SICK CLV61 Series, CLV61x FIELDBUS Series, CLV61x ECO Series, CLV61x CAN Series Technical Information

Page 1

CLV61x

Barcodescanner

Supplement to the operating instructions.

For mounting and electrical installation.

TECHNICAL INFORMATION

Page 2

Technical Information

CLV61x bar code scanner

Copyright

Copyright 2013 -2017

SICK AG

Erwin-Sick-Str. 1

79183 Waldkirch

Germany

Trademarks

Windows 2000

TM

, XPTM, VistaTM, Windows 7TM are registered trademarks or trademarks of

the Microsoft Corporation in the USA and other countries.

2 © SICK AG · Germany · All rights reserved · Subject to change without notice 8015592/ZNI9/2017-06-13

Page 3

Technical Information

CLV61x

Contents

Table of contents

1 About this document..................................................................................................... 5

1.1 Purpose.......................................................................................................................5

1.2 Target Group............................................................................................................... 5

1.3 Further Sources for Obtaining Information .............................................................. 5

1.4 Symbols used ............................................................................................................. 6

2 Safety Information ........................................................................................................ 7

2.1 General Notes.............................................................................................................7

2.2 Categories of Safety Notes ........................................................................................7

2.3 Laser Warning ............................................................................................................ 8

3 Mounting.......................................................................................................................11

3.1 Notes on Mounting...................................................................................................11

3.2 Optional Accessories................................................................................................11

3.3 Mounting the CDB620-001/ CDM420-0001 Connection Module.......................16

4 Electrical installation .................................................................................................. 17

4.1 Notes on the Electrical Installation.........................................................................17

4.2 Overview of all lnterfaces and Connection Options...............................................18

4.3 Pin Assignments of the 15-pin D-Sub HD Plug (Connection Cable) .....................19

4.4 Pin Assignments and Lead Color Assignments of Cables .....................................20

4.5 Prerequisites for the Safe Operation of the CLV61x in a System.........................21

4.6 Installation steps......................................................................................................24

4.7 Using the CDB620-001 Connection Module..........................................................29

4.8 Using the CDM420-0001 Connection Module.......................................................40

8015592/ZNI9/2017-06-13 © SICK AG · Germany · All rights reserved · Subject to change without notice 3

Page 4

Contents

Operating Instructions

CLV61x bar code scanner

4 © SICK AG · Germany · All rights reserved · Subject to change without notice 8015592/ZNI9/2017-06-13

Page 5

Technical Information Chapter 1

CLV61x

About this document

1 About this document

1.1 Purpose

Supplement to the

Operating Instructions

This document summarizes information about mounting and electrical installation which

complete the "CLV61x bar code scanner" operating instructions (no. 8015559):

Optional mounting accessories (brackets)

Prevention of ground potential equalization currents in applications with widely distrib-

uted systems

Pin and lead color assignments of cables

Electrical wiring diagrams for the CDB620-001 and CDM420-0001 connection mod-

ules relating to the CLV61x

The document is valid for all CLV61x variants in the following series:

CLV61x ECO

CLV61x CAN

CLV61x FIELDBUS

In the following the CLV61x bar code scanner is referred to in simplified form as "CLV61x",

except where a distinction is necessary.

1.2 Target Group

This document is intended for qualified and technical staff, authorized for mounting and

electrical installation.

1.3 Further Sources for Obtaining Information

"CLV61x bar code scanner" Operating Instructions“ (no. 8015559)

Notes on intended use, scope of delivery, mounting and electrical installation in principle,

commissioning, configuration with SOPAS ET, maintenance, transport and storage as well

as on repair is included in the "CLV61x bar code scanner" operating instructions.

Internet Product Page of the CLV61x

www.sick.com/CLV61x

Detailed technical data in the online data sheet (PDF)

Dimensional drawing and 3D CAD dimension models in various electronic formats

Reading field diagrams (PDF)

EC Declaration of Conformity (PDF)

SOPAS ET configuration software with online help function

CLV6 Series Product Information with an overview of the accessories (PDF)

CLV61x bar code scanner Operating Instructions (PDF)

This technical information (PDF)

Support is also available from your sales partner to be found under

www.sick.com/worldwide.

8015592/ZNI9/2017-06-13 © SICK AG · Germany · All rights reserved · Subject to change without notice 5

Page 6

Chapter 1 Technical Information

WARNING

About this document

CLV61x bar code scanner

1.4 Symbols used

Some information in this document is highlighted as follows to facilitate quick access to this

information.

1.4.1 Design of Safety Notes

Safety notes are marked by symbols. The safety notes are introduced by signal words in capital letters that indicate the extent of the danger.

Risk of Injury or Risk of Damage!

A warning refers to specific or potential dangers to the physical safety of the user. It is there

to protect the user against accidents.

The safety mark next to the warning, on the left, refers to the type of accident risk, e.g. electricity-related. The ascending warning levels (CAUTION, WARNING, DANGER) refer to the severity of the possible danger.

Always read the warnings carefully and make sure you comply with them.

1.4.2 Further Markings

Important! This important note is there to advise you on special aspects.

DATA PROCESSING This type of script denotes a term in the user interface of the SOPAS ET configuration soft-

ware.

This symbol refers to supplementary technical documentation.

6 © SICK AG · Germany · All rights reserved · Subject to change without notice 8015592/ZNI9/2017-06-13

Page 7

Technical Information Chapter 2

DANGER

WARNING

CAUTION

NOTICE

CLV61x

Safety Information

2 Safety Information

2.1 General Notes

This chapter is about the safety of commissioning personnel, as well as operators of the

system in which the CLV61x is integrated.

Read the CLV61x operating instructions (no. 8015559) carefully before starting any

work on the CLV61x in order to familiarize yourself with the device and its functions.

The operating instructions are considered a part of the device and must be kept in an

accessible location in the immediate vicinity of the CLV61x at all times!

Read additionally the notes on mounting and the electrical installation in this technical

information as supplement to the operating instructions.

Opening the screws of the CLV61x housing will invalidate any warranty claims against

SICK AG. For further warranty provisions, see the General Terms and Conditions of SICK

AG, e.g., on the delivery note of the CLV61x.

Repair work on the CLV61x may only be performed by qualified and authorized service

personnel from SICK AG.

2.2 Categories of Safety Notes

Risk of Injury!

The combination of symbol and signal word indicates a situation of imminent danger, which

will lead to a fatality or serious injuries if not prevented.

Risk of Injury!

T

he combination of symbol and signal word indicates a potentially dangerous situation,

which may lead to a fatality or serious injuries if not prevented.

Risk of Injury!

The combination of symbol and signal word indicates a potentially dangerous situation,

which may lead to minor/slight injuries if not prevented.

Risk of Damage!

A note indicates a potential risk of damage or impair on the functionality of the CLV61x bar

code scanner or other connected devices.

8015592/ZNI9/2017-06-13 © SICK AG · Germany · All rights reserved · Subject to change without notice 7

Page 8

Chapter 2 Technical Information

CAUTION

Housing with

front reading

window

Housing with

lateral reading

window

Safety Information

CLV61x bar code scanner

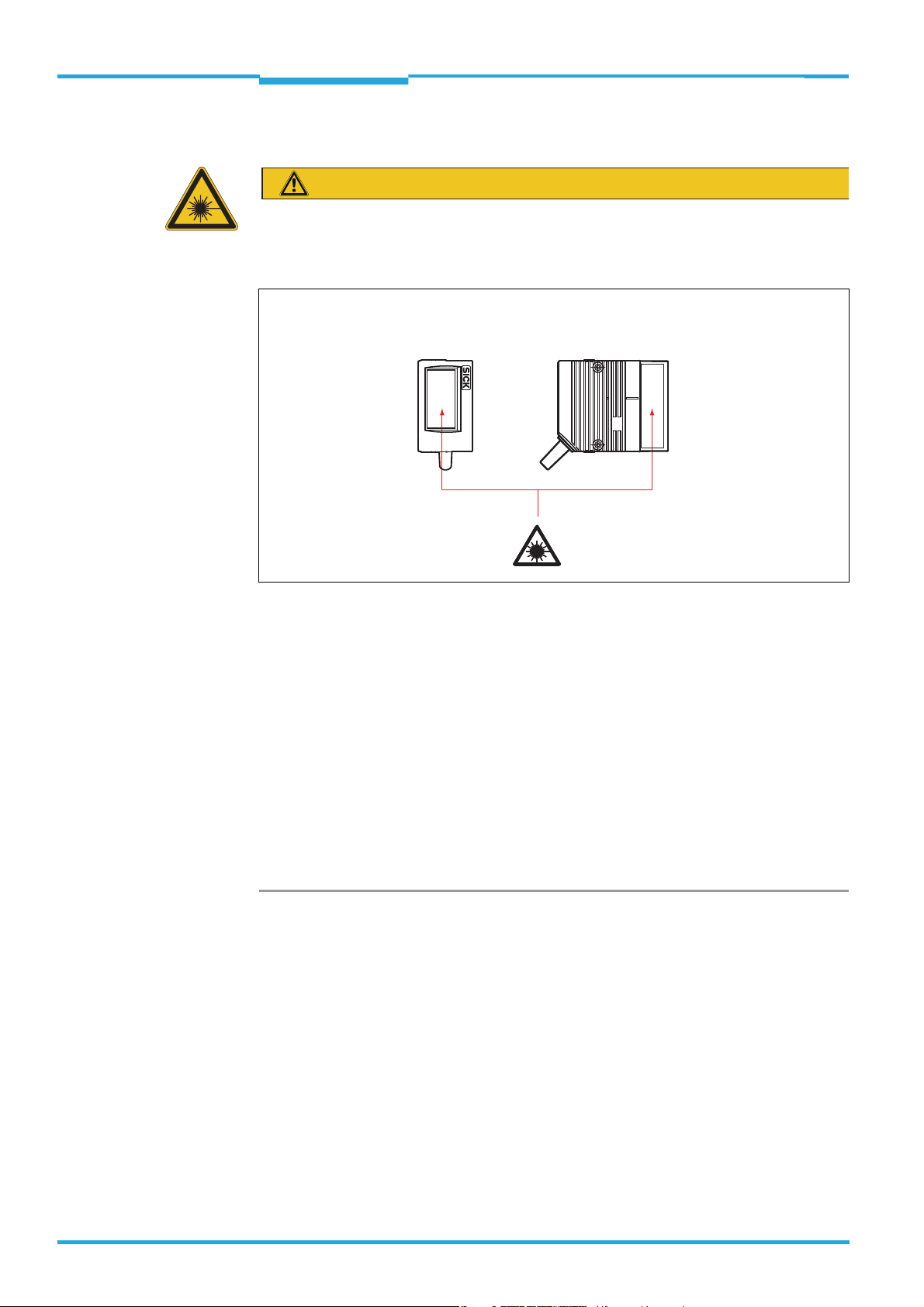

2.3 Laser Warning

Optical radiation: Laser class 2

The CLV61x uses a red light laser diode and corresponds to laser class 2.

The entire reading window is a laser output aperture.

The human eye is not at risk when briefly exposed to the radiation for up to 0.25 seconds.

Exposure to the laser beam for longer periods of time may cause damage to the retina. The

laser radiation is harmless to human skin.

Do not look into the laser beam intentionally.

Never point the laser beam at people's eyes.

