Page 1

AOS301-WWD

Object detection systems

OPERATING INSTRUCTIONS

Page 2

2

8023732/2018-09-10|SIC K

ORIGINAL OPERA TING INSTRUCT IONS | AOS301-WWD

Subject to change without notice

Product described

Product name: AOS301-WWD

Document identification

Title: AOS301-WWD operating instructions

Status: 2018-09-10

Manufacturer

SICK AG

Erwin-Sick-Str. 1 · 79183 Waldkirch · Germany

Legal notes

Original documents

This document is an original document of SICK AG.

Part number 8023732

This work is protected by copyright. The associated rights are reserved by SICK AG.

Reproduction of this document or parts of this document is only permissible within

the limits of the legal provisions of copyright law. Any modification, abridgment, or

translation of this document is prohibited without the express written permission of

SICK AG.

The trademarks mentioned in this document are the property of their respective

owners.

© SICK. All rights reserved

Page 3

3

8023732/2018-09-10|SIC K

Subject to change without notice

ORIGINAL OPERA TING INSTRUCT IONS | AOS301-WWD

Contents

CONTENTS

1 About this document ........................................................................................................ 6

1.1 Limitation of liability ............................................................................................. 6

1.2 Purpose of this document .................................................................................... 6

1.3 Target groups........................................................................................................ 6

1.4 Further information .............................................................................................. 7

1.5 Other relevant technical documentation/information ....................................... 7

1.6 Document conventions ........................................................................................ 7

2 Important safety notes ..................................................................................................... 8

2.1 Safety conventions ............................................................................................... 8

2.2 Supplementary safety note .................................................................................. 8

2.3 Requirements for the qualification of personnel................................................ 8

2.4 Intended use ......................................................................................................... 9

2.5 RoHS directive ...................................................................................................... 9

2.6 Safety notes ....................................................................................................... 10

3 System description ........................................................................................................ 11

3.1 Scope of delivery ............................................................................................... 11

3.2 System components.......................................................................................... 14

3.2.1 RMS3xx radar sensor......................................................................... 14

3.2.2 TDC-E200xx telematic data collector ................................................ 15

3.3 Operating principle ............................................................................................ 16

3.3.1 Vehicle detection and evaluation ...................................................... 16

3.3.2 Data output and interfaces ............................................................... 18

3.4 Project planning ................................................................................................ 19

3.5 System extension with tools and customer-specific applications .................. 22

4 Mounting ........................................................................................................................ 23

4.1 Mounting the RMS3xx ....................................................................................... 23

4.1.1 Mounting with holding bracket .......................................................... 24

4.1.2 Mounting via wall holder .................................................................... 25

4.1.3 Mounting with weather protection hood ........................................... 26

4.2 Mounting TDC-E ................................................................................................. 27

4.2.1 Mounting on a plate ........................................................................... 27

4.2.2 Mounting on DIN mounting rails ....................................................... 27

4.2.3 Inserting SIM card .............................................................................. 29

5 Electrical installation .................................................................................................... 31

5.1 Connection overview ......................................................................................... 31

5.2 Connecting the RMS3xx and TDC-E to the voltage supply .............................. 32

5.3 Connecting radar sensor to TDC-E ................................................................... 33

5.4 Connecting customer interface ........................................................................ 34

6 Commissioning .............................................................................................................. 35

6.1 Starting the system ........................................................................................... 35

6.2 Preparing the configuration PC ........................................................................ 36

6.3 Using TEMS Manager ........................................................................................ 37

6.3.1 Starting TEMS Manager ..................................................................... 37

6.3.2 Using a configuration file to load standard parameters .................. 37

6.3.3 The user interface .............................................................................. 38

Page 4

CONTENTS

4

8023732/2018-09-10|SIC K

ORIGINAL OPERA TING INSTRUCT IONS | AOS301-WWD

Subject to change without notice

6.3.4 Displaying the measurement site ......................................................40

6.3.5 Activating expert mode .......................................................................42

6.3.6 Displaying system parameters ...........................................................42

6.3.7 Visualizing radar measurement points and monitored area in

the live view .........................................................................................44

6.4 Adapting system parameters in TEMS Manager ..............................................45

6.4.1 Switching to editing mode ..................................................................45

6.4.2 Configuring the measurement site ....................................................46

6.4.3 Configuring radar sensor (system function RMS320) ......................48

6.4.4 Configuring monitored area (AOS RMS system function) .................50

6.4.5 Defining expected direction of travel (WWD system function) .........52

6.5 Configuring data output in TEMS Manager ......................................................53

6.5.1 Configuring I/O interface (TDC-E IO plug-in) ......................................53

6.5.2 Configuring call-up of MQTT messages .............................................57

6.6 Configuring in TEMS Manager ...........................................................................61

6.6.1 Checking proper measuring operation in TEMS Manager ................61

6.6.2 Save configuration ..............................................................................62

6.7 Checking measurement operation is working properly ...................................63

6.7.1 Displaying vehicles with measured values ........................................63

6.7.2 Accessing detailed information about a vehicle ...............................64

6.7.3 Saving vehicle data .............................................................................66

6.8 Using TDC Device Manager ...............................................................................67

6.8.1 Starting TDC-E Device Manager .........................................................67

6.8.2 The configuration interface ................................................................67

6.8.3 Adjusting Ethernet interface for data output ....................................68

6.8.4 Configuring wireless settings .............................................................69

7 Maintenance and repair ................................................................................................70

7.1 Visual inspection ................................................................................................70

7.2 Cleaning radar sensor........................................................................................71

7.3 Replacing the RMS3xx .......................................................................................72

7.4 Replacing TDC-E .................................................................................................73

8 Fault diagnosis ...............................................................................................................74

8.1 Fault diagnosis in TEMS Manager ....................................................................74

8.1.1 Warning and fault visualization ..........................................................74

8.1.2 Analyzing the error situation ..............................................................76

8.1.3 Detecting system errors using log files..............................................77

8.2 TDC-E Device Manager fault diagnosis .............................................................79

8.2.1 Displaying logs ....................................................................................79

8.2.2 Events ..................................................................................................80

8.2.3 Checking the network connection .....................................................80

9 Annex ...............................................................................................................................81

9.1 Technical data ....................................................................................................81

9.1.1 AOS301 data sheet ............................................................................81

9.1.2 RMS-343300 data sheet (excerpt) ....................................................82

9.1.3 TDC-E200 data sheet (excerpt) ..........................................................83

9.2 Dimensional drawings .......................................................................................84

9.2.1 RMS3xxx ..............................................................................................84

9.2.2 TDC-E ...................................................................................................86

Page 5

CONTENTS

5

8023732/2018-09-10|SIC K

Subject to change without notice

ORIGINAL OPERA TING INSTRUCT IONS | AOS301-WWD

9.3 Users and authorizations .................................................................................. 87

9.3.1 TDC-E Device Manager ...................................................................... 87

9.3.2 TEMS Manager ................................................................................... 88

9.4 TDC-E pin assignments ..................................................................................... 92

10 Disposal .......................................................................................................................... 93

Page 6

1 ABOUT THIS DOCUMENT

6

8023732/2018-09-10|SIC K

ORIGINAL OPERA TING INSTRUCT IONS | AOS301-WWD

Subject to change without notice

1 About this document

This document contains information that is required during the life cycle of the

AOS301-WWD (wrong way detection) object detection system.

The document must be made available to all those who work with the system.

▸

Read through the document carefully and ensure that you have full understood

▸

the content before working with the system.

1.1 Limitation of liability

Applicable standards and regulations, the latest technological developments, and

our many years of knowledge and experience have all been taken into account when

assembling the data and information contained in this document.

The manufacturer accepts no liability for damage caused by:

• Failure to observe this document.

• Non-compliance with notes and regulations.

• Unauthorized mounting and installation.

• Unauthorized technical and other changes.

• Use of unauthorized spare parts, wear and tear parts, and accessories.

• Unauthorized changes, adjustments and/or manipulations of software.

With special variants, where optional extras have been ordered, or owing to the latest

technical changes, the actual scope of delivery may differ from the features and

illustrations shown here.

1.2 Purpose of this document

The document is designed to give technical personnel instructions on the safe mounting,

parameterization, electrical installation, commissioning, operation, and maintenance of

the AOS301-WWD system.

1.3 Target groups

This document is intended for qualified persons who perform the following tasks with the

AOS301-WWD system

• Installation

• Commissioning

• Operating

• Repairing

Page 7

7

8023732/2018-09-10|SIC K

Subject to change without notice

ORIGINAL OPERA TING INSTRUCT IONS | AOS301-WWD

1.4 Further information

Special local conditions

The local laws, regulations, technical rules and internal company operating instructions

at the usage site must be observed.

Storage of documents

This document and other relevant technical documentation/information:

• Must be kept available for reference.

• Must be handed on to new operating entities/new specialist personnel.

1.5 Other relevant technical documentation/information

• Operating instructions for the following system components:

Component Manufacturer

ABOUT THIS DOCUMENT 1

RMS3xx radar measurement sensor operating

instructions

TDC-E (telematic data collector) operating

instructions

Technical information “Regulatory Compliance

Information”

Table 1: Other relevant technical documentation/information

1.6 Document conventions

Instructions.

▸

Instructions completed.

LED icons describe the status of a diagnostics LED.

SICK

SICK

SICK

Page 8

2 IMPORTANT SAFETY NOTES

8

8023732/2018-09-10|SIC K

ORIGINAL OPERA TING INSTRUCT IONS | AOS301-WWD

Subject to change without notice

2 Important safety notes

Read and observe all safety notes in this document.

▸

2.1 Safety conventions

Safety symbols on the system and on the system components, as well as safety notes

and safety labels, correspond to the current guidelines and standards.

The safety conventions for signal words used in this document correspond with

ANSI Z535.

DANGER! Refers to a hazard with a high level of risk that will result in serious injury

or death if not avoided.

WARNING! Refers to a hazard with a medium level of risk that may result in serious

injury or death if not avoided.

CAUTION! Refers to a hazard with a low level of risk that will result in a minor or

moderate injury if not avoided.

NOTE! indicates possible damage to property or material damage and useful information.

2.2 Supplementary safety note

WARNING!

Only qualified persons from the relevant departments are permitted to work on the

▸

system.

Follow operating processes.

▸

Follow local regulations.

▸

Only authorized persons are permitted to access the system.

▸

2.3 Requirements for the qualification of personnel

• Qualified persons have the specialist training, skills, and experience, as well as

knowledge of the relevant regulations and standards, to be able to perform work

assigned to them and to identify and avoid any potential dangers independently.

• Electricians have the professional training, skills and experience, and knowledge

of the relevant standards and provisions to work on electrical systems and to detect

and avoid any potential dangers independently.

Page 9

9

8023732/2018-09-10|SIC K

Subject to change without notice

ORIGINAL OPERA TING INSTRUCT IONS | AOS301-WWD

2.4 Intended use

The AOS301-WWD is an object detection system which uses a a radar sensor to identify

vehicles which move against the permitted direction of travel.

If an wrong-way driver is reliably detected in a defined monitoring area, a digital signal is

output to the customer system via the I/O interface.

In addition, the measurement data of the detected vehicles can be called up via a cloud

server in the form of MQTT messages. Data is transmitted via Ethernet or wireless

networks.

WARNING! The AOS301-WWD object detection system must only be used for the intended

purpose. Non-intended use of the system can pose a hazard to people and cause damage

to the system.

2.5 RoHS directive

This system has been designed for specific applications in industrial plants according to

article 2 (4) e, RoHS 2011/65 / EU, and must therefore only be used in such plants.

The product is neither suited nor certified for use outside of these plants. SICK therefore

cannot assume any type of warranty or liability for such use.

IMPORTANT SAFETY NOTES 2

Page 10

2 IMPORTANT SAFETY NOTES

10

8023732/2018-09-10|SIC K

ORIGINAL OPERA TING INSTRUCT IONS | AOS301-WWD

Subject to change without notice

▸

▸

2.6 Safety notes

DANGER!

HAZARDOUS ELECTRICAL VOLTAGE

The system is supplied with mains voltage. Risk of electric shocks. Contact causes

death, burns or shock.

Only qualified specialist personnel may conduct electrical work on the system.

▸

Interrupt the voltage supply.

▸

Check residual voltage on the system components.

▸

Pay extra attention.

▸

Always connect equipotential bonding (earthing).

▸

Do not disconnect or remove protective conductor.

DANGER!

DANGER AS A RESULT OF HIGH-FREQUENCY ELECTROMAGNETIC RADIATION

The RMS3xx radar sensor is designed for operation in accordance with ETSI EN 300 440.

During operation, the provisions of EN 62311 about human exposure must be

observed.

For short-term and long-term work in the radiation range of the antenna(s), suitable

▸

safety distances must be maintained in order to limit human exposure to electromagnetic fields.

Minimum distances between the antenna and the human body with continuous

▸

transmission: 20 cm.

