Page 1

AOS PRIME

Object Detection Systems

OPERATING INSTRUCTIONS

Page 2

2

8016800/ZPQ5/2017-08-15|SICK

OPERATING INSTRUCTIONS | AOS Prime

Subject to change without notice

Product described

Product name: AOS Prime

Document identification

Title: AOS Prime Operating Instructions

Status: 2017-08-15

Manufacturer

SICK AG

Erwin-Sick-Str. 1 · 79183 Waldkirch · Germany

Trademarks

IBM is a trademark of the International Business Machine Corporation.

only used here for identification purposes.

Original documents

The German version 8016731/ZPQ5 of this document is an original SICK AG

In case of doubt, contact SICK AG or your local agency.

Legal notes

Subject to change without notice

© SICK AG. All rights reserved

Part number: 8016800/ZPQ5

MS-DOS is a trademark of the Microsoft Corporation.

Windows is a trademark of the Microsoft Corporation.

Other product names in this document may also be trademarks and are

document.

SICK AG does not assume liability for the correctness of a non-authorized

translation.

Page 3

3

8016800/ZPQ5/2017-08-15|SICK

Subject to change without notice

OPERATING INSTRUCTIONS | AOS Prime

Contents

CONTENTS

1 About these operating instructions ..............................................................................6

1.1 Described software versions ............................................................................... 6

1.2 Purpose of this document .................................................................................... 6

1.3 Target group ......................................................................................................... 6

1.4 Information depth ................................................................................................ 7

1.5 Abbreviations used ............................................................................................... 7

1.6 Symbols used ....................................................................................................... 8

2 Safety ..............................................................................................................................9

2.1 Qualified personnel .............................................................................................. 9

2.2 Applications of the system ................................................................................... 9

2.3 Intended use ...................................................................................................... 10

2.4 General safety notes and protective measures .............................................. 11

2.4.1 Safety notes and icons ...................................................................... 11

2.4.2 General safety notes .......................................................................... 12

2.4.3 Potential hazardous points ................................................................ 13

2.5 Protecting the environment .............................................................................. 16

3 Product description .................................................................................................... 17

3.1 Scope of delivery ............................................................................................... 17

3.1.1 Scope of delivery, AOS501-AOS504 ................................................. 17

3.1.2 Scope of delivery, AOS101-AOS104 ................................................. 19

3.2 Components in the system ............................................................................... 21

3.2.1 The LMS511/LMS111 laser scanners ............................................. 21

3.2.2 The Flexi Soft control ......................................................................... 22

3.2.3 The test target .................................................................................... 23

3.2.4 The connection box of the laser scanner.......................................... 24

3.3 Principle of operation ........................................................................................ 25

3.4 Status indicators ............................................................................................... 27

3.4.1 LEDs on the LMS111 / LMS511 laser scanner ............................... 27

3.4.2 LEDs on the Flexi Soft ........................................................................ 28

3.5 Parameter memory ........................................................................................... 29

3.5.1 Parameter set on connector plug of the Flexi Soft control unit ....... 29

3.5.2 Parameter set in the laser scanner .................................................. 29

4 Mounting ..................................................................................................................... 30

4.1 Planning mounting locations ............................................................................ 30

4.2 Mounting the laser scanners ............................................................................ 30

4.2.1 General notes ..................................................................................... 30

4.2.2 Mounting the LMS511 laser scanner ............................................... 31

4.2.3 Mounting the LMS 111 laser scanner .............................................. 32

4.3 Mounting the Flexi Soft control ........................................................................ 33

4.4 Mounting and positioning the test targets ....................................................... 34

5 Electrical installation ................................................................................................. 36

5.1 Connecting Flexi Soft to the power supply ....................................................... 36

5.2 Connecting the LMS511 laser scanner ........................................................... 37

5.2.1 Connecting the connection box to the LMS511 laser scanner ....... 37

5.2.2 Connecting the installation cable in the connection box ................. 38

5.2.3 Wiring the installation cable wires to the Flexi Soft control ............. 39

5.2.4 Connecting additional LMS511 laser scanners to Flexi Soft .......... 40

Page 4

CONTENTS

4

8016800/ZPQ5/2017-08-15|SICK

OPERATING INSTRUCTIONS | AOS Prime

Subject to change without notice

5.3 Connecting the LMS111 laser scanner ............................................................41

5.3.1 Using the local connection box ..........................................................41

5.3.2 Using the pre-configured system cables ...........................................46

5.3.3 Connecting additional LMS111 laser scanners to the Flexi

Soft ......................................................................................................49

5.4 Connecting additional I/O modules ..................................................................49

6 Commissioning ............................................................................................................ 50

6.1 Switching on the supply voltage ........................................................................50

6.2 Checking the operating state of the components ............................................50

6.2.1 Checking the operating state of the modular control .......................50

6.2.2 Checking the operating state of the laser scanners .........................51

6.3 Configuring laser scanners using SOPAS .........................................................52

6.3.1 Overview ..............................................................................................52

6.3.2 Preparation work.................................................................................54

6.3.3 Loading laser scanners into the SOPAS project ................................56

6.3.4 Notes on the configuration interface .................................................61

6.3.5 Configuring monitoring fields .............................................................62

6.3.6 Configuring evaluation cases .............................................................73

6.3.7 Testing the infringement of the monitoring fields .............................75

6.3.8 Transferring and saving parameters to the device ...........................76

6.3.9 Exporting the device ...........................................................................77

6.4 Configuring the modular control with Flexi Soft Designer ..............................78

6.4.1 Preparation work.................................................................................79

6.4.2 Opening the project file containing the parameter set .....................81

6.4.3 Transferring the parameter set to the control unit ...........................82

6.4.4 Testing the configuration ....................................................................86

6.4.5 Verifying and saving the configuration ..............................................88

6.4.6 Preventing the configuration from being overwritten .......................89

6.4.7 Final steps ...........................................................................................89

6.5 Check the stopping and warning response of the application ........................90

7 Maintenance ................................................................................................................ 91

7.1 Overview of maintenance tasks ........................................................................91

7.2 Maintenance during operation ..........................................................................91

7.2.1 Visual inspection .................................................................................91

7.2.2 Cleaning the laser scanners ...............................................................92

7.3 Replacing components ......................................................................................92

7.3.1 Replacing a laser scanner ..................................................................93

7.3.2 Replacing Flexi Soft control modules ................................................93

8 Fault diagnosis ............................................................................................................ 95

8.1 Response to faults .............................................................................................95

8.2 SICK Support ......................................................................................................95

8.3 Component fault indicators ...............................................................................95

8.3.1 Fault indicator on the LMS511 / LMS111 laser scanners ..............95

8.3.2 Flexi Soft control fault indicator .........................................................96

8.4 Diagnostics .........................................................................................................98

8.4.1 Laser scanner diagnostics .................................................................98

8.4.2 Flexi Soft diagnostics ..........................................................................99

Page 5

CONTENTS

5

8016800/ZPQ5/2017-08-15|SICK

Subject to change without notice

OPERATING INSTRUCTIONS | AOS Prime

9 Technical specifications ........................................................................................... 101

9.1 AOS101 - AOS104 / AOS104 RTG ................................................................. 101

9.1.1 Features ............................................................................................ 101

9.1.2 Performance ..................................................................................... 101

9.1.3 Interfaces .......................................................................................... 101

9.1.4 Mechanics/electronics .................................................................... 101

9.1.5 Ambient data .................................................................................... 102

9.2 AOS501 - AOS504 / AOS502 STS .................................................................. 103

9.2.1 Features ............................................................................................ 103

9.2.2 Performance ..................................................................................... 103

9.2.3 Interfaces .......................................................................................... 103

9.2.4 Mechanics/electronics .................................................................... 103

9.2.5 Ambient data .................................................................................... 104

9.3 AOS Prime dimensional drawings .................................................................. 105

9.3.1 Dimensional drawing of the LMS511 laser scanner...................... 105

9.3.2 Dimensional drawing of the LMS111 laser scanner...................... 108

9.3.3 Dimensioned drawing of the FX3CPU0 main module with

system plug ...................................................................................... 110

9.3.4 Dimensional drawing of the FX3-XTIO expansion module ............. 110

9.4 Electrical wiring diagrams ............................................................................... 111

9.4.1 Connection tables ............................................................................ 111

9.4.2 AOS501 wiring diagram ................................................................... 113

9.4.3 AOS502 wiring diagram ................................................................... 116

9.4.4 AOS503 wiring diagram ................................................................... 119

9.4.5 AOS504 wiring diagram ................................................................... 122

9.4.6 AOS101 wiring diagram ................................................................... 125

9.4.7 AOS102 wiring diagram ................................................................... 128

9.4.8 AOS103 wiring diagram ................................................................... 131

9.4.9 AOS104 wiring diagram ................................................................... 134

10 Appendix .................................................................................................................... 137

10.1 List of tables .................................................................................................... 137

10.2 List of figures ................................................................................................... 138

