Page 1

AHS/AHM36 CANopen ABSOLUTE ENCODERS

FLEXIBLE, SMART, COMPACT

Product description

The AHS/AHM36 CANopen absolute encoder product family provides increased

exibility and diagnostics due to its mechanical adaptation, electrical connectivity, and CANopen communication. With

their rotating male connector or cable

outlets as well as the various mounting

hole patterns and adapter anges, these

encoders are suitable for nearly any

application. Individual adjustments can

be made to the singleturn/multiturn resolution, the counting direction, and other

parameters when integrating the encod-

ers into the CANopen network. The encoder also communicates diagnostic

data such as temperature or operating

time. Thanks to the large operating tem-

perature range from –40 °C ... +85 °C

and the protection class up to IP67, this

encoder family can be used in harsh

ambient conditions. The rugged, reliable,

fully magnetic sensor system provides

a maximum resolution of 14 bits for the

singleturn variant and 26 bits for the

multiturn variant.

G

1)

1)

UL 508 compliant.

More information

Fields of application . . . . . . . . . . .G-253

Detailed technical data. . . . . . . . .G-253

Type code. . . . . . . . . . . . . . . . . . . .G-256

Ordering information. . . . . . . . . . .G-258

Dimensional drawings . . . . . . . . .G-260

Proposed tting . . . . . . . . . . . . . . .G-263

PIN assignment. . . . . . . . . . . . . . .G-264

Recommended accessories. . . . .G-265

At a glance

• Compact 36 mm absolute encoder

with max. 26 bits (singleturn: 14 bits,

multiturn: 12 bits)

• Face mount ange, servo ange, blind

hollow shaft

• Rotating M12 male connector or

rotating cable outlet

• CANopen interface with programma-

ble conguration

Your benets

• Simple, time-saving mechanical

installation due to a rotating male

connector or cable outlet, various

mounting hole patterns, and many

different shafts

• Simple network installation with vari-

ous conguration options

• Intelligent diagnostic functions

evaluate maintenance intervals for

the entire system, thereby increasing

system reliability

• Diagnostic functions: temperature,

operating time, etc. (depending on

the type)

• Protection class up to IP67 (depend-

ing on the type)

• Operating temperature:

–40 °C ... +85 °C (depending on the

type)

• Easy setup for various applications

allowing binary, non-binary, and

non-integer resolutions with the round

axis functionality (advanced version)

• Reliable operation in harsh environ-

ments thanks to the rugged, reliable,

fully magnetic sensor system

• Space-efcient and cost-effective

design that is suitable for applications

where space is tight

• High performance at a cost-efcient

price

G-252

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 2

Fields of application

• Measures the absolute position in various industries,

machines, and tools, including automated guided systems

(AGS), industrial trucks, commercial vehicles, packaging

Detailed technical data

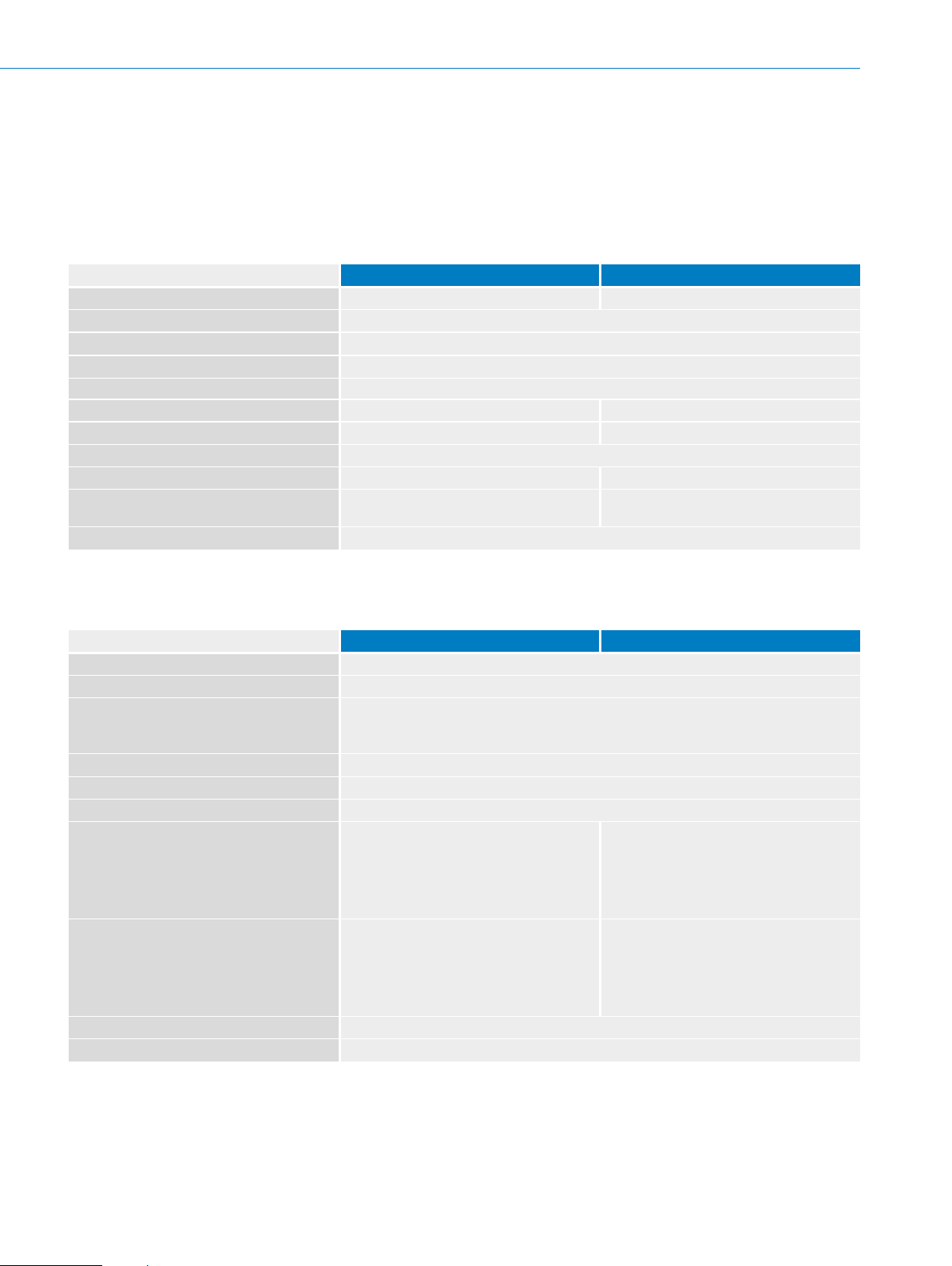

Performance

Max. number of steps per revolution

Max. number of revolutions

Absolute singleturn 1

Absolute multiturn 4,096 (12 bit)

Resolution

1)

Absolute singleturn 12 bit 14 bit

Absolute multiturn 12 bit x 12 bit 14 bit x 12 bit

Error limits

Repeatability

Measuring increment (360°/number of

steps per revolution)

Initialization time

1)

Programmable options via control unit.

