Page 1

New Connectivity

CDB420 and CDM490

CLV490

Bar Code Scanner

Advanced Line

OPERATING INSTRUCTIONS

Page 2

Operating Instructions

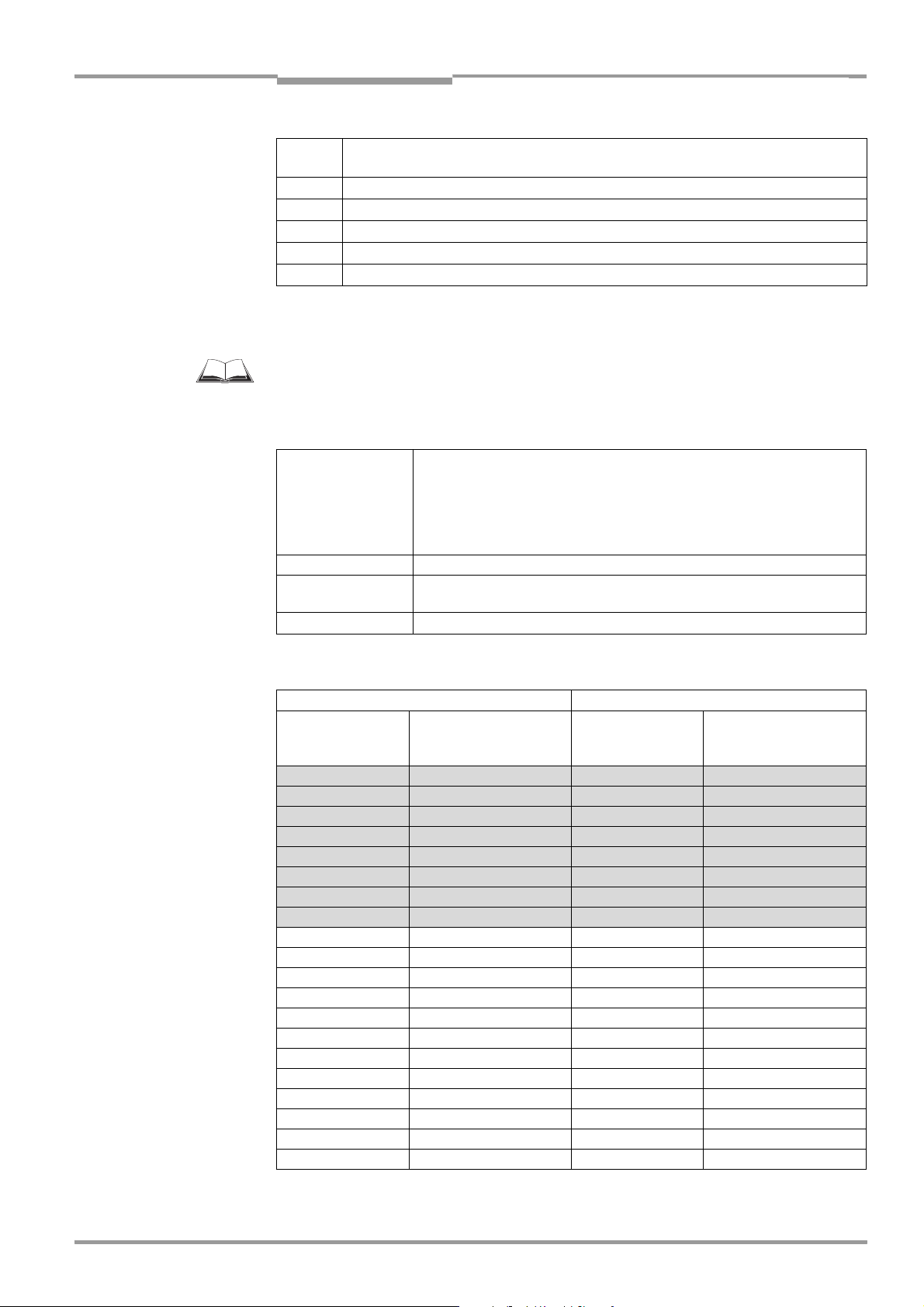

Software versions

CLV 490 Bar Code Scanner

Software versions

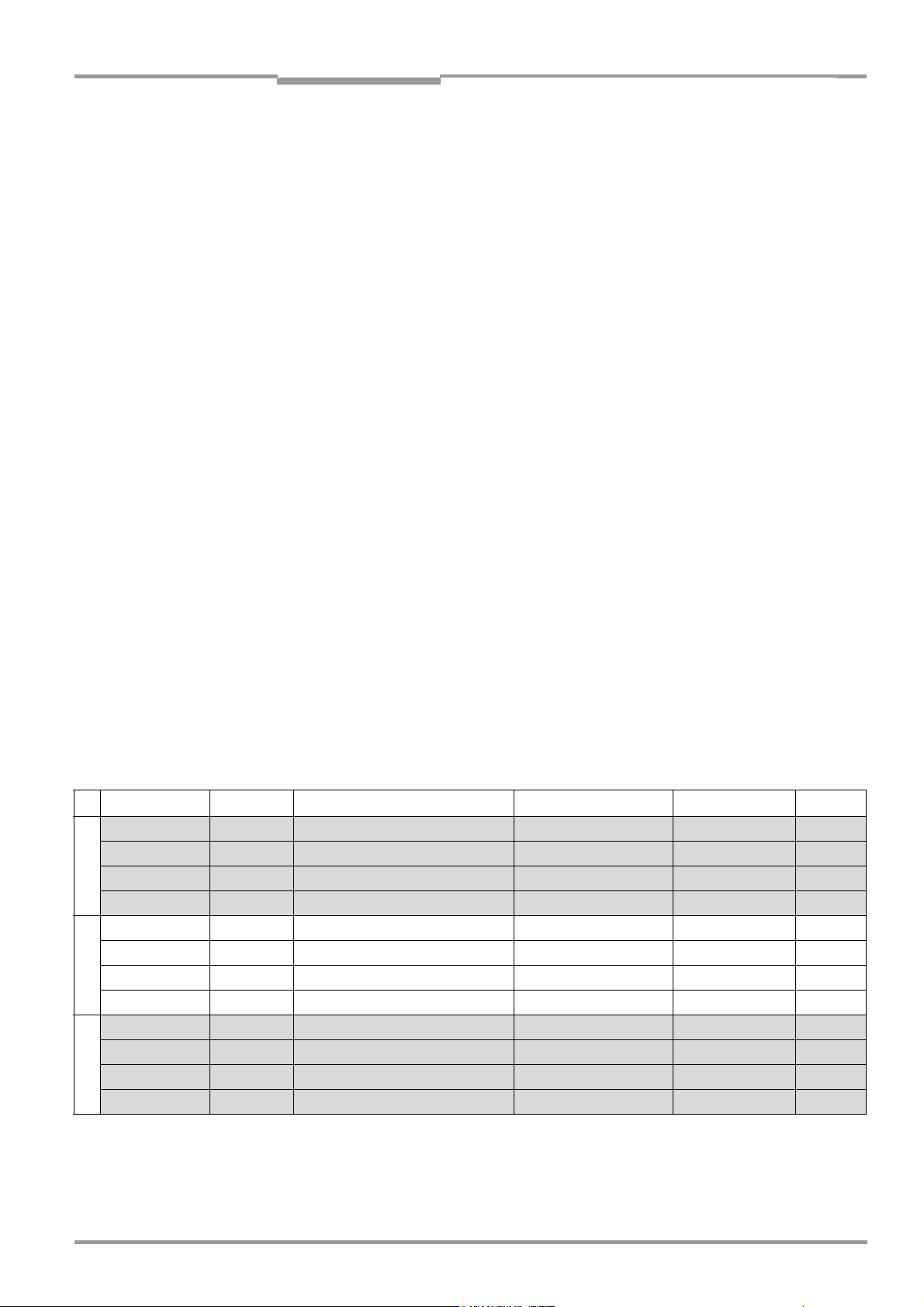

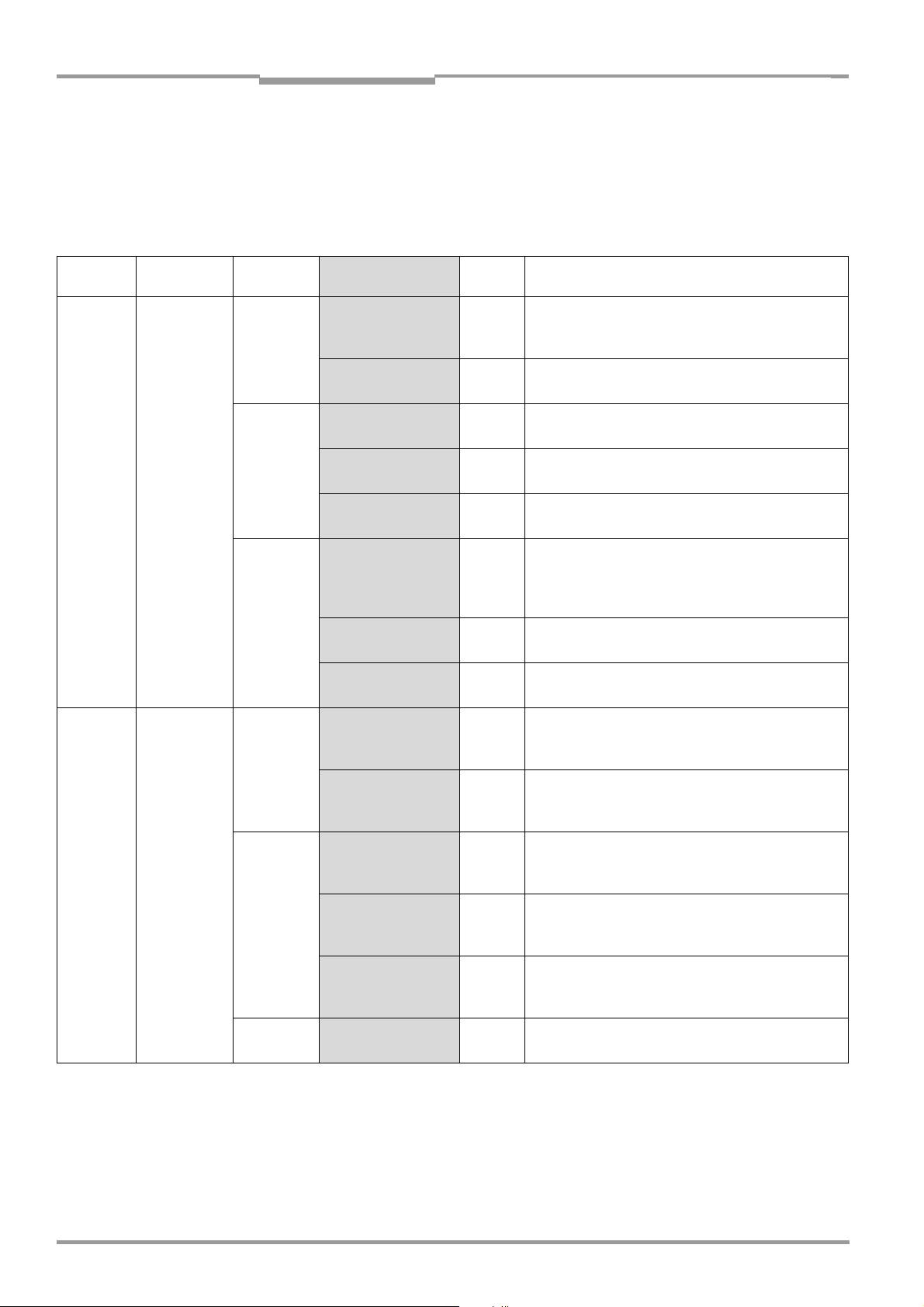

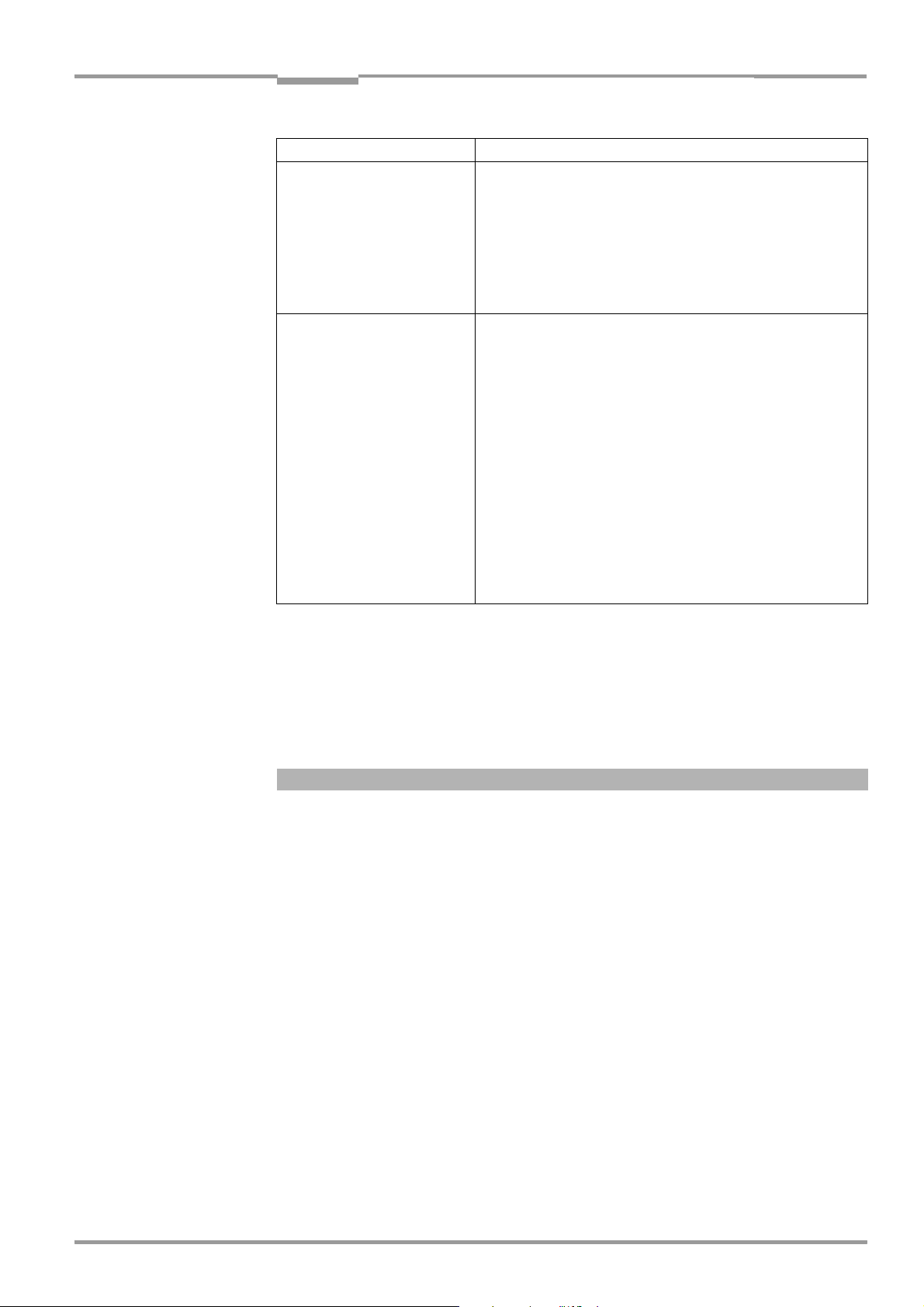

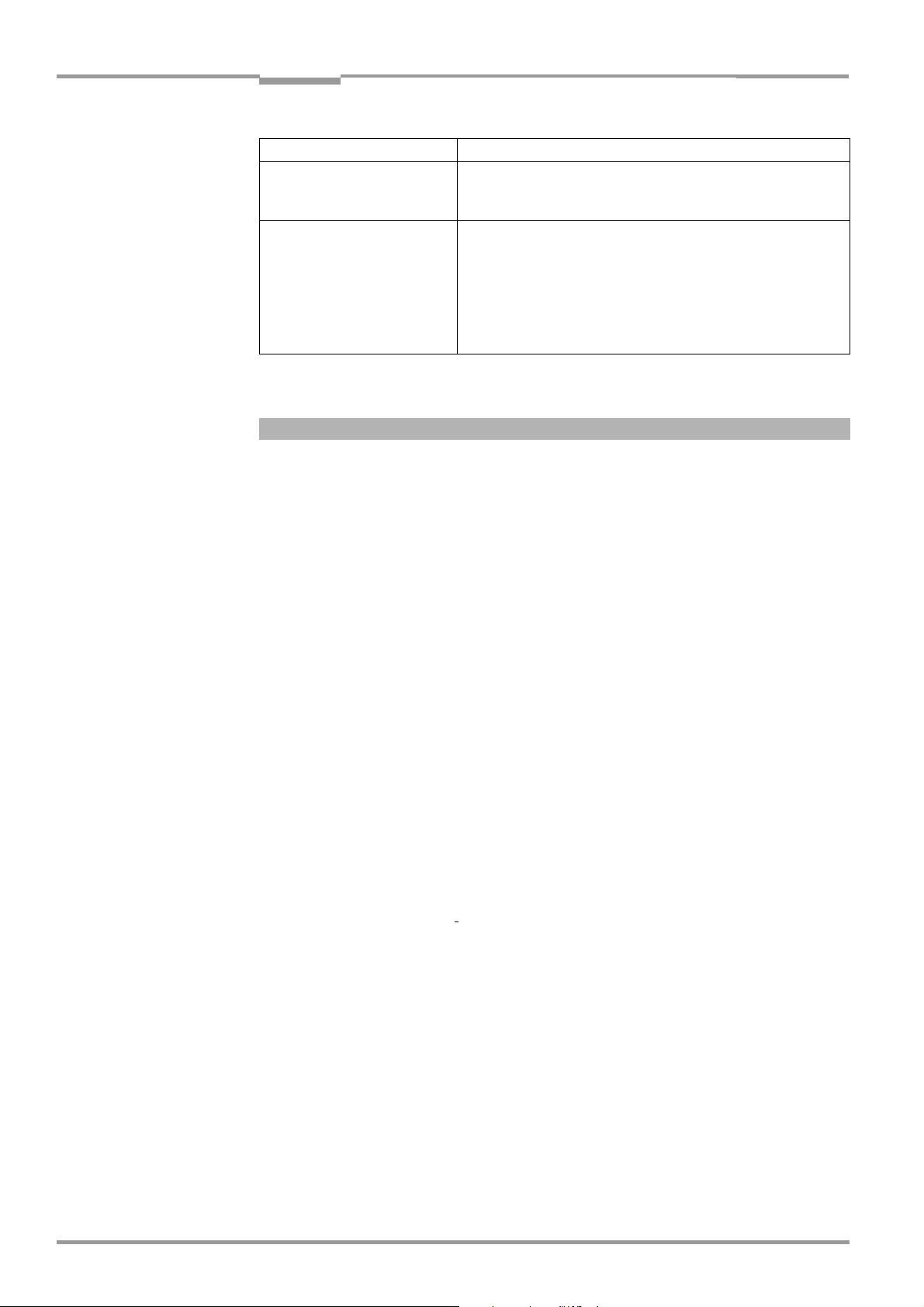

Software/Tool Function Version

CLV 490-0010/-0011 Firmware From V 3.5 O824

CLV 490-1010/-1011 Firmware From V 3.5 O824

CLV 490-6010/-6011 Firmware From V 3.5 O824

CLV 490-7010/-7011 Firmware From V 3.5 O824

CLV 490-2010/-2011 Firmware From V 3.5 O824

CLV 490-3010/-3011 Firmware From V 3.5 O824

CLV-Setup User interface (windows-based) From V 4.1 O508

CLV-Setup Help Online help (HTML) From V 4.1 O508

I-2 © SICK AG · Division Auto Ident · Germany · All rights reserved 8 009 993/O824/20-12-2004

Copyright

Copyright © 2004

SICK AG Waldkirch

Auto Ident, Reute Plant

Nimburger Strasse 11

79276 Reute

Germany

Trademarks

TM

Windows 95

Explorer

TM

are registered trademarks or trademarks of the Microsoft Corporation in the USA

TM

/98

, Windows NTTM, Windows 2000TM, Windows XPTM and Internet

and other countries.

