SIABS S.r.l. – ITALY Phone +39 02 90384081 E-mail commerciale@siabs.it

via Del Lavoro, 7 Fax +39 02 9029538 Web page www.siabs.com

20010 – Casorezzo (MILAN)

Luminous Infra-red Gas Heaters

MANUAL for INSTALLATION,

RUNNING and MAINTENANCE

Models: 4P, 6P, 8P, 10P, 12PR, 12P, 16P,

4PB, 6PB, 8PB, 10PB, 12PRB, 12PB, 16PB,

10+10P, 12+12P, 16+16P,

10+10PB, 12+12PB, 16+16PB,

10+10PS, 12+12PS, 16+16PS

10+10PSB, 12+12PSB, 16+16PSB

Version “DC and DCeco”

Manu_ENG_DC_DCeco_rev. 0_04_2012 page 2

CONTENT

General instruction 3

For Your safety 4

Warranty terms 4

Labels 5

. plate with technical data

5

. packing label

5

Technical data 6

. appliances version DC and version DCeco

6

Installation 7 to 19

. ventilation 7

. positioning 8 and 9

. handling 9

. MINIMUM height of installation (for people comfort) 10

. MINIMUM distances (from flammable surfaces) 11

. connection to GAS supply 12

. connection to ELECTRIC feeding 13

. SIT control unit, wiring diagram, ON-OFF version 14

. SIT control unit, TWO-STAGE version 15 and 16

. SIT control unit, wiring diagram, TWO-STAGE version 17

. gas group (gas valve and flame control), possible alternatives 18 and 19

Put in operation and First Start-up 20

. appliances version DC and version DCeco 20

Maintenance and Annual Check 21

. ordinary maintenance (suggestions)

21

. nozzle replacement

22

. trouble shooting

23

. serial number (bars code)

23

SPARE-PARTS, suggested list 24

Decommissioning and disposal (norms for user) 25

CE certificate 26

Service sheet 27

Manu_ENG_DC_DCeco_rev. 0_04_2012 page 3

GENERAL INSTRUCTIONS for INSTALLER,

USER and MAINTENANCE PERSONNEL

Thank you for your preference and trust granted! SIABS is pleased to have You among

his Customers; our appliances are designed and manufactured to the most modern and

rational processing systems and we do think that their use will be fully satisfactory.

To keep appliances perfectly working and safe, time passing, we invite you to read and

follow the instructions of this handbook and commit all installation and maintenance

(ordinary and extraordinary) operations only to skilled personnel, with specific

technical skills in the field of components of heating, preferably t o SIABS authorized Service

Centre.

For the INSTALLER:

- read carefully the warnings in the manual before performing any operation

as they provide important information concerning th e safety of installation, use and

the necessary maintenance operations to be performed

- this manual is integral and essential part of the product and must be delivered to

the user; retain it carefully for further consultations

- in case of non-compliance with the following instructions, the warranty

covering the product(s) will be null and void

- BEFORE THE INSTALLATION, verify that local gas distribution (type of gas and

pressure) and appliance settings are compatible

- appliance must be installed only in premises with adequate ventilation

- installation should be done in accordance with the Regulations in force in the

country of destination, to the state of art, following instructions by the Manufacturer

- incorrect installation can cause damage to people, animals and things; the

Manufacturer doesn’t accept any contractual and extra-contractual liability in tort

and contract for damages caused by errors in installation and use

- use only original accessories and modification kits

- after you have removed all items from packing box, make sure that all

components have been included and their integrity, in case of doubt not use

the appliance and contact the Manufacturer; elements of packaging are potentially

dangerous: therefore should not be left within the reach of children and must be

disposed according to regulations in force

- before any cleaning or maintenance operation, wait until the appliance is cold,

disconnect it from the electricity supply and bring the fuel shut-off valve in

the closed position

For the USER and OWNER of the plant:

- this manual is integral and essential part of the product and must be delivered to

the user; retain it carefully for further consultations

- in case of non-compliance with the following instructions, the warranty

covering the product(s) will be null and void

- use only original accessories and modification kits

- in case of failure and/or malfunction of the appliance, turn it off refraining from any

attempt to repair or direct intervention; contact SIABS authorized Service

Centre

- when you decide to stop using the appliance, for DISPOSAL or RESALE, you will

have to render harmless all parties which can be a source of potential danger; the

technical manual is integral and essential part of the product: it must be

preserved and accompany the appliance in case of property change, so that

it can be consulted by the new user and / or maintenance staff

Manu_ENG_DC_DCeco_rev. 0_04_2012 page 4

FOR YOUR SAFETY

IMPORTANT: appliances MUST NOT be used in domestic environments. This appliance

will be devoted only to the use for which it was expressly provided, all other uses will be

considered improper and therefore dangerous.

IMPORTANT: appliances MUST NOT be used in ambient with flammable materials,

liquids or vapours: non-compliance with these requirements may be cause of death, injury

to persons or damage to things.

Warranty

SIABS guarantees its products, whether installed by authorized personnel, for a period of 24

months from the invoice date. The warranty does not cover the components supplied by third

parties, these are subject to the conditions of the original warranty.

The guarantee is only the free supply on Ex-Works basis, of parts with manufacturing or

workmanship defects.

The guarantee does not cover problems due to carelessness, incorrect setting, misuse of the

appliance or fortuitous accidents, and not dependent on imperfection processing or defective

materials, and those due to dismantling or changes without prior authorization from SIABS.

The correct functioning of the appliances depends on a proper installation and start-up. Failure

to comply with these rules immediately involves the decay of the guarantee, and therefore of

responsibility by the manufacturer.

In case of gas smell: DO NOT operate the heating plant, vent the ambient,

DO NOT start apparatus or electric switches; contact the installer and gas

supply company and follow scrupulously their instruction

Manu_ENG_DC_DCeco_rev. 0_04_2012 page 5

Plate label

On each unit you will find a plate with technical data – do not remove – placed on the head of

the appliance (version DC) or on the reflectors (version DCeco).

Apparatus type A1, gas category II

2H3P

Plate label (example: appliance 16+16PB, version DC, two-stages, G20 natural gas)

Essential features of the appliance are given on the packing label, outside on the packing box.

Manu_ENG_DC_DCeco_rev. 0_04_2012 page 6

TECHNICAL DATA

Appliance model, ON-OFF version 4P 6P 8P 10P 12PR 12P 16P 10+10P 12+12P 16+16P

Appliance model, TWO-STAGES version 4PB 6PB 8PB 10PB 12PRB 12PB 16PB 10+10PB 12+12PB 16+16PB

Ceramic plates nr. 4 6 8 10 12 12 16 2 x 10 2 x 12 2 x 16

Electric feeding 230 Volt - singlephase - 50 Hz

MAX feeding pressure (mbar) 50.0

Gas group, type P, PR, PB and PRB nr. 1111111 2 2 2

Gas connection 1 x 1/2" 1 x 1/2" 1 x 1/2" 1 x 1/2" 1 x 1/2" 1 x 1/2" 1 x 1/2" 1 x 3/4" 1 x 3/4" 1 x 3/4"

Absorbed power (Watt) 24 24 24 24 24 24 24 2 x 24 2 x 24 2 x 24

Gas group, type PS and PSB nr. - - - - - - - 1 1 1

Gas connection - - - - - - - 1 x 1/2" 1 x 1/2" 1 x 1/2"

