Page 1

AFS/AFM60 PROFINET ABSOLUTE ENCODERS

INTELLIGENT, POWERFUL, PRECISE

Product description

Intelligent diagnostic functions and

rapid data transfer: High-resolution AFS/

AFM60 PROFINET absolute encoders

represent high-precision measurement

of absolute position and speed in the

area of industrial automation. Comprehensive functions for diagnosing parameters such as temperature or operating

time and early error detection increase

network reliability. Various conguration

options, such as modication of resolu-

At a glance

• High-resolution 30-bit absolute encod-

er (18-bit singleturn and 12-bit multiturn)

• Face mount ange, servo ange and

blind hollow shaft

• Connection type: 3 x M12 axial male

connector

tion, rotational direction or unit of speed

measurement simplify installation and

enable customized adjustment to each

application. Their compact design makes

AFS/AFM60 PROFINET absolute encoders suitable for use even in applications

with tight space available. Embedded

switch technology ensures maximum

system and equipment availability and

therefore helps increase productivity

• PROFINET-IO-RT interface

• Less than 5 ms data update time

• Round axis functionality

• Alarms, warnings and diagnostics

functions for speed, position, temperature, operating time, etc.

• Status display via 5 LEDs

G

1)

1)

UL 508 compliant.

More information

Fields of application . . . . . . . . . . .G-333

Detailed technical data. . . . . . . . .G-333

Maximum viewing number of

resolutions...................G-335

Ordering information. . . . . . . . . . .G-335

Sales kits ....................G-337

Dimensional drawings . . . . . . . . .G-340

PIN assignment. . . . . . . . . . . . . . .G-343

Recommended accessories. . . . .G-344

Your benets

• Increased productivity as a result of

intelligent diagnostics functions and

rapid data transfer

• Increase in network reliability due to

early error detection

• Simple installation with various con-

guration options

• Flexible, easy setup and high reso-

lutions for various applications with

binary, integer and “decimal point”

values based on round axis functionality

• Maximum system availability through

embedded switch technology

• Compact and cost-efcient design

G-332

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 2

Fields of application

• Measurement of absolute position and speed in various ma-

chines and systems used in industrial automation as well as

production and process technology, for example: warehouse

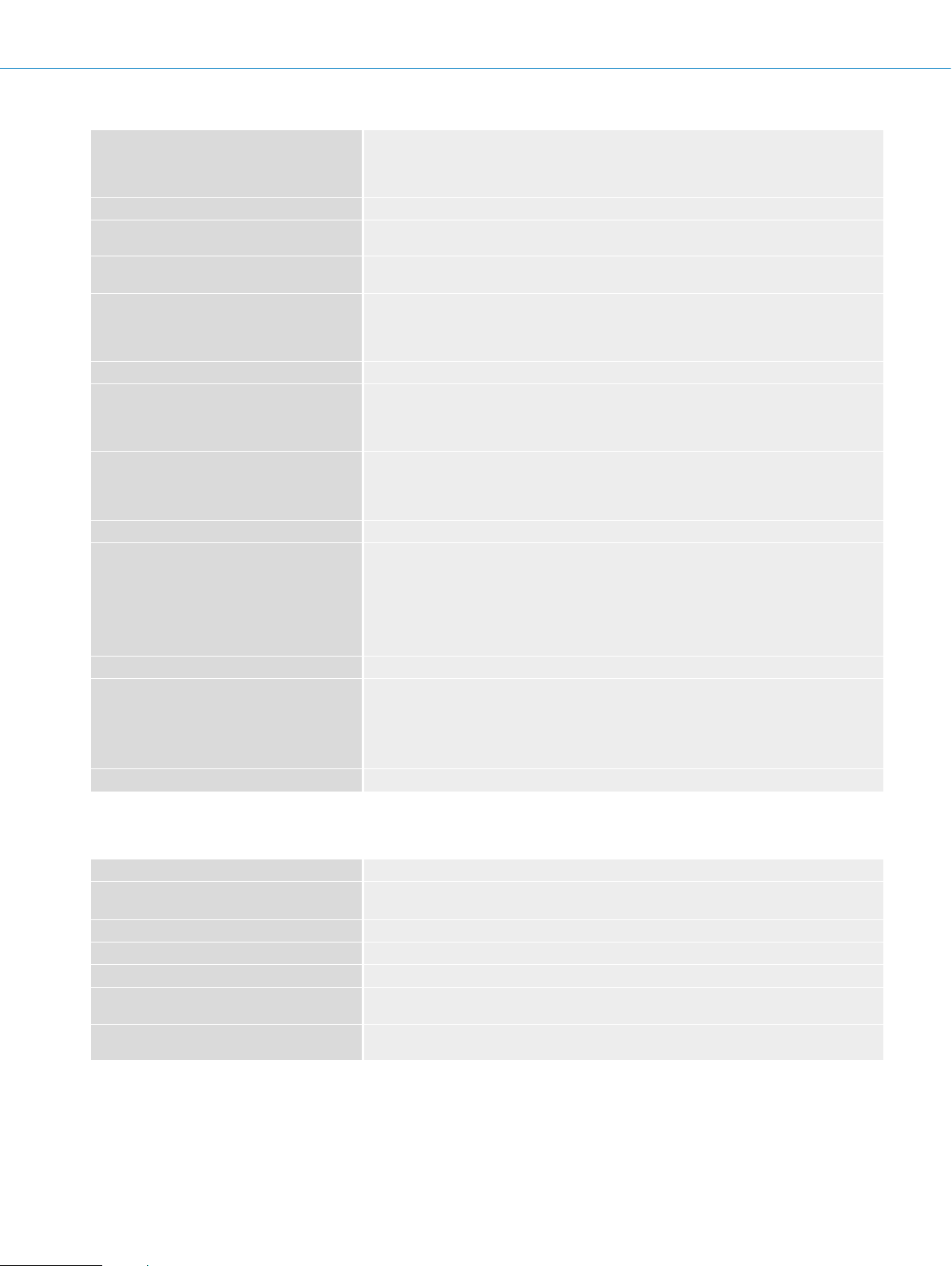

Detailed technical data

Performance

ABSOLUTE ENCODERS AFS/AFM60 PROFINET

systems, packaging machines, hydraulic presses, printing

machines, robots, rotating tables

Max. number of steps per revolution,

AFS60 and AFM60

Max. number of revolutions

Resolution

Error limits

Repeatability

Measurement increment deviation

Measuring increment (360 °/ number of

steps per revolution)

Initialization time

Interfaces

Electrical interface

Transfer rate

Transmission media

Encoder prole

Conguration data

Available diagnostic data

262,144 (18 bit)

(maximum viewing number of resolutions, page G-335)

AFM60 4,096 (12 bit)

AFS60 1

AFM60 18 x 12 bit

AFS60 18 bit

≤ 0.03°

≤ 0.002°

± 0.002°

0.001°

Approx. 12 s

PROFINET

10/100 MBit/s

CAT 5e cable

V4.1 Class3

Number of steps per revolution, number of revolutions, PRESET, counting direction, sampling

rate for speed monitoring, unit for output of the speed value, round axis functionality (multiturn

version only)

Current, minimum and maximum temperature, maximum speed, power-on counter, operating

hours counter, power-on/motion, counter of direction changes/number of

movements cw/number of movements ccw, maximum operating voltage

G

Electrical data

Power consumption max.

