Page 1

CFP CUBIC

Level sensor

OPERATING INSTRUCTIONS

en

Page 2

Product described

CFP Cubic

Manufacturer

SICK AG

Erwin-Sick-Str. 1

79183 Waldkirch

Germany

Legal notes

This work is protected by copyright. The associated rights are reserved by SICK AG.

Reproduction of this document or parts of this document is only permissible within

the limits of the legal provisions of copyright law.

Any modication, abridgment, or translation of this document is prohibited without

the express written permission of SICK AG.

The trademarks mentioned in this document are the property of their respective

owners.

© SICK AG. All rights reserved.

Original document

This document is an original document published by SICK AG.

2

OPERATING INSTRUCTIONS | CFP CUBIC 8021989 / 2017-10-20 | SICK AG

Subject to change without notice

Page 3

Content

1 About this document .......................................................................................6

1.1 Information on the operating instructions ...............................................................6

1.2 Scope .........................................................................................................................6

1.3 Explanation of symbols .............................................................................................6

1.4 Further information ...................................................................................................7

1.5 Customer service ......................................................................................................7

2 Safety information ...........................................................................................8

2.1 Intended use ..............................................................................................................8

2.2 Improper use .............................................................................................................8

2.3 Limitation of liability ..................................................................................................8

2.4 Modications and conversions .................................................................................8

2.5 Requirements for skilled persons and operating personnel ..................................9

2.6 Operational safety and specic hazards ..................................................................9

2.7 General safety notes .............................................................................................. 10

2.8 Repairs .................................................................................................................... 10

3 Product description ....................................................................................... 11

3.1 Product identication ............................................................................................. 11

3.1.1 Information on the housing .................................................................... 11

3.1.2 Type code ................................................................................................ 11

3.2 Product characteristics .......................................................................................... 12

3.2.1 Device view ............................................................................................. 12

3.2.2 Operating buttons ................................................................................... 12

3.3 Product features and functions ............................................................................. 12

3.3.1 Principle of operation ............................................................................. 12

3.3.2 Fields of application ............................................................................... 12

4 Transport and storage .................................................................................. 13

4.1 Transport ................................................................................................................. 13

4.2 Transport inspection .............................................................................................. 13

4.3 Storage .................................................................................................................... 13

5 Mounting......................................................................................................... 14

5.1 Installation conditions............................................................................................ 14

5.2 Installation in a container ...................................................................................... 14

6 Electrical installation .................................................................................... 15

6.1 Safety ...................................................................................................................... 15

6.1.1 Notes on the electrical installation ........................................................ 15

6.2 Electrical connection .............................................................................................. 16

6.2.1 Overview of the electrical connections ................................................. 16

6.2.2 Pin assignment, M12 plug connector, 5-pin

(depending on the variant) ..................................................................... 16

6.2.3 Pin assignment, M12 plug connector, 8-pin ......................................... 17

Subject to change without notice

OPERATING INSTRUCTIONS | CFP CUBIC8021989 / 2017-10-20 | SICK AG

3

Page 4

7 Commissioning .............................................................................................. 18

7.1 Quick commissioning (with factory settings) ........................................................ 18

7.2 Commissioning ....................................................................................................... 18

8 Operation ........................................................................................................ 20

8.1 Display and pushbuttons ....................................................................................... 20

8.1.1 Variants with two switching outputs ...................................................... 20

8.1.2 Variants with four switching outputs ..................................................... 20

8.1.3 IO-Link ..................................................................................................... 20

8.2 User and Exprt mode ............................................................................................. 20

8.2.1 User mode ............................................................................................... 20

8.2.2 Exprt mode .............................................................................................. 21

8.3 Conguring the switching outputs ......................................................................... 21

8.3.1 Switching hysteresis and window function ........................................... 21

8.3.2 Normally open with congurable hysteresis ......................................... 22

8.3.3 Normally closed with congurable hysteresis ....................................... 23

8.3.4 Normally open with window function..................................................... 24

8.3.5 Normally closed with window function .................................................. 25

8.3.6 Normally open with error signal ............................................................. 27

8.3.7 Switching output as input for processing external signals ................... 27

8.4 Conguration of analog outputs ............................................................................ 28

8.4.1 Automatic signal detection .................................................................... 28

8.4.2 Current output 4 to 20 mA ..................................................................... 29

8.4.3 Voltage output 0-10 V ............................................................................ 29

8.4.4 Behavior of outputs in the event of an error ......................................... 30

8.5 Advanced functions ................................................................................................ 30

8.5.1 Selecting display unit ............................................................................. 30

8.5.2 Setting an alternating display of measurands (DispA and DispB) ....... 30

8.5.3 Autocalibration ........................................................................................ 31

8.5.4 Performing empty adjustment ............................................................... 31

8.5.5 Locking the display without a password ............................................... 31

8.5.6 Locking the display with a password ..................................................... 32

8.5.7 Setting the medium adjustment ........................................................... 32

8.5.8 Filtering measured values ...................................................................... 32

8.5.9 Testing the conguration ........................................................................ 32

8.5.10 Evaluating signal quality ........................................................................ 34

8.5.11 Setting the offset .................................................................................... 35

8.5.12 Resetting the calibration ........................................................................ 36

9 Menu overview ............................................................................................... 37

9.1 User mode .............................................................................................................. 37

9.2 Exprt mode ............................................................................................................. 38

10 Overview of parameters ............................................................................... 41

4

OPERATING INSTRUCTIONS | CFP CUBIC 8021989 / 2017-10-20 | SICK AG

Subject to change without notice

Page 5

11 Troubleshooting ............................................................................................. 44

11.1 Error message on the display ................................................................................ 44

11.2 Operating the display ............................................................................................. 45

11.3 Outputs ................................................................................................................... 45

11.4 Error behavior ......................................................................................................... 45

12 Repair .............................................................................................................. 47

12.1 Maintenance ........................................................................................................... 47

12.2 Returns ................................................................................................................... 47

13 Disposal .......................................................................................................... 48

14 Technical data ................................................................................................ 49

14.1 Note for critical applications .................................................................................. 49

14.2 Features .................................................................................................................. 49

14.3 Performance ........................................................................................................... 49

14.4 Mechanics/materials ............................................................................................. 50

14.5 Reference conditions ............................................................................................. 50

14.6 Ambient conditions ................................................................................................ 50

14.7 Electrical connections ............................................................................................ 51

15 Dimensional drawings .................................................................................. 52

16 Factory setting ............................................................................................... 53

17 Accessories .................................................................................................... 54

Subject to change without notice

OPERATING INSTRUCTIONS | CFP CUBIC8021989 / 2017-10-20 | SICK AG

5

Page 6

1 ABOUT THIS DOCUMENT

1 About this document

1.1 Information on the operating instructions

These operating instructions provide important information on how to use sensors from

SICK AG.

Prerequisites for safe work are:

• Compliance with all safety notes and handling instructions supplied.

• Compliance with local work safety regulations and general safety regulations for

sensor applications.

The operating instructions are intended to be used by qualied personnel and electrical

specialists.

Note:

Read these operating instructions carefully before starting any work on the device,

in order to familiarize yourself with the device and its functions.

The instructions constitute an integral part of the product and are to be stored in the

immediate vicinity of the device so they remain accessible to staff at all times. Should

the device be passed on to a third party, these operating instructions should be handed

over with it.

These operating instructions do not provide information on operating the machine in

which the sensor is integrated. For information about this, refer to the operating instructions of the specic machine.

1.2 Scope

These operating instructions explain how to incorporate a sensor into a customer

system. Instructions are given in stages for all actions required.

These instructions apply to all available device variants of the sensor. For more detailed

information on identifying your device type, see “3.1.2 Type code”.

Available device variants are listed on the online product page:

b www.sick.com/CFP_Cubic

A number of device variants are used as examples for commissioning, based on the

default parameter settings for the relevant device.

1.3 Explanation of symbols

Warnings and important information in this document are labeled with symbols. The

warnings are introduced by signal words that indicate the extent of the danger. These

warnings must be observed at all times and care must be taken to avoid accidents,

personal injury, and material damage.

HAZARD

… indicates a situation of imminent danger, which will lead to a fatality or serious

injuries if not prevented.

WARNING

… indicates a potentially dangerous situation, which may lead to a fatality or serious

injuries if not prevented.

6

OPERATING INSTRUCTIONS | CFP CUBIC 8021989 / 2017-10-20 | SICK AG

Subject to change without notice

Page 7

CAUTION

… indicates a potentially dangerous situation, which may lead to minor/slight injuries if

not prevented.

IMPORTANT

… indicates a potentially harmful situation, which may lead to material damage if not

prevented.

HINT

… highlights useful tips and recommendations as well as information for efcient and

trouble-free operation.

1.4 Further information

HINT

All the documentation available for the sensor can be found on the online product page

at:

1ABOUT THIS DOCUMENT

www.sick.com

The following information is available for download from this page:

• Model-specic online data sheets for device variants, containing technical data,

dimensional drawings, and diagrams

• EU declaration of conformity for the product family

• Dimensional drawings and 3D CAD dimension models in various electronic formats

• These operating instructions, available in English and German, and in other languages

if necessary

• Other publications related to the sensors described here (e.g., IO-Link)

• Publications dealing with accessories

1.5 Customer service

If you require any technical information, our customer service department will be happy

to help. To nd your agency, see the nal page of this document.

HINT

Before calling, make a note of all sensor data such as type code, serial number, etc.,

to ensure faster processing.

Subject to change without notice

OPERATING INSTRUCTIONS | CFP CUBIC8021989 / 2017-10-20 | SICK AG

7

Page 8

2 SAFETY INFORMATION

2 Safety information

2.1 Intended use

The CFP Cubic is a level sensor based on a capacitive measurement principle. The level

is determined and the limit values are assessed by evaluating the capacitive elds.

The sensor is designed for both continuous level measurement and discontinuous level

measurement in nearly all liquids. Depending on the variant, temperature values can

also be processed continuously or as limit values.

The sensor fullls the requirements of EN 61326-2-3 for industrial environments.

2.2 Improper use

Any use outside of the stated areas, in particular use outside of the technical specications and the requirements for intended use, will be deemed to be incorrect use.

If the sensor is to be used under other conditions or in different environments, the

manufacturer’s service department may issue an operating license in consultation with

the customer and in exceptional cases.

2.3 Limitation of liability

Applicable standards and regulations, the latest technological developments, and

our many years of knowledge and experience have all been taken into account when

assembling the data and information contained in these operating instructions. The

manufacturer accepts no liability for damage caused by:

• Failing to observe the operating instructions

• Improper use

• Use by untrained personnel

• Unauthorized conversions

• Technical modications

• Use of unauthorized spare parts, consumables, and accessories

With special variants, where optional extras have been ordered, or owing to the latest

technical changes, the actual scope of delivery may vary from the features and illustra-

tions shown here.

2.4 Modications and conversions

IMPORTANT

Modications and conversions to the sensor and/or the installation may result in

unforeseeable dangers.

Interfering with or modifying the sensor or SICK software will invalidate any warranty

claims against SICK AG. This applies in particular to opening the housing, even as part

of mounting and electrical installation work.

Before making technical modications to or expanding the sensor, the prior written

approval of the manufacturer must be obtained.

8

OPERATING INSTRUCTIONS | CFP CUBIC 8021989 / 2017-10-20 | SICK AG

Subject to change without notice

Page 9

2.5 Requirements for skilled persons and operating personnel

WARNING

Risk of injury due to insufcient training.

Improper handling of the sensor may result in considerable personal injury and material

damage.

• All work must only ever be carried out by the stipulated persons.

The operating instructions state the following qualication requirements for the various

areas of work:

• Instructed personnel have been briefed by the operating entity about the tasks

assigned to them and about potential dangers arising from improper action.