Absorbed power (Watt) - - - - - - - 1 x 24 1 x 24 1 x 24

NOx class 4444444 4 4 4

V

ersion DC Weight (kg) 13 16 19 21 25 25 31 37 44 52

Length (mm) 420 605 790 980 1160 1160 1530 980 1160 1530

Gas group (mm) 250 250 250 250 250 250 250 300 300 300

Width (mm) 465 465 465 465 465 465 465 710 710 710

Height (mm) 350 350 350 350 350 350 350 350 350 350

V

ersion DCeco Weight (kg) 8 10 12 14 17 17 21 29 34 40

Length (mm) 420 605 790 980 1160 1160 1530 980 1160 1530

Gas group (mm) 250 250 250 250 250 250 250 300 300 300

Width (mm) 375 375 375 375 375 375 375 600 600 600

Height (mm) 250 250 250 250 250 250 250 250 250 250

GAS G20

Heat input MAX (Hs) (kW) 7,2 9,6 16,1 18,3 19,0 22,2 34,4 36,6 44,4 68,8

Heat input MAX (Hi) (kW) 6,5 8,6 14,5 16,5 17,1 20,0 31,0 33,0 40,0 62,0

Heat input MIN (Hs) (kW) 5,4 7,2 12,1 13,8 14,2 16,7 31,1 27,6 33,4 62,2

Heat input MIN (Hi) (kW) 4,9 6,5 10,9 12,4 12,8 15,0 28,0 24,8 30,0 56,0

GAS supply pressure (mbar) 20,0 20,0 20,0 20,0 20,0 20,0 20,0 20,0 20,0 20,0

NOZZLE pressure MAX (mbar) 15,5 14,0 14,0 15,0 13,5 16,0 14,0 15,0 16,0 14,0

NOZZLE pressure MIN (mbar) 8,5 7,5 8,0 9,0 7,5 9,5 10,5 9,0 9,5 10,5

Gas consumption MAX

(

Sm

3

/h)

0,69 0,91 1,53

1,75

1,81 2,12 3,43 3,50 4,24 6,70

Gas consumption MIN

(

Sm

3

/h)

0,52 0,69 1,15

1,31

1,35 1,59 2,95 2,62 3,18 5,90

Nozzle diameter (mm) 2,10 2,45 3,10 3,30 3,40 3,50 4,50 2 x 3,30 2 x 3,50 2 x 4,50

GAS G30

Heat input MAX (Hs) (kW) 7,0 9,3 13,5 17,9 17,8 21,7 33,6 35,8 43,4 67,2

Heat input MAX (Hi) (kW) 6,5 8,6 12,5 16,5 16,5 20,0 31,0 33,0 40,0 62,0

Heat input MIN (Hs) (kW) 5,3 7,0 10,2 13,4 15,7 16,3 27,1 26,8 32,6 54,2

Heat input MIN (Hi) (kW) 4,9 6,5 9,4 12,4 14,5 15,0 25,0 24,8 30,0 50,0

GAS supply pressure (mbar) 30,0 30,0 30,0 30,0 30,0 30,0 30,0 30,0 30,0 30,0

NOZZLE pressure MAX (mbar) 28,2 28,0 28,0 28,5 28,0 28,1 27,6 28,5 28,1 27,6

NOZZLE pressure MIN (mbar) 16,5 16,0 15,5 16,0 23,0 16,0 18,0 16,0 16,0 18,0

Gas consumption MAX

(kg/h)

0,51 0,68 0,99

1,30

1,30 1,58 2,42 2,60 3,16 4,84

Gas consumption MIN

(kg/h)

0,39 0,51 0,74

0,98

1,14 1,18 1,96 1,96 2,36 3,91

Nozzle diameter (mm) 1,30 1,50 1,80 2,10 2,10 2,30 2,80 2 x 2,10 2 x 2,30 2 x 2,80

GAS G31

Heat input MAX (Hs) (kW) 7,0 9,3 13,5 17,9 17,8 21,7 33,6 35,8 43,4 67,2

Heat input MAX (Hi) (kW) 6,5 8,6 12,5 16,5 16,5 20,0 31,0 33,0 40,0 62,0

Heat input MIN (Hs) (kW) 5,3 7,0 10,2 13,4 15,7 16,3 27,1 26,8 32,6 54,2

Heat input MIN (Hi) (kW) 4,9 6,5 9,4 12,4 14,5 15,0 25,0 24,8 30,0 50,0

GAS supply pressure (mbar) 37,0 37,0 37,0 37,0 37,0 37,0 37,0 37,0 37,0 37,0

NOZZLE pressure MAX (mbar) 36,2 35,7 35,7 36,2 35,7 36,2 35,5 36,2 36,2 35,5

NOZZLE pressure MIN (mbar) 22,0 20,0 20,0 20,0 28,0 20,0 23,5 20,0 20,0 23,5

Gas consumption MAX

(kg/h)

