Page 1

AFS/AFM60 SSI ABSOLUTE ENCODERS

PRECISE, FLEXIBLE, VERSATILE

Product description

With a high resolution of 18 bits (AFS60)

or 30 bits (AFM60) and a large selection

of programmable parameters, the AFS60

absolute singleturn encoder and the

AFM60 absolute multiturn encoder set

new standards when it comes to rotary

encoders. The high resolution combined

with the high IP protection class enables

use in a multitude of industrial applications. Both encoders are equipped with

the SSI interface while the AFM60 is also

available with the SSI + Incremental and

SSI + Sin/Cos combined interfaces. A

shaft bearing distance of 30 mm means

the AFS60/AFM60 product family has

signicantly better rotation accuracy than

encoders with blocked ball bearings. Yet

despite their large bearing distance, the

AFS60/AFM60 have a compact design.

The AFS and AFM60 SSI can be programmed via the same PC-based

programming tool (PGT-08-S) or the

hand-held PGT-10-Pro programming tool.

G

More information

Fields of application . . . . . . . . . . .G-269

Detailed technical data. . . . . . . . .G-269

Viewing number of resolutions. . .G-273

Ordering information. . . . . . . . . . .G-274

Dimensional drawings . . . . . . . . .G-292

PIN assignment. . . . . . . . . . . . . . .G-302

Signal outputs ................G-304

Interfaces....................G-305

Recommended accessories. . . . .G-306

At a glance

• High-resolution absolute encoder

with up to 30 bits (AFM60) or 18 bits

(AFS60)

• Face mount ange, servo ange, blind

hollow shaft or through hollow shaft

• SSI, SSI + incremental or SSI + sin/

cos interface

• Resolution, offset, etc. can be pro-

grammed (depending on the type)

Your benets

• The programmability of the encoder

results in reduced storage, high machine availability, and easy installation

• Precise positioning thanks to high

resolutions

• Large selection of mechanical

‚

interfaces and electrical contacting

options: suitable for all applications

• Connectivity: M12 or M23 male con-

nector or cable outlet

• Enclosure rating: IP67 (housing), IP65

(shaft)

• Operating temperature:

–40 °C ... +100 °C (depending on

the type)

• Suitable for applications with limited

space (extremely short installation

depth of 30 mm)

• Excellent concentricity properties due

to long bearing distance

• Suitable programming tools are

available as accessories for every

application

G-268

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 2

Fields of application

• Measurement of absolute position using one or more

revolutions in various machines and systems such as tool

Detailed technical data

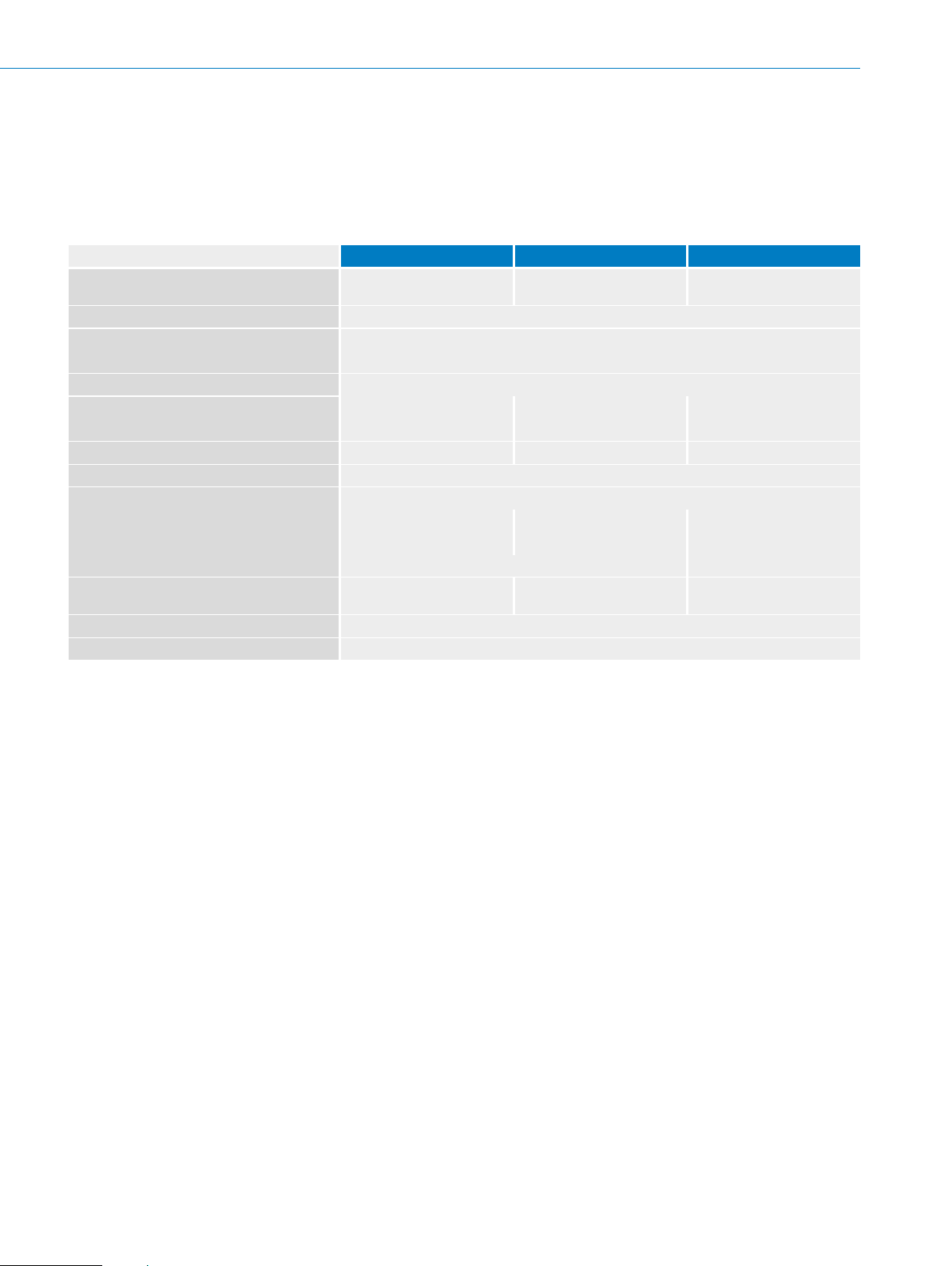

Performance

Max. number of steps per revolution (SSI

interface)

1)

Max. number of revolutions

Absolute singleturn 1

Absolute multiturn 4,096

Resolution

Absolute singleturn 12 bit 15 bit 18 bit

Absolute multiturn 12 x 12 bit 15 x 12 bit 18 x 12 bit

Error limits

Repeatability

Measurement increment deviation

1 ... 399 (steps per revolution) ± 0.2° ± 0.08° ± 0.04°

400 ... 40,000 (steps per revolution) ± 0.2° ± 0.01° ± 0.008°

> 40,000 (steps per revolution) – ± 0.002°

Measuring increment (360 °/ number of

steps per revolution)

Initialization time

Position forming time

1)

See maximum viewing number of resolutions

2)

Position can be read after this period.

4,096 32,768 262,144

± 0.2° ± 0.05° ± 0.03°

0.002°

0.09° 0.01° 0.014°

2)

50 ms

< 1 µs

ABSOLUTE ENCODERS AFS/AFM60 SSI

machines, packaging systems, wood processing machines,

presses, printing machines

Eco Basic Advanced

G

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

G-269

Page 3

AFS/AFM60 SSI ABSOLUTE ENCODERS

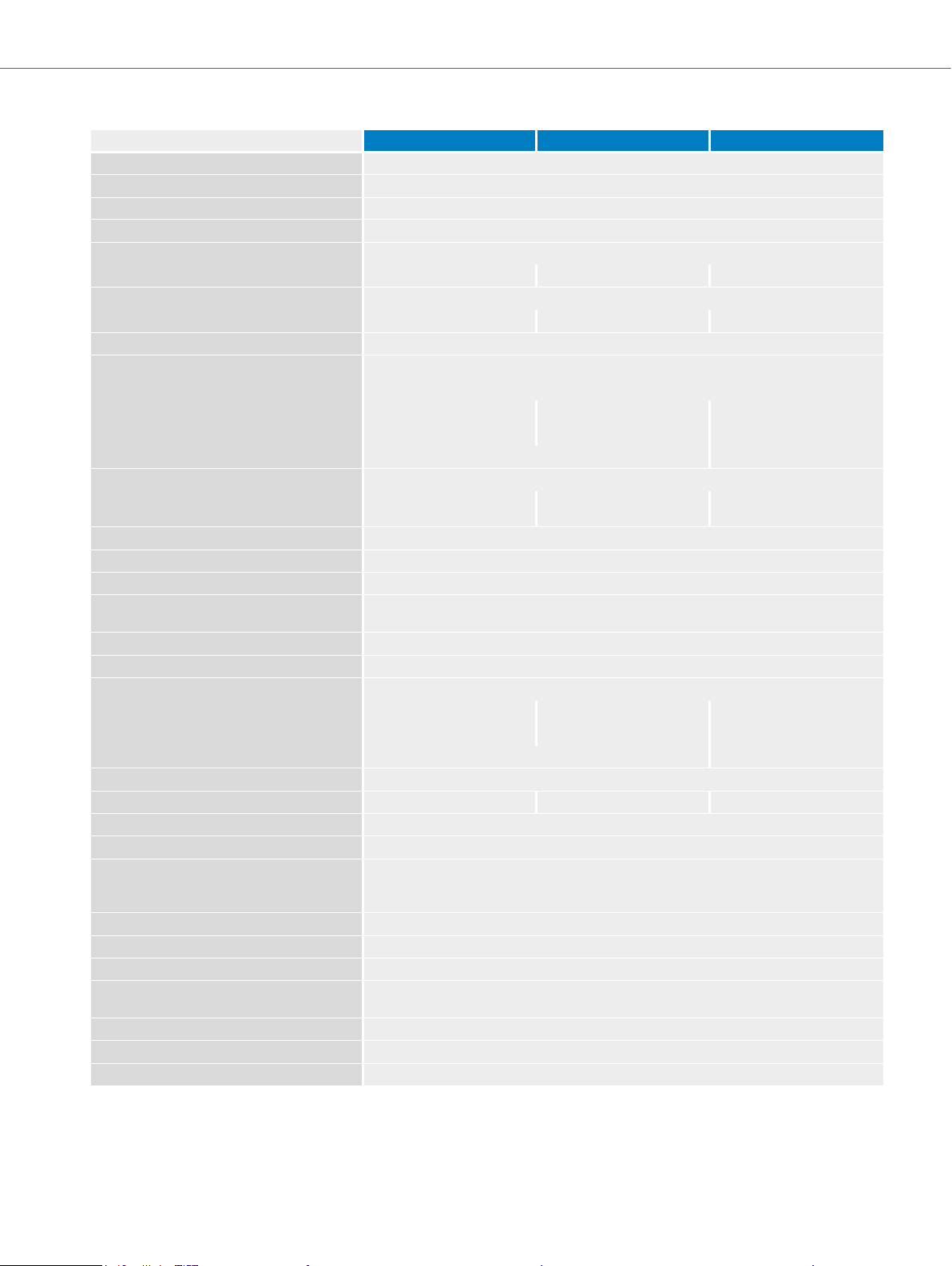

Interfaces

Electrical interface

Signal offset

Code type

Congurable code sequence

Measurement increment

360°/number of steps 0.09° 0.01° 0.0014°

Number of steps per revolution

AFS60 and AFM60

Number of revolutions (AFM60)

Measurement increment deviation

Number of steps per revolution

1 … 399 ± 0.2° ± 0.08° ± 0.04°

400 … 40,000 ± 0.2° ± 0.01° ± 0.008°

> 40,000 – ± 0.002°

Clock+, Clock–, Data+, Data–

SSI max. clock frequency 2 MHz,

and min. LOW level (Clock+): 500 ns

SET (electronic adjustment)

V/¯R (counting sequence when turning)

SSI

2.5 V ± 10%

Gray

CW/CCW

1)

4,096 32,768 262144

4,096

1 MHz 2 MHz 2 MHz

H active (L = 0 – 3 V; H = 4 – US V)

L active (L = 0 – 1.5 V; H = 2.0 – US V)

Eco Basic Advanced

G

Incremental interface TTL/HTL/programmable (AFM60 SSI + incremental)

Number of lines per revolution

Measurement increment

1/4 of number of SSI steps per revolution

90° electric/number of lines

Measurement increment deviation

Number of steps per revolution 1 ... 99 ± 0.2° ± 0.08° ± 0.04°

Number of steps per revolution 100 ... 10,000 ± 0.2° ± 0.01° ± 0.008°

Number of steps per revolution > 10,000 – ± 0.002°

Interface signals A, ¯A, B, ¯B

Max. output frequency

Load current

Digital, differential

300 kHz 600 kHz 820 kHz

30 mA

Incremental interface sine/cosine

4.5 V … 5.5 V, sine 0.5 VSS

(AFM60 SSI + sin/cos)

Number of lines per revolution

Max. output frequency

Load resistance

Interface signals

1,024

200 kHz

Min. 120 Ω

Analog, differential

Sin+, Sin–, Cos+, Cos–

Signal before difference at 120 Ω load

Signal offset before differential generation

Signal after difference at 120 Ω load

1)

