sampling probe

● Operating unit: Contains the electronic control unit, display and controls

● Terminal box: Interface between the operating unit and the analyzer

Provides the supply voltage for detector heating and the analyzer electronics

● V2 terminal module: Module with analog and digital inputs and outputs

Description of the device modules → p. 21, §2.4

Subject to change without notice

EuroFID3010 Inline UEG · Operating Instructions · 8016307/YL25/V 2-2/2018-04 · © SICK AG 19

Page 20

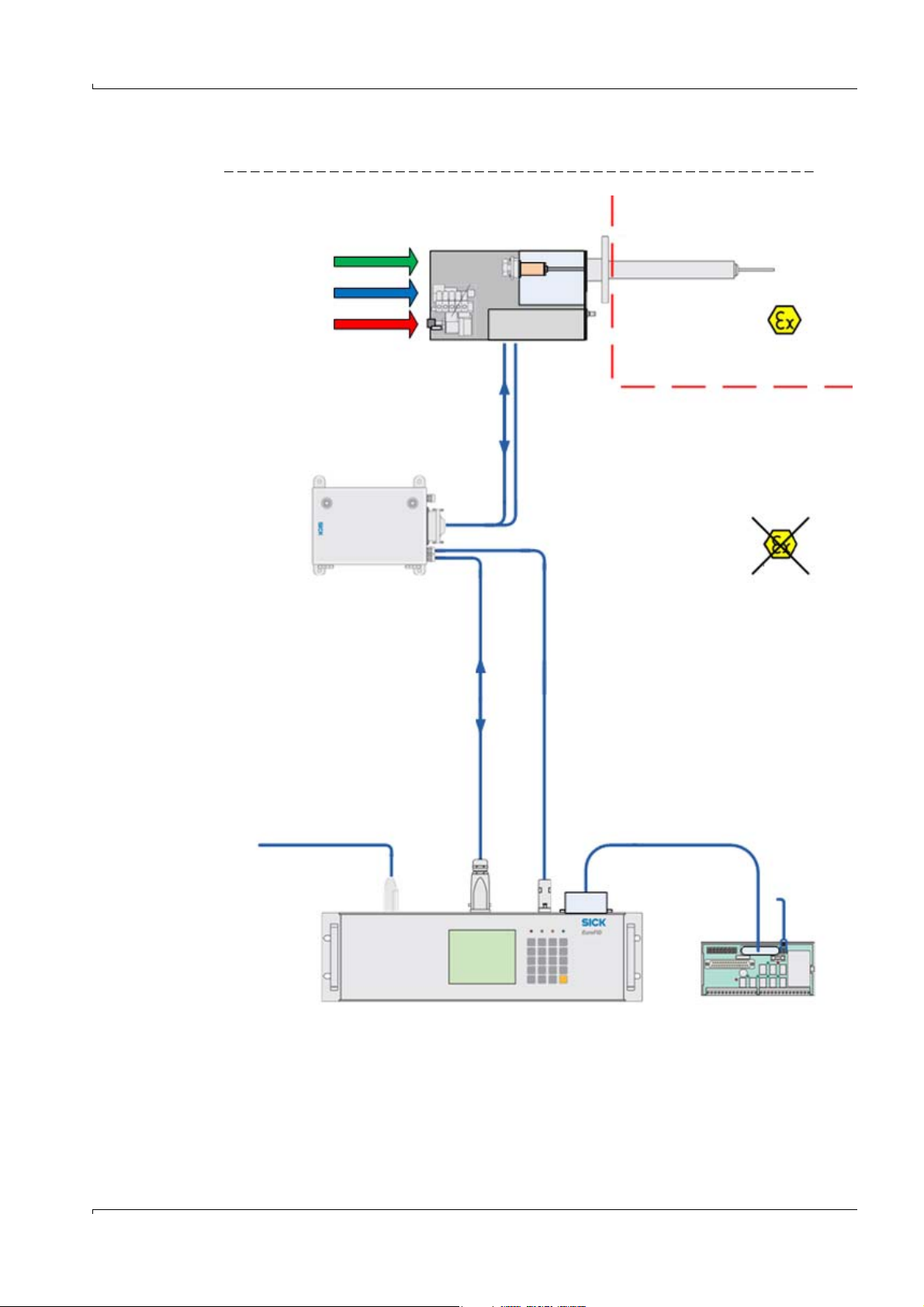