• Skilled personnel have the specialist training, skills, and experience, as well as

knowledge of the relevant regulations, to be able to perform tasks assigned to

them and to detect and avoid any potential dangers independently.

• Electricians have the specialist training, skills, and experience, as well as knowledge

of the relevant standards and provisions to be able to carry out work on electrical

systems and to detect and avoid any potential dangers independently. In Germany,

electricians must meet the specications of the BGV A3 Work Safety Regulations

(e.g., Master Electrician). Other relevant regulations applicable in other countries

must be observed.

2SAFETY INFORMATION

The following qualications are required for various activities:

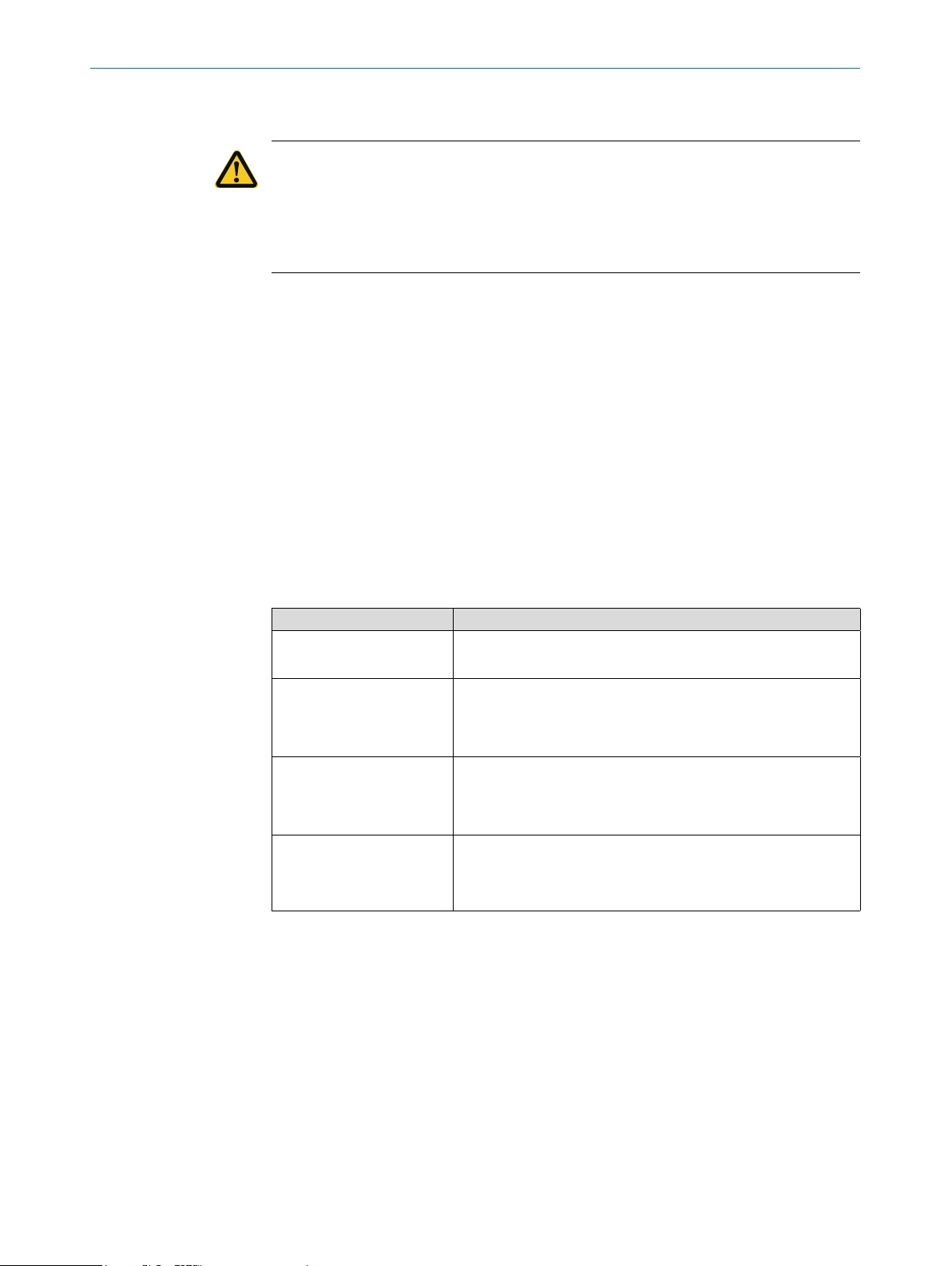

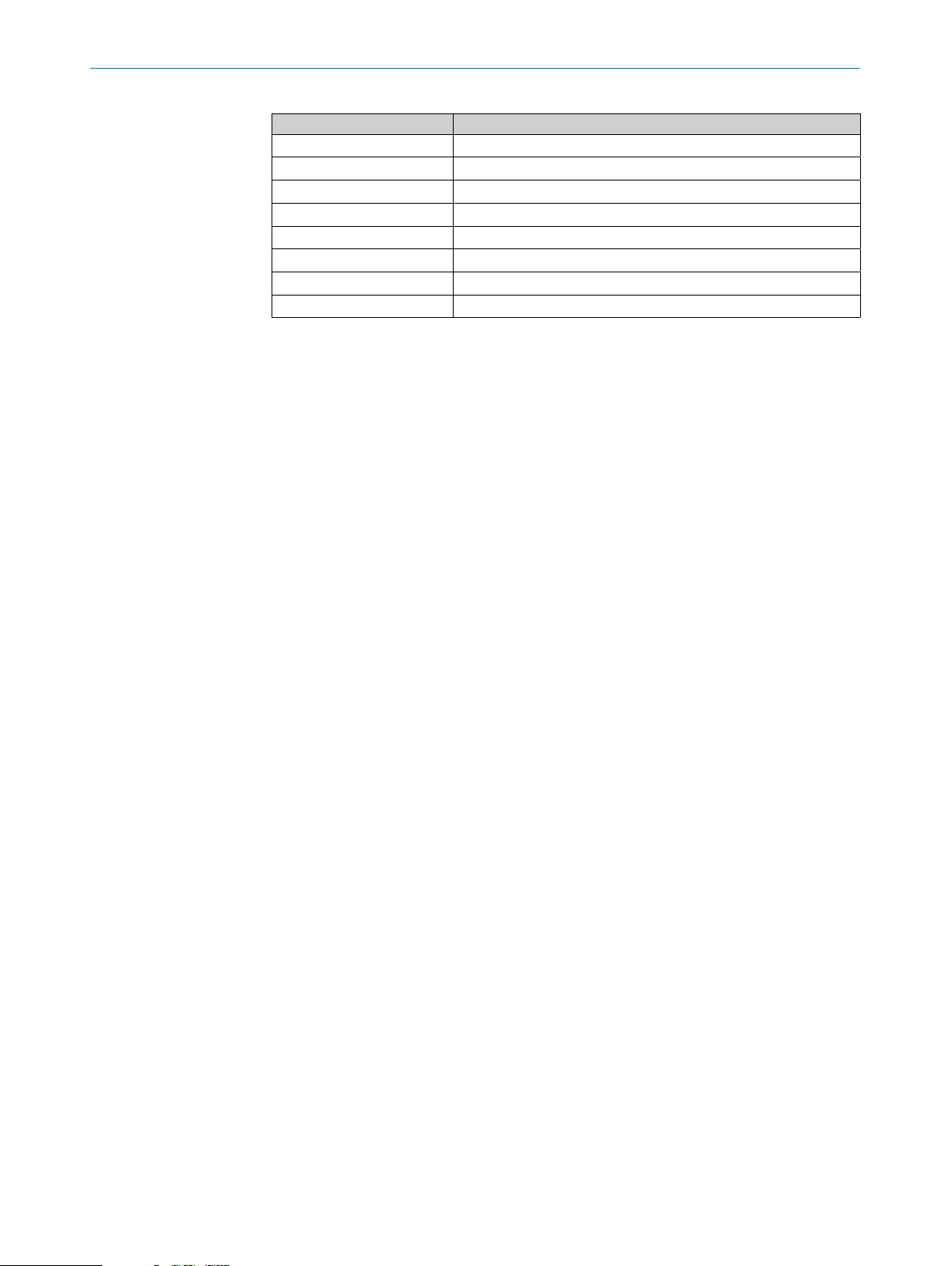

Tasks Qualication

Mounting, maintenance

Electrical installation,

device replacement

Commissioning,

conguration

Operation of the device for

the specic application

• Basic practical technical training

• Knowledge of the current safety regulations in the workplace

• Practical electrical training

• Knowledge of current electrical safety regulations

• Knowledge of device control and operation in the specic appli-

cation concerned (e.g., conveying line)

• Basic knowledge of the control system used

• Basic knowledge of the design and setup of the described

connections and interfaces

• Basic knowledge of data transmission

• Knowledge of device control and operation in the particular

application concerned (e.g., bottling plant)

• Knowledge of the software and hardware environment for the

particular application concerned (e.g., bottling plant)

2.6 Operational safety and specic hazards

Please observe the safety notes and the warnings listed here and in other chapters of

these operating instructions to reduce the possibility of risks to health and avoid dangerous situations.

Subject to change without notice

OPERATING INSTRUCTIONS | CFP CUBIC8021989 / 2017-10-20 | SICK AG

9

Page 10

2 SAFETY INFORMATION

2.7 General safety notes

• Read the operating instructions prior to commissioning.

• These operating instructions are valid for devices from rmware version 2.00.

• The CFP Cubic is not a safety component under the EU Machinery Directive.

• Observe national safety and work safety regulations.

• Wiring work and the opening and closing of electrical connections may only be

carried out when the power is switched off.

• The radiated power is far lower than that from telecommunication equipment.

According to current scientic research, the operation of this device can be classied as safe and non-hazardous.

2.8 Repairs

Repair work on the sensor may only be performed by qualied and authorized personnel

from SICK AG. Interference with or modications to the sensor on the part of the cus-

tomer will invalidate any warranty claims against SICK AG.

10

OPERATING INSTRUCTIONS | CFP CUBIC 8021989 / 2017-10-20 | SICK AG

Subject to change without notice

Page 11

3 Product description

3.1 Product identication

3.1.1 Information on the housing

Information for identication of the sensor and its electrical connection are printed on

the housing.