2)

Position can be read after this period.

4,096 (12 bit) 16,384 (14 bit)

± 0.35° (at 20 °C)

± 0.25° (at 20 °C) ± 0.2° (at 20 °C)

0.09° 0.022°

2)

2 s

ABSOLUTE ENCODERS AHS/AHM36 CANopen

machines, logistics applications, machine construction and

medical technology

Basic Advanced

Interfaces

Electrical interface

Bus interface

Encoder prole

Address setting

Data transmission rate (baud rate)

PDO data

Conguration data

Available diagnostic data

Status information

Bus termination

1)

See accessories.

Basic Advanced

CANopen

CANopen

CANopen CiA DS-301, V4.02

CiA DSP-305 LSS

Encoder Prole: - CiA DS-406, V3.2. - Class C2

0 ... 127, default: 5

20 kbit/s … 1,000 Mbit/s factory setting: 125 kbit/s

Position, speed, temperature

Number of steps per revolution, number of revolutions, PRESET, counting direction, sampling

rate for speed monitoring, unit for output of

the speed value

– Current, minimum and maximum temperature,

CANopen status via status LED

Via external terminator

®

Number of steps per revolution, number of

revolutions, PRESET, counting direction, sampling rate for speed monitoring, unit for output

of the speed value, round axis functionality

(multiturn version only), electronic cams

(2 channels x 8 cams)

maximum speed, power-on counter, operating

hours counter, power-on/motion, counter of

direction changes/number of movements cw/

number of movements ccw, minimum and

maximum operating voltage

1)

G

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

G-253

Page 3

G

AHS/AHM36 CANopen ABSOLUTE ENCODERS

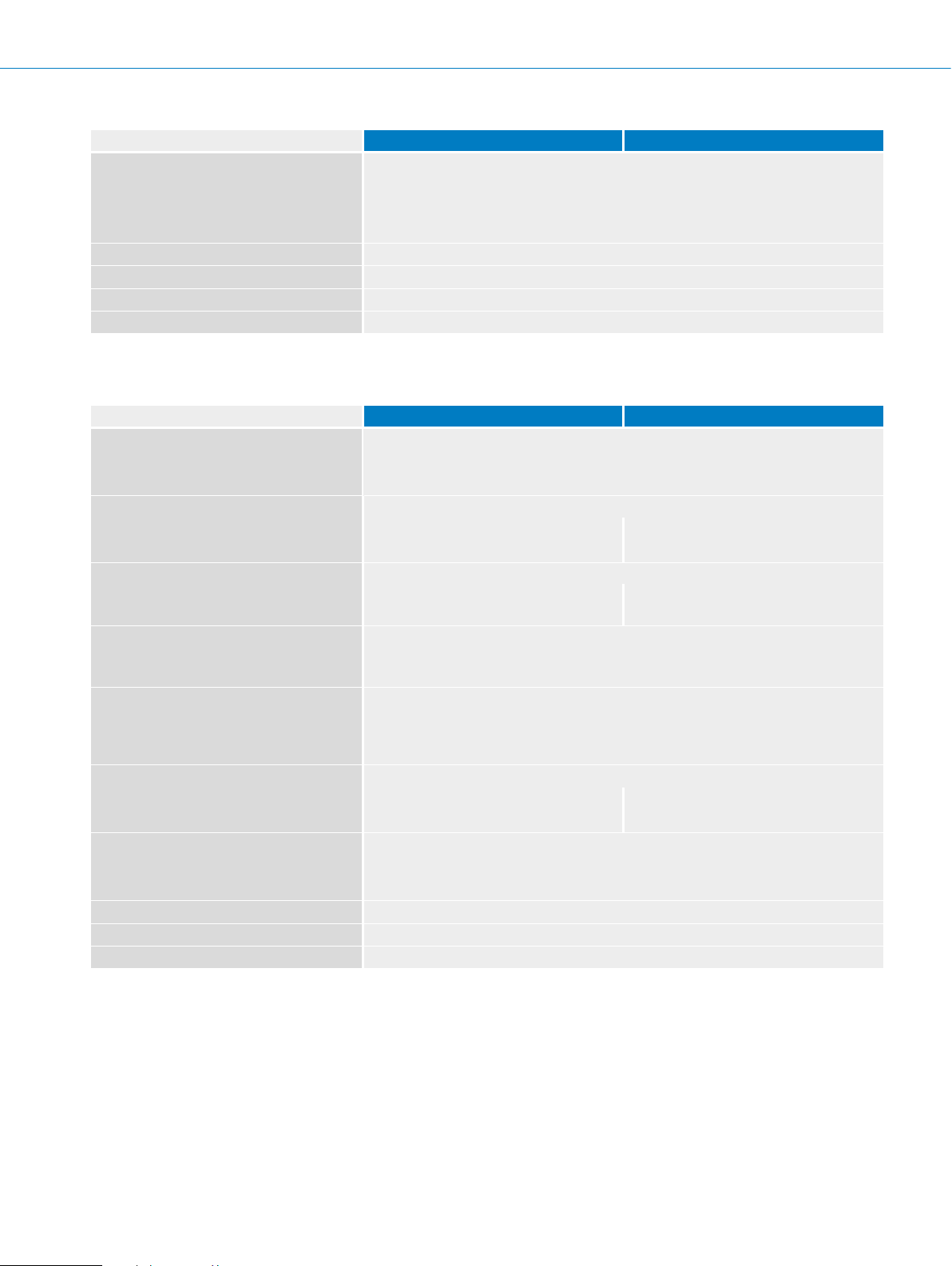

Electrical data

Basic Advanced

Connection type

Max. power consumption (without load)

Operating voltage range

Reverse polarity protection

MTTFd: mean time to dangerous failure

1)

This product is a standard product and does not constitute a safety component as dened in the Machinery Directive. Calculation based on nominal load of devices,

average ambient temperature 40 °C, frequency of use 8,760 h/a. All electronic failures are considered hazardous. For more information, see document no. 8015532.

