Page 1

CLV61x DualPort (PROFINET)

Bar code scanner

O P E R A T I N G I N S T R U C T I O N S

Page 2

Described product

25

CLV61x Dual Port (PROFINET)

Manufacturer

SICK AG

Erwin-Sick-Str. 1

79183 Waldkirch

Germany

Legal information

This work is protected by copyright. Any rights derived from the copyright shall be

reserved for SICK AG. Reproduction of this document or parts of this document is only

permissible within the limits of the legal determination of Copyright Law. Any modifica‐

tion, abridgment or translation of this document is prohibited without the express writ‐

ten permission of SICK AG.

The trademarks stated in this document are the property of their respective owner.

© SICK AG. All rights reserved.

Original document

This document is an original document of SICK AG.

2

O PE R AT I NG IN S TR U CT I ON S | CLV61x DualPort (PROFINET) 8017842/ZOK7/2019-02-01 | SICK

Subject to change without notice

Page 3

Contents

CONTENTS

1 About this document........................................................................ 5

1.1 Information on the operating instructions.............................................. 5

1.2 Scope......................................................................................................... 5

1.3 Explanation of symbols............................................................................ 5

1.4 Further information................................................................................... 6

2 Safety information............................................................................ 7

2.1 Intended use............................................................................................. 7

2.2 Improper use............................................................................................. 8

2.3 Internet protocol (IP) technology.............................................................. 8

2.4 Limitation of liability................................................................................. 8

2.5 Modifications and conversions................................................................ 9

2.6 Requirements for skilled persons and operating personnel.................. 9

2.7 Operational safety and particular hazards.............................................. 10

2.8 Switching off the device........................................................................... 12

2.9 Protection of the environment................................................................. 12

2.10 Repairs...................................................................................................... 12

3 Product description........................................................................... 13

3.1 Product ID.................................................................................................. 13

3.2 Product characteristics............................................................................ 16

4 Transport and storage....................................................................... 25

4.1 Transport................................................................................................... 25

4.2 Transport inspection................................................................................. 25

4.3 Storage...................................................................................................... 25

5 Mounting............................................................................................. 26

5.1 Overview of mounting procedure............................................................. 26

5.2 Preparation for mounting......................................................................... 26

5.3 Mounting location..................................................................................... 29

5.4 Mounting the device................................................................................. 32

6 Electrical installation........................................................................ 33

6.1 Safety......................................................................................................... 33

6.2 Prerequisites for safe operation of the device........................................ 35

6.3 Wiring instructions.................................................................................... 38

6.4 Pin assignments for electrical connections............................................ 38

7 Commissioning.................................................................................. 42

7.1 Overview of the commissioning steps..................................................... 42

7.2 Install and launch the SOPAS ET configuration software...................... 42

7.3 Adjust the device...................................................................................... 43

7.4 Initial commissioning................................................................................ 43

8017842/ZOK7/2019-02-01 | SICK OP E RA T IN G I N ST R UC T IO N S | CLV61x DualPort (PROFINET)

Subject to change without notice

3

Page 4

CONTENTS

8 Operation............................................................................................ 45

8.1 Operating and status indicators.............................................................. 45

9 Maintenance...................................................................................... 48

9.1 Maintenance............................................................................................. 48

9.2 Cleaning..................................................................................................... 48

10 Troubleshooting................................................................................. 51

10.1 Overview of possible errors and faults.................................................... 51

10.2 Detailed fault analysis.............................................................................. 51

10.3 Status log.................................................................................................. 52

10.4 Repairs...................................................................................................... 52

10.5 Returns...................................................................................................... 52

10.6 Replacing the device................................................................................ 53

11 Disposal.............................................................................................. 54

12 Technical data.................................................................................... 55

12.1 optical lens system................................................................................... 55

12.2 Performance............................................................................................. 55

12.3 Interfaces.................................................................................................. 56

12.4 Mechanics/electronics............................................................................. 56

12.5 Ambient data............................................................................................. 57

12.6 Dimensional drawings.............................................................................. 57

12.7 Reading fields........................................................................................... 57

13 Accessories........................................................................................ 61

13.1 Quick release in combination with mounting bracket............................ 61

14 Appendix............................................................................................. 63

14.1 EU declaration of conformity / Certificates............................................. 63

14.2 Certification in accordance with UL60950............................................. 63

14.3 Dimensional drawings (electronic).......................................................... 63

14.4 Signal assignment of cables with open cable end at one end.............. 63

14.5 Notes on PROFINET.................................................................................. 65

14.6 Configuration of the device using command strings.............................. 67

14.7 Abbreviations used................................................................................... 67

4

O PE R AT I NG IN S TR U CT I ON S | CLV61x DualPort (PROFINET) 8017842/ZOK7/2019-02-01 | SICK

Subject to change without notice

Page 5

1 About this document

1.1 Information on the operating instructions

These operating instructions provide important information on how to use devices from

SICK AG.

Prerequisites for safe work are:

Compliance with all safety notes and handling instructions supplied.

•

Compliance with local work safety regulations and general safety regulations for

•

device applications

The operating instructions are intended to be used by qualified personnel and electrical

specialists.

NOTE

Read these operating instructions carefully to familiarize yourself with the device and its

functions before commencing any work.

The instructions constitute an integral part of the product and are to be stored in the

immediate vicinity of the device so they remain accessible to staff at all times. Should

the device be passed on to a third party, these operating instructions should be handed

over with it.

ABOUT THIS DOCUMENT 1

1.2 Scope

These operating instructions do not provide information on operating the machine or

system in which the device is integrated. For information about this, refer to the operat‐

ing instructions of the specific machine.

These operating instructions explain how to incorporate the device into a customer sys‐

tem as an IO device. They are part of the documentation that is provided to users.

Additional information relevant to these operating instructions is provided by the sup‐

plementary information document “Bar code scanner CLV61x Dual Port (PROFINET)”

(German: no. 8017977, English: 8017978). This supplementary information provides a

more detailed description of the procedures for integrating the device in the PROFINET

controller.

Step-by-step instructions are given for all required actions.

These instructions apply to all available variants of the device. For more detailed infor‐

mation for identification of the available device types, see "Type code", page 13.

Available device variants are listed on the online product page at:

www.sick.com/CLV61x_Dual_Port

•

A device variant is used as an example for commissioning, based on the basic parame‐

ter settings for the device.

1.3 Explanation of symbols

Warnings and important information in this document are labeled with symbols. The

warnings are introduced by signal words that indicate the extent of the danger. These

warnings must be observed at all times and care must be taken to avoid accidents, per‐

sonal injury, and material damage.

8017842/ZOK7/2019-02-01 | SICK OP E RA T IN G I N ST R UC T IO N S | CLV61x DualPort (PROFINET)

Subject to change without notice

5

Page 6

1 ABOUT THIS DOCUMENT

DANGER

… indicates a situation of imminent danger, which will lead to a fatality or serious

injuries if not prevented.

WARNING

… indicates a potentially dangerous situation, which may lead to a fatality or serious

injuries if not prevented.

CAUTION

… indicates a potentially dangerous situation, which may lead to minor/slight injuries if

not prevented.

NOTICE

… indicates a potentially harmful situation, which may lead to material damage if not

prevented.

NOTE

… highlights useful tips and recommendations as well as information for efficient and

trouble-free operation.

1.4 Further information

NOTE

Further documentation for the device can be found on the online product page at:

www.sick.com/CLV61x_Dual_Port

•

The following information is available for download there:

Model-specific online data sheets for device variants, containing technical data,

•

dimensional drawing, and specification diagrams

EU declaration of conformity for the product family

•

Dimensional drawings and 3D CAD dimension models in various electronic for‐

•

mats

Device GSD file

•

This documentation, in English and German and other languages if applicable

•

Additional information “CLV61x dual port (PROFINET) bar code scanner" in English

•

(part no. 8017978) and German (part no. 8017977) to help with integrating the

device into PROFINET

Other publications related to the devices described here

•

Publications dealing with accessories

•

Documents on request

Overview of command strings for the device.

Information about configuration of the device can be found in the online help function

of the SOPAS ET configuration software.

6

O PE R AT I NG IN S TR U CT I ON S | CLV61x DualPort (PROFINET) 8017842/ZOK7/2019-02-01 | SICK

Subject to change without notice

Page 7

2 Safety information

2.1 Intended use

The device is an intelligent, opto-electronic SICK ID sensor and is used for automated,

fixed identification and decoding of bar codes on moving or stationary objects. The data

content of the decoded bar codes is sent by the device via PROFINET to the PROFINET

controller (PLC) for further coordinating processing.

NOTE

The bar codes being read must conform to at least quality level C in accordance with

ISO/IEC 15416.

Applications:

Package conveyor

•

Picking stations

•

SICK AG assumes no liability for losses or damage arising from the use of the product,

either directly or indirectly. This applies in particular to use of the product that does not

conform to its intended purpose and is not described in this documentation.

SAFETY INFORMATION 2

2.1.1 Operating restrictions

NOTICE

Radio interference may occur when the device is used in residential areas!

■

Only use the device in industrial environments (EN 61000-6-4).

2.1.2 Conditions for specified enclosure rating

To ensure compliance with the specified IP65 enclosure rating of the device during

operation, the following requirements must be met: If these requirements are not met,

the device does not fulfill any specified enclosure rating.

The cables plugged into the two electrical M12 female connectors must be

•

screwed on tightly.

Any electrical M12 female connector not in use at the end of a line must be sealed

•

with protective plugs that are screwed on tightly (as in the delivery condition).

The M12 male connector of the connecting cable must be tightly screwed to the

•

contacted female connector.

The black rubber cover fitted at the side over the corner must be flush with the

•

device.

NOTICE

Operate the device with the black cover open only for a short time for the following

(type-dependent) tasks as needed:

Inserting or removing the optional memory card

•

Temporary use of the optional USB interface as a service interface

•

During this time, protect the device against moisture and dust.

2.1.3 Conditions for devices with heating

When using heated devices, you must also keep in mind the following points:

■

Use cables suitable for the ambient conditions. When in doubt, please consult

SICK Service.

■

Restricted supply voltage range: 18 V DC ... 30 V DC

8017842/ZOK7/2019-02-01 | SICK OP E RA T IN G I N ST R UC T IO N S | CLV61x DualPort (PROFINET)

Subject to change without notice

7

Page 8

2 SAFETY INFORMATION

■

Connection work only within the temperature range: -25 °C ... +40 °C

■

During mounting, make sure that heat transfer between the device and the sur‐

rounding environment is kept as small as possible. Use appropriate holders

(optional accessories).

■

The device must be in a non-operating state (no mounting or connection work).

2.1.4 Using the USB interface

Device variants with USB interface

NOTE

The USB interface of the device is used in industrial environments only as a service

interface for temporary use (e.g. for configuration, troubleshooting). Permanent use in

real operation of the system as a host interface is not intended.

2.2 Improper use

Any use outside of the stated areas, in particular use outside of the technical specifica‐

tions and the requirements for intended use, will be deemed to be incorrect use.

The device does not constitute a safety component in accordance with the respec‐

•

tive applicable safety standards for machines.

The device must not be used in explosion-hazardous areas, in corrosive environ‐

•

ments or under extreme environmental conditions.

The device must not be used in forklift applications in low temperature conditions.

•

Any use of accessories not specifically approved by SICK AG is at your own risk.

•

WARNING

Danger due to improper use!

Any improper use can result in dangerous situations.

Therefore, observe the following information:

■

Device should be used only in accordance with its intended use.

■

All information in these operating instructions must be strictly observed.

2.3 Internet protocol (IP) technology

NOTE

SICK uses standard IP technology in its products. The emphasis is placed on availability

of products and services.

SICK always assumes the following prerequisites:

The customer ensures the integrity and confidentiality of the data and rights

•

affected by its own use of the aforementioned products.

In all cases, the customer implements the appropriate security measures, such as

•

network separation, firewalls, virus protection, and patch management.

2.4 Limitation of liability

Relevant standards and regulations, the latest technological developments, and our

many years of knowledge and experience have all been taken into account when com‐

piling the data and information contained in these operating instructions. The manufac‐

turer accepts no liability for damage caused by:

■

Non-adherence to the product documentation (e.g., operating instructions)

■

Incorrect use

8

O PE R AT I NG IN S TR U CT I ON S | CLV61x DualPort (PROFINET) 8017842/ZOK7/2019-02-01 | SICK

Subject to change without notice

Page 9

■

Use of untrained staff

■

Unauthorized conversions

■

Technical modifications

■

Use of unauthorized spare parts, consumables, and accessories

With special variants, where optional extras have been ordered, or owing to the latest

technical changes, the actual scope of delivery may vary from the features and illustra‐

tions shown here.

2.5 Modifications and conversions

NOTICE

Modifications and conversions to the device may result in unforeseeable dangers.

Interrupting or modifying the device or SICK software will invalidate any warranty claims

against SICK AG. This applies in particular to opening the housing, even as part of

mounting and electrical installation.

2.5.1 Exception: temporarily opening the cover on the device

NOTICE

The user may open the housing only in order to obtain temporary access to the optional

USB interface or the optional slot for a memory card, depending on type. For this pur‐

pose, the corresponding black rubber cover fitted at the side over the corner on the

device can be opened temporarily.

In open state, the device does not conform to a specified enclosure rating. The device

must be protected appropriately against moisture and dust.

SAFETY INFORMATION 2

Operate the device only for a short time without closed cover.

b

For further warranty provisions, see the General Terms and Conditions of SICK AG, e.g.

on the delivery note of the device.

2.6 Requirements for skilled persons and operating personnel

WARNING

Risk of injury due to insufficient training.

Improper handling of the device may result in considerable personal injury and material

damage.

■

All work must only ever be carried out by the stipulated persons.

This product documentation refers to the following qualification requirements for the

various activities associated with the device:

■

Instructed personnel have been briefed by the operator about the tasks assigned

to them and about potential dangers arising from improper action.

■

Skilled personnel have the specialist training, skills, and experience, as well as

knowledge of the relevant regulations, to be able to perform tasks delegated to

them and to detect and avoid any potential dangers independently.

■

Electricians have the specialist training, skills, and experience, as well as knowl‐

edge of the relevant standards and provisions to be able to carry out work on elec‐

trical systems and to detect and avoid any potential dangers independently. In Ger‐

many, electricians must meet the specifications of the BGV A3 Work Safety Regu‐

lations (e.g. Master Electrician). Other relevant regulations applicable in other

countries must be observed.

