Page 1

CLV 41x Bar Code Scanner

Standard line

O PERATING INSTRUCTIONS

Page 2

CLV 41x Bar Code Scanner

General

Software version

Operating Instructions

These Operating Instructions describe the procedure for installing and setting up the

CLV 41x using the default settings defined at the factory and the steps required to

replace the device (transferring the application-specific parameter set). The CLV 41x

is simply referred to as the CLV in the sections below.

Software Function Version

CLV Setup User interface (Windows-based) from V 1.1.0

CLV Setup Help Online help (HTML) from V 1.0.1

FCC class

This appliance meets FCC class B, subject to the FCC-regulations, paragraph 15.

Remark: To meet the FCC-regulations, the cables have to shielded including

connections from shielding to the connector casings.

2

© SICK AG • Auto Ident • Germany • All rights reserved

8 008 224/I982/08-00

Page 3

Operating Instructions

Contents

CLV 41x Bar Code Scanner

Section Page

1. Intended use................................................................................................................... 4

2. Scope of delivery .......................................................................................................... 4

3. System requirements .................................................................................................. 4

4. Laser protections ......................................................................................................... 4

5. Design ............................................................................................................................... 5

6. Beeper .............................................................................................................................. 5

7. Function of the LEDs ................................................................................................... 6

8. Electrical installation

8.1 Pin assignment of connector ...................................................................................... 6

8.2 Supply voltage .................................................................................................................. 7

8.3 Connecting the CLV to the AMV/AMS 40 .............................................................. 7

8.4 Connecting the PC to the CLV .................................................................................... 8

8.5 Connecting the interfaces ............................................................................................9

9. Assembly

9.1 Securing the CLV .......................................................................................................... 13

9.2 Mounting the polling reflector ................................................................................. 15

9.3 Mounting the external reading pulse sensor (alternative) ............................ 15

10. Power on and setup

10.1 Step-by-step setup instructions ............................................................................ 17

10.2 Default settings ............................................................................................................ 18

10.3 Profile programming ................................................................................................... 19

10.4 AutoSetup (code configuration) ............................................................................ 22

10.5 Parametrization with the CLV Setup software .................................................. 23

10.6 Operating modes/functions .................................................................................... 28

11. Replacing a CLV 410

11.1 Transferring the application-specific parameter set ..................................... 30

11.2 Disassembly and environmentally-friendly disposal of the CLV ............... 31

12. Troubleshooting

12.1 Self-monitoring function............................................................................................ 32

12.2 Error messages ........................................................................................................... 32

12.3 Causes of error and troubleshooting .................................................................. 32

13. Maintenance ................................................................................................................36

14.

Scannable bar codes (samples) ...................................................................37

15. Additional safety instructions (laser protection) ........................................... 37

16. Reading field diagrams ............................................................................................ 38

17. Technical data .............................................................................................................41

18. Dimensioned diagrams ............................................................................................ 42

19. Overview: supplementary technical documentation .................................... 43

20. Index ................................................................................................................................44

8 008 224/I982/08-00

© SICK AG • Auto Ident • Germany • All rights reserved

3

Page 4

CLV 41x Bar Code Scanner

1. Intended use

2. Scope of delivery

Operating Instructions

The CLV 41x with fixed focus is used to detect and decode bar codes in a

stationary reading station automatically, e.g. on objects on a conveyor belt. For this

purpose, it must be mounted securely on the station and supplied with an operating

voltage of 4.5...30 V DC to IEC 742. The CLV outputs the read result via its host

inteface to a higher-level computer for further processing.

The CLV 41x is supplied with the following:

• two polling reflectors for automatic reading pulse generation

• a note on device (yellow) with power connection diagram

• an additional set of laser warning labels (Class 2) in German and French

One or more of the following, depending on the number of devices ordered:

• CLV 41x Operating Instructions, in German and English

• a CD-ROM with the CLV Setup program for Windows™, the online CLV Setup Help

(HTML) software and the browser Iview™

• a fold-out card with 12 printed profile bar codes

3. System requirements

4. Laser protection

The following are required to set up and operate the CLV:

• a SICK AMV 40-011 Connection Module (no. 1 017 132) or AMS 40-013

(no. 1 017 13 5 )

Alternatively, an external power supply unit with an output voltage of 4.5 ... 30 V DC

to IEC 742 (functional extra-low voltage) and min. 3 W power output

• a PC with Windows-based GUI (Windows 3.1™, Windows 95™ or Windows NT™)

and serial port (COM x)

• an HTML browser (e.g. Netscape™) to use the online help

• an RS 232 data connection cable (e.g. no. 2 020 319).

Alternatively, the programming adapter for the LCV 410 (order no. available on

request) to connect the PC between the CLV 410 and AMV/AMS 40 as well as an

RS 232 data connection cable (e.g. no. 2 014 054) from the programming adapter

to the PC

• a 24 V DC ±20% operating voltage for the AMV 40 or 230 V AC (115V) ±10% for

the AMS 40

• a suitable sensor, e.g. a photoelectric switch, if the reading pulse is to be supplied

externally via the switching input on the CLV

Laser radiation!

The radiation emitted by the laser diode (red or IR light) on the CLV 410 is harmful to

the human eye. For this reason, do not look directly into the laser beam.

WARNING!

Opening the housing while the device is in operation does not prevent the laser diode

from being activated by the reading pulse.

The maximum output power of the laser beam at the reading window is 1 . 2 mW.

The CLV, therefore, is assigned to protection class 2.

Laser radiation, do not stare into the beam, class 2 laser product.

Max. output radiation: 1 . 2 mW (223

µµ

µs), emitted wavelength: 670 nm

µµ

See Section 15 for further safety instructions!

4

© SICK AG • Auto Ident • Germany • All rights reserved

8 008 224/I982/08-00

Page 5

Operating Instructions

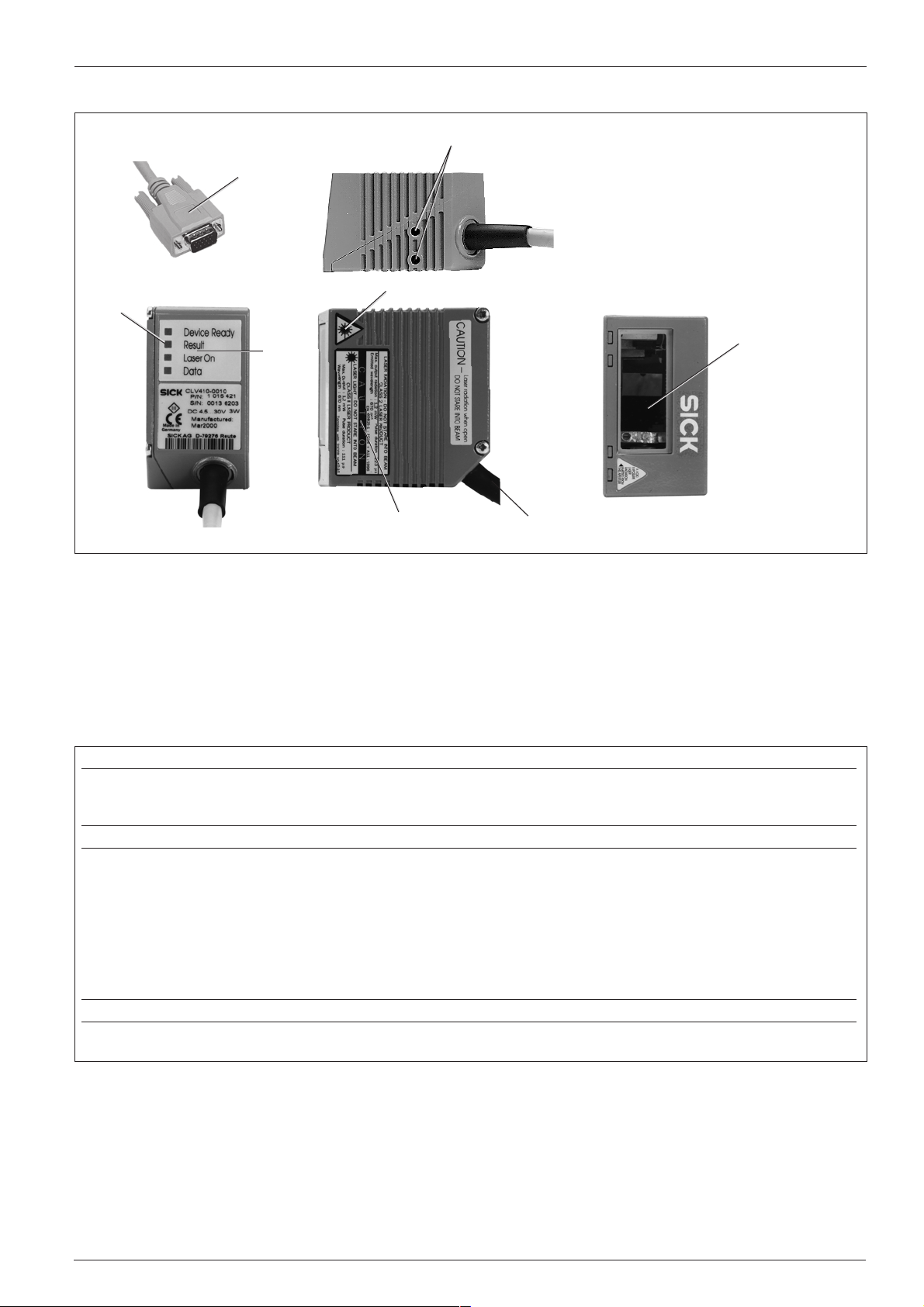

5. Design

CLV 41x Bar Code Scanner

/

Fig. 1. CLV 41x design

!

&

$

$

"

Key:

! D Sub HD connector, 15-pin

" Tapped blind hole M 4, depth: 6 mm

§ Reading window

$ Laser warning label

% Connection cable

& Sound opening of beeper (covered)

/ Function LEDs

§

%

6. Beeper function

The beeper

successfully or indicates a malfunction. The sound opening is located below the LED

label on the rear, narrow side of the device (Fig. 1).

Operating mode/function Beeper function Sequence

Reading mode

Percentage Evaluation The beeper confirms output of the reading result after every 100 reads 1. 1 tone

AutoSetup

Profile programming

Self-test The beeper signals successful completion of the self-test after power-up 1 . 1 tone

*)

After a laser timeout of 10 minutes (default), the beeper indicates with one long tone that the laser diode has been switched off

and that the reading pulse has been deactivated automatically.

Table 1

*)

*)

*)

1. The beeper confirms the start of reading mode when the device is switched on 1. 2 tones

after the wait time for teach-in mode has elapsed

2. The beeper confirms a good read (default setting) and output of the read result 2. 1 tone

1. The beeper confirms successful read of the presented profile bar code 1. 1 tone

for the start or end of AutoSetup

2. The beeper confirms successful read of the application-specific bar code 2. 1 tone

3. The beeper signals unsuccessful read of the application-specific bar code 3. 3 tones

after approx. 35 seconds

1. The beeper confirms successful read of the presented profile bar code 1. 1 tone

2. The beeper confirms the start of reading mode 10 s after the last profile 2. 2 tones

bar code has been read

6either provides an acoustic confirmation that a function was executed

8 008 224/I982/08-00

The beeper can be assigned a different result indicator function and the beeper

TIP:

volume changed (default: low) by means of the EDIT RESULT OUTPUTS field on the

D

EVICE CONFIGURATION card of the operating interface.

In these operating instructions, it is assumed that the beeper is operated

with the default settings.

© SICK AG • Auto Ident • Germany • All rights reserved

5

Page 6

CLV 41x Bar Code Scanner

Operating Instructions

7. Function of the LEDs

The LED function indicators 7 are located on the rear, narrow side of the device (Fig. 1).

LED Color Function

Device Ready green Indicates that the the CLV is ready (Reading mode). Lights up when the device is switched on, after

the self-test has been successfully completed and when the wait time for teach-in mode has expired.

The LED extinguishes when the device is switched to a different operating mode.

Result green Function depends on the operating mode of the scanner:

• In Reading Mode or Teach-in Mode, the LED indicates a successful read (good read).

If the match code comparison is activated, it lights up if the bar code read matches the specified

match code(s).

Device Ready

Result

Laser On

Data

Laser On green Lights up when the laser diode is activated for reading the bar code.

Data yellow Flickers when the CLV is transferring data to the host on the serial data interface

The LED lights up constantly until the start of the next reading pulse

• In Percentage Evaluation with 100 scans per reading interval, the LED indicates the trend in the

read quality as follows:

LED off good read rate < 30%

LED blinks (frequency 2 Hz) good read rate 30%...70%

LED blinks (frequency 5 Hz) good read rate 70% ... 90%

LED lights up constantly good read rate > 90%

• The LED lights up briefly when set to AutoSetup before it starts to scan the presented bar code

The laser diode is activated and deactivated by the reading pulse.

The laser diode is activated constantly in Percentage Evaluation and Free-running modes.

In Reflector Polling pulse mode, it is activated in accordance with the scanning frequency at every

20th scan (LED flickers).