See maximum viewing number of resolutions

0.5 VPP ± 20%

2.5 V ± 10%

1 VSS ± 20 %

G-270

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 4

ABSOLUTE ENCODERS AFS/AFM60 SSI

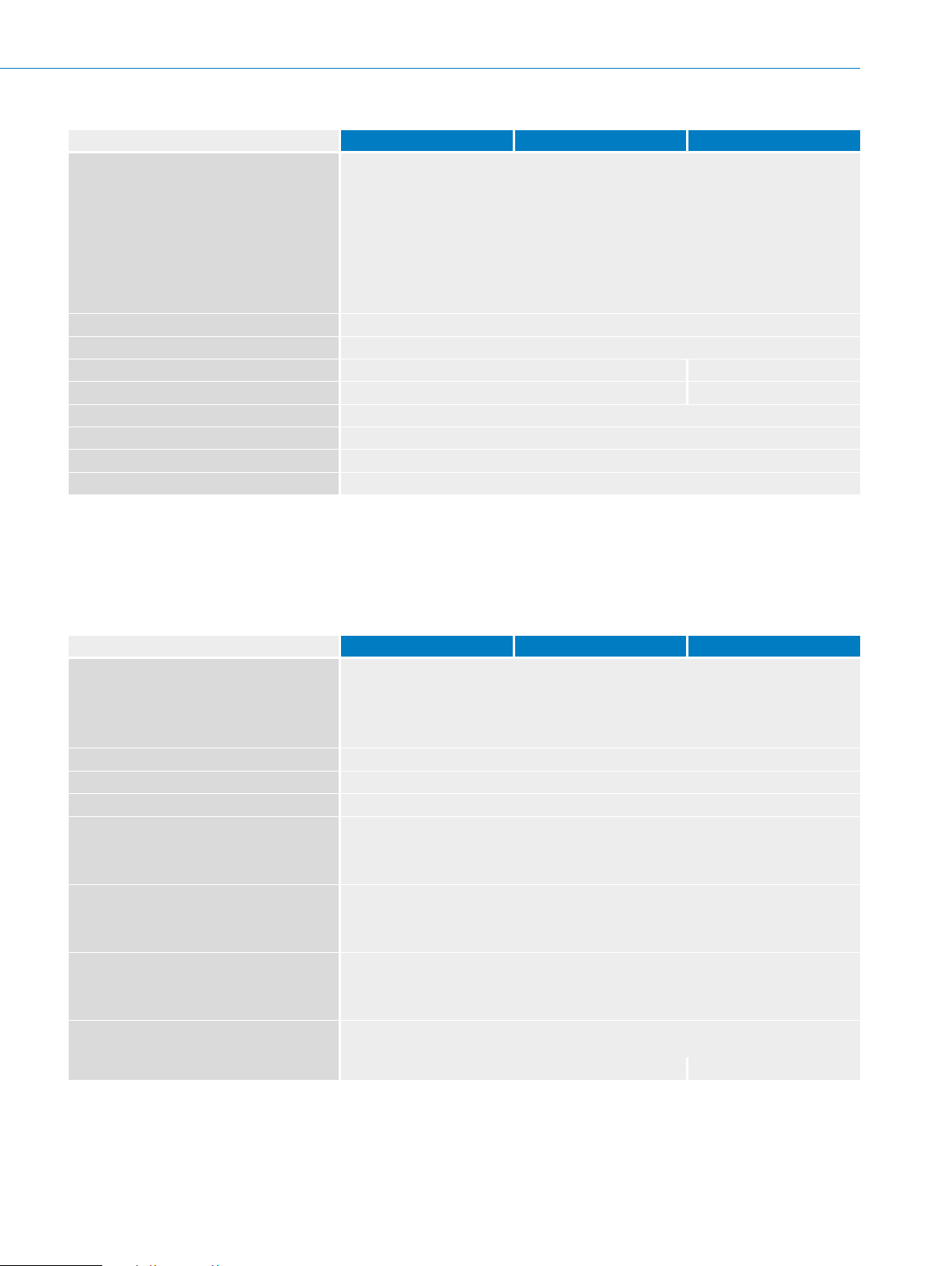

Electrical data

Eco Basic Advanced

Connection type

Power consumption

Operating voltage range

Min. load resistance

Maximum output frequency

Code type

Code sequence

Reverse polarity protection

MTTFd: mean time to dangerous failure

1)

The universal cable outlet is positioned so that it is possible to lay it without bends in a radial or axial direction.

2)

No UL certicate.

3)

This product is a standard product and does not constitute a safety component as dened in the Machinery Directive. Calculation based on nominal load of devices,

average ambient temperature 40 °C, frequency of use 8,760 h/a. All electronic failures are considered hazardous. For more information, see document no.

8015532.

M23 male connector, 12-pin, radial

M12 male connector, 8-pin, radial

Cable, 8-wire, universal, 1.5 m

Cable, 8-wire, universal, 3 m

Cable, 8-wire, universal, 5 m

Cable, 8-wire, universal, 10 m

Cable, 12-wire, radial, 1.5 m

Cable, 12-wire, radial, 3 m

Cable, 12-wire, radial, 5 m

1)

1)

1)

1)

2)

2)

2)

0.5 W (without load)

4.5 V DC ... 32 V DC

– ≥ 120 Ω

– ≤ 200 kHz

Gray

CW/CCW, congurable

l

250 years (EN ISO 13849-1)

3)

Mechanical data

Eco Basic Advanced

Shaft diameter

Face mount ange 10 mm x 19 mm

Servo ange 6 mm x 10 mm

Blind hollow shaft, through hollow shaft 8, 10, 12, 14, 15 mm and 3/8", 1/2", 5/8"

Shaft material Stainless steel

Flange material Aluminum

Housing material Aluminum die-cast

2)

Mass

Face mount ange, servo ange 0.3 kg

Blind hollow shaft, through hollow shaft 0.2 kg

Start up torque at 20 °C

Face mount ange, servo ange 0.5 Ncm

Blind hollow shaft, through hollow shaft 0.8 Ncm

Operating torque at 20 °C

Face mount ange, servo ange 0.3 Ncm

Blind hollow shaft, through hollow shaft 0.6 Ncm

Permissible shaft movement, axial static/

dynamic

Blind hollow shaft, through hollow shaft ± 0.5 mm, ± 0.2 mm ± 0.5 mm, ± 0.1 mm

1)

5/8" not available for multiturn.

2)

Relates to devices with cable outlet.

3)

Take into account self-warming of 3.3 K per 1,000 rpm when designing operating temperature range

1)

G

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

G-271

Page 5

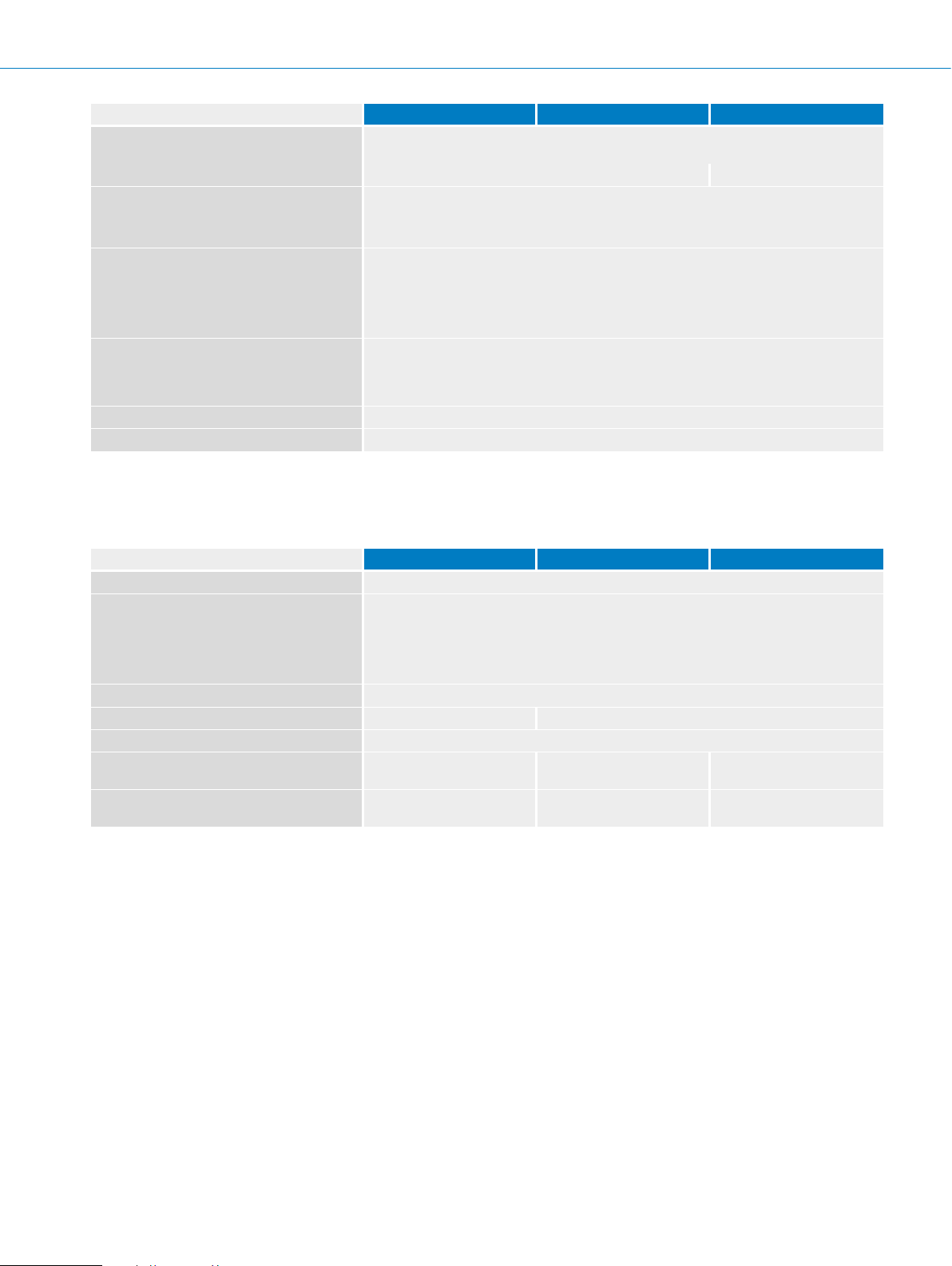

AFS/AFM60 SSI ABSOLUTE ENCODERS

Eco Basic Advanced

Permissible shaft movement, radial static/

dynamic

Blind hollow shaft, through hollow shaft ± 0.3 mm/ ± 0.1 mm ± 0.3 mm/ ± 0.05 mm

Permissible shaft loading

Face mount ange, servo ange 80 N (radial)

40 N (axial)

Maximum operating speed

Face mount ange, servo ange 9,000 rpm

Rotor moment of inertia

Face mount ange, servo ange 6.2 gcm²

Blind hollow shaft, through hollow shaft 40 gcm²

Bearing lifetime

Max. angular acceleration

1)

5/8" not available for multiturn.

2)

Relates to devices with cable outlet.

3)

Take into account self-warming of 3.3 K per 1,000 rpm when designing operating temperature range

3)

Blind hollow shaft 6,000 rpm

Through hollow shaft 9,000 rpm

3.0 x 109 revolutions

≤ 500,000 rad/s²

G

Ambient data

Eco Basic Advanced

EMC

Enclosure rating

On the shaft IP 65

On the housing, male connector outlet

On the housing, cable outlet IP 67

Permissible relative humidity

Operating temperature range

Storage temperature range

Resistance to shocks (according to

EN 60068-2-27)

Resistance to vibration (according to

EN 60068-2-6)

1)

The EMC according to the standards quoted is achieved if shielded cables are used.

2)

In an assembled male connector.

3)

When cables are xed in place.

According to EN 61000-6–2 and EN 61000-6–3

2)

IP 67

90% (condensation of optical surfaces not permitted)

0 °C ... +85 °C –40 °C 3) ... +100 °C

–40 °C ... +100 °C, without packaging

50 g/ 6 ms 70 g/ 6 ms 60 g/ 6 ms

20 g/ 10 Hz ... 2,000 Hz 30 g/ 10 Hz ... 2,000 Hz 20 g/ 10 Hz ... 2,000 Hz

1)