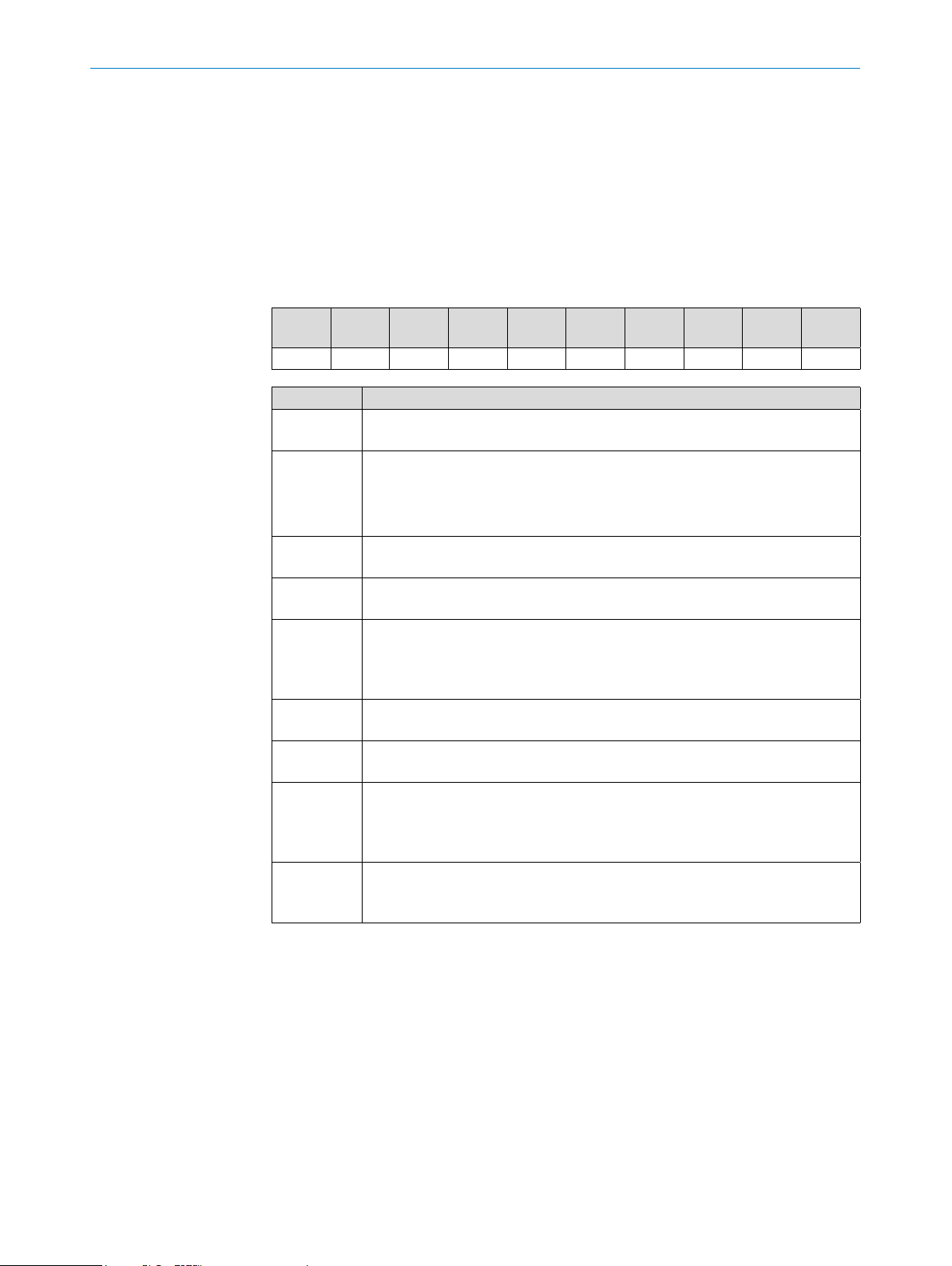

3.1.2 Type code

3PRODUCT DESCRIPTION

CFP

Cubic

1 2 3 4 5 6 7 8 9

Position Description

1 Product group

2 Probe length in mm

3 Certication

4 Probe design

5 Process connection

6 Application type

7 Housing

8 Electrical outputs

9 Additional options

0100 – X P Q N N C T

CFP Cubic: Capacitive level sensor CFP Cubic

0100:

100 mm

ascending in increments of 100 mm

...

1,000 mm

1,000:

X: Without certication

P: PP rod probe

X: Without process connection

A: G 3/4" A; PBT

B: 3/4" NPT; PBT

N: Oil and water applications

N: Plastic housing with display

A: 2 digital outputs

B: 2 digital outputs + 1 analog output

C: 4 digital outputs + 2 analog outputs

T: With temperature sensor

X: No additional options

Subject to change without notice

Not all variants of the type code can be combined!

OPERATING INSTRUCTIONS | CFP CUBIC8021989 / 2017-10-20 | SICK AG

11

Page 12

3 PRODUCT DESCRIPTION

3.2 Product characteristics

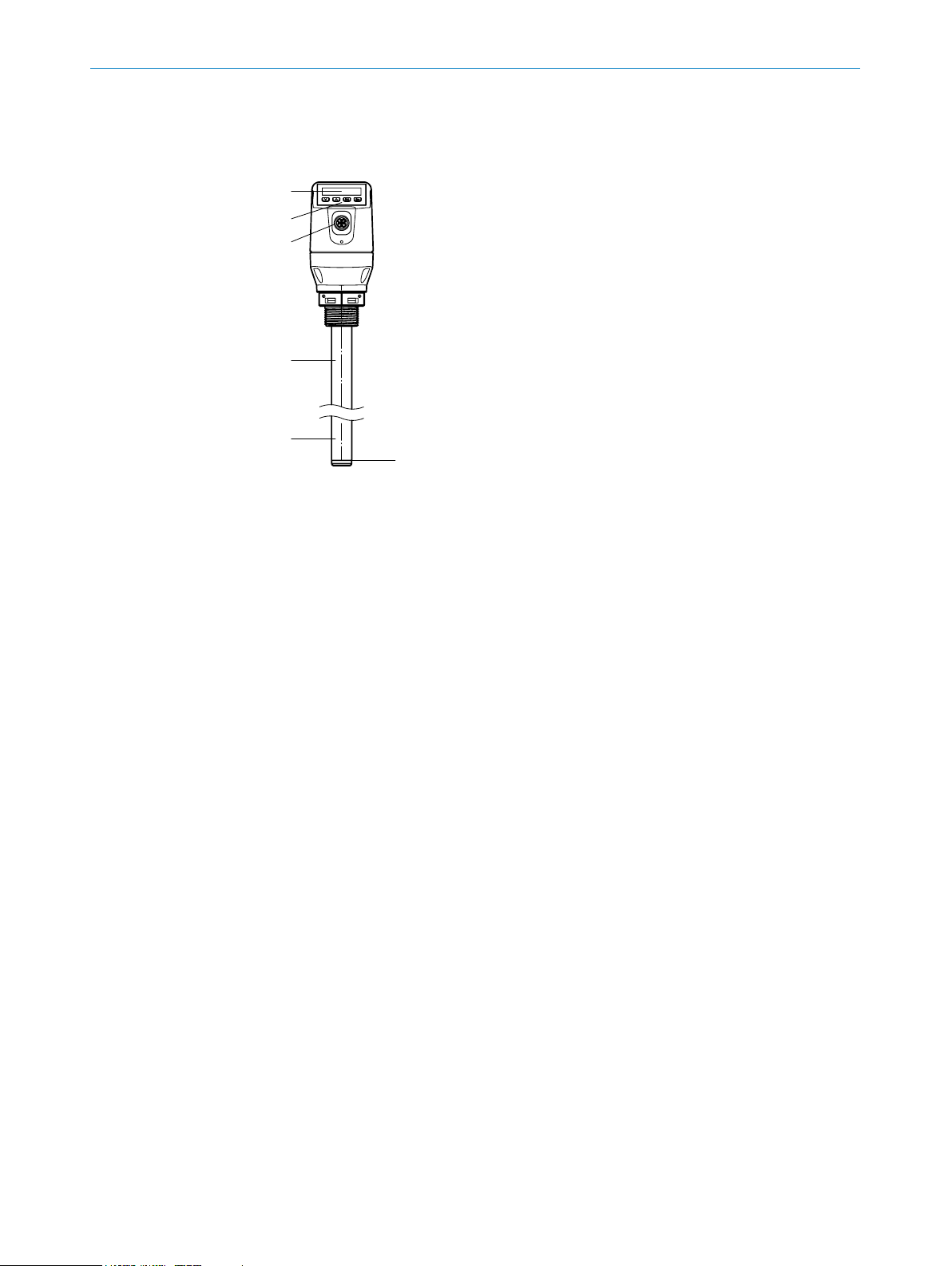

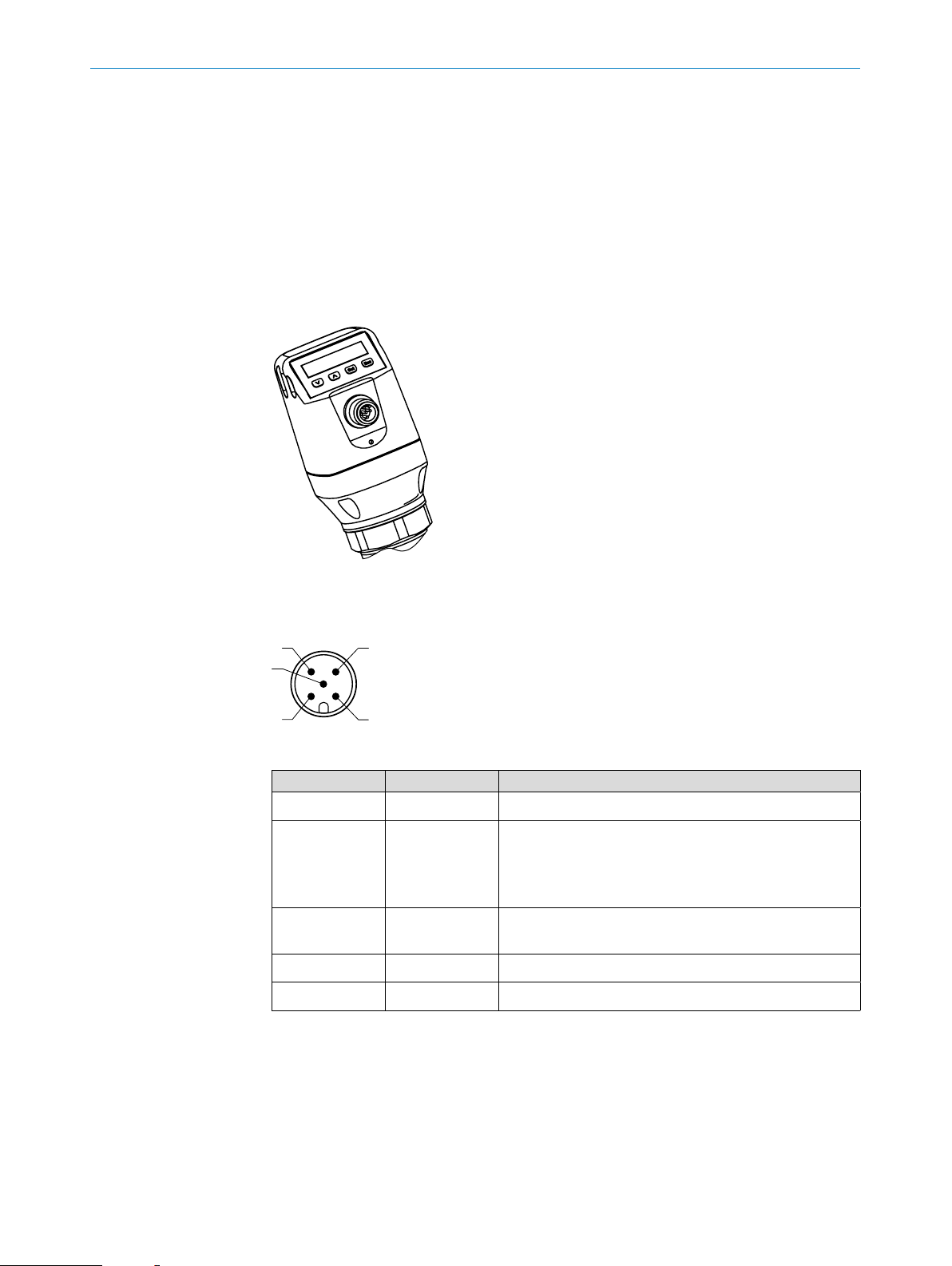

3.2.1 Device view

Fig. 1: CFP Cubic

1 Probe

2 Electrical connection

3 Operating buttons

4 Display

5 Temperature sensor (optional)

3.2.2 Operating buttons

The sensor is operated using the display and the operating buttons.

For a detailed description of the pushbuttons and their functions, see “8.1 Display and

pushbuttons”.