The scan line(s) are dimmed (with red-light scanner only)

Table 2

8. Electrical installation

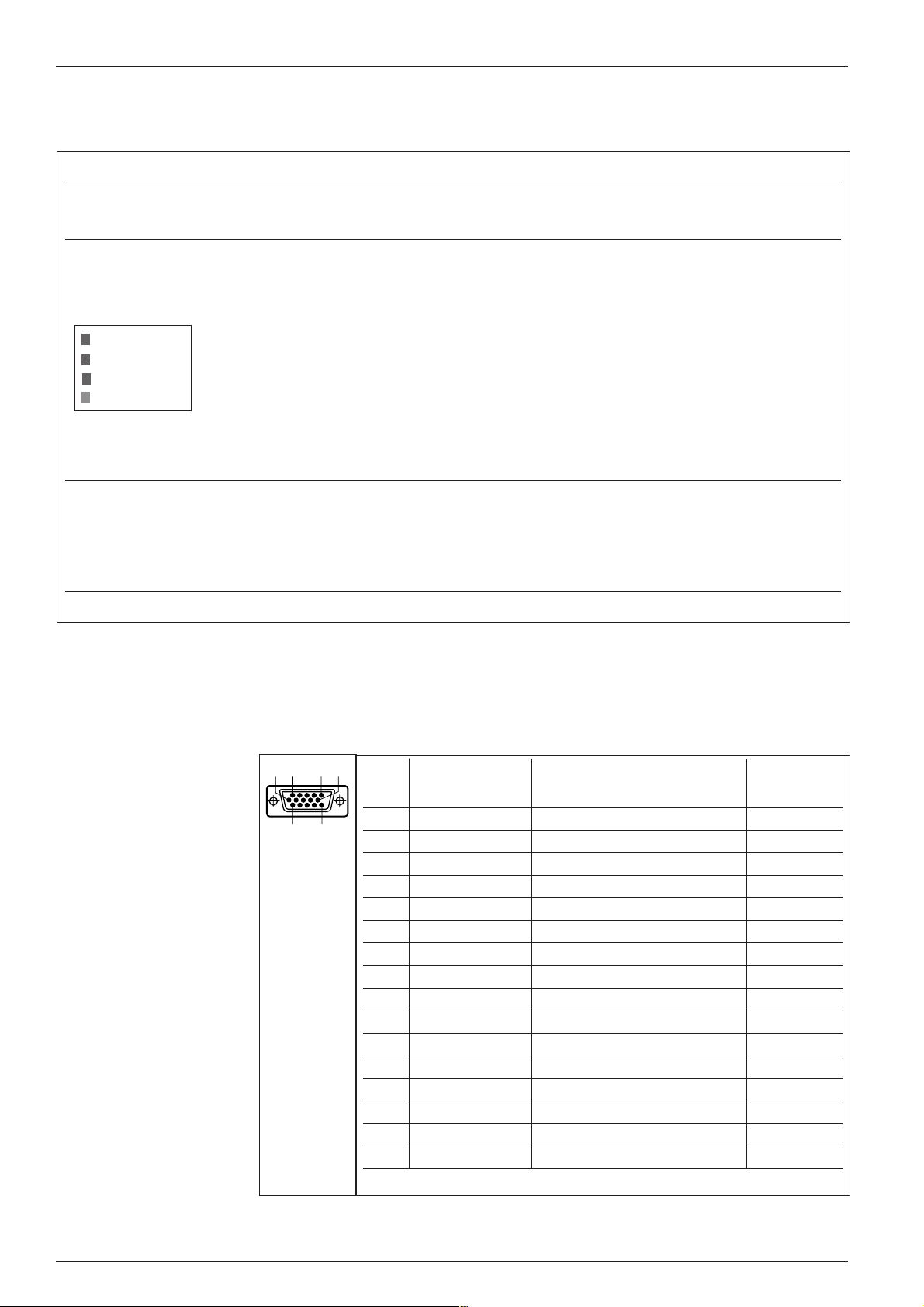

8. 1 Pin assignment of connector

Pin Signal Function Wire colors

10

1 DC +4.5...+30 V Supply voltage red

2 Sensor 2 Switching input teach-in (match code 1) purple

3 Result 3 Switching output (to PLC) yellow

4 Term RS 422 Termination for data interface 1 red/black

5 GND Ground black

6 RD+ (RS 422/485) Data interface 1 (receiver) light blue

7 RD- (RS 422/485) Data interface 1 (receiver) blue

8 TD+ (RS 422/485) Data interface 1 (transmitter) gray/turquoise

9 TD- (RS 422/485) Data interface 1 (transmitter) green

10 RxD (RS 232) Data interface 2 (receiver) gray

11 TxD (RS 232) Data interface 2 (transmitter) pink

12 Result 1 Switching output (to PLC) brown

13 Result 2 Switching output (to PLC) orange

14 Sensor 1 Switching input for ext. reading pulse white

15 SensorGND Common ground (all inputs) black/white

– – Shield white/green

1) Cable with 15-pin D Sub HD socket and open cable end

11

5 6

1

15

of cable

no. 6 010 137

1)

Table 3

6

© SICK AG • Auto Ident • Germany • All rights reserved

8 008 224/I982/08-00

Page 7

Operating Instructions

CLV 41x Bar Code Scanner

8. 2 Supply voltage

The CLV 41x requires a supply voltage of 4.5 ... 30 V DC to IEC 742 (safety extra-low

voltage, listed class II power supply).

8. 3 Connecting the CLV to the AMV/AMS 40 (Connection Module)

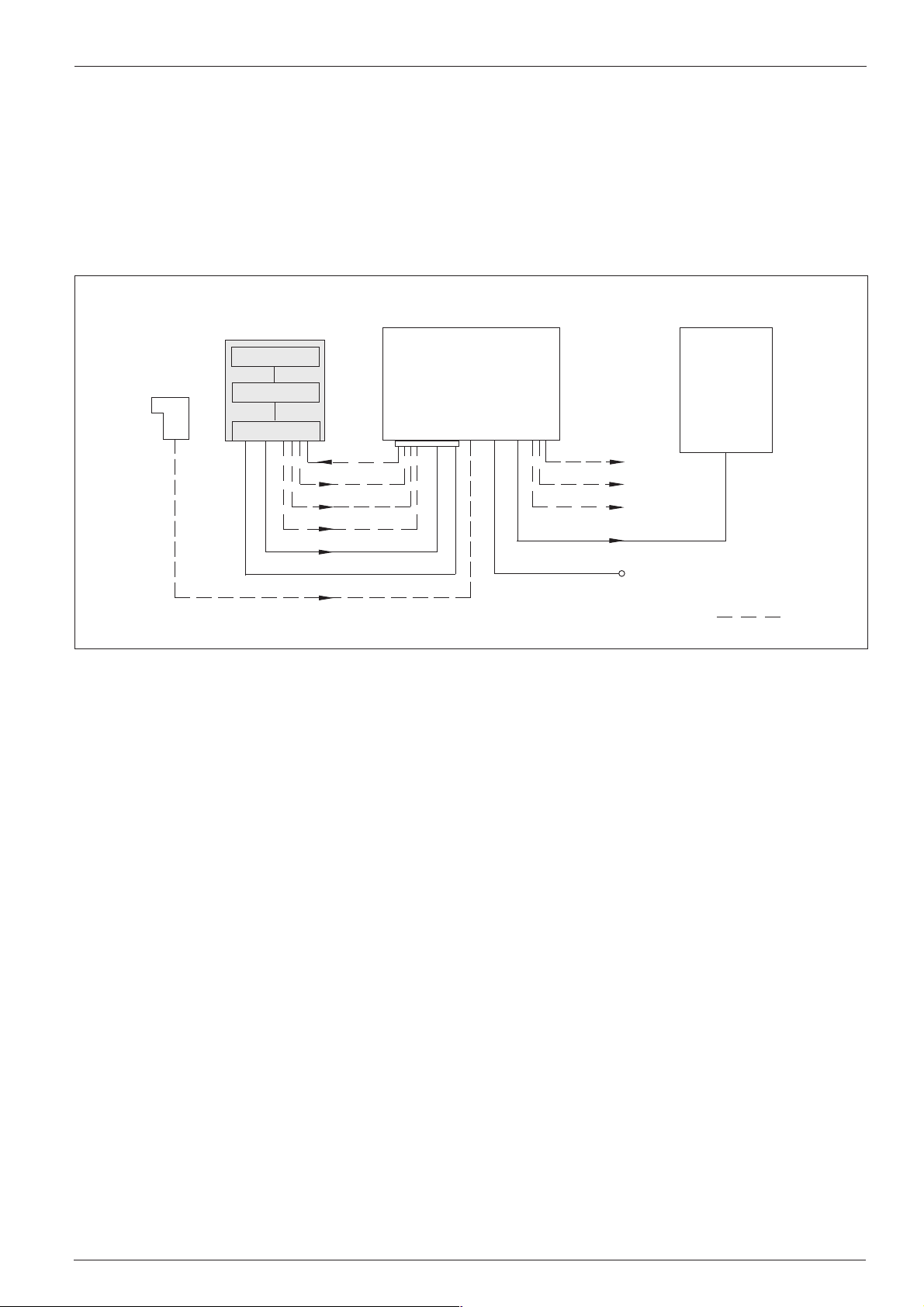

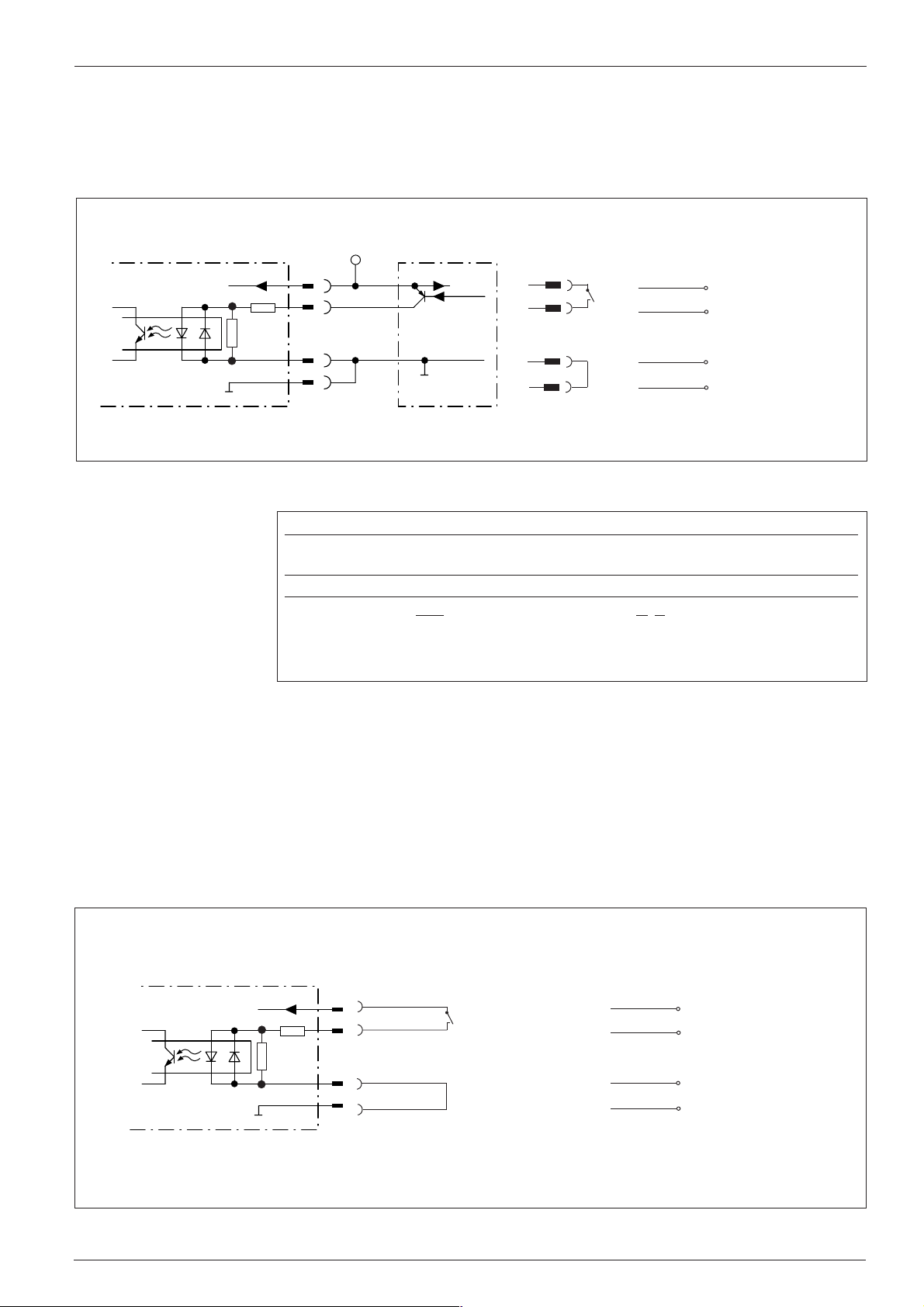

Before it can be used in the reading station, the CLV must be connected to the

AMV/AMS 40 Connection Module and the host/PLC/sensor as shown in Fig. 2.

