Page 1

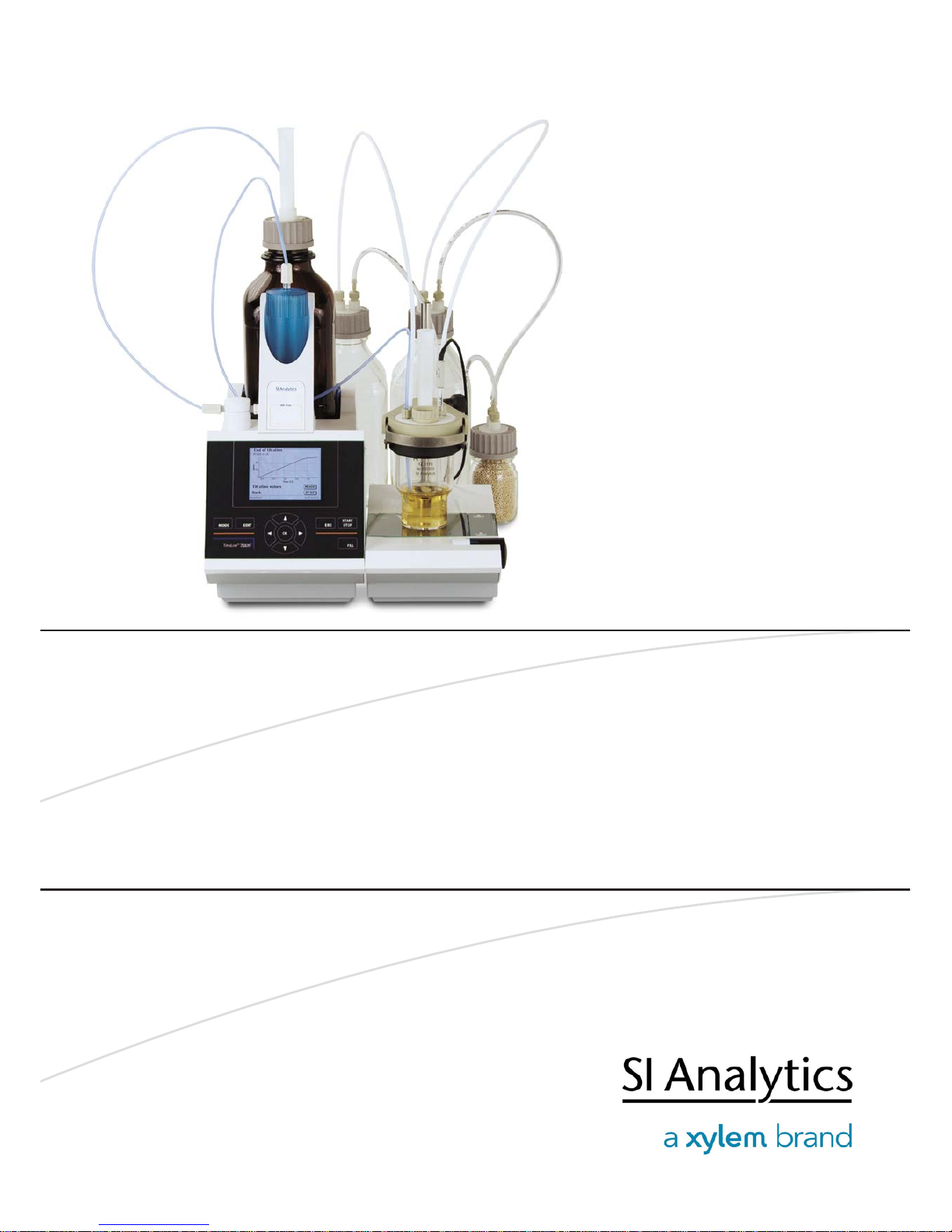

TitroLine®

7500 KF

TITRATOR

OPERATING INSTRUCTIONS

Page 2

Gebrauchsanleitung ...................................................................................................... Seite 5 ..... 72

Wichtige Hinwei se: Die Gebrauchsanlei tung vor der ersten Inbetriebnahm e des Tit rators TitroLine® 7500 KF

bitte sorgf älti g lesen und beac hten. Aus Sic herhei tsgrü nden darf der T i trator TitroLine

®

7500 KF ausschließlich

nur für die in dieser Gebr auc hsanl eitung beschriebenen Zwecke ei ngesetzt werden.

Bitte beachten Si e auc h die Gebrauc hsanl eitungen für die anzuschließenden Geräte.

Alle in dieser Gebr auc hsanl eitung enthalt enen A ngaben sind zum Zeitpunkt der Drucklegung gül tige Daten. Es

können jedoch von SI Analytics sowohl aus technischen und kaufmännischen Gründen, als auch aus der

Notwendigkeit heraus, gesetzliche Bestimmungen der verschiedenen Länder zu berücksichtigen,

Ergänzungen am Titrator TitroLine

®

7500 KF vorgenommen werden, ohne dass die beschriebenen

Eigenschaften beeinflusst werden.

Operating Instructions ................................................................................................ Page 73 .... 142

Important notes: Before initial operation of the Titration Unit TitroLine® 7500 KF, please read and observe

carefully the oper ating i nstructions. F or safety reasons the Titrati on Unit TitroLine

®

7500 KF may only be use d

for the purposes described i n these present oper ating instructions.

Please also observ e the operating instructions for t he units to be connected.

All specifications in this instruction manual are guidance values which are valid at the time of printing.

However, for techni cal or commercial reasons or in the neces sity to comply with the statuary stipulati ons of

various countri es, SI Analyti cs may perf orm additions to the Ti tration Unit TitroLine

®

7500 KF without changing

the described properties.

Page 3

Page 4

TABLE OF CONTENT PAGE

1 . Technical Specifications of the Titrator TitroLine® 7500 KF ................................ 75

1.1 Summary ............................................................................................................................ 75

1.2 Specifications Titrator TitroLine® 7500 KF............................................................................ 76

1.3 Warning and safety inf ormati on ........................................................................................... 79

2 . Unpacking and First Operation .............................................................................. 80

2.1 Unpacking ........................................................................................................................... 80

2.2 Installation and Connection of the TM 235 KF titration stand and t itration vessel .................. 80

2.3 Connecting the Titrator - Com bination with Accessories and Additional Dev ic es .................. 84

2.3.1 Back panel of the titr ator TitroLine® 7500 KF ...................................................................... 84

2.3.2 Connection port s of the Ti troLine® 7500 KF ........................................................................ 84

2.3.3 Connecting a print er ............................................................................................................ 84

2.3.4 Connecting a USB devi c e (manual controller, keyboard, memory device, hub) .................... 84

2.3.5 Connection of analy tical balances ....................................................................................... 85

2.4 Setting the Language of the Country ................................................................................... 85

2.5 Interchangeable unit WA ..................................................................................................... 86

2.5.1 Installing the interchangeable unit ....................................................................................... 86

2.6 Positioning and Replacing an Interchangeable Uni t ............................................................. 87

2.6.1 Placing an interc hangeable unit ........................................................................................... 87

2.6.2 Removing an interc hangeable unit ...................................................................................... 88

2.6.3 Programming the ti tration unit .............................................................................................. 88

2.7 Initial Filling or Rinsing of the Entire Interchangeable Unit .................................................... 90

2.8 Filling the titr ation vessel with solvent .................................................................................. 92

2.9 Replacing the Glass Cylinder and the PTFE Piston ............................................................. 92

3 . Working with the Titrator TitroLine® 7500 KF ........................................................ 95

3.1 Front Keyboard ................................................................................................................... 95

3.2 Display ................................................................................................................................ 95

3.3 Manual controller “mouse“ ................................................................................................... 96

3.4 External PC Keyboar d ......................................................................................................... 96

3.5 Menu Structur e ................................................................................................................... 97

3.6 Main Menu .......................................................................................................................... 99

3.6.1 Standard methods of KF Titration ........................................................................................ 99

3.6.2 Automatic KF Titration ....................................................................................................... 100

3.6.3 Dosage ............................................................................................................................. 104

3.6.4 Preparing Soluti ons ........................................................................................................... 107

4 . Method Parameters................................................................................................ 108

4.1 Method editing and new m ethod ........................................................................................ 108

4.2 Default methods ................................................................................................................ 108

4.3 Copy Methods ................................................................................................................... 109

4.4 Delete Methods ................................................................................................................. 109

4.5 Print method ..................................................................................................................... 110

4.6 Change Method Param eters.............................................................................................. 110

4.6.1 Method type ...................................................................................................................... 110

4.6.2 Result ............................................................................................................................... 111

4.6.3 Titration param eters .......................................................................................................... 119

4.6.4 Titration end ...................................................................................................................... 122

4.6.5 Dosing parameter.............................................................................................................. 124

4.6.6 Sample identification ......................................................................................................... 125

4.6.7 Documentation .................................................................................................................. 126

5 . System settings ..................................................................................................... 127

5.1 Interchangeabl e Unit - Reagents ....................................................................................... 127

5.2 RS232 Settings ................................................................................................................. 129

5.3 Date and Time .................................................................................................................. 131

5.4 Password .......................................................................................................................... 131

Page 5

5.5 RESET.............................................................................................................................. 131

5.6 Printer ............................................................................................................................... 132

5.7 Device Information ............................................................................................................ 132

5.8 System Tone ..................................................................................................................... 132

5.9 Software Update ............................................................................................................... 133

6 . Data Communication via RS232- and USB -B interface ...................................... 135

6.1 General Information .......................................................................................................... 135

Meaning / Descri ption ........................................................................................................................ 135

6.2 Chaining multiple devices —“Daisy Chain Concept“ .......................................................... 135

6.3 Instructi on S et f or RS-Communication ............................................................................... 135

7 . Connection of Analytical Balances and Printers ................................................ 137

7.1 Connection of Analytical Balances ..................................................................................... 137

7.1.1 Balance TZ-Number .......................................................................................................... 137

7.2 Balance data edit or ........................................................................................................... 138

7.3 Connection of Printers ....................................................................................................... 139

8 . Maintenance and Care of the TitroLine® 7500 KF ............................................... 140

9 . Storage and transportati on ................................................................................... 141

10 Recycling and Disposal ......................................................................................... 141

11 Index ....................................................................................................................... 142

Version 120829 US

Page 6

75

Chapter 1 – Specifications Titrator TitroLine® 7500 KF

1 Technical Specifications of the Titrator TitroLine® 7500 KF

1.1 Summary

The TitroLine® 7500 KF is suitable for the foll owing applications:

The possible range of titrations includes volumetric KF and Dead stop titrations with a maximum of 50

memorisable methods.

The examples of possible use of the TitroLine

®

7500 KF include:

− KF tit r ations with 1-component KF reagents

− KF tit r ations with 2-component KF reagents

− Dead stop ti t r ations such a bromine number and sulphur dioxide in

− Compatible with TitriSoft 3.0.

In addition, the Tit r oLine® 7500 KF comes with following functionalities of the TITRONIC® 500 piston burette:

− Dosing

− Preparation of solutions

Each method allows for the setting of a variety of dosing and filling rat es.

Solutions to be used:

Virtually, any li qui ds and soluti ons wit h a vi scosity of < = 10 mm² / s such as conce ntrat ed sulphuri c aci d m ay

be used. However, one has to avoi d the use of chemicals that may attack glass, PTFE or FEP or that are

explosive, such as hydrofluoric acid, sodium azide or bromine! Suspensions containing high solids

percentages may clog or ev en dam age the dosing syst em .

General pr ov isions:

The safety guidelines that are applicable to the handling of chemi c als have to be observed under all

circumstances. This applies in particular to inflammable and/or etching liquids.

Guarantee

We provide guarantee for the device described for two years from the date of purchase. This

guarantee covers manufacturing faults being discovered within the mentioned period of two years.

Claim under guarantee covers only the restoration of functionality, not any further claim for damages

or financi al loss .

Improper handling/use or illegitimate opening of the device results in loss of the guarantee rights.

The guarantee does not cover wear parts, as lobes, cylinders, valves and pipes including the thread

connections and the titration tips. The breach of glass parts is also excluded. To ascertain the

guarantee liability, please return the instrument and proof of purchase together with the date of

purchase freight paid or prepai d.

