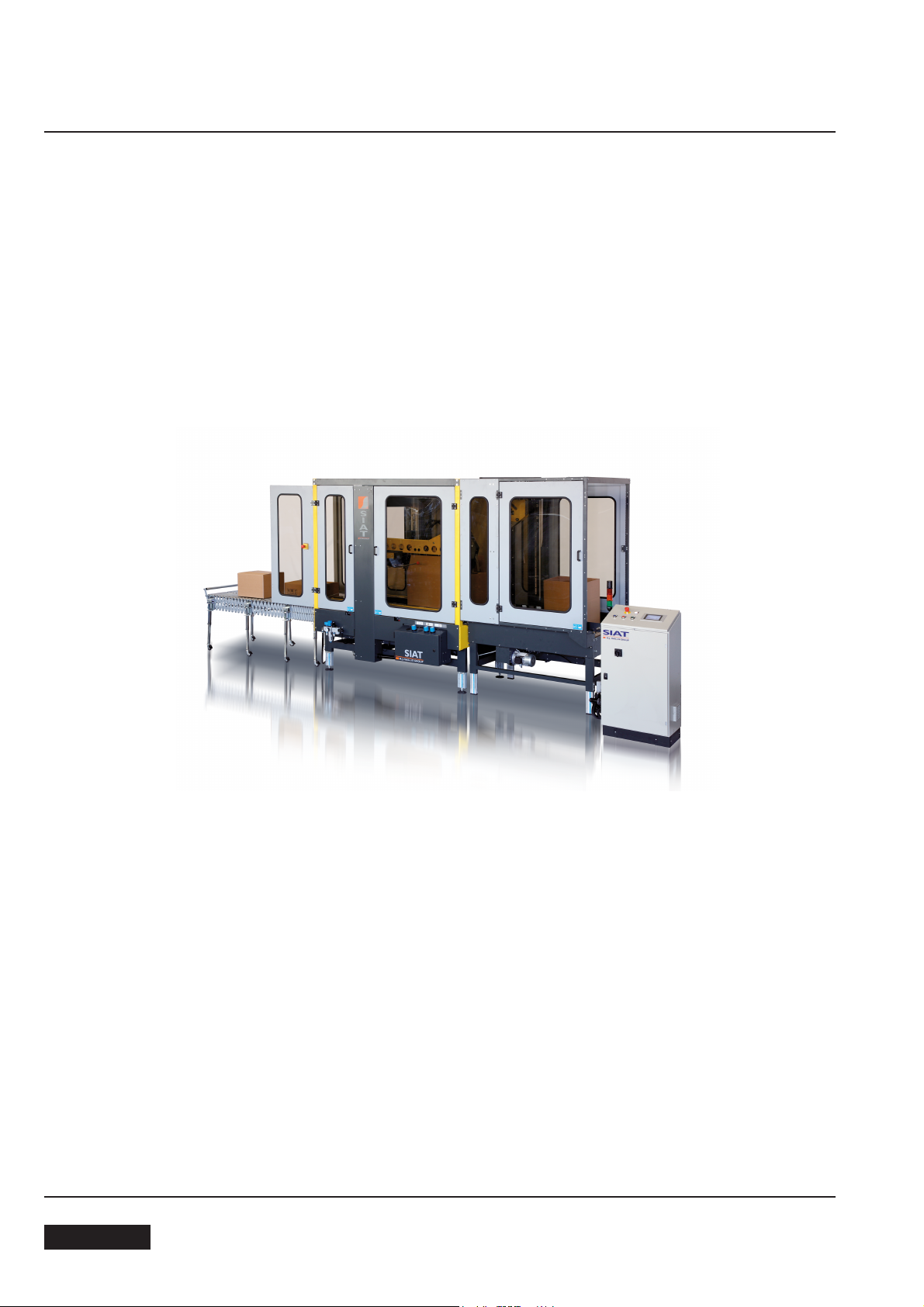

siat SM446 HS Instruction Manual And Spare Parts List

SM446 HS

NASTRATRICE AUTOMATICA

AUTOMATIC CASE SEALING MACHINE

MACHINE ENRUBANNEUSE AUTOMATIQUE

AUTOMATISCHE KARTONVERSCHLIESSMASCHINE

PRECINTADORA AUTOMATICA

MANUALE DI ISTRUZIONI E PARTI DI RICAMBIO

INSTRUCTIONS MANUAL AND SPARE PARTS LIST

MANUAL D’INSTRUCTIONS ET PIECES DETACHEES

BEDIENUNGSANLEITUNG UND ERSTAZTEILLISTE

MANUAL DE INSTRUCCIONES Y RECAMBIOS

Cod. pubbl.: SBC0023374

SIAT

Instruction manual for the use, maintenance, safety, shipment, storage, unpacking, set-up, repairing, trouble shooting, spare parts and disposal concerning the case sealing machine model SM446 HS.

This publication is property of SIAT S.P.A.

Via Puecher, 22 - 22078 TURATE (CO) - ITALY

Tel. 02-964951 - Fax. 02-9689727

Edition: April 2013

The reproduction of this manual is strictly forbidden.

All rights reserved ©Siat S.p.A. 2013

The manufacturer reserves the right to modify the product at any time without notice.

Publication n. SBC0023374

Version 0

S.p.A. - Via Puecher, 22 - 22078 TURATE (CO) ITALY - P.O. BOX 1

Tel. 02-964951 - Telefax 02-9689727

http://www.siat.com - E-Mail: siat@siat.com

SM446 HS

AUTOMATIC CASE SEALING MACHINE WITH DRIVE SIDE BELTS

- Maximum box size: h. 650 mm x w. 650 mm x l 800 mm

- Minimum box size: h. 150 mm x w. 160 mm x l 300 mm

- Adhesive tape: w. 50/70 mm

- Belt speed: 30 m/min.

- Production: 11 boxes/minute

- Average air consumption: 260 Nl/min approximately

ENGLISH

April 20132

INDEX

ABBREVIATIONS AND ACRONYMS

Section

Manufacturing specifications 1.1

Manual, how to use the 1.2

3ytefaS

1.2rebmuN laireS

After-sale service 2.2

3.2ytnarraW

Operators' skill levels 3.6

Technical specifications 4.2

6.4snoisnemiD

5noitatropsnarT

6gnikcapnU

7noitallatsnI

8slortnoC

9noitarepO

01secived ytefaS

Set-up and adjustments 11

21esu enihcaM

Tape replacement 12.3

Trouble shooting 12.7

31ecnanetniaM

Blade replacement 13.9

LIST OF ABBREVIATIONS, ACRONYMS AND UNUSUAL

TERMS TO BE FOUND IN THIS MANUAL

Dwg. = drawing

Encl. = enclosure

Ex. = example

Fig. = figure showing spare parts

Max. = maximum

Min. = minimum

Mod. = machine model

N. = number

N/A = not applicable

OFF = machine stopped

ON = machine running

OPP =

Pict. = picture

PLC = Programmable Logic Control

PP = polypropylene

PTFE = Polytetrafluorethylene

4.21gninaelC

5.31noitacirbuL

PVC = Polyvinylchloride

Ref. = reference mark

SIAT SPA = Società Internazionale Applicazioni

Tav. = Illustration

oriented polypropylene adhesive tape

Tecniche (Società per Azioni)

Belt replacement 13.10

Adjustment of belt tension 13.11

Additional Instructions 14

51serusolcnE

April 2013

w = width

h = height

noitces tsalstrap erapS

l = length

ol = overall length

cbh = conveyor bed height

3

ENGLISH

1-INTRODUCTION

1.1 MANUFACTURING SPECIFICATIONS

The automatic case sealing machine Mod. SM44 HS has been designed and manufactured compling with the

legal requirements in force at the date of its manufacture.

THE REFERENCE DOCUMENTS ARE:

Machines guidelines 2006/42/CE

Standards applied

NI EN 415-7

U

N 415-9:2009

E

Guidelines E

Standards applied

EI EN 60204-1:2006

C

N 61000-6-2:2005

E

E

N 61000-6-4:2007

1.2 HOW TO READ AND USE THE INSTRUCTION MANUAL

1.2.1 IMPORTANCE OF THE MANUAL

The manual is an important part of the machine; all information contained herein is intended to enable the equipment to be maintained in perfect condition and operated safely. Ensure that the manual is available to all operators of this equipment and is kept up to date with all subsequent amendments. Should the equipment be sold

or disposed of, please ensure that the manual is passed on. Electrical and pneumatic diagrams are included in

the manual. Equipment using PLC controls and/or electronic components will include relevant schematics or programmes in the enclosure, and in addition the relevant documentation will be delivered separately.

MC 2004/108/CE

1.2.2 MANUAL MAINTENANCE

Keep the manual in a clean and dry place near the machine. Do not remove, tear or rewrite parts of the manual

for any reason.

Use the manual without damaging it.

In case the manual has been lost or damaged, ask your after sale service for a new copy, quoting the code number of the document.

1.2.3 CONSULTING THE MANUAL

The manual is composed of:

- pages which identify the document and the machine

- index of the subjects:

- instructions and notes on the machine: sections 2÷14

- enclosures, drawings and diagrams:

sections 15÷16

- spare parts: last section.

All pages and diagrams are numbered. The spare parts lists are identified by the figure identification number.

All the notes on safety measures or possible dangers are identified by the symbol:

All the important warning notes related to the operation of the machine are identified by the symbol:

The parts typed in bold refer to technical data or technical notes on a specific subject.

1.2.4 HOW TO UPDATE THE MANUAL IN CASE OF MODIFICATIONS TO THE MACHINE

Modifications to the machine are subject to manufacturer’s internal procedures.

The user receives a complete and up-to-date copy of the manual together with the machine.

Afterwards the user may receive pages or parts of the manual which contain amendments or improvements

made after its first publication.

The user must use them update this manual.

;

ENGLISH

April 20134

2-GENERAL INFORMATION

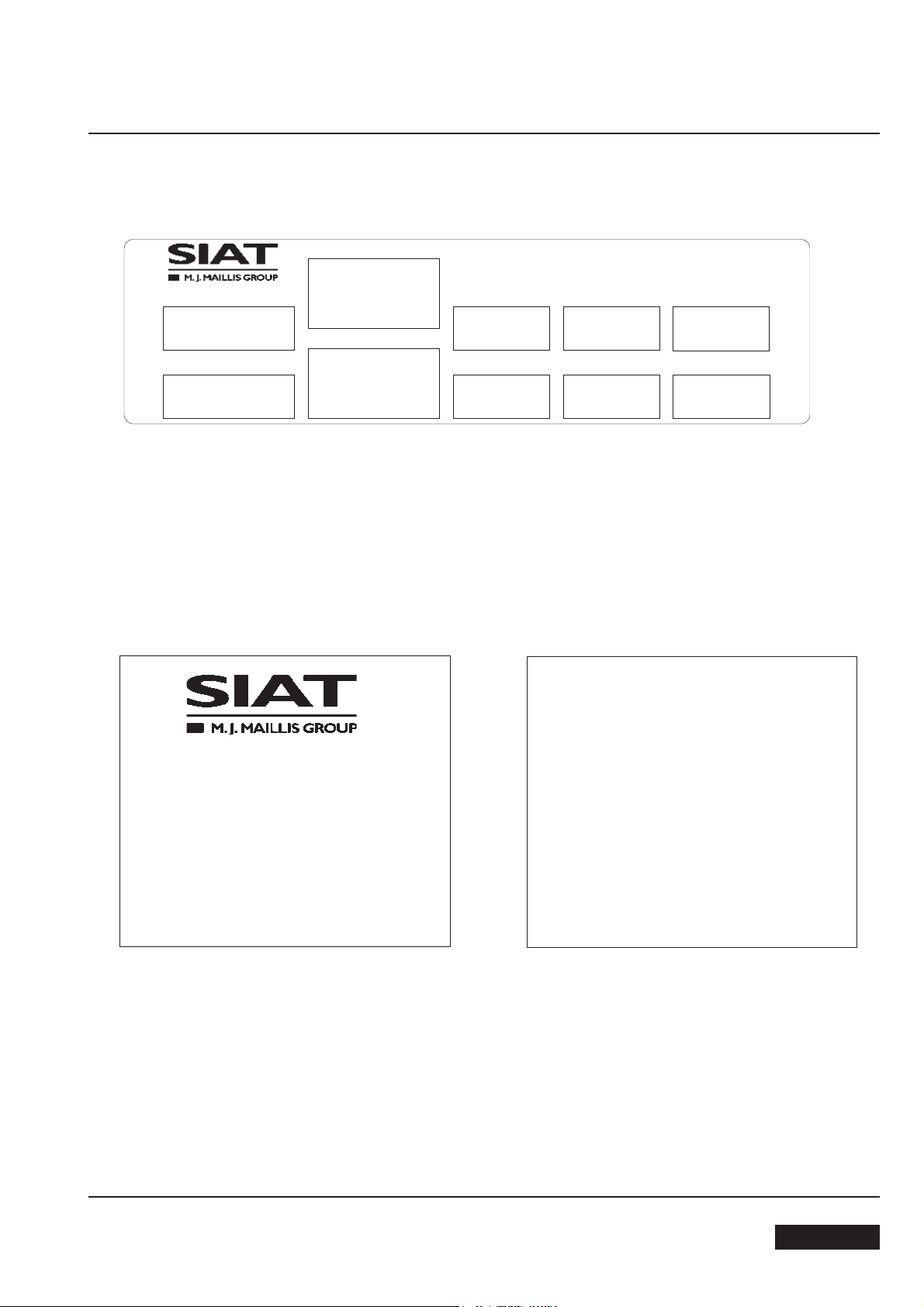

2.1 SERIAL NUMBER OF THE MACHINE AND NAME OF THE MANUFACTURER

Model

Type

Part Number

Year

Serial Number

Volt

SIATs.p.a.Via G.Puecher N°22

Turate (CO) ITALY

Ampere

Hertz

2.2 FOR AFTER-SALE SERVICE AND SPARE PARTS PLEASE APPLY TO:

Watt

Phase

Via Puecher, 22

22078 TURATE (CO) - ITALY

Tel. 02-964951

Fax. 02-9682239

E-mail siat@siat.com

AGENT/DISTRIBUTOR OR LOCAL

AFTER SALE SERVICE:

April 2013

5

ENGLISH

2-GENERAL INFORMATION

WARRANTY

Within the limits of what is set forth below, Seller agrees to repair or replace without cost to Buyer any defective goods when such defect occurs within a period of twelve (12) months from the date in which Seller's goods have been put into use, but in no event beyond

thirteen (13) months from the date of shipment.