Mechanical data

Shaft diameter

Solid shaft 6 mm, 1/4", 8 mm, 3/8", 10 mm

Blind hollow shaft 6 mm, 1/4", 8 mm, 3/8", 10 mm

Start up torque

Solid shaft 0.5 Ncm (at 20 °C) 1 Ncm (at +20 °C)

Blind hollow shaft 0.5 Ncm (at 20 °C) 1 Ncm (at +20 °C)

Operating torque

Solid shaft < 0.5 Ncm (at 20 °C) < 1 Ncm (at 20 °C)

Blind hollow shaft < 0.5 Ncm (at 20 °C) < 1 Ncm (at 20 °C)

Permissible shaft loading

Solid shaft 40 N (radial)

Permissible shaft load, static

dynamic

Blind hollow shaft ± 0.3 mm/± 0.1 mm radial

Max. operating speed

Singleturn 9,000 rpm

Multiturn 6,000 rpm

Bearing lifetime

Solid shaft 3.6 x 108 revolutions

Blind hollow shaft 2.0 x 10

Shaft material

Flange material

Housing material

1)

Take into account self-heating of 3.5 K per 1,000 revolutions/min when designing the operating temperature range.

2)

Take into account self-heating of 5.5 K per 1,000 revolutions/min when designing the operating temperature range.

3)

For Advanced type encoders, the shaft seal must be inspected regularly.

M12 male connector, 5-pin, universal

Cable, 5-wire, universal, 0.5 m

Cable, 5-wire, universal, 1.5 m

Cable, 5-wire, universal, 3 m

Cable, 5-wire, universal, 5 m

1.5 W

10 V DC ... 30 V DC

l

1)

270 years (EN ISO 13849-1)

Basic Advanced

20 N (axial)

± 0.3 mm/ ± 0.1 mm axial

1)

1)

9

revolutions

Stainless steel

Aluminum

Zinc

6,000 rpm

6,000 rpm

2), 3)

2), 3)

G-254

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 4

ABSOLUTE ENCODERS AHS/AHM36 CANopen

Basic Advanced

Cable material

Mass

Solid shaft 0.12 kg (related to devices with connector outlet)

Blind hollow shaft 0.12 kg (related to devices with connector outlet)

Rotor moment of inertia

Solid shaft 2.5 gcm²

Blind hollow shaft 15 gcm²

Max. angular acceleration

1)

Take into account self-heating of 3.5 K per 1,000 revolutions/min when designing the operating temperature range.

2)

Take into account self-heating of 5.5 K per 1,000 revolutions/min when designing the operating temperature range.

3)

For Advanced type encoders, the shaft seal must be inspected regularly.

Ambient data

EMC

Enclosure rating

Permissible relative humidity

Operating temperature range

Storage temperature range

Resistance to shocks

Resistance to vibrations

1)

In an assembled male connector.

2)

For Advanced type encoders, the shaft seal must be inspected regularly.

PUR

≤ 500,000 rad/s²

Basic Advanced

According to EN 61000-6-2 and EN 61000-6-3

IP 65 on housing side (acc. to IEC 60529)

1)

IP 65 on shaft side (acc. to IEC 60529)

90% (condensation not permitted)

–20 °C ... +70 °C –40 °C ... +85 °C

–40 °C ... +100 °C, without packaging

100 g, 6 ms (according to EN 60068-2-27)

20 g, 10 Hz ... 2,000 Hz (according to EN 60068-2-6)

IP 66 + IP 67, on housing side

(according to IEC 60529)

1)

IP 66 + IP 67, on shaft side

(according to IEC 60529)

2)

