Page 1

OPERATING INSTRUCTIONS

DOSIC

®

Flow sensor

en

Page 2

Product described

®

DOSIC

Manufacturer

SICK AG

Erwin-Sick-Str. 1

79183 Waldkirch

Germany

Legal notes

This work is protected by copyright. The associated rights are reserved by SICK AG. Reproduction of this document

or parts of this document is only permissible within the limits of the legal provisions of copyright law.

Any modication, abridgment, or translation of this document is prohibited without the express written permission

of SICK AG.

The trademarks mentioned in this document are the property of their respective owners.

© SICK AG. All rights reserved.

Original document

This document is an original document published by SICK AG.

2

OPERATING INSTRUCTIONS | DOSIC® 8020955 /11HD/ 2018-12-12 | SICK AG

Subject to change without notice

Page 3

Contents

1 About this document .......................................................................................6

1.1 Information on the operating instructions ................................................................ 6

1.2 Scope ..........................................................................................................................6

1.3 Explanation of symbols ..............................................................................................6

1.4 Further information ....................................................................................................7

1.5 Customer service ........................................................................................................7

2 Safety information ...........................................................................................8

2.1 Intended use ............................................................................................................... 8

2.2 Improper use...............................................................................................................8

2.3 Limitation of liability ................................................................................................... 8

2.4 Modications and conversions .................................................................................. 8

2.5 Requirements for skilled persons and operating personnel ...................................9

2.6 Operational safety and specic hazards ...................................................................9

2.7 Use at high operating temperatures .......................................................................10

2.8 General safety notes ................................................................................................10

2.9 Repairs ......................................................................................................................10

3 Product description ....................................................................................... 11

3.1 Product identication ...............................................................................................11

3.1.1 Information on the housing ......................................................................11

3.1.2 Type code ..................................................................................................11

3.2 Product characteristics ............................................................................................12

3.2.1 Device view ...............................................................................................12

3.2.2 Operating buttons .....................................................................................12

3.3 Product features and functions ...............................................................................13

3.3.1 Principle of operation ...............................................................................13

3.3.2 Fields of application .................................................................................13

4 Transport and storage .................................................................................. 14

4.1 Transport ...................................................................................................................14

4.2 Transport inspection ................................................................................................14

4.3 Storage ......................................................................................................................14

5 Mounting ......................................................................................................... 15

5.1 Installation conditions ..............................................................................................15

6 Electrical installation .................................................................................... 17

6.1 Safety ........................................................................................................................17

6.1.1 Notes on the electrical installation ..........................................................17

6.2 Electrical connection ................................................................................................18

6.2.1 Overview of the electrical connections ...................................................18

6.2.2 Pin assignment, M12 plug connector, 5-pin ...........................................18

6.2.3 Pin assignment, M12 plug connector, 8-pin ...........................................19

Subject to change without notice

OPERATING INSTRUCTIONS | DOSIC® 8020955/11HD / 2018-12-12| SICK AG

3

Page 4

7 Commissioning .............................................................................................. 20

7.1 Quick commissioning (with factory settings) ..........................................................20

7.2 Operation ..................................................................................................................20

7.2.1 Display and operating buttons .................................................................20

7.2.2 Display and operating elements ..............................................................20

7.2.3 IO-Link .......................................................................................................20

7.3 Conguration of digital switching inputs and switching outputs ...........................21

7.3.1 Selection of digital switching inputs and switching outputs ..................21

7.3.2 Conguration of the switching output .....................................................21

7.3.3 Normally open with congurable hysteresis ...........................................21

7.3.4 Normally closed with congurable hysteresis .........................................22

7.3.5 Normally open with window function ......................................................23

7.3.6 Normally closed with window function ....................................................24

7.3.7 Pulse output ..............................................................................................25

7.3.8 Frequency output ......................................................................................25

7.4 Conguration of analog outputs ..............................................................................26

7.4.1 Current output 4-20 mA ...........................................................................26

7.5 Advanced functions ..................................................................................................27

7.5.1 Measurement Mode .................................................................................27

7.5.2 Activate ltering ........................................................................................27

7.5.3 Zero ow cuto..........................................................................................27

7.5.4 Empty measurement channel ..................................................................28

7.5.5 Congure reverse ow direction ..............................................................29

7.5.6 Simulate ow or temperature ..................................................................29

7.5.7 Media compensation ................................................................................30

7.5.8 Sterilization detection ...............................................................................30

7.5.9 Evaluating signal quality ...........................................................................31

7.5.10 Activating the display lock ........................................................................31

7.5.11 Output options for Disp A and Disp B ......................................................32

7.5.12 Selecting display unit ...............................................................................32

7.5.13 Resetting to factory settings ....................................................................33

8 Menu overview ............................................................................................... 34

9 Overview of parameters ............................................................................... 40

10 Troubleshooting ............................................................................................. 42

10.1 Error message on the display ..................................................................................42

10.2 Outputs......................................................................................................................44

11 Repair .............................................................................................................. 43

11.1 Maintenance .............................................................................................................43

11.2 Returns ......................................................................................................................43

12 Disposal .......................................................................................................... 44

13 Technical data ................................................................................................ 45

13.1 Features ....................................................................................................................45

4

OPERATING INSTRUCTIONS | DOSIC® 8020955 /11HD/ 2018-12-12 | SICK AG

Subject to change without notice

Page 5

13.2 Performance .............................................................................................................45

13.3 Mechanics/materials ...............................................................................................46

13.4 Ambient conditions ..................................................................................................46

13.5 Electrical connections ..............................................................................................47

13.6 Temperature derating ...............................................................................................48

14 Dimensional drawings .................................................................................. 49

14.1 Process connection DN15 G 3/4 ............................................................................49

14.2 Process connection DN15 3/4" NPT ......................................................................49

14.3 Process connection DN15 clamp DIN 32676 ........................................................50

14.4 Process connection DN15 DIN 11851 ...................................................................50

14.5 Process connection DN25 G 1 1/4.........................................................................51

14.6 Process connection DN25 DIN 1 1/4" NPT ............................................................51

14.7 Process connection DN25 clamp DIN 32676 ........................................................52

14.8 Process connection DN25 DIN 11851 ...................................................................52

15 Factory settings ............................................................................................. 53

16 Accessories .................................................................................................... 55

Subject to change without notice

OPERATING INSTRUCTIONS | DOSIC® 8020955/11HD / 2018-12-12| SICK AG

5

Page 6

1 ABOUT THIS DOCUMENT

1 About this document

1.1 Information on the operating instructions

These operating instructions provide important information on how to use sensors from

SICK AG.

Prerequisites for safe work are:

• Compliance with all safety notes and handling instructions supplied.

• Compliance with local work safety regulations and general safety regulations for

sensor applications.

The operating instructions are intended to be used by qualied personnel and electrical

specialists.

Note:

Read these operating instructions carefully before starting any work on the device, in

order to familiarize yourself with the device and its functions.

The instructions must be kept in the immediate vicinity of the device so they remain

accessible to sta at all times. Should the device be passed on to a third party, these

operating instructions should be handed over with it.

These operating instructions do not provide information on operating any system in

which the sensor may be integrated. For information about this, refer to the operating

instructions of the particular system.

1.2 Scope

These operating instructions explain how to incorporate a sensor into a customer

system. Instructions are given in stages for all actions required.

These instructions apply to all available device variants of the sensor. For more detailed

information on identifying your device type, see “3.1.2 Type code”.

Available device variants are listed on the online product page:

b www.sick.com

A number of device variants are used as examples for commissioning, based on the

default parameter settings for the relevant device.

In this document, the sensor is referred to in simplied form as DOSIC

where it is necessary to make a distinction between device variants due to dierent

technical features or functions. In such cases, the complete type designation is used.

1.3 Explanation of symbols

Warnings and important information in this document are labeled with symbols. The

warnings are introduced by signal words that indicate the extent of the danger. These

warnings must be observed at all times and care must be taken to avoid accidents,

personal injury, and material damage.

®

, except in cases

HAZARD

… indicates a situation of imminent danger, which will lead to a fatality or serious injuries if not prevented.

6

OPERATING INSTRUCTIONS | DOSIC® 8020955 /11HD/ 2018-12-12 | SICK AG

Subject to change without notice

Page 7

WARNING

… indicates a potentially dangerous situation, which may lead to a fatality or serious

injuries if not prevented.

CAUTION

… indicates a potentially dangerous situation, which may lead to minor/slight injuries if

not prevented.

IMPORTANT

… indicates a potentially harmful situation, which may lead to material damage if not

prevented.

NOTE

… highlights useful tips and recommendations as well as information for ecient and

trouble-free operation.

1ABOUT THIS DOCUMENT

1.4 Further information

NOTE

All the documentation available for the sensor can be found on the online product page

at:

www.sick.com

The following information is available for download from this page:

• Model-specic online data sheets for device variants, containing technical data,

dimensional drawings, and diagrams

• EU declaration of conformity for the product family

• Dimensional drawings and 3D CAD dimension models in various electronic formats

• These operating instructions, available in English and German, and in other languag-

es if necessary

• Other publications related to the sensors described here (e.g., IO-Link)

• Publications dealing with accessories

1.5 Customer service

If you require any technical information, our customer service department will be happy

to help. To nd your representative, see the nal page of this document.

NOTE

Subject to change without notice

Before calling, make a note of all sensor data such as type code, serial number, etc., to

ensure faster processing.

OPERATING INSTRUCTIONS | DOSIC® 8020955/11HD / 2018-12-12| SICK AG

7

Page 8

2 SAFETY INFORMATION

2 Safety information

2.1 Intended use

With its measurement channel and stainless-steel housing, the ultrasonic owmeter is

suitable for measuring tasks in hygienic environments. The compact and rugged design

makes the sensor ideal for a wide range of applications, including those where space

restrictions or aggressive media play a role.

Installation is quick and easy, and does not require medium calibration. The seal-free,

self-draining measuring channel enhances process reliability. The straight shape of the

measuring channel reduces pressure loss, which in turn reduces energy costs.

The DOSIC

are FDA-compliant.

2.2 Improper use

Any use outside of the stated areas, in particular use outside of the technical specications and the requirements for intended use, will be deemed to be improper use.

