Shurflo 166-226-XX Installation Manual

LIMITED WARRANTY

SHURflo warrants FLOport Gas Pump model #166-226-XX to be free from material

and workmanship defects (under normal use and service) for a period of five (5)

year from the date of manufacture.

The limited warranty will not apply to pumps that were improperly installed,

misapplied, or not suitable with components of other manufacturers. The limited

warranty will not apply to pumps subjected to fluids that are incompatible with pump

materials, or pumps operated by a contaminated air supply. SHURflo will not

warrant any pump that is physically damaged or modified outside the SHURflo

factory.

All FLOport gas pumps are to be returned to SHURflo Ltd., West Sussex, England, postag e

prepaid. Package returns carefully; SHURflo is not responsible for damage.

SHURflo's obligation under this warranty policy is limited to repair or replacement.

Pumps found not defective (under the terms of this limited warranty) are subject to

charges to be paid by the returnee for the testing and packaging of "tested good"

units.

No credit or labor allowances will be given to the returnee for pumps returned as

defective. Warranty replacements will be shipped on a freight allowed basis.

SHURflo reserves the right to choose the method of transportation.

This limited warranty is in lieu of all other warranties, expressed or implied, and no

other person is authorized to give any other warranty or assume obligation or liability

on SHURflo's behalf. SHURflo shall not be liable for any labor, damage or other

expense, nor shall SHURflo be liable for any indirect, incidental or consequential

damages of any kind incurred by the reason of the use or sale of any defective

product or part. This limited warranty covers beverage products distributed within

the United States of America. Other world market areas should consult with the

distributor for any deviation from this document.

R

«««« ISO Cer tified Facility

SHURflo reserves the right to update specifications, prices, or make substitutions.

SHURflo «

5900 Katella Avenue

Cypress, CA 90630

(800) 854-3218 (562) 795-5200

FAX (562) 795-7564

Shipping: 5900 Katella Ave., Suite B

Cypress, CA 90630

«

««

SHURflo East

52748 Park Six Court

Elkhart, IN 46514-5427

((800) 762-8094

(219) 262-0478

FAX (219) 264-2169

© 1998 Printed in USA

a WICOR Company

SHURflo Ltd.

Unit 5 Sterling Park

Gatwick Road, Crawley

West Sussex, RH10 2QT

United Kingdom

+44 1293 424000

FAX +44 1293 421880

H.D.A. FLOport BEVERAGE GAS PUMP (166-226-XX)

