Shurflo 94-350-08 Installation Manual

AUTOMATIC SELECTOR VALVE

Installation and Operation Manual

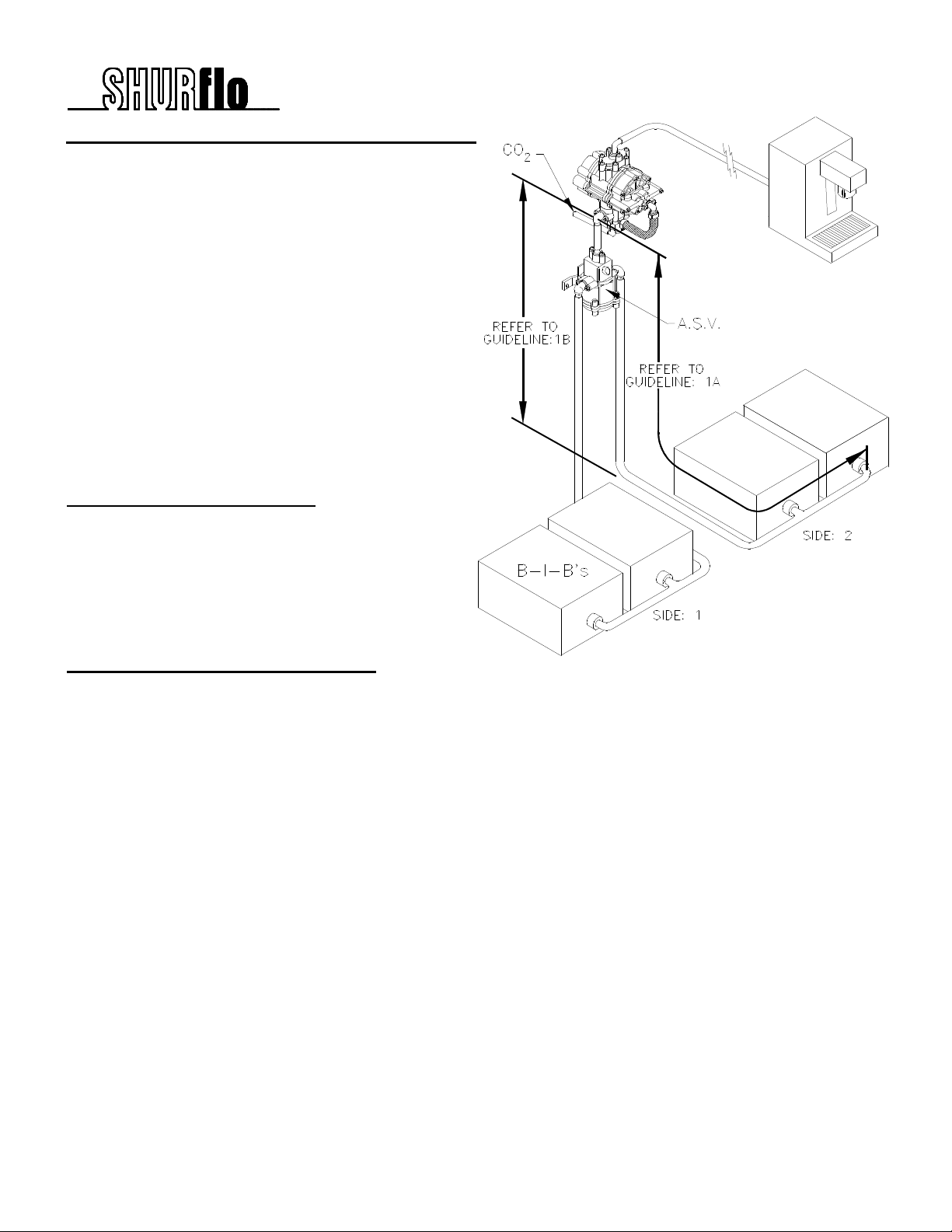

The Automatic Selector Valve (ASV) is for use in BagIn-Box (B-I-B) systems where multiple B-I-B's of one

flavor are necessary for high volume dispensing. The

ASV is designed to transfer concentrates that contain

solids classed as "round" (up to .025 in.[.6mm]).

The ASV permits two or more B-I-B's to be connected

at each inlet port (side). The Gas pump draws product

through one side (indicated by the pointer) of the ASV

until the B-I-B(s) are evacuated. Once vacuum is

obtained, the ASV automatically switches, drawing

product from the B-I-B(s) connected to the other side.

The ASV permits uninterrupted drink dispensing to the

customer, while store personal have the ability to

replace B-I-B's at a convenient time.

VACUUM SWITCH POINT

There are two versions of the ASV, the difference being

the level of vacuum at which the ASV will change sides.

ASV's labeled 18 in. Hg. [61 kPa.] are used in

conjunction with Gas Pumps.

For BRIX and Electric pump applications the ASV label

should indicate 12 in. Hg. [40 kPa.]activation.

INSTALLATION GUIDELINES

1. Mount the ASV between the B-I-B(s) and the pump. The outlet of the ASV should be mounted with the outlet port

pointed up. Never mount the ASV above the pump.

A) When using general beverage syrup/concentrates (typically 1-40 Centipose/cP.), maximum inlet tubing length

(horizontal & vertical) from the pump to the B-I-B(s) must not exceed 10 ft.[3M] The length of inlet tubing is

dependent upon concentrate viscosity. Heavier viscosity products use more of the available inlet vacuum.

