Shurflo 166-296-XX Installation Manual

PUMP

DISPENSER

OR

VRV/PUMP

TO NEXT

GAS TO NEXT

PUMP

SECOND

VRV

PUMP

FIRST

GAS IN

B-I-B

Page: 2 of 4

SHURflo for more information.

particular installation, including Pressurized Inlet Pumps or Accumulators. Contact

SHURflo can recommend several other methods to meet the requirements for a

reduced to zero, permitting syrup to be drawn in under vacuum.

By positioning a VRV at the inlet of the secondary pump, incoming pressure is

(VRV) allows the pump to receive liquid from a pressurized source.

Regulating Valve

Beverage pumps are not designed to have positive pressure on the inlet side. The SHURflo V acuum

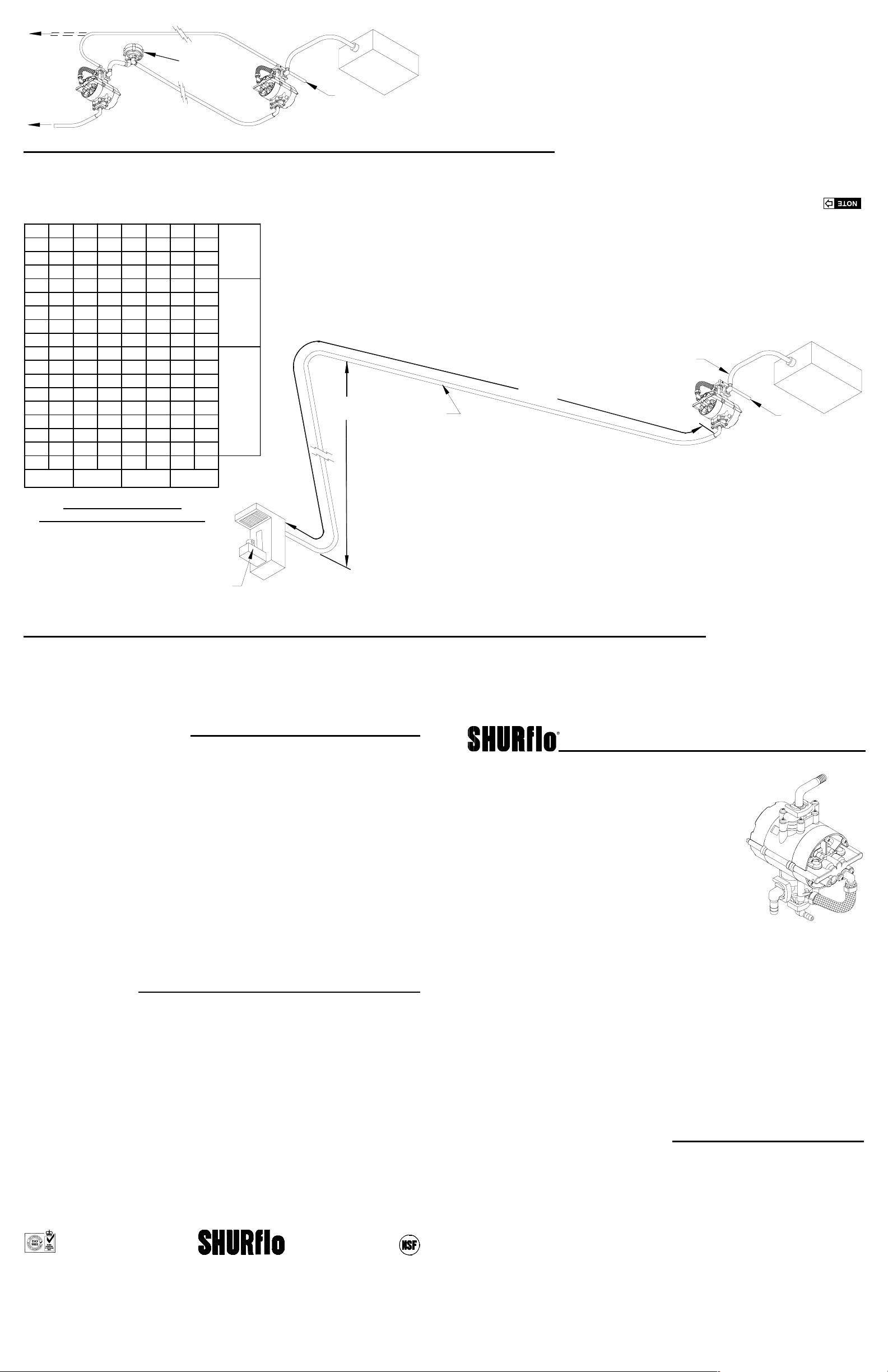

Long tubing runs or high vertical lift can be achieved by installing pumps in series. Standard SHURflo

PUMPS IN SERIES FOR LONG DISTANCES

129

152

152+

152+

112

152

152

152+

152+

152

152

152

152+

152+

152+

152+

152+

Meter

[2.38 bar]

425

500

500+

500+

366

500

500

500+

500+

500

500

500

500+

500+

500+

500+

500+

Feet

[13mm]

/2" I.D.

1

39

73

105

152

39

59

118

152

152

65

90

121

152

152+

152+

152+

152+

Meter

/8" I.D.

8

127

16

239

23

345

39

500

3

127

9

193

24

388

40

500

152

500

--

212

9

297

19

398

31

500

65

500+

138

500+

152

500+

152+

500+

Meter

Feet

[10mm]

3

VISCOSITY

BY

45

30

15

60

45

30

15

105

90

75

60

45

30

15

mL

1.5

1.0

22.5

.7 5

.5

2.0

1.5

1.0

22.5

.7 5

.5

3.5

3.0

2.5

2.0

1.5

1.0

22.5

.7 5

.5

OZ.

SEC.

/

26

53

75

129

10

32

79

133

500

-32

64

102

212

453

500

500+

Feet

[6 m m ]

/4" I.D .

1

