Shurflo 1901-0003 Installation Manual

Minimum Wire Size for a 10% voltage drop on a 12VDC, 10

•

Minimize plumbing elbows and valves

• Properly sized plumbing

Installation & Maintenance Manual

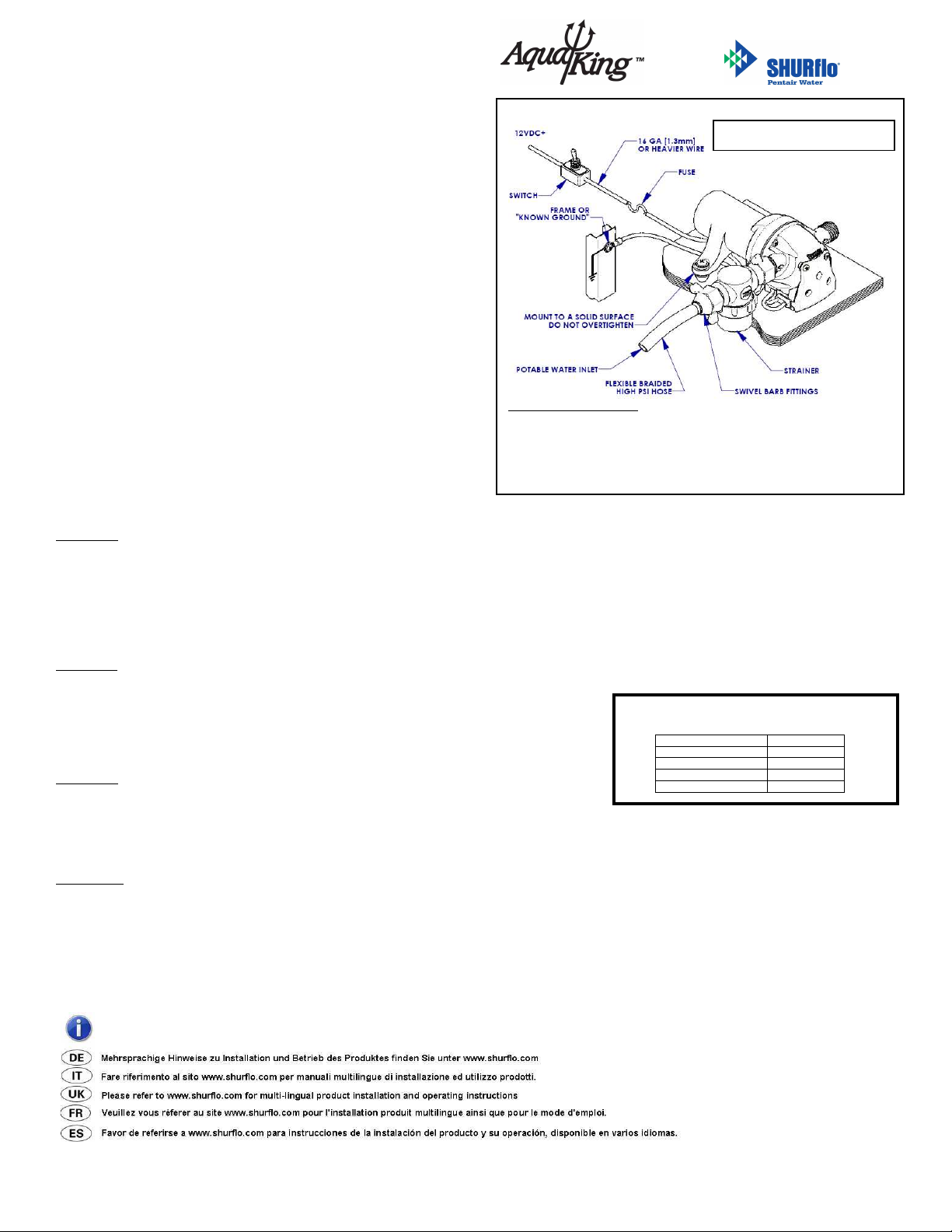

Typical Pump Installation

Installation Preparation

The goal of installation is to provide a quiet, easy-to-maintain installation

with good flow and low backpressure. This can be accomplished with the

following guidelines:

Follow all marine safety guidelines if installing in a watercraft,

including waterproof connections.

