Page 1

DBS60 Core INCREMENTAL ENCODERS

RUGGED, VERSATILE INCREMENTAL ENCODERS

FOR INDUSTRIAL APPLICATIONS

Product description

The DBS60 Core is a rugged incremental

encoder with a 58 mm diameter and

compact installation depth. It offers a

large range of mechanical and electrical

interfaces. The solid shaft models are

available with face mount ange and

servo ange. The hollow shaft design is

available as a blind hollow shaft and as

a through hollow shaft and can receive

shafts up to 5/8" (15.875 mm). The

optional shaft insulation and the shaft

clamping on the back of the encoder are

unique to the hollow shafts. In addition

to the standard interfaces 5 V and 24 V

TTL/RS422 and 24 V HTL/Push-Pull, the

DBS60 Core offers a exible universal

interface which combines the 5 V TTL

and 24 V HTL in one product. The high

enclosure rating IP 65 and the large ball

bearing distance ensure high robustness

and reliability, even in the case of high

shaft loads. With a resolution of up to

5,000 pulses, the DBS60 Core is the

ideal product for standard use in various

different industries.

F

Additional information

Fields of application . . . . . . . . . . .F-121

Detailed technical data. . . . . . . . .F-121

Type code. . . . . . . . . . . . . . . . . . . . F-124

Ordering information. . . . . . . . . . . F-128

Mounting suggestion for servo

ange .......................F-129

Dimensional drawings . . . . . . . . .F-130

Connection type ..............F-153

Viewing number of resolutions. . . F-153

Zero declaration ..............F-154

Signal outputs ................F-154

Recommended accessories. . . . . F-156

At a glance

• Face mount ange, servo ange, blind

and through hollow shaft

• Housing: Ø 58 mm; compact installa-

tion depth, large bearing distance

• Flange and stator couplings enable

diverse mounting options

• Number of lines: up to 5,000 pulses

Your benets

• Diverse installation options due to

different ange and shaft designs

• Universal cable outlet and radial con-

nector allow use in tight spaces and

make exible cable routing possible

• Compact housing dimensions save

valuable space Optional hollow

shaft clamp on the back facilitates

mounting

• Protects the encoder against high

shaft temperatures and currents

through optional isolated shafts

• Cable outlet, radial M23 or M12 male

connector

• TTL/RS-422 and HTL/Push-Pull,

universal interface TTL/HTL with

4.5 V DC to 30 V DC

• Hollow shafts: metal up to Ø 5/8",

isolated up to Ø 15 mm; clamping at

the front and back

• Flanges and stator couplings with

different mounting holes allow diverse

mounting options with one encoder

variant

• Rugged design with large bearing

distance allows high shaft loads and

a longer service life

• The TTL/HTL combination interface

enables less product variety and

reduces storage costs

F-120

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 2

Fields of application

Measuring of position, speed and distance in applications with

low to medium requirements on the encoder.

Developed for applications in factory and logistics automation,

e.g., in

Detailed technical data

Performance

Pulses per revolution

Measurement step

Measurement step deviation

< 3,600 pulses per revolution ± 18°/pulses per revolution

≥ 3,600 pulses per revolution ± 36°/pulses per revolution

Error limits

Duty cycle

< 3,600 pulses per revolution ≤ 0.5 ± 5%

≥ 3,600 pulses per revolution ≤ 0.5 ± 10 %

Initialization time

1)

For available pulses per revolution see type code.

2)

After this period valid signals can be read.

4 ... 5,000

90° electrical/pulses per revolution

Measurement step deviation x 3

< 5 ms

1)

2)

INCREMENTAL ENCODERS DBS60 Core

• Asynchronous motors

• Elevators

• Packaging machines

• Warehousing and transport logistics

Mechanical data

Solid shaft Blind hollow shaft Through hollow shaft

Mechanical design

Solid shaft, servo ange

Solid shaft, face mount ange

Shaft diameter

6 mm x 10 mm

10 mm x 19 mm

2)

Mass

Shaft material

Flange material

Housing material

1)

Other on request.

2)

Based on an encoder with a connector outlet or a cable with a connector outlet.

3)

Higher values possible by limiting the overall service life.

4)

Take into account self-heating of 3.2 K per 1000 revolutions/min when designing the working temperature range.

5)

Take into account self-heating of 2.6 K per 1,000 revolutions/min when designing the operating temperature range.

6)

Maximum speed which does not lead to any harm to the encoder. Impact on the service life and signal quality is possible. Please note the maximum output frequency.

0.3 kg

Stainless steel Stainless steel

Aluminum

Aluminum

1)

1)

Blind hollow shaft Through hollow shaft clamping

at the back

Through hollow shaft

6 mm

8 mm

3/8“

10 mm

12 mm

1/2“

14 mm

15 mm

5/8“

6 mm (shaft isolated)

8 mm (shaft isolated)

3/8“ (shaft isolated)

10 mm (shaft isolated)

12 mm (shaft isolated)

1/2“ mm (shaft isolated)

14 mm (shaft isolated)

15 mm (shaft isolated)

2)

0.25 kg

Stainless steel with plastic collar

F

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

F-121

Page 3

DBS60 Core INCREMENTAL ENCODERS

Solid shaft Blind hollow shaft Through hollow shaft

Cable material

Start up torque

Operating torque

Permissible shaft movement, axial static/

dynamic

Permissible shaft movement, radial

static/dynamic

Permissible shaft load, radial/axial

Operating speed

Maximum operating speed

Rotor moment of inertia

Bearing lifetime

Max. angular acceleration

1)

Other on request.

2)

Based on an encoder with a connector outlet or a cable with a connector outlet.

3)

Higher values possible by limiting the overall service life.

4)

Take into account self-heating of 3.2 K per 1000 revolutions/min when designing the working temperature range.

5)

Take into account self-heating of 2.6 K per 1,000 revolutions/min when designing the operating temperature range.

6)

Maximum speed which does not lead to any harm to the encoder. Impact on the service life and signal quality is possible. Please note the maximum output frequency.

PVC

1.2 Ncm (+20 °C) 0.5 Ncm (+20 °C)

1.1 Ncm (+20 °C) 0.4 Ncm (+20 °C)

– ± 0.5 mm, ± 0.2 mm

– ± 0.3 mm, ± 0.1 mm

100 N (radial)

50 N (axial)

6,000 / min

9,000 /min

3)

3)

4)

6)

–

6,000 / min

5)

33 gcm² 50 gcm²

3.6 x 10^9 revolutions

500,000 rad/s² 500,000 rad/s²

200,000 rad/s² (shaft isolated)

F

Electrical data

Solid shaft Blind hollow shaft Through hollow shaft

Electrical interface

4.5 V ... 5.5 V, TTL/RS422

10 V ... 30 V, TTL/RS422

10 V ... 27 V, HTL/Push Pull

4.5 V ... 30 V, TTL/HTL universal 1)

Connection type

M23 male connector, 12-pin, radial

M12 male connector, 8-pin, radial

Cable, 8-wire, universal, 0.5 m

Cable, 8-wire, universal, 1.5 m

Cable, 8-wire, universal, 3 m

Cable, 8-wire, universal, 5 m

Cable, 8-wire, universal, 10 m

Cable with male connector M12, 8-pin, universal, 0.5 m

Cable with male connector M23, 12-pin, universal, 0.5 m

Operating current without load

4.5 V...5.5 V, TTL/RS422 ≤ 50 mA

Max. power consumption without load

10 V ... 30 V, TTL/RS422 ≤ 0.5 W

10 V ... 27 V, HTL/Push Pull ≤ 1 W

4.5 V ... 30 V, TTL/HTL universal ≤ 0.5 W

Load current

Maximum output frequency

1)

6 channels unless otherwise specied.

2)

Output level depends on the supply voltage.

3)

The universal cable connection is positioned so that it is possible to lay it without bends in a radial or axial direction.

4)

M23 male connector with central mounting

5)

Up to 450 kHz on request.

6)

Short-circuit of another channel or GND permissible for a maximum of 60 s. No protection in the case of a short-circuit channel of US.

7)

Short-circuit of another channel US or GND permissible for a maximum of 30 s.

8)

This product is a standard product and does not constitute a safety component as dened in the Machinery Directive. Calculation based on nominal load of devices, average ambient temperature 40 °C, frequency of use 8760 h/a. All electronic failures are considered hazardous. For more information, see document no.

8015532.

≤ 30 mA per channel

300 kHz

5)

1)

1)

1)

2)

3)

3)

3)

3)

3)

3)

3) 4)

F-122

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 4

INCREMENTAL ENCODERS DBS60 Core

Solid shaft Blind hollow shaft Through hollow shaft

Reference signal, number

Reference signal, position

Reverse polarity protection

Short-circuit protection of the outputs

4.5 V–5.5 V, TTL/RS422

10 V ... 30 V, TTL/RS422

10 V ... 27 V, HTL/Push Pull

4.5 V ... 30 V, TTL/HTL universal

MTTFd: mean time to dangerous failure

1)

6 channels unless otherwise specied.

2)

Output level depends on the supply voltage.

3)

The universal cable connection is positioned so that it is possible to lay it without bends in a radial or axial direction.

4)

M23 male connector with central mounting

5)

Up to 450 kHz on request.

6)

Short-circuit of another channel or GND permissible for a maximum of 60 s. No protection in the case of a short-circuit channel of US.

7)

Short-circuit of another channel US or GND permissible for a maximum of 30 s.

8)

This product is a standard product and does not constitute a safety component as dened in the Machinery Directive. Calculation based on nominal load of devices, average ambient temperature 40 °C, frequency of use 8760 h/a. All electronic failures are considered hazardous. For more information, see document no.

8015532.

1

90° electric, logically gated with A and B

l

6)

l

7)

l

7)

l

7)

l

8)

500 years (EN ISO 13849-1)

Ambient data

EMC

Enclosure rating

Permissible relative humidity

Operating temperature range

4.5 V–5.5 V, TTL/RS422 –20 °C ... +85 °C

10 V ... 30 V, TTL/RS422 –30 °C ... +100 °C, at a maximum of 3,000 pulses per revolution

10 V ... 27 V, HTL/Push Pull –20 °C ... +85 °C

4.5 V ... 30 V, TTL/HTL universal –30 °C ... +100 °C, at a maximum of 3,000 pulses per revolution

Storage temperature range

Resistance to shocks

Resistance to vibrations

1)

In an assembled male connector.