If the equipment is used in a manner not specied by this document, the protection

provided by the equipment may be impaired.

®

is EHEDG-certied, and all materials that come into contact with the media

If the sensor is to be used under other conditions or in dierent environments, the man-

ufacturer’s service department may issue an operating license in consultation with the

customer and in exceptional cases.

2.3 Limitation of liability

Applicable standards and regulations, the latest technological developments, and

our many years of knowledge and experience have all been taken into account when

assembling the data and information contained in these operating instructions. The

manufacturer accepts no liability for damage caused by:

• Failing to observe the operating instructions

• Improper use

• Use by untrained personnel

• Unauthorized conversions

• Technical modications

• Use of unauthorized spare parts, consumables, and accessories

With special variants, where optional extras have been ordered, or owing to the latest

technical changes, the actual scope of delivery may vary from the features and illustra-

tions shown here.

2.4 Modications and conversions

IMPORTANT

Modications and conversions to the sensor and/or the installation may result in unforeseeable dangers.

Interfering with or modifying the sensor or SICK software will invalidate any warranty

claims against SICK AG. This applies in particular to opening the housing, even as part

of mounting and electrical installation work.

Before making technical modications to or expanding the sensor, the prior written

approval of the manufacturer must be obtained.

8

OPERATING INSTRUCTIONS | DOSIC® 8020955 /11HD/ 2018-12-12 | SICK AG

Subject to change without notice

Page 9

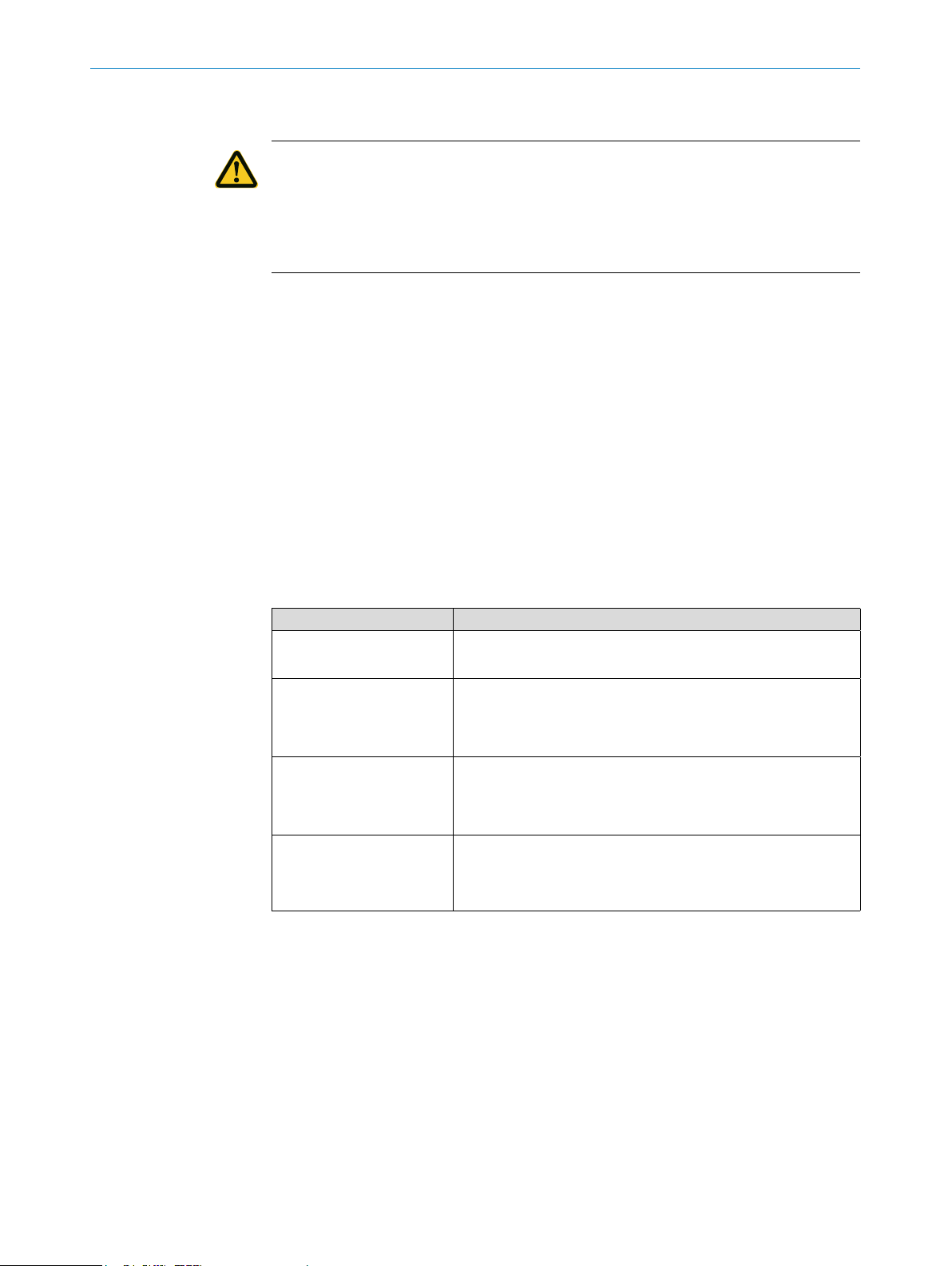

2.5 Requirements for skilled persons and operating personnel

WARNING

Risk of injury due to insucient training.

Improper handling of the sensor may result in considerable personal injury and material

damage.

• All work must only ever be carried out by the stipulated persons.

The operating instructions state the following qualication requirements for the various

areas of work:

• Instructed personnel have been briefed by the operating entity about the tasks

assigned to them and about potential dangers arising from improper action.

• Skilled personnel have the specialist training, skills, and experience, as well as

knowledge of the relevant regulations, to be able to perform tasks assigned to

them and to detect and avoid any potential dangers independently.

• Electricians have the specialist training, skills, and experience, as well as knowl-

edge of the relevant standards and provisions to be able to carry out work on

electrical systems and to detect and avoid any potential dangers independently.

In Germany, electricians must meet the specications of the BGV A3 Work Safety

Regulations (e.g., Master Electrician). Other relevant regulations applicable in other

countries must be observed.

2SAFETY INFORMATION

The following qualications are required for various activities:

Activities Qualication

Mounting, maintenance

Electrical installation, de-

vice replacement

Commissioning,

conguration

Operation of the device for

the specic application

• Basic practical technical training

• Knowledge of the current safety regulations in the workplace

• Practical electrical training

• Knowledge of current electrical safety regulations

• Knowledge of device control and operation in the specic application concerned (e.g., conveying line)

• Basic knowledge of the control system used

• Basic knowledge of the design and setup of the described

connections and interfaces

• Basic knowledge of data transmission

• Knowledge of device control and operation in the specic application concerned (e.g., CIP/SIP system)

• Knowledge of the software and hardware environment for the

specic application concerned (e.g., CIP/SIP system)

2.6 Operational safety and specic hazards

Please observe the safety notes and the warnings listed here and in other chapters of

these operating instructions to reduce the possibility of risks to health and avoid dan-

gerous situations.

Subject to change without notice

OPERATING INSTRUCTIONS | DOSIC® 8020955/11HD / 2018-12-12| SICK AG

9

Page 10

2 SAFETY INFORMATION

2.7 Use at high operating temperatures

When the process temperature is high, the sensor housing may get hot.

CAUTION

Risk of burning on sensor housing

• Only touch the hot housing if you are wearing safety gloves.

2.8 General safety notes

• Read the operating instructions prior to commissioning.

• These operating instructions are valid for devices from rmware version 2.00.

®

• The DOSIC

• Observe national safety and work safety regulations.

• Wiring work and the opening and closing of electrical connections may only be

carried out when the power is switched o.

• The radiated power is far lower than that from telecommunication equipment.

According to current scientic research, the operation of this device can be classied as safe and non-hazardous.

is not a safety component under the EU Machinery Directive.

2.9 Repairs

Repair work on the sensor may only be performed by qualied and authorized personnel from SICK AG. Interference with or modications to the sensor on the part of the

customer will invalidate any warranty claims against SICK AG.

The customer is only permitted to change the alignment of the display and to remove

the display cover in order to change its position.

10

OPERATING INSTRUCTIONS | DOSIC® 8020955 /11HD/ 2018-12-12 | SICK AG

Subject to change without notice

Page 11

3 Product description

3.1 Product identication

3.1.1 Information on the housing

Information for identication of the sensor and its electrical connection are marked on

the housing.

The serial number, the part number and the type code are printed on a label stuck on

the side of the display. It is visible after removing of the top cover of the sensor.