G-272

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 6

ABSOLUTE ENCODERS AFS/AFM60 SSI

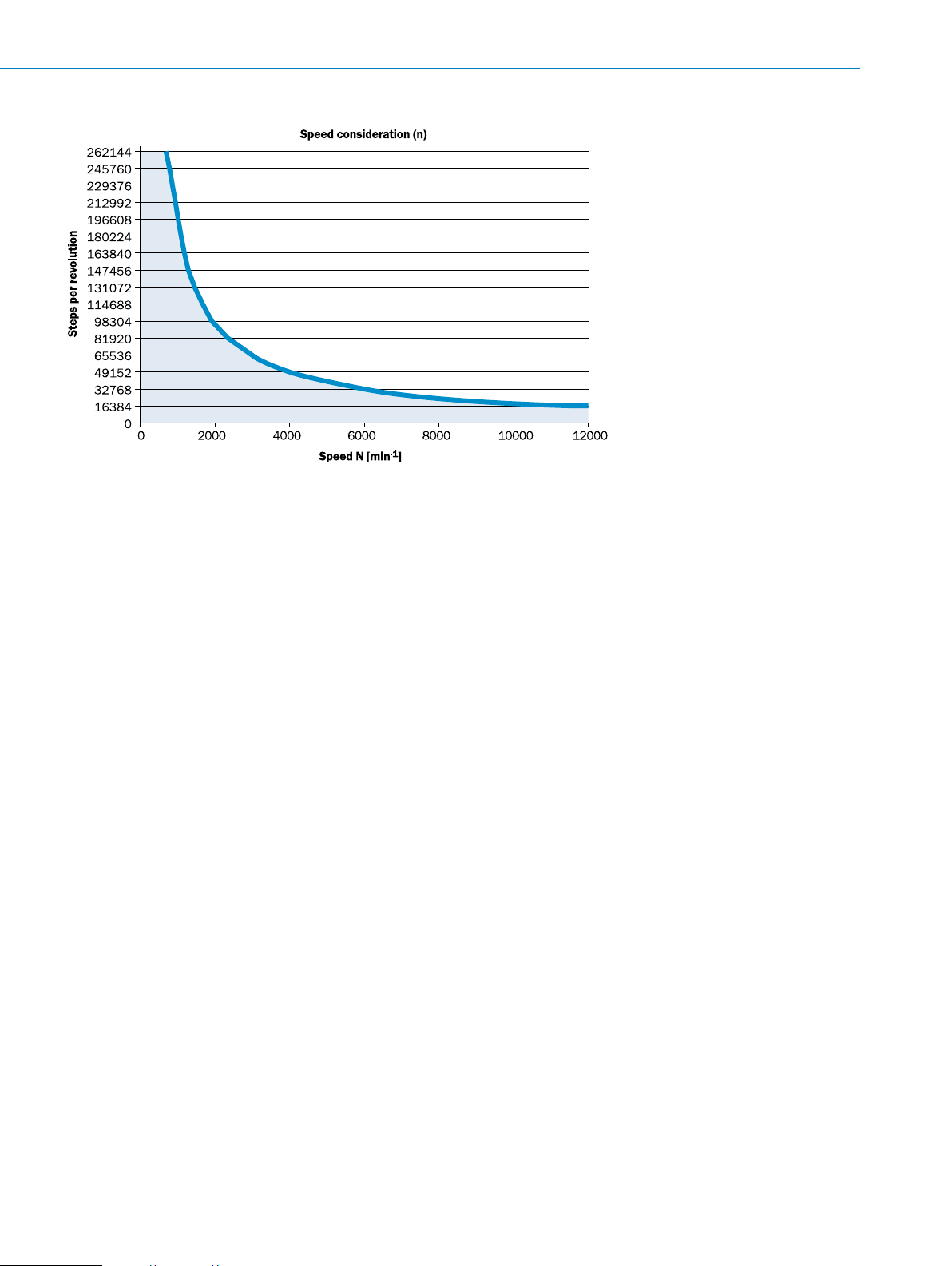

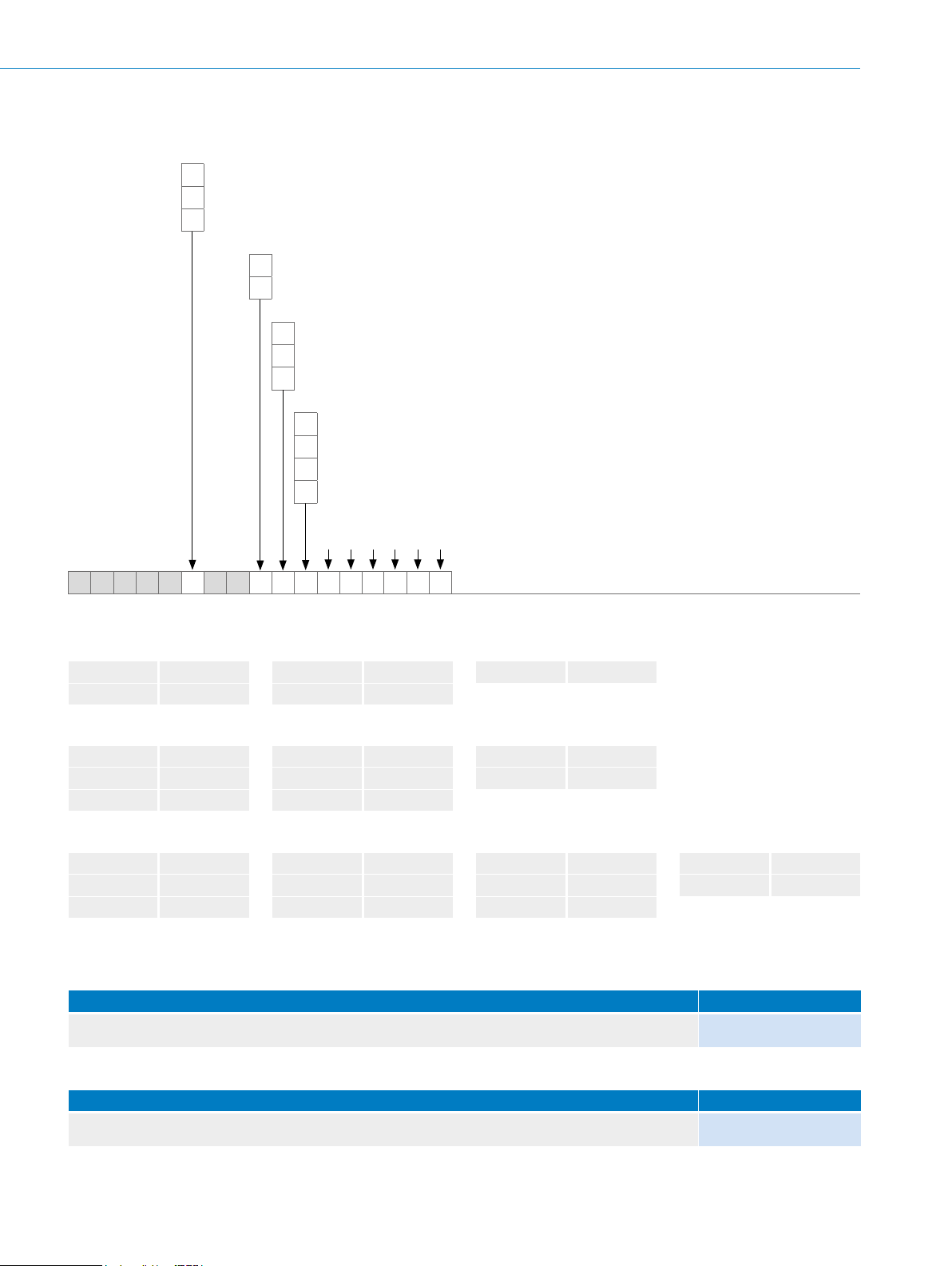

Maximum viewing number of resolutions depends on the selected number of steps per revolution

The maximum speed depends on the type of shaft.

G

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

G-273

Page 7

AFS/AFM60 SSI ABSOLUTE ENCODERS

Ordering information

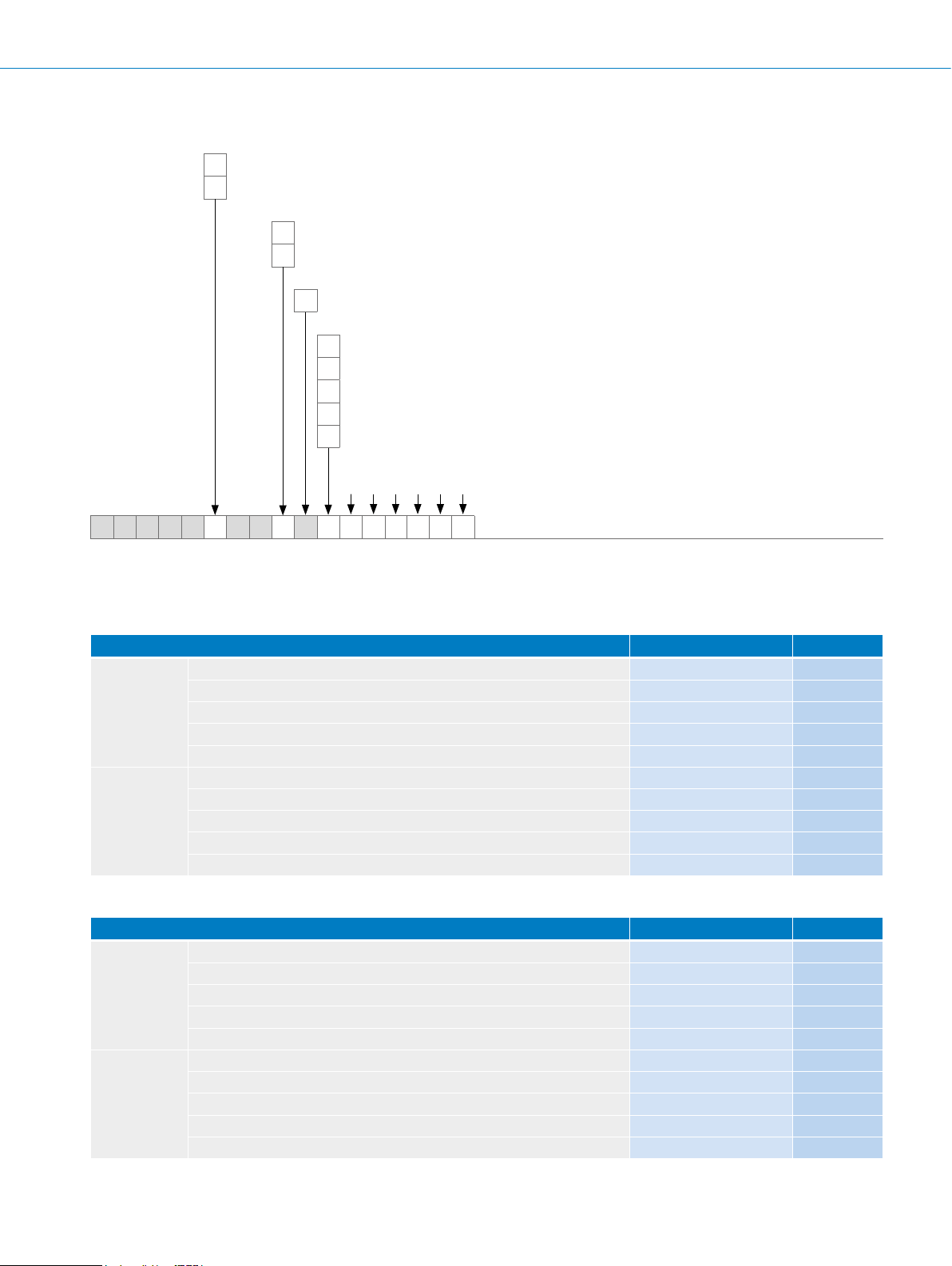

Type code AFS60 SSI absolute encoder, singleturn, solid shaft

Type

Type E (see technical data on page G-269)

E

Type B (see technical data on page G-269)

B

Type A (see technical data on page G-269)

A

Mechanical design

Servo ange, solid shaft, 6 x 10 mm

1

Face mount ange, solid shaft, 10 x 19 mm

4

Electrical interface

4.5 … 32 V SSI/Gray

A

Connection type

Male connector M23, 12-pin, radial

A

Male connector M12, 8-pin, radial

C

Cable, 8-wire, universal, 1.5 m

K

Cable, 8-wire, universal, 3 m

L

Cable, 8-wire, universal, 5 m

M

Resolution

Number of steps per revolution, selection depends on type, see below.

1)

1)

1)

G

A F S 6 0 – S A

1)

The universal cable outlet is positioned so that it is possible to lay it without bends in a radial or axial direction.

Number of steps per revolution

• Type E

000256 8 bit

000512 9 bit

• Type B

000256 8 bit

000512 9 bit

001024 10 bit

1)

Others available on request.

• Type A

000256 8 bit

000512 9 bit

001024 10 bit

1)

Others available on request.

1)

001024 10 bit

002048 11 bit

1)

002048 11 bit

004096 12 bit

008192 13 bit

1)

002048 11 bit

004096 12 bit

008192 13 bit

004096 12 bit

016384 14 bit

032768 15 bit

016384 14 bit

032768 15 bit

065536 16 bit

Example orders

• Servo ange

131072 17 bit

262144 18 bit

Type E, M12 male connector, 8-pin , radial, number of steps per revolution 1,024 (10 bit) AFS60E-S1AC001024

• Face mount ange

Type E, M12 male connector, 8-pin , radial, number of steps per revolution 1,024 (10 bit) AFS60E-S4AC001024

G-274

ENCODERS | SICK 8015560/2015-09-01

Servo ange design Type

Face mount ange design Type

Subject to change without notice

Page 8

ABSOLUTE ENCODERS AFS/AFM60 SSI

Type code AFS60 SSI absolute encoder, singleturn, solid shaft, programmable

Type

Type B (see technical data on page G-269)

B

Type A (see technical data on page G-269)

A

Mechanical design

Servo ange, solid shaft, 6 x 10 mm

1

Face mount ange, solid shaft, 10 x 19 mm

4

Electrical interface

4.5 … 32 V, SSI/Gray, programmable

P

Connection type

Male connector M23, 12-pin, radial

A

Male connector M12, 8-pin, radial

C

Cable, 8-wire, universal, 1.5 m

K

Cable, 8-wire, universal, 3 m

L

Cable, 8-wire, universal, 5 m

M

Resolution

Number of steps per revolution

1)

2)

2)

2)

1)

A F S 6 0 – S P

1)

Number of steps from 256 to 262144 can be programmed by the customer. Factory setting for Type B: 032768; Type A: 262144.

2)

The universal cable outlet is positioned so that it is possible to lay it without bends in a radial or axial direction.

Example orders

• Servo ange

Servo ange design Type Part no.

M23 male connector, 12-pin, radial, number of steps per revolution 32,768 AFS60B-S1PA032768 1037493

M12 male connector, 8-pin, radial, number of steps per revolution 32,768 AFS60B-S1PC032768 1037494

Type B

Type A

Cable, 8-wire, universal, 1.5 m, number of steps per revolution 32,768 AFS60B-S1PK032768 1037495

Cable, 8-wire, universal, 3 m, number of steps per revolution 32,768 AFS60B-S1PL032768 1037496

Cable, 8-wire, universal, 5 m, number of steps per revolution 32,768 AFS60B-S1PM032768 1037497

M23 male connector, 12-pin , radial, number of steps per revolution 262144 AFS60A-S1PA262144 1037498

M12 male connector, 8-pin, radial, number of steps per revolution 262144 AFS60A-S1PC262144 1037499

Cable, 8-wire, universal, 1.5 m, number of steps per revolution 262144 AFS60A-S1PK262144 1037500

Cable, 8-wire, universal, 3 m, number of steps per revolution 262144 AFS60A-S1PL262144 1037501

Cable, 8-wire, universal, 5 m, number of steps per revolution 262144 AFS60A-S1PM262144 1037502

• Face mount ange

Face mount ange design Type Part no.