Solid shaft Blind hollow shaft Through hollow shaft

According to EN 61000-6-2 and EN 61000-6-3

IP 67 on housing side (acc. to IEC 60529)

1)

IP 65 on shaft side (acc. to IEC 60529)

90% (condensation of optical surfaces not permitted)

–30 °C ... +85 °C, at more than 3,000 pulses per revolution

–30 °C ... +85 °C, at more than 3,000 pulses per revolution

–40 °C ... +100 °C, without packaging

250 g, 3 ms (according to

EN 60068-2-27)

250 g, 3 ms (according to EN 60068-2-27)

200 g, 3 ms, shaft isolated (according to EN 60068-2-27)

30 g/10 Hz ... 2,000 Hz (according to EN 60068-2-6)

IP 65 on housing side (acc. to

IEC 60529)

1)

IP 65 on shaft side (acc. to

IEC 60529)

F

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

F-123

Page 5

DBS60 Core INCREMENTAL ENCODERS

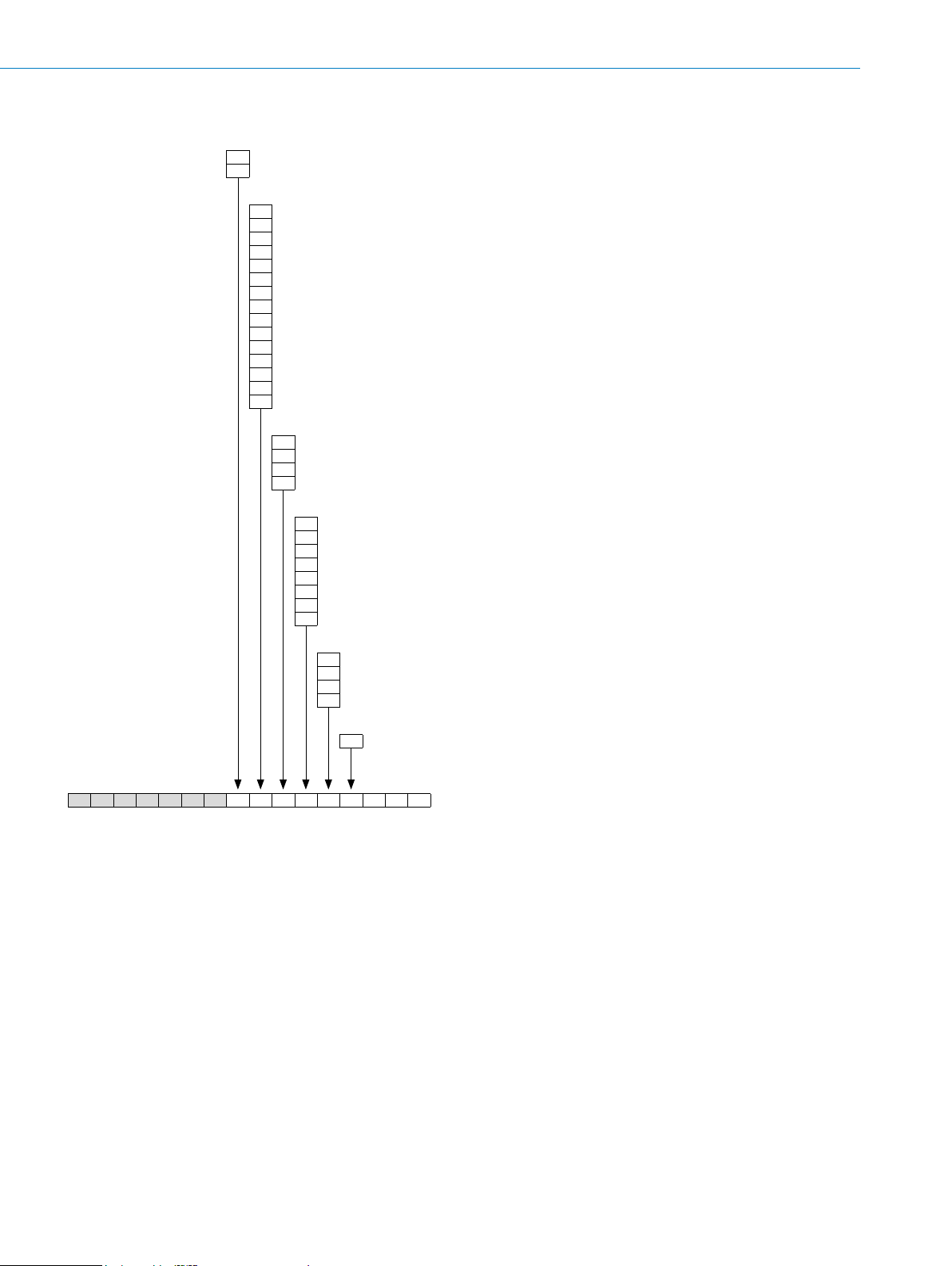

Type code

Solid shaft

Mechanical design

1 Servo ange, solid shaft, Ø 6 mm, length 10 mm

3 Face mount ange, solid shaft, Ø 6 mm, length 10 mm

4 Face mount ange, solid shaft, Ø 10 mm, length 19 mm

Electrical interface

A 4.5 … 5.5 V, TTL/RS-422, 6 channel

C 10 … 30 V, TTL/RS-422, 6 channel

E 10 … 27 V, HTL/Push Pull, 6 channel

F 4.5 … 30 V, TTL/HTL universal, 6 channel

Connection type

A Male connector M23, 12-pin, radial

C Male connector M12, 8-pin, radial

J Cable, 8-wire universal, 0.5 m

K Cable, 8-wire, universal, 1.5 m

L Cable, 8-wire, universal, 3 m

N Cable, 8-wire, universal, 10 m

P Cable, 8-wire universal, 0.5 m, with male connector M12

Q Cable, 8-wire, universal, 0.5 m, with male connector M23

Stator coupling/ange design

O Flange with 3 x M3 3 x M4

F

D B S 6 0 E - S

1)

Other pulse on request.

Resolution

0004 ... 5,000 pulses per revolution possible. For pulses see “Pulses per revolution”

1)

F-124

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 6

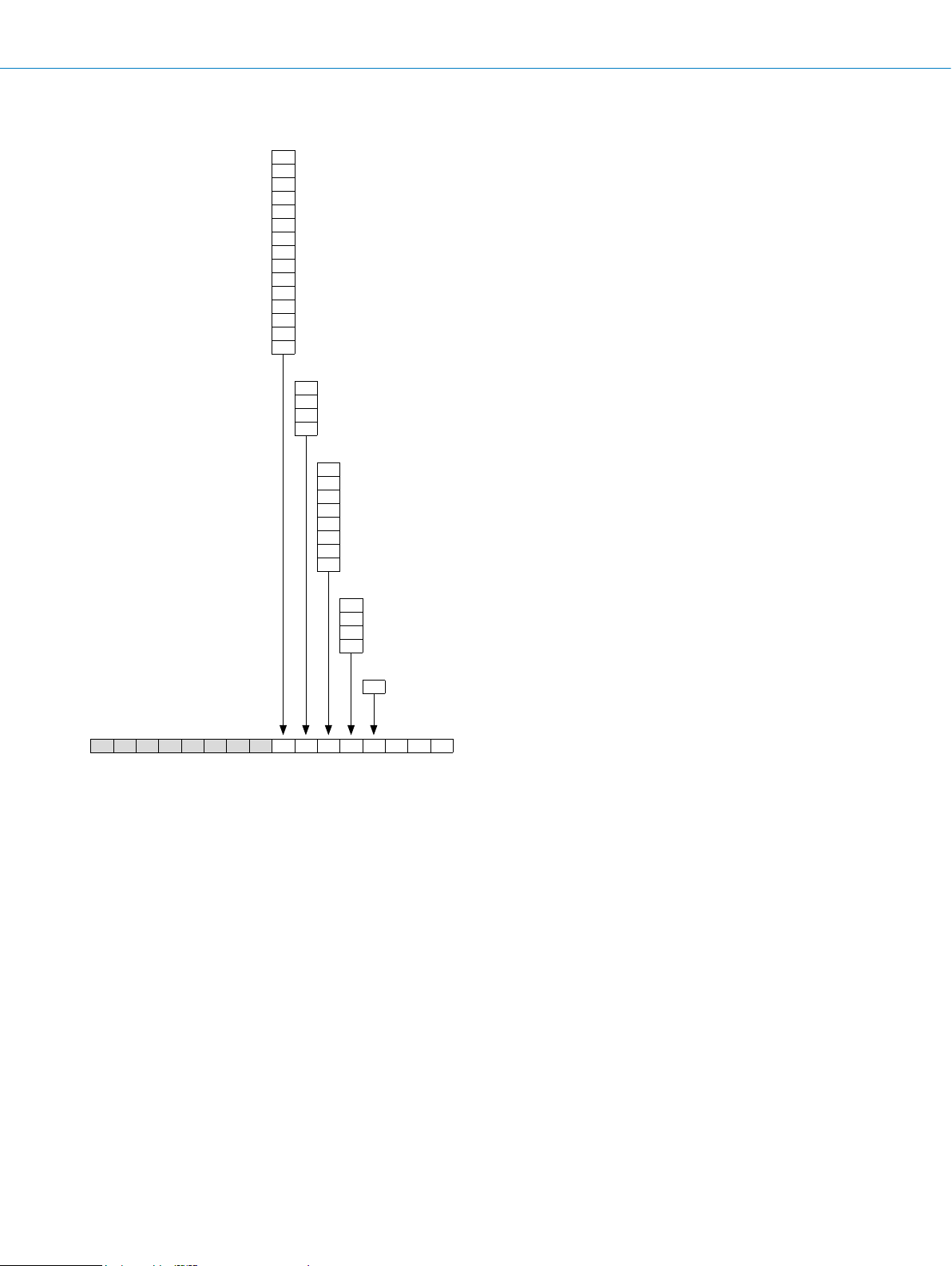

Through hollow shaft

Mechanics/ange

T Through hollow shaft

R Through hollow shaft clamping at the back (B side)

Mechanical design

B Through hollow shaft, metal, Ø 8 mm

C Through hollow shaft, metal, Ø 3/8"

D Through hollow shaft, metal, Ø 10 mm

E Through hollow shaft, metal, Ø 12 mm

F Through hollow shaft, metal, Ø 1/2"

G Through hollow shaft, metal, Ø 14 mm

H Through hollow shaft, metal, Ø 15 mm

J Through hollow shaft, metal, Ø 5/8"

2 Through hollow shaft, Ø 8 mm, isolated

3 Through hollow shaft, Ø 3/8", isolated

4 Through hollow shaft, Ø 10 mm, isolated

5 Through hollow shaft, Ø 1/2", isolated

6 Through hollow shaft, Ø 12 mm, isolated

7 Through hollow shaft, Ø 14 mm, isolated

8 Through hollow shaft, Ø 15 mm, isolated

Electrical interface

A 4.5 … 5.5 V, TTL/RS-422, 6 channel

C 10 … 30 V, TTL/RS-422, 6 channel

E 10 … 27 V, HTL/Push Pull, 6 channel

F 4.5 … 30 V, TTL/HTL universal, 6 channel

Connection type

A Male connector M23, 12-pin, radial

C Male connector M12, 8-pin, radial

J Cable, 8-wire, universal, 0.5 m

K Cable, 8-wire, universal, 1.5 m

L Cable, 8-wire, universal, 3 m

N Cable, 8-wire, universal, 10 m

P Cable, 8-wire universal, 0.5 m, with male connector M12

Q Cable, 8-wire, universal, 0.5 m, with male connector M23

Stator coupling/ange design

0 Two-sided stator coupling, slot, screw hole circle 63 mm - 83 mm

A Without stator coupling, ange with 4 x M2.5

C Locating pin assembly

D Stator coupling, 1-sided, slot, bolt circle 33 mm - 48.5 mm

1)

INCREMENTAL ENCODERS DBS60 Core

F

Resolution

0004 ... 5,000 pulses per revolution possible. For pulses see “Pulses per revolution”

D B S 6 0 E -

1)

Order collets for 6 mm (only plastic) 8 mm, 3/8", 10 mm, 12 mm, 1/2", 14 mm and 15 mm separately as accessories (see recommended accessories). No collets are

necessary for 5/8" shaft diameter. Also available as isolated design on request.

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

F-125

Page 7

DBS60 Core INCREMENTAL ENCODERS

Blind hollow shaft

Mechanical design

B Blind hollow shaft, metal, Ø 8 mm

C Blind hollow shaft, metal, Ø 3/8"

D Blind hollow shaft, metal, Ø 10 mm

E Blind hollow shaft, metal, Ø 12 mm

F Blind hollow shaft, metal, Ø 1/2"

G Blind hollow shaft, metal, Ø 14 mm

H Blind hollow shaft, metal, Ø 15 mm

J Blind hollow shaft, metal, Ø 5/8"

2 Blind hollow shaft, Ø 8 mm, isolated

3 Blind hollow shaft, Ø 3/8", isolated

4 Blind hollow shaft, Ø 10 mm, isolated

5 Blind hollow shaft, Ø 1/2", isolated

6 Blind hollow shaft, Ø 12 mm, isolated

7 Blind hollow shaft, Ø 14 mm, isolated

8 Blind hollow shaft, Ø 15 mm, isolated

Electrical interface

A 4.5 … 5.5 V, TTL/RS-422, 6 channel

C 10 … 30 V, TTL/RS-422, 6 channel

E 10 … 27 V, HTL/Push Pull, 6 channel

F 4.5 … 30 V, TTL/HTL universal, 6 channel

Connection type

A Male connector M23, 12-pin, radial

C Male connector M12, 8-pin, radial

J Cable, 8-wire, universal, 0.5 m

K Cable, 8-wire, universal, 1.5 m

L Cable, 8-wire, universal, 3 m

N Cable, 8-wire, universal, 10 m

P Cable, 8-wire universal, 0.5 m, with male connector M12

Q Cable, 8-wire, universal, 0.5 m, with male connector M23

1)

F

Stator coupling/ange design

0 Two-sided stator coupling, slot, screw hole circle 63 mm - 83 mm

A Without stator coupling, ange with 4 x M2.5

C Locating pin assembly

D Stator coupling, 1-sided, slot, bolt circle 33 mm - 48.5 mm

Resolution

0004 ... 5,000 pulses per revolution possible. For pulses see “Pulses per revolution”

D B S 6 0 E - B

1)

Order collets for 6 mm (only plastic) 8 mm, 3/8", 10 mm, 12 mm, 1/2", 14 mm and 15 mm separately as accessories (see recommended accessories). No collets are

necessary for 5/8" shaft diameter. Also available as isolated design on request.

