SICK AHS36 CANopen, AHM36 CANopen, AHS36 CANopen Inox, AHM36 CANopen Inox Operating Instructions Manual

Page 1

O P E R A T I NG I N S T R U CT I O NS

AHS/AHM36 CANopen

AHS/AHM36 CANopen Inox

Absolute Encoder

Page 2

2

OPERATING INSTRUC TIONS | AHS/AHM36 CANOP EN, AHS/AHM36 CANOPEN INOX 801 6869/1 2TG/2019-04-08 | SICK

Subject to change without notic e

Described product

AHS/AHM36 CANopen

AHS/AHM36 CANopen Inox

Manufacturer

SICK STEGMANN GmbH

Dürrheimer Str. 36

78166 Donaueschingen

Germany

Legal information

This document is protected by the law of copyright. Whereby all rights established

therein remain with the company SICK STEGMANN GmbH. Reproduction of this

document or parts of this document is only permissible within the limits of the legal

determination of Copyright Law. Any modification, expurgation or translation of this

document is prohibited without the express written permission of SICK STEGMANN

GmbH.

The trademarks stated in this document are the property of their respective owner.

© SICK STEGMANN GmbH. All rights reserved.

Original document

This document is an original document of SICK STEGMANN GmbH.

Page 3

CONTENTS

8016869/12TG/201 9-04-08 | S ICK OPERATING INSTUCTIONS |AHS/AHM36 CA NOPEN, AHS/A HM36 CANOPEN INOX

3

Subject to change without notic e

Contents

1 About this document......................................................................... 6

1.1 Function of this document ..................................................................................6

1.2 Target group ..........................................................................................................6

1.3 Information depth.................................................................................................6

1.4 Scope .....................................................................................................................7

1.5 Abbreviations used...............................................................................................7

1.6 Symbols used ........................................................................................................8

2 On safety ........................................................................................... 9

2.1 Authorized personnel ...........................................................................................9

2.2 Intended use .........................................................................................................9

2.3 General safety notes and protective measures ............................................ 10

2.4 Environmental protection ................................................................................. 10

3 Quick start instructions on the AHS36/AHM36 CANopen ..............11

3.1 Node ID/Baud rate ............................................................................................ 11

3.2 Parameterization ............................................................................................... 12

3.2.1 EDS file............................................................................................. 12

3.2.2 Save or restore parameters .......................................................... 12

3.3 Process data objects (PDOs)............................................................................ 13

3.3.1 PDO communication ...................................................................... 13

3.3.2 PDO mapping .................................................................................. 14

4 Product description .........................................................................15

4.1 Special features................................................................................................. 15

4.2 Operating principle of the encoder.................................................................. 17

4.2.1 Scaleable resolution....................................................................... 17

4.2.2 Preset function................................................................................ 17

4.2.3 Round axis functionality ................................................................ 18

4.2.4 Electronic cam mechanism ........................................................... 20

4.3 Controls and status indicators......................................................................... 20

5 Integration in CANopen ...................................................................21

5.1 Communication profile...................................................................................... 21

5.1.1 CANopen in the OSI model ............................................................ 21

5.1.2 Communication channels.............................................................. 21

5.1.3 Topology ........................................................................................... 22

5.2 Node IDs and COB-IDs ...................................................................................... 23

5.3 Baud rate ............................................................................................................ 24

5.4 Layer Setting Services (LSS) ............................................................................ 24

Page 4

CONTENTS

4

OPERATING INSTRUC TIONS | AHS/AHM36 CANOP EN, AHS/AHM36 CANOPEN INOX 801 6869/1 2TG/2019-04-08 | SICK

Subject to change without notic e

5.5 Network management (NMT)........................................................................... 28

5.5.1 CANopen state machine ................................................................ 28

5.5.2 Network Management Services.................................................... 29

5.5.3 Boot-up message............................................................................ 30

5.5.4 Node Guarding and Heartbeat...................................................... 30

5.6 Service Data Objects (SDO).............................................................................. 31

5.7 Process Data Objects (PDO)............................................................................. 33

5.7.1 PDO mapping .................................................................................. 33

5.7.2 PDO data transmission .................................................................. 34

5.7.3 Asynchronous or synchronous formation of the position.......... 36

5.8 Configurable functions...................................................................................... 37

5.8.1 EDS file............................................................................................. 37

5.8.2 Scaling parameters ........................................................................ 38

5.8.3 Preset function................................................................................ 40

5.8.4 Cyclic process data......................................................................... 41

5.8.5 Speed measurement...................................................................... 42

5.8.6 Round axis functionality ................................................................ 43

5.8.7 Electronic cam mechanism ........................................................... 45

6 Object library ...................................................................................46

6.1 Nomenclature .................................................................................................... 46

6.2 Standard objects ............................................................................................... 47

6.2.1 Detailed information on the standard objects............................ 48

6.3 Process Data Objects ........................................................................................ 54

6.3.1 Basic PDO structure ....................................................................... 54

6.3.2 Parameter of the Receive PDO ..................................................... 55

6.3.3 Parameter of the Transmit PDOs.................................................. 56

6.3.4 Transmission types......................................................................... 58

6.3.5 Objects and their subindices that can be mapped .................... 60

6.4 Encoder profile specific objects....................................................................... 61

6.4.1 Encoder parameters....................................................................... 62

6.4.2 Objects for the electronic cam mechanism (CAM)..................... 65

6.4.3 Objects for diagnostics .................................................................. 69

6.5 Manufacturer-specific objects ......................................................................... 74

6.5.1 Objects for the encoder configuration ......................................... 75

6.5.2 Objects that provide status information ...................................... 81

7 Commissioning ...............................................................................89

7.1 Electrical installation......................................................................................... 89

7.1.1 Connection of the AHS36/AHM36 CANopen.............................. 89

7.2 Settings on the hardware ................................................................................. 90

7.3 Configuration...................................................................................................... 91

7.3.1 Default delivery status ................................................................... 91

7.3.2 System configuration ..................................................................... 91

7.4 Tests before the initial commissioning ........................................................... 95

Page 5

CONTENTS

8016869/12TG/201 9-04-08 | S ICK OPERATING INSTUCTIONS |AHS/AHM36 CA NOPEN, AHS/A HM36 CANOPEN INOX

5

Subject to change without notic e

8 Fault diagnosis ................................................................................96

8.1 In the event of faults or errors ......................................................................... 96

8.2 SICK STEGMANN support................................................................................. 96

8.3 Error and status indications on the LED......................................................... 96

8.3.1 Meaning of the LED displays......................................................... 97

8.4 Diagnostics via CANopen.................................................................................. 97

8.4.1 Emergency Messages .................................................................... 97

8.4.2 Alarms, warnings and status......................................................... 98

8.4.3 Error during the SDO transfer ....................................................... 99

9 Annex ........................................................................................... 100

9.1 Conformity with EU directives ....................................................................... 100

10 List of illustrations........................................................................ 101

11 List of tables................................................................................. 103

Page 6

1 ABOUT THIS DOCUMENT

6

OPERATING INSTRUC TIONS | AHS/AHM36 CANOP EN, AHS/AHM36 CANOPEN INOX 801 6869/1 2TG/2019-04-08 | SICK

Subject to change without notic e

1 About this document

Please read this chapter carefully before working with this documentation and the

AHS/AHM36 CANopen and AHS/AHM36 CANopen Inox Absolute Encoder.

1.1 Function of this document

These operating instructions are designed to address the technical personnel of the

machine manufacturer or the machine operator in regards to correct configuration,

electrical installation, commissioning, operation and maintenance of the

AHS/AHM36 CANopen and AHS/AHM36 CANopen Inox Absolute Encoder.

1.2 Target group

The operating instructions are addressed at the planners, developers and operators of

systems in which one or more AHS/AHM36 CANopen and AHS/AHM36 CANopen Inox

Absolute Encoders are to be integrated. They also address people who initialize the use

of the AHS/AHM36 CANopen and AHS/AHM36 CANopen Inox or who are in charge of

servicing and maintaining the device.

These instructions are written for trained persons who are responsible for the

installation, mounting and operation of the AHS/AHM36 CANopen and AHS/AHM36

CANopen Inox in an industrial environment.

1.3 Information depth

These operating instructions contain information on the AHS/AHM36 CANopen and

AHS/AHM36 CANopen Inox Absolute Encoder on the following subjects:

product features

electrical installation

commissioning and configuration

fault diagnosis and troubleshooting

conformity

These operating instructions do not contain any information on the mounting of the

AHS/AHM36 CANopen and AHS/AHM36 CANopen Inox. You will find this information in

the mounting instructions included with the device.

They also do not contain any information on technical specifications, dimensional

drawings, ordering information or accessories. You will find this information in the

product information for the AHS/AHM36 CANopen and AHS/AHM36 CANopen Inox.

Planning and using measurement systems such as the AHS/AHM36 CANopen and

AHS/AHM36 CANopen Inox also requires specific technical skills beyond the

information in the operating instructions and mounting instructions. The information

required to acquire these specific skills is not contained in this document.

When operating the AHS/AHM36 CANopen and AHS/AHM36 CANopen Inox , the

national, local and statutory rules and regulations must be observed.

Additional information

You will find additional information at www.can-cia.org.

Page 7

ABOUT THIS DOCUMENT 1

8016869/12TG/201 9-04-08 | S ICK OPERATING INSTUCTIONS |AHS/AHM36 CA NOPEN, AHS/A HM36 CANOPEN INOX

7

Subject to change without notic e

1.4 Scope

NOTE

These operating instructions apply to the AHS/AHM36 CANopen and AHS/AHM36

CANopen Inox Absolute Encoder with the following type codes:

Singleturn Encoder Basic = AHS36B-xxCx004096

Multiturn Encoder Basic = AHM36B-xxCx012x12

Singleturn Encoder Advanced = AHS36A-xxCx016384

Multiturn Encoder Advanced = AHM36A-xxCx014x12

Singleturn Encoder Inox = AHS36I-xxCx016384

Multiturn Encoder Inox = AHM36I-xxC-x014x12

1.5 Abbreviations used

Controller Area Network

CANopen is a registered trademark of CAN in Automation e.V.

Counts per Measuring Range

Customized Number of Revolutions, Divisor = divisor of the customized number of

revolutions

Customized Number of Revolutions, Nominator = nominator of the customized number

of revolutions

Communication Object Identifier = address of the communication object

Change of State

Counts Per Revolution = resolution per revolution

Electronic Data Sheet

Electrically Erasable Programmable Read-only Memory

Emergency Message

Layer Setting Services = services for the configuration of Node ID and baud rate

Network Management

Node Identifier = node address

Process Data Object

Programmable Logic Controller

Physical Measuring Range

Physical Resolution Span (per revolution)

Remote Transmission Request = request telegram for PDOs

Service Data Object

CAN

CANopen®

CMR

CNR_D

CNR_N

COB-ID

CoS

CPR

EDS

EEPROM

EMGY

LSS

NMT

Node ID

PDO

PLC

PMR

PRS

RTR

SDO

Page 8

1 ABOUT THIS DOCUMENT

8

OPERATING INSTRUC TIONS | AHS/AHM36 CANOP EN, AHS/AHM36 CANOPEN INOX 801 6869/1 2TG/2019-04-08 | SICK

Subject to change without notic e

1.6 Symbols used

NOTE

Refer to notes for special features of the device.

LED symbols describe the state of a diagnostics LED. Examples:

The LED is illuminated constantly.

The LED flashes evenly.

The LED flashes with a short duty cycle.

The LED is off.

Take action …

Instructions for taking action are shown by an arrow. Read carefully and follow the

instructions for action.

WARNING

Warning!

A warning notice indicates an actual or potential risk or health hazard. They are

designed to help you to prevent accidents.

Read carefully and follow the warning notices.

Page 9

ON SAFETY 2

8016869/12TG/201 9-04-08 | S ICK OPERATING INSTUCTIONS |AHS/AHM36 CA NOPEN, AHS/A HM36 CANOPEN INOX

9

Subject to change without notic e

2 On safety

This chapter deals with your own safety and the safety of the equipment operators.

Please read this chapter carefully before working with the AHS/AHM36 CANopen

and AHS/AHM36 CANopen Inox or with the machine or system in which the

AHS/AHM36 CANopen and AHS/AHM36 CANopen Inox is used.

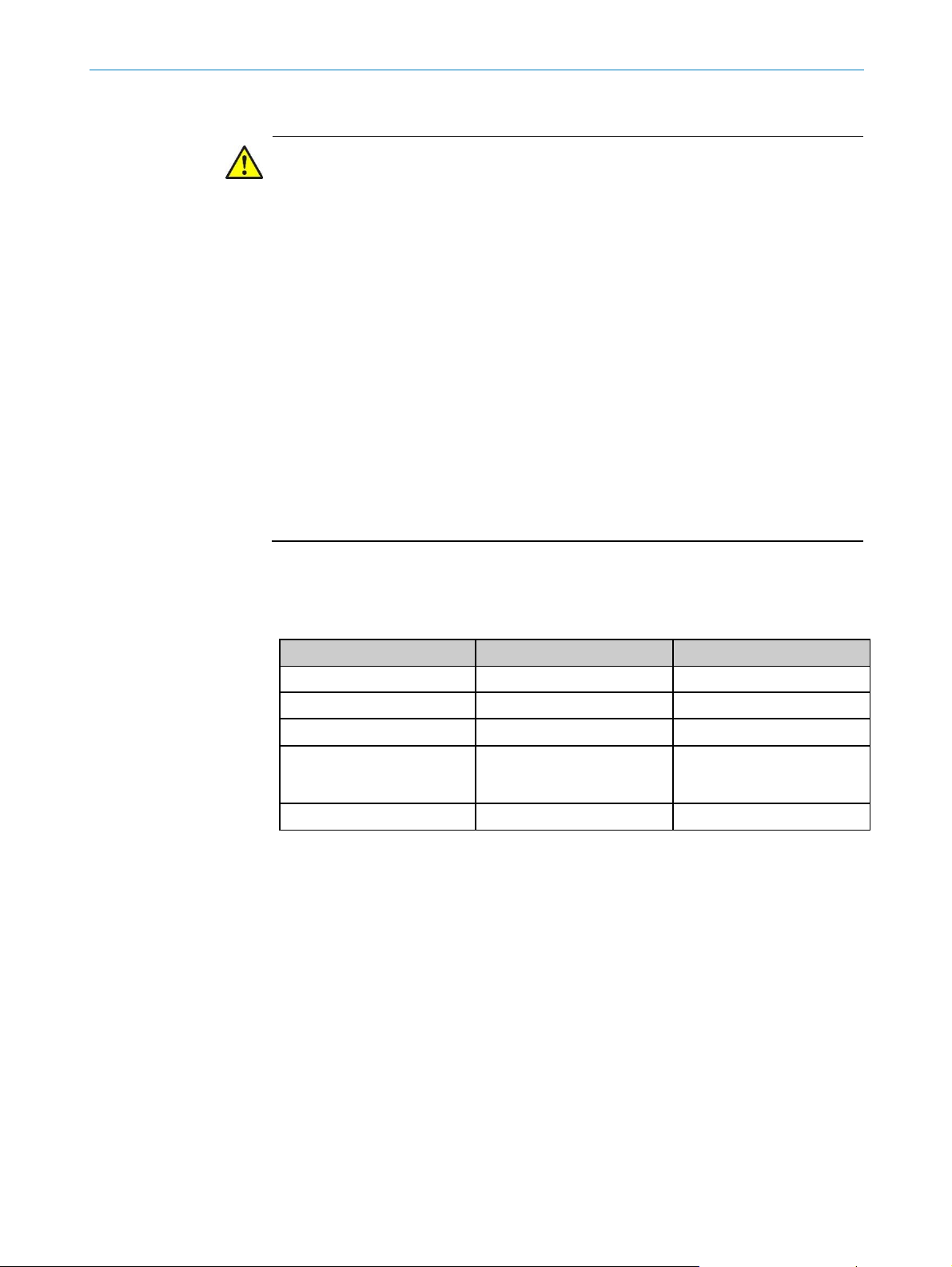

2.1 Authorized personnel

The AHS/AHM36 CANopen and AHS/AHM36 CANopen Inox Absolute Encoder must

only be installed, commissioned and serviced by authorized personnel.