10.3 Keywords index ............................................................................................... 140

Page 6

1 ABOUT THESE OPERATING INSTRUCTIONS

6

8016800/ZPQ5/2017-08-15|SICK

OPERATING INSTRUCTIONS | AOS Prime

Subject to change without notice

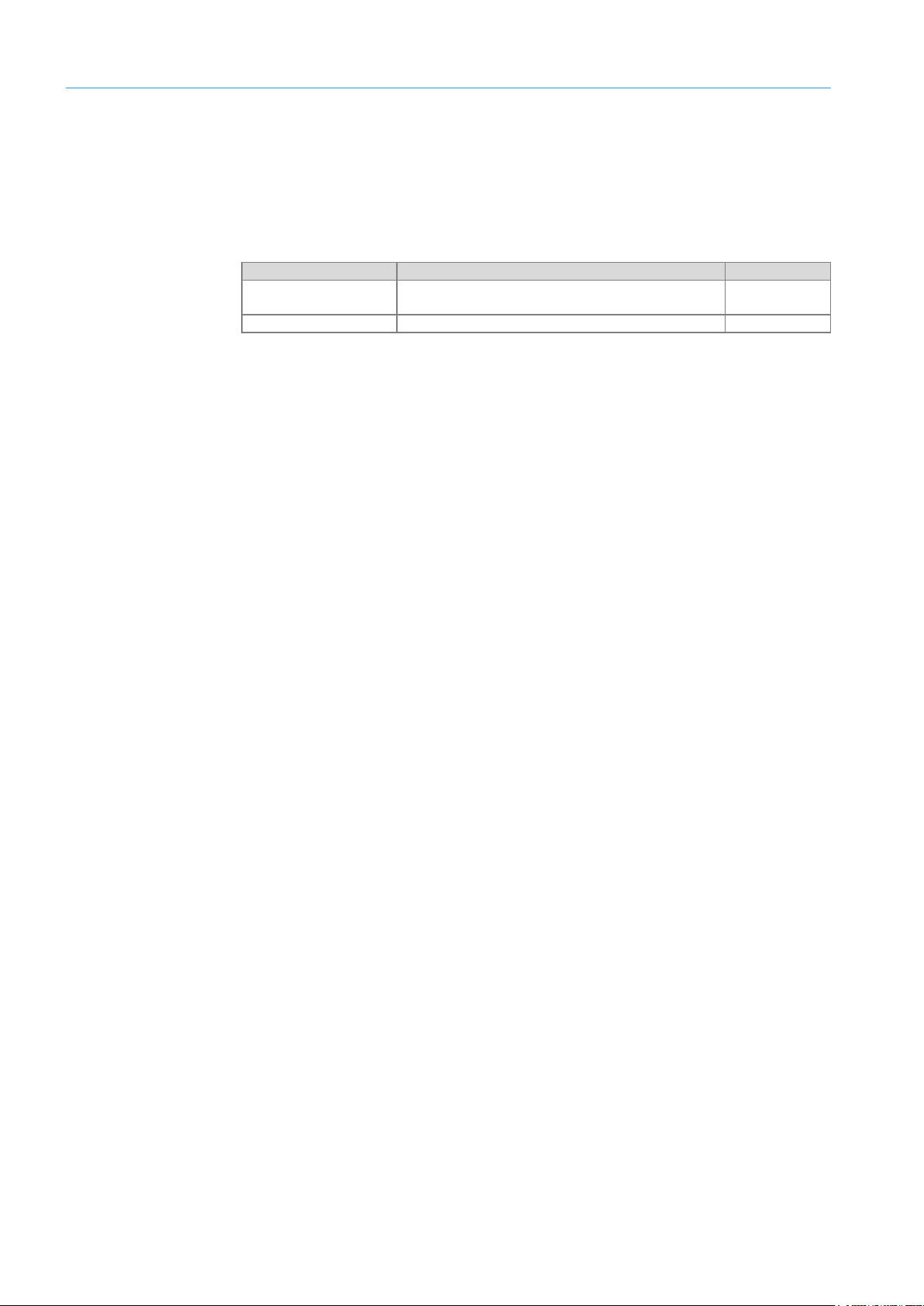

Software

Function

Status

SOPAS ET

SICK Engineering Tool for the configuration and

diagnostics of the AOS Prime

≥ V 3.0

FSD Flexi Soft Designer

Configuration and diagnostic software for the control

≥ V 1.7

1 About these operating instructions

Please read through this chapter carefully before you use the documentation and work

with the AOS Prime.

1.1 Described software versions

Tab. 1: Software versions

1.2 Purpose of this document

These operating instructions are designed to give technical personnel instructions on

the safe mounting, configuration, electrical installation, commissioning, operation, and

maintenance of the AOS Prime object detection systems.

These operating instructions do not provide information on operating the customer

system into which the AOS Prime has been or is going to be integrated. Additional

information on this can be found in the customer documentation.

1.3 Target group

These operating instructions are intended for persons integrating the AOS Prime into a

machine, system or vehicle and performing initial commissioning and operation. They

are also intended for the planners, developers and operating entities of machines and

systems.

Page 7

7

8016800/ZPQ5/2017-08-15|SICK

Subject to change without notice

OPERATING INSTRUCTIONS | AOS Prime

1.4 Information depth

ABOUT THESE OPERATING INSTRUCTIONS 1

Note

These operating instructions contain information about the AOS Prime object detection

system on the following topics:

• Product description

• Mounting

• Electrical installation

• Commissioning and configuration

• Maintenance and care

• Fault diagnosis and troubleshooting

• Technical data and dimensional drawings

When planning and using object detection systems such as the AOS Prime, technical skills

are required that are not covered by this document.

The applicable official and legal regulations at the application site must always be

complied with when operating the system.

Note

Further information about the device components used in the AOS Prime can be found in

the accompanying operating instructions.

1.5 Abbreviations used

AOS

LMS

AWG

SOPAS

FSD

EDM

ESD

PLC

Advanced object detection system

Measurement sensor = laser scanner from SICK AG

American wire gage = standardization and classification of wires and cables according to

type, diameter, etc.

SICK Engineering Tool = software for configuring and diagnosing the LMS111 and

LMS511 laser scanner

Flexi Soft Designer = software for Flexi Soft safety controller configuration and diagnostics

External device monitoring

Electrostatic discharge

Programmable logic control

Page 8

1 ABOUT THESE OPERATING INSTRUCTIONS

8

8016800/ZPQ5/2017-08-15|SICK

OPERATING INSTRUCTIONS | AOS Prime

Subject to change without notice

,

1.6 Symbols used

Recommendation

Note

1. / 2. ...

Step by step

Action

Recommendations are designed to assist you in the decision-making process with respect

to the use of a certain function or technical measure.

Notes provide information about the features of a device, application tips, or other useful

information.

Instructions that must be carried out in the described order are referred to as step-by-step

instructions and are indicated by numbered lists. Carefully read and follow the

instructions for action.

Instructions for taking action are indicated by an arrow. Carefully read and follow the

instructions for action.

LED icons describe the status of a diagnostics LED.

The LED is illuminated continuously.

The LED is flashing.

The LED is off.

Display symbols show the status of the 7-segment display:

Constant display of characters, e.g., U

Flashing display of characters, e.g., 8

Alternating display of characters, e.g., L and 2

Page 9

9

8016800/ZPQ5/2017-08-15|SICK

Subject to change without notice

OPERATING INSTRUCTIONS | AOS Prime

2 Safety

This chapter concerns your own safety and the safety of the system operator.

Please read through this chapter carefully before using the AOS Prime or the machines /

▸

systems monitored by the AOS Prime.

2.1 Qualified personnel

The AOS Prime must only be mounted, commissioned, and maintained by adequately

qualified personnel.

A qualified person

• has sufficient skills in the field of the respective equipment based on their technical

training and experience and

• has been instructed by the manufacturer in system operation and all applicable safety

guidelines and

• is familiar with all relevant country-specific occupational safety regulations, work safety

regulations, guidelines, and generally accepted technical rules and standards (e.g.,

DIN standards, VDE regulations, country-specific rules) to such an extent that he/

she is able to evaluate the safe condition of the power-driven machinery and he/she

• has access to and has read the operating instructions.

SAFETY 2

2.2 Applications of the system

The AOS Prime (Advanced Object Detection System) is a non-contact, self-testing object

detection system that is used to protect against collisions.

The AOS Prime is used in monitoring applications where a stand-alone laser scanner is

not sufficient and high operational reliability of the system provides added value.

Page 10

2 SAFETY

10

8016800/ZPQ5/2017-08-15|SICK

OPERATING INSTRUCTIONS | AOS Prime

Subject to change without notice

2.3 Intended use

AOS Prime may only be used as described in section 2.2 Applications of the system. It

may only be used by qualified personnel in the environment in which it was mounted and

initially commissioned by qualified safety personnel in accordance with these operating

instructions.

Note

Note

The AOS Prime object detection system is not a safety device for human protection

and it therefore does not comply with any safety standards. For safety applications,

please contact SICK AG.

The AOS does not offer protection from flying parts or against radiation.

The AOS satisfies the requirements of Class A (industrial application) of the generic

standard for radiated emission.

In the event of any other usage or of modification to the system – including in the context

of mounting and installation – any claims against SICK AG under the warranty will be

rendered void.

Page 11

11

8016800/ZPQ5/2017-08-15|SICK

Subject to change without notice

OPERATING INSTRUCTIONS | AOS Prime

2.4 General safety notes and protective measures

HAZARD

WARNING

WARNING

NOTE

2.4.1 Safety notes and icons

The following safety and hazard notes concern your own safety, the safety of third parties,

and the safety of the devices. You must therefore observe these symbols at all times.

Denotes an immediate hazard that may result in severe to fatal injuries.

The symbol shown on the left-hand side of the note refers to the type of hazard in

question (the example here shows a risk of injury resulting from electrical current).

Denotes a potentially dangerous situation that may result in severe to fatal injuries.

The symbol shown on the left-hand side of the note refers to the type of hazard in

question (the example here shows a risk of damage to the eye by laser beams).

SAFETY 2

Denotes a potentially dangerous situation that may result in minor personal injury or

possible material damage.

Denotes a potential risk of damage or functional impairment of the device or the devices

connected to it.

This icon refers to supplementary technical documentation.

Page 12

2 SAFETY

12

8016800/ZPQ5/2017-08-15|SICK

OPERATING INSTRUCTIONS | AOS Prime

Subject to change without notice

WARNING

WARNING

2.4.2 General safety notes

The AOS Prime has been designed in a way that allows for safe operation. Protective

devices reduce potential risks to the maximum possible extent. However, a certain level

of risk will always remain.

Awareness of potential hazardous points in the system will help you to work in a safer

manner and thus prevent accidents.

To avoid risks, please also observe the special warnings in each of the individual

chapters.

Safety notes

Observe the following to ensure the intended use of the AOS Prime as intended.

• The notes in these operating instructions (e.g. regarding use, mounting, installation,

or integration into the machine control) must be observed.

• All official and statutory regulations governing the operation of the system must be

complied with.

• The national and international legal specifications apply to the installation and use of

the system, to its commissioning, and to recurring technical inspections, in particular:

– Work safety regulations and safety rules

– Any other relevant safety provisions

• The manufacturer and user of the system are responsible for coordinating and

complying with all applicable safety specifications and regulations in cooperation with

the relevant authorities.

• The checks must be carried out by qualified safety personnel or specially qualified and

authorized personnel and must be recorded and documented to ensure that the tests

can be reconstructed and retraced at any time.

• These operating instructions must be made available to the operator of the system in

which the AOS Prime is used. The system operator must be instructed by qualified

safety personnel and must read the operating instructions.

• Maintenance and repair work must only be done by trained and authorized SICK AG

service technicians or qualified safety personnel of the customer.

