Page 1

Line scanner Raster scanner

β

OPERATING INSTRUCTIONS

en

CLV61x

Bar Code Scanner

CLV610-C0000 CAN Mid Range

CLV615-F2000 FIELDBUS Long Range

Intended Use

The CLV61x bar code scanner is an intelligent SICK 4Dpro

sensor and is used exclusively for automatic, stationary iden-

tication and decoding of bar codes on moving or stationary

objects. The data content of the decoded bar codes is sent

by the CLV61x to a superordinate computer for further processing. Depending on the model, this is either done directly

via a serial data interface (RS-232) or indirectly via the

SICK CAN sensor network on a coordinating device (e.g.,

master).

Correct use also includes compliance with all information in

these operating instructions as well as in the supplementary & “CLV61x Bar Code Scanner” Technical Information

(no. 8015592).

The product family CLV61x consists of the three series ECO,

CAN, and FIELDBUS (FIELDBUS in combination with the

optional CDF600-21xx eldbus module). Depending on the

model, the series offer the following options:

• Reading range variants (e.g., Short Range, Long Range)

• Line scanner or raster scanner

• Reading window on front or side

• Different connecting cable lengths

All devices have two serial data interfaces (HOST/AUX). The

CAN and FIELDBUS series also offer the SMART decoder for

identifying partly damaged or low-quality bar codes as well as

an additional CAN interface.

About This Document

The purpose of these operating instructions is to allow you

to put the CLV61x into operation quickly and easily and to

achieve initial read results as a stand-alone device.

The operating instructions describe the commissioning process for an application with a single CLV61x. This is done, for

example, using the device version CLV610-C0000 from the

CAN series and its default setting. The CDB620 connection

module, for example, is used for the industrial-standard signal

distribution of the CLV61x.

The operating instructions are valid for the following variants:

• CLV610-C0000 (CAN, Mid Range, line scanner, reading

window on front, SMART decoder)

• CLV615-F2000 (FIELDBUS, Long Range, line scanner,

reading window on side, CAN, SMART decoder)

In the following, the bar code scanner CLV61x is referred to in

simplied form as “CLV61x.”

Supplementary Documents

More detailed information about mounting and electrical installation as a stand-alone device is available in & “CLV61x

Bar Code Scanner” Technical Information (no. 8015592).

This document describes:

• Optional mounting accessories (brackets)

• The prevention of ground potential equalization currents in

applications with widely distributed systems

• Pin and lead color assignments of cables

• Electrical wiring plans for the CDB620 connection module

relating to the CLV61x

Operation of the CLV61x CAN in the SICK CAN Sensor

Network

The setup and wiring of the SICK-specic CAN network as well

as the integration of the CLV61x CAN and FIELDBUS series in

the network is described in the & SICK CAN Sensor Network

Operating Instructions.

Operation of the CLV61x FIELDBUS in PROFIBUS DP

The integration of the CLV61x FIELDBUS series in PROFI-

BUS DP via the CDF600-21xx eldbus module is described

in the & “CDF600-21xx Fieldbus Module PROFIBUS DP”

Operating Instructions (no. 8015335) and the supplementary

& “CDF600-21xx Fieldbus Module PROFIBUS DP” Technical

Information (no. 8015337).

Information about conguration can be found in the online

help function of the conguration software SOPAS ET.

The information can be accessed as a PDF on the CLV61x

product site on the web (www.sick.com/CLV61x).

Safety Information

• This chapter is about the safety of commissioning personnel, as well as operators of the system in which the CLV61x

is integrated.

• Read these operating instructions before starting any work

on the CLV61x in order to familiarize yourself with the

device and its functions. The operating instructions are

considered a part of the device and must be kept in an

accessible location in the immediate vicinity of the CLV61x

at all times!

• The CLV61x corresponds to laser class 2.

Laser warning notice see “Optical radiation: Laser class

2 Page 6”.

• Opening the screws of the CLV61x housing will invalidate

any warranty claims against SICK AG. For further warranty

provisions, see the General Terms and Conditions of SICK

AG, e.g., on the delivery note of the CLV61x.

Commissioning and Conguration

Scope of Delivery

• CLV61x in the ordered version (series, reading range, scanning method, reading window orientation)

• Accessories that can be optionally ordered such as e.g.

brackets

Step 1: Mounting

NOTE

Radio interference may occur when the CLV61x is used in

residential areas!

> The CLV61x must be used exclusively in industrial environ-

ments (EN 61000-6-4).

Equipment Required

• 2 x M5 screws for mounting the CLV61x on a mounting device (bracket). Screw length is dependent on the mounting

base (wall thickness of bracket). When using optional SICK

brackets, screws for the CLV61x are included.

Mounting Requirements

• The permitted ambient conditions for the operation of the

CLV61x must be complied with (e.g., temperature, radiated emission, ground potential see section “Technical

Specications (Excerpt) Page 5” and section “Risk of

injury/risk of damage via electrical current! Page 2”).