Latest manual version

For the latest version of this manual (PDF), see www.sick.com.

Page 3

Operating Instructions

CLV 490 Bar Code Scanner

Quick Finder

CLV 490 Bar Code Scanner

Quick Finder

• What is delivered with the device

– Chapter 3.1.1 Scope of delivery, Page 3-1

• CAUTION!

– Chapter 2 Safety information, Page 2-1

• Mounting the device at the reading station

– Chapter 4 Installation, Page 4-1

• Connecting the device

– Chapter 5 Electrical installation, Page 5-1

• Overview of the device and its functions

– Chapter 3 Product description, Page 3-1

– Chapter 6.2 Default settings, Page 6-1

– Chapter 6.5 Operating modes and outputing the reading result, Page 6-39

– Chapter 9 Technical data, Page 9-1

– Chapter 10.3 Installing and operating the external parameter memory (connector co-

ver), Page 10-34

• Starting the device with the default settings

– Chapter 6.3 Quick start, Page 6-3

• Installing the "CLV-Setup" program

– Chapter 10.6 Installing and operating the "CLV-Setup" program, Page 10-43

• Adapting the device to the reading application

– Chapter 6.4 Configuring (parameterization) the CLV, Page 6-5

• Troubleshooting

– Chapter 8 Troubleshooting, Page 8-1

• Finding information

– Table of contents, Page I-5

– Index, Page 10 -93

8 009 993/O824/20-12-2004 © SICK AG · Division Auto Ident · Germany · All rights reserved I-3

Page 4

Quick Finder

Operating Instructions

CLV 490 Bar Code Scanner

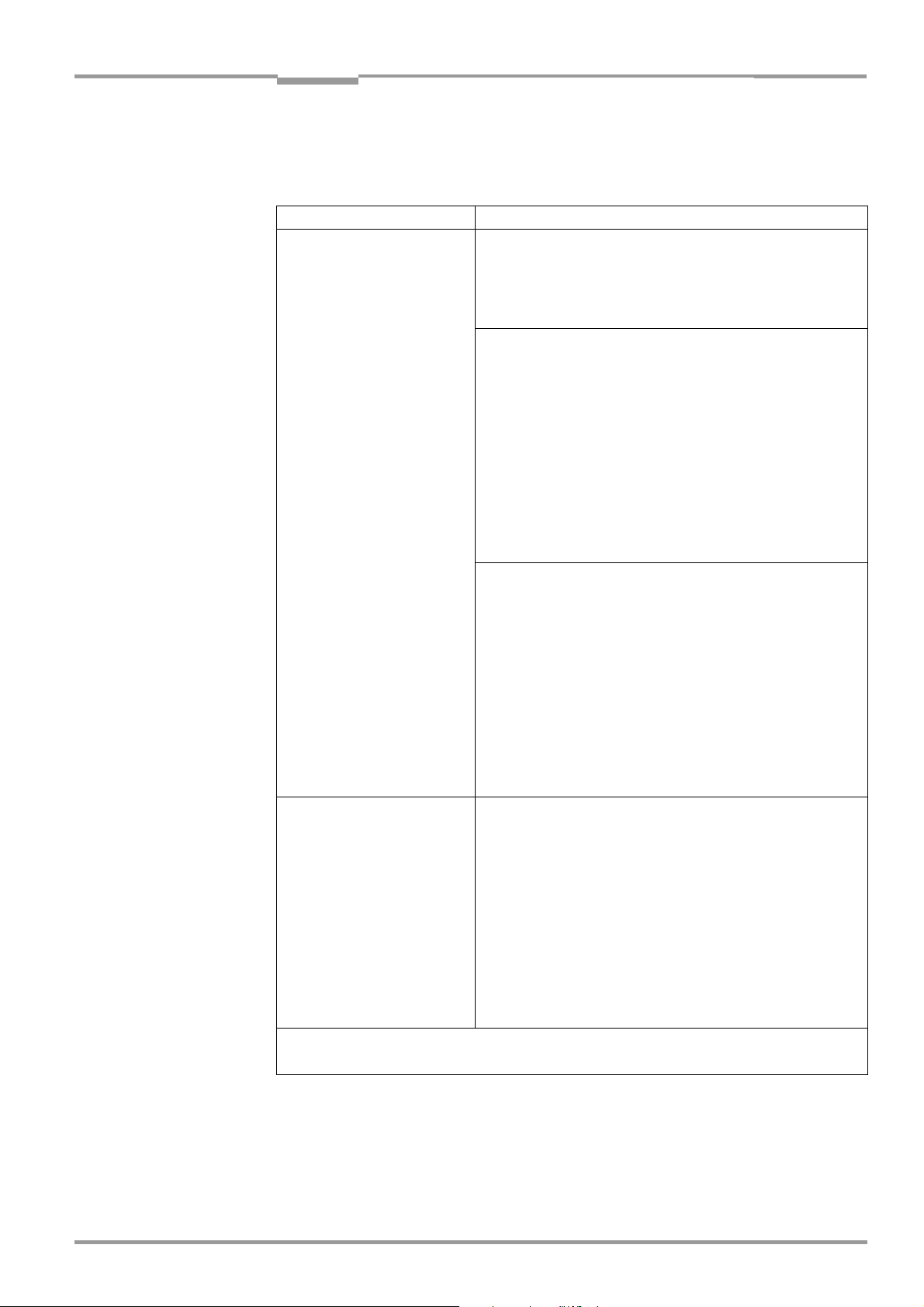

Installation procedure (overview)

CLV in stand-alone configuration

Start/stop mode: Reading trigger via “Sensor“ switching input (default setting)

1. Check the delivery to make sure that none of the components is missing.

2. Mount the CLV at the reading station and align it with the object carrying the bar code.

3. Mount the CDB 420 or CDM 490 Connection Module.

4. Connect the CLV as followed:

CDB 420 Connection Module: using the cable no. 2 027 046. Alternatively, connect

the CLV using the external parameter memory no. 2 030 023.

CDM 490 Connection Module: using two cables no. 2 020 302. Alternatively, connect

the CLV using the external parameter memory no. 2 020 307.

5. Mount the sensor for starting/stopping the reading pulse.

6. Connect the reading pulse sensor to the "Sensor (1)" switching input in the CDB 420

or CDM 490.

7. Connect the host to the host interface in the CDB 420 or CDM 490.

8. Switch on the power supply to the CDB 420 or CDM 490.

The "Device Ready" LED lights up after the CLV has started.

CLV with external empty parameter memory connected (no. 2 020 307 or 2 030 023):

After the CLV has started, it copies the internal parameter set to the external parameter

memory if no CMC 400 parameter memory is available in the CDB 420/CDM 490.

Line scanner with oscillating mirror:

In the default setting, the CLV deflects the scan line around the position CW = 50 with

a frequency of 1 Hz and an oscillating amplitude of max. ±20° (±40 CW).

9. Switch on your PC and start Windows

10. Install the "CLV-Setup" software and the online CLV-Setup Help from the CD-ROM

("Manuals & Software") on your PC.

11. Connect the PC to the terminal interface of the CLV.

To do so, connect a 3-core RS 232 data cable (null modem cable), e. g. no. 2 014 054

to the "Aux" plug in the CDB 420 or CDM 490.

12. Start the "CLV-Setup" program.

CLV-Setup establishes communication with the CLV and uploads the parameter set.

The parameters are then displayed on the tabs.

13. Carry out a test read using test bar codes (clock the CLV accordingly).

Display the reading result in the Terminal Emulator window of the "CLV-Setup" program.

14. Configure the CLV for the application using the settings on the tabs in CLV-Setup.

Copy (download) the modified parameter set to the CLV temporarily.

Do not switch off the power to the CDB 420 or CDM 490 (CLV)!

15. Test the application under realistic conditions.

16. Check whether the data is transmitted correctly between the CLV and host.

17. If necessary, correct and optimize the parameter values.

Copy (download) the parameter set permanently to the CLV.

CLV with external parameter memory connected:

Copy the modified parameter set to the external parameter memory when CLV-Setup

asks you for confirmation.

18. Save the parameter set as a configuration file "*.scl" in the "CLV-Setup" program.

TM

(minimum requirement: Windows 95TM).

The CLV can then be operated with the application-specific settings.

I-4 © SICK AG · Division Auto Ident · Germany · All rights reserved 8 009 993/O824/20-12-2004

Page 5

Operating Instructions

CLV 490 Bar Code Scanner

Contents

Table of contents

1 Notes on this document............................................................................................ 1-1

1.1 Purpose ....................................................................................................................................... 1-1

1.2 Target audience........................................................................................................................ 1-1

1.2.1 Mounting, electrical installation, maintenance and replacement.................... 1-1

1.2.2 Startup, operation and configuration ......................................................................... 1-1

1.3 Information content................................................................................................................. 1-2

1.4 Symbols....................................................................................................................................... 1-2

2 Safety information....................................................................................................... 2-1

2.1 Authorized users ...................................................................................................................... 2-1

2.1.1 Mounting and maintenance .......................................................................................... 2-1

2.1.2 Electrical installation and replacement ..................................................................... 2-1

2.1.3 Startup, operation and configuration ......................................................................... 2-1

2.2 Intended use.............................................................................................................................. 2-1

2.3 General safety instructions and protection measures.............................................. 2-2

2.4 Quick stop and quick restart................................................................................................ 2-4

2.4.1 Stopping the CLV............................................................................................................... 2-4

2.4.2 Restarting the CLV............................................................................................................ 2-4

2.5 Environmental information....................................................................................................2-4

2.5.1 Power requirements.........................................................................................................2-4

2.5.2 Disposal after removal from service.......................................................................... 2-4

3 Product description .................................................................................................... 3-1

3.1 Design .......................................................................................................................................... 3-1

3.1.1 Scope of delivery............................................................................................................... 3-1

3.1.2 Variants................................................................................................................................. 3-1

3.1.3 System requirements for stand-alone configuration........................................... 3-2

3.1.4 Product features and functions (overview) ............................................................. 3-3

3.1.5 Design ................................................................................................................................... 3-5

3.2 Method of operation............................................................................................................... 3-6

3.2.1 Autofocus function............................................................................................................ 3-7

3.2.2 Event-controlled dynamic focus control ................................................................... 3-8

3.2.3 Reading modes in stand-alone configuration......................................................... 3-8

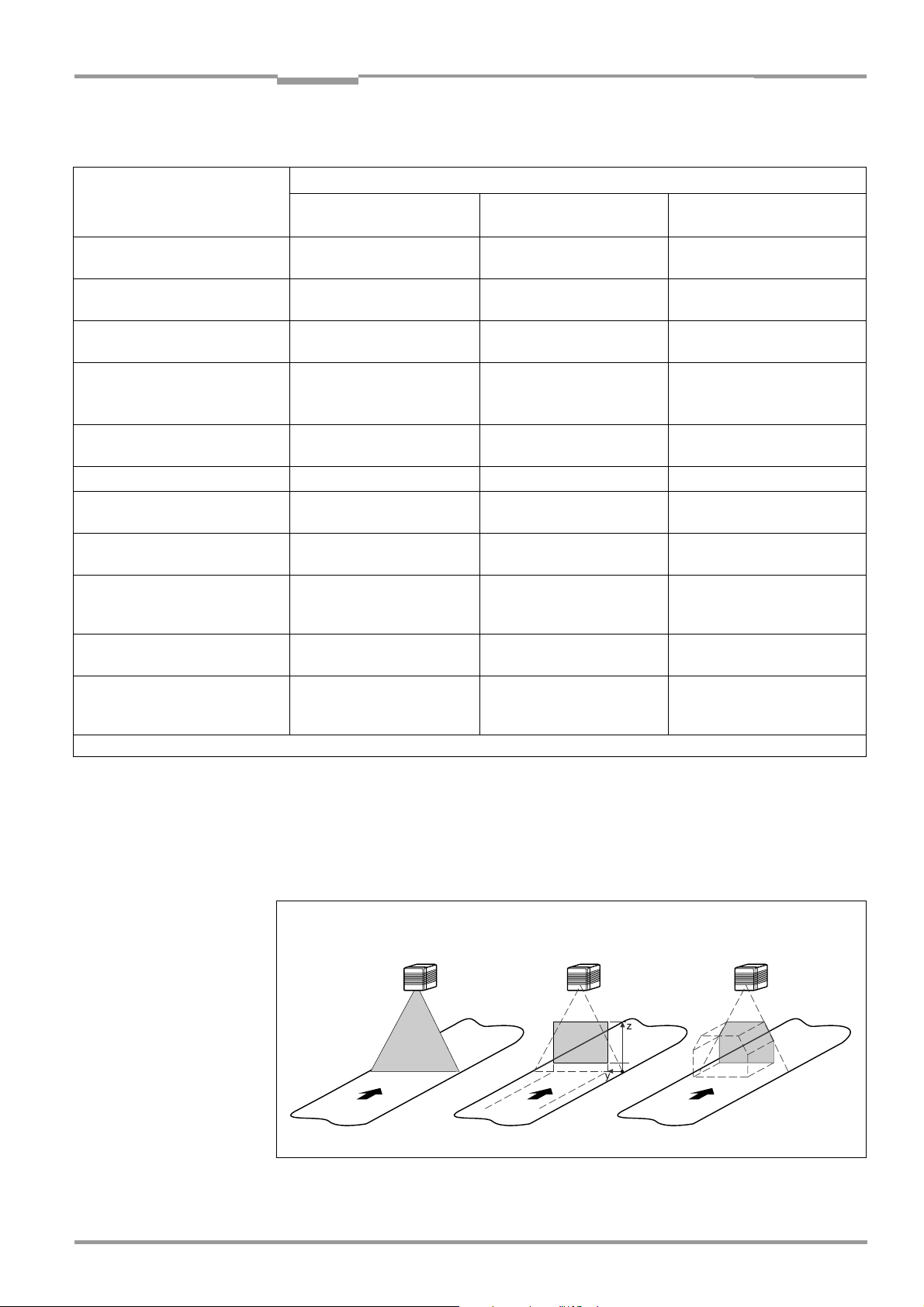

3.2.4 Scan procedure variants................................................................................................ 3-9

3.2.5 Additional components.................................................................................................3-10

3.3 Indicators and control elements ......................................................................................3-10

3.3.1 Control elements.............................................................................................................3-10

3.3.2 Function of the LEDs......................................................................................................3-11

4 Installation..................................................................................................................... 4-1

4.1 Installation sequence ............................................................................................................. 4-1

4.2 Preparations............................................................................................................................... 4-1

4.2.1 Required components..................................................................................................... 4-1

4.2.2 Required accessories...................................................................................................... 4-1

4.2.3 Required auxiliary parts .................................................................................................. 4-1

4.2.4 Replacing the laser warning label ............................................................................... 4-2

4.2.5 Selecting the mounting location .................................................................................. 4-2

4.2.6 Mounting accessories ..................................................................................................... 4-3

4.2.7 Distance between the CLV and the bar code........................................................ 4-4

4.2.8 Count direction of the code position CP and code angle CW.......................... 4-6

4.3 Mounting and adjusting the device................................................................................... 4-7

4.3.1 Mounting the CLV.............................................................................................................. 4-7

4.3.2 Adjusting the CLV .............................................................................................................. 4-8

4.3.3 Adjusting mode .................................................................................................................. 4-9

4.4 Mounting the external components................................................................................4-11

4.4.1 Mounting the CDB 420 or CDM 490 Connection Module .............................4-11

4.4.2 Mounting the external reading pulse sensor........................................................4-11

4.4.3 Installing incremental encoder ...................................................................................4-12

8 009 993/O824/20-12-2004 © SICK AG · Division Auto Ident · Germany · All rights reserved I-5

Page 6

Contents

4.4.4 Mounting the sensors for detecting the object distance................................4-13

4.5 Dismantling the device........................................................................................................ 4-14

