Page 1

deTem4 Core Ex

Multiple light beam safety device

O P E R A T I N G I N S T R U C T I O N S

Page 2

Described product

deT

em4 Core Ex

Manufacturer

SICK AG

Erwin-Sick-Str. 1

79183 Waldkirch

Germany

Legal information

his work is protected by copyright. Any rights derived from the copyright shall be

T

reserved for SICK AG. Reproduction of this document or parts of this document is only

permissible within the limits of the legal determination of Copyright Law. Any modifica‐

tion, abridgment or translation of this document is prohibited without the express writ‐

ten permission of SICK AG.

The trademarks stated in this document are the property of their respective owner.

© SICK AG. All rights reserved.

Original document

T

his document is an original document of SICK AG.

2

O PE R AT I NG IN S TR U CT I ON S | deTem4 Core Ex 8022875/2019-03-04 | SICK

Subject to change without notice

Page 3

Contents

CONTENTS

1 About this document........................................................................ 6

1.1 Function of this document....................................................................... 6

1.2 Scope......................................................................................................... 6

1.3 Target groups and structure of these operating instructions................ 6

1.4 Additional information.............................................................................. 7

1.5 Symbols and document conventions...................................................... 7

2 Safety information............................................................................ 9

2.1 General safety notes................................................................................ 9

2.2 Intended use............................................................................................. 9

2.3 Requirements for the qualification of personnel.................................... 11

3 Product description........................................................................... 13

3.1 Setup and function................................................................................... 13

3.2 Product characteristics............................................................................ 14

3.2.1 Status indicators...................................................................... 14

3.3 Example applications............................................................................... 16

4 Project planning................................................................................ 17

4.1 Manufacturer of the machine.................................................................. 17

4.2 Operating entity of the machine.............................................................. 17

4.3 Design........................................................................................................ 17

4.3.1 Scanning range and beam separation................................... 18

4.3.2 Minimum distance from the hazardous point....................... 18

4.3.3 Minimum distance from reflective surfaces.......................... 20

4.3.4 Protection against interference from systems in close prox‐

y to each other................................................................... 22

imit

4.4 Integrating into the electrical control....................................................... 22

4.4.1 Restart interlock...................................................................... 25

4.4.2 External device monitoring (EDM).......................................... 25

4.4.3 Connection diagrams.............................................................. 26

4.5 Testing plan............................................................................................... 26

4.5.1 Test rod check.......................................................................... 27

4.5.2 Visual check of the machine and the protective device........ 28

5 Mounting............................................................................................. 29

5.1 Safety......................................................................................................... 29

5.2 Unpacking.................................................................................................. 30

5.3 Mounting................................................................................................... 30

5.3.1 Mount the multiple light beam safety device in the explo‐

sion-proof enclosure (only if being used in North America).. 32

5.3.2 Mount the optional cable gland.............................................. 34

5.3.3 Mount the handles to the cover of the explosion-proof

enclosure.................................................................................. 34

5.3.4 Mount the multiple light beam safety device........................ 35

8022875/2019-03-04 | SICK O PE R AT I NG IN S TR U CT I ON S | deTem4 Core Ex

Subject to change without notice

3

Page 4

CONTENTS

6 Electrical installation........................................................................ 42

6.1 Safety......................................................................................................... 42

6.2 System connection (M12, 5-pin)............................................................. 44

6.3 System connection via connection cable (M12, 5-pin to 8-pin)............ 45

7 Commissioning.................................................................................. 46

7.1 Safety......................................................................................................... 46

7.2 Overview.................................................................................................... 46

7.3 Switching on.............................................................................................. 47

7.4 Sender and receiver alignment................................................................ 47

7.4.1 Aligning the sender and receiver............................................ 47

7.4.2 Aligning the sender, receiver, and deflector mirror................ 48

7.4.3 Alignment with the alignment bracket................................... 49

7.4.4 Indication of the alignment quality......................................... 50

7.5 Check during commissioning and modifications.................................... 51

8 Operation............................................................................................ 52

8.1 Safety......................................................................................................... 52

8.2 Regular thorough check........................................................................... 52

9 Maintenance...................................................................................... 53

9.1 Safety......................................................................................................... 53

9.2 Regular cleaning....................................................................................... 53

9.3 Regular thorough check........................................................................... 55

10 Troubleshooting................................................................................. 56

10.1 Safety......................................................................................................... 56

10.2 Diagnostic LEDs........................................................................................ 56

10.2.1 Fault indicators........................................................................ 56

11 Decommissioning............................................................................. 59

11.1 Protection of the environment................................................................. 59

11.2 Disposal..................................................................................................... 59

12 Technical data.................................................................................... 60

12.1 Data sheet................................................................................................. 60

12.2 Table of weights........................................................................................ 62

12.3 Dimensional drawings.............................................................................. 63

13 Ordering information........................................................................ 66

13.1 Scope of delivery....................................................................................... 66

13.2 Ordering information deTem4 Core Ex.................................................... 66

14 Accessories........................................................................................ 67

14.1 Brackets.................................................................................................... 67

14.2 Mounting accessories.............................................................................. 68

14.3 Connectivity............................................................................................... 68

4

O PE R AT I NG IN S TR U CT I ON S | deTem4 Core Ex 8022875/2019-03-04 | SICK

Subject to change without notice

Page 5

CONTENTS

14.4 Alignment aid............................................................................................ 68

14.5 Deflector mirrors....................................................................................... 69

14.5.1 Function and use..................................................................... 69

14.5.2 Change in scanning range using deflector mirrors................ 69

14.5.3 Deflector mirror – ordering information................................. 69

14.5.4 Deflector mirror PNS75 - ordering information...................... 69

14.5.5 Deflector mirror PNS125 - ordering information................... 69

14.6 Test rods.................................................................................................... 70

15 Annex.................................................................................................. 71

15.1 Compliance with EU directives................................................................. 71

15.2 Note on specified standards.................................................................... 72

15.3 Checklist for initial commissioning and commissioning........................ 73

16 List of figures..................................................................................... 74

17 List of tables....................................................................................... 75

8022875/2019-03-04 | SICK O PE R AT I NG IN S TR U CT I ON S | deTem4 Core Ex

Subject to change without notice

5

Page 6

BOUT THIS DOCUMENT

1 A

1 About this document

1.1 Function of this document

These operating instructions contain the information needed during the life cycle of the

iple light beam safety device.

mult

Operating instructions of the multiple light beam safety device must be made available

to all people who work with the device.

Please read these operating instructions carefully and make sure that you understand

the content fully before working with the multiple light beam safety device.

1.2 Scope

These operating instructions only apply to the deTem4 Core Ex multiple light beam

s

afety device with the following type label entry in the Operating Instructions field:

8022833

•

This document is included with the following SICK part numbers (this document in all

available language versions):

8022833

•

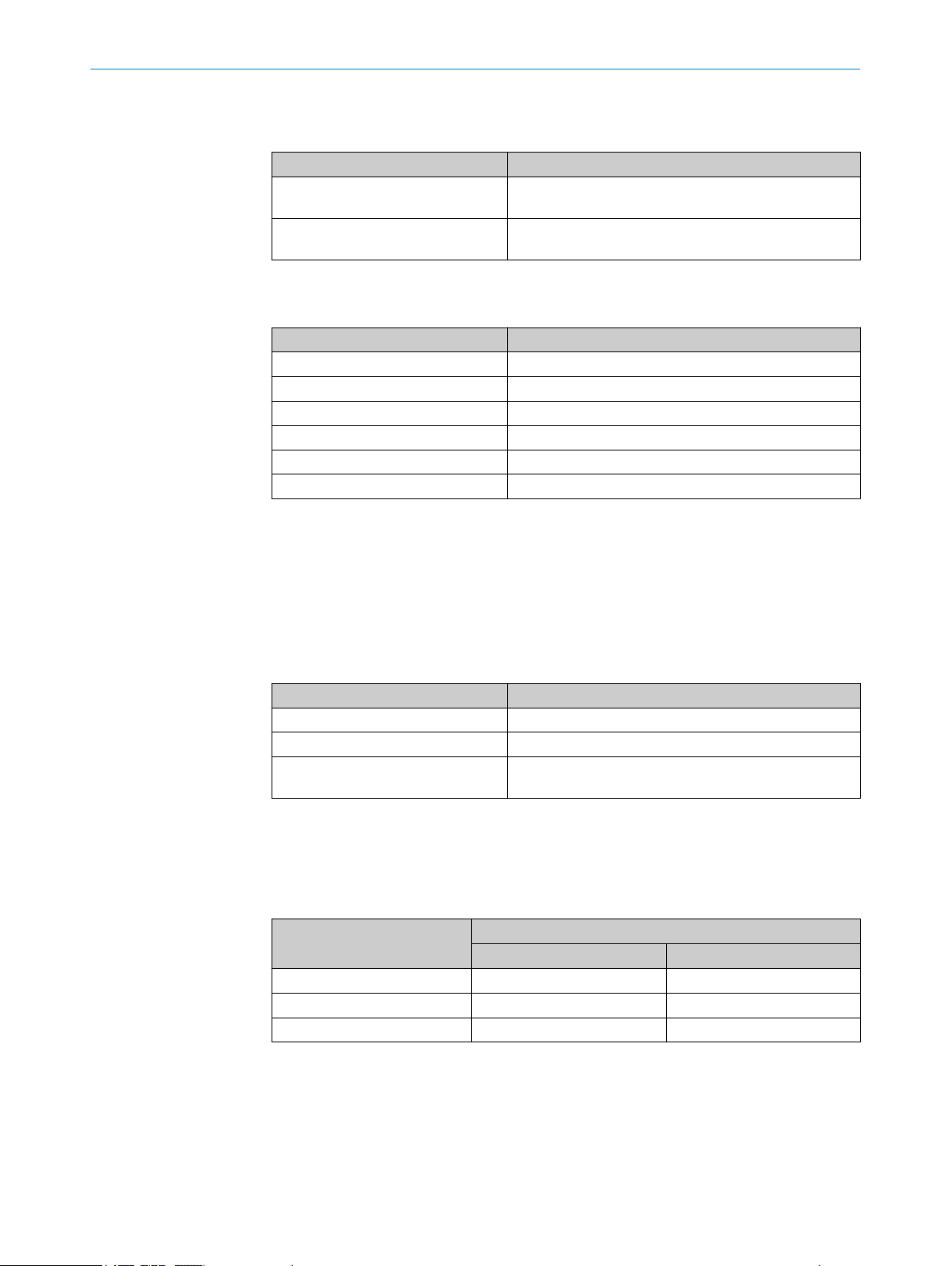

1.3 Target groups and structure of these operating instructions

These operating instructions are intended for the following target groups: project devel‐

oper

s (planners, developers, designers), installers, electricians, safety experts (such as

CE authorized representatives, compliance officers, people who test and approve the

application), operators, and maintenance personnel.

The structure of these operating instructions is based on the life cycle phases of the

multiple light beam safety device: project planning, mounting, electrical installation,

commissioning, operation, and maintenance.

In many applications, therefore, the target groups consist of the manufacturer and the

operating entity of the machine in which the multiple light beam safety device is inte‐

grated:

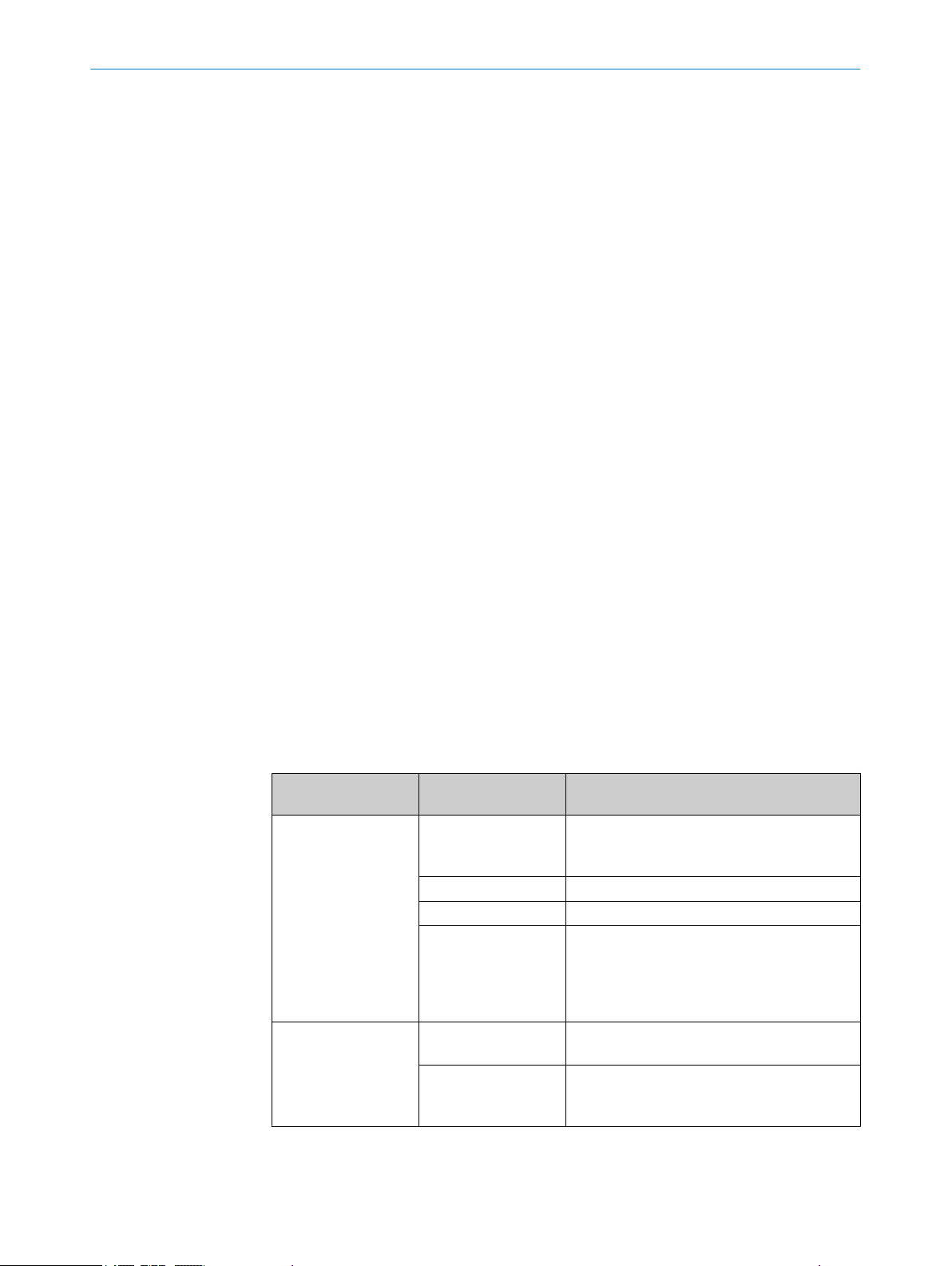

Area of responsibility Target group Special chapters of these operating instruc‐

Manufacturer Project developers

(planners, developers,

designers)

Installers Mounting, pa

Electricians Electrical installation, page 42

Safety experts Project planning, pa

Operating entity Operators Operation, pa

Maintenance person‐

l

ne

1

Chapters not listed here are intended for all target groups. All target groups must understand the safety

no

tes in all of the operating instructions!

1

t

ions

Project planning, page 17

Technical data, page 60

Accessories, page 67

Commissioning, page 46

Technical data, page 60

Checklist for initial commissioning and com‐

missioning, page 73

Troubleshooting, page 56

Maintenance, page 53

Troubleshooting, page 56

Ordering information, page 66

ge 29

ge 17

ge 52

6

O PE R AT I NG IN S TR U CT I ON S | deTem4 Core Ex 8022875/2019-03-04 | SICK

Subject to change without notice

Page 7

In other applications, the operating organization is also the manufacturer of the equip‐

ment w

ith the corresponding allocation of the target groups.