• The device must only be mounted using the pairs of

threaded mounting holes provided for this purpose.

• Stable mounting device with sufcient load-bearing capacity and suitable dimensions for the CLV61x.

Weight depends on model, max. 206 g (not including

cables). For dimension drawing, see section “Device

overview CLV61x” on page 3.

• Shock and vibration-free mounting.

• Clear view of the bar codes to be measured on the objects.

Mounting CLV61x

1. Select a suitable mounting location for the CLV61x with a

clear view of the object to be scanned. The mounting location and position depend on the respective reading range

of the CLV61x version. The available reading range is

dependent on the distance from the code and the required

resolution. The mounting location must therefore be cho-

sen whilst taking into account the respective reading eld

length and height, as well as resolution and depth of focus

( see section “Reading elds Page 5”).

2. Mount the CLV61x on a bracket using both screws.

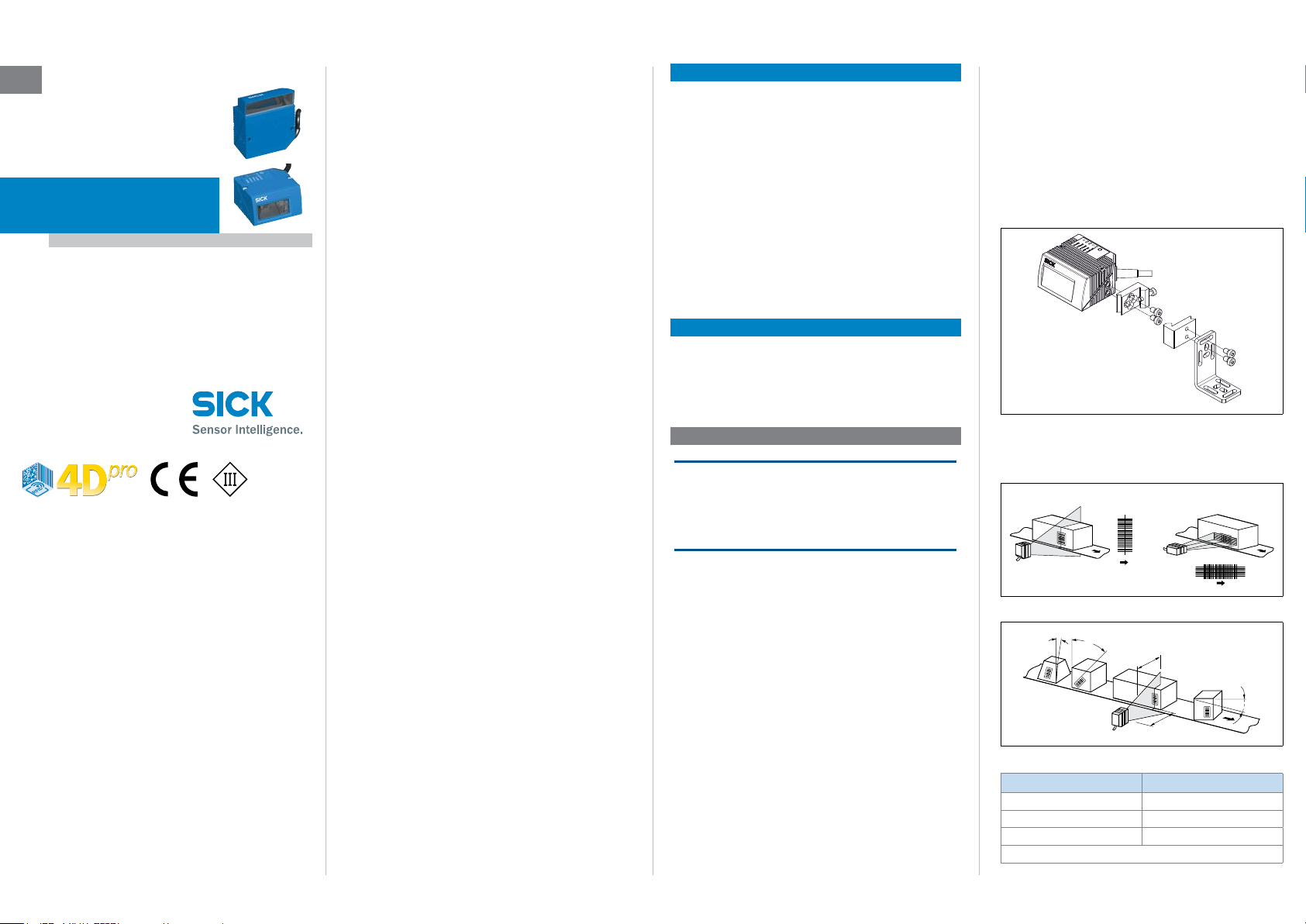

Mounting example: use of quick-clamping device (clamp bracket)

no. 2025526 in combination with the mounting bracket no. 2020410

3. Depending on the scanning method, roughly align the

CLV61x on the object with the bar code to be measured.