8017842/ZOK7/2019-02-01 | SICK OP E RA T IN G I N ST R UC T IO N S | CLV61x DualPort (PROFINET)

Subject to change without notice

9

Page 10

2 SAFETY INFORMATION

The following qualifications are required for various activities:

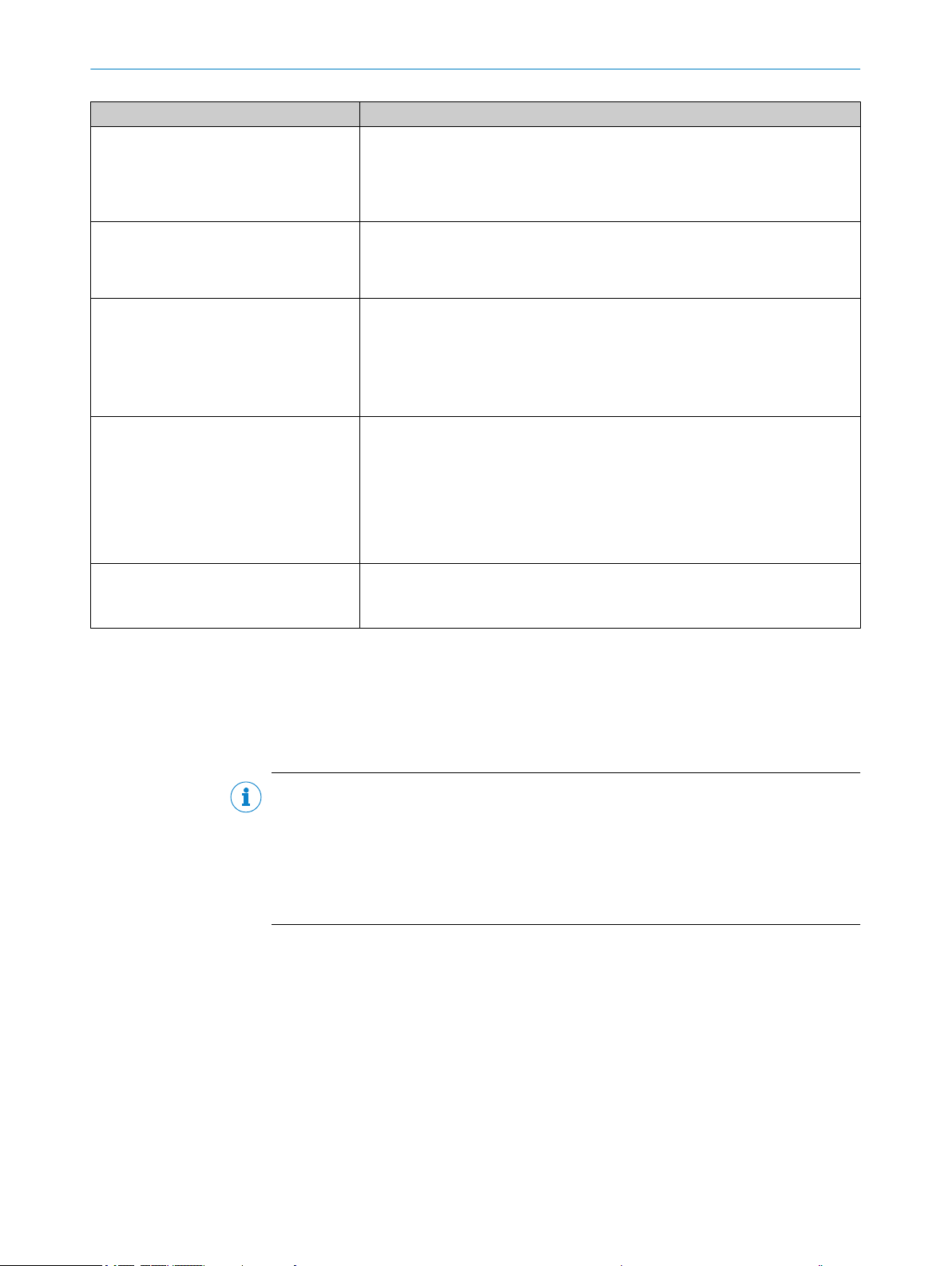

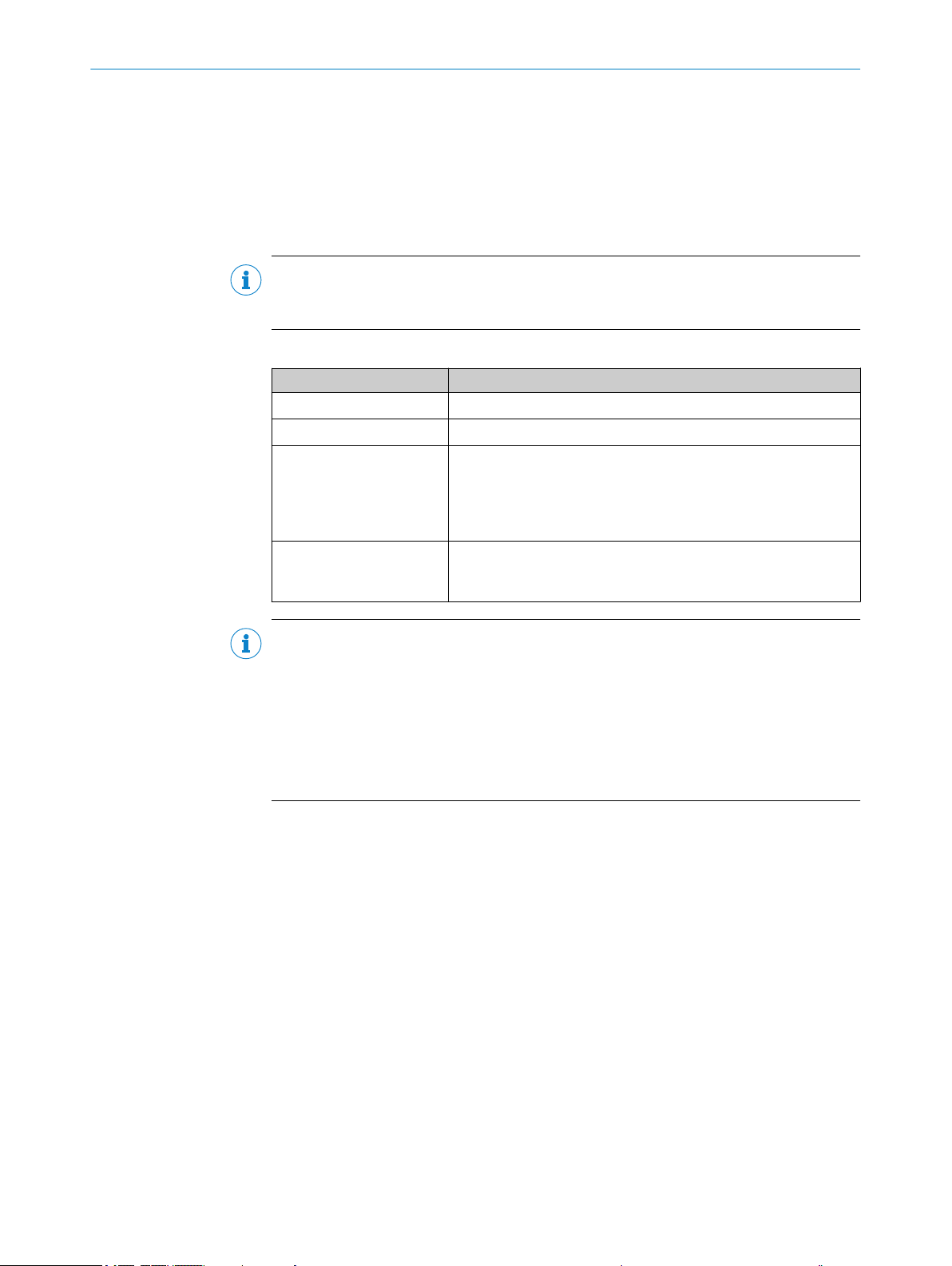

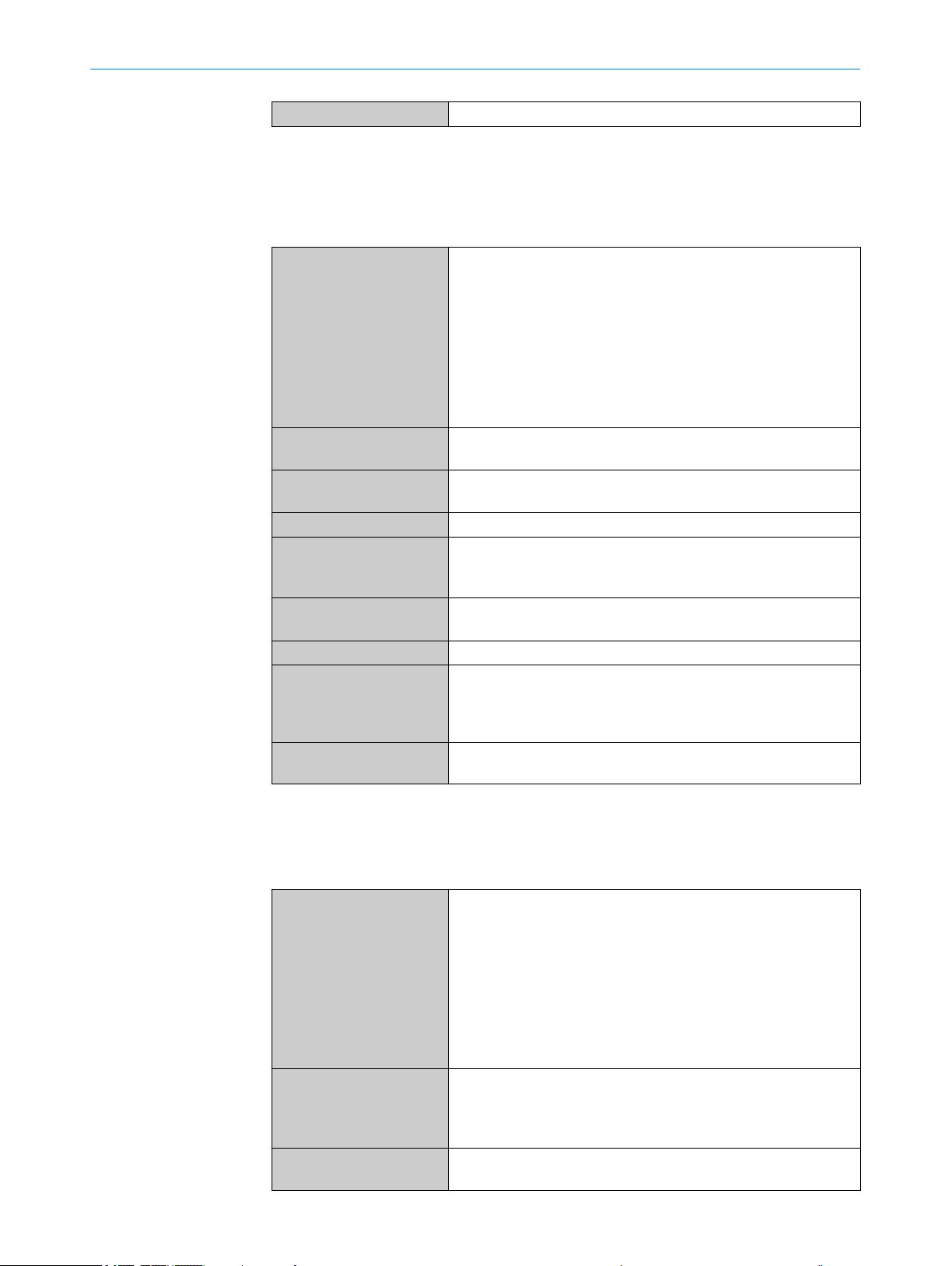

Table 1: Activities and technical requirements

Activities Qualification

Mounting, maintenance

Electrical installation,

device replacement

Commissioning, configura‐

tion

Operation of the device for

the particular application

2.7 Operational safety and particular hazards

Basic practical technical training

■

Knowledge of the current safety regulations in the workplace

■

Practical electrical training

■

Knowledge of current electrical safety regulations

■

Knowledge of the operation and control of the devices in their

■

particular application

Basic knowledge of the WindowsTM operating system in use

■

Basic knowledge of the design and setup of the described con‐

■

nections and interfaces

Basic knowledge of data transmission

■

Basic knowledge of bar code technology

■

Knowledge of the operation and control of the devices in their

■

particular application

Knowledge of the software and hardware environment for the

■

particular application

Please observe the safety notes and the warnings listed here and in other chapters of

this product documentation to reduce the possibility of risks to health and avoid dan‐

gerous situations.

CAUTION

Optical radiation: Laser class 2

The human eye is not at risk when briefly exposed to the radiation for up to 0.25 sec‐

onds. Exposure to the laser beam for longer periods of time may cause damage to the

retina. The laser radiation is harmless to human skin.

■

Do not look into the laser beam intentionally.

■

Never point the laser beam at people's eyes.

■

If it is not possible to avoid looking directly into the laser beam, e.g., during com‐

missioning and maintenance work, suitable eye protection must be worn.

■

Avoid laser beam reflections caused by reflective surfaces. Be particularly careful

during mounting and alignment work.

■

Do not open the housing. Opening the housing may increase the level of risk.

■

Current national regulations regarding laser protection must be observed.

WARNING

Electrical voltage!

Electrical voltage can cause severe injury or death.

■

Work on electrical systems must only be performed by qualified electricians.

■

The power supply must be disconnected when attaching and detaching electrical

connections.

■

The product must only be connected to a voltage supply as set out in the require‐

ments in the operating instructions.

■

National and regional regulations must be complied with.

■

Safety requirements relating to work on electrical systems must be complied with.

10

O PE R AT I NG IN S TR U CT I ON S | CLV61x DualPort (PROFINET) 8017842/ZOK7/2019-02-01 | SICK

Subject to change without notice

Page 11

1

2

P1

P2

LASER

2

SAFETY INFORMATION 2

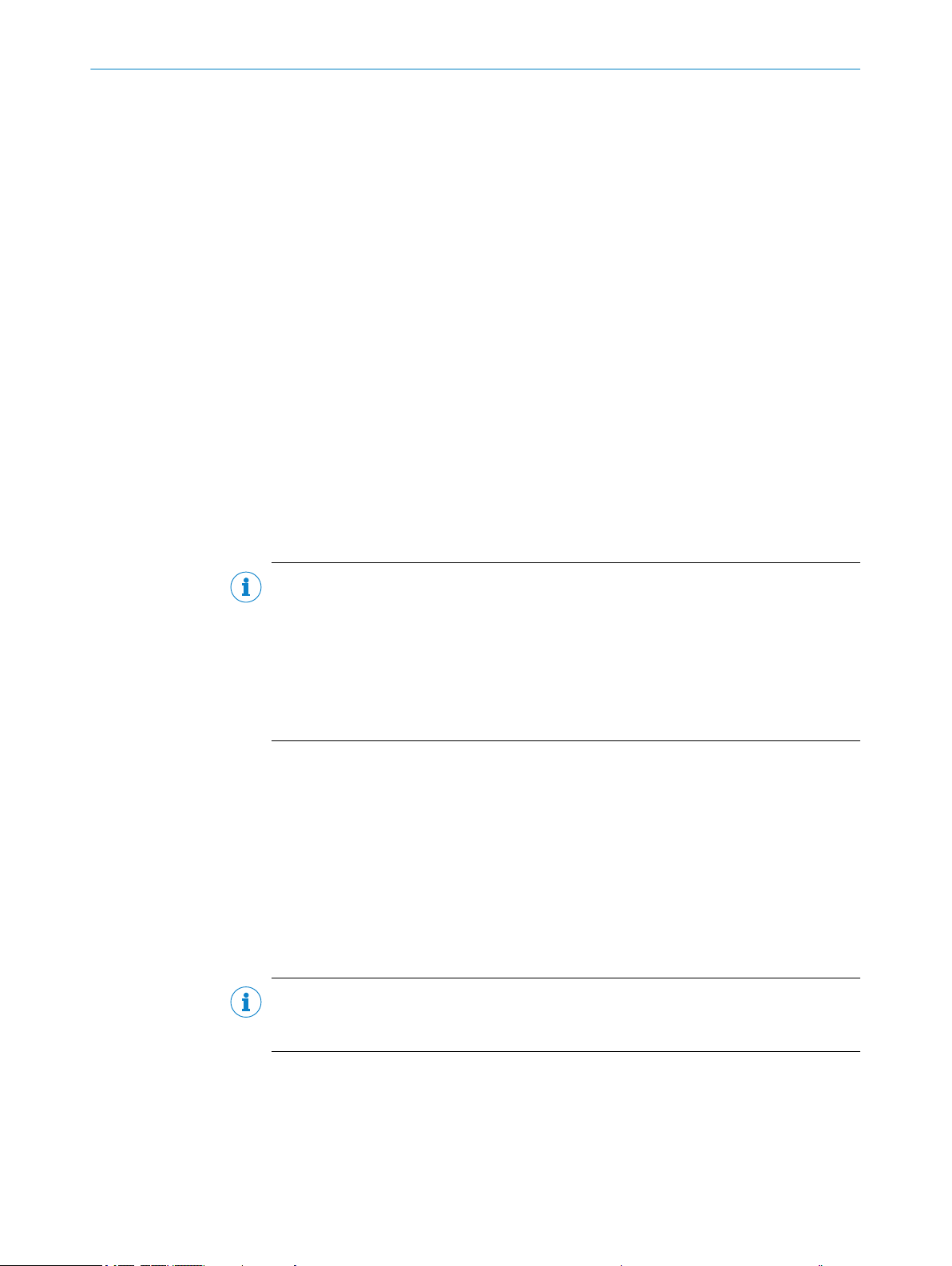

WARNING

Risk of injury and damage caused by potential equalization currents!

