Page 1

A3M60 PROFIBUS ABSOLUTE ENCODERS

COMPACT, RUGGED, POWERFUL

Product description

The A3M60 PROFIBUS is an extremely

rugged absolute multiturn encoder with

a 60 mm housing. Maximum reliability

even in the harshest of ambient conditions is attained by means of magnetic

scanning, both with singleturn and multiturn detection. New singleturn technology combines the durability of a magnetic

sensor with high resolutions, previously

only possible with optical systems. The

innovative gearless multiturn technology

keeps the number of moving compo-

nents on the A3M60 to a minimum. This

results in a longer service life with low

maintenance costs and consequently, optimum system availability. The

highly compact technology in single and

multiturn detection provides the user a

space-saving and cost-efcient solution.

Together with the integrated PROFIBUS

interface, the A3M60 is particularly

suited for applications where installation

space is tight

G

More information

Fields of application . . . . . . . . . . .G-373

Detailed technical data. . . . . . . . .G-373

Type code. . . . . . . . . . . . . . . . . . . .G-375

Ordering information. . . . . . . . . . .G-375

Sales kits ....................G-376

Dimensional drawings . . . . . . . . .G-378

PIN assignment...............G-378

Recommended accessories. . . . .G-380

At a glance

• Rugged absolute multiturn encoder

with up to 31 bits (14-bit singleturn

and 17-bit multiturn)

• Face mount ange, servo ange or

blind hollow shaft

• Compact design (<70 mm)

• Integrated PROFIBUS interface with

DP V0, V1, and V2 functionality (depending on type)

Your benets

• Maximum system availability, even

under extreme ambient conditions

• Reduced maintenance costs due to

wear-free magnetic singleturn and

multiturn scanning

• Space-saving and cost-efcient design

- the best solution, particularly when

installation space is limited

• Connectivity: 3 x M12 male connec-

tors

• Protection class up to IP67

• Operating temperature: -30 to +80 °C

(depending on type)

• High productivity thanks to fast com-

munication and position calculation

• Immune to contamination and con-

densation – ideal for tough ambient

conditions

• High performance at a cost-efcient

price

G-372

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 2

ABSOLUTE ENCODERS A3M60 PROFIBUS

Fields of application

• Measurement of absolute position in various machines and

systems such as pallet handling machines, high-bay ware-

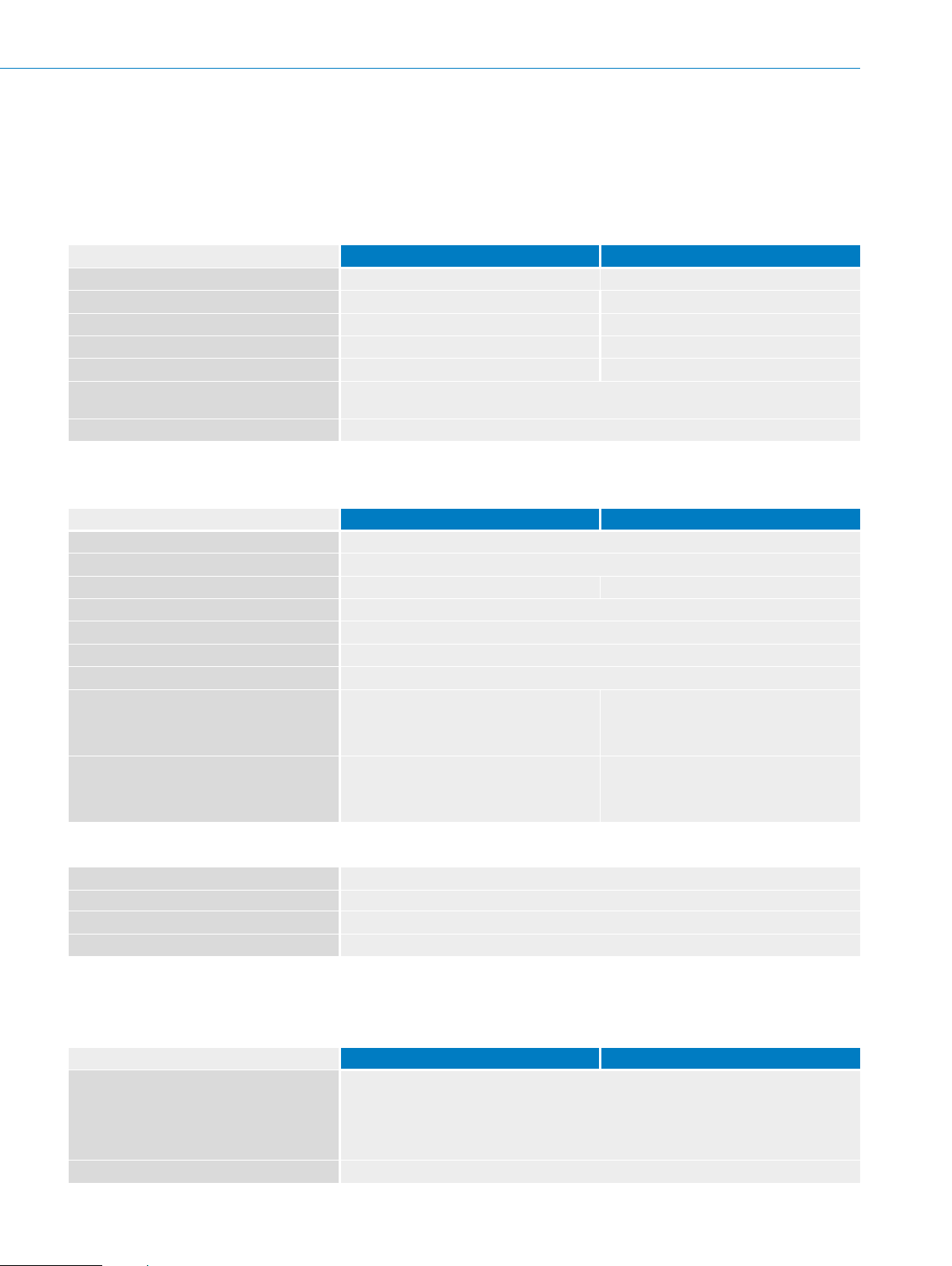

Detailed technical data

Performance

Max. number of steps per revolution

Max. number of revolutions

Resolution

Error limits

Repeatability

Measuring step (360 °/ number of steps

per revolution)

Initialization time

1)

Corresponds to the amount of time that passes after connecting the supply voltage until the data word can be read in correctly.