Allocation of scanning method to bar code and conveyor direction

α

Depth of

field

γ

Reading

distance

Possible read angle that could occur between scanning line and bar code

Angle Limit Value

Tilt a max. 30°

Pitch b max. 45°

Skew g max. 45°

*) depending on the module width

*)

8015589/ZNI9/2017-06-13 • Subject to errors and modications • © SICK AG • Waldkirch • Germany • www.sick.com CLV61X | SICK 1

Page 2

4. In order to avoid a total reection of the scanning line, tip

Line scanner

Line scanner

)(

CDB620

DC 10 V ... 30

the CLV61x with the following skew angle from the perpendicular to the bar code surface.

(front reading window)

(Top view

Avoid surface reection through correct arrangement

(lateral reading window)

105°105°

Top view)

Connection Module CDB620

> Mount the CDB620 connection module in the vicinity of

the CLV61x. Through the serial data interfaces (RS-232)

recommended cable length max. 5 m between both

devices. Mount the CDB620 in such a way that the device

can be accessed at all times. In relation to this, see &

“CDB620 Connection Module” Operating Instructions (no.

8012119).

Step 2: Electrical Connection

• The electrical installation must only be performed by

qualied electricians.

• The currently applicable safety regulations must be

observed when working in electrical systems!

• Electrical connections between the CLV61x and other de-

vices may only be created or xed when there is no power

to the system. Otherwise, the devices may be damaged.

• When using extension cables with open ends, ensure that

bare wire ends do not come into contact with each other

(risk of short-circuit when supply voltage is switched on!).

Wires must be appropriately insulated from each other.

• Wire cross sections of the supply cable from the customer's power system should be designed in accordance

with the applicable standards.

If the supply voltage for the CLV61x is not supplied via the

optional CDB620 connection module, the CLV61x must

be protected by a separate max. 2 A slow-blow fuse at the

beginning of the supply circuit.

• In order to retain the IP 65 enclosure rating for the CLV61x

connecting cable even when using an extension cable

(e.g., no. 6034417, 2 m/6.56 ft), insert rubber seal no.

4038847 between the plug and socket of the D-Sub plug

connection of the cables and screw in the plug connection.

• Circuits connected to the CLV61x must be designed as

SELV circuits (SELV = Safety Extra Low Voltage).

a DANGER

Risk of injury/risk of damage via electrical current!

The CLV61x is designed to be operated in a system with professional grounding of all connected devices and mounting

surfaces to the same ground potential.

Incorrect grounding of the CLV61x can, due to equipotential

bonding currents between the CLV61x and other grounded

devices in the system, place the metal housing under a dangerous voltage, cause malfunction and destruction of devices

as well as damage to the cable shielding through heating,

and thus cause cable res.

• Work on the electrical system must only be performed by

qualied electricians.

• Ensure ground potential at all grounding points.

n the event of damage to the cable insulation, immediately

• I

switch off the power supply and have the damage repaired.

> See the “Electrical Installation” chapter in the & “CLV61x

Bar Code Scanner” Technical Information (no. 8015592)

on the product site on the web (www.sick.com/CLV61x) for

measures to eliminate hazards.

1. Connect the 15-pin D-Sub-HD plug of the CLV61x cable to

the CDB620 connection module.

2. Connect a read pulse sensor, such as a photoelectric sen-

sor at the “Sens 1” switching input of the CDB620.

See the “Electrical Installation” chapter in the & “CLV61x

Bar Code Scanner” Technical Information (no. 8015592).

3. Connect the serial AUX interface (RS-232) of the CLV61x to

the PC (9-pin D-Sub plug) with a suitable data cable (e.g.,

no. 2014054, 2 m) using the internal plug “AUX” (9-pin

D-Sub) of the CDB620.

If the PC does not have an RS-232 interface, use a suitable adapter cable with RS-232 <> USB converter (e.g.,

no. 6042499, 1.5 m).