Improper grounding can lead to dangerous equipotential bonding currents, which may

in turn lead to dangerous voltages on metallic surfaces, such as the housing. Electrical

voltage can cause severe injury or death.

■

Work on electrical systems must only be performed by qualified electricians.

■

Follow the notes in the operating instructions.

■

Install the grounding for the product and the system in accordance with national

and regional regulations.

Additional information about laser radiation

The device uses a red light laser diode.

The entire reading window is a laser output aperture.

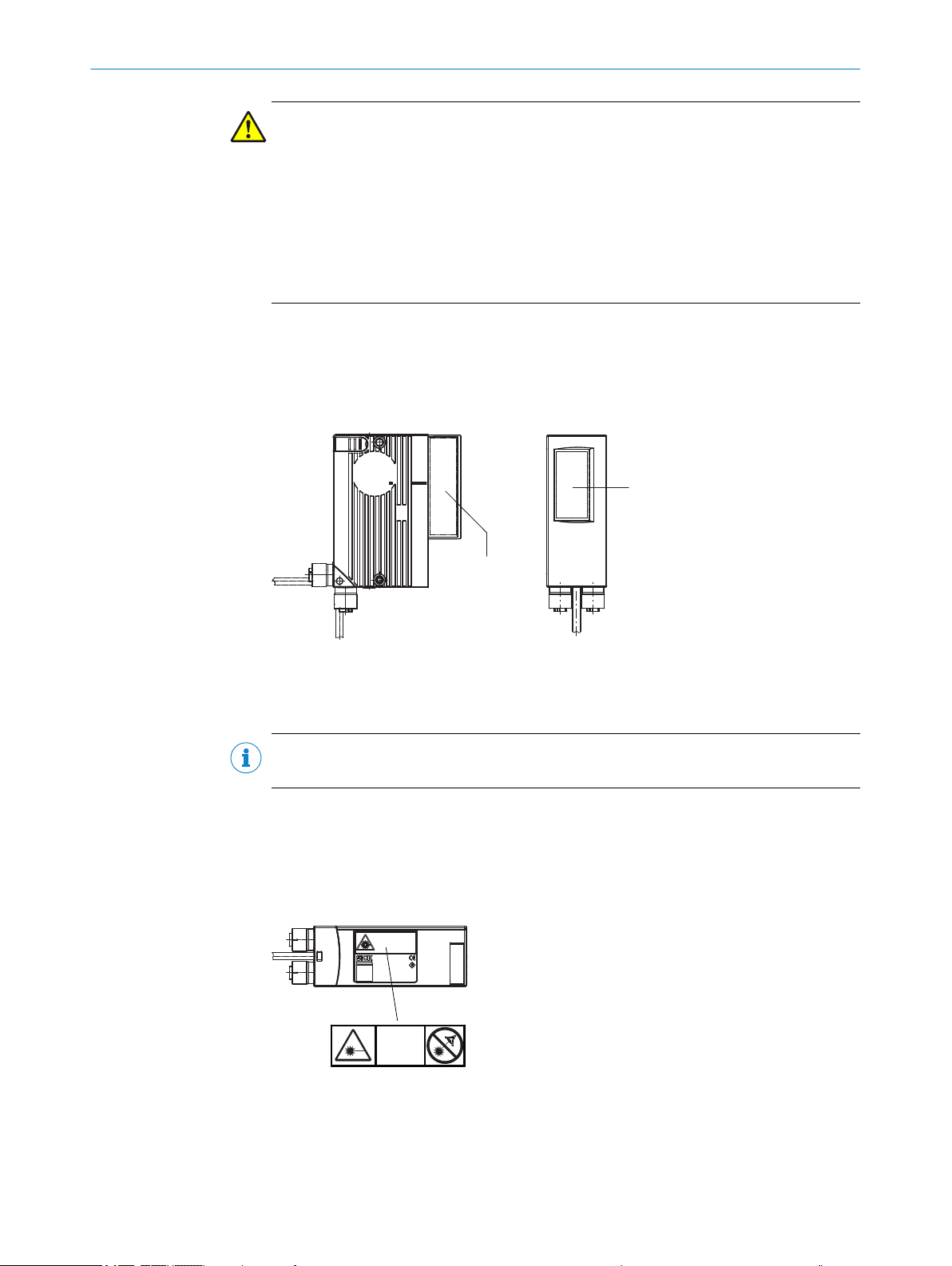

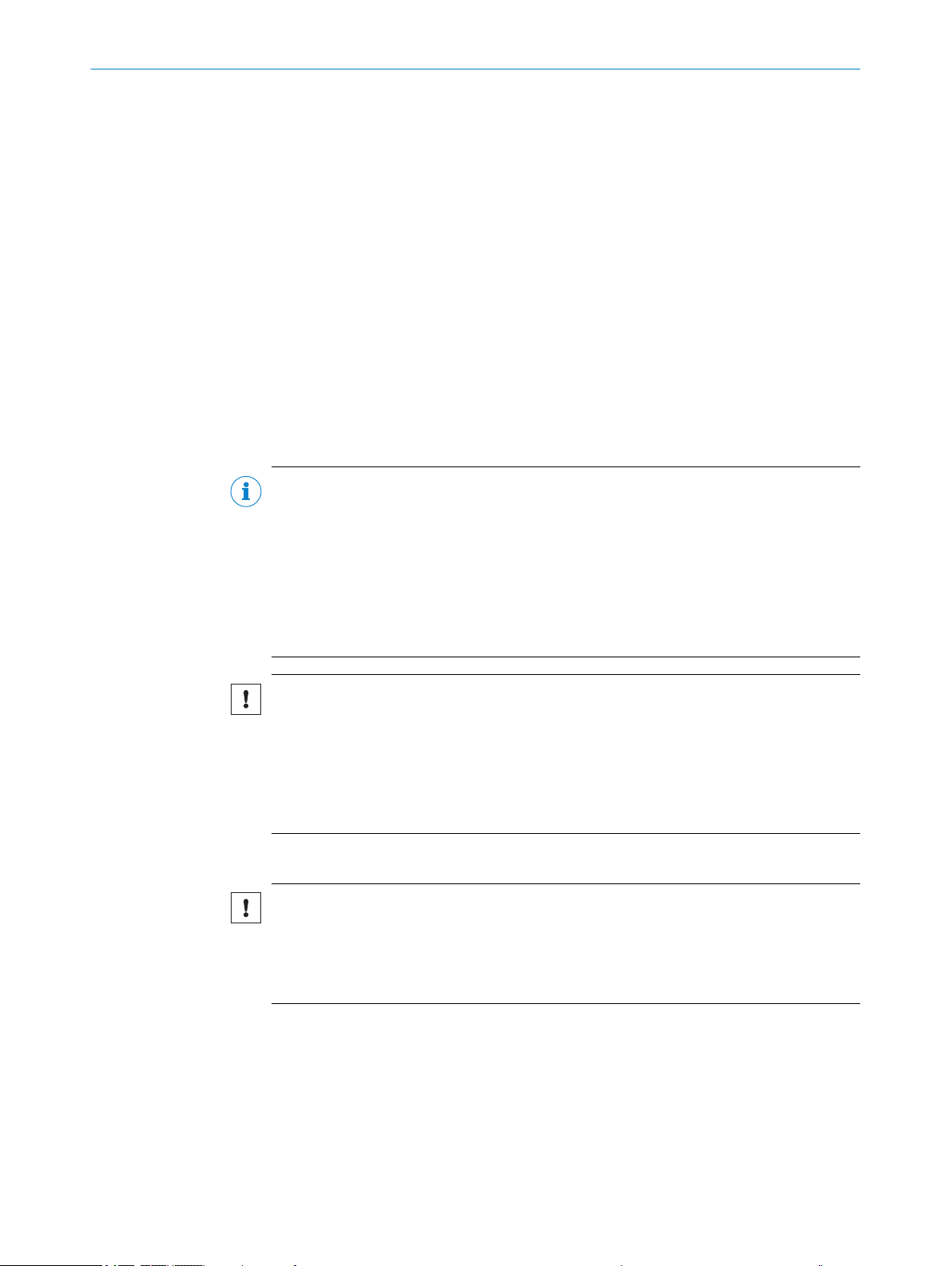

Figure 1: Laser output aperture in the housing

Laser output on side

1

Laser output on front

2

NOTE

No maintenance is required to ensure compliance with Laser Class 2.

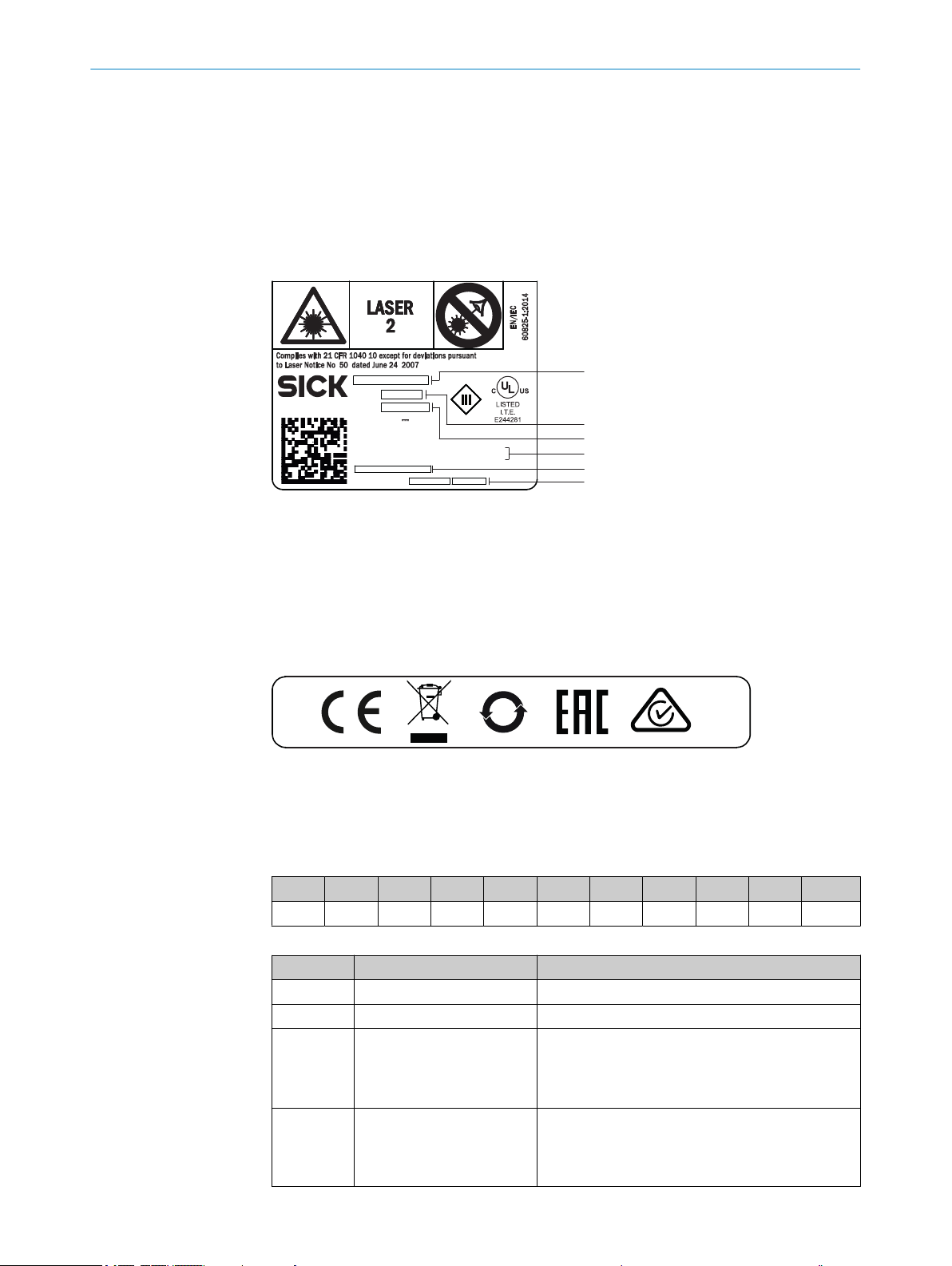

Warning symbol on the device

The laser warning label is affixed on the rear of the device in combination with the type

label.

In addition to other information, the type label also contains the relevant laser output

data.

Figure 2: Laser warning label

Meaning of the laser warning label:

Laser radiation – Never look into the light beam – Laser Class 2

8017842/ZOK7/2019-02-01 | SICK OP E RA T IN G I N ST R UC T IO N S | CLV61x DualPort (PROFINET)

Subject to change without notice

11

Page 12

2 SAFETY INFORMATION

NOTE

Additional laser warning label

If the laser warning label affixed to the device is concealed when the device is installed

into a machine or paneling, the laser beam outlet opening must be suitably labeled on

the machine. For this purpose, an additional warning label must be affixed next to the

output opening.

Controlling the laser diode

When operating properly in real conditions, the device will only switch the laser diode on

if there is an object in the reading area, or if a reading is required (pulsed reading oper‐

ation). This operating mode results in a longer laser diode service life than with a laser

diode that is switched on in continuous operation.

A laser timeout can switch off the laser diode automatically in this type of object trigger

control if the pulse has been active for too long (e.g., the conveyor system has

stopped). In this case, the current internal reading interval of the device remains open.

Depending on the selected parameterization type, the laser timeout can be set as fol‐

lows:

•

•

In the default setting, the laser timeout is deactivated.

Using the SOPAS ET configuration software, on the Illumination Control device page.

With GSD parameterization, using the “10_Object Trigger Ctrl” module.

The laser diode is permanently or repeatedly switched on in the following device sta‐

tuses:

■

In the “Percentage Evaluation” and “Auto Setup” operating modes (only used tem‐

porarily for configuration/diagnostics)

■

In reading operation in the pulsing types “Auto pulse” (adjustable pulse/pause

ratio) or “Free”.

If the timeout is activated, it will have no effect in this case.

NOTE

The device has no optical indicator (LED) for laser diode activity.

2.8 Switching off the device

When switching off the device, at the most, the following data will be lost:

■

Application-specific parameter sets that were only temporarily stored in the device

■

Last reading result

■

Daily operating hours counter

2.9 Protection of the environment

During construction of the device, attention was paid to achieving the smallest environ‐

mental impact possible. Apart from the housing, the device contains no materials using

silicon.

2.10 Repairs

12

O PE R AT I NG IN S TR U CT I ON S | CLV61x DualPort (PROFINET) 8017842/ZOK7/2019-02-01 | SICK

Repair work on the device may only be performed by qualified and authorized person‐

nel from SICK AG. Interruptions or modifications to the device by the customer will inval‐

idate any warranty claims against SICK AG.