8,192 16,384

8,192 131,072

13 bit x 13 bit 14 bit x 17 bit

± 0.5°, (at room temperature) ± 0.35°, (at room temperature)

± 0.25°, at room temperature ± 0.15°, at room temperature

0.022°

Approx. 1 s

1)

Interfaces

houses, cranes, presses, printing machines

Basic Advanced

Basic Advanced

Electrical interface

Bus interface

Data protocol

Data transmission rate (baud rate)

Bus termination

Status information

SET (electronic adjustment)

Conguration data

Available diagnostic data

PROFIBUS DP

PROFIBUS (RS485)

PROFIBUS DP V0 PROFIBUS DP V0 and DP V1 + V2

≤ 12 MBaud

Through DIP switch or external resistor

Through status LEDs

Via PRESET pushbutton or protocol

Number of steps per revolution, number of

revolutions, PRESET, counting direction

– Maximum speed, power-on counter, operating

Number of steps per revolution, number of revolutions, PRESET, counting direction, sampling

rate for calculating position, unit for output of

the speed value, round axis functionality

hours counter power-on/motion, counter of

direction changes/number of movements cw/

number of movements

Electrical data

Operating voltage range

Power consumption max.

Reverse polarity protection

MTTFd: mean time to dangerous failure

1)

This product is a standard product and does not constitute a safety component as dened in the Machinery Directive. Calculation based on nominal load of devices,

average ambient temperature 40 °C, frequency of use 8,760 h/a. All electronic failures are considered hazardous. For more information, see document no.

8015532.

10 V ... 32 V

1.5 W

l

60 years (EN ISO 13849-1)

1)

G

Mechanical data

Shaft diameter

Shaft material

Subject to change without notice

Basic Advanced

Face mount ange 10 x 19 mm

Servo ange 6 x 10 mm

Blind hollow shaft 8, 10, 12, 14, 15 mm and 3/8", 1/2", 5/8"