Concentrates above 40 cP. require substantially shorter inlet tubing lengths. Refer to the SHURflo Juice Pump

Manual #911-437 when pumping heavy viscosity concentrates.

B) The maximum vertical rise from the B-I-B(s) to the pump, including the ASV is 3 ft.[1M] The vertical distance that

may be achieved is dependent upon concentrate viscosity. High viscosity (thick) products (over 500 CPS); may

require

ASV/pump may need to be placed within one foot from the B-I-B, and slightly above the center of the B-I-B.

NOTE:High inlet vacuum due to high flow rates, product viscosity, or restrictions can evacuate air suspended in

2. When using multiple B-I-B's, plumb all B-I-B's horizontally, not vertically. Placing the B-I-B's one on top of the

other (vertically), results in the top B-I-B draining into the bottom B-I-B, which leads to poor product rotation.

However, the B-I-B(s) plumbed to "side one" of the ASV do not necessarily have to be on the same level as

the B-I-B(s) plumbed to "side two".

3. Use

connector, ASV, and the pumps' inlet.

4. Properly clamp all tubing connections and tie-wrap tubing securely to prevent kinks or sags that may inhibit

performance or cause damage to the pump/ASV fittings.

1

/

" I.D. [13mm] tubing with minimal vertical lift. In some instances no vertical lift can be achieved, the

2

some concentrates causing low brix or premature operation of the ASV.

3

/

" or

8

1

/

" I.D. [10 or 13mm] heavy wall (

2

1

/

" [3 mm]) clear, NSF listed vacuum tubing from the bag

8

911-458 REV. B 3/97 Page: 1 of 4

OPERATING GUIDELINES

• THE BENEFITS OF THE ASV CAN ONLY BE PROVIDED WHEN EMPTY B-I-B'S ARE REPLACED

BEFORE BOTH SIDES ARE EMPTIED. At a convenient time store personal should check for empty B-I-B's.

Replace empty B-I-B's once the pointer indicates the ASV is drawing from the other side. By insuring that full

B-I-B's are in place before the other side is evacuated, the ASV will provide uninterrupted drink dispensing.

• If both sides are emptied, the ASV will be vacuum locked. Do Not switch the indicator pointer. Connect full B-I-B's to

both sides. If only a single B-I-B is available, connected the B-I-B to the side the ASV pointer indicates. Always

leave bag connectors (Q.D.'s) attached to the empties until full B-I-B's are available. Doing so prevents air from

being drawn into the system and will keep the bag connector clean.

• NEVER FORCE THE INDICATOR POINTER! During normal use switching of the indicator pointer by hand is

not necessary and not recommended. Forcing the pointer to change sides during normal operation (under vacuum)

may damage the ASV.

TROUBLESHOOTING

• If the B-I-B's on one side are not completely evacuated; however, the ASV indicator points to the opposite side.

The pointer may have been moved manually, or the inlet vacuum level may have exceeded the switch point causing

the ASV to switch prematurely. High vacuum may be caused by one or more of the following:

ü High dispenser flow rate(s), max fow is 2 oz. p/s [60mL]

ü Kinked, pinched, improperly installed bag connectors or other restriction within the inlet tubing.

ü Substantial increase in the product viscosity (decrease in product temperature)

ü Changes in B-I-B position relative to pump/ASV mounting (see Installation Guidelines)

• The B-I-B's on one side are empty; although, the ASV will not switch to the full B-I-B's on the other side. This

indicates the pump is unable to maintain the level of vacuum necessary to switch the ASV. Vacuum leaks and/or

air within the B-I-B's will cause the ASV not to switch. Vacuum leaks/air may be caused by one or more of the

following:

ü Are any bag connectors (Q.D.'s) not attached to a B-I-B? An "open" or unused bag connector may be a source of the

vacuum leak. Always leave bag connectors (Q.D.'s) attached to the empty B-I-B's until full B-I-B's are available.

ü For a stream of air bubbles in the inlet tubing while the dispenser is operated. Inspect all the bag connectors,

tubing connections and inlet side fitting for air bubbles which is an indication of a vacuum leak.

ü B-I-B's for excessive amount of air due to improper fill process. Stand bag vertical and run dispenser until air is

purged.

ü Has the ASV been manually forced causing damage to internal components?

ü Gas pump CO2/air pressure supply. Is the system pressure reduced from normal?

• The ASV ability to switch by vacuum may be tested.

1. Remove a bag connector (Q.D.) from each side of the ASV. Depress both bag connector (Q.D.) plungers to

insure the ASV is not vacuum locked. Reconnect to B-I-B's that are sufficiently full.

2. With the vacuum released the indicator pointer can be switched manually. Switch the indicator back and forth

several times. The force and feel when switching the indicator should be the same in both direction. If it isn't

the ASV has been damaged and should be replaced.

3. The dispense valve must be flowing, to test the ASV. With the dispenser open, fold-over/kink (by hand) the

inlet tubing of the side the ASV pointer indicates it is drawing through. After the pump strokes several times to

obtain the necessary level of vacuum, the ASV should switch sides. After switching sides release the kink and

kink the (other side) tubing the ASV is now drawing through. After several strokes of the pump, the ASV

should switch back.

4. If the ASV doesn't function as described check for the problems indicated (ü) above. If none of the causes

above exist replace the ASV and re-test.

Loading...

Loading...