NOTE

Repairs to the AHS/AHM36 CANopen and AHS/AHM36 CANopen Inox are only allowed

to be undertaken by trained and authorized service personnel from SICK STEGMANN

GmbH.

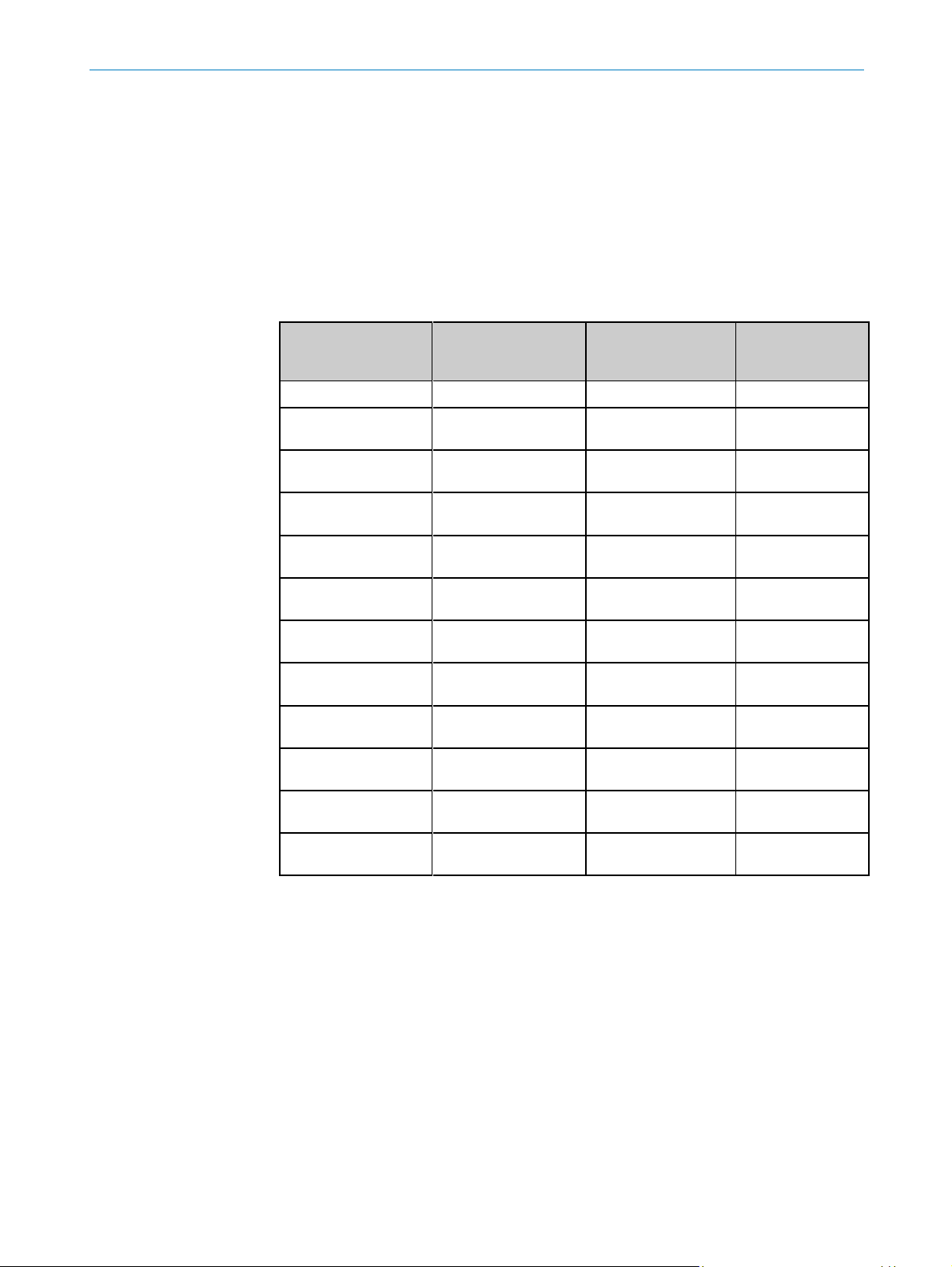

The following qualifications are necessary for the various tasks:

Activity

Qualification

Mounting

Basic technical training

Knowledge of the current safety regulations in the

workplace

Electrical installation and

replacement

Practical electrical training

Knowledge of current electrical safety regulations

Knowledge on the use and operation of devices in the

related application (e.g. industrial robots, storage and

conveyor technology)

Commissioning, operation

and configuration

Knowledge on the current safety regulations and the use

and operation of devices in the related application

Knowledge of automation systems

Knowledge of CANopen

®

Knowledge of automation software

Table 1: Authorized personnel

2.2 Intended use

The AHS/AHM36 CANopen and AHS/AHM36 CANopen Inox Absolute Encoder is a

measuring device that is manufactured in accordance with recognized industrial

regulations and meets the quality requirements as per ISO 9001:2008 as well as those

of an environment management system as per ISO 14001:2009.

An encoder is a device for mounting that cannot be used independent of its foreseen

function. For this reason an encoder is not equipped with immediate safe devices.

Measures for the safety of persons and systems must be provided by the constructor of

the system as per statutory regulations.

Due to its design, the AHS/AHM36 CANopen and AHS/AHM36 CANopen Inox can only

be operated within an CANopen network. It is necessary to comply with the CANopen

specifications and guidelines for setting up a CANopen network.

In case of any other usage or modifications to the AHS/AHM36 CANopen and

AHS/AHM36 CANopen Inox, e.g. opening the housing during mounting and electrical

installation, or in case of modifications to the SICK software, any claims against SICK

STEGMANN GmbH under warranty will be rendered void.

Page 10

2 ON SAFETY

10

OPERATING INSTRUC TIONS | AHS/AHM36 CANOP EN, AHS/AHM36 CANOPEN INOX 801 6869/1 2TG/2019-04-08 | SICK

Subject to change without notic e

2.3 General safety notes and protective measures

WARNING

Please observe the following procedures in order to ensure the correct and safe use

of the AHS/AHM36 CANopen and AHS/AHM36 CANopen Inox!

The encoder is to be installed and maintained by trained and qualified personnel with

knowledge of electronics, precision mechanics and control system programming. It is

necessary to comply with the related standards covering the technical safety

stipulations.

All safety regulations are to be met by all persons who are installing, operating or

maintaining the device:

The operating instructions must always be available and must always be followed.

Unqualified personnel are not allowed to be present in the vicinity of the system

during installation and maintenance.

The system is to be installed in accordance with the applicable safety stipulations

and the mounting instructions.

All work safety regulations of the applicable countries are to be followed during

installation.

Failure to follow all applicable health and work safety regulations may result in

injury or damage to the system.

The current and voltage sources in the encoder are designed in accordance with

all applicable technical regulations.

2.4 Environmental protection

Please note the following information on disposal.

Assembly

Material

Disposal

Packaging

Cardboard

Waste paper

Shaft

Stainless steel

Scrap metal

Flange

Aluminium / Stainless steel

Scrap metal

Housing

Aluminium die cast with Zinc

nickel coating / stainless

steel

Scrap metal

Electronic assemblies

Various

Electronic waste

Table 2: Disposal of the assembli es

Page 11

QUICK START INSTRUCTIONS ON THE AHS/AHM36 CANOPEN AND AHS/AHM36 CANOPEN

INOX 3

8016869/12TG/201 9-04-08 | S ICK OPERATING INSTUCTIONS |AHS/AHM36 CA NOPEN, AHS/A HM36 CANOPEN INOX

11

Subject to change without notic e

3 Quick start instructions on the AHS/AHM36 CANopen and

AHS/AHM36 CANopen Inox

3.1 Node ID/Baud rate

The following prerequisites must be met for the communication with the master:

A correct node ID must be set on the AHS/AHM36 CANopen and AHS/AHM36

CANopen Inox. Correct is:

○ a node ID that is not in use in the CANopen network

○ a node ID that the master expects

The same baud rate must be set on the AHS/AHM36 CANopen and AHS/AHM36

CANopen Inox as on the master.

The following parameters are set on the AHS/AHM36 CANopen and AHS/AHM36

CANopen Inox in the factory:

Node ID: 5

Baud rate: 125 kbit/s

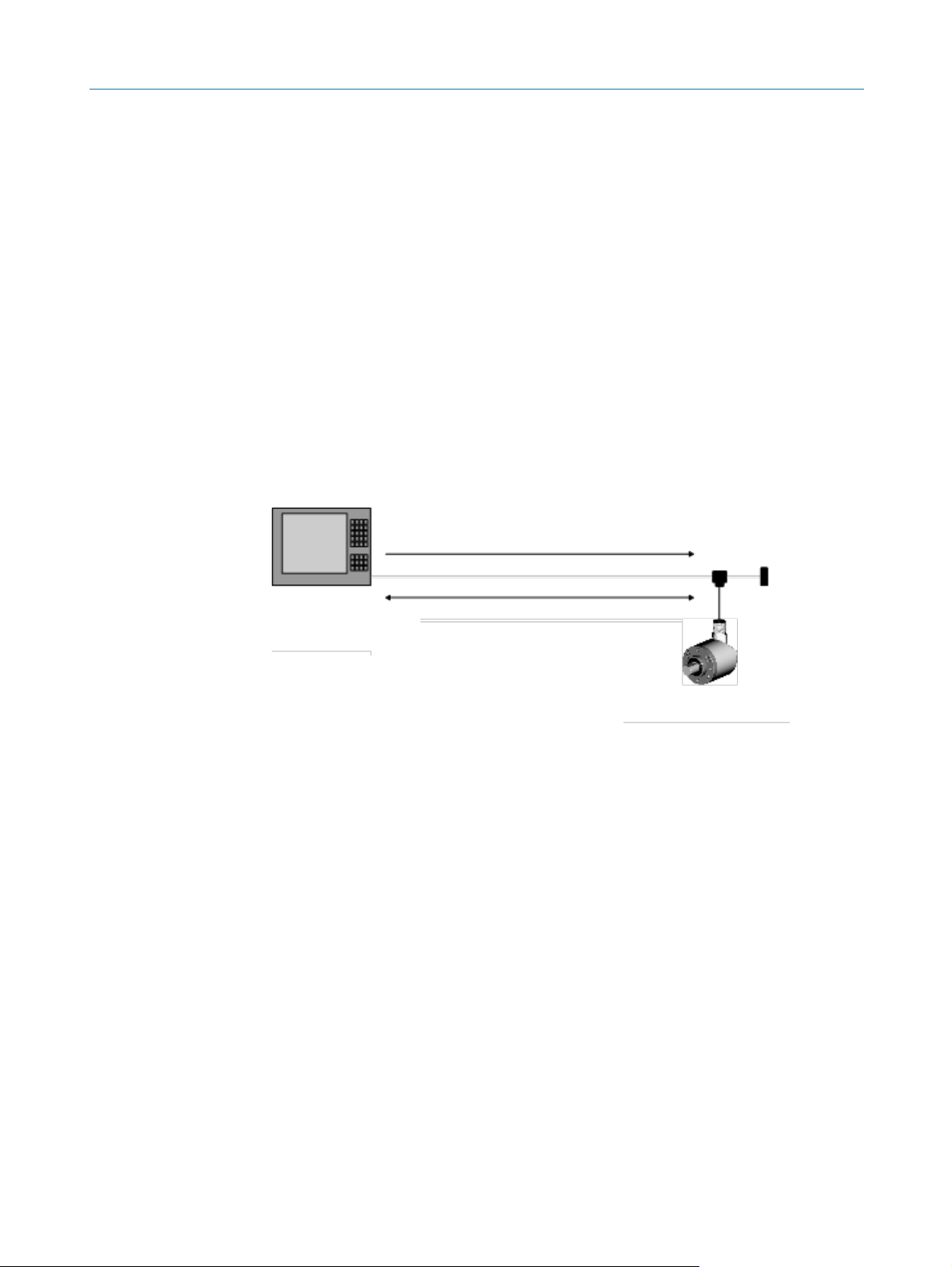

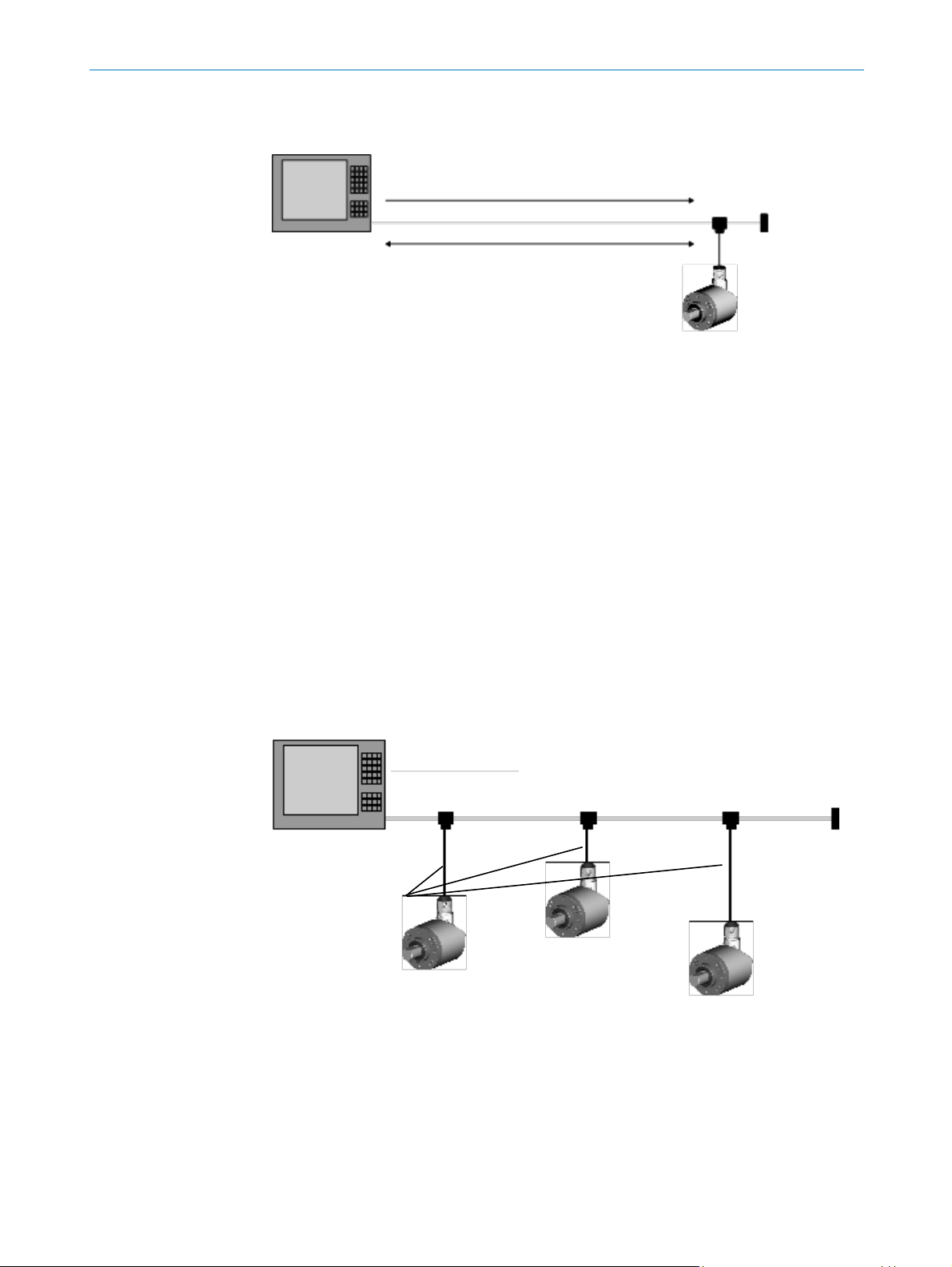

Figure 1: Encoder in the CANopen network

The following communication parameters can be assigned to the

AHS/AHM36 CANopen and AHS/AHM36 CANopen Inox:

Node ID: 1 to 127 (as a rule 0 is assigned to the master)

Baud rate: 10 kbit/s, 20 kbit/s, 50 kbit/s, 100 kbit/s, 125 kbit/s, 250 kbit/s,

500 kbit/s, 800 kbit/s, 1,000 kbit/s

Set the node ID and the baud rate as follows:

using the manufacturer-specific object 2009h

using Layer Setting Services (see section 5.4 on page 24)

Changing node ID and/or baud rate using the object 2009h

To change the node ID and/or the baud rate using the object 2009h, proceed as

follows:

Entering the access code in object 2009.1h: 98127634h

Change node ID and/or baud rate in the objects 2009.2h and 2009.3h

Save parameters with the aid of object 1010.1h: 65766173h (corresponds to

“save” in ASCII)

LSS, NMT

SDO, PDO, EMGY

Master

Node ID = 0

Slave

Node ID = 1 … 127

Page 12

3 QUICK START INSTRUCTIONS ON THE AHS/AHM36 CANOPEN AND AHS/AHM36 CANOPEN

INOX

12

OPERATING INSTRUC TIONS | AHS/AHM36 CANOP EN, AHS/AHM36 CANOPEN INOX 801 6869/1 2TG/2019-04-08 | SICK

Subject to change without notic e

NOTE

The changes will only be active after restarting the encoder (switch off and on again the

supply voltage).

Integration of several encoders

Integrate encoder 1 in the network and change the node ID (e.g. node ID 4).

Then integrate encoder 2 in the network and change the node ID if necessary.

NOTE

It is imperative you ensure there are not several encoders or other bus users with an

identical node ID in the same network.

3.2 Parameterization

3.2.1 EDS file

An EDS file is available for the straightforward interfacing of the AHS/AHM36 CANopen

and AHS/AHM36 CANopen Inox to a CANopen master. This file contains, amongst

others, the default parameters of the AHS/AHM36 CANopen and AHS/AHM36

CANopen Inox and the default configuration of the process data.

You can download the EDS file from www.sick.com:

Enter the seven-digit part number of your encoder directly in the Find field on the

homepage.

Click the related search result.

A page with all the information and files for your device will open.

Download the EDS file.

Integrate the EDS file in the engineering tool for your control.

3.2.2 Save or restore parameters

Saving modified parameters in the EEPROM – Save command

All parameters configured in the encoder’s EEPROM are saved using object 1010h.

For this purpose enter the command 65766173h (corresponds to “save” in ASCII)

in object 1010.1h.

NOTE

If the Save command is not run, the previous parameters will be loaded from the

EEPROM the next time the encoder is started.

Resetting encoders to default factory settings – Load command

The parameters are reset to the default factory settings using the object 1011h.

For this purpose enter the command 64616F6Ch (corresponds to “load” in ASCII)

in the object 1011.1h.

Page 13

QUICK START INSTRUCTIONS ON THE AHS/AHM36 CANOPEN AND AHS/AHM36 CANOPEN

INOX 3

8016869/12TG/201 9-04-08 | S ICK OPERATING INSTUCTIONS |AHS/AHM36 CA NOPEN, AHS/A HM36 CANOPEN INOX

13

Subject to change without notic e

NOTE

The node ID and baud rate set are not in general reset to the default factory settings.

The Save command must be run after the Load command. If the Save command is not

run, the previous parameters will be loaded from the EEPROM the next time the

encoder is started.

3.3 Process data objects (PDOs)

The AHS/AHM36 CANopen and AHS/AHM36 CANopen Inox supports four Transmit

PDOs and one Receive PDO.

Transmit PDOs

Data are sent by the encoder to the PLC using the four Transmit PDOs.

The four Transmit PDOs are defined by the following objects:

The objects 1800h … 1803h contain the communication parameters.

The objects 1A00h … 1A03h contain the mapping of the objects.

The mapping is variable and can be modified.

Receive PDO

Data are received from the PLC by the encoder using the Receive PDO. The mapping for

this Receive PDO is fixed and cannot be modified.

3.3.1 PDO communication

In the factory the transmission type for the Transmit PDOs is set to 255 in the objects

1800h … 1803h. This corresponds to the device-specific triggering.

NOTE

As an event timer is not configured, the Transmit PDOs are only transferred once on

changing to the Operational status!

Changing factory setting for transmission type

For the cyclic or acyclic output of the Transmit PDOs by the encoder, there are the

following options:

Change the event timer in the objects 1800h … 1803h (see Table 63 ff. from

page 56).

Configure a trigger event using the CoS event handling configuration (see

Table 119 on page 80).

Change the transmission type in the objects 1800h … 1803h (see Table 63 ff.

from page 56).

Pay attention to the inhibition time

The inhibition time for the PDOs (configured in the objects 1800.3h … 1803.3h) in

principle limits the communication of a device on the CANopen bus. It always has a

higher priority than the event timer, the CoS events and the sync triggering.

If, e.g., the event timer is set to 100 ms and the inhibition time is set to 1 s, the

corresponding PDO is only sent every second.

Page 14

3 QUICK START INSTRUCTIONS ON THE AHS/AHM36 CANOPEN AND AHS/AHM36 CANOPEN

INOX

14

OPERATING INSTRUC TIONS | AHS/AHM36 CANOP EN, AHS/AHM36 CANOPEN INOX 801 6869/1 2TG/2019-04-08 | SICK

Subject to change without notic e

3.3.2 PDO mapping

You will find which objects are mapped by default in the related transmit PDOs in

section 6.3.3 on page 56.

Page 15

PRODUCT DESCRIPTION 4

8016869/12TG/201 9-04-08 | S ICK OPERATING INSTUCTIONS |AHS/AHM36 CA NOPEN, AHS/A HM36 CANOPEN INOX

15

Subject to change without notic e

4 Product description

This chapter provides information on the special features and properties of the

Absolute Encoder AHS/AHM36 CANopen and AHS/AHM36 CANopen Inox. It describes

the construction and the operating principle of the device.

Please read this chapter before mounting, installing and commissioning the

device.

4.1 Special features

Figure 2: Connection types

With male connector

With cable outlet

Page 16

4 PRODUCT DESCRIPTION

16

OPERATING INSTRUC TIONS | AHS/AHM36 CANOP EN, AHS/AHM36 CANOPEN INOX 801 6869/1 2TG/2019-04-08 | SICK

Subject to change without notic e

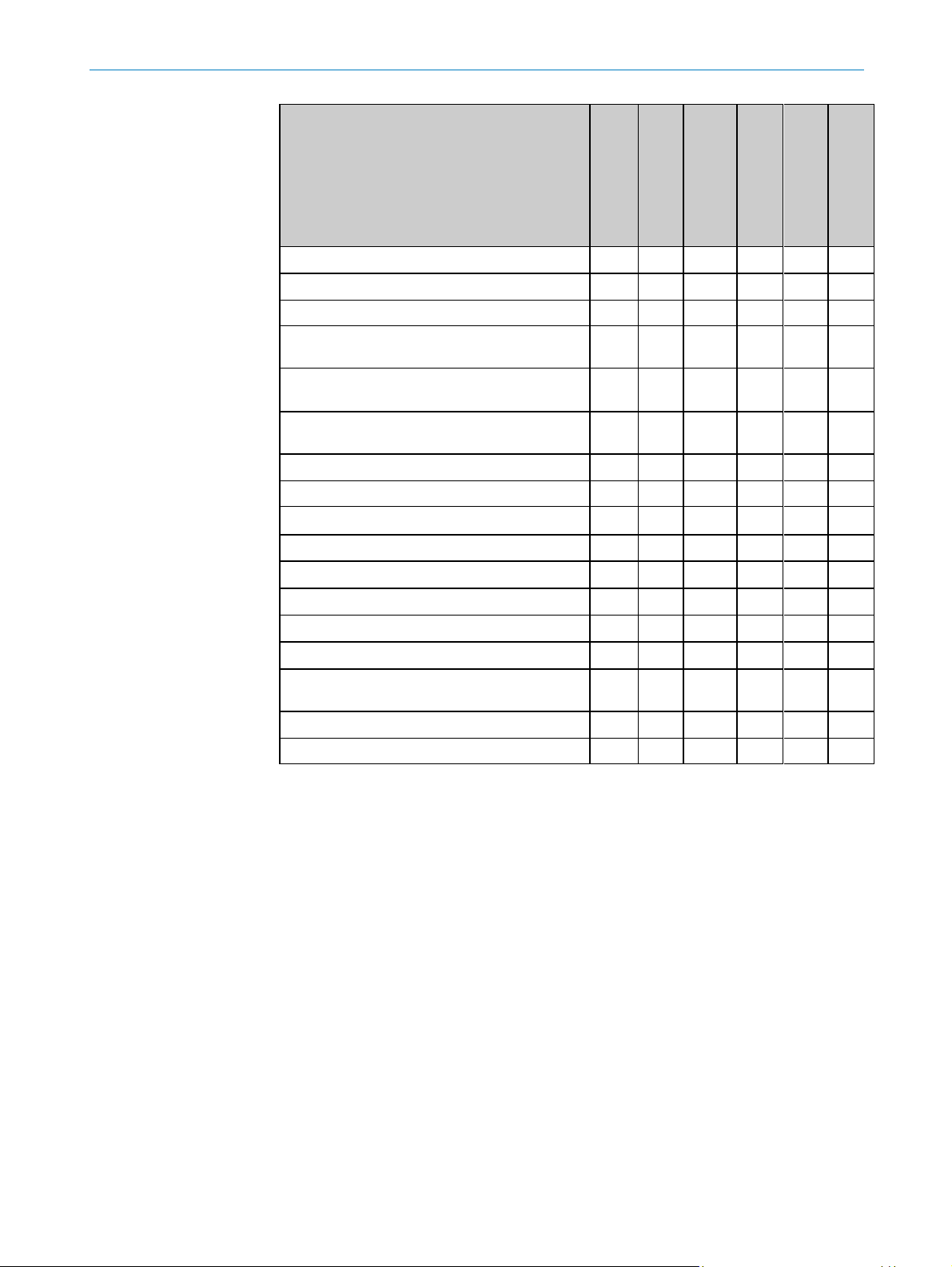

Properties

Singleturn Encoder

Basic

Multiturn Encoder

Basic

Singleturn Encoder

Advanced

Multiturn Encoder

Advanced

Singleturn Encoder

Inox

Multiturn Encoder

Inox

CANopen interface

Supports the encoder profile CiA DS-406

Diagnostic functions via CANopen

–

–

12 bit singleturn resolution

(1 to 4,096 steps)

– – –

–

14 bit singleturn resolution

(1 to 16,384 steps)

–

–

12 bit multiturn resolution

(1 to 4,096 revolutions)

– – –

24 bit total resolution

– – – –

–

26 bit total resolution

– – – –

Round axis functionality

– – – –

Absolute Encoder in 36 mm design

Electro-sensitive, magnetic scanning

Flexible cable outlet/M12 male connector

Large number of mechanical adaptation options

Compact design

Face mount flange, servo flange, blind hollow

shaft

Stainless steel variant

– – –

–

Enclosure rating IP69K

– – –

–

Table 3: Special features of the encoder variants

Page 17

PRODUCT DESCRIPTION 4

8016869/12TG/201 9-04-08 | S ICK OPERATING INSTUCTIONS |AHS/AHM36 CA NOPEN, AHS/A HM36 CANOPEN INOX

17

Subject to change without notic e

4.2 Operating principle of the encoder

The sensing system in the AHS/AHM36 CANopen and AHS/AHM36 CANopen Inox

Absolute Encoder is based on absolute acquisition of revolutions without an external

voltage supply or battery. As a consequence the encoder can immediately output its

absolute position again after switching off and switching back on.

The AHS/AHM36 CANopen and AHS/AHM36 CANopen Inox acquires the position of

rotating axes and outputs the position in the form of a unique digital numeric value.

The highest reliability is achieved by means of electro-sensitive, magnetic scanning.

The AHS36 CANopen and AHS36 CANopen Inox is a singleturn encoder.

Singleturn encoders are used if absolute acquisition of the rotation of a shaft is

required.

The AHM36 CANopen and AHM36 CANopen Inox is a multiturn encoder.

Multiturn encoders are used if more than one shaft revolution must be acquired

absolutely.

4.2.1 Scaleable resolution

The resolution per revolution and the total resolution can be scaled and adapted to the

related application.

The resolution per revolution can be scaled in integers from 1 … 4,096 (Basic) or from

1 … 16,384 (Advanced / Inox).

The total resolution of the AHM36 CANopen and AHM36 CANopen Inox must be 2ⁿ

times the resolution per revolution. This restriction is not relevant if the round axis

functionality is activated.

