Model MF4000

SIARGO MEMS FLOW SENSOR PRODUCTS

MEMS Mass Flow Meters

VB.4

© 2014 Siargo Ltd.

MEMS Mass Flow Meters

MF4000 Series

User Manual

Document No. 03-2014-2 EN

Issue date: 2014.03

Revision: VB.4

Siargo Ltd.

2041 Mission College Boulevard

Suite 250

Santa Clara, CA 95054

USA

Tel: +1(408)969.0368

Email: info@siargo.com

© Copyright 2014 by Siargo Ltd.

Siargo Ltd. and its subsidiaries reserve the rights to change the specifications and/or

descriptions without prior notice. For further information and updates, please visit:

www.Siargo.com

Contents

Features.............................................................................................................................

Introduction.......................................................................................................................

Applications........................................................................................................................

Working Principle and Package............................................................................................

Schematic of Electronics .....................................................................................................

The Meters ........................................................................................................................

Specifications.....................................................................................................................

Description.........................................................................................................................

Dimensions........................................................................................................................

Product Selection..............................................................................................................

Installation and User Interface..........................................................................................

Running Mode...................................................................................................................

Instant flow rate mode

Flow accumulation mode

Maximum / minimum mode

Menu Setting Mode..........................................................................................................

Keyboard lock

2

2

2

3

3

4

4

4

5

5

5

6

7

Flow accumulation reset

Automatic offset calibration

Response time setting

Display refresh setting

Maximum / minimum flow rate record clearing

System default retrieval

Decimal setting

Safety and Maintenance...................................................................................................

9

Wetted materials and compatibility

Safety precautions

Customer Service and Order.............................................................................................

Appendix RS232 Communication Protocol.......................................................................