5 Electrical installation ................................................................................................. 5-1

5.1 Installation sequence.............................................................................................................5-1

5.1.1 SICK Connection Modules (overview)......................................................................5-1

5.2 Electrical connections and cables .....................................................................................5-1

5.2.1 Wire cross-sections ..........................................................................................................5-1

5.2.2 Prefabricated cables (overview) .................................................................................. 5-2

5.2.3 Connections/cables for the CDB 420 Connection Modules............................5-3

5.2.4 Connections/cables for the CDM 490 Connection Module.............................5-5

5.2.5 Connections/cables for a non-SICK power pack..................................................5-6

5.3 Connector pin assignment....................................................................................................5-7

5.3.1 Terminals on the CLV.......................................................................................................5-7

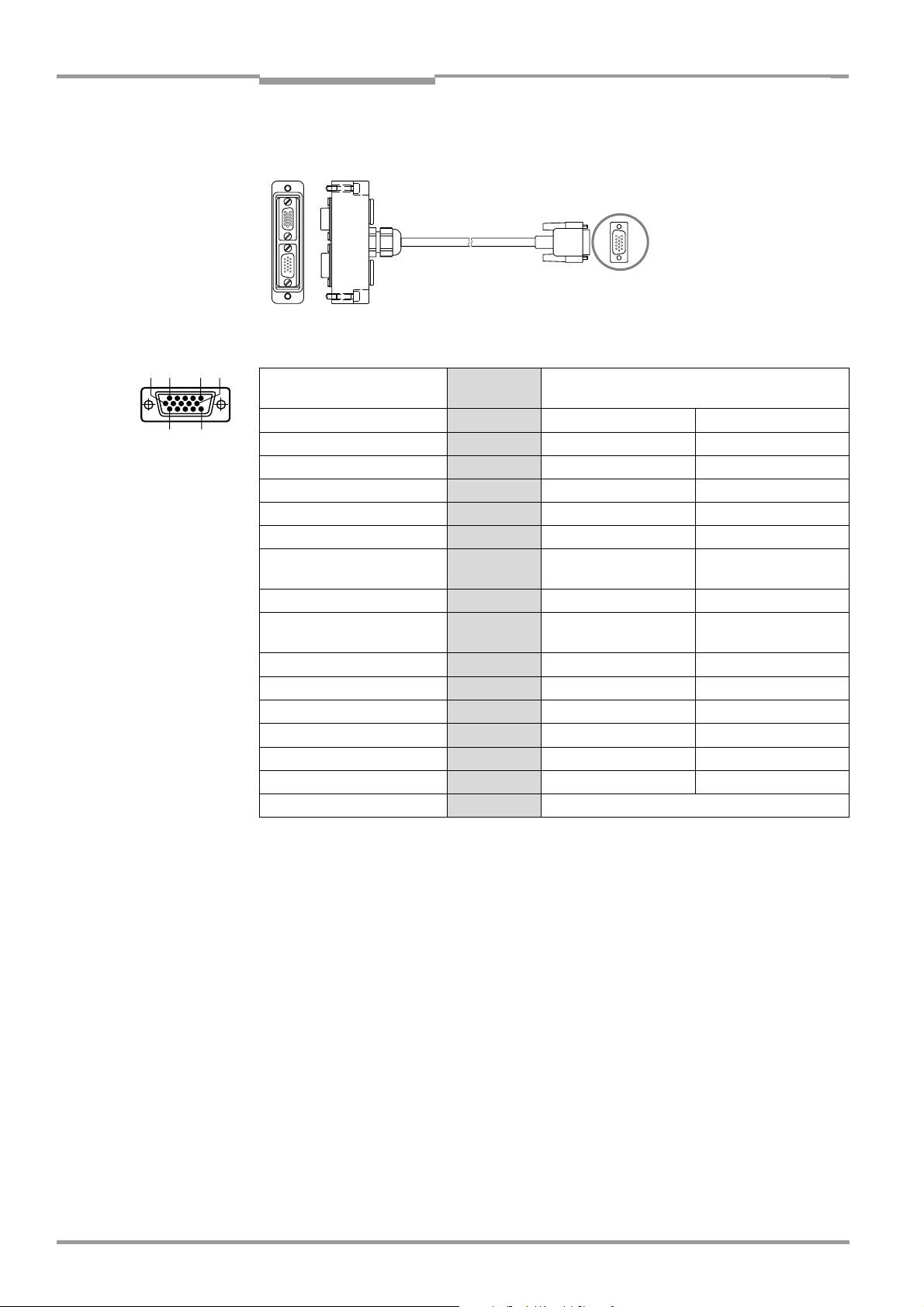

5.3.2 Cable no. 2 027 046 (connector cover)

Cable no. 2 030 023 (connector cover with parameter memory)................5-8

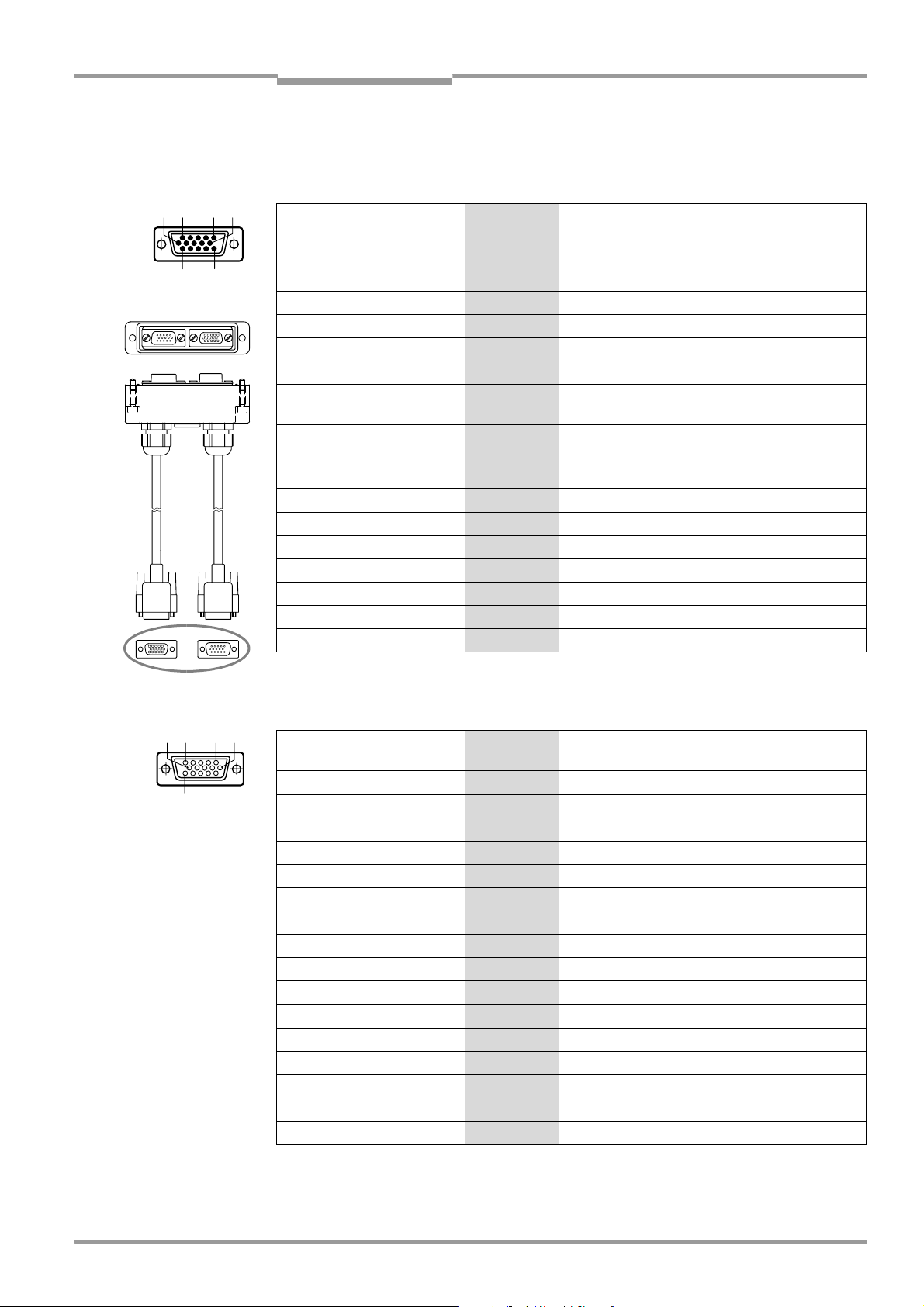

5.3.3 Cable no. 2 020 307 (connector cover with parameter memory)................5-9

5.3.4 Cable no. 2 033 126/2 033 127 (connector cover with

parameter memory) ...................................................................................................... 5-10

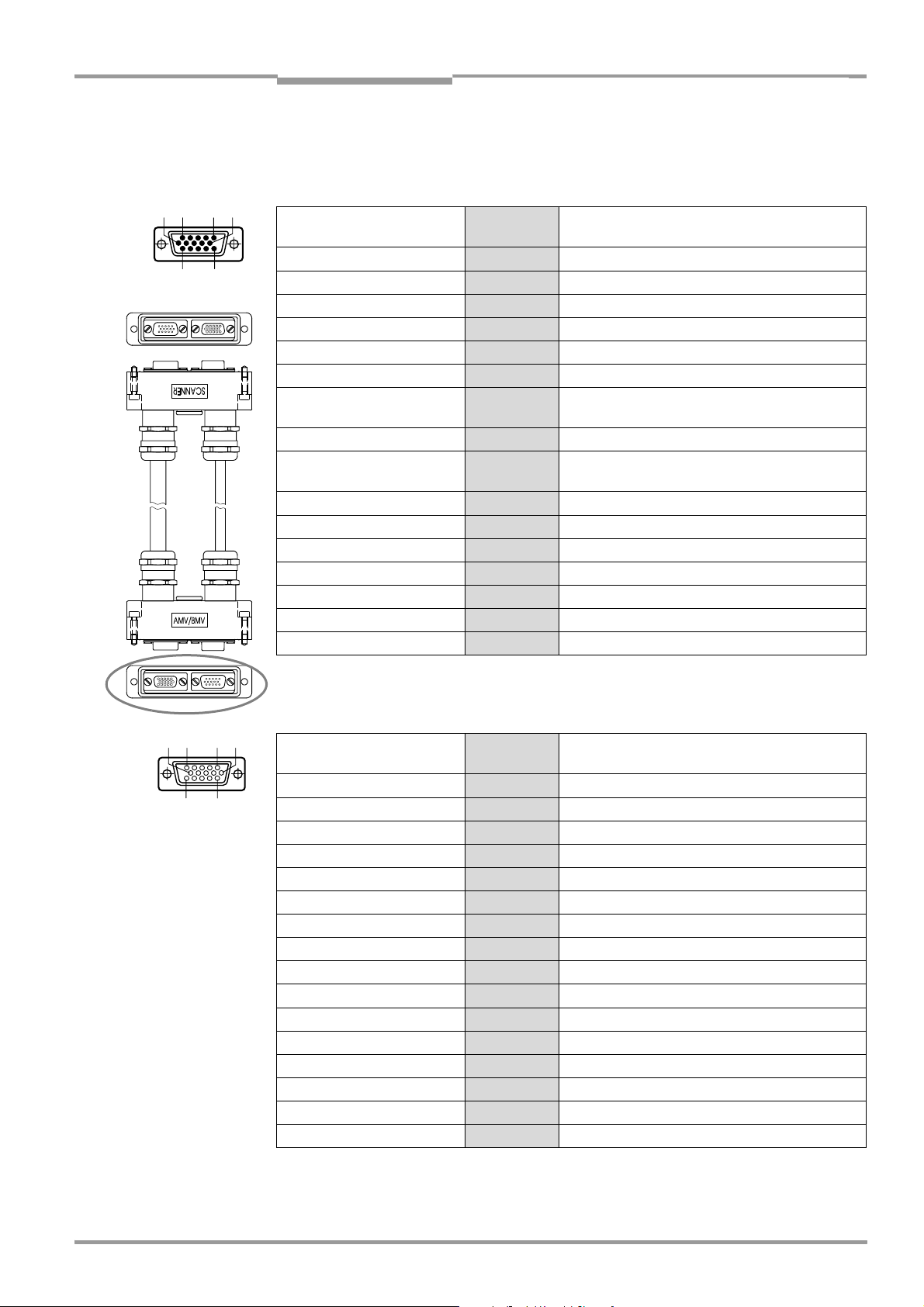

5.3.5 Cable no. 2 030 065/2 031 034 (connector cover with

parameter memory) ...................................................................................................... 5-11

5.3.6 Cable no. 2 027 543 (connector cover with parameter memory)............. 5-13

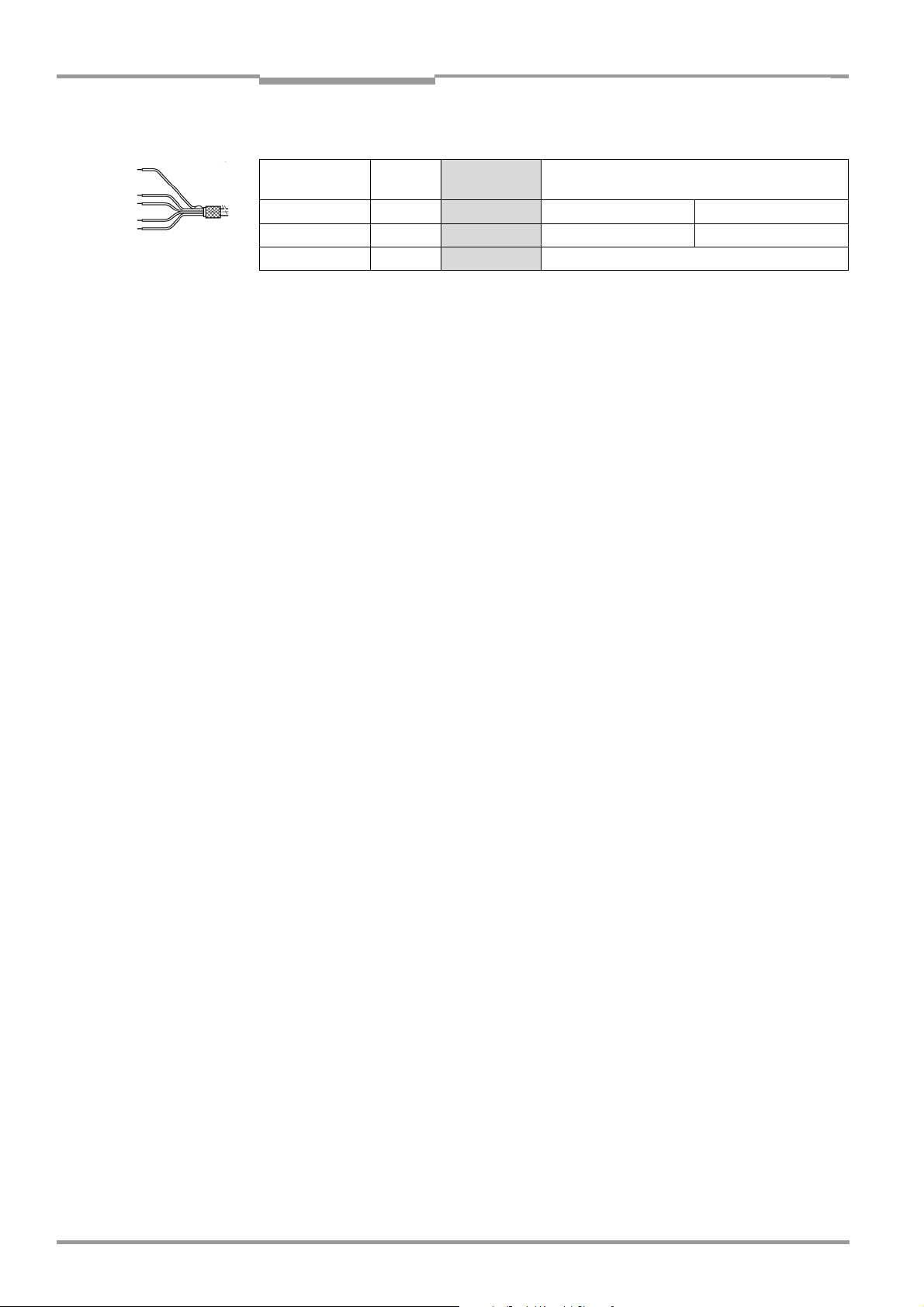

5.3.7 Cable no. 2 020 303....................................................................................................5-14

5.3.8 Cable no. 2 020 264....................................................................................................5-14

5.3.9 Cable no. 2 020 981 (connector cover with parameter memory)............. 5-15

5.3.10 Cable no. 2 021 267 (connector cover)...............................................................5-16

5.4 Preparations for electrical installation............................................................................5-17

5.4.1 Requirements for the host interface....................................................................... 5-17

5.4.2 Supply voltage ................................................................................................................. 5-17

5.4.3 Non-SICK Power supply unit/connections without the

Connection Module........................................................................................................ 5-18

5.5 Electrical installation procedure.......................................................................................5-19

5.5.1 Individual steps................................................................................................................ 5-19

5.5.2 Tools....................................................................................................................................5-19

5.5.3 Connecting the supply voltage ..................................................................................5-19

5.5.4 Connecting the host interface ...................................................................................5-21

5.5.5 Connecting the CAN interface ...................................................................................5-22

5.5.6 Connecting the PC..........................................................................................................5-22

5.5.7 Connecting the "Sensor" switching input.............................................................. 5-23

5.5.8 Connecting the "IN 0" to "IN 4" switching inputs............................................... 5-24

5.5.9 Connecting the "Result 1" to "Result 4" switching outputs...........................5-27

6 Operation ....................................................................................................................... 6-1

6.1 Overview of steps for starting up the CLV ......................................................................6-1

6.2 Default settings.........................................................................................................................6-1

6.2.1 Default settings of the line scanner CLV 490 (all variants)...............................6-2

6.2.2 Default settings of the line scanner with oscillating mirror

CLV 490 (all variants) ......................................................................................................6-2

