BLASTER

SERIES WASH-

DOWN PUMP

SHURflo's Blaster series pumps are designed to handle the harsh

marine environment. Blaster motors have

precision ball bearings

supporting the armature. Each motor is protected by an integral

thermal

breaker

, and are all

U/L Marine listed

. Blaster pressure

switches are

sealed

and the motors are finished with a baked-on

polyurethane

coating

to inhibit corrosion. The "Pro-Blaster" motor is sealed in an

exceptionally tough

epoxy powder coated finish

, allowing it to be in

environments where "splashed water" may be present. Blaster series

pumps are enclosed to prevent incidental moisture from entering;

however, they are not

submersible

units.

The Blaster delivers water on demand. W ith the spray nozzle off

(output

side closed)

the pump will turn off . As the nozzle is opened the pressure

within the hose

(output side)

drops. Once the pressure drops below a

predetermined point the pumps pressure switch closes and the pump

operates. Wit h the nozzle set at a fine mist the pump will cycle, as it is

able to pressurize the hose faster t han water being r eleased. If the spray

nozzle is held wide open the pump will operate continually. The pump

may momentarily operate even after the nozzle is closed, as it

pressurizes the hose. Once the pressure setting is reached the switch

opens and the pump stops.

DUTY CYCLE

Wash-down pumps are rated f or int ermittent duty (only), as they operate at higher than averag e pr essur es. Operating a pump continuously for more

than twenty (20) minutes, within an hour period, is not recommended. Actual dut y cycle is determined by amp draw, tem per at ure, and rate of cycling.

NOTE:

Rapid cycling should be minimized to ensure long life. Rapid cycling is defined as

ON/OFF

within two seconds.