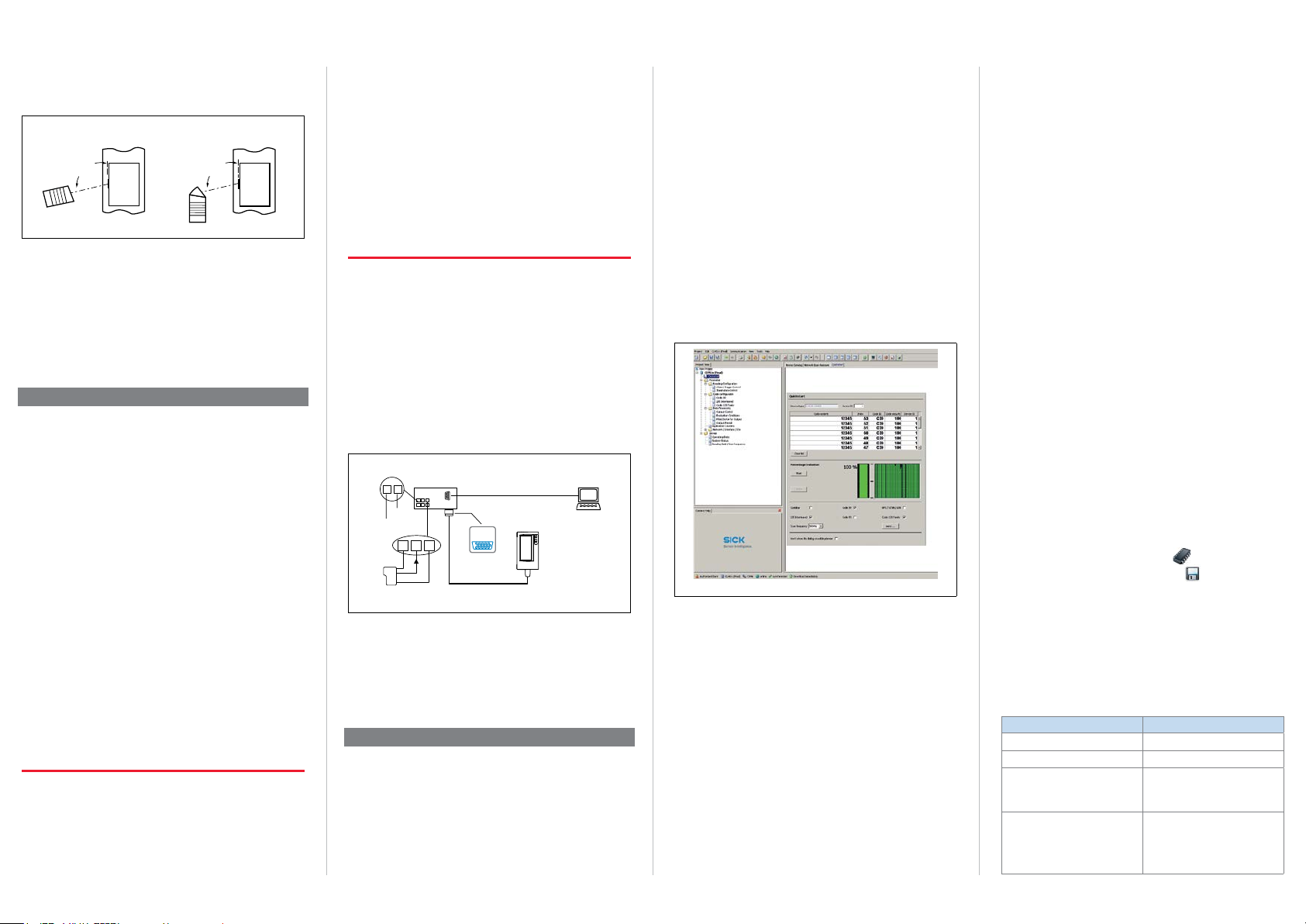

Connection

Module SOPASSOPAS

1

2

...

...

GND

V

11 10 12

V

s

Sens 1

SGND

Reading

clock

Electr. connection of the CLV61x for commissioning as a stand-alone device

Aux

SerialSerial

“HOST/AUX/I/O“

(RS-232)

“AUX“ (RS-232)

e.g. cable no. 2014054

(2 m)

CLV61x

Configuration

Diagnosis

4. Switch on the supply voltage for the CDB620 and the PC.

All LEDs on the CDB620 will light up briey.

The CLV61x starts with a delay and uses the default

parameters set in the factory for the initialization. After a

successful self-test, the LED on the CLV61x lights up blue

to indicate the “Device Ready” status.

Step 3: Conguration with PC

User Modes and Statuses of the CLV61x:

• Quick Start (initial commissioning for read operation)

• Read operation

• Percentage evaluation (for diagnostic purposes)

• Conguration via SOPAS ET conguration software

• Firmware download

Conguration

In case of error, the SOPAS ET conguration software is used

by default to adjust the CLV61x parameters to the application

and to the diagnostics.

Installing and Starting the Conguration Software

1. Download and install the SOPAS ET software on the PC

from the website “www.sick.com/software”. In this case,

select the “Complete” option as suggested by the install

wizard.

2. Start “Standard” user interface for standalone applica-

tions”.

3. Establish a connection between software and CLV61x e.g.,

via the serial AUX interface (57.6 kBd).

The connection wizard starts automatically. Under interface selection, select the standard protocol.

4. Select the CLV61x from the devices that are now available

and displayed. The

Quick Start device page appears.

SOPAS ET Program Window

Device tree (left), device page Quick Start (right)

User Level, Parameter Download

The user is automatically logged onto the CLV61x at user

level “Authorized Client” (password: client). The user can

change parameters, which will be immediately transferred to

the CLV61x (default). Initially they will have only temporary

effect there, without being saved, until the supply voltage is

switched off. If the parameters are to be retained, they must

be permanently saved ( see section “c. Completing the

Conguration Page 2”).

a. Conguration via the “Quickstart” Device Page

The “Quickstart” device page offers an overview of the most

important parameters and enables quick evaluation of code

content. Functions such as “Evaluation Window,” “Percentage

Evaluation,” “Code Conguration,” and “Scanning Frequency”

are available via the Quickstart.