(cPs.=Centipose)

LENGTHS

MAXIMUM HORIZONTAL TUBING

Diet

FLO W RATE

Distances shown are intended as a guidline only.

(syrup flow only)

/2 oz./sec. [15 mL]

1

FAST FLOW V AL VE

at the dispenser to maintain brix.

All distances assume a dynamic pressure of 35 psi.

ambient with a static pressure of 85 psi. [5.8 bar] to the pump.

Distances shown are the results of tests conducted at 70°F [21°C]

(35 cPs.±3)

Syrup

Soda

Heavy

(20 cPs.±3)

Syrup

Soda

Standard

(5 cPs.±3)

Syrup

Soda

ft.

=

30.5M.

= 110

[6.7M]

(4.56 x 6.7)

(22 x 5)

VERTICAL

22 ft.

TUBING

/8" I.D. [10mm]

3

[3% if meters].

(s) in series using a SHURflo V acuum Regulator .

consider a larger I.D. tubing or installation of a pump

Had the example above resulted in a value that was equal to, or less than the necessary total tubing run,

M.

M (152 - 30.5) = 121.5. The results indicate a 121.5M tubing run (horz./vert.) is

= 4.56. Which then is multiplied by the 6.7M vertical,

152 x 3%)

possible, while the example only requires a distance of 113

Subtract this product from the 152

Meters:Take 3% of 152M (

possible, while the example only requires a distance of 370 ft.

Subtract this product from the 500 ft.

Feet: Take 1

over a horizontal distance of 500 ft.

The chart indicates that heavy syrup with

SYRUP

HEAVY SODA

GAS IN

[113M]

=

390. The results indicate a 390 ft. tubing run (horz./vert.) is

/8" I.D. [10mm] tubing is used.

3

370 ft.

TOT AL TUBING RUN

(500 - 110)

%

= 5

. Which then is multiplied by the 22 ft. vertical,

(500 x 1%)

of 500 ft.

[152M] when

/2 oz./sec [15mL] flow-rate (per the illustration) can be sustained

1

TUBING (min.)