Subject to change without notice

Page 13

3 Product description

1240 0001

S/N:

DC 10...30V 2.8W

1

2

3

4

5

Manufactured:

D-79276 Reute

Made in Germany

λ = 655nm

Pmax=1.5mW

P<1.0mW average

Pulse duration <300µs

Imax=700mA

P/N: 1057125

CLV610-C000

MAC

6

25

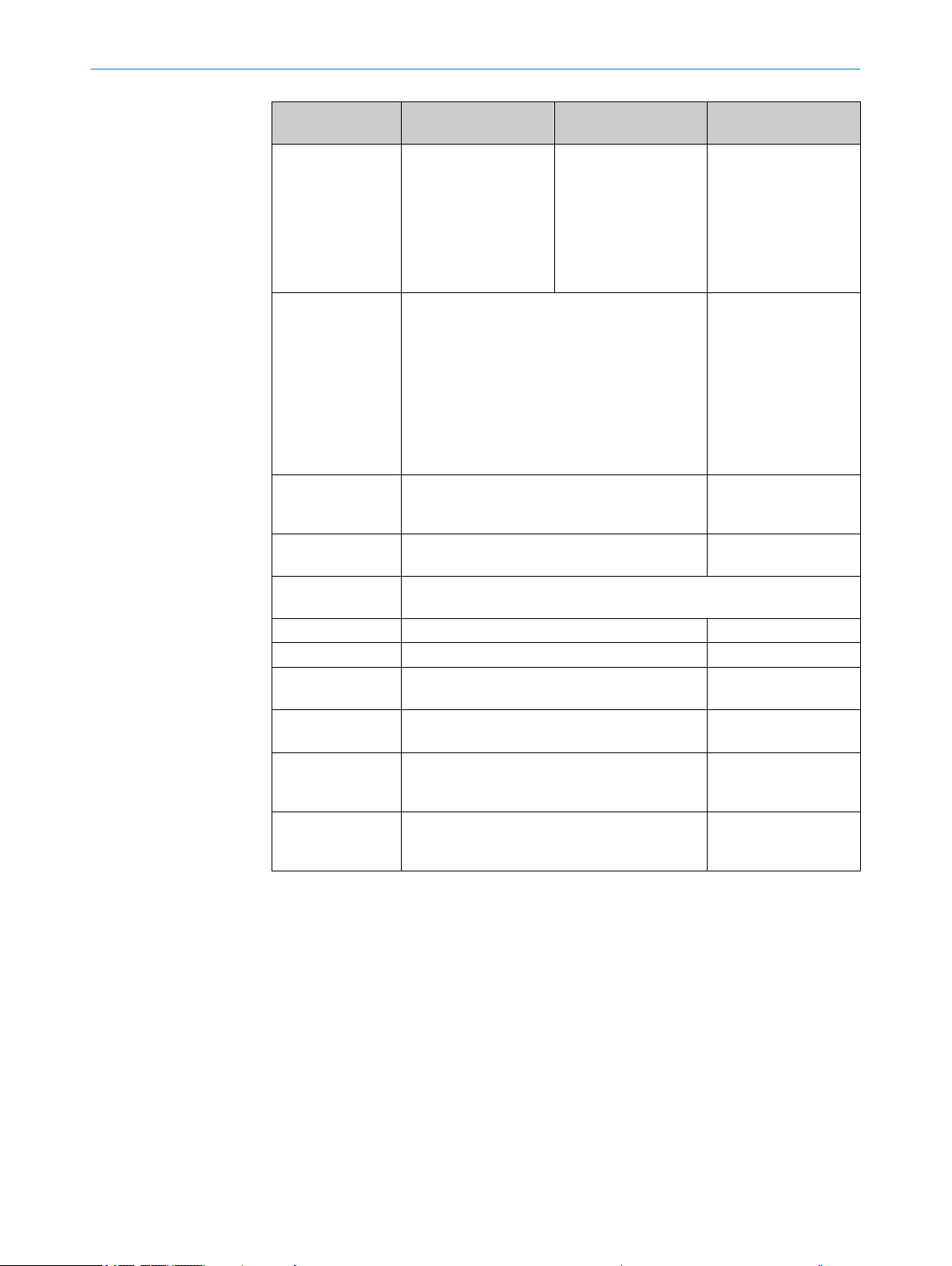

3.1 Product ID

3.1.1 Type label

The type label gives information for identification of the device. An existing UL certifica‐

tion can be found on the type label.

Figure 3: Type label design for the device, illustration may differ from actual type label

Type designation

1

Part number

2

Serial number

3

Laser output data

4

MAC address, if Ethernet interface is available

5

Date of manufacture

6

PRODUCT DESCRIPTION 3

3.1.2 Type code

The devices of the CLV61x product subfamily are classified according to the following

type code:

CLVxyz-abcdef

CLV x y z ‒ a b c d e f

1 2 3 4 5 6 7 8 9 10

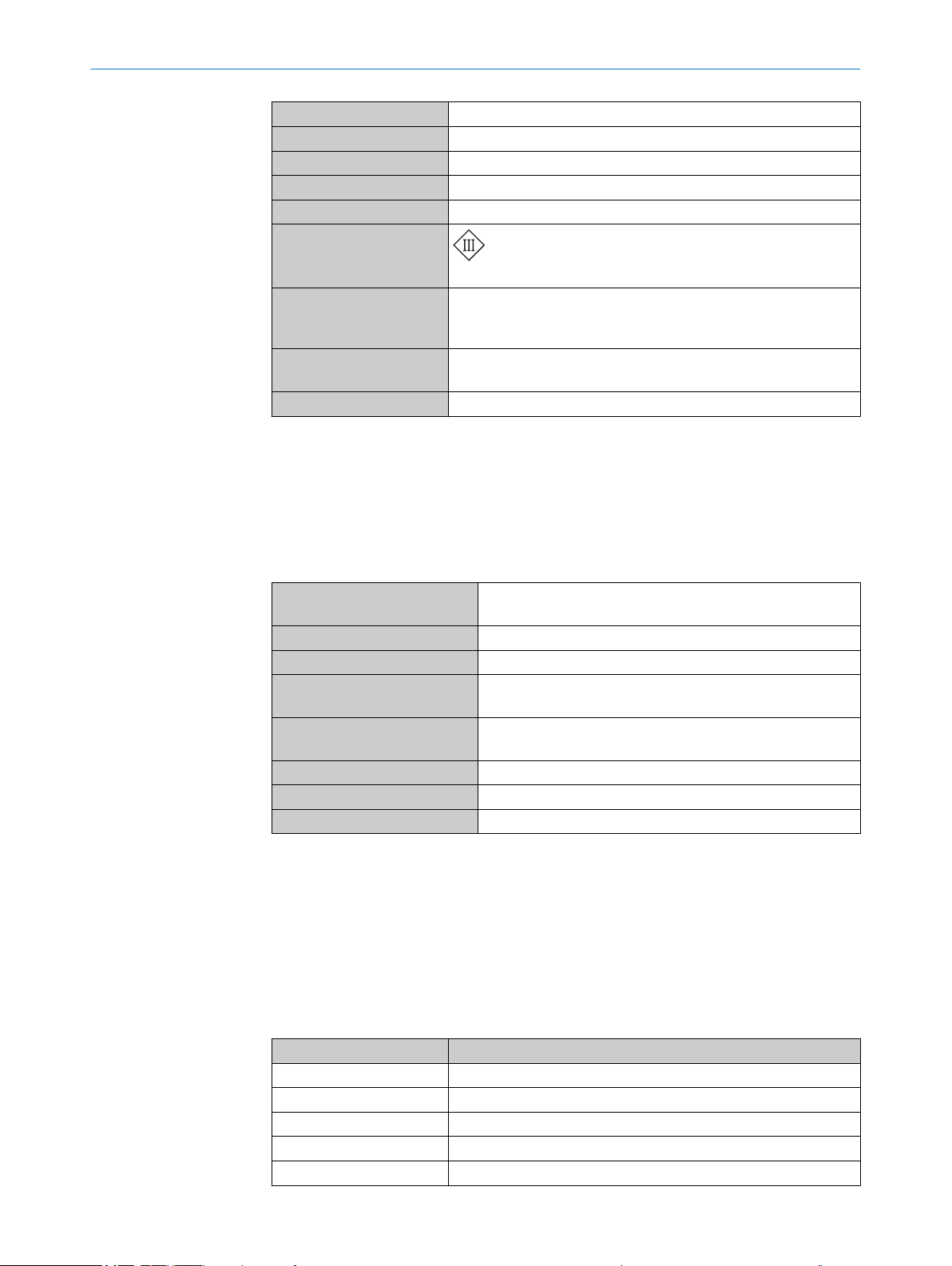

Table 2: Type code

Position Description Characteristic

1 Code reader, V-principle ‒

2 – 3 Product family 61: CLV61x

4 Working range 0: Mid range

2: Short range

5: Long range

8: Long range

5 Performance C: CAN

8017842/ZOK7/2019-02-01 | SICK OP E RA T IN G I N ST R UC T IO N S | CLV61x DualPort (PROFINET)

Subject to change without notice

D: Dual Port PROFINET

F: Fieldbus (Dual Port) over external fieldbus mod‐

ule CDF600-2

13

Page 14

3 PRODUCT DESCRIPTION

Position Description Characteristic

6 Scanning method, reading

7 Electrical connections

8 Interfaces 0: Host (RS-232), AUX (RS-232), digital I/Os

9 Front screen material 0: Glass

10 Application (ambient tem‐

1)

2 x digital switching inputs and 2 x digital switching outputs.

2)

USB interface only for temporary use as a service interface.

3)

For service functions such as parameter cloning.

window orientation

(design)

perature)

1)

0: Line scanner, reading window on front

1: Raster scanner, reading window on front

2: Line scanner, reading window on side

3: Raster scanner, reading window on side

0: Cable 0.9 m with male connector, D-Sub-HD,

15-pin

4: Swivel connector, 2 x female connectors, M12,

4-pin, D-coded +1 x cable 0.9 m with male connec‐

tor, M12, 4-pin, A-coded

5: Swivel connector, 2 x female connectors, M12,

4-pin, D-coded +1 x cable 0.9 m with male connec‐

tor, M12, 5-pin, A-coded

1)

1: Host (Ethernet), AUX (Ethernet, USB 2))

2: Host (Ethernet), AUX (Ethernet, USB 2)), 1 x digital

switching input

3: Host (Ethernet), AUX (Ethernet), 1 x external para‐

meter storage (microSD memory card)

3)

4: Host (Ethernet), AUX (Ethernet), 1 x external para‐

meter storage (microSD memory card) 3), 1 x digital

switching input

1: Plastic

Without label: Standard (0 °C ... +40 °C)

F0: With integrated heating (‒35 °C ... +40 °C)

NOTE

Not all combinations are possible according to the type code. The available device vari‐

ants can be found online at:

3.1.3 Device variants

The CLV61x product family consists of 3 variant lines:

Among other things, the variant lines differ with respect to the following features:

Table 3: Differences between the variant lines

www.sick.com/CLV61x_Dual_Port

•

CLV61x CAN

•

CLV61x FIELDBUS (in combination with the optional fieldbus module CDF600)

•

CLV61x Dual Port

•

Feature CLV61x CAN CLV61x FIELDBUS CLV61x Dual Port

(PROFINET)

Purpose Data output to host via

RS-232

Connection to fieldbus

via optional fieldbus

Direct integration in

line or ring topology

module CDF600

(Dual Port switch)

14

O PE R AT I NG IN S TR U CT I ON S | CLV61x DualPort (PROFINET) 8017842/ZOK7/2019-02-01 | SICK

Subject to change without notice

Page 15

PRODUCT DESCRIPTION 3

Feature CLV61x CAN CLV61x FIELDBUS CLV61x Dual Port

(PROFINET)

Electrical Interfaces

Type of electrical

connections

Power

•

RS-232

•

(Host, AUX)

CAN

•

2 digital switching

•

inputs

2 digital switching

•

outputs

Power

•

RS-232

•

(Host, AUX)

CAN

•

2 digital switching

•

inputs

2 digital switching

•

outputs

Power

•

Ethernet

•

(Host, AUX)

USB Micro-B or

•

microSD memory card

1) 2) 5)

1 digital switching

•

input

1)

1 x male connector, D-Sub-HD, 15-pin 2 x female connectors,

M12, 4-pin, D-coded in

swivel connector

1 x male connector, 4-

or 5-pin, A-coded

1 x female connector,

5-pin, USB Micro-B type

or

microSD memory card

1)

1)

Supply voltage DC 10 V ... 30 V DC 10 ... 30 V

DC 18 ... 30 V

Power consumption Typically 2.8 W

4)

Typically 4 W

Typically 15 W 3)

Special evaluation

SMART620 decoder

feature

Memory card – Optional 1)

Heating – Optional

Ambient operating

temperature

Storage tempera‐

ture

Dimensions for

device with front

0 °C ... +40 °C 0 °C ... +40 °C

–35 °C ... +40 °C 1)

–20 °C ... +70 °C –20 °C ... +70 °C

–35 °C ... +70 °C 1)

61 mm x 66 mm x 38 mm 61 mm x 96 mm x

38 mm

1)

reading window

Dimensions for

device with side

80 mm x 66 mm x 38 mm 80 mm x 96 mm x

38 mm

reading window

1)

Depending on type.

2)

USB interface only for temporary use as a service interface.

3)

For device variants with integrated heating.

4)

For switching outputs without load.

5)

USB interface or memory card shaft.

3)

4)

4)

5)

3)

3)

Designation of device variants

Device variants with serial data interfaces only (RS-232, RS422/485) are referred

•

to as “serial variants”. They also feature a CAN interface. The connecting cable

with a D-Sub male connector is permanently connected to the housing.

Device variants with serial data interfaces and two additional Ethernet interfaces

•

are referred to as “Dual Port variants”. They feature a swivel connector on the

housing with two M12 female connectors and a separate connecting cable with an

M12 male connector.

The corresponding number of digital switching inputs and outputs depends on the

•

design of the electrical connection.

8017842/ZOK7/2019-02-01 | SICK OP E RA T IN G I N ST R UC T IO N S | CLV61x DualPort (PROFINET)

Subject to change without notice

15

Page 16

1

42

ã

â

á

ß

65.3 (2.57)

38 (1.50)

Ready

G Read

N Read

HW Err

UserDef1

SF

BF

P1 LNK/ACT

P2 LNK/ACT

P1 P2

50°

61 (2.40)

96 (3.78)

(15

(0.59))

1

2

3

4

41.7

(1.64)

6.2 (0.24)

19.5 (0.77)

43.7

(1.72)

5

3

85 (3.35)

9 (0.35)

22

(0.87)

35.3

(1.39)

(25.7

(1.01))

65.3

(2.57)

(30.6

(1.20))

10 (0.39)

5.7 (0.22)

13.7 (0.54)

19.5 (0.77)

1

423

5

6

7

8

9

à

(15

(0.59))

15

(0.59)

(15

(0.59))

10 (0.39)

5.7 (0.22)

22.5

(0.89)

22.5

(0.89)

