Sices GC315, GC315Plus, GC400Link, GC400Mains, GC315LInk Technical Manual

...

Plus Link

Link

Mains Mains+Link

File name: EAAM045606EN.docx

Rev. 06 Date: 21/10//2015

ID Document: EAAM0456

Product: GC315xx +

GC400xxGC315 -GC315ETH

Revision

Date

Pages

Notes

00

28/03/2014

173

The first version of the manual, drawn-up for version 01.06 of

the controller.

01

21/05/2014

173

Modified section 4.2 and Chapters 3, 8 and 9.

02

19/09/2014

173

GC315Plus added

03

26/11/2014

177

Valid for the 01.11 revision of the controller: a second counter

has been added and a counter for the days left to the

maintenance. The following paragraphs have changed: 5.10.1,

5.14, 12.5.4.3, 12.5.4.10, 12.5.5.2, 14 (faults 39,40,50,57

added), 15.8, 15.10, 15.11. Chapters 12.5.2.15 and 12.5.4.10

have been added.

04

07/04/2015

177

Valid for the 01.15 revision of the controller.

The following paragraphs have changed: 8 and 9 to add device

option with max 100Vac.

05

24/06/2015

Addition of controllers GC315

Link

and GC400x. All controllers

names have been adjusted. Addition of par. 1.3. Various

paragraphs moved and added.

06

02/09/2015

Addition of controllers GC400

Mains

and GC400

Mains+Link

.

ii Technical Handbook

SUMMARY

1. Introduction ............................................................................................................ 16

1.1 Nomenclature ..................................................................................................... 16

1.2 Reference documents ......................................................................................... 16

1.3 Information on safety .......................................................................................... 17

1.4 Introduction and prerequisites ............................................................................ 17

1.5 Switch SW1 ........................................................................................................ 18

1.6 Notes on the configuration of the device parameters.......................................... 18

1.7 Definitions ........................................................................................................... 18

1.8 Conventions ........................................................................................................ 19

1.9 Software revisions .............................................................................................. 19

2. Views of the device ................................................................................................ 20

3. Technical features ................................................................................................. 24

3.1 Measurement resolution ..................................................................................... 27

3.2 Additional characteristics of GC315

Link

,GC400

Link

and GC400

Mains+Link

............... 27

4. Installation .............................................................................................................. 28

4.1 Mounting ............................................................................................................. 28

4.2 Wiring ................................................................................................................. 28