/8" I.D. [10mm]

3

For example:

(horz./vert.) tubing run that is obtainable for that flow rate, tubing I.D. and viscosity.

from the maximum horizontal distance. The resulting length is the total horizontal/vertical

The resulting number is multiplied by the vertical distance. This product is then subtracted

the vertical distance, use the chart to the right. Take 1% of the distance in feet

Vertical tubing runs will reduce total achievable tubing run length. To estimate the losses within

• Horizontal & vertical distance of the outlet tubing.

• Inside diameter of the inlet/outlet tubing, fittings, bag connector, etc.

(s) connected to a pump.

• Total syrup flow rate of valve

• Syrup viscosity and temperature (coldplate, re-circ., etc.).

SHURflo recommends estimating system losses by considering the following:

variances in system configuration and equipment, an accurate determination of pressure drop is difficult. Before deciding on a system’s tubing size,

The distance syrup can be delivered is limited by inherent factors (restrictions) within the inlet & outlet sides of the beverage dispensing system. Due to

PUMPING CAPABILITY

TECHNICAL SPECIFICATIONS

DESIGN: Twin Chamber Double Diaphragm

MATERIALS OF CONSTRUCTION: Polypropylene, EDPM, Santoprene, 300 Stainless Steel,

FDA sanctioned, NSF Listed, CE, S-K

POWER SOURCE: CO2, Nitrogen, or compressed filtered air

OPERATING PRESSURE: 20 psi. MIN. [1.4 bar] / 85 psi. MAX. [5.8 bar] static

MAXIMUM STROKE RATE: 2 strokes /sec; intermittent duty (consult factory)

DISPLACEMENT: 3.4 oz. per cycle [101 cc]

AUTOMATIC SOLD-OUT: 20–24"Hg. [68–81kPa] activation (wet). No reset required.

High altitude models: 16–18"Hg. [54–61kPa]

TEMPERATURE LIMITS: 34° – 120°F [1.1° – 49°C]

WEIGHT: 1 lb. [.45 kg]

AVAILABLE* LIQUID FITTINGS:

1

/4" [6mm], 3/8" [10mm], and 1/2" [13mm] barb elbows,

straights; and 90° configurations; plastic or stainless.

John Guest® straight tube; plastic.

AVAILABLE* CO2 / AIR / EXHAUST1/4" [6mm] barb elbows or "T"s; plastic or brass; with internal

FITTINGS: check valve.

*Pump assembly part number determines

fitting configuration.

Metric fittings dimensions are approximation

to U.S. inch size.

1

/4" [6mm] barb elbows or straights; plastic (no c/valve).

John Guest® straight tube; plastic (no c/valve).

Muffler assembly

LIMITED WARRANTY

SHURflo warrants new Beverage Gas Pumps to be free from material and workmanship defects (under

normal use and service) for a period of five (5) years from the date of manufacture. An additional 30

days may be added to allow for storage and transit delays. In any event, the total limited warranty

period will not exceed sixty one (61) months from date of manufacture.

The limited warranty will not apply to pumps that were improperly installed, misapplied, or not

suitable with components of other manufacturers. The limited warranty will not apply to pumps

subjected to fluids that are incompatible with pump materials, or pumps operated by a contaminated

air supply. SHURflo will not warrant any pump that is physically damaged or modified outside the

SHURflo factory.

All SHURflo gas pumps should be returned to the authorized distributor where they were purchased.

SHURflo's obligation under this warranty policy is limited to repair or replacement. Pumps found not

defective (under the terms of this limited warranty) are subject to charges to be paid by the returnee for

the testing and packaging of "sanitized & tested good" units.

No credit or labor allowances will be given to the returnee for pumps returned as defective. Warranty

replacements will be shipped on a freight allowed basis. SHURflo reserves the right to choose the

method of transportation.

This limited warranty is in lieu of all other warranties, expressed or implied, and no other person is

authorized to give any other warranty or assume obligation or liability on SHURflo's behalf. SHURflo shall

not be liable for any labor, damage or other expense, nor shall SHURflo be liable for any indirect, incidental

or consequential damages of any kind incurred by the reason of the use or sale of any defective product

or part. This limited warranty covers beverage products distributed within the United States of America.

