Page 1

SICK Optic-Electronic

CLV 410 / 412 Bar Code Scanners

Installation and Operation Manual

Page 2

SICK Optic-Electronic

Bar Code Scanners

© 1998

SICK Optic-Electronic, Inc.

6900 West 110th Street

Bloomington, Minnesota 55438 U.S.A.

Tel: 612-941-6780

Fax: 612-941-9287

Page 3

1

SICK Optic-Electronic

Bar Code Scanners

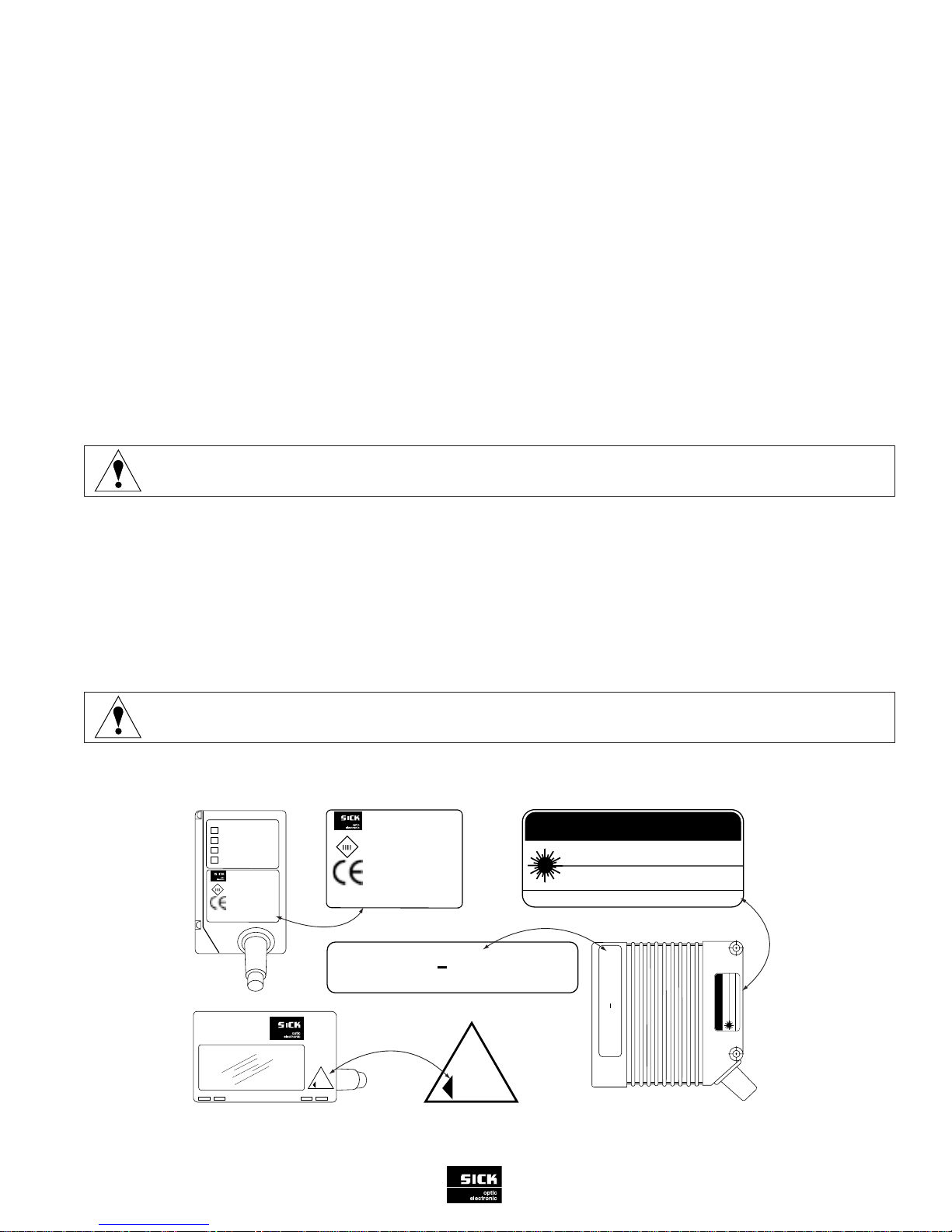

Laser Warning Labels

APPLICABLE WARNINGS and LABELS

FCC Compliance

The CLV has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses and can radiate radio frequency energy and, if not installed and used

in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment

in a residential area is likely to cause harmful interference, in which case the user will be required to correct the interference at

his own expense.

Personnel Safety Warning

The CLV emits a red light beam from a Class II laser diode. The beam is extremely bright and, like any bright light, may cause

eye damage unless you exercise caution. Please note the following warning.

WARNING: LASER LIGHT. Do not look directly at the light source. Laser light can cause eye injury after prolonged

exposure.

The CLV meets all safety requirements for Class II laser products. This includes standards of the United States Department of

Health and Human Services Center for Devices and Radiological Health; IEC 825, VDE 0837. The CLV laser warning labels are

shown in the following figures.

CDRH Laser Warning Labels

The illustrations below show the applicable CDRH laser warning labels used on the CLV 410 & 412 and their placement on the

scanner.

CAUTION: Use of controls or adjustments or performance of procedures other than those specified herein may

result in hazardous laser light exposure.

CAUTION

Device Ready

Result

Laser On

Data

CLV 410A0010

P/N: 1 017 044

S/N: 9802 0809

DC 4,5...30V 3W

Manufactured:

Jan 1998

SICK AG D-79276 Reute

Made in Germany

C A U T I O N

LASER LIGHTDO NOT STARE INTO BEAM

670 nm LASER LIGHT -1,0mW MAX OUTPUT

CLASS ll LASER PRODUCT

Product conforms to 21 CFR 1040

C A U T I O N

LASER LIGHT-

DO NOT STARE INTO BEAM

670 nm LASER LIGHT -1,0mW MAX OUTPUT

CLASS ll LASER PRODUCT

Product conforms to 21 CFR 1040

Laser radiation when open

DO NOT STARE INTO BEAM

CAUTION

Laser radiation when open

DO NOT STARE INTO BEAM

AVOID

EXPOSURE

LASER

RADIATION

EMITTED FROM

THIS APERTURE

AVOID

EXPOSURE

LASER

RADIATION

EMITTED FROM

THIS APERTURE

CLV 410A0010

P/N: 1 017 044

S/N: 9802 0809

DC 4,5...30V 3W

Manufactured:

Jan 1998

SICK AG D-79276 Reute

Made in Germany

Page 4

Table of Contents

2

SICK Optic-Electronic

Bar Code Scanners

Applicable Warnings and Labels............................................................................................................................................1

Welcome .................................................................................................................................................................................4

SECTION I-INTRODUCTION

Theory of Operation...........................................................................................................................................................5

Light Source.......................................................................................................................................................................5

Scanner Selection..............................................................................................................................................................6

Label Orientation ................................................................................................................................................................6

Line Scanner......................................................................................................................................................................7

Raster Scanner ..................................................................................................................................................................7

Programming ......................................................................................................................................................................7

Storage of Parameters.......................................................................................................................................................7

SECTION II - INSTALLATION

Receiving / Unpacking .......................................................................................................................................................8

Laser Protection.................................................................................................................................................................8

LED Functionality...............................................................................................................................................................8

End or Side Scanning ........................................................................................................................................................8

Mounting and Alignment.....................................................................................................................................................9

Connectors and Pinouts...................................................................................................................................................10

Power Supply Connections..............................................................................................................................................11

Physical Configurations of Scanners................................................................................................................................11

Point-to-Point Configurations............................................................................................................................................11

Daisy Chain Configuration ...............................................................................................................................................12

Network Configuration......................................................................................................................................................13

SECTION III - SOFTWARE CONFIGURATIONS

Uploading and Downloading............................................................................................................................................14

Modes of Operation..........................................................................................................................................................14

Code Configuration .........................................................................................................................................................15

Code Position .................................................................................................................................................................16

Number of Codes ...........................................................................................................................................................16

Code 39......................................................................................................................................................................17

Interleaved 2/5............................................................................................................................................................18

EAN ............................................................................................................................................................................19

UPC ............................................................................................................................................................................20

Codabar......................................................................................................................................................................21

Code 128 ................................................................................................................................................................. 22

Code 93......................................................................................................................................................................24

EAN 128 .....................................................................................................................................................................25

Pharmacode ...............................................................................................................................................................26

Reading Configuration .....................................................................................................................................................27

Minimum Bar Width.....................................................................................................................................................27

Minimum Distance......................................................................................................................................................27

Scan Frequency........................................................................................................................................................ 28

Minimum / Maximum Code Processing.................................................................................................................... 28

Reading Distance Test Conditions..............................................................................................................................29

Reading Distance for the CLV 410.............................................................................................................................30

Reading Distance Close Range Version....................................................................................................................31

Reading Distance for the CLV 412 High Density.......................................................................................................32

Device Configuration ............................................................................................................................................................33

Segmentation..............................................................................................................................................................33

Clock Pulse (Trigger Device) ......................................................................................................................................34

Page 5

Switching Outputs.......................................................................................................................................................35

Match Code ................................................................................................................................................................37

Teach-In Mode............................................................................................................................................................38

Device ID Number ......................................................................................................................................................38

Master / Slave.............................................................................................................................................................39

Host Communications...........................................................................................................................................................39

Baud Rate...................................................................................................................................................................39

Data and Parity Bits ....................................................................................................................................................40

Stop Bits .....................................................................................................................................................................40

Data String............................................................................................................................................................................40

Header........................................................................................................................................................................40

Separator....................................................................................................................................................................41

Terminator...................................................................................................................................................................41

Error String .................................................................................................................................................................41

Test String...................................................................................................................................................................41

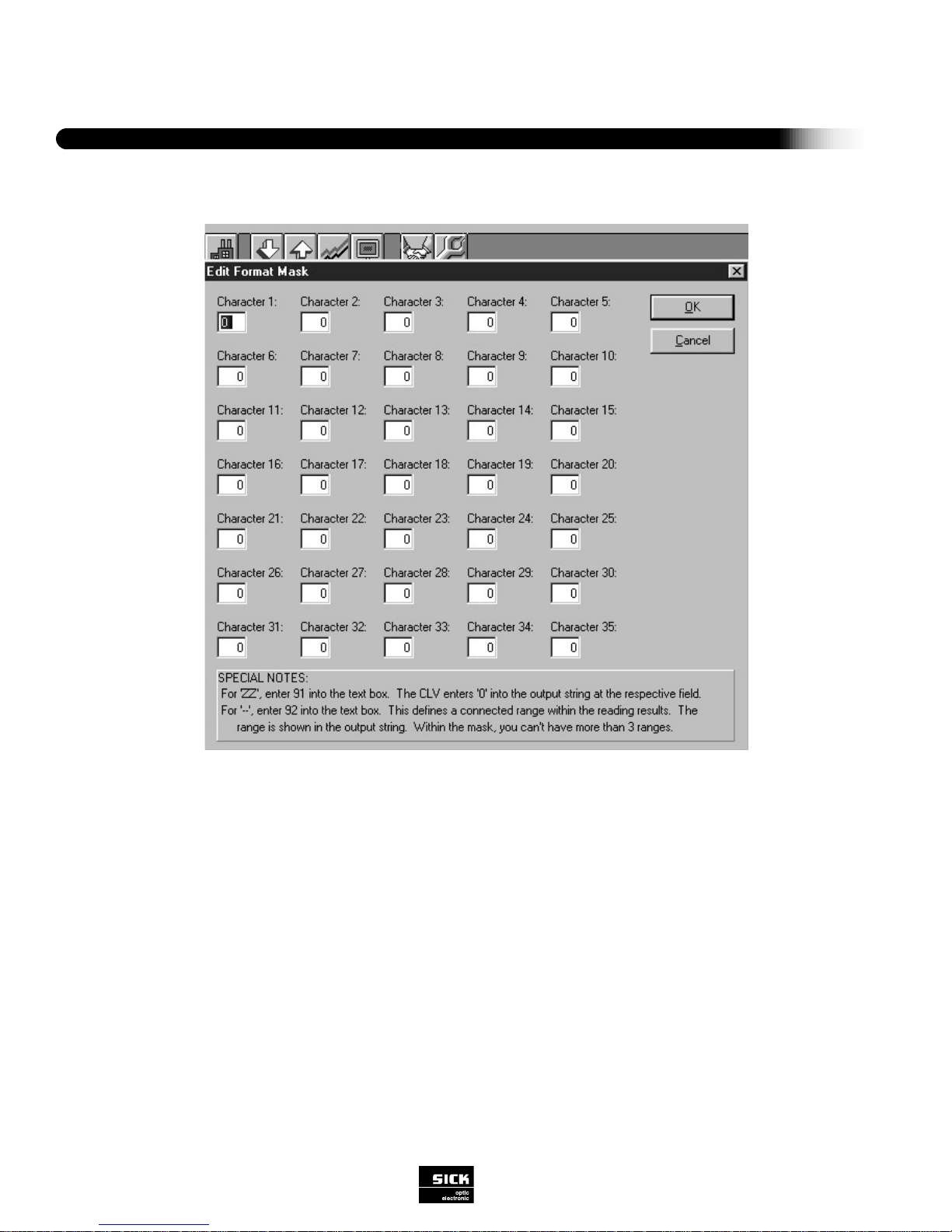

Format Mask ...............................................................................................................................................................42

Host Protocol........................................................................................................................................................................43

Standard Protocol.......................................................................................................................................................44

Network.......................................................................................................................................................................45

Sending Points............................................................................................................................................................45

Separator Position......................................................................................................................................................46

Output Code Sorting ...................................................................................................................................................47

Percent Evaluation...........................................................................................................................................................48

Operating Data .................................................................................................................................................................49

SECTION IV - OPERATION

Power-up..........................................................................................................................................................................51

Checking the Reading Mode............................................................................................................................................51

Optical Alignment .............................................................................................................................................................52

Indicator LEDs..................................................................................................................................................................52

Messages in the Reading Mode ......................................................................................................................................53

Read Quality ....................................................................................................................................................................53

Output Interpretation ........................................................................................................................................................54

Diagnostic Reading Data .................................................................................................................................................55

Determination of Diagnostic Reading Data......................................................................................................................57

Operation Using Host Command Language Strings........................................................................................................58

SECTION V - MAINTENANCE

Cleaning Optical Surfaces................................................................................................................................................59

CLV System Self Test.......................................................................................................................................................60

Error Messages................................................................................................................................................................60

SICK Optic-Electronic Service .........................................................................................................................................58

Error Messages in Reading Mode ...................................................................................................................................59

SECTION Vl - SPECIFICATIONS

Scanner Specifications.....................................................................................................................................................67

CLV 410/412 Side Scanning / End Scanning Dimensions...............................................................................................68

SECTION Vll - ACCESSORIES.....................................................................................................................................69

Mounting Brackets ...........................................................................................................................................................69

PS 52 Unit Dimensions....................................................................................................................................................69

APPENDICES

CLVCONFIGURATION DEFAULTS ................................................................................................................................71

ASCII CHARACTER SET ...............................................................................................................................................72

METRIC CONVERSION TABLE ......................................................................................................................................73

3

SICK Optic-Electronic

Bar Code Scanners

Table of Contents

Page 6

Introduction

4

SICK Optic-Electronic

Bar Code Scanners

1

WELCOME!

