Page 1

TEC HNICAL INFORMATIO

N

EFI – Enhanced Function Interface

Safe SICK device communication

en

Page 2

Technical information

This document is protected by the law of copyright, whereby all rights established therein remain with the

company SICK AG. Reproduction of this document or parts of this document is only permissible within the limits

of the legal determination of Copyright Law. Alteration or abridgement of the document is not permitted without

the explicit written approval of the company SICK AG.

EFI

2 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8012622/Z098/2016-11-07

Subject to change without notice

Page 3

Technical information

EFI

Contents

Contents

1 About this document.................................................................................................... 5

1.1 Function of this document................................................................................5

1.2 Abbreviations used........................................................................................... 5

1.3 Symbols used ...................................................................................................5

2 On safety.......................................................................................................................6

2.1 General safety notes and protective measures................................................6

3 Basics ........................................................................................................................... 7

3.1 Devices with EFI................................................................................................7

3.2 Function expansion by connecting ESPE..........................................................8

3.3 Function expansion using switching amplifiers ..............................................10

3.4 Applications with safety controllers................................................................11

3.5 Network solutions...........................................................................................12

4 Technical realization..................................................................................................13

4.1 Data exchange via EFI ....................................................................................14

4.1.1 Addressing.....................................................................................15

4.1.2 Sending and receiving of information............................................16

4.2 Firmware compatibility of the EFI devices ......................................................17

4.2.1 C4000 safety light curtain.............................................................17

4.2.2 M4000 multiple light beam safety device.....................................18

4.2.3 S300/S3000 safety laser scanners..............................................19

4.3 Description of the bytes and bits of the EFI communication ..........................19

4.3.1 Bytes of the EFI communication....................................................19

4.4 Status information and control options for the EFI devices............................26

4.4.1 C4000 safety light curtain.............................................................26

4.4.2 M4000 multiple light beam safety device.....................................28

4.4.3 S3000 safety laser scanner..........................................................29

4.4.4 S300 safety laser scanner ............................................................32

4.4.5 S300 Mini safety laser scanner.....................................................34

4.4.6 Flexi Soft FX3-CPU1, -CPU2, -CPU3 safety controller.....................36

4.4.7 UE4740 EFI gateway.....................................................................37

4.5 Application examples......................................................................................38

4.5.1 EFI gateway with M4000 multiple light beam safety device .........38

4.5.2 EFI gateway with M4000 and UE403 switching amplifier.............39

4.5.3 EFI gateway with two S3000 safety laser scanners ......................40

4.5.4 EFI gateways with S3000 or S300 host/guest systems with

local inputs....................................................................................40

4.5.5 EFI gateway with two S300 safety laser scanners ........................41

4.5.6 EFI gateway with safety controllers ...............................................42

4.5.7 Flexi Soft safety controller with M4000 multiple light beam

safety device .................................................................................43

4.5.8 Flexi Soft safety controller with two S3000 or S300 Mini.............44

4.5.9 Flexi Soft safety controller with S3000 or S300 host/guest

system (with local inputs)..............................................................44

8012622/Z098/2016-11-07 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 3

Subject to change without notice

Page 4

Contents

5 Configuration options via EFI.................................................................................... 47

5.1 Device groups with one EFI string.................................................................. 47

5.1.1 Cascaded system with the safety light curtain C4000.................. 47

5.1.2 Host/guest system with the S300/S300 Mini/S3000 safety

laser scanners .............................................................................. 48

5.1.3 M4000 with UE403 switching amplifier....................................... 48

5.1.4 Safety controller with one ESPE.................................................... 49

5.1.5 EFI gateway with ESPE(s) connected............................................ 49

5.2 Device groups with two EFI strings................................................................. 50

5.2.1 Safety controller with two ESPE.................................................... 50

5.2.2 EFI gateway with safety controller and ESPE connected .............. 51

5.2.3 EFI gateway with two safety controllers with ESPE connected...... 52

6 Technical specifications............................................................................................ 54

6.1 Electrical installation...................................................................................... 54

6.2 Interfaces....................................................................................................... 54

7 Annex ......................................................................................................................... 55

7.1 List of tables .................................................................................................. 55

7.2 List of illustrations.......................................................................................... 55

Technical information

EFI

4 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8012622/Z098/2016-11-07

Subject to change without notice

Page 5

Technical information Chapter 1

µ

EFI

About this document

1 About this document

Please read this chapter carefully before working with the technical description.

1.1 Function of this document

This technical information gives you an overview of the possibilities, expanded functionality

and the technical implementation of safety-related applications with the Enhanced

Function Interface from SICK AG.

1.2 Abbreviations used

CDS

EDM

EFI

ESPE

(F)PLC

OSSD

Note

= Take action …

WARNING

SICK Configuration & Diagnostic Software

External device monitoring

Enhanced function interface = safe SICK device communication

Electro-sensitive protective equipment (e.g. C4000, S300)

(Fail-safe) Programmable logic controller

Output signal switching device = signal output that drives the safety circuit

1.3 Symbols used

Refer to notes for special features of the device.

Instructions for taking action are shown by an arrow. Read carefully and follow the

instructions for action.

Warning!

A warning indicates an actual or potential risk or health hazard. They are designed to help

you to prevent accidents.

Read carefully and follow the warning notices!

Software notes show the location in the CDS (Configuration & Diagnostic Software) where

you can make the appropriate settings and adjustments. In the CDS open the menu View,

Dialog box and select the item File Cards to go straight to the stated dialog fields.

Alternatively, the software wizard will guide you through the appropriate setting.

8012622/Z098/2016-11-07 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 5

Subject to change without notice

Page 6

Chapter 2 Technical information

in the use of the device by qualified safety personnel and must

On safety

EFI

2 On safety

2.1 General safety notes and protective measures

Use the related operating instructions for the devices!

This technical information does not replace the operating instructions for the ESPE, safety

WARNING

controllers or the EFI gateway described in the following.

These operating instructions are to be made available to the operator of the system,

machine or vehicle on which an ESPE, a safety controller or an EFI gateway is used. The

operator is to be instructed

be instructed to read and observe the operating instructions.

6 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8012622/Z098/2016-11-07

Subject to change without notice

Page 7

Technical information Chapter 3

EFI

Basics

3 Basics

This chapter describes the possibilities offered by the Enhanced Function Interface (EFI).

The Enhanced Function Interface (EFI) was developed to implement safe communication

between ESPE, Flexi Soft modular safety controller or EFI gateway.

However, EFI is more than an interface for connecting together SICK devices. EFI expands

the functionality of the individual protective devices.

Using protective devices connected with EFI, safety-related applications can be

implemented that would otherwise only be possible with a large amount of circuitry or

extensive installation effort. These applications include, for example, simultaneous

protective field monitoring using the S3000 safety laser scanner, operating mode

switching on the C4000 or sampling status signals (e.g. for a contaminated front screen).

Status and control information is exchanged between devices via EFI. The applications can

be integrated into higher level bus systems using EFI gateways.

In addition the concurrent configuration of the devices in a project is possible.

You will find the advantages of EFI in SICK safety systems only.

3.1 Devices with EFI

The following product families are equipped with EFI:

• M4000 multiple light beam safety device: Advanced, Area

• UE403 switching amplifier

• C4000 safety light curtain: Standard, Advanced, Entry/Exit, Palletizer, Fusion,

