Page 1

deTec2 Core

Safety light curtain

O P E R A T I N G I N S T R U C T I O N S

Page 2

Described product deTec2 Core

Manufacturer SICK AG

Erwin-Sick-Str. 1

79183 Waldkirch, Germany

Germany

Legal information This work is protected by copyright. Any rights derived from the copyright shall be re‐

served for SICK AG. Reproduction of this document or parts of this document is only

permissible within the limits of the legal determination of Copyright Law. Any modifica‐

tion, expurgation or translation of this document is prohibited without the express writ‐

ten permission of SICK AG.

The trademarks stated in this document are the property of their respective owner.

© SICK AG. All rights reserved.

Original document This document is an original document of SICK AG.

2

O PE R AT I NG IN S TR U CT I ON S | deTec2 Core 8014276/2014-02-18 | SICK

Subject to change without notice

Page 3

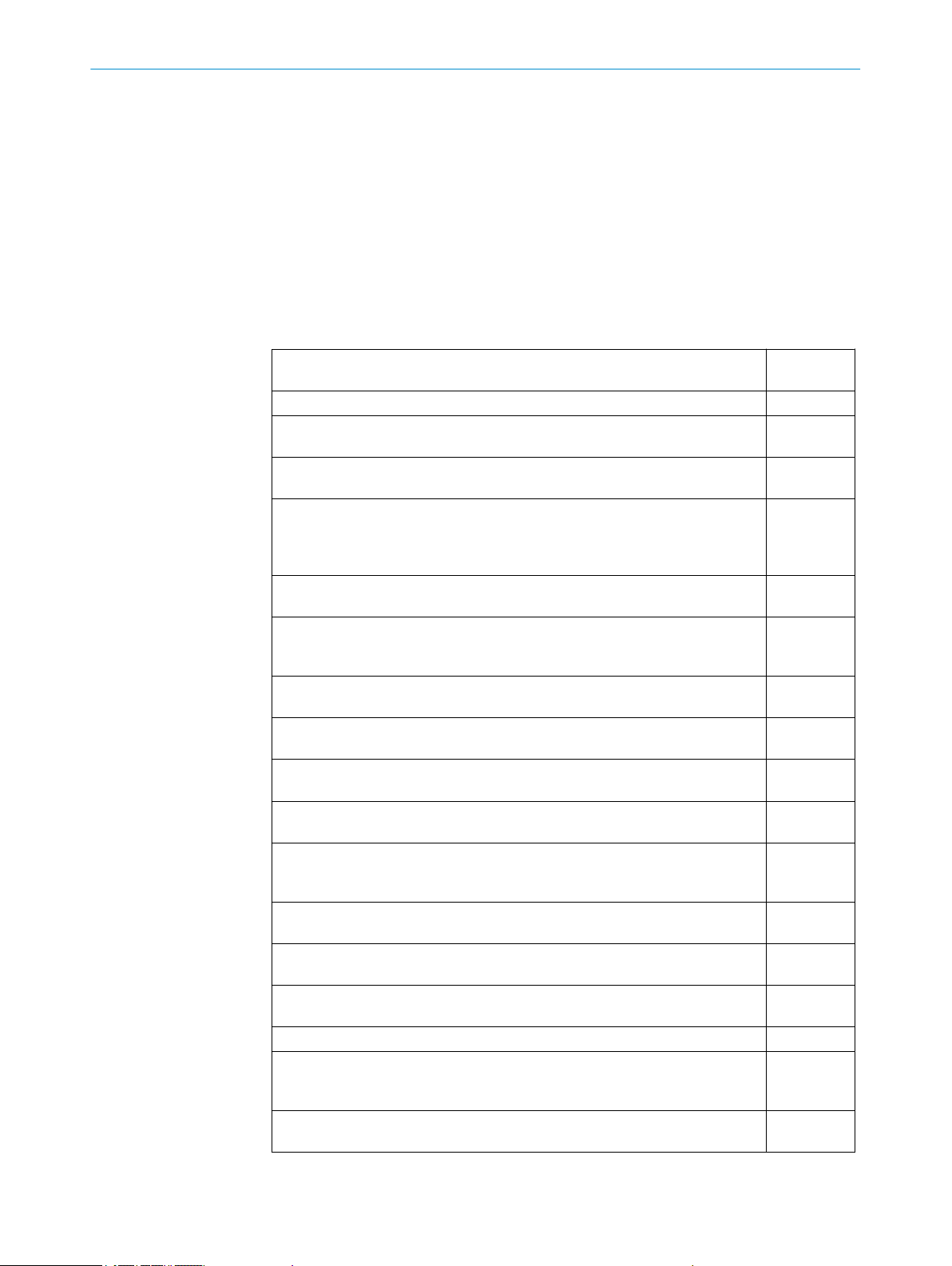

Contents

CONTENTS

1 About this document..............................................................................6

1.1 Scope............................................................................................................... 6

1.2 Target groups and structure of these operating instructions.......................6

1.3 Further information......................................................................................... 7

1.4 Symbols and document conventions.............................................................7

2 Safety information..................................................................................8

2.1 General safety notes....................................................................................... 8

2.2 Correct use.......................................................................................................8

2.3 Requirements for the qualification of personnel.......................................... 9

3 Product description..............................................................................10

3.1 Structure and function..................................................................................10

3.2 Product characteristics.................................................................................11

3.2.1 Absence of blind zones................................................................11

3.2.2 Automatic calibration of the protective field width....................11

3.2.3 Status indicators.......................................................................... 11

3.3 Example applications....................................................................................13

4 Project planning................................................................................... 15

4.1 Manufacturer of the machine...................................................................... 15

4.2 Operator of the machine.............................................................................. 15

4.3 Design............................................................................................................ 15

4.3.1 Scanning range and protective field width.................................16

4.3.2 Minimum distance from the hazardous point............................16

4.3.3 Minimum distance to reflective surfaces................................... 18

4.3.4 Protection against interference from systems in close proximity

to each other................................................................................ 20

4.4 Integration in electrical control.................................................................... 20

4.4.1 Restart interlock and external device monitoring......................22

5 Mounting................................................................................................24

5.1 Safety............................................................................................................. 24

5.2 Unpacking......................................................................................................24

5.3 Installation.....................................................................................................24

5.3.1 Mount the QuickFix bracket........................................................ 26

5.3.2 Mount optional FlexFix bracket...................................................27

5.3.3 Mount optional replacement bracket......................................... 30

5.4 Attach information label............................................................................... 32

8014276/2014-02-18 | SICK

Subject to change without notice

6 Electrical installation........................................................................... 33

6.1 Safety............................................................................................................. 33

6.2 Device connection (M12, 5-pin)...................................................................34

6.3 Device connection via connection cable (M12, 5-pin to 8-pin)................. 34

O PE R AT I NG IN S TR U CT I ON S | deTec2 Core

3

Page 4

CONTENTS

7 Initial commissioning.......................................................................... 35

7.1 Safety............................................................................................................. 35

7.2 Switching on.................................................................................................. 35

7.3 Align the sender and receiver...................................................................... 36

7.4 Checks........................................................................................................... 38

8 Operation...............................................................................................39

8.1 Safety............................................................................................................. 39

8.2 Daily check.................................................................................................... 39

9 Maintenance......................................................................................... 42

9.1 Safety............................................................................................................. 42

9.2 Regular cleaning........................................................................................... 42

9.3 Regular inspection........................................................................................ 43

10 Troubleshooting....................................................................................44

10.1 Safety.............................................................................................................44

10.2 Fault indicators............................................................................................. 44

11 Decommissioning................................................................................ 46

11.1 Protection of the environment..................................................................... 46

11.2 Disposal......................................................................................................... 46

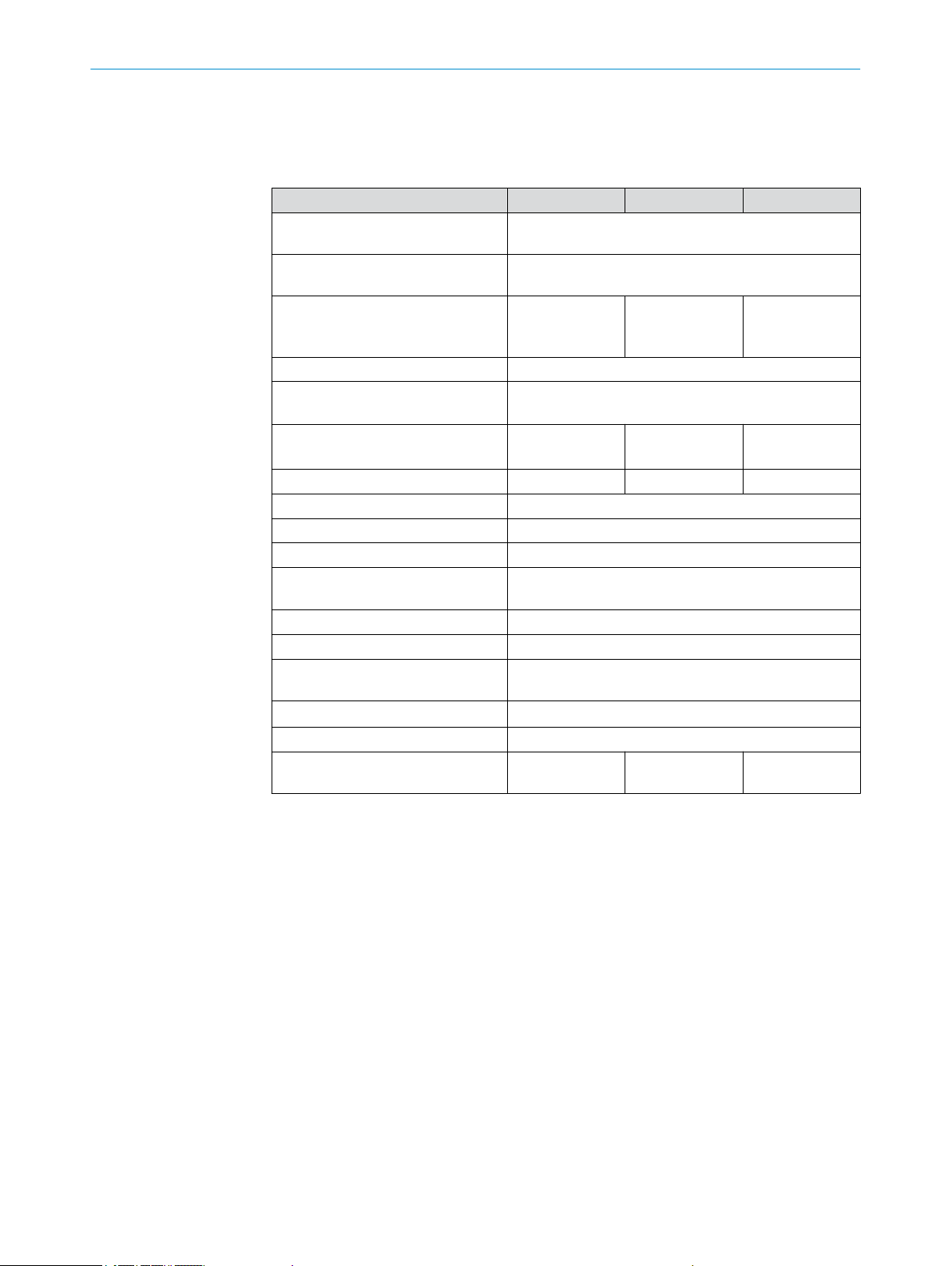

12 Technical data...................................................................................... 47

12.1 Data sheet..................................................................................................... 47

12.2 Response time.............................................................................................. 49

12.3 power consumption...................................................................................... 50

