Page 1

ATM60 PROFIBUS ABSOLUTE ENCODERS

RELIABLE, ESTABLISHED, AND MODULAR

Product description

The ATM60 PROFIBUS absolute multiturn

encoder from SICK provides reliable

positional and speed information even in

harsh ambient conditions, with a resolution of up to 26 bits. This product family,

which is proven in its eld, is based on

the principle of magnetic measurement.

The 13 bit singleturn range is scanned

by a sensor using permanent magnetic

elements. The 13 bit multiturn range

consists of a magnetic reduction gear.

At a glance

• Extremely rugged, tried-and-tested

absolute multiturn encoder with a

resolution of up to 26 bits

• Mechanical interface: face mount

ange, servo ange, blind hollow

shaft, and extensive adapter accessories

Equipped with a zero set pushbutton,

the encoder can be easily set to zero or

to any other user-programmed value on

site. The connection adapter, which can

be removed from the device, enables

simple user maintenance and mounting. With its magnetic scanning, rugged

IP 67-rated housing and high level of

resistance to shock and vibration, the

ATM60 is optimally suited for use in

harsh conditions.

• Zero-set and preset functions via

hardware or software

• Electrical interface: PROFIBUS DP as

per IEC61158 / RS 485 , electrically

isolated.

• Electronically adjustable, congurable

resolution

• Magnetic scanning

G

More information

Fields of application . . . . . . . . . . .G-387

Detailed technical data. . . . . . . . .G-387

Type code. . . . . . . . . . . . . . . . . . . .G-389

Ordering information. . . . . . . . . . .G-389

Dimensional drawings . . . . . . . . .G-390

PIN assignment. . . . . . . . . . . . . . .G-392

Mandatory accessories.........G-393

Recommended accessories. . . . .G-394

Your benets

• Fewer variants are required since one

freely programmable encoder offers

all singleturn and multiturn resolutions

• Easy setup due to various connectivity

options (3x PG, 3x M12)