Welcome to the Installation and Operation Manual for your CLV 410 /412 bar code scanner. Congratulations on purchasing one

of the fastest, smallest, smartest sensors on the market today!

The CLV 400 series is designed to be easy to set up and easy to use. This manual walks you through the basics, from

mechanical mounting and alignment to simple programming through the Windowsä based software that came with your scanner,

as well as providing detailed technical information.

Again, we are glad you chose SICK Optic-Electronic for your automatic identification project and we are happy to help if you have

any questions. Just call our bar code application engineers at 1-800-325-7425.

SICK Optic-Electronic, Inc.

6900 West 110th Street

Bloomington, MN 55438 USA

Phone: (612) 941-6780 Fax: (612) 941-9287

Page 7

5

SICK Optic-Electronic

Bar Code Scanners

1

Introduction

SECTION 1-INTRODUCTION

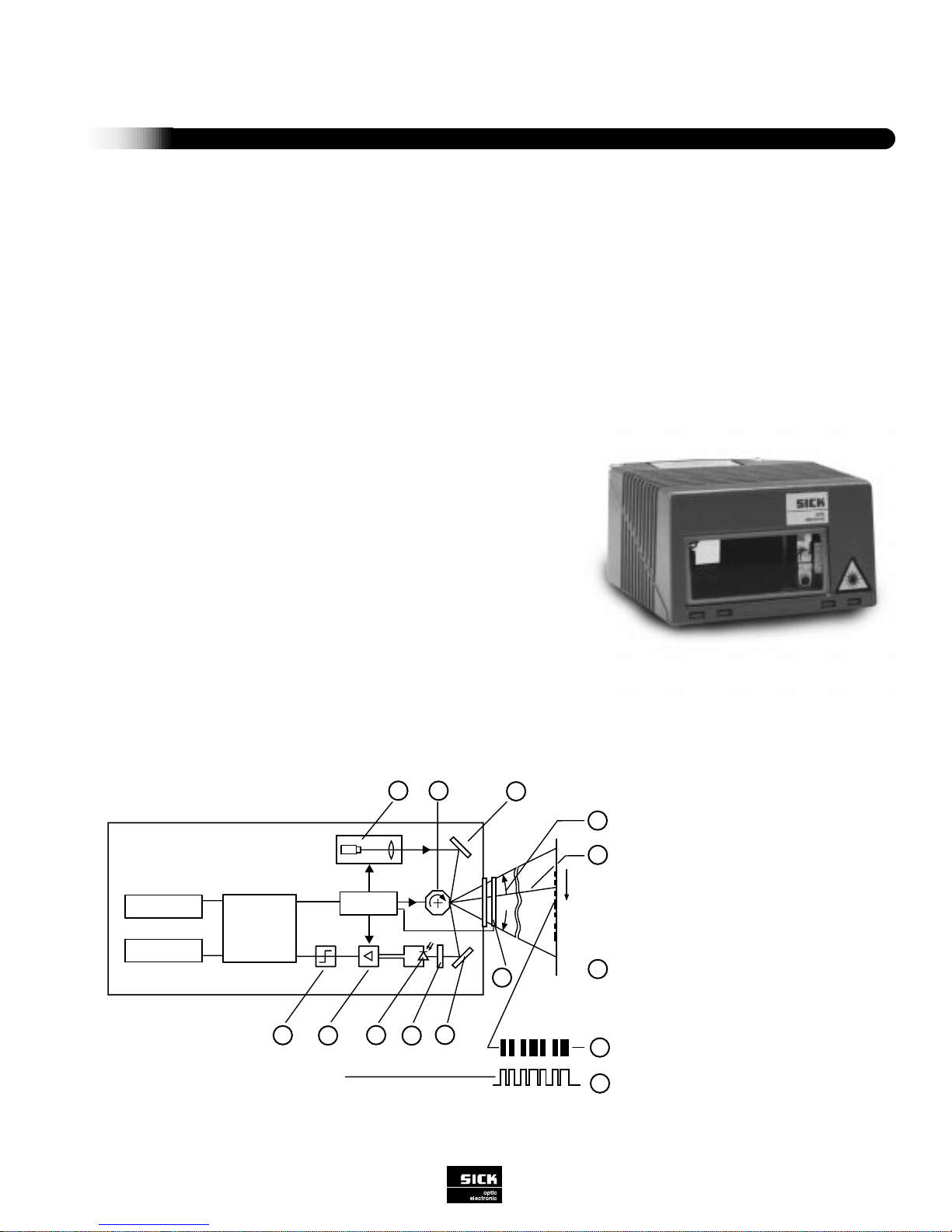

THEORY OF OPERATION

The CLV uses a scanning laser beam to detect the contrast between the

light and dark portions (bars and spaces) of a bar code. Figure 1-1 shows

the system in simplified form. In operation, light from the laser diode (1) is

directed by the corner mirror (3) onto one facet of the mirror wheel (2).

Rotation of the mirror wheel in the direction of the arrow causes the beam

exiting through the window to scan at a 60° degree total angle (4). When

the scanning beam strikes a bar code in the reading plane (6), a portion of

the incident light is reflected back through the window onto the mirror wheel

then onto the corner mirror. From the corner mirror, the reflected beam

passes through the filter (10), is converted to an electrical signal by the photoreceiver (11), amplified (12), and then digitized in the binary conversion

stage (13). This digitized signal (8) which now matches the bar code symbology (7) is routed to the integrated decoder where it is decoded to reconstruct the information contained in it. System output is transmitted to a terminal, a printer, or a host device.

LIGHT SOURCE

The standard CLV uses a visible red light (670 nm) laser diode for the scanning operation. An alternative infrared invisible laser source is available

where needed for optimum contrast. Maximum average power at the reading window is limited to 1.0 mW, giving a CDRH classification of safety class

II for both red light and infrared versions. The user is cautioned not to look

into the laser beam or at direct reflections of the beam.

This Installation and Operation Manual should provide you with the basic information you need to install and start operation of

your CLV 410/412 Bar Code Scanner. For information on using the CLV Utility Software, see SICK Optic-Electronic’s publication

“CLV Utility Software Guide ” part number 7 020 809. This extensive manual contains information applicable to many of the CLV

Bar Code Scanners.

60¡

1

2

3

6

10

4

5

Display

Evaluation

(Decoder)

Interfaces

Control

9

3

11

12

13

7

8

(1) Laser diode with focusing device

(2) Polygon mirror wheel

(3) Corner mirror

(4) Opening angle

(5) Reading beam

(6) Reading plane

(7) Bar code signal

(8) Digital signal

(9) Oscillating mirror

(10) Filter

(11) Photoreceiver

(12) Amplifier

(13) Binary conversion stage

Figure 1-1 Operation Principle of the CLV - Simplified

Page 8

Introduction

6

SICK Optic-Electronic

Bar Code Scanners

1

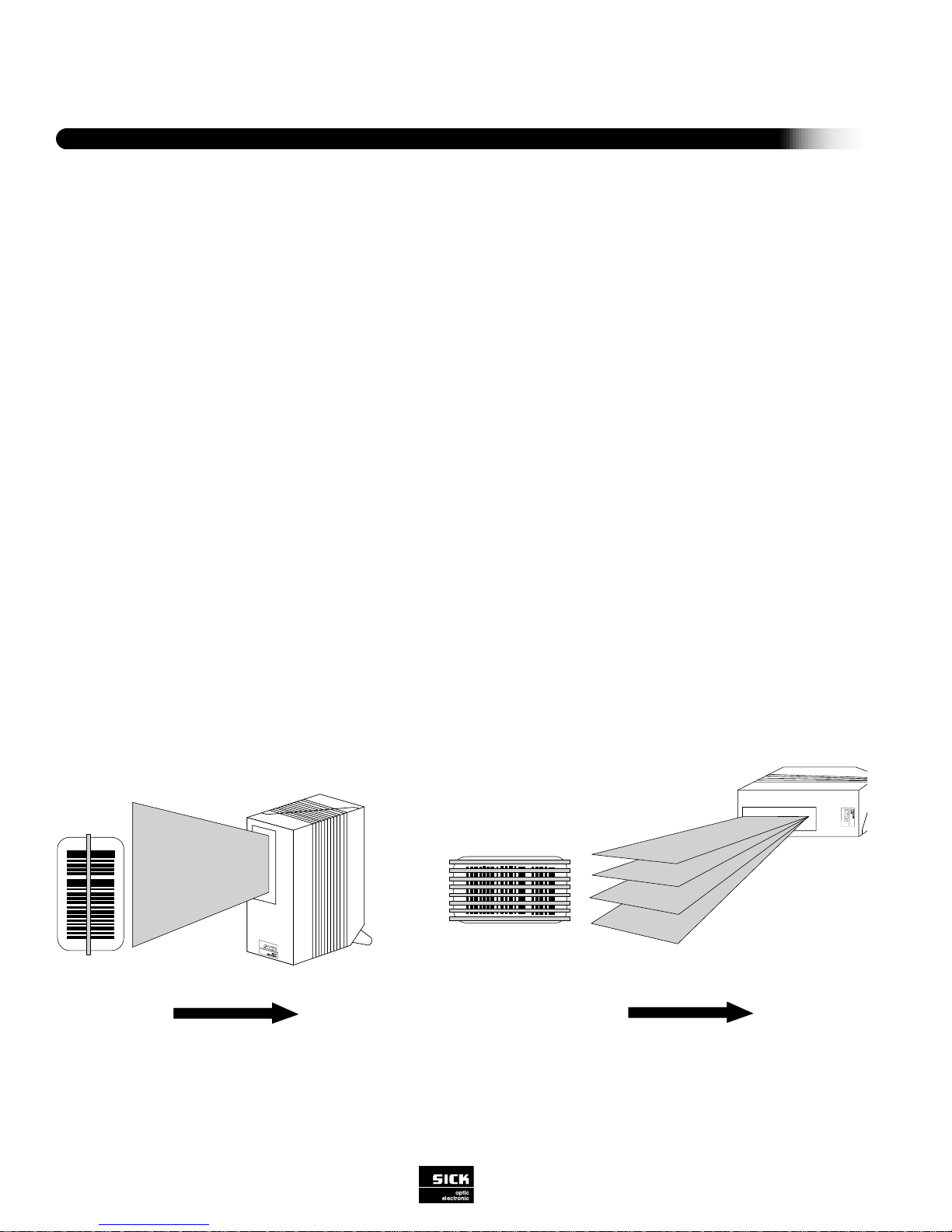

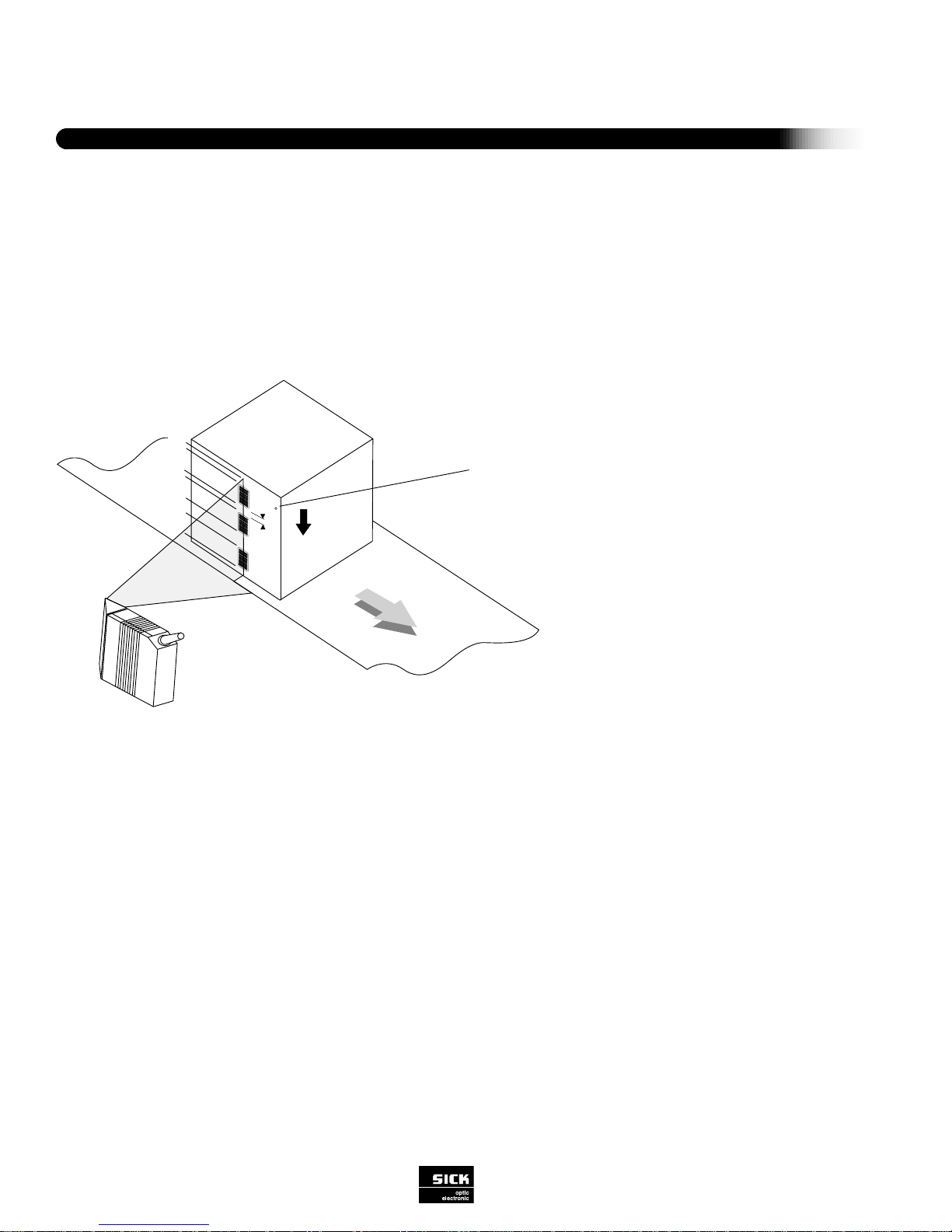

Figure 1-2 Bar Code Label Orientation

SCANNER SELECTION

The CLV 410/412 scanners are available in a line or raster version. The CLV 410 has a reading range of 2 in to16 in, depending

on the x-dimension of the bar code label. The scanner is designed to read medium to low resolution bar codes from .2 mm (.008

in) to 1.0 mm (.040 in). The CLV 412 has a reading range of 35 mm (1.38 in) to 95 mm (3.74 in), depending on the x-dimension.