Page 7

76

Chapter 1 – Specifications Titrator TitroLine® 7500 KF

1.2 Specifications Titrator TitroLine® 7500 KF

Status July. 01th 2012

CE sign:

EMC compatibility acc or ding to the Council Directive: 2004/108/EG;

applied harmoniz ed standar ds: E N 61326-1:2006

Low-voltage di r ectiv e ac c or ding to the Council Directive 2006/95/EG

Testing basis EN 61 010, P art 1

Country of origin: Germany, Made in Germany

The following solv ents/titration reagent s are allowed to be used:

− All c ommon ti tration solutions.

− As reagent water and al l non-aggressiv e non-organic and organi c fluids are al lowed. If using combustible

fluids fir e please adhere t o the Guidelines for Explosion Protec tion and Prevention of the chemical industr y .

− For f luids wit h higher v iscosity (≥ 5 mm

2

/s), lower boiling poi nt or affinity to outgas, t he filling and dosage

speed can be adjusted.

− Fluids with viscosity over 20mm

2

/s ca nnot be dosed.

Measurement i nput: Karl-Fischer (Dead-stop) connect or for double platinum electrode

Polarisation voltage variably adjustable from 40 … 220 mV.

Connector: 2 x 4 mm - sockets.

Measurement

range

Display resoluti on

Measurement

accuracy* withou

t

sensor probe

I [µA]

0 ... 100

0,1

0,2 ± 1 Digit

* The measurement uncert ainty of the sensor probe has to be taken into acc ount as well.

Page 8

77

Chapter 1 – Specifications Titrator TitroLine® 7500 KF

Display: 3.5 inches -1/4 VGA TFT display with 320x240 pixels.

Inputs: Measurement i nput µA: (Dead-Stop-) connector for double platinum electrode

Connection sockets: 2 x 4 mm)

Power supply: power supply 90-240 V; 50/60 Hz , power input: 30 VA

RS232-C Interface: RS232-C int erface separated galvanically through photocoupler

Daisy Chain function available.

Data bits: adjustable, 7 or 8 Bit (default: 8 Bit)

Stop bit: adjustable, 1 or 2 Bit (def ault: 1 Bit)

Start bit: static 1 Bit

Parity: adjustable: ev en / odd / none

Baud rate: adjustable: 1200, 2400, 4800, 9600, 19200 (Default 4800 baud)

Address: adjustable, (0 to 15, default: 01)

RS232-1 for computer, input Daisy Chain

RS232-2 devices of SI Analytics, titr ator TitroLine

6000/7000/7500,

- Burettes TITRONIC

500, TITRONIC 110 plus, TITRONIC universal,

- Balances of the types Mettler, Sartorius,

- Kern, Ohaus (for m or e, please contac t SI Analytics)

- Exit Daisy Chain

USB Interface: 2 x USB-type A and 1 x USB-ty pe B

USB –Typ B (“slave“) for connecting a PC

USB –Typ A (“master“) for connecting:

- USB keyboard

- USB printer

- USB “mouse“ (“mouse“),

- USB data media e.g. USB stick

- USB Hub

Stirrer/pump TMKF: 12V DC out, 500mA

power supply for sti r r er TM 235 and KF titration stand TM 235 KF

Housing material : Polypropylene

Front keyboard: polyester coated

Housing dimensions: 15.3 x 45 x 29.6 cm (W x H x D), height incl. interchangeable unit

Weight: ca. 2.3 kg for basic unit

ca. 3.5 kg for complete devic e inc l. interchangeable unit (with em pty r eagent bottle)

Ambient conditions: Ambient temperature: + 10 ... + 40 °C for operation and storage

Humidity according to EN 61 010, Part 1:

Max. relative humi dity 80 % for temperatures up to 31 °C,

linear decrease down to 50 % relative humidity at a temperatur e of 40 °

Page 9

78

Chapter 1 – Specifications Titrator TitroLine® 7500 KF

Status Aug. 23

rd

2011

Interchangeabl e un its

Compatibility: units are compatible to the titrat or s TitroLine

®

6000, TitroLine® 7000, TitroLine®

7500 KF and Piston Burette TITRONIC

®

500

Recognition: automatically through RFID. Recognition of unit size and characteristics of the

Titration- or dosi ng sol ution

Valve: volume neutral cone v alv e made fr om fluor oc ar bon poly mers (PTFE), TZ 3000

Cylinder: borosilic ate glass 3.3 (DURAN

®

)

Hoses: FEP hose set, blue

Bracket for supply bott le: suitable for square glas s bottle and misc. reagent bottles

Materials: borosilicat e glass DURAN

®

, fluorocarbon pol ymers (PTFE), stainless steel,

polypropylene,

Dimensions: 15 x 34 x 22.8 cm (W x H x D) incl. reagent bottle

Weight: approx. 1.2 kg for int er c hangeable unit WA incl. empty reagent bottle

Dosing accuracy: after DIN EN ISO 8655, part 3

Accuracy: 0.15 %

Precision: 0.05 - 0.07 %

(Depending on the used int er c hangeable unit)

Dosing accuracy of the Titrator TitroLine

®

7500 KF with WA interchangeable units:

Interchangeable.

unit

type No.

Volume

[ml]

Tolerances of t he Øi

of the glass cylinder

[mm]

Dosage error*

according to

100 % volume

[%]

Reproducibility

[%]

WA 0 5 5.00 ± 0.005 ± 0.15 0.07

WA 1 0 10.00 ± 0.005 ± 0.15 0.05

WA 2 0 20.00 ± 0.005 ± 0.15 0.05

WA 5 0 50.00 ± 0.005 ± 0.15 0.05

Page 10

79

Chapter 1 – Specifications Titrator TitroLine® 7500 KF

1.3 Warning and safety information

The TitroLine® 7500 KF corresponds to prot ection cl ass II. It was manuf actured and tested according to DI N

EN 61 010, Part 1, Protective Measures for El ectronic Measurement Devices and has left the fact ory in an

impeccabl e condition as concerns safet y technology. In order t o maintain this condi tion and to ensure safe

operation, the user should observe the notes and warning information contained in the present operating

instructi ons. Development and production i s done within a system which meets the requi rements lai d down in

the DIN EN ISO 9001 standard.

For reasons of saf ety, the ti trat or TitroLine

®

7500 KF must be open ed by aut hori sed person s only; thi s means,

for instance, that work on electrical equipment must only be performed by qualified speciali sts.

In the case of nonobservance of t hese provisions the titrator TitroLine® 7500 KFmay co nstitute a

danger: electrical accidents of persons or fire hazard. Moreover, in the case of unauthorised

intervention in the titrator TitroLine

®

7500 KF as well as in the case of negligently or deliberately

caused damage, the warranty will become void.

!

Prior to switchi ng the dev ice on i t has to be en sured that the operati ng v oltage of the t itrator TitroLine® 7500

KF matches the mains voltage. The operating voltage is indicated on the specification plat e. Nonobservance of

this provision may result in damage to the titrator TitroLine® 7500 KF or in personal injury or damage to

property.

If it has to be as sumed that safe oper ation is im possible, the tit rator TitroLine

®

7500 KF has to be put out of

operation and secur ed against inadvertent putting to operation. In this case please switch the t itrator TitroLine

®

7500 KF off, pul l plug of the mains cabl e out of the mains socket, and rem ove t he titrator TitroLine

®

7500 K F

from the place of work.

Examples for the assumption that a safe operation is no longer possible,

the package is damaged,

the titrator TitroLine

®

7500 KF shows visible damages,

titrator TitroLine

®

7500 KF does not function properly,

liquid has penetrated into the casing.

The titrator TitroLine

®

7500 KF must not be stored or operated in humid rooms.

For reasons of saf ety, t he tit rator TitroLine

®

7500 KF m ust onl y be used f or the range of appl i cation descri bed

in the present operati ng instructions.

In the case of dev iations from the intended proper use of the device, it is up to the user to evaluate the

occurring risks.

!

T he relevant reg ulations reg arding the h andling of th e substan ces used have to b e observed: The

Decree on Hazardou s Matters, the Chem icals Act, and the rul es and inform ation of the chemical s trade. It

has to be ensured on t he side of the u ser that the persons entr usted with the u se of the titr ator TitroLine

®

7500 KF are experts in the handli ng of substances used in the envir onment and in titrat or TitroLine

®

7500 KF

or that they are supervi sed by speci alised persons, respectively.

During all work with tit r ation solutions:

!

Please wear protective gl asses! !

The titrator TitroLine

®

7500 KF i s equipped with int egrated circuit s (EPROMs). X rays or other high energy

radiation may penetrate through the device’s casing and del ete the program.

For working with liquids, not beeing common titration solvents, especially the chemical resistance of the

construction m aterials of the t itrator TitroLine

®

7500 KF hav e to be considered (pl ease also refer to chapter

1.1).

For the use of liqui ds with hi gh vapour pressure or (mixture of) substance s not being m enti oned in chapt er 1.1

as allowed substances, t he safe and proper op erati on of the tit rator TitroLine

®

7500 KF has to be guaranteed

by the user.

When the piston moves upwards withi n t he cyli nder, a mi crofilm of dosing li qui d or titrati on solution wil l al ways

remain adhered to t he inner wall of the c ylinder, but t his has no i nfluenc e on the dosing acc uracy. T his small

residue of li quid, however, may ev aporate and t hus pe netrat e i nto t he zone underneat h the piston, and if nonadmitted liqui ds are being used, the m aterials of t he titrator TitroLine

®

7500 KF may be dissolved or c orroded

(please refer al so to c hapter 8 “Maintenance and Care of the titrator Titr oLine

®

7500 KF”).

Page 11

80 Chapter 2. Unpacking and First Operation

2 Unpack i ng an d Fir st Operation

2.1 Unpacking

The titrator it self as well as all r elated accessory and peripheral parts hav e been c ar efully checked at the factory

to ensure their cor r ect function and size. The TitroLine

®

7500 KF modules consists of:

• TitroLine

®

7500 basic unit

• An interchangeable dosing unit WA 05, WA 10 or WA 20

• The KF titration stand (pump and stirrer) TM 235 KF including waste (1 L clear bottle), solvent (1 L amber

bottle) and moisture bottle (100 ml) with all tubes.

• Titration vessel TZ 1770 including titration tip

• KF starter kit TZ 1789 with molec ular sieve, glass wool and a set of syringes with needl es.

• Electrode KF 1100

Please ensure that the sm all ac c essories are also removed in full from the packaging. For the scope of delivery,

please refer to the enclosed parts lists.