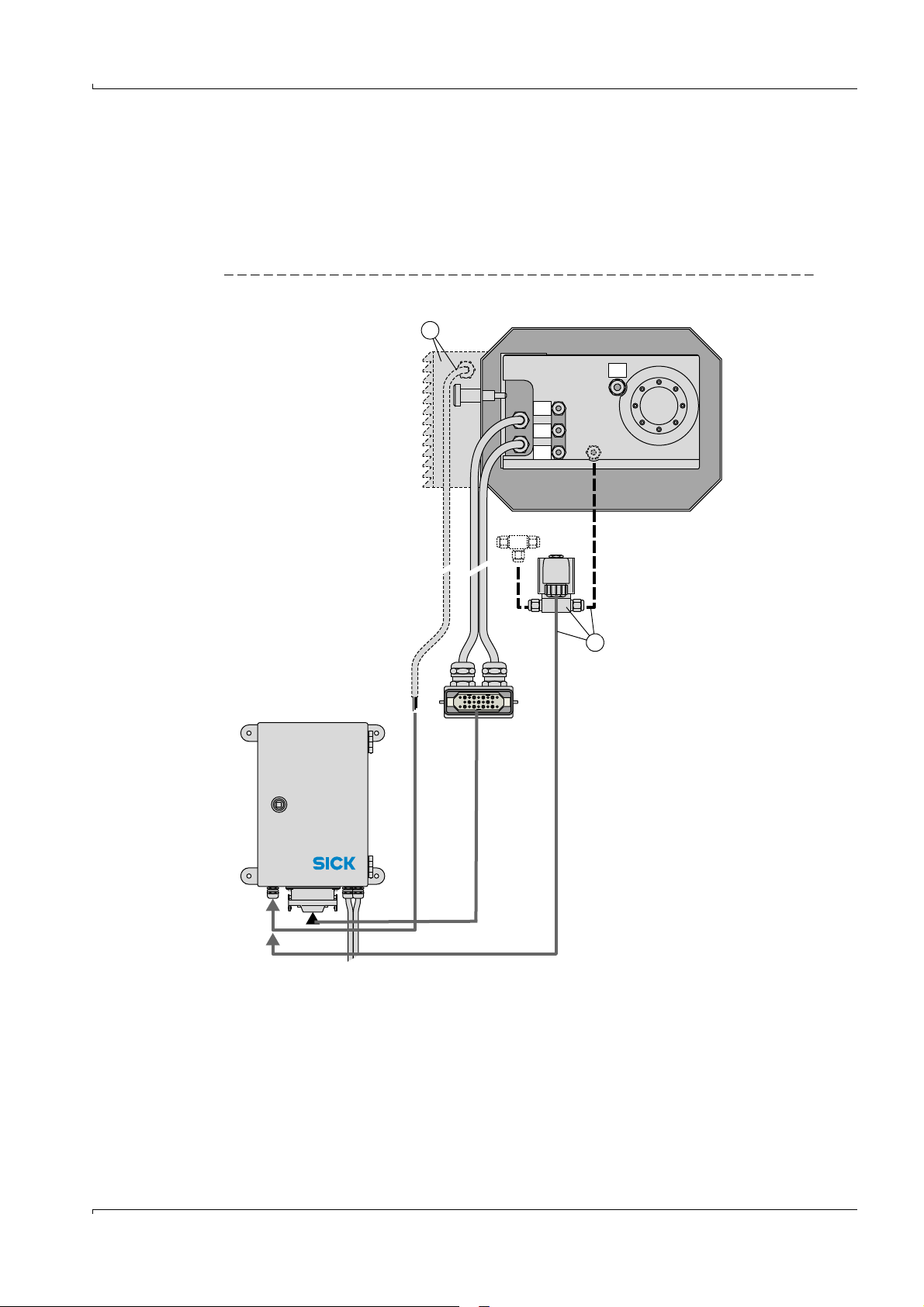

Fig. 2 EuroFID3010 Inline UEG device modules (overview)

R1R2

Analyzer unit

19” rack type operating unit ½-19” rack type operating unit

Terminal box

V2 terminal module

Explosionrisk zone

Product description

20 EuroFID3010 Inline UEG · Operating Instructions · 8016307/YL25/V 2-2/2018-04 · © SICK AG

Subject to change without notice

Page 21

Product description

1

2

3 4 5

7

6

8

9

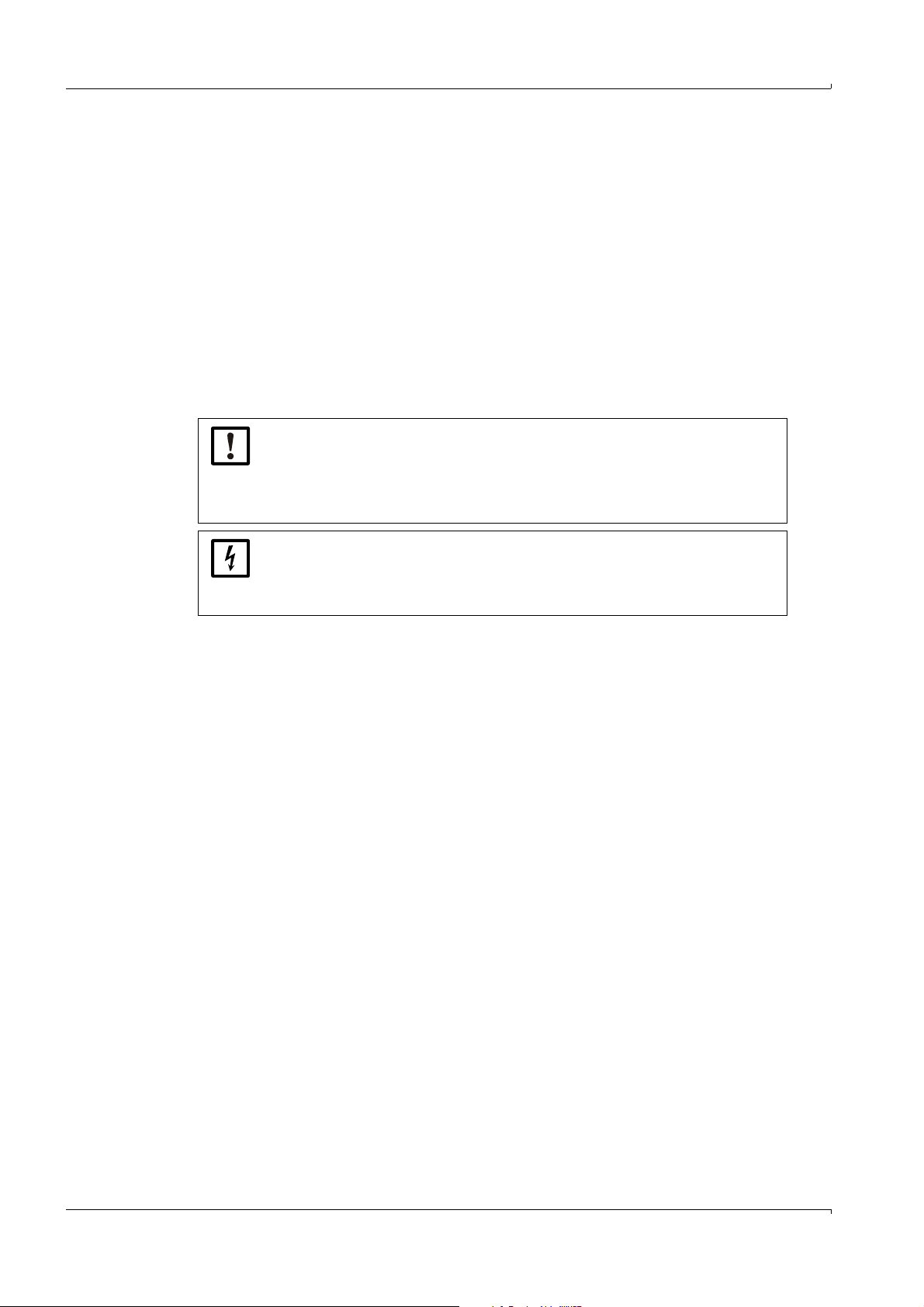

2.4 Device modules

2.4.1 Analyzer unit

The flange, sampling probe and analyzer are a single unit.