G

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

G-255

Page 5

AHS/AHM36 CANopen ABSOLUTE ENCODERS

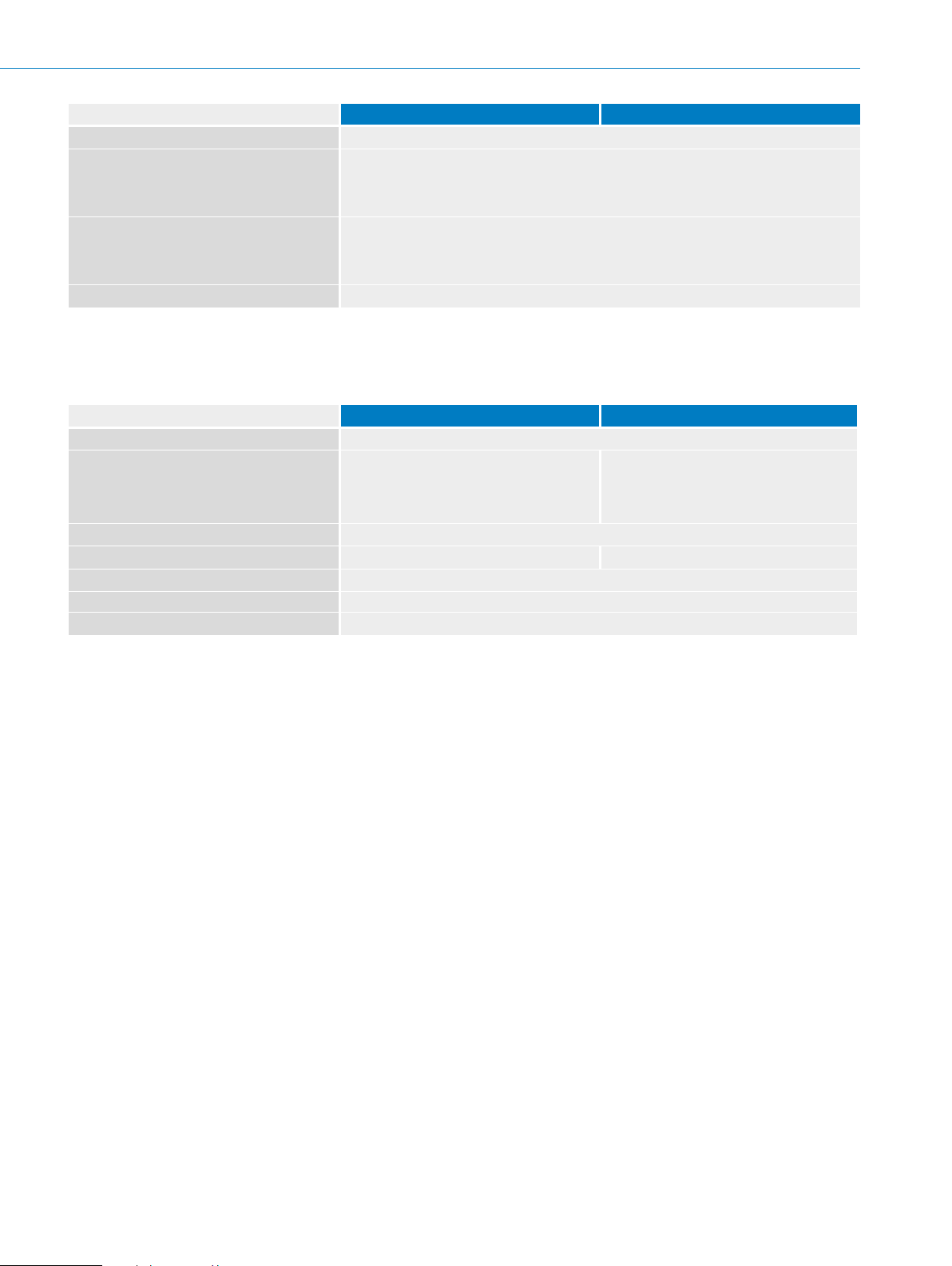

Type code

Singleturn

Type

B Basic

A Advanced

Mechanical design

B A Blind hollow shaft, 6 mm

B B Blind hollow shaft, 8 mm

B C Blind hollow shaft, 3/8"

B D Blind hollow shaft, 10 mm

B K Blind hollow shaft, 1/4"

S 1 Solid shaft, servo ange, 6x12 mm

S 9 Solid shaft, servo ange, 8x12 mm

S 2 Solid shaft, servo ange, 10x12 mm

S A Solid shaft, servo ange, 1/4"x12 mm

S B Solid shaft, servo ange, 3/8"x12 mm

S 3 Solid shaft, face mount ange, 6x12 mm

S 5 Solid shaft, face mount ange, 8x12 mm

S 4 Solid shaft, face mount ange, 10x12 mm

S 8 Solid shaft, face mount ange, 1/4"x12 mm

S 7 Solid shaft, face mount ange, 3/8"x12 mm

S C Solid shaft, face mount ange, 10x24 mm, for use with the adapters 2072298 and 2072295

1)

Electrical interface

C CANopen

2)

G

Connection type

C M12 x 5-pin, universal

J Cable, 5-wire, universal, 0.5 m

K Cable, 5-wire, universal, 1.5 m

L Cable, 5-wire, universal, 3 m

M Cable, 5-wire, universal, 5 m

Resolution

04,096 Steps per revolution (type B)

16,384 Steps per revolution (type A)

A H S 3 6 - O

1)

Flange adapters can be used for additional mechanical interfaces, see Mounting suggestions.

2)

Permissible shaft load lower than gure list in technical data.

3)

Number of steps programmable via control unit.

3)

3)

G-256

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 6

Multiturn

Type

B Basic

A Advanced

ABSOLUTE ENCODERS AHS/AHM36 CANopen

Mechanical design

B A Blind hollow shaft, 6 mm

B B Blind hollow shaft, 8 mm

B C Blind hollow shaft, 3/8"

B D Blind hollow shaft, 10 mm

B K Blind hollow shaft, 1/4"

S 1 Solid shaft, servo ange, 6x12 mm

S 9 Solid shaft, servo ange, 8x12 mm

S 2 Solid shaft, servo ange, 10x12 mm

S A Solid shaft, servo ange, 1/4"x12 mm

S B Solid shaft, servo ange, 3/8"x12 mm

S 3 Solid shaft, face mount ange, 6x12 mm

S 5 Solid shaft, face mount ange, 8x12 mm

S 4 Solid shaft, face mount ange, 10x12 mm

S 8 Solid shaft, face mount ange, 1/4"x12 mm

S 7 Solid shaft, face mount ange, 3/8"x12 mm

S C Solid shaft, face mount ange, 10x24 mm, for use with the adapters 2072298 and 2072295

S D Solid shaft, servo ange, 6x12 mm for adapting to 1.25 m Ecoline wire draw mechanism

1)

3)

Electrical interface

C CANopen

2)

Connection type

C M12 x 5-pin, universal

J Cable, 5-wire, universal, 0.5 m

K Cable, 5-wire, universal, 1.5 m

L Cable, 5-wire, universal, 3 m

M Cable, 5-wire, universal, 5 m

Resolution

12x12 bit (Type B)

14x12 bit (Type A)

A H M 3 6 - O

1)

Flange adapters can be used for additional mechanical interfaces, see Mounting suggestions.

2)

Permissible shaft load lower than gure list in technical data.

3)

Protection class on shaft side always IP 65.

4)

Programmable options for resolution via control unit.

4)

4)

G

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

G-257

Page 7

AHS/AHM36 CANopen ABSOLUTE ENCODERS

Ordering information

Absolute singleturn, solid shaft, servo ange

• Electrical interface: CANopen

• Programmable: l

Shaft diameter Connection type Number of steps Resolution Type Part no.

≤ 4,096 4,096 x 1

≤ 16,384 16,384 x 1

≤ 16,384 16,384 x 1

6 x 12 mm

M12 male connector,

5-pin, universal

Cable, 5-wire, universal,

1.5 m

Absolute multiturn, solid shaft, servo ange

• Electrical interface: CANopen

• Programmable: l

Shaft diameter Connection type Number of steps Resolution Type Part no.