Standard Guest, Advanced Guest

• M4000 multiple light beam safety device: Standard Curtain, Advanced Curtain

• UE402 switching amplifier

• S3000 safety laser scanner: Standard, Advanced, Professional, Expert, Remote,

Cold Store, Anti Collision

• S300 safety laser scanner: Standard, Advanced, Professional, Expert

• S300 Mini safety laser scanner: Remote

• UE4740 EFI gateway

• Flexi Soft FX3-CPU1, -CPU2, -CPU3 modular safety controller

8012622/Z098/2016-11-07 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 7

Subject to change without notice

Page 8

Chapter 3 Technical information

1

2

132

4

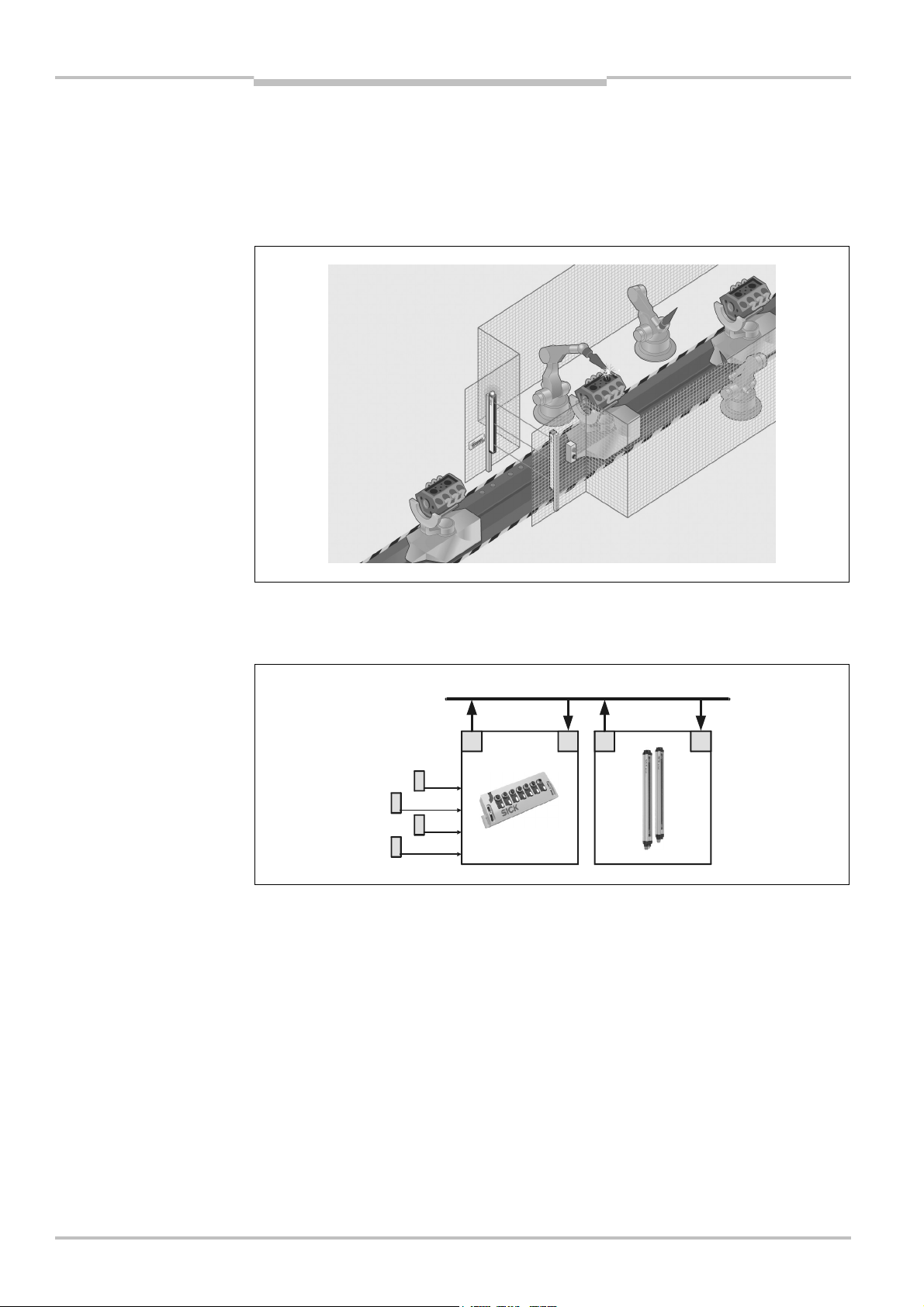

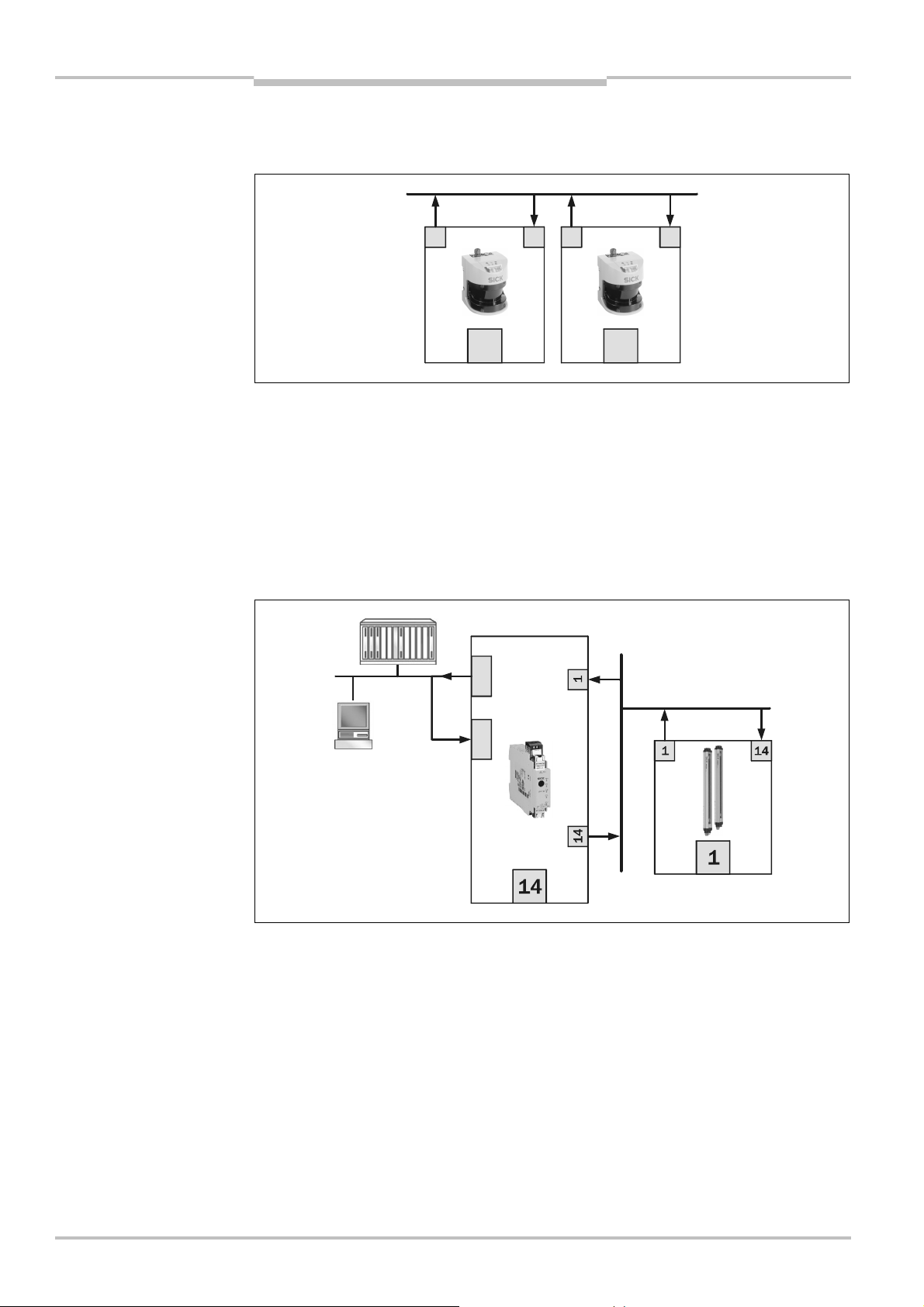

Fig.1:

Velocity

-

dependent

Fig.2:

Principle of the S300

Basics

EFI

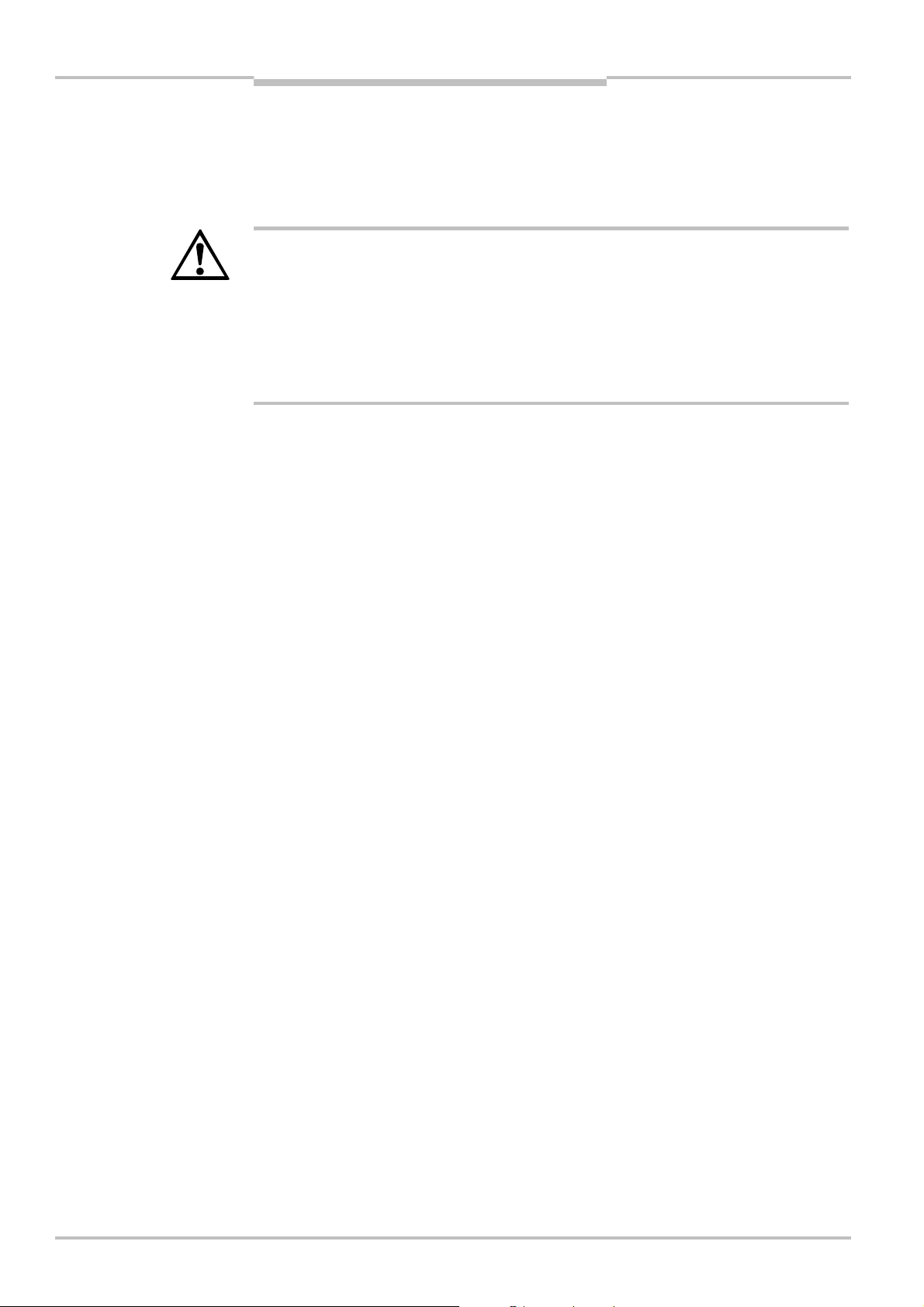

3.2 Function expansion by connecting ESPE

By connecting together individual ESPE via EFI additional applications become possible.

Example 1: Two S300 in host/guest operation

vehicle monitoring for bidirectional travel

3

4

The S300 safety laser scanners are connected to a host/guest system via an EFI connection. It is then possible, for instance, to realize vehicle monitoring in two directions of

movement.

The guest (2) receives the incremental encoder values (4) from the host (1) over the EFI

interface (3). It monitors the areas for the second direction of travel as a function of the

velocity. As soon as there is an object in the protective field, it switches the OSSDs on the

host via the EFI interface to the OFF state (5).

host/guest system

5

Advantages:

• less configuration effort:

– central interface for the configuration of the system

– concurrent monitoring case switching

• less wiring costs:

– The cables for the input signals only need to be connected to the host.

– One pair of OSSDs is sufficient for the entire system.

• simplified diagnostics on the host/guest system:

– combined error messages

– central interface for system diagnostics

8 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8012622/Z098/2016-11-07

Subject to change without notice

Page 9

Technical information Chapter 3

132

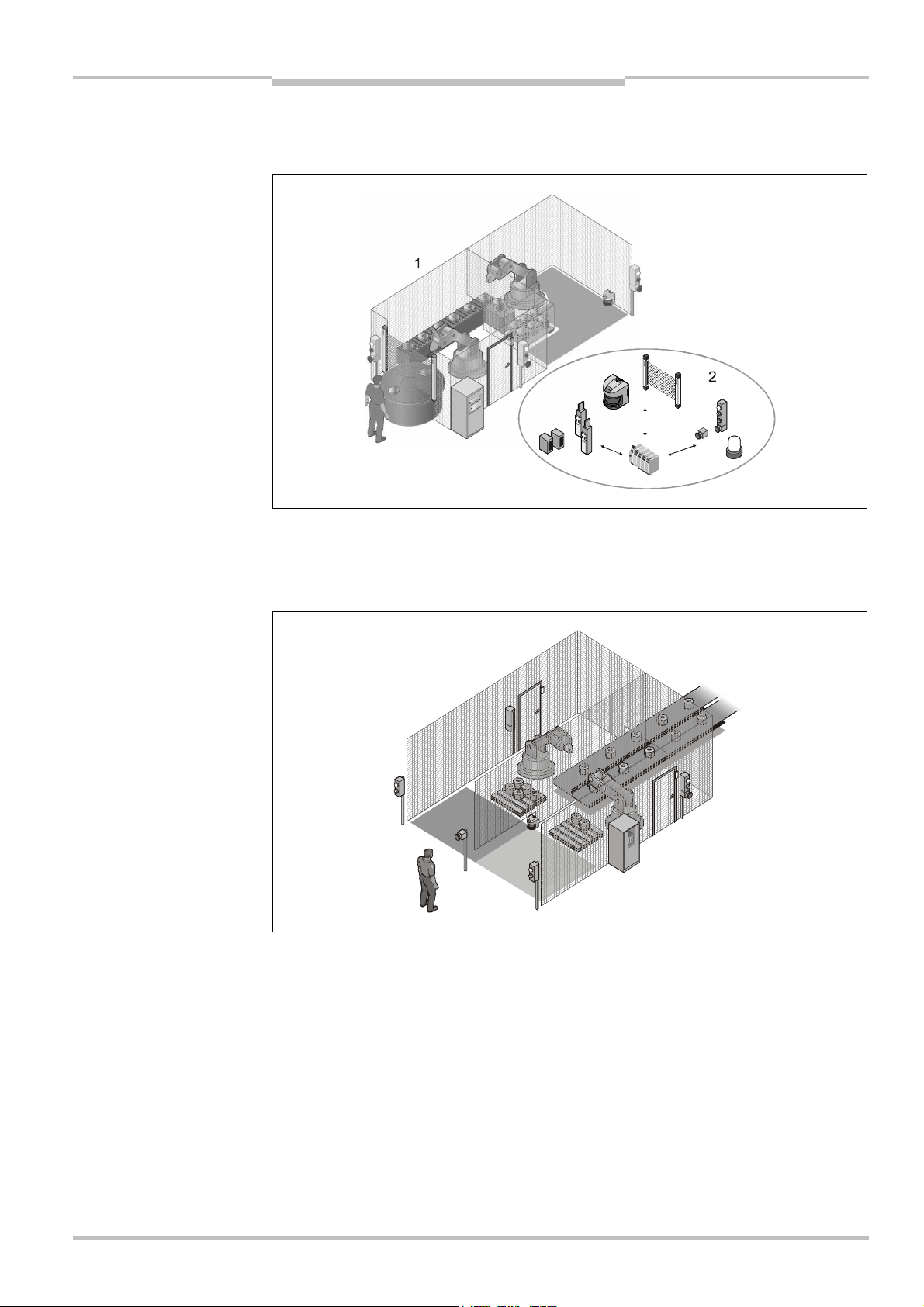

Fig.3:

Hazardous point

Fig.4:

Principle of the

EFI

Basics

Example 2: Two C4000 in operation as a cascaded system

protection with presence

detection

Two C4000 safety light curtains form a cascaded system. The C4000 Host (1) performs

the actual hazardous point protection on a press. The C4000 Guest (2) performs the

presence detection. The two C4000 are connected together using EFI. The OSSDs on the

C4000 Host are integrated into the machine controller (4). If the protective field of

the C4000 Guest is interrupted by standing behind or by an attempt at crawling

beneath/reaching under, the OSSDs on the C4000 Host are switched via EFI (3) to the

OFF state.

cascaded C4000 system

4

Advantages:

• Up to three safety light curtains can be connected to each other.

• No additional external circuitry required. Quick to connect.

• Resolution and protective field height may differ among the individual systems.

8012622/Z098/2016-11-07 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 9

Subject to change without notice

Page 10

Chapter 3 Technical information

3

4

Fig.5:

Access protection with

Fig.6:

Principle of the

Basics

EFI

3.3 Function expansion using switching amplifiers

Using the UE402 switching amplifiers for C4000 and UE403 for M4000 the functionality of

the C4000 safety light curtains and the M4000 multiple light beam safety devices can be

expanded.

Example: Muting with M4000 and UE403

muting

M4000 muting system

Two pairs of inductive muting sensors (1) connected to the UE403 detect the transport

platform. The UE403 switching amplifier (2) transmits signals via EFI (3) to the M4000

multiple light beam safety device (4) and controls the muting function.