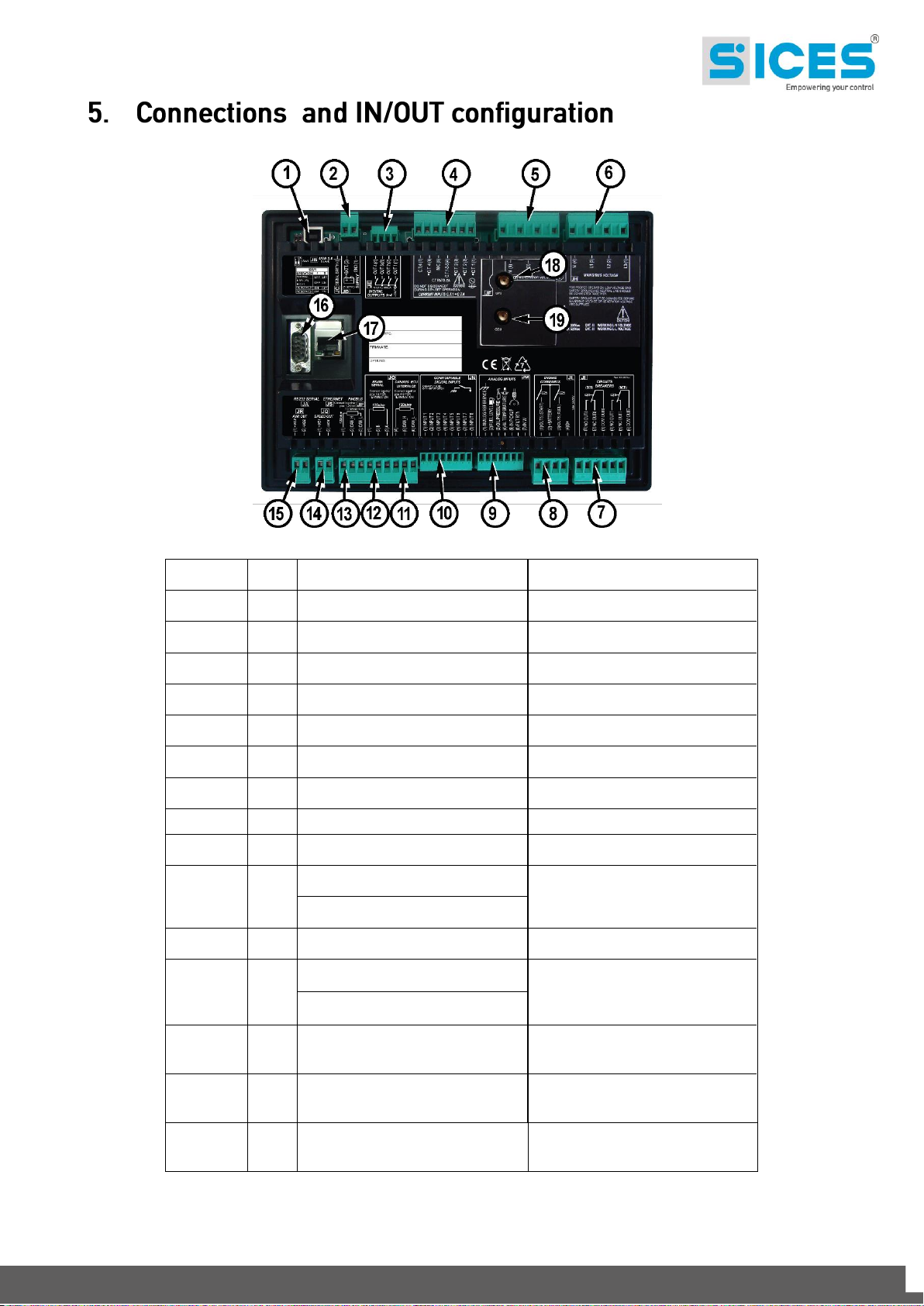

5. Connections and IN/OUT configuration .............................................................. 29

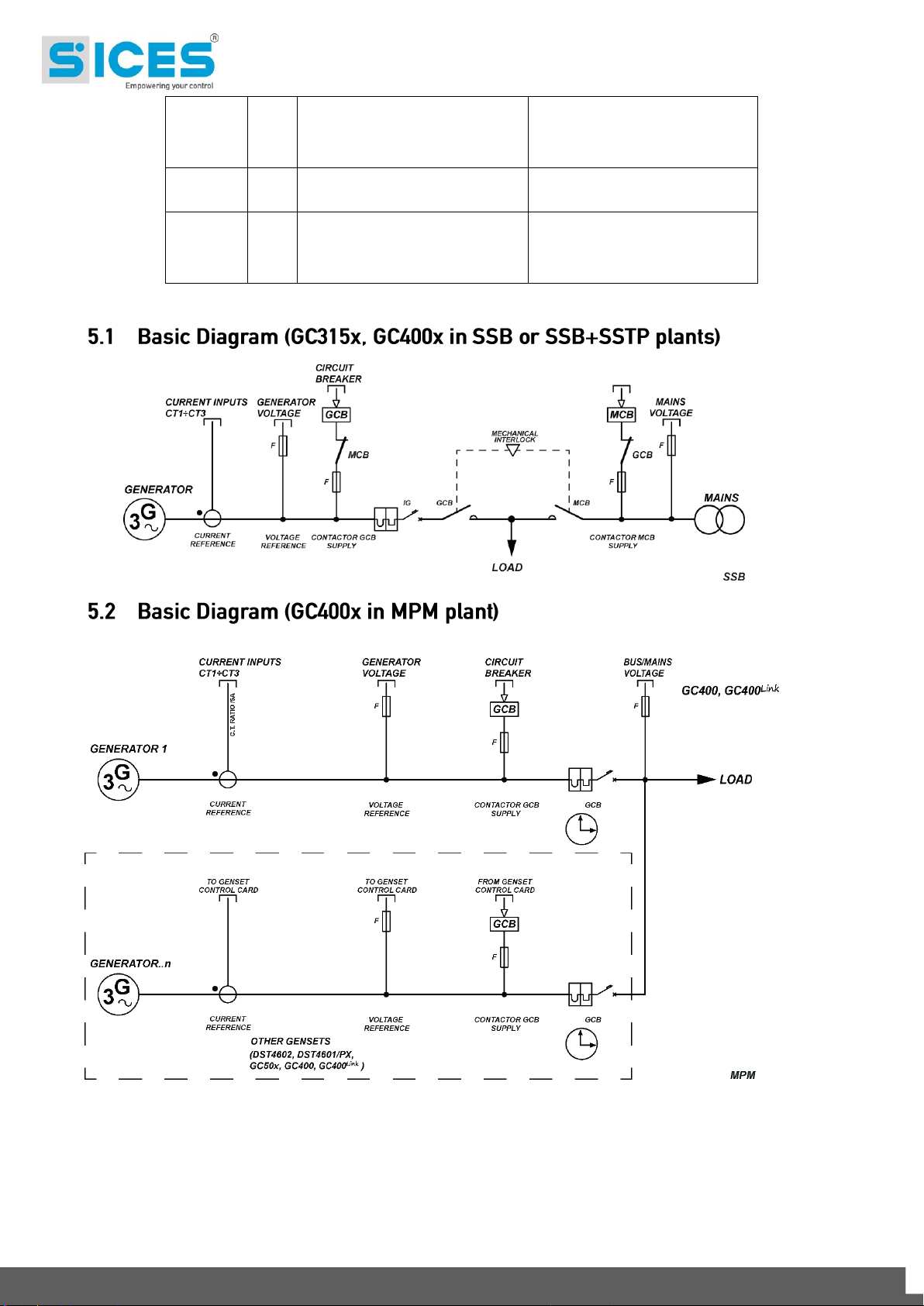

5.1 Basic Diagram (GC315x, GC400x in SSB or SSB+SSTP plants)....................... 30

5.2 Basic Diagram (GC400x in MPM plant) .............................................................. 30

5.3 Functional earth (JC) ................................................................ .......................... 31

5.4 Device (JD) supply.............................................................................................. 31

5.5 Digital inputs (JN, JM) ......................................................................................... 32

5.5.1 JN – Digital inputs ........................................................................................ 32

5.5.2 Virtual digital inputs ...................................................................................... 33

5.5.3 Configuration of the digital inputs ................................................................. 34

5.6 Digital outputs (JL, JI, JE) ................................................................................... 40

5.6.1 Engine commands (JL)................................................................................. 40

5.6.2 Outputs for JI loads change-over command ................................................. 43

5.6.3 Auxiliary outputs (JE) ................................................................................... 44

5.6.4 Digital outputs configuration ......................................................................... 45

5.6.5 AND/OR logics ............................................................................................. 50

5.7 Engine rotational speed measurement (PICK-UP or W) JM-5, JM-6, JM-7 ........ 54

5.7.1 Magnetic pick-up .......................................................................................... 54

5.7.2 W signal ........................................................................................................ 55

5.7.3 Revolutions measurement from frequency ................................................... 55

5.8 Analogue inputs (JM, JL) .................................................................................... 56

5.8.1 JM – Analogue Inputs ................................................................................... 56

5.8.2 JL-4 Analogue Input ..................................................................................... 57

5.8.3 Configuration of analogue inputs .................................................................. 58

5.8.4 Virtual ANALOGUE inputs ............................................................................ 61

5.8.5 Conversion curves ........................................................................................ 63

5.9 Analogue inputs (JQ, JR) .................................................................................... 65

5.9.1 Analogue outputs on the controller (only GC400x) ....................................... 65

5.9.2 Configuration of the ANALOGUE outputs..................................................... 65

5.10 Optional additional modules ......................................................................... 66

Technical Handbook iii

5.11 Connection to the public electric mains/parallel bars (JH) ............................ 67

5.11.1 Measurement of the mains neutral .......................................................... 68

5.12 Connection to the genset (JG) ...................................................................... 68

5.12.1 Measurement of the generator neutral .................................................... 69

5.13 Current transformer connection (JF) ............................................................ 70

5.13.1 Auxiliary current ...................................................................................... 71

5.14 Communication ............................................................................................ 72

5.14.1 Serial port 1 RS232 (JA) – Not available for GC315 .............................. 72

5.14.2 Serial port 2 RS485 (JO) – Not available for GC315 ............................... 73

5.14.3 USB (JB) ....................................................................................................... 74

5.14.4 Ethernet (JS) – Not available on GC315, GC315

Link

and GC400

Link

.............. 75

5.15.1 CAN-BUS (JO) connection – not available for GC315 ....................................... 77

5.15.2 CAN-BUS (JP) connection – only available for GC400x .................................... 78

This CAN-BUS interface is only available for GC400x and must only be used for plants

composed by more than one generator (MPM). It is useful to connect all SICES genset

controllers to each other (not necessarily only GC400x): through this communication

channel (PMBC – Power Management Communication Bus) the controllers exchange

all necessary data to manage the parallel functions (see doc. [12]). ............................ 78

The CAN-BUS interface is galvanically isolated. The bus itself can be also used for the

connection to the optional modules DITHERM, DIGRIN, DIVIT, DITEL and DANOUT: in

this case it is also required the use of a CAN-BRIDGE module to avoid that the

expansion modules data of a controller are sent to the other controllers connected to

this CAN-BUS too (see 5.10). ....................................................................................... 78

Connections: ................................................................................................................ 78

6. Link Controllers ..................................................................................................... 79

6.1 Preface ............................................................................................................... 79

6.2 HW Configuration ............................................................................................... 80

6.2.1 SIM insertion ................................................................................................ 81

6.2.2 GSM e GPS antenna .................................................................................... 82

6.2.3 Warning LED ................................................................................................ 82

6.3 Internal battery as option .................................................................................... 83

6.3.1 Connection/disconnection and recharge of the internal battery .................... 84

6.4 Parameters configuration .................................................................................... 85

6.4.1 GPRS/GSM Modem and SMS messages .................................................... 85

6.4.2 GPRS Configuration ..................................................................................... 86

6.4.3 GPS Receiver ............................................................................................... 86

6.5 “Si.Mo.Ne” system .............................................................................................. 87

6.6 Energy saving mode ................................................................ ........................... 88

7. Main functions ....................................................................................................... 90