The AOS Prime is not suitable for the protection of humans within the meaning of the

applicable safety standards for machines. The system therefore does not comply with

safety standards.

Page 13

13

8016800/ZPQ5/2017-08-15|SICK

Subject to change without notice

OPERATING INSTRUCTIONS | AOS Prime

2.4.3 Potential hazardous points

WARNING

HAZARD

Laser radiation

Damage to the eye by laser beam

The LMS111 or LMS511 laser scanners used in the AOS Prime conform to laser class 1

(eye-safe) criteria according to IEC 60825-1 (latest version); see laser warning plate on

the device for publication date. This ensures compliance with 21 CFR 1040.10 except for

the tolerances according to Laser Notice No. 50 of July 26, 2001.

The laser beam operates at a wavelength of γ = 905 nm (invisible infrared light). The laser

beam is not visible to the human eye.

The radiation emitted in normal operation is harmless to human skin and eyes.

WARNING

Important

Improper use (e.g., opening the housing and stopping the motor) can result in dangerous

exposure to radiation.

Never open the laser scanner housing. Opening the housing does not interrupt the

▸

operation of the laser beam.

Pay attention to the laser safety regulations as per IEC 60 8251 (latest version).

▸

• No maintenance is required to ensure compliance with laser class 1.

• The laser output aperture is the inspection window on the laser scanner.

• The laser warning is located on the right side of the laser scanner.

SAFETY 2

Electrical current

Risk of injury and damage caused by electrical current

Improper handling of live devices may lead to severe personal injury or death by electric

shock.

Electrical installation and maintenance work must always be carried out by personnel

▸

authorized to do so.

The power supply must be disconnected when attaching and detaching electrical

▸

connections.

Select and implement wire cross-sections and their correct fuse protection in accordance

▸

with the applicable standards.

Do not touch any live parts.

▸

In the event of danger, immediately disconnect the object detection system from the

▸

power supply.

Always use original fuses with the specified current rating.

▸

Report any damaged cables to the maintenance team without delay.

▸

Observe the up-to-date safety regulations when working on electrical systems.

▸

Page 14

2 SAFETY

14

8016800/ZPQ5/2017-08-15|SICK

OPERATING INSTRUCTIONS | AOS Prime

Subject to change without notice

HAZARD

HAZARD

WARNING

NOTE

Damaging potential equalization currents due to different ground potentials

The AOS Prime has been designed and tested for electrical safety in accordance with

EN 60 950-1 (2006-04) and EN 60 950-1/A11 (2009-03).

The AOS Prime is connected to the peripheral devices (power supply, PLC/host, any other

sensors, etc.) via shielded cables. The shield of each cable is connected to the metal

housing of the corresponding system components via the system plug.

If the peripheral devices have metal housings and if the cable shields are also connected

to these housings, it is assumed that all devices involved in the system have the same

ground potential.

This is achieved, for example, by complying with the following conditions:

• Mounting the devices on conductive metal surfaces.

• Correctly grounding the devices and metal surfaces in the system.

• Low-impedance and current-carrying equipotential bonding between areas with

different ground potentials, if necessary.

If these conditions are not met, e.g., on devices in a widely distributed system spanning

several buildings, different ground potentials may cause potential equalization currents to

flow along the cable shields between the devices, thereby creating hazards.

Risk of injury and damage caused by potential equalization currents

Potential equalization currents between the AOS Prime and the peripheral devices can

have the following effects:

• Dangerous voltages on the metal housing, e.g., of the laser scanner.

• Incorrect functioning of or irreparable damage to the devices

• Damage/irreparable damage to the cable shields due to heating and cable fires

Commissioning/operation/maintenance

Risk resulting from incorrect commissioning and configuration

Do not commission without testing by qualified personnel!

Before carrying out initial commissioning of the system, you must have it checked and

approved by qualified safety personnel.

Claims under the warranty rendered void

The housings of the devices must not be opened. The devices are sealed.

If the device is opened, any warranty claims against SICK AG will be void.

Page 15

SAFETY 2

15

8016800/ZPQ5/2017-08-15|SICK

Subject to change without notice

OPERATING INSTRUCTIONS | AOS Prime

WARNING

Risk resulting from faults

Cease operation if the cause of the malfunction has not been clearly identified.

Immediately stop system operation if you cannot clearly identify the fault and if you

▸

cannot safely remedy the problem.

Page 16

2 SAFETY

16

8016800/ZPQ5/2017-08-15|SICK

OPERATING INSTRUCTIONS | AOS Prime

Subject to change without notice

2.5 Protecting the environment

The components of the object detection system have been designed to minimize their

impact on the environment. They consume little power and natural resources.

Always act in an environmentally responsible manner at work. For this reason, please note

the following information regarding disposal.

Disposal after final decommissioning

Always dispose of unusable or irreparable devices in accordance with the applicable

▸

waste disposal regulations specific to your country.

Remove the plastic parts and recycle the aluminum housing of the laser scanner.

▸

Dispose of all electronic assemblies as hazardous waste. The electronic assemblies are

▸

easy to dismantle.

Note

SICK AG does not take back devices that are unusable or irreparable.

Page 17

17

8016800/ZPQ5/2017-08-15|SICK

Subject to change without notice

OPERATING INSTRUCTIONS | AOS Prime

3 Product description

NOTE

This chapter provides information on the special properties of the AOS Prime object

detection system. It describes the construction and operating principle of the system,

in particular the interaction of the different components.

Note

3.1 Scope of delivery

Always read this chapter before you mount, install, and commission the system.

The AOS Prime object detection system is available in two configuration groups: AOS10x

and AOS50x. Different expansion stages result corresponding to the number of LMS laser

scanners and the expansion modules of the control.

Thorough check for completeness

It is recommended that you carefully check for and report transport damage of any kind

▸

as soon as possible after receiving the system.

Also verify that the delivery includes all components listed on the delivery note.

▸

PRODUCT DESCRIPTION 3

3.1.1 Scope of delivery, AOS501-AOS504

The AOS501 configuration consists of a pre-configured LMS511 laser scanner, the

Flexi Soft control (comprising the main module and an I/O expansion module) and a

connection box for bridging large distances between the laser scanner and the terminal

compartment.

Fig. 1: Main components of the AOS Prime AOS501

Page 18

3 PRODUCT DESCRIPTION

18

8016800/ZPQ5/2017-08-15|SICK

OPERATING INSTRUCTIONS | AOS Prime

Subject to change without notice

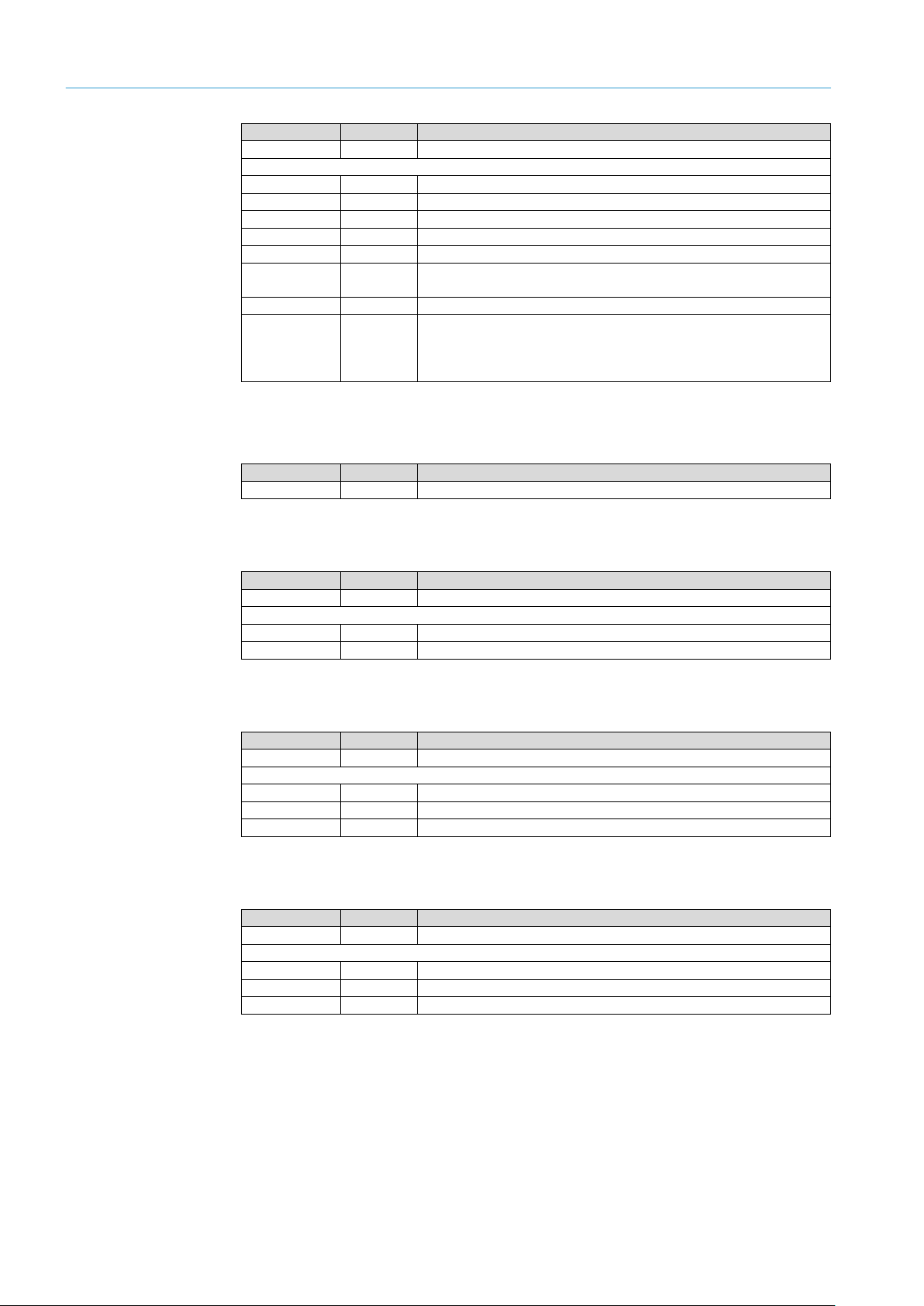

Part No.