Country-specific specifications are fulfilled and listed in the technical information

“Regulatory Compliance Information” contained in the scope of delivery.

DANGER!

RISK OF INJURY AND DAMAGE CAUSED BY ELECTRICAL CURRENT!

The RMS3xx radar sensor is designed for operation in a system with professional

grounding of all connected devices and mounting surfaces to the same ground

potential. Faulty earthing of the RMS3xx can lead to equipotential bonding currents

between the RMS3xx and other grounded devices in the system.

Proper grounding of the devices and metal surfaces in the system.

▸

Make sure that the ground potential is the same at all grounding points.

Page 11

11

8023732/2018-09-10|SIC K

Subject to change without notice

ORIGINAL OPERA TING INSTRUCT IONS | AOS301-WWD

3 System description

3.1 Scope of delivery

NOTE!

After delivery, inspect the system for transport damage and report any such damage

▸

immediately.

Check that the delivery includes all components listed on the delivery note.

▸

SYSTEM DESCRIPTION 3

Fig. 1: AOS301-WWD scope of delivery

Number Part no. Description

1 1093864 1 AOS301-WWD object detection system consisting of:

• TDC-E200R2

• RMS3xx radar sensor

• 2-pin cable for voltage supply of the TDC-E

• Quick Start guide including download link for the operating

instructions, system documentation, and interface

descriptions

OR

1 1093865 1 AOS301-WWD object detection system consisting of:

• TDC-E200R6

• RMS3xx radar sensor

• 2-pin cable for voltage supply of the TDC-E

• Quick Start guide including download link for the operating

instructions, system documentation, and interface

descriptions

Table 2: AOS301-WWD scope of delivery

Weather hood

Part no. Description

2095958 Weather hood for RMS3xx

Page 12

3 SYSTEM DESCRIPTION

12

8023732/2018-09-10|SIC K

ORIGINAL OPERA TING INSTRUCT IONS | AOS301-WWD

Subject to change without notice

Mounting accessories

Fig. 2: Mounting accessories

No. Part no. Description

1 2095955 Holding bracket for mounting the RMS3xx to poles, etc.

2 2095957 Wall holder for mounting the RMS3xx to walls.

3 6069266 DIN rail bracket for mounting the TDC-E on DIN rail brackets

Table 3: Mounting accessories

Cable accessories

Fig. 3: Cable accessories

No. Part no. Description

1 6068473 2-pin cable for voltage supply of the TDC-E

2 6068472 14-pin Microfit male connector with 14 color-coded open-ended

wires for connecting:

• Voltage supply (2 wires)

• Digital inputs and outputs

• Analog inputs

3

6036159

6042565

6042564

4

6034415

6030928

6036158

6045311

Table 4: Cable accessories

Cable for connecting the RMs3xx to the voltage supply

(M12 connection, open end)

5 m

10 m

20 m

Cable for connecting the RMS3xx to the TDC-E

(M12 connection, RJ45)

5 m

10 m

20 m

30 m

Page 13

SYSTEM DESCRIPTION 3

13

8023732/2018-09-10|SIC K

Subject to change without notice

ORIGINAL OPERA TING INSTRUCT IONS | AOS301-WWD

Replacement devices

Part no. Description

6067896 TDC-E200R2

6067536 TDC-E200R6

1083661 RMS3xx

6068463 GSM antenna

6068474 WLAN/WPAN antenna

Table 5: Replacement devices

Page 14

3 SYSTEM DESCRIPTION

14

8023732/2018-09-10|SIC K

ORIGINAL OPERA TING INSTRUCT IONS | AOS301-WWD

Subject to change without notice

3.2 System components

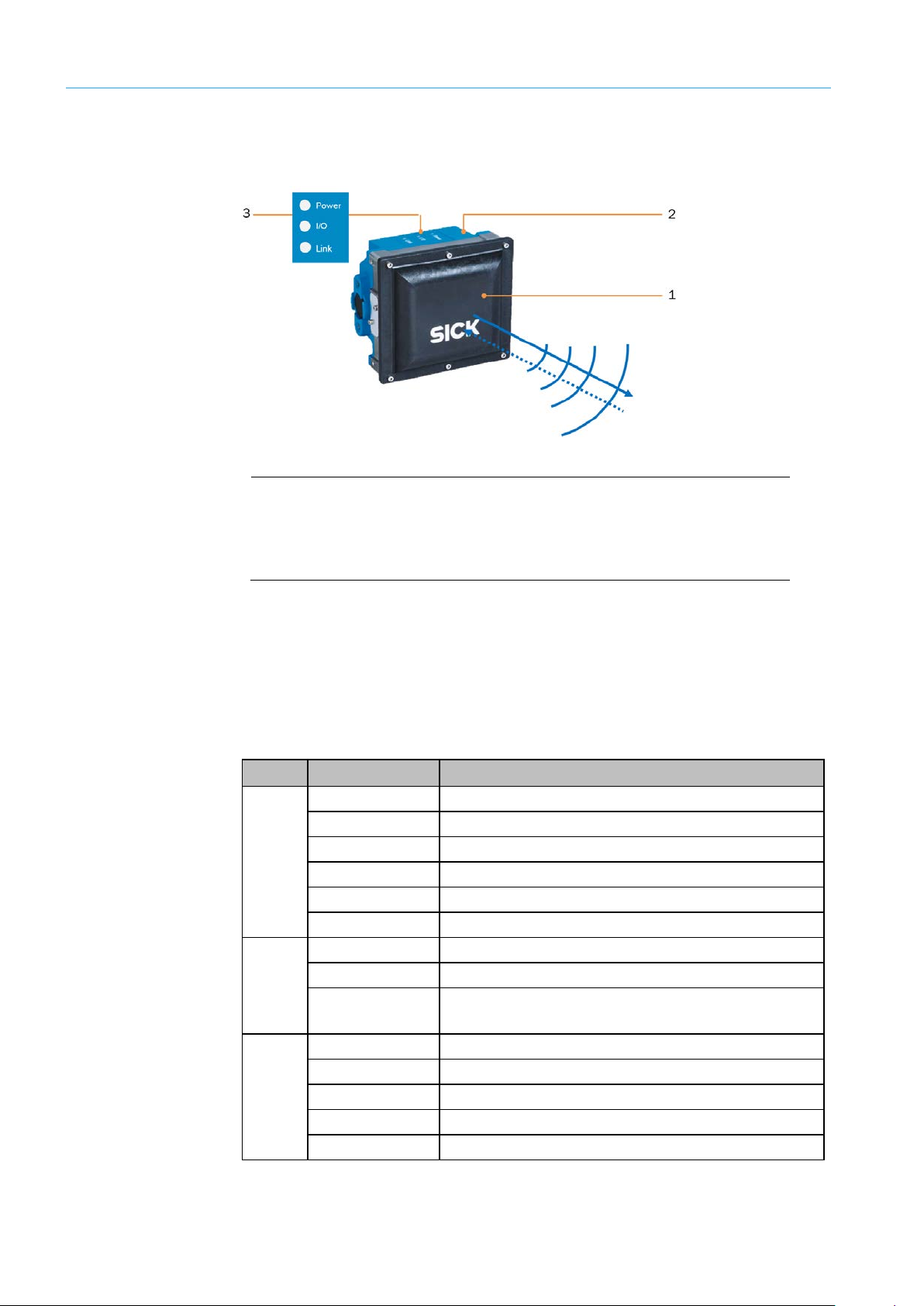

3.2.1 RMS3xx radar sensor

Fig. 4: RMS3xx radar sensor

Legend

1 Radar antenna (front end)

2 Control unit for sending signals to TDC-E

3 Status indicators

Properties

Status indicators

• The RMS3xx radar sensor consists of a radar antenna and a control unit.

• The radar sensor transmits electromagnetic waves.

• If these hit a moving object in the field of view of the radar sensor, the radar waves are

reflected back to the sensor.

• The control unit processes the received radar signals and passes all measured values

on to the TDC-E.

LED Color Meaning

Off Device is switched off.

Yellow Device is starting up.

Green Device is ready for use.

Power

Red (flashing) Device error.

Pink (flashing) Device update is running.

Green (flashing) Device update is complete.

Green No object detected in the field of view.

I/O

Yellow Object detected in the field of view

Red Warning field interrupted. The field interruption is not

used in the AOS301-WWD.

Off No Ethernet connection is present.

Green Ethernet connection is established.

Link

Green (flashing) Data transmission via Ethernet.

Yellow CAN connection is established.

Yellow (flashing) Data transmission via CAN bus.

Table 6: RMS3xx status indicators

Page 15

15

8023732/2018-09-10|SIC K

Subject to change without notice

ORIGINAL OPERA TING INSTRUCT IONS | AOS301-WWD

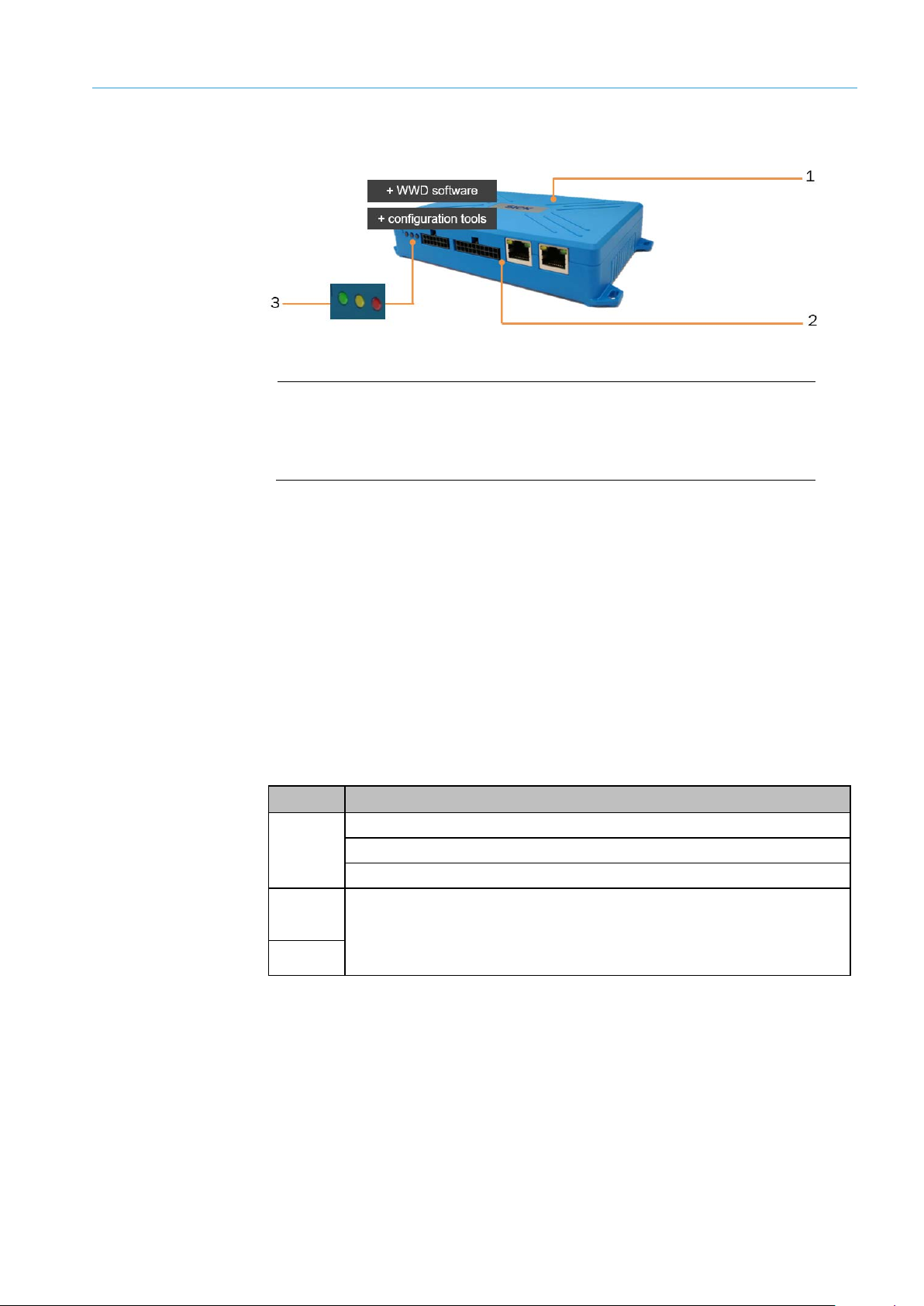

3.2.2 TDC-E200xx telematic data collector

Fig. 5: TDC-E200 telematic data collector

Legend

1 TDC-E with WWD software (TEMS recorder)

2 Interfaces

3 Status indicators

Properties

• The TDC-E with pre-installed WWD software (TEMS recorder) is the control unit of the

AOS301-WWD object detection system.

• The TDC-E receives all measured values received by the RMS3xx radar sensor,

evaluates them for a defined monitoring area (region of interest) and, using this data,

determines the speed and direction of movement of the detected object.

