Siare Perseo Service manual

PERSEO

Service manual

PERSEO

ANAESTESIA WORKSTATION

SERVICE MANUAL

P.N.:DU5028130 REV.3.0

1

PERSEO

Service manual

GENERAL INDEX

SERVICE MANUAL..................................................................................................................................1

1. USE OF THE SERVICE MANUAL .......................................................................................................3

1.1. Users of manual

1.2. General Notes

1.3. Safety Notes

WARNINGS..............................................................................................................................................4

2. GENERAL MAINTENANCE PROCEDURES .......................................................................................6

2.1. General Information

3. WORKSTATION DESCRIPTION .........................................................................................................7

3.1 General Information

3.2 Structure

3.3 AM5000/3 – AM5000/5 anaesthesia module

3.4 Breathing System

3.4.1. OPEN-SEMICLOSED VERSION (NON REBREATHING -REBREATHING) ........................12

3.4.2. OPEN VERSION (NON REBREATHING).............................................................................14

VM 2000 lung ventilator ............................................................................................................15

3.5.

A) MODE Section...............................................................................................................17

3.5.1.

B) RATE Section................................................................................................................18

3.5.2.

C) INSP FLOW - PEEP Section.........................................................................................19

3.5.3.

D) TIDAL VOLUME Section ...............................................................................................20

3.5.4.

E) AIRWAY PRESSURE section .......................................................................................21

3.5.5.

F) OXYMETER Section......................................................................................................22

3.5.6.

G) BELLOW section...........................................................................................................23

3.5.7.

RM 3000 Breathing Monitor ......................................................................................................24

3.6.

Vaporizer ..................................................................................................................................26

3.7.

3.8 Operating Principal

4. ASSEMBLY OF VALVE GROUP (BREATHING SYSTEM)................................................................33

5. CALIBRATION AND TEST.................................................................................................................43

5.1 Valve Group (Breathing System)

5.2 Final Test

6. PNEUMATICS....................................................................................................................................49

6.1. Pneumatic Diagram Of Perseo

6.2 Pneumatic Components

6.3 Pneumatic Diagram vm200

6.4 Pneumatic Diagram AM5000/3 – AM5000/5

7. ELECTRONICS..................................................................................................................................54

......................................................................................................................................47

.............................................................................................................................3

................................................................................................................................3

..................................................................................................................................4

.......................................................................................................................6

......................................................................................................................7

.......................................................................................................................................8

..................................................................................9

..........................................................................................................................12

.......................................................................................................................27

.................................................................................................43

....................................................................................................49

..............................................................................................................51

........................................................................................................51

.................................................................................53

Warning

SIARE is used throughout this manual as an abbreviation for

SIARE HOSPITAL SUPPLIES S.r.l.

Via Giulio Pastore, 18 - 40056 Crespellano (BO) – ITALY

Tel.: 051/969802

Fax: 051/969101

Manufacturer of the equipment described in this manual

P.N.:DU5028130 REV.3.0

2

PERSEO

Service manual

1. USE OF THE SERVICE MANUAL

1.1. Users of manual

This manual is strictly for use by SIARE technicians or qualified technicians authorized by SIARE:

The technician authorized by SIARE has available the appropriate tools and spare parts and is trained with

regards to the safety of the product.

SIARE declines all responsibility with regards to technical assistance to the unit without formal authorization

of SIARE.

The correct and safe use for the patient and the operator of the unit, requires the knowledge of the

instructions and advice written in this manual and the User’s manual.

1.2. General Notes

The symbol

the safety of the patient and operator.

The manual describes the unit and its operation with the help of electrical and pneumatic diagrams.

!

The following manuals are an integral part of this manual:

- PERSEO’S User Manual

- VM 2000 Service Manual

- RM 3000 Service Manual

- AM5000/3-AM 5000/5 Service Manual

The technician should have available a copy of the User’s manual and should known its contents before

performing any of the operations described in this manual.

!

placed near an instruction, calls the reader’s attention to important information regarding

P.N.:DU5028130 REV.3.0

3

PERSEO

Service manual

1.3. Safety Notes

WARNINGS

The unit has been designed and is manufactured in conditions that guarantee the quality of the product and

its components, in order to ensure the maximum level of reliability and the safety of the patient and the

operator.

Therefore its safety is guaranteed only if it is used as per the instructions contained in this manual and the

User’s manual which is an integral and unseparable part of the product documentation for the technical

assistance.

For safety reasons, it is necessary to strictly follow the scheduled maintenance described in the User’s

manual.

The maintenance and the replacement of any parts has to be performed by authorized SIARE service

dealers and only original SIARE parts or parts checked by SIARE should be used.

SIARE is not civically or criminally liable in the following cases:

1) Use in conditions and for reasons not stated or prescribed in this manual.

2) Lack or omission of scheduled maintenance as described in this manual.

3) Maintenance performed by personnel not authorized by SIARE.

4) Use of non original spare parts or spare parts not checked and approved by SIARE.

5) Connection with equipment that is not in compliance with relevant directives in effect for safety for

the indicated use.

P.N.:DU5028130 REV.3.0

4

PERSEO

Service manual

!

Do not use the equipment in the presence of flammable gases.

In order to avoid risk of explosion this unit should not be used in the in the presence of flammable

anaesthetic gases such as ether of ciclopropane. This unit can operate only with anesthetics that are not

flammable as per the directive relative to the electrical safety of the anaesthesia units.

!

Do not connect the unit to the patient using conductive antistatic tubes.

Due to the fact that this machine cannot be used with flammable anaesthetic agents, such as ether or

ciclopropane, the use of antistatic patient tubes is not necessary. Since the use of antistatic tubes can cause

burns when using surgical equipment at high frequencies, their use is not allowed in any administration with

this equipment.

!

The unit is not approved for use in areas with danger of explosion.

The unit cannot be used in the presence of explosive gases.

Before connecting the unit with other electrical equipment not described in this manual,

check with the manufacturer.

The electrical connection of the unit should be made according to the instructions in this

manual in order to eliminate the danger of electric shock to the patient or operator due to an

improper installation.

Regarding electro-medical equipment’s general safety, it is important to follow all rules regarding the

interaction between the equipment and the patient, the operator and the nearby environment.

In order to ensure proper and safe use of the equipment it is crucial to follow the instructions in this manual

and the User’s manual and pay attention to the notes furnished in this User’s manual.

In order to use this equipment, it is vital to know all the instructions in this manual.

The equipment should be inspected and the maintenance performed by SIARE authorized personnel every 6

(six) months. All maintenance performed by SIARE authorized personnel is recorded in the equipment’s

maintenance log.

Every repair should be performed by SIARE authorized personnel. Siare is not liable for direct or indirect

damage to people or things, due to technical assistance by personnel non-authorized by SIARE or improper

use of the equipment, that is to say a use not described in the User’s manual or technical manual.

In order to repair equipment that is malfunctioning, has defects or is broken, the operator should contact

SIARE or its authorized local service dealer. It is important, when requesting service, to specify the model

and serial number of the equipment.

Use only the recommended accessories.

The use of other accessories is authorized only by a written authorization from SIARE as per the safety

directives in effect.

The equipment’s operation is authorized only in areas that conform to the safety directives in effect.

P.N.:DU5028130 REV.3.0

5

PERSEO

Service manual

2. GENERAL MAINTENANCE PROCEDURES

2.1. General Information

!