M23 male connector, 12-pin, radial, number of steps per revolution 32,768 AFS60B-S4PA032768 1037483

M12 male connector, 8-pin, radial, number of steps per revolution 32,768 AFS60B-S4PC032768 1037484

Type B

Type A

Cable, 8-wire, universal, 1.5 m, number of steps per revolution 32,768 AFS60B-S4PK032768 1037485

Cable, 8-wire, universal, 3 m, number of steps per revolution 32,768 AFS60B-S4PL032768 1037486

Cable, 8-wire, universal, 5 m, number of steps per revolution 32,768 AFS60B-S4PM032768 1037487

M23 male connector, 12-pin , radial, number of steps per revolution 262144 AFS60A-S4PA262144 1037488

M12 male connector, 8-pin, radial, number of steps per revolution 262144 AFS60A-S4PC262144 1037489

Cable, 8-wire, universal, 1.5 m, number of steps per revolution 262144 AFS60A-S4PK262144 1037490

Cable, 8-wire, universal, 3 m, number of steps per revolution 262144 AFS60A-S4PL262144 1037491

Cable, 8-wire, universal, 5 m, number of steps per revolution 262144 AFS60A-S4PM262144 1037492

G

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

G-275

Page 9

AFS/AFM60 SSI ABSOLUTE ENCODERS

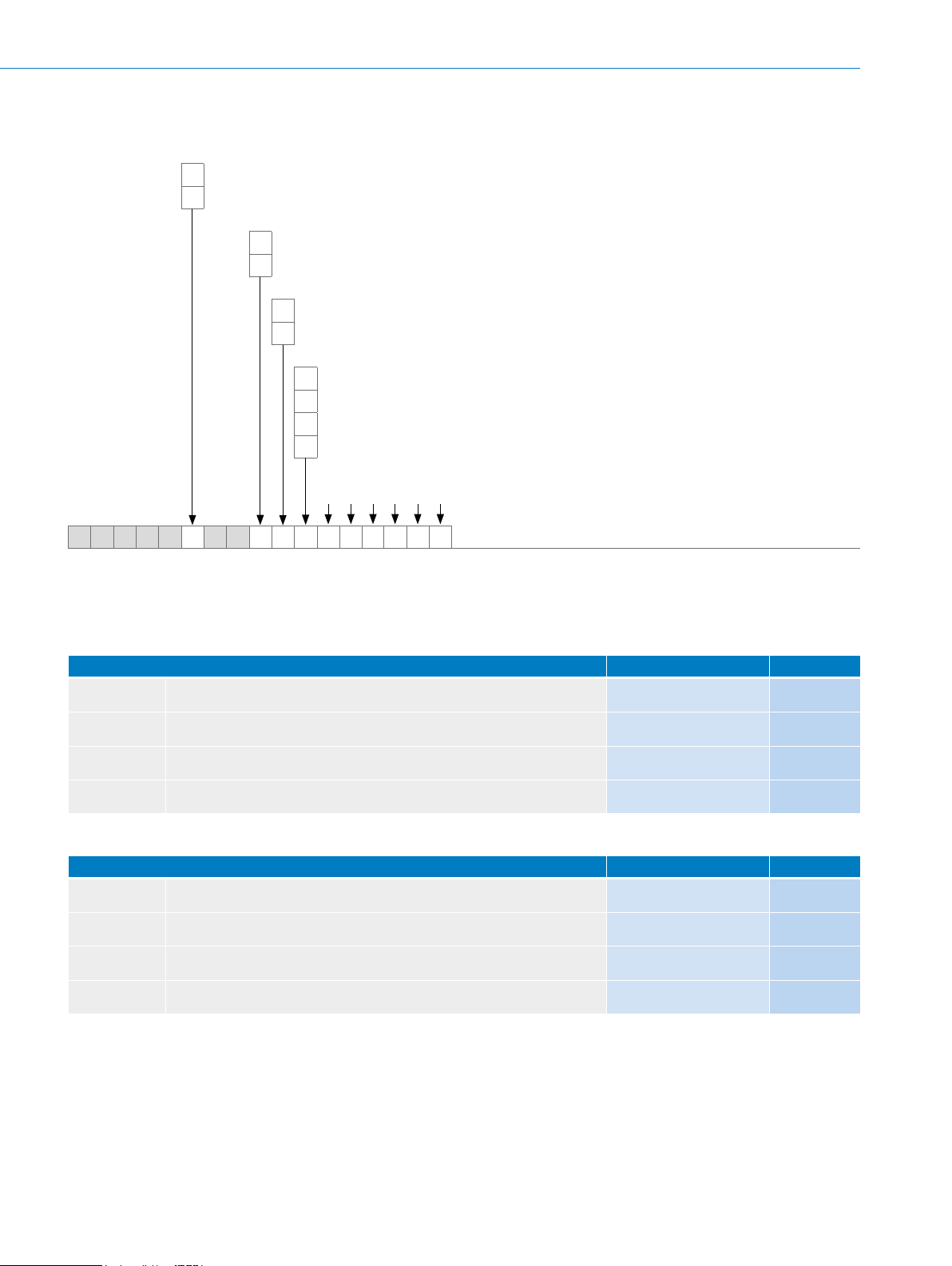

Type code AFM60 SSI/gray absolute encoder, multiturn, 4,096 revolutions, solid shaft

Type

Type E (see technical data on page G-269)

E

Type B (see technical data on page G-269)

B

Type A (see technical data on page G-269)

A

Mechanical design

Servo ange, solid shaft, 6 x 10 mm

1

Face mount ange, solid shaft, 10 x 19 mm

4

Electrical interface

4.5 … 32 V SSI/Gray

A

Connection type

Male connector M23, 12-pin, radial

A

Male connector M12, 8-pin, radial

C

Cable, 8-wire, universal, 1.5 m

K

Cable, 8-wire, universal, 3 m

L

Cable, 8-wire, universal, 5 m

M

Resolution

Number of steps per revolution, selection depends on type, see below.

1)

1)

1)

G

A F M 6 0 – S A

1)

The universal cable outlet is positioned so that it is possible to lay it without bends in a radial or axial direction.

Number of steps per revolution x 4,096 (12 bit)

• Type E

000256 8 bit

000512 9 bit

001024 10 bit

002048 11 bit

004096 12 bit

• Type B

000256 8 bit

000512 9 bit

001024 10 bit

002048 11 bit

004096 12 bit

008192 13 bit

016384 14 bit

032768 15 bit

• Type A

000256 8 bit

000512 9 bit

001024 10 bit

002048 11 bit

004096 12 bit

008192 13 bit

016384 14 bit

032768 15 bit

065536 16 bit

Example orders

• Servo ange

Servo ange design Type

Type E, cable, 8-wire, universal, 1.5 m, number of steps per revolution 4,096 (12 bits) AFM60E-S1AK004096

131072 17 bit

262144 18 bit

• Face mount ange

Type E, cable, 8-wire, universal, 1.5 m, number of steps per revolution 4,096 (12 bits) AFM60E-S4AK004096

G-276

ENCODERS | SICK 8015560/2015-09-01

Face mount ange design Type

Subject to change without notice

Page 10

ABSOLUTE ENCODERS AFS/AFM60 SSI

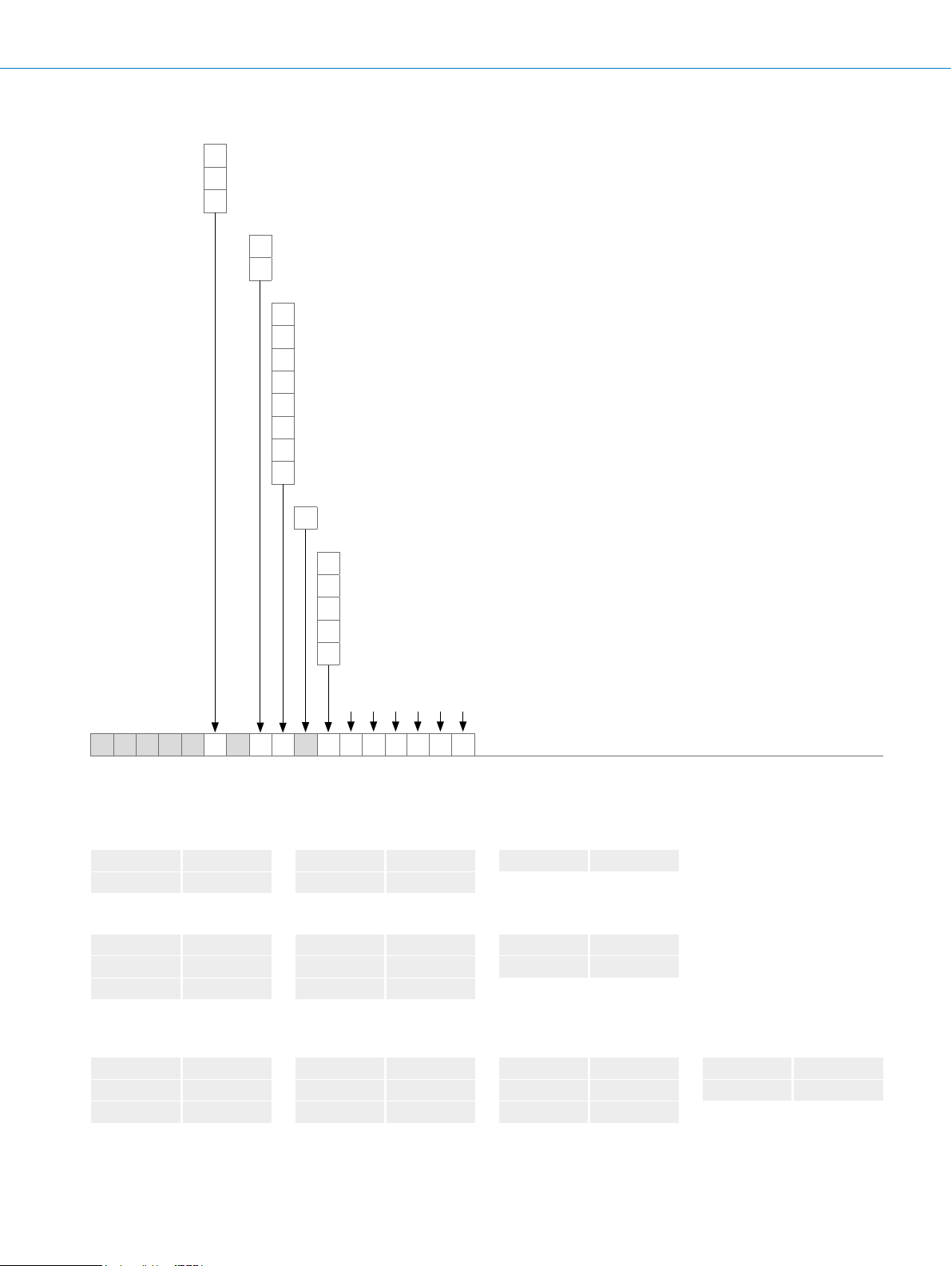

Type code AFM60 SSI/gray + incremental and SSI/gray + sin/cos, absolute encoder, multiturn, 4,096 revolutions, solid shaft

Type

Type E (see technical data on page G-269)

E

Type B (see technical data on page G-269)

B

Type A (see technical data on page G-269)

A

Mechanical design

Servo ange, solid shaft, 6 x 10 mm

1

Face mount ange, solid shaft, 10 x 19 mm

4

Electrical interface

4.5 … 32 V, SSI/Gray + incremental, HTL

L

4.5 … 32 V, SSI/Gray + incremental, TTL

T

4.5 … 32 V, SSI/Gray + Sin/Cos, 1,024 periods

K

Connection type

Male connector M23, 12-pin, radial

A

Cable, 12-wire, radial, 1.5 m

K

Cable, 12-wire, radial, 3.0 m

L

Cable, 12-wire, radial, 5.0 m

M

Resolution

Number of steps per revolution, selection depends on type, see below.

A F M 6 0 – S

Number of steps per revolution x 4,096 (12 bit), number of incremental lines in brackets

• Type E

000256 8 bit (64)

000512 9 bit (128)

001024 10 bit (256)

002048 11 bit (512)

004096 12 bit (1024)

• Type B

000256 8 bit (64)

000512 9 bit (128)

001024 10 bit (256)

002048 11 bit (512)

004096 12 bit (1024)

008192 13 bit (2048)

016384 14 bit (4096)

032768 15 bit (8192)

• Type A

000256 8 bit (64)

000512 9 bit (128)

001024 10 bit (256)

002048 11 bit (512)

004096 12 bit (1024)

008192 13 bit (2048)

016384 14 bit (4096)

032768 15 bit (8192)

065536 16 bit (16384)

Example orders

• Servo ange

Servo ange design Type

Type E, 4.5 ... 32 V, SSI/gray + incremental, TTL, M23 male connector, 12-pin , radial, number of steps per revolu-

tion 2,048 (11 bit)

G

131072 17 bit (32768)

262144 18 bit (65536)

AFM60E-S1TA002048

• Face mount ange

Face mount ange design Type

Type E, 4.5 ... 32 V, SSI/gray + incremental, TTL, M23 male connector, 12-pin , radial, number of steps per revolu-

tion 2,048 (11 bit)

Subject to change without notice

AFM60E-S4TA002048

ENCODERS | SICK8015560/2015-09-01

G-277

Page 11

AFS/AFM60 SSI ABSOLUTE ENCODERS

Type code AFM60 SSI/gray absolute encoder, multiturn, 4,096 revolutions, solid shaft, programmable

Type

Type B (see technical data on page G-269)

B

Type A (see technical data on page G-269)

A

Mechanical design

Servo ange, solid shaft, 6 x 10 mm

1

Face mount ange, solid shaft, 10 x 19 mm

4

Electrical interface

4.5 … 32 V, SSI/Gray, programmable

P

Connection type

Male connector M23, 12-pin, radial

A

Male connector M12, 8-pin, radial

C

Cable, 8-wire, universal, 1.5 m

K

Cable, 8-wire, universal, 3 m

L

Cable, 8-wire, universal, 5 m

M

Resolution

Number of steps per revolution

1)

2)

2)

2)

1)

G

A F M 6 0 – S P

1)

Number of steps from 256 (8 bit) to 262144 (18 bit) can be programmed by the customer. Factory setting for Type B: 032768; Type A: 262144.

2)

The universal cable outlet is positioned so that it is possible to lay it without bends in a radial or axial direction.

