Date Revision Nr

09.06.2004 00

Item Nr

Servicing Manual

MOBILE (OIL- OR KEROSENE-FIRED) EMERGENCY AIR HEATERS

MIRAGE - TORNADO

SIAL S.p.A

C.so Inghilterra, 15 - 12084 MONDOVI’ (CN)

Tel. 0174 560611 fax. 0174 481086

Website www.sialspa.it

e-mail: tec.com@sialspa.it

Copyright

No section of this document can be reproduced in any form or processed by means of electronic systems, copied or distributed

without written permission by SIAL S.p.A. The translation into other languages is also allowed only under written permission

by SIAL S.p.A. The use of this document is restricted to SIAL servicing centers and to distributors of SIAL products. This

manual is not intended for end users.

Technical changes

IAL S.p.A. has the right to modify any instruction, description and specification contained in this document without prior

S

notice.

1

Servicing Manual

FOREWORD

Thank you for choosing the SIAL MIRAGE-TORNADO heaters. We would like to remind you that, as

for any machine, you can get good operation and performance only if the heaters are correctly used and

always kept in perfect efficiency. If required, the SIAL Technical Service can give you suggestions and

assistance.

The SIAL MIRAGE-TORNADO heaters are especially intended for the professional heating of civil,

industrial and agricultural premises.

Read and follow carefully the instructions contained in this manual before starting any

servicing or maintenance operation.

SIAL S.p.A. will not accept any responsibility for damages to persons, goods, properties or to the

machine itself that may result from non-compliance with the instructions contained in this manual and

with the Laws and safety rules in force in the Country of destination.

2

Servicing Manual

INDEX OF CONTENTS

1 Operational diagrams and sequences

1.1 Indirect-fired heaters with flue

1.2 Direct-fired heaters without flue

1.3 Heaters with and without flue: operational sequence

1.4 Safety options in case of abnormal operation

2 Functional description of components

2.1 Casing/Frame

2.2 Motor/fan assembly

2.3 Fuel circuit

2.4 Burner head/Combustion chamber

2.5 Electrical board

3 Troubleshooting guide - Operating flow-chart

3.1 Checking the supply voltage

3.2 Checking/replacing the power cord

3.3 Checking/replacing the motor

3.4 Checking/replacing the fan

3.5 Exhaust gas analysis. Combustion air adjustment

3.6 Cleaning the fuel tank

3.7 Checking/cleaning/replacing the fuel filter

3.8 Checking/cleaning/replacing the fuel nozzle

3.9 Checking/cleaning/replacing the burner head and the whirl disc..

3.10 Cleaning the combustion chamber

3.11 Replacing the motor/pump joint

3.12 Checking/adjusting/replacing the fuel pump

3.13 Checking and replacing the fuel solenoid valve

3.14 Checking/cleaning/replacing the ignition electrodes

3.15 Checking/replacing the high voltage cables

3.16 Checking/replacing the ignition transformer

3.17 Replacing the fuse

3.18 Checking/cleaning/replacing the flame sensor

3.19 Checking/replacing the overheat thermostat

3.20 Checking operation of flame control unit

4.1 Setting chart - Indirect-fired heaters with flue

Setting chart - Direct-fired heaters without flue

Technical data sheets for indirect-fired heaters with flue

Technical data sheets for direct-fired heaters without flue

4.2 Wiring diagrams - Basic version and versions with filter and nozzle fuel pre-heater

4.3 Special tools for servicing

3

Servicing Manual

1. OPERATIONAL DIAGRAMS AND SEQUENCES

1.1 INDIRECT-FIRED HEATERS WITH FLUE

Flue

Burner head

Fuel pump

Combustion chamber

(closed)

Fuel tank

4

Motor

Fan

Servicing Manual

1.2 DIRECT-FIRED HEATERS WITHOUT FLUE

Burner head

Fuel pump

Combustion chamber

(open)

Fuel tank

5

Motor

Fan

Servicing Manual

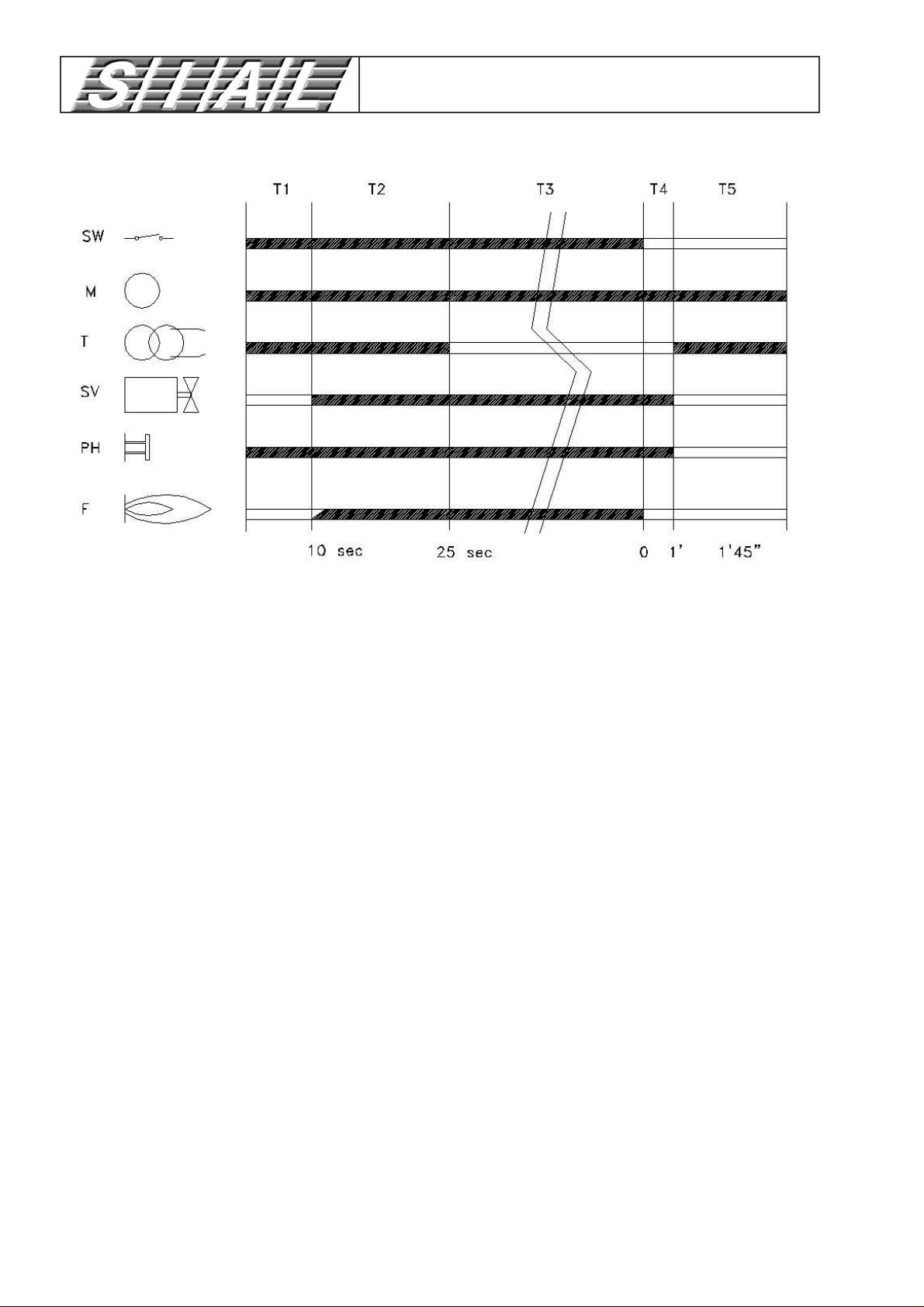

1.3 HEATERS WITH AND WITHOUT FLUE: OPERATIONAL SEQUENCE

T1

T2

T3

T4

T5

SW

M

T

SV

PH

F

Prepurge time

Ignition time

Operation time

Safety time at flame failure

Aftercooling time

Switch

Motor

Ignition transformer

Fuel solenoid valve

Flame sensor

Flame

Prepurge sequence

During the prepurge time (about 10 s) the fan blows air into the combustion chamber to expell any

residual exhaust gases. The ignition transformer T produces a spark so that any small fuel residuals

coming from the solenoid valve through the nozzle are completely burnt. At the same time the flame

control unit checks for presence of flame or spurious light inside the combustion chamber: should this

occur, the ignition sequence is interrupted and the heater locks out, that is all the electrical components

are immediately unpowered.