If it is not possible to avoid looking directly into the laser beam, e.g., during commission-

ing and maintenance work, suitable eye protection must be worn.

Avoid laser beam reflections caused by reflective surfaces. Be particularly careful dur-

ing mounting and alignment work.

Do not open the housing. Opening the housing will not switch off the laser. Opening the

housing may increase the level of risk.

Current national regulations regarding laser protection must be observed.

Caution – incorrect use can lead to the user being exposed to dangerous radiation.

Important! Maintenance is not necessary to ensure compliance with laser class 2.

8 © SICK AG · Germany · All rights reserved · Subject to change without notice 8015592/ZNI9/2017-06-13

Page 9

Technical Information Chapter 2

Safety Information

CLV61x

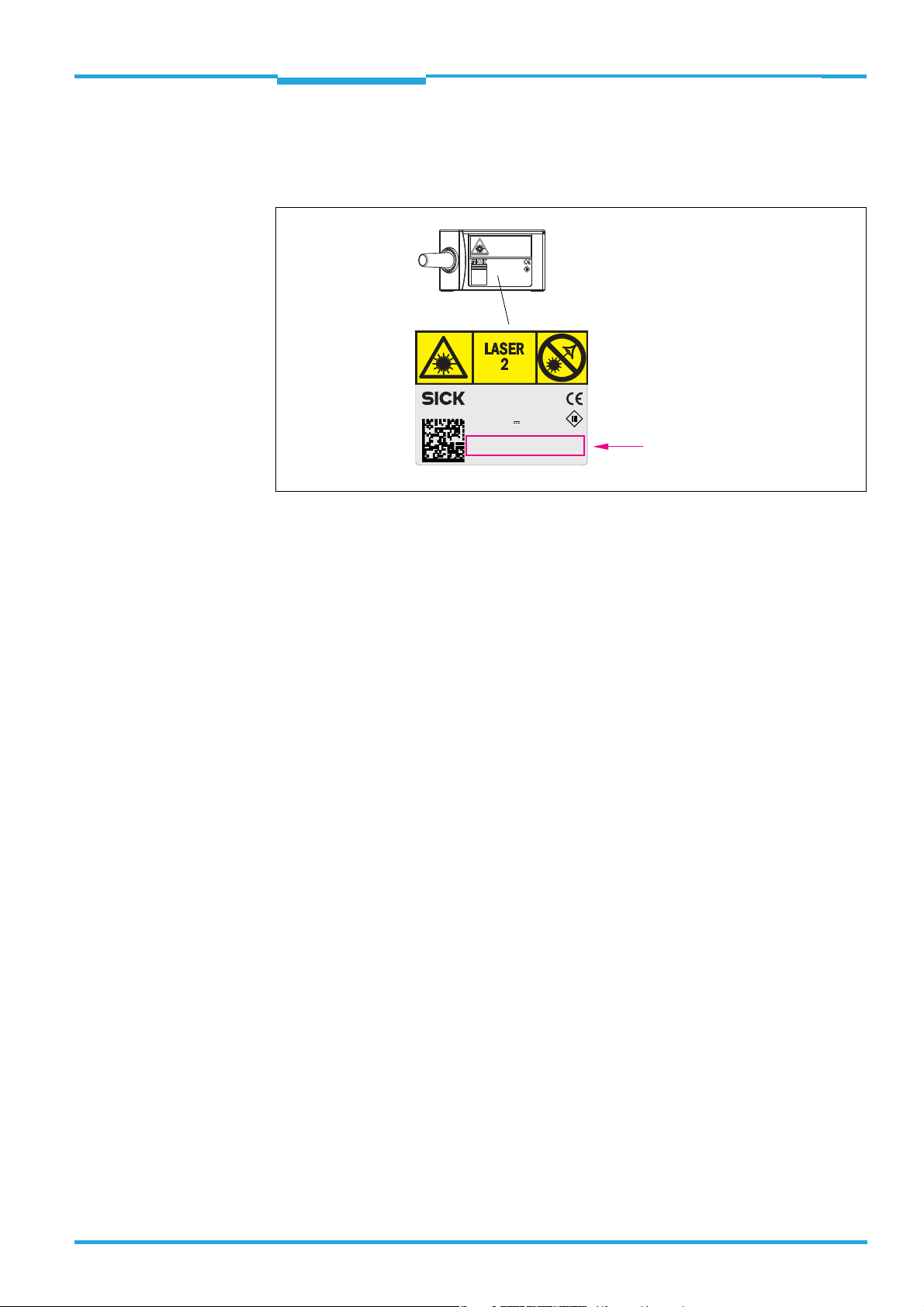

Laser Warning and Laser Specifications Labels

Installation site and design of the combination of black and yellow laser warning label and

type label with laser performance data:

CLV610-C0000

P/N: 1057125

D-79276 Reute

Made in Germany

S/N: 1540 0001

DC 10...30V

2.8W Imax=700mA

Pmax=1.5mW

Manufactured: October 2015

= 655nmλ

P<1.0mW average

Pulse duration <300μs

Laser performance data

Meaning of the laser warning label:

Laser radiation - Do not look into the laser beam - laser class 2.

Controlling the Laser Diode

In real operation (triggered reading mode), the CLV61x switches the laser diode on and off

again with the trigger signals of the conveyor system (object in reading range). Triggering occurs here via the switching inputs of the CLV61x or by a command via one of the data interfaces.

A laser timeout configured with SOPAS ET (device page I

LLUMINATION CONTROL) can be used

to automatically switch off the laser diode for this type of object trigger control if the pulse

has stopped for too long (e.g., conveyor system has stopped). The current internal reading

interval of the CLV61x remains open. If the function is activated, the laser timeout is 10 min

in the default settings.

The laser diode is permanently or repeatedly switched on in the following device statuses:

In the "Percentage Evaluation" and "Auto Setup" operating modes (only used temporar-

ily for configuration/diagnosis)

In reading operation in the pulsing types "Auto cycle" (adjustable pulse/pause ratio) or

"free".

If timeout is activated, it will have no effect here.

Important! The CLV61x has no optical indicator (LED) for laser diode activity.

8015592/ZNI9/2017-06-13 © SICK AG · Germany · All rights reserved · Subject to change without notice 9

Page 10

Chapter 2 Technical Information

Safety Information

CLV61x bar code scanner

10 © SICK AG · Germany · All rights reserved · Subject to change without notice 8015592/ZNI9/2017-06-13

Page 11

Technical Information Chapter 3

CLV61x

Mounting

3 Mounting

3.1 Notes on Mounting

The permitted ambient conditions for the operation of the CLV61x must be complied

with e.g., temperature, radiated emission, ground potential in situ.

See "CLV61x bar code scanner" operating instructions (no. 8015589)

The device must only be mounted to the optional SICK brackets using the pairs of

threaded mounting holes provided for this purpose.