• Maintenance-free encoder, long

service life

• Application exibility due to easily

interchangeable collets for the blind

hollow shaft

• Quick commissioning using the zero

set/preset function either at the press

of the button on the device or via

software

• Increased productivity due to highly

reliable shock and vibration resistance

• Worldwide availability and service

ensure quick and reliable customer

service

G-386

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 2

Fields of application

• Measurement of absolute position in various machines

and system such as wind power and solar plants, material

Detailed technical data

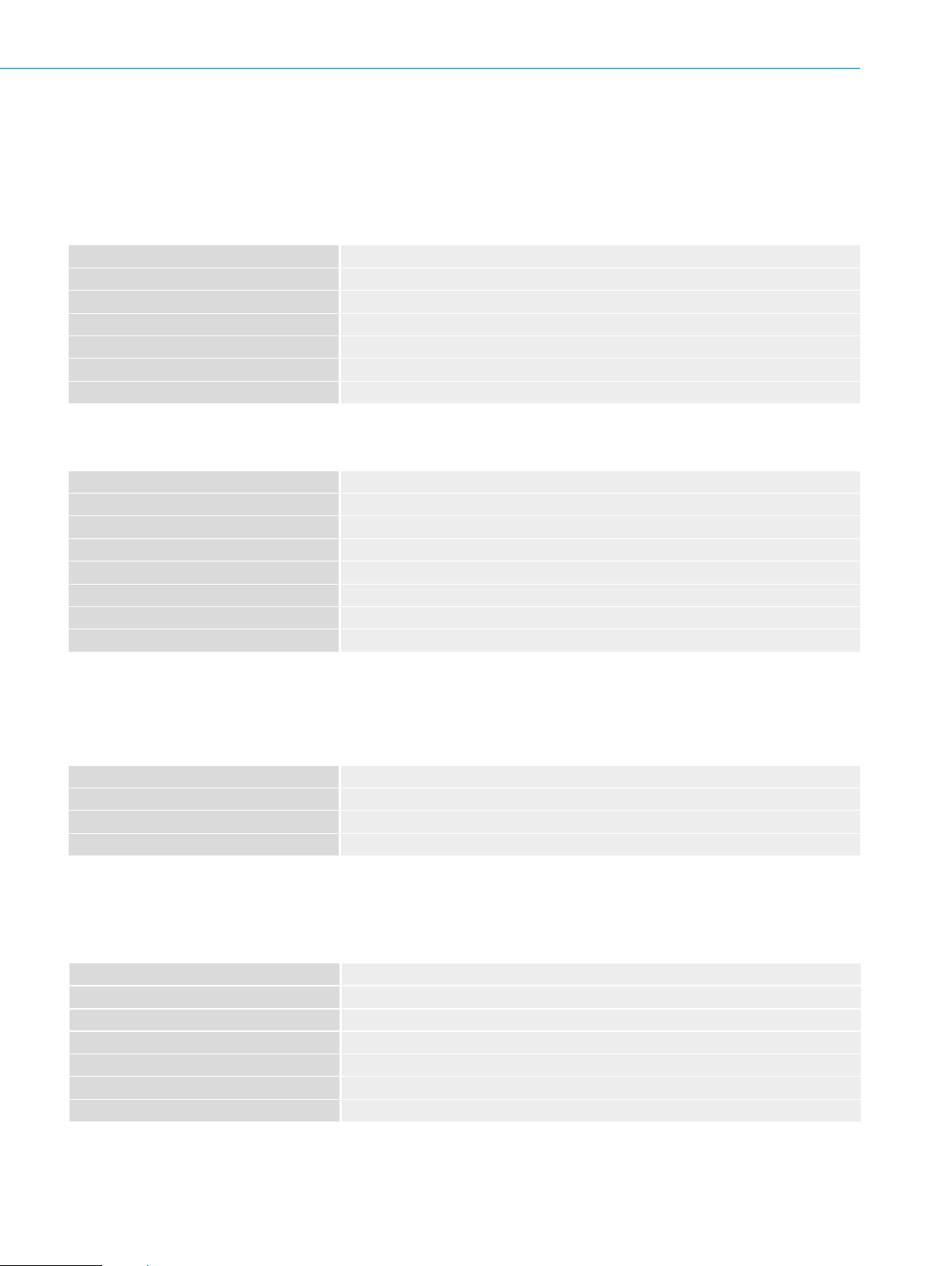

Performance

ABSOLUTE ENCODERS ATM60 PROFIBUS

transport equipment, textile machines, packaging systems,

rollers, harbor facilities, printing machines

Max. number of steps per revolution

Max. number of revolutions

Resolution

Error limits

Repeatability

Measurement step

Initialization time

1)

Valid positional data can be read once this time has elapsed.

≤ 8,192

≤ 8,192

13 bit x 13 bit

± 0.25°

0.1°

0.043°

1,250 ms

1)

Interfaces

Electrical interface

Bus interface

Set (electronic adjustment)

Data protocol

Address setting

Data transmission rate (baud rate)

Status information

Bus termination

1)

EN 50 170-2.

2)

DIN 19245 Part 1-3.

3)

Electrically isolated through optocoupler.

4)

Should only be connected in the nal device.

PROFIBUS

PROFIBUS DP, RS–485 1) 2)

3)

Via PRESET pushbutton or protocol

Prole for encoder (07hex) – Class 2

0 ... 127, DIP switch or protocol

9.6 kBaud to 12 Mbaud, autodetect

LED green (running), LED red (bus activity)

DIP switch

4)

Electrical data

Connection type

Operating voltage range

Max. power consumption without load

MTTFd: mean time to dangerous failure

1)

Please order the Probus adapter separately.

2)

This product is a standard product and does not constitute a safety component as dened in the Machinery Directive. Calculation based on nominal load of devices, average ambient temperature 40 °C, frequency of use 8760 h/a. All electronic failures are considered hazardous. For more information, see document no.

8015532.

Bus adapter with cable screw xings or round connectors

10 V ... 32 V

≤ 2 W

150 years (EN ISO 13849-1)

2)

1)

G

Mechanical data

Shaft diameter

Face mount ange 10 mm x 19 mm

Servo ange 6 mm x 10 mm

Blind hollow shaft 6 mm, 8 mm, 10 mm, 12 mm, 14 mm, 15 mm, 1/4", 3/8", 1/2"

2)

Mass

Shaft material

Flange material

1)

Order collets for 6, 8, 10, 12 and 14 mm or 1/4", 3/8" and 1/2" as separate extra accessories. No collets are necessary for 15 mm shaft diameter.

2)

Relates to devices with cable outlet.

3)

Take into account self-warming of 3.3 K per 1,000 rpm when designing operating temperature range

Subject to change without notice

0.59 kg

Stainless steel

Aluminum

1)

