siat ProWrap 16_L_PW, ProWrap 16_M_FM, ProWrap 16_M_M, ProWrap 16_M_PW, ProWrap 16_H_FM Operation And Maintenance Manual

...

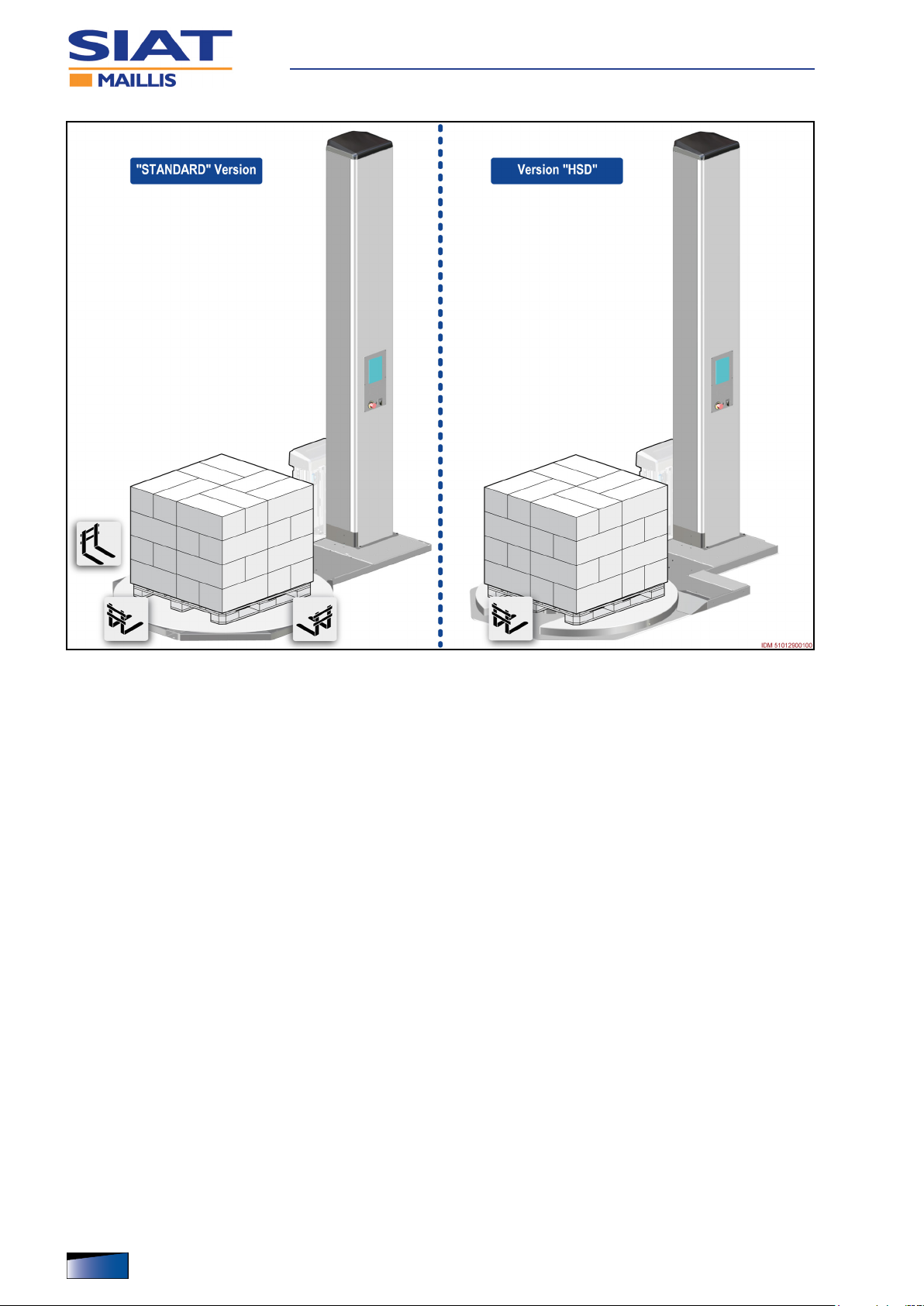

Semi-automatic pallet wrapper

ProWrap

Operation and maintenance

manual

Translation of the “ORIGINAL

INSTRUCTIONS”

Code SBC0035151 ed. 05-2018 - rev. 1

No part of this publication may be reproduced without the written consent of the Manufacturer. Pursuing a policy of continuous improvement, the Manufacturer reserves the right to change this

document without notice, provided that such changes do not create risks to safety.

Summary

Safety information

Purpose of the manual ............................................................................................................ 3

Glossary of the terms .............................................................................................................. 3

Attached documentation ......................................................................................................... 4

General safety warnings ......................................................................................................... 5

Safety Warnings for Handling and Installation ........................................................................ 5

Safety Warnings for Operation and Use.................................................................................. 6

Safety Manager Obligations ................................................................................................ 7

Safety Warnings on Misuse..................................................................................................... 7

Safety Warnings on Residual Risks ........................................................................................ 8

Safety Warnings for Maintenance and Adjustments................................................................ 8

Safety warnings for the electrical equipment .......................................................................... 9

Safety warnings for the environmental impact ...................................................................... 10

Safety and information symbols .............................................................................................11

Technical Specications

general description of the machine ....................................................................................... 13

Description of the main components ..................................................................................... 15

Manufacturer and machine identication .............................................................................. 16

Cycle ..................................................................................................................................... 17

Types of wrapping ................................................................................................................. 18

Residual risks ........................................................................................................................ 19

Incorrect uses that are reasonably expected ........................................................................ 20

Optional Accessories ............................................................................................................. 20

Description of the safety devices .......................................................................................... 21

Technical data of machine ..................................................................................................... 22

Dimensions and weights (Standard version) ..................................................................... 22

Dimensions and weights (version HSD) ............................................................................ 23

Technical specications ..................................................................................................... 23

Technical specications of pressing roller.......................................................................... 23

Specications of the accessories available on request ..................................................... 24

Technical data of reel ............................................................................................................ 24

Dimensions of lm reel ...................................................................................................... 24

Net reel dimensions ........................................................................................................... 24

Description of outer areas ..................................................................................................... 25

Safety and information symbols ............................................................................................ 26

IDM 510-128-1_Sommario

Maintenance

Recommendations for maintenance interventions ................................................................ 27

Scheduled maintenance intervals ......................................................................................... 28

Diagram of the points of lubrication ....................................................................................... 29

Problems, causes, remedies ................................................................................................. 30

Alarm message table ............................................................................................................ 32

Cleaning and replacement of the air lter ............................................................................. 34

Adjustment of chain controlling the rotation of platform ........................................................ 35

Sensitivity adjustment for the product to be wrapped detection photocell ............................ 37

Replacing the rotating platform wheels (standard version) ................................................... 38

Replacing the rotating platform wheels (version HSD) ......................................................... 39

Replacing the lifting belt of the carriage ................................................................................ 41

Pressing roller

Description of the main components of the Pressing Roller ................................................. 44

Disassembly and re-assembly of the Pressing Roller ........................................................... 45

Re-assembly of the Pressing Roller .................................................................................. 46

Reel holding carriage (M)

Reel holding carriage (M) ...................................................................................................... 47

Main components .............................................................................................................. 47

Film Coil Feeding ............................................................................................................... 48

English languageOperation and maintenance manual

1

Tension adjustment of lm ................................................................................................. 49

Cleaning and replacement of brake disc ........................................................................... 50

Replacing the outer surface of roller .................................................................................. 51

Reel holding carriage (FM)

Reel holding carriage (FM) .................................................................................................... 52

Main components .............................................................................................................. 52

Film Coil Feeding ............................................................................................................... 53

Cleaning and replacement of brake disc ........................................................................... 54

Adjustment of brake ........................................................................................................... 55

Replacing the outer surface of roller .................................................................................. 56

Reel holding carriage (PW)

Reel holding carriage (PW) ................................................................................................... 57

Main components .............................................................................................................. 57

Film Coil Feeding ............................................................................................................... 58

Adjustment of drive chain tensioning ................................................................................. 59

Pre-stretch percentage variation (lm pre-stretch kit ) ....................................................... 60

Disassembly and re-assembly of the reel holding carriage ............................................... 62

Control system

Recommendations on Operation and Use ............................................................................ 63

Control description ................................................................................................................ 64

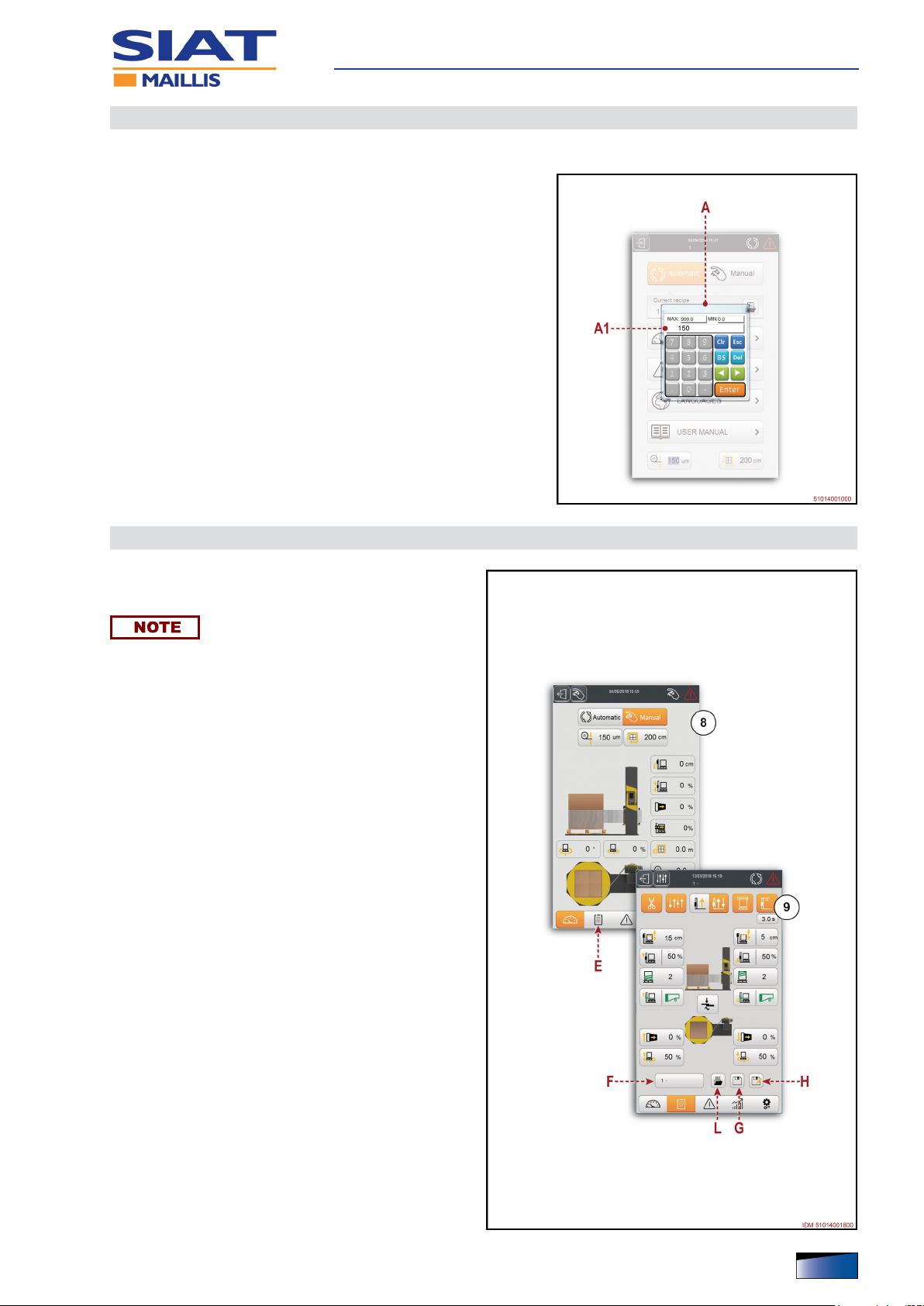

Description of the operator interface ..................................................................................... 65

Operator interface navigation diagram (standard) ................................................................ 66

Operator interface navigation diagram (advanced) ............................................................... 68

Description of a typical screen .............................................................................................. 70

Description of the keyboard .................................................................................................. 70