Operating voltage range with reverse polar-

ity protection

Reverse polarity protection

MTTFd: mean time to dangerous failure

1)

This product is a standard product and does not constitute a safety component as dened in the Machinery Directive. Calculation based on nominal load of devices,

average ambient temperature 40 °C, frequency of use 8,760 h/a. All electronic failures are considered hazardous. For more information, see document no.

8015532.

Subject to change without notice

3.0 W

10 ... 30 V

l

80 years (EN ISO 13849-1)

1)

ENCODERS | SICK8015560/2015-09-01

G-333

Page 3

G

AFS/AFM60 PROFINET ABSOLUTE ENCODERS

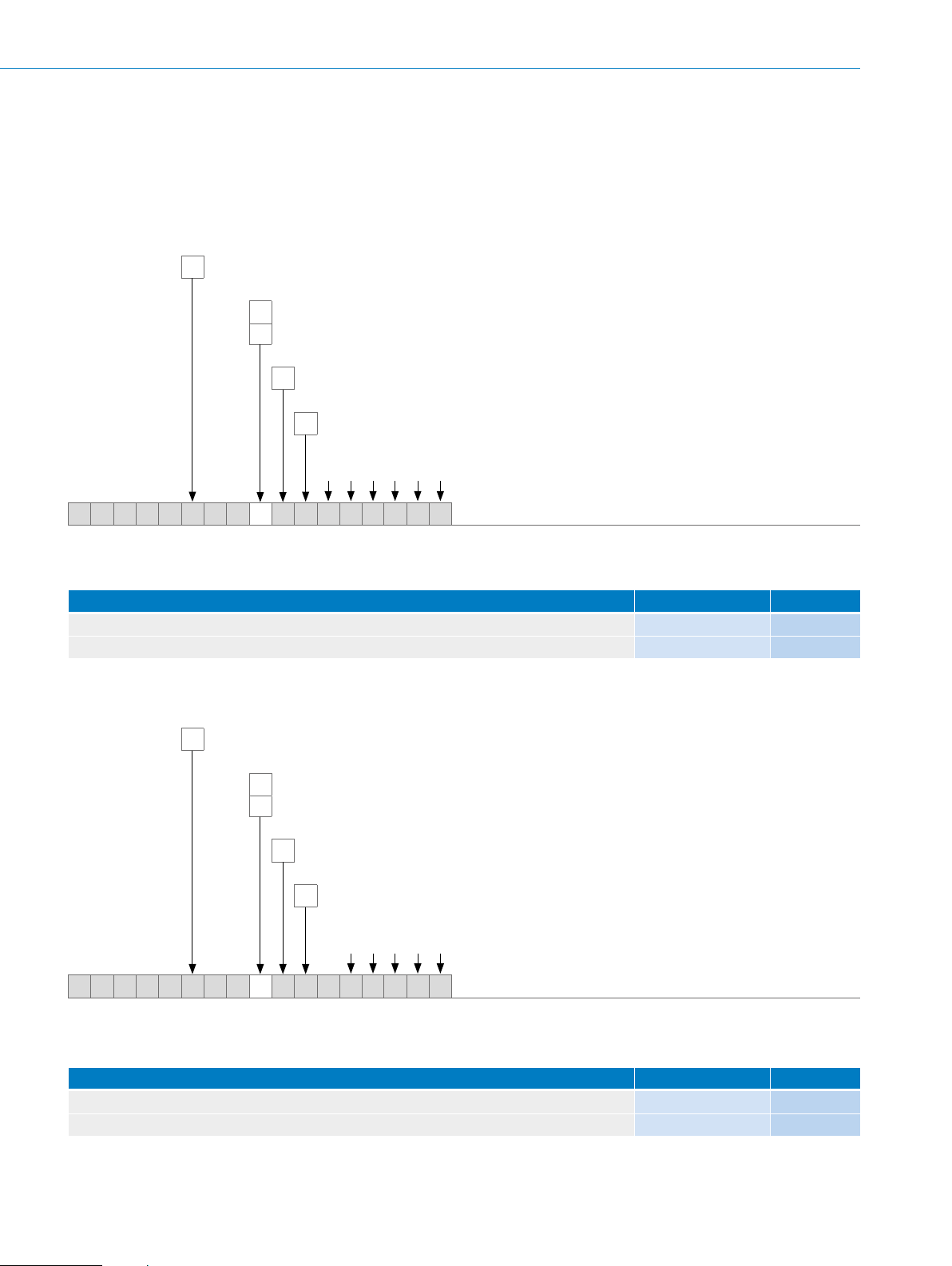

Mechanical data

Operating speed

Mass

Permissible shaft load, solid shaft

Permissible shaft movement of the drive

element, blind hollow shaft

Rotor moment of inertia

Bearing lifetime

Start up torque at 20 °C

Operating torque at 20 °C

Max. angular acceleration

Shaft diameter

Shaft material

Flange material

Housing material

1)

Take into account self-heating of 3.3 K per 1,000 revolutions/min when designing the operating temperature range.

1)

Solid shaft 9,000 rpm (maximum viewing number of resolutions, page G-335)

Blind hollow shaft 6,000 rpm

0.2 kg

80 N (radial);

40 N (axial)

± 0.3 / ± 0.05 mm (radial, static/dynamic)

± 0.5 / ± 0.1 mm (axial, static/dynamic)

Solid shaft ≤ 6.2 gcm²

Blind hollow shaft ≤ 40 gcm²

3 x 109 revolutions

Solid shaft 0.5 Ncm

Blind hollow shaft 0.8 Ncm

Solid shaft 0.3 Ncm

Blind hollow shaft 0.6 Ncm

5 x 105 rad/s

Face mount ange, solid shaft 10 x 19 mm

Servo ange, solid shaft 6 x 10 mm

Blind hollow shaft, AFM60 8, 10, 12, 14, 15 mm, 1/4", 1/2", 3/8"

Blind hollow shaft, AFS60 8, 10, 12, 14, 15 mm, 1/4", 1/2", 3/8", 5/8"

Stainless steel

Solid shaft Aluminum

Blind hollow shaft, AFM60 Aluminum

Blind hollow shaft, AFS60 Zinc die cast

Aluminum

(maximum viewing number of resolutions, page G-335)

2

Ambient data

EMC

Enclosure rating (as per IEC 60529)

Permissible relative humidity

Operating temperature range

Storage temperature range

Resistance to shocks (according to

EN 60068-2-27)

Resistance to vibration (according to

EN 60068-2-6)

1)

The EMC according to the standards quoted is achieved if shielded cables are used.

2)

When mating connector is inserted.

G-334

ENCODERS | SICK 8015560/2015-09-01

According to EN 61000-6–2 and EN 61000-6–3

IP 65, on the shaft side

IP 67, on the housing side

90% (condensation of optical surfaces not permitted)

–40 °C ... +85 °C

–40 °C ... +100 °C, without packaging

100 g/ 6 ms

30 g/ 10 Hz ... 2,000 Hz

1)

2)

Subject to change without notice

Page 4

ABSOLUTE ENCODERS AFS/AFM60 PROFINET

Maximum viewing number of resolutions

The maximum singleturn resolution (= 18 bit) can be operated with the maximum operating speed (blind hollow shaft 6,000 rpm

and solid shaft 9,000 rpm).

