Sibir Optics RM 1-D, RA 2-D, RM 2-D, RA 1-D User Manual

SIBIR

MANUAL

RA/RM - 1D

RA/RM - 2D

0402

V 110 GE

English page 3

Français page 7 Español pagina 11

822 70 50-01

V 170 GE

OPERATING AND INSTALLATION INSTRUCTIONS

FOR REFRIGERATORS V110 GE and V170 GE

INTRODUCTION

We are pleased that you have chosen this refrigerator

and hope you will derive muc h satisf action from using it,

but first a few well-meant words of advice:

It is important to read through these instructions c arefully before using the refrigerator .

T o ensur e good refrigeration and economical oper ation,

the refrigerator must be installed and used as described

in these instructions.

WARNING! The refrigerators are equipped with a lock.

The key should be kept away from children at a place

away fr om the refrigerator.

TRANSIT DAMAGE

Inspect the refrigerator for damage. Transit damage

must be reported to whoever is responsible for delivery

not later than seven days after the refrigerator was

delivered.

DATA PLATE

Check the data plate, inside the refrigerator, to ensure

that you have received the right model.

CONTENTS

OPERATING INSTRUCTIONS ........................ 4

CONTROLS ................................................ 4

STARTING THE REFRIGERATOR ............ 4

REGULATING T HE TEMPERAT URE .. ...... 4

DEFR O STING ...... .............. .................. ....... 4

CLEANING THE REFRIGERATOR ............ 4

TURNING OFF THE REFRIGERAT OR ...... 5

IF THE ‘FRIDGE FAILS T O WORK .... ...... .. 5

MAINTENANCE . ......................................... 5

SOME USEFUL HINT S ....... .... .... .... .... .... .... 5

TECHNICAL DATA ..................................... 5

INSTALLATION INSTRUCTIONS ................... 5

PLACEMENT OF THE REFRIGERATOR ... 5

LP GAS CONNECTION .............................. 5

ELECTRICAL CONNECTION ..................... 6

The right gas pressure is................. 30 mbar.

Check that the voltage supply corresponds with the

supply voltage given on the data plate.

The data plate contains e. g. the following details:

Model designation .........................................

Product number .............................................

Serial number ................................................

Since these details will be needed if you hav e t o contact

service personnel, it is a good idea to make a note of

them here.

3

OPERATING INSTRUCTIONS

CONTROLS

To terminate gas operation, turn knob (A) to 0.

Electric Operation

• Set the energy selector (A) to position I.