Ignition sequence

During the ignition time, after the prepurge time, the fuel solenoid valve EV opens and the spark

produced by the electrode ignites the fuel mist sprayed by the nozzle. The flame sensor (photoresistor)

PH must feel the presence of flame within 1 s (safety time), otherwise the flame control unit locks out and

the motor is stopped. If the flame sensor only feels a small flash and not a continuous flame, the whole

prepurge and ignition sequence is repeated and then, if ignition is still unsuccessful, the unit goes to lockout and stops.

6

Servicing Manual

Operational sequence

15 s after a regular flame ignition, the flame control unit de-energizes the ignition transformer and the

electrodes stop sparking. The heater goes on operating with self-sustained combustion. The flame control

unit monitors the regular presence of flame by means of the flame sensor. Any abnormal condition, such

as lack of fuel, blockage of air inlet/outlet, dirty or clogged nozzle, that impairs regular combustion has

the effect to close the fuel solenoid valve SV and to interrupt the fuel flow to the burner within the safety

time. The flame control unit will then start a new complete prepurge/ignition sequence, and, should the

problem repeat, the unit will lock out and the aftercooling sequence will start.

Restart sequence

If the flame shuts down for any reason, the flame control unit repeats the whole start sequence, consisting

of the prepurge and the ignition sequences. If there is no flame signal within the safety time T4, the

control unit goes to lock-out and the red lamp on the control panel lights up. If, on the contrary, a small

flame signal is detected within the safety time, the control unit repeats the start sequence. The whole

sequence will be repeated 3 times maximum and then the unit will definitely lock out. A maximum

number of 3 ignition tries has been fixed to avoid that excessive smoke is produced during the repeated

starting sequences. This effect could occur when the fuel tank is almost empty and the suction hose

contains fuel and air mixed, or when the nozzle is partially blocked or damaged, and therefore the

pressurized fuel is incorrectly sprayed.

Aftercooling sequence

During this time the heater is subjected to a cooling cycle to avoid excessive overheating of materials

and components that could occur if the motor/fan suddenly stopped. This sequence is also very important

from the point of view of efficiency, as all the residual heat that accumulates in the combustion chamber

can be recovered and sent in the space to be heated.

For safety reasons, it has been established that the high voltage ignition transformer must be energized

during the aftercooling time. By doing this, any small fuel residuals coming from the solenoid valve SV

will burn completely and will not accumulate inside the combustion chamber. Any explosion risk or

abnormal heat release during future ignition sequences is therefore prevented.

The aftercooling time is factory set and independent of the action of a limit control or similar devices on

the combustion chamber. The aftercooling time lasts about 1 minute and 45 seconds.

Lock-out sequence

In the event of flame shut down due to lack of fuel or to another reason (see also the par. “SAFETY

OPTIONS IN CASE OF ABNORMAL OPERATION”) the flame control unit will put the heater in a

safety condition starting the lock-out sequence. During this sequence the fuel solenoid valve SV is

immediately closed within the safety time T4 (< 1s) and then an aftercooling cycle will start to cool the

surfaces of the combustion chamber. The ignition transformer is powered, and therefore a spark is

produced by the electrodes, during the aftercooling cycle as described above.

eset sequence

R

The unit can be reset by pushing the red reset pushbutton with integral warning lamp on the control panel.

For safety reasons, reset will only be possible after about 30 s from lock-out. Also in the event of

electrical supply failure/restoration, reset will only be possible after 30 s approximately.

7

Servicing Manual

1.4. SAFETY OPTIONS IN CASE OF ABNORMAL OPERATION

• Spurious (external) light or anticipated ignition

During the prepurge time no flame signal must come to the flame control unit. A flame signal with no

flame could be due to external lights, short-circuit in the flame sensor or in the flame sensor leads, fault in

the flame signal amplifier, fire on board of the unit, or, should the solenoid valve SV not properly

interrupt the fuel flow to the nozzle, to anticipated ignition of the fuel/air mist during the prepurge time.

In this case after the prepurge time and the safety time, the unit goes to lock-out.

Special attention is required in the event that the heater is directly exposed to sunlight (e.g. when used

outdoors). It may happen that sunrays come into the combustion chamber and give a false flame signal,

especially when the heater is new and the inner surfaces are bright and reflect light.

• Flame failure at ignition

If there is no flame signal at the end of the safety time T4, the flame control unit goes to lock-out

condition.

• Flame failure during operation

If the flame signal fails during operation, the flame control unit closes the fuel solenoid valve, the fuel

flow to the nozzle is interrupted and a new prepurge/ignition cycle is started. In case of lock-out, the unit

can be manually reset after 30 s approx.

• Overheat thermostat activation

In the event of combustion chamber overheating, the overhat thermostat interrupts the electrical supply to

the flame control unit and to all components. The heater is immediately stopped.

The possible causes of overheating are described in par. 3 “TROUBLESHOOTING GUIDE”

2. FUNCTIONAL DESCRIPTION OF COMPONENTS

ASING/FRAME

2.1 C

Description

The heater casing consists of :

a tank made of galvanized steel which also acts as a support for the whole machine.

a support fixed on the tank to which the lower half-shell of the heater is connected. This support

also contains the electrical board.

a lower half-shell which, together with the upper half-shell, forms the air duct where heat is

transferred to the flowing air. All main components are directly fixed onto the lower shell.

an upper half-shell that completes the air duct and can be disassembled by unscrewing 6 screws

for servicing and maintenance. On the indirect-fired heaters with flue the upper shell includes a

circular hole for the flue collar.

on the upper shell you can also find an inspection door that allows operators to reach the

components inside the heater and to carry out most of the repair and maintenance operations.

on the rear, a protection guard is fitted on the air inlet to prevent any contact with the rotating

parts of fan/motor.

on the front, a half cylindrical protection shield if fitted between the combustion chamber and the

lower shell, to limit the temperature of such part, that is directly accessible and can be touched by

the operators.

8

Servicing Manual

On the front a diffuser outlet cone allows the warm air (on indirect-fired heaters) or the mixture of

warm air and exhaust gases (on direct fired heaters) to be released into the heated room. The axle

with wheels and the support foot are connected below the tank.

2.2 FAN/MOTOR ASSEMBLY

Description

An electrical motor drives both the fan and the oil pump. A helicoidal fan provides a constant air flow in

the axial direction, a part of which is used for the combustion ; the remaining part flows along the

surfaces of the combustion chamber and of the heat exchanger, and it is consequently heated. The fan is

connected to the motor shaft by means of a threaded pin.

The oil pump has the function to suck fuel from the tank and to drive it to the nozzle at the rated

pressure : the pump is connected to the motor shaft by a resin joint and fixed to the motor casing by

means of 3 threaded pins. Single-phase, 2- or 4-poles motors with rotational speeds of 2800 rpm or 1400

rpm are used according to the heater model. See technical data sheet for detailed motor specifications.

ILL. 1: particolare gruppo motore MIRAGE 85H – TORNADO 115

9

Servicing Manual

2.3 FUEL CIRCUIT

Description

The fuel circuit is basically composed of :

tank

suction and return hoses

fuel filter,

fuel pump,

fuel solenoid valve,

high pressure microhose

combustion head

nozzle

The gear pump, driven by the motor, sucks fuel from the tank and increases its pressure to the rated value.

At the pump outlet a fuel cut-out solenoid valve SV is fitted. The pump is controlled by the flame control

unit. During normal operation the valve is open and the pressurized fuel flows to the nozzle, where it is

atomized, mixed with primary combustion air and ignited by the electrode spark. The flow of primary air

to the burner is adjusted by an air lock on the combustion head.