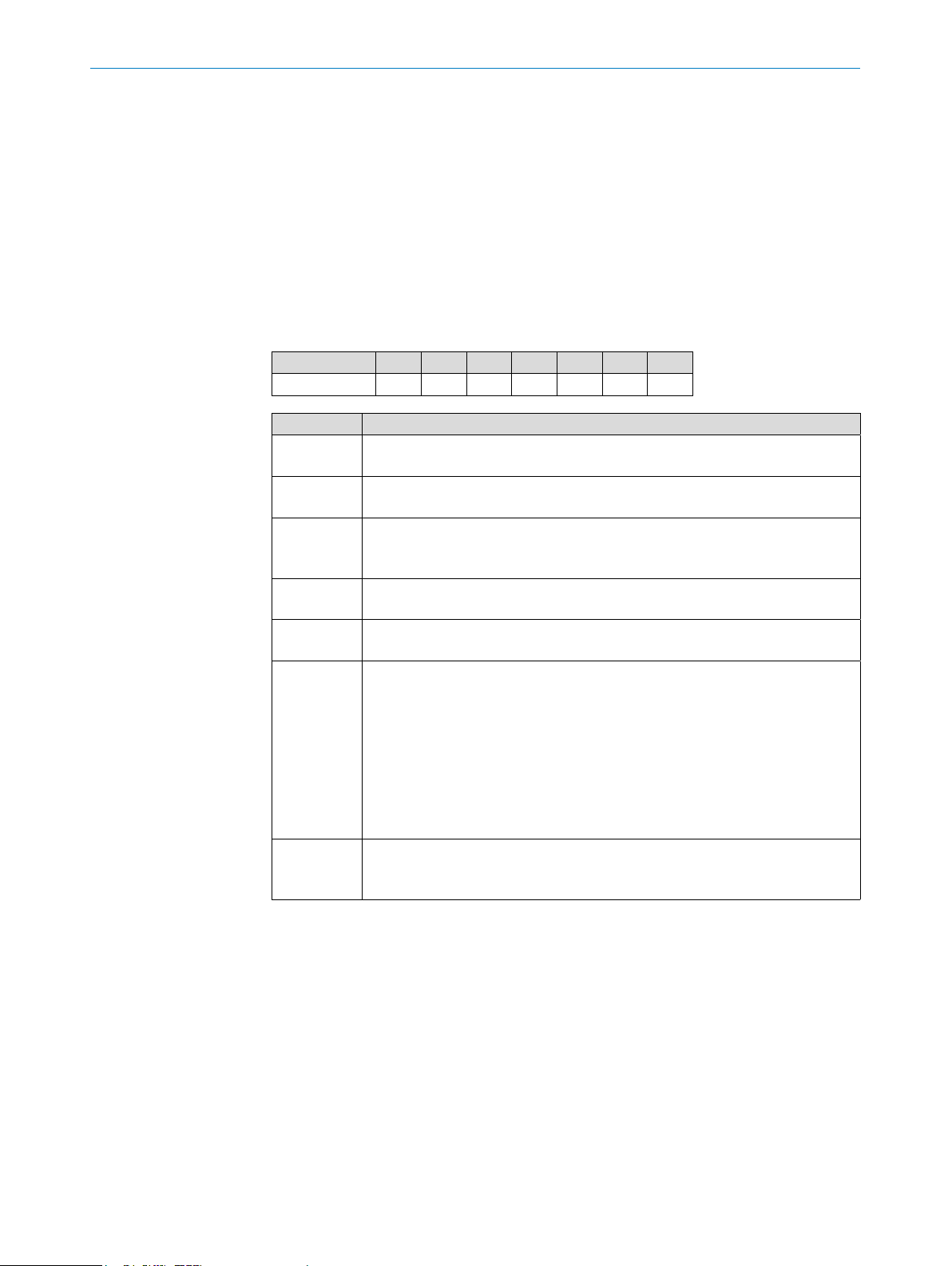

3.1.2 Type code

DOSIC® FUM - H 015 F 1 GC 5

1 2 3 4 5 6 7

Position Description

1 Product group

2 Variant

3 Channel size

4 Medium

5 Display

6 Process connection

7 Electrical connections

®

DOSIC

(ow sensors)

H: Hygienic

015: DN15

025: DN25

F: Liquids

1: Yes

GC: G 3/4 (DN15 only)

GE: G 1 1/4 (DN25 only)

CB: Clamp DN15 DIN 32676 (external diameter 34 mm)

CD: Clamp DN25 DIN 32676 (external diameter 50.5 mm)

MB: DIN 11851 DN15 (thread on both ends)

MD: DIN 11851 DN25 (thread on both ends)

NC: NPT 3/4 (DN15 only)

NE: NPT 1 1/4 (DN25 only)

5: M12, 5-pin (2 DI/O; 1 AO)

8: M12, 8-pin (2 DI/O; 2 AO)

3PRODUCT DESCRIPTION

Subject to change without notice

Not all variants of the type code can be combined!

OPERATING INSTRUCTIONS | DOSIC® 8020955/11HD / 2018-12-12| SICK AG

11

Page 12

3 PRODUCT DESCRIPTION

3.2 Product characteristics

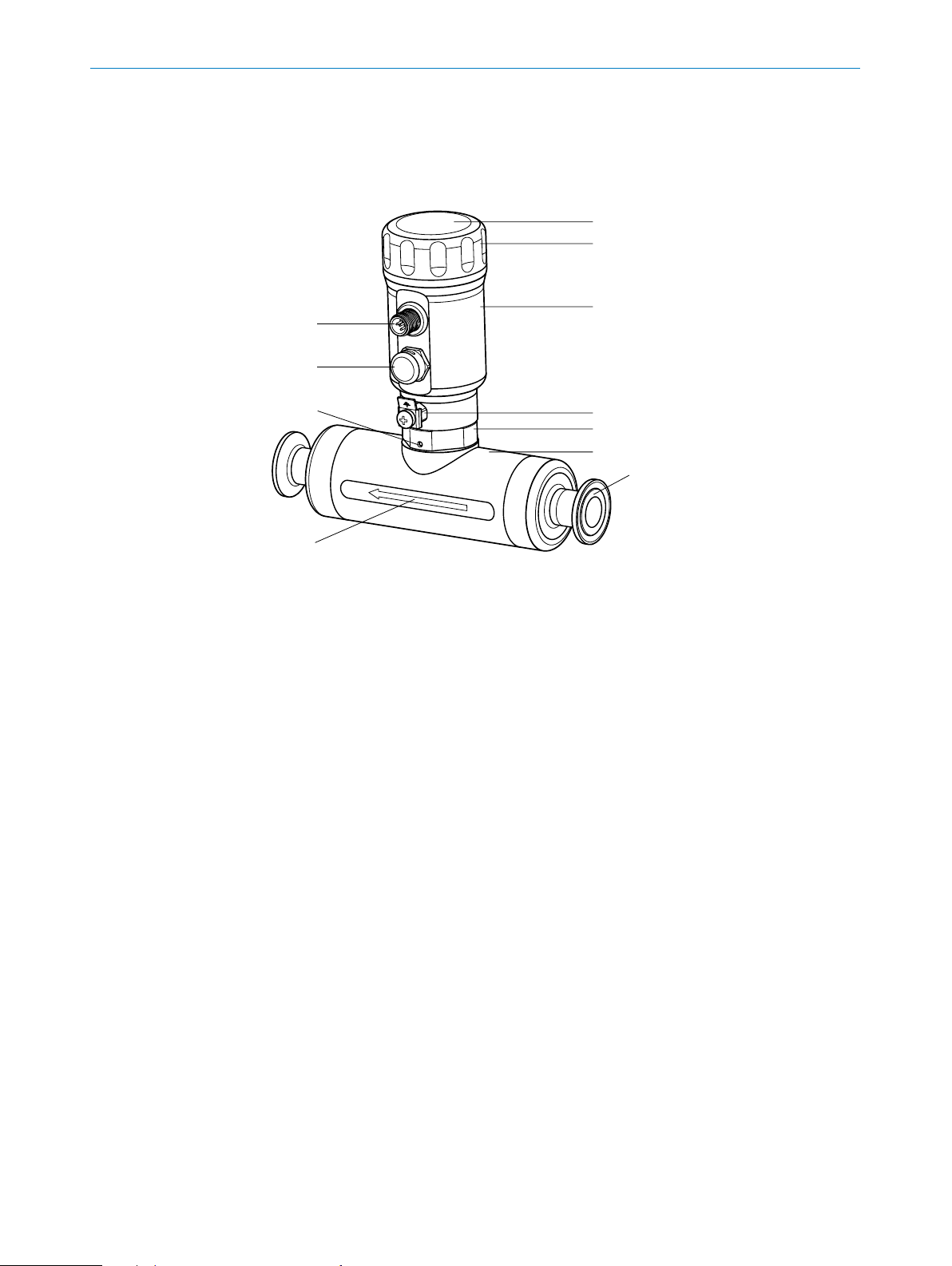

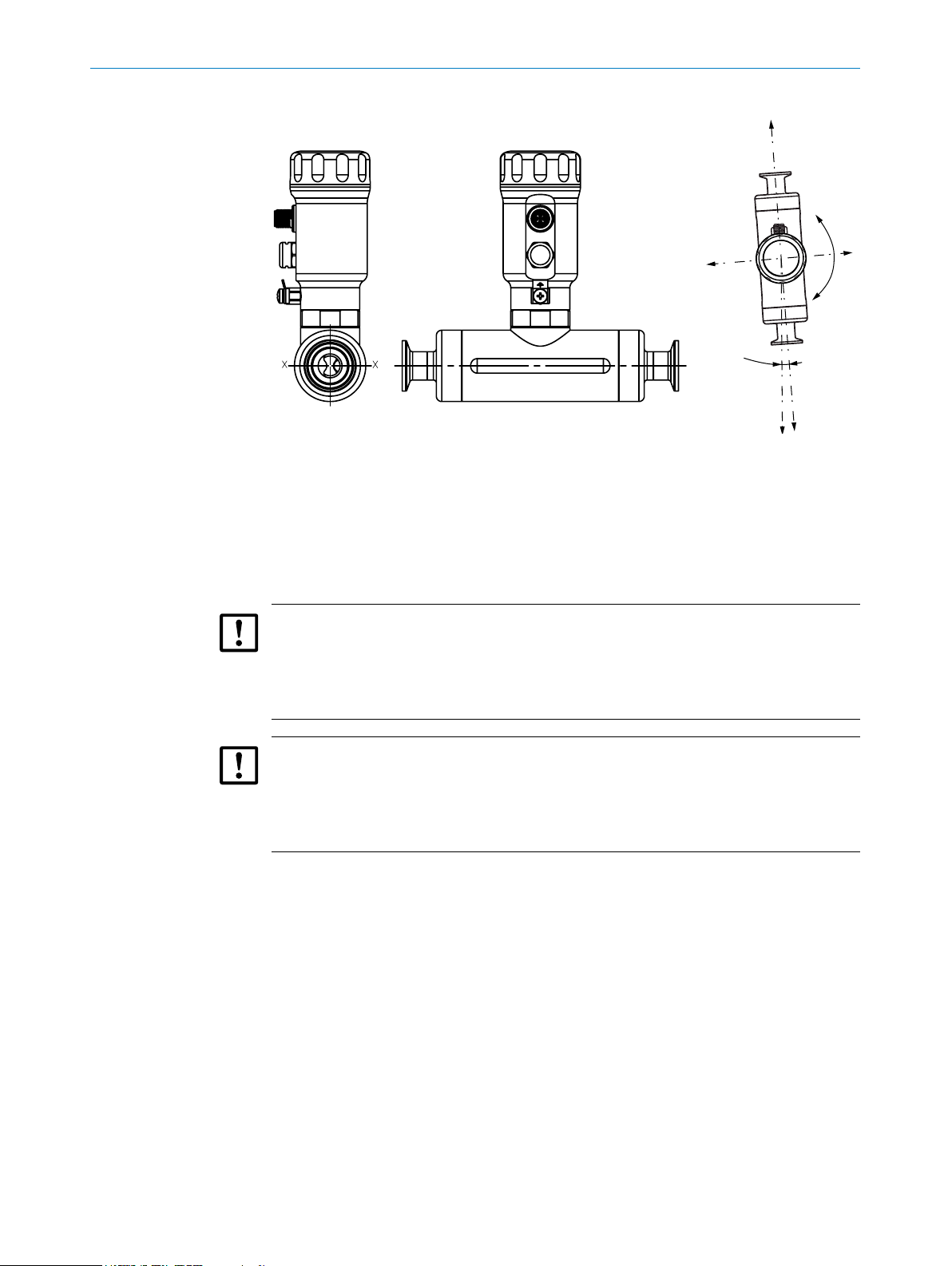

3.2.1 Device view

4

5

1

2

3

8

6

7

9

ß

à

Fig. 1: DOSIC® overview

1 Display and operating buttons

2 Upper cover

3 Upper housing

4 M12 electrical connection

5 Pressure compensation element (prevents build-up of condensate)

6 Connection for ground cable

7 Nut to unlock/lock housing rotation

8 Screw to unlock/lock screw nut 7

9 Measuring channel

ß Process connection

à Flow direction

3.2.2 Operating buttons

The sensor is operated using the display and the operating buttons.