F-126

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 8

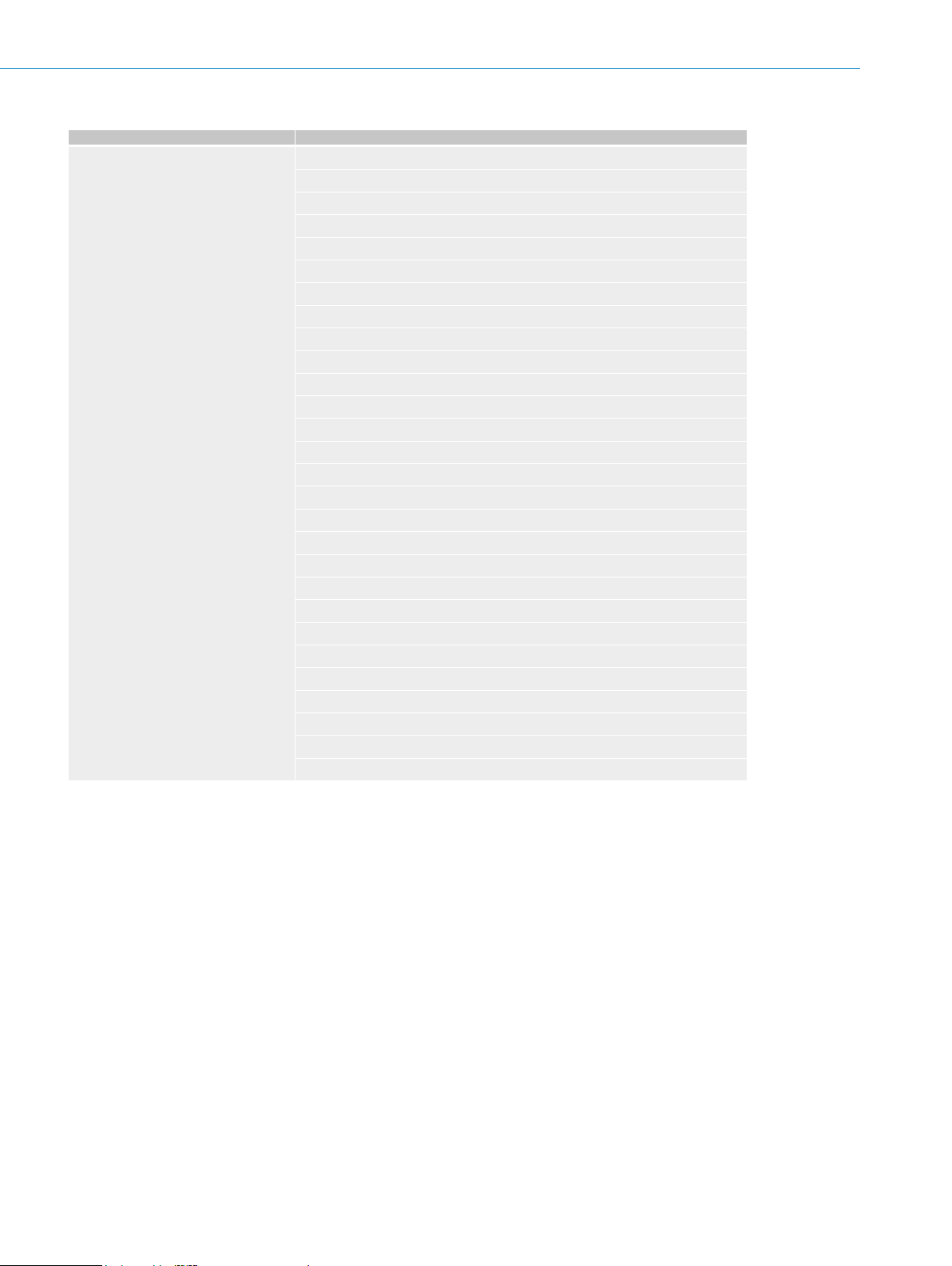

Pulses per revolution

Pulses per revolution

INCREMENTAL ENCODERS DBS60 Core

E

0004

0005

0010

0020

0048

0050

0060

0100

0125

0128

0180

0250

0360

0500

0512

0600

1000

1024

1200

1500

2000

2048

2400

2500

3000

3600

4096

5000

F

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

F-127

Page 9

DBS60 Core INCREMENTAL ENCODERS

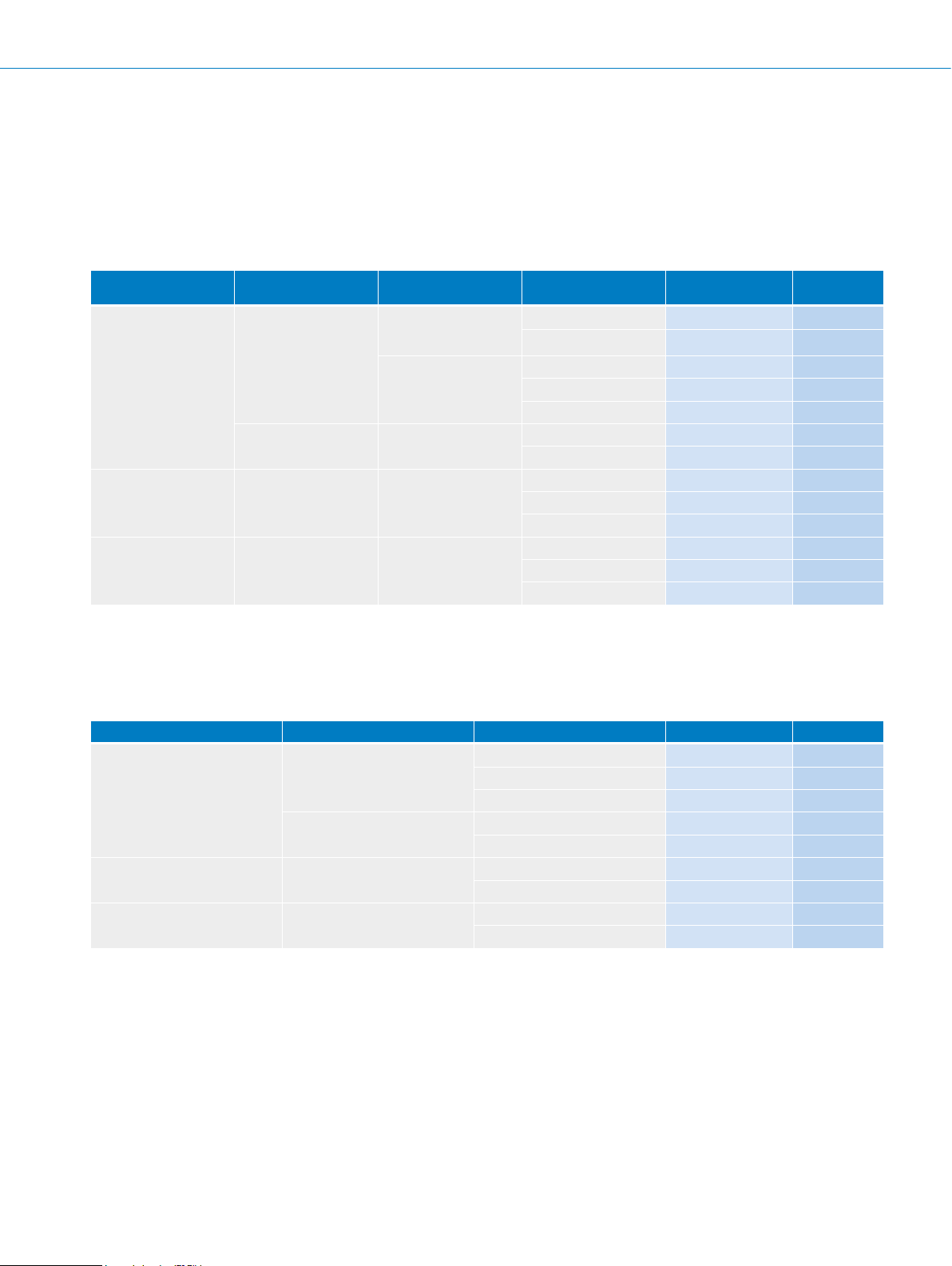

Ordering information

Blind hollow shaft

• Shaft diameter: 5/8"

• Connection type: cable, 8-wire, universal, 1.5 m

Through hollow shaft

• Shaft diameter: 5/8"

F

Electrical interface Voltage range Connection type Pulses per

revolution

4.5 V ... 5.5 V

TTL/RS422

10 V ... 30 V

HTL/Push Pull 10 V ... 27 V

TTL/HTL universal 4.5 V ... 30 V

Cable with male con-

nector M23, 12-pin,

universal, 0.5 m

Cable, 8-wire, universal,

1.5 m

Cable, 8-wire, universal,

1.5 m

Cable, 8-wire, universal,

1.5 m

Cable, 8-wire, universal,

1.5 m

1,024 DBS60E-TJAQ01024 1069756

2,048 DBS60E-TJAQ02048 1069757

1,024 DBS60E-TJAK01024 1069746

2,048 DBS60E-TJAK02048 1069747

4,096 DBS60E-TJAK04096 1069748

1,024 DBS60E-TJCK01024 1070615

2,048 DBS60E-TJCK02048 1070616

1,024 DBS60E-TJEK01024 1069758

2,048 DBS60E-TJEK02048 1069759

4,096 DBS60E-TJEK04096 1069760

1,024 DBS60E-TJFK01024 1070748

2,048 DBS60E-TJFK02048 1070749

4,096 DBS60E-TJFK04096 1070750

Type Part no.

Through hollow shaft clamping at the back

• Shaft diameter: 5/8"

• Connection type: cable, 8-wire, universal, 1.5 m

Electrical interface Voltage range Pulses per revolution Type Part no.