Example orders

• Servo ange

Servo ange design Type Part no.

M23 male connector, 12-pin, radial, number of steps per revolution 32,768 AFM60B-S1PA032768 1037513

M12 male connector, 8-pin, radial, number of steps per revolution 32,768 AFM60B-S1PC032768 1037514

Type B

Type A

Cable, 8-wire, universal, 1.5 m, number of steps per revolution 32,768 AFM60B-S1PK032768 1037515

Cable, 8-wire, universal, 3 m, number of steps per revolution 32,768 AFM60B-S1PL032768 1037516

Cable, 8-wire, universal, 5 m, number of steps per revolution 32,768 AFM60B-S1PM032768 1037517

M23 male connector, 12-pin , radial, number of steps per revolution 262144 AFM60A-S1PA262144 1037518

M12 male connector, 8-pin, radial, number of steps per revolution 262144 AFM60A-S1PC262144 1037519

Cable, 8-wire, universal, 1.5 m, number of steps per revolution 262144 AFM60A-S1PK262144 1037520

Cable, 8-wire, universal, 3 m, number of steps per revolution 262144 AFM60A-S1PL262144 1037521

Cable, 8-wire, universal, 5 m, number of steps per revolution 262144 AFM60A-S1PM262144 1037522

• Face mount ange

Face mount ange design Type Part no.

M23 male connector, 12-pin, radial, number of steps per revolution 32,768 AFM60B-S4PA032768 1037503

M12 male connector, 8-pin, radial, number of steps per revolution 32,768 AFM60B-S4PC032768 1037504

Type B

Type A

Cable, 8-wire, universal, 1.5 m, number of steps per revolution 32,768 AFM60B-S4PK032768 1037505

Cable, 8-wire, universal, 3 m, number of steps per revolution 32,768 AFM60B-S4PL032768 1037506

Cable, 8-wire, universal, 5 m, number of steps per revolution 32,768 AFM60B-S4PM032768 1037507

M23 male connector, 12-pin , radial, number of steps per revolution 262144 AFM60A-S4PA262144 1037508

M12 male connector, 8-pin, radial, number of steps per revolution 262144 AFM60A-S4PC262144 1037509

Cable, 8-wire, universal, 1.5 m, number of steps per revolution 262144 AFM60A-S4PK262144 1037510

Cable, 8-wire, universal, 3 m, number of steps per revolution 262144 AFM60A-S4PL262144 1037511

Cable, 8-wire, universal, 5 m, number of steps per revolution 262144 AFM60A-S4PM262144 1037512

G-278

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 12

ABSOLUTE ENCODERS AFS/AFM60 SSI

Type code AFM60 SSI/gray + incremental and SSI/gray + sin/cos, absolute encoder, multiturn, 4,096 revolutions, solid shaft, programmable

Type

Type B (see technical data on page G-269)

B

Type A (see technical data on page G-269)

A

Mechanical design

Servo ange, solid shaft, 6 x 10 mm

1

Face mount ange, solid shaft, 10 x 19 mm

4

Electrical interface

4.5 … 32 V, SSI/Gray + incremental, programmable

R

4.5 … 32 V, SSI/Gray programmable + sin/cos, 1,024 periods

S

Connection type

Male connector M23, 12-pin, radial

A

Cable, 12-wire, radial, 1.5 m

K

Cable, 12-wire, radial, 3.0 m

L

Cable, 12-wire, radial, 5.0 m

M

Resolution

Number of steps per revolution

1)

1)

1)

A F M 6 0 – S

1)

Number of steps from 256 (8 bit) to 262144 (18 bit) can be programmed by the customer. Factory setting for Type B: 032768; Type A: 262144. Number of incremen-

tal lines is always 1/4 of the number of SSI/gray lines.

Example orders

• Servo ange

Servo ange design Type Part no.

Type B

Type A

Type B

Type A

4.5 ... 32 V, SSI/gray + incremental, programmable, M23 male connector, 12pin, radial, number of steps per revolution 32,768

4.5 ... 32 V, SSI/gray + incremental, programmable, M23 male connector, 12-

pin , radial, number of steps per revolution 262144

4.5 ... 32 V, SSI/gray, programmable, + sin/cos, 1,024 periods, M23 male connector, 12-pin, radial, number of steps per revolution 32,768

4.5 ... 32 V, SSI/gray, programmable, + sin/cos, 1,024 periods, M23 male con-

nector, 12-pin , radial, number of steps per revolution 262144

AFM60B-S1RA032768 1052835

AFM60A-S1RA262144 1052837

AFM60B-S1SA032768 1054220

AFM60A-S1SA262144 1054219

• Face mount ange

Face mount ange design Type Part no.

Type B

Type A

Type B

Type A

4.5 ... 32 V, SSI/gray + incremental, programmable, M23 male connector, 12pin, radial, number of steps per revolution 32,768

4.5 ... 32 V, SSI/gray + incremental, programmable, M23 male connector, 12-

pin , radial, number of steps per revolution 262144

4.5 ... 32 V, SSI/gray, programmable, + sin/cos, 1,024 periods, M23 male connector, 12-pin, radial, number of steps per revolution 32,768

4.5 ... 32 V, SSI/gray, programmable, + sin/cos, 1,024 periods, M23 male con-

nector, 12-pin , radial, number of steps per revolution 262144

AFM60B-S4RA032768 1052833

AFM60A-S4RA262144 1052624

AFM60B-S4SA032768 1054222

AFM60A-S4SA262144 1054221

G

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

G-279

Page 13

AFS/AFM60 SSI ABSOLUTE ENCODERS

Type code AFS60 SSI absolute encoder, singleturn, hollow shaft

Type

Type E (see technical data on page G-269)

E

Type B (see technical data on page G-269)

B

Type A (see technical data on page G-269)

A

Mechanical design

Blind hollow shaft

B

Through hollow shaft

T

Hollow shaft diameter 8 mm

B

Hollow shaft diameter 3/8"

C

Hollow shaft diameter 10 mm

D

Hollow shaft diameter 12 mm

E

Hollow shaft diameter 1/2"

F

Hollow shaft diameter 14 mm

G

Hollow shaft diameter 15 mm

H

Hollow shaft diameter 5/8"

J

Electrical interface

4.5 … 32 V SSI/Gray

A

Connection type

Male connector M23, 12-pin, radial

A

Male connector M12, 8-pin, radial

C

Cable, 8-wire, universal, 1.5 m

K

Cable, 8-wire, universal, 3 m

L

Cable, 8-wire, universal, 5 m

M

Resolution

Number of steps per revolution, selection depends on type, see below.

1)

1)

1)

G

A F S 6 0 – A

1)

The universal cable outlet is positioned so that it is possible to lay it without bends in a radial or axial direction.

Number of steps per revolution

• Type E

000256 8 bit

000512 9 bit

• Type B

000256 8 bit

000512 9 bit

001024 10 bit

1)

Others available on request.

• Type A

000256 8 bit

000512 9 bit

001024 10 bit

1)

Others available on request.

1)

001024 10 bit

002048 11 bit

1)

002048 11 bit

004096 12 bit

008192 13 bit

1)

002048 11 bit

004096 12 bit

008192 13 bit

004096 12 bit

016384 14 bit

032768 15 bit

016384 14 bit

032768 15 bit

065536 16 bit

131072 17 bit

262144 18 bit

G-280

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 14

ABSOLUTE ENCODERS AFS/AFM60 SSI

Example orders

• Blind hollow shaft

Blind hollow shaft design Type

Type E, hollow shaft design 8 mm, M12 male connector, 8-pin , radial, number of steps per revolution 1,024 (10 bit) AFS60E-BBAC001024

• Through hollow shaft

Through hollow shaft design Type

Type E, hollow shaft design 8 mm, M12 male connector, 8-pin , radial, number of steps per revolution 1,024 (10 bit) AFS60E-TBAC001024

G

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

G-281

Page 15

AFS/AFM60 SSI ABSOLUTE ENCODERS

Type code AFS60 SSI absolute encoder, singleturn, hollow shaft, programmable

Type

Type B (see technical data on page G-269)

B

Type A (see technical data on page G-269)

A

Mechanical design

Blind hollow shaft

B

Through hollow shaft

T

Hollow shaft diameter 8 mm

B

Hollow shaft diameter 3/8"

C

Hollow shaft diameter 10 mm

D

Hollow shaft diameter 12 mm

E

Hollow shaft diameter 1/2"

F

Hollow shaft diameter 14 mm

G

Hollow shaft diameter 15 mm

H

Hollow shaft diameter 5/8"

J

Electrical interface

4.5 … 32 V SSI/Gray

P

Connection type

Male connector M23, 12-pin, radial

A

Male connector M12, 8-pin, radial

C

Cable, 8-wire, universal, 1.5 m

K

Cable, 8-wire, universal, 3 m

L

Cable, 8-wire, universal, 5 m

M

Resolution

Number of steps per revolution

1)

2)

2)

2)

1)

G

A F S 6 0 – P

1)

Number of steps from 256 to 262144 can be programmed by the customer. Factory setting for Type B: 032768; Type A: 262144.

2)

The universal cable outlet is positioned so that it is possible to lay it without bends in a radial or axial direction.

G-282

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 16

ABSOLUTE ENCODERS AFS/AFM60 SSI

Example orders

1)

• Blind hollow shaft

Blind hollow shaft design Type

M23 male connector, 12-pin, radial, number of steps per revolution 32,768 AFS60B-BxPA032768

Type B

Type A

1)

x stands for hollow shaft diameters B to J, please enter corresponding letters in position 9.

M12 male connector, 8-pin, radial, number of steps per revolution 32,768 AFS60B-BxPC032768

Cable, 8-wire, universal, 1.5 m, number of steps per revolution 32,768 AFS60B-BxPK032768

M23 male connector, 12-pin , radial, number of steps per revolution 262144 AFS60A-BxPA262144

M12 male connector, 8-pin, radial, number of steps per revolution 262144 AFS60A-BxPC262144

Cable, 8-wire, universal, 1.5 m, number of steps per revolution 262144 AFS60A-BxPK262144

• Through hollow shaft

Through hollow shaft design Type

M23 male connector, 12-pin, radial, number of steps per revolution 32,768 AFS60B-TxPA032768

Type B

Type A

1)

x stands for hollow shaft diameters B to J, please enter corresponding letters in position 9.

M12 male connector, 8-pin, radial, number of steps per revolution 32,768 AFS60B-TxPC032768

Cable, 8-wire, universal, 1.5 m, number of steps per revolution 32,768 AFS60B-TxPK032768

M23 male connector, 12-pin , radial, number of steps per revolution 262144 AFS60A-TxPA262144

M12 male connector, 8-pin, radial, number of steps per revolution 262144 AFS60A-TxPC262144

Cable, 8-wire, universal, 1.5 m, number of steps per revolution 262144 AFS60A-TxPK262144

G

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

G-283

Page 17

AFS/AFM60 SSI ABSOLUTE ENCODERS

Type code AFM60 SSI/gray absolute encoder, multiturn, 4,096 revolutions, hollow shaft

Type

Type E (see technical data on page G-269)

E

Type B (see technical data on page G-269)

B

Type A (see technical data on page G-269)

A

Mechanical design

Blind hollow shaft

B

Through hollow shaft

T

Hollow shaft diameter 8 mm

B

Hollow shaft diameter 3/8"

C

Hollow shaft diameter 10 mm

D

Hollow shaft diameter 12 mm

E

Hollow shaft diameter 1/2"

F

Hollow shaft diameter 14 mm

G

Hollow shaft diameter 15 mm

H

Electrical interface

4.5 … 32 V SSI/Gray

A

Connection type

Male connector M23, 12-pin, radial

A

Male connector M12, 8-pin, radial

C

Cable, 8-wire, universal, 1.5 m

K

Cable, 8-wire, universal, 3 m

L

Cable, 8-wire, universal, 5 m

M

Resolution

Number of steps per revolution, selection depends on type, see below.

1)

1)

1)

G

A F M 6 0 – A

1)

The universal cable outlet is positioned so that it is possible to lay it without bends in a radial or axial direction.

Number of steps per revolution x 4,096 (12 bit)

• Type E

000256 8 bit

000512 9 bit

001024 10 bit

002048 11 bit

004096 12 bit

• Type B

000256 8 bit

000512 9 bit

001024 10 bit

002048 11 bit

004096 12 bit

008192 13 bit

016384 14 bit

032768 15 bit

• Type A

000256 8 bit

000512 9 bit

001024 10 bit

002048 11 bit

004096 12 bit

008192 13 bit

016384 14 bit

032768 15 bit

065536 16 bit

131072 17 bit

262144 18 bit

G-284

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 18

ABSOLUTE ENCODERS AFS/AFM60 SSI

Example orders

• Blind hollow shaft

Blind hollow shaft design Type

Type E, hollow shaft diameter 8 mm cable, 8-wire, universal, 1.5 m, number of steps per revolution 4,096 (12 bits) AFM60E-BBAK004096

• Through hollow shaft

Through hollow shaft design Type

Type E, hollow shaft diameter 8 mm cable, 8-wire, universal, 1.5 m, number of steps per revolution 4,096 (12 bits) AFM60E-TBAK004096

G

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

G-285

Page 19

G

AFS/AFM60 SSI ABSOLUTE ENCODERS

Type code AFM60 SSI/gray + incremental and SSI/gray + sin/cos, absolute encoder, multiturn, 4,096 revolutions, hollow shaft

Type

Type E (see technical data on page G-269)

E

Type B (see technical data on page G-269)

B

Type A (see technical data on page G-269)

A

Mechanical design

Blind hollow shaft

B

Through hollow shaft

T

Hollow shaft diameter 8 mm

B

Hollow shaft diameter 3/8"

C

Hollow shaft diameter 10 mm

D

Hollow shaft diameter 12 mm

E

Hollow shaft diameter 1/2"

F

Hollow shaft diameter 14 mm

G

Hollow shaft diameter 15 mm

H

Electrical interface

4.5 … 32 V, SSI/Gray + incremental, HTL

L

4.5 … 32 V, SSI/Gray + incremental, TTL

T

4.5 … 32 V, SSI/Gray + Sin/Cos, 1,024 periods

K

Connection type

Male connector M23, 12-pin, radial

A

Cable, 12-wire, radial, 1.5 m

K

Cable, 12-wire, radial, 3.0 m

L

Cable, 12-wire, radial, 5.0 m

M

Resolution

Number of steps per revolution, selection depends on type, see below.

