Shurflo 94-068-01 Installation Manual

SOLD-OUT-SWITCH (S.O.S.) 94-068-01 (Low Profile)

Installation and Operation Instructions

Once a Bag-In-Box (B-I-B) container has emptied, and vacuum for shut-off is obtained, the gas pump automatically

stops. However, carbonated water still flows from the dispenser even though syrup flow has ceased. In the case of

"clear beverages" (lemon lime, tonic water, etc.) the user has no visual indication the drink is syrup starved.

When syrup line pressure drops below the S.O.S. setting, voltage to the dispensers’ solenoid valves is interrupted

stopping both water and syrup dispensing.. By stopping both water and syrup, employees realize a new B-I-B needs to

be installed. If the L.E.D. light is installed, it illuminates informing the user that product is "sold-out". With a new B-I-B

connected the pump automatically restarts and pressurizes the syrup line, resetting the S.O.S. The L.E.D. will go out

and drink dispensing resumes, without the need to manually reset.

NOTE: The S.O.S. is only intended for use with B-I-B systems which utilize electric solenoid dispensing valves.

The S.O.S. will not work with transfer tanks (figal system) and/or mechanical valves.

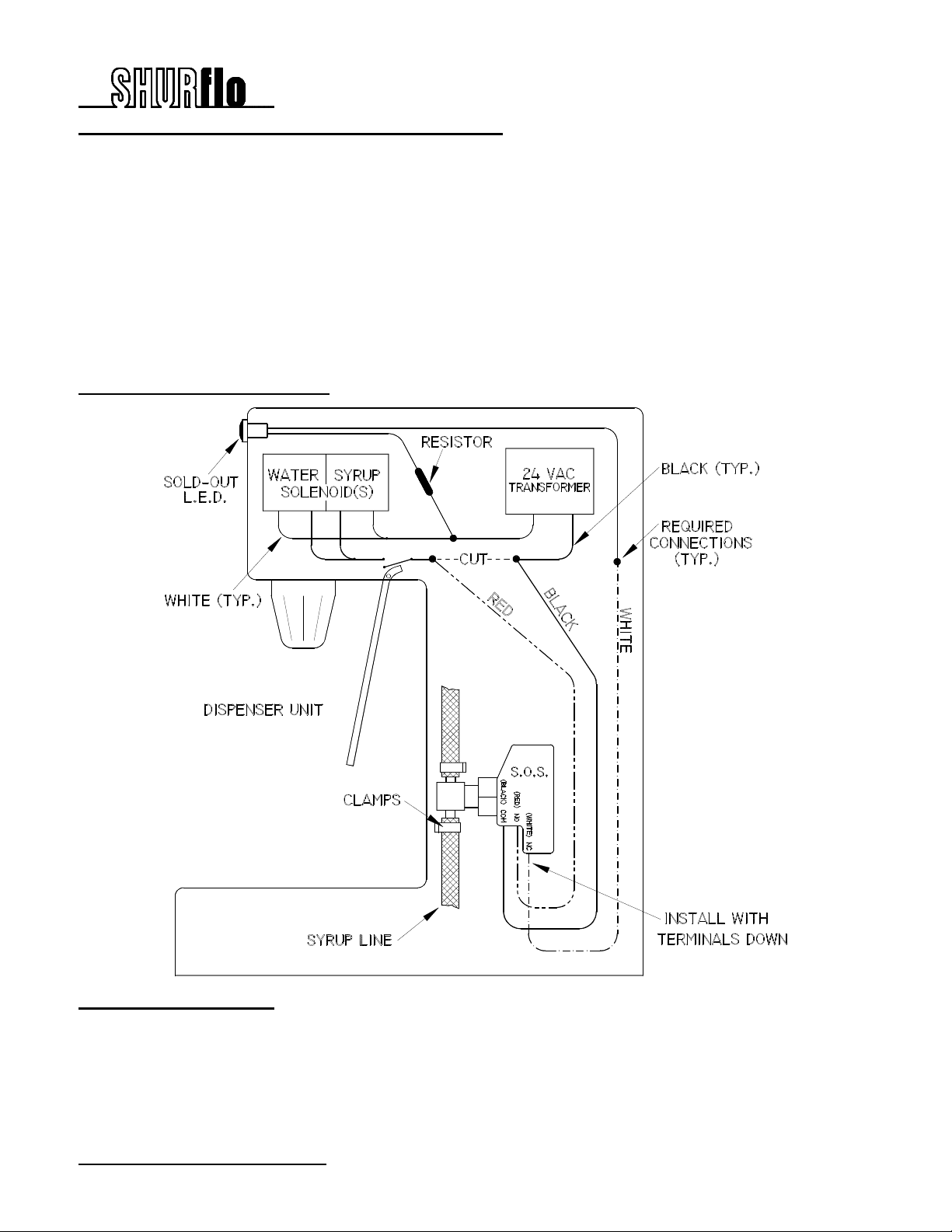

INSTALLATION SCHEMATIC

S.O.S. INSTALLATION

1. Turn off the CO2 or pressurized air supply to the syrup pump.

2. Open the dispenser valve of the syrup line that the S.O.S. is being installed in, relieving the pressure within the tubing.