Other countries should consult with the distributor for any deviation from this document.

ISO Certif ied Facility

«

Santa Ana, CA 92706-2100

(800) 854-3218 (714) 554-7709

Shipping/UPS:

SHURflo reserves the right to update specifications, prices, or make substitutions.

SHURflo

12650 Westminster Ave.

FAX (714) 554-4721

Garden Grove, CA 92843

«

12650 Westminster Ave.

Elkhart, IN 46514-5427

(800) 762-8094 (219) 262-0478

http://www.shurflo.com

a WICOR Company

SHURflo East

52748 Park Six Court

FAX (219) 264-2169

© 1998 Print e d in USA

911-487 Rev. C 10/01

COMPONENT

SHURflo Ltd.

Unit 5 Ste rling Park

Gatwick Road, Crawley

West Sussex, RH10 2QT

United Kingdom

+ 44 1293 424000

FAX + 44 1293 421880

Page: 4 of 4

BEVERAGE GAS PUMP 166-296-XX

Installation and Operation Manual

SHURflo’s Beverage Gas Pump supplies syrup under

pressure to a post-mix dispenser, which mixes the

syrup with water to an exact ratio

used in conjunction with non-pressurized Bag-In-Box

(B-I-B) containers and a bag connector (Q.D.) fitting.

The pump can be operated on regulated CO

or compressed filtered air. The compressed gas drives the

pump and is not in contact with the syrup. Separate syrup

and gas chambers prevent contamination, foaming and

purging of the tubing when the B-I-B has emptied.

The pump retains pressure in the outlet line, operating only when syrup is

needed. When the dispenser valve is opened, the pump reacts to the

pressure drop by operating to maintain pressure in the line. When the

dispenser is closed, the incoming gas and output syrup pressures equalize

and the pump stops. Actual dynamic line pressure is dependant upon

system losses as outlined in the section "Pumping Capability".

The automatic "sold-out" feature within the pump ensures consistent

syrup delivery right up to the moment the B-I-B is empty. Vacuum

produced by the pump evacuates the syrup within the bag. Once the

preset vacuum point is achieved and held, incoming gas pressure to

the pump is shutoff causing the outlet syrup pressure to drop to zero.

When a new B-I-B is installed, the vacuum drops, the pump automatically

restarts and pressurizes the system. The SHURflo Beverage Gas Pump

ensures quality from the first drink to the last.

APPLICATION INFORMATION

Beverage Gas Pumps are intended for soda syrups and low viscosity

concentrates that do not contain solids.

The use of a SHURflo Juice Pump

containing soft solids, classed as round, up to 0.025 in.

are of higher viscosity than soda syrups.

When concentrates contain pulp classed as long/stringy, seed particles or

®

are exceptionally viscous, the Particulate Juice Pump

as it can handle soft solids up to

Standard gas pump models are for installations where geographic

elevation is less than 5000 ft.

high altitude models with a reduced sold-out spring rate must be used to

compensate for the loss in atmosheric pressure.

For further application and model information please contact SHURflo.

911-487 Rev. C 10/01 Page: 1 of 4

(brix). The pump is

, nitrogen

2

(-09) is recommended for concentrates

[0.6 mm] or that

(-10) should be used

1

/4" [6 mm] cubed.

[1523 M]. For elevations above 5000 ft. specific

INSTALLATION GUIDELINES

•As indicated on the pump, the outlet port is to be mounted up Ý.

•Pumps are to be mounted at the same level or higher than the B-I-B. The best choice is to have the pump above the B-I-B.

•I

NLET tubing from the B-I-B to the pump use;

3

/8" I.D. [10mm] minimum, heavy wall (

have excessive length. Tubing that is allowed to drape down can trap air in the B-I-B creating a potential for pump "sold-out" problems.

The maximum vertical distance from the bottom of the B-I-B to the pump must not exceed 5 ft [1.5 M]. Maximum inlet tubing length is 10 ft. [3 M].

