Shurflo MIDI G Installation Manual

MIDI “G” WATER BOOST SYSTEM

3/8” (9.5 mm) barb

GAS PUMP SPECS ACCUMULATOR TANK SPECS

DESIGN Twin chamber double diaphragm NSF #7 TOTAL VOL.(gas & liquid): 2 gal [7.5 lt]

MATERIALS Polypropylene, EDPM, santoprene, 300

stainless steel, FDA sanctioned, NSF listed,

standard 18

POWER SOURCE: CO2, nitrogen or compressed filtered air. MAX. WORKING

OPER. PRESSURE 20 psi min. [1.4 bar]/ 85 psi max. [5.8 bar],

static

TEMP. LIMITS: 34 º - 120 º F [1.1 º - 49 º C] Outlet Fitting 3/8” barb [9.5 mm]

DUTY CYCLE Intermittent (max. 2 strokes/sec.) System Weight Dry – 14 lbs. [6.3 kg.]

LIMITED WARRANTY

SHURflo warrants new MIDI “G” Water Boost systems to be free from material and workmanship defects (under normal use and

service) for a period of one (1) year from the date of manufacture as indicated by the gas pump nameplate. An additional 30 days may

be added to allow for storage and transit delays. In any event, the total limited warranty period will not exceed 13 months from date of

manufacture.

The limited warranty will not apply to components that were improperly installed, misapplied, or not suitable with components of

other manufacturers. The limited warranty will not apply to components subjected to fluids that are incompatible with component

materials or of components operated by a contaminated air supply. SHURflo will not warrant any components that are physically

damaged or modified outside the SHURflo factory.

All SHURflo boost systems should be returned to the authorized distributor where they were purchased. SHURflo’s obligation under

this warranty policy is limited to repair or replacement. Components found not defective (under the terms of this limited warranty) are

subject to charges to be paid by the returnee for the testing and packaging of “sanitized & tested good” units.

No credit or labor allowances will be given to the returnee for components returned as defective. Warranty replacements will be

shipped on a freight allowed basis. SHURflo reserves the right to choose the method of transportation.

This limited warranty is in lieu of all other warranties, expressed or implied, and no other person is authorized to give any other

warranty or assume obligation or liability on SHURflo’s behalf. SHURflo shall not be liable for any labor, damage or other expense,

nor shall SHURflo be liable for any indirect, incidental or consequential damages of any kind incurred by the reason of the use or sale

of any defective product or part. This limited warranty covers booster products distributed within the United States of America. Other

countries should consult with the distributor for any deviation from this document.

DRAW DOWN VOL.

W/35 PSI [2.24 BAR] DIFF.

PRESSURE:

Bladder Material: Butyl NSF listed, standard

93 oz [2.75 lt]

SS = 100 PSI [6.8 bar]

Steel = 150 PSI [10.2 bar]

18 for SS, standard 61 for

Steel

Wet 18 lbs. [ 8.1 kg]

INSTALLATION AND OPERATION MANUAL

DESCRIPTION

The Midi “G” Water Boost system is composed of a Heavy Duty Advantage® gas pump, a pre-charged two-gallon [7.6 lt]

accumulator tank and mounting board. The system is designed to boost water pressure and flow in areas where city water

pressure is low and/or inconsistent. The system can be used for a non-carbonated drink system and as back-up for a small

carbonator, ice maker, coffee or tea machine, etc.

3/8” (9.5 mm) barb

Water outlet

Gas pump

Accumulator Tank

Pre-charge 40 psi

1/4” (6 mm) barb

CO2 or compressed air

Max. pressure is 85 psi ( 5.8 bar)

Air valve

Check pre-charged at 30 day intervals

USE ONLY COMPRESSED AIR

Nominal pressure is 75 psi (5.1 bar)

PRINCIPLES OF OPERATION

• The pump feeds water into the accumulator tank until the water pressure in the tank equalizes the inlet gas pressure

supply to the pump. When water is called for, pressure in the tank propels the water out of the tank. As the water is

evacuated, the gas pump starts operating.

• The booster system should have a “draw-down” volume larger than anticipated use. Consult with factory for duty cycle

Water inlet

and/or application information. Refer to the flow vs. pressure vs. time graph on page 3 and the specifications on page 4

« ISO Certified Facility

SHURflo reserves the right to update specifications, prices, or make substitutions.

SHURflo «

12650 Westminster Ave.

Santa Ana, CA 92706-2100

(800) 854-3218 (714) 554-7709

FAX (714) 554-4721

Shipping/UPS: 12650 Westminster Ave.