12.4 Table of weights............................................................................................ 50

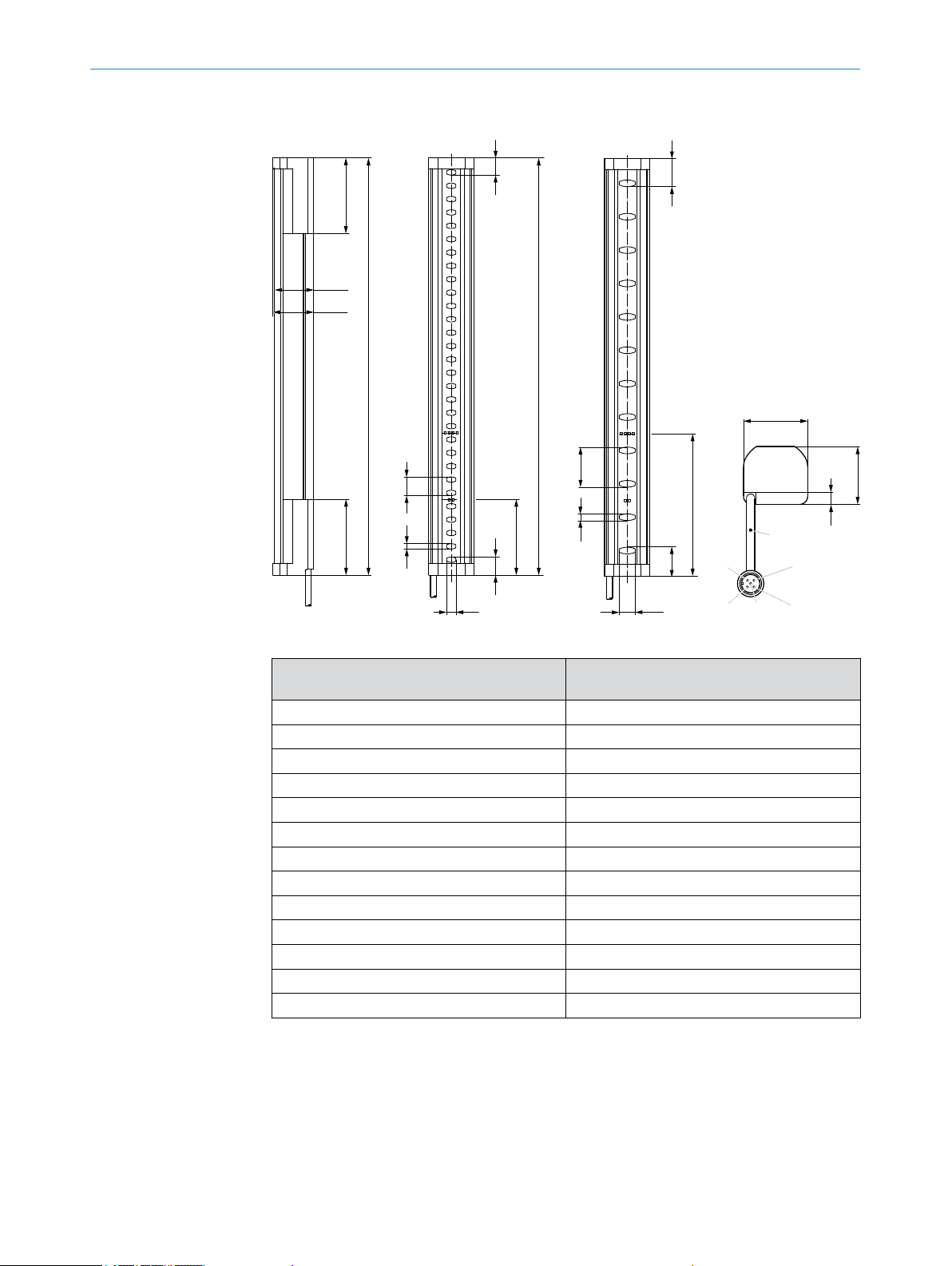

12.5 Dimensional drawings.................................................................................. 51

13 Ordering information........................................................................... 52

13.1 Scope of delivery...........................................................................................52

13.2 Ordering information ....................................................................................52

14 Accessories........................................................................................... 53

14.1 Ordering information, accessories...............................................................53

14.2 Weld spark guard..........................................................................................55

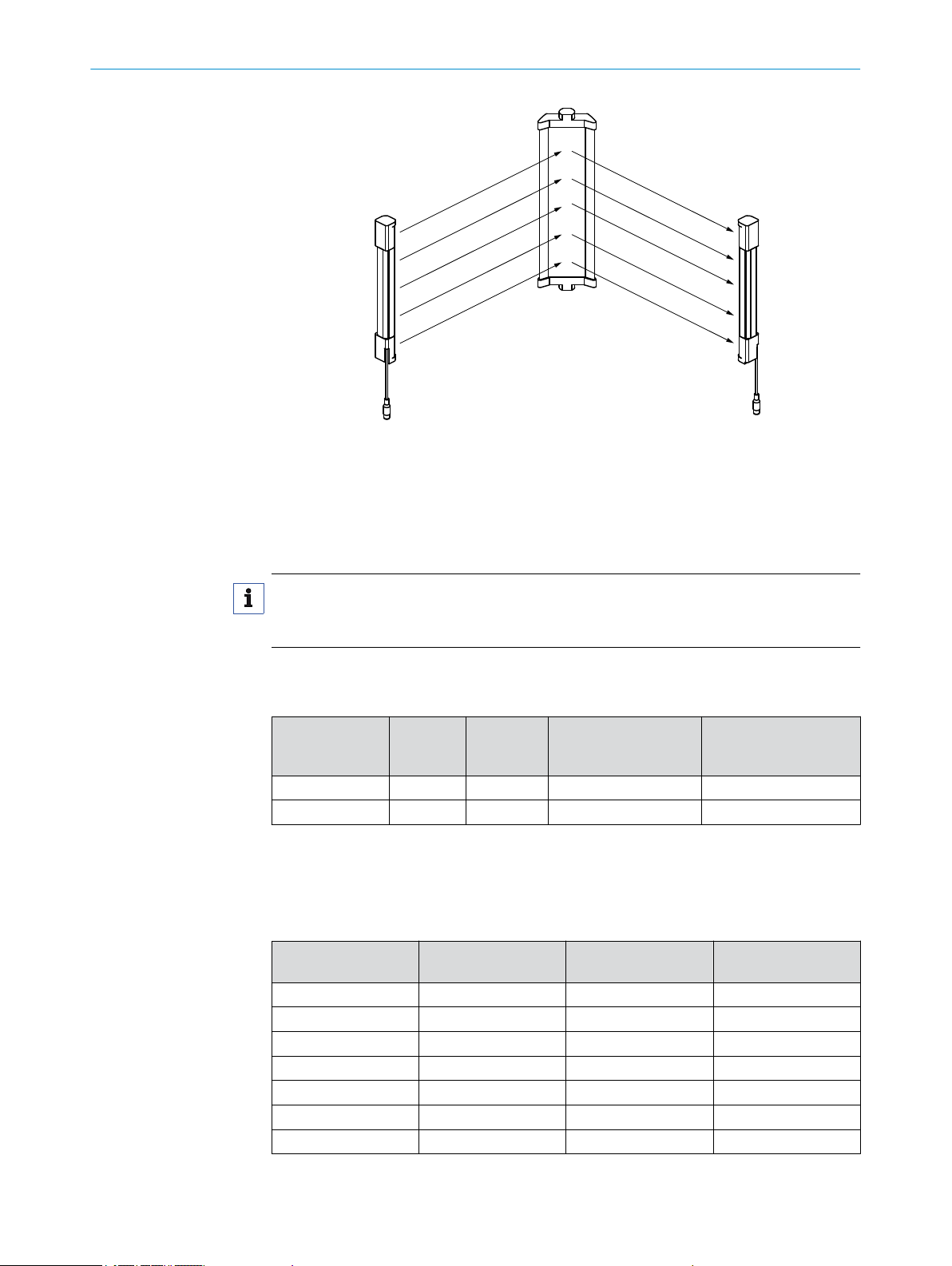

14.3 Deflector mirror.............................................................................................56

14.3.1 Mounting.......................................................................................57

14.3.2 Change in scanning range using deflector mirrors....................57

14.3.3 Deflector mirror PNS75 - ordering information..........................57

14.3.4 Deflector mirror PSN125 - ordering information....................... 58

14.4 Columns.........................................................................................................58

14.5 Test rods........................................................................................................59

15 List of figures........................................................................................ 60

4

O PE R AT I NG IN S TR U CT I ON S | deTec2 Core 8014276/2014-02-18 | SICK

Subject to change without notice

Page 5

CONTENTS

16 List of tables..........................................................................................61

17 Appendix................................................................................................62

17.1 Compliance with EC directives.....................................................................62

17.2 Checklist for initial commissioning and commissioning............................ 64

8014276/2014-02-18 | SICK

Subject to change without notice

O PE R AT I NG IN S TR U CT I ON S | deTec2 Core

5

Page 6

ABOUT THIS DOCUMENT

1

1 About this document

These operating instructions contain information required during the life cycle of the

safety light curtain.

These operating instructions are available to all those who work with the safety light

curtain.

Please read these operating instructions carefully and make sure that you understand

the content fully before working with the safety light curtain.

1.1 Scope

These operating instructions only apply to the deTec2 Core safety light curtain with the

following type label entry Operating Instructions: 8014274.

These operating instructions are included with SICK part number 8014274 (all availa‐

ble languages).

1.2 Target groups and structure of these operating instructions

These operating instructions are intended for the following target groups: project devel‐

opers (planners, developers, designers), installers, electricians, operators and mainte‐

nance personnel.

The structure of these operating instructions is based on the life cycle phases of the

safety light curtain: project planning, mounting, electrical installation, commissioning,

operation and maintenance.

In many applications, the audiences are assigned as follows to the manufacturer and

organization operating the machine, in which the safety light curtain is integrated:

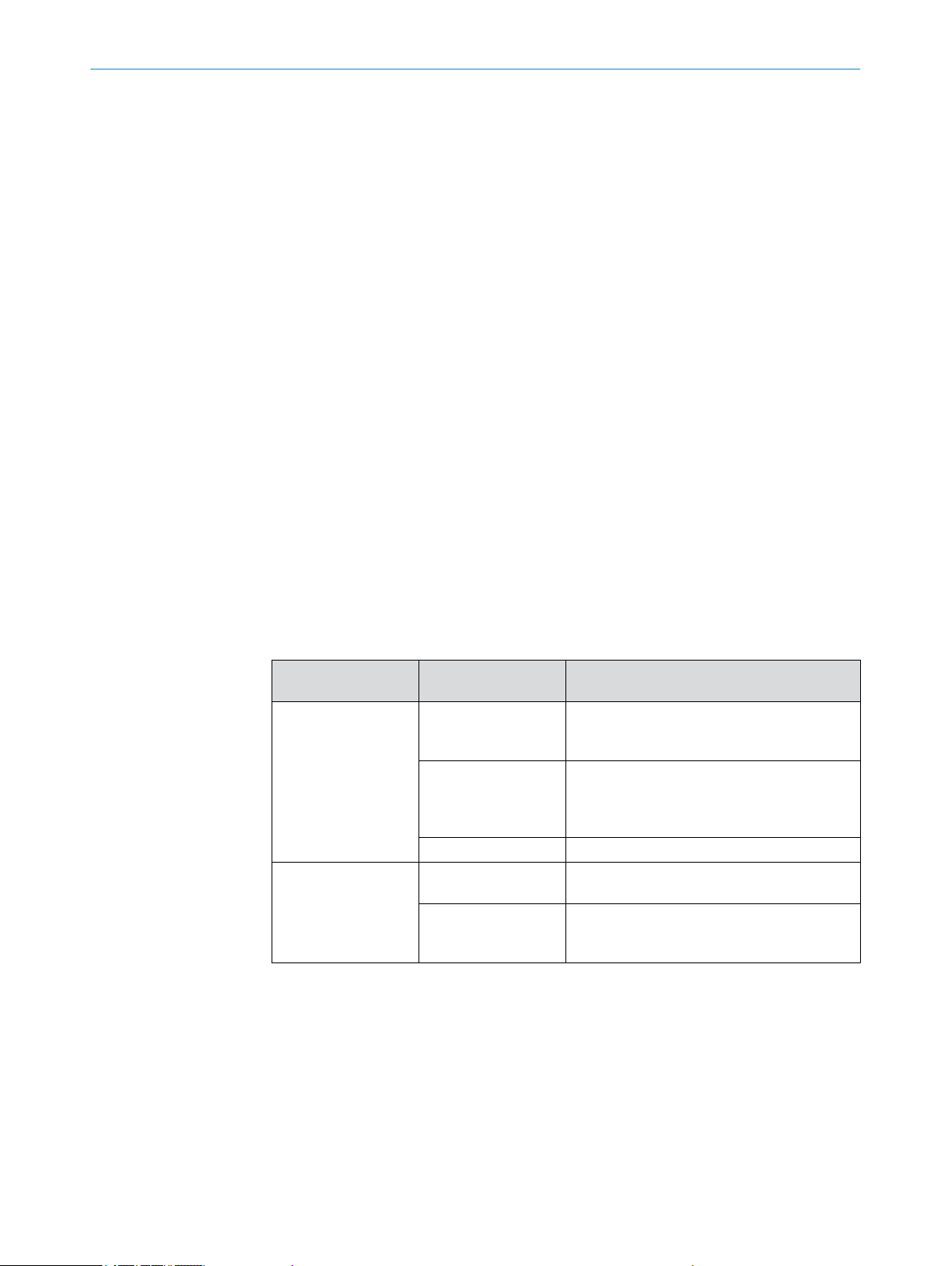

Area of responsibility Target group Special chapters of these operating instruc‐

Manufacturer Project developers

(planners, developers,

designers)

Installers "Mounting", Page 24

Electricians "Electrical installation", Page 33

operating company Operator "Operation", Page 39

Maintenance person‐

nel

1)

Chapters not listed here are intended for all target groups. All target groups must take into account the

safety and warning instructions of the complete operating instructions!

1)

tions

"Project planning", Page 15

"Technical data", Page 47

"Accessories", Page 53

"Initial commissioning", Page 35

"Checklist for initial commissioning and com‐

missioning", Page 64

"Troubleshooting", Page 44

"Maintenance", Page 42

"Troubleshooting", Page 44

"Ordering information", Page 52

In other applications, the operating organization is also the manufacturer of the equip‐

ment with the corresponding allocation of the target groups.

6

O PE R AT I NG IN S TR U CT I ON S | deTec2 Core 8014276/2014-02-18 | SICK

Subject to change without notice

Page 7

1.3 Further information

www.sick.com The following information is available on the Internet:

– Other language versions

– Data sheets and application examples

– CAD data of drawings and dimensional drawings

– Certificates (e.g. EC declaration of conformity)

– Guidelines for safe machines (accident prevention with opto-electronic protective de‐

vices)

ABOUT THIS DOCUMENT 1

1.4

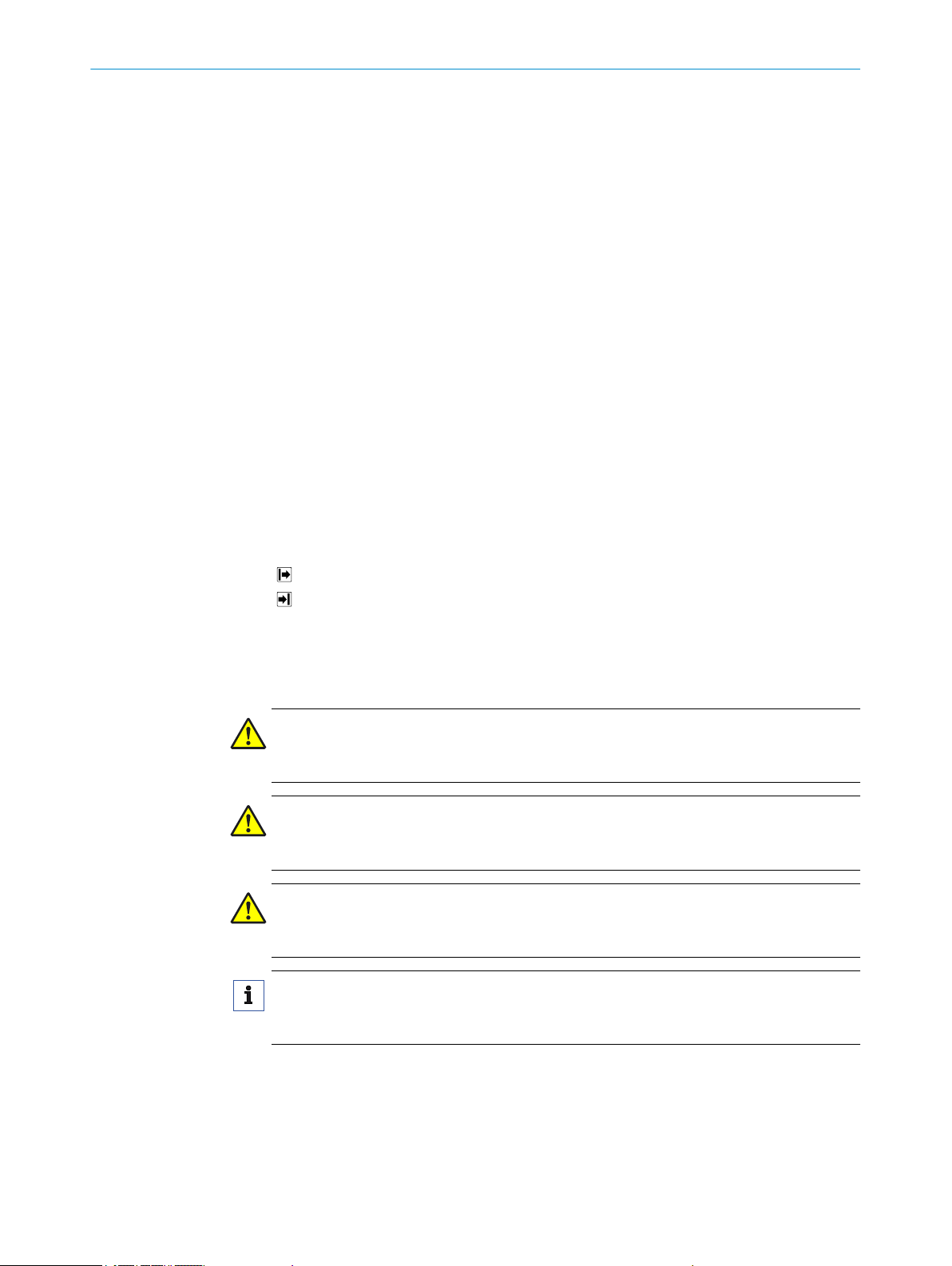

Symbols and document conventions

The following symbols are used in these operating instructions:

Instructions to actionbThe arrow denotes instructions to action. Read carefully and follow the instructions

for action.

LED symbols These symbols indicate the status of an LED:

The LED is off.

The LED is flashing.

The LED is illuminated continuously.

Sender and receiver These symbols indicate the sender and receiver of the safety light curtain:

The symbol indicates the sender.

The symbol indicates the receiver.

Warnings A warning indicates an actual or potential risk or dangers. It is designed to help you to

prevent accidents. Read carefully and follow the warnings!

The following warning types are used in these operating instructions:

CAUTION

Alerts you to a dangerous situation, which can result in a mild to moderate injury if not

avoided.

8014276/2014-02-18 | SICK

Subject to change without notice

WARNING

Alerts you to a dangerous situation, which can cause serious injury or death if not avoi‐

ded.

DANGER

Alerts you to a dangerous situation, which will cause serious injury or death if not avoi‐

ded.

NOTE

The "i" symbol denotes information and alerts you to possible damage and other impor‐

tant information.

O PE R AT I NG IN S TR U CT I ON S | deTec2 Core

7

Page 8

2 SAFETY INFORMATION

2 Safety information

This chapter contains information on general safety for the safety light curtain.

More safety information about specific usage situations of the safety light curtain is

available in the respective chapters.

2.1 General safety notes

DANGER

Risk of ineffectiveness of the protective device

Persons or parts of the body to be protected are not recognized in case of non-observ‐

ance.

Pay particular attention to all warnings in these operating instructions.

b

2.2 Correct use

The deTec2 Core safety light curtain is an electro-sensitive protective device (ESPE)

and is suitable for the following applications:

– Hazardous point protection

– Access protection

– Hazardous area protection

The deTec2 Core safety light curtain must be connected to the control such that the

machine cannot start while persons are present in the hazardous area. If a person can

stand behind the safety light curtain, there must be a restart interlock depending on

the applicable national regulations.

The deTec2 Core safety light curtain must be only used within the limits of the prescri‐

bed and specified technical data and operating conditions at all times.

The requirements defined in the technical specifications, e.g. power supply, cables and

ambient conditions, must be observed and maintained to allow the safety light curtain

to meet its warranted function.

If the product is used for any other purpose or modified in any way, any warranty claim

against SICK AG shall become void.