• Vehicles which move in the opposite direction are signaled to the connected customer

system via I/O interface.

• The TDC-E also supports transmission of measurement data as MQTT messages via

Ethernet or wireless networks.

• Tools pre-installed on the device at the factory enable commissioning based on a web-

based interface and system extensions.

SYSTEM DESCRIPTION 3

Status indicators

LED Meaning

Permanently OFF: The device is switched off.

Green

Permanently ON: The device is switched on but has not been booted up.

Intermittently flashing: The device has been successfully booted up.

Yellow

The yellow and red LEDs can be configured in the TDC-E Device Manager.

The modes available in the current version are ON, OFF, and HEARTBEAT

Red

Table 7: TDC-E200 status indicators

(= FLASHING).

Page 16

3 SYSTEM DESCRIPTION

16

8023732/2018-09-10|SIC K

ORIGINAL OPERA TING INSTRUCT IONS | AOS301-WWD

Subject to change without notice

3.3 Operating principle

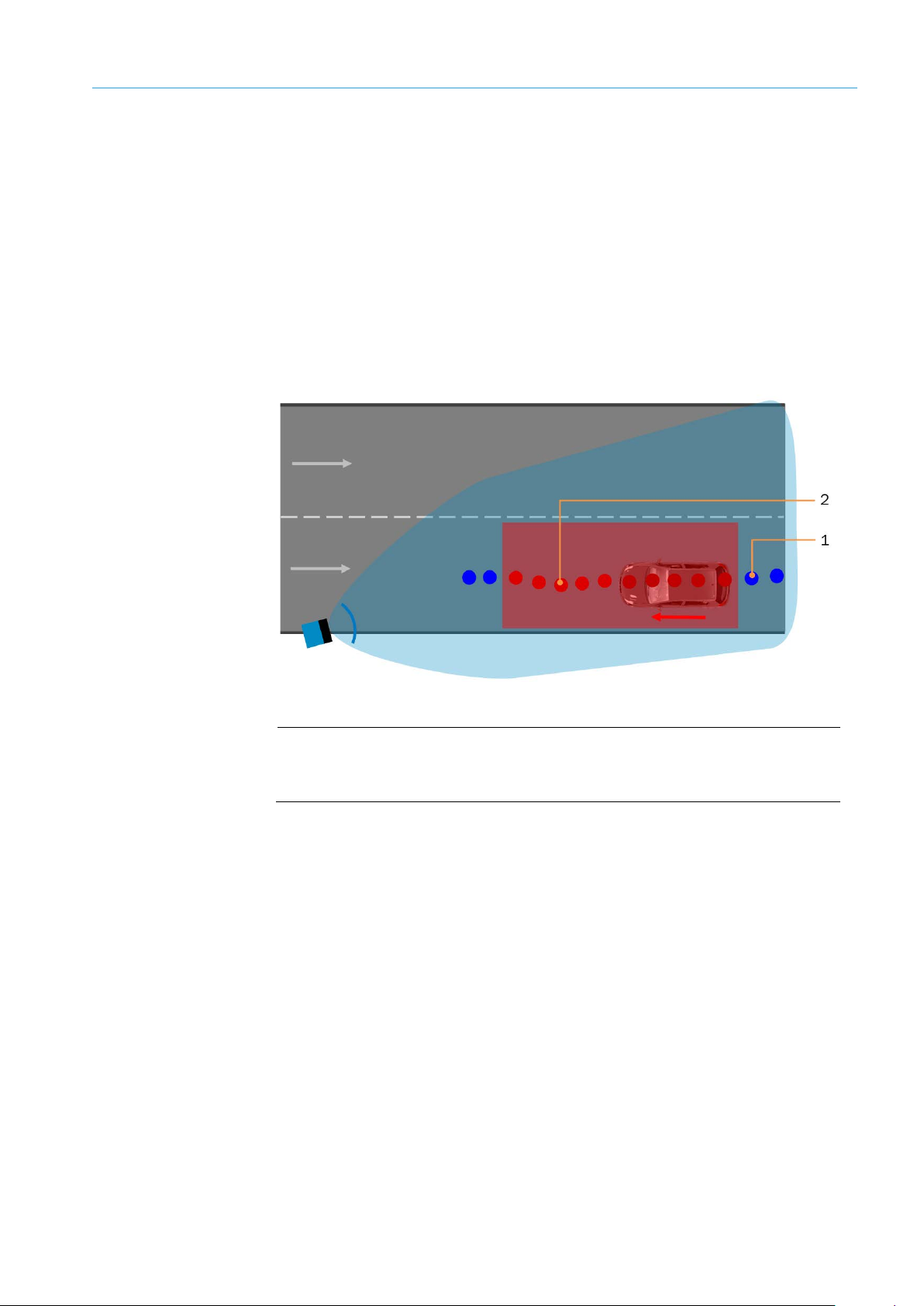

3.3.1 Vehicle detection and evaluation

The radar sensor is mounted on a vibration-free pole, gallows or portal. Radar waves emit

in the direction of travel, therefore opposite the wrong-way driver (see also chapter 3.4

Project planning).

Fig. 6: Vehicle detection with radar waves

Field of view and

monitored area

Fig. 7: Field of view and monitored area

Legend

1 Field of view of the radar sensor

2 Defined monitoring area

• A monitored area (region of interest) is defined in the field of view of the radar sensor.

The monitored area must be completely inside the field of view of the sensor.

• The monitored area determines which radar measurement points must be taken into

account by the AOS301-WWD. Only those measurement points which are in the defined

monitoring area are evaluated.

Page 17

SYSTEM DESCRIPTION 3

17

8023732/2018-09-10|SIC K

Subject to change without notice

ORIGINAL OPERA TING INSTRUCT IONS | AOS301-WWD

Vehicle detection

Data processing

• As soon as the radar sensor detects an object in the field of view, the positions of the

returned radar signals are forwarded to the TDC-E.

• In the first step, all object positions are discarded which are outside the defined

monitoring area.

• Only measurement points within the monitored area are evaluated.

• The object positions within the monitored area are tracked.

• Vehicle tracking begins as soon as the first measurement point can be assigned to the

monitored area and ends with the first measurement point outside of the monitored

area.

All object positions inside the monitored area are output as trajectories.

Fig. 8: Data processing – object points of the vehicle trajectory

Legend

1 Measurement points in the field of view of the radar sensor

2 Measurement points in the monitored area

• Every object point of the trajectory has a time stamp, the exact position of the

coordinate system and the speed.

• In the last step, the expected direction of travel is compared with the actual direction of

travel based on the object trajectory.

• The actual direction of movement of the vehicle is output as the result.

Page 18

3 SYSTEM DESCRIPTION

18

8023732/2018-09-10|SIC K

ORIGINAL OPERA TING INSTRUCT IONS | AOS301-WWD

Subject to change without notice

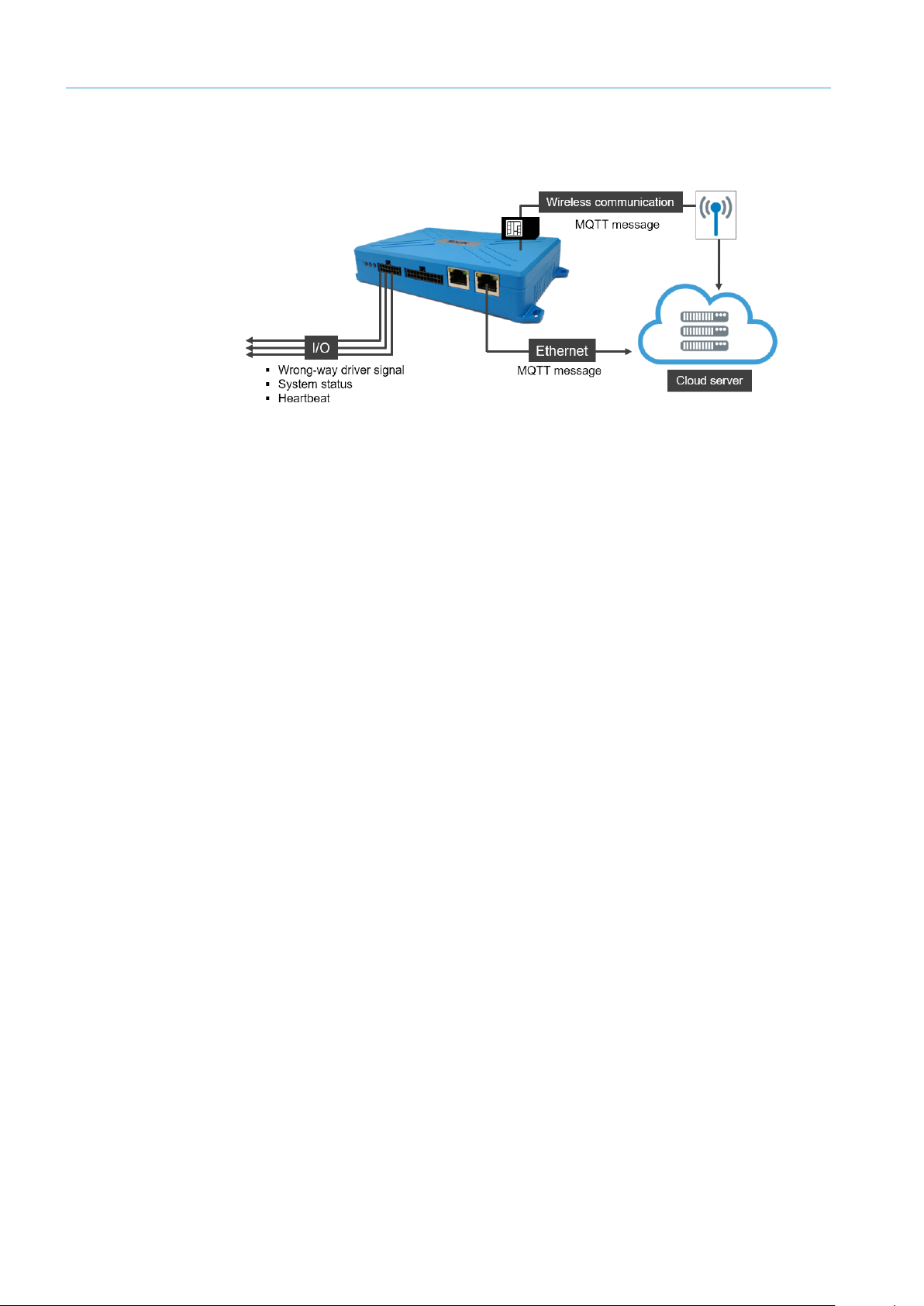

3.3.2 Data output and interfaces

The data is delivered via different optional interfaces.

Fig. 9: Data output and interfaces

I/O

MQTT message

Ethernet/

Wireless network

• If movement is recorded in the opposite direction of movement for a vehicle, a wrong-

way driver signal is output to the customer system via the digital interface of the TDC-E.

• Signaling via the I/O interface allows for quick response time.

• This requires corresponding infrastructure at the measurement site (cables, lights,

etc.).

• The system status and proper functioning of the system (heartbeat) can be signaled

using other digital contacts.

NOTE! Additional information can be found in chapter 6.5.1 Configuring I/O interface

(TDC-E IO plug-in).

• In addition, data of the AOS301-WWD can be called up using MQTT messages via an

MQTT message broker.

• The structure of the MQTT messages can be configured.

• MQTT messages can contain both information on the system status as well as the

measurement data of an object (such as the object positions of the created trajectory

with time stamp and speed and direction of movement).

NOTE! Additional information can be found in chapter 6.5.2 Configuring call-up of MQTT

messages.

• MQTT messages can be called up via the Ethernet interface of the TDC-E or a wireless

network. Calling up via a wireless network makes sense if no cables are laid at the

measurement site.

• The data can be used for analysis purposes and long-term observations, but also for

alarms (with a data connection of appropriate quality).

NOTE! Data transmission via wireless networks requires a SIM card of the country-specific

telecommunications provider (see chapter 4.2.3 Inserting SIM card). The connection

settings are saved in the TDC-E Device Manager (see chapter 6.8.4 Configuring wireless

settings).

Page 19

19

8023732/2018-09-10|SIC K

Subject to change without notice

ORIGINAL OPERA TING INSTRUCT IONS | AOS301-WWD

3.4 Project planning

SYSTEM DESCRIPTION 3

General system

requirements

Vehicles

Measurement location

Mounting position

Coordinate system

• Supply voltage 24 V DC (9 V DC ... 36 V DC) for the RMX3xx and TDC-E.

• I/O cable for processing the wrong-way driver signal by the customer system.

• An Ethernet cable for calling up MQTT messages (optional).

• Object detection at speeds of 10 km/h to 140 km/h.

• Straight and level passage.

• Monitoring of a maximum of two lanes.