CLV 41x

Photoelectric

switch

Fig. 2. Block diagram: connecting the CLV in the reading station via the AMV/AMS 40 Connection Module

Scanner

Decoder

Interface

Sensor 1

Result 1

Result 2

Result 3

Data

DC 24 V

Sensor 1

TIP:

A description of the basic wiring and configuration of the Connection Module is

AMV/AMS 40

Connection

Module

Result 1

Result 2

Result 3

Data

PLC

24 V DC (AMV)

230 V AC (AMS)

provided in the AMV/AMS 40 Operating Instructions (no. 8 008 292) supplied with

the module.

Ø Mount the AMV/AMS 40 as close as possible to the CLV

HOST/PLC

Optional

cable

Ø Connect the CLV to the 15-pin D Sub HD socket of the AMV/AMS 40

The connection cable can be extended with extension cable no. 6 010 075 (2 m).

Ø Do not exceed the max. cable lengths (host interface) between the CLV and the

host/PLC (see 8.5.1 Connecting the host interface)

Ø Connect a suitable, external reading pulse sensor via the AMV/AMS 40 if reflector

polling (default setting) is not to be used for automatic reading pulse generation

Ø If an external power supply unit is used instead of the AMV/AMS 40, it must be

able to provide a continuous output of at least 3 W and must comply with IEC 742

(functional extra-low voltage). The core cross-section for the CLV power supply

2

(pins 1 and 5) must be at least 0.09 mm

.

Use cable no. 6 010 137 (open wire ends) to connect the CLV. See Table 3 for

wire color assignment

8 008 224/I982/08-00

© SICK AG • Auto Ident • Germany • All rights reserved

7

Page 8

CLV 41x Bar Code Scanner

5

1

9

6

Operating Instructions

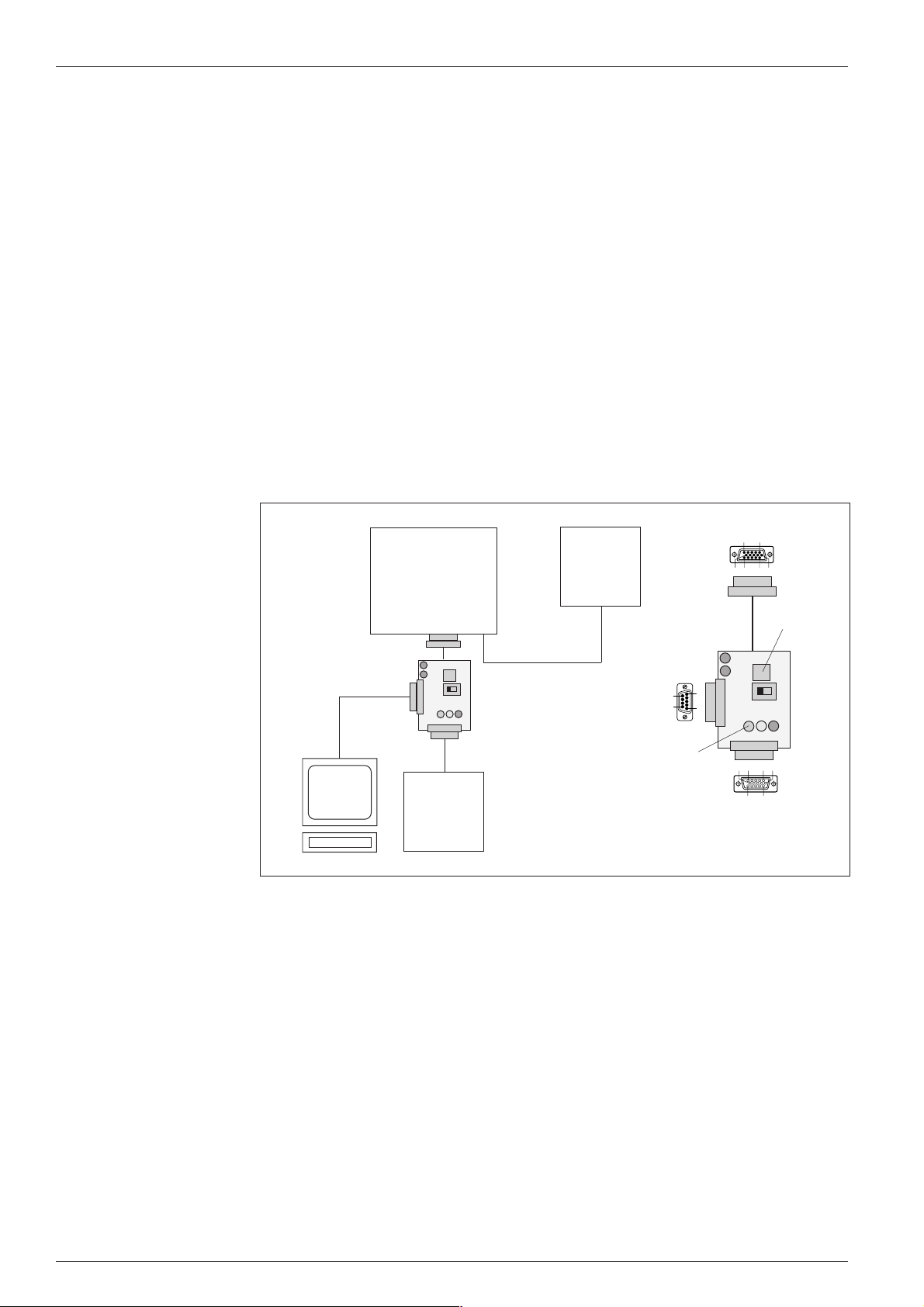

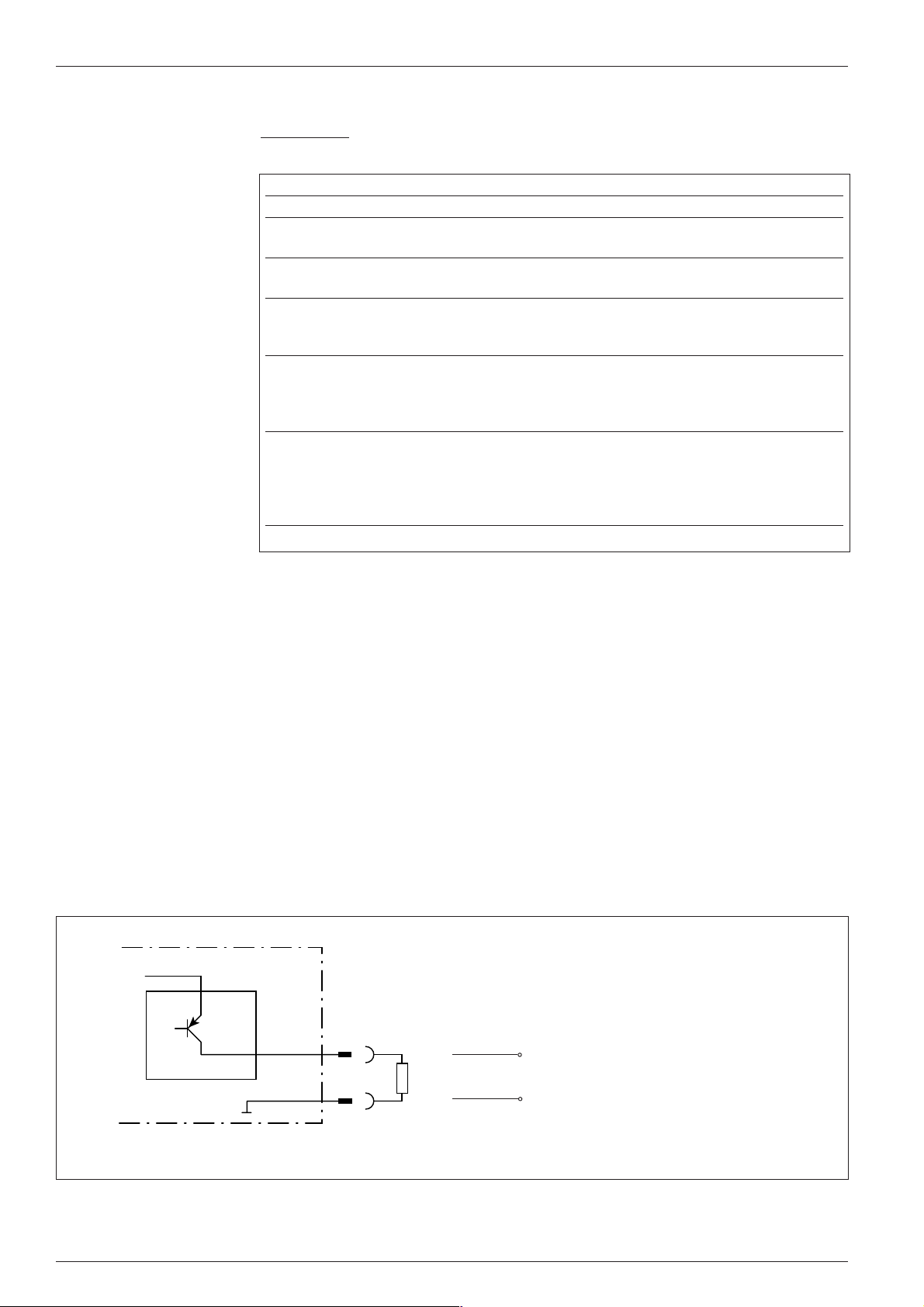

8. 4 Connecting the PC to the CLV

A PC with Windows™ must be connected to the RS 232 port on the CLV to operate

and parametrize the device. There are two ways of connecting the PC:

1. Connect the PC COM x port to the internal terminals on the AMV/AMS 40

Ø Switch off the power supply to the Connection Module and the PC and connect

the PC and Connection Module as described in the AMV/AMS 40 Operating

Instructions

Ø Disconnect the CLV from the host if they are already connected (RS 232

interface)

Ø Switch on the PC and AMV/AMS

Ø Copy the operating and parametrization software CLV Setup and the online help

CLV Setup Help to the hard disk of the PC and install the software accordingly

Ø Set the communication parameters in CLV Setup for port COM x (S

ERIAL PORT

under OPTIONS) as shown in Table 4 (Default setting on CLV)

2. Connecting the PC port COM x via the optional programming adapter

e.g. cable

order no.

2 014 054

PC with

Windows

AMV/AMS 40

Connection

Module

CLV 41x

Programming

adapter

to AMV/AMS 40

Host/PLC

to PC

LED for

switching

outputs

Programming adapter

(order no. available on request)

11

15

11

15

5 6

10

1

510 61

Term

1 10

5

15 611

to CLV 41x

Clock

Host

123

Button

Fig. 3. Connecting the PC to the optional programming adapter

Ø Switch off the power supply to the Connection Module and PC

Ø Disconnect the CLV connector from the Connection Module (Fig. 3)

Ø Connect the 15-pin cable connector of the programming adapter to the socket on

the AMV/AMS 40. Connect the free 15-pin socket of the programming adapter to

the CLV connector. The adapter is supplied with power from the Connection

Module

Ø Connect the PC port COM x to the 9-pin connector of the programming adapter via

an RS 232 cable (e.g. no. 2 014 054)

Ø Set the slide switch on the programming adapter to TERM (the CLV is then

disconnected from host and communicates with the PC only). The PC is

disconnected from the CLV when the switch is set to HOST

Ø Switch on the PC and AMV/AMS

8

© SICK AG • Auto Ident • Germany • All rights reserved

8 008 224/I982/08-00

Page 9

Operating Instructions

CLV 41x Bar Code Scanner

Parameter Value

COM port freely selectable

Baud rate 9600 bit/s

Data bits 8

Parity none

Stop bit 1

Table 4

Ø Copy the operating and parametrization software CLV Setup and the online help

CLV Setup Help to the hard disk of the PC and install the software accordingly

TIP:

CAUTION

Ø Set the communication parameters in CLV Setup for port COM x (S

O

PTIONS) as shown in Table 4 (default setting of the CLV)

ERIAL PORT under

With the CLV pulse mode “Sensor Input“, the reading pulse can be triggered with the

Clock button on the programming adapter. For this purpose, choose the pulse mode

via the E

DIT READING PULSE field on the DEVICE CONFIGURATION card of the user interface

and download it to the CLV.