3.2 Optional Accessories

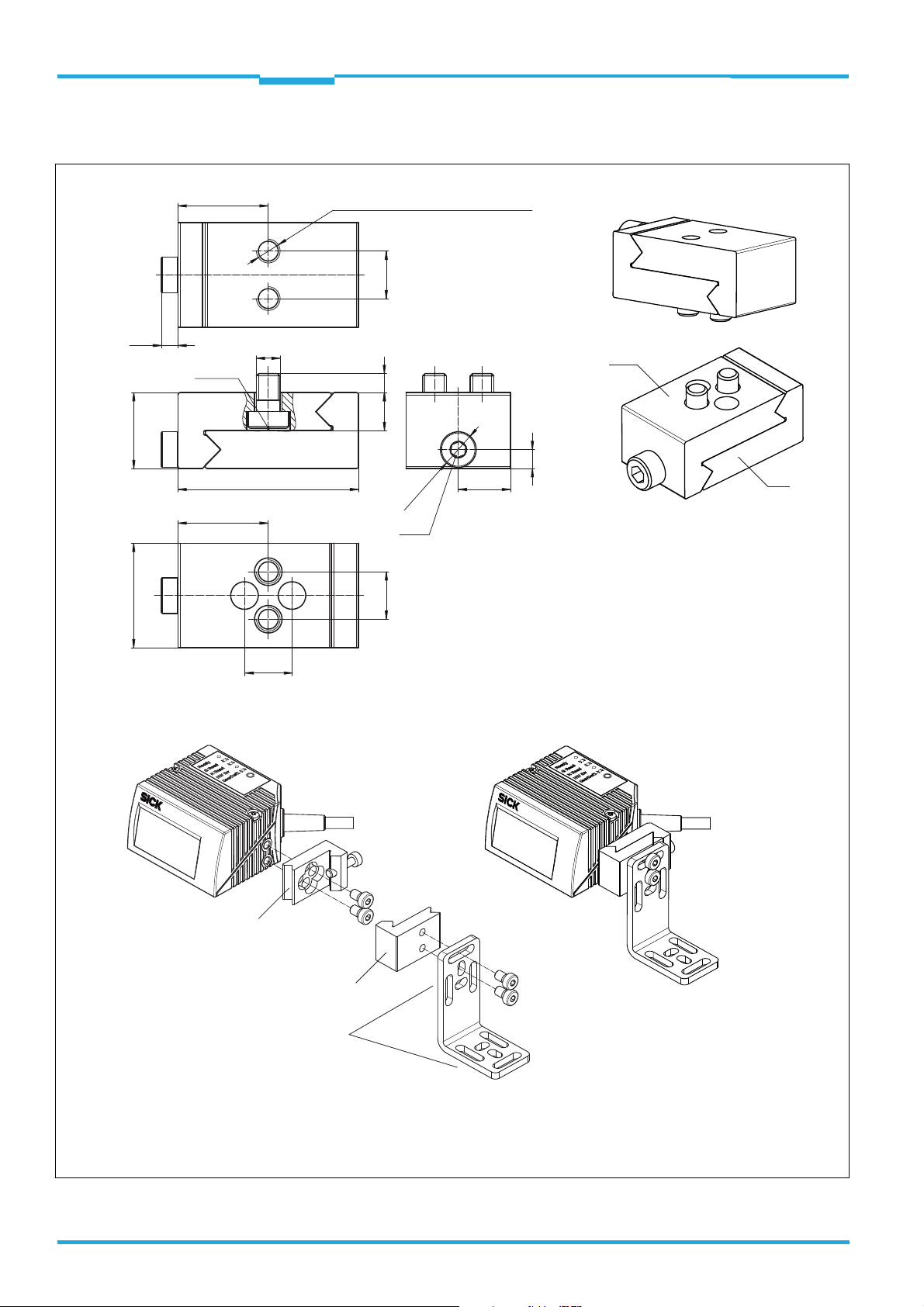

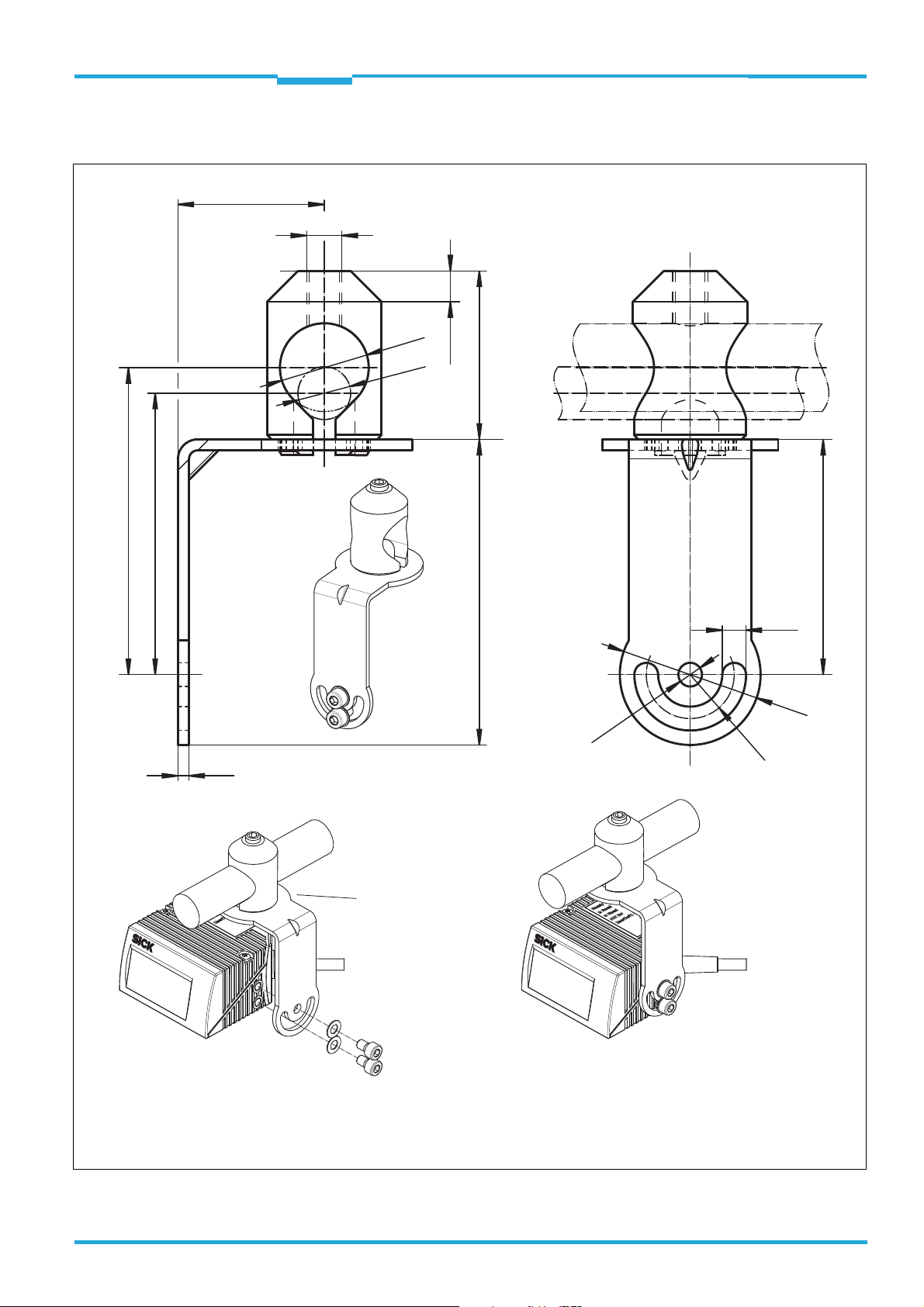

For fastening the CLV61x directly to a mounting device (base) 4 SICK brackets in all are

available (see the following pages).

Brackets for optional Mirror Hood No. 2046811

Views and dimensions of the two corresponding brackets no. 2048633 and no. 2046822

for the CLV6xx optional mirror hood are shown in the fitting instructions for "External mirror

hood for bar code scanners of the CLV6xx family " (no. 8013180, Ger./Engl. version).

8015592/ZNI9/2017-06-13 © SICK AG · Germany · All rights reserved · Subject to change without notice 11

Page 12

Chapter 3 Technical Information

(19)

(3.5)

10

11

4

(AF3)

38

10

48

16

22

10

19

(M5)

(Ø 7.5)

2

1

(SW3)

1

2

Quick release clamp

no. 2025526 (parts 1 and 2),

can be adjusted in 90°-steps

Bracket no. 2020410,

each angle leg adjustable in 90°

steps. Here shown as supplement.

Included to fix the bar code scanner to the quick release clamp:

2 x cylinder head screws M5 x 8, with hexagon socket (AF3), self-locking

M5, screw-in depth max. 8 mm

All length measures in mm

Mounting sample

(Bracket no. 2020410

not included in delivery

of quick release clamp)

Mounting

CLV61x bar code scanner

3.2.1 Dimensional Drawing of Quick Release Clamp No. 2025526

12 © SICK AG · Germany · All rights reserved · Subject to change without notice 8015592/ZNI9/2017-06-13

Page 13

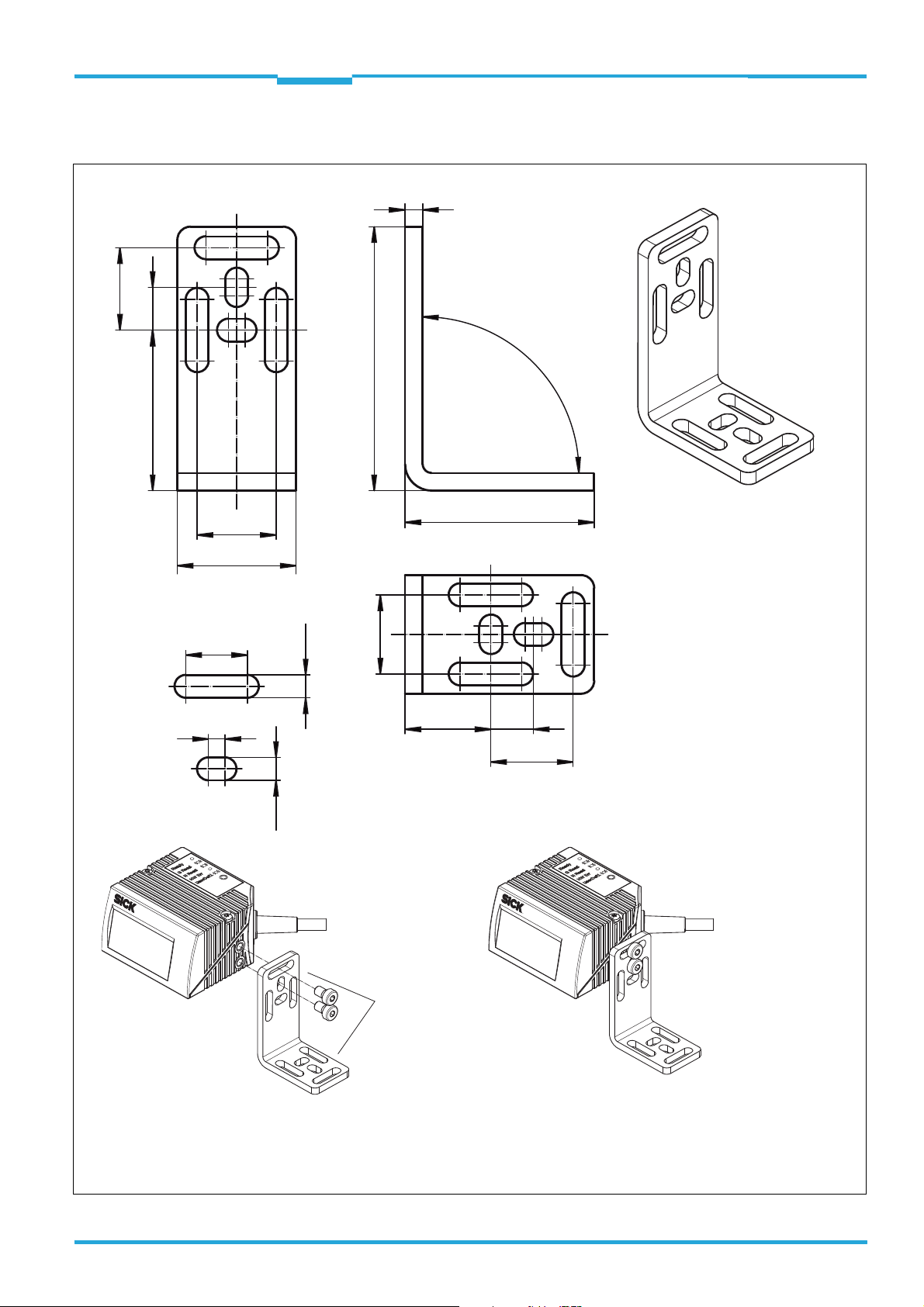

Included to fix the bar code scanner to the bracket:

2 x cylinder head screws M5 x 8, with hexagon socket (AF3), self-locking

43

60

4

90°

36.5

27

18

18.7

9.7

3.8

5.2

14

Elongated hole:

5.2

large:

small:

18

18.7

9.719.5

Mounting sample

All length measures in mm

Angle leg

adjustable in

90°steps

Technical Information Chapter 3

CLV61x

Mounting

3.2.2 Dimensional Drawing of Bracket No. 2020410

8015592/ZNI9/2017-06-13 © SICK AG · Germany · All rights reserved · Subject to change without notice 13

Page 14

Chapter 3 Technical Information

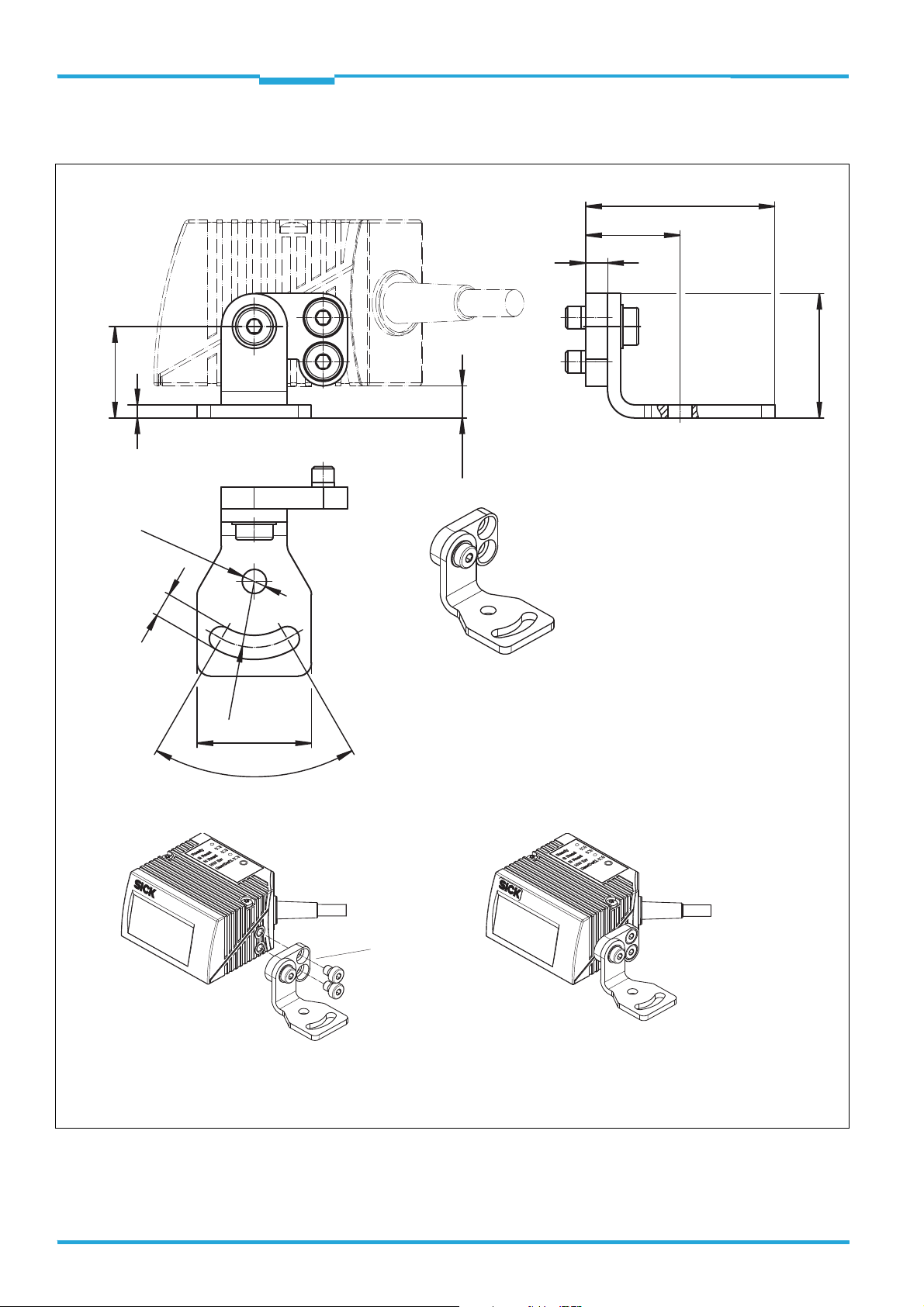

Included to fix the bar code scanner to the adapter plate:

2 x cylinder head screws M5 x 6, with hexagon head (AF3), self-locking

Mounting sample

All length measures in mm

Adapter plate

can be swivelled

and fixed freely

at the angle

20.8

3

(7.3)

43

21.5

5

28.3

26

60°

5.5

Ø 5.5

R 15

Mounting

CLV61x bar code scanner

3.2.3 Dimensional Drawing of the Bracket with Adapter Plate No. 2042902

14 © SICK AG · Germany · All rights reserved · Subject to change without notice 8015592/ZNI9/2017-06-13

Page 15

Technical Information Chapter 3

Ø

5. 4

R 10

5.4

53.5

Ø

32

Included to fix the bar code scanner to the bracket:

2 x cylinder head screws M5 x 8, with hexagan socket (AF3), self-locking

Mounting sample

All length measures in mm

Bracket can be

swivelled and fixed

freely on the rod

clamp

(rod not included in delivery)

33.3

38.369.5

Ø 20

Ø 12

M8

64

69.8

2.5

7 x 45°

Mounting

CLV61x

3.2.4 Dimensional Drawing of the Bracket with Rod Clamp No. 2042802

s

8015592/ZNI9/2017-06-13 © SICK AG · Germany · All rights reserved · Subject to change without notice 15

Page 16

Chapter 3 Technical Information

Mounting

CLV61x bar code scanner

3.3 Mounting the CDB620-001 or CDM420-0001 Connection Module

The mounting location for the connection module (distance to CLV61x) depends on the

physical design (RS-232) of the both serial data interfaces AUX and HOST and the transmission rates used:

Recommended cable length between CLV61x and connection module:

Max. 5 m when using max. data transmission rate 115.2 kBd of the HOST interface.

(fixed data transmission of AUX interface: 57.6 kBd)

For detailed information on mounting and the electrical installation of the connection module, please see:

"CDB620 connection module" operating instructions (part no. 8012119, Ger./Engl.

version) e.g. via www.sick.com/CDB

"CDM420-0001 connection module" operating instructions (part no. 8010004, Ger./

Engl. version) e.g. via www.sick.com/CDM

The corresponding operating instructions are enclosed in printed form with the connection

modules.

16 © SICK AG · Germany · All rights reserved · Subject to change without notice 8015592/ZNI9/2017-06-13

Page 17

Technical Information Chapter 4

CLV61x

Electrical installation

4 Electrical installation

4.1 Notes on the Electrical Installation

The electrical installation must only be performed by qualified electricians.

The currently applicable safety regulations must be observed when working in electri-

cal systems!

Electrical connections between the CLV61x and other devices must only be created and

disconnected when there is no power to the system. Otherwise, the devices may be

damaged.

When using extension cables with open ends, ensure that bare wire ends do not come

into contact with each other (risk of short-circuit when supply voltage is switched on!).

Wires must be appropriately insulated from each other.

Wire cross sections of the supply cable from the customer's power system should be

designed in accordance with the applicable standards.

In order to retain the IP 65 enclosure rating for the CLV61x connecting cable even when

using an extension cable (e.g., no. 2043413, 2 m), insert rubber seal no. 4038847 between the plug and socket of the D-Sub plug connection of the cables and screw in the

plug connection.

Circuits connected to the CLV61x must be designed as SELV circuits (SELV = Safety

Extra Low Voltage).

Do not switch on the supply voltage for the CLV61x/the CDB620-001/CDM420-0001

connection module until the connection work has been completed and the wiring work

has been tested thoroughly.

8015592/ZNI9/2017-06-13 © SICK AG · Germany · All rights reserved · Subject to change without notice 17

Page 18

Chapter 4 Technical Information

Input 2

(e.g. incremental encoder,

Teach-in matchcode)

Input 1

(e.g. external reading clock)

Output 1

(e.g. indicator lamp)

Output 2

(e.g. indicator lamp)

CLV61x ECO/CAN

CDB620

Connection module

SerialSerial

Configuration

Diagnostics

SOPASSOPAS

SerialSerial

“HOST (RS-232)/

AUX (RS-232)/

I/O”

...

...

1

2

DC 10 V ... 30 V

GND

HOST

PC

Furt her d ata

processing

e.g. cable no. 2014054 (2 m)

“AUX” (RS-232)

DC 10 V ... 30 V

Switching inputs/outputs = digital

“HOST” (RS-232)

Reading result

“CAN” (CLV61x CAN only)

CAN Sensor Network

CLV61x

Aux

RS-232

RS-232

CAN

*)

SOPAS ET

Configuration

Software

Further data

processing

Host

PC

HOST

*) CLV61x CAN and FIELDBUS series

◂ Configuration/data output ▸

◂ Configuration/data output ▸

Electrical installation

CLV61x bar code scanner

4.2 Overview of all lnterfaces and Connection Options

CLV61x ECO/CAN

CLV61x FIELDBUS

CLV61 FIELDBUS

DC 10 V ... 30 V

CAN Sensor Network

Input 1

(e.g. external reading clock)

Using the Data Interfaces

“AUX (RS-232)/

CAN/DC 10 V ... 30 V”

CDF600-21xx

PROFIBUS

Fieldbus module

PROFIBUS

“AUX” (USB)

e.g. cable

no. 6036106

(2 m)

Reading result

PROFIBUS

SOPASSOPAS

PC

Configuration

Diagnostics

Furt her d ata

processing

PLC

18 © SICK AG · Germany · All rights reserved · Subject to change without notice 8015592/ZNI9/2017-06-13

Page 19

Technical Information Chapter 4

Electrical installation

CLV61x

Possible interface HOST AUX

Assignable function

RS-232 RS-232

Read result output (format 1)

Read result output (format 2)

Read diagnosis output (fixed format)

Monitoring of HOST interface traffic

Communication with fieldbus module

CDF600-21xx PROFIBUS

Configuration (SOPAS, commands)

= Output of the same function simultaneously possible via the interfaces

= Access only via one of the interfaces (CLV61x

FIELDBUS serie)

= Access only makes practical sense via one of the interfaces (risk of collision)

Important Only one of several selectable functions can be allocated to each interface.

4.3 Pin Assignments of the 15-pin D-Sub HD Plug (Connection Cable)

CLV61x ECO

15-pin D-Sub HD plug

6

10

5

1

15

11

1

DC 10 V ... 30 V

2

RxD (RS-232), AUX

3

TxD (RS-232), AUX

4

Sensor 2 (switching input)

5

GND

6

N.C.

7

RxD (RS-232), HOST

8

N.C.

9

10

11

12

13

14

15

TxD (RS-232), HOST

N.C.

N.C.

Result 1 (switching output)

Result 2 (switching output)

Sensor 1 (switching input)

SensGND

CLV61x CAN / FIELDBUS

15-pin D-Sub HD plug

6

10

5

1

15

11

1

DC 10 V ... 30 V

2

RxD (RS-232), AUX

3

TxD (RS-232), AUX

4

Sensor 2 (switching input)

5

GND

6

N.C.

7

RxD (RS-232), HOST

8

N.C.

9

10

11

12

13

14

15

TxD (RS-232), HOST

CAN_H

CAN_L

Result 1 (switching output)

Result 2 (switching output)

Sensor 1 (switching input)

SensGND

N.C. = not connected

Shield of the CLV61x contacted with metal housing of 15-pin D-Sub HD plug.

8015592/ZNI9/2017-06-13 © SICK AG · Germany · All rights reserved · Subject to change without notice 19

Page 20

Chapter 4 Technical Information

15-pin D-Sub HD socket

(front view)

Braid shield contacted with metal housing of socket.

110

15611

5

9-pin D-Sub socket

(front view)

5

1

9

6

Electrical installation

CLV61x bar code scanner

4.4 Pin Assignments and Lead Color Assignments of Cables

4.4.1 Connection: CLV61x to a customer-specific Connection Box

Extension Cable No. 2043413 (2 m), open end

ss

Pin Signal Function Color of lead

1 DC 10 V ... 30 V Supply voltage Red

2 RxD (RS-232), Aux AUX interface (receiver) Purple

3 TxD (RS-232), Aux AUX interface (transmitter) Yellow

4 Sensor 2 Switching input 2 Red + black

5GND Ground Black

6N.c. – Light blue

7 RxD (RS-232), Host HOST interface (receiver) Blue

8 N.c. – Light gray or turquoise

9 TxD (RS-232), Host Host interface (transmitter) Green

10

11

CAN H

CAN L

*)

*)

12 Result 1 Switching output 1 Brown

13 Result 2 Switching output 2 Orange

14 Sensor 1 Switching input 1 White

15 SensGND Common ground for all switch-

*) Only with CLV61x CAN and CLV61x FIELDBUS series

CAN-Bus (IN/OUT) Gray

CAN-Bus (IN/OUT) Pink

White + black

ing inputs

20 © SICK AG · Germany · All rights reserved · Subject to change without notice 8015592/ZNI9/2017-06-13

4.4.2 Connection: CDB620-001 Connection Module to PC (HOST interface RS-232)

RS-232 Data Cable No. 2030319 (3 m), open end

Pin Signal Function Color of lead CDB620-001 terminals/

CDM420-0001 terminal

1– – – –

2 RxD (RS-232) Host interface (receiver) Brown 43 / 34 (TxD Host)

3 TxD (RS-232) Host interface (transmitter) Blue 44 / 35 (RxD Host)

4– – – –

5 GND Ground Black 42 / 36 (GND)

6 ... 9 – – – –

Page 21

Technical Information Chapter 4

DANGER

CLV61x

closed current loop

with equalizing currents

via cable shield

grounding point 2

grounding point 1

grounding potential difference

PLC

Reading clock

sensor

I

U

CDB620-

001

= metal housing = plastic housing

= shielded electrical cable

CLV61x

Electrical installation

4.5 Prerequisites for the Safe Operation of the CLV61x in aSystem

Risk of Injury/Risk of Damage due to Electrical Current!