•If plumbing multiple B-I-B’s to a pump, B-I-B's should be "Teed"

•O

UTLET tubing from the pump to the dispenser should be high pressure rated and NSF listed. Consult "Pumping Capability" (page 2) for appropiate tubing I.D.

•Always cut CO

•Use new

(clean),

N

EVER connect a transfer tank "system" in series with a B-I-B system. Syrup contaminants in old components may work their way through the air

and outlet tubing at least 2 ft. [.6 M] longer to provide a "service loop" so the B-I-B rack can be moved for cleaning or service.

2

1

/4" I.D. [6 mm], flexible, high pressure, braided tubing from the CO2 / air regulator to the pump.

side-by-side horizontally, rather than one on top of the other (vertically).

supply causing premature failure of the gas pump. Gas used to operate pumps

Air compressors may be used with proper particle filters and moisture separators. Air storage tanks should be drained regularly . Pumps subjected

to contaminated air are not covered by warranty.

1

/8" [3mm]) clear, NSF listed vacuum tubing. Inlet tubing should not

MUST be clean and contain no contaminants (syrup, oil, rust, water, etc).

High concentrations of CO

can be fatal as it will displace the air from non-ventilated areas. Pumps operated by CO2 must be in ventilated areas.

2

If placed in a confined area (basement, closet, cooler box, etc.), exhaust fans capable of changing the room air on a continuous basis should be used.

• All tubing connections must be secured with stainless steel, stepless Oetiker

®

clamps.

• Cable-tie all tubing securely to prevent kinks or sags that inhibit performance or cause damage to the pump fittings.

ST ART-UP PROCEDURE

1.Confirm that all tubing connections are properly clamped, fittings are

tight, and tubing is not kinked. Install bag connector to the B-I-B.

2. Adjust gas regulator to about 20 psi.

stroke slowly.

3. Operate the valve until all air trapped within the tubing has been purged.

4. Once the air has been purged, adjust the CO

necessary to maintain the desired brix. The most efficient gas usage

occurs at 40 psi. [2.8 bar]. MAXIMUM static gas pressure to the pump is

85 psi.

[5.8 bar], minimum 20 psi. [1.4 bar].

Flowrates that result in a stroke-rate of more than two strokes

per second will decrease pump life.

due to "overrunning" is not covered by the limited warranty.

To prevent air from entering the system always leave the bag

connector attached to the empty B-I-B until a new B-I-B can be

installed. Air entered into the system, via air in the bags or vacuum

leaks, may cause brix fluctuation, foaming, spitting, non-operation

of the vacuum sold-out or pump "run-on" with the valve closed.

Symptoms of this kind can lead to a misdiagnosis of the pump.