6.3 Quick start ...................................................................................................................................6-3

6.3.1 Starting up the CLV with the factory default settings...........................................6-3

6.4 Configuring (parameterization) the CLV...........................................................................6-5

6.4.1 Configuring the CLV via the user interface of CLV-Setup...................................6-5

6.4.2 Function of the tabs in CLV-Setup (overview) ........................................................6-7

6.4.3 Parameterizing example .................................................................................................6-9

6.4.4 Guide to parameterization menu.................................................................................6-9

6.5 Operating modes and outputing the reading result .................................................6-39

6.5.1 Reading mode (standard operating mode).......................................................... 6-39

6.5.2 Percentage evaluation.................................................................................................. 6-42

6.5.3 Adjusting mode................................................................................................................ 6-44

Operating Instructions

CLV 490 Bar Code Scanner

I-6 © SICK AG · Division Auto Ident · Germany · All rights reserved 8 009 993/O824/20-12-2004

Page 7

Operating Instructions

CLV 490 Bar Code Scanner

Contents

6.5.4 Background teach-in......................................................................................................6-45

6.5.5 Show CP-limits..................................................................................................................6-47

6.5.6 Background Analysis......................................................................................................6-48

6.5.7 I/O monitor in increment trigger ................................................................................6-49

6.5.8 Displaying and editing operating data .....................................................................6-54

6.5.9 Reading diagnosis...........................................................................................................6-55

6.5.10 Monitor Host Interface..................................................................................................6-55

6.5.11 Auxiliary input ....................................................................................................................6-57

6.5.12 Code statistics for RDT 400 .......................................................................................6-57

6.5.13 Self-test...............................................................................................................................6-58

6.5.14 Executing CLV functions interactively......................................................................6-59

6.6 CLV messages........................................................................................................................6-60

6.6.1 Displaying messages.....................................................................................................6-60

6.6.2 Error messages ...............................................................................................................6-61

6.7 Switching off the CLV............................................................................................................6-61

7 Maintenance ................................................................................................................. 7-1

7.1 Cleaning the CLV during operation.................................................................................... 7-1

7.2 Maintenance.............................................................................................................................. 7-2

7.3 Disposal....................................................................................................................................... 7-2

8 Troubleshooting ........................................................................................................... 8-1

8.1 Overview of possible errors and malfunctions ............................................................. 8-1

8.1.1 Mounting errors ................................................................................................................. 8-1

8.1.2 Electrical installation errors............................................................................................ 8-1

8.1.3 Parameter errors............................................................................................................... 8-1

8.1.4 Malfunctions........................................................................................................................ 8-1

8.2 Monitoring error and malfunctions.................................................................................... 8-1

8.3 Error messages ........................................................................................................................ 8-2

8.3.1 CLV without external parameter memory................................................................ 8-2

8.3.2 LED error messages for the external parameter memory

(connector cover).............................................................................................................. 8-3

8.3.3 Messages for errors accessing the external parameter memory

(connector cover).............................................................................................................. 8-5

8.4 ST error status in the reading result of a bar code..................................................... 8-7

8.5 Troubleshooting........................................................................................................................ 8-9

8.5.1 General malfunctions: CLV not ready........................................................................ 8-9

8.5.2 Malfunctions in Reading mode: reading trigger errors......................................8-10

8.5.3 Malfunctions in Reading mode: result output errors.........................................8-14

8.5.4 Malfunctions in Reading mode: errors in the result status output...............8-18

8.5.5 Malfunctions in Reading mode: oscillating mirror errors..................................8-19

8.6 SICK Support...........................................................................................................................8-20

9 Technical data.............................................................................................................. 9-1

9.1 Data sheet CLV 490-0010/-2010/-6010 bar code scanner............................... 9-1

9.2 Data sheet CLV 490-1010/-3010/-7010 bar code scanner............................... 9-2

9.3 Data sheet CLV 490-0011 /-2011/-6011 bar code scanner.............................. 9-2

9.4 Data sheet CLV 490-1011/-3011/-7011 bar code scanner............................... 9-3

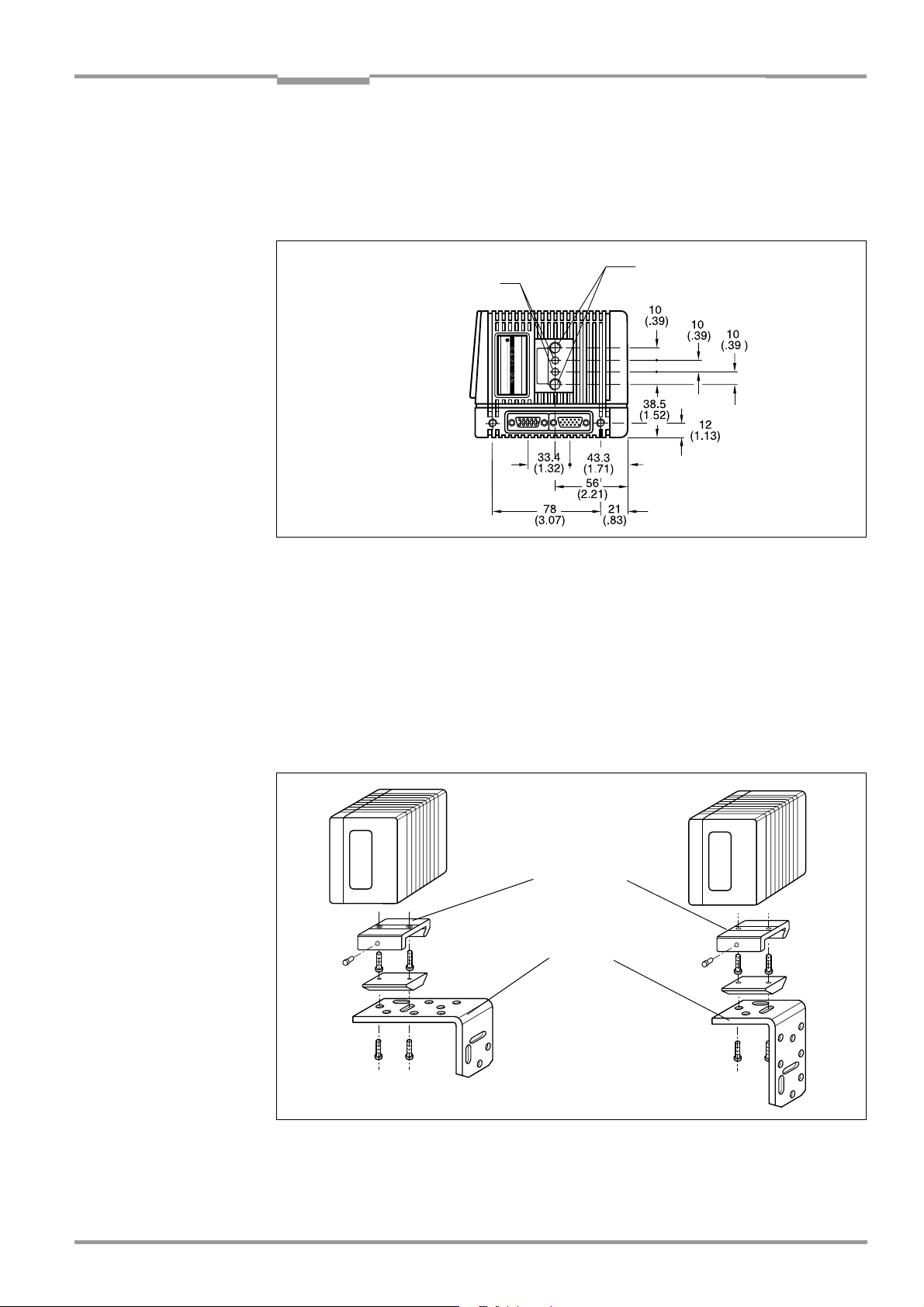

9.5 Dimensioned drawings – CLV............................................................................................. 9-3

9.5.1 Line scanner (standard device) without /with heater ......................................... 9-3

9.5.2 Line scanner with oscillating mirror (without/with heater)................................. 9-4

10 Appendix ..................................................................................................................... 10-1

10.1 Overview....................................................................................................................................10-1

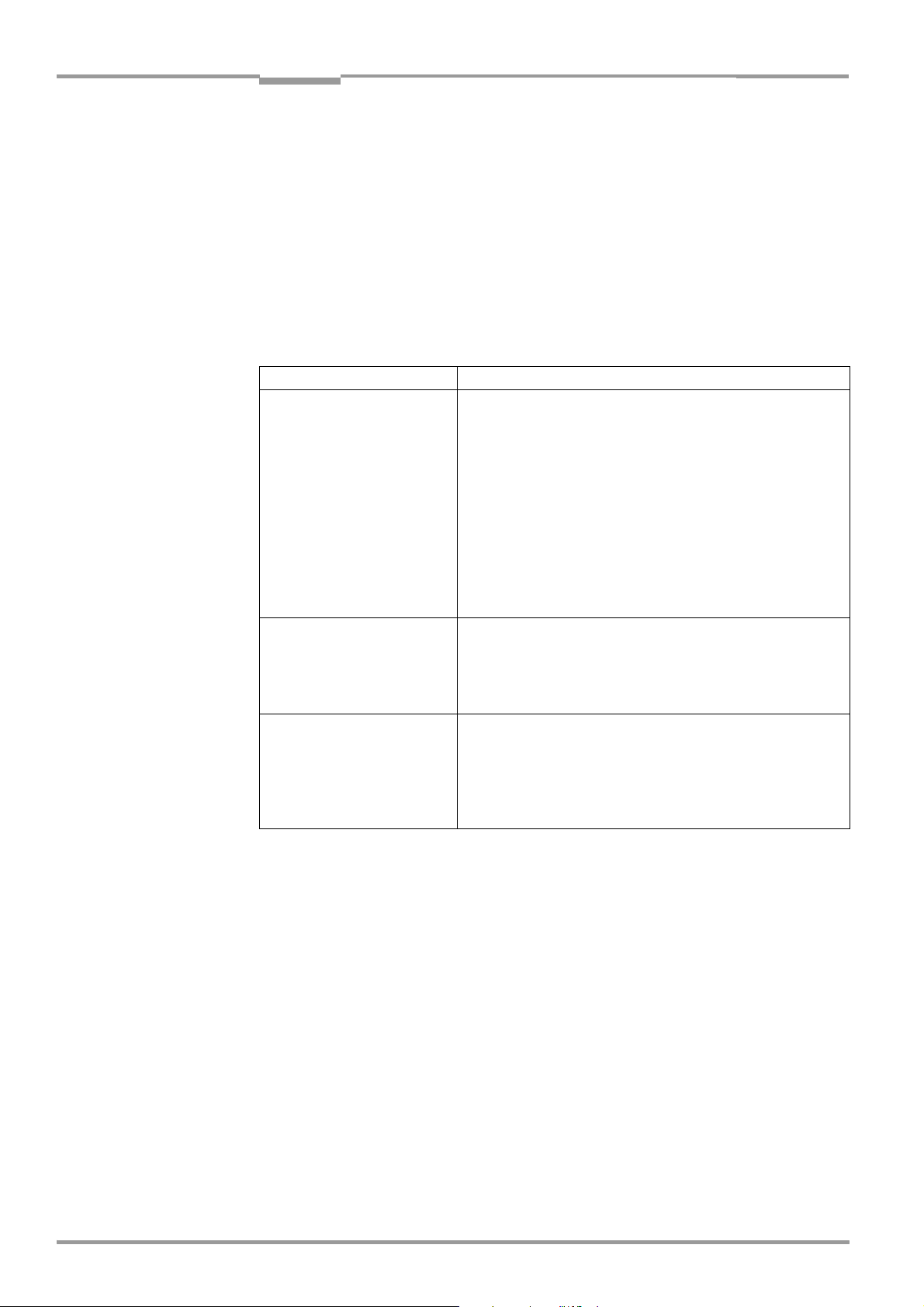

10.2 Specification diagrams.........................................................................................................10-1

10.2.1 Reading conditions for all diagrams.........................................................................10-1

10.2.2 Overview of diagrams....................................................................................................10-2

10.2.3 Standard density: Reading performance data of line scanner......................10-3

10.2.4 Standard density: Reading performance data of line scanner

with oscillating mirror .....................................................................................................10-

10.2.5 High density: Reading performance data of line scanner ............................10-16

9

8 009 993/O824/20-12-2004 © SICK AG · Division Auto Ident · Germany · All rights reserved I-7

Page 8

Contents

10.2.6 High density: Reading performance data line scanner

with oscillating mirror.................................................................................................. 10-21

10.2.7 Low density: Reading performance data of line scanner.............................10-27

10.2.8 Low density: Reading performance data of line scanner with

oscillating mirror........................................................................................................... 10-31

10.3 Installing and operating the external parameter memory

(connector cover)...............................................................................................................10-34

10.3.1 Function of the external parameter memory ....................................................10-35

10.3.2 Installation and electrical connection................................................................... 10-36

10.3.3 Operation ........................................................................................................................10-36

10.3.4 Switching on the device for the first time...........................................................10-37

10.3.5 Adjusting the parameter set in the external parameter memory

(connector cover) after it has been downloaded to the CLV..................... 10-37

10.3.6 Meaning of the LEDs.................................................................................................. 10-38

10.3.7 Error messages............................................................................................................10-38

10.3.8 Replacing a CLV ...........................................................................................................10-39

10.4 Optional heating.................................................................................................................. 10-40

10.4.1 Features.......................................................................................................................... 10-40

10.4.2 Design.............................................................................................................................. 10-40

10.4.3 Function........................................................................................................................... 10-40

10.4.4 Electrical installation ...................................................................................................10-41

10.4.5 Outdoor applications .................................................................................................. 10-41

10.5 System messages .............................................................................................................10-42

10.5.1 CLV without external parameter memory .......................................................... 10-42

10.5.2 CLV with external parameter memory connected .......................................... 10-42

10.6 Installing and operating the "CLV-Setup" program................................................ 10-43

10.6.1 Preparations .................................................................................................................. 10-43

10.6.2 Installing the software................................................................................................ 10-43

10.6.3 Starting CLV-Setup...................................................................................................... 10-46

10.6.4 User interface................................................................................................................ 10-48

10.6.5 Functions ........................................................................................................................ 10-49

10.6.6 Hot keys ..........................................................................................................................10-49

10.6.7 Opening and closing tabs.........................................................................................10-50

10.6.8 Online help – CLV-Setup Help ................................................................................ 10-50

10.6.9 Transferring parameter sets between CLV-Setup and the CLV ................10-51

10.6.10 Unknown parameters................................................................................................. 10-51

10.6.11 Log file in the Terminal Emulator ...........................................................................10-52

10.6.12 Starting CLV-Setup with an "INI file" as an argument....................................10-52

10.6.13 The CLV Assistant........................................................................................................10-52

10.7 Configuring a CLV with command strings.................................................................. 10-53

10.8 Calculating parameter values for setting the CLV.................................................. 10-55

10.8.1 Calculating the number of scans (for standard decoder)............................10-55

10.8.2 Calculating the start position and mirror speed for the forward

and return phase of the One-Shot function ...................................................... 10-57

10.8.3 Calculating the necessary bar code distance if several bar

codes are read on each object..............................................................................10-58

10.9 Tables .....................................................................................................................................10-59

10.9.1 Calculating the code length of a bar code......................................................... 10-59

10.10 Discussion of a parameterization example.............................................................. 10-60

10.10.1 Application Conditions ............................................................................................... 10-60

10.10.2 Purpose of this discussion.......................................................................................10-60

10.10.3 Instructions for solution – step by step.............................................................. 10-60

10.10.4 Important clarifications..............................................................................................10-61

10.10.5 Mounting and electrical connection ..................................................................... 10-61

10.10.6 Parameterize the CLV with the "CLV-Setup" program .................................. 10-62

10.10.7 Testing the application ..............................................................................................10-68

10.11 Special applications and procedures ......................................................................... 10-69

Operating Instructions

CLV 490 Bar Code Scanner

I-8 © SICK AG · Division Auto Ident · Germany · All rights reserved 8 009 993/O824/20-12-2004

Page 9

Operating Instructions

CLV 490 Bar Code Scanner

Contents

10.11.1 Auxiliary input via terminal interface......................................................................10-69

10.11.2 Connection to Profibus DP........................................................................................10-72

10.11.3 Connection to the DeviceNet ..................................................................................10-72

10.11.4 Connection to Ethernet TCP/IP...............................................................................10-72

10.11.5 Building a CAN Scanner Network...........................................................................10-72

10.11.6 Integration in an OPS reading system..................................................................10-72

10.12 Replacing a CLV (copying the parameter set).........................................................10-73

10.12.1 Downloading the parameter set.............................................................................10-73

10.12.2 Importing the parameter set from the external memory..............................10-74

10.13 Accessories...........................................................................................................................10-75

10.13.1 Mounting accessories ................................................................................................10-75

10.13.2 Connection modules...................................................................................................10-75

10.13.3 Extensions for connection modules......................................................................10-76

10.13.4 Cables, external parameter memories in connector cover,

connector covers .........................................................................................................10-77

10.13.5 Plug-in connections .....................................................................................................10-80

10.13.6 Reading pulse generators.........................................................................................10-80

10.13.7 Incremental encoder...................................................................................................10-81

10.14 Dimensioned drawings of the accessories...............................................................10-81

10.14.1 Angle bracket, single no. 2 013 824...................................................................10-81

10.14.2 Articulated bracket No. 2 018 435 ......................................................................10-81

10.14.3 Quick clamping device No. 2 016 110...............................................................10-81

10.15 Supplementary documentation.....................................................................................10-82

10.15.1 CLV Connect (from version 1.9) ...........................................................................10-82

10.16 Glossary..................................................................................................................................10-83

10.17 EC Declaration of Conformity .........................................................................................10-92

10.18 Index ........................................................................................................................................10-93

10.19 Bar code example ..............................................................................................................10-99

8 009 993/O824/20-12-2004 © SICK AG · Division Auto Ident · Germany · All rights reserved I-9

Page 10

Operating Instructions

Figures and tables

CLV 490 Bar Code Scanner

Abbreviations

AMV/S Connection Module with signal distribution/with additional power supply pack

BMV/S Bus Connection module with signal distribution/with additional power supply

CAN Controller Area Network (standard field bus system with message-orientated data ex-

change protocol)

CLV Code-Leser V-Prinzip.