Expressly excluded from this warranty are those parts subject to normal wear and tear (by way of illustration, but not limitation, such

parts as belts, rubber rollers, gaskets, brushes, etc.) and electrical pa

Buyer must immediately notify Seller of any defect, specifying the serial number of the machine.

Buyer shall send to Seller the defective item for repair or replacement. Seller will perform the repairs or provide a replacement within a

reasonable period of time.

Upon effecting such repair or replacement, Seller shall have fulfilled its warranty obligations. In the event the repairs or replacement

must be effected at the place where the machine is installed, all expenses for labor, travel and lodging of Seller's personnel shall be

sustained by the Buyer. Buyer wil

Seller is not responsible for defects resulting from:

- Improper use of the machine

- Lack of proper maintenance

- Tampering with the machine or repairs effected by the Buyer.

l be invoiced in conformity with Seller's standard charges for the services rendered.

rts.

Seller will not be liable for any injury to persons or things or for the failure of production. With respect to the materials not manufactured by Seller, such as motors and electrical equipment, Seller will grant to Buyer the same warranty Seller receives from its supplier of

such materials. Seller doe

be installed, nor does it warrant compliance with laws or standards relating to the prevention of accidents or pollution.

Adaptation of Seller's machines to the aforesaid laws or standards shall be the responsibility of Buyer who assumes all liability therefore.

Buyer shall indemnify and hold Seller harmless against any claim by third parties resulting from failure to comply with the aforesaid laws

and standards.

s not warrant the compliance of its machines with the laws of non-EEC countries in which the machines may

ENGLISH

6

April 2013

3-SAFETY

3.1 GENERAL SAFETY INFORMATION

Read all the instructions carefully before starting the work with the machine; please pay particular attention to

sections marked by the symbol

The machine is provided with a complete safety protection

and with a two LOCKABLE EMERGENCY STOP BUTTON

placed on the same protection and on the control panel;

when one button is pressed, it stops the machine at any point

in the working cycle.

Disconnect the machine from the mains before any maintenance operation.

.

Keep this manual in a handy place near the machine: its information will help you to maintain the machine in

good and safe working condition.

3.2 DEFINITION OF THE OPERATORS' QUALIFICATIONS

- Machine operator

- Maintenance technician

- Electrician

- Manufacturer’s technician

Only persons who have the skills described in the following page should be allowed to work on the machine.

It is the responsibility of the user to appoint the operators having the appropriate skill level and the appropriate

training for each category of job.

SKILL 1

MACHINE OPERATOR

This operator is trained to use the machine with the machine controls, to feed cases into the machine, make

adjustments for different case sizes, to change the tape and to start, stop and restart production.

N.B.: the factory manager must ensure that the operator has been properly trained on all the machine functions

before starting work.

April 2013

7

ENGLISH

3-SAFETY

SKILL 2

MECHANICAL MAINTENANCE TECHNICIAN

This operator is trained to use the machine as the MACHINE OPERATOR and in addition is able to work with

the safety protection disconnected, to check and adjust mechanical parts, to carry out maintenance operations

and repair the machine.

He is not allowed to work on live electrical components.

SKILL 2a

ELECTRICAL MAINTENANCE TECHNICIAN

This operator is trained to use the machine as the MACHINE OPERATOR and in addition is able to work with

the safety protection disconnected, to make adjustments, to carry out maintenance operations and repair the

electrical components of the machine.

He is allowed to work on live electrical panels, connector blocks, control equipment etc.

SKILL 3

SPECIALIST FROM THE MANUFACTURER

Skilled operator sent by the manufacturer or its agent to perform complex repairs or modifications, when agreed

with the customer.

3.3 INSTRUCTIONS FOR A SAFE USE OF THE MACHINE

Only persons who have the skills described on the following paragraph 3.6 are allowed to work on the machine.

It is responsibility of the user to appoint the operators having the appropriate skill level and the appropriate

training for each category of job.

3.4 STATE OF THE MACHINE

List of the modes which are possible with this machine:

- automatic running;

- running with safety protections removed or disabled;

- stopped by using the main switch;

- stopped by using the lockable emergency stop button;

- electric power disconnected;

- compressed air disconnected.

ENGLISH

April 20138

3-SAFETY

3.5 NUMBER OF THE OPERATORS

The operations described hereinafter have been analized by the manufacturer; the number of operators

shown for each operation is suitable to perform it in the best way.

A smaller or larger number of operators could be unsafe.

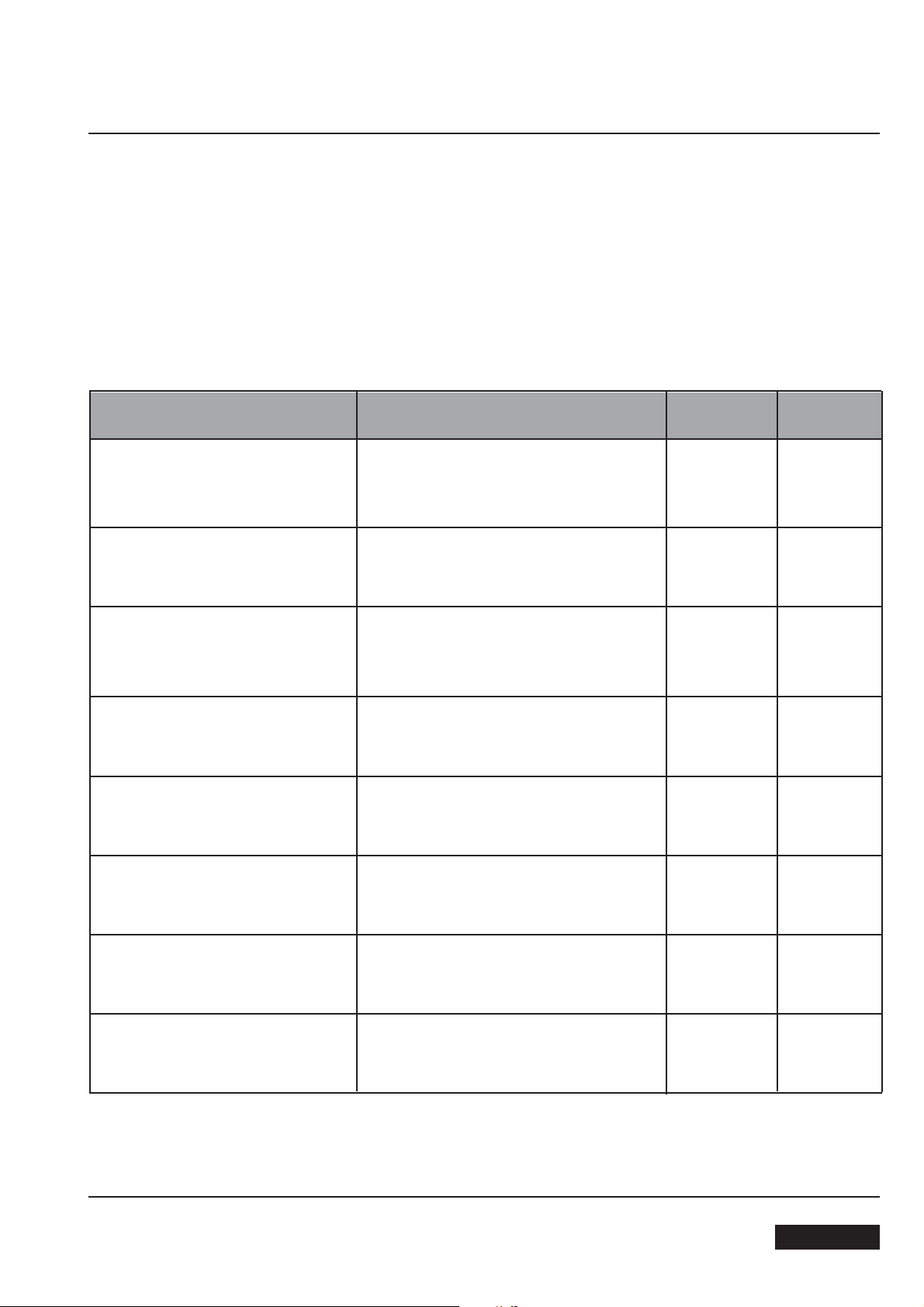

3.6 OPERATORS’ SKILL LEVELS

The table below shows the minimum operator's skill for each operation with the machine.

OPERATION

Installation and set up of the machine

Tape replacement

Replacement of blades

Replacement of drive belts

Ordinary maintenance

MACHINE MODE

Running with safety protections disabled.

Stopped by pressing the EMERGENCY

STOP button.

Electric power disconnected.

Electric power disconnected.

Electric power disconnected.

OPERATOR’S

SKILL

2 e 2a

1

2

2

2

NUMBER OF

OPERATORS

2

1

1

1

1

Extraordinary maintenance (mechanical)

Extraordinary maintenance (electrical)

Extraordinary maintenance (pneumatic)

April 2013

Running with safety protections disabled.

Running with safety protections disabled.

Stopped by pressing the EMERGENCY

STOP button.

9

3

2a

3

1

1

1

ENGLISH

3-SAFETY

3.7 RESIDUAL HAZARDS

The case sealer SM44 HS has been designed following the EC directives, and incorporates various safety protections which should never

be removed or disabled.

Notwithstanding the safety precautions conceived by the designers of

the machine, it is essential that the operator and service personnel be

warned that the following uneliminable residual hazards exis

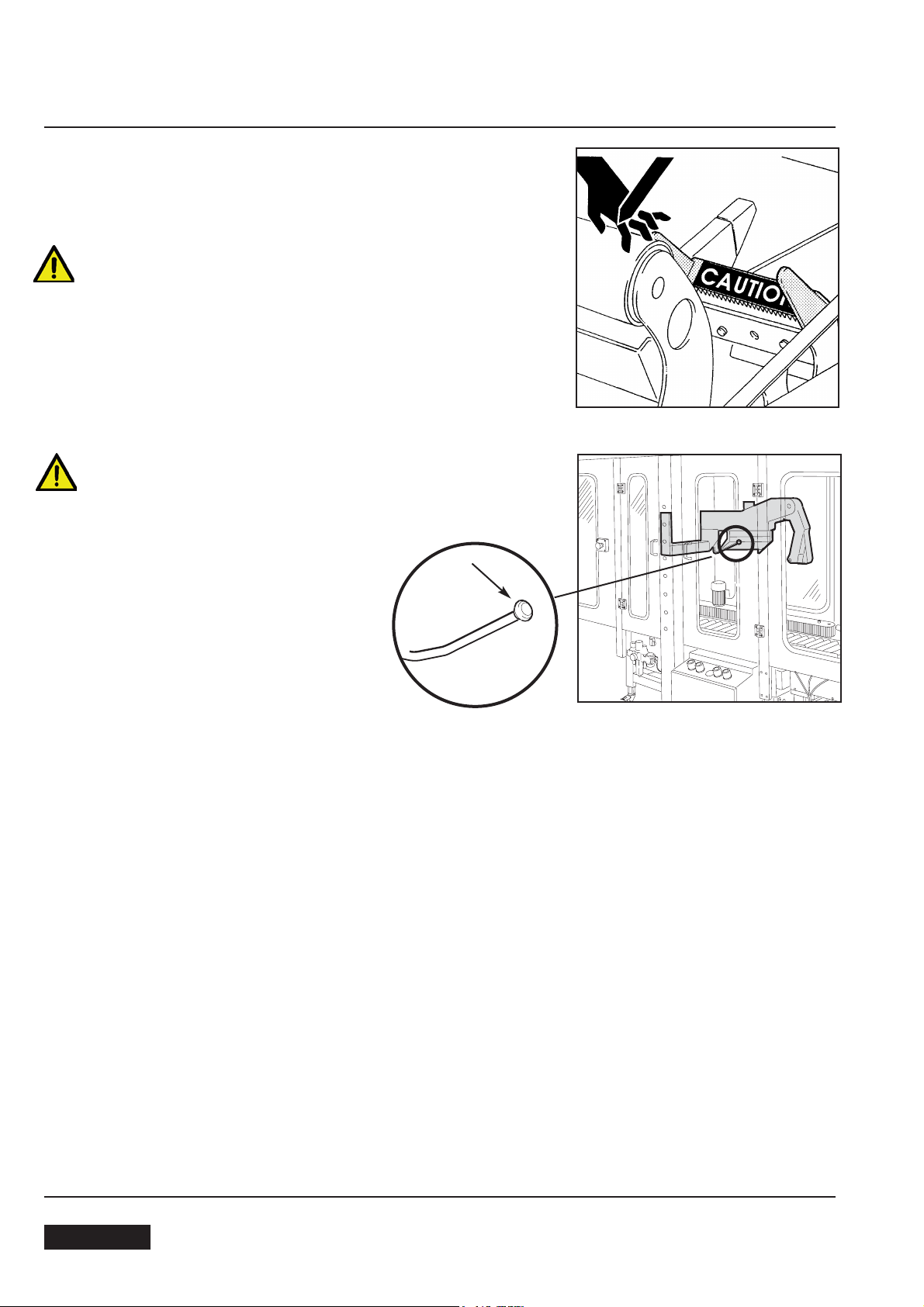

WARNING! Tape cutting blades.

