Shurflo 170-06X Installation Manual

POTABLE WATER STRAINER 170-06X

Installation and Maintenance I nstr ucti ons

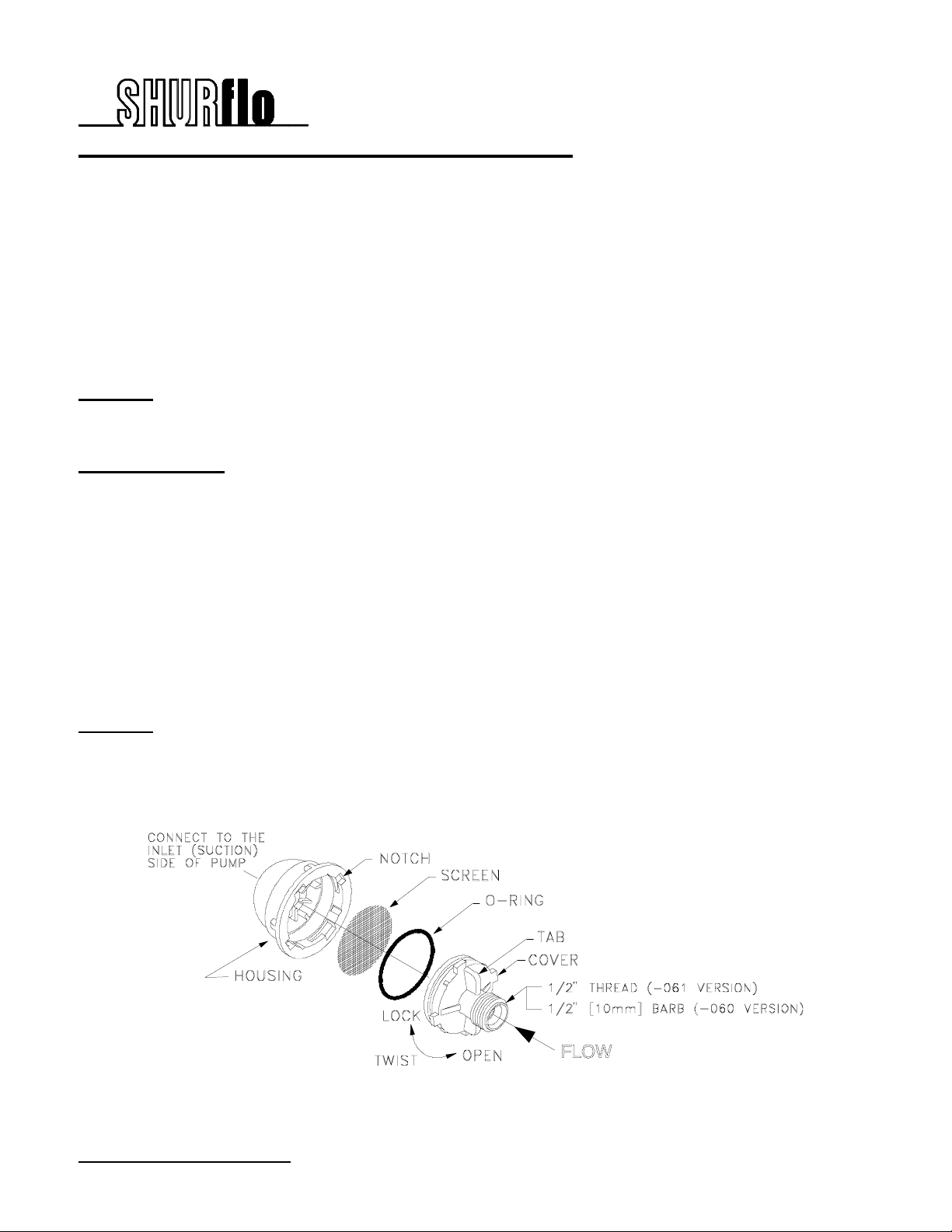

The SHURflo strainer prevents damage to the pump by trapping small particles and debris. The

strainer uses a #50 mesh screen to trap foreign debris and particulates larger than .02 in.[.3mm].

The strainer is designed for installation directly to the SHURflo pump (inlet side). The threaded

configuration (-061) is designed for use with SHURflo taper-seal swivel fittings, which work in

conjunction with the pumps threaded ports. The strainer can be installed in any convenient, visible,

easy to inspect location between the water supply (tank) and t he pump. The strainers transparent

material allows for quick visual inspection for determining if the stainless steel screen should be

cleaned. When correctly installed, no tools are required to open, hand disassembly is quick and

simple due to the twist-lock feat ure.