1.4 Additional information

www.sick.com

T

he following information is available on the Internet:

This document in other languages

•

Data sheets and application examples

•

CAD data and dimensional drawings

•

Certificates (e.g. EU declaration of conformity)

•

Guide for Safe Machinery Six steps to a safe machine

•

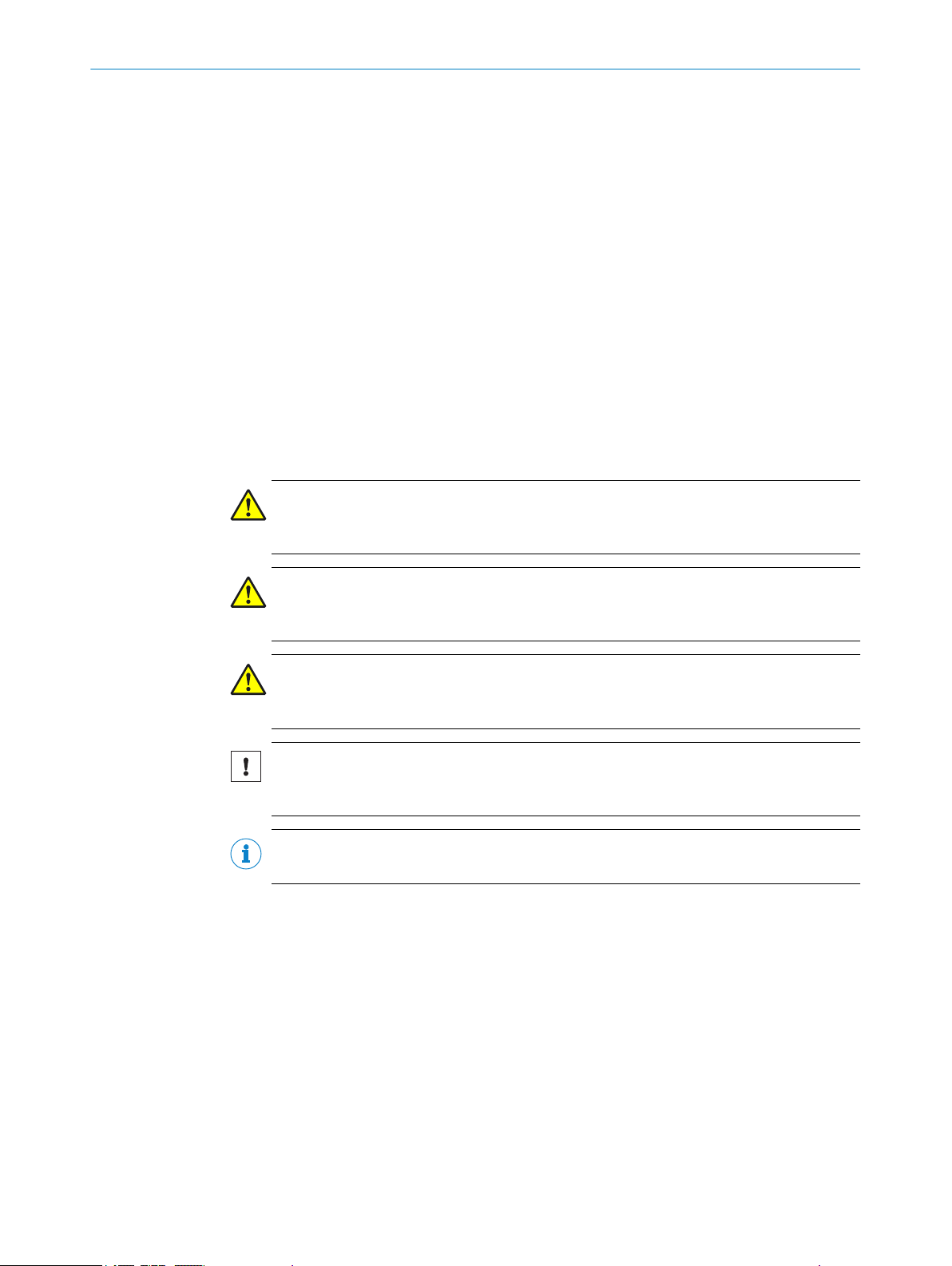

1.5 Symbols and document conventions

The following symbols and conventions are used in this document:

Safety notes and other notes

DANGER

Indic

ates a situation presenting imminent danger, which will lead to death or serious

injuries if not prevented.

ABOUT THIS DOCUMENT 1

WARNING

Indicates a situation presenting possible danger, which may lead to death or serious

injuries if not prevented.

CAUTION

ates a situation presenting possible danger, which may lead to moderate or minor

Indic

injuries if not prevented.

NOTICE

Indic

ates a situation presenting possible danger, which may lead to property damage if

not prevented.

NOTE

Indic

ates useful tips and recommendations.

Instructions to action

he arrow denotes instructions to action.

T

b

1. The sequence of instructions for action is numbered.

2. Follow the order in which the numbered instructions are given.

✓

The check mark denotes the result of an instruction.

LED symbols

These symbols indicate the status of an LED:

The LED is off.

o

The LED is flashing.

Ö

The LED is illuminated continuously.

O

8022875/2019-03-04 | SICK O PE R AT I NG IN S TR U CT I ON S | deTem4 Core Ex

Subject to change without notice

7

Page 8

1 A

BOUT THIS DOCUMENT

Sender and receiver

T

hese symbols indicate the sender and receiver of the device:

The symbol indicates the sender.

s

The symbol indicates the receiver.

r

8

O PE R AT I NG IN S TR U CT I ON S | deTem4 Core Ex 8022875/2019-03-04 | SICK

Subject to change without notice

Page 9

2 Safety information

2.1 General safety notes

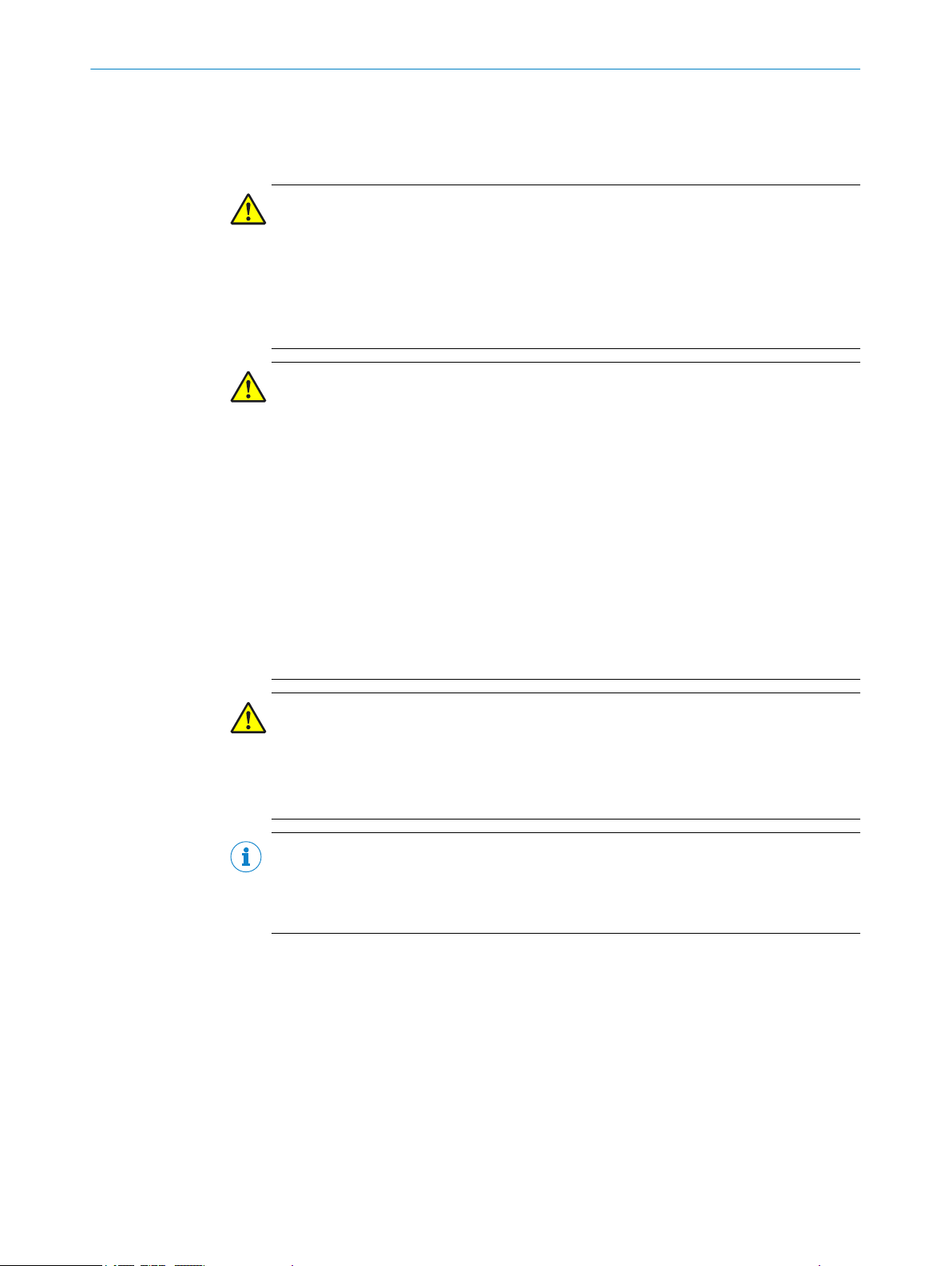

DANGER

H

azard due to lack of effectiveness of the protective device

In the case of non-compliance, it is possible that the dangerous state of the machine

may not be stopped or not stopped in a timely manner.

Please read this document carefully and make sure that you understand the con‐

b

tent fully before working with the device.

Follow all safety notes in this document.

b

WARNING

Risk of ineffectiveness of the protective device

Please observe the following information to ensure safe and correct use of the device

deTem4 Core Ex.

National and international regulations and guidelines must be observed when

b

mounting, using, and commissioning electrical devices as well as when carrying

out regular technical inspections in explosion-hazardous areas. Article 500 of the

National Electrical Code and ATEX Directive 2014/34/EU shall apply in particular.

Manufacturers of and entities operating machines using the device are responsi‐

ble for ensuring that all applicable safety regulations and guidelines are complied

with.

These operating instructions must be made available to the operator of the

b

machine on which the device is used. Qualified safety personnel must instruct the

operator in how to use the device. The operator must also be directed to read and

follow the operating instructions.

SAFETY INFORMATION 2

DANGER

Ris

Failure to observe this instruction can result in a risk of ignition from potential sparking.

b

NOTE

SIC

•

•

2.2 Intended use

Overview

T

device (ESPE) and is suitable for the following applications:

•

•

The multiple beam light beam safety device deTem4 Core Ex is suitable for use in

enc

defined in the National Electrical Code® and Canadian Electrical Code®:

k of ignition

Ensure that only accessories that are approved for explosion-hazardous areas are

used.

K provides more information about the following explosion-proof connections:

Joint between glass and cover

Joint between cover and explosion-proof enclosure

he deTem4 Core Ex multiple light beam safety device is an electro-sensitive protective

Single-sided access protection

Multi-sided access protection

losed spaces only. It has UL/cUL certification for the following hazardous areas

8022875/2019-03-04 | SICK O PE R AT I NG IN S TR U CT I ON S | deTem4 Core Ex

Subject to change without notice

9

Page 10

2 SAFETY INFORMATION

•

•

•

The multiple light beam safety device deTem4 Core Ex also complies with these stan‐

ards: EN 60079-0:2012/A11:2013/IEC 60079-0 Edition 6.0, EN 60079-1:2014/IEC

d

60079-1 Edition 7.0, EN 60079-31:2014/IEC 60079-31 Edition 2.0 and is certified for

the following hazardous areas:

•

•

•

•

DEMKO 14 ATEX 1315X

IECEx UL 14.0034X

The multiple light beam safety device deTem4 Core Ex does not emit any paint wetting

im

rials into the surrounding area.

The deTem4 Core Ex multiple light beam safety device must only be used within the lim‐

its of the prescribed and specified technical data and operating conditions at all times.

ss I, Groups C, D

Cla

Class II, Groups E, F, G

Class III

X II 2 G Ex db IIB T6

X II 2 D Ex tb IIIC T56 °C Db IP6X

Ex db IIB T6

Ex tb IIIC T56 °C Db IP6X

pairment substances or volatile silicones and does not expel any fixed parts or mate‐

Any instance of improper use, incorrect modification, or manipulation of the deTem4

Core Ex multiple light beam safety device shall void any warranty provided by SICK AG;

furthermore, SICK AG shall not accept any responsibility or liability for any resulting

damage and consequential damage.

Important information

DANGER

H

azard due to lack of effectiveness of the protective device

Persons and parts of the body to be protected may not be recognized in case of nonobservance.

The multiple light beam safety device works as an indirect protective measure and can‐

not provide protection from pieces thrown from application nor from emitted radiation.

Transparent objects are not detected.

Only use the multiple light beam safety device as an indirect protective measure.

b

DANGER

Ris

k of ignition

Failure to observe this information could result in a risk of ignition.

The sender, receiver, and cables delivered with the device deTem4 Core Ex are not

b

explosion-proof. The person purchasing, assembling, and using the safety light cur‐

tain is responsible for fitting the cables in suitable explosion-proof conduits and/or

cable glands to ensure the integrity of the system.

The type label on each individual explosion-proof enclosure contains information

b

on the device’s hazardous area class and group. Every device that penetrates the

explosion-proof enclosure must be suitable for the environment in which the explo‐

sion-proof enclosure is installed with regard to its hazardous area class and group

or zone.

10

O PE R AT I NG IN S TR U CT I ON S | deTem4 Core Ex 8022875/2019-03-04 | SICK

Subject to change without notice

Page 11

SAFETY INFORMATION 2

DANGER

k of ignition

Ris

Failure to observe this information could result in a risk of ignition.

Only if the device is used outside North America:

A cable gland must be mounted.

b

The cable gland must be certified for d and tb environments.

b

DANGER

k of ignition

Ris

Failure to observe this information could result in a risk of ignition.

Only if the device is used in North America:

Any conduit openings that are not in use must be sealed. Sealing fittings must turn

b

at least five (5) full revolutions and be at least 3.175 mm thick (1/8 of an inch).

Conduit sealing fittings must be applied in each installed conduit run (located a

b

maximum of 457 mm (18 inches) away from the explosion-proof enclosure) in

order to comply with the provisions of the most recent version of the National Elec‐

trical Code, Article 501.15 and/or 502.15, and all other applicable regulations.

Reasonably foreseeable misuse

g others, the deTem4 Core Ex multiple light beam safety device is not suitable for

Amon

the following applications:

Outdoors

•

Underwater

•

At altitudes over 3,000 m above sea level

•

In environments with increased levels of ionizing radiation

•

2.3 Requirements for the qualification of personnel

The multiple light beam safety device must be configured, installed, connected, com‐

sioned, and serviced only by qualified safety personnel.

mis

Project planning

For project planning, a person is considered competent when he/she has expertise and

experience in the selection and use of protective devices on machines and is familiar

with the relevant technical rules and national work safety regulations.

Mechanical mounting

For mechanical mounting, a person is considered competent when he/she has the

expertise and experience in the relevant field and is sufficiently familiar with the appli‐

cation of the protective device on the machine that he/she can assess its operational

safety status.

Electrical installation

For electrical installation, a person is considered competent when he/she has the

expertise and experience in the relevant field and is sufficiently familiar with the appli‐

cation of the protective device on the machine that he/she can assess its operational

safety status.

8022875/2019-03-04 | SICK O PE R AT I NG IN S TR U CT I ON S | deTem4 Core Ex

Subject to change without notice

11

Page 12

AFETY INFORMATION

2 S

Commissioning

F

or commissioning, a person is considered competent when he/she has the expertise

and experience in the relevant field and is sufficiently familiar with the application of

the protective device on the machine that he/she can assess its operational safety sta‐

tus.