The CLV 412 is designed to read high density bar codes from 0.1 mm (.04 in) to .20 mm (.008 in). The scan rate for both scanners is adjustable from 200 Hz to 800 Hz.

The following factors determine scanner selection:

• Bar code label orientation with respect to direction of transport (see below)

• Physical location of bar code and its alignment on the conveyed product

• Size of the scanning field required

• Space available for installation of bar code scanner

• Speed of conveyor line

LABEL ORIENTATION

The bar code will be presented to the bar code scanner in one of two ways: in the “ladder” orientation or in the “picket fence”

orientation.

In “ladder” orientation applications, the bar elements of the bar code are parallel to the direction of transport (Figure 1-2 A).

In “picket fence” orientation applications, the bar elements of the bar code are perpendicular to the direction of transport

(Figure 1-2 B).

A: Ladder Orientation B: Picket Fence Orientation

Page 9

LINE SCANNER

A single beam line scanner is used when the bar codes are being presented to the scanner in the “ladder” orientation (shown in

Figure 1-2 A). The scanning direction is perpendicular to the conveyed direction and the entire bar code is presented to the scanner. The usable length of the scan line, or “scan width,” is dependent on the scanning distance.

RASTER SCANNER

If the bar codes pass the scanner in a “picket fence” orientation, a raster scanner is

recommended to ensure complete scanning coverage of the bar code. See Figure

1-2 B. Refer to adjacent table to determine raster pattern height according to reading distance.

PROGRAMMING

The CLV is programmed at the factory with default settings for each parameter. The

default settings are considered temporary, for use at start-up or for testing the

system. In order to achieve optimal operation, the user can directly modify default

parameters for the intended application. Programming, or parameterization, can be

performed by using one of the following:

• Windows-based CLV Utility Software (included) via host port

• Host Command Language Strings via host port

The CLV 410/412 have a single interface port called the host interface. The table below shows the default parameters of the host

interface:

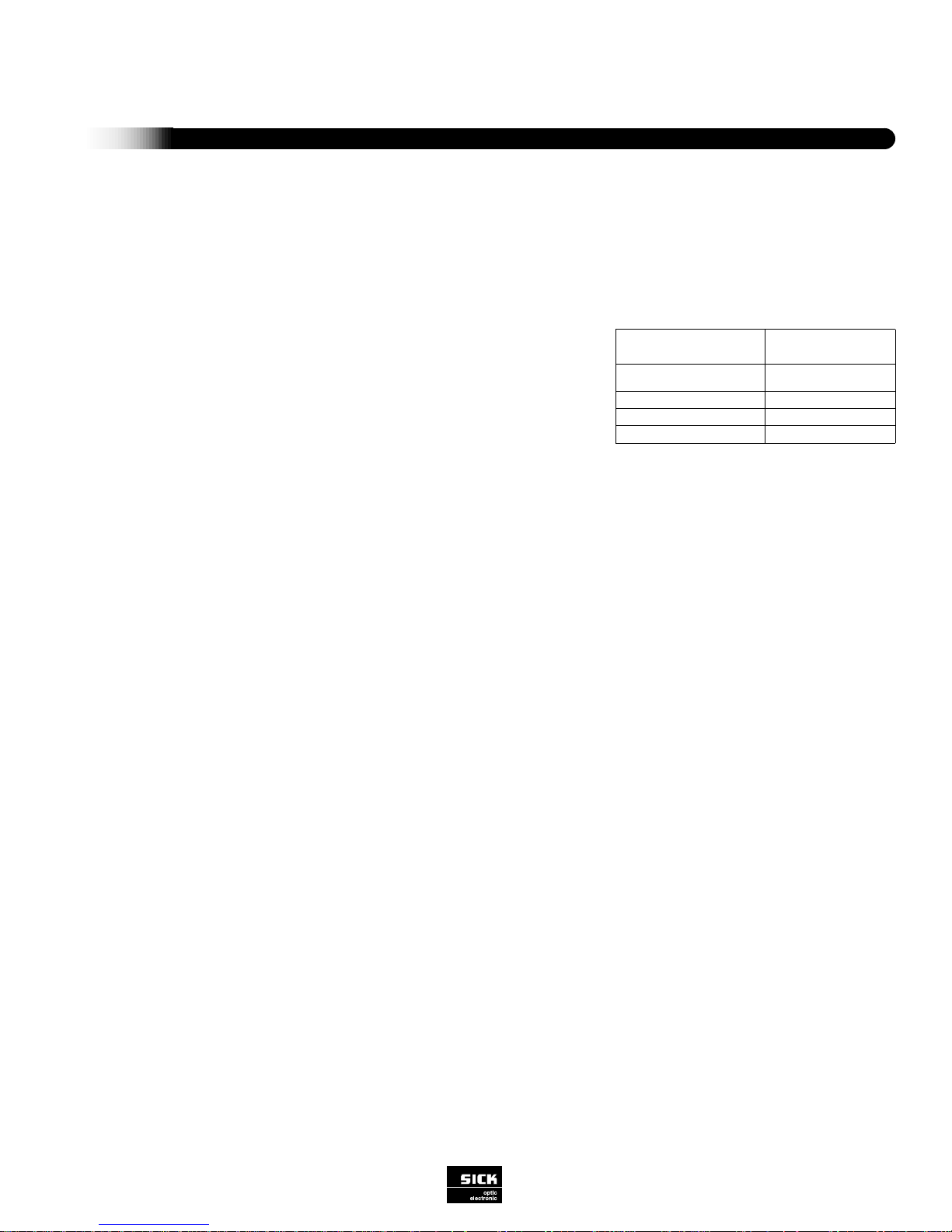

Parameters Setting

Type RS 232

Data transmission rate 9600 Baud

Parity; data bits None; 8 data bits

Stop bit 1

Protocol None

These communication default parameters are set temporarily for 5 seconds after power up to allow a user to program the CLV if

permanent settings are forgotten.

STORAGE OF PARAMETERS

The CLV stores all parameter values either temporarily in the working memory (RAM), where it remains until the system is turned

off, or permanently (non-volatile memory) in the EEPROM. The CLV Utility Software also stores the parameter values in a file that

can be saved on a disk.

7

SICK Optic-Electronic

Bar Code Scanners

1

Introduction

Reading Distance

100 mm (4 in)

200 mm (8 in)

300 mm (12 in)

400 mm (16 in)

Raster Height

8 mm (.3 in)

13 mm (.57 in)

18 mm (.70 in)

24 mm (.95 in)

Page 10

RECEIVING / UNPACKING

The CLV was completely tested under normal operating conditions and thoroughly inspected before shipment.

Unpack the CLV as follows:

1. Carefully remove and inspect all parts in the shipment for evidence of damage.

2. Check contents of shipment against the packing list.

LASER PROTECTION

All models of the CLV 410/412 line offer adequate safety to personnel by limiting the average emission power to 1.0 mW. If generation irregularities occur, internal protective circuits turn the laser off.

Laser warning labels on the CLV are reproduced on page 1 under “Applicable Warnings and Labels.”

LED FUNCTIONALITY

There are four indicator LEDs on the CLV:

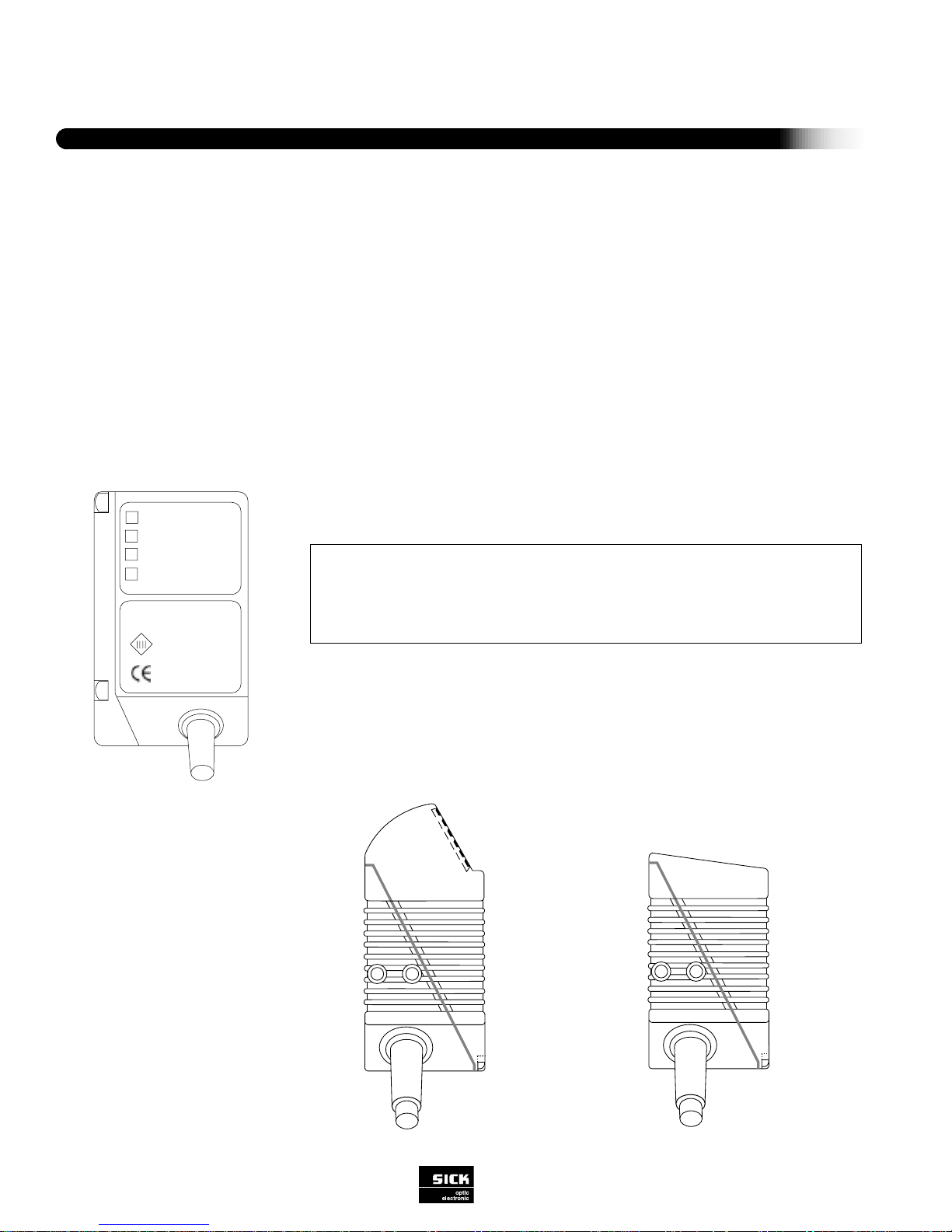

END OR SIDE SCANNING

The CLV 410/412 are available in a standard or a right angle version. This allows for

end scanning or side scanning.

Installation

8

SICK Optic-Electronic

Bar Code Scanners

2

SECTION II - INSTALLATION

Side Scanning

Device Ready

Result

Laser On

Data

End Scanning

Device Ready: Indicates that the scanner is powered and in the reading mode.

Result: Goes on or off (user-selectable) based on Good Read/Good Match or a No

Read/Wrong Read condition; default is Good Read.

Laser On: Indicates that a reading gate has been triggered and the laser is activated.

Data: Indicates that data is being transmitted to the host device via the host interface.