Garden Grove, CA 92843

SHURflo East

52748 Park Six Court,

Elkhart, IN 46514-5427

((800) 762-8094

(219) 262-0478

FAX (219) 264-2169

© 2000 Printed in USA

Unit 5 Sterling Park, Gatwick Road,

SHURflo Ltd.

Crawley, West Sussex, RH10 2QT

United Kingdom

+44 1293 424000

FAX +44 1293 421880

for draw down volume.

• It is “normal” for a CO2 or compressed air pump to exhaust a cloud of condensation or small water droplets out of the

exhaust port on initial start-up or if running at high flow rates. This happens due to the rapid expansion of gas across an

orifice, more so in humid conditions. This condensation should not be mistaken as a leaking gas pump.

If the pump is run at very high flow rates for more than a few minutes, it may/can cause ice particles to form on internal

components. This can lead to “mis-stroking” or “half-stroking” of the pump. When running in this condition, ice may form in

the exhaust port, and CO2 usage will be high. If the pump is run at its designed stroke rate with dry gas and used with an

intermittent duty cycle, this condition should not occur. Refer to the draw-down volume and flow/pressure graph on page 3

for more information.

911-562 Rev.A 7-17-01 4 of 4 911-562 Rev. A 7-17-01 1 of 4

WARNING:

• High concentrations of CO2 can be fatal as it will displace the air from non-ventilated areas. Pumps operated by CO

2

must be in ventilated areas. If placed in a confined area (basement, closet, cooler box, etc.), exhaust fans capable of

changing the room air on a continuous basis should be used.

• Do not exceed the maximum accumulator tank pressure as noted on its nameplate. Do not store or use in an ambient

temperature above 120 º F [ 49 º C].

• Do not use CO2 to pre-charge the accumulator tank. Use only clean, dry compressed air, or nitrogen.

• Do not store or ship (by ground transportation) an accumulator tank with more than a 20 PSI [1.35 bar] pre-charge. If

shipped by air, all pre-charge pressure must be removed from the accumulator tank.

• Booster systems that have been winterized and/or out of service for a period of time should be sanitized prior to being

placed back in service.

INSTALLATION GUIDELINES

A. Do not connect a CO2 syrup supply system in series with the G.P./accumulator system. Contaminants in other

components may work their way through the air supply causing premature failure of the gas pump. Gas used to operate

the pumps MUST be clean and contain no contaminants (syrup, oil, rust, water, etc). Air compressors may be used with

proper particle filters and moisture separators. Air storage tanks should be drained regularly. Pumps subjected to

contaminated air are not covered by warranty.

B. All tubing connections are to be secured with stainless steel, stepless Oetiker® clamps. Cable-tie all tubing securely to

prevent kinks or sags that inhibit performance or cause damage to the pump fittings.

C. Use NSF listed high pressure braided 3/8” I.D. [9.5 mm] tubing for the water in/outlet plumbing. Use new (clean), ¼”

I.D. [6 mm], flexible, high pressure, braided tubing from the CO2/air regulator to the pump.

Mount to wall or cabinet so that G.P. output port is vertical. If mounted horizontal and if air were to enter the system, a “run

away” pump may occur.

START-UP PROCEDURE

On start up, open the dispenser valve(s) and purge air/water for approximately 30-45 seconds. Close dispenser valve(s)

and let the pump fill the accumulator. Open all valve(s). Repeat this fill/empty cycle at least three times before

conducting a product taste/brix test(s).

The butyl bladder in the SHURflo stainless steel tank is removable. The painted steel tank has a non-replaceable

bladder.

SANITIZING/WINTERIZING

Sanitation of the SHURFLO gas pump is required. Factors, which affect the frequency of this procedure are:

temperature, water quality/volatility, facility conditions, installation and equipment. The sanitizing procedure fulfills a

required 10-minute contact time with 200 ppm Sodium Hypochlorite solution. Refer to SHURflo Service Bulletin #

1025 for the N.S.F. listed sanitizing procedure for the SHURflo pump (only).

Pump/accumulators that are subject to freezing (below 32°F [10°C]) must be purged of fluid to prevent damage. Refer to

SHURflo Service Bulletin # 1025 for the pump winterizing procedure.