1,024 DBS60E-RJAK01024 1069710

4.5 V ... 5.5 V

TTL/RS422

10 V ... 30 V

HTL/Push Pull 10 V ... 27 V

TTL/HTL universal 4.5 V ... 30 V

2,048 DBS60E-RJAK02048 1069711

4,096 DBS60E-RJAK04096 1069712

1,024 DBS60E-RJCK01024 1070609

2,048 DBS60E-RJCK02048 1070610

1,024 DBS60E-RJEK01024 1069713

2,048 DBS60E-RJEK02048 1069714

1,024 DBS60E-RJFK01024 1070744

2,048 DBS60E-RJFK02048 1070745

F-128

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 10

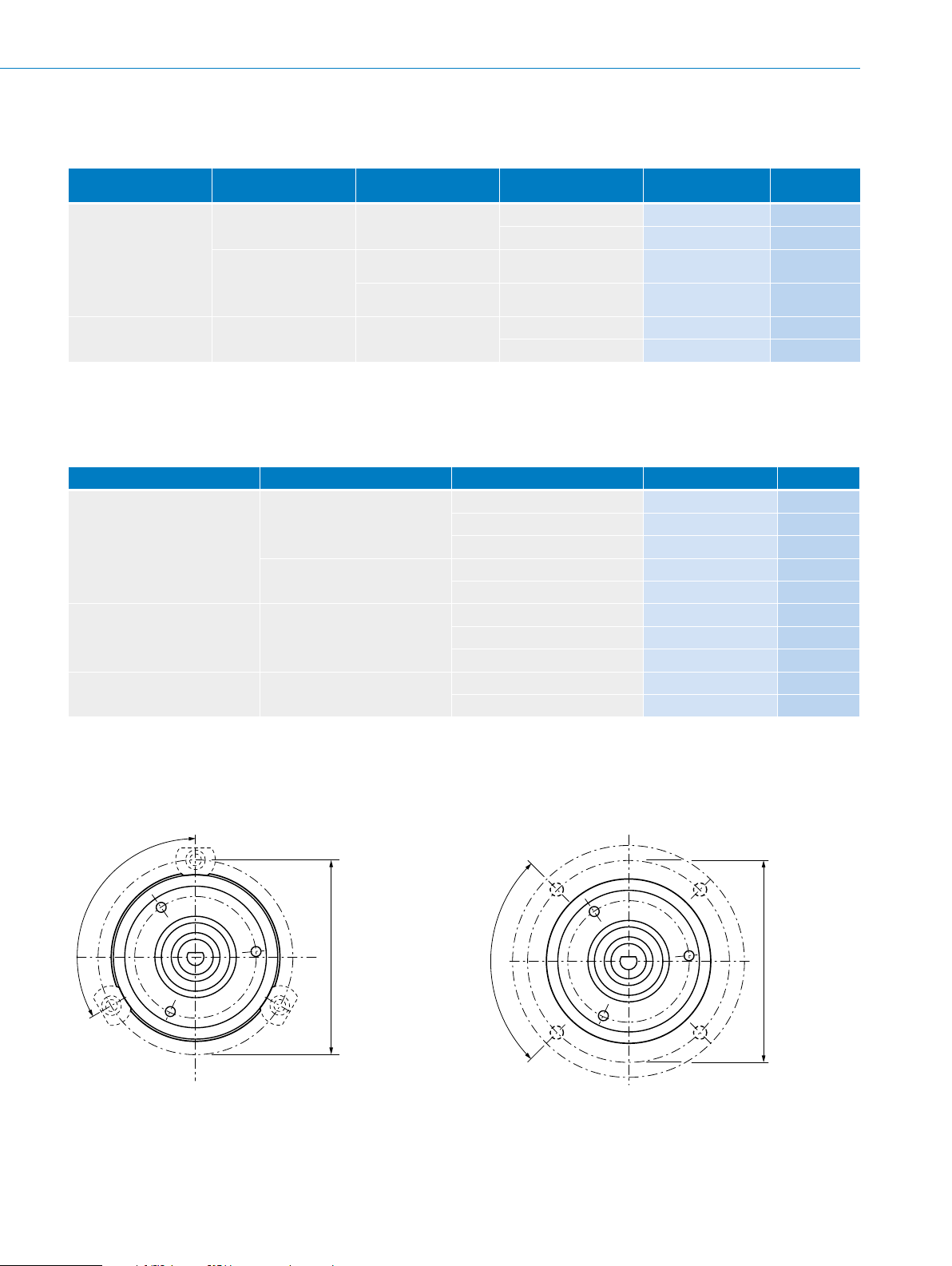

Solid shaft, servo ange

3 x 120°

All dimensions in mm (inch)

4 x 90°

All dimensions in mm (inch)

• Shaft diameter: 6 mm (other diameters available on request)

INCREMENTAL ENCODERS DBS60 Core

Electrical interface Voltage range Connection type Pulses per

revolution

4.5 V ... 5.5 V

TTL/RS422

10 V ... 30 V

HTL/Push Pull 10 V ... 27 V

Cable, 8-wire, universal,

1.5 m

Cable, 8-wire, universal,

1.5 m

Cable, 8-wire, universal,

1.5 m

Cable, 8-wire, universal,

1.5 m

1,000 DBS60E-S1AK01000 1069715

2,000 DBS60E-S1AK02000 1069716

1,000 DBS60E-S1CK01000 1070611

2,000 DBS60E-S1CK02000 1070612

1,000 DBS60E-S1EK01000 1069717

2,000 DBS60E-S1EK02000 1069718

Type Part no.

Solid shaft, face mount ange

• Shaft diameter: 10 mm (other diameters available on request)

• Connection type: cable, 8-wire, universal, 1.5 m

Electrical interface Voltage range Pulses per revolution Type Part no.

1,000 DBS60E-S4AK01000 1069719

4.5 V ... 5.5 V

TTL/RS422

10 V ... 30 V

HTL/Push Pull 10 V ... 27 V

TTL/HTL universal 4.5 V ... 30 V

2,000 DBS60E-S4AK02000 1069720

5,000 DBS60E-S4AK05000 1069721

1,000 DBS60E-S4CK01000 1070613

2,000 DBS60E-S4CK02000 1070614

1,000 DBS60E-S4EK01000 1069722

2,000 DBS60E-S4EK02000 1069723

5,000 DBS60E-S4EK05000 1069724

1,000 DBS60E-S4FK01000 1070746

2,000 DBS60E-S4FK02000 1070747

F

Mounting suggestion for servo ange

Mounting suggestion for small servo clamp (part number

2029166)

Ø 68 (2.68)

Subject to change without notice

Mounting suggestion for half-shell servo clamp (part number

2029165)

Ø 71 (2.80)

ENCODERS | SICK8015560/2015-09-01

F-129

Page 11

DBS60 Core INCREMENTAL ENCODERS

(0.28)

on housing

3 x M3 - depth 7

Dimensional drawings (dimensions in mm)

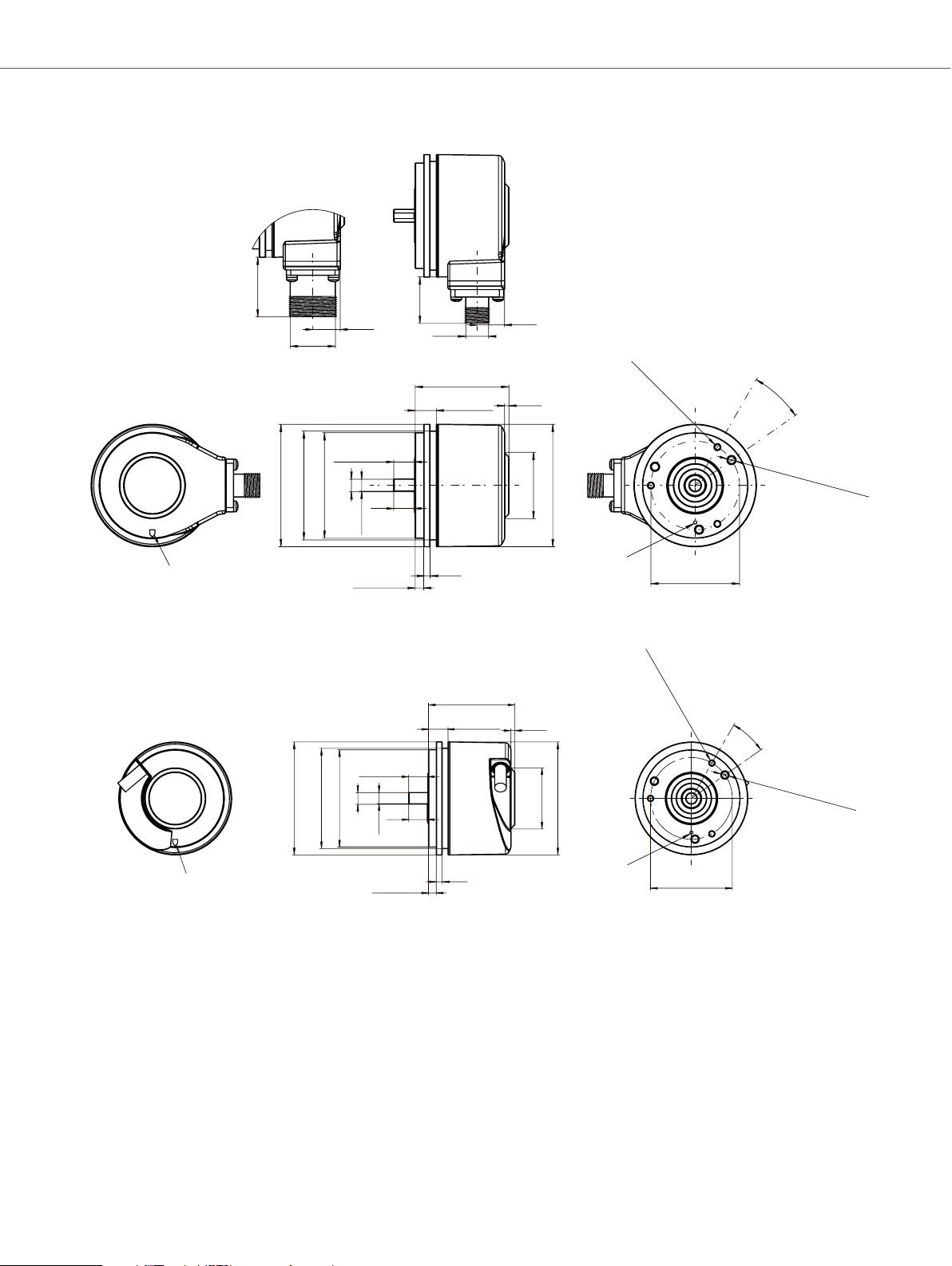

Solid shaft Ø 6 mm, servo ange, male connector connection (S1)

28.3

(1.11)

M23

13

(0.51)

22

(0.87)

M12

13

(0.51)

3 x M3 - depth 7

F

10 ±0.3

(0.39 ±0.01)

(0.24)

Ø 6 f7

9.5

(0.37)

5.7

(0.22)

4 +0.1

(0.16 +0.01)

Zero pulse mark

on housing

Ø 58 ±0.1 (2.28 ±0.01)

Ø 51.5 -0.2 (2.03 -0.01)

Ø 50 f8 (1.97)

Solid shaft Ø 6 mm, servo ange, cable connection

10 ±0.3

(0.39 ±0.01)

(2.03 -0.01)

Ø 51.5 -0.2

Ø 50 f8 (1.97)

Ø 6 f7 (0.24)

5.7

(0.22)

Ø 58 ±0.1

(2.28 ±0.01)

9.5

(0.37)

44.35

(1.75)

10 +0.1

(0.39 +0.01)

3

(0.12)

44.35

(1.75)

10 +0.1

(0.39 +0.01)

2

(0.08)

(0.08)

31.4 (1.24)

2

31.4 (1.24)

Ø 58 (2.28)

Zero pulse mark

on flange

Ø 58 (2.28)

3 x 120°

Ø 42 ±0.05

(1.65 ±0.01)

3 x 120°

(0.28)

(0.28)

25°

3 x M4 - depth 7

25°

3 x M4 - depth 7

3 x 120°

3 x 120°

(0.28)

F-130

3

Zero pulse mark

ENCODERS | SICK 8015560/2015-09-01

4 +0.1

(0.16 +0.01)

(0.12)

Zero pulse mark

on flange

Ø 42 ±0.05

(1.65 ±0.01)