3.3 Product features and functions

3.3.1 Principle of operation

The CFP Cubic works according to the capacitive measurement principle. This means

that electrodes are integrated in the probe to span and measure a capacitive eld. The

medium touching the probe inuences the measured capacitance. Linear to the level,

this change in capacitance is then evaluated in the sensor and output as a corresponding level.

The sensor can output this level as a continuous measured value (analog output)

and can also derive two or four freely positionable switching points from it (switching

outputs). IO-Link communication is also available for the switching output Q1,

see “8.1.3 IO-Link”.

3.3.2 Fields of application

The MCiM technology developed by SICK enables convenient and reliable level measurement irrespective of the container material.

The CFP Cubic is suitable for both continuous level measurement and discontinuous

level measurement in nearly all liquids. Furthermore, temperature values can also be

processed continuously or as a limit value depending on the variant.

12

OPERATING INSTRUCTIONS | CFP CUBIC 8021989 / 2017-10-20 | SICK AG

Subject to change without notice

Page 13

4 Transport and storage

4.1 Transport

For your own safety, please read and observe the following notes:

IMPORTANT

Damage to the sensor due to improper transport.

• The device must be packaged for transport with protection against shock and damp.

• Recommendation: Use the original packaging as it provides the best protection.

• Transport should be performed by specialist staff only.

• The utmost care and attention is required at all times during unloading and transpor-

tation on company premises.

• Note the symbols on the packaging.

• Do not remove packaging until immediately before starting installation work.

4.2 Transport inspection

Immediately upon receipt in Goods-in, check the delivery for completeness and for any

damage that may have occurred in transit. In the case of transit damage that is visible

externally, proceed as follows:

4TRANSPORT AND STORAGE

4.3 Storage

• Do not accept the delivery or only do so conditionally.

• Note the scope of damage on the transport documents or on the transport company's delivery note.

• File a complaint.

Note:

Complaints regarding defects should be led as soon as these are detected. Damage

claims are only valid before the applicable complaint deadlines.

Store the device under the following conditions:

• Recommendation: Use the original packaging.

• Do not store outdoors.

• Store in a dry area that is protected from dust.

• Do not store in an airtight container: this is so that any residual moisture present

can escape.

• Do not expose to any aggressive substances.

• Protect from sunlight.

• Avoid mechanical shocks.

Subject to change without notice

• Storage temperature: see “14 Technical data”.

• Relative humidity: see “14 Technical data”.

• For storage periods of longer than 3 months, check the general condition of all

components and packaging on a regular basis.

OPERATING INSTRUCTIONS | CFP CUBIC8021989 / 2017-10-20 | SICK AG

13

Page 14

5 MOUNTING

5 Mounting

5.1 Installation conditions

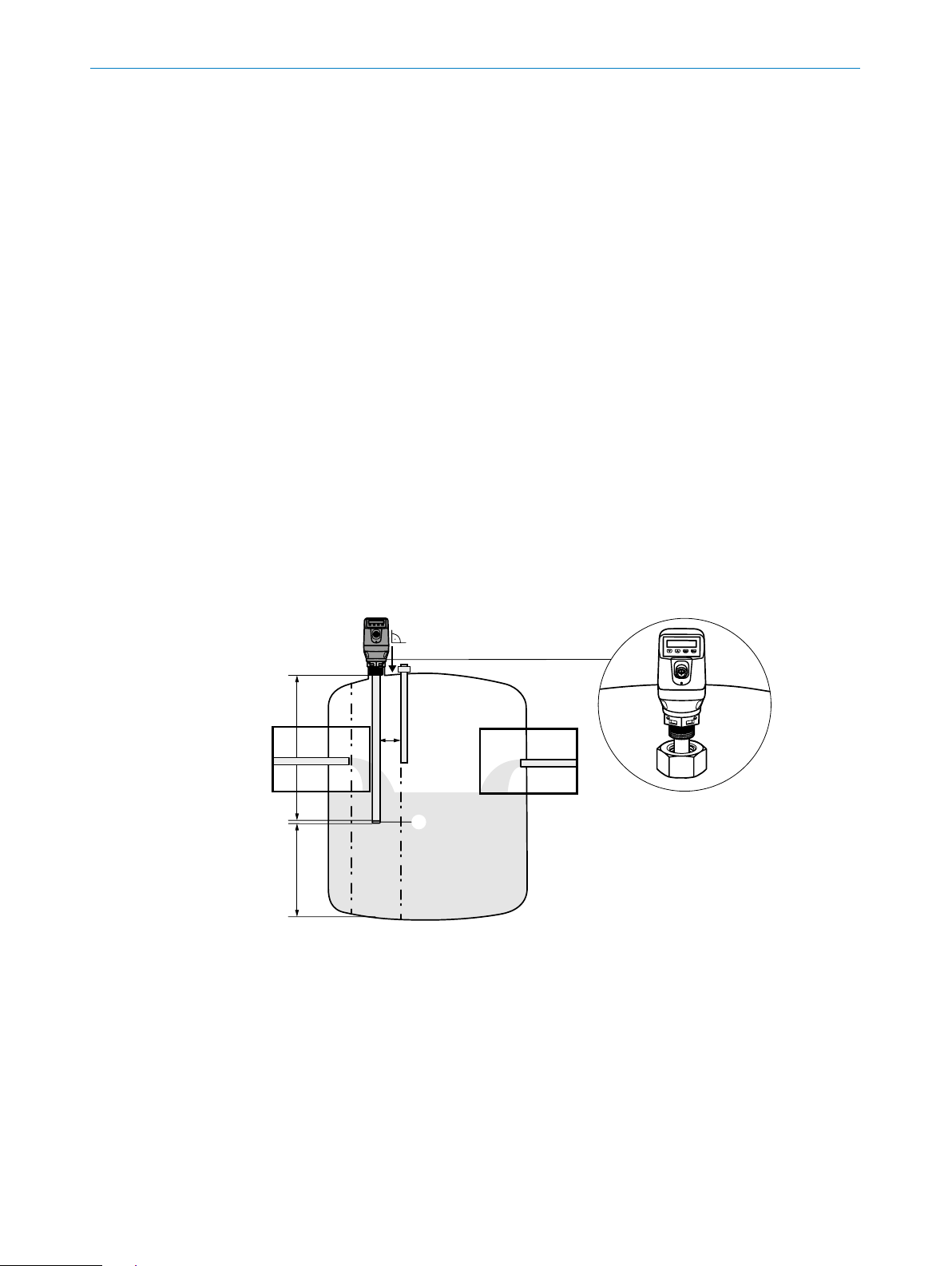

The CFP Cubic level sensor is mounted vertically from above into the container.

The sensor features a G 3/4 A, 3/4" NPT threaded connection or Easy Clamp bracket

(clamping bracket for innite adjustment of the required length).

A minimum connecting piece diameter in accordance with the following graphic must

be observed. The CFP Cubic is to be installed in such a way that, after it has been

mounted, there is a sufcient distance between it and other tank components (e.g.,

supply pipes, other measuring devices) as well as the sides and bottom of the con-

tainer.

These minimum distances are also specied in the following graphic. Observe a minimum distance of 30 mm to the container sides and to the tank components.

When operating the sensor, ensure that the ambient temperature is not above or below

the limits. Insulating the sensor housing is not permitted for tanks with hot media.

When positioning the device, ensure that the sensor is not directly exposed to the lling

ow and that at least 10 mm of the probe is covered by the medium to be measured on

all sides.

The sensor housing can be rotated 360°, allowing for the cable outlet to be positioned

freely. If the process temperature drops below 0 °C during operation, the probe must

not be subjected to transverse loads.

5.2 Installation in a container

1

X

4

Fig. 2: CFP Cubic in the container

1 100 ... 1,000 mm measuring range

2 min. 30 mm

3 10 mm inactive area at probe end

4 min. 10 mm

2

G 3/4" A

3/4" NPT

3

14

OPERATING INSTRUCTIONS | CFP CUBIC 8021989 / 2017-10-20 | SICK AG

Subject to change without notice

Page 15

6 Electrical installation

6.1 Safety

6.1.1 Notes on the electrical installation

IMPORTANT

Equipment damage due to incorrect supply voltage!

An incorrect supply voltage may result in damage to the equipment.

• Only operate the device using a protected low voltage and safe electrical insulation

as per protection class III.

IMPORTANT

Equipment damage or unpredictable operation due to working with live parts.

Working with live parts may result in unpredictable operation.

• Only carry out wiring work when the power is off.

• Only connect and disconnect electrical connections when the power is off.

6ELECTRICAL INSTALLATION

• The electrical installation must only be performed by electrically qualied person-

nel.

• Standard safety requirements must be met when working on electrical systems.

• Only switch on the supply voltage for the device when the connection tasks have

been completed and the wiring has been thoroughly checked.

• When using extension cables with open ends, ensure that bare wire ends do not

come into contact with each other (risk of short-circuit when supply voltage is

switched on!). Wires must be appropriately insulated from each other.

• Wire cross-sections in the supply cable from the user’s power system must be

designed in accordance with the applicable standards. In Germany, observe the

following standards:

DIN VDE 0100 (Part 430) and DIN VDE 0298 (Part 4) or DIN VDE 0891 (Part 1).

• Circuits connected to the device must be designed as SELV circuits

(SELV = Safety Extra Low Voltage).

• Protect the device with a separate fuse at the start of the supply circuit.

Notes on layout of data cables:

• To avoid interference, e.g., from switching power supplies, motors, clocked drives,

and contactors, always use suitable EMC cables and layouts.

• Do not lay cables over long distances in parallel with voltage supply cables and

motor cables in cable channels.

Subject to change without notice

The IP 67 enclosure rating for the device is only achieved under the following conditions:

• The cable on the M12 connection has been screwed on.

If this is not done, the device does not fulll any specied IP enclosure rating!

OPERATING INSTRUCTIONS | CFP CUBIC8021989 / 2017-10-20 | SICK AG

15

Page 16

6 ELECTRICAL INSTALLATION

12

4 3

5

6.2 Electrical connection

6.2.1 Overview of the electrical connections

The sensor is connected using a pre-assembled female cable connector with 1 x M12

plug connector (5-pin or 8-pin). With the power switched off, plug the female cable connector into the sensor and screw it tight.

Connect the cable according to its function. After the supply voltage has been applied,

the sensor carries out a self-test. Once installed, the sensor is ready for operation on

completion of the self-test (< 5 s) and the display shows the current measured value.

Fig. 3: CFP Cubic device view

6.2.2 Pin assignment, M12 plug connector, 5-pin (depending on the variant)

Fig. 4: M12 x 1 plug connector, 5-pin

Pin Identication Description

1 L+ Supply voltage

2 Q

3 M Ground, reference potential for

4 C/Q

5 Q

A

1

2

Current output 4 ... 20 mA

Or

Voltage output 0 ... 10 V

Variant-dependent

current/voltage output

Switching output 1, PNP / NPN / DRV (push-pull) / IO-Link

Switching output 2, PNP / NPN / DRV (push-pull)

16

OPERATING INSTRUCTIONS | CFP CUBIC 8021989 / 2017-10-20 | SICK AG

Subject to change without notice

Page 17

6.2.3 Pin assignment, M12 plug connector, 8-pin

5

8

6ELECTRICAL INSTALLATION

2

3

4

1

7

6

Fig. 5: M12 x 1 plug connector, 8-pin

Pin Identication Description

1 L+ Supply voltage

2 Q

2

Switching output 2, PNP / NPN / DRV (push-pull)

3 M Ground, reference potential for current / voltage output

4 C/ Q

5 Q

6 Q

7 Q

8 Q

3

4

A

B

1

Switching output 1, PNP / NPN / DRV (push-pull) / IO-Link

Switching output 3, PNP / NPN / DRV (push-pull)

Switching output 4, PNP / NPN / DRV (push-pull)

Analog current / voltage output

Analog current / voltage output

The wire colors for 8-pin cables are not uniform. Always note the pin assignment of the

sensor.