Ordering information

Type code AFS absolute encoder, singleturn, solid shaft

Type

A F S 6 0 A – S N B 2 6 2 1 4 4

1)

Number of steps programmable via control unit: Type A = 2 to 262144.

Max. number of steps per revolution = 262,144 (18 bits)

A

Mechanical design

Servo ange, 6 x 10 mm

1

Face mount ange, 10 x 19 mm

4

Electrical interface

PROFINET

N

Connection type

3 x M12, 4-pin, axial

B

Resolution

Factory setting: Type A = 262144

1)

Example orders

Mechanical design Type Part no.

Solid shaft, servo ange, Ø 6 mm, length 10 mm AFS60A-S1NB262144 1059051

Solid shaft, face mount ange, Ø 10 mm, length 19 mm AFS60A-S4NB262144 1059050

Type code AFM, multiturn absolute encoder, solid shaft

Type

Max. number of steps per revolution = 262,144 (18 bits)

A

Mechanical design

Servo ange, 6 x 10 mm

1

Face mount ange, 10 x 19 mm

4

Electrical interface

PROFINET

N

Connection type

3 x M12, 4-pin, axial

B

Resolution

Factory setting: Type A = 18 bit singleturn x 12 bit multiturn

A F M 6 0 A – S N B 0 1 8 x 1 2

1)

Programmable options for resolution via control unit.

G

1)

Example orders

Subject to change without notice

Mechanical design Type Part no.

Solid shaft, servo ange, Ø 6 mm, length 10 mm AFM60A-S1NB018x12 1059040

Solid shaft, face mount ange, Ø 10 mm, length 19 mm AFM60A-S4NB018x12 1059039

ENCODERS | SICK8015560/2015-09-01

G-335

Page 5

AFS/AFM60 PROFINET ABSOLUTE ENCODERS

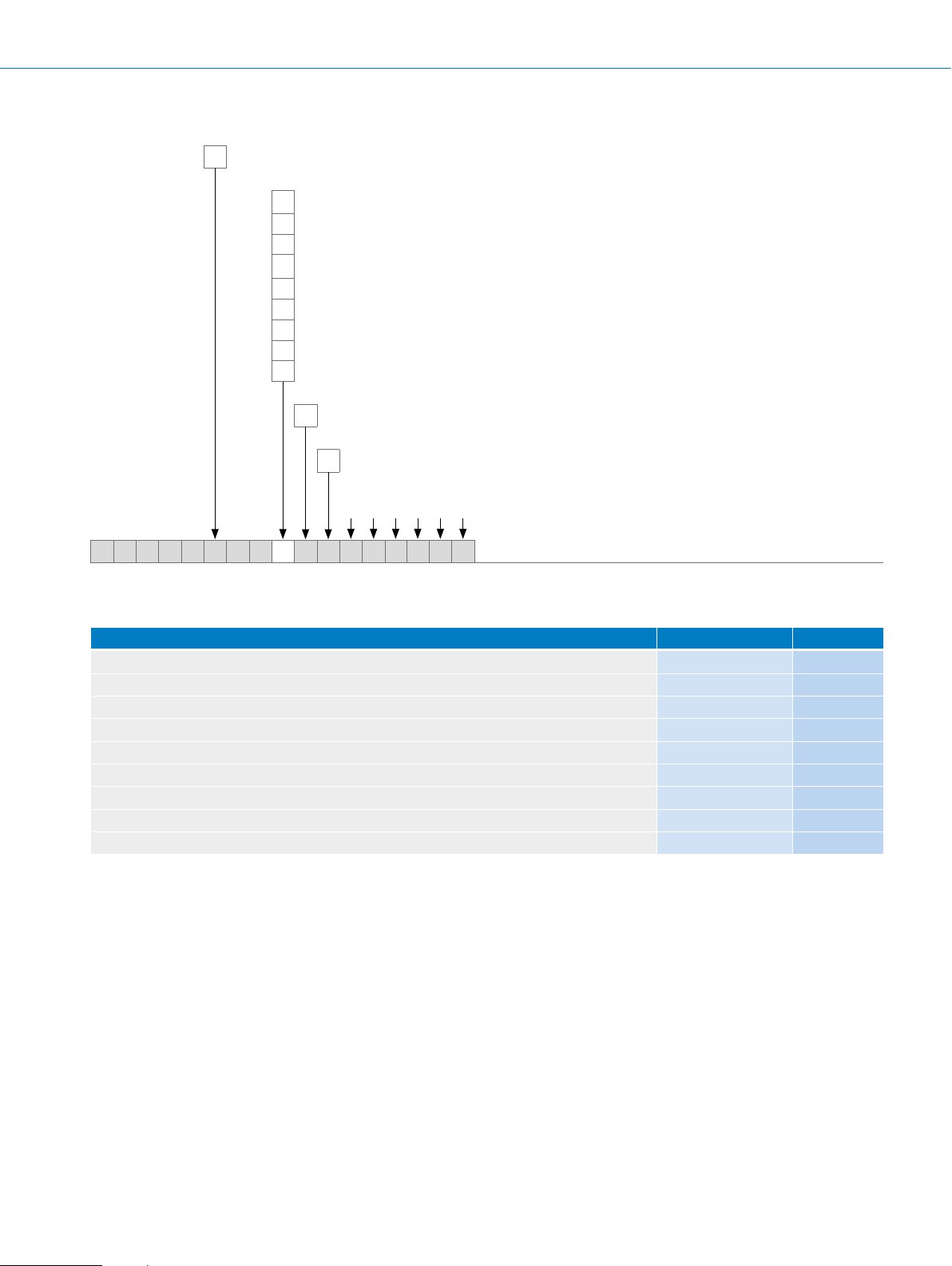

Type code AFS singleturn absolute encoder, solid shaft

Type

Max. number of steps per revolution = 262,144 (18 bits)

A

Mechanical design

Blind hollow shaft, 8 mm

B

Blind hollow shaft, 3/8"

C

Blind hollow shaft, 10 mm

D

Blind hollow shaft, 12 mm

E

Blind hollow shaft 1/2"

F

Blind hollow shaft, 14 mm

G

Blind hollow shaft 15 mm

H

Blind hollow shaft, 5/8"

J

Blind hollow shaft 1/4"

K

Electrical interface

PROFINET

N

Connection type

3 x M12, 4-pin, axial

B

Resolution

Factory setting: Type A = 262144

1)

G

A F S 6 0 A – B N B 2 6 2 1 4 4

1)

Number of steps programmable via control unit: Type A = 2 to 262144.

Example orders

Mechanical design Type Part no.