The analyzer unit is mounted with the flange directly in the process.

The outer housing protects the measuring system.

Optional: fan.

Optional: weatherproof cover.

Fig. 3 Analyzer unit

2.4.1.1

1 Electronics

2 Sensor block (heated)

3Ejector pump

4 Sample gas filter

5 Pneumatics (pressure regulator, flow controller, solenoid valve)

6 Sampling probe

7Thermal probe

8 Probe tube

9Flange

Sample gas filter

● The sample gas filter filters particles from the sample gas.

● Soiling of the filter is monitored.

If the filter is soiled, the error message “Service requirement” is displayed.

Filter change: → p. 134, §14.5

Subject to change without notice

EuroFID3010 Inline UEG · Operating Instructions · 8016307/YL25/V 2-2/2018-04 · © SICK AG 21

Page 22

2.4.2 Operating unit

Types

● 19” type – for installation in 19” racks (3 RU) (→ p. 50, § 6.2)

● ½-19” type – for installation in 19” racks (4 RU) (→ p. 50, § 6.3)

Elements

● Operating elements

– Display for measurements

–Keypad

– LEDs (indicator lights)

● V2 terminal module connection (→ p. 53, §7)

● AC power supply (→ p. 51, § 6.4)

● Optional: Electronic card for the “flow barrier” option.

2.4.3 Terminal box

● Voltage supply for the analyzer

● Connection for the housing fan

● Connection for the solenoid valve, flow barrier

Product description

2.4.4 V2 terminal module

● Analog outputs

– Measured value

– Reference value

● Digital outputs

–Alarm

–Status

● Digital inputs

–Calibration control

– Maintenance block

– Malfunction, gas supply

22 EuroFID3010 Inline UEG · Operating Instructions · 8016307/YL25/V 2-2/2018-04 · © SICK AG

Subject to change without notice

Page 23

Project planning

EuroFID3010 Inline UEG

3 Project planning

Included in delivery

Overview of installation

Operating materials

Gas supply

Exhaust gas venting

Subject to change without notice

EuroFID3010 Inline UEG · Operating Instructions · 8016307/YL25/V 2-2/2018-04 · © SICK AG 23

Page 24

3.1 Included in delivery

● 1 analyzer unit – with 3-m connection cable to the terminal box

● 1 operating unit

● 1 terminal box with 6-m connection cable to the operating unit

● 1 AC power supply cord, 3 m long – with plug to connect to the terminal box

● 4 flange screws + 1 flange gasket

● V2 terminal module

● 5-m cable to connect the operating unit to the V2 terminal module

● Declaration of clearance

● 1 test log

● 1 set of Operating Instructions

Available accessories (optional)

● Mounting flange

● Weatherproof cover

● Shut-off fitting (for gas supply)

● Solenoid valve (for the “flow barrier” option)

Project planning

3.2 Information about project planning and installation

● EN 60079-29-2: Explosive Atmospheres - Part 29-2: Gas detectors - Selection,

installation, use and maintenance of detectors for flammable gases and oxygen

● Pamphlet T 023 (BGI 518) “Gaswarneinrichtungen für den Explosionsschutz - Einsatz

und Betrieb” (Gas warning systems to protect against explosion) from the Employers'

Liability Insurance Association of the German Chemical Industry must be observed.

24 EuroFID3010 Inline UEG · Operating Instructions · 8016307/YL25/V 2-2/2018-04 · © SICK AG

Subject to change without notice

Page 25

Project planning

Analyzer unit

Test gas

Instrument air

Fuel gas

ZONE 1

ZONE

Terminal box

Power voltage

115 / 230 V

Operating unit

I/O module

24 VDC

Data

Data

115 / 230 V

115 / 230 V

3.3 Overview of installation work

Fig. 4 Overview of installation

Subject to change without notice

EuroFID3010 Inline UEG · Operating Instructions · 8016307/YL25/V 2-2/2018-04 · © SICK AG 25