ENCODERS | SICK8015560/2015-09-01

G-387

Page 3

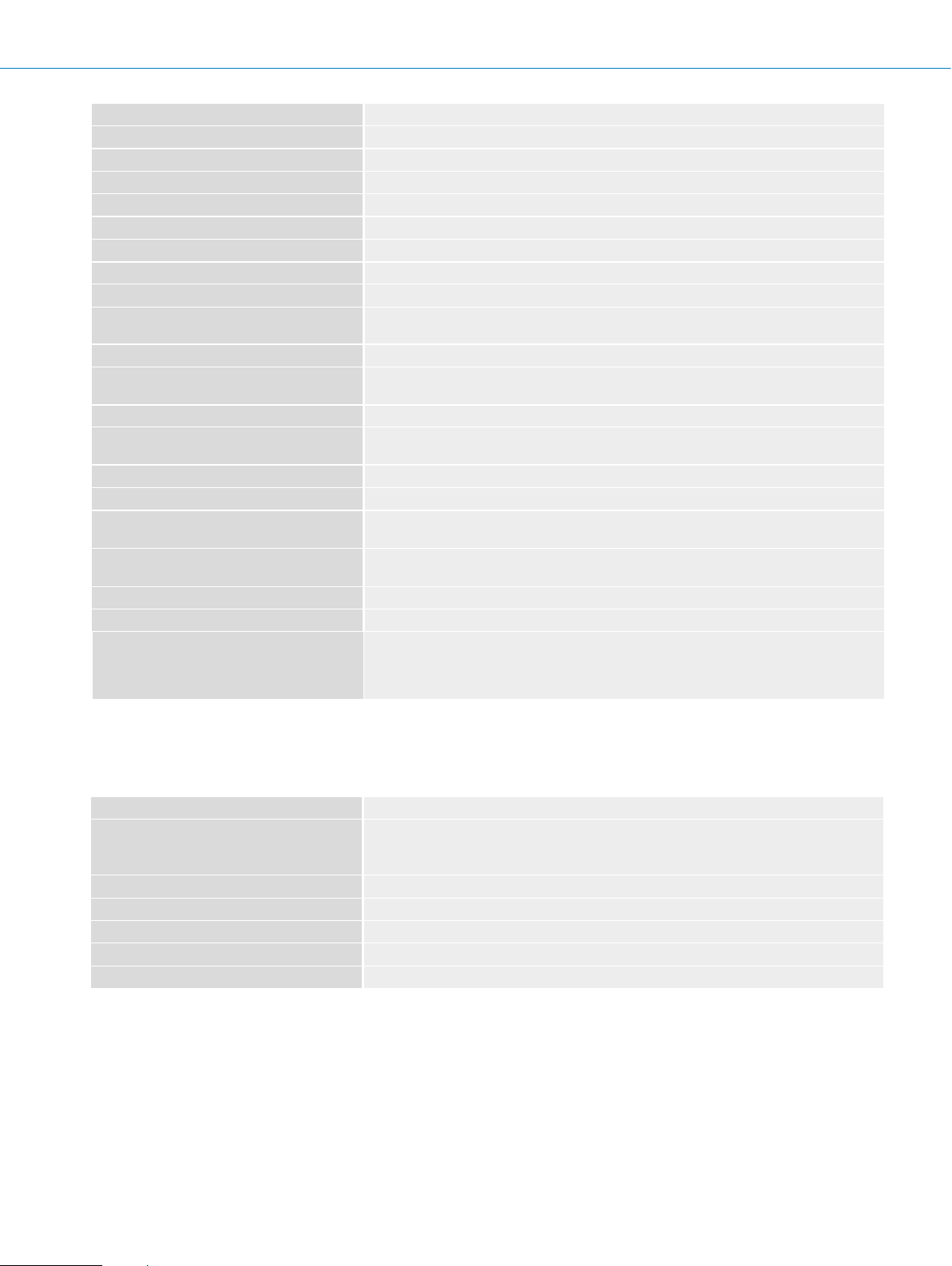

ATM60 PROFIBUS ABSOLUTE ENCODERS

G

Housing material

Aluminum die cast

Start up torque with shaft seal at 20 °C

Face mount ange, servo ange 2.5 Ncm

Blind hollow shaft 1.2 Ncm

Start up torque without shaft seal at 20 °C

Face mount ange, servo ange 0.5 Ncm

Operating torque with shaft seal at 20 °C

Face mount ange, servo ange 1.8 Ncm

Blind hollow shaft 0.8 Ncm

Operating torque without shaft seal at

20 °C

Face mount ange, servo ange 0.3 Ncm

Permissible shaft movement, axial static/

dynamic

Blind hollow shaft ± 0.5 mm, ± 0.2 mm

Permissible shaft movement, radial static/

dynamic

Blind hollow shaft ± 0.3 mm, ± 0.1 mm

Permissible shaft loading

Solid shaft 300 N (radial)

50 N (axial)

Rotor moment of inertia

35 gcm²

55 gcm²

Bearing lifetime

Max. angular acceleration

Operating speed

3)

3.6 x 10^9 revolutions

≤ 500,000 rad/s²

Face mount ange, servo ange 6,000 rpm

Blind hollow shaft 3,000 rpm

1)

Order collets for 6, 8, 10, 12 and 14 mm or 1/4", 3/8" and 1/2" as separate extra accessories. No collets are necessary for 15 mm shaft diameter.

2)

Relates to devices with cable outlet.

3)

Take into account self-warming of 3.3 K per 1,000 rpm when designing operating temperature range

Ambient data

EMC

Enclosure rating

Permissible relative humidity

Operating temperature range

Storage temperature range

Resistance to shocks

Resistance to vibrations

1)

When mating connector is inserted.

G-388

ENCODERS | SICK 8015560/2015-09-01

According to EN 61000-6-2 and EN 61000-6-3

IP 67 with shaft seal (acc. to IEC 60529)

1)

IP 43 without shaft seal, not sealed on encoder ange (acc. to IEC 60529)

IP 66 without shaft seal, sealed on encoder ange (acc. to IEC 60529)

1)

98%

–20 °C ... +85 °C

–40 °C ... +100 °C, without packaging

100 g, 6 ms (according to EN 60068-2-27)

20 g, 10 Hz ... 2,000 Hz (according to EN 60068-2-6)

Subject to change without notice

1)