Quantity

Description

1064409

1

AOS501

Consisting of:

1057618

1

Laser scanner LMS511-10100S02

1043783

1

Flexi Soft main module FX3-CPU000000

1043700

1

Flexi Soft system plug FX3-MPL000001

1044125

1

Flexi Soft I/O module FX3-XTIO84002

6034574

1

USB configuration connection DSL-8U04G02M025KM1

2073337

1

USB stick with configuration file (prepared configuration for control

and laser scanner) as well as device and system documentation

6030928

1

Ethernet connection cable SSL-2J04-G10ME

1059092

1

LMS511 laser scanner accessory set 1, consisting of:

connection box

Part No.

Quantity

Description

2063050

1

Weather hood 180° LMS511

Part No.

Quantity

Description

1066130

1

AOS502

Consisting of:

1057618

2

Laser scanner LMS511-10100S02

1059092

2

Laser scanner LMS511 accessory set 1

Part No.

Quantity

Description

1066131

1

AOS503

Consisting of:

1057618

3

Laser scanner LMS511-10100S02

1044125

2

Flexi Soft I/O module FX3-XTIO84002

1059092

3

Laser scanner LMS511 accessory set 1

Part No.

Quantity

Description

1066132

1

AOS504

Consisting of:

1057618

4

Laser scanner LMS511-10100S02

1044125

2

Flexi Soft I/O module FX3-XTIO84002

1059092

4

Laser scanner LMS511 accessory set 1

AOS501

The “SOPAS” and Flexi Soft Designer configuration tools can be downloaded at

www.sick.com.

Optional

AOS502

Scope of delivery includes the same items listed for the AOS501, except for the following

differences:

Connection box for power, I/O and RS-232/-422 data

Mounting kit for mounting the laser scanner and

AOS503

AOS504

Scope of delivery includes the same items listed for the AOS501, except for the following

differences:

Scope of delivery includes the same items listed for the AOS501, except for the following

differences:

Page 19

19

8016800/ZPQ5/2017-08-15|SICK

Subject to change without notice

OPERATING INSTRUCTIONS | AOS Prime

3.1.2 Scope of delivery, AOS101-AOS104

Part No.

Quantity

Description

1064408

1

AOS101

Consisting of:

1047516

1

Laser scanner LMS111-10100S01

1043783

1

Flexi Soft main module FX3-CPU000000

1043700

1

Flexi Soft system plug FX3-MPL000001

1044125

1

Flexi Soft I/O module FX3-XTIO84002

6034574

1

USB configuration connection DSL-8U04G02M025KM1

operating instructions

2062346

1

Connection box for power, I/O and RS-232/RS-422 data (not

Ethernet), with three pre-wired M12 cables, 8-pin

2046025

1

Mounting kit for laser scanner

6030928

1

Ethernet connection cable SSL-2J04-G10ME

Part No.

Quantity

Description

2046458

1

LMS111 weather hood 270°

Part No.

Quantity

Description

1066127

1

AOS102

Consisting of:

1047516

2

Laser scanner LMS111-10100S01

2062346

2

Connection box

2046025

2

Mounting kit for laser scanner

The AOS101 configuration consists of a pre-configured LMS111 laser scanner and the

Flexi Soft control, which consists of the main module and an I/O expansion module. The

laser scanner is connected to the Flexi Soft control via pre-wired configuration cables.

Fig. 2: Main components of the AOS Prime AOS101

AOS101

PRODUCT DESCRIPTION 3

Optional

AOS102

2073337 1 USB stick with configuration files and “AOS Prime”

The “SOPAS” and Flexi Soft Designer configuration tools can be downloaded at

www.sick.com.

Scope of delivery includes the same items listed for the AOS101, except for the following

differences:

Page 20

3 PRODUCT DESCRIPTION

20

8016800/ZPQ5/2017-08-15|SICK

OPERATING INSTRUCTIONS | AOS Prime

Subject to change without notice

Part No.

Quantity

Description

1066128

1

AOS103

Consisting of:

1047516

3

Laser scanner LMS111-10100S01

1044125

2

Flexi Soft I/O module FX3-XTIO84002

2062346

3

Connection box

2046025

3

Mounting kit for laser scanner

Part No.

Quantity

Description

1066129

1

AOS104

Consisting of:

1047516

4

Laser scanner LMS111-10100S01

1044125

2

Flexi Soft I/O module FX3-XTIO84002

2062346

4

Connection box

2046025

4

Mounting kit for laser scanner

AOS103

AOS104

Scope of delivery includes the same items listed for the AOS101, except for the following

differences:

Scope of delivery includes the same items listed for the AOS101, except for the following

differences:

Page 21

21

8016800/ZPQ5/2017-08-15|SICK

Subject to change without notice

OPERATING INSTRUCTIONS | AOS Prime

3.2 Components in the system

3.2.1 The LMS511/LMS111 laser scanners

The LMS511 or LMS111 laser scanners, whose use depends on the application requirements, are laser measurement sensors that scan their environment in two dimensions

using a time-of-flight method. When a sent laser beam is reflected by a target object, the

position of the object is determined as a distance and an angle and output to the data

interface and supplied to the internal field evaluation.

The laser output occurs at the front screen. It is indicated by a corresponding mark.

Fig. 3: Laser output aperture on the LMS511 / LMS111 laser scanner

Different monitoring fields are defined within the scanning range of the laser scanners

(scanning range). Each monitoring field is linked to at least one evaluation case; the

assigned switching output is triggered if the respective field is infringed (object detection

in the monitoring field).

The LMS511 laser scanner has a monitoring radius of 80 m / 38 m for black objects with

10% remission and a scanning angle of 190°. The monitoring radius of the LMS111 laser

scanner is 20 m / 18 m for black objects with 10% remission. The scanning angle is 270°.

All input and output signals from the laser scanner are directly connected to the central

Flexi Soft control, which evaluates the laser scanner information accordingly (see below).

The laser measurement sensors are designed for outdoor use in harsh ambient conditions.

In order to withstand such conditions, the devices have various filter technologies and an

internal heater. They are also equipped with weather hoods.

Both laser scanners feature automatic contamination measuring for the front screen.

The contamination signals can be merged using the central Flexi Soft control and can be

output via a shared application diagnostic output.

PRODUCT DESCRIPTION 3

Page 22

3 PRODUCT DESCRIPTION

22

8016800/ZPQ5/2017-08-15|SICK

OPERATING INSTRUCTIONS | AOS Prime

Subject to change without notice

Note

The laser scanner can evaluate multiple reflection pulses. Additional reflective pulses occur

when the laser beam hits smaller particles such as snowflakes or raindrops. In very harsh

environments, the laser scanner can also be switched to evaluate the last echo if necessary.

Fig. 4: Evaluation of reflection pulses by the laser scanner

For detailed information about the operating principle of the LMS laser scanner, please

refer to the operating instructions of the respective devices.

3.2.2 The Flexi Soft control

The Flexi Soft control consists of the CPU0 central main module (1) and at least one XTIO

I/O expansion module (2).

Note

Fig. 5: Flexi Soft safety control components

• The CPU0 main module is the central logic unit of the control. Here, all signals are

analyzed and evaluated within the configured logic. The result of this processing is

transmitted to the higher-level machine or system control via the I/O module.

The configuration can be edited and adapted to the requirements of the individual

application. For this purpose, the main module has an M8 configuration connection.

• The XTIO I/O expansion module provides the I/O input and output signals from

the AOS Prime. The communication with the connected laser scanners and with the

downstream machine control occurs via the switching signals of the AOS Prime.

One XTIO I/O expansion module is necessary for every two laser scanners. One laser

scanner uses three switching inputs in the basic version. Signals are communicated to

the upper-level system control via switching outputs.

It is possible to attach additional XTIO modules according to the expansion desired.

In total, the control can be used to operate up to 12 modules (144 I/O signals).

Different configurations are supplied for the Flexi Soft control. The appropriate control

configuration for the system can be carried out by downloading a file. This file already

contains all AOS functions necessary for checking both the object detection system and

the internal self-test of the sensors.

Page 23

23

8016800/ZPQ5/2017-08-15|SICK

Subject to change without notice

OPERATING INSTRUCTIONS | AOS Prime

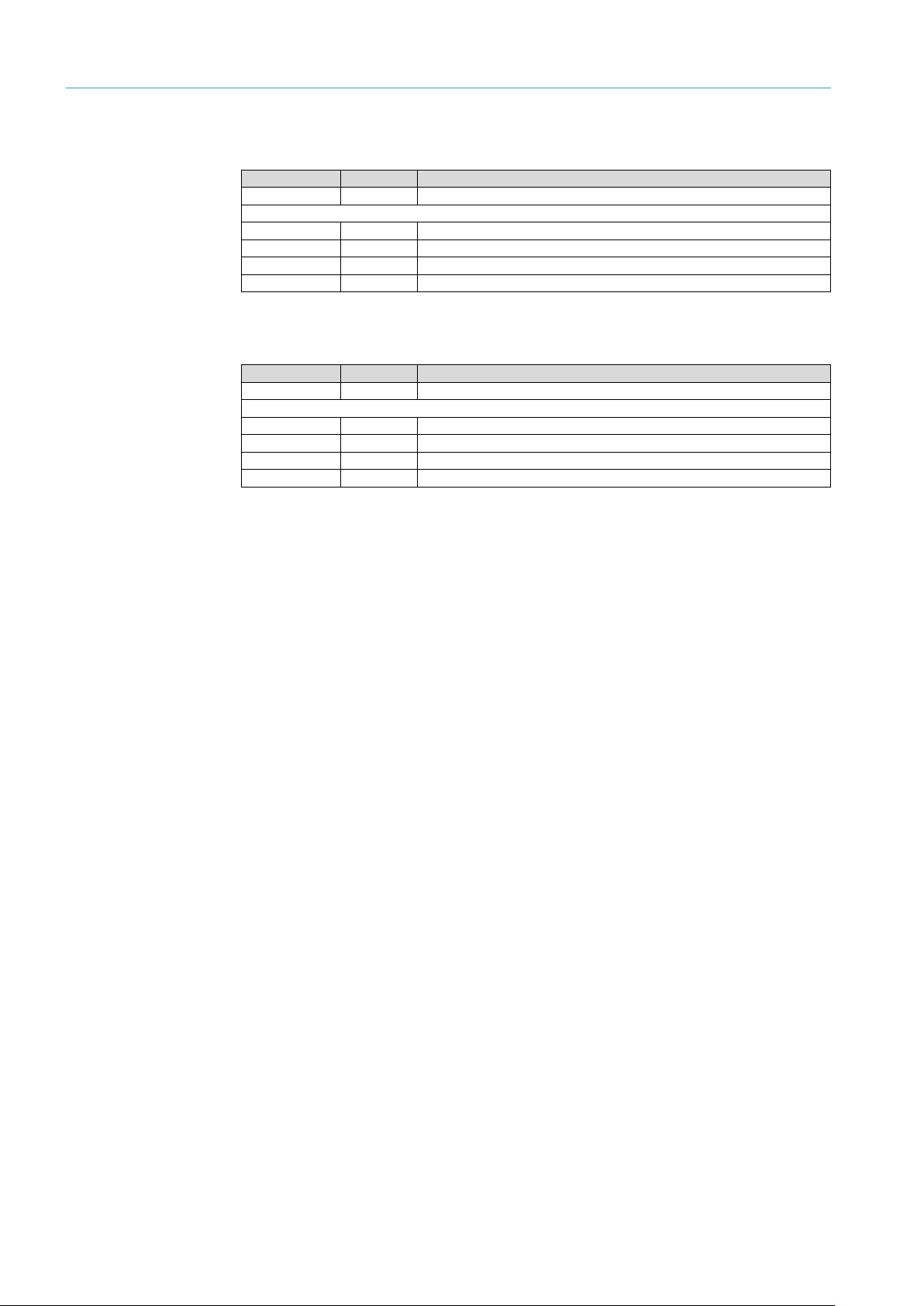

3.2.3 The test target

No.