≤ 4,096 4,096 x 4,096

≤ 16,384 16,384 x 4,096

≤ 16,384 16,384 x 4,096

6 x 12 mm

M12 male connector,

5-pin, universal

Cable, 5-wire, universal,

1.5 m

AHS36B-

S1CC004096

AHS36A-

S1CC016384

AHS36A-

S1CK016384

AHM36B-

S1CC012x12

AHM36A-

S1CC014x12

AH-

M36A-S1CK014x12

1066005

1066002

1066001

1065992

1065993

1065994

G

Absolute singleturn, solid shaft, face mount ange

• Electrical interface: CANopen

• Programmable: l

• Number of steps: ≤ 16,384

• Resolution: 16,384 x 1

Shaft diameter Connection type Type Part no.

8 x 12 mm M12 male connector, 5-pin, universal

Absolute multiturn, solid shaft, face mount ange

• Electrical interface: CANopen

• Programmable: l

• Number of steps: ≤ 16,384

• Resolution: 16,384 x 4,096

Shaft diameter Connection type Type Part no.

M12 male connector, 5-pin, universal

6 x 12 mm

Cable, 5-wire, universal, 1.5 m

AHS36A-

S5CC016384

AHM36A-

S3CC014x12

AHM36A-

S3CK014x12

1067268

1065999

1066000

G-258

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 8

Absolute singleturn, blind hollow shaft

• Electrical interface: CANopen

• Programmable: l

• Number of steps: ≤ 16,384

• Resolution: 16,384 x 1

Shaft diameter Connection type Type Part no.

6 mm

Absolute multiturn, blind hollow shaft

• Electrical interface: CANopen

• Programmable: l

• Number of steps: ≤ 16,384

• Resolution: 16,384 x 4,096

Shaft diameter Connection type Type Part no.

6 mm

ABSOLUTE ENCODERS AHS/AHM36 CANopen

M12 male connector, 5-pin, universal

Cable, 5-wire, universal, 1.5 m

M12 male connector, 5-pin, universal

Cable, 5-wire, universal, 1.5 m

AHS36A-

BACC016384

AHS36A-

BACK016384

AHM36A-

BACC014x12

AHM36A-

BACK014x12

1066004

1066003

1065990

1065991

G

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

G-259

Page 9

AHS/AHM36 CANopen ABSOLUTE ENCODERS

11.8

X = Measuring point for operating temperature

11.4

11.8 (0.46)

5.8

(0.23)

X = Measuring point for operating temperature

Dimensional drawings (dimensions in mm)

Solid shaft, servo ange, M12 male connector

2.5

(0.08)

(0.10)

0.08

0.08

B

43 (1.69)

0.02

+0.15

2.5 (0.10)

2

12 ±0.3

Ø D f7

0.03

(0.47)

11.5

(0.45)

A

X

–0.025

–0.064

H

Ø 33 (1.30)

B

B

B

–0.025

–0.064

Ø 33 (1.30)

0.03

Solid shaft, servo ange, cable output

2.5 (0.10)

+0.15

Ø 2.5

(0.10)

12

±0.3 (0.47)

2 (0.08)

11.5

B0.02

(0.45)

A

X

0.08

0.08

B

B

(0.45)

5.8 (0.23)

B

B

34.2 (1.35)

+0.3

–0.1

Ø 36 (1.41)

2.6

(0.10)

35.9 (1.41)

45°

4 x 90° = 360°

14.5

45°

14.5 (0.57)

M12 x 1

B

(0.57)

M3 x 5

60 (2.36)

A

26 ±0.05 (1.02)

Ø 0.05

Ø 0.05

A

(0.46)

61

(2.40)

M3 x 5

(4 x)

(4 x)

G

H

–0.025

–0.064

Ø D f7

Ø 33 (1.30)

0.03

B

B0.03

Bend radius of cable; R = 30 mm

B

43

(1.69)

2.6

(0.10)

–0.1

(1.41)

Ø 36

4 x 90° = 360°

Ø 26 ±0.05 (1.02)

B

G-260

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 10

Solid shaft, face mount ange, M12 male connector

11.8 (0.46)

14.5 (0.57)

5.8

(0.23)

X = Measuring point for operating temperature

11.4

14.5

(0.46)

ABSOLUTE ENCODERS AHS/AHM36 CANopen

(0.45)

(0.1)

(0.23)

2.6

12 ±0.3

(0.47)

11.5

ØD f7

(0.45)

X

A

H

B

0.03

B

0.02

B

-0.02

-0.05

(0.79)

Ø 20

0.03

X = Measuring point for operating temperature

(0.2)

5

B

43

(1.69)

Solid shaft, face mount ange, cable output

12 ±0.3 (0.47)

(0.20)

11.5

5

B0.02

(0.45)

X

A

(0.57)

5.8

34.2

(1.35)

3 x 120° = 360°

-0.1

+0.3

(1.42)

Ø 36

35.9 (1.41)

4 x 90° = 360°

3 x 120° = 360°

M12 x 1

B

M3 x 5

(10 x)

M3 x 5 (10 x)

3 x 120° = 360°

Ø 0.05

Ø 28 ±0.05

(1.1)

A

Ø 0.05

Ø 30 ±0.05

Ø 0.05

(1.18)

A

Ø 0.05

A

A

61

(2.3640)

60

(2.36)

11.8

H

–0.02

–0.05

Ø D f7

Ø 20 (0.79)

0.03

B

B0.03

Bend radius of cable; R = 30 mm

B

+0.3

–0.1

Ø 36 (1.41)

4 x 90° = 360°

B

2.6

(1.69)

(0.10)

43

3 x 120° = 360°

±0.05 (1.10)

Ø 28

Ø 30 ±0.05 (1.18)

G

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

G-261

Page 11

AHS/AHM36 CANopen ABSOLUTE ENCODERS

14.5 (0.57)

11.8 (0.46)

X = Measuring point for operating temperature

11.8 (0.46)

5.8 (0.23)

Blind hollow shaft, M12 male connector

11.4 (0.45)

(0.31)

8

3.25

(0.13)

5.8 (0.23)

M12 x 1

67.6

(2.66)

G

X

–0.1

Ø D f7

Ø 38.6 (1.52)