Page 26

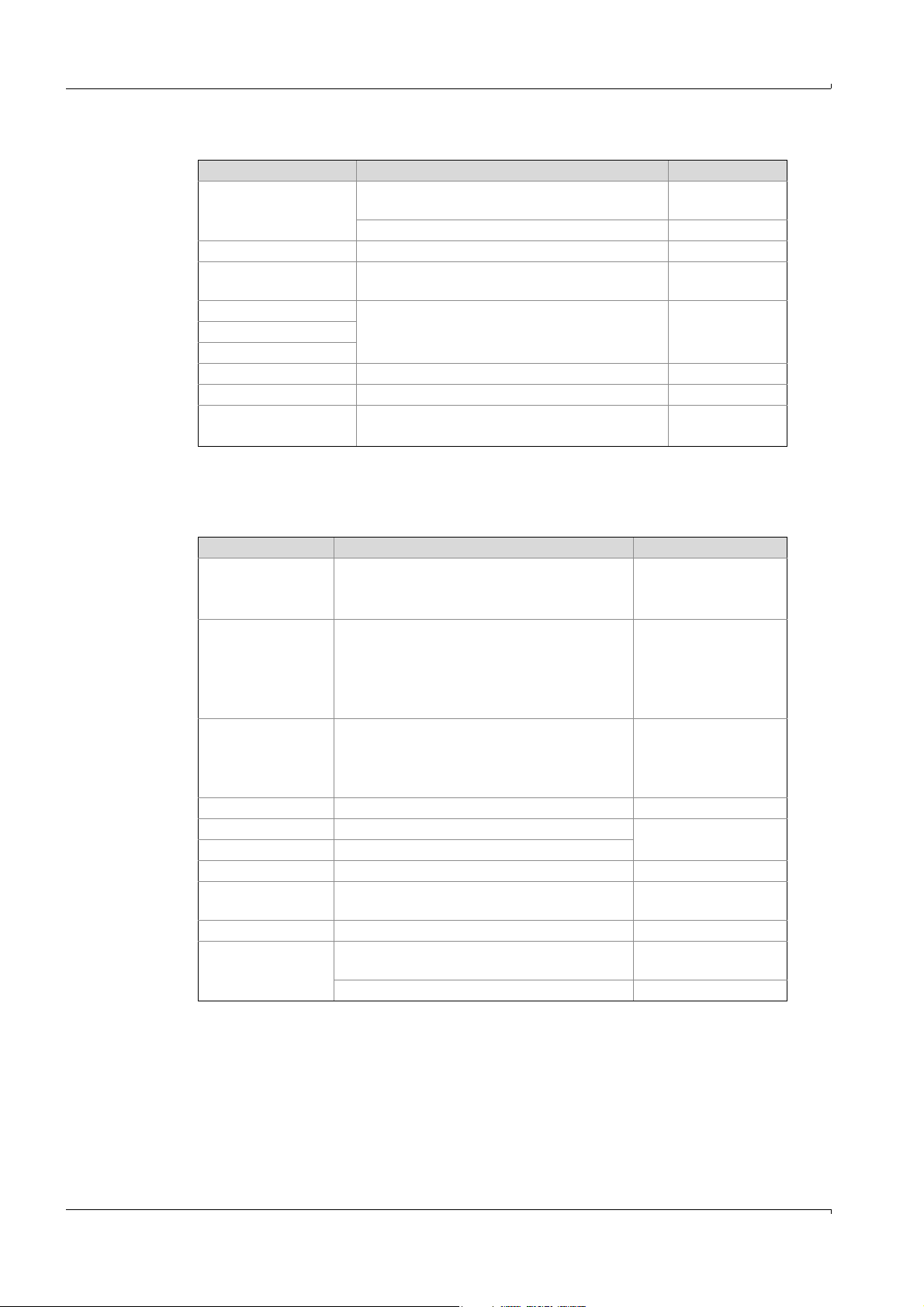

3.3.1 Required resources (overview)

Required resource Notes, requirements Information

Instrument air – Continuous supply of technical

compressed air to the analyzer unit

– Free of hydrocarbons → p. 166, § 16.8.1

Fuel gas – Continuous supply to the analyzer unit → p. 30, §3.4.4

Leakage detection

system

[1]

– To warn about explosion risk in the event of

H

leakage

2

Pressure reducer – For instrument air

[1]

Pressure monitor

Shut-off valves

[1]

–For fuel gas

–Test gas

Test gas – Only during calibration → p. 112, § 12.4.2

Exhaust gas line – Outlet → p. 31, § 3.5

Voltage supply – AC power connection at the operating unit

– Terminal module

[1] Recommended

3.3.2 Mechanical installations (overview)

The following system components must be installed:

Component Installation site, requirements Detailed information

Supply line for

instrument air

– Suitable pressure reducer

– Gas line to the analyzer unit

– Oil-free installation

Compressed gas

cylinder(s) for fuel

gas

– At a suitable location that meets the

safety requirements

– Suitable pressure reducer

– Gas line to the analyzer unit

– Leakage detection system

Compressed gas

cylinder(s) for test

gas

– At a suitable location that meets the

safety requirements

– Suitable pressure reducer

– Gas line to the analyzer unit

Analyzer unit – Ina mounting flange → p. 34, § 4.2

Shut-off fitting – Near the analyzer unit

Solenoid valve

Terminal box – Near the

Operating unit – Near the

[4]

– On the analyzer unit

[5]

analyzer unit

[6]

terminal box or the analyzer

unit

V2 terminal module – Near the operating unit

Electrical

connections

–Analyzer unit (→ terminal box) → analyzer

unit

–Signal connections as required → p. 52, § 6.5

[1] High-purity copper or stainless steel wiring

[2] (Recommended.)

[3] Pre-assembled shut-off fitting available as an accessory.

[4] Only for devices with the “flow barrier” option.

[5] Standard length of the connection cable: 3 m

[6] Standard length of the connection cable: 6 m (max. 500 m).

[7] Standard length of the connection cable: 5 m

[3]

[7]

Project planning

→ p. 29, § 3.4.3

→ p. 30, § 3.4.4

→ p. 29, § 3.4.3

→ p. 30, § 3.4.4

→ p. 51, § 6.4

→ p. 63, § 7.6

→ p. 29, § 3.4.3

[1]

→ p. 30, § 3.4.4

[1]

[2]

→ p. 30, § 3.4.4

[1]

→ p. 39, § 4.2.4

→ p. 43, § 5

→ p. 49, § 6

–

→ p. 33, § 4

Subject to change without notice

26 EuroFID3010 Inline UEG · Operating Instructions · 8016307/YL25/V 2-2/2018-04 · © SICK AG

Page 27

Project planning

3.3.3 AC power connection (overview)

● AC power for the analyzer is supplied via the operating unit (→ p. 51, §6.4).

● Recommended: Install a separate, external all-pole-disconnecting AC power switch and

fuses near the operating unit (max. power input of the EuroFID3010 Inline UEG →

Technical Data) (→ p. 51, § 6.4.1).

The terminal box receives AC voltage from the operating unit and in turn

supplies the analyzer unit with operating voltage.

Subject to change without notice

EuroFID3010 Inline UEG · Operating Instructions · 8016307/YL25/V 2-2/2018-04 · © SICK AG 27

Page 28

3.4 Supply of operational gases

3 bar

H2/He

Fuelgas

3 bar

Kalibriergas

Calibr.gas

3 bar

Instr.Luft

Instr. air

Auspuff

Outlet

Fuel gas

Calibration gas

Instrument air

Fig. 5 Gas connections

The analysis component requires 3 gases to operate:

● Fuel gas

● Calibration gas

● Instrument air

The gas lines must be able to be shut off for deinstallation.

