Page 1

Title Page

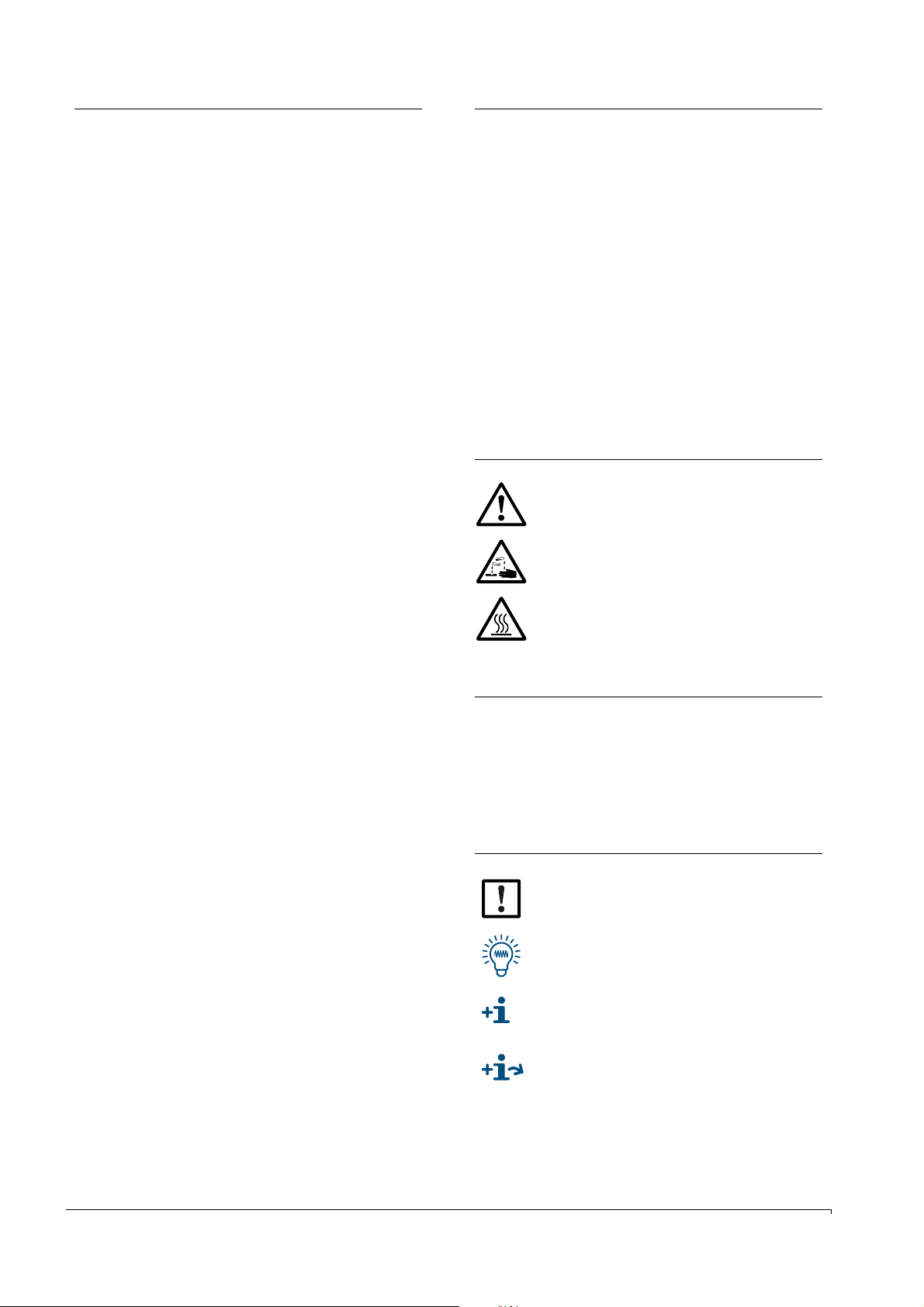

Analyzer Module DEFOR

for Series GMS800

Description

Operating Functions

Technical Data

SUPPLEMENTARY OPERATING INSTRUCTIONS

Page 2

Document Information

Glossary

Described Product

Product name: Analyzer Module DEFOR

Basic device: Series GMS800 gas analyzers

Document ID

Title: Supplementary Operating Instructions DEFOR

Part No.: 8013029

Version: 2.0

Release: 2012-12

Manufacturer

SICK AG

Erwin-Sick-Str. 1 · D-79183 Waldkirch · Germany

Phone: +49 7641 469-0

Fax: +49 7641 469-1149

E-mail: info.pa@sick.de

Trademarks

Viton is a trademark of DuPont Performance Elastomers.

Other product names used in this document may be trademarks

and are only used for identification purposes.

Original documents

The English edition 8013029 of this document is an original document of the manufacturer.

SICK AG assumes no liability for the correctness of an unauthorized translation.

Please contact the manufacturer in case of doubt.

Legal information

Subject to change without notice

Cl

2

S Hydrogen sulfide

H

2

IFC Interference Filter Correlation: Optical measure-

NH

3

NO Nitrogen monoxide

NO

2

SO

2

SOPAS SICK Open Portal for Applications and Systems:

SOPAS ET SOPAS Engineering Tool: PC application program to

PC Personal Computer

PTFE Polytetrafluorethylene

PVDF Polyvinylidene fluoride

Chlorine (gaseous)

ment method using two wavelength ranges.

Ammonia (gaseous)

Nitrogen dioxide

Sulphur dioxide

Family of computer programs to set parameters,

capture and calculate data.

configure modular system components.

Warning Symbols

Hazard (general)

Hazard by corrosive substances

© SICK AG. All rights reserved.

Hazard by high temperature or hot surfaces

Signal Words

CAUTION

Hazard or unsafe practice which could result in personal injury or

property damage.

NOTICE

Hazard which could result in property damage.