4.2.2 Preset function

The position value for an encoder can be set with the aid of a preset value. I.e. the

encoder can be set to any position within the measuring range. In this way, e.g., the

encoder’s zero position can be adjusted to the machine’s zero point.

On switching off the encoder, the offset, the difference between the real position value

and the value defined by the preset, is saved. On switching back on the new preset

value is formed from the new real position value and the offset. Even if the position of

encoder changes while it is switched off, this procedure ensures the correct position

value is still output.

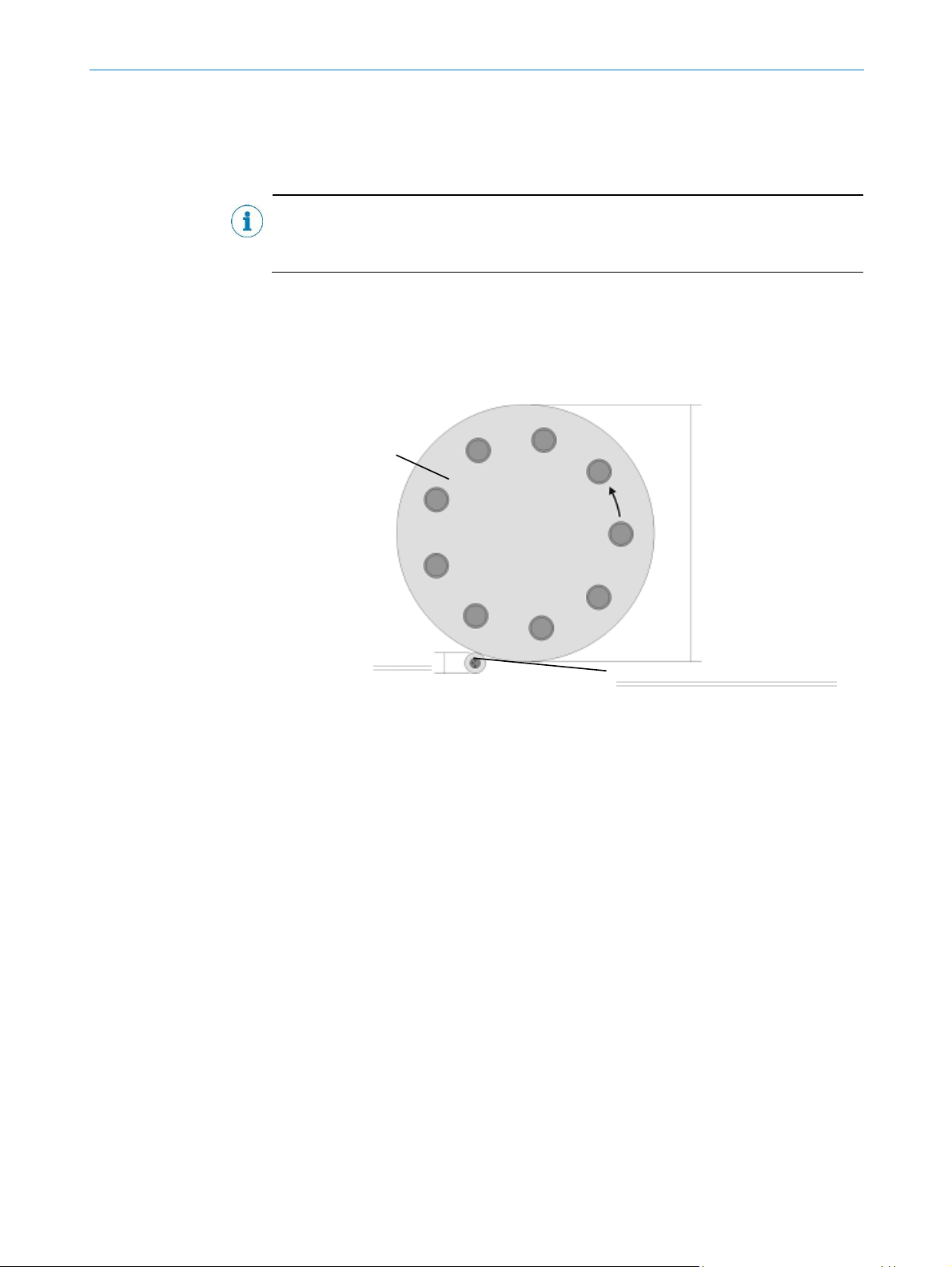

Figure 3: Saving the offset

= on switching off

= on switching back on

Offset

Encoder housing

Preset value

Difference

after switch-

ing back on

Offset

Encoder shaft

Page 18

4 PRODUCT DESCRIPTION

18

OPERATING INSTRUC TIONS | AHS/AHM36 CANOP EN, AHS/AHM36 CANOPEN INOX 801 6869/1 2TG/2019-04-08 | SICK

Subject to change without notic e

4.2.3 Round axis functionality

The encoder supports the function for round axes. The steps per revolution are set as a

fraction. As a result, the total resolution does not have to be configured to 2ⁿ times the

resolution per revolution and can also be a decimal number (e.g. 12.5).

NOTE

The output position value is adjusted with the zero point correction, the counting

direction set and the gearbox parameters entered.

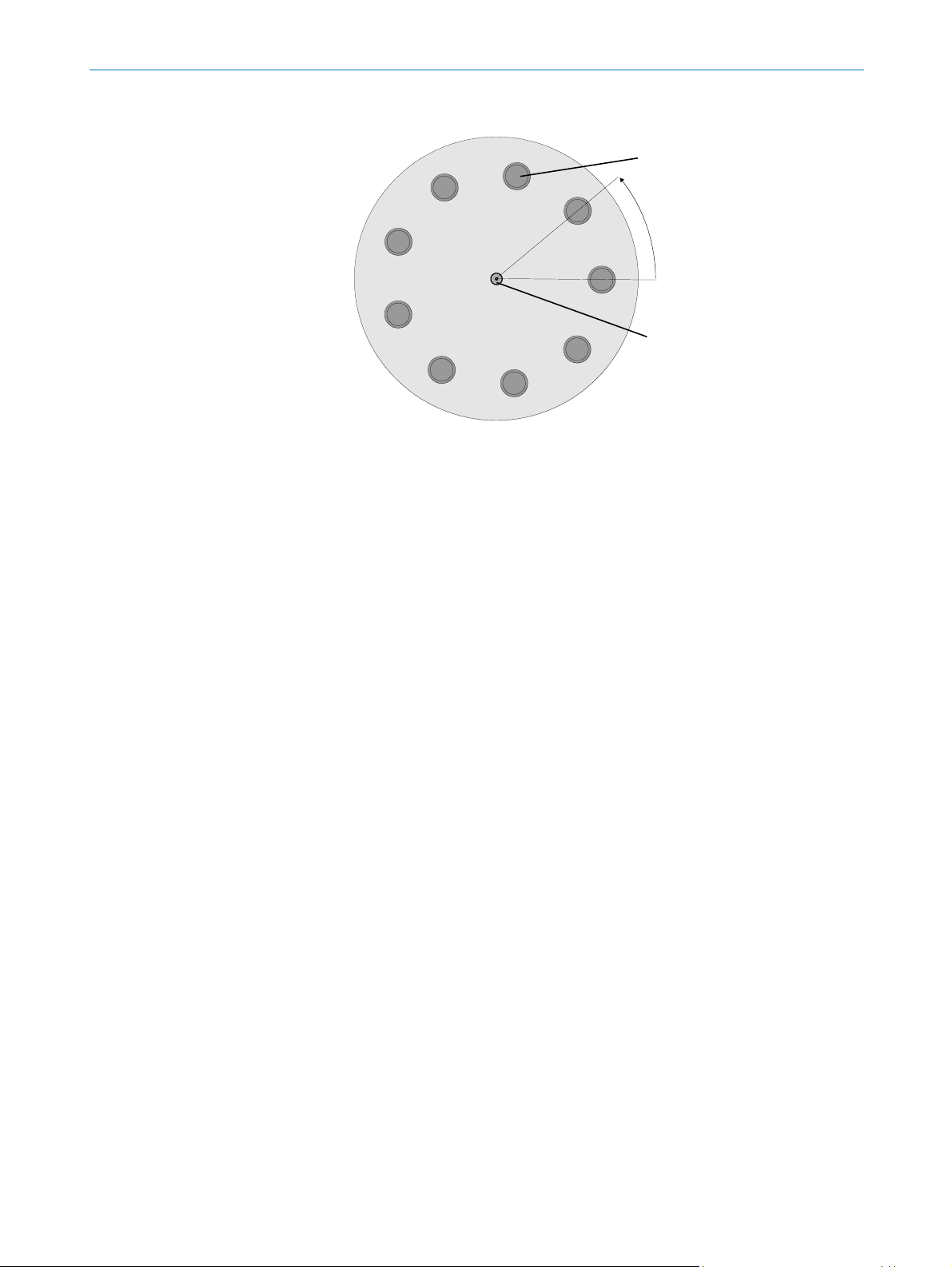

Example with transmission ratio

A rotating table for a filling system is to be controlled. The resolution per revolution is

pre-defined by the number of filling stations. There are nine filling stations. For the

precise measurement of the distance between two filling stations, 1,000 steps are

required.

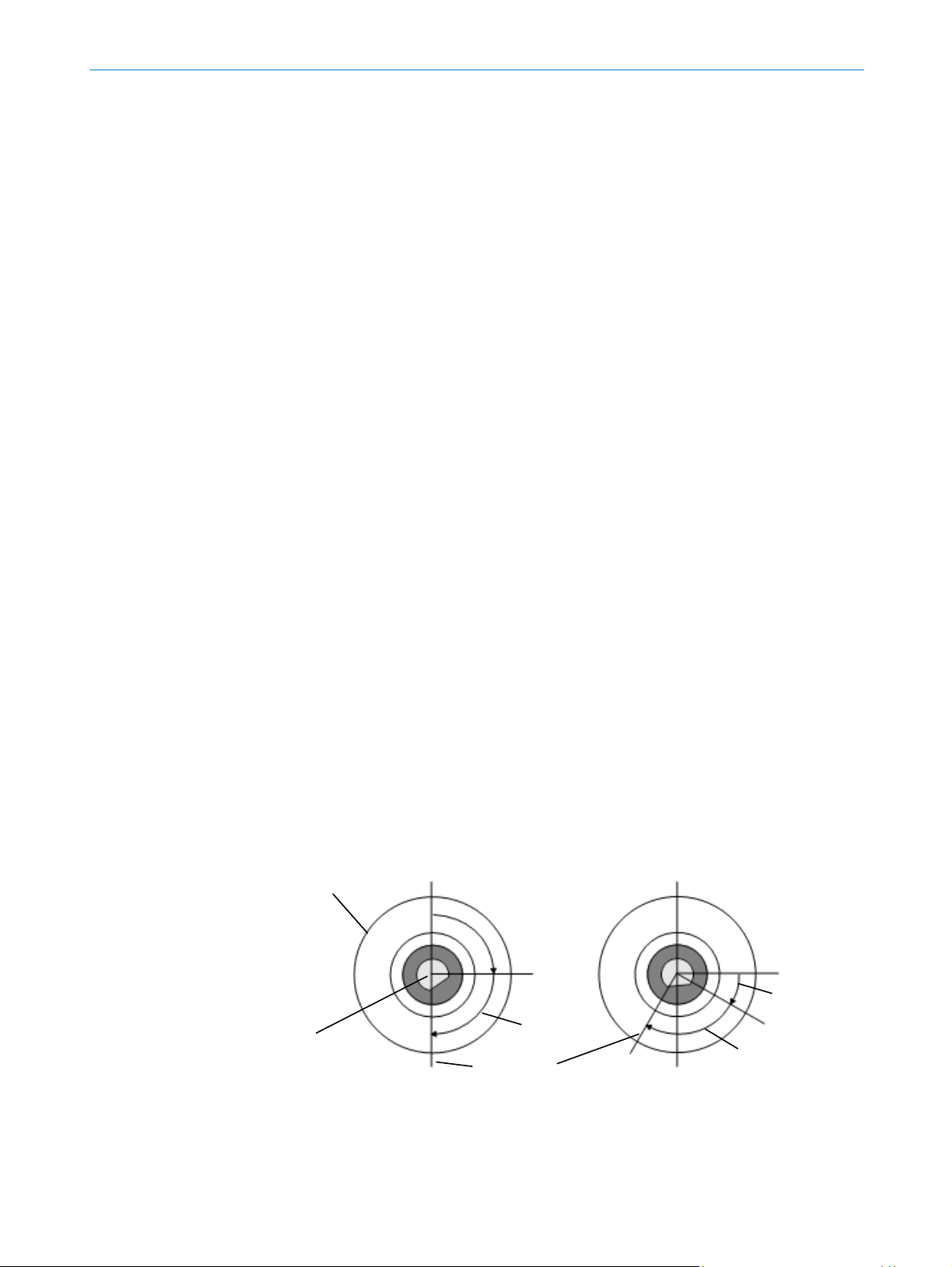

Figure 4: Example position measurement on a rotating table with transmission ratio

The number of revolutions is pre-defined by the transmission ratio = 12.5 of the

rotating table gearing.

The total resolution is then 9 × 1,000 = 9,000 steps, to be realized in 12.5 revolutions

of the encoder. This ratio cannot be realized via the resolution per revolution and the

total resolution, as the total resolution is not 2ⁿ times the resolution per revolution.

The application problem can be solved using the round axis functionality. Here the

resolution per revolution is ignored. The total resolution as well as the nominator and

divisor for the number of revolutions are configured.

9,000 steps are configured as the total resolution.

For the nominator for the number of revolutions 125 is configured, 10 as the divisor

(

125

/10 = 12.5).

After 12.5 revolutions (that is after one complete revolution of the rotating table) the

encoder reaches the total resolution of 9,000.

125

10

Rotating table with

nine filling

stations

Encoder

Page 19

PRODUCT DESCRIPTION 4

8016869/12TG/201 9-04-08 | S ICK OPERATING INSTUCTIONS |AHS/AHM36 CA NOPEN, AHS/A HM36 CANOPEN INOX

19

Subject to change without notic e

Example without transmission ratio

Figure 5: Example position measurement on a rotating table without transmission ratio

The encoder is mounted directly on the rotating table. The transmission ratio is 1:1.

The rotating table has 9 filling stations. The encoder must be configured such that it

starts to count with 0 at one filling station and counts to 999 on moving to the next

filling station position.

1,000 steps are configured as the total resolution.

For the nominator for the number of revolutions 1 is configured, 9 as the divisor (1/9

revolutions = 1,000).

After 1/9 revolutions of the encoder shaft there are 1,000 steps, then the encoder

starts to count at 0 again.