Stainless steel

ENCODERS | SICK8015560/2015-09-01

G-373

Page 3

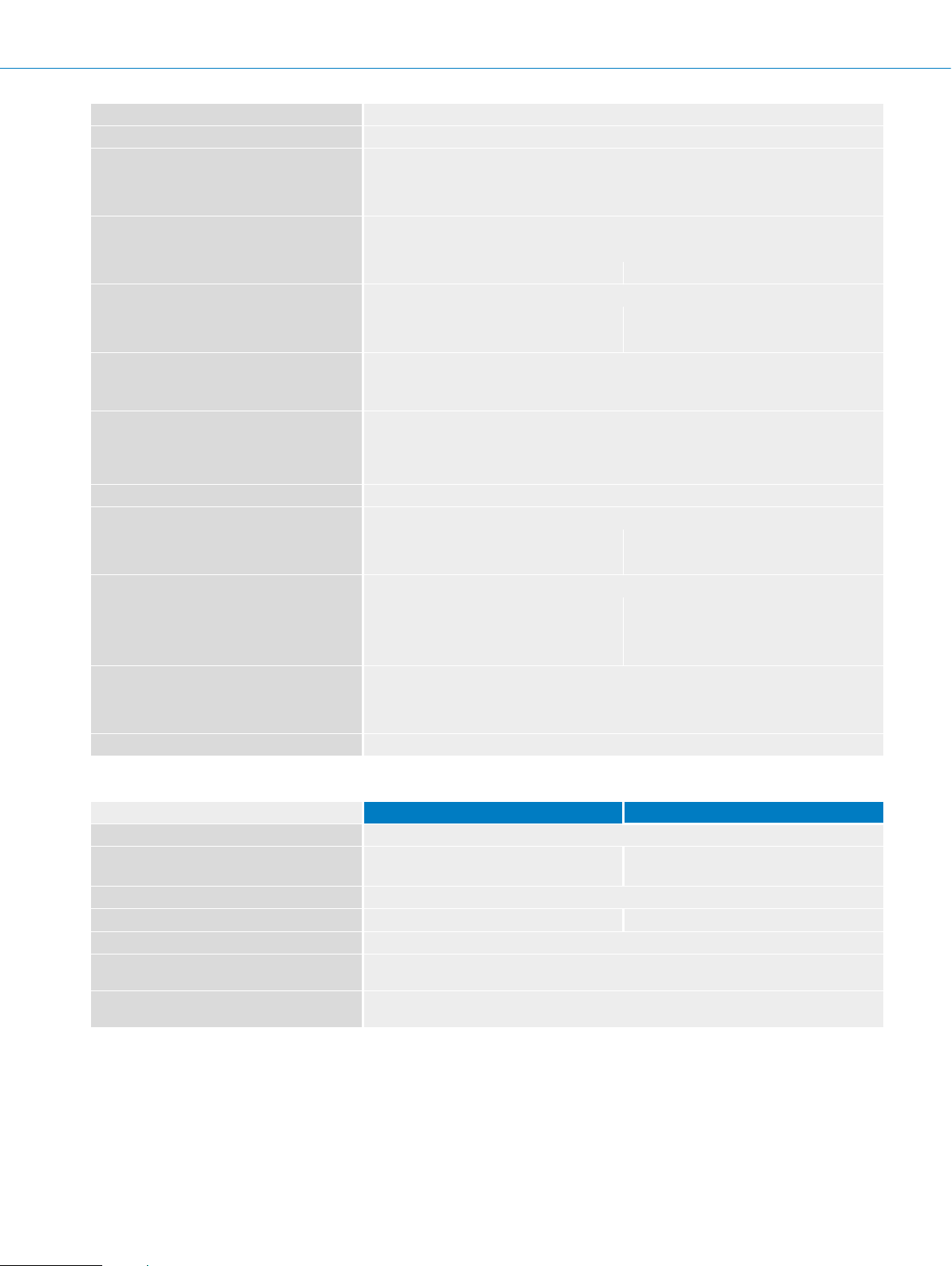

A3M60 PROFIBUS ABSOLUTE ENCODERS

G

Flange material

Housing material

Mass

Face mount ange, servo ange 0.28 kg

Blind hollow shaft 0.28 kg

Start up torque at 20 °C

Face mount ange, servo ange 1 Ncm with shaft seal

Blind hollow shaft 1 Ncm 2 Ncm

Operating torque at 20 °C

Face mount ange, servo ange 0.8 Ncm 0.8 Ncm

Blind hollow shaft 0.8 Ncm 1.6 Ncm

Permissible shaft loading

Face mount ange, servo ange 80 N radial

Permissible shaft movement of the drive

element, static/dynamic

Blind hollow shaft ± 0.3/ ± 0.1 mm radial

Max. angular acceleration

Operating speed

Face mount ange, servo ange 6,000 rpm 9,000 rpm

Blind hollow shaft 6,000 rpm 9,000 rpm

Self-warming at maximum speed

Face mount ange 30k 30k

Servo ange 15k 25k

Blind hollow shaft 45k 35k

Rotor moment of inertia

Face mount ange, servo ange 11.4 gcm²

Blind hollow shaft 20.8 gcm²

Bearing lifetime

Aluminum

Aluminum

40 N axial

± 0.5/ ± 0.2 mm axial

≤ 500,000 rad/s²

3 x 109 revolutions

Ambient data

EMC

Enclosure rating (as per IEC 60529)

Permissible relative humidity

Operating temperature range

Storage temperature range

Resistance to shocks (according to

EN 60068-2-27)

Resistance to vibration (according to

EN 60068-2-6)

1)

When mating connector is inserted.

G-374

ENCODERS | SICK 8015560/2015-09-01

Basic Advanced

According to EN 61000-6-2 and EN 61000-6-3

1)

IP 67, housing

IP 65, shaft

95% (condensation not permitted)

–10 °C ... +70 °C –30 °C ... +80 °C

–40 °C ... +100 °C

100 g/6 ms

30 g/10 Hz ... 2,000 Hz

IP 67, housing

IP 67, shaft

Subject to change without notice

Page 4

Type code

Type

A

B

Advanced

Basic

Shaft type

B B

B C

B D

B E

B F

B G

B H

B J

S 1

S 4

Blind hollow shaft, Ø 8 mm

Blind hollow shaft, Ø 3/8"

Blind hollow shaft, Ø 10 mm

Blind hollow shaft, Ø 12 mm

Blind hollow shaft Ø 1/2"

Blind hollow shaft, Ø 14 mm

Blind hollow shaft, Ø 15 mm

Blind hollow shaft, Ø 5/8"

Servo ange, solid shaft, 6 mm

Face mount ange, solid shaft, 10 mm

Electrical interface

PROFIBUS DP

P

Connection type

3 x M12 male connectors, 5-pin, axial outlet

B

Resolution

Factory setting: Type B = 13 bit singleturn x 13 bit multiturn

Type A = 14 bit singleturn x 17 bit multiturn

ABSOLUTE ENCODERS A3M60 PROFIBUS

1)

A 3 M 6 0 – P B 0 x

1)

Number of steps programmable via control unit: Type A = 2 to 262144.

Ordering information

Mechanical design/shaft diameter Resolution Type Part no.

Solid shaft, face mount ange, Ø 10 mm, length 19 mm 8,192 x 8,192 A3M60B-S4PB013X13 1038826

Solid shaft, servo ange, Ø 6 mm, length 10 mm 8,192 x 8,192 A3M60B-S1PB013X13 1051018

Blind hollow shaft / 8 mm 8,192 x 8,192 A3M60B-BBPB013X13 1051016

Blind hollow shaft, / 10 mm 8,192 x 8,192 A3M60B-BDPB013X13 1038824

Blind hollow shaft, / 12 mm 8,192 x 8,192 A3M60B-BEPB013X13 1038825

Blind hollow shaft / 15 mm 8,192 x 8,192 A3M60B-BHPB013X13 1051017

Blind hollow shaft / 3/8" 8,192 x 8,192 A3M60B-BCPB013X13 1053327

Blind hollow shaft / 1/2" 8,192 x 8,192 A3M60B-BFPB013X13 1053328

Blind hollow shaft / 14 mm 8,192 x 8,192 A3M60B-BGPB013X13 1051325

Blind hollow shaft / 5/8" 8,192 x 8,192 A3M60B-BJPB013X13 1053329

Solid shaft, face mount ange, Ø 10 mm, length 19 mm 16,384 x 131,072 A3M60A-S4PB014X17 1053341

Solid shaft, servo ange, Ø 6 mm, length 10 mm 16,384 x 131,072 A3M60A-S1PB014X17 1053342