Evaluation Window

The evaluation window shows the code content, the code

type, the increment index, the code security, and the device

number of the reading CLV61x.

Percentage Evaluation

The percentage evaluation permanently assesses the quality

of the reading. Bar codes are not assessed. Here, the bar

codes must not be subjected to any conveying movement.

The CLV61x performs 100 scans in each case and evaluates

the reading quality. The CLV61x continuously emits read

results every 2 s via the AUX interface, together with the read

diagnostic data.

Code Conguration

In the factory default setting, the CLV61x decodes the following code types:

• Code 39

• Interleaved 2 of 5

• Code 128 family

To activate or deactivate further code types:

Device tree > Parameters > Code conguration.

b. Summary of Further Useful Adaptation Options

Object Trigger Control

The CLV61x can, as described in the standard application,

be operated with a connected read pulse sensor, such as a

photoelectric sensor on the “Sensor 1” switching input. To

select a different pulse type or switching input:

Device tree > Parameters > Object trigger control.

c. Completing the Conguration

> Permanently save the entire conguration:

Parameter set in CLV61x: click the

Conguration le on the PC: click the

Important!

In order to commission the CLV61x CAN or FIELDBUS series

in the SICK CAN scanner network together with further SICK

products, select the “Advanced” user interface when starting

the conguration software program. Path: Start > Programs >

SICK > SOPAS ET Engineering Tool > SOPAS.

The “Standard” user interface option is not suitable for this.

Default Setting CLV61x (Summary)

Parameter Value

Scanning frequency 500 Hz

Laser timeout No

Code length

Reading trigger

button

button.

Free

(max. 1,500 characters in reading interval across all measured

codes)

Read operation:

Start: Sensor 1 switching input

Stop: Sensor 1 switching input

Quick Start:

START and STOP buttons for

percentage evaluation

CLV61X | SICK 8015589/ZNI9/2017-06-13 •Subject to errors and modications • © SICK AG • Waldkirch • Germany • www.sick.com2

Page 3

LED

Parameter Value

38.5

22.5

(0.89)

65.9 (2.59)

Host interface

57.6 kBd, 8, n, 1,

Output format: 1

AUX interface Output format: read diagnosis

Switching outputs

Password protection for

parameters

Result 1: Device Ready

Result 2: Good Read

No

Step 4: Fine Adjustment

1. Align the CLV61x so that the angle between the scanning

line and the bar code stripes is almost 90°.

2. Manually guide objects with bar codes successively into

the reading eld of the CLV61x in a realistic manner and

check the reading result. If objects are only guided in an

unstructured manner, it may be necessary to check several

different positions of the bar codes. Here, it must be

ensured that the limit values of the permitted read angles

are not exceeded.

3. Adjust the CLV61x so that the good read rate is 100%.

Description of the Device

Device overview CLV61x

Reading window on front

19.5 (0.77)

13.7 (0.54)

50°

(1.52)

37.9

61 (2.4)

Ready

G Read

N Read

HW Err

UserDef1

0.2

0.2

22.5

5.7

(0.89)

(0.01)

(0.01)

(0.22)

17.1 (0.67)

10 (0.39)

6.2

(0.24)

41.8 (1.65)

(1.94)

19.5

(0.77)

65.9 (2.59)

35.6

(1.4)

(25.4)

(1)

(1)

(27.4)

38.5

(1.52)

Legend:

1 2 x threaded mounting hole M5, 5 mm deep for mounting the

CLV61x

2 Internal impact point: rotation point of the variable direction laser

beam

3 Central position of the deected laser beam in the V-shaped aper-

ture angle

4 Cable outlet, standard cable 0.9 m/2.95 ft (+10%) with 15-pin D-

Sub-HD plug

5 Reading window

6 Status display (1 x RGB-LED) with signal color allocation

7 Reference point for reading distance (housing edge) from CLV61x to

object

Optical Status Indicators

Ready

G Read

N Read

HW Err

UserDef1

Signal

colors

Reading window on side

14.9

(0.59)

2

(.08)

10

(0.39)

0.2

0.2

(0.01)

(0.01)

59.4 (2.34)

79.9 (3.14)

105°

Ready

G Read

N Read

HW Err

UserDef1

22.5 (0.89)

50°

5.7

5.7

(0.22)

(0.22)

10

10

(0.39)

(0.39)

37.9 (1.49)

All length measures in mm (inch)

60.4 (2.38)

35.6

(1.4)

38.5

(1.52)

All length measures in mm (inch)

23.8

(0.94)

16.4 (0.64)

27.4

60.5 (2.38)

2.7

(1.08)

(0.11)

Indicator colors and behavior of LED status display

Indicator Color of LED Status

Lights up constantly after switching on

Blue

Ready

O

– –

G Read

N Read

HW Err

Further

indicators

O = lights up constantly or once briey

= ashes, = ashes alternately

O

O

O

O

and completion of successful self-test.