Under abnormal operating conditions (see also flow-chart) the flame control unit closes the solenoid

valve SV, fuel does not come to the nozzle but goes back to the tank through the return hose. An

adjustment screw is fitted on the front of the pump ; it allows to adjust the pressure and consequently the

fuel flow.

ILL. 2: particolare gruppo filtro gasolio

2.4 BURNER HEAD/COMBUSTION CHAMBER

ILL. 3: particolare pompa gasolio

10

Description

Servicing Manual

A certain amount of air coming from the fan flows around the combustion head, and, depending on the

air lock setting, a part of it - the so-called primary air - flows inside the burner head. The primary air is

distributed and mixed with the atomized fuel jet exiting the nozzle by means of a baffle disc. To get good

combustion and therefore high efficiency, the adjustment of the primary air/fuel ratio must be very

accurate. For this purpose, please carefully follow the setting specifications and instructions contained in

this manual.

The burner head includes :

nozzle holder

air lock

baffle disc (whirl disc)

fuel nozzle

ignition electrode

flame sensor (photoresistor)

The fuel coming out of the nozzle is atomized and mixed with primary air. Additional circumferential

openings on the burner head allow another amount of air, called secondary air, to flow into the chamber.

That is an additional air delivery that completes combustion.

During the whole ignition sequence the electrodes are powered by the high voltage transformer and

produce a spark that ignites the fuel-air mixture.

The function of the whirl disc is to induce a rotational component in the primary air flow and therefore to

decelerate it : this way the mixing of fuel and air is increased and the combustion improved.

The combustion chamber is made of stainless steel. It includes :

a rear end on which the combustion head is fitted

a front end with hole on direct heaters, without hole on indirect heaters

a front flame shield on direct heaters

the heat exchanger with gas passageways

the exhaust gas flue collar

the protection shield around the chamber

a manually resettable overheat thermostat

2.5 ELECTRICAL BOARD

ILL. 4: particolare testa di combustione

11

Description

Servicing Manual

ILL. 5: particolare cruscotto

The electrical board has the function to broadcast the electrical supply coming from the electrical system

through the power cord to all components, by means of a control/command electronic device, called

burner (flame) control unit. This part has also the task to monitor flame and to ensure safe operation of

the heater during all its operational sequences.

The electrical board consists of the following parts :

Control panel

Protecting cover (against water/dust)

Power cable with strain relief and plug

ON/OFF switch

Remote room thermostat socket with plastic cover and inner electrical bridge (closing circuit for

operation without thermostat)

Reset pushbutton with built-in warning lamp

high voltage ignition transformer

fuse with fuseholder

electronic burner (flame) control unit

3. TROUBLESHOOTING

12

Servicing Manual

SWITCH

ON

Check for correct voltage

rating ( see data plate)

Check that the green warning

lamp on the control panel is

alight

• Check all electrical connections

• Check the warning lamp

THE HEATER STARTS

yes

no

Check fuse (burn-outs,

damages, etc.)

Check the burner control unit

Check that the red lock-out

warning light is not alight

Check that the overheat

thermostat has not been

activated

• Replace with a new one with

identical ratings

• See chapter 3...

• Replace the burner control unit

• Wait 30 seconds and push to

reset

• Open the inspection cover and

push to reset

Check that the remote

thermostat is properly

connected and adjusted

For operation without remote

thermostat, check that the

thermostat socket cover is

correctly inserted

in the socket

13

• Check connections

• Set a temperature value higher

than room temperature

• Check the metal bridge inside

the cover

• Reinsert and lock

Servicing Manual

Check for damages/cracks in the

Check for presence of external

See technical data sheets section

THE HEATER STARTS, THE

Check that the oil tank is full

Check for air bubbles

in the oil filter

• Tighten the oil line fittings

•

oil hoses

PREPURGE SEQUENCE

STARTS BUT THEN THE

HEATER STOPS WITHOUT

IGNITION

no

yes

Check that the nozzle is clean

Check that the whirl disc is

clean

Ckeck that the flame sensor is

not damaged, clean and

properly fixed in its seat

Check the adjustment of air

lock

(spurious) lights

(sunlight, lamps)

• See chapter “Cleaning the

combustion head”

• See chapter “Cleaning the

combustion head”

• Clean the flame sensor with a

soft cloth and ethylic alcohol

• Replace the flame sensor if

damaged or burnt

•

• Look for - and eliminate - light

reflections due to sunrays,

lamps etc. that could reach and

disturb the flame sensor

• Look for fires inside the

machine

14

Servicing Manual

, dirty,

Check the nozzle size

• Look for the correct nozzle size

on the setting chart.

• Replace if necessary

THE HEATER STARTS,

FLAME IGNITES BUT

COMBUSTION IS NOT

GOOD

no

yes

Check the air lock adjustment

Check that the nozzle is clean

Check that the fuel filter is

clean

Check that the pump filter is

clean

Check that there are no air

bubbles in the fuel line

• See setting chart

• See chapter 3.8

• Replace the nozzle

• See chapter 3.7

• See chapter 3.12

• Tighten fittings

• Replace faulty pipes/hoses

Incorrect fuel pressure

Fuel is of incorrect type

polluted or contains water

15

• Measure and adjust the pressure

• Replace the pump (see chapter

3.12)

• Empty the tank and refill with

clean fuel of correct type

Wrong thermostat setting (use of

THE HEATER SUDDENLY

STOPS

no

OK

yes

Servicing Manual

Overheat thermostat

incorrectly activated

Excessive overheating of

combustion chamber

(overheat thermostat

correctly activated)

• Wrong location of overheat

thermostat (after incorrect

servicing, repairs etc.)

•

an incorrect type)

• Wrong (too large) nozzle size

(see specification chart)

• Wrong (too high) fuel pressure

(see specification chart)

• Insufficient ventilation due to

motor fault

• Insufficient ventilation due to

fan failure

• Blockage of airways due to dirt

or foreign objects

• Exhaust pipe partially

obstructed

• Combustion chamber clogged

by soot. (see chapter.3.10)

16

THE MAINTENANCE OPERATIONS

DESCRIBED IN THIS MANUAL MUST BE

CARRIED OUT BY QUALIFIED

PERSONNEL ONLY, IN COMPLIANCE

WITH THE ELECTRICAL SAFETY

STANDARDS IN FORCE.

ONLY USE ORIGINAL OR

RECOMMENDED SPARE PARTS.

3.1 CHECKING THE SUPPLY VOLTAGE

The supply voltage must match with the rated

voltage indicated on the data plate. The actual

input voltage must be within -15% and + 10% of

the rated voltage for good and safe operation.

• Measure the mains voltage, inserting the

multimeter tips into the electrical socket and

compare it with the rated voltage written on

the data plate.

If no voltage is found :

• Check the electrical system fuse(s) and the

main distribution board.

• Check the electrical socket.

Note : Only carry out maintenance/repairs on the

heater and not on the electrical system, for which

servicing by authorized personnel is required.

3.2 CHECKING AND REPLACING THE

POWER CORD

.

• Check that the green warning lamp lights up.

If it does not, this means the heater is not

powered.

• Check the conditions of cable and plug and

look for damages and failures.

• Unscrew the fixing screws of the control panel

and extract the electrical board.

Servicing Manual

Ill. 6

• Unscrew the fixing screw of the resin board

cover and remove the cover.

Ill. 7

• Check voltage between mains terminals (live

and neutral) on the cable strain relief. If no

voltage is found, check the fuse. If it is

damaged or burnt, replace it with one with

same current ratings (“slow-blow” type)

Ill. 8

17

To replace the power cord

• Only use H07RN-F power cords (Europe) or

SJT power cords (USA) with watersplashproof plug.

• Disconnect the line leads and earth leads from

terminals

Ill. 9

• Remove the defective cable.

• Insert the replacement cable into the strain

relief (inner lenght : about 5 cm).

• Fix the strain relief into its seat.