[1.4 bar] allowing the pump to

regulator to the pressure

2

(Consult factory) Pump failure

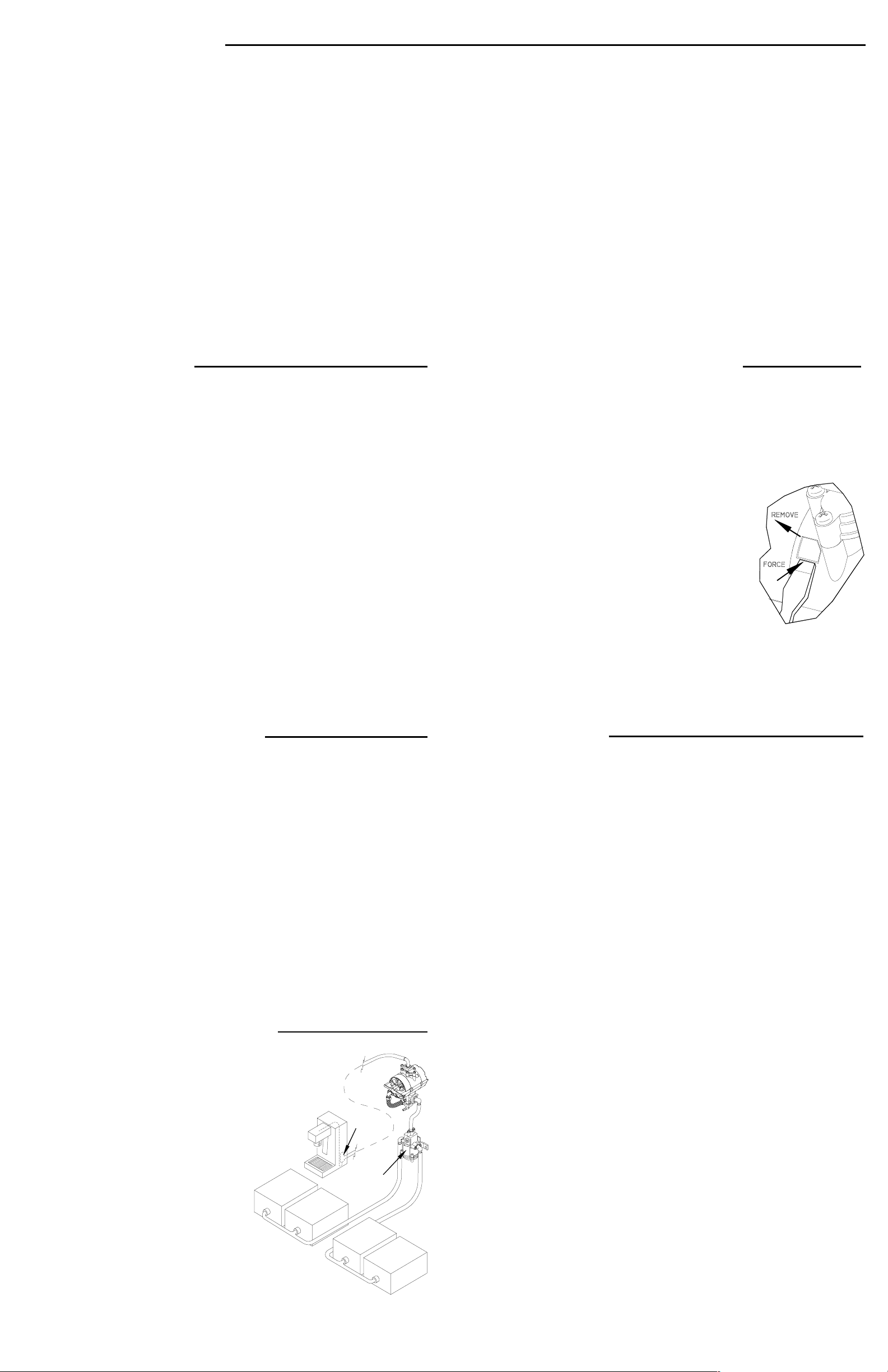

MOUNTING CLIP KNOCKOUT REMOVAL

Removal of the knockout tabs from the pump housing is only necessary if

the pump will be installed onto a SHURflo Mounting Board. Depending on

board style, spring clip orientation varies. Ensure spring clip position and

corresponding knockout tabs before removal.

The knockout tabs

Failure to remove the tab from the housing will cause the spring

clips not to engage completely, making the mounting insecure.

1.Position the pump on its side, in a

where the pump can be held firmly.

2.Place an appropriate sized flat blade screwdriver into

the indentation as shown.

Breaking the tabs at this particular indentation

facilitates complete tab removal.

3.Break the tabs loose by either pressing firmly, or

striking the screwdriver handle solidly with your palm.

4.The tab should break away from the housing, allowing

it to be popped-out with the screwdriver.

Removal of the aluminum mounting bracket may be required to permit full

must not be pushed into the housing cavity.

engagement of the spring clips. Screw torque 15-18 in/Lb.

secure location

[17-20 N•m]

PUMP SANITIZING / WINTERIZING

Sanitization of the SHURflo Beverage Gas Pump is required. The frequency

of Sanitization is dependant on the concentrate type and its

manufacturer’s requirements. Factors which also affect the frequency of

this procedure are: temperature, concentrate volatility, facility conditions,

installation and equipment. The sanitizing procedure fulfills a required

10 minute contact time with a 200 ppm Sodium Hypochlorite solution.