Meaning

1

Monitoring field

2

Test target

The self-diagnosis of the object detection system occurs via the continuous detection of

an external test target. During this process, the corresponding scanner monitoring field

is infringed by the test target. Only by using external test targets can the full functional

range of the AOS Prime object detection system be ensured.

At least one external test target is required for each laser scanner. It is also possible to

use a shared test target for multiple laser scanners.

A stationary body located outside the actual object detection monitoring area can be used

as a test target.

PRODUCT DESCRIPTION 3

Note

Fig. 6: Detection of a test target

Tab. 2: Status indicators on the Flexi Soft main module

The surface of the test target should be flat. For example, sheets, panels or even a

suitable part of the monitored machine are appropriate test targets. In order to avoid

reflections on the surface of the external test target, the area of the test target must not

be covered with a glossy coating. The color of the test target should be consistent with

the color of the objects that are to be detected.

The width of the test target must be at least 30 mm. The following applies to the minimum

width of the test target as a rule of thumb at distances > 1.5 m to the test target:

Width of test target [mm] = target scanning range [mm] / 50.

To determine the exact diameter of the light spot, please consult the operating

instructions for the corresponding laser scanner.

Alternatively, it is possible to use a stationary machine or system part as a test target.

Page 24

3 PRODUCT DESCRIPTION

24

8016800/ZPQ5/2017-08-15|SICK

OPERATING INSTRUCTIONS | AOS Prime

Subject to change without notice

3.2.4 The connection box of the laser scanner

Using the connection box, connecting the laser scanner and the control cabinet to the

Flexi Soft control is easy. The connection box is delivered with the AOS Prime systems by

default.

Separate installation cables are routed from the Flexi Soft to the connection box on-site

to produce the connection. The connection box is connected to the laser scanner via the

pre-configured cables (see chapter 5.1 Connecting the LMS511 laser scanner).

When using the AOS Prime in the AOS10x configuration, the LMS111 laser scanners

are also connected to the Flexi Soft using the configured connection box or using system

cables (max. 20 m) (see chapter 5.2 Connecting the LMS111 laser scanner).

Page 25

25

8016800/ZPQ5/2017-08-15|SICK

Subject to change without notice

OPERATING INSTRUCTIONS | AOS Prime

3.3 Principle of operation

The AOS Prime is a self-testing object detection system whose functionality as a whole is

monitored by the Flexi Soft safety control.

Monitoring fields and evaluation cases

The monitored area scanned by the laser scanners is divided into different fields. The size

and geometry of the monitoring fields can vary and must be configured on-site.

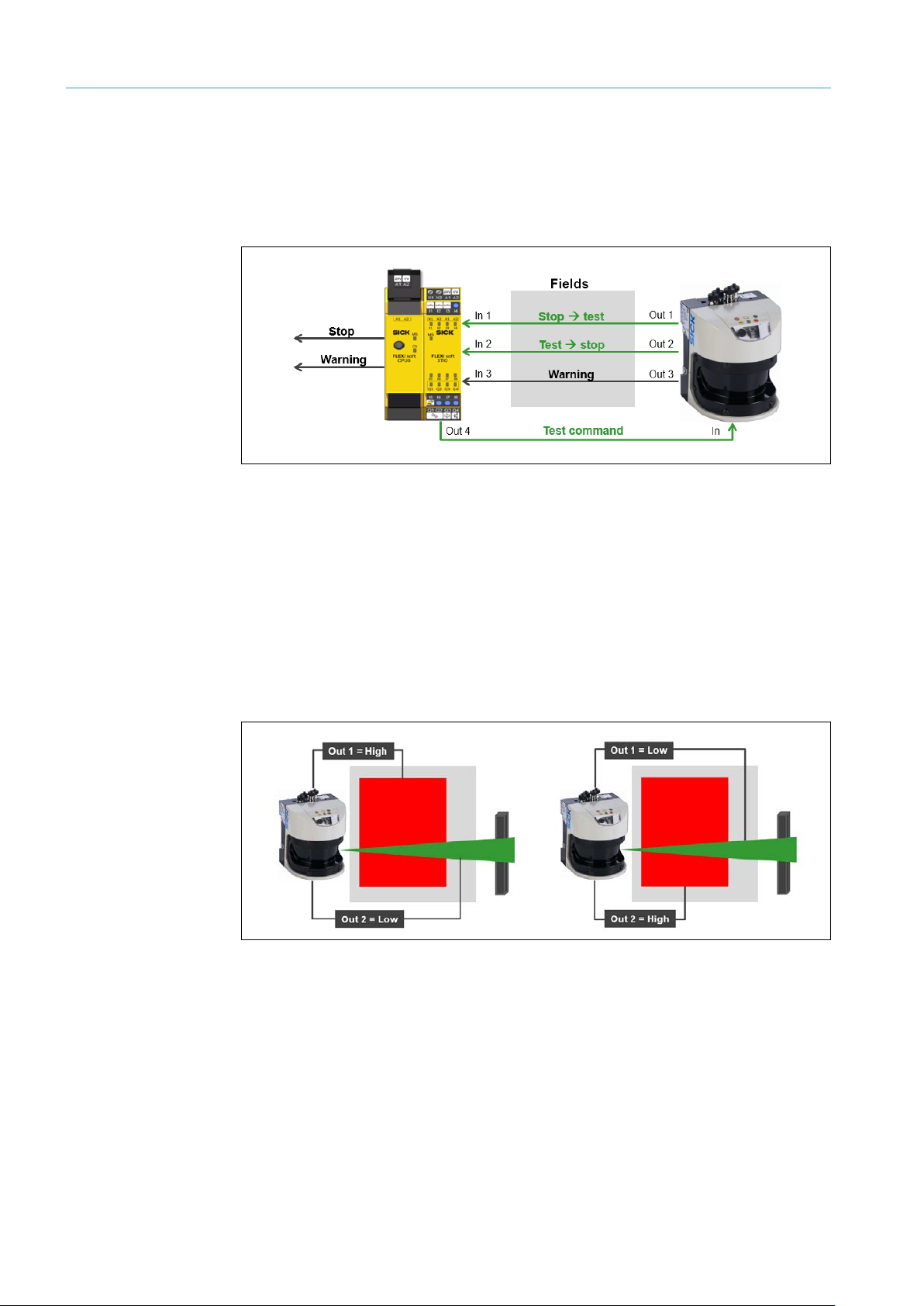

Fig. 7: Predefined monitoring fields in the AOS Prime

In the AOS Prime, the following standard monitoring fields are available:

• Stopping field (1) e.g., for stopping the system or a movement direction on a mobile

system.

• Warning field (2) e.g., for advance warning or reduction of speed on a mobile system.

• Test field (3) for detecting an external test target.

Switching signals in object detection

The laser scanners operate internally with so-called evaluation cases that are assigned

to the monitoring fields. If a monitoring field is infringed, this will be signaled by the

corresponding switching output on the laser scanner.

The Flexi Soft analyzes the information from the laser scanner and transmits the

corresponding results, such as “Warning field infringed” or “Stopping field infringed”,

to the upper-level system control.

PRODUCT DESCRIPTION 3

Note

Fig. 8: Switching signals for object detection

Additional control tasks, such as an emergency stop or the evaluation of, for example,

limit switches, are also possible with the Flexi Soft. However, they are not the primary

feature of the AOS Prime object detection system!