▸

Include shut-off valves in the operating gas lines (→ p. 170, §16.11.3)

Project planning

3.4.1 Screw fittings for the gas connections

● Standard: Clamping ring screw connections for tubes with a 6-mm outside diameter,

brand name “Swagelok.”

● When the screw connections are removed, inside threads are available:

– All gas connections: inside threads G1/8”

● Connections for the supply and test gases: G1/8 inside thread

● Male screw joints: metal with G1/8 thread (DIN/ISO228/1) and O-rings/seals rings.

28 EuroFID3010 Inline UEG · Operating Instructions · 8016307/YL25/V 2-2/2018-04 · © SICK AG

Subject to change without notice

Page 29

Project planning

3.4.2 General information on the gas supply

NOTICE:

The user is responsible for ensuring that the gas supply is leak-tight.

▸

Check the leak tightness of the gas lines after installation.

▸

Leak detection spray, sensor for combustible gases.

NOTICE:

Contaminated operating gases can falsify the measured values and damage

the analyzer unit.

▸

Make sure that the gas lines are clean:

– Free of particles (dust, shavings)

– Free of hydrocarbons (grease, oil, solvents).

NOTICE: Observe the reaction time of the FID during a hydrogen supply

failure

During a hydrogen supply failure, the flame of the FID keeps burning for some

time until it goes out completely.

It is possible that the measured value of the FID does not correspond to the

true value during this time.

The reaction time can be up to 50 seconds depending on the version of the

equipment.

▸

In order to monitor for a hydrogen supply failure, monitor the inlet pressure

of the fuel gas using a pressure controller, which emits an electric signal at

a certain minimum pressure (e.g. < 3 bar).

3.4.3 Connecting instrument air

The EuroFID3010 Inline UEG requires hydrocarbon-free instrument air to operate

(Specifications → p. 166, §16.8.1).

Instrument air is used for the following purposes:

– As propellant air for the ejector pump

–Sample gas dilution

–As combustion air

–As control air

– As zero gas for calibration

▸

Install a continuous supply of instrument air at the gas connection labeled “Instr.air.”

Subject to change without notice

EuroFID3010 Inline UEG · Operating Instructions · 8016307/YL25/V 2-2/2018-04 · © SICK AG 29

Page 30

3.4.4 Connecting fuel gas

▸

Install a continuous supply of fuel gas at the gas connection labeled “Fuel gas.”

WARNING: Risk of explosion if fuel gas line leaks.

The fuel gas is H

A leak in the fuel gas line may lead to an explosion.

▸

Implement safety precautions to prevent explosion.

– Install a volume flow limiter in the fuel gas supply line.

– Install a leak detector on the fuel gas supply line to emit a signal when

H

is discharged.

2

▸

Monitor the cylinder pressure of the fuel gas with a pressure monitor which emits an

electrical signal below a certain minimum pressure (e.g. < 3 bar).

Connect the signal from the pressure monitor to the digital input labeled “Fault Gas Supply”

(→ p. 60, §7.4).

3.4.5 Connecting the calibration gas (“span gas”)

▸

Install a continuous supply of calibration gas to the gas connection labeled “Calibr.gas.”

▸

Recommendation: Monitor the cylinder pressure of the calibration gas with a pressure

monitor which emits an electric signal at a certain minimum pressure (e.g. < 10 bar).

Connect the signal from the pressure monitor to the digital input labeled “Fault Gas Supply”

(→ p. 60, §7.4).

.

2

Project planning

3.4.6 Information on connecting a cylinder pressure monitor

A pressure monitor must be connected to terminals X20.13+X20.14 of the V2 terminal

module. When two pressure monitors are used, their contacts must be connected in series

and can only be processed as a composite signal.