• Connect the line and earth leads to terminals.

• Check for proper operation.

• Reassemble the electrical panel.

3.3 CHECKING AND REPLACING THE

MOTOR

• Extract the electrical board (see picture)

• Check voltage at the motor terminals using a

multimeter.

Servicing Manual

Ill. 10

• Check the capacitor.

• To replace the motor:

• Unpower the machine by unplugging it.

• Disconnect the motor leads on the burner

control unit (see picture #10).

• Remove the upper shell by unscrewing its 6

fixing screws.

Ill. 11

• Disassemble the fan. (see chapter 3.4)

• Loosen the fuel pump fixing screws and

disconnect the pump (see chapter 3.12).

• Unscrew the fixing screws of the motor

bracket on the lower support.

18

Servicing Manual

Viti fissaggio

otore

m

Ill. 12

• Unscrew the fixing screws of the motor on the

bracket.

Ill. 13

• Replace motor and fix it on the bracket.

Connect bracket to lower support. Connect

motor leads on the terminal board following

the wiring diagram.

• Check operation.

• Reassemble fan, fuel pump, rear guard, upper

shell and electrical board.

To replace the capacitor :

• Remove the inspection cover.

• Extract the capacitor from its support.

• Disconnect leads on the capacitor.

Ill. 14

• Replace the capacitor with one with same

capacity (µF rating).

• Connect, check operation and reassemble.

3.4 CHECKING AND REPLACING THE

FAN

WARNING : MAKE SURE THAT THE

HEATER IS NOT POWERED BEFORE

OPERATING ON MOVING PARTS

WITHOUT GUARDS IN PLACE. BODY

INJURY DANGER!

• Remove the rear guard and look for possible

damages or obstructions not allowing the fan

to rotate.

To replace a damaged fan:

• Unscrew the fixing screw on the fan hub.

Ill. 15

19

• Extract the damaged fan and replace it.

• Check by hand that the fan can rotate freely

without interference.

• Check operation after reassembling guards.

3.5 EXHAUST GAS ANALYSIS (for heater

with flue only). COMBUSTION AIR

ADJUSTMENT

Perform an exhaust gas analysis with the ShellBacharach method to check the quality of

combustion.

• Use a standard smokemeter (Shell-Bacharach

pump) .

Servicing Manual

• Insert the pump end into the flue extension.

Ill. 18

• With the heater operating in normal

conditions, draw in the exhaust gases for 10

times (IMPORTANT : 10 TIMES

EXACTLY), taking care to carry out all

movements slowly and using the complete

piston stroke.

• Extract the paper strip, check the colour and

compare it with the reference scale to assign a

smoke number.

Ill. 16

• Insert a test strip into the pump slot .

Ill. 17

• Connect an extension for exhaust gas analysis

to the flue adapter.

Ill. 19

Oil-fired heaters are factory set by the

manufacturer to give a smoke number equal to 0

(zero) of the Shell-Bacharach scale. A smoke

number greater than 1 indicates bad combustion.

Should this occur, the causes of the problem

should be detected and eliminated.

20

The most important factors that can cause high

smoke numbers are :

Clogged combustion chamber due to

incorrect installation (exhaust flue

obstructed or badly designed, see chapter

3.10 and user instruction manual)

Operation without flue adapter

Dirty combustion head, fuel lines and/or

nozzle (see chapter 3.9)

“Too closed” adjustment of air lock (see

chapter 3.9.

Ill. 20

Lack of combustion air due to installation

too close to a wall or in a small room

without openings towards outside.

AIR LOCK ADJUSTMENT

emove the inspection cover.

• R

• Unscrew the fin screw on the combustion

head.

• Move the air lock in the axial direction to

reach the position shown on the setting chart

supplied by the manufacturer (see setting chart

at the end of this manual)

Servicing Manual

Ill. 21

3.6 CLEANING THE FUEL TANK

To clean the fuel tank:

• Lift the heater at about 1 m height using a fork

truck or other suitable means.

• Place a proper container under the heater tank.

• Unscrew the drainage cap on the tank bottom

to discharge the fuel completely.

Ill. 22

To clean the fuel filler filter, extract the filter

from the tank filler cap, clean it and reassemble.

21

Ill. 23

3.7 CHECKING/CLEANING/REPLACING

THE OIL FILTER

Servicing Manual

• Clean the filter cartridge using a soft brush and

then blow compressed air.

To replace the complete filter:

• Loosen the filter fittings and unscrew the

filter/bracket fixing nut .

• Reassemble and connect fuel hoses.

3.8

CHECKING/CLEANING/ REPLACING THE

IL FILTER

O

• Remove the inspection panel.

• Remove the fixing screw on the burner head

(nozzle-holder)

Ill. 24

• Unscrew the lower filter body (glass).

• Pour out the fuel contained in the filter.

• Open the filter and extract the filter cartridge.

Ill. 25

Ill. 26

• Extract the nozzle holder by rotating it

clockwise to release it from the fixing hooks.

Ill. 27

22

Ill. 28

• Unscrew the nozzle taking care not to touch

the electrode, as impacts could damage the

electrode ceramic insulators and impair good

ignition.

Servicing Manual

• Remove the inspection cover.

• Loosen (do not unscrew completely) the fixing

screws of the end disc on the combustion head.

Ill. 30

• Slightly rotate the combustion head clockwise

so that the screw heads match with the big

holes on end disc. This will be helpful when

reassembling, as the screws will act as

supporting and centering means for the

combustion head.

Ill. 29

• Clean the nozzle blowing compressed air

inside it.

• If cleaning is not sufficient, replace the nozzle.

Only use the nozzle sizes and types

recommended by the manufacturer (see setting

chart).

• Reassemble the nozzle.

• Reassemble the burner head and the inspection

cover.

3.9 CHECKING/CLEANING/REPLACING

THE BURNER HEAD AND THE WHIRL

DISC.

Ill. 31

• Extract the combustion head.

23

Servicing Manual

Ill. 32

• Clean the whirl disc using a brush and then

blow compressed air on it. To get good

combustion the air flow openings in the whirl

disc should be perfectly clean and free.

Ill. 33

3.10 CLEANING THE COMBUSTION

CHAMBER

• Remove the upper shell.

• Disassemble the burner head (see chapter

3.8).

• Disassemble the combustion head (see chapter

3.9).

• Unscrew the fixing screws on the combustion

head.

Ill. 34

• Extract the combustion chamber and if

required clean using Diesel oil

• Eliminate any Diesel residuals, carefully dry

and reassemble the combustion head, the

burner head and the upper shell.

3.11 REPLACING THE MOTOR/PUMP

JOINT

• Loosen (do not unscrew completely) the 3

fixing screws on the fuel pump

Ill. 35

• Extract the pump sliding it in the axial

direction.

24

Ill. 36

• Check the conditions of the coupling and

replace it if required.

• Make sure that the motor shaft can rotate

freely (move the fan by hand to check)

• Reassemble.