Foreseeable misuse Among others, the deTec2 Core safety light curtain is not suitable for the following ap‐

plications:

– Outdoors

– Under water

– In potentially explosive atmospheres

8

O PE R AT I NG IN S TR U CT I ON S | deTec2 Core 8014276/2014-02-18 | SICK

Subject to change without notice

Page 9

SAFETY INFORMATION 2

DANGER

Risk of ineffectiveness of the protective device

Persons and parts of the body to be protected are not recognized in case of non-ob‐

servance.

The width of the protective field must not change during operation of the safety light

b

curtain, see "Scanning range and protective field width", Page 16.

The components of the safety light curtain must not be tampered with, opened or

b

changed. Otherwise, any warranty claim against SICK AG shall become void.

Improper repair of the protective device can lead to a loss of the protective function.

b

The protective device must be repaired by the manufacture or by someone author‐

ized by the manufacturer.

DANGER

Risk of ineffectiveness of the protective device

Persons and parts of the body to be protected are not recognized in case of non-ob‐

servance.

The safety light curtain works as an indirect protective measure and cannot provide

protection from parts thrown out nor from emitted radiation. Transparent objects are

not detected.

Only use the safety light curtain as an indirect protective measure!

b

2.3

Requirements for the qualification of personnel

The safety light curtain must be configured, installed, connected, commissioned and

serviced only by qualified safety personnel.

Project planning For project planning, a person is considered competent when he/she has expertise and

experience in the selection and use of safety equipment on machines and is familiar

with the relevant technical rules and national work safety regulations.

Mechanical installation

and commissioning

For mechanical installation and commissioning, a person is considered competent

when he/she has the expertise and experience in the relevant field and is sufficiently

familiar with the application of the protective device on the machine that he/she can

assess its work safety aspects.

Electrical installation For electrical installation and commissioning, a person is considered competent when

he/she has the expertise and experience in the relevant field and is sufficiently familiar

with the application of the protective device on the machine that he/she can assess its

work safety aspects.

Operation and mainte‐

nance

For operation and maintenance, a person is considered competent when he/she has

the expertise and experience in the relevant field and is sufficiently familiar with the ap‐

plication of the protective device on the machine and has been instructed by the ma‐

chine operator in its operation.

8014276/2014-02-18 | SICK

Subject to change without notice

An operator must clean and check the safety light curtain.

Additional information for the operator of the machine: see "Operation", Page 39 and

"Regular cleaning", Page 42.

O PE R AT I NG IN S TR U CT I ON S | deTec2 Core

9

Page 10

3 PRODUCT DESCRIPTION

3 Product description

This chapter provides information on the operation of the safety light curtain and shows

examples of its range of use.

3.1 Structure and function

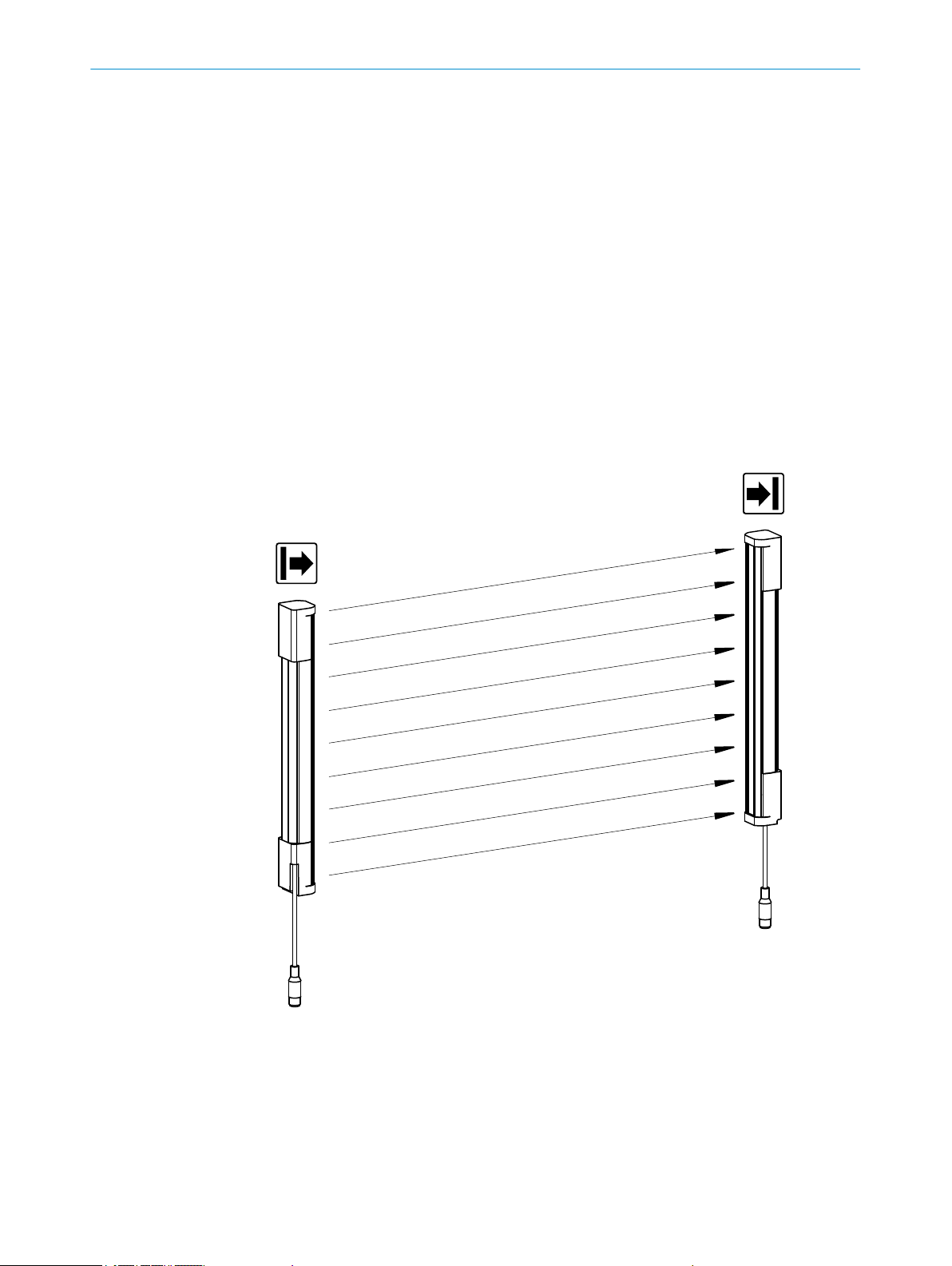

The deTec2 Core safety light curtain is an electro-sensitive protective device (ESPE)

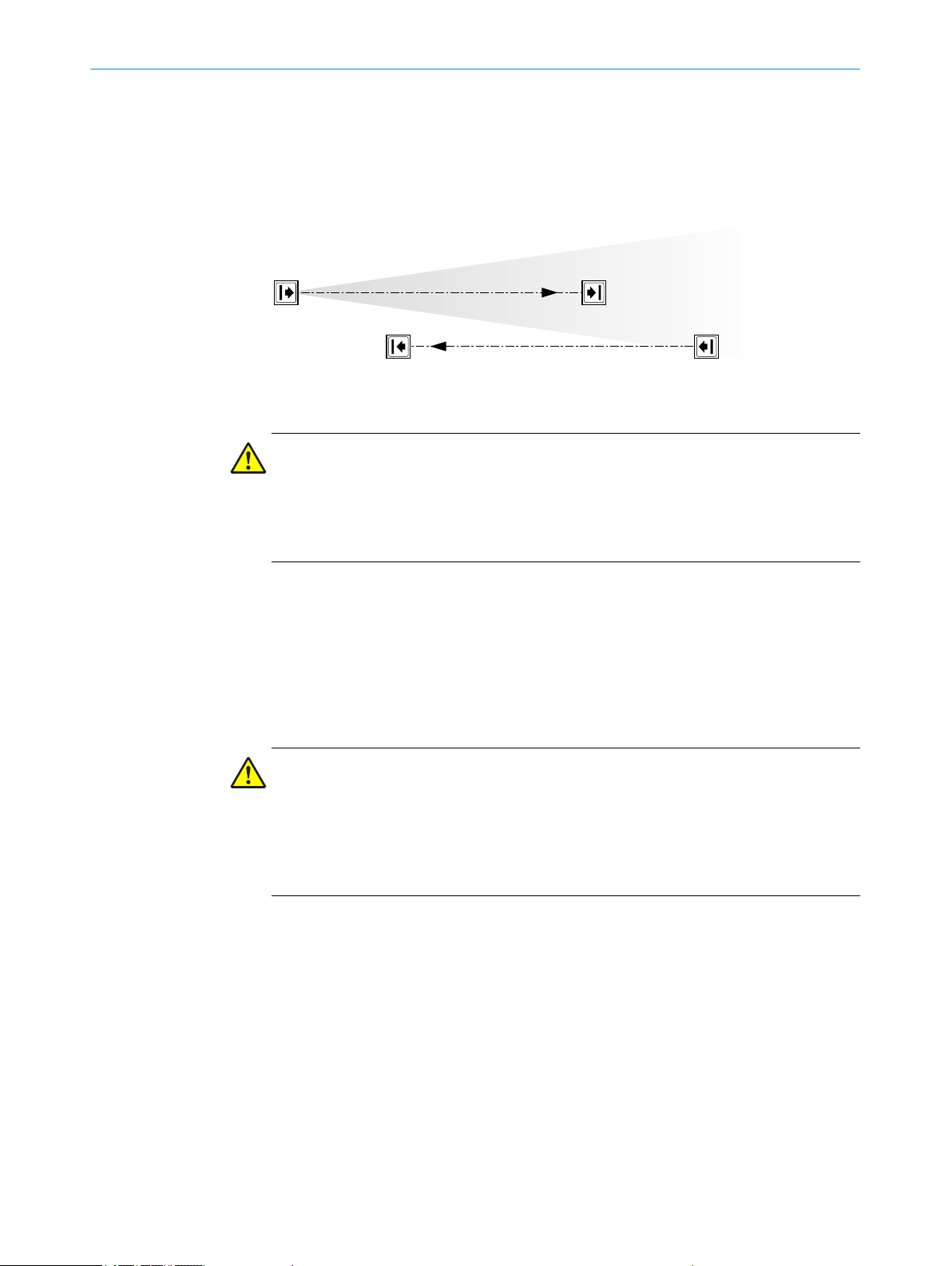

consisting of a sender and receiver.

A series of parallel infrared light beams form a protective field between sender and re‐

ceiver that protects the hazardous area (hazardous point, access and hazardous area

protection). When one or more beams are completely interrupted, the safety light cur‐

tain reports the interruption in the light path to the secure output signal switching devi‐

ces (OSSDs) by a signal change. The signal to stop the dangerous state of the machine

must be evaluated by a safe control or safety relay (contactors).

Sender and receiver automatically synchronize themselves optically. An electrical con‐

nection between both components is not required.

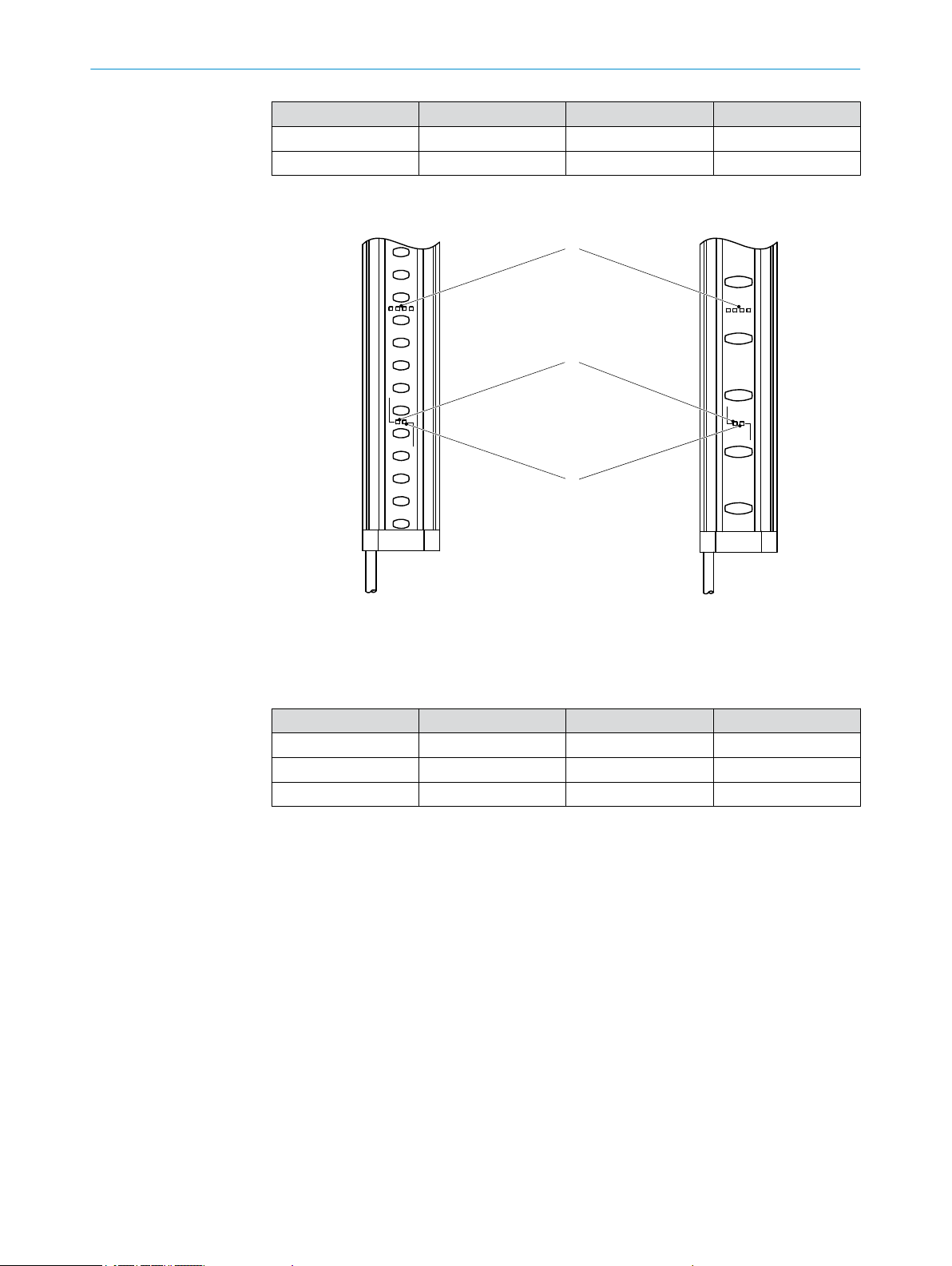

Figure 1: Sender and receiver

Protective field height The protective field height indicates the range within which the test rod belonging to

the safety light curtain is detected. The size of the safety light curtain determines the

protective field height. The design and construction of the safety light curtain deTec2

Core extends the protective function of a device to the end of the housing without any

blind spots.

10

O PE R AT I NG IN S TR U CT I ON S | deTec2 Core 8014276/2014-02-18 | SICK

Subject to change without notice

Page 11

Resolution 30 mmResolution 14 mm

ERR

PWR

ERR

PWR

PRODUCT DESCRIPTION

Protective field range Die Schutzfeldbreite ist die Länge des Lichtweges zwischen Sender und Empfänger. Sie

ist durch die Reichweite begrenzt. Informationen zu Schutzfeldhöhe, Auflösung und

Schutzfeldbreite: see "Data sheet", Page 47.

Resolution With the appropriate resolution, the safety light curtain provides finger and hand pro‐

tection. The resolution corresponds to the diameter of the test rod belonging to the

safety light curtain, which is reliably detected when in the protective field.

3

Interrelationship: Reso‐

lution and scanning

range

The deTec2 Core safety light curtain is available with a protective field height of 300

mm to 2100 mm (150 mm steps). The available resolution versions are 14 mm (0 - 7

m scanning range) and 30 mm (0 - 10 m scanning range).

The scanning range is reduced by using deflector mirrors and/or a weld spark guard.

Additional information: see "Deflector mirror", Page 56 and "Weld spark guard",

Page 55.

3.2 Product characteristics

3.2.1 Absence of blind zones

The design and construction of the safety light curtain extends the protective function

of a device to the end of the housing without any blind spots. The absence of blind

zones reduces the space requirement when integrated in the machine.

3.2.2 Automatic calibration of the protective field width

When switched on, the safety light curtain automatically calibrates to the protective

field width.