-Mount on a solid surface in an accessible location for strainer

cleaning and pump maintenance.

-Use flexible high-pressure hose on the pump inlet and outlet

[such as SHURflo Kit 94-591-00]. The pumps ports and strainer

should not be connected to plastic or rigid pipe, or the

pump's normal motion will transmit through rigid plumbing

causing noise, and possibly loosenening or cracking components.

-Pump must use an adequate 50-mesh strainer [such as SHURflo

255 series strainers].

-Use a minimum of 3/8" [9mm] Inner Diameter plumbing. Smaller ID

plumbing can cause high backpressure, cycling, low flow and noise.

-An accumulator can be used with these pumps.

-Pump is designed for intermittent duty only:

Do not use these pumps for running a Reverse-Osmosis [RO]

Filtration System. High pressure-continuous duty usage will

shorten the life of the pump and is not covered under warranty.

-Wire Size is 16 GA MINIMUM---See Wire Chart in Electrical Section.

-Minimum power requirement is a 10 Amp circuit.

-Reduce restrictions on inlet and outlet. This includes small inner diameter shut-off valves, winterizing valves and elbows.

Mounting

-Mount the pump within 5 feet of the tank for best performance and pump life. The farther it pulls the more work it does, increasing vibration and

noise, and reducing the output and pump life. Pump will prime a maximum of 5 vertical feet when new. This may decrease as the pump is used.

-Mount pump in a space of at least 1 cubic foot for adequate ventilation to prevent overheating.

-Pump may be mounted in any position.

-Mount pump for easy access for cleaning strainer, maintenance and service.

-Mount pump on a solid surface to prevent vibration and noise.

Electrical

-The pump works best on an individual filtered circuit, protected by the fuse or breaker specified on the label.

-A switch is recommended and should be on the positive lead.

-Wire Sizing: Proper wire sizing is required for good pump operation. If the wire is too small,

low voltage will affect the pump performance and can create a fire hazard.

SHUT OFF POWER TO THE PUMP WHEN RV OR BOAT IS UNATTENDED.

Plumbing

Installation of a strainer is required to prevent debris from entering the pump.

For noise and vibration reduction we recommend at least 18 in. [.5 M] of flexible high-pressure

hose to both ports. The pump ports and strainer should not be connected to plastic or rigid pipe. This hose should be anchored where it meets

the hard plumbing to reduce plumbing vibration.

Operation

This pump is designed for intermittent duty only.

The pump operates normally up to factory set shut-off at 30 PSI. As a faucet is opened back up, the pressure will drop, the switch will close and

full flow is again obtained. Pump cycling [On-Off-On] may occur if the faucet is not open enough to allow flow. This is normal, and can be reduced

by opening the fixture more or installing an accumulator after the pump. Performance will vary, of course, depending on the voltage to the pump;

lower voltage = lower flow, higher voltage = higher flow.

Remember your electrical safety: It is always best to shut power to the pump OFF when leaving the RV or boat unattended.

Installation Guidelines

• Solid surface within 5 feet of tank • Accessible location

• Minimize flow restrictions in the system • Strainer on pump inlet

• Accumulator can be used • Properly sized wiring

• Flexible hose on inlet and outlet • Proper electrical protection

Mini

Amp Circuit. Length is the distance from the power source

to pump and back to ground.