Operation and maintenance

For operation and maintenance, a person is considered competent when he/she has

the expertise and experience in the relevant field and is sufficiently familiar with the

application of the protective device on the machine and has been instructed by the

machine operator in its operation.

Maintenance and thorough checks should only be conducted by qualified, trained per‐

sonnel who are familiar with the regulations and instructions relating to explosion-haz‐

ardous environments, particularly:

Ignition protection methods

•

Mounting regulations

•

Regulations on distances to be maintained

•

An operator must clean the multiple light beam safety device. Additional information for

the operator of the machine: see "Operation", page 52, and see "Regular cleaning",

page 53.

12

O PE R AT I NG IN S TR U CT I ON S | deTem4 Core Ex 8022875/2019-03-04 | SICK

Subject to change without notice

Page 13

3 Product description

3.1 Setup and function

The deTem4 Core Ex multiple light beam safety device is an electro-sensitive protective

vice (ESPE) consisting of a sender and receiver.

de

Parallel infrared light beams between the sender and receiver protect the hazardous

area. When one or more light beams are completely interrupted, the multiple light beam

safety device reports the interruption in the light path to the secure output signal

switching devices (OSSDs) by a signal change. The machine or its control must safely

analyze the signals (for example using a safe control or safety relays) and stop the dan‐

gerous state.

Sender and receiver automatically synchronize themselves optically. An electrical con‐

nection between both components is not required.

PRODUCT DESCRIPTION 3

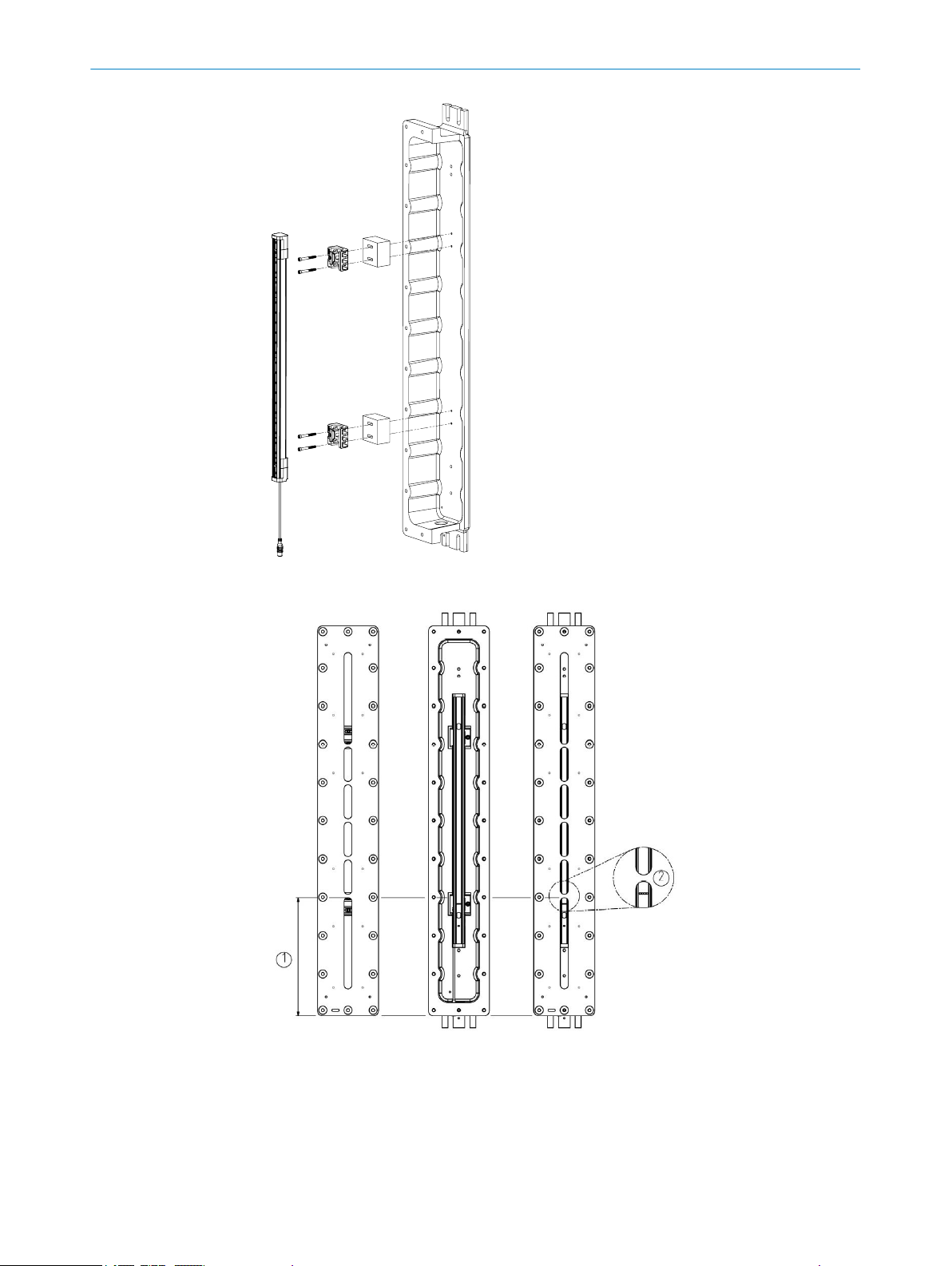

Figure 1: Sender and receiver

Beam separation and number of beams

T

he beam separation is the distance between two adjacent light beams, measured

from the center of one beam to the center of the next.

The beam separation and number of beams depend on the device variant.

Scanning range

T

he scanning range is the maximum dimension of the light path between sender and

receiver. It depends on the device variant.

The scanning range is reduced by using deflector mirrors.

8022875/2019-03-04 | SICK O PE R AT I NG IN S TR U CT I ON S | deTem4 Core Ex

Subject to change without notice

13

Page 14

ERR

PWR

2

1

3 P

RODUCT DESCRIPTION

Further topics

"D

ata sheet", page 60

•

"Deflector mirrors", page 69

•

3.2 Product characteristics

3.2.1 Status indicators

The sender and receiver light emitting diodes indicate the operational status.

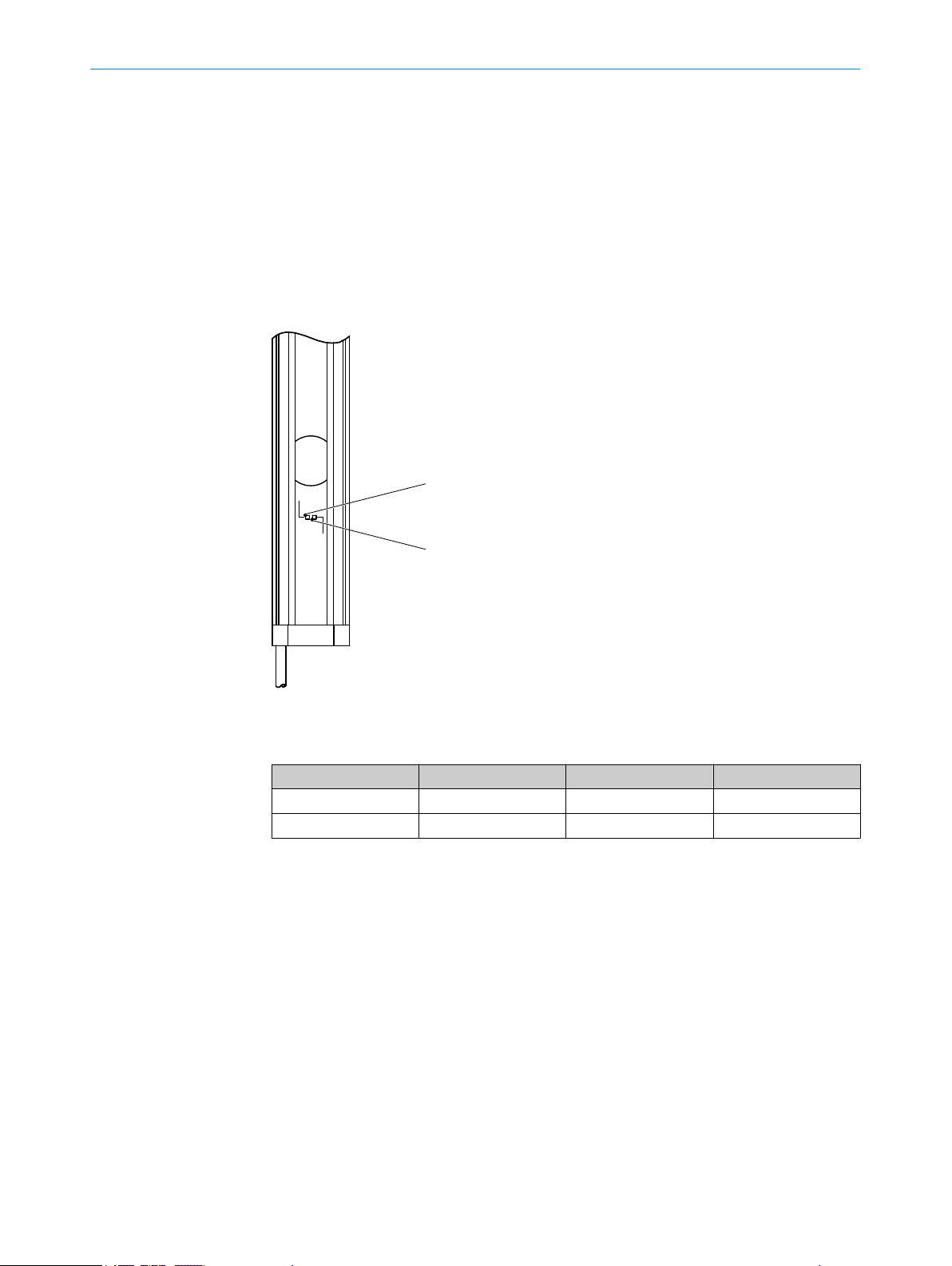

Sender indicators

Figure 2: Sender indicators

wo light emitting diodes on the sender indicate the operational status:

T

Position LED color Display Labeling

1

2

Yellow Status indicator PWR

Red Fault indicator ERR

Complete overview of the light emitting diode statuses and their meanings: see "Dia

nostic LEDs", page 56.

g‐

14

O PE R AT I NG IN S TR U CT I ON S | deTem4 Core Ex 8022875/2019-03-04 | SICK

Subject to change without notice

Page 15

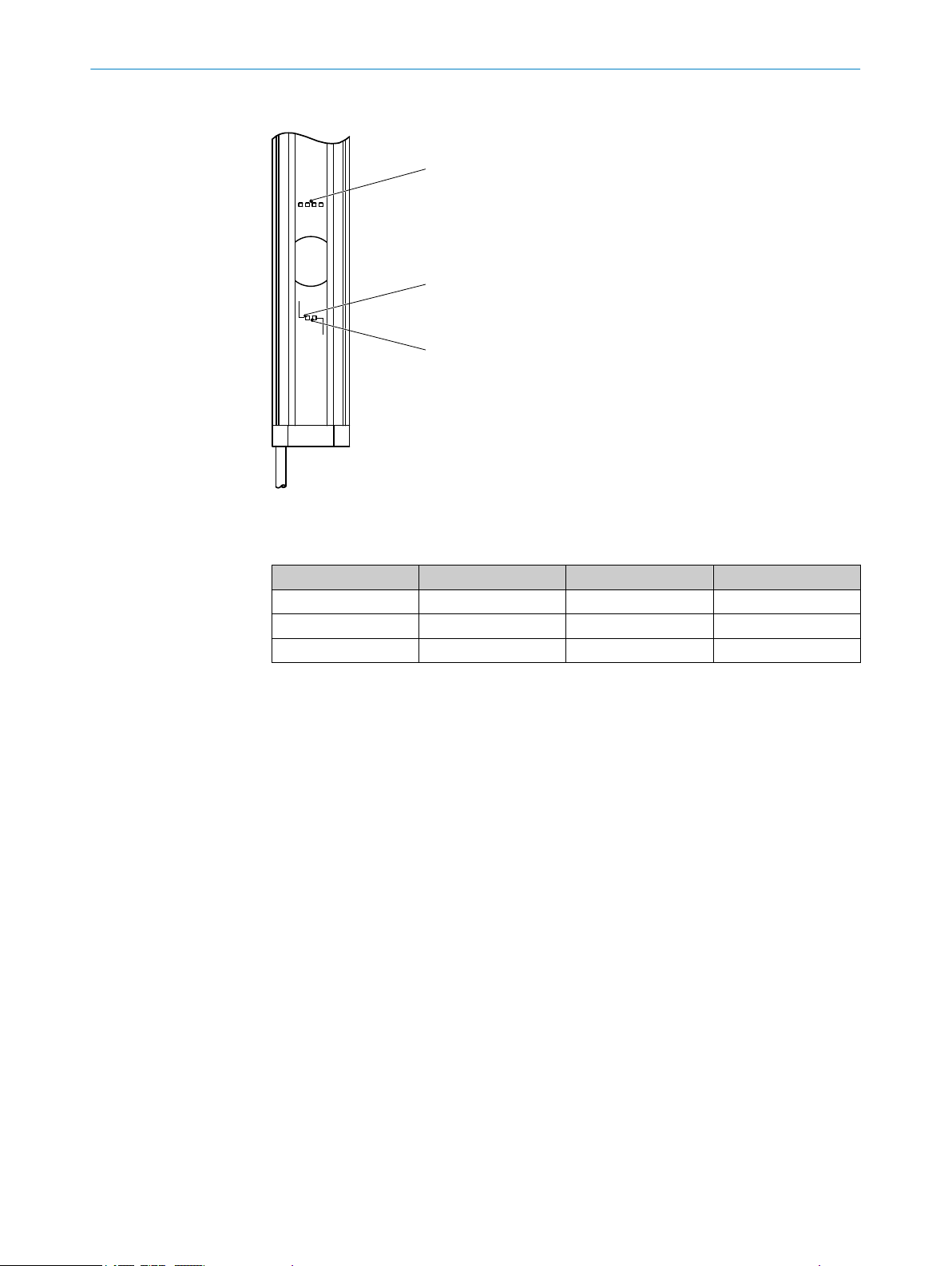

Receiver indicators

ERR

OSSD

1 2 3 4

2

1

3

Figure 3: Receiver indicators

PRODUCT DESCRIPTION 3

S

ix light emitting diodes on the receiver indicate the operational status:

Position LED color Display Labeling

1

2

3

Red/green OSSD status OSSD

Red Fault indicator ERR

Blue Alignment quality 1, 2, 3, 4

The blue alignment quality light emitting diodes in combination with the red flashing

R LED also denote faults.

ER

Complete overview of the light emitting diode statuses and their meanings: see "Diag‐

nostic LEDs", page 56.