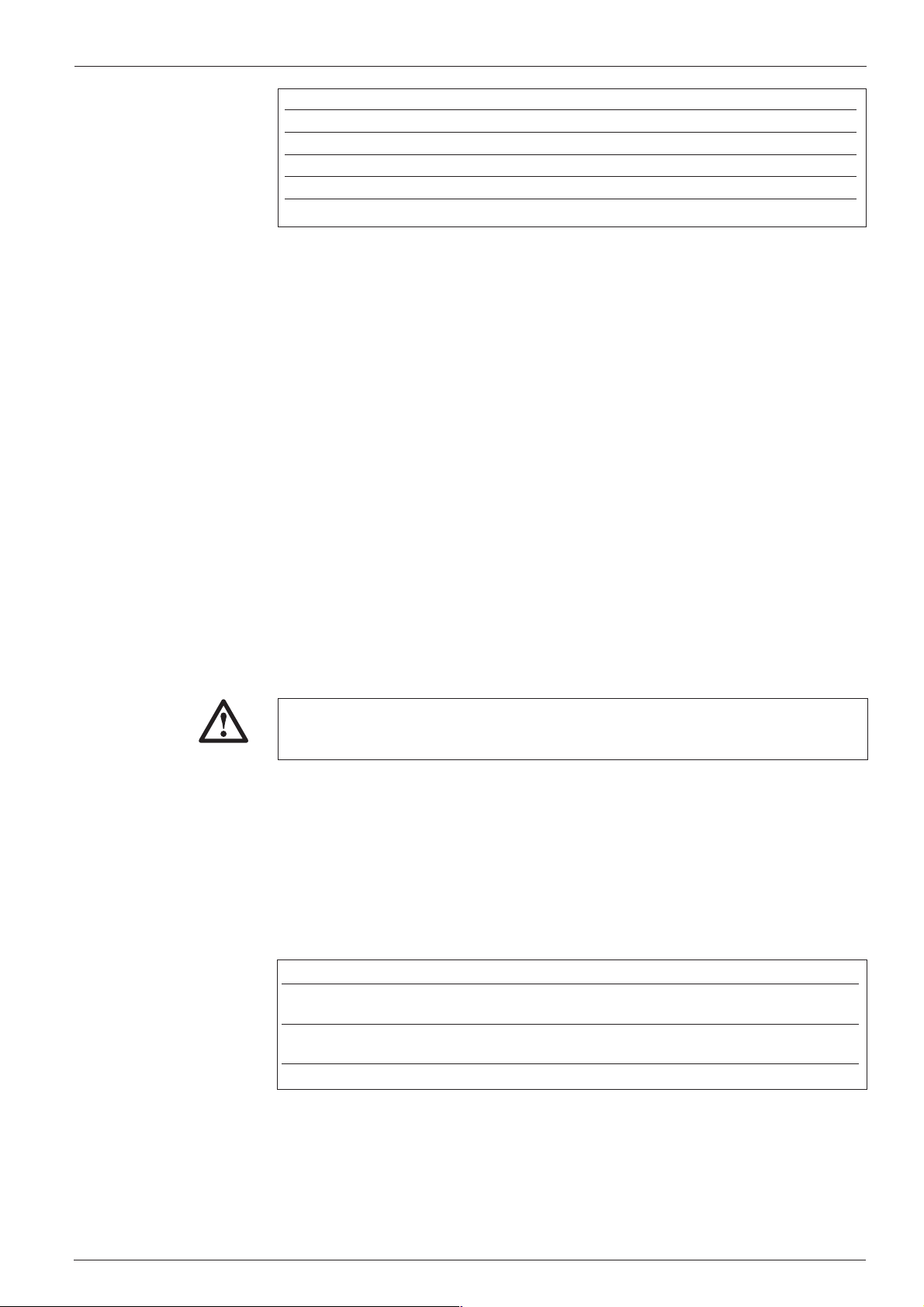

8. 5 Connecting the interfaces

All of the interfaces are routed via the 15-pin D Sub HD connector À (Table 3).

8. 5. 1 Connecting the host interface

The CLV is equipped with two host interfaces (RS 232 and RS 422/485). One of

these must be selected for data communication with the host/PC. If the RS 232

interface is not connected to the host, it can be used exclusively to monitor data

traffic on the parallel RS 422/482 interface.

The internal modules of the CLV may be damaged irreparably if the data interface

is connected incorreclty.

Ø Connect the host interface of the CLV to the host in accordance with the EMC

requirements using shielded cables(Fig. 4)

Ø To prevent interference, do not lay the data cables over a long distance parallel

to the power supply and motor cables, e.g. in cable ducts

Ø Apply the shield on one side (SICK recommendation)

Recommended max. cable lengths between the CLV and host:

Interface type Transmission rate Distance from host

RS 232 up to 19 200 bits/s max. 10 m

38 400 ... 57 600 bits/s max. 3 m

RS 422/485

1) with appropriate line termination

Table 5

1)

max. 38 400 bits/s max. 1 200 m

max. 57 600 bits/s max. 500 m

8 008 224/I982/08-00

© SICK AG • Auto Ident • Germany • All rights reserved

9

Page 10

CLV 41x Bar Code Scanner

Operating Instructions

RxD

RS 232

CLV 410

RS 422

CLV 410 Host

RS 485 (SICK Network): Connection diagram available on request

Fig. 4. Connecting the host interface

TxD

GND

RD+

RD–

TD+

TD–

GND

Term

10

11

5

6

7

8

9

5

4

TxD

RxD

GND

TD+

TD–

RD+

RD–

GND

Host

Terminal assignment

AMV 40-011/AMS 40-012, -013:

RxD

TxD

GND

R+

R-

T+

T-

GND

T. 10

T. 11

T. 5

T. 6

T. 7

T. 8

T. 9

T. 5

TIP:

IMPORTANT

The default communication parameters of the CLV host interface are as follows:

Parameter Value

Data transmission rate 9600 bit/s

Data bits 8

Parity none

Stop bit 1

Protocol Sick (start character: STX, stop character: ETX, no

repeat request: none, timeout: 50 ms)

Table 6

The parameters can be changed in the DATA FORMAT and INTERFACE PROTOCOL fields on

the H

OST INTERFACE card of the user interface.

By reading in profile bar code nos. 11 and 12 (Section 10.2 Default setting), you can

define the above default settings temporarily with a different parameter set to allow

the PC to communicate with the CLV.

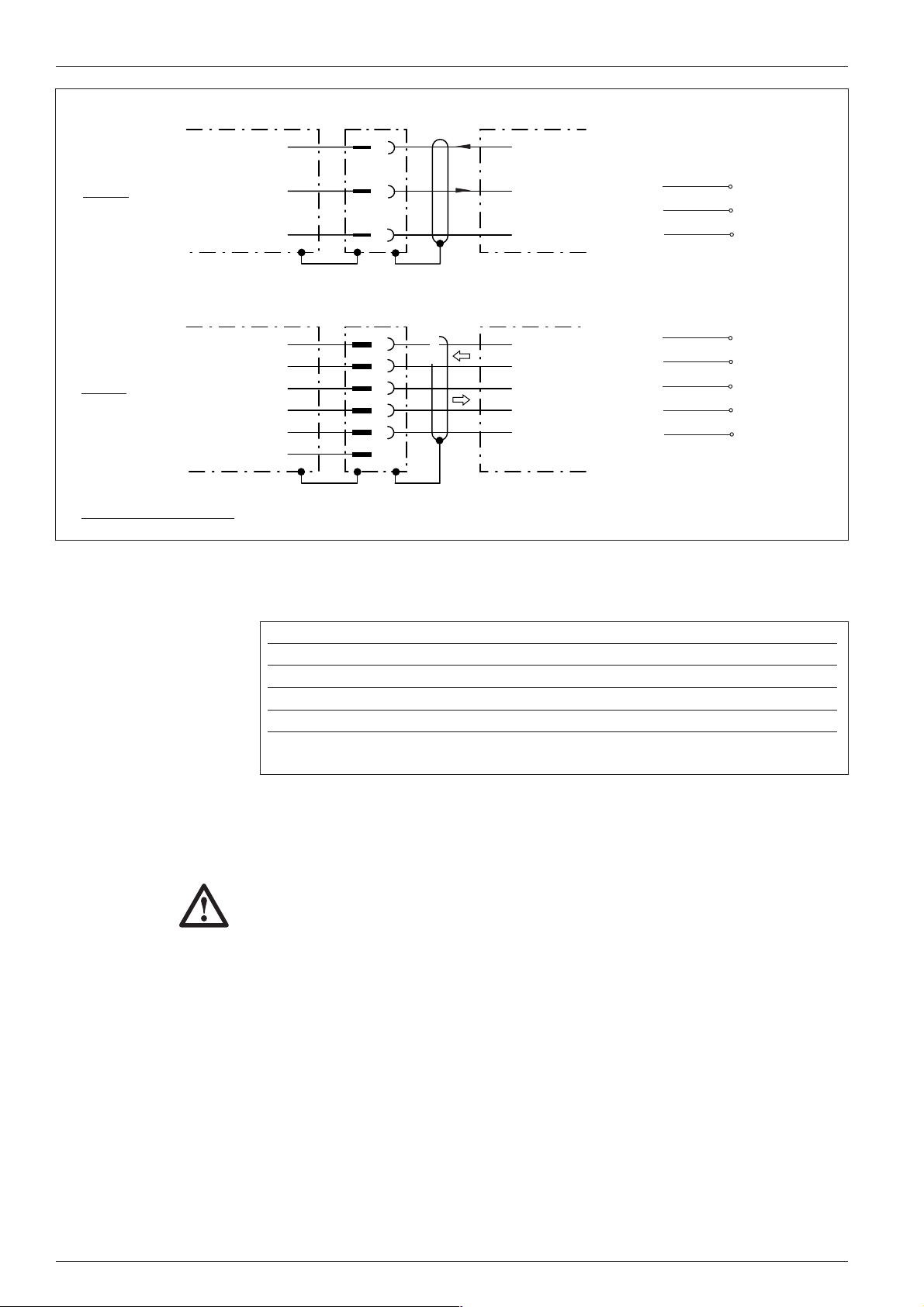

8. 5. 2 Connecting the functional interfaces

Sensor 1 switching input

In order to trigger a reading process, the CLV requires a suitable clock pulse in

Reading mode that signals the presence of a conveyor object in the reading field.

The clock pulse generates the reading interval (time window for evaluation) internally

in the CLV. In the default setting, the reading pulse is supplied by means of internal,

continuous reflector polling (see Section 9.2).

10

If an external sensor (e.g. photoelectric switch, switch) is to notify the CLV of the

presence of a conveyor object, the following steps must be performed:

Ø Connect the sensor to the CLV as shown in Fig. 5

© SICK AG • Auto Ident • Germany • All rights reserved

8 008 224/I982/08-00

Page 11

Operating Instructions

CLV 41x

CLV 41x Bar Code Scanner

Ø Set the trigger source to SENSOR INPUT via the EDIT READING PULSE field on the DEVICE

CONFIGURATION card of the user interface and download the parameter settings to

the CLV

An external clock pulse is not required for Percentage Evaluation operating mode.

Terminal assignment

V

S

DC 24V

PNP sensor

Switch

AMV 40-011/AMS 40-012 ,-013:

V

DC 24V

S

1K5

6K8

1K5

1

14

15

5

Sensor 1

Sensor

Sens GND

GND

DC 24V

V

S

GND

VS= +4.5...+30 V DC

Fig. 5. Connecting the Sensor 1 input to an external reading pulse sensor

Sensor 1 switching input

Switching Start internal reading interval when input

characteristics live (active high; default setting)

Properties opto-decoupled, non-interchangeable

Electrical values Low: -1V ≤ Vin ≤ +1 V High: -28 V ≤ Vin ≤ -3 V

-0.3 mA ≤ Iin ≤ +0.3 mA -18 mA ≤ Iin ≤ -1.4 mA

Table 7

1

14

15

5

V

S

SENS

SGND

GND

T. 18

T. 14

T. 15

T. 5

+3 V ≤ V

+1.4 mA ≤ Iin ≤ +18 mA

≤ +28 V

in

Sensor 2 switching input

This input is used exclusively to teach in match code 1. The teach-in procedure is

an alternative to entering the match code on the keyboard via the C

field on the DEVICE CONFIGURATION card of the user interface.

In order to teach in the match code, the input is connected briefly to the power

supply via a switch (Fig. 6). This can also take place in the Connection Module.

CLV 41x

V

DC 24V

S

1K5

6K8

1K5

Electrical values and properties:

as Sensor 1 (see Table 7)

VS= +4.5...+30 V DC

DC 24V

V

1

S

Sensor 2

2

14

Sensor

Sens GND

15

SensGND

5

GND

GND

DC 24V

Switch S

GND

ODE COMPARISON

Terminal assignment

AMV 40-011/AMS 40-012, -013:

V

S

Sensor 2

SGND

GND

T. 18

T. 2

T. 15

T. 5

Note:

Instead of the bridge the “GND-SGND“

Jumper can be set in the AMV/S 40.

Fig. 6. Connection of Sensor 2 input for teaching in match code 1

8 008 224/I982/08-00

© SICK AG • Auto Ident • Germany • All rights reserved

11

Page 12

CLV 41x Bar Code Scanner

Operating Instructions

Ø Procedure for teaching in match code 1

Prerequisite: CLV is in Reading mode and the current parameter set (if

application-specific) is stored permanently.

Step Action Response from CLV

1 Switch off CLV –

2 Close switch S and CLV switches to Reading mode and activates

switch on CLV again teach-in mode for the match code.

3 Open switch S CLV in teach-in mode and searches match

code.

4 Position match code at appropriate –

distance (see 16. Reading field

diagrams)

5 Trigger set reading pulse CLV reads the match code.

The Result LED lights up to confirm

successful read (good read; default setting).

Beeper emits a short acoustic signal.