Blind hollow shaft / 8 mm 16,384 x 131,072 A3M60A-BBPB014X17 1053330

Blind hollow shaft / 3/8" 16,384 x 131,072 A3M60A-BCPB014X17 1053334

Blind hollow shaft / 10 mm 16,384 x 131,072 A3M60A-BDPB014X17 1053331

Blind hollow shaft / 12 mm 16,384 x 131,072 A3M60A-BEPB014X17 1053332

Blind hollow shaft / 1/2" 16,384 x 131,072 A3M60A-BFPB014X17 1053335

Blind hollow shaft / 14 mm 16,384 x 131,072 A3M60A-BGPB014X17 1053336

Blind hollow shaft / 15 mm 16,384 x 131,072 A3M60A-BHPB014X17 1053333

Blind hollow shaft / 5/8" 16,384 x 131,072 A3M60A-BJPB014X17 1053337

G

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

G-375

Page 5

A3M60 PROFIBUS ABSOLUTE ENCODERS

Sales kits

Sales kit 01

A3M60 PROFIBUS

• + M12 female cable connector, 4-pin, angled, (DOS-1204-W, part number 6007303)

• + PROFIBUS IN: M12 female cable connector, 5-pin, angled, shielded (DOS-1205-WQ, part number 6041429)

Encoder type (singleturn) Description Type Part no.

A3M60B-S4PB013x13 Solid shaft, face mount ange, 10 x 19 mm

A3M60B-S1PB013x13 Solid shaft, servo ange, 6 x 10 mm

A3M60B-BBPB013x13 Blind hollow shaft, Ø 8 mm

A3M60B-BDPB013x13 Blind hollow shaft, Ø 10 mm

A3M60B-BEPB013x13 Blind hollow shaft, Ø 12 mm

A3M60B-BHPB013x13 Blind hollow shaft, Ø 15 mm

A3M60B-BGPB013x13 Blind hollow shaft, Ø 14 mm

Sales kit 02

A3M60B-S4P

sales kit 01

A3M60B-S1P

sales kit 01

A3M60B-BBP

sales kit 01

A3M60B-BDP

sales kit 01

A3M60B-BEP

sales kit 01

A3M60B-BHP

sales kit 01

A3M60B-BGP

sales kit 01

1052488

1052489

1052477

1052478

1052479

1052486

1053975

G

A3M60 PROFIBUS

• + M12 female cable connector, 5-pin, angled, (DOL-1202-W05MC, part number 6042067)

• + PROFIBUS IN: M12 female cable connector, 5-pin, angled (DOL-1205-W05MQ, part number 6041423)

Encoder type (singleturn) Description Type Part no.

A3M60B-S4PB013x13 Solid shaft, face mount ange, 10 x 19 mm

A3M60B-S1PB013x13 Solid shaft, servo ange, 6 x 10 mm

A3M60B-BBPB013x13 Blind hollow shaft, Ø 8 mm

A3M60B-BDPB013x13 Blind hollow shaft, Ø 10 mm

A3M60B-BEPB013x13 Blind hollow shaft, Ø 12 mm

A3M60B-BHPB013x13 Blind hollow shaft, Ø 15 mm

A3M60B-BGPB013x13 Blind hollow shaft, Ø 14 mm

A3M60B-S4P

sales kit 02

A3M60B-S1P

sales kit 02

A3M60B-BBP

sales kit 02

A3M60B-BDP

sales kit 02

A3M60B-BEP

sales kit 02

A3M60B-BHP

sales kit 02

A3M60B-BGP

sales kit 02

1052492

1052506

1052490

1052491

1052493

1052494

1053976

G-376

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 6

ABSOLUTE ENCODERS A3M60 PROFIBUS

Sales kit 03

A3M60 PROFIBUS

• + M12 female cable connector, 4-pin, angled, (DOS-1204-W, part number 6007303)

• + PROFIBUS IN: M12 female cable connector, 5-pin, angled, shielded, B-coded (DOS-1205-WQ, part number 6041429)

• + PROFIBUS OUT: M12 male cable connector, 5-pin, angled (STE-1205-WQ, part number 6041428)

Encoder type (singleturn) Description Type Part no.

A3M60B-S4PB013x13 Solid shaft, face mount ange, 10 x 19 mm

A3M60B-S1PB013x13 Solid shaft, servo ange, 6 x 10 mm

A3M60B-BBPB013x13 Blind hollow shaft, Ø 8 mm

A3M60B-BDPB013x13 Blind hollow shaft, Ø 10 mm

A3M60B-BEPB013x13 Blind hollow shaft, Ø 12 mm

A3M60B-BHPB013x13 Blind hollow shaft, Ø 15 mm

A3M60B-BGPB013x13 Blind hollow shaft, Ø 14 mm

Sales kit 04

A3M60B-S4P

sales kit 03

A3M60B-S1P

sales kit 03

A3M60B-BBP

sales kit 03

A3M60B-BDP

sales kit 03

A3M60B-BEP

sales kit 03

A3M60B-BHP

sales kit 03

A3M60B-BGP

sales kit 03

1052513

1052514

1052507

1052508

1052509

1052510

1053977

A3M60 PROFIBUS

• + M12 female cable connector, 5-pin, angled, (DOL-1202-W05MC, part number 6042067)

• + PROFIBUS IN: M12 female cable connector, 5-pin, angled (DOL-1205-W05MQ, part number 6041423)

• + PROFIBUS OUT: M12 male cable connector, 5-pin, angled (STL-1205-W05MQ, part number 6041426)

Encoder type (singleturn) Description Type Part no.