8022875/2019-03-04 | SICK O PE R AT I NG IN S TR U CT I ON S | deTem4 Core Ex

Subject to change without notice

15

Page 16

3 P

RODUCT DESCRIPTION

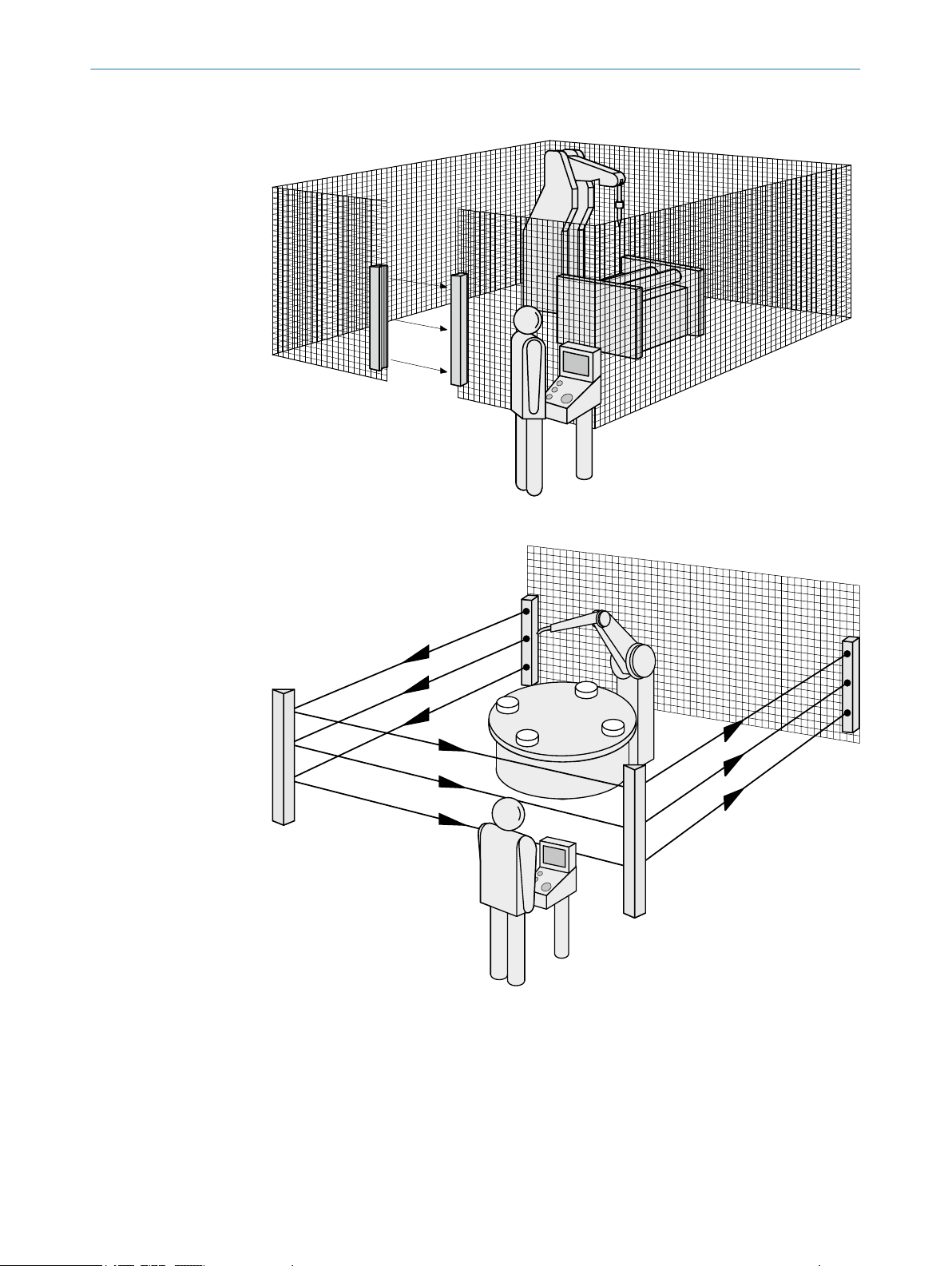

3.3 Example applications

Figure 4: Single-sided access protection

16

Figure 5: Multi-sided access protection

O PE R AT I NG IN S TR U CT I ON S | deTem4 Core Ex 8022875/2019-03-04 | SICK

Subject to change without notice

Page 17

4 Project planning

4.1 Manufacturer of the machine

DANGER

H

azard due to lack of effectiveness of the protective device

Persons and parts of the body to be protected may not be recognized in case of nonobservance.

Use of the multiple light beam safety device requires a risk assessment. Check

b

whether additional protective measures are required.

Comply with the applicable national regulations derived from the application (e.g.,

b

work safety regulations, safety rules, or other relevant safety guidelines).

Do not combine the components of the multiple light beam safety device with

b

components from other multiple light beam safety devices.

Apart from the procedures described in this document, the components of the

b

multiple light beam safety device must not be opened.

The components of the multiple light beam safety device must not be tampered

b

with or changed.

Improper repair of the protective device can lead to a loss of the protective func‐

b

tion. Do not carry out any repairs on the device components.

PROJECT PLANNING 4

4.2 Operating entity of the machine

DANGER

H

azard due to lack of effectiveness of the protective device

Persons and parts of the body to be protected may not be recognized in case of nonobservance.

Changes to the electrical integration of the multiple light beam safety device in the

b

machine control and changes to the mechanical mounting of the multiple light

beam safety device necessitate a new risk assessment. The results of this risk

assessment may require the operating entity of the machine to meet a manufac‐

turer’s obligations.

Apart from the procedures described in this document, the components of the

b

multiple light beam safety device must not be opened.

The components of the multiple light beam safety device must not be tampered

b

with or changed.

Improper repair of the protective device can lead to a loss of the protective func‐

b

tion. Do not carry out any repairs on the device components.

4.3 Design

This chapter contains important information about the design.

Information on the individual steps for mounting the device: see "Mounting", page 29.

8022875/2019-03-04 | SICK O PE R AT I NG IN S TR U CT I ON S | deTem4 Core Ex

Subject to change without notice

17

Page 18

ROJECT PLANNING

4 P

DANGER

azard due to lack of effectiveness of the protective device

H

Persons and parts of the body to be protected may not be recognized in case of non-

observance.

Make sure that the following design requirements are met so that the multiple

b

light beam safety device can fulfill its protective function.

Sender and receiver must be arranged such that persons or parts of the body

°

are reliably detected when they enter the hazardous area.

Ensure that nobody can pass under the lowest light beam, pass over the

°

highest light beam, get between two light beams, or pass by the side of the

protective device.

If people can stay between the protective device and the hazardous point

°

without being detected, check if additional protective measures (e.g., restart

interlock) are required.

4.3.1 Scanning range and beam separation

Important information

DANGER

H

azard due to lack of effectiveness of the protective device

Persons and parts of the body to be protected may not be recognized in case of nonobservance.

The multiple light beam safety device can only be mounted to machines on which

b

the protective field width does not change when the device is switched on.

Beam separation and number of beams

he beam separation is the distance between two adjacent light beams, measured

T

from the center of one beam to the center of the next.

The beam separation and number of beams depend on the device variant.

Scanning range

T

he scanning range is the maximum dimension of the light path between sender and

receiver. It depends on the device variant.

The scanning range is reduced by using deflector mirrors.

Further topics

"Minimum dis

•

"Technical data", page 60

•

"Deflector mirrors", page 69

•

4.3.2 Minimum distance from the hazardous point

A minimum distance must be maintained between the multiple light beam safety

de

vice and the hazardous point. This distance is required to prevent a person or part of

the body from reaching the hazardous area before the dangerous state of the machine

state has completed.

tance from reflective surfaces", page 20

18

Calculating the minimum distance according to ISO 13855

The calculation of the minimum distance is based on international or national stan‐

dards and statutory requirements applicable at the place of installation of the machine.

O PE R AT I NG IN S TR U CT I ON S | deTem4 Core Ex 8022875/2019-03-04 | SICK

Subject to change without notice

Page 19

If the minimum distance is calculated according to ISO 13855, then it depends on the

f

ollowing points:

Machine stopping time (time interval between triggering the sensor function and

•

the end of the machine’s dangerous state)

Response time of the protective device, see "Technical data", page 60

•

Approach speed of personnel

•

Type of approach: orthogonal (at right angles)

•

Parameters specified based on the application

•

For the USA (scope of OSHA and ANSI), different regulations may apply, e.g.:

a) Laws: Code of Federal Regulations, Title 29 (CFR29) Part 1910.217

b) Standards: ANSI B11.19

Complementary information

A

dditional information is available in the ISO 13855 standard and in the Guidelines

Safe Machinery.

SICK offers a stopping/run-down time measurement service in many countries.

4.3.2.1 Calculating minimum distance from the hazardous point

PROJECT PLANNING 4

Important information

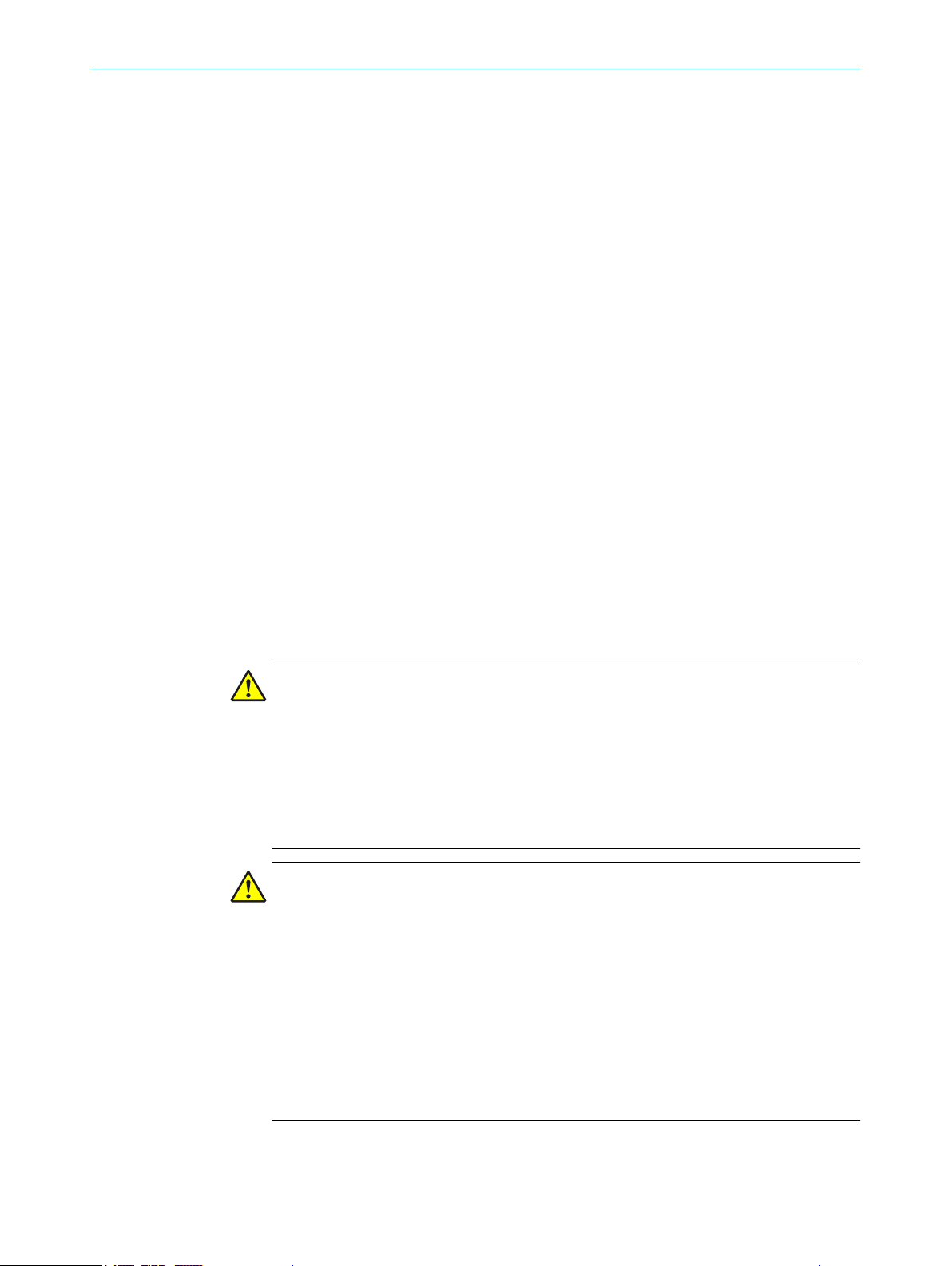

DANGER

Minimum distance from the hazardous point is too small

The dangerous state of the machine may not be stopped or not be stopped in a timely

manner due to a minimum distance that is too small.

Calculate the minimum distances for the machine in which the multiple light beam

b

safety device is integrated.

When mounting the multiple light beam safety device, observe the minimum dis‐

b

tance.

Approach

he example shows the calculation of the minimum distance for an orthogonal (at right

T

angles) approach to the multiple light beam safety device. Depending on the applica‐

tion and the ambient conditions, a different calculation may be required (e.g., at a dif‐

ferent angle to the direction of approach or an indirect approach).

1. Calculate S using the following formula:

S = 1,600 mm/s × T + C

where:

S = minimum dis

°

T = machine stopping time + response time of the protective device after

°

interruption in the light path in seconds (s)

C = supplement in accordance with ISO 13855:

°

The reach/approach speed is already included in the formula.

If it is not possible to reach over the protective device: C = 850 mm

•

If it is possible to reach over the protective device, the value CRO must be

•

used for C in accordance with ISO 13855, provided that this is greater

than 850 mm: C ≥ 850 mm and C ≥ C

tance in millimeters (mm)

RO

8022875/2019-03-04 | SICK O PE R AT I NG IN S TR U CT I ON S | deTem4 Core Ex

Subject to change without notice

19

Page 20

3

4

1

2

4 P

ROJECT PLANNING

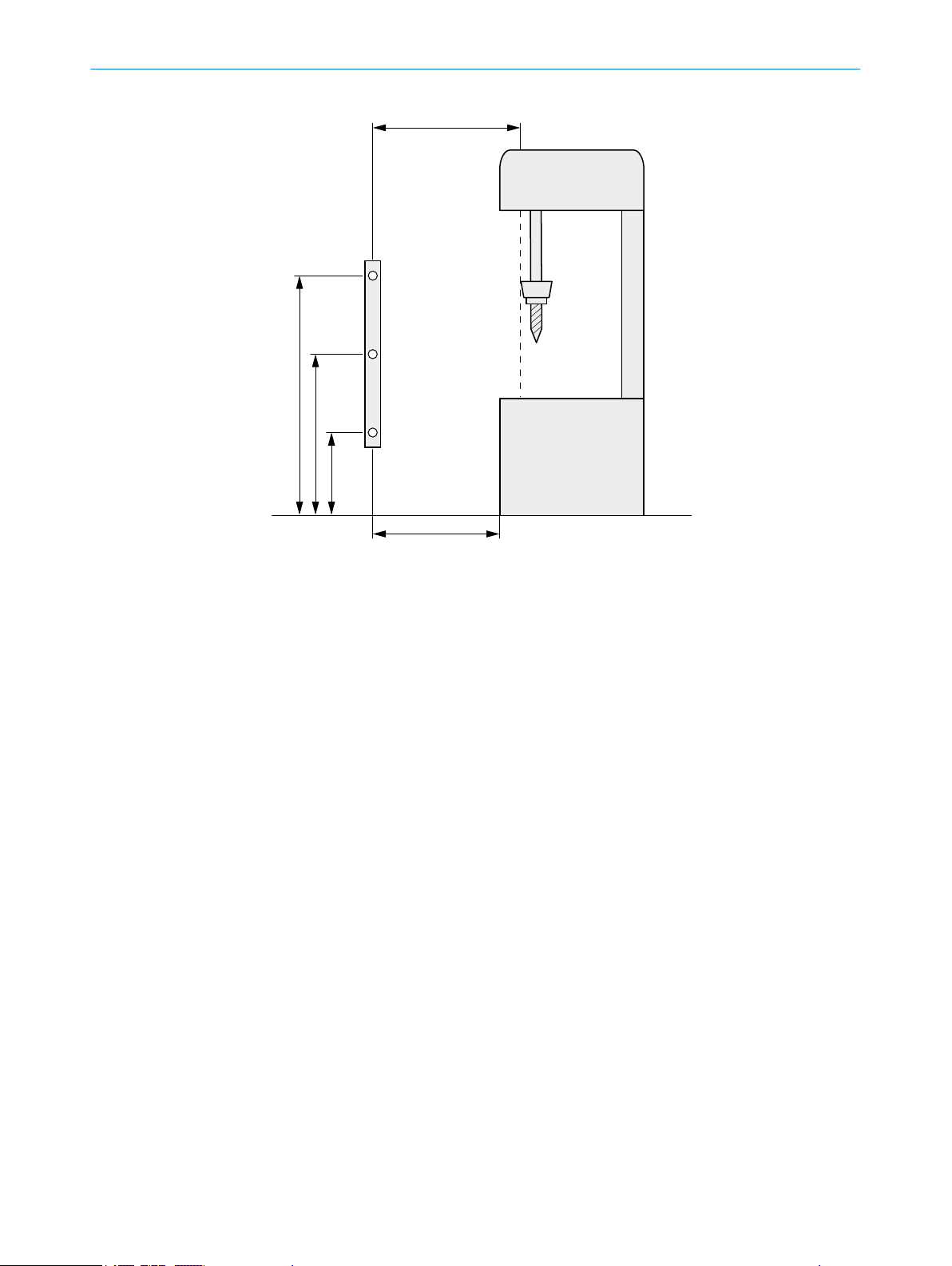

Figure 6: Minimum distance from the hazardous point

Minimum distance S

1

Height of the light beams above ground

2

Hazardous point

3

Depending on the application and distance, persons must be prevented from standing

4

be

hind the protective device.