10

11

Siargo MEMS Mass Flow Meters Siargo Ltd. Page 1

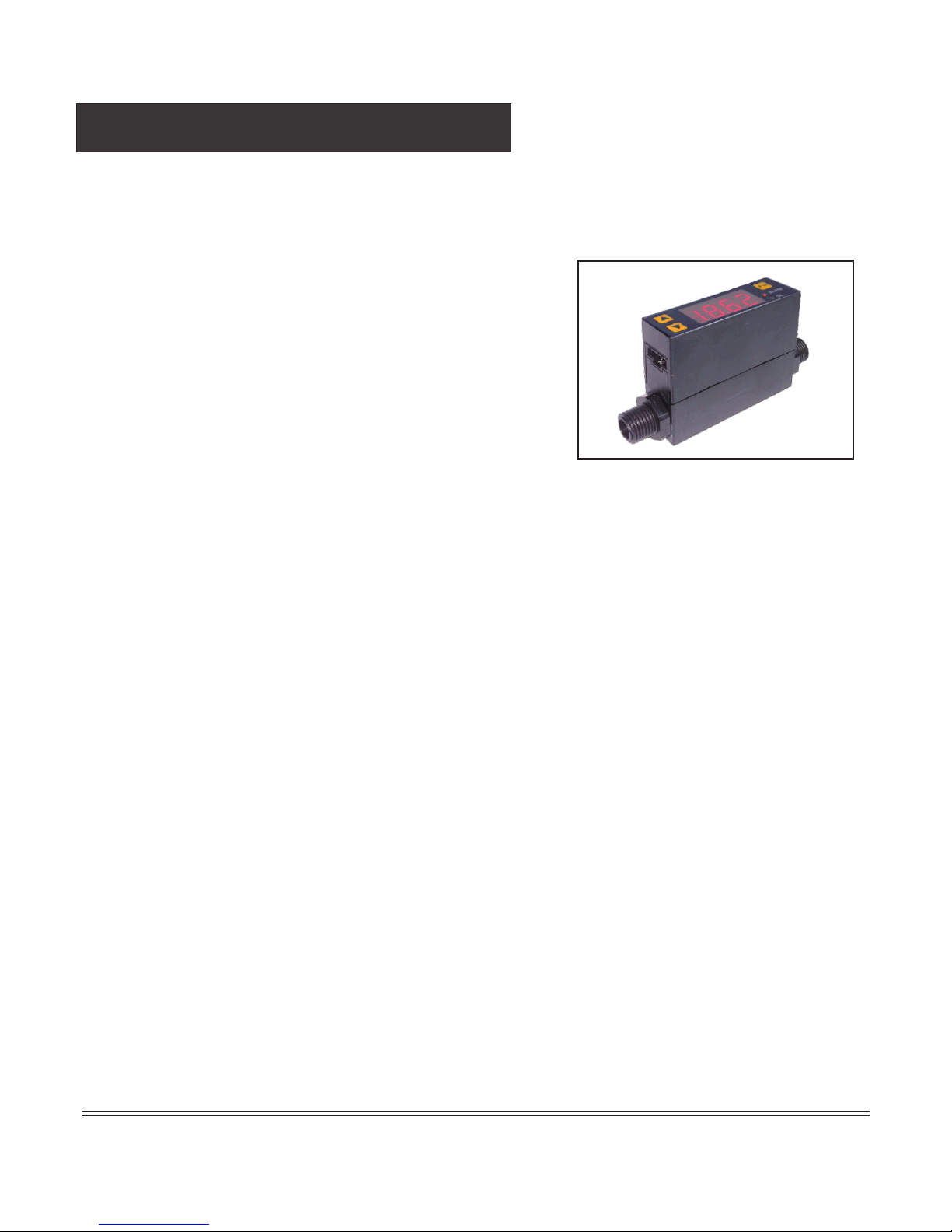

MEMS Mass Flow Meters

Model MF 4000

Features

Designed for gas flow in fixed flow channel of 3 mm and 8

mm, with accumulated flow

Compact design ready for manifold applications

Fast response time provides solutions for critical

applications

Excellent for electronic meters in anesthesia equipments

Exchangeable mechanical connectors for easy installation

at different applications

Intrinsic safe enclosure for wide applications

Low power consumption, can be operated by battery

Introduction

MF 4000 Series mass flow meters are designed for applications in gas flow within a flow channel diameter of 3 mm

and 8 mm, respectively. The compact design provides user friendly installation for multiple flow channel sensing

requirements. Plastic finishing with an easy change of the mechanical adaptors enables applications with different

connection thread requirements or one-touch approach. The meters can be used for electronic meters in

anesthesia equipments, environmental samplers and many other industrial applications.

The meters can be customized with flow range, gas specific requirements, user interface and others upon requests

to the manufacturer.