0,50 0,67 0,97

1,28

1,28 1,55 2,40 2,56 3,10 4,80

Gas consumption MIN

(kg/h)

0,38 0,50 0,73

0,96

1,13 1,16 1,94 1,92 2,32 3,90

Nozzle diameter (mm) 1,30 1,50 1,80 2,10 2,10 2,30 2,80 2 x 2,10 2 x 2,30 2 x 2,80

IMPORTANT: "GAS supply pressure", defined as the dynamic pressure of the circuit,

or part of the circuit downstream of the pressure reducer, with all the appliances running,

and must be detected in this condition. With lower pressure difficulties in start-up may

occur.

Manu_ENG_DC_DCeco_rev. 0_04_2012 page 7

INSTALLATION

Ventilation of the ambient

The unit leaves the combustion products into the environment in which it is used (appliance

type A1). It is therefore necessary to ensure ventilation and air changes of the premises

in which the appliance is installed, realizing appropriate air outlet openings on the

perimeter walls of the same, or creating a system of mechanical ventilation. To ensure a

sufficient air change, the flow of air needed can be calculated using the following equation (UNI

EN 13410):

V

tot

= Qnb x L

V

tot

air change flow rate in m

3

/h

Q

nb

total h e ating power installed in the premises in kW

L air change coefficient (must be 10 m

3

/h / kW)

IMPORTANT: air change coefficient “L” to be used MUST NOT

be lower than 10 m

3

/h for each kW of installed power

For NO reason

the appliance(s) can be installed:

in rooms smaller than 12 m³

in ambient used as residential ambient

where wind speed is higher than 2 m/s

Appliances must be installed in wellventilated and manned ambient, in

compliance with current legislation

Manu_ENG_DC_DCeco_rev. 0_04_2012 page 8

Positioning

The appliances can be installed on walls / pillars, or hanging at ceiling. On request, we can

provide supports (S hooks and chains are excluded) for suspension at ceiling (picture 1), or

wall brackets to fix the heaters on the wall (picture 2) with different angled positions for

the heater. The following figures will show you how to install all types of appliances.

picture 1 – Installation with chains DC picture 2 – Installation at wall DC

picture 1 – Installation with chains DCeco picture 2 – Installation at wall DCeco

The brackets provided by SIABS allow an angle of installation variable once mounted on a wall

or pillar, in order to get a better heat distribution (picture 3, supports for DCeco version)

picture 3 – different angles : 5° , 15° , 30° , 45°

Manu_ENG_DC_DCeco_rev. 0_04_2012 page 9

IMPORTANT!

at each side of the burner 2 hooks are provided with M8 inserts, for fixing to a wall or

at ceiling by means of appropriate brackets (not supplied, available on request); do not

create other anchor points on the carpentry of the heater and in particular on

the body burner, but use only those designed by the factory

we recommend SIABS original brackets for installation of the radiant heaters

for fixing brackets on a wall or pillars assess the consistency of walls and the load

applied, in order to choose the correct anchors to be used; in any case provide

blocks with M8 screw minimum diameter (e.g. anchor Fischer TA - M in steel, with M8

screw)

IMPORTANT: appliances must be installed in horizontal position, contact us in case of

different inclination. In any case, the system of fixing / suspension must allow thermal

expansion of appliance (some millimetres depending on the model).