Information Symbols

Important technical information for this product

Nice to know

Supplementary information

Link to information at another place

2 DEFOR · Supplementary Operating Instructions · 8013029 V2.0 · © SICK AG

Page 3

Contents

Contents

1Important Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 Main operating information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1.1 Noises . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1.2 UV lamp service life . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2 Application limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.3 Additional documentation/information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Measuring system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2 Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

2.2.1 Adjustment unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.2.2 Process cuvette. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3 Installation Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.1 Sample gas feed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.2 Purge gas feed for process cuvette . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

4 Functions in SOPAS ET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

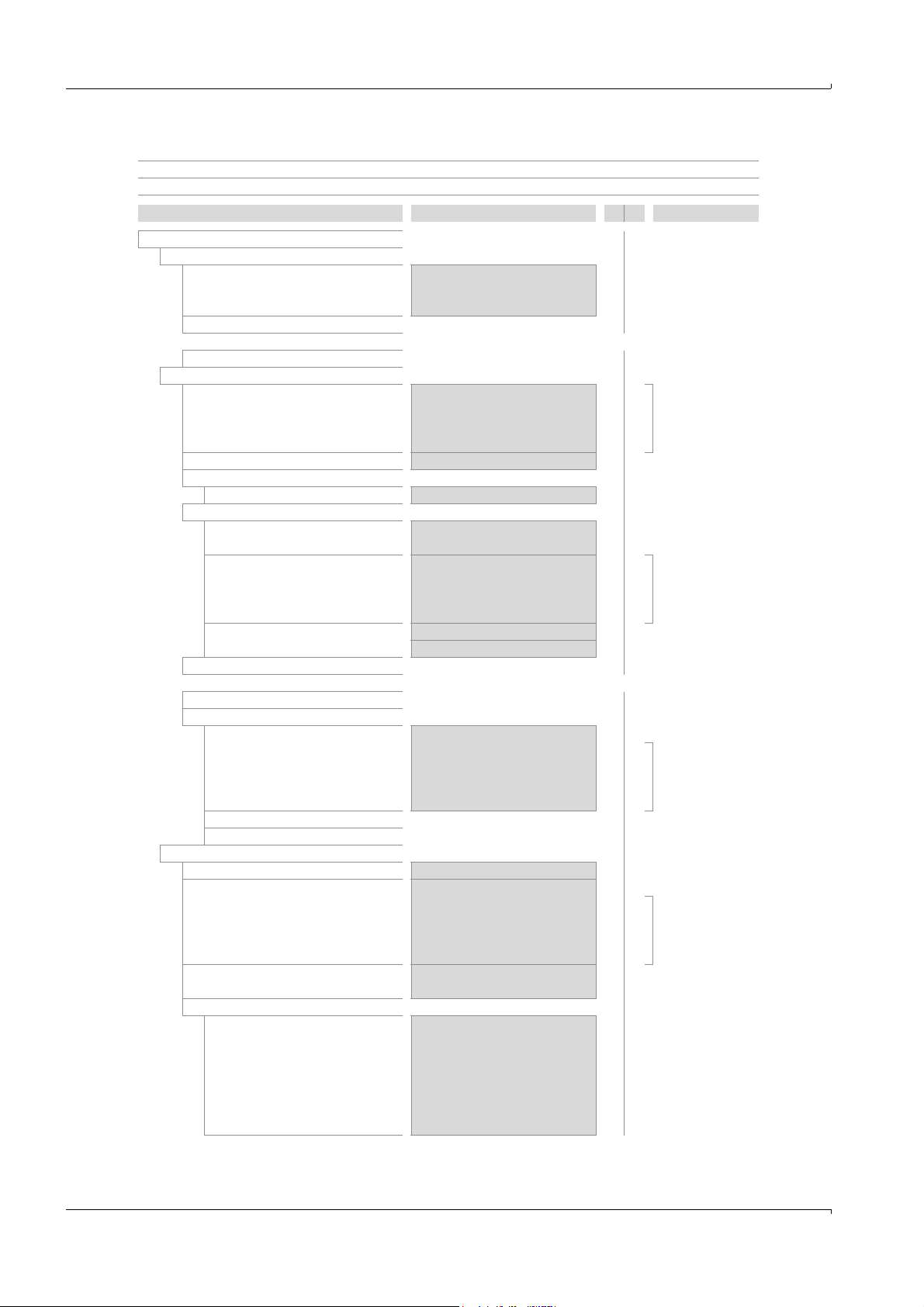

4.1 Menu tree in SOPAS ET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.2 Explanation of the menus in SOPAS ET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

4.3 Explanation of functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.3.1 Logbook in SOPAS ET. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.3.2 Upload (data synchronization) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

4.3.3 Damping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.3.4 Drift limit values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.3.5 Deleting adjustment results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

4.4 Adjustment Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.1 Installation location requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.2 Metrological specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.3 Technical gas specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

5.3.1 Sample gas. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.3.2 Purge gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

5.4 Materials with sample gas contact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.5 Measuring ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.6 Approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.7 UV lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

5.8 Auxiliary power supply for the module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

DEFOR · Supplementary Operating Instructions · 8013029 V2.0 · © SICK AG 3

Page 4

Contents

4 DEFOR · Supplementary Operating Instructions · 8013029 V2.0 · © SICK AG

Page 5

Important Information

DEFOR

1 Important Information

Operating information

Application limitations

Additional documentation

Subject to change w ithout notice

DEFOR · Supplementary Operating Instructions · 8013029 V2.0 · © SICK AG 5

Page 6

1.1 Main operating information

1.1.1 Noises

● Rhythmic noises are normal during operation.

● Specific noises can occur for several minutes after start-up.

1.1.2 UV lamp service life

The Analyzer module DEFOR uses a UV lamp as light source. The UV lamp has a limited service life and probably needs to be replaced several times during the overall operating time.

Status messages of increasing importance are activated automatically when the light

intensity of the UV lamp weakens (→ p. 16 [7]).

● UV lamp service life → p. 26, §5.7

● Display of the operating hours with the PC software “SOPAS ET” → p. 14,

§4.1

1.2 Application limitations

It is possible that another gas component contained in the sample gas can influence the

analysis of the desired measuring component (cross-sensitivity).

In such a case, a constant concentration of the “interfering gas” creates a constant deviation from the true measured value every time (constant characteristic curve offset). The

deviation varies accordingly when the interfering gas concentration fluctuates.

Important Information

● Cross-sensitivity against a certain gas is minimized automatically when the

DEFOR also measures the concentration of this gas.

● The cross-sensitivity can be minimized through computation in the control

unit when the interfering gas concentration is measured with a different

Analyzer module in the GMS800.

1.3 Additional documentation/information

This document supplements the Operating Instructions for GMS800 gas analyzers. It

extends the “GMS800“ Operating Instructions with technical information on the DEFOR.