Installation and Operation Manual

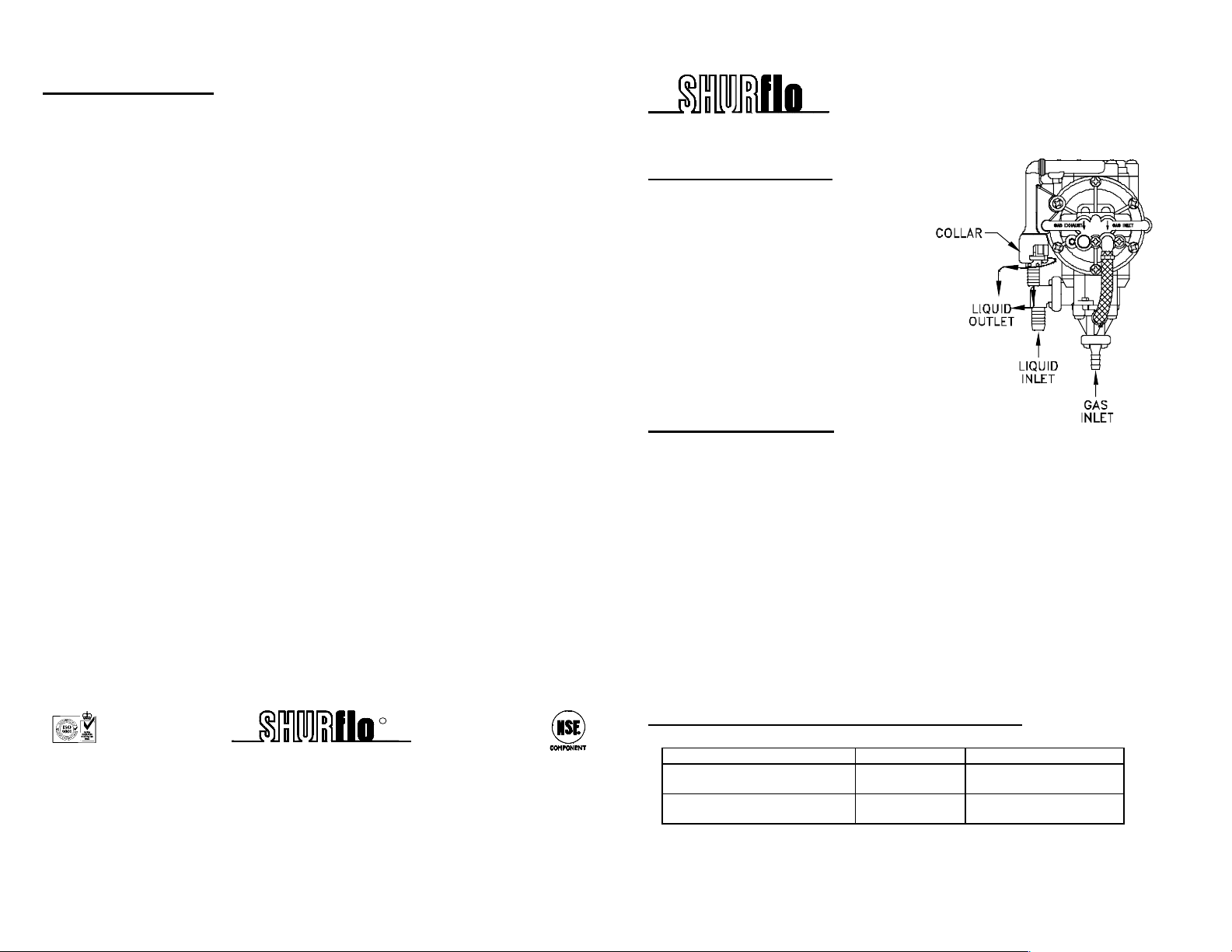

LIQUID OUTLET FITTING

REMOVAL / INSTALLATION:

1. Remove the CO

Operate the dispenser valve to relieve all

pressure within the outlet tubing.

2. Rotate the Locking Collar clockwise a ¼

turn and allow the Locking Collar and

outlet fitting to drop down.

3. Slide the fitting sideways through opening

in the Locking Collar.