Page 4

ABSOLUTE ENCODERS ATM60 PROFIBUS

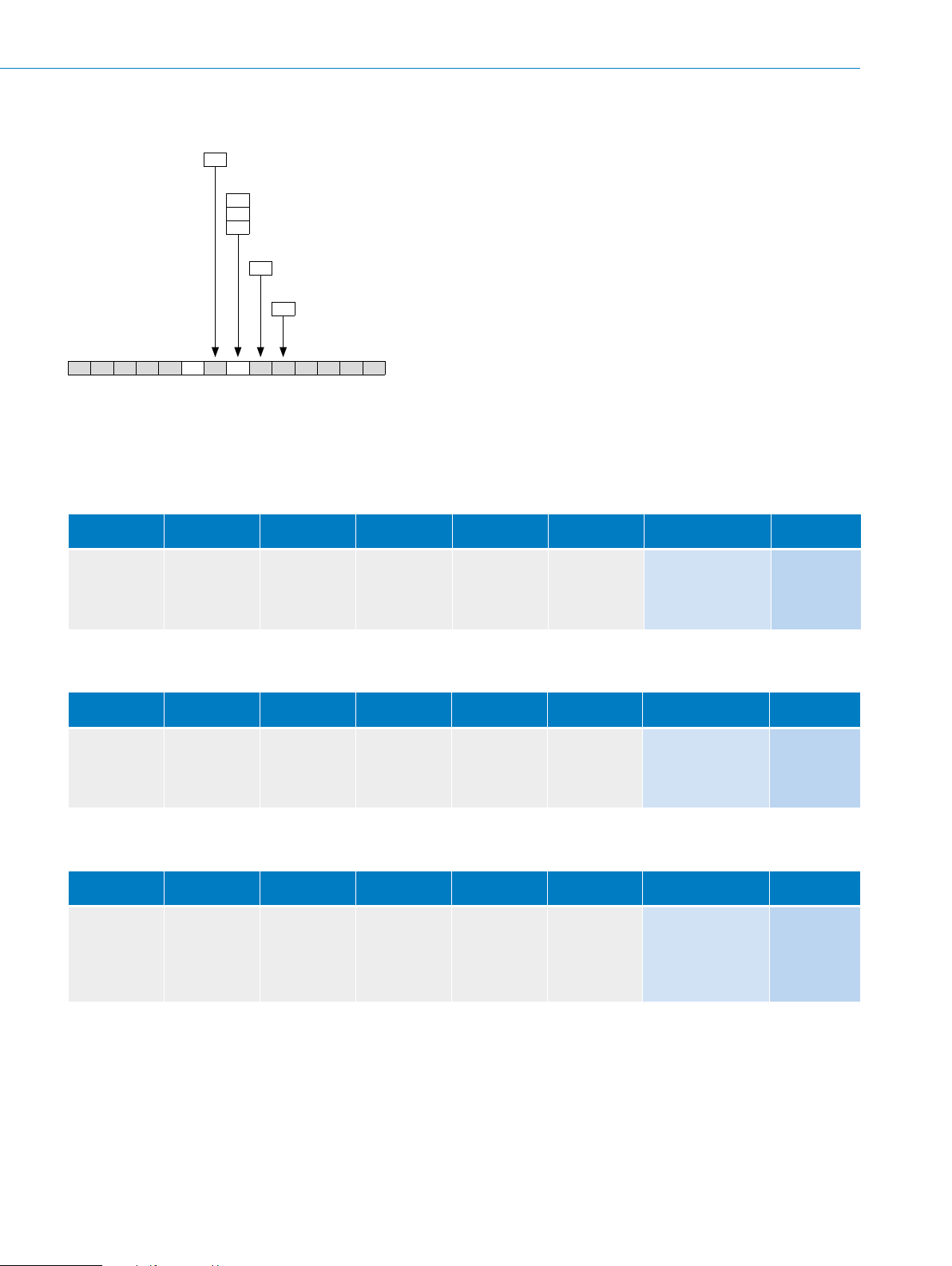

Type code

Electrical interface

P PROFIBUS DP

Mechanical design

1 Solid shaft, servo ange, Ø 6 mm, length 10 mm

4 Solid shaft, face mount ange, Ø 10 mm, length 19 mm

A Blind hollow shaft

Connection type

H Please order PROFIBUS adapter separately, see recommended accessories.

Resolution can be programmed by the customer

A T M 6 0 - P H 1 3 x 1 3

1)

Order collet for 6, 8, 10, 12 and 14 mm or 1/4", 3/8" and 1/2" as separate extra accessories (see recommended accessories). No collets are necessary for 15 mm

shaft diameter.

Ordering information

Solid shaft, face mount ange

1)

Factory setting:13 bit singleturn x 13 bit multiturn

Shaft diam-

eter

Ø 10 mm,

length 19 mm

Electrical

interface

10 V ... 32 V,

PROFIBUS

Connection

type

Bus adapter

with cable

screw xings or

round connec-

tors

Number of

Resolution Programma-

steps

≤ 8,192 8,192 x 8,192

ble

l

Type Part no.

ATM60-P4H13X13 1030013

Solid shaft, servo ange

Shaft diam-

eter

Ø 6 mm,

length 10 mm

Electrical

interface

10 V ... 32 V,

PROFIBUS

Connection

type

Bus adapter

with cable

screw xings or

round connec-

tors

Number of

Resolution Programma-

steps

≤ 8,192 8,192 x 8,192

ble

l

Type Part no.

ATM60-P1H13X13 1030014

Blind hollow shaft

Shaft diam-

eter

6 mm, 8 mm,

10 mm,

12 mm,

14 mm, 15 mm

1/4", 3/8",

1)

1/2"

1)

Order collets for 6, 8, 10, 12 and 14 mm or 1/4", 3/8" and 1/2" as separate extra accessories. No collets are necessary for 15 mm shaft diameter.