▸

Observe the delivered “GMS800” Operating Instructions.

The “GMS800” Operating Instructions also specify all further documents

belonging to the individual device.

NOTICE:

▸

Pay primary attention to any individual information provided.

6 DEFOR · Supplementary Operating Instructions · 8013029 V2.0 · © SICK AG

Subject to change w ithout notice

Page 7

Product Description

DEFOR

2 Product Description

Measuring principle

Measuring ranges

Subject to change w ithout notice

DEFOR · Supplementary Operating Instructions · 8013029 V2.0 · © SICK AG 7

Page 8

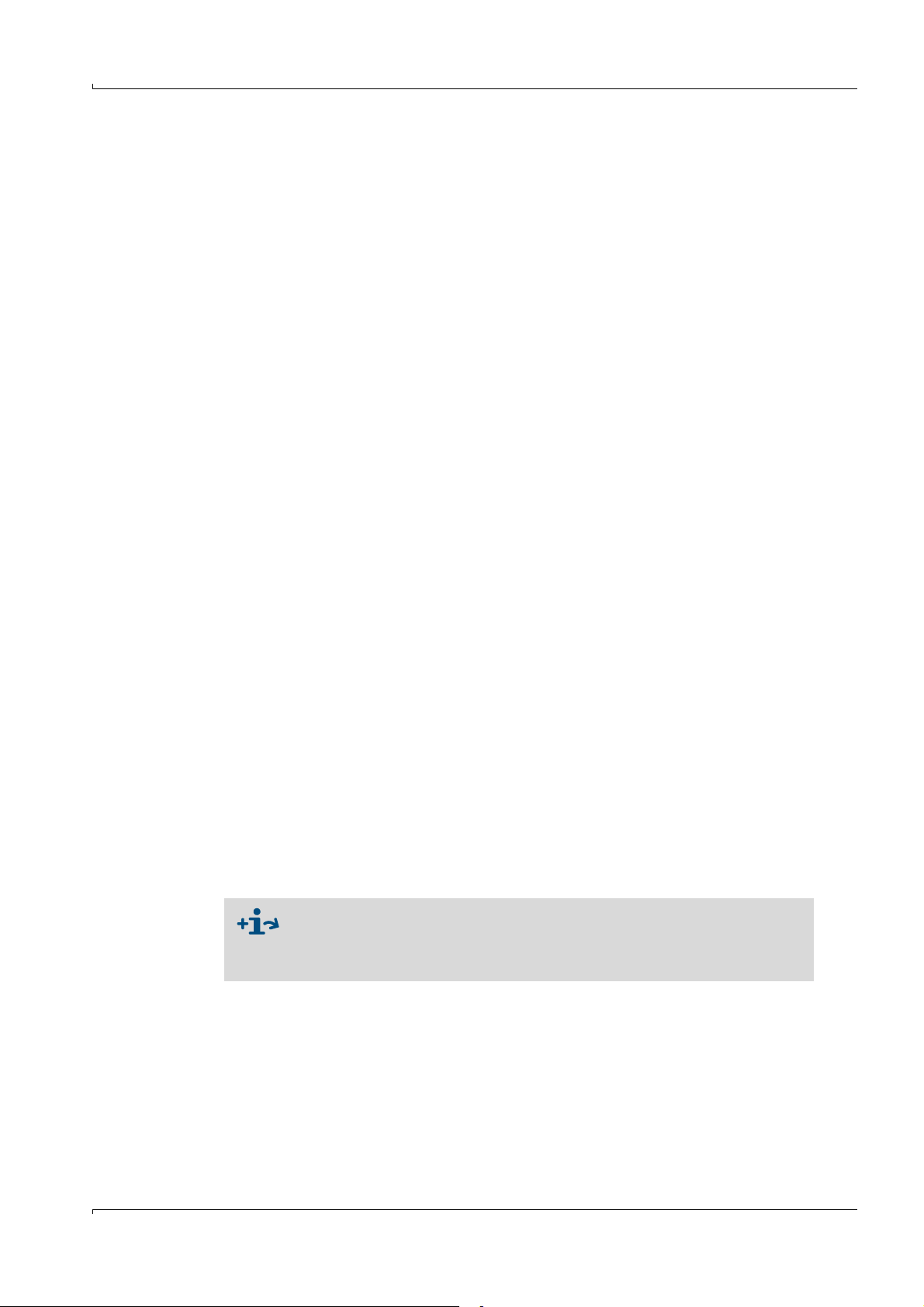

Fig. 1 Measuring principle

M

M M

M M

IFC IFC + UVRAS UVRAS

1UV lamp

2 Filter wheel unit

2a Filter wheel 1

2b Filter wheel 2

3 Collimator lens

4 Beam splitter

5Mirror

6 Sample cuvette

[1]

[1] Length = 0.4/1.5/5.6/21/80/300 mm, depending on the measuring range

7 Reference cuvette

[1]

8 Converging lens

9 Detector

10 Adjustment unit

M Motor

2a

1

3

4

5

2b

6

7

8 9

10

2a

2b

Product Description

M

M

8 DEFOR · Supplementary Operating Instructions · 8013029 V2.0 · © SICK AG

Subject to change w ithout notice

Page 9

Product Description

2.1 Measuring system

Measuring principle

The Analyzer module DEFOR uses the fact that some gases have a specific absorption

characteristic in the ultraviolet light range. For this purpose, UV light is radiated through the

sample gas. The concentration of a gas component in a gas mixture can be determined

through suitable selection of the light wavelength and selective absorption measurement.

The Analyzer module DEFOR can, in this way, analyze the concentration of the gases Cl

H

S, NO, NO2, NH3, SO2 and further gases.

2

The Analyzer module DEFOR can simultaneously measure up to 3 gas components.

Measuring method

● The Analyzer module DEFOR uses interference filter correlation (IFC) for most gas components. Measuring and reference radiation are created alternately by swiveling two different interference filters into the beam path (filter wheel [2a]).

● Gas filter correlation (UVRAS) is used for NO. This method creates the reference radiation by swiveling a gas filter filled with the relevant gas into the beam path (filter wheel

[2b]).

● Both measuring methods are combined for joint measurement of NO and other gases

(both filter wheels [2a]+[2b] are used).

