Page 1

AHS/AHM36 SSI ABSOLUTE ENCODERS

FLEXIBLE, SMART, COMPACT

Product description

The AHS/AHM36 SSI absolute encoder

product family provides increased exibility due to its mechanical adaptation,

electrical connectivity, and SSI communication. With their rotating male connector or cable outlets as well as the various

mounting hole patterns and adapter

anges, these encoders are suitable for

nearly any application. The encoders are

able to connect to a wide range of controls due to a programming tool that can

be used to make individual adjustments

to the structure of the SSI protocol, in

addition to adjusting the singleturn/multiturn resolution, the counting direction,

and other parameters. Thanks to the

large operating temperature range from

–40 °C ... +100 °C and the protection

class up to IP67, this encoder family can

be used in harsh ambient conditions.

The rugged, reliable, fully magnetic sensor system provides a maximum resolution of 14 bits for the singleturn variant

and 26 bits for the multiturn variant.

G

1)

1)

UL 508 compliant.

More information

Fields of application . . . . . . . . . . .G-233

Detailed technical data. . . . . . . . .G-233

Type code. . . . . . . . . . . . . . . . . . . .G-236

Ordering information. . . . . . . . . . .G-238

Dimensional drawings . . . . . . . . .G-239

Proposed tting . . . . . . . . . . . . . . .G-242

PIN assignment. . . . . . . . . . . . . . .G-244

Singleturn signal outputs .......G-245

Multiturn signal outputs ........G-247

Recommended accessories. . . . .G-249

At a glance

• Compact 36 mm absolute encoder

with max. 26 bits (singleturn: 14 bits,

multiturn: 12 bits)

• Face mount ange, servo ange, blind

hollow shaft

• Rotating M12 male connector or

rotating cable outlet

• SSI interface

Your benets

• Simple, time-saving mechanical

installation due to a rotating male

connector or cable outlet, various

mounting hole patterns, and many

different shafts

• Simple and exible electrical installa-

tion with various conguration options

and adjustable SSI protocol structure

(programmable SSI version)

• Programmable SSI version: Resolu-

tion, preset value, etc. can be programmed (depending on the type)

• Protection class up to IP67 (depend-

ing on the type)

• Operating temperature:

–40 °C ... +100 °C (depending on

the type)

• Easy setup for various applications

allowing binary, non-binary, and

non-integer resolutions with the round

axis functionality (programmable SSI

version)

• Reliable operation in harsh environ-

ments thanks to the rugged, reliable,

fully magnetic sensor system

• Space-efcient and cost-effective

design that is suitable for applications

where space is tight

• High performance at a cost-efcient

price

G-232

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 2

Fields of application

• Measures the absolute position in various industries,

machines, and tools, including automated guided systems

(AGS), industrial trucks, commercial vehicles, packaging

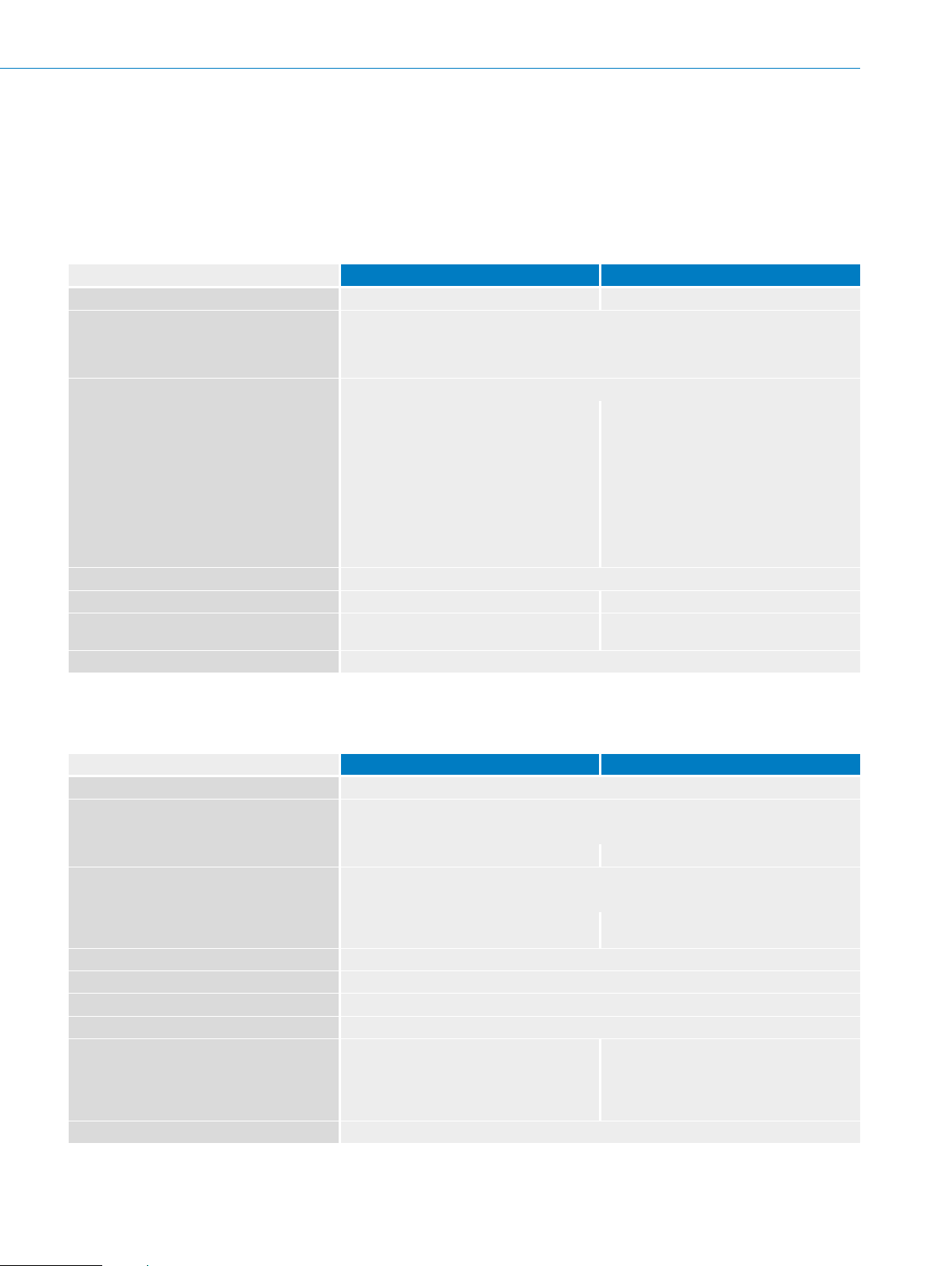

Detailed technical data

Performance

Max. number of steps per revolution

Max. number of revolutions

Absolute singleturn 1

Absolute multiturn 4,096 (12 bit)

Resolution

Absolute singleturn

Non-programmable 256, 360, 512, 720, 1,024, 2,048, 3,600,

Programmable

Absolute multiturn

Non-programmable 8x12 bit, 9x12 bit, 10x12 bit, 11x12 bit,

Programmable

Error limits

Repeatability

Measuring increment (360 °/ number of

steps per revolution)

Initialization time

1)

Can be programmed using SICK programming tools.

2)

Position can be read after this period.

4,096 (12 bit) 16,384 (14 bit)

4,096

1)

– 1 ... 16,384

12x12 bit

1)

– 0x0 bit ... 14x12 bit

± 0.35° (at 20 °C)

± 0.25° (at 20 °C) ± 0.2° (at 20 °C)

± 0.09° ± 0.022°

2)

100 ms

ABSOLUTE ENCODERS AHS/AHM36 SSI

machines, logistics applications, machine construction and

medical technology

Basic Advanced

256, 360, 512, 720, 1,024, 2,048, 3,600,

4,096, 8,192, 16,384

8x12 bit, 9x12 bit, 10x12 bit, 11x12 bit,

12x12 bit, 13x12 bit, 14x12 bit

Interfaces

Electrical interface

Code type

Non-programmable Gray

Programmable – Gray, binary

Code sequence

Non-programmable CW/CCW, congurable via cable

Programmable – CW/CCW, congurable via Programming Tool

Interface signals

Max. clock frequency

Set (electronic adjustment)

CW/CCW (counting sequence when turning)

Conguration data

Position forming time

1)

Min. LOW level (Clock +) 500 ns.