A F M 6 0 –

Number of steps per revolution x 4,096 (12 bit), number of incremental lines in brackets

• Type E

000256 8 bit (64)

000512 9 bit (128)

001024 10 bit (256)

002048 11 bit (512)

004096 12 bit (1024)

• Type B

000256 8 bit (64)

000512 9 bit (128)

001024 10 bit (256)

002048 11 bit (512)

004096 12 bit (1024)

008192 13 bit (2048)

016384 14 bit (4096)

032768 15 bit (8192)

• Type A

000256 8 bit (64)

000512 9 bit (128)

001024 10 bit (256)

G-286

ENCODERS | SICK 8015560/2015-09-01

002048 11 bit (512)

004096 12 bit (1024)

008192 13 bit (2048)

016384 14 bit (4096)

032768 15 bit (8192)

065536 16 bit (16384)

131072 17 bit (32768)

262144 18 bit (65536)

Subject to change without notice

Page 20

ABSOLUTE ENCODERS AFS/AFM60 SSI

Example orders

• Blind hollow shaft

Blind hollow shaft design Type

Type E, hollow shaft diameter 8 mm, 4.5 ... 32 V, SSI/gray + incremental, TTL, M23 male connector, 12-pin , radial,

number of steps per revolution 2,048 (11 bit)

• Through hollow shaft

Through hollow shaft design Type

Type E, hollow shaft diameter 8 mm, 4.5 ... 32 V, SSI/gray + incremental, TTL, M23 male connector, 12-pin , radial,

number of steps per revolution 2,048 (11 bit)

AFM60E-BBTA002048

AFM60E-TBTA002048

G

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

G-287

Page 21

AFS/AFM60 SSI ABSOLUTE ENCODERS

Type code AFM60 SSI/gray absolute encoder, multiturn, 4,096 revolutions, hollow shaft, programmable

Type

Type B (see technical data on page G-269)

B

Type A (see technical data on page G-269)

A

Mechanical design

Blind hollow shaft

B

Through hollow shaft

T

Hollow shaft diameter 8 mm

B

Hollow shaft diameter 3/8"

C

Hollow shaft diameter 10 mm

D

Hollow shaft diameter 12 mm

E

Hollow shaft diameter 1/2"

F

Hollow shaft diameter 14 mm

G

Hollow shaft diameter 15 mm

H

Electrical interface

4.5 … 32 V, SSI/Gray, programmable

P

Connection type

Male connector M23, 12-pin, radial

A

Male connector M12, 8-pin, radial

C

Cable, 8-wire, universal, 1.5 m

K

Cable, 8-wire, universal, 3 m

L

Cable, 8-wire, universal, 5 m

M

Resolution

Number of steps per revolution

1)

2)

2)

2)

1)

G

A F M 6 0 – P

1)

Number of steps from 256 (8 bit) to 262144 (18 bit) can be programmed by the customer. Factory setting for Type B: 032768; Type A: 262144.

2)

The universal cable outlet is positioned so that it is possible to lay it without bends in a radial or axial direction.

G-288

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 22

ABSOLUTE ENCODERS AFS/AFM60 SSI

Example orders

1)

• Blind hollow shaft

Blind hollow shaft design Type

M23 male connector, 12-pin, radial, number of steps per revolution 32,768 AFM60B-BxPA032768

Type B

Type A

1)

x stands for hollow shaft diameters B to H, please enter corresponding letters in position 9.

M12 male connector, 8-pin, radial, number of steps per revolution 32,768 AFM60B-BxPC032768

Cable, 8-wire, universal, 1.5 m, number of steps per revolution 32,768 AFM60B-BxPK032768

M23 male connector, 12-pin , radial, number of steps per revolution 262144 AFM60A-BxPA262144

M12 male connector, 8-pin, radial, number of steps per revolution 262144 AFM60A-BxPC262144

Cable, 8-wire, universal, 1.5 m, number of steps per revolution 262144 AFM60A-BxPK262144

• Through hollow shaft

Through hollow shaft design Type

M23 male connector, 12-pin, radial, number of steps per revolution 32,768 AFM60B-TxPA032768

Type B

Type A

1)

x stands for hollow shaft diameters B to H, please enter corresponding letters in position 9.

M12 male connector, 8-pin, radial, number of steps per revolution 32,768 AFM60B-TxPC032768

Cable, 8-wire, universal, 1.5 m, number of steps per revolution 32,768 AFM60B-TxPK032768

M23 male connector, 12-pin , radial, number of steps per revolution 262144 AFM60A-TxPA262144

M12 male connector, 8-pin, radial, number of steps per revolution 262144 AFM60A-TxPC262144

Cable, 8-wire, universal, 1.5 m, number of steps per revolution 262144 AFM60A-TxPK262144

G

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

G-289

Page 23

AFS/AFM60 SSI ABSOLUTE ENCODERS

Type code AFM60 SSI/gray + incremental and SSI/gray + sin/cos, absolute encoder, multiturn, 4,096 revolutions, hollow shaft, programmable

Type

Type B (see technical data on page G-269)

B

Type A (see technical data on page G-269)

A

Mechanical design

Blind hollow shaft

B

Through hollow shaft

T

Hollow shaft diameter 8 mm

B

Hollow shaft diameter 3/8"

C

Hollow shaft diameter 10 mm

D

Hollow shaft diameter 12 mm

E

Hollow shaft diameter 1/2"

F

Hollow shaft diameter 14 mm

G

Hollow shaft diameter 15 mm

H

Electrical interface

4.5 … 32 V, SSI/Gray + incremental, programmable

R

4.5 … 32 V, SSI/Gray programmable + sin/cos, 1,024 periods

S

Connection type

Male connector M23, 12-pin, radial

A

Cable, 12-wire, radial, 1.5 m

K

Cable, 12-wire, radial, 3.0 m

L

Cable, 12-wire, radial, 5.0 m

M

Resolution

Number of steps per revolution

1)

1)

1)

G

A F M 6 0 –

1)

Number of steps from 256 (8 bit) to 262144 (18 bit) can be programmed by the customer. Factory setting for Type B: 032768; Type A: 262144. Number of incremen-

tal lines is always 1/4 of the number of SSI/gray lines.

G-290

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 24

ABSOLUTE ENCODERS AFS/AFM60 SSI

Example orders

1)

• Blind hollow shaft

Blind hollow shaft design Type

Type B

Type A

Type B

Type A

1)

x stands for hollow shaft diameters B to H, please enter corresponding letters in position 9.

4.5 ... 32 V, SSI/gray + incremental, programmable, M23 male connector, 12-pin, radial, number

of steps per revolution 32,768

4.5 ... 32 V, SSI/gray + incremental, programmable, M23 male connector, 12-pin , radial, number

of steps per revolution 262144

4.5 ... 32 V, SSI/gray, programmable, + sin/cos, 1,024 periods, M23 male connector, 12-pin,

radial, number of steps per revolution 32,768

4.5 ... 32 V, SSI/gray, programmable, + sin/cos, 1,024 periods, M23 male connector, 12-pin ,

radial, number of steps per revolution 262144

• Through hollow shaft

Through hollow shaft design Type

Type B

Type A

Type B

Type A

1)

x stands for hollow shaft diameters B to H, please enter corresponding letters in position 9.

4.5 ... 32 V, SSI/gray + incremental, programmable, M23 male connector, 12-pin, radial, number

of steps per revolution 32,768

4.5 ... 32 V, SSI/gray + incremental, programmable, M23 male connector, 12-pin , radial, number

of steps per revolution 262144

4.5 ... 32 V, SSI/gray, programmable, + sin/cos, 1,024 periods, M23 male connector, 12-pin,

radial, number of steps per revolution 32,768

4.5 ... 32 V, SSI/gray, programmable, + sin/cos, 1,024 periods, M23 male connector, 12-pin ,

radial, number of steps per revolution 262144

AFM60B-BxRA032768

AFM60A-BxRA262144

AFM60B-BxSA032768

AFM60A-BxSA262144

AFM60B-TxRA032768

AFM60A-TxRA262144

AFM60B-TxSA032768

AFM60A-TxSA262144

G

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

G-291

Page 25

AFS/AFM60 SSI ABSOLUTE ENCODERS

Ø 0.05

C

A

Dimensional drawings (dimensions in mm)

Face mount ange

Universal cable outlet

A

(0.39)

±0.3

10

Ø 0.1

A

43.1 (1.70)

A

3 x 120°

Ø 60 (2.36)

Ø 0.05

B

C

18

(0.39) f7

(0.71)

9

(0.35)

19

0.03

Ø 36

(1.42) f8

Ø 10

B

A

General tolerances according to DIN ISO 2768-mk

1 Cable Ø = 5.6 mm ± 0.2 mm bend radius R = 30 mm

Radial cable outlet for AFM60 SSI + incremental and AFM60 SSI + sin/cos

3 x M4

(6-deep)

(1.89)

±0.05

Ø 48

G

10

18

±0.3

40.1

SW 14

A

Ø 60 (2.36)

±2

(0.69)

17.5

(1.42)

Ø 36 f8

0.03 A

Ø 0.05CB

(0.39)

Ø 10 f7

B

9

(0.39)

(0.71)

(0.35)

0.1 A

19

(0.75)

(1.58)

General tolerances according to DIN ISO 2768-mk

3 x 120°

25°

3 x M4

6 deep (0.24)

(1.89)

±0.05

Ø 48

Ø 0.1 C

±2°

G-292

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 26

M12 and M23 cable outlet

Ø 0.1

C

A

ABSOLUTE ENCODERS AFS/AFM60 SSI

18

(0.71)

±0.3

(0.75)

0.1

40.1 (1.58)

10

(0.39)

A

A

14.5

(0.57)

Ø 60 (2.36)

7.75

(0.31)

M12 x 1

26.1

0.03

Ø 36

(1.42) f8

Ø 10

B

A

Ø 0.05

(0.39) f7

B

C

19

9

(0.35)

General tolerances according to DIN ISO 2768-mk

(1.03)

M23 x 1

(3x) 120°

13

(0.51)

25°

±2°

3 x M4

(6-deep)

(1.89)

±0.05

Ø 48

G

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

G-293

Page 27

AFS/AFM60 SSI ABSOLUTE ENCODERS

5.

A

58

Servo ange

Universal cable outlet

A

(2.28)

±0.1

58

51.5–0.2 (2.03)

Ø 0.05

B

(0.12)

C

9.5

(0.37)

(0.24) f7

Ø 6

±0.3

10

B

Ø 50 (1.97) f8

(0.39)

7 (0.22)

3

+0.1

4

(0.16)

A

+0.1

10

(0.39)

43.1 (1.70)

0.1

0.1

A

A

3 x 120°

Ø 60 (2.36)

General tolerances according to DIN ISO 2768-mk

1 Cable Ø = 5.6 mm ± 0.2 mm bend radius R = 30 mm

Radial cable outlet for AFM60 SSI + incremental and AFM60 SSI + sin/cos

+0.1

4

(2.28)

±0.1

51.5–0.2 (2.03)

Ø 50 f8 (1.97)

Ø 0.05 B

C

(0.24)

Ø 6 f7

B

5.7

(0.16)

3

(0.12)

9.5

(0.37)

(0.22)

0.1 A

0.1 A

A

Ø 60 (2.36)

3 x 120°

Ø 0.05

3 x M4

(6-deep)

(1.65)

±0.05

Ø 42

C

3 x M4

6 deep (0.24)

(1.65)

±0.05

Ø 42

G

±0.3

0.03 A

10

(0.39)

10

(0.39)

+0.1

SW 14

7.75

40.1

(1.58)

(0.31)

General tolerances according to DIN ISO 2768-mk

±2

17.5

(0.69)

25°

±2°

Ø 0.1

C

G-294

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 28

M12 and M23 cable outlet

58

3 x 120°

4 x 90°

+0.1

4

(0.16)

A

(2.28)

±0.1

Ø 50 (1.97) f8

51.5–0.2 (2.03)

0.03

Ø 6

B

A

Ø 0.05

C

f7

(0.24)

(0.22)

5.7

9.5

(0.37)

10

(0.39)

B

±0.3

10

(0.12)

+0.1

(0.39)

3

14.5

M12 x 1

(1.58)

40.1

A

(0.57)

0.1

0.1

A

A

Ø 60 (2.36)

7.75

(0.31)

26.1

General tolerances according to DIN ISO 2768-mk

Mounting suggestion for small servo clamp

part number 2029166

(1.03)

M23 x 1

13

(0.51)

ABSOLUTE ENCODERS AFS/AFM60 SSI

3 x 120°

3 x M4

(6-deep)

(1.65)

±0.05

Ø 42

25°

±2°

C

Ø 0.1

Mounting suggestion for half-shell servo clamp

part number 2029165

Ø 68 (2.68)

General tolerances according to DIN ISO 2768-mk

Ø 71 (2.80)

G

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

G-295

Page 29

AFS/AFM60 SSI ABSOLUTE ENCODERS

47 (1.85)

A

Customer-side

Blind hollow shaft

Universal cable outlet

45.5

(1.79)

9.4

(0.37)

3.4 (0.13)

Ø X F7

Ø 35 (1.38)

Ø 60 (2.36)

2.5

(0.10)

+0.1

Ø 3.2

(0.13)

20°

20

(0.79)

(2.48)

(2.83)

±0.2

±0.3

72

Ø 63

G

Ø x j7

min. 15 (0.59)

max. 42 (1.65)