3 PRODUCT DESCRIPTION

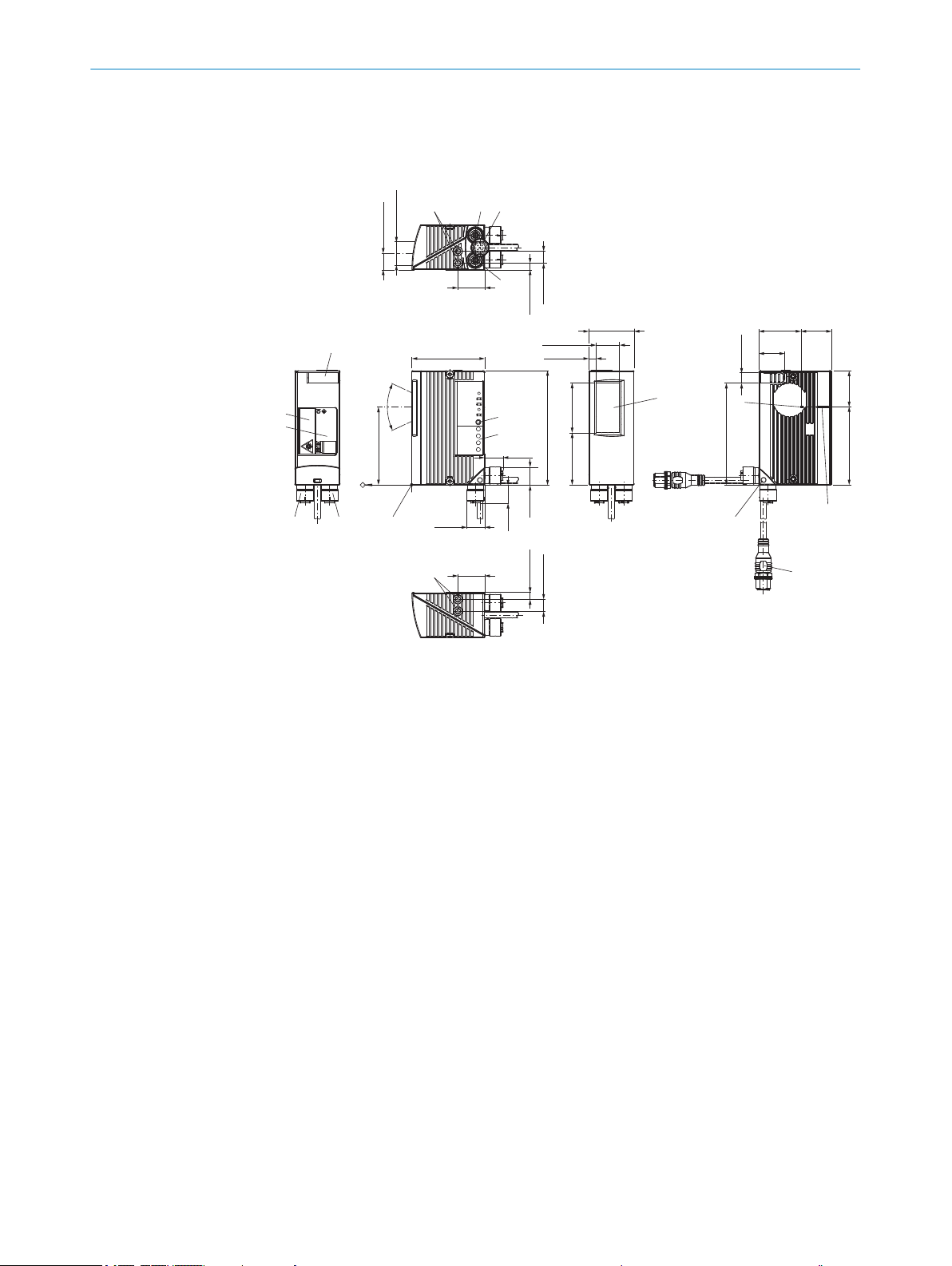

3.2 Product characteristics

3.2.1 Device view

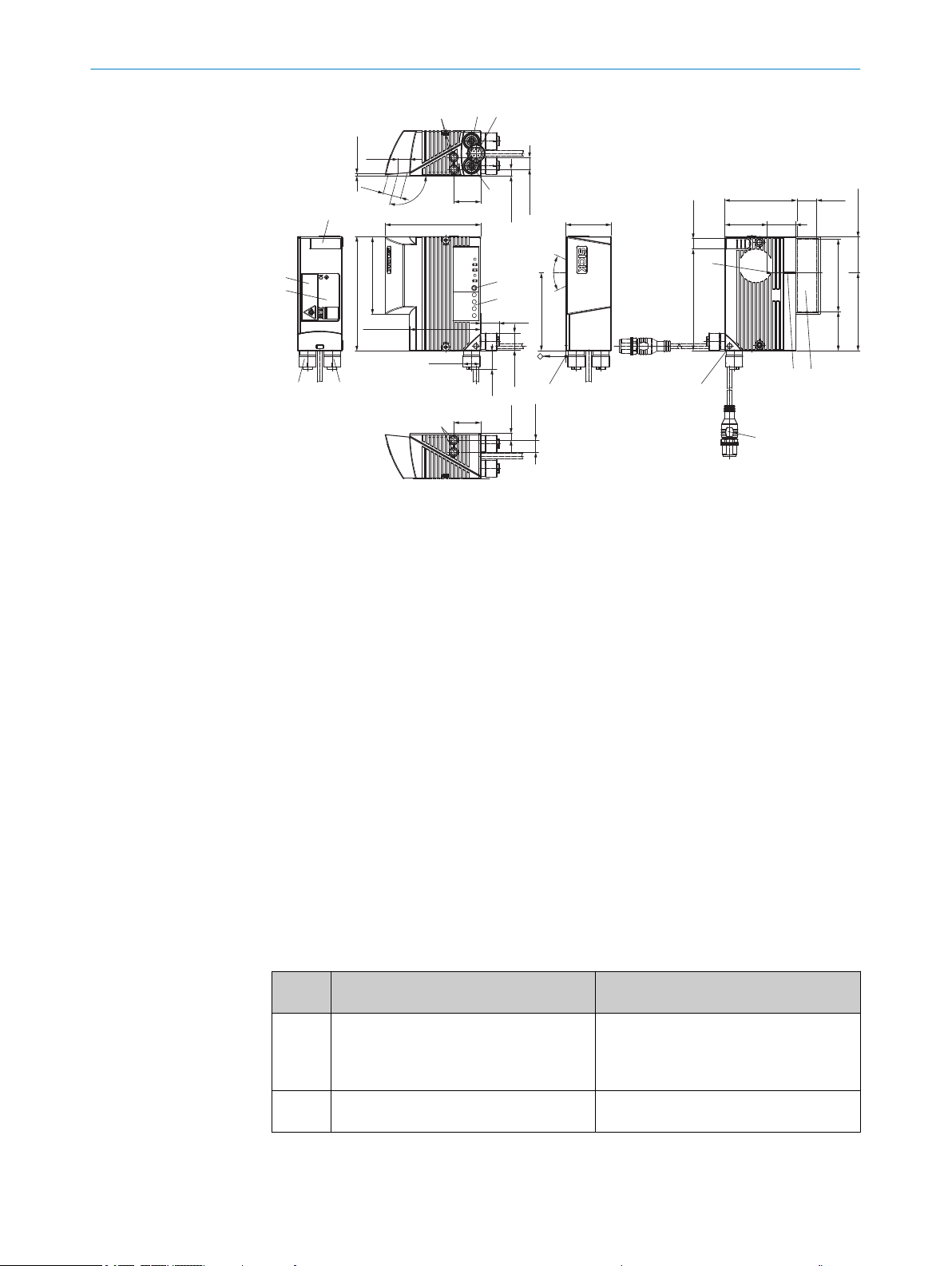

Figure 4: CLV61x Dual Port: design and device dimensions with front reading window (in mm or

inches)

M5 blind tapped holes, 5 mm deep (2 x), for mounting the device

1

P1 (PROFINET port 1) connection, female connector, M12, 4-pin, D-coded

2

Cable (0.9 m), type-dependent with POWER connection (male connector, M12, 4-pin, A-

3

coded) or with POWER + trigger input connection (male connector, M12, 5-pin, A-coded)

P2 (PROFINET port 2) connection, M12, female connector, 4-pin, D-coded

4

Internal impact point: Rotation point of the variable direction laser beam

5

Central position of the deflected laser beam in the V-shaped aperture angle

6

Swivel connector unit (max 180° rotation angle from end position to end position)

7

Reading window, orientation on front

8

RGB LED (1 x), status indicator with signal color allocation for events

9

LED (4 x), status indicator for PROFINET

ß

Reference point for reading distance from device (housing edge) to object

à

Type label

á

Laser warning label

â

Cover for USB connection 1) (female connector, 4-pin, Micro-B type) or for memory card

ã

shaft (microSD), type-dependent

1)

16

Service interface, for temporary use only

O PE R AT I NG IN S TR U CT I ON S | CLV61x DualPort (PROFINET) 8017842/ZOK7/2019-02-01 | SICK

Subject to change without notice

Page 17

15

(0.59)

10

(0.39)

22.5

(0.89)

2 (0.08)

5.7 (0.22)

105°

80 (3.15)

96 (3.78)

65 (2.56)

59.5 (2.34)

(15

(0.59))

(14.15

(0.56))

65.2 (2.57)

50°

38 (1.5)

60.4 (2.38)

16.4

(0.65)

35.3

(1.39)

(24.1

(0.95))

9 (0.35)85 (3.35)

(30.6 (1.2))

60.5 (2.38)

32.8

(1.29)

65.3 (2.57)

Ready

G Read

N Read

HW Err

UserDef1

SF

BF

P1 LNK/ACT

P2 LNK/ACT

1

4

2

3

1

2

3

4

6

5

7

3

1

P1

P2

42

8

ã

â

á

à

ß

9

10

(0.39)

5.7

(0.22)

22.5

(0.89)

10 (0.39)

(14.15

(0.56))

(15

(0.59))

PRODUCT DESCRIPTION 3

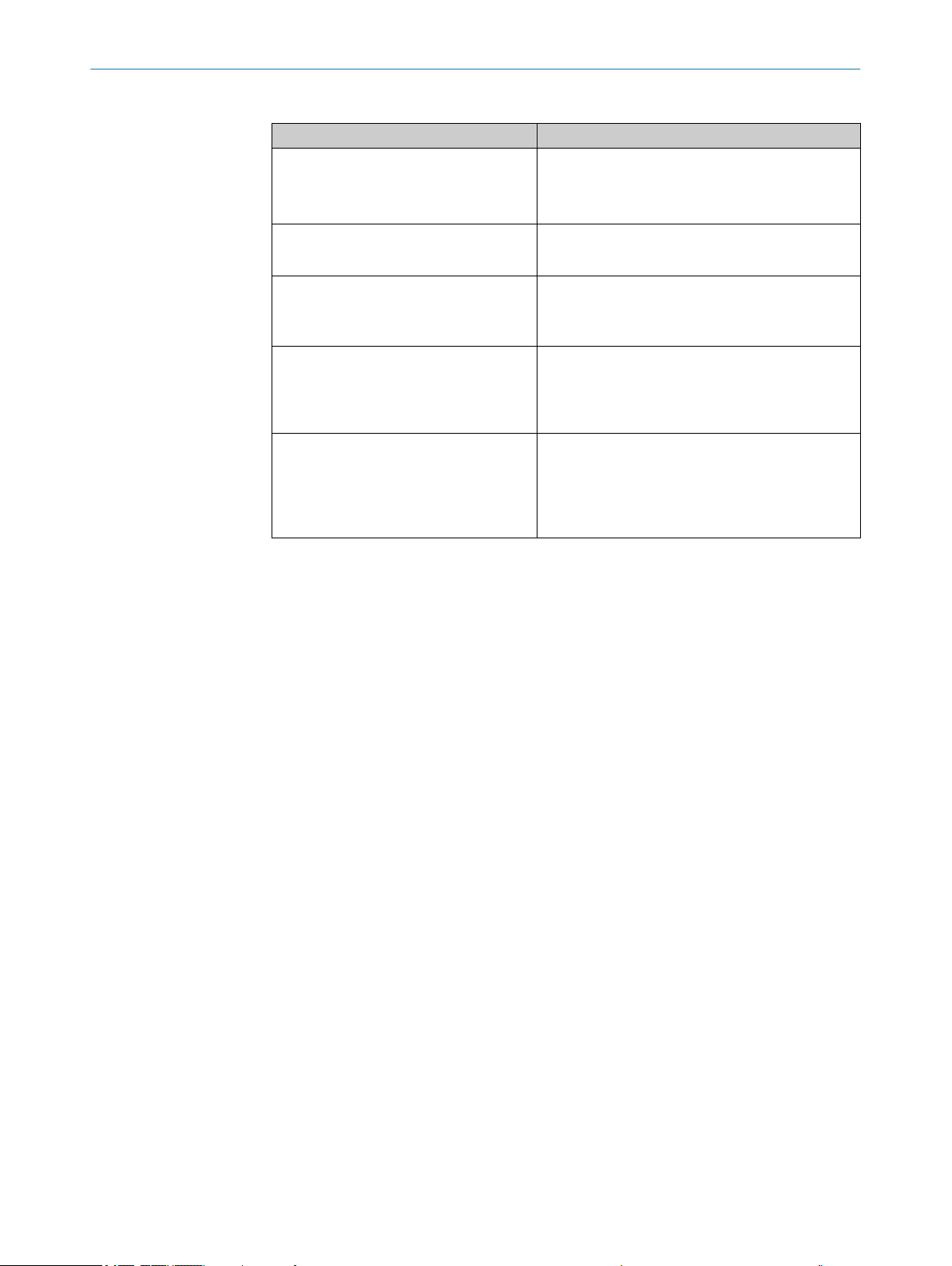

Figure 5: CLV61x Dual Port: design and device dimensions with side reading window (in mm or

inches)

M5 blind tapped holes, 5 mm deep (2 x), for mounting the device

1

P1 (PROFINET port 1) connection, female connector, M12, 4-pin, D-coded

2

Cable (0.9 m), type-dependent with POWER connection (male connector, M12, 4-pin, A-

3

coded) or with POWER + trigger input connection (male connector, M12, 5-pin, A-coded)

P2 (PROFINET port 2) connection, M12, female connector, 4-pin, D-coded

4

Internal impact point: Rotation point of the variable direction laser beam

5

Reading window, side orientation

6

Central position of the deflected laser beam in the V-shaped aperture angle

7

Swivel connector unit (max 180° rotation angle from end position to end position)

8

Reference point for reading distance from device (housing edge) to object

9

LED (4 x), status indicator for PROFINET

ß

RGB LED (1 x), status indicator with signal color allocation for events

à

Type label

á

Laser warning label

â

Cover for USB connection 2) (female connector, 4-pin, Micro-B type) or for memory card

ã

shaft (microSD), type-dependent

3.2.2 Scope of delivery

2)

8017842/ZOK7/2019-02-01 | SICK OP E RA T IN G I N ST R UC T IO N S | CLV61x DualPort (PROFINET)

Subject to change without notice

The delivery of the device includes the following components:

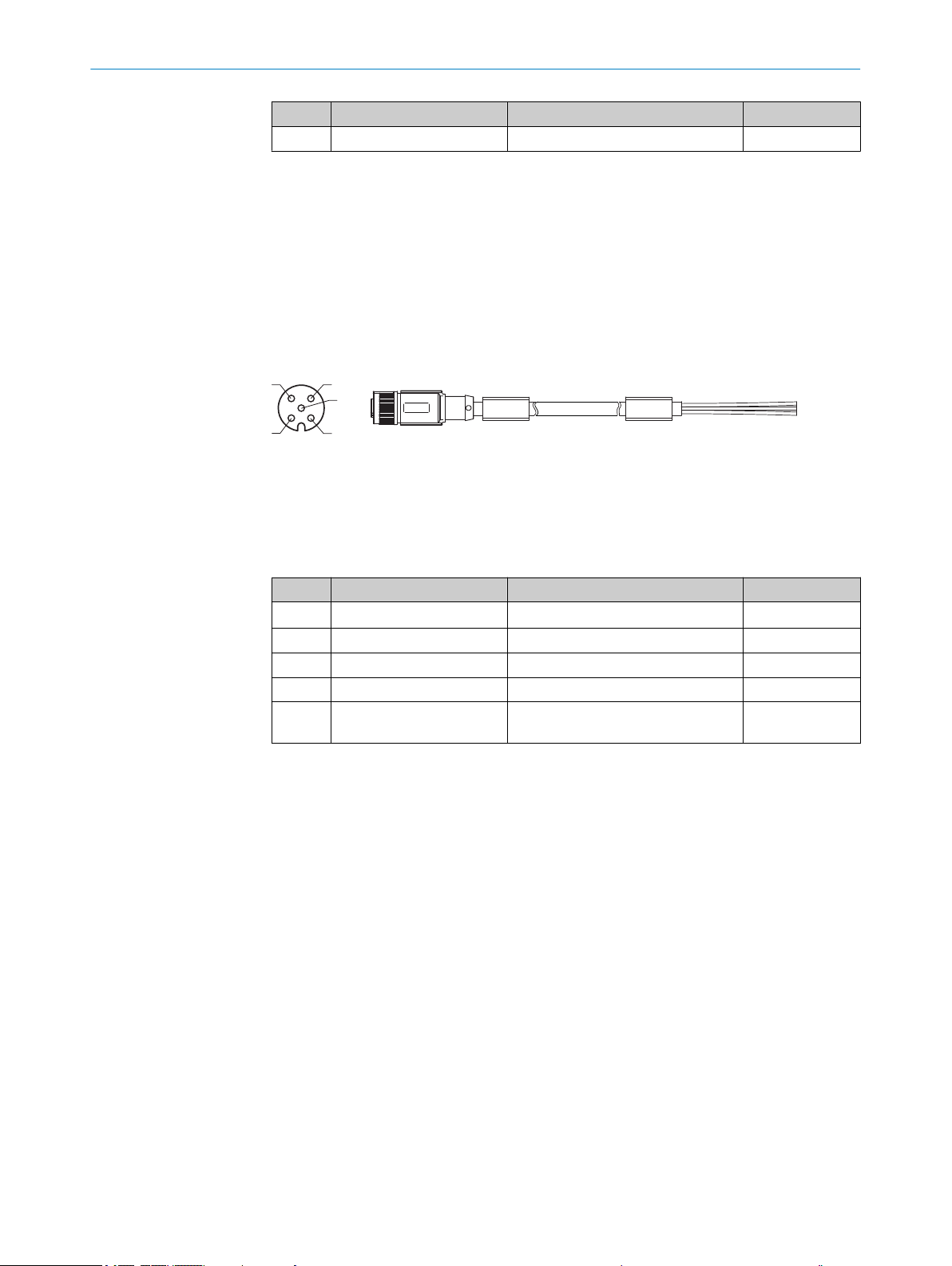

Table 4: CLV61x Dual Port (PROFINET): scope of delivery

No. of

units

1 Device in the version ordered Both M12 female connectors sealed with

Service interface, for temporary use only

1 Multilingual safety notes in a printed doc‐

Associated components not contained in the delivery:

Component Notes

tightly screwed on protective plugs.