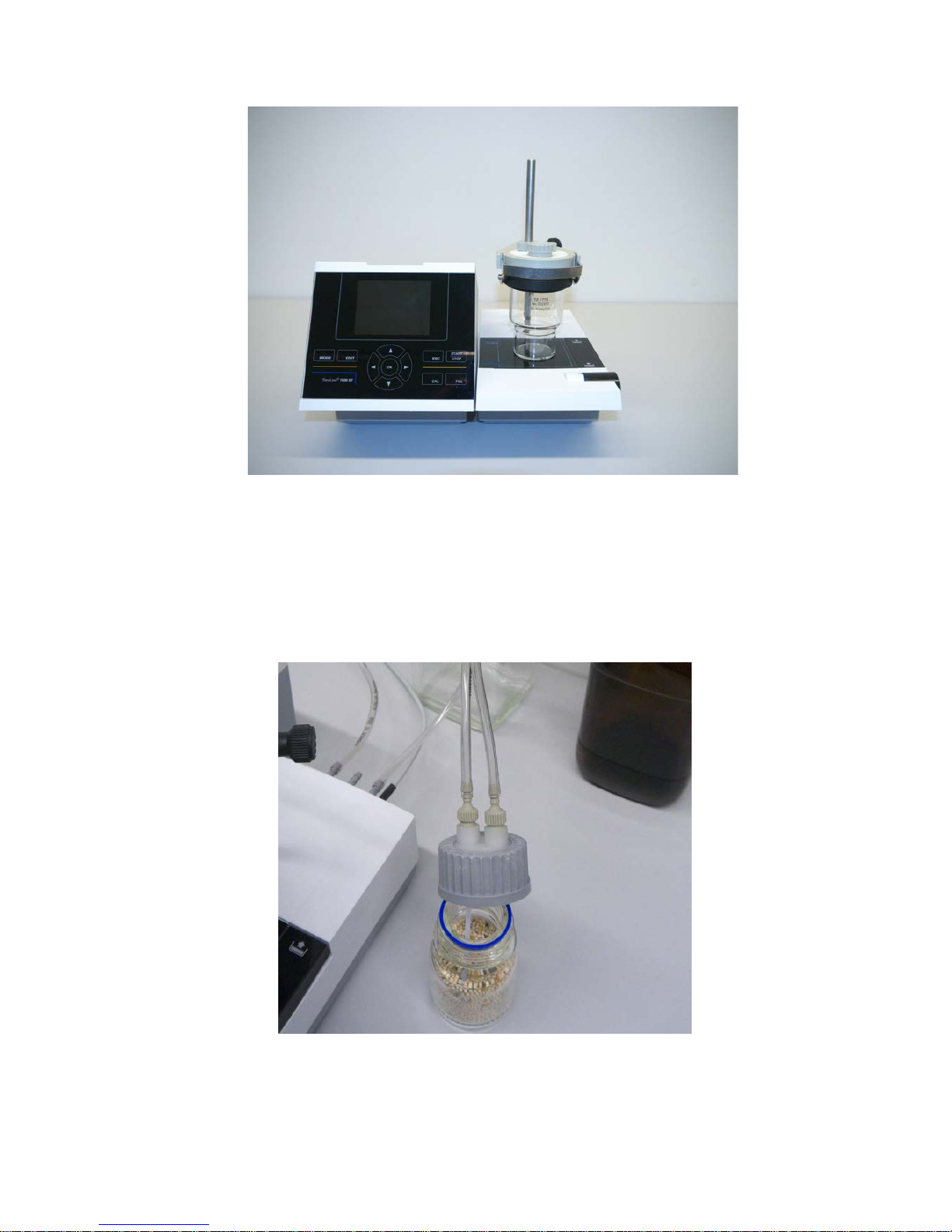

Fig. 1

2.2 Installation and Connection of the TM 235 KF titration stand and titration vessel

The titrator TitroLine® 7500 KF and the TM 235 KF may be placed on any flat surface.

As a rule, the TM 235 KF titration stand is arranged to the right of the titrator.

The pump/stirrer is connected to the 12V out-socket at the rear panel of the TitroLine

®

7500 KF using the TZ

1577 connection cable (scope of delivery of the basic device) (cp. ‘B ac k panel ’ illustration, chapter 2.4) .

The stand rod (scope of deliv er y of t he basi c device) is screwed into the thread of the TM 235 KF.

The titrati on v essel TZ 1770 is mount ed at the stand rod. Please take care that the m etal clam p is adj usted as

shown in the attached photo:

Page 12

81

Chapter 2. Unpacking and F ir s t O per ation

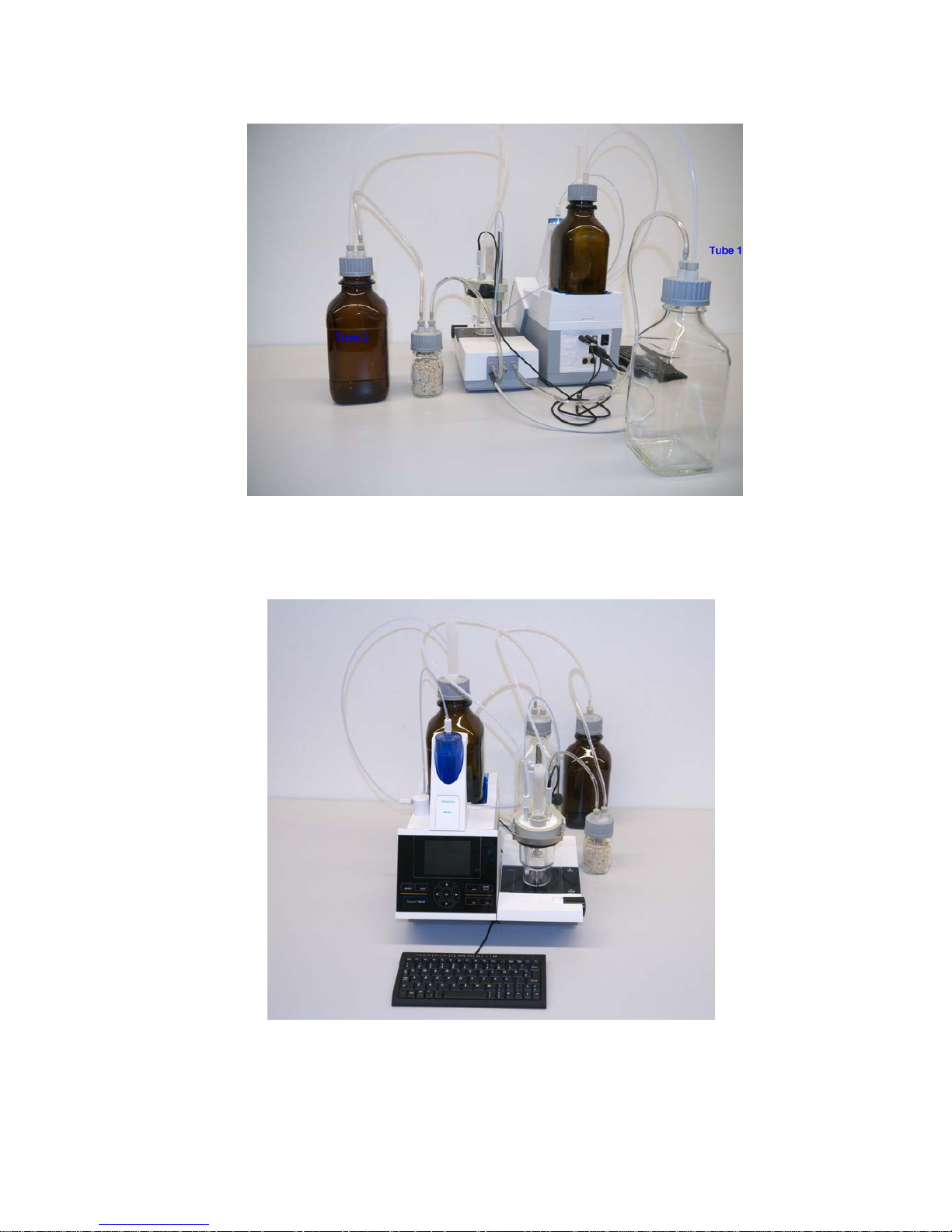

Fig. 2

Put all three white inner plastic adapters at the waste, solvent and moisture bottle.

Fill the moisture bottle with molecular sieve.

Connect the PVC and PTFE plastic tubes as shown in the next pictures.

The PVC tubes are connected t o the connectors at the back side of the TM 235 KF. The long PVC tube is used

for the connecti on of t he waste bott le. The two shorter PVC ones are used to connect the moisture bottle and the

solvent bottle.

Fig. 3

Page 13

82 Chapter 2. Unpacking and First Operation

The moisture bot tle is connected to the right connect or (view from above) of the TM 235 KF. The waste (clear)

bottle is connect ed to the left connector.

Fig. 4

The PTFE tube from the clear waste bottle is adjusted to the ground (tube 1) of the tit r ation vessel. The PTFE

tube from the solvent bottle (tube 2) is adjusted as shown in the next two pictures:

Fig. 5

Page 14

83

Chapter 2. Unpacking and F ir s t O per ation

Fig. 6

The burette tip is placed into the left NS 14 opening and connected to the valve of the interchangeable unit.

Put first some glass wool and then molecular sieve in the plastic moisture tube. Place it t o the ot her NS opening

as shown in the next picture.

Fig. 7

The electrode KF 1100 i s connected to the µA input.

The keyboard is connected to one of the USB –A ports.

Page 15

84 Chapter 2. Unpacking and First Operation

2.3 Connec ting the Titrator - Combination with Accessories and Additional Devices

2.3.1 Back panel of the titrator TitroLine® 7500 KF

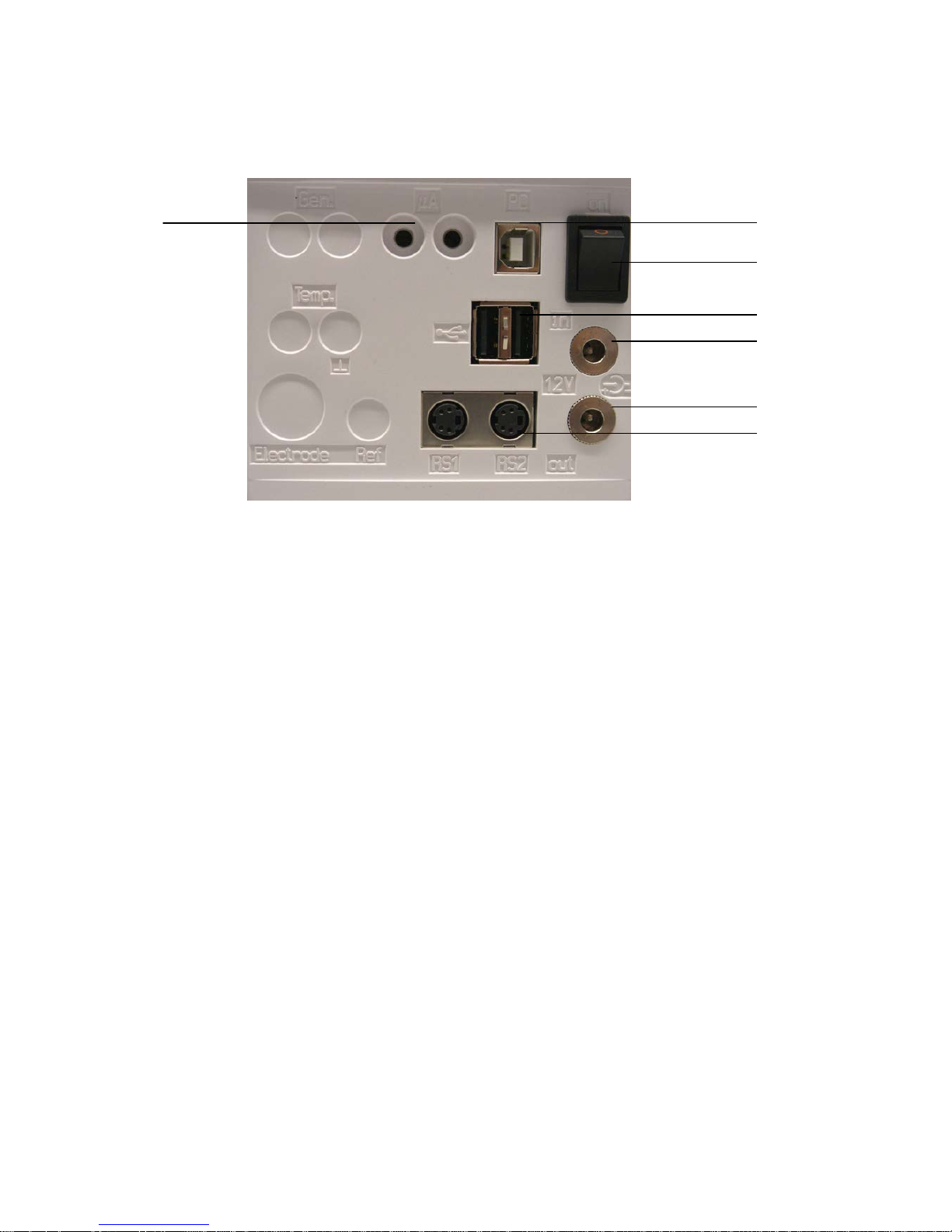

Fig. 8

2.3.2 Connection ports of the TitroLine

®

7500 KF

The TitroLine® 7500 KF is equipped with the following connections:

1) µA measurem ent input for the connection of doubl e platinum electrodes (KF 1100 or Pt 1200, Pt 1400)

2) USB-B interface for connection to a PC

3) On/Off switch

4) Two USB-A (“M aster “ ) interfaces for connecting USB devices such as a keyboard, printer, manual control

unit, USB memory devic e etc.

5) ”in“ : Connection of the external power pack

6) “out“: Connection of the TM 235 KF titration stand or TM 235 magnetic stirrer

7) Two RS232 ports, 4-channel (Mini-DIN):

RS1 for connection to the PC

RS2 for connection of a weighing balance and other devices from SI Analytic s (burettes a.s.o.)

2.3.3 Co nn ect ing a printer

Printers with a USB int erface are to be connected to one of the two USB-A interfaces. These pri nters have to

feature HP PCL emulation (3, 3GUI, 3 enhanced, 5, 5e). So-called GDI printers cannot be used!