Example calculation

Mac

hine stopping time = 290 ms

Response time after interruption of the light path = 20 ms

T = 290 ms + 20 ms = 310 ms = 0.31 s

S = 1,600 mm/s × 0.31 s + 850 mm = 1,346 mm

4.3.3 Minimum distance from reflective surfaces

Overview

T

he light beams from the sender may be deflected by reflective surfaces and dispersive

media. This can prevent an object from being detected.

Therefore, all reflective surfaces and objects (e.g., material bins, machine table, etc.)

must maintain a minimum distance (a) from the light beams. This minimum distance

(a) must be maintained on all sides of the light beams. This applies in horizontal, verti‐

cal, and diagonal directions as well as at the ends of the multiple light beam safety

device. The same area must be free of dispersive media (e.g., dust, fog, or smoke).

The minimum distance (a) depends on the distance (D) between sender and receiver.

20

O PE R AT I NG IN S TR U CT I ON S | deTem4 Core Ex 8022875/2019-03-04 | SICK

Subject to change without notice

Page 21

rs

D

a

10 20 30 40 50 60 70 D/

m

500

1000

2000

1500

2500

3000

3500

a/mm

131

3

PROJECT PLANNING 4

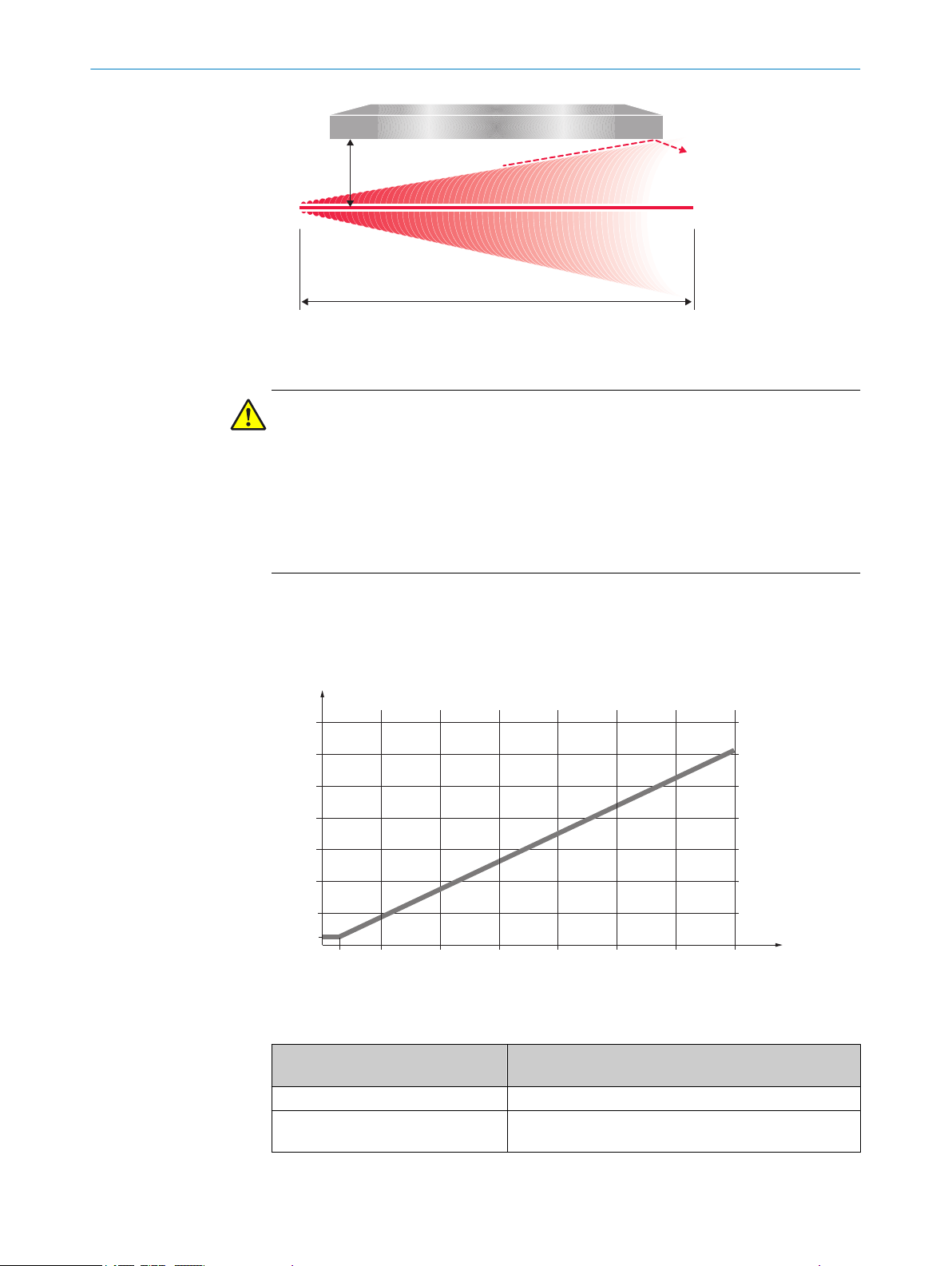

Figure 7: Minimum distance from reflective surfaces

Important information

DANGER

H

azard due to lack of effectiveness of the protective device

Reflective surfaces and dispersive media can prevent persons or parts of the body to

be protected from being properly reflected and therefore, they remain undetected.

Make sure that all reflective surfaces and objects maintain a minimum distance

b

from the light beams.

Make sure that no dispersive media (e.g., dust, fog, or smoke) are within the calcu‐

b

lated minimum distance from the light beams.

Determining minimum distance to reflective surfaces

1.

Determine the distance between sender and receiver D in meters (m)

2. Read the minimum distance a in millimeters (mm) in the graph or calculate it

based on the respective formula from table 1:

Figure 8: Graph, minimum distance from reflective surfaces

able 1: Formula for calculating the minimum distance from reflective surfaces

T

Distance between sender and

eceiver D in m

r

D ≤ 3 m a = 131 mm

D > 3 m a = tan (2.5°) × 1,000 mm/m × D = 43.66 × 1 mm/m ×

Calculating the minimum distance from reflective sur‐

faces a in mm

D

8022875/2019-03-04 | SICK O PE R AT I NG IN S TR U CT I ON S | deTem4 Core Ex

Subject to change without notice

21

Page 22

s

rs

r

!

"

"

!

s

rs

r

ROJECT PLANNING

4 P

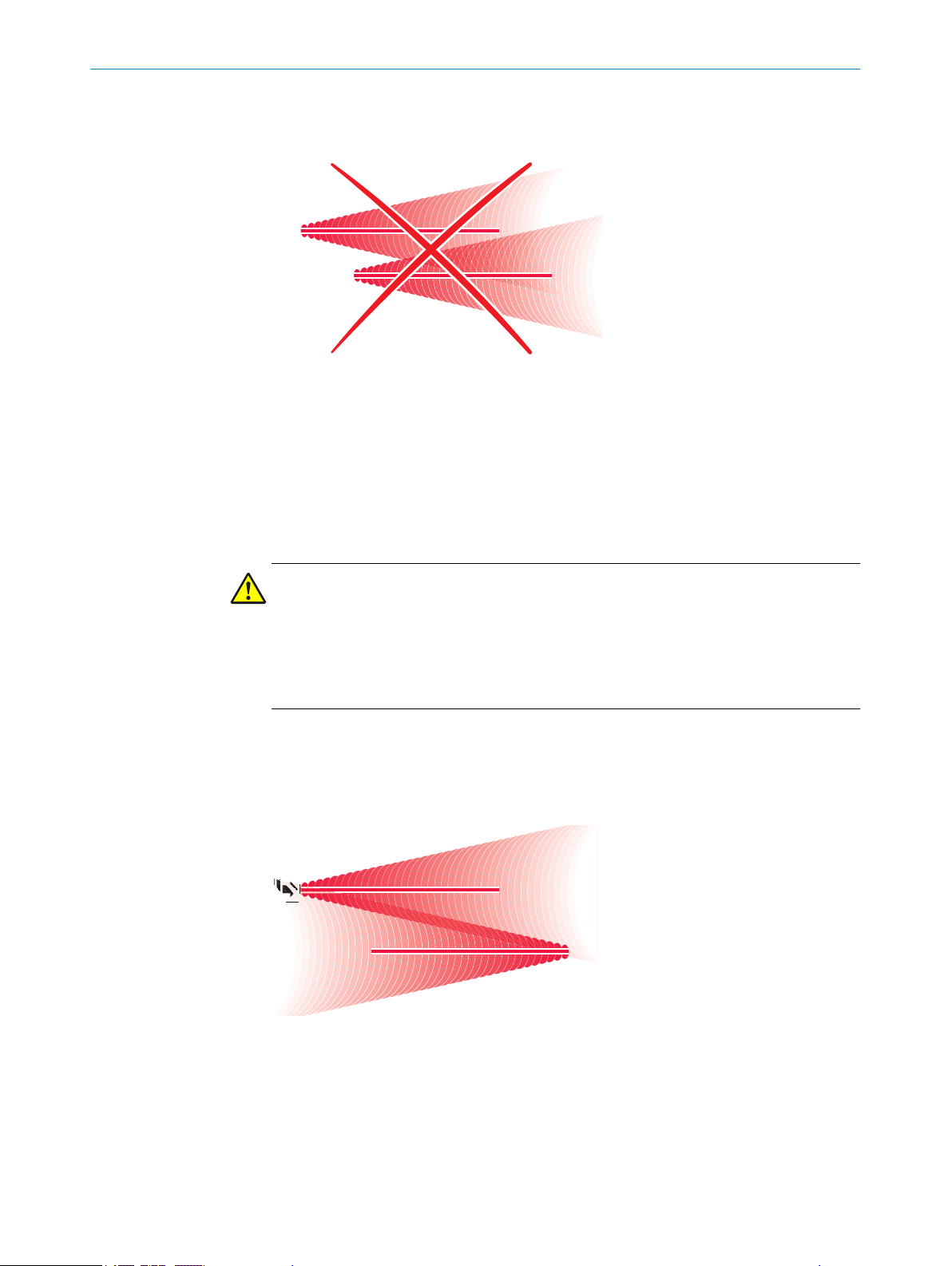

4.3.4 Protection against interference from systems in close proximity to each other

Overview

1

Figure 9: Preventing mutual interference from system

The infrared light beams of the sender of system 1 can interfere with the receiver of

system 2. This can disrupt the protective function of system 2. This would mean that

the operator is at risk.

Avoid such installation situations or take appropriate action, e.g., install optically

opaque partitions or reverse the direction of transmission of a system.

and system

2

Important information

DANGER

azard due to lack of effectiveness of the protective device

H

Systems of multiple light beam safety devices in close proximity to each other can

mutually interfere with each other.

Use suitable measures to prevent interference between systems in close proximity

b

to each other.

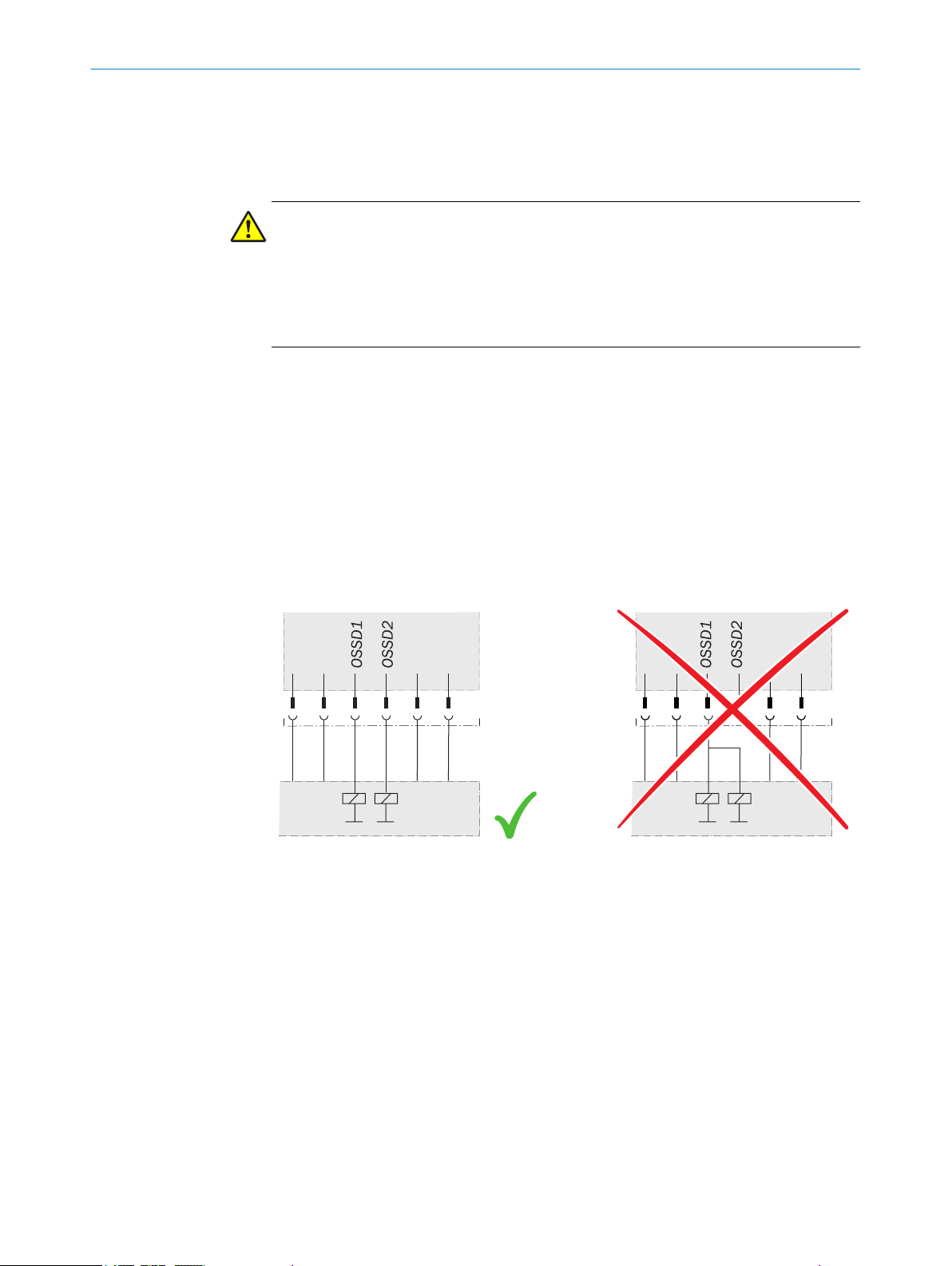

4.3.4.1 Using reversed direction of transmission

The direction of transmission of the system 2 c

switching the positions of the sender and receiver. With reversed direction of mounting,

the receiver 2 is not affected by the infrared light from the sender 1.

an be changed during mounting by

Figure 10: Trouble-free operation due to reversed direction of transmission of system

tem

2

4.4 Integrating into the electrical control

This chapter contains important information about integration in the electrical control.