General tolerances according to DIN ISO 2768-mk

1 Cable Ø = 5.6 mm ± 0.2 mm bend radius R = 30 mm

XF7 = Encoder shaft diameter, see type code

xj7 = Shaft diameter, on the customer side

G-296

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 30

Radial cable outlet for AFM60 SSI + incremental and AFM60 SSI + sin/cos

A

Customer-side

45.5 (1.79)

9.4

(0.37)

Ø X F7

3.4

(0.13)

2.5

(0.10)

(1.28)

Ø 32.6

(2.36)

Ø 60

±2

17.5

(0.69)

20

(0.79)

72

±0.3

ABSOLUTE ENCODERS AFS/AFM60 SSI

(2.83)

+0.1

Ø 3.2

(0.13)

20°

7.75

(0.31)

Ø x j7

min. 15

(0.59)

max. 42

(1.65)

SW 14

General tolerances according to DIN ISO 2768-mk

XF7 = Encoder shaft diameter, see type code

xj7 = Shaft diameter, on the customer side

47 (1.85)

Ø 63

±0.2

(2.48)

G

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

G-297

Page 31

AFS/AFM60 SSI ABSOLUTE ENCODERS

20°

A

Customer-side

M12 and M23 cable outlet

45.5

(1.79)

9.4

(0.37)

2.5

3.4 (0.13)

Ø X F7

(0.10)

72

±0.3

Ø 3.2

(2.83)

+0.1

(0.13)

G

Ø 60 (2.36)

Ø 32.6 (1.28)

14.5

(0.57)

min. 15 (0.59)

max. 42 (1.65)

7.75

(0.31)

26.1 (1.03)

M12 x 1

Ø x j7

13

(0.51)

M23 x 1

General tolerances according to DIN ISO 2768-mk

XF7 = Encoder shaft diameter, see type code

xj7 = Shaft diameter, on the customer side

20 (0.79)

Ø 63

47 (1.85)

±0.2

(2.48)

G-298

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 32

Through hollow shaft

47 (1.85)

A

Customer-side

Universal cable outlet

ABSOLUTE ENCODERS AFS/AFM60 SSI

Ø X F7

43 (1.69)

9.4 (0.37)

3.4 (0.13)

min. 15 (0.59)

Ø 60 (2.36)

Ø x j7

+0.1

Ø 3.2

(0.13)

20°

20

(0.79)

(2.48)

(2.83)

±0.2

±0.3

72

Ø 63

General tolerances according to DIN ISO 2768-mk

1 Cable Ø = 5.6 mm ± 0.2 mm bend radius R = 30 mm

XF7 = Encoder shaft diameter, see type code

xj7 = Shaft diameter, on the customer side

G

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

G-299

Page 33

AFS/AFM60 SSI ABSOLUTE ENCODERS

A

Customer-side

Radial cable outlet for AFM60 SSI + incremental and AFM60 SSI + sin/cos

43 (1.69)

9.4

(0.37)

3.4

(0.13)

72

±0.3

(2.83)

Ø 3.2

(0.13)

+0.1

G

Ø X F7

SW 14

min. 15

(0.59)

(2.36)17.5

Ø 60

±2

(0.69)

7.75

(0.31)

Ø x j7

20

General tolerances according to DIN ISO 2768-mk

XF7 = Encoder shaft diameter, see type code

xj7 = Shaft diameter, on the customer side

(0.79)

Ø 63

47 (1.85)

±0.2

(2.48)

20°

G-300

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 34

M12 and M23 cable outlet

20°

A

Customer-side

43 (1.69)

9.4 (0.37)

3.4 (0.13)

Ø X F7

72

±0.3

Ø 3.2

ABSOLUTE ENCODERS AFS/AFM60 SSI

(2.83)

+0.1

(0.13)

Ø 60 (2.36)

7.75

(0.31)

14.5

(0.57)

26.1 (1.03)

M12 x 1

Ø x j7

min. 15 (0.59)

General tolerances according to DIN ISO 2768-mk

XF7 = Encoder shaft diameter, see type code

xj7 = Shaft diameter, on the customer side

13

(0.51)

M23 x 1

20 (0.79)

47 (1.85)

Ø 63

±0.2

(2.48)

G

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

G-301

Page 35

AFS/AFM60 SSI ABSOLUTE ENCODERS

PIN assignment

V/¯R Forwards/Reverse: This input programs the counting direction for the encoder. When it is not connected, this input is set to

HIGH. If the encoder shaft is rotated clockwise (to the right) as viewed when facing the shaft, it counts in ascending order.

If it should count in ascending order when the shaft is rotated counterclockwise (to the left), then this connection must be

permanently set to LOW level (GND).

SET This input is for electronic zeroing. If the SET cable is set to U

for at least 1,000 ms or had been connected to GND, the mechanical position corresponds to the O value, i.e., the predetermined SET value.

M12 male connector, 8-pin and

cable outlet, cable, 8-wire

SSI/gray

View of M12 male device connector on encoder

Pin Wire colors SSI signal Explanation

1 Brown Data– Interface signals

2 White Data+ Interface signals

3 Black V/¯R Sequence in direction of rotation

4 Pink SET Electronic adjustment

5 Yellow Clock+ Interface signals

6 Violet Clock - Interface signals

7 Blue GND Ground connection

8 Red +U

Screen Screen connected to housing on encoder side. Connected to ground on control side.

S

Operating voltage

for more than 250 ms after it had previously been unassigned

S

G

M23 male connector, 12-pin

SSI/gray

View of M23 male device connector on encoder

Pin Signal Explanation

1 GND Ground connection

2 Data+ Interface signals

3 Clock+ Interface signals

4 N. C. Not connected

5 N. C. Not connected

6 N. C. Not connected

7 N. C. Not connected

8 U

9 SET Electronic adjustment

10 Data– Interface signals

11 Clock– Interface signals

12 V/¯R Sequence in direction of rotation

S

Screen Screen connected to housing on encoder side. Connected to ground on control side.

Operating voltage

G-302

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 36

ABSOLUTE ENCODERS AFS/AFM60 SSI

M23 male connector, 12-pin and

cable outlet, cable, 12-wire

SSI/gray + incremental

Pin Wire colors Signal Explanation

1 Red +U

2 Blue GND Ground connection

3 Yellow Clock+ Interface signal

4 White Data+ Interface signal

5 Orange SET Electronic adjustment

6 Brown Data– Interface signal

7 Violet Clock– Interface signal

8 Black ¯B Signal wire

9 Orange/black V/¯R Sequence in direction of rotation

10 Green ¯A Signal wire

11 Gray A Signal wire

12 Pink B Signal wire

S

Screen Screen connected to housing on encoder side. Connected to ground on control side.

M23 male connector, 12-pin and

cable outlet, cable, 12-wire

SSI/gray + sin/cos

Operating voltage

Pin Wire colors Signal Explanation

1 Red +U

2 Blue GND Ground connection

3 Yellow Clock+ Interface signal

4 White Data+ Interface signal

5 Orange SET Electronic adjustment

6 Brown Data– Interface signal

7 Violet Clock– Interface signal

8 Black Sin– Signal wire

9 Orange/black V/¯R Sequence in direction of rotation

10 Green Cos– Signal wire

11 Gray Cos+ Signal wire

12 Pink Sin+ Signal wire

S

Screen Screen connected to housing on encoder side. Connected to ground on control side.

Operating voltage

G

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

G-303

Page 37

AFS/AFM60 SSI ABSOLUTE ENCODERS

Clock +

Bi

C

Clock +

Bi

C

Clock +

Bi

C

Signal outputs

Singleturn SSI data format

t

12345678910 11 12 13 14 15 16 17 18 19 20 21

17 16 15 14 13 12 11 10 9 876543210

MSB

LSB

ERRDIG

ERRSI

Singleturn

ERRSYN

Bit 1–18: Position bits

• LSB: Least signicant bit

• MSB: Most signicant bit

Bit 19-21: Errorbits

• ERRDIG: Error message concerning speed. If this error occurs during the position forming process, it is displayed through the

ERRDIG bit.

• ERRSI: Light source error.

• ERRSYNC: Contamination of the code disk or read system. A error has occurred during the position detection process since the

last SSI data transmission. The errorbit is deleted during the next data transmission.

Evaluation of the error bits must be realized in the PLC.

The error bits output do not have to be used by the PLC.

Example

If the absolute value encoder is adjusted to a resolution of 13 bits, 16 bits are output: 13 databits and 3 errorbits.

If the errorbits cannot be evaluated in the PLC, the control unit must be set to an encoder resolution of 13 bits. The errorbits must

then be masked out at the control.

Multiturn SSI data format

30 bits

G

1

234567891011 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 2829 30 31 32 33

t

GGGGGGGGGGGGGGGGGGGGGGGGGGGGGG

+10A+11

AA+1A–1A–2A–3A–4A–5A–6A–7A–8A–9A

A+2A+3A+4A+5A+6A+7A+8A+9A

SingleturnMultiturn

–10A–11A–12A–13A–14A–15A–16A–17A–18

ERRDIG

ERRSI

ERRSYN

Bits 1–12: Multiturn position bits

Bits 13–30: Singleturn position bits

Bits 31–33: Errorbits

27 bits

1

234567891011 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 2829 30

t

GGGGGGGGGGGGGGGGGGGGGGGGGGG

+10A+11

AA+1A–1A–2A–3A–4A–5A–6A–7A–8A–9A

A+2A+3A+4A+5A+6A+7A+8A+9A

SingleturnMultiturn

–10A–11A–12A–13A–14A–15

ERRDIG

ERRSI

ERRSYN

Bit 1–12: Multiturn position bits

Bits 13–27: Singleturn position bits

Bits 28–30: Errorbits

Errorbits

• ERRDIG: Error message concerning speed. If this error occurs during the position forming process, it is displayed through the

ERRDIG bit.

• ERRSI: Light source error.

• ERRSYNC: Contamination of the code disk or read system. A error has occurred during the position detection process since the

last SSI data transmission. The errorbit is deleted during the next data transmission.

Evaluation of the error bits must be realized in the PLC.

The error bits output do not have to be used by the PLC. The multiturn resolution is xed to 12 bits.

Example

If the absolute value encoder is adjusted to a resolution of 27 bits, 30 bits are output: 27 databits and 3 errorbits.

If the errorbits cannot be evaluated in the PLC, the control unit must be set to an encoder resolution of 27 bits. The errorbits must

then be masked out at the control.

G-304

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 38

Interfaces

2.5

2.5

V

360° el.

COS+ ... COS–

SIN+ ... SIN–

V

V

360° el.

A

¯A

B

¯B

90° el.

ABSOLUTE ENCODERS AFS/AFM60 SSI

Electrical interfaces sin/cos 1.0 V

SS

Supply voltage Output

4.5 ... 32 V Sine 0.5 V

SS

Signals before difference at 120 Ω load

Signal diagram for clockwise shaft rotation, looking in direction “A” (shaft)

V

90° el.

V

COS+ COS–

SIN+ SIN–

Interface signals Sin, Sin, Cos, Cos Signals before difference at 120 Ω load Signal offset

Differential analog 0.5 V

0.5 V

0.5

± 20% 2.5 V ± 10%

SS

Signal after difference at 120 Ω load

Signal diagram for clockwise shaft rotation, looking in direction “A” (shaft)

0 V

90° el.

0 V

1

1

Incremental signal outputs for clockwise shaft rotation, looking in direction “A” (see dimensional drawing)

360° el.

Measuring step

G

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

G-305

Page 39

AFS/AFM60 SSI ABSOLUTE ENCODERS

Recommended accessories

Mounting systems

Mounting brackets and plates

Mounting bracket

Figure Brief description Type Part no.

G

Mounting bracket for encoder with centering hub 36 mm, including mounting kit for face

mount ange

Dimensional drawings g page K-725

BEF-WF-36 2029164

Flanges

Flange plate

Figure Brief description Type Part no.

Standard stator coupling BEF-DS00XFX 2056812

Stator coupling, 16.5 mm high BEF-DS05XFX 2057423

Stator coupling with hole circle diameter 63 mm BEF-DS07XFX 2059368

Flange adapter, adaptation of face mount ange with 36 mm centering hub to 50 mm

servo ange, aluminum, including 3 at head screws M4 x 10

Flange adapter, adaptation of face mount ange with 36 mm centering hub to 60 mm

square mounting plate, aluminum, including 3 at head screws M4 x 10

Flange adapter, adaptation of face mount ange with 36 mm centering hub to 58 mm

square mounting plate with shock absorbers, aluminum

BEF-FA-036-050 2029160

BEF-FA-036-060REC 2029162

BEF-FA-036-060RSA 2029163

Flange adapter, adaptation of face mount ange with 36 mm centering hub to 63 mm

square mounting plate, aluminum, including 3 at head screws M4 x 10

Flange adapter, adaptation of face mount ange with 36 mm centering hub to 100 mm

servo ange with 60 mm centering hub, aluminum

Dimensional drawings g page K-725

BEF-FA-036-063REC 2034225

BEF-FA-036-100 2029161

Other mounting accessories

Measuring wheels and measuring wheel systems

Figure Brief description Type Part no.

G-306

Measuring wheel with smooth plastic surface (Hytrel) for 10 mm solid shaft, circumference 200 mm

Measuring wheel with ridged plastic surface (Hytrel) for 10 mm solid shaft, circumference 200 mm

Measuring wheel with smooth plastic surface (Hytrel) for 10 mm solid shaft, circumference 500 mm

ENCODERS | SICK 8015560/2015-09-01

BEF-MR-010020 5312988

BEF-MR-010020G 5318678

BEF-MR-010050 5312989

Subject to change without notice

Page 40

ABSOLUTE ENCODERS AFS/AFM60 SSI

Figure Brief description Type Part no.