In order to ensure the safety of the patient and the operator, the unit should undergo an inspection and test

after 800 hours of use or every 6 months, whichever comes first. The inspection and test require a specific

knowledge of the unit, and therefore have to be made by specially trained SIARE authorized personnel.

The anesthetist or doctor is responsible for the ordinary maintenance of the unit, as described in this chapter.

Cleaning, disinfecting, sterilization and replacement of parts should be done as per the instructions in the

user’s manual in order to avoid damage to the equipment that could also endanger the safety of the patient

and operator.

The components used have been selected after technical and comparative tests in the designing phase of

the machine.

Furthermore, the same components are always tested during the manufacturing cycle in order to obtain the

maximum level of safety and reliability for the operator and patient.

Therefore whenever a part needs to be replaced, it must be an original spare part, which has been checked

and tested by SIARE.

SIARE assumes responsibility for all provisions of the law, if the unit is used and maintained as per the

instructions in this manual and the technical manual. The Technical Assistance Report, signed by the

authorized SIARE technician, is proof of the completion of the scheduled maintenance.

P.N.:DU5028130 REV.3.0

6

PERSEO

Service manual

3. WORKSTATION DESCRIPTION

3.1 General Information

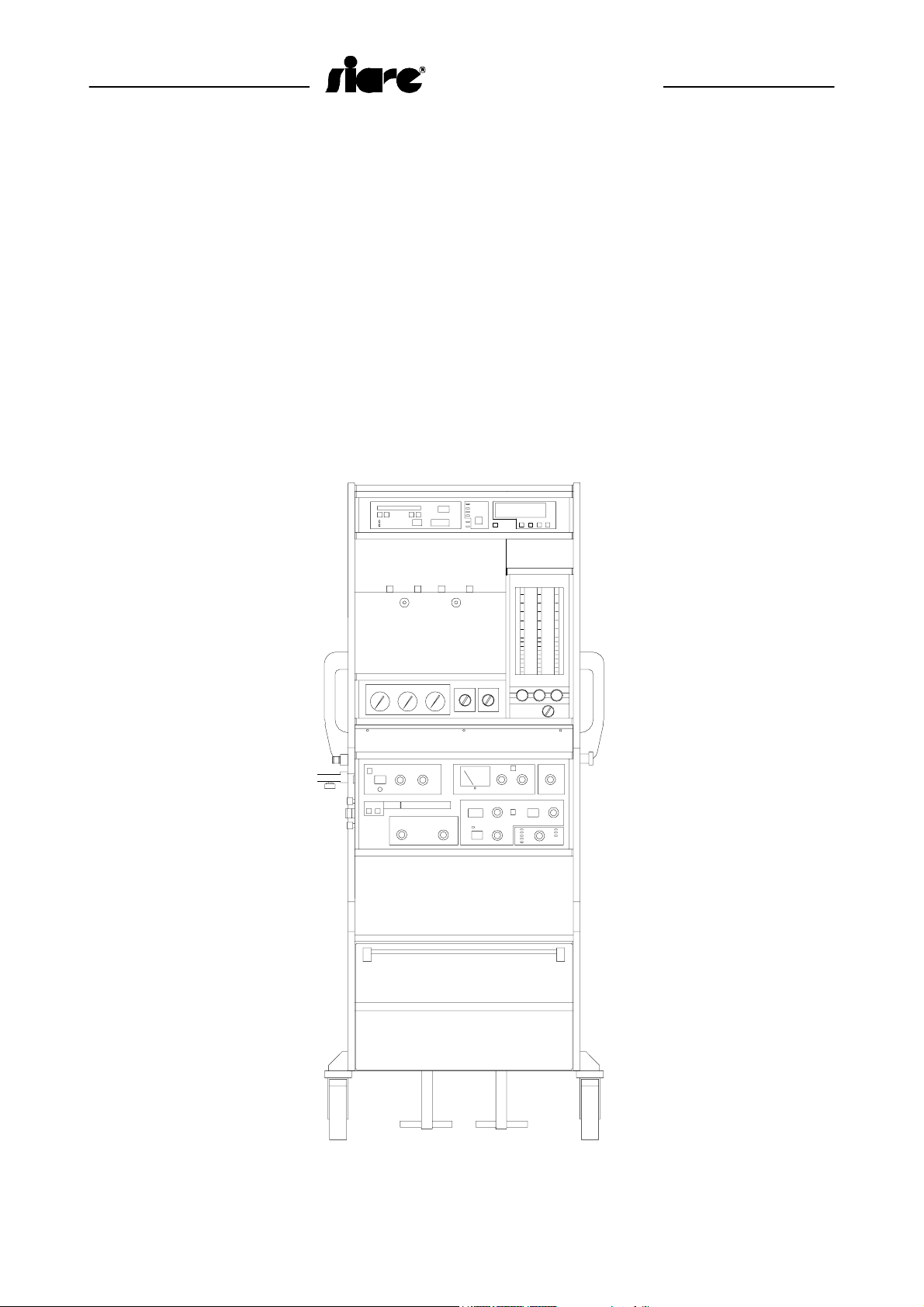

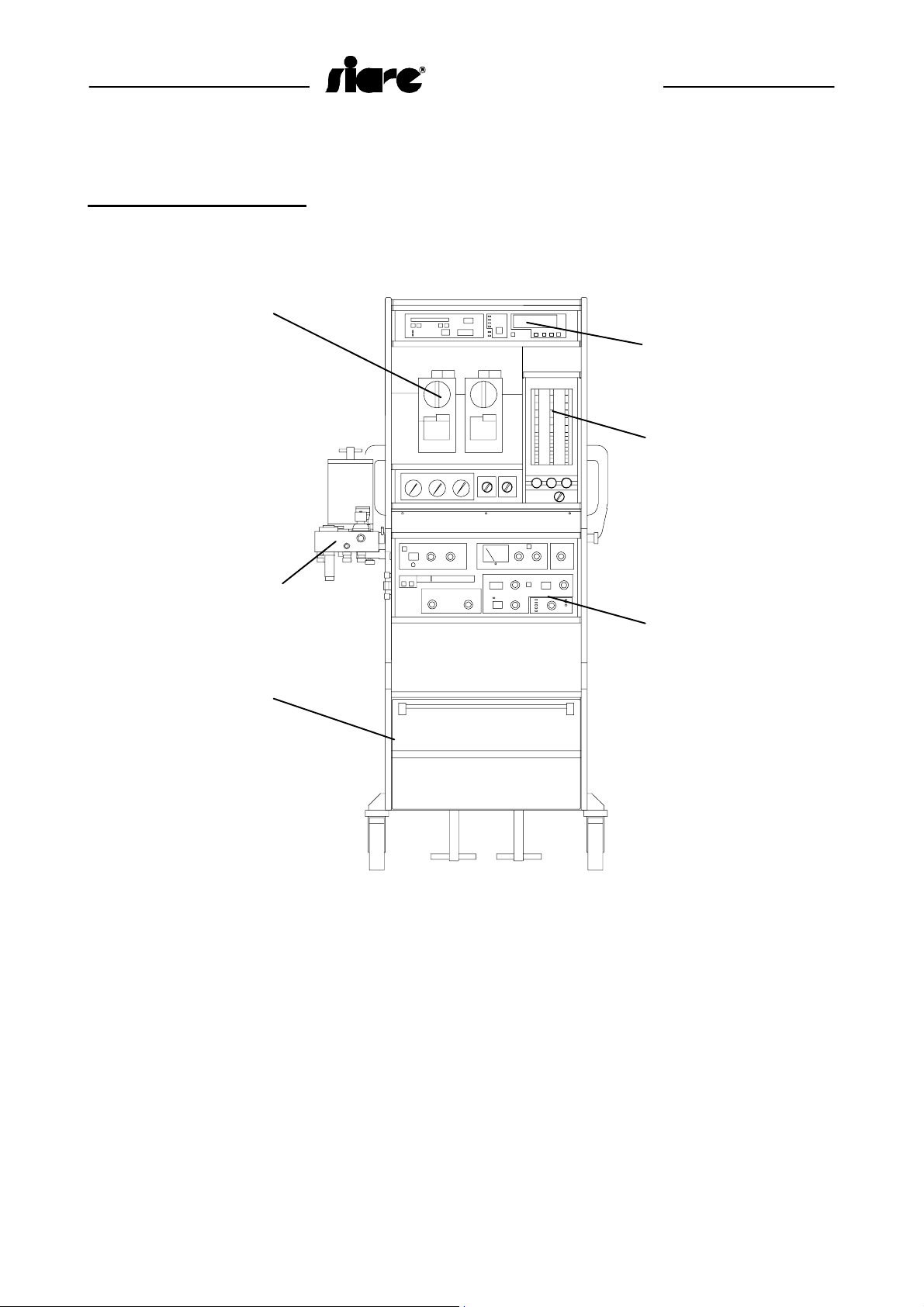

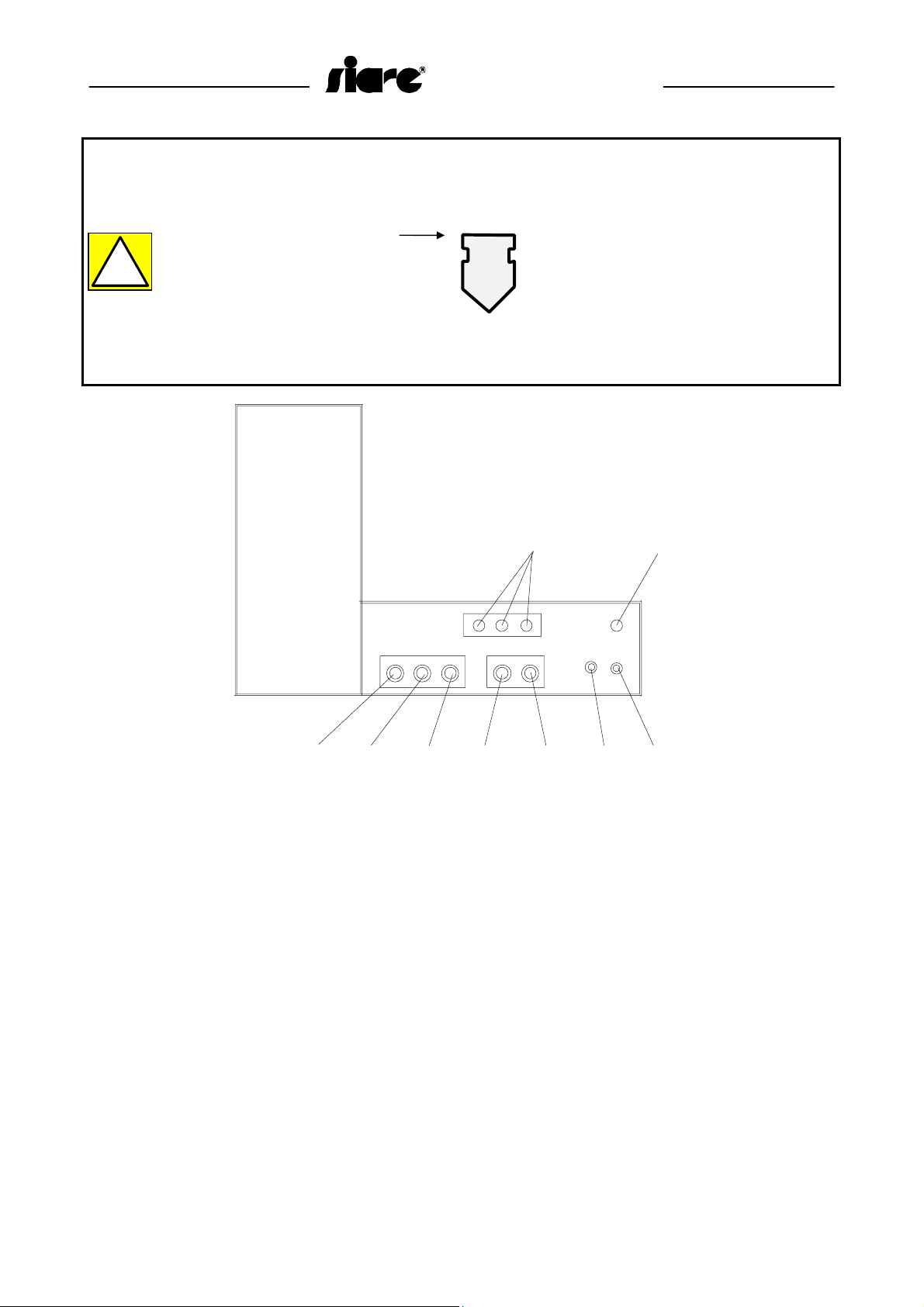

The PERSEO unit is composed of modules.

In its full optional configuration, it is composed of the following sections:

F

E

B

C

A

D

A Structure

B AM5000/3 – AM5000/5 anaesthesia module

C Breathing System

D VM 2000 lung ventilator

E RM 3000 breathing monitor

F Anaesthesia vaporizer

P.N.:DU5028130 REV.3.0

7

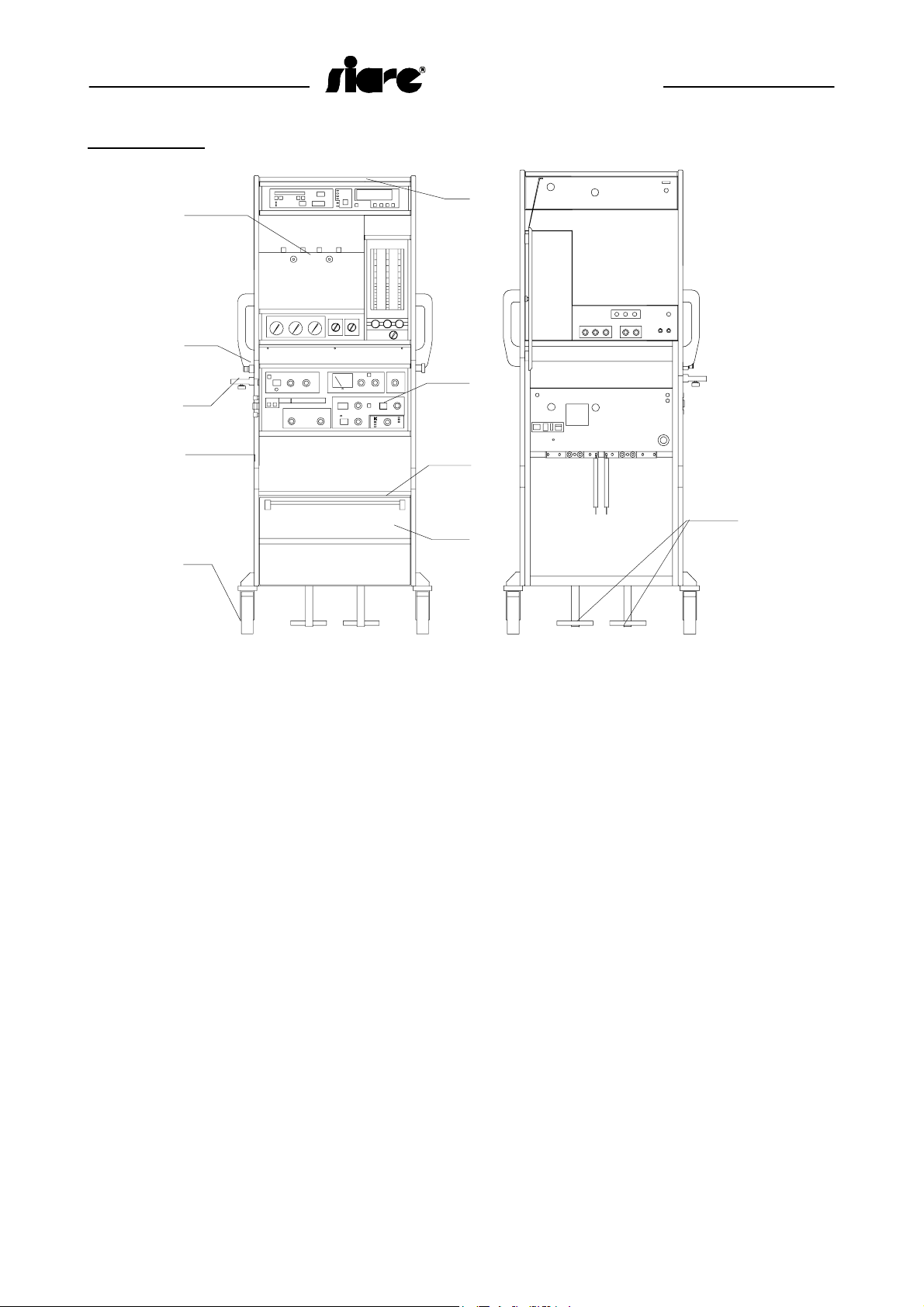

3.2 Structure

PERSEO

Service manual

G

F

I

E

H

A

D

L

C

B

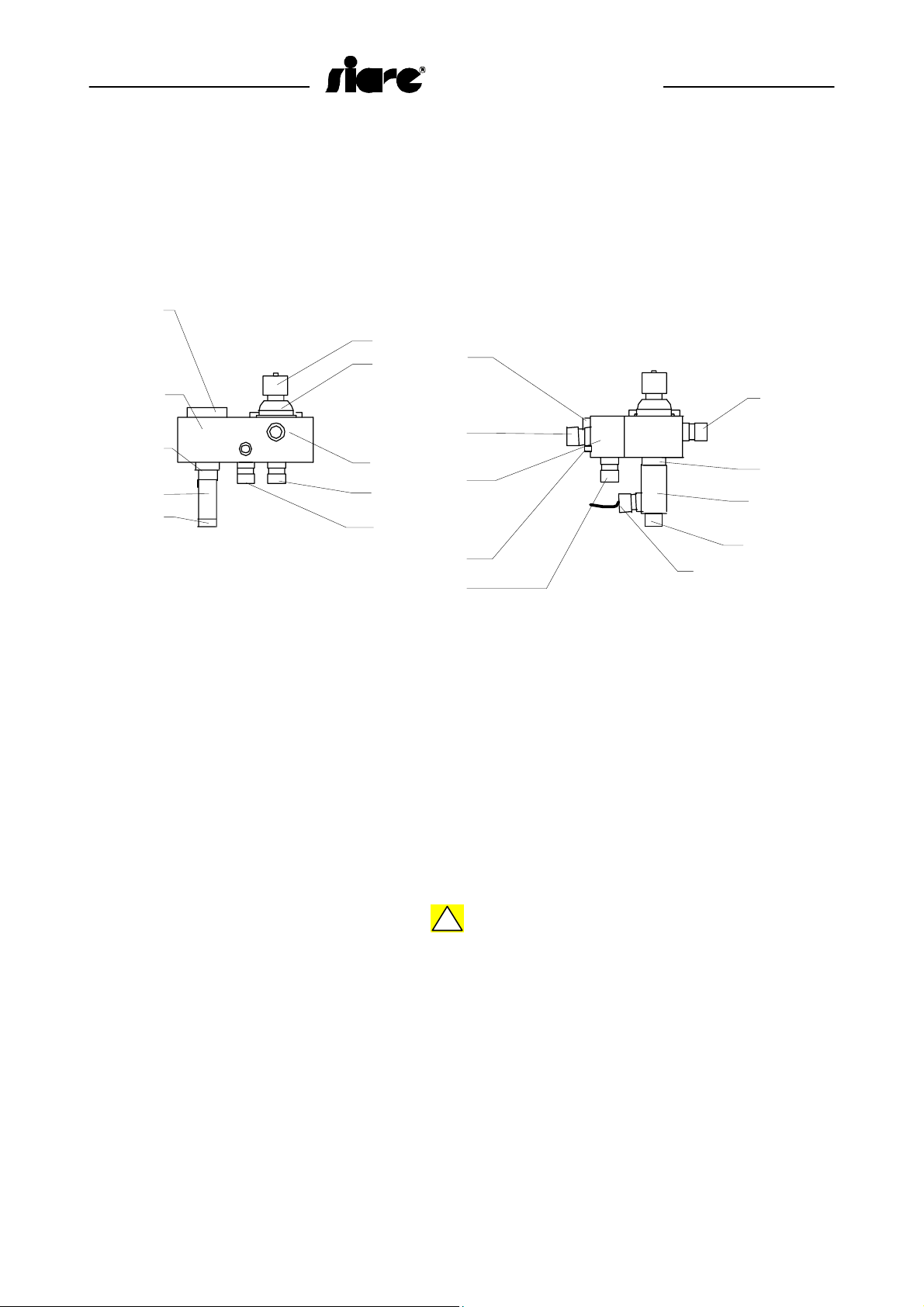

Front view Back view

A Aluminum and laminated plastic structure

B Antistatic pivoting wheels (the front wheels are equipped with a pedal brake)

C Removable drawer

D Instrument shelf

E Work shelf

F Monitor shelf

G Siaretex base for rapid connection of vaporizers (optional), Selectatec type and compatible with

vaporizer with interlock system (connection for second vaporizer is optional)