+0,2

Ø 20 (0.79)

51 (2.01)

2.6

(0.10)

34.2 (1.35)

+0.3

–0.1

Ø 36 (1.42)

±0.05 (0.12)

3.1

(2.05)

Ø 52

Ø46

Ø 40

±0.1 (1.81)

±0.1 (1.57)

max. Ø 24 (0.94)

12

(0.47)

Customer’s own shaft: insertion depth of at least 15 mm to max. of 22 mm, from contact surface, from stator coupling, recommended shaft tolerance of k7

Blind hollow shaft, cable outlet

14.5 (0.57)

8

(0.31)

3.25

(0.13)

X

–0.1

Ø D f7

Ø 38.6 (1.52)

+0.2

Ø 20 (0.79)

X = Measuring point for operating temperature

51 (2.01)

2.6

(0.10)

35.9 (1.42)

±0.05 (0.12)

3.1

+0.3

–0.1

Ø 36 (1.42)

Ø 52

(2.05)

Ø46

±0.1 (1.81)

Ø 40

±0.1 (1.57)

(0.94)

12

max. Ø 24

Bend radius of cable; R = 30 mm

Customer’s own shaft: insertion depth of at least 15 mm to max. of 22 mm, from contact surface, from stator coupling, recommended shaft tolerance of k7

69 (2.72)

G-262

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 12

ABSOLUTE ENCODERS AHS/AHM36 CANopen

M12 x 1

(0.46)

11.4

4

+0.1

11.4

(0.46)

11.4

(0.46)

M12 x 1

Ø 6 f7

-0.010

Proposed tting

Solid shaft, face mount ange with ange adapter, centering hub D20 to D50 (BEF-FA-020-050, 2072297)

(0.16)

3

0.02

B

10 ±0.3

(0.39)

(0.12)

A

X

5.4

(0.21)

-0.025

-0.064

(2.03)

(1.97)

51.5-0.2

Ø 50 f8

0.03

B

0.03

B

10

(0.39)

B

+0.1

X = Measuring point for operating temperature

Sample order for 6 mm shaft diameter: AHx36x-S3xx0xxxxx + BEF-FA-020-050 (adapter is not pre-assembled)

Solid shaft, face mount ange with ange adapter, centering hub D20 to D36 (BEF-FA-020-036, 2072298)

14

(0.55)

19

(0.75)

18

(0.71)

±0.3

X

8

(0.31)

+0.1

B

0.02

B

-0.013

-0.025

-0.064

(1.42)

Ø 36 f8

A

-0.028

(0.39)

Ø 10 f7

9

(0.35)

(1.77)

0.03

(0.45)

5.8

(0.23)

Ø 0.05

A

120° (3 x)

-0.010

-0.022

34.2

(1.35)

(0.24)

(1.42)

Ø 6 f7

(1.65)

Ø 42 ±0.05

3 x M4 3.6

25°

34.2

(1.35)

120° (3 x)

M12 x 1

Ø 58

(2.28)

(0.14)

3 x M4

Ø 48 ±0.05

(1.89)

Ø 0.05

A

-0.1

+0.3

Ø 36

2.6

(0.1)

45

(0.45)

5.8

(0.23)

B

-0.1

+0.3

(1.42)

-0.1

(2.12)

Ø 53.8

Ø 36

65

(2.56)

62

(2.44)

11.8

11.8

G

0.03

B

0.03

B

X = Measuring point for operating temperature

Sample order for 10 mm shaft diameter: AHx36x-SCxx0xxxxx + BEF-FA-020-036 (adapter is not pre-assembled)

Solid shaft, face mount ange with ange adapter, centering hub D20 to D36, 2 mm high (BEF-FA-020-036-002, 2072296)

12 ±0.3

(0.47)

11.5

(0.45)

X

-0.022

(0.24)

5.4

(0.21)

0.03

0.03

0.03

X = Measuring point for operating temperature

Sample order for 6 mm shaft diameter: AHx36x-S3xx0xxxxx + BEF-FA-020-036-002 (adapter is not pre-assembled)

A

B

B

B

(0.12)

3

3

(0.12)

(1.89)

B

2.6

(0.1)

48

(0.45)

5.8

(0.23)

Ø 0.1

B

(1.18)

3 x M3

(0.1)

34.2

(1.35)

-0.1

+0.3

(1.42)

Ø 36

Ø 30 ±0.05

2.6

6

(0.24)

Ø 59.5

(2.34)

(0.14)

60

(2.36)

120° (3 x)

-0.02

-0.05

(0.79)

Ø 20

3.6

11.8

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

G-263

Page 13

AHS/AHM36 CANopen ABSOLUTE ENCODERS

11.4

(0.46)

Ø 6 f7

-0.010

(0.46)

11.4

Ø 36.5

M12 x 1

4

1

3

2

5

PINSignalWire color Function

Solid shaft, face mount ange with ange adapter, centering hub D20 to D24 (BEF-FA-020-024, 2072294)

12 ±0.3

(0.47)

11.5

(0.45)

X

(0.24)

0.03

0.03

0.03

A

5.4

(0.21)

B

B

B

(0.12)

B

3

-0.022

X = Measuring point for operating temperature

(0.45)

2.6

(0.1)

5.8

(0.23)

+0.3

-0.1

Ø 36

(1.42)

Ø 0.1

34.2

(1.35)

(1.18)

Ø 30 ±0.05

3 x M3

Sample order for 6 mm shaft diameter: AHx36x-S3xx0xxxxx + BEF-FA-020-024 (adapter is not pre-assembled)

Solid shaft, face mount ange with ange adapter, centering hub D20 to D30 (BEF-FA-020-030, 2072295)

M12 x 1

A

120° (3 x)

-0.020

-0.053

(0.94)

Ø 24 f8

2

3.6

(0.14)

(0.08)

60

(2.36)

11.8

G

17

(0.67)

A

X

(1.44)

(1.18)

Ø 30 ±0.05

0.03

B

4

0.03 0.03

X = Measuring point for operating temperature

(0.16)

B

(0.16)

4

(0.16)

4

Ø 30

(1.18)

(0.45)

5.8

(0.23)

Ø 0.1

A

34.2

(1.35)

B

B

(0.1)