3.12 CHECKING/CLEANING/ADJUSTING

/REPLACING THE FUEL PUMP

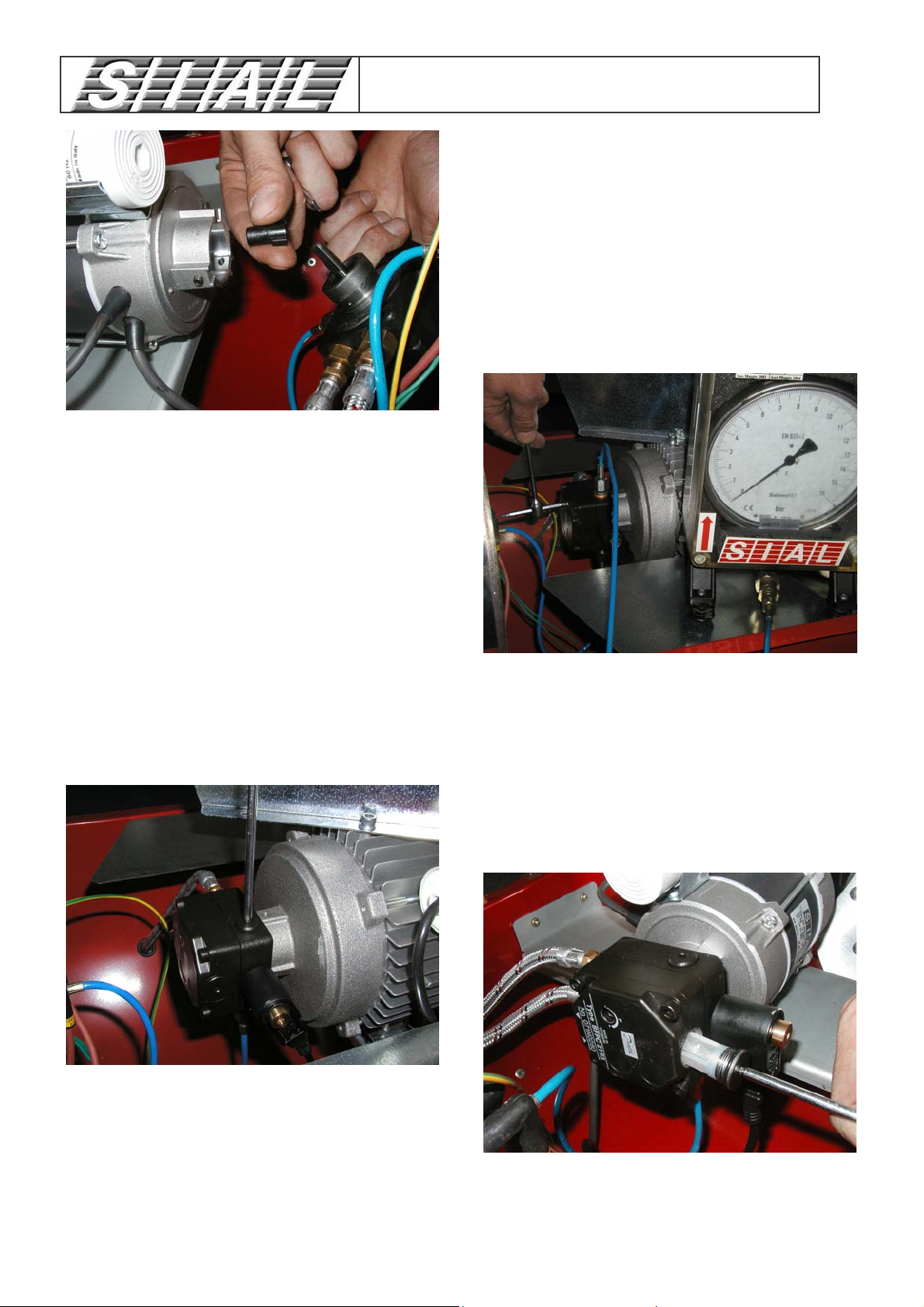

• Remove the inspection cover.

To measure the delivery pressure:

• Unscrew the screw on the upper part of the

pump

Servicing Manual

• Close the inspection panel and start a short

ignition cycle (10 s prepurge followed by 3 s

first ignition)

• Shut down the heater turning the ON/OFF

switch to 0 so that the aftercooling cycle starts

and the motor continues to rotate.

• Open the inspection cover and turn the screw

on the pump head clock- ot anticlockwise

(reading at the same time the pressure gauge)

until the correct pressure setting is reached.

Ill. 38

To measure the suction vacuum:

• Unscrew the screw marked with “V”.

• Connect a vacuum-meter to the port “V”.

To clean the pump filter:

• Unscrew the filter fixing screw on the pump

carter and extract the filter.

Ill. 37

• Connect a pressure gauge with a suitable

measuring range.

Ill. 39

25

• Clean the filter with compressed air or wash it

with clean Diesel oil.

• Reassemble

To replace the pump:

• Loosen the pump fixing screws.

• Make sure that the motor/pump resin joint is

correctly fitted.

• Replace the pump and reassemble the whole

unit

3.13 CHECKING AND REPLACING THE

FUEL SOLENOID VALVE

• Unscrew the solenoid valve fixing nut.

Servicing Manual

Ill. 41

• Extract the inner cylinder and clean it with

Diesel oil.

Ill. 42

Check that the inner cylinder can slide freely. If

required clean the piston.

To replace the solenoid valve:

• Open the electrical board.

• Check voltage at the solenoid valve terminals.

Ill. 40

• Extract the valve casing.

• Unscrew the fixing nut of the inner cylinder.

Ill. 43

If a voltage can be measured on the terminals

shown in the picture but the solenoid valve does

not work :

• Disconnect the valve leads from the burner

control unit.

• Replace the solenoid valve.

• Reconnect and check operation.

26

3.14 CHECKING/CLEANING/ADJUSTING/

REPLACING ELECTRODES

• Extract the burner head.

Ill. 44

• Check that the electrode tips are clean.

• If not, clean them with a soft brush and then

with compressed air.

• Check the clearances between electrode tips

and between electrode tips and nozzle.

• Adjust the clearances according to the diagram

low :

be

To check that ignition spark is regular:

nsert the nozzle holder into the burner head

• I

and fix it wih a proper screw.

• Completely open the air lock.

Servicing Manual

• Disconnect the solenoid fuel valve from

mains.

• Give power to the heater and allow a start

cycle to take place turning the ON/OFF switch

to I (ON).

• Visually check that the ignition electrodes

produce a regular spark .

Warning

At ignition, an 11 kW high voltage is produced

between the electrode tips. Carefully follow the

electrical safety regulations during all servicing

and maintenance operations.

• Reconnect the solenoid valve leads after

checking spark.

To replace the electrodes:

• Disconnect the high voltage leads from

electrodes.

• Unscrew the electrode fixing screws.

Ill. 45

• Replace the electrodes and reconnect the high

voltage leads.

• Reassemble the burner head.

3.15 CHECKING AND REPLACING HIGH

VOLTAGE CABLES

• Check that the high voltage cables are properly

connected.

• Check the conditions of high voltage cables

and look for possible damages.

Disconnect the high voltage cables from

electrodes and from the ignition transformer in

the electrical board.

27

Ill. 46

• Connect the new cables and check operation.

3.16 CHECKING/REPLACING THE

IGNITION TRANSFORMER

To replace the transformer:

• Unscrew the transformer fixing screw and nut

on the electrical board.

• Disconnect the high voltage cables from the

transformer.

• Disconnect the high voltage cables from the

burner control unit.

HT transformer

line

HT transformer

neutral

Servicing Manual

3.17 REPLACING THE FUSE

• Open the electrical board.

• Extract the fuse from the fuse holder in the

electrical board.

Ill. 48

• Check the conditions of fuse.

• Replace the faulty fuse with one with identical

current ratings. See technical specifications.

3.18 CHECKING, CLEANING AND

REPLACING THE FLAME SENSOR

• Extract the flame sensor from its seat in the

burner head disc, by turning it about ¼ turn to

loosen the fixing feet of flame sensor support.

Ill. 47

• Replace the transformer, reconnect cables to

transformer and burner control unit following

the wiring diagram shown on the label placed

on the electrical board cover.

Ill. 49

28

• Gently push the sensor leads to extract the

flame sensor. Clean the sensor glass with a

cloth soaked with ethylic alcohol to eliminate

any soot or dust residuals.

Ill. 50

It is possible to check the proper operation of the

flame sensor simply using a multimeter.

Connect the multimeter terminals to the sensor

leads and proceed as follows:

• Set the multimeter to measure resistance

• Expose the flame sensor to light.

• Under normal conditions, the tester should

show ohmic resistance quickly decreasing

illumination increases.

To replace the flame sensor:

• Disconnect the flame sensor leads from the

burner control unit (see wiring diagram ).

Ill. 51

as

Servicing Manual

• Replace the faulty sensor.

• Reconnect, reassmble and check operation.

3.19 CHECKING/REPLACING THE

OVERHEAT THERMOSTAT

• Remove the inspection cover and/or the upper

shell.