H Support bracket for “Breathing System” valve unit

I Support bracket for patient circuit arm

L Support for 5.3 Lt. Cylinders

M auxiliary guide for the assembly of optional accessories

P.N.:DU5028130 REV.3.0

8

PERSEO

Service manual

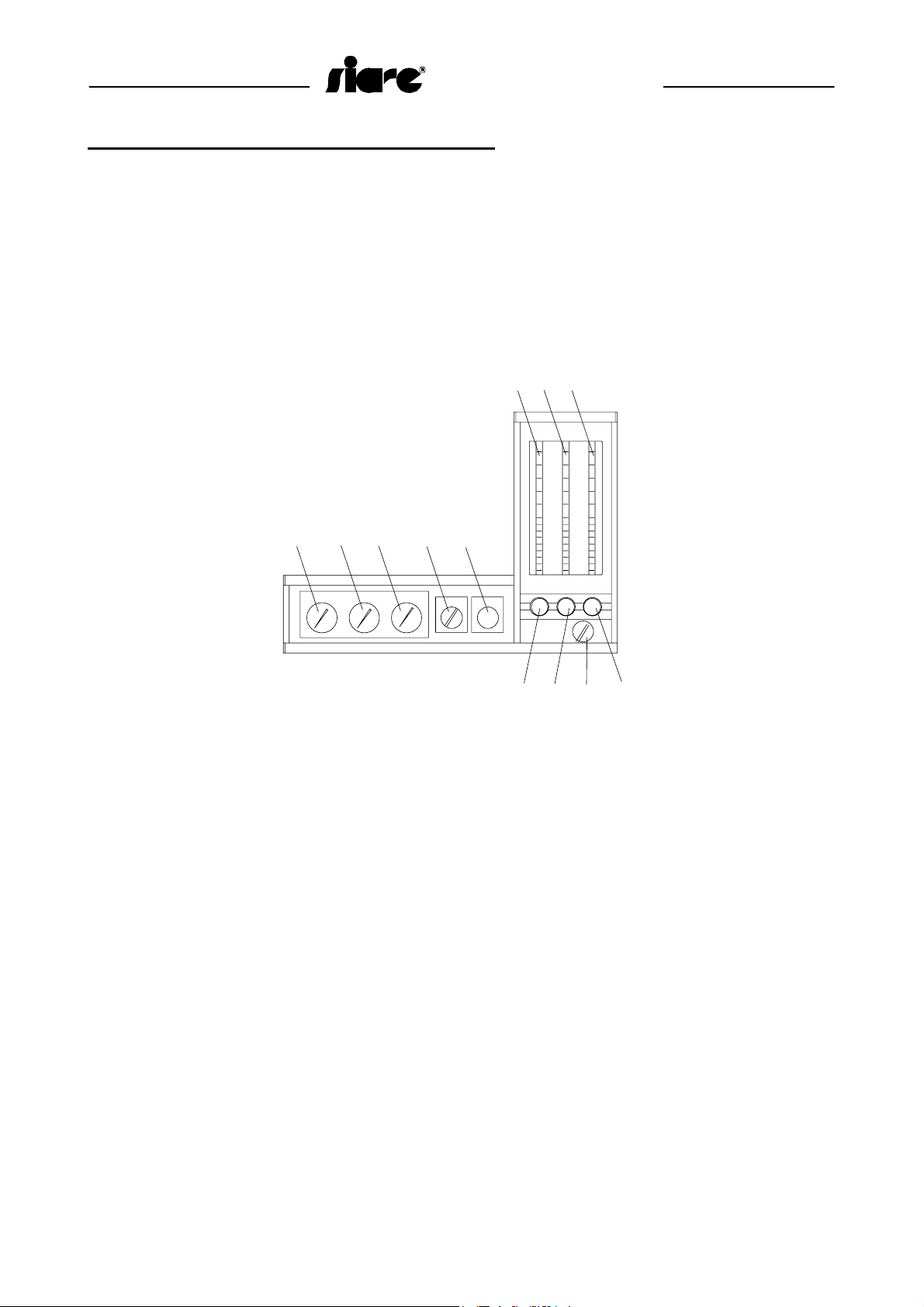

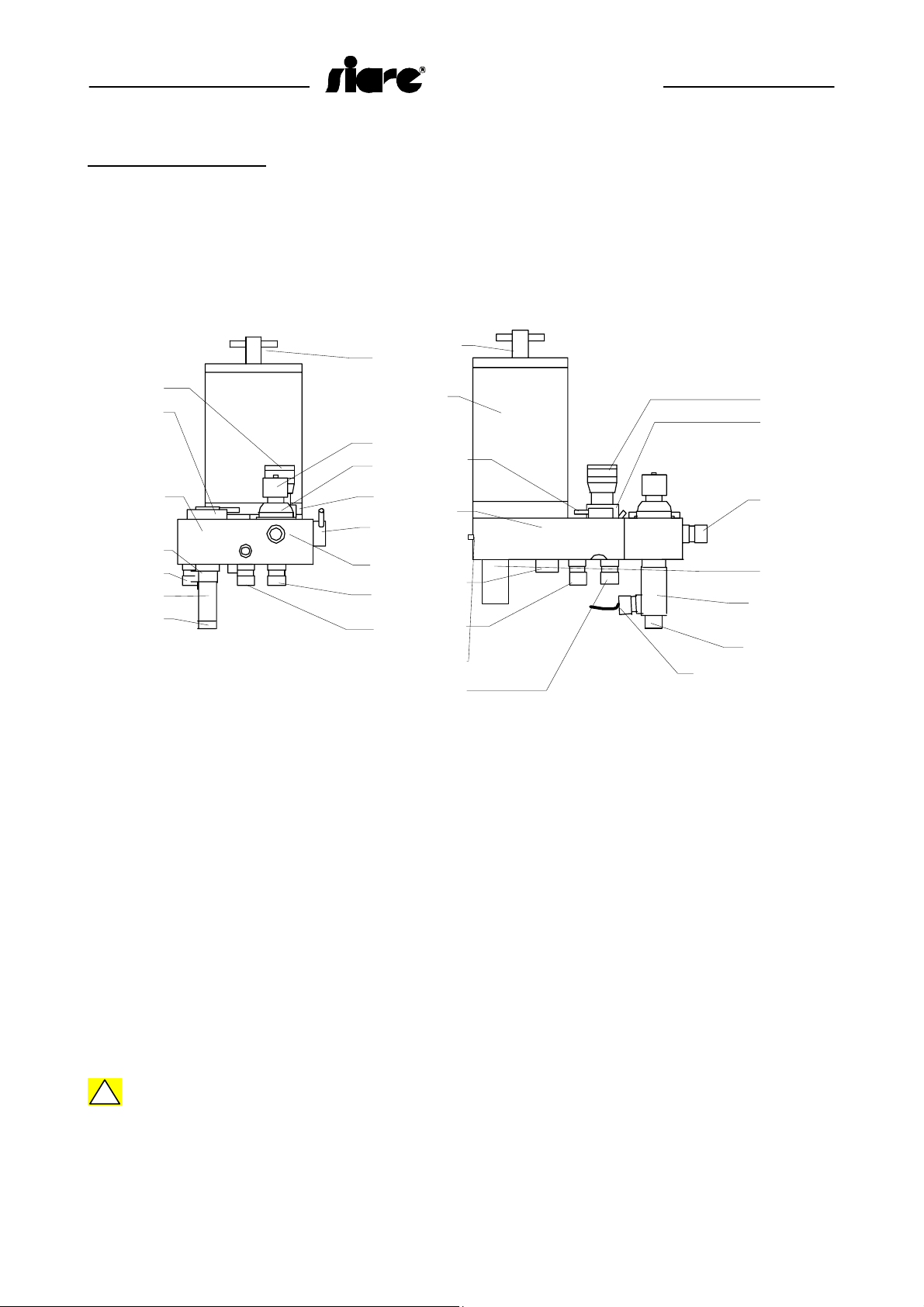

3.3 AM5000/3 – AM5000/5 anaesthesia module

AM5000/3 – AM5000/5 regulates the supply and concentration of the gas mixture (Air, O

supplies it to the anaesthetic gas vaporizer.