Fig. 10: Radar sensor mounting position

• Radar sensor mounting on a vibration-free pole, gallows or a portal. Radar waves

emit in the direction of travel, therefore opposite the wrong-way driver.

• Mounting height 2.5 to 5 m.

The radar sensor is positioned in a three-dimensional coordinate system.

Fig. 11: Coordinate system

• The horizontal axis (X-axis) points orthogonally across the lane.

• The vertical axis (Y-axis) points upward perpendicular to the road surface.

• The movement axis (Z-axis) points in the direction of travel.

NOTE! The zero point in the road coordination system of the AOS301-WWD is always

located on the outer edge of the lane at the height of the ground.

Page 20

3 SYSTEM DESCRIPTION

20

8023732/2018-09-10|SIC K

ORIGINAL OPERA TING INSTRUCT IONS | AOS301-WWD

Subject to change without notice

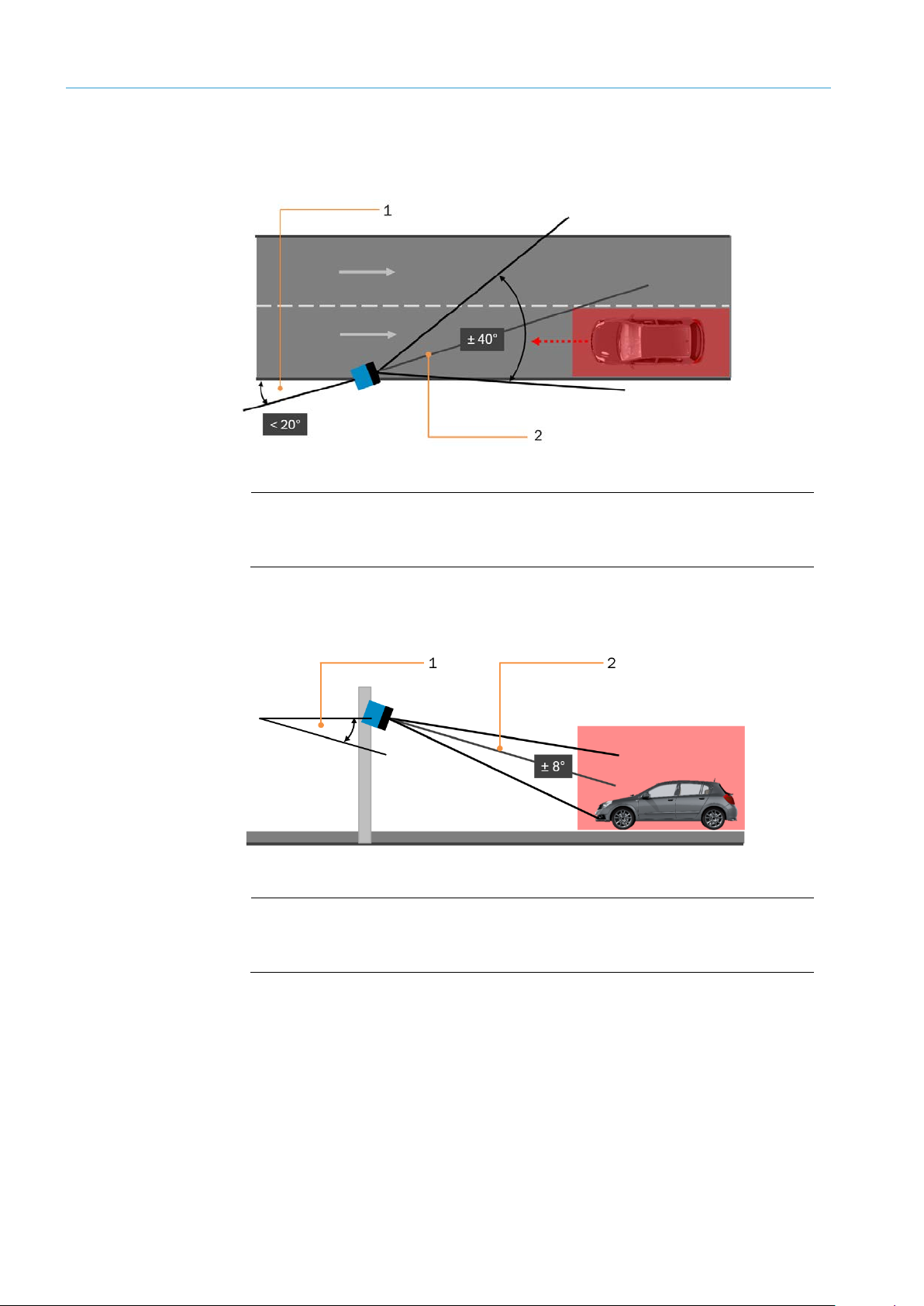

Alignment

The field of view of the RMS3xx is determined by the horizontal direction angle (± 40°),

the height aperture angle (± 8°) and the maximum scanning range of 40 m at 10 m

effective echo area (typical for cars).

Fig. 12: Alignment of RMS3xx – horizontal aperture angle and pivoting angle

Legend

1 Pivoting angle

2 Horizontal aperture angle

Align radar sensor toward the expected direction of travel

▸

The pivoting angle must not deviate from this direction by more than 20°.

▸

2

Fig. 13: Alignment of RMS3xx – height aperture angle and tilt angle

Legend

1 Tilt angle

2 Height aperture angle

Consider a height aperture angle of ± 8° when defining the monitored area.

▸

Select the optimal tilt angle depending on the mounting height of the RMS3xx. Low-

▸

hanging radar sensors have a flatter view than high-hanging ones. This means the

horizontal field of view is particularly large exactly where the vehicles to be detected

are moving.

Page 21

SYSTEM DESCRIPTION 3

21

8023732/2018-09-10|SIC K

Subject to change without notice

ORIGINAL OPERA TING INSTRUCT IONS | AOS301-WWD

Monitored area

The monitored area is placed in the field of view of the radar sensor and defined in the

TEMS Manager via a series of points (see 6.4.4 Configuring monitored area (AOS RMS

system function)). A point is determined by its coordinates on the road.

Fig. 14: Monitored area project planning

Consider the aperture angle, mounting position and maximum scanning range of the

▸

radar sensor.

Design the monitored area so that a vehicle with the maximum expected speed is in

▸

the monitored area for at least 500 ms.

A vehicle with a speed of 40 m/s for example needs a monitored area of 20 m to be

clearly detected.

Page 22

3 SYSTEM DESCRIPTION

22

8023732/2018-09-10|SIC K

ORIGINAL OPERA TING INSTRUCT IONS | AOS301-WWD

Subject to change without notice

3.5 System extension with tools and customer-specific applications

Fig. 15: TDC-E with container docker technology

Docker technology

• The Linux operating system that has been pre-installed on the TDC-E is based on a

powerful ARM processor and utilizes Docker container technology.

• Docker is a tool that makes it easier to create, deploy, and execute applications by

using containers. A container does not just hold the application itself but also all of the

resources required by the application during runtime.

• Thanks to the container technology, the AOS301-WWD can be rapidly extended by

adding customer-specific applications.

• To this end, the application is loaded into a container as a compiled image file and

executed immediately.

NOTE! For more information, please see the operating instructions for the TDC-E.

Page 23

23

8023732/2018-09-10|SIC K

Subject to change without notice

ORIGINAL OPERA TING INSTRUCT IONS | AOS301-WWD

4 Mounting

All transport, assembly, mounting, and electrical installation work must only be carried

out by qualified persons.

• Qualified persons have the specialist training, skills, and experience, as well as

knowledge of the relevant regulations and standards, to be able to perform work

assigned to them and to identify and avoid any potential dangers independently.

• Electricians have the professional training, skills and experience, and knowledge of

the relevant standards and provisions to work on electrical systems and to detect

and avoid any potential dangers independently.

4.1 Mounting the RMS3xx

According to the project planning, the radar sensor is mounted to a portal or to the side of

a gallows or a pole (see chapter 3.4 Project planning).

NOTE! Mount radar sensor so it is electrically insulated from conductive structures to

▸

protect against lightning damage.

A holding bracket or wall holder is available as an accessory.