Never remove the safety device which covers the blade on the top and

bottom taping units.

Blades are extremely sharp. Any error may cause serious injuries.:

WARNING!: Side flaps fold device guard knobs

Don’t remove the orange plastic guard knobs on the side flaps fold device ends.

3.8 RECOMMENDATIONS AND MEASURES TO PREVENT OTHER HAZARDS WHICH CANNOT BE ELIMINATED

The operator must stay on the working position shown on paragraph 12.1. He must never touch the running

driving belts or put his hands inside any cavity.

The box must be fed by keeping the hands in the right position.

The operator must pay attention to the blades during the tape replacement.

3.9 PERSONAL SAFETY MEASURES

(Safety glasses, safety gloves, safety helmet, safety shoes, air filters, ear muffs).

None is required, except when recommended by the user.

ENGLISH

April 201310

3-SAFETY

3.10 PREDICTABLE ACTIONS THAT ARE INCORRECT AND NOT ALLOWED

- Never try to stop or hold the box while it is being driven by the belts.

Use only the EMERGENCY STOP BUTTON.

- Never work without the safety protections.

Never remove or disable the safety devices.

-

- Only authorised personnel should be allowed to carry out the adjustments, repairs or maintenance which require operation with reduced safety protections. During such operations, access to the machine must be restricted. When the work is finished, the safety protections must immediately be reactivated.

- The cleaning and maintenance operations must be performed after disconnecting the electric power.

- Clean the machine using only dry cloths or light detergents. Do not use solvents, petrochemicals etc.

- Do not modify the machine or any part of it. The manufacturer will not be responsible for any modifications.

- We advise to apply directly to Siat for modifications.

- Follow carefully the installation instructions of this manual.

The manufacturer will notbe responsible for damages caused by improper installation.

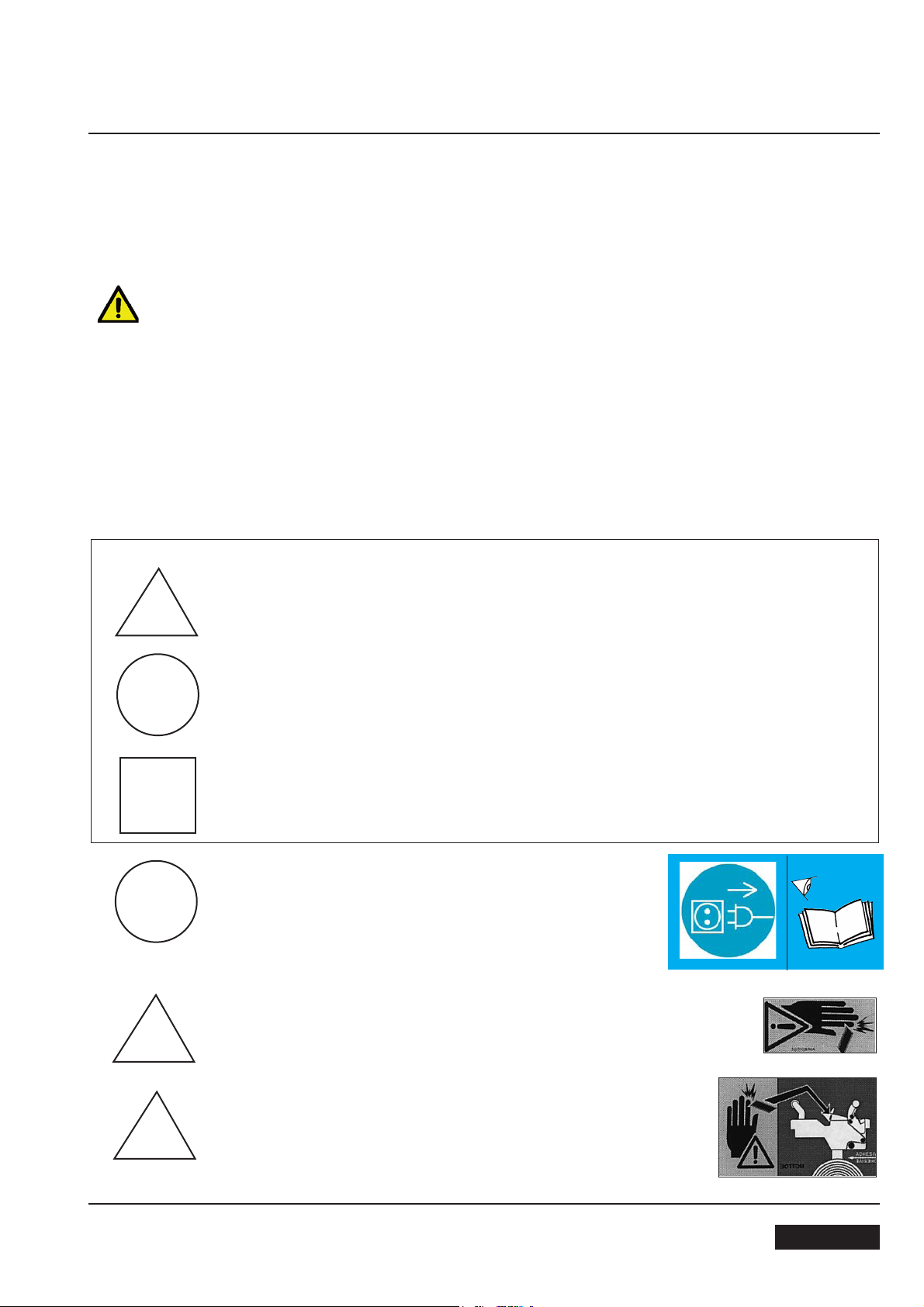

3.11 TABLE OF WARNINGS, LABELS, PLATES AND DRAWINGS TO BE FOUND ON THE MACHINE

SYMBOLS

DANGER AND PARTS IN MOVEMENT

COMPULSORY ACTIONS/PROHIBITION

CONTROLS AND INFORMATION

a

Before starting any maintenance operations the electrical power must be disconnected.

COLOURS

YELLOW COLOUR

RED COLOUR

LIGHT BLUE COLOUR

Label code

: 3.0.01097.96A

b

c

April 2013

Show the sharp knife on the taping head.

Tape threading path for bottom taping unit and position of the sharp knife.

11

Label code: 3.0.01028.96A

Label code: 3.0.01024.96A

ENGLISH

3-SAFETY

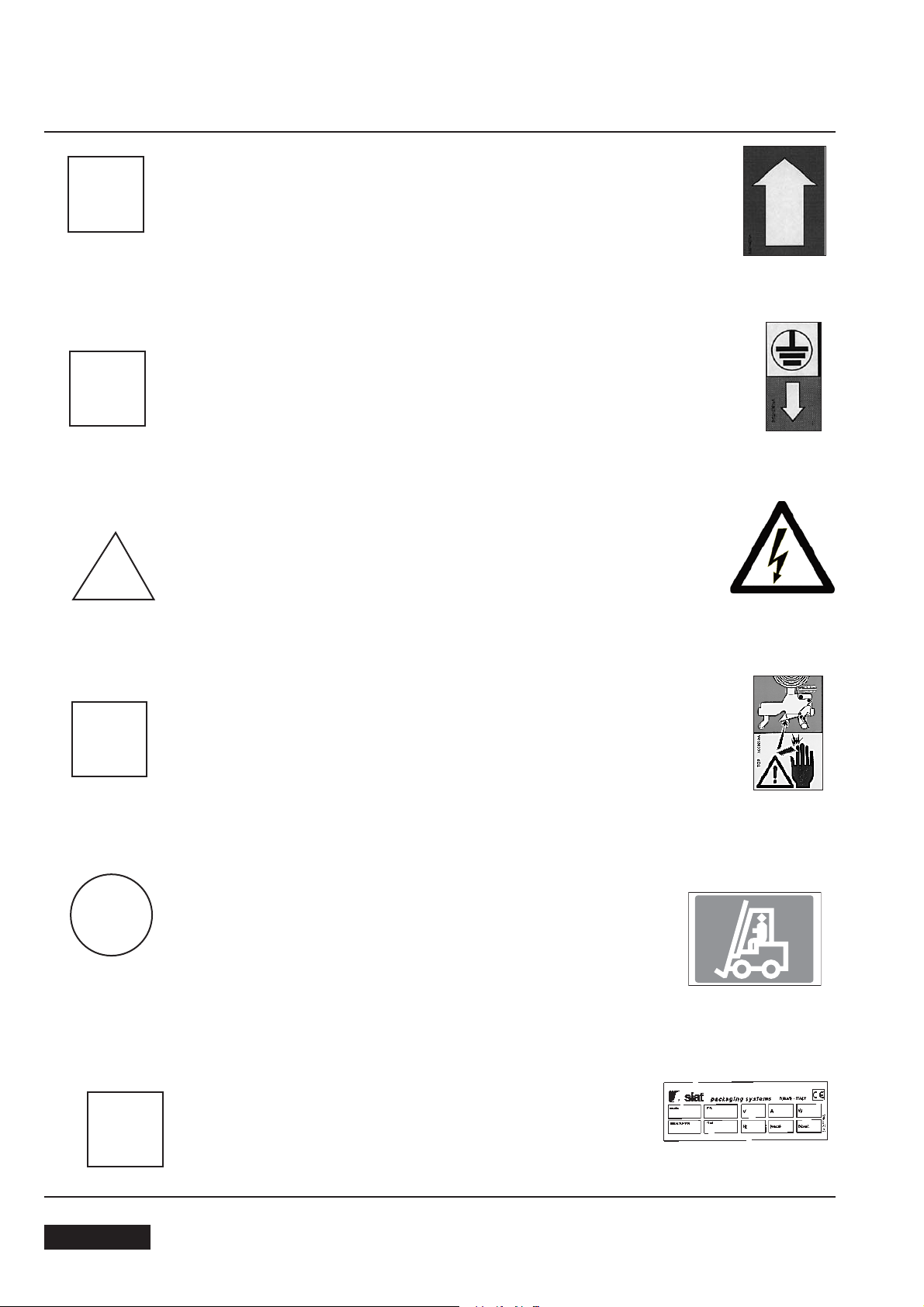

d

e

Shows the running direction of the belts.

Label code: 3.0.01040.96A

Show the earth wire connection point on the machine

frame.

Label code: 3.0.01039.96A

f

Caution!: High voltage

Label code: 3.0.01100.96A

g

Tape threading path for upper taping unit.

Label code: 3.0.01023.96A

h

Compulsory position to lift the machine with forktrucks or other suitable raising equipment.

Label code

SBC0010337

: SBC0010337

i

ENGLISH

Identification data for the machine model, serial number and manufacturer.