It also allows the selection of the gas mixture to be supplied (Air-O

oxygen) of the supplied gas mixture for emergencies. The AM5000/3 – AM5000/5 is also equipped with the

MIX-LIFE device that guarantees a minimum of 25% oxygen in all open-tap conditions.

By using the three gauges located on the front panel, the medical gases supply pressure coming from the

central gas installation can be continuously controlled (precision ± 10%).

The flowmeters permit the measurement of the flow the of the corresponding gases with a precision of ±

10% of the displayed value or ± 1% of the bottom of the scale, by choosing the highest of the two values.

S

L

I

M

N

O

, or N2O-O2) and the enrichment (with

2

T

U

, N2O), and also

2

P

Q

V

Front view AM5000/3

I OXYGEN supply gauge.

L NITROUS OXIDE supply gauge.

M AIR supply gauge.

N Selector switch for AIR / NITROUS OXIDE. This safety device:

avoids the contemporaneous supply of air and nitrous oxide

only the selected gas will be available on the flowmeters.

O OXYGEN BY-PASS key. By pressing this key pure oxygen is released into the anaesthesia circuit with

a flow of approximately 60 l/min.

P OXYGEN flow regulator for fresh gases. It opens counter-clockwise.

Q NITROUS OXIDE flow regulator for fresh gases. It opens counter-clockwise.

The opening of this regulator automatically supplies a flow of oxygen of about 25% of the total mixture.

The flow of oxygen can be viewed on flowmeter (S). This safety device (MIX LIFE) avoid the incorrect

administration of hypoxic mixtures.

R AIR flow regulator for fresh gases. It opens counter-clockwise.

S OXYGEN flowmeter (Max flow 12 l/min). In the model for low flows, there is a second flowmeter with a

lower scale of 1 liter.

T NITROUS OXIDE flowmeter (Max flow 12 l/min).. In the model for low flows there is a second

flowmeter with a lower scale of 1 liter.

U AIR flowmeter (Max flow 12 l/min).

V Selector switch for the exit of fresh gases (BREATHING SYSTEM or TO AND FRO).

For more details about the scales and the precision of the gauges and flowmeters, please refer to appendix

A «Technical data».

R

P.N.:DU5028130 REV.3.0

9

PERSEO

Avoid closing the regulators too tightly, so not as to wear or damage them.

The indicated flow value should be read at the upper level of the rim of the flowmeter

indicator when it rotates. If there is not rotation ask for technical assistance.

Reading level

!

CUT-OFF ALARM. If the anaesthesia module sounds a whistle, it means that the pressure

of the oxygen is too low. Immediately take action to reset the oxygen pressure. If the

pressure of the main system is not available, use the oxygen gas cylinder for emergencies.

Service manual

F

A

Back View

A OXYGEN inlet from the main medical gas installation.

B NITROUS OXIDE inlet from the main medical gas installation.

C COMPRESSED AIR inlet from the main medical gas installation.

D OXYGEN inlet from the cylinder’s pressure reducer.

E NITROUS OXIDE inlet from the cylinder’s pressure reducer.

F AIR/OXYGEN outlet for the supply of the lung ventilator, of the active scavenging system and the

tracheal aspiration unit.

In optimal conditions these connector supply COMPRESSED AIR.

If there is no COMPRESSED AIR or there is not enough pressure, the unit automatically switches the

distribution to OXYGEN.

These connectors are supplied standard with the machine if the relative accessories are in use

G Emergency OXYGEN outlet.

H Exit of fresh gases connector for TO and FRO.

I FRESH GAS outlet for the Breathing System. (please refer to chapter 4.4 “Breathing System Assembly”

in the PERSEO’S user manual)

B C D E H

I

G

P.N.:DU5028130 REV.3.0

10

PERSEO

!

DANGER OF FIRE! Do not connect devices that are not explicitly certified to function with

PURE OXYGEN to outlets F and G.

!

Do not make connections to the main medical gas installation or the gas cylinders before

reading section 4.2 “MEDICAL GAS CONNECTION” in the PERSEO’S user manual.

Service manual

P.N.:DU5028130 REV.3.0

11

PERSEO

A

A

Service manual

3.4 Breathing System

3.4.1. OPEN-SEMICLOSED VERSION (NON REBREATHING -REBREATHING)

It is the device that takes fresh gases towards the patient and that collects the expired gases towards the

CO

absorber and then to the lung ventilator to be supplied to the patient. The fresh gases supplied by the

2

AM5000 anaesthesia module are also added to the Breathing System.. With this cirucit it is also possible, by

simply rotating the selector (V), to change the system into an OPEN or NON-REBREATHING. The manual

ventilation is possible directly from the valve group or with the TO AND FRO system.

T

T

Q

P

S

Q

R

O

N

S

V

C

B

D

U

E

F

C

M

H

L

U

D

E

F

I

A Structure of the Breathing System.

B Selector form AUTOMATIC SPONTANEOUS or MANUAL (AUT.SPONT-MAN) ventilation.

C Inspiratory line connection to the patient circuit.

D Water trap

E Expiratory flow sensor.

F Expiratory line connection to the patient circuit.

G Mounting bracket for the flow sensor.

H Reservoir balloon connection.

I Connection for fresh gas input hose from AM 5000 anaesthesia module.

L Ambient air aspiration valve. Opens automatically when the quantity of fresh gases in the breathing

circuit is not enough to guarantee the set current volume.

M Connection to lung ventilator.

N Inspiratory valve plastic cover

O Oxygen sensor. It measures the O

mix reaches the patient.

P Expiratory valve.

Q APL valve. It regulates the maximum airway pressure during manual ventilation. The pressure

increases by turning the knob of the valve clockwise and lowers by turning it counter-clockwise. The

range of regulation is from approximately 2 to 30 cmH

!

During manual ventilation, the airway pressure can go over the limit set on the lung

ventilator. The pressure limit depends on the regulation of the APL valve.

concentration of the inspiratory mix, therefore right before the

2

H

2

O.

G

P.N.:DU5028130 REV.3.0

12

PERSEO

R mounting bracket of APL valve.

S Soda lime canister, capacity 1.5 Kg.

T Locking cap for closing and lifting the canister.

U Connection for exit of used breathing gases (

V REBREATHING or NON REBREATHING selector.

!

Service manual

to be connect to scavenging system).

P.N.:DU5028130 REV.3.0

13

PERSEO

A

A

3.4.2. OPEN VERSION (NON REBREATHING)

It is the device that takes fresh gases towards the patient and that collects the expired gases towards the

disposal. The fresh gases form the AM5000 modules are also collected on the Breathing System The

manual ventilation is possible only with the TO AND FRO system.

Service manual

P

O

N

L

C

D

V

E

F

C

M

H

D

E

F

I

A Structure of the Breathing System.

C Inspiratory line connection to the patient circuit.

D Flow sensor connection to the expiratory line.

E Expiratory flow sensor.

F Exspiratory line connection to the patient circuit

G Mounting bracket for the flow sensor.

H Reservoir balloon connection.

I Connection for fresh gas input hose from AM 5000 anaesthesia module.

L Ambient air aspiration valve. Opens automatically when the quantity of fresh gases in the breathing

circuit is not enough to guarantee the set current volume.

M Connection to lung ventilator.