7.1 Front panel GC315x ........................................................................................... 90

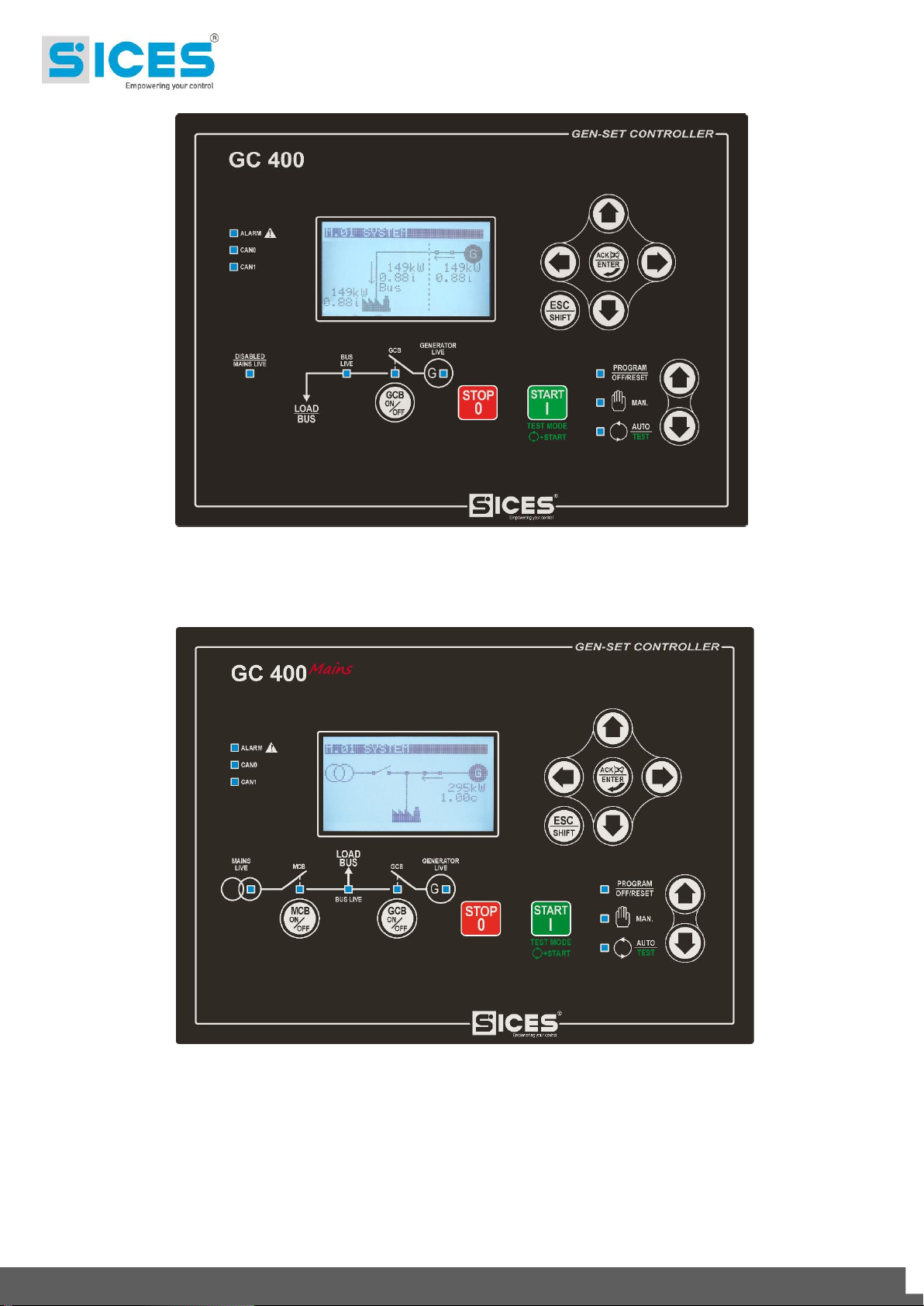

7.2 Front Panel GC400x ........................................................................................... 91

7.3 Front Panel GC400

Mains

and GC400

Mains+Link

....................................................... 92

7.4 Selector (ref. to fig. 1) ................................ ......................................................... 93

7.5 Indicators (ref. to fig. 1 and 2) ............................................................................. 96

7.6 Multifunctional display ......................................................................................... 98

7.6.1 LCD lighting .................................................................................................. 98

7.6.2 Contrast adjustment ..................................................................................... 98

7.6.3 Mode navigation ........................................................................................... 98

iv Technical Handbook

7.6.4 Display area layout (ref. to fig. 4) .................................................................. 99

7.6.5 Top status bar (ref. to fig. 5) ....................................................................... 100

7.7 Display mode .................................................................................................... 101

7.7.1 Programming (P.XX) ................................................................................. 101

7.7.2 Status information (S.xx) ................................................................ ............ 108

7.7.3 Electrical measurements (M.xx) ................................................................. 114

7.7.4 Engine measurements (E.xx) ..................................................................... 118

7.7.5 Measures from CAN-BUS PMCB (only for GC400x) (B.xx), ....................... 122

7.7.6 History logs (H.xx) ...................................................................................... 124

7.8 Selection of the language ................................................................................. 132

8. Working sequence ............................................................................................... 133

8.1 Operating modes .............................................................................................. 133

8.2 Mains ................................................................................................................ 136

8.2.1 Internal sensor ............................................................................................ 137

8.2.2 External sensor .......................................................................................... 141

8.2.3 Mains global status ..................................................................................... 141

8.2.4 Communication and events ........................................................................ 141

8.3 Generator ......................................................................................................... 142

8.3.1 Frequency .................................................................................................. 142

8.3.2 Voltages ..................................................................................................... 143

8.3.3 Overview .................................................................................................... 145

8.3.4 Communication and events ........................................................................ 145

8.4 Automatic intervention of the generator inhibited. ............................................. 145

8.4.1 Inhibition from contact ................................................................................ 146

8.4.2 Inhibition from clock .................................................................................... 146

8.5 Differences between Mains Simulation and Inhibition ...................................... 146

8.6 Engine .............................................................................................................. 147

8.6.1 Engine running/stopped status acknowledgement ..................................... 147

8.6.2 Engine commands ...................................................................................... 148

8.6.3 Manual control sequence ........................................................................... 149

8.6.4 Communication and events ........................................................................ 154

8.7 Breakers management ..................................................................................... 156

8.7.1 Digital outputs ............................................................................................. 156

8.7.2 Digital inputs ............................................................................................... 157

8.7.3 OFF/RESET management logic ................................................................. 158

8.7.4 MAN management logic ............................................................................. 158

8.7.5 Switching logic in AUTO mode .................................................................. 159

8.7.6 Switch ......................................................................................................... 159

8.7.7 Switch management ................................................................................... 159

8.7.8 Automatic power delivery of the generator inhibited. .................................. 159

8.7.9 Communication and events ........................................................................ 160

9. Anomalies ............................................................................................................ 162

9.1 Silencing the horn ............................................................................................. 163

9.2 Acknowledging anomaly ................................................................................... 163

9.3 Acknowledging anomaly ................................................................................... 164

9.4 Communication and events .............................................................................. 164

9.5 Protection OVERRIDE ...................................................................................... 165

9.6 Anomalies related to digital inputs .................................................................... 166

9.7 Anomalies related to analogue inputs ............................................................... 168

Technical Handbook v

9.8 Anomalies list ................................................................................................... 168

01 – Minimum generator voltage ................................................................................ 168

02 – Maximum generator voltage ............................................................................... 169

03 – Minimum generator frequency ............................................................................ 169

04 – Maximum generator frequency ........................................................................... 169

05 – Belt break (D+ battery-charger failure) ............................................................... 170

06 – Maximum current ................................................................................................ 170

07 – Manual stop while in AUTO ................................................................................ 172

08 – Operating conditions failure ................................................................................ 173

11 – Power reverse .................................................................................................... 173

13 – Mains circuit breaker (MCB) not closed .............................................................. 173

14 – Genset circuit breaker (GCB) not closed ............................................................ 173

16 – Short circuit on the generator ............................................................................. 174

17 – Overspeed (from contact) ................................................................................... 174

18 – Overspeed (from engine speed measurement) .................................................. 175

19 – Overspeed (from generator frequency) .............................................................. 175

21 – Failed stop .......................................................................................................... 175

22 – Overcrank ........................................................................................................... 176

23 – Mains circuit breaker (MCB) not open ................................................................ 176

24 – Genset circuit breaker (GCB) not open .............................................................. 176

26 – Minimum fuel level (from ANALOGUE sensor) ................................................... 177

27 – Low fuel level (from contact) ............................................................................... 177

28 – Low fuel level (from ANALOGUE sensor) ........................................................... 178

29 – High fuel level (from contact) .............................................................................. 178

30 – High fuel level (from ANALOGUE sensor) .......................................................... 178

31 – High coolant temperature (from contact) ............................................................ 178

32 – High coolant temperature (from ANALOGUE sensor) ........................................ 179

33 – Maximum coolant temperature (from contact) .................................................... 179

34 – Maximum coolant temperature (from ANALOGUE sensor) ................................ 180

35 – Maximum oil temperature (from ANALOGUE sensor) ........................................ 180

37 – Starter battery voltage, low ................................................................................. 180

38 – Starter battery voltage, high................................................................................ 181

39 – Service required (first counter) ........................................................................... 181

40 – Service required (second counter) ...................................................................... 181

41 – Minimum oil pressure (from contact) .................................................................. 182

42 – Minimum oil pressure (from ANALOGUE sensor) .............................................. 182

43 – Low oil pressure (from contact) .......................................................................... 183

44 – Low oil pressure (from ANALOGUE sensor) ...................................................... 183

45 – Maximum auxiliary current .................................................................................. 183

48 – Emergency stop .................................................................................................. 184

49 – Maximum power ................................................................................................. 184

50 – Service required (days counter) .......................................................................... 184

52 – Generator voltages asymmetry ........................................................................... 185

53 – Generator current asymmetry ............................................................................. 185

54 – High oil temperature (from ANALOGUE sensor) ................................................ 185

55 – Wrong phase sequence ...................................................................................... 186

56 – Low generator voltage ........................................................................................ 186

57 – Clock not valid ................................................................................................ .... 186

58 – Low generator frequency .................................................................................... 187

59 – High generator voltage ....................................................................................... 187

vi Technical Handbook

60 – High generator frequency ................................................................................... 187

61 – Lost Excitation .................................................................................................... 188

64 – Fuel pump failure ................................................................................................ 188

65 – Low coolant temperature (from ANALOGUE sensor) ......................................... 189

98 – Maximum time without CAN-BUS data (engine) ................................................. 189

100 – Maximum differential current ............................................................................ 189