-0.1

+0.3

(1.42)

Ø 36

2.6

Ø 24

(0.94)

9

(0.35)

M4 (4 x)

90° (4 x)

Ø 10 h11

(0.39)

Sample order for 10 mm shaft diameter: AHx36x-SCxx0xxxxx + BEF-FA-020-030 (adapter is not pre-assembled)

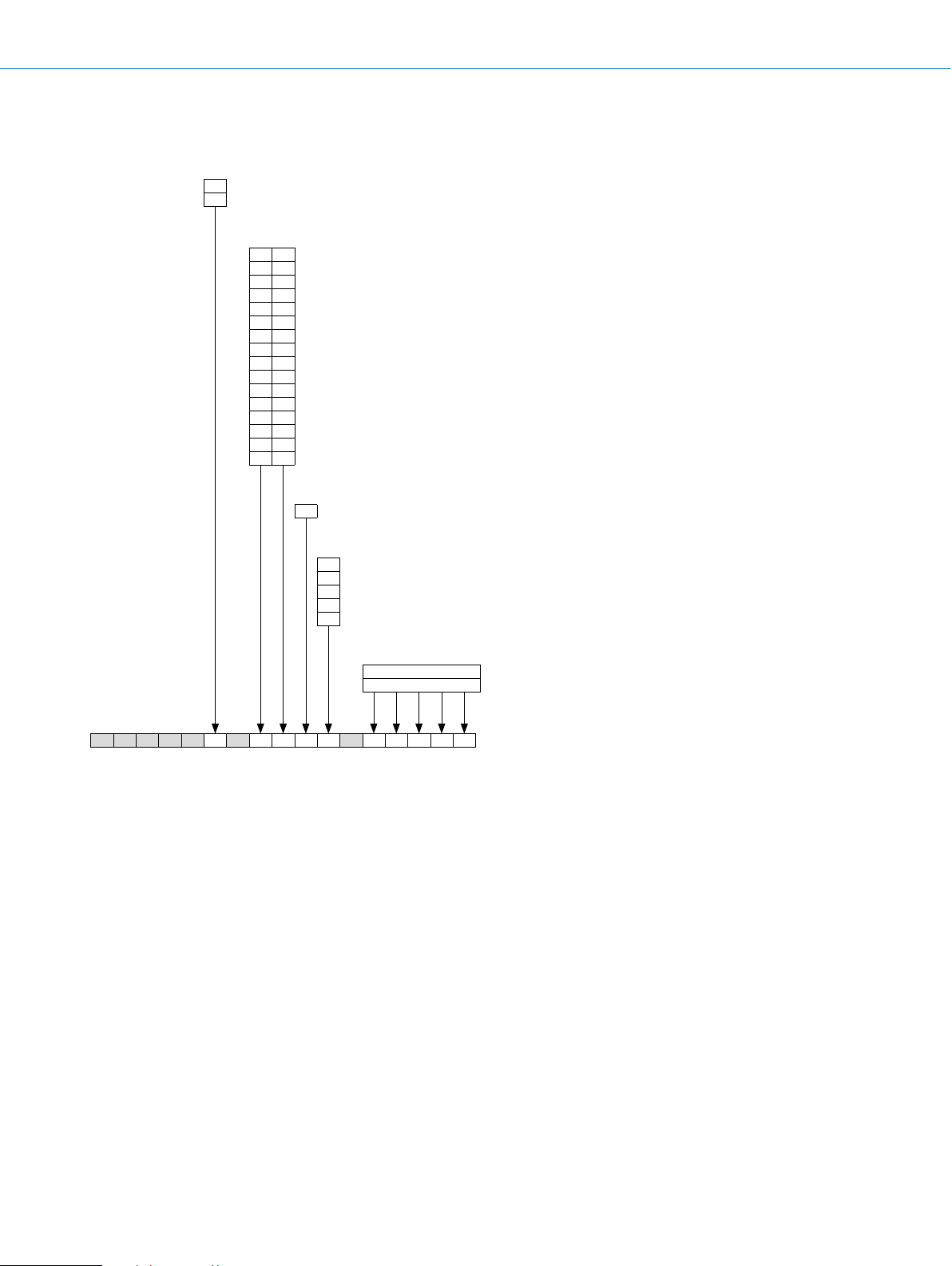

PIN assignment

View of M12 male device connector on encoder

(2.64)

67

11.8

View A

1CAN shield White Screen

2 VDC Red Encoder supply voltage:

3 GND / CAN GND Blue O V (GND)

4CAN high Black CAN signal

5CAN low Pink CAN signal

Housing --Screen

G-264

ENCODERS | SICK 8015560/2015-09-01

10 ... 30 V DC

Subject to change without notice

Page 14

ABSOLUTE ENCODERS AHS/AHM36 CANopen

Recommended accessories

Mounting systems

Mounting brackets and plates

Mounting bracket

Figure Brief description Type Part no.

Mounting bracket for encoder with centering hub 20 mm, including mounting kit for face

mount ange

Dimensional drawings g page K-725

BEF-WF-20 2066393

Flanges

Flange plate

Figure Brief description Type Part no.

Stator coupling on hole circle 63 mm BEF-DS08 2072206

Flange adapter centering hub D20 to D24 BEF-FA-020-024 2072294

Flange adapter centering hub D20 to D30 BEF-FA-020-030 2072295

Flange adapter centering hub D20 to D36 BEF-FA-020-036 2072298

Flange adapter centering hub D20 to D36, 2 mm high BEF-FA-020-036-002 2072296

Flange adapter centering hub D20 to D50 BEF-FA-020-050 2072297

Dimensional drawings g page K-725

Other mounting accessories

Measuring wheels and measuring wheel systems

Figure Brief description Type Part no.

Measuring wheel with O-ring (NBR70) for 6 mm solid shaft, circumference 200 mm BEF-MR006020R 2055222

Measuring wheel with O-ring (NBR70) for 6 mm solid shaft, circumference 300 mm BEF-MR006030R 2055634

O-ring for measuring wheels (circumference 200 mm) BEF-OR-053-040 2064061

O-ring for measuring wheels (circumference 300 mm) BEF-OR-083-050 2064076

Dimensional drawings g page K-725

Servo clamps

Figure Brief description Type Part no.