Alternatively the thermo-compact printer Seiko S 445 c an be connect ed.

2.3.4 Co nn ect ing a USB device (manual controller, keyboard, memory device, hub)

The following USB devi c es can be connec ted to the USB-A interfaces:

• PC-keyboard

• TZ 3880 manual controller (in the following: ”mouse“)

• Printer

• USB stor age dev ices, e.g. USB sticks

• USB hub

• USB bar c ode scanners

1

2

3 4 5

6

7

Page 16

85

Chapter 2. Unpacking and F ir s t O per ation

2.3.5 Connection of ana ly t ic al balances

Analytical balanc es are t o be c onnec ted to the RS232-2 using an appropriate cable

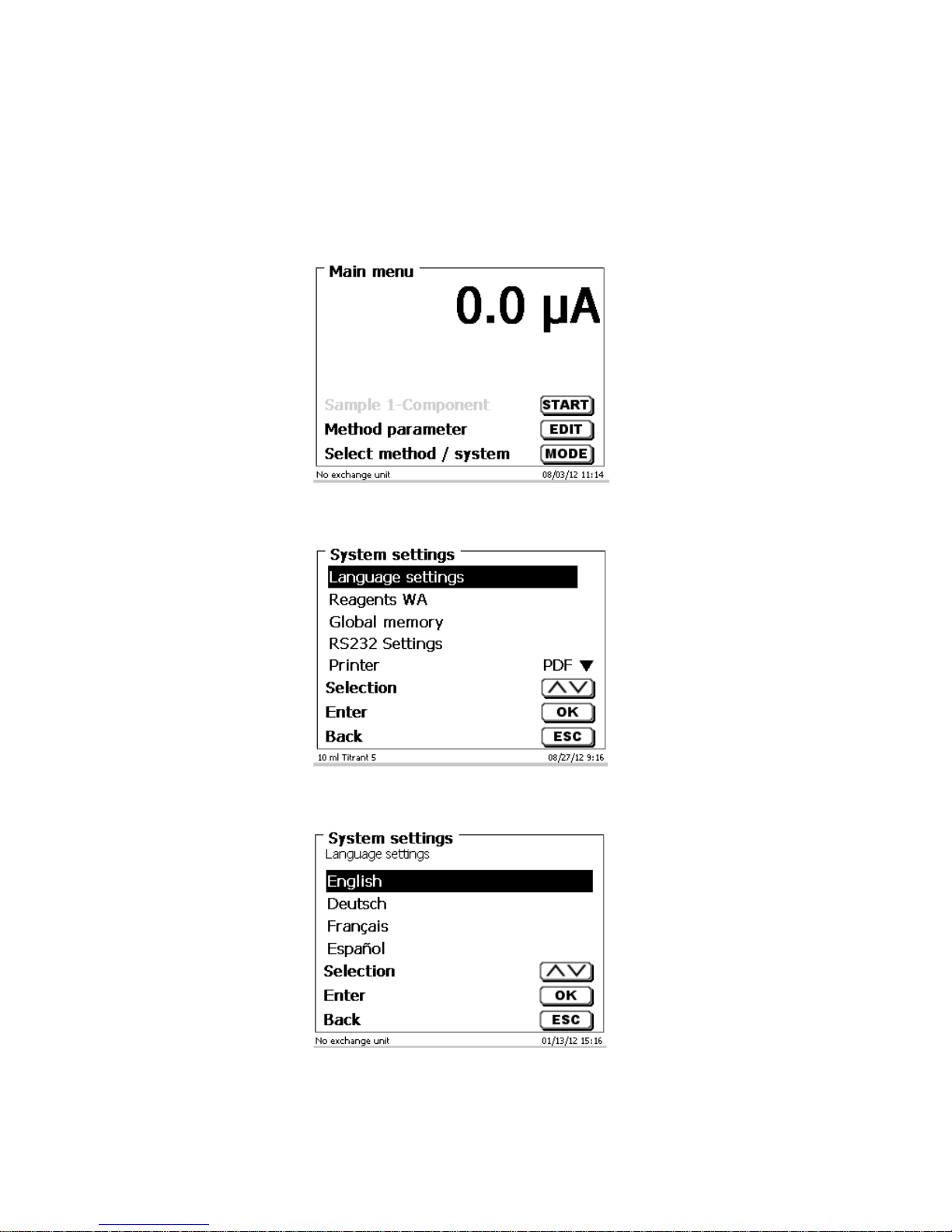

2.4 Setting the Language of the Country

The ex-factory default language setting is English. When the piston burette is switched on, the mai n menu will

appear once the boot sequence is completed:

Fig. 8

Using <SYS/<F7> or <MODE>, followed by <System settings> you navigate to the system settings. The very first

menu is to be used for setting t he language of the country:

Fig. 9

Use <ENTER>/<OK> to call the menu. S elec t t he national language using the <↑↓> arrow keys, confi rm it with

<ENTER>/<OK>:

Fig. 10

The selected language wil l appear immediately. Pressing the <ESC> key twice will return the user to the main

menu.

Page 17

86 Chapter 2. Unpacking and First Operation

2.5 Interchangeable unit WA

Fig. 11

1) TZ 3871 - sucti on hose

2) TZ 38 72 - connection hose

3) TZ 3873 - dosing hose wit hout dosing tip and holding bracket;

TZ 3874 - dosing hose with dosing tip and holding bracket

4) TZ 3801 - valve cov er lid

5) TZ 3000 - 3/2-way valve

6) TZ 2003 - drying t ube

7) TZ 3802 - threaded c ap with borehole GL 45, incl. adapter with 2 openings for drying tube and suction

hose

8) TZ 3803 - 1 litre reagent bottle, brown

9) TZ 3900 - UV protecti on, blue transparent

10) TZ 3875 - shaft for titration tip and

TZ 3356 - titrati on tip unit, blue or micro titration tip white TZ 3285, adapter TZ 1525

11) TZ 1507 - plastic drip-down tubule

2.5.1 Installing the interchangeable unit

Fig. 11 shows a completely assembled interchangeable unit.

• Remove the valve with the attached hoses from the pack, and then push it on the valve support until it

snaps in position.

• Slip on the valve cover lid on the valve as is shown in the ill ustr ation.

• Insert the TZ 3872 connection hose in the threaded hole prov ided in the burette cylinder, and then tighten

it by hand.

• Insert the TZ 3871 suction hose into the threaded openi ng of t he GL 45 or S 40 adapter s, and then

tighten it manually.

• Remove the standard dosing hose TZ 3874 from the valve and c onnec t t he dosi ng hose i nc luding from

the KF titrati on vessel TZ 1770

6 3 1 2 4 5 7 8 9

11

Page 18

87

Chapter 2. Unpacking and F ir s t O per ation

2.6 Positioning and Replacing an Interchangeable Unit

The base unit comes with an RFID r eader , and all the interchangeable units are equi pped with an RFID

transponder. Thi s tr ansponder can be use d to store the following information:

• Uni t size (cannot be changed)

• Uni t ID (cannot be changed)

• Reagent name (default: blank)

• Concent r ation (default: 1.000000)

• Concent r ation determined on: (Date)

• To be used until: (Date)

• Opened/Produced on: (Date)

• Test ac c or ding to ISO 8655: (Date)

• Charge description: (default: no c har ge)

• Last modification: (Date)

Each time an interc hangeable unit is pushed onto the base unit, t he data is automatically read out of the

transponder.

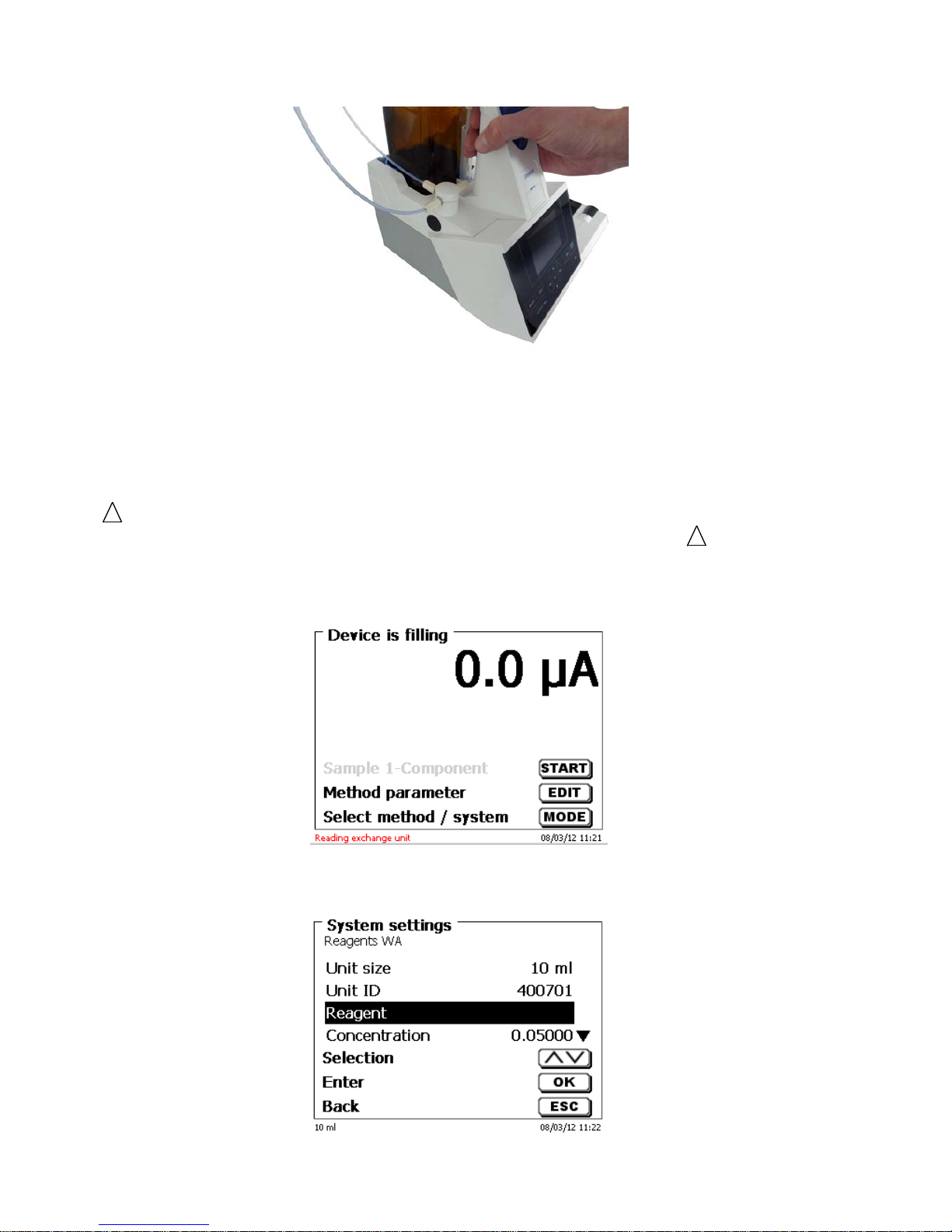

2.6.1 Placing an interchangeable unit

The interchangeabl e unit is to be placed on the device unit as is shown in fig. 12 a-c; subsequentl y , it is to be

pushed downwards until the black button latches on the left side.

Fig. 12.a

Fig. 12.b

Page 19

88 Chapter 2. Unpacking and First Operation

Fig. 12.c

2.6.2 Remo ving an interchangeable uni t

Removing the int erchangeable unit is done in reverse order:

• Depress the black button on the left, and then pull the interchangeable unit forward as is shown in fig. 12

c – 12 a.

!

Please note: Removing the interchangeable unit is only possible as long as the piston is in the lower

position (zero position). Possibl y, i t may be necessary to press the <FILL> key first.

!