Page 11

9

SICK Optic-Electronic

Bar Code Scanners

2

Installation

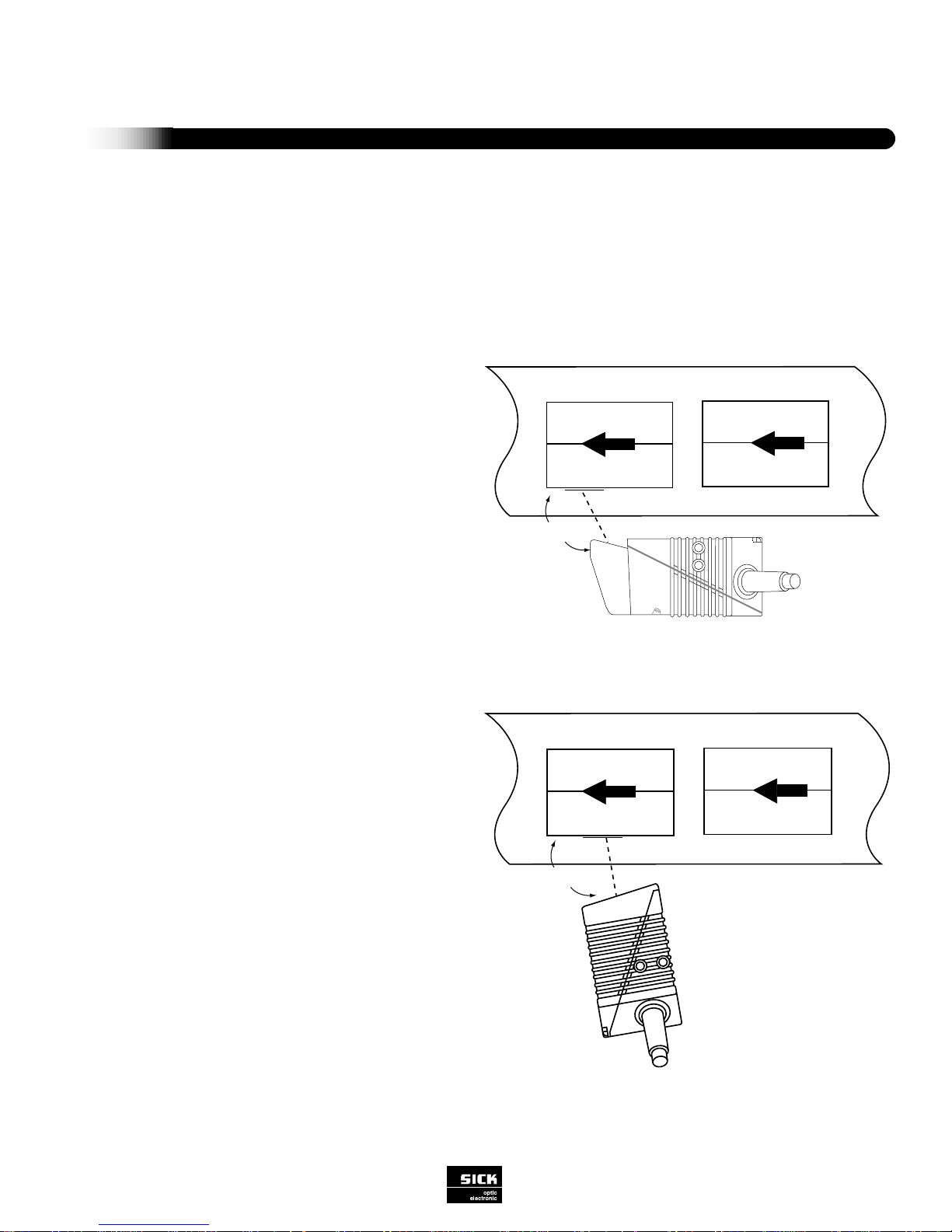

MOUNTING AND ALIGNMENT

The CLV should be mounted to permit alignment in three planes, with consideration for the bar code orientation on the conveyed

product. The CLV has two 5 mm (0.197 in) deep M4 tapped mounting holes located adjacent to the connectors.

Side Scanning

The illustration to the right shows the scanner in the side

scanning configuration. Simply mount the scanner with

the scanner body parallel to the surface to be read. The

position of the exit window provides the recommended 15

degree reading angle (skew angle) which reduces surface reflection.

End Scanning

The illustration shows the scanner in the end scanning

configuration. In order to reduce surface reflection, mount

the unit so that the body of the scanner is approximately

15 degrees from being perpendicular to the surface for

reading

105¡

105¡

Figure 2-1 Skew Angle for Side Scanning

Figure 2-2 Skew Angle for End Scanning

Page 12

Terminal

Host CLV

CLV 410

To Host Device for data transmission

(PLC, computer, etc.)

Installation

10

SICK Optic-Electronic

Bar Code Scanners

2

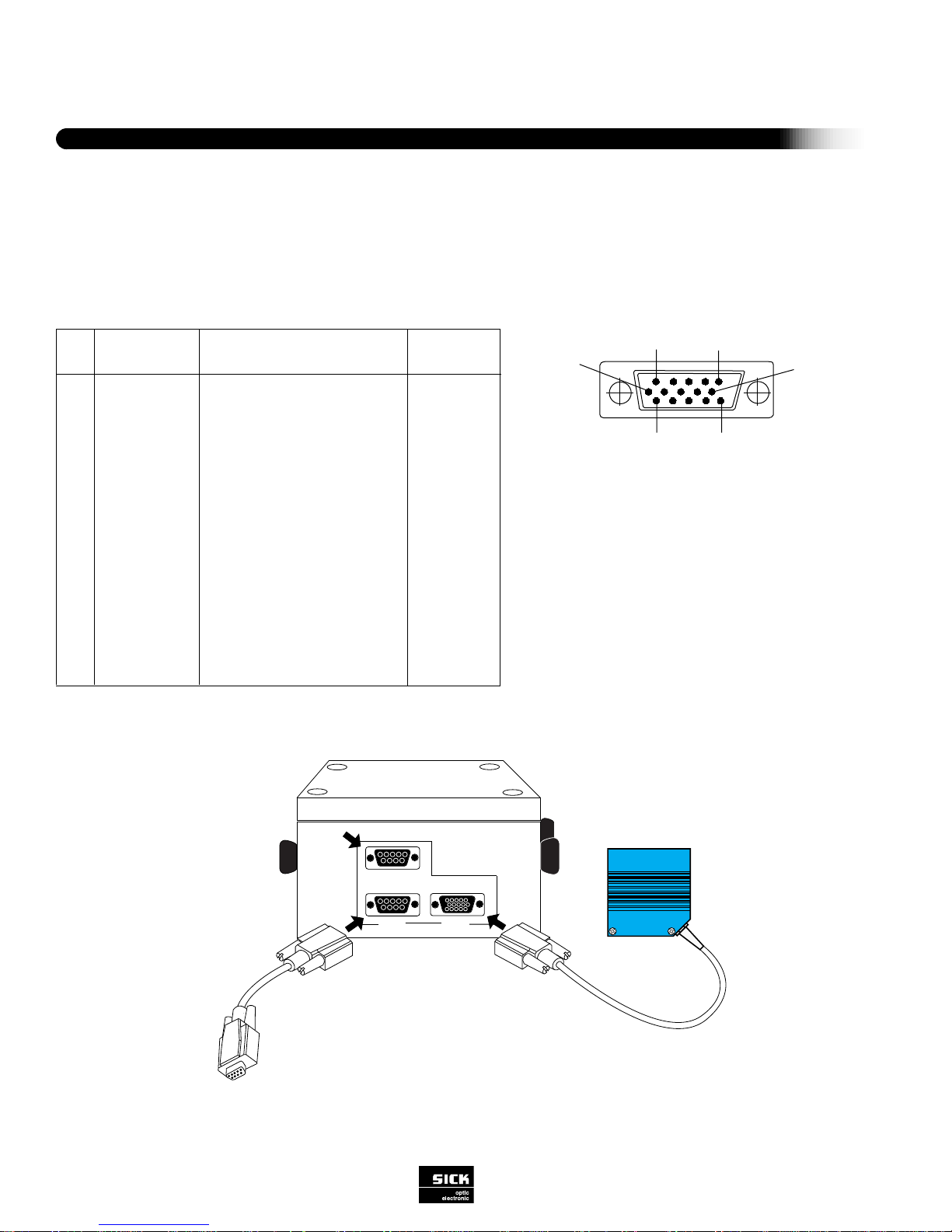

CONNECTORS AND PINOUTS

Make signal and power connections as explained below under “Power Supply Connections.” As a general precaution, shield all

lines carrying data and keep them as short as possible. Do not route them adjacent to other cables that could cause electromagnetic interference. CLV interface connections consist of a single 15-pin connector. Refer to Figure 2-3.

1

5

1611

10

Figure 2-3 CLV Interface Ports

(1) 24 V DC input for Teach Mode

(2) 24 V DC Output

(3) External Sensor input (24 V DC @

100mA) for trigger

Figure 2-4 PS 52 Power Supply Connectivity

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

-

DC +4.5...+30 V

Sensor 2

Result 3

Term RS 422

GND

RD+ (RS 422/485)

RD- (RS 422/485)

TD+ (RS 422/485)

TD- (RS 422/485)

RxD (RS 232)

TxD (RS 232)

Result 1

Result 2

Sensor 1

Sensor GND

-

Supply voltage

Switching input teach-in (match code 1)

Switching output (to PLC)

Termination for data interface 1

Ground

Data interface 1 (receiver)

Data interface 1 (receiver)

Data interface 1 (transmitter)

Data interface 1 (transmitter)

Data interface 2 (receiver)

Data interface 2 (transmitter)

Switching output (to PLC)

Switching output (to PLC)

Switching input for ext. reading pulse

Common ground (all inputs)

Shield

red

orange

green

yellow

black

pink

violet

white

gray

blue

brown

black/white

turquoise

red/white

brown/white

-

FunctionSignalPin

Wire colors

of cable

no. 6010137

6

Page 13

POWER SUPPLY CONNECTIONS

The CLV requires a power source of 5 V DC to 30 V DC. Current requirement for the CLV is 100 mA. Power supplies suitable

for the CLV include:

1. Power supply from SICK Optic-Electronic, Inc.

2. Another power supply provided by the customer. This power supply must meet the following specifications:

The 24 V DC output circuit must be isolated from the input circuit by double insulation and an isolating transformer. (Ref. IEC 742

and DIN / VDE 0551.)

Output voltage: 5 V DC ± 5% to 30 V DC ± 20%

Power output: minimum 15 VA

Current output: peak current maximum 1 A/continuous current minimum 500 mA

PHYSICAL CONFIGURATIONS OF SCANNERS

Host communication configurations include: point-to-point, daisy-chain (master/slave or pass-through), and network (RS 485

multidrop).

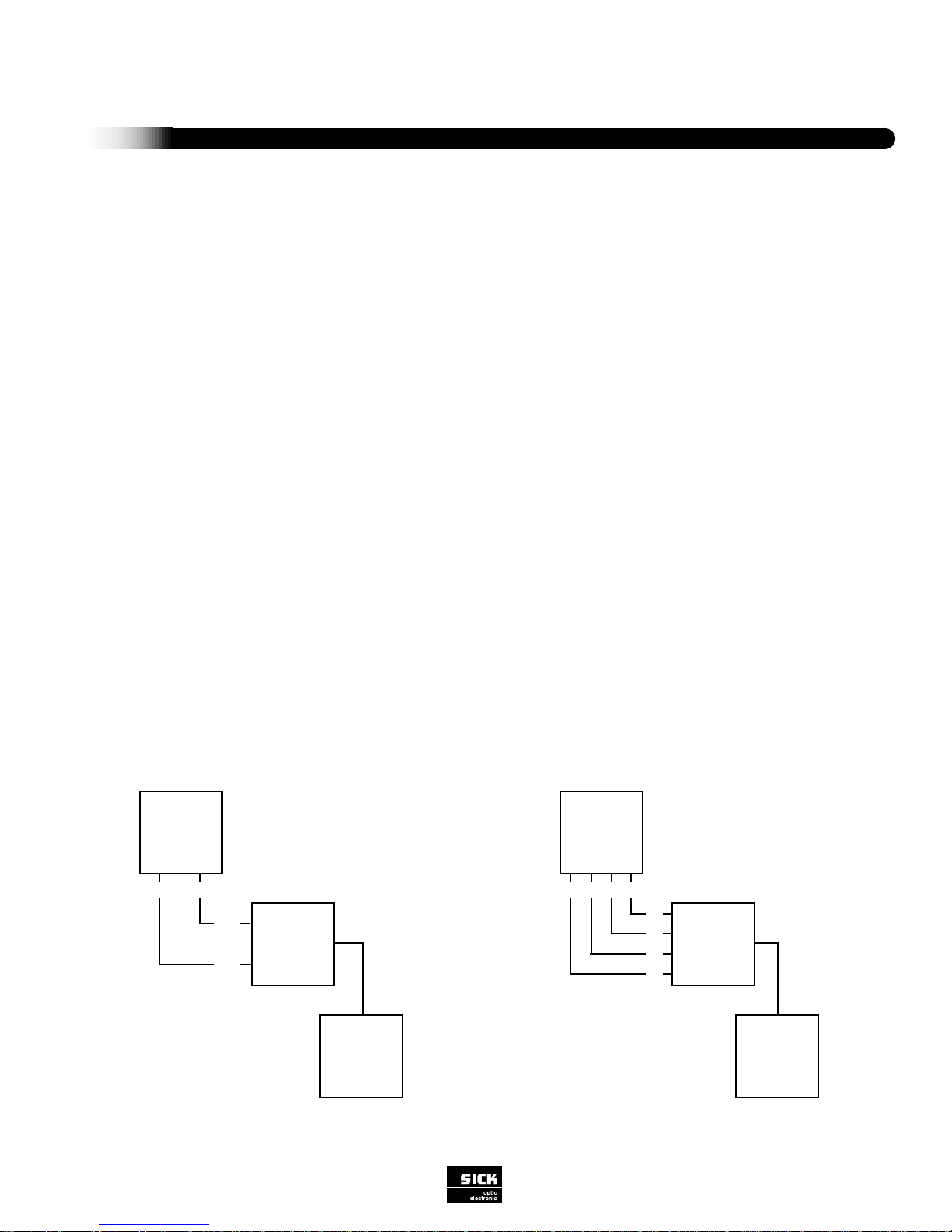

POINT-TO-POINT CONFIGURATIONS

In a point-to-point configuration, the CLV is connected directly to the host device via a power supply distribution unit. Figure 2-5

shows both of these point-to-point configurations. Functions include:

• Transmission of decoded bar code information from CLV to host

• Transfer of selected diagnostic reading data from CLV to host

• Relay of error strings from CLV to host

• Trigger of reading gate from host to CLV

• Programming and operation via command strings from host to CLV

11

SICK Optic-Electronic

Bar Code Scanners

2

Installation

Figure 2-5 Point-to-Point Configuration with RS 232 or RS 422 via Host Port

HOST DEVICE

DISTRIBUTION

UNIT

CLV

RxD TxD

RxD

TxD

HOST DEVICE

DISTRIBUTION

UNIT

CLV

T+ R-

T-

R+

T+

T-

R-

R+

RS 232

RS 422

Page 14

Installation

12

SICK Optic-Electronic

Bar Code Scanners

2

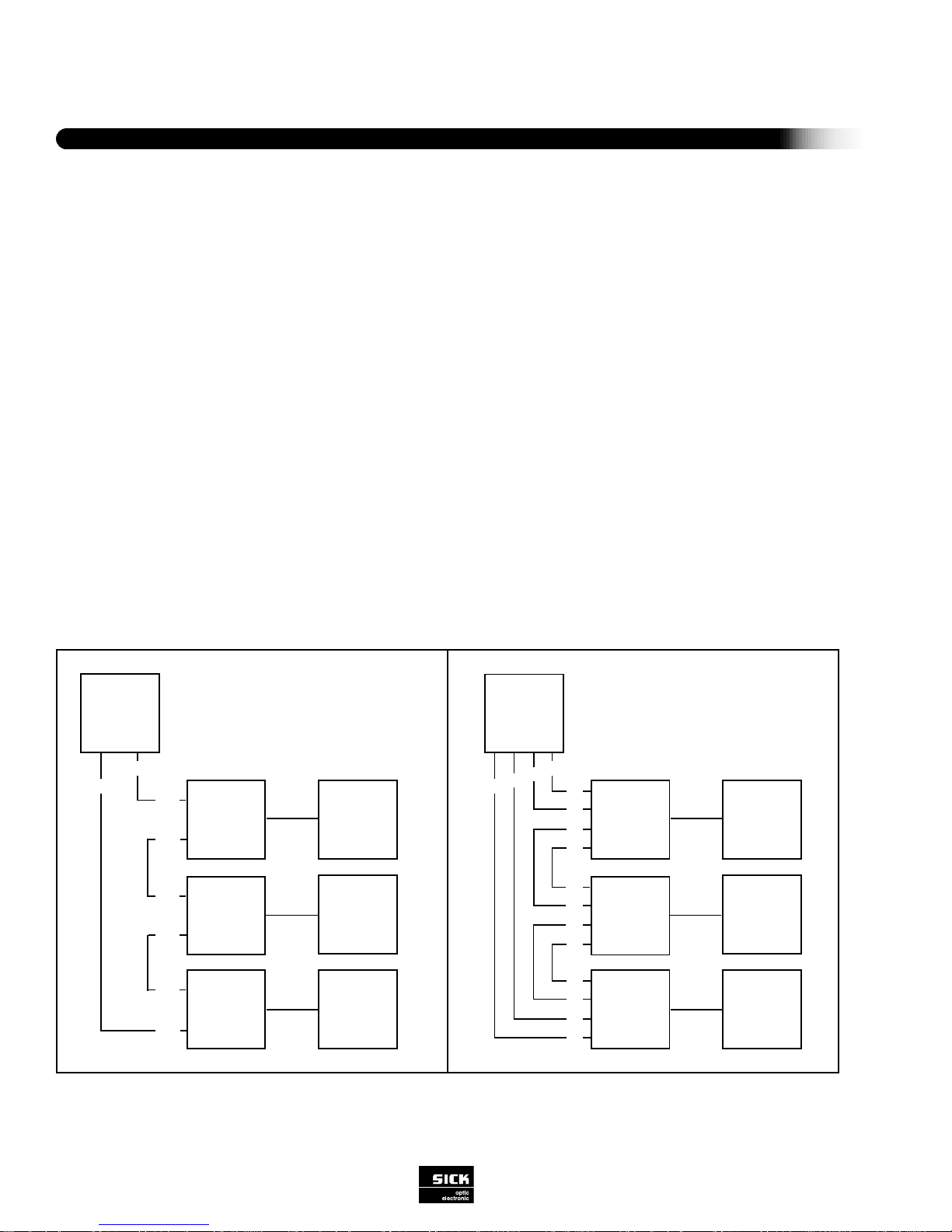

Figure 2-6 Daisy Chain Configuration via CLV Host Port

DAISY CHAIN CONFIGURATION

This configuration allows connection of several scanners to one interface port of the host device. There are two modes of operation in this configuration: master/slave or pass-through. There should be no more than 8 scanners used in these modes. Refer to

Figure 2-6 for an illustration of a daisy chain configuration.

Master/Slave Mode

For guidance in operating the scanners in the master/slave mode, refer to page 39.

Pass-Through Mode

In this mode of operation, the data from one scanner is passed to the next scanner in line and this is passed on again, etc. The

last scanner in line then transmits the data to the host device.

There is no time delay in this mode of operation, since each scanner provides a virtual connection.

The procedure required to activate this mode includes conditioning the output of each scanner to contain <STX>/“Data” <ETX>.

The “/” (forward slash) character is entered into the first position of the “Header” section.

The CLV uses the variable protocol framing <STX> and <ETX> characters which are selected in the Host Interface: Protocol sec-

tion. The forward slash is a special character to indicate the pass-through mode. Thus, the CLV receives the information and

immediately transmits the data to the host or to the next scanner in line.

2 Modes of Operation:

* Pass-Through Mode

* Master/Slave Mode

HOST DEVICE

DISTRIBUTION

UNIT

CLV

(master)

CLV

CLV

T-

R-

T-

R+

T+

T+

DISTRIBUTION

UNIT

T-

T+

R+

R-

DISTRIBUTION

UNIT

T-

T+

R+

R-

R-

R+

HOST DEVICE

DISTRIBUTION

UNIT

CLV

(master)

CLV

CLV

TxD

RxD

TxD

DISTRIBUTION

UNIT

TxD

RxD

DISTRIBUTION

UNIT

TxD

RxD

RxD

RS 232 RS 422

2 Modes of Operation:

* Pass-Through Mode

* Master/Slave Mode

Page 15

13

SICK Optic-Electronic

Bar Code Scanners

2

Installation

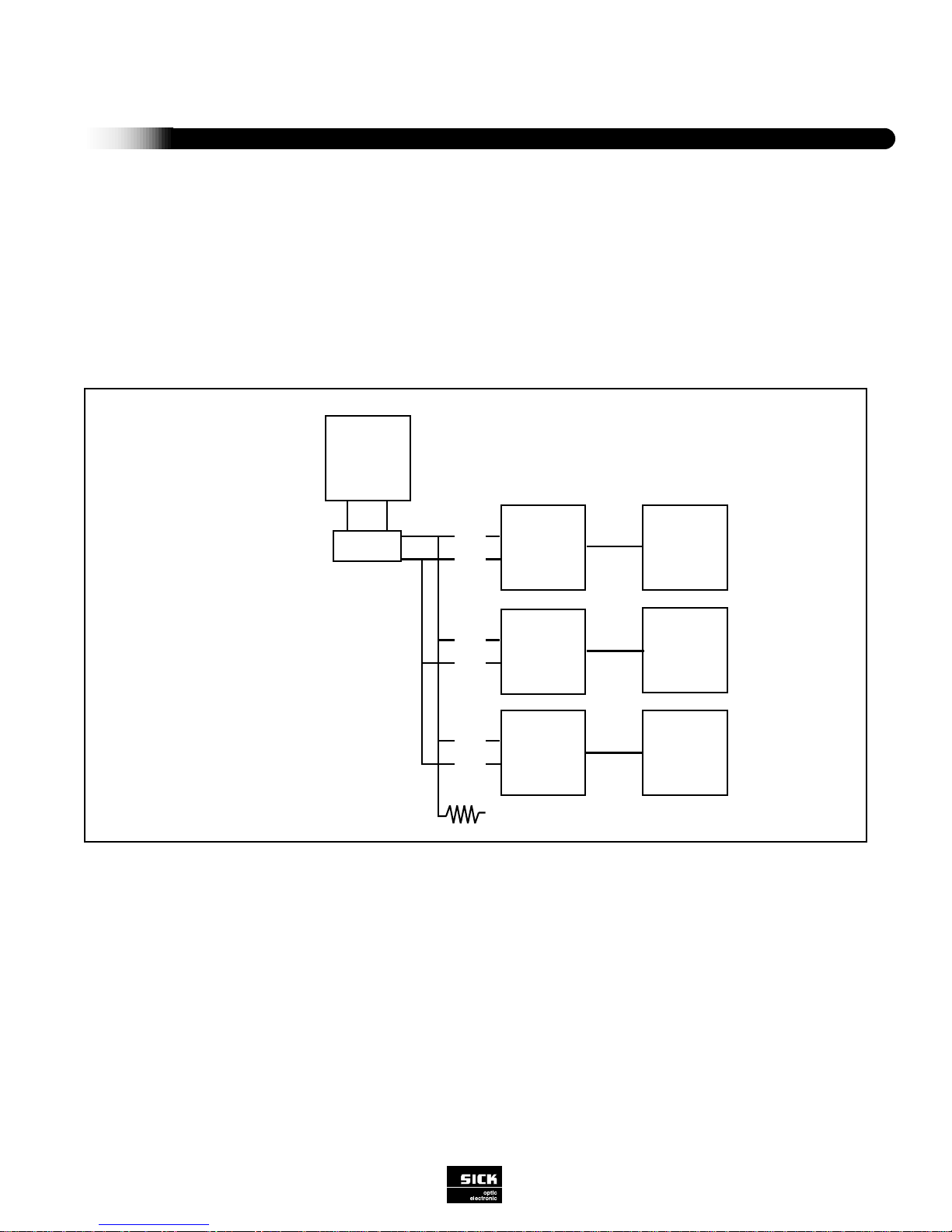

NETWORK CONFIGURATION

The CLV can be used as part of a multidrop network of bar code reading stations which communicate with a host device as

shown in Figure 2-6. Using an RS 485 bus consisting of a two-conductor cable, the system can address up to 31 devices. The

SICK CLX 200 Network Controller is used to organize data and control polling.

Figure 2-7 RS 485 Network Configuration via CLV Host Port

HOST DEVICE

DISTRIBUTION

UNIT

CLV

CLV

CLV

CLX 200

RS 422 or RS 232

R/T+

DISTRIBUTION

UNIT

DISTRIBUTION

UNIT

R/T-

R/T+

R/T-

R/T+

R/T-

Resistor Terminator

•

•

•

•

•

•

RS 485

RS 485

RS 485

RS 485

Page 16

To program the CLV scanner, activate the CLV Utility

Software and use the “Upload” icon to upload the contents

of the CLVscanner. Refer to figure 3-2. This procedure

displays the current settings of the CLVscanner and creates a working parameter file. Other options to create a

working file are to select “New” or “Open” on an existing file

saved to the disk. Once a working file has been created

you can make the necessary changes. After changes are

completed, use the “Download” icon to download the new

changes to the CLV scanner.

If you want the CLV scanner to retain the new changes

permanently in the EE prom, select “Permanent” when the

“Choose Download Options” box is displayed. Refer to

Figure 3-2. If you select “Temporary” the new changes will

be held in the CLV scanner’s RAM memeory.

Note: Since the CLV only has a single communications

interface there are certain parameters (baud rate, protocol

framing characters, network mode) which will prevent the

CLV from communicating with the CLV utility software. The

software will automatically determine baud rate and protocol framing characters. Use the icons

shown to the right or the “default” bar code to

establish communication. The Configuration

Profile default parameter bar code is included. Simply scan it to set communication defaults or

program the CLV within 5 seconds after power up as the

communication default are set temporarily.

Software Configurations

14

SICK Optic-Electronic

Bar Code Scanners

3

UPLOADING AND DOWNLOADING

This section describes the modes of CLV operation and includes an extensive discussion of parameterization, the process used

to configure the CLV to best accommodate your particular application.

The CLV can be programmed using the Windows-based CLV Utility Software (included) or a host device using the CLV Host

Command Language strings. This manual uses the CLV Utility Software as its basis.

MODES OF OPERATION

The CLV has two major modes of operation: the Reading Mode (entered automatically after power-up) and programming configuration mode. The programming/configuration options (Parameterization, Percent Evaluation, and Operating Data) are explained

in detail below.

Parameterization: Used to program the CLV scanner to best meet the demands of the desired application.

Percent evaluation: Continuous scanning mode that generates statistical information used mainly for alignment and adjustment

(optimal beam position) when installing the CLV.

Operating data: Used for polling and resetting internal operating data of the CLV. The submenu of this operating mode is

explained following “Percent Evaluation”

Download Button

Upload Button

Figure 3-2 Download Saving Options

Figure 3-1 Download / Upload Options Selection

SECTION lll SOFTWARE CONFIGURATION

Page 17

15

SICK Optic-Electronic

Bar Code Scanners

3

Software Configurations

Figure 3-1 Code Configuration

CODE CONFIGURATION

This function is used to program the scanner to accept certain types and numbers of bar codes. The default settings for code

configuration can be referenced in Appendix B, Table 1. To activate/deactivate individual sybologies click on the respective check

box.

Note: To edit individual symbologies, select the “Edit codes” bar.

Page 18

10

0

5

25

35

55

70

80

100

SCAN

DIRECTION

CODE POSITION

MINIMUM DISTANCE BETWEEN LABELS

Software Configurations

16

SICK Optic-Electronic

Bar Code Scanners

3

Figure 3-4 Determining Code Position

Numeric Symbologies:

•Interleaved 2/5

•UPC version A/E (standard/with add-on)

•EAN 13/8-digit (standard/with add-on)

•Pharmacode

Alphanumeric Symbologies:

•Code 39 (standard full ASCII)

•Code 93 (standard full ASCII)

•Code 128

•Codabar

•EAN 128

Each type of bar code is introduced below with

a brief explanation of the composition of the

code. In one reading gate, up to ten bar code

labels (up to ten different symbologies) can be

decoded. The bar codes may appear simultaneously in a single scan or consecutively during

the reading gate.

The CLV is capable of reading and evaluating the following bar code symbologies:

Number of Codes

Minimum (1-10) (Minimum Number of Codes)

If more than one code is to be read in a reading gate, the minimum number of codes (1-10) that will be presented to the scanner

during the reading gate must be entered. If, at the end of the reading gate, the minimum number of bar codes were not decoded

and if the error status valve is activated, the CLV sends the data and an error status code (ST=2).

Maximum (1-10) (Maximum Number of Codes)

The maximum number of codes (1-10) that will be presented to the scanner during the reading gate must be entered. The CLV

will transmit only the number of bar codes specified here, even if the actual number of codes presented to it exceed this value. At

the very least, maximum = minimum number of codes.

Code Position (Compare/Minimum Distance of Labels)

The CLV performs code position comparison, i.e. the scanner recognizes the position of bar codes in order to identify whether

identical readings are a result of the same or different bar code labels. The CLV scanner breaks the scan line into 100 units

referred to as “code positions” (Figure 3-3). If CP-Comp. Multir. is activated, the CLV will determine the bar code position for each

read. If the bar code positions differ more than the “minimum distance between labels” setting, the scanner will acknowledge multiple labels. Valid range for the “minimum distance between labels” parameter is 0.4 in to 39 in (10 mm to 999 mm).