6 Close switch S again CLV stores the match code and its code type

in the valid parameter set and permanently

in the EEPROM.

From this point on, it compares each match

code read with the match code taught in.

1) We recommend that you connect the PC with the CLV Setup interface to check the read result

Table 8

1)

Notes:

1. In order to replace the match code taught in in this way with a different match

code, you can repeat steps 3 to 6 without having to switch off the CLV.

2. If match code 1 is set using the teach-in method, it must not be modified with the

user interface (or command strings) until the CLV is switched off again. The

methods used to set the match code cannot be mixed. This does not affect

match code 2.

Result 1 to Result 3 switching outputs

The three outputs (Fig. 7) can each be assigned different result functions. When the

associated result occurs, the corresponding output becomes live for the selected

pulse duration at the end of the reading interval. The pulse duration can be set

separately for each output.

V

S

„Result 1“

12

5

CLV 41x

Configuration of Result 2 (pin 13/terminal 13) and Result 3 (pin 3/terminal 3): as Result 1 output

Fig. 7. Connection example: Result 1 output

Terminal assignment

AMV 40-011/AMS 40-012, -013:

Result 1

V

o

GND

T. 12

T. 5

VS= depending on

operating voltage applied

(+4.5...+30 V DC)

Pulse duration:

10 ms ... 9.9 s or static

(to end of next reading

pulse)

12

© SICK AG • Auto Ident • Germany • All rights reserved

8 008 224/I982/08-00

Page 13

Operating Instructions

9. Assembly

CLV 41x Bar Code Scanner

Result 1 to Result 3 switching outputs

Switching PNP-switching to supply voltage V

characteristics

Properties short-circuit + temperature-protected, not electrically isolated from V

Function assignment Result 1: Device Ready, polarity: not inverted

(default setting) Result 2: Good Read, polarity: not inverted

Result 3: No Read, polarity: not inverted

Pulse duration: 100 ms

Electrical values 0 V ≤ V

I

Out

Table 9

The function assignment, pulse duration and polarity of the signals can be modified

TIP:

via the E

DIT RESULT OUTPUTS field on the DEVICE CONFIGURATION card of the user interface.

≤ V

Out

≤ 600 mA

Guaranteed: V

S

S

≤ VS − 1.5 V at I

Out

The Result LED is not affected by this and lights up in Reading mode for a Good

Read until the end of the next reading pulse.

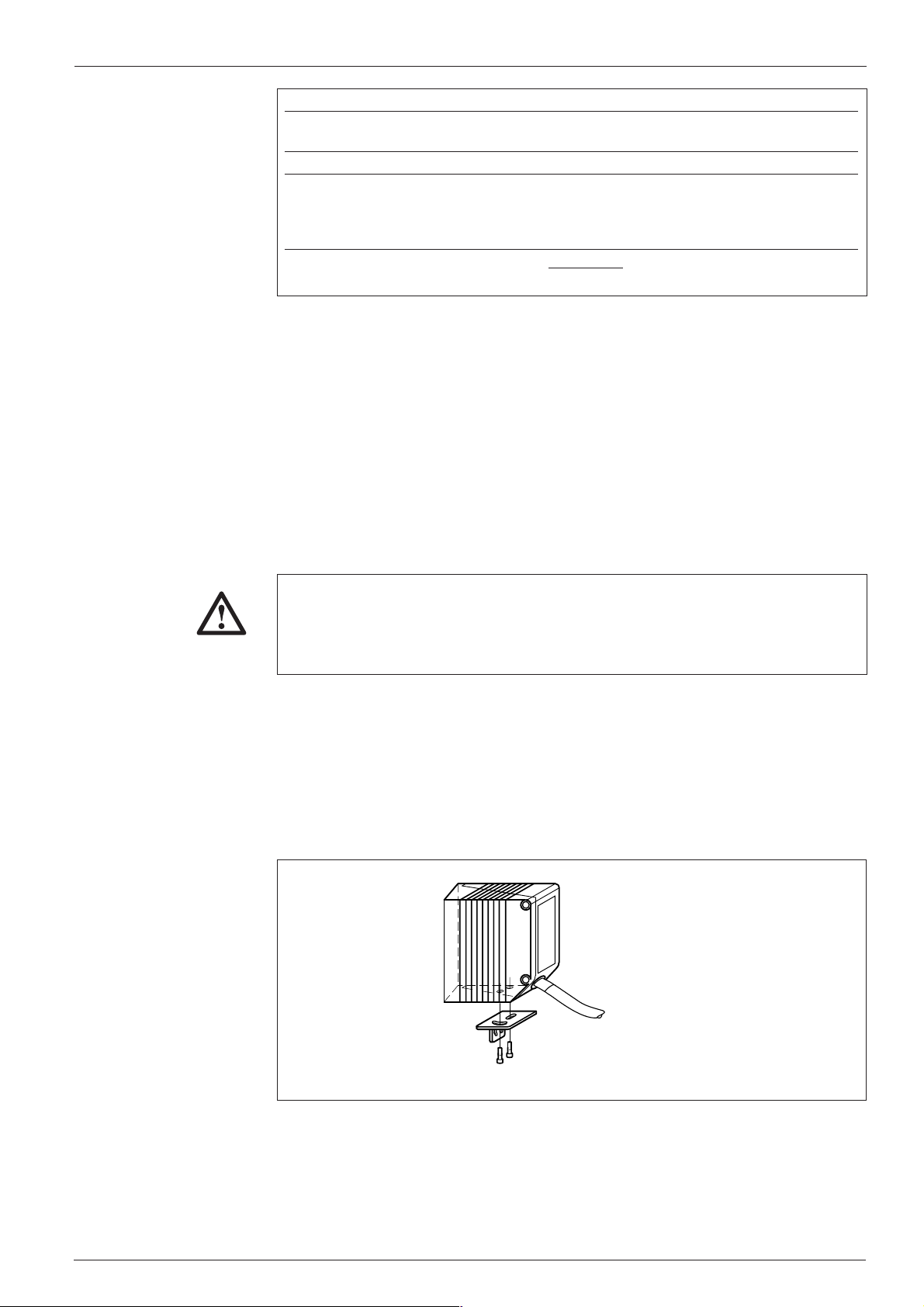

9. 1 Securing the CLV

≤ 600 mA

Out

S

CAUTION

The two fastening threads (2, Fig. 1) on the bottom, narrow side of the housing are

used to secure the CLV. The thread dimensions are shown in Section18. Dimensioned

diagrams.

Risk of damage to the housing

The max. depth of engagement of the two M 4 tapped blind holes is 6 mm from

the housing surface. Do not exceed this depth.

Mounting accessories

The CLV can be easily secured to the base to suit the relevant application using one

of the two optional mounting brackets (Fig. 8). This facilitates precise adjustment in

two planes. The dimensions of these brackets are shown in Section 18.

Dimensioned drawings. The elongated holes in the brackets allow the CLV to be

adjusted with a freedom of rotation of approx. ± 15°.

8 008 224/I982/08-00

Mounting bracket (small)

no. 2 020 077

Fig. 8. Mounting example: securing the CLV using the mounting bracket (accessory)

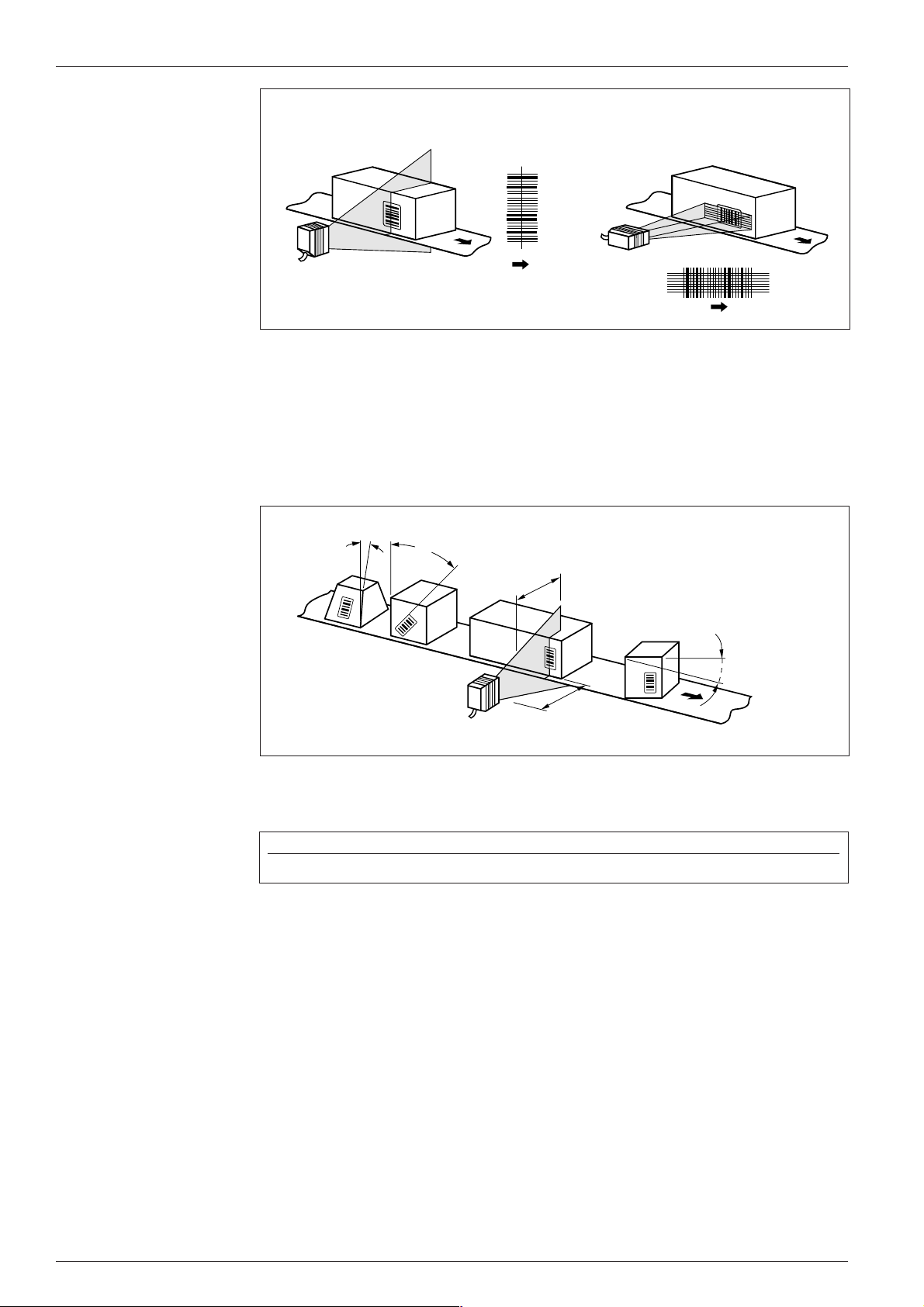

Aligning the CLV with the bar code

The alignment between the CLV and line or raster scanner depends on the

application. The basic alignment between the two scanning methods and the

conveyor object is shown in Fig. 9.