MOUNTING 4

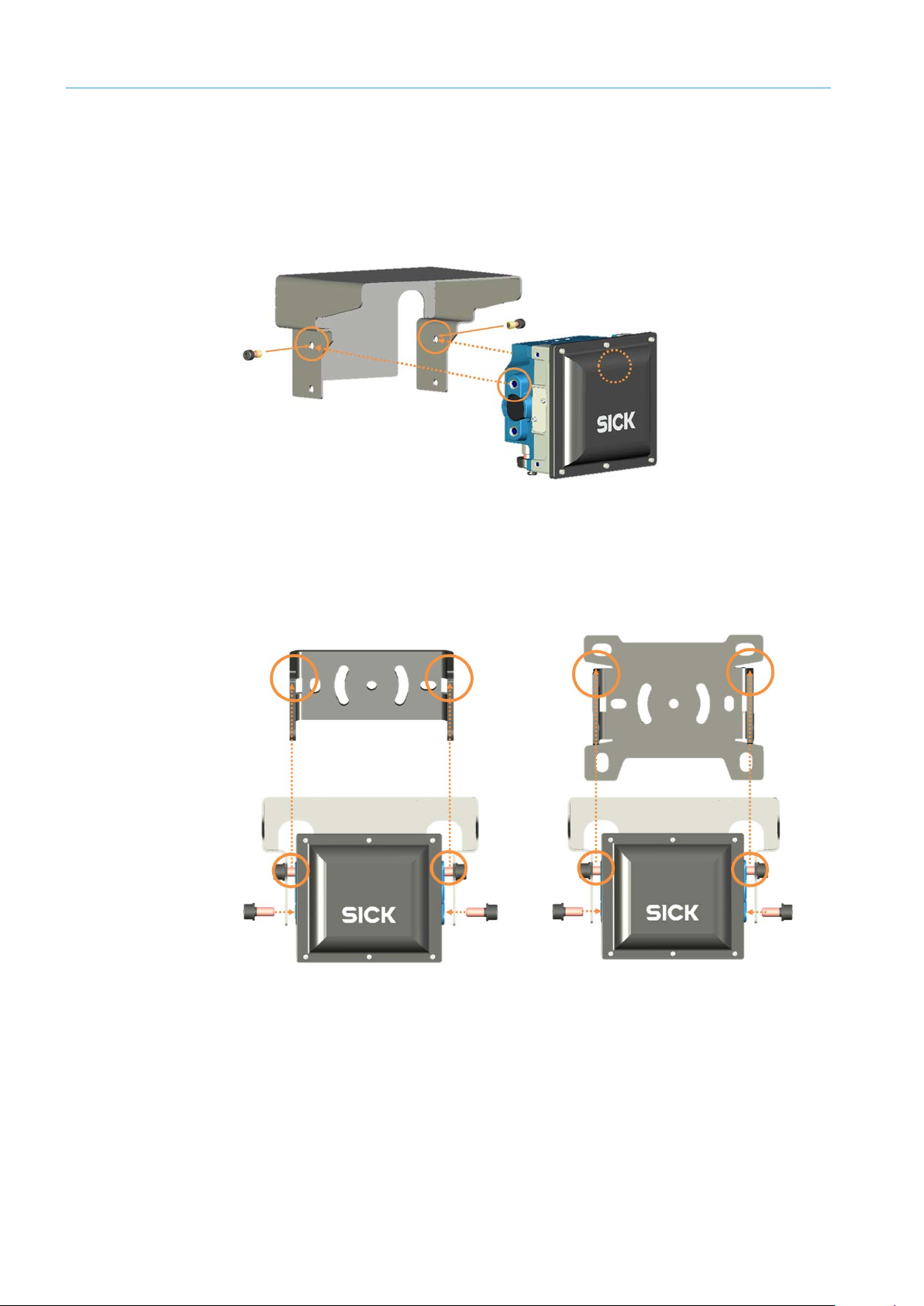

Fig. 16: Brackets for mounting the RMS3xx

Legend

1 Holding bracket

2 Wall holder

Page 24

4 MOUNTING

24

8023732/2018-09-10|SIC K

ORIGINAL OPERA TING INSTRUCT IONS | AOS301-WWD

Subject to change without notice

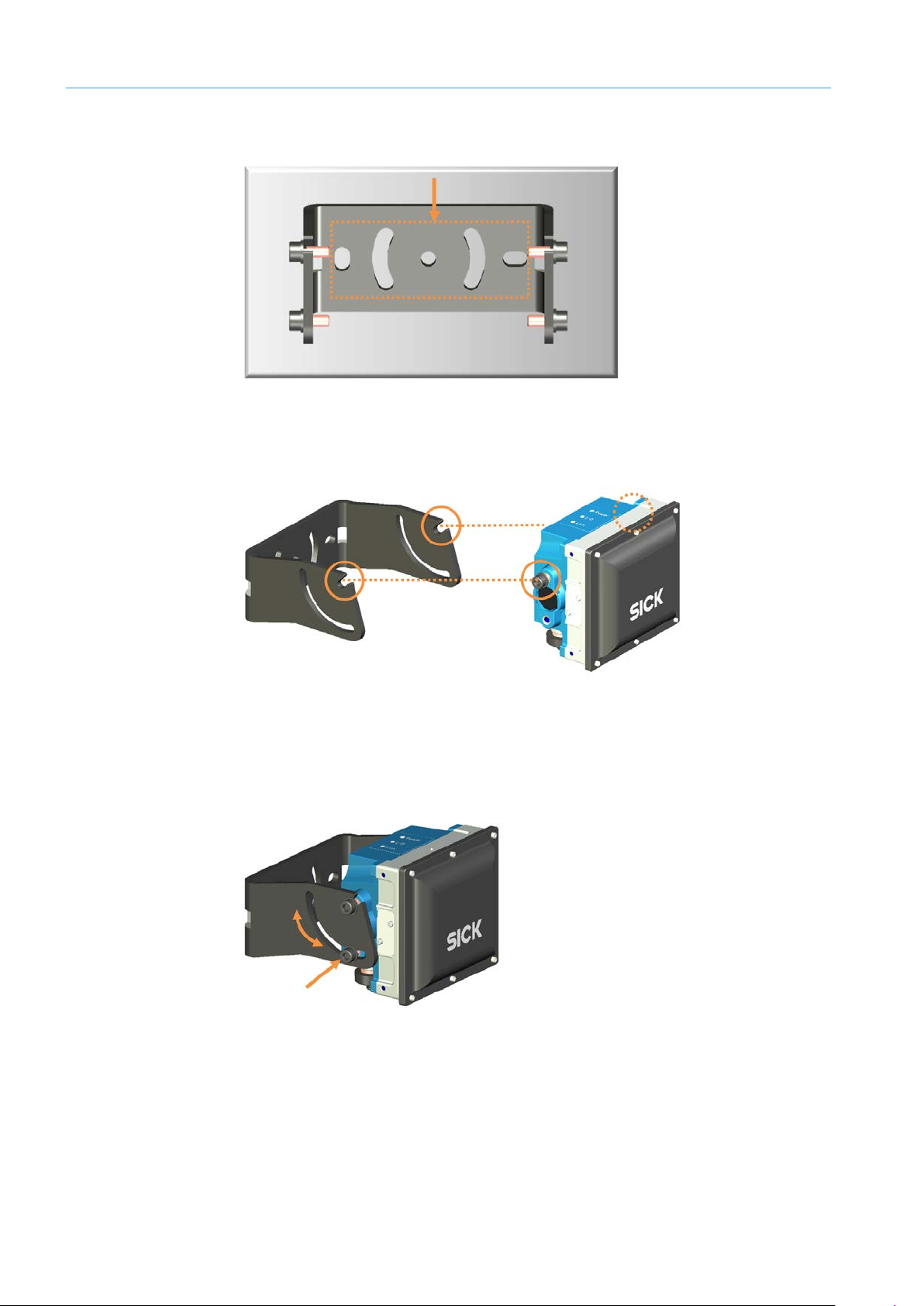

4.1.1 Mounting with holding bracket

Mounting holding

bracket

Fig. 17: Mounting holding bracket on a wall or panel

Mount holding bracket on a wall or a panel.

▸

Installing radar sensor

Fig. 18: Inserting radar sensor into mounting bracket

Screw cylinder screws into the upper thread on both sides as shown.

▸

Insert the radar sensor into the notches of the holding bracket with the screws.

▸

Slightly tighten screws.

▸

Fig. 19: Aligning and fastening radar sensor into the holding bracket

Align radar sensor and fasten it in the holding bracket with two more cylinder screws.

Page 25

25

8023732/2018-09-10|SIC K

Subject to change without notice

ORIGINAL OPERA TING INSTRUCT IONS | AOS301-WWD

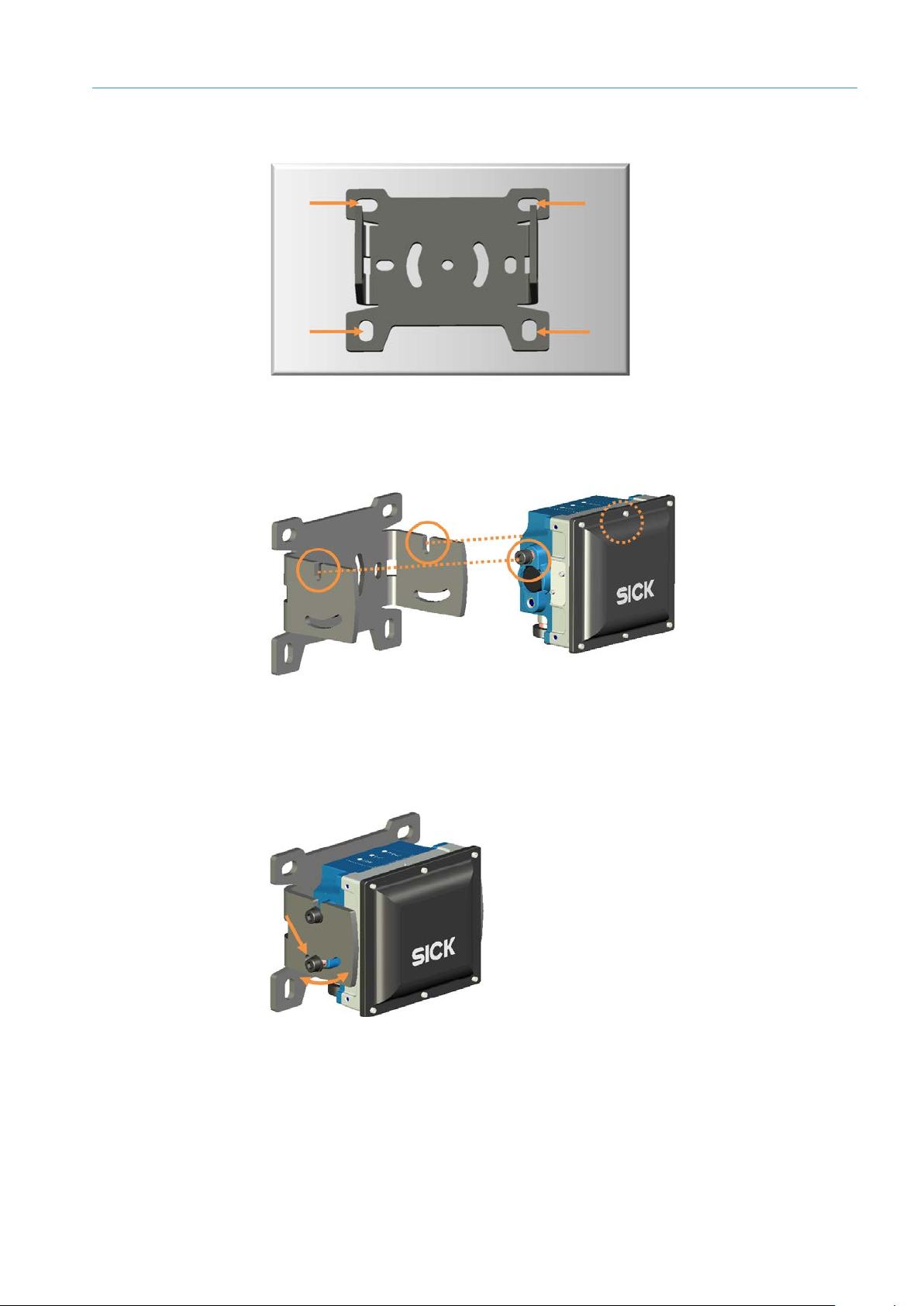

4.1.2 Mounting via wall holder

Mounting wall holder

Fig. 20: Mounting wall holder to wall

Mount the wall holder to the wall with four screws.

▸

Installing radar sensor

MOUNTING 4

Fig. 21: Inserting radar sensor into wall holder

Screw cylinder screws into the upper thread on both sides as shown.

▸

Insert the radar sensor into the notches of the wall holder with the screws.

▸

Slightly tighten screws.

▸

Fig. 22: Aligning and fastening radar sensor in wall holder

Align radar sensor and fasten it in the wall holder with two more cylinder screws.

Page 26

4 MOUNTING

26

8023732/2018-09-10|SIC K

ORIGINAL OPERA TING INSTRUCT IONS | AOS301-WWD

Subject to change without notice

4.1.3 Mounting with weather protection hood

The weather hood fits on both fastening types.

Mounting bracket

Mounting radar sensor

to the weather hood

Mount the holding bracket or wall holder as described.

▸

Fig. 23: Mounting radar sensor to weather hood

Stick cylinder screws through the upper holes on both sides as shown and insert into

▸

the upper thread of the radar sensor.

Only slightly screw in the screws.

▸

Mounting radar sensor

Fig. 24: Mounting radar sensor with weather hood to bracket

Insert the radar sensor with mounted weather hood into the notches of the bracket

▸

with the screws.

Align radar sensor and fasten it in the bracket with two more cylinder screws.

Page 27

27

8023732/2018-09-10|SIC K

Subject to change without notice

ORIGINAL OPERA TING INSTRUCT IONS | AOS301-WWD

4.2 Mounting TDC-E

Ideally, the TDC-E should be mounted at a suitable place in the control cabinet of the

measurement site near the higher-level control but never in the vicinity of transformers or

other power units.

NOTE! Take lightning protection measures for all in- and outgoing connections of the

▸

control cabinet.

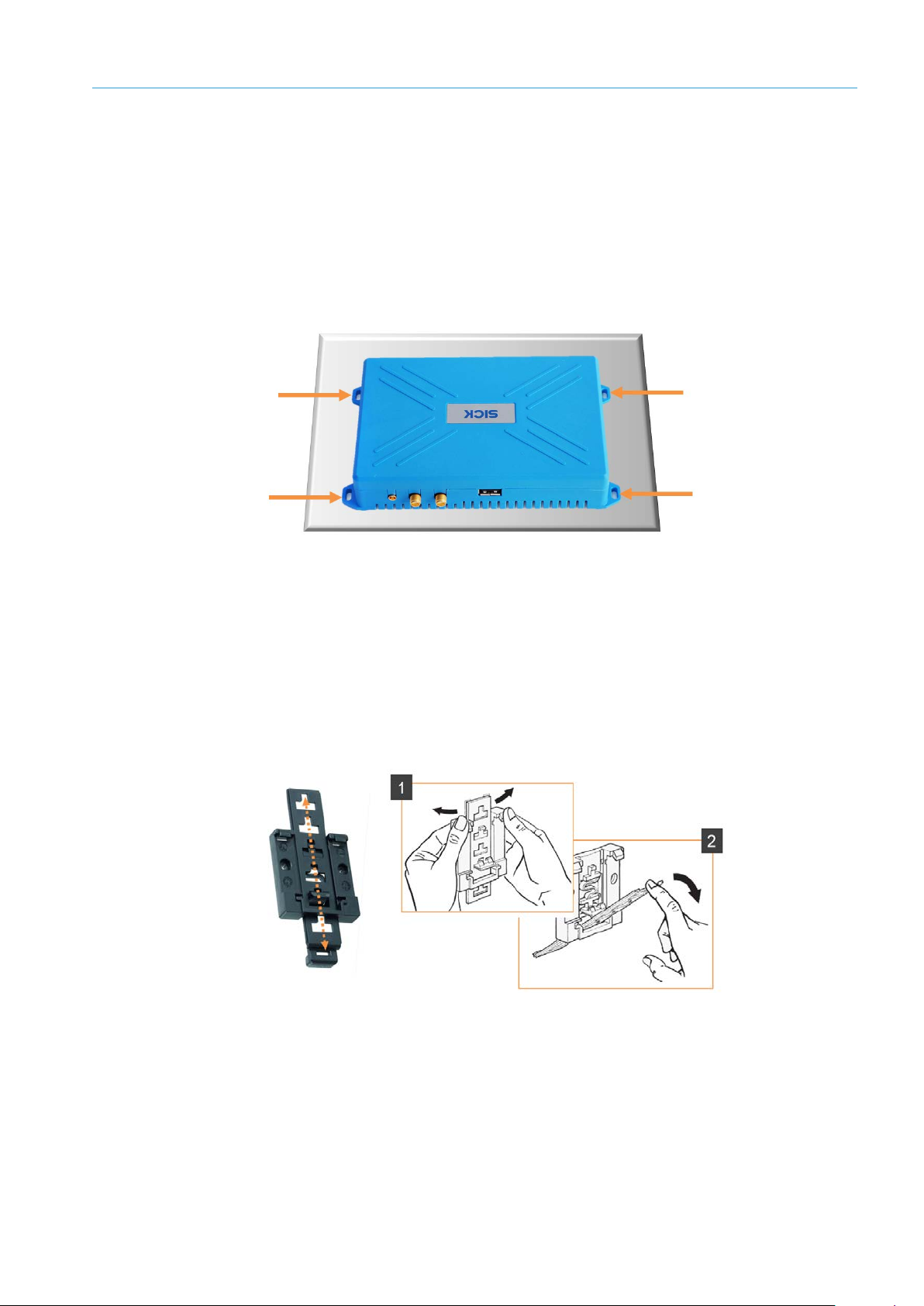

4.2.1 Mounting on a plate

MOUNTING 4

Fig. 25: Mounting TDC-E on a plate

Use the mounting holes on the bottom of the device to mount it.