For a detailed description of the buttons and their functions, see “7.2.1 Display and

operating buttons”.

12

OPERATING INSTRUCTIONS | DOSIC® 8020955 /11HD/ 2018-12-12 | SICK AG

Subject to change without notice

Page 13

3.3 Product features and functions

3.3.1 Principle of operation

®

The DOSIC

method, making the sensor suitable for measuring both conductive and non-conductive

liquids.

The sensor has two congurable digital inputs and outputs and up to two analog outputs. The switching output (Q1) also features an IO-Link interface; see “7.2.3 IO-Link”.

3.3.2 Fields of application

With its measurement channel and stainless-steel housing, the ultrasonic owmeter is

suitable for measuring tasks in hygienic environments. The compact and rugged design

makes the sensor ideal for a wide range of applications, including those where space

restrictions or aggressive media play a role.

Installation is quick and easy, and does not require medium calibration. The seal-free,

self-draining measuring channel enhances process reliability. The straight shape of the

measuring channel reduces pressure loss, which in turn reduces energy costs.

The DOSIC

are FDA-compliant.

This makes the DOSIC

measures ow volume using ultrasonic technology and the time-of-ight

®

is EHEDG-certied, and all materials that come into contact with the media

®

suitable for use in applications such as:

3PRODUCT DESCRIPTION

− The food industry

− CIP/SIP systems

− Filter systems

− Osmosis systems

− Measurements with high-purity water

NOTE

Due the ultrasonic technology used is always recommended to perform evaluation tests

on media that dier from water. To perform a rst evaluation test it is enough to ll the

channel of the sensor and close the two process connections of the sensor with blind

plugs. Should the sensor show zero ow without any error message there is a good

probability that the medium can be measured. In any case a test in the nal installation conditions provides the denitive answer if the DOSIC

®

can measure the specic

medium.

Subject to change without notice

OPERATING INSTRUCTIONS | DOSIC® 8020955/11HD / 2018-12-12| SICK AG

13

Page 14

4 TRANSPORT AND STORAGE

4 Transport and storage

4.1 Transport

For your own safety, please read and observe the following notes:

IMPORTANT

Damage to the sensor due to improper transport.

• The device must be packaged for transport with protection against shock and damp.

• Recommendation: Use the original packaging as it provides the best protection.

• Transport should be performed by specialist sta only.

• The utmost care and attention is required at all times during unloading and transportation on company premises.

• Note the symbols on the packaging.

• Do not remove packaging until immediately before starting installation work.

4.2 Transport inspection

Immediately upon receipt in Goods-in, check the delivery for completeness and for any

damage that may have occurred in transit. In the case of transit damage that is visible

externally, proceed as follows:

4.3 Storage

• Do not accept the delivery or only do so conditionally.

• Note the scope of damage on the transport documents or on the transport compa-

ny's delivery note.

• File a complaint.

NOTE

Complaints regarding defects should be led as soon as these are detected. Damage

claims are only valid before the applicable complaint deadlines.

Store the device under the following conditions:

• Recommendation: Use the original packaging.

• Do not store outdoors.

• Store in a dry area that is protected from dust.

• Do not store in an airtight container: this is so that any residual moisture present

can escape.

• Do not expose to any aggressive substances.

• Protect from sunlight.

• Avoid mechanical shocks.

14

• Storage temperature: see “13 Technical data”.

• For storage periods of longer than 3 months, check the general condition of all

components and packaging on a regular basis.

OPERATING INSTRUCTIONS | DOSIC® 8020955 /11HD/ 2018-12-12 | SICK AG

Subject to change without notice

Page 15

5 Mounting

5.1 Installation conditions

Install the sensor in line with the ow direction of the measurement medium (refer to

the arrow on the measurement channel). The measurement medium must ll the mea-

surement channel completely.

The formation of gas in the measurement medium can aect the measurement. For

this reason, the sensor should be installed in a section where no gas formation is to be

expected (in a vertical position where possible 1).

Where pumps are used, we recommend installing the sensor after the pump (pressure

side). Solid particles will aect the measurement. Ensure that no solid particles can

aect the measurement (e.g., by using lters).

The installation of inlet and outlet zones in the system is recommended. The inlet zone

is a straight section of pipe of 5 x DN length 2. The outlet zone is a section of 3 x DN

length3. Increase the inlet zone to 15 x DN when the sensor is installed after a pump.

Increase the inlet zone to 15 x DN when the sensor is installed after a valve. The tubes

must not cause turbulences.

To ensure that the measurement channel is kept full with the medium to be measured

at all times, the sensor should not be mounted in front of or in down pipes, or at the

highest point in the system 4.

5MOUNTING

The sensor head can be turned to facilitate optimum installation. To turn the sensor

head, the nut and the locking screw on the base of the sensor head must be loosened,

and then tightened again once the sensor head has been turned (nut: 30 Nm ... 40 Nm;

locking screw: 0.7 Nm ... 0.9 Nm).

The X-axis of the measurement channel should be installed at a horizontal angle to the

ground 5. Where the sensor is being installed vertically and in an EHEDG-compliant

installation, we recommend that the oset angle between inlet and outlet zone and

Y-axis not exceed 4°, in order to allow self-drainage to take place 6.

For EHEDG-compliant installation, EHEDG-certied seals must be used (not supplied).

4

1

3

2

Subject to change without notice

Fig. 2: Recommended installation

OPERATING INSTRUCTIONS | DOSIC® 8020955/11HD / 2018-12-12| SICK AG

15

Page 16

5 MOUNTING

5

6

+ Y

X

-Y

g

Fig. 3:

X

4°

DOSIC installation conditions

1Installation in section without gas formation

2Inlet zone of 5 x DN length

3Outlet zone of 3 x DN length

4Not installed in front of or in down pipes or at the highest point

5X-axis of measurement channel installed at a horizontal angle to the ground

6Oset between inlet and outlet zone and Y-axis not exceeded 4°

IMPORTANT

The display cover at the top end of the housing must be screwed into position manually,

by turning it until it no longer moves (see “3.2.1 Device view” on page 12., item num-

ber 2). The M12 connection must also be properly secured to ensure that the IP67/

IP69 enclosure rating is achieved.

IMPORTANT

The tightening torque on the process connection threads must not exceed 35 Nm

(DN15) and 80 Nm (DN25). Do not push or pull the upper housing while the process

connections are being tightened or while other work is being carried out. The force ap-

plied to the upper housing must not exceed 280 N (DN15) and 350 N (DN25).

16

OPERATING INSTRUCTIONS | DOSIC® 8020955 /11HD/ 2018-12-12 | SICK AG

Subject to change without notice

Page 17

6 Electrical installation

6.1 Safety

6.1.1 Notes on the electrical installation

IMPORTANT

Equipment damage due to incorrect supply voltage!

An incorrect supply voltage may result in damage to the equipment.

• Only operate the device using a protected low voltage and safe electrical insulation

as per protection class III.

IMPORTANT

Equipment damage or unpredictable operation due to working with live parts.

Working with live parts may result in unpredictable operation.

• Only carry out wiring work when the power is o.

• Only connect and disconnect electrical connections when the power is o.

6ELECTRICAL INSTALLATION

• The electrical installation must only be performed by electrically qualied person-

nel.

• Standard safety requirements must be met when working on electrical systems.

• Only switch on the supply voltage for the device when the connection tasks have

been completed and the wiring has been thoroughly checked.

• When using extension cables with open ends, ensure that bare wire ends do not

come into contact with each other (risk of short-circuit when supply voltage is

switched on!). Wires must be appropriately insulated from each other.

• Wire cross-sections in the supply cable from the user's power system must be

designed in accordance with the applicable standards. In Germany, observe the

following standards:

DIN VDE 0100 (Part 430) and DIN VDE 0298 (Part 4) or DIN VDE 0891 (Part 1).

• Circuits connected to the device must be designed as SELV circuits (SELV = Safety

Extra Low Voltage).

• Protect the device with a separate fuse at the start of the supply circuit.

Notes on layout of data cables:

• Use screened data cables with twisted-pair wires.

• Implement the screening design correctly and completely.

• To avoid interference, e.g., from switching power supplies, motors, clocked drives,

and contactors, always use suitable EMC cables and layouts.

• Do not lay cables over long distances in parallel with voltage supply cables and motor cables in cable channels.

Subject to change without notice

The IP67 and/or IP69 enclosure rating for the device is only achieved under the following conditions:

• The cable on the M12 connection has been screwed on.

• The top cover is screwed (no gap between the upper cover and upper housing).

OPERATING INSTRUCTIONS | DOSIC® 8020955/11HD / 2018-12-12| SICK AG

17

Page 18

6 ELECTRICAL INSTALLATION

If this is not done, the device does not fulll any specied IP enclosure rating!