1,000 steps

Rotating table with nine filling stations

Encoder

Page 20

4 PRODUCT DESCRIPTION

20

OPERATING INSTRUC TIONS | AHS/AHM36 CANOP EN, AHS/AHM36 CANOPEN INOX 801 6869/1 2TG/2019-04-08 | SICK

Subject to change without notic e

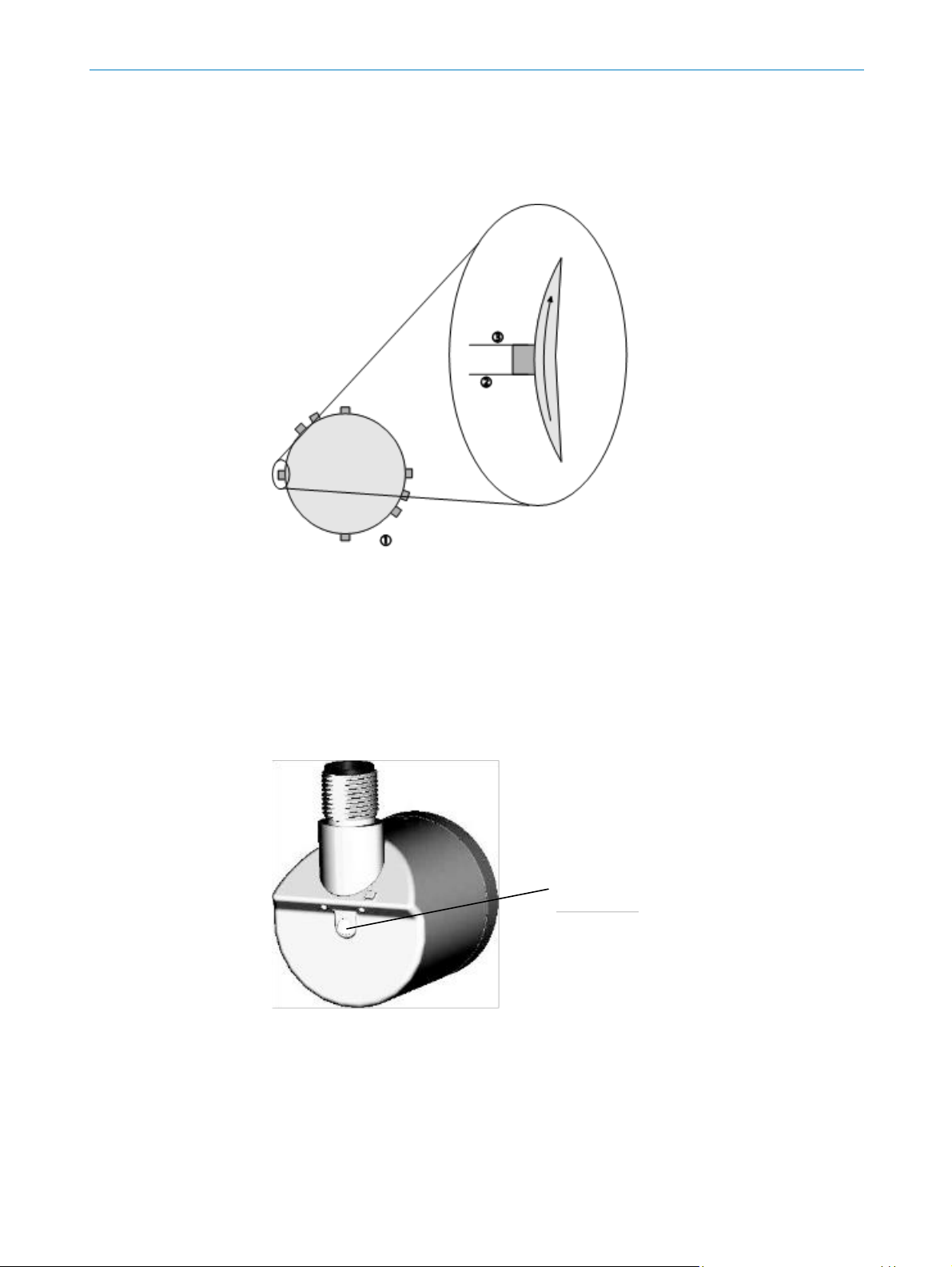

4.2.4 Electronic cam mechanism

An electronic cam mechanism can be configured using the encoder. Two so-called CAM

channels with up to eight cam switching positions are supported . This is a limit

switch for the position.

Figure 6: Example electronic cam mechanism

Among other parameters, each cam has parameters for the lower switching point

and the upper switching point , which can be configured via CANopen (see section

6.4.2 on page 65).

4.3 Controls and status indicators

The AHS/AHM36 CANopen and AHS/AHM36 CANopen Inox Absolute Encoder has one

status LED.

Figure 7: Position of the LED

The LED is multi-colored. Table 138 on page 97 shows the meaning of the signals.

LED

Page 21

INTEGRATION IN CANOPEN 5

8016869/12TG/201 9-04-08 | S ICK OPERATING INSTUCTIONS |AHS/AHM36 CA NOPEN, AHS/A HM36 CANOPEN INOX

21

Subject to change without notic e

5 Integration in CANopen

5.1 Communication profile

The CANopen communication protocol (documented in CiA DS-301) defines how the

devices exchange data with each other in a CANopen network.

5.1.1 CANopen in the OSI model

The CANopen protocol is a standardized layer-7 protocol for the CAN bus. This layer is

based on the CAN Application Layer (CAL).

The relevant objects in the encoder profile DS-406 are implemented in the

AHS/AHM36 CANopen and AHS/AHM36 CANopen Inox (see section 6.4 on page 61).

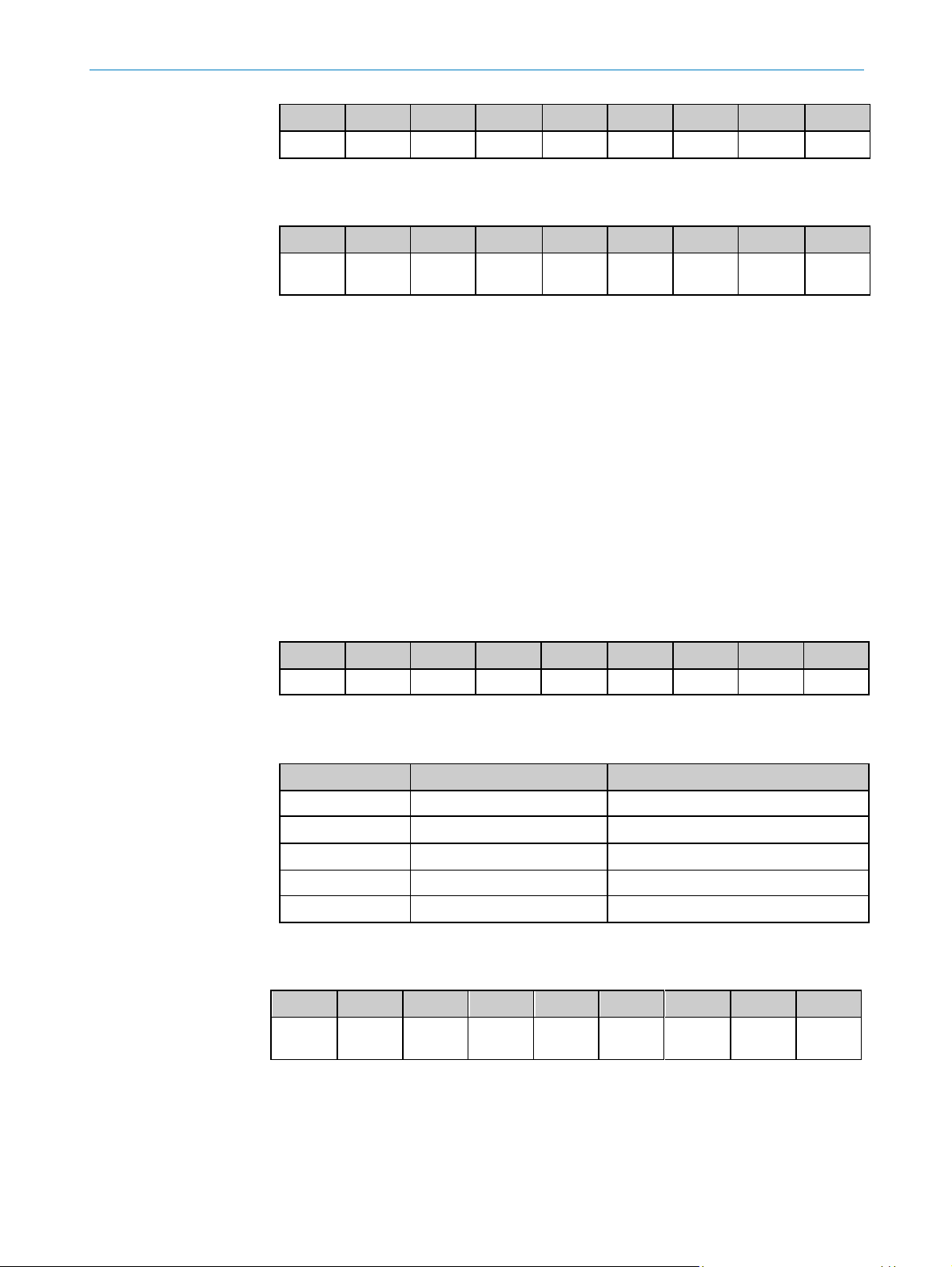

Figure 8: CANopen i n the OSI model

NOTE

Layers 3 … 6 are not used with CANopen.

5.1.2 Communication channels

CANopen has various communication channels (SDO, PDO, Emergency Messages).

These channels are formed with the aid of the Communication Object Identifier

CAN Application Layer (CAL), defined by DS-301

Bit transport layer

Data link layer

E.g. DS 401

E.g. DS 402

DS 406

Encoder

Page 22

5 INTEGRATION IN CANOPEN

22

OPERATING INSTRUC TIONS | AHS/AHM36 CANOP EN, AHS/AHM36 CANOPEN INOX 801 6869/1 2TG/2019-04-08 | SICK

Subject to change without notic e

(COB-ID). The COB-IDs are based on the node IDs for the individual devices on the

CANopen bus (see section 5.2 on page 23).

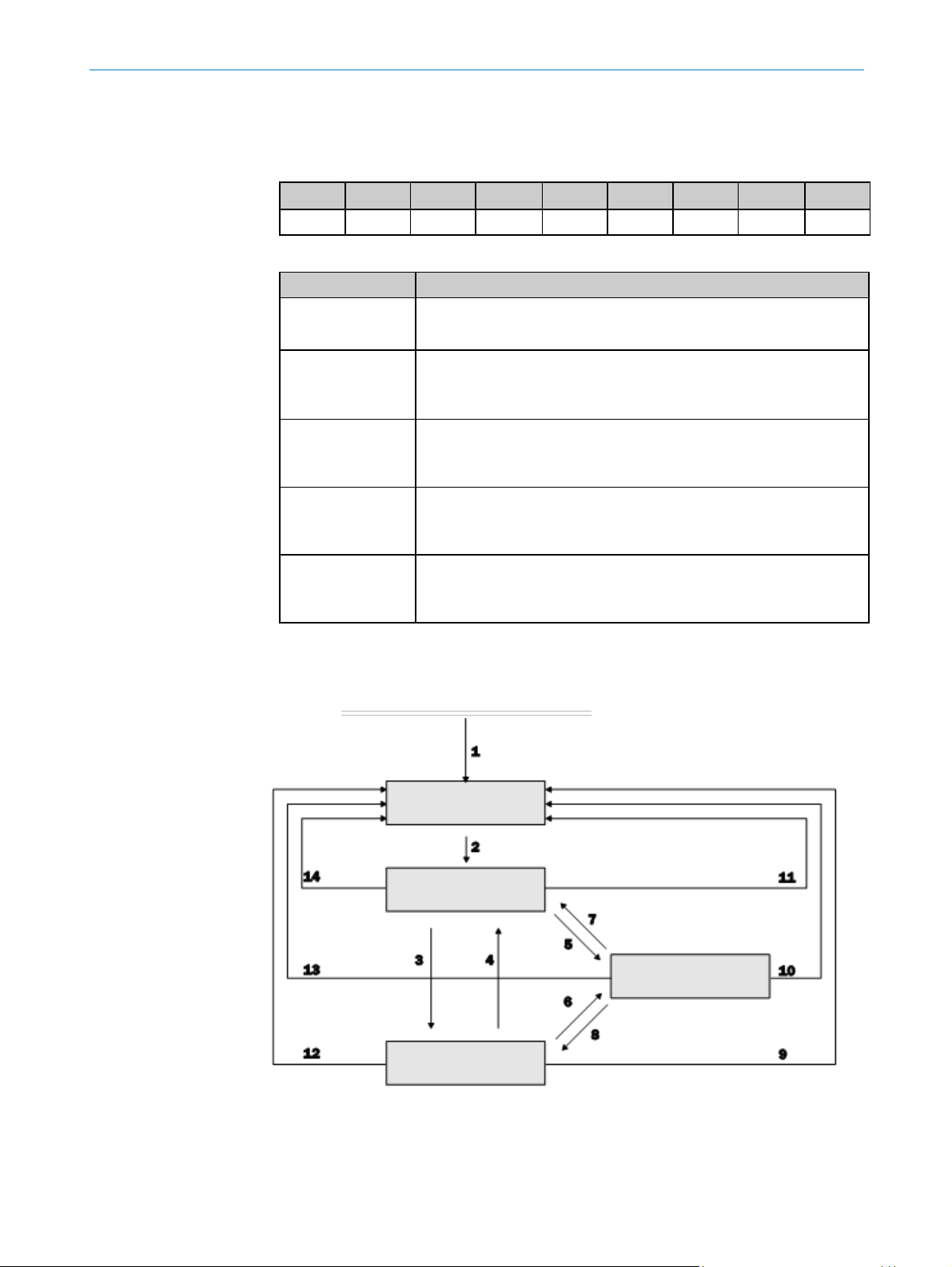

Figure 9: Communication channels

To set the encoder’s node ID, so-called Layer Setting Services (LSS) are used (see

section 5.4 on page 24).

Then communication with the encoder via the Network Management Services

(NMT) is possible (see section 5.5 on page 28) and its CANopen state machine

can be switched to the required status (Pre-operational, Operational or Stopped)

by the master.

In the Pre-operational status, Service Data Objects (SDO) can be used for commu-

nication and configuration (see section 5.6 on page 31). In the Operational status,

Process Data Objects (PDO) and Emergency Messages (EMGY) can also be used

for communication (see section 5.7 on page 33).

5.1.3 Topology

The AHS/AHM36 CANopen and AHS/AHM36 CANopen Inox is integrated in the

CANopen trunk using T-connectors (the T-connectors are available as accessories). The

trunk must be terminated at the end using a 120-Ohm terminator. In this way

reflections are prevented. This action is not necessary on the stubs to the encoders.

Figure 10: AHx36 in the CANopen topologie

Table 137 on page 90 shows the maximum length of the stubs for different baud rates.