Handling

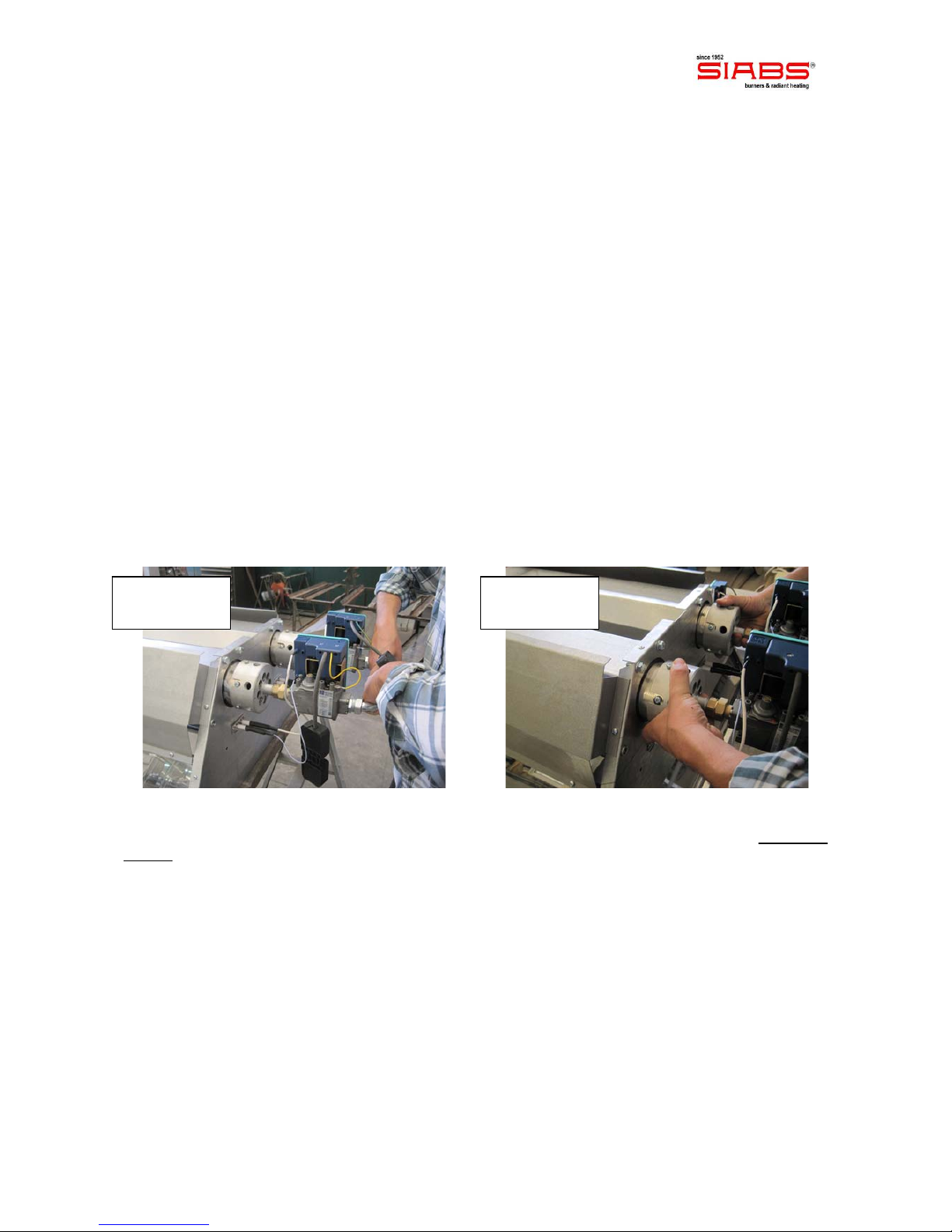

During extraction of the appliances from package and for all operations of handling till final

place of installation, gas valves / flame controls or flanges of the injection group must NOT be

used as lifting points, as in the pictures below.

Appliances must be taken at the installation point / height inside its package or using M8

inserts: all other parts of the appliances are NOT designed to withstand its weight.

NO !! NO !!

Loading...

Loading...