REGULATING THE TEMPERATURE

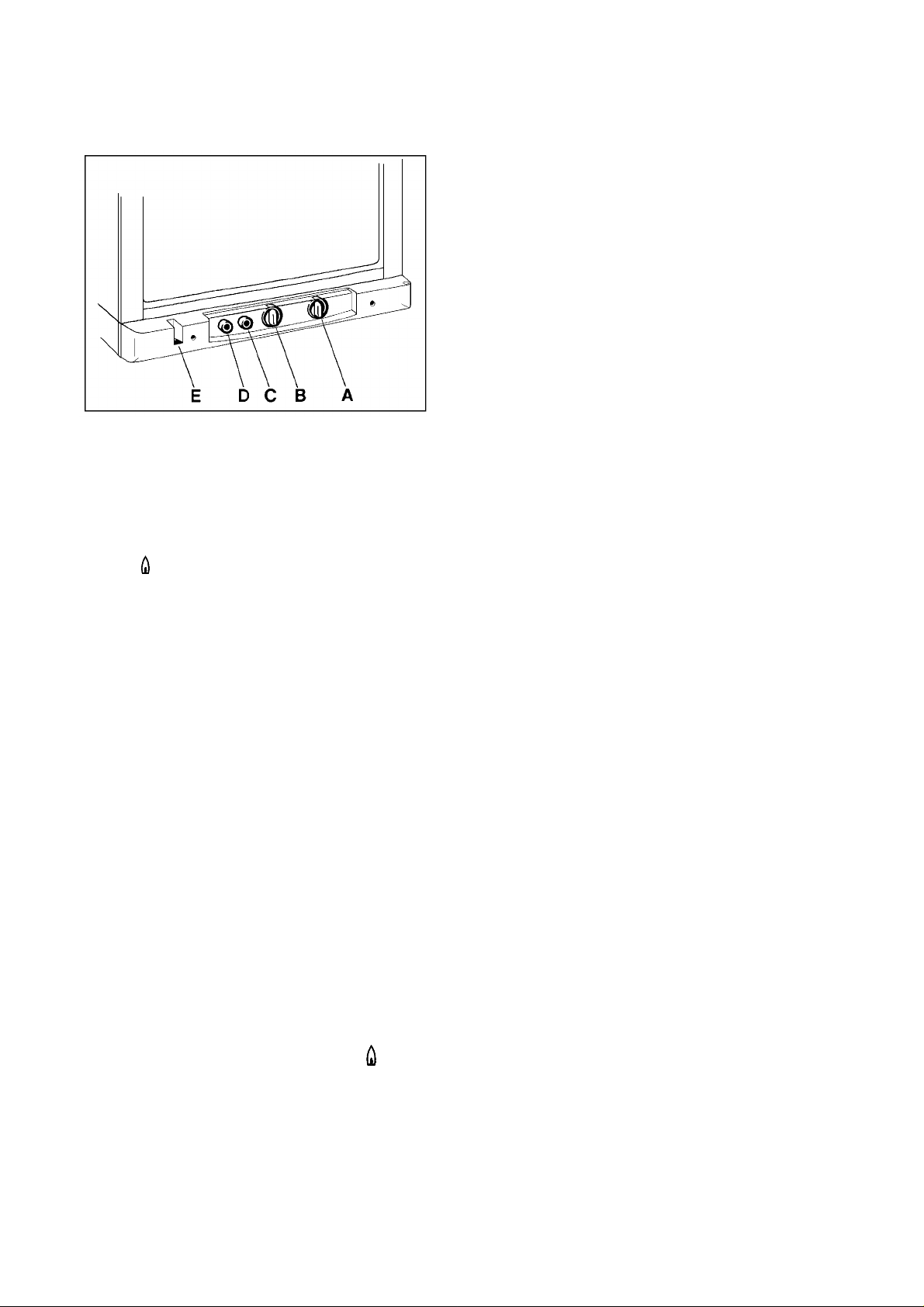

The position number ref ers to fig. 1.

It will take several hours for the refrigerator to reach

normal operating temperature.

The temperature of the main compartment of the refrigerator is controlled by a thermostat. The thermostat knob

(B) should be set at 3-5. If a lower (colder) temperature

is desired, set the thermostat to a higher figure.

FIG. 1

The refrigerator can be run on either mains electric or

LP gas. Changing between t hese modes of operation is

carried out by means of control buttons positioned as

shown in fig. 1.

The energy selector (A) can be set at either I (= mains

electric), (= LP gas) or 0 (= off).

The refrigerator temperature is controlled by a thermostat (B). Please note that the thermostat has no "off"

position.

The refrigerator is fitted with a safety de vice which automatically shuts off the supply of gas if the flame goes

out. The safety device can be opened manually by

depressing knob (C).

The piezoelectric igniter discharges sparks over the

burner when the button (D) is depressed.

In the flame viewer (E) you can see a b lue light when the

flame is alight.

STARTING THE REFRIGERATOR

The position numbers ref er to fig. 1.

LP Gas operation

After initial installation, servicing, or changing gas cylinders etc., the gas pipes may contain some air which

should be allowed to escape by briefly turning on the

refrigerator or other appliances. This will ensure that the

flame lights immediately.

1. Make sure that all valves between the gas container

and th e r efriger at or are op e n.

2. Turn the energy se lector (A) to posi tion .

3. Depress the safety device control (C) and hold it

down while depre ssing t he piez oele ctri c igni ter bu tton (D) repeatedly.

4. Check the flame indicator (E) to see whether the

flame is alight.

5. Keep the saf ety dev ice cont rol depr essed for a further

10-15 seconds.

6. Release the safety device control and again check to

see that the flame is alight.

DEFROSTING

Frost will gradually accumulat e on the refrigerating surfaces. It must not be allowed to grow too thick as it acts

as an insulator and adversely aff ects ref rigerator perf ormance.

Check the formation of frost regularly every week and

when it gets about 3 mm thick, defrost the refrigerator.

T o defrost the refrigerato r, turn it off and remove all items .

Do not try to accelerate defrosting by using any kind of

heating appliance, as this might damage the plastic

surfaces of the refrigerator. Neither should any sharp

objects be used to scrape off the ice.

The defrost water runs from a collector channel to a

receptacle at the rear of the ref rigerator where it e v ap orates.

Defrost water in the freezer compartment should be

mopped up with a cloth. When all ice has melted, wipe

the refrigerator dry and restart it.

CLEANING THE REFRIGERATOR

Clean the inside of the refrigerator regularly to keep it

fresh and h ygienic.

Soak a cloth in a solution consisting of a teaspoon of

bicarbonate of soda to half a litre of warm water. Wring

out the cloth and use it to clean the interior of the

refrigerator and its fittings.