Subject to change without notice

Page 12

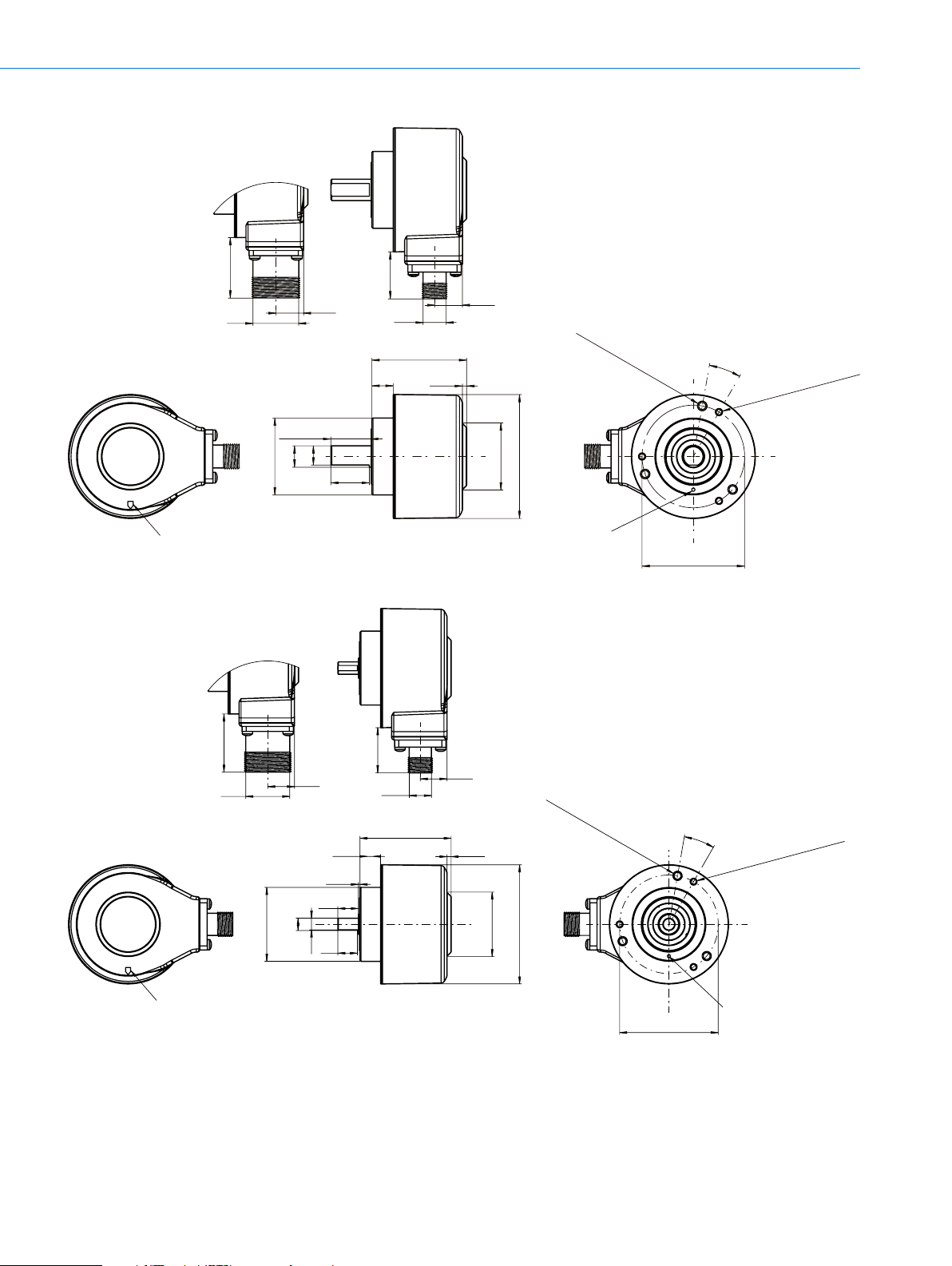

Solid shaft Ø 10 mm, face mount ange, male connector connection (S4)

28.3

(1.11)

M23

19 ±0.3

(0.75 ±0.01)

Ø 36 f8

Ø 10 f7

9

13

(0.51)

(0.35)

18

(0.71)

22

10

(0.39)

(0.87)

M12

44.35

(1.75)

2

(0.08)

13

(0.51)

INCREMENTAL ENCODERS DBS60 Core

3 x M4 - depth 6

3 x 120°

31.4 (1.24)

Ø 58 (2.28)

(0.24)

20°

3 x M3 - depth 6

3 x 120°

(0.24)

Zero pulse mark

on housing

Solid shaft Ø 6 mm, face mount ange, male connector connection (S3)

28.3

(1.11)

M23

(1.42)

Ø 36 f8

13

(0.51)

(0.24)

Ø 6 f7

5.7

9.5

(0.37)

(0.22)

10

(0.39)

0.8

(0.03)

10 ±0.3

(0.39)

22

(0.87)

M12

44.35

(1.75)

13

(0.51)

(0.08)

2

31.41

(1.24)

Ø 58

(2.28)

Zero pulse mark

on flange

3x M4 - depth 6 mm

3x 120°

(0.24)

Ø 48 ±0.05

(1.89 ±0.01)

20°

3x M3 - depth 6 mm

3x 120°

F

(0.24)

Zero pulse mark

on housing

Subject to change without notice

Ø 48 ±0.05

(1.89)

Zero pulse mark

on flange

ENCODERS | SICK8015560/2015-09-01

F-131

Page 13

DBS60 Core INCREMENTAL ENCODERS

3 x M4 - dept

3x M4 - depth 6 mm

on housing

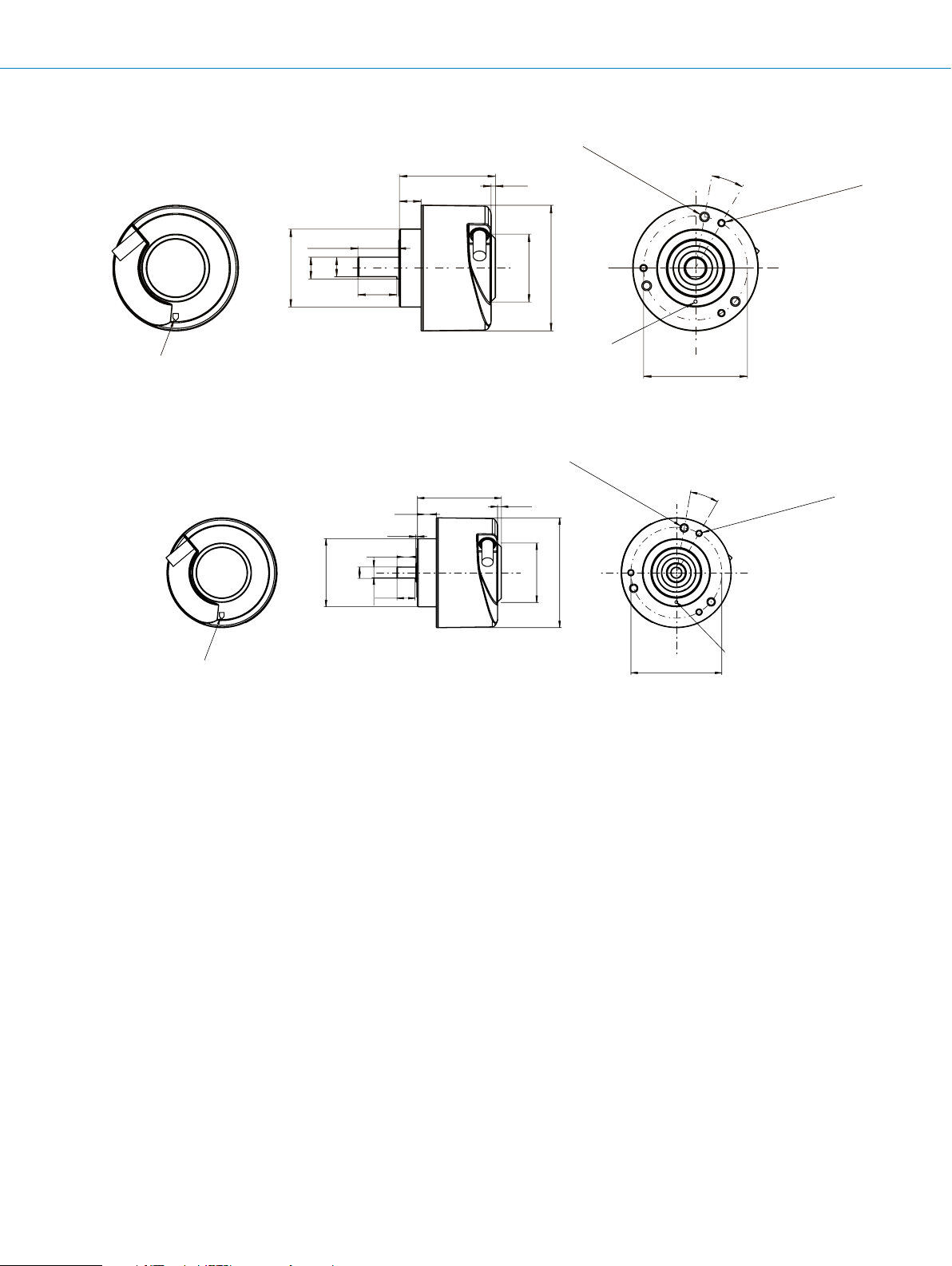

Solid shaft Ø 10 mm, face mount ange, cable connection (S4)

44.35

(1.75)

10

(0.39)

19 ±0.3

(0.75 ±0.01)

9

Ø 10 f7

(0.35)

18

(0.71)

Zero pulse mark

on housing

Ø 36 f8

Solid shaft Ø 6 mm, face mount ange, cable connection (S3)

44.35

(1.75)

(1.42)

Ø 36 f8

(0.24)

Ø 6 f7

10 ±0.3

(0.39)

(0.37)

5.7

(0.22)

9.5

(0.39)

0.8

(0.03)

10

2

(0.08)

(0.08)

2

(1.24)

31.4

31.4

(1.24)

(2.28)

Ø 58

Zero pulse mark

on flange

Ø 58

(2.28)

3 x 120°

3x 120°

h 6

(0.24)

(0.24)

Ø 48 ±0.05

(1.89 ±0.01)

20°

20°

3 x M3 - depth 6

3 x 120°

3x M3 - depth 6 mm

3x 120°

(0.24)

(0.24)

F

Zero pulse mark

Ø 48 ±0.05

(1.89)

Zero pulse mark

on flange

F-132

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 14

INCREMENTAL ENCODERS DBS60 Core

Without stator coupling

on flange

Blind hollow shaft, male connector connection, two-sided stator coupling, slot, screw hole circle 63 mm – 83 mm

28,3

(1.11)

M23

13

(0.51)

9.4

(0.37)

22

(0.87)

M12

43.8

(1.72)

13

(0.51)

(0.08)

3.2 +0.1

(0.13 +0.01)

2

Ø X F7

50 (1.97)

Zero pulse mark

on housing

Blind hollow shaft, male connector connection, no stator coupling

28.3

(1.11)

13

(0.51)

M23

22

(0.87)

M12

(2.28)

Ø 58

31.41 (1.24)

Zero pulse mark on flange

under stator coupling

13

(0.51)

4 x M2.5 - depth 5

(0.20)

25

(0.98)

63 (2.48)

(3.27)

83

94 (3.70)

F

Zero pulse mark

on housing

Subject to change without notice

42.9

(1.69)

37.6°

Zero pulse mark

ENCODERS | SICK8015560/2015-09-01

37.6°

Ø 49.65 (1.95)

F-133

Page 15

DBS60 Core INCREMENTAL ENCODERS

3.5

Zer

on housing

,

Customer-side

Blind hollow shaft, male connector connection, with locating pin assembly

(0.14)

28.3

(1.11)

M23

5.2 (0.20) (slot depth)

13

(0.51)

22

(0.87)

M12

42.9 (1.69)

41.4 (1.63)

7 (0.28)

13

(0.51)

2 (0.08)

37.6°

120°

3.4

(0.13)

Rubber insert

material: NBR

F

o pulse mark

Removable pin

Installation example for blind hollow shaft

min. 15

(0.59)

max. 40

(1.57)

Ø X F7

15 (0.59)

-0.006

Ø 4 fg 6 -0.014

-0.001

(0.16 fg 0.24 )

-0.001

(1.24)

31.41

Ø 58

(2.28)