Electrical

interface

10 V ... 32 V,

PROFIBUS

Connection

type

Bus adapter

with cable

screw xings or

round connec-

tors

Number of

Resolution Programma-

steps

≤ 8,192 8,192 x 8,192

ble

l

Type Part no.

ATM60-PAH13X13 1030015

G

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

G-389

Page 5

ATM60 PROFIBUS ABSOLUTE ENCODERS

0.2 A

Ø 59.5 (2.34)

120°

Ø 59.5 (2.34)

Dimensional drawings (dimensions in mm)

Face mount ange

18

(0.71)

B

A

(2.12)

+0.1

Ø 53.8

Ø 36 f8 (1.42)

(0.39)

Ø 10 f6

9

(0.35)

0.1 A

0.2 A

19

(0.75)

10

(0.39)

27.8

(1.09)

3

(0.12)

6

(0.24)

74.8 (2.94)

General tolerances according to DIN ISO 2768-mk

Servo ange

0.1 A

A

X

3 x M4

7 (0.28) deep

0.2 B

deep

3 x M4

(0.28)

7

35°

(1.89)

±0.1

Ø 48

120°

G

(0.24)

Ø 6 f6

(2.03)

+0.1

Ø 58 (2.28)

General tolerances according to DIN ISO 2768-mk

Ø 50 f8 (1.97)

51.5

(0.39)

0.2

10

±1

(0.16)

A

4

3

(0.12)

3

(0.12)

27.8

(1.09)

74.8 (2.94)

0.2 A

X

(1.65)

±0.1

Ø 42

25°

G-390

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 6

Blind hollow shaft

83.3 (3.28)

Ø 59.5 (2.34)

Contact edge for customer

on stator coupling

39.3

3.8

(0.15)

2

(0.08)

Ø XF7

(1.55)

max. 30 (1.18)

min. 15 (0.59)

General tolerances according to DIN ISO 2768-mk

ABSOLUTE ENCODERS ATM60 PROFIBUS

30°

(2.48)

Ø 63

X

20

(0.79)

20°

Ø 3.2

+0.1

(0.13)

G

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

G-391

Page 7

ATM60 PROFIBUS ABSOLUTE ENCODERS

2

PIN assignment

Male connector,

Terminal strip

1 1 – – US (24 V) Operating voltage 10 ... 32 V

2 3 – – 0 V (GND) Ground (0 V)

3 – – 4 B B cable PROFIBUS DP (out)

4 – – 2 A A cable PROFIBUS DP (out)

5 – 4 – B B cable PROFIBUS DP (in)

6 – 2 – A A cable PROFIBUS DP (in)

7 – – 1 2P5

8 – – 3 2M

– 2 1 – N. C. –

– 4 3 – N. C. –

– – 5 5 Screen Housing potential

1)

Encoders with a PROFIBUS adapter are equipped with screws (metric/PG) for connecting bus and supply cables. The adapter is unscrewed from the full device to

connect the cables. The following gure shows how the pins are assigned within the adapter.

2)

Use for external bus terminations or to supply the sender/receiver with a optical ber transmission.

4 pin

Male connector,

5 pin

Female connector,

5 pin Signal Explanation

2)

2)

+ 5 V (potential free)