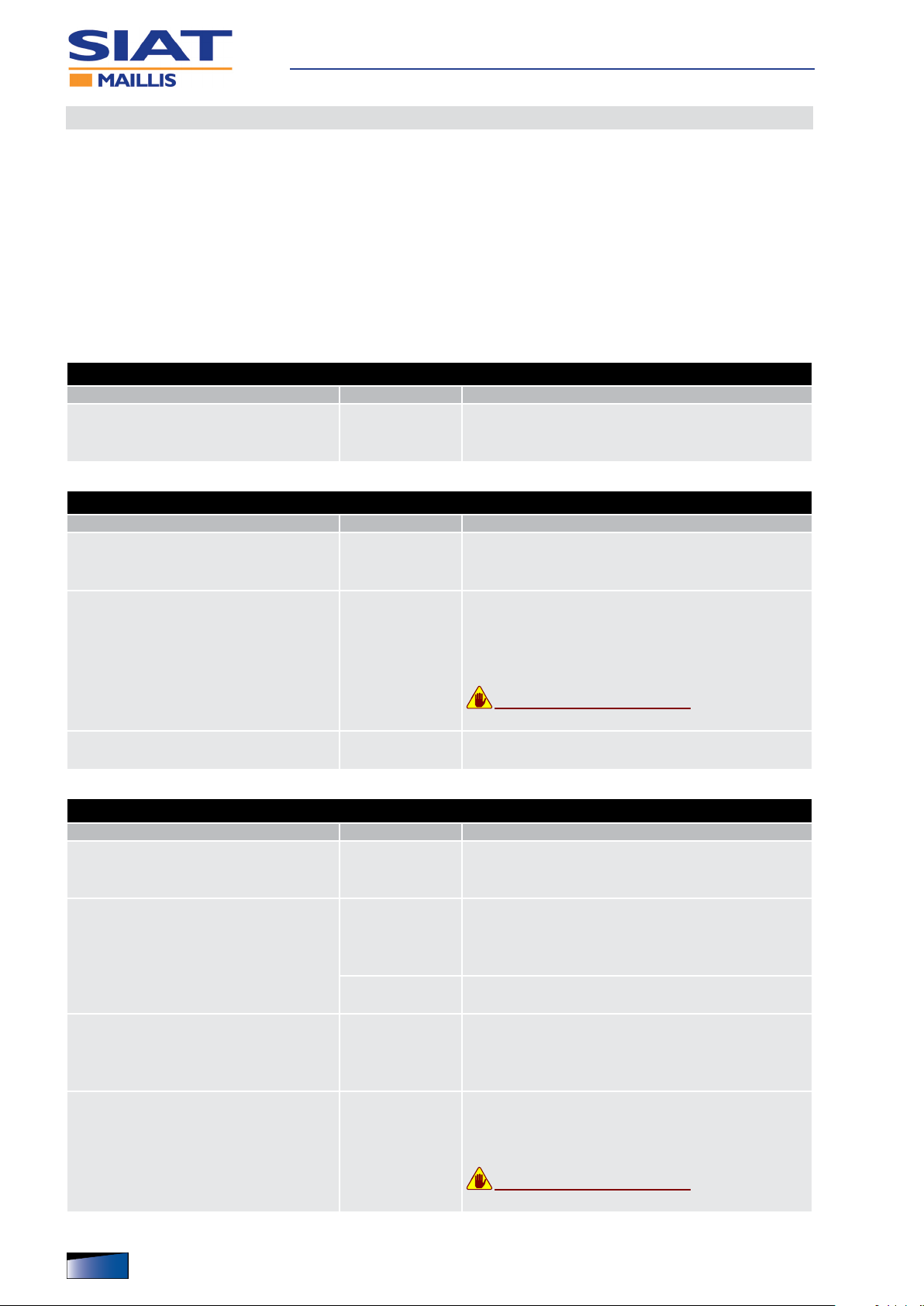

Function description of the displayed icons .......................................................................... 71

Programming icons (shaded gray background) ................................................................. 71

Display icons (gray background) ....................................................................................... 73

Non-release hold keys (shaded gray background) ............................................................ 74

Single-action keys (orange or shaded gray) ...................................................................... 74

Language selection mode ..................................................................................................... 76

Password entering mode ...................................................................................................... 76

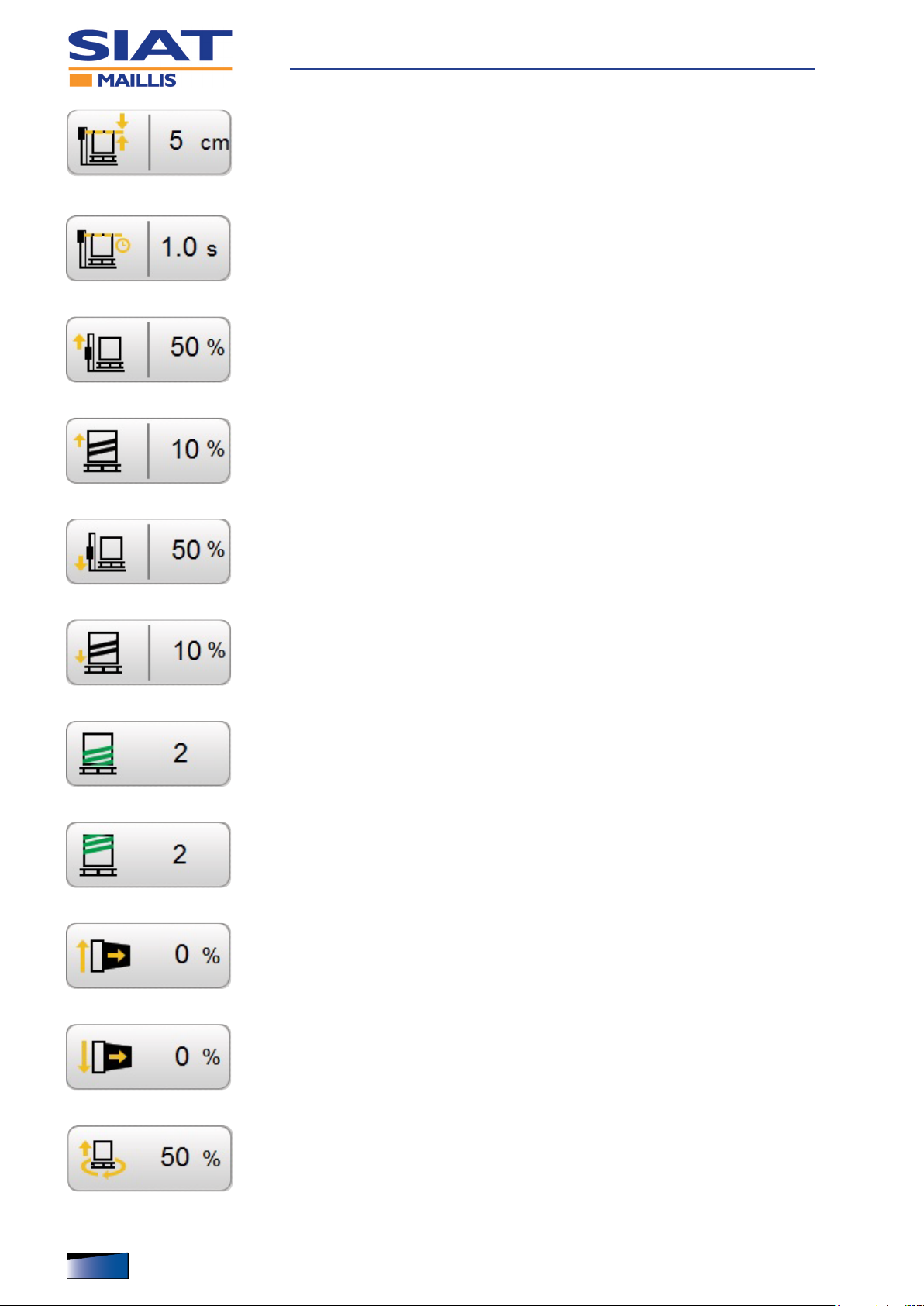

How to programme or edit the parameters ........................................................................... 77

Recipe management ............................................................................................................. 77

How to programme a new recipe ....................................................................................... 77

Modifying a recipe .............................................................................................................. 78

How to load a recipe in the PLC ........................................................................................ 79

How to programme the bands and the wrapping reinforcements ......................................... 80

How to display the wrapping statistics .................................................................................. 84

How to display the Setup parameters ................................................................................... 86

Manual wrapping ................................................................................................................... 88

Normal stop ....................................................................................................................... 89

(Single or double) automatic wrapping .................................................................................. 90

Normal stop ....................................................................................................................... 91

(Single or double) automatic wrapping with sheet feeder ..................................................... 92

Normal stop ....................................................................................................................... 93

Stop in alarm conditions and restart ...................................................................................... 94

Emergency stop and new start-up ........................................................................................ 95

Use of the weighing unit (optional) ........................................................................................ 96

Calculation of lm pre-stretch ................................................................................................ 97

Calculation of lm tensioning ................................................................................................ 98

1Disposal and scrapping

Machine Disposal and Scrapping .......................................................................................... 99

Analytical index ................................................................................................................... 101

2

English language Operation and maintenance manual

IDM 510-128-1_Sommario

Purpose of the manual

– The purpose of the manual is to inform and train operators so that they can inter-

act with the machine in SAFE CONDITIONS.

– Its aim is also to prevent risks, to reduce the social costs resulting from accidents

and damage to the health of people, property and to the environment.

– In some cases, accidents may be due to the Operator using the machine

carelessly.

– Caution is always necessary. Safety is also the responsibility of all the per-

sons interacting with the machine throughout its operating life.

– Remember that it is too late to think about safety issues when the accident

has already occurred.

– It is important to dedicate enough time to read the “Instruction Manual” in

order to minimise the risks and to avoid any unpleasant accidents.

– The content of this manual was originally edited by the Manufacturer in the moth-

er tongue (ITALIAN), in compliance with the professional writing standards and

the regulations in force.

Safety information

– Any translation of the manuals shall be carried out directly and without alterations

from the texts of the ORIGINAL INSTRUCTIONS.

– This applies also to the translations carried out by the agent or by the person who

is in charge of delivering the equipment in the specic linguistic area.

– The Manufacturer reserves the right to update the documentation, should this

prove necessary.

– All information supplied by the recipients represents an important contribution to

the improvement of the after-sales service that the manufacturer will offer to his/

her customers.

– All supplied information is organised into an index and a table of contents, so as

to easily track specic topics of interest.

– The SAFETY WARNINGS and the INSTALLATION MANUAL are supplied as

hard-copy publications.

– The USE AND MAINTENANCE MANUAL, operation diagrams and all other

post-sale documents can be downloaded from the INTERNET.

– Keep the manual and the attached documents in a place known and easily trace-

able, so that you may refer to them whenever necessary.

Glossary of the terms

The glossary includes some terms used when processing information, with

their denition, in order to facilitate understanding.

IDM 510-004-5

– Training: A process aiming at transferring the knowledge, skills and behaviours

required to work in an autonomous, correct and hazard-free manner.

– Assistant: person chosen, trained and coordinated in an appropriate manner to

minimize the risks in carrying out their tasks.

– Emergency stop: voluntary activation of the special control that stops the dan-

gerous elements of the work unit in the case of imminent risk.

– Stop in alarm conditions: this state causes the components to stop and is acti-

vated when the control system detects a problem in the machine operation.

– General shut down: In addition to the normal stop this state also causes the in-

terruption of all the power sources (electrical, pneumatic, etc.).

English languageOperation and maintenance manual

3

– Operating Stop: state that does not cut off power supply to the actuators, but

ensures control system monitoring in safe conditions.

– Size change: a set of interventions to be carried out before beginning to work

with specications different with respect to the ones previously in use.

– Test-run: a series of operations required to ensure compliance to the design

specications, and to commission the machine under safety conditions.

– Installer: a technician chosen and authorized by the manufacturer or his author-

ized representative, among those who full the requirements for installation and

testing of the machine or plant in question.

– Maintenance Operator: a technician chosen and authorized, among those who

full the requirements, to carry out routine and extraordinary maintenance operations on the machine. Therefore, the maintenance operator shall possess precise

knowledge and skills, with particular skills in the relevant eld.

– Routine Maintenance: all the operations necessary to maintain the functionality

and efciency of the machine. Normally, these operations are scheduled by the

manufacturer, who denes the necessary skills and methods of action.

– Operator: a person chosen and authorized, among those who full the require-

ments, having the knowledge and skills necessary to operate the machine and

carry out routine maintenance interventions.

Safety information

– Production Manager: technician with expertise and knowledge on the use of

packaging machines and similar equipment, who is authorised to supervise the

production activity.

– Person in charge of the installation: a technical expert who must carry out the

installation in compliance with the laws applicable to the workplace and, at the

end, assess its compliance.

– Residual risks: all the risks remain even if all the safety solutions have been

adopted and integrated when the machine has been designed.

– Expert Technician: A person authorised by the Manufacturer and/or his represent-

ative to carry out services that require specic technical skills and abilities.

– Forwarder and Handler: Authorized persons with recognized expertise in the

use of means of transport and lifting devices, in safety conditions.

– Foreseeable improper use: reasonably foreseeable use other than that recom-

mended in the instruction manual, which may result from human behaviour.

Attached documentation

The SAFETY WARNINGS and the INSTALLATION MANUAL are supplied as

hard-copy publications.

– The USE AND MAINTENANCE MANUAL, operation diagrams and all other post-

sale documents can be downloaded from the INTERNET.

– The list shows the documentation supplied with the machine.