Feet [Meters] AWG [mm2]

0–25 [0-7.6] 16 [1.3]

25–50 [7.6-15.2] 14 [2.1]

50–70 [15.2-21.3] 12 [3.3]

70–110 [21.3-33.5] 10 [5.3]

911-733 Rev C 12/08 ECO #: 16135 Page 1 of 2

Maintenance

PUMP WILL N

OT SHUT

-

OFF / RUNS WHEN FAUCET IS CLOSED:

1

2

3

4

5

Normal pump maintenance is all that is needed: Checking and cleaning of the strainer, normal sanitizing and winterizing and occasionally checking all plumbing hardware and fittings for

tightness. Lack of sanitizing is the number one reason for premature pump failure and poor performance over time. Lack of sanitizing will cause scale build-up on the diaphragm and valves,

causing low flow and leak back [occasional pump cycling with no faucets open or tank filling up when hooked up to city water].

Sanitizing

Potable water systems require periodic maintenance to keep components working properly and deliver a consistent flow of fresh water.

Sanitizing is recommended: prior to storing, after a period of storage, or any time the system is opened or contaminated, as follows:

NOTE: Check your RV or Watercraft Owner’s Manual for specific instructions. By-pass any filters or remove filter cartridges.

1. Determine the amount of common household bleach needed to sanitize the tank.

A) 2 ounces of bleach per 15 gallon tank size: 60 gallon tank [15 x 4] = 4 x 2 ounces = 8 ounces of bleach

B) 1 ml bleach per 1 liter tank size: 300 liter tank = 300 milliliters of bleach.

2. Mix the bleach with water in a container such as a gallon jug. If tank is filled through a pressurized fitting, pour the bleach into the hose before attaching the hose to the city water entry.

3. Pour the bleach solution into the tank and fill the tank with potable water. Rock RV or boat back and forth to coat top and sides of potable water tank.

4. Open all faucets (Hot & Cold) allowing the water to run until the odor of chlorine is detected. Allow four (4) hours of contact time to disinfect completely. Doubling the solution

concentration allows for a contact time of one (1) hour.

5. Drain the tank. Refill the tank and flush the system once or twice until the odor has decreased. The residual chlorine odor and taste is not harmful.

Winterizing Refer to the RV or watercraft owner’s manual for specific winterizing instructions.

If water is allowed to freeze in the system, serious damage to the plumbing and the pump may occur. Failures of this type will void the warranty. The best guarantee against damage is to

completely drain the pump. When used per the manufacturers recommendations non-toxic antifreeze for potable water is safe for use with SHURflo pumps.

To drain the pump perform the following:

1. Drain the water tank. If the tank doesn't have a drain valve, open all faucets allowing the pump to operate until the tank is empty.

2. Open all the faucets (including the lowest valve or drain in the plumbing), allow the pump to purge the water from the plumbing, and then turn the pump OFF.

3. Using a pan to catch the remaining water, remove the plumbing at the pump's inlet/outlet ports. Turn the pump ON, allowing it to operate until the water is expelled. Turn OFF power to

the pump once the plumbing is emptied. Do not reconnect the pump plumbing. Make a note at tank filler as a reminder: "Plumbing is disconnected".

4. All faucets must be left open to guard against any damage.

5. Potable anti-freeze may be poured down drains and toilets to protect p-traps and toilet seals. Sanitize the plumbing system before putting the plumbing system back in service.

Troubleshooting

Vibration induced by driving and boating can loosen plumbing, strainers and pump hardware. Check for system components that are loose.

PUMP WILL NOT START/ BLOWS CIRCUIT:

Electrical connections, fuse or breaker, main switch, and ground connection.

Is the motor hot? Thermal breaker may have triggered; it will reset when cool.

Is voltage present at the switch? Bypass the pressure switch. Does the pump operate?

Charging System for correct voltage (±10%) and good ground.

For an open or grounded circuit, or motor; or improperly sized wire.

For seized or locked diaphragm assembly (water frozen?).

WILL NOT PRIME/SPUTTERS: (No discharge/Motor runs)

Is the strainer clogged with debris?

Is there water in the tank, or has air collected in the hot water heater?