N Inspiratory valve plastic cover

O Oxygen sensor. It measures the O

mix reaches the patient.

P Expiratory valve.

V Connection for exit of used breathing gases (

concentration of the inspiratory mix, therefore right before the

2

H

!

to be connect to scavenging system).

G

P.N.:DU5028130 REV.3.0

14

PERSEO

A

Service manual

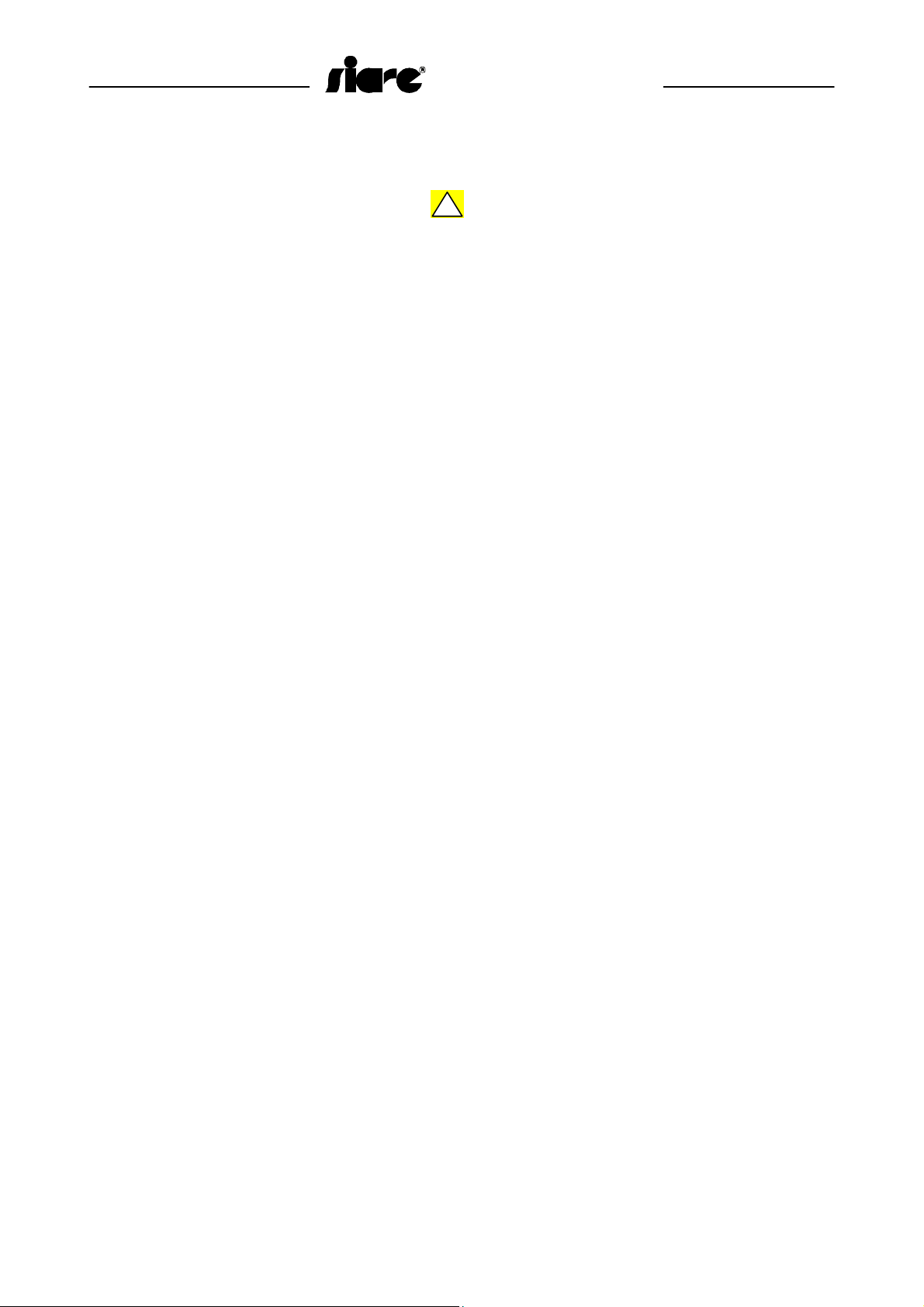

3.5. VM 2000 lung ventilator

VM2000 lung ventilator is the device that mechanically controls the breathing activity of the patient when the

patient is being automatically ventilated. Other than the regulations of the patient’s ventilation mode, the

VM2000 also enables checking the airway pressure and oxygen concentration of the patient’s gas mixture.