Applications

Environmental Monitoring

Aeration cable

Gas generated plasma monitor

Vacuum applications

Preservation of oxygen devices

Anesthesia

Ventilator

Ventilation equipment detection devices

Other industrial applications such as welding

Siargo MEMS Mass Flow Meters Siargo Ltd. Page 2

Amplifier

00

A/D

Converter

u1x1

(Pin3)VCC

MEMS

Sensor Chip

Buffer

Filter

Power

Module

Driving

Circuit

5V Power Supply

Signal Conditioning Circuit

5V / 3.3V

High-Speed 8-Bit

Microcontroller

RS232

Analog

Output

Select

(Pin2)Vout

(Pin4)GND

(Pin1)TX

(Pin5)RX

(Pin4)GND

EEPROM

D/A

Converter

u1x1

(8-24)V

DC

Display

and Key

Driver

4-digit

LED

display

Test-Key

Interface

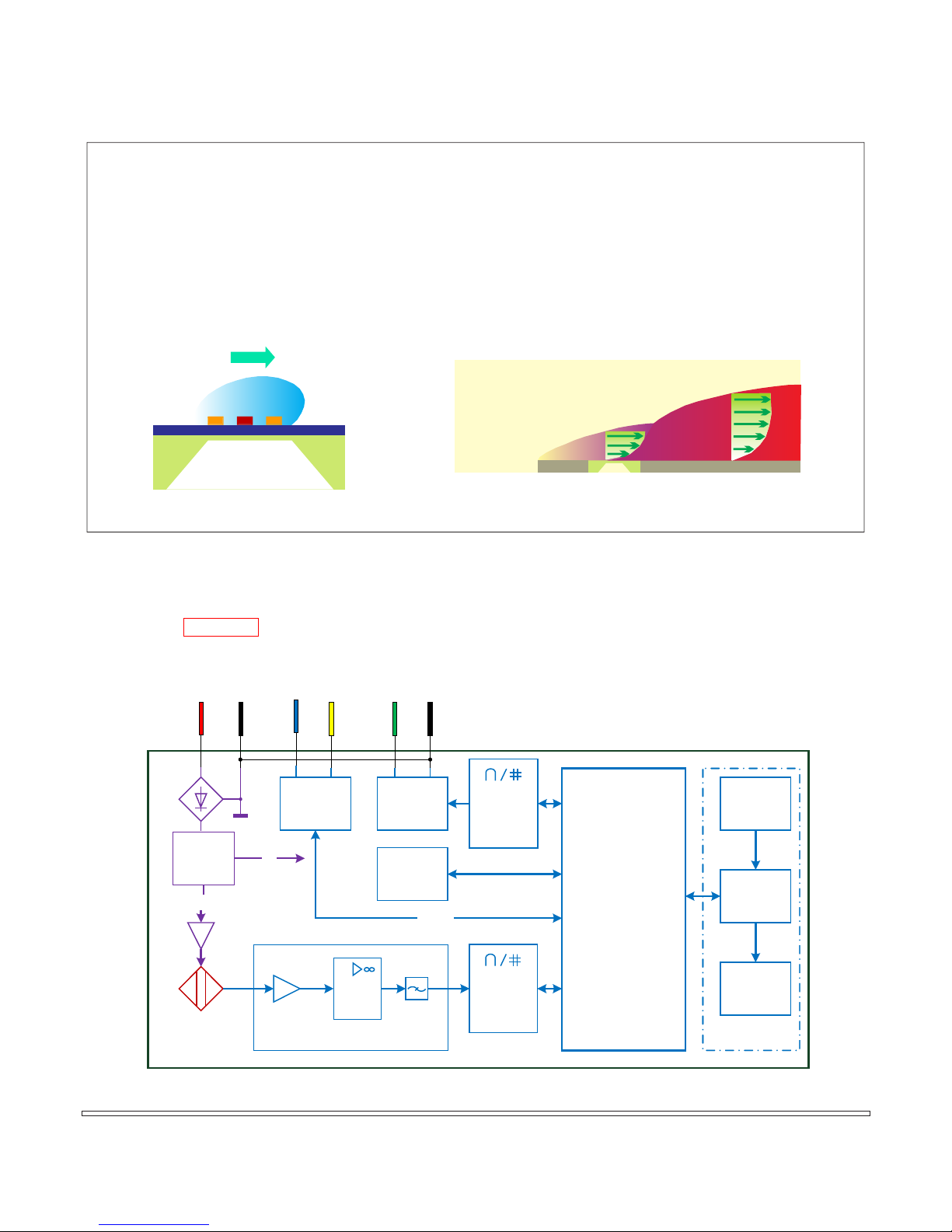

Working Principle and Package

The MEMS calorimetric sensor is installed at the flow channel wall forming a plate that serves as an

additional flow conditioner from the boundary layer configuration resulting in a laminar flow. The mass

flow measurement is established as the fluid carries heat away from the heater causing the redistribution

of the temperature field. Accurate flow rate is obtained by calibration with the standard fluid at the preset

conditions.

Schematic of Electronics

Flow direction

MF4003 MF4008

Time-averaged velocity profile boundary layer

Free stream

Laminar

Sensor

Turbulent

Siargo MEMS Mass Flow Meters Siargo Ltd. Page 3

The Meters

The meters is packaged into the standard poly-carbonate enclosure with which the maximum detectable mass flow

rate can be customized within 2 SLPM to 50 SLPM by modification of the circuitry so that the various flow can be

achieved to meet customers’ best requirements. The calibration is done with air at 20°C and 1 bar pressure. It can

nonetheless be calibrated at other customer specific conditions upon requests.