Is the inlet tubing/plumbing sucking in air at plumbing connections (vacuum leak)?

Is inlet/outlet plumbing severely restricted or kinked? Restrictive valves?

Proper voltage with the pump operating (±10%).

For debris in pump inlet/outlet valves or swollen/dry valves.

Pump housing for cracks or loose drive assembly screws.

RAPID CYCLING:

For restrictive plumbing and flow restrictions in faucets/shower heads.

Water filter/purifier should be on separate feed line.

Output side (pressure) plumbing for leaks, and inspect for leaky valves or toilet.

For air trapped in outlet side (water heater) or pump head.

For correct voltage to pump (±10%).

For loose drive assembly or pump head screws.

Are the valves held open by debris or is the rubber swollen?

Pressure switch operation.

NOISY OR ROUGH OPERATION:

For plumbing which may have vibrated loose.

For a restricted inlet (clogged strainer, kinked hose, restrictive valves).

Is the pump plumbed with rigid pipe causing noise to transmit?

Does the mounting surface amplify noise (flexible)? Does it bang like a drum?

For mounting feet that are loose or are compressed too tight.

For air in the system. Check all fixtures for air and bleed system.

The motor with pump head removed. Is noise from motor or pump head?

LEAKS FROM PUMP HEAD OR SWITCH:

For loose screws at switch, by-pass or pump head.

Switch diaphragm ruptured or pinched.

For punctured diaphragm if water is present in the drive assembly.

Exploded View _ No repair kits available_

LIMITED WARRANTY

SHURflo warrants its aftermarket retail 1900 Series Aqua King Mini potable water pumps to be free from material and workmanship defects under normal use and service for 1 year from the date of purchase with

purchase receipt or 1 year from the date of manufacture indicated on the motor nameplate if no purchase receipt is available, as outlined in documents MS-030-152 and SB-1050. Pumps installed as original equipment fall

under the warranty supplied by the manufacturer, as outlined in documents MS-030-123 and SB-1050.

This limited warranty is in lieu of all other warranties, expressed or implied (including without limitation implied warranties of merchantability and fitness for a particular purpose), and no other person is authorized to give

any other warranty or assume obligation or liability on SHURflo's behalf. SHURflo shall not be liable for any labor, damage or other expense, nor shall SHURflo be liable for any indirect, incidental or consequential

damages of any kind incurred by the use or sale of any defective Product or part. This limited warranty covers Products distributed within the United States of America and Canada. Other world market areas should

consult with the distributor for any deviation from this document. The limited warranty will not apply to pumps that were improperly installed, misapplied, or are incompatible with components not manufactured by

SHURflo. Product failure due to foreign debris is not covered under the terms of this limited warranty. SHURflo will not warrant any Product that is physically damaged, or altered outside SHURflo.

Warranty claims may be resolved by an authorized dealer service center, or by a SHURflo service center. Returns are to be shipped with charges pre-paid. Package all returns carefully. SHURflo will not be responsible

for freight damage incurred during shipping to a service center. For complete Limited Warranty details, consult SHURflo.

SHURFLO reserves the right to update specifications, prices, or make substitutions.

SHURflo, LLC Headquarters

5900 Katella Avenue

Cypress, California 90630

Phone (562) 795-5200 Toll Free (800) 854-3218

Fax (562) 795-7564

911-733 Rev-C Patent pending Page 2 of 2

©2008 SHURflo, LLC All Rights Reserved www.shurflo.com

SHURflo, LLC East

52748 Park Six Court

Elkhart, Indiana 46514-5427

Phone (562) 795-5200 Toll Free (800) 854-3218

Fax (574) 264-2169

SHURflo Europe, Middle East, Africa

Pentair Water Belgium bvba,

Industriepark Wolfstee, Toekomstlaan 30

B-2200 Herentals, Belgium

Phone +32-14-283500 Fax +32-14-283505

Loading...

Loading...