Without holders and bus connecting

cables.

Provides information about the require‐

ument

ments for safe use of the product.

17

Page 18

3 PRODUCT DESCRIPTION

Table 5: CLV61x Dual Port (PROFINET): scope of delivery, other components

Component Notes

SOPAS ET configuration software and

device description file (*.sdd file for

SOPAS ET) for the CLV61x Dual Port

(PROFINET)

GSD file for the PROFINET system con‐

troller (PLC)

Function block, e.g., for system controller

S7 (PLC)

CLV61x Dual Port (PROFINET) operating

instructions as PDF in English, German

and French. Other languages also avail‐

able online where applicable.

CLV61x Dual Port (PROFINET) supplemen‐

tary information as PDF in English and

German.

Available online at:

www.sick.com/SOPAS_ET

•

Available online at:

www.sick.com/CLV61x_Dual_Port

•

When is it needed?

Available online at:

www.sick.com/CLV61x_Dual_Port

•

Provides information about mounting, electrical

installation and technical data for the device.

Available online at:

www.sick.com/CLV61x_Dual_Port

•

Provides additional description of the procedure for

integrating the device into PROFINET from a data

technology standpoint (line or ring topology).

Available online at:

www.sick.com/CLV61x_Dual_Port

•

3.2.3 Operating principle

The device consists of a laser scanner (laser diode and optics) with fixed focus and an

electronics unit with integrated decoder, as well as a PROFINET module. The laser scan‐

ner and electronic unit are encased in a compact metal housing.

The light is emitted through the reading window in the industrial housing, and the

reflected light from the bar code then returns through this window.

The use of various focusing settings, resolutions, scan processes, possibly integrated

heating, mounting options and optics enables use in most industrial applications.

Because of the integrated D-sub shell, when the reading window is on the side the laser

beam is emitted at angle of 105° relative to the longitudinal axis of the device. The

device has three M12 round connectors available for continuous electrical connection.

Interfaces to external timers, such as photoelectric sensors or incremental encoders,

enable reading pulses independent of the control. The reading results are provided for

further processing by the data interfaces. In principle, the codes can be identified on

any one side of stationary or moving objects in a conveyor system (single-side reading).

By combining several devices, multiple sides can be recorded in one passage (multiside reading). The device produces a scanning line (line scanner) in order to identify the

code. In the grid scanner version, the device produces eight scanning lines that are off‐

set parallel to one another.

18

O PE R AT I NG IN S TR U CT I ON S | CLV61x DualPort (PROFINET) 8017842/ZOK7/2019-02-01 | SICK

Subject to change without notice

Page 19

Configuration

Diagnostics

(local)

SOPAS ETSOPAS ET

PC

CLV61x Dual Port

(CLV61x-Dx41x)

Aux (USB)

Host /Aux (Ethernet, port 2)Host /Aux (Ethernet, port 1)

V

s

PROFINETPROFINET

Scanner 2

Decoder 3

Interfaces 4

5

1

Configuration

1)

Diagnostics

(local)

SOPAS ETSOPAS ET

PC

CLV61x Dual Port

(CLV61x-Dx52x)

Aux (USB)

Host /Aux (Ethernet, port 2)Host /Aux (Ethernet, port 1)

V

s

PROFINETPROFINET

Read trigger

(switching input) 1

Scanner 2

Decoder 3

Interfaces 4

T distributor 2) 6

1) Alternative: GSD configuration (centrally via the PROFINET controller) 8

2) Male connector, M12, 4-pin, A-coded splitted to 2 x female connector M12, 5-pin, A-coded) 9

5

7

PRODUCT DESCRIPTION 3

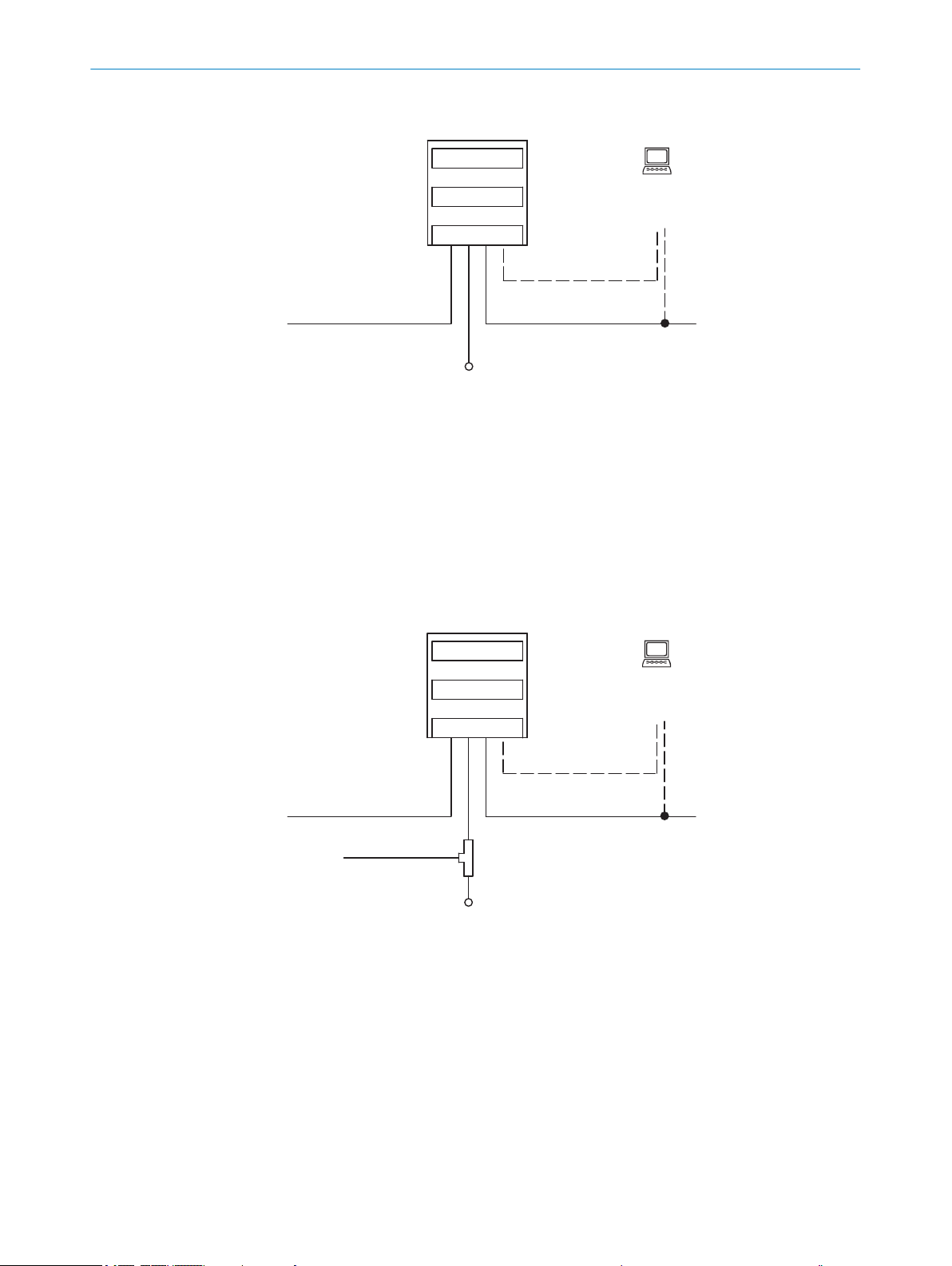

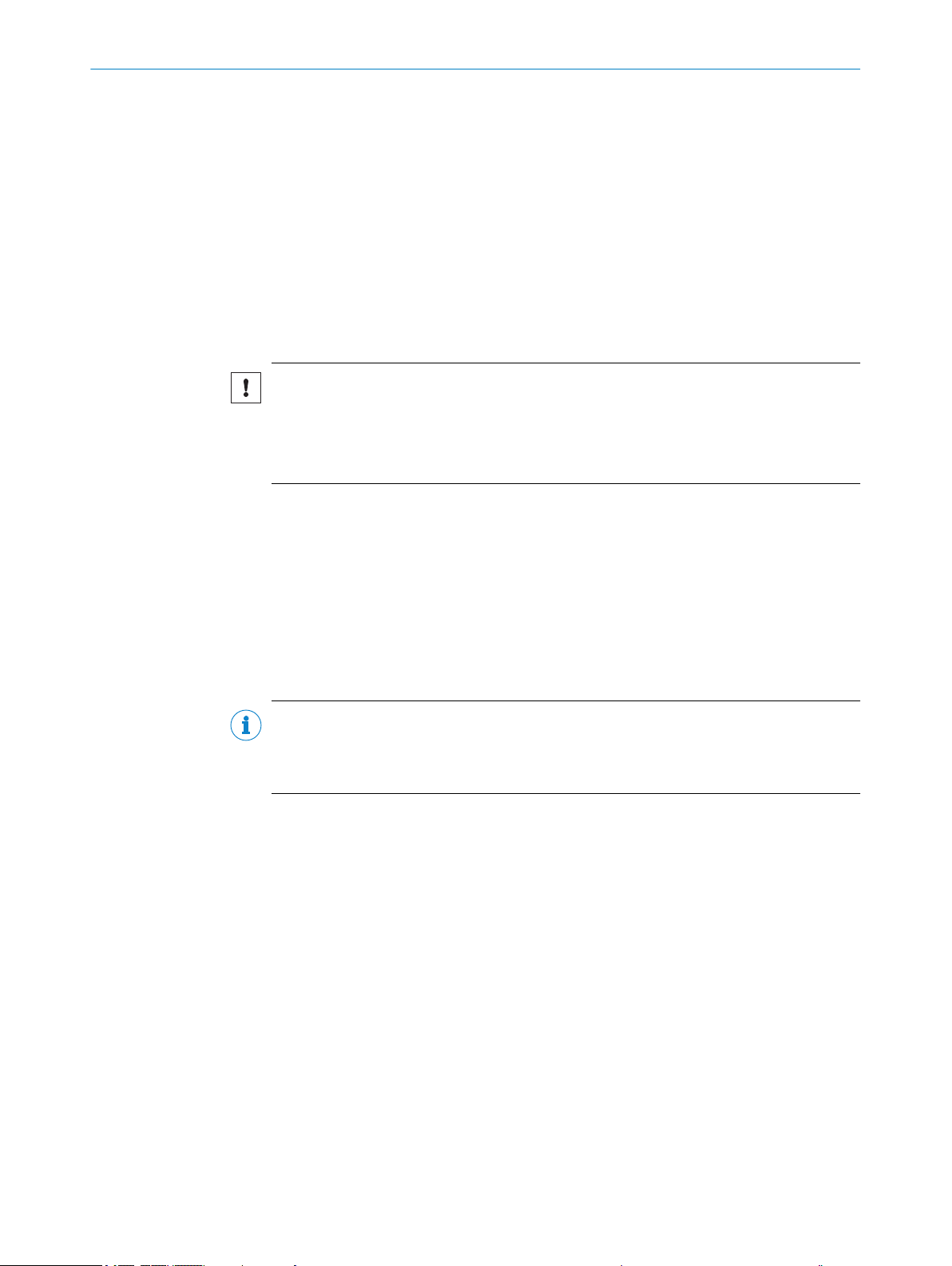

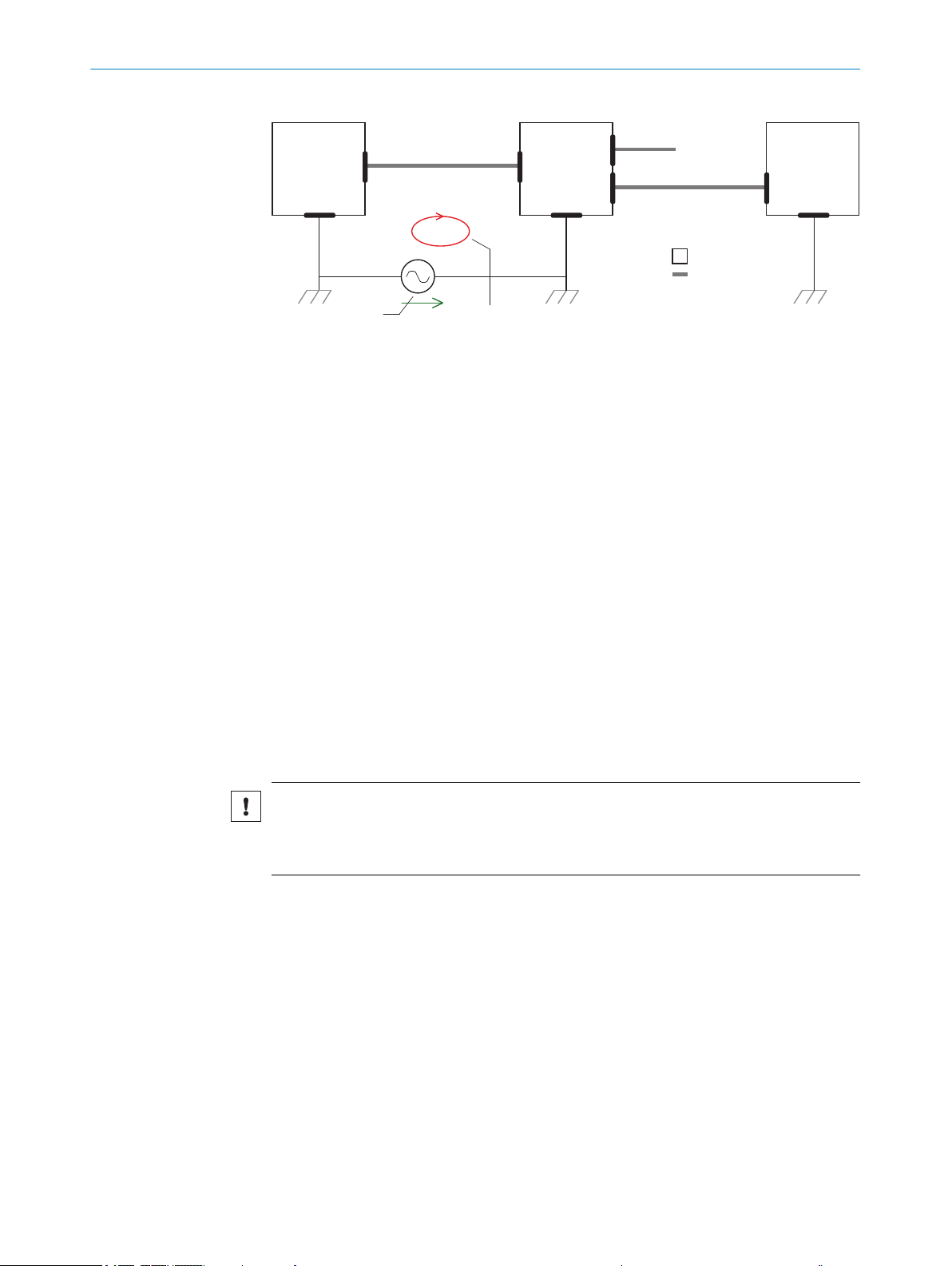

Figure 6: Block diagram for CLV61x-Dx41x (without switching input)

Scanner

1

Decoder

2

Interfaces

3

USB interface 3) depending on type. Not present on device variants with a memory card

4

slot.