105 – Battery charger failure (from CAN-BUS). .......................................................... 189

106 – Maximum reactive power exported (only GC400x) ...................................... 190

118 – Maximum speed from CAN BUS ...................................................................... 190

132 – High coolant temperature from CAN-BUS ........................................................ 190

134 – Maximum coolant temperature from CAN-BUS ................................................ 190

135 – Minimum coolant level from CAN-BUS. ............................................................ 191

136 – Low coolant level from CAN BUS ..................................................................... 191

137 – Low battery voltage from CAN BUS ................................................................. 191

142 – Minimum oil pressure from CAN BUS .............................................................. 191

144 – Low oil pressure from CAN BUS ...................................................................... 192

158 – High oil temperature from CAN BUS ................................................................ 192

159 – Maximum oil temperature from CAN BUS ........................................................ 192

160 – Water in fuel from CAN BUS ............................................................................ 192

198 – Warnings – Yellow lamp (from CAN-BUS) ........................................................ 193

199 – Alarms cumulative – Red lamp (from CAN-BUS) ............................................. 193

200 – CAN-BUS connection 1 (PMCB) failed (only GC400x) ................................ 193

201 – Address conflict on CAN-BUS bus 1 (PMCB) (only GC400x) ...................... 193

202 – Errato numero di generatori sul bus CAN-BUS 1 (PMCB) (solo GC400x) ... 194

203 – Negative sequence ........................................................................................... 194

204 – Failed closure of NECB breaker (only GC400x) .......................................... 194

205 – Failed opening of NECB breaker (only GC400x) ......................................... 194

252 – CAN-BUS (EXBUS) expansion modules missing ............................................. 195

253 – CAN-BUS (EXBUS) missing measure .............................................................. 195

254 – CAN-BUS (EXBUS) duplicate address ............................................................. 195

255 - Connection with CAN-BUS (EXBUS) sensor timed out. .................................... 195

271 – Input parallel failed (only GC400x) ............................................................... 196

272 – Mancato parallelo di rientro (solo GC400x).................................................. 196

273 – Incoherent parameters (only GC400x) ......................................................... 196

274 – Sectioned auto production line (only GC400x) ............................................. 196

275 – Interface device not open (only GC400x)..................................................... 197

276 – Alarm from CAN-BUS master controller 1 (PMCB) (only GC400x) .............. 197

279 – Bar voltage not coherent (only GC400x) ...................................................... 197

10. Other functions .................................................................................................... 197

10.1 Fuel pump ......................................................................................................... 197

10.1.1 Use with an ANALOGUE level transducer ............................................ 198

10.1.2 To use this function requires: ................................................................ 199

10.1.3 Level evaluation .................................................................................... 199

10.1.4 Automatic pump control ........................................................................ 199

10.1.5 Manual pump control............................................................................. 200

10.1.6 Protections ............................................................................................ 200

10.2 Engine Coolant preheating ............................................................................... 200

10.3 Loads protection from mains breaker damages ................................................ 200

10.4 Load thresholds ................................................................................................ 202

10.4.1 Low load ................................................................................................ 202

Technical Handbook vii

10.4.2 High load ............................................................................................... 202

10.5 Alternative parameters configuration ................................................................ 203

10.6 EJP function ..................................................................................................... 204

10.7 Maintenance ..................................................................................................... 205

10.7.1 Counter for the hours left to maintenance 1 ................................................ 205

10.7.2 Counter for the hours left to maintenance 2 .......................................... 206

10.7.3 Counter for the days left to maintenance .................................................... 206

10.8 Counters ........................................................................................................... 206

10.8.1 Counters reset ...................................................................................... 208

10.9 Clock ................................................................................................................. 208