Page 19

17

SICK Optic-Electronic Bar Code Scanners

3

Software Configurations

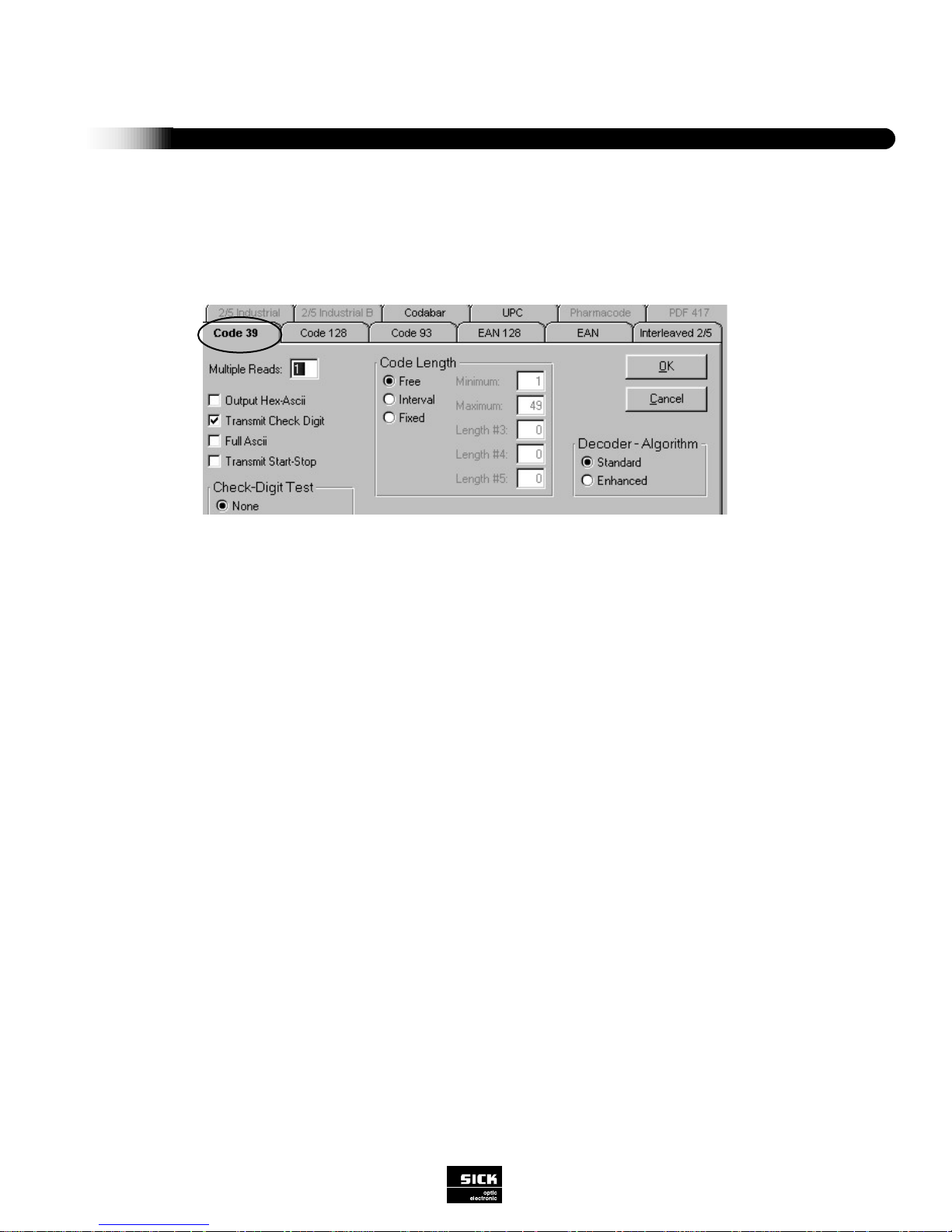

Code Length (free/interval/fixed)

The scanner can be programmed to read bar codes of any length or only those of a particular length (entered by the user):

“free” - Bar codes of any length between 1 and 49 characters will be read.

“interval” - User may enter a range of lengths within which the scanner will read the codes. Valid entries are from 1 to 49.

“fixed” - User may program up to five different fixed lengths to be read by the scanner. Valid entries are from 1 to 49.

Code length for Code 39 is calculated as follows:

number of bars – 10

Code Length = –––––––––––––––––––––

5

Multiple Reads (1-99)

Enter the number of identical reads the scanner must decode (in one reading gate) before transmitting the result to the host

device. This process increases output reliability. The selected scanning frequency and the speed at which the bar code is moving

past the CLV should be considered when making this selection. If the number of multiple reads specified by the user is not fulfilled, the CLV will send the bar code string or error string (software selectable) to the host along with the error status ST=5, if the

ST value has been placed in the separator.

Check Digit Test

For printed bar codes with an integrated check digit in the useful characters (last position before stop character), the check digit

increases error detection and therefore reading reliability. With a “yes” response, the decoder activates a routine to compare the

printed check digit with the check digit being calculated. The decoder then outputs the bar code data with the error status as follows: If the check digit test is successful, ST=0 (good read); if the check digit test is not successful, ST=1 (wrong check digit).

The error status is output only if the error status value is activated as part of the data string. If the user responds here with a “no,”

no check digit test will be carried out.

Transmit Check Digit

A “yes” allows the check digit to be transmitted to the host device. With a “no” response, the check digit is not transmitted.

Note: The CLV automatically truncates the last digit of the data if “no” to transmit check digit is selected.

CODE 39 (Code 3 of 9)

An alphanumeric code using the following character set:

10 numbers (0 to 9); 26 capital letters (A-Z); 7 special characters; and one start/stop character.

Figure 3-5 Code 39

Page 20

Software Configurations

18

SICK Optic-Electronic

Bar Code Scanners

3

Transmit Star t/Stop Character

A “yes” allows the start and stop characters to be transmitted to the host device. With a “no” response, the start and stop characters are not transmitted.

Full ASCII

A “yes” selects Full ASCII, which directs the decoder to evaluate the existing code as an extended Code 39. With a “no”

response, the existing code is evaluated and output as a standard Code 39.

Output Hex ASCII

A “yes” directs the decoder to output the code content in hex ASCII format. With a “no” response, ASCII output format is used.

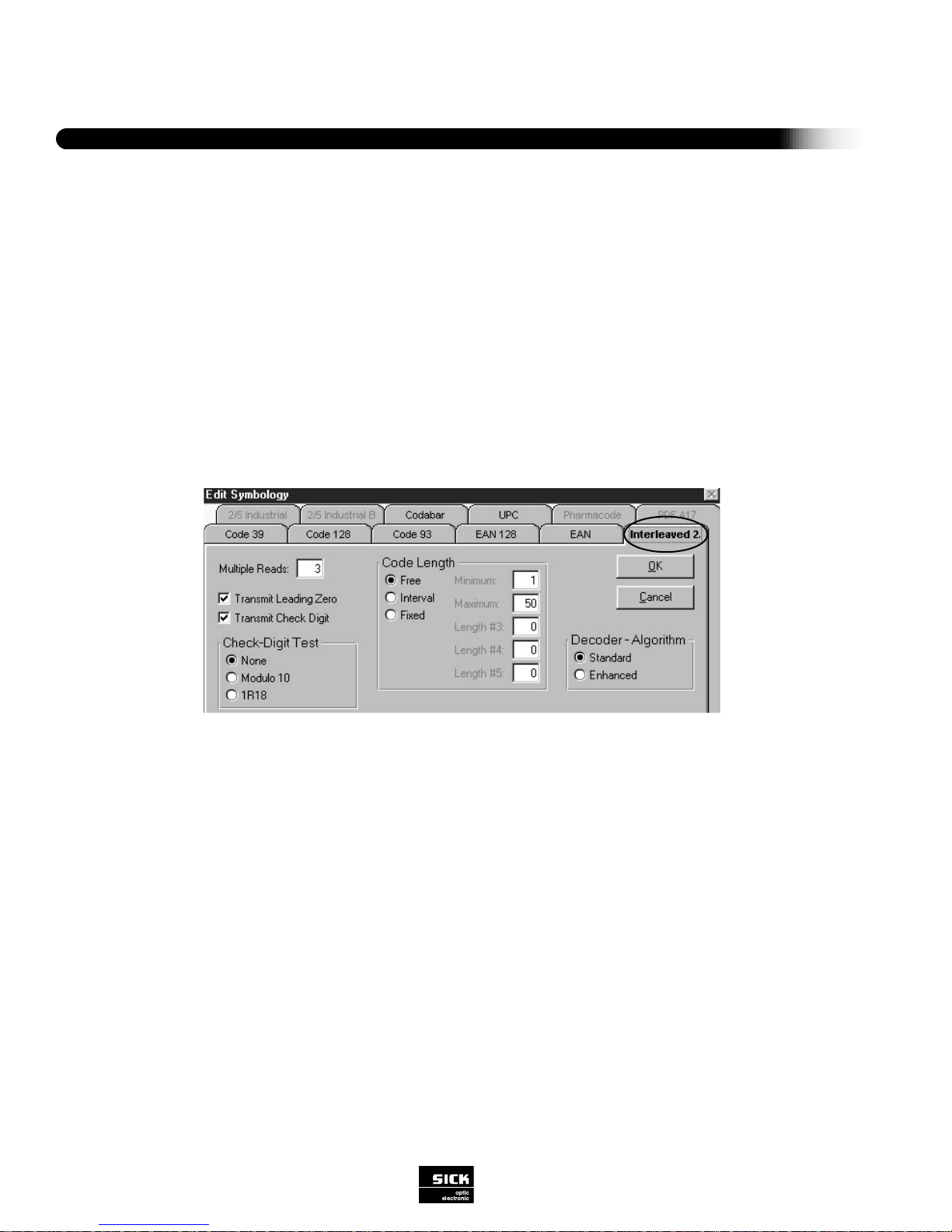

INTERLEAVED 2/5 (Interleaved 2 of 5)

A numerical code with the following character set: 10 digits (0 to 9); one start character; one stop character.

Figure 3-6 Interleaved 2/5

Code Length (free/interval/fixed)

The scanner can be programmed to read bar codes of any length or only those of a particular length (entered by the user):

“free” - Bar codes of any length between 1 and 49 characters will be read.

“interval” - User may enter a range of lengths within which the scanner will read the codes. Valid value 1 to 49.

“fixed” - User may program up to five different fixed lengths to be read by the scanner. Valid value 1 to 49.

Code length for Interleaved 2/5 includes the number of useful characters plus the check digit and is determined from the total

number of wide elements (bars or gaps) as follows:

(wide elements – 1)

Code Length = ––––––––––––––––––––

2

Multiple Reads (1-99)

Enter the number of identical reads the scanner must decode (in one reading gate) before transmitting the result to the host

device. This process increases output reliability. The selected scanning frequency and the speed at which the bar code is moving

past the CLV should be considered when making this selection. If the number of multiple reads specified by the user is not fulfilled, the CLV will send the bar code string or error string (software selectable) to the host, along with the error status ST=5 if the

ST value has been placed in the separator.

Page 21

19

SICK Optic-Electronic

Bar Code Scanners

3

Software Configurations

Check Digit Test

For printed bar codes with an integrated check digit in the useful characters (last position before stop character), the check digit

increases error detection and therefore reading reliability. With a “yes” response, the decoder activates a routine to compare the

printed check digit with the check digit being calculated. The decoder then outputs the bar code data with the error status as follows: If the check digit test is successful, ST=0 (good read); if the check digit test is not successful, ST=1 (wrong check digit).

The error status is output only if the error status value is activated as part of the data string. If the user responds here with a “no,”

no check digit test will be carried out.

Transmit Check Digit

A “yes” allows the check digit to be transmitted to the host device. With a “no” response, the check digit is not transmitted.

Note: The CLV automatically truncates the last digit of the data if “no” to transmit check digit is selected.

Transmit Leading Zero

Individual characters in the code overlap so that digits can be represented in pairs only. If the code is made up of an odd digit

sequence (useful characters), it is filled out with a leading zero. With a “yes” response, the zero is included in the output. With a

“no” response, the zero is suppressed.

EAN (European Article Numbering)

A numerical code with the following character set: 10 digits (0 to 9 per bar code character set), one edge character, one dividing

character.

Figure 3-7 EAN (European Article Numbering)

13-Digit

Code length of 13 digits.

8-Digit

Code length of 8 digits.

With Add-on (none/2 digit/5-digit/both)

The add-on is an additional bar code of two or five digits that follows the 8 or 13 digits of the EAN. Selectable commands are:

none =Add-on is not evaluated

2-digit =Evaluate and output 2-digit add-on

5-digit =Evaluate and output 5-digit add-on

both =Evaluate and output 2-digit AND 5-digit add-on

Page 22

Software Configurations

20

SICK Optic-Electronic

Bar Code Scanners

3

Multiple Reads (1-99)

Enter the number of identical reads the scanner must decode (in one reading gate) before transmitting the result to the host

device. This process increases output reliability. The selected scanning frequency and the speed at which the bar code is moving

past the CLV should be considered when making this selection. If the number of multiple reads specified by the user is not fulfilled, the CLV will send the bar code string or error string (software selectable) to the host along with the error status ST=5, if the

ST value has been placed in the separator.

Transmit Check Digit

A “yes” allows the check digit to be transmitted to the host device. With a “no” response, the check digit is not transmitted.

Note: The CLV automatically truncates the last digit of the data if “no” to transmit check digit is selected.

Decoding Algorithm (enhanced/standard)

Selecting “enhanced” will direct the CLV to use a 2-step decoding process; “standard” executes a rapid, 1-step decoding process.

UPC (Universal Product Code)

A numerical code with two versions, A and E. The character set for Version A is: 10 digits (0 to 9); the number system character;

the module check character. The character set for Version E is: 6 digits (0 to 9).

Figure 3-8 UPC Selection

Code Length: UPC-A: 12-digit (normal version)

UPC-E: 6-digit (short version)

Each contains a check digit.

With Add-on (none/2 digit/5-digit/both)

The add-on is an additional bar code of two or five digits that follows the digits of version Aor E code. Selectable commands are:

none = Add-on is not evaluated

2-digit = Evaluate and output 2-digit add-on

5-digit = Evaluate and output 5-digit add-on

both = Evaluate and output 2-digit AND 5-digit add-on

Page 23

21

SICK Optic-Electronic

Bar Code Scanners

3

Software Configurations

Multiple Reads (1-99)

Enter the number of identical reads the scanner must decode (in one reading gate) before transmitting the result to the host

device. This process increases output reliability. The selected scanning frequency and the speed at which the bar code is moving

past the CLV should be considered when making this selection. If the number of multiple reads specified by the user is not fulfilled, the CLV will send the bar code string or error string (software selectable) to the host along with the error status ST=5, if the

ST value has been placed in the separator.