– CE Declaration of conformity

– Operation and maintenance manual

– Installation manual

– Wiring diagrams

– Pneumatic system diagrams

– Specic Manuals for installed components or sub-assemblies available commer-

cially

IDM 510-004-5

4

English language Operation and maintenance manual

General safety warnings

– The machine has been designed and built with all the precautionary measures

aimed at minimising the possible risks over its expected life cycle.

– Tampering with and bypassing the safety devices may lead to severe risks for the

Operators.

– Before interacting with the machine, and in particular, before its rst use, read the

SAFETY WARNINGS contained in the manual.

– Spend some of your time reading this information to avoid any risk for people’s

health and safety as well as economic damage.

– Respect the SAFETY WARNINGS. Avoid any IMPROPER USE of the machine

and assess the RESIDUAL RISKS.

– When operating the machine, DO NOT wear clothes and/or accessories that

could become caught in the moving or protruding parts.

– Before machine use and/or maintenance, read the information contained in the

reference documents and accurately implement the described procedures.

– Carry out the interventions ONLY according to the modes recommended by the

Manufacturer in the “Instructions for use”.

Safety information

– The personnel in charge of carrying out interventions on the machine must have

suitable and proven experience in this specic eld.

– Please keep safety signs and information legible and follow the instructions.

– The information signals may be of different shapes and colours, to indicate dan-

gers, obligations, prohibitions and indications.

– Signals which are no longer legible must be replaced and repositioned in the

same place of origin.

– The non-compliance with the information provided herein may lead to risks

for the safety and health of the persons involved and may also lead to economic damages.

Safety Warnings for Handling and Installation

– The manufacturer has attached special attention to the packaging of the ma-

chine, to minimise the risks associated with the shipping, handling and transport

phases.

– The personnel authorised to handle the machine (loading and unloading) must

have acknowledged technical skills and professional ability.

– Before handling, please read the instructions, in particular those on safety, con-

tained in the installation manual, on the packages and/or on the removed parts.

IDM 510-004-5

– In order to make transport easier, the equipment can be shipped with a few dis-

assembled and properly protected and packaged components.

– Loading and transport must be carried out with equipment of adequate capacity

by anchoring it to specic points indicated on the packages.

– DO NOT attempt to by-pass the instructions concerning the lifting requirements

and special points provided for lifting and handling each item and/or disassembled part.

– Slowly lift the pack to the minimum necessary height and move it very carefully in

order to avoid dangerous vibrations.

English languageOperation and maintenance manual

5

– The packs being shipped must be properly fastened to the means of transport in

order to ensure safe conditions during transfer and the integrity of their contents.

– During some handling phases, the support of one or more operators may be re-

quired; these operators must be trained and informed about the tasks assigned

to them.

– Download packages in the immediate vicinity of the machine setting, which must

be sheltered from bad weather.

– Do not stack the packs onto each other in order to avoid any damage and to avoid

the risk of sudden and dangerous movements.

– In case of prolonged storage, regularly check that the component stocking condi-

tions do not change.

– The installation area is to be prepared so as to be able to carry out the operations

as specied in the manuals and in conditions of safety.

– Ensure that the installation environment is protected against atmospheric agents,

free of corrosive substances and free of any risk of explosion and/or re.

– Signal and delimit the installation area in a proper way in order to prevent non

authorised personnel from accessing the installation area.

Safety information

– The connections to the power sources (electric, pneumatic, etc.) must be per-

formed correctly, as shown in the diagrams and in compliance with the regulatory

and legal requirements in force.

– ONLY qualied and experienced personnel are allowed to carry out the electrical

connections.

– After completing the connections, perform a general check to ensure that all the

interventions have been carried out properly and that the requirements have

been met.

– The installation manager, before commissioning, must check that all the safety

devices are properly installed and functioning.

– At the end of operations check that there are no other tools or other material near

the moving parts or in dangerous areas.

– Dispose of all packing in accordance with the laws in force in the country of instal-

lation.

– The non-compliance with the information provided herein may lead to risks

for the safety and health of the persons involved and may also lead to economic damages.

Safety Warnings for Operation and Use

– The machine must be used by one single operator ONLY, who must be trained

and capable of performing the work and be in suitable conditions.

– Consult the user manual, in particular during the rst use, and make sure that you

fully understand its content.

– Find out the position and function of the controls and simulate some operations

(in particular start and stop) in order to acquire familiarity.

– The machine shall be used ONLY for the purposes and complying with the proce-

dures specied by the Manufacturer.

– Make sure that all the safety devices are properly installed and efcient.

– The machine should be used ONLY with the original safety devices installed by

the Manufacturer.

6

English language Operation and maintenance manual

IDM 510-004-5

Safety information

– Ensure the area around the machine, especially the control post, is ALWAYS

unobstructed and in good condition to minimize the risks for the Operator.

– According to the type of operation to carry out, wear the Personal Protective

Equipment listed in the “Instructions for use” and that indicated by the Labour

laws.

– The non-compliance with the information provided herein may lead to risks

for the safety and health of the persons involved and may also lead to economic damages.

Safety Manager Obligations

▀

– The safety manager must train the operator and help him or her familiarise and

interact with the machine in an independent, adequate and risk-free manner.

– The operator must be informed about the PROPER USE of the machine and

about the remaining RESIDUAL RISKS.

– The operator must demonstrate that he has acquired the relevant skills and has

understood the “User Instructions” in such a way as to carry out his activities

safely.

– The operator must be able to recognise the safety signals and demonstrate that

he is in suitable condition to carry out his assigned duties.

– The safety manager must release educational material to trainees and document

the delivered training, so as to be able to produce such documentation in case of

litigation.

IDM 510-004-5

Safety Warnings on Misuse

– ONLY trained, documented and authorized Operators are allowed to use the ma-

chine.

– DO NOT use or allow other persons to use the machine if the safety devices are

faulty, disabled and/or incorrectly installed.

– DO NOT use or allow other persons to use the machine for purposes and in ways

different from what specied by the Manufacturer.

– DO NOT use the machine in home environments.

– DO NOT wear clothes and/or accessories that could become caught in the mov-

ing or protruding parts.

– When operating the machine, ALWAYS wear the Personal Protective Equipment

specied by the Manufacturer and by the current regulations on safety at work.

– If troubles arise, do NOT continue to use the machine. Stop it immediately and

restart only after restoring the normal operating condition.

– DO NOT use the machine if the scheduled routine maintenance interventions

have not been carried out.

– DO NOT tamper with, override, bypass or eliminate the safety devices installed

on the machine.

– DO NOT modify the manufacturing and functional characteristics of the machine

in any manner whatsoever.

– DO NOT perform any interventions other than those specied in the Operation

Manual without the explicit authorization of the Manufacturer.

– DO NOT carry out any intervention when the machine is being operated. Stop the

machine and put it in safety condition before carrying out any intervention.

– DO NOT clean or wash the machine with water, steam or aggressive products

that might irreversibly damage the components.

English languageOperation and maintenance manual

7

– DO NOT replace the components with non-genuine spare parts or other compo-

nents with different design and manufacturing specications.

– DO NOT dump in the environment any materials, polluting liquids and mainte-

nance waste generated during the operations. Dispose of them according to the

regulations in force.

– DO NOT leave the machine unattended during operation and DO NOT leave it at

the end of the work without stopping it to safety conditions.

– The non-compliance with the information provided herein may lead to risks

for the safety and health of the persons involved and may also lead to economic damages.

Safety Warnings on Residual Risks

Residual risks: all the risks remain even if all the safety solutions have been

adopted and integrated when the machine has been designed.

– Upon designing and building the machine, the Manufacturer has paid particular

attention to the RESIDUAL RISKS that may affect the safety and health of the

Operators.

Safety information

– For specic information about residual risks, please refer to the machine user

manual.

Safety Warnings for Maintenance and Adjustments

– Always keep the machine in optimum operating condition and carry out the rou-

tine maintenance according to the intervals and procedures specied by the Manufacturer.

– A good maintenance will ensure a stable performance over time, longer

working life and constant compliance with the safety requirements.

– The personnel authorized to carry out the ordinary maintenance must have qual-

ied expertise and specic skills in the eld of intervention.

– Any work on the electrical system must ONLY be performed by technicians with

acknowledged, eld-specic skills.

– Mark the intervention area and prevent access to the devices that, if activated,

may cause unexpected hazards and jeopardize the safety level.

– According to the type of operation to carry out, wear the Personal Protective

Equipment listed in the “Instructions for use” and that indicated by the Labour

laws.

– Respect the SAFETY WARNINGS. Avoid any IMPROPER USE of the machine

and assess the RESIDUAL RISKS.

– Before carrying out any intervention, activate all the safety measures, and assess

any residual energy which may still be present.

– Carry out the operations in areas which are difcult to access or hazardous ONLY

after disconnecting all power sources.

This operating mode is necessary in order to work under safe conditions.

– Carry out the operations according to the procedures and modes shown by the

Manufacturer in the “Instruction Manual”.

– All operations must be carried out ONLY with suitable tools which shall be in good

condition, in order to avoid damaging any components and parts of the machine.

– Replace the components and/or safety devices ONLY with original spare parts in

order not to alter the required safety level.

IDM 510-004-5

8

English language Operation and maintenance manual

Safety information

– The use of similar but not genuine spare parts can lead to non-compliant repairs,

impaired performance and economic damage.

– Use the lubricants (oils and greases) recommended by the Manufacturer or lubri-

cants of equivalent chemical and physical characteristics.

– At work completion, restore all the security conditions aimed to prevent and min-

imize the risks during the human-machine interaction.

– At the end of operations check that there are no other tools or other material near

the moving parts or in dangerous areas.

– Refer to the Technical Assistance Service of the Manufacturer, in case interven-

tions not described in the “Instructions for use” are needed.

– All EXTRAORDINARY MAINTENANCE interventions shall be performed only by

authorized Technicians with proven and gained experience in the eld.

– Some operations may require the use of support devices and/or equipment that

shall be used properly in order to avoid any safety risks.

– The non-compliance with the information provided herein may lead to risks

for the safety and health of the persons involved and may also lead to economic damages.

Safety warnings for the electrical equipment

The electrical equipment has been built in accordance with the applicable

standards and its efciency is ensured if the listed conditions are met.

– Ambient temperature and relative humidity between maximum and minimum per-

mitted limits.

– Absence of environmental electromagnetic noise and radiation (X-rays, laser,

etc.).

– Absence of environment areas with gas and dust concentration levels potentially

explosive and/or at risk of re.

– Use of products and materials free from contaminants and corrosive agents.

Products containing chemicals, acids, salts, etc. can come into contact with the

electrical components and cause irreversible damage.

– Transport and storage temperatures between minimum and maximum permitted

limits.

– Altitude not exceeding the maximum permitted limits.

Do not carry out the installation under conditions that are different from those allowed.

– Power Cable with section suitable for the current power and intensity values indi-

cated in the data plate.

IDM 510-004-5

– Protection class in accordance with data plate indications.

– The power supply line to which the machine must be connected must have iden-

tical characteristics to those mentioned in the data plate.

Important

All the listed requirement values are contained in the technical specications

table.

– If one or more of the listed requirements cannot be met, alternative solu-

tions should be agreed at the ordering stage.

English languageOperation and maintenance manual

9

Safety warnings for the environmental impact

Each organization is responsible for implementing procedures aimed at identifying, evaluating and controlling the environmental impact of its own activities (products, services, etc.).

– Procedures for identifying signicant environmental impact must take account of

the factors listed.

- Discharges for liquids and lubricants

- Waste disposal

- Soil contamination

– In order to minimize the environmental risks during the man-machine interaction

follow the recommended instructions.

- Dispose of all packing in accordance with the laws in force in the country of installation.

- Keep noise level to the minimum to reduce noise pollution.

- Select materials on the basis of their composition and provide for differentiated

disposal in accordance with the laws in force.

- Avoid dumping polluting materials and products in the environment (oils, greases, electrical and electronic apparatus etc.).

- All the components of Electrical and Electronic Apparatus contain dangerous

substances and are appropriately marked.

- Dispose of Electrical and Electronic Apparatus Waste properly, at authorised

collection centres, to avoid harmful and damaging effects.

- Incorrect disposal of dangerous waste is punishable with sanctions regulated by

the laws in force on the territory in question.

Safety information

– The non-compliance with the information provided herein may lead to risks

for the safety and health of the persons involved and may also lead to economic damages.