4. Install in reverse order.

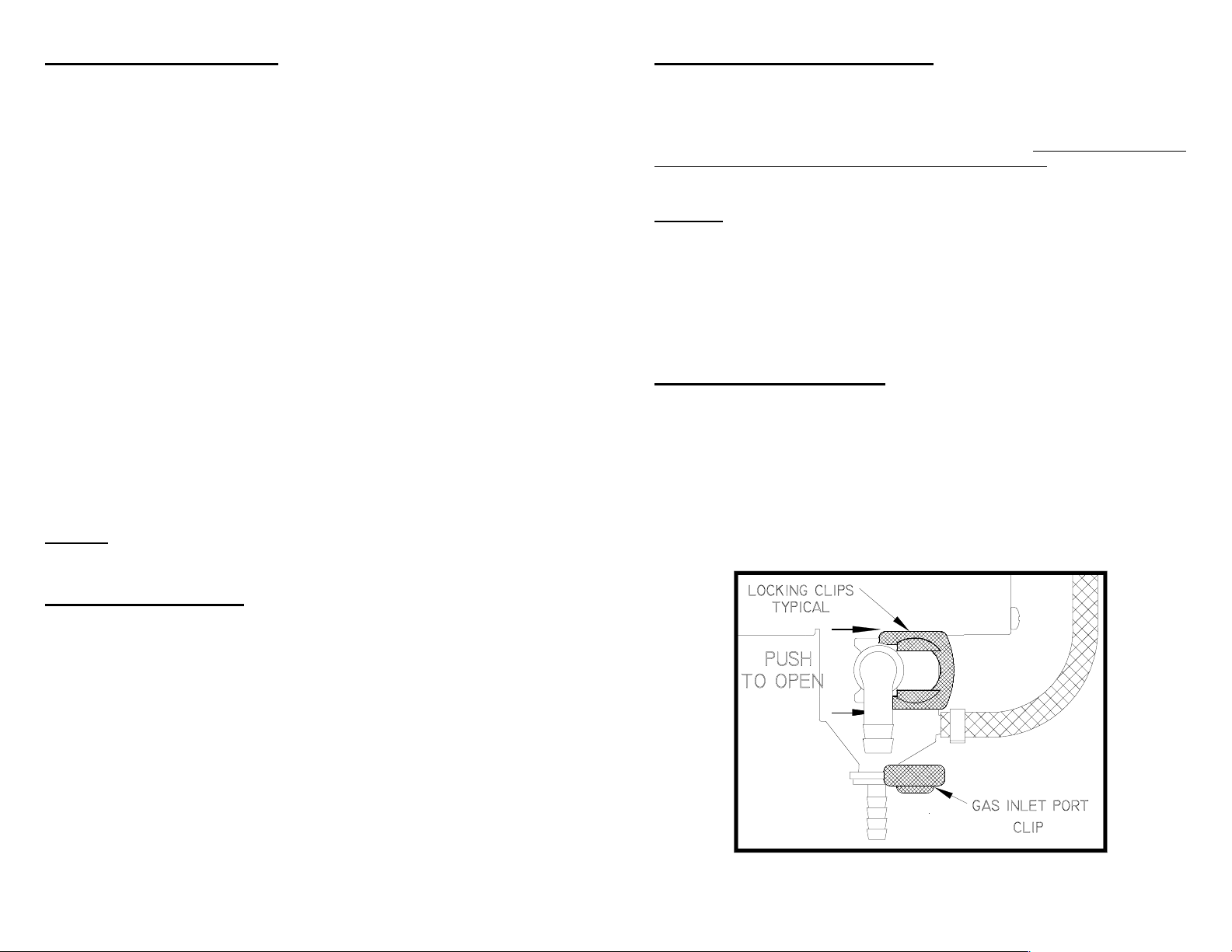

*Q.D. operation for CO

inlet fittings illustrated on page: 3.

PUMPING CAPABILITY

Due to diversity of both the installations and equipment used within beverage

systems, it is difficult to calculate/predict total pumping distance. The ability to

deliver fluid is limited by the dynamics of the fluid (flow) and pump displacement at

pressure. Consider the following factors when estimating pressure drop within a

beverage system.

• Fluid viscosity and temperature.

• Inside diameter of the inlet/outlet tubing, fittings, etc.

• Total flow rate of valve(s) connected to a pump.

• Horizontal distance of the outlet tubing.

• The pressure drop per foot within vertical tubing runs is significant. To estimate the

losses use the appropriate distance given by Max. Horz. Dist. Chart. Take 3% of that

distance. Multiply the vertical distance by that number. Subtract the product from the

original Max. Horz. distance. The result is the total tubing run (includes vertical) that

should be attempted for that flow rate, tubing I.D., and viscosity.

MAXIMUM HORIZONTAL DISTANCE by VISCOSITY

TABLES ARE TO BE USED AS A GUIDELINE ONLY (Centipose = cP.)

SYRUP TYPE/VISCOSITY FLOWRATE 10

Standard Sugar (15-30 cP.)

Heavy Soda (30-45 cP.)

Diet soda syrups are substantially less viscous (3 cP.) The tables above are the

results of tests conducted with 5.8 bar (to the pump), with a minimum of 2.38 bar at

the dispenser valve (to m aint ain brix). Am bient t em perat ure = 21°C.

2/gas inlet fitting*.

2/gas and liquid

15 cc/sec

30 cc/sec

15 cc/sec

30 cc/sec

MM I.D. TUBING

152+ meters

118 meters

150 meters

73 meters

911-532 Rev. A 03/02 Page: 4 of 4

Page: 1 of 4

911-532 Rev. A 03/02

INSTALLATION GUIDELINES

• Mount the pump so the CO2 inlet and liquid outlet fittings are point down.

NOTE: The right bracket keyhole slot is not accessible with a screwdriver. The

screw must be installed first allowing clearance to slip the keyhole slot over

screwhead. Tighten the left mounting screw securely.

• The pump should be mounted above the B-I-B or at least at the same level. Pumps

placed lower than the B-I-B’s will increase the ability to entrap air in the B-I-B.

• The

MAXIMUM length of INLET tubing is 3 M, with NO MORE than a 1.5 M vertical lift.