2

1

Advantages:

• less wiring due to local connection of all signals

• less wiring between switching amplifier and ESPE due to EFI

10 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8012622/Z098/2016-11-07

Subject to change without notice

Page 11

Technical information Chapter 3

3

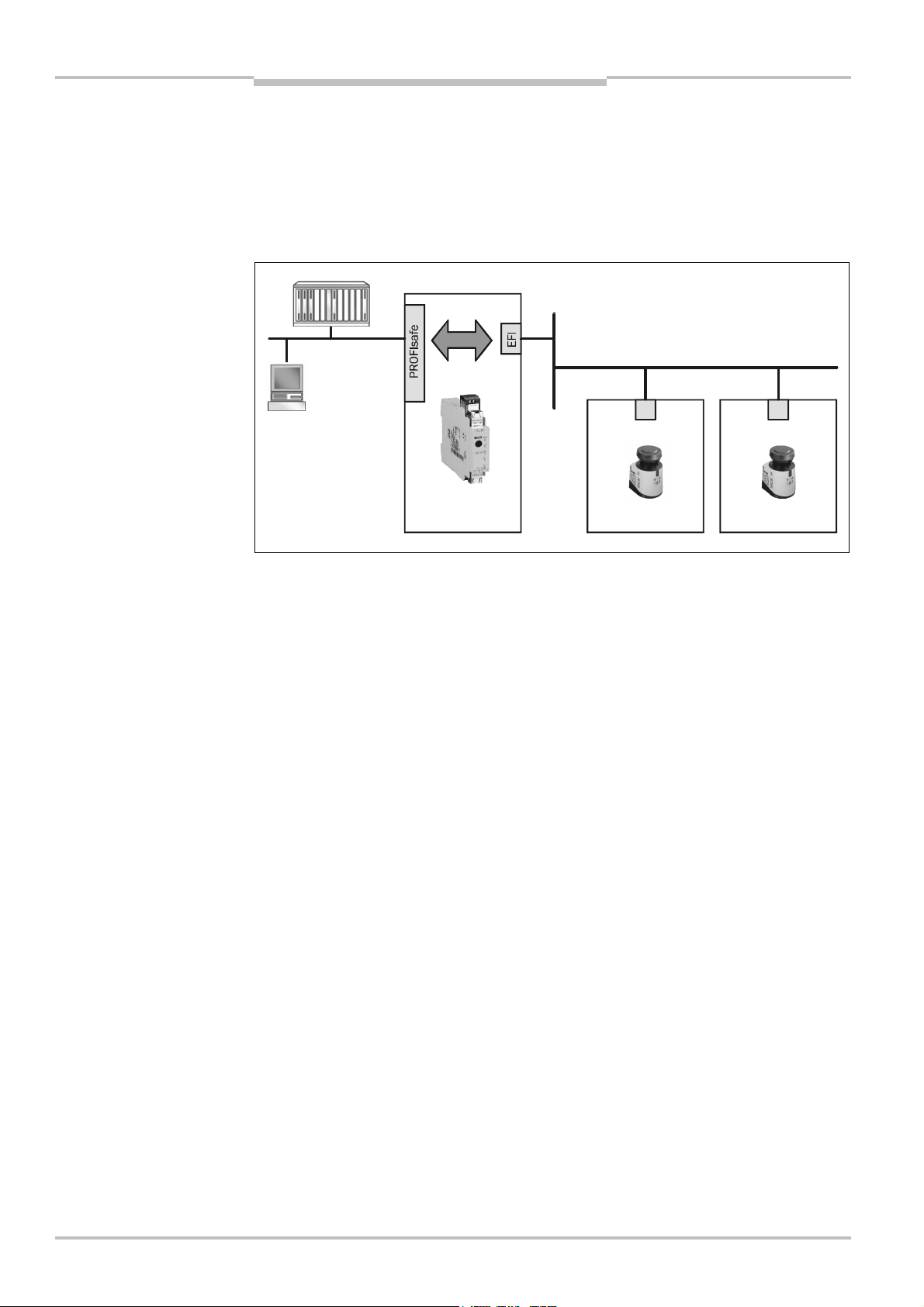

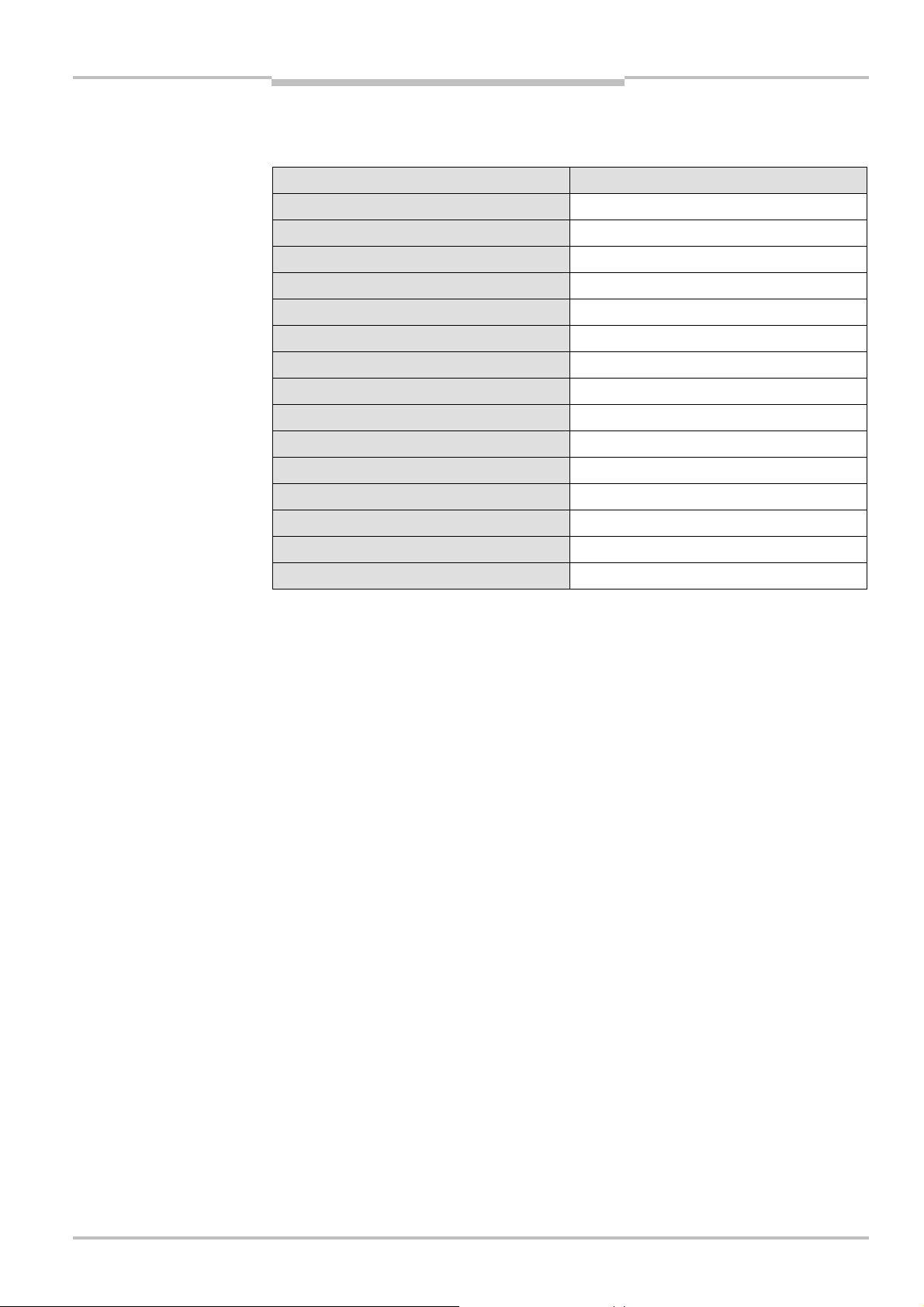

Fig.7:

Safety application with

Fig.8:Simultaneous

EFI

Basics

3.4 Applications with safety controllers

Complex safety applications can be solved specifically using safety controllers.

a Flexi Soft safety controller

protective field monitoring

with S3000 and a safety

controller

In the insertion station with rotary table shown and the downstream robot station (1) all

the safety-related functions (hazardous point protection, hazardous area protection, door

contacts, emergency stop, restart) are realized using a Flexi Soft safety controller (2). The

ESPE are integrated into the safety application via EFI.

1

2

One S3000 simultaneously monitors two protective fields (1 and 2). Via EFI it signals the

states of the protective fields to the Flexi Soft safety controller (3). The safety controller

has two OSSDs for separate safe shut down. The related industrial robot is shut down by

an object in one of the protective fields. The second station continues to operate.

Advantages:

• all safety-relevant functions in one application

• one ESPE saved due to simultaneous protective field monitoring

• increased availability of the system, as only the robots related to the hazardous

situation are stopped and not the complete system

8012622/Z098/2016-11-07 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 11

Subject to change without notice

Page 12

Chapter 3 Technical information

Fig.9:

Integration of two

Basics

EFI

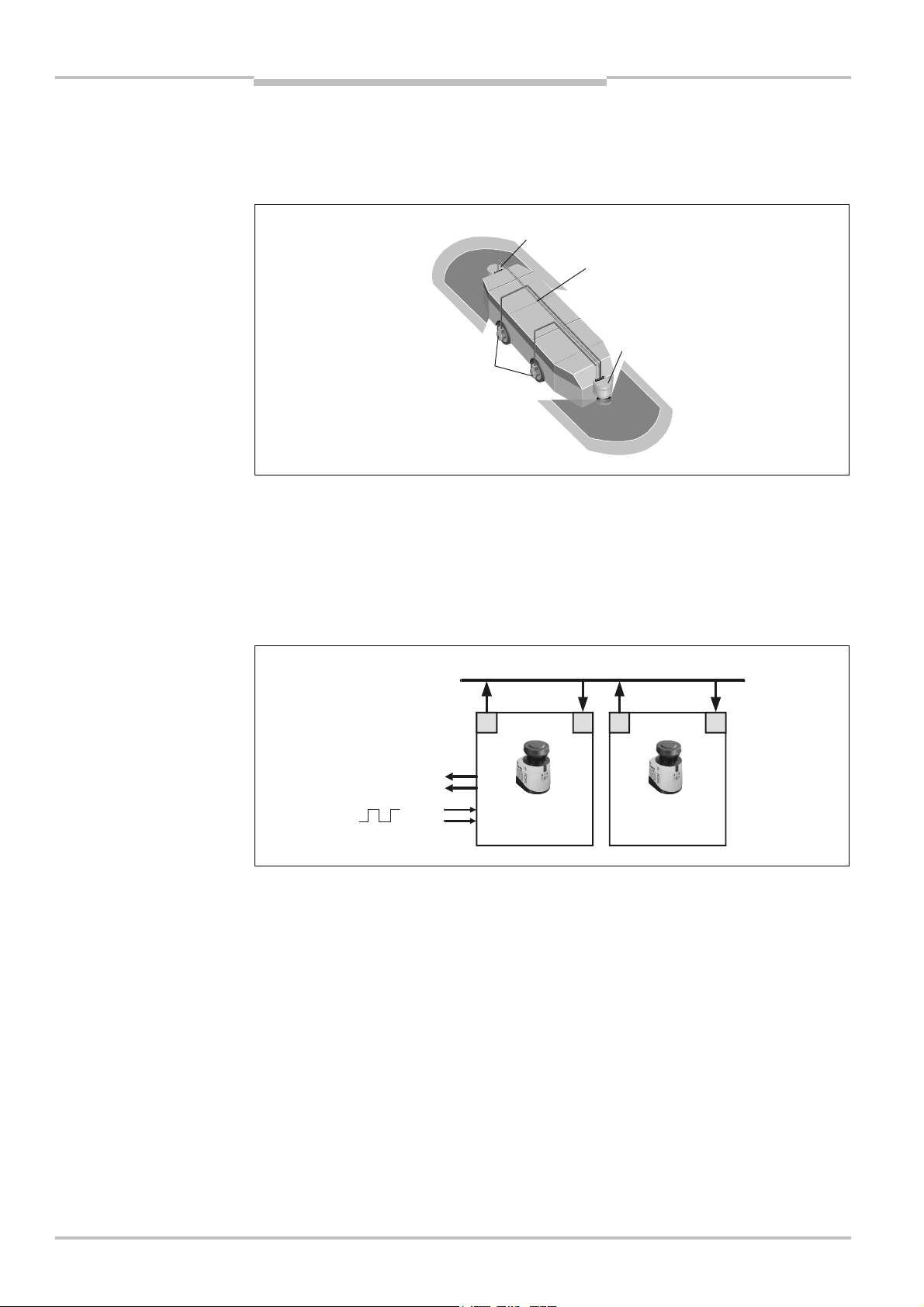

3.5 Network solutions

By integrating ESPE with the aid of the EFI gateway it is possible to bidirectionally transmit

configuration, status and diagnostics functions from the ESPE to the bus system

PROFINET IO PROFIsafe.