Specifications

MF4003

DN

Flowrate Range

Turn-down

Accuracy %

Repeatability %

Null Shif

Output Shift % / °C

Response Time ms

Power Supply

Output

Display

Units

Display Resolution 0.001, 0.01, 0.1 selectable 0.01, 0.1 selectable SLPM

Pressure Drop 100 600 Pa

Max. Pressure MPa

Working Temperature °C

Storage Temperature °C

Humidity %RH

Mechanical Connection

Keyboard

Pins Out

Calibration

Package

Weight g

t mV

100 (Default, 10, 20, 50, 200 ,500, 1000 selectable)

Linear; RS232 / RS485, Analog 0.5~4.5Vdc

Instant flow rate: SLPM; Flow accumlation: SL

BSPT 1/4 (R 1/4), 4mm / 6mm / 8mm One-touch

74(with O4,O8 connection), 71(with O6 connection)

3 8

0 ~ 2, 3, 4, 5 0 ~ 10, 20, 30, 40, 50 SLPM

>100:1

±(1.5+0.2FS)

0.25

±30

0.12

8~24Vdc, 50mA

4-digit, 7-segment LED,2 Status LED

0.5

-10~+55

-20~+65

<95%RH (No icing or condensation)

3 keys

5 Pins, NS-TECH CD R-5

Air @ 20°C,101.325kPa

Polycarbonate

55 (with BSPT 1/4 (R 1/4) connection)

MF4008

mm

BSPT 1/4 (R 1/4)

Description

Siargo MEMS Mass Flow Meters Siargo Ltd. Page 4

Dimensions

For R 1/4 connection

MF 4003 MF4008

For One-touch connection

One-touch Connection L D

ID=8mm 91.0

ID=6mm 83.0

ID=4mm 80.0

Product Selection

MF40

* Max. flow rate number only, for example, 5 meaning full scale flow rate of 5 SLPM.

For CO and N O, selectable: 2, 3 or 4 SLPM (without 5 SLPM) for MF4003; 10, 20, 30 or 40 SLPM (without 50 SLPM) for MF4008;

2 2

** The meter standard output is analog. Digital outputs are optional.

Φ8.0

Φ6.0

Φ4.0

Gas (A - air; B - N O; C- CO ; N - N ; O - O ; R - Ar;

for other gases, please contact Siargo)

Output*** (B - RS485; C - RS232; V - analog output; Options: V / BV / CV)

Mechanical connection** (R - BSPT 1/4 (R 1/4);

O4/O6/O8 - 4 mm/6 mm/8 mm one-touch connector;

for MF4003 - R, O4, O6 and O8 selectable; for MF4008 - R selectable.)

Max. Flow Rate* (for MF4003 - 2, 3, 4 or 5 SLPM;

for MF4008 - 10, 20, 30, 40 or 50 SLPM)

Product Series Name (03-DN3,08-DN8)

2 2 2 2

Siargo MEMS Mass Flow Meters Siargo Ltd. Page 5

Installation and User Interface

C▄◘Ŏ

Accumulation

4 Less

Significant Digits

(LED Display)

Instant Flow

Rate

Flow

Accumulation

4 More

Significant Digits

(LED Display)

Auto change

Maximum Flow

Rate

(LED Blink)

Minimum Flow

Rate

(LED Blink)

I-LED on II-LED on

Push and keep for

more than 2sec

Push

/

/

Push

Fn

I-LED on

II-LED on

RUNNING MODE

Power

on

Push

The product at the time of shipment is fully inspected for product quality and meets all safety

requirements. Additional safety measures during the installation should be applied. This includes, but is

not limited to leakage verification procedures if applicable, standard ESD (electrostatic discharge)

precautions, and DC voltage precautions. Other tasks such as calibration, part replacement, repair, and

maintenance must only be performed by trained personnel. Upon requests, manufacturer will provide

necessary technical support and/or training of the personnel.