A3M60B-S4PB013x13

A3M60B-S1PB013x13 Solid shaft, servo ange, 6 x 10 mm

A3M60B-BBPB013x13 Blind hollow shaft, Ø 8 mm

A3M60B-BDPB013x13 Blind hollow shaft, Ø 10 mm

A3M60B-BEPB013x13 Blind hollow shaft, Ø 12 mm

A3M60B-BHPB013x13 Blind hollow shaft, Ø 15 mm

A3M60B-BGPB013x13 Blind hollow shaft, Ø 14 mm

Solid shaft, face mount ange,

10 x 19 mm

A3M60B-S4P

sales kit 04

A3M60B-S1P

sales kit 04

A3M60B-BBP

sales kit 04

A3M60B-BDP

sales kit 04

A3M60B-BEP

sales kit 04

A3M60B-BHP

sales kit 04

A3M60B-BGP

sales kit 04

1052519

1052520

1052515

1052516

1052517

1052518

1053978

G

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

G-377

Page 7

A3M60 PROFIBUS ABSOLUTE ENCODERS

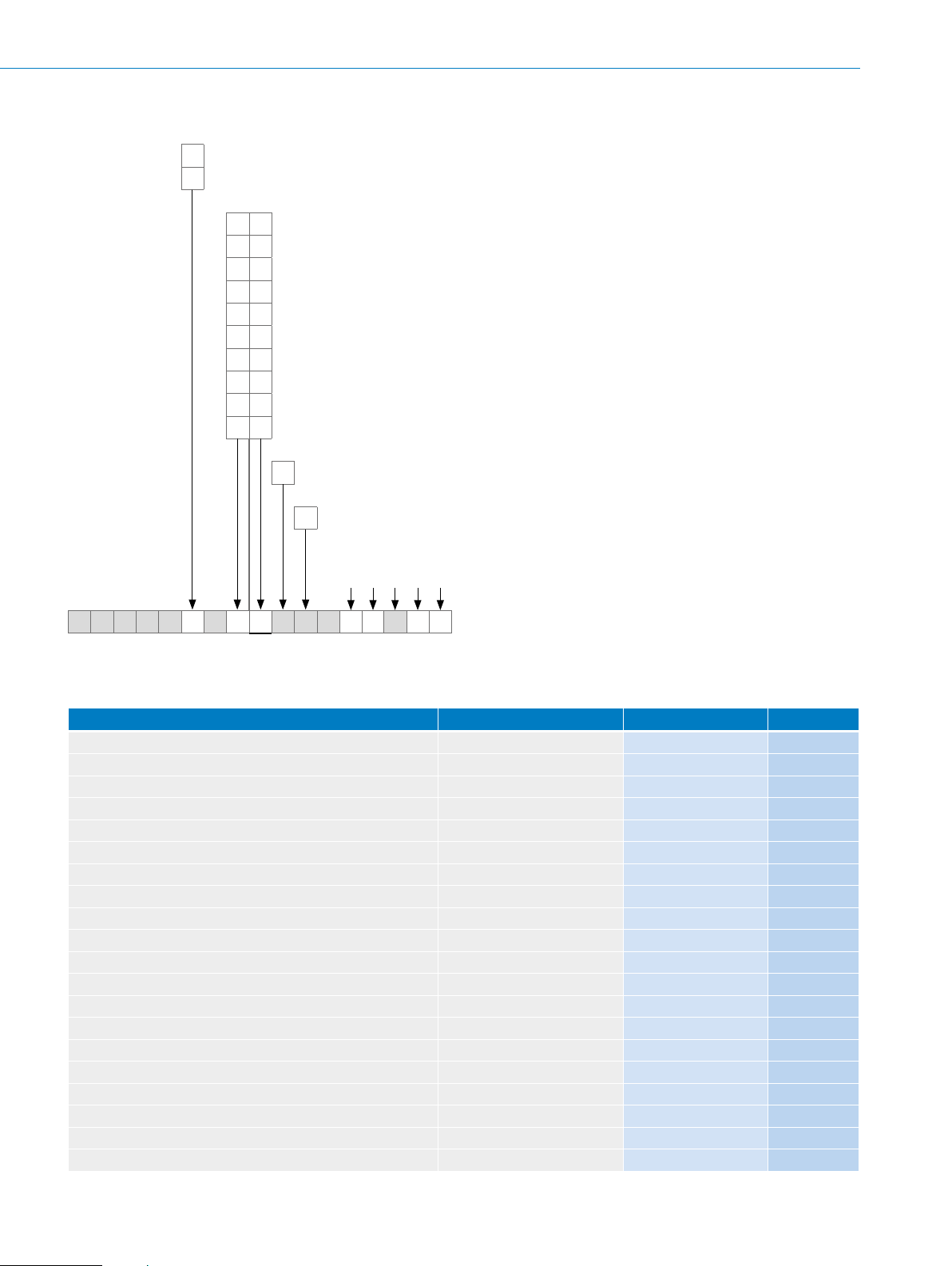

Dimensional drawings (dimensions in mm)

Face mount ange

General tolerances according to DIN ISO 2768-mk

Servo ange

G

General tolerances according to DIN ISO 2768-mk

Blind hollow shaft

Ø x j7

,

General tolerances according to DIN ISO 2768-mk

XF7 = Encoder shaft diameter, see type code

xj7 = Shaft diameter, on the customer side

G-378

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 8

PIN assignment

Supply voltage

PROFIBUS OUT

PROFIBUS IN

PROFIBUS IN

PIN Explanation

1 Not assigned

2 PROFIBUS Data A

3 Not assigned

4 PROFIBUS Data B

5 Screen

WARNING: Connect screen to housing.

ABSOLUTE ENCODERS A3M60 PROFIBUS

PROFIBUS OUT

PIN Explanation

1 +5 V (2P5)

2 PROFIBUS Data A

3 0 V (2M)

4 PROFIBUS Data B

5 Screen

1)

For external bus termination.

WARNING: Connect screen to housing.