DC Distance Configuration

DOF Depth Of Field

EEPROM Electrically Erasable Programmable Read Only Memory

HD High Density

HTML Hyper Text Markup Language (page-description language on the internet)

LED Light Emitting Diode

MTBF Mean Time Between Failure

PLC Programmable Logic Controller

RAM Ramdom Acces Memory

ROM Read Only Memory

RTF Rich Text Format (standard document format with format descriptions)

SMART SICK Modular Advanced Recognition T

echnology

Tables

Table 3-1: CLV variants ........................................................................................................................ 3-1

Table 3-2: Meaning of LEDs: CLV without external parameter memory .........................3-11

Table 3-3: Meaning of LEDs: CLV with external parameter memory in

the connector cover.......................................................................................................3-12

Table 4-1: Permissible reading angles between the scan line and bar code ................. 4-5

Table 5-1: Connection Modules for the CLV ................................................................................ 5-1

Table 5-2: Cables for connecting the CLV..................................................................................... 5-2

Table 5-3: Pin assignment of the 15-pin D Sub HD "Host/Term" plug ............................. 5-7

Table 5-4: Pin assignment of the 15-pin D Sub HD "I/O" socket........................................ 5-7

Table 5-5: Pin assignment: 15-pin D Sub HD plug of the cable no. 2 027 046/

no. 2 030 023...................................................................................................................5-8

Table 5-6: Pin assignment: 15-pin D Sub HD plug of the cable no. 2 020 307........... 5-9

Table 5-7: Pin assignment: 15-pin D Sub HD socket of the cable no. 2 020 307...... 5-9

Table 5-8: Pin assignment: 15-pin D Sub HD plug of the cable no. 2 033 126/

no. 2 033 127.................................................................................................................5-10

Table 5-9: Pin assignment: open end of the cable no. 2 033 126/

no. 2 033 127.................................................................................................................5-10

Table 5-10: Pin assignment: 15-pin D Sub HD plug of the cable no. 2 030 065/

no. 2 031 034.................................................................................................................5-11

Table 5-11: Pin assignment: 15-pin D Sub HD socket of the cable

no. 2 030 065/no. 2 031 034.................................................................................5-11

Table 5-12: Pin assignment: open end of the cable no. 2 030 065/

no. 2 031 034.................................................................................................................5-12

Table 5-13: Pin assignment: 15-pin D Sub HD plug of the cable no. 2 027 543.........5-13

Table 5-14: Pin assignment: 15-pin D Sub HD socket of the cable no. 2 027 543....5-13

Table 5-15: Pin assignment: 15-pin D Sub HD socket/wire colors of cable

no. 2 020 303.................................................................................................................5-14

Table 5-16: Pin assignment: 15-pin D Sub HD plug/wire colors of cable

no. 2 020 264.................................................................................................................5-14

I-10 © SICK AG · Division Auto Ident · Germany · All rights reserved 8 009 993/O824/20-12-2004

Page 11

Operating Instructions

Figures and tables

CLV 490 Bar Code Scanner

Table 5-17: Wire colors of cable no. 2 020 981, cable 1 ("Host/Term"

connection) .......................................................................................................................5-15

Table 5-18: Wire colors of cable no. 2 020 981, cable 2 ("I/O" connection)................5-15

Table 5-19: Wire colors of cable no. 2 021 267, cable 1 (connection for data

and function interfaces) ............................................................................................... 5-16

Table 5-20: Wire colors of cable no. 2 021 267, cable 2 (connection for

power supply)...................................................................................................................5-16

Table 5-21: Maximum cable lengths between the CLV and host ........................................5-17

Table 5-22: Power consumption of the CLV.................................................................................5-17

Table 5-23: Power-up delay as a function of the device number GN ................................5-17

Table 5-24: Communication parameters for the host interface (default setting) ..........5-21

Table 5-25: Characteristic data of the "Sensor" switching input..........................................5-23

Table 5-26: Pin assignment for "IN 0" to IN 4" switching inputs..........................................5-25

Table 5-27: Characteristic data of the "IN 0" to "IN 4" switching inputs ..........................5-25

Table 5-28: Dynamic focus control: switching inputs/distance configuration

assignment table ............................................................................................................5-25

Table 5-29: Combination of the functions of the "IN 0" to "IN 4" switching inputs...... 5-26

Table 5-30: Pin assignment for "Result 1" to "Result 4" switching outputs .................... 5-27

Table 5-31: Characteristic data of the "Result 1" to "Result 4" switching outputs.......5-27

Table 6-1: Extract: Default parameter settings of the line scanner

CLV 490-0010/-0011....................................................................................................6-2

Table 6-2: Extract: Default parameter settings of the line scanner with

oscillating mirror CLV 490.............................................................................................. 6-2

Table 6-3: Reading distances for default settings......................................................................6-4

Table 6-4: Guide: Configuring the reading area........................................................................6-11

Table 6-5: Guide: Selecting the focus control mode..............................................................6-12

Table 6-6: Guide: Configuring the autofocus function (part 1)...........................................6-13

Table 6-7: Configuring the autofocus function (part 2) .........................................................6-15

Table 6-8: Guide: Configuring focus position switchover......................................................6-16

Table 6-9: Guide: Configuring oscillating mirror functions ....................................................6-18

Table 6-10: Overview: CLV applications in stand-alone configuration or in

arrangement with OTS 400........................................................................................6-22

Table 6-11: Guide: Parameterizing the reading trigger for start/stopp mode in

stand-alone configuration............................................................................................6-23

Table 6-12: Guide: Parameterzing internal object tracking..................................................... 6-28

Table 6-13: Guide: Parameterizing the reading mode for tracking mode in

stand-alone configuration............................................................................................6-30

Table 6-14: Guide: Parameterizing focus control in CLV for master/slaves

arrangement with

OTC 400.............................................................................................................................6-31

Table 6-15: Guide: Parameterizing reading trigger in the CLV for master/slave

arrangement with

OTC 400.............................................................................................................................6-32

Table 6-16: Guide: Parameterizing slave mode in the CLV for arrangement

with OTC 400 (master).................................................................................................6-32

Table 6-17: Guide: Parameterizing operation mode in the OTC 400 for

master/slaves arrangement.......................................................................................6-33

Table 6-18: Guide: Parameterizing focus control in CLV for object tracking

mode with OTC 400 ......................................................................................................6-34

Table 6-19: Guide: Parameterizing reading trigger in the CLV for object tracking

mode with OTC 400 ......................................................................................................6-35

Table 6-20: Guide: Parameterizing tracking in the CLV for object tracking

mode with OTC 400 ......................................................................................................6-35

Table 6-21: Guide: Parameterizing slave mode in the CLV for object tracking

mode with OTC 400 ......................................................................................................6-36

Table 6-22: Guide: Parameterizing tracking mode in the OTC 400 ....................................6-36

Table 6-23: Guide: Parameterizing the laser timeout ...............................................................6-37

8 009 993/O824/20-12-2004 © SICK AG · Division Auto Ident · Germany · All rights reserved I-11

Page 12

Operating Instructions

Figures and tables

CLV 490 Bar Code Scanner

Table 6-24: Guide: Parameterizing the separation of identical bar codes........................6-37

Table 6-25: "Monitor Host Interface" function.............................................................................6-55

Table 8-1: Error messages output on the terminal interface ................................................ 8-2

Table 8-2: LED error messages for access to the external parameter

memory (connector cover)............................................................................................ 8-3

Table 8-3: Messages for problems accessing the external parameter

memory (connector cover)............................................................................................ 8-5

Table 8-4: Meaning of the ST error status in the reading result .......................................... 8-7

Table 8-5: Troubleshooting: restoring operation (Reading mode)....................................... 8-9

Table 8-6: Troubleshooting: reading trigger errors in Reading mode

(CLV in stand-alone configuration) ...........................................................................8-10

Table 8-7: Troubleshooting: reading trigger errors in Reading mode

(CLV integrated in OTS 400 Omni Tracking System) ........................................8-13

Table 8-8: Troubleshooting: result output errors in Reading mode

(CLV in stand-alone configuration) ...........................................................................8-14

Table 8-9: Troubleshooting: result output errors in Reading mode

(CLV integrated in the OTS 400 Omni Tracking System) ................................8-17

Table 8-10: Troubleshooting: errors in the result status output in Reading mode ........8-18

Table 8-11: Troubleshooting: oscillating mirror errors in Reading mode ...........................8-19

Table 9-1: Technical specifications of the CLV 490-0010/-2010/-6010....................... 9-1

Table 9-2: Technical specifications of the CLV 490-1010/-3010/-7010....................... 9-2

Table 9-3: Technical specifications of the CLV 490-0011/-2011/-6011....................... 9-2

Table 9-4: Technical specifications of the CLV 490-1011/-3011/-7011....................... 9-3

Table 10-1: Reading conditions for specification diagrams ....................................................10-1

Table 10-2: Overview of specification diagrams for the line scanner .................................10-2

Table 10-3: Overview of specification diagrams for the line scanner with

oscillating mirror...............................................................................................................10-2

Table 10-4: Types of the external parameter memory in the connector cover ...........10-34

Table 10-5: CLV system messages ..............................................................................................10-42

Table 10-6: Additional CLV system messages for the connected

parameter memory .....................................................................................................10-42

Table 10-7: Default settings in CLV-Setup..................................................................................10-46

Table 10-8: Formulas for calculating the code length of a bar code ...............................10-59

Table 10-9: Communication parameters on the terminal/PC for the

auxiliary input .................................................................................................................10-71

Table 10-10: Communication parameter settings for the SICK Hand-held

Scanner from the IT 38xx/46xx/48xx/58xx series........................................10-71

Table 10-11: Accessories: mounting accessories .....................................................................10-75

Table 10-12: Accessories: connection modules.........................................................................10-75

Table 10-13: Accessories: Extensions for connection modules...........................................10-76

Table 10-14: Accessories: Cables and connector covers for CLVs without heater......10-77

Table 10-15: Accessories: Cables and connector covers for CLVs with heater ............10-79

Table 10-16: Accessories: plug-in connections ..........................................................................10-80

Table 10-17: Accessories: incremental encoder........................................................................10-81

Table 10-18: Supplementary documentation..............................................................................10-82

I-12 © SICK AG · Division Auto Ident · Germany · All rights reserved 8 009 993/O824/20-12-2004

Page 13

Operating Instructions

Figures and tables

CLV 490 Bar Code Scanner

Figures

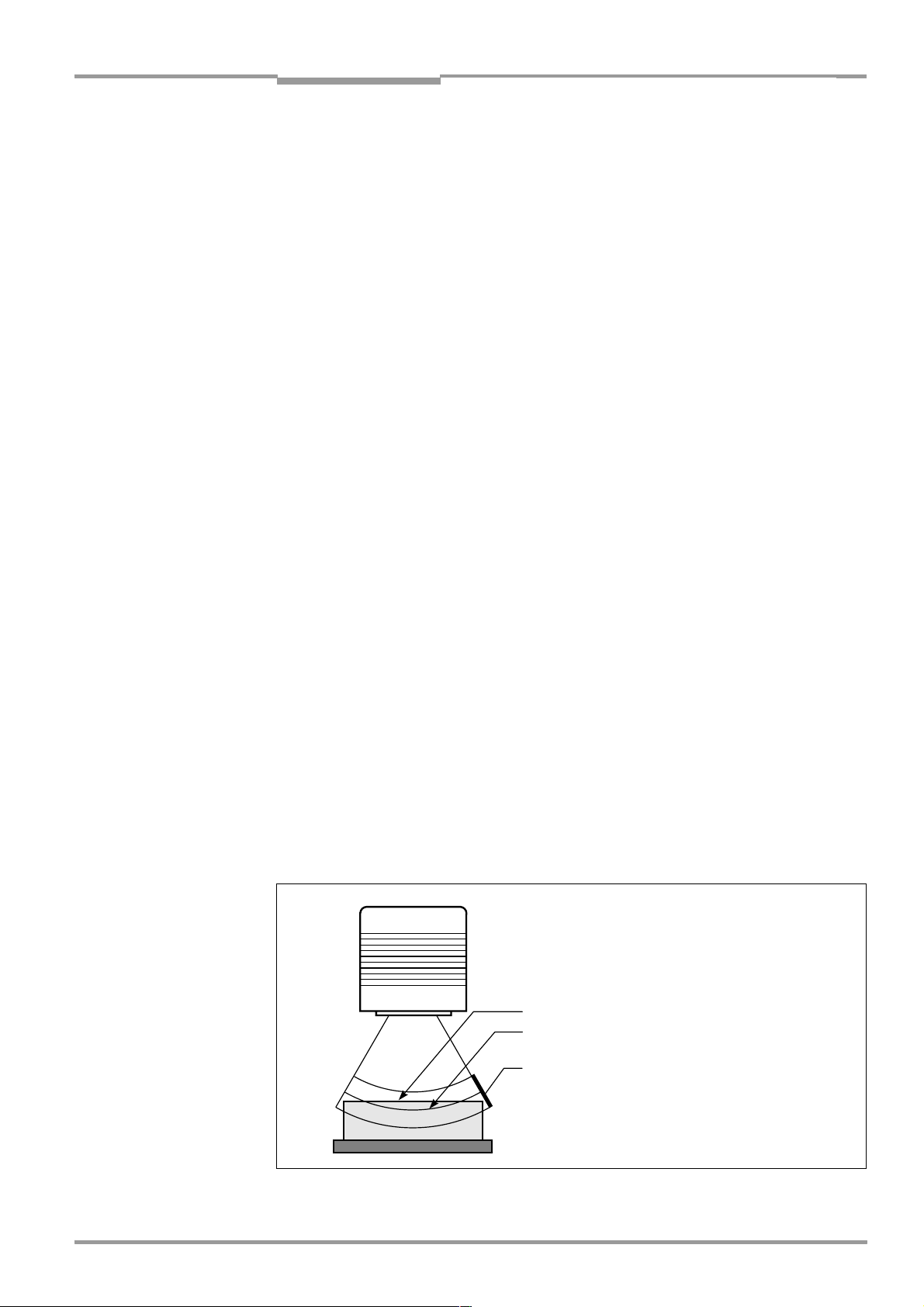

Fig. 2-1: Laser warning labels on the CLV.....................................................................................2-3

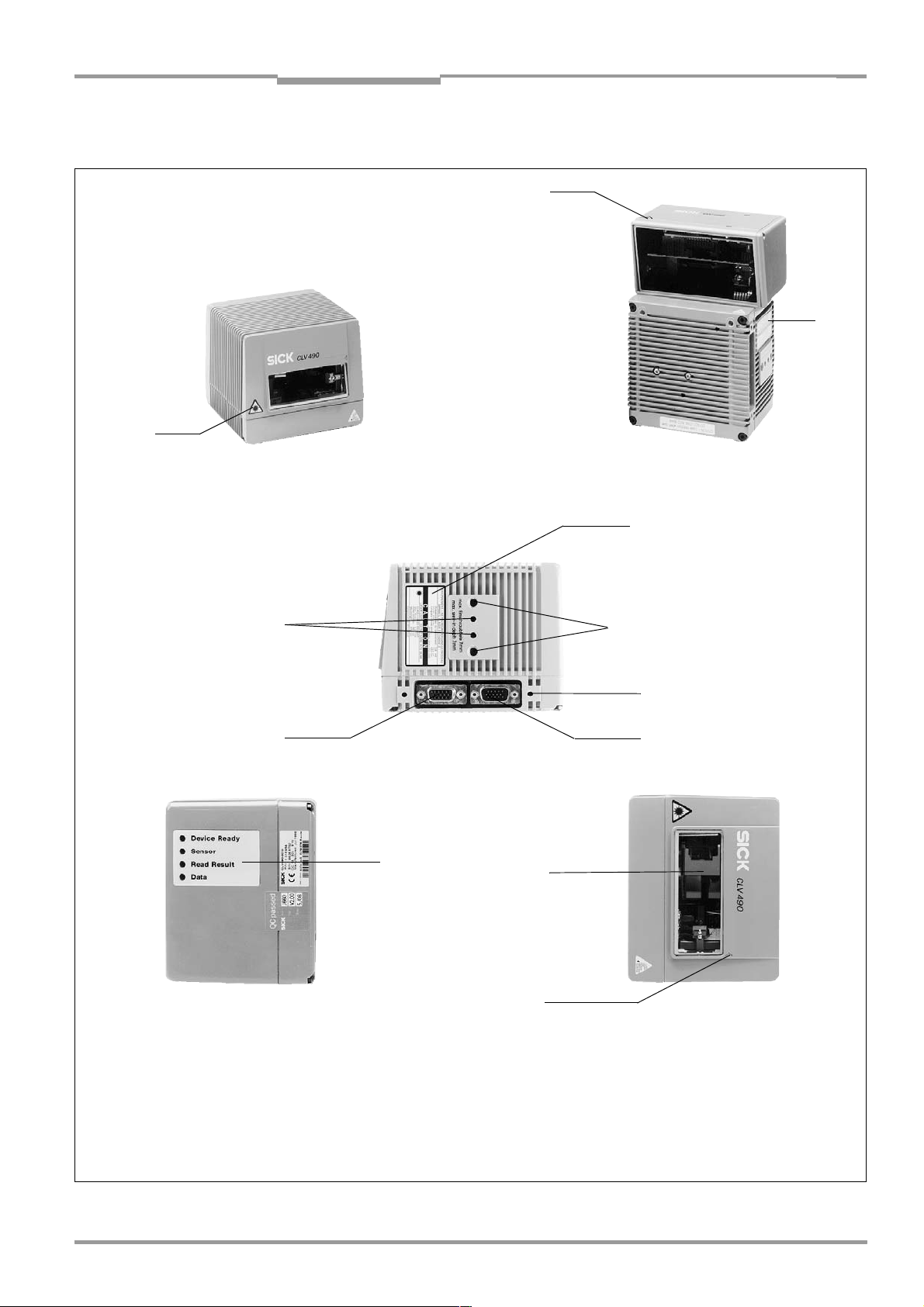

Fig. 3-1: Design of the CLV 490 .......................................................................................................3-5