Page 26

3 PRODUCT DESCRIPTION

26

8016800/ZPQ5/2017-08-15|SICK

OPERATING INSTRUCTIONS | AOS Prime

Subject to change without notice

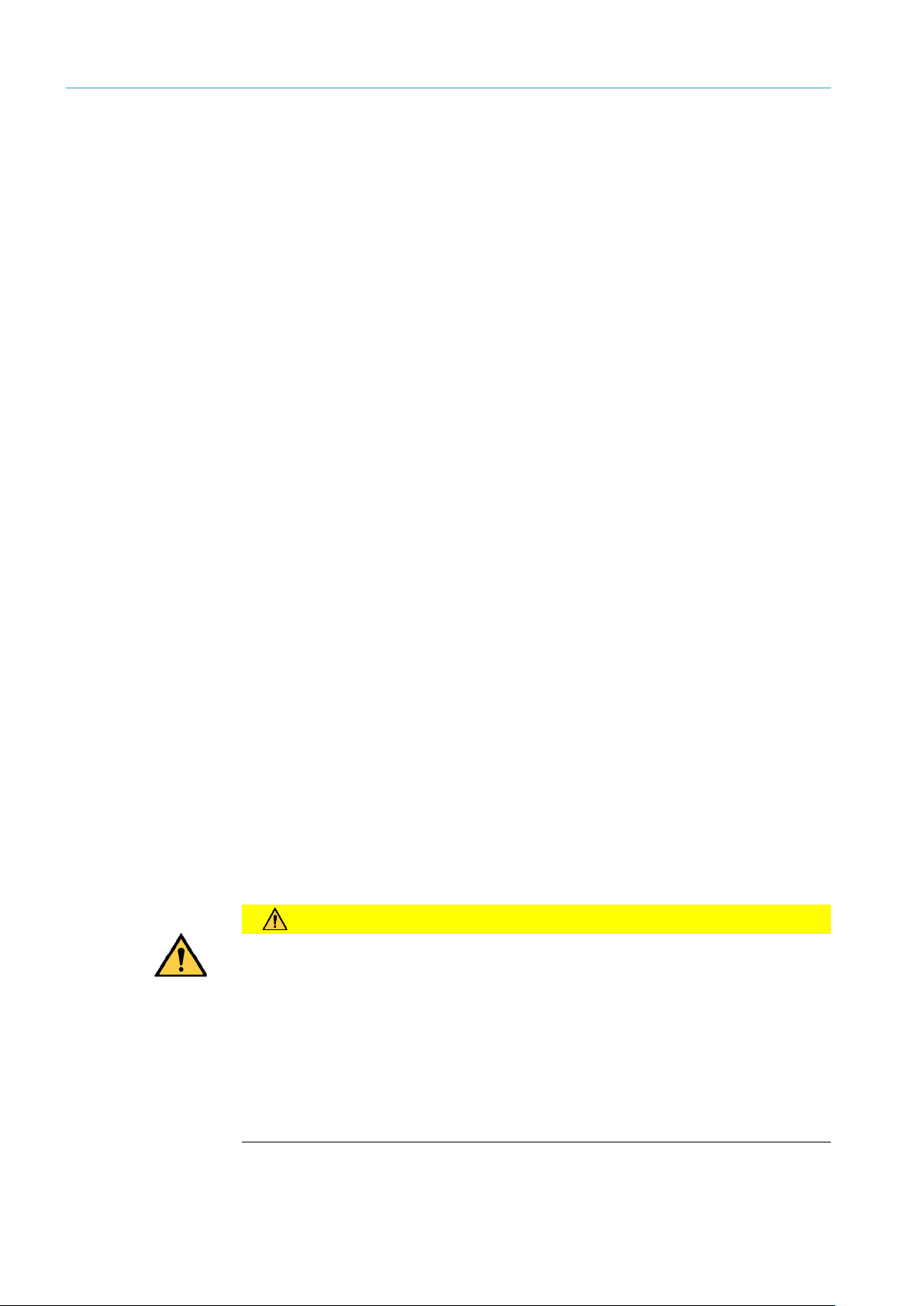

Switching signals in self-diagnostics

The Flexi Soft control also handles the internal self-testing of the laser scanners. For this

purpose, the control cyclically sends a changeover signal to the laser scanner to switch

the assignment of the monitoring and test fields to the switching output (= switching

evaluation fields).

Fig. 9: Switching signals for the internal self-testing of the AOS Prime

The change in the assignment of stopping and warning fields causes the switching outputs

to respond with a signal change from High to Low or, conversely, from Low to High. The

control performs the safety-related plausibility check of the individual changes expected in

the laser scanner switching signals.

In the example below, output Out 1 reports an intact stopping field prior to the changeover

signal (test command) by sending a High signal, and output Out 2 reports the detected

test target by sending a Low signal.

After the changeover signal, output Out 1 reports the detected test target (Low signal)

and output Out 2 reports the intact stopping field (High signal).

Note

Fig. 10: Switching signals of the self-test

The test response from the laser scanner (on/off switching operation at the outputs)

occurs once the response time set on the laser scanner has expired, e.g., after 180 msec.

The Flexi Soft wait time for the test response from the laser scanner must always be

longer than the actual response time of the laser scanner (e.g. wait time = 1 sec., laser

scanner response time = 500 msec.).

In exceptional cases, the predefined wait time must be adjusted via the Flexi Soft

parameters.

Page 27

27

8016800/ZPQ5/2017-08-15|SICK

Subject to change without notice

OPERATING INSTRUCTIONS | AOS Prime

What errors can be detected?

Display

Meaning

Laser scanner in operation, no evaluation cases are reporting an event

Optics cover is dirty

Switching output switched

Laser scanner is in teach-in mode

The internal self-test ensures that the test target is continuously detected by the laser

scanner. If a correct response is not given, the control is locked and sends a stop signal

to the upper-level machine control.

Incorrect responses can, for example, have the following causes:

• Defective laser scanner

• Missing test target

• Improper laser scanner adjustment (mechanical error or manipulation)

• Physically defective switching output on the laser scanner or short-circuit to VDC,

cross-talk or short to ground

• Cable break

3.4 Status indicators

Status indicators are located on the laser scanners and the Flexi Soft control.

3.4.1 LEDs on the LMS111 / LMS511 laser scanner

PRODUCT DESCRIPTION 3

In normal operation, the laser scanner is fully automatic—no operator intervention is

required. The LEDs and 7-segment display signal the operational status of the LMS111

and LMS511 laser scanner.

Fig. 11: Laser scanner status indicators (pictured: the LMS511 laser scanner)

Laser scanner in operation, at least one evaluation case reports an event

Tab. 3: Status indicators on the laser scanner

The 7-segment display is used for diagnostics when errors or faults occur (see chapter 8.3

Fault indicator on the LMS511 / LMS111 laser scanners).

Page 28

3 PRODUCT DESCRIPTION

28

8016800/ZPQ5/2017-08-15|SICK

OPERATING INSTRUCTIONS | AOS Prime

Subject to change without notice

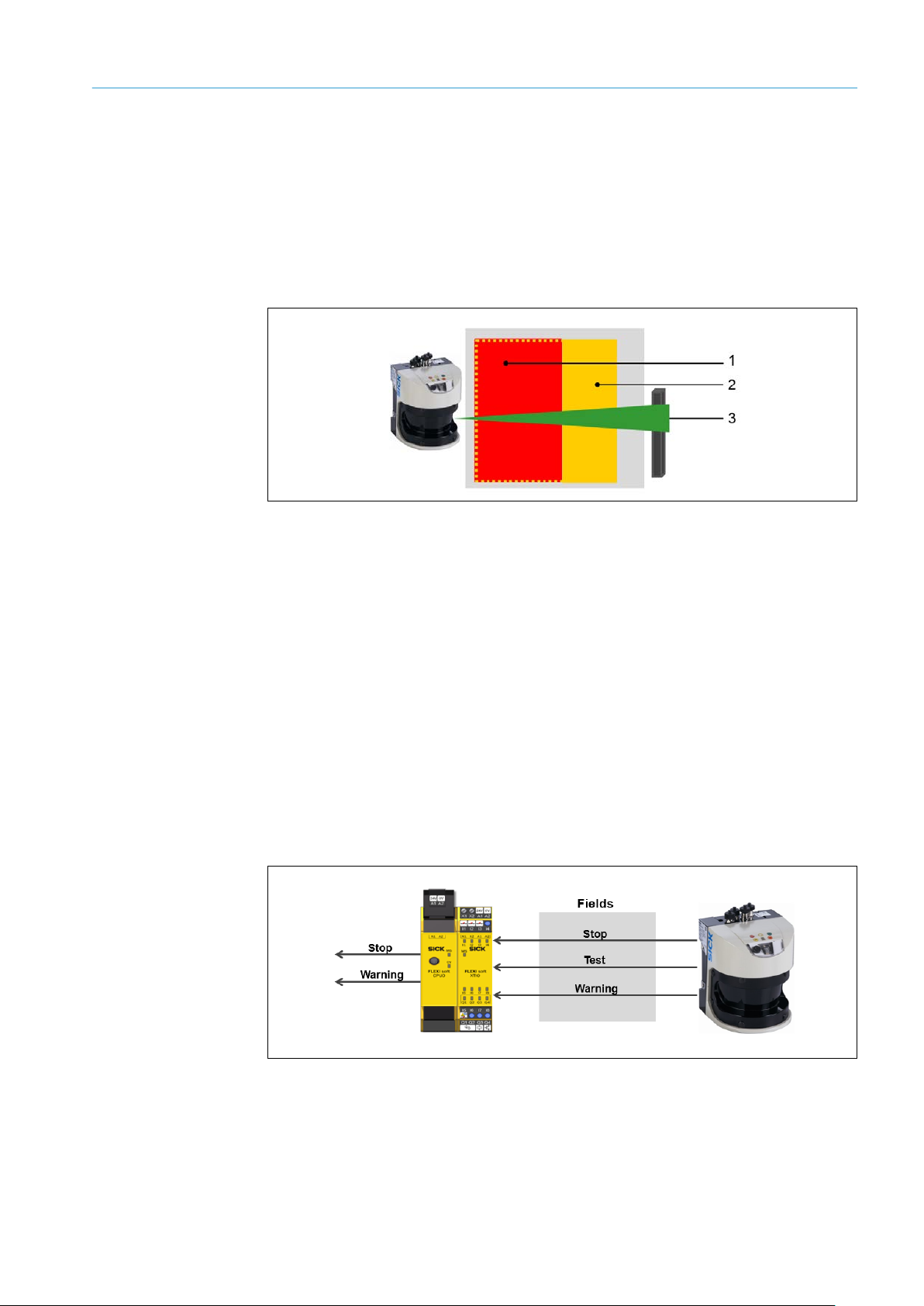

LED

Display

Meaning

MS Green

Module status, illuminated green during proper control operation.

MS Green

(1 Hz)

System in stopped status. Start application in Flexi Soft Designer.

CV

Configuration in process.

CV Yellow

(2 Hz)

The configuration is being permanently saved. Do not disconnect

from power supply until save process has been completed.

CV Yellow

(1 Hz)

Unverified configuration. The configuration must be verified by

the Flexi Soft Designer.

CV Yellow

Verified configuration, illuminated yellow once configuration has

been verified.

LED

Display

Meaning

MS

Module status, illuminated green during proper operation of

expansion module.

MS

System in stopped status. Start application in Flexi Soft Designer.

I/O Input/output is deactivated.

CV

Input/output is deactivated.

3.4.2 LEDs on the Flexi Soft

Main module

CPU0

Fig. 12: Status indicators on the Flexi Soft main module

I/O module

Tab. 4: Status indicators on the Flexi Soft main module

Fig. 13: Status indicators on the Flexi Soft expansion module

Green

Green

Green

Tab. 5: Status indicators on the Flexi Soft expansion module

Page 29

29

8016800/ZPQ5/2017-08-15|SICK

Subject to change without notice

OPERATING INSTRUCTIONS | AOS Prime

3.5 Parameter memory

3.5.1 Parameter set on connector plug of the Flexi Soft control unit

The system configuration parameters are saved on the connector plug of the Flexi Soft

CPU0 main module. This allows the main or expansion modules to be replaced without

having to reconfigure the Flexi Soft control (see chapter 7.3.2 Replacing Flexi Soft

safety control modules).