22

O PE R AT I NG IN S TR U CT I ON S | deTem4 Core Ex 8022875/2019-03-04 | SICK

ormation about the individual steps for electrical installation of the device: see "Elec‐

Inf

trical installation", page 42.

1

and sys‐

Subject to change without notice

Page 23

PROJECT PLANNING 4

Requirements for use

T

he output signals of the protective device must be analyzed by downstream controllers

in such a way that the dangerous state of the machine is ended safely. Depending on

the safety concept, the signal is analyzed by, e.g., safety relays or a safety controller.

DANGER

azard due to lack of effectiveness of the protective device

H

In the case of non-compliance, it is possible that the dangerous state of the machine

may not be stopped or not stopped in a timely manner.

Make sure that the following control and electrical requirements are met so that

b

the multiple light beam safety device can fulfill its protective function.

t be possible to electrically influence the control of the machine.

It mus

•

The electrical control of the machine must meet the requirements of IEC 60204-1.

•

Depending on the regulations which apply at the place of installation, a restart

•

interlock may be required. Because the multiple light beam safety device does not

have this function, it must be implemented in the external control if required.

When using a safety controller, different signal levels of both OSSDs must be

•

detected depending on the regulations which apply at the place of installation or

the required reliability of the safety function. The maximum discrepancy time toler‐

ated by the control must be selected according to the application.

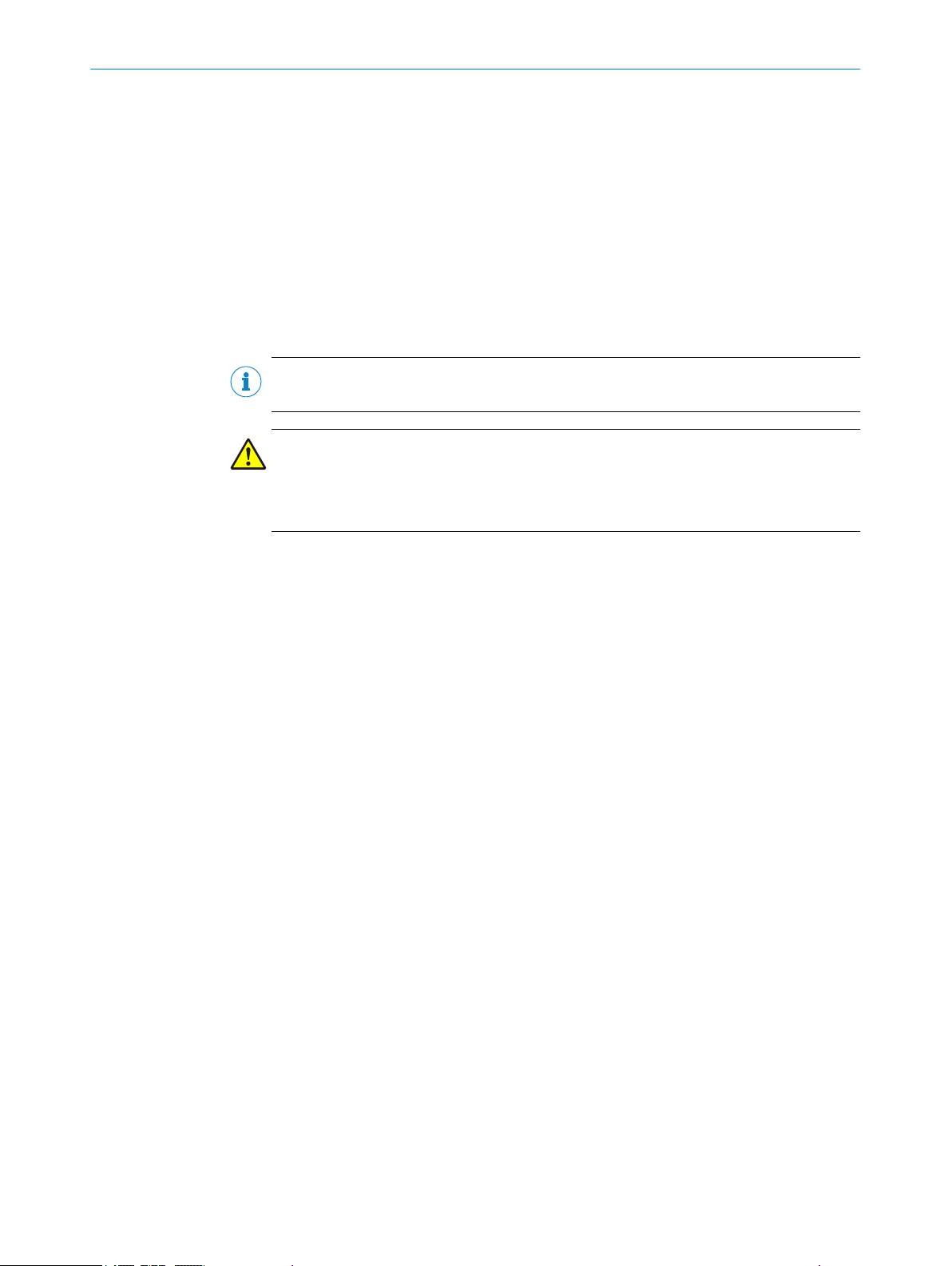

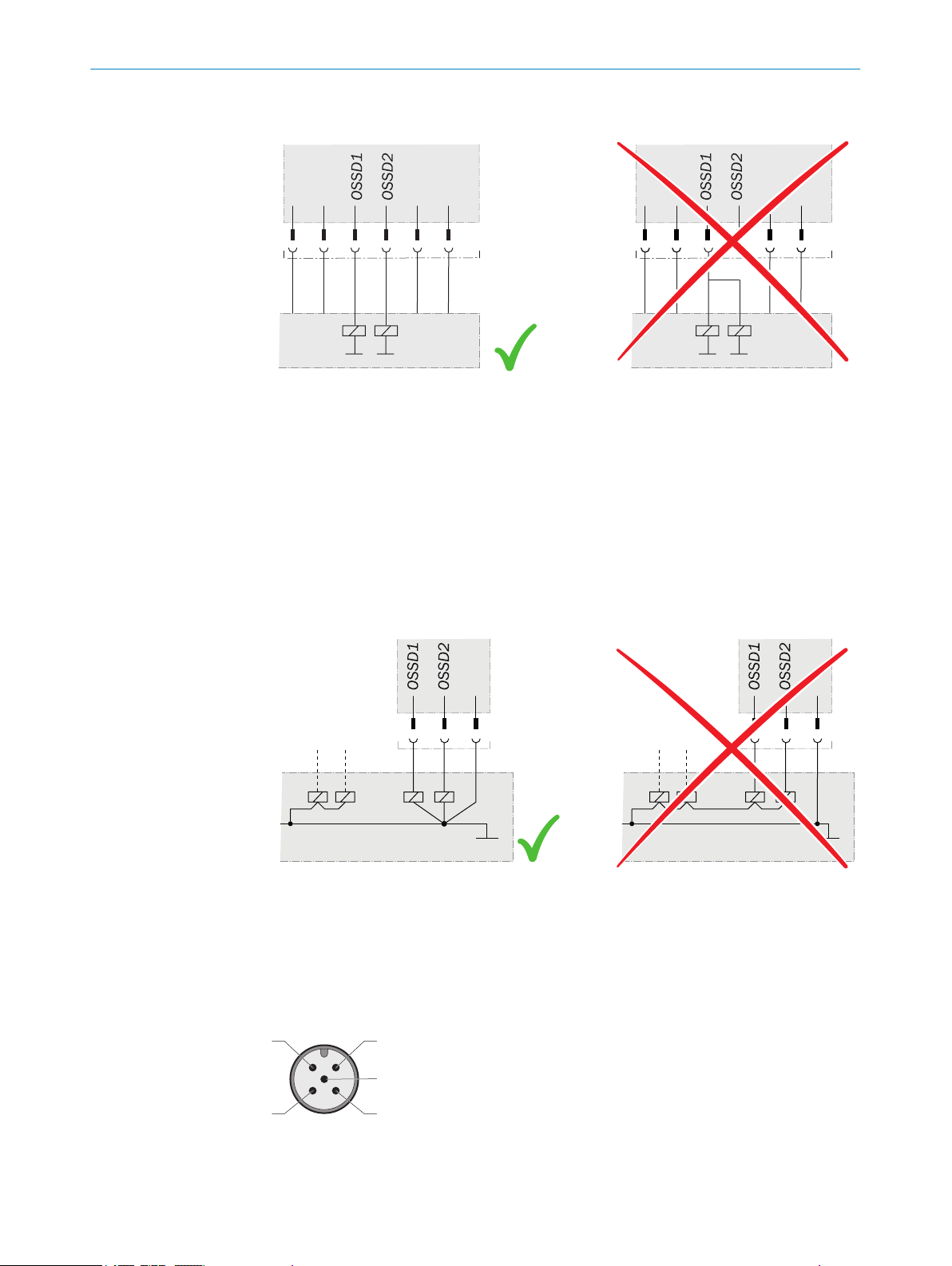

The OSSD1 and OSSD2 output signals must not be connected to each other.

•

In the machine controller, the signals of both OSSDs must be processed sepa‐

•

rately.

Figure 11: Dual-channel and isolated connection of OSSD1 and OSSD2

he machine must switch to the safe state at any time if at least one of the two

T

•

OSSDs switches to the OFF state.

Prevent the formation of a potential difference between the load and the protec‐

•

tive device. If you connect loads to the OSSDs (output signal switching devices)

that then also switch if controlled with negative voltage (e.g., electro-mechanical

contactor without reverse polarity protection diode), you must connect the 0 V con‐

nections of these loads and those of the corresponding protective device individu‐

ally and directly to the same 0 V terminal strip. In the event of a fault, this is the

only way to ensure that there can be no potential difference between the 0 V con‐

nections of the loads and those of the corresponding protective device.

8022875/2019-03-04 | SICK O PE R AT I NG IN S TR U CT I ON S | deTem4 Core Ex

Subject to change without notice

23

Page 24

ROJECT PLANNING

4 P

Figure 12: No potential difference between load and protective device

DANGER

H

azard due to lack of effectiveness of the protective device

In the case of non-compliance, it is possible that the dangerous state of the machine

may not be stopped or not stopped in a timely manner.

Downstream contactors must be positively guided and monitored depending on applic‐

able national regulations or required reliability of the safety function.

Make sure that downstream contactors are monitored (external device monitoring,

b

EDM).

Bec

b

ause the multiple light beam safety device does not have integrated external

device monitoring, this must be implemented in the external control, if required.

Requirements for the electrical control of the machine

th outputs are short-circuit protected to 24 V DC and 0 V. When the light path is

Bo

clear, the OSSDs are in the ON state. When a switch-off condition is present (e.g., inter‐

ruption in the light path), the OSSDs are in the OFF state. In the event of a device fault,

at least one OSSD is in the OFF state.

The multiple light beam safety device complies with the rules for electromagnetic com‐

patibility (EMC) for the industrial sector (Radio Safety Class A). Radio interference can‐

not be ruled out when used in residential areas.

DANGER

azard due to lack of effectiveness of the protective device

H

In the case of non-compliance, it is possible that the dangerous state of the machine

may not be stopped or not stopped in a timely manner.

Make sure that the following control and electrical requirements are met so that

b

the multiple light beam safety device can fulfill its protective function.

he external voltage supply of the multiple light beam safety device must be capa‐

T

•

ble of buffering brief power failures of 20 ms as specified in IEC 60204-1.

The power supply unit must provide safe isolation according to IEC 61140

•

(SELV/PELV). Suitable power supply units are available as accessories from SICK,

see "Accessories", page 67.

24

O PE R AT I NG IN S TR U CT I ON S | deTem4 Core Ex 8022875/2019-03-04 | SICK

Subject to change without notice

Page 25

4.4.1 Restart interlock

!

§" $

Overview

D

epending on the regulations which apply at the place of installation, a restart interlock

may be required.

The restart interlock prevents the machine from automatically starting up, for example

after a protective device has responded while the machine is operating or after chang‐

ing the machine’s operating mode.

NOTE

Because the multiple light beam safety device does not have an integrated restart inter‐

lock, this must be implemented in the external control, if required.

Principle of operation

Be

PROJECT PLANNING 4

fore the machine can be restarted, the operator must reset the restart interlock.

Figure 13: Schematic representation of operation with restart interlock

The dangerous state of the machine (!) is brought to an end if the light path is inter‐

rupted (") and is not re-enabled (§) until the operator presses the reset pushbutton

located outside the hazardous area ($). The machine can then be restarted.

Depending on the applicable national regulations, there must be a restart interlock if a

person can stand behind the protective field. Observe IEC 60204-1.

4.4.2 External device monitoring (EDM)

Overview

T

he external switching elements (external device monitoring, EDM) must be inspected

in line with the regulations which apply at the place of installation or the required relia‐

bility of the safety function.

The external device monitoring (EDM) monitors the status of downstream contactors.

In order to use the external device monitoring, positively guided contactors must be

used to switch off the machine. If the auxiliary contacts of the positively guided contac‐

tors are connected to the external device monitoring, the external device monitoring

checks whether the contactors drop off when the OSSDs are switched off.

Important information

NOTE

Because the multiple light beam safety device does not have integrated external device

monitoring, this must be implemented in the external control, if required.

8022875/2019-03-04 | SICK O PE R AT I NG IN S TR U CT I ON S | deTem4 Core Ex

Subject to change without notice

25

Page 26

S34 S21S35 S22

S33 S12S11 S31

14A2 24 32

13A1 23 31

UE48-2OS2D2

K1 K2

S1

K1

K2

OSSD1

OSSD2

n.c.

GND

+24V

1

2

3

4

5

+24V

n.c.

GND

n.c.

n.c.

1

2

3

4

5

24 VDC

0 VDC

4 P

ROJECT PLANNING

4.4.3 Connection diagrams

Connection diagram for UE48-2OS with restart interlock and external device monitor‐

in

g

4.5 Testing plan

Figure 14: Connection diagram for UE48-2OS with restart interlock and external device monitor‐

g

in

The multiple light beam safety device can be connected to the UE48-2OS switching

amplifiers. It is operated with restart interlock and external device monitoring.

Operating principle

When the protective field is clear, the OSSD1 and OSSD2 outputs carry voltage. The

system can be switched on when K1 and K2 are in the de-energized position. Pressing

the S1 button switches on the UE48 switching amplifier. Contacts 13-14 and 23-24 of

the UE48 activate the K1 and K2 contactors.

When the protective field is interrupted, the OSSD1 and OSSD2 outputs carry no volt‐

age. The UE48 switches off and K1, K2 are deactivated.

Fault analysis

Failure of K1 and K2 does not cause the loss of the shut-down function. Cross-circuits

and short-circuits of the OSSD1 and OSSD2 outputs are recognized and lead to the

locking state. It is recognized if the K1 or K2 contactors do not de-energize.

The manufacturer of the machine and the operating entity must define all required

c

hecks. The definition must be based on the application conditions and the risk assess‐

ment and must be documented in a traceable manner.

When defining the check, please note the following:

b

Define the type and execution of the check.

°

Define the frequency of the check.

°

Notify the machine operators of the check and instruct them accordingly.

°

26

O PE R AT I NG IN S TR U CT I ON S | deTem4 Core Ex 8022875/2019-03-04 | SICK

Subject to change without notice

Page 27

PROJECT PLANNING 4

The following checks are often defined in connection with a protective device:

Chec

•

•

Check during commissioning and modifications

The check must detect if it is possible to enter the hazardous area without being

detected.