Subject to change without notice

OPERATING INSTRUCTIONS | CFP CUBIC8021989 / 2017-10-20 | SICK AG

17

Page 18

7 COMMISSIONING

7 Commissioning

7.1 Quick commissioning (with factory settings)

General requirements

− Installation according to reference conditions (safety distances, etc.)

− Can only be used if installed using G3/4" A or 3/4

Quick commissioning

1. Mount the sensor as appropriate to the installation conditions, see “5 Mounting”.

2. Adapt the level so that approximately 50% of the probe is covered with the measuring medium.

3. Automatically adjust the medium.

• Adjust using AUTCAL.

• The successful AUTCAL function is conrmed with !CALOK.

4. Congure outputs, see “8.3 Conguring the switching outputs”.

Note:

The following parameters are automatically adjusted while executing the AUTCAL function:

• The EXPRT / MEAS / TRSHLD parameter is adjusted.

• The EXPRT / MEAS / ADAPT = 60 s parameter is adjusted.

Note:

If the AUTCAL function was conrmed with !FAILD, relaunch commissioning.

" NPT process connection

This menu can be accessed via EXPRT and USER.

In the event of problems during commissioning, see “11 Troubleshooting”.

7.2 Commissioning

Advanced commissioning must always be performed if the required measurement

performance is not achieved after quick commissioning. This may be the case if, for

example, media with very low DC values (e.g., silicone oils) are to be measured.

Advanced commissioning must also be performed during assembly with an Easy Clamp

bracket.

General requirements

− Installation according to reference conditions (safety distances, etc.)

− Installation using G3/4" A or 3/4

− Installation using Easy Clamp

18

OPERATING INSTRUCTIONS | CFP CUBIC 8021989 / 2017-10-20 | SICK AG

" NPT process connection

Subject to change without notice

Page 19

Commissioning

1. Mount the sensor as appropriate to the installation conditions, see “5 Mounting”.

2. The level must be at least 10 mm below the end of the probe.

3. Perform empty adjustment.

4. Adapt the level in the container until approx. 50% of the probe is covered with the

5. Automatically adjust the medium.

6. Analyze the signal quality, see “8.5.10 Evaluating signal quality”.

7. Congure the lter, see “8.5.8 Filtering measured values”.

7COMMISSIONING

This menu can be accessed via EXPRT and USER.

• Perform the adjustment using CALEMP.

• The successful empty adjustment is conrmed with !CALOK.

measuring medium.

• Adjust using AUTCAL.

• The successful AUTCAL function is conrmed with !CALOK.

Perform the following steps if the signal quality is not sufcient:

• Reduce the value in the MEAS / TRSHLD menu.

8. Congure outputs, see “8.3 Conguring the switching outputs”.

Note:

If the AUTCAL function was conrmed with !FAILD, relaunch commissioning.

Note:

The following parameters are automatically adjusted while executing the AUTCAL function:

• The EXPRT / MEAS / TRSHLD parameter is adjusted.

• The EXPRT / MEAS / ADAPT = 60 s parameter is adjusted.

Note:

If the CalEmp function was conrmed with !FAILD, relaunch commissioning.

Note:

If a quick adjustment to a new medium is required, the EXPRT / MEAS / ADAPT parameter has to be reduced.

In the event of problems during commissioning, see “11 Troubleshooting”.

Subject to change without notice

OPERATING INSTRUCTIONS | CFP CUBIC8021989 / 2017-10-20 | SICK AG

19

Page 20

8 OPERATION

8 Operation

8.1 Display and pushbuttons

All lengths specied in the menu refer to the end of the probe and/or with a congured

offset (see “8.5.11 Setting the offset”) to the tank bottom.

8.1.1 Variants with two switching outputs

Q1 Q2

1000 mm

Arrow pushbuttons: For navigating in the menu and changing values

Set pushbutton: For saving and conrming

Esc pushbutton: To exit the operating menu one step at a time

Note:

The status of the switching outputs is indicated in millimeters by the bars above the

mm unit symbol. This display is not available when inches are selected as the unit.

8.1.2 Variants with four switching outputs

Q1/2/3/4

1000 mm

Arrow pushbuttons: For navigating in the menu and changing values

Set pushbutton: For saving and conrming

Esc pushbutton: To exit the operating menu one step at a time

39.4 in

39.4 in

8.1.3 IO-Link

For operation via IO-Link 1.1 with data storage, the following les can be downloaded

from www.sick.com:

− IODD le

− Description of the available telegram parameters

8.2 User and Exprt mode

The two menu structures User mode and Exprt mode are available for users. The Exprt

mode contains additional functions for advanced settings.

You can access the menu by pressing the Set pushbutton for at least three seconds.

8.2.1 User mode

The User mode makes it easy to commission many standard applications. The number

of parameters that can be set on the display is reduced.

20

OPERATING INSTRUCTIONS | CFP CUBIC 8021989 / 2017-10-20 | SICK AG

Subject to change without notice

Page 21

8.2.2 Exprt mode

8OPERATION

The Exprt mode offers the full functionality of the display.

Advanced functions are available for:

− Switching outputs

• Output: Process variable, hysteresis/window, polarity, simulation, electrical

property (NPN / PNP / DRV (push-pull))

• Using the switching output as input for initiating actions (minLvl, maxLvl, etc.)

− Analog outputs

• Switching the process variable, 4–20 mA/0–10 V, error signal, simulation

− Conguration

• Display, units, offset, lock

− Measurement

• Detailed signal quality, lter, TrsHld

Note:

Exprt mode is automatically activated when IO-Link is used.

8.3 Conguring the switching outputs

8.3.1 Switching hysteresis and window function

2 or 4 outputs depending on variant

Level

SP

RP

high

low

high

low

HNO

HNC

If the level is uctuating around the set

value (e.g., ripple movement during ll

ing), the hysteresis keeps the switching

t

status of the outputs stable. When the

-

level is increasing, the output switches

when the respective switching point

(SP) is reached; if the level sinks again,

the output switches back only after the

reset switching point (RP) has been

reached.

Subject to change without notice

OPERATING INSTRUCTIONS | CFP CUBIC8021989 / 2017-10-20 | SICK AG

21

Page 22

8 OPERATION

2 or 4 outputs depending on variant

Level

FH

FL

high

low

high

low

8.3.2 Normally open with congurable hysteresis

Applications

− Dry run protection

− Empty signal

FNC

FNO

The window function enables monitor-

ing of a dened range. If the level is

between window high (FH) and window

low (FL), the output will be active

(normally open) or inactive (normally

closed).

t

The error status of the measuring

device reects the cable break monitoring. During an error status, the measur-

ing device switches to a safe state; i.e.

the switching outputs become inactive.

As far as the downstream signal evalu-

ation is concerned, this corresponds to

a cable break.

Conguration

Congure the Qx switching output as normally open (using Q1 as an example).

Note:

The switching output designation (Q1 in the example here) changes according to the

selected process variable to be output.

The following conguration is only possible if the value is set to LEVEL or TEMPER under

PROC1.

1. Log in to Exprt mode, see “8.2.2 Exprt mode”.

2. Congure the switching output as output in the Q1-### / MODE1 / OUTPUT menu.

3. Congure the process variable to be output.

• Set the value to LEVEL or TEMPER in the Q1-### / PROC1 menu.

4. Set the Hysteresis mode in the Q1-### / OUT1 / HYST. menu.

• Set the parameter to NO in the Q1-### / POL1 menu.

5. Set the switching point.

• Set the value in the Q1-### / SP1 menu to level in mm (e.g., 500 mm).

6. Set the reset point.

• Set the value in the Q1-### / RP1 menu to level in mm (e.g., 450 mm).

22

7. Select the electrical property (NPN/PNP/DRV [push/pull]).

Select the parameter in the Q1-### / TYP1 menu.

The following rules apply:

OPERATING INSTRUCTIONS | CFP CUBIC 8021989 / 2017-10-20 | SICK AG

Subject to change without notice

Page 23

• PNP = Switching output in PNP circuit

t

disable

• NPN = Switching output in NPN circuit

• DRV = Switching output in push/pull function

Switching output behavior

Level

SP

RP

8OPERATION

active

d

Switching output PNP NPN DRV Error status

Normally open/HNO

1)

Pulldown only

2)

Pullup only

active U

disabled 0 V

8.3.3 Normally closed with congurable hysteresis

Applications

− Overll protection

− Full signal

Conguration

Congure the Qx switching output as normally closed (using Q1 as an example).

Note:

Error signal

0 V Uv (PNP switched)

v

1)

Uv 2) 0 V (NPN switched)

disabled

Subject to change without notice

The switching output designation (Q1 in the example here) changes according to the

selected process variable to be output.

1. Log in to Exprt mode, see “8.2.2 Exprt mode”.

2. Set the Output mode in the Q1-### / MODE1 / OUTPUT menu.

3. Congure the process variable to be output.

• Set the parameter to the required value in the Q1-### / PROC1 menu.

4. Set the Hysteresis mode in the Q1-### / OUT1 / HYST. menu.

5. Congure the switching output.

• Set the parameter to NC in the Q1-### / POL1 menu.

OPERATING INSTRUCTIONS | CFP CUBIC8021989 / 2017-10-20 | SICK AG

23

Page 24

8 OPERATION

Switching output behavior

6. Set the switching point.

• Set the value in the Q1-### / SP1 menu to level in mm (e.g., 500 mm).

7. Set the reset point.

• Set the value in the Q1-### / RP1 menu to level in mm (e.g., 450 mm).

8. Select the electrical property (NPN/PNP/DRV [push/pull]).

Select the parameter in theQ1-LVL / TYP1 menu.

The following rules apply:

• PNP = Switching output in PNP circuit

• NPN = Switching output in NPN circuit

• DRV = Switching output in push/pull function

Level

SP

RP

t

Error signal

active

disabled

Switching output PNP NPN DRV Error status

Normally closed/

HNC

1)

Pulldown only

2)

Pullup only

active U

disabled 0 V

0 V Uv (PNP switched) disabled

v

2)

1)

U

0 V (NPN switched)

v

8.3.4 Normally open with window function

Application

Thecritical lling level for the application is within the FHx and FLx window thresholds.

Conguration

Congure the Qx switching output as normally open (using Q1 as an example).

24

Note:

The switching output designation (Q1 in the example here) changes according to the

selected process variable to be output.

1. Log in to Exprt mode, see “8.2.2 Exprt mode”.

OPERATING INSTRUCTIONS | CFP CUBIC 8021989 / 2017-10-20 | SICK AG

Subject to change without notice

Page 25

2. Set the Output mode in the Q1-### / MODE1 / OUTPUT menu.

3. Congure the process variable to be output.

• Set the parameter to the required value in the Q1-### / PROC1 menu.

4. Set the Window mode in the Q1-### / OUT1 / WINDOW menu.

5. Congure the switching output as normally open.

• Set the parameter to NO in the Q1-### / POL1 menu.

6. Set the switching point.

• Set the value in the Q1-### / FH1 menu to level in mm (e.g., 500 mm).

7. Set the reset point.

• Set the value in the Q1-### / FL1 menu to level in mm (e.g., 400 mm).

8. Select the electrical property (NPN/PNP/DRV [push/pull]).

Select the parameter in the Q1-### / TYP1 menu.