● The physical state of the measuring system is captured and compensated using a reference beam path through a reference cuvette.

,

2

Analyzer module layout

– Beam source is a special UV gas discharge lamp (→ p. 8, Fig. 1 [1]) that emits both broad-

band as well as NO-specific radiation components.

– Thermostat-controlled filter wheel unit [2] keeps the optic filters at a constant tempera-

ture. This minimizes the influence of external temperature changes.

– Lenses [3][8], beam splitter [4] and mirror [5] direct the beam path.

– Sample gas flows through sample cuvette [6]. Reference cuvette [7] is either filled with

a neutral gas or has span gas flowing through (option).

– Detectors [9] capture the radiation intensity created with the various filters.

– Measurement signals are amplified electronically and digitally evaluated. The structure

symmetry compensates proportional and symmetric signal drifts in the best possible

way.

–The measuring system can be fitted with an adjustment unit ([10] → p. 10, § 2.2.1).

The specific properties of the desired measuring components and the desired

physical measuring range each demand an individual metrological concept for

the Analyzer module.

Subject to change w ithout notice

DEFOR · Supplementary Operating Instructions · 8013029 V2.0 · © SICK AG 9

Page 10

2.2 Options

A

A

A A

1 Purge gas compartment

2 Measuring compar tment

3 Purge gas compartment

4 Process cuvette

5 Spacer tube

6 Reference cuvette

41 2 3 65

2.2.1 Adjustment unit

The adjustment unit simplifies and accelerates routine adjustments.

Zero gas flows through the Analyzer module during an adjustment procedure with an

adjustment unit. The first step is a zero point adjustment. An optical filter is swiveled automatically into the beam path of the sample cuvette for the subsequent reference point

adjustment – and thus simulates the presence of a span gas in the sample cuvette. The

nominal values of this simulation are determined at the manufacturer's factory.

This means only a zero gas is required for an adjustment procedure with adjustment unit; a

span gas for reference point adjustment is not necessary. The procedure can be started

manually or can run automatically (requires automated zero gas feed).

The adjustment unit should be checked and readjusted in larger intervals during operation (recommendation: Every 6 months). For this purpose, the Analyzer module must be adjusted with real test gases beforehand.

2.2.2 Process cuvette

The versions with process cuvette are intended for applications with dangerous sample

gases where it must be ensured the sample gas does not flow into the gas analyzer when a

window of the sample cuvette becomes leaky.

In the process cuvette, the measuring compartment is flanked by purge gas compartments

through which purge gas flows continuously (→ Fig. 2). When a measuring compartment

window is leaky, the emerging sample gas flows into the purge gas compartment and from

there out of the gas analyzer with the purge gas.

The GMS800 therefore requires continuous purge gas for versions with a process cuvette

(→ p. 12, §3.2).

Product Description

Fig. 2 Process cuvette

Subject to change w ithout notice

10 DEFOR · Supplementary Operating Instructions · 8013029 V2.0 · © SICK AG

Page 11

Installation Information

DEFOR

3 Installation Information

Sample gas feed

Purge gas feed for process cuvette

Subject to change w ithout notice

DEFOR · Supplementary Operating Instructions · 8013029 V2.0 · © SICK AG 11

Page 12

3.1 Sample gas feed

▸

Observe the information on sample gas feed in the “Series GMS800” Operating Instructions.

3.2 Purge gas feed for process cuvette

Only valid for versions with process cuvette (option → p. 10, §2.2.2 )

In versions with process cuvette, the GMS800 enclosure has additional “purge gas inlet”

und “purge gas outlet” gas connections.

Gas connections type and version → Supplementary Operating Instructions for

Enclosure

1 Install an external continuous purge gas supply for GMS800.

Suitable purge gas: Chemically neutral gas (inert gas) or gas mixture suitable for diluting and transporting the measured gas without danger.

2 Feed the purge gas through the “purge gas inlet“ gas connection on the enclosure.

Allowable pressure and volume flow: → p. 25, §5.3.2

3 Install a gas line on the “purge gas outlet” through which the purge gas and emerged

sample gas are reliably discharged.

▸

Lead the gas line to a safe position where emerged sample gas cannot create any

danger.

▸

Recommendation: Attach appropriate warning signs to the gas line or gas outlet

informing about the hazardousness of the sample gas.

Installation Information

12 DEFOR · Supplementary Operating Instructions · 8013029 V2.0 · © SICK AG

Subject to change w ithout notice

Page 13

Functions in SOPAS ET

DEFOR

4 Functions in SOPAS ET

Menu functions in the PC program “SOPAS ET”

Menu tree

Explanations

● Instructions for the PC program “SOPAS ET” → User Information for the pro-

gram

● Exemplary menu representations → Technical Information “Basic Control

Unit (BCU)” (contains information for operating with SOPAS ET)

Subject to change w ithout notice

DEFOR · Supplementary Operating Instructions · 8013029 V2.0 · © SICK AG 13

Page 14

4.1 Menu tree in SOPAS ET

User level: O Operator (standard) A Authorized operator

Access rights: ○ Viewing ● Setting up/starting

Directory Menu contents O A Explanation

S800_DEFOR ○○

Measured value display ○○

Measuring component 1

Measuring component 2

[1]

↓

Measuring component 10

[1]

Diagnosis ○○

Module state Failure ○○

Logbook

Operating hours – ○

Lamp h–○→p. 16 [5]

Measuring component 1 ○○

Name / unit

State

Validation measurement (QAL3) Zero point ○○

Measuring component 2

[1]

↓

Measuring component 10

[1]

UV lamp – ○

Physical component 1

Physical component 2

Physical component 3

[1]

[1]

Parameter ○○

Sampling point

RS485 interface Module address – ○→p. 16 [9]

Operating mode

Measuring component 1 ○○

Physical meas. range

Functions in SOPAS ET

Component ○○ →p. 16 [1]

Measured value ○○ →p. 16 [2]

Unit ○○ →p. 16 [3]

○○

○○

Maintenance request ○○ →p. 16 [4]

Function(s) active ○○

Uncertain state ○○

Pos.|Date|Source| … – ○→p. 18, §4.3.1

Component ○● →p. 16 [1]

Unit ○○ →p. 16 [2]

Failure ○○

Maintenance request ○○ →p. 16 [4]