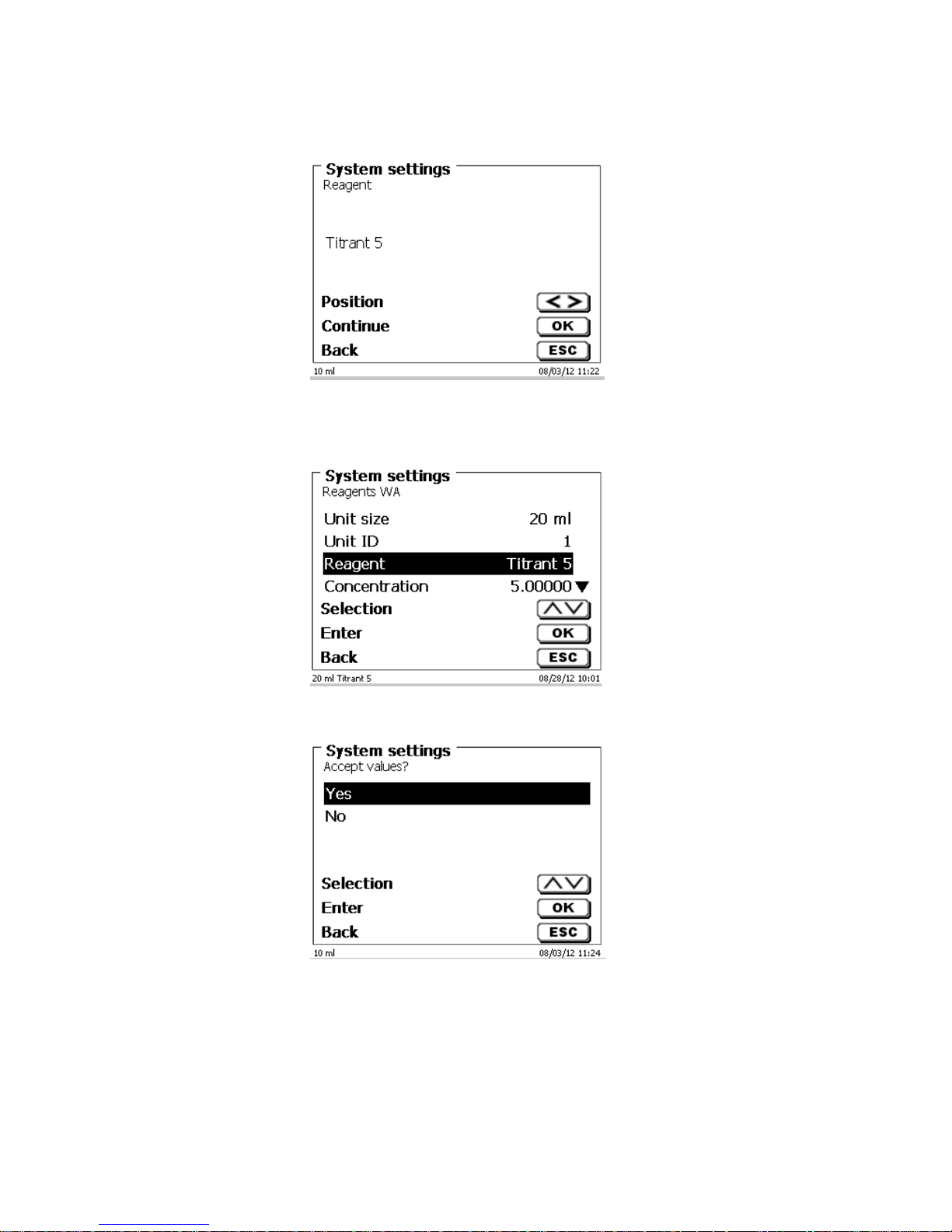

2.6.3 Programming the titration unit

The data from the RFID transponder of the interchangeable uni t will be read immediately (fig. 13).

Fig. 13

Following the reading operation, the input menu for the input of t he r eagents will be shown for approx. 10

seconds (fig. 14). The size of the interchangeable unit is displayed on the left side of the display (here 10 ml).

Fig. 14

Page 20

89

Chapter 2. Unpacking and F ir s t O per ation

When used for the first time, it is recommended to enter here at least the name of the reagent being used. To do

so, confirm the “Reagent “selection with <ENTER>, then ty pe the name and possibly the concentrati on (fig. 12).

Fig. 15

Press <OK>/<ENTER> to confirm (fig. 15). Following the optional input of additional parameter, press <ESC> to

leave the reagent s menu (fig. 16). The approximate concentrati on of t he KF tit r ant (e.g. 5 or 2) should be entered

under concentration. Thereby the drift in µg/min can be calc ulated in the right dimensions.

Fig. 16

You will be prompted for a confirmation of the values (fig. 17):

Fig. 17

If you selected <Yes>, the values will be written into the interchangeable unit. You can see this from a message

in red colour displayed at the bottom. Upon completion, the lef t bot tom corner of the display will show the new

name of the reagent (fig. 18). In t he pr esent c ase this is Titrant 5.

Page 21

90 Chapter 2. Unpacking and First Operation

Fig. 18

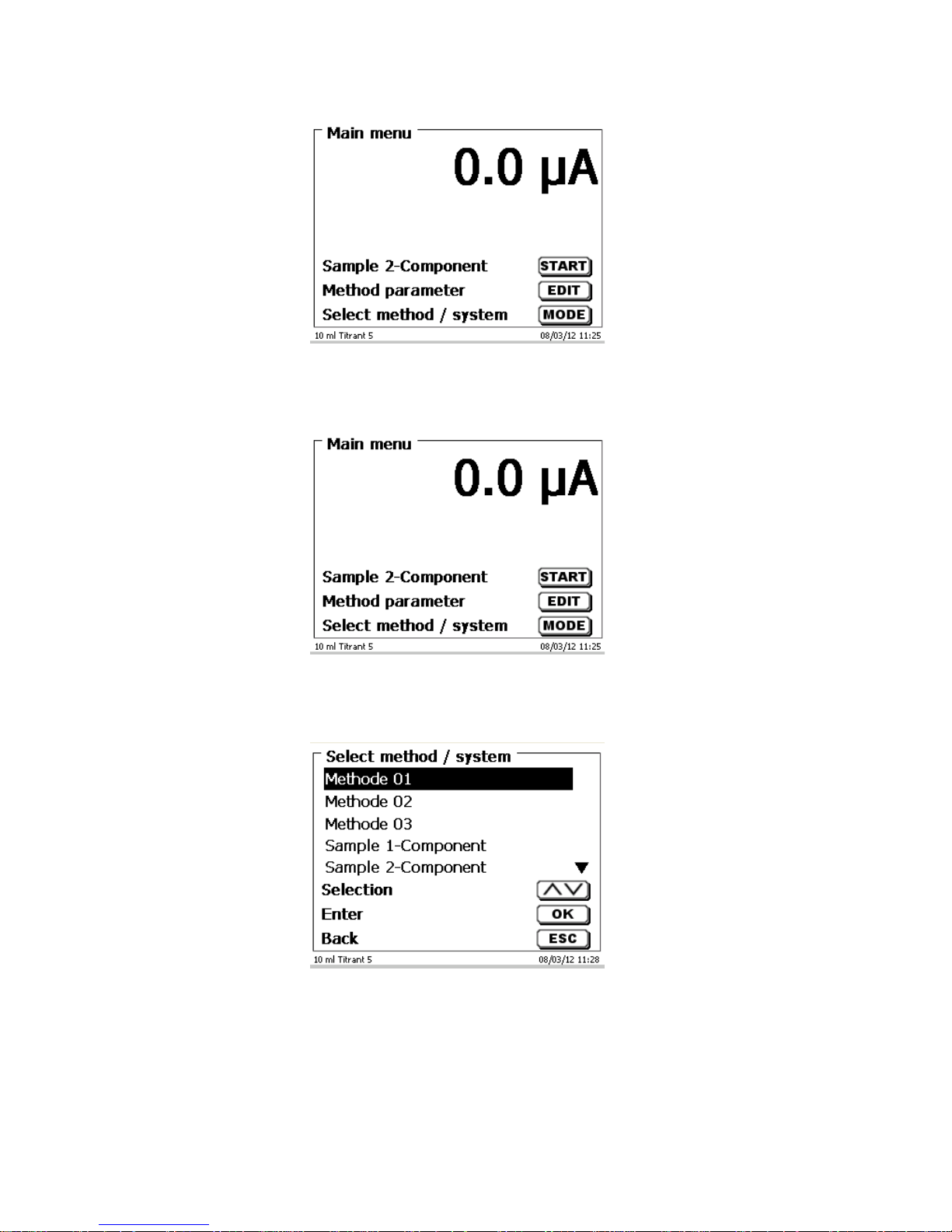

2.7 Initial Filling or Rinsing of the Entire Interchangeable Unit

Initial filli ng of the interchangeable unit is done using the <rinsing > rinsing programme.

Fig. 19

On the main menu (fig. 19), press <MODE> key to navigate t o the methods/system (fig. 20).

Fig. 20

Pressing <↑> twice will take you to the <Rinsing> selection immediately (fig. 21).

Page 22

91

Chapter 2. Unpacking and F ir s t O per ation

Fig. 21

Confirm the selection by pressing <ENTER>:

Fig. 22

At this point you can selec t t he num ber of rinsi ng cycl es (Fig. 19). I ni tial f illing r equir es a m i nimum of two rinsi ng

cycles. You can stop t he rinsing operation (F ig. 20) at any tim e by pressing <STOP> and then resume ri nsing

with <START>.

Fig. 23

While the i nitial filling or ri nsing programme is being run, pl ease place a suffic iently dimensioned waste v essel

under the titration tip. The best is when the titration tip is mount ed in the KF titration vessel.

Page 23

92 Chapter 2. Unpacking and First Operation

2.8 Filling the titration vessel with solvent

The solvent is pumped from the solvent bottl e into the titration v essel by pushi ng down the front part of the rocker

switch on the titration stand TM 235 KF. Pump solvent into the titration vessel until the titration tip and the

electrode are c om pletely immersed. This will be approx. 35-40 ml of solvent:

Fig. 24

2.9 Replacing the Glass Cylinder and the PTFE Piston

Replacing the glass cylinder and the pi ston does not require any additional tools. In certain cases the piston

extractor has to be used.

• Remove the interchangeable unit from the base unit.

• Unscrew the hose between the glass cylinder and the valv e from the glass cylinder.

• Rotate the blue UV protection 5 to 6 times to the left t o loosen it.

• You can r em ov e the UV protection and pull out of the glass cylinder toget her with the piston inside it.

• Insert a new glass cyl inder and piston (F ig. 25) into the i nterchangeable uni t, and then sli p on the blue

UV protection again.

• Tighten the blue UV protection again by rot ating it 5 to 6 times to the right.

• The pi ston rod shoul d proj ect 1-2 cm out of the interchangeable uni t (Fi g. 26 a). At thi s point , til t t he unit

forward unt il the slant ed bott om side is in fl at c ontact wit h the lab t able (Fig. 26 b). This forc es the piston

into its correc t position. Should the piston be f orced som ewhat t oo far into the glass cylinder, simply pull it

out and place it in the correct position according to the procedure descri bed above.

Filling

35-40 ml

Page 24

93

Chapter 2. Unpacking and F ir s t O per ation

Fig. 24

Fig. 25 a

Piston rod

Piston rod

Glass cylinder

Page 25

94 Chapter 2. Unpacking and First Operation

Fig. 25 b

Basically, it should be noted that within one and the same interchangeable unit only the specified cylinder size

may be installed, sinc e otherwise the coding which is memorised within the interchangeable unit will no longer

match the cylinder si z e. Thi s will entail incorrect dosage. And for the sake of dosi ng and analytical accuracy, it is

also recommended to replace the PTFE pistons each time a defective glass cyl inder is replaced. This applies in

particular to glass breakage, since broken glass may damage the sealing rings of the PTFE piston.

Please note: As a rule, the hoses and cylinders will contain chemic als which may spi ll or be spl ashed around in

the course of disassembly. The relevant safety precaution measures applicable to the handling of the chemicals

concerned have t o be observed.

Page 26

95

Chapter 3 – Working with the titr ator TitroLine® 7500 KF

3 Working w it h th e Titr a tor TitroLin e® 7500 KF

3.1 Front Keyboard

Apart f rom alphanumeric i nput (a-z, A-Z, 0-9) and a few other functions, alm ost all functions can be performed

using the front keyboard.

<Mode>: Methods selection, rinsing, system setti ngs

<EDIT>: Changing the current method, new method, copy and delete method

<ESC>: <ESC> will take you back t o the prev ious menu level.

<START>: Start and Stop of a current method

<FILL>: Filling the unit

The individual functions are described in detail in Chapter 3.4, E xt ernal PC Keyboard.

3.2 Display

The display consists of a gr aphic al LCD display with a resolution of 320 x 240 pix els.