Basic Advanced

SSI

or cable

Clock +, Clock -, Data +, Data-

60 kHz ... 2 MHz

H active (L = 0 ... 3 V, H = 4 ... Us V)

L active (L = 0 ... 1 V, H = 2 ... Us V)

– Number of steps per revolution, number of

125 μs

1)

revolutions (multiturn only), PRESET, counting

direction, code type, offset, position bits,

position of error bit, round axis functionality

(multiturn version only), SSI mode

G

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

G-233

Page 3

G

AHS/AHM36 SSI ABSOLUTE ENCODERS

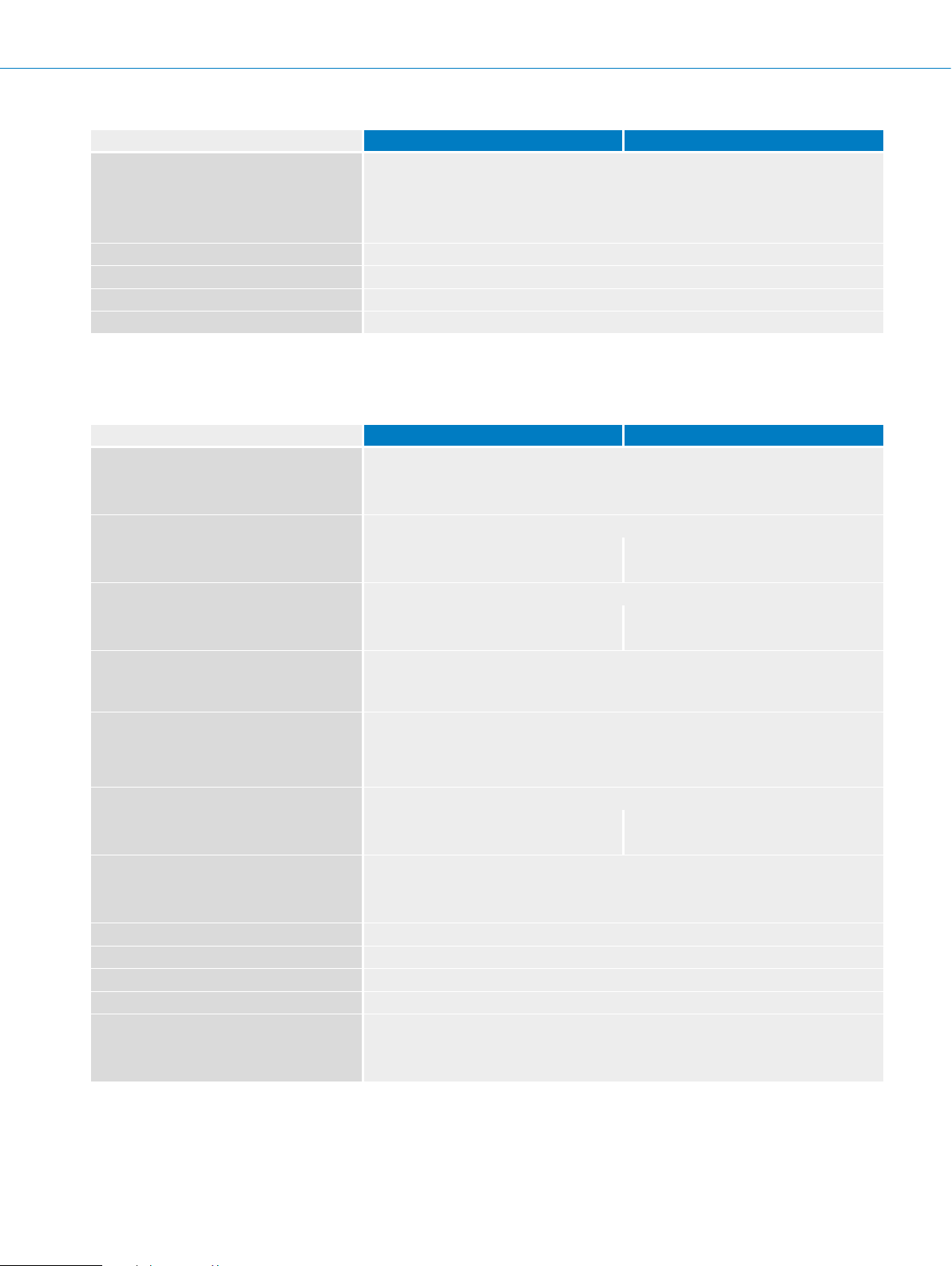

Electrical data

Basic Advanced

Connection type

Operating voltage range

Max. power consumption without load

Reverse polarity protection

MTTFd: mean time to dangerous failure

1)

This product is a standard product and does not constitute a safety component as dened in the Machinery Directive. Calculation based on nominal load of devices, average ambient temperature 40 °C, frequency of use 8760 h/a. All electronic failures are considered hazardous. For more information, see document no.

8015532.

Mechanical data

Shaft diameter

Solid shaft 6 mm, 1/4", 8 mm, 3/8", 10 mm

Blind hollow shaft 6 mm, 1/4", 8 mm, 3/8", 10 mm

Start up torque

Solid shaft 0.5 Ncm (at 20 °C) 1 Ncm (at 20 °C)

Blind hollow shaft 0.5 Ncm (at 20 °C) 1 Ncm (at 20 °C)

Operating torque

Solid shaft < 0.5 Ncm (at 20 °C) < 1 Ncm (at 20 °C)

Blind hollow shaft < 0.5 Ncm (at 20 °C) < 1 Ncm (at 20 °C)

Permissible shaft loading

Solid shaft 40 N (radial)

Permissible shaft movement, static/dynamic

Blind hollow shaft ± 0.3 mm / ± 0.1 mm radial

Max. operating speed

Singleturn 9,000 rpm

Multiturn 6,000 rpm

Bearing lifetime

Solid shaft 3.6 x 108 revolutions

Blind hollow shaft 2.0 x 10

Shaft material

Flange material

Housing material

Cable material

Mass

Solid shaft 0.12 kg (related to encoder with connector outlet)

Blind hollow shaft 0.12 kg (related to encoder with connector outlet)

1)

Take into account self-heating of 3.5 K per 1,000 revolutions/min when designing the operating temperature range.

2)

Take into account self-heating of 5.5 K per 1,000 revolutions/min when designing the operating temperature range.

3)

For Advanced type encoders, the shaft seal must be inspected regularly.

M12 male connector, 8-pin, universal

Cable, 8-wire, universal, 0.5 m

Cable, 8-wire, universal, 1.5 m

Cable, 8-wire, universal, 3 m

Cable, 8-wire, universal, 5 m

4.5 V DC ... 32 V DC

≤ 1.5 W

l

1)

230 years (EN ISO 13849-1)

Basic Advanced

20 N (axial)

± 0.3 mm / ± 0.1 mm axial

1)

1)

9

revolutions

Stainless steel

Aluminum

Zinc

PUR

6,000 rpm

6,000 rpm

2), 3)

2), 3)

G-234

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 4

ABSOLUTE ENCODERS AHS/AHM36 SSI

Basic Advanced

Rotor moment of inertia

Solid shaft 2.5 gcm²

Blind hollow shaft 15 gcm²

Max. angular acceleration

1)

Take into account self-heating of 3.5 K per 1,000 revolutions/min when designing the operating temperature range.