Function(s) active ○○

Uncertain state ○○

Reference point ○○

○○

○○

Intensity …% – ○→p. 16 [6]

Failure – ○

Uncertain – ○→p. 16 [7]

Maintenance – ○

OK – ○

– ○

– ○

Description – ●→p. 16 [8]

Baud rate – ●

Data bits – ●→p. 16 [10]

Stop bits – ●

Parity – ●

Actual – ○→p. 16 [11]

Tar get – ○→p. 16 [12]

Component ○● →p. 16 [1]

Unit ○○ →p. 16 [3]

Start value ○○ →p. 16 [13]

End value ○○ →p. 16 [14]

Base value ○○ →p. 16 [15]

Measuring channel ○○ →p. 16 [16]

Precision ○○ →p. 17 [17]

Subject to change w ithout notice

14 DEFOR · Supplementary Operating Instructions · 8013029 V2.0 · © SICK AG

Page 15

Functions in SOPAS ET

Directory Menu contents O A Explanation

Adjustment ○○

Maintenance – ○

Factory settings ○○

[1] If fitted.

Damping – ●

Damping (el. T90%) Time constant [s] – ●

Dynamic damping Status [On/Off] – ● → p. 19, § 4.3.3

Time constant [s] – ●

Threshold – ●

Measuring component 2

[1]

○○

↓

Measuring component 10

[1]

○○

Measuring component 1 ○○

Drift limit value

Zero point – ○→p. 20, § 4.3.4

Reference point – ○

Adjustment results ○○

Adjustment result Zero point ○○

Reference point ○○

Drifts Zero point ○○ →p. 17 [18]

Reference point ○○

Delete results

Measuring component 2

[1]

[Delete] – ●→p. 20, §4.3.5

○○

↓

Measuring component 10

[1]

○○

Maintenance flag [On]/[Off] – ●→p. 17 [20]

Settings – ○

User settings

[Backup] – ●

[Restore last user settings] – ●→p. 17 [21]

[Restore next to last user settings] – ●

Factory settings [Restore] – ●→p. 17 [22]

Identification ○○

ID numbers

Serial number ○○

Material No. ○○

Hardware version ○○ →p. 17 [23]

Software version ○○

Software date ○○

Production release

Year | Month | Day – ○→p. 17 [24]

Subject to change w ithout notice

DEFOR · Supplementary Operating Instructions · 8013029 V2.0 · © SICK AG 15

Page 16

4.2 Explanation of the menus in SOPAS ET

Description Explanation

No.

1 Component Name of measuring component

2 Measured value Actual measured value of measuring component

3 Unit Physical unit of measured value

4 Failure LED symbol

● Significance: Module not ready for operation

● Possible causes: Malfunction, defect

Maintenance request LED symbol

● Significance: Advance warning before internal technical

limits reached.

● Possible causes: Drift limit, operating hours, lamp intensity

Function(s) active LED symbol

● Significance: At least one internal function active that

impairs or hinders normal module measuring function.

● Possible causes: Adjustment procedure running, validation

measurement running

Uncertain state LED symbol

● Significance: Actual measured values are unreliable.

● Possible causes: Heating up phase, internal over/under

temperature, adjustment procedure programming not

plausible

5 Operating hours Number of operating hours of the UV lamp fitted

6 Intensity …% Actual light intensity in the reference beam path for the asso-

ciated measured component (with the specific optical filter in

the beam path) relative to the new condition of the UV lamp;

evaluated automatically (

5.7)

7 Failure UV lamp status (evaluation of intensity); “OK” = full intensity,

Uncertain

Maintenance

OK

“Maintenance” = UV lamp replacement recommended;

“Uncertain” = correct measuring function questionable; “Failure” = measurement no longer possible. The module status

flags are activated accordingly (

8 Description Freely selectable text for module name

9 Module address Internal CAN bus address of module (defined by hardware set-

ting in module)

10 Baud rate Transfer speed (standard: 9600)

Data bits Number of data bits (standard: 8)

The GMS800 only uses the 7-bit range (ASCII code 0 … 127)

but can also communicate in 8-bit format.

Stop bits Number of stop bits (1 or 2; standard: 2)

Parity Additional identification for automatic monitoring of character

transfers; [Even], [Odd], [None]. – Standard: None

11 Actual Internal operating module state:

● [Heating] = heating up phase (measured values unreliable)

● [Measuring] = measuring operation (normal operating

mode)

● [Halt] = stopped electronically (not ready for operation)

12 Target Default operating mode through entry or software function;

should become actual operating mode af ter a certain time

(can take up to 1 hour during the heating up time after start-

up).

13 Start value Start value of physical measuring range

14 End value End value of physical measuring range

15 Base value Internal physical base value of measuring range

16 Measuring channel Internal measuring channel for measuring component

Functions in SOPAS ET

→ [7]; UV lamp service life → p. 26,

→ [4]).

Subject to change w ithout notice

16 DEFOR · Supplementary Operating Instructions · 8013029 V2.0 · © SICK AG

Page 17

Functions in SOPAS ET

Description Explanation

No.

17 Precision [On] = higher measuring precision is available for measuring

range 2 (effective in range 0 … 20% of physical measuring

range)

18 Drifts

● Last = since last adjustment

● Total = since last drift calculation initialization

19 Delete results [Delete] = Set all drift values to “0”.

20 Maintenance flag [On] = Status “Maintenance” is activated (here as signal for

active maintenance work)

21 User settings

22 Factory settings Overwrite the actual module settings with the original settings

● Backup = save a copy of the actual module settings.

● Restore = overwrite the actual module settings with the

saved copy.

from the factory.

▸

Recommendation: Save the current module settings first

[1]

[1]

(→ “User settings”).

23 Serial number Individual module serial number

Material No. Identification number of module version

Hardware version Module electronics version number

Software version Module software version number

Software date Module software revision

24 Production release Module date of manufacture

[1] A warm star t is then done automatically.

Subject to change w ithout notice

DEFOR · Supplementary Operating Instructions · 8013029 V2.0 · © SICK AG 17

Page 18

4.3 Explanation of functions

1 2 3 4 5 6 7

4.3.1 Logbook in SOPAS ET

The Logbook Table shows the last 20 internal messages.