Using the EFI gateway, one or more ESPE or even entire applications realized with safety

controllers can be integrated into, for example, an (F)PLC.

S300 in host/guest operation

into a bus system

12 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8012622/Z098/2016-11-07

Subject to change without notice

Page 13

Technical information Chapter 4

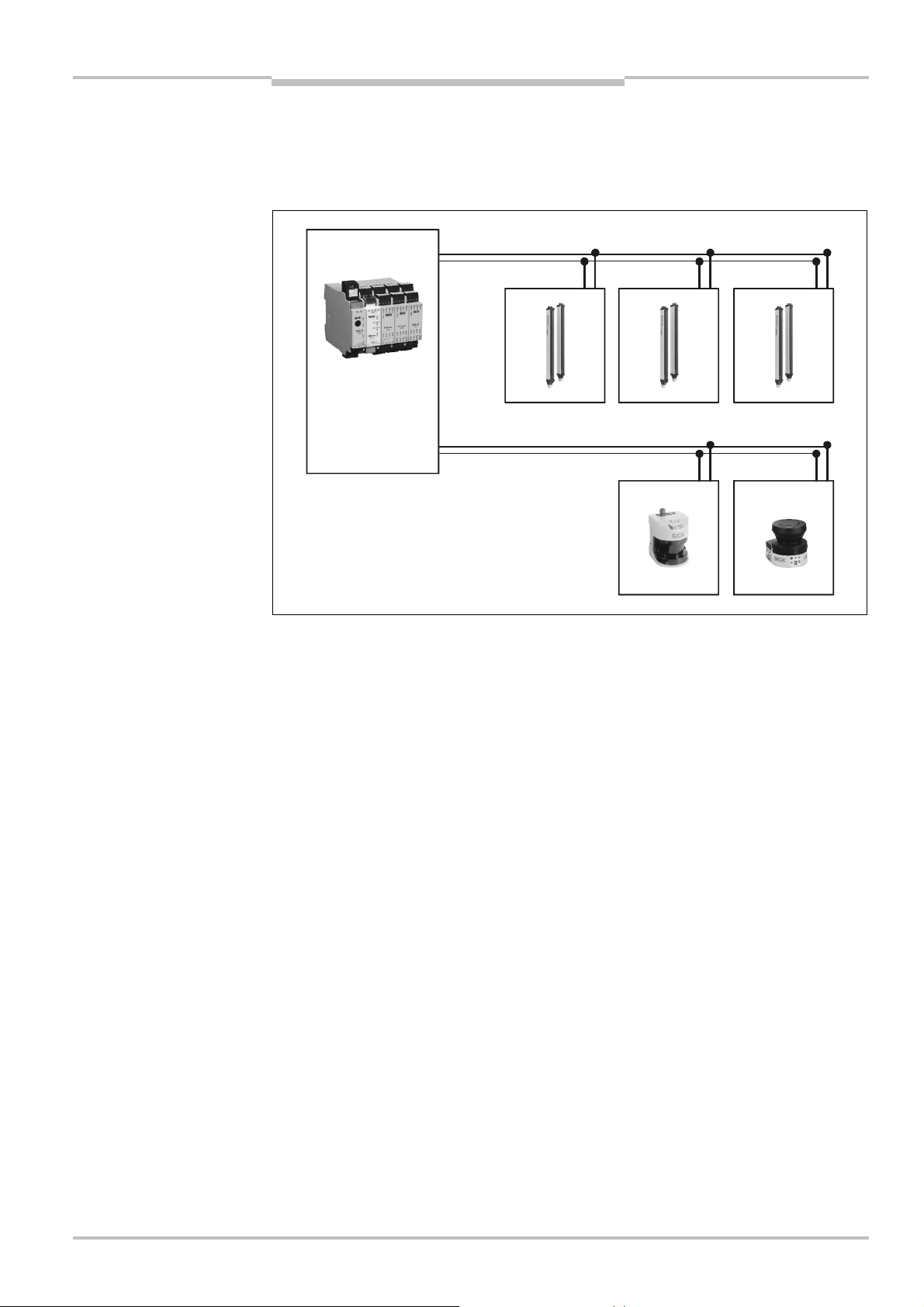

Fig.10:

Safety controller with

EFI

Technical realization

4 Technical realization

EFI is a linear bus system. Up to four devices can be connected to this bus system. The

actual number of devices depends on the related application or product family.

ESPE connected via two EFI

strings

Twisted-pair cable with a characteristic impedance of 108 … 132 Ω is used as the bus

medium (see also chapter 6 “Technical specifications” on page 54).

8012622/Z098/2016-11-07 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 13

Subject to change without notice

Page 14

Chapter 4 Technical information

8

887

Fig.11:

Example data

Fig.12:

Example data

Technical realization

EFI

4.1 Data exchange via EFI

To enable data to be exchanged via EFI, each device connected has a unique address.

exchange between two

S3000

7

7

In the example the S3000 Host has the address 7, the S3000 Guest the address 8. The

host receives via address 8 the status information on the OSSDs and the diagnostics

messages from the guest on contamination. The guest however receives the incremental

encoder values from the host over the address 7.

The safety controllers receive via these addresses status information on the

electrosensitive protective devices (C4000, S3000 etc.) or they control functions on the

ESPE via these addresses (muting, operating mode switching etc.).

If an EFI system is connected via an EFI gateway to a PROFINET IO, these data can be

forwarded to an (F)PLC or control tasks performed by the (F)PLC.

exchange between an (F)PLC

and an M4000 via an EFI

gateway

In the example the (F)PLC can write data to the M4000 via the routing in the EFI gateway

(address 14). I.e. muting signals can be simulated by the control system. Conversely,

status information including the output information from the M4000 (address 1) can be

transferred to the (F)PLC via the routing in the EFI gateway.

14 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8012622/Z098/2016-11-07

Subject to change without notice

Page 15

Technical information Chapter 4

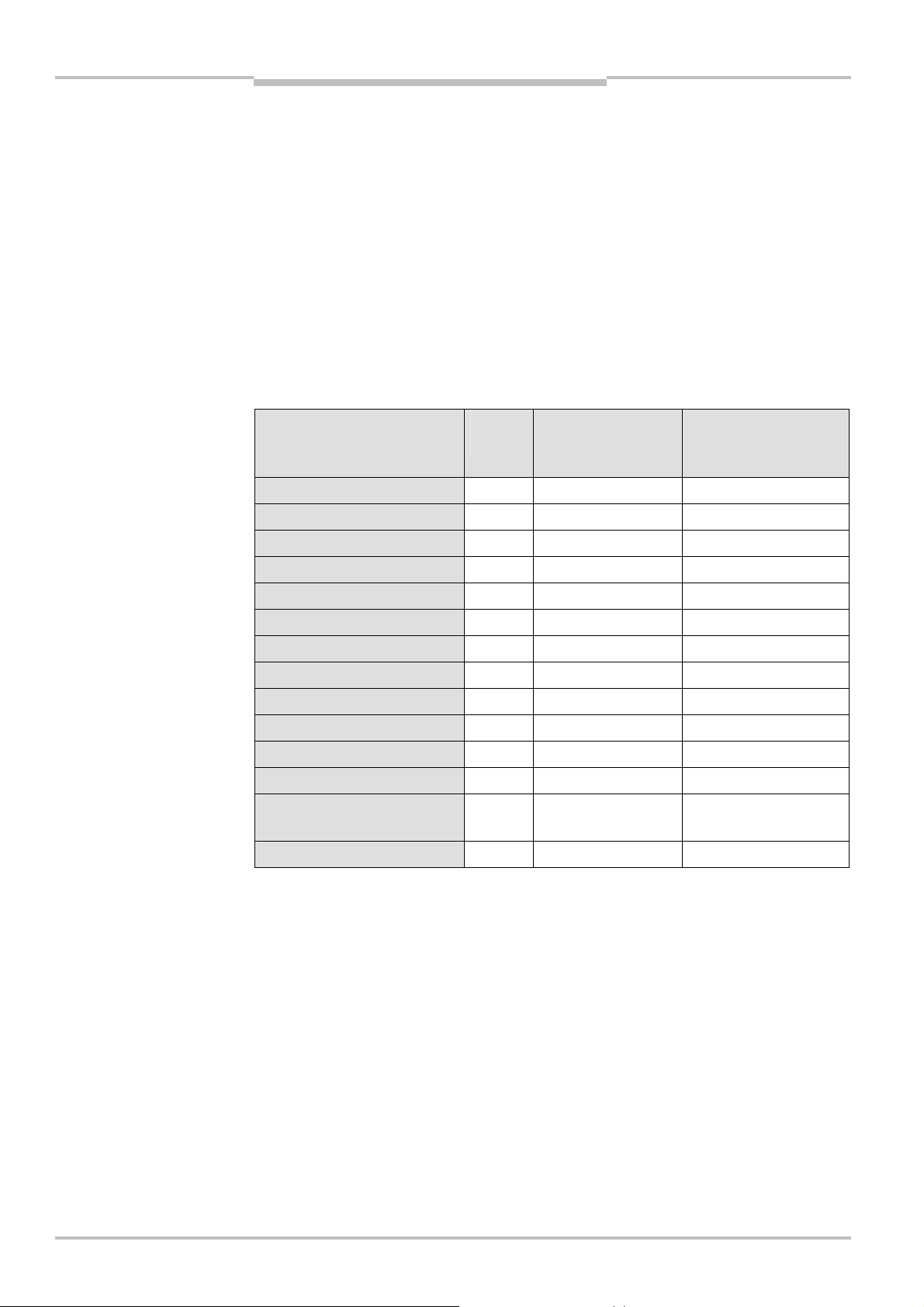

Tab.1:

Product family

EFI

Technical realization

4.1.1 Addressing

The SICK product families have the following addresses on the EFI:

addresses on the EFI

Notes

Product families Device address

C4000 receiver (Host) 1

C4000 receiver (Guest 1) 2

C4000 receiver (Guest 2) 3

C4000 sender (Host) 4

C4000 sender (Guest 1) 5

C4000 sender (Guest 2) 6

M4000 receiver 1

M4000 sender 4

S3000 (Host/Guest) 7/8

S300 (Host/Guest) 7/8

S300 Mini (Host/Guest) 7/8

UE402 14

UE403 11/12/13/14

Flexi Soft FX3-CPU1, -CPU2, -CPU3 11/12/13/14

UE4740 EFI gateway 13/14

• Devices with the same address cannot be operated on the EFI at the same time.

• If there are several C4000 safety light curtains on the EFI string, the addresses for the

cascaded system are assigned automatically.

The addresses are saved in non-volatile memory in the device memory in the C4000.

The device can no longer be used as a standalone device or in a different system

position.

Reset the system position saved in the C4000 using the CDS configuration software or

using the Host-Guest Plug available as an accessory.

• In an EFI system with two safety laser scanners, set the address of one of the scanners

to guest! The procedure for addressing is described in the related operating instructions

in the chapter “Electrical installation” (S300 Mini, S300, S3000).

• For the UE4740 EFI gateway, the UE403 and the Flexi Soft FX3-CPU1, -CPU2, -CPU3 the

EFI device address can be modified using CDS or Flexi Soft Designer.

To change the addresses of the EFI gateway, connect to the EFI gateway in the CDS.

Right click the symbol for the EFI gateway and on the context menu choose Operate

service/gateway with control system.

To change the addresses of the Flexi Soft FX3-CPU1, -CPU2, -CPU3, connect to the Flexi

Soft Designer and the CPU. Right click the symbol for the CPU, a menu then appears

where you can select the required EFI device address.