LSS, NMT

SDO, PDO, EMGY

Master

Node ID = 0

Slave

Node ID = 1 … 127

Trunk

Stubs

Termination

PLC

Page 23

INTEGRATION IN CANOPEN 5

8016869/12TG/201 9-04-08 | S ICK OPERATING INSTUCTIONS |AHS/AHM36 CA NOPEN, AHS/A HM36 CANOPEN INOX

23

Subject to change without notic e

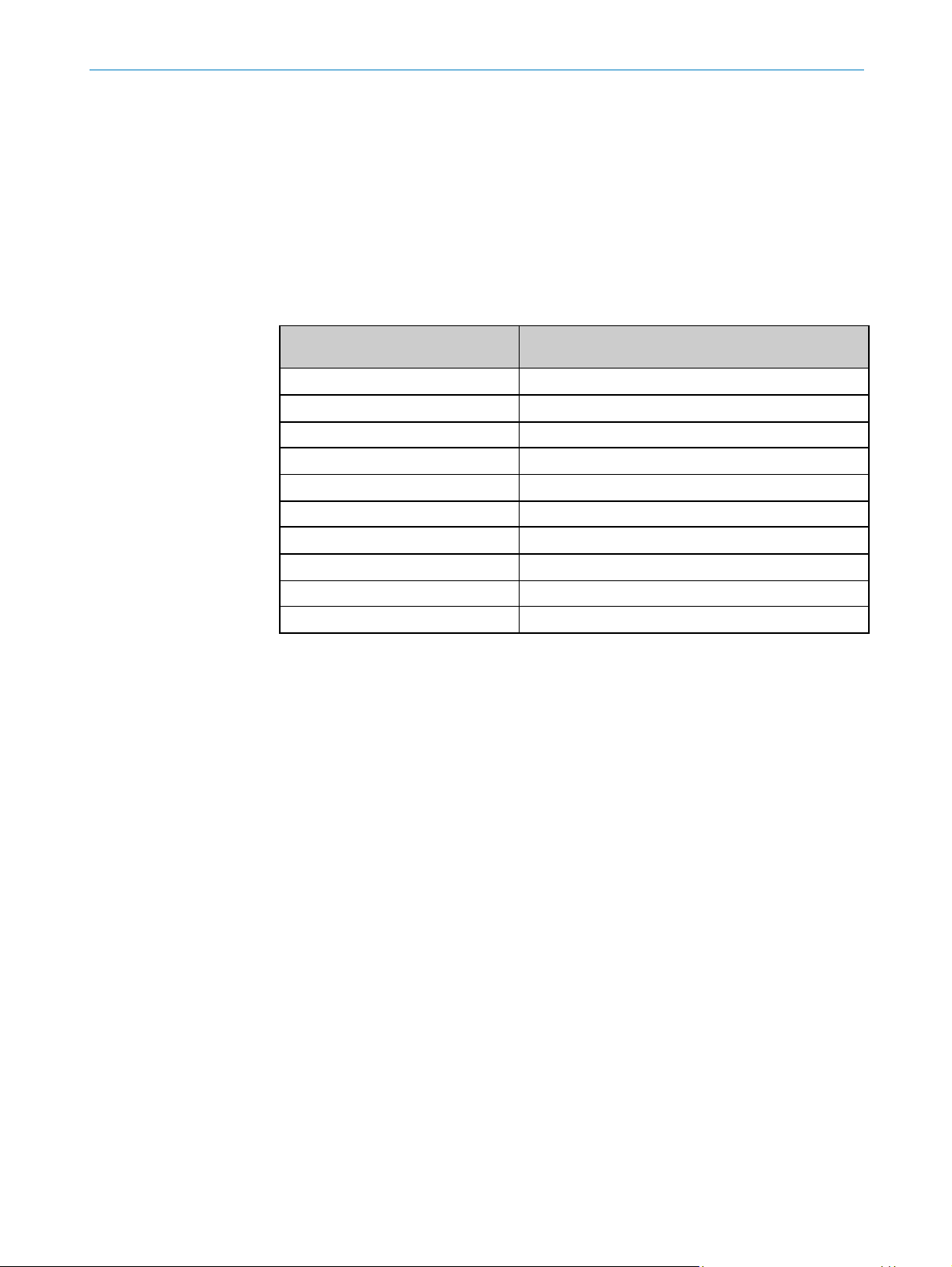

5.2 Node IDs and COB-IDs

The encoder’s node ID can be configured with the aid of the following methods:

SDO access to the manufacturer-specific object 2009h – Network Configuration

(see Table 122 on page 81)

access via Layer Setting Services (see section 5.4 on page 24)

There can be a maximum of 128 devices in a CANopen network, one master and up to

127 slaves. Each device is given a unique node ID (node address).

The COB-IDs (Communication Object Identifier) derive the communication channels

from this ID.

COB-ID calculation

[Dec]

[Hex]

ID ranges

[Dec]

[Hex]

Function

Direction as seen

from the encoder

0 0 Network management

Receive

128 + Node ID

0080h + Node ID

129 … 255

0081h … 00FFh

Emergency Message

Send

384 + Node ID

0180h + Node ID

385 … 511

0181h … 01FFh

Transmit PDO 1

Send

512 + Node ID

0200h + Node ID

513 … 639

0201h … 027Fh

Receive PDO 1

Receive

640 + Node ID

0280h + Node ID

641 … 767

0281h … 02FFh

Transmit PDO 2

Send

896 + Node ID

0380h + Node ID

897 … 1023

0381h … 03FFh

Transmit PDO 3

Send

1152 + Node ID

0480h + Node ID

1153 … 1279

0481h … 04FFh

Transmit PDO 4

Send

1408 + Node ID

0580h + Node ID

1409 … 1535

0581h … 05FFh

Transmit SDO

Send

1536 + Node ID

0600h + Node ID

1537 … 1663

0601h … 067Fh

Receive SDO

Receive

1792 + Node ID

0700h + Node ID

1793 … 1919

0701h … 077Fh

Node Guarding,

Heartbeat, Boot-Up

Send

2020

07E4h

2020

07E4h

Transmit LSS

Send

2021

07E5h

2021

07E5h

Receive LSS

Receive

Table 4: Communication object i dentifier for the encoder

Example:

The encoder is given the node ID = 5, it then sends emergency messages via the

ID 133, Transmit PDOs via the ID 389, 645, 901 as well as 1157 and the Transmit

SDO via the ID 1413.

Page 24

5 INTEGRATION IN CANOPEN

24

OPERATING INSTRUC TIONS | AHS/AHM36 CANOP EN, AHS/AHM36 CANOPEN INOX 801 6869/1 2TG/2019-04-08 | SICK

Subject to change without notic e

5.3 Baud rate

The transmission speed on the CANopen bus is defined using the baud rate. Pay

attention to the following criteria:

The same baud rate must be set on the AHS/AHM36 CANopen and AHS/AHM36

CANopen Inox as on the master.

The higher the baud rate in the CANopen network, the lower the bus load.

The longer the cables used, the lower the possible baud rate. Pay attention to the

maximum lenghts of the stubs depending on the baud rate (see Table 137 on

page 90).

The encoder supports the following baud rates:

Baud rate

Supported by the AHS/AHM36 CANopen and

AHS/AHM36 CANopen Inox

1,000 kbit/s

Yes

800 kbit/s

Yes

500 kbit/s

Yes

250 kbit/s

Yes

125 kbit/s

Yes

100 kbit/s

Yes

50 kbit/s

Yes

20 kbit/s

Yes

10 kbit/s

No

Automatic detection

No

Table 5: Supported baud rates

The encoder’s baud rate can be configured with the aid of the following methods:

SDO access to the manufacturer-specific object 2009h – Network Configuration

(see Table 122 on page 81)

access via Layer Setting Services (see section 5.4 on page 24)

5.4 Layer Setting Services (LSS)

To set the node ID and the baud rate of the AHS/AHM36 CANopen and AHS/AHM36

CANopen Inox, the Layer Setting Services are supported.

The LSS slave is accessed via its LSS address (identity object), which is saved in object

1018h (see Table 57 on page 53). The LSS address comprises:

manufacturer ID

product Code

revision number

serial number

Via the LSS the master requests the individual services that are then executed by the

AHS/AHM36 CANopen and AHS/AHM36 CANopen Inox. The communication between

the LSS master and LSS slave is undertaken using the LSS telegrams.

The following COB-IDs are used:

07E4h = LSS slave to LSS master

07E5h = LSS master to LSS slave

Page 25

INTEGRATION IN CANOPEN 5

8016869/12TG/201 9-04-08 | S ICK OPERATING INSTUCTIONS |AHS/AHM36 CA NOPEN, AHS/A HM36 CANOPEN INOX

25

Subject to change without notic e

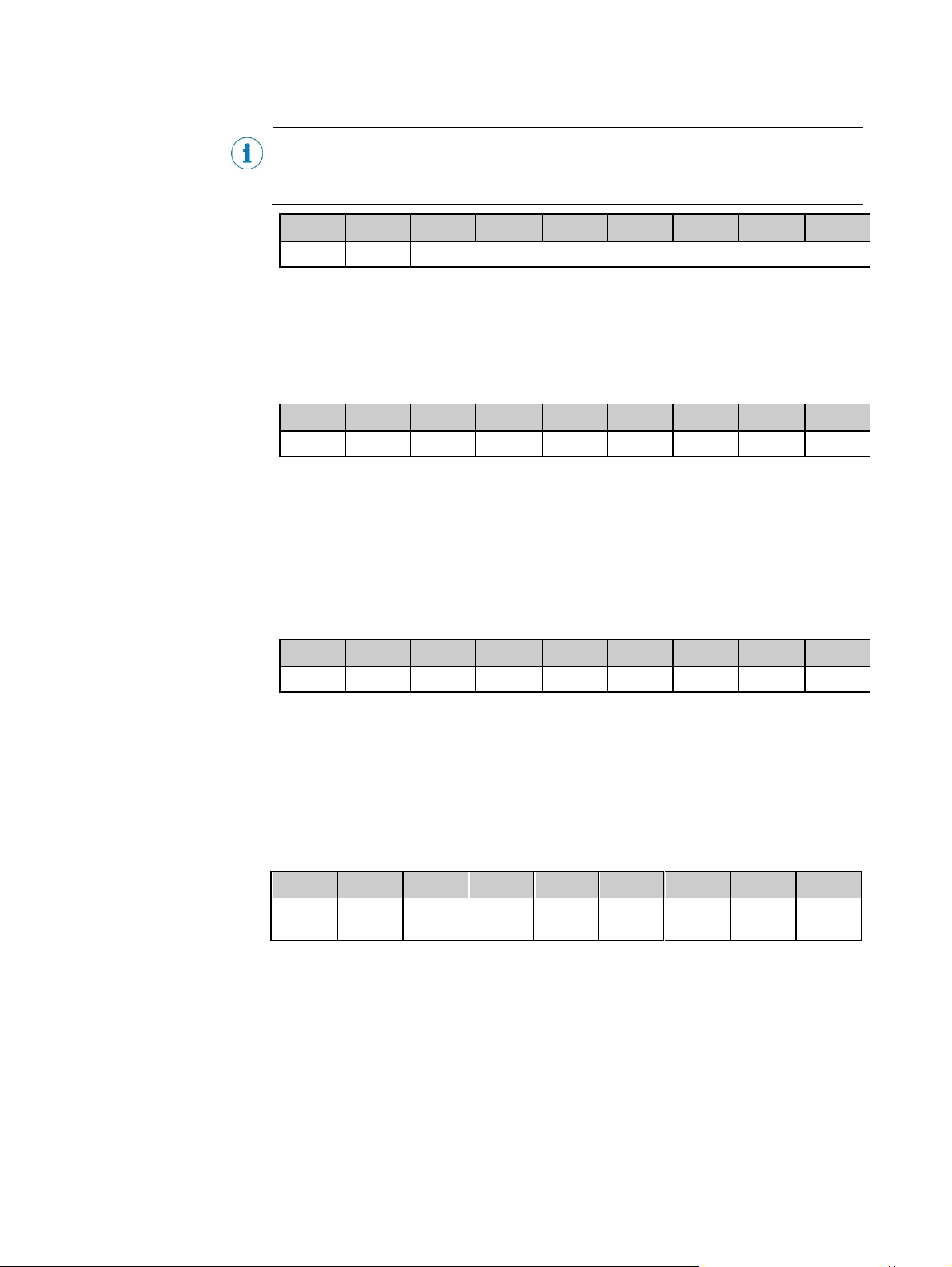

Format of an LSS telegram

NOTE

An LSS telegram is always 8 bytes long. Byte 0 contains the Command Specifier (CS),

followed by 7 bytes for the data. All unused bytes must be set to zero.

COB-ID

Byte 0

Byte 1

Byte 2

Byte 3

Byte 4

Byte 5

Byte 6

Byte 7

CS

Data

Table 6: Format of an LSS telegram

Switch Mode Global

The Switch Mode Global command switches on or off the configuration mode. The

command is not acknowledged, the AHS/AHM36 CANopen and AHS/AHM36 CANopen

Inox does not respond.

COB-ID

Byte 0

Byte 1

Byte 2

Byte 3

Byte 4

Byte 5

Byte 6

Byte 7

07E5h

04h

Mode

00h

00h

00h

00h

00h

00h

Table 7: Format of the Switch Mode Global command

Byte 1 mode:

00h = switches off the LSS configuration mode

01h = switches to the LSS configuration mode

Configure Node ID

The node address is configured with the aid of this command.

COB-ID

Byte 0

Byte 1

Byte 2

Byte 3

Byte 4

Byte 5

Byte 6

Byte 7

07E5h

11h

Node ID

00h

00h

00h

00h

00h

00h

Table 8: Format of the Configure Node ID command

Byte 1 node ID:

01h = node address 1

…

7Fh = node address 127

Response:

COB-ID

Byte 0

Byte 1

Byte 2

Byte 3

Byte 4

Byte 5

Byte 6

Byte 7

07E4h

11h

Error

code

Error

extend

00h

00h

00h

00h

00h

Table 9: Response to the Configure Node ID command

Byte 1 error code:

00h = parameterization successful

01h = parameter invalid

FFh = contains a specific error code

Byte 2 error extend:

The error extension is manufacturer-specific and always 00h on the

AHS/AHM36 CANopen and AHS/AHM36 CANopen Inox.