The following rules apply:

• PNP = Switching output in PNP circuit

• NPN = Switching output in NPN circuit

8OPERATION

• DRV = Switching output in push/pull function

Switching output behavior

Level

FH

FL

active

disabled

Switching output PNP NPN DRV Error status

Normally open/FNO

1)

Pulldown only

2)

Pullup only

Error signal

active U

v

disabled 0 V

t

0 V Uv (PNP switched)

1)

2)

Uv

0 V (NPN switched)

disabled

8.3.5 Normally closed with window function

Application

The critical lling level for the application is outside the FHx and FLx window thresholds.

Subject to change without notice

OPERATING INSTRUCTIONS | CFP CUBIC8021989 / 2017-10-20 | SICK AG

25

Page 26

8 OPERATION

Conguration

Congure the Qx switching output as normally closed (using Q1 as an example).

Note:

The switching output designation (Q1 in the example here) changes according to the

selected process variable to be output.

1. Log in to Exprt mode, see “8.2.2 Exprt mode”.

2. Set the Output mode in the Q1-### / MODE1 / OUTPUT menu.

3. Congure the process variable to be output.

• Set the parameter to the required value in the Q1-### / PROC1 menu.

4. Set the Window mode in the Q1-### / OUT1 / WINDOW menu.

5. Congure the Q1 switching output as normally closed.

• Set the parameter to NC in the Q1-### / POL1 menu.

6. Set the switching point.

• Set the value in the Q1-### / FH1 menu to level in mm (e.g., 500 mm).

7. Set the reset point.

• Set the value in the Q1-### / FL1 menu to level in mm (e.g., 400 mm).

8. Select the electrical property (NPN/PNP/DRV [push/pull]).

Select the parameter in the Q1-### / TYP1 menu.

The following rules apply:

• PNP = Switching output in PNP circuit

• NPN = Switching output in NPN circuit

• Drv = Switching output in push/pull function

Switching output behavior

Level

FH

FL

active

disabled

Error signal

t

26

OPERATING INSTRUCTIONS | CFP CUBIC 8021989 / 2017-10-20 | SICK AG

Subject to change without notice

Page 27

Switching output PNP NPN DRV Error status

8OPERATION

Normally closed/FNC

1)

Pulldown only

2)

Pullup only

8.3.6 Normally open with error signal

Application

If there is an error message on the CFP Cubic, this can be output using a switching

output.

Conguration

Congure the Qx switching output as normally open for error signals (using Q1 as an

example).

Note:

The switching output designation (Q1 in the example here) changes according to the

selected process variable to be output: Q1-LVL or Q1-TEMP is now Q1-STA.

1. Log in to Exprt mode, see “8.2.2 Exprt mode”.

active U

disabled 0 V

v

0 V Uv (PNP switched)

1)

2)

Uv

0 V (NPN switched)

disabled

2. Congure Q1 as output.

• Set the parameter to OUTPUT in the Q1-### / MODE1 menu.

3. Congure the process variable to be output.

• Set the parameter to STATUS in the Q1-### / PROC1 menu.

4. Set the status to be output in the Q1-STA / STAT1 menu.

• Set the parameter to FAILURE in the Q1-STA / STAT1 menu.

5. Congure the Q1 switching output as normally open.

• Set the parameter to NO (normally open) in the Q1-STA / POL1 menu.

6. Select the electrical property (NPN/PNP/DRV [push/pull]).

Select the parameter in the Q1-TYP1 menu.

The following rules apply:

• PNP = Switching output in PNP circuit

• NPN = Switching output in NPN circuit

• DRV = Switching output in push/pull function

8.3.7 Switching output as input for processing external signals

Application

Switching outputs can also be used as inputs for the CFP Cubic. This enables you to

integrate external signals (e.g., from a tuning fork). In this way, the CFP Cubic can be

used as a mini PLC and reduces the number of cables to the PLC.

Subject to change without notice

OPERATING INSTRUCTIONS | CFP CUBIC8021989 / 2017-10-20 | SICK AG

27

Page 28

8 OPERATION

Conguration

Congure the Qx switching output as input (using Q1 as a redundant overll protection

example).

Note:

The switching output designation (Q1 in the example here) changes according to the

selected process variable to be output: Q1-LVL or Q1-TEMP is now Q1-INP.

1. Log in to Exprt mode, see “8.2.2 Exprt mode”.

2. Congure Q1 as input.

• Set the parameter to INPUT in the Q1-### / MODE1 menu.

3. Congure the action to be performed when the signal is present.

• Set the parameter to MAXLVL in the Q1-INP / ACTIO1 menu (if the external

signal is present, the CFP Cubic outputs the MAXLVL status).

4. Congure the form of the external signal.

• Set the parameter to NO (normally open) in the Q1-INP / POL1 menu.

8.4 Conguration of analog outputs

8.4.1 Automatic signal detection

The CFP Cubic can automatically detect if a 4–20 mA or 0–10 V signal is required

using the connected output load.

The following rules apply:

• 4 mA to 20 mA if load < 500 ohms at U

• 4 mA to 20 mA if load < 350 ohms at U

• 0 V to 10 V if load > 750 ohms at U

Conguration

Note:

The analog output designation (QA in the example here) changes according to the

selected process variable to be output.

1. Perform automatic signal detection.

• Set the parameter to AUTO in the QA-### menu.

Note:

Automatic signal detection is only active when the device is switched on for the rst

time. After this, the function can be activated again with AUTO in the QA-### menu.

V

V

≥ 14 V

V

> 15 V

> 12 V

28

OPERATING INSTRUCTIONS | CFP CUBIC 8021989 / 2017-10-20 | SICK AG

Subject to change without notice

Page 29

8.4.2 Current output 4 to 20 mA

Conguration

Note:

The analog output designation (QA in the example here) changes according to the

selected process variable to be output.

1. Log in to Exprt mode, see “8.2.2 Exprt mode”.

2. Dene the output as temperature or level (temperature sensor depends on variant).

• Set the parameter to TEMPER or LEVELin the QA-### / QAPROC menu.

3. Set the upper limit value for the level or temperature at which 20 mA is output.

• Set the parameter in the QA-### / QAHIGH menu to level in mm or tempera-

ture in °C (e.g., 500 mm).

4. Set the lower limit value for the level or temperature at which 4 mA is output.

• Set the parameter in the QA-### / QALOW menu to level in mm or tempera-

ture in °C (e.g., 10 mm).

8OPERATION

5. Invert the signal.

The analog signal can be inverted in the QAPOL menu.

Set the parameter to INVERT in the QA-### / QAPOL menu.

• Normal = Analog output signal as congured

• Invert = Analog output signal is inverted; QaHigh 4 mA and

6. Select electrical signal.

• Set the parameter in the QA-### / QATYP menu to 4 to 20 mA.

8.4.3 Voltage output 0-10 V

Conguration

Note:

The analog output designation (QA in the example here) changes according to the

selected process variable to be output.

1. Log in to Exprt mode, see “8.2.2 Exprt mode”.

2. Dene the output as temperature or level (temperature sensor depends on variant).

3. Set upper limit value (10 V).

• Set the parameter in the QA-### / QAHIGH menu to level in mm or tempera-

QaLow 20 mA

ture in °C (e.g., 500 mm).

Subject to change without notice

4. Set lower limit value (0 V).

• Set the parameter in the QA-### / QALOW menu to level in mm or tempera-

ture in °C (e.g., 10 mm).

5. Invert the signal.

The analog signal can be inverted in the QAPOL menu.

Set the parameter to INVERT in the QA-### / QAPOL menu.

• Normal = Analog output signal as congured

OPERATING INSTRUCTIONS | CFP CUBIC8021989 / 2017-10-20 | SICK AG

29

Page 30

8 OPERATION

• Invert = Analog output signal is inverted; QaHigh 0 V and QaLow 10 V

6. Select electrical signal.

Set the parameter in the QA-### / QATYP menu to 0–10 V.

8.4.4 Behavior of outputs in the event of an error

Conguration

Note:

The analog output designation (QA in the example here) changes according to the selected process variable to be output.

This function is only available if 4 to 20 mA is selected under QA-TYP.

1. Log in to Exprt mode, see “8.2.2 Exprt mode”.

2. Select electrical signal.

• Select the parameter in the QA-### / QA-TYP menu and set the value to 4 to

20 mA.

3. Dene the signal in the event of an error.

• Select the parameter in the QA-### / QA-FAIL menu and set to the required

value.

8.5 Advanced functions

8.5.1 Selecting display unit

The following units can be selected for the measured values:

− UnitLv: mm, inch

− UnitTm: °C, °F

Conguration

1. Log in to Exprt mode, see “8.2.2 Exprt mode”.

2. Set the unit for level.

• Set the unit in the CONFIG / UNITLV menu (mm/inch).

Or

1. Log in to Exprt mode, see “8.2.2 Exprt mode”.

2. Set the unit for temperature.

• Set the unit in the CONFIG / UNITTM menu (°C/°F).

8.5.2 Setting an alternating display of measurands (DispA and DispB)

Up to two measured values can be displayed alternately.

30

Function Description

Level Level in mm/inch

Level % Level in %

1)

Tem p

1)

QaSign

OPERATING INSTRUCTIONS | CFP CUBIC 8021989 / 2017-10-20 | SICK AG

Temperature in °C/°F

Qa analog output signal in mA/mV

Subject to change without notice

Page 31

1)

Conguration

1. Log in to Exprt mode, see “8.2.2 Exprt mode”.

2. Set the unit in the CONFIG / DISPA or DISPB menu.

8.5.3 Autocalibration

Autocalibration automatically determines the ideal setting for the TRSHLD (EXPRT /

MEAS / TRSHLD) and ADAPT (EXPRT / MEAS / ADAPT) parameters. The container must

be lled to 50% during calibration.

Autocalibration should always be performed in the following situations:

Function Description

1)

QbSign

QxSign Qx switching output status

variant-dependent

Qb analog output signal in mA/mV

− Commissioning has been carried out

− There has been a change in medium

8OPERATION

− The sensor's measurement performance is declining

Conguration

1. Log in to Exprt mode, see “8.2.2 Exprt mode”.

2. Perform autocalibration using AUTCAL.

• Conrm LEVEL AT 50%? using Set.

• The successful AUTCAL function is conrmed with !CALOK.

8.5.4 Performing empty adjustment

An empty adjustment must be performed if, for example, the signal quality is not sufcient or the sensor was mounted with an Easy Clamp bracket.

An empty adjustment is also performed during advanced commissioning,

see “7.2 Commissioning” on page 18.

Conguration

1. Log in to Exprt mode, see “8.2.2 Exprt mode”.

2. Perform the adjustment using MEAS / CALEMP.

• The successful empty adjustment is conrmed with !CALOK.

8.5.5 Locking the display without a password

Local operation on the sensor is immediately locked when the Local User Interface Lock

is activated via IO-Link. The Local User Interface Lock can only be activated via IO-Link.

Subject to change without notice

The !LOCKD message is displayed if you try to open the menu.

The display lock can be unlocked with the following steps:

− Via IO-Link by resetting the Local User Interface Lock

− Via the display by pressing the Set pushbutton for at least 10 seconds

OPERATING INSTRUCTIONS | CFP CUBIC8021989 / 2017-10-20 | SICK AG

31

Page 32

8 OPERATION

8.5.6 Locking the display with a password

1. Log in to Exprt mode, see “8.2.2 Exprt mode”.

2. Activate or deactivate the display lock using CONFIG / LOCK.

If the display lock is activated:

− The display is locked after a timeout of 5 minutes has elapsed

− The display is unlocked temporarily by entering the password 000237

Note:

When the display is locked, only the congured measured value display can be seen.

8.5.7 Setting the medium adjustment

This setting is used to congure the speed of the medium adjustment. The medium

adjustment allows the sensor to adapt to changing measuring media. The slower this

adjustment occurs, the more stable the measurement.

Note:

The value is automatically set to 60 s when AUTCAL is performed.