0 V (potential free)

G

1 2 3 4 5 6 7 8 9

US

OV

B

A

B

A

2P5

2M

RTS

1 = Internal plug connector to the encoder

2 = External connection to the bus

1

18

915

G-392

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 8

ABSOLUTE ENCODERS ATM60 PROFIBUS

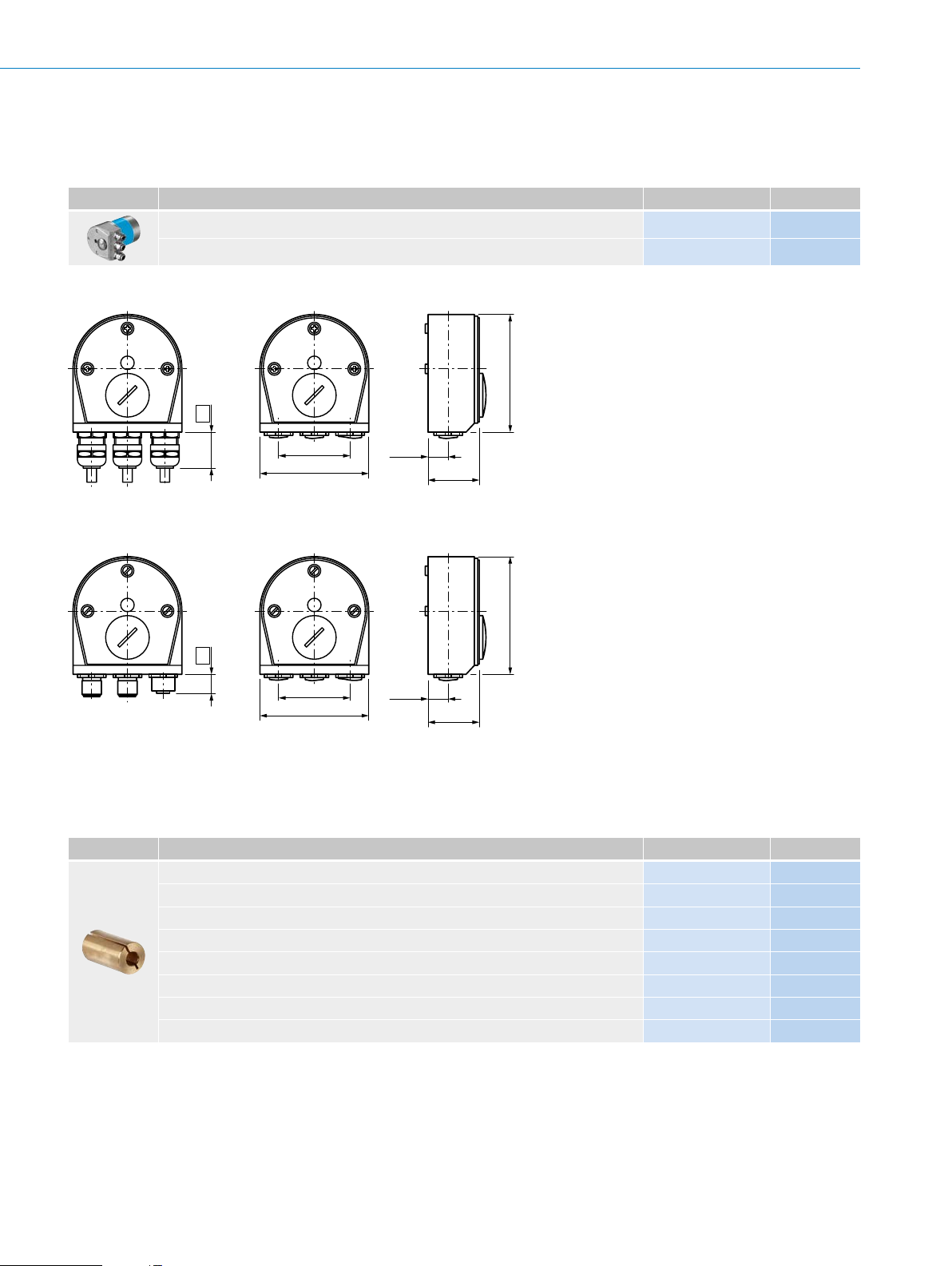

Mandatory accessories

Adapters and distributors

Bus adapters

Figure Brief description Type Part no.

PROFIBUS DP, connection adapter KR3, 3 x PG AD-ATM60-KA3PR 2029225

PROFIBUS DP, connection adapter SR3, 3 x M12, 5-pin AD-ATM60-SR3PR 2031985

AD-ATM60-KA3PR

70

20

43,2

65

12,25

31

General tolerances according to DIN ISO 2768-mk

AD-ATM60-SR3PR

70

13

43,2

65

12,25

31

General tolerances according to DIN ISO 2768-mk

Shaft adaptation

Collets and clamping rings

Figure Brief description Type Part no.

Collet for blind hollow shaft, shaft diameter 6 mm, external diameter 15 mm SPZ-006-AD-A 2029174

Collet for blind hollow shaft, shaft diameter 8 mm, external diameter 15 mm SPZ-008-AD-A 2029176

Collet for blind hollow shaft, shaft diameter 10 mm, external diameter 15 mm SPZ-010-AD-A 2029178

Collet for blind hollow shaft, shaft diameter 12 mm, external diameter 15 mm SPZ-012-AD-A 2029179

Collet for blind hollow shaft, shaft diameter 14 mm, external diameter 15 mm SPZ-014-AD-A 2048863

Collet for blind hollow shaft, shaft diameter 1/2" (12.7 mm), external diameter 15 mm SPZ-1E2-AD-A 2029180

Collet for blind hollow shaft, shaft diameter 1/4" (6.35 mm), external diameter 15 mm SPZ-1E4-AD-A 2029175

Collet for blind hollow shaft, shaft diameter 3/8" (9.525 mm), external diameter 15 mm SPZ-3E8-AD-A 2029177

G

Dimensional drawings g page K-725

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

G-393

Page 9

ATM60 PROFIBUS ABSOLUTE ENCODERS

Recommended accessories

Mounting systems

Mounting brackets and plates

Mounting bracket

Figure Brief description Type Part no.

G

Mounting bracket for encoder with centering hub 36 mm, including mounting kit for face

mount ange

Dimensional drawings g page K-725

BEF-WF-36 2029164

Flanges

Flange plate

Figure Brief description Type Part no.

Flange adapter, adaptation of face mount ange with 36 mm centering hub to 50 mm

servo ange, aluminum, including 3 at head screws M4 x 10

Flange adapter, adaptation of face mount ange with 36 mm centering hub to 60 mm

square mounting plate, aluminum, including 3 at head screws M4 x 10

Flange adapter, adaptation of face mount ange with 36 mm centering hub to 58 mm

square mounting plate with shock absorbers, aluminum

Flange adapter, adaptation of face mount ange with 36 mm centering hub to 100 mm

servo ange with 60 mm centering hub, aluminum

Dimensional drawings g page K-725

BEF-FA-036-050 2029160

BEF-FA-036-060REC 2029162

BEF-FA-036-060RSA 2029163

BEF-FA-036-100 2029161

Other mounting accessories

Measuring wheels and measuring wheel systems

Figure Brief description Type Part no.