Page 26

5 INTEGRATION IN CANOPEN

26

OPERATING INSTRUC TIONS | AHS/AHM36 CANOP EN, AHS/AHM36 CANOPEN INOX 801 6869/1 2TG/2019-04-08 | SICK

Subject to change without notic e

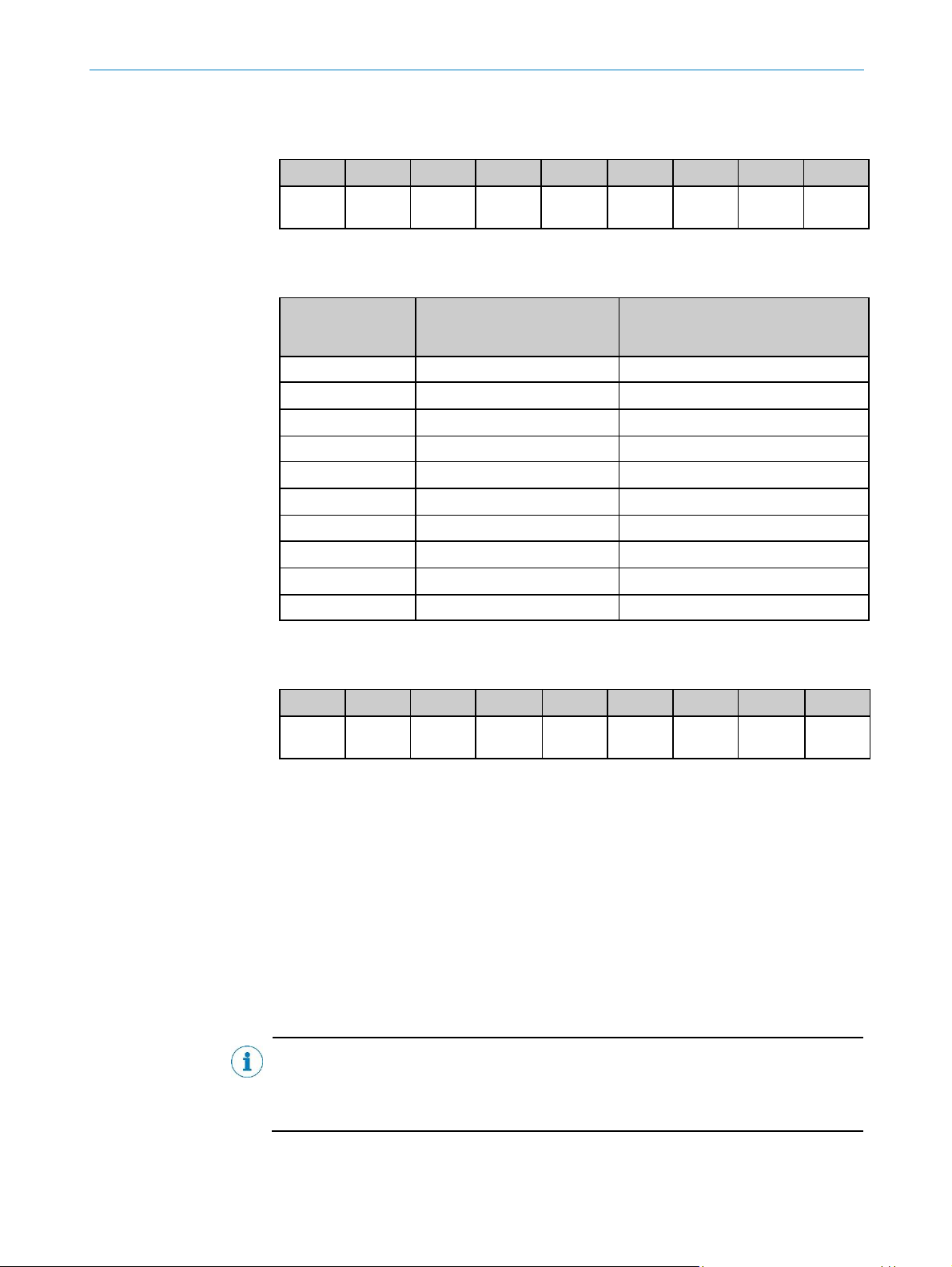

Configure Bit Timing Parameters

The baud rate is configured based on a baud rate table using this command.

COB-ID

Byte 0

Byte 1

Byte 2

Byte 3

Byte 4

Byte 5

Byte 6

Byte 7

07E5h

13h

00h

Table

index

00h

00h

00h

00h

00h

Table 10: Format of the Configure Bit Timing Parameters command

Byte 1 table index from the baud rate table:

Table index

Baud rate

Supported by the

AHS/AHM36 CANopen and

AHS/AHM36 CANopen Inox

0

1,000 kbit/s

Yes 1 800 kbit/s

Yes

2

500 kbit/s

Yes

3

250 kbit/s

Yes 4 125 kbit/s

Yes

5

100 kbit/s

Yes

6

50 kbit/s

Yes

7

20 kbit/s

Yes

8

10 kbit/s

No

9

Automatic detection

No

Table 11: Baud rate table

Response:

COB-ID

Byte 0

Byte 1

Byte 2

Byte 3

Byte 4

Byte 5

Byte 6

Byte 7

07E4h

13h

Error

code

Error

extend

00h

00h

00h

00h

00h

Table 12: Response to the Configure Bit Timing Parameters command

Byte 1 error code:

00h = parameterization successful

01h = parameter invalid

FFh = contains a specific error code

Byte 2 error extend:

The error extension is manufacturer-specific and always 00h on the

AHS/AHM36 CANopen and AHS/AHM36 CANopen Inox.

Store Configuration

This command saves the configuration.

NOTE

However, the configuration is not saved in non-volatile memory (EEPROM). This action

must be undertaken using the object 1010h – Save Parameters (see Table 50 on

page 51).

Page 27

INTEGRATION IN CANOPEN 5

8016869/12TG/201 9-04-08 | S ICK OPERATING INSTUCTIONS |AHS/AHM36 CA NOPEN, AHS/A HM36 CANOPEN INOX

27

Subject to change without notic e

COB-ID

Byte 0

Byte 1

Byte 2

Byte 3

Byte 4

Byte 5

Byte 6

Byte 7

07E5h

17h

00h

00h

00h

00h

00h

00h

00h

Table 13: Format of the Store Config uration command

Response:

COB-ID

Byte 0

Byte 1

Byte 2

Byte 3

Byte 4

Byte 5

Byte 6

Byte 7

07E4h

17h

Error

code

Error

extend

00h

00h

00h

00h

00h

Table 14: Response to the Store Configuration command

Byte 1 error code:

00h = save successful

01h = Store Configuration command is not supported

02h = memory error occurred

FFh = contains a specific error code

Byte 2 error extend:

The error extension is manufacturer-specific and always 00h on the

AHS/AHM36 CANopen and AHS/AHM36 CANopen Inox.

Inquire LSS address service

Using this command the encoder’s node ID and the manufacturer ID, the product code,

the revision number and the serial number can be read from object 1018h (see

Table 57 on page 53).

COB-ID

Byte 0

Byte 1

Byte 2

Byte 3

Byte 4

Byte 5

Byte 6

Byte 7

07E5h

CMD

00h

00h

00h

00h

00h

00h

00h

Table 15: Format of the Inqui re LSS address servi ce command

Byte 1 CMD from the command table:

CMD

Parameter

Subindex of object 1018h

5Eh

Node ID

5Dh

Serial Number

.4

5Ch

Revision Number

.3

5Bh

Product Code

.2

5Ah

Vendor ID

.1

Table 16: Command table

Response

COB-ID

Byte 0

Byte 1

Byte 2

Byte 3

Byte 4

Byte 5

Byte 6

Byte 7

07E4h

CMD

Data-X

{LsB}

Data-X

Data-X

Data-X

{MsB}

00h

00h

00h

Table 17: Response to the Inqui re LSS address service command

Page 28

5 INTEGRATION IN CANOPEN

28

OPERATING INSTRUC TIONS | AHS/AHM36 CANOP EN, AHS/AHM36 CANOPEN INOX 801 6869/1 2TG/2019-04-08 | SICK

Subject to change without notic e

NOTE

The data are 4 bytes long, in the byte order “Little Endian”. If the data read are shorter

than 4 bytes, the remaining bytes are filled with 0.

Identify Non-Configured Slave Device

Devices that have not been configured can be identified by with the aid of this

command.

COB-ID

Byte 0

Byte 1

Byte 2

Byte 3

Byte 4

Byte 5

Byte 6

Byte 7

07E5h

4Ch

00h

00h

00h

00h

00h

00h

00h

Table 18: Format of the Identify Non Configured Slave Device command

Response

COB-ID

Byte 0

Byte 1

Byte 2

Byte 3

Byte 4

Byte 5

Byte 6

Byte 7

07E4h

50h

00h

00h

00h

00h

00h

00h

00h

Table 19: Response to the Identify Non-Configured Slave Device command

5.5 Network management (NMT)

The Network Management (NMT) has the task of initializing users on a CANopen

network, adding the users to the network, stopping and monitoring them.

In a CANopen network there is always only one NMT master (Network Management

Master), all other devices, that is also the AHS/AHM36 CANopen and AHS/AHM36

CANopen Inox, are NMT slaves. The NMT master has control of all devices and can

change their status.

Typically an NMT master is realized by a PLC or a PC.

5.5.1 CANopen state machine

As in every CANopen slave, a so-called CANopen state machine is implemented in the

AHS/AHM36 CANopen and AHS/AHM36 CANopen Inox. A differentiation is made

between the following statuses:

Status

Description

Initializing

The initialization starts. The device application and the device

communication are initialized. Then the node switches automatically to

the Pre-operational status.

Pre-operational

The encoder is ready for configuration, acyclic communication can take

place via SDO. However, the encoder is not yet able to participate in

PDO communication and also does not send any emergency messages.

Operational

In this status the encoder is fully operational and can transmit

messages independently (PDOs, emergency messages).

Stopped

In this status the encoder is disabled for communication (active

connection monitoring via node guarding remains active).

Table 20: Status of the CANopen state machine

Page 29

INTEGRATION IN CANOPEN 5

8016869/12TG/201 9-04-08 | S ICK OPERATING INSTUCTIONS |AHS/AHM36 CA NOPEN, AHS/A HM36 CANOPEN INOX

29

Subject to change without notic e

5.5.2 Network Management Services

The specific status of the CANopen state machine is changed via the NMT services. The

NMT telegrams for device control use the COB-ID 0 and are given the highest priority.

COB-ID

Byte 0

Byte 1

Byte 2

Byte 3

Byte 4

Byte 5

Byte 6

Byte 7

00h

CCD

Node ID

00h

00h

00h

00h

00h

00h

Table 21: Format of the NMT telegram

Byte 0, CCD

Parameter

01h

Start Remote Node

Places the encoder in the Operational status.

02h

Stop Remote Node

Places the encoder in the Stopped status and stops its communication

(active connection monitoring via node guarding remains active).

80h

Enter Pre-operational

Places the encoder in the Pre-operational status. All communication

channels except the PDOs can be used.

81h

Reset node

Resets the value for the profile parameters to the default value. Then

the encoder changes to the Reset Communication status.

82h

Reset communication

Places the encoder in the Reset Communication status. Then the

encoder changes to the Initialization status.

Table 22: Meaning of byte 0

Transitions between the individual operating statuses

Figure 11: Transitions between the operating statuses

Initialization

Power-up or reset

Pre-operational

Operational

Stopped

Page 30

5 INTEGRATION IN CANOPEN

30

OPERATING INSTRUC TIONS | AHS/AHM36 CANOP EN, AHS/AHM36 CANOPEN INOX 801 6869/1 2TG/2019-04-08 | SICK

Subject to change without notic e

Transition

Description

1

After power-up the encoder enters the Initialization status.

2

After initialization the encoder automatically switches to the

Pre-operational status.

3 and 8

The encoder switches to the Operational status with the Start Remote

Node command.

4 and 7

The encoder switches back to the Pre-operational status with the Enter

Pre-operational State command.

5 and 6

The encoder switches to the Stopped status with the Stop Remote Node

command.

9, 10 and 11

The encoder switches to the Initialization status with the Reset Node

command.

12, 13 and 14

The encoder switches to the Initialization status with the Reset

Communication command.

Table 23: Transitions between the operating statuses

5.5.3 Boot-up message

To signal that a device is ready for operation after switching on, a so-called boot-up

message is sent. This message uses the ID from the NMT Error Control protocol and is

permanently linked to the device address set (700h + node ID).

5.5.4 Node Guarding and Heartbeat

The AHS/AHM36 CANopen and AHS/AHM36 CANopen Inox can be monitored

permanently using the Node Guarding protocol or the Heartbeat protocol.

NOTE

It is not possible to use the Node Guarding protocol and the Heartbeat protocol on one

node. If the Heartbeat Time parameter in the object 1017h is not equal to 0 (see

Table 56 on page 53), the Heartbeat protocol is used.

Node guarding

The status of the encoder is checked at regular intervals using the Node Guarding

telegram. The encoder responds within the response time configured in the objects

100Ch and 100Dh (see Table 48 on page 50).

COB-ID

Byte 0

Byte 1

Byte 2

Byte 3

Byte 4

Byte 5

Byte 6

Byte 7

700h +

Node ID

Status

00h

00h

00h

00h

00h

00h

00h

Table 24: Format of the Node Guarding telegram

Byte 0, status

Parameter

Bit 7

0

Bit 6 … 0

Operating status of the encoder:

127 = Pre-operational

5 = Operational

4 = Stopped

0 = boot up

Table 25: Meaning of byte 0

Page 31

INTEGRATION IN CANOPEN 5

8016869/12TG/201 9-04-08 | S ICK OPERATING INSTUCTIONS |AHS/AHM36 CA NOPEN, AHS/A HM36 CANOPEN INOX

31

Subject to change without notic e

Example for an encoder in the Operational status:

85h, 05h, 85h = no error

85h, 05h, 05h = error

NOTE

If node guarding is active, the encoder expects a corresponding status request from the

NMT master within a specific interval. If this is not the case, the slave changes to the

Pre-operational status.

Heartbeat

If the Heartbeat telegram is used, the encoder sends its status autonomously at regular

intervals. This status can be monitored by any other user in the network.

The heartbeat time is configured using object 1017h (see Table 56 on page 53).

COB-ID

Byte 0

Byte 1

Byte 2

Byte 3

Byte 4

Byte 5

Byte 6

Byte 7

700h +

Node ID

Status

00h

00h

00h

00h

00h

00h

00h

Table 26: Format of the Heartbeat tel egram

Byte 0, status

Parameter

Bit 7

Toggle bit

The bit changes its value after each request.

Bit 6 … 0

Operating status of the encoder:

127 = Pre-operational

5 = Operational

4 = Stopped

0 = Boot up

Table 27: Meaning of byte 0

5.6 Service Data Objects (SDO)

The Service Data Objects (SDO) form the communication channel for the transmission

of device parameters (e.g. programming the encoder resolution) and are used for

status requests.

Data of any length can be transmitted using SDOs. The data may need to be divided

between several CAN messages. An SDO is always transmitted with confirmation, i.e.

the reception of each message is acknowledged by the receiver.

Transmit SDO and Receive SDO

The AHS/AHM36 CANopen and AHS/AHM36 CANopen Inox has one Transmit SDO

channel and one Receive SDO channel to which two CAN identifiers are assigned.

The SDO communication is compliant with the client-server model. In this process the

encoder represents an SDO server.

The SDO client (e.g. the PLC) specifies in its request the parameter, the access type

(read/write) and, if necessary, the value. The encoder undertakes the write or read

access and responds to the request.