Do not open the product cover or alter any part of the product. Any such actions will forfeit the terms of

the warranty and cause the liability to any damages thereafter.

The interface is defined in the table below:

Pin Colour Definition

1 Blue TX, RS232 Transmit (output) / RS48 B5

2 Green Vout, Analog output

3 Red VCC, Power supply (8 - 24 Vdc)

4 Black GND, Ground

5 Yellow RX, RS232 Receive (input) / RS48 A5

NOTE: Upon open the package, if any component listed above is missing or any visible mechanical

damage is found, please contact supplier or distributors immediately. For additional assistance

of installation, please contact supplier or customer service.

Running Mode

The display consists of a 4-digit LED panel and two LED

indicators (i.e., I-LED and II-LED). Under the running mode,

the 4-digit LED panel will show Instant flow rate, flow

accumulation, or maximum/minimum flow rates. There

are three different display modes: instant flow rate mode,

flow accumulation mode, and maximum/minimum mode.

The two LED indicators will illustrate which display mode is

undergoing.

F

Instant flow rate mode

1. This is the default display mode, in which the two LED indicators are off.

2. The instant flow rate is displayed by the 4-digit LED panel with one decimal digit available.

The flow rate unit is SLPM.

3. When the flow rate exceeds the maximum allowable flow rate, I-LED will blink.

4. When the flow rate exceeds the minimum allowable flow rate, II-LED will blink.

Siargo MEMS Mass Flow Meters Siargo Ltd. Page 6

Flow

5. When the flow rate exceeds the maximum displayable reading, both I-LED and II-LED will

blink simultaneously, which implies that the reading is incorrect (since the reading has been

rounded off to fit the display, although the measurement may still be correct).

Flow accumulation mode

1. In this display mode, the two LED indicators are turned on.

2. The flow accumulation is displayed as an 8-digit numeric number in a time-division scheme.

When the first LED indicator (I-LED) turns on, the 4-digit LED panel displays the more

significant digits of the flow accumulation. After 1 second, the second LED indicator (II-LED)

turns on and the 4-digit LED panel displays the less significant digits of the flow accumulation.

3. The flow accumulation unit is SL. The flow accumulation reading can be reset to zero by a

key operation.

NOTE: The flow accumulation will be saved every 3 minutes. For instance:

1, The flow accumulation will not be saved if power off @ 2 minutes.

2, The flow accumulation will be the value of 33 minutes if power off @ 34 minutes.

Maximum / minimum mode

1. In this mode, the maximum flow rate and the minimum flow rate (since the last power-on or

the last maximum/minimum flow rate resetting) will be displayed.

2. When the maximum flow rate is shown, I-LED will turn on and the 4-digit LED panel will blink.

3. When the minimum flow rate is shown, II-LED will turn on and the 4-digit LED panel will blink.

Menu Setting Mode

Under the menu setting mode, various operations including keyboard lock/unlock, flow accumulation

reset, automatic offset calibration, gas selection, response time setting, display refresh setting,

maximum/minimum flow rate reset can be performed.

Keyboard lock

1. Prevent unintentional modifications of system parameters.

2. After the keyboard is locked, the user will be unable to perform any other menu settings

unless the keyboard is unlocked by the user.

Flow accumulation reset

Reset the flow accumulation reading to 0 SL, and the flow accumulation counts re-starting

at 0 SL.

Automatic offset calibration

Perform offset calibration, which is used for resolving the possible offset drifting after certain

period of operation.

NOTE: Before performing automatic offset calibration, please ensure that the gas in the pipe is

static, i.e., at zero flow. Otherwise, it may cause inaccuracy during the measurement.