8012622/Z098/2016-11-07 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 15

Subject to change without notice

Page 16

Chapter 4 Technical information

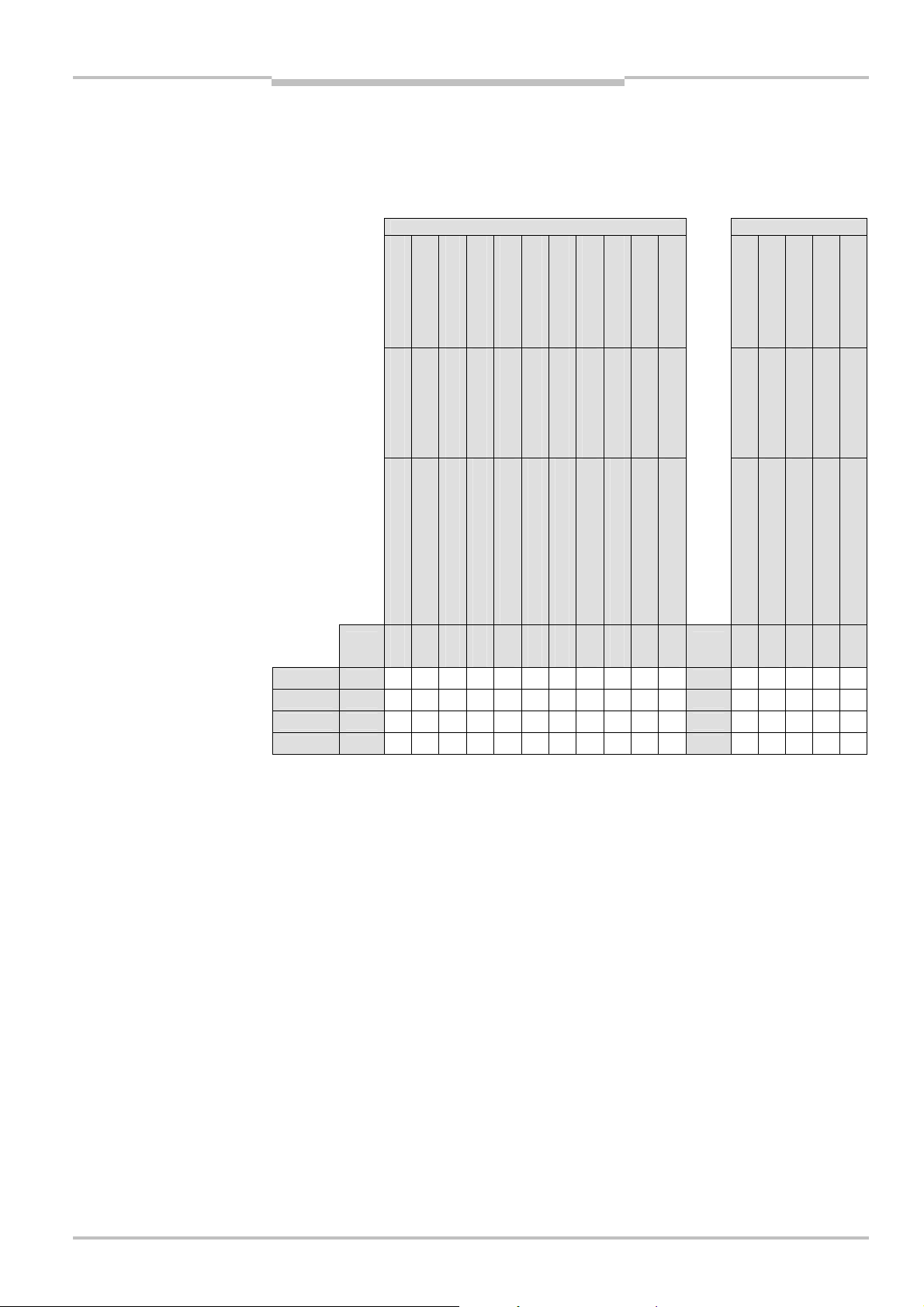

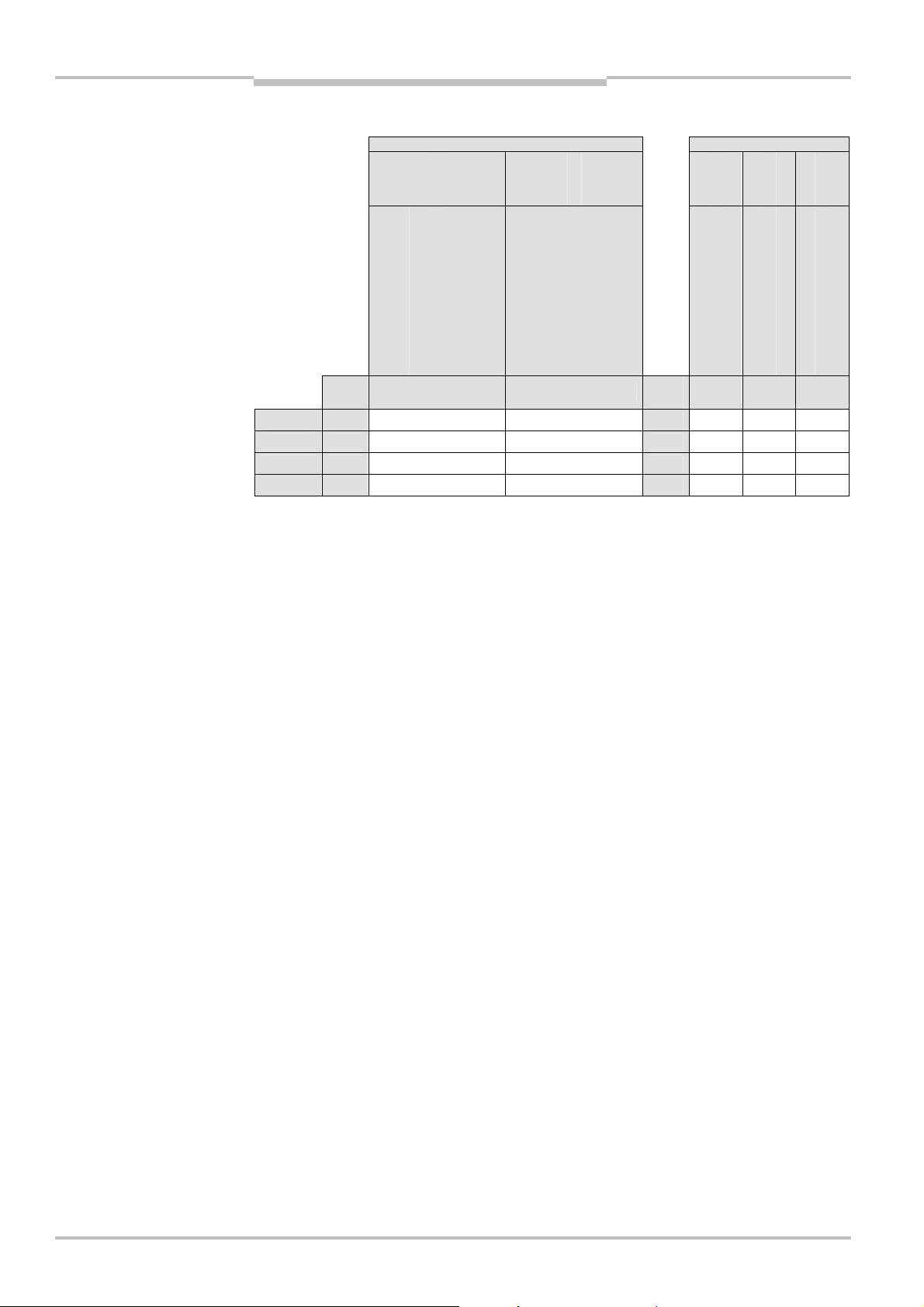

Tab.2:

Maximum number of

Technical realization

EFI

4.1.2 Sending and receiving of information

Send

Each device sends exactly one item of status information with a length of up to 26 bits of

data (C4000 and M4000 senders do not provide any information, this is provided by the

C4000 or M4000 receivers).

The status information is not addressed to a specific user on the EFI string, i.e. all users on

the EFI string can receive the status information.

Receive

The product families differ in the number of items of status information received.

The maximum number of items of status information received and their addresses are

listed in the following table by product family. The table shows the items of status

information received per EFI string.

items of status information

received

Product family

Device

address

Max. number of items

of status information

received

Device addresses from

which items of status

information are received

M4000 receiver 1 1 11, 12, 13 or 14

C4000 receiver (Host) 1 3 2, 3 and 14

C4000 receiver (Guest 1) 2 – –

C4000 receiver (Guest 2) 3 – –

S3000 (Host) 7 1 8, 13 or 14

S3000 (Guest) 8 1 7, 13 or 14

S300 (Host) 7 1 8, 13 or 14

S300 (Guest) 8 1 7, 13 or 14

S300 Mini (Host) 7 1 13 or 14

S300 Mini (Guest) 8 1 7, 13 or 14

UE402 14 1 1

UE403 14 1 1

Flexi Soft FX3-CPU1, -CPU2,

11-14 3 1-8, 11-14

-CPU3

UE4740 EFI gateway 13/14 3 1-8, 13/14

16 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8012622/Z098/2016-11-07

Notes

• The maximum number of items of status information received defines the number of

devices from which a device can receive information (e.g. C4000 Host from the two

guests and a safety controller).

• The devices addresses in column 4 define the devices to which a device can be

connected. The C4000 Host receives, e.g., only the addresses 2 and 3 (C4000 Guests)

and 14 (safety controllers or EFI gateways). The connection of an M4000 (1) or an

S3000 (7) is not possible.

• Also pay attention to the information given in section 4.2 “Firmware compatibility of the

EFI devices” on page 17.

Subject to change without notice

Page 17

Technical information Chapter 4

Tab.3:

Firmware

Technical realization

EFI

4.2 Firmware compatibility of the EFI devices

The following tables show which ESPE can be connected to which device.

4.2.1 C4000 safety light curtain

compatibility

C4000/UE devices

C4000 receiver C4000 sender

C4000 Advanced

C4000 Standard

C4000 Guest

C4000 Guest

C4000 Advanced

C4000 Standard

C4000 Strd./Adv.

C4000 Guest

C4000 Strd./Adv.

Flexi Soft V1.00

UE4740 V1.11

UE402 V1.10

UE403 –

Legend

Possible

Not possible

On request

?

C4000 Advanced

C4000 Standard

C4000 Advanced

C4000 Standard

C4000 Advanced

C4000 Standard

C4000 Entry/Exit

Firmware

V3.31

V3.31

V3.31

V3.31

V3.31

V3.31

V5.05

?

?

?

C4000 Palletizer

C4000 Palletizer II

C4000 Fusion

C4000 Guest

Firm-

V5.05

V6.11

ware

V7.21

V3.33

V1.00

V1.11

C4000 Standard/Advanced

C4000 Standard/Advanced

V6.00

V6.00

–

–

C4000 Standard/Advanced

C4000 Entry/Exit

C4000 Palletizer

V6.00

V6.00

V6.00

8012622/Z098/2016-11-07 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 17

Subject to change without notice

Page 18

Chapter 4 Technical information

Tab.4:

Firmware

Technical realization

EFI

4.2.2 M4000 multiple light beam safety device

M4000 receiver M4000 sender

compatibility

M4000/UE devices

UE403

M4000 Advanced

M4000 Advanced Curtain

M4000 Advanced A/P

Firmware

Flexi Soft V1.11

UE4740 V1.12

UE402 –

UE403 V1.51

M4000 Area

V1.50 V1.50

M4000 Advanced

M4000 Advanced Curtain

M4000 Advanced A/P

M4000 Area

Firmware

V1.00

V1.11

–

–

M4000 Advanced Curtain

V1.10 V1.10 V1.10

M4000 Advanced

M4000 Area

Legend

Possible

Not possible

18 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8012622/Z098/2016-11-07

Subject to change without notice

Page 19

Technical information Chapter 4

Tab.5:

Firmware compatibi

-

Tab.6:

Bytes of the EFI

Technical realization

EFI

4.2.3 S300/S3000 safety laser scanners

lity S300/S3000/UE devices

Standalone device

on an EFI partner device

Guest

Host/Guest

on an EFI partner device

S3000 Anti Collision

S3000

S3000 Coldstore

S300

S300

S300 Mini Remote

S300 Mini Remote, S3000 or S300

S3000, S300, S300 Mini Remote

S300, S300 Mini Remote

communication

Note

S3000 in compatibility mode

S3000 Coldstore in compatibility mode

S300 in compatibility mode

S3000 in compatibility mode

S3000 Coldstore in compatibility mode

S300 i in compatibility mode

S300 Mini Remote

S300

S3000 Coldstore

S3000 Anti Collision

Flexi Soft V1.00

UE4740 V1.11

UE402 –

UE403 –

S3000

V1.11

V1.11

Host

S3000 Anti Collision

S3000

S3000 Coldstore

S300

S3000 or S300

–

–

Legend

Possible

Not possible

Compatibility with the S3000 is provided if the sensor head as well as the I/O module have

a serial number of 1221XXX or later.

4.3 Description of the bytes and bits of the EFI communication

4.3.1 Bytes of the EFI communication

Byte Description

Byte 0 General data

Byte 1 General and device-specific data

S300 Mini Remote

S3000 Expert

S3000

S300

8012622/Z098/2016-11-07 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 19

Subject to change without notice

Byte 2 Device specific data

Byte 3 Device specific data

Byte 4 CRC LB

Byte 5 CRC HB

1)

CRC (covers data and device code) Low Byte.

2)

CRC ( covers data and device code) High Byte.