Goes out when downloading conguration data from the CLV61x

Green Lights up briey after Good Read

Red Lights up briey after No Read

Lights up constantly in case of

Red

hardware error

Red

Firmware download:

Blue

Indicator ashes alternately

Firmware download:

Red

Lights up constantly in case of error

8015589/ZNI9/2017-06-13 • Subject to errors and modications • © SICK AG • Waldkirch • Germany • www.sick.com CLV61X | SICK 3

Page 4

Overview of all interfaces and connection options for CLV61x ECO/CAN

In

(e.g. incr

Te

In

(e.g.

Output

(e.g. indicat

Output

(e.g. indicat

CDB620

Configuration

PC

DC 10 ... 30

Switching inputs/outputs = digital

Configuration

PC

DC 10 ... 30

CAN Sensor Network

CDF600-21xx

In

(e.g.

Result 1 (switching output)

Result 2 (switching output)

SerialSerial

e.g. cable no. 2014054 (2 m/6.56 ft)

SerialSerial

“HOST (RS-232)/

AUX (RS-232)/

CLV61x ECO/CAN

I/O”

“HOST” (RS-232)

“CAN” (CLV61x CAN only)

“AUX” (RS-232)

V

put 1

external reading clock)

put 2

emental encoder,

ach-in matchcode)

1

or lamp)

2

or lamp)

1

2

GND

DC 10 ... 30 V

Connection module

...

...

Overview of all interfaces and connection options for CLV61x FIELDBUS

V

put 1

external reading clock)

CLV61 FIELDBUS

CAN/DC 10...30 V”

“AUX (RS-232)/

PROFIBUS

Fieldbus module

PROFIBUS PROFIBUS

Reading result

CAN Sensor Network

“AUX” (USB)

e.g. cable

no. 6036106

(2 m/6.56 ft)

Reading result

Diagnosis

Further data

processing

SOPASSOPAS

Diagnosis

Further data

processing

PLC

SOPASSOPAS

HOST

Overview of pin assignment

CLV61x ECO

15-pin D-Sub HD plug

6

1

11

N.C. = not connected

CLV61x CAN / FIELDBUS

15-pin D-Sub HD plug

10

5

15

1

DC 10 ... 30 V

2

RxD (RS-232), AUX

3

TxD (RS-232), AUX

4

Sensor 2 (switching input)

5

GND

6

N.C.

7

RxD (RS-232), HOST

8

N.C.

9

TxD (RS-232), HOST

10

N.C.

11

N.C.

12

Result 1 (switching output)

13

Result 2 (switching output)

14

Sensor 1 (switching input)

15

SensGND

10

6

5

1

15

11

1

DC 10 ... 30 V

2

RxD (RS-232), AUX

3

TxD (RS-232), AUX

4

Sensor 2 (switching input)

5

GND

6

N.C.

7

RxD (RS-232), HOST

8

N.C.

9

TxD (RS-232), HOST

10

CAN_H

11

CAN_L

12

13

14

Sensor 1 (switching input)

15

SensGND

8015589/ZNI9/2017-06-13 • Subject to errors and modications • © SICK AG • Waldkirch • Germany • www.sick.com CLV61X | SICK 4

Page 5

Reading elds

(15.75)

(-5.91)

(-3.94)

(-7.87)

(-1.97)

Reading field height in mm (inch)

(13.78)

(-5.91)

(-3.94)

(-1.97)

Reading field height in mm (inch)

CLV610: Mid Range, reading window on front

200

(7.87)

150

(5.91)

100

50

(1.97)

0

-50

-100

-150

-200

0 100 200 300 400

CLV615: Long Range, reading window on side

150

(5.91)

100

(3.94)

50

(1.97)

0

-50

-100

-150

050 100 150 200 250 300 350

(3.94)

Resolution

a: 0.2 mm (7.9 mil)

c: 0.50 mm (19.7 mil)

(1.97)

(3.94)

Resolution

b: 0.35 mm (13.8 mil)

a

b

c

d

(7.87) (11.81)

Reading distance in mm (inch)

b: 0.35 mm (11.8 mil)

d: 1.00 mm (39.5 mil)

b

c

(5.91) (7.87) (9.84) (11.81)

Reading distance in mm (inch)

c: 0.50 mm (19.7 mil)

Acoustic Status Indicator (Beeper)

Depending on the user mode of the CLV61x, the beeper uses

different melodies or single tones to indicate the following

results:

• Fulllment/non-fulllment of a congured condition in read

operation (e.g., Good Read)

• The completion of device functions triggered by the user or

ended by quitting (conrmation of operation steps)

• Completion of functions (positive/negative conrmation)

User Mode Function/Sound

Switching on

Read operation

Percentage

Evaluation

Conguration

Firmware

download

*) Allocation, e.g., via conguration software SOPAS ET

Beeper Default Setting:

Switched on, volume: quiet, read operation: output condition

“Good Read”.

Successful self-test and start of read operation:

melody

Conrmation of Good Read in default setting:

a tone.