• Check that the thermostat is properly fixed and

connected.

To replace the thermostat:

• Disconnect the thermostat cables.

• Replace the thermostat.

• Reconnect and reassemble.

To reset the overheat thermostat:

• Unplug the heater

• Remove the inspection door

• Push the reset button

Ill. 52

3.20 CHECKING OPERATION OF

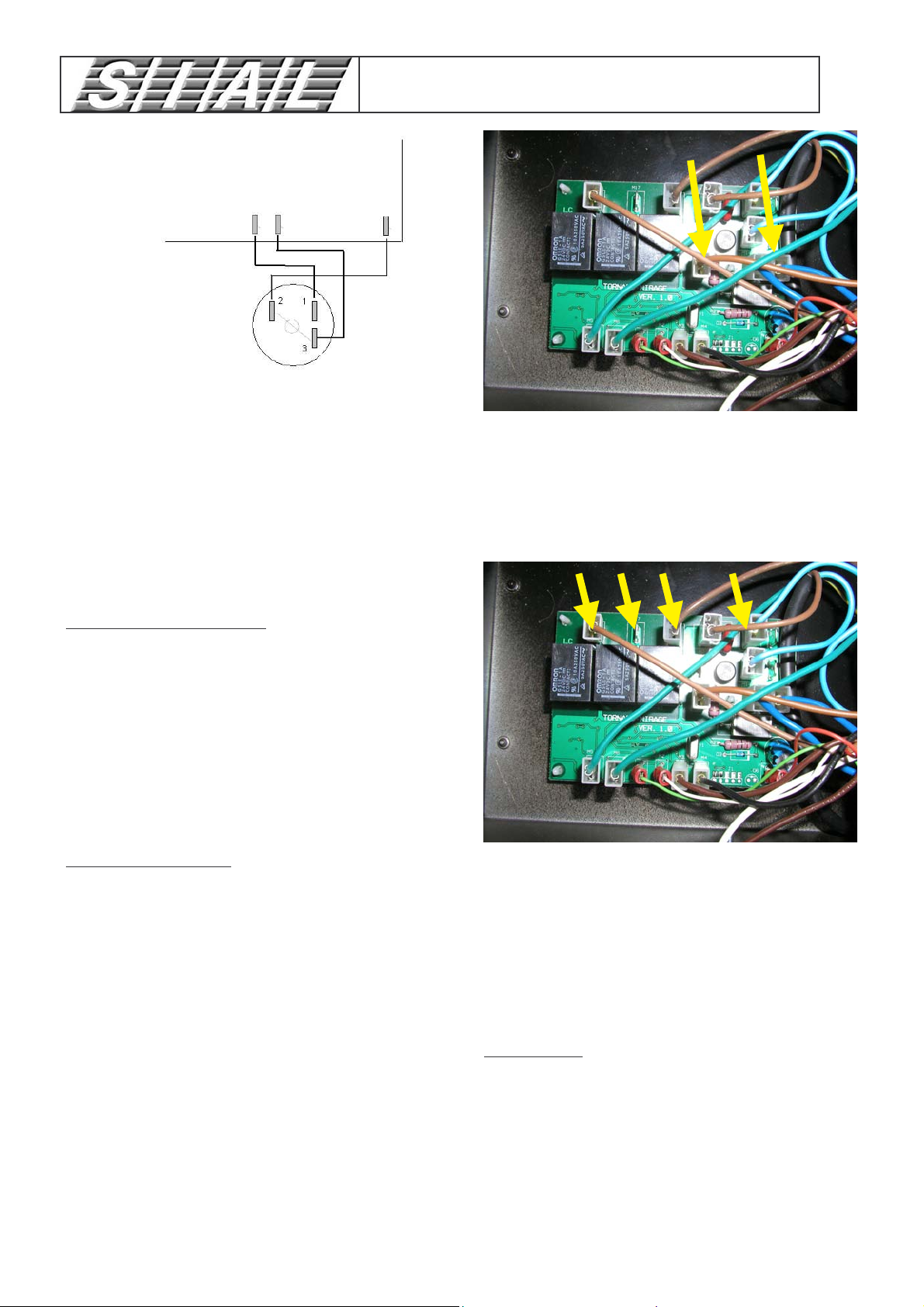

BURNER (FLAME) CONTROL UNIT

Perform the following tests to check operation of

the burner control unit.

Check reset pushbutton/ lock-out warning lamp

Ensure that the lock-out warning lamp is

correctly connected (see diagram)

29

Servicing Manual

M1 M2

M19

Check that there is electrical continuity

between the terminals 1 and 3 of the reset

pushbutton.

Check that there is a 18-20V voltage

between the terminals M2 and M19 of the

burner control unit when the unit is in

lock out condition (the lamp is alight).

Electrical continuity check

Unplug the heater

Turn switch to I (ON)

Set the room thermostat in a operating

(closed) position

Check that the overheat thermostat is

closed

Check electrical continuity between

terminals M3 and M4 of the electronic

control unit (with all wires connected).

Power supply to loads

Plug the heater.

Turn switch to I (ON)

Set the room thermostat in a operating

(closed) position

Using a multimeter, check that the burner

control unit is powered

Ill. 53

Check voltage on the transformer, motor

and solenoid valve terminals and that they

are correctly energized according to the

operational cycle.

Ill. 54

The voltage supply to components must match

with the mains voltage.

Should this not occur, or should the components

not be correctly energized according to the

operational cycle, replace the flame control unit

with a new one.

Lock-out test

Start the heater and wait that the ignition cycle is

completed. (wait until the ignition spark stops).

Disconnect the flame sensor fast-on from

terminal M5 on the burner control unit.

The heater must immediately lock-out.

The red warning lamp must light up.

30

Reset must be possible only after at least

30 seconds.