2)

Take into account self-heating of 5.5 K per 1,000 revolutions/min when designing the operating temperature range.

3)

For Advanced type encoders, the shaft seal must be inspected regularly.

Ambient data

EMC

Enclosure rating

Permissible relative humidity

Operating temperature range

Storage temperature range

Resistance to shocks

Resistance to vibrations

1)

In an assembled male connector.

2)

For Advanced type encoders, the shaft seal must be inspected regularly.

≤ 500,000 rad/s²

Basic Advanced

According to EN 61000-6-2 and EN 61000-6-3

IP 65 on housing side (acc. to IEC 60529)

1)

IP 65 on shaft side (acc. to IEC 60529)

90% (condensation not permitted)

–20 °C ... +70 °C –40 °C ... +100 °C

–40 °C ... +100 °C, without packaging

100 g/6 ms (according to EN 60068-2-27)

20 g/10 Hz ... 2,000 Hz (according to EN 60068-2-6)

IP 66 + IP 67, on housing side (acc.

to IEC 60529)

IP 66 + IP 67, on shaft side (acc. to

IEC 60529)

1)

2)

G

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

G-235

Page 5

AHS/AHM36 SSI ABSOLUTE ENCODERS

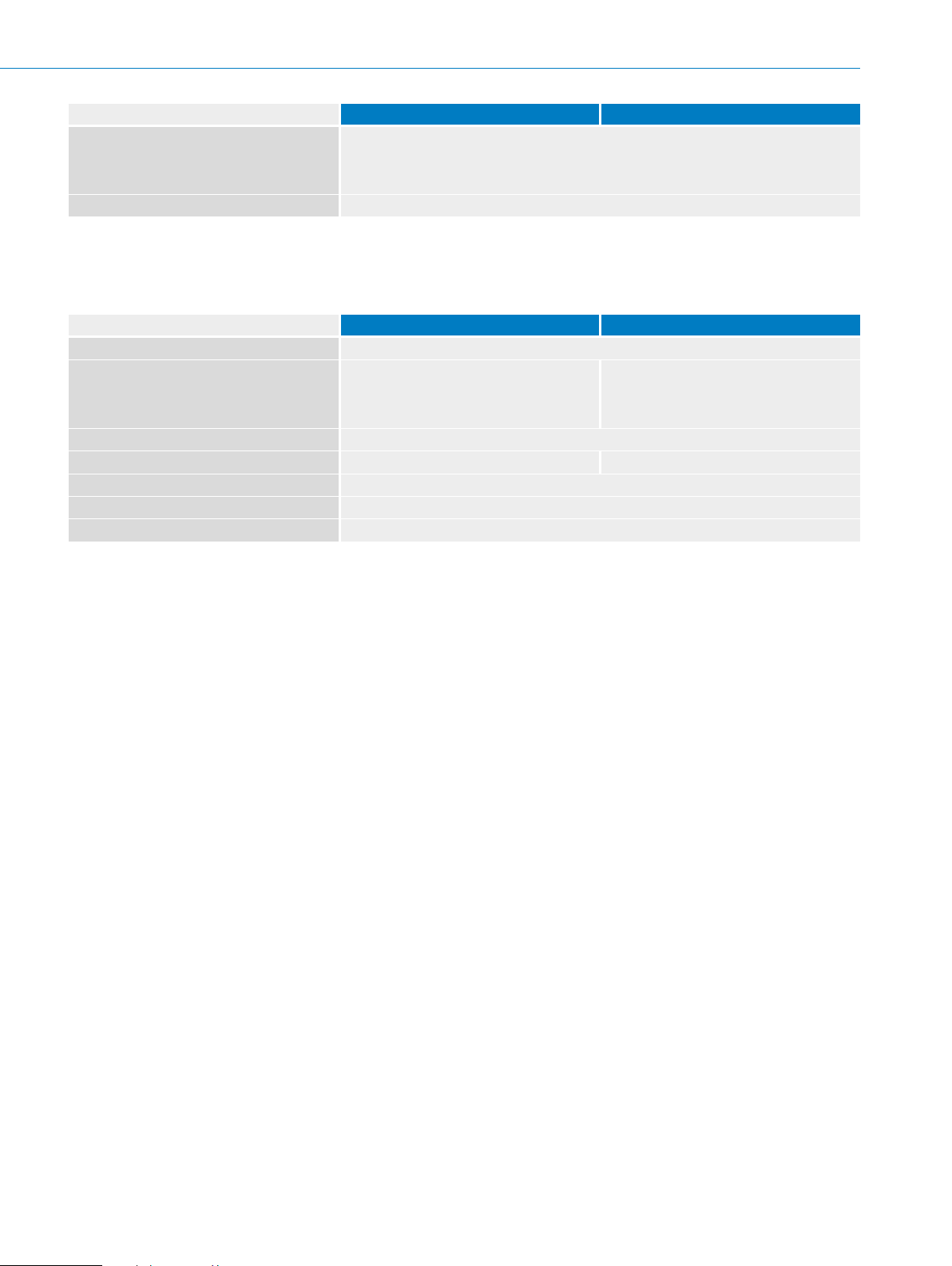

Type code

Singleturn

Type

B Basic

A Advanced

Mechanical design

B A Blind hollow shaft, 6 mm

B B Blind hollow shaft, 8 mm

B C Blind hollow shaft, 3/8"

B D Blind hollow shaft, 10 mm

B K Blind hollow shaft, 1/4"

S 1 Solid shaft, servo ange, 6x12 mm

S 9 Solid shaft, servo ange, 8x12 mm

S 2 Solid shaft, servo ange, 10x12 mm

S A Solid shaft, servo ange, 1/4"x12 mm

S B Solid shaft, servo ange, 3/8"x12 mm

S 3 Solid shaft, face mount ange, 6x12 mm

S 5 Solid shaft, face mount ange, 8x12 mm

S 4 Solid shaft, face mount ange, 10x12 mm

S 8 Solid shaft, face mount ange, 1/4"x12 mm

S 7 Solid shaft, face mount ange, 3/8"x12 mm

S C Solid shaft, face mount ange, 10x24 mm, for use with the adapters 2072298 and 2072295

1)

Electrical interface

A 4,5 … 32 V, SSI, gray

P 4.5 … 32 V, SSI, gray/binary, programmable (type A only)

2)

G

Connection type

C M12, 8-pin, universal

J Cable, 8-wire, universal, 0.5 m

K Cable, 8-wire, universal, 1.5 m

L Cable, 8-wire, universal, 3 m

M Cable, 8-wire, universal, 5 m

3)

3)

3)

3)

Resolution

00256 ... 04,096 Steps per revolution (type B)

00256 ... 16,384 Steps per revolution (type A)

4)

4)

A H S 3 6 - O

1)

Flange adapters can be used for additional mechanical interfaces, see Mounting suggestions.

2)

Permissible shaft load lower than gure list in technical data.

3)

NRTL certicate only valid for operating temperatures from –40 °C ... + 85 °C.

4)

Number of steps for non-programmable devices: Basic: 256, 360, 512, 720, 1,024, 2,048, 3,600, 4,096 Advanced: 256, 360, 512, 720, 1,024, 2,048, 3,600,

4,096, 8,192, 16,384. Other steps available on request. Number of steps for programmable devices (Advanced only): 16,384, programmable using Programming Tool.