10

English language Operation and maintenance manual

IDM 510-004-5

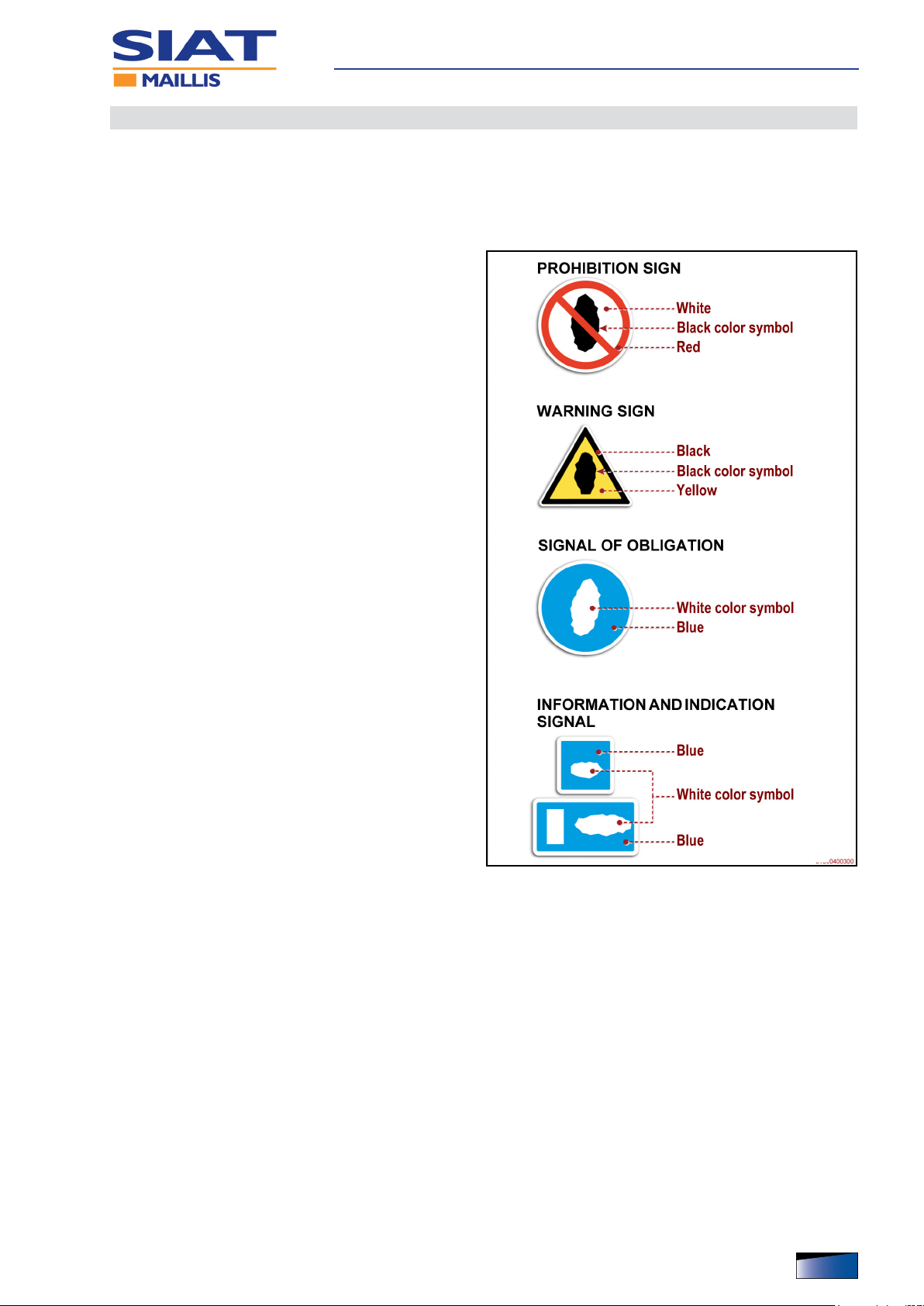

Safety and information symbols

– The information signals may be of different shapes and colours, to indicate dan-

gers, obligations, prohibitions and indications.

– The illustrations show the shapes of the signals that can be applied, with the

function indicated

– For more details on the type and position of the

signals applied, refer to the paragraph “Position

of safety signals and information”.

– Please keep safety signs and information legible

and follow the instructions.

– Signals which are no longer legible must be re-

placed and repositioned in the same place of origin.

Safety information

IDM 510-004-5

English languageOperation and maintenance manual

11

Safety information

12

English language Operation and maintenance manual

IDM 510-004-5

general description of the machine

Technical Specications

IDM 510-129-1

The semi-automatic wrapper series “ProWrap” is designed to secure products

loaded on pallets using stretch lm.

– To wrap loads, commercially available reels of stretch lm are used.

– The products to be wrapped must be contained in packages (cases, containers

for liquids, etc.) having a regular shape or in any case, such as to allow for stable

palletising.

– The containers of liquids or uids should be hermetically sealed and with suitable

characteristics to avoid spilling any content.

– The products to be wrapped have ALWAYS to be positioned in the middle and

must NOT protrude from the rotating platform in order to avoid the risk of collision.

– The wrapping surface shall be uniform and smooth (without projections or re-

cesses) in order to prevent the risk of lm breaking.

– The products are loaded and unloaded using forklift trucks of suitable capacity.

– Loading should ONLY be carried out from the orthogonal sides of the support

base (see gure).

– The machine has been designed, built and equipped by applying integrated safe-

ty principles.

– The machine is for professional use only and must be installed in industrial-type

settings - factories or workshops.

– The premises must have no areas with gas and dust concentration levels that are

potentially explosive and/or at risk of re.

English languageOperation and maintenance manual

13

Technical Specications

– On request, the machine may be equipped with accessories, either when it is

ordered or later.

See “Optional Accessories” for further details.

– The machine must be used by one single operator ONLY, who must be trained

and capable of performing the work and be in suitable conditions.

– The operator is in charge of programming and controlling the production cycle,

perform the relling and the scheduled maintenance.

IDM 510-129-1

14

English language Operation and maintenance manual

Technical Specications

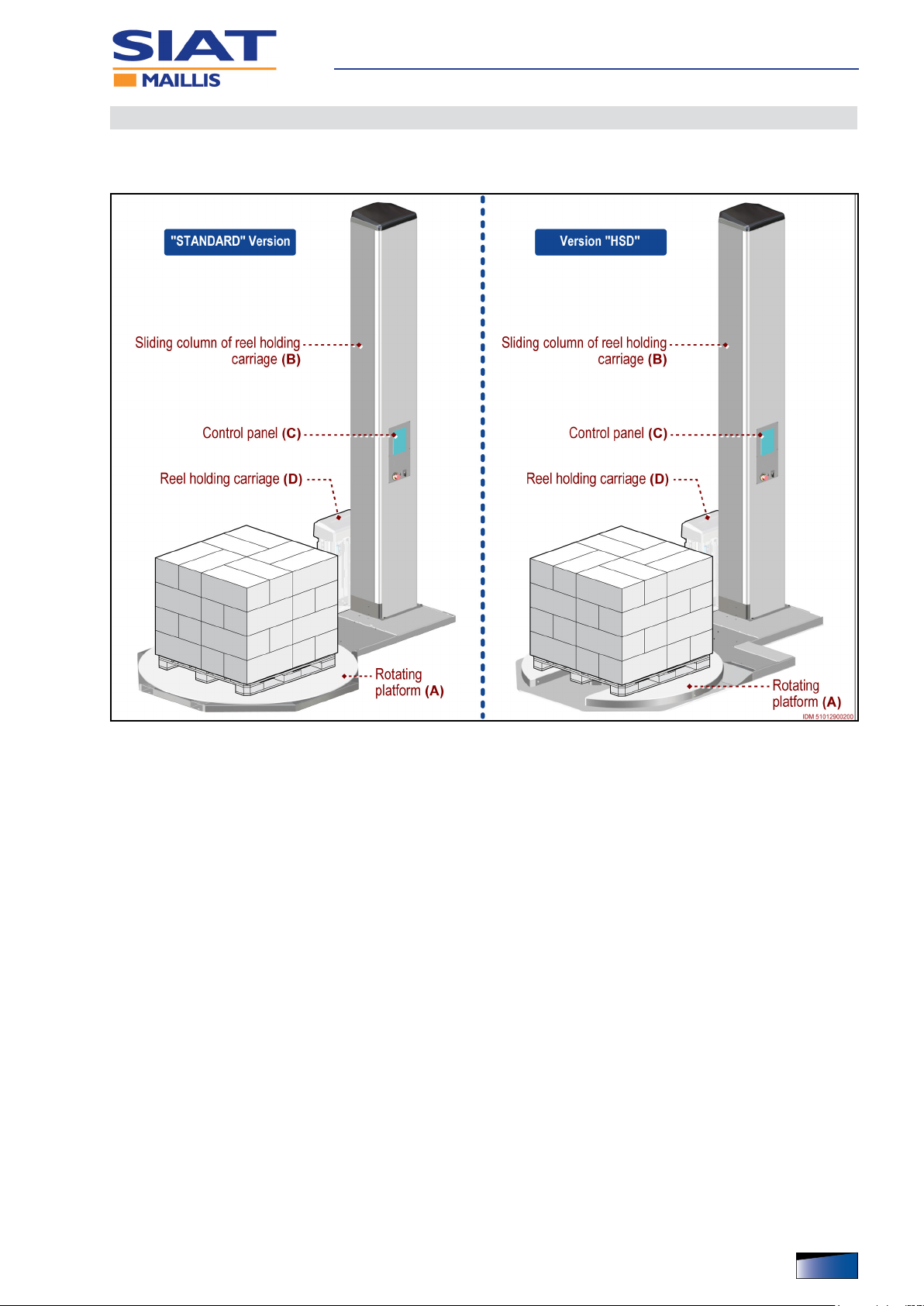

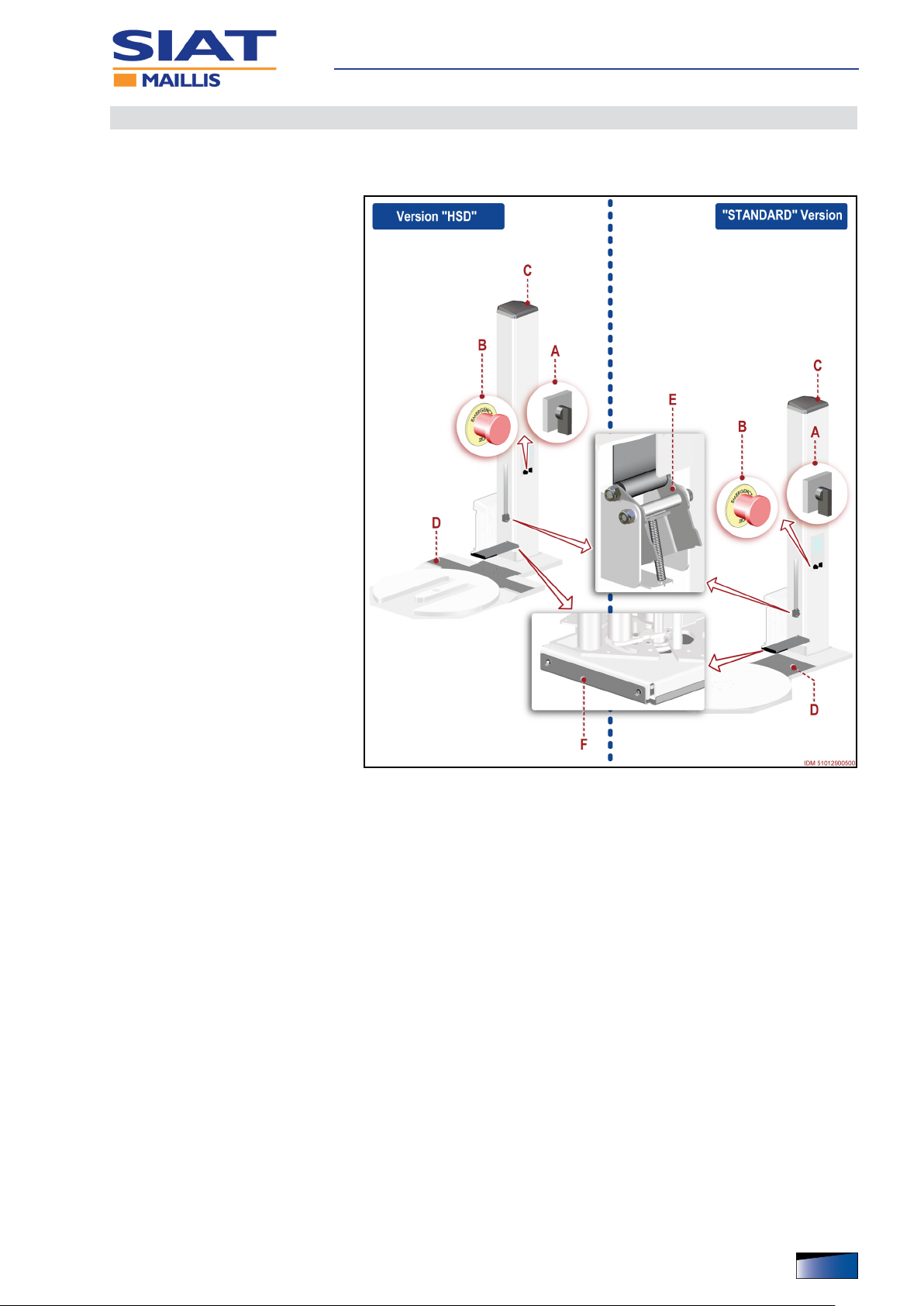

Description of the main components

The image shows the main components and the list reports their description

and function.

IDM 510-129-1

A) Rotating platform: area on which are loaded the products to be wrapped.

– The rotating platform is driven by a gear-motor with a chain drive.

B) Column: it is used for vertical movement of reel holding carriage D.