Fig. 3-2: Block diagram: CLV functions...........................................................................................3-6

Fig. 3-3: Optimization of the depth of field for the object .......................................................3-7

Fig. 3-4: Dynamic focus control: classification of the reading range in distance

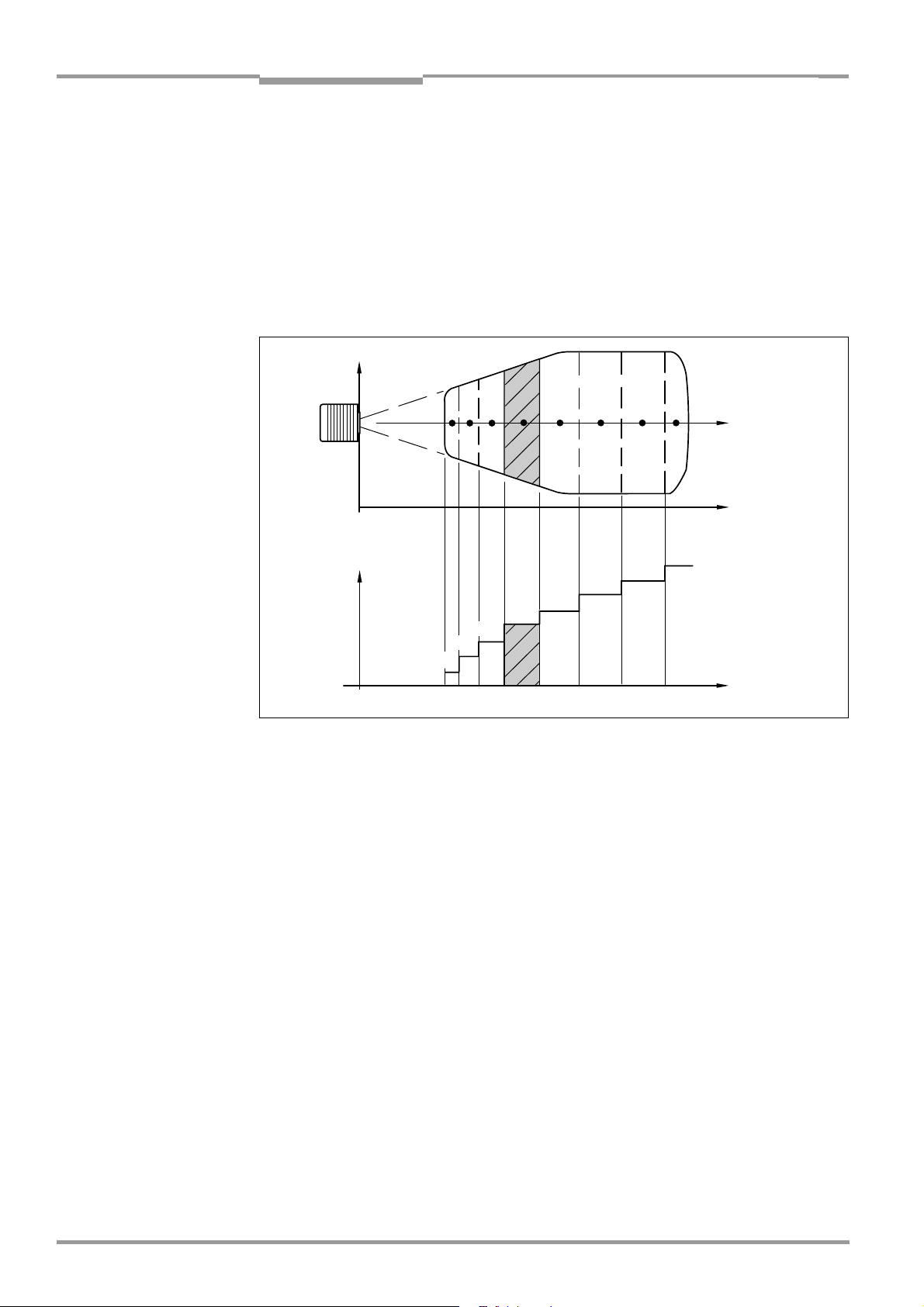

configurations.........................................................................................................................3-8

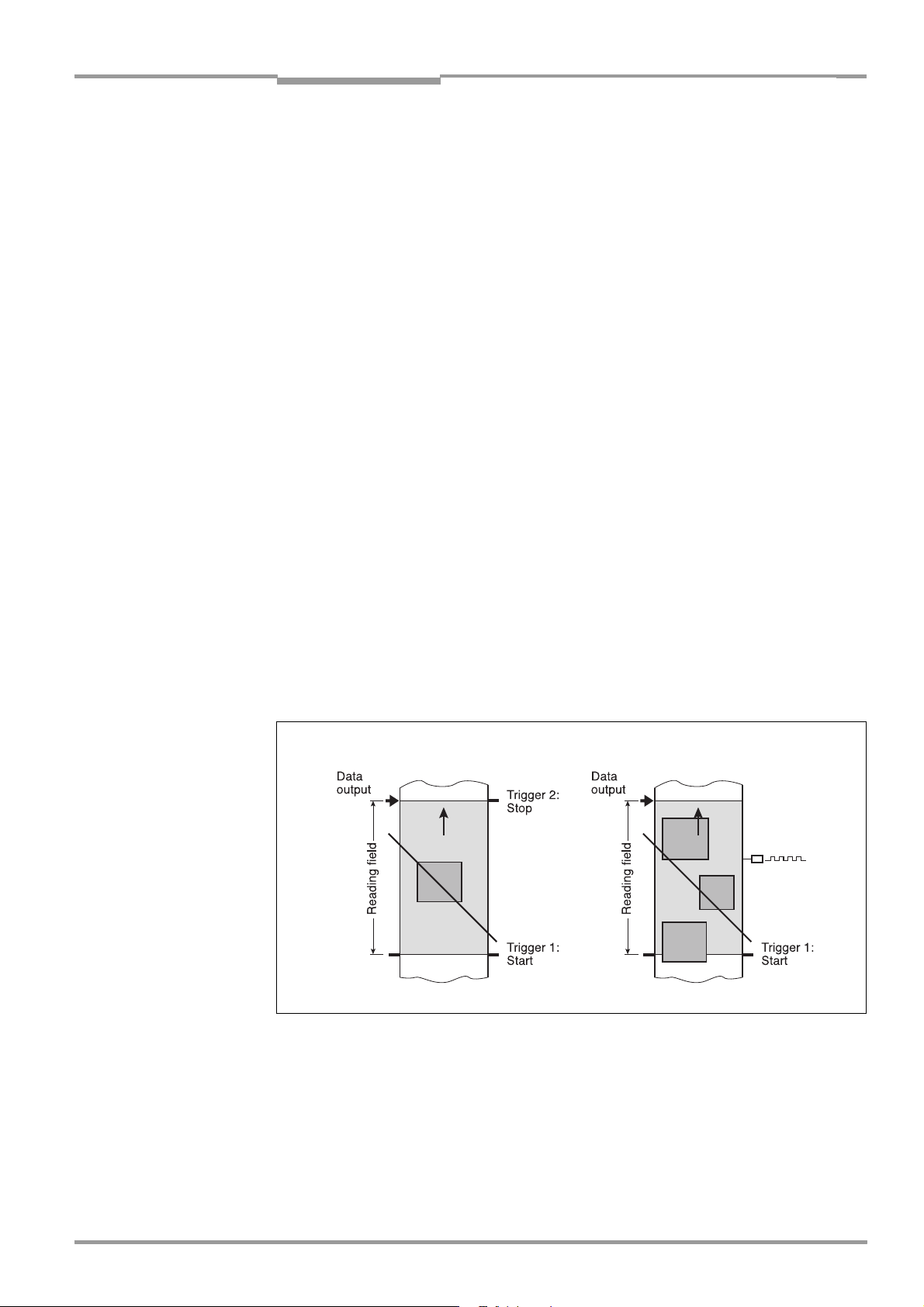

Fig. 3-5: Reading modes of the CLV in stand-alone configuration ...................................... 3-9

Fig. 3-6: LEDs........................................................................................................................................3-11

Fig. 4-1: Line scanner: replacing the laser warning labels......................................................4-2

Fig. 4-2: Line scanner: position of the securing threads on the CLV..................................4-3

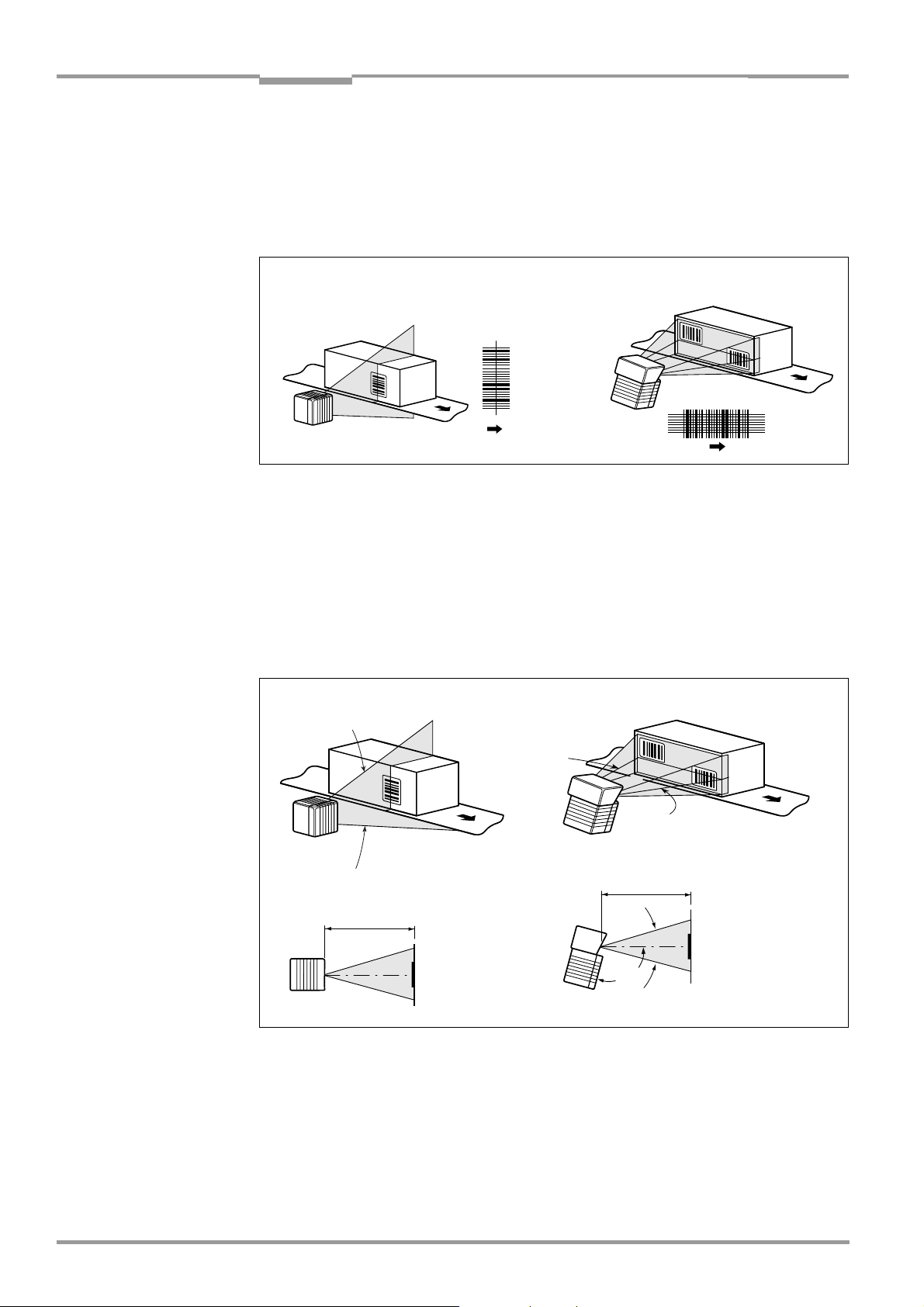

Fig. 4-3: Line scanner: Mounting possibilities of the CLV........................................................4-3

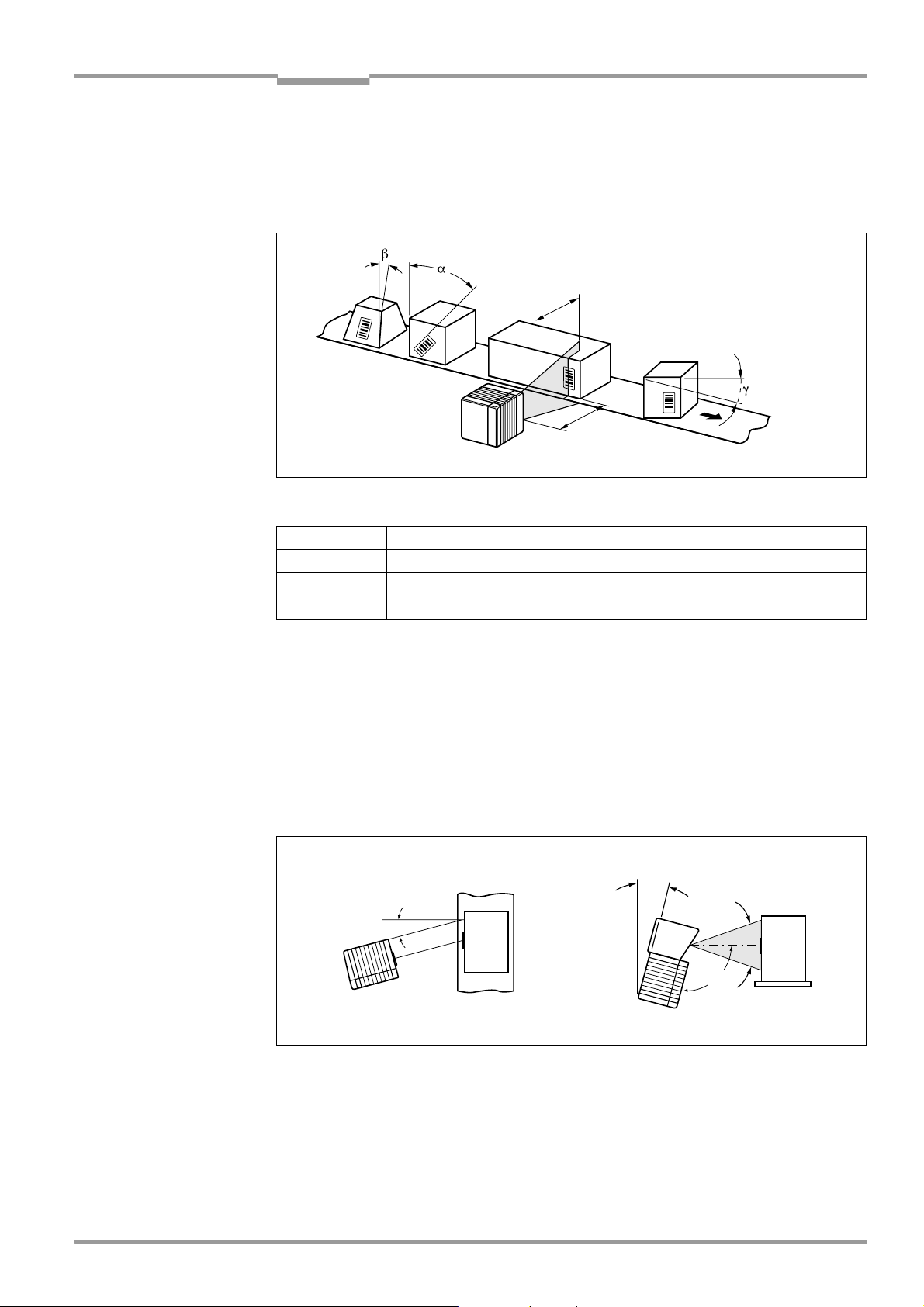

Fig. 4-4: Scanning methods: alignment with bar code and conveyor direction..............4-4