Servo clamps, small, for servo ange (clamps, eccentric fastener), 3 pcs., without

mounting material

Dimensional drawings g page K-725

BEF-WK-RESOL 2039082

G

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

G-265

Page 15

G

AHS/AHM36 CANopen ABSOLUTE ENCODERS

Shaft adaptation

Shaft couplings

Figure Brief description Type Part no.

Bellows coupling, shaft diameter 6 mm / 6 mm, maximum shaft offset: radial

± 0.25 mm, axial ± 0.4 mm, angular ± 4°; max. speed 10,000 rpm, –30 °C ... +120 °C,

max. torque 80 Ncm; material: stainless steel bellows, aluminum hub

Bellows coupling, shaft diameter 6 mm / 10 mm, maximum shaft offset: radial

± 0.25 mm, axial ± 0.4 mm, angular ± 4°; max. speed 10,000 rpm, –30 °C ... +120 °C,

max. torque 80 Ncm; material: stainless steel bellows, aluminum hub

Bellows coupling, shaft diameter 10 mm/10 mm; maximum shaft offset: radial

± 0.25 mm, axial ± 0.4 mm, angular ± 4°; max. revolutions 10,000 rpm,

–30 °C .... +120 °C, max. torque 80 Ncm; material: stainless steel bellows, aluminum

clamping hubs

Bellows coupling, shaft diameter 10 mm/12 mm; maximum shaft offset: radial

± 0.25 mm, axial ± 0.4 mm, angular ± 4°; max. revolutions 10,000 rpm,

–30 °C ... +120 °C, max. torque 80 Ncm; material: stainless steel bellows, aluminum

clamping hubs

Double-loop coupling, shaft diameter 6 mm/10 mm, maximum shaft offset: radial

± 2.5 mm, axial ± 3 mm, angular ± 10°; max. speed 3,000 rpm, –30 °C ... +80 °C,

max. torque 1.5 Nm; material: polyurethane, galvanized steel ange

Double-loop coupling, shaft diameter 8 mm/10 mm, maximum shaft offset: radial

± 2.5 mm, axial ± 3 mm, angular ± 10°; max. speed 3,000 rpm, –30 °C ... +80 °C,

max. torque 1.5 Nm; material: polyurethane, galvanized steel ange

Double-loop coupling, shaft diameter 10 mm/10 mm, maximum shaft offset: radial

± 2.5 mm, axial ± 3 mm, angular ± 10°; max. speed 3,000 rpm, –30 °C ... +80 °C,

max. torque 1.5 Nm; material: polyurethane, galvanized steel ange

Double-loop coupling, shaft diameter 10 mm/12 mm, maximum shaft offset: radial

± 2.5 mm, axial ± 3 mm, angular ± 10°; max. speed 3,000 rpm, –30 °C ... +80 °C,

max. torque 1.5 Nm; material: polyurethane, galvanized steel ange

Spring washer coupling, shaft diameter 6 mm/10 mm, maximum shaft offset: radial

± 0.3 mm, axial ± 0.4 mm, angular ± 2.5°; max. speed 12,000 rpm, –10 °C ... +80 °C,

max. torque 60 Ncm; material: aluminum ange, ber-glass reinforced polyamide mem-

brane and tempered steel coupling pin

Spring washer coupling, shaft diameter 10 mm / 10 mm, maximum shaft offset: radial

± 0.3 mm, axial ± 0.4 mm, angular ± 2.5°; max. speed 12,000 rpm, –10 °C ... +80° C,

max. torque 60 Ncm; material: aluminum ange, glass ber-reinforced polyamide mem-

brane and hardened steel coupling pin

Dimensional drawings g page K-725

KUP-0606-B 5312981

KUP-0610-B 5312982

KUP-1010-B 5312983

KUP-1012-B 5312984

KUP-0610-D 5326697

KUP-0810-D 5326704

KUP-1010-D 5326703

KUP-1012-D 5326702

KUP-0610-F 5312985

KUP-1010-F 5312986

G-266

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 16

ABSOLUTE ENCODERS AHS/AHM36 CANopen

Connectivity

Adapters and distributors

T-piece

Figure Brief description Type Part no.

CANopen, T-piece

Dimensional drawings g page K-725

Plug connectors and cables

Connecting cables with female connector

Figure Brief description Length

Head A: female connector, M12, 5-pin, straight

Head B: cable

Cable: suitable for drag chain, shielded, 2 x 0.34 mm² + 2 x 0.25 mm²

+ 1 x 0.34 mm², Ø 6.7 mm

A-coded

Dimensional drawings g page K-725

Connection cables with female and male connector

Figure Brief description Length

Head A: female connector, M12, 5-pin, straight

Head B: male connector, M12, 5-pin, straight

Cable: suitable for drag chain, PUR, halogen-free, shielded, 2 x 0.34 mm²

+ 2 x 0.25 mm² + 1 x 0.34 mm², Ø 6.7 mm, A-coded

DSC-

1205T000025KM0

6030664

Type Part no.

of

cable

2 m DOL-1205-G02MY 6053041

5 m DOL-1205-G05MY 6053042

10 m DOL-1205-G10MY 6053043

Type Part no.

of

cable

2 m DSL-1205-G02MY 6053044

5 m DSL-1205-G05MY 6053045

10 m DSL-1205-G10MY 6053046

Dimensional drawings g page K-725

Female connectors (ready to assemble)

Figure Brief description Type Part no.

Head A: female connector, M12, 5-pin, straight, shielded, for cable diameter

4.5 mm ... 7 mm

Head B: -

Dimensional drawings g page K-725

DOS-1205-GA 6027534

Male connector (ready to assemble)

Figure Brief description Type Part no.

Head A: male connector, M12, 5-pin, straight, A encoded, shielded, for cable diameter

4 mm ... 8 mm

Head B: -

Dimensional drawings g page K-725

STE-1205-GA 6027533

Other plug connectors and cables

Figure Brief description Type Part no.

Head A: male connector, M12, 5-pin, straight, shielded

Cable: terminator

Dimensional drawings g page K-725

- For additional accessories, please see page K-668 onwards

STE-1205-GKEND 6037193

G

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

G-267

Loading...

Loading...