Conguration

1. Log in to Exprt mode, see “8.2.2 Exprt mode”.

2. Set the parameter in the MEAS / ADAPT menu.

The possible values are 60 s, 30 s, 10 s, 5 s, 1 s.

If the medium remains the same, a value of 60 s is recommended.

8.5.8 Filtering measured values

Activating ltering

The lter supports the smoothing of the measured value; e.g., in the case of ripples on

level surfaces. For fast level changes, the average of the measured values over x sec-

onds is indicated.

1. Log in to Exprt mode, see “8.2.2 Exprt mode”.

2. Set the parameter in the MEAS / FILTER menu.

The possible values are Off, 500 ms, 1 s, 2 s, 5 s, 10 s.

8.5.9 Testing the conguration

32

Testing outputs

Switching and analog outputs can be simulated. This allows for the wiring and signal

values on the connected systems, such as a PLC, to be checked.

OPERATING INSTRUCTIONS | CFP CUBIC 8021989 / 2017-10-20 | SICK AG

Subject to change without notice

Page 33

Conguration

Activating the Qx switching output

Note:

The switching output designation (Q1 in the example here) changes according to the

selected process variable to be output.

1. Log in to Exprt mode, see “8.2.2 Exprt mode”.

2. Activate the Q1 switching output

• Set the parameter to ON in the Q1-### / SIMQ1 menu.

Further options:

− Off = switching output off

− Norm = switching output in measuring operation

− On = switching output is active

Note:

8OPERATION

The simulation is automatically deactivated if the supply voltage is interrupted.

Activate the QA analog output

The sensor's analog outputs can be activated for simulation; for example, to check the

settings of a PLC.

Note:

The analog output designation (QA in the example here) changes according to the selected process variable to be output.

Conguration (using current output for level as an example)

1. Log in to Exprt mode, see “8.2.2 Exprt mode”.

2. Dene the level setting.

• Set the parameter to LEVEL in the QA-### / QAPROC menu.

3. Dene the current output.

• Set the parameter in the QA-### / QATYP menu to 4 to 20 mA.

4. Activate the simulation.

Simulating the level

Subject to change without notice

• Set the parameter in the QA-### / SIMQA menu to a value between 3.5 mA

and 21.5 mA.

A simulated level can be set to test the completed conguration in the sensor.

All parameters and outputs are then set according to the simulated level.

OPERATING INSTRUCTIONS | CFP CUBIC8021989 / 2017-10-20 | SICK AG

33

Page 34

8 OPERATION

Conguration

Parameter selection

1. Log in to Exprt mode, see “8.2.2 Exprt mode”.

2. Set the parameter to the desired ll level as a % in the CONFIG / SIMLEV menu.

3. Activate the simulation.

• Set the parameter to the required value in the QA-### / SIMQA menu.

Note:

The level simulation refers to the probe length and/or container level (probe length +

offset) if an offset is congured.

The simulation is only active when there are no error messages. The simulation is automatically deactivated if the supply voltage is interrupted.

If Simulation mode is active during Run mode, !SIMUL is displayed alternately with the

simulated values.

− SimOff: Off

− Fill level 0%

− Fill level 25%

− Fill level 50%

− Fill level 75%

− Fill level 100%

8.5.10 Evaluating signal quality

The parameters describe the quality of the measuring signal and can be accessed

under EXPRT / INFO.

SigQu1

Characteristic for the robustness of the EXPRT / MEAS / TRSHLD setting.

• Value range: 0 to 100%

• Good signal: > 40%

Measures in the event of a poor signal: Reduce the value in the EXPRT / MEAS /

TRSHLD menu to increase SigQu1.

The EXPRT / MEAS / TRSHLD value must be set as high as possible so that no defective level is detected in the empty state.

SigQu2

34

Characteristic for the robustness of the medium detection in the event of interferences

(deposits/tank components).

• Value range: 0 to 100%

• Good signal: > 50%

A high characteristic describes a stable detection of the measuring medium. A low

characteristic indicates an unstable detection. In this case, a possible interference can

cause a stronger signal than the actual level and lead to faulty measurements.

OPERATING INSTRUCTIONS | CFP CUBIC 8021989 / 2017-10-20 | SICK AG

Subject to change without notice

Page 35

SigQu3

8OPERATION

Measures in the event of a poor signal:

• Check the installation conditions, see “5.1 Installation conditions”

• Free the probe from deposits

• Perform empty adjustment, see “8.5.4 Performing empty adjustment”

Characteristic for signal noise and electromagnetic interference, see “11 Trouble-

shooting”.

• Value range: 0 to 100%

• Good signal: > 75%

• Poor signal: < 50%

Check this value if the level value emits a signal noise or is unstable.

Measures in the event of a poor signal:

• Activate the lter, see “8.5.8 Filtering measured values”

• Improve ltering

SigQu4

Characteristic for the quality of the probe in the empty state.

Measures in the event of a poor signal:

SigQua

Summarizes the evaluation of SigQu1 – SigQu4 and indicates the measurement

quality. This characteristic is only visible via the User role.

8.5.11 Setting the offset

This setting makes it possible to indicate the level value on the display in relation to

the tank bottom instead of the end of the probe. The actual container level is then

indicated on the display.

• Remove possible EMC interferences

• Value range: 0 to 100%

• Good signal: > 50%

• Check the installation conditions, see “5.1 Installation conditions”

• Free the probe from deposits

• Perform empty adjustment, see “8.5.4 Performing empty adjustment”

Conguration

Subject to change without notice

1. Log in to Exprt mode, see “8.2.2 Exprt mode”.

2. Enter the required value in the CONFIG / OFFSET menu and conrm with Set. Pos-

sible values are 0 to 3,000 mm.

Note:

All parameters related to the level (e.g., SP/RP) are adapted according to the offset

setting.

OPERATING INSTRUCTIONS | CFP CUBIC8021989 / 2017-10-20 | SICK AG

35

Page 36

8 OPERATION

3

1

2

Fig. 6: CFP Cubic measuring range

1 Level

2 Offset

3 Measuring range

Note:

If the offset parameter is changed, the SPx/RPx/FLx/FHx/QaLow/QaHigh parameters

are automatically adjusted.

8.5.12 Resetting the calibration

Executing this function resets the empty adjustment that was carried out by the customer, and the threshold value (EXPRT / MEAS / TRSHLD) and the lter time of the

medium adjustment (EXPRT / MEAS / ADAPT) are reset to the default value.

Conguration

1. Log in to Exprt mode, see “8.2.2 Exprt mode”.

36

2. Select MEAS / RESET and conrm using Set.

3. Conrm the RESET? safety prompt using Set.

OPERATING INSTRUCTIONS | CFP CUBIC 8021989 / 2017-10-20 | SICK AG

Subject to change without notice

Page 37

9MENU OVERVIEW

9 Menu overview

9.1 User mode

3 s

RUN

510 mm

Set Esc

Set

User

Expert

Always available

Conguration-dependent

Sub-menu-dependent

Variant-dependent

Set

AutCal

SP1

Pol1

SP2

Pol2

SP3

Pol3

SP4

Pol4

QaHigh

QaLow

QbHigh

QbLow

Filter

CalEmp

FrmVer

SigQu

RstFac

Passwd

Set

Level at 50%

Esc

Set

Esc

Set

Esc

Set

Esc

Set

Esc

Set

Esc

Set

Esc

Set

Esc

Set

Esc

Set

Esc

Set

Esc

Set

Esc

Set

Esc

Set

Esc

Set

Probe is free?

Esc

Set

Esc

Set

Esc

Set

Esc

Set

Esc

###

###

###

###

###

###

###

###

###

###

###

###

Para

###

###

OK?

###

Set

Set

Set

Set

Set

Set

Set

Set

Set

Set

Set

Set

Set

Set

Set

Set

Set

OK

Subject to change without notice

OPERATING INSTRUCTIONS | CFP CUBIC8021989 / 2017-10-20 | SICK AG

37

Page 38

9 MENU OVERVIEW

9.2 Exprt mode

RUN

510 mm

Set Esc

3 s

Set

User

Exprt

Set

AutCal

Q1-###

Always available

Conguration-dependent

Sub-menu-dependent

Variant-dependent

Set

Esc

Mode1

Set

Esc

Set

Esc

Output Input

Proc1 Proc1 Actio1 Actio1

Set

Esc

Proc1 Actio1

Set

Esc

Set

Esc

Status

Set

Esc

minLvl

Set

Esc

maxLvl setErrLevel Temp

Stat1Out1 Out1

Set

Esc

Hyst, Window Hyst, Window

Set

Esc

Set

Esc

Failur

Set

Esc

SP1 SP1

Set

Esc

Set

Esc

### mm ### °C

RP1 RP1

Set

Esc

Set

Esc

### mm ### °C

Pol1

Set

Esc

no, nc

SimQ1

Set

Esc

on, off, norm

Typ 1 Typ 1

Set

Esc

NPN, PNP, DRV

Pol1 Pol1 Pol1 Pol1 Pol1

Set

Esc

no, nc no, nc no, nc no, nc no, nc

SimQ1 SimQ1 SimQ1 SimQ1 SimQ1

Set

Esc

on, off, norm on, off, norm on, off, norm on, off, norm on, off, norm

Typ 1

Set

Esc

NPN, PNP, DRV

Set

Esc

Set

Esc

Set

Esc

NPN, PNP, DRV

SP1

Set

Esc

### mm

RP1

Set

Esc

### mm

Set

Esc

Set

Esc

SP1

Set

Esc

### mm

RP1

Set

Esc

### mm

Set

Esc

Set

Esc

Set

Esc

Set

Esc

38

OPERATING INSTRUCTIONS | CFP CUBIC 8021989 / 2017-10-20 | SICK AG

Subject to change without notice

Page 39

Q2-###

Q3-###

Q4-###

Qa-###

9MENU OVERVIEW

Always available

Conguration-dependent

Set

see Q1

Esc

Set

see Q1

Esc

Set

see Q1

Esc

Set

Esc

Qa-Proc

Set

Esc

Level Temp

Sub-menu-dependent

Variant-dependent

Set

Esc

QaTyp QaTyp QaTyp QaTyp

Set

Esc

QaTyp QaTyp

Set

Esc

Auto# 0 ... 10 V

Set

Esc

Set

Esc

4 ... 20 mA4 ... 20 mA

Set

Esc

Auto#

QaPolQaPol QaPol

Set

Esc

Normal, Invert Normal, Invert

QaHigh QaHigh

Set

Esc

### mm ### mm

QaLow QaLow

Set

Esc

### mm ### mm

QaFail

Set

Esc

3.5 mA, 21.5 mA

Set

Esc

Set

Esc

Normal, Invert

QaHigh

Set

Esc

Set

Esc

### °C

QaLow

Set

Esc

Set

Esc

### °C

QaFail

Set

Esc

3.5 mA, 21.5 mA

Set

Esc

0 ... 10 V

QaPol

Set

Esc

Normal, Invert

QaHigh

Set

Esc

### °C

QaLow

Set

Esc

### °C

Subject to change without notice

SimQa

Set

Esc

SimQa

Set

Esc

SimQa

Set

Esc

Off, 3.5...21.5 mA Off, 0...10 VOff, 3.5...21.5 mA

OPERATING INSTRUCTIONS | CFP CUBIC8021989 / 2017-10-20 | SICK AG

SimQa

Set

Esc

Off, 0...10 V

39

Page 40

9 MENU OVERVIEW

Qb-###

Config

Meas

Info

RstFacRstFac

Passwd

Always available

Conguration-dependent

Set

see Qa

Esc

Set

Esc

Disp A

Disp B

UnitLv

UnitTm

SimLvl

SimTmp

Offset

Lock

Set

AutCal

Esc

Filter

TrsHld

Adapt

CalEmp

Lock

Reset

MEN

Set

Lock

SigQu1

MEN

Esc

Lock

SigQu2

MEN

Lock

SigQu3

MEN

Lock

SigQu4

MEN

Lock

FrmVer

MEN

Lock

SerNo

MEN

Lock

AppTag

MEN

Lock

DevTag

MEN

Set

Esc

Set

Esc

Ok ?

