Shurflo 1700-020-030, 1700-010-030, 1700-000-030 Installation Manual

MAG-DRIVE BAIT SENTRY Installation & Operation Manual

SHURflo’s 12 vdc Magnetic Drive Bait Sentry is available in three distinct flow rates relative to the capacity of the

bait tank or live well. The actual pump flow rate is dependent upon plumbing looses and “head” (push or rise) from

the pump to the top of the water level in the tank. It is also important to know the tank’s true “working capacity”. The

three sizes are: 500 suitable with tanks of 15 to 30 gallons [50 to 114 Lt], 800 with tanks of 20 to 45 gallons [75 to

170 Lt], and 1100 with tanks of 35 to 60 gallons [132 to 227 Lt] capacity. Reference Specifications for proper

selection. There are various factors for determining the appropriate tank size and pump which will permit bait fish

(or live well fish) to survive in the hostile environment of a tank. The amount of water in relation to the number,

weight, or “scoop(s)” of bait/fish in the tank is crucial. A general recommendation is 20 gallons [75 Lt] capacity to

maintain 6 to 11 pounds [3 to 4.5 Kg] of bait/fish, which is usually, considered a scoop. Tank shape will affect the

water currents within the tank. An ideal shape is oval. A deep tank is much better than a shallow one. Water within

the tank should circulate counterclockwise at an extremely slow rate to keep the bait oriented in one direction. The

tank fill tube should be positioned from top to bottom within the tank. Water must enter at the top of the tank to

prevent drain back when the pump is off. A series of graduated holes or slots that allows slightly more flow at the

bottom of the tank is desirable. Currents at the bottom of the tank should angle upward slightly to insure waste

from the bait/fish is continually flushed from the tank. The tank drain should be three times the area of the input

tubing, as it must be able to pass the full volume entering the tank under pressure. The fresher the water in the

tank, the healthier the bait/fish. Water temperature is critical. Typically, when the water is 60°F [15°C] or less,

most bait/fish will stay healthy and active. As the water temperature approaches 70°F [21°C] or above, there is

less oxygen and the bait/fish become lethargic and more subject to being injured. The time that it takes to fill or

change water in the tank will be referred to as "water turns". If a pump has too high of flow for tank capacity,

water turns will be too often. Also, strong currents will cause the bait/fish to tire swiftly and die. If on the other

hand, the pump flow is too low, there will not be sufficient water turns and not enough fresh oxygenated water

enters the tank to flush out waste. When the water is warm (approaching 70°F [21°C]), water turns as often as 7

minutes are desirable. If the water is cooler (60°F [15ºC] or less), the water turns may be up to 10 minutes apart.

With open impeller or centrifugal type pumps (such as the SHURflo MDBS), a flow-adjusting valve is an asset

within the bait system. Restricting the flow actually decreases the amp draw of the motor, which will not cause

damage. Use a gate or ball valve that has an opening I.D. as large as the tubing I.D. With the boat sitting in the

water turn the flow-adjust valve wide open. Start the pump and note the time it takes to fill the tank. If the tank

fills in less than 7 minutes, close off the valve to obtain the appropriate fill time (7 to 10 min.). If tank head/

capacity was used to select the pump, the valve should only require minor adjustments to obtain the proper water

turns. If a pump has too high of a flow for the tank, the valve will be almost closed in order to obtain the proper

water turns. In this condition, if aerated the pump may lose prime and become air locked. Aeration can be a real

problem in rough seas or at speed over choppy water. Under such conditions large amounts of air can

continually enter into the thru-hull fitting. Straight thru-hull fittings are not recommended as they can act as a

venturi. At high speed they may/can pull water out of the tank. Only use a scooped or clam shell style thru-hull

fitting When the boat is moving forward at high speed, water is forced into the thru-hull fitting and pump. When a

boat is moving at 30 mph [48 kph], the flow jumps to almost double! Higher speeds equal much higher flows.