Incorrect grounding of the CLV61x can, due to equipotential bonding currents between the

CLV61x and other grounded devices in the system, place the metal housing under a dangerous voltage, cause malfunction and destruction of devices as well as damage to the cable shielding through heating, and thus cause cable fires.

Work on the electrical system must only be performed by qualified electricians.

Ensure ground potential at all grounding points.

In the event of damage to the cable insulation, immediately switch off the power supply

and have the damage repaired.

Where local conditions are unfavorable and thus do not meet conditions for a safe

earthing method (same ground potential at all grounding points), take measures in

accordance with the following explanations.

The CLV61x is designed and tested for electrical safety according to EN 60950-1: 2011-01.

It is connected to the peripheral devices (power supply, reading pulse sensor(s), PLC, Host

etc.) via shielded cables. The cable shield, for example, for the data cable rests against the

metal housing of the CLV61x. The device can either be grounded through the cable shield

or through one of the threaded blind holes.

If the peripheral devices have metal housings and if the cable shields also lie on their housings, it is assumed that all devices involved in the installation have the same ground poten-

tial.

This is achieved for instance by complying with the following conditions:

Mounting the devices on conductive metal surfaces

Correctly grounding the devices/metal surfaces in the system

If necessary, low-impedance and current carrying equipotential bonding between areas

with different ground potentials.

8015592/ZNI9/2017-06-13 © SICK AG · Germany · All rights reserved · Subject to change without notice 21

Page 22

Chapter 4 Technical Information

grounding point 1

Electro-

optical

signal

isolator

Electro-

optical

signal

isolator

PLC

Reading

clock sensor

grounding point 2

CLV61x

shielded electrial cablemetal housing fiber optic cable

Electrical installation

CLV61x bar code scanner

If these conditions are not met, e.g. on devices in a widely distributed system over several

buildings, potential equalization currents may, due to different ground potentials, flow along

the cable shields between the devices, which can lead to hazards.

Remedial Measures

The most common solution to prevent potential equalization currents on cable shields is to

ensure low-impedance and current carrying equipotential bonding. If this is not possible, the

following solution approaches serve as a suggestion.

Important! We expressly advise against opening up the cable shields. Doing this means that the EMC

limit values can no longer be complied with and that the safe operation of the device data

interfaces can no longer be guaranteed.

a) Measures for widely distributed System Installations

On widely distributed system installations with correspondingly large potential differences,

we recommend setting up local islands and connecting them using commercially available

electro-optical signal isolators. This measure achieves a high degree of resistance to electromagnetic interference while at the same time complying with all the requirements of

EN 60950-1.

The ground loop is isolated by using the electro-optical signal isolator between the islands.

Within the islands, a stable equipotential bonding prevents equalizing currents at the cable

shields.

22 © SICK AG · Germany · All rights reserved · Subject to change without notice 8015592/ZNI9/2017-06-13

Page 23

Technical Information Chapter 4

electrically

insulatetd

grounding point 2 grounding point 3grounding point 1

grounding potential difference

U

shielded electrial cable

PLC

Reading clock

sensor

CLV61x

CLV61x

Electrical installation

b) Measures for small System Installations

For smaller installations with only slight potential differences, insulated installation of the

CLV61x and of peripheral devices may be a sufficient solution.

Even in the event of large differences in the ground potential, ground loops are effectively

prevented, meaning that equalizing currents can no longer flow via the cable shields and

metal housing.

Important! The power supply for the CLV61x and the connected peripheral devices must also guaran-

tee the required level of insulation.

Under certain circumstances, a tangible potential can develop between the insulated metal

housings and the local ground potential.

Special national Regulations for Sweden and Norway

Varning och atjarder

Utrustning som ar kopplad till skyddsjord via jordat vagguttag och/eller via annan utrustning

och samtidigt ar kopplad till kabel-TV nat kan i vissa fall medfora risk for brand.

For att undvika detta skall vid anslutning av utrustningen till kabel-TV nat galvanisk iso-

lator finnas mellan utrustningen och kabel-TV natet.

Advarsel og tiltaker

Utstyr som er koplet til beskyttelsesjord via nettplugg og/eller via annet jordtilkoplet utstyr

- og er tilkoplet et kabel - TV nett, kan forarsake brannfare.

For a unnga dette skal det ved tilkopling av utstyret til kabel-TV nettet installeres en gal-

vanisk isolator mellom utstyret og kabel-TV nettet.

8015592/ZNI9/2017-06-13 © SICK AG · Germany · All rights reserved · Subject to change without notice 23

Corresponding English Translation

Devices which are connected to the electrical system PE of the building via a mains connection or other devices with a connection to the PE, and which are connected to a cable distribution system with coaxial cables, can under certain circumstances cause a risk of fire.

Connections to a cable distribution system must therefore be made such that electrical

insulation is offered below a certain frequency range (galvanic separating link).

Page 24

Chapter 4 Technical Information

“DC 10 V ... 30 V”

“Sensor 2”

“Host 1” (serial)

“Aux 1” (serial)

“Result 2”

“Result 1”

“CAN”

1)

“Sensor 2”

“Sensor 1”

“External input 2”

2)

“External input 1”

2)

“Sensor 1”

DC 10 V ... 30 V

Application

Scanner

Interfaces

“AUX”

PC

HOST/PLC

PLC

CAN bus

1)

PLC

“Result 1”

“Result 2”

PLC

PLC

“External output 1”

2)

“External output 2”

2)

CDB620-001/CDM420-0001

Connection module

CLV61x

Photoelectric

switch

Reading clock

Incremental

encoder

Path increment

Further

functions

“HOST” (serial)

“AUX” (serial)

RS-232

RS-232

CMC600

1) NOT for CLV61x ECO series

2) An optional CMC600 Parameter Cloning Module is required to provide the additional switching inputs and outputs

Futher data

processing

Configuration

Diagnosis

2)

Electrical installation

CLV61x bar code scanner

4.6 Installation steps

4.6.1 Block diagram: Wiring the CDB620-001/CDM420-0001 Connection Module

The commissioning/configuration of the connection modules as well as the technical data

are described in the:

"CDB620 connection module" operating instructions (part no. 8012119, Ger./Engl.

version) e.g. via www.sick.com/CDB

"CDM420-0001 connection module" operating instructions (part no. 8010004, Ger./

Engl. version) e.g. via www.sick.com/CDM.

The corresponding operating instructions are enclosed in printed form with the connection

modules.

Important! Wiring the Signals without SICK Connection Module

If a customer-specific connection box is used, the wiring in principle of the data interfaces

and switching interfaces signals can be designed according to the following wiring diagrams

for the SICK connection modules (from page 29 on).

If the 15-pin D-Sub HD plug of the CLV61x is not compatible with the customer-specific connection box, the extension cable no. 2043413 (2 m) with corresponding socket and open

leads is available. See Chapter 4.4.1 Connection: CLV61x to a customer-specific Connec-

tion Box, Page 20.

24 © SICK AG · Germany · All rights reserved · Subject to change without notice 8015592/ZNI9/2017-06-13

Page 25

Technical Information Chapter 4

CLV61x

Electrical installation

4.6.2 Connecting the Supply Voltage

The CLV61x requires a power supply unit with the following characteristics:

Supply voltage DC 10 V to 30 V (stabilized safety extra-low voltage [SELV]).

The power supply unit must satisfy the requirements of SELV in accordance with the

currently applicable EN 60950-1.

The power source must be able to provide at least 3.5 W output or max. 700 mA.

Additional 0.5 W output power when using the optional CMC600 parameter cloning

module in the CDB620-001 or CDM420-0001 connection module.

Protection of Supply Cables

To ensure protection against short-circuits/overload in the supply cables from the customer's power system, the lead cross sections used have to be selected and protected

according to the national standards.

The supply voltage is fed via the connection module, for to do so please see:

Connection module Interface Chapter

CDB620-001 Supply voltage

CDM420-0001 Supply voltage

Chapter 4.7.2 Wiring the Supply Voltage in the CDB620001 Connection Module, Page 30

Chapter 4.8.2 Wiring the Supply Voltage in the CDM4200001 Connection Module, Page 41

The connection modules have each one fuse (0.8 A slow blow) in the electrical circuit downstream of the S1 switch.

Wiring without SICK Connection Module

The CLV61x must be protected using a separate fuse of max. 2 A slow blow, in the supplying

circuit at the start of the supply cable.

8015592/ZNI9/2017-06-13 © SICK AG · Germany · All rights reserved · Subject to change without notice 25

Page 26

Chapter 4 Technical Information

NOTICE

Electrical installation

CLV61x bar code scanner

4.6.3 Wiring serial Data Interfaces

The maximum data transmission rate for the serial interface depends on the cable length

and on the type of interface (RS-232). The following recommendations apply:

Type of interface Data transmission rate Distance to the target computer (Host)

RS-232 Up to 19.2 kBd

38.4 kBd ... 115.2 kBd

Max. 10 m

Max. 5 m

Risk of Damage to Internal Interface Module

If the serial data interfaces are wired incorrectly, then electronic components of the CLV61x

could get damaged.

Observe the information on wiring.

Carefully check the wiring prior to switching on the CLV61x.

The wiring is done using the connection module, for to do so please see:

Connection module Data interface Chapter

CDB620-001 RS-232

CDM420-0001 RS-232

Chapter 4.7.3 Wiring the RS-232 serial Host Data Interface in the CDB620-001 Connection Module, Page 30

Chapter 4.8.3 Wiring the RS-232 Serial Host Data Interface in the CDM420-0001 Connection Module, Page 41

Recommendation Use shielded data cables (twisted pair leads).

To prevent interference factors, do not lay data cables over a longer route in parallel

with power supply cables and motor cables, in cable channels, for example.

4.6.4 Wiring the Digital Switching Inputs

The two physical switching inputs "Sensor 1" and "Sensor 2" of the CLV61x can be used for

starting and/or ending the reading clock or for connecting an incremental signal.

Expansion: Additional logical switching inputs in the CLV61x converted to physical "external“ switching inputs in the optional connection module

Thanks to the optional CMC600 parameter cloning module in combination with the

CDB620-001/CDM420-0001 connection module, the two additional switching inputs

"External input 1" and "External input 2" on the terminals in the connection module are available.

Important! These two external switching inputs are not suitable for time critical applications.