Label code:S340277700A

April 201312

4 - PRELIMINARY INFORMATION

4.1 GENERAL DESCRIPTION OF THE MACHINE

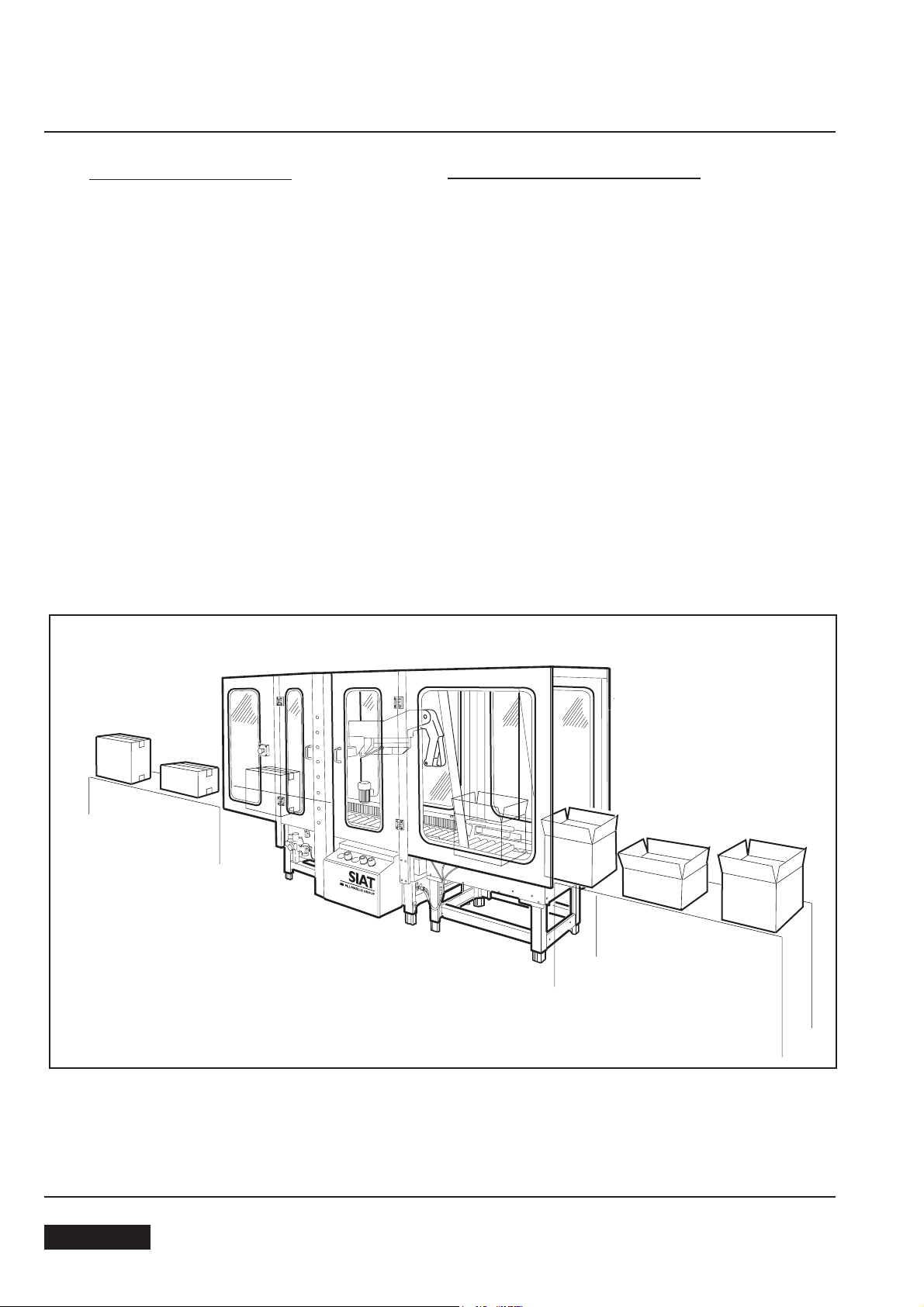

The SM446 HS case sealer with side drive belts is designed to seal boxes by applying two tape strips on the

top and bottom flaps simultaneously. No operator is required.

The machine adjusts itself automatically to the case size and folds the 4 upper flaps. The introduction of the

cases into the machine is performed by the indexing system AS24. All the operations are managed by a PLC

located in the controls board.

4.2 TECHNICAL SPECIFICATIONS

- Production = 660 boxes/hour (average)

- Standard power supply = see plate

- Installed power: 2,388 kW + 0,370 kW (AS26 HS)

- Taping units K11 or K12, tape width 50/75 mm

- Machine+control board+AS24 weight=480+70+90 kg

- Compressed air = 6 BAR; feeding pipe diameter 10 mm

- Belts speed = 30 m/min.

- Infeed conveyor speed: 21 m/min.

- Air consumption: 260 Nl/min

A

C

B

TAPE DIMENSIONS

Suitable adhesive tapes:

PVC

OPP

ADHESIVE PAPER

4.3 PURPOSE OF THE MACHINE

The purpose of this machine is the sealing with adhesive tape of boxes having the dimensions (in millimeters)

shown in the table below:

h

BOXES DIMENSIONS

SM44 HS

min. 160 150 300

w h l

A = 410 mm max

B = 50/75 mm

C = 76 mm

l

w

max. 650 650 800

CASE WEIGHTS

min.: 2 kg

max.: 30 kg

Warning: The machine supplied with the standard electric system is not designed for use in atmosphere with risk of

deflagration. In such conditions the machine must be equipped with anti-deflagration components and/or air motors.

April 2013

13

ENGLISH

4-PRELIMINARY INFORMATION

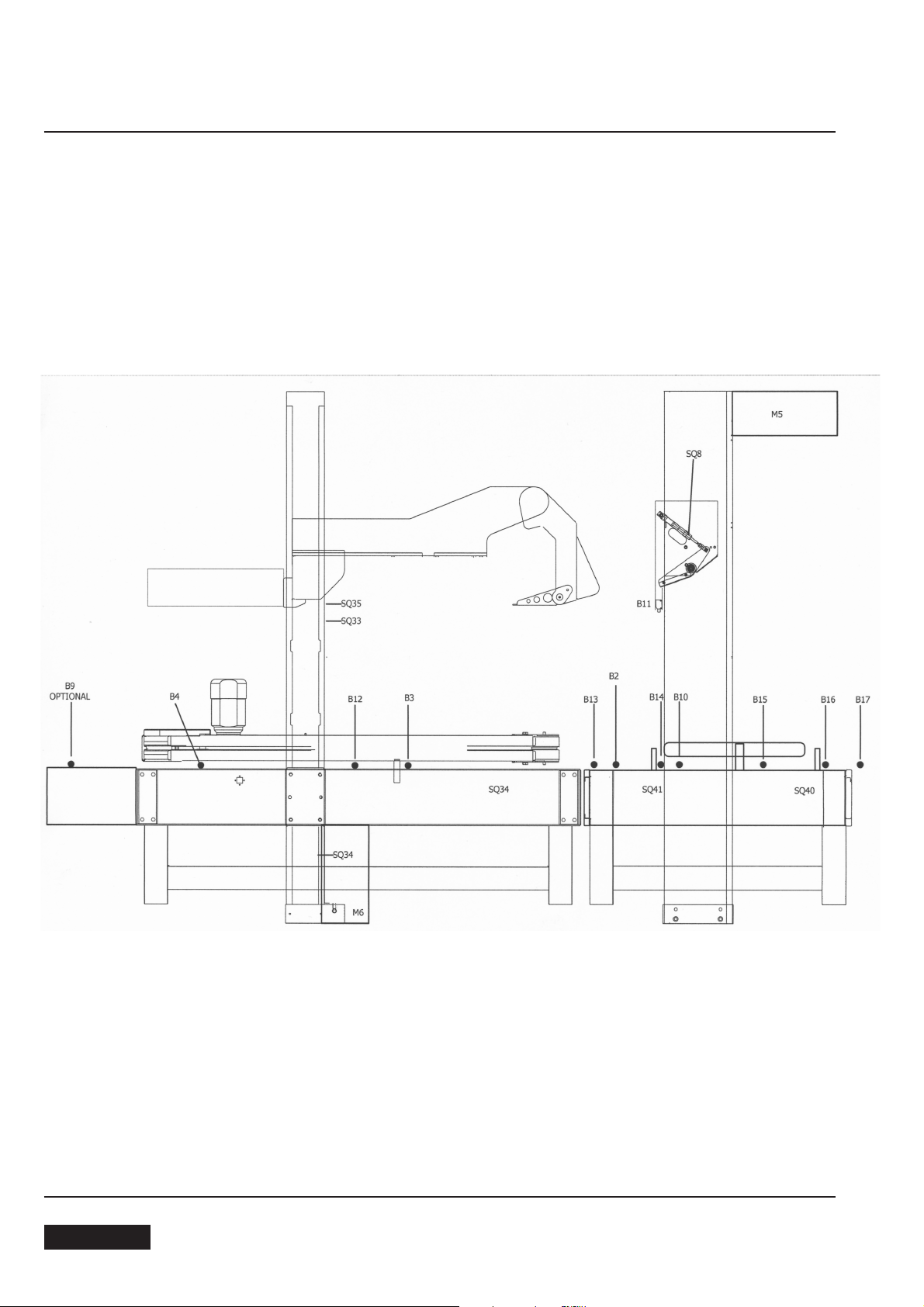

4.4 MAIN COMPONENTS

The machine is composed of:

n. 1 frame

n. 4 adjustable legs

n. 2 columns

n. 2 taping units

n. 1 top head

n. 2 side drive belts

n. 2 electric motors

n. 1 safety guard

n. 2 emergency stop button

n. 1 controls board

For the technical features of the electric parts refer to section 15-ENCLOSURES

4.5 OPERATIVE FLOW

The boxes, coming from the filling stations, are centred, gated and fed to the machine by the indexing unit

AS26 HS.

The same indexing unit is equipped with a reading head for the identification of the format of the introduced box

and the position of the following upper forming group correctly by appropriate electro-pneumatic interface devices.

The driving belts transport the box during the different phases, from flaps folding to the following sealing, to the

exit of the same box.

The infeed conveyor is composed of:

n. 1 frame

n. 4 adjustable legs

n. 1 electric motor

n. 1 motorized belt

4.6 MACHINE NOISE MEASUREMENT

Acoustic pressure at 1 meter distance from the machine with the tape roll inserted: 73 dB. Acoustic pressure

at a height of 1,6 meter above the

The measurement has been performed by a SPYRI-MICROPHON phonometer..

machine

with the tape roll inserted: 73 dB.