It also offers the possibi lity to display graphics, e.g. t he m easuring curve while or after the titration i s/was running:

Page 27

96

Chapter 3 – Working with the titr ator TitroLine® 7500 KF

3.3 Manual controller “mouse“

The “mouse“ (Fig. 23) can be used dosing applications and sample preparation methods. The mouse is not

included in the scope of delivery of the TL 7500 basic unit.

Fig. 26

Mode

Black key

Grey Key

Dosage through Dosage method

Start dosage

Filling

Preparation of solutions

Start dosage

Filling

3.4 External PC Keyboard

Keys

Function

<ESC>

<ESC> will take the user to the previous level on the

menu.

<F1>/<START>

Start of a selected met hod

<F2>/<STOP>

Stop of the current method

<F3>/<EDIT>

Change of the current method, new method, copy method

<F4>/<FILL>

Fill the interchangeable unit

<F5>/

Display and modific ation of the balance data. With <Shift +

F5> display and modification of t he global m em ori es

<F6>/<MODE>

Selection of met hod, rinsing, system settings

<F7>/<SYS>

System settings (language selection, time/dat e .. .)

<F8/<CAL>

Without function

<F9>/+ / -

Change of sign

<F10>/<DOS>

Call dosing menu

Num/ Scroll

Lock/ Lock

Without function

Prt Sc

Sys Rq

Without function

<ESC>

Selection of the m ethod-selection menu from the main

menu.

Elders: <ESC> will take you back to the prev ious l ev el in

the menu.

< ↑> < ↓ > <←> <→>

Selection of i ndiv idual menus and numeric values

0...9

Input of numeric values

<ENTER>

Confirmati on of input par am eters

< ←Backspace >

Deletion of one input digit / an input character to the left of

the blinking cursor

Letters,

ASCII-symbols

Alphanumeric input possible. Uppercase and lowercase

possible.

All other keys

Do not have any function

Page 28

97

Chapter 3 – Working with the titr ator TitroLine® 7500 KF

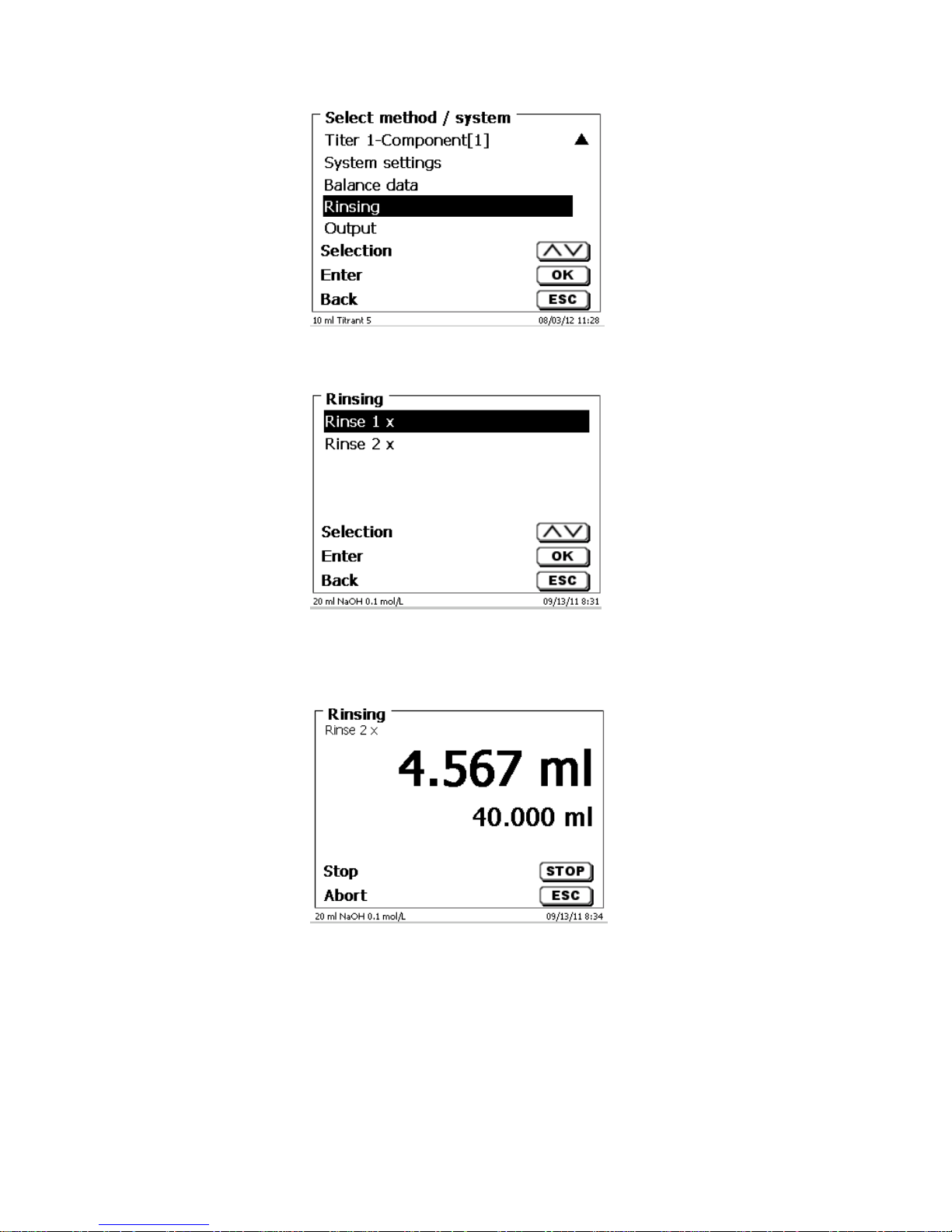

3.5 Menu Structure

There are 4 selection menus:

• Start or main menu

• Met hod par ameters

• Met hod sel ec tion

• System settings

After power-up, the main m enu is always the fi rst menu to appear. The method di splayed will always be the last

method that was used (Fi g. 27).

Fig. 27

Pressing <START > will result in the immediate ex ecution of the m ethod shown. <EDIT>/F 3 will take you t o the

method parameters (Fi g. 28).

Fig. 28

At this point you can

• modify the current method

• create a new method

• call and memorise standard methods

• copy or delete an existing method

Use the <↓> und <↑> keys to select the submenus, confirm your selection with <OK>/<ENTER>. <ESC> will take

you back to the main menu.

Page 29

98

Chapter 3 – Working with the titr ator TitroLine® 7500 KF

<MODE>/F6 leads you to the “sel ec t method“ menu (Fig. 29).

Fig. 29

Existing methods can be selected by pressing the <↓> und <↑> keys and confirming the selection with

<OK>/<ENTER>. O nce the selecti on made, you wil l return to t he main menu wit h the newly s elected m ethod. If

no method is selected, < ESC> will also tak e y ou bac k to the main m enu.

To navigate dir ectly to the system settings (Fi g. 30 and Fi g. 31) you can use the <SYS>/F7 key; you can als o

navigate there through the method selection menu.

Fig. 30

Fig. 31

Page 30

99

Chapter 3 – Working with the titr ator TitroLine® 7500 KF

3.6 Main Menu

After power-up, the main m enu is always the fi rst menu to appear. The method di splayed will always be the last

method that was used (Fi g. 32).

Fig. 32

3.6.1 Standard methods of KF Titration

If no titration has been performed yet, it is recommended to load one of the standard methods. These methods

have default par am eters and can generally be used immediately wit hout changes. From the main menu, press

F3/EDIT to access the methods menu:

Fig. 33

From this menu, select the appropriate standard method:

Fig. 34

Page 31

100

Chapter 3 – Working with the titr ator TitroLine® 7500 KF

Standard methods KF Application

Titer 1-Component (li quid standard) Determinati on of t he c onc entration of the titration

agent. Suitable for 1-component reagents. Standard is

a liquid standard in ampoules with a concentration of

10 mg/g.

Titer 1-Component ( soli d standar d) Determinati on of t he c onc entration of the titration

agent. Suitable for 1-component reagents Standard is

the standard substance sodium tartrat dihydrate with a

water amount of 15.66 %.

Titer 1-Component ( water) Determinati on of t he c onc entration of the titration

agent. Suitable for 1-component reagents Standard is

pure water

Titer 2-Component (li quid standard) Determinati on of t he c onc entration of the titration

agent. Suitable for 2-component reagents. Standard is

a liquid standard in ampoules with a concentration of

10 mg/g.

Titer 2-Component ( soli d standar d) Determinati on of t he c onc entration of the titration

agent. Suitable for 2-component reagents Standard is

the standard substance sodium tartrat dihydrate with a

water amount of 15.66 %.

Titer 2-Component ( water) Determinati on of t he c onc entration of the titration

agent. Suitable for 1-component reagents Standard is

pure water

Sample 1-Component Method for sample titr ations with 1-component

reagents

Sample 2-Component Method for sampl e tit r ations with 2-component

reagents

Statistic s are switched on. The mean value of the titer in mg/ml is automatically saved in the attachment. It i s then

used automatically in the sample titration.

The results of the sample titration are calculated in %. If needed, t he unit can be converted into other units of

measure, such as ppm.

3.6.2 Automatic KF Titration

The method being di splayed c an now be carri ed out im m ediately wit h <START>. The precondi ti oning is run f ir st.

The solvent and the titration vessel contai n m oisture (water) that should not influence the calc ulation of the result.

The conditioning is run automatically after the Start button or t he F1 key are pressed. The final conditions are t he

same as the conditions of the actual sample titration.

Page 32

101

Chapter 3 – Working with the titr ator TitroLine® 7500 KF

Fig. 35

When the final criteria are met, then there is an audible signal and Conditioning ready is shown on the display:

Fig. 36

The conditi oning remains activ e until the act ual titr ation is started by pre ssing <F1/START>. You are prom pted

immediately to add t he sample:

Fig. 37

After the sample or the standard is added, you must press <F1/START> again. Dependi ng on the method

settings, you will be pr om pted f or the sam ple identification (Fig. 38) and the weighed-i n quantity (Fig. 39). You

can use an external PC keyboard f or entering a 20-digit alphanumeric sample I D.

Page 33

102

Chapter 3 – Working with the titr ator TitroLine® 7500 KF

Fig. 38

Fig. 39

The balance data can be ent ered usi ng the f r ont key board or an ex ternal keyboar d. T he input i s to be conf i rmed

with <OK>/<ENTER>.

In the case of an automatic acceptance of the balance data, the weighed-in quantities will be read in f rom a

memory. If t he memory does not contain any bal ance data, a message will appear to indicate that no balanc e

data are present:

Fig. 40

Pressing the Pri nt k ey will t ransf er t he balanc e data, t oo. T i tration wil l then begi n di rect ly aft er t he transf er of the

balance data without any further confirmation being necessary. The display shows either

the use in ml with the drift in µg/min

or the drift with the measured value in µA

or the titration curve in ml/time [s].

You can switch between the individual displays with the <F6/MODE> k ey: The graphics are scaled automatically:

Page 34

103

Chapter 3 – Working with the titr ator TitroLine® 7500 KF

Fig. 41

Fig. 42

Fig. 43

Scaling of the c hart will be done aut omatic ally. T he result will be display ed at the end of the tit rati on (Fig. 44 and

45).

Fig. 44

Page 35

104

Chapter 3 – Working with the titr ator TitroLine® 7500 KF

<MODE>/<F6> can be used to view the titration curve or further results:

Fig. 45

If a print er is connected, t he results wil l either be printed accordi ng to the sett ings made f or the met hod, or el se

they will be memori sed in the form of a PDF- and CSV-file file on a connected USB stick. If no printer or USB

stick is connected, the bottom left corner of the display will show the message “no printer“ or “no USB

stick”.<ES C> will t ak e you back to t he mai n menu where you can start the next titration immediately .

3.6.3 Dosage

To start a dosage method, please use the <S TART>/<F1> or the black key of the “mouse“.

Fig. 46

Fig. 47

The dosed volume will be bri efly displayed before the display ret ur ns to the main m enu.

Page 36

105

Chapter 3 – Working with the titr ator TitroLine® 7500 KF

Fig. 48

Fig. 49

The next dosage oper ation can be star ted immediately. Filling of the unit will occur autom atically. This option c an

be switched off. T hen the cylinder will be filled when the m aximum cylinder volume is reached. The unit can be

filled at any time usi ng <FILL>.