Measuring wheel with smooth plastic surface (Hytrel) for 10 mm solid shaft, circumference 200 mm

Measuring wheel with ridged plastic surface (Hytrel) for 10 mm solid shaft, circumference 200 mm

Measuring wheel with smooth plastic surface (Hytrel) for 10 mm solid shaft, circumference 500 mm

Measuring wheel with O-ring (NBR70) for 6 mm solid shaft, circumference 200 mm BEF-MR006020R 2055222

Measuring wheel with O-ring (NBR70) for 6 mm solid shaft, circumference 300 mm BEF-MR006030R 2055634

Measuring wheel with O-ring (NBR70) for 10 mm solid shaft, circumference 300 mm BEF-MR010030R 2049278

Dimensional drawings g page K-725

BEF-MR-010020 5312988

BEF-MR-010020G 5318678

BEF-MR-010050 5312989

Mounting bell

Figure Brief description Type Part no.

Mounting bell for encoders with a servo ange, centering hub 50 mm, including mounting kit

Dimensional drawings g page K-725

G-394

ENCODERS | SICK 8015560/2015-09-01

BEF-MG-50 5312987

Subject to change without notice

Page 10

ABSOLUTE ENCODERS ATM60 PROFIBUS

Servo clamps

Figure Brief description Type Part no.

Half-shell servo clamps (2 pcs.) for servo anges with a 50 mm centering hub BEF-WG-SF050 2029165

Servo clamps, large, for servo anges (clamps, eccentric fastener), 3 pcs., without

mounting material

Dimensional drawings g page K-725

BEF-WK-SF 2029166

Miscellaneous

Figure Brief description Type Part no.

Mounting kit for servo ange encoder on the bearing block, 1 bar coupling SKPS

1520 06/06 1 hexagon socket wrench SW1.5 DIN 911, 3 mounting eccentric BEMN

1242 49 3 screws M4 x 10 DIN 912, 1 hexagon socket wrench SW3 DIN 911

Bearing block for hollow shaft encoder, including xing screws BEF-FA-B12-010 2042728

Bearing block for servo and face mount ange encoder BEF-FA-LB1210 2044591

Dimensional drawings g page K-725

BEF-MK-LB 5320872

Shaft couplings

Figure Brief description Type Part no.

Bellows coupling, shaft diameter 6 mm / 6 mm, maximum shaft offset: radial

± 0.25 mm, axial ± 0.4 mm, angular ± 4°; max. speed 10,000 rpm, –30 °C ... +120 °C,

max. torque 80 Ncm; material: stainless steel bellows, aluminum hub

Bellows coupling, shaft diameter 6 mm / 10 mm, maximum shaft offset: radial

± 0.25 mm, axial ± 0.4 mm, angular ± 4°; max. speed 10,000 rpm, –30 °C ... +120 °C,

max. torque 80 Ncm; material: stainless steel bellows, aluminum hub

Bellows coupling, shaft diameter 10 mm/10 mm; maximum shaft offset: radial

± 0.25 mm, axial ± 0.4 mm, angular ± 4°; max. revolutions 10,000 rpm, -30° to

+120 °C, max. torque 80 Ncm; material: stainless steel bellows, aluminum clamping

hubs

Bellows coupling, shaft diameter 10 mm/12 mm; maximum shaft offset: radial

± 0.25 mm, axial ± 0.4 mm, angular ± 4°; max. revolutions 10,000 rpm, -30° to

+120 °C, max. torque 80 Ncm; material: stainless steel bellows, aluminum clamping

hubs

Bar coupling, shaft diameter 6 mm / 6 mm, maximum shaft offset: radial ± 0.3 mm,

axial ± 0.2 mm, angle ± 3°; max. speed 10,000 rpm, -10° to +80 °C, max. torque

80 Ncm; material: ber-glass reinforced polyamide, aluminum hub

Bar coupling, shaft diameter 6 mm / 8 mm, maximum shaft offset radial ± 0.3 mm, ax-

ial ± 0.2 mm, angle ± 3°; max. speed 10,000 rpm, torsion spring rigidity 38 Nm/wheel;

material: ber-glass reinforced polyamide, aluminum hub

Bar coupling, shaft diameter 6 mm/10 mm, maximum shaft offset: radial ± 0.3 mm,

axial ± 0.2 mm, angular ± 3°; max. speed 10,000 rpm, -10° to +80 °C, max. torque

80 Ncm; material: ber-glass reinforced polyamide, aluminum hub

Bar coupling, shaft diameter 8 mm / 10 mm, maximum shaft offset: radial ± 0.3 mm,

axial ± 0.2 mm, angular ± 3°; torsion spring rigidity 38 Nm/wheel; material: ber-glass

reinforced polyamide, aluminum hub

Bar coupling, shaft diameter 10 mm / 10 mm, maximum shaft offset radial ± 0.3 mm,

axial ± 0.2 mm, angle ± 3°; max. speed 10,000 rpm, torsion spring rigidity 38 Nm/

wheel; material: ber-glass reinforced polyamide, aluminum hub

KUP-0606-B 5312981

KUP-0610-B 5312982

KUP-1010-B 5312983

KUP-1012-B 5312984

KUP-0606-S 2056406

KUP-0608-S 5314179

KUP-0610-S 2056407

KUP-0810-S 5314178

KUP-1010-S 2056408

G

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

G-395

Page 11

ATM60 PROFIBUS ABSOLUTE ENCODERS

Figure Brief description Type Part no.