Servicing Manual

31

out. dia.=76mm

CHAMBER

MIRAGE

37 H

USA

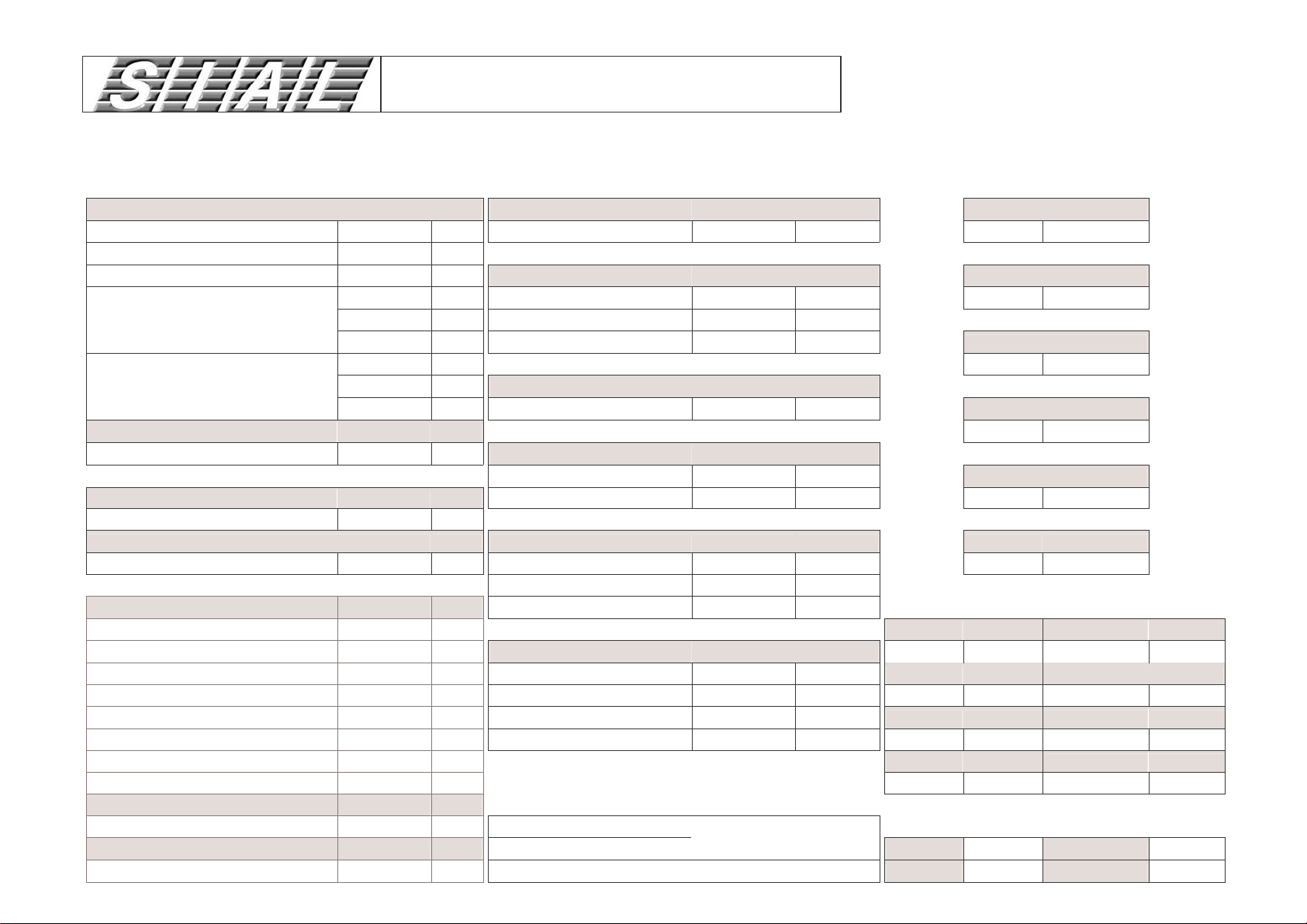

SETTING CHART - INDIRECT-FIRED HEATERS (WITH FLUE)

INLET

# 8 holes

6 mm dia.

FAN WHIRL

(BAFFLE)

dia.=350mm

3 blades

18°

in. dia.=27mm

Servicing Manual

4.1

FUEL

PUMP

DISC

DANFOSS

R3

10 blades

FUEL

PRESSURE

12 bar DANFOSS

BURNER

NOZZLE

0.65 60° H

AIR LOCK

OPENING

3 mm

lock position

1

OVERHEAT

THERMOSTAT

170 °C

(red markings)

MIRAGE

55 H

USA

MIRAGE

85 H

USA

# 8 holes

6 mm dia.

# 8 holes

10 mm dia.

dia.=350mm

3 blades

18°

dia.=500mm

4 blades

33°

out. dia.=76mm

in. dia.=27mm

10 blades

out. dia.=76mm

in. dia.=22mm

10 blades

DANFOSS

R3

DANFOSS

R5

32

12 bar DANFOSS

1.00 60° H

12 bar DELAVAN

1.50 80° W

7 mm

lock position

2

14 mm

lock position

3.5 - 4

170 °C

(red markings)

170 °C

(red markings)

CHAMBER

Servicing Manual

SETTING CHART - DIRECT-FIRED HEATERS (WITHOUT FLUE)

INLET

FAN WHIRL

(BAFFLE) DISC

FUEL

PUMP

FUEL

PRESSURE

BURNER

NOZZLE

AIR LOCK

OPENING

OVERHEAT

THERMOSTAT

TORNADO

67

USA

TORNADO

115

# 8 holes

dia. 6 mm

# 8 holes

dia. 10 mm

dia.=350mm

3 blades

18°

dia.=500mm

4 blades

33°

out. dia.=76mm

in. dia.=27mm

10 blades

out. dia.=76mm

in. dia.=27mm

10 blades

DANFOSS

R3

DANFOSS

R5

12 bar DANFOSS

1.25 60° H

12 bar DELAVAN

2.25 80° W

4 mm

lock position

1.5

13 mm

lock position

3.5

100 °C

(black markings)

100 °C

(black markings)

33

Servicing Manual

TECHNICAL DATA SHEET FOR INDIRECT FIRED OIL HEATERS – 37 kW MODEL

Thermal Specifications

Maximum Thermal Power (Diesel Oil)

Consumption Kg/hr

at 3°C (37F)

2,88

U.S. gal/hr 0,90

Efficiency %

Power Input kcal/hr 31304

kW 36,40

BTU/hr 125216

Power Output kcal/h 27266

kW 31,70

Fuel Pressure

BTU/hr 109063

12 bar 175 psi

Smoke Index

1,00

Air Lock Adjustment

mm 3,0

Maximum Thermal Power (Kerosene)

Consumption Kg/hr 2,64

Efficiency % 87,10

Power Input kcal/hr 29106

kW 33,84

BTU/hr 116425

Power Output kcal/hr 25352

kW 29,48

BTU/hr 101406

Fuel Pressure

psi 12,00

Air Lock Adjustment

mm 3,00

Airflow Specifications

Air Flow Rating

m³/h

2000 m³/h 1180 ft³/min

Fan Diameter

87,10

mm 350 mm 14 in

Blade # 3 sickle-shaped

Pitch 18°

Temperature Rise (Delta)

at 20°C (68 F)

54°C 97 F

Noise Level at 1 m at 2 m

dB(A) average 77 75

with original hood

Nozzle Type

Manufacturer DANFOSS A 15 slow-blow

Type 60° H

Flow Rate GPH 0,65

Air Ducting

Hose Diameter

315 mm 12 in

Maximum Hose Lenght

8 m 25 ft

*oil gross heating value Kcal/kg 10869,44

*kerosene gross heating value Kcal/kg 11.025,08

34

according to standard prEN 13842:2002

Electrical Specifications

Rated Voltage

V/Hz 110/60

Rated Current

A 7,0

Rated Power

W 460

Motor Power

W 430

Rotational Speed

rpm 3400

Fuse

Size Specifications

Weight Tank Capacity

70 kg 154 lb 51 liters 14 U.S. gal

Lenght Outlet Diameter

1188 mm 47 in 308 mm 12 in

Width Flue Diameter

620 mm 24 in 150 mm 6 in

Height

790 mm 31 in

Package Specifications

Lenght

Width

1250 mm

530 mm

Height

Weight

830 mm

72 Kg

Servicing Manual

TECHNICAL DATA SHEET FOR INDIRECT FIRED OIL HEATERS – 55 kW MODEL

Thermal Specifications

Maximum Thermal Power (Diesel Oil)

Consumption Kg/hr

at 3°C (37F)

4,16

U.S. gal/hr 1,29

Efficiency %

87,10

Power Input kcal/hr 45217

kW 52,58

BTU/hr 180868

Power Output kcal/h 39384

kW 45,80

BTU/hr 157536

Fuel Pressure

12 bar 175 psi

Smoke Index

1,00

Air Lock Adjustment

mm 4,0

Maximum Thermal Power (Kerosene)

Consumption Kg/hr 3,81

Efficiency % 87,10

Power Input kcal/hr 42006

kW 48,84

BTU/hr 168022

Power Output kcal/hr 36587

kW 42,54

BTU/hr 146347

Fuel Pressure

psi 12,00

Air Lock Adjustment

mm 7,00

Airflow Specifications

Air Flow Rating

m³/h

2500 m³/h 1475 ft³/min

Fan

mm 350 mm 14 in

Blade # 3 sickle-shaped

Pitch 18°

Temperature Rise (Delta)

at 20°C (68 F)

73°C 131 F

Noise Level at 1 m at 2 m

dB(A) average 75 73

with original hood

Nozzle Type

Electrical Specifications

Rated Voltage

V/Hz 110/60

Rated Current

A 7,0

Rated Power

W 460

Motor Power

W 430

Rotational Speed

rpm 3400

Fuse

Manufacturer DANFOSS A 15 slow-blow

Type 60° H

Flow Rate GPH 1,00

Air Ducting

Hose Diameter

315 mm 12 in

Maximum Hose Lenght

8 m 25 ft

*oil gross heating value Kcal/kg 10869,44

*kerosene gross heating value Kcal/kg 11.025,08

35

according to standard prEN 13842:2002

Size Specifications

Weight Tank Capacity

76 kg 167 lb 51 liters 14 U.S. gal

Lenght Outlet Diameter

1405 mm 55 in 308 mm 12 in

Width Flue Diameter

620 mm 24 in 150 mm 6 in

Height

790 mm 31 in

Package Specifications

Lenght

Width

1470 mm

530 mm

Height

Weight

830 mm

80 Kg

Servicing Manual

TECHNICAL DATA SHEET FOR INDIRECT FIRED OIL HEATERS – 85 kW MODEL

Thermal Specifications

Maximum Thermal Power (Diesel Oil)