3.2.3 Status indicators

The sender and receiver LEDs indicate the operating status of the safety light curtains.

Status indicators of the

sender

8014276/2014-02-18 | SICK

Subject to change without notice

Figure 2: Sender indicators

The sender has two LEDs, which indicate the operating status:

O PE R AT I NG IN S TR U CT I ON S | deTec2 Core

11

Page 12

Resolution 30 mmResolution 14 mm

ERR

OSSD

ERR

OSSD

1 2 3 4

1 2 3 4

2

1

3

PRODUCT DESCRIPTION

3

Status indicators of the

receiver

Item LED color Display Labeling

1 Yellow Status indicator PWR

2 Red Fault indicator ERR

For a complete overview of the fault indications: see "Fault indicators", Page 44.

Figure 3: Receiver indicators

The receiver has six LEDs, which indicate the operating status:

Item LED color Display Labeling

1 Red/green OSSD status indicator OSSD

2 Red Fault indicator ERR

3 Blue Alignment quality 1, 2, 3, 4

Blue LEDs in combination with the red flashing ERR LED also denote fault indications.

For a complete overview of the fault indications: see "Fault indicators", Page 44.

12

O PE R AT I NG IN S TR U CT I ON S | deTec2 Core 8014276/2014-02-18 | SICK

Subject to change without notice

Page 13

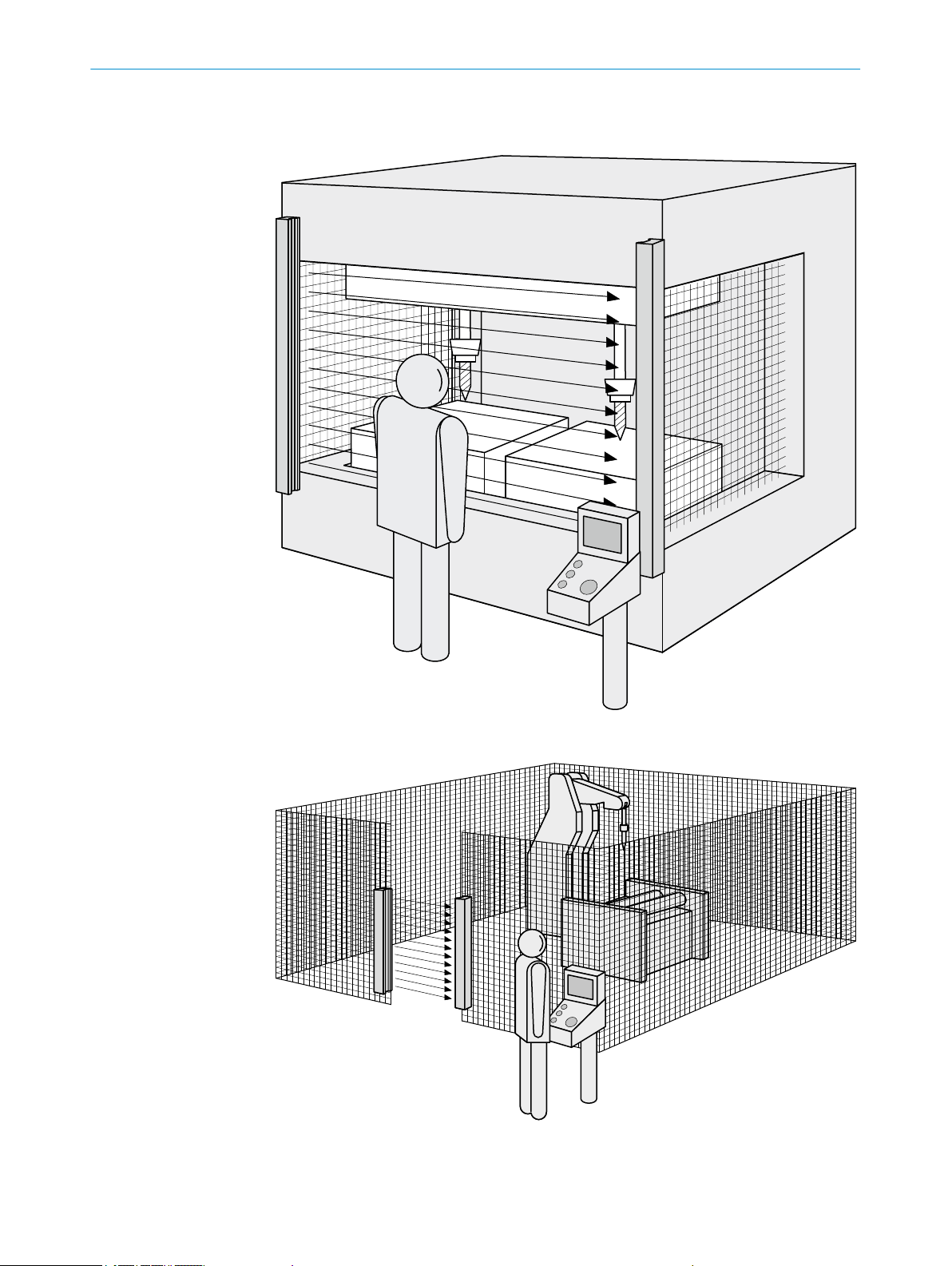

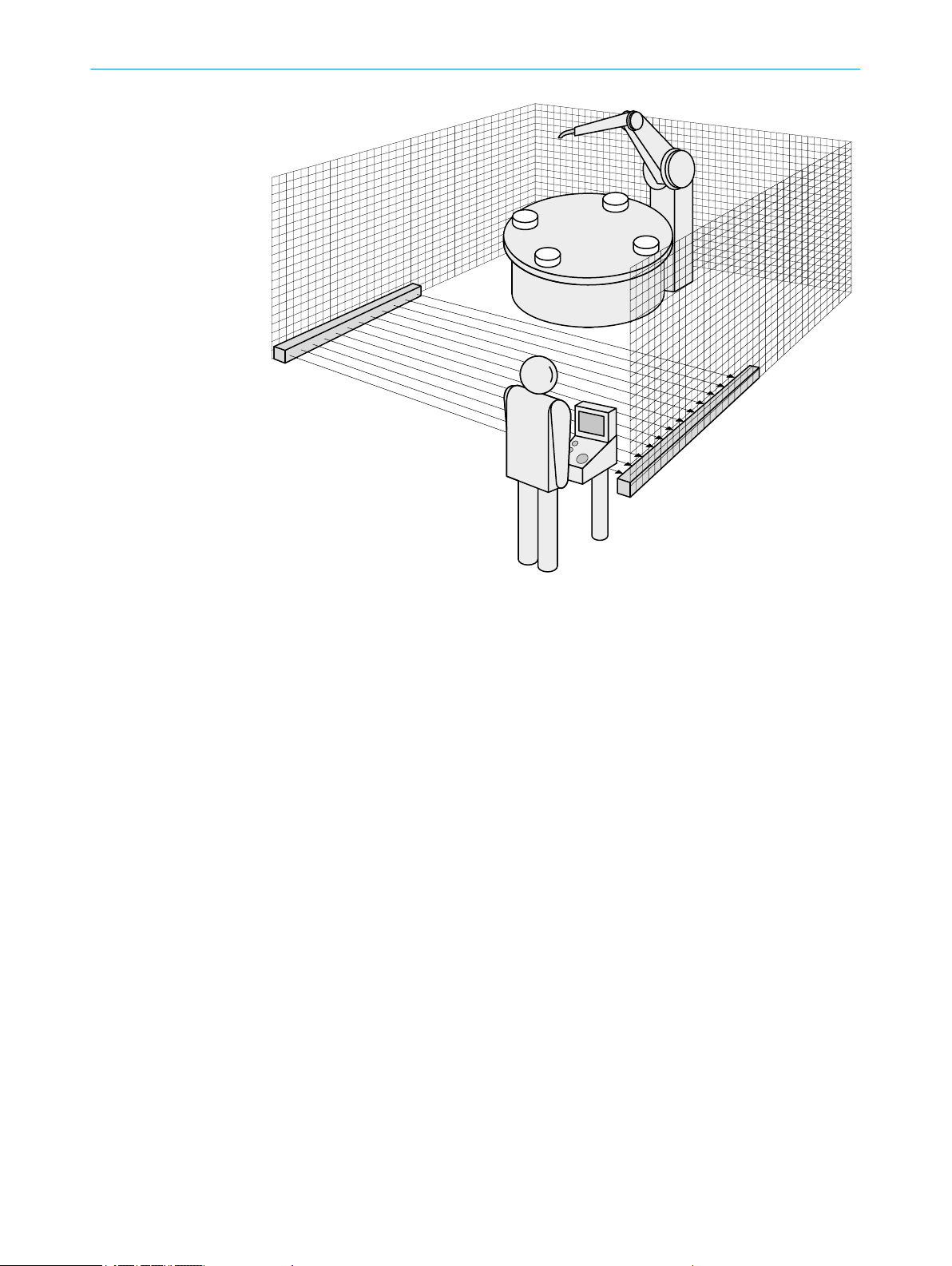

3.3 Example applications

PRODUCT DESCRIPTION

3

Figure 4: Hazardous point protection

Figure 5: Access protection

8014276/2014-02-18 | SICK

Subject to change without notice

O PE R AT I NG IN S TR U CT I ON S | deTec2 Core

13

Page 14

PRODUCT DESCRIPTION

3

Figure 6: Hazardous area protection

14

O PE R AT I NG IN S TR U CT I ON S | deTec2 Core 8014276/2014-02-18 | SICK

Subject to change without notice

Page 15

4 Project planning

This chapter includes important information about the proper integration of the safety

light curtain in machines for planners, developers and designers.

4.1 Manufacturer of the machine

DANGER

Risk of ineffectiveness of the protective device

Persons and parts of the body to be protected are not recognized in case of non-ob‐

servance.

Use of the safety light curtain requires a risk analysis. Check whether additional pro‐

b

tective measures are required.

Comply with the applicable national regulations derived from the application (e.g.

b

work safety regulations, safety rules or other relevant safety guidelines).

Do not combine the components of the safety light curtain with components from

b

other safety light curtains.

The components of the safety light curtain must not be tampered with, opened or

b

changed. Otherwise, any warranty claim against SICK AG shall become void.

Improper repair of the protective device can lead to a loss of the protective function.

b

The protective device must be repaired by the manufacture or by someone author‐

ized by the manufacturer.

PROJECT PLANNING 4

4.2 Operator of the machine

DANGER

Risk of ineffectiveness of the protective device

Persons and parts of the body to be protected are not recognized in case of non-ob‐

servance.

Changes to the electrical integration of the safety light curtain in the machine control

b

and changes to the mechanical installation of the safety light curtain require another

risk analysis.

The results of the risk analysis may require the operator of the machine to meet the

b

obligations of a manufacturer.

The components of the safety light curtain must not be tampered with, opened or

b

changed. Otherwise, any warranty claim against SICK AG shall become void.

Improper repair of the protective device can lead to a loss of the protective function.

b

The protective device must be repaired by the manufacture or by someone author‐

ized by the manufacturer.

4.3 Design

This chapter contains important information about the design.

Information about the individual steps for installation of the device: see "Mounting",

Page 24.

8014276/2014-02-18 | SICK

Subject to change without notice

O PE R AT I NG IN S TR U CT I ON S | deTec2 Core

15

Page 16

4 PROJECT PLANNING

DANGER

Risk of ineffectiveness of the protective device

Persons and parts of the body to be protected are not recognized in case of non-ob‐

servance.

Make sure that the following design requirements are met such that the safety light

b

curtain can fulfill its protective function.

– Sender and receiver must be arranged such that persons or parts of the body are

reliably detected when they enter the hazardous area.

– Reaching under, over and around as well as moving the safety light curtain must be

prevented.

– If people can stop between the protective device and the hazardous point without

being detected, check if additional protective measures (e. g. restart interlock with a

reset button) are required.

4.3.1 Scanning range and protective field width

Scanning range The scanning range limits the maximum protective field width. The protective field

width cannot change during operation see "Technical data", Page 47.

The scanning range, see "Deflector mirror", Page 56 and "Weld spark guard",

Page 55 is reduced by using deflector mirrors and/or a weld spark guard.

Protective field range The protective field range is the dimension of the light path between sender and receiv‐

er. It is automatically calibrated with switching on the safety light curtain during initiali‐

zation and must not be changed during operation.

DANGER

Risk of ineffectiveness of the protective device

Persons and parts of the body to be protected are not recognized in case of non-ob‐

servance.

The safety light curtain can only be mounted to machines on which the protective

b

field width does not change when the safety light curtain is switched on.

4.3.2 Minimum distance from the hazardous point

A minimum distance must be maintained between the safety light curtain and the haz‐

ardous point. This distance is required to prevent a person or part of the body from

reaching the hazardous area before the dangerous state of the machine state has com‐

pleted.

DANGER

Risk of ineffectiveness of the protective device

The dangerous state of the machine is not stopped or not stopped in a timely manner

for non-compliance.

Calculate minimum dis‐

tance

16

O PE R AT I NG IN S TR U CT I ON S | deTec2 Core 8014276/2014-02-18 | SICK

Calculate the required minimum distance for your machine.

b

Mount the safety light curtain taking this calculation into account.

b

The calculation of the minimum distance is based on international and national stand‐

ards and statutory requirements applicable at the place of installation of the machine.

If the minimum distance is calculated according to ISO 13855, then it depends on the

following points:

Subject to change without notice

Page 17

PROJECT PLANNING

– Machine stopping time (time interval between triggering the sensor function and the

end of the dangerous state of the machine)

– Response time of the protective device see "Response time", Page 49

– Reach or approach speed of the person

– Resolution (detection capability) of the safety light curtain

– Type of approach: orthogonal or parallel

– Parameters specified based on the application

For the USA (scope of OSHA and ANSI), the following regulations apply among others:

a) Laws: Code of Federal Regulations, Title 29 (CFR29) Part 1910.217

b) Standards: ANSI B11.19

NOTE

Additional information is available in the ISO 13855 standard and in the Guidelines

Safe Machinery.

NOTE

SICK offers to measure the stopping/run-down time as a service in many countries.

4

8014276/2014-02-18 | SICK

Subject to change without notice

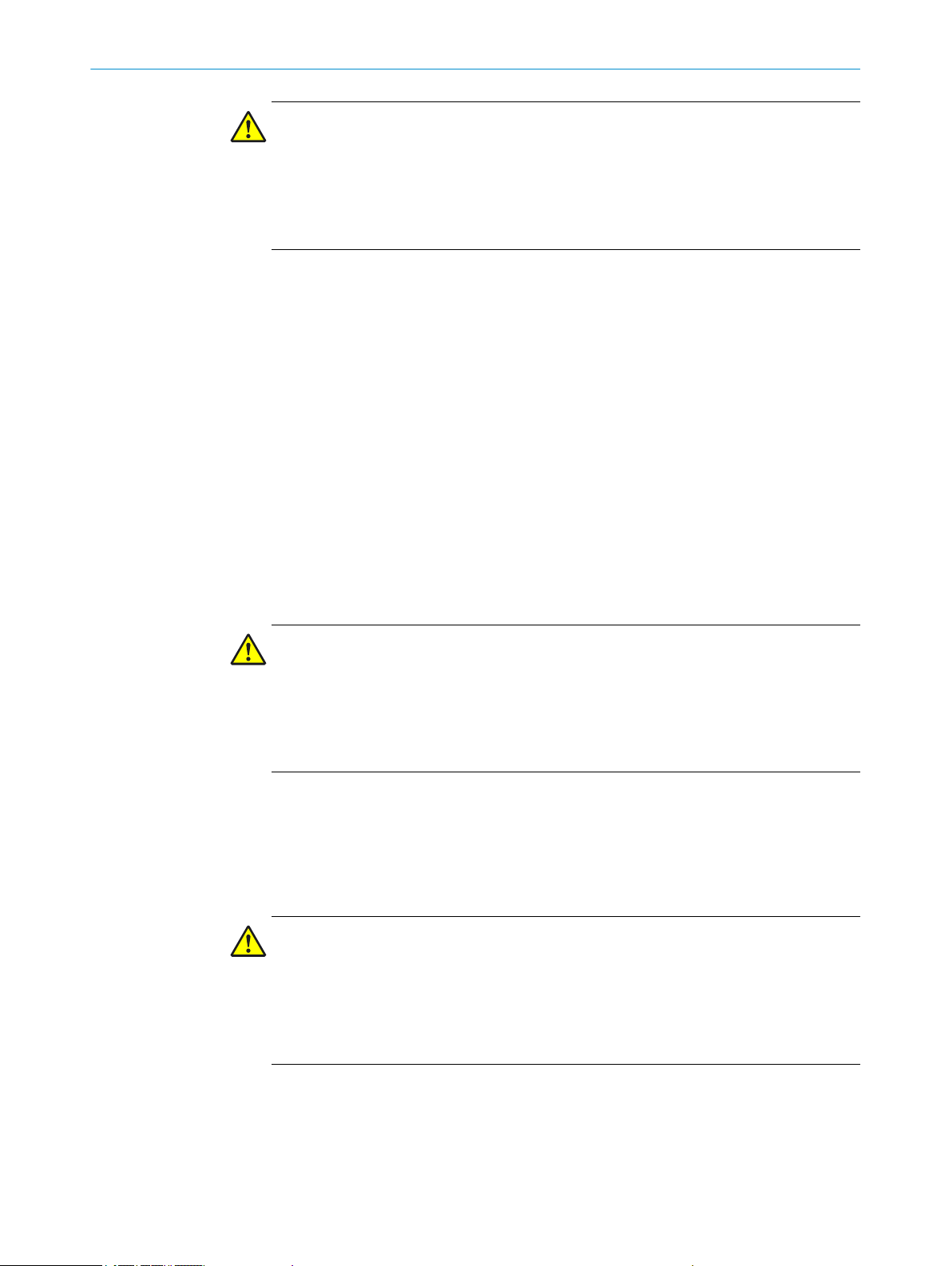

Figure 7: Minimum distance to hazardous point for orthogonal approach to protective field

Calculation example of the minimum distance S according to ISO 13855

The example shows the calculation of the minimum distance for orthogonal approach

to the protective field. Depending on the application and the ambient conditions (e.g. a

protective field parallel or at an arbitrary angle to the direction of approach or an indi‐

rect approach), a different calculation may be required.