CAUTION: The 170 Strainer series is not approved for marine raw water applications. Only the SHURflo 252

series strainer is approved for marine raw water/below water line applications. T he 252 series is

designed with screen capacity and durability necessary for the rigors of raw water use.

INSTALLATION

1. Close the valve or drain water source (tank) as necessary. OPEN a f aucet to relieve pressure within

the line, then switch OFF power to the pump. This procedure will purge most of the water in the inlet

(suction) water line, however use a pan or bucket to collect any remaining water.

NOTE: Other electrical components in the vicinity should be switched OFF to prevent electrical shock.

2. When installed directly to the inlet (suction) side of a SHURflo pump (male threads) or other plast ic

fitting, hand-tighten until snug (max. torque 3 ft/Lb. [1.4 Kg]).

NOTE:Do not use any thread sealer or Teflon tape on pump threads.

3. The inlet of the strainer should be plumbed with flexible tubing approved for potable water use. The

use of flexible tubing allows convenient disassembly for cleaning and reduces noise transmission

during pump operation. Securely clamp all tubing connections with stainless steel clamps.

CAUTION: Impact or vibrations transmitted through rigid (plastic/metal) pipe could cause the strainer to crack.

4. Check that the cover is in the locked (clock wise) position. Open the water source valve and switch ON

any power turned off previously. Open the faucet and allow the pump to operat e, purging t he system of

any trapped air. Inspect strainer and connections for leaks.

STRAINER CLEANING

911-425 Rev. F 9/98 Page: 1 of 2

1. Close the valve or drain water source (tank) as necessary. OPEN a f aucet to relieve pressure within

the line, then switch OFF power to the pump. This procedure will purge most of the water in the inlet

(suction) water line, however use pan or bucket to collect any remaining water.

NOTE: Other electrical components in the vicinity should be switched OFF to prevent electr ical shock.

2. Support the housing while turning the cover "ears" counterclockwise, until the tabs align in the

notches. Carefully wiggle the cover out of t he housing to overcome the seal of the O-r ing .

3. The strainer screen can be removed to aid in cleaning.

4. Reinstall the screen in the housing. Apply petroleum jelly to the O-ring to assure a positive seal.

5. Align the locking tabs of the cover in the notches of the housing . Push together then turn clock wise

until in the "locked" position.

6. Open the water source valve and switch ON any power turned off previously. Open the f aucet and

allow the pump to operate. Inspect strainer and connections for leaks.

LIMITED WARRANTY

SHURflo warrants its 170 series Strainers to be f ree from def ects in materials and workmanship (under

normal use and service) for a period of one year from the dat e of manufacture or one (1) year of use

with proof of purchase. In no case will the terms of this warranty extend beyond two (2) years of

manufactured date.

This limited warranty will not apply to any SHURflo product that is improperly installed, misapplied, or

incompatible with components not manufactured by SHURflo. SHURflo will not warrant any product

which is modified or damaged outside the SHURf lo factory.

SHURflo’s obligation under this warrant y policy is limited to replacing or repairing (whichever it deems

advisable) any such product or part which is returned to SHURflo's factory with transportation charges

prepaid and which, upon SHURflo's inspection is found defective under the terms of this warranty.

Refer to SHURflo Service Bulletin #1047 for complete details of t his limited warranty.

R

«

« ISO Certified Facility

««

SHURflo reserves the right to update specifications, prices, or make substituti ons.

SHURflo «

12650 Westm i nster Ave.

Santa Ana, CA 92706-2100

(800) 854-3218 (714) 554-7709

FAX (714) 554-4721

Shipping/UPS: 12650 Westminster Ave.

Garden Grove, CA 92843

«

««

SHURflo East

52748 Park Six Court

Elkhart, IN 46514-5427

((800) 762-8094

(219) 262-0478

FAX (219) 264-2169

© 1998 Printed in USA

a WICOR Company

SHURflo Ltd.

Unit 5 Sterling Park

Gatwick Road, Crawley

West Sussex, RH10 2QT

United Kingdom

+44 1293 424000

FAX +44 1293 421880

911-425 Rev. F 9/98 Page: 2 of 2

Loading...

Loading...