Never use detergents, scouring powder, strongly scented products or wax polish to clean the interior of the

refrigerator as they may damage the surfaces and leave

a strong odour.

The exterior of the refrigerator should be wiped clean

now and again, using a damp cloth and a small quantity

of detergent. But not the door gask et, which should only

be cleaned with soap and water and then thoroughly

dried.

The cooling unit behind the refrigerator should be cleaned with a brush from time to time, but make sure that

the refrigerator is switched off when doing this.

4

TURNING OFF THE REFRIGERATOR

If the refrigerator is not to be used for some time:

1. Shut off any valve in the gas line to the refrigerator.

2. Set the energy selector (A) to 0.

3. Empty the refrigerator. Defrost and clean it as described earlier. Leave the doors of th e refrigerato r and

the frozen food compartment ajar.

IF THE ‘FRIDGE FAILS TO WORK

Check the following points bef ore calling a service technician:

1. Th at the ST ARTING THE REFRIGER ATOR instructions have been followed.

2. The refrigerator is level.

3. If it is possible to sta rt the refrigera tor on any o f the

connected sources of energy.

4. If the refrigerator fails to wo rk on g as, che ck:

• That the gas bottle is not empty.

• That all LP-gas valves are open.

5. If the refrigerator fails to work on mains electric,

check:

• That the mains electric supply is connected to

the refrigerator.

• That the fuse is intact.

• There is a free air circulation over the cooling unit at

the rear of the refrigerator .

TECHNICAL DATA

Overall dimensions: V110 GE V 170 GE

Height ................................ 1019 1456 mm

Width ................................. 592 592 mm

Depth ................................. 623 623 mm

Capacity

Gross, total ........................ 110 185 lit.

freezer . ............................ .... 15 47 lit.

Weight (without pack aging) ...... 50 68 kg

Electrical data

Input 120, 230, 240 V ......... 325 325 watt

Lp gas data

Input max ............................ 0.33 0.48 kW

Cooling medium ......................... Ammonia

Sodium chromate is used f or corrosion protection (less

than 2 weight % of the coolant).

INSTALLATION INSTRUCTIONS

This appliance must be installed by an authorised

person and conform to all relevant authorities.

If the refrigerator is not cold enough it may be

because:

1. The ventilation of th e coolin g unit is in adequate; see

the paragraph PLACEMENT OF THE REFRIGERA-

TOR.

2. The evaporator is frosted up.

3. The temperature control setting is incorrect.

4. The gas pres sure is inc orrect - chec k the pre ssure

regulator at the gas container.

5. The door is not properly closed or the magnetic

sealing strip is defective.

If the refrigerator still does not work properly, call a

service technician.

The sealed cooling system must not be opened,

since it contains corroding chemicals under

high pressure.

MAINTENANCE

Inspect the gas hose periodically for cracks or deep

chafing marks. Connections can be tested for leaks

using a soap solution. DO NOT USE AN OPEN FLAME!

If there is any suspicion of damage, call for a service

technician.

We recommend that a service technician check the

refrigerator once a year .

SOME USEFUL HINTS

Make sure that:

• Defrosting is carried out periodically.

• The refrigerator is clean and dry with the door left

open when it is not to be used for some time.

• Liquids or item s w i t h a s t r o n g o dour are well pack-

aged.

PLACEMENT OF THE REFRIGERATOR

The room should have a capacity (length x width x

height) of at least 20 m

lated as well as follow all relevant national and local

regulations.

Further the room should have a window (which can be

opened) or a door to the outside.

It is important that the refrigerator is not subject to

radiation of heat from a stove etc.

For best perf ormance also at high ambient temperatures

there must be a free air circulation over the cooling unit

at the rear of the refrigerator.

The refrigerator is designed for a free-standing installation and the clearance to the rear wall and to possible

side walls, should be at least 25 mm. The clearance

above the refrigerator should be at least 100 mm.

The refrigerator must be adjusted to a vertical position

in both directions, see bubble level at the bottom of the

refrigerator . Use the feet on the refrigerator to adjust its

position.

3

and must be adequately venti-

LP GAS CONNECTION

The refrigerator is designed for operation on LP gas, the

pressure of which must be 30 mbar for Propane. Check

that this is stated on the data plate.

The refrigerator is not designed for operation on town

gas or natural gas.

CAUTION! CHECK THAT THE GAS SUPPLIED

TO THE REFRIGERATOR IS AT THE CORRECT

PRESSURE. SEE THE REDUCING VALVE ON

THE LP GAS CONTAINER.

5

Loading...

Loading...