6.2 Electrical connection

6.2.1 Overview of the electrical connections

The sensor is connected using a pre-assembled female cable connector with M12 x

1 plug connector (5-pin or 8-pin). With the power switched o, plug the female cable

connector into the sensor and screw it tight.

Connect the cable according to its function. After the supply voltage has been applied,

the sensor carries out a self-test. Once installed, the sensor is ready for operation on

completion of the self-test. The display shows the current measured value.

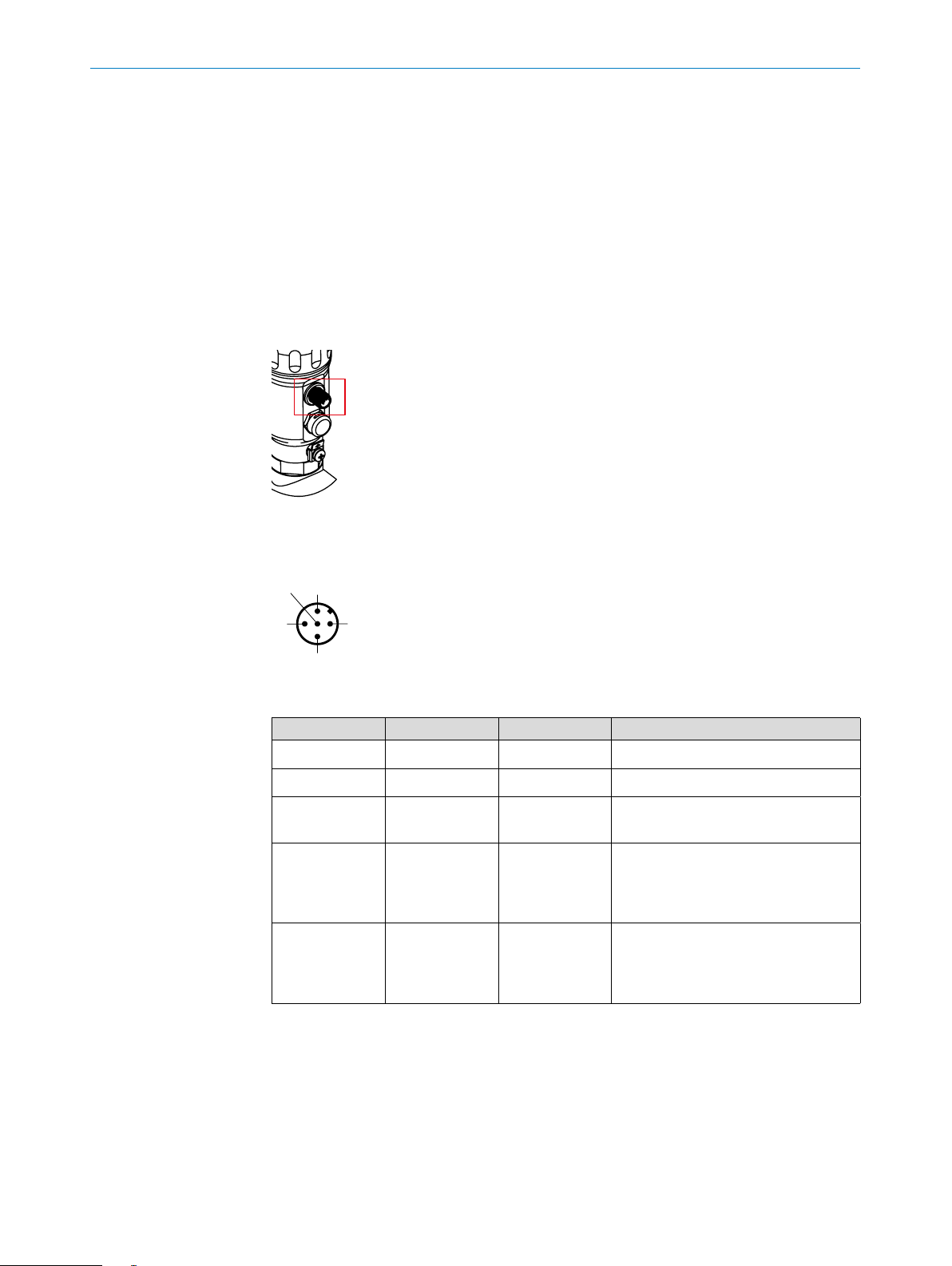

Fig. 4: DOSIC® M12 male connector

6.2.2 Pin assignment, M12 plug connector, 5-pin

Fig. 5: M12 x 1 plug connector, 5-pin

Contact Identication Wire color Description

1 L+ Brown Supply voltage

2 Q

3 M Blue Ground, reference potential for current

4 C/ Q

5 Q

A

1

2

White Analog current output 4 mA ... 20 mA

output

Black Digital input or digital output (PNP/

NPN/push-pull/open collector). IO-Link

communication (available only if Q1 is

dened as PNP or push-pull).

Gray Digital input or digital output (PNP/

NPN/push-pull/open collector). Switching/frequency/pulse output available

only if Q2 is dened as a digital output.

18

The table above shows only the standard pin assignment. Other pin assignments are

possible.

OPERATING INSTRUCTIONS | DOSIC® 8020955 /11HD/ 2018-12-12 | SICK AG

Subject to change without notice

Page 19

6.2.3 Pin assignment, M12 plug connector, 8-pin

6ELECTRICAL INSTALLATION

Fig. 6: M12 x 1 plug connector, 8-pin

Contact Identication Description

1 L+ Supply voltage

2 Q

2

3 M Ground, reference potential for current output

4 C/Q

1

5 No function

6 No function

7 Q

8 Q

A

B

The table above shows only the standard pin assignment. Other pin assignments are

possible.

Digital input or digital output (PNP/NPN/push-pull/open

collector). Switching/frequency/pulse output available

only if Q2 is dened as a digital output.

Digital input or digital output (PNP/NPN/push-pull/open

collector). IO-Link communication available only if Q

dened as PNP or push-pull.

is

1

Analog current output 4 mA ... 20 mA

Analog current output 4 mA ... 20 mA

The wire colors for 8-pin cables are not uniform. Always note the pin assignment of the

sensor.

Subject to change without notice

OPERATING INSTRUCTIONS | DOSIC® 8020955/11HD / 2018-12-12| SICK AG

19

Page 20

7 COMMISSIONING

7 Commissioning

7.1 Quick commissioning (with factory settings)

Quick commissioning is used in applications under reference conditions see “5.1 Instal-

lation conditions”.

Commissioning

1. Install the sensor in line with the installation conditions in “5 Mounting” During the

2. Switch on the supply voltage.

In the event of problems during commissioning, see “10 Troubleshooting”.

®

DOSIC

The sensor performs a self-test and is then ready for operation. The display shows

the current measured value.

installation process, the pipe system must be empty.

7.2 Operation

7.2.1 Display and operating buttons

The display automatically alternates between various states, which can be pre-congured using the menu.

You can access the menu by pressing the Set pushbutton for at least 2 seconds.

Set display A and display B

1. Make your selection in the Cong menu and conrm using Set.

2. Select Disp A or Disp B and conrm using Set.

3. Select the display value and conrm using Set.

7.2.2 Display and operating elements

7.2.3 IO-Link

20

OPERATING INSTRUCTIONS | DOSIC® 8020955 /11HD/ 2018-12-12 | SICK AG

57.00

Arrow pushbuttons: For navigating in the menu and changing values

Set pushbutton: For saving and conrming values and selecting the sub-menu

Esc pushbutton: For exiting the operating menu one step at a time

For operation via IO-Link, an IODD le, function blocks of common PLCs and a descrip-

tion of the available telegram parameters can be downloaded from www.sick.com.

IO-Link is available only if Q1 is dened as output and under Q1Type is dened as PNP

or Push-Pull.

L/min

Subject to change without notice

Page 21

7.3 Conguration of digital switching inputs and switching outputs

7.3.1 Selection of digital switching inputs and switching outputs

For Q1Mode (Q2Mode), you can choose either digital switching input or digital switching

output. If Q1 (Q2) has been set as an input, the switching behavior for this input is

dened in Q1Act (Q2Act). ResetV and CutO are available as options.

If Q1Mode (Q2Mode) is set as output, you can choose the behavior between ow,

temperature, and state (under Q1Proc or Q2Proc). If Q1Proc (Q2Proc) is set as a State,

Q1Stat (Q2Stat) can be selected as a Fail, Empty, Steril or Negatv.

If Q1Mode (Q2Mode) has been set as an output, you can choose hysteresis or window

function as switching output behavior. You can only choose between switch, frequency

and pulse if Q2Mode has been set as an output.

If Q1Mode (Q2Mode) has been set as an output, you can choose between the electrical

mode PNP, NPN, Push-Pull and open collector. The output type can be set to normally

open or normally closed with the parameter Q1Pol (Q2Pol).

Simulated values can be generated for Q1 and Q2 when chosen as output. The sim-

ulation mode can be set under QxSim. The available values are SimO, Active, and

Inactive. The values for active and inactive depend on the settings congured under

QxType and QxPol.

7COMMISSIONING

Note:

The following conguration options apply to both Q1 and Q2. They apply to Q2 only

when Q2Func is set to switch.

7.3.2 Conguration of the switching output

If the ow (or temperature) is uctuating around the set value, the hysteresis keeps the

switching status of the outputs stable.

When the ow (or temperature) is increasing, the output switches when the respective

switching point (SP) is reached; if the ow (or temperature) sinks again, the output

switches back only after the reset switching point (RP) has been reached.

The window function enables monitoring of a dened range. If the ow (or temperature)

is between window high (FH) and window low (FL), the output will be active (normally

open) and/or inactive (normally closed).

The error status of the measuring device reects the cable break monitoring. During an

error status, the measuring device switches to the safe state; i.e., the switching outputs

become inactive.

As far as the downstream signal evaluation is concerned, this corresponds to a cable

break.

7.3.3 Normally open with congurable hysteresis

Conguration (based on Q1 as an example)

Subject to change without notice

1. Congure the Q1 switching output as normally open.

• Select no in the Q1Pol menu and conrm using Set.

2. Congure hysteresis.

• Select Hyst in the Q1Out menu and conrm using Set.