Fig. 3 Menu “[Module name]/Diagnosis/Logbook” in PC program “SOPAS-ET” (example)

Column Meaning

1 Sequential number in Logbook

2

Time of last message change

3

4 “System” = measuring system (hardware)

“MV” = measuring component (measurement)

5 Short message text, e.g. “F measured value”.

The character prefix classifies the message:

F = Failure

C = Check (adjustment/validation)

U = Uncertain (extra information)

M = Maintenance

E = Extended (status message)

6 Current message status

7 Total count of activations

Functions in SOPAS ET

4.3.2

Upload (data synchronization)

Only applicable when the “SOPAS ET” PC software is used. Not applicable for systems

without control unit (special versions).

The new data are not transferred automatically to “SOPAS ET” after settings for a module

have been changed with the menu functions of the control unit. “SOPAS ET” continues

using the previous data.

▸

To transfer the current data of a module to “SOPAS ET”: Start the “Upload all parame-

ters from device” function in “SOPAS ET” once.

18 DEFOR · Supplementary Operating Instructions · 8013029 V2.0 · © SICK AG

Subject to change w ithout notice

Page 19

Functions in SOPAS ET

4.3.3 Damping

Constant damping

When “damping” has been programmed, the average value from the current measured

value and the previous measured values (floating averaging) are displayed instead of the

current measured value.

Possible uses include:

– Damping metrological measured value fluctuations (noise)

– Smoothing fluctuating measured values when only the average value is relevant

Damping is done in the Analyzer module and therefore affects all measured value displays

and outputs. It is also active during an adjustment procedure.

● Increasing damping normally increases the reaction time (90% time) of the

gas analysis system accordingly.

● Reducing damping can possibly increase the measurement signal “noise”

(measuring turbulence).

● Time constant = 0 s means: No damping.

CAUTION: Risk of incorrect adjustment

The “Measuring time, test gas” must be at least 150% of the set damping time

constant during adjustments.

▸

When damping has been reset or increased: Check whether adjustment

settings need to be adapted.

Dynamic damping

“Dynamic damping” serves to compensate measured value fluctuations without significantly increasing the reaction time. Dynamic damping is automatically deactivated when

the measured value changes rapidly and strongly as against “normal” damping. This allows

“smoothing” continuous minor measured value fluctuations but rapid measured value

changes are still displayed without delay. Dynamic behavior is determined with the “Threshold” parameter:

– When the measured values change only slowly, dynamic damping functions as constant

damping.

– When the difference of successive measured values is greater than the set limit,

dynamic damping is terminated automatically and remains disabled as long as the

measured values continue to change rapidly.

– Dynamic damping is active again when measured value differences are below the limit

again (which means measured values changes remain slight).

Dynamic damping also affects all measured value displays and outputs.

Subject to change w ithout notice

DEFOR · Supplementary Operating Instructions · 8013029 V2.0 · © SICK AG 19

Page 20

4.3.4 Drift limit values

Purpose

Analyzer module drifts are caused, for example, by contamination, mechanical changes or

aging effects. The total drift (i.e. the deviation from original state) increases gradually. It is

not practical to keep compensating an ever increasing total drift through computation.

Inspect and reset the Analyzer module when total drift has become very large.

Drift limit values monitor total drift automatically. These also protect against erroneous

adjustments.

Functionality

After every adjustment, an Analyzer module compares the calculated total drift with the

drift limit value. Drift limit value violation is reported in two stages:

● Status “M” (Maintenance request) is activated when the total drift reaches 100 … 120%

of the drift limit value.

● Status “F” (Failure) is activated when the total drift reaches more than 120% of the drift

limit value.

● When an adjustment procedure shows that a calculated drift has reached more than

150% of the drift limit value, the result from this adjustment procedure is ignored and

the previous adjustment remains valid.

Functions in SOPAS ET

● The drift limit values are set in the factory (standard value: 10%).

● A Service function is available to reset all drift values to “0” (Drift reset).

This is useful after Analyzer module maintenance when this has established a new original state.

4.3.5 Deleting adjustment results

The “Delete results” function deletes all determined drift values of a measuring component. Drift limit values then refer to new drift values.

The data of the previous adjustment which was performed before are then no longer displayed. Test gas settings (e. g. nominal value) are not changed.

CAUTION: Risk of incorrect adjustment

If very large drift values are displayed after a manual adjustment procedure

(→ Operating Instructions “Basic Control Unit (BCU)”), a test gas used probably

did not match the relevant test gas setting or gas feed was interrupted – and

the adjustment result was still accepted.

▸

Do not delete incorrect adjustment results, but repeat the adjustment carefully.

▸

Do not use the deletion of adjustment results to nullify large drift values

caused by extensive physical changes of an Analyzer module. Instead,

clean the Analyzer module or perform an adjustment.

▸

After an Analyzer module has been cleaned, altered or exchanged:

Delete the relevant adjustment results and perform an adjustment.

[1] By the manufacturer's Customer Service or authorized skilled persons with appropriate training.

[1]

20 DEFOR · Supplementary Operating Instructions · 8013029 V2.0 · © SICK AG

Subject to change w ithout notice

Page 21

Functions in SOPAS ET

4.4 Adjustment Information

The control unit controls the adjustments.

▸

Individual adjustment of each shown measuring component and each measuring

range.

▸

Information concerning purpose, prerequisites and frequency of adjustments → Operat-

ing Instructions “Series GMS800”

▸

Programming of the adjustment parameters for each measuring component of the

GMS800 → Technical Information “Basic Control Unit (BCU)”

▸

Manual start of an adjustment procedure → Operating Instructions of the control unit

Subject to change w ithout notice

DEFOR · Supplementary Operating Instructions · 8013029 V2.0 · © SICK AG 21

Page 22

Functions in SOPAS ET

22 DEFOR · Supplementary Operating Instructions · 8013029 V2.0 · © SICK AG

Subject to change w ithout notice

Page 23

Technical Data

DEFOR

5 Technical Data

Ambient conditions

Sample gas specifications

Metrological specifications

Subject to change w ithout notice

DEFOR · Supplementary Operating Instructions · 8013029 V2.0 · © SICK AG 23

Page 24

5.1 Installation location requirements

Geographic height at installation location: ≤ 2500 m altitude

Ambient air pressure: 700 … 1200 hPa

Allowable oscillations/jolts

– Displacement: 0.035 mm (in range 5 … 59 Hz)

– Activation acceleration amplitude: 5 m·s

Usage position: Max. ±15° tilt to every spatial axis

[1] Higher altitudes can be realized (option); compensation for height influence.