C) Control panel: it contains the devices to start and control all the operation func-

tions.

D) Reel holding carriage

– According to production requirements, in the ordering phase the machine can be

equipped with one of the listed carriages.

– Reel holder carriage (type M): suitable for wrapping, allows the operator to ad-

just the lm tension manually using the ring nut of the mechanical brake.

– Reel-holder carriage (type FM): suitable for wrapping, allows the operator to

adjust the lm tension from the control panel.

– Reel holding carriage (type PW): specic for wrapping with motorised lm

pre-stretching and transmission gear ratio adjustment (replacement of the pulleys).

English languageOperation and maintenance manual

15

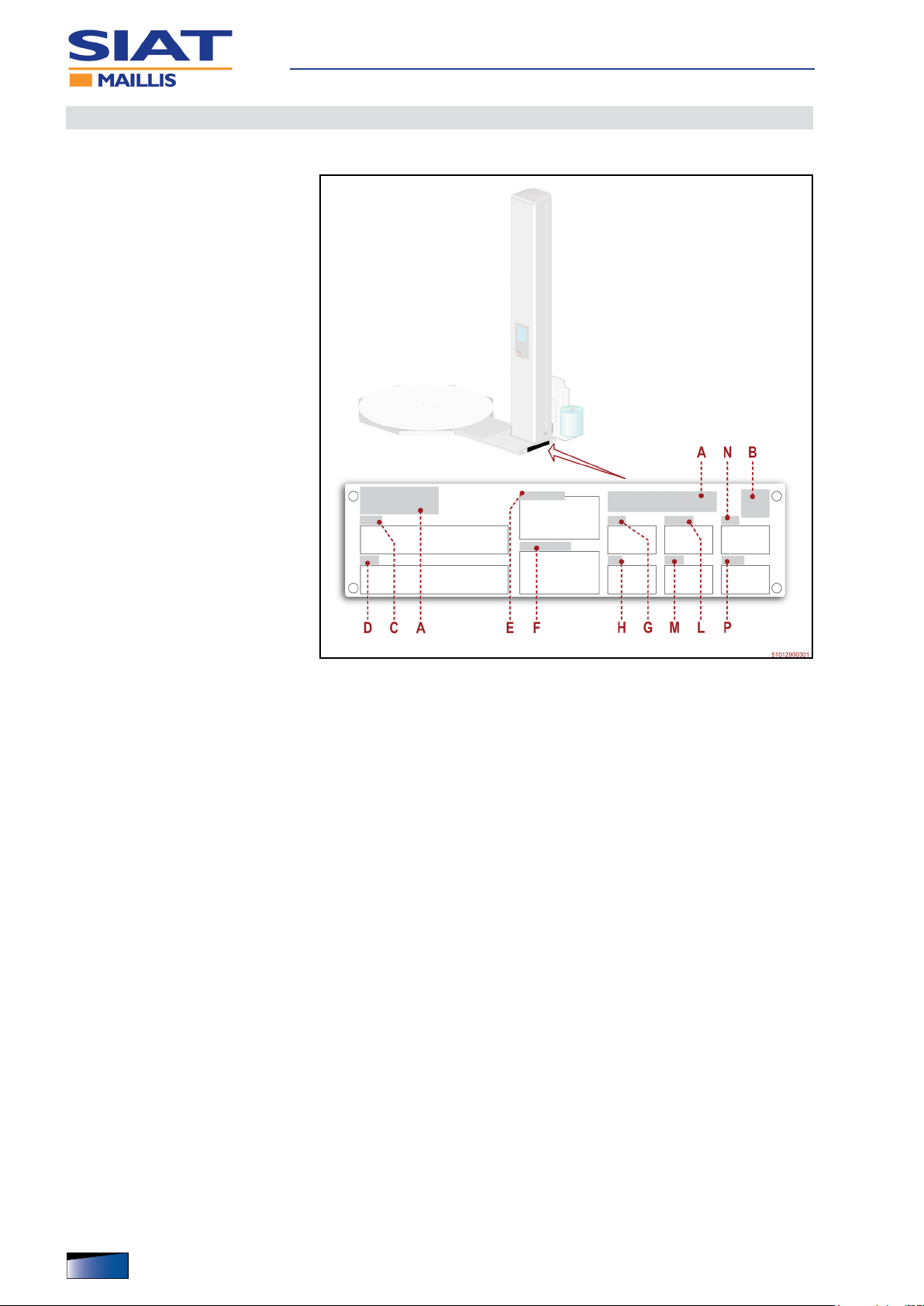

Manufacturer and machine identication

The identication plate (pictured) is afxed directly to the machine.

– In addition to the references for

identication provided by the

Manufacturer, they also list all

the essential information for a

safe operation.

A) Manufacturer identication

B) Space reserved for CE compli-

ance marking

C) Machine model

D) Machine type

E) Serial number

F) Serial number

G) Year of fabrication

Technical Specications

H) Power supply voltage

L) Electrical power consumption

M) Power supply frequency

N) Absorbed power

P) Power supply phases

16

English language Operation and maintenance manual

IDM 510-129-1

Technical Specications

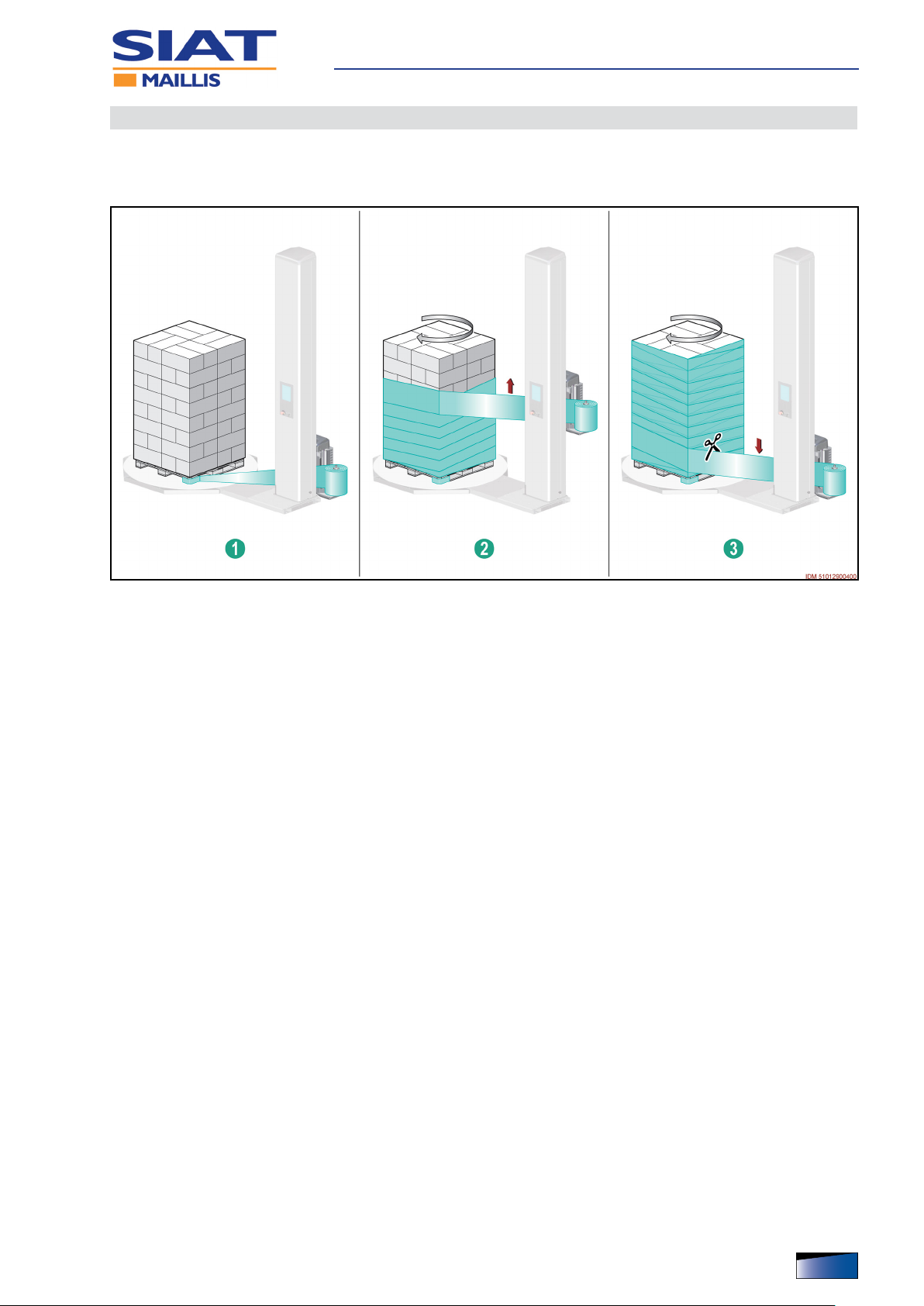

Cycle

The gure shows the operating cycle and indicates the main operating areas.

Stage Ê

– Correctly load the new product to be wrapped in the middle of rotating platform.

– Tie the trailing end of the lm to the base of the product to be wrapped.

Stage Ë

– Start the wrapping cycle that will be performed based on the previously set pa-

rameters.

– Manual wrapping: start the platform and keep the special control pressed to

start the wrapping process.

– Release control when wrapping has reached the desired height.

– Automatic wrapping: set up the desired parameters and press the special con-

trol to start the cycle.

– The machine carries out wrapping and at the end of the set-up cycle it stops au-

tomatically.

Stage Ì

– Manually cut the lm and cause it to adhere to the wrapped product.

– Remove the wrapped product to be able to load the next one to wrap.

– The machine is ready for a new wrapping cycle.

IDM 510-129-1

English languageOperation and maintenance manual

17

Technical Specications

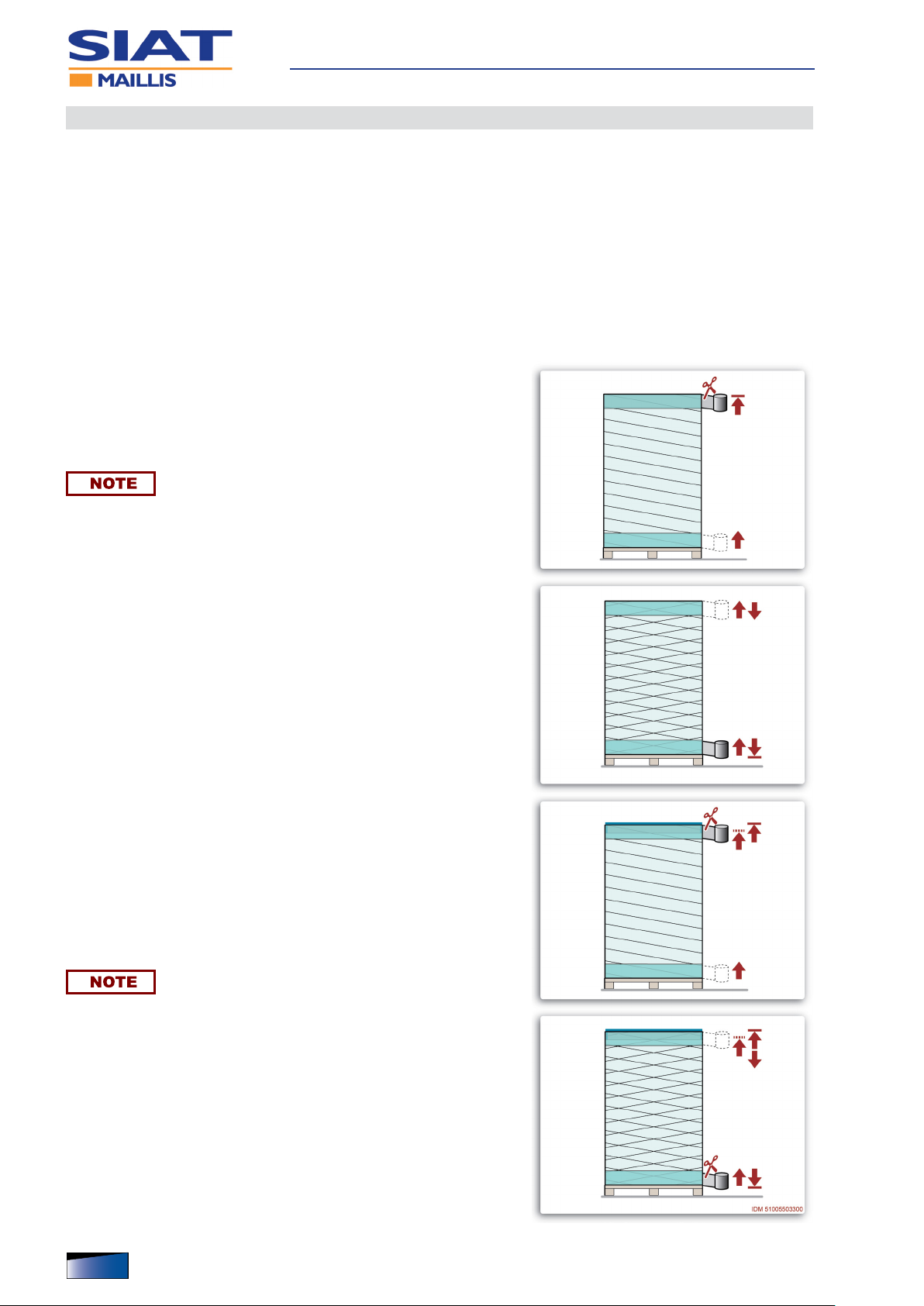

Types of wrapping

The wrapping can be made in manual or automatic mode.