The wiring of the switching inputs is done using the connection module, please see:

26 © SICK AG · Germany · All rights reserved · Subject to change without notice 8015592/ZNI9/2017-06-13

Page 27

Technical Information Chapter 4

CLV61x

Electrical installation

Connection module Switching input Chapter

CDB620-001 Sensor 1

Sensor 2

External input 1

(„Ext. In 1“)

External input 2

(„Ext. In 2“)

CDM420-0001 Sensor 1

Sensor 2

External input 1

(„Aux In 1“)

External input 2

(„Aux In 2“)

Chapter 4.7.5 Wiring the "Sensor 1" Switching Input in

the CDB620-001 Connection Module, Page 32

Chapter 4.7.6 Wiring the "Sensor 2" Switching Input in

the CDB620-001 Connection Module, Page 33

Chapter 4.7.7 Wiring the "External input 1" Switching

Input in the CDB620-001 Connection Module, Page 34

Chapter 4.7.8 Wiring the "External input 2" Switching

Input in the CDB620-001 Connection Module, Page 35

Chapter 4.8.5 Wiring the "Sensor 1" Switching Input in

the CDM420-0001 Connection Module, Page 43

Chapter 4.8.6 Wiring the "Sensor 2" Switching Input in

the CDM420-0001 Connection Module, Page 44

Chapter 4.8.7 Wiring the "External input 1" Switching

Input in the CDM420-0001 Connection Module,

Page 45

Chapter 4.8.8 Wiring the "External input 2" Switching

Input in the CDM420-0001 Connection Module,

Page 46

4.6.5 Wiring the Digital Switching Outputs

The two physical switching outputs "Result 1" and "Result 2" of the CLV61x can be allocated

independently of each other with various functions for the output of events in the reading

process. If the allocated event occurs, the corresponding switching output is live after the

end of the reading clock for the selected pulse duration.

Expansion: Additional logical switching outputs in the CLV61x converted to physical "external“ switching outputs in the optional connection module

Thanks to the optional CMC600 parameter cloning module in combination with the

CDB620-001/CDM420-0001 connection module, the two additional switching outputs

"External output 1" and "External output 2" on the terminals in the connection module are

available.

Important! These two external switching outputs are not suitable for time critical applications.

The wiring of the switching outputs is done using the connection module, please see:

Connection module Switching output Chapter

CDB620-001 Result 1

Result 2

External output 1

(„Ext. Out 1“)

External output 2

(„Ext. Out 2“)

Chapter 4.7.9 Wiring the "Result 1" Switching Output in

the CDB620-001 Connection Module, Page 36

Chapter 4.7.10 Wiring the "Result 2" Switching Output

in the CDB620-001 Connection Module, Page 37

Chapter 4.7.11 Wiring the "External output 1" Switching Output in the CDB620-001 Connection Module,

Page 38

Chapter 4.7.12 Wiring the "External output 2" Switching Output in the CDB620-001 connection module,

Page 39

8015592/ZNI9/2017-06-13 © SICK AG · Germany · All rights reserved · Subject to change without notice 27

Page 28

Chapter 4 Technical Information

Electrical installation

Connection module Switching output Chapter

CDM420-0001 Result 1

Result 2

External Input 1

(„Aux Out 1“)

External Input 2

(„Aux Out 2“)

Chapter 4.8.9 Wiring the "Result 1" Switching Output in

the CDM420-0001 Connection Module, Page 47

Chapter 4.8.10 Wiring the "Result 2" Switching Output

in the CDM420-0001 Connection Module, Page 48

Chapter 4.8.11 Wiring the "External output 1" Switching Output in the CDM420-0001 Connection Module,

Page 49

Chapter 4.8.12 Wiring the "External output 2" Switching Output in the CDM420-0001 Connection Module,

Page 50

CLV61x bar code scanner

Important! Capacitive loads on the switching outputs have an effect on the switch-on and switch-off

behavior. The maximum capacity of 100 nF is a limit value.

28 © SICK AG · Germany · All rights reserved · Subject to change without notice 8015592/ZNI9/2017-06-13

Page 29

Technical Information Chapter 4

CDB620-001 Connection Module

CMC600 parameter cloning module

(optional)

ONOFF

POWER

S1

0.8 A T

Ter m C AN

Term 485RS

SGND - GND

422 485

ONOFF

NO

YES

ONOFF

ONOFF

S2 S3

S7S6

S4

CMC

10 11 12 13 14 15 16 17 18

Sens 1

In 1

In 2

U

IN

*

U

IN

*

Sens 2

SGND

SGND

SGND

LEDs

20 21 22 23 24

Res 1

Res 2

Out 1

Out 2

GND

30 31 32 33 34

CAN_H

CAN_L

T+

R+

GND

40 41 42 43 44

CAN_H

CAN_L

T‒/TxD

R‒/RxD

GND

SCANNER

AUX interface

6110 5

1115

5

1

9

6

U

IN

U

IN

GND

GND

Shield

Shield

Shield

Shield

1234567 8

= an CMC600 is required to provide the additional switching inputs and outputs

DC 10 V ... 30 V

External

reading

clock sensor

(e.g. photoelectric

switch)

V

S

Out

GND

Result 1

PLC

GND

Result 2

to PC

to

CLV61x

Pin

2: RxD

3: TxD

5: GND

Host

RS-232

TxD

RxD

GND

VS = DC 10 V ... 30 V on terminal UIN = UIN* after fuse F and switch S1

F

RS-232

Electrical installation

CLV61x

4.7 Using the CDB620-001 Connection Module

4.7.1 Wiring overview (one switching input used)

8015592/ZNI9/2017-06-13 © SICK AG · Germany · All rights reserved · Subject to change without notice 29

Page 30

Chapter 4 Technical Information

6

1

10

5

11

15

CLV61x

CDB620

VS

V

S

1

5

5

Shield

1U

IN

2 GND

UIN*

GND

S1

F

Shield

D-Sub HD plug,

15-pin

GND

.

.

.

.

.

.

ON

OFF

S1 : POWER

DC 10 V to 30 V

UIN*

Switch S1:

ON:

Power supply voltage U

IN

switched to UIN* via fuse to CDB620 and CLV61x.

Power supply voltage U

IN

* additionally available on terminals 11 and 14.

OFF:

CDB620 and CLV61x disconnected from power supply voltage.

Recommended position during all electrical installation work.

POWER

VS = DC 10 V to 30 V on terminal UIN = UIN* after fuse F and switch S1

6

1

10

5

11

15

CLV61x CDB620 Host

D-Sub

HD plug,

15-pin

5

.

.

.

TxD

RxD

RxD

TxD

GND

GND

GND

9

7

43

T‒/TxD

44

R

‒/RxD

42

GND

6

Shield

RS-232 RS-232

422

485

S6 : RS

ON

OFF

S7: Term 485

S6

422485

Electrical installation

CLV61x bar code scanner

4.7.2 Wiring the Supply Voltage in the CDB620-001 Connection Module

4.7.3 Wiring the RS-232 serial Host Data Interface in the CDB620-001 Connection Module

30 © SICK AG · Germany · All rights reserved · Subject to change without notice 8015592/ZNI9/2017-06-13

Page 31

Technical Information Chapter 4

amongst

others

CAN

amongst

others

CAN

amongst

others

CAN

Host

Shield

30 31 32 6

30 31 32 6

30 31 32 6

33

34

43

44

6

30 31 32 6

40 41 42 7

40 41 42 7

CDB620

CDB620

CDB620

(Slave)

(Slave)

(Slave)

GN = 01

CLV61x CAN

CLV61x FIELDBUS

CLV61x CAN

CLV61x FIELDBUS

CLV61x CAN

CLV61x FIELDBUS

CLV61x CAN

CLV61x FIELDBUS

(Master)

GN = 63

GN = 02

GN = 03

(max. 32 participants)

Switch

ON

OFF

S2 (TermCAN):

Switch

ON

OFF

S2 (TermCAN):

Switch

ON

OFF

S2 (TermCAN):

21 22 23 6

31 32 33 7

CDM420

Switch

ON

OFF

S4 (TermCAN):

CAN_H

CAN_L

Shield

GND

CAN_H

CAN_L

Shield

GND

CAN_H

CAN_L

Shield

GND

CAN_H

CAN_L

Shield

GND

CAN_H

CAN_L

Shield

GND

GND

GND

RxD

TxD

RS-232

T‒/TxD

R‒/RxD

T+

R+

CDB620

42

CAN

CAN

CAN

amongst

others

CAN

Connection of power supplies as well

as of reading clock sensor e.g. to the

master here not shown.

Switch

ON

OFF

S2 (TermCAN):

Serial Host interface

Alternative connection module:

422

485

S6 (RS):

GN = Device number

Stub

CLV61x

Electrical installation

4.7.4 Wiring the CAN Data Interface in the CDB620-001 Connection Module

8015592/ZNI9/2017-06-13 © SICK AG · Germany · All rights reserved · Subject to change without notice 31

Page 32

Chapter 4 Technical Information

6

1

10

5

11

15

CLV61xCDB620

PNP sensor

V

S

VS

V

S

GND

SensGND

3.32 K

6.64 K

Sensor 1

V

in

UIN* = DC 10 V to 30 V

a) Sensor supplied by CDB620

b) Sensor connected electrically isolated/externally supplied

d) Switch connected electrically isolated/externally supplied

c) Switch supplied by CDB620

14

15

1

5

12

SGND

6

Shield

11

U

IN

*

10 Sens 1

Out

U

IN

*

GND

S3

e.g. photo-electric switch

CDB620

PNP sensor

VS

GND

Connect the switch as shown in b)

12

SGND

6

Shield

11 UIN*

10 Sens 1

Out

U

IN

*

GND

S3

e.g. photo-electric

switch

Function assignment to "Sensor 1" switching input

via SOPAS ("Sensor/Input 1"):

- Start of reading clock

- Stop of reading clock

- Start teach-in matchcode/start code comparison

- Increment input

- if required further functions in the future

UIN*

CDB620

12 SGND

6 Shield

11

U

IN

*

10

Sens 1

GND

S3

ON

OFF

S3 : SGND-GND

ON

OFF

S3 : SGND-GND

ON

OFF

S3 : SGND-GND

V

S ext

Shield

D-Sub HD plug,

15-pin

GND

.

.

.

Shield

Shield

Vin = max. 32 V

Ratings for "Sensor 1" switching input

Power fed to the input starts the assigned

function, e.g. start of reading clock.

(default setting: logic not inverted [active high],

debouncing 10 ms)

– Optodecoupled, reverse polarity protected

– Can be wired with the PNP output of a sensor

– SensGND reference potential valid for all

switching inputs

Low: V

in

≤ 2 V; Iin ≤ 0.3 mA

High: 6 V ≤ V

in

≤ 32 V;

0.7 mA ≤ I

in

≤ 5 mA

Switching

behavior

Features

Electrical

values

Switch S3: SGND-GND

ON: GND of the sensor connected to GND

of CDB620/CLV61x.

OFF: GND of the sensor connected to

SensGND of CDB620/CLV61x

(Sensor connected electrically isolated

to the CDB620/CLV61x).

Selected reference potential valid for all

switching inputs ("Sensor 1/2" and "In 1/2")

SensGND

GND

Electrical installation

CLV61x bar code scanner

4.7.5 Wiring the "Sensor 1" Switching Input in the CDB620-001 Connection Module

32 © SICK AG · Germany · All rights reserved · Subject to change without notice 8015592/ZNI9/2017-06-13

Page 33

Technical Information Chapter 4

Power fed to the input starts the assigned

function, e.g. stop of reading clock.