G-236

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 6

Multiturn

Type

B Basic

A Advanced

ABSOLUTE ENCODERS AHS/AHM36 SSI

Mechanical design

B A Blind hollow shaft, 6 mm

B B Blind hollow shaft, 8 mm

B C Blind hollow shaft, 3/8"

B D Blind hollow shaft, 10 mm

B K Blind hollow shaft, 1/4"

S 1 Solid shaft, servo ange, 6x12 mm

S 9 Solid shaft, servo ange, 8x12 mm

S 2 Solid shaft, servo ange, 10x12 mm

S A Solid shaft, servo ange, 1/4"x12 mm

S B Solid shaft, servo ange, 3/8"x12 mm

S 3 Solid shaft, face mount ange, 6x12 mm

S 5 Solid shaft, face mount ange, 8x12 mm

S 4 Solid shaft, face mount ange, 10x12 mm

S 8 Solid shaft, face mount ange, 1/4"x12 mm

S 7 Solid shaft, face mount ange, 3/8"x12 mm

S C Solid shaft, face mount ange, 10x24 mm, for use with the adapters 2072298 and 2072295

S D Solid shaft, servo ange, 6x12 mm for adapting to 1.25 m Ecoline wire draw mechanism

1)

5)

Electrical interface

A 4,5 … 32 V, SSI, gray

P 4.5 … 32 V, SSI, gray/binary, programmable (type A only)

2)

Connection type

C M12, 8-pin, universal

J Cable, 8-wire, universal, 0.5 m

K Cable, 8-wire, universal, 1.5 m

L Cable, 8-wire, universal, 3 m

M Cable, 8-wire, universal, 5 m

3)

3)

3)

3)

Resolution

8x12 … 12x12 bit (Type B)

8x12 … 14x12 bit (Type A)

4)

4)

A H M 3 6 - O

1)

Flange adapters can be used for additional mechanical interfaces, see Mounting suggestions from page 17.

2)

Permissible shaft load lower than gure list in technical data.

3)

NRTL certicate only valid for operating temperatures from –40 °C ... + 85 °C.

4)

Resolution for non-programmable devices: Basic: 8x12, 9x12, 10x12, 11x12, 12x12. Advanced: 8x12, 9x12, 10x12, 11x12, 12x12, 13x12, 14x12. Other resolutions

on request. Resolution for programmable devices (Advanced only): 14x12, programmable using Programming Tool.

5)

Protection class on shaft side always IP65.

G

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

G-237

Page 7

AHS/AHM36 SSI ABSOLUTE ENCODERS

Ordering information

Absolute singleturn, solid shaft, servo ange

• Electrical interface: SSI

Shaft diameter Connection type Number of steps Resolution Programmable Type Part no.

6 x 12 mm

6 x 12 mm

M12 male connec-

tor, 8-pin, universal

M12 male connec-

tor, 8-pin, universal

Cable, 8-wire,

universal, 1.5 m

4,096 4,096 x 1 –

≤ 16,384 16,384 x 1

≤ 16,384 16,384 x 1

l

l

Absolute multiturn, solid shaft, servo ange

• Electrical interface: SSI

Shaft diameter Connection type Number of steps Resolution Programmable Type Part no.

6 x 12 mm

6 x 12 mm

M12 male connec-

tor, 8-pin, universal

M12 male connec-

tor, 8-pin, universal

Cable, 8-wire,

universal, 1.5 m

4,096 4,096 x 4,096 –

≤ 16,384 16,384 x 4,096

≤ 16,384 16,384 x 4,096

l

l

AHS36B-

S1AC004096

AHS36A-

S1PC016384

AHS36A-

S1PK016384

AHM36B-

S1AC012x12

AHM36A-

S1PC014x12

AHM36A-

S1PK014x12

1066017

1066014

1066013

1066012

1066009

1066008

G

Absolute singleturn, solid shaft, face mount ange

• Electrical interface: SSI

Shaft diameter Connection type Number of steps Resolution Programmable Type Part no.

8 x 12 mm

M12 male connec-

tor, 8-pin, universal

16,384 16,384 x 1 –

AHS36A-

S5AC016384

1067269

Absolute multiturn, solid shaft, face mount ange

• Electrical interface: SSI

Shaft diameter Connection type Number of steps Resolution Programmable Type Part no.

6 x 12 mm

M12 male connec-

tor, 8-pin, universal

Cable, 8-wire,

universal, 1.5 m

≤ 16,384 16,384 x 4,096

≤ 16,384 16,384 x 4,096

l

l

AHM36A-

S3PC014x12

AHM36A-

S3PK014x12

1066007

1066006

Absolute singleturn, blind hollow shaft

• Electrical interface: SSI

Shaft diameter Connection type Number of steps Resolution Programmable Type Part no.

6 mm

M12 male connec-

tor, 8-pin, universal

Cable, 8-wire,

universal, 1.5 m

≤ 16,384 16,384 x 1

≤ 16,384 16,384 x 1

l

l

AHS36A-

BAPC016384

AHS36A-

BAPK016384

1066016

1066015

G-238

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 8

ABSOLUTE ENCODERS AHS/AHM36 SSI

X = Measuring point for operating temperature

11.8 (0.46)

5.8

(0.23)

X = Measuring point for operating temperature

Absolute multiturn, blind hollow shaft

• Electrical interface: SSI

Shaft diameter Connection type Number of steps Resolution Programmable Type Part no.

M12 male con-

6 mm

nector,

8-pin, universal

Cable, 8-wire,

universal, 1.5 m

≤ 16,384 16,384 x 4,096

≤ 16,384 16,384 x 4,096

Dimensional drawings (dimensions in mm)

Solid shaft, servo ange, M12 male connector

11.4

(0.45)

5.8 (0.23)

B

B

0.02

2.5

(0.08)

(0.10)

0.08

0.08

B

+0.15

2.5 (0.10)

2

12 ±0.3

Ø D f7

(0.47)

11.5

(0.45)

A

X

–0.025

–0.064

H

Ø 33 (1.30)

B

–0.025

–0.064

Ø 33 (1.30)

34.2 (1.35)

+0.3

–0.1

Ø 36 (1.41)

45°

4 x 90° = 360°

14.5 (0.57)

M12 x 1

M3 x 5

(4 x)

26 ±0.05 (1.02)

l

l

Ø 0.05

A

AHM36A-

BAPC014x12

AHM36A-

BAPK014x12

60 (2.36)

1066011

1066010

11.8 (0.46)

0.03

B

0.03

B

43 (1.69)

Solid shaft, servo ange, cable output

2.5 (0.10)

+0.15

Ø 2.5

(0.10)

12

±0.3 (0.47)

2 (0.08)

11.5

A

Ø D f7

(0.45)

X

H

B0.02

–0.025

–0.064

Ø 33 (1.30)

0.03

B

B0.03

Bend radius of cable; R = 30 mm

0.08

B

0.08

B

B

43

(1.69)

2.6

(0.10)

2.6

(0.10)

B

(0.57)

14.5

45°

61

(2.40)

A

Ø 0.05

M3 x 5

35.9 (1.41)

–0.1

Ø 36 (1.41)

4 x 90° = 360°

B

(4 x)

±0.05 (1.02)

Ø 26

G

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

G-239

Page 9

AHS/AHM36 SSI ABSOLUTE ENCODERS

2.5

11.4

11.4

14.5

(0.46)

11.8

(0.46)

14.5

(0.57)

5.8

Solid shaft, servo ange, for adapting to 1.25 m Ecoline wire draw mechanism, SD mechanical design

0.02

(0.10)

+0.15

2.5

(0.15 +0.01)

1.6

(0.06)

12 ±0.3

(0.01)

0.08

0.08

A

(0.45)

5.8

(0.23)

A

A

X

A

43

(1.69)

2.6

(0.10)

+0.3

-0.1

Ø 36

(1.42)

-0.004

0.03

-0.012

Ø 6 g6 ( )

-0,025

-0.064

(1.30

Ø 33 f8 ( )

0.03

-0.006

(0.24)

A

A

-0.031

2 p9 ( )

Solid shaft, face mount ange, M12 male connector

(0.45)

5.8

(0.23)

34.2

-0.1

+0.3

(1.42)

Ø 36

0.02

12 ±0.3

(0.47)

11.5

ØD f7

(0.45)

A

H

B

-0.02

-0.05

(0.79)

Ø 20

5

(0.2)

X

B

34.2

(1.35)

(1.35)

3 x 120° = 360°

4 x 90° = 360°

14.5

(0.57)