Adjustable event condition*)

Start: melody

100 scans per read: a tone

End: melody

Parameter download to CLV61x:

Start: melody, successful completion: melody

Parameter upload from CLV61x: no sound

Firmware:

Start: a tone, successful completion: a tone

Reboot CLV61x:

Successful completion: melody

Loading the sdd le to the CLV61x:

Successful completion: melody

Technical Specications (Excerpt)

Models CLV610-C0000 (no. 1057125)

Series CLV610-C0000: CAN

Scanning method Line scanner

Reading window CLV610-C0000: on front

Reading range/

Code resolution

Code types All current 1D code types

Focus Fixed focus

Scanning frequency 400 Hz ... 1,000 Hz

Light source Visible red light (655 nm)

Laser class Class 2 according to EN/IEC 60825-1:2014

Ambient light

compatibility

Optical indicators 1 RGB-LED, multi-colored

Acoustic indicators Beeper, can be deactivated, can be allocated

Host interface Serial (RS-232), 2.4 kBd... 115.2 kBd

AUX interface Serial (RS-232), 57.6 kBd (xed)

CAN interface CAN sensor network

Fieldbus connection CLV615-F2000 only:

Switching inputs 2 x physical, 2 x additional external via

Switching outputs 2 x physical, 2 x additional external via

Electrical

connection

Supply voltage DC 10 V ... 30 V, SELV in accordance with IEC

Power consumption Typically 2.8 W

Housing (color)/

reading window

2)

Weight

Electrical safety EN 60950-1: 2011-01

Protection class III (VDE 016 / IEC 10110-1)

Enclosure rating IP 65 (DIN 40 050)

EMC Radiated emission:

Vibration resistance

Shock resistance

Ambient temperature

Permissible relative

air humidity

1) With switching outputs without load

2) Without connecting cable and plug

CLV615-F2000 (no. 1058334)

CLV615-F2000: FIELDBUS

CLV615-F2000: on side

CLV610: Mid range/ 0.2 mm ... 1.0 mm

CLV615: Long range/ 0.35 ... 1.0 mm

(identical to EN/IEC 60825-1:2007)

Complies with 21 CFR 1040.10 except for

the tolerance according to Laser Notice No.

50 from June 24, 2007 and its followers.

2,000 lx (on bar code)

function for event signaling

20 kBit/s ... 1 MBit/s

Via serial interface to external CDF600-21xx

eldbus module (PROFIBUS DP)

optional CMC600 module

= max. 30 V, Iin= max. 5 mA

V

in

Opto-decoupled, reverse polarity protected

optional CMC600 module

= VS– 1.5 V, I

V

out

Short-circuit protected, temperature

protected

Standard cable 0.9 m/2.95 ft (+10%) with

15-pin D-Sub-HD plug

6034-4-41: 2005. Reverse polarity protected

Aluminum die casting (RAL 5012)/

Glass (optionally plastic)

181 g (with reading window on front)

206 g (with reading window on side)

EN 61000-6-4: 2007-01 + A1: 2011

Electromagnetic immunity:

EN 61000-6-2: 2005-08

EN 60068-2-6: 2008-02

EN 60068-2-27: 2009-05

Operation: 0°C ... +40°C

Storage: –20°C ... +70°C

90%, non-condensing

≤ 100 mA.

out

1)

CLV61X | SICK 8015589/ZNI9/2017-06-13 •Subject to errors and modications • © SICK AG • Waldkirch • Germany • www.sick.com5

Page 6

For detailed technical specications, see the

Housing with

fr

windo

Housing with

Online Data Sheet on the product site on the web

(www.sick.com/CLV61x).

Warnings

a CAUTION

Optical radiation: Laser class 2

The CLV61x uses a red laser diode and corresponds to laser

class 2.

The entire reading window is a laser output aperture.

ont reading

w

Outlet opening for the laser radiation on the reading window of the

CLV61x

The human eye is not at risk when briey exposed to the

radiation for up to 0.25 seconds. Exposure to the laser beam

for longer periods of time may cause damage to the retina.

The laser radiation is harmless to human skin.

> Do not look into the laser beam intentionally.

> Never point the laser beam at people’s eyes.

> If it is not possible to avoid looking directly into the laser

beam, e.g., during commissioning and maintenance work,

suitable eye protection must be worn.

> Avoid laser beam reections caused by reective surfaces.

Be particularly careful during mounting and alignment

work.

> Do not open the housing. Opening the housing will not

switch off the laser. Opening the housing may increase the

level of risk.

> Current national regulations regarding laser protection

must be observed.

Incorrect use can lead to the user being exposed to dangerous radiation.

Important!

Maintenance is not necessary to ensure compliance with

laser class 2.

lateral reading

window

CLV610-C0000

D-79276 Reute

Made in Germany

Installation site and design of the combination of black and yellow laser

warning label and type label with laser performance data.