The following points are often helpful for the definition of the check:

•

•

•

•

•

•

•

•

b

k during commissioning and modifications

Regular check

Does the check have to be completed by quality safety personnel?

Can the check be completed by personnel specially qualified and authorized per‐

sonnel?

Does the check have to be documented in a traceable manner?

Can the check be carried out according to a check list (see "Checklist for initial

commissioning and commissioning", page 73)?

Do the machine operators know the function of the protective device?

Have the machine operators been trained to work on the machine?

Have the machine operators been notified about modifications on the machine?

Does the hazardous area to be secured have to be checked with a test rod, see

"Test rod check", page 27?

Define all guidelines for the check.

4.5.1 Test rod check

Regular check

T

he check must detect if it is possible to enter the hazardous area without being

detected. Such possibilities may exist due to modifications, manipulations or external

influences.

The following points are often helpful for the definition of the check:

Which check must be carried out and how is it carried out?

•

Test rod check, page 27

°

Visual check of the machine and the protective device, page 28

°

How often does the check have to be carried out?

•

Do the machine operators have to be notified of the check and do they need to be

•

instructed accordingly?

Define all guidelines for the check.

b

Overview

T

he light beam is covered with an opaque test rod (minimum diameter of 30 mm).

When the light beam is covered, the OSSD LED on the receiver must light up red. The

check is carried out for each light beam and at multiple positions between the sender

and the receiver.

Important information

DANGER

azard due to unexpected starting of the machine

H

Make sure that the dangerous state of the machine is and remains switched off

b

during the check.

Make sure that the outputs of the multiple light beam safety device do not affect

b

the machine during the check.

8022875/2019-03-04 | SICK O PE R AT I NG IN S TR U CT I ON S | deTem4 Core Ex

Subject to change without notice

27

Page 28

ROJECT PLANNING

4 P

DANGER

azard due to lack of effectiveness of the protective device

H

Persons and parts of the body to be protected may not be recognized in case of non-

observance.

Do not operate the machine if the OSSD LED lights up green during the test!

If the OSSD LED lights up green during the test, even if only briefly, work must stop

b

at the machine.

In this case, the mounting and electrical installation of the multiple light beam

b

safety device must be checked by appropriately qualified safety personnel.

Prerequisites

he OSSD LED lights up green.

T

•

Approach

1. Cover a light beam completely.

✓

The OSSD LED on the receiver lights up red.

2. Enable the light beam.

✓

The OSSD LED on the receiver lights up green.

3. Carry out the check for each light beam.

4. Carry out the check at the following positions:

Immediately in front of the sender

°

In the middle, between the sender and the receiver (or between the deflector

°

mirrors)

Immediately in front of the receiver

°

Directly before and after each deflector mirror (if installed)

°

4.5.2 Visual check of the machine and the protective device

The following points are often helpful for the definition of the check:

H

as the machine been retrofitted?

•

Have machine parts been removed?

•

Have modifications been made to the surroundings of the machine?

•

Have the protective device or its parts been dismantled?

•

Is it possible to enter the hazardous area without being detected?

•

Is the protective device damaged?

•

Is the protective device severely contaminated?

•

Is the front screen contaminated, scratched or destroyed?

•

Are there any damaged cables or open cable ends?

•

If one of the points applies, the machine should be shut down immediately. In this case,

the machine and the protective device must be checked by appropriately qualified

safety personnel.

28

O PE R AT I NG IN S TR U CT I ON S | deTem4 Core Ex 8022875/2019-03-04 | SICK

Subject to change without notice

Page 29

5 Mounting

5.1 Safety

MOUNTING 5

Important information

DANGER

Ris

k of ignition or explosion

Disconnect the voltage supply before starting to mount the explosion-proof enclo‐

b

sure to avoid igniting hazardous atmospheres.

Only reconnect the voltage supply once you have completed the mounting process.

b

DANGER

k of ignition or explosion

Ris

If you have to remove the cover when working on the multiple light beam safety

b

device, make sure that the joints and o-ring are clean and undamaged before refit‐

ting the cover.

DANGER

k of ignition or explosion

Ris

The multiple light beam safety device must be mounted so that there is a gap of

b

more than 30 mm between all other objects and the flange joints between the

housing and the cover.

DANGER

D

angerous state of the machine

Make sure that the dangerous state of the machine is (and remains) switched off

b

during mounting, electrical installation, and commissioning.

Make sure that the outputs of the multiple light beam safety device do not affect

b

the machine during mounting, electrical installation, and commissioning.

DANGER

H

azard due to lack of effectiveness of the protective device

If unsuitable brackets are used or if subjected to excessive vibrations, the device may

become detached or damaged.

Persons and parts of the body to be protected may not be recognized in case of nonobservance.

Only use SICK-approved brackets for mounting.

b

Take appropriate measures for vibration damping if vibration and shock specifica‐

b

tions exceed the values and test conditions specified in the data sheet.

8022875/2019-03-04 | SICK O PE R AT I NG IN S TR U CT I ON S | deTem4 Core Ex

Subject to change without notice

29

Page 30

5 MOUNTING

DANGER

azard due to lack of effectiveness of the protective device

H

Persons and parts of the body to be protected may not be recognized in case of non-

observance.

Do not do repair work on device components.

b

Do not make changes to or manipulate device components.

b

Apart from the procedures described in this document, the device components

b

must not be opened.

CAUTION

k of injury due to heavy weight

Ris

Lifting and moving heavy loads may cause injury.

Unsecured heavy loads may, for example, fall over and cause bruising.

Only lift the device using equipment or two persons.

b

Wear suitable protective clothing and safety shoes.

b

NOTE

Mount t

he device in the following order.

5.2 Unpacking

5.3 Mounting

Prerequisites

T

he multiple light beam safety device has been designed correctly.

•

Further topics

"Design", page 17

•

Approach

1.

Check the components for completeness and the integrity of all parts.

2. Please contact your respective SICK subsidiary should you have any complaints.

Further topics

"Scope of delivery", page 66

•

Important information

NOTE

ead this section in full before mounting the brackets.

R

b

Read the information on aligning the sender and receiver, see "Sender and

b

receiver alignment", page 47

30

DANGER

Ris

k of ignition or explosion

Disconnect the voltage supply before starting to mount the explosion-proof enclo‐

b

sure to avoid igniting hazardous atmospheres.

Only reconnect the voltage supply once you have completed the mounting process.

b

O PE R AT I NG IN S TR U CT I ON S | deTem4 Core Ex 8022875/2019-03-04 | SICK

Subject to change without notice

Page 31

MOUNTING 5

DANGER

k of ignition or explosion

Ris

If you have to remove the cover when working on the multiple light beam safety

b

device, make sure that the joints and o-ring are clean and undamaged before refit‐

ting the cover.

DANGER

H

azard due to lack of effectiveness of the protective device

Persons or parts of the body to be protected may not be recognized or not recognized in

time in case of non-observance.

Take account of the minimum distances calculated for the machine: see "Mini‐

b

mum distance from the hazardous point", page 18, see "Minimum distance from

reflective surfaces", page 20.

Mount multiple light beam safety devices such that nobody can pass under the

b

lowest light beam, pass over the highest light beam, get between two light beams,

or pass by the side of the protective device.

DANGER

H

azard due to lack of effectiveness of the protective device

Persons and parts of the body to be protected may not be recognized in case of nonobservance.

The end with the cable connection must point in the same direction for the sender

b

and receiver.

Mounting instructions

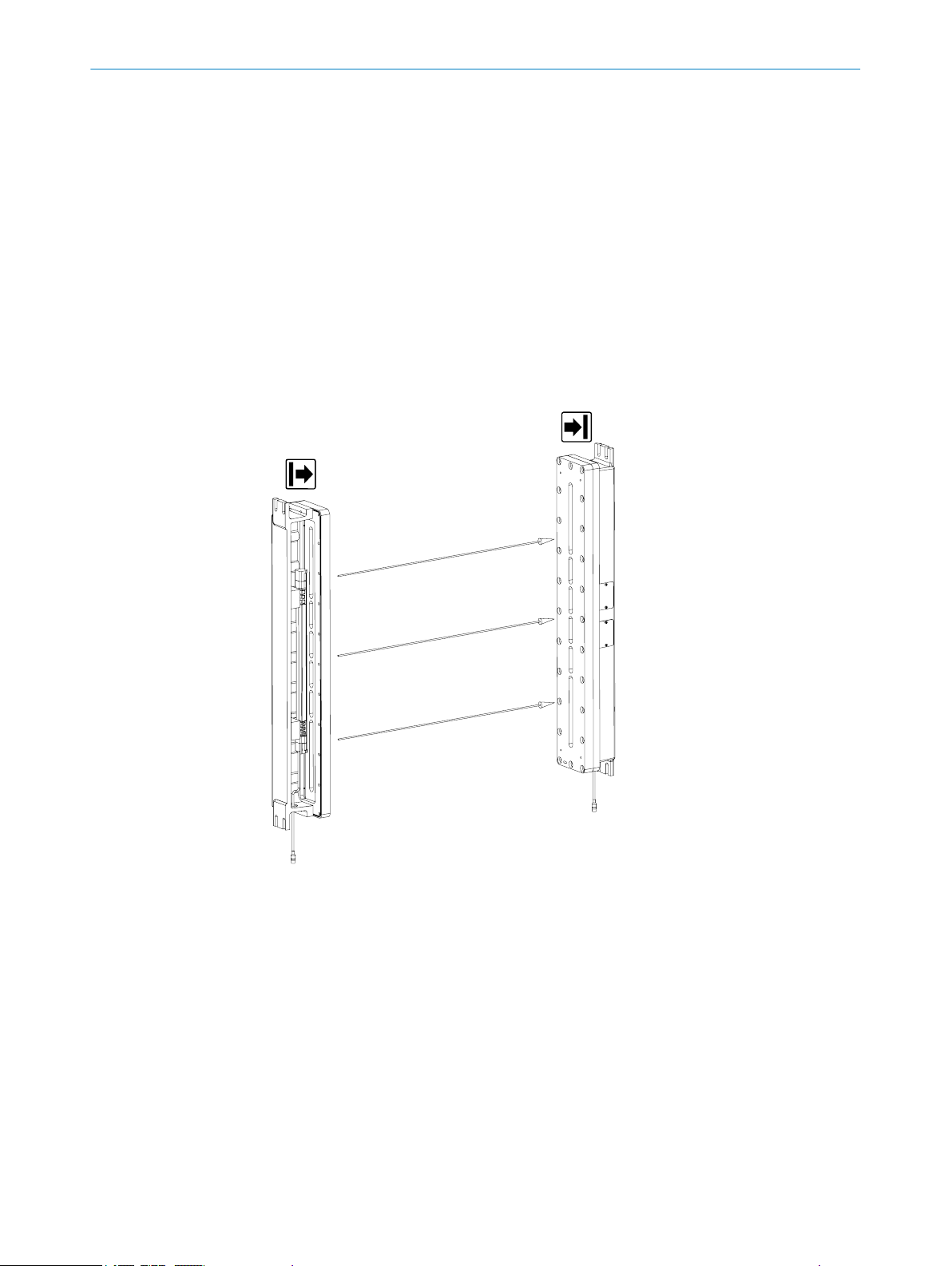

Figure 15: Sender and receiver must not be installed at 180° rotated relative to each other

Approach

If the multiple light beam safety device in pre-mounted condition has been pur‐

1.

chased, please skip this step.

First mount the multiple light beam safety device in the explosion-proof enclosure

using the two supplied FlexFix brackets and risers. The FlexFix bracket makes it

possible to rotate the sender and receiver around the axis of the device and to

8022875/2019-03-04 | SICK O PE R AT I NG IN S TR U CT I ON S | deTem4 Core Ex

Subject to change without notice

31

Page 32

5 MOUN

TING

align them accurately. In addition to the FlexFix brackets, the risers must also be

used t

o mount the multiple light beam safety device as close to the window on the

cover as possible.

2. Install the cable glands if necessary.

3. Secure the handles supplied onto the enclosure cover.

4. Mount the multiple light beam safety device in the explosion-proof enclosure on

the machine. The explosion-proof enclosure can either be attached directly or

using the alignment bracket (available as an accessory).

5.3.1 Mount the multiple light beam safety device in the explosion-proof enclosure (only if being used in

Nor

th America)

Important information

NOTE

If t

he device in pre-mounted condition has been purchased, please skip this section.

DANGER

Risk of ignition or explosion

Use fixing screws with a yield point of at least 640 MPa to attach the cover to the

b

explosion-proof enclosure.

Approach

1.

Unscrew the fixing screws on the cover and remove the cover from the explosionproof enclosure.

2. Secure the risers and the FlexFix brackets in the explosion-proof enclosure using

the supplied M5 screws.

3. Tighten the fixing screws on the FlexFix mount brackets with a torque of 5 to 6 Nm.

Too high a torque could damage the brackets while too low a torque does not pro‐

vide sufficient protection against vibration.

4. Mount the multiple light beam safety device on the FlexFix brackets so that the

connecting cable is at the same end of the explosion-proof enclosure as the 3/4"

NPT opening. Do not tighten the fixing screws at this point.

32

O PE R AT I NG IN S TR U CT I ON S | deTem4 Core Ex 8022875/2019-03-04 | SICK

Subject to change without notice

Page 33

MOUNTING 5

Figure 16: Mount the multiple light beam safety device in the explosion-proof enclosure.

Figure 17: Align the multiple light beam safety device in the explo‐

oof enclosure.

sion-pr

Measure the distance from the end of the cover to the first rib. Position the multiple light

1

am safety device so that the rib is between two optical lenses.

be

Detailed view

2

8022875/2019-03-04 | SICK O PE R AT I NG IN S TR U CT I ON S | deTem4 Core Ex

Subject to change without notice

33

Page 34

5 MOUN

TING

Approach

5.

Rotate the multiple light beam safety device in the FlexFix brackets so that the

front screen of the device faces the opening in the explosion-proof enclosure. The

infra-red rays must be able to pass through the window in the cover without

obstruction.

6. Tighten the screws used to secure the multiple light beam safety device in the

FlexFix brackets with a torque of 2.5 to 3 Nm.

7. Guide the connecting cable through the 3/4" NPT opening.

8. If a cable gland is required, follow the instructions to mount the gland, see "Mount

the optional cable gland", page 34.

9. Fit the cover to the explosion-proof enclosure using the supplied fixing screws and

washers. Tighten the fixing screws with a torque of 11.5 to 14.5 Nm.

NOTE

he washers must be used to obtain enclosure rating IP 66.

T

5.3.2 Mount the optional cable gland

Overview

D

epending on national regulations and requirements, a cable gland may have to be

installed. The cable gland is available as an accessory.

Important information

DANGER

Risk of ignition or explosion

Check the 3/4" NPT opening on the thread for damage.

b

Do not use the device if the thread for the 3/4" NPT opening is damaged.

b

Approach

Guide the cable through the cable gland.

1.

2. Screw the cable gland into the 3/4" NPT opening on the explosion-proof enclosure.

3. Pull the collar on the cable gland so that the cable is securely attached.

5.3.3 Mount the handles to the cover of the explosion-proof enclosure

Approach

1.

Use the supplied M6 screws to secure the two handles onto the cover of the explo‐

sion-proof enclosure.

2. Tighten the screws with a torque of 4.5 to 5 Nm.

34

O PE R AT I NG IN S TR U CT I ON S | deTem4 Core Ex 8022875/2019-03-04 | SICK

Subject to change without notice

Page 35

Figure 18: Mounting of the handles

MOUNTING 5

5.3.4 Mount the multiple light beam safety device

General notes

F

ind a place to mount the multiple light beam safety device that is stable enough

b

to hold its weight.

Mount the sender and receiver on a level surface.

b

Mount the sender and receiver at the same height.

b

The end with the connecting cable must point in the same direction for both

b

devices.