M12 x 1

M12 x 1

(0.57)

M3 x 5 (10 x)

Ø 28 ±0.05

60

(2.36)

11.8

(0.46)

Ø 0.05

A

Ø 0.05

A

(1.1)

(1.18)

Ø 30 ±0.05

60

(2.36)

11.8

G

0.03

B

0.03

B

X = Measuring point for operating temperature

43

(1.69)

(0.1)

2.6

Solid shaft, face mount ange, cable output

(0.23)

12 ±0.3 (0.47)

11.5

(0.45)

B0.02

X

A

H

–0.02

–0.05

Ø D f7

Ø 20 (0.79)

0.03

B

B0.03

X = Measuring point for operating temperature

Bend radius of cable; R = 30 mm

5

(0.20)

B

2.6

(1.69)

(0.10)

43

+0.3

–0.1

Ø 36 (1.41)

3 x 120° = 360°

35.9 (1.41)

4 x 90° = 360°

B

3 x 120° = 360°

M3 x 5

(10 x)

3 x 120° = 360°

A

Ø 0.05

Ø 0.05

Ø 28 ±0.05 (1.10)BØ 30 ±0.05 (1.18)

61

A

(2.3640)

G-240

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 10

Blind hollow shaft, M12 male connector

14.5 (0.57)

11.8 (0.46)

X = Measuring point for operating temperature

11.8 (0.46)

5.8 (0.23)

11.4 (0.45)

(0.31)

8

3.25

(0.13)

5.8 (0.23)

M12 x 1

ABSOLUTE ENCODERS AHS/AHM36 SSI

67.6

(2.66)

X

–0.1

Ø D f7

Ø 38.6 (1.52)

+0,2

Ø 20 (0.79)

51 (2.01)

2.6

(0.10)

34.2 (1.35)

+0.3

–0.1

Ø 36 (1.42)

±0.05 (0.12)

3.1

(2.05)

Ø 52

Ø46

Ø 40

±0.1 (1.81)

±0.1 (1.57)

max. Ø 24 (0.94)

12

(0.47)

Customer’s own shaft: insertion depth of at least 15 mm to max. of 22 mm, from contact surface, from stator coupling, recommended shaft tolerance of k7

Blind hollow shaft, cable outlet

14.5 (0.57)

8

(0.31)

3.25

(0.13)

X

–0.1

Ø D f7

Ø 38.6 (1.52)

+0.2

Ø 20 (0.79)

X = Measuring point for operating temperature

51 (2.01)

2.6

(0.10)

35.9 (1.42)

±0.05 (0.12)

3.1

+0.3

–0.1

Ø 36 (1.42)

Ø 52

(2.05)

Ø46

±0.1 (1.81)

Ø 40

±0.1 (1.57)

(0.94)

12

max. Ø 24

Bend radius of cable; R = 30 mm

Customer’s own shaft: insertion depth of at least 15 mm to max. of 22 mm, from contact surface, from stator coupling, recommended shaft tolerance of k7

69 (2.72)

G

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

G-241

Page 11

AHS/AHM36 SSI ABSOLUTE ENCODERS

M12 x 1

(0.46)

11.4

4

+0.1

11.4

(0.46)

11.4

(0.46)

M12 x 1

Ø 6 f7

-0.010

Proposed tting

Solid shaft, face mount ange with ange adapter, centering hub D20 to D50 (BEF-FA-020-050, 2072297)

(0.16)

3

0.02

B

10 ±0.3

(0.39)

(0.12)

A

X

5.4

(0.21)

-0.025

-0.064

(2.03)

(1.97)

51.5-0.2

Ø 50 f8

0.03

B

0.03

B

10

(0.39)

B

+0.1

X = Measuring point for operating temperature

Sample order for 6 mm shaft diameter: AHx36x-S3xx0xxxxx + BEF-FA-020-050 (adapter is not pre-assembled)

Solid shaft, face mount ange with ange adapter, centering hub D20 to D36 (BEF-FA-020-036, 2072298)

(1.77)

(0.45)

5.8

(0.23)

Ø 0.05

A

120° (3 x)

-0.010

-0.022

34.2

(1.35)

(0.24)

(1.42)

Ø 42 ±0.05

(1.65)

Ø 6 f7

3 x M4 3.6

Ø 58

(2.28)

(0.14)

-0.1

+0.3

Ø 36

2.6

(0.1)

45

62

(2.44)

11.8

14

(0.55)

(0.75)

18

(0.71)

+0.1

8

(0.31)

X

B

0.02

B

19 ±0.3

A

-0.013

-0.028

(0.39)

Ø 10 f7

-0.025

-0.064

9

(1.42)

(0.35)

Ø 36 f8

0.03

(0.45)

5.8

(0.23)

B

34.2

(1.35)

120° (3 x)

-0.1

+0.3

(1.42)

-0.1

(2.12)

Ø 53.8

Ø 36

25°

M12 x 1

3 x M4

Ø 48 ±0.05

(1.89)

Ø 0.05

A

65

(2.56)

11.8

G

0.03

B

0.03

B

X = Measuring point for operating temperature

Sample order for 10 mm shaft diameter: AHx36x-SCxx0xxxxx + BEF-FA-020-036 (adapter is not pre-assembled)

Solid shaft, face mount ange with ange adapter, centering hub D20 to D36, 2 mm high (BEF-FA-020-036-002, 2072296)

12 ±0.3

(0.47)

11.5

(0.45)

X

-0.022

Sample order for 6 mm shaft diameter: AHx36x-S3xx0xxxxx + BEF-FA-020-036-002 (adapter is not pre-assembled)

A

(0.12)

3

(0.24)

5.4

0.03

0.03

0.03

(0.21)

B

B

B

X = Measuring point for operating temperature

(0.12)

3

(1.89)

2.6

(0.1)

48

(0.45)

5.8

(0.23)

Ø 0.1

B

34.2

(1.35)

6

(0.24)

Ø 59.5

(2.34)

120° (3 x)

60

(2.36)

B

(0.1)

-0.1

+0.3

(1.42)

Ø 36

2.6

Ø 30 ±0.05

(1.18)

3 x M3

3.6

(0.14)

-0.02

-0.05

(0.79)

Ø 20

11.8

G-242

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 12

ABSOLUTE ENCODERS AHS/AHM36 SSI

11.4

(0.46)

M12 x 1

Ø 6 f7

-0.010

(0.46)

11.4

Ø 36.5

M12 x 1

Solid shaft, face mount ange with ange adapter, centering hub D20 to D24 (BEF-FA-020-024, 2072294)

12 ±0.3

(0.47)

11.5

(0.45)

X

-0.022

(0.24)

A

B

5.4

(0.21)

0.03

B

0.03

B

0.03

B

(0.12)

3

(0.45)

2.6

(0.1)

5.8

(0.23)

Ø 0.1

B

34.2

(1.35)

-0.1

+0.3

(1.42)

Ø 36

Ø 30 ±0.05

(1.18)

3 x M3

3.6

(0.14)

120° (3 x)

-0.02

-0.05

(0.79)

Ø 20

X = Measuring point for operating temperature

Sample order for 6 mm shaft diameter: AHx36x-S3xx0xxxxx + BEF-FA-020-024 (adapter is not pre-assembled)

Solid shaft, face mount ange with ange adapter, centering hub D20 to D30 (BEF-FA-020-030, 2072295)

(0.45)

5.8

(0.23)

Ø 0.1

A

34.2

(1.35)

B

-0.1

+0.3

(1.42)

Ø 36

Ø 24

(0.94)

9

(0.35)

90° (4 x)

Ø 10 h11

(0.39)

(1.44)

Ø 30 ±0.05

(1.18)

0.03

B

A

17

(0.67)

X

(0.16)

4

(0.16)

4

Ø 30

(1.18)

(2.36)

(2.64)

60

11.8

67

11.8

4

0.03 0.03

(0.16)

B

2.6

(0.1)

B

M4 (4 x)

G

X = Measuring point for operating temperature

Sample order for 10 mm shaft diameter: AHx36x-SCxx0xxxxx + BEF-FA-020-030 (adapter is not pre-assembled)

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

G-243

Page 13

AHS/AHM36 SSI ABSOLUTE ENCODERS

PIN assignment

View of M12 male device connector on encoder

G

PIN, 8-pin,

M12 male

connector

1Brown Data- Interface signals

2White Data+ Interface signals

3Black

4PinkSET Electronic adjustment

5YellowClock+ Interface signals

6Lilac Clock– Interface signals

7BlueGND Ground connection

8Red +USOperating voltage

Screen Screen Screen

R¯/VForwards / Reverse: This input programs the counting direction for the

encoder. When it is not connected, this input is set to HIGH. If the encoder

shaft is rotated clockwise (to the right) as viewed when facing the shaft, it

counts in ascending order. If it should count in ascending order when the

shaft is rotated counterclockwise (to the left), then this connection must be

permanently set to LOW level (GND).