(default setting: logic not inverted [active high],

debouncing 10 ms)

– Optodecoupled, reverse polarity protected

– Can be wired with the PNP output of a sensor

– SensGND reference potential valid for all

switching inputs

Low: V

in

≤ 2 V; Iin ≤ 0.3 mA

High: 6 V ≤ V

in

≤ 32 V;

0.7 mA ≤ I

in

≤ 5 mA

Switching

behavior

Features

Electrical

values

6

1

10

5

11

15

CLV61xCDB620

PNP sensor

V

S

VS

V

S

GND

SensGND

3.32 K

6.64 K

Sensor 2

V

in

UIN* = DC 10 V to 30 V

a) Sensor supplied by CDB620

b) Sensor connected electrically isolated/externally supplied

d) Switch connected electrically isolated/externally supplied

c) Switch supplied by CDB620

4

15

1

5

15

SGND

7

Shield

14

U

IN

*

13 Sens 2

Out

U

IN

*

GND

S3

e.g. photo-electric switch

CDB620

PNP sensor

VS

GND

Connect the switch as shown in b)

15

SGND

7

Shield

14 UIN*

13 Sens 2

Out

U

IN

*

GND

S3

e.g. photo-electric

switch

Function assignment to "Sensor 2" switching input

via SOPAS ("Sensor/Input 2"):

- Start of reading clock

- Stop of reading clock

- Start teach-in matchcode/start code comparison

- Increment input

- if required further functions in the future

UIN*

CDB620

15 SGND

7 Shield

14

U

IN

*

13

Sens 2

GND

S3

ON

OFF

S3 : SGND-GND

ON

OFF

S3 : SGND-GND

ON

OFF

S3 : SGND-GND

V

S ext

Shield

D-Sub HD plug,

15-pin

GND

.

.

.

Shield

Shield

Vin = max. 32 V

Ratings for "Sensor 2" switching input

SensGND

Switch S3: SGND-GND

ON: GND of the sensor connected to GND

of CDB620/CLV61x.

OFF: GND of the sensor connected to

SensGND of CDB620/CLV61x

(Sensor connected electrically isolated

to the CDB620/CLV61x).

Selected reference potential valid for all

switching inputs ("Sensor 1/2" and "In 1/2")

GND

CLV61x

Electrical installation

4.7.6 Wiring the "Sensor 2" Switching Input in the CDB620-001 Connection Module

8015592/ZNI9/2017-06-13 © SICK AG · Germany · All rights reserved · Subject to change without notice 33

Page 34

Chapter 4 Technical Information

CDB620

18 SGND

8 Shield

11

U

IN

*

16

In 1

CDB620

PNP sensor

V

S

GND

18

SGND

8

Shield

11

U

IN

*

16

In 1

Out

GND

S3

e.g. photo-electric

switch

V

S ext

CLV61xCDB620

PNP sensor

VS

GND

3.32 K

6.64 K

UIN* = DC 10 V to 30 V Vin = max. 32 V

18

SGND

8

Shield

11

U

IN

*

16

In 1

Out

GND

S3

e.g. photo-electric switch

CMC600

UIN*

GND

S3

UIN*

CMC600

CMC600

UIN*

a) Sensor supplied by CDB620

b) Sensor connected electrically isolated and externally supplied

d) Switch connected electrically isolated and externally supplied

c) Switch supplied by CDB620

Connect the switch as shown in b)

Serial Aux

(RS-232)

Function assignment to "External input 1" via SOPAS:

- Start of reading clock

- Stop of reading clock

- Start teach-in matchcode/start code comparison

- if required further functions in the future

Switch S3: SGND-GND

ON: GND of the sensor connected to GND

of CDB620/CMC600.

OFF: GND of the sensor connected to

SensGND of CDB620/CMC600

(Sensor connected electrically isolated

to the CDB620/CMC600).

Selected reference potential valid for all

switching inputs ("Sensor 1/2" and "In 1/2")

ON

OFF

S3 : SGND-GND

No

YES

S4 : CMC

ON

OFF

S3 : SGND-GND

No

YES

S4 : CMC

No

YES

S4 : CMC

ON

OFF

S3 : SGND-GND

V

in

V

in

V

in

Software-controlled, the CMC600 transfers the

switching status of its physical "In 1" input

automatically via the cable to the serial Aux data

interface of the CLV61x.

The CLV61x converts the status internally to its

logical "External input 1“.

"External

input 1"

Ratings for "External input 1"

("In 1“ switching input)

Power fed to the input starts the

assigned function, e.g. start of reading

clock.

(default setting: logic not inverted

[active high], debouncing 10 ms)

– Optodecoupled, reverse polarity

protected

– Can be wired with the PNP output of

a sensor

– SensGND reference potential valid

for all switching inputs

Low: V

in

≤ 2 V; Iin ≤ 0.3 mA

High: 6 V ≤ V

in

≤ 32 V;

0.7 mA ≤ I

in

≤ 5 mA

Switching

behavior

Features

Electrical

values

SensGND

SensGND

SensGND

Electrical installation

CLV61x bar code scanner

4.7.7 Wiring the "External input 1" Switching Input in the CDB620-001 Connection Module

34 © SICK AG · Germany · All rights reserved · Subject to change without notice 8015592/ZNI9/2017-06-13

Page 35

Technical Information Chapter 4

CDB620

18 SGND

8 Shield

14

U

IN

*

17

In 2

CDB620

PNP sensor

V

S

GND

18

SGND

8

Shield

14 UIN*

17 In 2

Out

GND

S3

e.g. photo-electric

switch

V

S ext

CLV61xCDB620

PNP sensor

VS

GND

3.32 K

6.64 K

UIN* = DC 10 V to 30 V Vin = max. 32 V

18

SGND

8

Shield

14

U

IN

*

17

In 2

Out

GND

S3

e.g. photo-electric switch

CMC600

UIN*

GND

S3

UIN*

CMC600

CMC600

UIN*

a) Sensor supplied by CDB620

b) Sensor connected electrically isolated and externally supplied

d) Switch connected electrically isolated and externally supplied

c) Switch supplied by CDB620

Connect the switch as shown in b)

Serial Aux

(RS-232)

Function assignment to "External input 2" via SOPAS:

- Start of reading clock

- Stop of reading clock

- Start teach-in matchcode/start code comparison

- if required further functions in the future

Ratings for "External input 2"

("In 2“ switching input)

Power fed to the input starts the

assigned function, e.g. stop of reading

clock.

(default setting: logic not inverted

[active high], debouncing 10 ms)

– Optodecoupled, reverse polarity

protected

– Can be wired with the PNP output of

a sensor

– SensGND reference potential valid

for all switching inputs

Low: V

in

≤ 2 V; Iin ≤ 0.3 mA

High: 6 V ≤ V

in

≤ 32 V;

0.7 mA ≤ I

in

≤ 5 mA

Switching

behavior

Features

Electrical

values

ON

OFF

S3 : SGND-GND

No

YES

S4 : CMC

ON

OFF

S3 : SGND-GND

No

YES

S4 : CMC

No

YES

S4 : CMC

ON

OFF

S3 : SGND-GND

V

in

V

in

V

in

Software-controlled, the CMC600 transfers the

switching status of its physical "In 2" input

automatically via the cable to the serial Aux data

interface of the CLV61x.

The CLV61x converts the status internally to its

logical "External input 2“.

"External

input 2"

Switch S3: SGND-GND

ON: GND of the sensor connected to GND

of CDB620/CMC600.

OFF: GND of the sensor connected to

SensGND of CDB620/CMC600

(Sensor connected electrically isolated

to the CDB620/CMC600).

Selected reference potential valid for all

switching inputs ("Sensor 1/2" and "In 1/2")

SensGND

SensGND

SensGND

CLV61x

Electrical installation

4.7.8 Wiring the "External input 2" Switching Input in the CDB620-001 Connection Module

8015592/ZNI9/2017-06-13 © SICK AG · Germany · All rights reserved · Subject to change without notice 35

Page 36

Chapter 4 Technical Information

6

1

10

5

11

15

CLV61x

CDB620

U

IN

* = DC 10 V to 30 V

Load (e.g. PLC)

D-Sub HD plug,

15-pin

12

5

.

.

.

20Res 1

22

GND

5Shield

UIN*V

S

GND

Quenching circuit:

Install an anti-surge

diode directly at the

load!

For inductive load:

V

out

Result 1

GND

1

Ratings for "Result 1" switching output

PNP switching against the supply voltage V

S

(default setting: Device Ready (static),

logic: not inverted [active high])

– Short-circuit proof + temperature protected

– Galvanically not separated from V

S

0 V ≤ V

out

≤ V

S

Guaranteed:

(V

S

− 1.5 V) ≤ V

out

≤ VS with I

out

≤ 100 mA

Switching

behavior

Features

Electrical

values

Electrical installation

CLV61x bar code scanner

4.7.9 Wiring the "Result 1" Switching Output in the CDB620-001 Connection Module

36 © SICK AG · Germany · All rights reserved · Subject to change without notice 8015592/ZNI9/2017-06-13

Page 37

Technical Information Chapter 4

6

1

10

5

11

15

PNP switching against the supply voltage V

S

(default setting: Good Read, 100 ms,

logic: not inverted [active high])

– Short-circuit proof + temperature protected

– Galvanically not separated from V

S

0 V ≤ V

out

≤ V

S

Guaranteed:

(V

S

− 1.5 V) ≤ V

out

≤ VS with I

out

≤ 100 mA

Switching

behavior

Features

Electrical

values

CLV61x

CDB620

U

IN

* = DC 10 V to 30 V

Load (e.g. PLC)

D-Sub HD plug,

15-pin

13

5

.

.

.

21Res 2

22

GND

5Shield

UIN*V

S

GND

Quenching circuit:

Install an anti-surge

diode directly at the

load!

For inductive load:

V

out

Result 2

GND

1

Ratings for "Result 2" switching output

Electrical installation

CLV61x

4.7.10 Wiring the "Result 2" Switching Output in the CDB620-001 Connection Module

8015592/ZNI9/2017-06-13 © SICK AG · Germany · All rights reserved · Subject to change without notice 37

Page 38

Chapter 4 Technical Information

Load (e.g. PLC)

GND

Quenching circuit:

Install an anti-surge

diode directly at the

load!

For inductive load:

V

out

Ratings for "External output 1" ("Out 1“ switching output)

PNP switching against the supply voltage UIN*

(default setting: no function/disabled,

logic: not inverted [active high])

– Short-circuit proof + temperature protected

– Galvanically not separated from U

IN

*

0 V ≤ V

out

≤ UIN*

Guaranteed:

(U

IN

* −1.5 V) ≤ V

out

≤ UIN* with I

out

≤ 100 mA

Switching

behavior

Features

Electrical

values

CLV61x

Serial Aux

(RS-232)

CDB620

U

IN

* = DC 10 V to 30 V

CMC600

UIN*

The CLV61x indicates the switching status of its

logical "external output 1" via the serial Aux data

interface.

Software-controlled, the status is automatically

taken over by the CMC600 via the cable and

converted to the physical "Out 1" output in the

CDB620.

"External

output 1"

23Out 1

22

GND

6Shield

Electrical installation

CLV61x bar code scanner

4.7.11 Wiring the "External output 1" Switching Output in the CDB620-001 Connection Module

38 © SICK AG · Germany · All rights reserved · Subject to change without notice 8015592/ZNI9/2017-06-13

Page 39

Technical Information Chapter 4

Load (e.g. PLC)

GND

Quenching circuit:

Install an anti-surge

diode directly at the

load!