[2] Allowable surface tilt during operation; keep constant during operation; readjust after changing the tilt.

5.2 Metrological specifications

Measured variable: Volume concentration of a gas component

Measuring ranges: See specification for individual device

Detection limit (2σ):

[3]

– Standard measuring ranges: < 0.5% of measurement span

– Small measuring ranges:

[4]

< 1% of measurement span

Linearity deviation: < 1% of measurement span

Zero point drift

– Standard measuring ranges: < 1% of measurement span per week

– Small measuring ranges:

– Measured components NO, NO

[4]

, SO2: < 1% of measurement span per day

2

< 2% of measurement span per week

Reference point drift: < 1% of measurement span per week

Ambient temperature influence:

– Standard measuring ranges: < 1%

– Small measuring ranges:

Setting time (t

): 4 s

90

[4]

< 2%

Run-in time: < 60 minutes

[1] → p. 26, § 5.5

[2] Possible measuring ranges → p. 26, § 5.5.

[3] Values valid with constant damping T

[4] Valid for measuring ranges < 2x smallest measuring range.

[5] Of respective measuring range.

[6] Typical value for sample gas volume flow = 60 l/h and T

=10s + dynamic damping T

T

90, el.

volume flow.

= 10 s; for measuring component NO: With constant damping

90, el.

=60s.

90, dyn.

90, el.

[1]

-2

(in range 59 … 160 Hz)

[2]

[1]

[2]

[5]

/10 K

[5]

/10 K

[6]

= 1 s; depending on cuvette length and sample gas

Technical Data

If not specified otherwise, the metrological specifications in relation to the

physical measuring range are applicable (see order documents). The physical

measuring range is usually identical with the largest measuring range. The

same values apply for all other measuring ranges.

If, however, the Analyzer module was manufactured with “higher measuring

precision” (option), measuring precision is increased in range 0 … 20% of the

physical measuring range. The measurement specifications in this range are

then applicable in relation to 20% of the physical measuring range.

24 DEFOR · Supplementary Operating Instructions · 8013029 V2.0 · © SICK AG

Subject to change w ithout notice

Page 25

Technical Data

5.3 Technical gas specifications

5.3.1 Sample gas

Allowable sample gas temperature:

– Minimum: 5 °C (41 °F)

– Maximum: 55°C (131°F)

Allowable sample gas dew point: Below ambient temperature

Particles in the sample gas: Sample gas should be free from dust and aerosols

Allowable sample gas pressure

Sample gas volume flow

[1]

– Minimum: 20 l/h (333 cm3/min)

– Maximum: 120 l/h (2000 cm

– Recommended: 30…60l/h (500…1000cm

– Standard: 30 l/h (500 cm

[1] On the sample gas inlet. Keep constant during operation.

[2] When a sample gas cooler is used: Always above the cooler temperature (dew point).

[3] With “heated sample gas path” option: Up to +80 °C, depending on the temperature set.

[4] On the sample gas inlet.

[5] Relative to the ambient/atmospheric air pressure.

[5]

[1]

[2]

[3]

–200 … +300 hPa (–0.2 … +0.3 bar)

3

/min)

3

/min)

3

/min)

[4]

5.3.2 Purge gas

Only valid for version with process cuvette (→ p. 10, §2.2.2)

Suitable purge gas: Dry inert gas (chemically neutral gas/gas mixture

without condensable components)

Allowable purge gas pressure

[1]

15 … _30 hPa

Purge gas volume flow

– Minimum: 20 l/h (333 cm

– Maximum: 100 l/h (167 cm

– Recommended: 20 … 60 l/h (333 … 1000 cm

– Standard: 30 l/h (500 cm

[1] Relative to the ambient/atmospheric air pressure.

5.4 Materials with sample gas contact

Component Material

Cuvette: Aluminium or stainless steel

Optical window: CaF2 or quartz

Synthetics: Viton B, PVDF, PTFE

[1] Depending on version.

3

3

[1]

/min)

3

/min)

/min)

[1]

[1]

3

/min)

Subject to change w ithout notice

DEFOR · Supplementary Operating Instructions · 8013029 V2.0 · © SICK AG 25

Page 26

5.5 Measuring ranges

Technical Data

Measuring

component

Cl

2

COS 250 670 – 100

CS

2

H

S 25 40 – 100

2

NH

3

NO 10 15 50 100

NO

2

SO

2

[1] Approvals→ p. 26, §5.6.

[2] For operation in air-conditioned environment (±2 °C temperature deviation) and daily zero point adjustment.

● Conversion from ppm to mg/m

● All specifications valid for a mixture of the measuring components and N

5.6 Approvals

Conformities DEFOR

EN 15267-3 ●

EN 14181 ●

2000/76/EC (17th BImSchV) ●

2001/80/EC (13th BImSchV) ●

27th BImSchV ●

Smallest measuring range Largest measuring

Technical Performance-

ppm mg/m

3

[1]

tested

ppm % by vol.

range

125 400 – 100

50 170 – 30

50 40 – 100

50 (10)

25 (10)

[2]

[2]

105 (20)

3

relative to 20°C, 1013 hPa.

75 (30)

[2]

[2]

50 100

75 100

.

2

5.7 UV lamp

Design: Electrode-less discharge lamp, EDL

Service life: Approx. 2 years (= 17500 hours)

5.8 Auxiliary power supply for the module

Voltage supply: 24 VDC

Power input: ≤ 134 W

Subject to change w ithout notice

26 DEFOR · Supplementary Operating Instructions · 8013029 V2.0 · © SICK AG

Page 27

Technical Data

··· Empty page ···

Subject to change w ithout notice

DEFOR · Supplementary Operating Instructions · 8013029 V2.0 · © SICK AG 27

Page 28

Keywords

Index

A

Actual (display) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Adjustment result

Adjustment results

Approvals

Auxiliary power supply

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

. . . . . . . . . . . . . . . . . . . . . . . . . . . 15

. . . . . . . . . . . . . . . . . . . . . . . . . . 15

. . . . . . . . . . . . . . . . . . . . . . . . 26

B

Backup (user settings) . . . . . . . . . . . . . . . . . . . . . . . 15

Backup copy (user settings)

Base value (display)