Transmit Check Digit

A “yes” allows the check digit to be transmitted to the host device. With a “no” response, the check digit is not transmitted.

Note: The CLV automatically truncates the last digit of the data if “no” to transmit check digit is selected.

Decoding Algorithm (enhanced/standard)

Selecting “enhanced” will direct the CLV to use a 2-step decoding process; “standard” executes a rapid, 1-step decoding process.

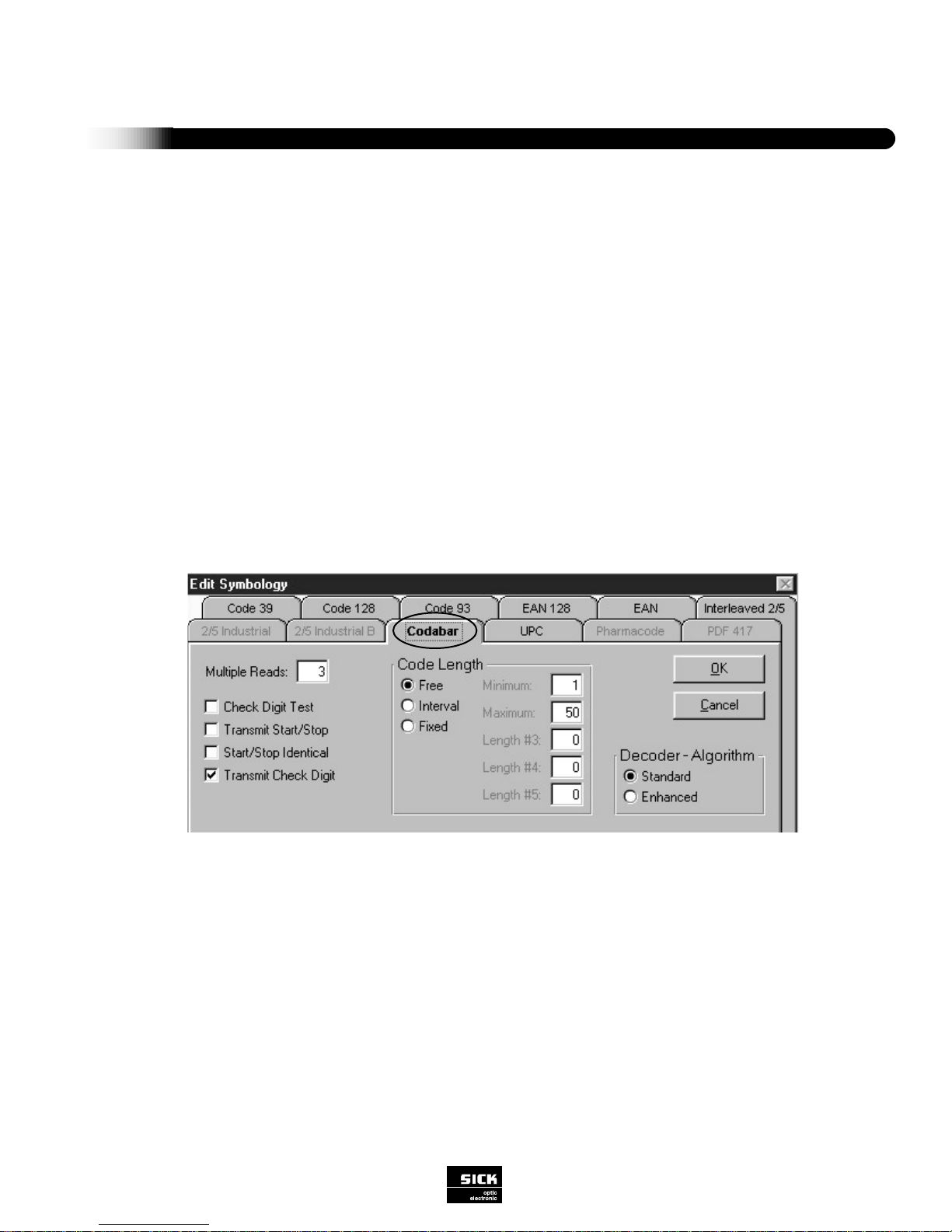

CODABAR

An alphanumeric code with the following character set: 10 digits (0 to 9); six special characters; four start/stop characters.

Figure 3-9 Codabar

Code Length (free/interval/fixed)

The scanner can be programmed to read bar codes of any length or only those of a particular length (entered by the user):

“free” - Bar codes of any length between 1 and 50 characters will be read.

“interval” - User may enter a range of lengths within which the scanner will read the codes.

“fixed” - User may program up to five different fixed lengths to be read.

The code length of the printed bar code, including the useful characters plus check digit, can be determined from the number of

wide bars as follows:

(number of bars - 8)

Code Length = –––––––––––––––––––––

4

Page 24

Multiple Reads (1-99)

Enter the number of identical reads the scanner must decode (in one reading gate) before transmitting the result to the host

device. This process increases output reliability. The selected scanning frequency and the speed at which the bar code is moving

past the CLV should be considered when making this selection. If the number of multiple reads specified by the user is not fulfilled, the CLV will send the bar code string or error string (software selectable) to the host along with the error status ST=5, if the

ST value has been placed in the separator.

Check Digit Test

For printed bar codes with an integrated check digit in the useful characters (last position before stop character), the check digit

increases error detection and therefore reading reliability. With a “yes” response, the decoder activates a routine to compare the

printed check digit with the check digit being calculated. The decoder then outputs the bar code data with the error status as follows: If the check digit test is successful, ST=0 (good read); if the check digit test is not successful, ST=1 (wrong check digit).

The error status is output only if the error status value is activated as part of the data string. If the user responds here with a “no,”

no check digit test will be carried out.

Transmit Check Digit

A “yes” allows the check digit to be transmitted to the host device. With a “no” response, the check digit is not transmitted.

Note: The CLV automatically truncates the last digit of the data if “no” to transmit check digit is selected.

Transmit Star t/Stop

A “yes” response directs the decoder to output information with start/stop characters “a,” “b,” “c” or “d,” together with useful char-

acters. A“no” response suppresses the output of start/stop characters.

Identical Start/Stop

A “yes” response directs the decoder to output only printed bar codes having the same start and stop characters. A “no” response

allows any combination of start and stop characters to be output.

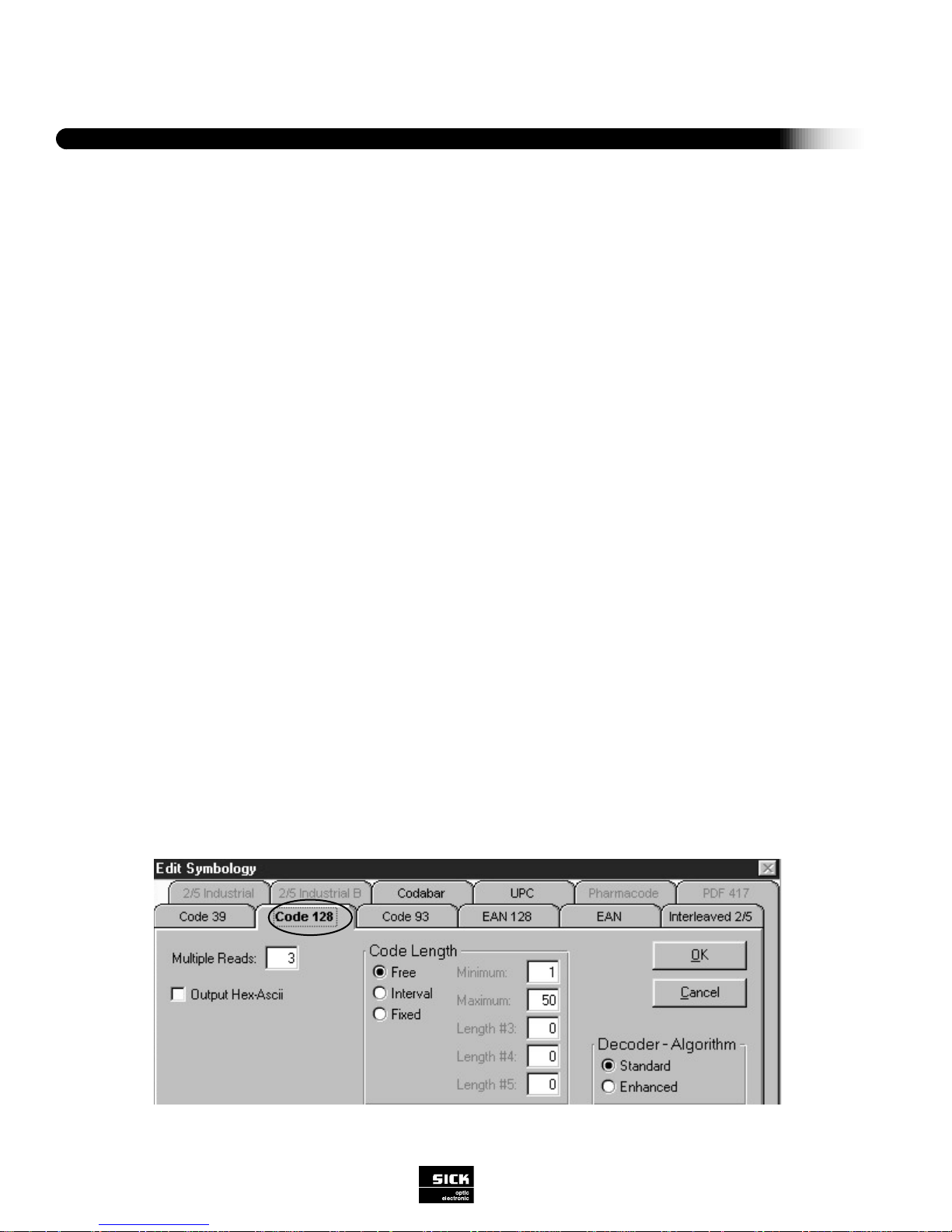

CODE 128

An alphanumeric code with the following character set: 128 ASCII characters; four special characters; four control characters;

three start characters; one stop character. Character sets A, B, or C can be represented (these character sets can be referenced

in the Uniform Symbology Specification).

A check digit test is always performed, but does not print out.

Software Configurations

22

SICK Optic-Electronic

Bar Code Scanners

3

Figure 3-10 Code 128

Page 25

23

SICK Optic-Electronic

Bar Code Scanners

3

Software Configurations

Code Length (free/interval/fixed)

The scanner can be programmed to read bar codes of any length or only those of a particular length to be entered by the user:

“free” - Bar codes of any length between 1 and 49 characters will be read.

“interval” - User may enter a range of lengths within which the scanner will read the codes. Valid Values 1 to 49.

“fixed” - User may program up to five different fixed lengths to be read by the scanner. Valid Values 1 to 49.

The code length of a printed bar code is calculated as follows:

(number of bars - 7)

Code Length = –––––––––––––––––––––

3

The code length must be input without start/stop characters and without a check digit.

Multiple Reads (1-99)

Enter the number of identical reads the scanner must decode (in one reading gate) before transmitting the result to the host

device. This process increases output reliability. The selected scanning frequency and the speed at which the bar code is moving

past the CLV should be considered when making this selection. If the number of multiple reads specified by the user is not fulfilled, the CLV will send the bar code string or error string (software selectable) to the host along with the error status ST=5, if the

ST value has been placed in the separator.

Output Hex ASCII

A “yes” directs the decoder to output in hex ASCII. A “no” response directs the decoder to output in ASCII.

Decoding Algorithm (enhanced/standard)

Selecting “enhanced” will direct the CLV to use a 2-step decoding process; “standard” executes a rapid, 1-step decoding process.

Page 26

Software Configurations

24

SICK Optic-Electronic

Bar Code Scanners

3

Figure 3-11 Code 93

Code Length (free/interval/fixed)

The scanner can be programmed to read bar codes of any length or only those of a particular length (entered by the user):

“free” - Bar codes of any length between 1 and 49 characters will be read.

“interval” - User may enter a range of lengths within which the scanner will read the codes. Valid Values 1 to 49.

“fixed” - User may program up to five different fixed lengths to be read by the scanner. Valid Values 1 to 49.

The code length of a printed bar code is calculated as follows:

(number of bars - 7)

Code Length = –––––––––––––––––––––

3

The code length must be input without start/stop characters and without a check digit.

Multiple Reads (1-99)

Enter the number of identical reads the scanner must decode (in one reading gate) before transmitting the result to the host

device. This process increases output reliability. The selected scanning frequency and the speed at which the bar code is moving

past the CLV should be considered when making this selection. If the number of multiple reads specified by the user is not fulfilled, the CLV will send the bar code string or error string (software selectable) to the host, along with the error status ST=5 if the

ST value has been placed in the separator.

Output Hex ASCII

A “yes” directs the decoder to output in hex ASCII. A “no” response directs the decoder to output in ASCII.

Decoding Algorithm (enhanced/standard)

Selecting “enhanced” will direct the CLV to use a 2-step decoding process; “standard” executes a rapid, 1-step decoding process.

CODE 93

An extended alphanumeric code with the following character set: 128 characters (complete ASCII character set); one start/stop

character. A check digit test is always performed, but not output.

Page 27

25

SICK Optic-Electronic

Bar Code Scanners

3

Software Configurations

Code Length (free/interval/fixed)

The scanner can be programmed to read bar codes of any length or only those of a particular length (entered by the user):

“free” - Bar codes of any length between 1 and 49 characters will be read.

“interval” - User may enter a range of lengths within which the scanner will read the codes. Valid values – 1 to 49.

“fixed” - User may program up to five different fixed lengths to be read by the scanner. Valid values – 1 to 49.

The code length of a printed bar code is calculated as follows:

(number of bars - 7)

Code Length = –––––––––––––––––––––

3

The code length must be input without start/stop characters and without a check digit.