P/N: 1057125

S/N: 1540 0001

DC 10...30V

2.8W Imax=700mA

Pmax=1.5mW

Manufactured: October 2015

= 655nmλ

P<1.0mW average

Pulse duration <300µs

Meaning of the laser warning label: laser radiation -

Do not look into the laser beam - laser class 2

Controlling the Laser Diode

In real operation (triggered read mode), the CLV61x switches

the laser diode on and off again with the trigger signals of the

conveyor system (object in reading range). Triggering occurs

here via the switching inputs of the CLV61x or by a command

via one of the data interfaces.

A laser timeout congured with SOPAS ET (device page

illumination control) can be used to automatically switch

off the laser diode for this type of object trigger control if the

pulse has stopped for too long (e.g., conveyor system has

stopped). If the function is activated, the laser timeout is

10 min (default). The current internal reading interval of the

CLV61x remains open.

The laser diode is permanently or repeatedly switched on in

the following device statuses:

• In the “Percentage Evaluation” and “Auto Setup” user

modes (only used temporarily for conguration or diagnosis)

• In reading operation in the pulsing types “Auto cycle”

(adjustable pulse/pause ratio) or “free.”

If timeout is activated, it will have no effect here.

Important!

The CLV61x has no optical indicator (LED) for laser diode

activity.

Maintenance and Care

The CLV61x operates without the need for maintenance, except for cleaning the reading window if it gets contaminated.

> In order to obtain maximum reading performance from

the CLV61x, the reading window must be checked for contamination at regular intervals (e.g., weekly). This applies

especially when using the CLV61x in harsh environments

(dust, abrasion, moisture, etc.).

For reading, the reading window has to be generally clean

and dry.

Cleaning the Reading Window

The type of screen material used in the reading window can

be found on the type label of the device:

CLV61x-xxxxy

• y = 0: Glass

• y = 1: Plastic

NOTE

Damage to the Reading Window!

Reduced reading performance due to scratches or streaks

on the reading window.

> Do NOT use any aggressive cleaning agents with powder

additives (increased abrasion) or agents e.g., acetone for

cleaning.

> Avoid any movements that could cause scratches or abra-

sions on the reading window.

1. Switch off the device for the duration of the cleaning (laser

protection!) or if this is not possible, wear laser protection

goggles, which absorb the wavelength used and effectively

prevent damage to the eyes.

2. Remove dust from the reading window (glass) using a soft

clean brush.

Plastic reading windows must only be wet-cleaned!

3. Clean the reading window (plastic /additionally for glass

if required) with a clean, soft, damp cloth (mild, anti-static

cleaning agent).

Important!

If the reading window is scratched or damaged (cracked,

broken), the window must be replaced by SICK service personnel. Contact SICK Service to arrange this.

Static charge causes dust particles to adhere to the reading

window. This effect can be avoided by using the SICK antistatic plastic cleaner (no. 5600006) in combination with the

SICK lens cloth (no. 4003353).

Transport and Storage

The CLV61x must be transported and stored in its original

packaging. The device must not be stored in airtight containers, so that any residual moisture is able to escape.

Storage conditions: dry, dust-free. no direct sunlight, –20 °C

... +70°C, relative air humidity max. 90% (non-condensing).

Repairs

Repair work on the CLV61x may only be performed by quali-

ed and authorized service personnel from SICK AG.

Disassembly and Disposal

Any CLV61x which can no longer be used must be disposed of

in an environmentally friendly manner in accordance with the

respective applicable country-specic waste disposal regula-

tions. The CLV61x is electronic waste and must under no

circumstances be disposed of with general waste! SICK

AG is not currently able to take back devices that can no

longer be used.

Sources for Obtaining Additional Information

Additional information about the CLV61x and its optional

accessories can be found on the following online product

page:

CLV61x

www.sick.com/CLV61x

• Ordering information

• Operating instructions in German (no. 8015588) and

English (no. 8015589), in other languages if applicable

• Technical information for CLV61x bar code scanners in

German (no. 8015591) and English (no. 8015592)

• EC Declaration of Conformity

• Detailed technical specications (online data sheet)

• Dimensional drawing and 3D CAD dimension models in

various electronic formats

• SOPAS ET conguration software with online help

• Information about suitable accessories (e.g. cables,

mouting brackets, trigger sensors)

• Publications dealing with accessories

Integration of CLV61x FIELDBUS in PROFIBUS DP

www.sick.com/CDF600-2

• CDF600-21xx PROFIBUS DP eldbus module operating

instructions in German (no. 8015334) and English

(no. 8015335)

• Technical information for CDF600-21xx PROFIBUS

DP eldbus module (no. 8015336) and English

(no. 8015337)

Documents on Request

• Overview of command strings for CLV61x

Support is also available from your sales partner:

www.sick.com/worldwide

8015589/ZNI9/2017-06-13 ∙ MT_8M ∙ Printed in Germany

8015589/ZNI9/2017-06-13 • Subject to errors and modications • © SICK AG • Waldkirch • Germany • www.sick.com CLV61X | SICK 6

Loading...

Loading...