ENGLISH

April 201314

4-PRELIMINARY INFORMATION

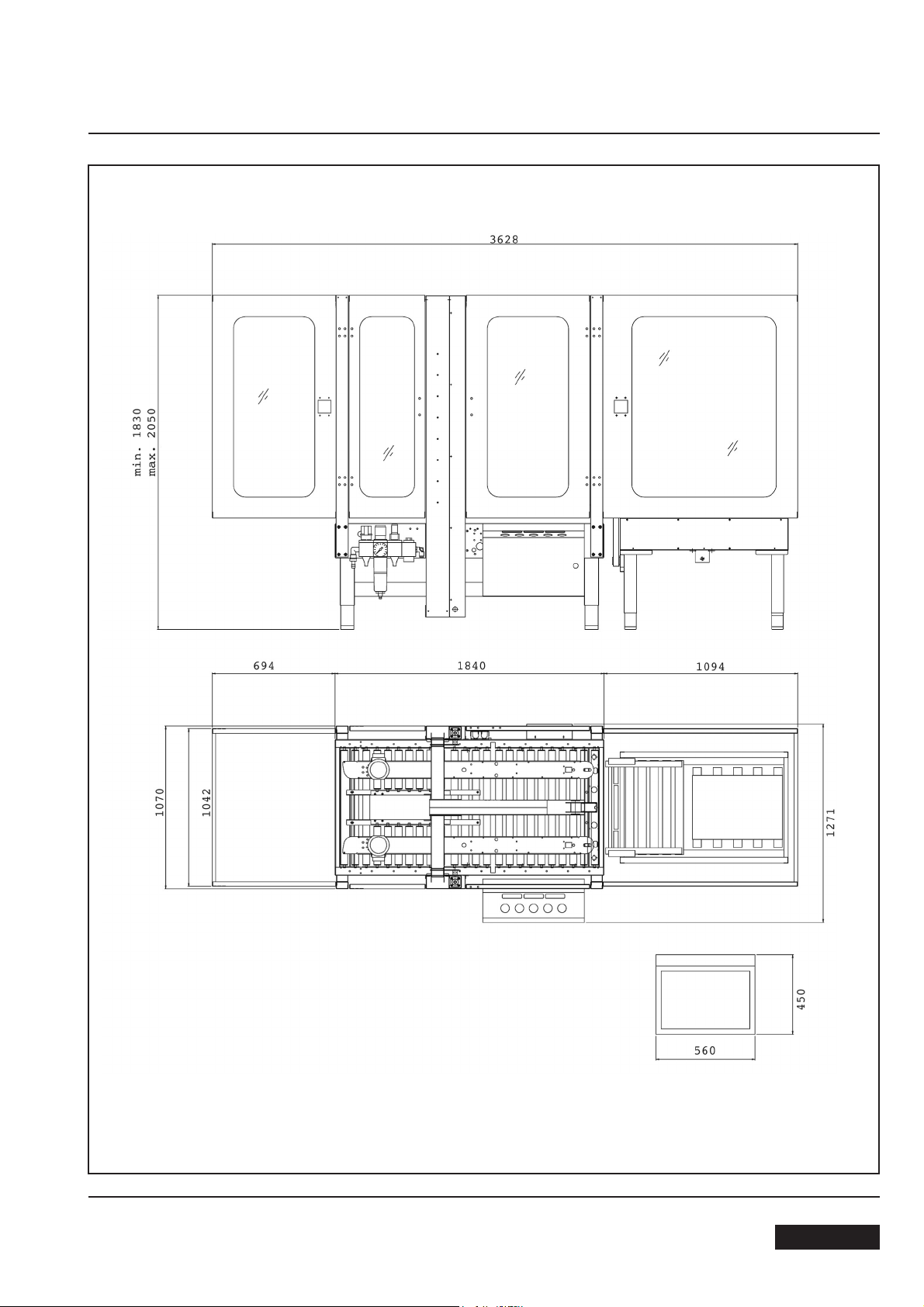

4.7 OVERALL DIMENSIONS

April 2013

15

ENGLISH

5-SHIPMENT - HANDLING - STORAGE

5.1

MACHINE TRANSPORTATION AND HANDLING

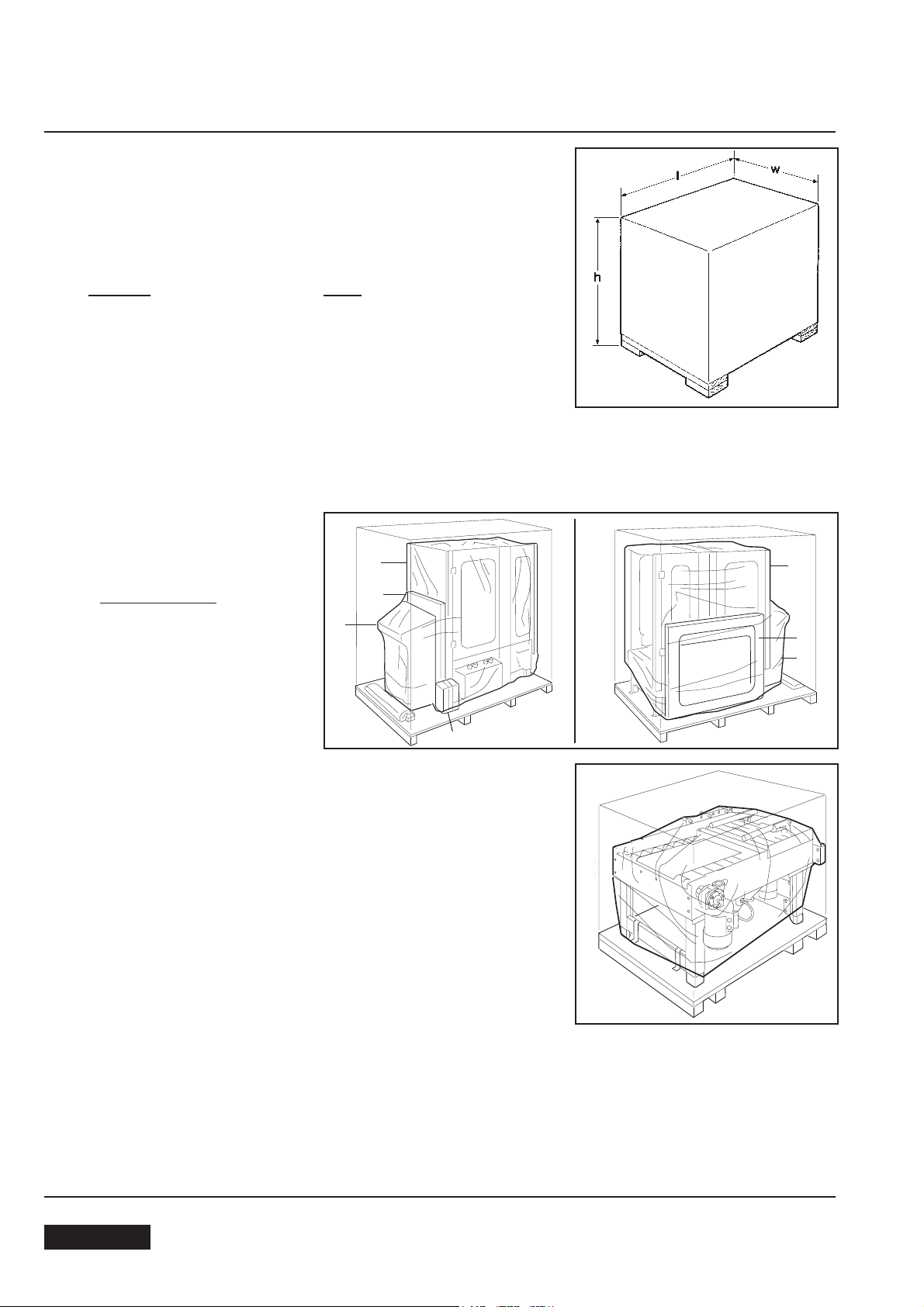

The machine and the infeed conveyor are shipped in 2 separate packings, fixed on a wooden pallet. They can be lifted with a normal fork

lift. The standard packing is suitable for surface and air transportation.

Oversea packing on request.

Packing dimensions

SM44HS

l= length: 2600 mm l: length: 2600 mm

w= width: 2250 mm w= width: 2250 mm

h= height: 1500 mm h= height: 1500 mm

Weight: 850 kg Weight: 350 kg

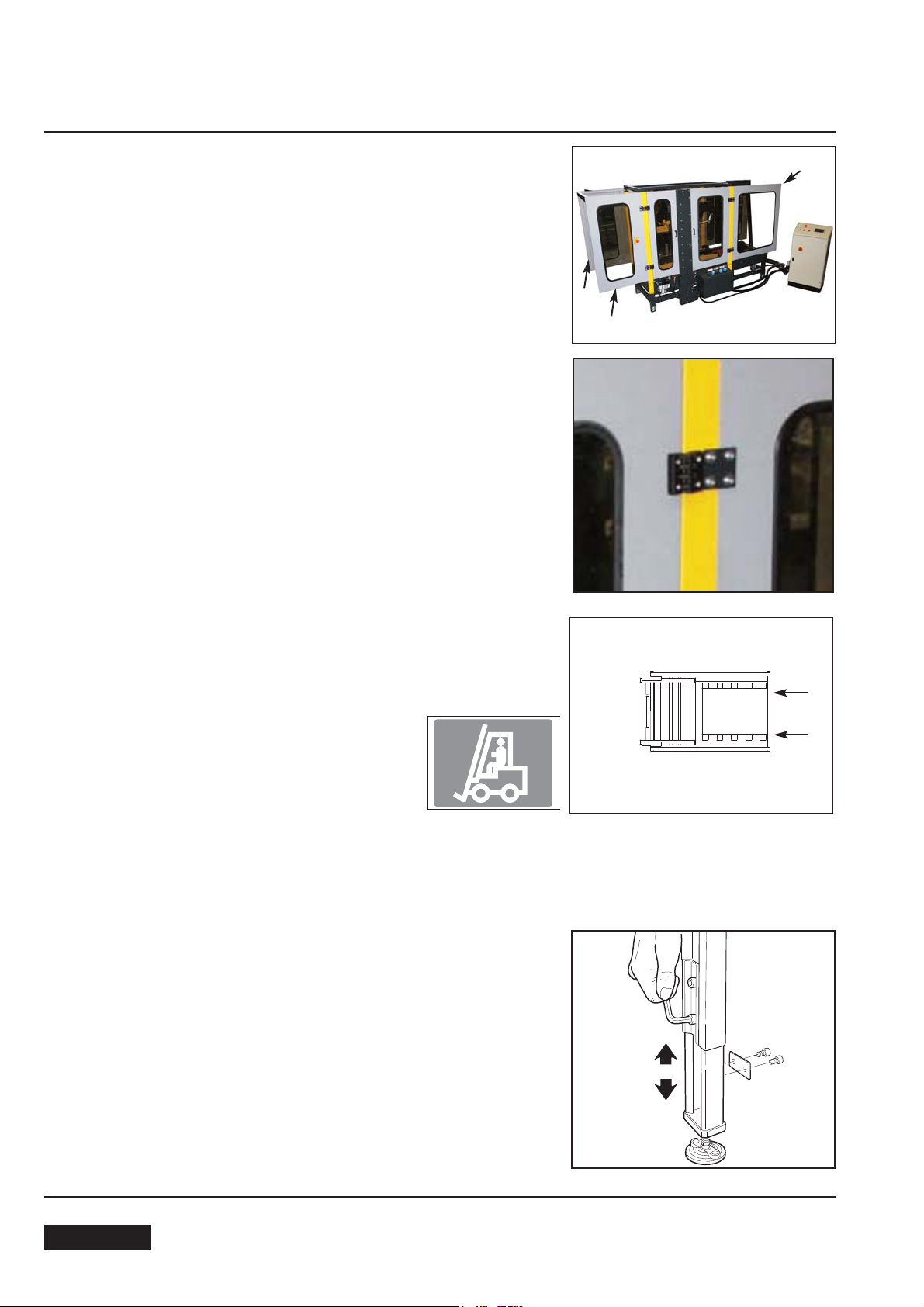

5.2 PACKING FOR OVERSEAS SHIPMENT

(OPTIONAL)

The machines shipped by sea freight are covered by an aluminium/polyester (Vacupol) bag which contains dhydrating salts.

AS24

Machine packing

-machine 1

-control board 2

-guards 3

-accessories 4.

Indexing unit packaging.

1

3

2

4

1

3

2

5.3 STORAGE OF THE PACKED OR UNPACKED MACHINE

In case the machine must stay inactive for a long period, please take the following precautions:

- store the machine in a dry and clean place;

- if the machine is unpacked it is necessary to protect it from the dust;

- do not stack anything on top of the machine;

ENGLISH

April 201316

6-UNPACKING

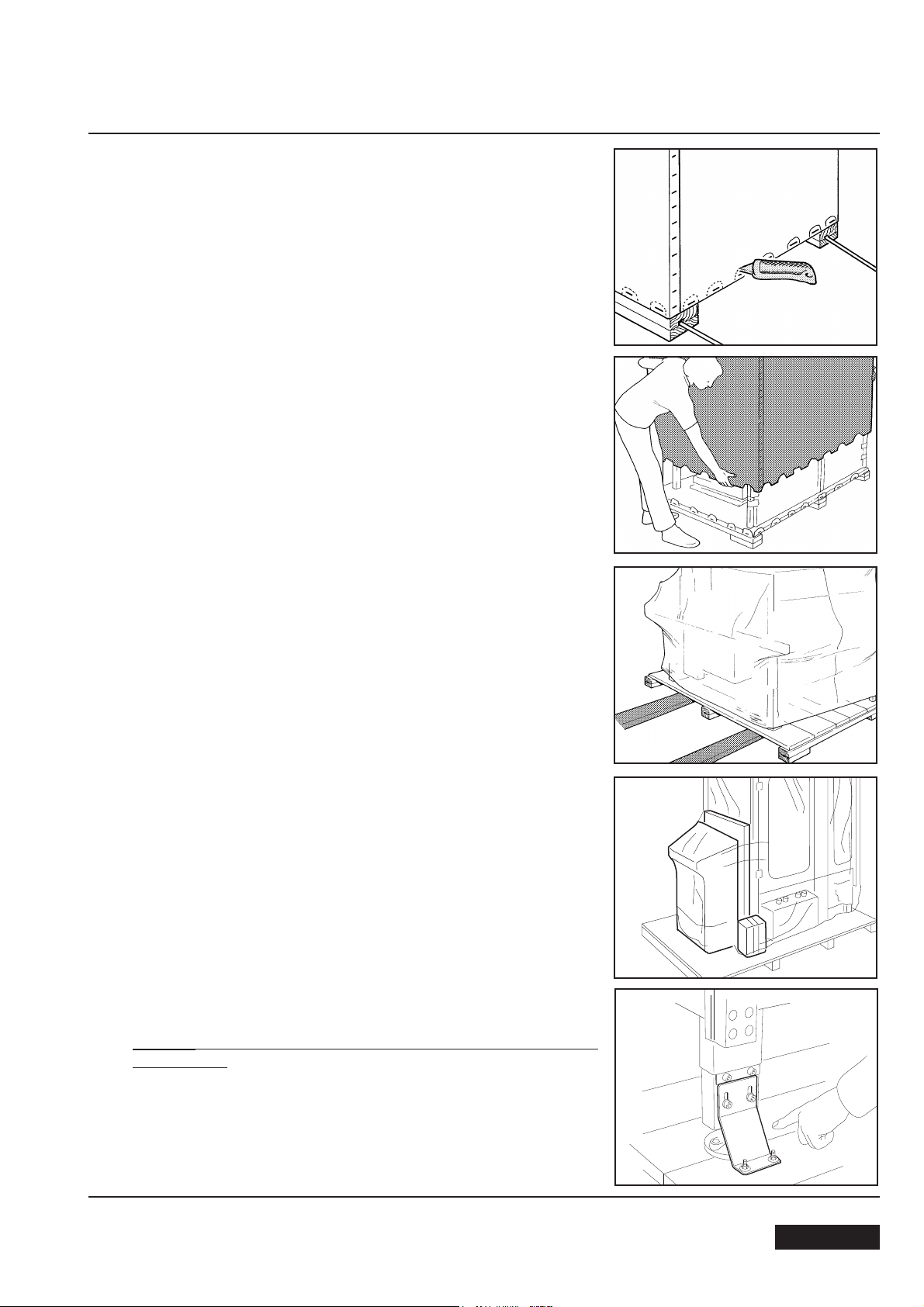

6.1 Cut the polypropylene straps.

Use a cutter to remove the part of the carton fixed by the staples

along the entire perimeter of the packing. (Otherwise remove the

staples by using a suitable tool)

After having cut the carton or removed the staples, lift the packing up

in order to free the machine. (2 persons)

Move the machine and the infeed conveyor to where they will be located.

Cut the stretch film and remove the control board, the guard panels

and the accessories box.

Sealing machine brackets removal

Caution:

one at a time.

the operations must be accomplished on all the four legs

Remove the screws 1;

Unscrew the nut 2 and remove the bracket;.

Replace and tighten the screws 1;

Acting in similar way on the other legs, in sequence.