Configuration or diagnostics (local)

5

Supply voltage VS = U

6

V

Figure 7: Block diagram for CLV61x-Dx52x (with switching input)

1

2

3

4

5

6

7

3)

Service interface, for temporary use only

8017842/ZOK7/2019-02-01 | SICK OP E RA T IN G I N ST R UC T IO N S | CLV61x DualPort (PROFINET)

Subject to change without notice

Scanner

Decoder

Interfaces

USB interface 3) depending on type. Not present on device variants with a memory card

slot.

Configuration or diagnostics (local)

T-connector

Supply voltage V

s

19

Page 20

3 PRODUCT DESCRIPTION

Read trigger (switching input)

8

Alternative: GSD configuration (central via PROFINET controller)

9

Male connector, M12, 4-pin, A-coded, split into 2 x female connectors, M12, 5-pin, A-

ß

coded

3.2.4 Product features and functions

Table 6: Overview of product features and functions of the device

Product feature/function Characteristic

CLV61x Dual Port bar code scanner

Safety and ease of use

Easy configuration/operation

Reading Operation Mode

Read pulse generation

Bar code evaluation

Data Processing

Fixed focus

■

Red light line scanner or grid scanner

■

Reading range: Long range, optimized for intralogistics applications

■

Medium resolution

■

Additional scanning frequency range (400 Hz ... 1,000 Hz)

■

Option to adapt to code print quality

■

Evaluation range of scanning line can be limited

■

Trigger input for reading pulse, type-dependent, identifier see "Type code",

■

page 13

Rugged, compact metal housing, CE marking

■

Laser Class 2, laser switches off if the output power is exceeded

■

Automatic self-test on system start

■

Diagnostic tools for device setup and (remote) device monitoring

■

Configurable output of reading diagnostic data in two reading results formats

■

Operating data polling, in case of error, issue of error code if required

■

Test string function (heartbeat) can be activated to signal that the device is

■

ready for operation

Password-protected configuration mode via SOPAS ET

■

Protection of centrally configured parameter values in the PROFINET con‐

■

troller (e.g., PLC) via GSD parameterization

Optional backup of locally configured parameter values on microSD memory

■

card in the device, type-dependent, identifier see "Type code", page 13

Future-proof through firmware update (FLASH PROM) via data interface

■

Future-proof SOPAS ET configuration software

■

Low power consumption

■

Additional supply voltage range

■

Wide range of ambient operating temperatures

■

Device variants suitable for cold stores, type-dependent, identifier see "Type

■

code", page 13)

Configuration centrally using PROFINET controller (e.g., PLC) via GSD parame‐

■

terization or locally via SOPAS ET configuration software (incl. online help

function)

Status display by five LEDs

■

Configuration via profile programming with bar codes, generated and printed

■

with the help of SOPAS ET

Start/stop operation (one bar-code bearing object per reading pulse)

■

Pulse source for start: Fieldbus input, data interface (command), auto pulse,

■

free

Pulse source for stop: Read pulse source, data interface (command), timer,

■

condition

All current 1D code types

■

Max. number of bar codes: 50 per read pulse

■

Separation of identical codes of the same code type by read angle

■

Influencing the output of the reading data by event-dependent evaluation con‐

■

ditions

Influencing the output string by filtering and output sorting

■

20

O PE R AT I NG IN S TR U CT I ON S | CLV61x DualPort (PROFINET) 8017842/ZOK7/2019-02-01 | SICK

Subject to change without notice

Page 21

Product feature/function Characteristic

Data communication

Host interface: Ethernet, PROFINET protocol, data output format can be con‐

■

figured

AUX interface: USB (2.0) 1). Type-dependent, identifier see "Type code",

■

page 13. Data output format configurable

Aux interface: Ethernet TCP/IP, data output format configurable

■

PROFINET

PROFINET with integrated switch (Dual Port) in accordance with IEEE 802.3

■

for incorporation in line or ring network topologies

Local trigger input (hardware) for reading pulse, type-dependent, identifier

■

see "Type code", page 13

Electrical interfaces

Host interface (also AUX interface): 2 x Ethernet

■

Aux interface: 1 x USB 1), type-dependent, identifier see "Type code", page 13

■

MicroSD memory card, type-dependent, identifier see "Type code", page 13

■

Digital switching input (hardware): 1 x, type-dependent, identifier see "Type

■

code", page 13

Power supply

■

Wiring technique (design)

Space-saving, swivel connector on the device with two M12 round connec‐

■

tors, female connector, 4-pin, D-coded for Ethernet (PROFINET)

Cable (0.9 m), line connection integrated into the control unit.

■

Type-dependent in the following forms:

With POWER connection (male connector, M12, 4-pin, A-coded), type-

°

dependent, identifier see "Type code", page 13

With POWER connection + trigger input (male connector, M12, 5-pin, A-

°

coded), identifier see "Type code", page 13

Housing

Compact, industrial version in metal, IP 65, protection class III

■

Small dimensions, low weight

■

Various installation options via comprehensive range of mounting accessories

■

PRODUCT DESCRIPTION 3

1)

Service interface, for temporary use only

3.2.5 Memory card

Depending on the type, the device has a card slot integrated in the housing. This slot

accommodates a memory card in microSD format.

NOTE

The memory card is optional and is not included with the delivery of the device.

To ensure that the memory card functions reliably, only use card types (industrial stan‐

dard) approved by SICK. You can find these as accessories online at:

The memory card has no write protection that can be activated.

Functions

An inserted memory card serves as a local external storage medium for the device out‐

side the internal device memory, see "Initial commissioning", page 43.

The device can execute the following functions using the memory card:

www.sick.com/CLV61x_Dual_Port

•

Cloning function: saving the currently valid parameter set

•

Automated additional storage of the parameter set with the configuration data of

the device on an external storage medium that is quickly accessible to the user.

This takes place as part of the recommended backup concept for the parameter

sets of the 4Dpro devices. The externally stored parameter set is also updated

automatically each time the currently valid configuration data is permanently

saved.

8017842/ZOK7/2019-02-01 | SICK OP E RA T IN G I N ST R UC T IO N S | CLV61x DualPort (PROFINET)

Subject to change without notice

21

Page 22

3 PRODUCT DESCRIPTION

•

The first time a parameter set is stored, we recommend using an empty memory card.

b

Device access to the memory card

NOTE

The device does not directly signal access (read, write) to the memory card.

By observing the sensor LED, it is possible to tell when the storage process has been

completed when the parameter set is saved with the “permanent” option:

The cloning function serves as a basis for performing the following tasks, for

°

example:

Manually transferring an identical parameter set to multiple devices of

•

the same type on the PROFINET network (cloning). The PN name of each

device must be adjusted in coordination with the PROFINET controller.

In the event of a device fault, a convenient and rapid manual transfer of

•

the currently valid parameter set to an exchange unit of the same type in

the read station.

Automated saving to the external storage medium is triggered by saving the para‐

meter set in the device with the “permanent” option, e.g., via the SOPAS ET config‐

uration software.

Other functions available on request.

If necessary, check and delete the contents of your current card on the PC using a

card reader.

When the device starts saving, the sensor LED in the “Device Ready” indicator

•

function goes out.

When the device has finished saving, the sensor LED in the “Device Ready” indica‐

•

tor function LED lights up blue again.

NOTICE

Possible data loss!

Do not remove the memory card or switch off the supply voltage as long as the

b

following initiated operations are still being executed on the device using the

SOPAS ET configuration software:

■

Permanent change to the parameter set by saving with the “permanent”

option.

Inserting the memory card in the device:

NOTICE

Risk of damage to the memory card!

To avoid damaging the memory card, make sure the device is de-energized when

b

you insert or remove the card. For this purpose, disconnect the device from the

supply voltage accordingly.

Access to the card slot

22

The card slot for the memory card is located beneath the black rubber cover fitted at

the side over the corner on the device.

O PE R AT I NG IN S TR U CT I ON S | CLV61x DualPort (PROFINET) 8017842/ZOK7/2019-02-01 | SICK

Subject to change without notice

Page 23

1 2

PRODUCT DESCRIPTION 3

Figure 8: Slot for microSD memory card (only CLV61x-DxxXxx, with x = 3 oder 4), illustration may

differ

Open cover on the device

1

MicroSD memory card

2

1. Switch off the supply voltage to the device.

2. Open the black rubber cover.

To do so, carefully lift the flap of the rubber cover.

3. Making sure it is in the correct position, insert the memory card into the slot until

it locks into place. When doing this, position the contacts so that they are facing to

the rear and upwards, see the card symbol on the device.

4. Close the rubber cover. Make sure that the cover is completely flush with the hous‐

ing.

5. Switch on the supply voltage for the device.

Interpretation of the stored parameter set

Once it is switched on, the device automatically detects the presence of a memory card

and, depending on the card’s content, behaves as follows:

■

If the card is empty or if it contains a parameter set that cannot be interpreted by

the device, the device saves the currently valid internal parameter set to the card

(provided there is sufficient storage space). The device then starts with the inter‐

nal parameter set.

■

If the card contains a parameter set that can be interpreted by the device, the

device permanently overwrites the currently valid internal parameter set with this

external parameter set. The device then starts with the new valid parameter set.

■

The goal is for the internal parameter set and the parameter set saved externally

to always be identical.

The highest-ranking parameter set is used by the device when operated in the

PROFINET with the following sequence hierarchy:

8017842/ZOK7/2019-02-01 | SICK OP E RA T IN G I N ST R UC T IO N S | CLV61x DualPort (PROFINET)

Subject to change without notice

23

Page 24

3 PRODUCT DESCRIPTION

1 After starting, the device loads the last permanently stored internal parameter set

2 The device then searches for a valid parameter set in the optional memory card

3 If the PROFINET controller sends a parameter set via the PROFINET with central

Removing the memory card from the device:

NOTICE

Risk of damage to the memory card!

b

1. Switch off the supply voltage to the device.

2. Open the black rubber cover.

3. Unlock the memory card in the slot and remove it.

4. Close the rubber cover. Make sure that the cover is completely flush with the hous‐

5. Switch on the supply voltage for the device.

to its working memory.

slot. If there is a positive search result, the device uses this parameter set to over‐

write the existing parameter set in its working memory.

configuration of the bus users, the device again overwrites corresponding parame‐

ter values in its working memory. These changes are lost again when the device is

switched off. The PROFINET controller must then again send the most recently

valid parameter values each time the device is restarted (supply voltage is

switched on).

To avoid damaging the memory card, make sure the device is de-energized when

you insert or remove the card. For this purpose, disconnect the device from the

supply voltage accordingly.

To do so, carefully lift the flap of the rubber cover.

To do so, carefully press down once on the memory card.

ing.

Support Portal

NOTE

In the SICK Support Portal (supportportal.sick.com, registration required) you will find,

besides useful service and support information for your product, further detailed infor‐

mation on the available accessories and their use.

24

O PE R AT I NG IN S TR U CT I ON S | CLV61x DualPort (PROFINET) 8017842/ZOK7/2019-02-01 | SICK

Subject to change without notice

Page 25

4 Transport and storage

4.1 Transport

For your own safety, please read and observe the following notes:

NOTICE

Damage to the product due to improper transport.

■

The device must be packaged for transport with protection against shock and

damp.

■

Recommendation: Use the original packaging as it provides the best protection.

■

Transport should be performed by trained specialist staff only.

■

The utmost care and attention is required at all times during unloading and trans‐

portation on company premises.

■

Note the symbols on the packaging.

■

Do not remove packaging until immediately before you start mounting.

TRANSPORT AND STORAGE 4

4.2

Transport inspection

4.3 Storage

Immediately upon receipt in Goods-in, check the delivery for completeness and for any

damage that may have occurred in transit. In the case of transit damage that is visible

externally, proceed as follows:

■

Do not accept the delivery or only do so conditionally.

■

Note the scope of damage on the transport documents or on the transport com‐

pany's delivery note.

■

File a complaint.

NOTE

Complaints regarding defects should be filed as soon as these are detected. Damage

claims are only valid before the applicable complaint deadlines.

Store the device under the following conditions:

■

Recommendation: Use the original packaging.

■

Electrical connections are provided with protective caps and plugs (as they are on

delivery).

■

Do not store outdoors.

■

Store in a dry area that is protected from dust.

■

So that any residual damp can evaporate, do not package in airtight containers.

■

Do not expose to any aggressive substances.

■

Protect from sunlight.

■

Avoid mechanical shocks.

■

Storage temperature: see "Technical data", page 55.

■

Relative humidity: see "Technical data", page 55.

■

For storage periods of longer than 3 months, check the general condition of all

components and packaging on a regular basis.

8017842/ZOK7/2019-02-01 | SICK OP E RA T IN G I N ST R UC T IO N S | CLV61x DualPort (PROFINET)

Subject to change without notice

25

Page 26

5 MOUNTING

5 Mounting

5.1 Overview of mounting procedure

Selecting and preparing the mounting location.

•

Mounting the device.

•

Align device towards object with bar code.

•

Connect device to data cable (PROFINET) and supply cable.

•

Adjust the device.

•

WARNING

Risk of injury due to damage to the device

For reasons of safety, a device which is visibly damaged must not be operated or must

be immediately taken out of operation. Damage includes, for example:

Housing: Cracked or broken

•

Reading window lens: Cracked or broken

•

Device with connector: Over-rotation of the connector, cracks, or being torn from

•

the housing

Device with fixed cable: Damage to the cable outlet or cable itself

•

5.2 Preparation for mounting

5.2.1 Mounting requirements

NOTICE

Radio interference may occur when the device is used in residential areas!

Only use the device in industrial environments (EN 61000-6-4).

Space requirements

■

Typical space requirement for device, see type-specific dimensional drawing and

reading field diagram.

■

The device requires a direct, unimpeded line of sight to the codes being read.

Environmental influences

■

Comply with technical data, such as the permitted ambient conditions for opera‐

tion of the device (e.g., temperature range, EMC interference emissions, ground

potential), see "Technical data", page 55.

■

To prevent the formation of condensation, avoid exposing the device to rapid

changes in temperature.

■

Keep the device out of direct sunlight. The prevents additional external heating

and potential optical dazzle of the device.

Mounting

■

The device must only be mounted using the pairs of blind tapped holes provided

for this purpose.

■

Mount the device in a shock- and vibration-insulated manner.

26

Equipment required

■

Mounting device (bracket) with sufficient load-bearing capacity and suitable

dimensions for the device.

■

2 x M5 screws – the maximum screw-in depth in the device is 5 mm from the

housing surface

O PE R AT I NG IN S TR U CT I ON S | CLV61x DualPort (PROFINET) 8017842/ZOK7/2019-02-01 | SICK

Subject to change without notice

Page 27

MOUNTING 5

NOTE

The screws are for mounting the device on mounting equipment (bracket) supplied

by the user. The screw length depends on the mounting base (wall thickness of the

bracket). When using an optional SICK bracket, the screws for mounting the device

are included in the scope of delivery for the bracket.

■

Tool and tape measure

5.2.2 Instructions for mounting the device when the ambient temperature can fall below 0 °C

NOTE

For the electrical installation procedure, see "Instructions for electrical installation when

the ambient temperature can fall below 0 °C", page 33

The devices with integrated heating (CLV61x-DxxxxxF0) can be operated at low ambient

temperatures down to –35 °C.

Prerequisites:

Only perform mounting and connection work at ambient temperatures between

•

–25 °C and 40 °C.

The device may only be in a non-operating state at ambient temperatures below

•

0 °C.

During mounting, make sure that heat transfer between the device and the sur‐

•

rounding environment is kept as small as possible. Use appropriate holders

(optional accessories).

NOTICE

Operating the device at the lower limit of the permissible ambient temperature range

The ensure that the device can produce the required heating power, do not expose it to

strong air flows (e.g. from a ventilation system).

b

NOTICE

If the ambient temperature is below 0 °C, please note:

•

•

5.2.3 Mounting device

The device is mounted on the bracket using at least two M5 blind hole threads that are

in pairs on both of the narrow sides of the device, see "Device view", page 16.