1)

1)

G

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

G-379

Page 9

A3M60 PROFIBUS ABSOLUTE ENCODERS

Supply voltage

PIN Explanation

1 Operating voltage

2 Do not connect

3 Ground (0 V)

4 Do not connect

5 Not assigned

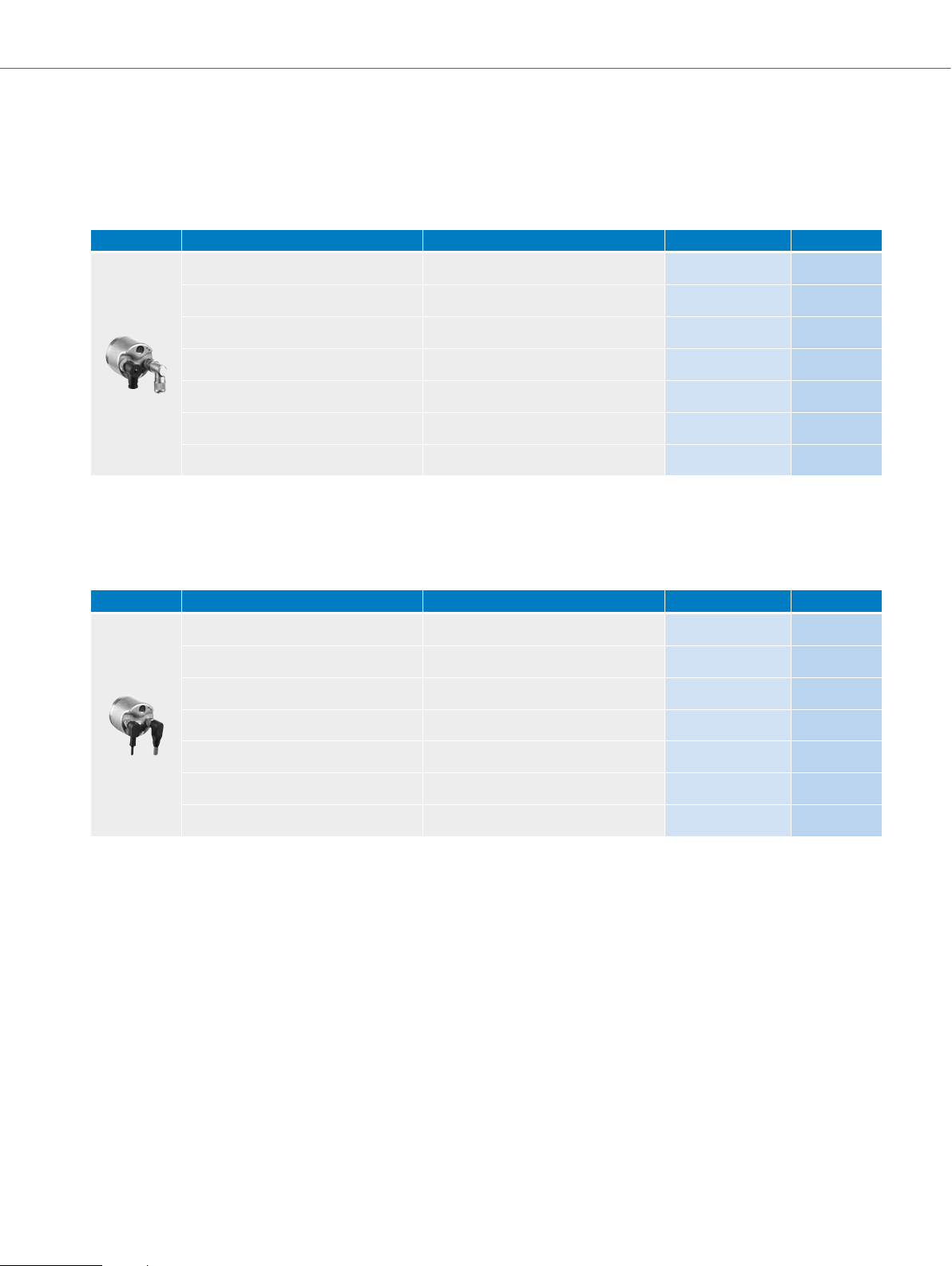

Recommended accessories

Mounting systems

Mounting brackets and plates

Mounting bracket

G

Figure Brief description Type Part no.

Mounting bracket for encoder with centering hub 36 mm, including mounting kit for face

mount ange

Dimensional drawings g page K-725

BEF-WF-36 2029164

Flanges

Flange plate

Figure Brief description Type Part no.

Flange adapter, adaptation of face mount ange with 36 mm centering hub to 50 mm

servo ange, aluminum, including 3 at head screws M4 x 10

Flange adapter, adaptation of face mount ange with 36 mm centering hub to 60 mm

square mounting plate, aluminum, including 3 at head screws M4 x 10

Flange adapter, adaptation of face mount ange with 36 mm centering hub to 58 mm

square mounting plate with shock absorbers, aluminum

Flange adapter, adaptation of face mount ange with 36 mm centering hub to 63 mm

square mounting plate, aluminum, including 3 at head screws M4 x 10

Flange adapter, adaptation of face mount ange with 36 mm centering hub to 100 mm

servo ange with 60 mm centering hub, aluminum

BEF-FA-036-050 2029160

BEF-FA-036-060REC 2029162

BEF-FA-036-060RSA 2029163

BEF-FA-036-063REC 2034225

BEF-FA-036-100 2029161

Dimensional drawings g page K-725

G-380

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 10

ABSOLUTE ENCODERS A3M60 PROFIBUS

Other mounting accessories

Measuring wheels and measuring wheel systems

Figure Brief description Type Part no.

Measuring wheel with smooth plastic surface (Hytrel) for 10 mm solid shaft, circumference 200 mm

Measuring wheel with ridged plastic surface (Hytrel) for 10 mm solid shaft, circumference 200 mm

Measuring wheel with smooth plastic surface (Hytrel) for 10 mm solid shaft, circumference 500 mm

Measuring wheel with O-ring (NBR70) for 6 mm solid shaft, circumference 300 mm BEF-MR006030R 2055634

Measuring wheel with O-ring (NBR70) for 10 mm solid shaft, circumference 300 mm BEF-MR010030R 2049278

Dimensional drawings g page K-725

BEF-MR-010020 5312988

BEF-MR-010020G 5318678

BEF-MR-010050 5312989

Mounting bell

Figure Brief description Type Part no.