Figure 19: The sender and receiver are mounted incorrectly

Sender and r

b

Make sure that the sender and receiver are aligned correctly. The optical lens sys‐

b

eceiver must not be installed at 180° rotated relative to each other.

tems of the sender and the receiver must be located opposite one another.

8022875/2019-03-04 | SICK O PE R AT I NG IN S TR U CT I ON S | deTem4 Core Ex

Subject to change without notice

35

Page 36

4 x

4 x

WS

13 mm

Scope of delivery

Required tools

5 MOUN

TING

ssary, use a water level to check that the components are parallel.

If nece

b

The alignment bracket makes it possible to rotate the sender and receiver around

b

the axis of the device and to align them accurately; see "Sender and receiver align‐

ment", page 47.

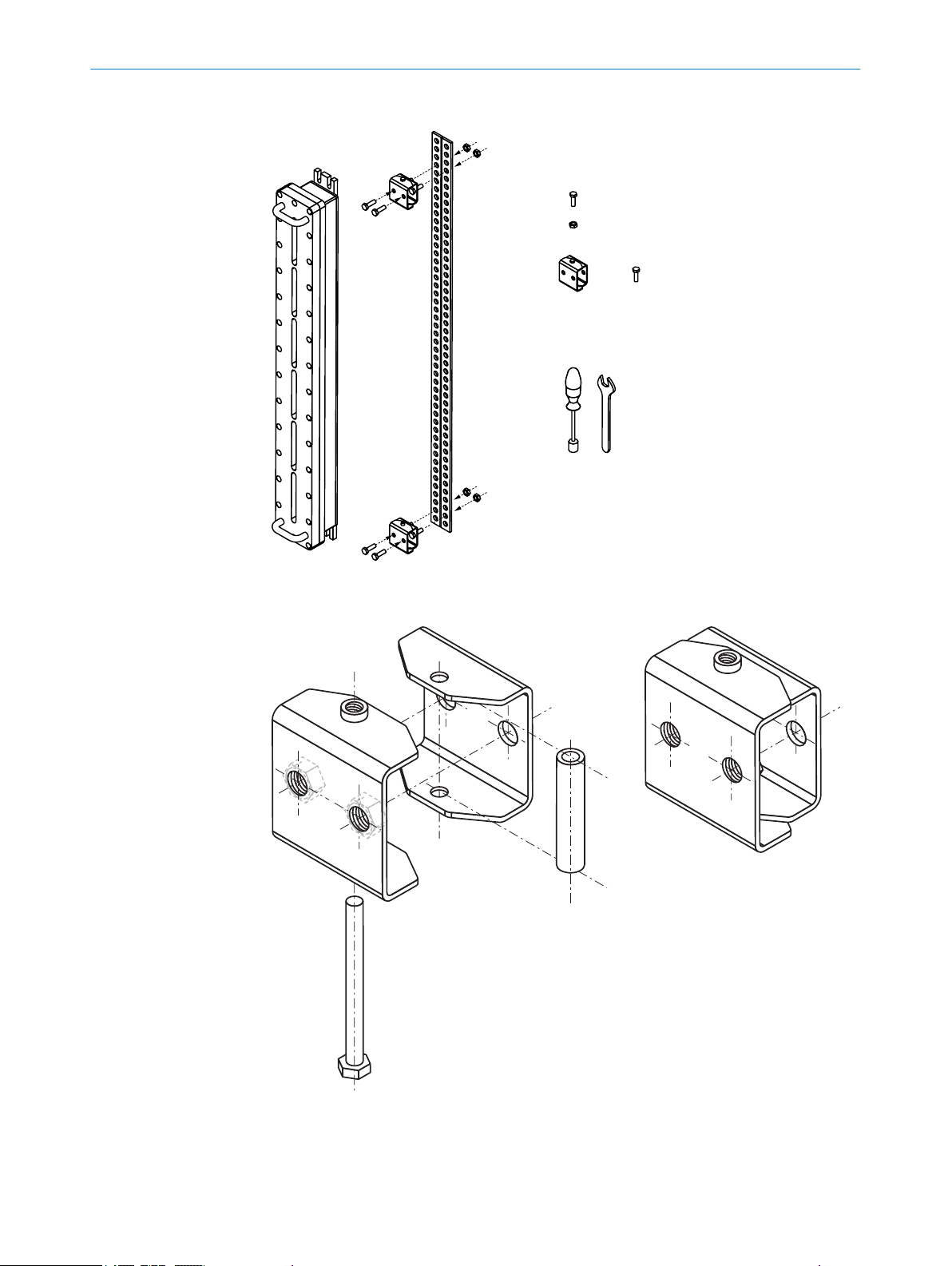

5.3.4.1 Mounting the multiple light beam safety device without the alignment bracket

Figure 20: Mounting the multiple light beam safety device without the alignment bracket

Approach

rench size 13 mm.

Use w

b

Figure 21: Mounting the multiple light beam safety device without the alignment bracket:

S

tep 1

1. Using 6 to 8 revolutions, screw in the two M8 screws for mounting the lower end of

t

he explosion-proof enclosure. Make sure you leave enough space between the

screws and the mounting surface for the lower end of the explosion-proof enclo‐

sure.

36

O PE R AT I NG IN S TR U CT I ON S | deTem4 Core Ex 8022875/2019-03-04 | SICK

Subject to change without notice

Page 37

MOUNTING 5

Figure 22: Mounting the multiple light beam safety device without the alignment bracket:

tep 2

S

2. Position the explosion-proof enclosure on the two screws so that the mounting

hole

s are directly over the partly-tightened screws.

Figure 23: Mounting the multiple light beam safety device without the alignment bracket:

S

teps 3 and 4

3. Fix the upper end of the explosion-proof enclosure to the mounting surface using

t

wo M8 screws.

4. Tighten the two lower M8 screws.

8022875/2019-03-04 | SICK O PE R AT I NG IN S TR U CT I ON S | deTem4 Core Ex

Subject to change without notice

37

Page 38

2 x

Part no. 2072525

4 x

4 x

4 x

WS

13 mm

Scope of delivery

Required tools

5 MOUN

TING

5.3.4.2 Mounting the multiple light beam safety device with the alignment bracket

Figure 24: Mounting the multiple light beam safety device using the alignment brackets

38

Figure 25: Assembling the alignment brackets

O PE R AT I NG IN S TR U CT I ON S | deTem4 Core Ex 8022875/2019-03-04 | SICK

Subject to change without notice

Page 39

MOUNTING 5

Approach

1.

Mount the lower alignment bracket so that the threaded hole faces up and the

head of the lock screw faces down.

2. Rotate the alignment bracket as far to one side as possible. Secure the alignment

bracket on the open side by screwing the first M8 screw into the through hole.

3. Rotate the lower alignment bracket to the other side. Secure the alignment

bracket using the second M8 screw.

4. Mount the upper alignment bracket so that the threaded hole faces down and the

head of the lock screw faces up.

5. Rotate the upper alignment bracket as far to one side as possible. Secure the

alignment bracket on the open side by screwing the first M8 screw into the

through hole.

6. Rotate the upper alignment bracket to the other side. Secure the alignment

bracket using the second M8 screw.

Figure 26: Mounting the multiple light beam safety device using the alignment brackets:

teps 1 to 6

S

7. Using 6 to 8 revolutions, screw the two M8 screws for mounting the lower end of

t

he explosion-proof enclosure into the lower alignment bracket. Make sure you

leave enough space between the screws and the alignment bracket for the lower

end of the explosion-proof enclosure.

8022875/2019-03-04 | SICK O PE R AT I NG IN S TR U CT I ON S | deTem4 Core Ex

Subject to change without notice

39

Page 40

5 MOUN

TING

Figure 27: Mounting the multiple light beam safety device using the alignment brackets:

tep 7

S

8. Position the explosion-proof enclosure on the two screws so that the mounting

hole

s are directly over the partly-tightened screws.

Figure 28: Mounting the multiple light beam safety device using the alignment brackets:

S

tep 8

9. Fix the upper end of the explosion-proof enclosure to the upper alignment bracket

usin

g two M8 screws.

10. Tighten the two lower screws.

40

Figure 29: Mounting the multiple light beam safety device using the alignment brackets:

S

teps 9 and 10

11. Turn the multiple light beam safety device so that they face one another and so

t

hat the receiver receives the strongest signal possible.

O PE R AT I NG IN S TR U CT I ON S | deTem4 Core Ex 8022875/2019-03-04 | SICK

Subject to change without notice

Page 41

28 Nm to 28.5 Nm

28 Nm to 28.5 Nm

MOUNTING 5

Figure 30: Mounting the multiple light beam safety device using the alignment brackets:

teps 11 and 12

S

12. Tighten the locking screws on all alignment brackets with a torque of 28 to

28.5 Nm in or

der to secure the multiple light beam safety device in this position.

8022875/2019-03-04 | SICK O PE R AT I NG IN S TR U CT I ON S | deTem4 Core Ex

Subject to change without notice

41

Page 42

6 ELECTRICAL INSTALLATION

6 Electrical installation

6.1 Safety

Important information

DANGER

H

azard due to electrical voltage

Hazard due to unexpected starting of the machine

Make sure that the machine is (and remains) disconnected from the power supply

b

during the electrical installation.

Make sure that the dangerous state of the machine is (and remains) switched off

b

during electrical installation.

Make sure that the outputs of the multiple light beam safety device do not affect

b

the machine during electrical installation.

Only use an appropriate voltage supply, see "Technical data", page 60.

b

DANGER

ion Hazard

Ignit

Failure to observe this information could result in a risk of ignition

Always switch the voltage supply off before disconnecting a connecting cable from

b

the device.

Ensure that all electrical connections to the device or to the connections are pro‐

b

tected.

The IP enclosure rating for the connections and therefore for the device is only

b

guaranteed if the connections are protected. Otherwise foreign objects can get

into the terminal compartment. This can cause an explosion the next time the

device is switched on.

Put in place measures for ensuring supply reliability and delivery dependability.

b

DANGER

k of ignition or explosion

Ris

If you have to remove the cover when working on the multiple light beam safety

b

device, make sure that the joints and o-ring are clean and undamaged before refit‐

ting the cover.

DANGER

k of ignition or explosion

Ris

Disconnect the power supply before opening the explosion-proof enclosure to

b

avoid igniting hazardous atmospheres.

Do not reconnect the power supply until you have completed the electrical installa‐

b

tion.

42

O PE R AT I NG IN S TR U CT I ON S | deTem4 Core Ex 8022875/2019-03-04 | SICK

Subject to change without notice

Page 43

ELECTRICAL INSTALLATION 6

DANGER

k of ignition or explosion

Ris

Each connection to the protection earth (PE) on the explosion-proof enclosure

b

must use at least one wire with a cross-section meeting the requirements of the

table below.

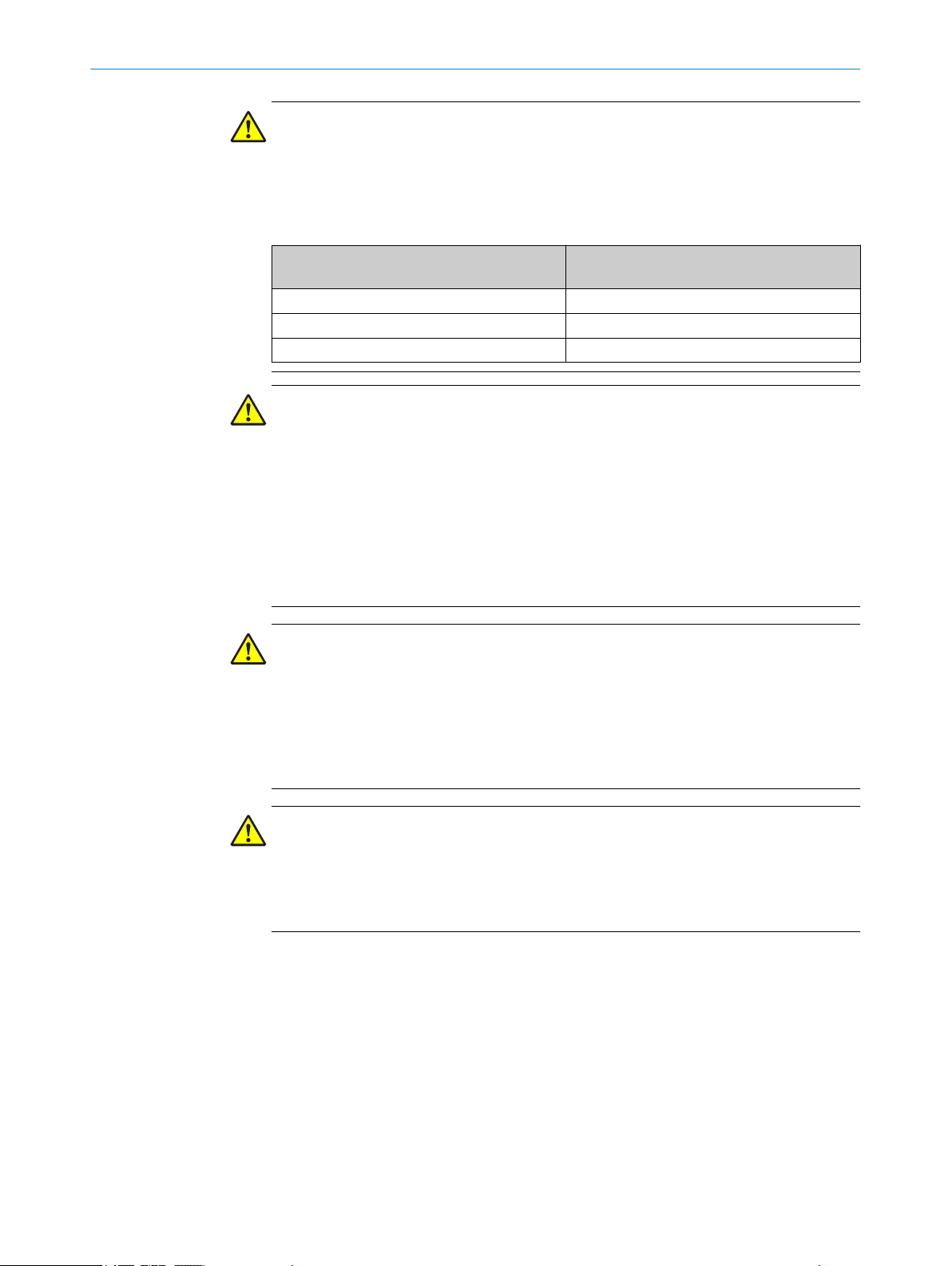

Table 2: Minimum wire cross-section for protection earth (PE)

Wire cross-section of outer cable S Minimum wire cross-section of the corre‐

spondin

S ≤ 16 mm

16 mm2 < S

S > 35 mm

2

≤ 35 mm

2

S

2

16 mm

0.5 S

DANGER

H

azard due to electrical voltage

Hazard due to unexpected starting of the machine

Make sure that the machine is (and remains) disconnected from the power supply

b

during the electrical installation.

Make sure that the dangerous state of the machine is (and remains) switched off

b

during electrical installation.

Make sure that the outputs of the multiple light beam safety device do not affect

b

the machine during electrical installation.

Only use an appropriate voltage supply, see "Technical data", page 60.

b

g protection earth wire S

2

P

DANGER

H

azard due to lack of effectiveness of the protective device

The dangerous state may not be stopped in the event of non-compliance.

Always connect the two OSSDs separately. The two OSSDs must not be connected

b

to each other.

Connect the OSSDs such that the machine controller processes both signals sepa‐

b

rately.

DANGER

H

azard due to lack of effectiveness of the protective device

The dangerous state may not be stopped in the event of non-compliance.

Prevent the formation of a potential difference between the load and the protec‐

b

tive device.

Prerequisites

he multiple light beam safety device has been safely integrated into the control

T

•

system and the electrical system of the machine.