Consumption Kg/hr

at 3°C (37F)

6,64

U.S. gal/hr 2,06

Efficiency %

88,50

Power Input kcal/hr 72173

kW 83,92

BTU/hr 288692

Power Output kcal/hr 63873

kW 74,27

BTU/hr 255493

Fuel Pressure

12 bar 175 psi

Smoke Index

1,00

Air Lock Adjustment

mm 14,0

Maximum Thermal Power (Kerosene)

Consumption Kg/hr 4,86

Efficiency % 88,50

Power Input kcal/hr 53582

kW 62,30

BTU/hr 214328

Power Output kcal/hr 47420

kW 55,14

BTU/hr 189680

Fuel Pressure

psi 12,00

Air Lock Adjustment

mm 14,00

Airflow Specifications

Air Flow Rating

m³/h

4500 m³/h 2650 ft³/min

Fan

Diameter 500 mm 20 in

Blade # 3 sickle-shaped

Pitch 28°

Temperature Rise (Delta)

at 20°C (68 F)

72°C 130 F

Noise Level at 1 m at 2 m

dB(A) average 73 71

with original hood

Nozzle Type

Electrical Specifications

Rated Voltage

V/Hz 110/60

Rated Current

A 12,0

Rated Power

W 800

Motor Power

W 750

Rotational Speed

rpm 1700

Fuse

Manufacturer DELAVAN A 20 slow-blow

Type 80° W

Flow Rate GPH 1,50

Air Ducting

Hose Diameter

450 mm 18 in

Maximum Hose Lenght

16 m 52 ft

*oil gross heating value Kcal/kg 10869,44

*kerosene gross heating value Kcal/kg 11.025,08

36

according to standard prEN 13842:2002

Size Specifications

Weight Tank Capacity

121 kg 267 lb 100 liters 26 U.S. gal

Lenght Outlet Diameter

1680 mm 66 in 443 mm 17 in

Width Flue Diameter

690 mm 27 in 150 mm 6 in

Height

938 mm 37 in

Package Specifications

Lenght

Width

1760 mm

650 mm

Height

Weight

965 mm

124 Kg

Servicing Manual

TECHNICAL DATA SHEET FOR DIRECT FIRED OIL HEATERS – 67 kW MODEL

Thermal Specifications

Maximum Thermal Power (Diesel Oil)

Consumption Kg/hr

at 3°C (37F)

5,22

U.S. gal/hr 1,62

Efficiency %

Power Input kcal/hr 56739

kW 65,98

BTU/hr 226954

Power Output kcal/hr

kW

BTU/hr

Fuel Pressure

12 bar 175 psi

Smoke Index

1,00

Air Lock Adjustment

mm 4,0

Maximum Thermal Power (Kerosene)

Consumption Kg/hr

Efficiency %

Power Input kcal/hr 0,00

kW 0,00

BTU/hr 0,00

Power Output kcal/hr 0,00

kW 0,00

BTU/hr 0,00

Fuel Pressure

psi 0,00

Air Lock Adjustment

mm 0,00

Airflow Specifications

Air Flow Rating

2800m³/h 1650 ft³/min

Fan

Diameter 350 mm 14 in

Blade # 3 sickle-shaped

Pitch 18°

Temperature Rise (Delta)

at 20°C (68 F)

Noise Level at 1 m at 2 m

dB(A) average 75 73

Nozzle Type

Manufacturer DELAVAN

Type 60° S

Flow Rate GPH 1,25

Air Ducting

Hose Diameter

Maximum Hose Lenght

*oil gross heating value Kcal/kg 10869,44

*kerosene gross heating value Kcal/kg 11.025,08

37

according to standard prEN 13842:2002

Electrical Specifications

Rated Voltage

V/Hz 110/60

Rated Current

A 6,0

Rated Power

W 460

Motor Power

W 430

Rotational Speed

rpm 3400

Fuse

A 10 slow-blow

Size Specifications

Weight Tank Capacity

65 kg 143 lb 51 liters 14 U.S. gal

Lenght Outlet Diameter

1405 mm 55 in 308 mm 12 in

Width Flue Diameter

620 mm 24 in

Height

750 mm 30 in

Package Specifications

Lenght

Width

1470 mm

530 mm

Height

Weight

830 mm

76 kg

Servicing Manual

TECHNICAL DATA SHEET FOR INDIRECT FIRED OIL HEATERS – 115 kW MODEL

Thermal Specifications

Maximum Thermal Power (Diesel Oil)

Consumption Kg/hr

at 3°C (37F)

9,12

U.S. gal/hr 2,83

Efficiency %

Power Input kcal/hr 99129

kW 115,27

BTU/hr 396517

Power Output kcal/h 0

kW 0,00

BTU/hr 0

Fuel Pressure

12 bar 175 psi

Smoke Index

1,00

Air Lock Adjustment

mm 13,0

Maximum Thermal Power (Kerosene)

Consumption Kg/hr

Efficiency %

Power Input kcal/hr 0,00

kW 0,00

BTU/hr 0,00

Power Output kcal/hr 0,00

kW 0,00

BTU/hr 0,00

Fuel Pressure

psi 0,00

Air Lock Adjustment

mm 0,00

Airflow Specifications

Air Flow Rating

m³/h

4800 m³/h 2850 ft³/min

Fan

mm 500 mm 14 in

Blade # 3 sickle-shaped

Pitch 28°

Temperature Rise (Delta)

at 20°C (68 F)

Noise Level at 1 m at 2 m

dB(A) average 75 73

Nozzle Type

Electrical Specifications

Rated Voltage

V/Hz 110/60

Rated Current

A 12,0

Rated Power

W 800

Motor Power

W 750

Rotational Speed

rpm 1760

Fuse

Manufacturer DANFOSS A 20 slow-blow

Type 80° W

Flow Rate GPH 2,25

Air Ducting

Hose Diameter

Maximum Hose Lenght

*oil gross heating value Kcal/kg 10869,44

*kerosene gross heating value Kcal/kg 11.025,08

38

according to standard prEN 13842:2002

Size Specifications

Weight Tank Capacity

101 kg 222 lb 100 liters 14 U.S. gal

Lenght Outlet Diameter

1680 mm 66 in 308 mm 12 in

Width Flue Diameter

690 mm 25 in 150 mm 6 in

Height

898 mm 35 in

Package Specifications

Lenght

Width

1760 mm

650 mm

Height

Weight

965 mm

116 Kg

4.2 WIRING DIAGRAM

Basic version

Servicing Manual

EV

TR

M

SL

TS

FS

FC

PL

IN

TH

FR

Fuel solenoid valve

High voltage transformer

Motor

Warning lamp

Overheat thermostat

Fuse

Flame sensor

Reset pushbutton

Switch

Remote (room) thermostat

Heated filter (optional)

39

Version with heated filter and nozzle pre-heater

Servicing Manual

EV

TR

M

SL

TS

FS

FC

PL

IN

TH

FR

Fuel solenoid valve

High voltage transformer

Motor

Warning lamp

Overheat thermostat

Fuse

Flame sensor

Reset pushbutton

Switch

Remote (room) thermostat

Heated filter (optional)

40

Servicing Manual

4.3 SPECIAL SERVICING TOOLS

1. Smokemeter

2. Strips for smokemeter

3. Shell-Bacharach reference scale

4. Pressure gauge for oil pressure measurement

5. Electrical multimeter

2

3

1

5

4

Ill. 55

Ill. 56

41

Loading...

Loading...