Use clear, 10mm I.D., vacuum rated heavy wall (3 mm), food grade tubing from the B-I-B

to the pump inlet.

• If necessary to connect B-I-B’s together, plumb (Tee) B-I-B's side-by-side

horizontally, rather than one on top of the other, vertically.

• OUTLET tubing from the pump to the dispenser should be 10mm I.D.. high

pressure, food grade, braided tubing. Always cut outlet tubing longer than

necessary to provide a "service loop" so the B-I-B rack can be moved for cleaning

or service.

• Tie-wrap all tubing securely to prevent kinks or sags that inhibit performance or

cause damage to the pump fittings.

• Use only new 6mm I.D., CO

regulator and the pump.

NOTE: NEVER connect a transfer tank "system" in series with a B-I-B system.

Syrup contaminants in old components may work their way through the air

supply causing premature failure to the gas pump. The gas used to drive the

pump MUST be clean and contain no contaminants (syrup, oil, rust, water,

etc.). Air compressors may be used with proper particle filters and moisture

separators. Air storage tanks should be drained weekly. Pumps subjected to

contaminated air are not covered by warranty.

CAUTION: Pumps driven with CO

used in a confined area (basement, closet, cooler box, etc.), CO2

exhaust should be vented to the outside.

2 approved high pressure tubing between low pressure

2 are to be operated in well-ventilated areas. If

PUMP SANITIZING / WINTERIZING

The SHURflo pump is only one piece of a beverage dispensing system. Therefore,

frequent sanitization of the pump and ALL equipment in the system is required.

Sanitization is dependent on the syrup or beverage type and its manufacturer’s

requirements. Factors which also affect the frequency of this procedure are

temperature, facility conditions, installation, and equipment. Consult other equipment

manufacturer's instructions for their sanitizing requirements. Refer to SHURflo

Service Bulletin #1025 for the N.S.F. listed sanitizing procedure for the SHURflo

pump (only).

CAUTION:Never use pressurized tanks to sanitize or purge the pump of fluid (operating

or not). Applying pressure to the pump inlet could damage internal

components.

If the pump is subjected to temperatures of 0ºC or lower, the system must be drained of

all liquid to prevent damage due to freezing. It is suggested that when taking a pump

out of service, the pump and lines, etc. must be sanitized and purged of all fluid. Refer

to the equipment manufacturer's recommendation on purging lines and dispenser

equipment. Refer to SHURflo Service Bulletin

#

1025 for complete winterizing

procedure.

GENERAL SPECIFICATIONS

DESIGN:

MATERIALS OF CO N STRUCTION:

POWER SOURCE:

OPERATING PRESSURE: 1.4 bar

DISPLACEMENT:

SOLD OUT:

MAX. STROKE RATE:

TEMPERATURE LIMITS:

Twin Chamber Double Diaphragm

Polypropylene, Celcon, EDPM, Santoprene,

Stainless Steel, FDA sanctioned, NSF list ed

CO

2, Nitrogen, or dry compress ed f i ltered air

MIN. / 5.9 bar MAX.

100 cc per cycle

Automatic-No reset required, activated at 508 mm/Hg

min.

2 strokes per second; i nt ermittent duty

1.1°

49°C

START-UP PROCEDURE

1. Confirm that all tubing connections are properly clamped, fittings are locked, and

tubing is not kinked.

2. Connect the bag connector/inlet tube onto the bag fitting. Open the dispenser

valve (syrup side).

3. Adjust gas regulator to about 1.4 bar, allowing the pump to stroke slowly. Once

the pump is primed the regulator can be adjusted up.

4. Continue dispensing syrup until all the air trapped within the tubing has been purged.

5. Once the air has been purged, adjust the CO2 regulator to the pressure necessary

to maintain the brix. The most efficient gas usage occurs at 2.8 bar. Maximum

gas pressure to the pump is 5.9 bar; minimum is 1.4 bar.

NOTE: To prevent air from entering the system always leave the bag connector

connected to the empty B-I-B until a new B-I-B can be installed. Air entered into the

system, via air in the bags or vacuum leaks, may cause brix fluctuation, foaming, spitting,

non-operation of the vacuum shut-off, or the pump to run while the dispenser is closed.

Symptoms of this kind can lead to a misdiagnosis of the pump as the problem.

Page: 2 of 4 Page: 3 of 4

Loading...

Loading...