SET This input is for electronic zeroing. If the SET cable is set to US for more

than 250 ms, the mechanical position corresponds to the O value, i. e., the

predetermined SET value.

Wire colors,

cable outlet

Signal Explanation

Sequence for direction of rotation

R¯/V

Screen connected to housing

on encoder side. Connected to

ground on control side.

G-244

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 14

ABSOLUTE ENCODERS AHS/AHM36 SSI

Clock +

Bi

B

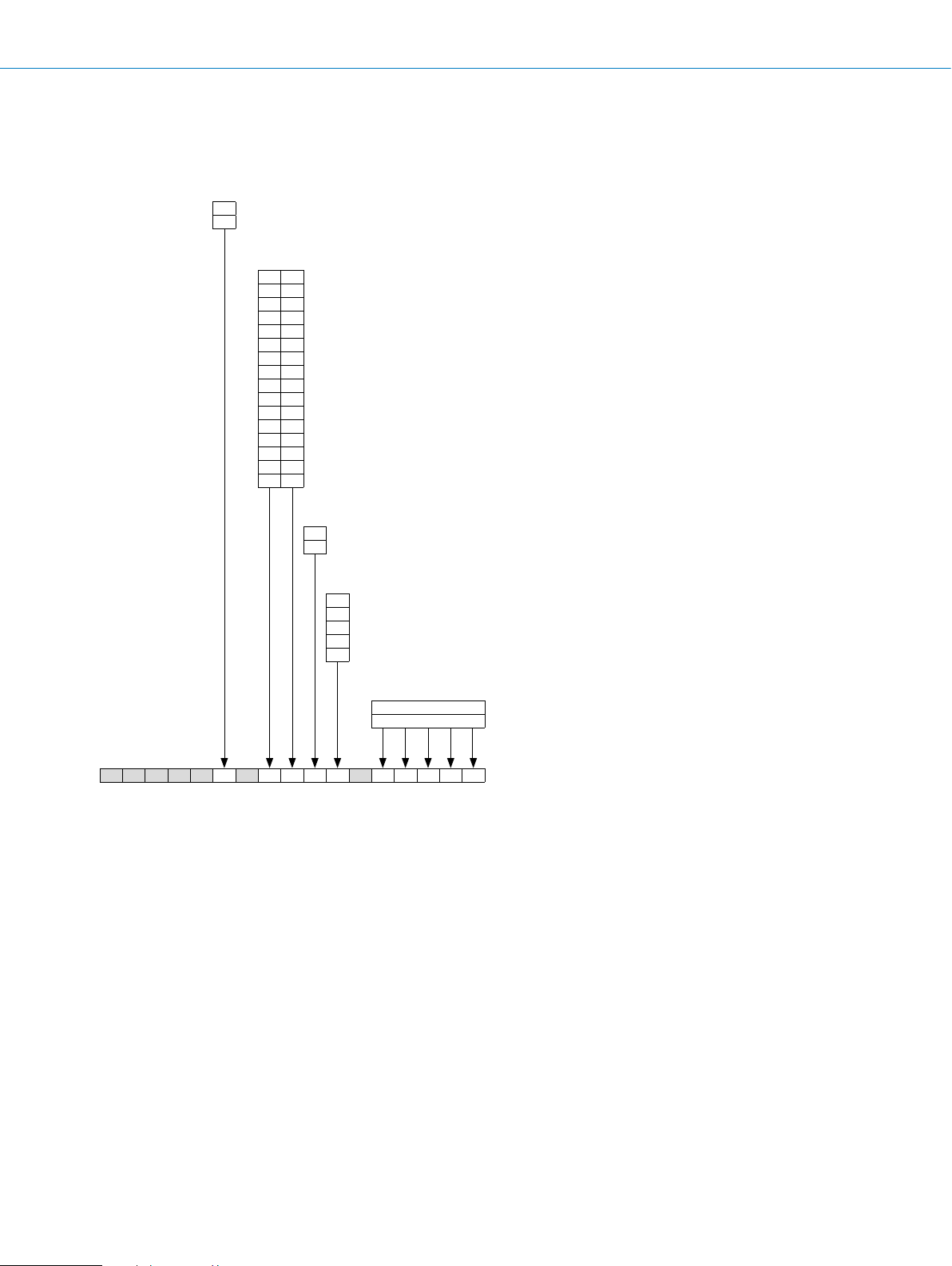

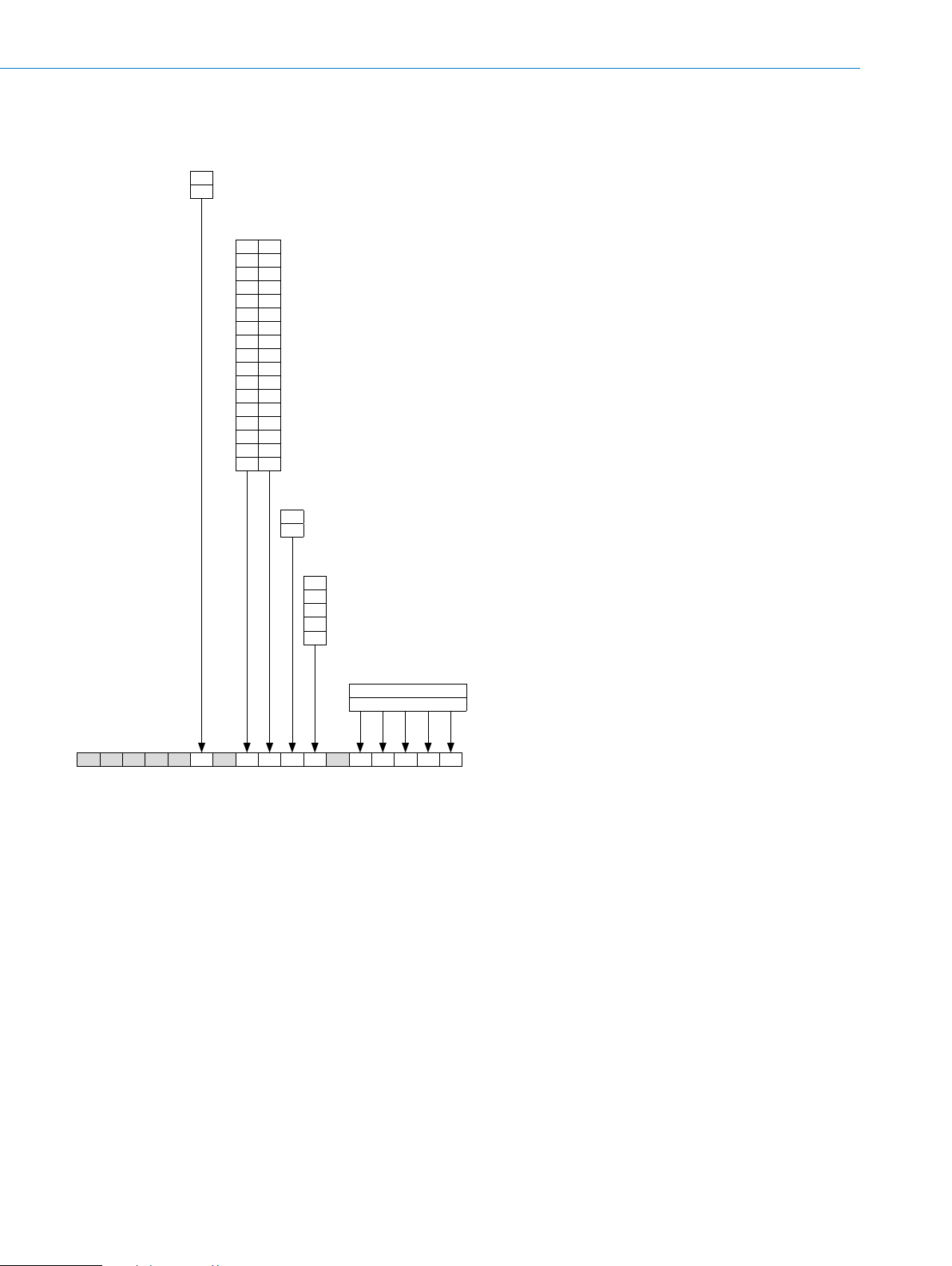

Singleturn signal outputs

Singleturn SSI data format

Cycle 1–14: position bits

Cycle 15: errorbit

LSB

Singleturn

ERROR

t

12345678910 11 12 13 14 15

13 12 11 10 9 8765 43210

MS

Non-programmable encoder

Non-programmable encoders always output the SSI position MSB-justied (left-justied).

• 14 bits + 1 errorbit are always output (irrespective of the type and resolution selected)

• For resolutions below 14 bits, non-assigned bits are lled with 0.

Programmable encoder

• Per default, programmable encoders output the SSI position MSB-justied (left-justied).

• The operating modes “binary” and “non-binary” can be selected to set the resolution.

• All formats (left and right-justied) can be covered by shifting the bits in the programming interface accordingly using the arrow

keys.

Errorbit

ERROR: general error This bit is set as soon as an error occurs in the encoder. This bit remains set as long as the error is present.

In non-programmable encoders, the errorbit is always output as the 15th bit. In programmable encoders, it can also be output as

the 15th bit or can be transmitted directly after the position bits.

The evaluation of the errorbit must be implemented in the control unit.

The errorbit output need not be used by the control unit.

If the errorbits cannot be evaluated in the control unit, the control unit must be set to the encoder resolution.

The errorbits must then be masked out at the control.

SSI mode:

Non-programmable encoders work in asynchronous SSI mode.

In programmable encoders, the programming interface enables users to choose between asynchronous and synchronous SSI

mode. Asynchronous SSI mode is selected as the default setting.

Asynchronous SSI mode:

The position is always formed and made available every 125 µs. The time for calculating the position is not related to the master

clock. In asynchronous SSI mode, the break between two clock bursts must remain constant with a maximum deviation of ± 20%

and must not exceed 600 ms.

Synchronous SSI mode:

The position is formed in sync with the master clock output, i.e., the time of the position values is related to the time of the master

clock.

The position formation process begins 20 µs following the end of a clock burst. The position is then made available after 125 µs.

The next position is formed a further 20 µs after the end of the subsequent clock burst. The break between two clock bursts must

be at least 150 µs.

G

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

G-245

Page 15

AHS/AHM36 SSI ABSOLUTE ENCODERS

Programming interface and legend

Operating mode: binary

Operating mode: non binary

G

G-246

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 16

ABSOLUTE ENCODERS AHS/AHM36 SSI

Clock

Bi

Multiturn signal outputs

Multiturn SSI data format

+

12345678910 11 1213 1415 16 1718 19 20 21 22 2324 25 2627

t

MSB

1415 13 12 11 10 987654321016171819202122232425

SingleturnMultiturn

ERROR

LSB

Non-programmable encoder

Non-programmable encoders always output the SSI position MSB-justied (left-justied).

• For non-programmable multiturn encoders, the number of revolutions is set to a xed 4,096 (12 bits).

• 26 bits + 1 errorbit are always output (irrespective of the type and resolution selected).

For resolutions below 26 bits, non-assigned bits are lled with 0.

Programmable encoder