A dosing operation can al so be perform ed without any dosing m ethod wit h the <DOS>/<F 10> key of the external

keyboard:

Fig. 50

This is the point to input the volum e whic h will be dose d f ollowing the confirmation wit h <ENTER>/ <OK>:

Page 37

106

Chapter 3 – Working with the titr ator TitroLine® 7500 KF

Fig. 51

Pressing the <ENTE R>/<OK> k ey will c ause the nex t dosing oper ation to be performed immediately:

Fig. 52

In this case further dosages can be perform ed using <ENTE R>/<OK>. Fill ing of t he unit following dosage will not

occur automatic ally here, unless the maxim um cylinder volume has been reached. T he unit can be filled at any

time using <FILL>. <E S C> will t ak e you back to the main menu.

Page 38

107

Chapter 3 – Working with the titr ator TitroLine® 7500 KF

3.6.4 Preparing Solutions

The so-called “P reparing solutions“ m ethod is a special dosi ng method. In this proces s, a solvent is dosed to a

sample weight of a substance until the desired target concentrat ion is reached:

Fig. 53

Fig. 54

Fig. 55

If the calculated volume is greater than the maximum volume, an error message will be displayed and dosage will

be suppressed for saf ety r easons:

Fig. 56

Page 39

108

Chapter 4 Method Param eters

4 Method Parameters

From the main menu (Fig. 53), <EDIT>/<F3> will take you to the method parameters:

Fig. 57

4.1 Method editing and new method

If you select < edit m ethod> or <new method> you will be taken to the modif ication or new creati on of a method.

Selecting < new m ethod> will always lead to the prompt for the input of a met hod name (Fig. 58). This prompt will

not appear in the case of the m odification of an already created method.

Fig. 58

The method name can contain up to 21 characters. Special characters are also possible. If no keyboard is

connected, the m ethod name being displayed has to be adopted (in the present case “Method 04“). Numbering of

methods will occur automatically. P r ess <OK >/< E NTER> to confirm the input. The method name can be changed

at any time. Please continue at this point with Chapter 4.5.

4.2 Default methods

The <Default methods> item of the TitroLine® 7500 KF contains a series of ready-made standar d methods which

can be conveniently selected (Fig. 59).

Fig. 59

Once the selecti on m ade, you ar e dir ectly pr om pted for the input of the method name.

Page 40

109

Chapter 4 Method Param eters

Fig. 60

The standard name may be adopted or modified. Subsequently, you will be taken to the <Change method

parameters> item. Please cont inue at this point with Chapter 4.6

4.3 Copy Methods

Methods can be copied or stored with a new name. If you select this function, the cur r ent method will be copied

and you can include a new name

Fig. 61

A new name with t he suffix [1] i s assigned automatically in order to avoid t he existence of two m ethods having

the same name. Subsequentl y, you will be taken t o the <Change method param eters> item. Then you proceed

with Chapt er 4.6.

4.4 Delete Methods

If this function is select ed, you will be prompt ed to know whether the current m ethod is actually to be del eted.

You have to reply <Yes> in explicit terms and also confirm this reply with <OK>/<ENTER>.

Fig. 62

Page 41

110

Chapter 4 Method Param eters

4.5 Print method

The currently selec ted method can be printed on a connected printer or stored on an US B drive as PDF file

Fig. 63

4.6 Change Method Parameters

The input or modific ation of the method name was already described in Chapt ers 4.1 and 4.3.

Fig. 64

4.6.1 Method type

On the <Method ty pe> you can select whether you wi sh to perform a manual or aut omatic tit ration, a dosage or

whether you wish to prepare a solut ion.

Fig. 65

The selection of the Method type will have an influence on the further parameterisation of the method. For

instance, if you select the dosi ng mode, neither a sel ection of a formula nor a change of the autom atic titration

mode (KF and dead stop) will be available.

Page 42

111

Chapter 4 Method Param eters

For an automatic titration, you can select from the following modes:

• KF titration

• Dead St op titration

4.6.1.1 KF and Dead stop titration

KF titrati on is a specif i c form of dead-stop t itr ation. In norm al dead-stop ti tr ation, titr ation i s to the specif i ed value

in µA, which must be maintai ned for a defined time. In KF titration, this still occurs, but a specified drift criterion in

µg/min must also be met. With KF tit ration, a conditi oning step i s also is preset in or der to eliminate any moisture

in the titrati on v essel and t he solvent.

The first stage of t he Dead stop and K F t it ration c onsists in t he conti nuous do sing up t o a del t a v alue away f rom

the set end point . The do sing speed can b e adju sted. Subsequentl y, ti tration i s performed wit h linear step sizes

between the delt a val ue and the end point.

The following titr ation parameters can be set for the dead-stop and KF titr ation:

Titration paramet er Dead-stop titration KF t itrat ion

µA-Endpoint X X

Delta µA-value X X

Linear steps in ml X X

Endpoint del ay in s X X

Delay time (between linear steps) X X

Start delay time / extraction time X X

Conditioning on/off - X

Pre - titration in ml X X

Polarization voltage in mV X X

Minimum und maximum titration time in s -

Max. titration volume X X

Drift in µg/min X X

Dosing speed in %

4.6.2 Result

Result offers the following sett ings:

Fig. 71 d

The Result text may cont ain up to 21 alphanumeric characters including special characters.

Page 43

112

Chapter 4 Method Param eters

Fig. 72

Please confirm your input with <OK</<ENTER>.

4.6.2.1 Calculation Formula

The appropriat e c alc ulation formula is selected on the Formula selectio n submenu:

Fig. 73 a

The following calculation formulae are available for automatic titration mode:

Formula

Additional information

EP

Formula for calculating only the ml

consumption

(EP-B)*T*M*F1/(W*F2)

Formula for calculating the

concentration of a sample taking into

account a blank value in terms of ml.

(W*F2)/(EP-B)*M*F1)

Formula for calc ulating a titer (T) of a

titration solution.

The abbreviati ons used here have the following meaning:

EP: Consumption at the end point in ml

B: Blank value in ml. Mostly determined by way of tit r ation

T: Titer of the titration solution (e.g. 5.012)

M: Mol; mol- or equiv alenc e weight of the sample

F1-F5 Factor 1-5. conversion factors

W “Weight“, weighed-in quantity in g or volume in ml.”

Page 44

113

Chapter 4 Method Param eters

After selecting a formula, please confirm your selection with <OK>/<E NTER>:

Fig. 69

The values for the blank value and the factors can be entered manually or read from a global m emory. The

values from a global memory were defi ned in advance by a titration or were manually entered.

Fig. 70

Fig. 71

The used global memory is displ ay ed. Here in the example it is MO1 and MO2:

Fig. 72

Page 45

114

Chapter 4 Method Param eters

Storing results i n global memories is described in Chapter 4.6.3.7

The values of the individual parameters of the sel ected cal c ulation formula can now be input one by one.

Fig. 73

4.6.2.2 Sample weight and volume (sample quantity)

Fig. 74

Fig. 75

The Sample Quantity (W) item is used to select whether one is wishing to use a sample weight or a sample

volume for titrati on or sol ution preparation.

You have the following options:

• Manual sample weight: The sample weight is enqui red by a prompt at the start of the method/after

conditioni ng ( KF)

• Automat ic sample weight: The sample weight is automatically transferr ed by a connected balance.

• Fixed sample weight: A fixed sample weight i s i nput in g. This weight will then aut om atically be used for

each start of the method.

• Man ual sample volume: The sample v olume in ml is prompted at the start of the method and manual ly

input.

• Fixed sample volume: A fixed sample volume is input in ml. This v olum e will then automatically be used

for each test of the method.

Page 46

115

Chapter 4 Method Param eters

4.6.2.3 Formula unit

The formula unit can be select ed in the Unit submenu.

Fig. 76

Once the selecti on m ade (e.g. %), t he unit will also be displayed as piece of information on the display.

Fig. 77

Page 47

116

Chapter 4 Method Param eters

4.6.2.4 Formulae for the Preparation of Solutions

A selection of special calculation formulae is available for the Prepare Solutions mode. The appropriate

calculation formula is selected on the Formula Selecti on submenu:

Fig. 78

A selection of 3 differ ent calculation formulae is available:

W*(100-Fa-Fb)*Fc/Fd - W*(100-Fb) / (100*Fe) +Ff

W*(100-Fa-Fb)*(Fd/Fg ) - W*(100-Fb) / (100*Fg) +Ff

W*(100-Fa-Fb)*Fc / (10 0 * Fd)

Meaning of the individual factors:

W: Weight of the sam ple in g

Fa: Soluble foreign-matters portion in %

Fb: insoluble foreign-matter porti on in %

Fc: Conversion factor for it unit

g/l = 10

mg/l und ppm = 10000

g/100 ml = 1

% = 1

Fd: Target concentration of the solution to be prepared in g/l, m g/l (ppm ) , g/ 100 ml , or %

Fe: Specific weight of the weighed-in sample in g/cm³

Ff: Volum e c or r ection in ml. this volume correction is the required surpl us dosage for compensating the

volume contracti on and the specific-weight difference between the sample weight and the solvent (pl ease

observe the note on volum e c orrection)

Fg: Specific weight of the solvent used in g/cm³

Note on volume correction:

The user has to decide on a case-by-case basis whether a v olume correction is necessary and according to

which procedure thi s corr ec tion is to be performed. As a rule, this volume correction may be omitted in the case

of solutions with v er y l ow percent ages of diluted substance.

Page 48

117

Chapter 4 Method Param eters

4.6.2.5 Decimal digits

To conclude, it is possible to determine the number of decimal digits from 2-6. The standard setting is 2.

Fig. 79

4.6.2.6 Statistics

The mean value and relative standard deviation can be automatically calculated and documented by using

statistics.

Fig. 80

The calculati on of the mean value i s already possible fr om two individual values. The calculati on of the relativ e

standard deviation is only possible from 3 single values. The maximum quantity is 10.

Fig. 81

The mean value and the relative standard deviation (RSD) are shown directl y on the display .

Page 49

118

Chapter 4 Method Param eters

4.6.2.7 Global Memories

Results of titrations can be writt en into one of the 50 global memories (M01 - M50) for additional calculations.

Fig. 82

The mean v alue is writt en i nto t he global mem ory when t he stat i stic is switc hed on. You ent er the subm enu wit h

<Enter/OK>. If a global memory has not been created, a memory can be created by using the insert key <Ins>.

The titrat or proposes a memory name, such as M01 (M01- M50). The name of the memory can be changed i n

reference to the application. Here in this example of “M01” for “Blank value”.

Fig. 83

This simplifies later the allocation of the global memor y in another m ethod.

Example Titer d etermination: The titer in mg/ml is defi ned with an extra Ti ter met hod. The result in mg/ml is

thereby automati c ally written into global memory “Exchangeable unit”.

Fig. 84

The menu for the global memory can always be accessed by pressing Shift+F5 or vi a system settings. The name

or values can be changed by using EDIT /F 3 and have the methods shown that are used in the global mem ori es.

Page 50

119

Chapter 4 Method Param eters

Fig. 85

4.6.3 Titration parameters

The <Titration parameter> submenu is used to determine the actual parameters of the method. T he par am eters

were already introduced in chapter 4.6.2.1:

Fig. 86

Fig. 87

Generally applicable titration parameters

Depending on the t itration mode (KF or dead stop titrati on) it is possible to ent er a variety of parameters. The

following parameters are valid for the KF and dead stop titr ation modes:

• Initial waiting time

• Fixed delay

• St ep si z e

• Pretitration

• Polarization voltage

• End of tit r ation

Page 51

120

Chapter 4 Method Param eters

Start delay time/ E xt ract io n time (KF):

With dead-stop ti tration, the start wait time passes at the begi nning of titrati on. In KF titration, t he star t wait time =

the extracti on time. The extracti on time ends after the sample is supplied. The start wait/ extraction time can be

specified bet ween 0 and 999 seconds.

Fig. 88

Conditioning

Conditioning ( only KF) is activated for every KF method. It can be shut off via a PC for exter nal c ontrol:

Fig. 89

Fixed delay time

The fixed delay ti me i s the waiting time between the li near titration steps at the end of the titration until the

Endpoint. The fixed delay time can be set between 0 and 999 seconds:

Fig. 90

Step size

The step size can be set from 0.001 to 5. 000 ml . typical value for the KF titration are 0.002 – 0.01 ml.