– First, calculate S using the following formula:

S = 2000 × T + 8 × (d – 14) [mm]

where

O PE R AT I NG IN S TR U CT I ON S | deTec2 Core

17

Page 18

4 PROJECT PLANNING

– T = machine stopping time + response time of the protective device after interrup‐

tion in the light path [s]

– d = resolution of the safety light curtain [mm]

– S = minimum distance [mm]

The reach/approach speed is already included in the formula.

– If the result S ≤ is 500 mm, then use the determined value as the minimum dis‐

tance.

– If the result S is > 500 mm, then recalculate S as follows:

S = 1600 × T + 8 × (d – 14) [mm]

– If the new value S is > 500 mm, then use the newly determined value as the mini‐

mum distance.

– If the new value S is ≤ 500 mm, then use 500 mm as the minimum distance.

Example calculation Machine stopping time = 290 ms

Response time after interruption of the light path = 30 ms

Resolution of the safety light curtain = 14 mm

T = 290 ms + 30 ms = 320 ms = 0.32 s

S = 2000 × 0.32 + 8 × (14 – 14) = 640 mm

S > 500 mm, therefore:

S = 1600 × 0,32 + 8 × (14 – 14) = 512 mm

Taking reaching over in‐

to account

If access to the hazardous area cannot be ruled out by reaching over a vertical protec‐

tive field, the height of the protective field and minimum distance of the ESPE must be

determined. This is done by comparing the calculated values based on the possible de‐

tection of limbs or body parts with the values resulting from reaching over the protec‐

tive field. The greater value resulting from this comparison must be used. This compari‐

son is to be carried out according to ISO 13855, Section 6.5 or national regulations.

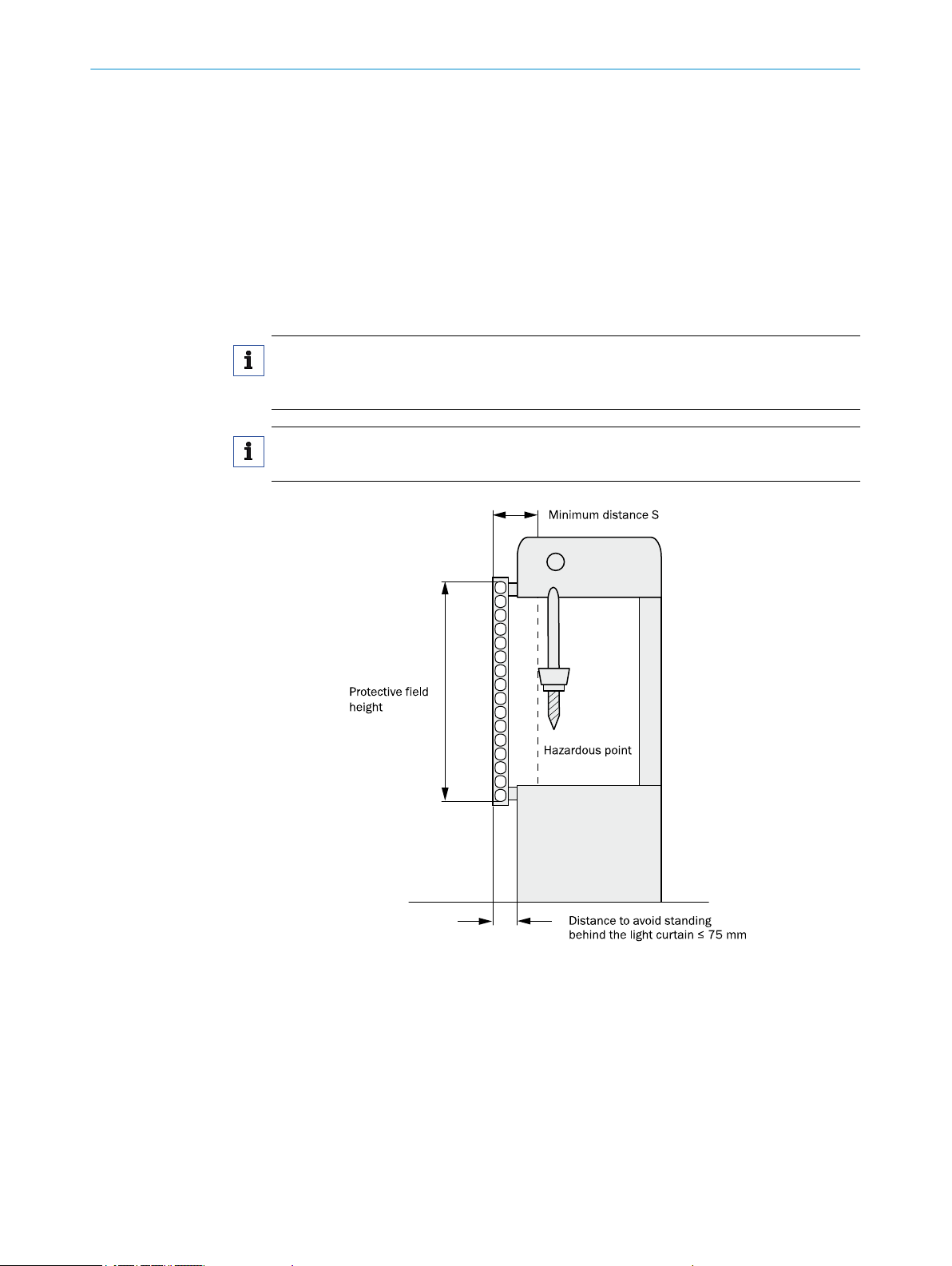

Figure 8: Representation of the accessibility of ESPE by reaching over. Left: Protective field that

cannot be reached over. Right: Protective field that can be reached over.

4.3.3 Minimum distance to reflective surfaces

18

DANGER

Risk of ineffectiveness of the protective device

Reflective surfaces and dispersive media can prevent persons or parts of the body to

be protected from being properly reflected and therefore, remain undetected.

Make sure that all reflective surfaces and objects maintain a minimum distance

b

from the protective field.

Make sure that no dispersive media is found within the calculated minimum dis‐

b

tance from the protective field.

O PE R AT I NG IN S TR U CT I ON S | deTec2 Core 8014276/2014-02-18 | SICK

Subject to change without notice

Page 19

D

a

a [mm]

1100

1000

900

800

700

600

500

400

300

200

100

0,5 1 1,5 2 2,5 3 3,5 4 4,5 5 5,5 6 6,5 7 7,5 8 8,5 9 9,5 10 11 12 D [m]

PROJECT PLANNING 4

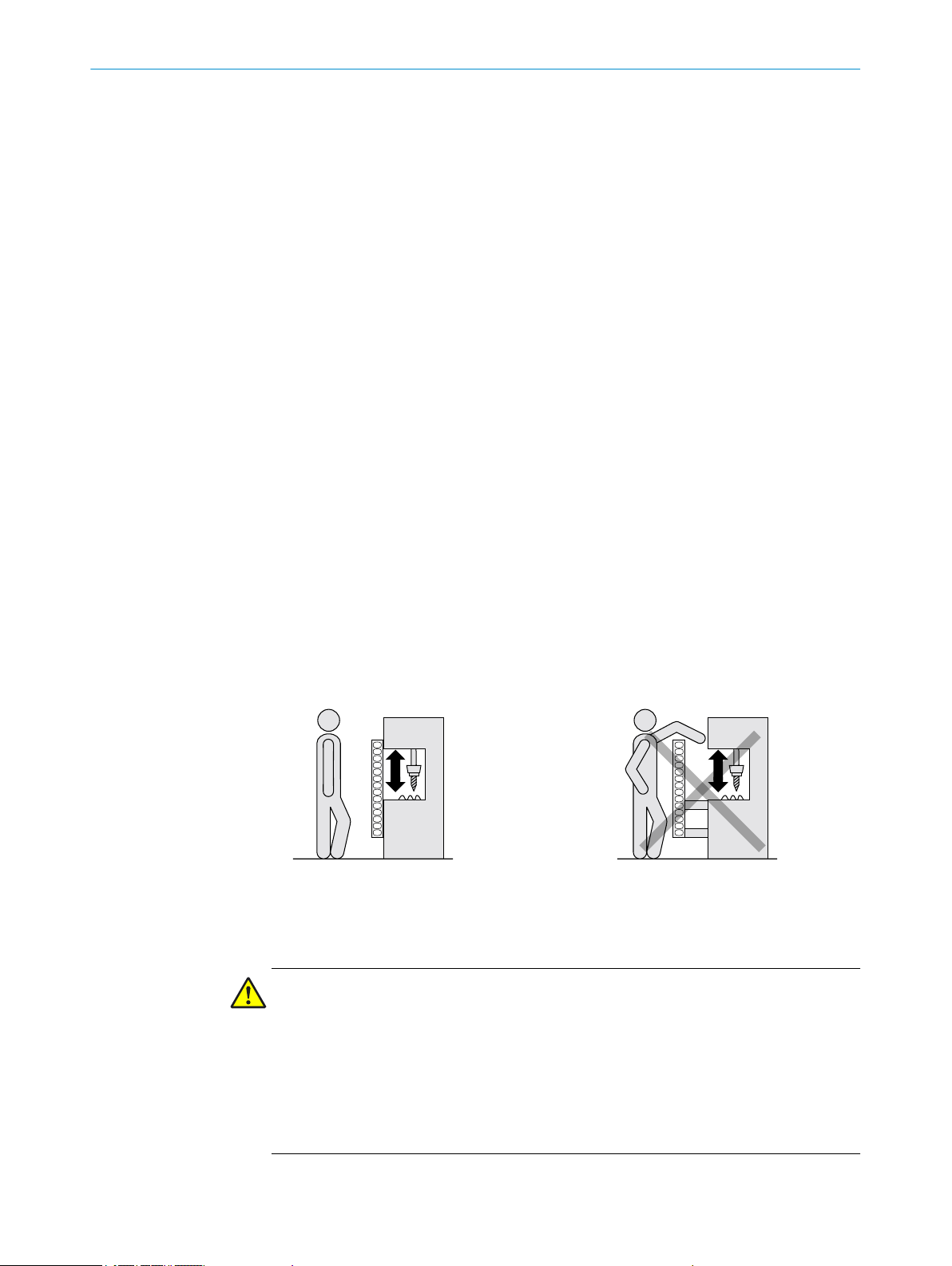

The light beams from the sender may be deflected by reflective surfaces and dispersive

media. This can result in non-detection of an object.

Therefore, all reflective surfaces and objects (e.g. material bins, machine table, etc.)

must maintain a minimum distance (a) from the protective field. This minimum dis‐

tance (a) must be maintained on all sides of the protective field. This applies in horizon‐

tal, vertical and diagonal directions as well as at the end of the safety light curtain.

Make sure that no dispersive media is found within the calculated minimum distance

from the protective field.

The minimum distance (a) depends on the distance (D) between sender and receiver

(protective field width).

Figure 9: Minimum distance to reflective surfaces

How to determine the minimum distance from reflective surfaces:

Determine the distance D [m], sender – receiver.

b

Read the minimum distance a [mm] in the graph or calculate it based on the respec‐

b

tive formula from Tab. 1:

Figure 10: Graph, minimum distance from reflective surfaces

8014276/2014-02-18 | SICK

Subject to change without notice

Distance (D) [m]

Sender–receiver

D ≤ 3 m a [mm] = 262

D > 3 m a [mm] = tan (5°) × 1000 × D [m] = 87,49 × D [m]

Table 1: Formula for calculating the minimum distance from reflective surfaces

Calculation of the minimum distance (a) from reflective

surfaces

O PE R AT I NG IN S TR U CT I ON S | deTec2 Core

19

Page 20

System 1

System 2

PROJECT PLANNING

4

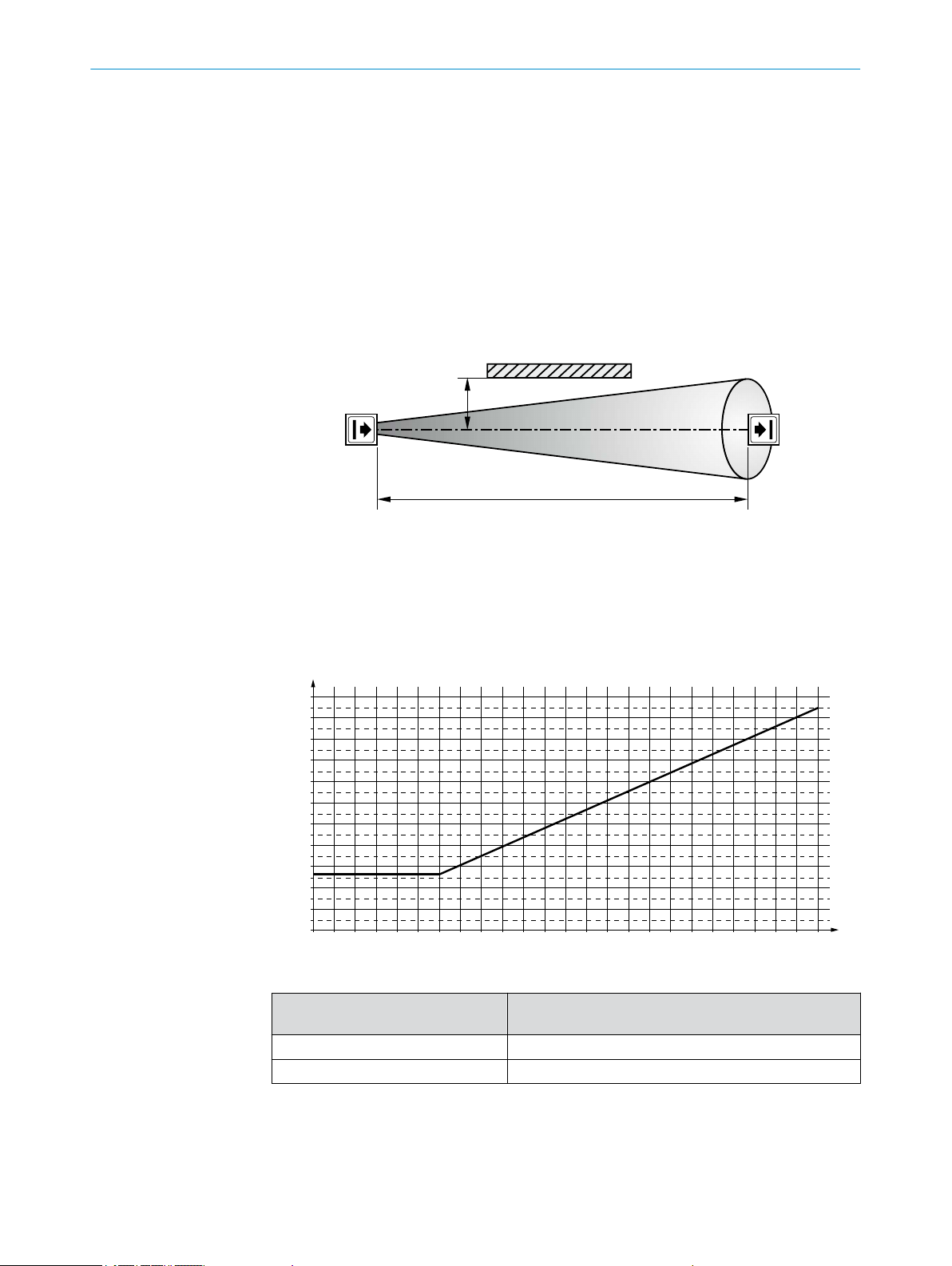

4.3.4 Protection against interference from systems in close proximity to each other

The infrared light beams of the sender of system 1 can interfere with the receiver of

system 2. This can disrupt the protective function of system 2. This would mean that

the operator is at risk. Avoid such installation situations or take appropriate action, e.g.

install optically opaque partitions or reverse the direction of transmission of a system.