• Per default, programmable encoders output the SSI position MSB-justied (left-justied).

• The operating modes “binary”, “non-binary” and “round axis functionality” can be selected to set the resolution.

• All formats (left and right-justied, 25 bit mode and r-tree format) can be covered by shifting the bits in the programming inter-

face accordingly using the arrow keys.

Errorbit

ERROR: general error This bit is set as soon as an error occurs in the encoder. This bit remains set as long as the error is present.

In non-programmable encoders, the errorbit is always output as the 27th bit. In programmable encoders, it can also be output as

the 27th bit or can be transmitted directly after the position bits.

Cycle 1-12: multiturn position bits

Cycle 13-26: singleturn position bits

Cycle 27: errorbit

The evaluation of the errorbit must be implemented in the control unit.

The errorbit output need not be used by the control unit.

If the errorbits cannot be evaluated in the control unit, the control unit must be set to the encoder resolution.

The errorbits must then be masked out at the control.

SSI mode:

Non-programmable encoders work in asynchronous SSI mode.

In programmable encoders, the programming interface enables users to choose between asynchronous and synchronous

SSI mode. Asynchronous SSI mode is selected as the default setting.

Asynchronous SSI mode:

The position is always formed and made available every 125 µs. The time for calculating the position

is not related to the master clock. In asynchronous SSI mode, the break

between two clock bursts must remain constant with a maximum deviation of ± 20% and

must not exceed 600 ms.

Synchronous SSI mode:

The position is formed in sync with the master clock output, i.e., the time of the position values

is related to the time of the master clock.

The position formation process begins 20 µs following the end of a clock burst. The position is then

made available after 125 µs. The next position is formed a further 20 µs after the end of the subsequent

clock burst. The break between two clock bursts must be at least 150 µs.

G

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

G-247

Page 17

AHS/AHM36 SSI ABSOLUTE ENCODERS

Round axis functionality

The programmable multi-turn encoder supports the gear functions for rotary axes (endless shaft). Here, the number of revolutions

is set a break; a total number of steps is also set. The total number of steps is distributed over the set number of revolutions, e. g.

100 steps to 12.5 revolutions (see example for the programming interface on the next page).

The round axis functionality can be used to implement a number for the overall resolution that is not a 2n multiple of the number

of steps per revolution. It is also possible to set a non-integer number both for the number of revolutions and for the number of

steps per revolution.

Programming interface and legend

Operating mode: binary

G

Operating mode: non binary

Operating mode: rotary axis

G-248

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 18

ABSOLUTE ENCODERS AHS/AHM36 SSI

Recommended accessories

Mounting systems

Mounting brackets and plates

Mounting bracket

Figure Brief description Type Part no.

Mounting bracket for encoder with centering hub 20 mm, including mounting kit for face

mount ange

Dimensional drawings g page K-725

BEF-WF-20 2066393

Flanges

Figure Brief description Type Part no.

Stator coupling on hole circle 63 mm BEF-DS08 2072206

Flange adapter centering hub D20 to D24 BEF-FA-020-024 2072294

Flange adapter centering hub D20 to D30 BEF-FA-020-030 2072295

Flange adapter centering hub D20 to D36 BEF-FA-020-036 2072298

Flange adapter centering hub D20 to D36, 2 mm high BEF-FA-020-036-002 2072296

Flange adapter centering hub D20 to D50 BEF-FA-020-050 2072297

Dimensional drawings g page K-725

Other mounting accessories

Measuring wheels and measuring wheel systems

G

Figure Brief description Type Part no.