Double-loop coupling, shaft diameter 6 mm/10 mm, maximum shaft offset: radial

± 2.5 mm, axial ± 3 mm, angular ± 10°; max. speed 3,000 rpm, –30 °C ... +80 °C,

max. torque 1.5 Nm; material: polyurethane, galvanized steel ange

Double-loop coupling, shaft diameter 8 mm/10 mm, maximum shaft offset: radial

± 2.5 mm, axial ± 3 mm, angular ± 10°; max. speed 3,000 rpm, –30 °C ... +80 °C,

max. torque 1.5 Nm; material: polyurethane, galvanized steel ange

Double-loop coupling, shaft diameter 10 mm/10 mm, maximum shaft offset: radial

± 2.5 mm, axial ± 3 mm, angular ± 10°; max. speed 3,000 rpm, –30 °C ... +80 °C,

max. torque 1.5 Nm; material: polyurethane, galvanized steel ange

Double-loop coupling, shaft diameter 10 mm/12 mm, maximum shaft offset: radial

± 2.5 mm, axial ± 3 mm, angular ± 10°; max. speed 3,000 rpm, –30 °C ... +80 °C,

max. torque 1.5 Nm; material: polyurethane, galvanized steel ange

Spring washer coupling, shaft diameter 6 mm/10 mm, maximum shaft offset: radial

± 0.3 mm, axial ± 0.4 mm, angular ± 2.5°; max. speed 12,000 rpm, -10° to +80 °C,

max. torque 60 Ncm; material: aluminum ange, ber-glass reinforced polyamide mem-

brane and tempered steel coupling pin

Spring washer coupling, shaft diameter 10 mm / 10 mm, maximum shaft offset: radial

± 0.3 mm, axial ± 0.4 mm, angular ± 2.5°; max. speed 12,000 rpm, –10° to +80 °C,

max. torque 60 Ncm; material: aluminum ange, glass ber-reinforced polyamide mem-

brane and hardened steel coupling pin

Dimensional drawings g page K-725

Connectivity

KUP-0610-D 5326697

KUP-0810-D 5326704

KUP-1010-D 5326703

KUP-1012-D 5326702

KUP-0610-F 5312985

KUP-1010-F 5312986

G

Plug connectors and cables

Connecting cables with female connector

Figure Brief description Length

Head A: female connector, M12, 5-pin, straight

Head B: cable

Cable: suitable for drag chain, PUR, halogen-free, shielded, 2 x 0.34 mm², Ø

8.0 mm

Head A: female connector, M12, 4-pin, straight

Head B: cable

Cable: for power supply, suitable for drag chain, PVC, unshielded,

4 x 0.25 mm², Ø 5.0 mm

Dimensional drawings g page K-725

Connecting cables with male connector

Figure Brief description Length

Head A: male connector, M12, 5-pin, straight, B-coded

Head B: cable

Cable: suitable for drag chain, PUR, halogen-free, shielded, 2 x 0.34 mm², Ø

8.0 mm

Wire shielding: AL-PT foil, total shield, tin-plated C shield

Type Part no.

of

cable

5 m DOL-1205-G05MQ 6026006

10 m DOL-1205-G10MQ 6026008

12 m DOL-1205-G12MQ 6032636

15 m DOL-1205-G15MQ 6032637

20 m DOL-1205-G20MQ 6032638

30 m DOL-1205-G30MQ 6032639

50 m DOL-1205-G50MQ 6032861

5 m DOL-1204-G05M 6009866

Type Part no.

of

cable

5 m STL-1205-G05MQ 6026005

10 m STL-1205-G10MQ 6026007

12 m STL-1205-G12MQ 6032635

Dimensional drawings g page K-725

G-396

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 12

ABSOLUTE ENCODERS ATM60 PROFIBUS

Female connectors (ready to assemble)

Figure Brief description Type Part no.

Head A: female connector, M12, 4-pin, straight, unshielded, for power supply, for cable

diameter 4 mm ... 6 mm

Head B: -

Head A: female connector, M12, 5-pin, straight, B-coded, shielded, for cable diameter

4 mm ... 9 mm

Head B: -

Dimensional drawings g page K-725

Cables (ready to assemble)

DOS-1204-G 6007302

DOS-1205-GQ 6021353

Figure Brief description Length

Type Part no.

of

cable

Head A: cable

Head B: cable

Cable: suitable for drag chain, PUR, shielded, 2 x 0.25 mm², Ø 8.0 mm

By the

meter

LTG-2102-MW 6021355

Other plug connectors and cables

Figure Brief description Type Part no.

Head A: male connector, M12, 4-pin, straight, B-coded

Cable: terminator

Dimensional drawings g page K-725

STE-END-Q 6021156

Male connectors (ready to assemble)

Figure Brief description Type Part no.

Head A: male connector, M12, 5-pin, straight, B-coded, shielded, for cable diameter

4 mm ... 9 mm

Head B: -

Dimensional drawings g page K-725

- For additional accessories, please see page K-668 onwards

STE-1205-GQ 6021354

G

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

G-397

Loading...

Loading...