For inductive load:

V

out

Ratings for "External output 2" ("Out 2“ switching output)

PNP switching against the supply voltage UIN*

(default setting: no function/disabled,

logic: not inverted [active high])

– Short-circuit proof + temperature protected

– Galvanically not separate from U

IN

*

0 V ≤ V

out

≤ UIN*

Guaranteed:

(U

IN

* −1.5 V) ≤ V

out

≤ UIN* with I

out

≤ 100 mA

Switching

behavior

Features

Electrical

values

CLV61x

Serial Aux

(RS-232)

CDB620

U

IN

* = DC 10 V to 30 V

CMC600

UIN*

The CLV61x indicates the switching status of its

logical "external output 2" via the serial Aux data

interface.

Software-controlled, the status is automatically

taken over by the CMC600 via the cable and

converted to the physical "Out 2" output in the

CDB620.

"External

output 2"

24Out 2

22

GND

6Shield

Electrical installation

CLV61x

4.7.12 Wiring the "External output 2" Switching Output in the CDB620-001 connection module

8015592/ZNI9/2017-06-13 © SICK AG · Germany · All rights reserved · Subject to change without notice 39

Page 40

Chapter 4 Technical Information

ON

OFF

ON

OFF

ON

OFF

CDM420-0001 Connection module

CMC600 parameter cloning module

(optional)

0.8 A T

S8

No CMC ->

SCANNER

AUX interface

6110 5

1115

LEDs

31 32 33 34 35 36 37 38 39 40

T‒/TxD

R‒/RxD

+24 V*

Sensor 1

Aux Out 1

GND

GND

SGND

CAN_H

CAN_L

11 12 13 14 15 16 17 18 19 20

Result 1

Result 2

Aux In 2

Aux In 1

SGND

GND

GND

SGND

internal

internal

21 22 23 24 25 26 27 28 29 30

T+

R+

+24 V*

Sensor 2

Aux Out 2

GND

GND

SGND

CAN_H

CAN_L

1234

+24 V

+24 V

GND

GND

5678

Shield

Shield

Shield

Shield

POWER

Sensor 1

Sensor 2

Result 1

Result 2

S1

POWER

ON

OFF

S2 S3 S4 S6

ON

OFF

ON

OFF

RS485

Term422

Ter mCA N

SGND

to

CLV61x

15

69

to PC

Pin

2: RxD

3: TxD

5: GND

Result 1

PLC

GND

Result 2

External

reading clock sensor

(e.g. photo- electric switch)

V

S

Out

GND

TxD

Host

RxD

GND

RS-232

= An CMC600 is required to provide the additional switching inputs and outputs

VS = DC 10 V ... 30 V on terminal +24 V = +24 V* after fuse F and switch S1

F

V

S

= DC 10 V ... 30 V

RS-232

Electrical installation

CLV61x bar code scanner

4.8 Using the CDM420-0001 Connection Module

4.8.1 Wiring overview (one switching input used)

40 © SICK AG · Germany · All rights reserved · Subject to change without notice 8015592/ZNI9/2017-06-13

Page 41

Technical Information Chapter 4

6

1

10

5

11

15

CLV61x

CDM420-0001

VS

V

S

VS = DC 10 V to 30 V

1

5

5

Shield

1 +24 V

2 GND

+24 V*

GND

S1

F

Shield

D-Sub HD plug,

15-pin

GND

.

.

.

.

.

.

ON

OFF

S1 : POWER

DC 10 V to 30 V

+24 V*

Switch S1:

ON:

Power supply voltage U

V

(+24 V) switched as UV (+24 V*) via fuse to

CDM420-0001 and CLV61x.

U

V

(+24 V*) additionally available on terminals 29 and 39.

OFF:

CDM420-0001 and CLV61x disconnected from power supply voltage.

Recommended position during all electrical installation work.

POWER

VS on terminal "+24 V" complies with terminal "+24 V*" after fuse F and switch S1

6

1

10

5

11

15

CLV61x CDM420-0001 Host

D-Sub

HD plug,

15-pin

5

.

.

.

TxD

RxD

RxD

TxD

GND

GND

GND

9

7

34

T‒/TxD

35

R

‒/RxD

36

GND

6

Shield

RS-232

RS-232

ON

OFF

S2 : RS 485

ON

OFF

S3: Term 422

S2

OFF485

Electrical installation

CLV61x

4.8.2 Wiring the Supply Voltage in the CDM420-0001 Connection Module

4.8.3 Wiring the RS-232 Serial Host Data Interface in the CDM420-0001 Connection Module

8015592/ZNI9/2017-06-13 © SICK AG · Germany · All rights reserved · Subject to change without notice 41

Page 42

Chapter 4 Technical Information

amongst

others

CAN

amongst

others

CAN

amongst

others

CAN

amongst

others

CAN

Shield

30 31 32 6

24

25

34

35

7

40 41 42 7

CDM420

CDM420

CDM420

(Slave)

(Slave)

(Slave)

GN = 01

(Master)

GN = 63

GN = 02

GN = 03

(max. 32 participants)

Stub

Switch

ON

OFF

S4 (TermCAN):

Switch

ON

OFF

S4 (TermCAN):

Switch

ON

OFF

S4 (TermCAN):

21 22 23 6

21 22 23 6

31 32 33 7

21 22 23 6

21 22 23 6

31 32 33 7

CDB620

Switch

ON

OFF

S2 (TermCAN):

CAN_H

CAN_L

Shield

GND

CAN_H

CAN_L

Shield

GND

CAN_H

CAN_L

Shield

GND

CAN_H

CAN_L

Shield

GND

CAN_H

CAN_L

Shield

GND

GND

Host

GND

RxD

TxD

RS-232

T‒/TxD

R‒/RxD

T+

R+

CDM420

26

CAN

CAN

CAN

Switch

ON

OFF

S4 (TermCAN):

Serial Host interface

Alternative connection module:

ON

OFF

S2 (RS485):

Connection of power supplies as well

as of reading clock sensor e.g. to the

master here not shown.

CLV61x CAN

CLV61x FIELDBUS

CLV61x CAN

CLV61x FIELDBUS

CLV61x CAN

CLV61x FIELDBUS

CLV61x CAN

CLV61x FIELDBUS

GN = Device number

Electrical installation

CLV61x bar code scanner

4.8.4 Wiring the CAN Data Interface in the CDM420-0001 Connection module (CLV61x CAN and FIELDBUS series)

42 © SICK AG · Germany · All rights reserved · Subject to change without notice 8015592/ZNI9/2017-06-13

Page 43

Technical Information Chapter 4

6

1

10

5

11

15

CLV61xCDM420-0001

PNP sensor

VS

V

S

V

S

GND

SensGND

3.32 K

6.64 K

Sensor 1

V

in

+24 V* = DC 10 V to 30 V

a) Sensor supplied by CDM420-0001

b) Sensor connected electrically isolated/externally supplied

d) Switch connected electrically isolated/externally supplied

c) Switch supplied by CDM420-0001

14

15

1

5

Out

+24V*

+24V*

+24V*

GND

S6

e.g. photo-electric switch

CDM420-0001

PNP sensor

VS

GND

Connect the switch as shown in b)

Out

GND

S6

e.g. photo-electric

switch

CDM420-0001

GND

S6

ON

OFF

S6 : SGND

ON

OFF

S6 : SGND

ON

OFF

S6 : SGND

V

S ext

Shield

D-Sub HD plug,

15-pin

GND

.

.

.

Shield

Shield

38

Sensor 1

37

SGND

6

Shield

39

+24 V*

38

Sensor 1

37

SGND

6

Shield

39

+24 V*

38

Sensor 1

37

SGND

6

Shield

39

+24 V*

Vin = max. 32 V

Function assignment to "Sensor 1" switching input via SOPAS

("Sensor/Input 1"):

- Start of reading clock

- Stop of reading clock

- Start teach-in matchcode/start code comparison

- Increment input

- if required further functions in the future

Ratings for "Sensor 1" switching input

SensGND

Switch S6: SGND-GND

ON: GND of the sensor connected to GND

of CDM420-0001/CLV61x.

OFF: GND of the sensor connected to

SensGND of CDM420-0001/CLV61x

(Sensor connected electrically isolated

to the CDM420-0001/CLV61x).

Selected reference potential valid for all

switching inputs ("Sensor 1/2" and "In 1/2")

Power fed to the input starts the assigned

function, e.g. start of reading clock.

(default setting: logic not inverted [active high],

debouncing 10 ms)

– Optodecoupled, reverse polarity protected

– Can be wired with the PNP output of a sensor

– SensGND reference potential valid for all

switching inputs

Low: V

in

≤ 2 V; Iin ≤ 0.3 mA

High: 6 V ≤ V

in

≤ 32 V;

0.7 mA ≤ I

in

≤ 5 mA

Switching

behavior

Features

Electrical

values

GND

CLV61x

Electrical installation

4.8.5 Wiring the "Sensor 1" Switching Input in the CDM420-0001 Connection Module

8015592/ZNI9/2017-06-13 © SICK AG · Germany · All rights reserved · Subject to change without notice 43

Page 44

Chapter 4 Technical Information

6

1

10

5

11

15

CLV61xCDM420-0001

PNP sensor

VS

V

S

V

S

GND

SensGND

3.32 K

6.64 K

Sensor 2

V

in

+24 V* = DC 10 V to 30 V

a) Sensor supplied by CDM420-0001

b) Sensor connected electrically isolated/externally supplied

d) Switch connected electrically isolated/externally supplied

c) Switch supplied by CDM420-0001

4

15

1

5

Out

+24V*

+24V*

+24V*

GND

S6

e.g. photo-electric switch

CDM420-0001

PNP sensor

VS

GND

Connect the switch as shown in b)

Out

GND

S6

e.g. photo-electric

switch

CDM420-0001

GND

S6

ON

OFF

S6 : SGND

ON

OFF

S6 : SGND

ON

OFF

S6 : SGND

V

S ext

Shield

D-Sub HD plug,

15-pin

GND

.

.

.

Shield

Shield

28

Sensor 2

27

SGND

7

Shield

29

+24 V*

28

Sensor 2

27

SGND

7

Shield

29

+24 V*

28

Sensor 2

27

SGND

7

Shield

29

+24 V*

V

in

= max. 32 V

Function assignment to "Sensor 2" switching input

via SOPAS ("Sensor/Input 2"):

- Start of reading clock

- Stop of reading clock

- Start teach-in matchcode/start code comparison

- Increment input

- if required further functions in the future

Ratings for "Sensor 2" switching input

SensGND

Switch S6: SGND-GND

ON: GND of the sensor connected to GND

of CDM420-0001/CLV61x.

OFF: GND of the sensor connected to

SensGND of CDM420-0001/CLV61x

(Sensor connected electrically isolated

to the CDM420-0001/CLV61x).

Selected reference potential valid for all

switching inputs ("Sensor 1/2" and "In 1/2")

Power fed to the input starts the assigned

function, e.g. stop of reading clock.

(default setting: logic not inverted (active high),

debouncing 10 ms)

– Optodecoupled, reverse polarity protected

– Can be wired with the PNP output of a sensor

– SensGND reference potential valid for all

switching inputs

Low: V

in

≤ 2 V; Iin ≤ 0.3 mA

High: 6 V ≤ V

in

≤ 32 V;

0.7 mA ≤ I

in

≤ 5 mA

Switching

behavior

Features

Electrical

values

GND

Electrical installation

CLV61x bar code scanner

4.8.6 Wiring the "Sensor 2" Switching Input in the CDM420-0001 Connection Module