– With the manual mode, platform rotates at a reduced speed, while reel holding

carriage is activated by a non-release control.

This mode allows for the wrapping to be made on an occasional basis, according

to the specications of the load to be wrapped (See “Control system.”).

– With the manual mode the wrapping can be programmed according to the spec-

ications of the load batch to be wrapped.

– The gures show the types of wrapping that can be programmed with the auto-

matic mode operation.

– Single wrapping: it starts at the base of the load to be wrapped

(with stabilisation wraps) and ends at the top of the load, after

completing the closing wrapping.

– Move the reel carriage to fully lowered position from the control

panel to start a new wrapping.

The operator can decide whether to cut the lm when the carriage is in the high position or in the low position.

– Double wrapping: it starts at the base of the load to be

wrapped (with stabilisation wraps) and ends at the top of the

load.

– After completing the reinforcement at the top of the load, the

wrapping continues downwards and stops after the closing

wrapping.

– Single wrapping with sheet feeder: it starts at the base of the

load to be wrapped (with stabilisation wraps) and stops temporarily at the top of the load.

– After inserting the covering sheet the operator must enable the

control to restart the wrapping.

– After completing the upper reinforcement, the wrapping stops.

– Move the reel carriage to fully lowered position from the control

panel to start a new wrapping.

The operator can decide whether to cut the lm when the carriage is in the high position or in the low position.

– Double wrapping with sheet feeder: it starts at the base of

the load to be wrapped (with stabilisation wraps) and stops

temporarily at the top of the load.

– After inserting the covering sheet the operator must enable the

control to restart the wrapping.

– After completing the reinforcement at the top of the load, the

wrapping continues downwards and stops after the closing

wrapping.

18

English language Operation and maintenance manual

IDM 510-129-1

Technical Specications

Residual risks

Residual risks are dened as: “Any risk that remains notwithstanding the safety

solutions adopted and integrated during the design phase”.

– Each residual risk is signalled with a special sign. Some of them are applied close

to the areas where the risk is present, others are placed in an easily visible position.

– The list includes the residual risks that may persist on this type of machine.

– Risk of projection of objects: during operation there may be a risk linked with

wrapping product stability characteristics in the event of excessive operation

speed.

– The operator must adjust the wrapping speed according to the product features

and during operation he/she shall not halt near the machine.

– Risk of slipping: do not climb onto or approach the platform during operation.

– Do not climb on the platform using the lifting equipment during operation.

– Risk of body part crushing: do not stand near and/or approach the area be-

tween the column and the product to be wrapped during operation.

– Risk of crushing upper limbs: do not introduce or place upper limbs in/next to

any machine moving parts during operation.

– Risk of crushing or shearing lower limbs: keep lower limbs away from the

platform during operation (fork inserting points version HSD).

– In addition to the precautions for the signalled risks, the following measures must

be implemented.

- Do NOT approach or allow people to approach the moving parts of the machine

in order to avoid dangerous collisions.

- When the lm is inserted, pay special attention in order to prevent collisions,

abrasion and crushing of the upper limbs.

IDM 510-129-1

English languageOperation and maintenance manual

19

Technical Specications

Incorrect uses that are reasonably expected

Improper use: reasonably foreseeable use different from what is specied in the

use manual, that may be caused by human behaviour.

– ONLY trained, documented and authorized Operators are allowed to use the ma-

chine.

– DO NOT use or allow other persons to use the machine for purposes and in ways

different from what specied by the Manufacturer.

– NEVER use the tool if the scheduled maintenance interventions have not been

carried out accordingly

– DO NOT use the machine in places that are at risk of re and / or explosion.

– When the products are wrapped, the radius of action of the machine must be kept

free from people.

– DO NOT carry out any intervention when the machine is being operated. Stop the

machine and put it in safety condition before carrying out any intervention.

– DO NOT clean or wash the machine using aggressive products that may damage

its components.

– DO NOT leave the machine unattended during operation and DO NOT leave it at

the end of the work without stopping it to safety conditions.

Optional Accessories

Some accessories designed to improve the performance and versatility of the

machine are available from the manufacturer. This list contains a description

of the main ones.

– Ramp: it makes product loading and unloading easier when a pallet truck driven

by a ground-level operator is used.

– Lifting frame: structure under the support base, used to load/unload the prod-

ucts to be wrapped by means of a “stackers”pallet truck.

– Burying frame: structure used to bury the support base of the machine.

– Weighing Unit: device used to weigh the palletised product located on the rotat-

ing platform.

– Pressing roller: this device keeps the product stabilised during wrapping.

20

English language Operation and maintenance manual

IDM 510-129-1

Technical Specications

Description of the safety devices

The machine is equipped with safety devices that reduce the risks during the

man-machine interaction.

A) Isolator switch: safety control

to disconnect electric power

supply.

B) Emergency stop button:

safety control that, in case of an

imminent risk, stops all parts

whose function might constitute

a risk.

For further details on devices

A-B, refer to paragraph “Description of the controls.”

C) Fixed guard: safety device

that prevents access to the

parts whose operation may be

dangerous.

– The device is secured and it

can be opened only by means

of tools.

– Guard can be removed only

when the machine is stopped

under safe conditions and must

be installed before starting it.

D) Fixed guard: safety device

that prevents access to the

parts whose operation may be

dangerous.

– The device is secured and it

can be opened only by means of tools.

– Guard can be removed only when the machine is stopped under safe conditions

and must be installed before starting it.

E) Fall arrest system: safety device that prevents the risk of a fall of the carriage in

the event of lifting strap breaking.

– System is equipped with a spring device that locks the reel holding carriage after

a fall of 10 mm.

F) Feeler: safety device that stops the descent of the reel holding carriage in the

presence of an obstacle.

IDM 510-129-1

English languageOperation and maintenance manual

21

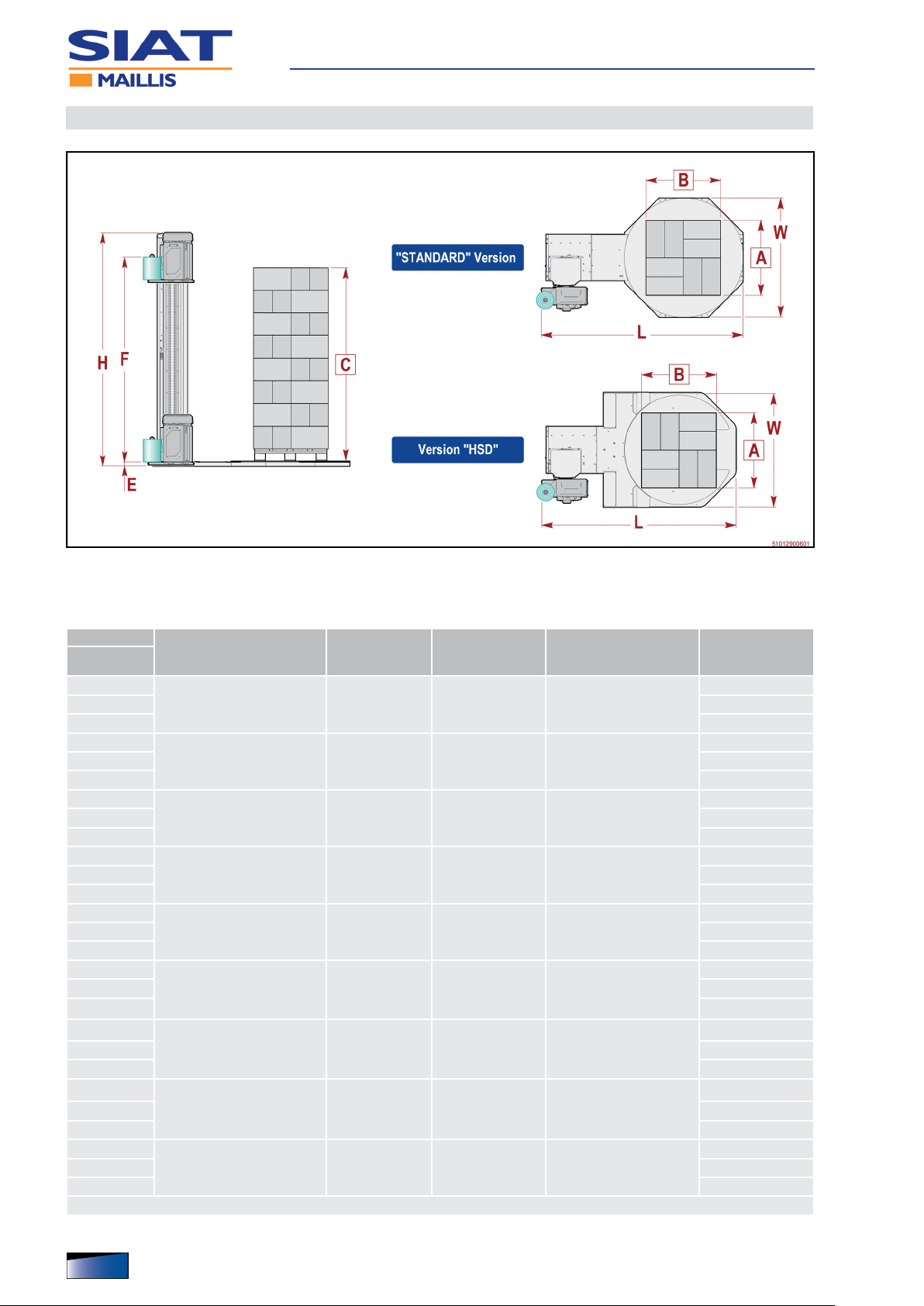

Technical data of machine

Technical Specications

Dimensions and weights (Standard version)

▀

ProWrap

Model

16_L_FM

16_L_M 526

16_L_PW 549

16_M_FM

16_M_M 541

16_M_PW 564

16_H_FM

16_H_M 545

16_H_PW 568

18_L_FM

18_L_M 552

18_L_PW 575

18_M_FM

18_M_M 567

18_M_PW 590

18_H_FM

18_H_M 571

18_H_PW 594

22_L_FM

22_L_M 660

22_L_PW 683

22_M_FM

22_M_M 675

22_M_PW 698

22_H_FM

22_H_M 679

22_H_PW 702

Size of the load to be

wrapped AxBxC (mm)

Min 600x600x700

Max 1000x1200x2200

Min 600x600x700

Max 1000x1200x2600

Min 600x600x700

Max 1000x1200x3000

Min 600x600x700

Max 1200x1200x2200

Min 600x600x700

Max 1200x1200x2600

Min 600x600x700

Max 1200x1200x3000

Min 600x600x700

Max 1500x1500x2200

Min 600x600x700

Max 1500x1500x2600

Min 600x600x700

Max 1500x1500x3000

Weight of the

load to be

wrapped (kg)

Diameter of the

platform (mm)

Dimensions of the

machine LxWxH (mm)

xx ÷ 2400 1650 2831x1650x2714

xx ÷ 2400 1650 2831x1650x3114

xx ÷ 2400 1650 2831x1650x3514

xx ÷ 2400 1800 2982x1800x2714

xx ÷ 2400 1800 2982x1800x3114

xx ÷ 2400 1800 2982x1800x3514

xx ÷ 2400 2200 3382x2200x2714

xx ÷ 2400 2200 3382x2200x3114

xx ÷ 2400 2200 3382x2200x3514

Max weight of the

machine (kg)

526

541

545

552

567

571

660

675

679

Height above ground of the platform 75 mm

IDM 510-129-1

22

English language Operation and maintenance manual

Dimensions and weights (version HSD)

▀

Technical Specications

ProWrap

Model

HS_L_FM

HS_L_M 718

HS_L_PW 741

HS_M_FM

HS_M_M 733

HS_M_PW 756

16_M_FM

16_M_M 737

16_M_PW 760

Maximum size of the load to

be wrapped AxBxC (mm)

Min 600x600x700

Max 800x1200x2200

Min 600x600x700

Max 800x1200x2600

Min 600x600x700

Max 800x1200x3000

Max weight of

the load to be

wrapped (kg)

Diameter of the

platform (mm)

Dimensions of the

machine LxWxH (mm)

xx ÷ 1200 1650 2874x1736x2732

xx ÷ 1200 1650 2874x1736x3132

xx ÷ 1200 1650 2874x1736x3532

Max weight of the

machine (kg)

718

733

737

Height above ground of the platform 83 mm

Technical specications

▀

Unit of

measurement

Value

OPERATING PROPERTIES

Height of wrapping start E mm 20 ÷ 120

Height of wrapping end F

- Model L mm 2400

- Model M mm 2800

- Model H mm 3200

Rotation speed of the platform rpm 6 ÷ 12

Maximum level of noise dB(A) 72.0

Electric supply

The power supply specications are those shown in the identication plate

applied to the machine.