The device can be installed using optional SICK brackets or customer-specific brackets.

SICK offers prefabricated brackets which are optimally suited for the mounting of the

device in a wide range of applications. See:

•

Example: The design of the bracket and adapter plate supports many different installa‐

tion variants, for example, as well as the alignment of the device on two axes.

If necessary, take appropriate measures to shield the device from air flows.

The black rubber cover fitted at the side over the corner must be flush with the

device.

Do not move the swivel connector on the device.

www.sick.com/CLV61x_Dual_Port

8017842/ZOK7/2019-02-01 | SICK OP E RA T IN G I N ST R UC T IO N S | CLV61x DualPort (PROFINET)

Subject to change without notice

27

Page 28

1

1

1

1

5 MOUNTING

Figure 9: Example mounting of a device with bow-shaped mounting bracket (SICK accessories,

illustration of the device can differ)

Devices with heating

NOTE

Three plastic insulation panes are to be used across from the bracket for heat insula‐

tion on devices with heating. These panes are included with the mounting brackets for

thermal decoupling (SICK accessories).

28

Figure 10: Example mountings of a device with external heating using bow-shaped mounting

brackets (SICK accessories). Illustration of the device may differ.

Plastic insulation panes

1

User-supplied brackets

The brackets should meet the following requirements:

■

Stable mounting device

O PE R AT I NG IN S TR U CT I ON S | CLV61x DualPort (PROFINET) 8017842/ZOK7/2019-02-01 | SICK

Subject to change without notice

Page 29

– Alignment of the device in the x and y axes can be adjusted.

line scanner raster scanner

1 2

– The mounting device must be able to bear the weight of the device and con‐

necting cables without shock.

– The housing must be thermally isolated from the bracket for devices with

heating. To do so, attach appropriate plastic insulating slabs to the fixing

screws between the housing and the bracket.

■

Two or three M5 screws for mounting the device

– The screw length depends on the wall thickness of the mounting device.

– The maximum screw in depth in the device is 5 mm from the housing sur‐

face.

5.3 Mounting location

When selecting the mounting location, the following factors are significant:

Basic allocation of the scan line to the bar code.

•

Reading distance to the bar code and aperture angle α

•

Angular alignment of the device

•

Avoidance of surface reflections

•

Count direction of the reading angle (position of the bar code along the scan line)

•

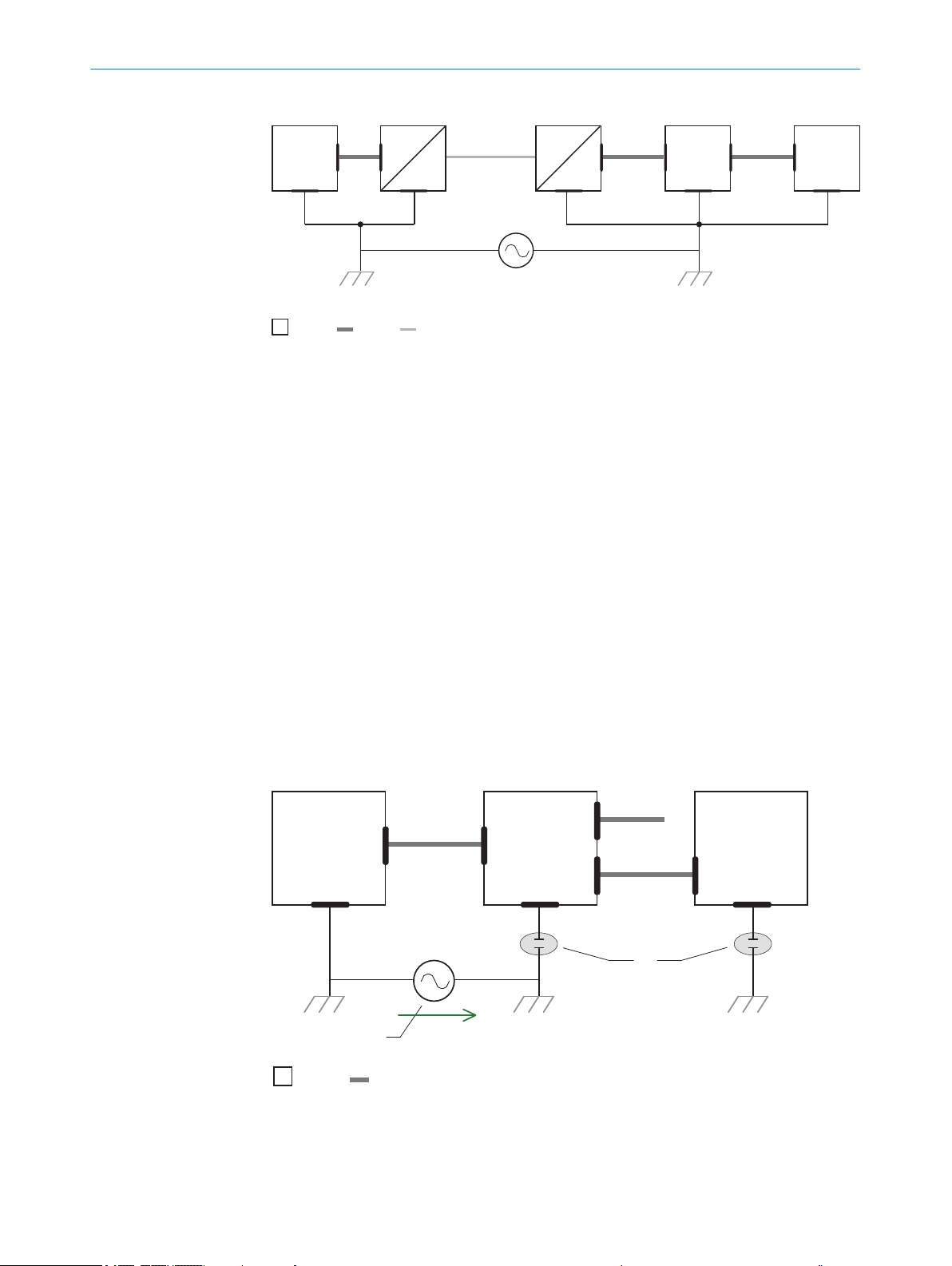

5.3.1 Basic allocation of the scan line to the bar code

MOUNTING 5

The basic allocation of the scan line to the bar code on the object depends on the ver‐

sion of the device (line scanner or grid scanner).

Figure 11: Allocation of scanning line(s) to bar code and conveyor direction

Line scanner

1

Grid scanner

2

5.3.2 Reading distance to the bar code and aperture angle α

The maximum distance from the reading window of the device to the bar code may not

exceed the design values for the device. Because of the V-shaped deflection of the

beams, the usable length of the scan line for evaluation (reading field height) depends

on the reading distance.

8017842/ZOK7/2019-02-01 | SICK OP E RA T IN G I N ST R UC T IO N S | CLV61x DualPort (PROFINET)

Subject to change without notice

29

Page 30

line scanner raster scanner

reading distance reading distance

1 2

3

3

β

α

γ

1

2

5 MOUNTING

Figure 12: Definition of the reading distance and the aperture angle α

Line scanner

1

Grid scanner

2

Reading distance

3

In the specification diagrams (see "Reading field diagrams", page 58), the height of

the reading field is shown as a function of the reading distance for differing resolutions

(module widths).

5.3.3 Angle alignment of the device

The optimum alignment of the device is achieved when the scan line crosses the

stripes of the bar code as close to a right angle as possible (tilt and inclination). Possi‐

ble reading angles that can arise between scan line and bar code at all three levels in

the area must be taken into account.

In order to prevent surface reflections, the angle of rotation must be approx. 15° out of

plumb to the bar code, see "Avoidance of surface reflections", page 31.

Figure 13: Line scanner: Read angle occurring between scanning line and bar code

Depth of field

1

Reading distance

2

NOTE

30

O PE R AT I NG IN S TR U CT I ON S | CLV61x DualPort (PROFINET) 8017842/ZOK7/2019-02-01 | SICK

The specified maximum values can only be reached in optimum conditions. The actual

maximum depends on module width, code type, print contrast, ambient light, distance

and scanning frequency.

Subject to change without notice

Page 31

Table 7: Permitted read angle between scanning line and bar code

Line scanner

(reading window on front)

Line scanner

(reading window on side)

(Top view)(Top view)

105° 105°

1 2

3

3

RA

0

100

Angle Limit Value

Tilt α Max. 30°

Pitch β Max. 45°

Skew γ Max. 45°

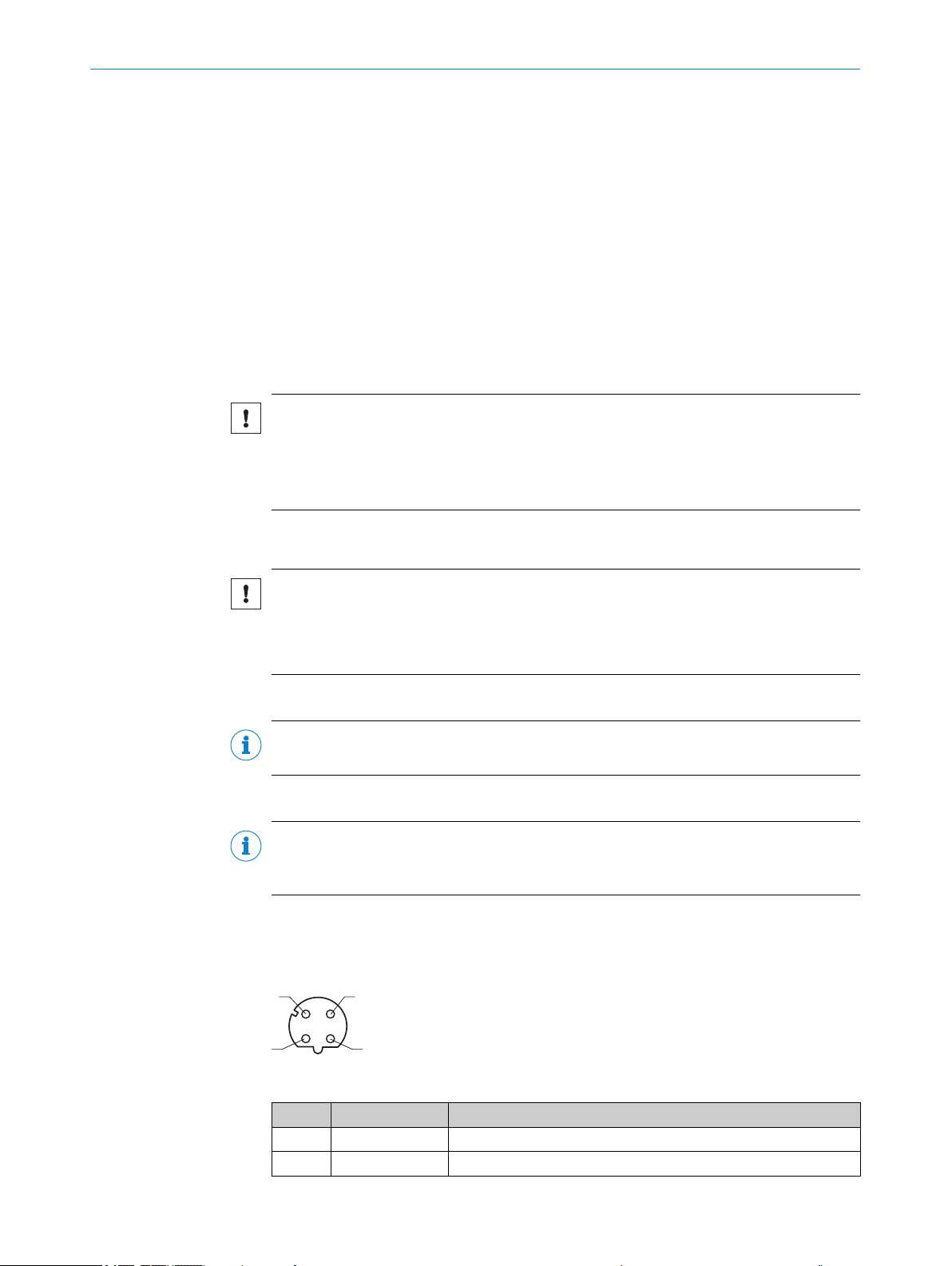

5.3.4 Avoidance of surface reflections

If the light of the scan line(s) hit(s) the surface of the bar code precisely vertically, this

may cause interference when the light reflected back is received. To prevent this effect,

the device must be mounted so that the light emitted is tilted relative to the vertical.

Figure 14: Avoiding surface reflections on the example line scanner: Angle between light emitted

and bar code (tilting away from vertical)

Line scanner (reading window on front)

1

Line scanner (reading window on side)

2

Supervision

3

MOUNTING

5

5.3.5 Count direction of the reading angle and the code angle

The device can scan and decode several bar codes at each reading.

At the same time, the location-specific reading diagnostics data are determined for

each of them.

■

The reading angle, starting from the reading window, at which the device detects

the bar code center on the red scanning line of the deflected scanning beam can

be outputted as an RA (reading angle) value.

By determining the respective RA value, identical bar codes (code type, code length,

and data content) can be separated, and the bar code data can be assigned based on

its position on the object.

Figure 15: Counting direction of the reading angle RA in the scanning line on devices with front

and side reading windows

8017842/ZOK7/2019-02-01 | SICK OP E RA T IN G I N ST R UC T IO N S | CLV61x DualPort (PROFINET)

Subject to change without notice

31

Page 32

MOUNTING

5

5.4 Mounting the device

NOTICE

Risk of damaging the device!

Observe the maximum screw-in depth of the blind hole thread. Longer screws than

specified damage the device.

Use screws of suitable length.

b

1. Prepare the base for mounting the bracket of the device, see "Preparation for

mounting", page 26.

2. Place the object with the bar code in the view of the device in the position where

the reading is to take place (conveyor static).

3. Align device with the bar code by eye. When doing so, be aware of the following:

– For a device with the reading window at the front, ensure that the rear side

– For a device with the reading window at the side, ensure that the side panel

– During reading, note the reading angle that occurs see "Angle alignment of

– If the position of the bar code within the scanning line is relevant for the eval‐

4. Mount the device bracket onto the base.

5. Screw screws through the bracket into the blind hole threads of the device and

slightly tighten.

6. Configure the device, see "Adjust the device", page 43.

with the laser warning label points in the direction of the observer and is

aligned as near as possible to being parallel to the bar code surface.

with the LEDs points in the direction of the observer and is aligned almost

parallel to the bar code surface.

the device", page 30.

uation, bear in mind the count direction of the code position see "Count direc‐

tion of the reading angle and the code angle", page 31.

32

O PE R AT I NG IN S TR U CT I ON S | CLV61x DualPort (PROFINET) 8017842/ZOK7/2019-02-01 | SICK

Subject to change without notice

Page 33

6 Electrical installation

6.1 Safety

6.1.1 Notes on the electrical installation

■

The electrical installation must only be performed by electrically qualified person‐

nel.

■

Standard safety requirements must be met when working on electrical systems.

■

Only switch on the supply voltage for the device when the connection tasks have

been completed and the wiring has been thoroughly checked.

■

When using extension cables with open ends, ensure that bare wire ends do not

come into contact with each other (risk of short-circuit when supply voltage is

switched on!). Wires must be appropriately insulated from each other.

■

Wire cross-sections in the supply cable from the customer's power system must be

selected in accordance with the applicable standards. When this is being done in

Germany, observe the following standards: DIN VDE 0100 (Part 430) and DIN VDE

0298 (Part 4) and/or DIN VDE 0891 (Part 1).

■

Circuits connected to the device must be designed as SELV circuits (SELV = Safety

Extra Low Voltage).

■

Protect the device with a separate fuse (type-specific max. 2 A (unheated) or 3 A

(heated)) at the start of the supply circuit.

ELECTRICAL INSTALLATION 6

NOTE

Layout of data cables

■

Use screened data cables with twisted-pair wires.

■