Page 52

121

Chapter 4 Method Param eters

Fig. 91

In this type of titr ation, linear step width is used after the continuous titration stage.

Titration direction (only dead stop titration mode)

The titrati on direction can be set to “increase“ or “decrease“. For instance, i f you wish to perf orm a sulfurous

titration with iodine solution you have to select “increase“. For an iodometric back titrating with Sodium

thiosulfate you have to select “decrease“.

Fig. 92

Pretitration

If the titration agent consumption is roughly known, you can set a pretitration volume on the <Pretitration>

menu. In this process, a defined volume is dosed ( = pretitrated) following the initial waiting time. After the

addition of the preti tration v olume, another def i ned span of t ime is observ ed as the waiti ng time bef ore the nex t

titration step is added. The pretitration volume is autom atically added to the titration agent consumption. The

pretitration v olum e can be set from 0.000 and 99. 999 ml , the possible range for setti ng the waiti ng tim e following

pretitration is between 0 and 999 seconds.

Fig. 93

Polarization voltage

Polarisation voltage in mV can be set for KF and dead stop titration.

Page 53

122

Chapter 4 Method Param eters

Fig. 94

The values can be set between 40 and 220 m. The pr e-setti ng is 100 mV.

Low polarisation voltage: insensitive

High polarisation voltage: sensitive

4.6.4 Titration end

The end of a titration is reached, and the result will be calculated as soon as, or if, respectively:

• The def ined End value i n µA value has been reached

• The E ndpoint delay in seconds has been adhered

• The dr ift value in µg/min has been reached

• The pr edefined value ml has been reached (Maximum t itr a t io n v olume)

• The conditions for minimum and maximum titration time are maintained

Fig. 95

Fig. 96

Maximum titration time

The maximum t itration time c an be set between 0 – 9999 seco nds. The defaul t setting is 600 seconds. The

maximum titration time is generally used for KF titration, which can create a high continuous drift from a

secondary reaction and thus cannot reach a stable endpoint.

Page 54

123

Chapter 4 Method Param eters

Minimum titration time

The minimum titration time can be set between 0 – 9999 seconds. The default setting is 10 seconds. The

minimum tit rati on time prevent s prem ature t erminati on of the t itrati on if t here i s a delay in t he ex tracti on of water

from the sampl e. The minim um titration t ime is used in com binati on with the ext raction tim e. It ex pires while the

extraction time is still active.

Maximum titration volu me

Setting of the maximum titration volume should always make sense. It also serves as a safety criteria to

prevent exc essive titration, i.e. a possible overflow of the ti tration vessel. T he maximum titration v olume can be

set between 1.000 und 999.999 ml:

Fig. 97

The default setting is 50 ml. The volume for conditioning is included in the count!

Drift

The drift i s calculat ed in µg/mi n fr om the titr ation mean c onsumpt ion/t im e x concentrati on of t he tit rati on solution.

A stable drift at the beginni ng and end of the titration is im port ant if y ou want to o btai n reproduc ibl e result s. Thi s

applies in part icular to sam ples with low water content in the bott om percentage range (<0, 1%). The drif t value

should also not be set too low because the ti tration time will increase considerably. An airtight and dry titration

vessel has a drif t of < 50 µg/mi n. This corresponds to consum pti on of 10 µl ( 0,01 ml) of ti trant at a concent rati on

of 5 mg/ml. For many applicati ons, a drift value of 100 – 150 µg/mi n is entirely sufficient. T he default drift value

setting is 100 or 150 µg/min for sample titration. 50 µg/min is the def ault setting for titer methods.

Endpoint µA

The range of t he µA input c an be selected bet ween 0.0 and 100. 0. For K F titr ation, values between 10 – 30 µA

are practical. The standard value is 20 µA.

Delta Endpoint µA

The Delta value in µA is one of the most impor tant parameters for KF and dead-stop t itration. T he lower the Delta

value is, t he longer the ti tration (dosing) i s at a conti nuous speed. W hen using single-component reagents an d

pure methanol as a solvent, the Delta value shoul d be set at < 5 µA. Values of 2 or 3 µA are pract ical. This i s

because the KF reaction in methanol runs relatively slowly. When using double-component reagents or also

when using combinati on solv ent s, the Delt a value must be set at > 10 t o prevent r apid ov ertitrati on. V alues of 14

or 15 µA are practical.

Endpoin t de la y

The endpoi nt del ay is set in second s. It can be set fr om 0 – 100000 second s. The standard value is 10 seconds.

Brief endpoint delay s (5 seconds) are practical when

• using very small increments (e.g., 0,001 ml)

• using a titer of 1 mg/ml

• creating a secondary r eac tion with a higher drift value

Page 55

124

Chapter 4 Method Param eters

4.6.5 Dosing parameter

Fig. 98

The dosing param eters (dosing speed, f illing speed and m ax. dosing/titrati on volume) are determined f or each

method. This applies to all types of methods such as automatic titration, dosing and Solution Prepar ation.

Fig. 99

The dosing speed can be set in % fr om 1 to 100 %. 100 % is the maximum dosi ng speed.

Interchangeabl e un it

Max. dosing speed [ml/min]

WA 05

10

WA 1 0

20

WA 2 0

40

WA 5 0

100

The filling speed can be set in t er ms of seconds f r om 20 to 999. The standard setti ng of this val ue is 30 seconds.

For dil uted aqueous solutions the f illing speed can be six to 20 second s. For non-aqueous solut ions the filling

speed should be set to the 30 seconds. In t he case of highly viscous solutions such as concentrated sulphur ic

acid the filling speed should be further reduced down to 40 - 60 seconds.

Depending on the met hod type, the (maxim um) living volume or tit ration volume can be set to 999. 999 or even

9999.999.

The following fill ing options can be set for the dosing mode:

Page 56

125

Chapter 4 Method Param eters

Fig. 100

If”off“is selected for filling, filling it will not occ ur autom atically after each dosing step.

If “intelli gent before“ is select ed for filli ng, a verificati on will be performed each time pri or to the next dosing st ep

in order to det ermine whether the dosing step can still be made wit hout a filling operation. Should this prove to be

impossible, the first thing to occur is filling, followed by the dosing step.

If “intelligent after“ is selected for filling, a verification will be performed after the next dosing step to find out

whether the next dosi ng step c an still be made without filling.

If „always“ is selected for filling, filling will occ ur autom atically after each dosing step.

4.6.6 Sample identification

In the manual titration and in the preparation of solutions it is possible to input a sample identification. The

possible input includes manual, automatic or no sample descript ion at all.

Fig. 101

For a sample description of t he ’manual’, a prompt for the sample description will always be displayed at the start

of the method (Cp. also chapter 3. 6, Main m enu). For an ‘autom atic’ sampl e descripti on there will be selected a

master descripti on (in the current case this is water, cp. Fig. 102), which will then aut omatically be num bered

starting on 01.

Fig. 102

After a new power-up, numbering will resume with 01.

Page 57

126

Chapter 4 Method Param eters

4.6.7 Documentation

Fig. 103

Three different format settings are av ailable for documentation on a printer or USB device: “short”, “standard

(with curve)” and “GLP ”:

Fig. 104

Method type

Short documentation

Standard

documentation

GLP-Documentation

Automatic titration

Method name, date, time, duration

of titrati on, sam ple description,

weight/volum e, starting and end

measurement values, results and

calculation formula

Same as ‘Short

documentation’ + titration

curve

Same as ‘Standard

documentation’ +

method contents

Dosing

Method name, date, time

N/A

Same as ‘Short

documentation’ +

method contents

Prepare soluti ons

Method name, date, tim e, sam ple

designation, weight/sample,

results and calculation formula

N/A

Same as ‘Short

documentation’ +

method contents

Page 58

127

Chapter 5 - System Settings

5 System settings

Fig. 105

From the main menu (Fig. 107), <SYS>/<F7> will get you to the system setti ngs:

Fig. 106

Setting the nati onal language was already described in Chapter 2.5.

5.1 Interchangeable Unit - Reagents

Each interchangeabl e unit is equipped with an RFID transponder. T his transponder can be used to store the

following inf ormation:

• Uni t size: (the default setting, c annot be changed)

• Uni t ID: (default setting, cannot be changed)

• Reagent name: (default: blank)

• Concentration: (default: 1.000000)

• Concent r ation determined on: (Date)

• To be used until: (Date)

• Opened/ P r oduc ed on: (Date)

• Test ac c or ding to ISO 8655: (Date)

• Charge description: (def ault: no c har ge)

• Last modification: (Date)

Page 59

128

Chapter 5 - System Settings

Fig. 107

Fig. 108

Fig. 109

If you leave the <Reagents WA> menu using <E S C>, you wil l always be prompted to know whether you wish to

adopt the values:

Fig. 110

If <Yes> is selected, the updat ed v alues will be written into the RFID transponder of the interchangeable unit.

Page 60

129

Chapter 5 - System Settings

5.2 RS232 Settings

The <RS232 setti ngs> item can be used to deter mi ne the device address of the TitroLine® 7500 KF and set the

parameters of the t wo RS232 i nterfaces independent from each other:

Fig. 111

The device address can be set from 0 – 15. Addr ess 1 is the def ault setting:

Fig. 112

The baud rate is preset to 4800. It m ay be set to 1200 – 19200:

Fig. 113

Page 61

130

Chapter 5 - System Settings

Fig. 114

The parity can be selected am ongst <No>, <Even> and <Odd>. <No> is the default setting.

Fig. 115

You may select between 7 and 8 data bits. 8 bits is the default setting.

Fig. 116

The RS232 parameter s can be set t o the factor y settings.

Page 62

131

Chapter 5 - System Settings

5.3 Date and Time

The factory tim e setting is Central European Time. This setti ng m ay be changed, where necessary:

Fig. 117

5.4 Password

The activation of t he password has not yet been implemented for the current ver si on 12_18. Please contact SI

Analytics for sending you an update version.

5.5 RESET

RESET will reset all settings to the factory setting.

Please note: All methods wil l also be del eted. So pl ease print the m et hods or export /c opy them to a connected

USB storage medium (this will be possible with a higher update!).

The RESET has to be confirm ed separatel y onc e again:

Fig. 118

Page 63

132

Chapter 5 - System Settings

5.6 Printer

For connecting printers please refer to chapter 7.3.

Fig. 1 19

5.7 Device Information

<Device Informati on> contains information about

• the c ur r ent software version

• the serial number of the device

• printer driver and update version

• device address

• number of measurements (Starts of a method)

• a number of strokes/filling cycl es

Fig. 120

5.8 System Tone

This is the poi nt t o set the volume of the system sounds and the fr ont keyboard of the device. The system sound s

become audible e.g. at the end of the titration or in case of an erroneous operation. The keys of the front

keyboard produce a cli c ki ng sound if the key was used successfully.

Page 64

133

Chapter 5 - System Settings

Fig. 121

No sounds will occur when the external keyboard is used.

5.9 Software Update

Fig. 122

An update of t he dev ic e software requi re s a USB sti ck c ontai ni ng a new v er sion. F or t his operati on, t he two fi l es

that are needed hav e to be located in the root directory of the USB device:

Plug the USB device into a free USB-A port, wait for some seconds, and then select the Software Update

function. The v alid software update s will be shown on t he display. In the present case thi s is Version “16_11 “ of

19 April 2011.

Page 65

134

Chapter 5 - System Settings

Fig. 123

After starti ng the updat e usi ng <O K/E NTER>, next thing to appear is the following gr aphic:

Fig. 124

which will change aft er a few seconds to the f ollowing display:

Fig. 125

Upon completion of the update (approx. 2-3 minutes), the device will shut down the software completely and

proceed to a new start.

Important: In the course of an update, the methods will not be deleted! You can conti nue to use them.

If no valid update file is stored on t he US B sti c k, the f ollowing message will appear:

Fig. 126

Page 66

135

Chapter 6 Data Communication via RS232 and USB-B interface

6 Data Communication via RS232- and USB-B interface

6.1 General Inf ormation

The burette TitroLine® 7500 KF has two serial RS232-C interf aces to communicat e data with other devices. By

means of these two interfaces it is possible to operate sever al dev ic es on one computer (PC) interface.

In addition to that, the TitroLine® 7500 KF also has an alternatively USB-B interface, which can only be used to

connect a PC.