Blind hollow shaft, Ø 8 mm AFS60A-BBNB262144 1059049

Blind hollow shaft, Ø 3/8" AFS60A-BCNB262144 1059048

Blind hollow shaft, Ø 10 mm AFS60A-BDNB262144 1059047

Blind hollow shaft, Ø 12 mm AFS60A-BENB262144 1059046

Blind hollow shaft Ø 1/2" AFS60A-BFNB262144 1059045

Blind hollow shaft, Ø 14 mm AFS60A-BGNB262144 1059044

Blind hollow shaft, Ø 15 mm AFS60A-BHNB262144 1059043

Blind hollow shaft, Ø 5/8" AFS60A-BJNB262144 1059042

Blind hollow shaft Ø 1/4" AFS60A-BKNB262144 1059041

G-336

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 6

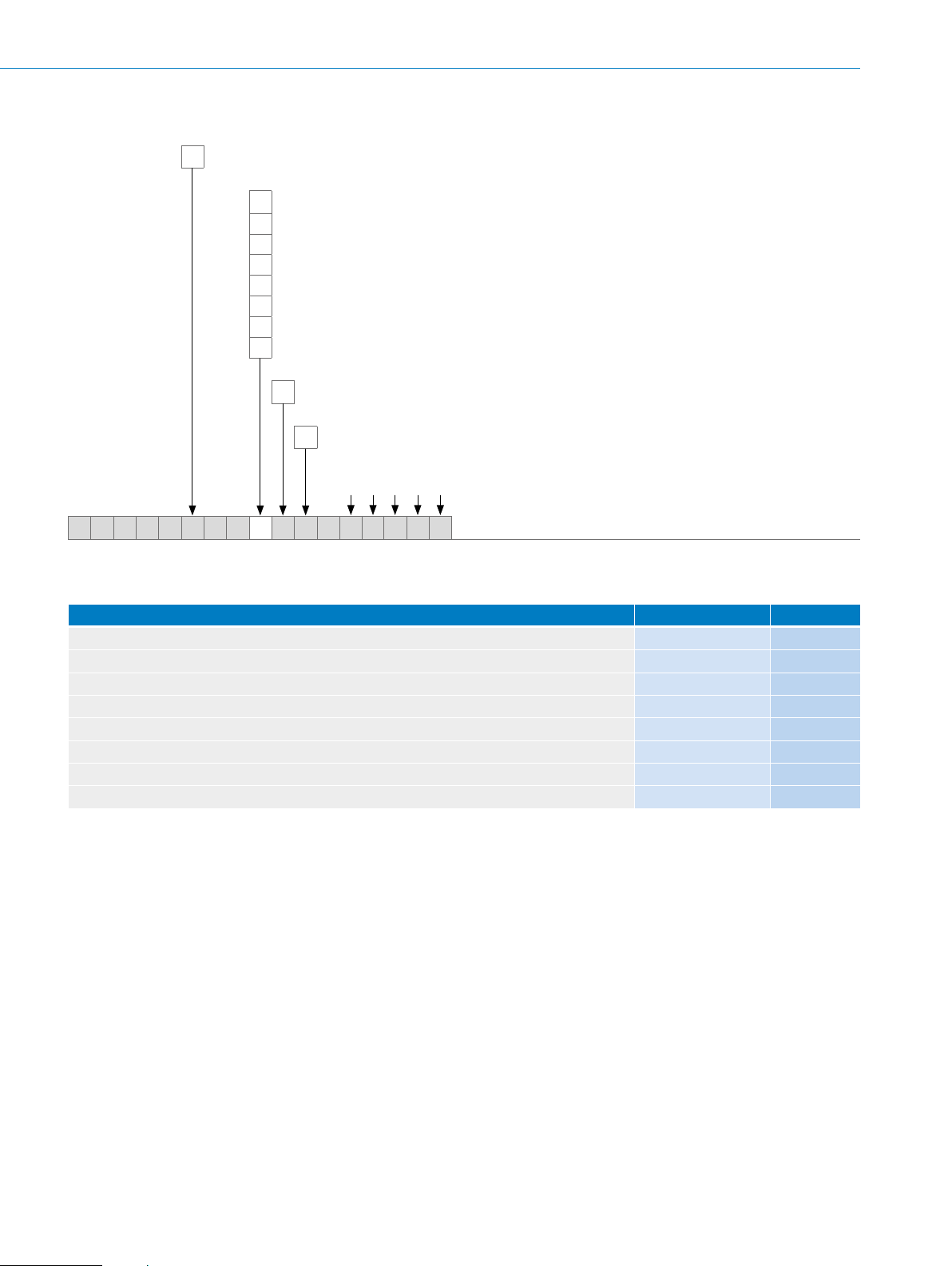

Type code AFM, multiturn absolute encoder, blind hollow shaft

Type

Max. number of steps per revolution = 262,144 (18 bits)

A

Mechanical design

Blind hollow shaft, 8 mm

B

Blind hollow shaft, 3/8"

C

Blind hollow shaft, 10 mm

D

Blind hollow shaft, 12 mm

E

Blind hollow shaft 1/2"

F

Blind hollow shaft, 14 mm

G

Blind hollow shaft 15 mm

H

Blind hollow shaft 1/4"

K

Electrical interface

PROFINET

N

Connection type

3 x M12, 4-pin, axial

B

Resolution

Factory setting: Type A = 18 bit singleturn x 12 bit multiturn

ABSOLUTE ENCODERS AFS/AFM60 PROFINET

1)

A F M 6 0 A – B N B 0 1 8 x 1 2

1)

Programmable options for resolution via control unit.

Example orders

Mechanical design Type Part no.

Blind hollow shaft, Ø 8 mm AFM60A-BBNB018x12 1059038

Blind hollow shaft, Ø 3/8" AFM60A-BCNB018x12 1059036

Blind hollow shaft, Ø 10 mm AFM60A-BDNB018x12 1059035

Blind hollow shaft, Ø 12 mm AFM60A-BENB018x12 1059034

Blind hollow shaft Ø 1/2" AFM60A-BFNB018x12 1059033

Blind hollow shaft, Ø 14 mm AFM60A-BGNB018x12 1059032

Blind hollow shaft, Ø 15 mm AFM60A-BHNB018x12 1059031

Blind hollow shaft Ø 1/4" AFM60A-BKNB018x12 1059029

G

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

G-337

Page 7

AFS/AFM60 PROFINET ABSOLUTE ENCODERS

Sales kits

Sales kit 01

PROFINET encoder

• + Female connector, supply voltage, angled (DOS-1204-W, part number. 6007303)

• + Male cable connector, PROFINET signal, angled, (STE-1204-WZ, part number 6048262)

Encoder type (singleturn) Description Type Part no.

AFS60A-S1NB262144 Solid shaft, servo ange, 6 x 10 mm

AFS60A-S4NB262144 Solid shaft, face mount ange, 10 x 19 mm

AFS60A-BDNB262144 Blind hollow shaft, Ø 10 mm

AFS60A-BENB262144 Blind hollow shaft, Ø 12 mm

AFS60A-BHNB262144 Blind hollow shaft, Ø 15 mm

Encoder type (multiturn) Description Type Part no.