April 2013

17

ENGLISH

6-UNPACKING

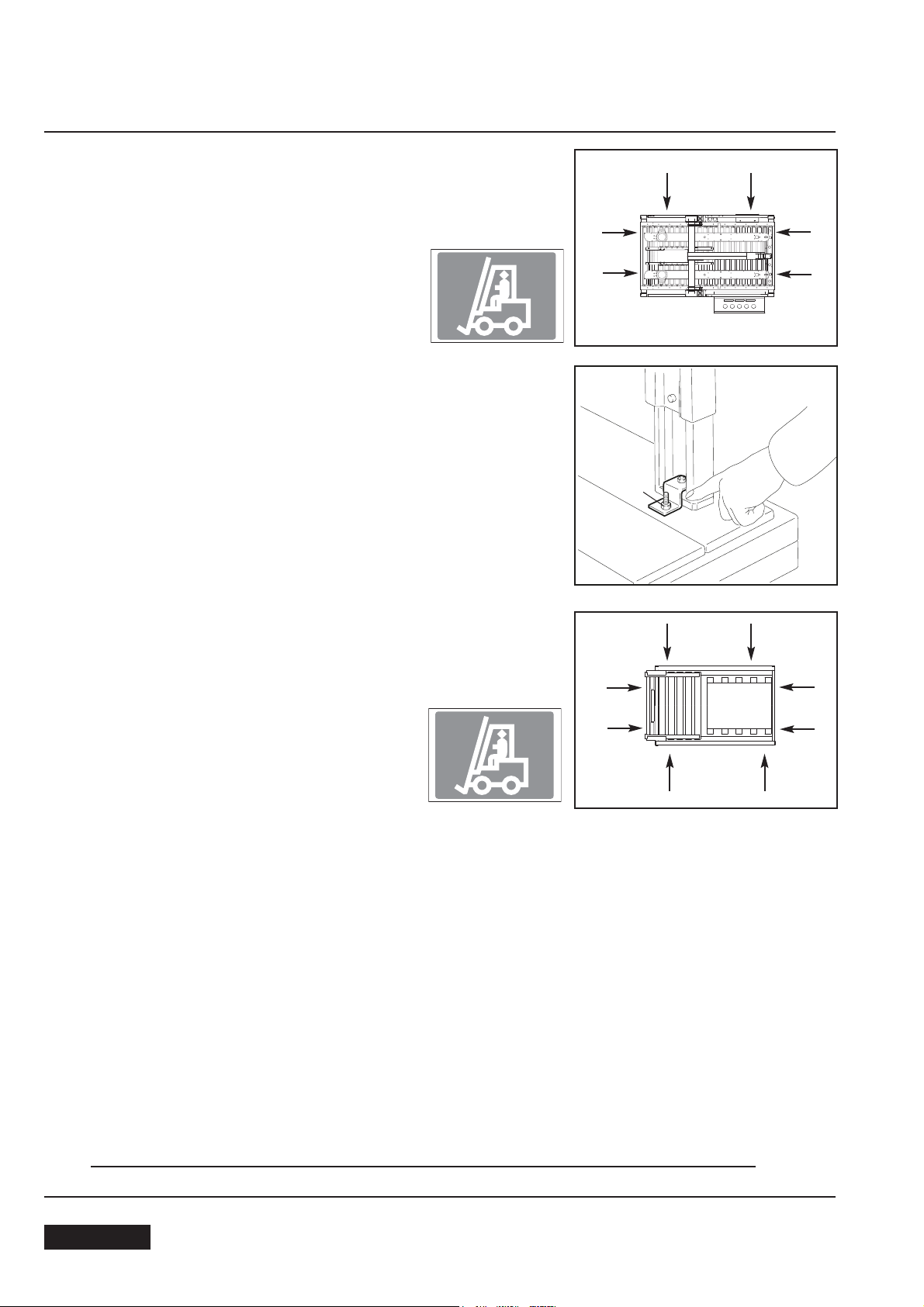

To lift the machine up, position the lift forks where there are the labels

on right hand side or front-back sides and remove the pallet.

Machine weight + control board: 480 + 100 kg.

Conveyor brackets removal

Loosen the nuts 1 and remove the brackets.

SBC0010337

Back sdie

1

RH side

Front sdie

To lift the conveyor, position the lift forks where there are the labels

on front or back side and remove the pallet.

Conveyor weight: 90 kg

6.4 PACKING DISPOSAL

The packing of the machine Mod. SM44 HS

is composed of:

- wooden pallet

- carton box

- wooden supports

- steel fixing brackets

- polythene foam protection

- plastic straps (PP)

- clay dehydrating pouches

- aluminum/polyester/polythene bag

(only for seafreight shipments)

SBC0010337

Back sdie

RH side

Front sdie

LH side

For the disposal of these materials please follow the provisions of the law in your country.

ENGLISH

April 201318

7-INSTALLATION

7.0. SAFETY MEASURES

Read carefully chapter 3.

7.1. ENVIRONMENTAL CONDITIONS REQUIRED

-Temperature min. = 5 °C; max. 40 °C

-Umidity min 30%; max. 80%

-Dust free environment

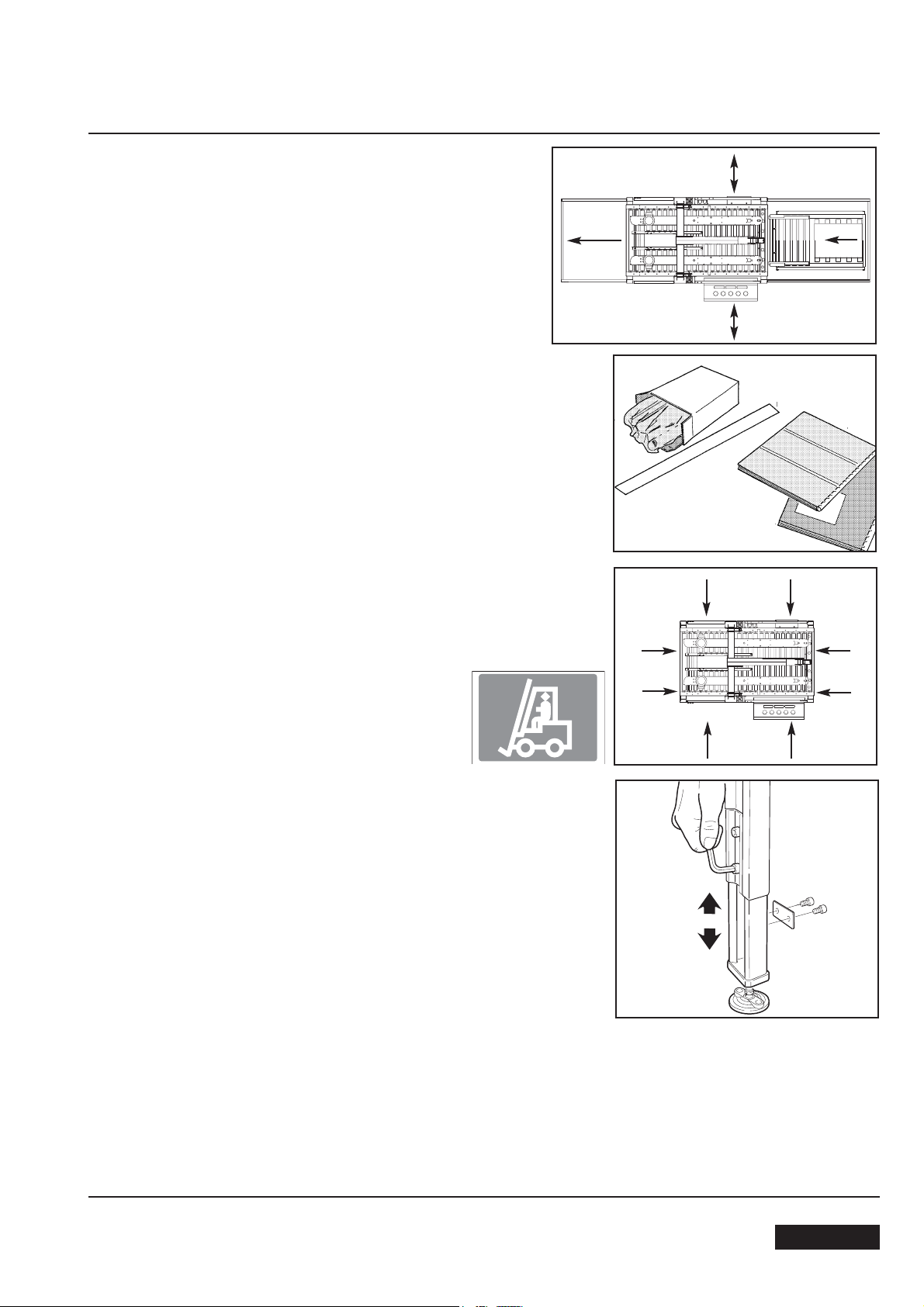

7.2. SPACE REQUIRED FOR MACHINEOPERATION AND

MAINTENANCE

Min. distance from the wall: A = 1500 mm; B = 1000 mm;

Min. height:= 2500 mm

7.3 SPARE PARTS AND THREADING TOOL FOR TAPING HEADS

For a detailed description of the tools kit see section 13.1.

B

A

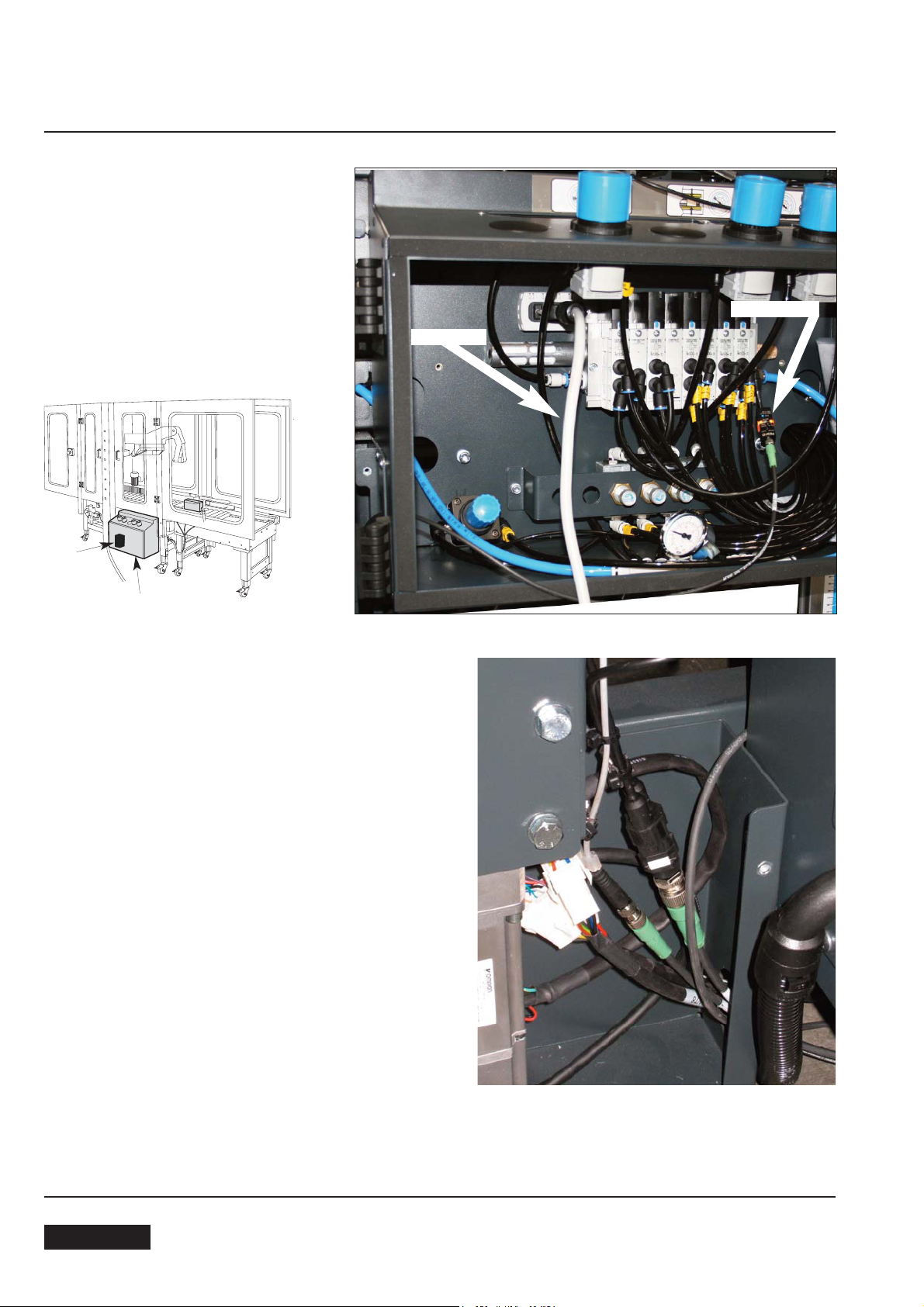

7.4 MACHINE POSITIONING

Raise the machine with a fork lift positioning the lift forks under the

points where there are the labels.

7.4.1 WORK HEIGHT ADJUSTMENT

Lift the machine as shown in picture.

Unlock the screws and take the legs out looking for the desired con-

veyor bed height on the graduated label.

Then lock the screws again.