3. Set the switching point.

OPERATING INSTRUCTIONS | DOSIC® 8020955/11HD / 2018-12-12| SICK AG

21

Page 22

7 COMMISSIONING

Switching output behavior

• Set the value for Flow or Temperature in the Q1SP menu and conrm using

Set.

4. Set the reset point.

• Set the value for Flow or Temperature in the Q1RP menu and conrm using

Set.

5. Select the electrical property (NPN/PNP/DRV/OC).

Select the parameter in the Q1Type menu and conrm using Set.

The following rules apply:

• Q1-PNP = Switching output in PNP circuit

• Q1-NPN = Switching output in NPN circuit

• Q1-DRV = Switching output in Push-Pull function

• Q1-OC = Switching output in open collector function

Flow/temperature

SP

RP

active

deactivated

Switching

Error signal

PNP NPN DRV OC Error status

output

Normally open/

HNO

Active High Low High (PNP switched) Low

Inactive Low High Low (NPN switched) High

7.3.4 Normally closed with congurable hysteresis

Conguration (based on Q1 as an example)

1. Congure the Q1 switching output as normally closed.

• Set the parameter in the Q1Pol menu to nc and conrm using Set.

2. Congure hysteresis.

t

Inactive

22

• Set the parameter in the Q1Out menu to Hyst and conrm using Set.

3. Set the switching point.

• Set the value for Flow or Temperature in the Q1SP menu and conrm using

Set.

4. Set the reset point.

• Set the value for Flow or Temperature in the Q1RP menu and conrm using

Set.

5. Select the electrical property (NPN/PNP/DRV/OC).

OPERATING INSTRUCTIONS | DOSIC® 8020955 /11HD/ 2018-12-12 | SICK AG

Subject to change without notice

Page 23

Select the parameter in the Q1Type menu and conrm using Set.

The following rules apply:

• NPN = Switching output in NPN circuit

• PNP = Switching output in PNP circuit

• DRV = Switching output in Push-Pull function

• OC = Switching output in open collector function

Switching output behavior

Flow/temperature

SP

RP

7COMMISSIONING

t

active

deactivated

Switching

output

Normally

closed/HNC

Active High Low High (PNP switched) Low

Inactive Low High Low (NPN switched) High

7.3.5 Normally open with window function

Conguration (based on Q1 as an example)

1. Congure the Q1 switching output as normally open.

• Set the parameter in the Q1Pol menu to no and conrm using Set.

2. Congure window mode.

• Set the parameter in the Q1Out menu to Window and conrm using Set.

3. Set the switching point.

• Set the value for Flow or Temperature in the Q1FH menu and conrm using

Set.

Error signal

PNP NPN DRV OC Error status

Inactive

Subject to change without notice

4. Set the reset point.

• Set the value for Flow or Temperature in the Q1FL menu and conrm using

Set.

5. Select the electrical property (NPN/PNP/DRV/OC).

Select the parameter in the Q1Type menu and conrm using Set.

The following rules apply:

• NPN = Switching output in NPN circuit

• PNP = Switching output in PNP circuit

• DRV = Switching output in Push-Pull function

OPERATING INSTRUCTIONS | DOSIC® 8020955/11HD / 2018-12-12| SICK AG

23

Page 24

7 COMMISSIONING

Switching output behavior

• OC = Switching output in open collector function

Flow/temperature

FH

FL

t

active

deactivated

Switching

output

Active High Low High (PNP switched) Low

Normally open/

FNO

Inactive Low High Low (NPN switched) High

7.3.6 Normally closed with window function

Conguration (based on Q1 as an example)

1. Congure the Q1 switching output as normally closed.

• Set the parameter in the Q1Pol menu to nc and conrm using Set.

2. Congure window mode.

• Set the parameter in the Q1Out menu to Window and conrm using Set.

3. Set the switching point.

Error signal

PNP NPN DRV OC Error status

Inactive

• Set the value for Flow or Temperature in the Q1FH menu and conrm using

Set.

4. Set the reset point.

• Set the value for Flow or Temperature in the Q1FL menu and conrm using

Set.

5. Select the electrical property (NPN/PNP/DRV/OC).

Select the parameter in the Q1Type menu and conrm using Set.

The following rules apply:

• NPN = Switching output in NPN circuit

• PNP = Switching output in PNP circuit

• DRV = Switching output in Push-Pull function

• OC = Switching output in open collector function

24

OPERATING INSTRUCTIONS | DOSIC® 8020955 /11HD/ 2018-12-12 | SICK AG

Subject to change without notice

Page 25

Switching output behavior

Flow/temperature

FH

FL

active

deactivated

7COMMISSIONING

t

Error signal

7.3.7 Pulse output

Switching

output

Normally

closed/FNC

Active High Low High (PNP switched) Low

Inactive Low High Low (NPN switched) High

PNP NPN DRV OC Error status

Inactive

If pulse has been selected as output for Q2, PlsVal can be used to dene the pulse

value (denition of the volume that generates a pulse). PlsWid can be used to dene

the pulse width (duration of a pulse in μs).

Example:

PulsVal = 1000 ml, PulsWid = 50 μs

A pulse will be generated when 1000 ml are counted and the pulse duration will be 50

μs.

It is important to ensure that the pulse width set is as short as possible and as long as

necessary so that the device connected to the digital output still recognizes the pulse

(to avoid overlapped pulses). If the set pulse value is reached, a pulse is sent out at the

digital output.

If the pulse valency chosen by the user is too low, the pulse repetition rate can get too

high, leading to the sensor outputting a lower number of pulses than it should. If this is

the case, the sensor will show the warning [i]HiFrq on the display (and “Q2 frequency

too high” over the active notications of IO-Link).

Example:

Conguration: PlsVal = 100 μL

Measured owrate = 60 L/min --> Pulse repetition rate clipped to 100 ns -->

Warning [i]HiFrq

7.3.8 Frequency output

If frequency has been selected as the output for Q2, FrqMax and FrqMin can be used to

dene the maximum and minimum frequencies.

The maximum frequency corresponds to the fullscale value. The minimum frequency

corresponds to the intial scale value.

The fullscale value and the initial scale value are dened by Q2SP and Q2RP respectively.

Subject to change without notice

OPERATING INSTRUCTIONS | DOSIC® 8020955/11HD / 2018-12-12| SICK AG

25

Page 26

7 COMMISSIONING

Q2SP can be used to dene the maximum ow, and Q2RP can be used to dene the

minimum ow.

Example:

FrqMax = 10.000 (Hz)

FrqMin = 0 (Hz)

Q2SP = 36.00 (L/min)

Q2RP = 0 (L/min)

With these settings, the output frequency varies between 0 and 10.000 Hz when the

ow is changed from 0 to 36 L/min. If the ow is 18 L/min, for example, the output

frequency is 5.000 Hz.

The frequency output can be simulated under Q2Sim.

Depending on the parameterization of the frequency output, the output frequency can

be higher than 10 kHz or lower than 0 Hz. In case the frequency is too high, the sensor

will show the warning [i]HiFrq on the display (and “Q2 frequency too high” over the

active notications of IO-Link).

In case the frequency is too low, the sensor will show the warning [i]LoFrq on the display

(and “Q2 frequency too low” over the active notications of IO-Link).

Example:

Conguration: FrqMax = 10kHz, FrqMin = 0Hz, Q2SP = 10.0L/min, Q2RP = 0.0L/min

Measured owrate = 20 L/min --> Output frequency clipped to 10 kHz à Warning [i]

HiFrq

Measured owrate = -20 L/min --> Output frequency clipped to 0 kHz à Warning [i]LoFrq

7.4 Conguration of analog outputs

Conguration

1. Select the QaType or QbType (only 8-pin variant) menu using the arrow pushbut-

tons and conrm using Set.

The available values are O or 4-20 mA.

7.4.1 Current output 4-20 mA

The analog current outputs Qa and Qb can be congured as ow or/and temperature.

However, Qb can only be congured in the 8-pin variant.

Conguration (based on Qa as an example)

1. Set the parameter in the QaType menu to 4-20 mA.

2. Select ow or temperature (under QaProc).

26

3. Set the upper limit value (20 mA or 4 mA, depending on the setting under QaPol).

• In the QaHigh menu, set the value for ow range (e.g., 100.0) or temperature

(e.g., 60 °C).

4. Set the lower limit value (4 mA or 20 mA, depending on the setting under QaPol).

• In the QaLow menu, set the value for ow range (e.g., 50.0) or temperature

(e.g., 40 °C).

5. Invert the signal.

The analog signal can be inverted in the QaPol menu.

Set the parameter to “Inverted” in the QaPol menu.

OPERATING INSTRUCTIONS | DOSIC® 8020955 /11HD/ 2018-12-12 | SICK AG

Subject to change without notice

Page 27

• Normal = Analog output signal as congured

• Inverted = Analog output signal is inverted; the value congured for QaHigh

6. Set QaFail to 3.5 mA or 21.5 mA.

In the event of an error, a corresponding signal is output.

7.5 Advanced functions

7.5.1 Measurement Mode

Two dierent application specic measurement modes are available:

• Standard: standard measurement mode with high measurement accuracy for

• Dynamic: fast measurement mode suitable for dynamic applications (e.g.

Conguration

1. Set the parameter Mode in the Meas menu.

The available values are: Stndrd, Dynamc

7COMMISSIONING

corresponds to 4 mA and the value congured for QaLow corresponds to 20

mA

steady/slow changes processes.

pulsating ow pumps).

NOTE

When using the Dynamc measurement mode, it is recommended to increase the sen-

sitivity of the sensor in order to react to changes in the owrate as quickly as possible.

This may be done by using the following settings in the CutO menu (see 7.5.3 Zero

ow cuto):

Set = 0.15 L/min

Reset = 0.05 L/min .

7.5.2 Activate ltering

Smoothing of the measured value, e.g., if ow is irregular (e.g. when pumps are starting

and stopping). For fast changes, the average of the measured values over a predened

number of seconds is output.

Conguration

1. Set the parameter in the Filter menu.

7.5.3 Zero ow cuto

As the DOSIC

smallest movements in the medium. If the ow rate of a medium is zero, this can result

in inaccurate measurements.

The available values are: O, 500 ms, 1 s, 2 s, 5 s, 10 s.