Flows that result in “water turns” faster than 7 minutes and are sustained for more than 20 minutes can/will cause

the bait/fish harm or kill them. If your fishing involves long, high speed runs, it will be necessary to establish two

flow adjust valve positions. The first setting is for stopped or low speed operation per the adjustment procedure on

page 1. The second setting is for sustained high speed operation. With the tank empty, turn the flow adjust valve

approximately ½ open. Turn on the pump and quickly accelerate to your desired "high speed". Note the time

required to fill the tank. If necessary, drain the tank, reset the valve, and repeat test until a moving fill time of

approximately 7 minutes is reached. CAUTION: When stopped, or going slow, remember to turn the flow adjust

valve BACK to the stopped position. When plumbed correctly, the SHURflo MDBS can clear air trapped in the

pump within a few seconds. Actual times will vary depending on system configuration. MDBS design features will

cause trapped air to clear as long as the thru-hull/impeller remain flooded. The pump’s ability to clear air may be

hindered by: plumbing that is horizontal or sagging below horizontal, improper sizing of the pump in relation to the

tank head/capacity, or substantial back pressure due to restrictive plumbing. The thru-hull should be located

approximately 6 in. [15cm] off the center line of the keel, to the stern of the boat. It should not be located

directly in-line with any other obstructions such as water pick-ups, transducers, rivet heads, or running strakes.

Such items may cause turbulence in the water resulting in a disrupted or aerated flow when the boat is moving.

This simply means that air is pulled from the water and forced into the tank. This is not desirable and will rapidly

kill the bait if operated under such conditions for a period of time.

911-466 Rev L 11/08 ECO#: 16079 Page 1 of 3

NOTES AND CAUTIONS

1. To prevent cavitation of main drive engine, thru-hulls, transducers, etc. should not be located in-line

with the water pick up for the engine.

2. All thru-hulls MUST have a sea-cock shut-off valve in case of an emergency.

3. DO NOT use a wrench to tighten pump to the sea-cock valve.

Snug by hand only. DO NOT EXCEED 30 FT-LBS OF TORQUE. Properly seal all pipe threads to

prevent leaks.

1. Tubing should be rated for below water-line usage. Tubing I.D. must be smooth wall. "Bellows" type

tubing may cause as much as 50% loss in flow.

2. Always double clamp all tubing connections that are below the water line.

3. Do not cut pump wire leads. Wire connections should be made above possible bilge water level. Seal

wire connections to prevent corrosion and electrolysis.

GENERAL SAFETY PRECAUTIONS

1. Never operate the engine or electrical equipment if fuel vapors are detected. Locate the source of the

fuel vapor and properly vent.

2. When the vessel is not in use, the main power switch and sea-cock valve(s) should be OFF/CLOSED.

However, if left afloat, the bilge pump(s) should still have power.