AFM60A-S1NB262144 Solid shaft, servo ange, 6 x 10 mm

AFM60A-S4NB262144 Solid shaft, face mount ange, 10 x 19 mm

AFM60A-BDNB262144 Blind hollow shaft, Ø 10 mm

AFM60A-BENB262144 Blind hollow shaft, Ø 12 mm

AFM60A-BHNB262144 Blind hollow shaft, Ø 15 mm

AFS60A-S1NB

sales kit 01

AFS60A-S4NB

sales kit 01

AFS60A-BDNB

sales kit 01

AFS60A-BENB

sales kit 01

AFS60A-BHNB

sales kit 01

AFM60A-S1NB

sales kit 01

AFM60A-S4NB

sales kit 01

AFM60A-BDNB

sales kit 01

AFM60A-BENB

sales kit 01

AFM60A-BHNB

sales kit 01

1059352

1059356

1059357

1059358

1059359

1059360

1059361

1059362

1059363

1059364

G

Sales kit 02

PROFINET encoder

• + Female cable connector, supply voltage, angled, pre-wired with 5 m cable (DOL-1204-W05MC, part number 6025904)

• + Female cable connector, PROFINET signal, angled, pre-wired with 5 m cable (STL-1204-W05MZ90, part number 6048257)

Encoder type (singleturn) Description Type Part no.

AFS60A-S1NB262144 Solid shaft, servo ange, 6 x 10 mm

AFS60A-S4NB262144 Solid shaft, face mount ange, 10 x 19 mm

AFS60A-BDNB262144 Blind hollow shaft, Ø 10 mm

AFS60A-BENB262144 Blind hollow shaft, Ø 12 mm

AFS60A-BHNB262144 Blind hollow shaft, Ø 15 mm

Encoder type (multiturn) Description Type Part no.

AFM60A-S1NB262144 Solid shaft, servo ange, 6 x 10 mm

AFM60A-S4NB262144 Solid shaft, face mount ange, 10 x 19 mm

AFM60A-BDNB262144 Blind hollow shaft, Ø 10 mm

AFM60A-BENB262144 Blind hollow shaft, Ø 12 mm

AFM60A-BHNB262144 Blind hollow shaft, Ø 15 mm

AFS60A-S1NB

sales kit 02

AFS60A-S4NB

sales kit 02

AFS60A-BDNB

sales kit 02

AFS60A-BENB

sales kit 02

AFS60A-BHNB

sales kit 02

AFM60A-S1NB

sales kit 02

AFM60A-S4NB

sales kit 02

AFM60A-BDNB

sales kit 02

AFM60A-BENB

sales kit 02

AFM60A-BHNB

sales kit 02

1059365

1059366

1059368

1059369

1059370

1059372

1059373

1059375

1059376

1059377

G-338

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 8

ABSOLUTE ENCODERS AFS/AFM60 PROFINET

Sales kit 03

PROFINET encoder

• + Female connector, supply voltage, angled (DOS-1204-W, part number. 6007303)

• + 2 male cable connectors, PROFINET signal, angled, (STE-1204-WZ, part number 6048262)

Encoder type (singleturn) Description Type Part no.

AFS60A-S1NB262144 Solid shaft, servo ange, 6 x 10 mm

AFS60A-S4NB262144 Solid shaft, face mount ange, 10 x 19 mm

AFS60A-BDNB262144 Blind hollow shaft, Ø 10 mm

AFS60A-BENB262144 Blind hollow shaft, Ø 12 mm

AFS60A-BHNB262144 Blind hollow shaft, Ø 15 mm

Encoder type (multiturn) Description Type Part no.

AFM60A-S1NB262144 Solid shaft, servo ange, 6 x 10 mm

AFM60A-S4NB262144 Solid shaft, face mount ange, 10 x 19 mm

AFM60A-BDNB262144 Blind hollow shaft, Ø 10 mm

AFM60A-BENB262144 Blind hollow shaft, Ø 12 mm

AFM60A-BHNB262144 Blind hollow shaft, Ø 15 mm

AFS60A-S1NB

sales kit 03

AFS60A-S4NB

sales kit 03

AFS60A-BDNB

sales kit 03

AFS60A-BENB

sales kit 03

AFS60A-BHNB

sales kit 03

AFM60A-S1NB

sales kit 03

AFM60A-S4NB

sales kit 03

AFM60A-BDNB

sales kit 03

AFM60A-BENB

sales kit 03

AFM60A-BHNB

sales kit 03

1059379

1059380

1059381

1059382

1059383

1059384

1059385

1059386

1059387

1059388

Sales kit 04

PROFINET encoder

• + Female cable connector, supply voltage, angled, pre-wired with 5 m cable (DOL-1204-W05MC, part number 6025904)

• + 2 female cable connectors, PROFINET signal, angled, pre-wired with 5 m cable (STL-1204-W05MZ90, part number 6048257)

Encoder type (singleturn) Description Type Part no.

AFS60A-S1NB262144 Solid shaft, servo ange, 6 x 10 mm

AFS60A-S4NB262144 Solid shaft, face mount ange, 10 x 19 mm

AFS60A-BDNB262144 Blind hollow shaft, Ø 10 mm

v

AFS60A-BENB262144 Blind hollow shaft, Ø 12 mm

AFS60A-BHNB262144 Blind hollow shaft, Ø 15 mm

Encoder type (multiturn) Description Type Part no.

AFM60A-S1NB262144 Solid shaft, servo ange, 6 x 10 mm

AFM60A-S4NB262144 Solid shaft, face mount ange, 10 x 19 mm

AFM60A-BDNB262144 Blind hollow shaft, Ø 10 mm

AFM60A-BENB262144 Blind hollow shaft, Ø 12 mm

AFM60A-BHNB262144 Blind hollow shaft, Ø 15 mm

AFS60A-S1NB

sales kit 04

AFS60A-S4NB

sales kit 04

AFS60A-BDNB

sales kit 04

AFS60A-BENB

sales kit 04

AFS60A-BHNB

sales kit 04

AFM60A-S1NB

sales kit 04

AFM60A-S4NB

sales kit 04

AFM60A-BDNB

sales kit 04

AFM60A-BENB

sales kit 04

AFM60A-BHNB

sales kit 04

1059426

1059427

1059428

1059429

1059430

1059431

1059433

1059434

1059437

1059439

G

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

G-339

Page 9

AFS/AFM60 PROFINET ABSOLUTE ENCODERS

Ø 0.1

C

62.3 (2.45)

Ø 36 (1.42) f8

Dimensional drawings (dimensions in mm)

Face mount ange

10

18

(0.71)

±0.3

19

(0.75)

(0.39)

61.5 (2.42)

65

Ø 0.05

B

9 (0.35)

10f7

C

0.1

A

±0.5

10.3

(0.41)

A

(2.56)

General tolerances according to DIN ISO 2768-mk

M12 x 1

Ø 60 (2.36)

2 x M12 x 1

3 x 120°

25°

±5°

3 x M4

6 deep

(0.24)

(1.89)

±0.05

Ø 48

G

G-340

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 10

Servo ange

C

62.3 (2.45)

Ø 58

3 x 120°

4 x 90°

Ø 0.05

B

(0.37)

9.5

4

(0.16)

3

(0.12)

0.1

0.1

ABSOLUTE ENCODERS AFS/AFM60 PROFINET

A

10.3

(0.41)

A

M12 x 1

3 x M4

8 deep

(0.31)

3 x 120°

(2.28)