30 EuroFID3010 Inline UEG · Operating Instructions · 8016307/YL25/V 2-2/2018-04 · © SICK AG

Subject to change without notice

Page 31

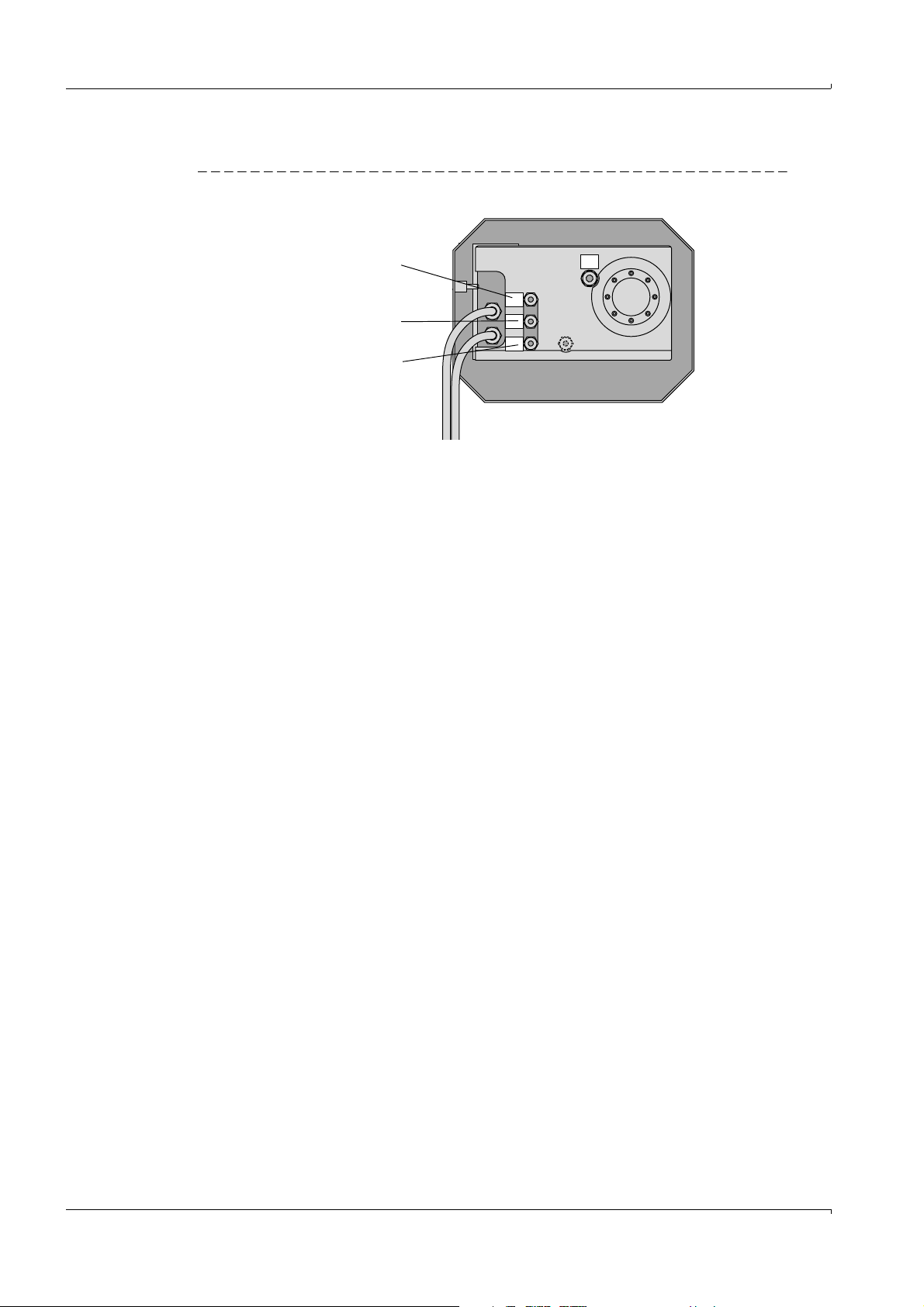

Project planning

1

2

3

3.5 Exhaust gas lines

Fig. 6 Exhaust gas connections

1Gas outlet “Outlet”

2 Gas outlet “Bypass”

3 Gas inlet (probe tube)

3.5.1 Connecting the “Outlet” gas outlet

The exhaust gas from the combustion chamber exits at “Outlet”.

Important: The exhaust gas contains water vapor (condensation).

▸

Use corrosion-resistant tube material for the exhaust gas line (e.g. stainless steel or

Teflon tubes).

▸

Inside diameter: 4 mm.

▸

Max. length: 3 m.

▸

Install the exhaust gas lines at a continuous downward angle so that condensed liquid

can reliably drain away.

▸

Route the exhaust gas line to a collection point:

– Atmospheric pressure

– No pronounced pressure fluctuations.

WARNING: Risk of explosion

The exhaust gas from the “outlet”

▸

may not be returned to the process;

▸

must be drained off to a non-potentially explosive atmosphere in a safe

manner.

NOTICE:

Condensate is generated in the exhaust gas line.

▸

Arrange the exhaust lines so that they cannot become obstructed by

condensing liquid.

▸

Protect exhaust gas lines against freezing.

CAUTION: Contaminants in the condensate

Condensate from the exhaust gas contains substances from the sample gas.

These substances may be chemically corrosive and/or must be disposed of

separately.

▸

If necessary: Collect the condensate from the exhaust line and dispose of

Subject to change without notice

EuroFID3010 Inline UEG · Operating Instructions · 8016307/YL25/V 2-2/2018-04 · © SICK AG 31

properly.

Page 32

NOTICE:

Backpressure and pressure fluctuations at the exhaust gas connection

– Can affect the measured values

– Can prevent ignition of the FID flame.

▸

If the EuroFID3010 Inline UEG is installed in a ventilated or air-conditioned

enclosed area and the ventilation/air conditioning system in this area can

generate overpressure or pressure fluctuations: Do not allow the exhaust

gas line to discharge into this area.

3.5.2 Gas outlet “Bypass”

Excess gas from the ejector pump (a mixture of instrument air and sample gas) exits at the

“Bypass”

and is returned to the process via the thermal probe.

3.6 Sample gas supply

For sample gas requirements, refer to Technical data (→ p. 167, § 16.9)

Sample gas supply → p. 38, §4.2.3

Project planning

32 EuroFID3010 Inline UEG · Operating Instructions · 8016307/YL25/V 2-2/2018-04 · © SICK AG

Subject to change without notice

Page 33

Installing the analyzer unit

EuroFID3010 Inline UEG

4 Installing the analyzer unit

Mechanical installation

Gas connections

Electrical connections

Subject to change without notice

EuroFID3010 Inline UEG · Operating Instructions · 8016307/YL25/V 2-2/2018-04 · © SICK AG 33

Page 34

4.1 Preparing for Installation

WARNING: Risk of fire when measuring combustible gases

Feeding ignitable gases or gas mixtures is not allowed.

No special requirements exist when measuring combustible gases when the

sample gas concentration does not exceed 25% of the lower explosion limit

(LEL).

Meet the following requirements when exceeding the 25% LEL limit:

▸

Check the leak tightness of the hydrogen feed line to the equipment at

regular intervals.

▸

Observe the correct pressure for the hydrogen feed.

● Compare the information on the type plate with the operating conditions.

● Check ambient temperature (refer to “Technical data”).

● Make sure that the classification temperature is below the ignition temperature of the

combustible gases.

● Perform work on the EuroFID3010 Inline UEG in a non-explosive area only.

4.2 Installation

CAUTION: Risk of injury through incorrect lifting and carrying the equipment

Injuries can occur due to the weight and projecting enclosure parts when the

equipment tips over or drops. Observe the following information to avoid such

accidents:

▸

Do not use protruding parts on the enclosure to carry the equipment (apart

from the wall fixture or carrying grips).

▸

Never lift the equipment using the open equipment door.

▸

Consider the equipment weight before lifting.

▸

Observe the regulations for protective clothing (e.g., safety shoes, non-slip

gloves)

▸

Grip underneath the equipment when possible to carry it safely.

▸

Use a hoist or transport equipment as an option.

▸

Use the help of a second person when necessary.