10.9.1 Automatic update of the clock ............................................................... 208

10.9.2 Engine TEST start-up weekly planning. ................................................ 209

10.9.3 Weekly scheduling of engine operating time intervals. ......................... 209

10.10 Non-volatile memory .................................................................................. 210

viii Technical Handbook

INDEX

A

AIF.0000 43; 60

AIF.0100 60

AIF.1000 60; 61

AIF.1001 60

AIF.1100 60; 61; 179

AIF.1101 60; 174; 179

AIF.1110 60; 61

AIF.1111 60

AIF.1200 60; 61

AIF.1201 60

AIF.1210 60; 61

AIF.1211 60

AIF.1220 60; 61

AIF.1221 60

AIF.1300 43; 60; 142; 163

AIF.1601 60

AIF.1603 60

AIF.1605 60

AIF.1641 60

AIF.2001 58; 60; 64; 118

AIF.2003 58; 60; 64; 118

AIF.2005 58; 60; 64; 118

AIF.2051 58; 60

AIF.2101 60

AIF.2103 60

AIF.2105 60

AIF.2107 61

AIF.2109 61

AIF.2111 61

AIF.2201 61

AIF.2211 61

AIF.2301 61

AIF.2303 61

AIF.2305 61

AIF.2307 61

AIF.2401 61

AIF.2403 61

AIF.2405 61

AOF.0000 65

AOF.0102 65

AOF.1000 65

AOF.1001 65

AOF.1002 65

AOF.1003 65

AOF.3001 65; 66

AOF.3011 65

AOF.3013 65

AOF.3015 65

AOF.3023 65

AOF.3025 65

AOF.3035 66

AOF.3101 64; 66

AOF.3111 66

AOF.3121 66

AOF.3201 66

AOF.3211 66

AOF.3221 66

D

DIF.0000 34; 35

DIF.1001 35; 152

DIF.1002 35; 152

DIF.1003 35; 152

DIF.1004 35; 152

DIF.1031 36; 152

DIF.1032 36; 152

DIF.1033 36; 152

DIF.1034 36; 152

DIF.2001 36; 158

DIF.2031 36; 131

DIF.2032 36; 131

DIF.2033 36; 144

DIF.2034 36; 148

DIF.2061 36; 146

DIF.2062 36; 39; 159

DIF.2063 36; 39; 159

DIF.2064 36; 159

DIF.2092 36

DIF.2093 36

DIF.2094 36

DIF.2095 36

DIF.2096 36

DIF.2099 36

DIF.2121 36

DIF.2151 36; 198

DIF.2152 36; 198

DIF.2153 37; 198

DIF.2154 37; 198

DIF.2181 37

DIF.2211 37

DIF.2241 37

DIF.2242 37

DIF.2243 37

DIF.2271 37; 129

DIF.2272 37; 129

DIF.2273 37; 129

DIF.2330 37

DIF.2331 37

DIF.2332 37

DIF.2333 37

DIF.2501 34; 37; 141

DIF.2502 37; 154; 199

DIF.2701 37; 131; 199

DIF.2702 34; 37

DIF.2703 37; 196; 197

DIF.2704 37; 71; 177

DIF.2705 37

DIF.2706 37; 130; 131; 145; 148; 157; 158

DIF.2708 37

DIF.2709 38; 145

DIF.2710 38

DIF.2711 38

Technical Handbook ix

DIF.2712 38

DIF.2713 38

DIF.2714 38

DIF.2715 38

DIF.2716 38

DIF.3001 34; 38; 151; 167; 170

DIF.3002 38; 151; 167; 170

DIF.3003 38

DIF.3004 38

DIF.3005 38; 188

DIF.3101 38; 132; 136

DIF.3102 38

DIF.3103 38

DIF.3201 38; 107

DIF.3202 38; 107

DIF.3203 38; 107

DIF.3204 38; 107

DIF.3205 38; 107

DIF.3206 39; 107

DIF.3301 39; 193

DIF.3302 39; 193

DIF.4001 34; 39; 160

DIF.4002 39; 160

DIF.4003 39; 160

DIF.4004 34; 39; 160

DIF.4011 39; 161

DIF.4012 39; 160; 161

DIF.4013 39; 160; 161

DIF.4014 39; 160; 161

DIF.4021 39; 161

DIF.4022 39; 161

DIF.4023 39; 161

DIF.4024 39; 161

DIF.4031 39; 161

DIF.4032 39; 161

DIF.4033 39; 161

DIF.4034 39; 161

DIF.4041 39; 161

DIF.4042 40; 161

DIF.4043 40; 161

DIF.4044 40; 161

DIF.4051 40; 161; 194

DIF.4052 40; 161

DIF.4053 40; 161

DIF.4054 40; 161

DIF.4062 40; 160; 161

DIF.4063 40; 160; 161

DIF.4064 40; 160; 161

DIF.4211 40; 160; 171; 193

DIF.4212 34; 40; 171; 193

DIF.4213 40; 172; 193

DIF.4221 34; 40; 143; 145; 176

DIF.4222 40; 143; 145; 177

DIF.4231 40; 172; 173

DIF.4232 34; 40

DIF.4241 40; 168

DIF.4251 40; 168

DIF.4261 41; 190

DOF.0000 46; 47

DOF.0102 47

DOF.0103 47; 50

DOF.1001 47; 144

DOF.1002 47; 144

DOF.1003 41; 47; 144

DOF.1004 39; 40; 47; 144

DOF.1005 41; 47; 144

DOF.1006 46; 47; 144

DOF.1007 47; 144; 146

DOF.1008 47; 147

DOF.1009 47; 147

DOF.1031 47; 194

DOF.1032 47; 182; 192

DOF.1033 47; 144

DOF.1034 47; 192

DOF.2001 47; 150; 151

DOF.2002 47; 150

DOF.2003 47; 150

DOF.2004 44; 47; 151; 170

DOF.2031 47; 151

DOF.2032 44; 47; 151

DOF.2033 44; 47; 151

DOF.2034 44; 47; 151; 154; 170

DOF.2061 47; 188

DOF.2091 47

DOF.2092 47

DOF.3001 48; 132

DOF.3002 48; 132

DOF.3003 48; 132

DOF.3004 48; 132

DOF.3005 48; 132

DOF.3011 48; 132

DOF.3012 48; 132

DOF.3031 48

DOF.3032 48; 140

DOF.3033 48; 137

DOF.3034 48

DOF.3035 48

DOF.3036 48

DOF.3037 48

DOF.3061 48

DOF.3062 48

DOF.3091 48

DOF.3092 48

DOF.3093 48

DOF.3094 48

DOF.3095 48

DOF.3096 48

DOF.3121 48; 196

DOF.3151 48; 158

DOF.3152 46; 48; 156; 158

DOF.3153 48

DOF.3180 48

DOF.3181 48

DOF.3182 48

DOF.3183 48

DOF.3184 48

DOF.4001 48; 158

DOF.4002 48; 158

DOF.4003 48; 158

DOF.4004 48; 158

x Technical Handbook

DOF.4005 48; 158

DOF.4031 48; 158

DOF.4032 49; 158

DOF.4033 49; 159

DOF.4034 50; 159

DOF.4035 50; 159

E

EVT.1001 122; 132

EVT.1002 122; 132

EVT.1003 122; 132

EVT.1004 122; 132

EVT.1005 122; 132

EVT.1010 122; 137

EVT.1011 122; 137

EVT.1012 122; 137

EVT.1013 122; 141

EVT.1014 122; 141

EVT.1020 122; 140

EVT.1021 122; 140

EVT.1022 122; 140

EVT.1030 122; 155

EVT.1031 122; 155

EVT.1032 122; 155

EVT.1033 122; 155

EVT.1035 122; 155

EVT.1036 122; 155

EVT.1037 122; 155

EVT.1038 122; 155

EVT.1040 122; 149

EVT.1041 122; 149

EVT.1042 122; 149

EVT.1043 122; 149

EVT.1044 122; 149

EVT.1045 122; 149

EVT.1050 122; 149

EVT.1051 122; 149

EVT.1052 122; 149

EVT.1053 122; 149

EVT.1054 122; 149

EVT.1055 122; 149

EVT.1056 122; 149

EVT.1057 122; 150

EVT.1058 122; 150

EVT.1059 122; 150

EVT.1060 122; 150

EVT.1061 122; 150

EVT.1062 122; 150

EVT.1063 122; 150

EVT.1070 123

EVT.1071 123

EVT.1074 123

EVT.1075 123

EVT.1076 123; 202

EVT.1077 123

EVT.1078 123

EVT.1080 123; 155

EVT.1081 123; 155

EVT.1082 123; 160

EVT.1083 123; 160

EVT.1091 123

EVT.1092 123

EVT.1093 123

EVT.1094 123

EVT.1095 123

EVT.1096 123

EVT.1097 123

EVT.1098 123

EVT.1099 123

EVT.1100 123

EVT.1101 123

EVT.1102 123

EVT.1103 123

EVT.1104 123

EVT.1105 123

EVT.1151 123

EVT.1152 123

EVT.1153 123

EVT.1154 123

EVT.1155 123

EVT.1156 123

EVT.1157 123

EVT.1158 123

EVT.1160 123

EVT.1161 123

EVT.1162 123

EVT.1163 123

EVT.1164 123

EVT.1165 123

P

P.0000 98; 99

P.0001 98; 99

P.0002 98; 99

P.0003 98; 99

P.0004 130; 131; 144; 145; 148; 153; 154; 157;

158

P.0101 69; 138; 162; 163; 164; 168; 179; 180;

181; 197

P.0102 101; 138; 139; 162; 163; 164; 168; 179;

180; 181; 197

P.0103 69; 138; 197

P.0104 69; 138; 197

P.0105 133; 134; 137; 163; 169; 181; 197

P.0106 101; 163; 164; 168; 179; 188; 197

P.0107 71; 197

P.0108 71; 177; 197

P.0109 197

P.0110 55; 142; 169

P.0111 55; 142; 169

P.0116 132; 133; 134; 135; 197

P.0117 68; 133; 197

P.0118 68; 133; 197

P.0119 68; 133; 197

P.0124 71; 113; 197

P.0125 167; 178; 196; 197

P.0126 67; 133; 197

P.0127 55; 142; 169

P.0128 69; 198

P.0129 68; 198

Technical Handbook xi

P.0130 71; 198

P.0131 71; 112; 177; 198

P.0133 97; 169; 198

P.0134 169; 198

P.0135 198

P.0139 71; 198

P.0140 66; 71; 177

P.0141 66; 188; 189

P.0142 66; 188; 189

P.0143 66; 189

P.0144 66; 189

P.0151 69; 138

P.0152 68; 133

P.0201 133; 134

P.0202 137; 138; 139; 162; 180; 181

P.0203 133; 134

P.0204 133; 134

P.0207 141

P.0208 141

P.0209 145

P.0210 144

P.0211 146; 170

P.0212 146

P.0213 149

P.0214 149; 169

P.0215 148

P.0216 39; 40; 161; 172; 173; 174; 176; 177; 179;