▸

Securely attach the device using four M3 fillister head screws.

▸

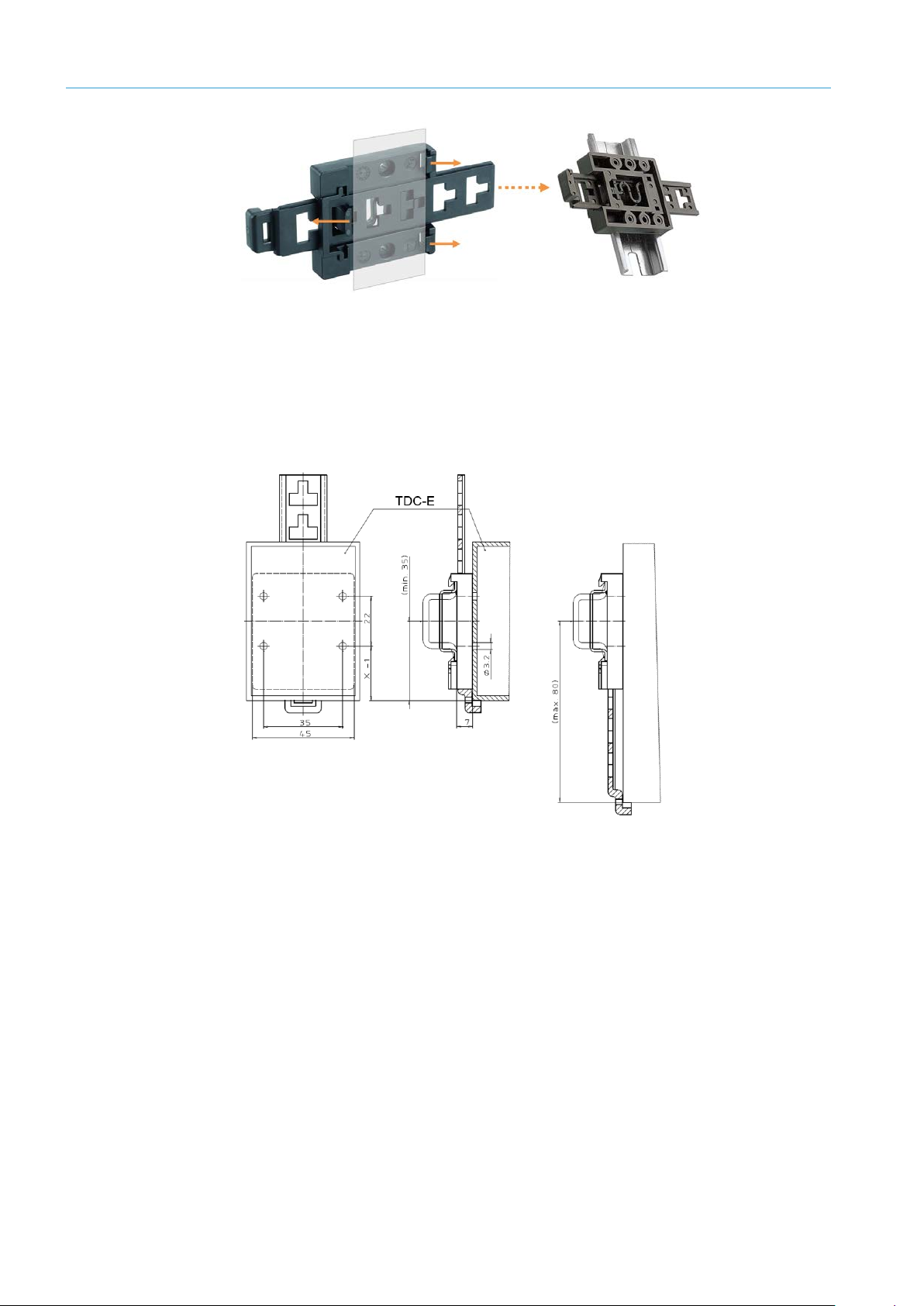

4.2.2 Mounting on DIN mounting rails

A mounting rail bracket is available as an accessory for mounting the TDC-E on DIN

mounting rails.

Adjusting the mounting

rail bracket to the

housing dimensions

Fig. 26: Adjusting the mounting rail bracket to the housing dimensions

Move the bar of the mounting rail bracket into the appropriate position and click it into

▸

place.

While clicking the bar out of one position and into another, gently bend the top section

▸

of the base with your hands.

At the same time, push the actuating bar forward. This will avoid damaging the lug in

the bar guide.

Page 28

4 MOUNTING

28

8023732/2018-09-10|SIC K

ORIGINAL OPERA TING INSTRUCT IONS | AOS301-WWD

Subject to change without notice

Attaching the mounting

rail bracket to the

mounting rail

Mounting the TDC-E on

the mounting rail

bracket

Fig. 27: Attaching the mounting rail bracket to the mounting rail

Attach the mounting rail bracket to the mounting rail via the lugs, making sure it

▸

audibly engages.

Place the TDC-E on the bar and use the mounting holes on the mounting rail bracket

to screw it on.

Fig. 28: Mounting the TDC-E on the mounting rail bracket

Page 29

29

8023732/2018-09-10|SIC K

Subject to change without notice

ORIGINAL OPERA TING INSTRUCT IONS | AOS301-WWD

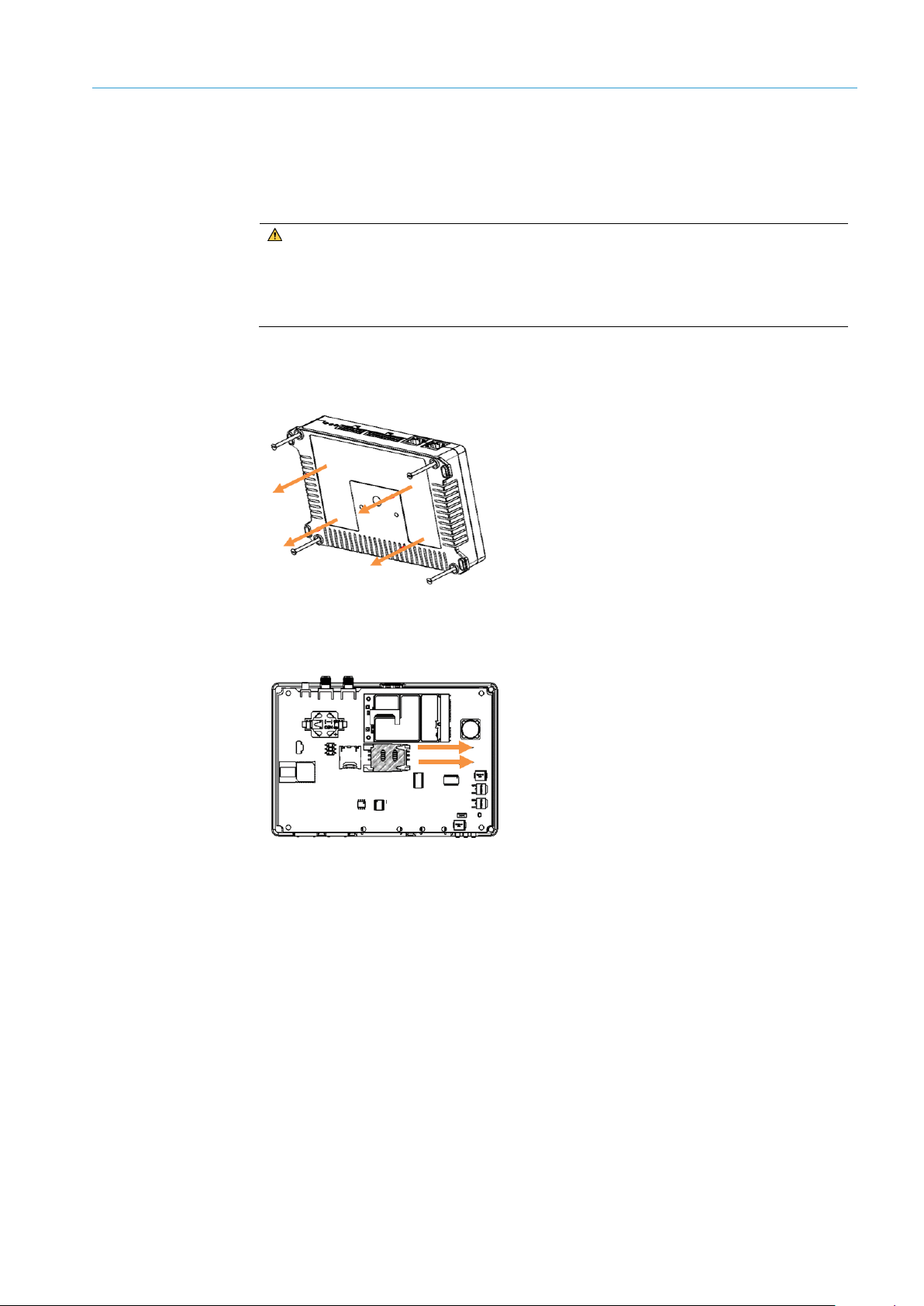

4.2.3 Inserting SIM card

▸

To allow for data transmission via a wireless network, the SIM card of a telecommunications provider must be inserted into the TDC-E.

WARNING!

RISK OF DAMAGE

Use only M2M SIM cards.

▸

Only insert the SIM card when the device is switched off.

Make sure that the device is switched off.

▸

Unscrew the plastic cover on the bottom of the device and remove it.

▸

MOUNTING 4

Slide the plastic cover of the SIM card holder to one side. There is an indicator arrow on

▸

the holder.

Remove the factory-installed SIM card for EU operation.

▸

Page 30

4 MOUNTING

30

8023732/2018-09-10|SIC K

ORIGINAL OPERA TING INSTRUCT IONS | AOS301-WWD

Subject to change without notice

Insert the SIM card from your telecommunications provider into the card holder with

▸

the contacts facing down.

Slide the plastic SIM cover back into place and lock it.

▸

Reattach the housing cover to the bottom of the device and screw it tight.

Note:

Set up APN in TDC-E Device Manager (for more, see chapter 6.8.4 Configuring wireless

▸

settings).

Page 31

31

8023732/2018-09-10|SIC K

Subject to change without notice

ORIGINAL OPERA TING INSTRUCT IONS | AOS301-WWD

5 Electrical installation

All electrical work may only be performed by qualified persons.

• Qualified persons have the specialist training, skills, and experience, as well as

knowledge of the relevant regulations and standards, to be able to perform work

assigned to them and to identify and avoid any potential dangers independently.

• Electricians have the professional training, skills and experience, and knowledge of

the relevant standards and provisions to work on electrical systems and to detect and

avoid any potential dangers independently.

DANGER!

HAZARDOUS ELECTRICAL VOLTAGE

The system is supplied with mains voltage. Risk of electric shocks. Contact causes

death, burns or shock.

Only qualified specialist personnel may conduct electrical work on the system.

▸

Interrupt the voltage supply.

▸

Check residual voltage on the system components.

▸

Pay extra attention.

▸

Always connect equipotential bonding (earthing).

▸

Do not disconnect or remove protective conductor.

▸

The power supply must be disconnected when attaching or detaching electrical

▸

connections.

ELECTRICAL INSTALLATION 5

5.1 Connection overview

Fig. 29: Connection overview

Page 32

5 ELECTRICAL INSTALLATION

32

8023732/2018-09-10|SIC K

ORIGINAL OPERA TING INSTRUCT IONS | AOS301-WWD

Subject to change without notice

PWR

5.2 Connecting the RMS3xx and TDC-E to the voltage supply

The RMS3xx and TDC-E are connected to a separate voltage supply.

Fig. 30: Connection to voltage supply – RMS3xx and TDC-E

Connecting the

RMS3xx

Plug the 5-pin M12 male connector to the Power connection using a suitable cable on

▸

the RMS3xx and tighten the plug connector.

Pin Wire color Connection

1 Brown Voltage supply 9.5 V ... 36 V

TDC-E connection

2 White IN1

3 Blue GND

4 Black OUT1

5 Gray GND IN1/2

Table 8: Connection to the voltage supply – pin assignment RMS3xx

Connect blue and brown wire to the voltage supply.

▸

Non-connected wires must be insulated with a heat-shrinkable sleeve and secured to

▸

prevent electrical connections.

NOTE!

If possible, lay cables inside poles.

▸

Never lay cables so they are hanging.

▸

Use the red and black wires of the connecting cable to connect the TDC-E to the voltage

▸

supply.