© SICK AG • Auto Ident • Germany • All rights reserved

13

Page 14

CLV 41x Bar Code Scanner

Operating Instructions

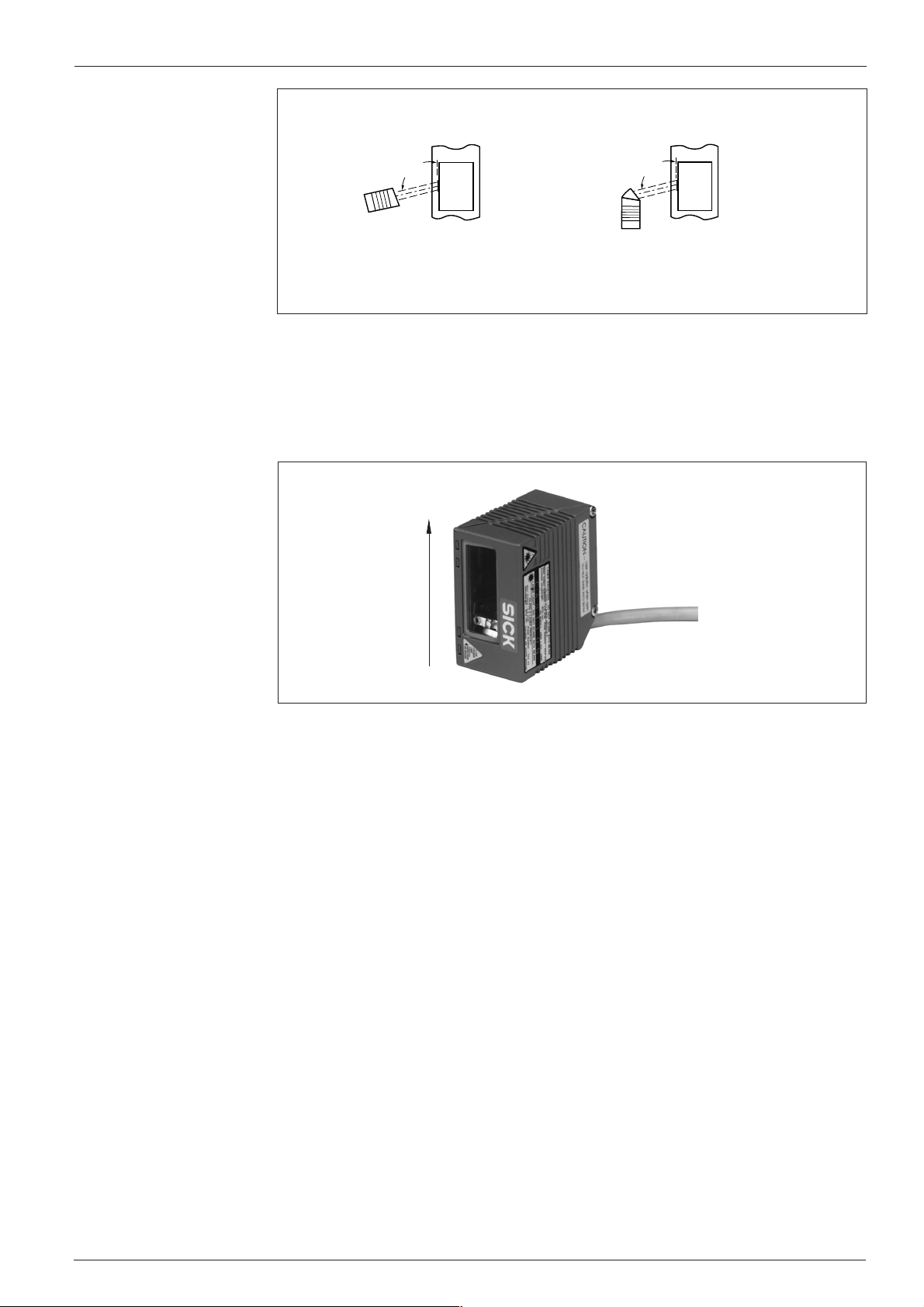

Line scanner Raster scanner

Fig. 9. Scanning method alignment relative to the bar code and conveyor direction

Reading angle and distance

When mounting the device, ensure that all of the possible reading angles at which the

bar code can be positioned relative to the scan line are taken into account. Fig. 10

shows this using a line scanner as an example. The reading window and code should

be almost parallel, whereby total surface reflection (see below) should be avoided.

β

α

Reading

range

α: Tilt

β: Pitch

γ: Skew

γ

Reading

distance

Fig. 10. Mounting example of CLV with line scanner: reading angles taken into account

The following angle limits should not be exceeded (CLV):

Angle Tilt α Pitch β Skew γ

Limit value 15° (depening on code print) 45° 45°

Table 10

When selecting the mounting location for the device, the limit values of the reading

range for the selected bar code resolution and the useful aperture angle (max. 60°

with front light emission) must be taken into account. See also Section 16. Reading

field diagrams.

14

Avoiding surface reflection

If the reading beam strikes the surface of the bar code vertically, reflection

interference may be caused when the returned light is received.

Ø Mount the CLV with front light emission (a) in such a way that the scan line(s) strike

the bar code at an angle less than approx. 15° from the vertical reference (Fig. 11).

Ø The CLV with lateral light emission (b) must be mounted flush so that the scan line

is emitted at an angle less than 105° relative to the housing.

© SICK AG • Auto Ident • Germany • All rights reserved

8 008 224/I982/08-00

Page 15

Operating Instructions

105°

CLV 41x Bar Code Scanner

Line scanner (Top view)

105°

a) CLV with front light emission b) CLV with lateral light emission

(flush mounting)

Fig. 11. Preventing surface reflection by rotating the CLV from the perpendicular

Count direction of code position CP

The CLV determines the position of the bar code within the scan line (CP value),

Fig. 12. This can be used to separate several identical bar codes (identical code

type, length and content) and output them accordingly.

100

CP

0

Fig. 12. CLV 41x: Count direction of the code position CP

9. 2 Mounting the polling reflector

In order to generate the reading pulse automatically using internal reflector polling

(default setting), one of the two polling reflectors supplied (special bar code) must

be mounted opposite the CLV behind the conveyor section.

Ø Note the maximum ranges of the two reflectors (Fig. 13)

Ø Mount the polling reflector (self-adhesive) opposite the CLV (in the alignment line)

in such a way that the CLV can view the reflector freely in the gaps between the

conveyor objects and can scan it reliably (center of scan line).

The scan line of the CLV should scan the code lines of the polling reflector

vertically.

8 008 224/I982/08-00

Ø Check the polling reflector installation for 100% read quality using the

Percentage Evaluation mode in the T

ERMINAL option of the user interface (see

Section 10.6). The CLV outputs the code content of the polling reflector and

signals REPO as the code type.

Function of reflector polling

In Reflector Polling pulse mode, the CLV activates the laser diode with every 20th

scan and checks whether it detects the reflector:

- if the reflector is still detected, the CLV repeates the procedure after the 20th

scan

© SICK AG • Auto Ident • Germany • All rights reserved

15

Page 16

CLV 41x Bar Code Scanner

Operating Instructions

blue

144

Distance:

500 ... 800 mm

50

144

• Reading distances (REPO)

Other distances must be respected

for CLV 412 and CLV 414. Only blue

REPO is allowed.

• Reading distances (REPO) CLV 412: 150 ... 350 mm

• Reading distances (REPO) CLV 414: 230 ... 650 mm

Fig. 13. Mounting the polling reflector (REPO)

white

50

Polling

reflector

Distance:

40 ... 500 mm

- the CLV starts the reading interval when the reflector is concealed by a conveyor

object in the reading field. The interval ends when the CLV detects the reflector

again. It then repeats the procedure above.

Notes:

This clock mode (max. delay approx. 100 ms at a scan rate of 200 Hz) is only

suitable for applications that are not critical with respect to time.

When the CLV is switched on, it must be able to detect the polling reflector. The first

reading interval can only start if this is the case.

In Reading mode, the CLV does not output the content of the polling reflector.

9. 3 Mounting the external reading pulse sensor (alternative)

If an external sensor (e.g. photoelectric switch) is used to generate the reading

pulse, it must be mounted on the CLV in a suitable manner. Ensure that objects of

different size carrying bar codes trigger the internal reading pulse in such a way that

sufficient time is provided to read the code. Examples of the CLV with line scanner

are provided in Fig. 14.

Bar code in the center or at the

end of the conveyor object

a

Bar code at the start of

the conveyor object

a

16

b

Fig. 14. Example of the position of the external reading pulse generator

b < a

b

b < a

Ø Choose the external sensor as the trigger source via the SENSOR INPUT field under

EDIT READING PULSE on the DEVICE CONFIGURATION card of the user interface and then

download the parameters to the CLV

© SICK AG • Auto Ident • Germany • All rights reserved

8 008 224/I982/08-00

Page 17

Operating Instructions

10. Power on and setup

CLV 41x Bar Code Scanner

Bar code sample

Code type: Code 39

Module width: 0.5 mm

UVWXYZ

10. 1 Step-by-step setup instructions

Quick start

Profile

programming

Ø Setup with the default settings

1. Connect the CLV to the 4.5...30 V DC power supply

(see also Section 8.1 Pin assignment of the connector)

2. Align the CLV with the white polling reflector supplied (special code),

distance approx. 300 mm

(see also Section 9.2 Mounting the polling reflector)

3. Present the bar code sample above at a distance of approx. 200 mm and

cover the polling reflector

(see also Section 10.6.1 Reading mode )

4. Uncover the polling reflector again

The CLV confirms that the read was successful with acoustic signal from the

beeper and the Result LED lights up

5. The CLV can now be operated with the default settings!

(see Section 10.2 Default settings of the CLV for the default settings)

Ø

Setup with profile bar codes (change parameter set)

1. Present the required printed profile bar code(s) on the card supplied

to the CLV

The CLV confirms every good read of the profile bar code with an acoustic signal

from the beeper. If a further bar code is not presented to the CLV within 10 s, the

CLV switches to Reading mode and outputs two consecutive acoustic signals

(see also Section 10.3 Profile programming)

Teaching in application-

specific bar codes

8 008 224/I982/08-00

2. The CLV can now be operated with the modified settings!

Ø

AutoSetup (modified code configuration)

1. Present bar code no. 10 to the CLV

The CLV confirms the start of AutoSetup by means of an acoustic signal from the

beeper and the Result LED lights up for an extended period of time.

(see also Section 10.4 AutoSetup)

2. Present the application-specific bar code to the CLV at the maximum

reading distance in the application

The CLV confirms the good read by means of an acoustic signal from the beeper

and the Result LED lights up. It then switches to Reading mode and outputs two

consecutive acoustic signals.

3. The CLV can now be operated with the modified code configuration!

The code type presented to the CLV is then evaluated

© SICK AG • Auto Ident • Germany • All rights reserved

17

Page 18

CLV 41x Bar Code Scanner

Operating Instructions

Alternative

procedure

Setup with CLV Setup software (change parameter set)

Ø

1. Connect the PC to the CLV

(see also Section 8.4 Connecting the PC to the CLV)

2. Start the CLV Setup program on the PC

(see also Section 10.5 Parametrization with the CLV Setup software)

3. Upload the configuration from the CLV

4. Change the configuration cards as required.

The parameters and their functions are explained in the online help.

5. Download the configuration to the CLV and store the values permanently

6. Save the modified parameter set on the PC as a configuration file!

Alternative:

5. Print out the profile bar codes and present them to the CLV in the specified

sequence

(see also Section 10.3 Profile programming)

Ø

Setup with command strings from the host

(not described here, further information is available on request)

10. 2 Default settings

A concise overview of the default CLV settings that are effective when the device is

switched on for the first time after delivery is shown in Table 11.

The tried-and-tested default parameters have been selected so that CLV can be

used directly in many applications without requiring modification.

Parameter Default setting (CLV 410)

Code types (active) Code 39, Code 128, Code 93, Codabar, EAN, EAN 128, UPC, 2/5

Interleaved

Code length Freely definable (all code types, except EAN and UPC, 2/5 Interleaved: 4...50

characters)

Multiple read 3 (all code types)

Min./max. no. of codes 1

Resolution 0.5 mm

Scanning frequency 500 Hz

Min. reading distance 50 mm

Reading pulse generation Start: polling reflector End: polling reflector

Beeper Result function: Good Read, volume: low

Switching outputs Result 1: Device Ready; Result 2: Good Read; Result 3: No Read

Protocol (Host) Start character: STX, stop character: ETX

Transmission rate (host) 9600 bits/s

Data format (host) 8 data bits, no parity, 1 stop bit

Output format (host) Header: blank, separator: blank, terminator: blank, error string: NOREAD+separator

Output sequence Code position

Output time Read result: end of pulse Separator: after code

Test string Inactive

18

Table 11

TIP:

You can call up the entire default settings from the CLV Setup program as follows:

Ø Choose F

ACTORY DEFAULTS in the FILE menu or

Ø Click the symbol.

© SICK AG • Auto Ident • Germany • All rights reserved

8 008 224/I982/08-00

Page 19

Operating Instructions

CLV 41x Bar Code Scanner

Printing out the

default settings

IMPORTANT

The CLV must not be connected with the PC (offline mode). The default setting

values are stored permanently in the user interface and on the CLV. The parameter

values are displayed in the menu options of the individual configuration cards. You

can print out the entire default settings by clicking the icon.

Note:

When you make changes to the default settings, we recommend that you save them

as a different configuration file (*.scl) on the PC using the S

AVE AS option in the

program.

Temporary host interface defaults

In order to allow you to access the CLV with the PC at any time, you can set the

host interface temporarily to the default setting (9600 bits/s, 8 data bits/1 stop

bit, no parity) using the profile bar codes:

Ø Present profile bar code no. 11 to the CLV in Reading mode and supply

an appropriate clock pulse to the device.

The CLV resets the host interface to the default values and confirms this with

an acoustic signal from the beeper. It then resumes Reading mode

immediately

Ø To restore the previous host interface configuration on the CLV, present

profile bar code no. 12 to the CLV.

The CLV confirms that the values have been reset with an acoustic signal and

resumes Reading mode immediately.

Parametrization

without a PC

IMPORTANT

Alternative:

Ø Switch the CLV off and on again to return to the original configuration

10. 3 Profile programming

Profile programming uses special bar codes to change the CLV parameters directly

without having to connect the PC with user interface. The profile bar codes are

simply presented to the CLV. The device then transfers the coded parameter values

to the current parameter set and stores them permanently. The changes remain valid

after the programming procedure has been completed and affect the further reading

procedure. The CLV waits 10 s after each profile bar code. If no more profile bar

codes are presented, it resumes standard Reading mode and confirms with two

consecutive acoustic signals.

Since the CLV overwrites important parameter values (e.g. those generated with

AutoSetup) without requiring confirmation, we recommend that you upload the valid

parameter set to the PC and store it as a configuration file (*.scl) with the S

option in the user menu before you change the parameter settings.

You can program the CLV at any time in Reading mode. Alternatively, you can present

one or more profile bar codes to the CLV for reading within 5 seconds after the

device has been switched on and the self-test has been completed (free-running).