37.6°

6 x Ø 2.9 (0.11) - depth

Ø 5↓4

(0.20) (0.16)

Pin is the

zero pulse mark

Ø 49.65

(1.95)

150°

18.9

(0.74)

F-134

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 16

INCREMENTAL ENCODERS DBS60 Core

under stator coupling

Customer-side

Blind hollow shaft, male connector connection, stator coupling, 1-sided, slot, bolt circle 33 mm – 48.5 mm

28.3

(1.11)

M23

Zero pulse mark

on housing

Installation example for blind hollow shaft

min. 15

(0.59)

max. 40

(1.57)

22

(0.87)

13

(0.51)

83

26.7

(3.27)

Ø X F7

(1.05)

M12

9.4 (0.37)

43.8

(1.72)

13

(0.51)

31.41

2 (0.08)

(1.24)

Ø 58

(2.28)

54 (2.13)

(1.91)

48.5

31.5 (1.24)

5.1 (0.20)

Zero pulse mark on flange

25

(0.98)

37.6°

37.6°

37.6°

F

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

F-135

Page 17

DBS60 Core INCREMENTAL ENCODERS

3.2 +0.1

Customer-side

Without stator coupling

4 x M2.5 - depth 5

Customer-side

Blind hollow shaft, cable connection, two-sided stator coupling, slot, screw hole circle 63 mm – 83 mm

Zero pulse mark

on housing

Installation example for blind hollow shaft

min. 15

(0.59)

max. 40

(1.57)

43.8

9.4

(0.37)

50

(1.97)

Ø X F7

(1.72)

2

(0.08)

(2.28)

Ø 58

31.41 (1.24)

Zero pulse mark on flange

under stator coupling

(0.13 +0.01)

25

(0.98)

63 (2.48)

83 (3.27)

94 (3.70)

F

Blind hollow shaft, cable connection, no stator coupling

Zero pulse mark

on housing

Installation example for blind hollow shaft

min. 15

(0.59)

max. 40

(1.57)

42.9

(1.69)

(0.20)

37.6°

37.6°

Zero pulse mark

on flange

(1.95)

Ø 49.65

F-136

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 18

Blind hollow shaft, cable connection, with locating pin assembly

3.5

Zer

on housing

,

erial: NBR

Customer-side

(0.14)

42.9 (1.69)

41.4 (1.63)

o pulse mark

5.2 (0.20) (slot depth)

Ø X F7

Removable pin

15 (0.59)

7 (0.28)

Ø 4 fg 6 -0.014

(0.16 fg 0.24 )

-0.006

-0.001

-0.001

2 (0.08)

(1.24)

31.41

INCREMENTAL ENCODERS DBS60 Core

Ø 58

(2.28)

6 x Ø 2.9 (0.11) - depth

37.6°

Ø 5↓4

(0.20) (0.16)

120°

37.6°

Pin is the

zero pulse mark

3.4

(0.13)

Ø 49.65

(1.95)

Rubber insert

mat

150°

18.9

(0.74)

Installation example for blind hollow shaft

min. 15

(0.59)

max. 40

(1.57)

F

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

F-137

Page 19

DBS60 Core INCREMENTAL ENCODERS

2 (0.08)

under stator coupling

Customer-side

Blind hollow shaft, cable connection, stator coupling, 1-sided, slot, bolt circle 33 mm – 48.5 mm

Ø X F7

Ø 58

(2.28)

(1.24)

31.41

83

26.7

(3.27)

Zero pulse mark

on housing

Installation example for blind hollow shaft

(1.05)

9.4 (0.37)

43.8

(1.72)

(2.13)

54

31.5 (1.24)

48.5 (1.91)

5.1 (0.20)

25

(0.98)

37.6°

37.6°

37.6°

Zero pulse mark on flange

F

min. 15

(0.59)

max. 40

(1.57)

F-138

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 20

INCREMENTAL ENCODERS DBS60 Core

6.8

(0.27)

Customer-side

Through hollow shaft clamping at the back, male connector connection, two-sided stator coupling, slot, screw hole circle

63 mm – 83 mm

28.3

(1.11)

M23

13

(0.51)

22

(0.87)

M12

13

(0.51)

Zero pulse mark

on housing

Installation example for through hollow shaft

min. 54

(2.13)

9.4

(0.37)

50

(1.97)

48.6

(1.91)

(0.98)

Ø 25

Ø 58 (2.28)

Ø X F7

Zero pulse mark on flange

under stator coupling

3.2 +0.1

(0.13 +0.01)

25

(0.98)

63 (2.48)

83 (3.27)

94 (3.70)

F

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

F-139

Page 21

DBS60 Core INCREMENTAL ENCODERS

on housing

Customer-side

Through hollow shaft clamping at the back, male connector connection, no stator coupling

28,3

(1.11)

22

Zero pulse mark

M23

13

(0.51)

(0.87)

M12

Ø X F7

13

(0.51)

Ø 58

Ø 25

37,6°

Without stator coupling

4 x M2,5 - tiefe 5

(0.20)

83

Zero pulse mark

on flange

37,6°

Ø 49,65 (1.95)

F

Installation example for through hollow shaft

min. 54

(2.13)

F-140

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 22

INCREMENTAL ENCODERS DBS60 Core

zero pulse mark

Customer-side

Through hollow shaft clamping at the back, male connector connection, with locating pin assembly

3.5

(0.14)

28.3

(1.11)

M23

13

(0.51)

22

(0.87)

M12

13

(0.51)

46.2 (1.82)

39.4 (1.55)

15 (0.59)

7 (0.28)

Ø 4 fg 6 -0.014

(0.16 fg 0.24 )

5.2 (0.20) (slot depth)

Zero pulse mark

on housing

Removable pin

Installation example for through hollow shaft

min. 54

(2.13)

-0.006

-0.001

-0.001

6.8 (0.27)

Ø 25

Ø X F7

Ø 58

(2.28)

(0.98)

6 x Ø 2.9 (0.11) - depth

37.6°

Ø 5↓4

(0.20) (0.16)

120°

37.6°

Pin is the

3.4

(0.13)

Ø 49.65

(1.95)

150°

18.9

(0.74)

Rubber insert,

material: NBR

F

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

F-141

Page 23

DBS60 Core INCREMENTAL ENCODERS

under stator coupling

Customer-side

Through hollow shaft clamping at the back, male connector connection, one-sided stator coupling, slot, screw hole cir-

cle 33 mm – 48.5 mm

F

28.3

(1.11)

M23

Zero pulse mark

on housing

Installation example for through hollow shaft

min. 54

(2.13)

22

(0.87)

13

(0.51)

83

(3.27)

26.7

(1.05)

M12

9.4 (0.37)

48.6

(1.91)

13

(0.51)

Ø 25

Ø X F7

(0.98)

Ø 58

(2.28)

54 (2.13)

(1.24)

48.5 (1.91)

31.5

5.1 (0.20)

Zero pulse mark on flange

25

(0.98)

37.6°

37.6°

37.6°

F-142

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 24

INCREMENTAL ENCODERS DBS60 Core

Customer-side

Zer

on housing

4 x M2.5 - depht

Customer-side

Through hollow shaft clamping at the back, cable connection, two-sided stator coupling, slot, screw hole circle 63 mm – 83 mm

48.6

(1.91)

Zero pulse mark

on housing

Installation example for through hollow shaft

min. 54

(2.13)

9.4

(0.37)

50 (1.97)

6.8

(0.27)

(2.28)

Ø 25 (0.98)

Ø 58

Ø X F7

Zero pulse mark on flange

under stator coupling

3.2 +0.1

(0.13 +0.01)

25

(0.98)

63 (2.48)

83 (3.27)

94 (3.70)

Through hollow shaft clamping at the back, cable connection, no stator coupling

37.6°

o pulse mark

Without stator coupling

Installation example for through hollow shaft

min. 54

(2.13)

(0.20)

F

5

(1.95)

37.6°

Ø 49.65

Zero pulse mark

on flange

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

F-143

Page 25

DBS60 Core INCREMENTAL ENCODERS

3.5

Zer

on housing

,

Customer-side

Through hollow shaft clamping at the back, cable connection, with locating pin assembly

(0.14)

F

5.2 (0.20) (slot depth)

o pulse mark

15 (0.59)

Removable pin

Installation example for through hollow shaft

min. 54

(2.13)

46.2 (1.82)

39.4 (1.55)

7 (0.28)

-0.006

Ø 4 fg 6 -0.014

(0.16 fg 0.24 )

-0.001

-0.001

6.8 (0.27)

Ø 25

Ø X F7

(0.98)

Ø 58

(2.28)

37.6°

6 x Ø 2.9 (0.11) - depth

Ø 5↓4

(0.20) (0.16)

120°

37.6°

Pin is the

zero pulse mark

3.4

(0.13)

Ø 49.65

(1.95)

Rubber insert

material: NBR

150°

18.9

(0.74)

F-144

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 26

INCREMENTAL ENCODERS DBS60 Core

Customer-side

Through hollow shaft clamping at the back, cable connection, one-sided stator coupling, slot, screw hole circle 33 mm – 48.5 mm

37.6°

25

Ø 58

(0.98)

Zero pulse mark

on housing

(2.28)

83

(3.27)

26.7

(1.05)

9.4 (0.37)

48.6

(1.91)

Ø X F7

6.8 (0.27)

(2.13)

54

48.5 (1.91)

31.5 (1.24)

5.1 (0.20)

Zero pulse mark on flange

25

(0.98)

under stator coupling

37.6°

37.6°

Installation example for through hollow shaft

min. 54

(2.13)

F

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

F-145

Page 27

DBS60 Core INCREMENTAL ENCODERS

Customer-side

Through hollow shaft clamping at the front, male connector connection, two-sided stator coupling, slot, screw hole circle

63 mm – 83 mm

F

28.3

(1.11)

M23

Zero pulse mark

on housing

Installation example for through hollow shaft

min. 15

(0.59)

13

(0.51)

9.4

(0.37)

50 (1.97)

22

(0.87)

Ø X F7

M12

41.8

(1.65)

13

(0.51)

Ø 58 (2.28)

Zero pulse mark on flange

under stator coupling

3.2 +0.1

(0.13 +0.01)

25

(0.98)

63 (2.48)

(3.27)

83

(3.70)

94

F-146

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 28

INCREMENTAL ENCODERS DBS60 Core

on housing

Customer-side

Through hollow shaft clamping at the front, male connector connection, no stator coupling

Zero pulse mark

Installation example for through hollow shaft

min. 15

(0.59)

28.3

(1.11)

M23

(0.51)

40.9

(1.61)

22

(0.87)

13

M12

Without stator coupling

(0.51)

4 x M2.5 - depth 5

(0.20)

37.6°

13

(1.95)

37.6°

Ø 49.65

Zero pulse mark

on flange

F

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

F-147

Page 29

DBS60 Core INCREMENTAL ENCODERS

3.5

Zer

on housing

,

Customer-side

Through hollow shaft, male connector connection, with locating pin assembly

(0.14)

28.3

(1.11)

M23

5.2 (0.20) (slot depth)

o pulse mark

Removable pin

13

(0.51)

22

Ø X F7

15 (0.59)

(0.87)

M12

40.9 (1.61)

39.4 (1.55)

7 (0.28)

Ø 4 fg 6 -0.014

(0.16 fg 0.24 )

-0.006

-0.001

-0.001

13

(0.51)

Ø 58

(2.28)

6 x Ø 2.9 (0.11) - depth

37.6°

Ø 5↓4

(0.20) (0.16)

Pin is the

zero pulse mark

37.6°

120°

3.4

(0.13)

Ø 49.65

(1.95)

Rubber insert

material: NBR

150°

18.9

(0.74)

F

Installation example for through hollow shaft

min. 15

(0.59)

F-148

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 30

INCREMENTAL ENCODERS DBS60 Core

under stator coupling

Customer-side

Through hollow shaft, male connector connection, stator coupling, 1-sided, slot, bolt circle 33 mm – 48.5 mm