Measuring wheel with O-ring (NBR70) for 6 mm solid shaft, circumference 200 mm BEF-MR006020R 2055222

Measuring wheel with O-ring (NBR70) for 6 mm solid shaft, circumference 300 mm BEF-MR006030R 2055634

Measuring wheel with O-ring (NBR70) for 6 mm solid shaft, circumference 500 mm BEF-MR006050R 2055225

Measuring wheel with O-ring (NBR70) for 10 mm solid shaft, circumference 200 mm BEF-MR010020R 2055224

Measuring wheel with O-ring (NBR70) for 10 mm solid shaft, circumference 300 mm BEF-MR010030R 2049278

Measuring wheel with O-ring (NBR70) for 10 mm solid shaft, circumference 500 mm BEF-MR010050R 2055227

O-ring for measuring wheels (circumference 200 mm) BEF-OR-053-040 2064061

O-ring for measuring wheels (circumference 300 mm) BEF-OR-083-050 2064076

Dimensional drawings g page K-725

Modular measuring wheel system

Brief description Type Part no.

Measuring wheel system, desired mounting position: left, for DBS60-S4, DFS60-S4, AFS60-S4, and

AFM60-S4

Measuring wheel system, desired mounting position: right, for DBS60-S4, DFS60-S4, AFS60-S4, and

AFM60-S4

Dimensional drawings g page K-725

BEF-MRS-10-1 2071958

BEF-MRS-10-2 2071957

Mounting bell

Figure Brief description Type Part no.

Mounting bell for encoders with a servo ange, centering hub 50 mm, including mounting kit

Dimensional drawings g page K-725

BEF-MG-50 5312987

Servo clamps

Figure Brief description Type Part no.

Half-shell servo clamps (2 pcs.) for servo anges with a 50 mm centering hub BEF-WG-SF050 2029165

Servo clamps, large, for servo anges (clamps, eccentric fastener), 3 pcs., without

mounting material

Dimensional drawings g page K-725

BEF-WK-SF 2029166

Miscellaneous

Figure Brief description Type Part no.

Mounting kit for servo ange encoder on the bearing block, 1 bar coupling SKPS

1520 06/06 1 hexagon socket wrench SW1.5 DIN 911, 3 mounting eccentric BEMN

1242 49 3 screws M4 x 10 DIN 912, 1 hexagon socket wrench SW3 DIN 911

BEF-MK-LB 5320872

G

Bearing block for hollow shaft encoder, including xing screws BEF-FA-B12-010 2042728

Bearing block for servo and face mount ange encoder BEF-FA-LB1210 2044591

Dimensional drawings g page K-725

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

G-307

Page 41

G

AFS/AFM60 SSI ABSOLUTE ENCODERS

Shaft adaptation

Shaft couplings

Figure Brief description Type Part no.

Bellows coupling, shaft diameter 6 mm / 6 mm, maximum shaft offset: radial

± 0.25 mm, axial ± 0.4 mm, angular ± 4°; max. speed 10,000 rpm, –30 °C ... +120 °C,

max. torque 80 Ncm; material: stainless steel bellows, aluminum hub

Bellows coupling, shaft diameter 6 mm / 10 mm, maximum shaft offset: radial

± 0.25 mm, axial ± 0.4 mm, angular ± 4°; max. speed 10,000 rpm, –30 °C ... +120 °C,

max. torque 80 Ncm; material: stainless steel bellows, aluminum hub

Bellows coupling, shaft diameter 10 mm/10 mm; maximum shaft offset: radial

± 0.25 mm, axial ± 0.4 mm, angular ± 4°; max. revolutions 10,000 rpm,

–30° ... +120 °C, max. torque 80 Ncm; material: stainless steel bellows, aluminum

clamping hubs

Bellows coupling, shaft diameter 10 mm/12 mm; maximum shaft offset: radial

± 0.25 mm, axial ± 0.4 mm, angular ± 4°; max. revolutions 10,000 rpm,

–30 °C ... +120 °C, max. torque 80 Ncm; material: stainless steel bellows, aluminum

clamping hubs

Bar coupling, shaft diameter 6 mm / 6 mm, maximum shaft offset: radial ± 0.3 mm,

axial ± 0.2 mm, angle ± 3°; max. speed 10,000 rpm, –10 °C ... +80 °C, max. torque

80 Ncm; material: ber-glass reinforced polyamide, aluminum hub

Bar coupling, shaft diameter 6 mm / 8 mm, maximum shaft offset radial ± 0.3 mm, ax-

ial ± 0.2 mm, angle ± 3°; max. speed 10,000 rpm, torsion spring rigidity 38 Nm/wheel;

material: ber-glass reinforced polyamide, aluminum hub

Bar coupling, shaft diameter 6 mm/10 mm, maximum shaft offset: radial ± 0.3 mm,

axial ± 0.2 mm, angular ± 3°; max. speed 10,000 rpm, –10 °C ... +80 °C, max. torque

80 Ncm; material: ber-glass reinforced polyamide, aluminum hub

Bar coupling, shaft diameter 8 mm / 10 mm, maximum shaft offset: radial ± 0.3 mm,

axial ± 0.2 mm, angular ± 3°; torsion spring rigidity 38 Nm/wheel; material: ber-glass

reinforced polyamide, aluminum hub

Bar coupling, shaft diameter 10 mm / 10 mm, maximum shaft offset radial ± 0.3 mm,

axial ± 0.2 mm, angle ± 3°; max. speed 10,000 rpm, torsion spring rigidity 38 Nm/

wheel; material: ber-glass reinforced polyamide, aluminum hub

Double-loop coupling, shaft diameter 6 mm/10 mm, maximum shaft offset: radial

± 2.5 mm, axial ± 3 mm, angular ± 10°; max. speed 3,000 rpm, –30 °C ... +80 °C,

max. torque 1.5 Nm; material: polyurethane, galvanized steel ange

Double-loop coupling, shaft diameter 8 mm/10 mm, maximum shaft offset: radial

± 2.5 mm, axial ± 3 mm, angular ± 10°; max. speed 3,000 rpm, –30 °C ... +80 °C,

max. torque 1.5 Nm; material: polyurethane, galvanized steel ange

Double-loop coupling, shaft diameter 10 mm/10 mm, maximum shaft offset: radial

± 2.5 mm, axial ± 3 mm, angular ± 10°; max. speed 3,000 rpm, –30 °C ... +80 °C,

max. torque 1.5 Nm; material: polyurethane, galvanized steel ange

Double-loop coupling, shaft diameter 10 mm/12 mm, maximum shaft offset: radial

± 2.5 mm, axial ± 3 mm, angular ± 10°; max. speed 3,000 rpm, –30 °C ... +80 °C,

max. torque 1.5 Nm; material: polyurethane, galvanized steel ange

Spring washer coupling, shaft diameter 6 mm/10 mm, maximum shaft offset: radial

± 0.3 mm, axial ± 0.4 mm, angular ± 2.5°; max. speed 12,000 rpm, –10 °C ... +80 °C,

max. torque 60 Ncm; material: aluminum ange, ber-glass reinforced polyamide mem-

brane and tempered steel coupling pin

Spring washer coupling, shaft diameter 10 mm / 10 mm, maximum shaft offset: radial

± 0.3 mm, axial ± 0.4 mm, angular ± 2.5°; max. speed 12,000 rpm, –10° ... +80° C,

max. torque 60 Ncm; material: aluminum ange, glass ber-reinforced polyamide mem-

brane and hardened steel coupling pin

KUP-0606-B 5312981

KUP-0610-B 5312982

KUP-1010-B 5312983

KUP-1012-B 5312984

KUP-0606-S 2056406

KUP-0608-S 5314179

KUP-0610-S 2056407

KUP-0810-S 5314178

KUP-1010-S 2056408

KUP-0610-D 5326697

KUP-0810-D 5326704

KUP-1010-D 5326703

KUP-1012-D 5326702

KUP-0610-F 5312985

KUP-1010-F 5312986

Dimensional drawings g page K-725

G-308

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 42

Connectivity

Plug connectors and cables

Connecting cables with female connector

ABSOLUTE ENCODERS AFS/AFM60 SSI

Figure Brief description Length

Head A: female connector, M12, 8-pin, straight

Head B: cable

Cable: suitable for drag chain, PVC, shielded, 4 x 2 x 0.25 mm², Ø 7.0 mm

Head A: female connector, JST, 8-pin, straight

Head B: cable

Cable: suitable for drag chain, PUR, halogen-free, shielded, 4 x 2 x 0.15 mm²,

Ø 5.6 mm

Head A: female connector, M23, 12-pin, straight

Head B: cable

Cable: suitable for drag chain, PUR, halogen-free, shielded, 4 x 2 x 0.15 mm²,

Ø 5.6 mm

Head A: female connector, M23, 12-pin, straight

Head B: cable

Cable: suitable for drag chain, PUR, shielded, 4 x 2 x 0.25 mm² + 2 x 0.5 mm²

+ 1 x 0.14 mm², Ø 7.8 mm

1)

Suitable for SSI interfaces, not suitable for SSI + Incremental or SSI + Sin/Cos interfaces.

2)

Suitable for SSI + Incremental and SSI + Sin/Cos interfaces.

Dimensional drawings g page K-725

1)

2)

Type Part no.

of

cable

2 m DOL-1208-G02MAC1 6032866

5 m DOL-1208-G05MAC1 6032867

10 m DOL-1208-G10MAC1 6032868

20 m DOL-1208-G20MAC1 6032869

0.5 m DOL-0J08-G0M5AA6 2048589

1.5 m DOL-0J08-G1M5AA6 2048590

3 m DOL-0J08-G3M0AA6 2048591

5 m DOL-0J08-G5M0AA6 2048593

10 m DOL-0J08-G10MAA6 2048594

0.5 m DOL-2308-G0M5AA6 2048595

1.5 m DOL-2308-G1M5AA6 2048596

3 m DOL-2308-G03MAA6 2048597

5 m DOL-2308-G05MAA6 2048598

10 m DOL-2308-G10MAA6 2048599

1.5 m DOL-2312-G1M5MD2 2062284

3 m DOL-2312-G03MMD2 2062300

5 m DOL-2312-G05MMD2 2062301

10 m DOL-2312-G10MMD2 2062302

20 m DOL-2312-G20MMD2 2062303

30 m DOL-2312-G30MMD2 2062304

G

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

G-309

Page 43

AFS/AFM60 SSI ABSOLUTE ENCODERS

Female connectors (ready to assemble)

Figure Brief description Type Part no.

Head A: female connector, M12, 8-pin, straight, A encoded, shielded, for cable diameter

4 mm ... 8 mm

Head B: -

Operating temperature: –40 °C ... +85 °C

Head A: female connector, M23, 12-pin, straight, shielded, for cable diameter

5.5 mm ... 10.5 mm

Head B: -

Operating temperature: –20 °C ... +130 °C

Head A: female connector, M23, 12-pin, straight, shielded, for cable diameter

5.5 mm ... 10.5 mm

Head B: Operating temperature:

–40 °C ... +125 °C

Head A: female connector, M23, 12-pin, angled, shielded, for cable diameter

4.2 mm ... 6.6 mm

Head B: -

Operating temperature: –20 °C ... +130 °C

Head A: female connector, M23, 21-pin, straight, shielded, for cable diameter

5.5 mm ... 12 mm

Head B: -

Dimensional drawings g page K-725

DOS-1208-GA01 6045001

DOS-2312-G 6027538

DOS-2312-G02

DOS-2312-W01 2072580

DOS-2321-G 6027539

2077057

G

Cables (ready to assemble)

Figure Brief description Length

Type Part no.

of

cable

Head A: cable

Head B: cable

Cable: suitable for drag chain, PUR, halogen-free, shielded, 4 x 2 x 0.15 mm²,

Ø 5.6 mm

Head A: cable

Head B: cable

Cable: suitable for drag chain, PUR, halogen-free, shielded, UV and saltwater-resistant, 4 x 2 x 0.25 mm² + 2 x 0.5 mm² + 2 x 0.14 mm², Ø 7.8 mm

Dimensional drawings g page K-725

By the

meter

By the

meter

LTG-2308-MWENC 6027529

LTG-2612-MW 6028516

Male connectors (ready to assemble)

Figure Brief description Type Part no.

Head A: male connector, M12, 8-pin, straight, A encoded, shielded, for cable diameter

4 mm ... 8 mm

Head B: -

Operating temperature: –40 °C ... +85 °C

Head A: male connector, M23, 12-pin, straight, shielded, for cable diameter

5.5 mm ... 10.5 mm

Head B: -

Operating temperature: –20 °C ... +130 °C

Dimensional drawings g page K-725

STE-1208-GA01 6044892

STE-2312-G 6027537

G-310

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 44

Connection cables with female and male connector

ABSOLUTE ENCODERS AFS/AFM60 SSI

Figure Brief description Length

Type Part no.

of

cable

Head A: female connector, M12, 8-pin, straight

Head B: male connector, D-Sub, 9-pin, straight

Cable: PUR, halogen-free, shielded, 4 x 2 x 0.15 mm²

Head A: female connector, M23, 12-pin, straight

Head B: male connector, D-Sub, 9-pin, straight

Cable: suitable for drag chain, PUR, halogen-free, shielded, 4 x 2 x 0.15 mm²

Head A: female connector, M23, 12-pin, straight

1)

Suitable for use with SSI interfaces, not suitable for use with SSI + Incremental interface or SSI + Sin/Cos.

2)

Suitable for use with SSI + Incremental or SSI + Sin/Cos interfaces.

Dimensional drawings g page K-725

Head B: male connector, D-Sub, 9-pin, straight, 8-wire

2)

0.5 m DSL-2D08-G0M5AC2 2048439

0.5 m DSL-3D08-G0M5AC2 2048440

1)

0.5 m DSL-3D08-G0M5AC4 2059270

Other accessories

Programming and conguration tools

Figure Brief description Type Part no.

Programming unit USB, for programmable SICK encoders AFS60, AFM60, DFS60,

VFS60, DFV60 and wire draw encoders with programmable encoder.

Programming unit display for programmable SICK DFS60, DFV60, AFS/AFM60, AHS/

AHM36 encoders, and wire draw encoders with DFS60, AFS/AFM60, and AHS/AHM36.

Compact dimensions, low weight, and intuitive operation.

PGT-08-S 1036616

PGT-10-Pro 1072254

Dimensional drawings g page K-725

- For additional accessories, please see page K-668 onwards

G

Subject to change without notice