The CLV does not output any reading results during profile programming and does

not respond to an external reading pulse.

AVE AS

8 008 224/I982/08-00

© SICK AG • Auto Ident • Germany • All rights reserved

19

Page 20

CLV 41x Bar Code Scanner

IMPORTANT

Operating Instructions

Printed profile bar codes

A total of 12 selected profile bar codes are provided on the „Configuration Profiles

for CLV 41x Bar Code Scanner“ card to make important changes (from the default

settings or the application-specific parameter set respectively). By folding the

individual segments of the card, you can ensure that the CLV only reads the

required profile bar code. The function of the profile bar codes is explained in

Table 12.

If you cannot access the host interface of the CLV from the “CLV Setup” user

interface (e.g. baud rate or data format not in line with default settings), the profile

bar code no. 11 can be used temporarily to set the CLV to the default settings

(host interface). To reset the system, use profile bar code no. 12 or switch off CLV.

Barcode Function

Profile 1 Default settings for all parameter values on the CLV

(Code configuration: all code types are enabled for evaluation).

Overwrites the code configuration generated by AutoSetup!

Profile 2 Changes the configuration on the host interface only:

- Data transmission rate: 38400 Bits/s

- Data format: 8 data bits, no parity, 1 stop bit

- Repeat request: none

Profile 3 Changes the configuration on the host interface only:

- Activates RS 422/485 interface

- SICK network protocol (standard)

- Data transmission rate: 38400 Bits/s

- Data format: 7 data bits, odd parity, 1 stop bit

- Device number: 99

Profile 4 Changes the configuration on the host interface only:

Outputs the read result immediately after the evaluation criteria have been fulfilled

Profile 5 Changes the configuration on the host interface only:

- Outputs the error status ST in the separator

- CLV outputs: CR LF in terminator (at the start of the line after every code)

Profile 6 Parameterizes the CLV as Master in master/slave configuration

- No. of slaves: 1

- Timeout: automatic

Profile 7 As profile 6, but no. of slaves: 2

Profile 8 Parameterizes the CLV as Slave in master/slave configuration

Profile 9 Parameterizes the CLV for pass-through mode:

Outputs “ / “ and the device number in the header

Profile 10 Starts or ends AutoSetup

Profile 11 Resets the host interface parameters to the defaults temporarily

Profile 12 Returns the host interface parameters to the original values

20

Table 12

The function of the individual parameters is explained in the online CLV Setup Help.TIP:

© SICK AG • Auto Ident • Germany • All rights reserved

8 008 224/I982/08-00

Page 21

Operating Instructions

CLV 41x Bar Code Scanner

Ø Profile programming procedure

Prerequisite: Valid parameter set (default settings or application specific)

stored permanently in CLV (EEprom).

Step Action Response from CLV

1 Present the required, printed profile CLV confirms a good read with an acoustic

bar code or the profile bar code signal and transfers the new values to the

generated with the software valid parameter set. This does not have any

(in the order in which it was effect yet

printed) to the CLV at a distance of CLV sets the timer and waits 10 s for the

approx. 200 mm. next profile bar code (the reading interval

Trigger reading pulse! remains active).

2 If the CLV is switched off, switch CLV switches to teach-in mode for 5

on the device and continue as seconds after the acoustic signal

described in step 1, reading (free-running mode).

pulse is generated automatically

3 Present the next profile bar code As described in step 1.

within 10 s

4 Complete the procedure by waiting CLV now stores the new values permanently

10 s after the last profile bar code in the EEPROM and switches to Reading

has been presented mode (two consecutive acoustic signals

from the beepers). The new parameters

take effect immediately.

1) in the case of profile nos. 11 and 12, the host interface parameters are affected immediately

1)

.

Printing out

profile bar codes

Table 13

Note:

When changing the reading pulse type, we recommend that you present the

corresponding profile bar code (3 LT...) last so that reading of further profile bar

codes in free-running mode is not interrupted.

Printing out profile bar codes via the user interface

You can print out the profile bar codes offline (CLV not connected to PC), for

example, using the modified values in the configuration cards. One or more profile

bar codes are printed out on a page, depending on the number of changes made to

the default settings. You can set the size, position and number of codes printed out

on the page as required. Longer profile bar codes must be printed out in landscape

format (using the printer configuration window).

Ø Procedure for printing out profile bar codes

Step Action

1 Start the CLV Setup program on the PC

2 Open the stored configuraiton file (*.scl) for the CLV

3 Change the relevant parameters in the configuration cards

4 Define the print conditions using the C

in the PROFILES menu or accept the defaults

5 Print out the profiles using the PRINT PROFILES menu option in the

PROFILES menu

6 Save the modified parameter set to a new configuration file (*new.scl)

ONFIGURE PRINTING menu option

8 008 224/I982/08-00

Table 14

© SICK AG • Auto Ident • Germany • All rights reserved

21

Page 22

CLV 41x Bar Code Scanner

Operating Instructions

10. 4 AutoSetup (code configuration)

Teaching in application-

specific bar codes

IMPORTANT

The AutoSetup function allows you to set the application-specific parameters

automatically to read

• a bar code (from a code type with a fixed code length)

• at a fixed reading distance.

For this purpose, the PC with the user interface must not be connected .

During AutoSetup, the CLV automatically determines the code type, code length and

the optimum scanning rate in free-running mode for the bar code presented at the

maximum reading distance. All other code types are disabled for further

evaluation. The CLV writes the parameter values to the parameter set directly and

stores it permanently (EEPROM).

Since the CLV overwrites important code configuration parameters without requiring

confirmation from the user, we recommend that you upload the valid CLV parameter

set to the PC and store it as a configuration file (*.scl) using the S

AVE AS menu option

in the user interface before you change the CLV parameters.

AutoSetup can be started at any time in Reading mode by presenting profile bar

code no. 12 and triggering the corresponding reading pulse. Alternatively, the CLV

can read profile bar code no. 12 in free-running mode directly after the device has

been switched and within the wait time of 5 seconds after the self-test has been

completed.

The CLV does not output any reading results during teach-in mode and does not

respond to an external reading pulse.

Note:

The CLV does not enter any real values for the Minimum Distance and Minimum Bar

Width parameters, since it cannot determine absolute dimensions. When you upload

the parameter set from the CLV to the PC, therefore, the values in the R

CONFIGURATION card do not correspond to the actual values.

AutoSetup can also be called under the T

TIP:

choosing the corresponding entry in the V

ERMINAL menu of the user interface by

IEW menu. The CLV, however, does not

output any reading results here. By connecting the PC, you can also subsequently

check the read quality of the bar code that was read in by switching to P

EVALUATION mode.

Ø AutoSetup procedure with profile barcodes

Prerequisite: Valid parameter set (defaults or application-specific)

stored permanently in the CLV (EEPROM).

Step Action Response from CLV

1 Present profile bar code no. 10 CLV confirms the good read with an acoustic

printed on the card at a distance signal and the Result LED lights up for an

of approx. 200 mm. extended period of time.

Trigger reading pulse! AutoSetup is started, the CLV is in

free-running mode.

2 If the CLV is switched off, CLV switches to teach-in mode for 5

switch on the device, seconds after the first acoustic signal

then proceed as described in step 1, (free-running mode).

reading pulse is triggered automatically

EADING

ERCENTAGE

22

Table 15

© SICK AG • Auto Ident • Germany • All rights reserved

8 008 224/I982/08-00

Page 23

Operating Instructions

CLV 41x Bar Code Scanner

Step Action Response from CLV

3 Present the application-specific a) CLV confirms the good read with an

bar code at the maximum acoustic signal and permanently

reading distance in the application overwrites the corresponding parameters

for up to 10 seconds (see also in the code configuration.

16. Reading field diagrams) It then outputs two consective

acoustic signals and switches to Reading

mode. The Device Ready LED lights up.

b) If the CLV does not detect a bar code

within approx. 35 s (e.g. incorrect reading

distance, poor print quality), three

acoustic signals are output. AutoSetup

is then restarted automatically.

4 After the three acoustic signals, adjust a) As 1 a

the reading distance or skew (scan b) The CLV cancels AutoSetup automatically

line angle relative to bar code) after three unsuccessful attempts

5 Cancel AutoSetup prematurely: CLV cancels Autosetup automatically and

present profile bar code no. 10 switches to Reading mode (two consecutive

again acoustic signals). The current parameter

set is not modified.

Table 15 (contd)

Ø Test read of the bar code taught in with AutoSetup

Prerequisite: AutoSetup successfully completed

Step Action Response from CLV

1 Call PERCENTAGE E VALUATION mode CLV displays the evaluation results for

from the TERMINAL menu 100 scans.

of the user interface

(see also Section 10.6 Operating

modes/functions)

2 Present the application-specific CLV displays the reading quality obtained

bar code again. at the corresponding distance.

Table 16

10. 5 Parametrization with the CLV Setup software

10. 5. 1 Installing the user and parametrization software

In order to switch between operating modes and set the parameters manually, you

need the Windows-based CLV Setup software supplied with the device. The program runs on Windows 3.11™, Windows 95™ and Windows NT™. The user interface

can also be used when it is not connected to the CLV to configure applicationspecific parameter sets (offline mode). The CLV must be connected to the PC,

however, to transfer modified parameter values (download) directly (online mode).

8 008 224/I982/08-00

Ø Copy the CLV Setup and CLV Setup Help software to the hard disk of your PC and

install the programs.

The user interface (Fig. 16) is largely self-explanatory. The introduction and online

CLV Setup Help function demonstrate how easy it is to use.

The data displayed on the configuration cards is first stored temporarily to the main

memory of the PC. You can save this data permanently to a configuration file (*.scl)

on the PC using the S

© SICK AG • Auto Ident • Germany • All rights reserved

AVE AS command in the FILE menu.

23

Page 24

CLV 41x Bar Code Scanner

Operating Instructions

From this point onwards, it is assumed that the user has started the program

and that the CLV is connected to the PC. Any existing data connections to the

host must be disconnected.

IMPORTANT

Fig. 15. Windows-based CLV Setup program

Initial steps after the user interface has been started

Displaying the default settings in the configuration cards

The program then loads the internal description of the CLV as well as the default

parameter values and displays them on the tabs. Finally, CLV Setup uploads the

current parameter set from the RAM of the CLV and displays the values on the tabs

instead of the default values.

You can edit the current parameter set on the tabs. The default values are displayed when

the device is used for the first time.

Troubleshooting

If the CLV-setup screen shows “no connection” in the lower right menu bar, the

program couldn’t connect to the CLV. There may be two reasons, either the CLV is

not connected or the communication parameters of CLV and PC do not match. The

CLV setup program stores the type of CLV which was successfully contacted before

in the list field “appliance” of the symbol bar. When calling the CLV setup program

for the first time the CLV type is by default “CLV 41x”. For this CLV type, the

program loads the internal appliance description and the default parameters from its

data base and displays the values in the corresponding tabs.

24

Displaying the active CLV parameter set

To view the active CLV parameter set and change it via the configuration cards, you

must first either

Ø transfer (upload) it from the CLV to the PC or

Ø open the active configuration file (*.scl) on the PC.

© SICK AG • Auto Ident • Germany • All rights reserved

8 008 224/I982/08-00

Page 25

Operating Instructions

CLV 41x Bar Code Scanner

Temporary default host interface settings

If you cannot access the CLV via the host interface after you start the device (red

indicator at the bottom right displays N

O CONNECT!)

IMPORTANT

IMPORTANT

IMPORTANT

Ø upload the parameter set from the CLV or

Ø present profile bar code no. 11 after you switch on the CLV (see also Section

10.3 Profile parametrization)

10. 5. 2 Setting the parameters via the configuration cards

After the start of the CLV setup program, the cards display the parameter values of the

current CLV.

Upload

The ”CLV Setup” loads the current parameter settings of the CLV to the database

and displays the values of the configuration cards. During the data transfer, the

„Device Ready“ LED is off.

If the ”CLV Setup” software is unable to read the loaded parameters during the

upload, a warning is issued. Unknown parameters can be edited in the “EXTRAS”

tab, following the general rules for command strings. When saving the parameter

set, these parameters are taken into account.

Download

The changes made to the configuration cards do not take effect until they have

been transfered to the CLV. When you download the file, the CLV asks you whether

you want to store the new parameter set temporarily or permanently.

TIP:

Quick help

TIP:

If the current parameter set has been changed and transferred to the CLV

permanently, we recommend that you back up this parameter set by saving it as a

configuration file (*new.scl) on the PC using the S

AVE AS command.

Online Help function

The parametrization procedure is supported by the online CLV Setup Help function.

The online help runs on an HTML browser (e.g. Netscape™ or Internet Explorer™).

The PC searches for this browser and opens it automatically. If it cannot be found, a

window is displayed asking you to specify the directory in which the browser is

stored on the hard disk.

You can call context-sensitive help on the parameter you are currently processing by

pressing F1. You can choose the configuration card on which you want help in the

top, horizontal frame. The associated parameters are then displayed in the left-hand

frame. When you click one of these parameters, a detailed description is displayed

in the right-hand frame. To display the help overview, choose the C

ONTENTS command

in the HELP menu.