- -

- With single-phase power supply: install a circuit breaker “A” in the line. - -

- With three-phase power supply: install a circuit breaker “B” in the line. - -

Electric protection class - IP 54

Environmental conditions

Maximum operating height (asl) m 1000

Relative humidity (detected at a temperature included between 20°C and 40°C) - 80%

Ambient functioning temperature °C +5 ÷ 40

Environmental brightness LUX 150

IDM 510-129-1

Technical specications of pressing roller

▀

Unit of

measurement

Value

Weight kg Operating pressure bar 6

Air consumption at the working pressure

- Model L Nl/cycle 9,32

- Model M Nl/cycle 11,77

- Model H Nl/cycle 13,73

Height of the load to be wrapped

- Model L mm 1500 ÷ 2200

- Model M mm 1600 ÷ 2600

- Model H mm 1800 ÷ 3000

Height of the load to be wrapped (with optional extension)

- Model L mm 750 ÷ 2200

- Model M mm 850 ÷ 2600

- Model H mm 1050 ÷ 3000

English languageOperation and maintenance manual

23

Specications of the accessories available on request

▀

Technical Specications

Unit of

measurement

Weight Capacity

Ramp kg 58 1000

Weighing unit kg 260 2000

Floating weighing unit kg 270 2000

Lifting frame kg 260 2000

Burying frame kg 150 -

Technical data of reel

Dimensions of lm reel

▀

Unit of

measurement

Maximum external diameter D mm 250

Inside Diameter d mm 76

Maximum height h mm 500

Maximum height h (Machine with reel holding

carriage of type PW750).

Film thickness (Machine with reel holding

carriage of type EM - M - FM).

Film thickness (Machine with reel holding

carriage of type PW - DM).

mm 750

µm 9-12-17-23

µm 17 ÷ 23

Max Weight kg 17

Value

Net reel dimensions

▀

Unit of

measurement

Value

Maximum external diameter D mm 250

Inside Diameter d mm 76

Maximum height h mm 500

Maximum height h (Machine with reel holding

carriage of type PW750).

mm 750

Max Weight kg 17

IDM 510-129-1

24

English language Operation and maintenance manual

Technical Specications

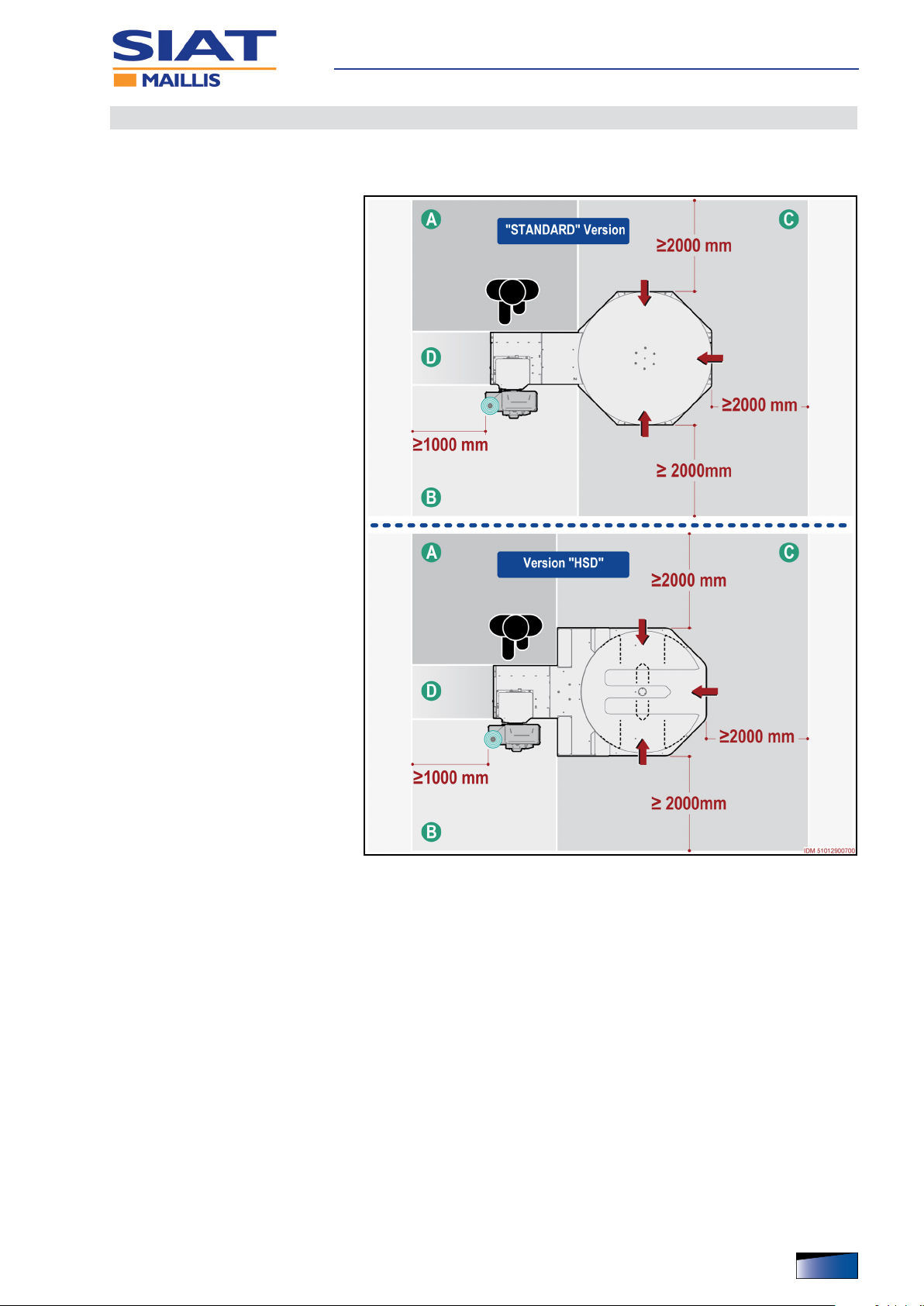

Description of outer areas

The gure shows different areas to be considered in the planning of the installation area.

A) Operator control and stand-

ing area

B) Rell area for reel

C) Loading/unloading area for

the products to be wrapped

D) Perimeter area

IDM 510-129-1

English languageOperation and maintenance manual

25

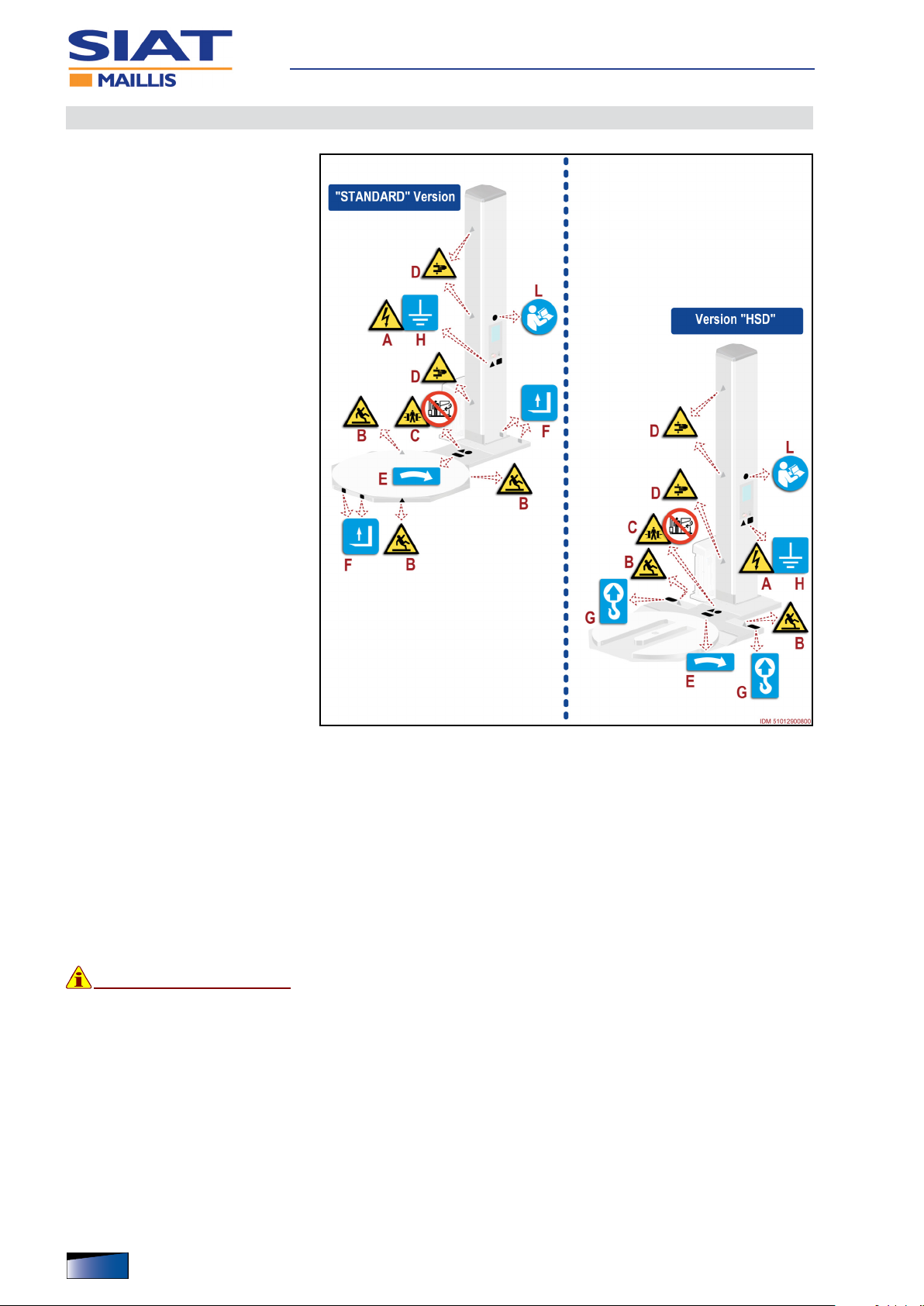

Safety and information symbols

The gure shows the applied

signals and the list includes the

description of the shown residual risk.

A) Electrical shock or electrocu-

tion hazard: hazard signal that

warns the operator from accessing the areas under voltage in order to avoid risks.

B) Risk of slipping: danger sig-

nal indicating that attention

should be paid during transfers

on at surfaces.

C) Risk of crushing body parts:

danger signal warning to stay

out of the active machine work

range.

Technical Specications

D) Risk of crushing upper limbs:

danger signal warning to keep

upper limbs out of the active

machine work range.

E) Information Signal: indicates

the required direction of rotation for operation.

F) Information Signal: indicates

the lifting points for fork-type

devices.

G) Information sign: it indicates the points where to attach the hooks of the lifting

device.

H) Information Signal: indicates the earthing point.

L) Information warning sign: read the operation and maintenance manual careful-

ly before performing any operations.

– Please keep safety signs and information legible and follow the instructions.

– Signals which are no longer legible must be replaced and repositioned in the

same place of origin.

Important

At the time of ordering provide the code of each signal to be replaced that is

specied in the spare parts catalogue.

26

English language Operation and maintenance manual

IDM 510-129-1

Recommendations for maintenance interventions

– The recommendations represent a summary of those shown in the SAFETY

WARNINGS section.

– The personnel authorized to carry out the ordinary maintenance must have qual-

ied expertise and specic skills in the eld of intervention.

– Any work on the electrical system must ONLY be performed by technicians with

acknowledged, eld-specic skills.

– Mark the intervention area and prevent access to the devices that, if activated,

may cause unexpected hazards and jeopardize the safety level.

– According to the type of operation to carry out, wear the Personal Protective

Equipment listed in the “Instructions for use” and that indicated by the Labour

laws.

– Before carrying out any intervention, activate all the safety measures, and assess

any residual energy which may still be present.

– Carry out the interventions ONLY according to the modes recommended by the

Manufacturer in the “Instructions for use”.

Maintenance

– All operations must be carried out ONLY with suitable tools which shall be in good

condition, in order to avoid damaging any components and parts of the machine.

– At work completion, restore all the security conditions aimed to prevent and min-

imize the risks during the human-machine interaction.

– At the end of operations check that there are no other tools or other material near

the moving parts or in dangerous areas.

– Refer to the Technical Assistance Service of the Manufacturer, in case interven-

tions not described in the “Instructions for use” are needed.

– In order to avoid safety hazards for the operators and nancial losses, fol-

low not only the recommendations but also the information in the SAFETY

WARNINGS section.

IDM 510-129-1

English languageOperation and maintenance manual

27

Scheduled maintenance intervals

Att

Att

Always keep the machine in optimum operating condition and carry out the

routine maintenance according to the intervals and procedures specied by

the Manufacturer.

– In case of prolonged inactivity, carry out some maintenance operations in order

to preserve functionality and prevent further damages.