Figure 11: The direction of transmission of systems in close proximity to each other is reversed.

The sender of the 2nd system is not affected by the beams 1st system.

DANGER

Risk of ineffectiveness of the protective device

Several systems of safety light curtains in close proximity to each other can interfere

with each other.

Prevent interference from systems in close proximity to each other.

b

4.4 Integration in electrical control

This chapter contains important information about integration in the electrical control.

Information about the individual steps for electrical installation of the device: see "Elec‐

trical installation", Page 33.

Requirements for use Depending on the safety concept, the signal to stop the dangerous state of the ma‐

chine must be evaluated by a safe control or safety relay (external control).

DANGER

Risk of ineffectiveness of the protective device

Persons and parts of the body to be protected are not recognized in case of non-ob‐

servance.

Make sure that the following control and electrical requirements are met such that

b

the safety light curtain can fulfill its protective function.

– The control of the machine must allow electrical interference.

– The electrical control of the machine must meet the requirements of IEC 60204-1.

– A restart interlock must be implemented depending on applicable national regula‐

tions or required reliability of the safety function. Because the safety light curtain

does not have this function, it must be implemented in the external control if re‐

quired.

– When using a safe control, different signal levels of both OSSDs must be detected

depending on applicable national regulations or required reliability of the safety

function. The maximum time tolerated by the control during which the OSSDs may

exhibit different states must be selected according to the application.

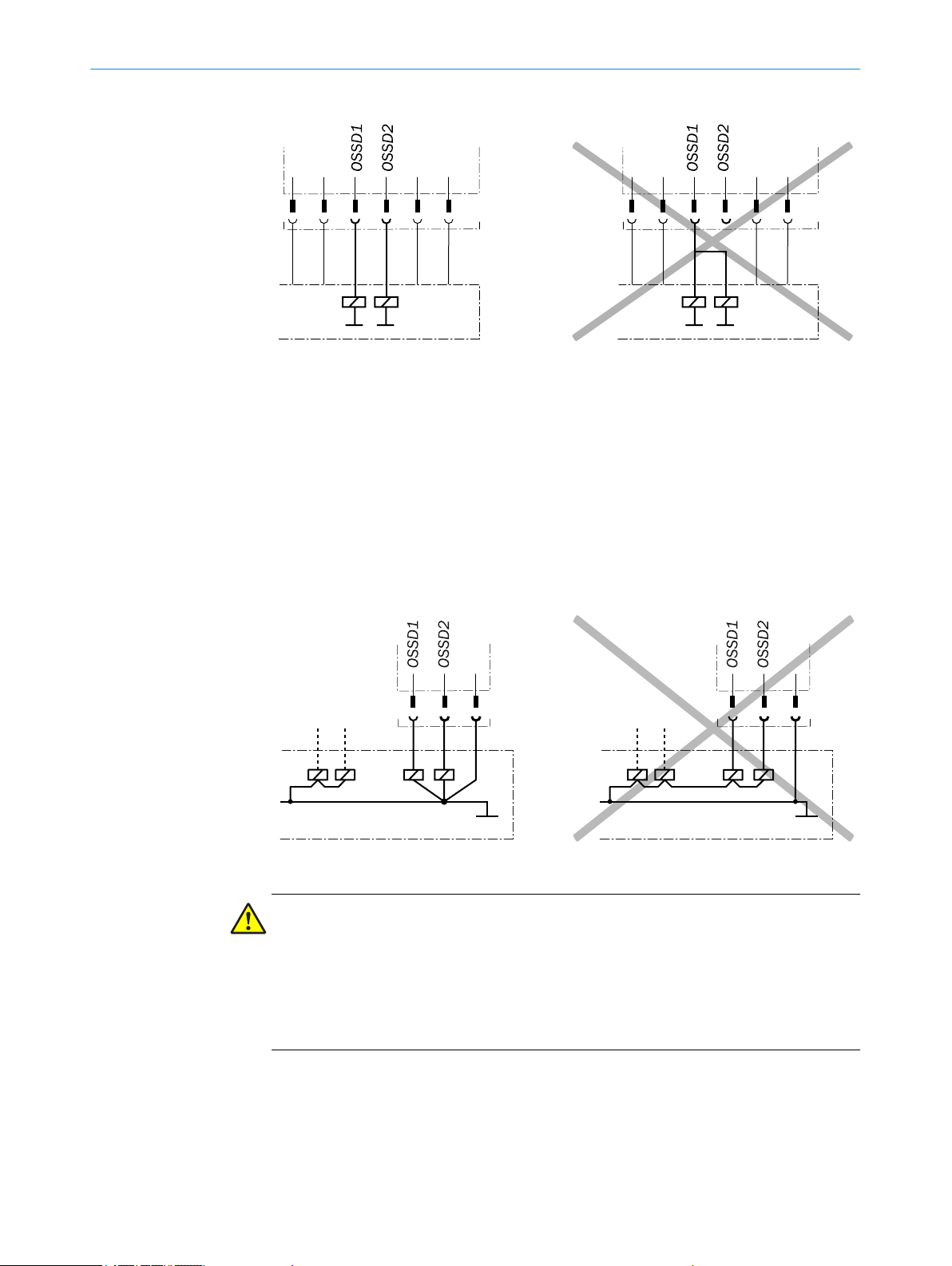

– The OSSD1 and OSSD2 output signals must not be connected to each other.

– In the machine controller, the signals of both OSSDs must be processed separately.

20

O PE R AT I NG IN S TR U CT I ON S | deTec2 Core 8014276/2014-02-18 | SICK

Subject to change without notice

Page 21

PROJECT PLANNING

Figure 12: Dual-channel and isolated connection of OSSD1 and OSSD2

– The machine must switch to the safe state at any time if at least one of the two

OSSDs switches to the LOW state.

– Prevent the formation of a potential difference between the load and the protective

device. If you connect loads to the OSSDs (safety outputs) that then also switch if

controlled with negative voltage (e.g. electro-mechanical contactor without reverse

polarity protection diode), you must connect the 0 V connections of these loads and

those of the corresponding protective device individually and directly to the same 0

V terminal strip. In the event of a fault, this is the only way to ensure that there can

be no potential difference between the 0 V connections of the loads and those of the

corresponding protective device.

4

8014276/2014-02-18 | SICK

Subject to change without notice

Figure 13: No potential difference between load and protective device

DANGER

Risk of ineffectiveness of the protective device

Persons and parts of the body to be protected are not recognized in case of non-ob‐

servance.

Contactors connected in series must be positively guided and monitored.

Make sure that contactors connected in series are monitored!

b

– When using external switching elements (e.g. positively guided contactors), verifica‐

tion of the external switching elements (external device monitoring) must be imple‐

mented depending on applicable national regulations or required reliability of the

safety function. Because the safety light curtain does not have this function, it must

be implemented in the external control if required.

O PE R AT I NG IN S TR U CT I ON S | deTec2 Core

21

Page 22

4 PROJECT PLANNING

Requirements for the

electrical control of the

machine

The two outputs are protected against short-circuits to 24 V DC and 0 V. When the pro‐

tective field is clear, the signal level on the outputs is HIGH (at potential) and when the

light beams are interrupted or there is a device fault the outputs are LOW (over 1.5 kΩ

towards 0 V).

The safety light curtain complies with the rules for electromagnetic compatibility (EMC)

for the industrial sector (Radio Safety Class A). Radio interference cannot be ruled out

when used in residential areas.

DANGER

Risk of ineffectiveness of the protective device

Persons and parts of the body to be protected are not recognized in case of non-ob‐

servance.

Make sure that the following requirements for electrical control of the machine are

b

met such that the safety light curtain can fulfill its protective function.

– The external power supply of the safety light curtain must be capable of buffering

brief power failures of 20 ms as specified in EN 60204-1.

– The power supply unit must provide safe isolation according to IEC 61140

(SELV/PELV). Suitable power supplies are available as accessories from SICK, see

"Ordering information, accessories", Page 53.

4.4.1 Restart interlock and external device monitoring

A restart interlock and/or verification of the external switching elements (external de‐

vice monitoring) must be implemented depending on applicable national regulations or

required reliability of the safety function.

Restart interlock A restart interlock prevents the machine from starting again as long as the operator

does not explicitly reset it. The dangerous state of the machine (1) is stopped if the

light path is interrupted (2) and is not re-enabled (3) until the operator presses the re‐

set device (4).

Figure 14: Schematic representation of operation with restart interlock

The restart interlock should not be confused with the start interlock of the machine.

The start interlock prevents the machine from starting after switching on. The restart

interlock prevents the machine from starting again after a fault or an interruption in the

protective field.

22

There must be a restart interlock depending on the applicable national regulations

when a person can stand behind the safety light curtain. The safety light curtain does

not have an internal restart interlock. Therefore, a restart interlock must be implemen‐

ted externally via the circuitry or the control, e.g. in connection with the SICK switching

amplifier UE48-2OS/UE48-3OS.

O PE R AT I NG IN S TR U CT I ON S | deTec2 Core 8014276/2014-02-18 | SICK

Subject to change without notice

Page 23

S34 S21S35 S22

S33 S12S11 S31

14A2 24 32

13A1 23 31

UE48-2OS2D2

K1 K2

S1

K1

K2

OSSD1

OSSD2

n.c.

GND

+24V

1

2

3

4

5

+24V

n.c.

GND

n.c.

n.c.

1

2

3

4

5

24 VDC

0 VDC

PROJECT PLANNING

4

External device monitor‐

ing (EDM)

Connection diagram for

UE48-2OS with restart

interlock and external

device monitoring

The external device monitoring checks if the contactors used to end the dangerous

state of the machine de-energize (switch off) when the protective device responds.

NOTE

Because the safety light curtain does not have external device monitoring, it must be

implemented in the external control.

Figure 15: Connection diagram for UE48-2OS with restart interlock and external device monitor‐

ing

The safety light curtain can be connected to the UE48-2OS switching amplifiers. It is

operated with restart interlock and external device monitoring.

Functionality

When the protective field is clear, the OSSD1 and OSSD2 outputs carry voltage. The

system can be switched on when K1 and K2 are in the de-energized position. Pressing

the S1 button switches on the UE48 switching amplifier. Contacts 13-14 and 23-24 of

the UE48 activate the K1 and K2 contactors.

When the protective field is interrupted, the OSSD1 and OSSD2 outputs carry no volt‐

age. The UE48 switches off and K1, K2 are deactivated.

Fault analysis

Failure of K1 and K2 does not cause the loss of the shut-down function. Cross-circuits

and short-circuits of the OSSD1 and OSSD2 outputs are recognized and lead to the

locking state. It is recognized if the K1 or K2 contactors does not de-energize.

8014276/2014-02-18 | SICK

Subject to change without notice

O PE R AT I NG IN S TR U CT I ON S | deTec2 Core

23

Page 24

5 MOUNTING

5 Mounting

5.1 Safety

This chapter describes how to mount the safety light curtain using the included Quick‐

Fix bracket.

A FlexFix bracket is also available with extended adjustment possibilities, see "Accesso‐

ries", Page 53.

The following steps are necessary after mounting and installation:

– "Electrical installation", Page 33

– "Align the sender and receiver", Page 36

– "Initial commissioning", Page 35

NOTE

Mount the safety light curtain in the following order.

Information about the requirements for properly mounting the safety light curtain see

"Design", Page 15.

5.2 Unpacking

5.3 Installation

DANGER

Dangerous state of the machine

Make sure that the dangerous state of the machine is (and remains) switched off.

b

Make sure that the outputs of the safety light curtain have no effect on the machine.

b

DANGER

Risk of ineffectiveness of the protective device

Persons or parts of the body to be protected are not recognized in case of non-observ‐

ance.

Only use brackets recommended by SICK for mounting.

b

Take appropriate measures for vibration dampening if the vibration and shock re‐

b

quirements are above the values and test conditions specified in the data sheet, see

"Data sheet", Page 47.

Check the components for completeness and the integrity of all parts, see "Scope of

b

delivery", Page 52.

Please contact your respective SICK subsidiary should you have any complaints.

b

24

The QuickFix bracket or the optional FlexFix bracket is used to mount the sender and

receiver. In many cases, the QuickFix bracket is enough for installation. The FlexFix

bracket makes it possible to rotate sender and receiver around the axis of the device

and to align it accurately.

O PE R AT I NG IN S TR U CT I ON S | deTec2 Core 8014276/2014-02-18 | SICK

Subject to change without notice

Page 25

DANGER

Risk of ineffectiveness of the protective device

Persons or parts of the body to be protected are not recognized or not recognized in

time in case of non-observance.

It is vital that you observe the minimum distance calculate for your machine: see

b

"Minimum distance from the hazardous point", Page 16 and see "Minimum distance

to reflective surfaces", Page 18

Mount the safety light curtain such that the hazardous point cannot be reached from

b

below, above or behind the safety light curtain and that the light curtain cannot be

repositioned.

NOTE

Read this section completely before mounting the brackets.

b

Read the section "Align the sender and receiver", Page 36

b

Mounting instructionsbMount the sender and receiver on a level surface.

Mount the sender and receiver at the same height. For minor adjustments when

b

aligning, the sender and receiver can be adjusted vertically in the brackets, see

"Fig. 27: QuickFix bracket: adjust vertically", Page 36 and see "Fig. 28: FlexFix

bracket: adjust vertically / rotate", Page 37.

When possible, mount the top bracket at a height such that the offset in the housing

b

of the safety light curtain sites on the bracket to prevent the safety light curtain from

sliding down.