Siargo MEMS Mass Flow Meters Siargo Ltd. Page 7

Instant Flow

Rate

(LED Display )

Push and keep for

Keyboard

Unlock

0.unL(Blink)

Fn

Push

Keep the Flow

Accumulation

1.oFF(Blink)

Fn

Push

Fn

more than 2 sec

Push

/

Push Push

/

Keyboard

Locked

0.Loc(Blink )

Clear the Flow

Accumulation

1.on(Blink )

Push

MENU SETTING MODE

Fn

Flow

Fn

accumulation

Zeroing

Donđt perform

offset calibration

2.oFF(Blink)

Fn

Push

Response

time=10ms

4.001(Blink)

Fn

Push

Display refresh

time =250ms

5.025(Blink)

Fn

Push

Keep Max ./Min.

Flow Rate

6.oFF(Blink)

Fn

Push

Keep current

Setting

7.oFF(Blink)

Fn

Push

No decimal

digits

8. 0(Blink )

Push

/

Perform Offset

Calibration

2.on(Blink )

Push

Fn

Automatic offset

calibration

Response

time=1000ms

4.100(Blink)

Push

Fn

Push

/

Push

/ / / /

Response

time=20ms

4.002(Blink)

Push

Response

time=50ms

4.005(Blink)

Push

Response

time=100ms

4.010(Blink)

Push

Fn

Push

/

/

Display refresh

time =500ms

5.050(Blink)

/

Display refresh

time =1s

5.100(Blink)

/

Display refresh

time =2s

5.200(Blink)

PushPushPush

Push

Fn

Clear Max ./Min.

/

Flow Rate

6.on(Blink )

PushPush

Fn

Clear Max ./Min.

Flow Rate

Push

Fn

/

System default

retrieval

7.on(Blink )

PushPush

Fn

System default

retrieval

Push

Fn

Push

/

Push

/

Decimal digits =1

8. 1(Blink )

Push

/

Decimal digits =2

8. 2(Blink )

Push

/

Decimal digits =3

8. 3(Blink )

Push

/

Push

Response

time=500ms

4.050(Blink)

Push

Response

time=200ms

4.020(Blink)

/

Fn Fn Fn Fn

Push Push

Siargo MEMS Mass Flow Meters Siargo Ltd. Page 8

Push

Push

Response time setting

1. Set the response time of the analog output signal;

2. Set the time interval for the digital output signal;

3. After each setting is completed, it is in effect immediately. However, it is stored in the

internal EEPROM only when a new menu operation is invoked. If the power is off before a

new menu operation is invoked, the setting will be discarded without being stored.

Display

Response Time

Display refresh setting

4.001 4.002 4.005 4.010 4.020 4.050 4.100

10 ms 20 ms 50 ms 100 ms 200 ms 500 ms 1000 ms

1. Set the time interval for the display refresh;

2. After each setting is completed, it is in effect immediately. However, it is stored in the internal

EEPROM only when a new menu operation is invoked. If the power is off before a new menu

operation is invoked, the setting will be discarded without being stored.

Display

Refresh Time

Maximum / minimum flow rate record clearing

5.025 5.050 5.100 5.200

250 ms 500 ms 1000 ms 2000 ms

1. Reset the maximum/minimum flow rate register, and the maximum/minimum flow rates will

be re-starting from the initial state.

2. The maximum/minimum flow rate record will be automatically reset when the meter is

power off.

System default restore

Reset all the system parameters to the default values specified in the factory.

Decimal setting

Set the number of decimal digits.

NOTE: The maximum number of decimal digits is depended on the maximum flow rate. For

example, when the maximum flow rate is 10,20,30,40,50 L/min, the number of decimal

digits can be at most 2, e.g., 49.99 L/min.

Safety and Maintenance

Wetted materials and compatibility

The meter body is made of medical compatible plastics. Sensor comprise of silicon, silicon nitride and

silicon dioxide and the sensor surfaces are passivated with silicon nitride and silicon dioxide. The

electronic sealing is provided by RTV (room temperature vulcanizing) silicone sealant WR-704 composed

of HOCH3 (SiO) nCH3H.