Baud rate

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

. . . . . . . . . . . . . . . . . . . . . . . . . 16

. . . . . . . . . . . . . . . . . . . 15

C

Conformities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Constant damping

. . . . . . . . . . . . . . . . . . . . . . . . . . . 19

D

Damping

- Constant damping (el. T90%)

- Dynamic damping

-el.T90% (constant damping)

Data bits

Detection limit

Diagnosis

Drift

- Specifications

- Viewing actual values

- Viewing drift limit values

Drift limit values

- Purpose, functionality

Dynamic damping

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

. . . . . . . . . . . . . . . . . . . . . 15, 19

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

. . . . . . . . . . . . . . . . . . . . . . 15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

. . . . . . . . . . . . . . . . . . . . . . 20

. . . . . . . . . . . . . . . . . . . . . . . 15, 19

. . . . . . . . . . . . . . . . 19

. . . . . . . . . . . . . . . . 15

. . . . . . . . . . . . . . . . . . . . 15

E

el. T90% (constant damping) . . . . . . . . . . . . . . . . . . 19

End value (display)

. . . . . . . . . . . . . . . . . . . . . . . . . . 16

F

Factory settings, restoring . . . . . . . . . . . . . . . . . . . . 15

Failure

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

FICA

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Filter wheel

Flow (volume flow)

- Purge gas

-Sample gas

Function(s) active

Functions in SOPAS ET

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

. . . . . . . . . . . . . . . . . . . . . . . . . . . 16

. . . . . . . . . . . . . . . . . . . . . . . 13

G

Gas filter correlation . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Glossary

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

H

Hardware version (display) . . . . . . . . . . . . . . . . . . . . 15

I

ID numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Identification

IFC

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Information symbols

Installation information

Intensity …%

Interference filter (correlation)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

. . . . . . . . . . . . . . . . . . . . . . . . . . 2

. . . . . . . . . . . . . . . . . . . . . . . 11

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

. . . . . . . . . . . . . . . . . . 9

L

Logbook . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14, 18

M

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Maintenance flag

Maintenance request

Material No.

Materials

Materials with sample gas contact

Measured value display

- Constant damping

- Dynamic damping

-In SOPASET

Measuring channel (display)

Measuring components

- Display name and physical unit

- Displaying physical measuring ranges

- Measuring ranges

-Show status

Measuring principle

Measuring ranges

Menu tree

Menus in SOPAS ET

Module address

Module state

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

. . . . . . . . . . . . . . . . . . . . . . . . 16

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

. . . . . . . . . . . . . 25

. . . . . . . . . . . . . . . . . . . . . . . . . 19

. . . . . . . . . . . . . . . . . . . . . . . . . 19

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

. . . . . . . . . . . . . . . . . . 16

. . . . . . . . . . . . . . 14

. . . . . . . . . 14

. . . . . . . . . . . . . . . . . . . . . . . . . 26

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

. . . . . . . . . . . . . . . . . . . . . . . . . . . 9

. . . . . . . . . . . . . . . . . . . . . . . . . . . 26

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

. . . . . . . . . . . . . . . . . . . . . . . . . . 13

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

N

Name (sampling point) . . . . . . . . . . . . . . . . . . . . . . . 16

Noises

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

O

OK (status) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Measuring range 2

Operating mode

Options

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

. . . . . . . . . . . . . . . . . . . . . . . . . . 14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

28 DEFOR · Supplementary Operating Instructions · 8013029 V2.0 · © SICK AG

Page 29

Index

P

Parity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Power input

Precision (display)

Pressure

-Purge gas

-Sample gas

Process cuvette

- Description

-Purge gas feed

Product description

Product variants

Production release

Purge gas

- Connections, feed

-Purpose (process cuvette)

-Specifications

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

. . . . . . . . . . . . . . . . . . . . . . . . . . . 17

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

. . . . . . . . . . . . . . . . . . . . . . . . . . 7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

. . . . . . . . . . . . . . . . . . . . . . . . . . 15

. . . . . . . . . . . . . . . . . . . . . . . . . 12

. . . . . . . . . . . . . . . . . . 10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Q

QAL3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

R

Reference cuvette . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

RS485 interface

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

S

Safety information

- Drift reset

Sample cuvette

Sample gas feed

Serial number

Settings

Settings, back up/restore

Signal words

Software date

Software version

SOPAS ET (important information)

SOPAS ET

Start value (display)

Stop bits

Symbols (explanation)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

. . . . . . . . . . . . . . . . . . . . 15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

. . . . . . . . . . . . . 18

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

. . . . . . . . . . . . . . . . . . . . . . . . . 16

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

. . . . . . . . . . . . . . . . . . . . . . . . 2

T

Target (display) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Technical data

- Materials with sample gas contact

-Measuring ranges

- Metrological specifications

-Power input

- Technical gas specifications

-UV lamp

- Voltage supply

Temperature

-Purge gas

-Sample gas

Threshold (dynamic damping)

Time constant

- el. T90% (constant damping)

- for dynamic damping

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

. . . . . . . . . . . 25

. . . . . . . . . . . . . . . . . . . . . . . . . 26

. . . . . . . . . . . . . . . . . . 24

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

. . . . . . . . . . . . . . . . . 25

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

. . . . . . . . . . . . . . . . . 15

. . . . . . . . . . . . . . . . 15

. . . . . . . . . . . . . . . . . . . . . . 15

U

Uncertain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Uncertain state

Upload all parameters from device

User settings, back up/restore

UV lamp

- Operating hours, display

-Service life

- Service life (important information)

-Show status

UVRAS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

. . . . . . . . . . . . . 18

. . . . . . . . . . . . . . . . 15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

. . . . . . . . . . . . . . . . . . . . 14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

. . . . . . . . . . . . 6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

V

Validation measurement (result) . . . . . . . . . . . . . . . 14

Voltage supply

Volume flow

-Purge gas

-Sample gas

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

W

Warning symbols, warning levels . . . . . . . . . . . . . . . 2

DEFOR · Supplementary Operating Instructions · 8013029 V2.0 · © SICK AG 29

Page 30

DEFOR

SICK worldwide

You will find our local subsidiary

or agency at:

www.sick.com

8013029/V2.0/2012-12 |Subject to change without notice

Your local sales and service partner

SICK AG | Waldkirch | Germany | www.sick.com

Loading...

Loading...