The end with the cable connection must point in the same direction for both devices.

b

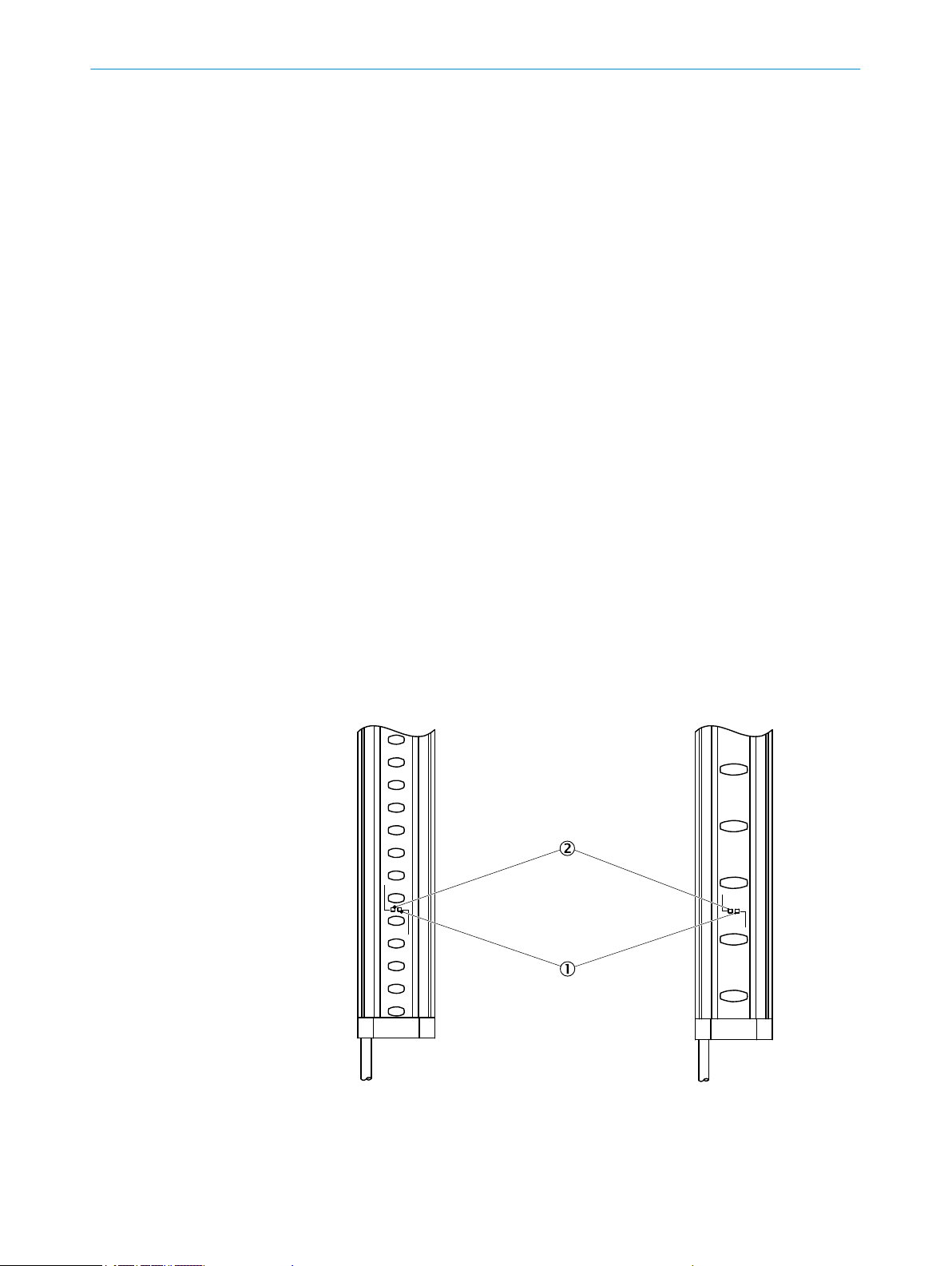

MOUNTING

5

8014276/2014-02-18 | SICK

Subject to change without notice

Figure 16: Sender and receiver must not be installed at 180° rotated relative to each other.

O PE R AT I NG IN S TR U CT I ON S | deTec2 Core

25

Page 26

5 MOUNTING

Tighten the screws used to mount the bracket at a torque of 5 - 6 Nm. Tighten the

b

screws used to secure the safety light curtain in the bracket at a torque of 2.5 - 3

Nm. Higher torques can damage the bracket while lower torques do not provide ade‐

quate fixation to prevent the safety light curtain from moving in the event of vibra‐

tions.

When mounting, make sure that sender and receiver are aligned correctly. The opti‐

b

cal lens systems of sender and receiver must be located in opposition to each other.

If necessary, use a water level to check the parallelism of the components.

b

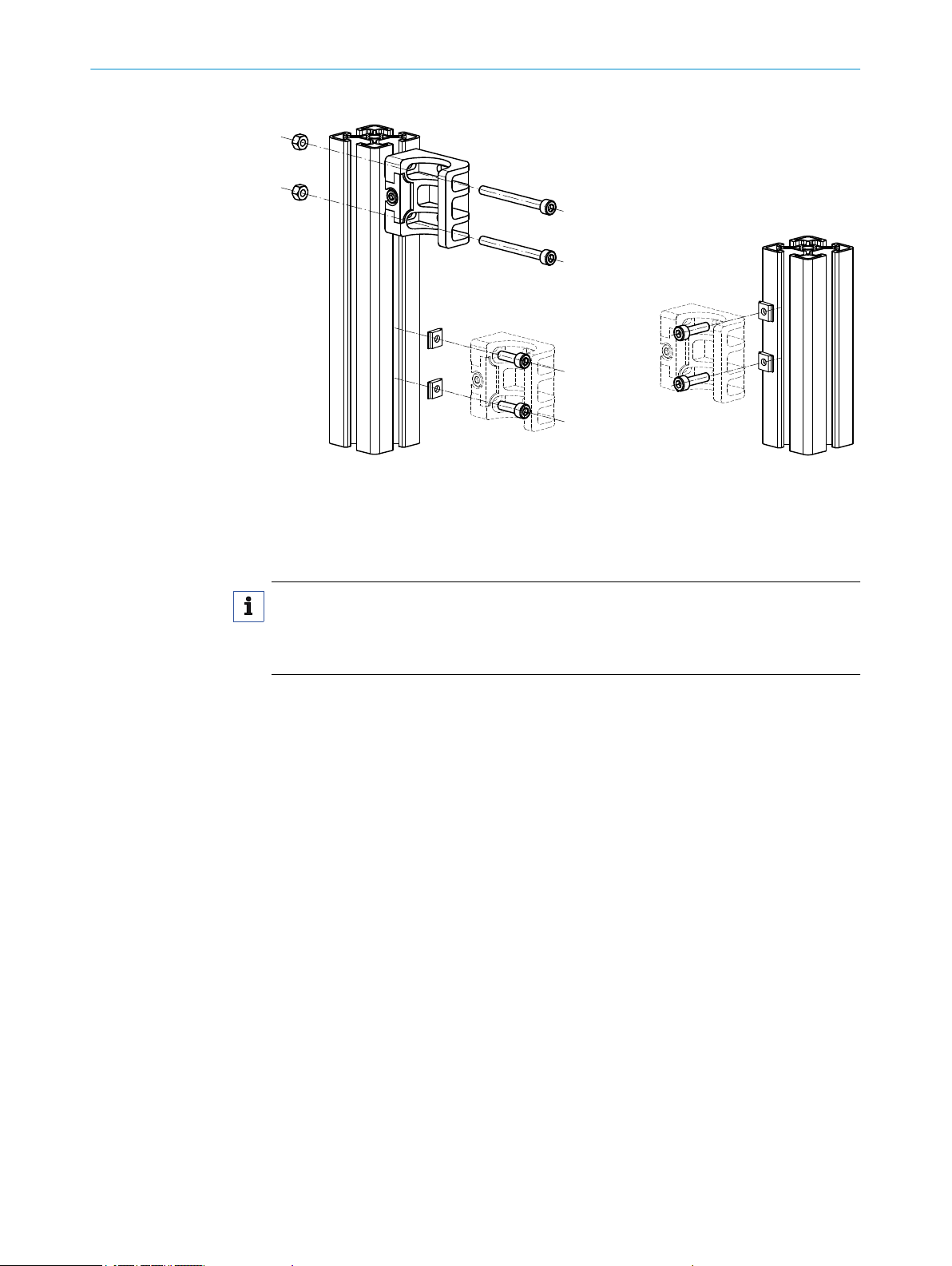

5.3.1 Mount the QuickFix bracket

QuickFix brackets can be mounted in two ways:

– On the side

– On the back

The two mounting surfaces for the brackets of the sender or receiver must not be an‐

gled more than 0.5° to each other. If not possible, use the optional FlexFix bracket.

Mount QuickFix bracket

on the side of a ma‐

chine or profile frame

Two QuickFix brackets are used to mount the sender and receiver.

The QuickFix bracket consists of two parts, which are pushed into each other. An M5

screw is used to join both parts and to clamp the housing (sender or receiver).

Mounting can be carried out in two ways:

With the M5 screw through the QuickFix bracket to the machine or profile frame. A

b

screw nut or threaded hole is required on the machine or profile frame.

With the M5 screw through the machine or profile frame to the QuickFix bracket. A

b

screw nut is required for each QuickFix bracket.

When choosing the length of the M5 screw (hexagon head or cylinder head screw),

b

consider the QuickFix bracket and the machine or profile frame.

CAUTION

Risk of injury from protruding screws thread

When mounting through the machine or profile frame to the QuickFix bracket, the M5

screw can present an injury risk if too long.

Select an appropriate screw length to prevent any risk of injury from an overrun.

b

26

O PE R AT I NG IN S TR U CT I ON S | deTec2 Core 8014276/2014-02-18 | SICK

Subject to change without notice

Page 27

Figure 17: Mount QuickFix bracket to a profile

MOUNTING 5

NOTE

The QuickFix bracket has cable routing. Depending on the installation, the cable routing

can make mounting easier.

5.3.2 Mount optional FlexFix bracket

In the FlexFix bracket, sender and receiver can be flexibly rotated by +/− 15°. FlexFix

brackets can be mounted in two ways:

– On the side

– On the back

NOTE

Use flat head screws for rear-side mounting of FlexFix holders so that the safety light

curtain housing cannot be scratched by any protruding screw heads.

Mount FlexFix bracket

on the side of a ma‐

chine or profile frame

Two FlexFix brackets are used to mount the sender and receiver at the designated

points.

The M5 screws are used to mount through the FlexFix bracket to the machine or profile

frame. A screw nut or threaded hole is required on the machine or profile frame.

8014276/2014-02-18 | SICK

Subject to change without notice

O PE R AT I NG IN S TR U CT I ON S | deTec2 Core

27

Page 28

5 MOUNTING

Figure 18: Mount FlexFix bracket to a profile frame

After mounting the FlexFix brackets, screw the sender or receiver into the FlexFix

b

brackets from the front and align the sender and receiver, see "Align the sender and

receiver", Page 36.

NOTE

The safety light curtain can only be screwed in when both FlexFix brackets are in align‐

ment. A water level can be used to help. If necessary, use a water level to check the

parallelism of the components.

28

O PE R AT I NG IN S TR U CT I ON S | deTec2 Core 8014276/2014-02-18 | SICK

Subject to change without notice

Page 29

MOUNTING 5

Mount FlexFix bracket

to the back of a device

column

8014276/2014-02-18 | SICK

Subject to change without notice

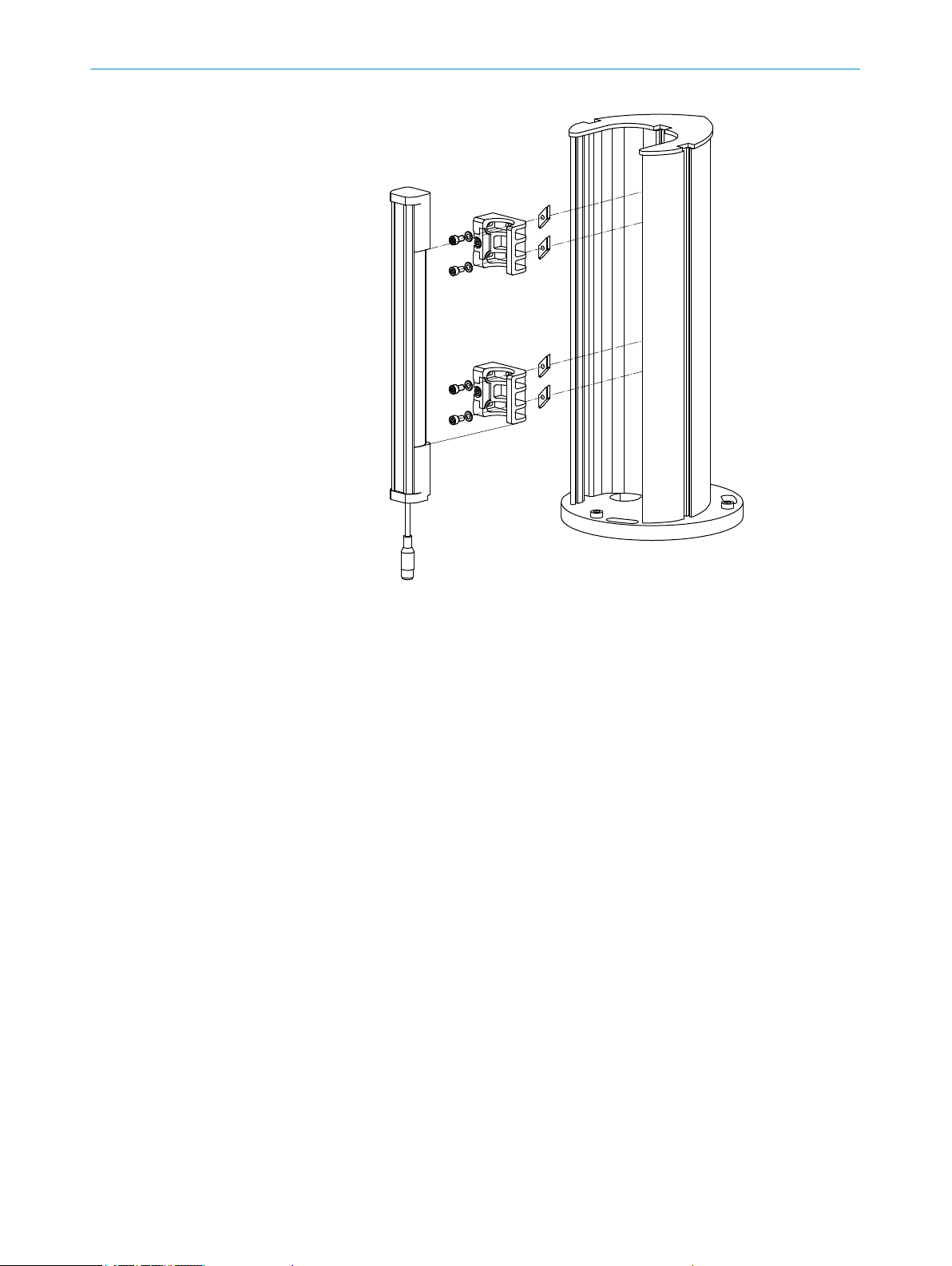

Figure 19: Inserting the safety light curtain in the FlexFix brackets

Use an M5 screw to fix the position of the sender and receiver in the FlexFix bracket.

b

Two FlexFix brackets are used to mount the sender and receiver. Two M5 screws are

required to mount a FlexFix bracket. A FlexFix bracket can be mounted to a device col‐

umn with two sliding nuts in the groove of the device column.

NOTE

The BEF-1SHABBKU2 mounting kit contains two FlexFix brackets and the required

screws and sliding nuts, see "Ordering information, accessories", Page 53.

After mounting the FlexFix brackets, screw the sender or receiver into the FlexFix

b

brackets from the front and align the sender and receiver, see "Align the sender and

receiver", Page 36.

Use an M5 screw to fix the position of the sender and receiver in the FlexFix bracket.

b

O PE R AT I NG IN S TR U CT I ON S | deTec2 Core

29

Page 30

5 MOUNTING

Figure 20: Mount FlexFix bracket to a device column (accessory)

5.3.3 Mount optional replacement bracket

If an existing C2000 safety light curtain is mounted with a swivel-mount bracket or with

a side bracket, it can be replaced with a deTec2 Core safety light curtain using a re‐

placement bracket. There is no need to drill new holes, since the existing ones can be

used for the replacement bracket.

Use one of the following installation versions independent of the existing situation

b

that prevails:

To replace a swivel mount bracket (article number 2019649 or 2019659): installa‐

•

tion version A or B

To replace a side bracket (article number 2019506): installation version C

•

30

O PE R AT I NG IN S TR U CT I ON S | deTec2 Core 8014276/2014-02-18 | SICK

Subject to change without notice

Page 31

MOUNTING 5

Figure 21: Replacement bracket, installation version A

Figure 22: Replacement bracket, installation version B

8014276/2014-02-18 | SICK

Subject to change without notice

O PE R AT I NG IN S TR U CT I ON S | deTec2 Core

31

Page 32

5 MOUNTING

5.4

Figure 23: Replacement bracket, installation version C

Attach information label

Use the "Important Information" label in the language of the operator of the ma‐

b

chine. Use several information labels if additional languages are required for other

operators.

Affix "Important Information" label to the machine in close proximity to sender and

b

receiver. The information label is self-adhesive.

Affix the information label such that it is easily visible by each operator during opera‐

b

tion. After attaching additional objects and equipment, the information label must

not be concealed from view.

32

O PE R AT I NG IN S TR U CT I ON S | deTec2 Core 8014276/2014-02-18 | SICK

Subject to change without notice

Page 33

6 Electrical installation

This chapter describes the electrical installation of the safety light curtain.

6.1 Safety

Information about the requirements that must be met for safe integration of the safety

light curtain in the control and electronics of the machine: see "Integration in electrical

control", Page 20.

Mounting should be completed before electrical installation.