SBC0010337

April 2013

19

ENGLISH

7-INSTALLATION

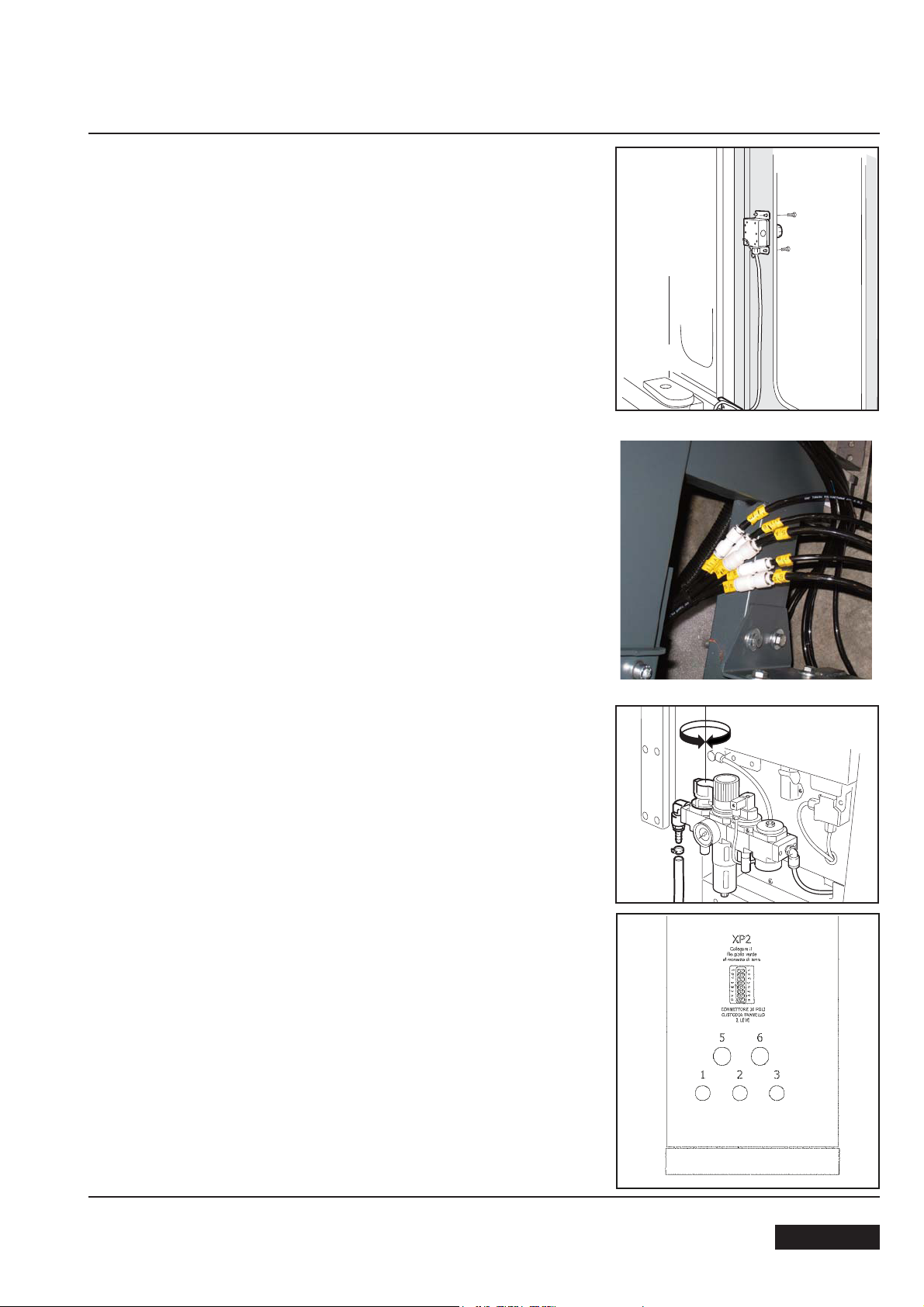

7.5 SAFETY GUARDS: INSIDE AND OUTSIDE MACHINE

EMERGENCY STOP PUSH-BUTTON

Position and assemble the inside (A) and outside (B) guard panels

with the upper and bottom brackets and stiffening frofile plates as

shown in the pictures.

7.5.1. INSIDE SAFETY GUARDS

Support brackets (upper and bottom); 2+2 socket head screws each

bracket.

A

B

B

7.6 CONNECTION BETWEEN THE INDEXING UNIT AS24 AND THE

MACHINE SM44 HS

Lift the indexing unit by placing the forks under the points where the

labels are.

7.6.1 Move the indexing unit to the machine and fix it using the screws previously removed.

7.6.2 Unlock the screws of the legs, move the legs down to the floor and

lock the screws.

SBC0010337

ENGLISH

April 201320

7-INSTALLATION

7.7 EMERGENCY STOP BUTTON

Furthermore mount the complete bracket with emergency stop button.

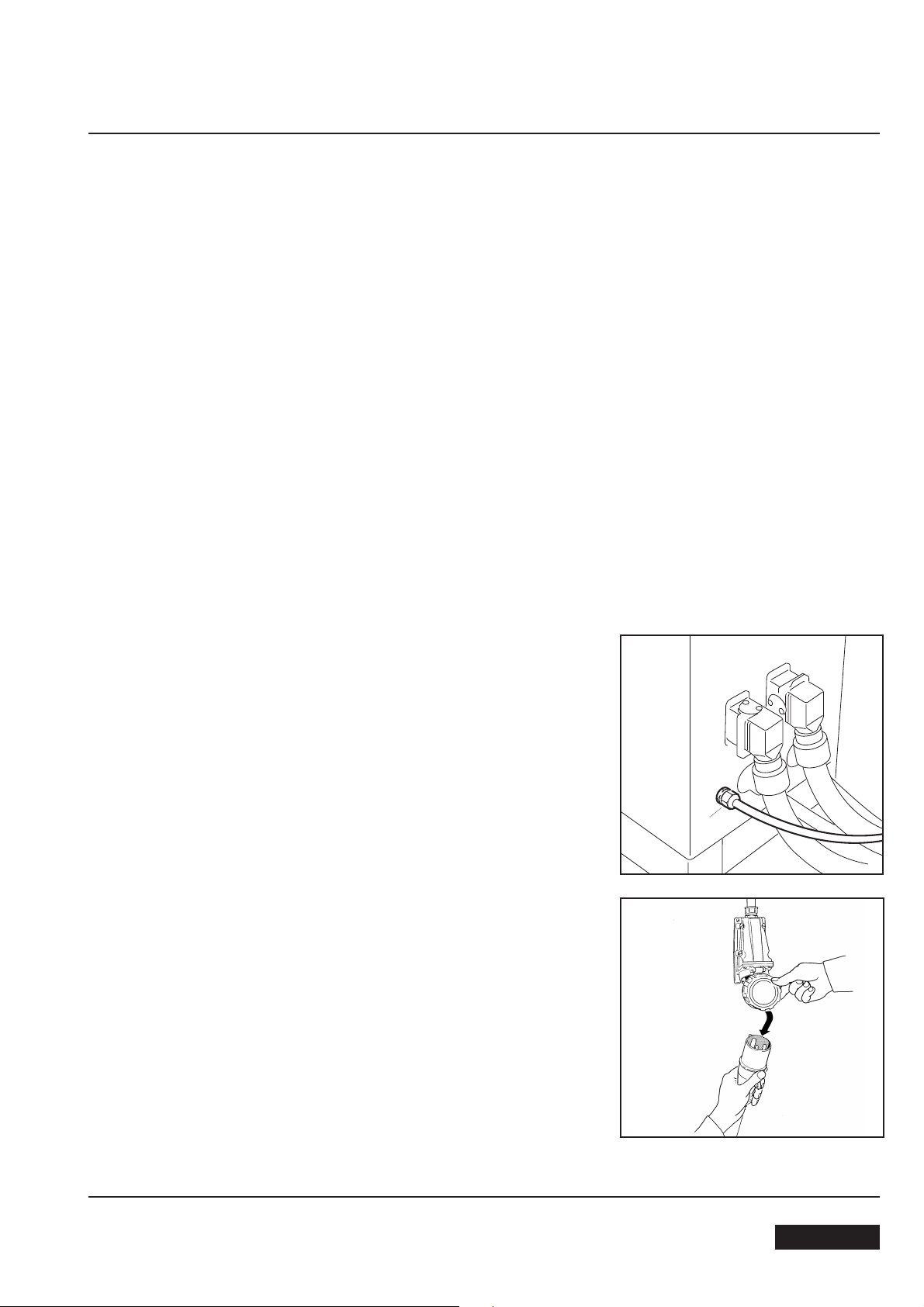

7.8 PNEUMATIC CONNECTION

Connect air pipes from the sealing machine to the conveyor centring

guides cylinder connectors and to infeed conveyor cylinders.

Fitting acronyms shown in the picture identify the pipes number

coming from the machine.

5A – 5B – 7B – 11A – 11B

7.9 MAIN PNEUMATIC CONNECTION

Connect an air pipe to the ON-OFF valve and fix it with a strap.

Min. inside diameter of the pipe 10mm.

Air pressure 6÷7 BAR

Give air to the machine by the ON-OFF valve.

7.10 CONTROL BOARD CONNECTION

Place the control board near the machine.

Feeding cables:

Connect the two cables with multipolar connectors from the machine

and from the indexing unit to the control board.

1. Feeding cable (net)

2. Carton sealer front box (CA1)

3. Carton sealer rear box

5. Indexing unit box and vertical electrical axis motors.

6. Carton sealer front boxes (CA2)

April 2013

21

ENGLISH

7-INSTALLATION

7.11 Carton sealer front box

Box CA1

Cables n.3 and 6

CA2

Cable n. 6

Cable n. 3

CA1

Carton sealer front box

Box CA2

Cable n. 6

Connectors:

W77 Motor

W78

ENGLISH

April 201322

7-INSTALLATION

7.12 Carton sealer rear box

Cable n. 5

Indexing unit box and vertical axes motors

Cable n.4

Connectors:

W15

XP17

W76-76 motor + ground wire on the fixing screw

April 2013

23

ENGLISH

7-INSTALLATION

Infeed conveyor photocell connection

ENGLISH

April 201324

7-INSTALLATION

7.13 PRELIMINARY ELECTRIC CHECK-OUT

Before connecting the machine to the mains please carry out the following operations:

7.13.1Make sure that the socket is provided with a ground protection circuit and that both the mains voltage and frequency meet the indications on the name plate of the machine.

7.13.2Check that the connection of the machine to the mains meets the provisions of law and/or the safety regulations

in your country.

7.14 MACHINE CONNECTION TO THE MAINS AND CHECK-OUT

Installed power = 2,388 kW

-Connect the power cable (A) of the control board to an electric

socket.

-Standard power supply 400Volt 50 Hz 3Ph + neutral + ground.

A

April 2013

25

ENGLISH

8-CONTROLS

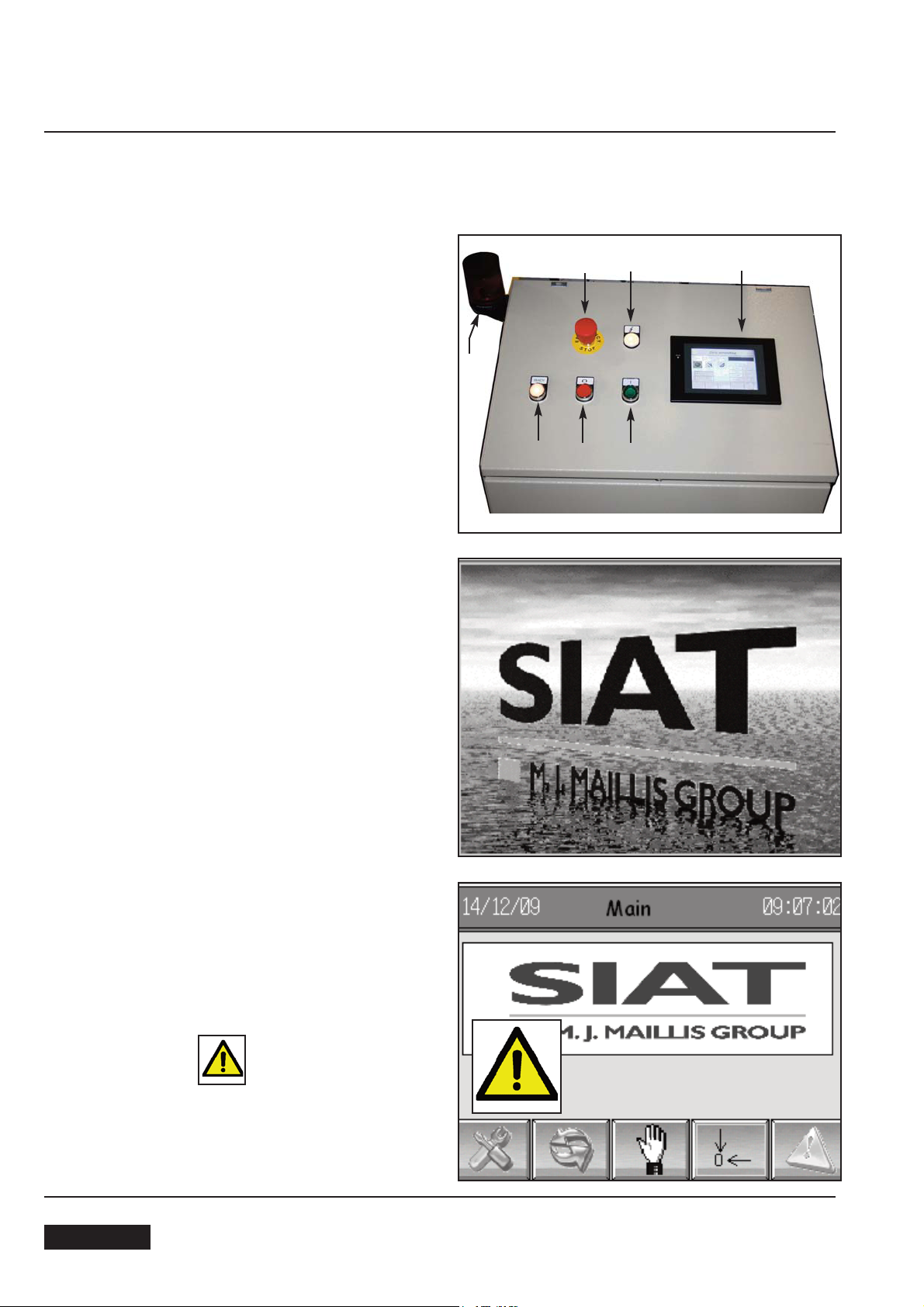

8.1 CONTROL BOARD

1. Main switch

2. Voltage warning light

3. Auxiliaries push button

(control board electrical components enabling)

4. Stop button

5. Start button

6. Touch screen control panel

7. Warning (flashing light + buzzer)

8. Emergency stop button

8

7

3

4

2

5

6

1

8.2 REAR BOX

1 Centering guide pressure regulator

2. Side belts (motorizations) pressure regulator

3. Box height pick-up pressure regulator

WARNING!