Refer to SHURflo Service Bulletin

procedure for the SHURflo pump

Pumps that are subjected to freezing

of fluid to prevent damage. Refer to SHURflo Service Bulletin

#

1025 for the N.S.F. listed sanitizing

(only).

(below 32° F [0°C]) must be purged

#

1025 for

complete winterizing procedure.

Refer to the equipment manufacturer’s instructions for sanitizing and

winterizing procedure for carbonators, dispensers and tubing.

Pumps that have been winterized and/or out of service for a period

of time should be sanitized prior to being placed back in service.

Never apply pressure to the pump’s liquid inlet. Pressurized

tanks may damage internal components if used to sanitize or

purge fluid from the pump

(operating or not).

BEVERAGE SYSTEM ACCESSORIES

AUTOMA TIC SELECTOR V AL VE (ASV)

Eliminate the chore of replacing B-I-B’s during peak

business periods. Teeing B-I-B’s together still causes

them to empty at the same time. An ASV permits

multiple B-I-B’s to be connected to a particular

pump. Once the B-I-B

completely emptied the ASV automatically

switches sides to full B-I-B’s. An ASV allows

uninterrupted drink dispensing with the

ability to replace empty B-I-B’s at a

more convenient time.

SOLD-OUT-SWITCH (SOS)

The SOS kit prevents the dispensing of

syrup starved drinks by interrupting water

flow at the dispenser valve. An exceptionally

useful feature for lemon lime

thru windows. The SOS senses the pressure drop in the

syrup line caused by an empty B-I-B and interrupts power to

the valves’ electric solenoid. The SOS automatically resets with

the installation of a full B-I-B.

(s) on one side have

(clear) sodas and drive-

SOS

ASV

Page: 3 of 4

TROUBLESHOOTING

DOES NOT OPERA TE / GAS APPLIED / DISPENSER VALVE OPEN

ü B-I-B empty or inlet tubing pinched off activating vacuum "sold-out".

ü Gas regulator over-pressurizing.

ü Outlet tube kinked or restricted.

ü Operated without fluid for excessive period.

ü Transfer tube and gas lines contaminated (syrup, rust, oil, etc.)

[ensure clean gas supply, change out all contaminated pumps]

ü Internal damage of control cover.

OPERA TES BUT WILL NOT PRIME / DISPENSER VALVE OPEN

[consult Start-up Procedure for proper priming]

ü Pump valves have no moisture/dry.

[add water/syrup to the inlet port with pump stroking slowly]

ü Vacuum leaks at Q.D., barb fitting clamps, or inlet fitting o-ring.

ü Debris in valve seats or warped/swollen valves.

DOES NOT ACHIEVE SOLD-OUT WITH EMPTY B-I-B

ü Vacuum leaks at Q.D., barb fitting clamps, or inlet fitting o-ring.

ü Excessive amount of air in B-I-B from improper packaging.

ü Air trapped in outlet tubing and/or pump fluid chambers.

AIR IN INLET AND/OR OUTLET TUBING

ü Vacuum leaks at Q.D. o-ring or barb fitting clamps.

ü Vacuum leaks at inlet fitting; o-ring pinched or missing.

ü Large amounts of air noticed only in the outlet tubing when pump operates.

[diaphragm/piston assemblies ruptured]

STROKES WITH DISPENSER V AL VE CLOSED

ü Air trapped in outlet tubing and/or pump fluid chambers.

[open outlet and purge air, check for vacuum leaks, or air in B-I-B]

ü Debris in outlet valves or warped/swollen valves.

FLUID FROM EXHAUST OR VISIBLE WITHIN GAS INLET TUBING

ü Carbonator check valve.

ü Ensure clean gas supply.

ü Diaphragm/piston assemblies ruptured.

[change out all contaminated pumps]

GAS BLOWING FROM EXHAUST CONTINUOUSL Y

ü Control cover subjected to contaminated gas supply or damaged.

[ensure clean gas supply, change out all contaminated pumps]

(Pump stalled)

(Dry run)

Loading...

Loading...