1)

2)

Page 20

Chapter 4 Technical information

Technical realization

EFI

Description of bit 0 to 7 of byte 0

Byte 0 0.0

3)

General Dynamic

Counter

C4000 receiver Dynamic

Counter

M4000 receiver Dynamic

Counter

S3000 in

compatibility

4)

mode

Dynamic

Counter

S3000 Dynamic

Counter

S3000 Anti

Collision

S300 in

compatibility

4)

mode

Dynamic

Counter

Dynamic

Counter

S300 Dynamic

Counter

S300 Mini Dynamic

Counter

UE402 Dynamic

Counter

UE403 Dynamic

Counter

UE4740 Dynamic

Counter

Flexi Soft Dynamic

Counter

Tab. 7: Byte 0 of the EFI communication

3)

0.1

Dynamic

Counter

Dynamic

Counter

Dynamic

Counter

Dynamic

Counter

Dynamic

Counter

Dynamic

Counter

Dynamic

Counter

Dynamic

Counter

Dynamic

Counter

Dynamic

Counter

Dynamic

Counter

Dynamic

Counter

Dynamic

Counter

3)

0.2

Dynamic

Counter

Dynamic

Counter

Dynamic

Counter

Dynamic

Counter

Dynamic

Counter

Dynamic

Counter

Dynamic

Counter

Dynamic

Counter

Dynamic

Counter

Dynamic

Counter

Dynamic

Counter

Dynamic

Counter

Dynamic

Counter

0.3 0.4 0.5 0.6 0.7

OSSD1 OSSD2 Warning

Field 1

OSSD1 (HW

OSSD State)

OSSD2

(virtual)

Not used Weak

Weak

(pollution

warning)

(pollution

Reset Switch

Input (button

pressed)

Reset Switch

Input

warning)

OSSD1 (HW

OSSD State)

OSSD2

(virtual)

Not used Weak

(pollution

warning)

Reset Switch

Input

≥V01.20

Reset/RES/

OVR Switch

Input (MI2)

OSSD

S3000_1

OSSD

S3000_2

Status

Warning

Field

OSSD Speed Valid Status

Warning

Field 1

Weak

(pollution

warning)

Weak

(pollution

warning)

OSSD Speed Valid Not used Weak

(pollution

Reset (button

pressed)

Reset (button

pressed)

Reset (button

pressed)

warning)

OSSD

S300_1

OSSD

S300_2

Status

Warning

Field 1

OSSD Speed Valid Status

Warning

Field

Not used Not used Status

Warning

Field

0 0 Input Pin B1

conditional

Override

(identical to

bit info tech

in terminal

status)

0 0 Not used

(Input Pin B1

Bypass)

Weak

(pollution

warning)

Weak

(pollution

warning)

Weak

(pollution

warning)

Input Pin B2

conditional

Override

(identical to

bit info tech

in terminal

status)

Not used

(Input Pin B2

Bypass)

Reset (button

pressed)

Reset (button

pressed)

Not used

0

RES/OVR

Switch Input

(UI2)

Byte 0, Bit 3 Byte 0, Bit 4 Byte 0, Bit 5 Byte 0, Bit 6 Byte 0, Bit 7

Byte 0, Bit 3 Byte 0, Bit 4 Byte 0, Bit 5 Byte 0, Bit 6 Byte 0, Bit 7

3)

Bit is device internal predefined. Read only.

4)

For information on the compatibility mode see the operating instructions for the devices.

20 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8012622/Z098/2016-11-07

Subject to change without notice

Page 21

Technical information Chapter 4

Technical realization

EFI

Description of bit 0 to 7 of byte 1

Byte 1 1.0 1.1

General Reset

5)

I/O error Diagnostic

Required

(Reset Lamp)

C4000 receiver Reset

I/O error Diagnostic

Required

State

M4000 receiver Reset

I/O error Diagnostic

Required

State

S3000 in

compatibility

7)

mode

Reset

Required

(Reset Lamp)

S3000 Reset

I/O error Diagnostic

I/O error Diagnostic

Required

(Reset Lamp)

S3000 Anti

Collision

S300 in

compatibility

7)

mode

Reset

Required

(Reset Lamp)

Reset

Required

(Reset Lamp)

S300 Reset

I/O error Diagnostic

I/O error Diagnostic

I/O error Diagnostic

Required

(Reset Lamp)

S300 Mini Not used I/O error Not used Not used Not used Not used Not used Not used

UE402 0 I/O error Diagnostic

UE403 Muting/Over-

I/O error Diagnostic

ride Lamp

Error Status

UE4740 Byte 1, Bit 0 Byte 1, Bit 1

(I/O Error)

Flexi Soft Byte 1, Bit 0 Byte 1, Bit 1

(I/O Error)

Tab. 8: Byte 1 of the EFI communication

6)

1.2

classification

classification

classification

classification

classification

classification

classification

classification

classification

classification

Diagnostic

classification

Diagnostic

classification

6)

1.3

Diagnostic

classification

Diagnostic

classification

Diagnostic

classification

Diagnostic

classification

Diagnostic

classification

Diagnostic

classification

Diagnostic

classification

Diagnostic

classification

Diagnostic

classification

Diagnostic

classification

Diagnostic

classification

Diagnostic

classification

1.4 1.5 1.6 1.7

Specific

device data

Specific

device data

Specific

device data

Specific

device data

User Modes User Modes User Modes EStop status

Not used Not used Not used C1/CBS

Switch Input

(MI1)

Input Pin A1 Input Pin A2 Input Pin B1 Input Pin B2

Input Pin A1 Input Pin A2 Input Pin B1 Input Pin B2

Input Pin A1 Input Pin A2 Input Pin B1 Input Pin B2

Input Pin A1 Input Pin A2 Input Pin B1 Input Pin B2

Input Pin A1/

Input Pin C1

Input Pin A2/

8)

Input Pin C2

Input Pin B1 Input Pin B2

8)

Input Pin A1 Input Pin A2 Input Pin A3 Input Pin A4

Not used

(Input Pin A1)

Not used

(Input Pin A2)

Not used

(Input Pin A3)

Not used

(Input Pin A4)

Byte 1, Bit 4 Byte 1, Bit 5 Byte 1, Bit 6 Byte 1, Bit 7

Byte 1, Bit 4 Byte 1, Bit 5 Byte 1, Bit 6 Byte 1, Bit 7

5)

The bit cannot be freely used.

6)

Bit is device internal predefined. Read only.

7)

For information on the compatibility mode see the operating instructions for the devices.

8)

Configuration dependent: Without speed routing/with speed routing.

8012622/Z098/2016-11-07 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 21

Subject to change without notice

Page 22

Chapter 4 Technical information

Technical realization

EFI

Description of bit 0 to 7 of byte 2

Byte 2 2.0 2.1 2.2 2.3 2.4 2.5 2.6 2.7

General Specific

device data

C4000 receiver Teach-In

active

M4000 receiver Not used Not used Not used Not used Not used Not used Not used Not used

S3000 in

compatibility

7)

mode

Input Pin C1 Input Pin C2 Input Pin D1 Input Pin D2 Not used Not used Not used Not used

S3000 Input Pin C1/

Speed Bit 0

S3000 Anti

Collision

S300 in

compatibility

7)

mode

Input Pin C1/

Speed Bit 0

Input Pin C1 Input Pin C2 Not used Not used Not used Not used Not used Not used

S300 Input Pin C1/

Speed Bit 0

S300 Mini Not used Not used Not used Not used Not used Not used Not used Not used

UE402 Input Pin A5 Input Pin A6 Input Pin A7 Input Pin A8 0 0 0 0

UE403 Not used

(Input Pin A5)

UE4740 Byte 2, Bit 0 Byte 2, Bit 1 Byte 2, Bit 2 Byte 2, Bit 3 Byte 2, Bit 4 Byte 2, Bit 5 Byte 2, Bit 6 Byte 2, Bit 7

Flexi Soft Byte 2, Bit 0 Byte 2, Bit 1 Byte 2, Bit 2 Byte 2, Bit 3 Byte 2, Bit 4 Byte 2, Bit 5 Byte 2, Bit 6 Byte 2, Bit 7

Tab. 9: Byte 2 of the EFI communication

Specific

device data

Key-Switch

state

Input Pin C2/

9)

Speed Bit 1

Input Pin C2/

9)

Speed Bit 1

Input Pin C2/

9)

Speed Bit 1

Not used

(Input Pin A6)

Specific

device data

Take

snapshot

Input Pin D1/

9)

Speed Bit 2

Input Pin D1/

9)

Speed Bit 2

Speed Bit 2 Speed Bit 3 Speed Bit 4 Speed Bit 5 Speed Bit 6 Speed Bit 7

9)

Not used

(Input Pin A7)

Specific

device data

Field status

(red/green)

Input Pin D2/

9)

Speed Bit 3

Input Pin D2/

9)

Speed Bit 3

Not used

(Input Pin A8)

Specific

device data

Specific

device data

Specific

device data

Field status Field status EStop

Channel 1

Speed Bit 4 Speed Bit 5 Speed Bit 6 Speed Bit 7

9)

Speed Bit 4 Speed Bit 5 Speed Bit 6 Speed Bit 7

9)

Muting

Sensor A1

Muting

Sensor A2

Muting

Sensor B1

Specific

device data

EStop

Channel 2

Muting

Sensor B2

9)

Configuration dependent: Without speed routing/with speed routing.

22 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8012622/Z098/2016-11-07

Subject to change without notice

Page 23

Technical information Chapter 4

Technical realization

EFI

Description of bit 0 to 7 of byte 3

Byte 3 3.0 3.1 3.2 3.3 3.4 3.5 3.6 3.7

General

C4000 receiver

M4000 receiver

S3000 in

compatibility

11)

mode

S3000

S300 Anti

Collision

S300 in

compatibility

11)

mode

S300

S300 Mini

UE402

UE403

UE4740

Flexi Soft

Tab. 10: Byte 3 of the EFI communication

Specific

device data

10)

ADO

10)

ADO

Not used Not used Not used Not used Switch off

Specific

device data

CoState

Specific

device data

Specific

device data

Not used Not used Not used Not used Virtual

Bypass State

Not used Muting State Muting Lamp

status

Specific

device data

Delivery

Status Flag

1. monitoring

area

Specific

device data

PU Data

Valid Flag

Status

Warning

Field

1. monitoring

Specific

device data

photoelectric

switch 2

Mode Switch

state on PU

Switch off

2. monitoring

area

Specific

device data

Virtual

photoelectric

switch 1

Select Switch

state on PU

Status

Warning Field

2. monitoring

area

area

12)

13)

Warning

Field 2/Sim.

Protective

Field 2/

Warning

12)

Field 2

Sim. Collision

Protection

Field 1/

Collision

protection

13)

field 2

Speed Bit 8 Speed Bit 9 Speed Bit 10 Speed Bit 11 Protective

Field 1/

Protective

Field 1/

Protective

12)

Field 1

Speed Bit 8 Speed Bit 9 Speed Bit 10 Speed Bit 11 Protective

Field 1/

Protective

13)

Field 1

Not used Not used Not used Not used Switch off

1. monitoring

area

Warning

Field 1/

Protective

Field 2/

Warning

12)

Field 1

Collision

Protection

Field 1 /

Collision

Protection

13)

Field

Status

Warning

Field

Sim.

Protective

Field 1/Sim.

Protective

Field 1/–

Sim.

Protective

Field 1/–

Not used Not used

1. monitoring

area

Speed Bit 8 Speed Bit 9 Speed Bit 10 Speed Bit 11 Protective

Field 1

Not used Not used Not used Not used Protective

Field 1

Warning

Field 1

Warning

Field 1

Not used Warning

Field 2

Not used Warning

Field 2

Lock-out Info Lock-out Info Lock-out Info Lock-out Info Input Pin B1 Input Pin B2 Input Pin B3 Input Pin B4

Not used Not used Not used Not used C1/CBS/OVR

Switch Input

(UI1)

Byte 3, Bit 0 Byte 3, Bit 1 Byte 3, Bit 2 Byte 3, Bit 3 Byte 3, Bit 4 Byte 3, Bit 5 Byte 3, Bit 6 Byte 3, Bit 7

Byte 3, Bit 0 Byte 3, Bit 1 Byte 3, Bit 2 Byte 3, Bit 3 Byte 3, Bit 4 Byte 3, Bit 5 Byte 3, Bit 6 Byte 3, Bit 7

10)

ADO can be used for non-safety-related evaluations, e.g. weak signal output.

11)

For information on the compatibility mode see the operating instructions for the devices.

12)

Dual (1 protective field, 1 warning field)/Dual protective fields (2 protective fields)/Triple (1 protective field,

2 warning fields).

13)

Dual collision protection (1 protective field, 1 collision protection field)/Triple collision protection (1 protective

field, 2 collision protection fields)

8012622/Z098/2016-11-07 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 23

Subject to change without notice

Page 24

Chapter 4 Technical information

Technical realization

EFI

Description of bit 0 to 7 of byte 4

Byte 4 4.0 4.1 4.2 4.3 4.4 4.5 4.6 4.7

General CRC

C4000 receiver CRC

M4000 receiver CRC

S3000 in

compatibility

15)

mode

S3000 CRC

S3000 Anti

Collision

S300 in

compatibility

15)

mode

S300 CRC

S300 Mini CRC

UE402 CRC

UE403 CRC

UE4740 CRC

Flexi Soft CRC

Low Byte

Low Byte

Low Byte

CRC

Low Byte

Low Byte

CRC

Low Byte

CRC

Low Byte

Low Byte

Low Byte

Low Byte

Low Byte

Low Byte

Low Byte

Tab. 11: Byte 4 of the EFI communication

CRC

14)

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

CRC

Low Byte

14)

CRC (covers data and device code) Low Byte.