±0.1

Ø 51.5–0.2 (2.03)

Ø 50 (1.97) f8

C

0.03

Ø 6

(0.24) f7

B

5.7

(0.22)

±0.3

10

(0.39)

A

10

(0.39)

A

61.5 (2.42)

±0.5

65

General tolerances according to DIN ISO 2768-mk

Mounting suggestion for small servo clamp

(part number 2029166)

Ø 68 (2.68)

(2.56)

(1.65)

±0.05

Ø 60 (2.36)

Ø 42

2 x

M12 x 1

Ø 0.1

25°

±5°

Mounting suggestion for half-shell servo clamp

(part number 2029165)

Ø 71 (2.80)

G

General tolerances according to DIN ISO 2768-mk

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

G-341

Page 11

AFS/AFM60 PROFINET ABSOLUTE ENCODERS

68.8 (2.71)

Ø X F7

+0.1

Blind hollow shaft

9.4

(0.37)

3.4

(0.13)

10.3

(0.41)

72 (2.83)

G

M12 x 1

68 (2.68)

±0.5

71.5

(2.81)

General tolerances according to DIN ISO 2768-mk

Mounting suggestion

min. 15

(0.59)

xj7

Ø 3.2

(0.13)

(2.36)

Ø 60

2 x

M12 x 1

20 (0.79)

47 (1.85)

Ø 63

±0.3

(2.48)

20°

Diameter X F7

AFS60 singleturn absolute

encoder

Blind hollow shaft 1/4" Blind hollow shaft 1/4"

Blind hollow shaft, 8 mm Blind hollow shaft, 8 mm

Blind hollow shaft, 3/8" Blind hollow shaft, 3/8"

Blind hollow shaft, 10 mm Blind hollow shaft, 10 mm

Blind hollow shaft, 12 mm Blind hollow shaft, 12 mm

Blind hollow shaft 1/2" Blind hollow shaft 1/2"

Blind hollow shaft, 14 mm Blind hollow shaft, 14 mm

Blind hollow shaft 15 mm Blind hollow shaft 15 mm

Blind hollow shaft, 5/8"

AFM60 multiturn absolute

encoder

General tolerances according to DIN ISO 2768-mk

xj7 = Shaft diameter, on the customer side

G-342

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 12

PIN assignment

2

1

3

4

WARNING

1P

a

Decade switches: out of operation

1

2

4

3

M12 – 4-pin (D-coded)

ABSOLUTE ENCODERS AFS/AFM60 PROFINET

Port 1

Signal

Pin

Wire colors

T x D+ R x D+ T x D– R x D–

1 2 3 4

Yellow White Orange Blue

Port 2

Signal

Pin

Wire colors

T x D+ R x D+ T x D– R x D–

1 2 3 4

Yellow White Orange Blue

M12 – 4-pin (A-coded)

L/A1

Port

2

3

SF

BF

GND

0

1

9

2

8

7

4

6

5

x100 x1

x10

9

8

7

3

4

1

2

4

6

5

1

Encoder

10–30 V DC

3

0

1

9

2

8

3

7

4

6

5

L/A2

ort 2

Preset

push-button

DO NOT

USE

Supply voltage

Signal

Pin

Wire

US 10 ... 30 V

Not assigned

GND

Not as-

signed

1 2 3 4

Brown White Blue Black

G

colors

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

G-343

Page 13

AFS/AFM60 PROFINET ABSOLUTE ENCODERS

Recommended accessories

Mounting systems

Mounting brackets and plates

Mounting bracket

Figure Brief description Type Part no.

G

Mounting bracket for encoder with centering hub 36 mm, including mounting kit for face

mount ange

Dimensional drawings g page K-725

BEF-WF-36 2029164

Flanges

Flange plate

Figure Brief description Type Part no.

Standard stator coupling BEF-DS00XFX 2056812

Stator coupling, one-sided, 81 mm long with slot BEF-DS01DFS/VFS 2047428

Stator coupling, one-sided, 179 mm long with slot BEF-DS02DFS/VFS 2047430

Stator coupling, one-sided, 248 mm long with slots BEF-DS03DFS/VFS 2047431

Stator coupling, 16.5 mm high BEF-DS05XFX 2057423

Stator coupling with hole circle diameter 63 mm BEF-DS07XFX 2059368

Flange adapter, adaptation of face mount ange with 36 mm centering hub to 50 mm

servo ange, aluminum, including 3 at head screws M4 x 10

Flange adapter, adaptation of face mount ange with 36 mm centering hub to 60 mm

square mounting plate, aluminum, including 3 at head screws M4 x 10

Flange adapter, adaptation of face mount ange with 36 mm centering hub to 58 mm

square mounting plate with shock absorbers, aluminum

Flange adapter, adaptation of face mount ange with 36 mm centering hub to 63 mm

square mounting plate, aluminum, including 3 at head screws M4 x 10

Flange adapter, adaptation of face mount ange with 36 mm centering hub to 100 mm

servo ange with 60 mm centering hub, aluminum

Dimensional drawings g page K-725

G-344

ENCODERS | SICK 8015560/2015-09-01

BEF-FA-036-050 2029160

BEF-FA-036-060REC 2029162

BEF-FA-036-060RSA 2029163

BEF-FA-036-063REC 2034225

BEF-FA-036-100 2029161

Subject to change without notice

Page 14

ABSOLUTE ENCODERS AFS/AFM60 PROFINET

Other mounting accessories

Measuring wheels and measuring wheel systems

Figure Brief description Type Part no.

Measuring wheel with smooth plastic surface (Hytrel) for 10 mm solid shaft, circumference 200 mm

Measuring wheel with ridged plastic surface (Hytrel) for 10 mm solid shaft, circumference 200 mm

Measuring wheel with smooth plastic surface (Hytrel) for 10 mm solid shaft, circumference 500 mm

Measuring wheel with O-ring (NBR70) for 6 mm solid shaft, circumference 200 mm BEF-MR006020R 2055222

Measuring wheel with O-ring (NBR70) for 6 mm solid shaft, circumference 300 mm BEF-MR006030R 2055634

Measuring wheel with O-ring (NBR70) for 10 mm solid shaft, circumference 200 mm BEF-MR010020R 2055224

Measuring wheel with O-ring (NBR70) for 10 mm solid shaft, circumference 300 mm BEF-MR010030R 2049278

Measuring wheel with O-ring (NBR70) for 10 mm solid shaft, circumference 500 mm BEF-MR010050R 2055227

O-ring for measuring wheels (circumference 200 mm) BEF-OR-053-040 2064061

O-ring for measuring wheels (circumference 300 mm) BEF-OR-083-050 2064076

Dimensional drawings g page K-725

BEF-MR-010020 5312988

BEF-MR-010020G 5318678

BEF-MR-010050 5312989

Modular measuring wheel system

Brief description Type Part no.

Measuring wheel system, desired mounting position: left, for DBS60-S4, DFS60-S4, AFS60-S4, and

AFM60-S4

Measuring wheel system, desired mounting position: right, for DBS60-S4, DFS60-S4, AFS60-S4, and

AFM60-S4

BEF-MRS-10-1 2071958

BEF-MRS-10-2 2071957

Dimensional drawings g page K-725

Mounting bell

Figure Brief description Type Part no.