To prevent several browser windows from being opened, we recommend that you

use the ALT + TAB keys in Windows to switch quickly between the CLV Setup and

CLV Setup Help applications.

8 008 224/I982/08-00

© SICK AG • Auto Ident • Germany • All rights reserved

25

Page 26

CLV 41x Bar Code Scanner

Operating Instructions

Note:

Printing out parameter sets

TIP:

You can print out and archive new parameter sets by clicking the

icon.

The manual entitled Menu-Driven Parametrization of the CLV Bar Code Scanner

explains the parameters and their functions and can be used as a reference for

more complex applications.

Ø Procedure for setting parameters via the configuration cards

Step Action

1 Connect the CLV to the PC

2 Start the CLV Setup program on the PC

2 Open the configuration file (*.scl) for the relevant CLV or click the

(upload) icon (CLV transfers the active parameter set to the PC)

3 Modify the required parameters in the configuration cards

4 Click the (download) icon (CLV receives the modified parameter set)

5 Choose the storage option*) for the CLV in the dialog window

6 Save the modified parameter set as a new configuration file (*new.scl) on the PC

*) permanently?:

The CLV saves the modified parameter set in the main memory (RAM) to the EEprom.

These values remain stored when you switch off the device. The next time you switch on the CLV, these

values are loaded to the main memory of the CLV and are used as the active parameter set.

temporary?:

The CLV only transfers the modified parameter set to the main memory (RAM). These values are lost

when you switch off the device. The parameter set last stored in the EEprom is loaded to the main

memory and used as the active parameter set the next time you switch on the CLV.

Table 17

Function of the configuration cards

Reading Configuration

This card is used to change the scanning frequency, reading distance, resolution,

start/stop ratio and the evaluation range of the scan line.

Device Configuration

This card is used to change the device number, reading pulse, output time of the

reading result and the separator in the data output string as well as the functional

assignment of the three switching outputs Result 1...3 and the beeper.

Code Configuration

This card is used to activate/deactivate the individual code types that are to be

evaluated and to change the number of identical reads as well as the minimum and

maximum number of bar codes to be read/output.

We recommend that you only activate those codes that are actually relevant in order

to enhance the reading reliability with fast applications.

26

© SICK AG • Auto Ident • Germany • All rights reserved

8 008 224/I982/08-00

Page 27

Operating Instructions

CLV 41x Bar Code Scanner

Host Interface

This card is used to change the protocol, start and stop characters, data format and

the transmission rate.

Data Strings

This card is used to change the data output format of the host interface. ASCII

characters and reading diagnosis data can be transferred to the host in the header,

separator and terminator (default setting: no characters). The output format for no

reads and the content of the error string can be modified. The test string function

can also be activated here. If more than one bar code is to be read during each

reading pulse, you can specify the output sequence and sort criteria.

Extras

If required, these tabs are used to treat parameters, which are unknown to the CLV

setup program after an upload from the CLV.

Note:

The program “CLV-Setup Help” describes the functionality and the allowed values of

the parameters. Call “CLV-Setup Help” by pressing “F1”.

8 008 224/I982/08-00

© SICK AG • Auto Ident • Germany • All rights reserved

27

Page 28

CLV 41x Bar Code Scanner

Operating Instructions

10. 6 Operating modes/functions

The CLV features the following operating modes/functions:

• Reading mode

• Percentage evaluation

• Profile programming

• AutoSetup

• Parametrization

• Operating data

10. 6. 1 Reading mode

Standard mode

Read quality

evaluation

The CLV switches to this mode automatically when it is switched on and after the

self-test has been successfully completed. In the default setting, the CLV generates

the reading pulse by means of reflector polling. The reading result is output at the

end of the reading pulse.

You can use the software to display the reading result from the CLV directly:

Ø Choose the T

window is then displayed in R

ERMINAL command in the FILE menu or click the icon. The terminal

EADING MODE

Ø Present the polling reflector to the CLV (start of reading interval), and then the bar

code to be read followed by the polling reflector again (end of reading interval)

10. 6. 2 Percentage evaluation

This temporary operating mode is only accessible via the user interface and is used

to assess the quality of the reading function. In this case, the CLV evaluates 100

scans statistically (independent of the set pulse type) in free-running mode. It

outputs the reading result continuously. You can view the results with the user

interface.

Ø Choose the T

Ø Click the terminal mode P

ERMINAL command as described above

ERCENT EVA L on the right of the screen (Fig. 17)

28

Fig. 16. Percentage Evaluation in the TERMINAL option of the user interface

© SICK AG • Auto Ident • Germany • All rights reserved

8 008 224/I982/08-00

Page 29

Operating Instructions

Good Read:

CLV 41x Bar Code Scanner

Ø Present the bar code shown in Fig. 18, for example, to the CLV at a reading

distance of approx. 200 mm (see Section 14. Sample bar codes for further

patterns). The CLV reads the bar code and displays the result on the screen. An

acoustic signal is output at the same time to confirm the read. The Result LED

lights up or blinks, depending on the read quality (see also Section 7. Function of

the LEDs).

T T= _ _210 ms MG=_46 % n=_1

C39 100% ST=0 CP=_50 CL=_6 CA=100 CS=100 CK=100

UVWXYZ

where:

*)

= Duration of reading interval

T T

MG*)= Time average of identification quality

*)

= Number of codes detected

n

C39*)= ID, code type Code 39

100%*)= Identification quality

ST*)= Read status (0= Good read)

CP*)= Code position

CL*)= Code length

*)

= Required scans

CA

CS*)= Code reliability

CK*)= Code continuity

UVWXYZ= Code content

No Read:

T T= _ _210 ms MG=_46 % n=_0

no code !

where:

*)

= Duration of reading interval

T T

MG*)= Time average of identification quality

n*)= Number of codes detected

no code = No codes detected

Sample code (Code 39):

UVWXYZ

Module width 0.5 mm

Note:

Profile bar codes (see 10.3 Profile

programming) read in by the CLV in

Percentage Evaluation mode do not

modify the parameter set and,

therefore, do not affect the reading

process. You also cannot use this

method to teach in match code 1.

*)

Reading diagnosis data - the CLV does not send this data to the host in Reading mode (default settings)

Fig. 17. Percentage Evaluation mode: reading results display

10. 6. 3 Profile programming and AutoSetup

These functions are used to modify parameter values automatically.

See Section 10.3 Profile programming and 10.4 AutoSetup.

10. 6. 4 Parametrization mode

This function allows you to enter command strings directly in the T

the user interface (e.g. error query) and can be used to configure special device.

To call the function, choose the P

TERMINAL menu if the CLV is connected.

8 008 224/I982/08-00

© SICK AG • Auto Ident • Germany • All rights reserved

ERMINAL menu of

ARAMETERIZE command in the VIEW menu or in the

29

Page 30

CLV 41x Bar Code Scanner

11. Replacing a CLV 41x

Operating Instructions

10. 6. 5 Operating data

This function allows you to interrogate and reset important counters in the user

interface that are updated continuously by the CLV during the reading procedure.

To open the dialog window, click the icon with the CLV connected. The CLV data

is then loaded to the window directly and displayed.

11. 1 Transferring the application-specific parameter set

If you have to replace a CLV on site and therefore transfer the active parameter set

to the new device, there are two methods of doing so. The parameter set can only

be transferred to a device of the same type.

Transferring the parameter set locally using profile bar codes

Prerequisite: the active parameter set is available in archived form as printed

profile bar codes.

It is not necessary to connect the PC to the CLV Setup program.

Step Action

1 Disconnect the power supply to the AMV/AMS Connection Module

2 Disconnect the CLV connector from the AMV/AMS Connection Module.

Remove the CLV from the bracket on the reading station.

Mark the position and alignment on the bracket/station.

3 Mount the new CLV and connect it to the AMV/AMS

4 Reconnect the power supply to the AMV/AMS Connection Module

5 Present the first archived profile bar code to the CLV within

acoustic signal.

The CLV confirms the good read with an acoustic signal and waits 10 s for the

next profile bar code.

6 Present all of the other profile bar codes consecutively in the order in which they

were printed.

7 Finally, allow the last 10 s wait time to expire.

The CLV then outputs two consecutive acoustic signals and switches to Reading

mode. The Device Ready LED lights up.

The new CLV can now be used with the transferred parameter set.

Table 18

5 seconds5 seconds

5 seconds after the first

5 seconds5 seconds

Notes:

The procedure for printing out the profile bar codes is described in Table 14 in

Section 10.3 Profile programming.

If none of the profile bar codes of the parameter set for the device to be replaced

has been printed out and if the configuration file (*.scl) has not been saved on the

PC, you can try, depending on the reason why the device is to be replaced, to

upload the parameter set from the CLV to be replaced to the user interface and then

download it to the new CLV.

30

Ø Transferring the parameter set by means of a download

If the profile bar codes of the parameter set have not been printed out but a

configuration file (*.scl) does exist, you must connect the PC with the CLV Setup

software to the new CLV (see Section 8.4 Connecting the PC to the CLV).

In the following section, it is assumed that the new CLV is using the default settings.

© SICK AG • Auto Ident • Germany • All rights reserved

8 008 224/I982/08-00

Page 31

Operating Instructions

CLV 41x Bar Code Scanner

Step Action

1 Replace the CLV as described in steps 1 to 3 in Table 18

2 Disconnect any data connections to the host

3 Connect an RS 232 data connection cable to the AMV/AMS and PC

4 Reconnect the power supply to the AMV/AMS Connection Module

5 Start the CLV Setup program on the PC

6 If you cannot access the new CLV (red display NO CONNECT! at bottom right)

click the (upload) icon (CLV transfers its parameter set to the PC)

7 Open the configuration file (*.scl) stored for the old CLV

8 Click the (Download) icon (new CLV receives the application-specific parameter set)

9 Choose the Permanently storage option for the CLV in the dialog window

10 Close the configuration file (*.scl) again.

11 Disconnect the RS 232 data connection cable from the CLV

12 Re-establish the data connection to the host.

Table 19

If a parameter set is duplicated on other devices with the same application

TIP:

conditions, you may have to change the device number of the individual CLVs

subsequently using the D

EVICE CONFIGURATION card for this parameter set so that it can

be evaluated in the host and then download the parameter set again.

11. 2 Disassembly and environmentally friendly disposal of the CLV

If the CLV is to be disposed of (after it has reached the end of its service life), the

national waste disposal regulations applicable at the time at which the device is

taken out of service must be observed.

• The housing of the CLV (chassis and cover) is made of die-cast zinc and can be

submitted for recycling after the glass plate of the reading window has been

removed.

• The electronic modules and connection cables can be easily removed. However,

they must not be disposed of as domestic waste but rather sent to a suitable

plant for treatment as problem waste.

8 008 224/I982/08-00

© SICK AG • Auto Ident • Germany • All rights reserved

31

Page 32

CLV 41x Bar Code Scanner

12. Troubleshooting

Operating Instructions

12. 1 Self-monitoring function

The CLV is equipped with the following monitoring functions:

• After it is switched on, the device always performs a self-test before it is initialized

in order to check the important hardware components.

• During operation, the CLV constantly monitors the function of its laser diode and

the speed of its polygon mirror wheel. A watchdog circuit also responds to any

malfunctions in the device.

• If the CLV detects a malfunction during the self-test or operation, it outputs the

error status ST=3 if this has been enabled for transfer to the host in the separator

of the output string (default setting: no).

12. 2 Error messages

The CLV does not output any error messages apart from the error status ST.

12. 3 Causes of error and troubleshooting

The following tools and resources are required to perform the troubleshooting

measures described in Table 20:

• these Operating Instructions

• set of tools

• a measuring tape

• a multimeter for measuring voltage and current values

• a PC with the CLV Setup software

• an RS 232 data connection cable, e.g. no. 2 020 319 from SICK

Malfunction

1. The CLV is not

ready.

- The Dev. Rdy. LED

is not lit

- The Result 1 switching

output (default: Dev. Rdy)

is disabled

2a. Reading mode:

(Dev. Rdy. LED lit)

Pulse: reflector polling

The CLV cannot be

clocked.

- The Laser On LED flickers

but is not lit constantly.

- Red-light scanner: the

scan line is very faint

Table 20

We recommend that you perform the troubleshooting measures in the following order.

Possible cause

1. The operating voltage (4.5 ...30V

DC) is not connected

2. The CLV is not in Reading mode

3. The CLV has detected a

malfunction during the self-test

1. Incorrect reading pulse source set

in parameters

2. Reading distance incorrect

3. Polling reflector incorrect

4. Incorrect pulse sequence

(reflector is not covered to

start the reading interval)

Check

1a.Check power supply.

1b.Mechanical noise?

2. Return to Reading mode

3a. Switch the device off and on

again. Does the LED now

light up after approx. 10 s?

3b. Has the CLV sent the status

ST=3 in the data output

string (prerequisite: ST is

enabled for output in the

separator)?

1. Are the device parameter

settings for the reading pulse

correct?

2. Is the reading distance within

the defined reading field?

3. Is the polling reflector suitable

for the reading distance?

4. Is the reflector polling