Pin Wire color Connection

14 Red VIN (9 V–36 V voltage supply)

7 Black GND for voltage supply

Table 9: Connection to voltage supply – TDC-E pin assignment

Page 33

33

8023732/2018-09-10|SIC K

Subject to change without notice

ORIGINAL OPERA TING INSTRUCT IONS | AOS301-WWD

5.3 Connecting radar sensor to TDC-E

The RMS3xx and TDC-E are connected via an Ethernet cable.

Fig. 31: Connecting RMS3xx and TDC-E

Plug the 4-pin M12 male connector to the Ethernet connection using a suitable cable

▸

on the RMS3xx and tighten the plug connector.

ELECTRICAL INSTALLATION 5

Pin Signal Function

1 TD+ Transmit_Data +

2 RD+ Receive_Data +

Table 10: Ethernet cable RMS3xx --> TDC-E – pin assignment

Connect cable to TDC-E with the Eth0 connection using the RJ45 male connector.

▸

NOTE! Take lightning protection measures at the entry to the control cabinet.

▸

NOTE!

If possible, lay cables inside poles.

▸

Never lay cables so they are hanging.

▸

3 TD- Transmit_Data –

4 RD- Receive_Data +

Page 34

5 ELECTRICAL INSTALLATION

34

8023732/2018-09-10|SIC K

ORIGINAL OPERA TING INSTRUCT IONS | AOS301-WWD

Subject to change without notice

5.4 Connecting customer interface

Connect the digital interface of the TDC-E for output of the wrong-way driver message via

I/O signal. Other I/O interfaces can be used to signal the system status and the

Heartbeat.

Connect the Ethernet interface of the TDC-E to call up the measurement data via MQTT

messages. Alternatively, connect the wireless network.

Fig. 32: Connecting customer interface

Ethernet

I/O

Connect the Ethernet cable to the customer system via the Eth1 Ethernet connection.

▸

NOTE! Take lightning protection measures at the outlet of the control cabinet.

▸

Define IP address of the interface in the TDC-E Device Manager (see chapter 6.8.3

▸

Adjusting Ethernet interface for data output).

Wrong-way driver signal, system status and Heartbeat are each output via a separate

digital output.

Plug the Microfit male connector at the end of the optional connecting cable into the

▸

14-pin female connector on the TDC-E.

Connect the TDC-E to the customer system using one of the following wires of the

▸

14-pin Micro-Fit male connector.

NOTE! Take lightning protection measures at the outlet of the control cabinet.

▸

Pin Wire color Connection

Table 11: Digital interfaces on TDC-E – pin assignment

▸

Wireless

communication

▸

▸

13 Yellow DIO_A

6 White DIO_B

12 Blue DIO_C

5 Pink DIO_D

11 Gray DIO_E

4 Violet DIO_F

Activate interfaces via the TEMS Manager and configure them as outputs (for more,

see chapter 6.5.1 Configuring I/O interface (TDC-E IO plug-in)).

Activate and configure connection settings of the SIM card in the TDC-E Device

Manager (for more, see chapter 6.8.4 Configuring wireless settings).

NOTE! Take into account lightning protection when taking an antenna from the control

cabinet.

Page 35

35

8023732/2018-09-10|SIC K

Subject to change without notice

ORIGINAL OPERA TING INSTRUCT IONS | AOS301-WWD

6 Commissioning

Commissioning may only be performed by qualified persons.

• Qualified persons have the specialist training, skills, and experience, as well as

knowledge of the relevant regulations and standards, to be able to perform work

assigned to them and to identify and avoid any potential dangers independently.

• Electricians have the professional training, skills and experience, and knowledge of

the relevant standards and provisions to work on electrical systems and to detect

and avoid any potential dangers independently.

6.1 Starting the system

Connect the voltage supply.

▸

All hardware and software components of the system are started up and checked for

operational readiness.

• The TDC-E is delivered with the pre-installed applications. When a cold start is

performed, a device that is still in this original state will be ready for operation after

approx. 120 s.

• When a warm start is performed via TDC-E Device Manager, all applications are shut

down first. The operating system and containers are then restarted.

A warm start takes approx. 180 s.

Check the operational status of the components by looking at the status indicators.

▸

COMMISSIONING 6

Page 36

6 COMMISSIONING

36

8023732/2018-09-10|SIC K

ORIGINAL OPERA TING INSTRUCT IONS | AOS301-WWD

Subject to change without notice

6.2 Preparing the configuration PC

The TDC-E is configured using a PC which is connected to the TDC-E via Ethernet. The

TEMS Manager Web and TDC-E Device Manager configuration tools installed on the TDC-E

are started via Ethernet connection.

The configuration tools contain both a browser-based interface and allow for a convenient

system set-up.

Fig. 33: Connecting the TDC-E device and the configuration PC

On delivery, the two Ethernet interfaces on the TDC-E have the following IP addresses:

Notes

Component Default IP address

Eth0 192.168.0.100

Internal interface for radar sensor.

Eth1 192.168.1.100

Customer interface for data output via Ethernet

configuration interface.

Make sure that the configuration PC is in the number range of the TDC-E.

▸

If necessary, change the IP address of the configuration PC.

▸

Connect the configuration PC to the TDC-E via the Eth1 Ethernet port.

▸

Page 37

37

8023732/2018-09-10|SIC K

Subject to change without notice

ORIGINAL OPERA TING INSTRUCT IONS | AOS301-WWD

6.3 Using TEMS Manager

6.3.1 Starting TEMS Manager

Start the web browser on the configuration PC. This browser must support HTML5 and

▸

WebGL.

Start TEMS Manager Web with the following URL:

▸

http://192.168.1.100:80

As soon as the connection to the TDC-E has been established, the TEMS Manager web

interface opens.

COMMISSIONING 6

6.3.2 Using a configuration file to load standard parameters

The AOS301-WWD standard parameters are delivered in an XML file. The parameters are

imported in TEMS Manager, where they are subsequently adjusted to the measurement

site.

In TEMS Manager, click the icon for Load site configuration and start/edit it.

▸

The authorization must be Authorized user or higher Service.

Click on the User name field, enter Service as user name and log in with the default

▸

password set up for this purpose (for more, see appendix at 9.3 Users and

authorizations).

Page 38

6 COMMISSIONING

38

8023732/2018-09-10|SIC K

ORIGINAL OPERA TING INSTRUCT IONS | AOS301-WWD

Subject to change without notice

Select configuration file and click on Start location configuration.

▸

The configuration is loaded in TEMS Manager.

6.3.3 The user interface

The menu bar contains the main registers of the TEMS Manager. This bar remains visible

in all working contexts.

Page 39

COMMISSIONING 6

39

8023732/2018-09-10|SIC K

Subject to change without notice

ORIGINAL OPERA TING INSTRUCT IONS | AOS301-WWD

Registers

• For users with the Operator and Authorized user authorizations, the Location,

Wrong-Way driver objects, Normal-way driver objects, Logs and Info registers are

available.

• The Settings register is restricted to users with the Service authorization.

Register Meaning

Location Shows the measurement site in a live view.

It also allows displaying and editing the system parameters

and delivers information on the system status.

Wrong-way driver

objects

Displays measurement results of vehicles for which a

movement in the opposite direction of movement has been

detected.

Display is done during operation of the AOS301-WWD.

Normal-way driver

objects

Displays measurement results of vehicles for which a

movement in the current direction of movement has been

detected.

Display is done during operation of the AOS301-WWD.

Settings Contains administrative functions. This allows changing user

passwords or updating the system, for example.

Logs Contains the system log files.

Info Provides information on the TEMS Recorder.

Login information

NOTE!

• Clicking on the program name reloads TEMS Manager with the Location register.

• The menu bar also contains notes on system faults.

Display of the logged-in user and the operating status on the right side of the menu bar.

▸

The user symbol opens a menu with the following functions:

▸

Function Meaning

Resetting page

settings

Sets all display settings (zoom, rotation in 3D displays,

table displays, etc.) back to standard values.

Change users Log out current user and log in another user.

Logout Log out current user.

Page 40

6 COMMISSIONING

40

8023732/2018-09-10|SIC K

ORIGINAL OPERA TING INSTRUCT IONS | AOS301-WWD

Subject to change without notice

Display format on small

screens

The TEMS Manager user interface automatically adjusts to the size of the screen. On a

smartphone or tablet, the content is arranged from top to bottom.

Call up registers of the TEMS Manager using the menu icon.

▸

6.3.4 Displaying the measurement site

The Site register is divided into two.

Navigation area

Live view

Legend

1 Live view

2 Navigation area

• Contains system components and system functions with the parameters of the

measurement site, e.g. the system component RMS320 with the radar sensor.

• Data output is configured via plug-ins in the bottom area.

• Visualizes the measurement site along with the system components, their installation

site, and their status display.

• Displays the detected vehicles as 3D models during operation.

• Visualizes all measurement points of the sensor (raw data) as well as the calculated

object points of the vehicle trajectories.

Page 41

COMMISSIONING 6

41

8023732/2018-09-10|SIC K

Subject to change without notice

ORIGINAL OPERA TING INSTRUCT IONS | AOS301-WWD

Rotate

Symbols

Adapting the graphic

display

Symbol Meaning

Load site configuration and start/edit it

• Allows you to load a configuration file.

• You can either start the configuration or open it in editing mode instead.

Stop current site configuration

• Stops the current configuration.

Edit site configuration

• Changes to edit mode.

Activate/deactivate expert mode

• Switches expert mode on or off.

• Expert mode displays all system functions in the navigation area and

functions for editing the parameter values, etc.

Save current site configuration on hard drive

• Saves the current site configuration onto a data card.

Adapting the view of the measurement site with the tools in your browser.

▸

Function Meaning

Rotates the site clockwise or counterclockwise on the GUI when you

press and hold the left mouse button.

Control with hand

movements

Moves the site up, down, right, and left when you press and hold the right

mouse button.

Enlarges or reduces the display of the site via the mouse wheel when the

mouse pointer is on the graphical display.

If you want to increase or decrease the zoom increments, press and hold

the Shift key at the same time.

Table 12: Functions for displaying the measurement site in TEMS Manager

Controlling with hand movements using a computer with touchscreen display.

▸

Function Meaning

Two-finger gestures (zoom in/zoom out)

• Moving the thumb and pointer finger apart zooms in on the graphical

display.

• Pushing the thumb and pointer finger together (pinching) zooms out on

the graphical display.

Rotate

• Press your finger on the graphical display and pull in the desired

direction to make the measurement site rotate accordingly.

Table 13: Controlling the display of the measurement site in TEMS Manager using hand

movements

Page 42

6 COMMISSIONING

42

8023732/2018-09-10|SIC K

ORIGINAL OPERA TING INSTRUCT IONS | AOS301-WWD

Subject to change without notice

6.3.5 Activating expert mode

In expert mode, functions appear which allow system and device parameters and plug-in

settings to be displayed and edited.

In the menu bar, click on the De-/Activate expert mode icon. The icon appears blue if

▸

expert mode is activated.

6.3.6 Displaying system parameters

The system parameters for the relevant system function/system component can be

visualized by opening the detail window.

NOTE! When location configuration is running, it is only possible to display parameters,

not edit them. Change to editing mode for editing (see chapter 6.4.1 Switching to editing

mode).

In the tree, click on the gear icon of a system function or system component

▸

At first, the detail window shows several key parameters (e.g mounting position of the

▸

radar sensor).

Page 43

COMMISSIONING 6

43

8023732/2018-09-10|SIC K

Subject to change without notice

ORIGINAL OPERA TING INSTRUCT IONS | AOS301-WWD

Displaying all

parameters

Displaying the device

status

Click on the Parameter link. The number of displayed parameters depends on the

▸

authorizations of the logged-in user.

Click on the Status link.

▸

Read off status information on the system component.

▸

Page 44

6 COMMISSIONING

44

8023732/2018-09-10|SIC K

ORIGINAL OPERA TING INSTRUCT IONS | AOS301-WWD

Subject to change without notice

6.3.7 Visualizing radar measurement points and monitored area in the live view

In the live view, the measurement values recorded in the field of view of the radar sensor

as well as the tracked object positions in the monitored area can be hidden during

configuration.

Go to the device level in the navigation area and click the Visualize live data for device

▸

RMS 320

icon. The functions for visualizing the measurement points in the live view appear.

Display the measurement points of the radar sensor in the field of view with (Raw)

▸

targets.

AOS Rms

Display the tracked object points in the monitored area with Objects.

▸

In the navigation area on the level of the AOS Rms system function, click on the

▸

Inspect live data of the component. The functions for visualizing the monitored area

appear.

With Region of interest, display the geometry of the monitored area (for more, see

▸

chapter 6.4.4 Configuring monitored area (AOS RMS system function).

Click on the folded-down function again to hide the measurement points and monitored

area.