15)

For information on the compatibility mode see the operating instructions for the devices.

24 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8012622/Z098/2016-11-07

Subject to change without notice

Page 25

Technical information Chapter 4

Technical realization

EFI

Description of bit 0 to 7 of byte 5

Byte 5 5.0 5.1 5.2 5.3 5.4 5.5 5.6 5.7

General CRC

High Byte

C4000 receiver CRC

High Byte

M4000 receiver CRC

High Byte

S3000 in

compatibility

17)

mode

CRC

High Byte

S3000 CRC

Low Byte

S3000 Anti

Collision

S300 in

compatibility

17)

mode

CRC

Low Byte

CRC

High Byte

S300 CRC

Low Byte

S300 Mini CRC

Low Byte

UE402 CRC

High Byte

UE403 CRC

High Byte

UE4740 CRC

High Byte

Flexi Soft CRC

High Byte

Tab. 12: Byte 5 of the EFI communication

16)

CRC

High Byte

CRC

High Byte

CRC

High Byte

CRC

High Byte

CRC

Low Byte

CRC

Low Byte

CRC

High Byte

CRC

Low Byte

CRC

Low Byte

CRC

High Byte

CRC

High Byte

CRC

High Byte

CRC

High Byte

CRC

High Byte

CRC

High Byte

CRC

High Byte

CRC

High Byte

CRC

Low Byte

CRC

Low Byte

CRC

High Byte

CRC

Low Byte

CRC

Low Byte

CRC

High Byte

CRC

High Byte

CRC

High Byte

CRC

High Byte

CRC

High Byte

CRC

High Byte

CRC

High Byte

CRC

High Byte

CRC

Low Byte

CRC

Low Byte

CRC

High Byte

CRC

Low Byte

CRC

Low Byte

CRC

High Byte

CRC

High Byte

CRC

High Byte

CRC

High Byte

CRC

High Byte

CRC

High Byte

CRC

High Byte

CRC

High Byte

CRC

Low Byte

CRC

Low Byte

CRC

High Byte

CRC

Low Byte

CRC

Low Byte

CRC

High Byte

CRC

High Byte

CRC

High Byte

CRC

High Byte

CRC

High Byte

CRC

High Byte

CRC

High Byte

CRC

High Byte

CRC

Low Byte

CRC

Low Byte

CRC

High Byte

CRC

Low Byte

CRC

Low Byte

CRC

High Byte

CRC

High Byte

CRC

High Byte

CRC

High Byte

CRC

High Byte

CRC

High Byte

CRC

High Byte

CRC

High Byte

CRC

Low Byte

CRC

Low Byte

CRC

High Byte

CRC

Low Byte

CRC

Low Byte

CRC

High Byte

CRC

High Byte

CRC

High Byte

CRC

High Byte

CRC

High Byte

CRC

High Byte

CRC

High Byte

CRC

High Byte

CRC

Low Byte

CRC

Low Byte

CRC

High Byte

CRC

Low Byte

CRC

Low Byte

CRC

High Byte

CRC

High Byte

CRC

High Byte

CRC

High Byte

16)

CRC (covers data and device code) High Byte.

17)

For information on the compatibility mode see the operating instructions for the devices.

8012622/Z098/2016-11-07 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 25

Subject to change without notice

Page 26

Chapter 4 Technical information

Tab.13:

Status information

Technical realization

EFI

4.4 Status information and control options for the EFI devices

Status information and control commands are exchanged between the devices via EFI.

The following tables show the status information that can be accessed and the control

commands that are possible for ESPE, safety controllers as well as EFI gateways.

Note

The information in square brackets reflects the names used in the CDS and in the

Flexi Soft Designer.

4.4.1 C4000 safety light curtain

of the C4000 (data from the

C4000)

Status information Meaning/effect

OSSD on [OSSD]

• Logical 1, if the OSSD of the C4000 is switched

on (green)

• Logical 0, if the OSSD of the C4000 is switched

off (red)

Notes:

Host: In the case of a cascaded system, the

OSSD bit is a group indication for the entire

host/guest or host/guest/guest cascade

Guest 1/guest 2: The OSSD bit corresponds to

the status of the related guest.

Contamination [Weak] • Logical 1, on contamination of the front screen

Reset button pressed [Res. Pressed] • Logical 1, if the reset button is pressed

Reset required [Res. Req.] • Logical 1, if reset required

Status of the emergency stop

[EStop Active]

Logical 1, if the button connected to the

emergency stop input on the C4000 has been

pressed.

Teach-in active [Teach Active]

• Logical 1, if a teach-in key-operated switch

connected to the C4000 has been operated

Note

Status application diagnostic output

18)

(ADO)

[ADO]

• Logical 1, if the configurable application

diagnostic output (ADO) on the C4000 is

signaling, e.g., the contamination status, the

OSSD status or the emergency stop status

Note: The message type depends on the

configuration of the C4000.

Status bypass [Bypass Active]

• Logical 1, if a key-operated pushbutton for

bypass connected to the C4000 has been

operated

Virtual photoelectric switch 2 [VLS2] • Logical 1 = beam unoccupied

• Logical 0 = beam interrupted

Virtual photoelectric switch 1 [VLS1] • Logical 1 = beam unoccupied

• Logical 0 = beam interrupted

With the exception of the OSSD information, all status information always relates to the

safety light curtain polled (host, guest 1 or guest 2).

18)

ADO can be used for non-safety-related evaluations, e.g. weak signal output.

26 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8012622/Z098/2016-11-07

Subject to change without notice

Page 27

Technical information Chapter 4

Tab.14:

Control features on

EFI

Technical realization

the C4000 (data to the

C4000)

Control feature Meaning/effect

Bypass B1 [In Bypass 1]

• Logical 1, stimulates bit B1 for the key-

operated pushbutton for bypass

Bypass B2 [In Bypass 2]

• Logical 1, stimulates bit B2 for the key-

operated pushbutton for bypass

Operating mode 1 [In A1]

• Logical 1, switches to operating mode 1 of the

C4000

• Logical 0, makes it possible to select a

different operating mode

Operating mode 2 [In A2]

• Logical 1, switches to operating mode 2 of the

C4000

• Logical 0, makes it possible to select a

different operating mode

Operating mode 3 [In A3]

• Logical 1, switches to operating mode 3 of the

C4000

• Logical 0, makes it possible to select a

different operating mode

Operating mode 4 [In A4]

• Logical 1, switches to operating mode 4 of the

C4000

• Logical 0, makes it possible to select a

different operating mode

19)

Operating mode 5 [In A5]

Operating mode 6 [In A6]

Overrun monitoring SCC [In SCC]

Bottom dead center BDC [In BDC]

Top dead center TDC [In TDC]

I/O error [I/O Error]

• Logical 1, switches to operating mode 5 of the

C4000

• Logical 0, makes it possible to select a

different operating mode

• Logical 1, switches to operating mode 6 of the

C4000

• Logical 0, makes it possible to select a

different operating mode

• Logical 1, stimulates the SCC bit for overrun

monitoring on the C4000

• Logical 1, stimulates the BDC bit for PSDI

integration on the C4000

• Logical 1, stimulates the TDC bit for PSDI

integration on the C4000

• Logical 0, if there is no error on a connected

device

• Logical 1, if there is an error on a connected

device

8012622/Z098/2016-11-07 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 27

Subject to change without notice

19)

If two bits are logical 1, there will be an error on the C4000.

Page 28

Chapter 4 Technical information

Tab.15:

Status information

Tab.16:

Control features on

Technical realization

EFI

4.4.2 M4000 multiple light beam safety device

of the M4000 (data from the

M4000)

the M4000 (data to the

M4000)

Status information Meaning/effect

OSSD on [OSSD]

• Logical 1, if the OSSD of the M4000 is

switched on (green)

• Logical 0, if the OSSD of the M4000 is

switched off (red)

Contamination [Weak] • Logical 1, on contamination of the front screen

Reset button pressed [Res. Pressed]

• Logical 1, if the reset button is pressed on the

M4000

Reset required [Res. Req.] • Logical 1, if reset required

Status application diagnostic output

20)

(ADO)

[ADO]

• Logical 1, if the configurable application

diagnostic output (ADO) for the M4000 is

indicating the contamination status or the

OSSD status

Muting status [Muting] • Logical 1, if M4000 muting is active

• Logical 0, if M4000 muting is inactive

Additional signal C1 or Belt

stop [In BS/C1]

Control feature Meaning/effect

Reset/override [In RES/OVR]

• Logical 1, if a function is activated on the

M4000

• Logical 1, stimulates the function configured in

the M4000

Status muting lamp/override lamp

Muting Sensor A1 [In A1]

Muting Sensor A2 [In A2]

Muting Sensor B1 [In B1]

Muting Sensor B2 [In B2]

Override or Additional signal C1 or

Belt stop [In BS/C1]

I/O error [I/O Error]

• Logical 1, stimulates an error message for the

external muting lamp

• Logical 1, stimulates muting sensor A1 for

M4000

• Logical 1, stimulates muting sensor A2 for

M4000

• Logical 1, stimulates muting sensor B1 for

M4000

• Logical 1, stimulates muting sensor B2 for

M4000

• Logical 1, stimulates the related function

configured in the M4000

• Logical 0, if there is no error on a connected

device

• Logical 1, if there is an error on a connected

device

28 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8012622/Z098/2016-11-07

20)

ADO can be used for non-safety-related evaluations, e.g. weak signal output.

Subject to change without notice

Page 29

Technical information Chapter 4

Tab.17:

Status information

EFI

Technical realization

4.4.3 S3000 safety laser scanner

of the S3000 (data from the

S3000)

Status information Meaning/effect

OSSD on [OSSD]

• Logical 1, if the internal OSSD of the S3000 is

in the ON state (green)

• Logical 0, if the OSSD of the S3000 is in the

OFF state (red)

Warning field bit [WF LED]

• Logical 1, if warning field 1 and warning field 2

of the S3000 are unoccupied or not used

Contamination [Weak] • Logical 1, if the front screen is contaminated

Reset required [Res. Req] • Logical 1, if reset required

Reset button pressed [Res. Pressed]

• Logical 1, if the reset button is pressed on the

S3000

I/O error [I/O Error] • Logical 0, if there is no error on the S3000

• Logical 1, if there is an error on the S3000

Control input A1 [In A1]

• Logical 1, if the connection of control input A1

is HIGH

21)

Note: The control inputs on the S3000 are

used to switch the monitoring cases on the

S3000.

Control input A2 [In A2]

• Logical 1, if the connection of control input A2

is HIGH

21)

Control input B1 [In B1]

Control input B2 [In B2]

Control input C1 [In C1]

Control input C2 [In C2]

Control input D1 [In D1]

Control input D2 [In D2]

Allocated protective field

unoccupied [PF]

• Logical 1, if the connection of control input B1

is HIGH

21)

• Logical 1, if the connection of control input B2

is HIGH

21)

• Logical 1, if the connection of control input C1

is HIGH

21)

• Logical 1, if the connection of control input C2

is HIGH

21)

• Logical 1, if the connection of control input D1

is HIGH

21)

• Logical 1, if the connection of control input D2

is HIGH

21)

• In dual field mode, in dual protective field

mode and in triple field mode and in dual and

triple collision protection mode: Logical 1, if the

active allocated protective field is unoccupied.

8012622/Z098/2016-11-07 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 29

Subject to change without notice

21)

Only if the inputs are activated in the CDS.

Page 30

Chapter 4 Technical information

Technical realization

EFI

Status information Meaning/effect

Allocated warning field unoccupied

[WF]

or

allocated protective field 2

unoccupied [PF2]

Allocated collision protection field

unoccupied [CPF1]

Simultaneous protective field

unoccupied [Sim. PF]

Simultaneous warning field

unoccupied [Sim. WF]

or

simultaneous protective field 2

unoccupied [Sim. PF2]

or

allocated warning field 2

unoccupied [WF2]

Simultaneous collision protection

field unoccupied [Sim. CPF]

or

allocated collision protection field 2

unoccupied [CPF2]

Velocity valid

Velocity

22)

22)

• In dual field mode: Logical 1, if the active

allocated warning field is unoccupied

• In dual protective field mode: Logical 1, if the

active allocated protective field 2 is

unoccupied

• In triple field mode: Logical 1, if the active

allocated warning field is unoccupied

• In dual collision protection mode: Logical 1, if

active allocated collision protection field is

unoccupied

• In triple collision protection field: Logical 1, if

active allocated collision protection field is

unoccupied

• In dual field mode and in dual protective field

mode: Logical 1, if the simultaneously

monitored protective field is unoccupied

• In triple field mode: No function

• In dual collision protection mode: Logical 1, if

the simultaneously monitored protective field is

unoccupied

• In triple collision protection mode: No function

• In dual field mode: Logical 1, if the

simultaneously monitored warning field is

unoccupied

• In dual protective field mode: Logical 1, if the

simultaneously monitored protective field 2 is

unoccupied

• In triple field mode: Logical 1, if the active

allocated warning field 2 is unoccupied

• In dual collision protection field mode:

Logical 1, if the simultaneously monitored

collision protection field is unoccupied

• In triple collision protection mode: Logical 1, if

the active allocated collision protection field 2

is unoccupied

• Logical 1, if a valid velocity is present on the

incremental encoder inputs

• Logical 0, if an invalid velocity is present on the

incremental encoder inputs

• 12 bits for the transmission of the velocity

100000110000 = –2000 cm/s

000000000000 = 0 cm/s

011111010000 = +2000 cm/s

22)

Not in the compatibility mode.