3. Install the S.O.S. inside the dispenser cabinet in a convenient location near the solenoid valves. Mount with the

terminals facing down to prevent liquid from entering. Cut the syrup line and place appropriately sized

stainless steel, stepless Oetiker® clamps over the tubing. Install the S.O.S. using the correct sized barbed "T"

fitting (¼" NPT) for that particular tubing I.D. Clamp the tubing to the fittings to prevent leaks.

ELECTRICAL CONNECTION

911-316 Rev. J 1/98 Page: 1 of 2

NOTE:The terminals "Normally Open" (N.O.) and "Normally Closed" (N.C.) on the S.O.S. indicate switch contact

positions with pressure not applied.

1. Disconnect all power to the dispenser unit.

2. Locate the wire(s) (typically black) from the solenoid(s) to the 24VAC transformer, which has current interrupted

with the dispenser switch. Cut the wire and strip back ¼" [6mm] of insulation at both ends.

NOTE:Depending on the dispenser configuration, the valves in the dispenser head may have one solenoid

operating both water and syrup or two solenoids that operate each individually on a separate circuit.

3. Connect the RED S.O.S. wire (N.O.) to the wire coming from the solenoid using the wire nuts (supplied).

Connect the BLACK S.O.S. wire (common) to the other end of the wire that was cut.

4. To install the L.E.D. (optional) locate a position on the front panel that doesn't interfere with internal components

of the dispenser. Drill a ¼" [6mm] hole for the L.E.D. retainer clip. Snap the retainer clip in the front side of the

panel, then snap the L.E.D. into place from the backside.

5. Wire the L.E.D. by splicing into the other wire (typ. white) from the transformer and connecting either lead from

the light with a wire nut. Connect the other lead to the WHITE (N.C.) wire from the S.O.S.

START-UP

1. Turn the power ON at the dispenser unit. If the L.E.D. was installed it should be illuminated at this time.

2. Restart the gas pump by turning on the gas supply. The pump should start to cycle and pressurize the syrup line,

causing the L.E.D. to go out.

3. Open the dispenser valve and purge any air that entered while installing the S.O.S. The system is now fully operational.

4. To determine if the S.O.S. will function as intended, pinch off the inlet tubing to the pump. Open the dispenser

and pour a drink, causing the pump to obtain vacuum shut-off. At this point the dispenser should stop flowing and

the L.E.D. should illuminate. Remove the inlet restriction. The pump should operate causing the S.O.S. to

automatically reset.

The S.O.S. is preset to "open" at pressures below 15 psi. [1 bar] and will "close" at syrup pressures above 20 psi.

[1.4 bar]. Depending on variables of particular B-I-B installations the S.O.S. may require a slight adjustment. If the

S.O.S. is not operating as described (chatters, doesn't turn OFF/ON, interrupts operation before B.I.B. is emptied)

contact SHURflo. Detailed adjustment instructions are outlined in Service Bulletin #1031.

S.O.S. LIMITED WARRANTY

SHURflo Sold-Out-Switches are warranted to be free of defects in material and workmanship under normal use, for

a period of one (1) year from the date of manufacture, or one (1) year of use, with proof of purchase. This limited

warranty will not exceed two (2) years, in any event.

The limited warranty will not apply to Sold-Out-Switches that were improperly installed, misapplied, or incompatible with

fluids or components not manufactured by SHURflo. Failure due to foreign debris is not covered under the terms of

this limited warranty. SHURflo will not warrant any S.O.S. which is damaged or modified outside the SHURflo factory.

Returns are to be shipped postage prepaid to the authorized distributor where purchased. SHURflo shall not be

liable for freight damage incurred during shipping, package returns carefully.

For complete warranty details consult S/B #1049.

R

« ISO Certified Facility

SHURflo reserves the right to update specifications, prices, or make substitutions.

SHURflo «

12650 Westminster Ave.

Santa Ana, CA 92706-2100

(800) 854-3218 (714) 554-7709

FAX (714) 554-4721

Shipping/UPS: 12650 Westminster Ave.

Garden Grove, CA 92843

a WICOR Company

SHURflo East

52748 Park Six Court

Elkhart, IN 46514-5427

((800) 762-8094

(219) 262-0478

FAX (219) 264-2169

© 1998 Printed in USA

SHURflo Ltd.

Unit 5 Sterling Park

Gatwick Road, Crawley

West Sussex, RH10 2QT

United Kingdom

+44 1293 424000

FAX +44 1293 421880

COMPONENT

911-316 Rev. J 1/98 Page: 2 of 2

Loading...

Loading...