Multiple Reads (1-99)

Enter the number of identical reads the scanner must decode (in one reading gate) before transmitting the result to the host

device. This process increases output reliability. The selected scanning frequency and the speed at which the bar code is moving

past the CLV should be considered when making this selection. If the number of multiple reads specified by the user is not fulfilled, the CLV will send the bar code string or error string (software selectable) to the host along with the error status ST=5, if the

ST value has been placed in the separator.

Output Hex ASCII

A “yes” directs the decoder to output in hex ASCII. A “no” response directs the decoder to output in ASCII.

Figure 3-12 EAN 128

EAN 128 (European Article Numbering 128)

A fixed-length numeric code. A check digit test is always performed, but does not print out.

Page 28

Note: If selected, all other symbologies will be automatically deactivated.

Code Length (fixed code length 0-16)

The user can program one fixed length to read by the scanner. Valid entries are from 0 to 16. Default is 4.

Multiple Reads (1-99)

Enter the number of identical reads the scanner must decode (in one reading gate) before transmitting the result to the host

device. This process increases output reliability. The selected scanning frequency and the speed at which the bar code is moving

past the CLV should be considered when making this selection. If the number of multiple reads specified by the user is not fulfilled, the CLV will send the bar code string or error string (software selectable) to the host along with the error status ST=5.

Module Width (auto/.50 mm/.33 mm)

The module width refers to the width of the bar elements of the code. “Auto” is selected for a pharmacode label that has a combination of wide and narrow bar elements (1’s & 0’s). “.50” or “.33” are selected when the bar elements of the pharmacode label

are all the same (all 1’s or 0’s). In the later case, the use is required to select the one that best represents the bar element width

of the pharmacode label..

Direction (forward/reverse)

Since pharmacode does not have start and stop characters, the scanning direction will affect the data set order. If “forward” is

selected, the scanner will transmit the data set according to the scan direction. If “reverse” is selected, the scanner will transmit

the data set in reverse order of the scanning direction. This feature is very useful when the orientation of the label changes and

the scanner can accommodate this change without physically rotating the scanner.

Software Configurations

26

SICK Optic-Electronic

Bar Code Scanners

3

Figure 3-13 Pharmacode

Interpret FC1 (FC1 First Char ...... 3 values/FC1 in Code String ...... 3 values)

FC1 (Function Character 1) is a special character in the bar code label which carries out a certain function. In place of this FC1

value, the decoder inserts a sequence of up to 3 user-definable characters in the output string (exceptions are 06 hex, 11 hex, 13

hex, 15 hex, in addition to stop and start characters). The FC1 can be placed at the beginning of the data string or somewhere

within the data string.

Decoding Algorithm (enhanced/standard)

Selecting “enhanced” will direct the CLV to use a 2-step decoding process; “standard” executes a rapid, 1-step decoding process.

PHARMACODE

Pharmacode is one of the oldest bar codes. It is used primarily in the pharmaceutical packaging industry. Pharmacode is a

numeric code which consists of two element sizes - wide or narrow. The wide bar represent a “1”, and the narrow bar indicates a

“0”. There are no start and stop characters associated with the pharmacode. Thus, depending on the scan direction, different data

sets may occur. Also, since there are no start and stop characters, adequate quiet zone is required.

Page 29

27

SICK Optic-Electronic

Bar Code Scanners

3

Software Configurations

READING CONFIGURATION

This function allows the user to program the CLV to read at selectable frequencies and select the appropriate minimum bar width

of the bar code to be read.

Fig. 3-14 Reading Configuration

Custom Settings (Minimum Bar Width/Minimum Distance/Scanning Frequency)

Minimum Bar Width ...... mm (millimeters)

Minimum bar width is adjustable in steps of 0.004 in (0.01 mm). This refers to the X-dimension (narrowest bar element width), of

the bar code. Set the scanner accordingly. The valid range is listed below..

default

CLV 410 .008 in to .040 in (.2 mm to 1.0 mm) .008 in (.20 mm)

CLV 412 .004 in to .008 in (.1 m to .2 m) .008 in (.20 mm)

Minimum Distance

This represents the closest distance from the scanner that the object will need to be scanned. Valid range listed below in 1 mm

(.04") increments:

default

CLV 410/412 .80 in to 16 in (20 mm to 400 mm) 1.0 in (25 mm)

Page 30

“Ladder” Orientation Equation

Scan Frequency = (V x N) Number of Scans = H

––––––– –––– x SF

HV

“Picket Fence” Orientation Equation

Scan Frequency = (V x N) Number of Scans = (W - L) x SF

––––––– ––––––––––––

W-L V

Following is an example for calculating scan frequency for a bar code in “ladder” orientation:

- Conveyor speed (V) = 100 ft/min = 20 in/sec

- Bar height (H) = .5 in

- Printed bar code 100% readable (material, printing, surface)

- Optimal adjustment of CLV (reading distance, angle, resolution)

- Required scans per code (N) = 10

20 x 10

SF= ——–——-

0.5

SF= 400 Hz

10 to 15 scans per code is usually sufficient. Any further increase does not produce better reading results. However, slower scan

rates can help the scanner read codes that are harder to read. Some causes for this reduction are: a dusty lens on the CLV,

small minimum width of the bar code, or bar code quality (i.e. poor print contrast).

Code Position Read Zone

This function allows the user to create an electronic mask. The scan line of the scanner is divided into 100 positions called Code

Position (CP) values. By entering minimum and maximum CP values, you effectively create a reading zone within the scan line.

This is very useful when the spacing of the objects to be scanned is small. The valid choices are 0 to 100 in 1 value increments:

Minimum CP ...... 0 to 100 default 0

Maximum CP ...... 0 to 100 default 100

Software Configurations

28

SICK Optic-Electronic

Bar Code Scanners

3

= Scan frequency

= Label velocity (inches/second)

= Number of scans required

= Bar height

= Scan width

= Label length

SF

V

N

H

W

L

The following variables and

equations are valid:

Scan Frequency

Sets the scan rate of the scanner, from 200 to 800 Hz, in 50 Hz increments. The conveyor speed and the scanning frequency of

the CLV determine the number of reads theoretically possible per bar code. The higher the scanning frequency, the greater the

number of scans possible as the bar code passes the scanner (assuming a constant conveyor speed). With this information, a

large number of scans can be checked for agreement of information content. This increases reading reliability. The variable scanning frequency thus enables the reading process to be optimally matched to the conveyor speed and the number of multiple

reads required. See following page for valid variable examples.

Page 31

29

SICK Optic-Electronic

Bar Code Scanners

3

Software Configurations

CLV 410 / 412 Test Conditions

O

60

20

O

CLV

20

O

O

60

Test Code

Print Ratio

Code Print Contrast

Scan Frequency

(0.1...0.2 mm Code

Skew

Tilt

Ambient Light

Good Read Rate

Code 39/ITF

3:1

>90%

200...250 Hz

200 Hz)

15°

±10°

<2000 lx

>75%

Test Conditions

Figure 3-15 Reading Distance Test Conditions

Page 32

Software Configurations

30

SICK Optic-Electronic

Bar Code Scanners

3

CLV 410

200 (7.8)

150 (5.9)

100 (3.9)

50 (1.9)

0

200 (7.8)

150 (5.9)

100 (3.9)

50 (1.9)

0.2 m

.35 mm

.50 mm

1.0 m

(.008 in)

(.014 in)

(.020 in)

(.040 in)

200

(7.8)

150

(5.9)

100

(3.9)

50

(1.9)

250

(9.8)

300

(11.7)

350

(13.7)

400

(15.6)

0

CLV 410 / 412

Dimensions in mm (in)

Subtract 18 mm from reading range if angled hood is used.

Dimensions in mm(in)

Reading Distance

Scan Frequency (Hz)

Dimensions in mm(in)

Subtract 18 mm from reading range if angled hood is used.

Page 33

print ratio: 2:1

60

40

20

0

-20

-40

-60

0604020 80 100 120

(.008 in)

(2.4)

(1.6)

(.80)

(-.80)

(-1.6)

(-2.4)

(2.4)(1.6)(.80) (3.2) (4.0) (4.8)

.20 mm

31

SICK Optic-Electronic

Bar Code Scanners

3

Software Configurations

CLV 410 Close Range Version

Reading distance mm(in)

Reading distance mm(in)

Subtract 18 mm from reading range if angled hood is used.

Page 34

Software Configurations

32

SICK Optic-Electronic

Bar Code Scanners

3

CLV 412 High Density

1000

900

800

700

600

500

400

300

200

100

0

0 10 20 30 40 50 60 70 80 90 100

(39.0)

(35.1)

(31.2)

(27.3)

(23.4)

(19.5)

(15.6)

(11.7)

(7.8)

(3.9)

(.40) (.80) (.12) (.16) (2.0) (2.4) (2.8) (3.1) (3.5) (3.9)

0.1 mm (.004)

0.12 mm (.005)

0.15 mm (.006)

0.2 mm (.008)

60 (2.4)

45 (1.8)

30 (1.2)

15 (.6)

0

0.2 m

.35 mm

.50 mm

1.0 m

35

(1.4)

0

75 (3.0)

45

(1.8)

55

(2.2)

65

(2.6)

75

(3.0)

85

(3.4)

15

(0.6)

25

(1.0)

-60 (2.4)

-45 (-1.8)

-30 (-1.2)

-15 (-3.0)

-75 (3.0)

.20 mm

(.008 in)

.15 mm

(.006 in)

.1 mm

(.004 in)

95

(3.8)

Scan Frequency (Hz)

Reading distance mm/(in)

Reading distance mm(in)

Reading distance mm(in)

Page 35

33

SICK Optic-Electronic

Bar Code Scanners

3

Software Configurations

Segmentation (Start/Stop Ratio/Absolute Quiet Zone)

This allows the user to adapt the CLV to the quiet zone of the bar code label if it is less than the specified 10 times the width of

the narrowest bar element or less than .250 in (6 mm).

“Start/Stop Ratio”

The start/stop ratio refers to the quiet zones of the bar code label. The scanner can be optimized for the appropriate width of the

quiet zones. The numerical values 4-11 are multiples of the minimum bar width. “Auto” is 10 times the width of the minimum bar

width.

“Absolute Quiet Zone”

This refers to the quiet zones of the bar code label. The CLV can be optimized for the appropriate width of the quiet zones. The

numerical value, .004 in to 1 in (1 mm to 25.5 mm), corresponds directly to the actual width of the quiet zone.

Note: This function relies on the Minimum Reading Distance, such that the Minimum Reading Distance setting has to reflect the

actual distance from the face of the CLV to the bar code label. If the Minimum Reading Distance setting is not set accordingly, the

CLV will not be able to read the label. Therefore, a small or-no-depth of field can be achieved by the CLV in this mode.

Figure 3-16 Device Configuration

DEVICE CONFIGURATION

This function allows you to program the CLV mechanical features and the CLV decoder to provide selected output data. See

Appendix B, Tables 2 and 3 for default settings for these parameters.

Page 36

Software Configurations

34

SICK Optic-Electronic

Bar Code Scanners

3

CLOCK PULSE

The reading gate is initiated by a clock pulse (trigger device), which synchronizes the scanning process with the occurrence of a

printed bar code in the field of view. The CLV accepts these different trigger sources: an external clock pulse generator (hardware

trigger), [host device command strings (serial interface)], [internal clock pulse generation (free-running)] and reflector polling (use

of a special bar code for automatic triggering). The different trigger sources are shown in Figure 3-19.

Source Clock Pulse

Select one of the following options to configure the source of the clock pulse:

“Sensor Input”(active high), is selected if the clock pulse originates from a switching

input such as a photoelectric device. “Sensor Input” (active low) is selected when the

sensor input is high (+24 V DC, PNP) and brings it to 0 V DC when something is

detected, or low (0 V DC) and switches to high (+24 V DC, PNP) when something is

detected. [“Active High”, which holds the sensor input low (0 V DC) and switches to

high (+24 V DC, PNP) when something is detected.]

Note: If the photoelectric device is powered by the scanner, the “INGND” and “GND”

lines need to be connected. Refer again to Figure 2-3 if connecting a photoelectric

device directly to the scanner.

“Serial Interface” is selected if the clock pulse originates from a host computer as

a serial interface signal via the CLV host interface port (the integrated host command

language is set to trigger the scanner).

- If the “Standard” choice is selected, the host command to start the reading gate is:

<STX> 21 <ETX>. The host command to stop the reading gate is: <STX> 22 <ETX>.

The <STX> and <ETX> are variable host protocol framing characters which are

selected under Host Interface; Protocol; Start Char, Stop Char.

- If the “Single Character” choice is selected, the user can select a single character

to trigger the reading gate and a single character to stop the reading gate. This character is transmitted to the CLV via the host interface port only. This character does not require the Host Protocol framing “Start Char

Receive” and “Stop Char Receive” characters.

“Free-Running” (*010 x (.01); min - 001; max. - 999) is selected to set the CLV to constant reading mode. The user must

select a “time out” interval, i.e. the minimum time interval (in seconds) between bar code labels. This “time out” function enables

the scanner to discriminate between different bar codes. The reading gate starts when the decoder has found and evaluated the

first bar code label, according to prescribed criteria. It ends when no further bar code label is detected within the selected time

interval (“time out”). No error string is transmitted in this mode.

“Reflector Polling” If this mode of trigger is selected, the CLV 410 will activate the reading gate automatically if it can not

read the unique polling reflector bar code. The CLV 410 looks for this special bar code. If it reads it, it deactivates the laser

diode. This happens every 20 scans. Therefore, based on the scan rate, the trigger delay time can be calculated. There are two

reflector polling bar codes are packaged with the scanner. One is used for a scanning range up to .5 m and the second one has

reflective properties for a scanning range up to 1 m.

End Clock Pulse (Source Cl. Pulse/Timer)

This determines when to end the reading gate of the CLV. If “Source Clock Pulse” is selected, the reading gate will end according

to the clock pulse condition. If “Timer” is selected, the CLV will end the reading gate automatically after time has elapsed, regardless of the clock pulse method or condition. The timer begins when the CLV is triggered via the clock pulse. Valid Range is 0 to

9.9 seconds.

Note: This feature can not be used in the free-running mode of operation.

Figure 3-17 Clock Pulse Trigger

Page 37

35

SICK Optic-Electronic

Bar Code Scanners

3

Software Configurations

SWITCHING OUTPUTS

This is used to condition the three discrete outputs and the beeper of the CLV.

Figure 3-18 Switching Outputs Configuration

Host System