▸

Secure the equipment during transport.

▸

Before transporting, ensure obstacles that could cause falls or collisions

are cleared away.

Installing the analyzer unit

CAUTION: Accident risk through inadequate fastening of the device

▸

Consider the device weight specifications when planning the mounting

supports.

▸

Check the load capacity/condition of the wall/rack on/in which the device

is to be installed.

● The installation location must be free of oscillations and vibrations.

NOTICE: Absence of vibration

In the frequency range from 10-150 Hz, vibratory stress may not exceed

0.2 g (= 1.96 m/s²).

● The ambient air must be free of dust and other impurities that could corrode materials

in the device.

34 EuroFID3010 Inline UEG · Operating Instructions · 8016307/YL25/V 2-2/2018-04 · © SICK AG

Subject to change without notice

Page 35

Installing the analyzer unit

Sampling probe

Fig. 7 Lifting points

● A high-temperature mounting flange is available for applications with process

temperatures above 300°C.

NOTICE:

The sampling probe is equipped with a glass vacuum tube,

which is fragile.

▸

Make sure no force is applied to the sampling probe when handling the

analyzer unit.

▸

Lift the analyzer unit by the housing only (→ Fig. 7).

Subject to change without notice

EuroFID3010 Inline UEG · Operating Instructions · 8016307/YL25/V 2-2/2018-04 · © SICK AG 35

Page 36

4.2.1 Clearance for the analyzer unit

Interior wall

Exterior wall

Thickness of insulation in the process

equipment

Fig. 8 Clearance for the analyzer unit

Installing the analyzer unit

36 EuroFID3010 Inline UEG · Operating Instructions · 8016307/YL25/V 2-2/2018-04 · © SICK AG

Subject to change without notice

Page 37

Installing the analyzer unit

Thermal probe

Mounting flange

Sealing ring

Bolt M12 x 60

Interior wall of

process

Insulation Exterior wall of

process

4.2.2 Preparing to install the analyzer unit

The analyzer unit is mounted at the process wall according to the following diagram.

Fig. 9 Installation overview

● A mounting flange is required to attach the analyzer unit.

● Permissible angle of the analyzer unit: ±35° to the horizontal.

The user is responsible for installing the flange.

● Weight of the analyzer unit: 25 kg.

Supporting struts may need to be added to ensure the mechanical stability of the

analyzer unit.

Dimensions of the sampling probe → p. 158, Fig. 33

Fig. 10 Mounting flange heat decoupling unit

Subject to change without notice

EuroFID3010 Inline UEG · Operating Instructions · 8016307/YL25/V 2-2/2018-04 · © SICK AG 37

Page 38

4.2.3 Installing the analyzer unit on the flange

Sampling

probe

Sample gas

Probe tube

Bypass outlet

WARNING: Hazard from process gases

For processes with overpressure, hot or toxic gases may escape when the

sampling point is opened.

▸

Undertake suitable safety measures.

NOTICE:

▸

2 persons should install the analyzer unit on the flange.

● The probe tube must freely protrude into the process gas stream.

WARNING: Incorrect measured values due to improper installation

If the gas inlet is too short, the EuroFID3010 Inline UEG draws in the exhaust

gas, which dilutes the sample gas as a result.

▸

Do not shorten the probe tube.

The bypass exhaust gas stream emerges from the thermal probe of the

sampling probe.

▸

Do not install any components so close to the sampling probe that the

bypass exhaust gas stream could be drawn in again by the probe tube.

Fig. 11 Exhaust gas exit

Installing the analyzer unit

Attachment

1 Position a flange seal between the mounting flange and the flange of the analyzer unit.

▸

If the analyzer unit is used for hot processes (> 300°C): Use the heat insulation

flange instead of the flange seal (→ p. 169, Fig. 39).

2 Carefully insert the sampling probe into the flange tube.

3 Connect the flange with the supplied screw fittings.

38 EuroFID3010 Inline UEG · Operating Instructions · 8016307/YL25/V 2-2/2018-04 · © SICK AG

Subject to change without notice

Page 39

Installing the analyzer unit

4.2.4 Gas connections

Gas connection Gas Installation work

Instr. air

Instr. air

Fuel gas

Fuel gas

Calibration gas

Calibr. gas

Outlet Exhaust gas

WARNING: Risk of explosion if gas connections are mixed up

● Observe the labels on the gas inlets.

Recommendation: To be able to stop the gas supply to the device manually,

▸

install a shut-off valve in the gas feed.

The shut-off valve is available as an option (→ p. 170, § 16.11.3).

Instrument

air

Fuel gas

Span gas

▸

Observe the information on instrument air (→ p. 29,

§3.4.3).

▸

Connect the instrument air supply to the “Instr.air”

gas connection.

On devices with the “flow barrier” option:

▸

Also connect the instrument air supply to a gas

connection of the solenoid valve.

▸

Connect the other gas connection of the solenoid

valve to the “flow barrier” gas connection.

▸

Observe the information on fuel gas (→ p. 30, § 3.4.4).

▸

Connect the fuel gas supply to the “Fuel gas” gas

connection.

▸

Supply suitable span gas.

▸

Observe the information on span gas supply

(→ p. 30, §3.4.5).

▸

Connect the span gas supply to the “Calibr. gas” gas

connection.

▸

Connect an exhaust gas line to the “Outlet”

connection. Suitable material: Corrosion-resistant

hose with an inside diameter of 6 mm.

▸

Observe the information on installing the exhaust

gas connections (→ p. 31, § 3.5).

Subject to change without notice

EuroFID3010 Inline UEG · Operating Instructions · 8016307/YL25/V 2-2/2018-04 · © SICK AG 39

Page 40

4.3 Electrical connections

4.3.1 Electrical compliance

4.3.1.1 Electrical safety through disconnector switches properly installed

WARNING: Endangerment of electrical safety during installation and

maintenance work when the power supply is not switched off

An electrical accident can occur during installation and maintenance work

when the power supply to the device and/or lines is not switched off using a

disconnector switch/circuit breaker.