®

is a highly sensitive piece of equipment, the sensor detects even the

Subject to change without notice

The leak ow volume suppression feature helps prevent these measurements from

triggering unwanted switching behavior or causing incorrect meter readings. With this

feature, the sensor treats very low values as zero ow readings. If the ow drops below

a dened reset value, the display and output are reset to zero. When the ow rises

above the dened set value once more, the measurements continue.

OPERATING INSTRUCTIONS | DOSIC® 8020955/11HD / 2018-12-12| SICK AG

27

Page 28

7 COMMISSIONING

Conguration

NOTE

The analog output outputs the current which has been set for Q = 0 L/min.

The frequency output outputs the frequency set for Q = 0 L/min.

The pulse output does not output any pulses at Q = 0 L/min.

1. Select the Meas menu using the arrow pushbuttons and conrm using Set.

2. Select the Cuto menu using the arrow pushbuttons and conrm using Set.

3. Select the Mode menu using the arrow pushbuttons and conrm using Set.

The available values are Active and Inactive.

4. Select the value and conrm using Set.

5. Set the parameter in the Set menu.

• Select the value and conrm using Set.

6. Set the parameter in the Reset menu.

• Select the value and conrm using Set.

7.5.4 Empty measurement channel

You can pre-congure the required switching behavior that will take eect if the measurement channel is empty.

Conguration

1. Select the Meas menu using the arrow pushbuttons and conrm using Set.

2. Select the Empty menu using the arrow pushbuttons and conrm using Set.

The available values are 0-Flow and Fail.

3. Select the value and conrm using Set. For temperature the unit is shown as cho-

sen in the Units menu.

Parameter selection

Parameter Function

0-Flow The analog output is set to the relevant

Fail The error signal is output via Qx-Sta if

When the Q1Stat (Q2Stat) is selected as Fail or Empty the following situation and condition can be found on the output of the device:

value dened for QxLow.

QxStat is set as Fail.

28

State of channel Mapping of

QxStat

Filled with the

medium

Empty Empty ZeroFlow Ok High

Empty Empty Failure Fail Low (safe state)

OPERATING INSTRUCTIONS | DOSIC® 8020955 /11HD/ 2018-12-12 | SICK AG

Empty or Failure ZeroFlow or

Empty behavior System state Qx state

(normally open, as

long as no other

failure is present)

Ok Low

Failure

Subject to change without notice

Page 29

7COMMISSIONING

State of channel Mapping of

Empty Failure ZeroFlow Ok Low

Empty Failure Failure Fail High

7.5.5 Congure reverse ow direction

If the measurement medium ows through the sensor against the ow direction (see

arrow on sensor housing), the sensor can be congured to prevent negative measured

values.

Conguration

1. Select the Meas menu using the arrow pushbuttons and conrm using Set.

2. Select the Revrsl menu using the arrow pushbuttons and conrm using Set.

The available values are Active, Inactive and Abs.

3. Select the value and conrm using Set.

7.5.6 Simulate ow or temperature

Even if there is no liquid in the measurement channel yet, it is possible to select a ow

or temperature in the menu in order to test the sensor conguration.

When simulating a ow, all outputs on the DOSIC

guration. The function should not be selected until a conguration is complete.

QxStat

Empty behavior System state Qx state

®

are set according to the dened con-

(normally open, as

long as no other

failure is present)

Conguration

1. Select the Cong menu using the arrow pushbuttons and conrm using Set.

2. Select the SimFlw or SimTmp menu using the arrow pushbuttons and conrm

using Set.

3. Select the value and conrm using Set.

For temperature the unit is shown as chosen in the Units menu.

Parameter selection

SimFlw SimTmp

SimO: O SimO: O

-100 % ow 0 °C (32 °F)

-80 % ow 20 °C (68 °F)

-60 % ow 40 °C (104 °F)

-40 % ow 60 °C (140 °F)

-20 % ow 80 °C (176 °F)

0 % ow 100 °C (212 °F)

+20 % ow

+40 % ow

+60 % ow

+80 % ow

+100 % ow

Subject to change without notice

OPERATING INSTRUCTIONS | DOSIC® 8020955/11HD / 2018-12-12| SICK AG

29

Page 30

7 COMMISSIONING

NOTE

When the sensor is switched o and on again, the simulation mode is reset. The sensor

resumes live measurement.

7.5.7 Media compensation

This functions allows the sensor to be calibrated for a new medium via the 0-Flow menu

item or scaling the measured value with a dened factor via the Linear menu.

Conguring calibration for new medium

1. Select the Meas menu using the arrow pushbuttons and conrm using Set.

2. Select 0-Flow using the arrow pushbuttons and conrm using Set.

3. Select AutoCal using the arrow pushbuttons and conrm using Set.

The automatic calibration process is executed.

NOTE

• The measurement channel must be completely lled with medium.

• There must be no air in the measurement channel.

• The medium must not be owing while conguration takes place.

Conguring to compensate measurements

1. Select the Meas menu using the arrow pushbuttons and conrm using Set.

2. Select Linear using the arrow pushbuttons and conrm using Set.

3. Select LinFac using the arrow pushbuttons and conrm using Set.

Select the value and conrm using Set.

The measured value is multiplied by the relevant factor and output.

Default value is 1000 (corresponds to 100 %). Flow is represented 1:1.

Example:

LinFac = 1200 (corresponds to 120 %). Flow is increased by 20 %.

LinFac = 800 (corresponds to 80 %). Flow is reduced by 20 %.

7.5.8 Sterilization detection

The detection of a sterilization cycle is be performed by monitoring the process temperature. The following parameters are used under the menu Steril located under the

menu Meas:

Set (Sterilization temperature set point)

Reset (Sterilization temperature reset point)

Time (Sterilization time)

A sterilization cycle is detected, if the process temperature exceeds the sterilization

temperature set point and stays above the sterilization temperature reset point for at

least as long as the sterilization time.

30

Conguration

1. Select the Meas menu using the arrow pushbuttons and conrm using Set.

2. Select the Steril menu item using the arrow pushbuttons and conrm using Set.

OPERATING INSTRUCTIONS | DOSIC® 8020955 /11HD/ 2018-12-12 | SICK AG

Subject to change without notice

Page 31

3. Select Set using the arrow pushbuttons and conrm using Set.

4. Select the value and conrm using Set.

5. Select Reset using the arrow pushbuttons and conrm using Set.

6. Select the value and conrm using Set.

7. Select Time using the arrow pushbuttons and conrm using Set.

8. Select the value and conrm using Set.

A notication of the sterilization cycle can be output over a status output conguring

under the Q1Stat (Q2Stat) as Steril.

7.5.9 Evaluating signal quality

The signal quality is evaluated on the base of four dierent parameters: SigQu1,

SigQu2, SigQu3 and SigQu4.

These are described as follows.

SigQu1:

Indication for the robustness of the measurement environment. A low signal quality is

an indication for disturbances such as strong vibration on the measurement pipe or

turbulence formation due to a not correct installation conditions.

7COMMISSIONING

Value range: 0 to 100%

Good signal: > 50 %

SigQu2:

Indication for the attenuation of the ultrasound signal caused by the measured

medium. A low signal quality is an indication that some medium parameters could inuence the measurement (e.g. as viscosity or density too high).

Value range: 0 to 100%

Good signal: > 10 %

SigQu3:

Indication for the robustness of the ultrasound signals. A low signal quality is an indication for interferences on the signal path (e.g. gas bubbles or solid particles).

Value range: 0 to 100%

Good signal: > 30 %

SigQu4:

Not used. Available for future developments (always shown at 100 %).

7.5.10 Activating the display lock

To prevent the sensor from being tampered with, password protection can be activated

for the display.

Conguration

Subject to change without notice

When the protection is active, the expert password (036742) must be entered before

the menu can be accessed.

The menu is only unlocked once the correct password is entered.

1. Select the Cong menu using the arrow pushbuttons and conrm using Set.

2. Select the Lock menu item using the arrow pushbuttons and conrm using Set.

OPERATING INSTRUCTIONS | DOSIC® 8020955/11HD / 2018-12-12| SICK AG

31

Page 32

7 COMMISSIONING

3. The password protection is activated using Activate.

NOTE

• The user is logged out again after 5 minutes of inactivity.

• When the display is locked, only the congured measured value display can be seen.

7.5.11 Output options for Disp A and Disp B

Outside of the menu, the display alternates between dierent values, which can be

pre-congured via Disp A and Disp B.

• Flow (Flow)

• Fl+Unt (Flow and measuring unit)

• Volume (Volume)

• Temper (Temperature)

• QaCurr (Current value)

• QbCurr (Current value)

• QxStat (Status of the output)

• c (m/s) (Speed of sound)

• v (m/s) (Flow velocity)

7.5.12 Selecting display unit

This setting enables you to congure the units used for ow, volume, and temperature.

Conguration

1. Select the Cong menu using the arrow pushbuttons and conrm using Set.

2. Select the Units sub-menu using the arrow pushbuttons and conrm using Set.

Set values: Flow, Volume, Temper.

3. Select the value and conrm using Set.

Depending on the parameter, the following units are available:

Parameter Unit

Flow • L/min

Volume • L

Temper • °C

• L/h

3

/h

• m

• G/min

• Gal/h

3

• m

• Gal

• °F

32

OPERATING INSTRUCTIONS | DOSIC® 8020955 /11HD/ 2018-12-12 | SICK AG

Subject to change without notice

Page 33

7.5.13 Resetting to factory settings

Resetting all parameters to factory settings

1. Select the RstFac menu using the arrow pushbuttons and conrm using Set.

2. Press Set again.

7COMMISSIONING

Subject to change without notice

OPERATING INSTRUCTIONS | DOSIC® 8020955/11HD / 2018-12-12| SICK AG

33

Page 34

8 MENU OVERVIEW

2 s

8 Menu overview

RUN

RUN

RUN

RUN

RUN

RUN

Set Esc

DispA

DispB

[PRIO1]

[PRIO2]

[PRIO3]

Unit

L/min

L/h

m³/h

G/min

Gal/h

0.00

Esc

Set

Q1-##

MEN

Q1-Flw

MEN

Q1-Tmp

MEN

Q1-Sta

MEN

Q1-In

MEN

Set

Q1Mode

MEN

Esc

Q1Proc

MEN

Q1Act

MEN

Q1Out

MEN

Q1SP

MEN

Q1RP

MEN

Q1FH

MEN

Q1FL

MEN

Q1Stat

MEN

Set

Esc

Set

Esc

Set

Set

Esc

Set

Set

Set

Set

Set

SET

Output

SET

Input

SET

Flow

SET

Temper

SET

Status

SET

ResetV, CutOff

SET

Hyst

SET

Window

SET

###

SET

###

SET

###

SET

###

SET

Fail

SET

Empty

SET

Steril

Set

Set

Set

Always available

Conguration-dependent

Sub-menu-dependent

Variant-dependent

Failure

Set

Set

Set

Set

Set

Set

Set

Set

Set

Set

Set

Set

MEN

MEN

MEN

Q1Pol

Q1Sim

Q1Type

Set

Esc

Set

Esc

Set

Esc

SET

Negatv

SET

no, nc

SimOff,

SET

Inactv, Active

DRV, OC,

SET

NPN, PNP

Set

Set

Set

Set

Q1Proc is visible when Q1Mode is set as an Output.