30 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8012622/Z098/2016-11-07

Subject to change without notice

Page 31

Technical information Chapter 4

Tab.18:

Control f

eatures on

EFI

Technical realization

the S3000 (data to the

S3000)

Control feature Meaning/effect

Static input information A1 [In A1]

• Logical 1, stimulates control input A1 of the

S3000

Static input information A2 [In A2]

• Logical 1, stimulates control input A2 of the

S3000

Static input information B1 [In B1]

• Logical 1, stimulates control input B1 of the

S3000

Static input information B2 [In B2]

• Logical 1, stimulates control input B2 of the

S3000

Static input information C1 [In C1]

• Logical 1, stimulates control input C1 of the

S3000

Static input information C2 [In C2]

• Logical 1, stimulates control input C2 of the

S3000

Static input information D1 [In D1]

• Logical 1, stimulates control input D1 of the

S3000

Static input information D2 [In D2]

• Logical 1, stimulates control input D2 of the

S3000

Static input information E1 [In E1]

23)

• Logical 1, stimulates control input E1 of the

S3000

Static input information E2 [In E2]

23)

• Logical 1, stimulates control input E2 of the

S3000

Stand-by

23)

• Logical 1, stimulates operational status

Stand-by (individually for host and guest)

Velocity valid

23)

• Logical 1, valid velocity is present on the

incremental encoder inputs

• Logical 0, invalid velocity is present on the

incremental encoder inputs

Velocity

23)

• 12 bits for the transmission of the velocity

100000110000 = –2000 cm/s

000000000000 = 0 cm/s

011111010000 = +2000 cm/s

I/O error [I/O Error]

• Logical 0, if there is no error on the connected

partner device

• Logical 1, if there is an error on the connected

partner device

23)

Not in the compatibility mode.

8012622/Z098/2016-11-07 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 31

Subject to change without notice

Page 32

Chapter 4 Technical information

Tab.19:

Status information

Technical realization

EFI

4.4.4 S300 safety laser scanner

of the S300 (data from the

S300)

Status information Meaning/effect

OSSD on [OSSD]

• Logical 1, if the internal OSSD of the S300 is in

the ON state (green)

• Logical 0, if the OSSD of the S300 is in the OFF

state (red)

Warning field bit [WF LED]

• Logical 1, if both warning fields of the S300 are

unoccupied

• Logical 0, if one of the warning fields of the

S300 is infringed

Contamination [Weak] • Logical 1, if the optics cover is contaminated

Reset required [Res. Req] • Logical 1, if reset required

Reset button pressed [Res. Pressed]

• Logical 1, if the reset button is pressed on the

S300

I/O error [I/O Error] • Logical 0, if there is no error on the S300

• Logical 1, if there is an error on the S300

Control input A1 [In A1]

• Logical 1, if the connection of control input A1

is HIGH

Note: The control inputs on the S300 are used

to switch the monitoring cases on the S300.

Control input A2 [In A2]

• Logical 1, if the connection of control input A2

is HIGH

Control input B1 [In B1]

• Logical 1, if the connection of control input B1

is HIGH

Control input B2 [In B2]

• Logical 1, if the connection of control input B2

is HIGH

Control input C1 [In C1]

• Logical 1, if the connection of control input C1

is HIGH

Control input C2 [In C2]

• Logical 1, if the connection of control input C2

is HIGH

Protective field [PF] • Logical 1, if the protective field is unoccupied

Warning field 1 [WF1]

• Logical 1, if the active allocated warning field is

unoccupied

Warning field 2 [WF2]

• Logical 1, if the active allocated warning field is

unoccupied

Velocity valid

24)

• Logical 1, if a valid velocity is present on the

incremental encoder inputs

• Logical 0, if an invalid velocity is present on the

incremental encoder inputs

Velocity

24)

• 12 bits for the transmission of the velocity

100000110000 = –2000 cm/s

000000000000 = 0 cm/s

011111010000 = +2000 cm/s

32 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8012622/Z098/2016-11-07

24)

Not in the compatibility mode.

Subject to change without notice

Page 33

Technical information Chapter 4

Tab.20:

Control features on

EFI

Technical realization

the S300 (data to the S300)

Control feature Meaning/effect

Static input information A1 [In A1]

• Logical 1, stimulates control input A1 of the

S300

Static input information A2 [In A2]

• Logical 1, stimulates control input A2 of the

S300

Static input information B1 [In B1]

• Logical 1, stimulates control input B1 of the

S300

Static input information B2 [In B2]

• Logical 1, stimulates control input B2 of the

S300

Static input information C1 [In C1]

• Logical 1, stimulates control input C1 of the

S300

Static input information C2 [In C2]

• Logical 1, stimulates control input C2 of the

S300

Static input information D1

25)

[In D1]

Static input information D2

25)

[In D2]

Static input information E1 [In E1]

• Logical 1, stimulates control input D1 of the

S300

• Logical 1, stimulates control input D2 of the

S300

25)

• Logical 1, stimulates control input E1 of the

S300

Static input information E2 [In E2]

25)

• Lo gical 1, stimulates control input E2 of the

S300

Stand-by

25)

• Logical 1, stimulates operational status

Stand-by (individually for host and guest)

Velocity valid

25)

• Logical 1, valid velocity is present on the

incremental encoder inputs

• Logical 0, invalid velocity is present on the

incremental encoder inputs

Velocity

25)

• 12 bits for the transmission of the velocity

100000110000 = –2000 cm/s

000000000000 = 0 cm/s

011111010000 = +2000 cm/s

8012622/Z098/2016-11-07 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 33

Subject to change without notice

I/O error [I/O Error]

25)

Not in the compatibility mode.

• Logical 0, if there is no error on the connected

partner device

• Logical 1, if there is an error on the connected

partner device

Page 34

Chapter 4 Technical information

Tab.21:

Status information

Technical realization

EFI

4.4.5 S300 Mini safety laser scanner

of the S300 Mini (data from

the S300 Mini)

Status information Meaning/effect

Warning field bit [WF]

• Logical 1, if both warning fields of the S300

Mini are unoccupied

• Logical 0, if one of the warning fields of the

S300 Mini is infringed

Protective field [PF] • Logical 1, if the protective field is unoccupied

Warning field 1 [WF1]

• Logical 1, if the active allocated warning field is

unoccupied

Warning field 2 [WF2]

• Logical 1, if the active allocated warning field is

unoccupied

Contamination [Weak] • Logical 1, if the optics cover is contaminated

I/O error [I/O Error] • Logical 0, if there is no error on the S300 Mini

• Logical 1, if there is an error on the S300 Mini

34 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8012622/Z098/2016-11-07

Subject to change without notice

Page 35

Technical information Chapter 4

Tab.22:

Control features on

EFI

Technical realization

the S300 Mini (data to the

S300 Mini)

Control feature Meaning/effect

Static input information A1 [In A1]

• Logical 1, stimulates control input A1 of the

S300 Mini

Static input information A2 [In A2]

• Logical 1, stimulates control input A2 of the

S300 Mini

Static input information B1 [In B1]

• Logical 1, stimulates control input B1 of the

S300 Mini

Static input information B2 [In B2]

• Logical 1, stimulates control input B2 of the

S300 Mini

Static input information C1 [In C1]

• Logical 1, stimulates control input C1 of the

S300 Mini

Static input information C2 [In C2]

• Logical 1, stimulates control input C2 of the

S300 Mini

Static input information D1 [In D1]

• Logical 1, stimulates control input D1 of the

S300 Mini

Static input information D2 [In D2]

• Logical 1, stimulates control input D2 of the

S300 Mini

Static input information E1 [In E1]

• Logical 1, stimulates control input E1 of the

S300 Mini

Static input information E2 [In E2]

Stand-by

Velocity valid

Velocity

25)

• Logical 1, stimulates control input E2 of the

S300 Mini

• Logical 1, stimulates operational status

Stand-by

• Logical 1 signals a valid velocity being present

on the incremental encoder inputs.

• Logical 0 signals a invalid velocity being

present on the incremental encoder inputs

(velocity in a range that is not configured or

difference allowed between the incremental

encoders exceeded).

• 12 bits for the transmission of the velocity

100000110000 = –2000 cm/s

000000000000 = 0 cm/s

011111010000 = +2000 cm/s

8012622/Z098/2016-11-07 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 35

Subject to change without notice

Page 36

Chapter 4 Technical information

Tab.23:

Status information

Tab.24:Control features on

Technical realization

EFI

4.4.6 Flexi Soft FX3-CPU1, -CPU2, -CPU3 safety controller

on the Flexi Soft (data from

the Flexi Soft)

the Flexi Soft (data to the

Flexi Soft)

Status information Meaning/effect

I/O error [Byte 1, Bit 1]

• Logical 0, if there is no error on the Flexi Soft

CPU

• Logical 1, if there is an error on the Flexi Soft

CPU

Note: This status is to be provided in the

operational status “Executing/Run” on the Flexi

Soft-CPU using programmed logic.

If signals are pre-processed on the Flexi Soft

station and forwarded to EFI users, it is

necessary to program the error states from this

pre-processing as status information. If this

status information is not programmed, it is only

allowed to send signals without pre-processing

to the EFI users.

All except [Byte 1, Bit 1]

• Freely programmable signals correspond to the

requirements for the EFI devices connected

Control feature Meaning/effect

I/O error [Byte 1, Bit 1]

• Logical 0, if there is no error on a connected

device

• Logical 1, if there is an error on a connected

device

Note: Indicates that the data on this EFI

interface are currently invalid and represent

substitute values. This situation occurs, for

example, on EFI gateways if the controlling

(F)PLC is not (yet) operating.

All except [Byte 1, Bit 1]

• Freely useable information for usage in the

Flexi Soft logic.

Note: On the usage of this information the status

of the received I/O error bits is also to be

evaluated.

36 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8012622/Z098/2016-11-07

Subject to change without notice

Page 37

Technical information Chapter 4

Tab.25:

Status information

Tab.26:

Control features on

EFI

Technical realization

4.4.7 UE4740 EFI gateway

on the EFI gateway (data

from the EFI gateway)

the EFI gateway (data to the

EFI gateway)

Status information Meaning/effect

I/O error [Byte 1, Bit 1] • Logical 0, if there is no error on the EFI gateway

• Logical 1, if there is an error on the EFI gateway

Note: The I/O error is calculated automatically

from the validity of the data on the interfaces

connected and as a function of the usage of the

data (in the gateway routing). Indicates that the

data on this EFI interface are currently invalid

and represent substitute values. This situation

occurs, for example, on EFI gateways if the

controlling (F)PLC is not (yet) operating.

All except [Byte 1, Bit 1]

• Freely programmable signals correspond to the

requirements for the EFI devices connected

Control feature Meaning/effect

I/O error [Byte 1, Bit 1]

• Logical 0, if there is no error on a connected

device

• Logical 1, if there is an error on a connected

device

Note: Indicates that the data on this EFI

interface are currently invalid.

All except [Byte 1, Bit 1]

• Freely useable information for further data

routing.

Note: On the usage of this information the status

of the received I/O error bits is also to be

evaluated.

8012622/Z098/2016-11-07 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 37

Subject to change without notice

Page 38

Chapter 4 Technical information

Fig.13:

Example data

Technical realization

EFI

4.5 Application examples

4.5.1 EFI gateway with M4000 multiple light beam safety device

The (F)PLC can access the M4000 via the routing in the EFI gateway. In this way it can

send muting signals to the M4000 and receive output information (e.g. from M4000

OSSDs).

exchange between an (F)PLC

and an M4000 via an EFI

gateway

Used addresses via EFI: 14 for the EFI gateway, 1 for the M4000

38 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8012622/Z098/2016-11-07

Subject to change without notice

Page 39

Technical information Chapter 4

Fig.14:

Example status

Fig.15:

Example of an invalid

EFI

Technical realization

4.5.2 EFI gateway with M4000 and UE403 switching amplifier

In this case the M4000 receives the muting signals from the UE403 (address 14). The EFI