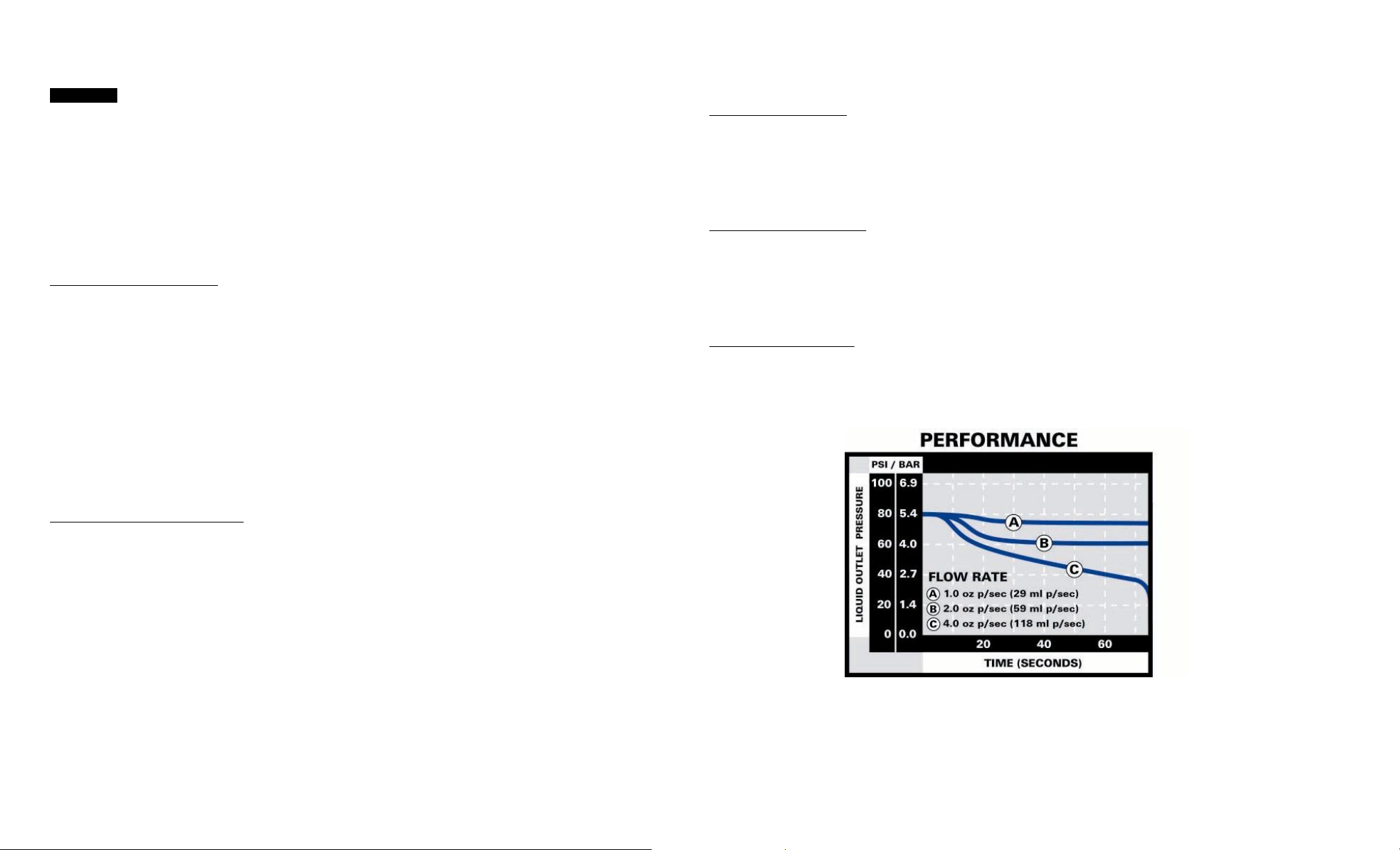

SYSTEM PERFORMANCE

The following curves were obtained with a static gas inlet pressure to the pump of 75 psi [5.1 bar], a 40 psi [2.7 bar] precharge pressure to the tank and with a city water inlet static pressure of 20 psi [1.4 bar].

TANK PRE-CHARGE PROCEDURE

To set or check tank pre-charge pressure, you must:

A. Turn off city water supply

B. Turn off CO2 supply or remove yellow elbow check valve CO2 fitting from the gas pump.

C. Open dispenser valve(s) on output of accumulator tank until all water pressure is exhausted.

D. Charge/check accumulator tank @ 40 psi [2.7 bar] (see note) with compressed air/nitrogen.

NOTE: Tank should be pre-charged at the minimum required pressure of the application. In most cases 40 psi [2.7

bar] will provide the required pressure at a typical beverage dispense system. Typically, the gas pump would be

set at 75 psi [5.1 bar].

For further information consult the factory.

2 of 4 3 of 4

Loading...

Loading...