180; 188

P.0217 147; 166

P.0218 48

P.0219 45; 154

P.0220 45; 154

P.0221 167; 195

P.0222 129

P.0223 146

P.0224 142

P.0225 142

P.0226 138; 139; 143

P.0227 139; 143

P.0228 137; 143

P.0229 137; 138; 143

P.0230 43; 142; 163

P.0231 43; 142; 163

P.0232 142

P.0233 146

P.0234 42; 149

P.0235 153

P.0236 133; 134

P.0237 133; 134

P.0238 133; 135

P.0239 133; 135

P.0241 146

P.0242 145

P.0244 133; 135

P.0246 150

P.0247 151

P.0301 139; 140; 162

P.0302 140; 162

P.0303 139; 140; 162

P.0304 140; 162

P.0305 137; 138; 163

P.0306 138; 163

P.0307 137; 138; 163

P.0308 138; 163

P.0309 163; 164

P.0310 163; 164; 165

P.0311 168

P.0312 168

P.0313 167

P.0314 167

P.0315 179

P.0316 179

P.0317 179

P.0318 179

P.0319 180

P.0320 180

P.0321 182

P.0322 182

P.0323 164; 165; 168

P.0324 164; 165; 166; 168

P.0325 188

P.0326 183; 188

P.0328 138; 139; 162; 180; 181

P.0331 169

P.0332 169

P.0333 169

P.0334 169

P.0335 173

P.0336 173

P.0337 58; 173; 174

P.0338 174

P.0339 145; 177

P.0340 177

P.0341 145; 176

P.0342 176

P.0343 172; 193

P.0344 172

P.0345 172; 193

P.0346 172

P.0347 171; 193

P.0348 171

P.0349 43; 163

P.0350 178

P.0351 178

P.0352 178

P.0353 182; 183

P.0354 183

P.0355 194; 195

P.0356 194; 195

P.0357 43; 163

P.0361 178

P.0362 174

P.0363 174

P.0364 175

P.0365 175

P.0367 71; 177

P.0368 71; 177

P.0373 179; 180

P.0374 179; 180

P.0375 174

xii Technical Handbook

P.0376 174

P.0377 71; 183

P.0378 71; 183

P.0379 184

P.0380 184

P.0391 180

P.0392 180

P.0393 181

P.0394 181

P.0395 181

P.0396 181

P.0397 181

P.0398 181; 182

P.0400 192

P.0401 193

P.0402 193

P.0403 193

P.0404 182; 194

P.0405 192

P.0406 192

P.0409 202; 203

P.0410 202; 203

P.0418 130; 180; 181; 203

P.0419 130; 203

P.0420 130; 180; 181; 203

P.0421 141; 180; 181; 204

P.0422 141; 180; 181; 204

P.0423 141; 180; 181; 204

P.0424 175; 199; 200; 202

P.0425 175; 199; 200

P.0426 131

P.0427 131

P.0428 131

P.0436 175; 176; 200; 202

P.0437 175; 176; 200

P.0438 178; 181; 200

P.0441 121; 131; 137; 140; 141; 149; 155

P.0442 124; 125

P.0443 124; 126

P.0450 84

P.0451 73; 115

P.0452 73; 187

P.0453 73

P.0454 73

P.0456 76; 84

P.0469 99; 100

P.0470 73

P.0472 74

P.0473 74

P.0474 74

P.0475 74

P.0478 75

P.0479 75

P.0481 196

P.0482 197

P.0483 196; 197

P.0484 196

P.0485 196; 197

P.0486 197

P.0491 157

P.0492 94

P.0493 94

P.0494 111

P.0495 91; 92; 144; 148; 166

P.0500 75; 76

P.0501 75; 76

P.0502 75; 76

P.0503 75; 76

P.0504 75

P.0505 75

P.0508 75; 76

P.0509 75; 76

P.0510 75; 76

P.0511 75; 76

P.0513 75

P.0514 75

P.0530 86; 110

P.0531 86

P.0532 86

P.0533 86

P.0534 86

P.0535 86

P.0536 86

P.0537 86

P.0539 86

P.0542 86

P.0551 85

P.0552 85

P.0553 85

P.0554 85

P.0555 85

P.0556 85

P.0557 85

P.0558 85

P.0559 85

P.0580 85

P.0581 86

P.0582 86

P.0583 85

P.0584 85

P.0700 78; 115; 116; 117; 127; 143; 169; 173;

174; 176; 177; 179; 182; 183; 184; 185; 186;

187

P.0703 78; 182

P.0704 183; 184; 185; 186; 187

P.0709 182; 183

P.0710 146

P.0711 183

P.0800 78; 119; 187; 188; 191

P.0802 189; 190; 191

P.0803 187; 188

P.0804 154

P.0840 38

P.0847 152

P.0852 189; 190

P.0853 190

P.0854 152; 189; 190

P.0855 152; 154; 190

P.0856 65

P.0857 65

Technical Handbook xiii

P.0862 65

P.0863 65

P.0880 36

P.0884 36; 38

P.0900 190

P.0902 36

P.0922 37

P.0924 37

P.0974 38

P.1604 198

P.1605 198

P.2000 35

P.2001 35; 160; 167; 168; 170; 171; 172; 173;

176; 177; 190; 194; 195; 196; 199

P.2002 35; 151; 160; 161; 167; 168; 170; 171;

172; 173; 176; 177; 190; 194; 195; 199

P.2003 35; 160; 194

P.2004 199

P.2100 35

P.2151 34

P.2152 34

P.2153 34

P.2200 35

P.2250 35

P.3000 46; 47

P.3001 144; 182; 188; 196

P.3005 42

P.3006 42

P.3200 46

P.3201 182

P.3250 46; 47

P.4017 58; 176; 177

P.4018 58; 118

P.4019 58

P.4020 58

P.4021 58

P.4022 58

P.4023 58

P.4024 58

P.4025 173; 174; 179; 182; 183

P.4033 171; 172; 174

P.4041 43; 57; 142; 163

P.4051 59

P.4052 59

P.4053 59

P.4054 59

P.4055 59

P.4056 59

P.4057 59

P.4058 59

P.4131 174

P.6001 65

P.6002 65

S

ST_000 51

ST_001 51

ST_002 51

ST_003 51

ST_004 52

ST_008 52

ST_009 52

ST_010 52

ST_011 52

ST_012 52

ST_013 52

ST_014 52

ST_015 52

ST_016 52

ST_017 52

ST_018 52

ST_019 52

ST_020 52

ST_024 52

ST_025 52

ST_026 52

ST_027 52

ST_028 52

ST_032 52

ST_033 52

ST_035 52

ST_036 52

ST_037 52

ST_038 52

ST_039 52

ST_040 52

ST_041 52

ST_048 52

ST_051 52

ST_052 52

ST_053 52

ST_054 52

ST_055 52

ST_056 52

ST_057 52

ST_058 52

ST_059 52

ST_060 52

ST_061 52

ST_062 52

ST_063 52

ST_064 52

ST_065 52

ST_066 52

ST_068 52

ST_069 52

ST_070 52

ST_071 52

ST_072 52

ST_073 52

ST_074 52

ST_075 52

ST_080 52

ST_081 52

ST_082 52

ST_083 52

ST_084 52

ST_085 52

ST_088 52

ST_089 52

xiv Technical Handbook

ST_090 52

ST_091 52

ST_092 52

ST_093 52

ST_096 52

ST_097 52

ST_098 52

ST_099 52

ST_100 53

ST_101 53

ST_102 53

ST_103 53

ST_104 53

ST_108 53

ST_109 53

ST_110 53

ST_111 53

ST_112 53

ST_113 53

ST_114 53

ST_128 53

ST_129 53

ST_130 53

ST_131 53

ST_132 53

ST_133 53

ST_134 53

ST_135 53

ST_136 53

ST_144 53

ST_145 53

ST_146 53

ST_147 53

ST_148 53

ST_149 53

ST_150 53

ST_151 53

ST_152 53

ST_153 53

ST_154 53

ST_155 53

ST_156 53

ST_157 53

ST_158 53

ST_159 53

ST_176 53

ST_998 53

ST_999 53

Technical Handbook xv

Controller

USB

RS232

RS485

Ethernet

Modem

GPRS

included

CAN

engine

CAN

sharing

ANALOGUE

outputs

GC315

Yes

GC315

Plus

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

GC315

Link

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

GC400x

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

GC400

Link

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

GC400

Mains

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

GC400

Mains+Link

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

This manual is valid for all models of the controllers GC315 and GC400. The controllers

models are different in the communication options available and in the presence of

ANALOGUE outputs. The following table shows the options available on each model.

In the manual, when referring to the controllers, the model name will be used to refer to the

specific model. Otherwise:

GC315x: to refer to all models GC315, GC315

GC400x: to refer to all models GC400, GC400

Link

, GC315

Link

, GC400

Plus

.

Mains

and GC400

Mains+Link

In order to avoid misunderstanding, the basic models GC315 and GC400 will be referred as

GC315x and GC400x: they are used only in the manual, they do not appear on the

controller front facia.

[1] SICES EAAM0448xx Parameters Table GC315.

[2] SICES EAAM0504xx Parameters Table GC400.

[3] SICES EAAM0458xx Software Manual BoardPRG3.xx.

[4] SICES EAAS0341xx Serial Communication and SMS Protocol.

[5] SICES EAAS0449xx Modbus Registers GC315.

[6] SICES EAAS0505xx ModBus Registers GC400.

[7] SICES EAAM0136xx User Manual J1939 interfaces.

[8] CAN open – Cabling and Connector Pin Assignment – CiA Draft Recommendation DR-

303-1.

[9] BOSCH CAN Specification – Version 2.0 – 1991, Robert Bosch Gmbh.

16 GC315xx and GC400xx Technical Manual

[10] SICES EAAP0457xxXA USB driver installation guide.

[11] EAAM0410xx User Manual SI.MO.NE.

[12] SICES EAAM0199xx Paralel Functions Manual DST4602/GC500/GC400x.

A lot of accidents are caused by the insufficient knowledge or by the lacking of application of

the safety rules to apply during the operating or maintenance procedures.

In order to avoid accidents, before carrying out any operating or maintenance procedure, read,

understand and follow the precautions and warnings in this manual.

This manual contains the following indications:

CAUTION! This indication is used in the safety messages of the manual when there

are possible danger situations that may cause injuries or death if the danger is not

avoided.

This safety messages describe the normal precautions needed to avoid danger. Ignoring this

instructions may cause serious damages to things and/or people.

WARNING! This indication is used in the safety messages for dangers that, if not

avoided, may cause injuries, damages or malfunctioning.