3.5.2 Parameter set in the laser scanner

All monitoring field with the basic field geometries as well as the necessary evaluation

cases are already pre-configured and permanently saved (factory settings) in this laser

scanner. Changes to the configuration (e.g. field geometries) are done using SOPAS

configuration software. The configuration can be saved in a file and transferred to the

replacement device when a laser scanner is replaced (see chapter 7.3.1 Replacing a

laser scanner).

PRODUCT DESCRIPTION 3

Page 30

4 MOUNTING

30

8016800/ZPQ5/2017-08-15|SICK

OPERATING INSTRUCTIONS | AOS Prime

Subject to change without notice

WARNING

4 Mounting

4.1 Planning mounting locations

The reliable and problem-free operation of the AOS Prime depends primarily on the proper

planning and mounting of the laser scanners.

Laser scanner

• The laser scanners must have sufficient mechanical protection. Only with optimal

positioning is it possible to adequately protect the system against collisions.

• Always be sure that the laser scanner has an unobstructed view of the areas that are

to be monitored.

• The laser scanners must be mounted in such a manner that they can detect objects

that penetrate the monitored area.

Test target

The test target must be mounted in such a way that the laser beam impinges on the

surface of the test target as vertically as possible.

Notes on the scanning field

When planning to mount the laser scanners, be sure to consider the fact that the laser

beam widens as the distance from the laser to mount the laser scanner increases.

As a result, the ground or a wall panel within the scanned area could end up being

permanently detected under unfavorable conditions because it is being hit by the laser

beam.

Recommendation

Detailed information on the operating principle of the laser measurement sensors can

be found in the operating instructions for the LMS511 and LMS111 laser scanners.

4.2 Mounting the laser scanners

4.2.1 General notes

Mount the laser scanners at the designated locations. Be sure to observe the detailed

drawings and information in the operating instructions for the LMS511 or LMS111 laser

scanner.

Be sure to closely observe the following notes during mounting:

Mount the laser scanner so that it is protected from dirt and damage.

▸

Ensure that the field of view of the entire front screen is not restricted.

▸

Always mount the laser scanner such that you are able to insert and remove the

▸

connector plug.

Avoid excessive shock and vibration exposure of the laser scanner.

▸

For systems that vibrate heavily, use shock absorbers to prevent the possibility of

▸

fixing screws coming loose unintentionally.

Page 31

MOUNTING 4

31

8016800/ZPQ5/2017-08-15|SICK

Subject to change without notice

OPERATING INSTRUCTIONS | AOS Prime

Weather hood

Because of the ambient conditions, a weather hood is always recommended.

The weather hood also protects the laser scanner from direct sunlight on the scanner

housing (overheating) and, to a great extent, from dazzling resulting from sunlight or other

light sources.

4.2.2 Mounting the LMS511 laser scanner

The LMS511 laser scanner is ideally mounted so that the connector plug faces down

so that the contamination diagnostics are not affected – regardless of whether or not a

weather hood is being used.

Fig. 14: Mounting the 511 laser scanner

Mounting the LMS511 laser scanner

Fig. 15 Mounting kit for the LMS511 laser scanner

1. Mount the wall-mounting kit on the desired mounting surface.

2. Mount the mounting bracket with the adapter plate on the wall-mounting kit.

3. Mount the connector box on the adapter plate of the mounting bracket.

4. Mount the LMS511 laser scanner on the mounting bracket.

5. Adjust the LMS511 laser scanner longitudinally and crosswise.

Mounting the connection box

Mount the local connection box next to or above the LMS111

▸

Page 32

4 MOUNTING

32

8016800/ZPQ5/2017-08-15|SICK

OPERATING INSTRUCTIONS | AOS Prime

Subject to change without notice

4.2.3 Mounting the LMS 111 laser scanner

The preferred mounting position of the LMS111 laser scanner is with the connector

plugs facing up. The weather hood should be mounted on the device accordingly (see the

operating instructions for the LMS511 laser scanner).

Fig. 16: Mounting the 111 laser scanner

Mounting the LMS111 laser scanner

Fig. 17 Mounting kit for the LMS111 laser scanner

1. Mount the lower part of the mounting bracket on the mounting surface.

2. Mount the LMS111 laser scanner on the upper part of the mounting bracket.

3. Mount the LMS111 laser scanner on the lower part of the bracket with the upper part.

Fig. 18: LMS111 laser scanner with mounting kit and weather hood

Mounting the connection box

Mount the local connection box next to or above the LMS111

▸

Page 33

33

8016800/ZPQ5/2017-08-15|SICK

Subject to change without notice

OPERATING INSTRUCTIONS | AOS Prime

4.3 Mounting the Flexi Soft control

WARNING

Consider the protection class

The Flexi Soft control has an IP 20 protection class and must always be mounted in an

electric or control cabinet.

The Flexi Soft control should be mounted in a suitable location in the control cabinet.

Ideally, it should be mounted near the higher-level control but never in the vicinity of

transformers, contactors or other power units.

In order to accommodate the leads and wiring, there must be enough terminals available.

Mounting

Mount the Flexi Soft control modules in a suitable location on the mounting rail in the

control cabinet.

1. Hang the module on the mounting rail.

MOUNTING 4

Note

Fig. 19: Mounting the Flexi Soft modules

2. Ensure the correct fit of the grounding spring. The grounding spring of the module must

be flush against the mounting rail such that it is secure and can suitably conduct

electricity.

3. Snap the module into place on the mounting rail by applying slight pressure in the

direction of the arrow.

If multiple modules are present, slide each of the modules together in the direction of the

arrow until the side-mounted plug connector engages.

Install end pieces on the left and right sides.

Page 34

4 MOUNTING

34

8016800/ZPQ5/2017-08-15|SICK

OPERATING INSTRUCTIONS | AOS Prime

Subject to change without notice

4.4 Mounting and positioning the test targets

Because the LMS511 and LMS111 laser scanners have different detection sensitivities,

the related test targets must be positioned differently. The test target must always be

located within the scanning range of the respective laser scanner, but it must be located

outside of the monitoring field.

Check whether there is a system part that would be suitable for use as a test target. If

none can be found, mount a suitable test target. The distances indicated below serve as

standard values.

Laser scanner LMS511

If using an LMS511 laser scanner (1), do not mount the test target (2) too close to the

LMS511. The standard value for the minimum distance from the laser scanner is 0.5 m.

Fig. 20: Mounting the test target for the LMS511 laser scanner

Page 35

35

8016800/ZPQ5/2017-08-15|SICK

Subject to change without notice

OPERATING INSTRUCTIONS | AOS Prime

Note

MOUNTING 4

Laser scanner LMS111

If using an LMS111 laser scanner (1), mount the test target (2) at close range. The

standard value is a distance of 500 mm from the device.

Fig. 21: Mounting the test target for the LMS111 laser scanner

Because the LMS111 laser scanner has a scanning angle of 270°, test targets can also

be positioned to the rear or the side.

The laser beam should hit the test target perpendicularly.

Page 36

5 ELECTRICAL INSTALLATION

36

8016800/ZPQ5/2017-08-15|SICK

OPERATING INSTRUCTIONS | AOS Prime

Subject to change without notice

HAZARD

HAZARD

Wire cross-section

mm2

AWG

Solid wire

0.2 to 2.5 mm2

AWG 24 to 12

Stranded wire (flexible)

0.34 to 1.5 mm2

AWG 22 to 16

Main module / Expansion module

Power supply

A1

+24 V

A2

0 V

5 Electrical installation

Disconnect the power to the system

Make sure that all AOS Prime components are disconnected from the power supply

▸

during electrical installation.

Risk of injury due to electrical current

Standard safety requirements must be met when working on electrical systems.

▸

The power supply must be disconnected when attaching and detaching electrical

▸

connections.

5.1 Connecting Flexi Soft to the power supply

The connections on the Flexi Soft control can be used with cables of solid wire or stranded

wire. The following table shows the proper wire cross-sections for connection to the

terminals.

Note

Tab. 6: Wire cross-sections for the Flexi Soft control connections

The Flexi Soft and the laser scanners must be connected to the same power supply.

If using multiple power supplies, a 0 V equalization between the individual power supplies

must be established.

Attach the Flexi Soft main module and the I/O expansion modules to the power supply.

▸

Fig. 22: Connecting the Flexi Soft main module and I/O module to the power supply

Wire the modules to the power supply as follows:

▸

Tab. 7: Connecting the Flexi Soft main module and I/O module to the power supply

Page 37

37

8016800/ZPQ5/2017-08-15|SICK

Subject to change without notice

OPERATING INSTRUCTIONS | AOS Prime

5.2 Connecting the LMS511 laser scanner

Cable no. (in picture)

Laser scanner connection

1

I/O cable

2

Data/Input cable

3

Power supply

The connection of the LMS511 laser scanner to the Flexi Soft control takes place via the

connection box.

Prerequisites

It is assumed that a separate installation cable has been routed from the control cabinet

to the connection box or to the LMS511 laser scanner.

• It is necessary to use a shielded cable.

• The cable must have at least 6 wires (recommendation: 9 wires).

• You should also include spare wires (e.g., if you wish to energize the heater on the laser

scanner separately or lead optional signals).

Note

Recommendation

Take into account the voltage drop with long cables, especially when operating the heater.

Cabling principle

The cabling concept is always the same, regardless of whether you are connecting one

laser scanner or multiple laser scanners to the control. The number of connected laser

scanners is signaled to the Flexi Soft control by the control file provided. The respective

file is transferred to the control using Flexi Soft Designer (download).

Be sure to also observe the electrical diagrams contained in the annex to these

operating instructions!

ELECTRICAL INSTALLATION 5

5.2.1 Connecting the connection box to the LMS511 laser scanner

The connection box and the LMS511 laser scanner are connected via the pre-mounted

cables on the connection box.

Fig. 23: Connection of the LMS511 laser scanner and the connection box

Using the M12 round connectors, screw the pre-mounted cables onto the connections

▸

on the LMS511 laser scanner as indicated below.