28.3

(1.11)

M23

Zero pulse mark

on housing

Installation example for through hollow shaft

min. 15

(0.59)

83

(0.51)

(3.27)

13

26.7

(1.05)

22

(0.87)

Ø X F7

M12

9.4 (0.37)

41.8

(1.65)

13

(0.51)

Ø 58

(2.28)

54 (2.13)

48.5 (1.91)

31.5 (1.24)

5.1 (0.20)

Zero pulse mark on flange

25

(0.98)

37.6°

37.6°

37.6°

F

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

F-149

Page 31

DBS60 Core INCREMENTAL ENCODERS

3.2 +0.1

Zer

on housing

41.8

Customer-side

Zer

on housing

Customer-side

Through hollow shaft clamping at the front, cable connection, two-sided stator coupling, slot, screw hole circle 63 mm – 83 mm

50

(1.97)

o pulse mark

Installation example for through hollow shaft

min. 15

(0.59)

9.4

(0.37)

Ø X F7

(1.65)

Ø X F7

Ø 58

(2.28)

Zero pulse mark

on flange under

stator coupling

(0.13 +0.01)

25 (0.98)

63 (2.48)

83 (3.27)

94 (3.70)

F

Through hollow shaft clamping at the front, cable connection, no stator coupling

4 x M2.5 - depth 5 (0.20)

o pulse mark

40.9

(1.61)

Without stator coupling

Installation example for through hollow shaft

min. 15

(0.59)

37.6°

(1.95)

37.6°

Ø 49.65

Zero pulse mark

on flange

F-150

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 32

Through hollow shaft, cable connection, with locating pin assembly

3.5

Zer

on housing

,

Customer-side

(0.14)

40.9

(1.61)

39.4 (1.55)

15 (0.59)

7 (0.28)

-0.006

Ø 4 fg 6 -0.014

-0.001

(0.16 fg 0.24 )

-0.001

Ø 58

(2.28)

5.2 (0.20) (slot depth)

Ø X F7

o pulse mark

Removable pin

INCREMENTAL ENCODERS DBS60 Core

37.6°

6 x Ø 2.9 (0.11) - depth

Ø 5↓4

(0.20) (0.16)

120°

37.6°

Pin is the

zero pulse mark

3.4

(0.13)

Ø 49.65

(1.95)

Rubber insert

material: NBR

150°

18.9

(0.74)

Installation example for through hollow shaft

min. 15

(0.59)

F

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

F-151

Page 33

DBS60 Core INCREMENTAL ENCODERS

Customer-side

Through hollow shaft, cable connection, stator coupling, 1-sided, slot, bolt circle 33 mm – 48.5 mm

Ø X F7

Ø 58

(2.28)

83

(3.27)

26.7

Zero pulse mark

on housing

(1.05)

9.4 (0.37)

(2.13)

54

31.5 (1.24)

48.5 (1.91)

37.6°

37.6°

37.6°

F

Installation example for through hollow shaft

min. 15

(0.59)

5.1 (0.20)

Zero pulse mark on flange

25

(0.98)

under stator coupling

F-152

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 34

INCREMENTAL ENCODERS DBS60 Core

8-core cable

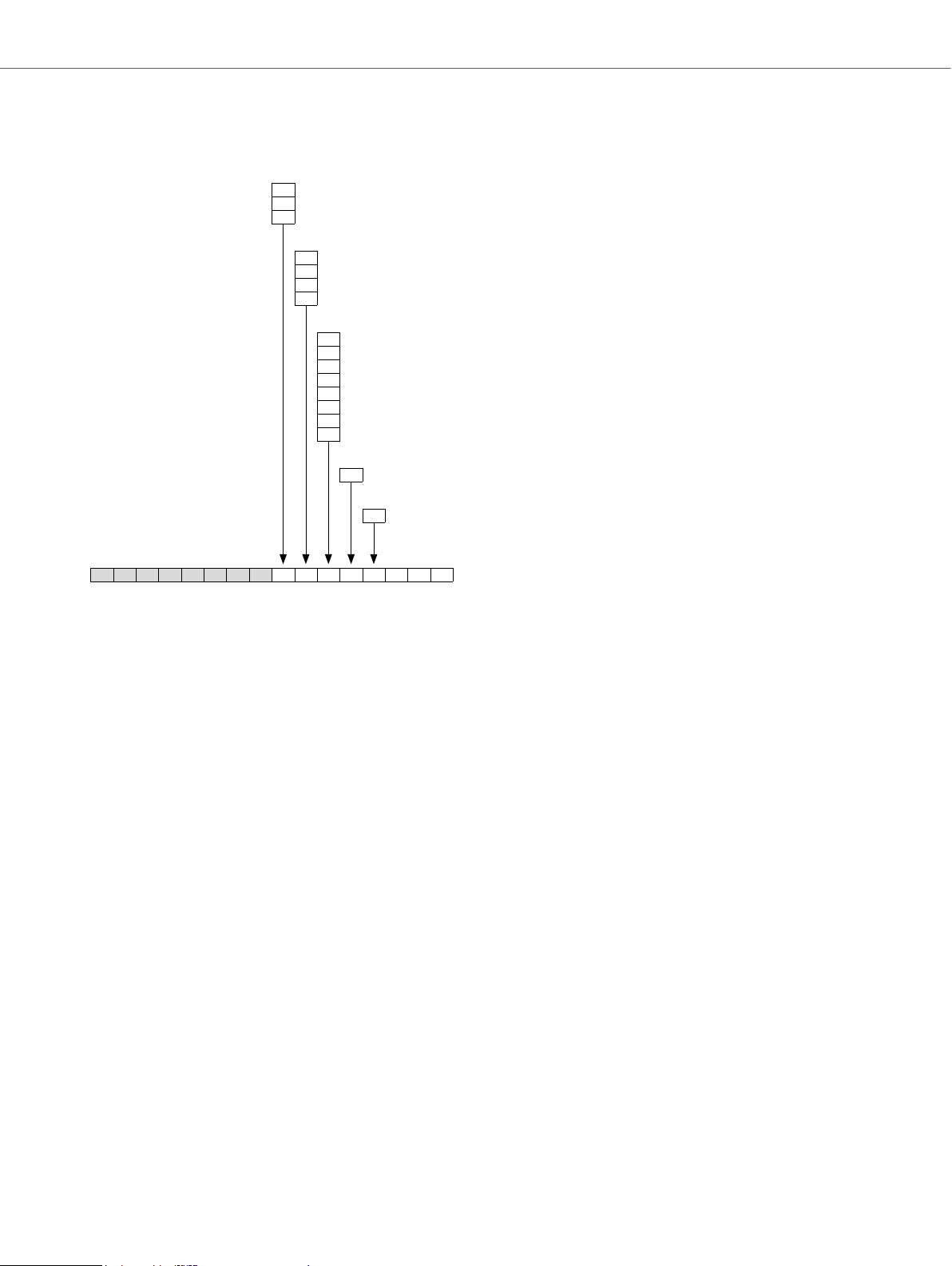

5.120

4.096

3.072

2.048

1.024

Pulses/Revolution

Speed N [min

]

9.000

Connection type

View of M12 device connector on View of M23 device connector on cable

cable/housing cable/housing

Colour of wires Pin 12-pole in

Brown1 6 Not connectedA- Signal line

White2 5AA Signal line

Black 31Not connectedB- Signal line

Pink 48BB Signal line

Yellow5 4 Not connectedZ- Signal line

Lilac 6 3 ZZ Signal line

Blue 7 10 GND GND

Red8 12 +Us+Us Supply voltage

--9Not connected Not connected Not connected

--2Not connected Not connected Not connected

--11 Not connected Not connected Not connected

--7Not connected Not connected Not connected

Screen Screen Screen Screen Screen

Viewing number of resolutions

M12

Pin 12-pole in

M23

Signal OC Signal TTL; HTL Explanation

Ground connection

of the Encoder

Screen (Screen

connected to

Encoder housing.

F

Subject to change without notice

0

0

2.0001.000 3.000 4.000 5.000 6.000 8.0007.000

–1

ENCODERS | SICK8015560/2015-09-01

F-153

Page 35

DBS60 Core INCREMENTAL ENCODERS

housing mark

housing mark

use shaf

zer

k

Zero declaration

Hollow shaft, clamping at front

Zero pulse mark on flange

Attention!

Zero pulse is active when

screw of clamping is in

line with zero pulse

mark on flange or

Hollow shaft, clamping at back

If stator coupling is mounted,

the zero pulse mark can be

hidden by the stator coupling

F

Solid shaft

t flat for zero mark alignment with

o mark on flange or housing

Zero pulse is active when

screw of clamping is in

line with zero pulse

mark on flange or

Zero pulse mar

on flange

F-154

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 36

Signal outputs

Signal outputs for electrical interfaces TTL and HTL

INCREMENTAL ENCODERS DBS60 Core

Supply voltage Output

4.5 ... 5.5 V TTL

10 ... 30 V TTL

10 ... 27 V HTL

4.5 ... 30 V TTL/HTL universal

CW with view on the encoder shaft in direction “A”, compare dimensional drawing.

F

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

F-155

Page 37

DBS60 Core INCREMENTAL ENCODERS

Recommended accessories

Mounting systems

Mounting brackets and plates

Mounting bracket

Figure Brief description Type Part no.

F

Mounting bracket for encoder with centering hub 36 mm, including mounting kit for face

mount ange

BEF-WF-36 2029164

Flanges

Flange plate

Figure Brief description Type Part no.

Two-sided stator coupling, screw hole circle diameter 63 mm, slot width 3.2 mm BEF-DS-09 2076214

Two-sided stator coupling, slot, slot radius 63 mm – 83 mm, slot width 3.2 mm BEF-DS-10 2076215

One-sided stator coupling, slots, slot radius 32.75 mm – 142.65 mm, slot width 4.5 mm BEF-DS-11 2076216

One-sided stator coupling, slot, slot radius 33 mm – 48.5 mm, slot width 5.1 mm BEF-DS-12 2076217

Flange adapter (for hollow shaft) for locating pin assembly (PIN 4 mm) BEF-DS-13 2076218

One-sided stator coupling, slot, slot radius 32.1 mm – 37.6 mm, slot width 4.5 mm BEF-DS-14 2076678

Flange adapter, adaptation of face mount ange with 36 mm centering hub to 50 mm

servo ange, aluminum, including 3 at head screws M4 x 10

Flange adapter, adaptation of face mount ange with 36 mm centering hub to 60 mm

square mounting plate, aluminum, including 3 at head screws M4 x 10

Flange adapter, adaptation of face mount ange with 36 mm centering hub to 58 mm

square mounting plate with shock absorbers, aluminum

Flange adapter, adaptation of face mount ange with 36 mm centering hub to 63 mm

square mounting plate, aluminum, including 3 at head screws M4 x 10

BEF-FA-036-050 2029160

BEF-FA-036-060REC 2029162

BEF-FA-036-060RSA 2029163

BEF-FA-036-063REC 2034225

F-156

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 38

INCREMENTAL ENCODERS DBS60 Core

Other mounting accessories

Measuring wheels and measuring wheel systems

Figure Brief description Type Part no.

Measuring wheel with smooth plastic surface (Hytrel) for 10 mm solid shaft, circumference 200 mm

Measuring wheel with ridged plastic surface (Hytrel) for 10 mm solid shaft, circumference 200 mm

Measuring wheel with smooth plastic surface (Hytrel) for 10 mm solid shaft, circumference 500 mm

Measuring wheel with O-ring (NBR70) for 6 mm solid shaft, circumference 200 mm BEF-MR006020R 2055222

Measuring wheel with O-ring (NBR70) for 6 mm solid shaft, circumference 300 mm BEF-MR006030R 2055634

Measuring wheel with O-ring (NBR70) for 6 mm solid shaft, circumference 500 mm BEF-MR006050R 2055225

Measuring wheel with O-ring (NBR70) for 10 mm solid shaft, circumference 200 mm BEF-MR010020R 2055224

Measuring wheel with O-ring (NBR70) for 10 mm solid shaft, circumference 300 mm BEF-MR010030R 2049278

Measuring wheel with O-ring (NBR70) for 10 mm solid shaft, circumference 500 mm BEF-MR010050R 2055227

O-ring for measuring wheels (circumference 200 mm) BEF-OR-053-040 2064061

O-ring for measuring wheels (circumference 300 mm) BEF-OR-083-050 2064076

O-ring for measuring wheels (circumference 500 mm) BEF-OR-145-050 2064074

BEF-MR-010020 5312988

BEF-MR-010020G 5318678

BEF-MR-010050 5312989

Mounting bell

Figure Brief description Type Part no.