The message can be also used only for few dangers that may cause damages to things and/or

people.

INFORMATION! This term indicates that the message includes useful information

for the development of the operation or procedures clarifications.

For the appropriate use of this manual it is required knowledge of the use and of the

installation of generator groups.

WARNING!!!

All interventions must be carried out only by qualified personnel, because dangerous voltages

are present on the terminals of the device; prior to performing any operation on the same,

make sure you have opened the circuit breakers and generator set switches, or that you have

removed their fuses.

Do not remove or modify any of the connections while the generator set is operating

Do not, for any reason, disconnect the terminals of the current transformers (CTs).

Incorrect interventions on the connections can result in disconnection of the users from the

mains or from the generator.

Before installing and using the device, carefully read this handbook.

The device uses a large number of configurable parameters and it is therefore

impossible to describe all their possible combinations and effects.

In this document it is not present a description detailed of all the programming parameters: to

this purpose see [1] [2]. These documents should be considered integral part of this manual.

The devices are supplied with a generic "default" configuration; is the responsibility of

the installer to adjust the operating parameters to his/her specific application.

GC315xx and GC400xx Technical Manual 17

SICES srl makes considerable efforts for a continuous improvement and upgrading of its own

products; therefore, they are subject to modifications both in hardware and software, without

prior notice. Some of the features described in this manual may therefore differ from those

present in your device.

IMPORTANT! Both the SW1 switches must remain in OFF position.

The SW1 switches are reserved for accessing special features that are not part of the normal

operation of the device.

If the device is powered with one of the two switches in ON position, it will not turn on.

To restore normal operation you need to cut the power to the same, turn the switches OFF

and power it again.

In case the device does not turn on when powered, the first thing you have to do is to check

the position of the switches.

Although most of the parameters and features can be accessed and configured by directly

operating on the device, some particular features or configurations, due to their nature,

can only be set or changed through the PC program SICES Board Programmer3

(hereinafter referred to as “BoardPrg3”) downloadable for free after registration on the SICES

srl websites www.sices.eu and www.sicesbrasil.com.br.

It greatly simplifies the configuration of the device and its use is strongly recommended. It also

allows you to save the current configuration of the device on a file and to reuse it on other

identical devices,

The program also allows the configuration, saving or loading of the characteristic curves of

non standard ANALOGUE sensors with resistive or live output.

BoardPrg3 can be used on all the SICES devices; connection to the PC can be realized both

directly, via the RS232 serial port, USB, or remotely via modem, RS485 serial port or ethernet

network. To use the program refer to document [3] .

In this document, the term “ALARM” is used to indicate a fault that prevents the generator set

from operating and causes the automatic emergency shutdown of the generator (skipping the

cool down phase).

The term “DE-ACTIVATION” is used to indicate a fault that prevents the generator set from

operating and causes the automatic standard shutdown of the generator (including the cool

down phase). The controller automatically opens the GCB circuit breaker in case of this type

of fault.

In this document, the term “” is used to indicate a fault that makes the genset operation

impossible, and causes the automatic shutdown of the genset with standard procedure.

The term “WARNING” is used to indicate a fault that requires the intervention of the operator

with no need for automatic shutoff of the generator (including the cool down phase). If possible,

GC400x controllers gradually reduce to zero the power supplied by the genset before opening

the GCB circuit breaker. This type of fault is available only for the GC400x controllers.

The codes that identify functions for input, output, status or other functions are preceded by

the following acronyms:

DIF (“Digital Input Function”): the following is a code for the configuration of the digital inputs.

DOF (“Digital Output Function”): the following is a code for the configuration of the digital

outputs.

18 GC315xx and GC400xx Technical Manual

AIF (“ANALOGUE Input Function”): the following is a code for the configuration of the

ANALOGUE inputs.

AOF (“ANALOGUE Output Function”): the following is a code for the configuration of the

ANALOGUE outputs.

AVF (“ANALOGUE Virtual Function”): the following is a code for the configuration of the virtual

ANALOGUE inputs.

EVT (“Event”): the following is an event code

ST (“Status”): the following code shows the status of a dimension or a condition of the device

or of one of its functions.

In this document a vertical bar on the right margin or a grey background indicates that the

chapter or the paragraph has been amended respect to the previous document’s version.

Changes in the fields of a table are highlighted with a grey background colour.

Several parts of this manual refer to the controller's software revisions. These revisions are

marked with the assigned SICES code (shown on the rear panel of the controller). Software

code version has the following format: EB0250231XXYY, where "XX" is the main revision

number and "YY" is the secondary revision number. Thus, the code EB02502310100 refers to

the controller's software release "1.00". The software revision is also displayed on page “S.06”

(GC315x) or “S.03” (GC400x) of the LCD display.

The software codes available at the release date are:

EB0250231xxyy: GC315.

EB0250248xxyy: GC400.

GC315xx and GC400xx Technical Manual 19

Front GC315

Back GC315

20 GC315xx and GC400xx Technical Manual

Back GC315

Plus

Back GC315

Link

GC315xx and GC400xx Technical Manual 21

Front GC400x

Front GC400

Mains

22 GC315xx and GC400xx Technical Manual

Back GC400 and GC400

Mains

Back GC400

Link

and GC400

Mains+Link

GC315xx and GC400xx Technical Manual 23

Supply power voltage

Vbatt:

GC315 and GC400:

7..32VDC with continuous operation.

GC315

Link

, GC400

Link

e GC400

Mains+Link

:

8..32VDC with continuous operation.

Protection against polarity reversal with built-in self-resetting fuse.

Operation during engine start is guaranteed up to Vbatt =5VDC indefinitely.

The device identifies the plant operation at 12 or 24V, to manage its alarms

when powered up and whenever OFF/RESET mode is selected.

Power consumption in

stand-by:

For GC315:

300mA @ Vbatt =13.5VDC display lamp on

280mA @ Vbatt =13.5VDC display lamp off

170mA @ Vbatt =27 VDC display lamp on

160mA @ Vbatt =27 VDC display lamp off

For GC400:

400mA @ Vbatt =13.5VDC display lamp on

310mA @ Vbatt =13.5VDC display lamp off

210mA @ Vbatt =27 VDC display lamp on

190mA @ Vbatt =27 VDC display lamp off

On the Link controller the consumption depend on the data exchange activity

with the Provider of the telephone service, on the quality of the connection and

the status of charge of the optional internal battery.

With battery out of power, the consumption is maximum; in stand-by:

GC315

Link

, GC400

Link

and GC400

Mains+Link:

about 650mA @ Vbatt=13.5VDC internal battery in charge

about 350mA @ Vbatt=27 VDC internal battery in charge

Maximum power

consumption in operating

condition (relays, alarm,

LCD lamp and digital

inputs enabled; static

outputs disabled)

For GC315:

Max 700mA @ 7 VDC

400mA @ 27 VDC

450mA @ 13.5 VDC

For GC400:

Max 800mA @ 7 VDC

430mA @ 27 VDC

480mA @ 13.5 VDC

On the Link controller the consumption depend on the data exchange activity

with the Provider of the telephone service, on the quality of the connection and

the status of charge of the optional internal battery.

With battery out of power, the consumption is maximum; in stand-by:

GC315

Link

and GC400

Link:

about 140mA @ Vbatt=8VDC

24 GC315xx and GC400xx Technical Manual

Electric measurements for

mains/generator set

voltage and currents:

ANALOGUE/digital conversion at 12bit; sampling frequency 10kHz. True RMS

measurements (TRMS).

Measurement of the L-N phase voltages and of the L-L concatenated voltages;

measurements of the neutral voltages referred to the power supply minus of the

device.

Input impedance of the voltage measurements:

>280kohm L-L

>270kohm L-GND

>210kohm N-GND

>150kohm L-L

Measurement of three currents with electrical return and C.T. report. In

common, plus a fourth independent current for Neutral current measurement or

differential protection or mains voltage measurement.

It is required the use of current transformers with a secondary current of 1 to 5A

(5A recommended) and minimum power of 1VA. It is mandatory to connect the

return poles of the current transformers to the supply minus of the device.

Maximum mains/generator

voltages allowed:

MAX 300Vac in CAT.IV for measures L-N

MAX 520Vac in CAT.IV for measures L-L

Maximum currents

allowed:

5Aac nominal values; possible sinusoidal transient voltage surges up to 20Aac

with progressive loss of the measurement accuracy depending on the amplitude

of the surge.

Frequency

measurements:

Nominal frequencies of 50 or 60Hz.

Obtained from the L1 phase voltage both for the mains and for the generator.