In the box there’s a pressure regulator of the compensation

cylinder on the machine vertical axis (dancer).

The regulator is adjusted by the manufacturer during machine assembly and testing (2,5 BAR); the settled value

should never be changed.

ENGLISH

3

2

1

April 201326

9-OPERATION

9.1 Turn on the air to the machine by the ON/OFF valve; set the

main switch in ON position; close the safety guards; release

the EMERGENCY STOP button; press Auxiliaries button and

Start Button (if there are no alarm signalling).

9.2 Start button activation: motors start (machine and indexing

unit) and lifting of the indexing unit drive belt.

Obscuring photocell n. 1: lowering of indexing unit drive belt

and stop of the corresponding motorization.

Obscuring photocell n. 2: Descent of the reading head and

contemporary closing of the indexing unit levers that line the

box up as necessary; in this phase the “box measurement”

is executed.

Once the measurement is finished the forming-sealing group

is positioned at the corresponding height of the reading + 20

mm, on a floating position, to allow a proper box closing in

any condition.

After the forming-sealing group positioning a lifting of the indexing unit plan follows and the re-start of the corresponding

motorization; the machine works on the box.

Obscuring photocell n. 2: activation of electronic control logic

(cycle start – machine occupied).

Free photocell n. 1: lowering of indexing unit drive belt: with

new photocell obscuring the following box will cause the stop

of the corresponding motorization.

Obscuring photocell n. 3: rear flap folder check.

Obscuring photocell n. 4: motorizations closing.

Free photocell n. 3: start of closing operation of the box rear

flap by the corresponding arm with flap folder device; furthermore, during the

box closing operation.

Obscuring photocell n. 5: rear flap folder check.

transport, the side flap folders compete the

1

4

7

3

2

6

5

Note: during the transit in “area 2” (between photocells n. 4

and n. 5), if the standing box on the indexing unit has got the

same dimensions of the previous one, it’s introduced into the

machine immediately.

Free photocell n. 7: cycle conclusion.

April 2013

27

ENGLISH

9-OPERATION

9.3. OPERATION MODES DESCRIPTION

The carton sealer works only in automatic: closed safety protection, free emergency stop button, enabled

control panel and start button activated, open compressed air circuit.

MACHINE START:

- Press auxiliaries button (3); verify the lighting of

the incorporated pilot lamp.

- Wait for the lighting of the control panel (6); this is

a touch screen panel, so to activate a function or to

move amoungst the pages it’s enough to touch the

screen with a finger on the corresponding text or pictures.

7

8

3

4

2

5

6

- Touch any point on the screen to enter the main

page

- In case of alarm signalling in progress, touch the

corresponding symbol with a finger to enter the

alarms page.

ENGLISH

SM446 -HS

April 201328

9-OPERATION

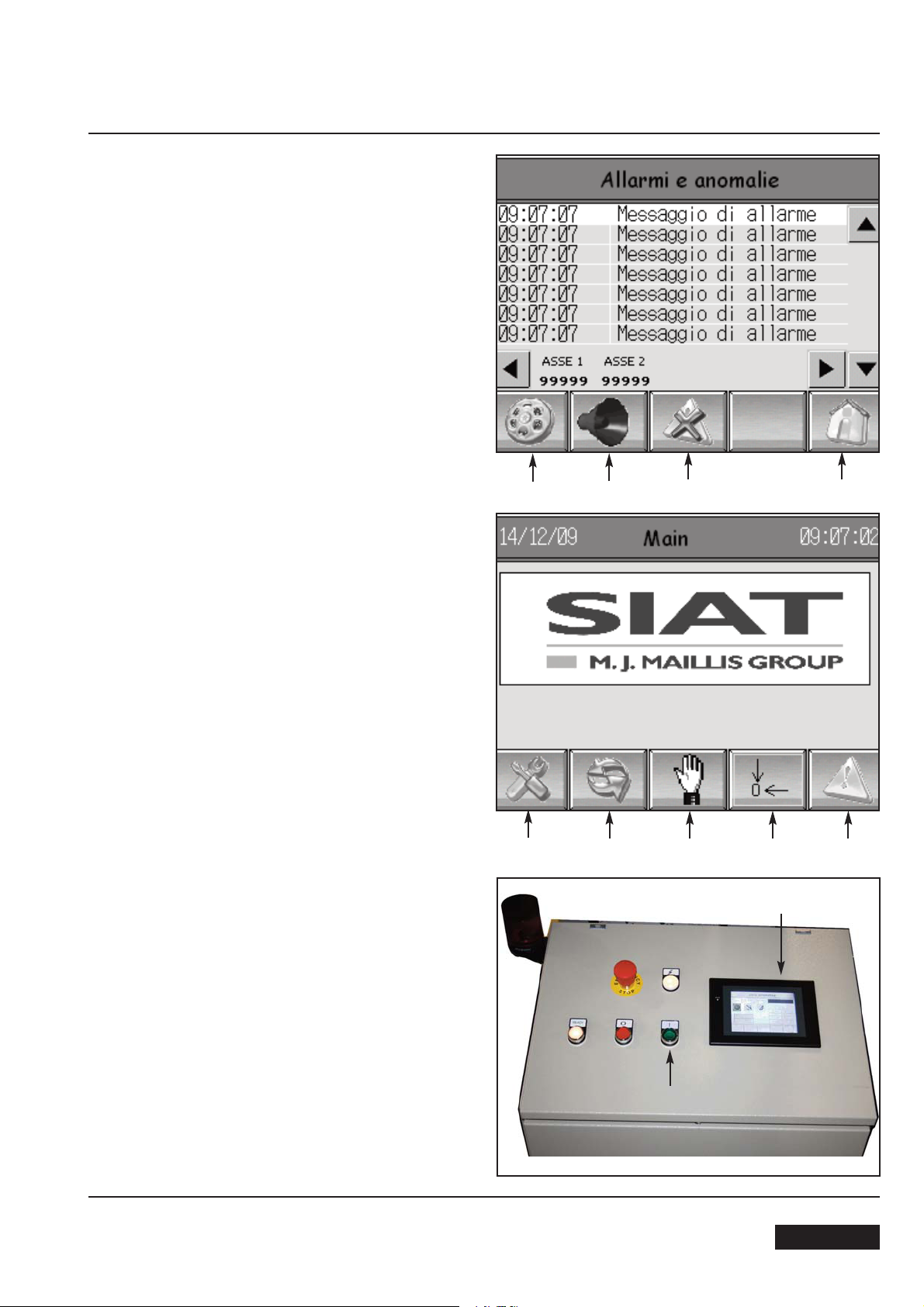

- Reset as necessary after intervention for the elimination

of the problem that caused the alarm signalling.

- Press B

A: Main page

B: Alarm reset

C: Reset acoustic signalling

D: Alarms log

Return to main menu mode (A).

E: Alarms page

F: Machine general reset

G: Page mode of manual machine axes drive

H: Page operation automatic cycle

I: Page of system settings and diagnostics

D

C

B A

SM446-HS

I

H

G

F

6

E

- Press F (reset)

- Press Start button (5), obtaining in this way the rollers

and the indexing unit belt start, the motorizations start

and the visualization of the operation automatic cycle

page (H) on the control board (6).

April 2013

29

5

ENGLISH

ENGLISH

September 201030

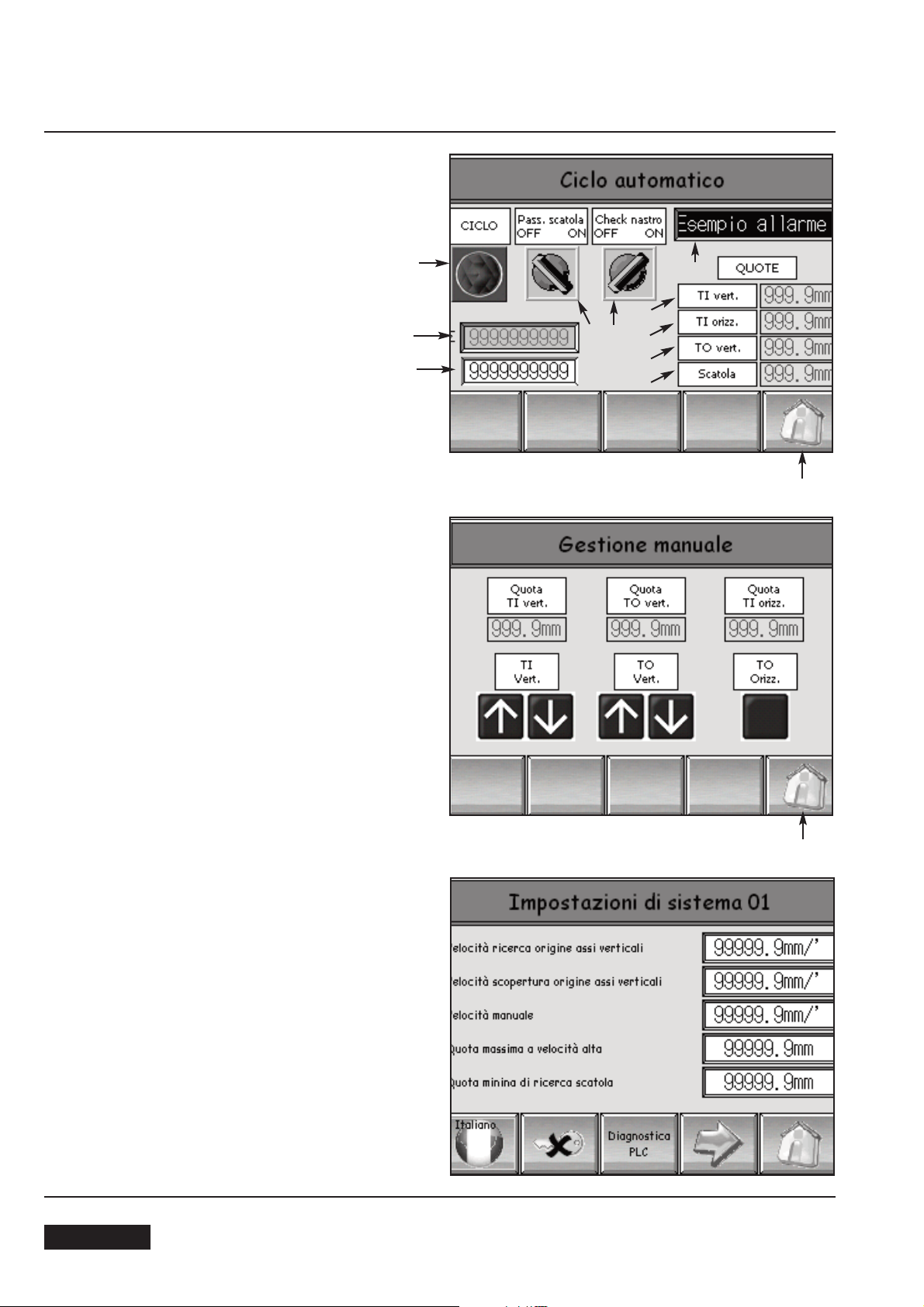

- Mode of page of operation automatic cycle

- In this condition the machine results ready for the starting of the sealing cycle as foreseen.

J- Box counter (total non resettable)

K: Box counter (partial resettable)

L: Indexing unit vertical axe (only visualization)

M: Indexing unit horizontal axe (only visualization)

N: Machine vertical axe (only visualization)

O: Box height (only visualization)

P: Sealing cycle on/off (lighting signalling)

Q: Box upper sealing on/off or “transit” without sealing removing also the top taping unit

R: Alarms signalling tape end/breakage on/off

S: Only visualization: tape end and full line

- Page mode of manual machine axes drive (G)

- Page of system settings and diagnostics (I)

Warning: Values are protected by passwords, in order to

avoid unauthorized changes that could to compromise the

regular machine operation.

Only the machine administrator or authorized personnel

of after sales service can enter the pages of machine management data.

A

J

K

L

M

N

O

P

Q

R

S

A

9-OPERATION

Loading...

Loading...