L

F H

G

I

E

C

D

B

M

Back view

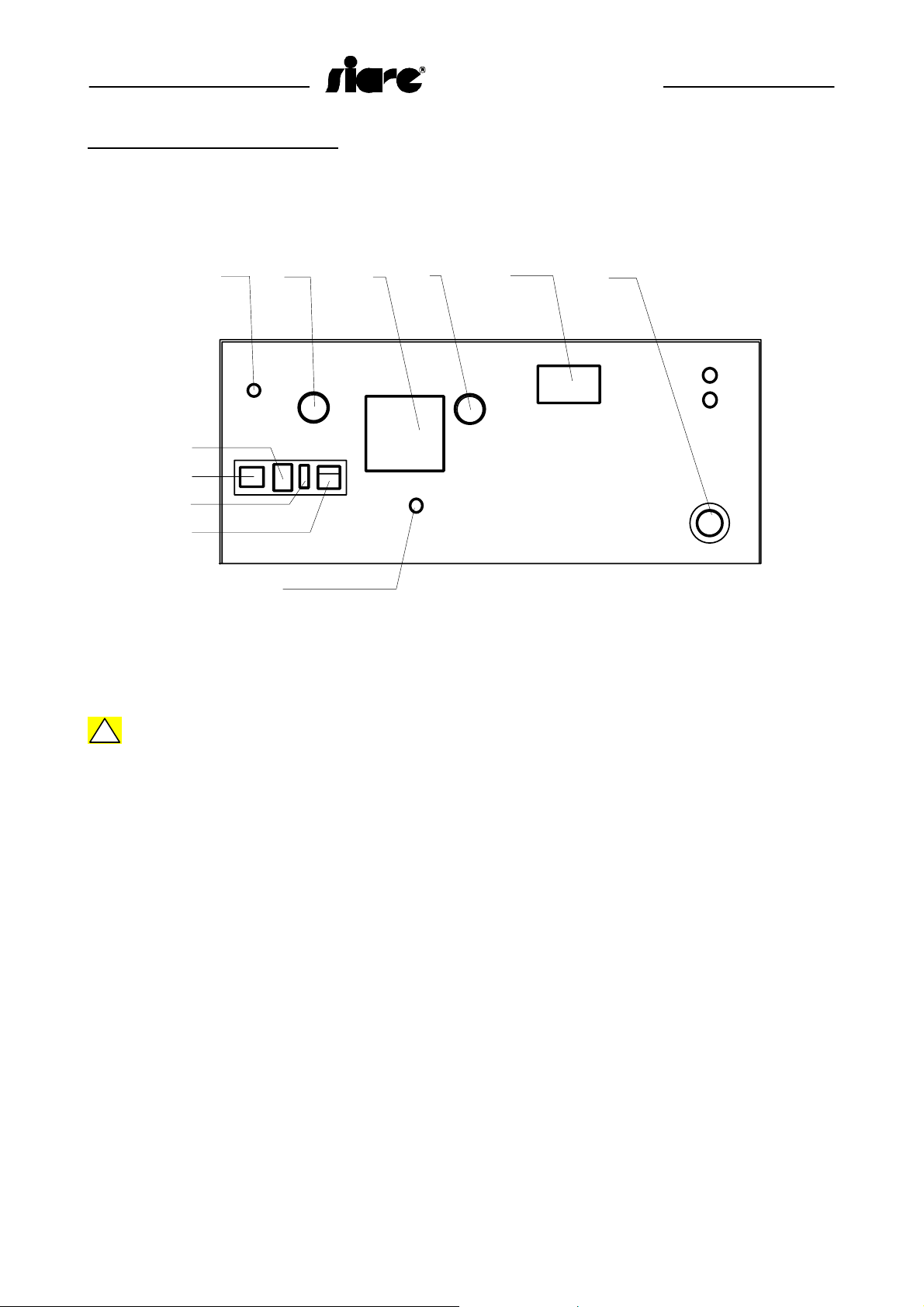

A Main ON/OFF switch

B Safety fuses

!

ATTENTION!. The specification of the fuse to be used is indicated on the identification tag(I).

Never use fuses with a different specification.

C Inlet for main power cable.

D Inlet for auxiliary power (MAX 6 Ampere).

E Inlet for AIR - OXYGEN (3.5 Bar ± 0.75).

F Outlet for power cable for RM3000 monitor.

G Outlet for synchronizing cable for RM3000 monitor.

H Cooling fan.

I Identification tag.

The following specifications are displayed:

- MODEL

- SERIAL NUMBER

- POWER SUPPLY

- POWER FREQUENCY

- POWER CONSUMPTION

- FUSE SPECIFICATION

L Battery safety fuse (5A T).

M equipotential connector.

P.N.:DU5028130 REV.3.0

15

PERSEO

A

Service manual

F

Front View

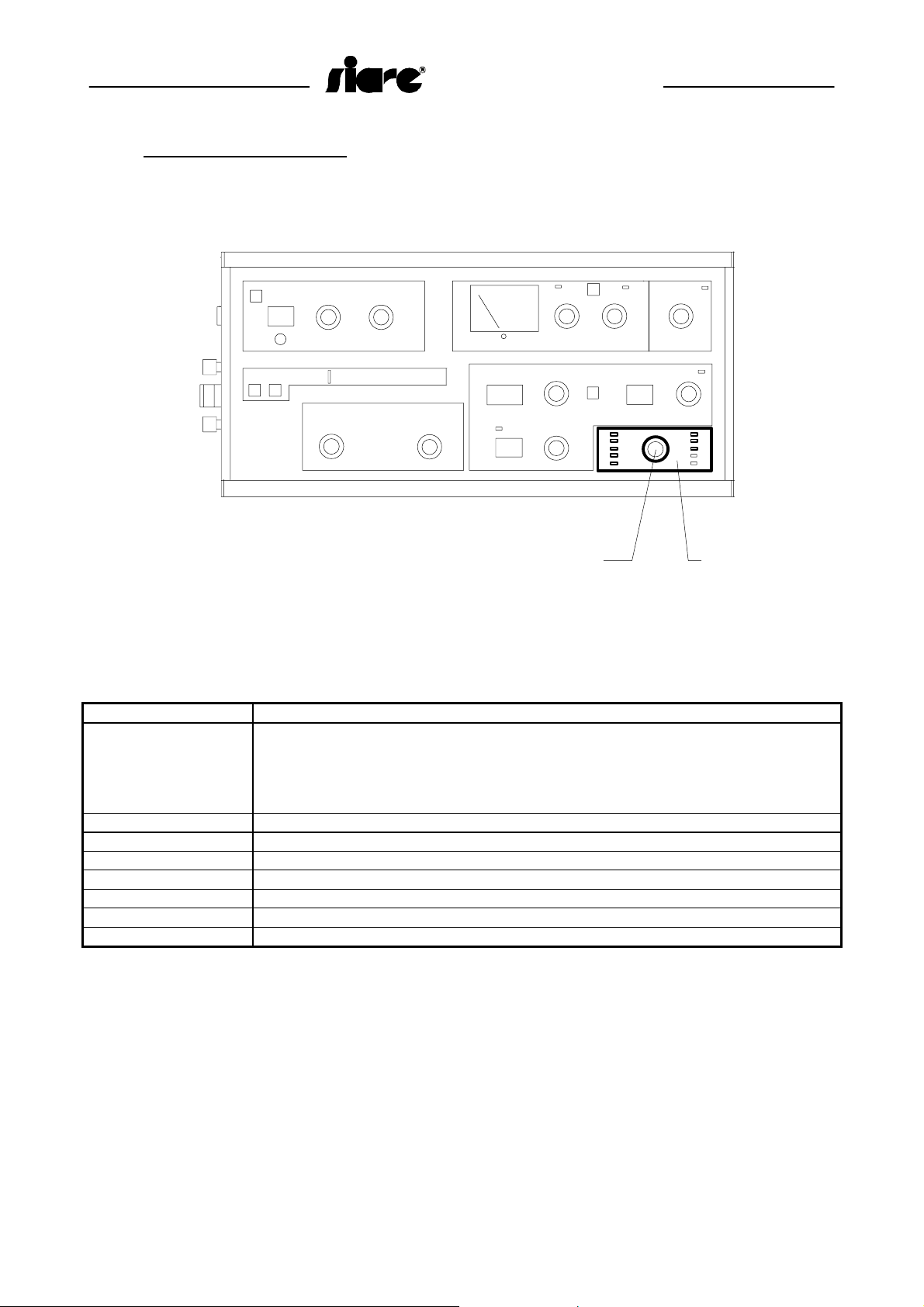

A MODE section for setting ventilation modes of the lung ventilator

B RATE section for setting breathing rate.

C FLOW-PEEP section for setting inspiratory flow and the positive end expiratory pressure (PEEP).

D TIDAL VOLUME section for setting tidal volume for the breathing act.

E AIRWAY PRESSURE section for setting minimum and maximum alarm limit for the airway pressure,

therefore check the maximum airway pressure, that the VM2000 can reach when in operation.

F OXYMETER section for measurement and alarm for airway gas concentration.

G BELLOW section

E

BCDG

P.N.:DU5028130 REV.3.0

16

PERSEO

A

Service manual

3.5.1. A) MODE Section

1

Operating modes of the lung ventilator can be selected by turning the knob of the MODE section (1).

The selection of a operating mode is indicated when its corresponding LED turns ON.

OPERATING MODES:

POSITION DESCRIPTION

OFF Machine off displays the status of the power supply when one of the following

operating modes are selected. With the main power supply the OFF led is on and it

is green. When the unit is supplied by battery and the battery is charged, the led

becomes orange. When the battery is low the led becomes red and the audible

alarm comes on.

STAND-BY Stand-by (pause) mode for setting parameters.

MANUAL - SPONT Manual and spontaneous ventilation mode

CONTROL Controlled ventilation mode

CONTROL + ASS Controlled-Assisted ventilation mode

ASS Assisted ventilation mode

SIMV Synchronized intermittent mandatory ventilation mode

IMV Non-synchronized intermittent mandatory ventilation mode

P.N.:DU5028130 REV.3.0

17

Loading...

Loading...