Mounting bell for encoders with a servo ange, centering hub 50 mm, including mounting kit

Dimensional drawings g page K-725

BEF-MG-50 5312987

Servo clamps

Figure Brief description Type Part no.

Half-shell servo clamps (2 pcs.) for servo anges with a 50 mm centering hub BEF-WG-SF050 2029165

Servo clamps, large, for servo anges (clamps, eccentric fastener), 3 pcs., without

mounting material

Dimensional drawings g page K-725

BEF-WK-SF 2029166

Miscellaneous

Figure Brief description Type Part no.

Mounting kit for servo ange encoder on the bearing block, 1 bar coupling SKPS

1520 06/06 1 hexagon socket wrench SW1.5 DIN 911, 3 mounting eccentric BEMN

1242 49 3 screws M4 x 10 DIN 912, 1 hexagon socket wrench SW3 DIN 911

Bearing block for hollow shaft encoder, including xing screws BEF-FA-B12-010 2042728

Bearing block for servo and face mount ange encoder BEF-FA-LB1210 2044591

Dimensional drawings g page K-725

BEF-MK-LB 5320872

G

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

G-381

Page 11

G

A3M60 PROFIBUS ABSOLUTE ENCODERS

Shaft adaptation

Shaft couplings

Figure Brief description Type Part no.

Bellows coupling, shaft diameter 6 mm / 6 mm, maximum shaft offset: radial

± 0.25 mm, axial ± 0.4 mm, angular ± 4°; max. speed 10,000 rpm, –30 °C ... +120 °C,

max. torque 80 Ncm; material: stainless steel bellows, aluminum hub

Bellows coupling, shaft diameter 6 mm / 10 mm, maximum shaft offset: radial

± 0.25 mm, axial ± 0.4 mm, angular ± 4°; max. speed 10,000 rpm, –30 °C ... +120 °C,

max. torque 80 Ncm; material: stainless steel bellows, aluminum hub

Bellows coupling, shaft diameter 10 mm/10 mm; maximum shaft offset: radial

± 0.25 mm, axial ± 0.4 mm, angular ± 4°; max. revolutions 10,000 rpm,

–30° C ... +120 °C, max. torque 80 Ncm; material: stainless steel bellows, aluminum

clamping hubs

Bellows coupling, shaft diameter 10 mm/12 mm; maximum shaft offset: radial

± 0.25 mm, axial ± 0.4 mm, angular ± 4°; max. revolutions 10,000 rpm,

–30° C ... +120 °C, max. torque 80 Ncm; material: stainless steel bellows, aluminum

clamping hubs

Bar coupling, shaft diameter 6 mm / 6 mm, maximum shaft offset: radial ± 0.3 mm,

axial ± 0.2 mm, angle ± 3°; max. speed 10,000 rpm, –10° C ... +80 °C, max. torque

80 Ncm; material: ber-glass reinforced polyamide, aluminum hub

Bar coupling, shaft diameter 6 mm / 8 mm, maximum shaft offset radial ± 0.3 mm, ax-

ial ± 0.2 mm, angle ± 3°; max. speed 10,000 rpm, torsion spring rigidity 38 Nm/wheel;

material: ber-glass reinforced polyamide, aluminum hub

Bar coupling, shaft diameter 6 mm/10 mm, maximum shaft offset: radial ± 0.3 mm,

axial ± 0.2 mm, angular ± 3°; max. speed 10,000 rpm, –10° C ... +80 °C, max. torque

80 Ncm; material: ber-glass reinforced polyamide, aluminum hub

Bar coupling, shaft diameter 8 mm / 10 mm, maximum shaft offset: radial ± 0.3 mm,

axial ± 0.2 mm, angular ± 3°; torsion spring rigidity 38 Nm/wheel; material: ber-glass

reinforced polyamide, aluminum hub

Bar coupling, shaft diameter 10 mm / 10 mm, maximum shaft offset radial ± 0.3 mm,

axial ± 0.2 mm, angle ± 3°; max. speed 10,000 rpm, torsion spring rigidity 38 Nm/

wheel; material: ber-glass reinforced polyamide, aluminum hub

Double-loop coupling, shaft diameter 6 mm/10 mm, maximum shaft offset: radial

± 2.5 mm, axial ± 3 mm, angular ± 10°; max. speed 3,000 rpm, –30 °C ... +80 °C,

max. torque 1.5 Nm; material: polyurethane, galvanized steel ange

Double-loop coupling, shaft diameter 8 mm/10 mm, maximum shaft offset: radial

± 2.5 mm, axial ± 3 mm, angular ± 10°; max. speed 3,000 rpm, –30 °C ... +80 °C,

max. torque 1.5 Nm; material: polyurethane, galvanized steel ange

Double-loop coupling, shaft diameter 10 mm/10 mm, maximum shaft offset: radial

± 2.5 mm, axial ± 3 mm, angular ± 10°; max. speed 3,000 rpm, –30 °C ... +80 °C,

max. torque 1.5 Nm; material: polyurethane, galvanized steel ange

Double-loop coupling, shaft diameter 10 mm/12 mm, maximum shaft offset: radial

± 2.5 mm, axial ± 3 mm, angular ± 10°; max. speed 3,000 rpm, –30 °C ... +80 °C,

max. torque 1.5 Nm; material: polyurethane, galvanized steel ange

Spring washer coupling, shaft diameter 6 mm/10 mm, maximum shaft offset: radial

± 0.3 mm, axial ± 0.4 mm, angular ± 2.5°; max. speed 12,000 rpm, –10 °C ... +80 °C,

max. torque 60 Ncm; material: aluminum ange, ber-glass reinforced polyamide mem-

brane and tempered steel coupling pin

Spring washer coupling, shaft diameter 10 mm / 10 mm, maximum shaft offset: radial