Siargo MEMS Mass Flow Meters Siargo Ltd. Page 9

Safety precautions

The product is designed for use with general purpose gases such as air and nitrogen. It is advised that the

products are best used for non-explosive clean gases. The sensors cannot be used for gas metrology of

fluoride or fluoride containing gases. For updates of the product certification information, please contact

manufacturer or visit www.Siargo.com. Use for other gases such as extreme corrosive and toxic may

cause the product malfunctioning or even severe damages. The product sealing is ensured to work under

working pressure of 0.5 MPa and is leakage proof before the shipment. But cautions and further leakage

test are important at installation as well since any leakage could cause severe safety issue. The power

supply for this product is 8~24 VDC, all precautions and measures for electrical voltage handling must

apply.

Attention: Any alternation and/or improper use of the product without the permission of the

manufacturer can cause unpredicted damages and even injuries or other severe situations. Siargo Ltd or

any of its employees, subsidiaries shall not be hold and indemnified against such consequences due to

such circumstances via improper use of the product.

All maintenance of the meter should be done by trained and certified personnel by Siargo, Ltd. products.

Customer Service and Order

Siargo Ltd.

2041 Mission College Blvd, Ste 250, Santa Clara, California 95054 USA, info@Siargo.com; +01(408)969-0368

In Japan, please contact

Marubeni Information Systems Co., Ltd.

Device Solutions Department, 3-12-18 Shibuya, Shibuya-ku, Tokyo 150-0002; +81-3-5778-8661

Siargo@Marubeni-sys.com

Siargo MEMS Mass Flow Meters Siargo Ltd. Page 10

Appendix RS232 Communication Protocol

Serial Port Settings

PROPERTIES RS232 RS485

Physical interface TIA/EIA-232-E TIA/EIA-485-A

Transmission cable 3-core shielded cable

Cable length ≤ 3m ≤ 1200m

Communication interface UART, Half-duplex

Data link protocol point to point point to point; point to multiple

Baud rate (Bits per

second)

Port

Setting

Data bits 8 bits

Frame_header 1 bit Mark

Parity

Error checking method XOR

Others 1 bit Space

Stop bits 1 bit

Flow control None

38400 bps

Protocol Structure

This protocol includes three working layers: physical

layer, data link layer, and user layer.

Physical layer protocol

Every byte contains 11bits, which is defined as

follows:

Start_bit D0 D1 D2 D3 D4 D5 D6 D7 D8 Stop_bit

a) Start_bit:

1bit, a logic low;

b) Data bits (D0~D7):

8 bits, representing the data byte under

transmission, which is ordered from the

least-

significant digit to the most-significant digit;

c) Frame_header flag (D8):

1bit, a flag to indicate whether the data byte

under transmission is a type of datum or

frame_header.

* When transmitting a frame_header (or address)

from master, D8 must be set to 1. When

transmitting another datum (such as command

code, data length, data segment, checksum or

frame_end), D8 can be set to 0 or 1. We suggest

customer set D8 to 0, when transmitting other

datum;

* For the byte sent from MF4000, D8 is always 0;

d) Stop_bit:

1bit, a logic high.

Data link layer protocol

Both the master and slave (MF4000) have the same

frame format, each byte of which is hexadecimal (nonASCII code). Specifically, the frame format is defined

as below:

Frame_header 1 byte

Command code 1 byte

Length 1 byte

Data Variable-length

Checksum 1 byte

Frame_end 1 byte

a) Frame_header:

For RS-232, this frame header is a constant byte:

0x9D, representing the start of a data frame.

For RS-485, this frame header is the address of

the slave under query (i.e., the salve device to

whom the data is sent). If the slave responds, the

slave will need to return its own slave address.