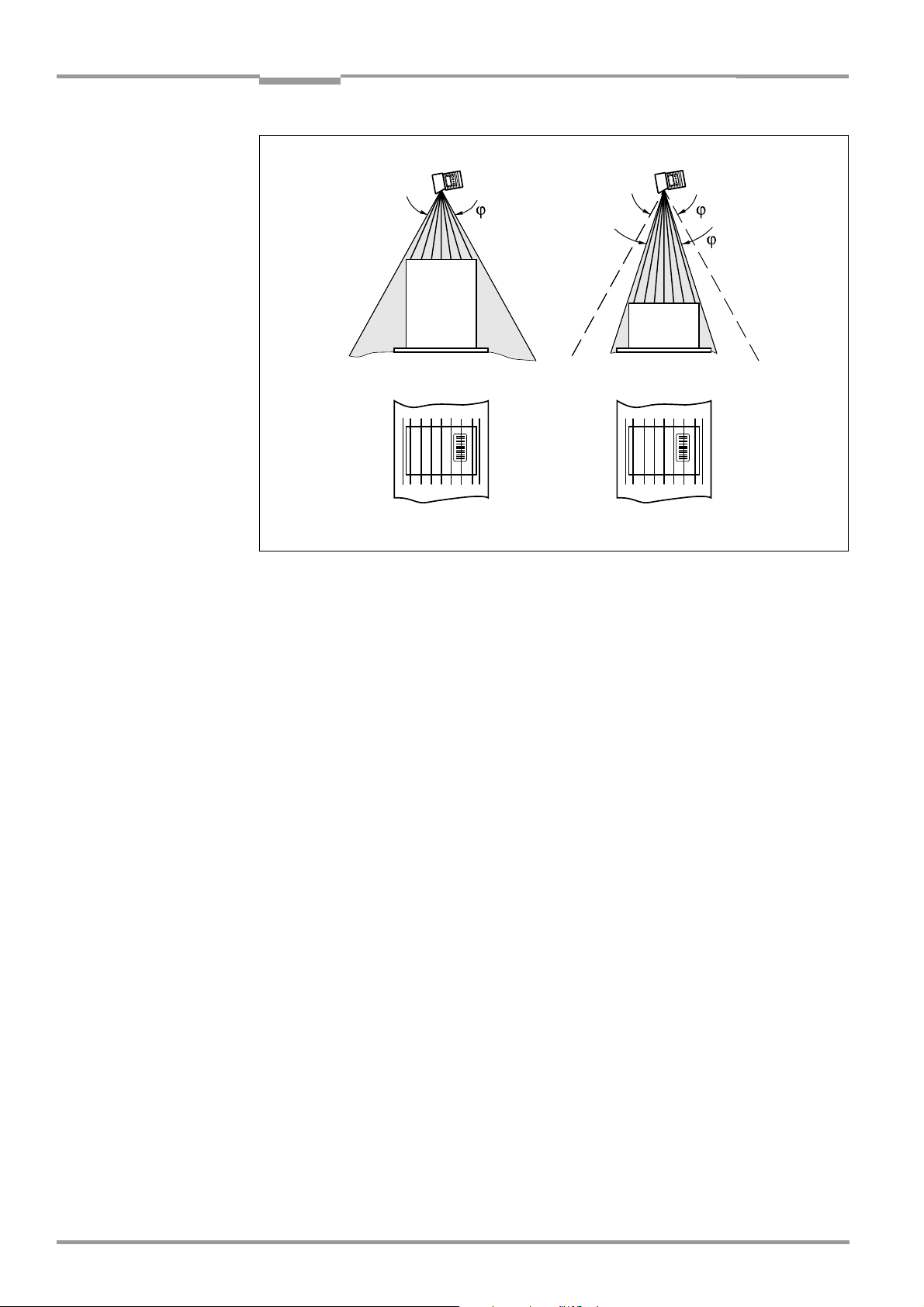

Fig. 4-5: Definition of the reading distance "a" and of the aperture angle a...................4-4

Fig. 4-6: Line scanner: Reading angle between the scan line and the bar code...........4-5

Fig. 4-7: Avoiding surface reflections: Angle between the emitted light and

the bar code (tilted away from the vertical axis).......................................................4-5

Fig. 4-8: Count direction of the code position CP in the scan line and of the

code angle CW for the oscillating mirror ......................................................................4-6

Fig. 4-9: Line scanner: scan line in Adjusting mode..................................................................4-9

Fig. 4-10: Line scanner: mounting example for the external reading pulse sensor .....4-11

Fig. 4-11: Mounting example for object distance detection ..................................................4-13

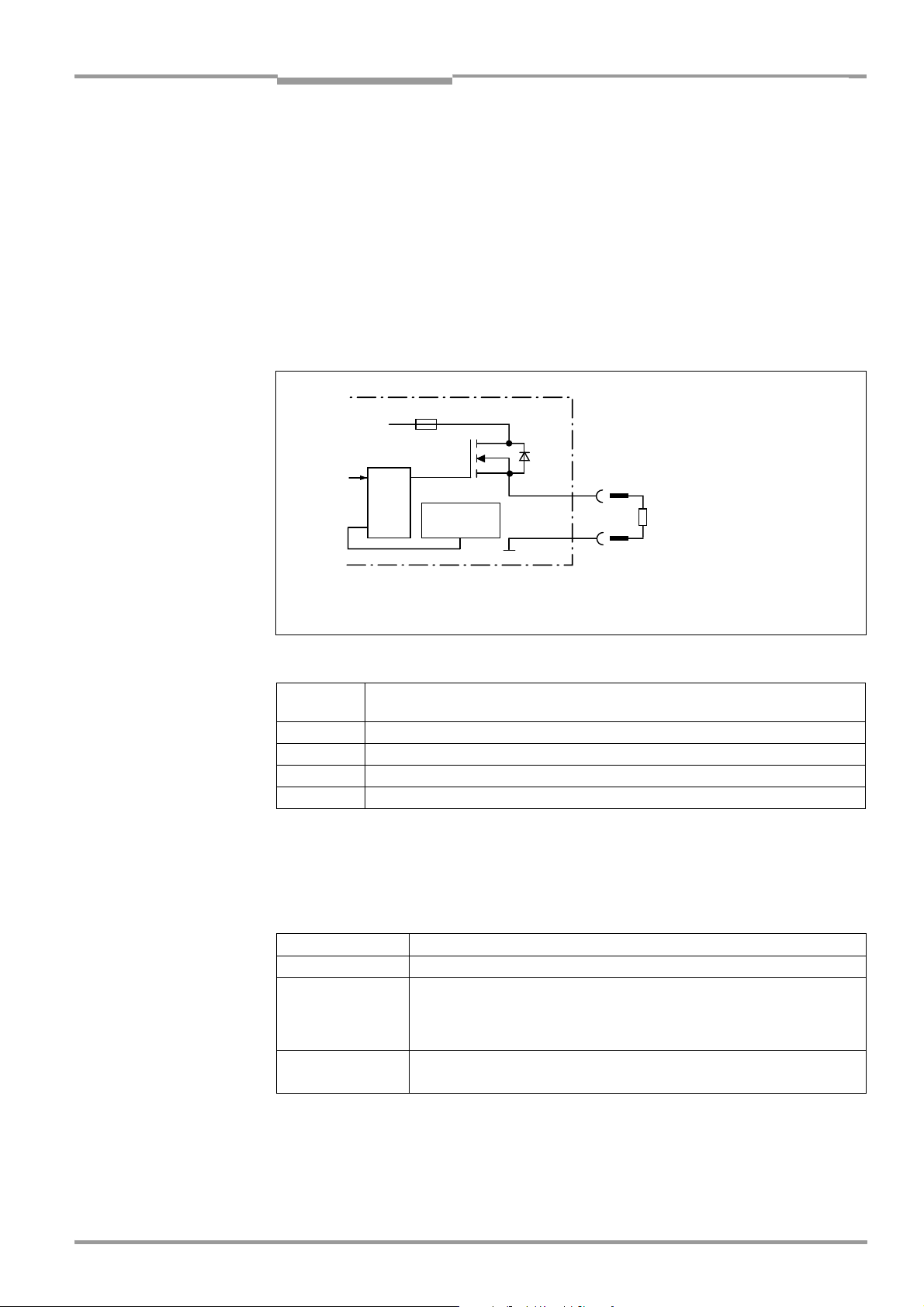

Fig. 5-1: Block diagram: Connection of the CLV 490 to the CDB 420

connection module...............................................................................................................5-3

Fig. 5-2: Block diagram: Connection of the CLV 490 to the CDM 490

connection module...............................................................................................................5-5

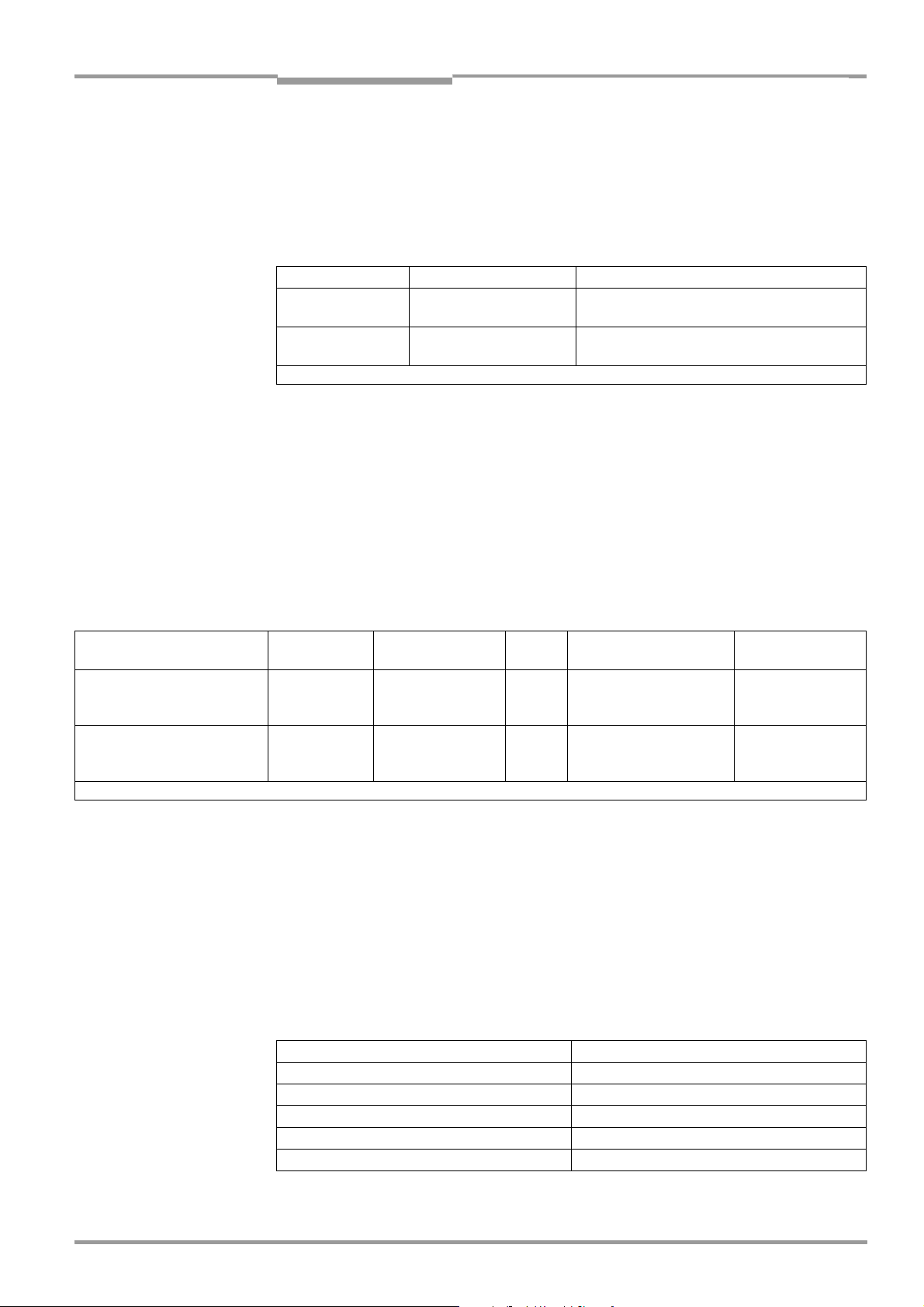

Fig. 5-3: Connecting the host interface.......................................................................................5-21

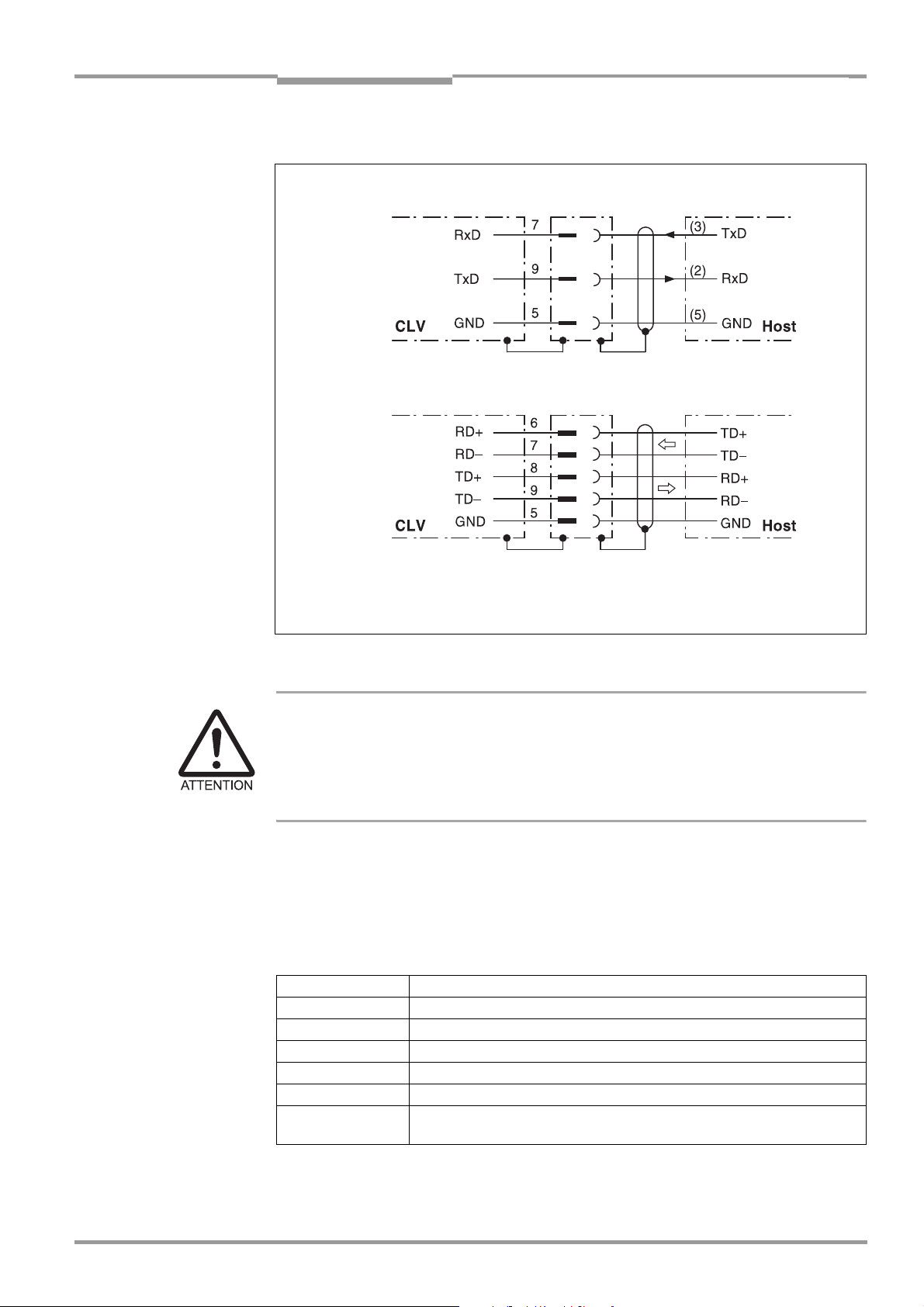

Fig. 5-4: Connecting the terminal interface ...............................................................................5-22

Fig. 5-5: Connections of the "Sensor" switching input..........................................................5-23

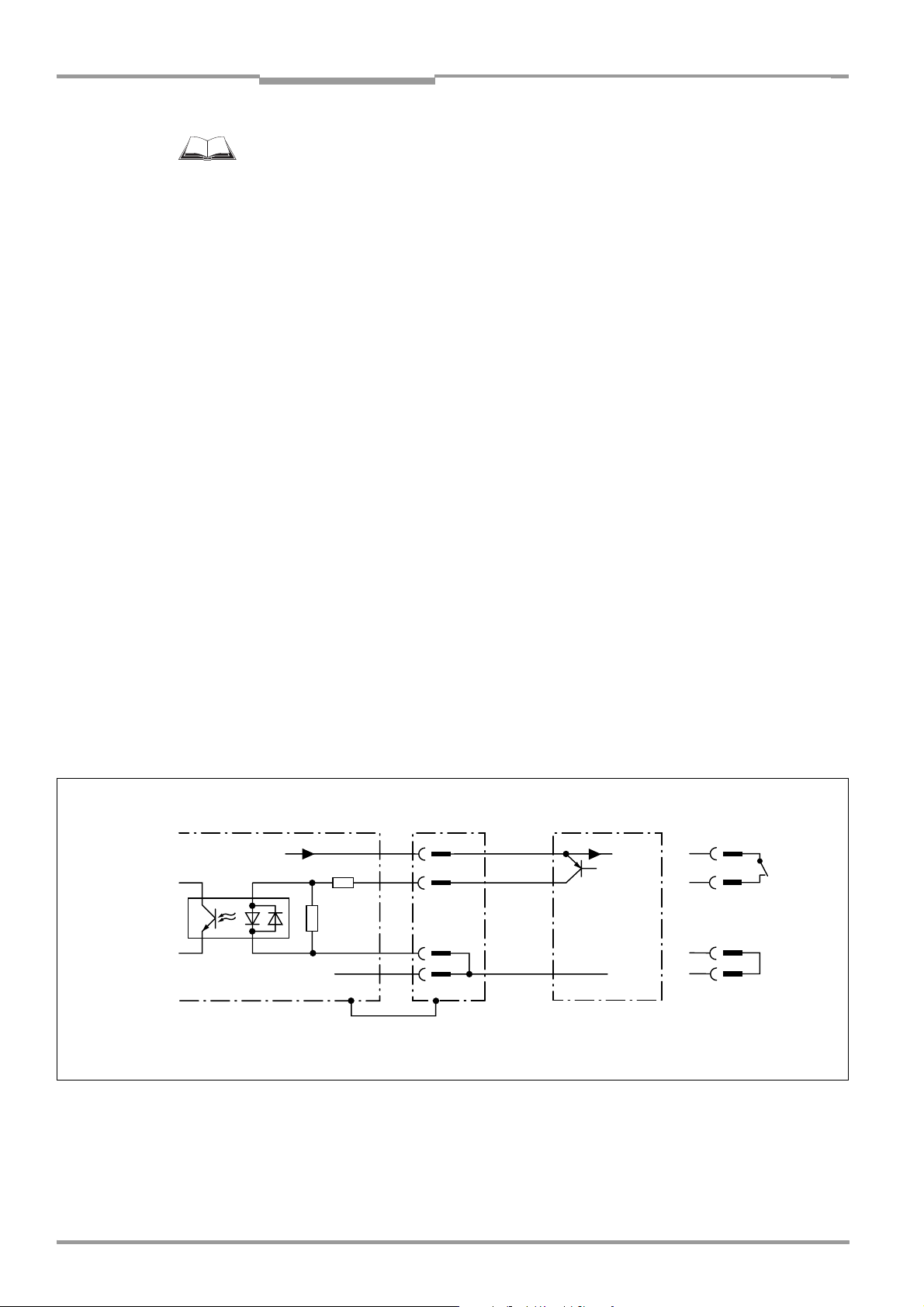

Fig. 5-6: Connections of the "IN 0" to "IN 4" switching inputs ..........................................5-24