Mains frequency minimum sensitivity:

35Vrms L-N @ 50Hz

For the generator the sensitivity is decreasing with the frequency for the

recognition of the started engine and for greater disturbances rejection:

10Vrms L-N @ 5Hz

17Vrms L-N @ 50Hz

20Vrms L-N @ 50Hz

Digital inputs

8 digital inputs; GND supply minus activation. When opened, the voltage on the

input terminals is Vbatt.

Activation/deactivation threshold 2.5VDC

Typical current with closed contact:

6.5mA @ Vbatt= 13.5VDC

12mA @ Vbatt= 27VDC

Relay outputs:

Two relays with positive common input, max 3A @30VDC for starter motor and

fuel solenoid valve. Surge protection diodes incorporated.

The common plus also acts as input for the emergency stop. The voltage

measure at the common input is displayed on page S.14 of the display (EM-S)

Two relays with dry changeover contacts for remote control switching, max. 10A

@250Vac.

All the relay outputs can be reset regardless of the parameter.

SSR outputs

Four independent configurable outputs to battery plus, max 500 continuous mA

each; internal limitation to approximately 4A max. on transients <150us and

then thermal protection intervention. Protection against overload, short-circuit

and surge and integrated reverse polarity.

The output voltage is supplied through the positive supply terminal of the JD (2)

+BATT. device.

ANALOGUE ouputs (only

for GC400x)

Two insulated independent outputs (3kV insulation). The range goes from 10Vdc to +10Vdc. The resolution is 16bit (0,3 mV/bit).

Excitation output for

recharge alternator +D

Maximum current switched automatically, depending on the supply voltage

Vbatt:

200mA @ 13.5 VDC

100mA @ 27 VDC

If not used for the battery recharge alternator, you can configure the +D terminal

as ANALOGUE input, to acquire voltage measures ranging from 0 to 32V, or as

additional digital input with +Vbatt activation.

The voltage measure acquired is displayed in page S.15 of the display (D+)

Engine instruments

ANALOGUE inputs

Three inputs for resistive sensors plus one input for measuring and

compensation of the reference potential of their common minus.

Resistance measuring range:

rated 0..500 ohm with < 0.2% error

0..2k ohm with < 1% error

The three measurement inputs can also be used as digital inputs with GND

activation.

Voltage compensation range of the reference point:

-2.7..+5VDC

GC315xx and GC400xx Technical Manual 25

Pick-up input for engine

speed measurement

Filtered for DC currents blocking.

Minimum voltage 3Vac; maximum voltage 60Vac.

W input for engine speed

measurement

Use the pick-up input, with inner interference suppressor, to be inserted by

interconnecting pins 5 and 6 of the JM connector.

CANBUS Connection

Only GC315

Plus

and GC400:

CANBUS connection with insulation up to 1kV with SAE J1939 and MTU

protocols.

Only GC400:

Additional CANBUS connection with insulation up to 1kV with SICES protocol

PMCBus for the communication with other devices.

RS485 Connection

Only GC315

Plus

and GC400:

RS485 connection with insulation up to 1kV with MODBUS RTU protocol

Display

Graphic transflective LCD, size 70x38mm, resolution 128x64

Operating conditions

From -25°C to +60°C

GC315

Link

and GC400

Link

with internal battery charger:

From -25°C to +60°C

Size

247(L)x187(H)x40(P)mm

Weight

GC315 600g

GC315

Plus

620g

GC315

Link

650g with optional internal battery

GC400 650g

GC400

Link

750g with optional internal battery

GC400

Mains

650g

GC400

Mains/Link

750g with optional internal battery

Dimensions of the

mounting place

218x159mm

26 GC315xx and GC400xx Technical Manual

Mains voltages and generator

1Vrms

accuracy <0.5% F.S.

Current

Min. 0.1A (depends on the C.T.),

accuracy <0.2% F.S.

Mains frequencies and generator

0.1Hz ± 50ppm, 35ppm/C typical

Powers

Min. 0.1 kW/kVA/kvar (depends on the C.T. ratio)

Power Factor

0.01

Energy

1 kWh/kvarh

Engine speed

1 rpm

Oil pressure

0.1bar (below 10bar)

Coolant temperature

0.1°C

Fuel level

0.1%

Modem

Quad band 850/900/1800/1900 MHz

Modem operation

GSM/GPRS

Data transfer (GPRS)

Class 8/10, max download 85.6kbps

GPS Receiver

33 tracking/99 acquisition per channel

GPS Receiver perception

Tracking: -167 dBm

Reacquisition: -157 dBm

Cold starts: -148 dBm

First fix time

Cold start: 28s

Warm start: 26s

Hot start: <1s in ideal conditions

Accuracy

< 2.5m

Optional internal battery recharge

About 6h with complete unloaded battery; the time

depends also on the level of the GSM/GPRS signal and

on the data transmission interval

Internal battery duration

Minimum about 6h with SI.MO.NE data transmission

interval of 3 min and good signal level; it is higher using

the saving sleep-mode.

Antenna Impedance

GSM/GPRS 50 ohm

GPS 50 ohm; it requires an amplified antenna. The

alimentation is automatically supplied by the GPS

receiver.

Link Link Mains+Link

GC315xx and GC400xx Technical Manual 27

The device must be mounted permanently on an electrical panel or cabinet. The back of the

device must be accessed only through the use of keys or tools, and only by personnel

authorized to perform maintenance operations. The device must be mounted so as to make it

impossible to remove it without using tools.

The dimensions of the mounting slot are 250x159mm. The device is mounted with four hooks

with locking screws: once you have put the device in place, insert the hooks in the side slots

and tighten the screws. Be careful not to overtighten the screws to avoid damaging the

coupling slots on the casing of the device.

Due to high voltages associated to the measurement circuits of the controller, all the

conductive parts of the electrical panel must necessarily be connected to the protective

earth by means of permanent connections.

Installing an overcurrent protection device is required for each phase of the mains and

generator voltage inputs. 1A fuses can be conveniently used.

The conductor cross-section of the protective earth of the electrical panel must be at least

equal to the section of the wires used for wiring the mains or generator voltage to the panel.

In addition, it must comply with the limit value of the overcurrent protection used.

For CAT.III applications, the maximum phase-to-neutral voltage allowed is 300Vac, while the

phase-to-phase voltage is 520Vac. Maximum voltage with respect to the protective earth is

300Vac.

The device can operate in CAT.III only if the supply minus terminal of the device and the

neutral terminal of the generator are connected to the protective earth.

28 GC315xx and GC400xx Technical Manual

No.

NAME

DESCRIPTION

CONNECTOR

1

JA

Interface RS232 (Only GC315

Plus

)

9 Poles Male Canon

2

JB

USB

USB B

3

JD

Power supply

2 poles x2.5mm2 Screw terminal

3

JE

Auxiliary Outputs

4 poles x1.5mm2 Screw terminal

4

JF

Currents Input

7 poles x2.5mm2 Screw terminal

5

JG

Generator Voltages

4 poles x2.5mm2 Screw terminal

6

JH

Mains Voltages

4 poles x2.5mm2 Screw terminal

7

JI

Remote control switches

6 poles x2.5mm2 Screw terminal

8

JL

Engine commands

4 poles x2.5mm2 Screw terminal

10

JM

Pick-Up / W

7 poles x1.5mm 2 Screw terminal

Engine tools

11

JN

Digital inputs

8 poles x1.5mm 2 Screw terminal

12

JO

RS485 Interface (not available on

GC315)

3 poles x2.5mm2 Screw terminal

ECU Can-bus J1939 (not available

on GC315)

13

JP

PCMBUS Interface for parallel

functions (available only for

GC400x)

3 poles x2.5mm2 Screw terminal

14

JQ

ANALOGUE output for speed

regulator (available only for

GC400x)

3 poles x2.5mm2 Screw terminal

15

JR

ANALOGUE output for voltage

regulator (available only for

GC400x)

3 poles x2.5mm2 Screw terminal

GC315xx and GC400xx Technical Manual 29

16

JS

Ethernet (not available on GC315,

GC315

Link

, GC400

Link

and

GC400

Mains+Link

)

RJ45

17

GPS

GPS receiver interface (available

only for GC315

Link

and GC400

Link

)

1 SMA female connector

18

GSM

GSM Modem interface (available

only for GC315

Link

, GC400

Link

and

GC400

Mains+Link

)

1 SMA female connector

30 GC315xx and GC400xx Technical Manual

Loading...

Loading...