The allowable slave address code is an integer

between 1~128. When this frame header is set to

0, it is in the broadcast mode, in which all the

slave devices will be in effective to accept the

data but not be allowed to return their addresses

after receiving the data.

b) Command code:

The commend code, an integer between 0 and

255 excepting 0x9D, defined in the User Layer to

achieve various functionality.

c) Length:

The length of the data, an integer between 0 and

102 depending on the commend code. If the

command code has no data, the length should be

0. If the MF4000 unit detects the length larger

than 102, the MF4000 unit will not send any

response;

d) Data:

The body of the data, whose length varies

depending on the command code. If the

command code has no data, the length should be

0;

e) Checksum:

XOR;

f) Frame_end:

0x0D;

g) Overtime

1sec. This is to prevent MF4000 from running into

a deadlock because of the master failures or

communication failures. When MF4000 receives

a correct byte, a timer will begin. If MF4000 does

not receive other correct byte within 1sec, it will

interrupt the communication and prepare to

receive next byte. The interval time from MF4000

to the master is less than 10msec (which can be

used for the master to judge the overtime).

Siargo MEMS Mass Flow Meters Siargo Ltd. Page 11

Appendix RS232 Communication Protocol

User layer protocol

Command Code F0 Read instant flow rate

Master query 9D F0 01 08 CRC 0D

MF4000 response 9D F0 03 FRH FRM FRL CRC 0D

Description

Command Code FF Read the sensor series number

Master query 9D FF 00 CRC 0D

Mf4000 response

Description

Command Code 02 Change the response time

Master query 9D 02 02 RTH RTL CRC 0D

MF4000 response 9D 02 01 STATE CRC 0D

Description

Command Code 03 Change the GDCF of the sensors

Master query 9D 03 02 GDCFH GDCFL CRC 0D

MF4000 response 9D 03 01 STATE CRC 0D

Description

Command Code 72 Calibrate sensor offset (Auto)

Master query 9D 72 01 55 CRC 0D

MF4000 response 9D 72 02 OFFSETH OFFSETL CRC 0D

Description

Command Code 78 Reset all the parameters to default.

Master query 9D 78 01 55 CRC 0D

MF4000 response 9D 78 01 STATE CRC 0D

Description

3 bytes.

FR (Instant flow rate) = (FRH * 65536 + FRM * 256 + FRL)/ 1000;

Unit: SLPM,Decimal digits: 3.

9D FF 0C SN1 SN2 SN3 SN4 SN5 SN6 SN7 SN8 SN9 SN10 SN11

SN12 CRC 0D

12 bytes.

It is the series number of the sensor made up of 12 ASCII

characters.

1 byte.

Unit: msec.

RT ( response time ) = RTH * 256 + RTL;

Selectable: 10, 50, 100, 200, 500 and 1000.

STATE: if the operation is successful, STATE = 1, otherwise STATE

= 0.

1 byte.

GDCF = GDCFH * 256 + GDCFL.

STATE: if the operation is successful, STATE = 1, otherwise STATE

= 0.

2 bytes.

Ensure there is no flow in the sensor pipe during calibrating offset.

Offset = OFFSETH * 256 + OFFSETL.

The normal range is from -32767 to +32767.

1 byte.

Reset all the parameters to default (Automatic)

1, Reset the default response time (10msec);

2, Reset the default GDCF (1000);

3, Reset the default offset.

Command Code 82 Read the response time

Master query 9D 82 00 CRC 0D

MF4000 response 9D 82 02 RTH RTL CRC 0D

Description

Command Code 83 Read GDCF

Master query 9D 83 00 CRC 0D

MF4000 response 9D 83 02 GDCFH GDCFL CRC 0D

Description

2 bytes.

RT ( response time ) = RTH * 256 + RTL;

2 bytes.

GDCF = GDCFH * 256 + GDCFL.

Flow chart (master to MF4000)

Set frame_header

flag to 1(D8 = 1)

Send

frame_header

No

No

No

Set frame_header

flag to 0(D8 = 0)

Send command

code and length

Send data

All data have been

sent?

Yes

Send checksum

and frame_end

Yes

Receive frame_head,

command code and

length

Receive data

All data have been

received?

Yes

Receive checksum

and frame_end

Is checksum correct?

Yes

Is frame_end correct?

Yes

Processing data

Continue to send

other frame?

No

Over

Siargo MEMS Mass Flow Meters Siargo Ltd. Page 12

Loading...

Loading...