– After prolonged inactivity, carefully check that the operating functionality has re-

mained unaltered.

– A good maintenance will ensure a stable performance over time, longer working

life and constant compliance with the safety requirements.

Maintenance schedule

Every working day

Component Operation required Procedures to implement

- Make sure that the listed devices are efficient.

Safety devices Checking

- Emergency stop button.

- Main electric disconnector

Maintenance

Every 40 work hours (max 1 week)

Component Operation required Procedures to implement

Lifting belt for the reel holding carriage Checking

Reel holding carriage sliding guides Cleaning

Load to be wrapped detection photocell Cleaning

Every 2000 work hours (max 6 months)

Component Operation required Procedures to implement

Air lter (if any) Cleaning

Checking

Rotating platform rotation chain

Lubrication

Film pre-stretch belt (Only for reel holding

carriages of type PW).

Film drawing-in rollers (Only for reel

holding carriages of type PW).

Checking

Cleaning

- Check this component for wear.

- Replace the belt in case it is excessively worn. (See

“Replacing the lifting belt of the carriage”).

- Remove any impurities with a plastic scraper.

- Clean with a soft cloth soaked in a non-flammable

and non-corrosive detergent.

- Properly dry the surfaces.

ention

Warning

Do not use water jets.

- Clean the detection area of the photocell.

- Use a clean, dry (not abrasive) cloth.

- Clean the filter or replace it with an original spare

part, if necessary (See “Cleaning and replacement of

the air filter”).

- Check the tension of component.

- Adjust tension as required - if necessary (See

“Adjustment of chain controlling the rotation of

platform”).

- Lubricate all the greasing points (See “Diagram of

the points of lubrication”).

- Check the tension of component.

- Adjust tension as required - if necessary (See

“Adjustment of drive chain tensioning”).

- Replace the belt in case it is excessively worn.

- Clean with a soft cloth soaked in a non-flammable

and non-corrosive detergent.

- Properly dry the surfaces.

ention

Warning

Do not use water jets.

IDM 510-129-1

28

English language Operation and maintenance manual

Every 5000 work hours (max 12 months)

Component Operation required Procedures to implement

Vertical movement wheels of the reel

holding carriage

Rotation wheels of rotating platform Checking

Checking

- Check this component for wear.

- Replace the component, if it is worn out

- Check this component for wear.

- Replace the component, if it is worn out

Diagram of the points of lubrication

Lubricate the parts indicated according to the frequency and methods shown.

– Use the lubricants (oils and

greases) recommended by the

Manufacturer or lubricants of

equivalent chemical and physical characteristics.

– Some components (reducers,

bearings, etc.) do not request

lubrication because they are

self-lubricating or life lubricated.

Maintenance

– If the ambient temperature is in-

cluded between -10°C and

+35°C, use lubricants with SAE

20 ISO VG50 or SAE 50 ISO

VG 300 viscosity grade.

If the ambient temperature is not

included in the indicated range,

contact the Manufacturer for

more information on the type of

lubricant to be used.

IDM 510-129-1

English languageOperation and maintenance manual

29

Problems, causes, remedies

The table shows the list of faults that can occur during the standard operation

and it highlights possible remedies.

Table: Operation failures

Problem Cause Remedy

- Identify the causes that have caused

With isolator switch G on ON, pilot

light does not turn off when button F is

pressed.

When button Start B is pressed, the

rotating platform does not start.

The reel holding carriage will not go

up.

The reel holder carriage raises but

does not stop at the top of the load to

be wrapped.

The ends of the load are wrapped with

an excessive amount of reinforcing

bands.

The lm is too tightly stretched or too

loose.

Emergency stop button pressed

The photocell did not detect the load

to be wrapped

Rotating platform not correctly timed. - Press key D.

The photocell did not detect the load

to be wrapped

Reel holding carriage not correctly

timed.

Top limit stop detecting microswitch

failure

Failure of the inverter of the reel

holding carriage

The photocell did not detect the load

to be wrapped

Top reinforcing band quantity not

correctly set

Bottom reinforcing band quantity not

correctly set

Tension of lm not properly adjusted - Adjust the tension of film.

the stop.

- Restore normal running conditions

- Unlock the emergency stop button

with a voluntary action.

- Check the functionality of the

component.

- The component must be adjusted

(See “Sensitivity adjustment for the

product to be wrapped detection

photocell”).

- Check the functionality of the

component.

- The component must be adjusted

(See “Sensitivity adjustment for the

product to be wrapped detection

photocell”).

- Press key D.

- Check the functionality of the

component.

- The component must be adjusted.

- Check the error code.

- Check the functionality of the

component.

- The component must be adjusted

(See “Sensitivity adjustment for the

product to be wrapped detection

photocell”).

- Modify the programming.

- Modify the programming.

Maintenance

30

English language Operation and maintenance manual

IDM 510-129-1

Problem Cause Remedy

The machine stops with the reel

holding carriage not correctly

positioned.

Rotating platform jogging motion.

The noise level is too high.

Reel holding carriage jogging motion.

Presence of residues or dust on the

reel holding carriage sliding guides

There is an obstacle under the reel

holder carriage.

Braking or excessive wear of the reel

holder carriage lifting belt

Rotating platform rotation chain not

properly tensioned

Presence of residues or dust on the

wheels

Rotating platform rotation chain not

properly tensioned

Wheels of rotating platform worn out

or damaged

Failure of gearmotor driving the

rotating platform

Presence of residues or dust on the

reel holding carriage sliding guides

Maintenance

- Remove any residues.

Use brushed with soft plastic bristles.

Press key D.

- Remove the obstacle.

Press key D.

- Replace belt (See “Replacing the

lifting belt of the carriage”).

- The component must be adjusted

(See “Adjustment of chain controlling

the rotation of platform”).

- Remove any residues.

Use brushed with soft plastic bristles.

- The component must be adjusted

(See “Adjustment of chain controlling

the rotation of platform”).

- Replace the component.

- Check the functionality of the

component.

- Remove any residues.

Use brushed with soft plastic bristles.

IDM 510-129-1

English languageOperation and maintenance manual

31

Maintenance

Alarm message table

no. Type of failure Remedy

Machine alarms

Sensor does not detect the rotation of

01

platform.

(Lower and upper) sensors do not detect the

02

end of stroke of the reel holding carriage.

Failure of the relays that power the inverter

03

power circuit.

The carriage drive chain is not correctly

05

tensioned.

The photocell does not detect any load to be

06

wrapped.

Elements that prevent the correct detection are

07

between sensors of the rotating platform

(version HSD).

08 The lm reel is exhausted. - Replace reel (See “Film Coil Feeding”).

Rotating platform inverter alarms

The inverter parameters are not properly set

10

up.

The activation of the inverter electric power is

11

not correctly enabled.

The electric motor is damaged due to a short

12

circuit.

The heat protection is damaged because of

13

the overheating of the electric motor.

14 Inverter bis power circuit failure. - Contact the Manufacturer’s Technical Assistance Service.

15 Inverter module failure due to overheating.

Overvoltage of the hardware electric power

16

supply (higher than 4 A).

Communication was interrupted because of an

17

internal error.

- Check the connections and/or the position of sensor.

- Press control F to silence the alarm.

- Check the connections and/or the position of sensors.

- Press control F to silence the alarm.

- Press control F or turn the power of the electronic board off and on to

silence the alarm.

- If the problem persists, disconnect the electric power and contact the

Manufacturer’s Technical Assistance Service.

- Make sure that the reel holding carriage can move freely and without

obstacles.

- Check the connections and/or the position of the photocells.

- Press control F to silence the alarm.

- Control D lights up.

- Press control D.

Reel holding carriage moves upwards and then it moves downwards

again in order to phase the operating units.

- Make sure that the load to be wrapped is properly positioned.

- Check the connections and/or the position of the photocell.

- Remove the obstacles.

- Make sure that the load to be wrapped is positioned on the rotating

platform.

- Check the connections and/or the position of the photocells.

- Contact the Manufacturer’s Technical Assistance Service.

- Contact the Manufacturer’s Technical Assistance Service.

- Contact the Manufacturer’s Technical Assistance Service.

- Let the motor cool down.

- Press control F or deactivate and re-activate power (even more than

once) to silence the alarm.

- If the problem persists, disconnect the electric power and contact the

Manufacturer’s Technical Assistance Service.

- Check if the fan system works properly and if there are obstacles in the

air flow.

- If the problem persists, disconnect the electric power and contact the

Manufacturer’s Technical Assistance Service.

- Contact the Manufacturer’s Technical Assistance Service.

- Contact the Manufacturer’s Technical Assistance Service.

IDM 510-129-1

32

English language Operation and maintenance manual

Maintenance

no. Type of failure Remedy

Reel holder carriage inverter alarms

The inverter parameters are not properly set

20

up.

The activation of the inverter electric power is

21

not correctly enabled.

The electric motor is damaged due to a short

22

circuit.

The heat protection is damaged because of

23

the overheating of the electric motor.

24 Inverter bis power circuit failure. - Contact the Manufacturer’s Technical Assistance Service.

25 Inverter module failure due to overheating.

Overvoltage of the hardware electric power

26

supply (higher than 4 A).

Communication was interrupted because of an

27

internal error.

- Contact the Manufacturer’s Technical Assistance Service.

- Contact the Manufacturer’s Technical Assistance Service.

- Contact the Manufacturer’s Technical Assistance Service.

- Let the motor cool down.

- Press control F or deactivate and re-activate power (even more than

once) to silence the alarm.

- If the problem persists, disconnect the electric power and contact the

Manufacturer’s Technical Assistance Service.

- Check if the fan system works properly and if there are obstacles in the

air flow.

- If the problem persists, disconnect the electric power and contact the

Manufacturer’s Technical Assistance Service.

- Contact the Manufacturer’s Technical Assistance Service.

- Contact the Manufacturer’s Technical Assistance Service.

IDM 510-129-1

English languageOperation and maintenance manual

33

Cleaning and replacement of the air lter

Att

The operation must be carried out by the maintenance technician or by personnel with suitable competences, skills and knowledge.

Make sure to full the required requirements in order to work under safe conditions.

– The intervention must be carried out with the machine stopped in safety condi-

tions.

– The gure shows the points of intervention and the description shows the proce-

dures to be adopted.

1. Mark the intervention area and

prevent access to the devices

that, if activated, may cause

unexpected hazards and jeopardize the safety level.

ention

Warning

Always wear suitable personal

protective equipment in order to

avoid safety and health hazards.

Maintenance

2. Rotate main disconnector to

position “O” (OFF) to deactivate the power supply.

3. Unhook the grid A.

4. Remove the lter B.

5. Clean the lter with dry com-

pressed air.

Replace the lter with an original spare part, if it is damaged.

6. Re-install the lter B.

7. Attach the grid A.

– At the end of operations,

check that there are no tools

or other material near the

moving parts or in dangerous areas.

34

English language Operation and maintenance manual

IDM 510-129-1

Adjustment of chain controlling the rotation of platform

Att

The operation must be carried out by the maintenance technician or by personnel with suitable competences, skills and knowledge.

Make sure to full the required requirements in order to work under safe conditions.

– This service should be carried out with the reel holding carriage lowered and the

machine safely at a stop.

– The gure shows the points of intervention and the description shows the proce-

dures to be adopted.

1. Mark the intervention area and

prevent access to the devices

that, if activated, may cause

unexpected hazards and jeopardize the safety level.

ention

Warning

Always wear suitable personal

protective equipment in order to

avoid safety and health hazards.

Maintenance

2. Rotate main disconnector to

position “O” (OFF) to deactivate the power supply.

3. To reach high, not easily accessible or otherwise hazardous

areas, implement adequate

safety measures to avoid risks.

4. Disassemble the pressing roller

(See “Disassembly and re-assembly of the Pressing Roller”).

5. Disassemble the reel holding

carriage (See “Disassembly

and re-assembly of the reel

holding carriage”).

Important

Only for reel holding carriages

of type PW

1°

6. Remove the fastening elements A and remove the component B.

IDM 510-129-1

2°

7. Attach the column C to a lifting device.

3°

8. Disassemble the guards K-W.

9. Loosen the screws D.

English languageOperation and maintenance manual

35

4°

10. Bring the column to a horizontal

position.

– Insert the shim E under the

column to keep it horizontal.

5°

11. Slightly loosen the nuts F.

12. Adjust the tension of chain G by

means of the adjusting system

H.

Important

Do not overtighten so as not to

cause any malfunctioning.

13. Tighten the nuts F.

6°

14. Lift the column to its vertical position.

Maintenance

15. Introduce and tighten the

screws D.

16. Remove the lifting device.

17. Re-install the guards K-W.

7°

18. Install the component B and

lock it in place with the fastening elements A.

19. Install the reel holding carriage

(See “Disassembly and re-assembly of the reel holding carriage”).

Important

Only for reel holding carriages

of type PW

20. Install the pressing roller (See

“Disassembly and re-assembly

of the Pressing Roller”).

– At the end of operations,

check that there are no tools

or other material near the

moving parts or in dangerous areas.

21. Start the machine and make

sure that the operation has