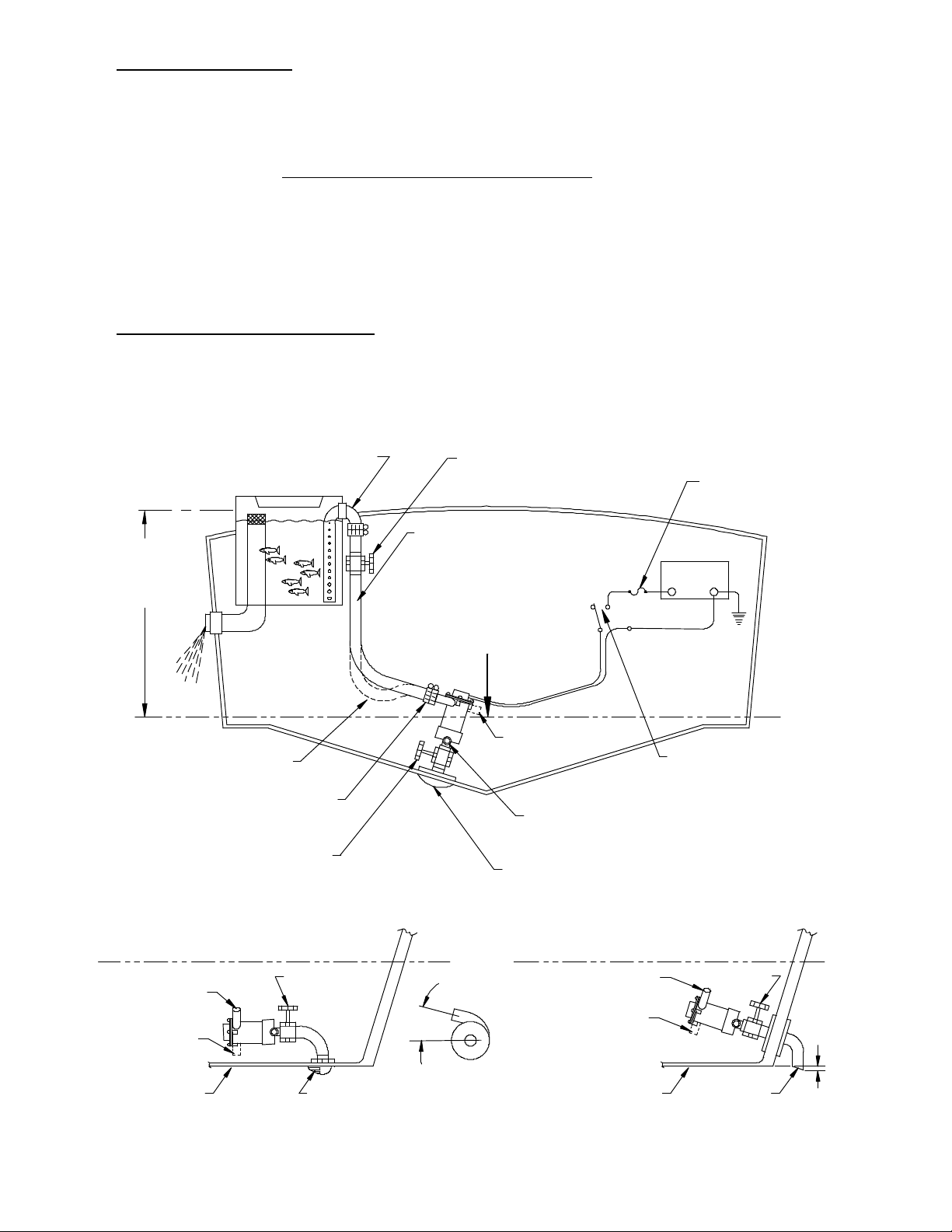

MUST "ENTER" AT

TOP OF TANK

MAX. "HEAD"

BASED UPON

TANK

SIZE/DISTANCE.

(REF. CHART PAGE: 3)

DRAIN

WATER

LINE

DO NOT ALLOW TUBING TO SAG.

ALWAYS USE DOUBLE STAINLESS STEEL*

CLAMPS FOR PLUMBING BELOW WATER LINE.

SEA-COCK SAFETY VALVE* REQUIRED.

BE SURE VALVE OPENING IS AS LARGE AS BAIT

PUMP DISCHARGE PORT I.D.

FLOW-ADJUST VALVE*

VALVE OPENING SHOULD BE THE

SAME AS PUMP DISCHARGE PORT I.D.

TUBING MUST TRAVEL UPWARD

FROM PUMP TO BAIT TANK.

IF TUBING SAGS BELOW HORIZONTAL

PUMP MAY BECOME AIR-LOCKED.

(IF AERATED)

(OFF)

PUMP IMPELLER MUST BE

BELOW WATER-LEVEL

BROWN (+)

WRONG POSITION

FOR DISCHARGE PORT

½" NPT PORT FOR CONNECTION TO A WASH-DOWN PUMP.

REF. S/B #1066 FOR SUGGESTED INTEGRATED PLUMBING ARRANGEMENT.

LOCATE A SCOOP OR CLAM SHELL STYLE THRU-HULL* FITTING

APPROX. 6 IN. [15CM] OFF KEEL, TO THE STERN.

RED

(ON)

SLOW-BLOW FUSE*

(REFER TO SPECS. FOR SIZE)

12 VDC BATT.

_

+

BLACK

U/L MARINE APPROVED, IGNITION

PROTECTED ON/OFF SWITCH*.

10 AMP RATING (MINIMUM).

HORIZONTAL MOUNT

CORRECT POSITION

FOR DISCHARGE PORT

WRONG POSITION

FOR DISCHARGE PORT

KEEL

* NOT SUPPLIED

VALVE

THRU-HULL

(SCOOP OR CLAM SHELL)

UP 15°

(OR MORE)

WATER-LINE

DISCHARGE

PORT

PUMP END VIEW

CORRECT POSITIONSEA-COCK

FOR DISCHARGE PORT

WRONG POSITION

FOR DISCHARGE PORT

TRANSOM MOUNT

SEA-COCK

VALVE

KEEL

RAW WATER

PICK-UP

1

/

8

" [3MM]

911-466 Rev L Page 2 of 3

Loading...

Loading...