▸

Ensure that the power supply of the device can be switched off in

accordance with DIN EN 61010 using a disconnector switch/circuit

breaker.

▸

Make sure the disconnector switch is easily accessible.

▸

An additional disconnecting device is mandatory when the disconnector

switch is difficult to access or cannot be accessed when connecting the

equipment after installation.

▸

After completion of the work or for test purposes, the power supply may only

be activated again by authorized personnel complying with the safety

regulations.

Installing the analyzer unit

4.3.1.2 Electrical safety through lines with correct rating

WARNING: Endangerment of electrical safety through power cable with

incorrect rating

When a removable power cable is used, electrical accidents can occur when

the specifications are not fully observed.

▸

Always observe the exact specifications in the Operating Instructions

(Technical Data Section) when replacing a removable power cable.

4.3.1.3 Grounding the equipment

CAUTION: Device damage through incorrect or missing grounding.

During installation and maintenance work, it must be ensured that the

protective grounding to the devices and/or lines involved is effective in

accordance with EN 61010-1.

40 EuroFID3010 Inline UEG · Operating Instructions · 8016307/YL25/V 2-2/2018-04 · © SICK AG

Subject to change without notice

Page 41

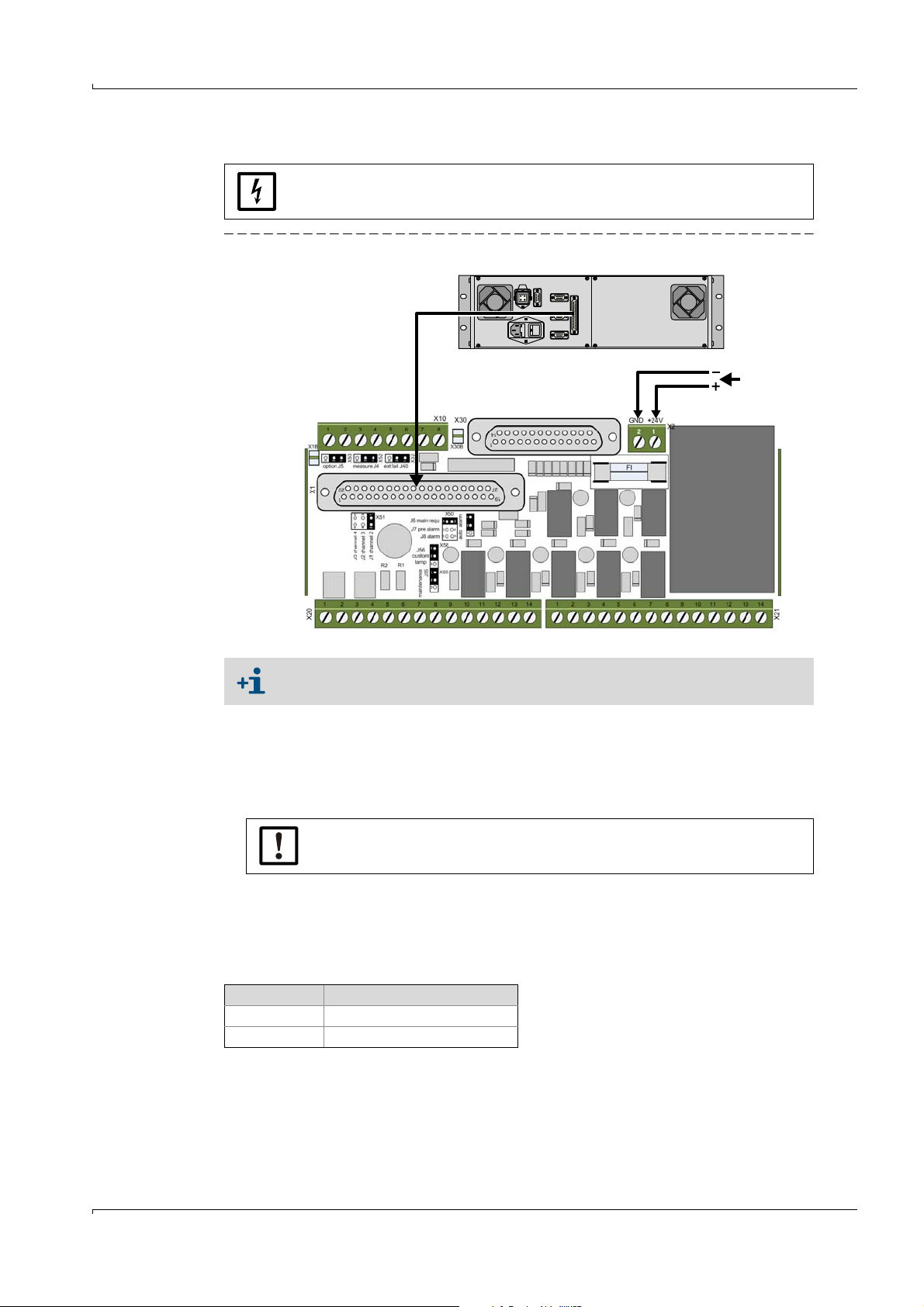

Installing the analyzer unit

A Only with “fan” option

B Solenoid valve – only with “flow barrier” option

3 bar

H2/He

Fuelgas

3 bar

Kalibriergas

Calibr.gas

3 bar

Instr.Luft

Instr. air

Auspuff

Outlet

A

B

Terminal box

Analyzer

4.3.2 Procedure

▸

Connect the plug connector to the terminal box with the double cable.

▸

On devices with the “flow barrier” option: Connect the solenoid valve to the terminal box

(→ p. 44, § 5.2).

▸

On devices with the “Fan” option: Connect the fan’s cable to 24 VDC in the terminal box

(→ p. 44, § 5.2).

Fig. 12 Analyzer: connections

Subject to change without notice

EuroFID3010 Inline UEG · Operating Instructions · 8016307/YL25/V 2-2/2018-04 · © SICK AG 41

Page 42

Installing the analyzer unit

42 EuroFID3010 Inline UEG · Operating Instructions · 8016307/YL25/V 2-2/2018-04 · © SICK AG