Page 32

5 INTEGRATION IN CANOPEN

32

OPERATING INSTRUC TIONS | AHS/AHM36 CANOP EN, AHS/AHM36 CANOPEN INOX 801 6869/1 2TG/2019-04-08 | SICK

Subject to change without notic e

The data area of a CAN telegram, maximum 8 bytes long, is configured by an SDO as

follows:

COB-ID

CCD

Index

Subindex

Data

600h +

Node ID

Byte 0

Byte 1

Byte 2

Byte 3

Byte 4

Byte 5

Byte 6

Byte 7

Table 28: Format of the SDO

The Command Code (CCD) identifies whether data are to be read or written. In the case

of an error, the data area contains a 4-byte error code that provides information on the

origin of the error (see section 8.4.3 on page 99).

Figure 12: Example for Transmit SDO and Receive SDO

In the example the encoder (ID = 5) receives from the PLC via the ID 0605h (Receive

SDO 0600h + encoder ID) a read request (CCD = 40h) for the object 1000h (see

Table 37 on page 48).

The encoder responds via ID 0585h (Transmit SDO 0580h + encoder ID) with the

return message (CCD = 43h) 0200h = multiturn encoder, 9601h device profile =

encoder.

Requirement

Response

Page 33

INTEGRATION IN CANOPEN 5

8016869/12TG/201 9-04-08 | S ICK OPERATING INSTUCTIONS |AHS/AHM36 CA NOPEN, AHS/A HM36 CANOPEN INOX

33

Subject to change without notic e

5.7 Process Data Objects (PDO)

Process data objects (PDO) are used for the quick and efficient exchange of real time

data (e.g. I/O data, set or actual values).

A PDO is transmitted without acknowledgment.

The AHS/AHM36 CANopen and AHS/AHM36 CANopen Inox supports one Receive PDO

and four Transmit PDOs.

Figure 13: Example for Transmit PDO and Receive PDO

8 data bytes are available on the transmission of the process data.

COB-ID

Data

0180h +

Node ID

Byte 0

Byte 1

Byte 2

Byte 3

Byte 4

Byte 5

Byte 6

Byte 7

Table 29: Format of the Transmit PDOs

5.7.1 PDO mapping

The format of the Transmit PDOs between the master and the encoder must be

harmonized by means of so-called PDO mapping. The process data can be arranged as

required in the PDO message. For this purpose the address (that is the index and

subindex) from the object directory as well as the size (number of bits) are entered in

the mapping object (see Table 68 ff. from page 58).

Example:

Object 1A00h contains the following objects by default:

6004.00h – Position Value

2010.01h – Device Status Word, S_STAT-A

2010.02h – Device Status Word, S_STAT-B

The contents of the objects are transmitted in the Transmit PDO.

COB-ID

Data

0180h +

Node ID

00

00

00

01

00

00

00

00

Position value = 1

No error

No error

Table 30: Example for a Transmit PDO

Receive PDO

Transmit PDO

Page 34

5 INTEGRATION IN CANOPEN

34

OPERATING INSTRUC TIONS | AHS/AHM36 CANOP EN, AHS/AHM36 CANOPEN INOX 801 6869/1 2TG/2019-04-08 | SICK

Subject to change without notic e

5.7.2 PDO data transmission

Bus load

Please note:

The more PDOs and the more often these PDOs are sent, the higher the bus load

in the CANopen network.

The higher the baud rate in the CANopen network, the lower the bus load.

The longer the cables used, the lower the possible baud rate.

For optimal communication a compromise therefore needs to be found between all

three factors mentioned.

If a Transmit PDO is not used, it should be deactivated. For this purpose set bit 31 to 1

in subindex .1 of the related object 180xh.

The PDOs can be transmitted cyclically or acyclically. This aspect is defined by the

objects 180xh and the transmission type defined in their subindex .02.

Object

Subindex

Designation

Data values

180xh

Communication

Parameter for the

1st Transmit PDO

–

.0

Number of entries

5

.1

COB-ID

00000180h + Node ID

.2

Transmission Type

0 Transmission only on switching on the encoder

1 … 240 Cyclic transmission. Cyclic with the SYNC

messages

252 Request by RTR telegram (synchronous

transmission)

253 Request by RTR telegram (asynchronous

transmission)

254 Application-specific triggering

255 Device-specific triggering

.3

Inhibition Time

0 … 65,535

.4

Reserved

–

.5

Event Timer

0 … 65,535

Table 31: Example for the communication parameters

Page 35

INTEGRATION IN CANOPEN 5

8016869/12TG/201 9-04-08 | S ICK OPERATING INSTUCTIONS |AHS/AHM36 CA NOPEN, AHS/A HM36 CANOPEN INOX

35

Subject to change without notic e

Cyclic data transmission

For cyclic data transmission there are the following options:

The process data are sent with the master’s SYNC messages. The cycle is formed

from a multiple of the Sync messages. The factor can be between 1 and 240.

The process data are sent using an event timer to suit the specific application or

device. An event timer is available for each PDO. It can be configured between 0

and 65,535 ms.

Acyclic data transmission

For acyclic data transmission the encoder is triggered by one of the following criteria:

On application-specific/device-specific triggering

The transmission of the PDOs is controlled by an event (CoS triggering). This event

is defined in object 2007h (see Table 119 on page 80).

On request (RTR telegram)

In this case another bus user (as a rule the master) requests the process data.

NOTE

The combination of cyclic and acyclic data transmission by event timer and CoS

triggering is not permitted.

Event timer and CoS triggering do not limit each other!

If an object is to be transmitted cyclically and acyclically, it must be mapped to two

different PDOs.

NOTE

In the factory the encoder’s Transmit PDOs are set to device-specific triggering. As a

consequence the encoder outputs all Transmit PDOs once on start-up. However the

event timer is at 0. For this reason the Transmit PDOs are initially only output once.

For the cyclic or acyclic output of the Transmit PDOs by the encoder, there are the

following options:

Change the event timer in the objects 1800h … 1803h (see Table 63 ff. from

page 56).

Configure a trigger event using the CoS event handling configuration (see

Table 119 on page 80).

Change the transmission type in the objects 1800h … 1803h (see Table 63 ff.

from page 56).

Inhibition time

The inhibition time for the PDOs (configured in the objects 1800.3h … 1803.3h) in

principle limits the communication of a device on the CANopen bus. It always has a

higher priority than the event timer, the CoS events and the sync triggering.

If, e.g., the event timer is set to 100 ms and the inhibition time is set to 1 s, the

corresponding PDO is only sent every second.

NOTE

The inhibition time has no effect on triggering by RTR telegrams.

Page 36

5 INTEGRATION IN CANOPEN

36

OPERATING INSTRUC TIONS | AHS/AHM36 CANOP EN, AHS/AHM36 CANOPEN INOX 801 6869/1 2TG/2019-04-08 | SICK

Subject to change without notic e

Figure 14: Sending Transmit PDOs

5.7.3 Asynchronous or synchronous formation of the position

With bit 15 of object 6000h (see Table 74 on page 62) you can define whether the

position is formed asynchronously or synchronously.

Asynchronous formation of the position

The formation of the position by the encoder is not synchronized. It operates

autonomously using its own cycle. The encoder determines the position every

250 µs

1

)

with a jitter of 20 µs. A PDO always “takes” the last position value, which

may already be 250 µs old.

Synchronous formation of the position

The formation of the position by the encoder is synchronized to the Sync messages from the master. The AHS/AHM36 CANopen and AHS/AHM36 CANopen Inox

forms the position on the reception of a SYNC message. In this case it is not

possible to determine a speed value, the speed is output as 0.

NOTE

The output data from the master (essentially for the preset function) cannot be

synchronized.

The input data for the master (essentially the position data) can be synchronized.

1

)

Additional latency time due to sensor-internal processes: 500 µs.

From the master

Inhibition

time

reached?

RTR telegram

One PDO (e.g. Transmit PDO 1) to the master

SYNC telegram

Event timer

CoS triggering

Device-specific

Application specific

Yes

No

Page 37

INTEGRATION IN CANOPEN 5

8016869/12TG/201 9-04-08 | S ICK OPERATING INSTUCTIONS |AHS/AHM36 CA NOPEN, AHS/A HM36 CANOPEN INOX

37

Subject to change without notic e

5.8 Configurable functions

The AHS/AHM36 CANopen and AHS/AHM36 CANopen Inox is configured, e.g., in the

TwinCAT® configuration tool with the aid of various objects.

The most important objects for the configuration of the functions are listed in the

following. A complete list of the objects can be found in chapter 6 “Object library” on

page 46.

WARNING

During the configuration of the encoder, make sure there are no persons in a

system’s hazardous area!

All parameter changes have a direct effect on the operation of the encoder. For this

reason the position value may change during configuration, e.g. due to the

implementation of a preset or change of scale. This change could cause an unexpected

movement that may result in a hazard for persons or damage to the system or other

items.

NOTE

All functions described in the following for which parameters can be set can also be

configured in the encoder’s start-up configuration.

5.8.1 EDS file

To be able to integrate the AHS/AHM36 CANopen and AHS/AHM36 CANopen Inox

straightforwardly in a CANopen master, there is an EDS file. This file contains the

following information on the features of the AHS/AHM36 CANopen and AHS/AHM36

CANopen Inox:

information on the manufacturer of the device

name, type and version number of the device

type and version number of the protocol used for this device

default parameters of the AHS/AHM36 CANopen and AHS/AHM36 CANopen Inox

and default configuration of the process data

Figure 15: EDS file

PLC

EEPROM

AHS/AHM36 CANopen and

AHS/AHM36 CANopen Inox

Page 38

5 INTEGRATION IN CANOPEN

38

OPERATING INSTRUC TIONS | AHS/AHM36 CANOP EN, AHS/AHM36 CANOPEN INOX 801 6869/1 2TG/2019-04-08 | SICK

Subject to change without notic e

5.8.2 Scaling parameters

The scaling parameters are configured by the objects 6000h, 6001h and 6002h.

Figure 16: Objects 6000h, 6001h and 6002h in TwinCAT®

6000h – Operating Parameters

Using the object 6000h (see Table 74 on page 62) the parameters Support additional

Error Code, Scaling and Code sequence are configured. The object is configured using

a bit sequence 16 bits wide.

Example:

Bit 0 = code sequence ccw = 1

Bit 2 = scaling on = 1

Bit

15

14

13

12

11

10 9 8 7 6 5 4 3 2 1 0

Value 0 0 0 0 0 0 0 0 0 0 0 0 0 1 0 1

Table 32: Example for binary code

The binary value must be converted into a hexadecimal value and entered in the

configuration dialog box.

101b = 5h

Figure 17: Example for the parameterization of object 6000h

Scaling

This parameter makes it possible to scale the resolution per revolution and the total

resolution.

NOTE

Only if the parameter Scaling is configured to 1 are the values entered for the

resolution and total resolution applied.

Code sequence

The code sequence defines which direction of rotation increases the position value; the

direction of rotation is defined looking at the shaft.

clockwise (cw) = increasing position value on clockwise revolution of the shaft

counterclockwise (ccw) = increasing position value on counter clockwise

revolution of the shaft

Page 39

INTEGRATION IN CANOPEN 5

8016869/12TG/201 9-04-08 | S ICK OPERATING INSTUCTIONS |AHS/AHM36 CA NOPEN, AHS/A HM36 CANOPEN INOX

39

Subject to change without notic e

6001h – Counts Per Revolution (CPR)

The resolution per revolution is configured using the object 6001h (see Table 76 on

page 63).

NOTE

The parameter is not used if the round axis functionality is activated.

Figure 18: Example for the parameterization of object 6001h

The resolution of the AHS/AHM36 CANopen Basic is max. 4,096 steps per revolution.

The resolution can be scaled from 1 … 4,096 as an integer.

The resolution of the AHS/AHM36 CANopen Advanced / Inox is max. 16,384 steps per

revolution. The resolution can be scaled from 1 … 16,384 as an integer.

6002h – Total Measuring Range

The total resolution is configured using the object 6002h (see Table 77 on page 63).

Figure 19: Example for the parameterization of object 6002h

The total resolution, that is the measuring range of the AHM36 CANopen Basic, is max.

16,777,216 steps. The total resolution of the AHM36 CANopen Advanced / Inox is

max. 67,108,864 steps.

The total resolution must be 2ⁿ times the resolution per revolution.

NOTE

This restriction is not relevant if the round axis functionality is activated.

Resolution per revolution

n

Total resolution

1,000

3

8,000

8,179

5

261,728

2,048

11

4,194,304

Table 33: Examples for total resolution

Page 40

5 INTEGRATION IN CANOPEN

40

OPERATING INSTRUC TIONS | AHS/AHM36 CANOP EN, AHS/AHM36 CANOPEN INOX 801 6869/1 2TG/2019-04-08 | SICK

Subject to change without notic e

NOTE

The parameters are only written to the non-volatile memory in the EEPROM using the

object 1010h with the aid of the data word 65766173h = “save” (see Table 50 on

page 51).

5.8.3 Preset function

The position value for an encoder can be set with the aid of the preset function. I.e. the

encoder can be set to any position within the measuring range.

NOTE

The preset value must lie within the measuring range configured.

WARNING

Before triggering the preset function, check whether there is a hazard from the

machine or system in which the encoder is integrated!

The preset function results in a change in the position value output by the encoder.

This change could cause an unexpected movement that may result in a hazard for

persons or damage to the system or other items.

The preset value can be set with the aid of the following methods:

using acyclic communication (SDO) with the object 6003h

using cyclic communication (PDO) with the object 2000h. The value from object

2005h is used.

Acyclic communication (SDO)

The preset value is transferred directly to the encoder using the object 6003h – Preset

Value (see Table 78 on page 63). The encoder immediately adopts the preset value

that is written to the object as the new position value.

Figure 20: Example for the parameterization of object 6003h

The function is available if the encoder is in the Pre-operational or Operational status.

Page 41

INTEGRATION IN CANOPEN 5

8016869/12TG/201 9-04-08 | S ICK OPERATING INSTUCTIONS |AHS/AHM36 CA NOPEN, AHS/A HM36 CANOPEN INOX

41

Subject to change without notic e

Cyclic communication (PDO)

The preset value is initially transferred to the encoder using the object 2005h –

Configuration Preset Value (see Table 117 on page 78), but is not yet applied as a

new position value.

Figure 21: Example for the parameterization of object 2005h

The function is triggered using the object 2000h – Control Word 1 (see Table 111 on

page 75).

The function is available if the encoder is in the Operational status.

The object is configured using a bit sequence 16 bits wide.

Example:

Bit 12 = preset is set = 1

Bit 11 = preset mode shift positive = 1

Bit

15

14

13

12

11

10 9 8 7 6 5 4 3 2 1 0

Value 0 0 0 1 1 0 0 0 0 0 0 0 0 0 0 0

Table 34: Example for binary code

The binary value must be converted into a hexadecimal value and entered in the

configuration dialog box.

1100000000000b = 1800h