Page 45

45

8023732/2018-09-10|SIC K

Subject to change without notice

ORIGINAL OPERA TING INSTRUCT IONS | AOS301-WWD

6.4 Adapting system parameters in TEMS Manager

6.4.1 Switching to editing mode

The standard parameters are adjusted to the measurement site in edit mode.

Click on the Edit location configuration icon in the menu bar.

▸

NOTE! A user with the Authorized user or Service authorizations must be logged in to

switch (for more, see appendix at 9.3 Users and authorizations).

Work through the hierarchical structure of the navigation tree from top to bottom when

▸

editing the system parameters.

NOTES ON LINKS

Do not change the links to other system functions that have been set up using the

chain-link icon

.

COMMISSIONING 6

Symbols

The toolbar above the navigation tree offers the following functions:

Symbol Meaning

Load site configuration and start/edit it

• Allows you to load a configuration file.

• You can either start the configuration or open it in editing mode instead.

Start current site configuration

• Starts the configuration that is currently open in editing mode.

• A red number in the icon indicates that the configuration is erroneous.

Erroneous configurations cannot be started.

Page 46

6 COMMISSIONING

46

8023732/2018-09-10|SIC K

ORIGINAL OPERA TING INSTRUCT IONS | AOS301-WWD

Subject to change without notice

Symbol Meaning

Edit site configuration

• To quit editing mode, click the blue icon. The configuration remains

loaded.

• To reopen the configuration file in editing mode, click the icon again.

• Click the

Activate/deactivate expert mode

Switches expert mode on or off.

Expert mode displays all system functions in the navigation area and

functions for editing the parameter values, etc.

Save current site configuration on hard drive.

Saves the current site configuration onto a data card.

• Reset site configuration.

• Resets all the changes that have been made to the system parameters

in editing mode, but only after you confirm the prompt.

• The navigation tree will then be completely blank.

• The icon only appears in expert mode.

icon to restart the loaded configuration file.

6.4.2 Configuring the measurement site

Notes on entering data

Designating the

measurement site

Designating the road

• All the designations underlined in blue can be changed by clicking the relevant

designation.

• An input field then appears so that you can enter the desired text.

In the header, click on the current designation.

▸

Enter name.

▸

Confirm with Enter.

Click the road name underlined in blue in the navigation tree.

▸

Change the designation and confirm with Enter.

▸

Page 47

COMMISSIONING 6

47

8023732/2018-09-10|SIC K

Subject to change without notice

ORIGINAL OPERA TING INSTRUCT IONS | AOS301-WWD

Configuring road

Signing the

configuration

Click the Edit road configuration icon on the road level.

▸

An input line appears underneath the road per lane.

Adjust values underlined in blue.

▸

Define the number of lanes and the lane width to be monitored.

▸

NOTE! The side strip is also counted as a lane in the default settings. It can also be

monitored like the regular lines if the monitored area is set accordingly.

Monitoring the hard shoulder is recommended since wrong-way drivers might very well

drive on these.

Define permitted direction of travel display. With the normal setting, the arrow in the

▸

live view points from the top left to the bottom right.

NOTE! If the road is configured with the existing lanes, the normal-way and wrong-way

drivers are assigned to a lane (see chapter 6.4.5 Defining expected direction of travel

(WWD system function)). The display of the direction of travel improves the view in the

live view since it gives the actual status. This particularly helps with configuration since

the real world and its representation in the live view can be better compared. For

example, a quick check can be done to determine whether the radar measurement

points are displayed between lane 1 and 2 as expected.

By applying a signature, you can – for example – document that a particular configuration

has been checked and approved. The signature is encrypted. It is generated when the

configuration is saved and written to the XML configuration file. Among other things, the

signature contains a reference to the configuration PC, the details of the logged-in user,

and the date of saving.

NOTE! A signed configuration cannot be changed without losing the signature. This offers

a reliable way of checking whether the configuration has been changed (e.g., following the

latest standardization procedure).

Page 48

6 COMMISSIONING

48

8023732/2018-09-10|SIC K

ORIGINAL OPERA TING INSTRUCT IONS | AOS301-WWD

Subject to change without notice

Click on the Sign road configuration icon on the road level.

▸

Two input fields appear underneath the road.

Enter person which has released the configuration.

▸

Document the release with a note.

▸

Click on Sign. The signature information is supplemented by a date field. Once the

▸

signature has been applied, the Name, Notes, and Date fields are deactivated and can

no longer be changed.

The Sign road configuration icon turns green.

To hide the signature area, click the Sign road configuration icon again.

▸

Quitting editing mode

6.4.3 Configuring radar sensor (system function RMS320)

Click the Edit road configuration icon.

▸

The enter line in the navigation tree is hidden.

RMS320 system

System function

parameters

function

The RMS320 system function receives and processes all measurement data which is in

the field of view of the radar sensor.

The exact mounting position of the radar sensor in the coordinate system is determined

via the parameters of the RMS320 system function.

NOTE! The network parameters of the radar sensor are specified by loading the

configuration file. Adjustment is not necessary.

Page 49

COMMISSIONING 6

49

8023732/2018-09-10|SIC K

Subject to change without notice

ORIGINAL OPERA TING INSTRUCT IONS | AOS301-WWD

Rough alignment in

live view

Exact mounting

position

Click on the radar sensor in the live view.

▸

Click on the component again and hold the mouse button down. A grid appears to

▸

serve as a guide.

NOTE! The orientation of the grid will automatically adapt to the current perspective

of the live view.

Rotate the measurement site in the live view to switch between displaying the grid

▸

along the X-axis and the Z-axis, respectively.

Then move the component within the desired level.

▸

On the radar sensor level in the navigation tree, click the Edit system component

▸

position icon.

The input lines appear. These already contain the position values defined during rough

alignment.

The position and angle can be defined using either the slide controls or by entering the

▸

values manually.

Adapt the view so that the effects of the entries are clearly visible in the graphic

▸

interface.

NOTE!

Position cursor on a controller and turn the mouse wheel.

▸

The values increase/decrease in “standard” increments.

▸

To increase/decrease the zoom increments, simultaneously press and hold the Shift

▸

key or the Ctrl key, respectively.

Page 50

6 COMMISSIONING

50

8023732/2018-09-10|SIC K

ORIGINAL OPERA TING INSTRUCT IONS | AOS301-WWD

Subject to change without notice

6.4.4 Configuring monitored area (AOS RMS system function)

AOS RMS

system function

System function

parameters

Entering dimensions

The AOS RMS system function processes the measurement points passed on by the

RMS320 system function. All object positions which are outside the defined monitoring

area are thereby discarded. The object positions within the monitored area are tracked.

Vehicle tracking begins as soon as the first measurement point can be assigned to the

monitored area and ends with the first measurement point outside of the monitored area.

All object positions inside the monitored area are output as trajectories by the AOS RMS

system function. Every object point of the trajectory has a time stamp, the exact position

of the coordinate system and the speed.

The geometry of the monitored area is defined by the parameters of the AOS RMS system

function. The monitored area must be completely in the field of view of the sensor.

The dimensions of the monitored area are defined as point sequences. The coordinates of

the individual points are entered separated by a semicolon.

Fig. 34: Entering dimensions of the monitored area

Page 51

COMMISSIONING 6

51

8023732/2018-09-10|SIC K

Subject to change without notice

ORIGINAL OPERA TING INSTRUCT IONS | AOS301-WWD

Click on the Show details icon on the level of the AOS RMS system function.

▸

Enter polygon points separated by a semicolon.

▸

NOTE! If the side strip is to be monitored, it must be taken into account by the polygon.

Object tracking is set by default.

▸

Click on Save.

▸

NOTE! The geometry of the monitored area can be displayed in the live view (for more, see

chapter 6.3.7 Visualizing radar measurement points and monitored area in the live view).

Page 52

6 COMMISSIONING

52

8023732/2018-09-10|SIC K

ORIGINAL OPERA TING INSTRUCT IONS | AOS301-WWD

Subject to change without notice

6.4.5 Defining expected direction of travel (WWD system function)

The WWD system function evaluates the object trajectories received by the AOS RMS

system function. The expected direction of travel is compared with the actual direction of

travel here. The actual direction of movement of the vehicle is output as the result.

System function

parameters

The direction of travel expected in the monitored area is stored via the WWD system

function parameters.

On the level of the WWD system function, click on the Show details icon.

▸

Set the Z-direction to +1 or –1 in the ExpectedDrivingDirectionZ parameter.

▸

The Z-direction corresponds to the Z-direction of the road coordinate system as shown

in the live view.

NOTE! The expected direction of travel is not related to a lane, but to the defined

monitoring area. The monitored area can be placed regardless of the lanes and can

therefore be outside lanes or cross several ones. Since the direction of travel may not

be clear by looking at the lane, it must be specified separately in relation to the road

coordinate system.

Specify minimum and maximum vehicle speed to get a valid wrong-way driver

▸

evaluation. Measurements of vehicles whose speeds are over or under this are

considered invalid.

NOTE! The AOS301-WWD system supports object detection at speeds of 10 km/h to

140 km/h.

Click on Save.

▸

Page 53

53

8023732/2018-09-10|SIC K

Subject to change without notice

ORIGINAL OPERA TING INSTRUCT IONS | AOS301-WWD

6.5 Configuring data output in TEMS Manager

6.5.1 Configuring I/O interface (TDC-E IO plug-in)

The data output is configured in TEMS Manager using plug-ins.

The TDC-E IO plug-in controls the output of the wrong-way driver signal to the customer

system via a digital I/O interface of the TDC-E. The system status and the Heartbeat can

also be output via this plug-in.

The TDC-E IO plug-in is created when the configuration file is loaded.

At the level of the TDC-E IOplug-in, click on theShow details icon.

▸

COMMISSIONING 6

Interfaces

• The TDC-E IO plug-in basically activates all digital interfaces of the TDC-E.

• They are configured in the DIO_A_Direction, DIO_B_Direction etc. parameters, each

as an output (Out). They can also be configured as an input (In).

• The DIO_A_Value, DIO_B_Value etc. parameters belonging to the interface define the

initial state set for the respective output.

If the value of an output is set to True, it is initialized with a high level when the

configuration is started, otherwise with a low level. This value is ignored for interfaces

configured as inputs.

Page 54

6 COMMISSIONING

54

8023732/2018-09-10|SIC K

ORIGINAL OPERA TING INSTRUCT IONS | AOS301-WWD

Subject to change without notice

•

•

•

Rule file

• A rule file determines which digital outputs are addressed by which events.

• The AOS301-WWD system is delivered with the Default Rules for TDC-E I/O Plugin rule

file. This already contains settings for the standard case.

Output Description

DIO_A

The plug-in has been loaded and connection to the TDC-E

hardware manager has been established.

• Static signal.

DIO_B

The configuration is running.

• Static signal.

DIO_C • Wrong-way driver message.

• Pulsating signal in fixed interval.

DIO_E

Normal-way driver message.

• Pulsating signal in fixed interval.

NOTE! If needed, remove, add or change rules in the rule file (see below).

Page 55

55

8023732/2018-09-10|SIC K

Subject to change without notice

ORIGINAL OPERA TING INSTRUCT IONS | AOS301-WWD

Watchdog

Editing rule file

COMMISSIONING 6

In the WatchDogOutput parameter, define the output through which the Heartbeat

▸

signal should be sent out.

In the WatchDogInterval parameter, define the length of time between the on/off

▸

states of the watchdog output.

NOTE! A time space of 0 (ms) deactivates the heartbeat signal.

The rule file can be opened and edited. Existing rules can be changed or additional rules

supplemented. New rule files can also be created and used in the AOS301-WWD.

An example for a useful additional rule is wrong-way driver detection in a tunnel which can

be completely blocked with a traffic light. If the signal of the red traffic light is laid on the

input of the TDC-E, normal-way drivers which cross over the red light can be output as

wrong-way drivers via a digital output.

NOTE! For convenient data editing, log in as a user with the Service authorization

▸

directly in the TEMS Manager.

With Info Files, you can open the list of previously downloaded files.

▸

Page 56

6 COMMISSIONING

56

8023732/2018-09-10|SIC K

ORIGINAL OPERA TING INSTRUCT IONS | AOS301-WWD

Subject to change without notice

▸

▸

▸

▸

Open TdceIoRules-Default rule file using the gear icon for editing

With the Service authorization, you can edit the contents of the XML file directly in

TEMS Manager (for more, see the appendix at 9.3 Users and authorizations).

Click on Save changes.

Change to the Location register and reload the last loaded location configuration.

Click the Edit location configuration icon. The site configuration is opened in edit

mode.

Page 57

57

8023732/2018-09-10|SIC K

Subject to change without notice

ORIGINAL OPERA TING INSTRUCT IONS | AOS301-WWD

6.5.2 Configuring call-up of MQTT messages

The MQTT plug-in can be used to call up information on the system status as well as

measurement data of the recorded vehicles (such as the object positions of the created

trajectory with time stamp and speed and direction of movement) via MQTT messages.

The MQTT messages must be configured accordingly.

Publish/