Mounting bell for encoders with a servo ange, centering hub 50 mm, including mounting kit

Dimensional drawings g page K-725

BEF-MG-50 5312987

Servo clamps

Figure Brief description Type Part no.

Half-shell servo clamps (2 pcs.) for servo anges with a 50 mm centering hub BEF-WG-SF050 2029165

Servo clamps, large, for servo anges (clamps, eccentric fastener), 3 pcs., without

mounting material

Dimensional drawings g page K-725

BEF-WK-SF 2029166

G

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

G-345

Page 15

G

AFS/AFM60 PROFINET ABSOLUTE ENCODERS

Miscellaneous

Figure Brief description Type Part no.

Mounting kit for servo ange encoder on the bearing block, 1 bar coupling SKPS

1520 06/06 1 hexagon socket wrench SW1.5 DIN 911, 3 mounting eccentric BEMN

1242 49 3 screws M4 x 10 DIN 912, 1 hexagon socket wrench SW3 DIN 911

Bearing block for hollow shaft encoder, including xing screws BEF-FA-B12-010 2042728

Bearing block for servo and face mount ange encoder BEF-FA-LB1210 2044591

Dimensional drawings g page K-725

Shaft adaptation

Shaft couplings

Figure Brief description Type Part no.

Bellows coupling, shaft diameter 6 mm / 6 mm, maximum shaft offset: ra-

dial ± 0.25 mm, axial ± 0.4 mm, angular +/- 4°; max. speed 10,000 rpm,

–30 °C ... +120 °C, max. torque 80 Ncm; material: stainless steel bellows, aluminum

hub

Bellows coupling, shaft diameter 6 mm / 10 mm, maximum shaft offset: radial

± 0.25 mm, axial ± 0.4 mm, angular ± 4°; max. speed 10,000 rpm, –30 °C ... +120 °C,

max. torque 80 Ncm; material: stainless steel bellows, aluminum hub

Bellows coupling, shaft diameter 10 mm/10 mm; maximum shaft offset: radial

± 0.25 mm, axial ± 0.4 mm, angular ± 4°; max. revolutions 10,000 rpm,

–30° C ... +120 °C, max. torque 80 Ncm; material: stainless steel bellows, aluminum

clamping hubs

Bellows coupling, shaft diameter 10 mm/12 mm; maximum shaft offset: radial

± 0.25 mm, axial ± 0.4 mm, angular ± 4°; max. revolutions 10,000 rpm,

–30° C ... +120 °C, max. torque 80 Ncm; material: stainless steel bellows, aluminum

clamping hubs

Bar coupling, shaft diameter 6 mm / 6 mm, maximum shaft offset: radial ± 0.3 mm,

axial ± 0.2 mm, angle ± 3°; max. speed 10,000 rpm, –10° C ... +80 °C, max. torque

80 Ncm; material: ber-glass reinforced polyamide, aluminum hub

Bar coupling, shaft diameter 6 mm / 8 mm, maximum shaft offset radial ± 0.3 mm, ax-

ial ± 0.2 mm, angle ± 3°; max. speed 10,000 rpm, torsion spring rigidity 38 Nm/wheel;

material: ber-glass reinforced polyamide, aluminum hub

Bar coupling, shaft diameter 6 mm/10 mm, maximum shaft offset: radial ± 0.3 mm,

axial ± 0.2 mm, angular ± 3°; max. speed 10,000 rpm, –10° C ... +80 °C, max. torque

80 Ncm; material: ber-glass reinforced polyamide, aluminum hub

Bar coupling, shaft diameter 8 mm / 10 mm, maximum shaft offset: radial ± 0.3 mm,

axial ± 0.2 mm, angular ± 3°; torsion spring rigidity 38 Nm/wheel; material: ber-glass

reinforced polyamide, aluminum hub

Bar coupling, shaft diameter 10 mm / 10 mm, maximum shaft offset radial ± 0.3 mm,

axial ± 0.2 mm, angle ± 3°; max. speed 10,000 rpm, torsion spring rigidity 38 Nm/

wheel; material: ber-glass reinforced polyamide, aluminum hub

Double-loop coupling, shaft diameter 6 mm/10 mm, maximum shaft offset: radial

± 2.5 mm, axial ± 3 mm, angular ± 10°; max. speed 3,000 rpm, –30 °C ... +80 °C,

max. torque 1.5 Nm; material: polyurethane, galvanized steel ange

Double-loop coupling, shaft diameter 8 mm/10 mm, maximum shaft offset: radial

± 2.5 mm, axial ± 3 mm, angular ± 10°; max. speed 3,000 rpm, –30 °C ... +80 °C,

max. torque 1.5 Nm; material: polyurethane, galvanized steel ange

Double-loop coupling, shaft diameter 10 mm/10 mm, maximum shaft offset: radial

± 2.5 mm, axial ± 3 mm, angular ± 10°; max. speed 3,000 rpm, –30 °C ... +80 °C,

max. torque 1.5 Nm; material: polyurethane, galvanized steel ange

Double-loop coupling, shaft diameter 10 mm/12 mm, maximum shaft offset: radial

± 2.5 mm, axial ± 3 mm, angular ± 10°; max. speed 3,000 rpm, –30 °C ... +80 °C,

max. torque 1.5 Nm; material: polyurethane, galvanized steel ange

BEF-MK-LB 5320872

KUP-0606-B 5312981

KUP-0610-B 5312982

KUP-1010-B 5312983

KUP-1012-B 5312984

KUP-0606-S 2056406

KUP-0608-S 5314179

KUP-0610-S 2056407

KUP-0810-S 5314178

KUP-1010-S 2056408

KUP-0610-D 5326697

KUP-0810-D 5326704

KUP-1010-D 5326703

KUP-1012-D 5326702

G-346

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 16

ABSOLUTE ENCODERS AFS/AFM60 PROFINET

Figure Brief description Type Part no.

Spring washer coupling, shaft diameter 6 mm/10 mm, maximum shaft offset: radial

± 0.3 mm, axial ± 0.4 mm, angular ± 2.5°; max. speed 12,000 rpm, –10 °C ... +80 °C,

max. torque 60 Ncm; material: aluminum ange, ber-glass reinforced polyamide mem-

brane and tempered steel coupling pin

Spring washer coupling, shaft diameter 10 mm / 10 mm, maximum shaft offset: radial

± 0.3 mm, axial ± 0.4 mm, angular ± 2.5°; max. speed 12,000 rpm, –10° ... +80° C,

max. torque 60 Ncm; material: aluminum ange, glass ber-reinforced polyamide mem-

brane and hardened steel coupling pin

Dimensional drawings g page K-725

KUP-0610-F 5312985

KUP-1010-F 5312986

G

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

G-347

Page 17

AFS/AFM60 PROFINET ABSOLUTE ENCODERS

Connectivity

Power supply

Mechanical parameters

Number of pins 4

Cable diameter 4.7 mm

Minimum bend radius, secured in place 47 mm

Minimum bend radius, movable 47 mm

Maximum length of cable between participants 100 m

Material

Outer sheath PUR

Conductor Bare copper strand

Color of outer sheath Black RAL 9005

Cable parameters

AWG 22

Wire cross-section 0.34 mm²

Wire colors Brown, white, blue, black

Conductor resistance ≤ 58 Ω/km

Temperature range

Fixed in place –50 °C … +80 °C

Moving –25 °C … +80 °C

Specic features

Flame resistance UL horizontal ame test/CSA FT2

Halogen-free state PUR halogen-free

Microbe resistance Excellent

Hydrolysis resistance Excellent

Power supply (A-coded)