DANGER

Risk of electric shock

Risk of the machine starting unexpectedly

Make sure that the machine is (and remains) disconnected from the power supply

b

during the electrical installation.

Make sure that the dangerous state of the machine is (and remains) switched off.

b

Only use an appropriate power supply, see "Technical data", Page 47.

b

Make sure that the outputs of the safety light curtain have no effect on the machine

b

during the electrical installation.

ELECTRICAL INSTALLATION 6

DANGER

Risk of ineffectiveness of the protective device

Connect OSSD1 and OSSD2 separately. OSSD1 and OSSD2 must not be connected

b

to each other. Otherwise, signal safety will not be ensured.

Figure 24: Connection of OSSD1 and OSSD2

DANGER

Risk of ineffectiveness of the protective device

8014276/2014-02-18 | SICK

Subject to change without notice

Prevent the formation of a potential difference between the load and the protective

b

device.

O PE R AT I NG IN S TR U CT I ON S | deTec2 Core

33

Page 34

6 ELECTRICAL INSTALLATION

If you connect loads to the OSSDs (safety outputs) that then also switch if controlled

b

with negative voltage (e.g. electro-mechanical contactor without reverse polarity pro‐

tection diode), you must connect the 0 V connections of these loads and those of the

corresponding protective device individually and directly to the same 0 V terminal

strip. In the event of a fault, this is the only way to ensure that there can be no po‐

tential difference between the 0 V connections of the loads and those of the corre‐

sponding protective device.

Figure 25: No potential difference between load and protective device

6.2 Device connection (M12, 5-pin)

Figure 26: Sender and receiver

Pin Wire color Sender Receiver

1 brown 24 V DC input (power sup‐

2 White Reserved OSSD1 (output signal

3 Blue 0 V DC input (power sup‐

4 black Reserved OSSD2 (output signal

5 gray Not yet assigned Not yet assigned

Table 2: Device connection pin assignment (M12, 5-pin)

Connection diagram for the electrical installation: see "Integration in electrical control",

Page 20.

ply)

ply)

24 V DC input VDC24 (pow‐

er supply)

switching device 1)

0 V DC input (power sup‐

ply)

switching device 2)

6.3 Device connection via connection cable (M12, 5-pin to 8-pin)

An optional connection cable is available to connect the 5-pin device connection to an

existing 8-pin socket. The connection cable can be used to replace an existing C2000

safety light curtain with a deTec2 Core, without having to route new cables.

34

O PE R AT I NG IN S TR U CT I ON S | deTec2 Core 8014276/2014-02-18 | SICK

Subject to change without notice

Page 35

7 Initial commissioning

The mounting and electrical installation must be completed before initial commission‐

ing as described in the following chapters.

– "Design", Page 15

– "Integration in electrical control", Page 20

– "Mounting", Page 24

– "Electrical installation", Page 33

7.1 Safety

DANGER

Risk of ineffectiveness of the protective device

When changes are made to machines, the effectiveness of the protective device may

be affected unintentionally.

After every change to the machine and changes to the integration and/or operation‐

b

al and secondary conditions of the safety light curtain, check the protective device

for effectiveness and recommission as specified in this chapter.

INITIAL COMMISSIONING 7

DANGER

Dangerous state of the machine

b

DANGER

Risk of ineffectiveness of the protective device

b

b

b

b

b

7.2 Switching on

After switching on, initialize the sender and receiver. All LEDs of the sender and receiv‐

er briefly light up. After initialization, the receiver displays the alignment quality using

four blue LEDs. The alignment indicator goes out after a certain time after the safety

light curtain is aligned (OSSD LED: green) and only the PWR LED of the sender and

OSSD LED of the receiver illuminate.

Make sure that the dangerous state of the machine is (and remains) switched off.

Before you operate a machine protected by the safety light curtain for the first time,

make sure that the machine is first checked and released by qualified safety person‐

nel.

Make sure that the optical properties of the front screen of the sender and receiver

are not changed by beading water, mist, frost or ice formation.

Make sure that all reflective surfaces and objects maintain a minimum distance

from the protective field.

Make sure that no dispersive media is found within the calculated minimum dis‐

tance from the protective field.

Only operate the machine when the protective function of the safety light curtain is

operating properly.

8014276/2014-02-18 | SICK

Subject to change without notice

In the event of a fault, the red fault LED flashes on the respective device. The red fault

LED in combination with the blue LEDs show the cause of the fault on the side of the

receiver, see "Troubleshooting", Page 44.

O PE R AT I NG IN S TR U CT I ON S | deTec2 Core

35

Page 36

*) Exception for protective field height 300 mm

H

≤ L/4*

L

≤ L/4

7 INITIAL COMMISSIONING

7.3 Align the sender and receiver

After mounting and the electrical installation, the sender and receiver must be aligned

with each other.

DANGER

Dangerous state of the machine

Make sure that the outputs of the safety light curtain have no effect on the machine

b

during the alignment process.

Alignment with the

QuickFix bracket

You have the following adjustment options with the QuickFix bracket:

– Adjust vertically (H)

Figure 27: QuickFix bracket: adjust vertically

NOTE

If the alignment cannot be adjusted with the QuickFix bracket, use the optional FlexFix

bracket.

36

O PE R AT I NG IN S TR U CT I ON S | deTec2 Core 8014276/2014-02-18 | SICK

Subject to change without notice

Page 37

*) Exception for protective field height 300 mm

H

≤ L/4*

L

≤ L/4

+/–15°

INITIAL COMMISSIONING

7

Indication of the align‐

ment quality

Aligning with the FlexFix

bracket or with the re‐

placement bracket

Display Meaning

Blue LEDs OSSD LED

No LED lights up Red Alignment is insufficient or the protective field is inter‐

rupted at least partially. The receiver cannot synchronize

with the sender.

1 LED lights up Red Alignment is insufficient or the protective field is inter‐

rupted at least partially.

2 LEDs light up Red Alignment is poor or the protective field is interrupted at

least partially.

2 LEDs light up Green Alignment is not yet sufficient for stable availability.

3 LEDs light up Green Alignment is good, stable availability.

1)

4 LEDs light up Green Alignment is very good.

Table 3: Blue LEDs to indicate the alignment quality

1)

At a typical scanning range, there is a possibility that all four LEDs to indicate alignment quality do not

light up even when alignment is good.

NOTE

Once the system is aligned, at least two blue LEDs light up and the OSSD LED is green.

You have the following adjustment options with the FlexFix bracket or the replacement

bracket:

– Adjust vertically (H)

– Rotate (+/− 15 °)

Figure 28: FlexFix bracket: adjust vertically / rotate

8014276/2014-02-18 | SICK

Subject to change without notice

O PE R AT I NG IN S TR U CT I ON S | deTec2 Core

37

Page 38

7 INITIAL COMMISSIONING

Align the sender and re‐

ceiver to each other

How to align sender and receiver with FlexFix bracket or with the replacement bracket:

Switch on the power supply to the safety light curtain.

b

Pay attention to the mounting heights of sender and receiver.

b

Provide a rectangular protective field.

b

Roughly align the sender to the receiver by rotating the sender.

b

Roughly align the receiver to the sender by rotating the receiver.

b

Look for the four blue LEDs of the receiver. The LEDs signal the alignment quality.

b

Adjust the sender and receiver such that as many blue LEDs illuminate as possible.

If the receiver switches to "Green", secure the components in the brackets at a tor‐

b

que of 2.5 - 3 Nm.

Switch off the power supply and on again.

b

Check the blue LEDs to make sure that the components are still correctly aligned

b

with each other.

NOTE

Once three blue LEDs illuminate, alignment is good and availability is stable.

NOTE

The optional laser alignment aid AR60 can be used for alignment, see "Ordering infor‐

mation, accessories", Page 53.

Since the laser alignment assistant is placed in the protective field of the safety light

curtain with the adapter, the indicator for the alignment quality shows a maximum of

two blue LEDs and the OSSD LED is red. To check whether the OSSD LED of the receiv‐

er is illuminating green, remove the laser alignment assistant.

7.4 Checks

Checks before initial

commissioning/

commissioning

The purpose of the checks described in the following is to confirm the safety require‐

ments specified in the national/international rules and regulations, especially the safe‐

ty requirements in the Machine (EU Conformity) or Work Equipment Directive.

These checks are also used to check the effectiveness of the protective device.

These checks must therefore always be performed.

The checks must be carried out by qualified safety personnel or specially qualified

b

and authorized personnel and must be recorded and documented to ensure that the

tests can be reconstructed and retraced at any time.

Check the effectiveness of the protective device for all operating modes selectable

b

on the machine "Checklist for initial commissioning and commissioning", Page 64

in the appendix.

Make sure that the operating personnel have been instructed in the function of the

b

protective device before being allowed to operate the machine. Instructing the oper‐

ating personnel is the responsibility of the organization operating the machine and

must be conducted by qualified personnel.

Please note the test notes for the operator in chapter "Daily check", Page 39.

b

38

O PE R AT I NG IN S TR U CT I ON S | deTec2 Core 8014276/2014-02-18 | SICK

Subject to change without notice

Page 39

8 Operation

8.1 Safety

OPERATION 8

This chapter describes the operation of the safety light curtain that primarily consists of

checking the effectiveness of the protective device on a daily basis.

These operating instructions do not provide information on operating the machine in

which the safety light curtain is integrated.

DANGER

Risk of ineffectiveness of the protective device after changes

Persons and parts of the body to be protected are not recognized in case of non-ob‐

servance.

Maintenance work, alignment work, fault diagnoses and any changes to the integra‐

b

tion of the safety light curtain in the machine must only be carried out by qualified

personnel.

Then check the effectiveness of the protective device and recommission as speci‐

b

fied in chapter "Initial commissioning", Page 35.

8.2 Daily check

Checking the effective‐

ness with the test rod

DANGER

Risk of ineffectiveness of the protective device

Persons and parts of the body to be protected are not recognized in case of non-ob‐

servance.

Make sure that the optical properties of the front screen of the sender and receiver

b

are not changed by beading water, mist, frost or ice formation.

Make sure that all reflective surfaces and objects maintain a minimum distance

b

from the protective field, see "Minimum distance to reflective surfaces", Page 18.

Make sure that no dispersive media is found within the calculated minimum dis‐

b

tance from the protective field.

The effectiveness of the protective device must be checked daily using the included

test rod. The diameter of the test rod corresponds to the resolution of the light curtain.

Before introducing the test rod, check if the OSSD LED illuminates green. If not, then

you must first change this state. The check is otherwise meaningless.

DANGER

Risk of ineffectiveness of the protective device

Persons and parts of the body to be protected are not recognized in case of non-ob‐

servance.

8014276/2014-02-18 | SICK

Subject to change without notice

Only use the included test rod with the diameter specified on the type label of the

b

safety light curtain.

Do not use any test rods with a similar or the same diameter of other safety light

b

curtains.

O PE R AT I NG IN S TR U CT I ON S | deTec2 Core

39

Page 40

OPERATION

8

DANGER

Risk of the machine starting unexpectedly

Make sure that the dangerous state of the machine is (and remains) switched off

b

during the check.

Make sure that the outputs of the safety light curtain have no effect on the machine

b

while checking the components.

Move the test rod slowly through the protective field to be tested as indicated by the

b

arrow in Fig. 29.

Watch the OSSD LED on the receiver during the check. The OSSD LED on the receiv‐

er should continuously light up red. The OSSD LED may not light up green.

Figure 29: Daily checks of the protective device: Step 1

Guide the test rod along the edges of the protective field as indicated by the arrow in

b

Fig. 30.

Watch the OSSD LED on the receiver during the check. The OSSD LED on the receiv‐

er should continuously light up red. The OSSD LED may not light up green.

40

O PE R AT I NG IN S TR U CT I ON S | deTec2 Core 8014276/2014-02-18 | SICK

Subject to change without notice

Page 41

Figure 30: Daily checks of the protective device: Step 2

OPERATION 8

If you use one or more deflector mirrors (see "Accessories", Page 53), then also

b

guide the test rod slowly through the protective field directly in front of the deflector

mirrors.

Watch the OSSD LED on the receiver during the check. The OSSD LED on the receiv‐

er should continuously light up red. The OSSD LED may not light up green.

DANGER

Risk of ineffectiveness of the protective device

Persons and parts of the body to be protected are not recognized in case of non-ob‐

servance.

Do not operate the machine if the OSSD LED lights up green during the test!

If the OSSD LED lights up green during the test even if only briefly, work must stop at

b

the machine.

In this case, the mounting and electrical installation of the safety light curtain must

b

be checked by qualified safety personnel, see "Mounting", Page 24, "Electrical instal‐

lation", Page 33.

8014276/2014-02-18 | SICK

Subject to change without notice

O PE R AT I NG IN S TR U CT I ON S | deTec2 Core

41

Page 42

9 MAINTENANCE

9 Maintenance

The safety light curtain is maintenance-free. Depending on the ambient conditions, reg‐

ular cleaning is required.

9.1 Safety

DANGER

Risk of ineffectiveness of the protective device

Persons and parts of the body to be protected are not recognized in case of non-ob‐

servance.

Do not conduct any repairs on the device components (sender, receiver).

b

Do not open the device components.

b

9.2 Regular cleaning

DANGER

Risk of ineffectiveness of the protective device

Persons and parts of the body to be protected are not recognized in case of non-ob‐

servance.

Regularly check the degree of contamination on all components based on the appli‐

b

cation conditions.

Please observe the chapter "Daily check", Page 39.

b

Depending on the ambient conditions of the safety light curtain, the front screens must

be cleaned regularly and in the event of contamination. Static charges can cause dust

particles to be attracted to the front screen. The weld spark guard and deflector mirror

must be cleaned regularly and in the event of contamination.

DANGER

Risk of ineffectiveness of the protective device

Persons and parts of the body to be protected are not recognized in case of non-ob‐

servance.

Make sure that the optical properties of the front screens of the sender and receiver

b

are not changed by:

– beading water, mist, frost or ice formation. If necessary, remove any residues of

this type or any other form of contamination and restart the receiver.

– Scratches or damage. If necessary, replace the respective sender or receiver if its

front screen is scratched or damaged.

Make sure that all reflective surfaces and objects maintain a minimum distance

b

from the protective field.

Make sure that no dispersive media is found within the calculated minimum dis‐

b

tance from the protective field.

42

O PE R AT I NG IN S TR U CT I ON S | deTec2 Core 8014276/2014-02-18 | SICK

Subject to change without notice

Page 43

MAINTENANCE 9

DANGER

Risk of the machine starting unexpectedly

Make sure that the dangerous state of the machine is (and remains) switched off

b

while cleaning.

While cleaning, the outputs of the safety light curtain are not allowed to have any

b

effect on the machine.

NOTE

Do not use aggressive cleaning agents.

b

Do not use abrasive cleaning agents.

b

We recommend anti-static cleaning agents.

b

We recommend the use of anti-static plastic cleaner (SICK part number 5600006)

b

and the SICK lens cloth (SICK part number 4003353).

How to clean the front screen

Use a clean, soft brush to remove dust from the front screen.

b

Then wipe the front screen with a clean, damp cloth.

b

Check the position of sender and receiver after cleaning.

b

Check the effectiveness of the protective device. Information on the testing proce‐

b

dure, see "Daily check", Page 39.

9.3 Regular inspection

DANGER

Risk of ineffectiveness of the protective device

Persons and parts of the body to be protected are not recognized in case of non-ob‐

servance.

The checks must be carried out by qualified safety personnel or specially qualified

b

and authorized personnel and must be recorded and documented to ensure that the

tests can be reconstructed and retraced at any time.

Check the machine following the inspection intervals specified in the national rules

b

and regulations. This procedure ensures that any changes to the machine or manip‐

ulations of the protective device are detected after initial commissioning.

Check the machine again according to the checklist in the appendix, see "Checklist

b

for initial commissioning and commissioning", Page 64:

– If changes are made to the machine or protective devices (e.g. changes to the

mechanical, electrical, optical connection)

– If sender or receiver have been replaced

Safety signs, informa‐

tion labels

Regularly check the information labels for the following points:

b

– Presence

– Readability

Replace the information labels if missing, damaged or illegible.

b

Please observe the chapter "Attach information label", Page 32.

b

8014276/2014-02-18 | SICK

Subject to change without notice

O PE R AT I NG IN S TR U CT I ON S | deTec2 Core

43

Page 44

10 TROUBLESHOOTING

10 Troubleshooting