######

Set

Set

Esc

Esc

Set

Set

Esc

Esc

Set

Set

Esc

Esc

Set

Set

Esc

Esc

Set

Set

Esc

Esc

Set

Set

Esc

Esc

Set

Set

Esc

Esc

Set

Set

Esc

Esc

Set

Set

Esc

Esc

Set

Set

Esc

Esc

Set

Set

Esc

Esc

Set

Set

Esc

Esc

Set

Set

Esc

Esc

Set

Set

Esc

Esc

Set

Set

Esc

Esc

Set

Set

Esc

Esc

Set

Set

Esc

Esc

Set

Set

Esc

Esc

Set

Set

Esc

Esc

Set

Set

Esc

Esc

Set

Set

Esc

Esc

Set

Set

Esc

Esc

Set

Set

Esc

Esc

Set

Level

Level%

Temp

QaSign

QbSign

QxSign

mm, inch

°C, °F

### %

### %

0...3000 mm

inactive, active

Level at 50%?

Off, 1s, 2s, 5s, 10s, 500ms

20...500%

1s, 5s, 10s, 30s, 60s

Probe is free?

reset Meas conf?

0...100%

0...100%

0...100%

0...100%

###

###

***

***

Load deflt conf?

Sub-menu-dependent

Variant-dependent

Set

Set

Set

Set

Set

Set

Set

Set

Set

Set

Set

Set

Set

Set

Set

Set

Set

40

OPERATING INSTRUCTIONS | CFP CUBIC 8021989 / 2017-10-20 | SICK AG

Subject to change without notice

Page 41

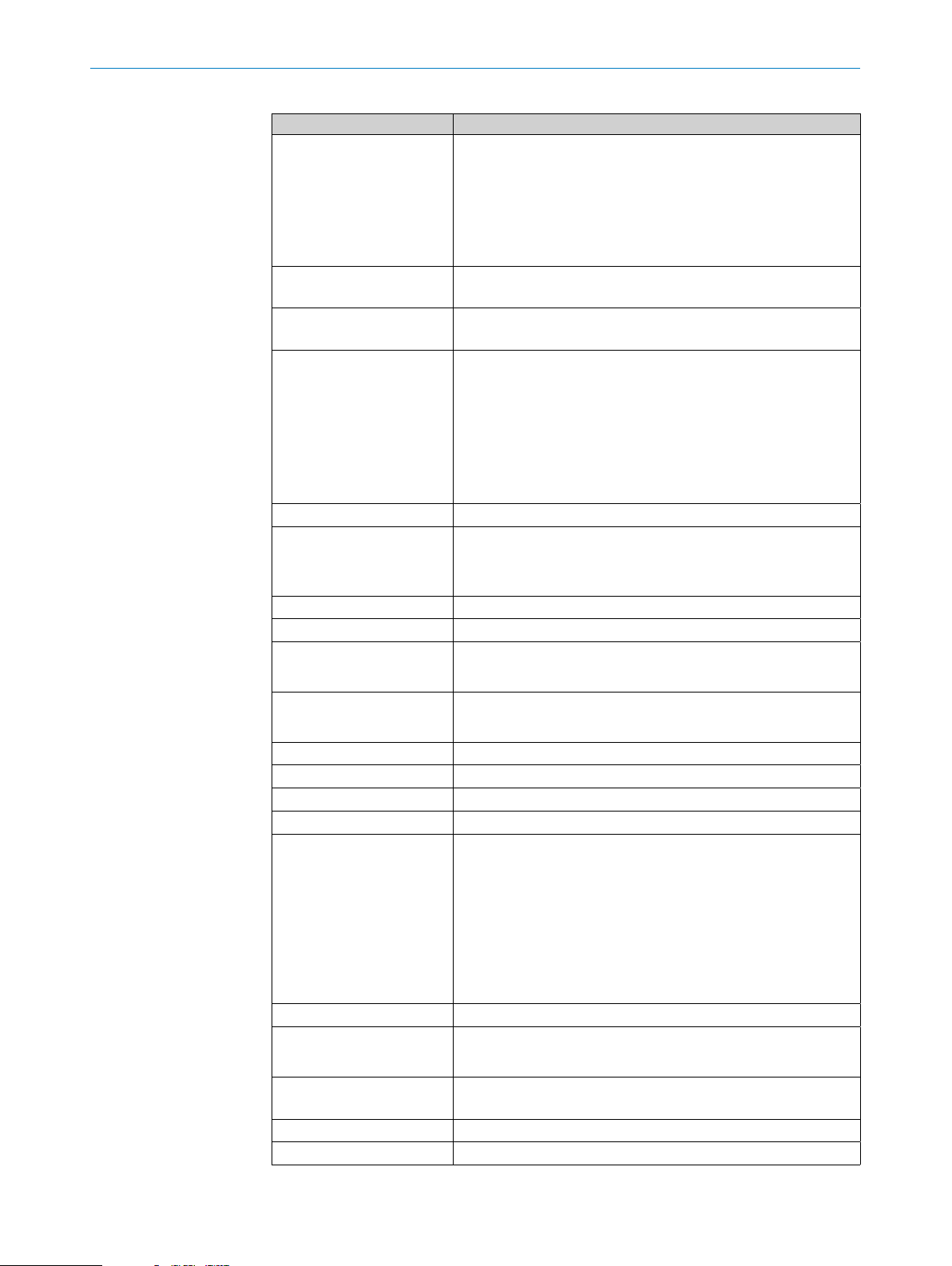

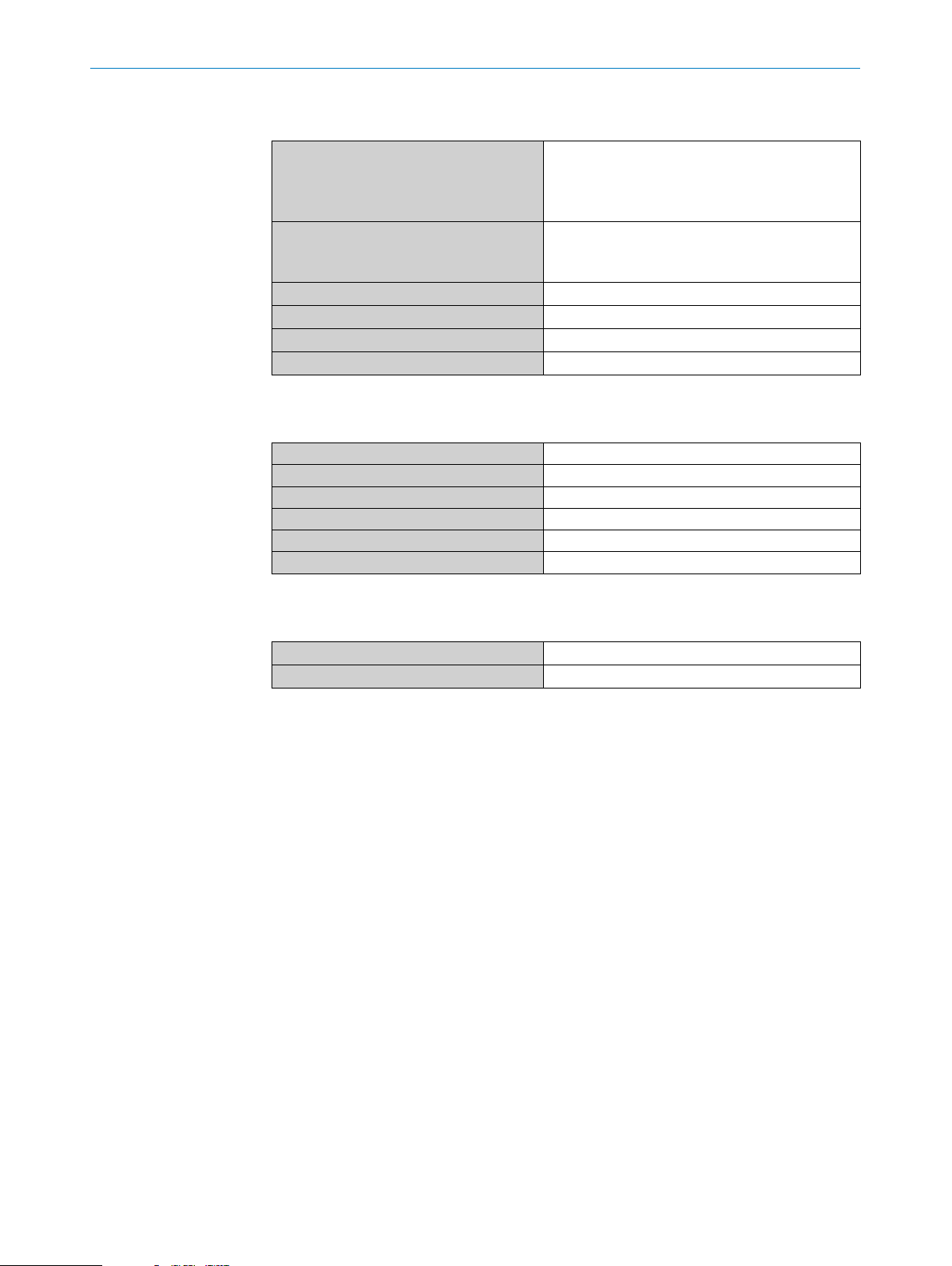

10 Overview of parameters

Parameter Description

Menu for switching

outputs

Based on example:

Q1-Lvl

Mode1 Switching point output mode.

Proc1

10OVERVIEW OF PARAMETERS

See “8.2 User and Exprt mode”.

Note:

The switching output designation changes according to

the selected process variable to be output – in this case:

Lvl (Level).

Output: The switching output is used as output.

Input: The switching output is used as input for an external

signal.

Switching output process parameters:

Note:

Can only be selected

for Mode1 / Output

Level, temperature, or status

The corresponding switching point is marked with a reference to the selected parameter. Example: Q1-Lvl.

Out1 Switching function, switching output.

SP1

RP1

Switching point, switching output (SPx > RPx).

Reset switching point, switching output

Note: Not displayed if the switching output is used to output the status (Proc1/Status) or if window is selected as

the output function.

FH1

FL1

Upper threshold (high) window function, switching output

(FHx > FLx)

Lower threshold (low) window function, switching output

Note:

Not displayed if the switching output is used to output the

status (Proc1/Status) or if hysteresis is selected as the

output function.

Pol1 Switching output property:

Normally open – no

Normally closed – nc

SimQ1 See “8.5.9 Testing the conguration”.

Typ1 Switching output execution:

Subject to change without notice

PNP = Switching output in PNP circuit

NPN = Switching output in NPN circuit

Q1-Drv = Switching output executed in push/pull function

Menu for analog outputs

See “8.4 Conguration of analog outputs”.

Based on example:

Qa-Lvl

QaProc Analog output process parameters:

Level, temperature.

QaTyp Analog output output signal:

4 to 20 mA, 0 to 10 V or automated.

OPERATING INSTRUCTIONS | CFP CUBIC8021989 / 2017-10-20 | SICK AG

41

Page 42

10 OVERVIEW OF PARAMETERS

Parameter Description

QaPol The analog output signal can be inverted.

QaHigh Input of the ll level in mm/°C for 20 mA / 10 V signal

QaLow Input of the ll level in mm (inch)/°C (F) for 4 mA / 0 V