Tab. 8: Connection of LMS511 laser scanner and connection box

Page 38

5 ELECTRICAL INSTALLATION

38

8016800/ZPQ5/2017-08-15|SICK

OPERATING INSTRUCTIONS | AOS Prime

Subject to change without notice

Pin

Wire no.

Connection

19 1 Voltage 24 V

20 2 Ground

06 3 Input 1 (test signal from Flexi Soft)

4 Not assigned (spare)

11 5 Output 1 (stop/test field status)

12 6 Output 2 (test/stop field status)

13 7 Output 3 (warning)

5.2.2 Connecting the installation cable in the connection box

The wires of the routed installation cable must be connected in the terminal block of the

connection box on the LMS511 laser scanner.

Note

To provide a clearer overview, the wires in the figures below are numbered.

Connect the wires in the terminal block of the connection box as follows:

▸

Notes

Fig. 24: Connecting wires in the connection box (min. wiring)

Tab. 9: Connecting wires in the connection box (min. wiring)

• The wire jumpers indicated for voltage and ground are not contained in the connection

box at delivery. You must lay the bridges on the connection side.

• When using a common power supply unit for the sensor and heater, the power supply

unit must fulfill the requirements of the sensor part.

• If two separate power supply units are used for the sensor and the heater, terminals

19-21 and 20-22 are not jumpered. The 0-V outputs of both power supply units must

be connected for potential equalization.

Page 39

39

8016800/ZPQ5/2017-08-15|SICK

Subject to change without notice

OPERATING INSTRUCTIONS | AOS Prime

5.2.3 Wiring the installation cable wires to the Flexi Soft control

No.

Connection

Voltage supply

1

Voltage

+24 V

2

Ground

0 V

The individual wires of the installation cable are connected in the control cabinet and

wired to the Flexi Soft control module.

Wiring the power supply in the control cabinet

Connect the wires for the power supply to the terminals in the control cabinet.

▸

ELECTRICAL INSTALLATION 5

Fig. 25: Connecting the power supply to terminals in the control cabinet (LMS511 laser scanner)

Connect the wires to the power supply in the control cabinet as follows:

▸

Tab. 10: Connecting the power supply to terminals in the control cabinet (LMS511 laser scanner)

Page 40

5 ELECTRICAL INSTALLATION

40

8016800/ZPQ5/2017-08-15|SICK

OPERATING INSTRUCTIONS | AOS Prime

Subject to change without notice

No.

Connection

I/O expansion module

3

Switching output (test signal to LMS)

Q4

5

Switching input (stop/test field status)

I1 6 Switching input (test/stop field status)

I2

7

Switching input (warning field status)

I3

Connection

Voltage

supply

I/O expansion module

Voltage

+24 V

Ground

0 V

Switching output (test signal to LMS)

Q4

Switching input (stop/test field status)

I5

Switching input (test/stop field status)

I6

Switching input (warning field status)

I7

Wiring inputs and outputs in the control cabinet

Connect the wires for the input and output switching signals in the control cabinet as

▸

follows:

Fig. 26: Wiring the switching inputs and outputs in the control cabinet (LMS511 laser scanner)

Connect the wires to the I/O expansion module as follows:

▸

Tab. 11: Wiring the switching inputs and outputs in the control cabinet (LMS511 laser scanner)

5.2.4 Connecting additional LMS511 laser scanners to Flexi Soft

Connecting a second LMS511 laser scanner to the Flexi Soft takes place as indicated in

the following table:

Tab. 12: Connecting a second LMS511 laser scanner to the Flexi Soft

A second I/O expansion module is required to connect a third and fourth LMS511 laser

scanner. Connection follows the same principle as for the first I/O expansion module.

Note

The appropriate configuration file for configuring the Flexi Soft control must be loaded

according to the number of laser scanner connected. This file is included in the AOS Prime

scope of delivery.

Page 41

41

8016800/ZPQ5/2017-08-15|SICK

Subject to change without notice

OPERATING INSTRUCTIONS | AOS Prime

5.3 Connecting the LMS111 laser scanner

The LMS111 laser scanner can be connected using one of two methods:

• Using the local connection box (= scope of delivery).

• Using system cables (= existing systems).

5.3.1 Using the local connection box

The connection of the LMS111 laser scanner to the Flexi Soft control takes place via the

connection box.

Prerequisites

It is assumed that a separate installation cable has been routed from the control cabinet

to the connection box or to the LMS511 laser scanner.

• It is necessary to use a shielded cable.

• The cable must have at least 7 wires.

• You should also include spare wires (e.g., if you wish to energize the heater on the laser

scanner separately or lead optional signals).

Note

Recommendation

Take into account the voltage drop with long cables, especially when operating the heater.

Cabling principle

The cabling concept is always the same, regardless of whether you are connecting one

laser scanner or multiple laser scanners to the control. The number of connected laser

scanners is signaled to the Flexi Soft control by the control file provided.

Be sure to also observe the electrical diagrams contained in the annex to these operating

instructions!

ELECTRICAL INSTALLATION 5

Page 42

5 ELECTRICAL INSTALLATION

42

8016800/ZPQ5/2017-08-15|SICK

OPERATING INSTRUCTIONS | AOS Prime

Subject to change without notice

Cable no. (in picture)

Laser scanner connection

1

I/O cable

2

Data/Input cable

3

Voltage supply

5.3.1.1 Connecting the connection box to the LMS111 laser scanner

The connection box and the LMS111 laser scanner are connected via the pre-mounted

cables on the connection box.

Fig. 27: Connection of the LMS511 laser scanner and the connection box

Using the M12 round connectors, screw the pre-mounted cables onto the connections

▸

on the LMS111 laser scanner as indicated below.

Tab. 13: Connection of LMS111 laser scanner and connection box

Page 43

43

8016800/ZPQ5/2017-08-15|SICK

Subject to change without notice

OPERATING INSTRUCTIONS | AOS Prime

5.3.1.2 Connecting the installation cable in the connection box

Pin

Wire no.

Connection

17 1 Voltage 24 V

18 2 Ground

06 3 Input 1 (test signal from Flexi Soft)

4 Not assigned (spare)

12 5 Output 1 (stop/test field status)

13 6 Output 2 (test/stop field status)

14 7 Output 3 (warning)

The wires of the routed installation cable must be connected in the terminal block of the

connection box on the LMS111 laser scanner.

Note

To provide a clearer overview, the wires in the figures below are numbered.

Connect the wires in the terminal block of the connection box as follows:

▸

ELECTRICAL INSTALLATION 5

Notes

Fig. 28: Connecting wires in the connection box (min. wiring)

Tab. 14: Connecting wires in the connection box (min. wiring)

• The wire jumpers indicated for voltage and ground are not contained in the connection

box at delivery. You must lay the bridges on the connection side.

• When using a common power supply unit for the sensor and heater, the power supply

unit must fulfill the requirements of the sensor part.

• If two separate power supply units are used for the sensor and the heater, terminals

17-19 and 18-20 are not jumpered. The 0-V outputs of both power supply units must

be connected for potential equalization.

Page 44

5 ELECTRICAL INSTALLATION

44

8016800/ZPQ5/2017-08-15|SICK

OPERATING INSTRUCTIONS | AOS Prime

Subject to change without notice

No.

Connection

Voltage supply

1

Voltage

+24 V

2

Ground

0 V

5.3.1.3 Wiring the installation cable wires to the Flexi Soft control

The individual wires of the installation cable are connected in the control cabinet and

wired to the Flexi Soft control module.

Wiring the power supply in the control cabinet

Connect the wires for the power supply to the terminals in the control cabinet.

▸

Fig. 29: Connecting the power supply to terminals in the control cabinet (LMS111 laser scanner)

Connect the wires to the power supply in the control cabinet as follows:

▸

Tab. 15: Connecting the power supply to terminals in the control cabinet (LMS111 laser scanner)

Page 45

ELECTRICAL INSTALLATION 5

45

8016800/ZPQ5/2017-08-15|SICK

Subject to change without notice

OPERATING INSTRUCTIONS | AOS Prime

No.

Connection

I/O expansion module

3

Switching output (test signal to LMS)

Q4 5 Switching input (stop/test field status)

I1

6

Switching input (test/stop field status)

I2

7

Switching input (warning field status)

I3

Wiring inputs and outputs in the control cabinet

Connect the wires for the input and output switching signals in the control cabinet as

▸

follows:

Fig. 30: Wiring the switching inputs and outputs in the control cabinet (LMS111 laser scanner)

Connect the wires to the I/O expansion module as follows:

▸

Tab. 16: Wiring the switching inputs and outputs in the control cabinet (LMS111 laser scanner)

Page 46

5 ELECTRICAL INSTALLATION

46

8016800/ZPQ5/2017-08-15|SICK

OPERATING INSTRUCTIONS | AOS Prime

Subject to change without notice

NOTE

No.

Cable

Plug connector

1

Voltage supply (female connector – open)

M12 female connector, 5-pin,

straight, A-coded, cable, 20 m, 4-wire

2

Data/Input configuration cable, shielded

(female connector – open)

M12 female connector, 8-pin,

straight, A-coded, cable, 20 m, 8-wire

3

I/O configuration cable, shielded

(male connector – open)

M12 male connector, 8-pin, straight,

A-coded, cable, 20 m, 8-wire

5.3.2 Using the pre-configured system cables

5.3.2.1 Overview of pre-configured system cables

The following description is only valid for already-existing systems.

Cabling the LMS111 laser scanner to the Flexi Soft control is done via pre-configured

cables that are included in the AOS Prime 10x scope of delivery. The cables have an M12

plug connector on one side. The other end is open with a shield.

Fig. 31: Pre-configured cables for connecting the LMS111 laser scanner

Tab. 17: Pre-configured cables for connecting the LMS111 laser scanner

5.3.2.2 Wiring the system cables in the control cabinet

The cabling concept is always the same, regardless of whether you are connecting one

laser scanner or multiple laser scanners to the control.

The number of connected laser scanners is signaled to the Flexi Soft control by the control

file provided. The file is transferred to the control using Flexi Soft Designer.

1. Screw the M12 round connector on the LMS111 laser scanner onto the corresponding

connector.

2. Run the cable to the control cabinet.

3. Connect the wires to the terminals of the control cabinet and wire the terminals

accordingly.

Recommendation

Be sure to also observe the electrical diagrams contained in the annex to these

operating instructions!

Page 47

ELECTRICAL INSTALLATION 5

47

8016800/ZPQ5/2017-08-15|SICK