Q1Act is visible when Q1Mode is set as an Input.

Q1Out is visible when Q1Mode is set as an Output and Q1Proc is set as Flow or Temper.

Q1SP and Q1RP are visible when Q1Out is set as Hyst.

Q1FH and Q1FL are visible when Q1Out is set as Window.

Q1Stat is visible when Q1Proc is set as Status.

34

OPERATING INSTRUCTIONS | DOSIC® 8020955 /11HD/ 2018-12-12 | SICK AG

Subject to change without notice

Page 35

MEN

Q1Pol

Q1Sim

Q1Type

Esc

Set

Esc

Set

Esc

Set

MEN

Q1RP

MEN

Q1FH

MEN

Q1FL

MEN

Set

Set

Set

###

SET

###

SET

###

SET

Q1Stat

MEN

Fail

SET

Empty

SET

Steril

SET

Set

Set

no, nc

SET

SimOff,

Inactv, Active

SET

DRV, OC,

NPN, PNP

SET

Set

Set

Set

Set

MEN

MEN

MEN

Negatv

SET

Set

Set

Set

Set

Set

MEN

MEN

MEN

MEN

Q2-##

Q2-Flw

Q2-Tmp

Q2-Sta

Q2-In

Set

Q2Mode

MEN

Esc

Q2Proc

MEN

Q2Func

MEN

Q2SP

MEN

Q2RP

MEN

Q2FH

MEN

8MENU OVERVIEW

Set

SET

Output

Esc

SET

Input

Set

SET

Flow

MEN

Esc

SET

Temper

SET

Status

Set

SET

Pulse

Esc

SET

Freq

SET

Switch

Set

SET

###

Set

SET

###

Set

SET

###

Set

Set

Set

Set

Set

Set

Set

Set

Set

Set

Set

Always available

Conguration-dependent

Sub-menu-dependent

Variant-dependent

Failure

MEN

MEN

MEN

MEN

MEN

MEN

MEN

MEN

MEN

MEN

MEN

Q2FL

PlsVal

PlsWid

FrqMax

FrqMin

Q2Act

Q2Out

Q2Stat

Q2Pol

Q2Sim

Q2Type

Set

SET

Set

Set

Set

Set

Set

Set

Esc

Set

Esc

Set

Esc

Set

Esc

Set

Esc

###

SET

###

SET

###

SET

###

SET

###

SET

ResetV, CutOff

SET

Hyst

SET

Window

SET

Fail

SET

Empty

SET

Steril

SET

Negatv

SET

no, nc

SimOff, Inactv,

SET

Active

DRV, OC,

SET

NPN, PNP

Set

Set

Set

Set

Set

Set

Set

Set

Set

Set

Set

Set

Set

Set

Set

Q2Proc is visible when Q2Mode is set as an Output.

Q2Act is visible when Q2Mode is set as an Input.

Q2Func is visible when Q2Mode is set as anOutput and Q2Proc is set as Flow.

Q2Out is visible when Q2Func is set as Switch and Q2Proc is set as Temper.

Q2SP and Q2RP are visible when Q2Out is set as Hyst and Q2Func as Freq.

Q2FH and Q2FL are visible when Q2Out is set as Window.

FrqMax and FrqMin are visible when Q2Func is set as Freq.

PlsVal and PlsWidare visible when Q2Func is set as Pulse.

Q2Stat is visible when Q2Proc is set as Status.

Subject to change without notice

OPERATING INSTRUCTIONS | DOSIC® 8020955/11HD / 2018-12-12| SICK AG

35

Page 36

8 MENU OVERVIEW

Q2-##

MEN

Q2-Flw

MEN

Q2-Tmp

MEN

Q2-Sta

MEN

Q2-In

MEN

Esc

Set

MEN

Q2Mode

MEN

Q2Proc

Esc

Set

Esc

Set

Output

SET

Input

SET

MEN

Q2Func

Esc

Set

Pulse

SET

Freq

SET

Switch

SET

Q2SP

Q2RP

Q2FH

Q2FL

MEN

MEN

MEN

MEN

MEN

Set

Set

Set

Set

###

SET

###

SET

###

SET

###

SET

PlsVal

MEN

Set

ResetV, CutOff

SET

MEN

MEN

MEN

Q2Pol

Q2Sim

Q2Type

Esc

Set

Esc

Set

Esc

Set

no, nc

SET

SimOff, Inactv,

Active

SET

DRV, OC,

NPN, PNP

SET

Q2Stat

MEN

Esc

Set

Fail

SET

Empty

SET

Steril

SET

Set

Set

Flow

SET

Temper

SET

Status

SET

Set

Set

Set

Set

Set

Set

Set

Set

Set

Set

Set

PlsWid

Esc

Set

Hyst

SET

Window

SET

Set

Set

MEN

FrqMax

Q2Act

Q2Out

FrqMin

Set

Set

Set

Set

###

SET

###

SET

###

SET

###

SET

Set

Set

Set

Set

Set

Set

Set

MEN

MEN

MEN

MEN

Set

Set

Set

Negatv

SET

Set

QaProc, QaPol, QaHigh, QaLow, QaFail and QaSim are visible when QaType is set as 4-20 mA.

Qa-##

MEN

Qa-Off

MEN

Qa-Flw

MEN

Qa-Tmp

MEN

Set

QaType

MEN

Esc

QaProc

MEN

QaPol

MEN

QaHigh

MEN

QaLow

MEN

QaFail

MEN

QaSim

MEN

Set

SET

Esc

SET

Set

SET

Esc

SET

Set

SET

SET

Set

Set

SET

Set

SET

Esc

Set

SET

Esc

Off

4 - 20mA

Flow

Temp

Normal, Invrtd

###

###

###

###

Set

Set

Set

Always available

Conguration-dependent

Sub-menu-dependent

Variant-dependent

Failure

Set

Set

Set

Set

Set

Set

36

OPERATING INSTRUCTIONS | DOSIC® 8020955 /11HD/ 2018-12-12 | SICK AG

Subject to change without notice

Page 37

Q2RP

Q2FH

Q2FL

MEN

MEN

MEN

Set

Set

Set

###

SET

###

SET

###

SET

PlsVal

MEN

Set

ResetV, CutOff

SET

MEN

MEN

MEN

Q2Pol

Q2Sim

Q2Type

Esc

Set

Esc

Set

Esc

Set

no, nc

SET

SimOff, Inactv,

Active

SET

DRV, OC,

NPN, PNP

SET

Q2Stat

MEN

Esc

Set

Fail

SET

Empty

SET

Steril

SET

QaProc

MEN

Esc

Set

Flow

SET

Temp

SET

QaHigh

MEN

QaLow

MEN

Set

Set

###

SET

###

SET

QaPol

MEN

Set

Normal, Invrtd

SET

QaFail

MEN

QaSim

MEN

Esc

Set

Esc

Set

###

SET

###

SET

Set

Set

Set

Set

PlsWid

Esc

Set

Hyst

SET

Window

SET

Set

Set

MEN

FrqMax

Q2Act

Q2Out

FrqMin

Set

Set

Set

Set

###

SET

###

SET

###

SET

###

SET

Set

Set

Set

Set

Set

Set

Set

MEN

MEN

MEN

MEN

Set

Set

Set

Qa-##

MEN

Qa-Off

MEN

Qa-Flw

MEN

Qa-Tmp

MEN

Esc

Set

MEN

QaType

Esc

Set

Off

4 - 20mA

SET

SET

Set

Set

Set

Set

Set

Set

Set

Set

Set

Negatv

SET

Set

8MENU OVERVIEW

Qb-##

MEN

Qb-Off

MEN

Qb-Flw

MEN

Qb-Tmp

MEN

QbProc, QbPol, QbHigh, QbLow, QbFail and QbSim are visible when QbType is set as 4-20 mA.

Set

QbType

MEN

Esc

QbProc

MEN

QbPol

MEN

QbHigh

MEN

QbLow

MEN

QbFail

MEN

QbSim

MEN

Set

SET

Esc

SET

Set

SET

Esc

SET

Set

SET

SET

Set

Set

SET

Set

SET

Esc

Set

SET

Esc

Off

4 - 20mA

Flow

Temp

Normal, Invrtd

###

###

###

###

Set

Set

Always available

Conguration-dependent

Sub-menu-dependent

Set

Variant-dependent

Failure

Set

Set

Set

Set

Set

Set

Subject to change without notice

OPERATING INSTRUCTIONS | DOSIC® 8020955/11HD / 2018-12-12| SICK AG

37

Page 38

8 MENU OVERVIEW

Always available

Conguration-dependent

Sub-menu-dependent

Variant-dependent

Failure

38

OPERATING INSTRUCTIONS | DOSIC® 8020955 /11HD/ 2018-12-12 | SICK AG

Subject to change without notice

Page 39

8MENU OVERVIEW

Config

MEN

Meas

MEN

Esc

Set

Esc

Set

MEN

Disp A

MEN

MEN

MEN

Units

SimFlw

SimTmp

MEN

Lock

MEN

Disp B

MEN

Filter

MEN

CutOff

MEN

Revrsl

MEN

Empty

MEN