± 0.3 mm, axial ± 0.4 mm, angular ± 2.5°; max. speed 12,000 rpm, –10° ... +80° C,

max. torque 60 Ncm; material: aluminum ange, glass ber-reinforced polyamide mem-

brane and hardened steel coupling pin

KUP-0606-B 5312981

KUP-0610-B 5312982

KUP-1010-B 5312983

KUP-1012-B 5312984

KUP-0606-S 2056406

KUP-0608-S 5314179

KUP-0610-S 2056407

KUP-0810-S 5314178

KUP-1010-S 2056408

KUP-0610-D 5326697

KUP-0810-D 5326704

KUP-1010-D 5326703

KUP-1012-D 5326702

KUP-0610-F 5312985

KUP-1010-F 5312986

Dimensional drawings g page K-725

G-382

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 12

Connectivity

Plug connectors and cables

Connecting cables with female connector

ABSOLUTE ENCODERS A3M60 PROFIBUS

Figure Brief description Length

Head A: female connector, M12, 5-pin, angled

Head B: cable

Cable: for power supply, PUR, halogen-free, shielded, 3 x 0.34 mm², Ø 4.2 mm

Head A: female connector, M12, 5-pin, straight

Head B: cable

Cable: for power supply, suitable for drag chain, PUR, halogen-free, shielded,

5 x 0.34 mm², Ø 5.9 mm

Head A: female connector, M12, 5-pin, straight

Head B: cable

Cable: suitable for drag chain, PUR, halogen-free, shielded, 2 x 0.34 mm²,

Ø 8.0 mm

Head A: female connector, M12, 5-pin, angled, B-coded

Head B: cable

Cable: suitable for drag chain, PUR, shielded, 2 x 0.64 mm², Ø 7.8 mm

Dimensional drawings g page K-725

Connecting cables with male connector

Figure Brief description Length

Head A: male connector, M12, 5-pin, straight, B-coded

Head B: cable

Cable: suitable for drag chain, PUR, halogen-free, shielded, 2 x 0.34 mm²,

Ø 8.0 mm

Wire shielding: AL-PT foil, total shield, tin-plated C shield

Head A: male connector, M12, 5-pin, angled, B-coded

Head B: cable

Cable: suitable for drag chain, PUR, shielded, 2 x 0.64 mm², Ø 7.8 mm

Type Part no.

of

cable

5 m DOL-1202-W05MC 6042067

10 m DOL-1202-W10MC 6042068

5 m DOL-1205-G05MAC 6036384

10 m DOL-1205-G10MAC 6036385

20 m DOL-1205-G20MAC 6036386

5 m DOL-1205-G05MQ 6026006

10 m DOL-1205-G10MQ 6026008

12 m DOL-1205-G12MQ 6032636

15 m DOL-1205-G15MQ 6032637

20 m DOL-1205-G20MQ 6032638

30 m DOL-1205-G30MQ 6032639

50 m DOL-1205-G50MQ 6032861

5 m DOL-1205-W05MQ 6041423

10 m DOL-1205-W10MQ 6041425

Type Part no.

of

cable

5 m STL-1205-G05MQ 6026005

10 m STL-1205-G10MQ 6026007

12 m STL-1205-G12MQ 6032635

5 m STL-1205-W05MQ 6041426

10 m STL-1205-W10MQ 6041427

G

Dimensional drawings g page K-725

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

G-383

Page 13

A3M60 PROFIBUS ABSOLUTE ENCODERS

Female connectors (ready to assemble)

Figure Brief description Type Part no.

Head A: female connector, M12, 4-pin, straight, unshielded, for power supply, for cable

diameter 4 mm ... 6 mm

Head B: -

Head A: female connector, M12, 4-pin, angled, unshielded, for power supply, for cable

diameter 3 mm ... 6.5 mm

Head B: -

Head A: female connector, M12, 5-pin, straight, B-coded, shielded, for cable diameter

4 mm ... 9 mm

Head B: -

Head A: female connector, M12, 5-pin, angled, B-coded, shielded, for cable diameter

4 mm ... 8 mm

Head B: -

Dimensional drawings g page K-725

Cables (ready to assemble)

DOS-1204-G 6007302

DOS-1204-W 6007303

DOS-1205-GQ 6021353

DOS-1205-WQ 6041429

G

Figure Brief description Length

Type Part no.

of

cable

Head A: cable

Head B: cable

Cable: suitable for drag chain, PUR, shielded, 2 x 0.25 mm², Ø 8.0 mm

By the

meter

LTG-2102-MW 6021355

Other plug connectors and cables

Figure Brief description Type Part no.

A3M60 accessories sales set comprising: Female cable connector supply voltage M12

angled (6007303) Female cable connector M12 angled (6041429) Male cable connector M12 angled (6041428)

Head A: male connector, M12, 4-pin, straight, B-coded

Cable: terminator

Dimensional drawings g page K-725

DOS-3XM12-W 2058177

STE-END-Q 6021156

Male connectors (ready to assemble)

Figure Brief description Type Part no.

Head A: male connector, M12, 5-pin, straight, B-coded, shielded, for cable diameter

4 mm ... 9 mm

Head B: -

Head A: male connector, M12, 5-pin, angled, B-coded, shielded, for cable diameter

4 mm ... 8 mm

Head B: -

STE-1205-GQ 6021354

STE-1205-WQ 6041428

Dimensional drawings g page K-725

- For additional accessories, please see page K-668 onwards

G-384

ENCODERS | SICK 8015560/2015-09-01

Subject to change without notice

Page 14

ABSOLUTE ENCODERS A3M60 PROFIBUS

G

Subject to change without notice

ENCODERS | SICK8015560/2015-09-01

G-385

Loading...

Loading...