G

Plug connectors and cables

Connecting cables with female connector

Figure Brief description Length

Head A: female connector, M12, 4-pin, straight

Head B: cable

Cable: for power supply, suitable for drag chain, PUR, halogen-free, unshielded,

4 x 0.34 mm², Ø 4.7 mm

Head A: female connector, M12, 4-pin, angled

Head B: cable

Cable: for power supply, suitable for drag chain, PUR, halogen-free, unshielded,

4 x 0.34 mm², Ø 4.7 mm

Dimensional drawings g page K-725

Type Part no.

of

cable

2 m DOL-1204-G02MC 6025900

5 m DOL-1204-G05MC 6025901

10 m DOL-1204-G10MC 6025902

25 m DOL-1204-G25MC 6034751

2 m DOL-1204-W02MC 6025903

5 m DOL-1204-W05MC 6025904

10 m DOL-1204-W10MC 6025905

25 m DOL-1204-W25MC 6034754

G-348

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 18

Mechanical parameters

Number of pins 4

Coding type D-coded

Cable diameter 6.50 mm

Minimum bend radius, secured in place 19.5 mm

Minimum bend radius, movable 45.5 mm

Maximum length of cable between participants 100 m

Material

Cable material PVC

Conductor Tin-plated copper strand

Cable color Green RAL 6018

Electrical parameters

Transmission properties (category) CAT5 (IEC 11801:2002), CAT5e (TIA 568B:2001)

Cable parameters

Signal type PROFINET

Cable structure 1x4xAWG22/7; SF/Q

Wire colors White, yellow, blue, orange

Wire cross-section 0.34 mm

Conductor resistance ≤ 120 Ω/km

Shielding Braided tin-plated copper wires

Temperature range

Male connector, pre-wired with cable

Fixed in place –25 °C … +60 °C

Moving –5 °C … +50 °C

M12 connector

Ambient temperature (operation) –40 °C ... +85 °C

RJ45 connector

Ambient temperature (operation) –10 °C ... +60 °C

Specic features

Flame resistance According to IEC 60332-1

ABSOLUTE ENCODERS AFS/AFM60 PROFINET

Data cable

2

G

Connecting cables with male connector

Figure Brief description Length

Head A: male connector, M12, 4-pin, straight, D-coded

Head B: cable

Cable: PVC, shielded, 4 x 0.34 mm², Ø 6.5 mm

Head A: male connector, M12, 4-pin, angled, D-coded

Head B: cable

Cable: PVC, shielded, 4 x 0.34 mm², Ø 6.5 mm

Dimensional drawings g page K-725

Subject to change without notice

Type Part no.

of

cable

2 m STL-1204-G02MZ90 6048247

5 m STL-1204-G05MZ90 6048248

10 m STL-1204-G10MZ90 6048249

2 m STL-1204-W02MZ90 6048256

5 m STL-1204-W05MZ90 6048257

10 m STL-1204-W10MZ90 6048258

25 m STL-1204-W25MZ90 6048259

ENCODERS | SICK8015560/2015-09-01

G-349

Page 19

AFS/AFM60 PROFINET ABSOLUTE ENCODERS

Female connectors (ready to assemble)

Figure Brief description Type Part no.

Head A: female connector, M12, 4-pin, straight, D-coded, shielded, for cable diameter

4 mm ... 8 mm

Head A: female connector, M12, 4-pin, angled, unshielded, for power supply, for cable

diameter 3 mm ... 6.5 mm

Head B: -

Head A: female connector, M12, 4-pin, angled, D-coded, shielded, for cable diameter

4 mm ... 8 mm

Dimensional drawings g page K-725

DOS-1204-GZ 6048263

DOS-1204-W 6007303

DOS-1204-WZ 6048264

Other plug connectors and cables

Figure Brief description Type Part no.

Head A: female connector, M12, 4-pin, D-coded

Head B: female connector, RJ45, 8-pin

Cable: shielded

Switch cabinet feedthrough

Dimensional drawings g page K-725

Feedthrough female

connector Ethernet

RJ45

Male connectors (ready to assemble)

Figure Brief description Type Part no.

Head A: male connector, RJ45, 4-pin, straight, shielded, for cable diameter

4.5 mm ... 8 mm

STE-0J04-GZ 6048260

6048180

G

Head A: male connector, M12, 4-pin, straight, D-coded, shielded, for cable diameter

4 mm ... 8 mm

Head A: male connector, M12, 4-pin, angled, D-coded, shielded, for cable diameter

4 mm ... 8 mm

Dimensional drawings g page K-725

STE-1204-GZ 6048261

STE-1204-WZ 6048262

G-350

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 20

Connection cables with male and male connector

ABSOLUTE ENCODERS AFS/AFM60 PROFINET

Figure Brief description Length

Head A: male connector, M12, 4-pin, angled, D-coded

Head B: male connector, M12, 4-pin, straight

Cable: PVC, shielded, 4 x 0.34 mm², Ø 6.5 mm

Head A: male connector, M12, 4-pin, straight, D-coded

Head B: male connector, M12, 4-pin, straight

Cable: PVC, shielded, 4 x 0.34 mm², Ø 6.5 mm

Head A: male connector, M12, 4-pin, angled, D-coded

Head B: male connector, M12, 4-pin, angled, D-coded

Cable: PUR, halogen-free, shielded, 4 x 0.34 mm², Ø 6.5 mm

Head A: male connector, RJ45, 4-pin, straight, D-coded

Head B: male connector, M12, 4-pin, angled

Cable: PVC, shielded, 4 x 0.34 mm², Ø 6.5 mm

Head A: male connector, M12, 4-pin, straight, D-coded

Head B: male connector, RJ45, 4-pin, straight

Cable: PVC, shielded, 4 x 0.34 mm², Ø 6.5 mm

Dimensional drawings g page K-725

- For additional accessories, please see page K-668 onwards

Type Part no.

of

cable

2 m SSL-1204-F02MZ90 6048250

5 m SSL-1204-F05MZ90 6048251

10 m SSL-1204-F10MZ90 6048252

2 m SSL-1204-G02MZ90 6048241

5 m SSL-1204-G05MZ90 6048242

10 m SSL-1204-G10MZ90 6048243

2 m SSL-1204-W02MZ 6050635

5 m SSL-1204-W05MZ 6050636

10 m SSL-1204-W10MZ 6050637

2 m SSL-2J04-F02MZ 6048253

5 m SSL-2J04-F05MZ 6048254

10 m SSL-2J04-F10MZ 6048255

2 m SSL-2J04-G02MZ60 6048244

5 m SSL-2J04-G05MZ60 6048245

10 m SSL-2J04-G10MZ60 6048246

G

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

G-351

Loading...

Loading...