Fig. 5-7: Connections of the "Result 1" to "Result 4" switching outputs.......................5-27

Fig. 6-1: Bar code pattern (Code 39; module width 0.35 mm (11.8 mil);

Print ratio 2:1) ........................................................................................................................6-4

Fig. 6-2: Narrowing the reading space using limit values.....................................................6-10

Fig. 6-3: Narrowing the autofocus range using limit values ................................................6-15

Fig. 6-4: Oscillating mirror: "Oscillating with fixed amplitude" mode ................................ 6-19

Fig. 6-5: Oscillating mirror: "Oscillating with variable amplitude" mode ..........................6-20

Fig. 6-6: One-Shot: Object tracking (bar code read from front).........................................6-21

Fig. 6-7: CLV-Setup: Displaying the reading result of the termianl interface

in the Terminal Emulator .................................................................................................6-40

Fig. 6-8: Reading result of the terminal interface: structure for "Good Read"............. 6-41

Fig. 6-9: Reading result of the terminal interface: structure for "No Read" ..................6-41

Fig. 6-10: CLV-Setup: Displaying the percentage evaluation in the

Terminal Emulator..............................................................................................................6-43

Fig. 6-11: CLV-Setup: Dialog window for running the background teach-in.....................6-45

Fig. 6-12: CLV-Setup: Display of th learned background ........................................................6-46

Fig. 6-13: Appearance of scan line in the "Show CP-limits" mode ..................................... 6-47

Fig. 6-14: CLV-Setup: Example of output in the "Background Analysis" dialog box.....6-48

Fig. 6-15: CLV-Setup: Selection of the signals to be displayed in I/O Monitoring......... 6-50

Fig. 6-16: CLV-Setup: Example of output in the "I/O Monitoring" dialog box..................6-51

Fig. 6-17: CLV-Setup: "Operating Data" dialog box...................................................................6-54

Fig. 6-18: CLV-Setup: Displaying the reading result of the host interface in

the Terminal Emulator with direction identifier at the beginning

(in this case: O = Output)................................................................................................ 6-56

Fig. 6-19: CLV-Setup: Displaying the self-test result in the Terminal Emulator .............. 6-58

Fig. 6-20: CLV-Setup: Dialog box for executing Show limits ..................................................6-59

Fig. 6-21: CLV-Setup: Displaying the system messages in the Terminal

8 009 993/O824/20-12-2004 © SICK AG · Division Auto Ident · Germany · All rights reserved I-13

Page 14

Operating Instructions

Figures and tables

CLV 490 Bar Code Scanner

Emulator when starting the CLV....................................................................................6-60

Fig. 7-1: Cleaning the reading window ........................................................................................... 7-1

Fig. 7-2: Cleaning the external optical sensors (reading pulse generator,

object-height detector)....................................................................................................... 7-2

Fig. 9-1: Dimensions of the CLV 490 line scanner, front reading window....................... 9-3

Fig. 9-2: Dimensions of the CLV 490: line scanner with oscillating mirror,

side reading window............................................................................................................ 9-4

Fig. 10-1: CLV 490-0010/-0011 (Standard density): Reading field height as

a function of the reading distance and resolution.................................................10-3

Fig. 10-2: CLV 490-0010/-0011 (Standard density): Min. and Max. reading

distance (measured radially) as a function of the focus position at a

resolution of 0.35 mm (13.8 mil) and an aperture angle of

Fig. 10-3: CLV 490-0010/-0011 (Standard density): Min. and Max. reading

distance (measured radially) as a function of the focus position at a

resolution of 0.35 mm (13.8 mil) and an aperture angle of

Fig. 10-4: CLV 490-0010/-0011 (Standard density): Min. and Max. reading

distance (measured radially) as a function of the focus position at a

resolution of 0.50 mm (19.7 mil) and an aperture angle of

Fig. 10-5: CLV 490-0010/-0011 (Standard density): Min. and Max. reading

distance (measured radially) as a function of the focus position at a

resolution of 0.50 mm (19.7 mil) and an aperture angle of

Fig. 10-6: Characteristics field CLV 490-0010/-0011 (Standard density): Scanning

frequency as a function of the radial reading distance and resolution .........10-8

Fig. 10-7: CLV 490-1010/-1011 (Standard density): Reading field height as a

function of the reading distance and resolution....................................................10-9

Fig. 10-8: CLV 490-1010/-1011 (Standard density): Min. and Max. reading

distance (measured radially) as a function of the focus position at a

resolution of 0.35 mm (13.8 mil) and an aperture angle of

Fig. 10-9: CLV 490-1010/-1011 (Standard density): Min. and Max. reading

distance (measured radially) as a function of the focus position at a

resolution of 0.35 mm (13.8 mil) and an aperture angle of

Fig. 10-10: CLV 490-1010/-1011 (Standard density): Min. and Max. reading

distance (measured radially) as a function of the focus position at a

resolution of 0.50 mm (19.7 mil) and an aperture angle of

Fig. 10-11: CLV 490-1010/-1011 (Standard density): Min. and Max. reading

distance (measured radially) as a function of the focus position at a

resolution of 0.50 mm (19.7 mil) and an aperture angle of

Fig. 10-12: Characteristics field CLV 490-1010/-1011 (Standard density):

Scanning frequency as a function of the radial reading distance

and resolution...................................................................................................................10-14

Fig. 10-13: CLV 490-1010/-1011 (Standard density): deflection range as a

function of radial reading distance, deflection angle and resolution ...........10-15

Fig. 10-14: CLV 490-2010/-2011 (High density): Reading field height as a

function of the reading distance and resolution..................................................10-16

Fig. 10-15: CLV 490-2010/-2011 (High density): Min. and Max. reading

distance (measured radially) as a function of the focus position at a

resolution of 0.25 mm (9.8 mil) and an aperture angle of

Fig. 10-16: CLV 490-2010/-2011 (High density): Min. and Max. reading distance

(measured radially) as a function of the focus position at a resolution

of 0.35 mm (13.8 mil) and an aperture angle of

Fig. 10-17: CLV 490-2010/-2011 (High density): Min. and Max. reading distance

(measured radially) as a function of the focus position at a resolution

of 0.35 mm (13.8 mil) and an aperture angle of

Fig. 10-18: Characteristics field CLV 490-2010/-2011 (High density): Scanning

frequency as a function of the radial reading distance and resolution ......10-20

Fig. 10-19: CLV 490-3010/-3011 (High density): Reading field height as a

function of the reading distance and resolution..................................................10-21

α =40° .............................10-18

α =56° .............................10-19

α =40° ...........10-4

α =56° ...........10-5

α =40° ...........10-6

α =56° ...........10-7

α =40° ........10-10

α =50° ........10-11

α =40° ........10-12

α =50° ........10-13

α =40°...........10-17

I-14 © SICK AG · Division Auto Ident · Germany · All rights reserved 8 009 993/O824/20-12-2004

Page 15

Operating Instructions

Figures and tables

CLV 490 Bar Code Scanner

Fig. 10-20: CLV 490-3010/-3011: (High density) Min. and Max. reading distance

(measured radially) as a function of the focus position at a resolution

of 0.25 mm (9.8 mil) and an aperture angle of

Fig. 10-21: CLV 490-3010/-3011 (High density): Min. and Max. reading distance

(measured radially) as a function of the focus position at a resolution

of 0.35 mm (13.8 mil) and an aperture angle of

Fig. 10-22: CLV 490-3010/-3011 (High density): Min. and Max. reading distance

(measured radially) as a function of the focus position at a resolution

of 0.35 mm (13.8 mil) and an aperture angle of

Fig. 10-23: Characteristics field CLV 490-3010/-3011 (High density): Scanning

frequency as a function of the radial reading distance and resolution...... 10-25

Fig. 10-24: CLV 490-3010/-3011 (High density): Deflection range as a function

of radial reading distance, deflection angle and resolution............................10-26

Fig. 10-25: CLV 490-6010/-6011 (Low density): Reading field height as a

function of the reading distance and the tilt at a resolution of 0.5 mm

(19.7 mil)............................................................................................................................10-27

Fig. 10-26: CLV 490-6010/-6011 (Low density): Min. and Max. reading distance

(measured radially) as a function of the focus position at a resolution

of 0.5 mm (19.7 mil) and an aperture angle of

Fig. 10-27: CLV 490-6010/-6011 (Low density): Min. and Max. reading distance

(measured radially) as a function of the focus position at a resolution

of 0.5 mm (19.7 mil) and an aperture angle of

Fig. 10-28: Characteristics field CLV 490-6010/-6011 (Low density): Scanning

frequency as a function of the radial reading distance and resolution...... 10-30

Fig. 10-29: CLV 490-7010/-7011 (Low density): Reading field height as a

function of the reading distance and tilt at a resolution of 0.5 mm

(19.7 mil)............................................................................................................................10-31

Fig. 10-30: Characteristics field CLV 490-7010/-7011 (Low density): Scanning

frequency as a function of the radial reading distance and resolution...... 10-32

Fig. 10-31: CLV 490-7010/-7011 (Low density): Deflection range as a function

of radial reading distance, deflection angle and tilt at a resolution of

0.5 mm (19.7 mil) .......................................................................................................... 10-33

Fig. 10-32: External parameter memory, installed on the CLV ............................................10-34

Fig. 10-33: CLV-Setup: "Device configuration" tab with the CLV start options..............10-36

Fig. 10-34: CLV-Setup: dialog box for adjusting the external parameter memory .......10-38

Fig. 10-35: CLV with heater: temperature curve inside the housing..................................10-40

Fig. 10-36: CLV-Setup: Result display of the AutoBaud Detect function..........................10-47

Fig. 10-37: User interface of the "CLV-Setup" software......................................................... 10-48

Fig. 10-38: CLV-Setup: entering commands in the Terminal Emulator.............................10-53

Fig. 10-39: Line scanner: calculating the number of scans for ladder-type bar

code arrangements........................................................................................................10-55

Fig. 10-40: Line scanner: calculating the number of scans for fence-type bar

code arrangements........................................................................................................10-55

Fig. 10-41: Line scanner with oscillating mirror: calculating the number of scans

for fence-type bar code positioning.........................................................................10-56

Fig. 10-42: One-Shot: Line scanner with oscillating mirror: calculating the number

of scans for fence-type bar code positioning ...................................................... 10-57

Fig. 10-43: Required distance between the bar codes on an object ................................ 10-58

Fig. 10-44: Parameterization example: prepare a sketch of the reading situation...... 10-61

Fig. 10-45: Parameterization example: settings on the "Reading Configuration" tab . 10-62

Fig. 10-46: Parameterization example: "Autofocus Parameters" tab................................ 10-63

Fig. 10-47: Parameterization example: "Autofocus Limits" tab ........................................... 10-63

Fig. 10-48: Parameterization example: "Autofocus Optimizations" tab............................10-64

Fig. 10-49: Parameterization example: Buttons on the "Device Configuration" tab.... 10-65

Fig. 10-50: Parameterization example: "Scanner Position Parameters" tab..................10-65

Fig. 10-51: Parameterization example: Settings on the "Device Configuration" tab... 10-66

Fig. 10-52: Parameterization example: settings on the "Code Configuration" tab....... 10-67

α =40°................................10-22

α =40°.............................10-23

α =50°.............................10-24

α =40°................................10-28

α =60°................................10-29

8 009 993/O824/20-12-2004 © SICK AG · Division Auto Ident · Germany · All rights reserved I-15

Page 16

Operating Instructions

Figures and tables

CLV 490 Bar Code Scanner

Fig. 10-53: Parameterization example: "2/5 Interleaved" tab..............................................10-67

Fig. 10-54: Parameterization example: "Host interface" tab (default setting)................10-68

Fig. 10-55: Parameterization example: "Data Strings" tab (default setting) ...................10-68

Fig. 10-56: Auxiliary input via the terminal interface of the CLV ...........................................10-69

Fig. 10-57: CLV-Setup: auxiliary input via the Terminal Emulator ........................................10-70

Fig. 10-58: Dimensions of the angle bracket, single No. 2 013 824................................10-81

Fig. 10-59: Dimensions of the articulated bracket No. 2 018 435....................................10-81

Fig. 10-60: Front view of quick clamping device No. 2 016 110 with angle

braket No. 2 013 824...................................................................................................10-81

Fig. 10-61: Copy of the Declaration of Conformity (Page 1, scaled down)......................10-92

Fig. 10-62: Scannable bar codes with various module widths (print ratio 2:1) .............10-99

I-16 © SICK AG · Division Auto Ident · Germany · All rights reserved 8 009 993/O824/20-12-2004

Page 17

Operating Instructions Chapter 1

CLV 490 Bar Code Scanner

Notes on this document

1 Notes on this document

1.1 Purpose

This document is a guide to the operation of the bar code scanner

• CLV 490 with auto-focus

in the following variations:

• Line scanner

– CLV 490-2010, resolution from 0.20 mm (7.9 mil) (high density)

– CLV 490-2011, resolution from 0.20 mm (7.9 mil) (high density), with heater

– CLV 490-0010, resolution from 0.30 mm (11.8 mil) (standard density)

– CLV 490-0011, resolution from 0.30 mm (11.8 mil) (standard density), with heater

– CLV 490-6010, resolution from 0.40 mm (15.7 mil) (low density)

– CLV 490-6011, resolution from 0.40 mm (15.7 mil) (low density), with heater

• Line scanner with oscillating mirror

– CLV 490-3010, resolution from 0.20 mm (7.9 mil) (high density)

– CLV 490-3011, resolution from 0.20 mm (7.9 mil) (high density), with heater

– CLV 490-1010, resolution from 0.30 mm (11.8 mil) (standard density)

– CLV 490-1011, resolution from 0.30 mm (11.8 mil) (standard density), with heater

– CLV 490-7010, resolution from 0.40 mm (15.7 mil) (low density)

– CLV 490-7011, resolution from 0.40 mm (15.7 mil) (low density), with heater

This document provides information on

• Mounting and connecting the device

• Startup

• Operating and configuring (parametrizing) the device

• Maintenance

• Exchanging the device without losing the parameter set

• Special applications and procedures

The bar code scanner with all its variants will in this manual be referred to as the "CLV",

except where a distinction is necessary.

1.2 Target audience

This document is intended for persons who are responsible for the following activities:

1.2.1 Mounting, electrical installation, maintenance and replacement

Electricians and service technicians.

1.2.2 Startup, operation and configuration

Technicians and engineers.

8 009 993/O824/20-12-2004 © SICK AG · Division Auto Ident · Germany · All rights reserved 1-1

Page 18

Chapter 1 Operating Instructions

Notes on this document

CLV 490 Bar Code Scanner

1.3 Information content

This document contains all the information required to mount, install, and start up the CLV

with the factory settings.

A series of step-by-step instructions is provided for each of these activities.

Configuration of the CLV for the application-specific reading situations is carried out with

the Windows-oriented PC software "CLV-Setup". Further assistance is also available in the

form of the online help system CLV-Setup Help. The procedure for installing and operating

the software is described in the appendix.

For further information on the design of the bar code scanner or on bar code technology in

general, please contact the Division Auto Ident at SICK AG.

Internet address: www.sick.com.

1.4 Symbols

Some of the information in this document is marked specially so that you can access it

quickly:

Warning

Warnings are provided to prevent injury to operating personal or serious damage to the bar

code scanner.

¾ Always read warnings carefully and observe them at all times.

Note Indicates special features or characteristics.

Explanation Explanations provide background information on technical features.

Recommendation Recommendations help you carry out certain procedures more effectively.

Tip Tips explain settings in the user interface of the "CLV-Setup" program.

Default Marks a section containing the factory defaults.

S

CANNING FREQUENCY This typeface is used to refer to a term in the "CLV-Setup" program.

Icons refer to buttons in the "CLV-Setup" program.

"Host receive fault" This typeface is used for messages output via the terminal interface of the CLV.

This symbol is used to mark sections that describe steps carried out with the "CLV-Setup"

program.

This symbol refers to additional technical documentation.

¾ An action must be performed. This symbol characterizes single-step operating instructions.

Multiple-step operating instructions are characterized by sequential numbers.

Ö Here you select a function of the "CLV-Setup" user interface.

1-2 © SICK AG · Division Auto Ident · Germany · All rights reserved 8 009 993/O824/20-12-2004

Page 19

Operating Instructions Chapter 2

CLV 490 Bar Code Scanner

Safety information

2 Safety information

2.1 Authorized users

For the CLV to function correctly and safely, it must be mounted and operated by sufficiently

qualified personnel.

The end user must be supplied with the operating instructions.

The end user must be provided with expert tuition and is advised to read the operating

instructions.

The following qualifications are required for the various tasks involved:

2.1.1 Mounting and maintenance

• General technical training

• Knowledge of the standard guidelines relating to safety at the workplace

2.1.2 Electrical installation and replacement

• Practical training in electrical engineering

• Knowledge of the standard safety guidelines relating to electrical engineering

• Experience operating the devices in the relevant application (e. g. conveyor belt)

2.1.3 Startup, operation and configuration

• Experience operating the devices in the relevant application (e. g. conveyor belt)

• Knowledge of the hardware and software environment of the relevant application

(e. g. conveyor belt)

• Basic understanding of Windows 95

Windows XP

• Ability to use an HTML browser (e. g. Internet ExplorerTM)

• Basic understanding of data transfer methods

• Basic understanding of bar code technology

TM

TM

/98TM, Windows NT4.0TM, Windows 2000TM or

2.2 Intended use

The CLV is designed to detect and decode bar codes automatically. It is mounted in a