Measuring wheel with O-ring (NBR70) for 6 mm solid shaft, circumference 200 mm BEF-MR006020R 2055222

Measuring wheel with O-ring (NBR70) for 6 mm solid shaft, circumference 300 mm BEF-MR006030R 2055634

O-ring for measuring wheels (circumference 200 mm) BEF-OR-053-040 2064061

O-ring for measuring wheels (circumference 300 mm) BEF-OR-083-050 2064076

Dimensional drawings g page K-725

Servo clamps

Figure Brief description Type Part no.

Servo clamps, small, for servo ange (clamps, eccentric fastener), 3 pcs., without

mounting material

Dimensional drawings g page K-725

Subject to change without notice

BEF-WK-RESOL 2039082

ENCODERS | SICK8015560/2015-09-01

G-249

Page 19

G

AHS/AHM36 SSI ABSOLUTE ENCODERS

Shaft adaptation

Shaft couplings

Figure Brief description Type Part no.

Bellows coupling, shaft diameter 6 mm / 6 mm, maximum shaft offset: radial

± 0.25 mm, axial ± 0.4 mm, angular ± 4°; max. speed 10,000 rpm, –30 °C ... +120 °C,

max. torque 80 Ncm; material: stainless steel bellows, aluminum hub

Bellows coupling, shaft diameter 6 mm / 10 mm, maximum shaft offset: radial

± 0.25 mm, axial ± 0.4 mm, angular ± 4°; max. speed 10,000 rpm, –30 °C ... +120 °C,

max. torque 80 Ncm; material: stainless steel bellows, aluminum hub

Bellows coupling, shaft diameter 10 mm/10 mm; maximum shaft offset: radial

± 0.25 mm, axial ± 0.4 mm, angular ± 4°; max. revolutions 10,000 rpm,

–30 °C ... +120 °C, max. torque 80 Ncm; material: stainless steel bellows, aluminum

clamping hubs

Bellows coupling, shaft diameter 10 mm/12 mm; maximum shaft offset: radial

± 0.25 mm, axial ± 0.4 mm, angular ± 4°; max. revolutions 10,000 rpm,

–30 °C ... +120 °C, max. torque 80 Ncm; material: stainless steel bellows, aluminum

clamping hubs

Double-loop coupling, shaft diameter 6 mm/10 mm, maximum shaft offset: radial

± 2.5 mm, axial ± 3 mm, angular ± 10°; max. speed 3,000 rpm, –30 °C ... +80 °C,

max. torque 1.5 Nm; material: polyurethane, galvanized steel ange

Double-loop coupling, shaft diameter 8 mm/10 mm, maximum shaft offset: radial

± 2.5 mm, axial +/-± 3 mm, angular ± 10°; max. speed 3,000 rpm, –30 °C ... +80 °C,

max. torque 1.5 Nm; material: polyurethane, galvanized steel ange

Double-loop coupling, shaft diameter 10 mm/10 mm, maximum shaft offset: radial

± 2.5 mm, axial ± 3 mm, angular ± 10°; max. speed 3,000 rpm, –30 °C ... +80 °C,

max. torque 1.5 Nm; material: polyurethane, galvanized steel ange

Double-loop coupling, shaft diameter 10 mm/12 mm, maximum shaft offset: radial

± 2.5 mm, axial ± 3 mm, angular ± 10°; max. speed 3,000 rpm, –30 °C ... +80 °C,

max. torque 1.5 Nm; material: polyurethane, galvanized steel ange

Spring washer coupling, shaft diameter 6 mm/10 mm, maximum shaft offset: radial

± 0.3 mm, axial ± 0.4 mm, angular ± 2.5°; max. speed 12,000 rpm, –10 °C ... +80 °C,

max. torque 60 Ncm; material: aluminum ange, ber-glass reinforced polyamide mem-

brane and tempered steel coupling pin

Spring washer coupling, shaft diameter 10 mm / 10 mm, maximum shaft offset: radial

± 0.3 mm, axial ± 0.4 mm, angular ± 2.5°; max. speed 12,000 rpm, –10 °C ... +80 °C,

max. torque 60 Ncm; material: aluminum ange, glass ber-reinforced polyamide mem-

brane and hardened steel coupling pin

Dimensional drawings g page K-725

KUP-0606-B 5312981

KUP-0610-B 5312982

KUP-1010-B 5312983

KUP-1012-B 5312984

KUP-0610-D 5326697

KUP-0810-D 5326704

KUP-1010-D 5326703

KUP-1012-D 5326702

KUP-0610-F 5312985

KUP-1010-F 5312986

Connectivity

Plug connectors and cables

Connecting cables with female connector

Figure Brief description Length

of

cable

2 m DOL-1208-G02MAC1 6032866

Head A: female connector, M12, 8-pin, straight

Head B: cable

Cable: suitable for drag chain, PVC, shielded, 4 x 2 x 0.25 mm², Ø 7.0 mm

Dimensional drawings g page K-725

5 m DOL-1208-G05MAC1 6032867

10 m DOL-1208-G10MAC1 6032868

20 m DOL-1208-G20MAC1 6032869

Female connectors (ready to assemble)

Figure Brief description Type Part no.

Head A: female connector, M12, 8-pin, straight, A encoded, shielded, for cable diameter

4 mm ... 8 mm

Head B: -

Operating temperature: –40 °C ... +85 °C

G-250

ENCODERS | SICK 8015560/2015-09-01

Type Part no.

DOS-1208-GA01 6045001

Subject to change without notice

Page 20

ABSOLUTE ENCODERS AHS/AHM36 SSI

Dimensional drawings g page K-725

Male connectors (ready to assemble)

Figure Brief description Type Part no.

Head A: male connector, M12, 8-pin, straight, A encoded, shielded, for cable diameter

4 mm ... 8 mm

Head B: -

Operating temperature: –40 °C ... +85 °C

Head A: male connector, M23, 12-pin, straight, shielded, for cable diameter

5.5 mm ... 10.5 mm

Head B: -

Operating temperature: –20 °C ... +130 °C

Dimensional drawings g page K-725

Cables (ready to assemble)

STE-1208-GA01 6044892

STE-2312-G 6027537

Figure Brief description Length

Head A: cable

Head B: cable

Cable: suitable for drag chain, PUR, halogen-free, shielded, 4 x 2 x 0.15 mm²,

Ø 5.6 mm

Head A: cable

Head B: cable

Cable: suitable for drag chain, PUR, halogen-free, shielded, UV and saltwater-resistant, 4 x 2 x 0.25 mm² + 2 x 0.5 mm² + 2 x 0.14 mm², Ø 7.8 mm

Dimensional drawings g page K-725

Connection cables with female and male connector

Figure Brief description Length

Head A: female connector, M12, 8-pin, straight

Head B: male connector, D-Sub, 9-pin, straight

Cable: PUR, halogen-free, shielded, 4 x 2 x 0.15 mm²

Dimensional drawings g page K-725

Other accessories

Programming and conguration tools

Type Part no.

of

cable

LTG-2308-MWENC 6027529

By the

meter

LTG-2612-MW 6028516

Type Part no.

of

cable

0.5 m DSL-2D08-G0M5AC2 2048439

G

Figure Brief description Type Part no.

Programming unit USB, for programmable SICK encoders AFS60, AFM60, DFS60,

VFS60, DFV60 and wire draw encoders with programmable encoder.

Programming unit display for programmable SICK DFS60, DFV60, AFS/AFM60, AHS/

AHM36 encoders, and wire draw encoders with DFS60, AFS/AFM60, and AHS/AHM36.

Compact dimensions, low weight, and intuitive operation.

Dimensional drawings g page K-725

- For additional accessories, please see page K-668 onwards

Subject to change without notice

PGT-08-S 1036616

PGT-10-Pro 1072254

ENCODERS | SICK8015560/2015-09-01

G-251

Loading...

Loading...