Mounting bell for encoders with a servo ange, centering hub 50 mm, including mounting kit

BEF-MG-50 5312987

F

Servo clamps

Figure Brief description Type Part no.

Half-shell servo clamps (2 pcs.) for servo anges with a 50 mm centering hub BEF-WG-SF050 2029165

Servo clamps, large, for servo anges (clamps, eccentric fastener), 3 pcs., without

mounting material

BEF-WK-SF 2029166

Shaft adaptation

Collets and clamping rings

Figure Brief description Type Part no.

Metal collet for hollow shaft, shaft diameter 8 mm, outer diameter 5/8" (15.875 mm),

metal

Metal collet for hollow shaft, shaft diameter 3/8 " (9.525 mm), outer diameter 5/8"

(15.875 mm), metal

Metal collet for hollow shaft, shaft diameter 10 mm, outer diameter 5/8" (15.875 mm),

metal

Metal collet for hollow shaft, shaft diameter 12 mm, outer diameter 5/8" (15.875 mm),

metal

Metal collet for hollow shaft, shaft diameter 1/2" (12.7 mm), outer diameter 5/8"

(15.875 mm), metal

Metal collet for hollow shaft, shaft diameter 14 mm, outer diameter 5/8" (15.875 mm),

metal

SPZ-58Z-008-M 2076219

SPZ-58Z-38Z-M 2076224

SPZ-58Z-010-M 2076220

SPZ-58Z-012-M 2076221

SPZ-58Z-12Z-M 2076225

SPZ-58Z-014-M 2076222

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

F-157

Page 39

DBS60 Core INCREMENTAL ENCODERS

Figure Brief description Type Part no.

F

Metal collet for hollow shaft, shaft diameter 15 mm, outer diameter 5/8" (15.875 mm),

metal

Plastic isolated collet for hollow shaft, shaft diameter 6 mm, outer diameter 5/8"

(15.875 mm), plastic

Plastic isolated collet for hollow shaft, shaft diameter 8 mm, outer diameter 5/8"

(15.875 mm), plastic

Plastic isolated collet for hollow shaft, shaft diameter 3/8" (9.525 mm), outer diameter

5/8" (15.875 mm), plastic

Plastic isolated collet for hollow shaft, shaft diameter 10 mm, outer diameter 5/8"

(15.875 mm), plastic

Plastic isolated collet for hollow shaft, shaft diameter 12 mm, outer diameter 5/8"

(15.875 mm), plastic

Plastic isolated collet for hollow shaft, shaft diameter 1/2" (12.7 mm), outer diameter

5/8" (15.875 mm), plastic

Plastic isolated collet for hollow shaft, shaft diameter 14 mm, outer diameter 5/8"

(15.875 mm), plastic

Plastic isolated collet for hollow shaft, shaft diameter 15 mm, outer diameter 5/8"

(15.875 mm), plastic

SPZ-58Z-015-M 2076223

SPZ-58Z-006-P 2076228

SPZ-58Z-008-P 2076229

SPZ-58Z-38Z-P 2076226

SPZ-58Z-010-P 2076230

SPZ-58Z-012-P 2076231

SPZ-58Z-12Z-P 2076227

SPZ-58Z-014-P 2076232

SPZ-58Z-015-P 2076233

Shaft couplings

Figure Brief description Type Part no.

Bellows coupling, shaft diameter 6 mm / 6 mm, maximum shaft offset: radial

± 0.25 mm, axial ± 0.4 mm, angular +/- 4°; max. speed 10,000 rpm, –30 °C to

+120 °C, max. torque 80 Ncm; material: stainless steel bellows, aluminum hub

Bellows coupling, shaft diameter 6 mm / 10 mm, maximum shaft offset: radial

± 0.25 mm, axial ± 0.4 mm, angular +/- 4°; max. speed 10,000 rpm, –30 °C to

+120 °C, max. torque 80 Ncm; material: stainless steel bellows, aluminum hub

Bellows coupling, shaft diameter 10 mm / 10 mm, maximum shaft offset: radial

± 0.25 mm, axial ± 0.4 mm, angular +/- 4°; max. speed 10,000 rpm, –30 °C to

+120 °C, max. torque 80 Ncm; material: stainless steel bellows, aluminum hub

Bellows coupling, shaft diameter 10 mm/12 mm; maximum shaft offset: radial +/-

0.25 mm, axial +/- 0.4 mm, angular +/- 4°; max. revolutions 10,000 rpm, –30 °C to

+120 °C, max. torque 80 Ncm; material: stainless steel bellows, aluminum clamping

hubs

Bar coupling, shaft diameter 6 mm / 6 mm, maximum shaft offset: radial ± 0.3 mm,

axial ± 0.2 mm, angle ± 3°; max. speed 10,000 rpm, –10 °C to +80 °C, max. torque

80 Ncm; material: ber-glass reinforced polyamide, aluminum hub

Bar coupling, shaft diameter 6 mm / 8 mm, maximum shaft offset radial ± 0.3 mm, ax-

ial ± 0.2 mm, angle ± 3°; max. speed 10,000 rpm, torsion spring rigidity 38 Nm/wheel;

material: ber-glass reinforced polyamide, aluminum hub

Bar coupling, shaft diameter 6 mm/10 mm, maximum shaft offset: radial ± 0.3 mm,

axial ± 0.2 mm, angular ± 3°; max. speed 10,000 rpm, –10 °C to +80 °C, max. torque

80 Ncm; material: ber-glass reinforced polyamide, aluminum hub

Bar coupling, shaft diameter 8 mm / 10 mm, maximum shaft offset: radial ± 0.3 mm,

axial ± 0.2 mm, angular ± 3°; torsion spring rigidity 38 Nm/wheel; material: ber-glass

reinforced polyamide, aluminum hub

Bar coupling, shaft diameter 10 mm / 10 mm, maximum shaft offset radial ± 0.3 mm,

axial ± 0.2 mm, angle ± 3°; max. speed 10,000 rpm, torsion spring rigidity 38 Nm/

wheel; material: ber-glass reinforced polyamide, aluminum hub

Spring washer coupling, shaft diameter 6 mm/10 mm, maximum shaft offset: radial

± 0.3 mm, axial ± 0.4 mm, angular ± 2.5°; max. speed 12,000 rpm, –10 °C to +80 °C,

max. torque 60 Ncm; material: aluminum ange, ber-glass reinforced polyamide mem-

brane and tempered steel coupling pin

Spring washer coupling, shaft diameter 10 mm / 10 mm, maximum shaft offset: radial

± 0.3 mm, axial ± 0.4 mm, angular ± 2.5°; max. speed 12,000 rpm, –10 °C to +80°

Celsius, max. torque 60 Ncm; material: aluminum ange, glass ber-reinforced polyam-

ide membrane and hardened steel coupling pin

KUP-0606-B 5312981

KUP-0610-B 5312982

KUP-1010-B 5312983

KUP-1012-B 5312984

KUP-0606-S 2056406

KUP-0608-S 5314179

KUP-0610-S 2056407

KUP-0810-S 5314178

KUP-1010-S 2056408

KUP-0610-F 5312985

KUP-1010-F 5312986

F-158

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 40

Connectors

Plug connectors and cables

Connecting cables with female connector

INCREMENTAL ENCODERS DBS60 Core

Figure Brief description

Head A: female connector, M12, 8-pin, straight

Head B: cable

Cable: suitable for drag chain, PVC, shielded, 4 x 2 x 0.25 mm², Ø 7.0 mm

Head A: female connector, M23, 12-pin, straight

Head B: cable

Cable: incremental, PUR, shielded, 4 x 2 x 0.25 mm² + 2 x 0.5 mm² +

1 x 0.14 mm², Ø 7.8 mm

Head A: female connector, M23, 12-pin, straight

Head B: cable

Cable: incremental, suitable for drag chain, PUR, shielded, 4 x 2 x 0.25 mm²

+ 2 x 0.5 mm² + 1 x 0.14 mm², Ø 7.8 mm

1)

Warning! Only in combination with electrical interfaces A, C, E and P.

1)

Length

Type Part no.

of

cable

2 m DOL-1208-G02MAC1

5 m DOL-1208-G05MAC1

10 m DOL-1208-G10MAC1

20 m DOL-1208-G20MAC1

2 m DOL-2312-G02MLA3

7 m DOL-2312-G07MLA3

10 m DOL-2312-G10MLA3

1)

15 m DOL-2312-G15MLA3

20 m DOL-2312-G20MLA3

25 m DOL-2312-G25MLA3

30 m DOL-2312-G30MLA3

1.5 m DOL-2312-G1M5MA3

3 m DOL-2312-G03MMA3

5 m DOL-2312-G05MMA3

10 m DOL-2312-G10MMA3

20 m DOL-2312-G20MMA3

30 m DOL-2312-G30MMA3

6032866

6032867

6032868

6032869

2030682

2030685

2030688

2030692

2030695

2030699

2030702

2029212

2029213

2029214

2029215

2029216

2029217

F

Female connectors (ready to assemble)

Figure Brief description Type Part no.

Head A: female connector, M12, 8-pin, straight, A encoded, shielded, for cable diameter

4 mm ... 8 mm

Head B: Operating temperature:

–40 °C ... +85 °C

Head A: female connector, M23, 12-pin, straight, shielded, for cable diameter

5.5 mm ... 10.5 mm

Head B: Operating temperature:

–20 °C ... +130 °C

DOS-1208-GA01

DOS-2312-G

6045001

6027538

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

F-159

Page 41

DBS60 Core INCREMENTAL ENCODERS

Cables (ready to assemble)

F

Figure Brief description Length

Type Part no.

of

cable

Head A: cable

Head B: cable

Cable: suitable for drag chain, PUR, halogen-free, shielded, 4 x 2 x 0.15 mm²,

Ø 5.6 mm

Head A: cable

Head B: cable

Cable: PUR, shielded, 4 x 2 x 0.25 mm² + 2 x 0.5 mm² + 1 x 0.14 mm²,

Ø 7.5 mm

Head A: cable

Head B: cable

Cable: suitable for drag chain, PUR, halogen-free, shielded, 4 x 2 x 0.25 mm²

+ 2 x 0.5 mm² + 2 x 0.14 mm², Ø 7.8 mm

Head A: cable

Head B: cable

Cable: suitable for drag chain, PUR, halogen-free,

shielded, UV and saltwater resistant, 4 x 2 x

0.25 mm² + 2 x 0.5 mm² +

2 x 0.14 mm², Ø 7.8 mm

By the

meter

LTG-2308-MWENC 6027529

LTG-2411-MW 6027530

LTG-2512-MW 6027531

LTG-2612-MW 6028516

Male connector (ready to assemble)

Figure Brief description Type Part no.

Head A: male connector, M12, 8-pin, straight, A encoded, shielded, for cable diameter

4 mm ... 8 mm

Head B: Operating temperature:

–40 °C ... +85 °C

Head A: male connector, M23, 12-pin, straight, shielded, for cable diameter 5.5 mm ...

10.5 mm

Head B:

Operating temperature:

–20 °C ... +130 °C

- For additional accessories, please see page K-668 onwards

STE-1208-GA01 6044892

STE-2312-G 6027537

F-160

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 42

INCREMENTAL ENCODERS DBS60 Core

F

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

F-161

Loading...

Loading...