911-444 Rev. E 10/98

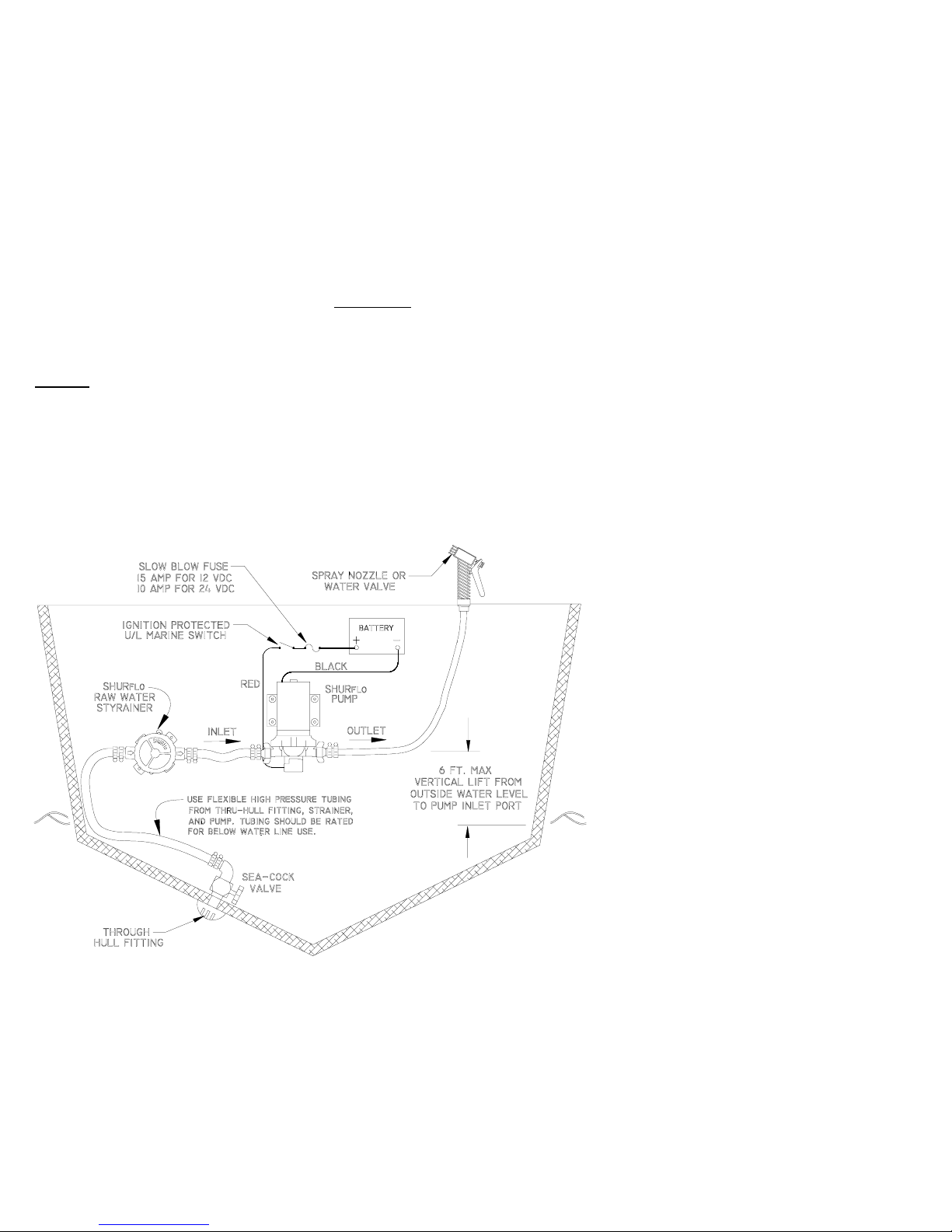

MOUNTING

•

Consider a dry location that allows easy access

if maintenance is required. The pump should

not be located in an area of less than one cubic

foot unless adequate ventilation is provided.

Excessive heat may trigger the integral thermal

breaker and interrupt operation. When the

temperature drops the breaker will automatically

reset and start operation.

•

Mount higher than the outside water (sea)

level. The pump is capable of a 6 ft. [2

M

]

vertical prime above the outside water level.

The pump can be mounted in any position. If

mounting the pump vertically, the pump head

should be in the down position.

CAUTION:

Do not drive screws through the

vessel's hull.

•

Use

#

8 stainless steel hardware to fasten the

pump. Choose a solid surface

(bulkhead or

stringer)

that will not amplify pump sound. The

mounting feet are int ended to isolate the pump

from the mounting surface; over-tightening,

flattening, or oversized screws will reduce the

mounting pads ability to isolate vibration/noise.

ELECTRICAL

•

The pump should be on a dedicated

(individual)

circuit protected on the positive (+

red) lead with the proper size "slow blow"

fuse. For all 12

VDC

pumps use a 15 amp

fuse, on 24

VDC

pumps use a 10 amp fuse.

The total current draw on the circuit must not

exceed 15 amps.

INSTALLATION AND OPERATION MANUAL

•

An ignition protected switch (U/L approved

marine duty) rated at or above 15 amps is

recommended, and must interrupt current flow

on the positive (+ red) lead.

CAUTION:

Use of "open" type switches (not ignition

protected) may cause an explosion of fuel vapors.

•

Wire size

(gauge/Mm2)

is based on the distance

from the power source to the pump. The

min imu m recommended wire size is

#

14 gauge

[2.5Mm

2

].

For lengths of 20-50 ft

.

[6-15M]

use #12

gauge

[4Mm2].

•

The pump must be grounded to a "known

ground" (battery). The ground wire must be

the same size as the positive wire.

PLUMBING

•

SHURflo swivel barb fittings provide easy

removal if maintenance or access is required.

The fittings are designed with a "taper-seal",

creating a water tight connection when hand-

tightened. Always secure barb tubing

connections with properly sized stainless steel

clamps to prevent leaks. Retail pump kits

include two ¾" swivel barb fittings

(straight/

elbow)

and an adapter to connect a standard

garden hose to the pump outlet fitting.

•

Avoid any sharp radius in tubing that may kink

over time. Route tubing away from any heat

(exhaust manifolds etc.)

and fasten securely.

•

Inlet tubing

(½"I.D. min.)

from the sea-cock

valve to the pump should be rated for

vacuum. If rigid pipe is utilized, SHURflo

recommends that the pump inlet port be

plumbed with 1 ft. [.3

M

] of flexible tubing.

Standard garden hose is not suitable as inlet

tubing as it may collapse under vacuum,

reducing water flow.

•

The pump outlet port should not be connected

to rigid

(plastic)

pipe. Normal oscillation of the

pump may transmit through rigid plumbing

causing noise and possibly loosen or crack

components. A 1ft.

[.3M]

length of flexible high

pressure tubing is suggested.

Loading...

Loading...